Patents

Literature

509results about How to "Improve conversion ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

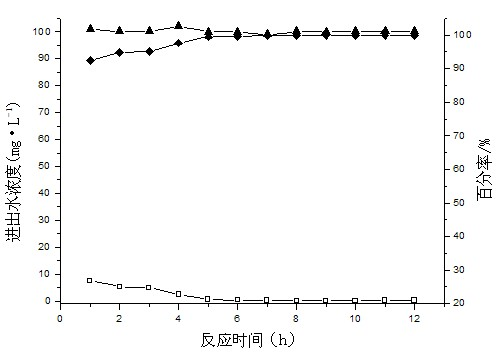

Sphingomonas strain and application thereof in water treatment

InactiveCN102168054APromote degradationReduce concentrationBacteriaMicroorganism based processesIndustrial waste waterWater source

The invention belongs to the technical fields of environmental engineering and bioengineering and particularly relates to a sphingomonas strain and applications thereof in the aspects of shortcut nitrification-denitrification of nitrogen-containing industrial waste water and domestic sewage and treatment of a polluted water source. The sphingomonas strain is separated from a Taihu water in China,is a local strain and has high safety; and the strain can be grown in a basic medium, wherein in the basic medium, CO2 is used as a carbon source and energy or CO2 and an organism are used as a mixedcarbon source and energy, and ammonia nitrogen or nitrate nitrogen is used as a nitrogen source. The bacterium liquid, the dormancy cell and the immobilized strain of the sphingomonas can decompose ammonia nitrogen into nitrite nitrogen and simultaneously can decompose the ammonia nitrogen into nitrogen, can be used as denitrification microorganism for converting the ammonia nitrogen into the nitrite nitrogen and the nitrogen, thereby achieving the shortcut nitrification-denitrification. The strain can rapidly decompose the ammonia nitrogen and is suitable for treating the nitrogen-containingindustrial waste water and domestic sewage as well as polluted water source.

Owner:NANJING UNIV

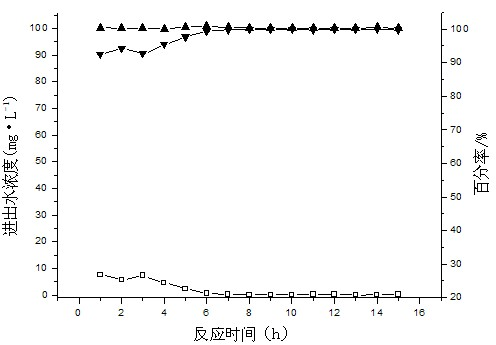

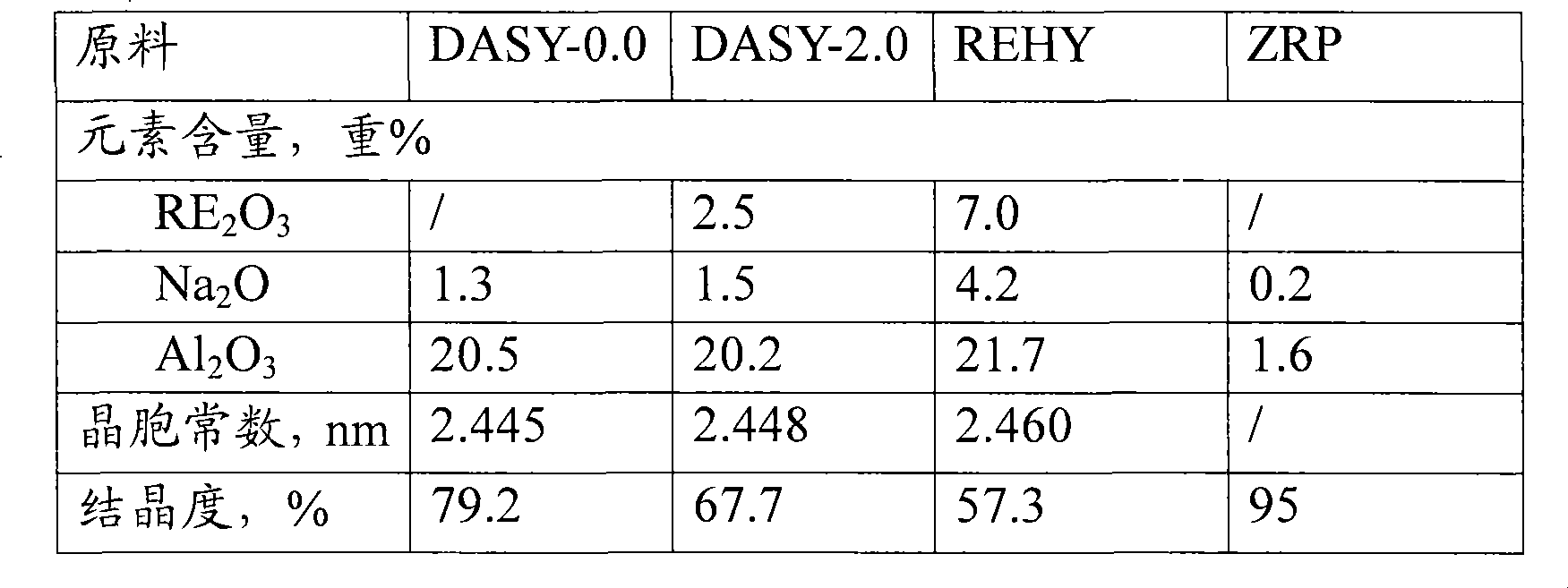

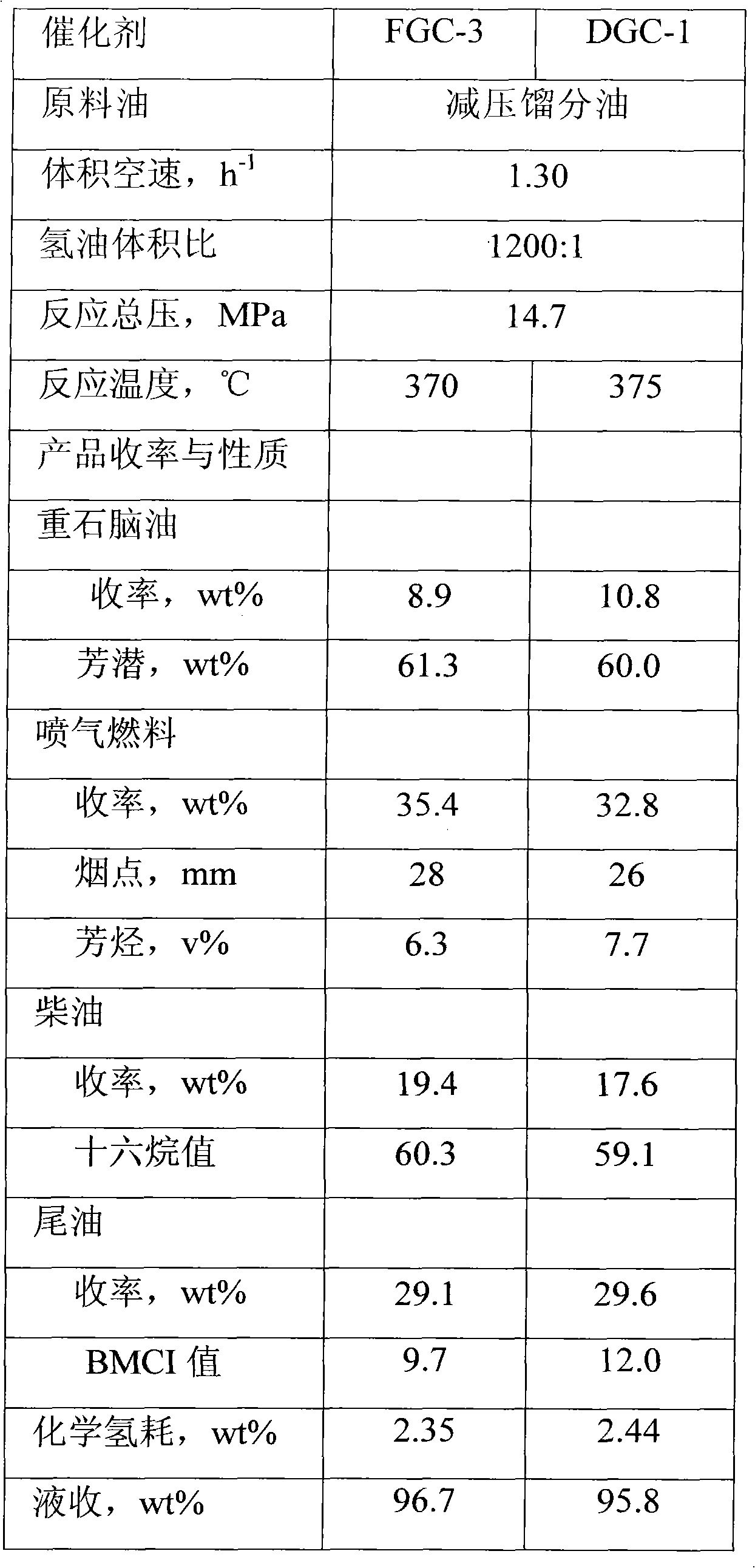

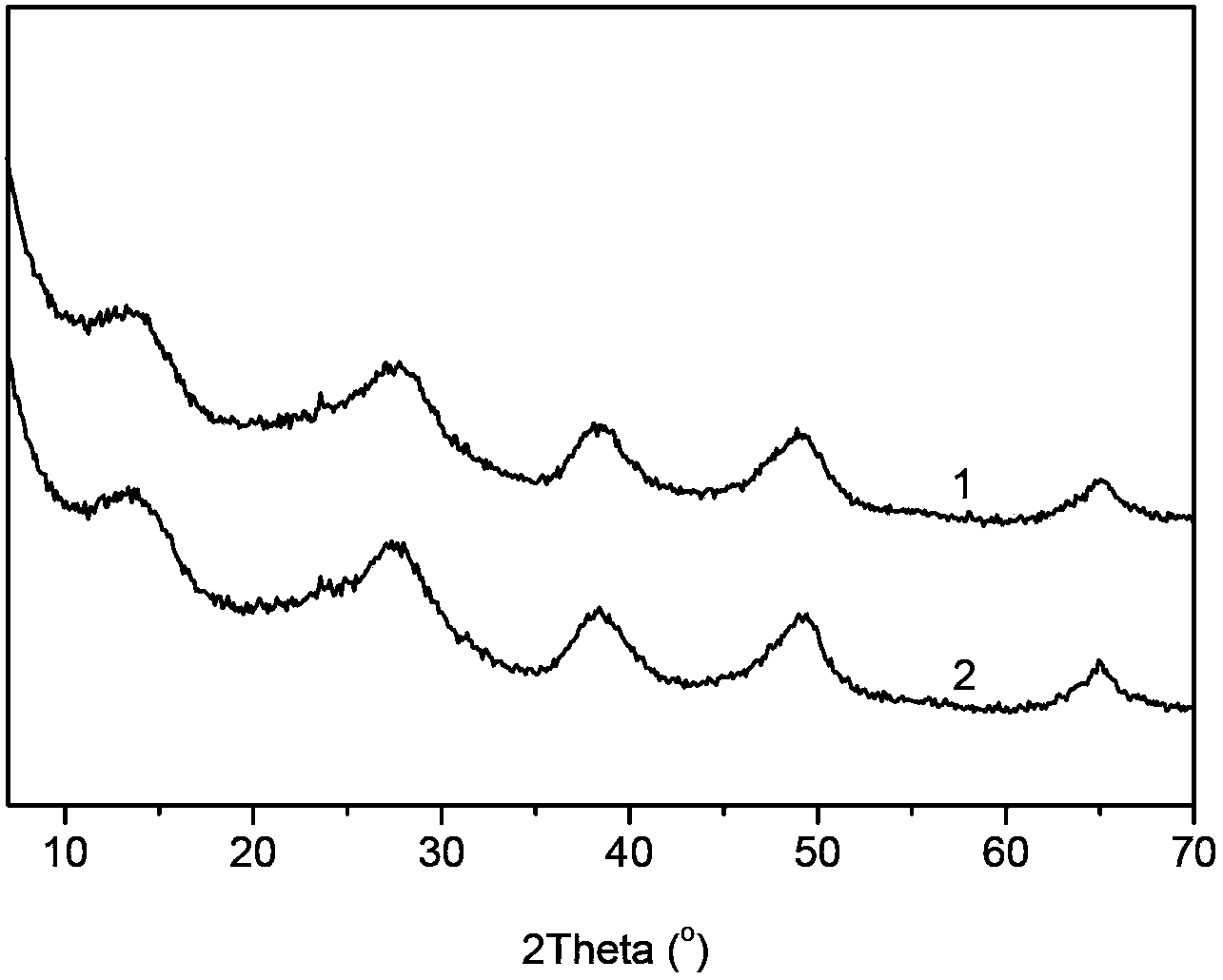

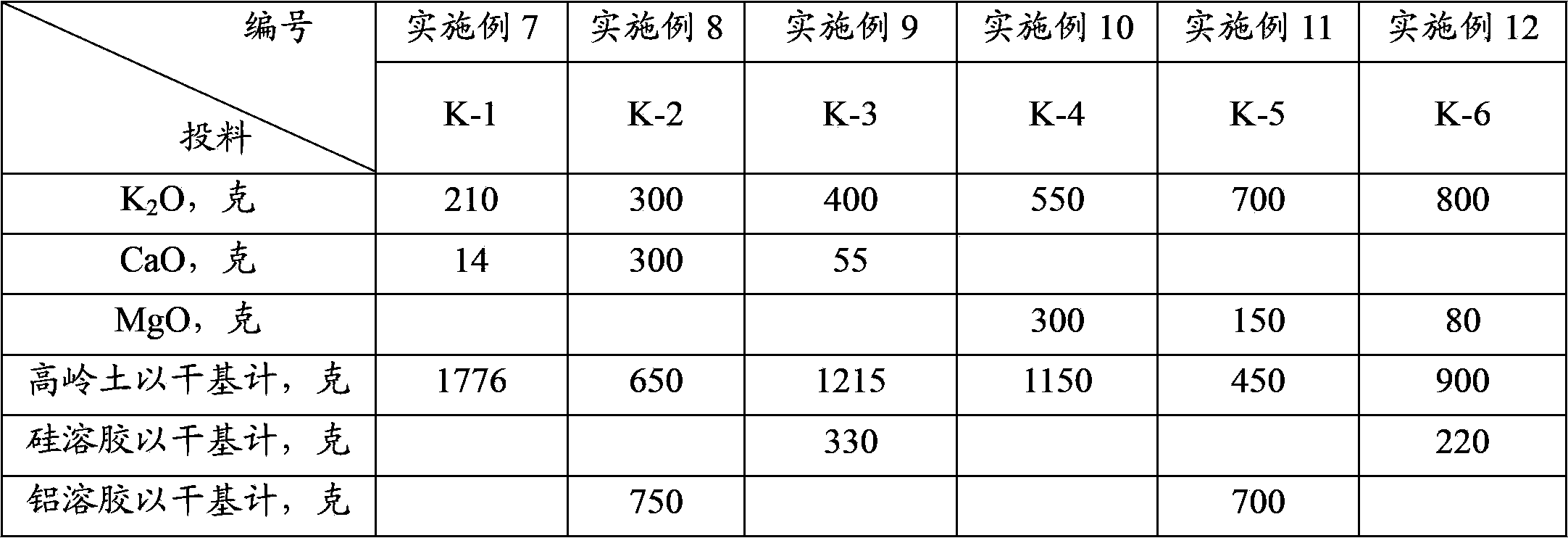

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

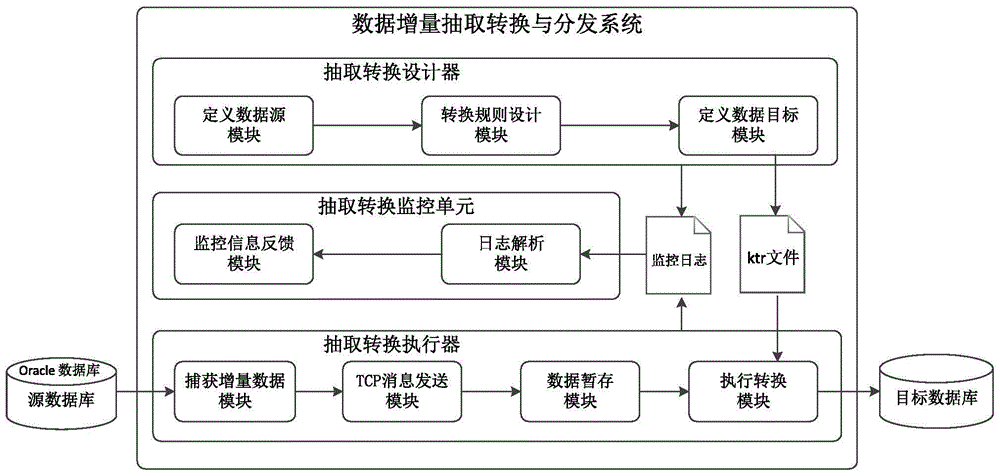

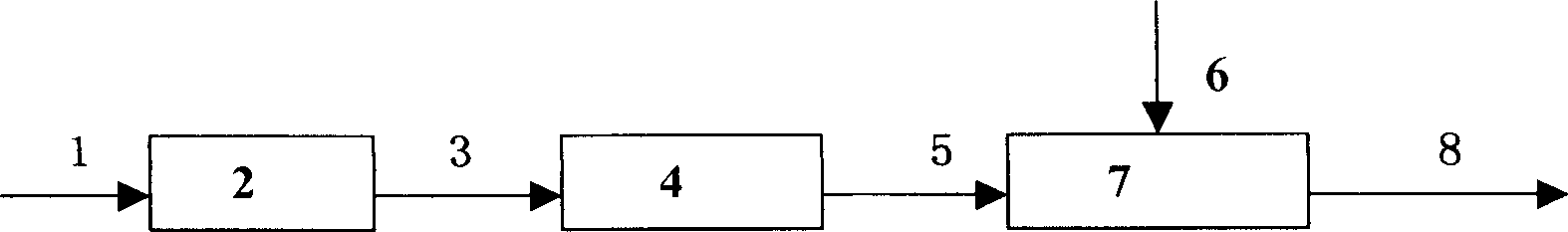

System and method for extraction, transformation and distribution of data increments

ActiveCN105069142ASynchronous real-timeStrong technical supportSpecial data processing applicationsData synchronizationData source

The present invention discloses a system and a method for extraction, transformation and distribution of data increments. The system comprises an extraction transformation designer, an extraction transformation actuator and an an extraction transformation monitoring unit, wherein the extraction transformation designer is used for defining a data source of a source database, designing a transformation rule, then defining a data target, and packaging the designed transformation rule into a KTR file; the extraction transformation actuator is used for capturing incremental data of the source database in real time, analyzing the source of the incremental data, transmitting the incremental data to a server which analyzes the obtained information and selectively calls the corresponding transformation rule to perform transformation processing, the KTR file is executed in batches; and the extraction transformation monitoring unit can monitor the running condition of the rule and can control the start and the stop of data synchronization. A technology combining a log analysis technology and ETL is adopted, so that the functions of capturing the incremental data of the source database in real time, performing transformation processing on the incremental data, and finally loading the incremental data into a target database in a quasi-realtime manner are realized.

