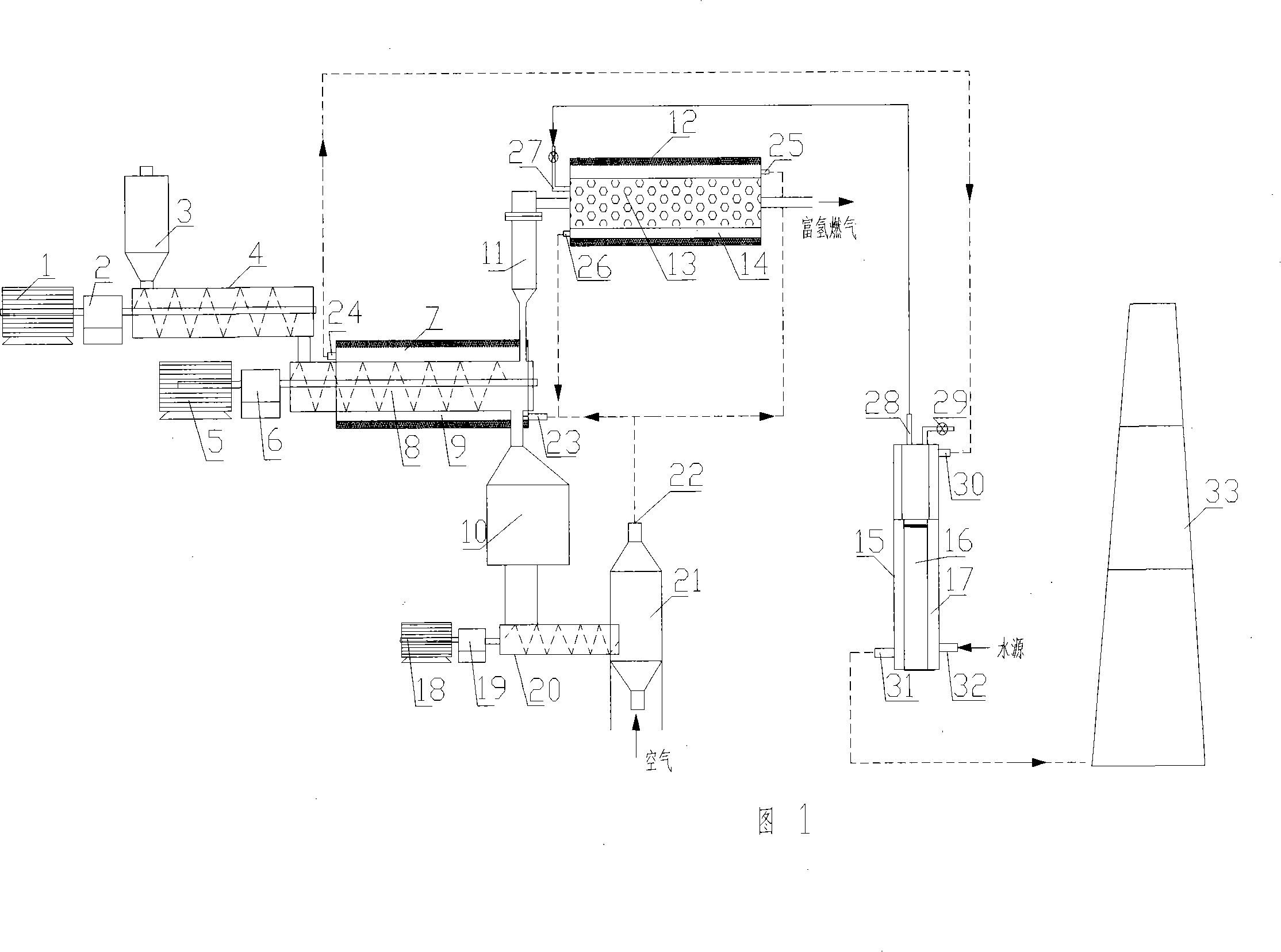

Method and device for preparing biomass hydrogen-rich combustion gas

A preparation device and biomass technology, which are applied in the preparation of biofuels, liquid hydrocarbon mixtures, chemical instruments and methods, etc., to achieve the effects of reducing carbon deposition, realizing energy conservation and emission reduction, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

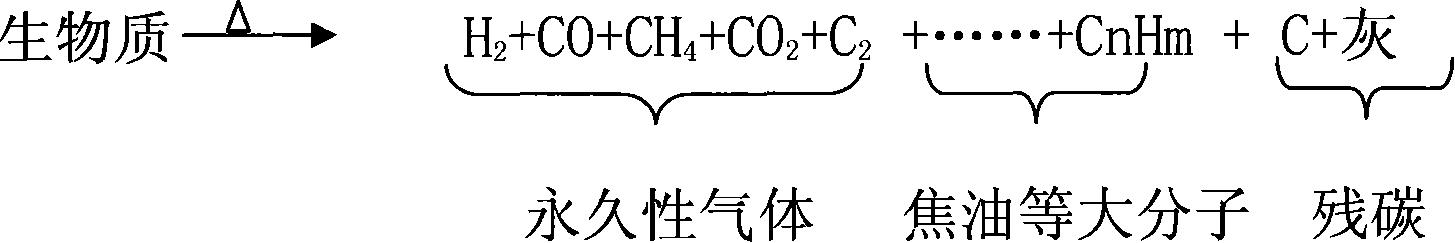

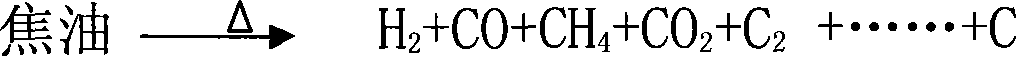

Method used

Image

Examples

Embodiment 1

[0031] Example 1: rice husk powder is the raw material, the moisture content of the raw material is 12%, the pyrolysis temperature is 550°C, the residence time in the pyrolysis reaction chamber is 6.5 minutes, the cracking temperature is 850°C, the cracking reaction time is 3 seconds, a dolomite catalyst is used, and water vapor is added The amount is 10% of the biomass mass, and the gas composition (volume content) is: hydrogen 35.9%, carbon monoxide 24.0%, carbon dioxide 25.5%, methane 12.1%.

Embodiment 2

[0032] Example 2: rice husk powder is the raw material, the moisture content of the raw material is 12%, the pyrolysis temperature is 600°C, the residence time in the pyrolysis reaction chamber is 6.5 minutes, the cracking temperature is 900°C, the cracking reaction time is 4.5 seconds, a dolomite catalyst is used, and water vapor is added The amount is 20% of the biomass mass, and the gas composition (volume content) is: hydrogen 45.6%, carbon monoxide 14.7%, carbon dioxide 30.8%, methane 7.4%.

Embodiment 3

[0033] Example 3: rice husk powder is the raw material, the moisture content of the raw material is 12%, the pyrolysis temperature is 650°C, the residence time in the pyrolysis reaction chamber is 8 minutes, the cracking temperature is 950°C, the cracking reaction time is 4.5 seconds, and the secondary cracking section adopts dolomite catalyst , the amount of steam added is 30% of the biomass mass, and the gas composition (volume content) is: hydrogen 52.1%, carbon monoxide 9.8%, carbon dioxide 33.2%, methane 3.2%. It can be seen that the increase of the secondary cracking temperature and the addition of water vapor can significantly increase the hydrogen yield and reduce the methane content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com