Patents

Literature

7240 results about "Continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In telecommunication, continuous operation is an operation in which certain components, such as nodes, facilities, circuits, or equipment, are in an operational state at all times. Continuous operation usually requires that there be fully redundant configuration, or at least a sufficient X out of Y degree of redundancy for compatible equipment, where X is the number of spare components and Y is the number of operational components.

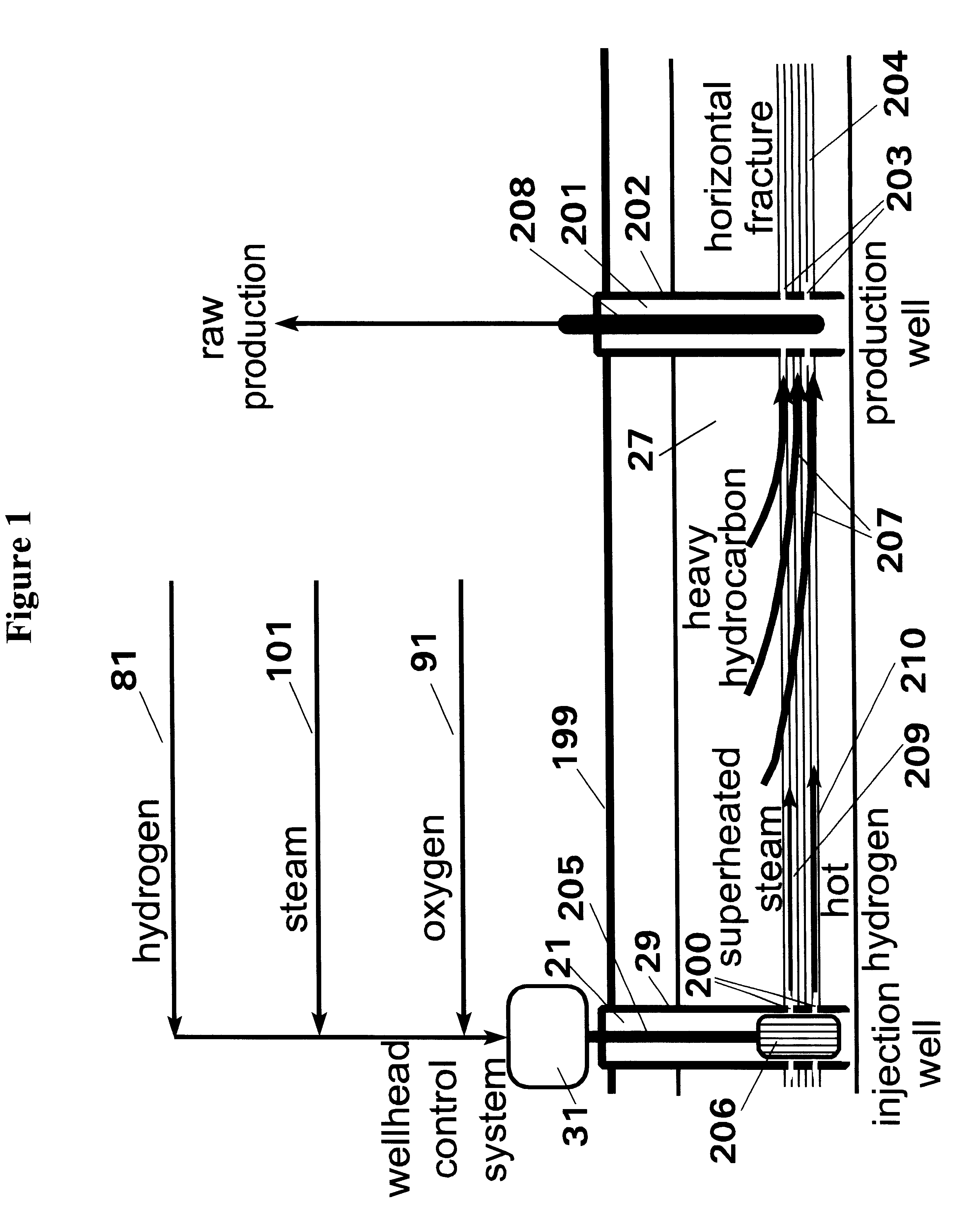

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

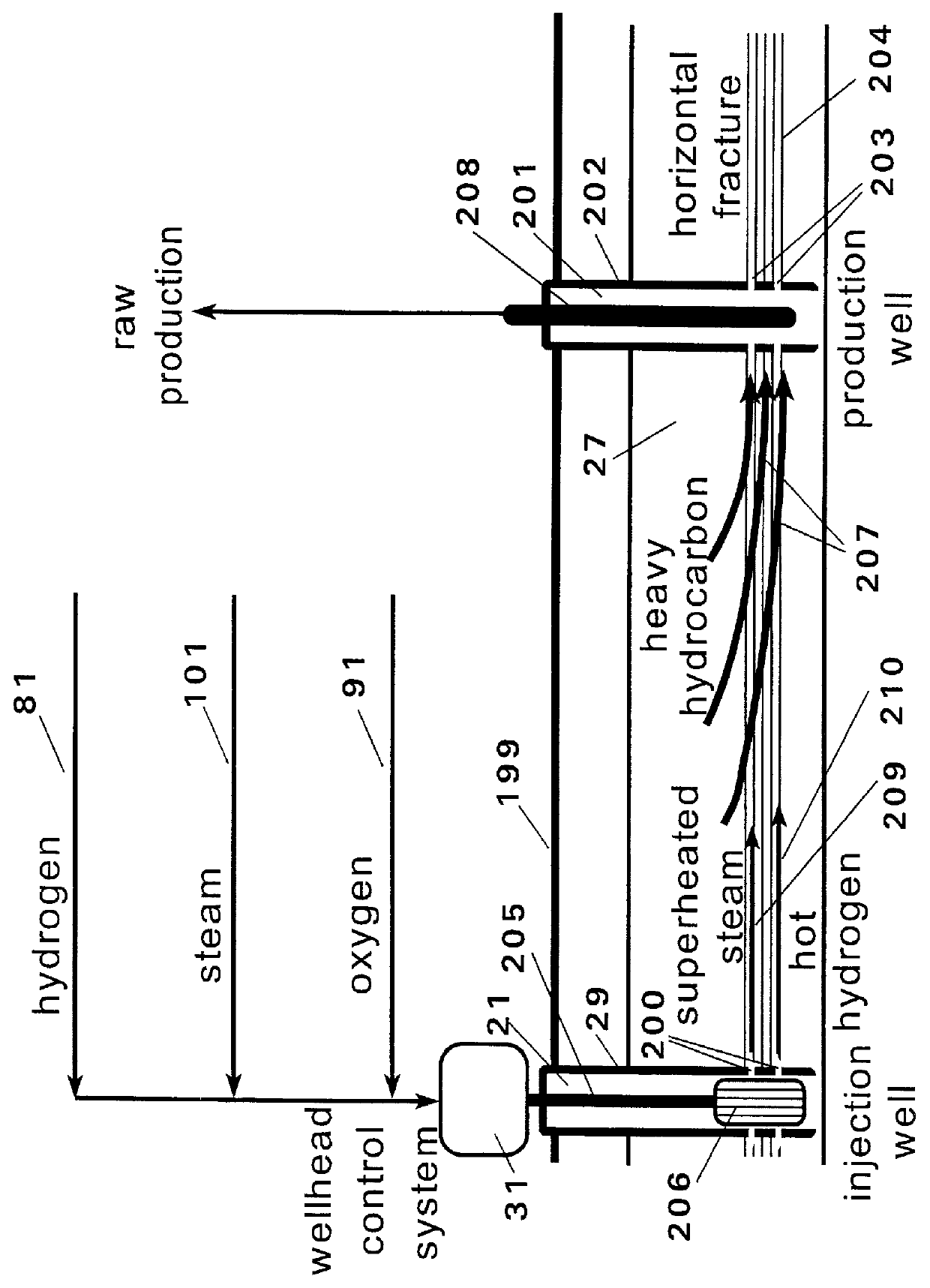

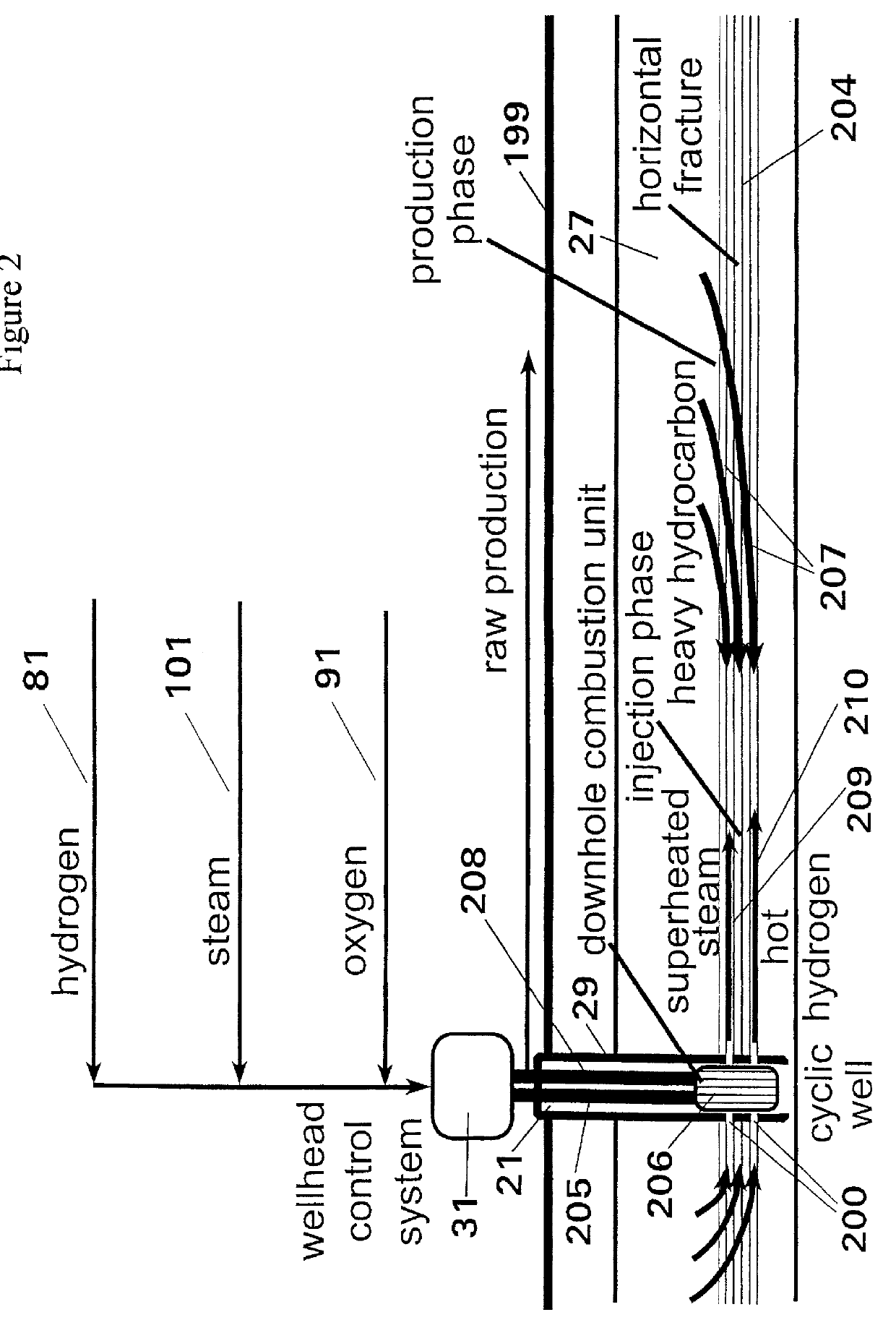

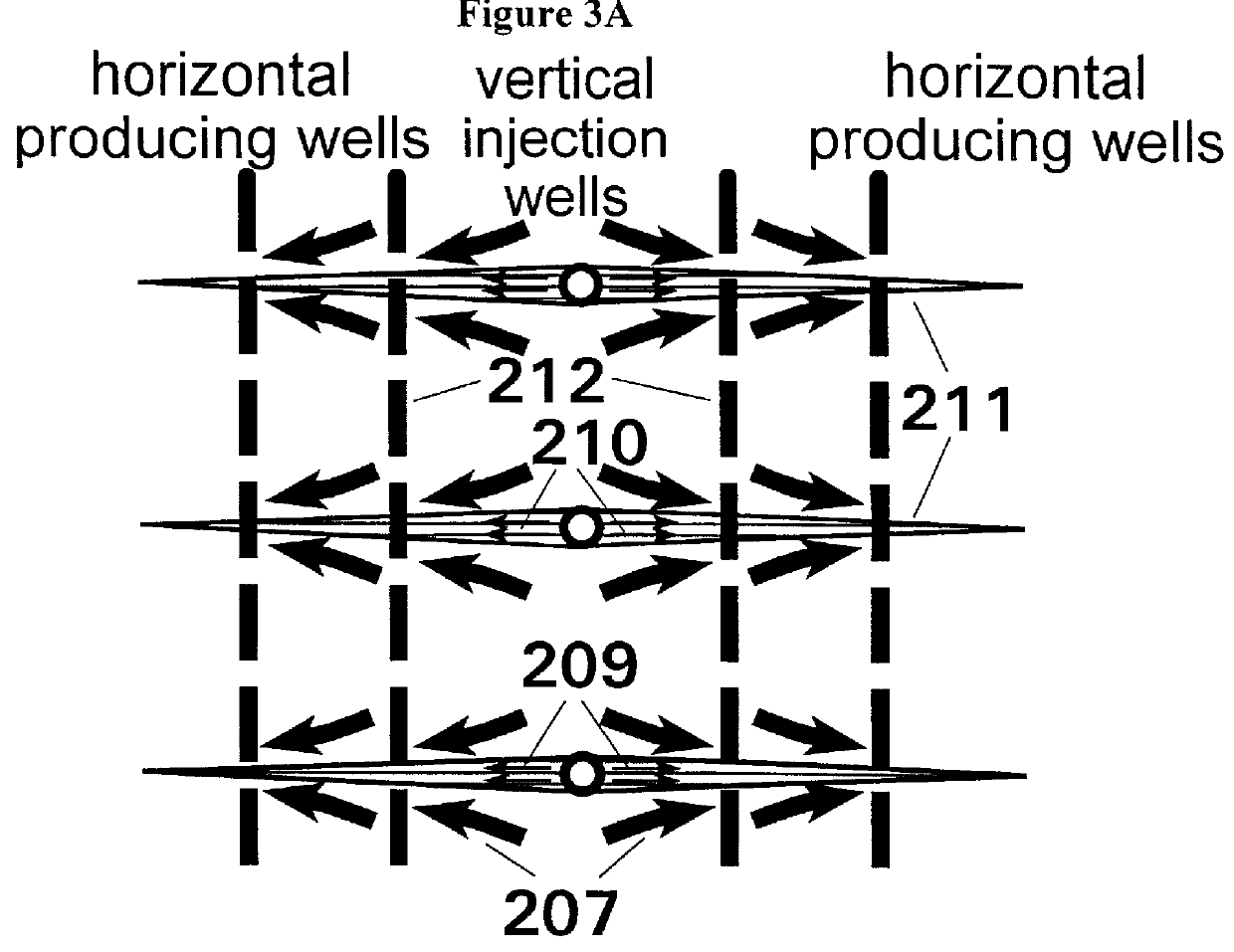

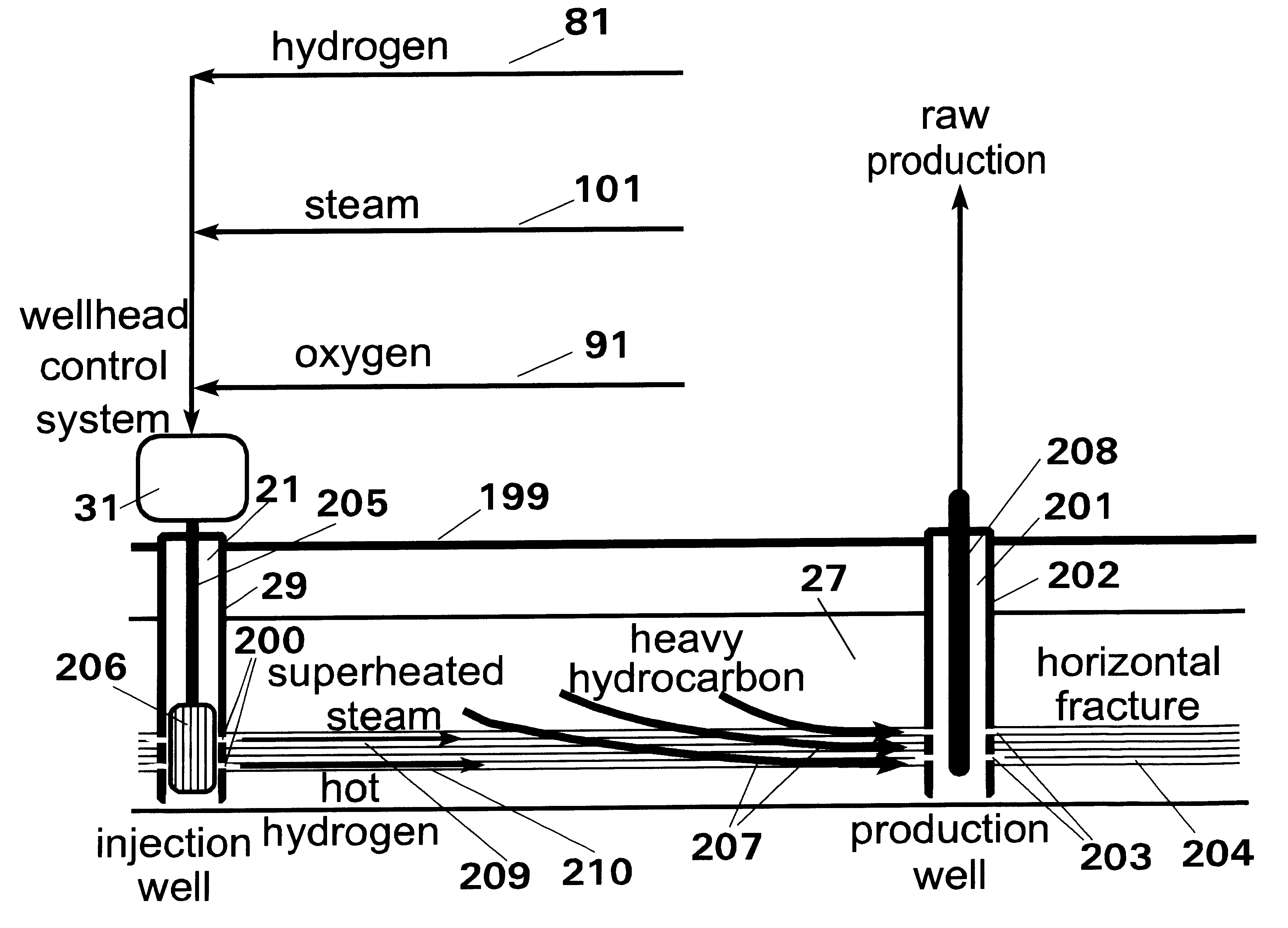

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

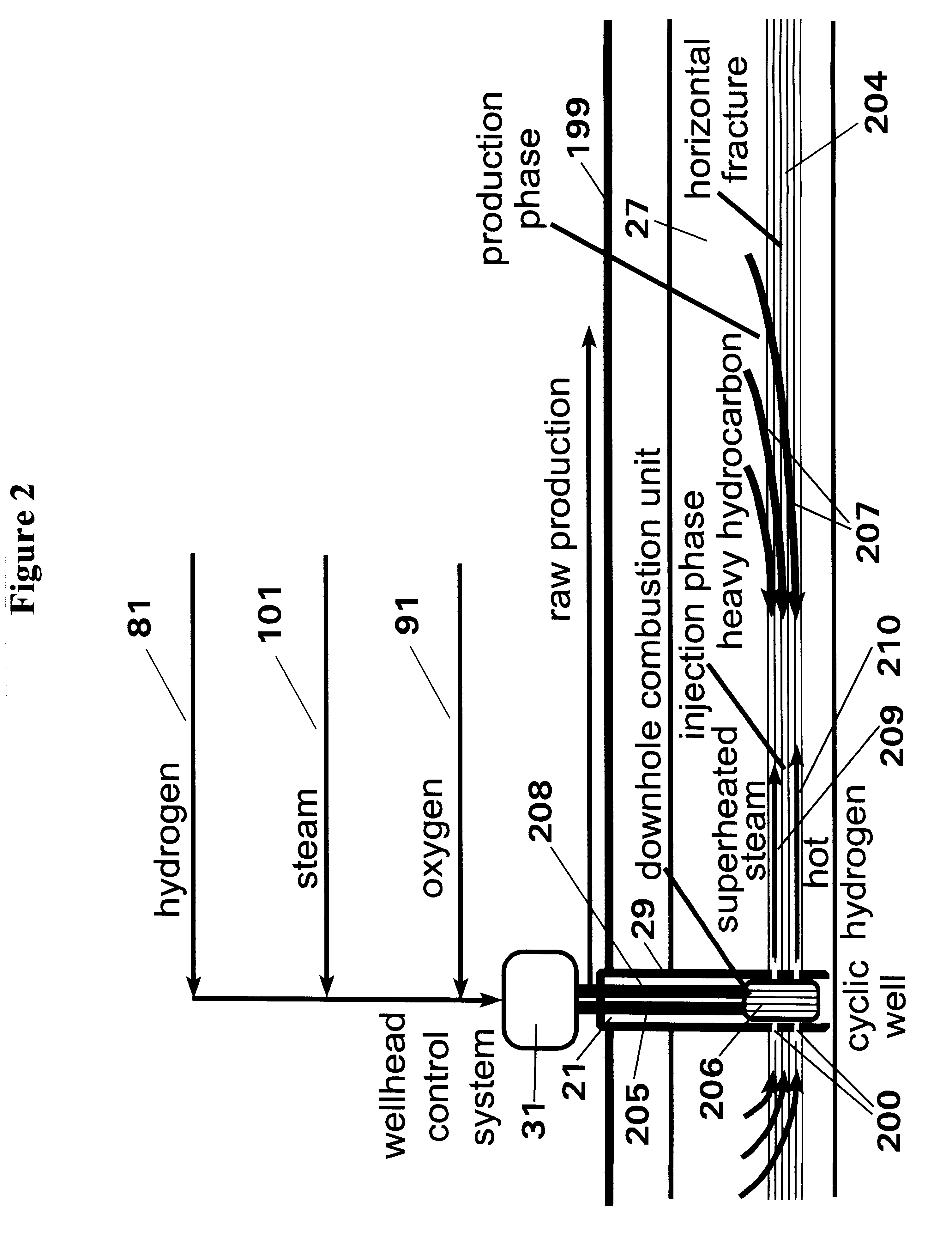

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

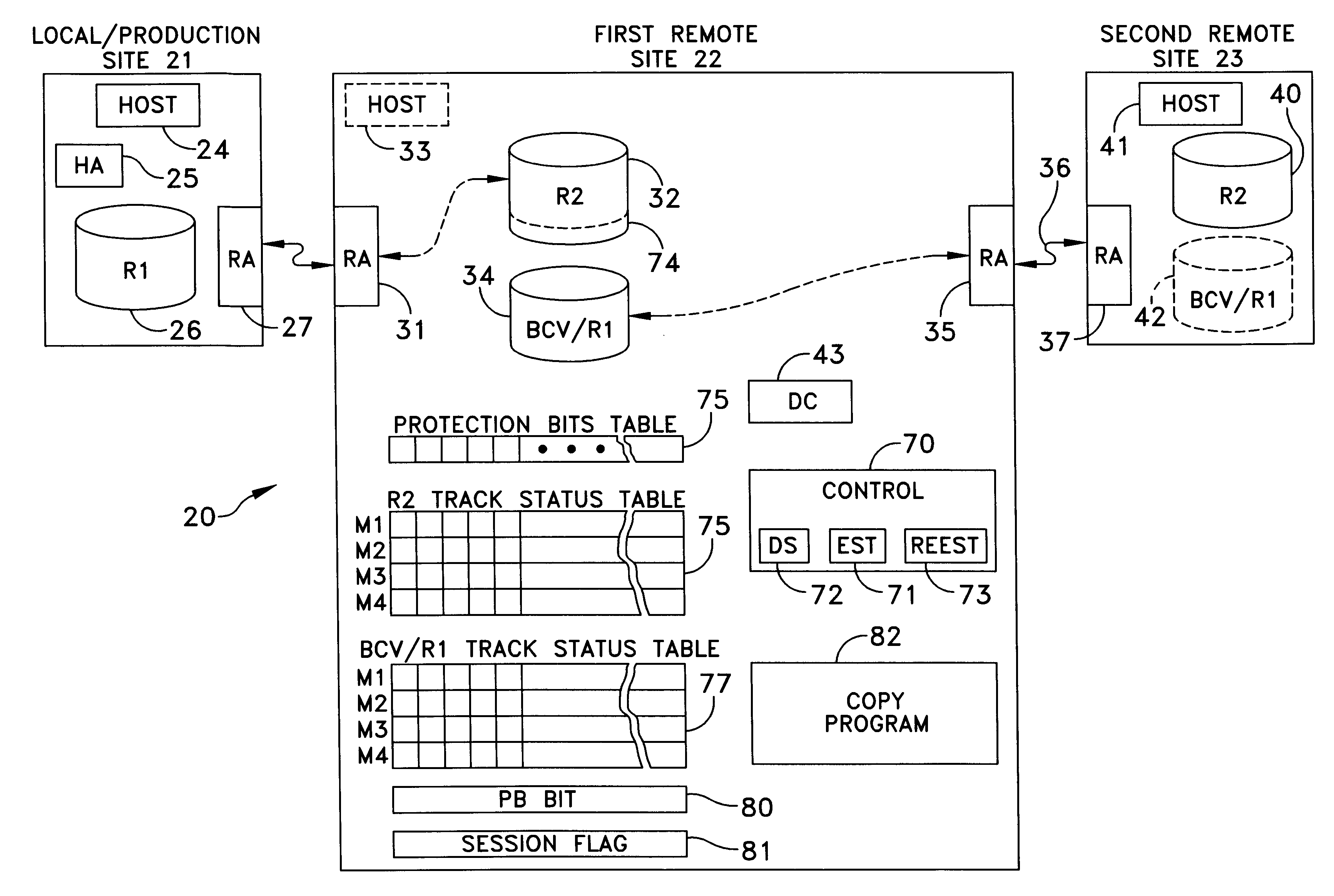

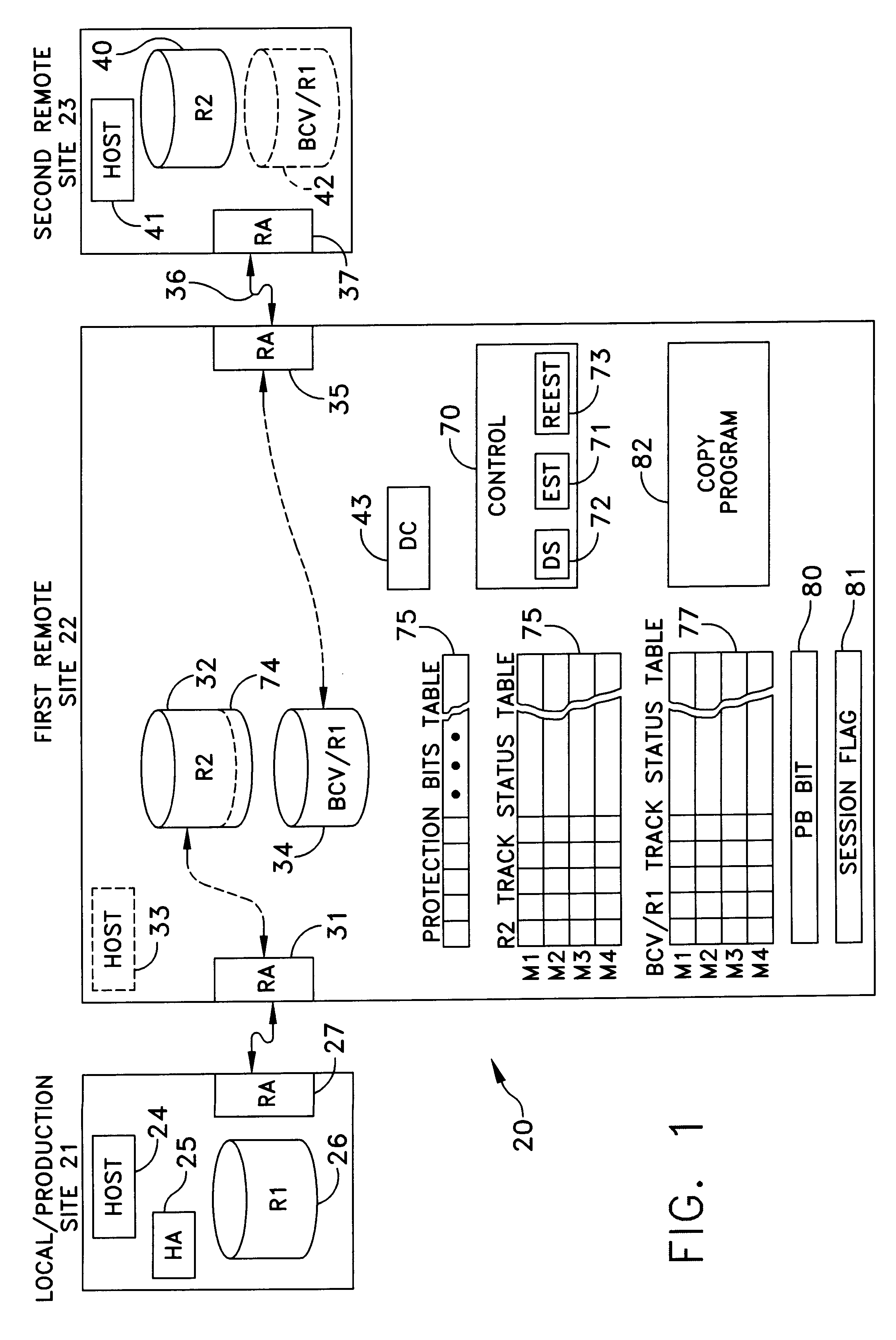

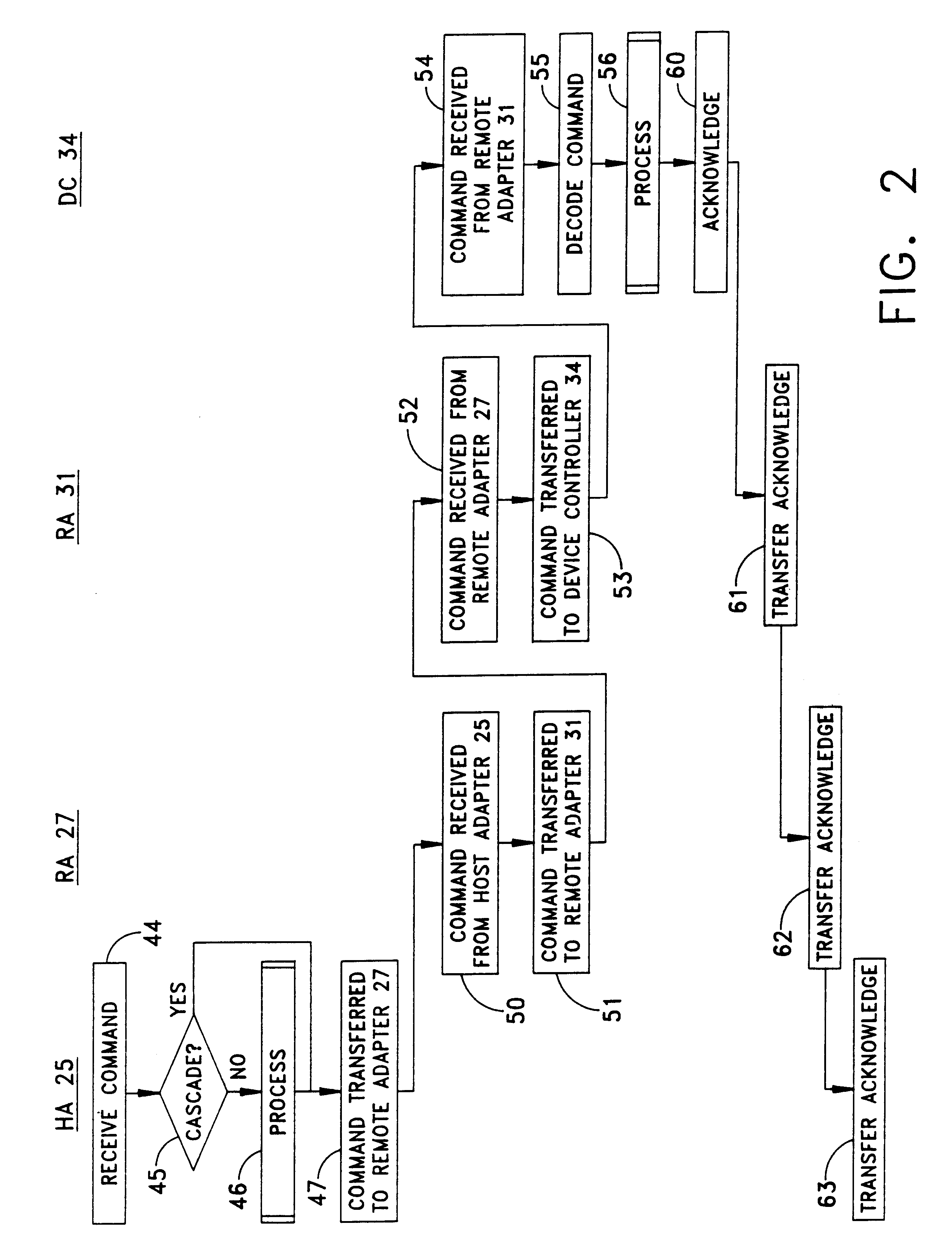

Method and apparatus for cascading data through redundant data storage units

A data storage facility for transferring data from a data altering apparatus, such as a production data processing site to a remote data receiving site. The data storage facility includes a first data store for recording each change in the data generated by the data altering apparatus. A register set records each change on a track-by-track basis. A second data store has first and second operating modes. During a first operating mode the second data store becomes a mirror of the first data store. During a second operating mode the second data store ceases to act as a mirror and becomes a source for a transfer of data to the data receiving site. Only information that has been altered, i.e., specific tracks that have been altered, are transferred during successive operations in the second operating mode. Commands from the local production site initiate the transfers between the first and second operating modes.

