Patents

Literature

1905 results about "Light hydrocarbons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

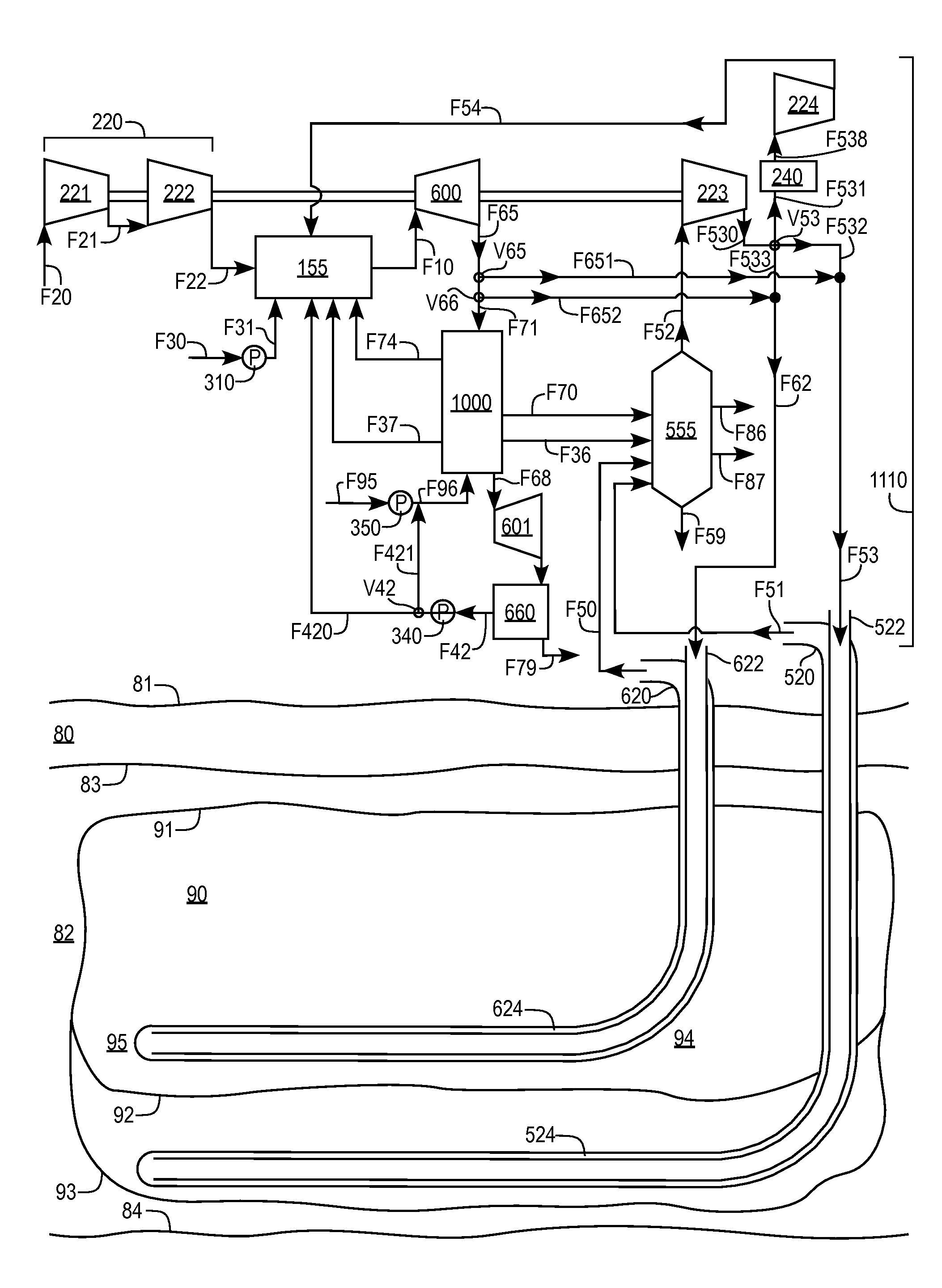

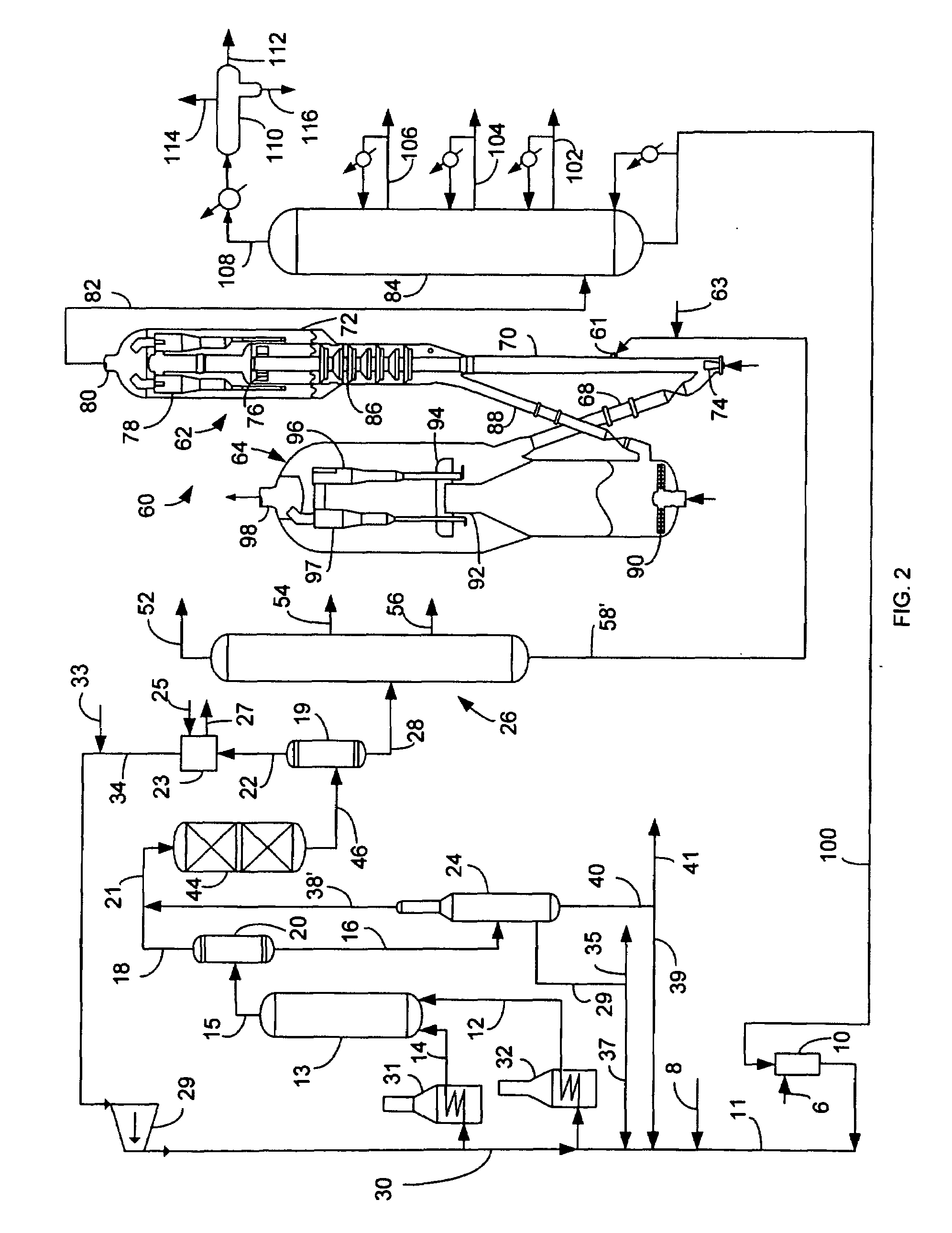

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

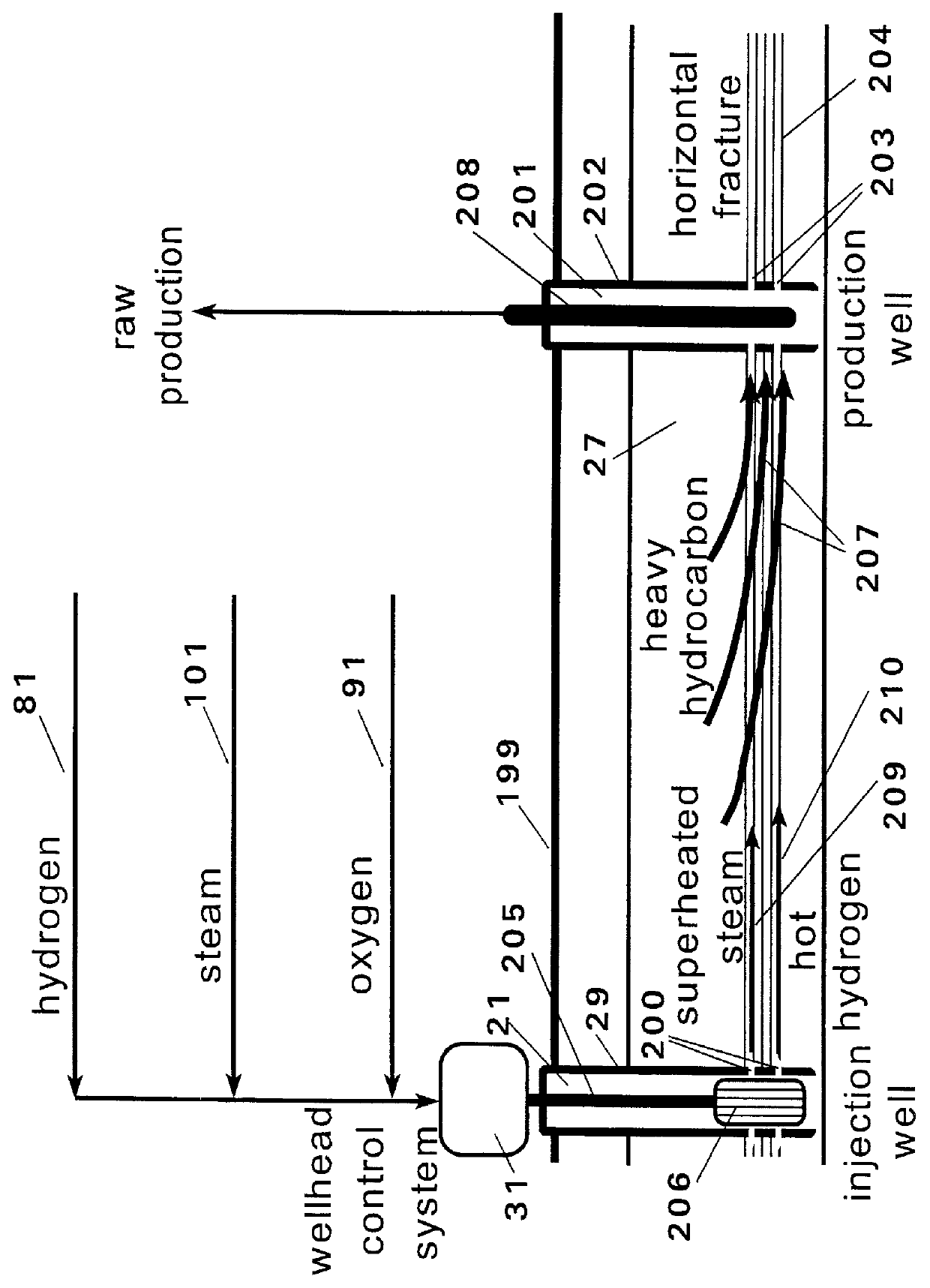

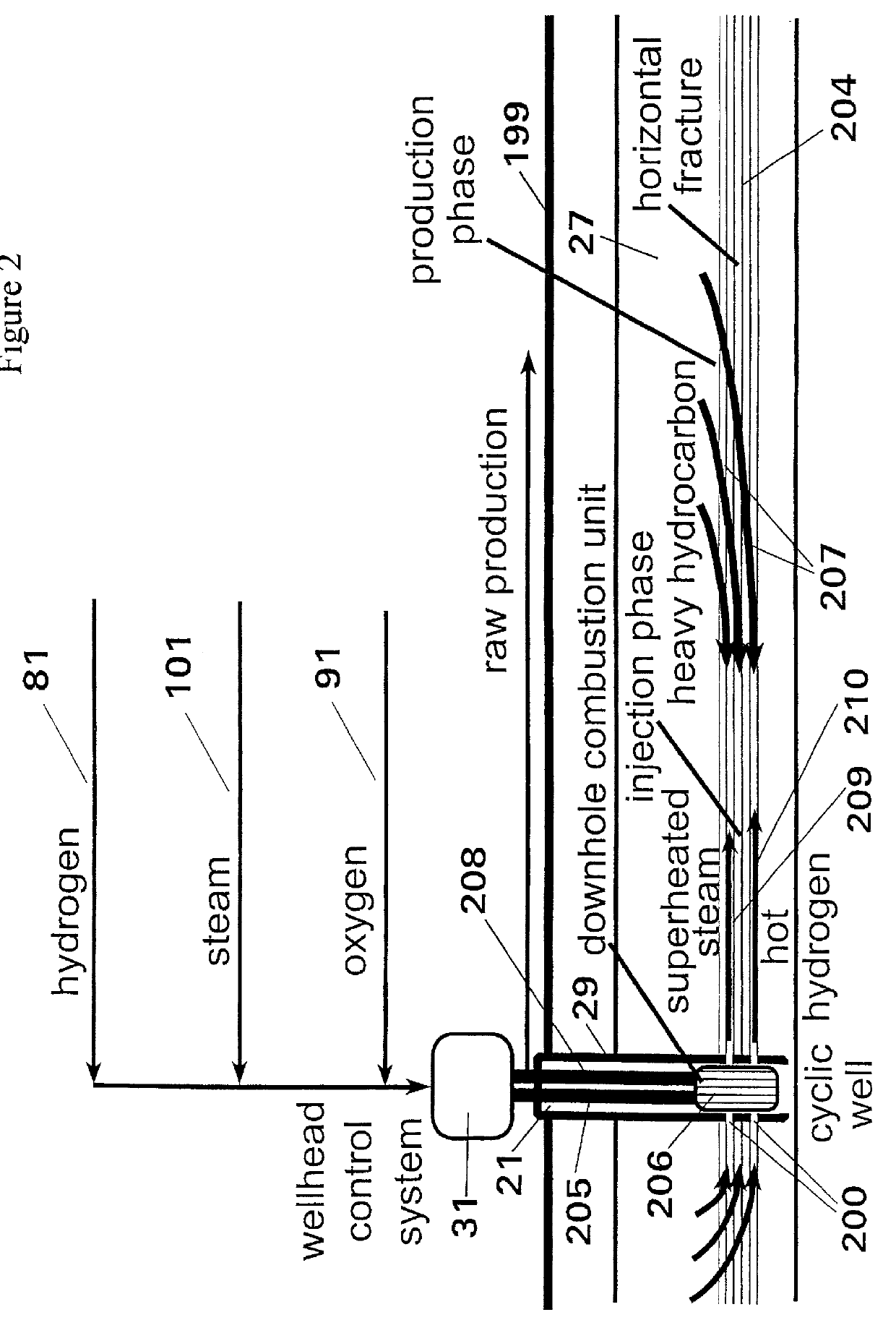

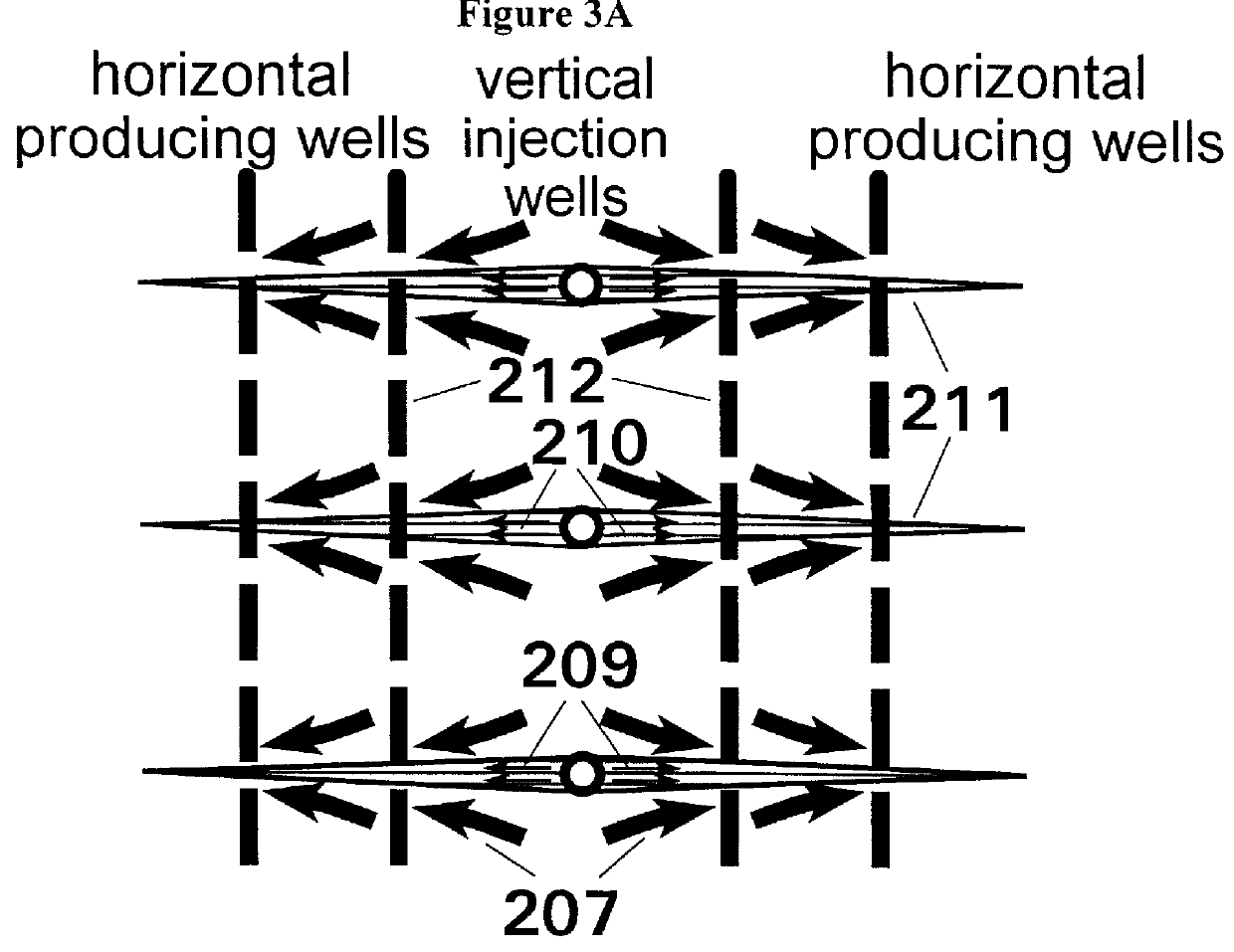

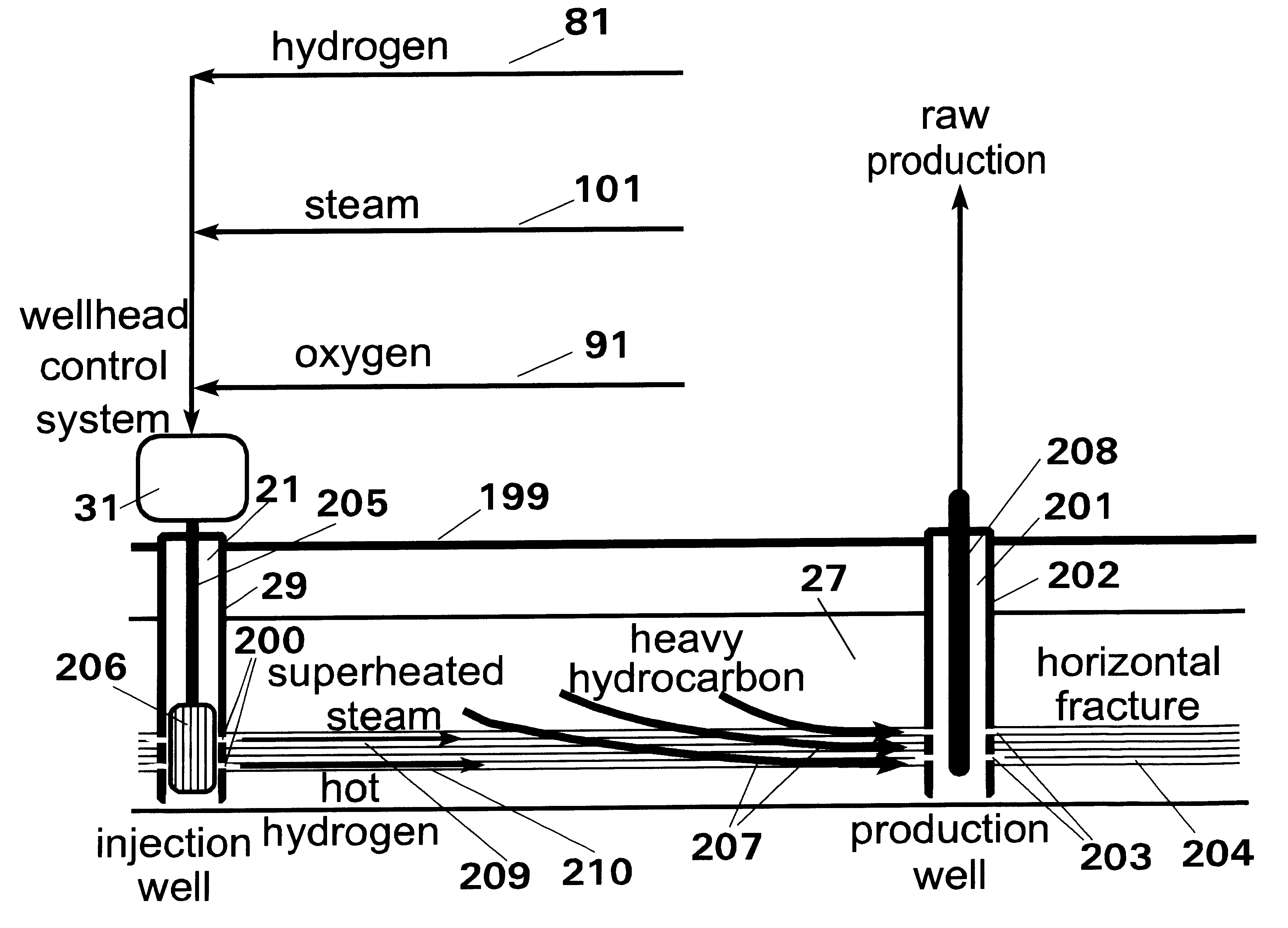

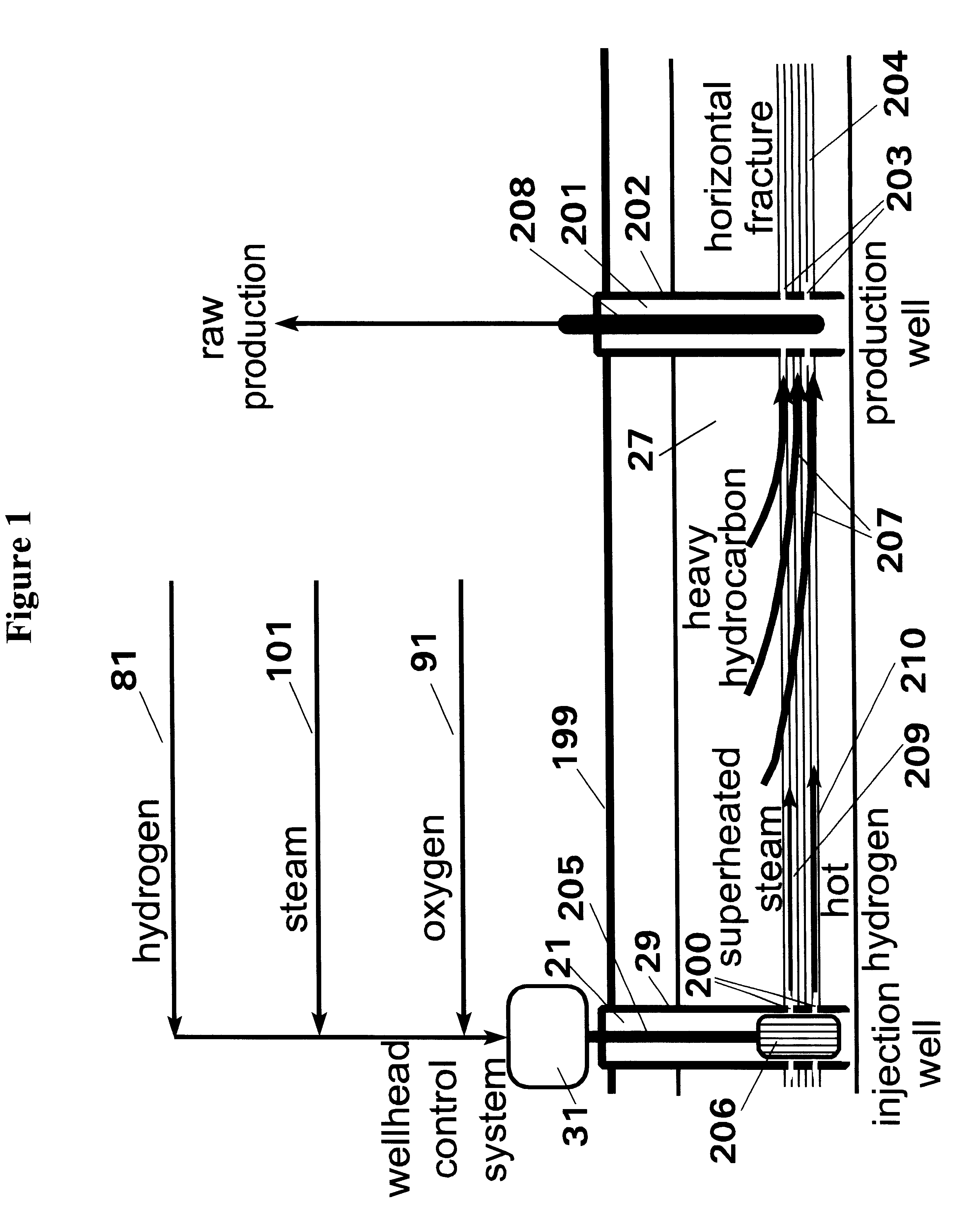

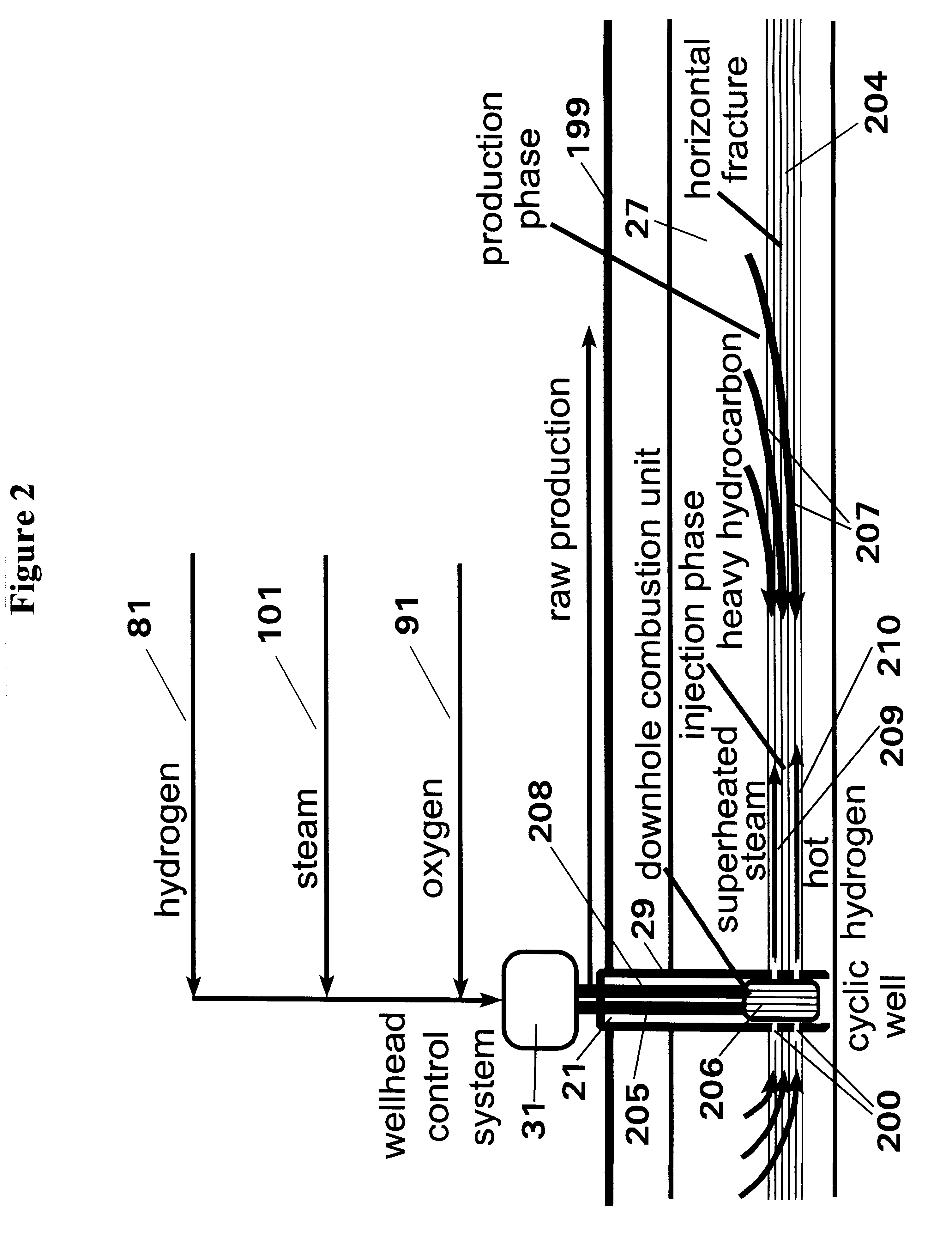

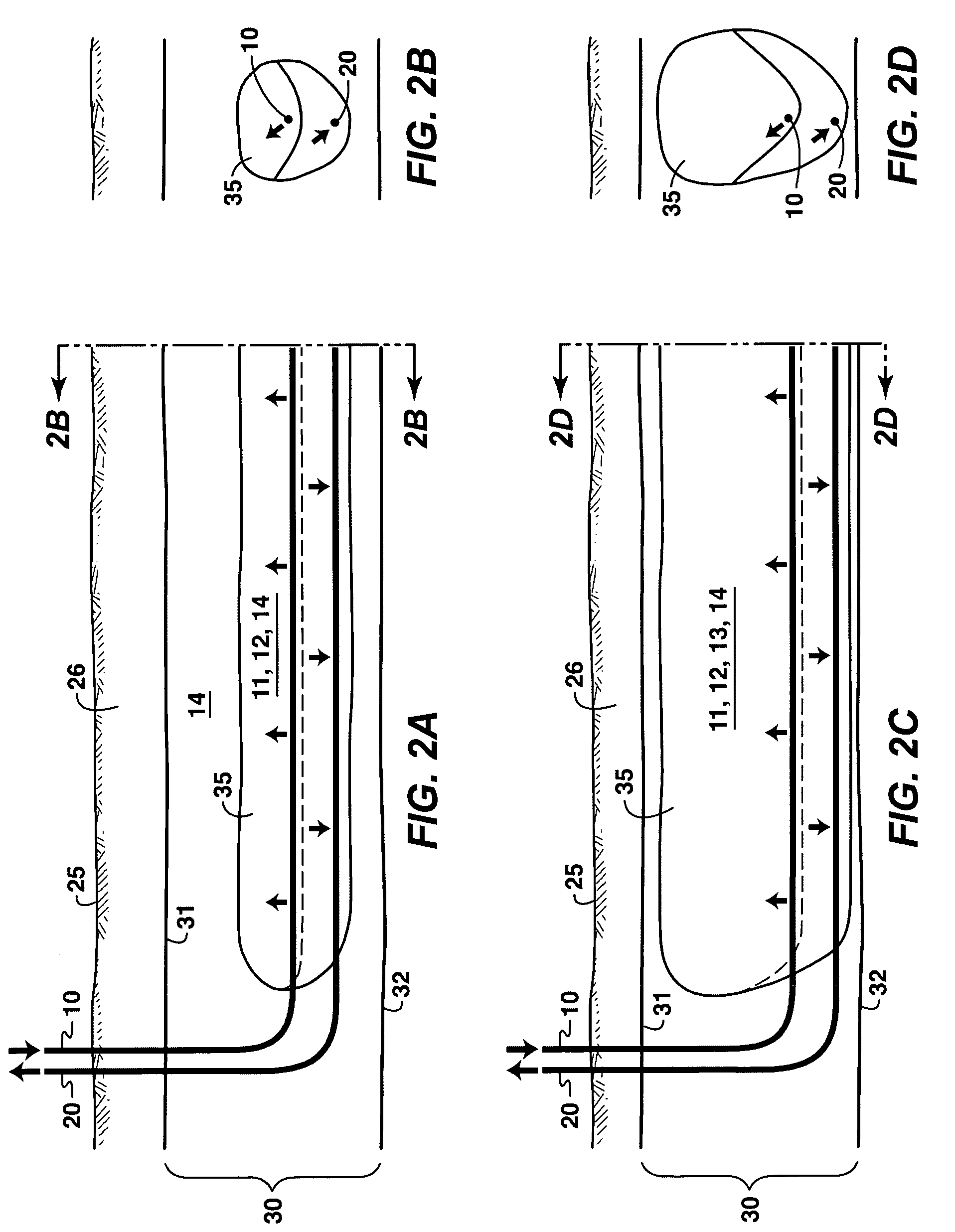

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

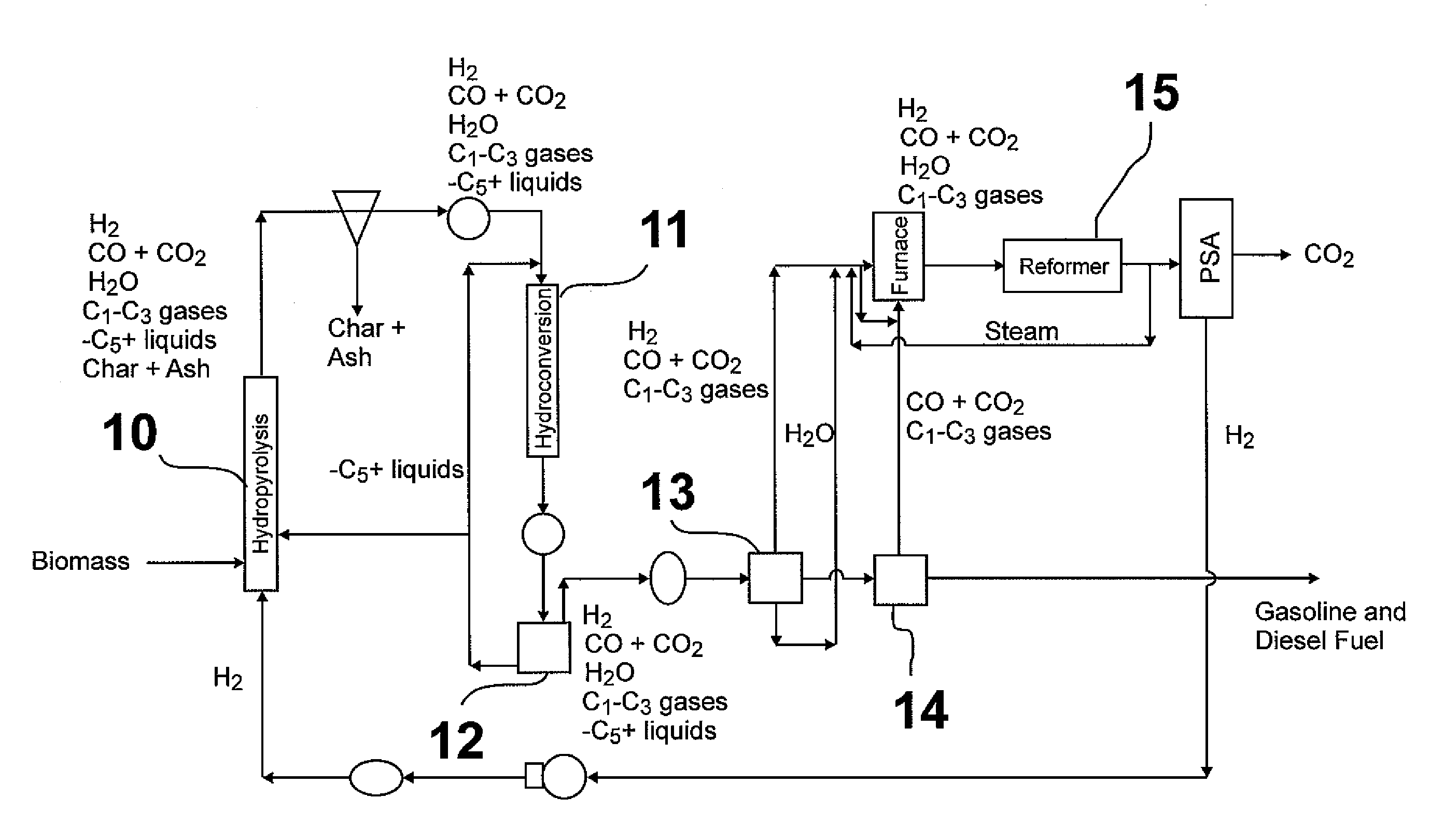

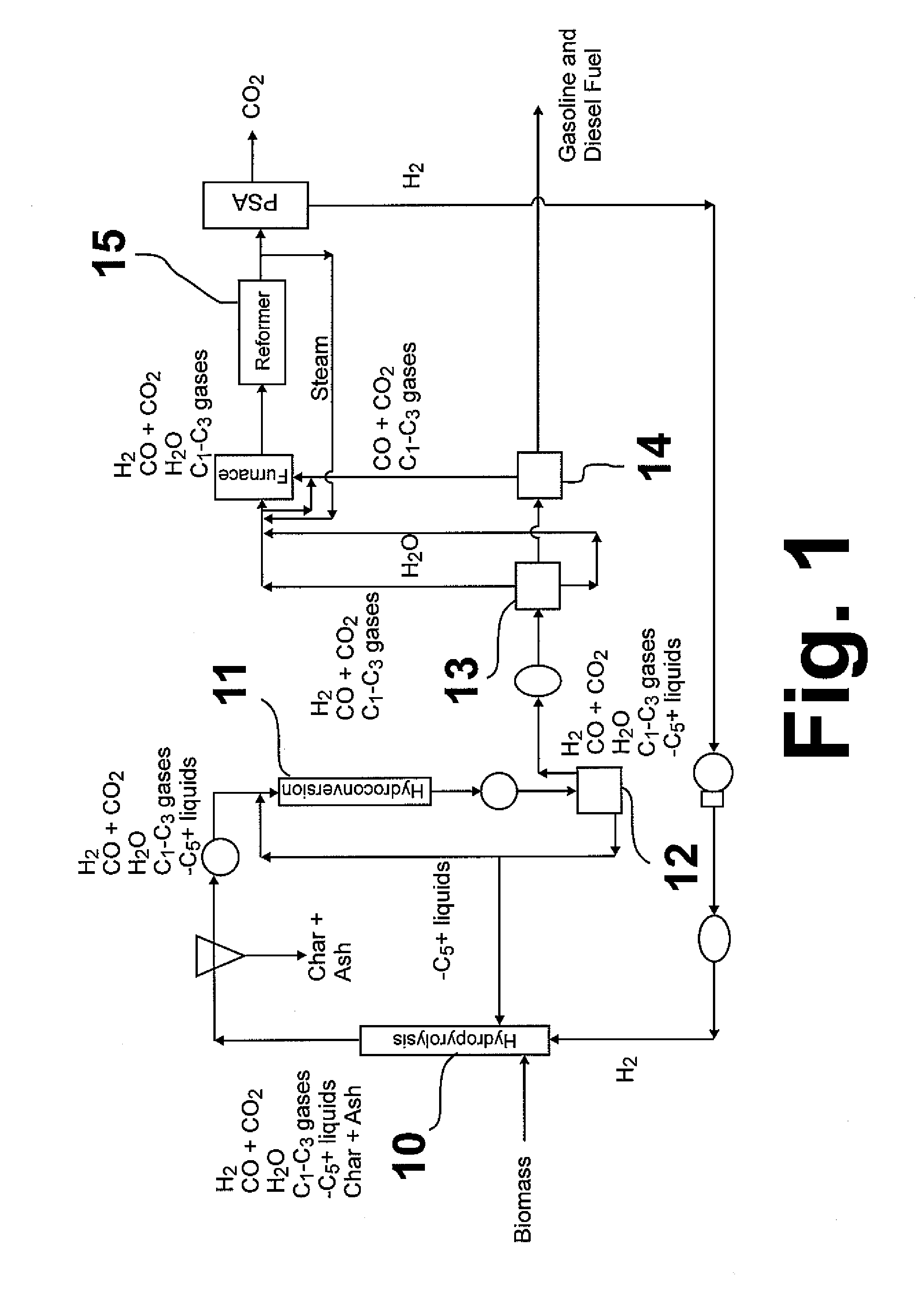

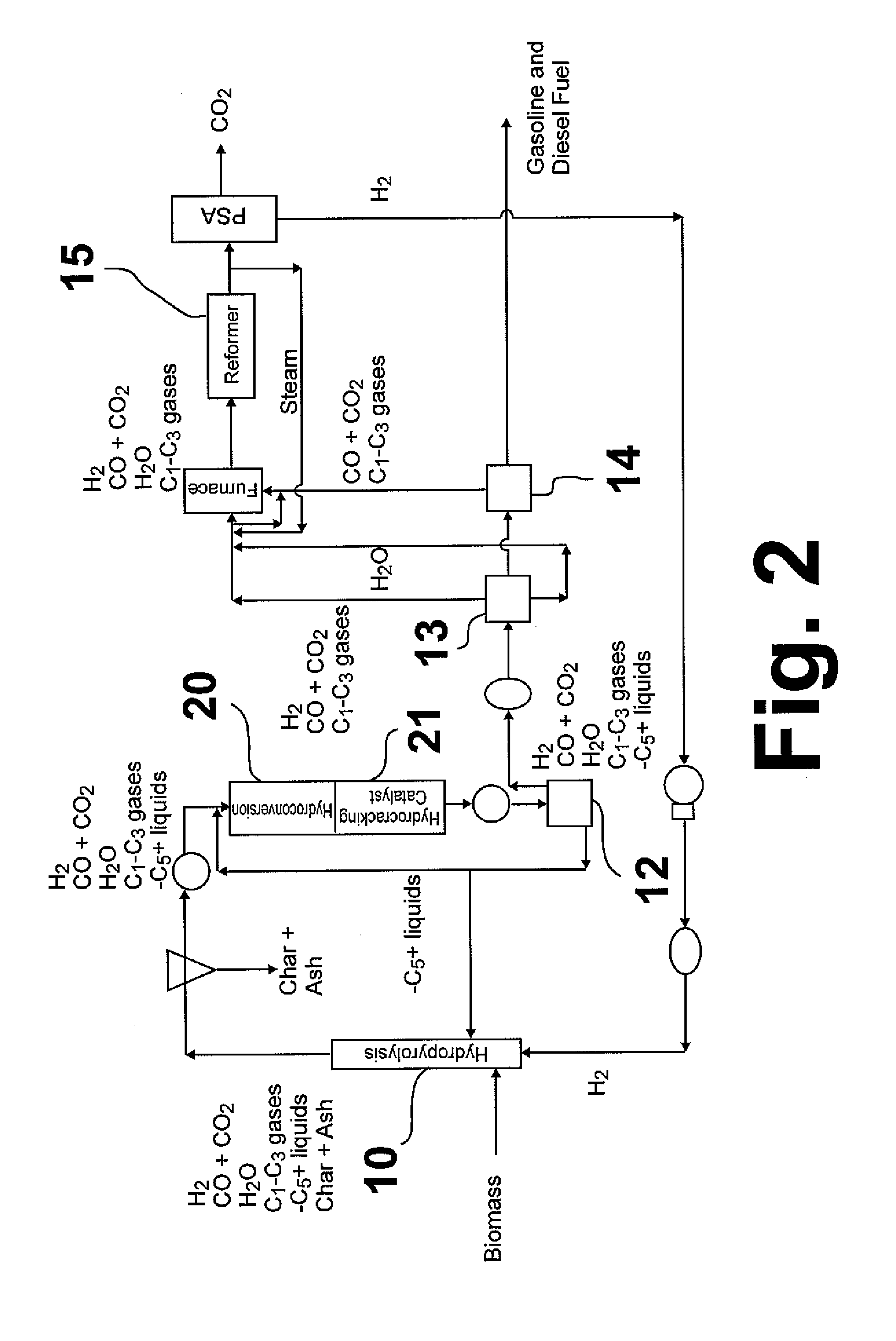

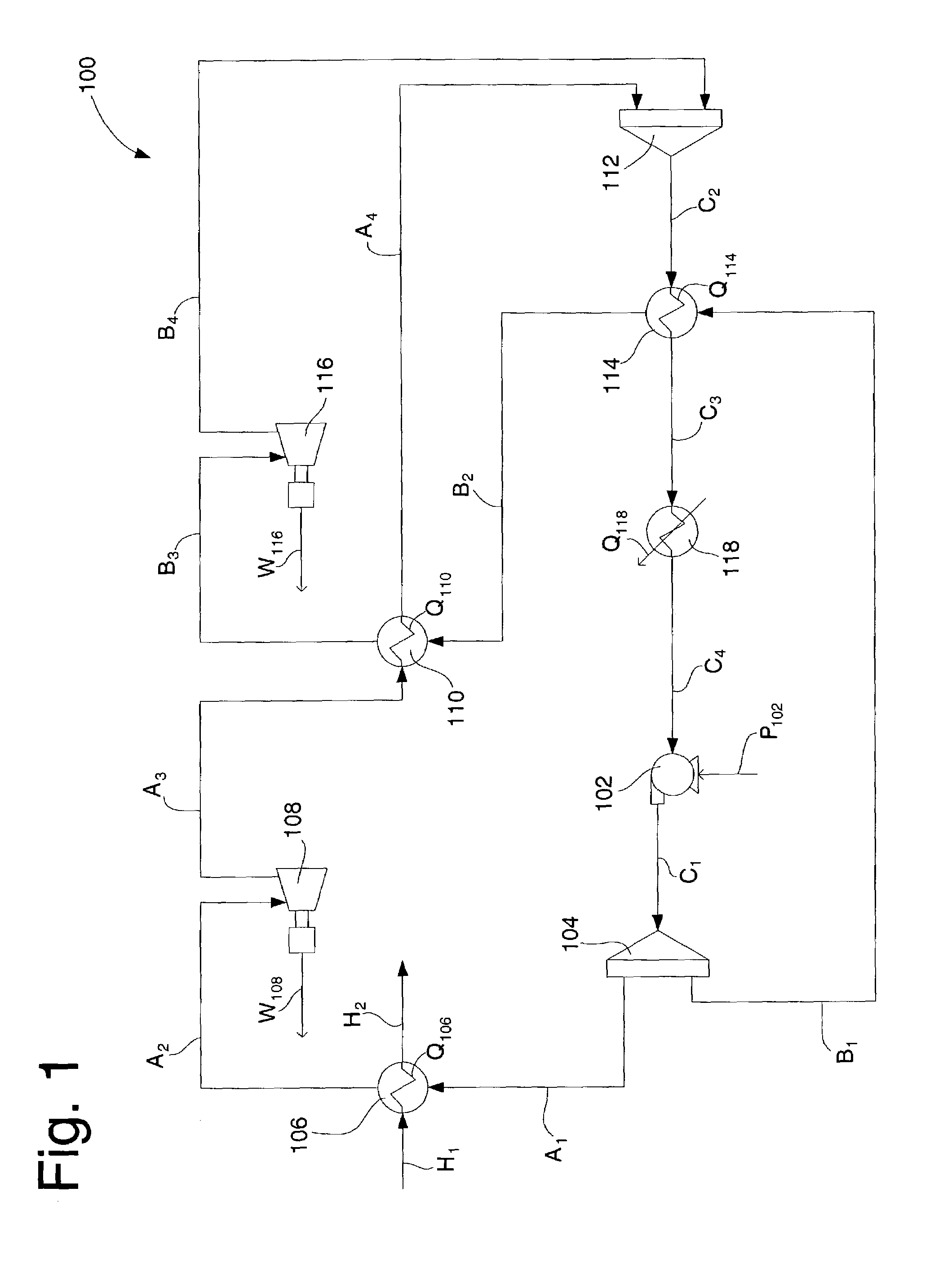