Owner:DAREWAY SOFTWARE

Strain producing long chain dibasic acid, and application thereof

ActiveCN102839133AImprove conversion abilityWide applicabilityFungiMicroorganism based processesAlkaneCandida tropicalis

The invention discloses a strain producing long chain dibasic acid, which is candida tropicalis CAT N145 with a collection number of CCTCC M 2011192. The invention also discloses an application of the strain and a method for producing dibasic acid by using the strain. The candida tropicalis CAT N145 provided by the invention has high conversion capacities upon n-alkanes, fatty acids, and fatty acid derivatives with different carbon chain lengths, and mixtures thereof. Miscellaneous acid content of the produced dibasic acid is low. The application range of the candida tropicalis CAT N145 is wide. With the strain and the application, the controlling over a fermentation process can be greatly simplified, and extraction and purification are easy. The strain has good market application prospect.

Owner:CATHAY R&D CENT CO LTD

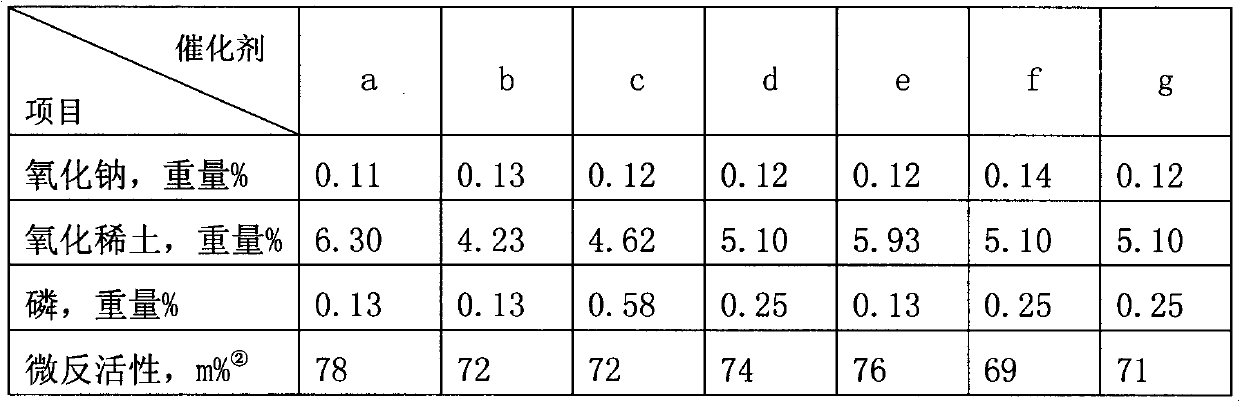

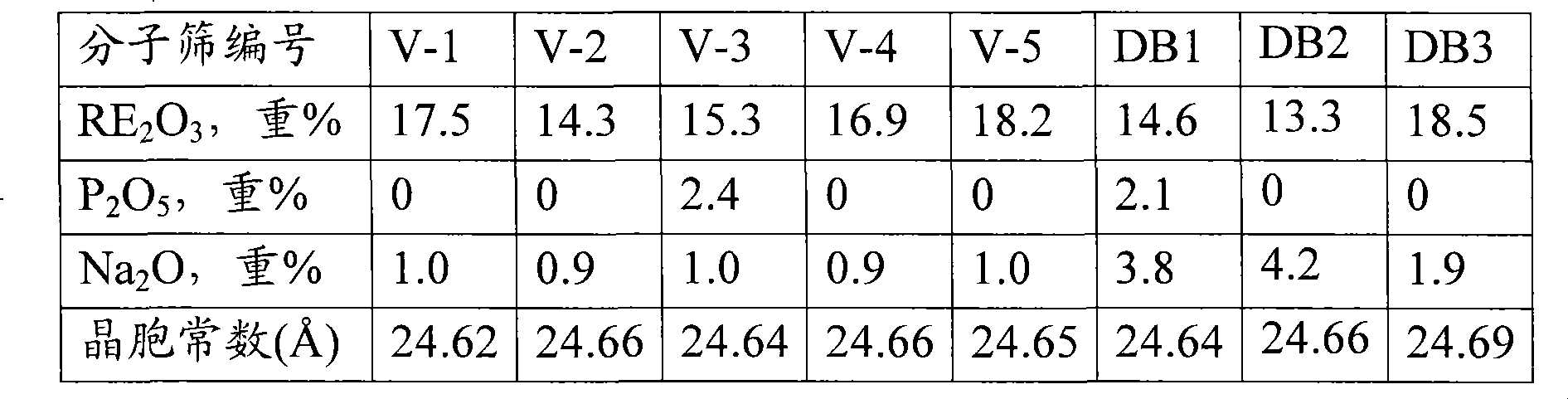

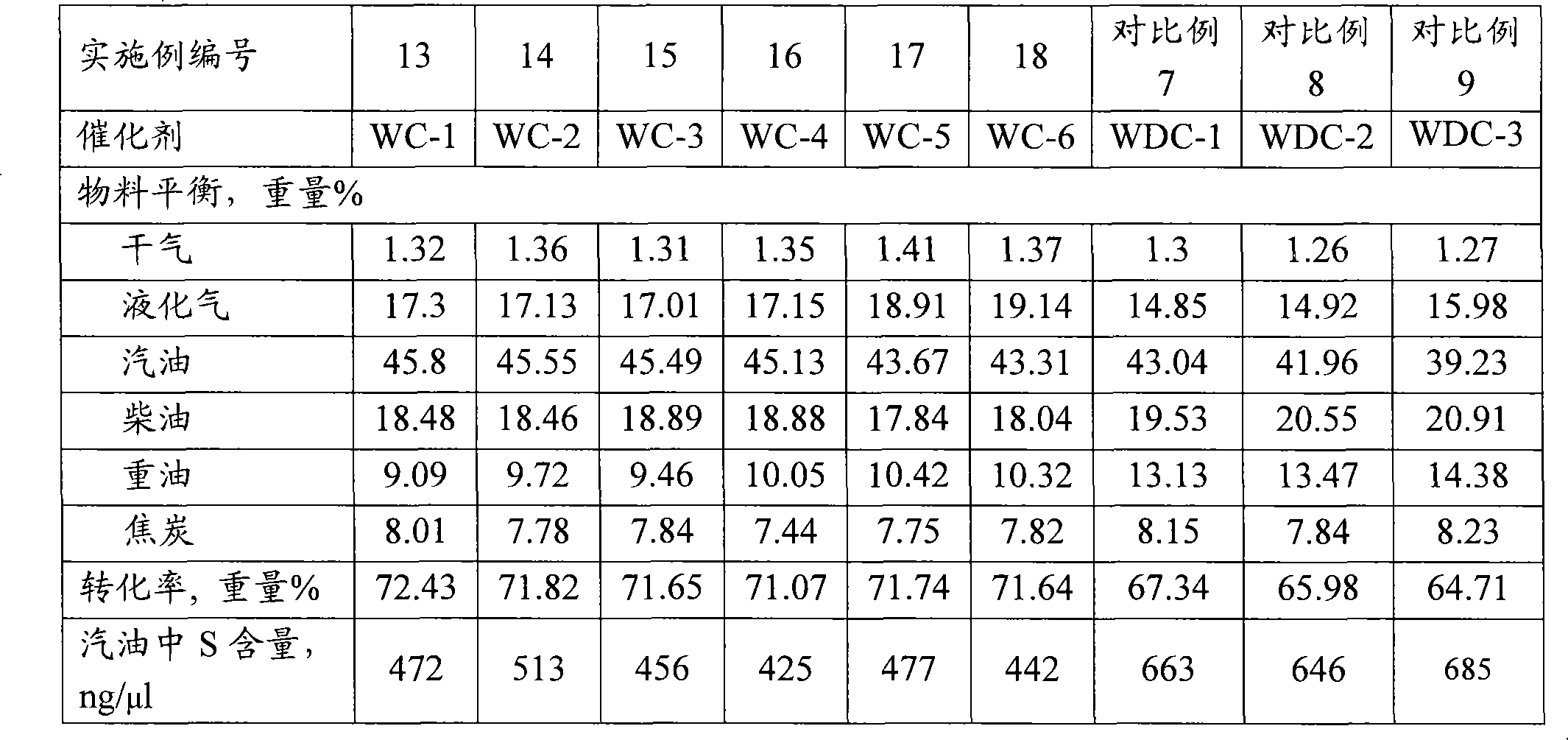

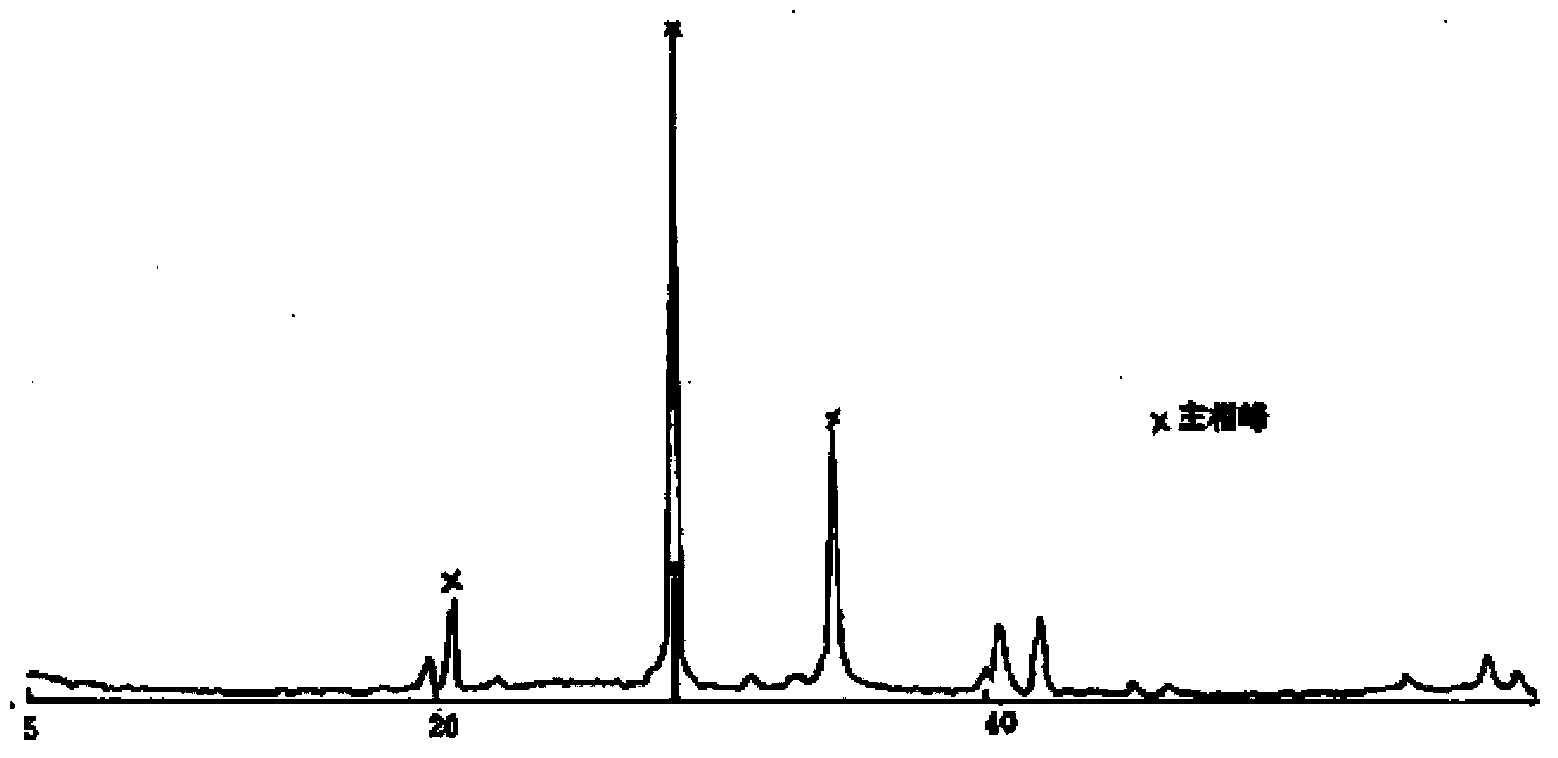

Modified Y molecular sieve-containing catalytic cracking catalyst

ActiveCN102019195AImprove conversion abilityGood choiceCatalytic crackingMolecular sieve catalystsMolecular sieveWater vapor

The invention discloses a modified Y molecular sieve-containing catalytic cracking catalyst. The modified Y molecular sieve is prepared by the following steps of: performing an exchange reaction on a NaY molecular sieve and rare earth solution; introducing a precursor of phosphorus into exchange size for further reaction; and filtering, washing, and roasting the filter cake under the water vapor condition. The catalyst comprises 2 to 45 weight percent of modified Y molecular sieve, 0 to 30 weight percent of one or more kinds of other modified molecular sieves, 10 to 70 weight percent of clay and 10 to 45 weight percent of high-temperature resistant inorganic oxide. The molecular sieves, the clay and the precursor of the high-temperature resistant inorganic oxide are uniformly mixed according to a certain ratio, are subjected to spray molding and are washed to prepare the catalyst, and the prepared catalyst has high heavy oil conversion capacity and high coke selectivity.