Owner:EMC IP HLDG CO LLC

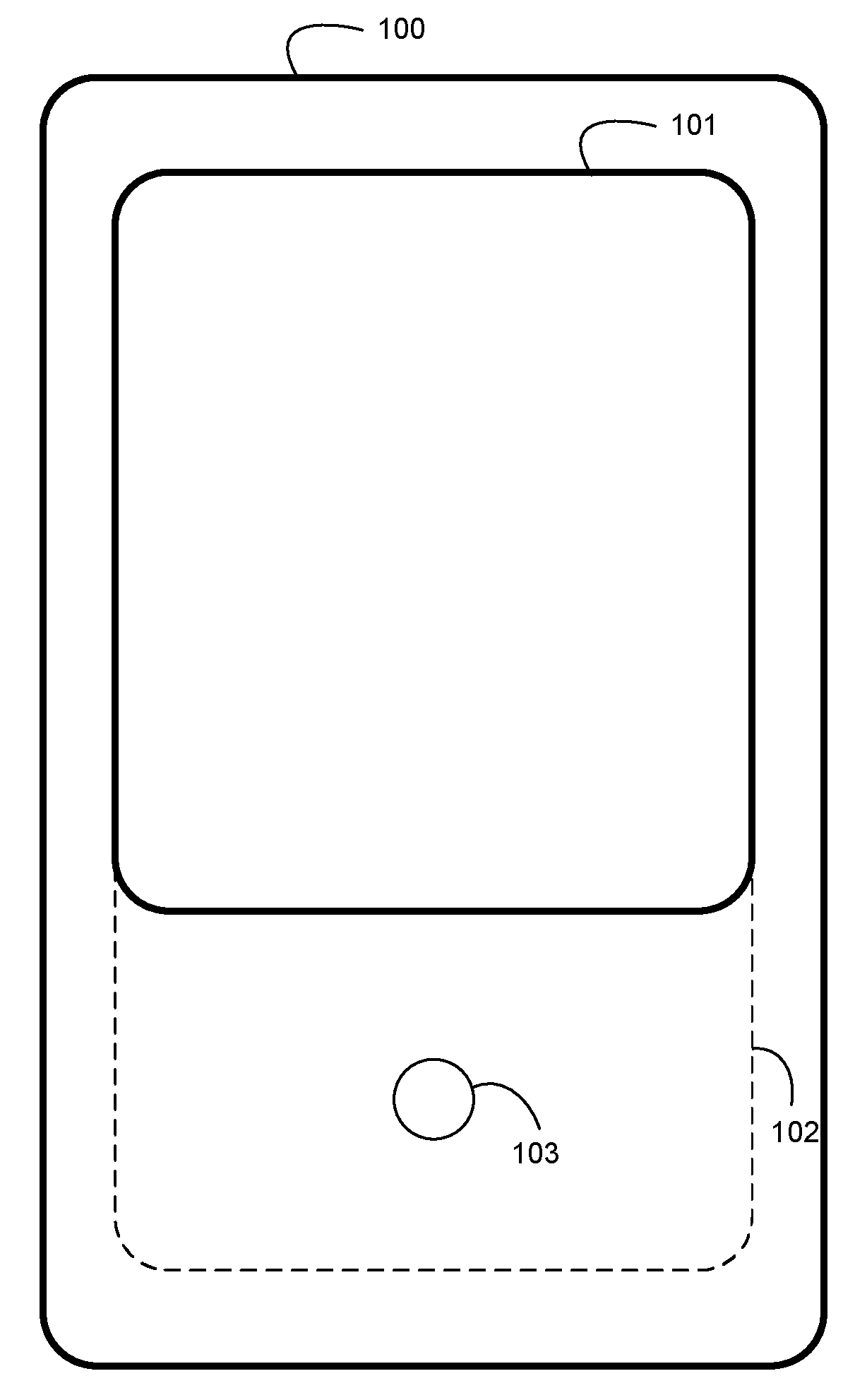

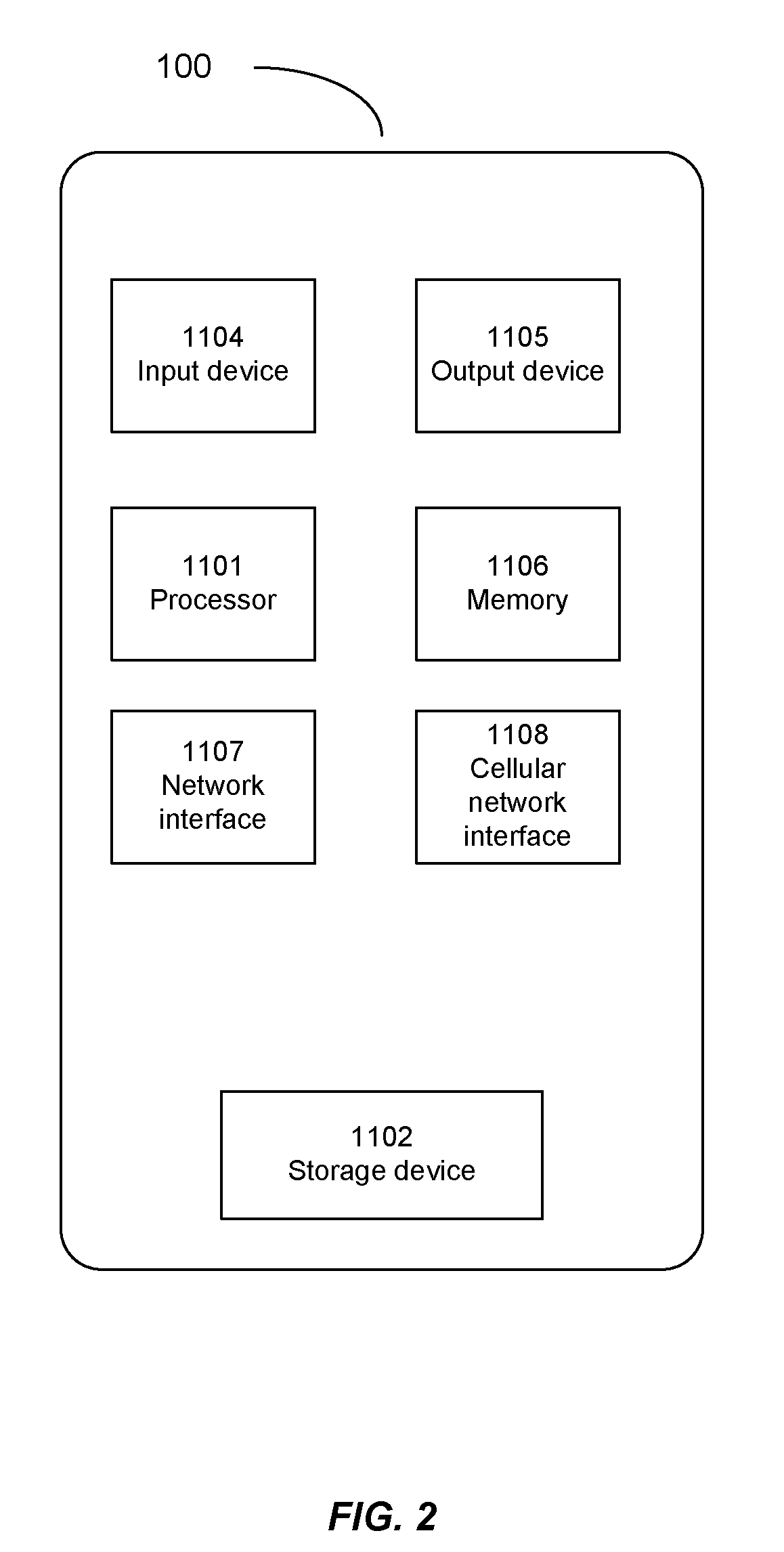

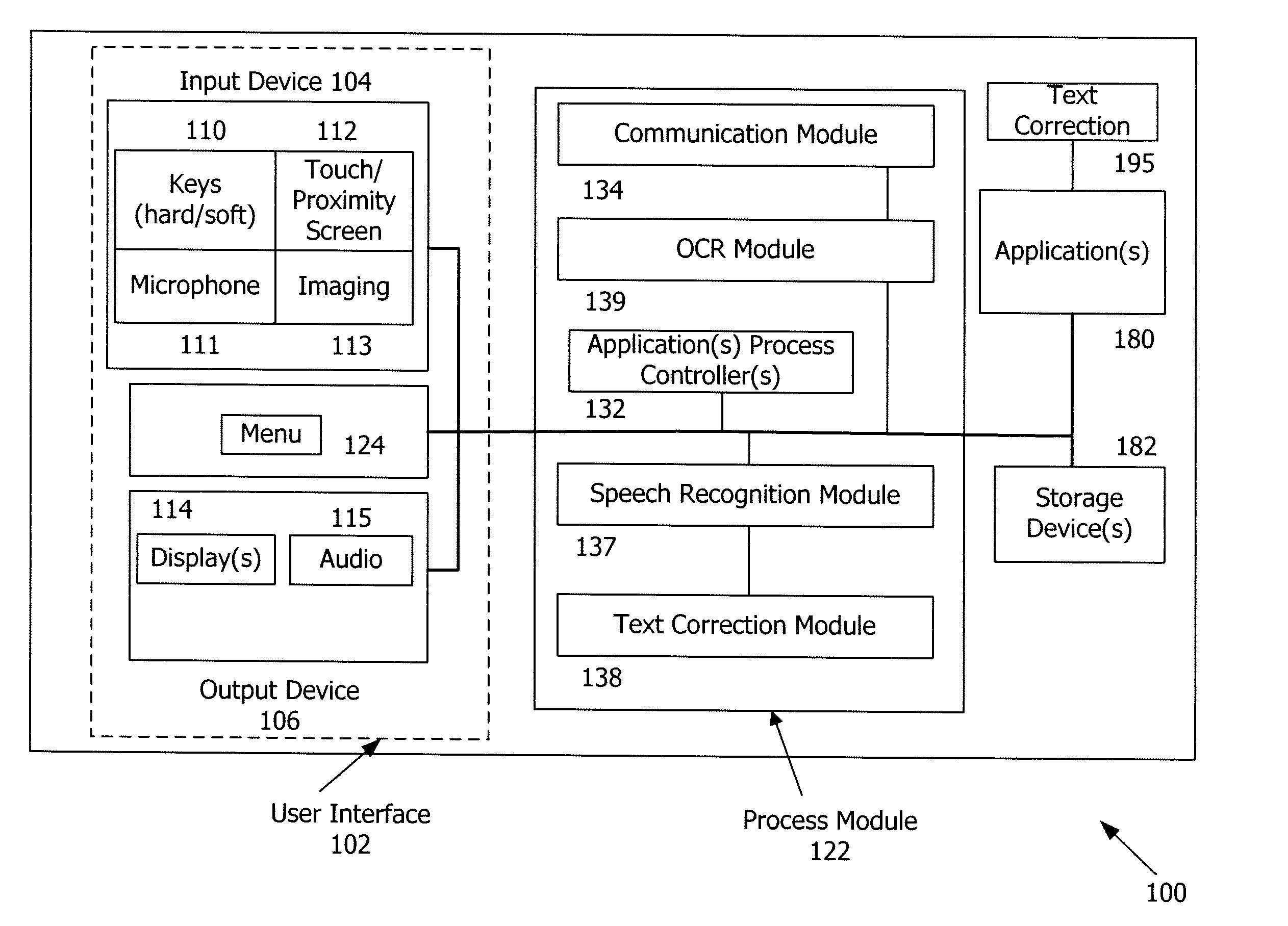

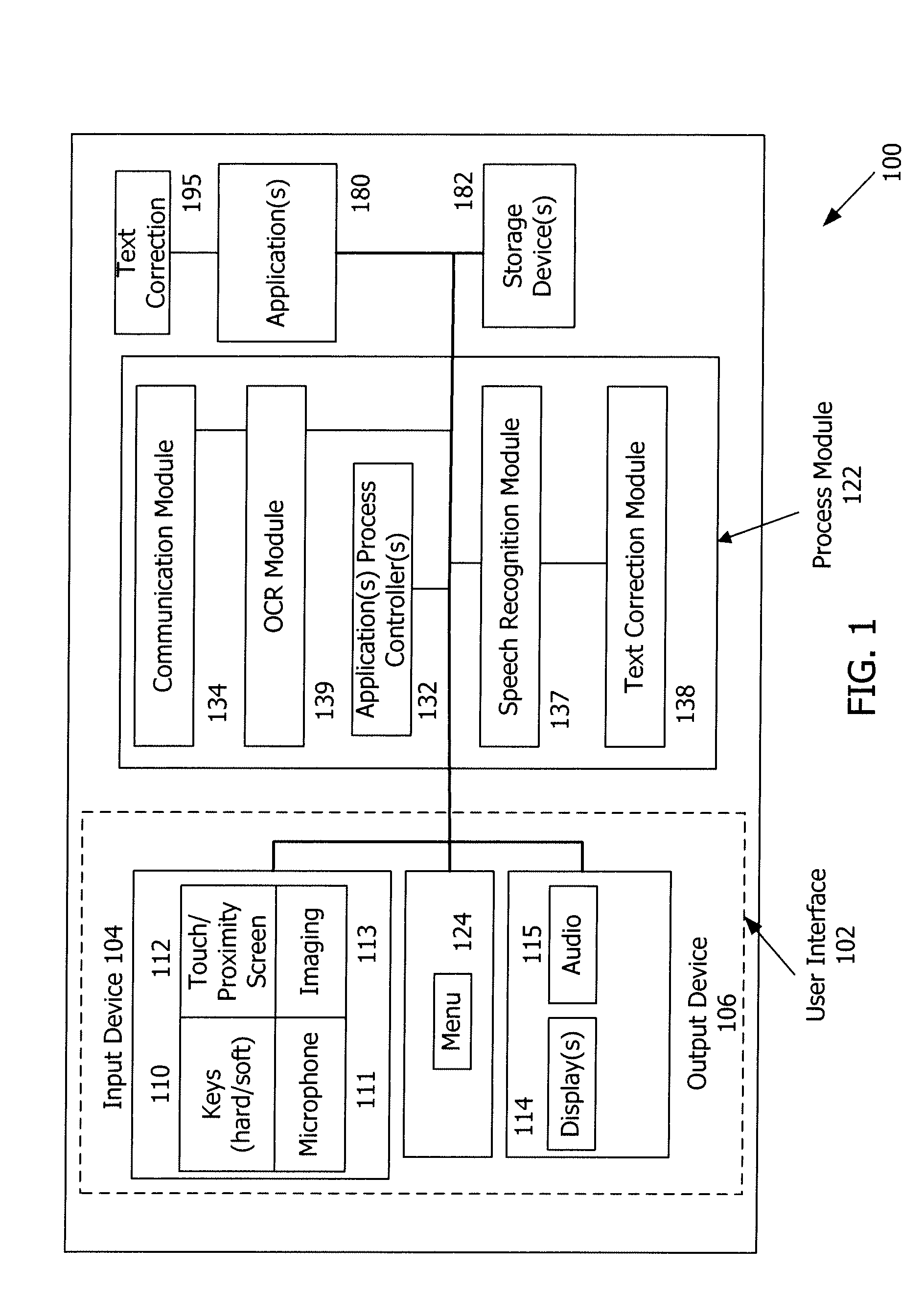

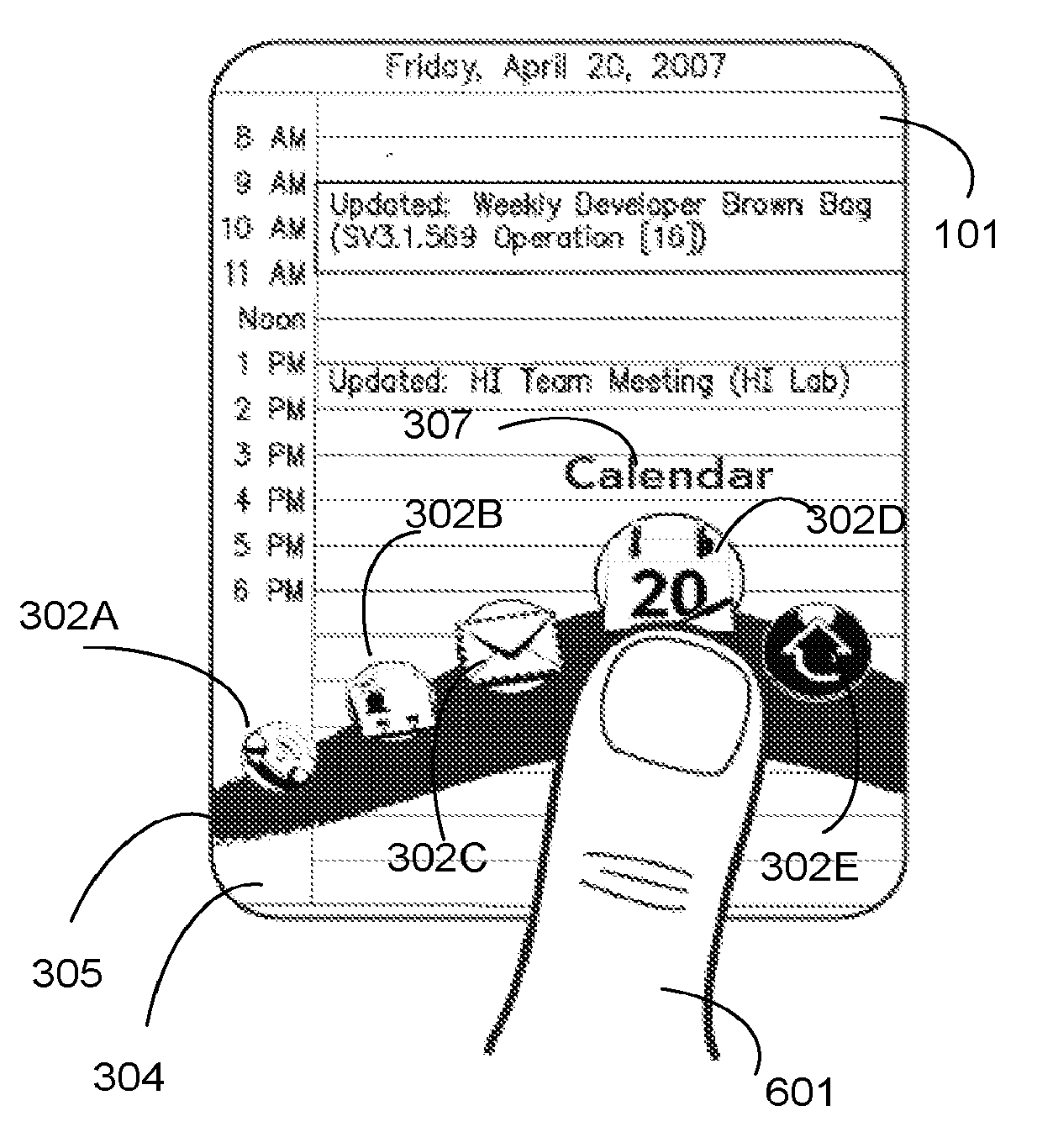

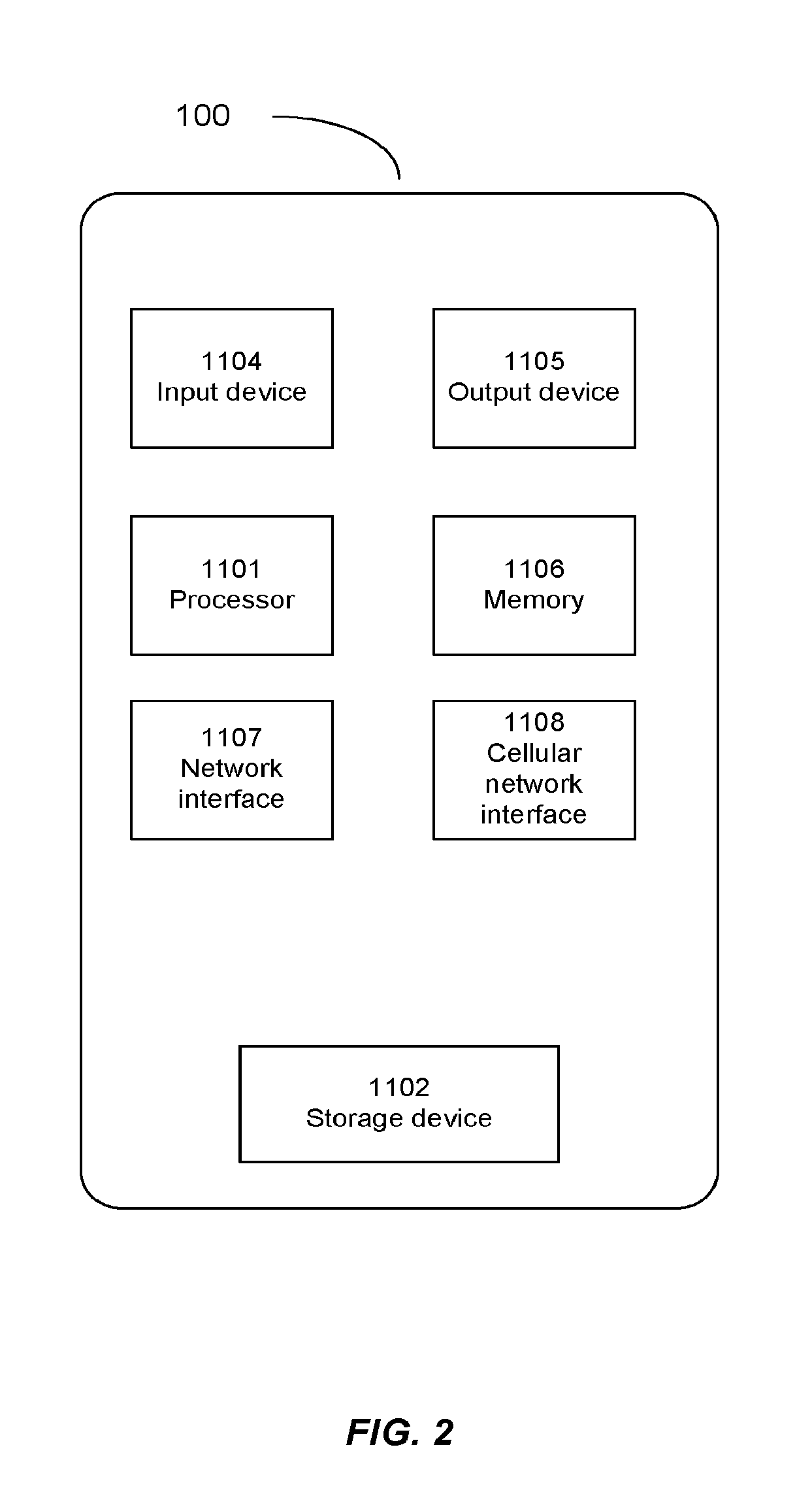

User Interface For Initiating Activities In An Electronic Device

ActiveUS20100185989A1Improve expediencyImprove convenienceCathode-ray tube indicatorsInput/output processes for data processingHome screenTouchscreen

In one embodiment, a user interface is presented for initiating activities in an electronic device. The user interface includes an element referred to as a “launch wave”, which can be activated at substantially any time, even if the user is engaged with an activity, without requiring the user to first return to a home screen. In various embodiments, the user can activate the launch wave by performing a gesture, or by pressing a physical button, or by tapping at a particular location on a touchscreen, or by activating a keyboard command. In one embodiment, activation of the launch wave and selection of an item from the launch wave can be performed in one continuous operation on a touch-sensitive screen, so as to improve the expediency and convenience of launching applications and other items.

Owner:QUALCOMM INC

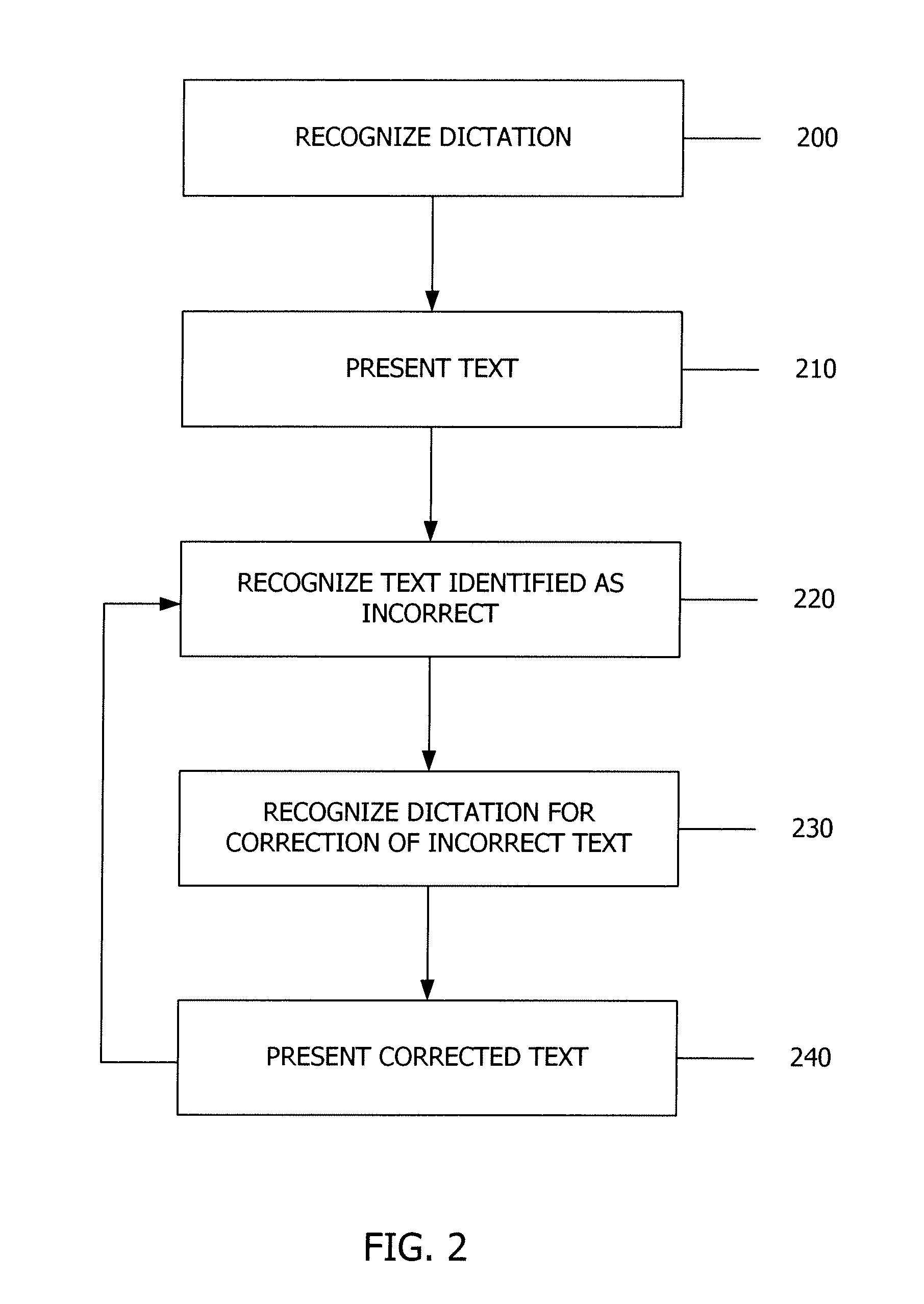

Multiword text correction

A method including detecting a selection of a plurality of erroneous words in text presented on a display of a device, in an automatic speech recognition system, receiving sequentially dictated corrections for the selected erroneous words in a single, continuous operation where each dictated correction corresponds to at least one of the selected erroneous words, and replacing the plurality of erroneous words with one or more corresponding words of the dictated corrections where each erroneous word is matched with the one or more corresponding words of the dictated corrections in an order the erroneous words appear according to a reading direction of the text.