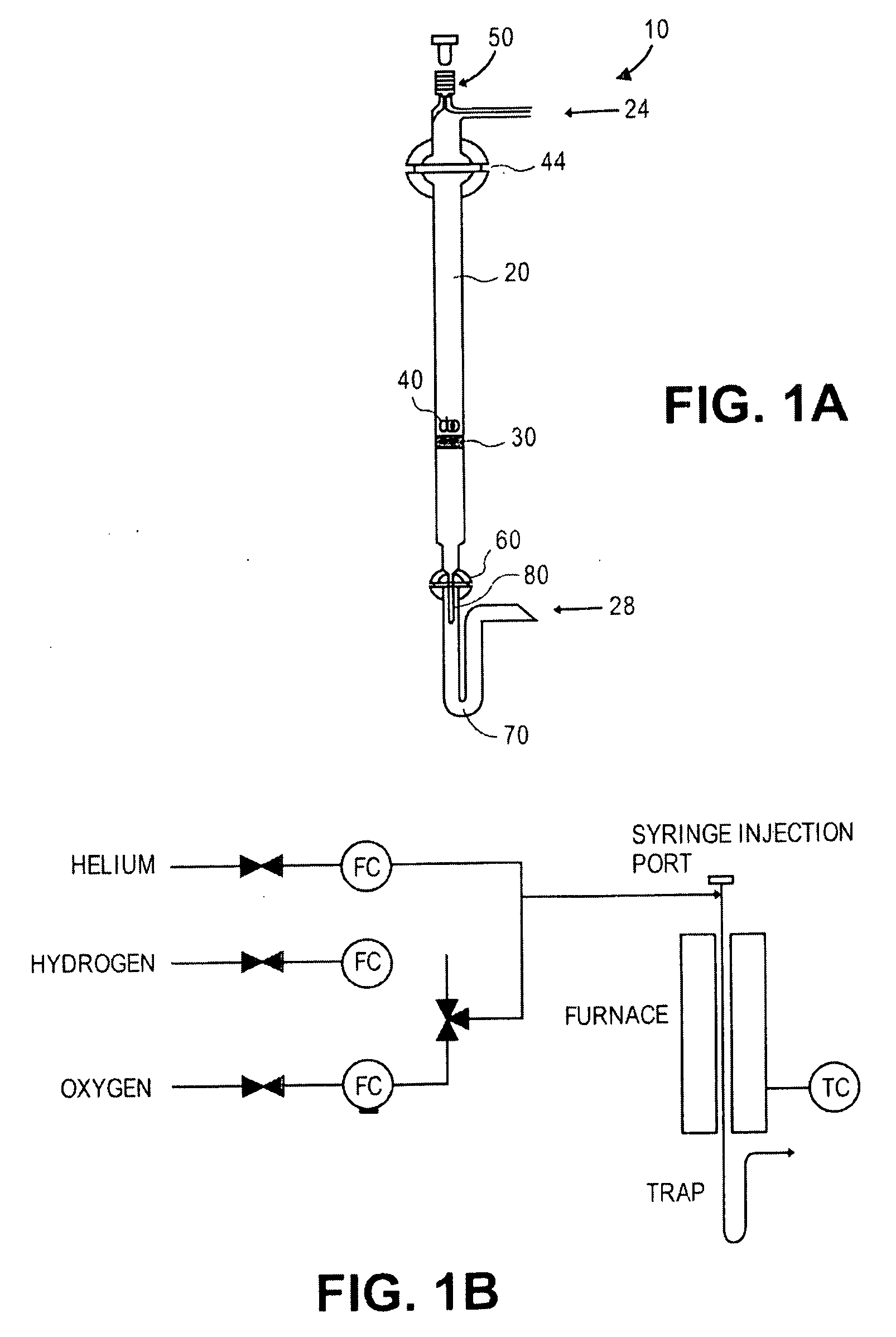

Hydropyrolysis of biomass for producing high quality liquid fuels

A self-sustaining process for producing high quality liquid fuels from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, producing a partially deoxygenated hydropyrolysis liquid, which is hydrogenated using a hydroconversion catalyst, producing a substantially fully deoxygenated hydrocarbon liquid and a gaseous mixture comprising CO and light hydrocarbon gases (C1-C3). The gaseous mixture is reformed in a steam reformer, producing reformed molecular hydrogen, which is then introduced into the reactor vessel for hydropyrolizing the biomass. The deoxygenated hydrocarbon liquid product is further separated to produce diesel fuel, gasoline, or blending components for gasoline and diesel fuel.

