Slag washing water filter

A technology of filter and slag flushing, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of loss, intermittent heating shortage, etc., and achieve the goal of reducing additional costs and downtime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

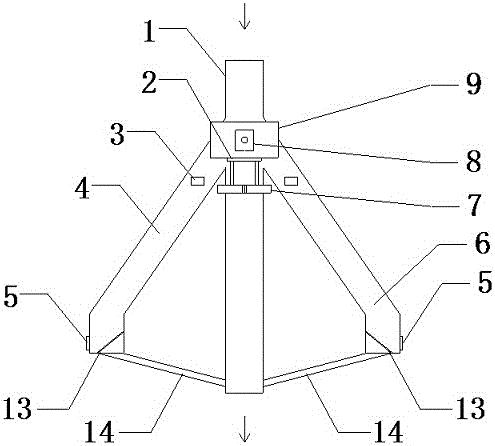

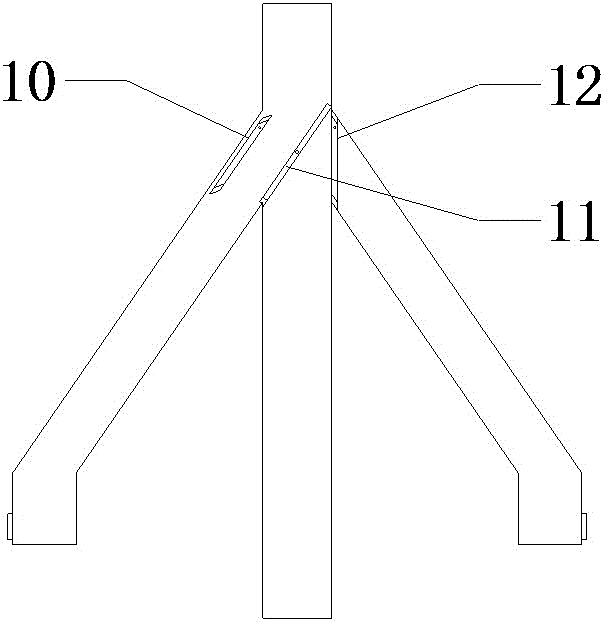

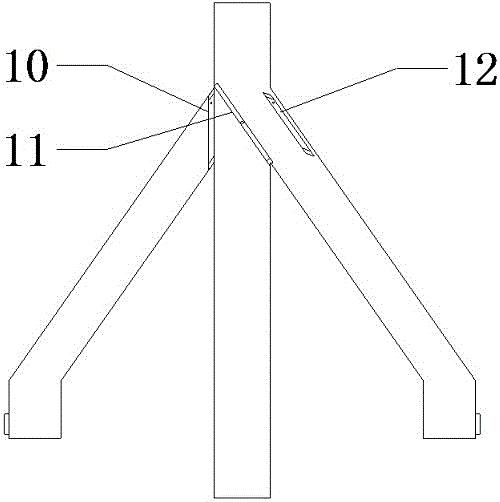

[0047] Embodiment: a kind of slag flushing water filter, its structure is as Figure 1-3 shown, including:

[0048] vertical water inlet pipe 1;

[0049] The left side of the water inlet pipe 1 communicates with the first slag storage bin 4, and the right side of the water inlet pipe 1 communicates with the second slag storage bin 6;

[0050] A flange 7 is installed on the water inlet pipe 1, a support frame 2 is installed on the flange 7, and a gearbox 9 is arranged on the support frame 2;

[0051] The gearbox 9 has a first output shaft 9-2, a second output shaft 9-5 and a third output shaft 9-9;

[0052] Wherein, the first output shaft 9-2 is connected to the top of the first sealing plate 10, and the first sealing plate 10 is used to control the on-off of the water inlet pipe 1 and the first slag storage bin 4;

[0053] The second output shaft 9-5 is connected with the middle of the screen holder 11;

[0054] The third output shaft 9-9 is connected to the top of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com