Owner:NOKIA CORP

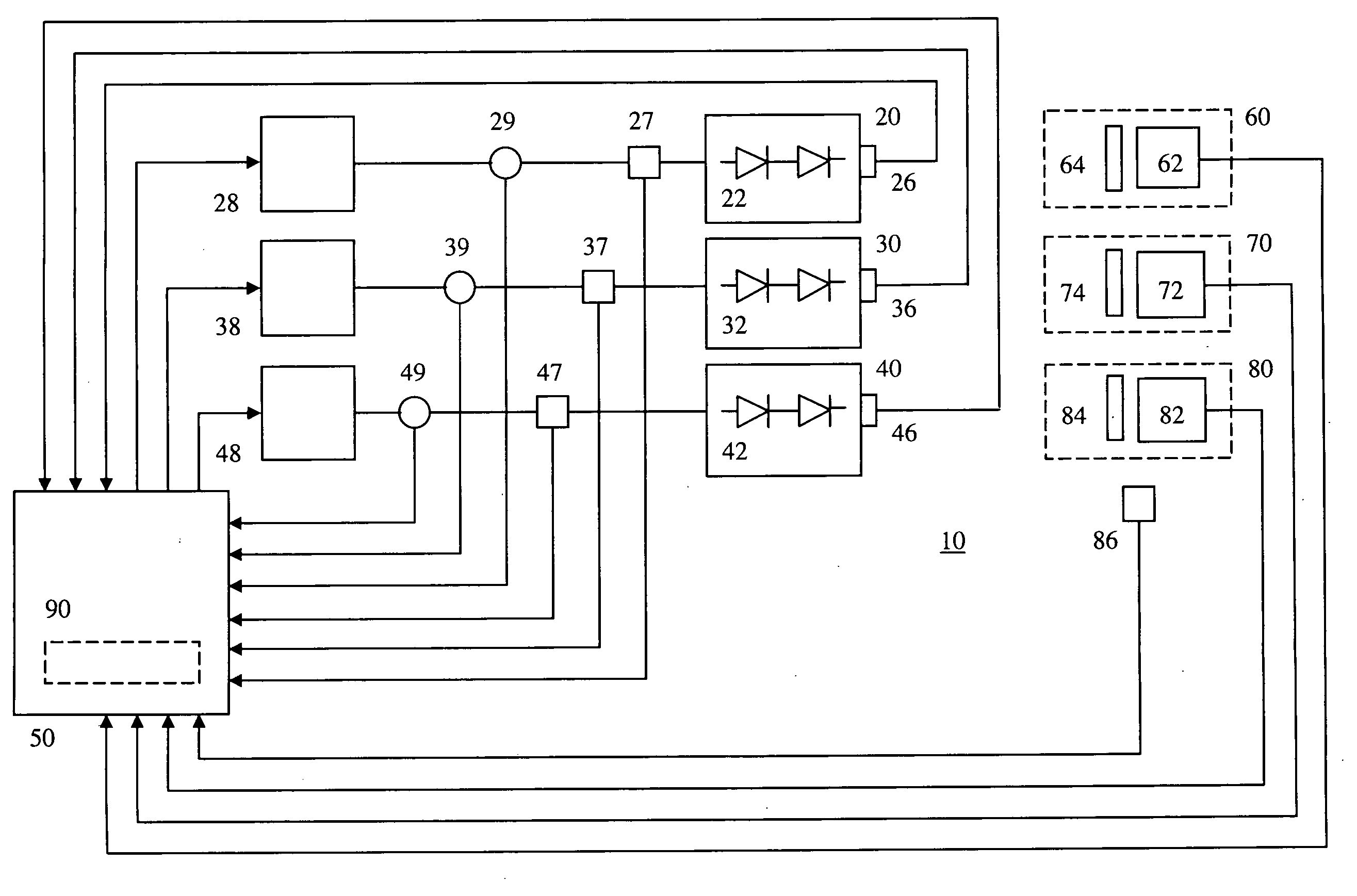

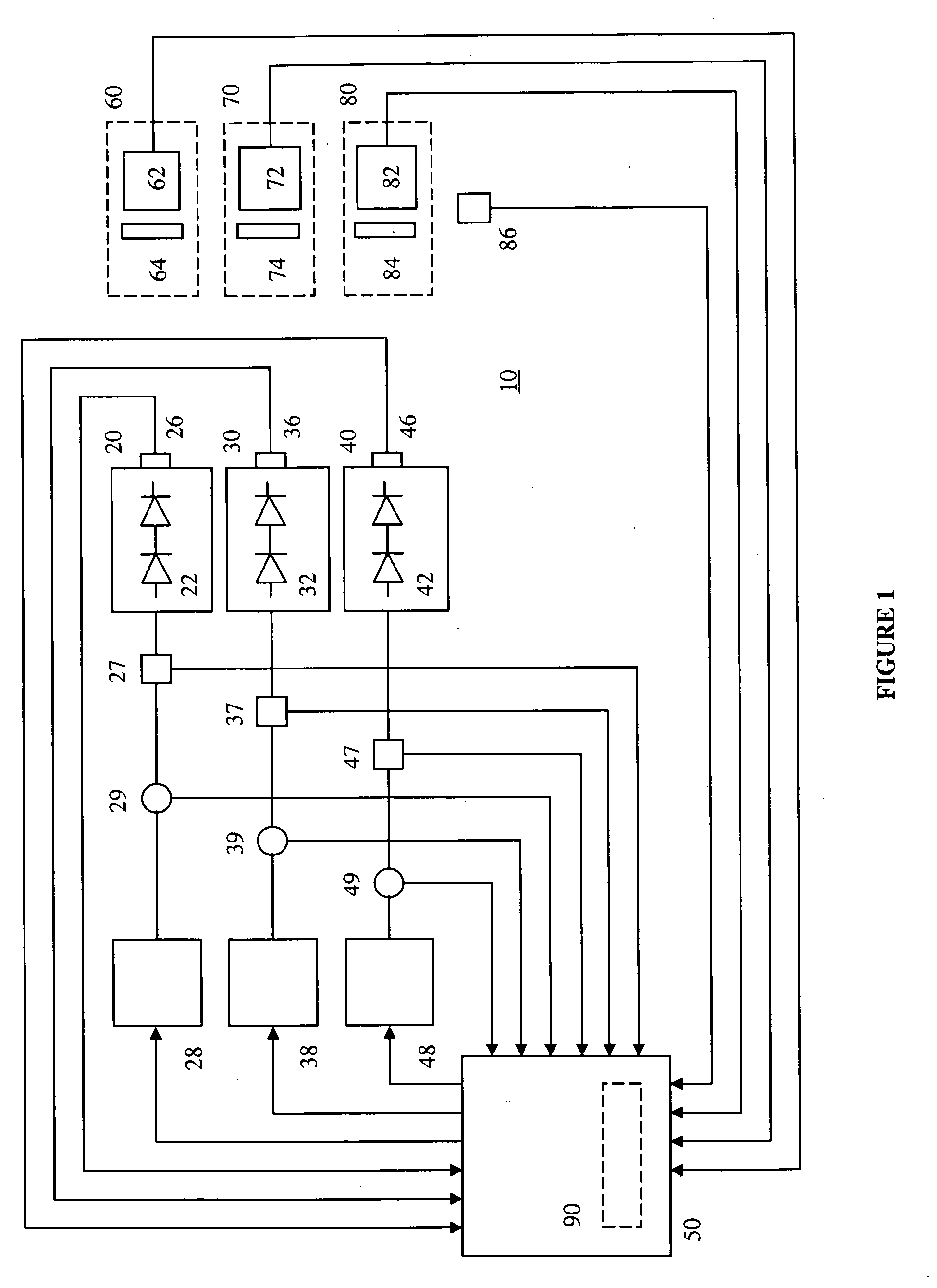

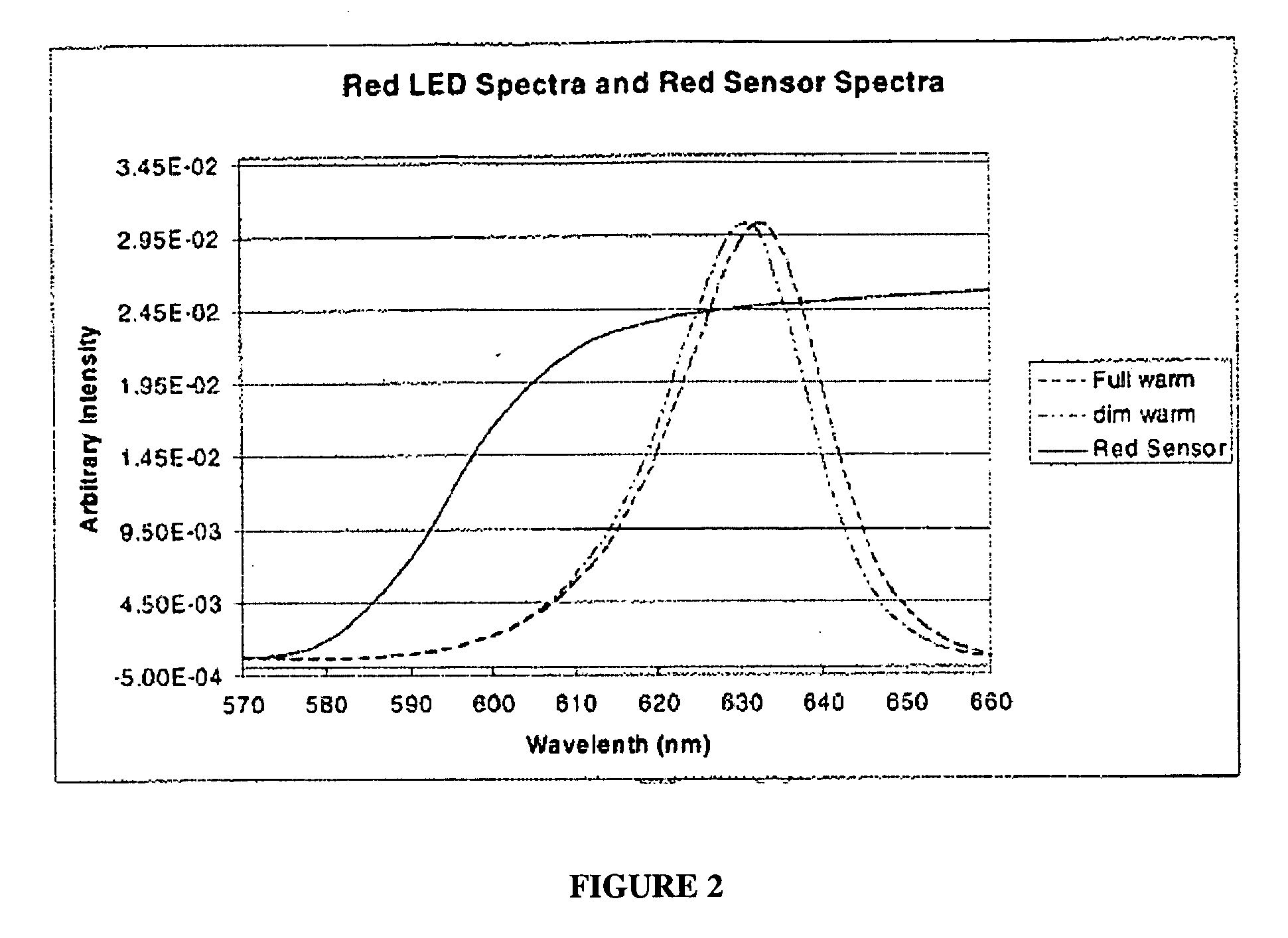

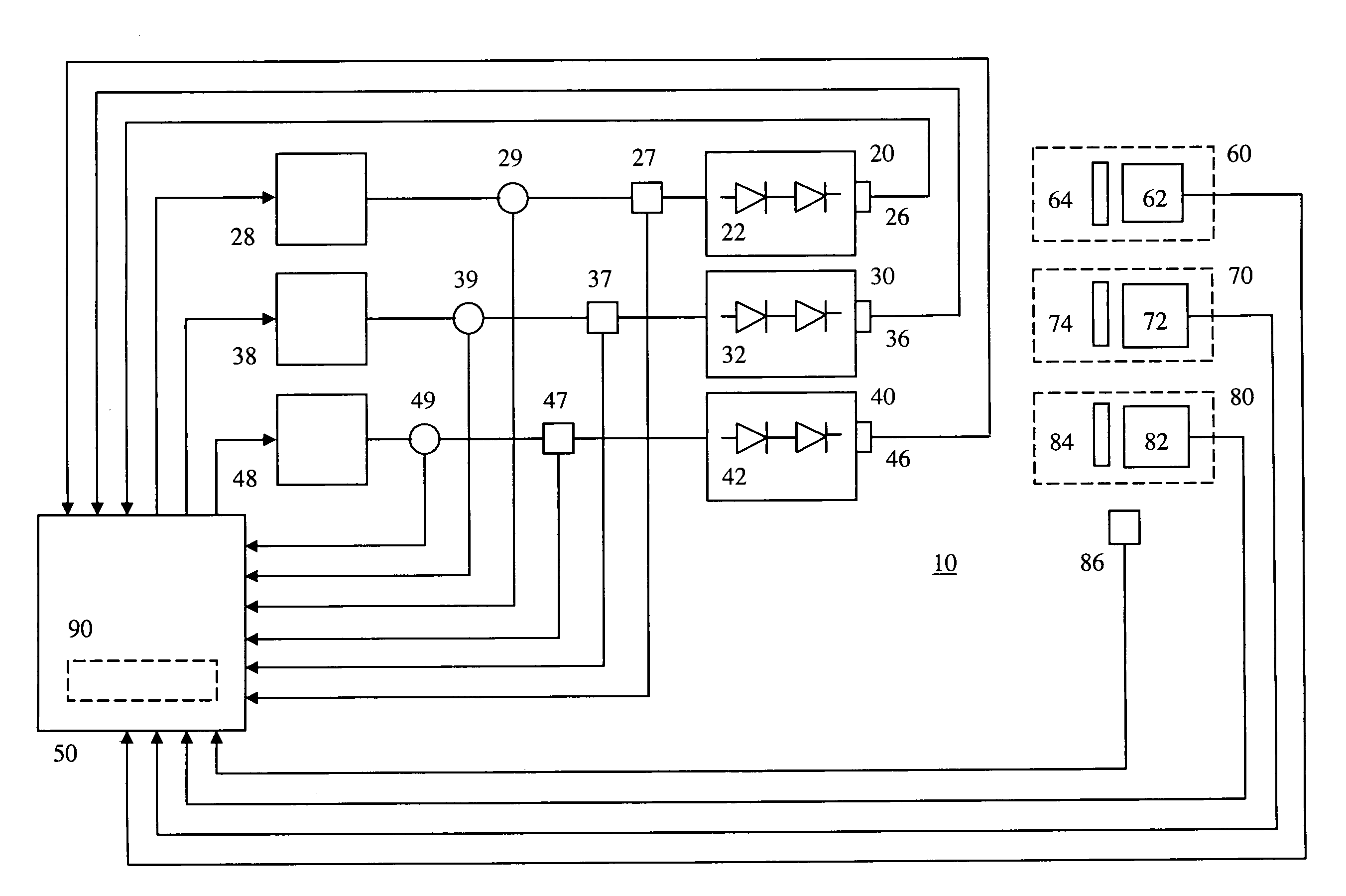

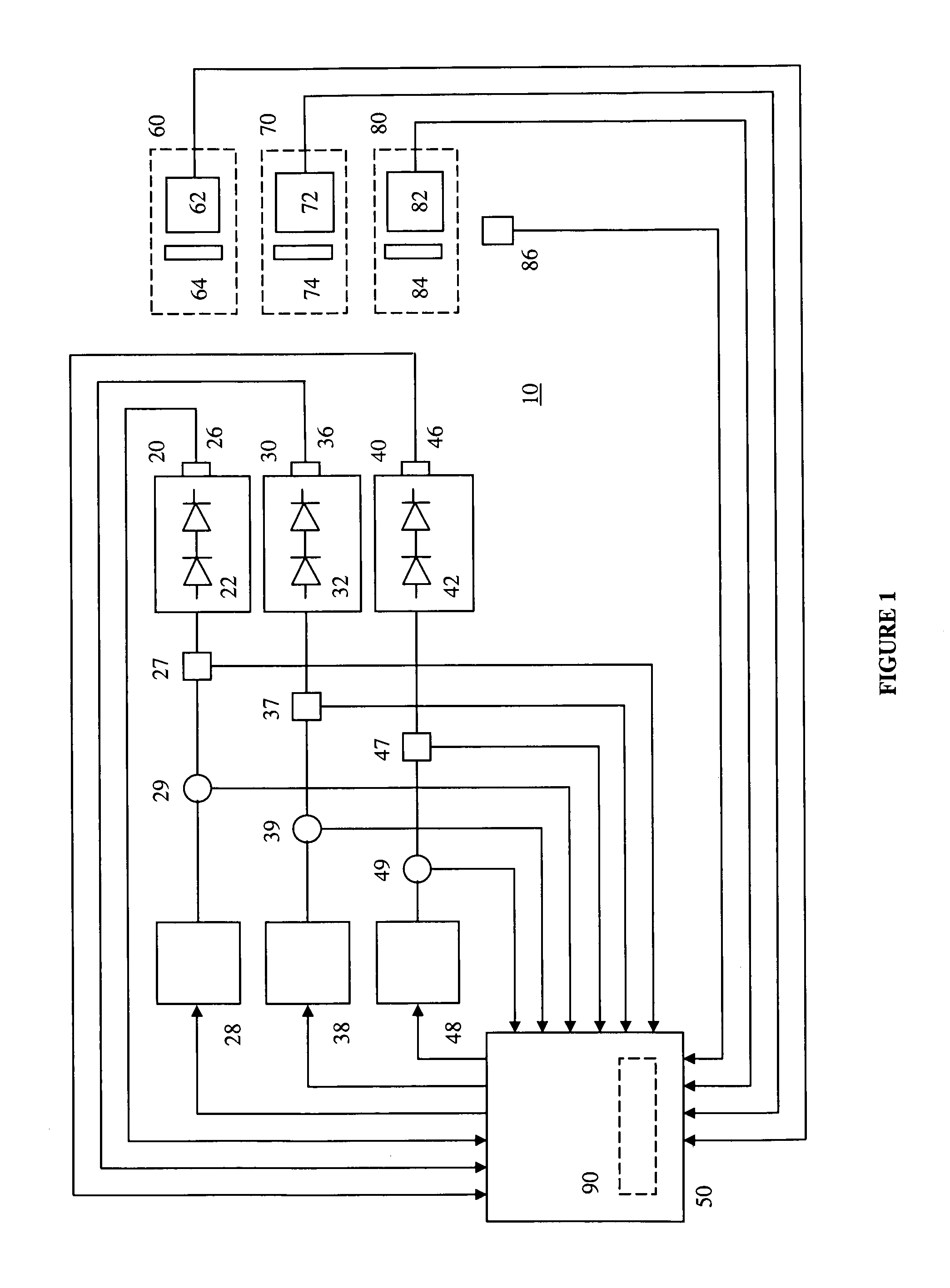

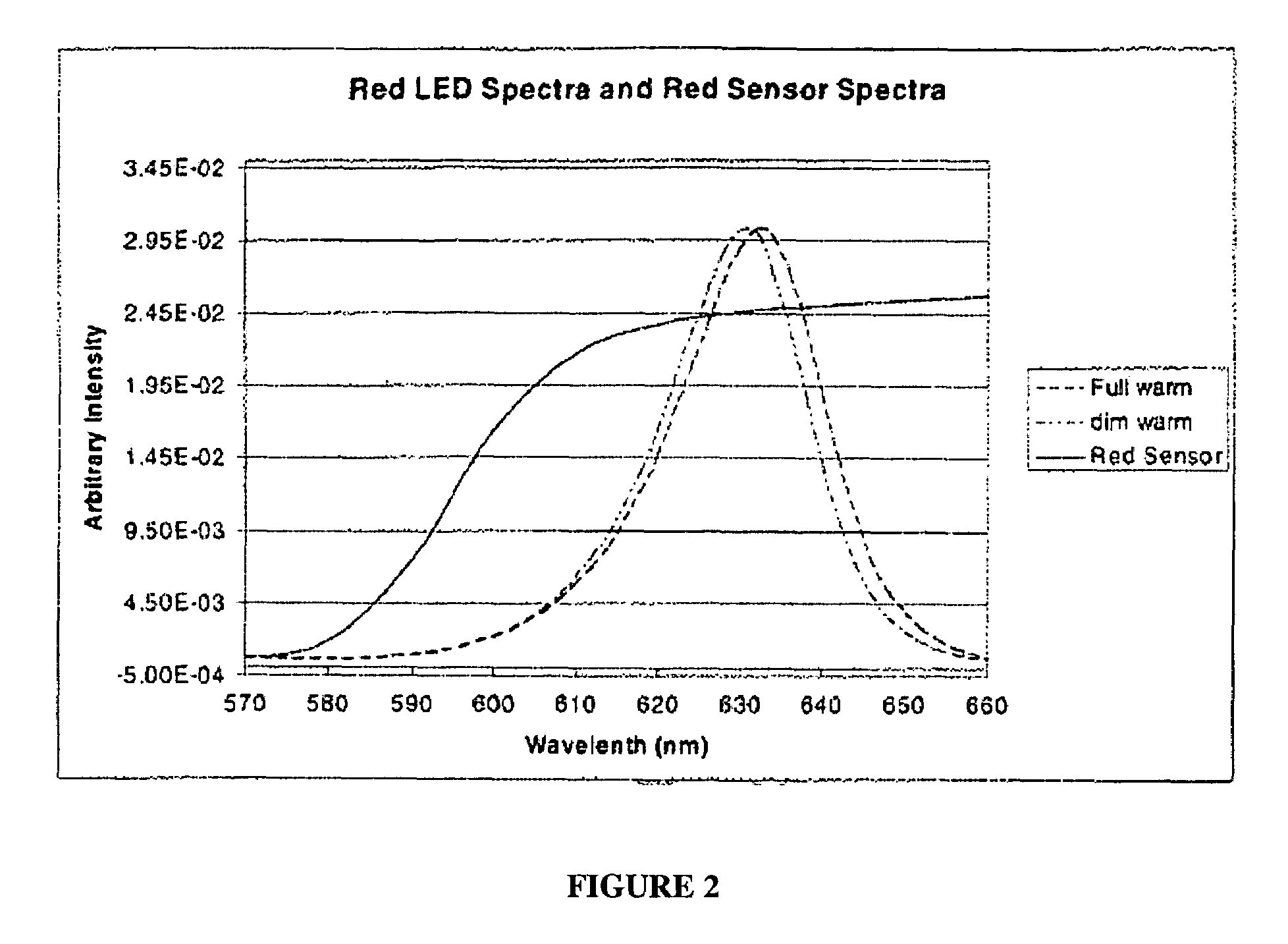

Digitally controlled luminaire system

InactiveUS20070040512A1Radiation pyrometryBeam/ray focussing/reflecting arrangementsJunction temperatureEngineering

The present invention provides a luminaire system capable of generating light of a desired chromaticity and luminous flux output during continuous operation with varying ambient operating temperature. The luminaire system can be further capable of maintaining a desired correlated colour temperature during dimming of the luminaire. The luminaire system comprises one or more arrays of light-emitting elements for generating light with a current driver system coupled thereto for selectively supplying electrical drive current to each of the arrays, wherein the current driver system is responsive to drive signals received from a controller. The luminaire system further comprises an optical sensor system for generating optical signals representative of chromaticity and luminous flux output of the light. A heat sensing system is operatively coupled to the one or more arrays for generating signals representative of the junction temperatures of arrays of light-emitting elements during operation. The luminaire system further comprises a controller that is operatively connected to the current driver system, the optical sensor system and the heat sensing system for receiving the signals generated by each of these systems and is configured to generate one or more drive signals for transmission to the current driver system in response to the optical signals and thermal signals received from the optical system and the heat sensing system, respectively, thereby enabling a desired level of control of the output light.

Owner:SIGNIFY HLDG BV

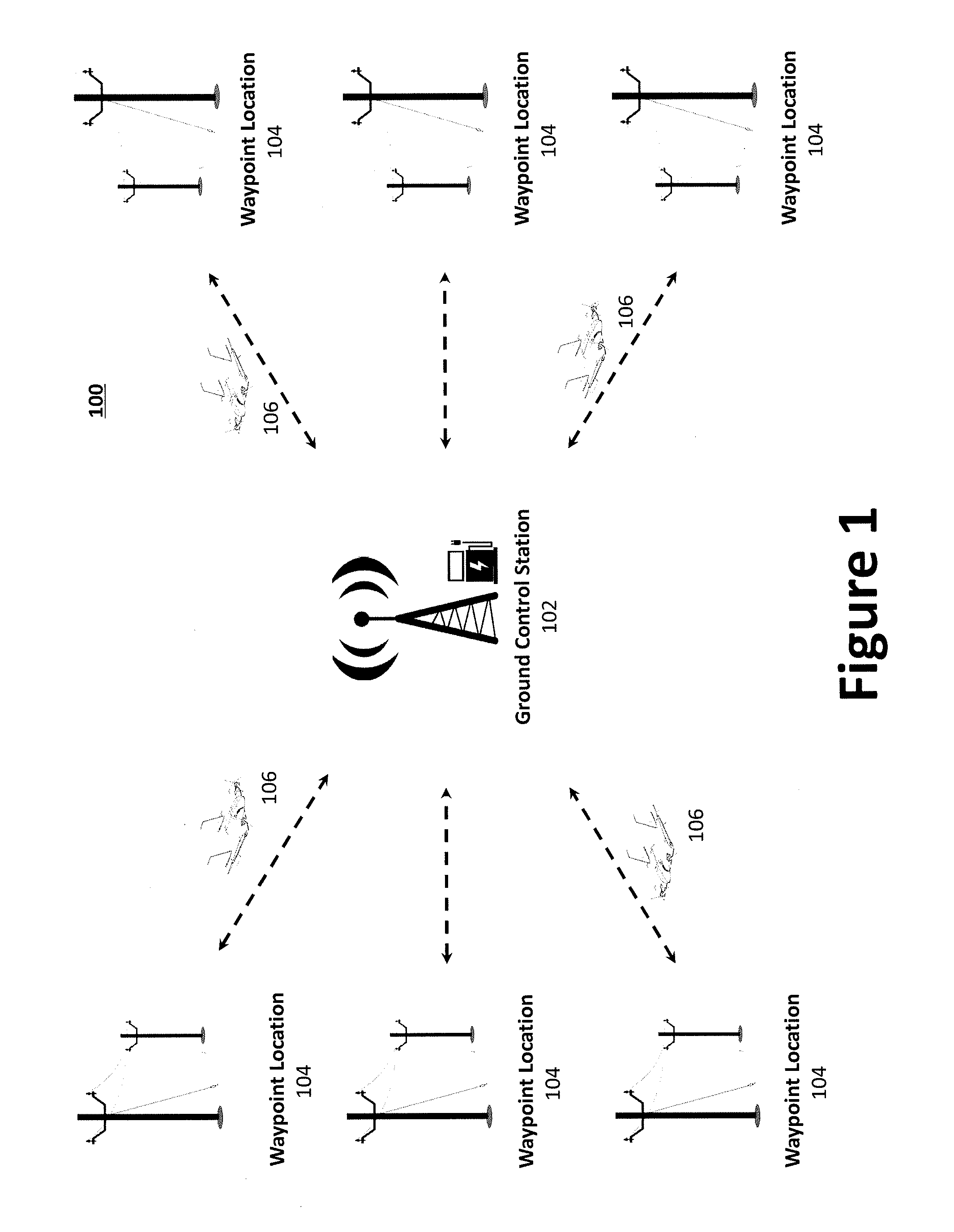

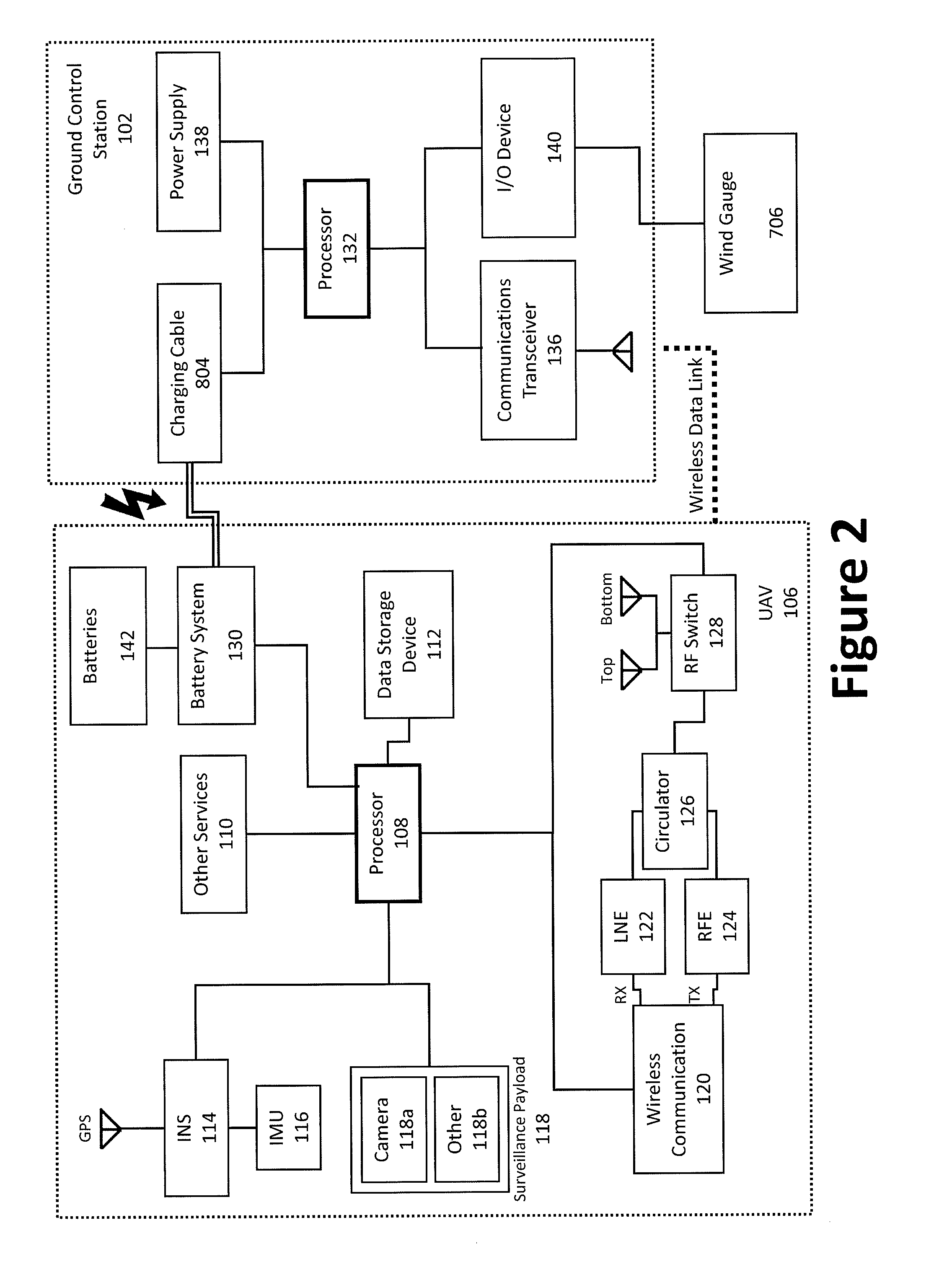

Aerial system and vehicle for continuous operation

ActiveUS20160137311A1Analogue computers for vehiclesArrester hooksContinuous operationSurveillance data

An aerial vehicle system for gathering data may comprise a Waypoint Location, wherein the Waypoint Location comprises an arresting cable; a Ground Control Station, wherein the Ground Control Station comprises a charging cable; and an aerial vehicle, wherein the aerial vehicle comprises an onboard battery, a capturing hook and a sensor payload for generating surveillance data. The aerial vehicle may be configured to autonomously travel between the Waypoint Location and the Ground Control Station. The aerial vehicle may be configured to couple with the arresting cable via the capturing hook. The aerial vehicle may be configured to electronically couple with the charging cable via the capturing hook to facilitate charging the aerial vehicle's onboard battery.

Owner:AURORA FLIGHT SCI CORP

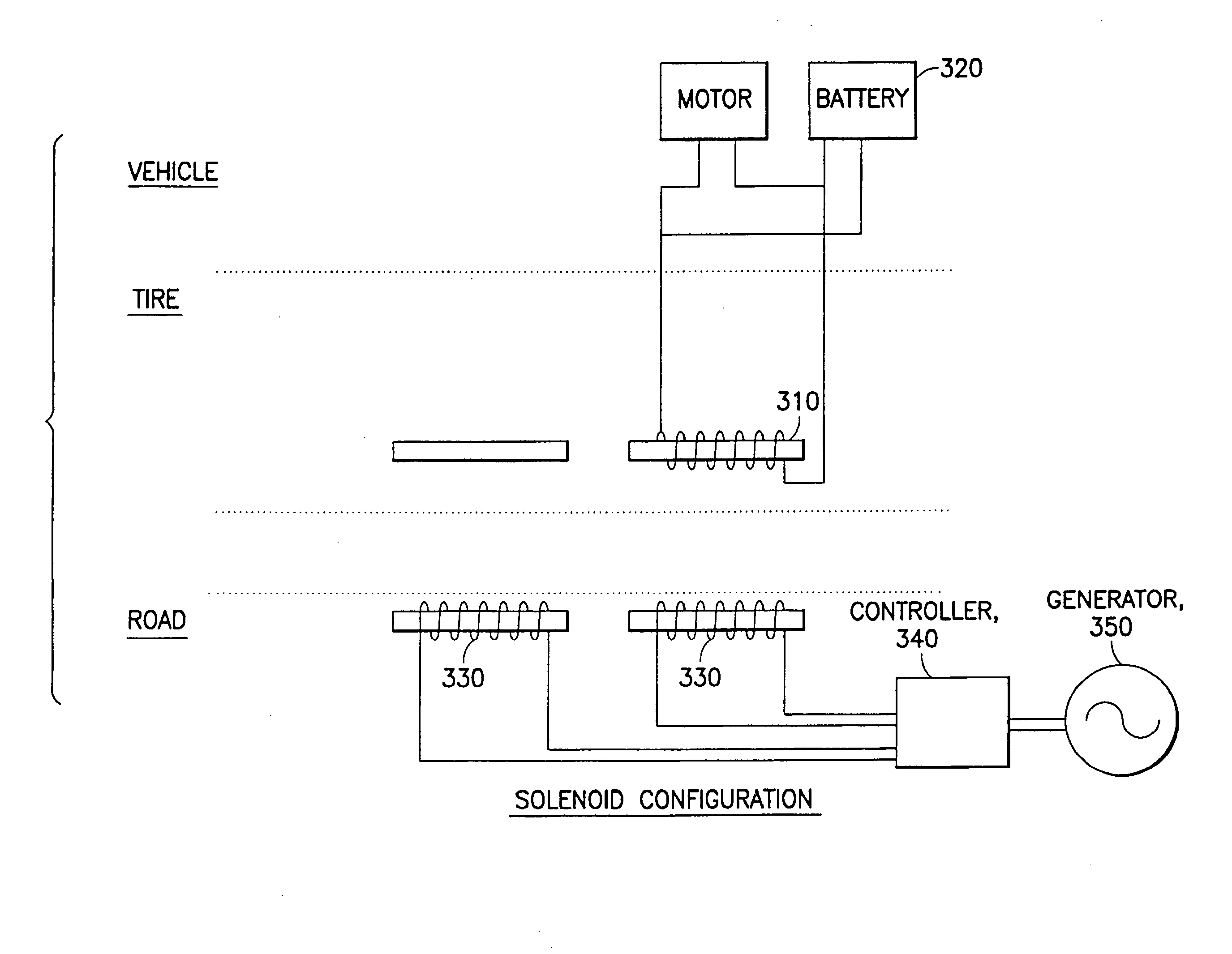

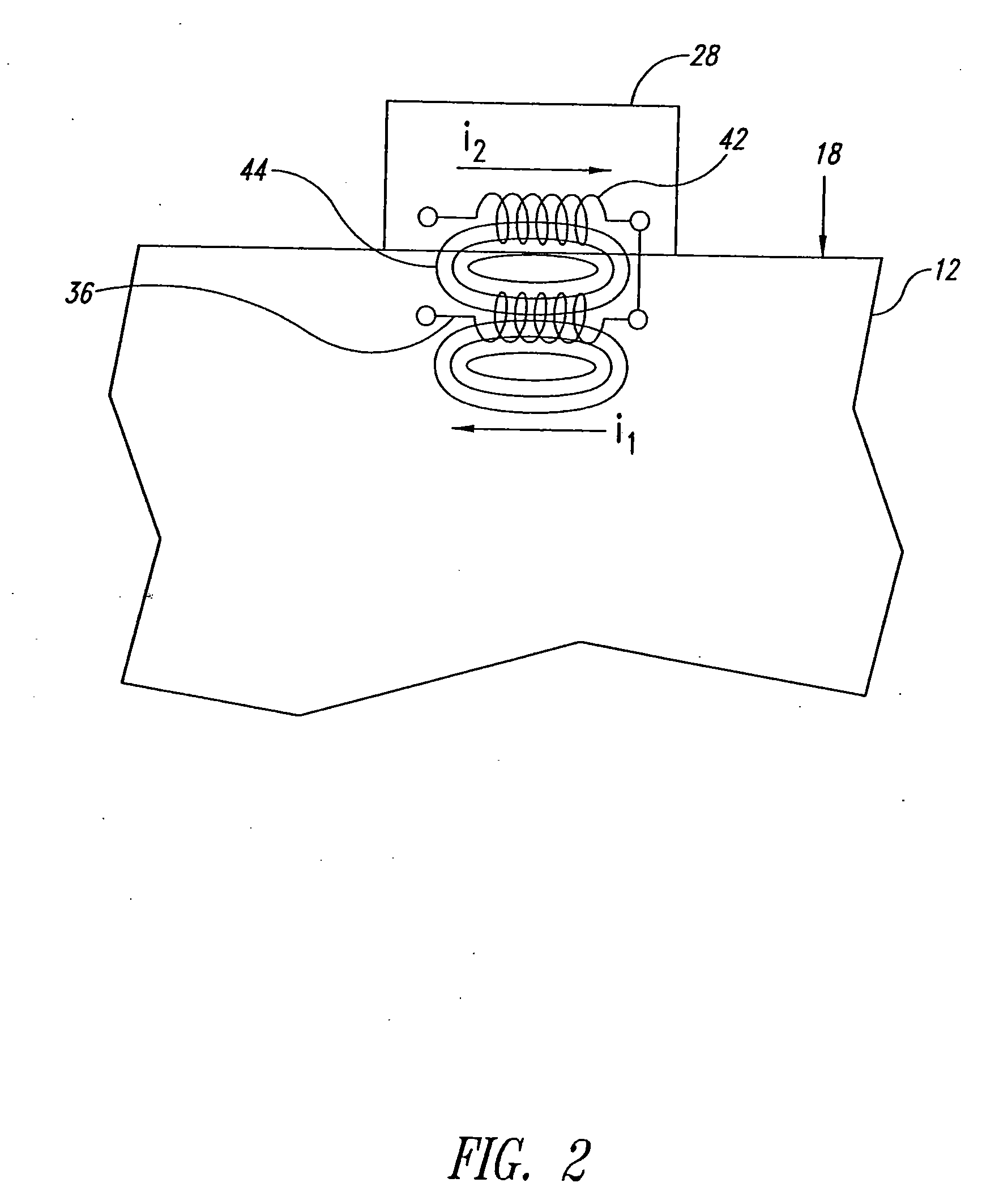

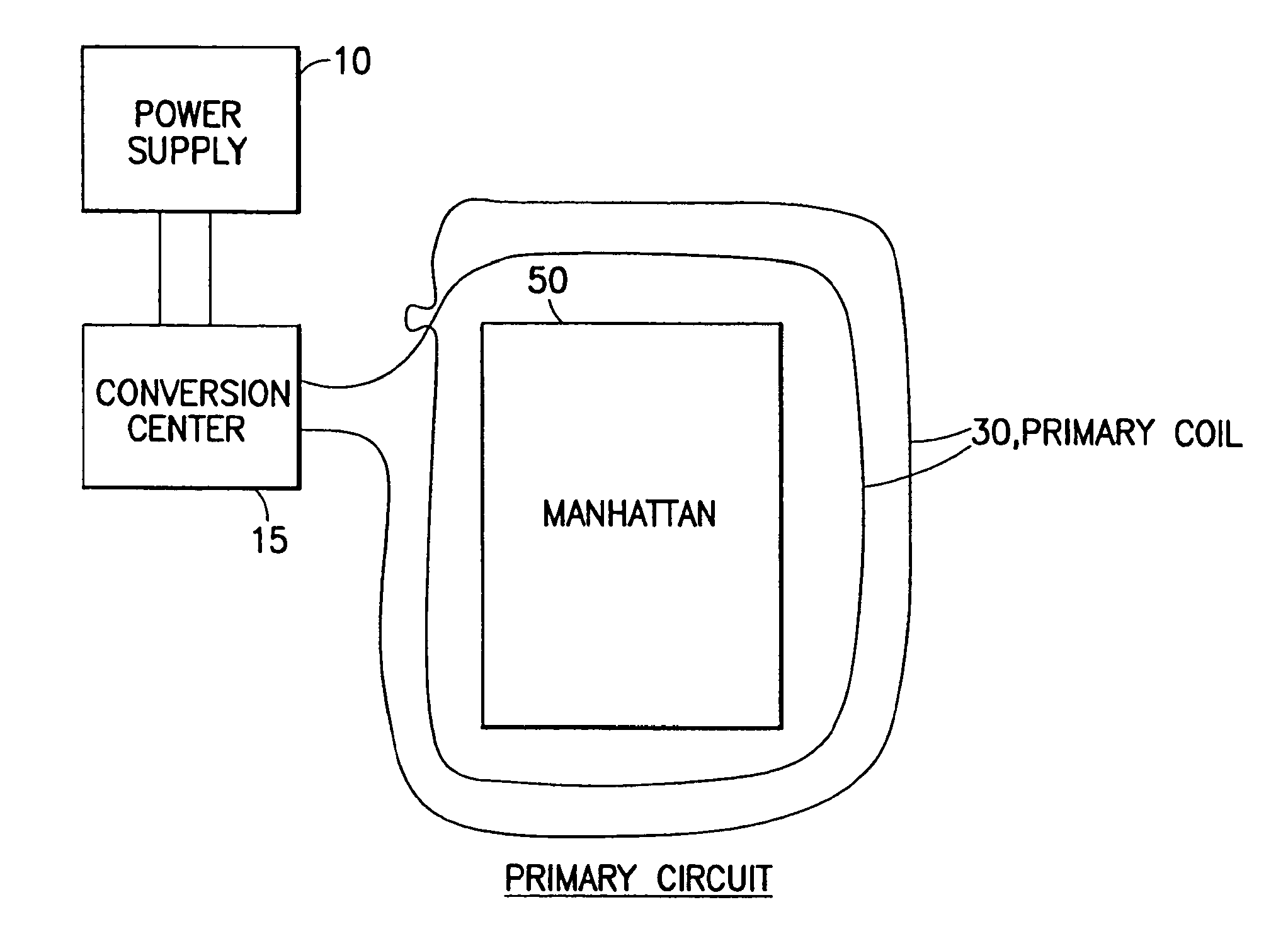

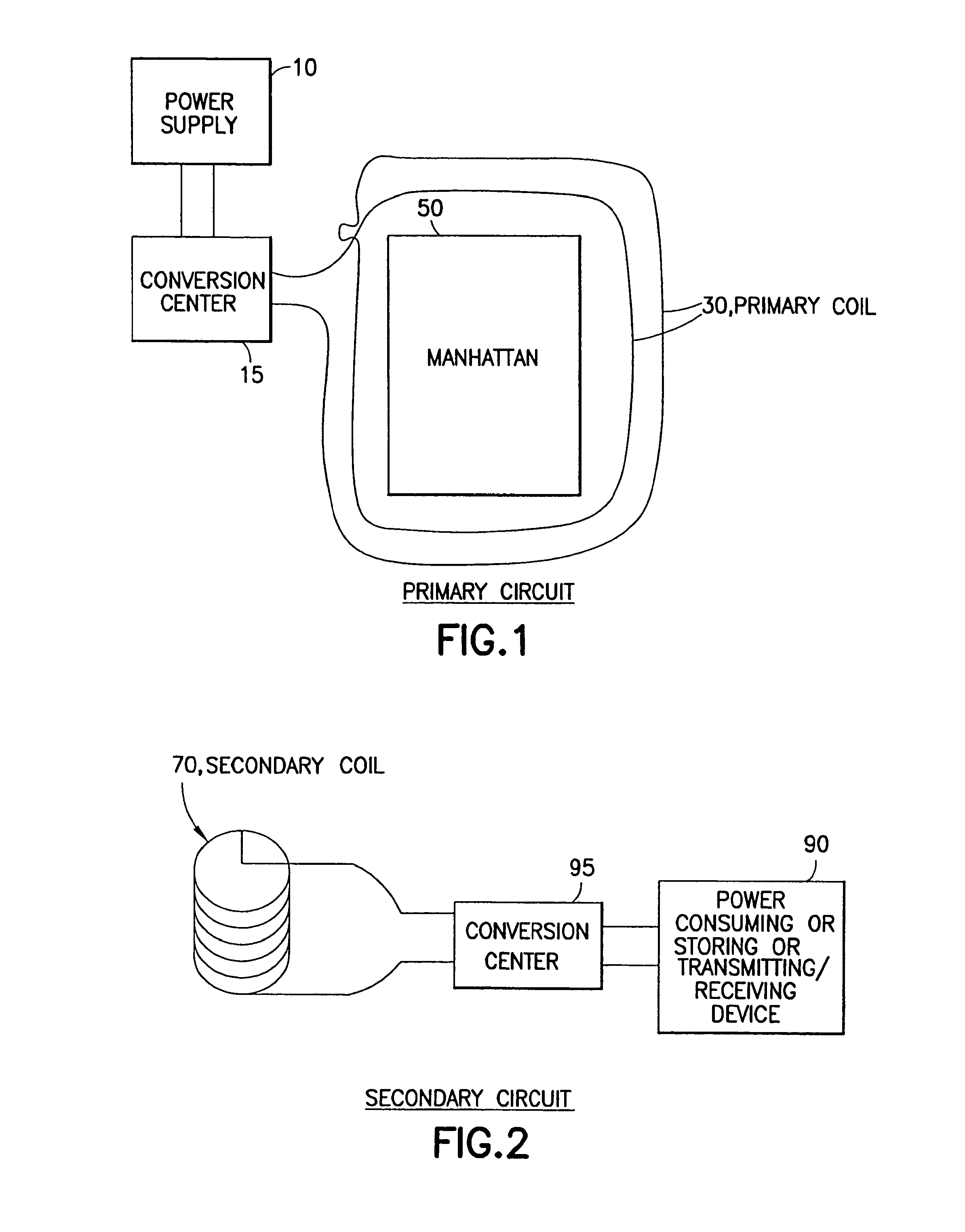

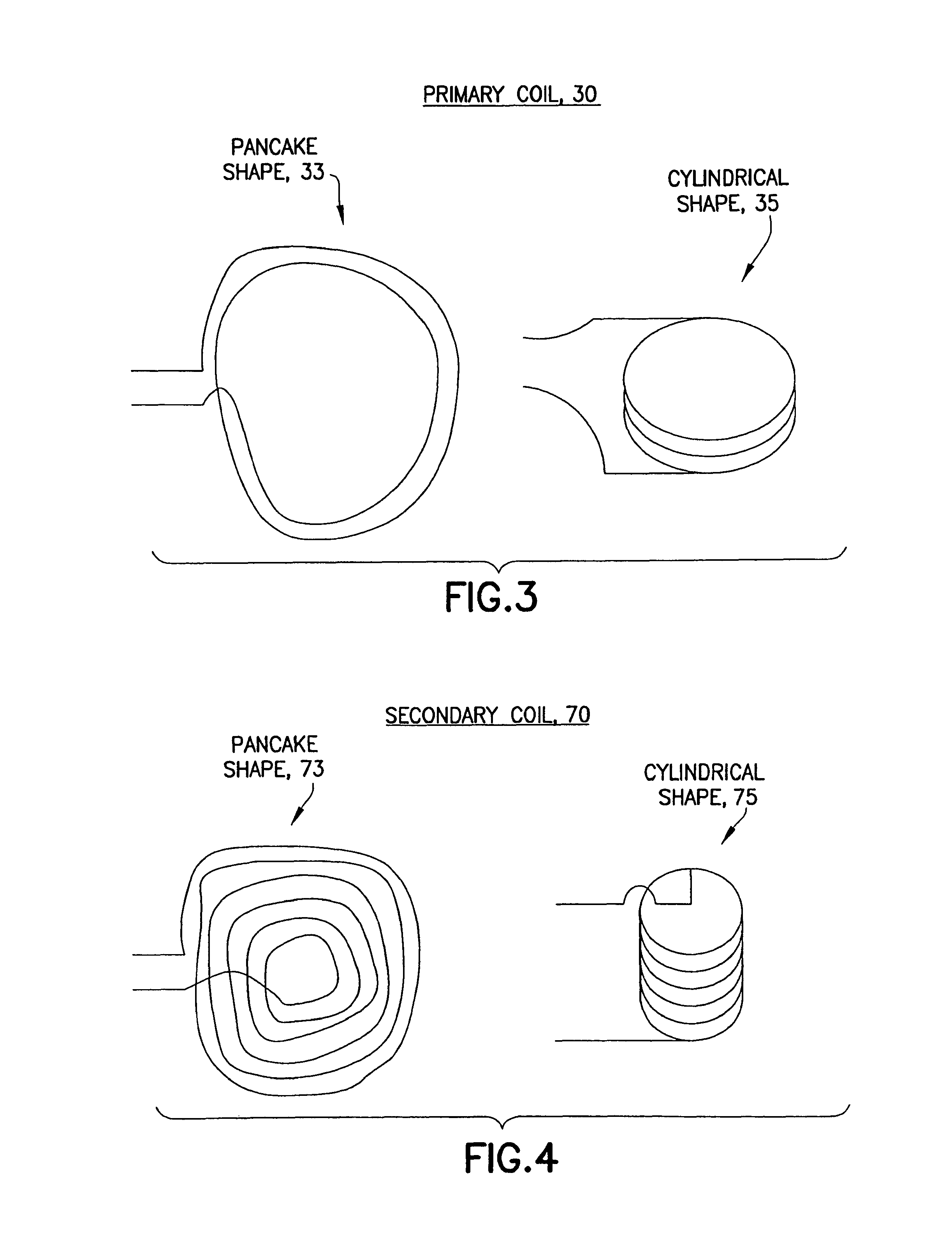

Self-Charging Electric Vehicles and Aircraft, and Wireless Energy Distribution System

InactiveUS20100231163A1Increase rangeImprove transmission efficiencyCharging stationsElectrodynamic brake systemsElectric power systemTransmitted power

A method and system for efficient distribution of power using wireless means, and a system and method for wireless power distribution to provide electric devices, such as vehicles with a way to continuously and wirelessly collect, use and charge their power systems and thereby use the transmitted power for operation. The system and method allows a hybrid, simplified and less costly way to charge devices, such as vehicles so that the devices continuously operate while charging / recharging.