Owner:GAS TECH INST

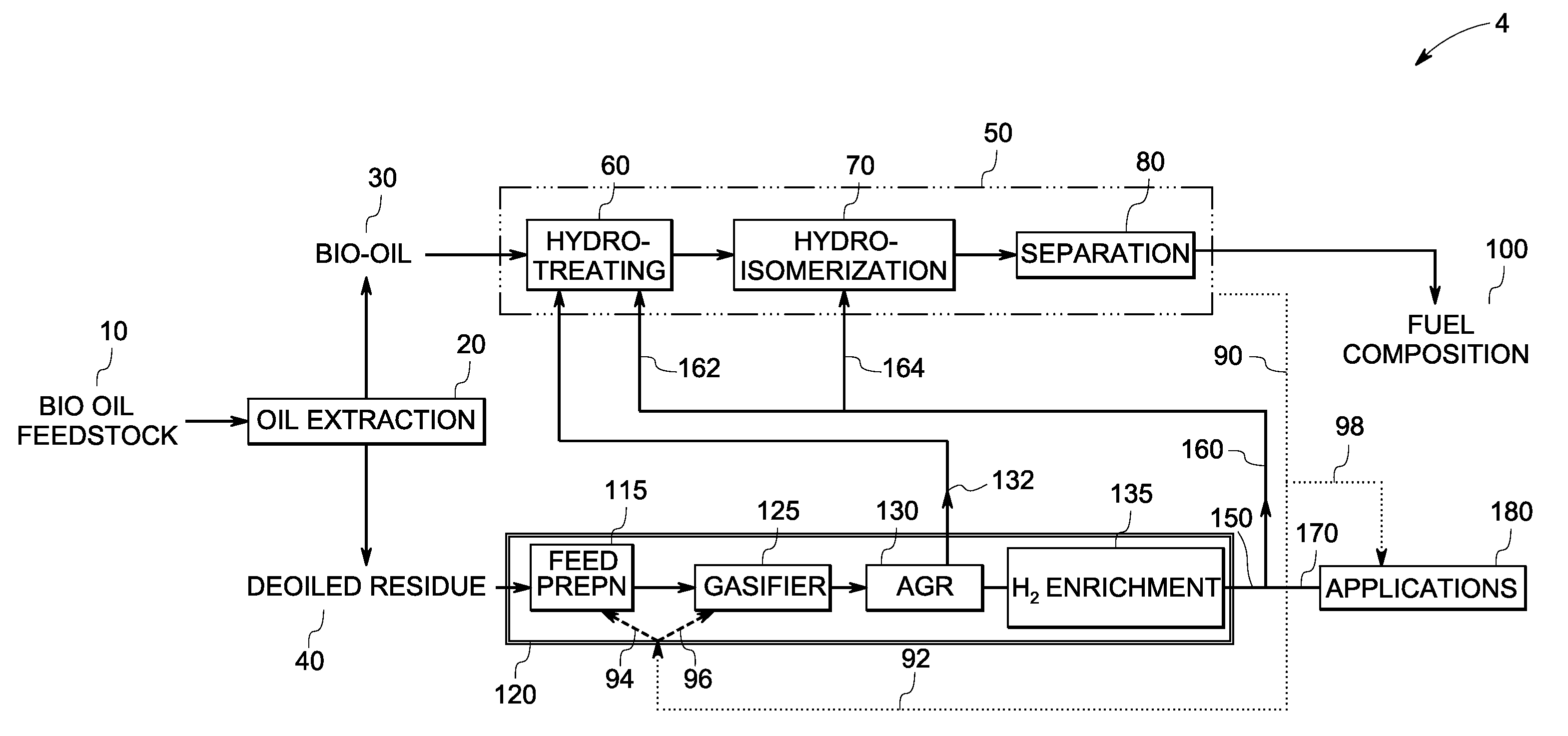

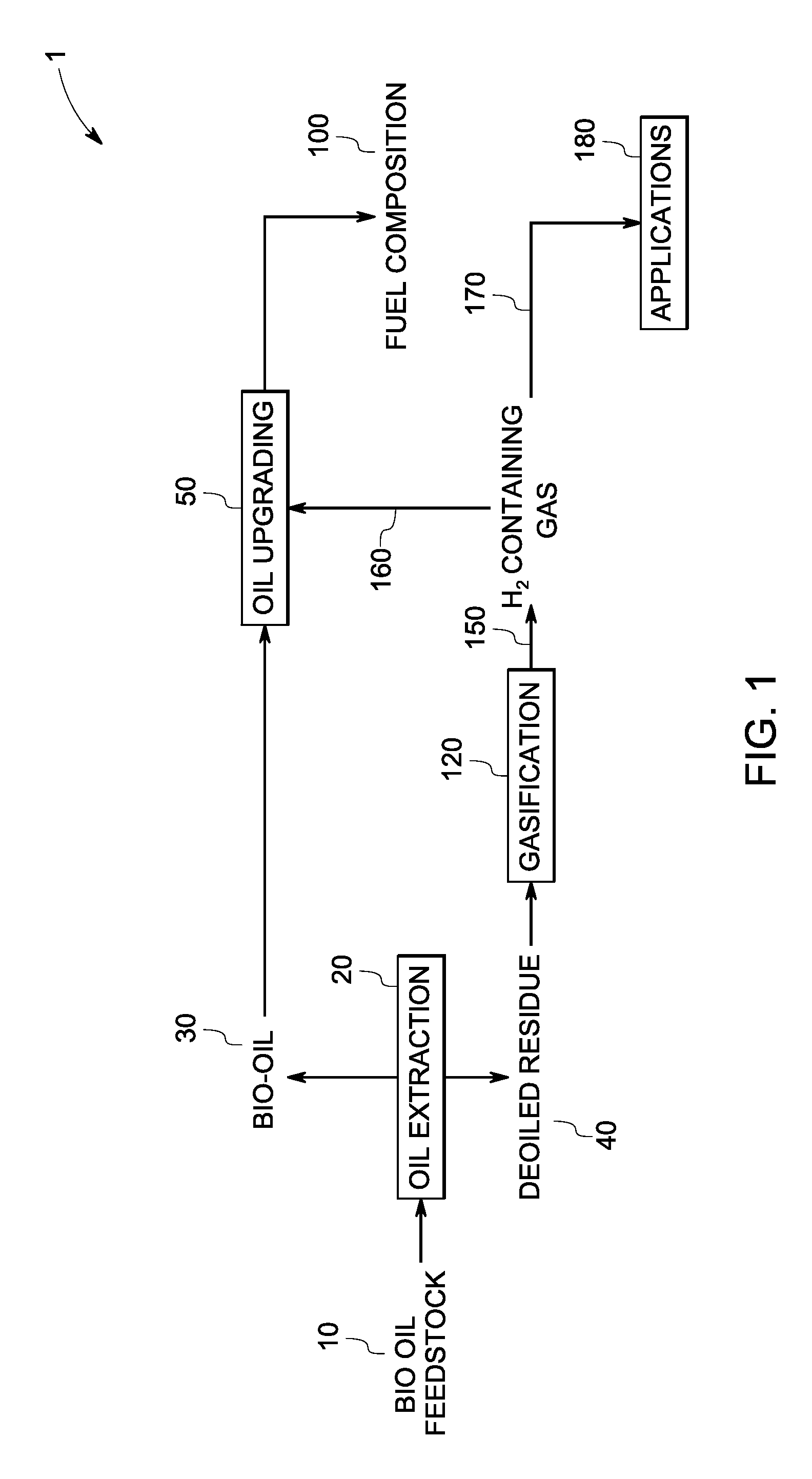

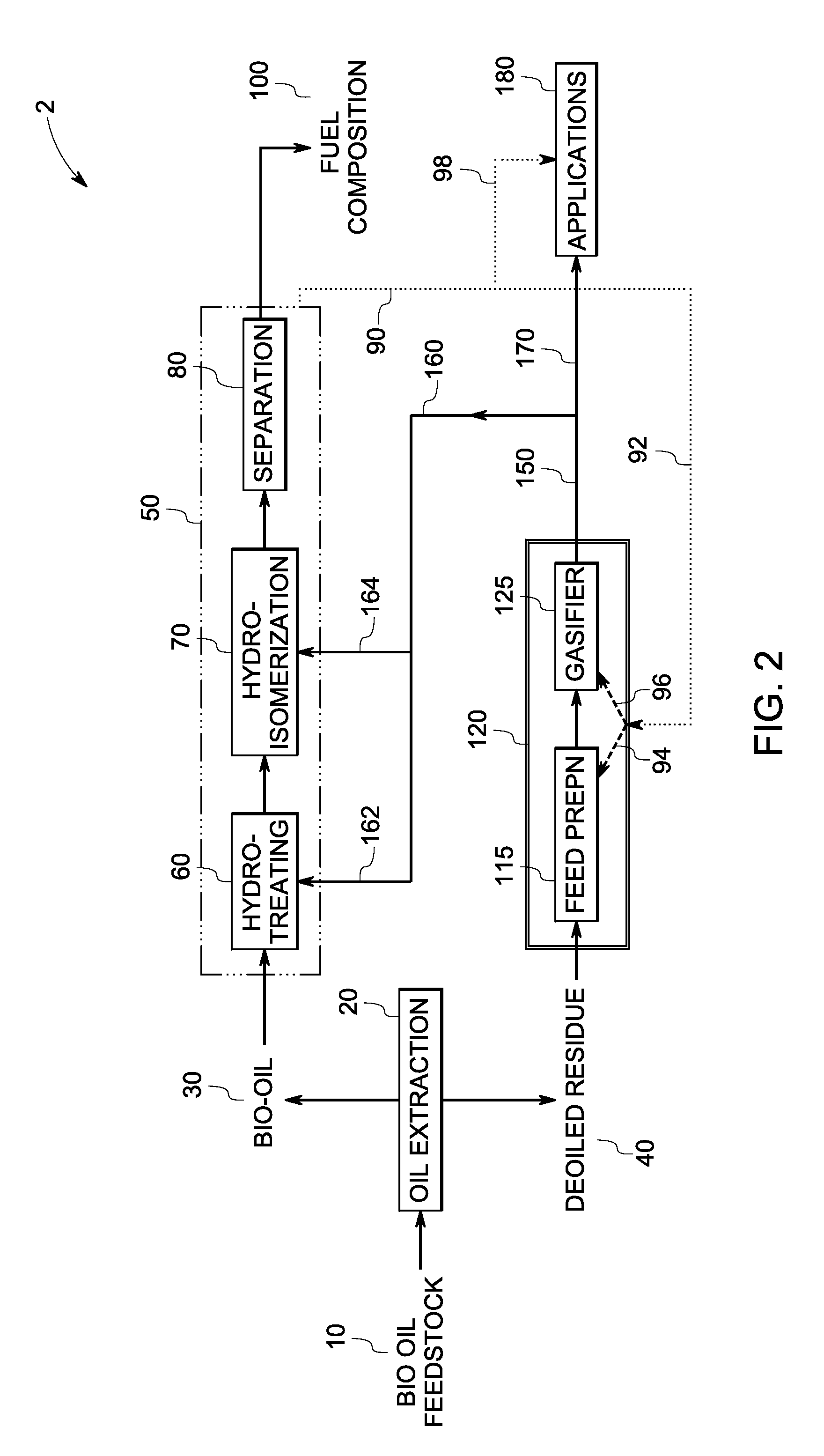

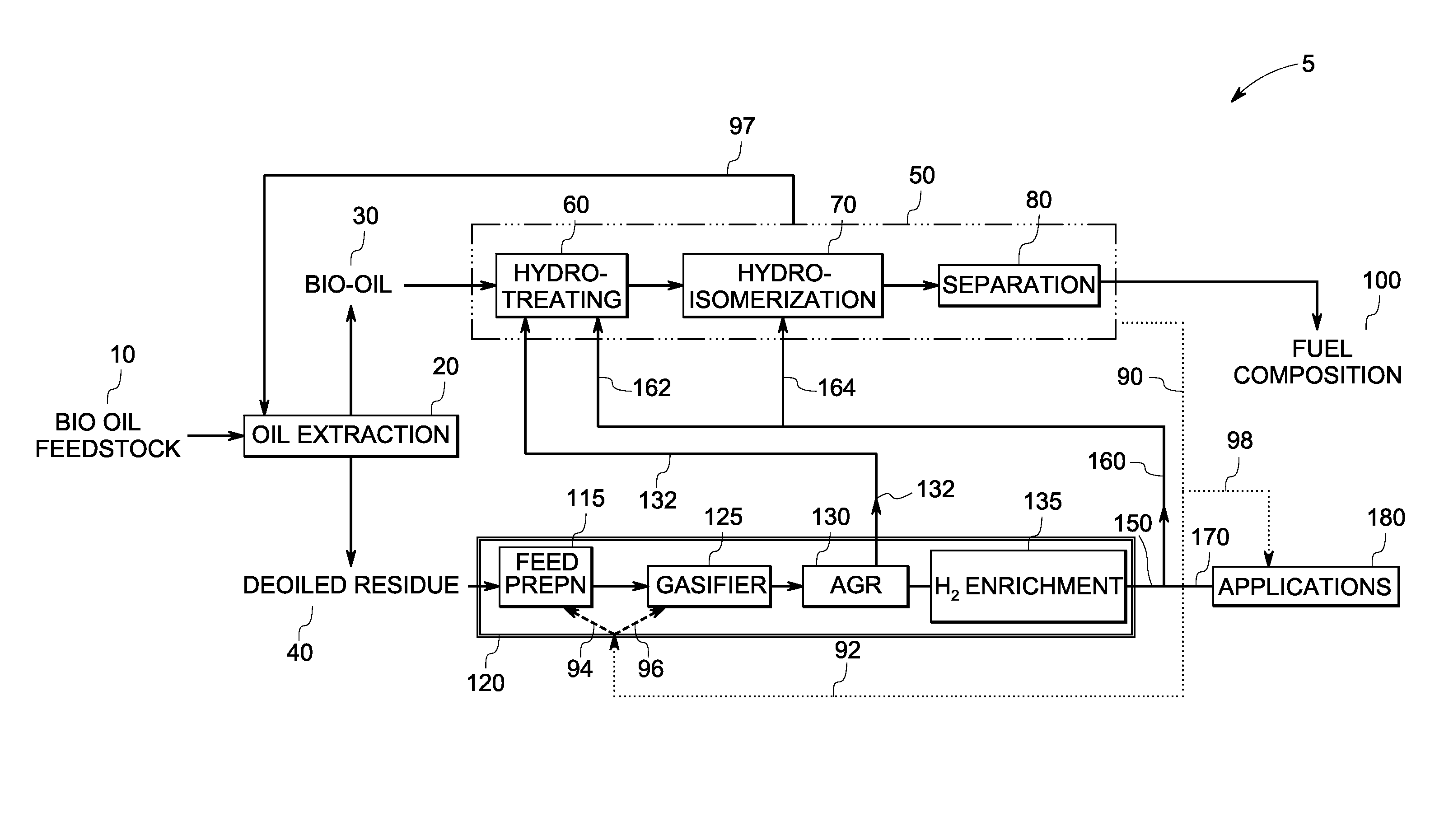

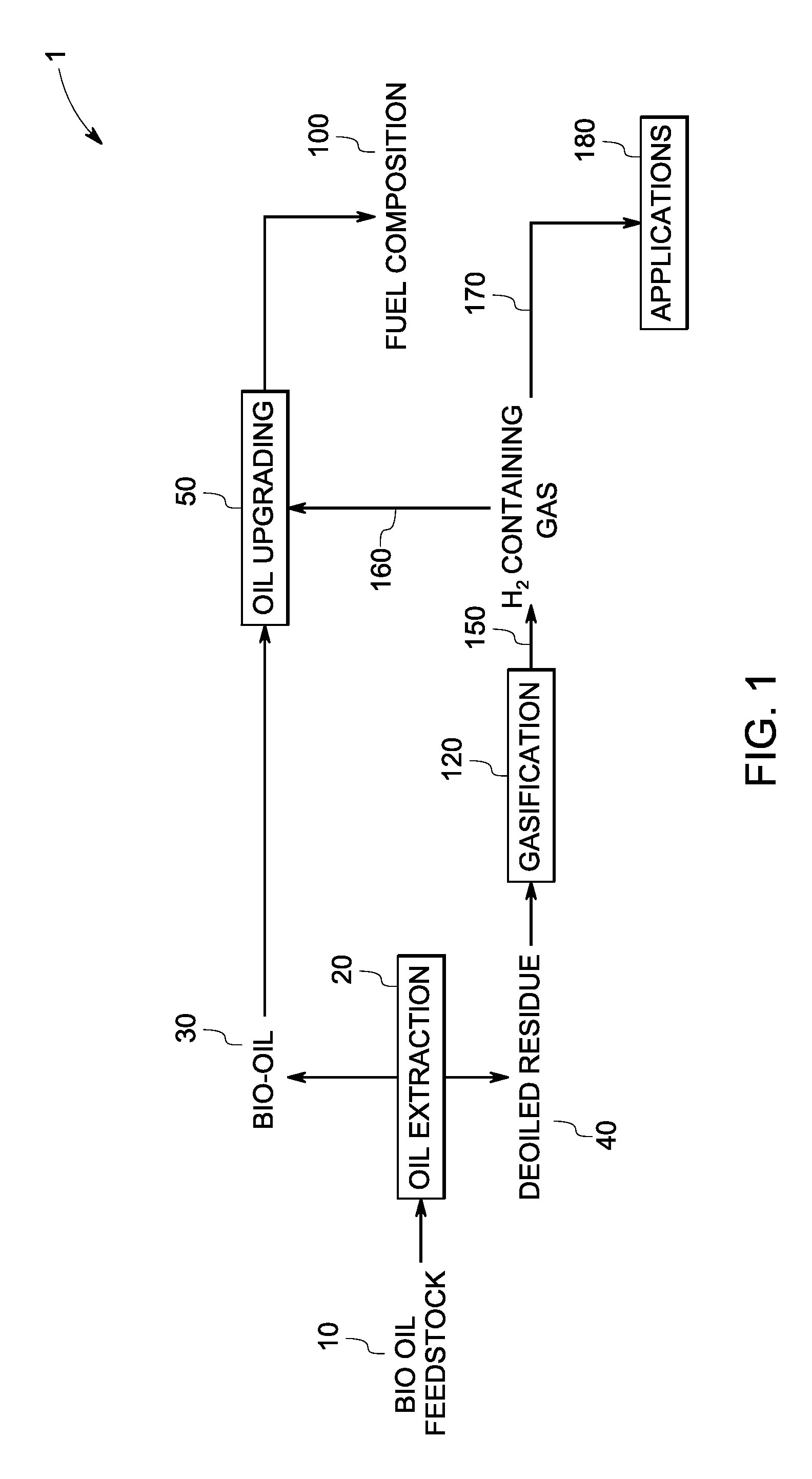

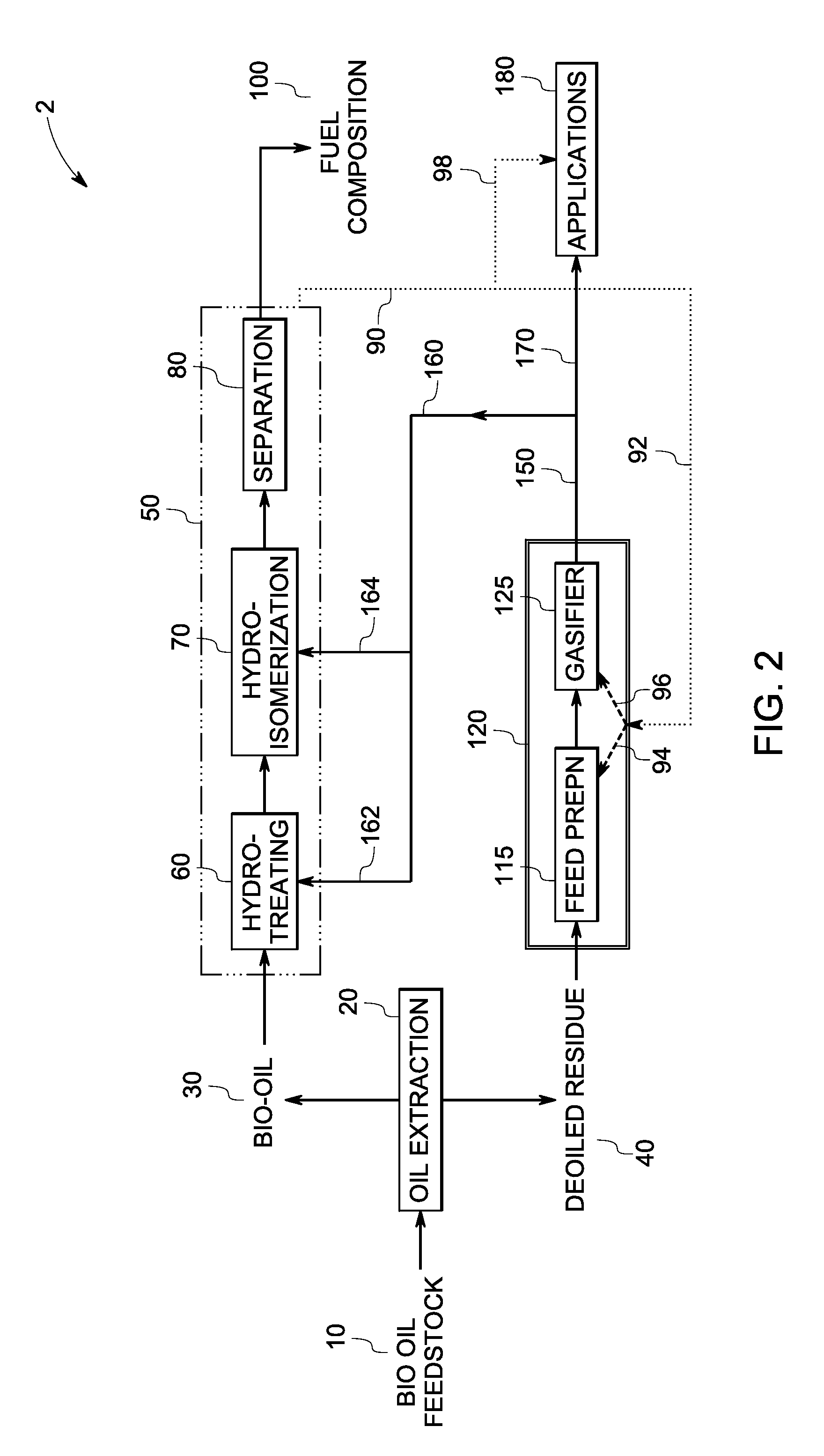

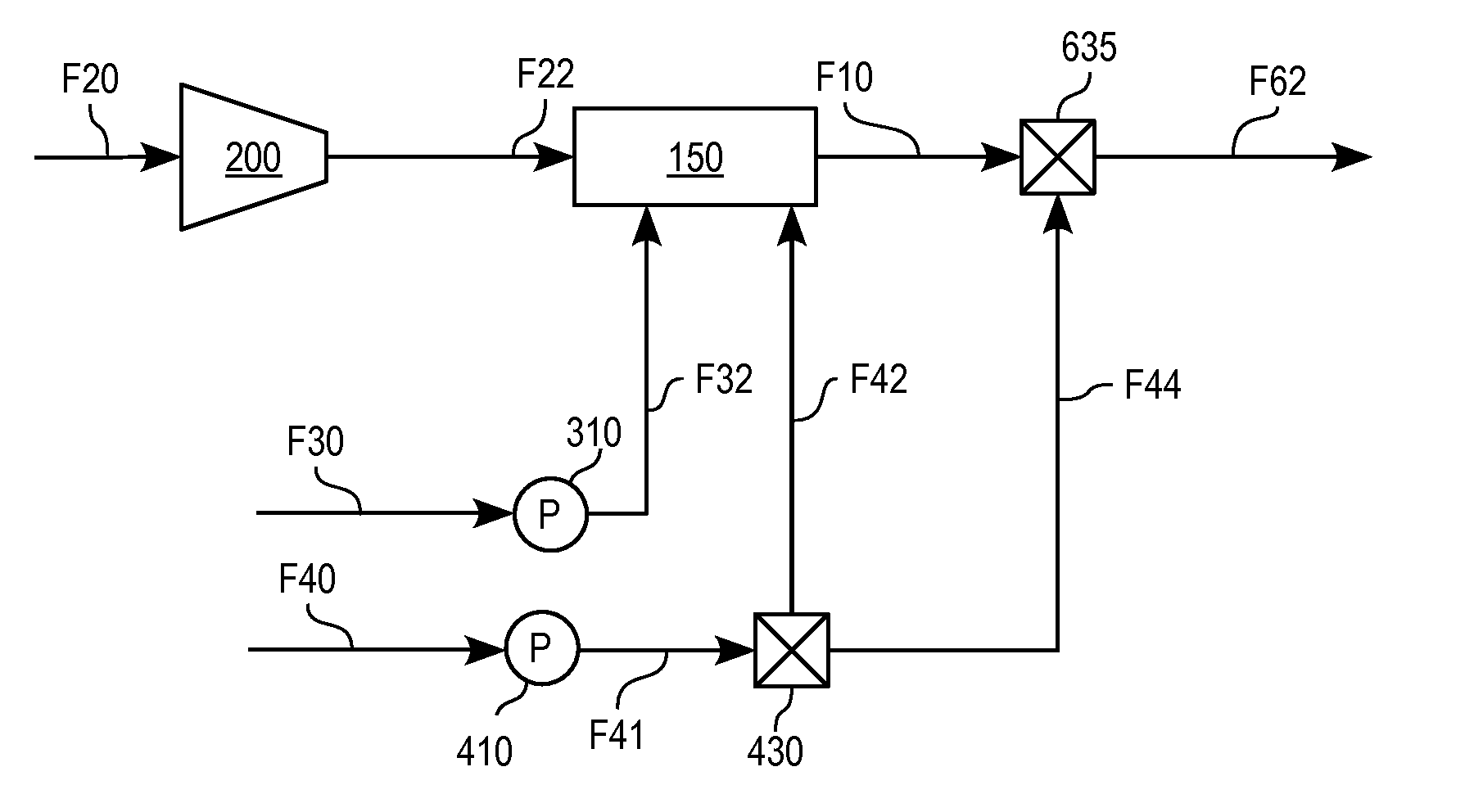

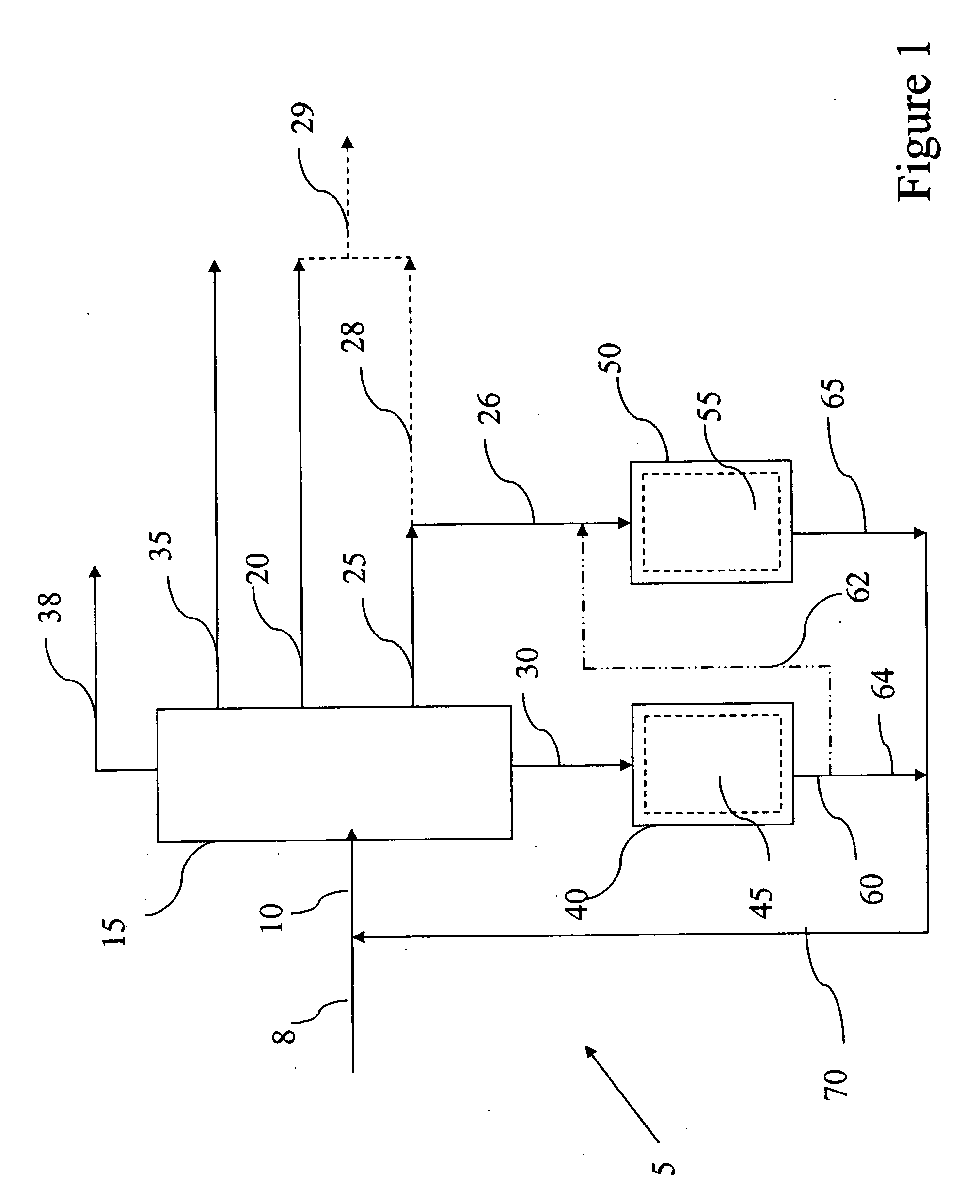

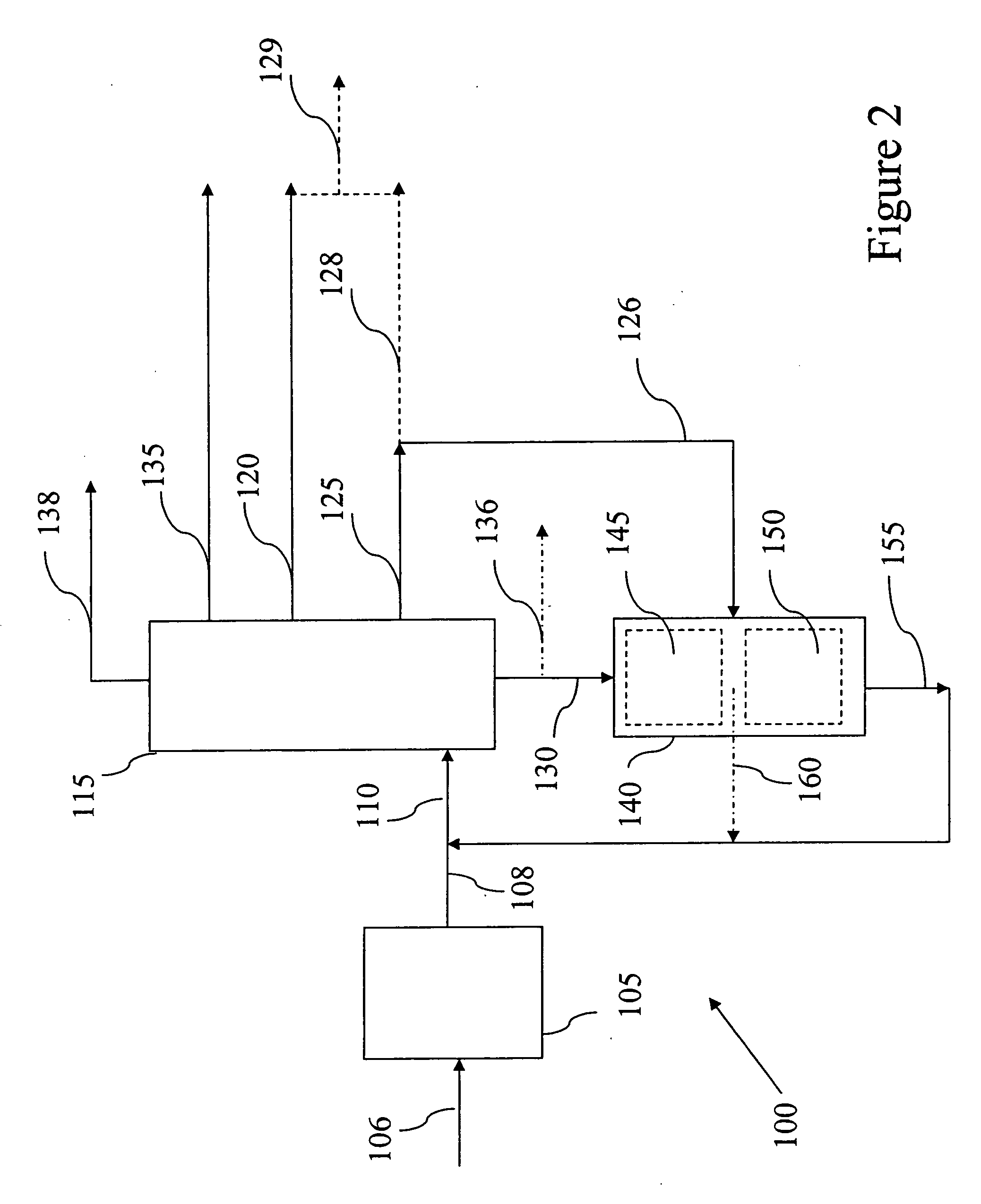

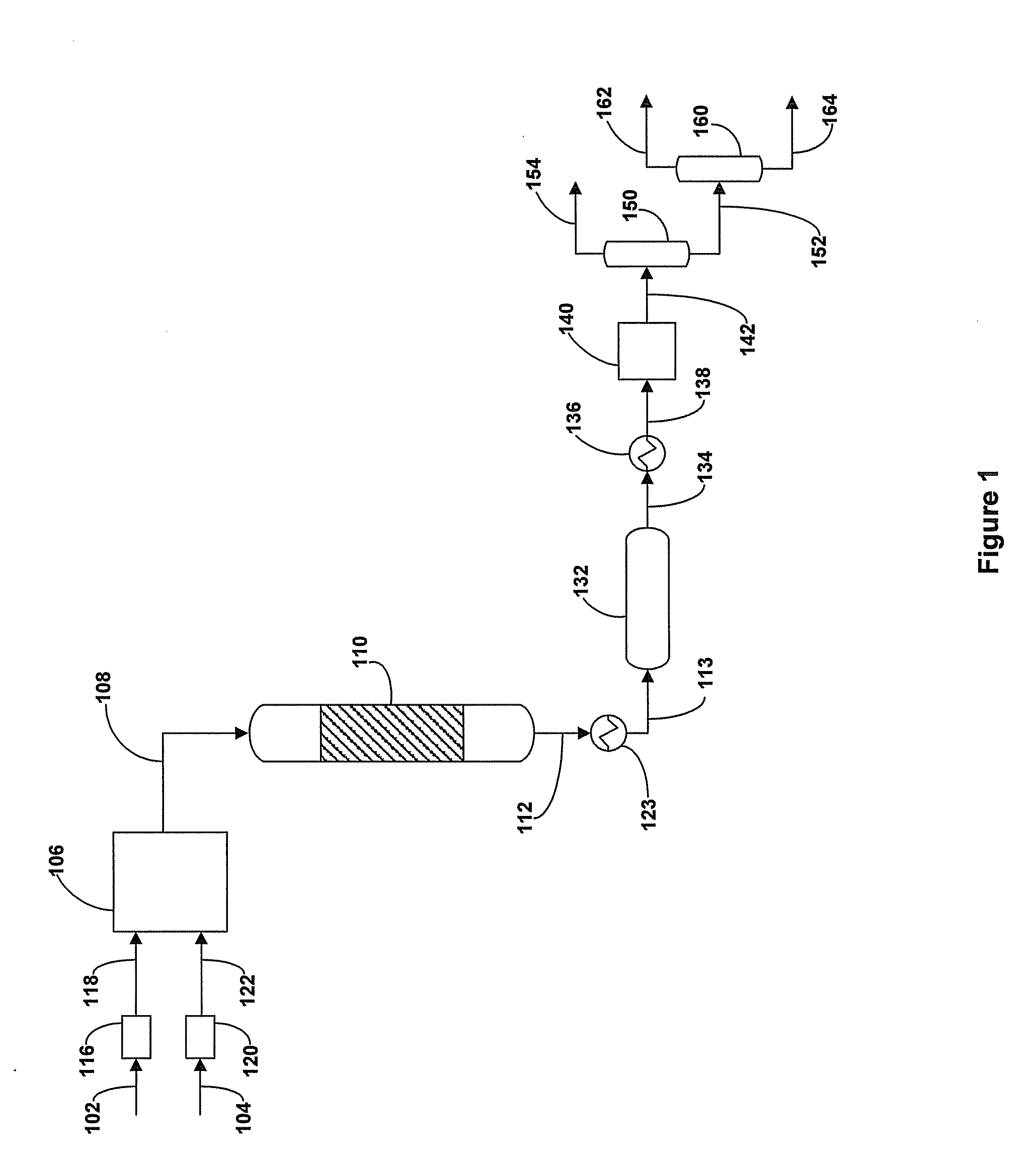

Integrated system and method for producing fuel composition from biomass

InactiveUS7888540B2Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentHydrogenTar

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

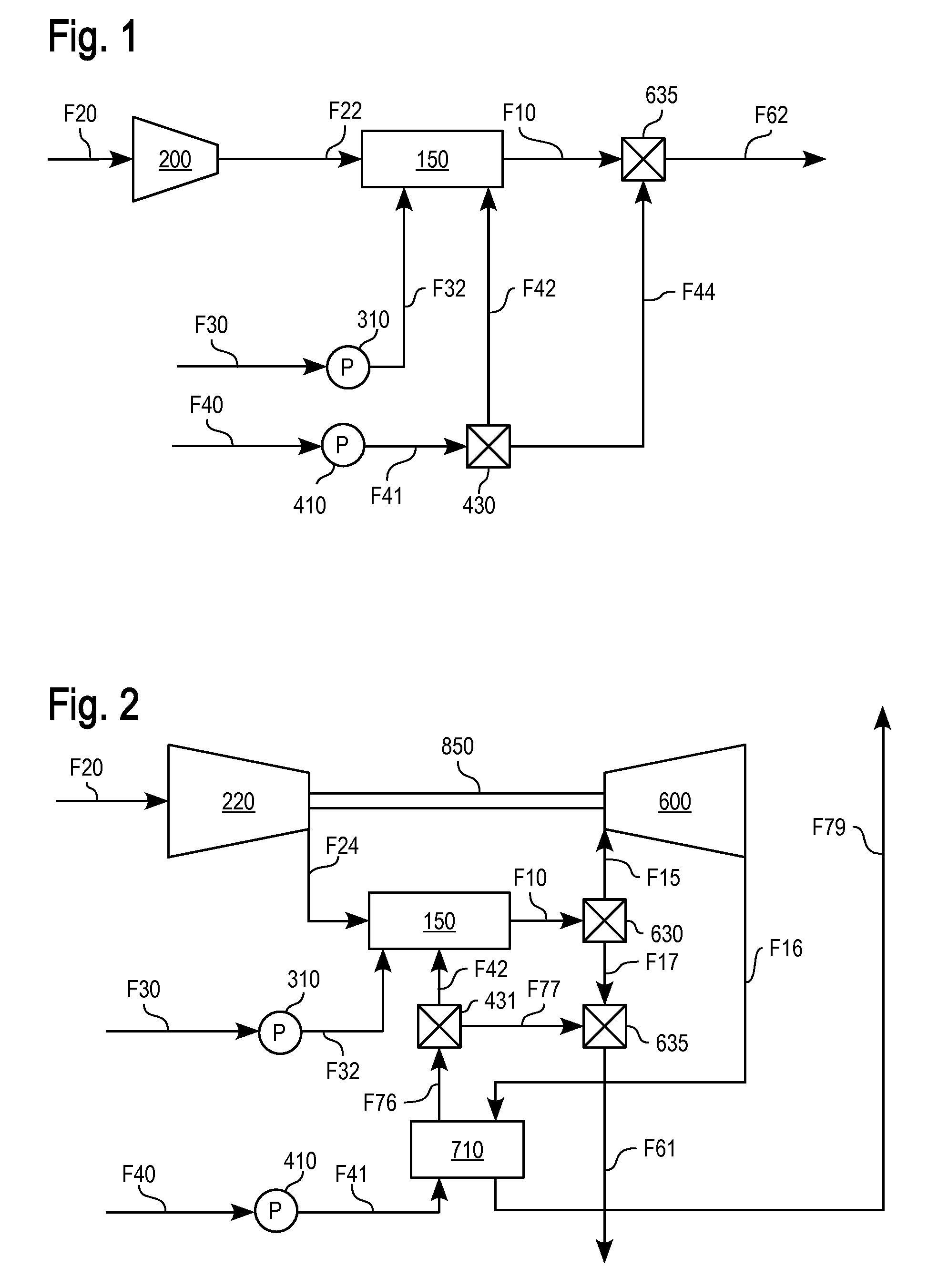

Cascading closed loop cycle power generation

InactiveUS7096665B2Improve power efficiencyIncrease pressureEnergy industrySteam accumulatorsLiquid propaneSteam condensation

Owner:UNIVERSAL TECH

Integrated system and method for producing fuel composition from biomass

InactiveUS20090259082A1Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentThermodynamicsProcess engineering