Owner:PETROCHINA CO LTD

Cracking catalyst containing mesoporous silica-alumina materials

ActiveCN102078821AIncrease productivityHigh solid contentCatalytic crackingMolecular sieve catalystsAdhesiveActive component

The invention discloses a cracking catalyst containing mesoporous silica-alumina material, wherein the cracking catalyst is composed of cracking active components: clay, adhesive and mesoporous silica-alumina material. The mesoporous silica-alumina material is of a pseudo-boehmite crystal phase structure. In case of the weight of oxide, the anhydrous chemical expression formula is: (0-0.3) Na2O (40-90) Al2O3 (10-60) SiO2, the specific surface area is 200-400m<2> / g, pore volume is 0.5-2.0ml / g, the average pore size is 8-20nm, and the most probable pore size is 5-15nm. The adhesive is selected from one or two mixtures of silica sol or aluminum sol. Compared with the conventional catalyst with pseudo-boehmite, the cracking catalyst has the advantages of low production cost and better crude oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

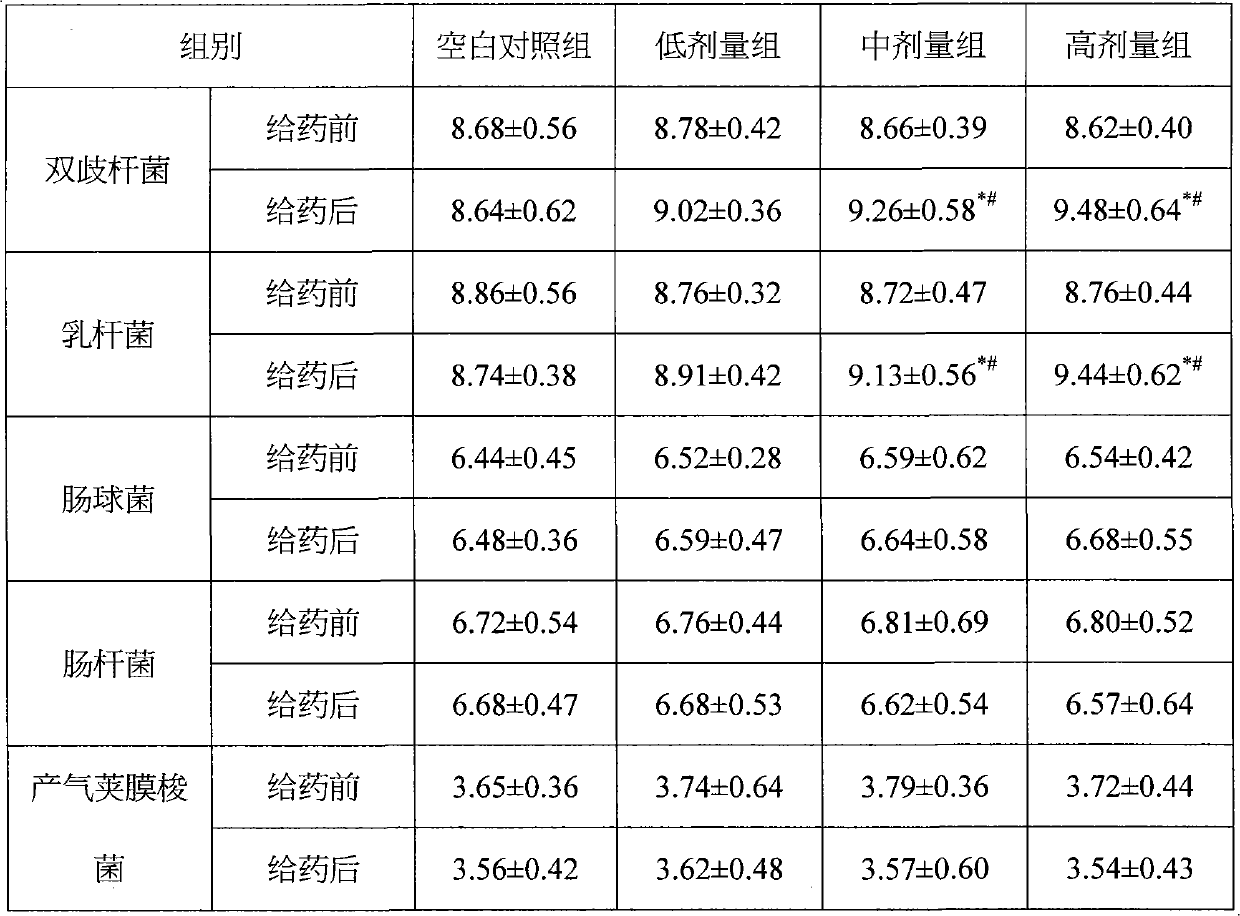

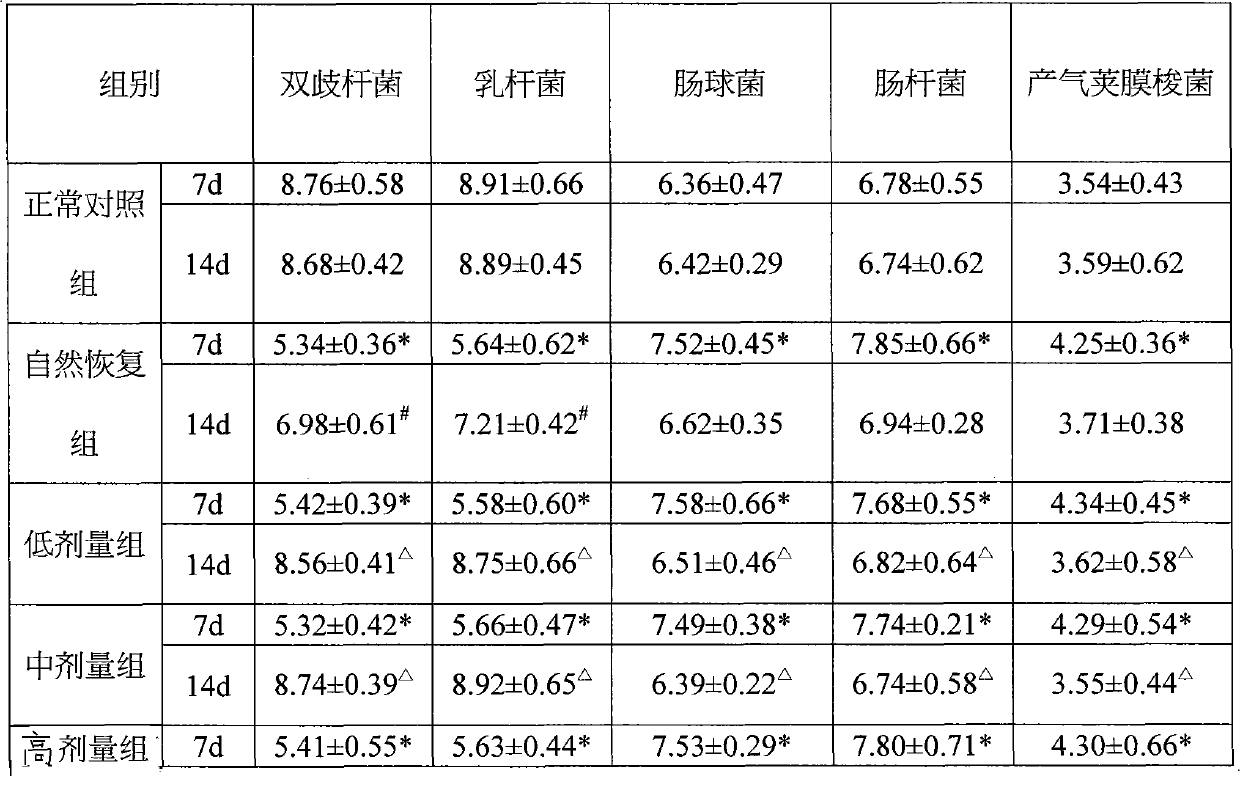

Composition containing bifidobacteria for adjusting intestinal flora and enhancing immunity

InactiveCN102018216AHigh densityIncrease specific production rateHeavy metal active ingredientsHydroxy compound active ingredientsBifidobacteriumDrug product

A composition containing bifidobacteria for adjusting intestinal flora and enhancing immunity is characterized by comprising, by weight, 0.01-10% of bifidobacteria, 10-50% of oligosaccharide, 0.01-10% of vitamin, and 0.01-10% of metals, with the balance being auxiliary materials. The composition containing bifidobacteria provided by the invention has functions of adjusting intestinal flora and enhancing immunity. The composition can be made into capsules, soluble granules, granules, tablets, etc., and applied in food, health product and pharmaceutical fields.

Owner:菲伯纳生物医药有限责任公司

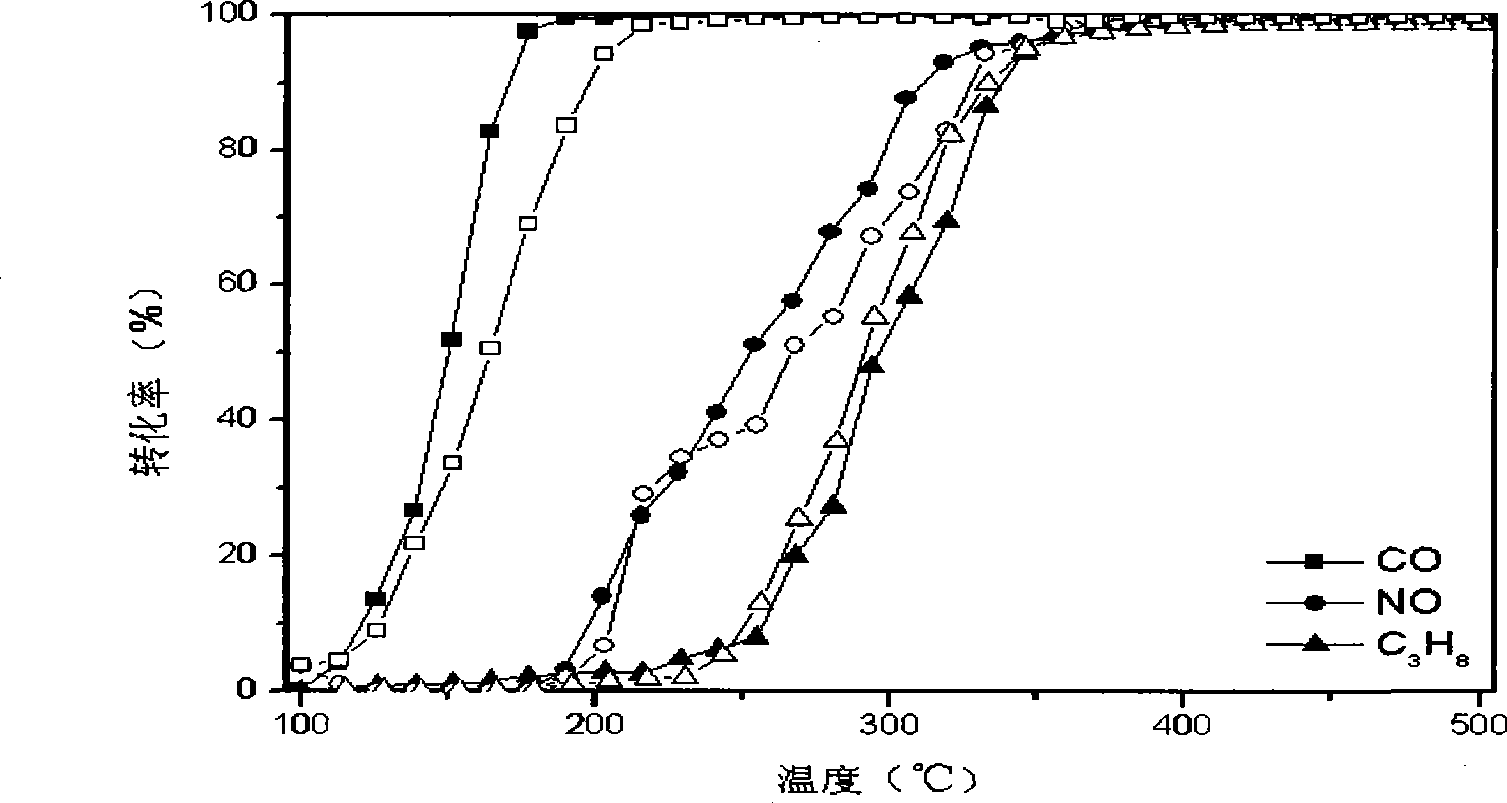

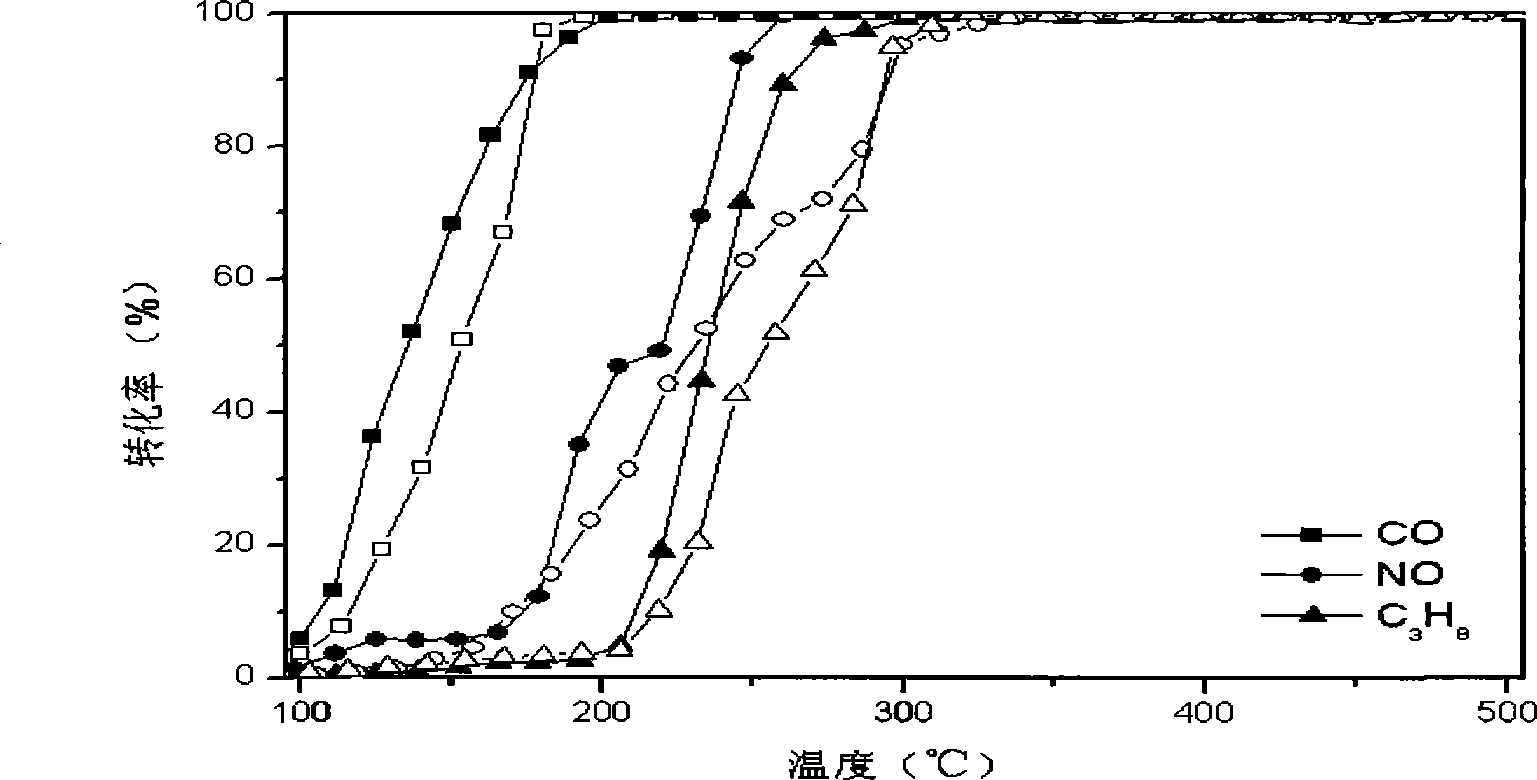

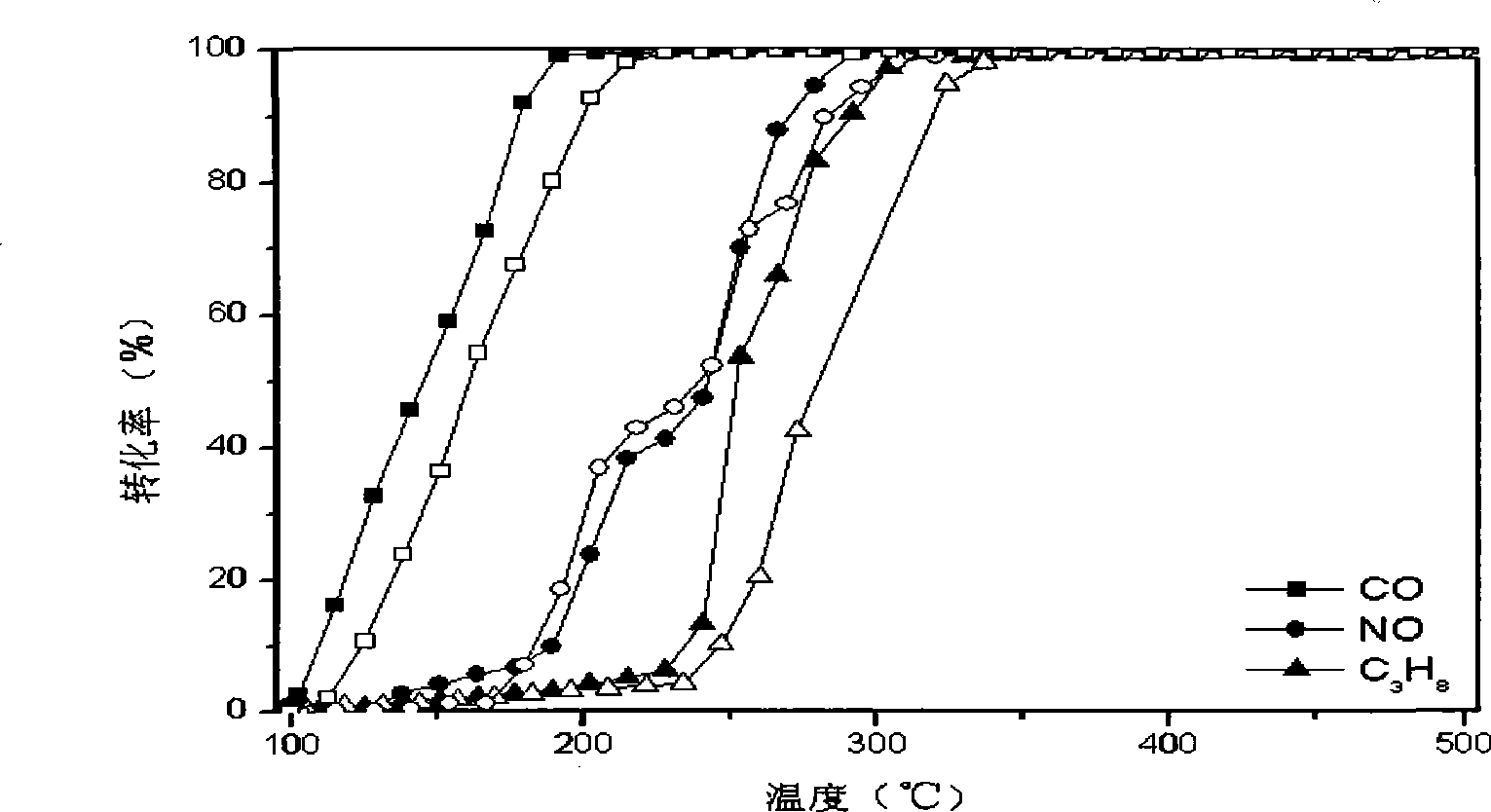

Cerium-based composite oxides supported precious metal three-effect catalyst and preparation method thereof

InactiveCN101433846AImprove conversion abilityEfficient removalInternal combustion piston enginesDispersed particle separationMass ratioCerium

The invention relates to a cerium-based composite oxide loaded noble metal three-way catalyst and a preparation method thereof. The method comprises the steps that soluble cerium, zirconium salt, aluminum salt and soluble modified elements as raw materials are used to prepare a carrier material gamma-Al2O3 and Ce1-xZrxMyO2 by a coprecipitation method, wherein x is between 0.25 and 0.75 by molar fraction; M can be lanthanum, praseodymium, strontium or copper; y is between 0 and 0.1 by weight percentage; the mass ratio of alumina to ceria-zirconia is between 0.5 and 2; and 0.25 to 3.0 percent of noble metal of the catalyst is loaded on the carrier by an equal volume method to prepare the high-performance cerium-based composite oxide loaded noble metal three-way catalyst. The three-way catalyst which is controllably prepared by the method can furthest improve the transformation performance of the catalyst, and can effectively remove carbon monoxide (CO), nitrogen oxide (NOx) and hydrocarbon (HC). The preparation method has the advantages of simple process and good repetitiveness, and is favorable for industrial production.