Owner:GOVERNING DYNAMICS INVESTMENT +1

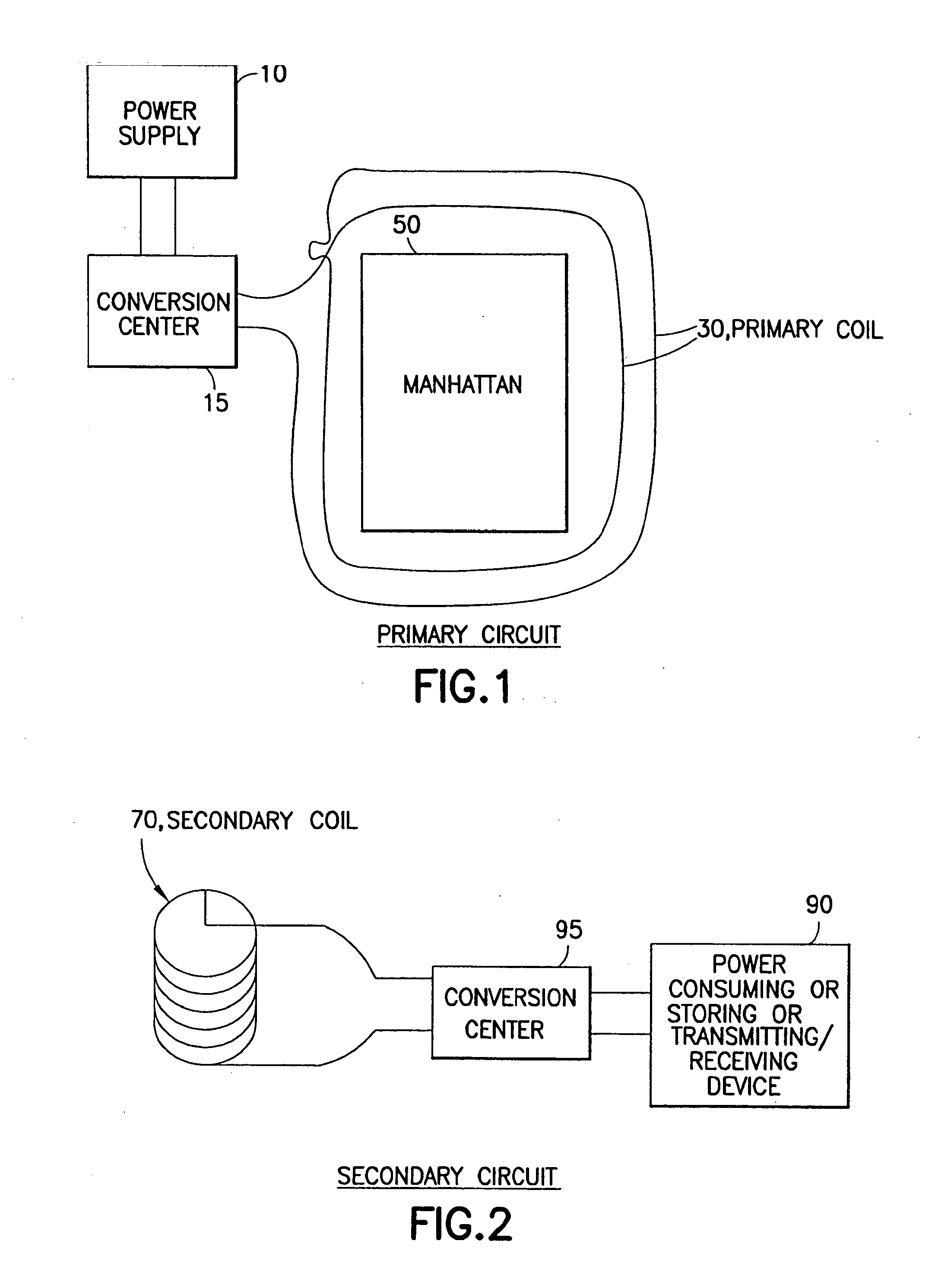

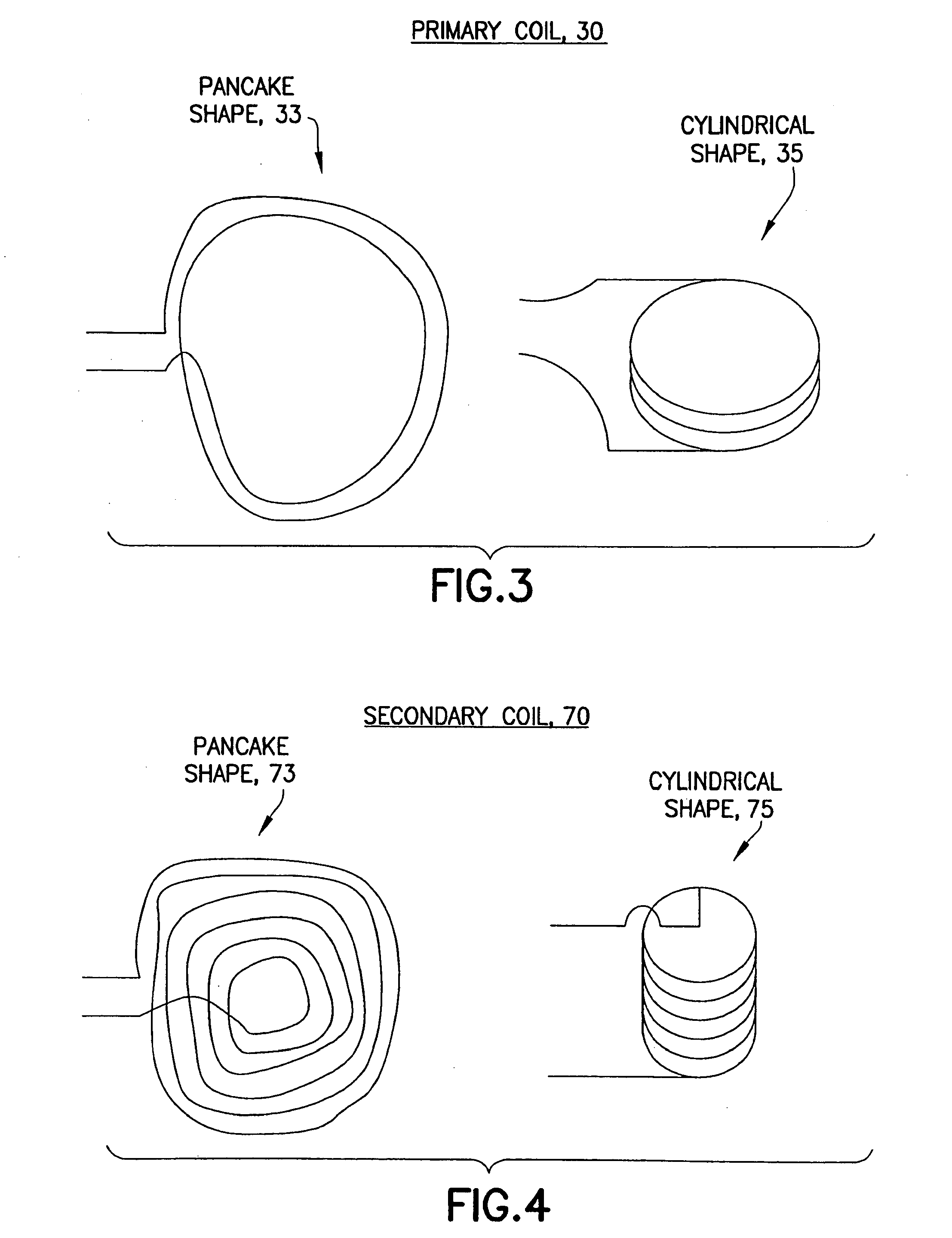

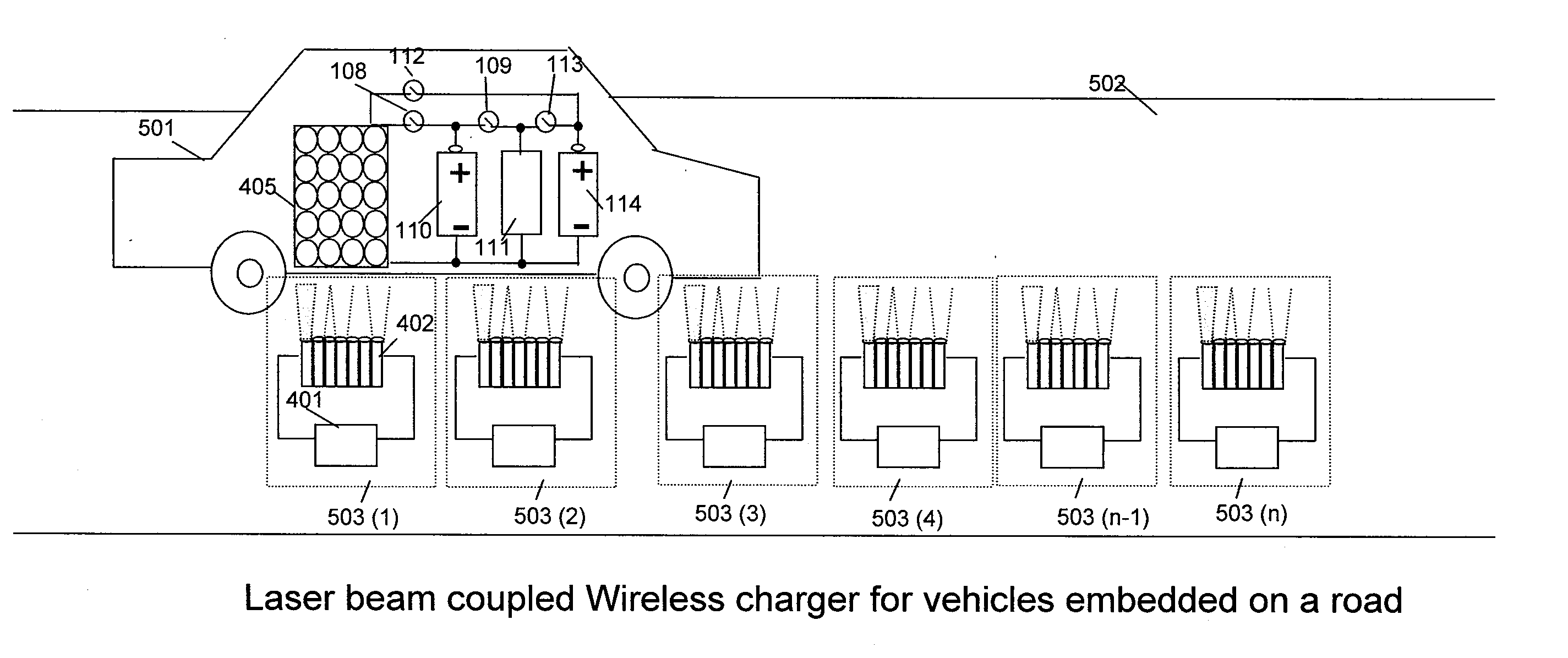

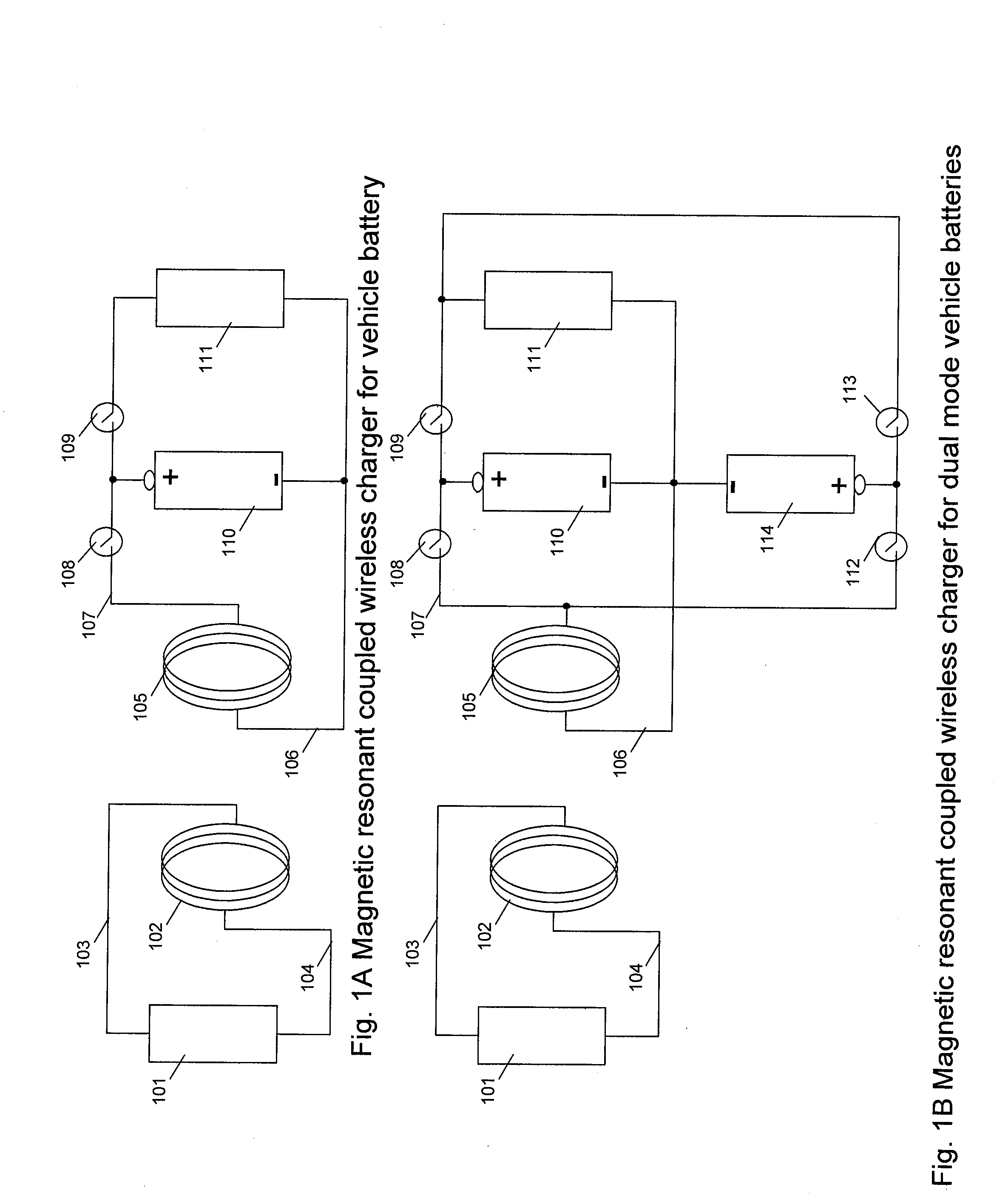

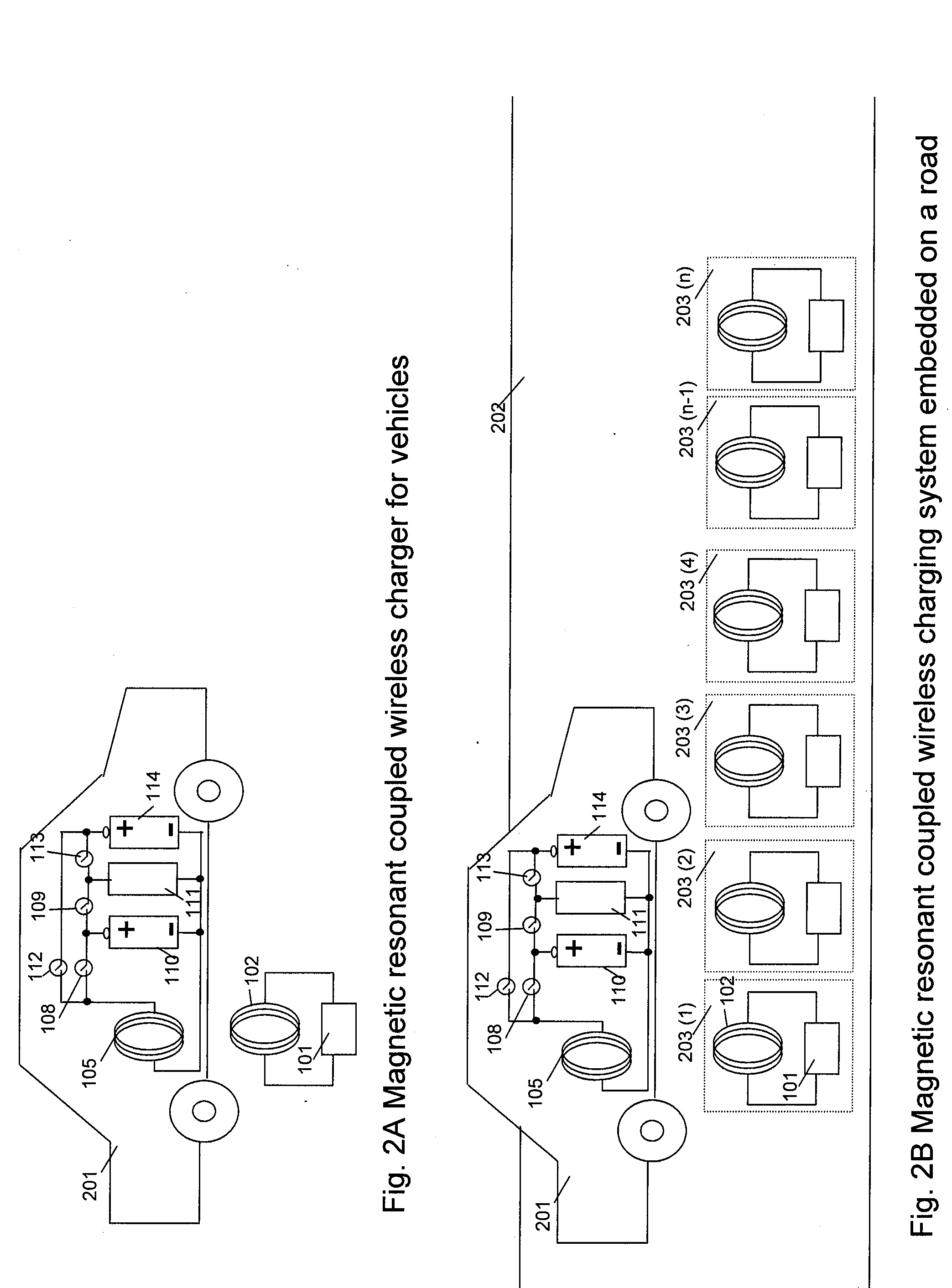

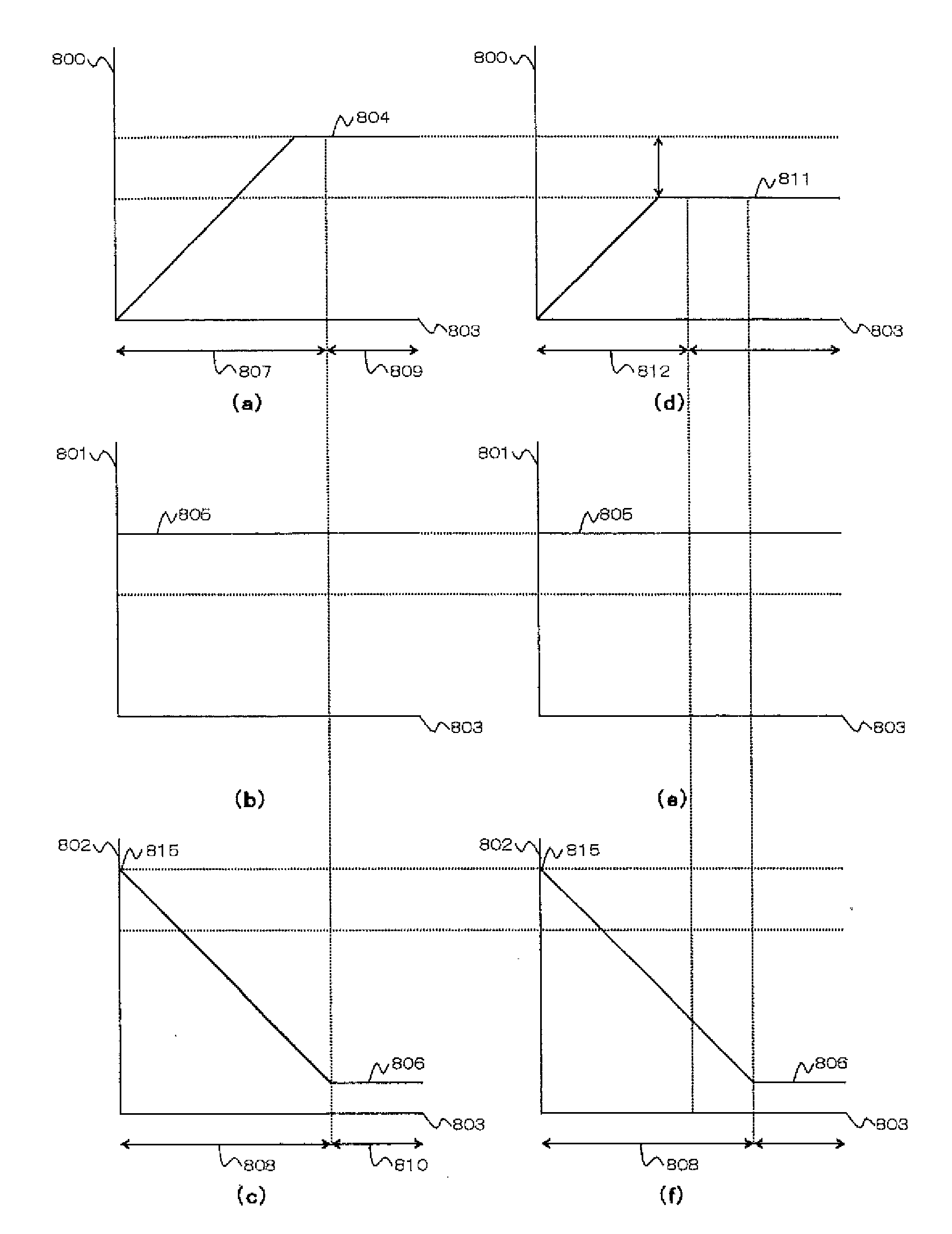

Wireless Charging System for Vehicles

ActiveUS20090045773A1Eliminate needBatteries circuit arrangementsIn situ pavingsElectric power transmissionTransmitted power

A system of energy storage and charging usable in vehicles and other applications that eliminate the battery capacity and automotive range issues is described. In our invention, vehicles are equipped with charging mechanisms to charge and recharge onboard batteries using wireless electricity and power transmission using magnetic resonant coupling between tuned electromagnetic circuits. The batteries may be charged using wireless charging systems installed along the roads while the vehicle is in use on the road. Charging system may optionally utilize infrared laser beam radiation to transmit power for charging the batteries on board a vehicle while it is in use as well. The onboard vehicle batteries may also be charged when the vehicle is not being driven either by plugging in the vehicle into wall electricity using wired power connection or may be wirelessly charged using the magnetic resonant coupling. By locating the charging circuits on roads, a continuous operation of electric-only mode of hybrid vehicles or pure electric-only vehicles can be accomplished and fully eliminate the need for gasoline usage

Owner:PANDYA RAVI A +1

Communication device

ActiveUS20130310020A1Suppress power consumptionExtend continuous operation timePower managementCurrent supply arrangementsEngineeringLimit value

Provided is a wireless transmitter-receiver capable of suppressing undesirable power consumption and elongating the continuous operation time by operation of a user with the intention of controlling transmission power and also suitable to secure the “symmetry of communication”.The wireless transmitter-receiver decreases the upper limit value of transmission power by an operation of an operation means 114 and decreases the reception sensitivity in accordance with the decreased upper limit value of transmission power. Thereby, a user can determine the upper limit value of transmission power of the wireless transmitter-receiver and manage the transmission power to suppress power consumption and elongate a continuous operation time. Moreover, the wireless transmitter-receiver can eliminate the influence of radio frequency electromagnetic field on a human body. Furthermore, the degree of imbalance in the “symmetry of communication” can be minimized.

Owner:KAZUHIRO YAMAMOTO

Digitally controlled luminaire system

InactiveUS7319298B2Radiation pyrometryBeam/ray focussing/reflecting arrangementsJunction temperatureLuminous flux

The present invention provides a luminaire system capable of generating light of a desired chromaticity and luminous flux output during continuous operation with varying ambient operating temperature. The luminaire system can be further capable of maintaining a desired correlated colour temperature during dimming of the luminaire. The luminaire system comprises one or more arrays of light-emitting elements for generating light with a current driver system coupled thereto for selectively supplying electrical drive current to each of the arrays, wherein the current driver system is responsive to drive signals received from a controller. The luminaire system further comprises an optical sensor system for generating optical signals representative of chromaticity and luminous flux output of the light. A heat sensing system is operatively coupled to the one or more arrays for generating signals representative of the junction temperatures of arrays of light-emitting elements during operation. The luminaire system further comprises a controller that is operatively connected to the current driver system, the optical sensor system and the heat sensing system for receiving the signals generated by each of these systems and is configured to generate one or more drive signals for transmission to the current driver system in response to the optical signals and thermal signals received from the optical system and the heat sensing system, respectively, thereby enabling a desired level of control of the output light.

Owner:SIGNIFY HLDG BV

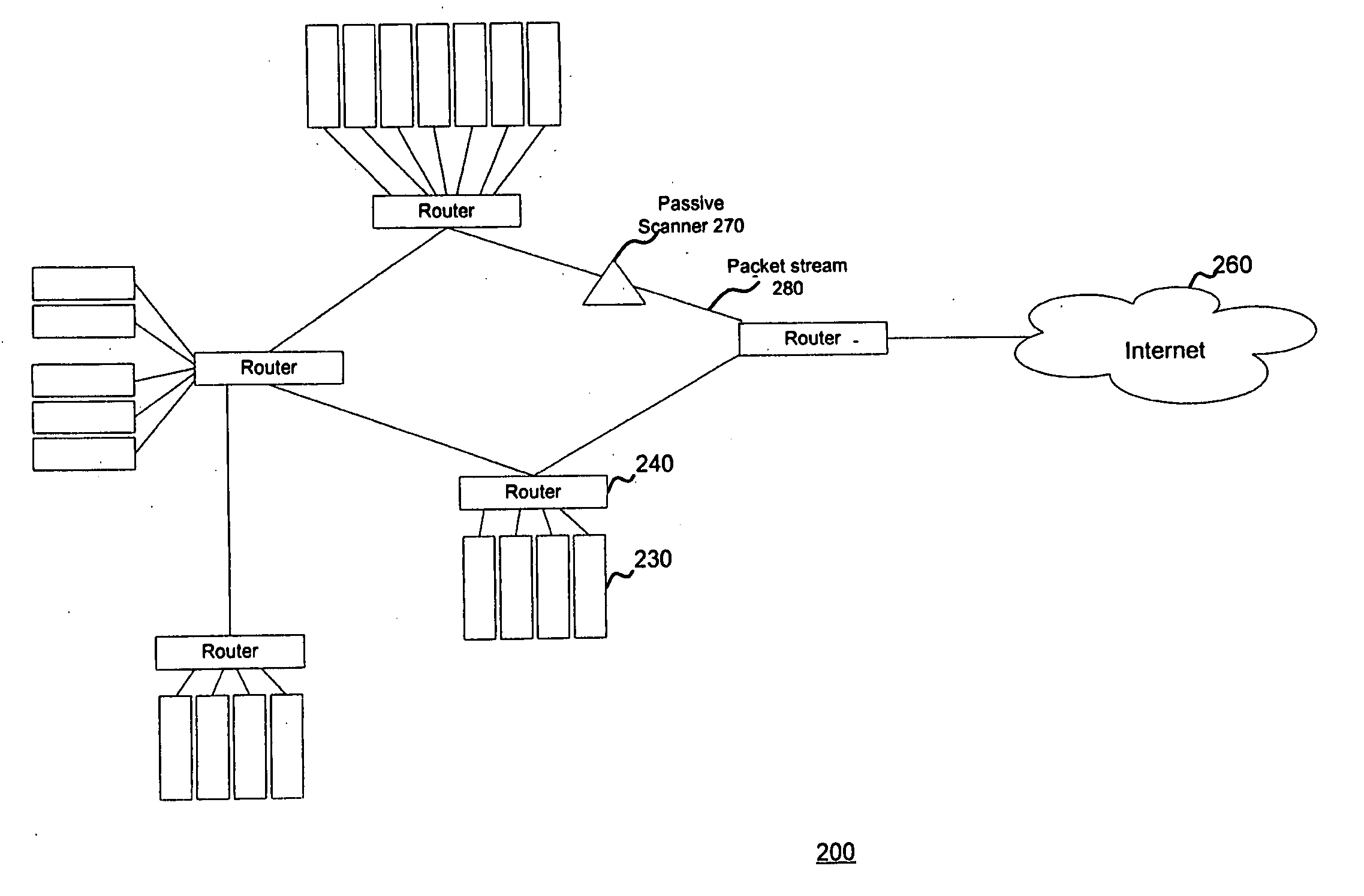

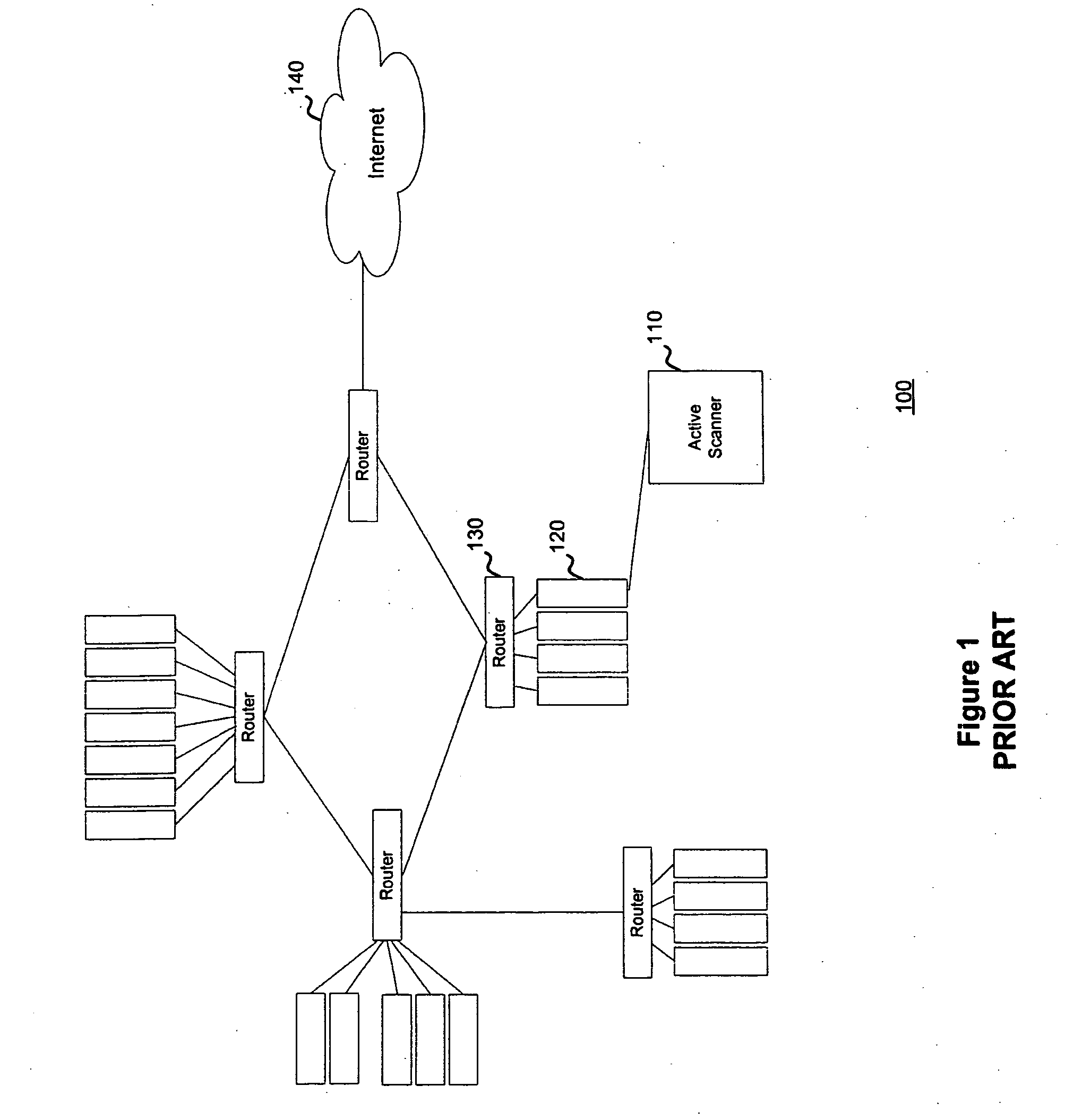

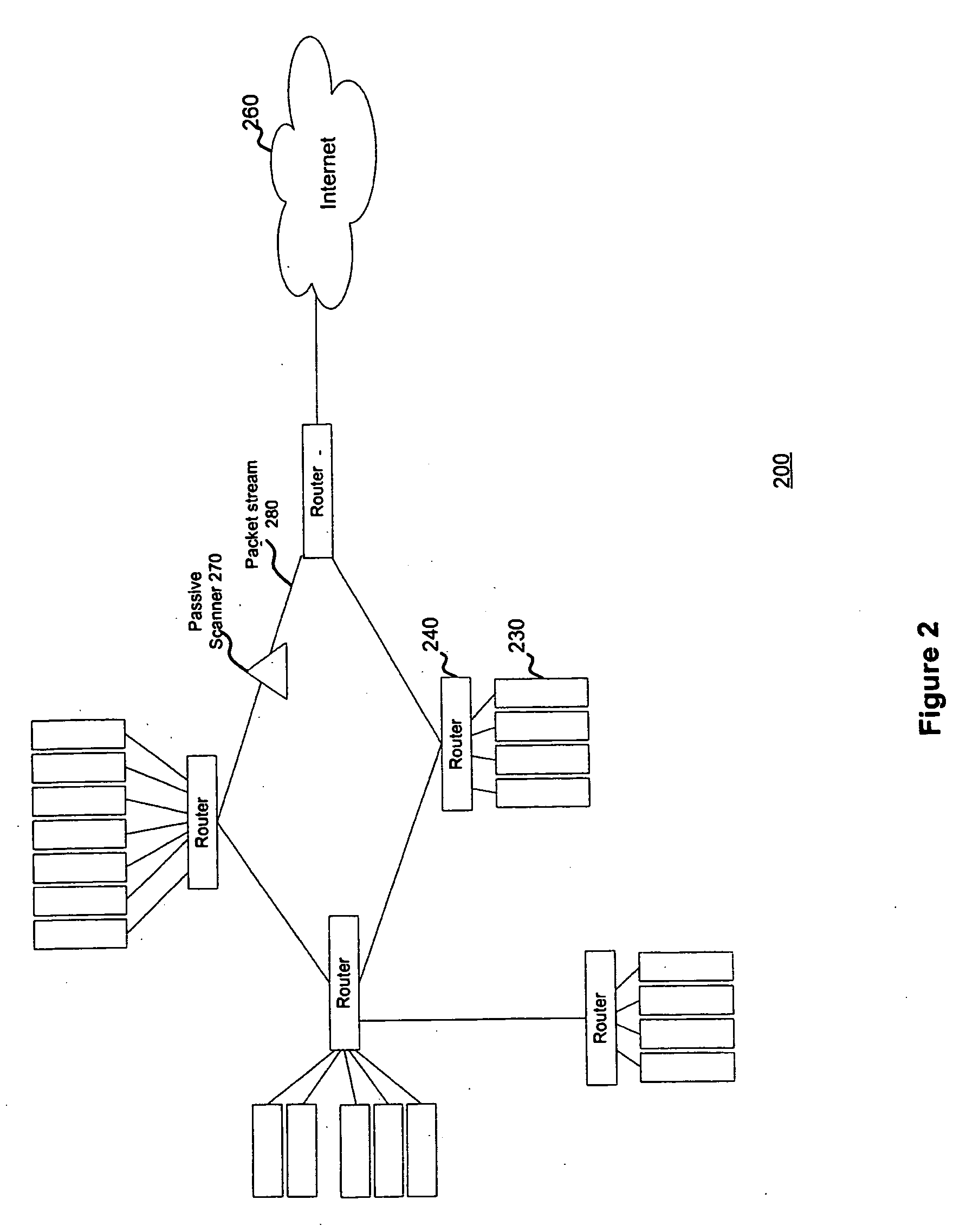

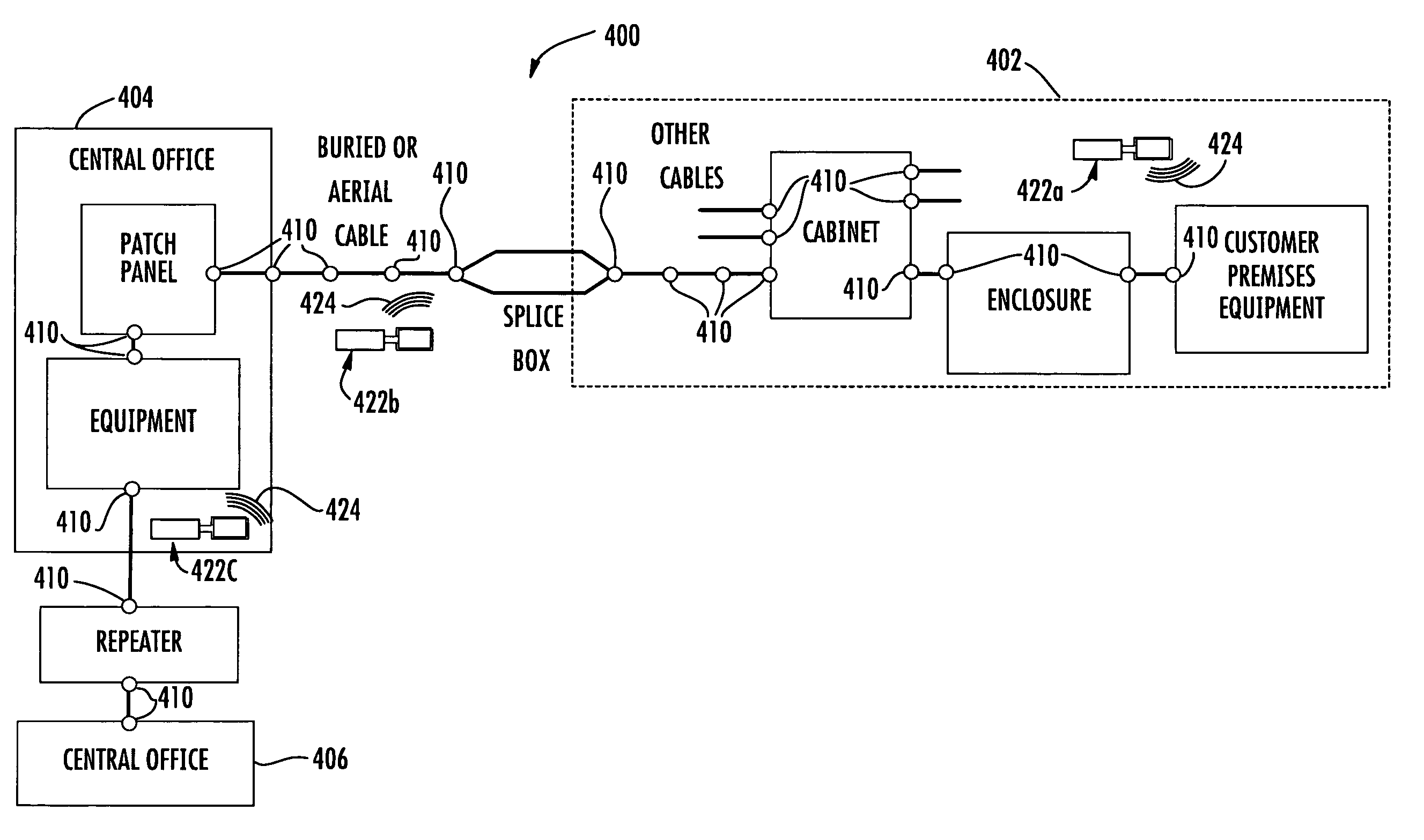

System and method for scanning a network

ActiveUS20050229255A1Memory loss protectionDigital data processing detailsClient-sideContinuous operation

Systems and methods to passively scan a network are disclosed herein. The passive scanner sniffs a plurality of packets traveling across the network. The passive scanner analyzes information from the sniffed packets to build a topology of network devices and services that are active on the network. In addition, the passive scanner analyzes the information to detect vulnerabilities in network devices and services. Finally, the passive scanner prepares a report containing the detected vulnerabilities and the topology when it observes a minimum number of sessions. Because the passive scanner operates passively, it may operate continuously without burdening the network. Similarly, it also may obtain information regarding client-side and server side vulnerabilities.