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

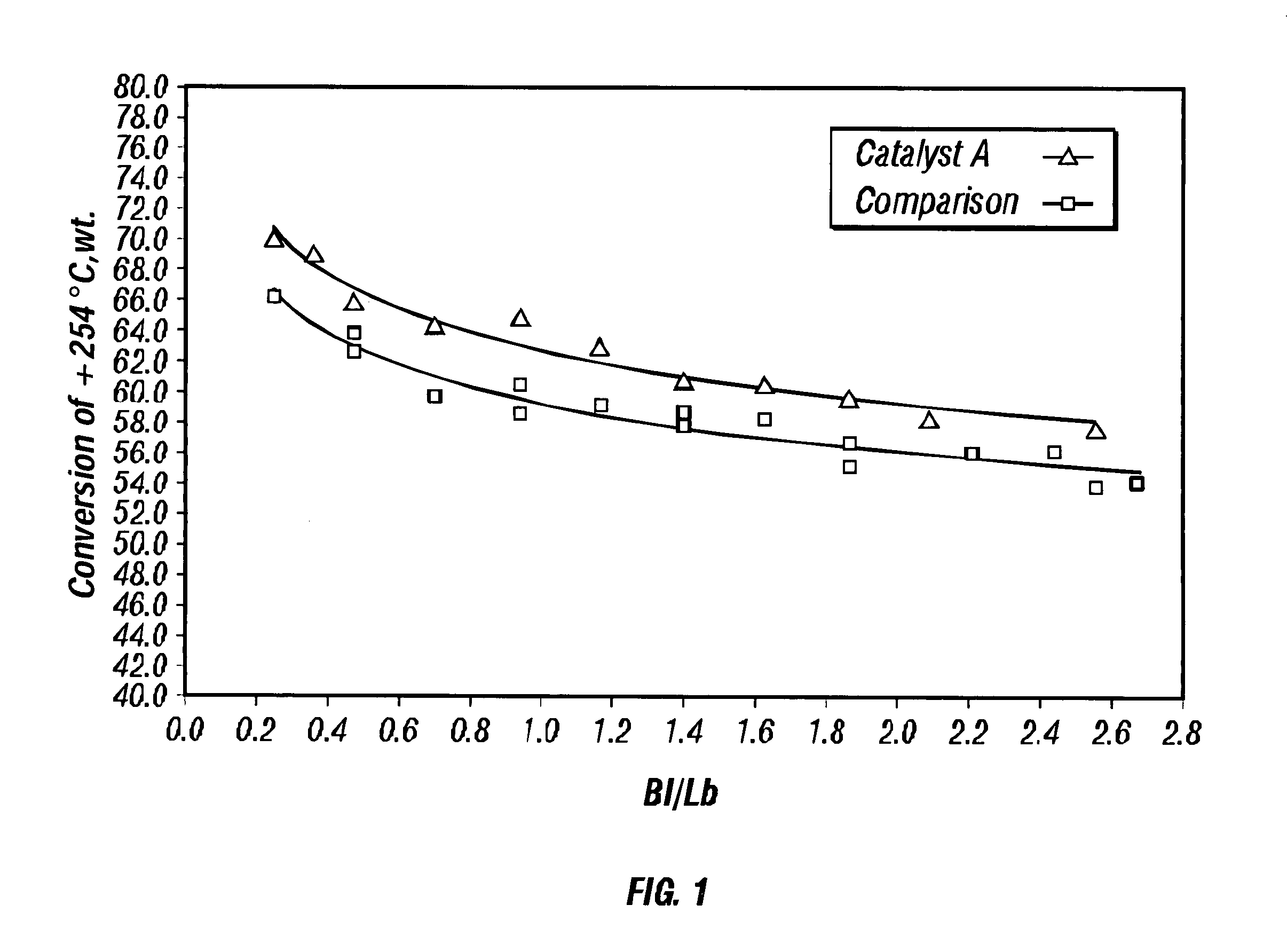

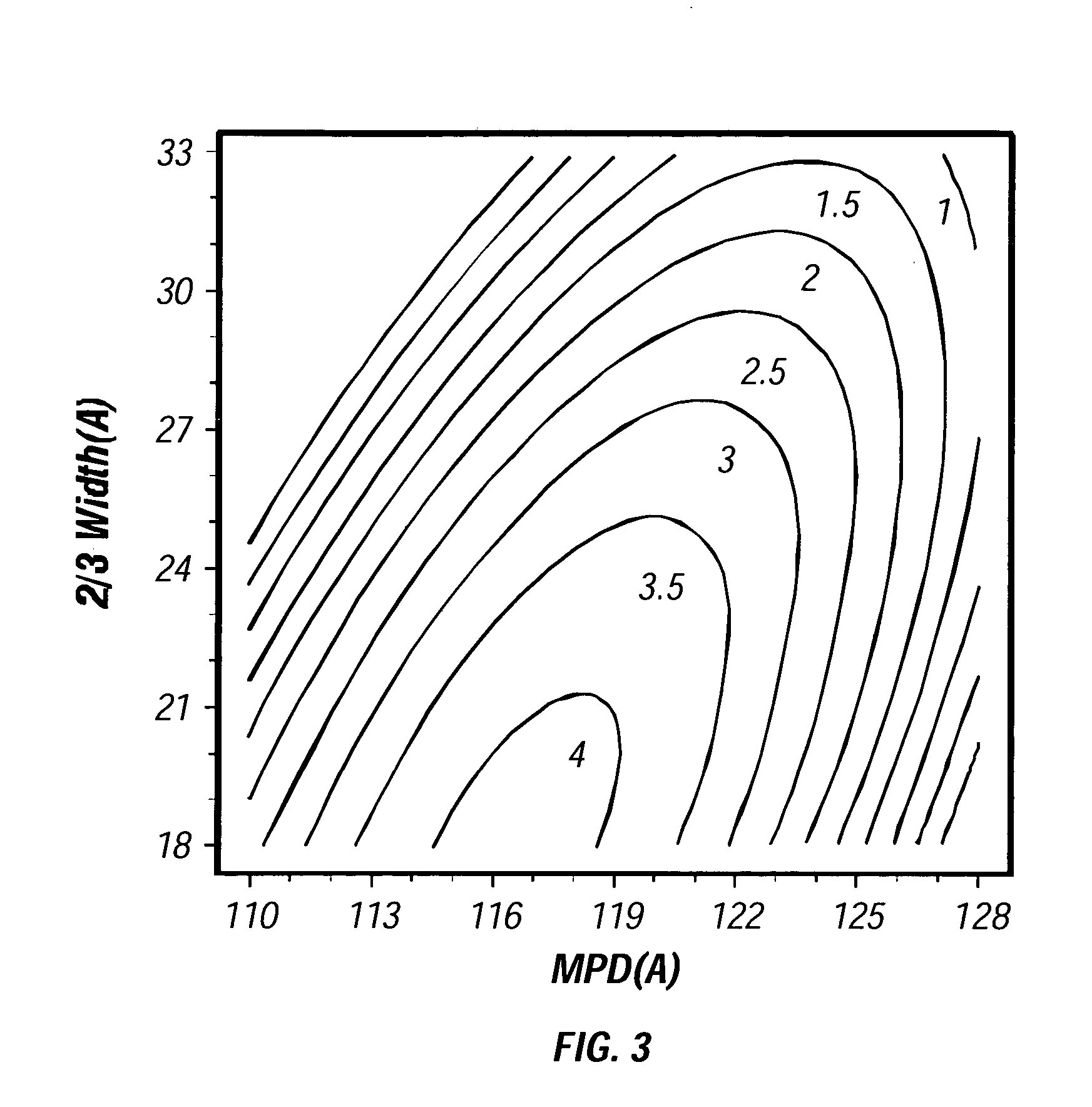

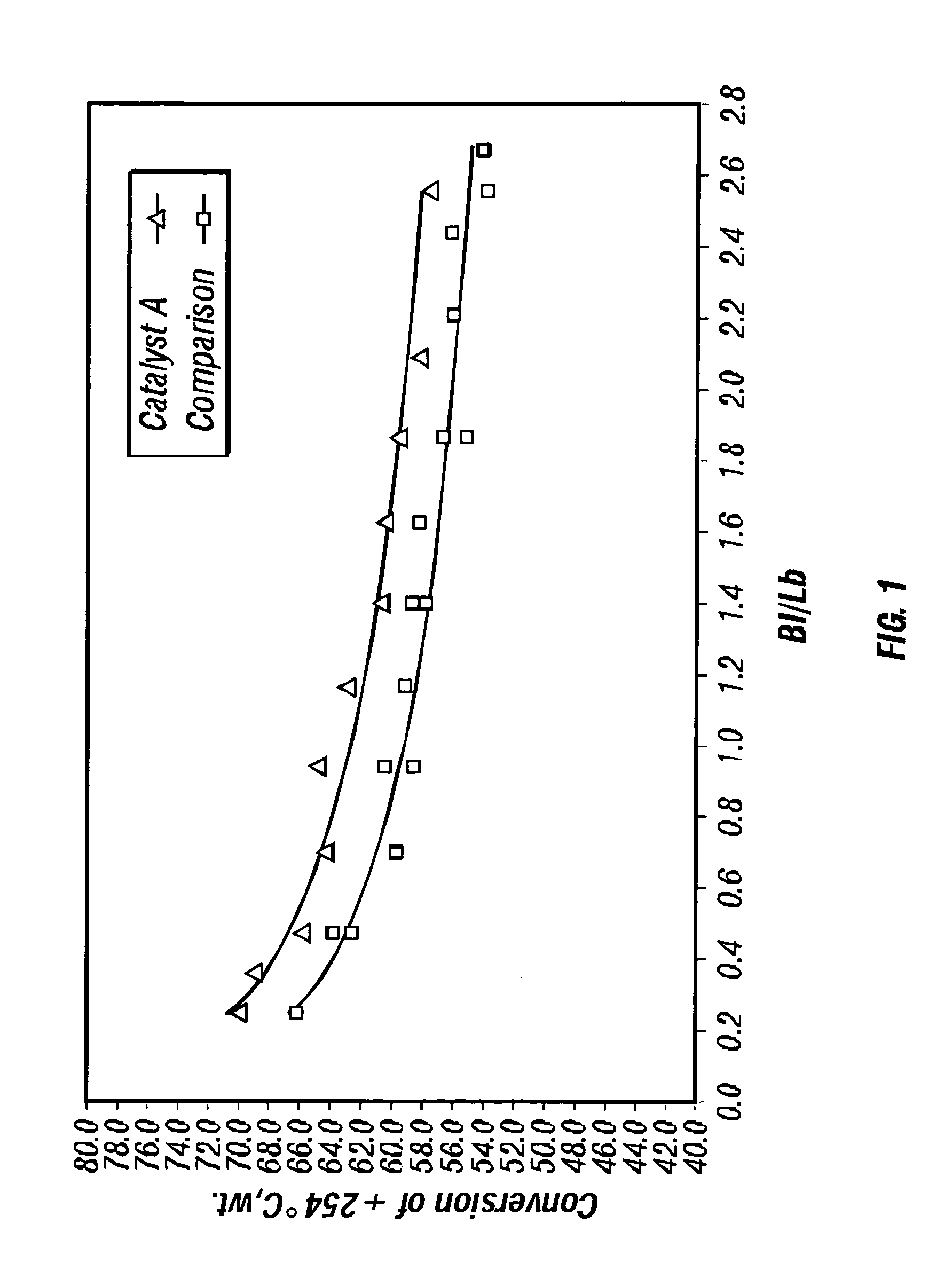

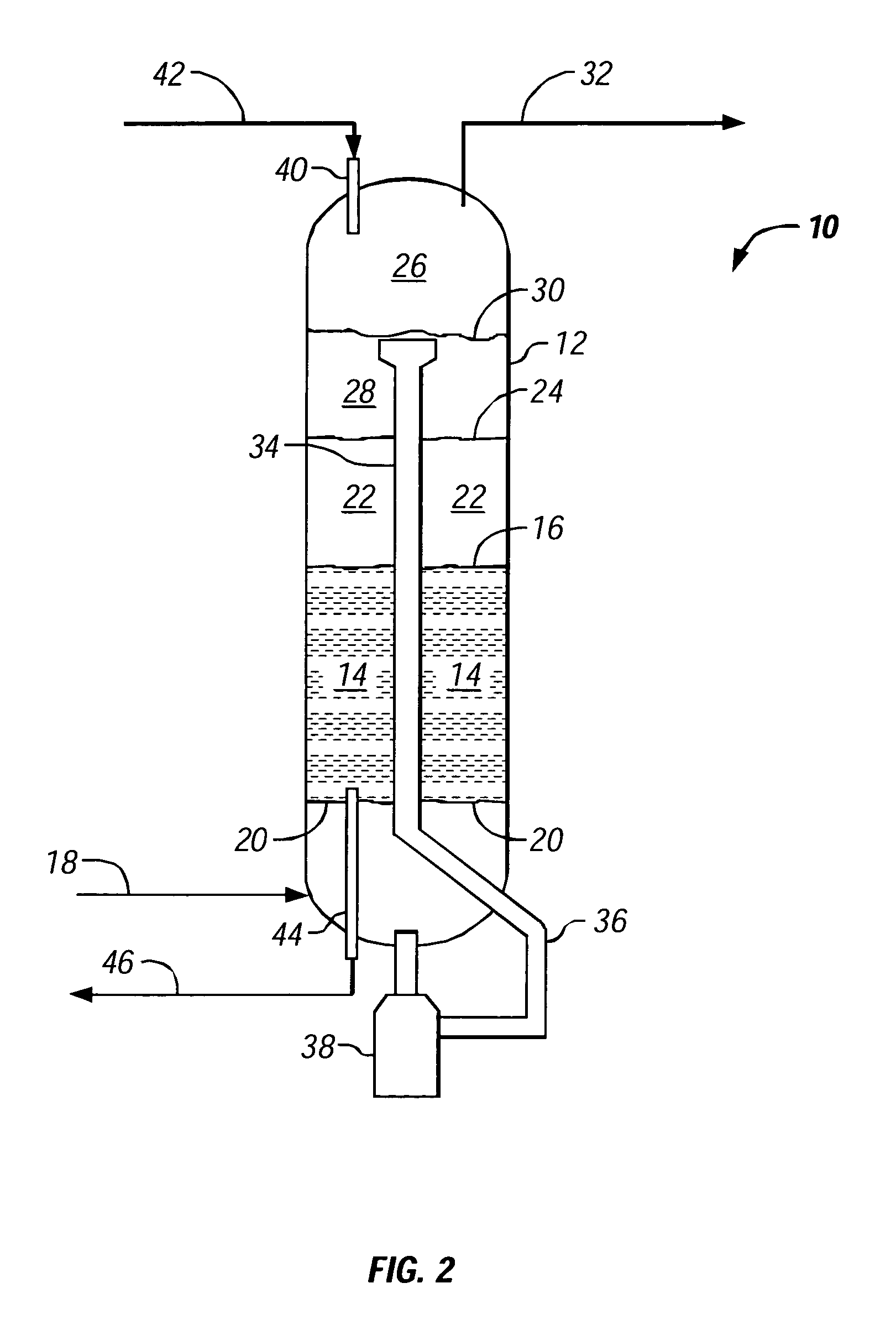

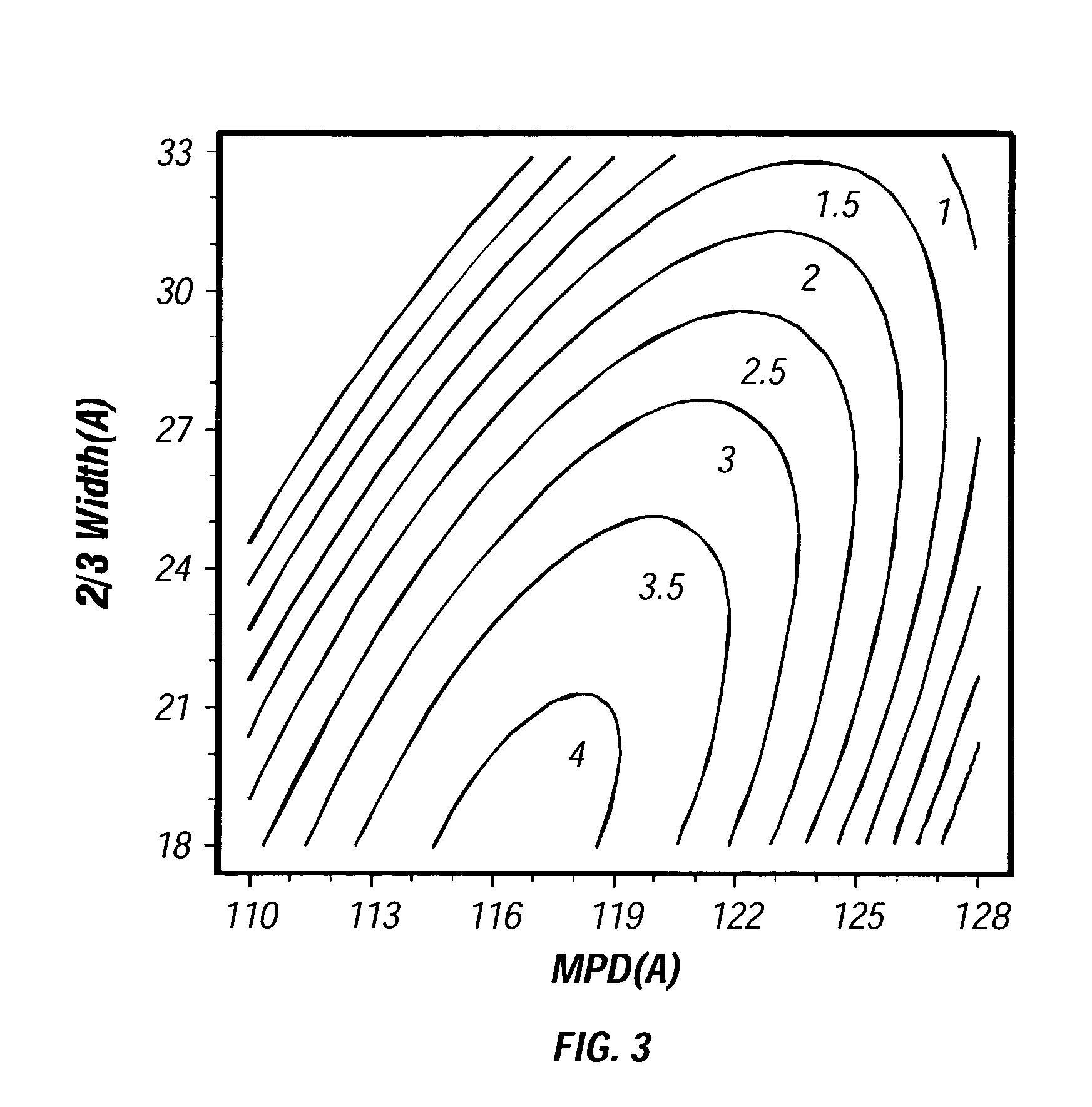

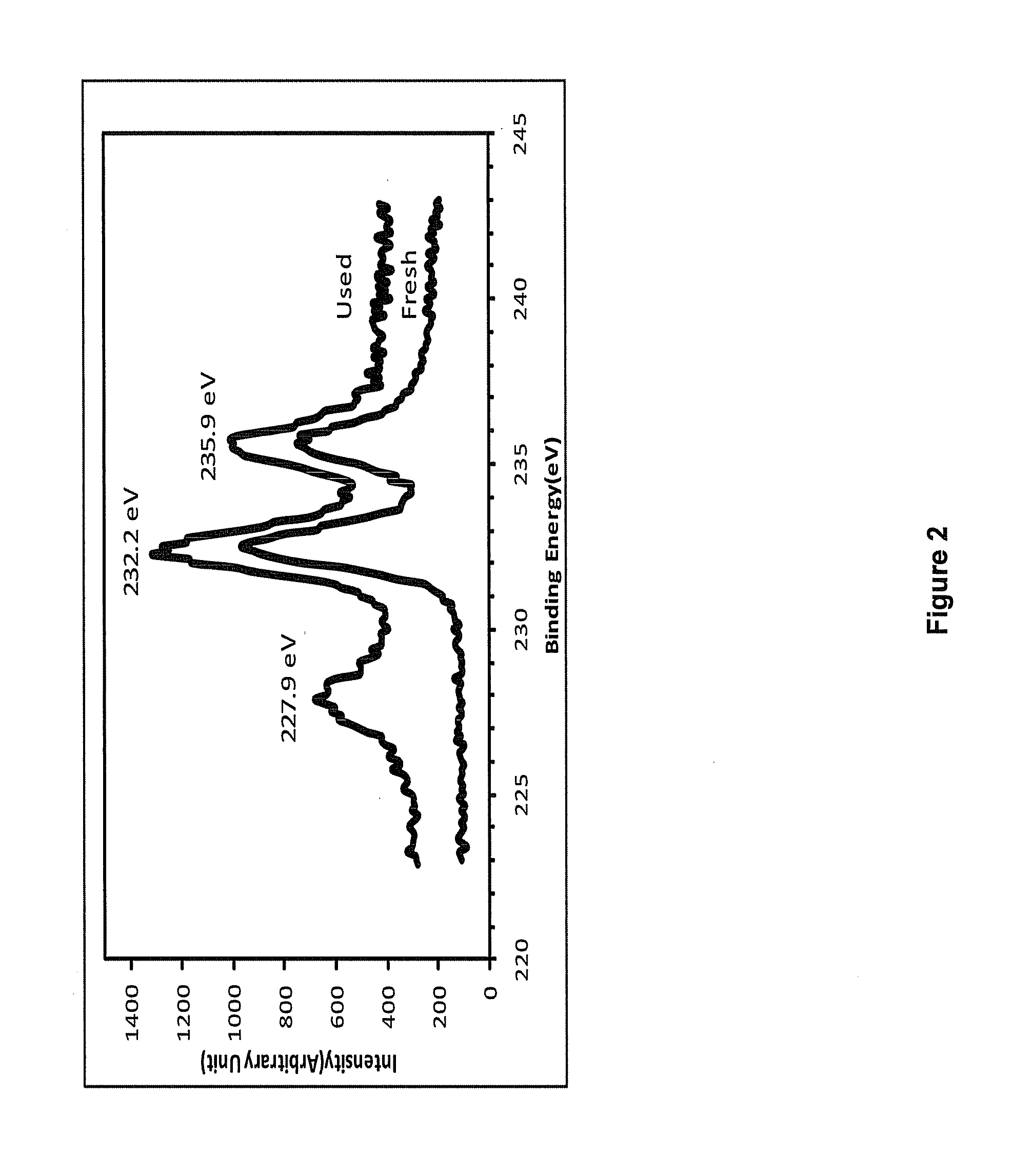

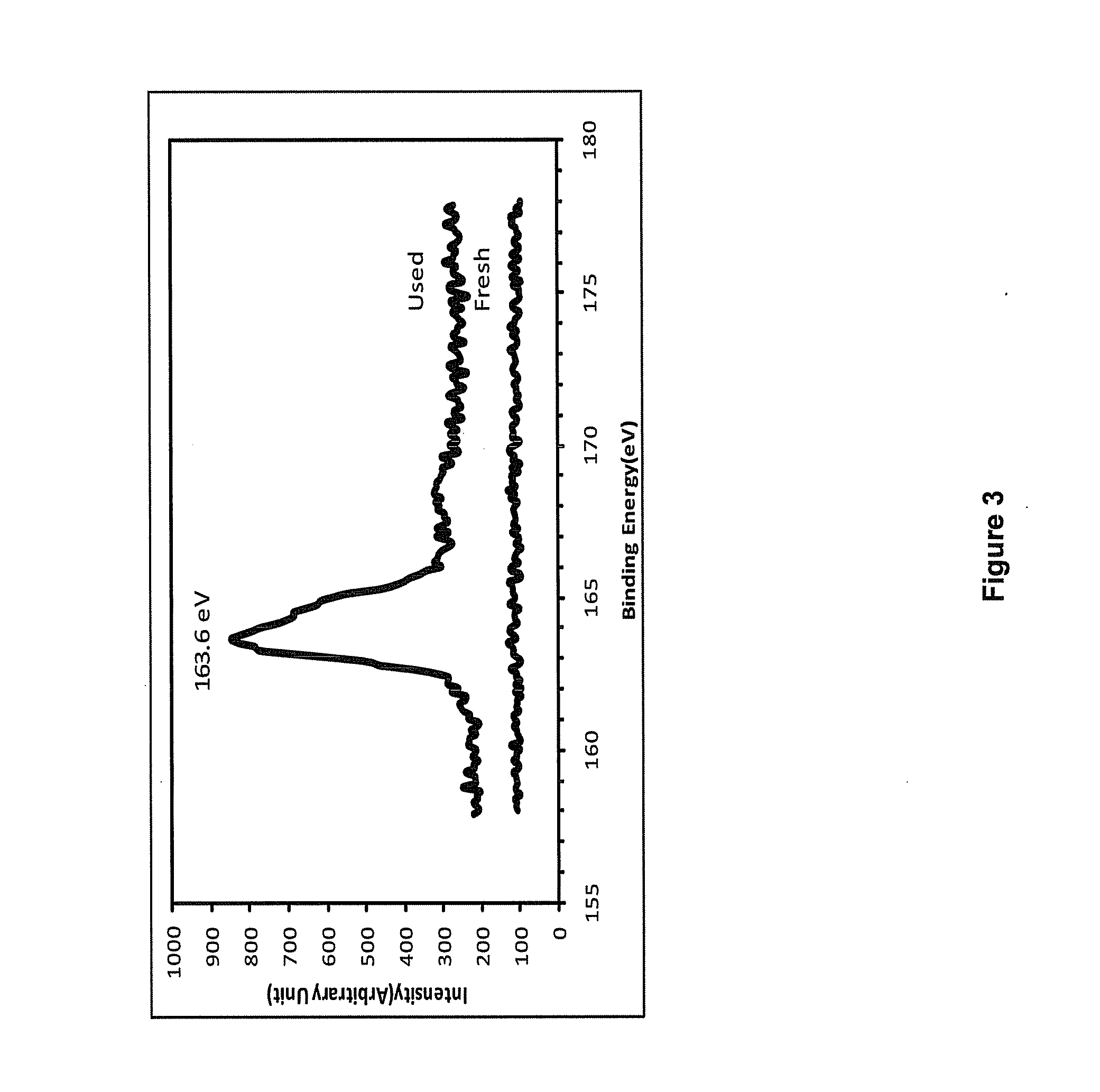

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

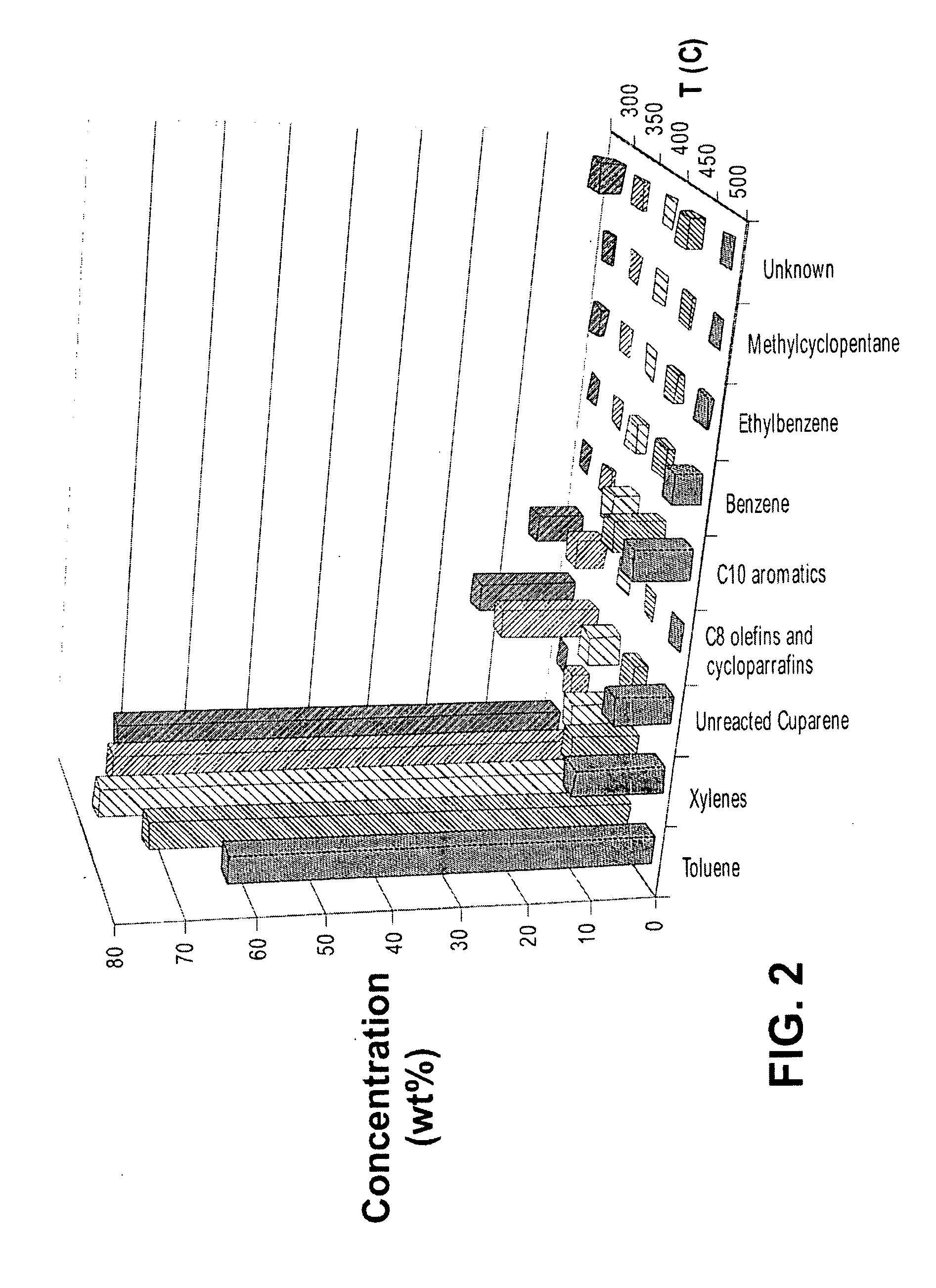

Methods of refining hydrocarbon feedstocks

Processes of converting to feedstocks comprising hydrocarbons to compositions comprising light hydrocarbon products are described herein. Also described are processes and methods of producing and refining compositions comprising terpenes from biomass that can be suitable as a fuel product.