Owner:TIANJIN UNIV

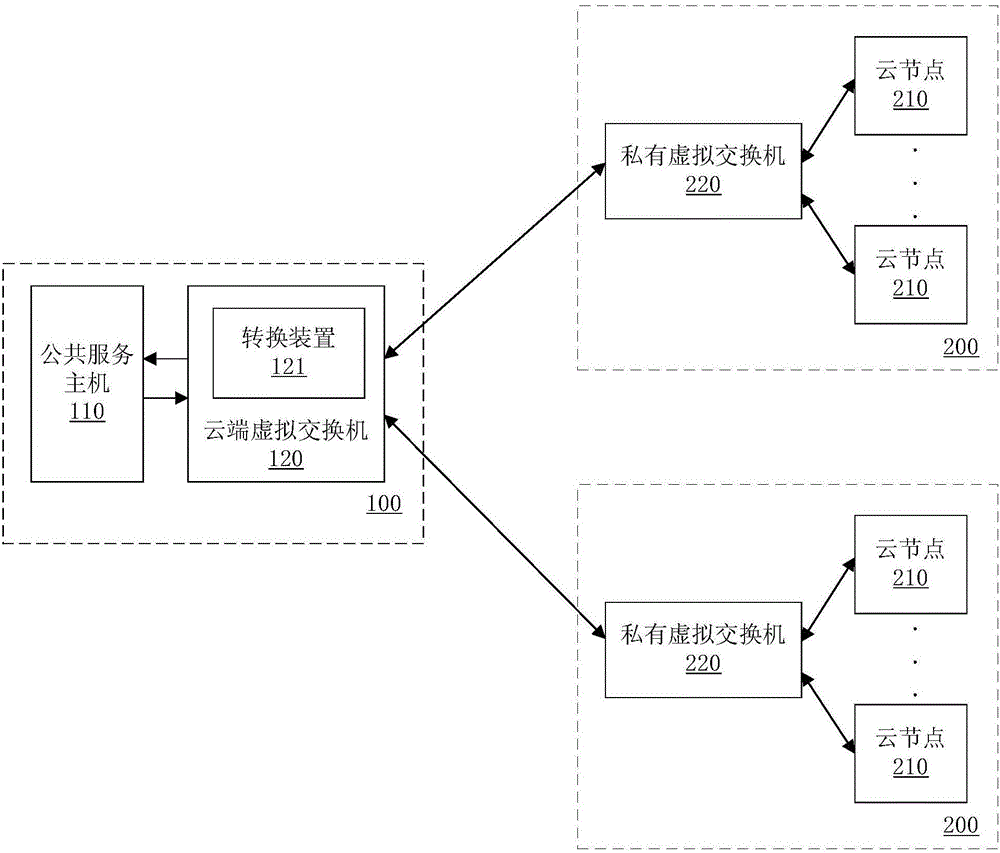

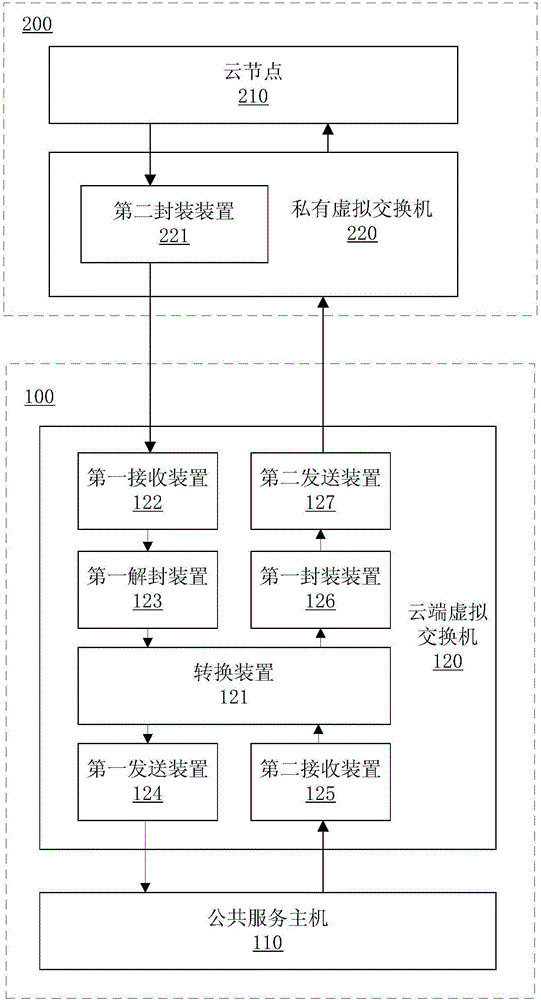

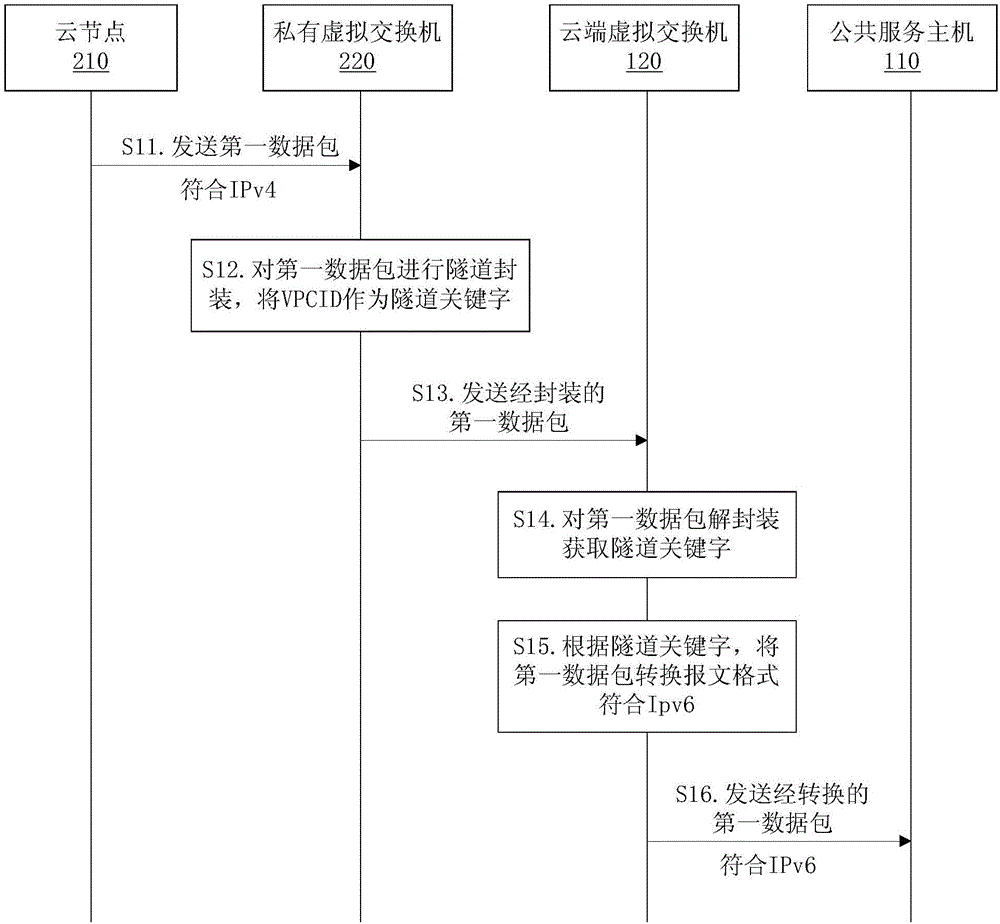

Cloud system, cloud public service system and mutual access method for cloud system

ActiveCN106559511AImprove performanceEfficient exchange of visitsTransmissionProtocol for Carrying Authentication for Network AccessService system

The invention provides a cloud system, a cloud public service system and a mutual access method for the cloud system. The cloud public service system includes: at least one public service mainframe which supports a second network protocol; a cloud virtual switch which includes: a switching apparatus which is configured to, based on the only identifier of the virtual private cloud which conducts mutual access with the public service mainframe, convert a first packet transmitted to the public service mainframe by a virtual private cloud from the message format of a first network protocol to the message format of the second network protocol; and / or convert a second packet transmitted to the virtual private cloud by the public service mainframe from the message format of the second network protocol to the message format of the first network protocol, wherein the source destination address in the message format of the second network protocol is longer than that of the first network protocol. According to the invention, the cloud system, the cloud public service system and the mutual access method for the cloud system can realize efficient mutual access.

Owner:UCLOUD TECH CO LTD

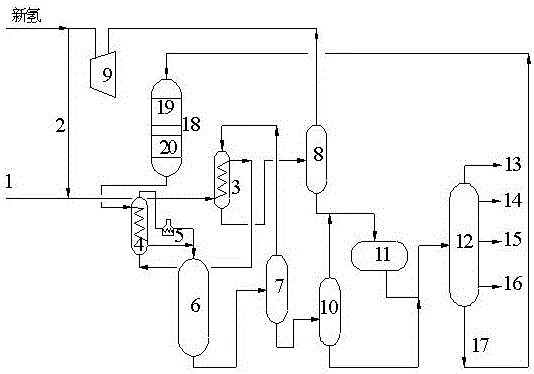

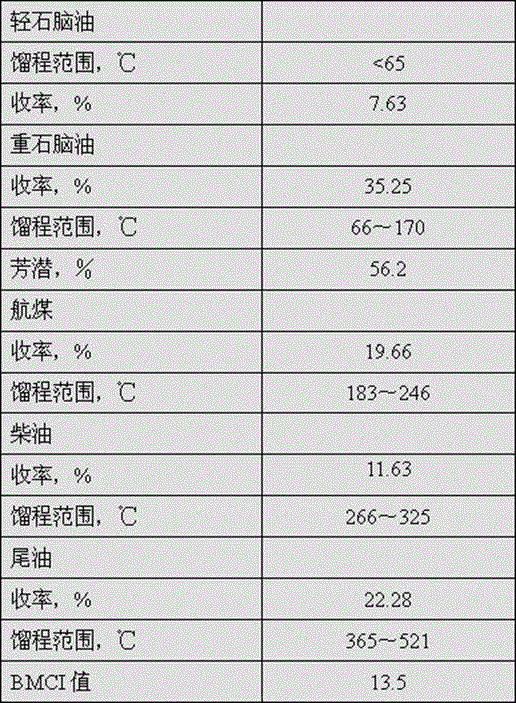

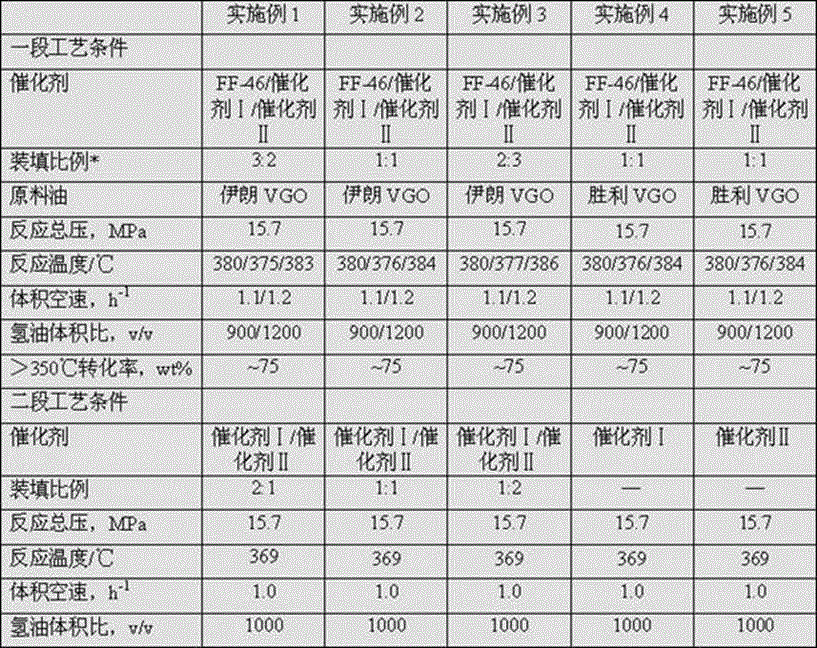

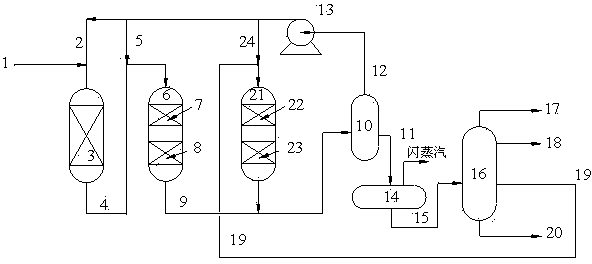

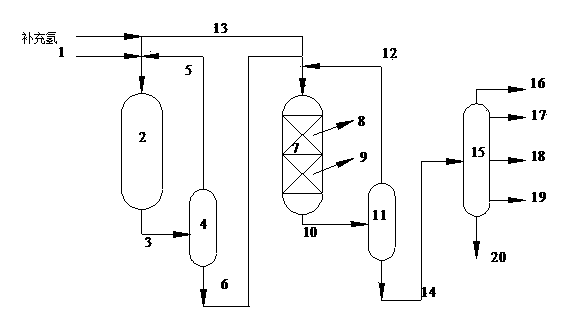

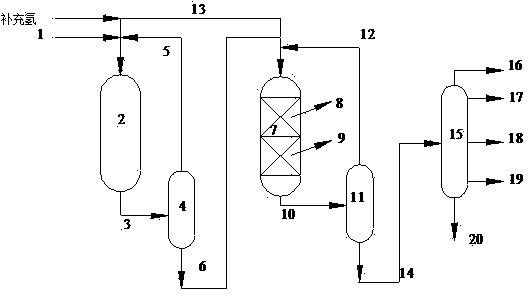

A low-energy hydrocracking method for processing inferior raw materials

ActiveCN104611020BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesHydrocarbon oils treatment productsOperating energyFractionation

The present invention discloses a low energy consumption hydrocracking method for processing a poor-quality raw material. According to the method, a raw material and hydrogen gas are mixed, are subjected to heat exchange two times, pass through a heating furnace, and then are subjected to a hydrorefining reaction; the refining effluent is subjected to separation and fractionation; the obtained tail oil enters a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50 wt% of a modified Y molecular sieve, the catalyst II contains 3-30 wt% of the modified Y molecular sieve, and the modified Y molecular sieve content in the catalyst I is 10-25% higher than the modified Y molecular sieve content in the catalyst II; and the hydrocracking effluent and poor-quality raw material oil are mixed and then enter a hydrorefining reaction zone. According to the method of the present invention, the high temperature high pressure countercurrent heat transfer technology and the hydrocracking catalyst grading technology are organically combined, and the hydrocracking reaction heat is comprehensively utilized, such that the catalyst selectivity is maintained while the target product quality is improved, and the project investment and the operating energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

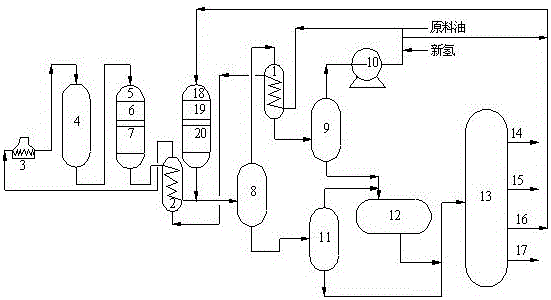

A hydrocracking method with low energy consumption and high yield of high-quality chemical raw materials