Owner:TENABLE INC

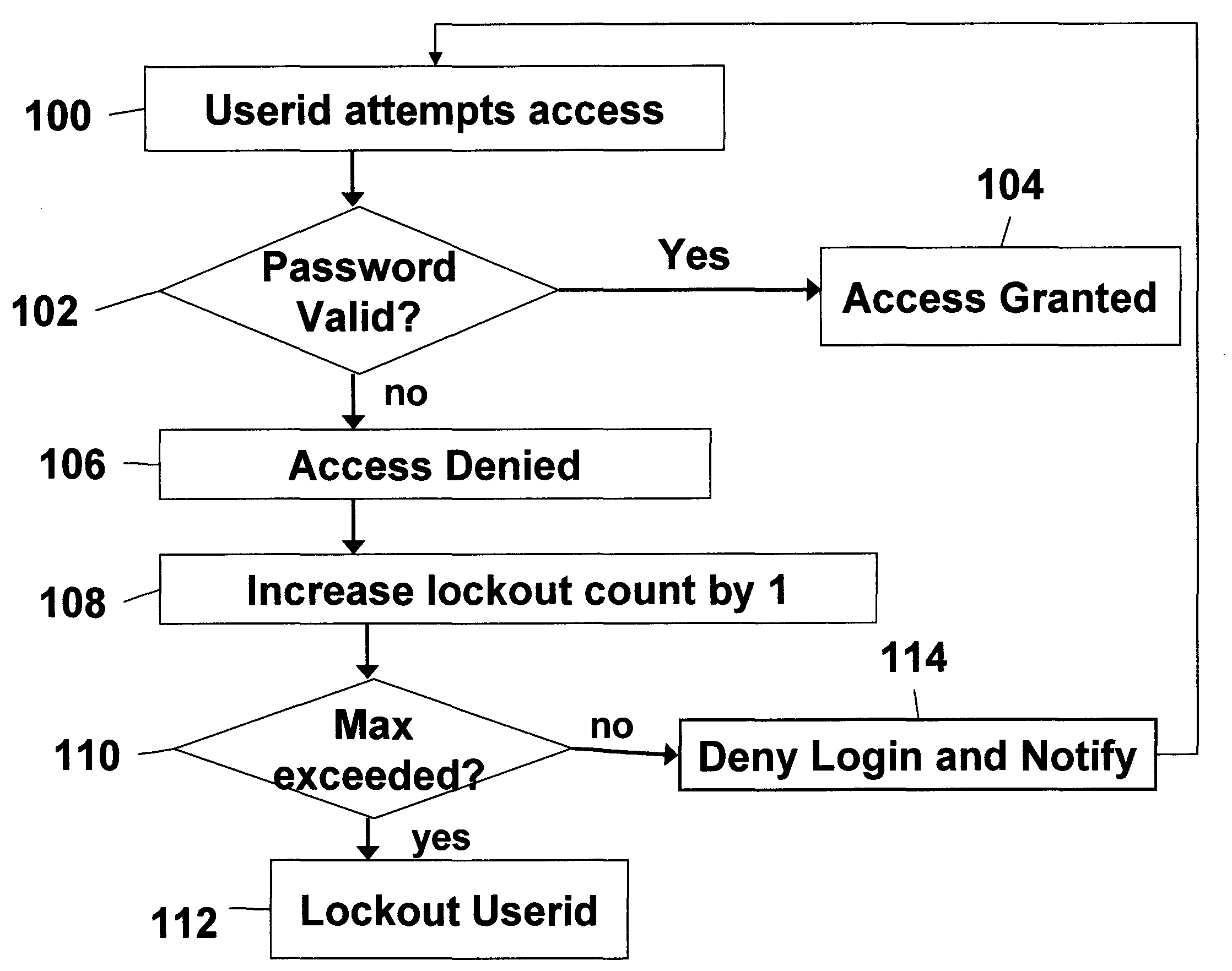

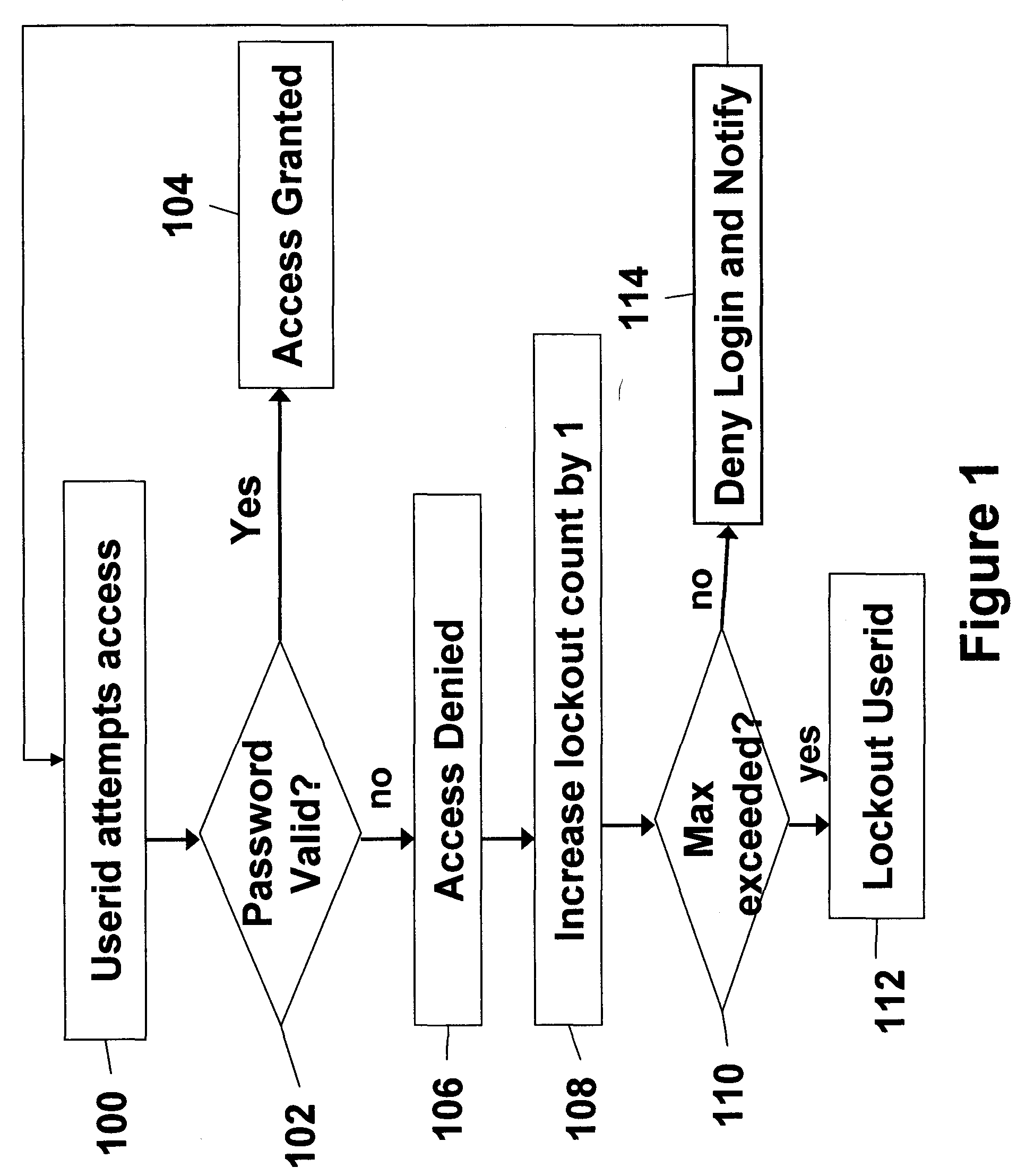

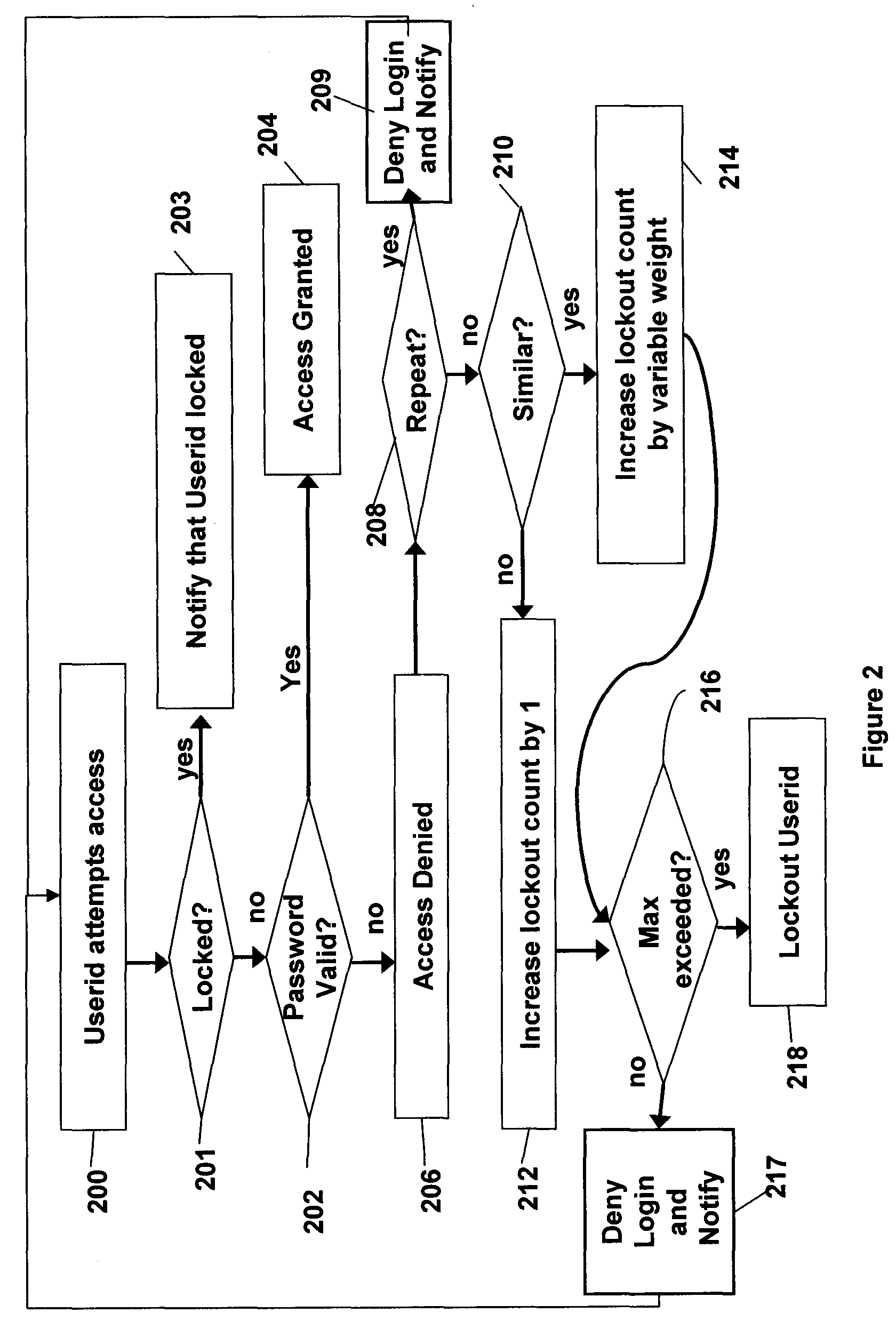

Systems and methods of securing resources through passwords

InactiveUS20060041756A1Mitigates password coordination problemMitigating password coordination problemDigital data processing detailsUser identity/authority verificationPasswordData file

Disclosed is a method of authorizing access to an item that maintains a lockout count and blocks access to the item if the lockout count exceeds a predetermined value. One feature is that the invention “variably” increments the lockout count if the presented password fails to exactly match the stored password. In this process the invention increments the lockout count different amounts depending upon how closely the presented password matches the stored password. The invention also provides a methodology that allocates a plurality of the same passwords to a plurality of users who share the same userid. The invention allows continuous operation of the item being accessed by providing that each of the passwords has a different expiration date. Also, when dealing with situations where a plurality of users who share the same userid also share the same password, the invention maps information associated with the users to the password in a data file and periodically updates the data file.

Owner:IBM CORP

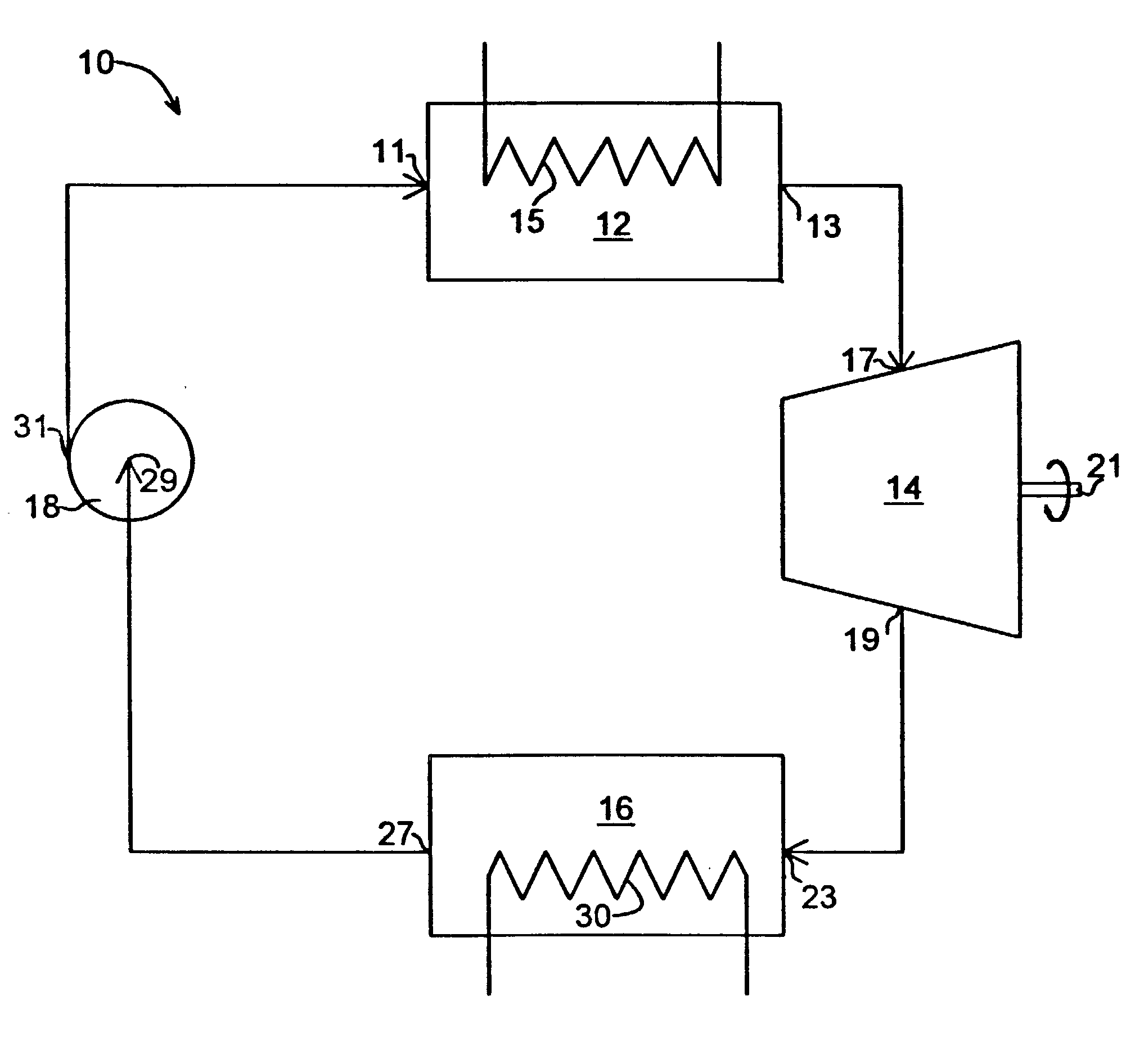

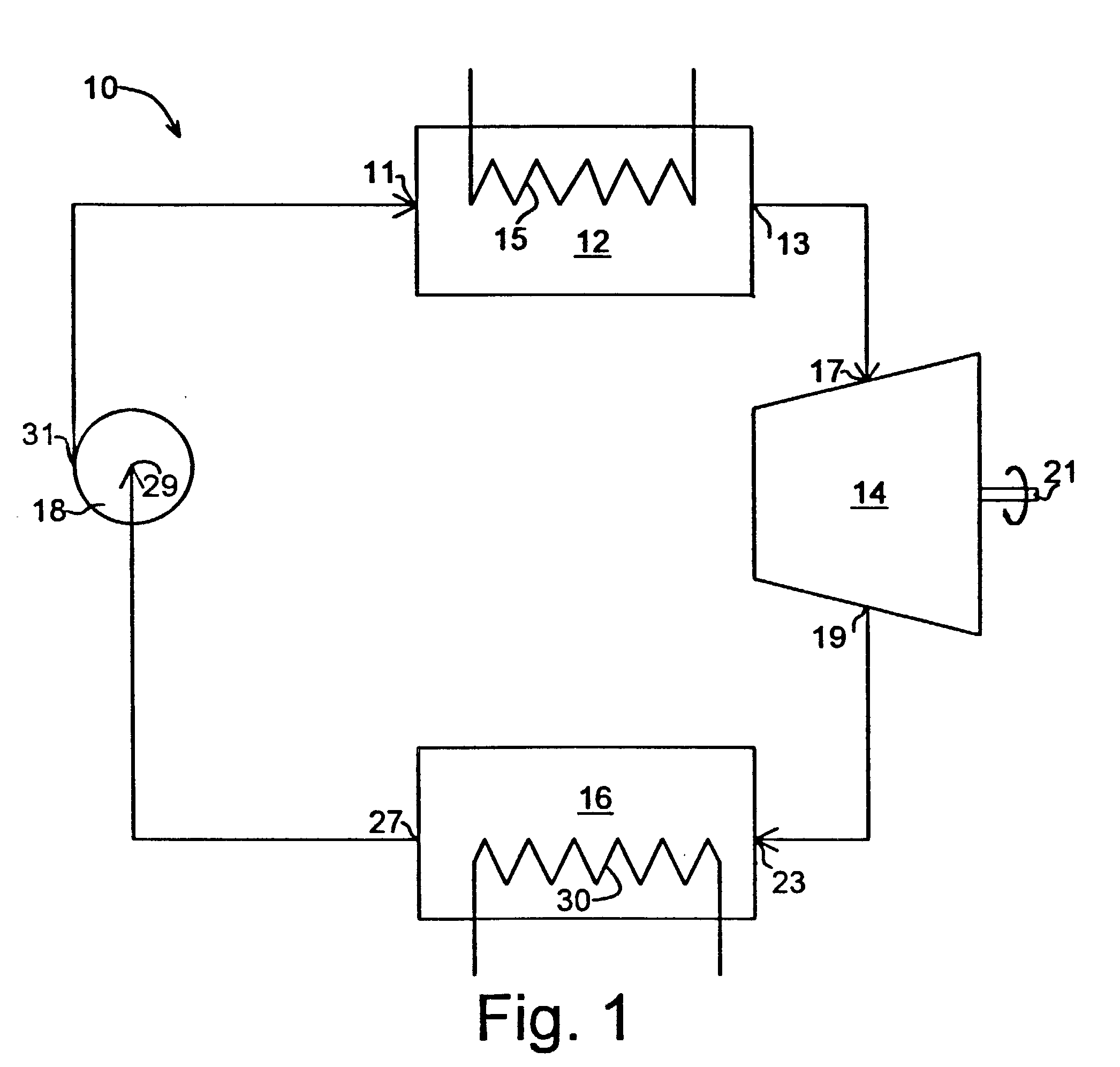

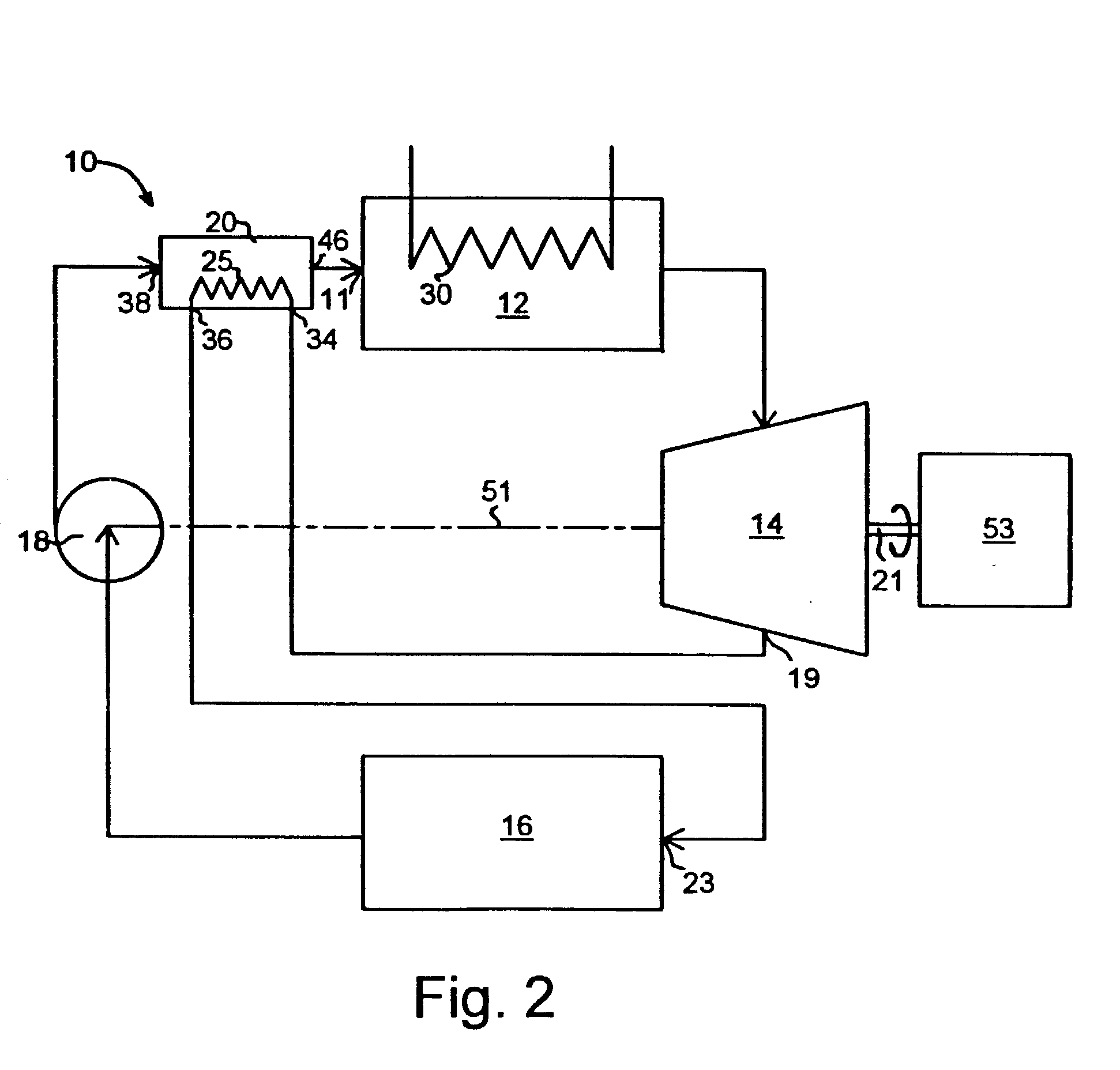

Heat engine

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

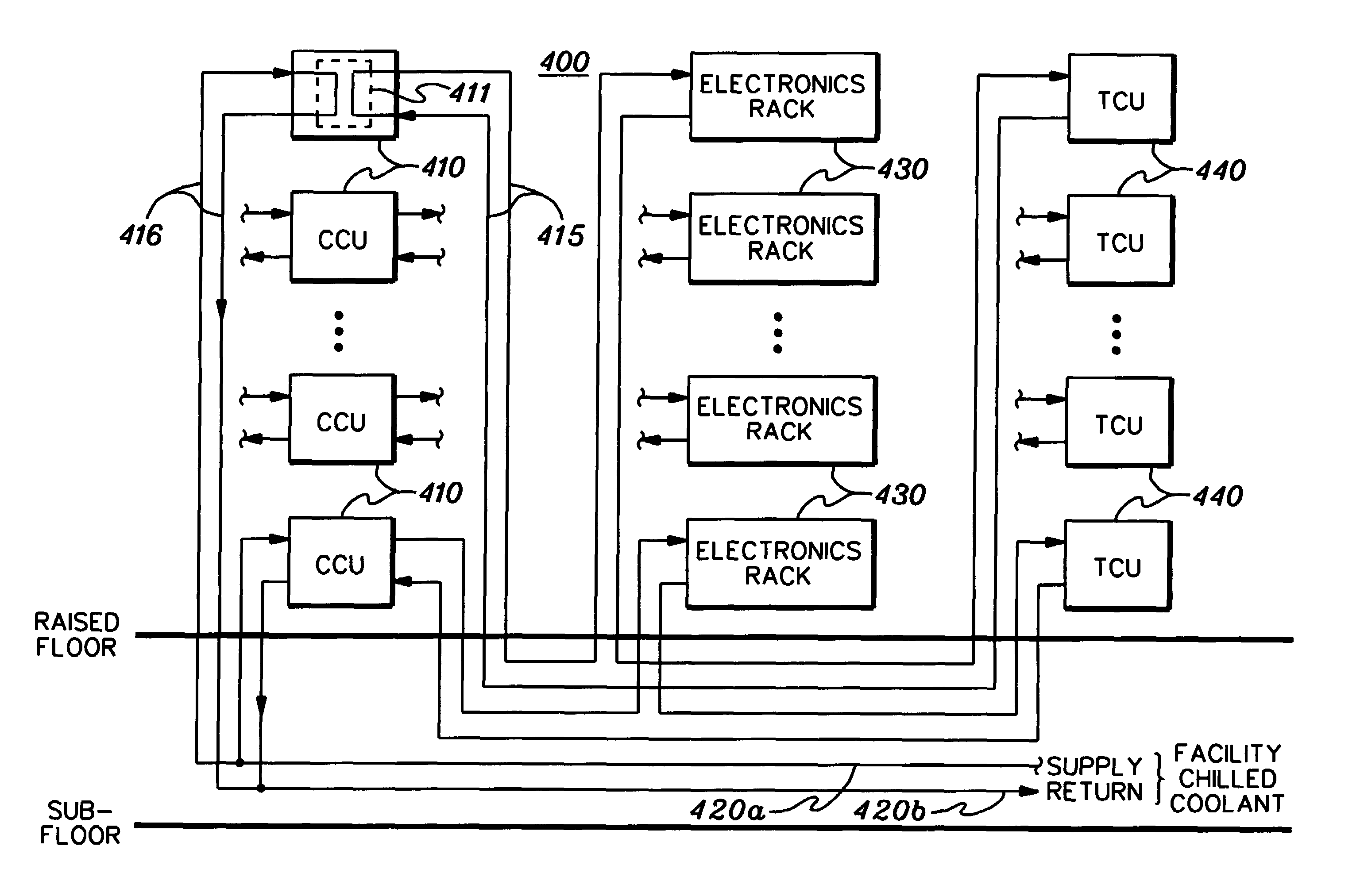

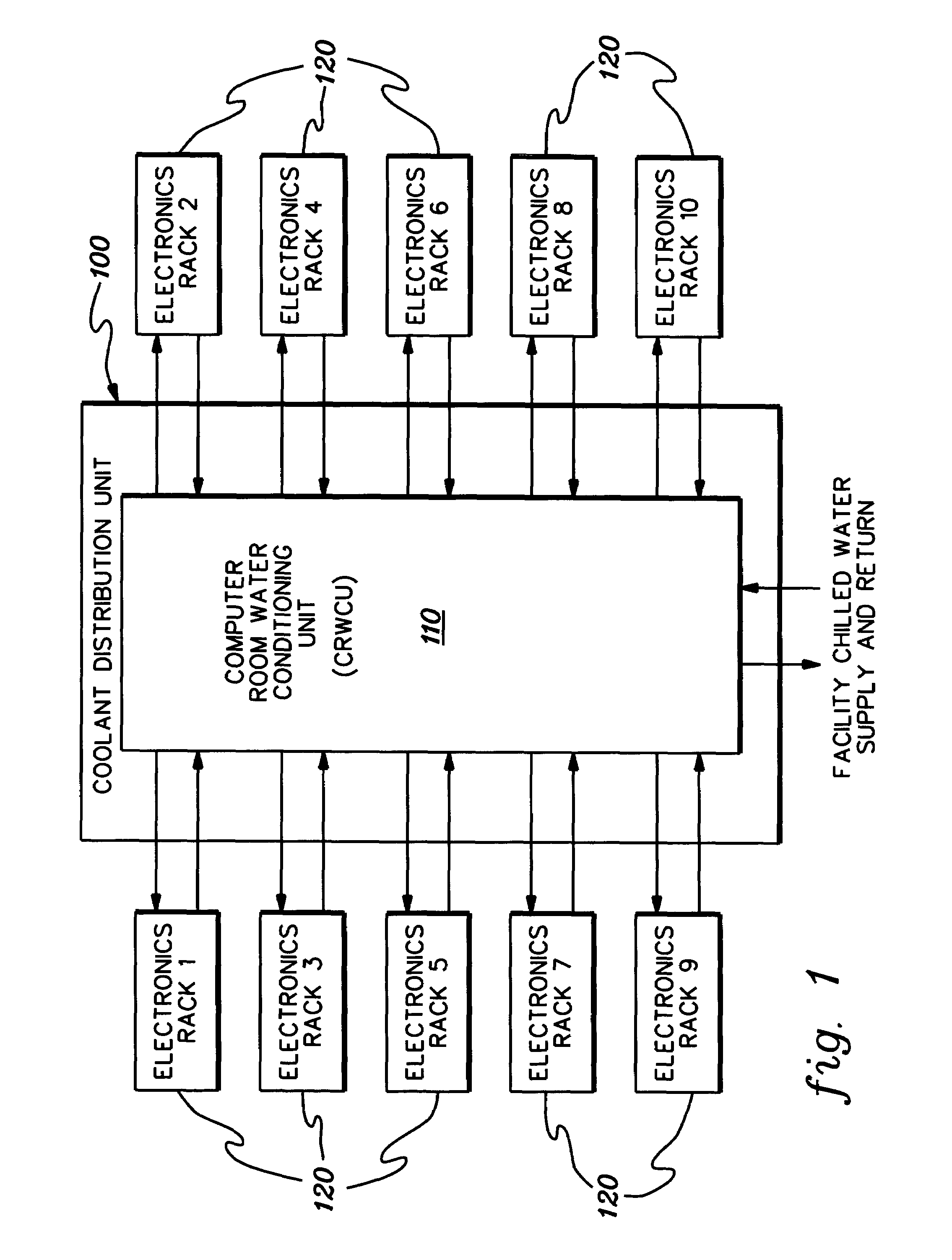

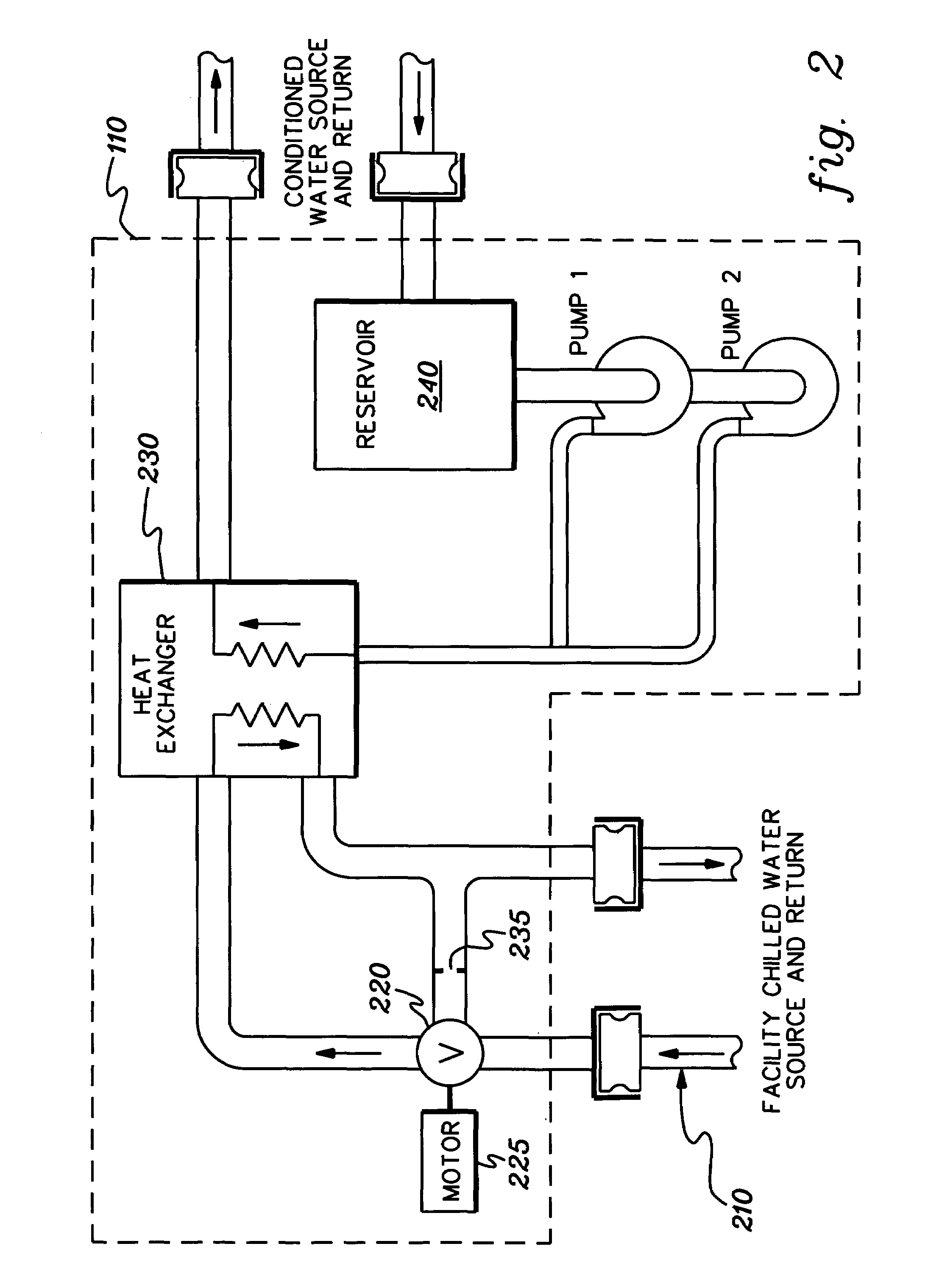

Cooling system and method employing auxiliary thermal capacitor unit for facilitating continuous operation of an electronics rack

ActiveUS7086247B2Heat storage plantsSemiconductor/solid-state device detailsNuclear engineeringReceiving facility

A cooling approach is provided for cooling an electronics subsystem, such as an electronics rack. The cooling approach includes a coolant conditioning unit and a thermal capacitor unit. The coolant conditioning unit has a heat exchanger, a first cooling loop and a second cooling loop. The first cooling loop receives facility coolant from a facility coolant source and passes at least a portion thereof to the heat exchanger. The second cooling loop provides system coolant to the electronics subsystem, and expels heat in the heat exchanger from the electronics subsystem to the facility coolant in the first cooling loop. The thermal capacitor unit is in fluid communication with the second cooling loop to maintain temperature of the system coolant within a defined range for a period of time upon shutdown or failure of the facility coolant in the first cooling loop, thereby allowing continued operation of the electronics subsystem.

Owner:LENOVO GLOBAL TECH INT LTD

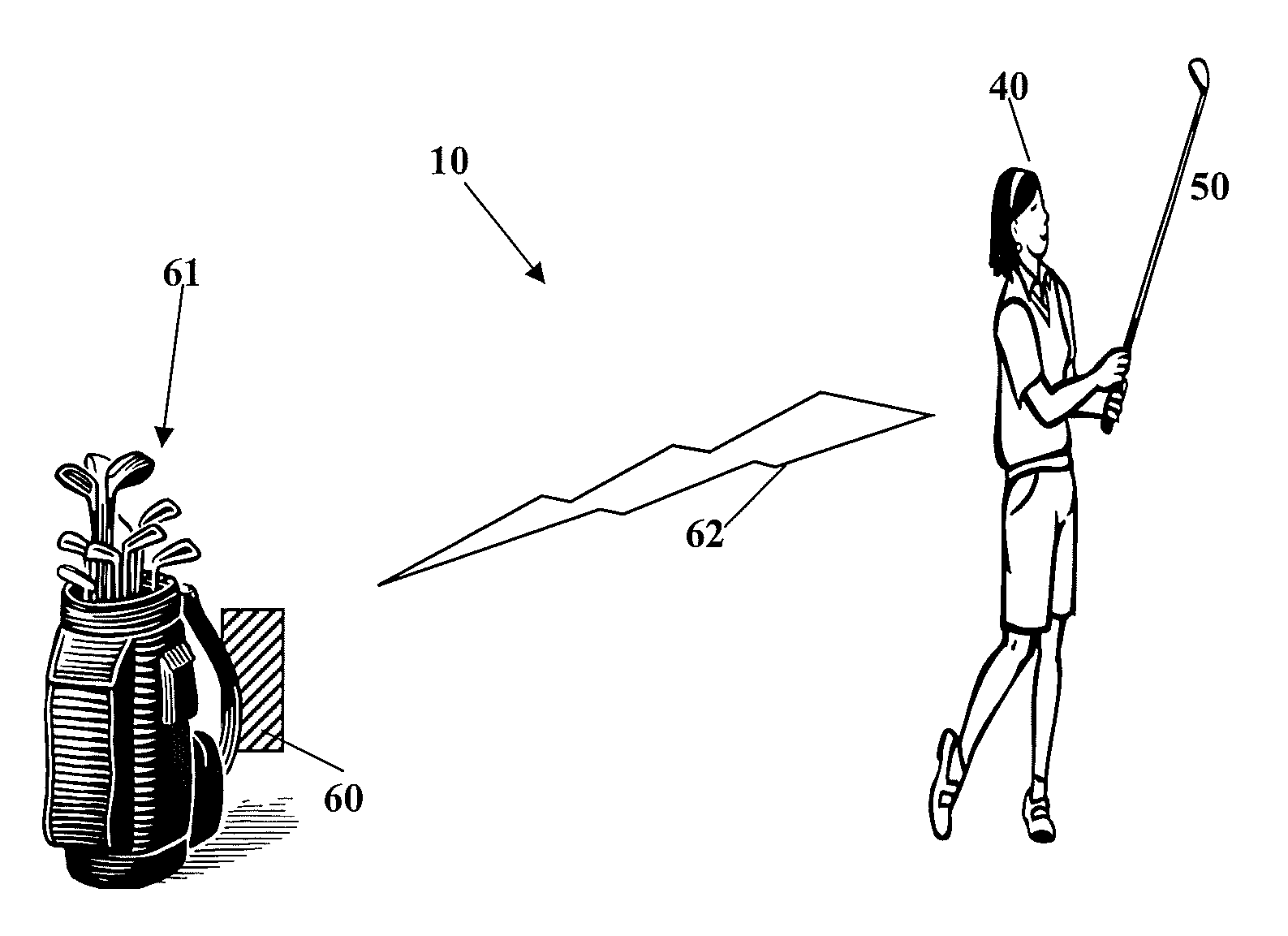

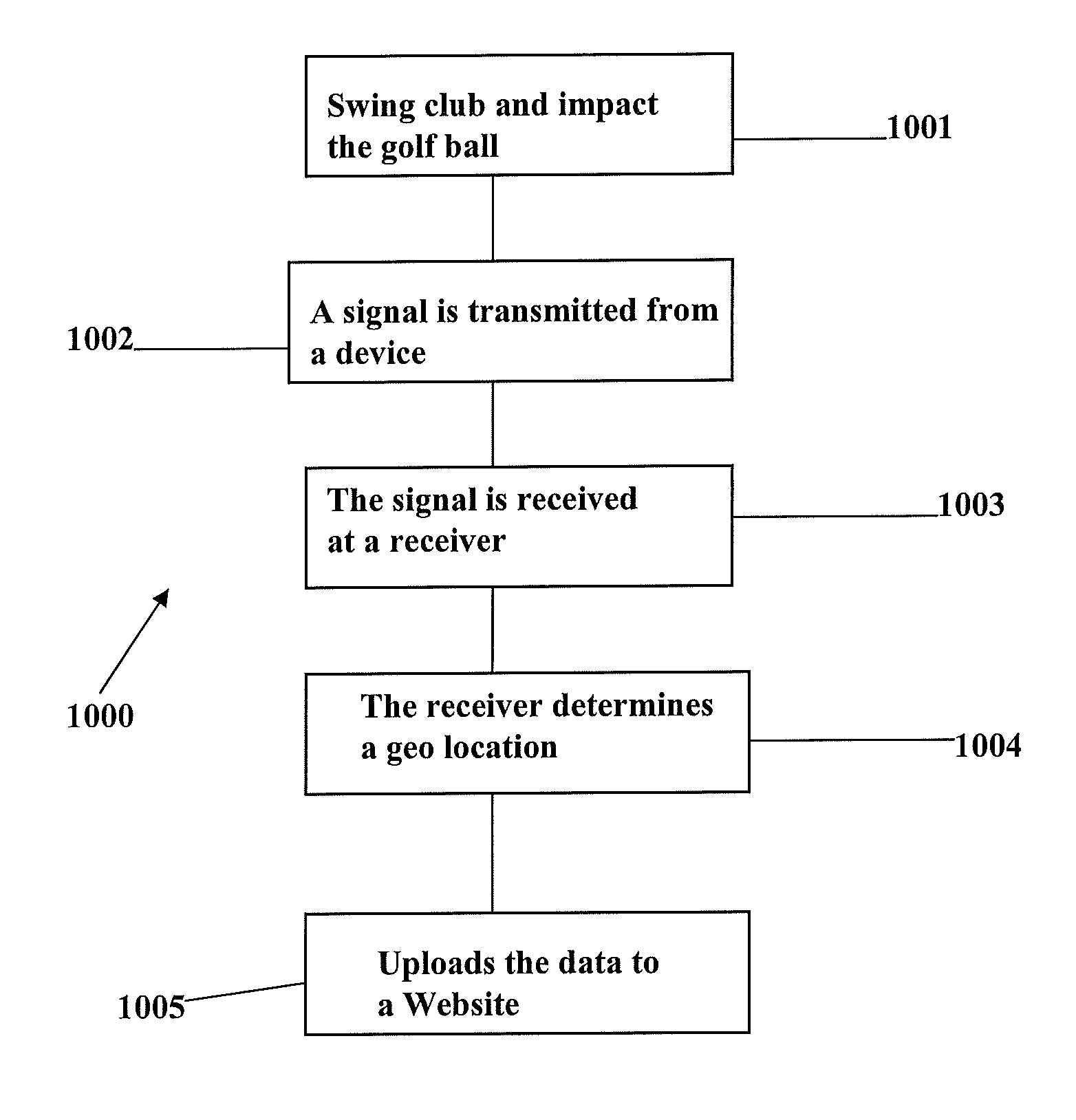

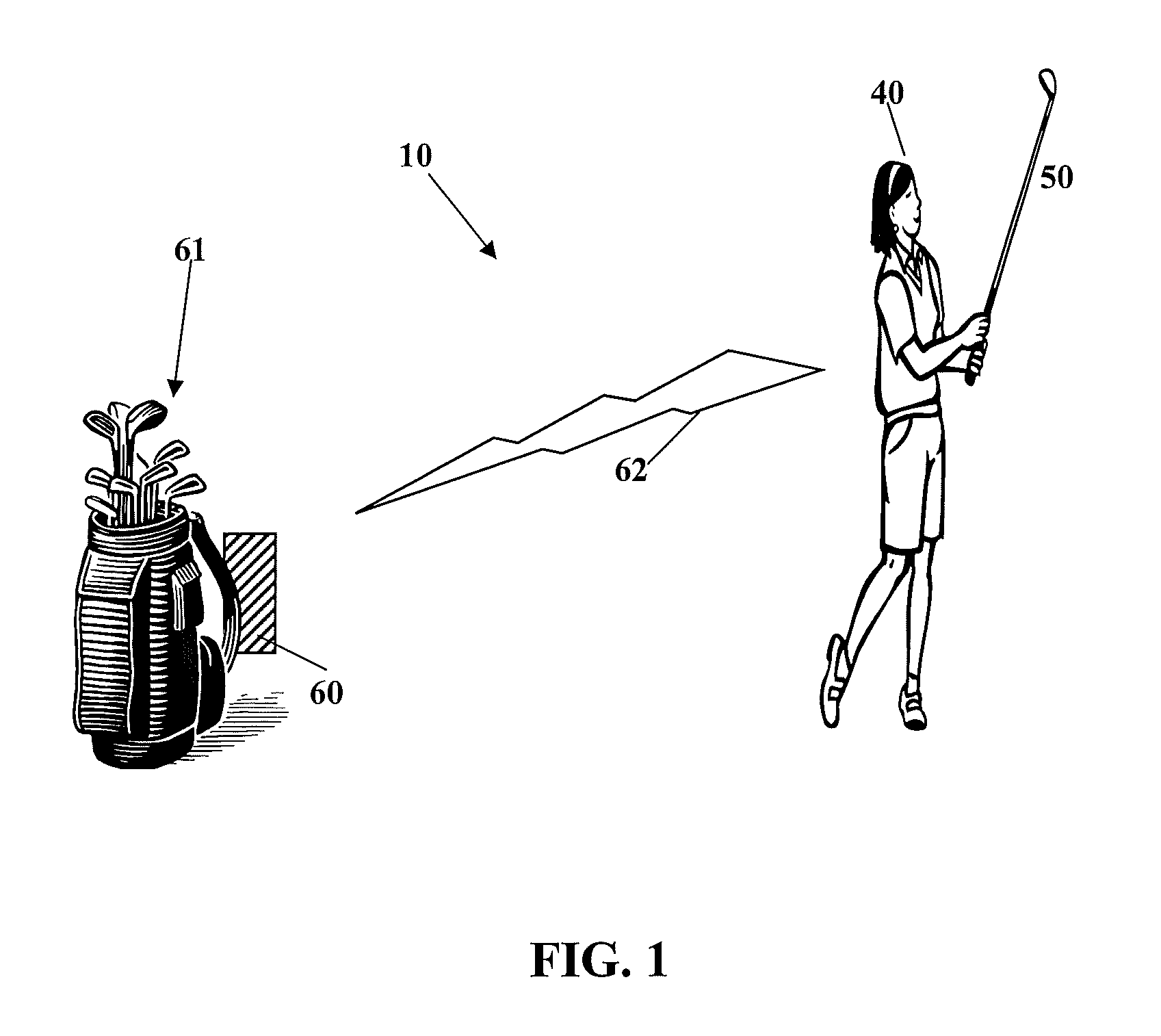

Method and system for shot tracking

ActiveUS7800480B1Save powerPrecise functionMultiplex system selection arrangementsData processing applicationsAccelerometerContinuous operation

A method for transmitting a RFID signal while conserving the battery power for a circuit in continuous operation is disclosed herein. The circuit includes a RFID component, a microprocessor, an accelerometer and a battery. The battery preferably has no more than 225 milliamp hours of power. The accelerometer is preferably a multiple axis accelerometer. The circuit is preferably utilized with a device for shot tracking.