Owner:RENEW BIOPHARMA INC +1

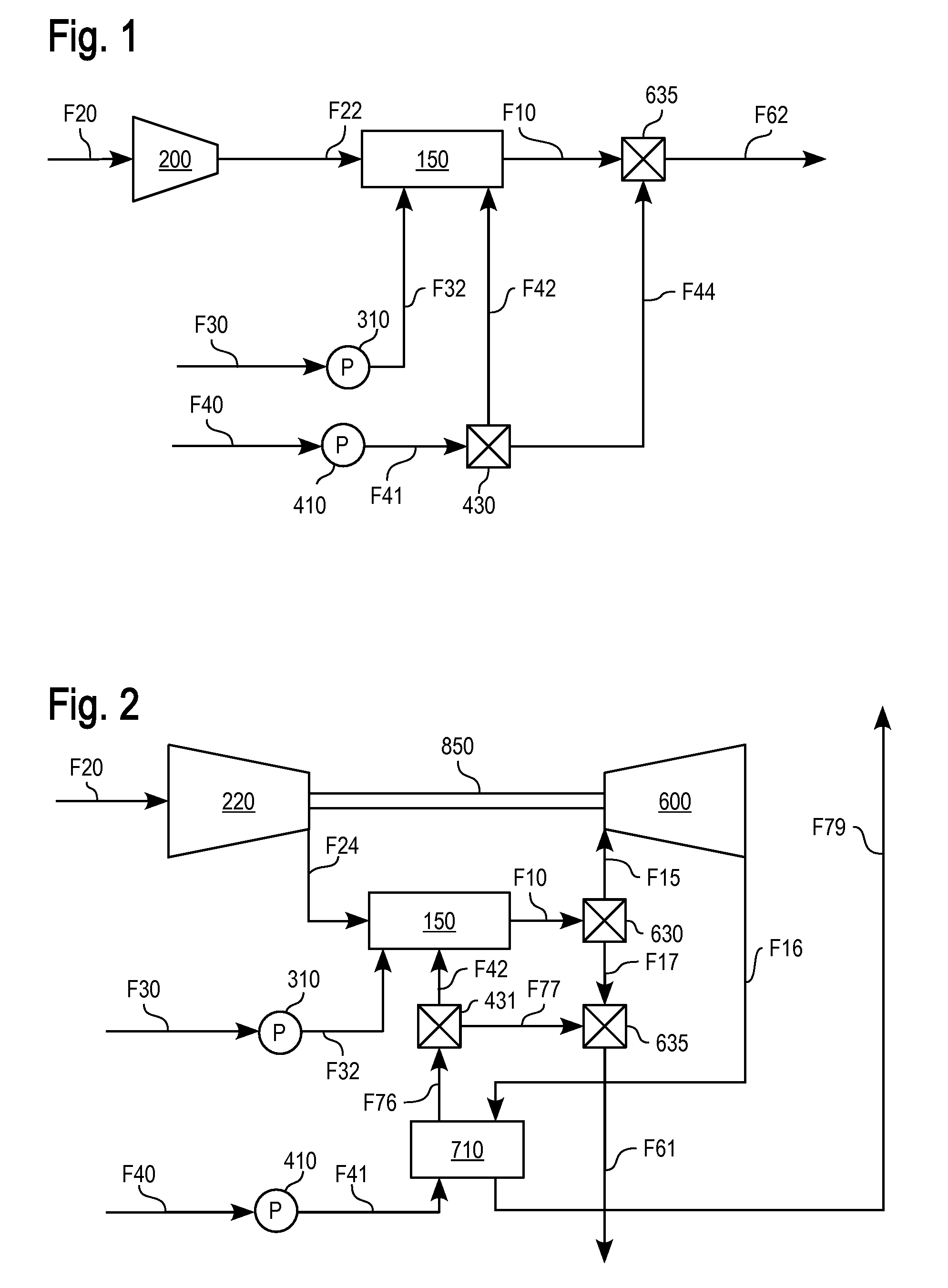

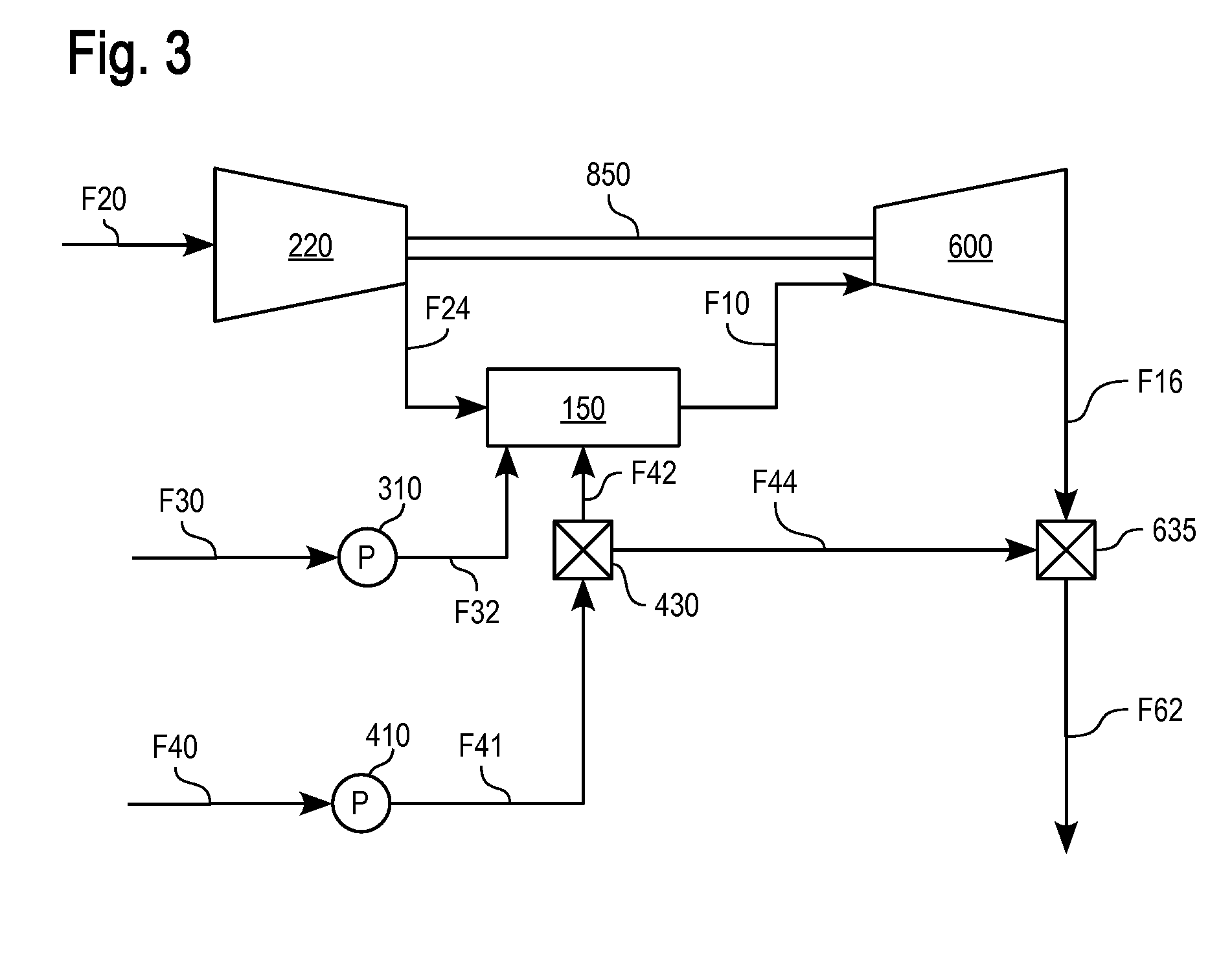

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

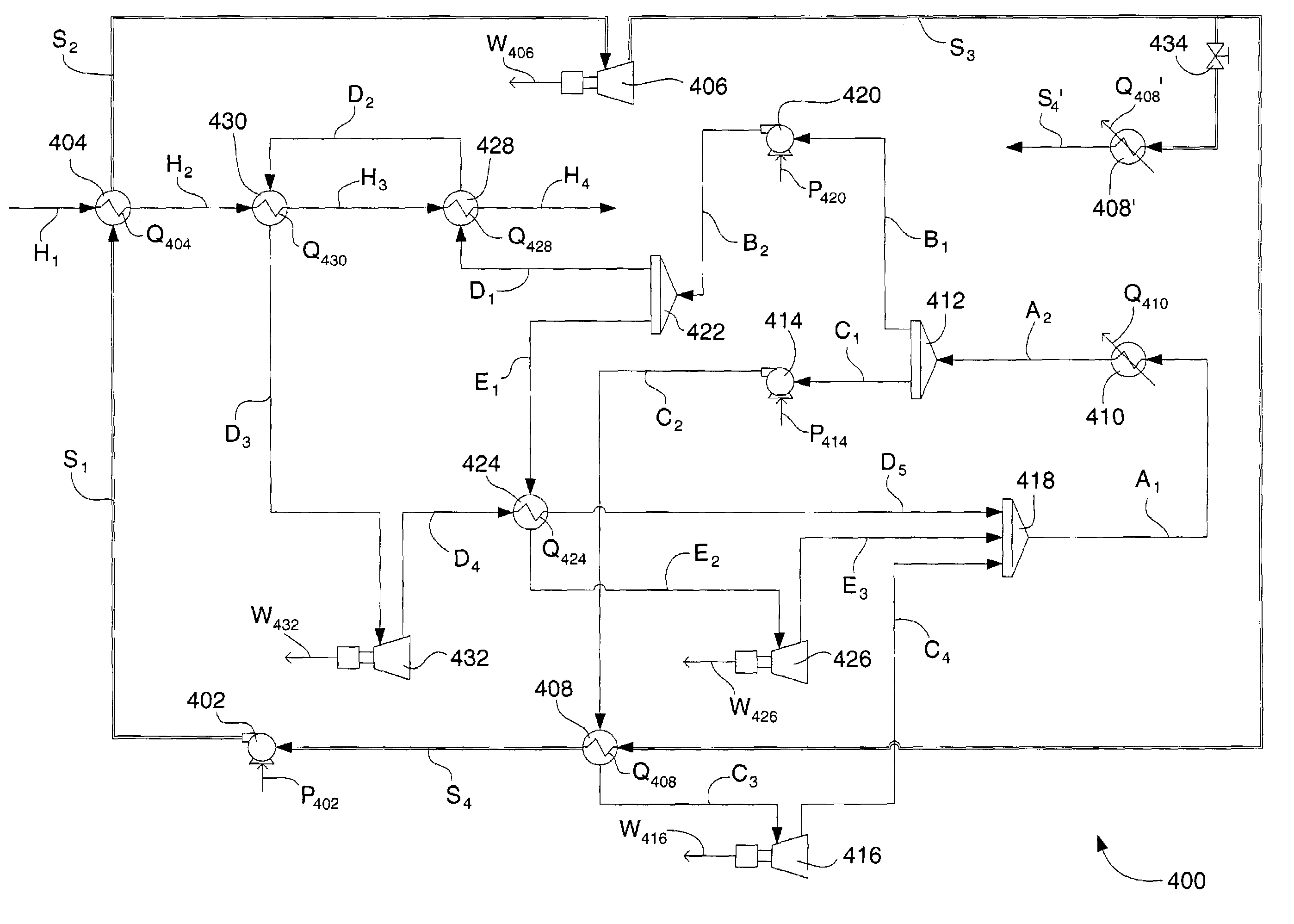

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Extra light hydrocarbon liquids

The present invention relates to an extra light hydrocarbon liquid derived from highly paraffinic wax. This extra light hydrocarbon liquid is suitable for use as a lubricant additive diluent oil in oil soluble additive concentrates. This extra light hydrocarbon liquid derived from highly paraffinic wax has a viscosity of between about 1.0 and 3.5 cSt at 100° C. and a Noack volatility of less than 50 weight % and comprises greater than 3 weight % molecules with cycloparaffinic functionality and less than 0.30 weight percent aromatics. The extra light hydrocarbon liquid makes an excellent lubricant additive diluent oil because it has low volatility, low viscosity, good additive solubility, and excellent solubility in lubricant base oil stocks. The present invention also relates to finished lubricants comprising the oil soluble additive concentrates made with the extra light hydrocarbon liquid and finished lubricants comprising the oil soluble additive concentrates. The present invention further relates to processes for making these lubricant additive diluent oils, oil soluble additive concentrates, and finished lubricants.

Owner:CHEVROU USA INC

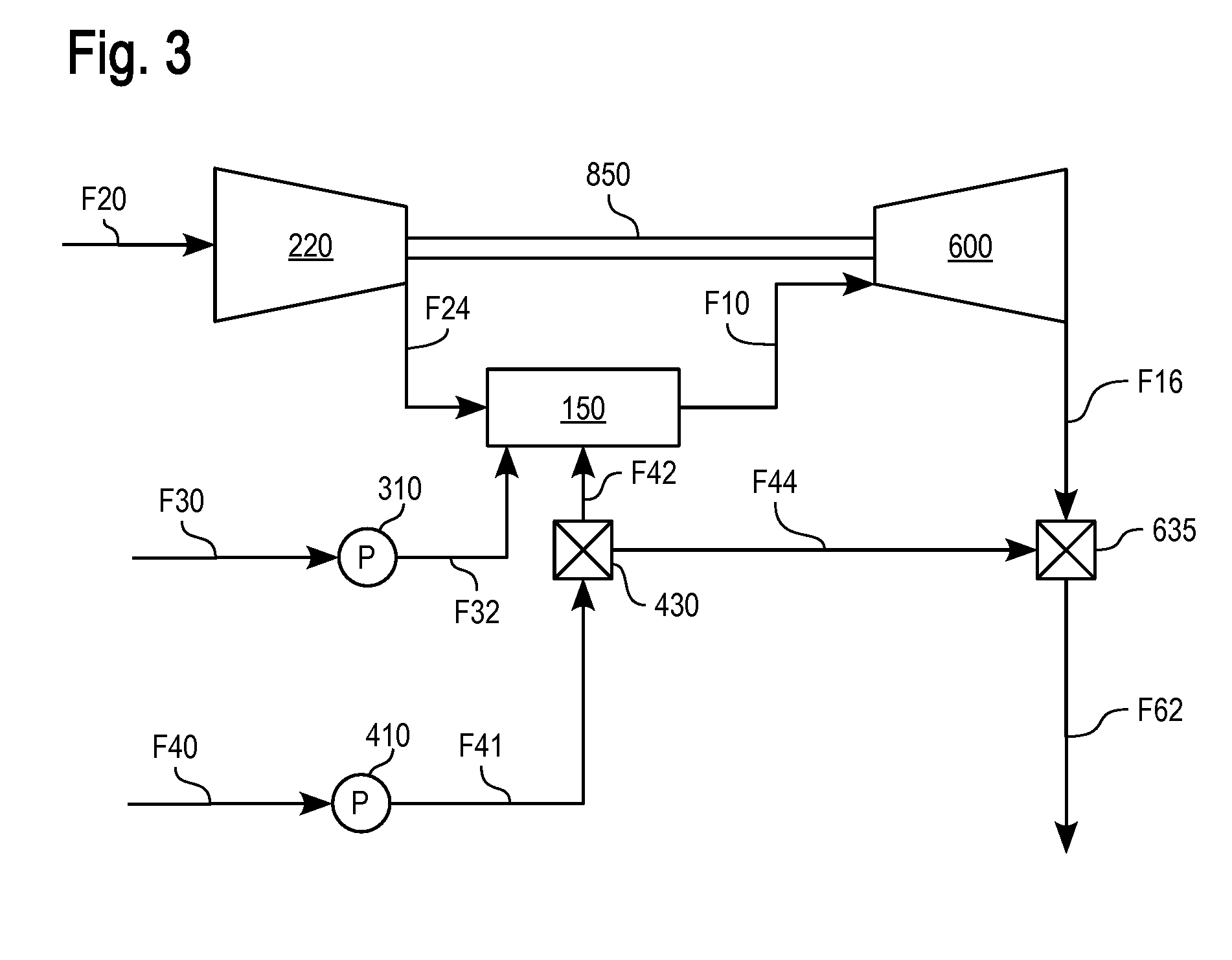

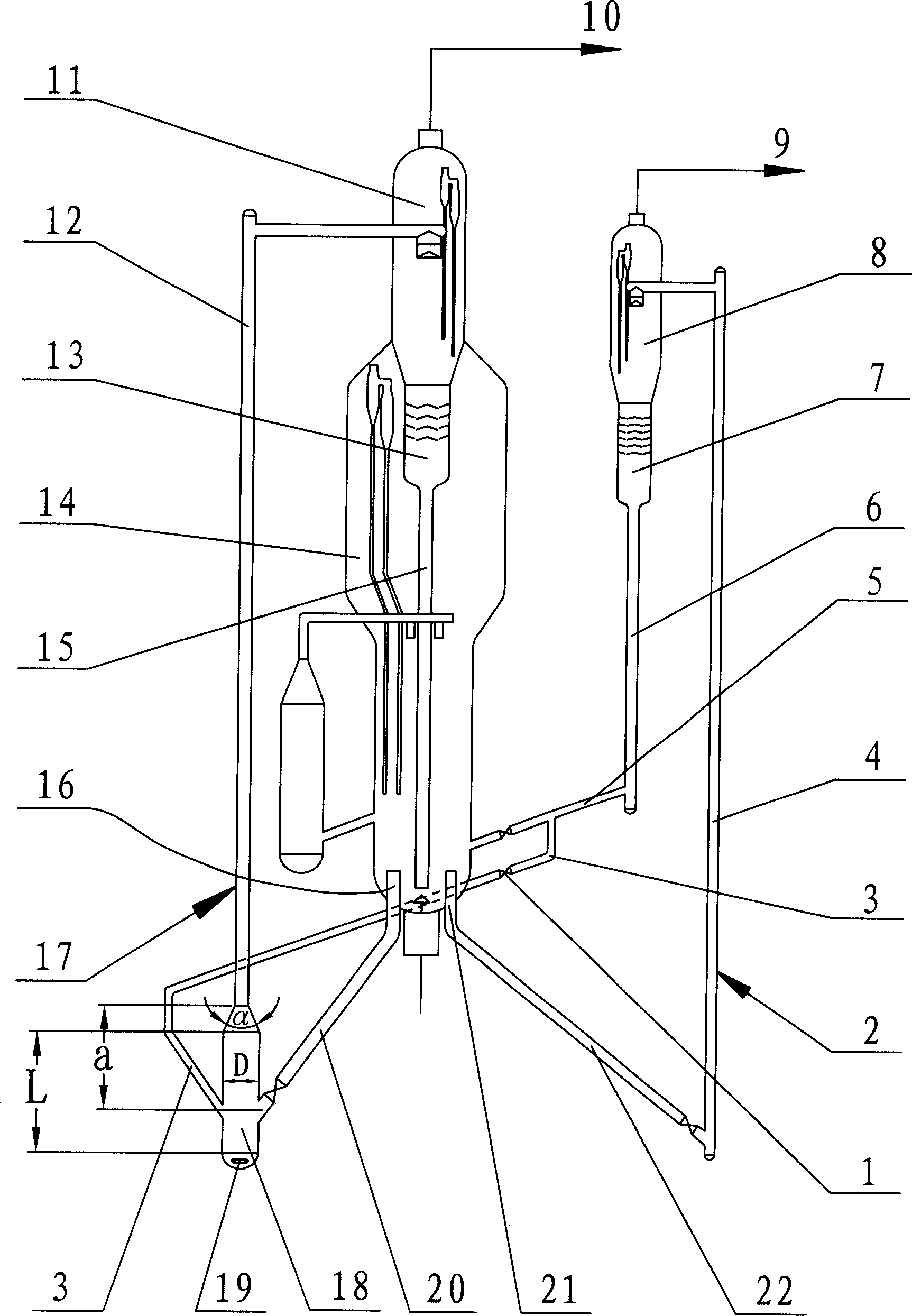

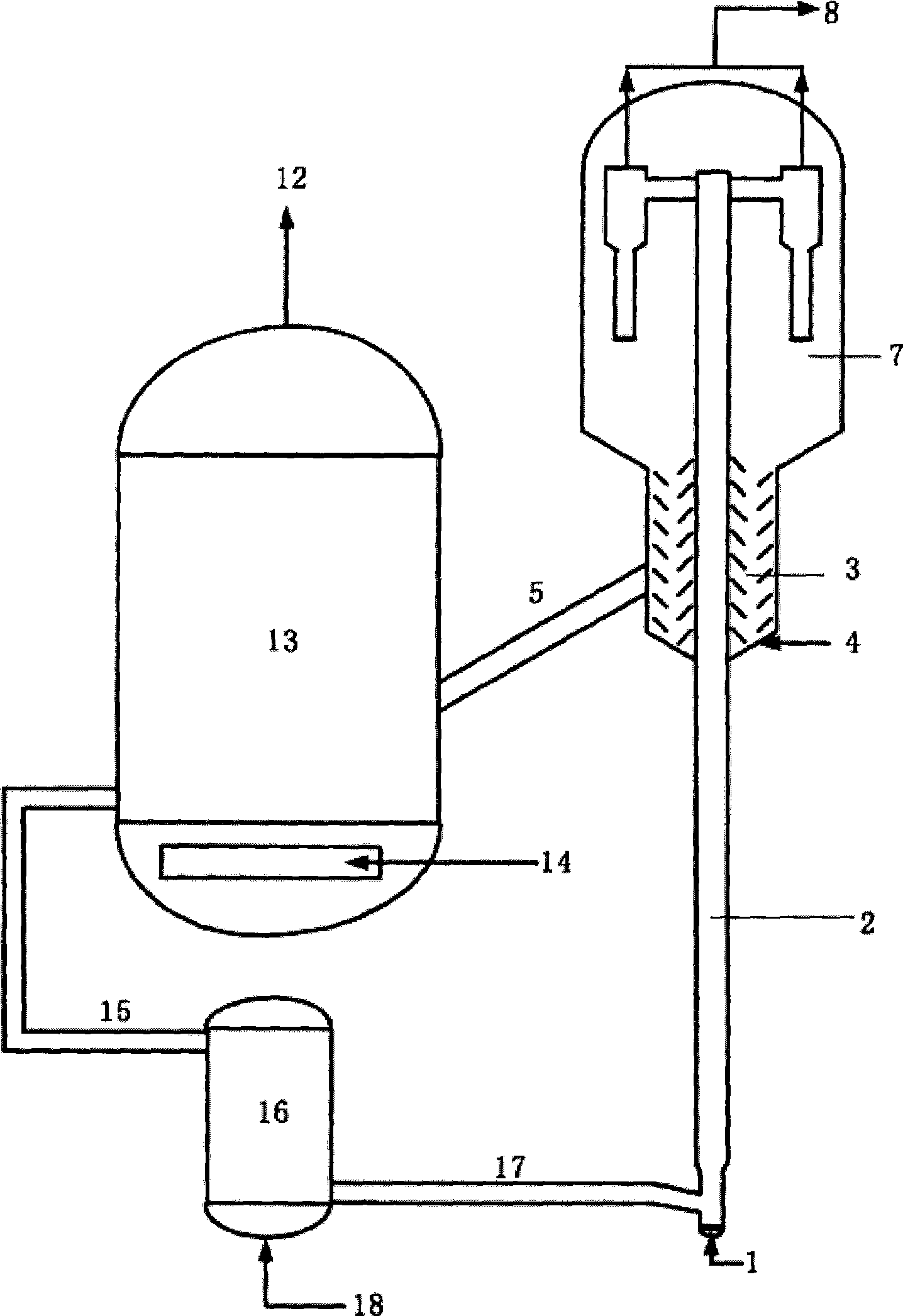

Catalytic cracking method and apparatus

The invention discloses a kind of catalysis crack method and its device in petroleum chemical industry, to solve the problems as the whole activeness reduction of mixed catalysts and the flexibility lack of adjusting the agent-oil proportion of heavy oil riser reactor caused by the mixing wise of the spend catalyst and regenerating catalyst of the present two-riser catalysis crack device. The main characteristics of the invention method are: part of the spent catalyst from the light hydrocarbon riser reactor (4) gets into catalyst mixer through the spent catalyst duct (3) set flow control valve (1) after water vapour stripped in the stripping section (7) of the second settler, and gets into heavy oil riser reactor (12) to react after mixed by the effect of water vapour with the regenerating catalyst form regenerator (14) in catalyst mixer. The method of the invention is suitable to be used in the two-riser catalysis crack craft and the three-riser catalyst crack craft set heavy oil riser reactor; the invention has disclosed related devices.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Heavy oil recovery with fluid water and carbon dioxide

Diluted wet combustion forms a hot process fluid or VASTgas including carbon dioxide (CO2) and fluid water which is delivered to geologic formations and / or to surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be used to pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into a well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Processes for producing extra light hydrocarbon liquids

The present invention relates to an extra light hydrocarbon liquid derived from highly paraffinic wax. This extra light hydrocarbon liquid is suitable for use as a lubricant additive diluent oil in oil soluble additive concentrates. This extra light hydrocarbon liquid derived from highly paraffinic wax has a viscosity of between about 1.0 and 3.5 cSt at 100° C. and a Noack volatility of less than 50 weight % and comprises greater than 3 weight % molecules with cycloparaffinic functionality and less than 0.30 weight percent aromatics. The extra light hydrocarbon liquid makes an excellent lubricant additive diluent oil because it has low volatility, low viscosity, good additive solubility, and excellent solubility in lubricant base oil stocks. The present invention also relates to finished lubricants comprising the oil soluble additive concentrates made with the extra light hydrocarbon liquid and finished lubricants comprising the oil soluble additive concentrates. The present invention further relates to processes for making these lubricant additive diluent oils, oil soluble additive concentrates, and finished lubricants.

Owner:CHEVROU USA INC

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

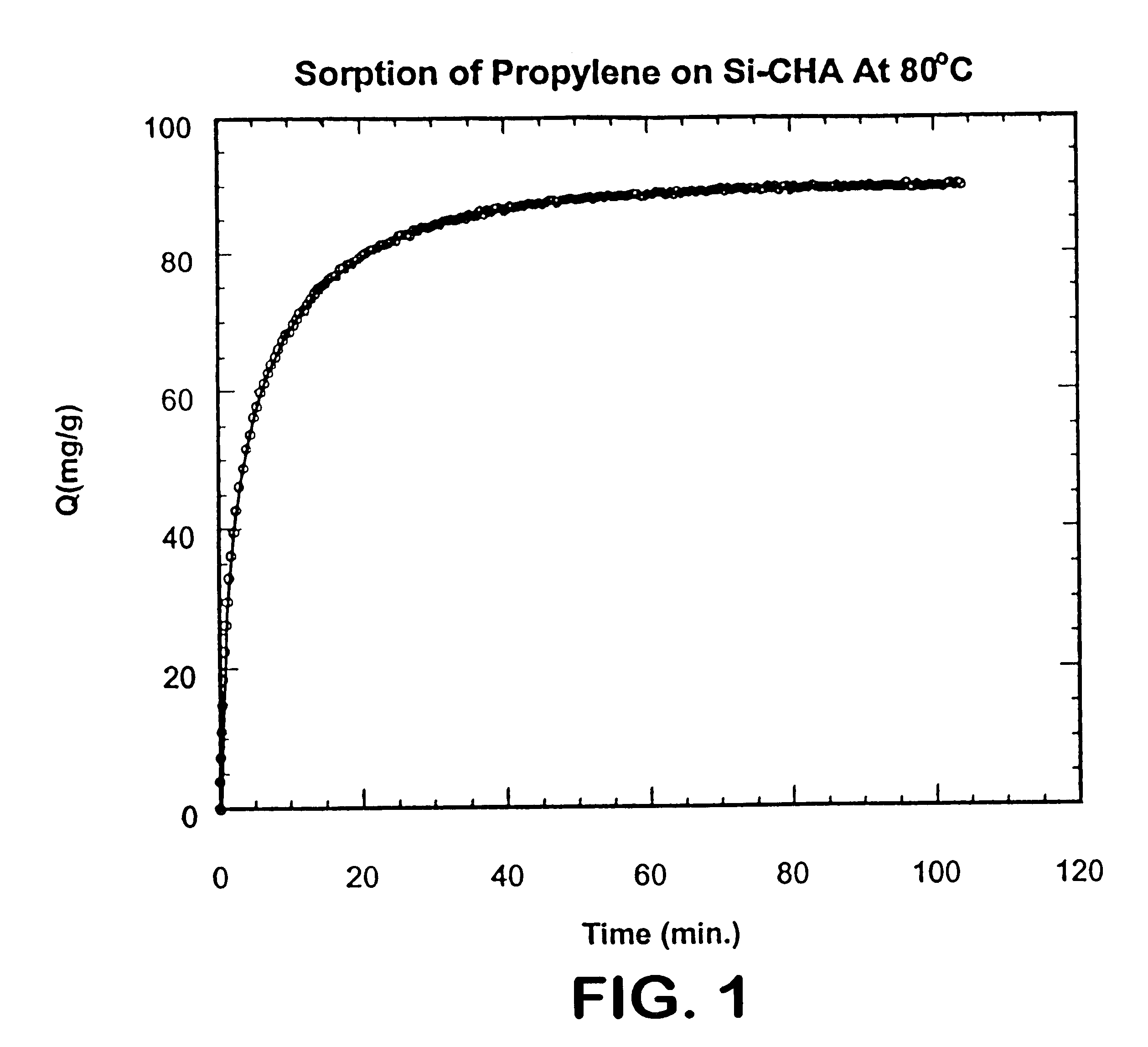

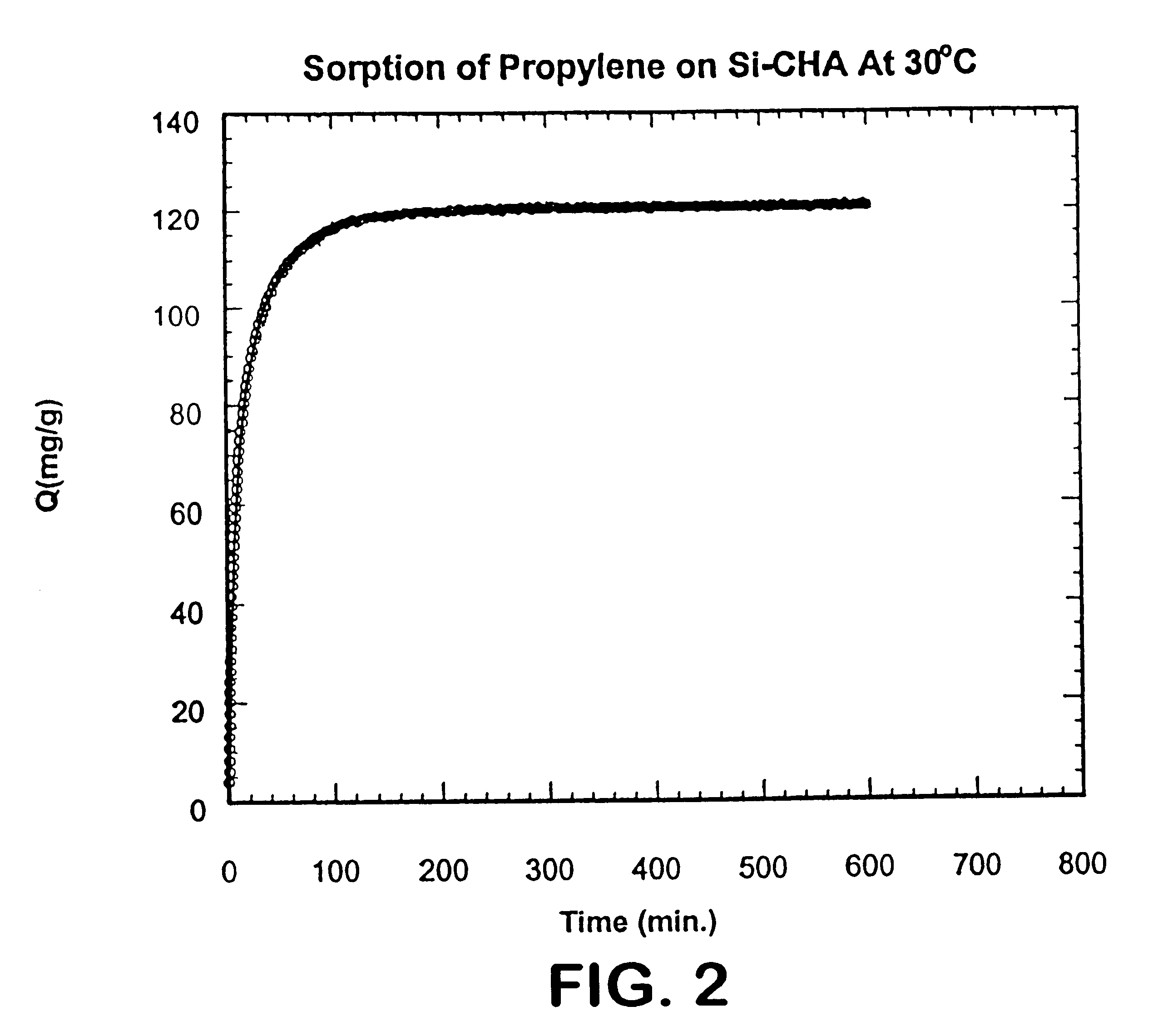

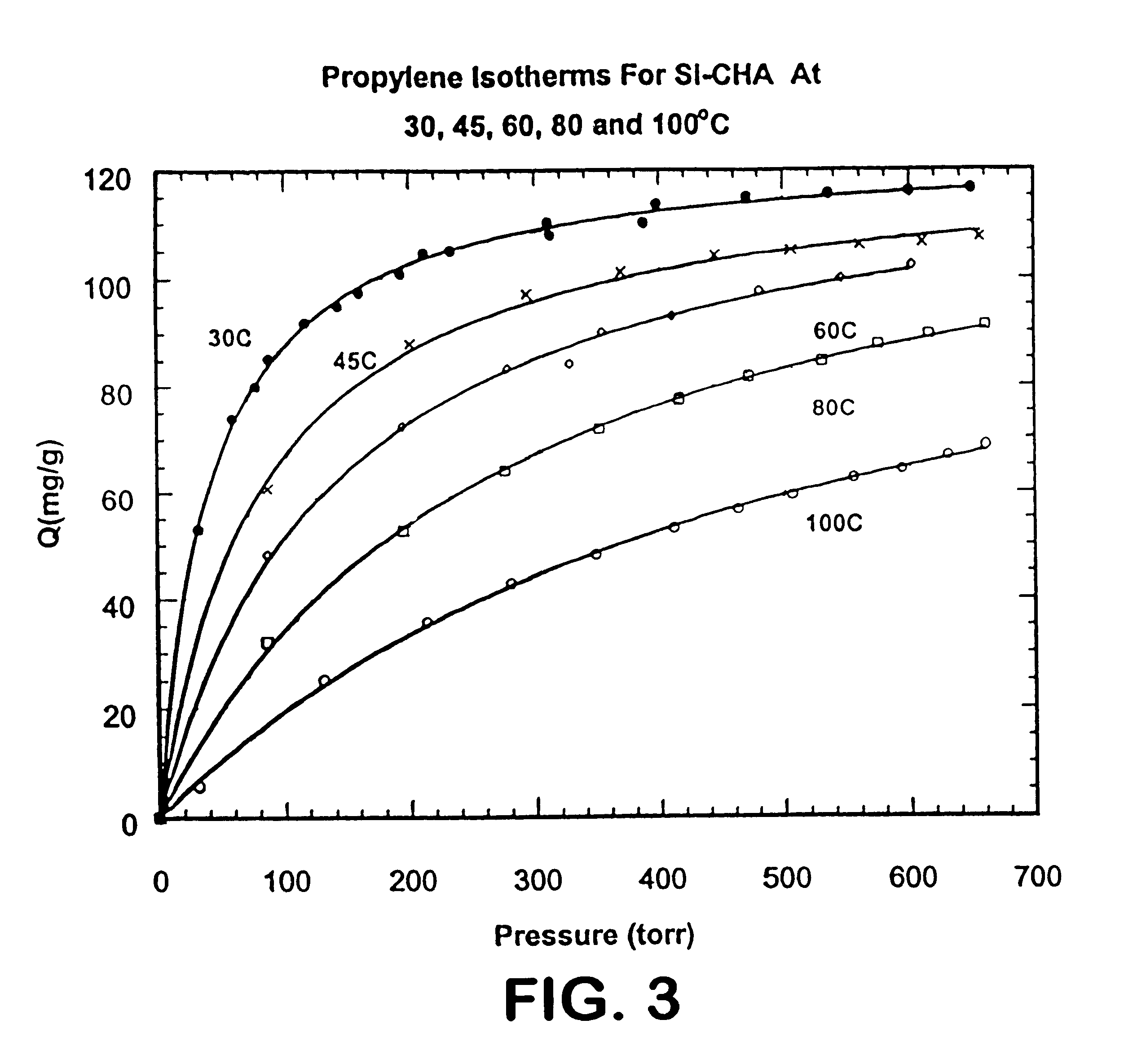

Light hydrocarbon separation using 8-member ring zeolites

InactiveUS6488741B2Improve efficiencyImprove diffusivityGas treatmentIsotope separationSorbentPropane

A method of selectively adsorbing propylene in mixtures of propylene / propane and propylene / olefins through the use of zeolites having structures with a maximum of 8-member rings of tetraheda controlling the diffusion rate. Suitable zeolite adsorbents are those having the CHA and ITE structure types. Other 8-member ring zeolites, including aluminosilicates, with a Si:Al molar ratio of at least about 200 and having substantially no free acid are also suitable adsorbents.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