ActiveCN105018139BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

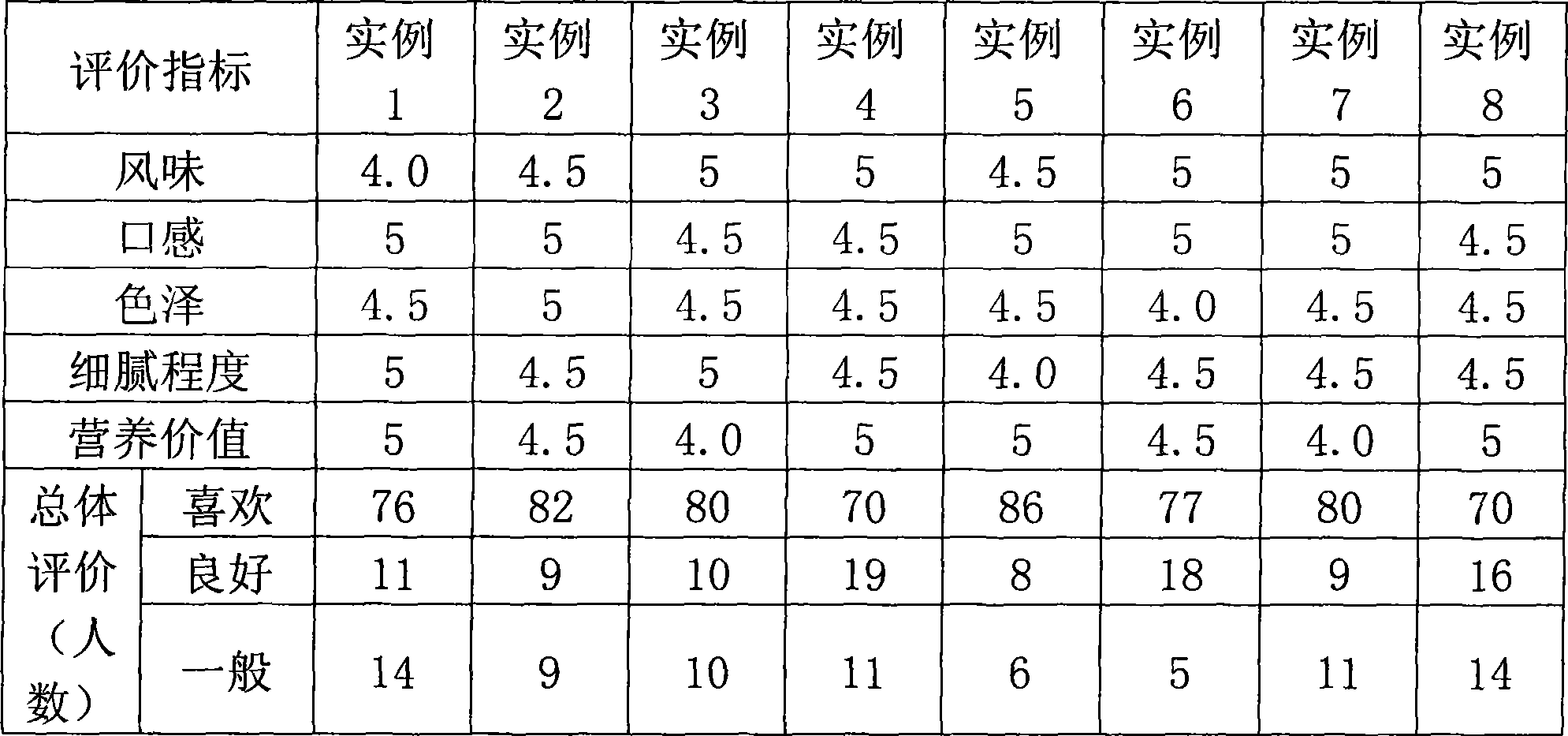

Non-fermentation type sour milk and preparation method thereof

The invention relates to non-fermentation type sour milk and a preparation method thereof. The non-fermentation type sour milk uses fresh cow milk as principal raw material. After being hydrolyzed by milk sugar, the cow milk is pasteurized and concentrated in vacuum to be 40 percent of the original volume. After the cow milk is cooled, probiotic powder is added. The invention has the core that transglutaminase is added at an optimal temperature; under the action of the transglutaminase, milk protein is connected together to form a protein network, thereby a uniform stable gelatin system is easily formed; delta-gluconolactone is then added, and the gelatin system and the delta-gluconolactone are heated at 35-40 DEG C in a water bath way for 2 to 3 hours so that the uniform, stable and exquisite non-fermentation type sour milk like a quark can be obtained. The invention has simple preparing process, no requirement for fermentation, and full utilization of resources. The non-fermentation type sour milk can be used as a base to develop various products, such as corn non-fermentation type sour milk for breakfast, jelly non-fermentation type sour milk, and the like, and can satisfy the requirements of consumers in nutrition, mouthfeel, texture, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Method for preparing selenium enriched oyster mushroom powder

InactiveCN1951221AStrong conversion ability of organic seleniumImprove conversion abilityFungi medical ingredientsFood preparationBiotechnologyOyster

The invention relates to a method for preparing selenium-abundant mushroom powder. Wherein, it plants the mushroom seed into PDA culture medium to cultivate seed in tube; plants tube seed into PDA selenium-abundant culture medium to process solid product seed cultivation; cultivating the solid product seed in PDB selenium-abundant container to process solid mother cultivation; plants liquid mother into PDB selenium-abundant culture medium to process selenium-abundant little mushroom cultivation; separates the selenium-abundant little mushroom from culture medium; drying and breaking into powder. The invention has high culture speed and low material consumption. And the product has high organic selenium convert ability, and high selenium content.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

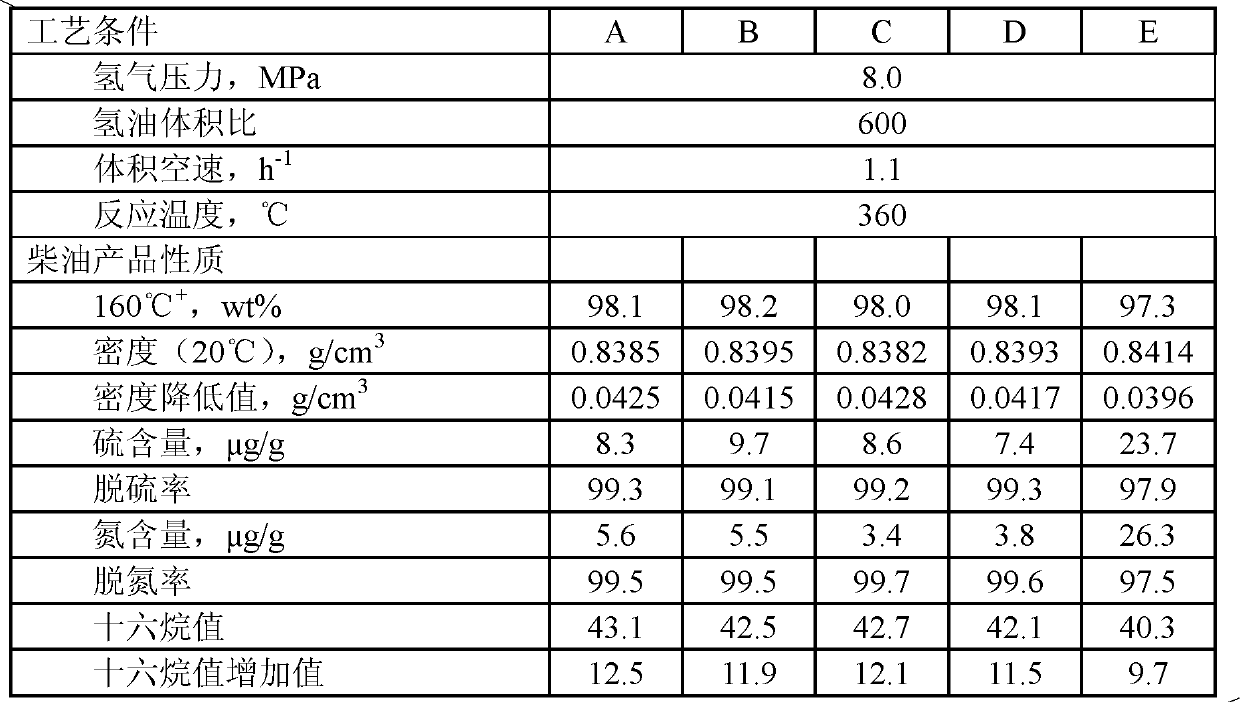

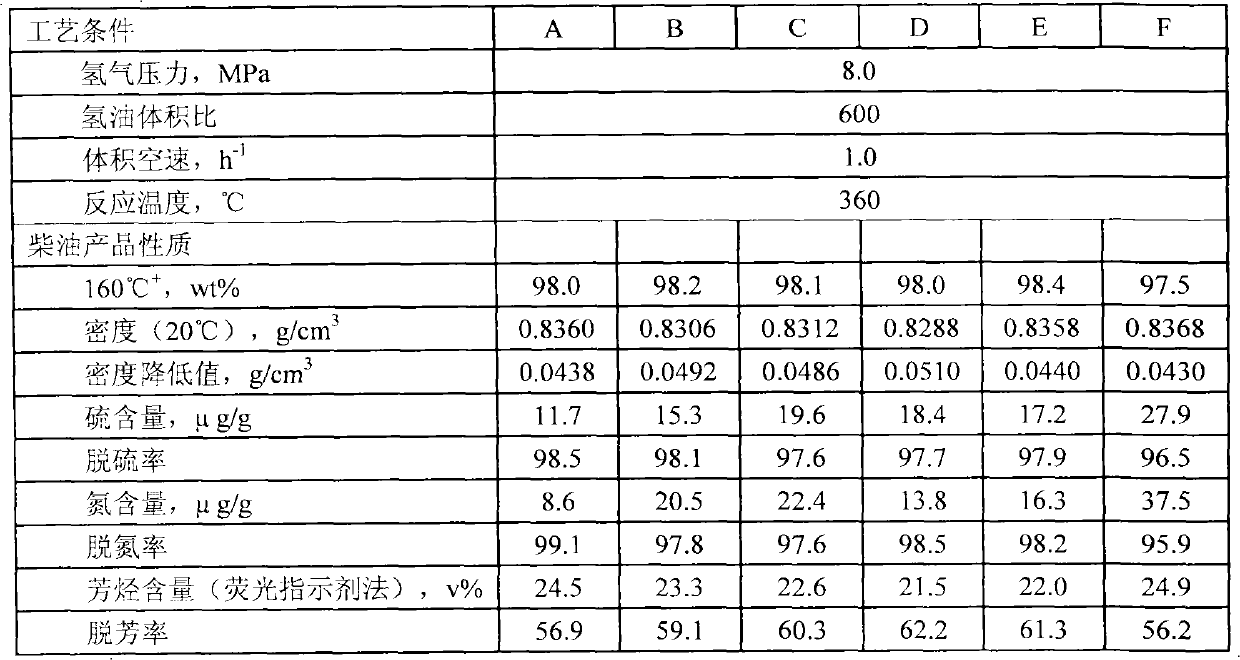

Catalytic cracking diesel oil hydro-upgrading catalyst and application thereof

InactiveCN103372457AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveAmorphous silicon

The invention relates to a catalytic cracking diesel oil hydro-upgrading catalyst and applications thereof. The catalyst is composed of VIII-group and VIB-group hydrogenation active metal components and a carrier containing a modified Y molecular sieve, amorphous silicon aluminum and alumina; the modified Y molecular sieve is prepared from a NaY molecular sieve by the steps of carrying out ammonium exchange twice, carrying out roasting one time and carrying out hydro-thermal treatment one time. The catalyst is used for carrying out hydro-upgrading on distillate or catalytic cracking diesel oil at a temperature of 160-380 DEG C. After inferior diesel distillate of which the sulfur content is higher than 1000 mu g / g, the nitrogen content is higher than 1000 mu g / g, the aromatics content is higher than 55v% is treated by using the catalyst, the desulfurization rate and the denitrification rate are both higher than 98%, the cetane number is increased by more than 10 units, and the yield of the diesel distillate is over 98wt%.

Owner:PETROCHINA CO LTD

Catalyst for heavy oil catalytic cracking and preparation method thereof

ActiveCN101451074AGood hydrothermal stabilityImprove conversion abilityCatalytic crackingAluminum IonHeat treated

The invention provides a catalytic cracking catalyst and a method for preparing the same. The catalyst comprises an REY molecular sieve with effective quantity and a substrate. The invention is characterized in that the method for preparing the REY molecular sieve comprises: after a NaY molecular sieve is contacted with an aqueous solution containing rare-earth ions, or is contacted with the aqueous solution containing rare-earth ions and a solution containing aluminum ions or colloid, the solution is contacted with an additional precipitator so that part of rare earth is precipitated on the molecular sieve; the solution is subjected to hydrothermal treatment and is finally contacted with an aqueous ammonium salt solution; the substrate contains hydrated alumina modified by transition metal oxide; and the catalyst is prepared by the pulping, spraying and drying of the REY molecular sieve and the substrate. The catalyst is used for cracking the heavy oil, has strong capacity for cracking the heavy oil, high gasoline yield, low sulphur content in the gasoline and strong capacity for resisting vanadium pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

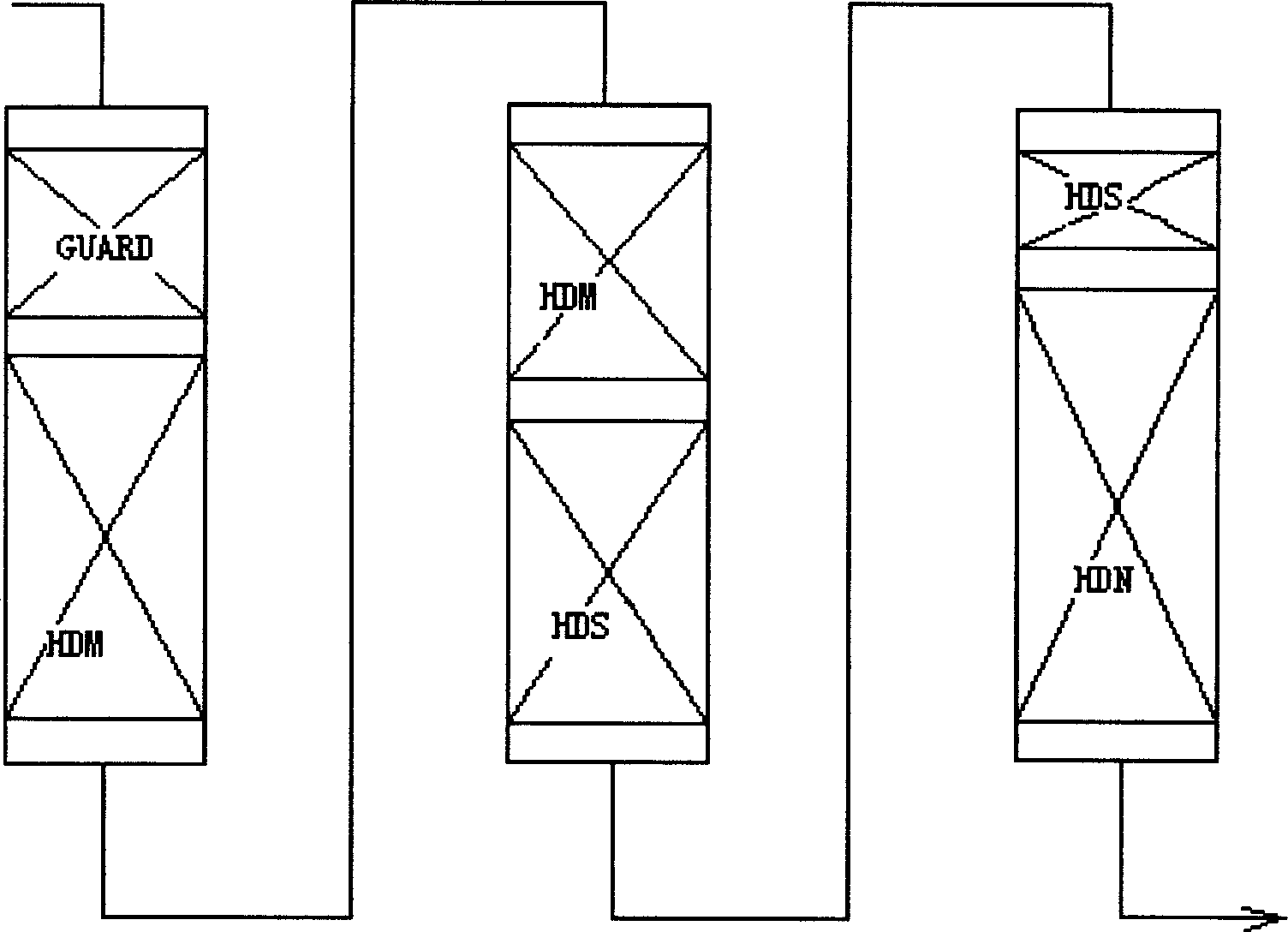

Heavy slag oil fixed bed hydrogenating treatment process

The invention relates to a residual oil fixed bed hydrogenating process, arranging denitrogenation catalyst between hydrodesulfation and hydrodenitrogenation catalysts of the routine fixed bed hydrogenating process, the aperture of the residual carbon hydro-removal catalyst is larger than that of the hydrodesulfation catalyst, the activity of the residual carbon hydro-removal catalyst is higher or equivalent to that of the hydrodesulfation catalyst, and the residual carbon hydro-removal catalyst and the hydronitrogenation catalyst form a stage bed with gradually decreasing aperture and gradually increasing activity. It can effectively convert fragrant macromolecular components such as asphalt, heavy colloid, etc, and remove the impurities. It can be used in the process of fixed bed hydrogenation of various heavy and residual oils.