Owner:TOPGOLF CALLAWAY BRANDS CORP

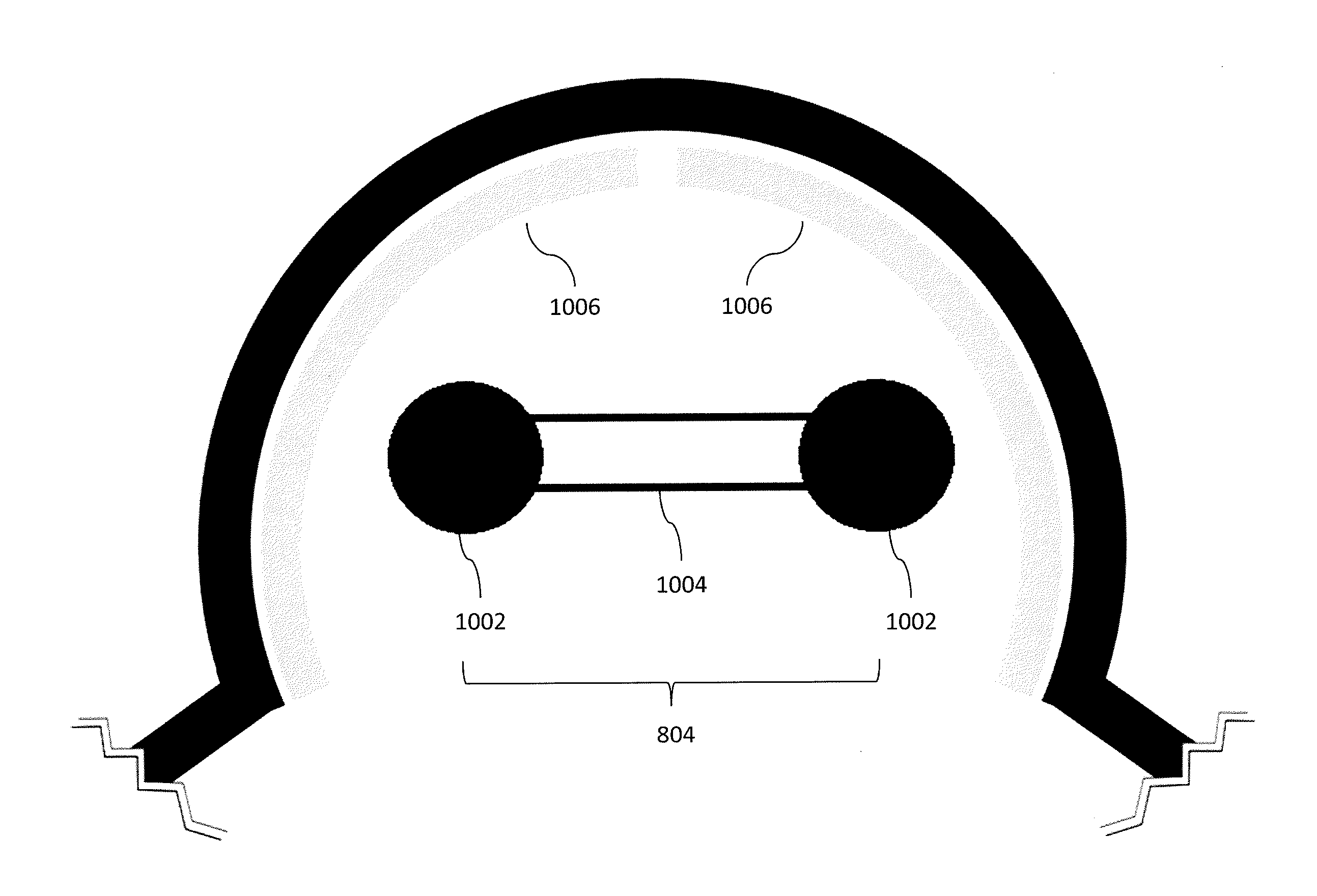

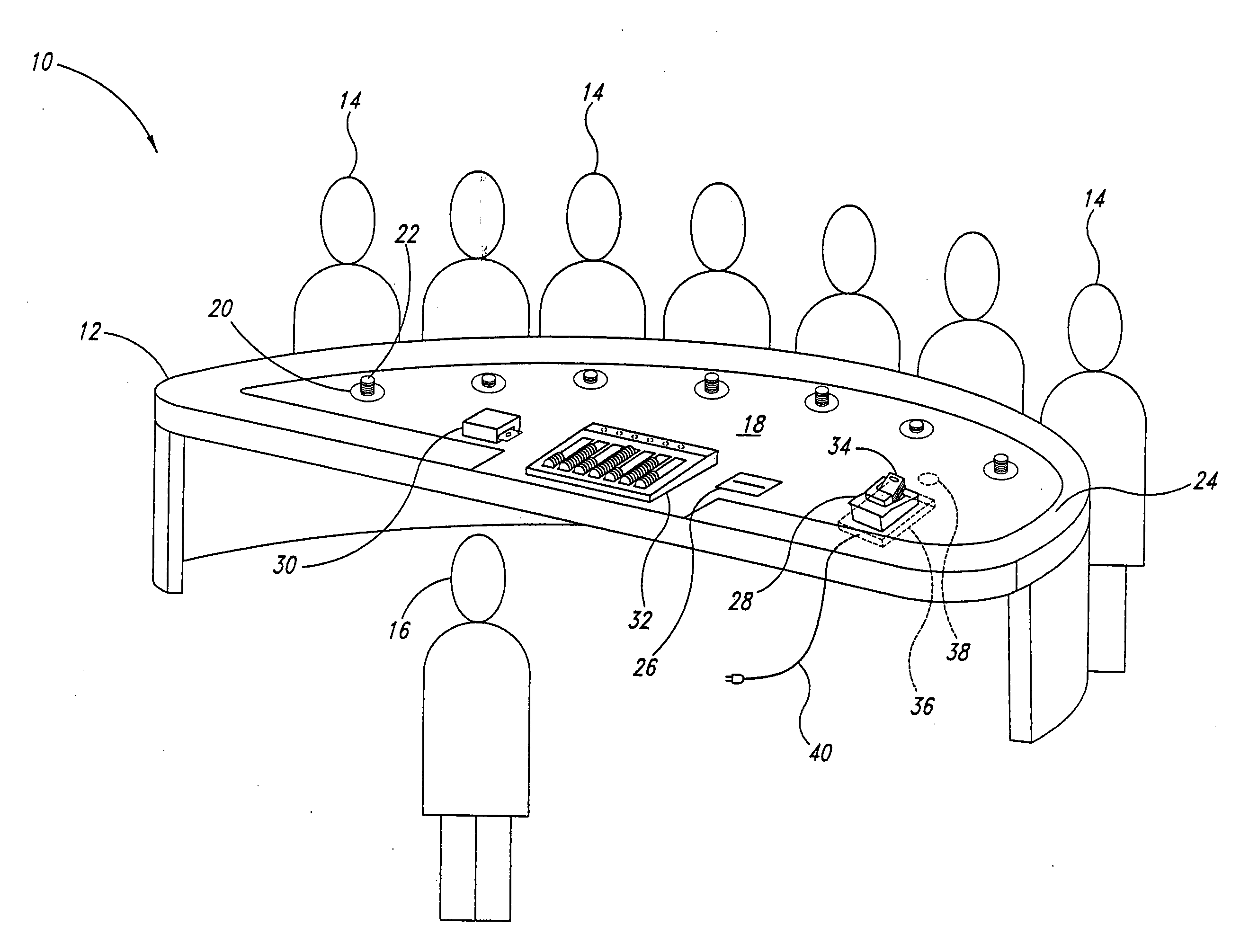

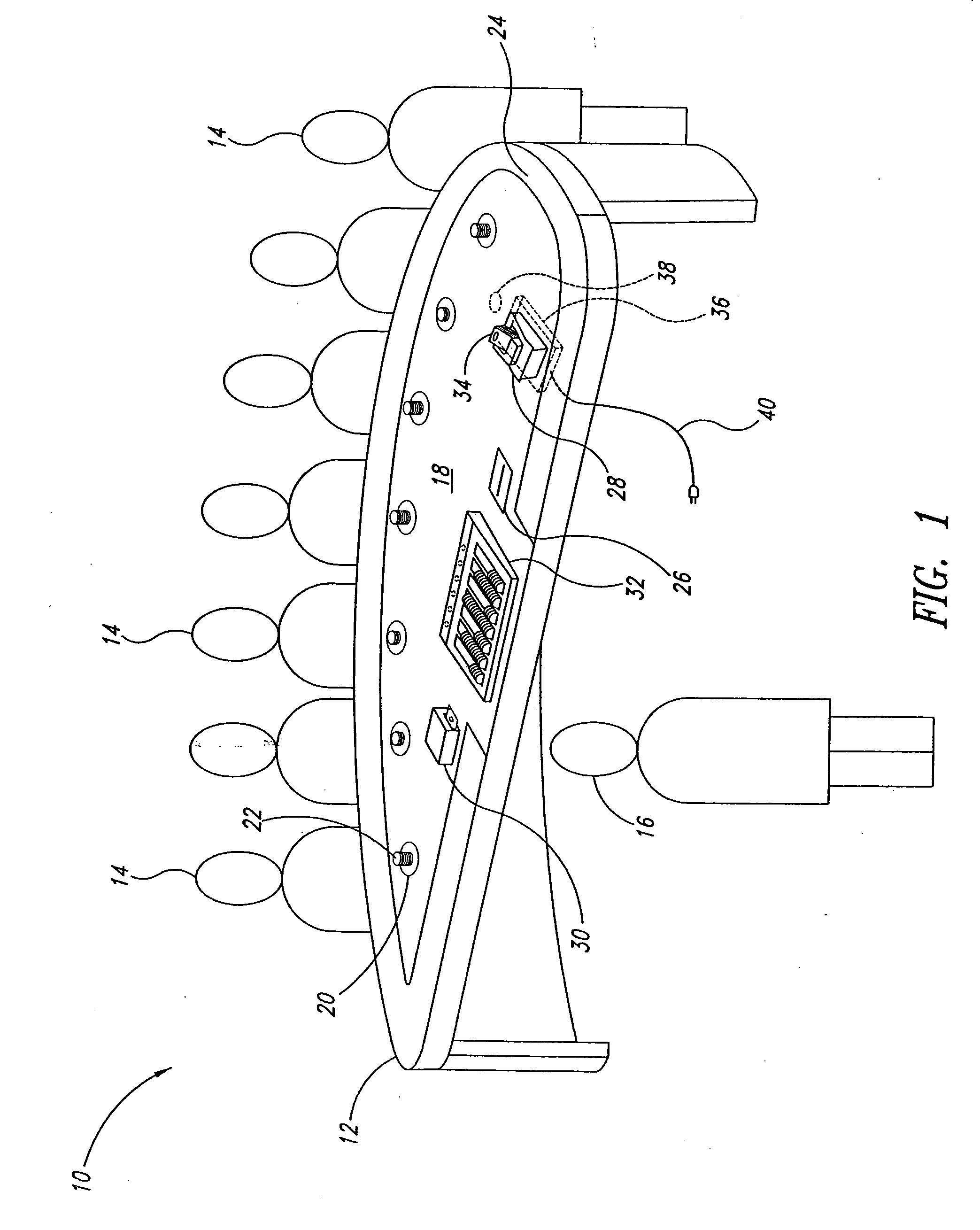

Gaming table having an inductive interface and/or a point optical encoder

InactiveUS20070045959A1Board gamesApparatus for meter-controlled dispensingComputer hardwareElectromagnetic field

A gaming table includes an inductive interface and / or a point optical encoder. The inductive interface is located beneath a playing surface of the gaming table and electromagnetically communicates with devices on the gaming table, such as a card shoe. The inductive interface generates an electromagnetic field between the source and the device without these items being in physical contact. Both electrical power and data are transferable through the electromagnetic field. Both the inductive interface and the devices are programmable. The point optical encoder can be in electromagnetic communication with the inductive interface and operate to optically read cards, successively, as the cards are individually removed from the card shoe. The inductive interface generates an electromagnetic field between the source and the device without these items being in physical contact. Both electrical power and data are transferable through the electromagnetic field. Both the inductive interface and the devices are programmable.

Owner:BALLY GAMING INC

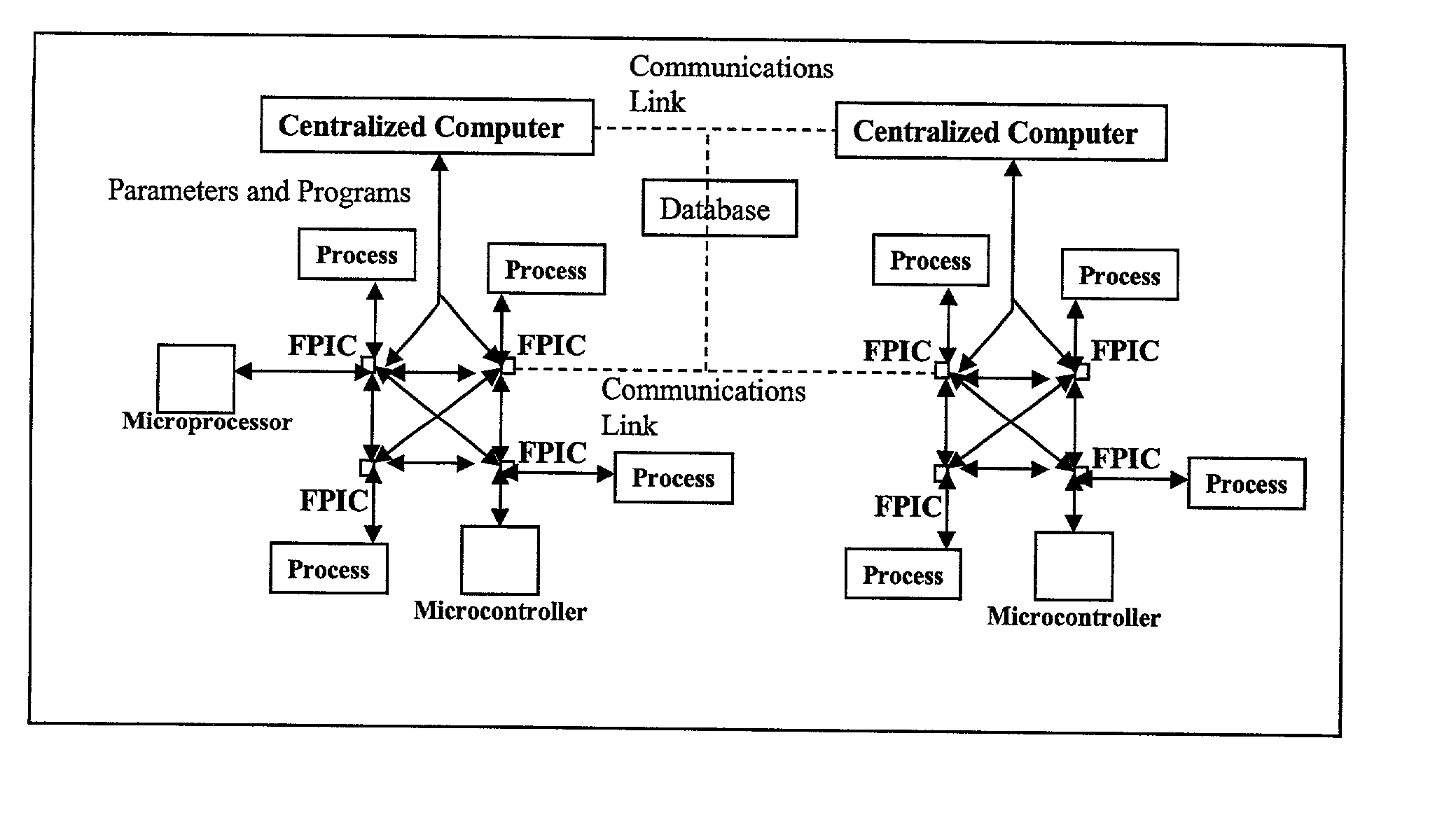

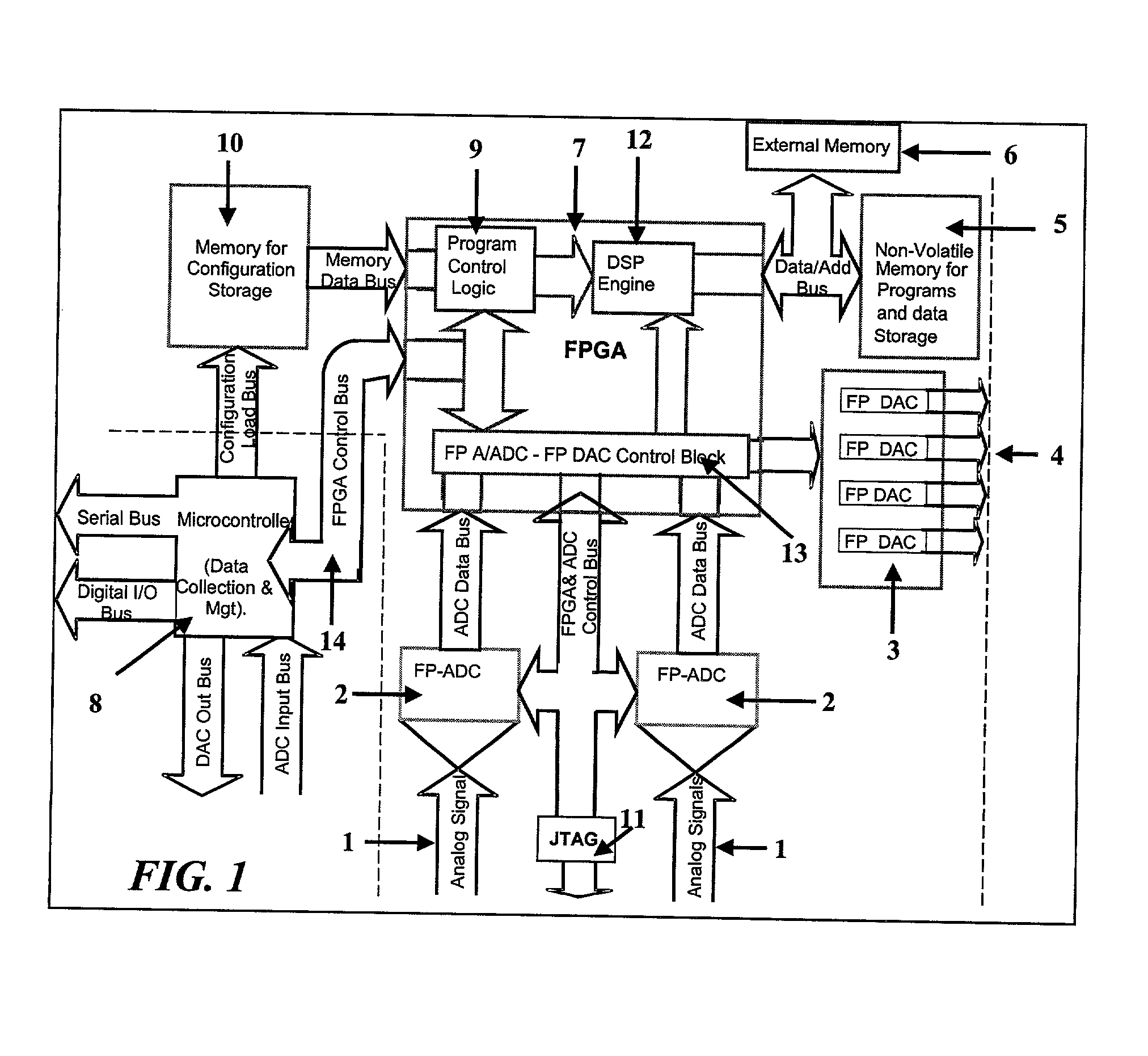

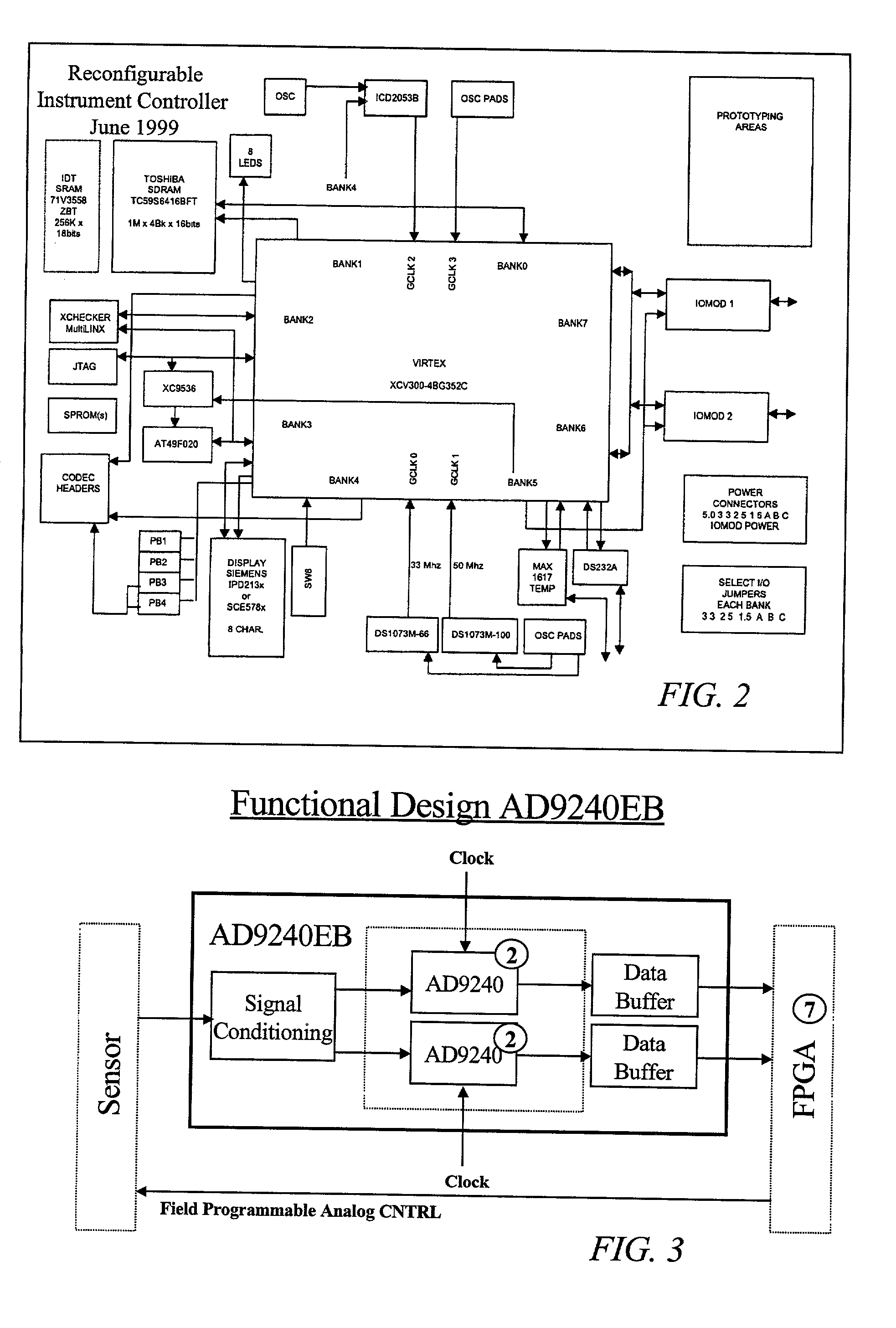

High performance hybrid micro-computer

The Field Programmable Instrument Controller (FPIC) is a stand-alone low to high performance, clocked or unclocked multi-processor that operates as a microcontroller with versatile interface and operating options. The FPIC can also be used as a concurrent processor for a microcontroller or other processor. A tightly coupled Multiple Chip Module design incorporates non-volatile memories, a large field programmable gate array (FPGA), field programmable high precision analog to digital converters, field programmable digital to analog signal generators, and multiple ports of external mass data storage and control processors. The FPIC has an inherently open architecture with in-situ reprogrammability and state preservation capability for discontinuous operations. It is designed to operate in multiple roles, including but not limited to, a high speed parallel digital signal processing; co-processor for precision control feedback during analog or hybrid computing; high speed monitoring for condition based maintenance; and distributed real time process control. The FPIC is characterized by low power with small size and weight.

Owner:BLEMEL KENNETH G

User interface for initiating activities in an electronic device

ActiveUS20120216143A1Improve expediencyImprove convenienceInput/output processes for data processingHome screenTouchscreen

In one embodiment, a user interface is presented for initiating activities in an electronic device. The user interface includes an element referred to as a “launch wave”, which can be activated at substantially any time, even if the user is engaged with an activity, without requiring the user to first return to a home screen. In various embodiments, the user can activate the launch wave by performing a gesture, or by pressing a physical button, or by tapping at a particular location on a touchscreen, or by activating a keyboard command. In one embodiment, activation of the launch wave and selection of an item from the launch wave can be performed in one continuous operation on a touch-sensitive screen, so as to improve the expediency and convenience of launching applications and other items.

Owner:QUALCOMM INC

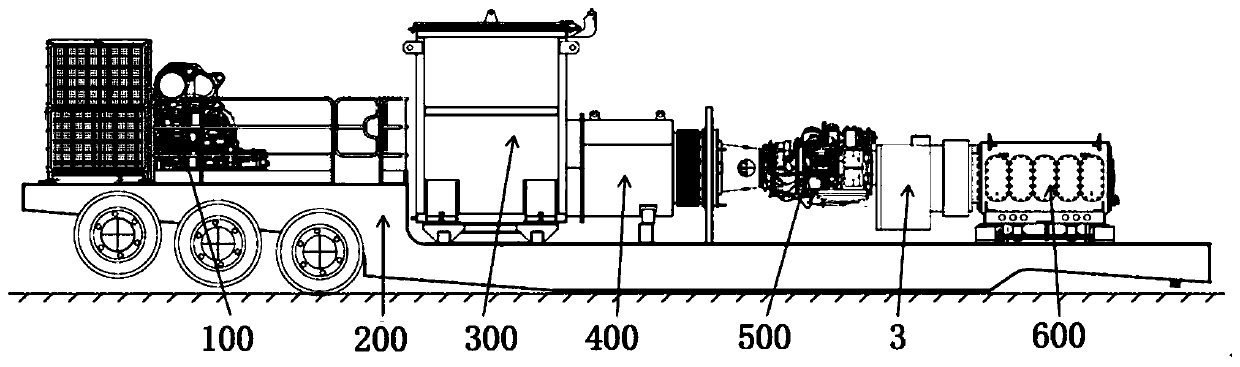

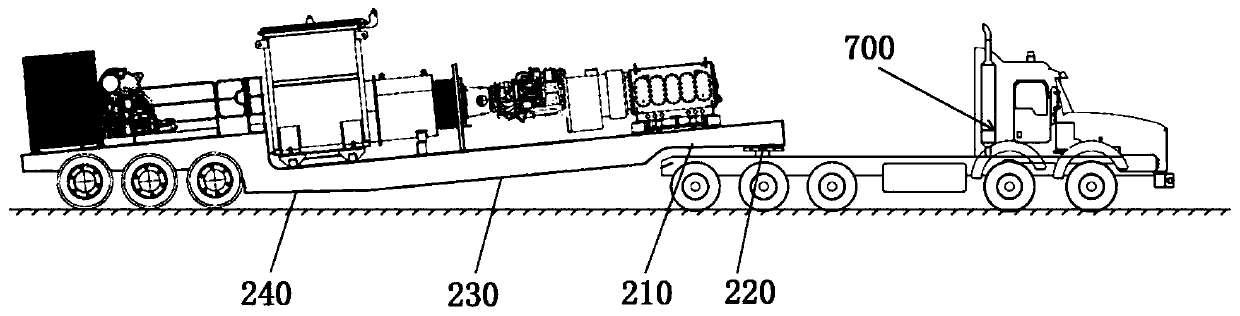

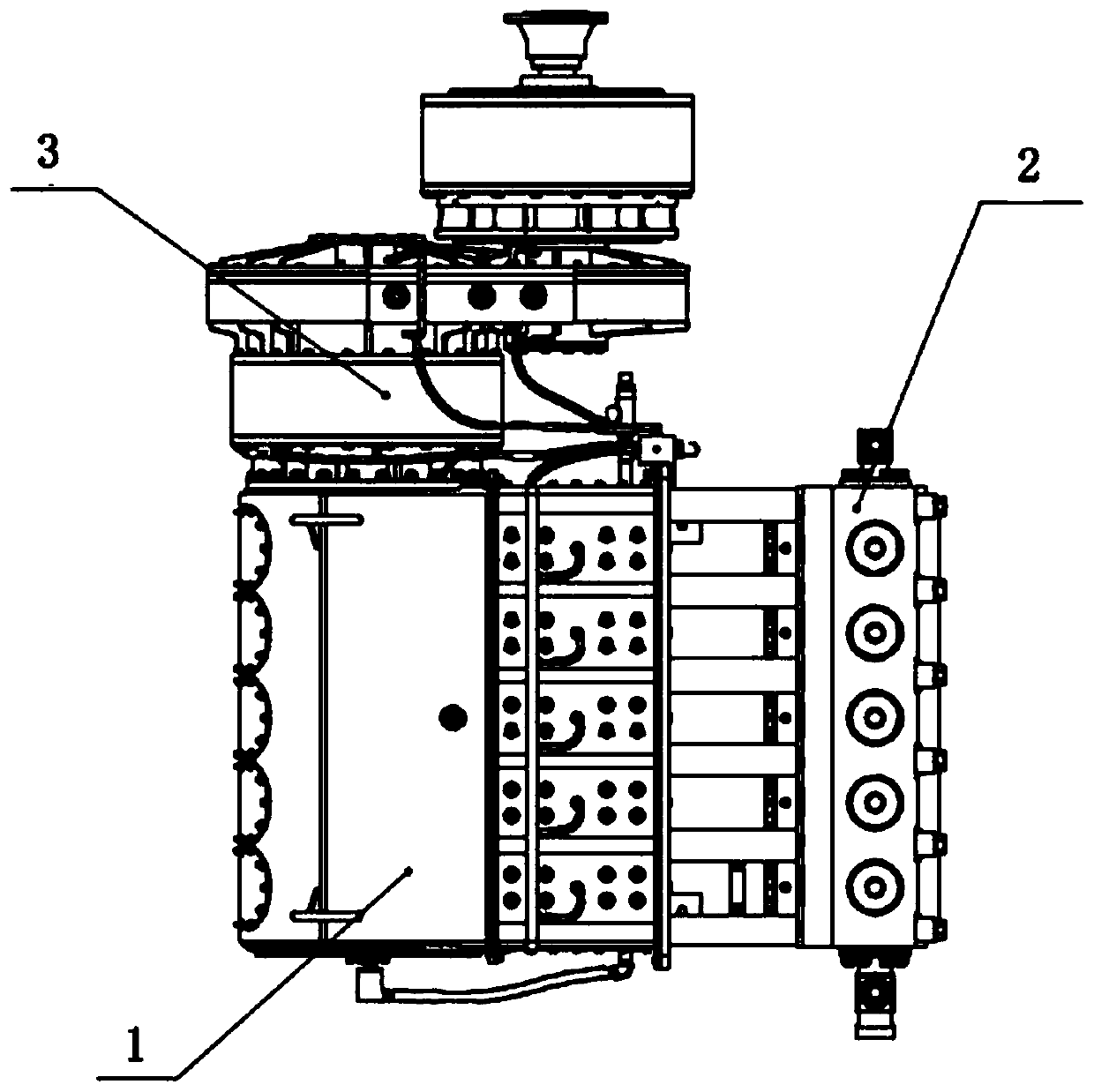

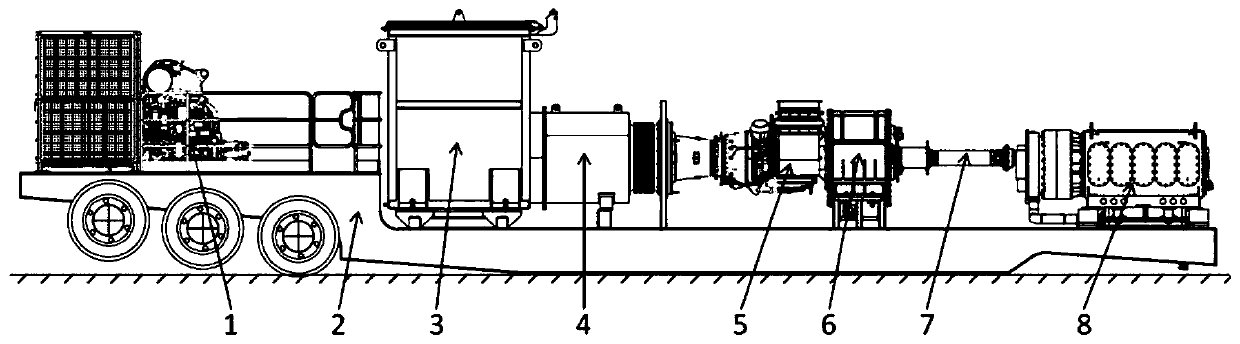

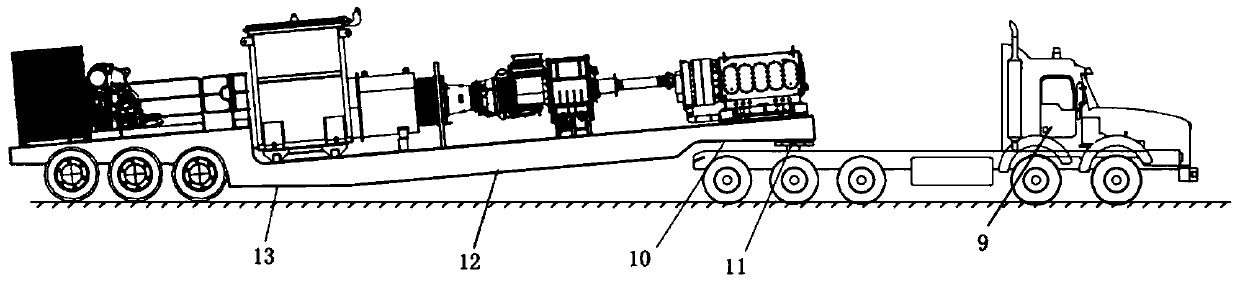

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Circuit for transmitting a RFID signal

ActiveUS7831212B1Save powerPrecise functionPower managementMeasurement devicesAccelerometerEngineering

A circuit for transmitting a RFID signal while conserving the battery power for a circuit in continuous operation is disclosed herein. The circuit includes a RFID component, a microprocessor, an accelerometer and a battery. The battery preferably has no more than 225 milliamp hours of power. The accelerometer is preferably a multiple axis accelerometer. The circuit is preferably utilized with a device for shot tracking.