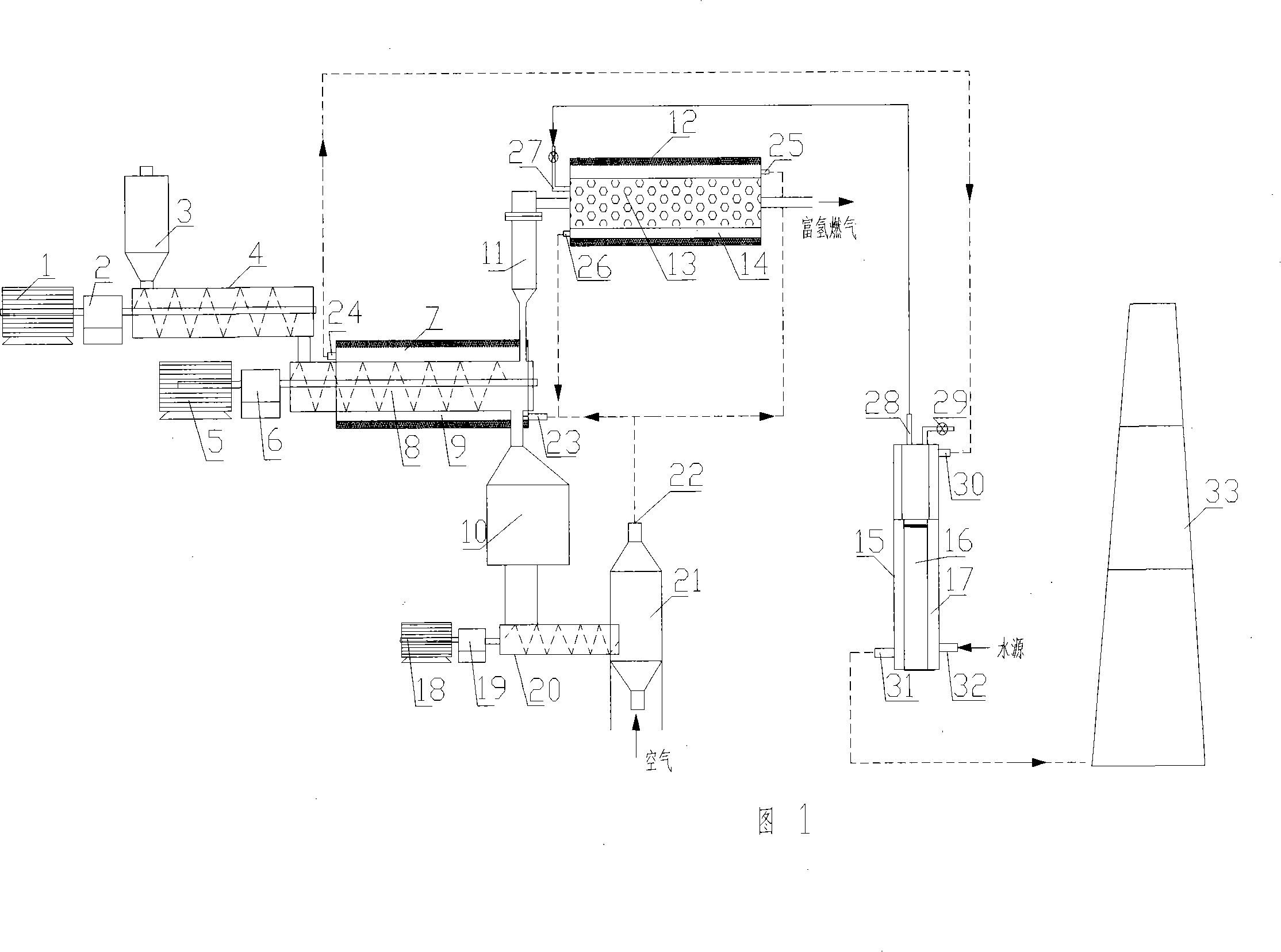

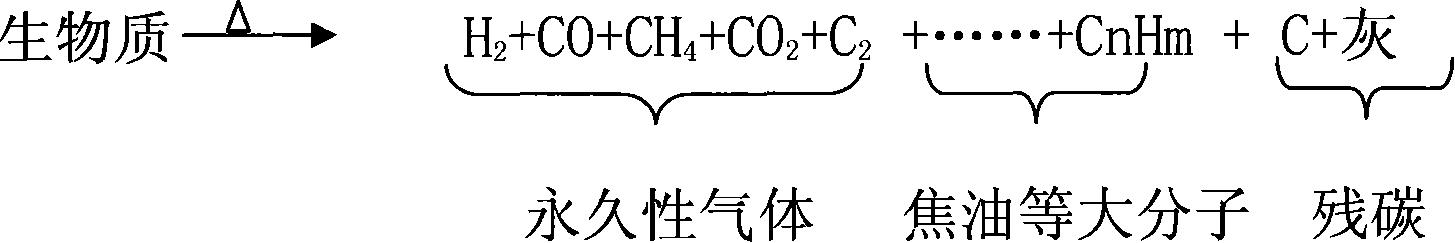

Method and device for preparing biomass hydrogen-rich combustion gas

InactiveCN101100621AReduce material requirementsReduce control requirementsHydrogenGaseous fuelsWater vaporGas phase

Production of biomass hydrogen-enriching fuel gas is carried out by thermal cracking for biomass raw materials at 550-650 deg. C under isolated air, converting it into gas-phase product and residual carbon, separating residual carbon from gas-phase product, transferring out of reacting system, burning to obtain heat energy, cracking at 800-950 deg. C and reforming into hydrogen, methane and other light hydrocarbons. It combines bitter spar catalyst and steam; it can eliminate tar, decrease methane content and increase hydrogen content. Hydrogen content reaches to 30%-55 wt%.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

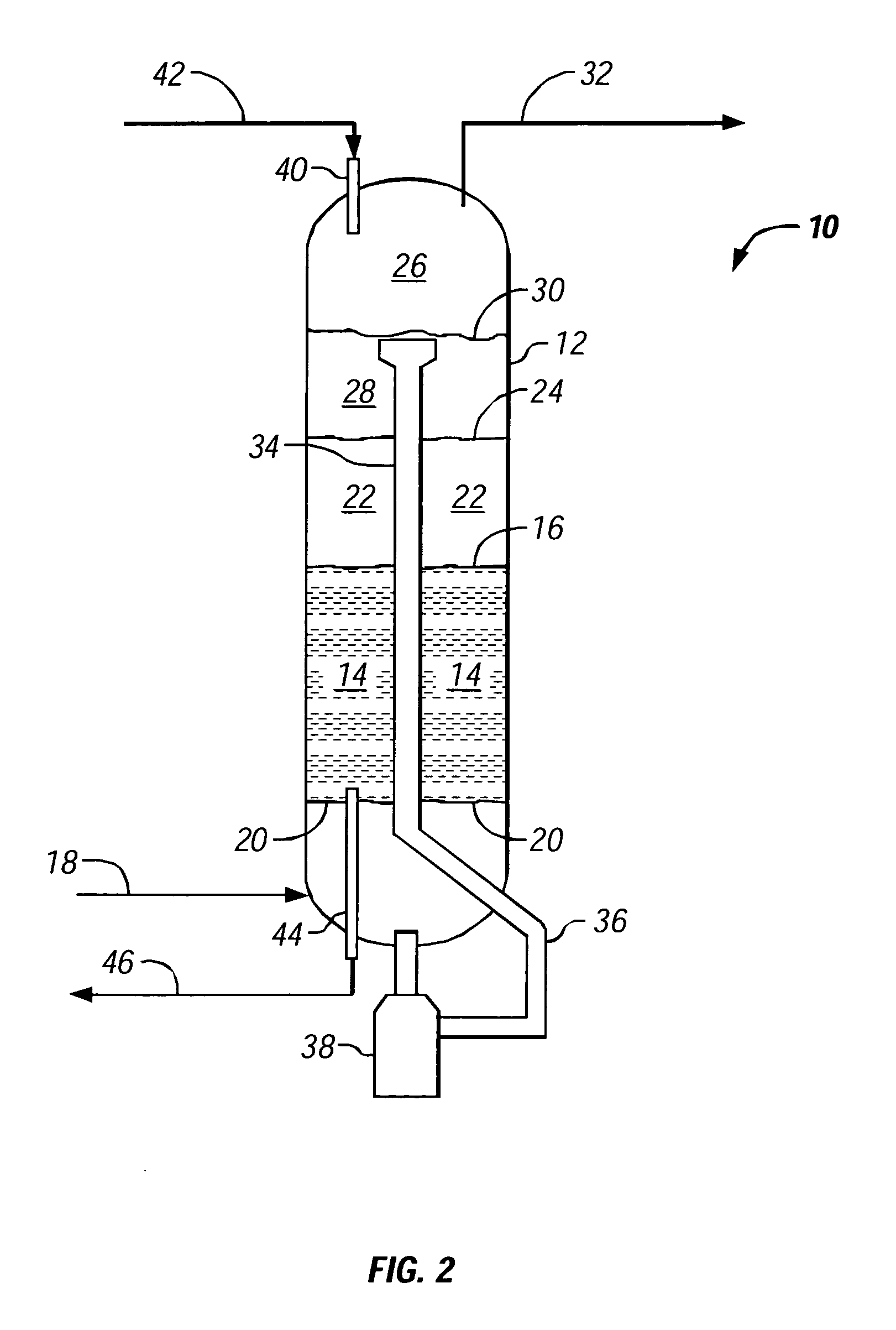

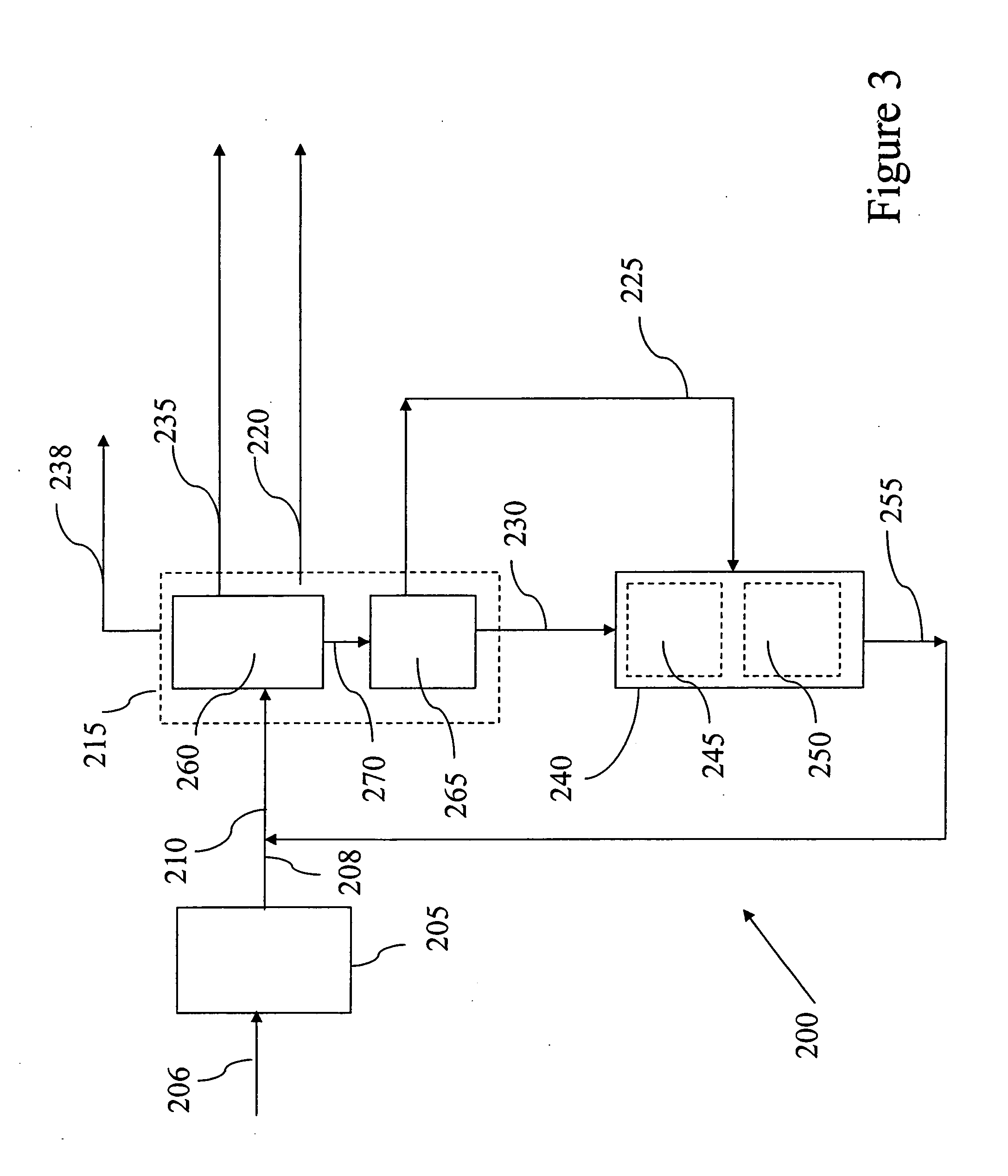

Hydroprocessing methods and apparatus for use in the preparation of liquid hydrocarbons

ActiveUS20050205462A1Easy to prepareEnhancing yield and cold-flow propertyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyWaxProduction rate

The present invention is generally related towards enhancing the yield and / or cold-flow properties of certain hydrocarbon products, increasing the degree of isomerization in a diesel product and / or increasing the production rate of a diesel product. The embodiments generally include reducing the residence time of lighter hydrocarbon fractions during hydrocracking, thereby decreasing secondary cracking, by various configurations of introducing at least two hydrocarbon feedstreams of different boiling ranges at different entry points in a hydrocracking unit. A method further includes forming a hydrocarbons stream comprising primarily C5+ Fischer-Tropsch hydrocarbon products; fractionating hydrocarbons stream to form at least a wax fraction and an intermediate fraction which serve as separate feedstreams to a hydrocracking unit comprising at least two hydroconversion zones. One embodiment comprises the use of a bifunctional catalyst in one of the hydrocracking zones so as to favor hydroisomerization of hydrocarbons to favor the formation of branched paraffins boiling in the diesel range.

Owner:PHILLIPS 66 CO

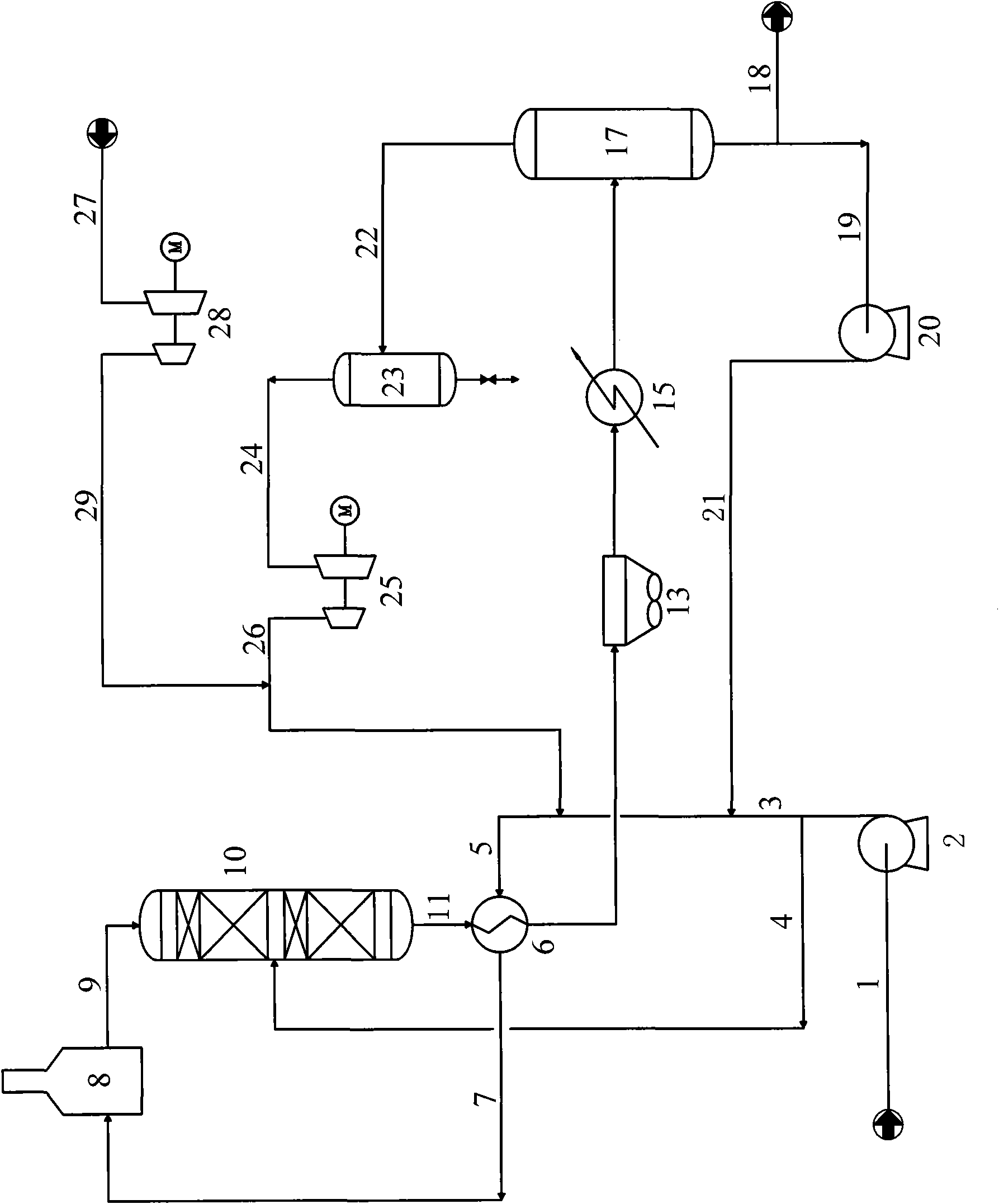

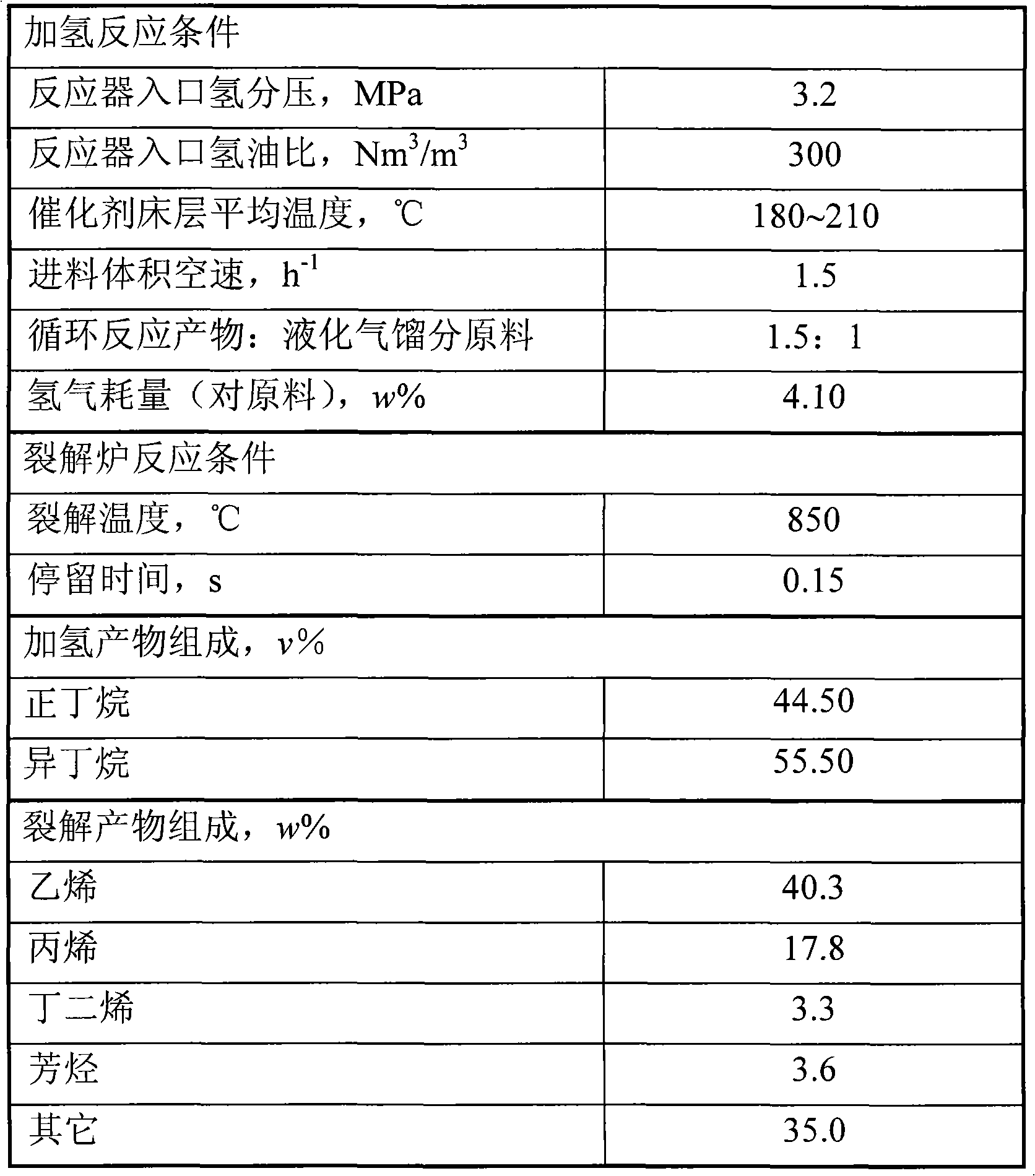

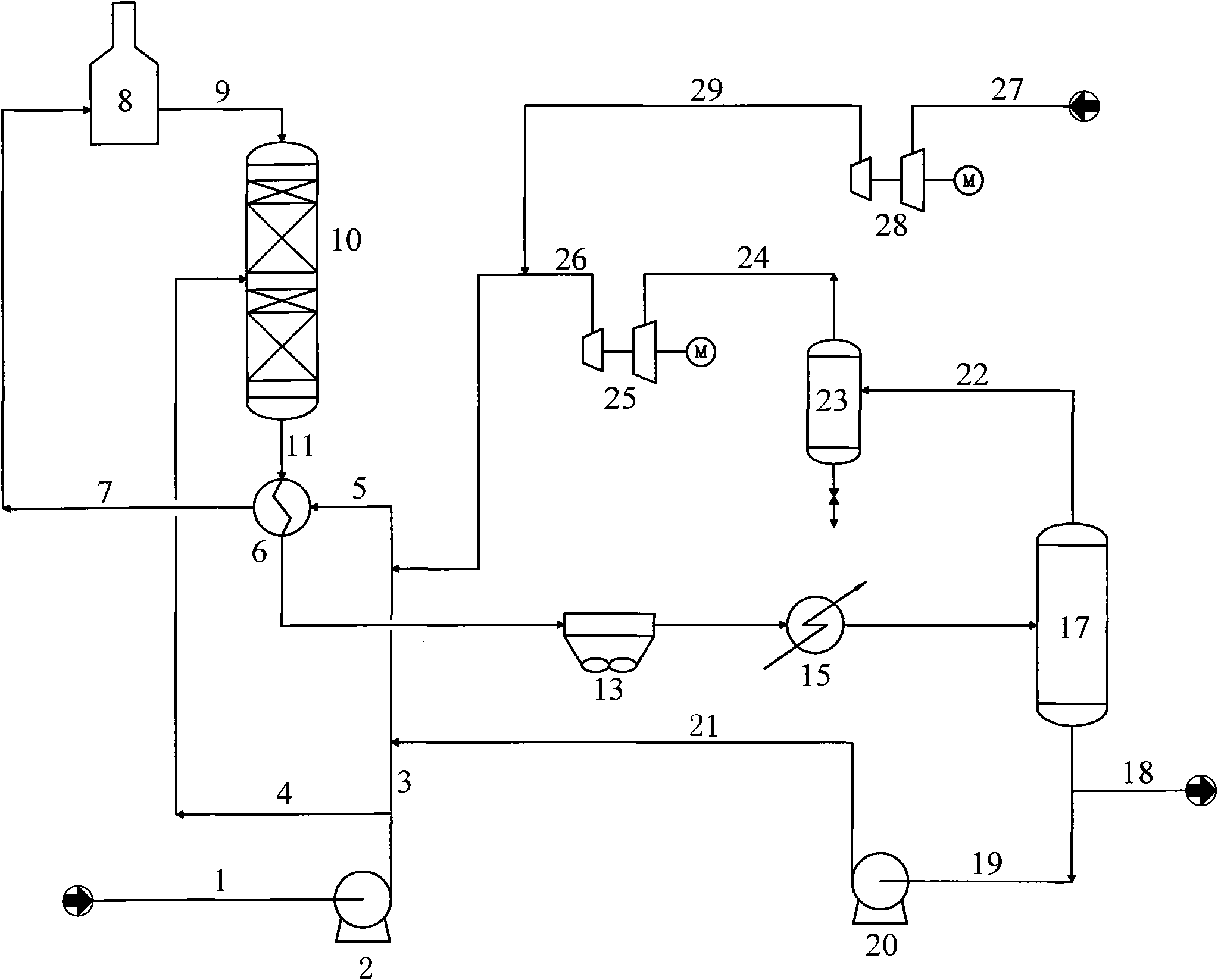

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

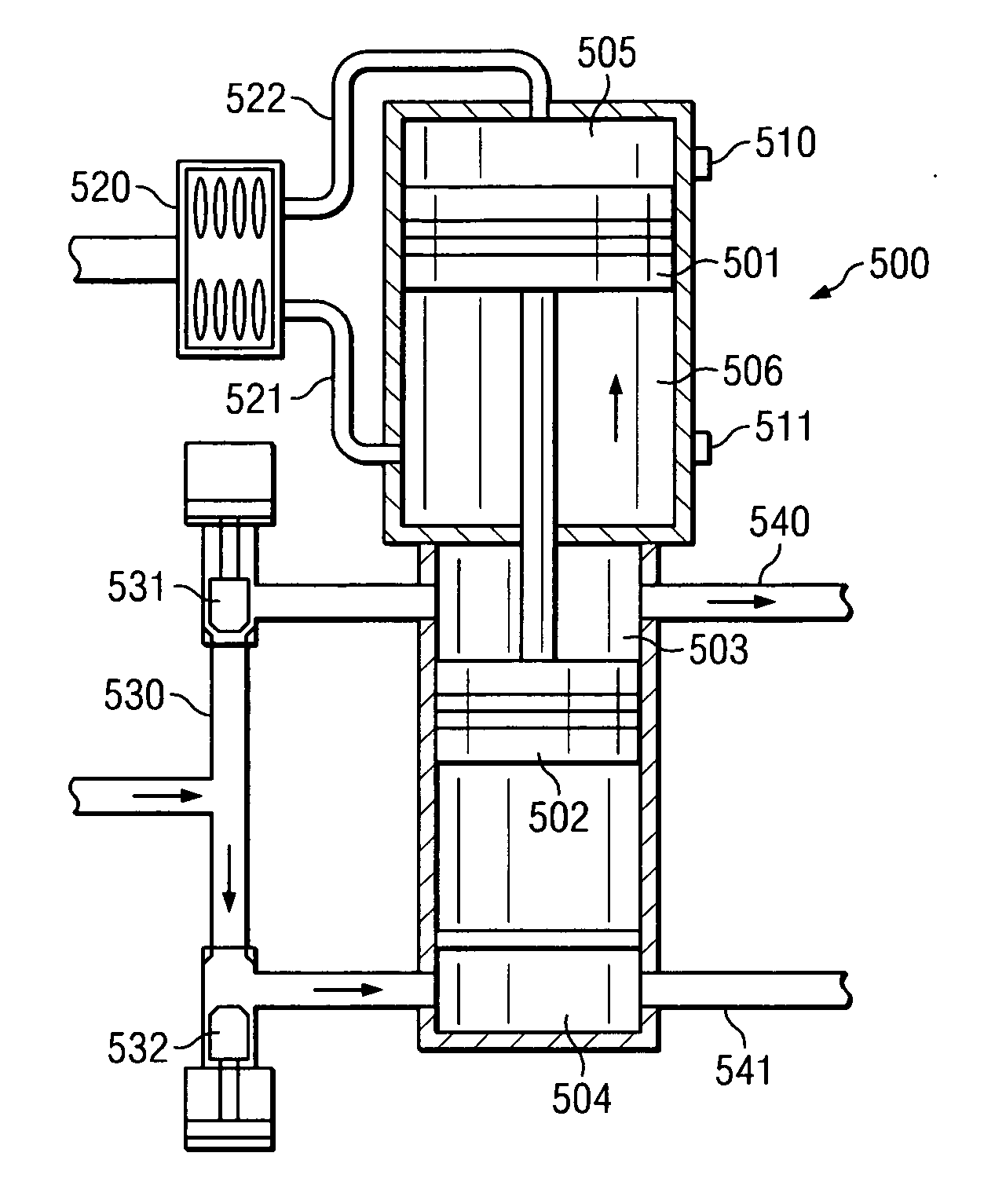

Sorbent for reducing sulfur content in hydrocarbon oils

ActiveCN101433821AHigh desulfurization activityEvenly distributedOther chemical processesHydrocarbon oils refiningSorbentRare earth

The invention relates to a sorbent for reducing sulfer content in hydrocarbon oil, which comprises 1 to 30 weight percent of rare earth faujasite, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide. The mixture of the rare earth faujasite and the carrier is preformed into porous heat-resistant solid particles which are introduced with the metal active ingredient to prepare the sorbent; sulfer-containing light hydrocarbon oil raw material and hydrogen donors enter a reactor filled with the sorbent for separating reaction; materials and products after the separating reaction are sent to a subsequent separation system for product separation; sorbent to be regenerated after the reaction is burnt to be regenerated after steam stripping; and the regenerated sorbent is reduced by the hydrogen donors and returned to the reactor for recycling. The sorbent realizes deep removal of sulfer in the light hydrocarbon oil; meanwhile, the product gasoline has high octane number, low benzene content and high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