Owner:CHINA PETROLEUM & CHEM CORP +1

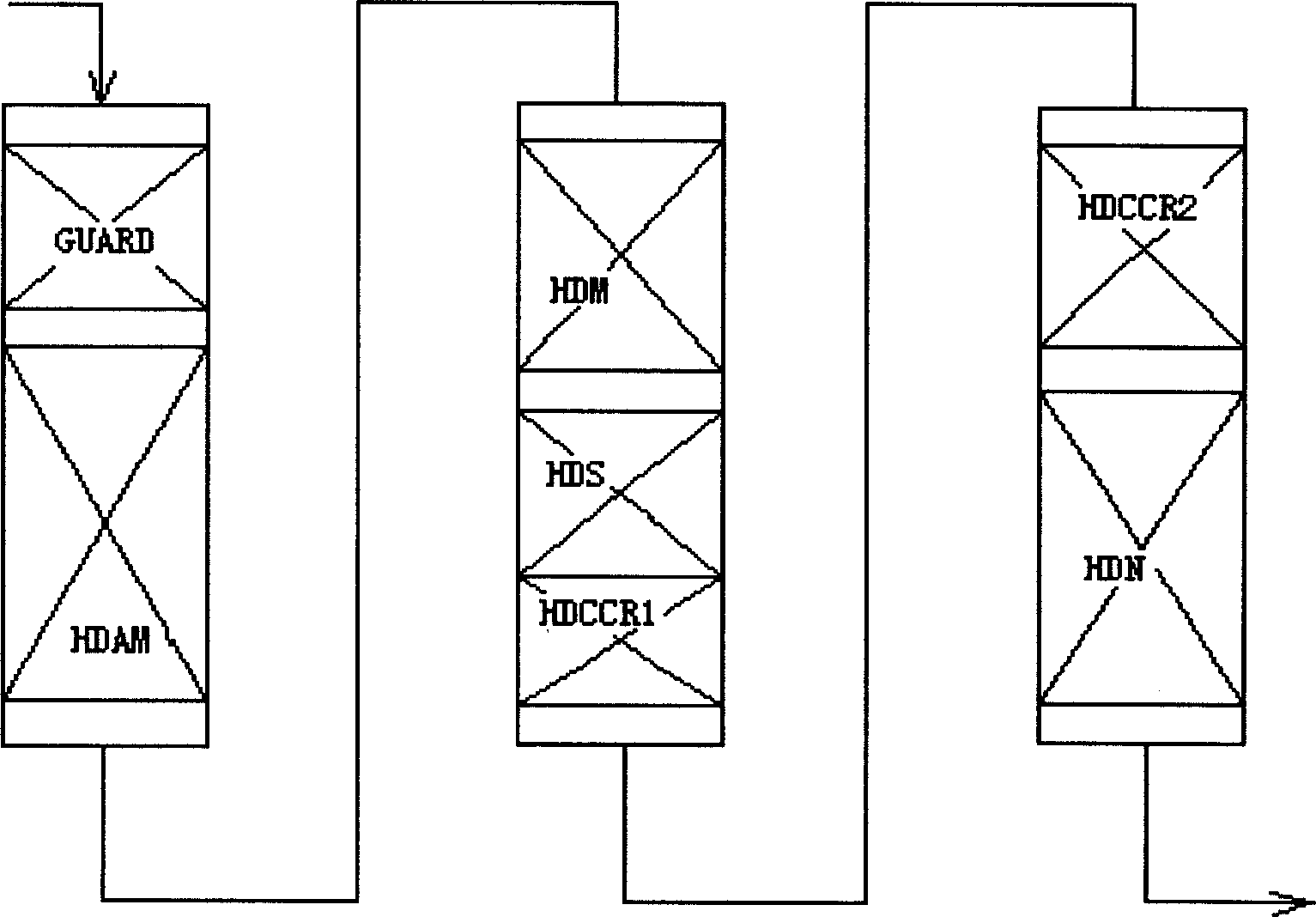

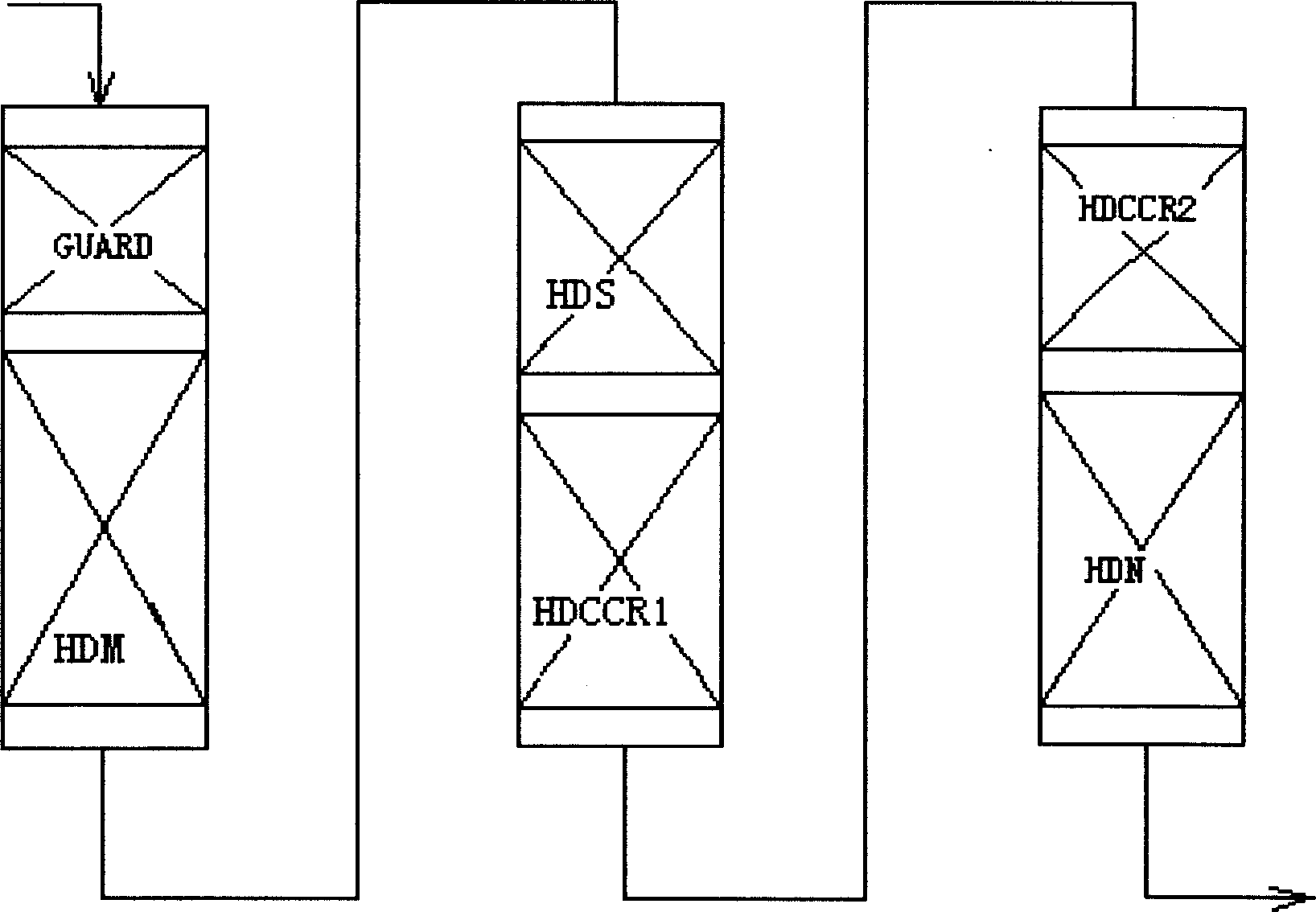

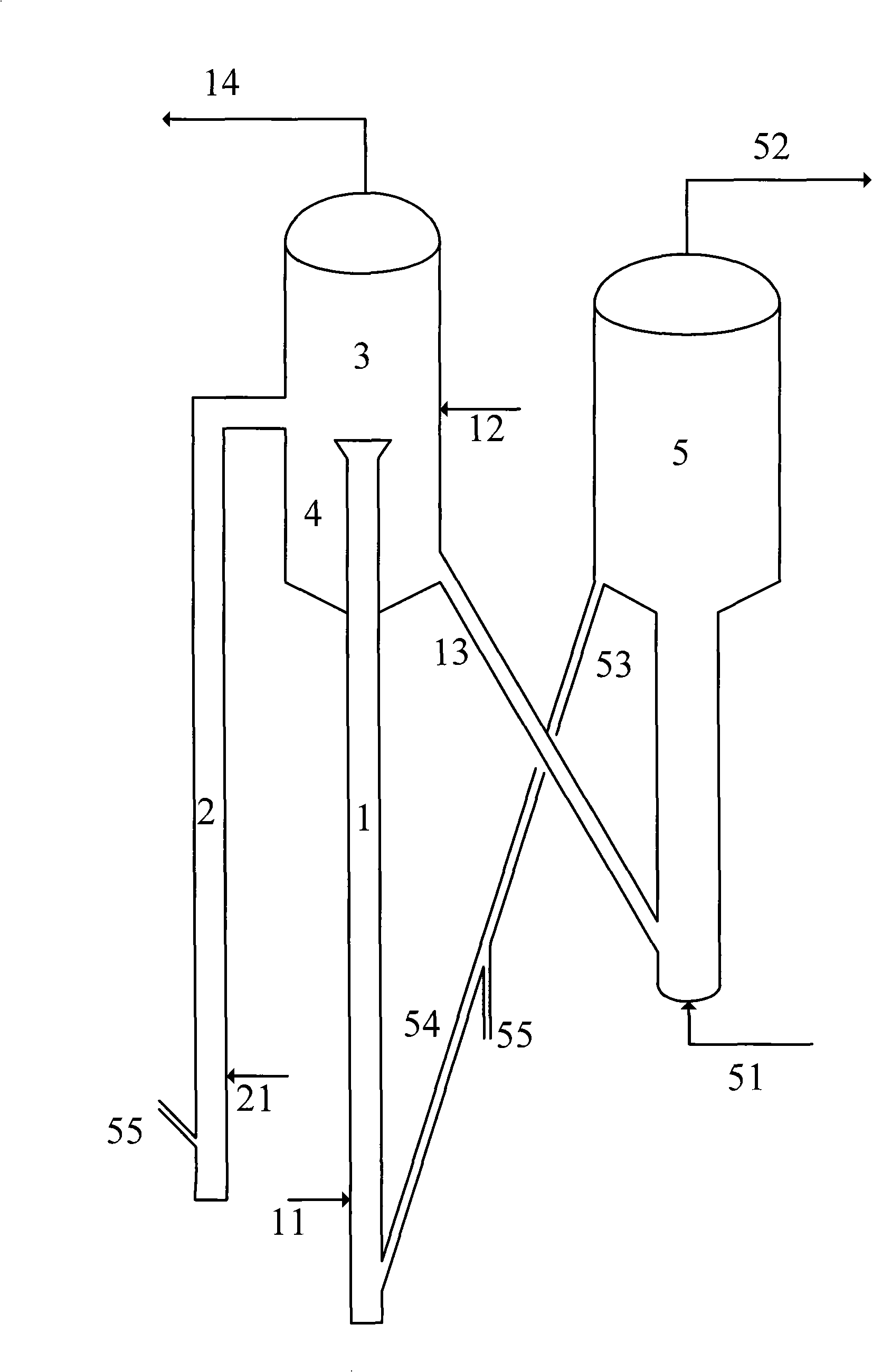

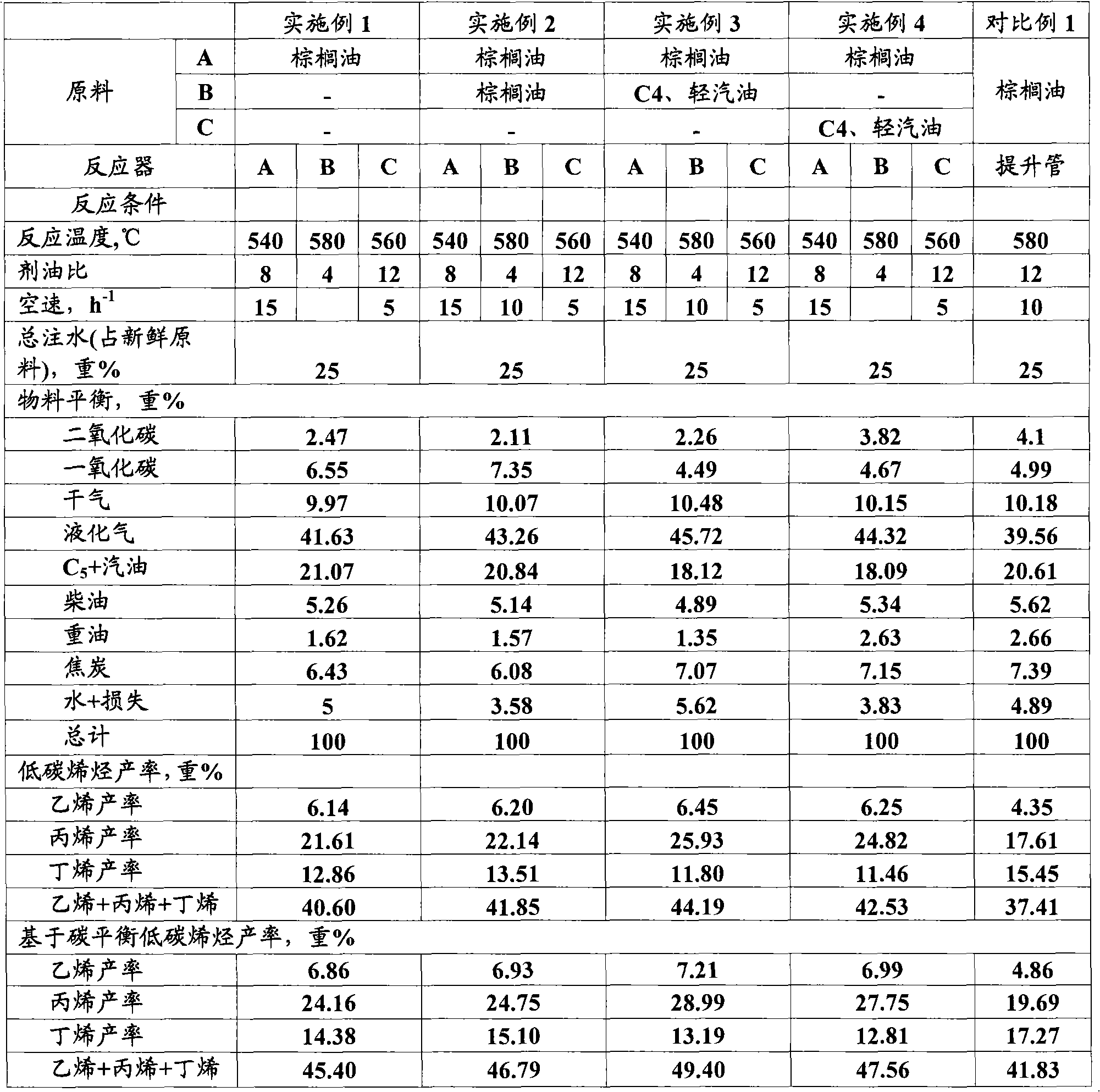

Catalytic conversion method for vegetable fat and/or animal oil and fat

ActiveCN101314748AImprove conversion abilityHigh and low carbon olefinsFatty acid chemical modificationMolecular sieve catalystsFractionationGasoline

A catalytic conversion method of vegetable oil and fat or / and animal oil and fat is characterized in that the raw material of the vegetable oil and fat or / and the animal oil and fat is in contact with a modified Beta-zeolite-containing catalyst in a composite reactor to carry out the catalytic cracking reaction; the reaction product is separated from the spent catalyst; the separated spent catalyst returns to the reactor for reutilization after being stripped and regenerated by burning coke; and the separated reaction product is subjected to fractionation to obtain the target products including low-carbon olefin, gasoline, diesel oil and heavy oil. The method adopts the modified Beta-zeolite and the catalyst which contains zeolite with the MFI structure as the essential active composition, so as to achieve higher yield of the low-carbon olefin, particularly propylene. The total yield of C2-C4 olefins based on the carbon balance is over 45wt%, and the yield of propylene is as high as more than 24wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