Owner:TOPGOLF CALLAWAY BRANDS CORP

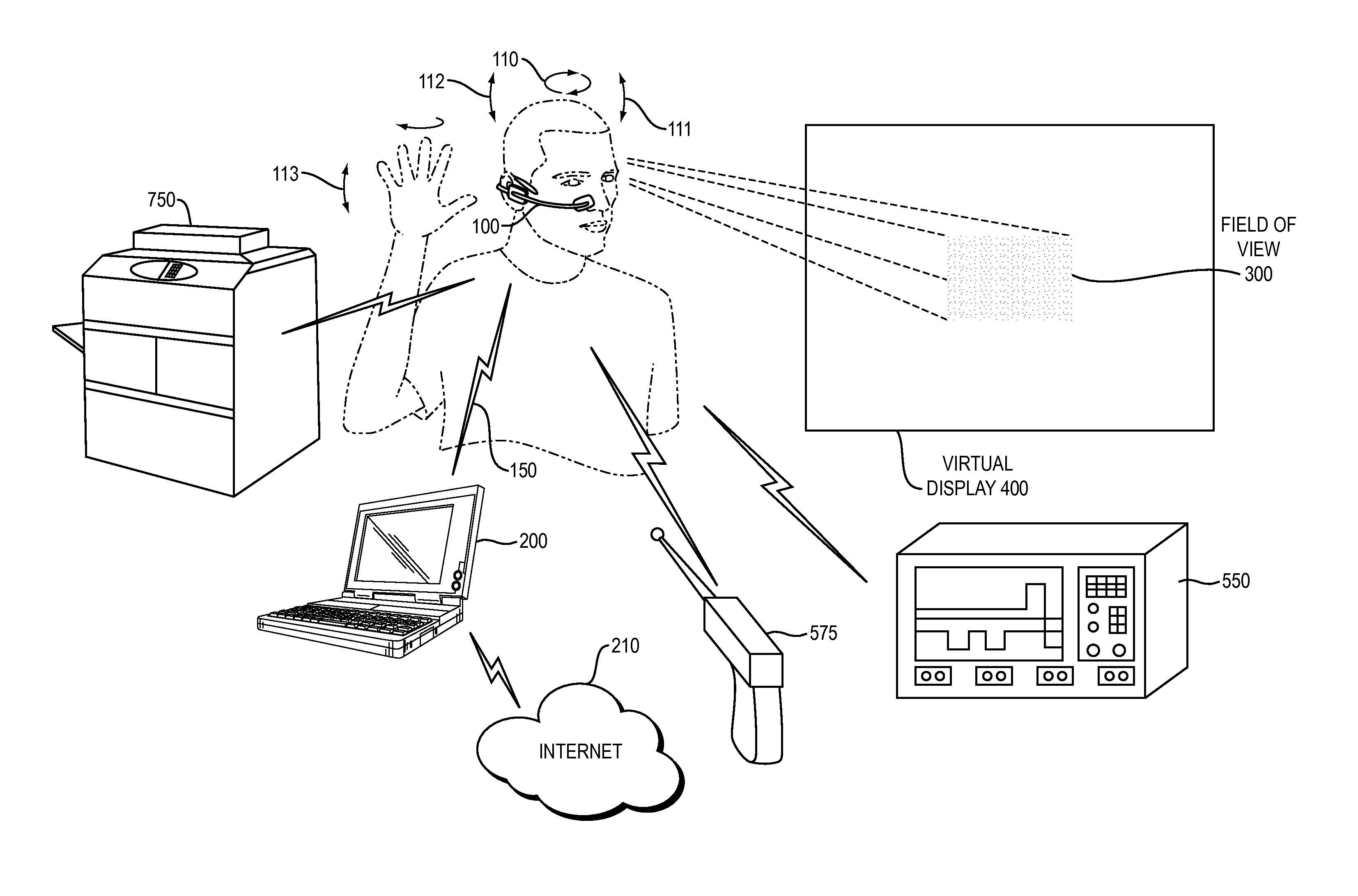

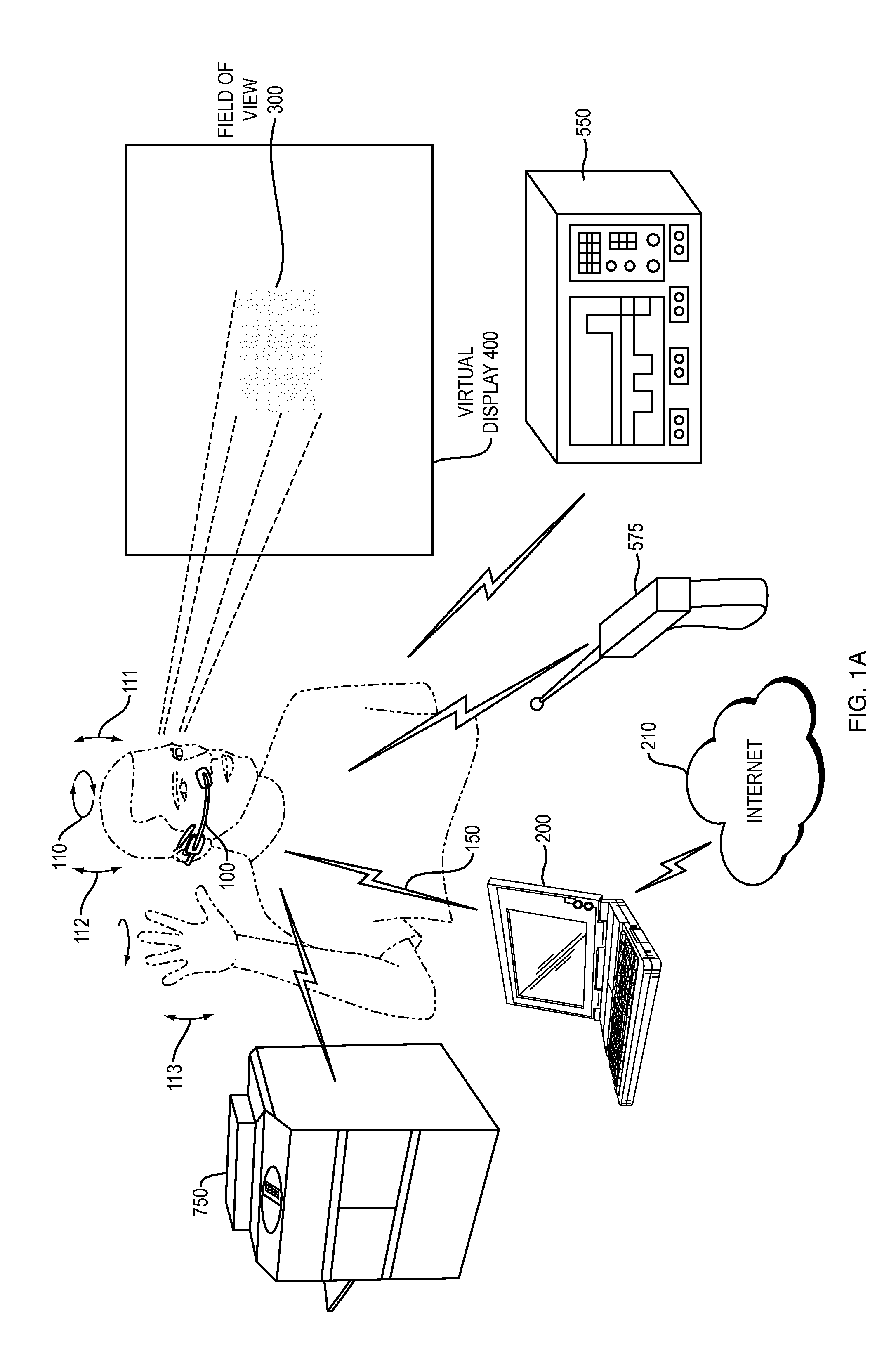

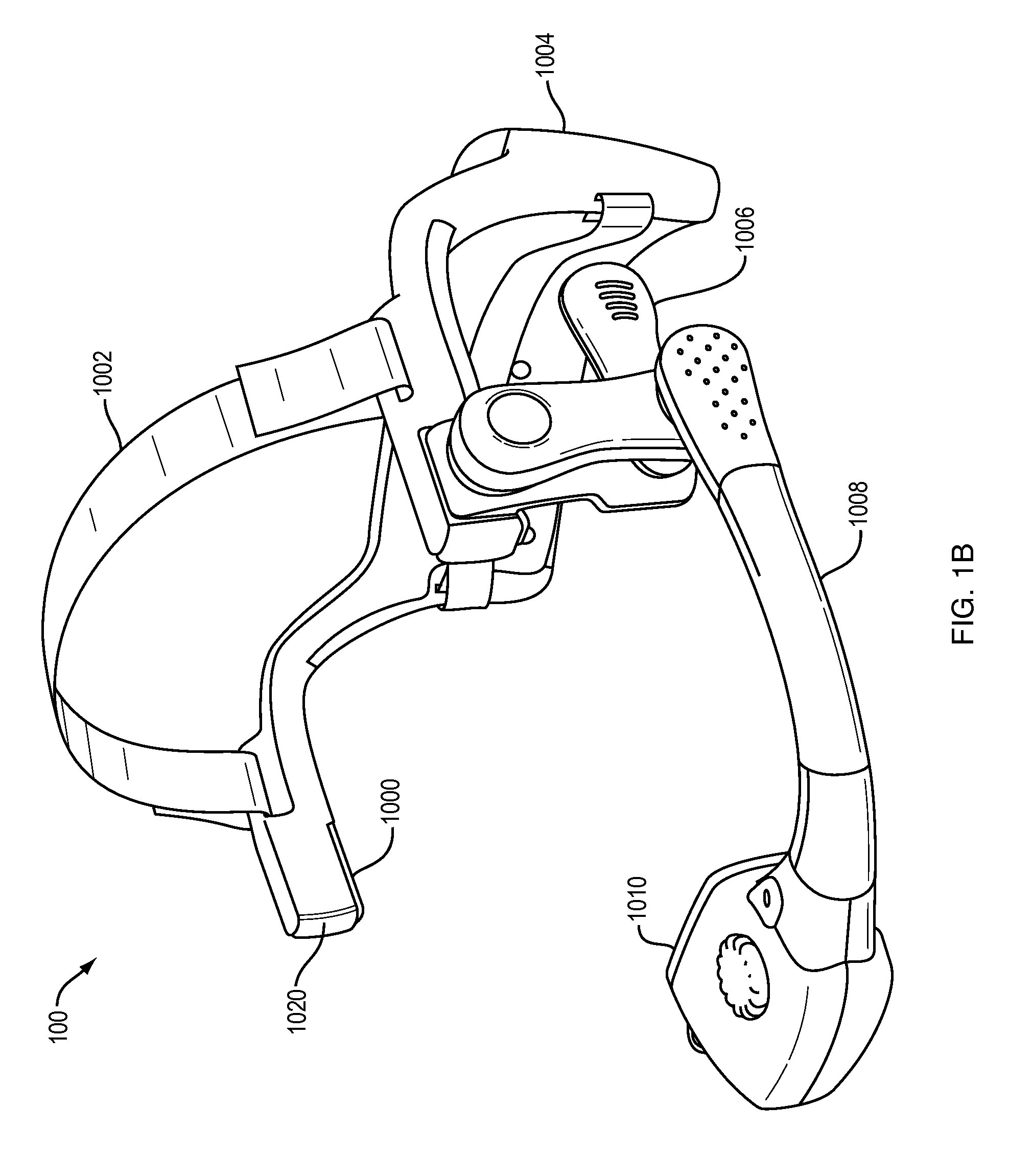

Wireless Hands-Free Computing Head Mounted Video Eyewear for Local/Remote Diagnosis and Repair

ActiveUS20130174205A1Easy accessClosed circuit television systemsDetails for portable computersGraphicsHands-free computing

The present application relates to human / computer interfaces and more particularly to a wireless computing headset with one or more microdisplay devices that can provide hands-free remote control of attached or remote peripheral devices, systems and / or networks. A wireless hands-free video computing headset, and corresponding method, enabling communication with a host processor to provide the user omnipresent expertise is disclosed. The wireless hands-free video computing headset, which includes a microdisplay device to present information to the user graphically, communicates with a host processor to provide the user with an expert resource. The expert resource may take numerous forms, such as diagnostic software, or live human support. The wireless hands-free video computing headset is useful by enabling the user to focus his or her attention, and maintain his or her focus, on a physical subject by enabling hands-free control, enabling the user the ability to continuously manipulate the subject manually with his or her hands as needed.

Owner:KOPIN CORPORATION

Passive RFID elements having visual indicators

ActiveUS7965186B2Electric/electromagnetic visible signallingCoupling light guidesEngineeringVisual perception

There are provided components, connectors, receptacles, cables, and systems wherein passive RFID functionality is incorporated. Also provided are passive RFID elements in general. The passive RFID elements power visual indicators based on receipt of external RF signals. Passive energy storage devices may be employed to provide electrical energy to the visual indicators. The passive energy storage devices may be charged by the external RF signals. The visual indicators may operate continuously or according to a predetermined flashing pattern.

Owner:FIBER MOUNTAIN INC

Turbine fracturing equipment

PendingCN110485982AReduce volumeReduce weightPositive displacement pump componentsTurbine/propulsion engine coolingOperational costsGravity center

The invention discloses turbine fracturing equipment. The turbine fracturing equipment comprises a transporting device, a turbine engine, a reduction gearbox, a transmission mechanism and a fracturingpump, wherein the output end of the turbine engine is connected with one end of the reduction gearbox; the other end of the reduction gearbox is in transmission connection with the fracturing pump; the transportation device is used for bearing the turbine engine, the reduction gearbox, the transmission mechanism and the fracturing pump and comprises a chassis; the chassis is provided with a transporting section, a bearing section and a lapping section which are connected in sequence; when the turbine fracturing equipment is in a working state, the bearing section can be contacted with the ground; and when the turbine fracturing equipment is in a transporting state, the bearing section does not make contact with the ground. The turbine fracturing equipment has the beneficial effects that the equipment adopts the design of linear connection and a special chassis, so that the gravity center of the turbine fracturing equipment is doubly reduced, and the stability and the safety are well ensured; the structure is simpler, and the investment cost and the operation cost are reduced; the collapse risk of the whole fracturing site is reduced; and the turbine fracturing equipment is good intransmission property and is suitable for long-time and bulky load continuous operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Self-charging electric vehicles and aircraft, and wireless energy distribution system

InactiveUS8890472B2Rapid collection and storageIncrease rangeMobile unit charging stationsPropulsion by batteries/cellsElectric power systemTransmitted power

A method and system for efficient distribution of power using wireless means, and a system and method for wireless power distribution to provide electric devices, such as vehicles with a way to continuously and wirelessly collect, use and charge their power systems and thereby use the transmitted power for operation. The system and method allows a hybrid, simplified and less costly way to charge devices, such as vehicles so that the devices continuously operate while charging / recharging.

Owner:GOVERNING DYNAMICS INVESTMENT +1

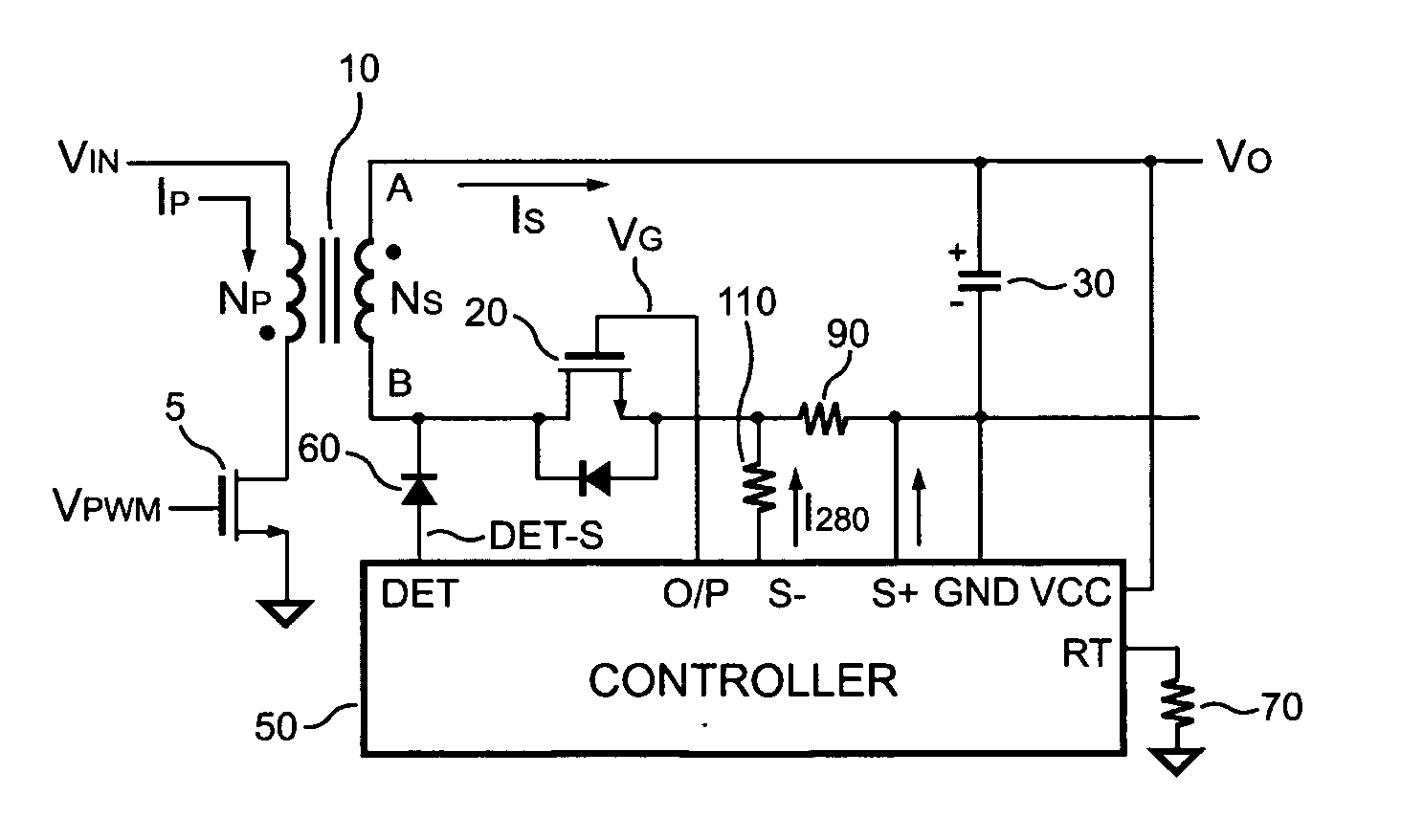

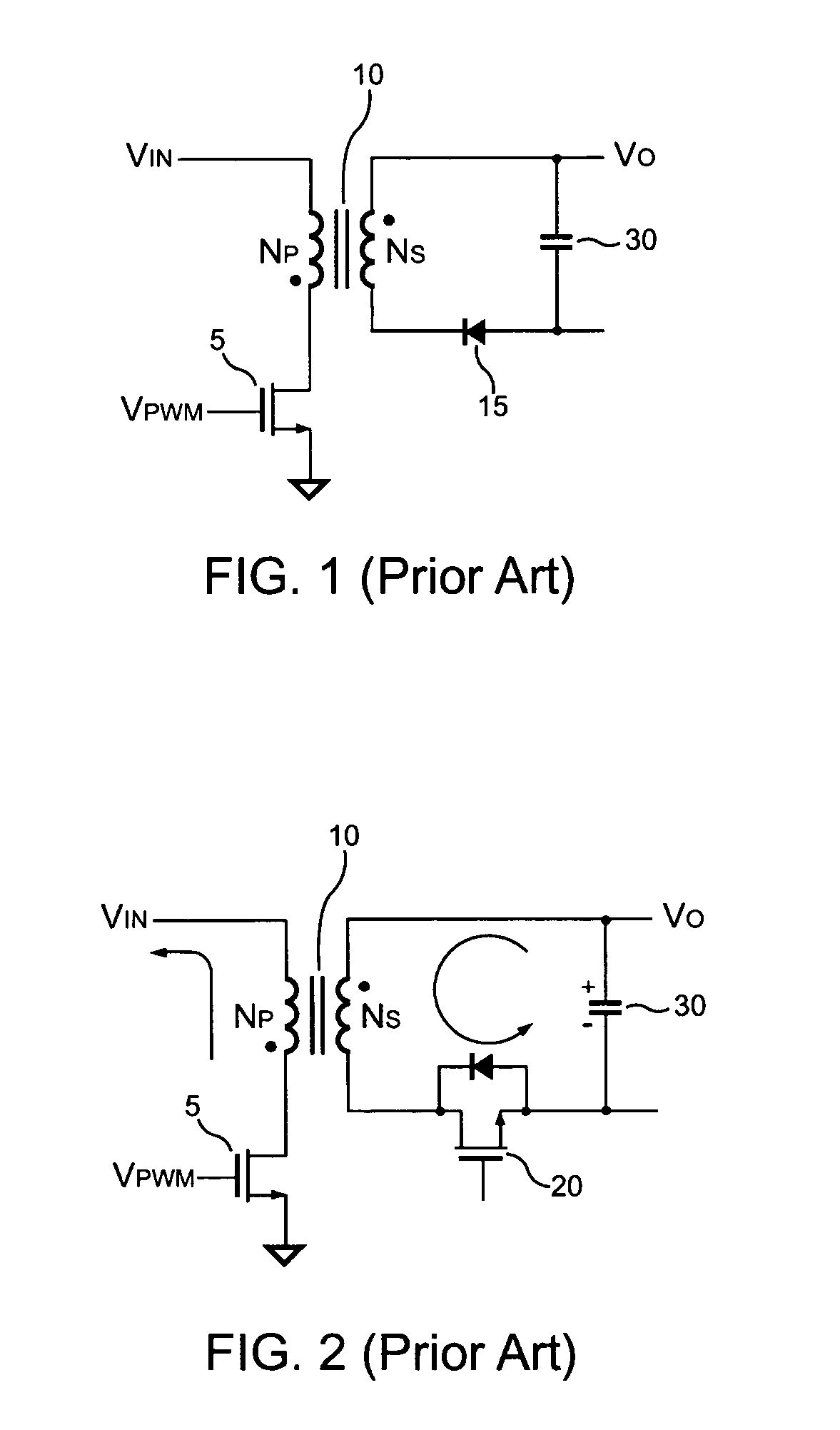

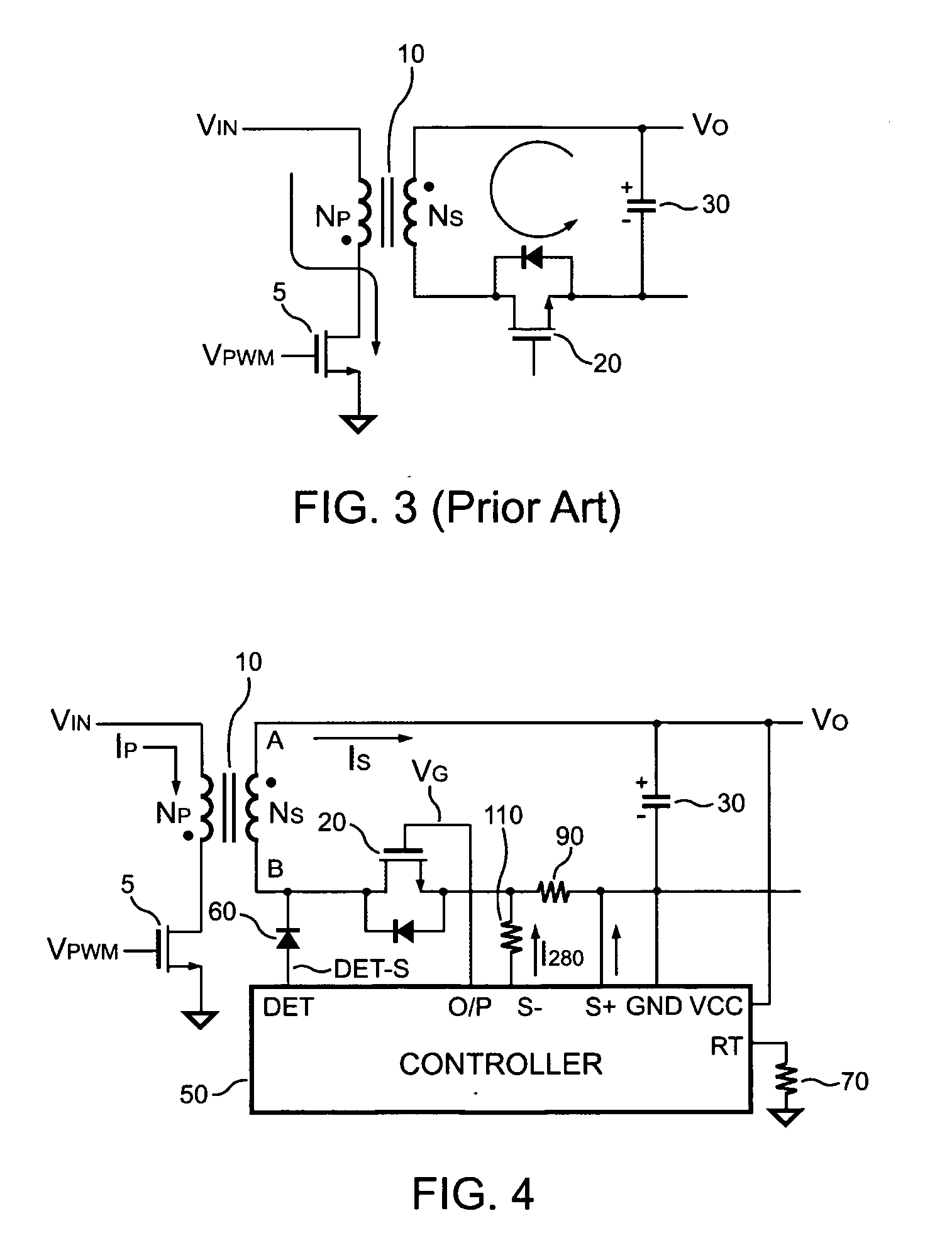

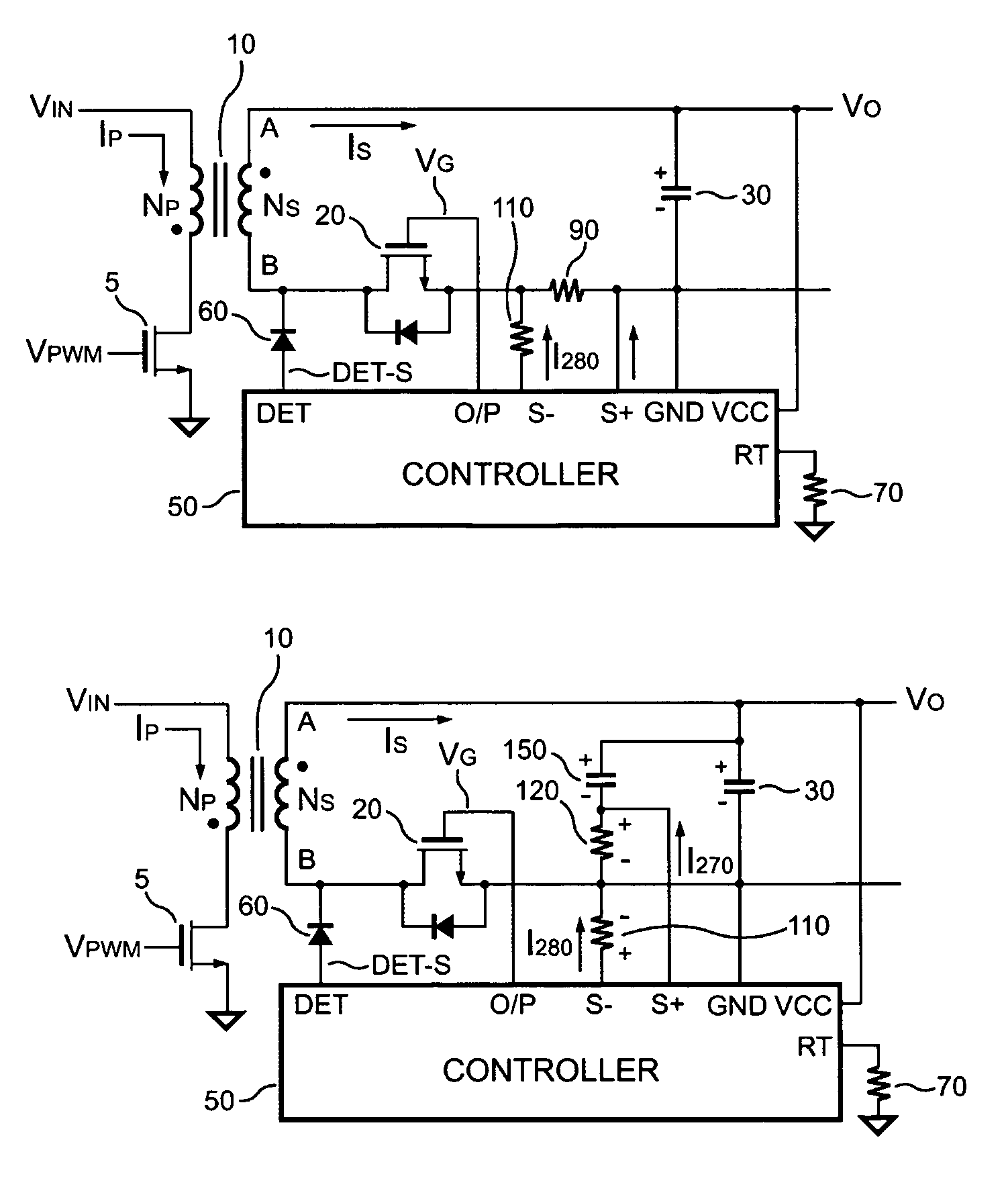

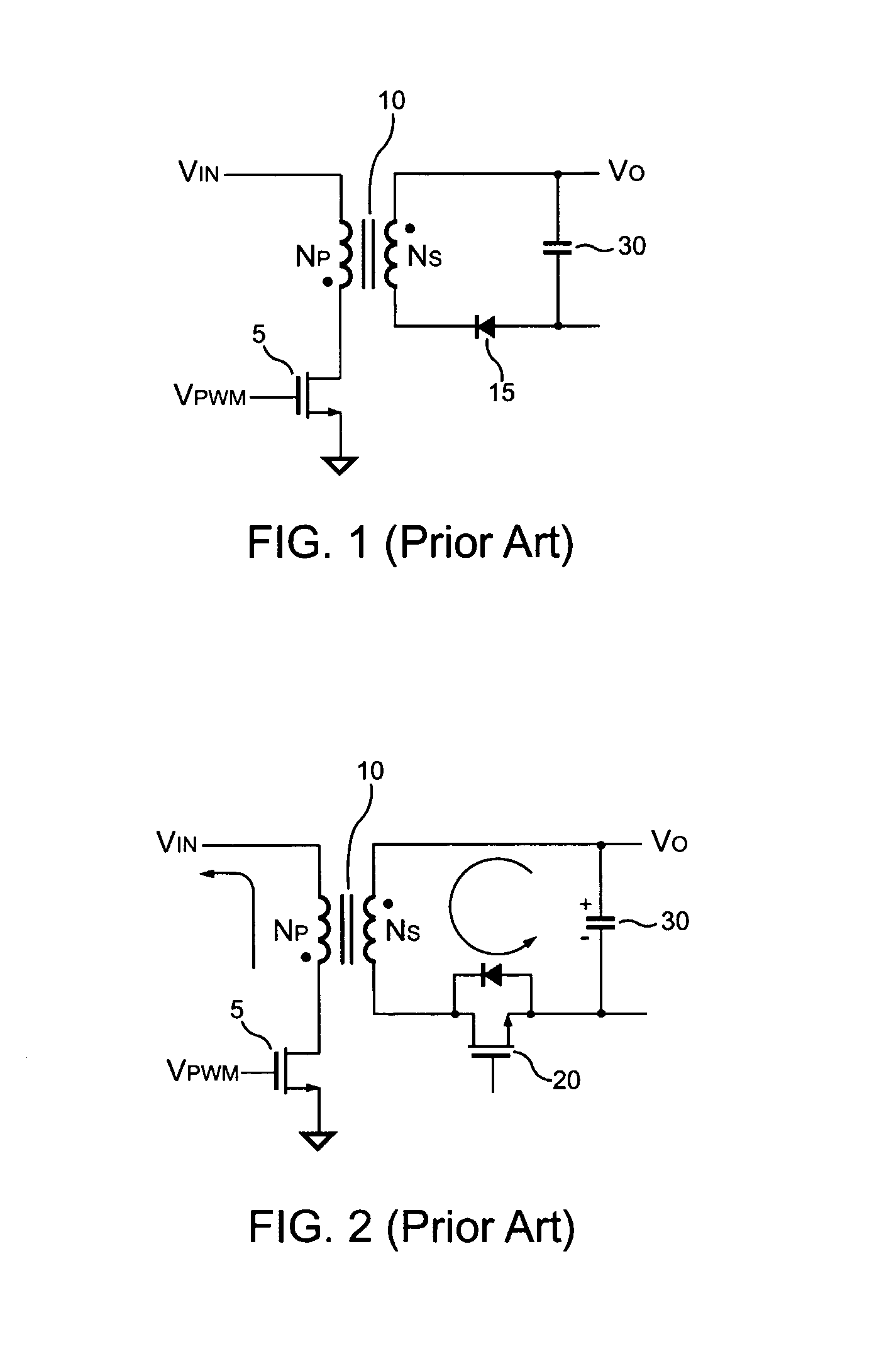

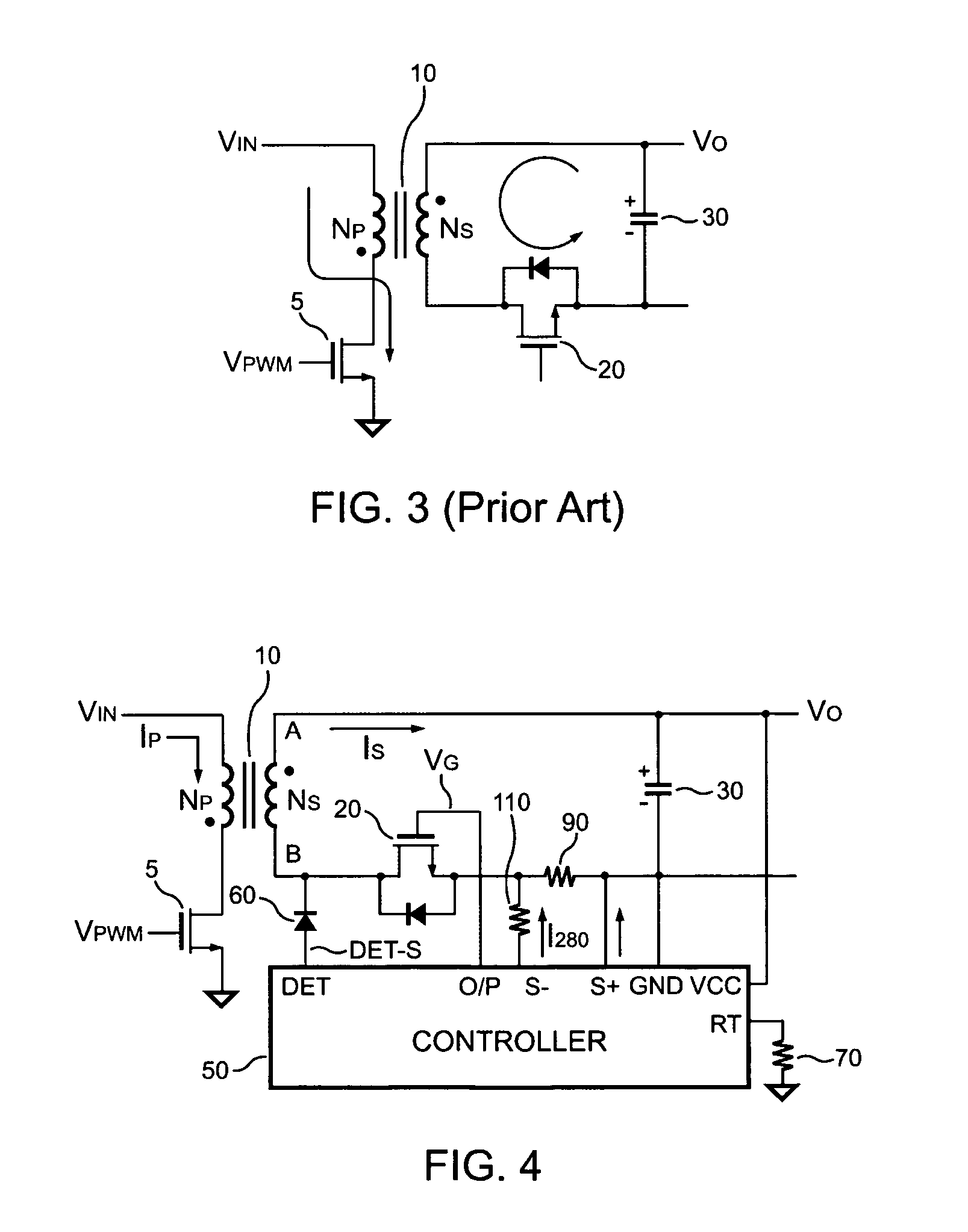

Pwm controller for synchronous rectifier of flyback power converter

A synchronous rectifier PWM (SR-PWM) controller controls a MOSFET in response to the value of a secondary current and the status of a synchronous signal for both discontinuous and continuous operation mode. The secondary current is generated in a secondary circuit and is detected by two threshold-detection terminals of the SR-PWM controller. The SR-PWM controller produces the synchronous signal by detecting a switching signal of the transformer via a detection terminal of the SR-PWM controller. Furthermore, a delay-time is inserted after the MOSFET is turned off and before the next switching cycle starts to ensure a proper operation of the MOSFET. In one embodiment, an equivalent series resistance (ESR) of an output capacitor can be used as a sensor to detect the secondary current. Therefore, no additional current sensor is required and the efficiency can be improved.