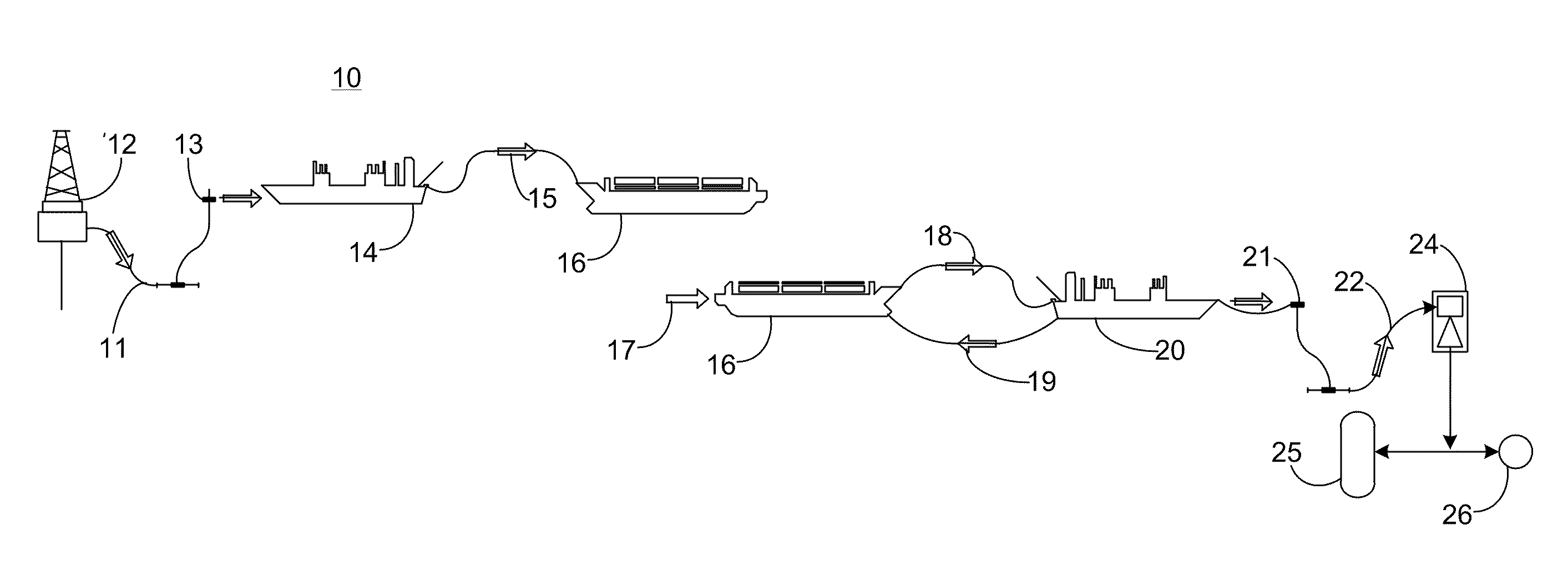

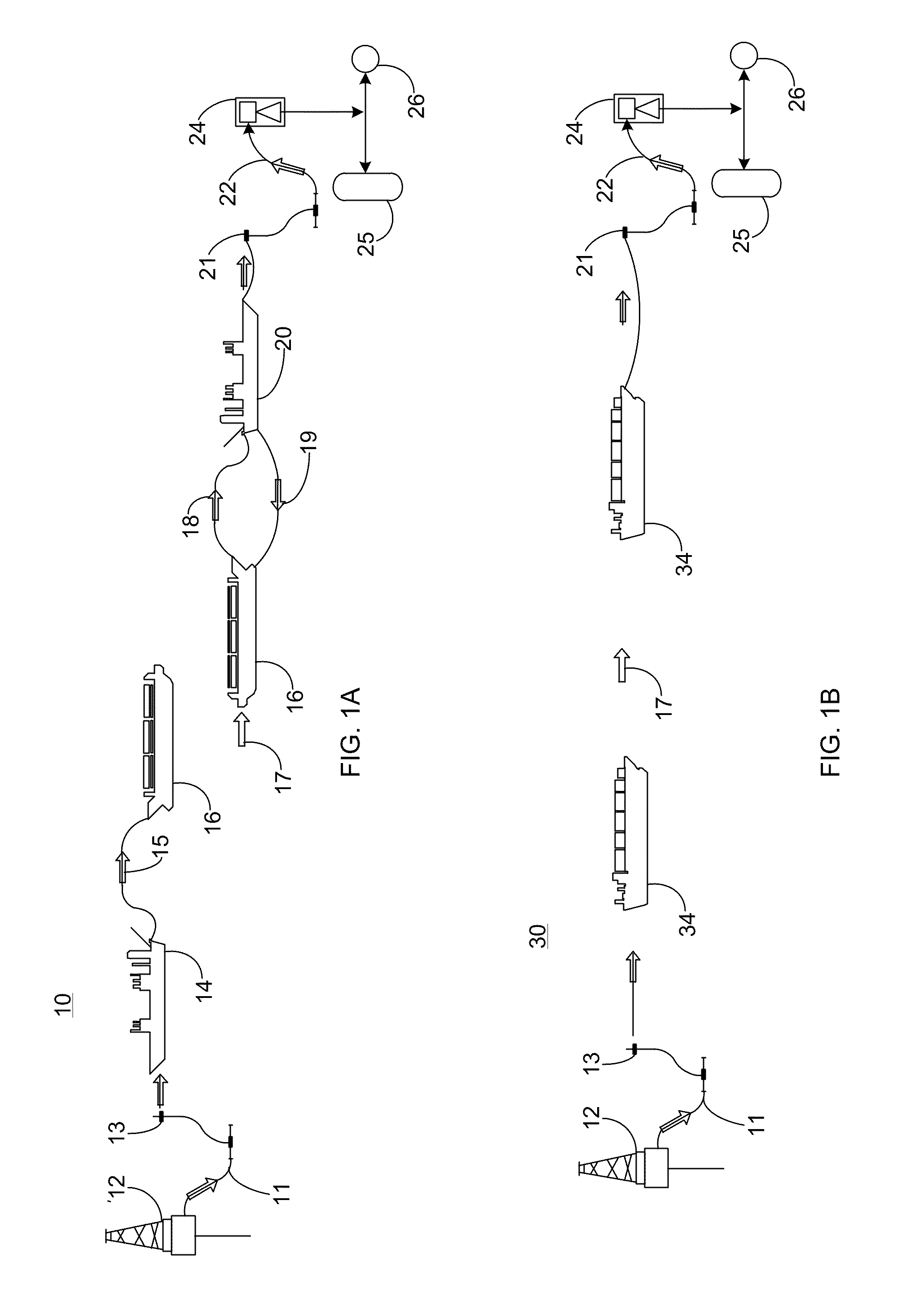

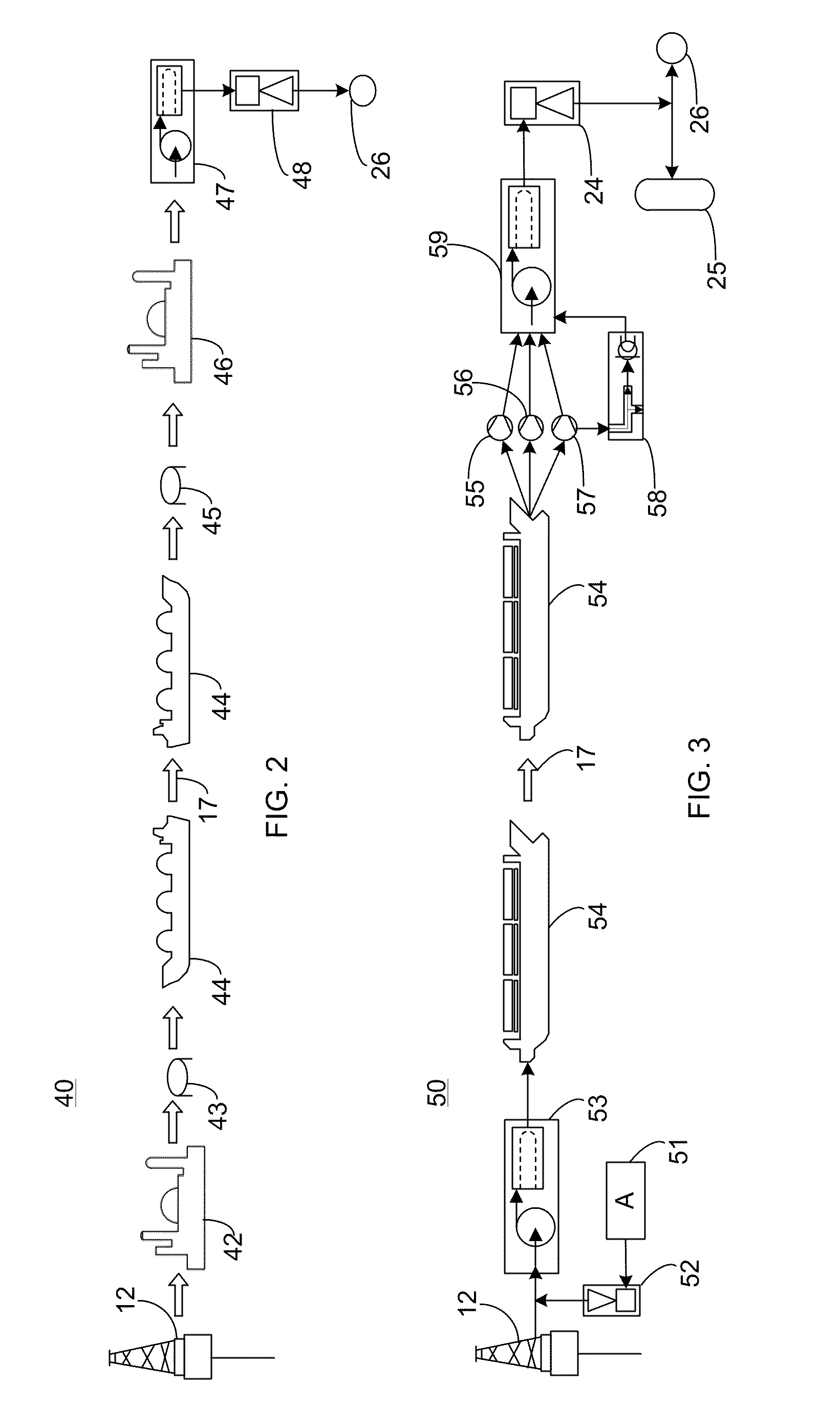

Comprehensive system for the storage and transportation of natural gas in a light hydrocarbon liquid medium

ActiveUS20100000252A1Rapid economic developmentRaise the ratioSolidificationLiquefactionProcess systemsLiquid medium

This invention provides a means of loading, processing and conditioning raw production gas, production of CGL, storage, transport, and delivery of pipeline quality natural gas or fractionated products to market. The CGL transport vessel utilizes a pipe based containment system to hold more densely packed constituents of natural gas held within a light hydrocarbon solvent than it is possible to attain for natural gas alone under such conditions. The containment system is supported by process systems for loading and transporting the natural gas as a liquid and unloading the CGL from the containment system and then offloading it in the gaseous state. The system can also be utilized for the selective storage and transport of NGLs to provide a total service package for the movement of natural gas and associated gas production. The mode of storage is suited for both marine and land transportation and configured in modular form to suit a particular application and / or scale of operation.

Owner:SEAONE HLDG

Nickel-rhodium based catalysts for synthesis gas production

InactiveUS6878667B2High levelHigh selectivityHydrogenCatalyst activation/preparationPartial oxidationManganese

A nickel-rhodium alloy based catalyst for catalyzing the production of synthesis gas from a light hydrocarbon and O2 by a net catalytic partial oxidation process is disclosed. Preferred nickel-rhodium alloy based catalysts comprise about 1-50 weight percent nickel and about 0.01-10 weight percent rhodium on a porous refractory support structure. In certain embodiments, the catalyst also contains a lanthanide element, zirconium, cobalt, manganese or magnesium.

Owner:CONOCOPHILLIPS CO

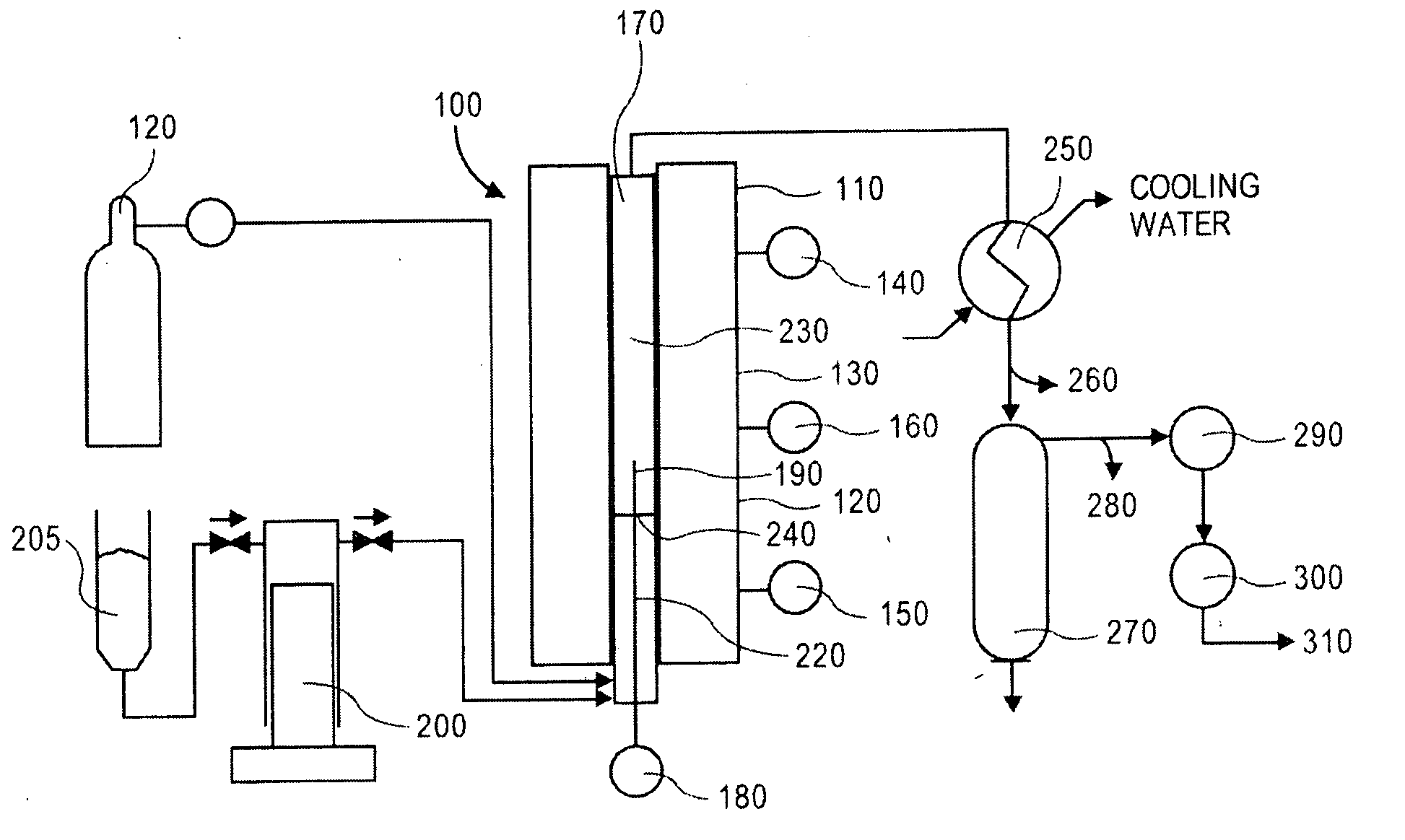

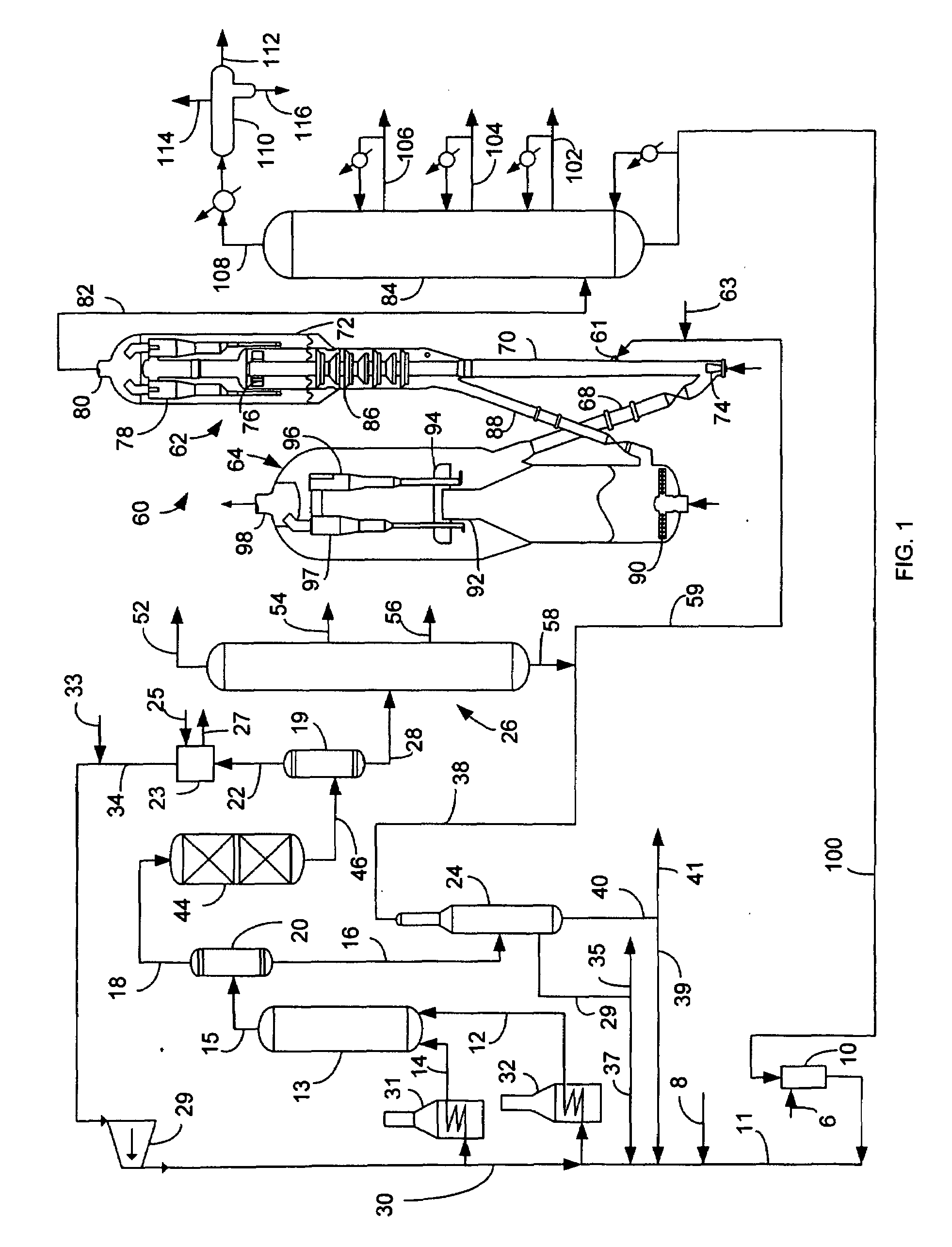

Process and Apparatus for Integrated Heavy Oil Upgrading

InactiveUS20090127161A1Improve performanceMaximize and optimize gasoline yieldCatalytic crackingHydrocarbon oil crackingParticulatesGasoline

A process and apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked to produce vacuum gas oil (VGO). A light portion of the VGO may be hydrotreated and subjected to fluid catalytic cracking to produce fuels such as gasoline. A heavy portion of the VGO may be recycled to the slurry hydrocracking reactor. FCC slurry oil may be recycled to the slurry for hydrocracking.

Owner:UOP LLC

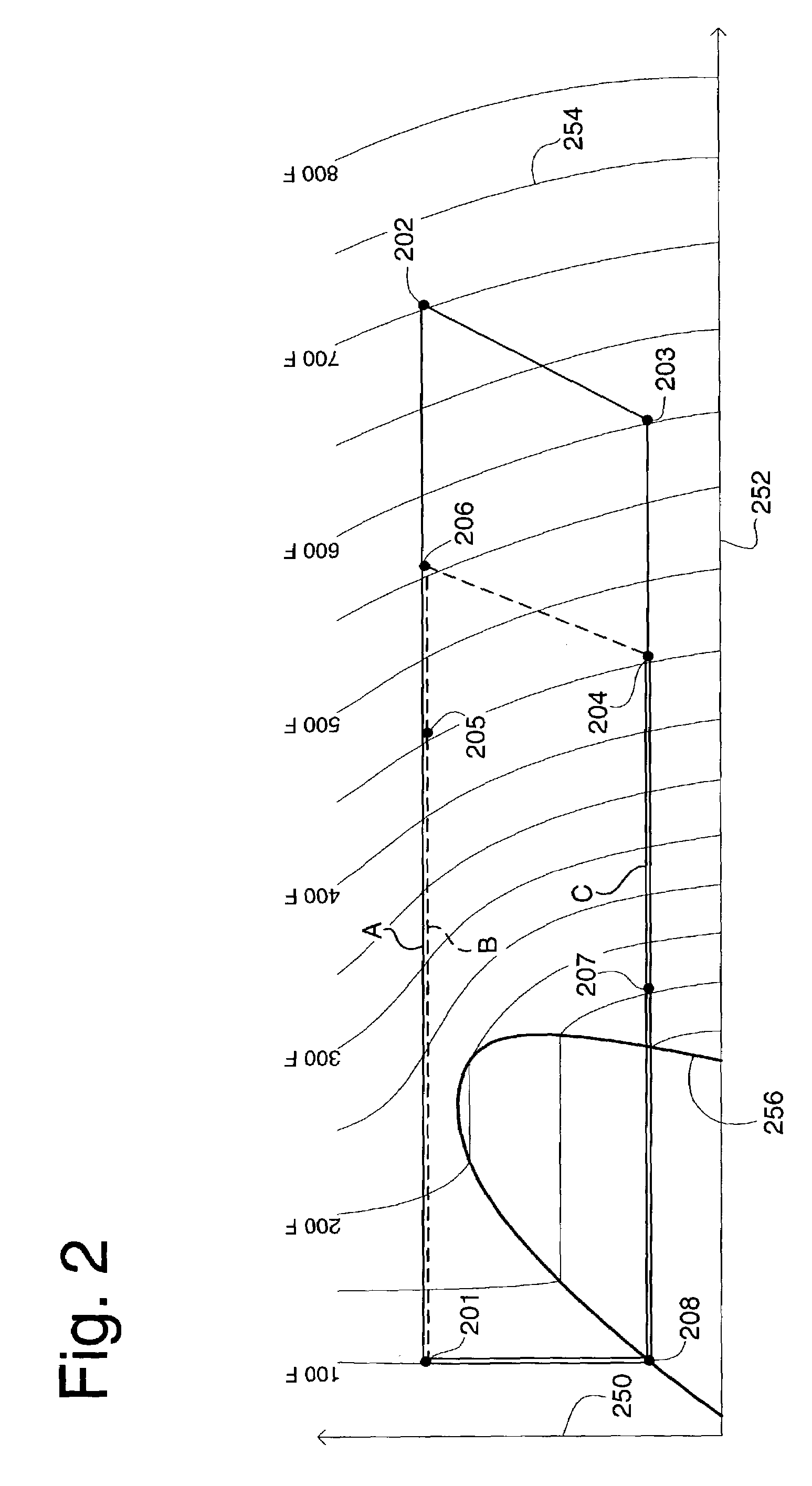

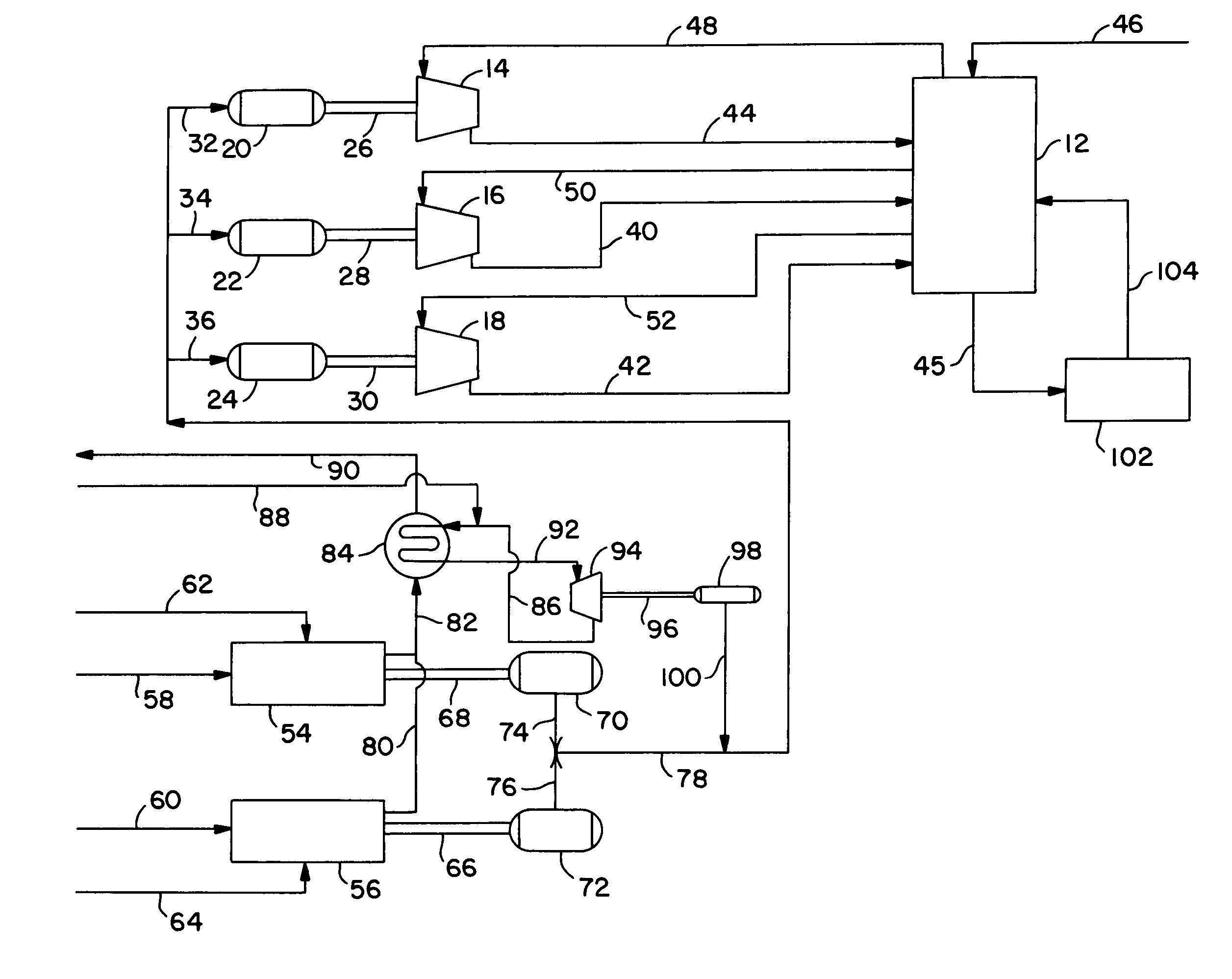

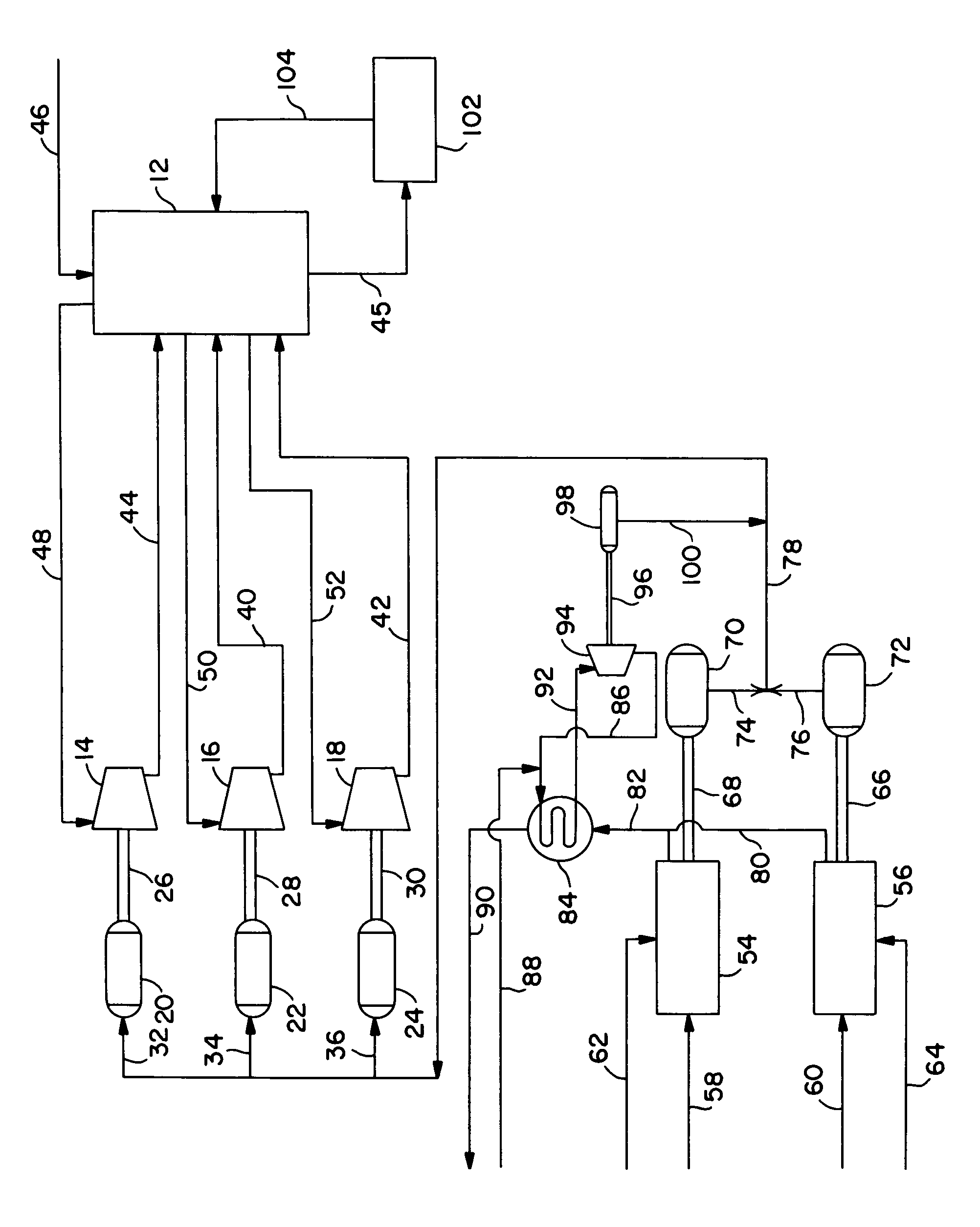

Hydrocarbon gas conversion system and process for producing a synthetic hydrocarbon liquid

InactiveUS6130259AEliminates high capital costCost effectiveCombustion enginesGas turbine plantsLiquid productCombustion chamber

A system and process are provided for converting a light hydrocarbon gas to a synthetic heavier hydrocarbon liquid. The system includes an autothermal reformer, a Fischer-Tropsch reactor and a Brayton cycle that are structurally and functionally integrated. In the practice of the process, a mixture of a hydrocarbon feed gas, a compressed air feed and process steam is fed to the autothermal reformer to produce a synthesis gas. The synthesis gas is fed to the Fischer-Tropsch reactor where it is catalytically reacted to produce heavy hydrocarbons. The outlet from the Fischer-Tropsch reactor is separated into water, a low heating value tail gas, and the desired hydrocarbon liquid product. The water is pressurized and heated to generate process steam. The tail gas is heated and fed with compressed air and steam to the Brayton cycle having a combustor and a series of power turbines and compressors. The tail gas and air feed are burned in the combustor to produce a combustion gas that is used to drive a power turbine linked by a shaft to an air compressor, thereby driving the air compressor. The system further includes a plurality of heat exchangers that enable heat to be recovered from the outlet of the autothermal reformer. The recovered heat is used to make the process steam as well as to preheat the hydrocarbon feed gas before it is fed to the autothermal reformer, preheat the synthesis gas before it is fed to the Fischer-Tropsch reactor and preheat the tail gas before it is fed to the combustor.