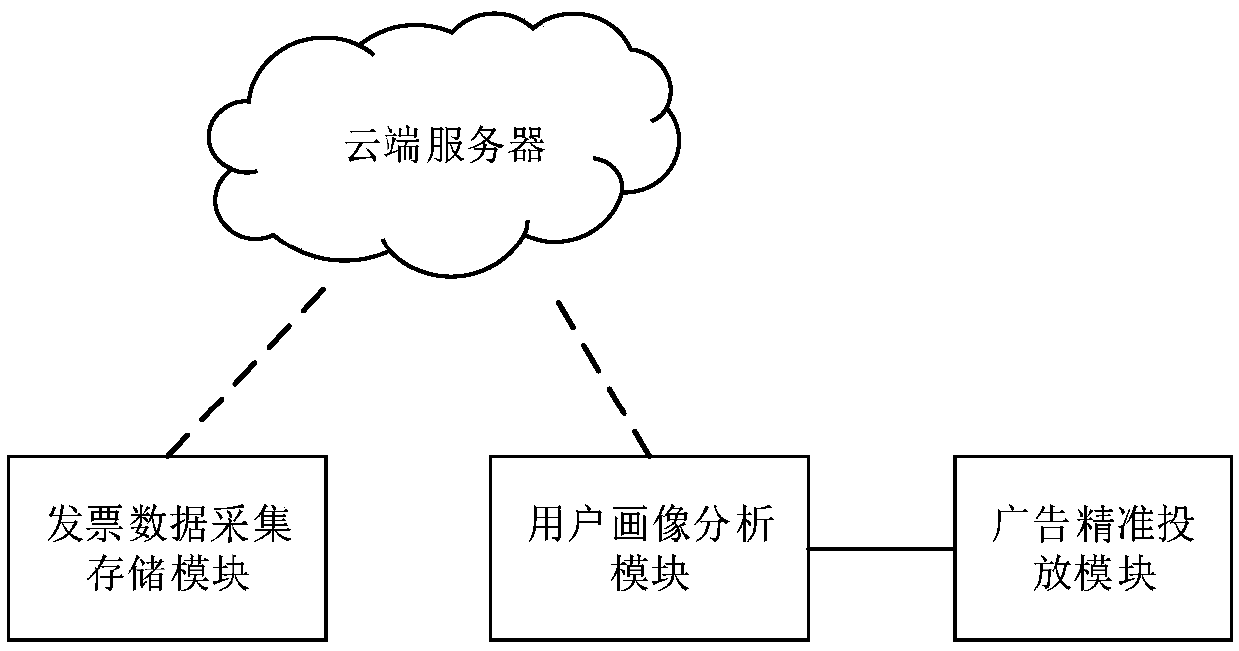

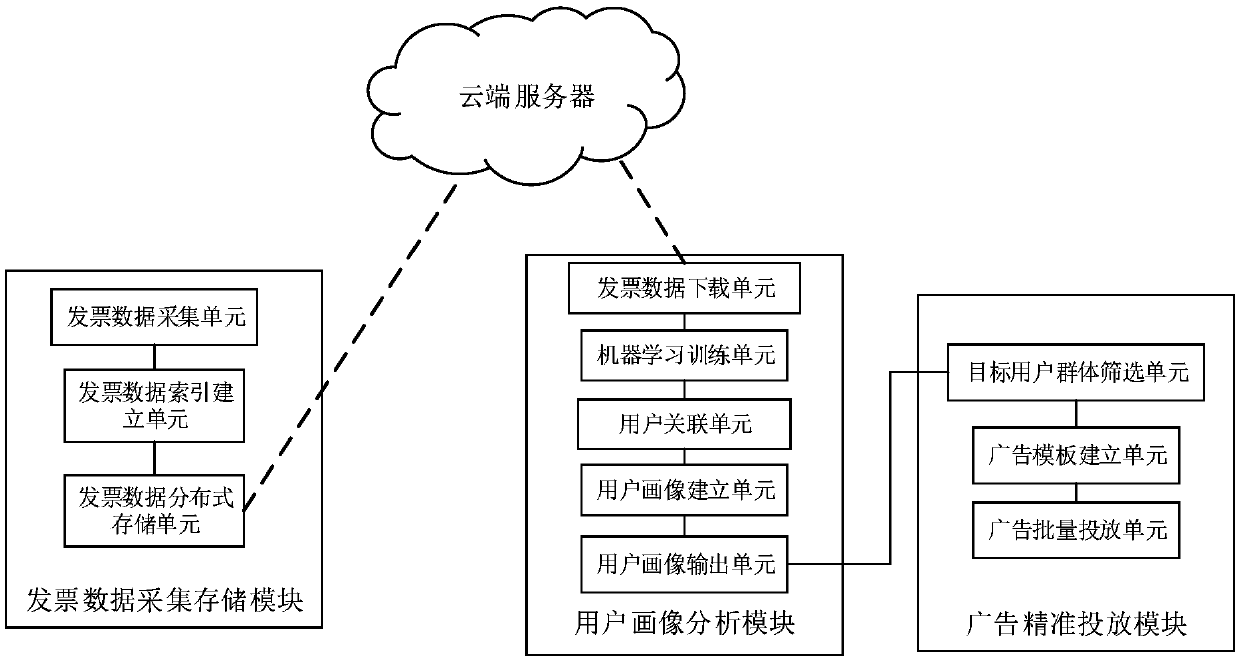

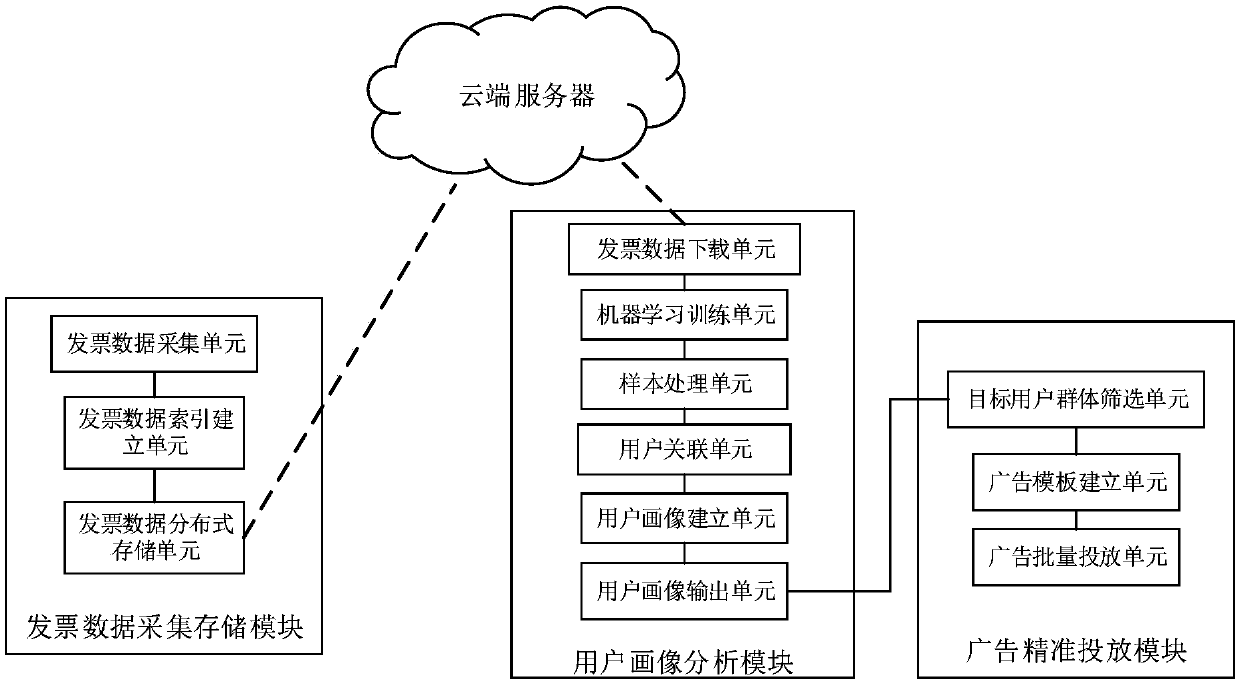

Precise advertisement putting system and method based on invoice data

InactiveCN109615429AGuaranteed stabilityShare in timeCharacter and pattern recognitionMarketingLearning basedData information

The invention relates to a precise advertisement putting system and method based on invoice data. The system comprises an invoice data acquisition and storage module, a cloud server, a user portrait analysis module and an advertisement accurate delivery module, wherein the invoice data acquisition and storage module acquires invoice data information issued by a user, performs distributed storage and uploads the invoice data information to the cloud server in batches; after downloading the invoice data information, the user portrait analysis module adopts a KNN classification algorithm to carryout training analysis learning based on a big data analysis technology, carries out user association on the invoice data information subjected to the training analysis learning to establish a uniqueuser, and then analyzes the invoice data information from a plurality of dimensions to construct a user portrait; and the advertisement accurate putting module screens out the target user group according to the user portrait, then establishes a matched advertisement template and supports a plurality of advertisement putting modes to carry out point-to-point automatic accurate advertisement puttingon the target user group in batches, so that the fitting degree and the conversion effect of advertisements are greatly enhanced.

Owner:大象慧云信息技术有限公司

Cracking catalyst capable of increasing octane number of catalytic cracking gasoline

ActiveCN103962176ABoost octaneImprove conversion abilityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a cracking catalyst capable of increasing the octane number of catalytic cracking gasoline. The cracking catalyst is characterized by comprising, by dry weight, taking the catalyst as 100%: 10-50% of rare-earth ultrastable Y-type molecular sieves, 20-50% of clay, 5-35% of a binder, 0-10% of shape-selective molecular sieves with an MFI structure, and 0-20% of REY and / or other REUSY molecular sieves. The content of rare earth in the catalyst is 1.0-4.0% by weight. The rare-earth ultrastable Y-type molecular sieves are obtained by the steps that: a fresh NaY molecular sieve crystallization slurry is subjected to filtration and separation, and a molecular sieve filter cake is washed with lye; the molecular sieve filter cake is subjected to beating; and through ion exchange of rare earth and ion exchange of ammonium salts, the rare-earth ultrastable Y-type molecular sieves are obtained. The catalyst is capable of significantly increasing the octane number of gasoline, and has good coke selectivity and excellent heavy oil conversion capability.

Owner:PETROCHINA CO LTD

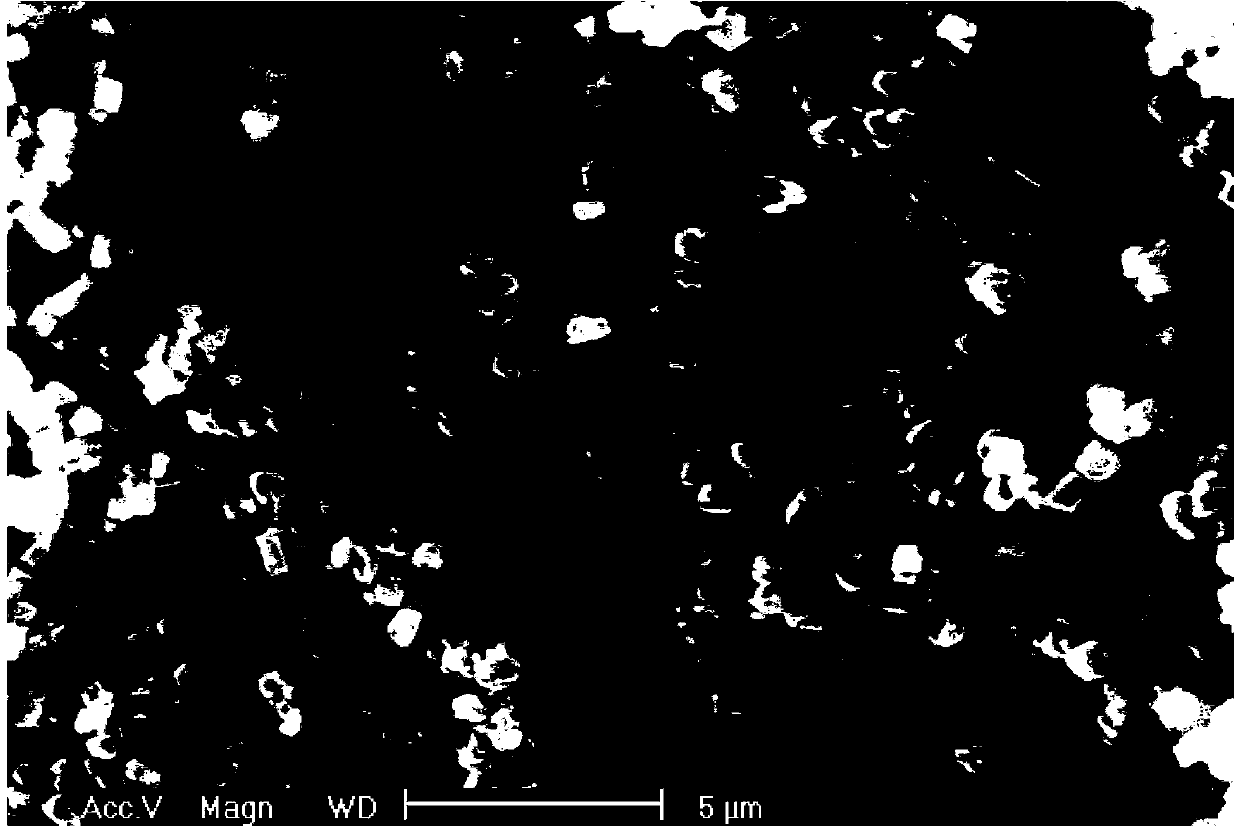

Method for hydro-dearomatization in catalytic cracking of diesel

InactiveCN102533315AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sieveCrystallinity

The invention relates to a method for hydro-dearomatization in catalytic cracking of diesel. According to the invention, Ni and W are adopted as hydrogenation active metal components of a catalyst and modified Y molecular sieve, modified Beta molecular sieve, amorphous silica-alumina and alumina are adopted as carriers of the catalyst, wherein the average crystal size of the modified Y molecular sieve is 100-400nm, the mole ratio of SiO2 / Al2O3 is 5-40:1; the relative crystallinity is greater than 90% and the specific surface area is 700-1000m<2> / g; the average crystal size of the modified Beta molecular sieve is 50-200nm, the mole ratio of SiO2 / Al2O3 is 50-200:1; the relative crystallinity is greater than 85% and the specific surface area is 700-900m<2> / g. When the method is adopted to process inferior diesel fraction, the desulfurization rate and the denitrification rate are up to more than 97.5%, the dearomatization rate is up to more than 55% and the diesel fraction yield is up to more than 98wt%.

Owner:PETROCHINA CO LTD

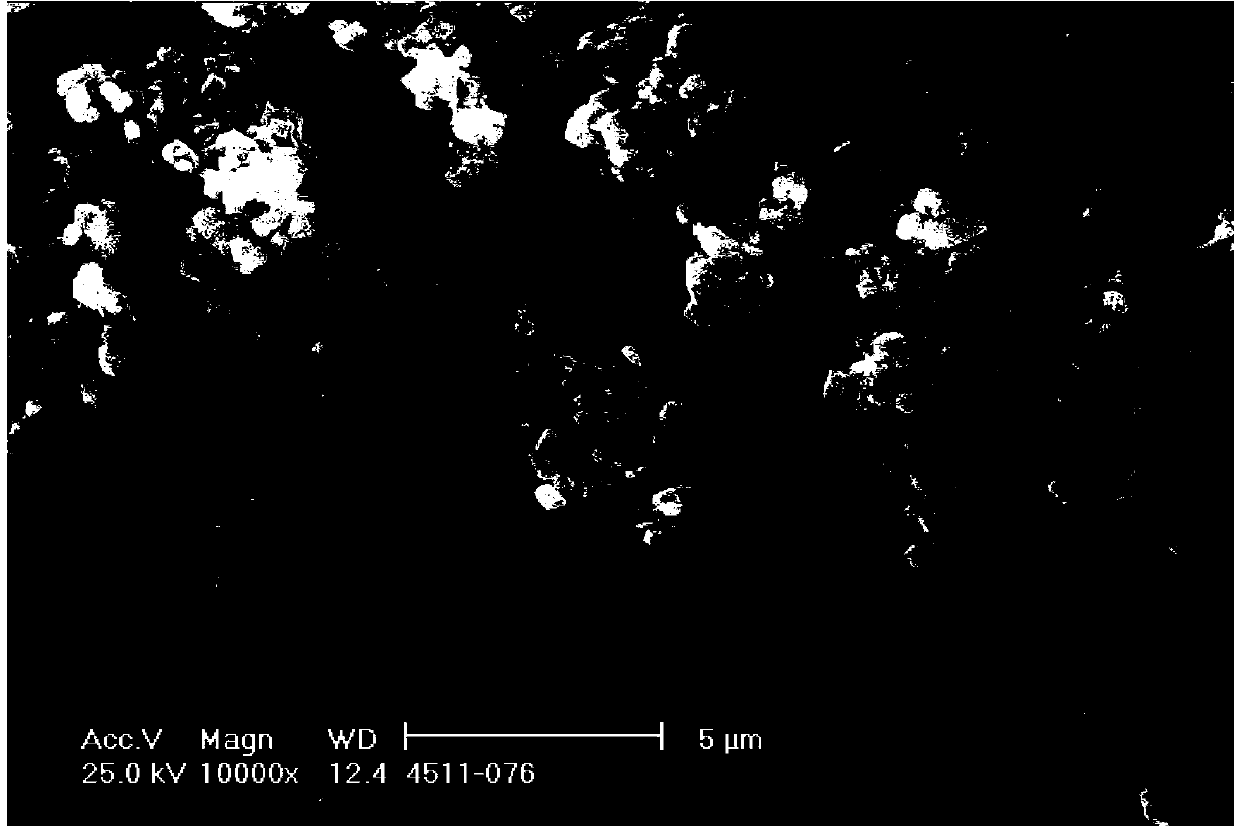

Small crystal particle Y-shaped molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN102049306AImprove hydrogenation performanceHigh activityCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