Owner:SEMICON COMPONENTS IND LLC

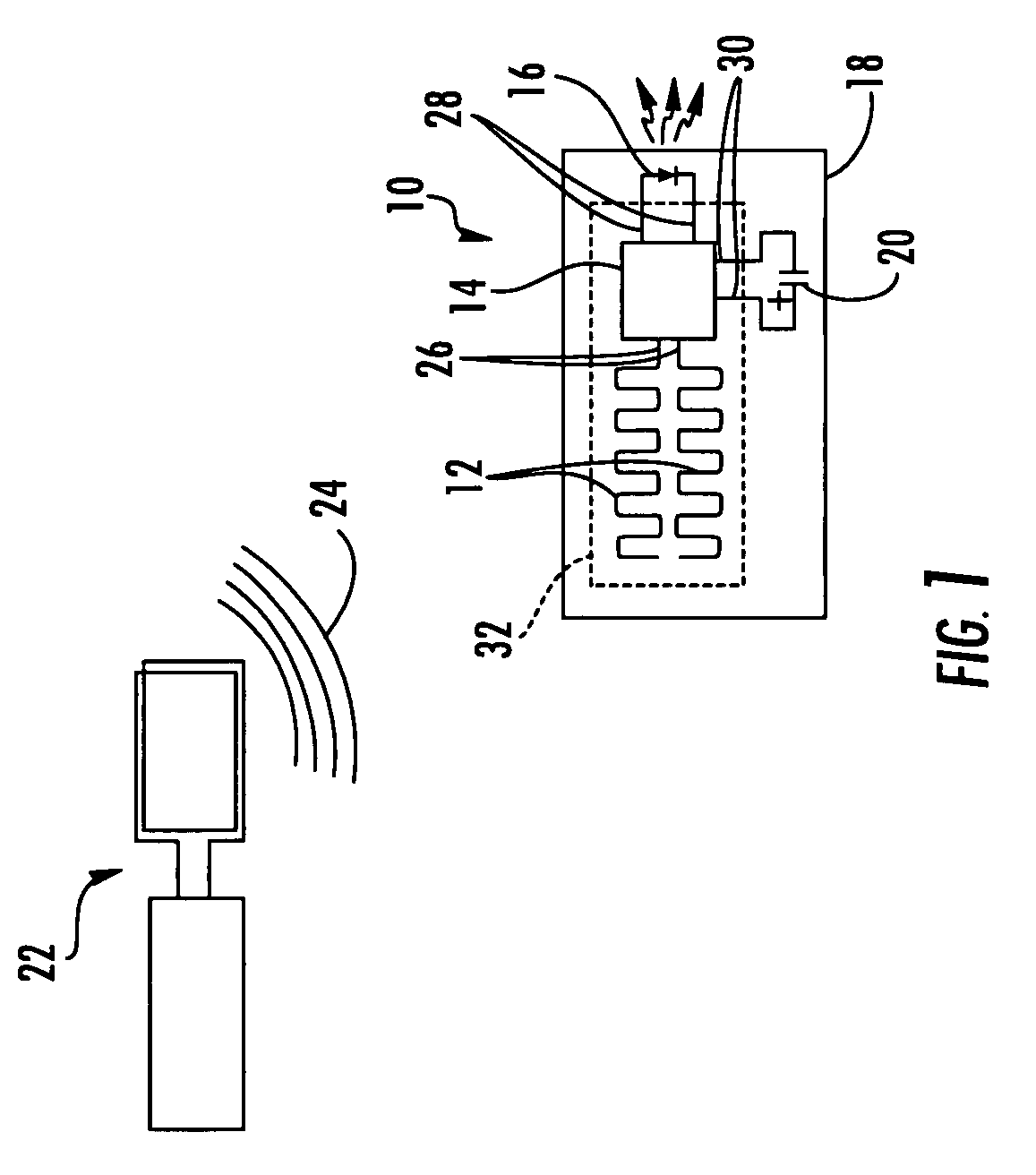

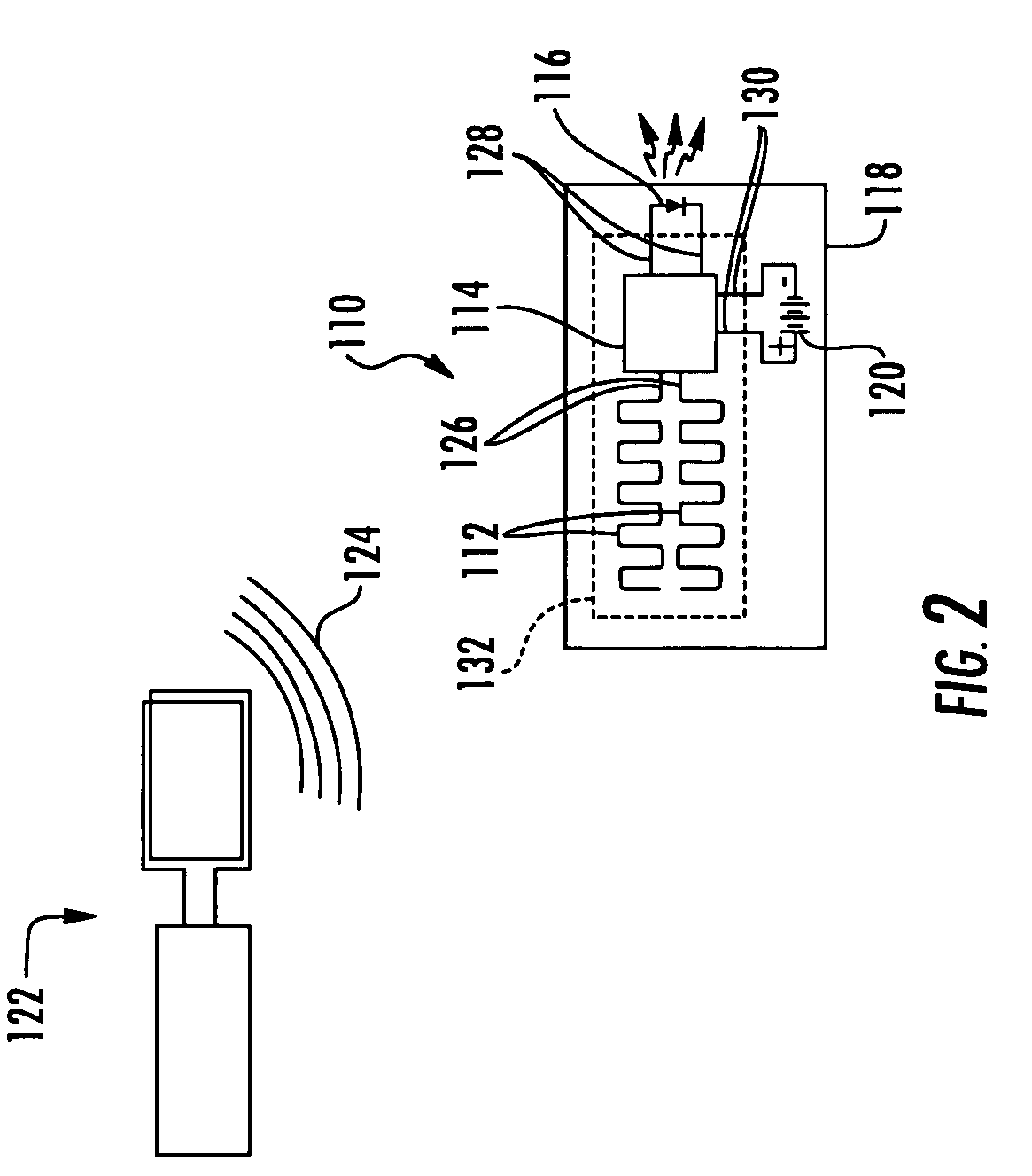

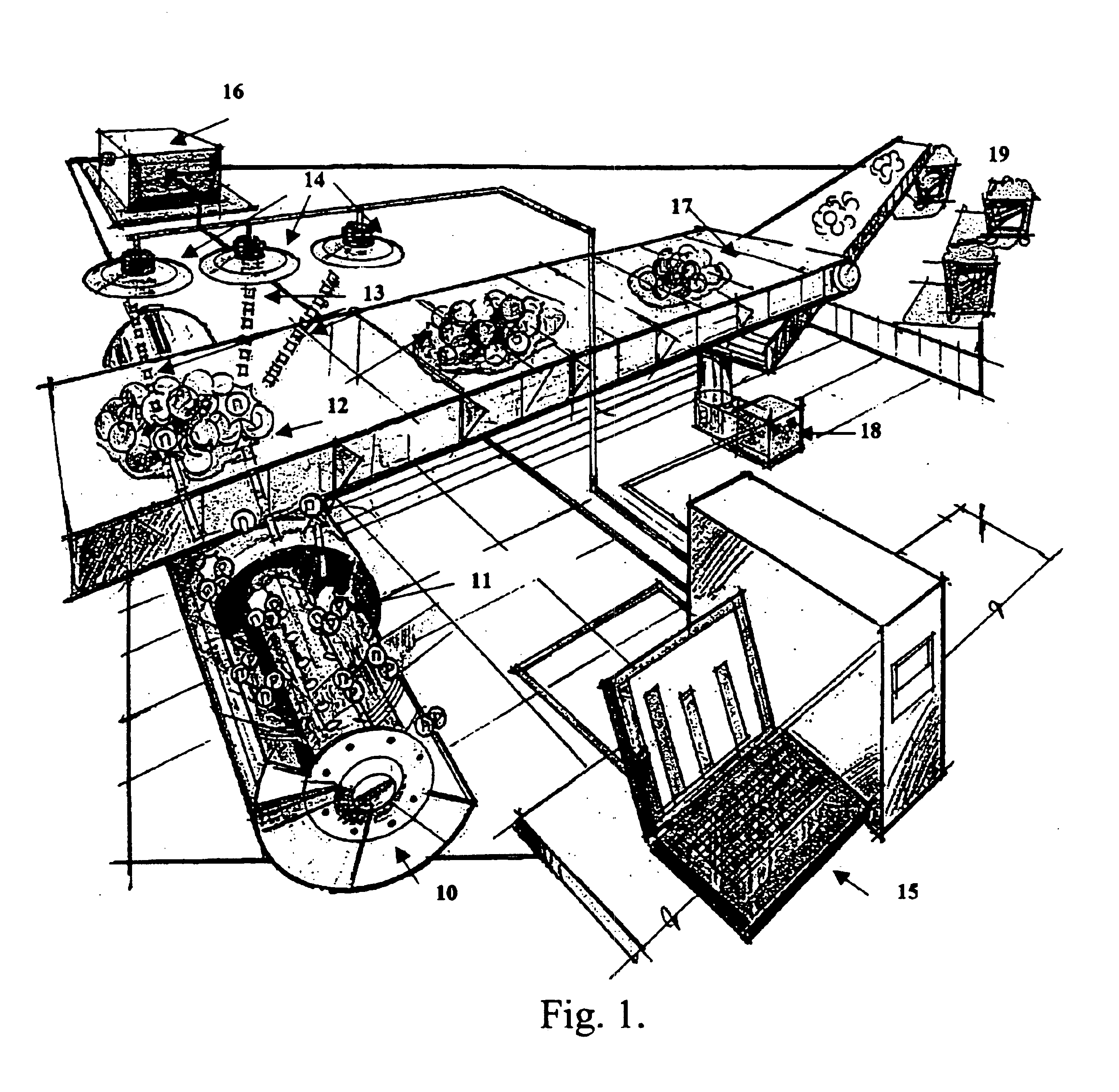

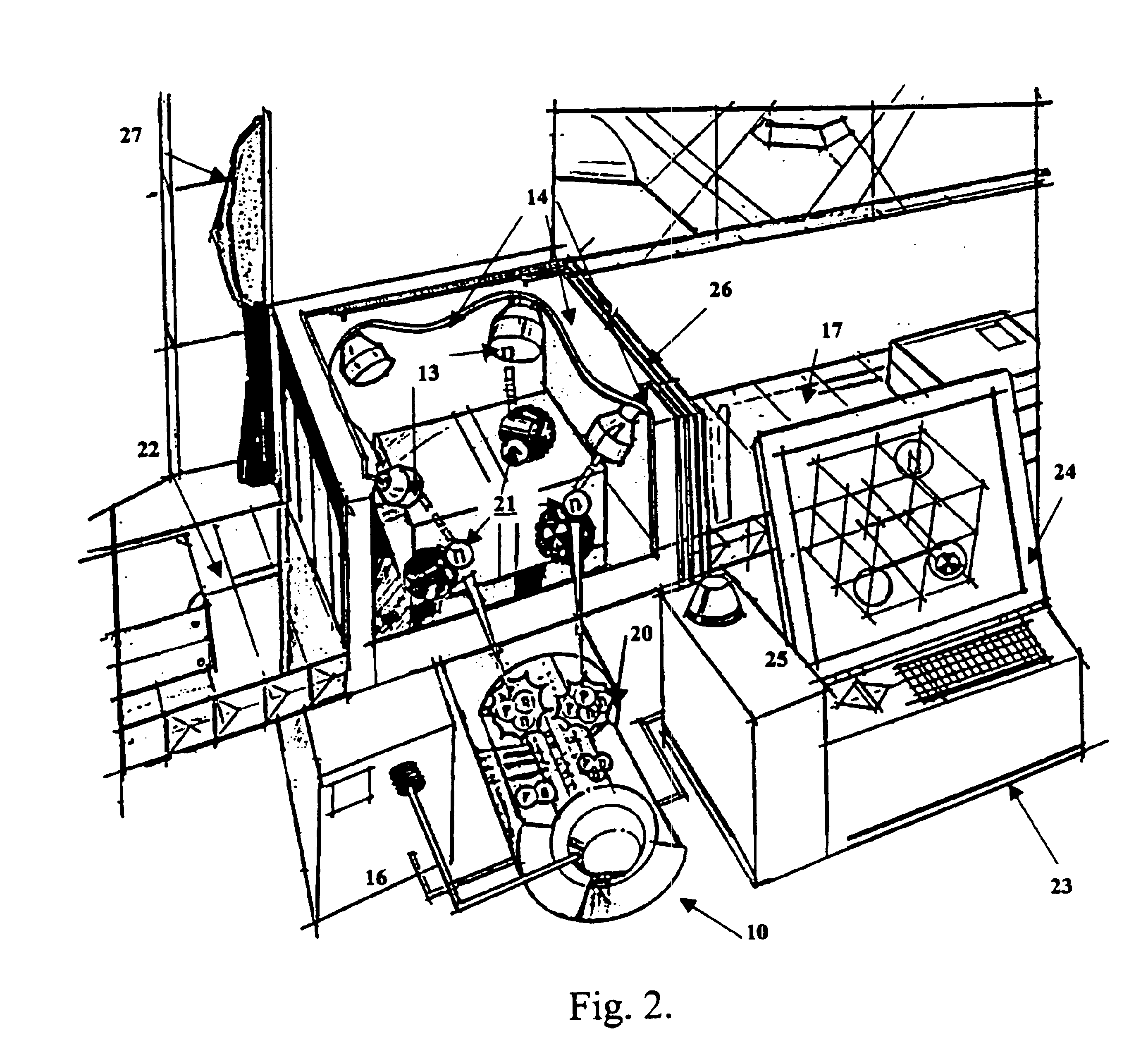

Gas-target neutron generation and applications

InactiveUS6922455B2Improve performanceMaximize productionNuclear energy generationX-ray tube electrodesHigh resistanceNeutron emission

Described herein are integrated systems for generating neutrons to perform a variety of tasks including: on-line analysis of bulk material and industrial process control (as shown in FIG. 1), security interrogation (as shown in FIG. 2), soil and environmental analysis, and medical diagnostic treatment. These systems are based on novel gas-target neutron generation which embodies the beneficial characteristics of replenishable fusible gas targets for very long lifetime, stability and continuous operation, combined with the advantageous features common to conventional accelerator neutron tubes including: on / off operation, hermetically sealed operation, and safe storage and transport. Innovative electron management techniques provide gas-target neutron production efficiencies that are comparable or surpass existing sources. The high-pressure high-resistance gaseous discharge is presented as a favorable gas-target neutron generator embodiment, combining ion source regions, accelerator regions, gas-target regions and electron management components within a single simple cost-effective device that is adaptable to various geometric configurations that provide specific neutron emission profiles for greater analysis capacity.

Owner:STARFIRE INDS MANAGEMENT

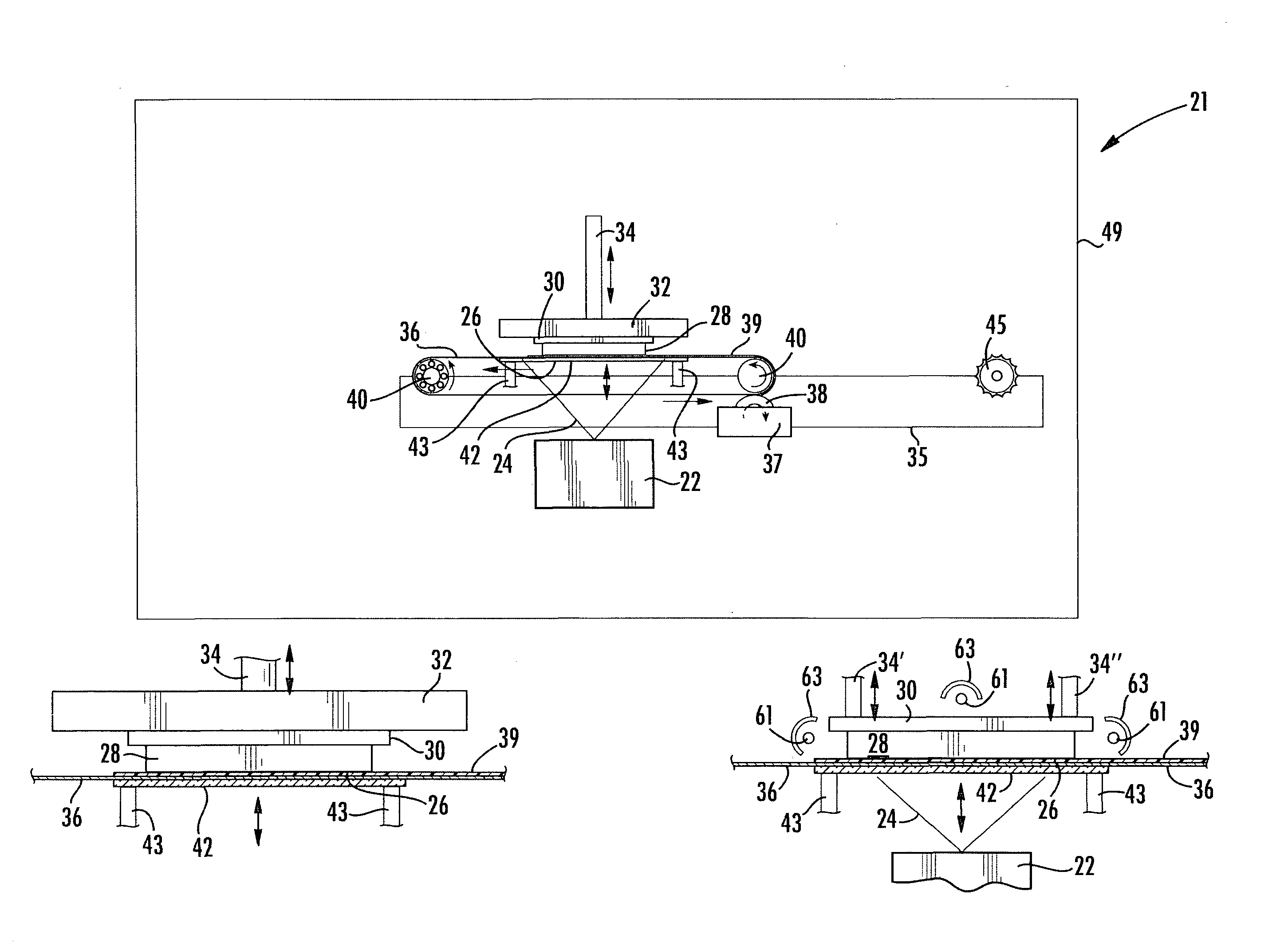

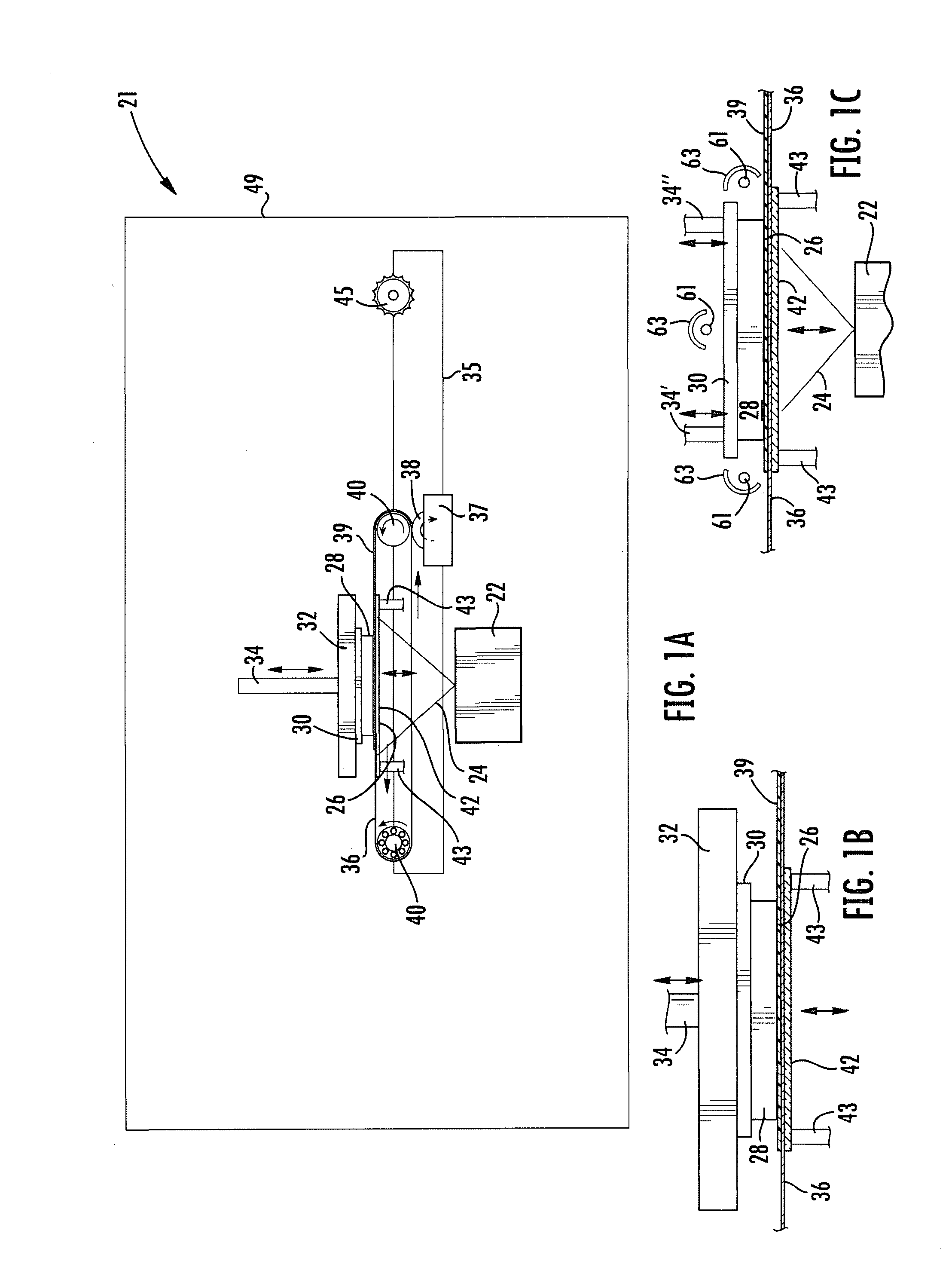

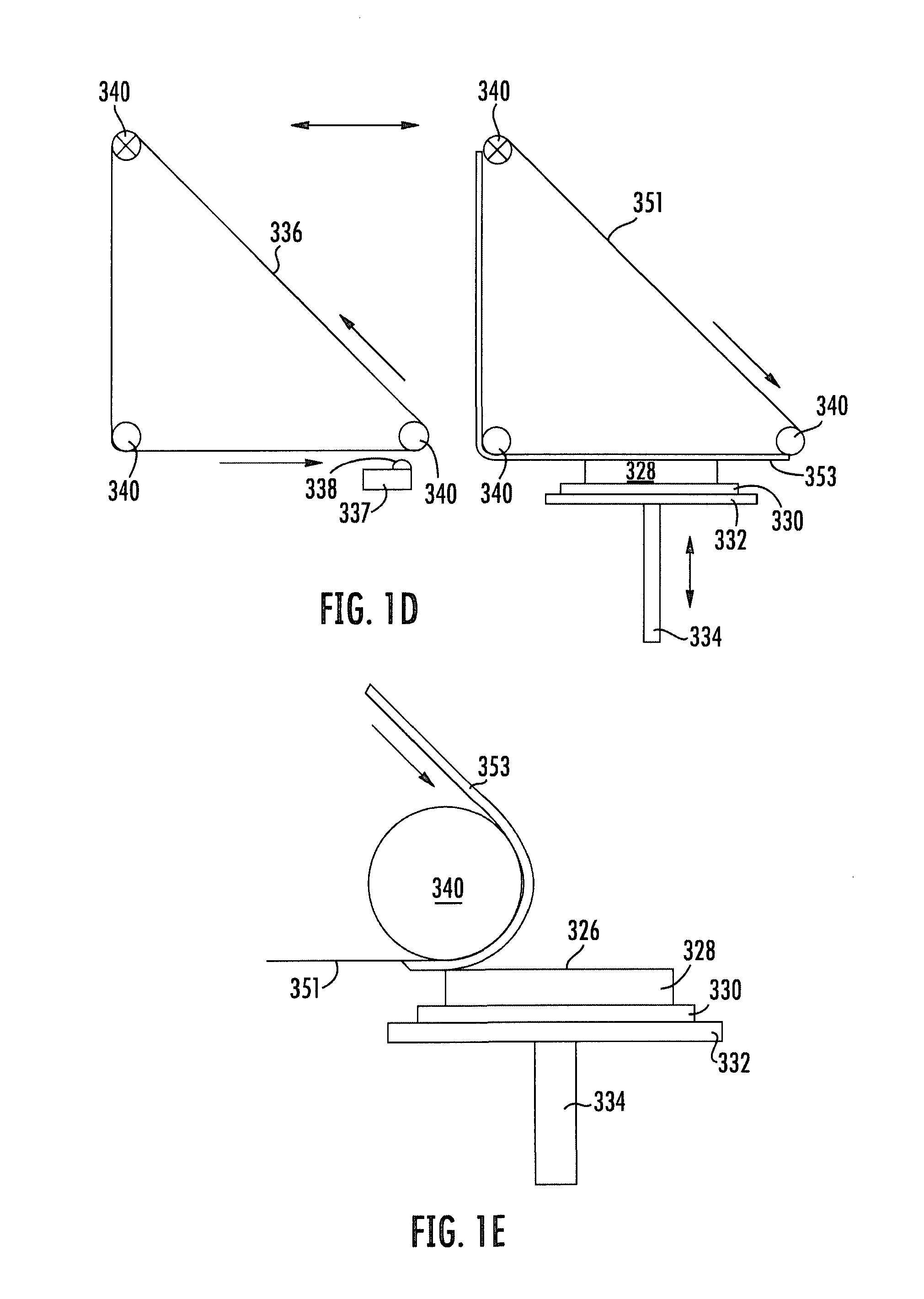

Inkjet Solid Imaging System and Method for Solid Imaging

InactiveUS20080226346A1Reduced post-build processing requirementPrecise alignmentAdditive manufacturing with liquidsElectrographic process apparatusEngineeringUltimate tensile strength

Solid imaging apparatus and methods for use are disclosed that reduce the amount of uncured solid imaging build material remaining on a completed build object following the completion of the solid imaging build process. The amount of uncured build material is reduced through the use of either an uncoating web that removes excess build material from the build object during the course of the building process or an ink jet source of build material that uses only as much build material as is necessary for the fabrication of the build part. Also disclosed is an imager assembly for use with such a solid imaging apparatus that incorporates two or more individual imagers in an array and accounts for variations in the intensity and alignment of adjacent imagers. The apparatus can be modified for semi-continuous operation and for integrating into a manufacturing operation, if desired.

Owner:3D SYST INC

PWM controller for synchronous rectifier of flyback power converter

A synchronous rectifier PWM (SR-PWM) controller controls a MOSFET in response to the value of a secondary current and the status of a synchronous signal for both discontinuous and continuous operation mode. The secondary current is generated in a secondary circuit and is detected by two threshold-detection terminals of the SR-PWM controller. The SR-PWM controller produces the synchronous signal by detecting a switching signal of the transformer via a detection terminal of the SR-PWM controller. Furthermore, a delay-time is inserted after the MOSFET is turned off and before the next switching cycle starts to ensure a proper operation of the MOSFET. In one embodiment, an equivalent series resistance (ESR) of an output capacitor can be used as a sensor to detect the secondary current. Therefore, no additional current sensor is required.

Owner:SEMICON COMPONENTS IND LLC

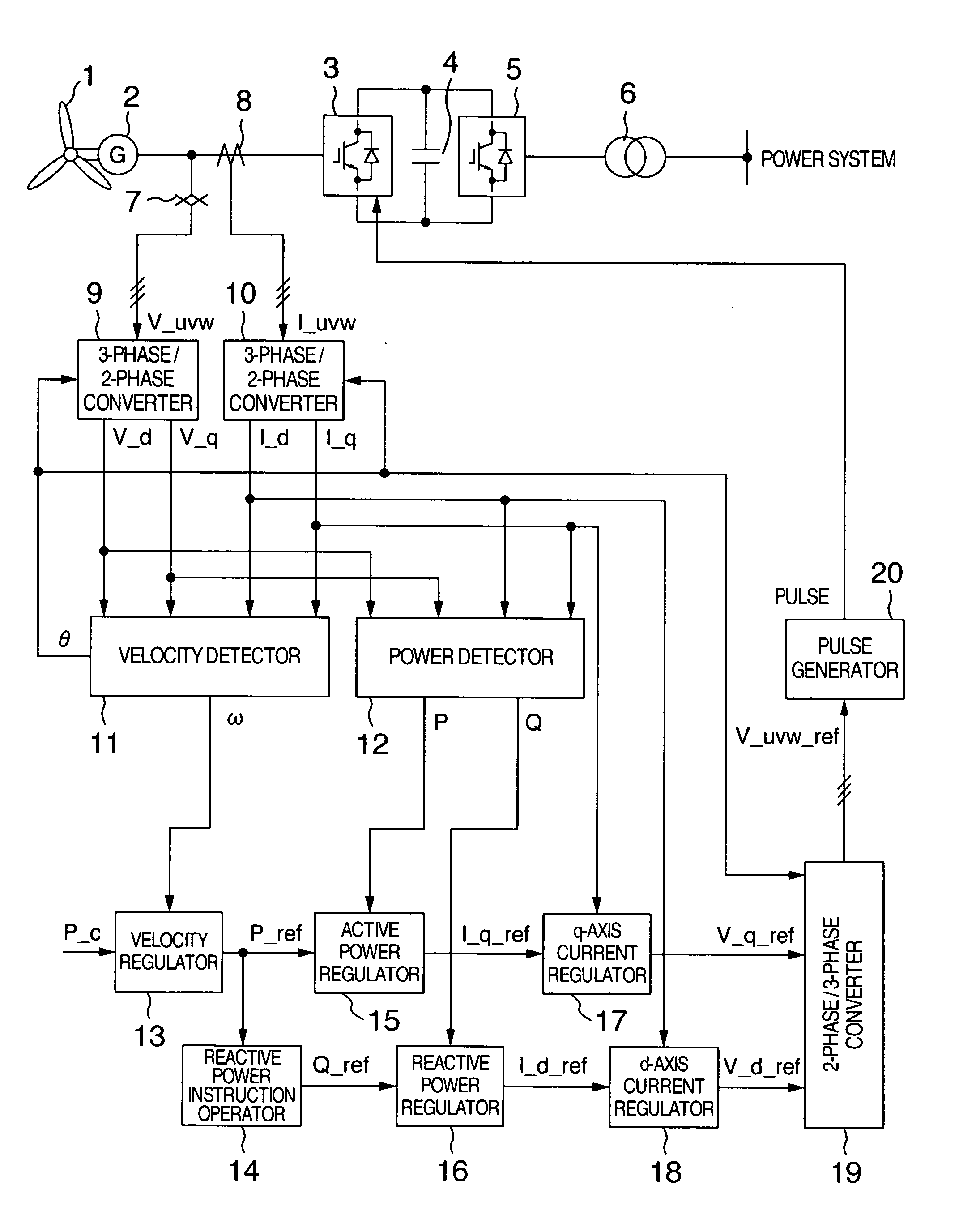

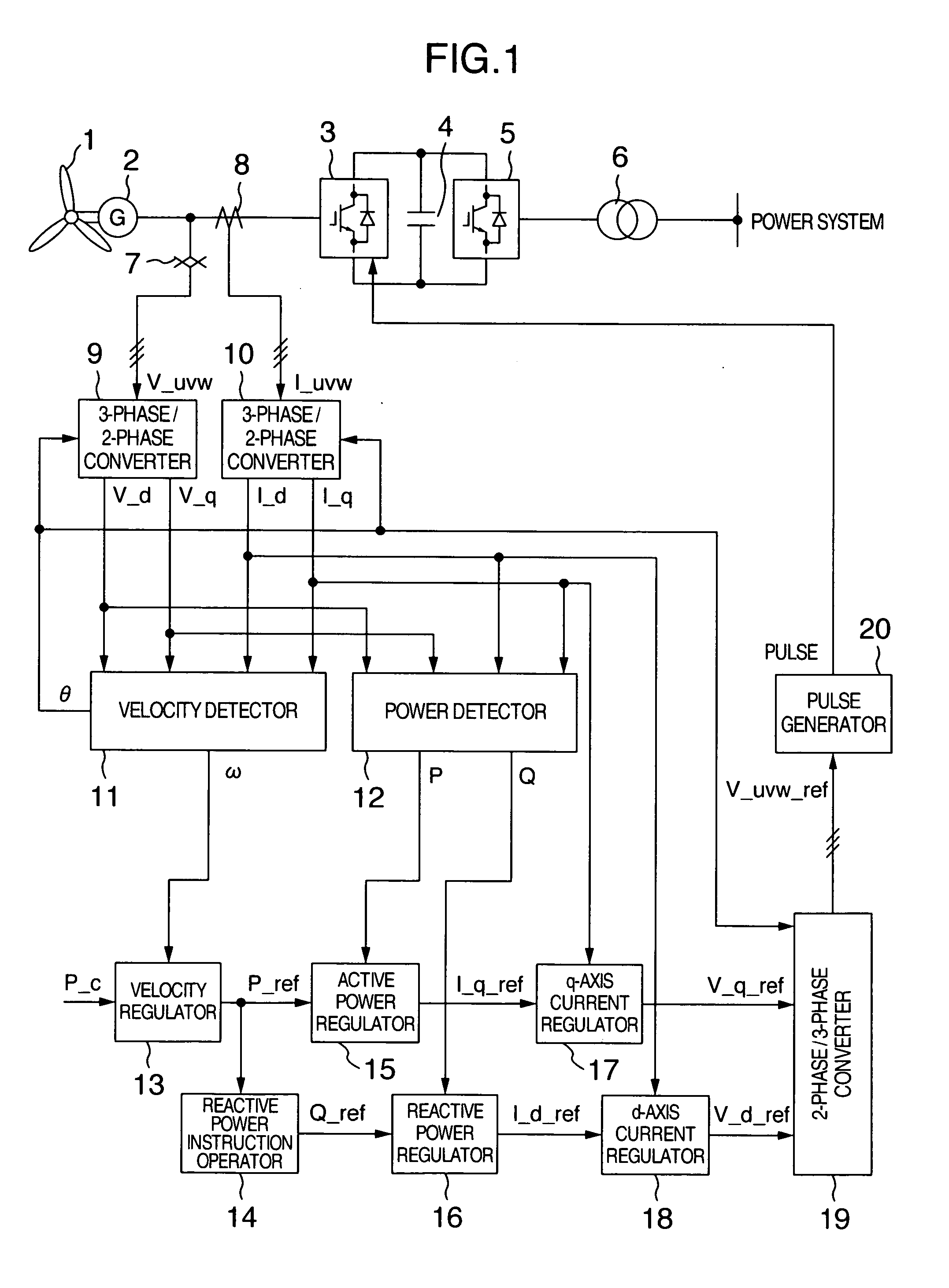

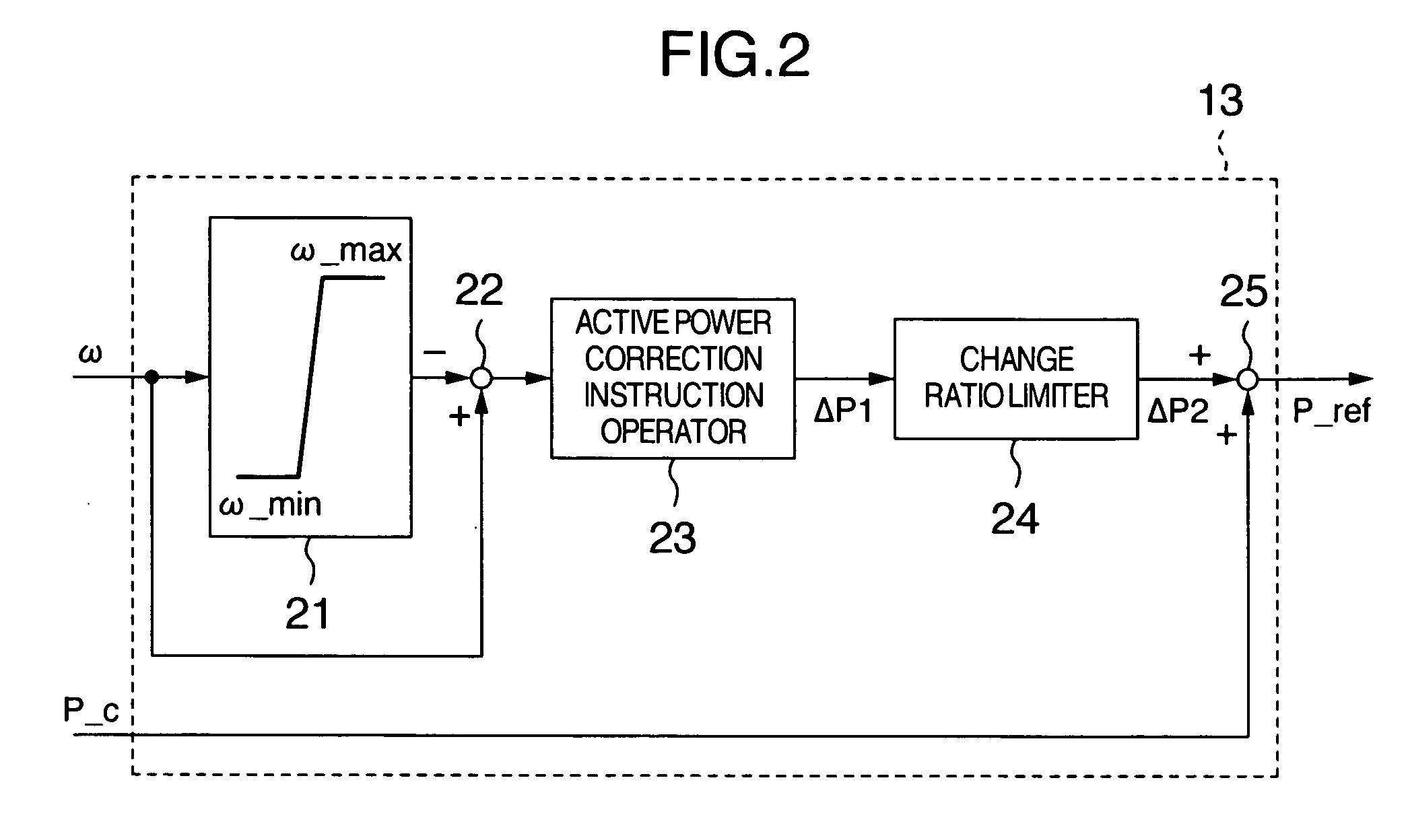

Wind turbine generator system

ActiveUS20060028025A1Suppress rotational velocityAvoid stopWind motor controlStatic indicating devicesTurbineContinuous operation

A wind turbine generator system can regulate the rotational velocity of the wind turbine within an operation range even when the wind velocity suddenly changes and can perform continuous operation of the wind turbine. The wind turbine generator system includes a generator connected to the shaft of the wind turbine and a converter connected to the generator. When the rotational velocity of the wind turbine is within a predetermined range, power outputted from the generator is controlled so as to follow the instruction concerning the generator output given from the wind turbine to the converter. When the rotational velocity of the wind turbine is out of the predetermined range, the power outputted from the generator is controlled without following the instruction concerning generator output given from the wind turbine to the converter.

Owner:HITACHI IND PROD LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com