Owner:REG SYNTHETIC FUELS LLC +1

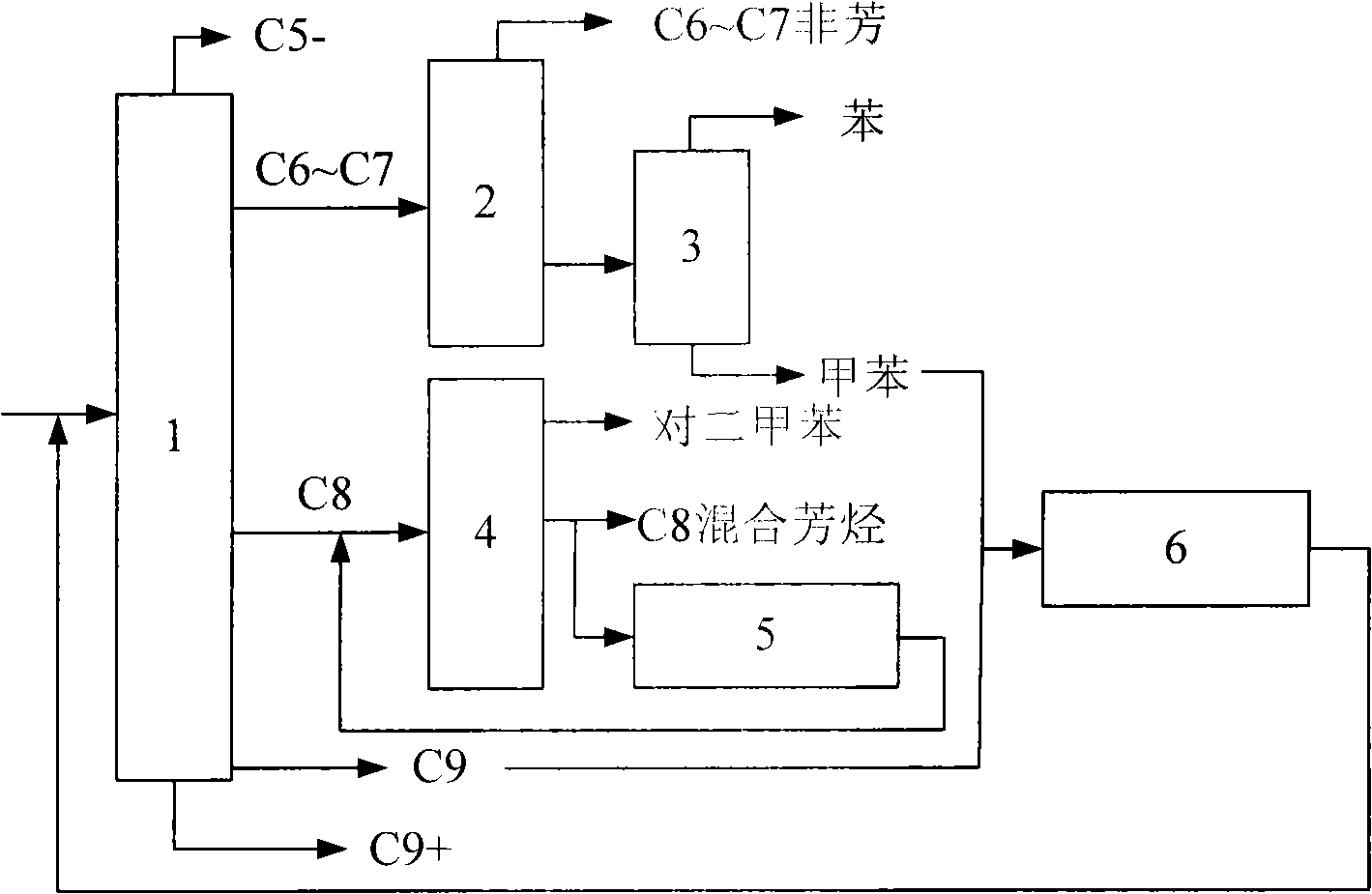

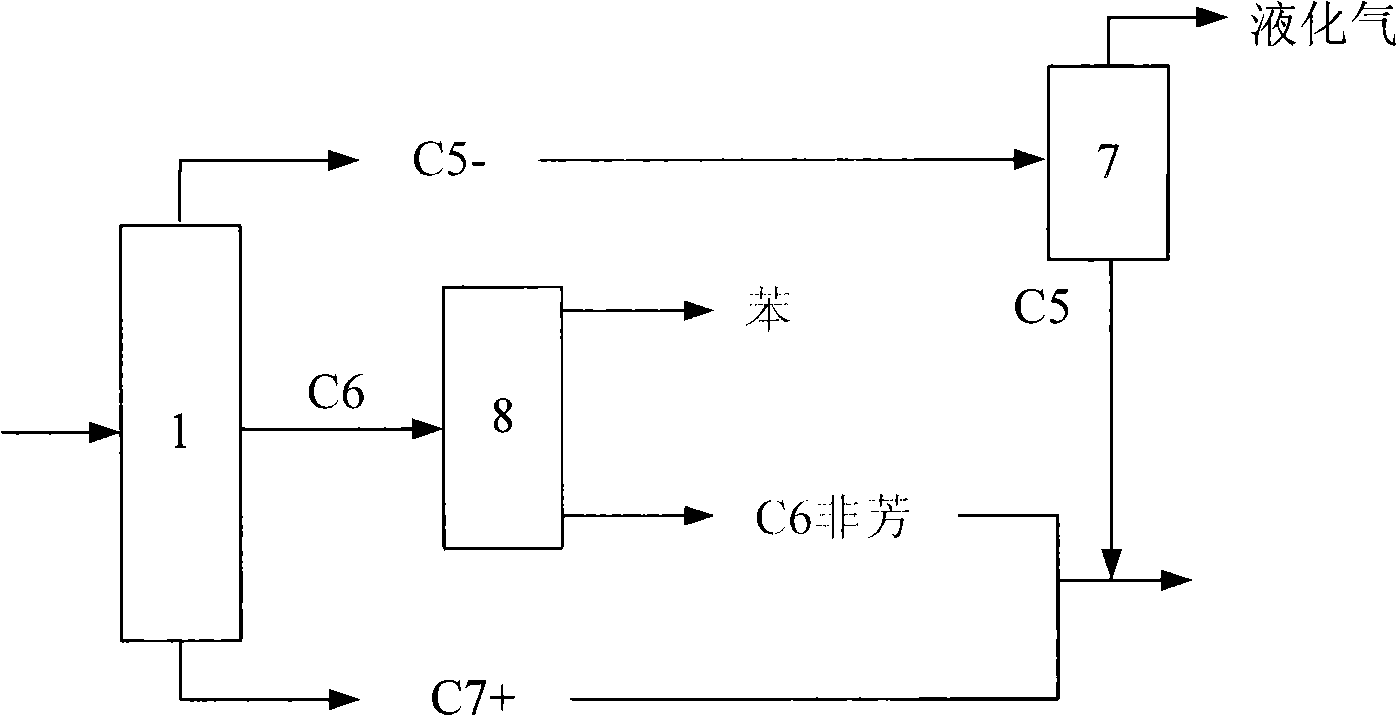

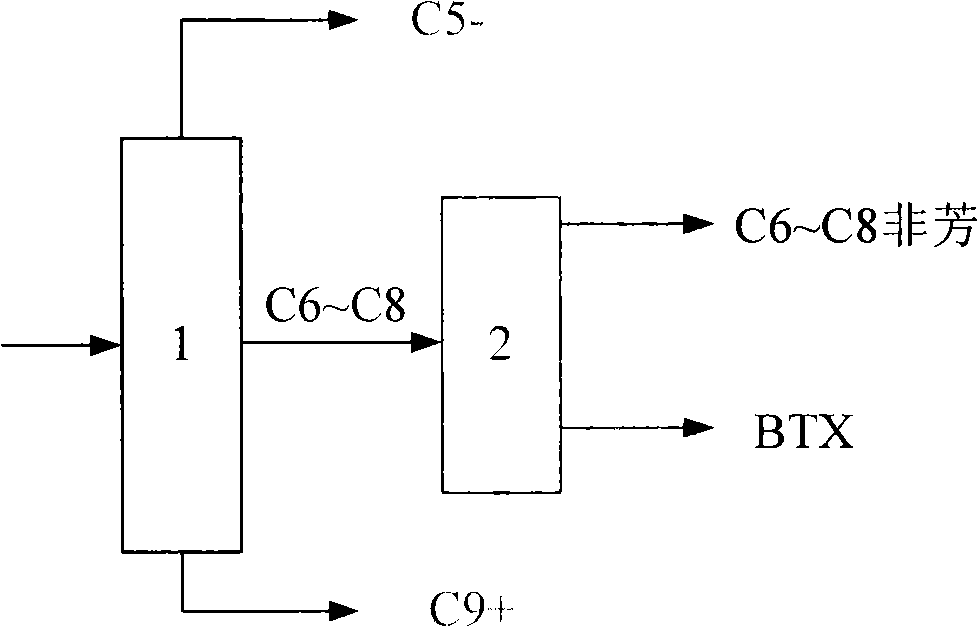

Method for catalyzing and transforming naphtha

ActiveCN101570698AWide boiling point rangeExpand sourceTreatment with hydrotreatment processesNaphthaIsomerization

The invention relates to a method for catalyzing and transforming naphtha with the boiling range of 40-260 DEG C, comprising the following steps: (1) hydrofining the naphtha under the catalysis of hydrofining catalyst, distilling the hydrofined naphtha and cutting the hydrofined naphtha into the light-weight distillate, the middle-weight distillate and the heavy-weight distillate; (2) dischargingthe light-weight distillate from a device or enabling the light-weight distillate to contact with light-hydrocarbon isomerization catalyst for light-hydrocarbon isomerization reaction; (3) dividing the middle-weight distillate into one or a plurality of distillate for segmental refroming reaction; and (4) enabling the heavy-weight distillate to contact with light-weight catalyst for light-weight reaction. By dividing the hydrofined naphtha into a plurality of distillate and processing the distillate by segments with different catalysts, all components of the naphtha can be effectively utilizedand can be transformed to light-weight aromatic hydrocarbon or high-octane gasoline components, the source of the naphtha is widened, and the distillation range of the applied naphtha is enlarged.

Owner:CHINA PETROLEUM & CHEM CORP +1

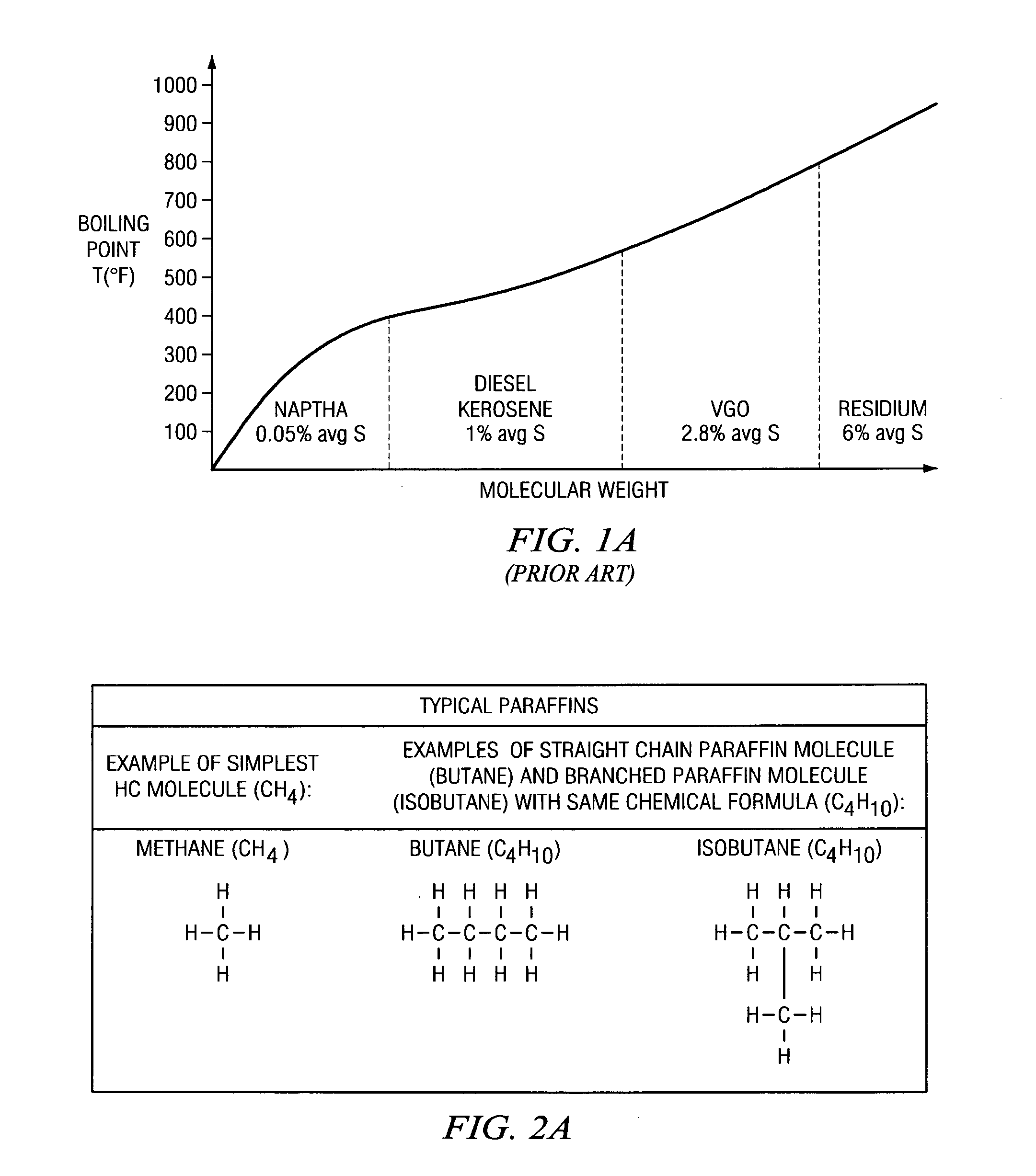

Petroleum Upgrading and Desulfurizing Process

ActiveUS20120181217A1Reduce dwell timeSmall sizeThermal non-catalytic crackingMolecular sieve catalystsSorbentWater flow

A petroleum feedstock upgrading method is provided. The method includes supplying a mixed stream that includes hydrocarbon feedstock and water to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream having an increased concentration of lighter hydrocarbons and / or concentration of sulfur containing compounds. The modified stream is then supplied to an adsorptive reaction stage charged with a solid adsorbent operable to remove at least a portion of the sulfur present to produce a trimmed. The trimmed stream is then separated into a gas and a liquid streams, and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

System for improving crude oil

InactiveUS20060231462A1Increase heightEnhancing crude oilThermal non-catalytic crackingSemi-permeable membranesAPI gravityFiltration

Crude oil can be refined through a filtration media. Cavitation bubbles having localized areas of very high temperatures and pressures may be created thereby causing several physical and chemical phenomena, including thermal cracking of carbon-carbon bonds as the crude moves through the flux cartridge membrane. Heavy hydrocarbons are residues are thereby cracked into smaller lowering boiling molecules having a higher API gravity. Once the relatively smaller hydrocarbons pass through the flux cartridge membrane into the flux cartridge, the effluent can be routed to a second separator annulus. It should also be pointed out that lighter hydrocarbons formed can volatilize and special provisions may be needed to efficiently capture these gases.

Owner:LJC TECH

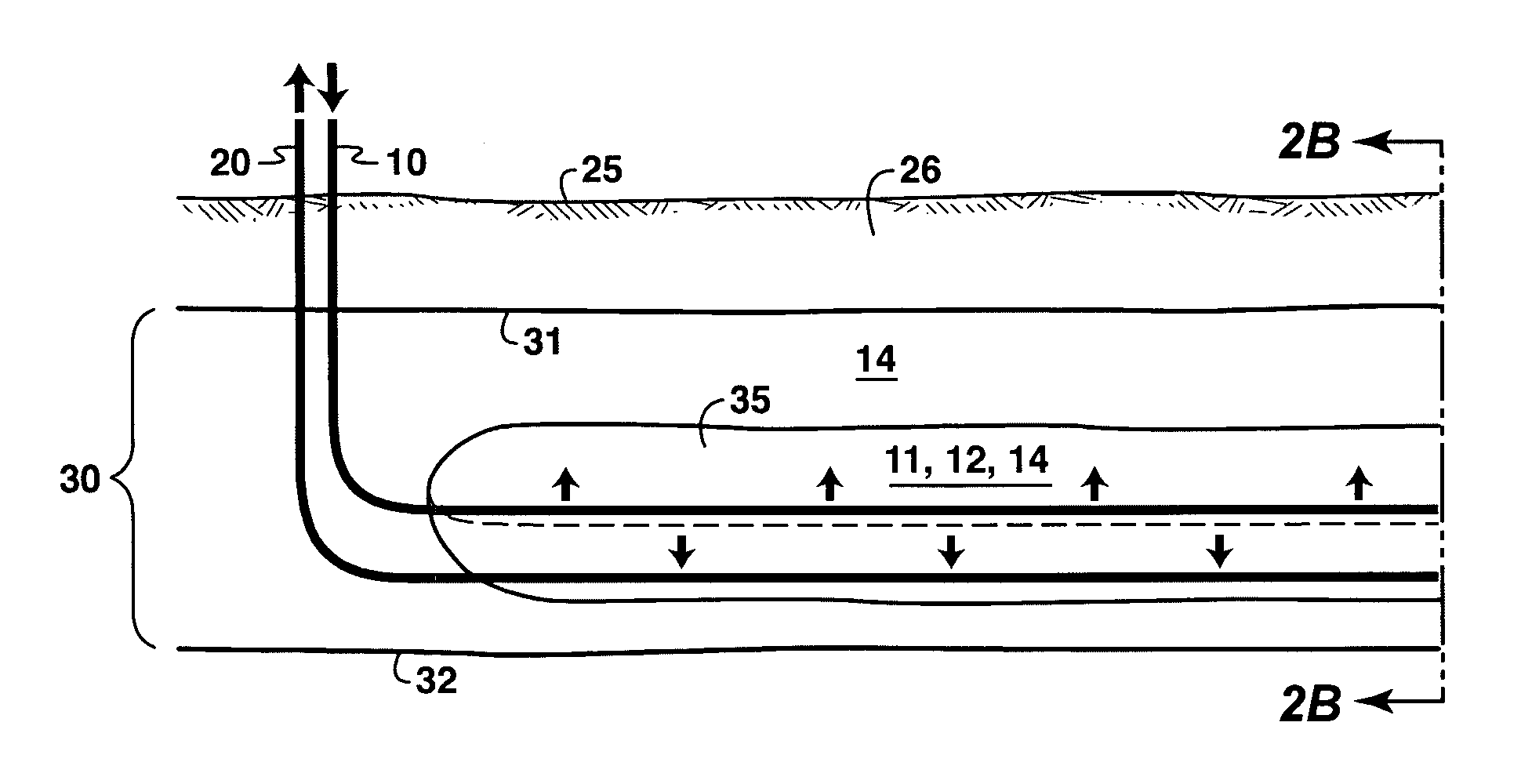

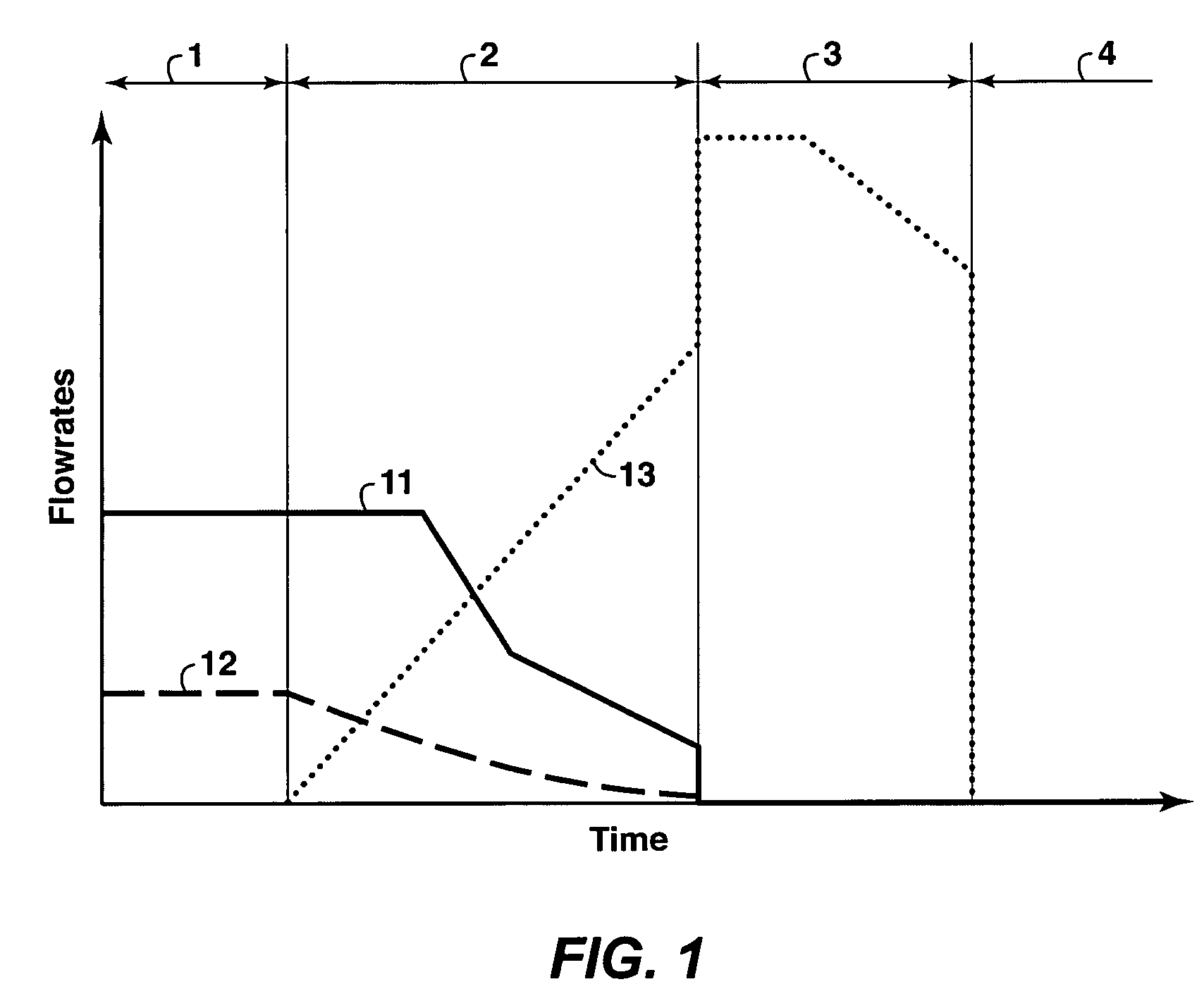

Process for in situ recovery of bitumen and heavy oil

A process is described for in situ recovery of bitumen or heavy oil from a reservoir having a horizontal injection well and a horizontal production well. The process includes a first phase in which steam and a heavy hydrocarbon solvent are injected into the reservoir, a second phase in which the steam and heavy hydrocarbon injections are transitioned to a light hydrocarbon solvent injection, and a third phase in which a light hydrocarbon solvent is injected without further steam or heavy hydrocarbon injection. A displacement gas may be added during any of the phases, and production of hydrocarbons continues throughout all phases. The process employs a high-production start-up phase, followed by lower cost phases which progress a depletion chamber within the reservoir.

Owner:EXXONMOBIL UPSTREAM RES CO

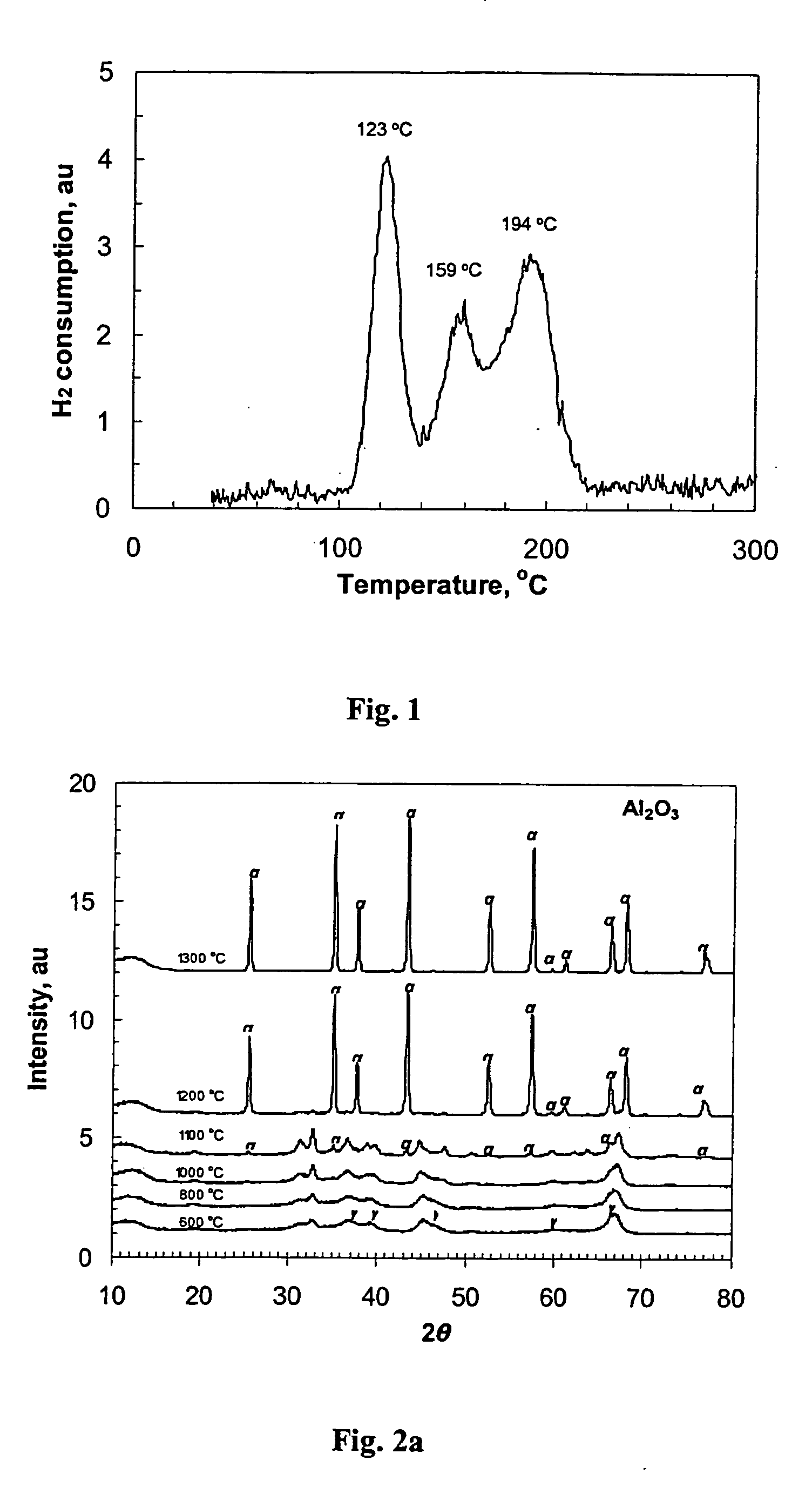

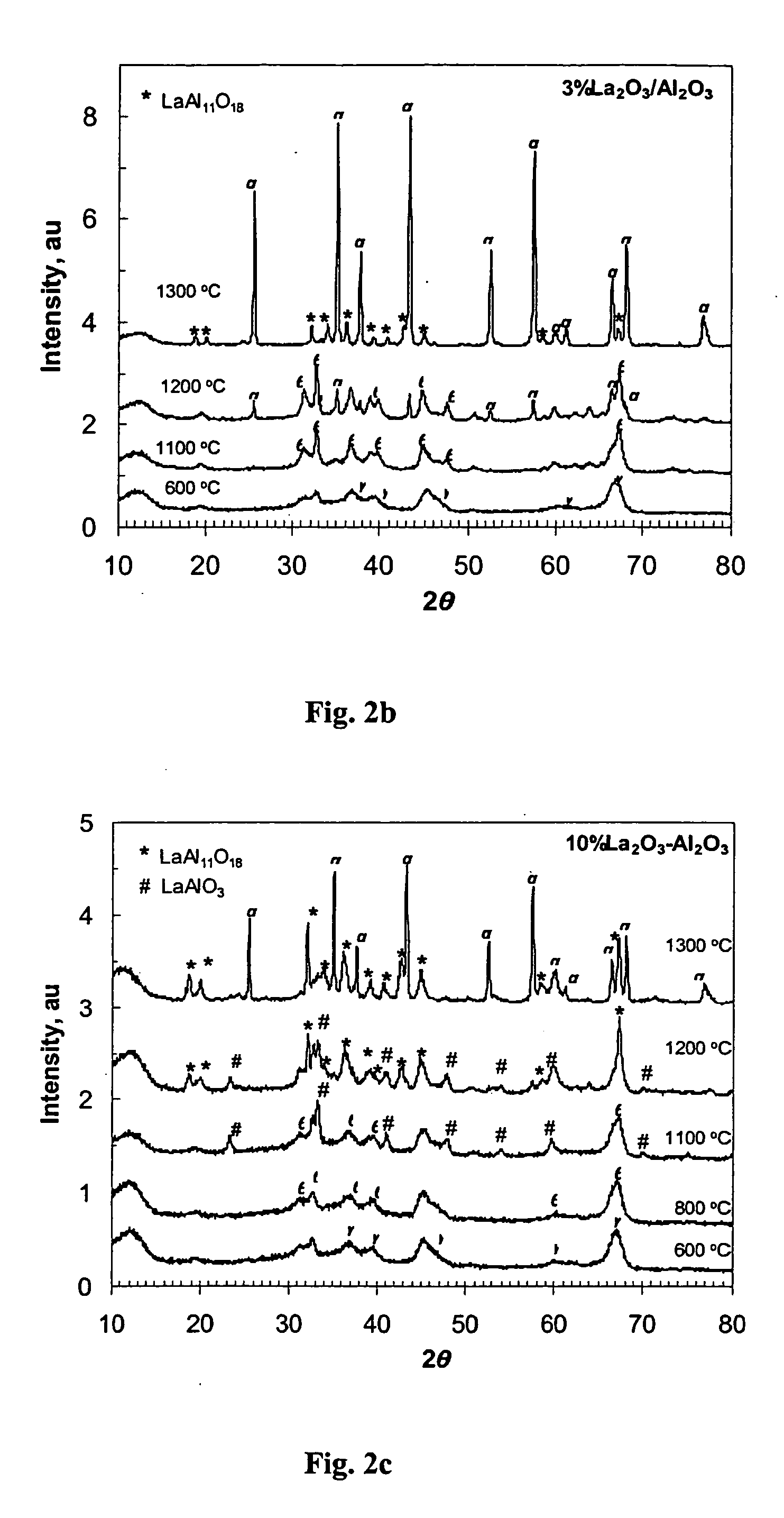

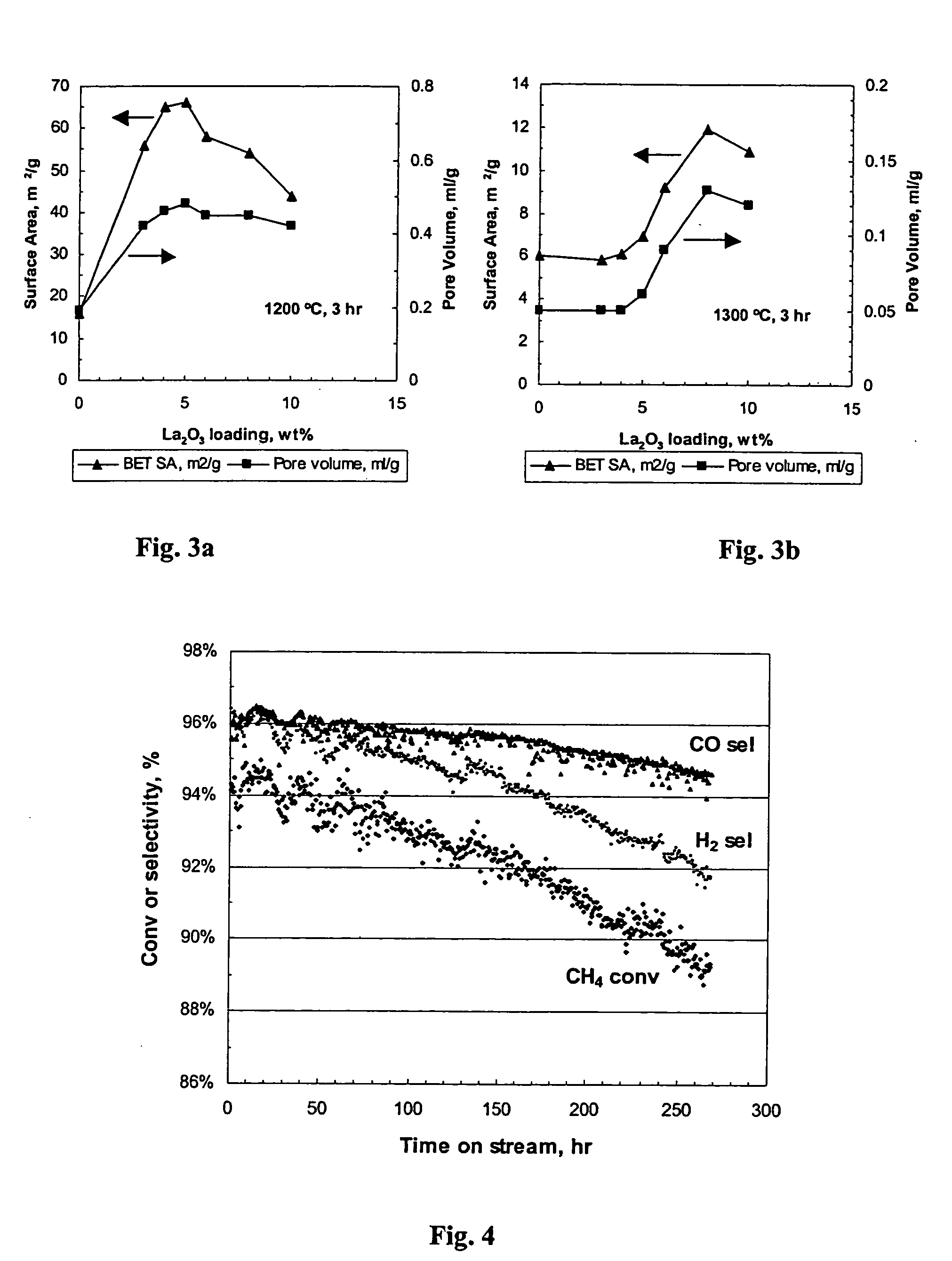

Supports and catalysts comprising rare earth aluminates, and their use in partial oxidation

InactiveUS20050265920A1Large specific surface areaHydrogenHeterogenous catalyst chemical elementsAluminatePartial oxidation

The present invention relates to thermally stable supports and catalysts for use in high temperature operation, and methods of preparing such supports and catalysts, which includes adding a rare earth metal to an aluminum-containing precursor prior to calcining. The present invention can be more specifically seen as a support, process and catalyst wherein the thermally stable support comprises two rare earth aluminates of different molar ratios of aluminum to rare earth metal, and optionally, alumina and / or a rare earth oxide. More particularly, the invention relates to the use of noble metal catalysts comprising the thermally stable support for synthesis gas production via partial oxidation of light hydrocarbon (e.g., methane) with minimal deactivation over long-term operations and further relates to gas-to-liquids conversion processes.

Owner:CONOCOPHILLIPS CO

All electric LNG system and process

ActiveUS7114351B2Improve efficiencyReduce carbon dioxide emissionsSolidificationLiquefactionEngineeringProcess engineering

A reduced carbon dioxide emissions system and method for providing power for refrigerant compression and shared electrical power for a light hydrocarbon gas liquefaction process.

Owner:BP CORP NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com