The invention discloses a small crystal particle Y-shaped molecular sieve-containing hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a small crystal particle Y-shaped molecular sieve, amorphous silicon aluminium, and alumina, wherein the small crystal particle Y-shaped molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 5.0-20.0; the average diameter of the crystal grains is 100 to 700nm; the crystal retention rate is over 95 percent; the specific surface area is 800 to 900m<2> / g; the pore volume is 0.35 to 0.45ml / g; the relative crystallinity is 90 to 130 percent; the cell parameter is 2.434 to 2.440nm; the infrared acid quantity is 0.3 to 0.8mmol / g; the B acid / L acid is more than 7.0; and the sodium oxide content isless than or equal to 0.05 weight percent. A hydrocracking catalyst prepared from the carrier has the characteristics of high catalytic activity, high target product selectivity, high production flexibility and the like, can be used for producing products such as heavy naphtha, aviation fuel and diesel oil, and ensures high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

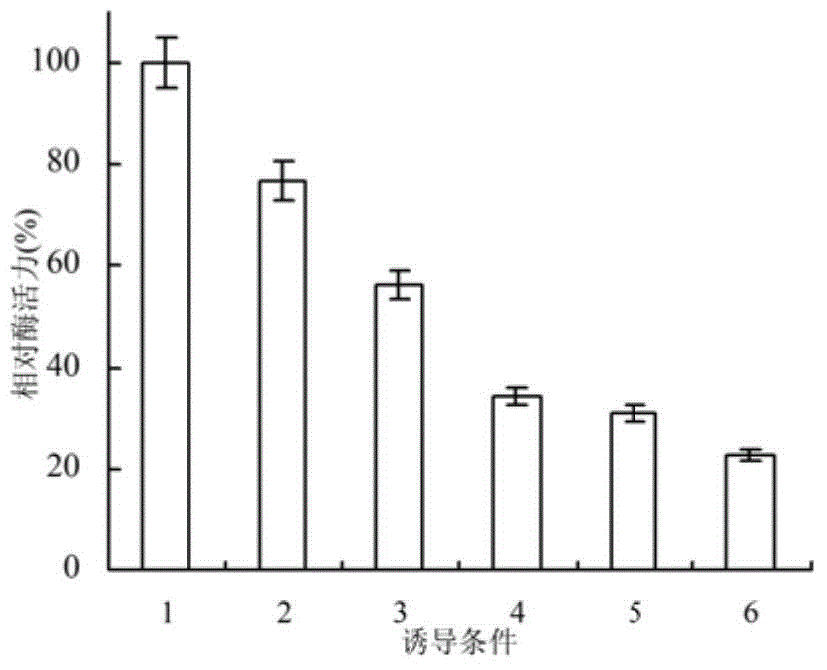

Carbonyl reductase ChKRED20 mutant and application thereof

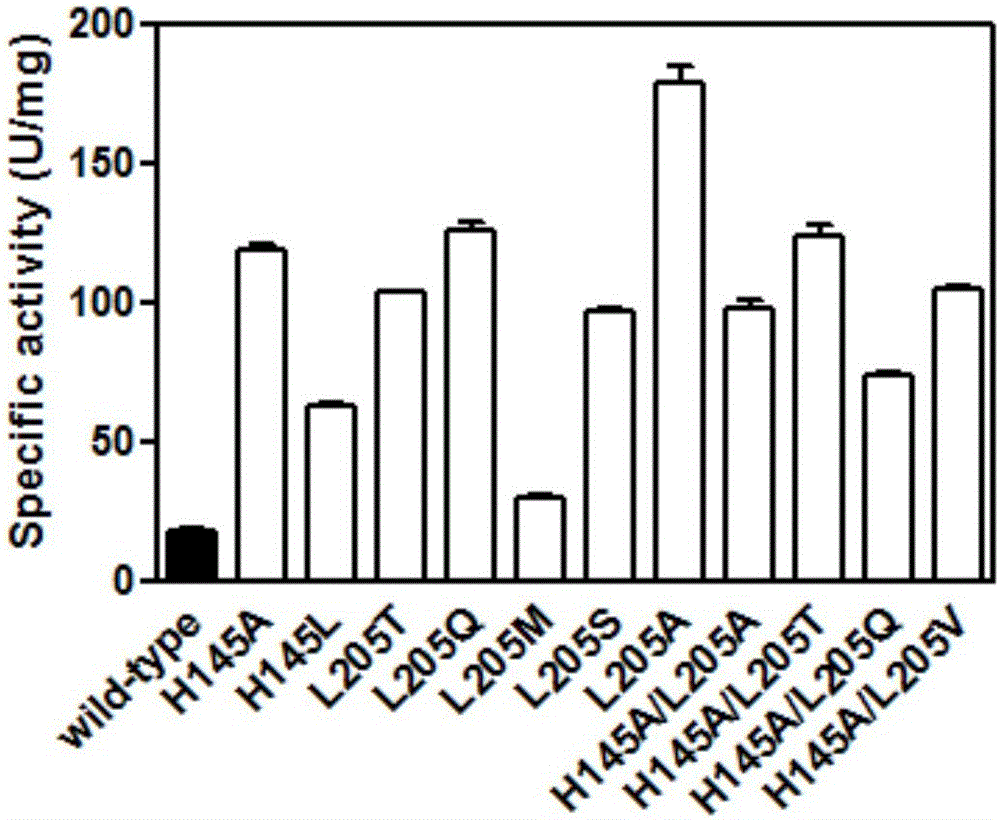

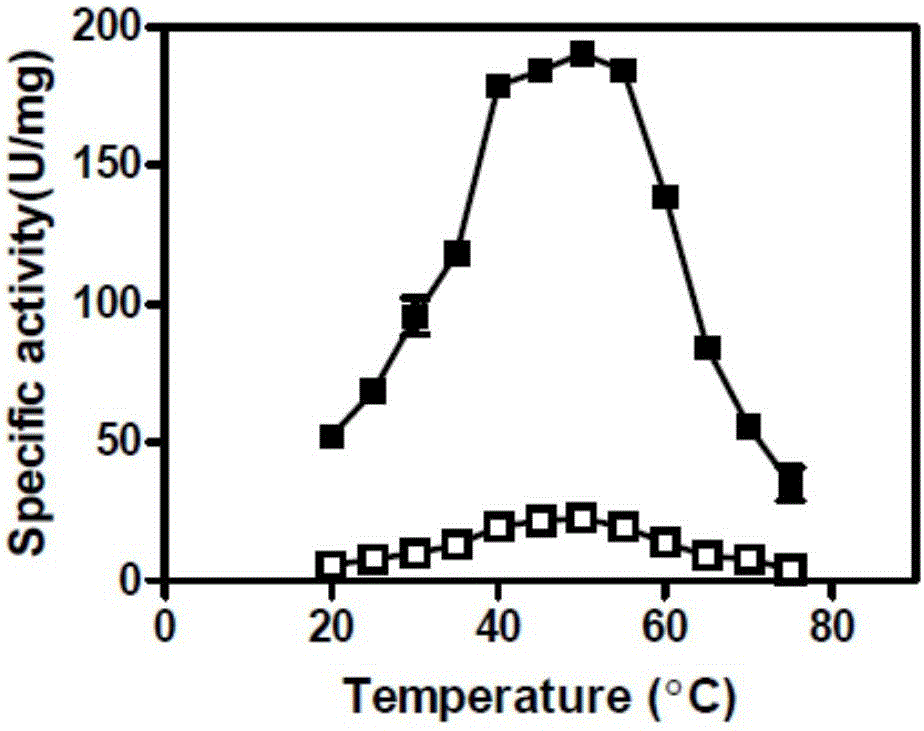

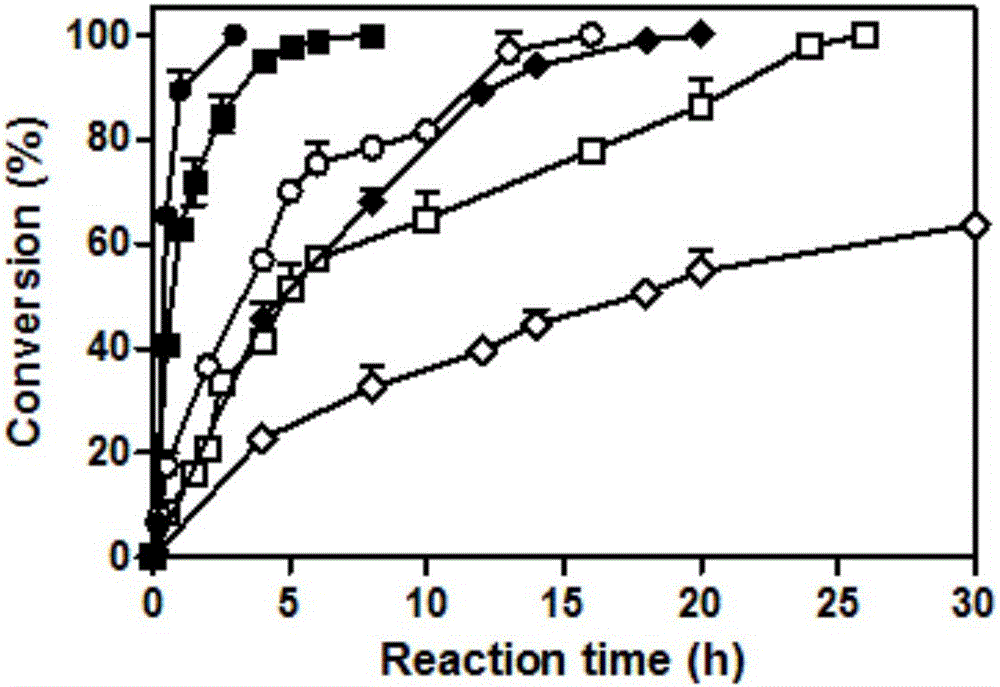

ActiveCN106047828AQuick responseHigh space-time efficiencyOxidoreductasesFermentationTicagrelorGene engineering

The invention belongs to the technical field of gene engineering and enzyme engineering, and particularly relates to a carbonyl reductase mutant and application thereof. The carbonyl reductase ChKRED20 can realize asymmetric reduction of 2-chloro-1-(3,4-difluoro-phenyl)-ethanone to obtain a Ticagrelor intermediate (S)-2-chloro-1-(3,4-difluorophenyl)ethanol (the e. e. value is larger than 99%), and the error-prone PCR technology and the single-point saturation mutagenesis technology are utilized to realize orthogenesis of enzyme molecules to obtain 11 mutants of which the enzyme activities are improved by 1.6-10 times, so that the application potential in biocatalysis is shown.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

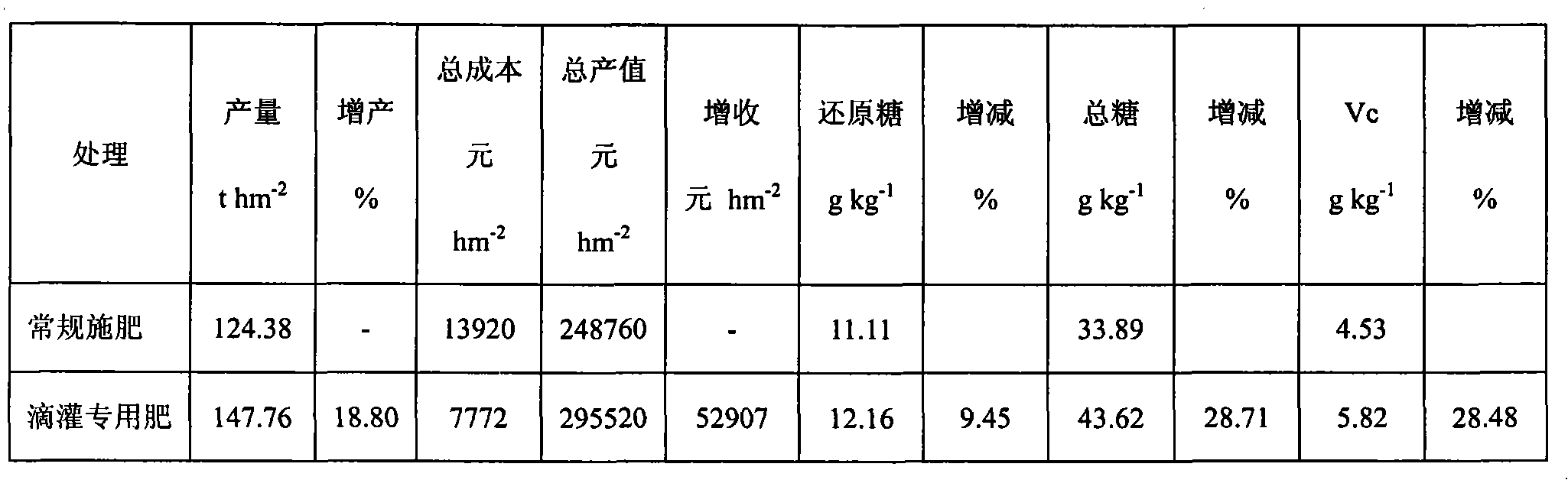

Compound fertilizer special for drip irrigation of cucumber in greenhouse and preparation method thereof

InactiveCN101913935AThere are few types of solutionsSolve solubilityFertilizer mixturesAgricultural scienceGreenhouse

The invention discloses a compound fertilizer special for drip irrigation of cucumber in a greenhouse, which comprises the following nutritive elements in each hm<-2>: 391.41 kg of N, 255.43 kg of P2O5, 416.91 kg of K2O, 65.25 kg of CaO, 46.50 kg of MgO, 26.46 kg of Fe, 17.60 kg of Mn, 9.70 kg of Cu, 6.46 kg of Zn, 3.00 kg of B and 1.50 kg of Mo. The compound fertilizer special for the drip irrigation of the cucumber in the greenhouse with high applicability is prepared by a physical method through field trails and verification research based on a nutrient preserving capability and a water requirement principle and a nutrient requirement principle of the cucumber.

Owner:NINGXIA UNIVERSITY

Method for preparing composite material containing Y-type molecular sieve

InactiveCN1781600AHigh selectivityImprove conversion abilityCatalytic crackingMolecular sieve catalystsMolecular sieveAluminate

The process of preparing composite material containing type-Y molecular sieve includes the following steps: the first synthesis of NaY molecular sieve guiding agent; the subsequent preparing molecular sieve gel with water glass, guiding agent, acid aluminum salt and sodium meta-aluminate; adding material capable of being used as carrier into the gel and crystallizing; and final filtering, washing and drying. The process results in compact combination between type-Y molecular sieve and the carrier and raised molecular sieve stability, and the prepared composite material may be modified as common molecular sieve and has medium holes specific surface area greater than 60 sq m / g and medium holes volume greater than 0.15 ml / g.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method of high-yield high-quality chemical raw material

ActiveCN103773452AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sievePetroleum naphtha

The invention discloses a hydrocracking method of a high-yield high-quality chemical raw material. According to the hydrocracking method comprises following steps: raw oil and hydrogen are subjected to hydrofinishing and are delivered through a first cracking reaction zone successively, and middle fraction oil is obtained via separation, and is delivered to a second cracking reaction zone for cracking; the first cracking reaction zone comprises two cracking catalysts, an upper zone is filled with a catalyst I, and a lower zone is filled with a catalyst II; the catalyst I comprises 30 to 70% of modified Y molecular sieve; the catalyst II comprises 15 to 50% of modified Y molecular sieve; and the content of the modified Y molecular sieve in the catalyst I is 10 to 30% higher than that in the catalyst II. Acid center of the catalyst I matches hydrogenation center, and the catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that demands of the high-yield high-quality chemical raw material are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional catalysis composition

ActiveCN103566962AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMolecular sieve catalystsBoehmiteOxide

A multifunctional catalysis composition comprises 1-50wt% of a mesoporous aluminosilicate material, 1-40wt% of a gasification active component, 1-60wt% of a cracking active component, 0-70wt% of clay and 5-97wt% of a heatproof inorganic oxide matrix, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm The catalysis composition can reduce the gasification temperature of the cracking gasification conversion of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrocracking method

ActiveCN103773463AIncrease hydrogen partial pressureImprove conversion abilityTreatment with hydrotreatment processesMolecular sieveAlkane

The invention discloses a two-stage hydrocracking method. The two-stage hydrocracking method comprises following steps: (1) inferior raw oil is mixed with hydrogen for hydrofinishing; (2) a hydrofinishing effluent is subjected to gas-liquid separation so as to obtain a gas material and a liquid material; (3) the liquid material is delivered into a hydrocracking reaction zone for hydrocracking, wherein the hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain needed products. According to the two-stage hydrocracking method, the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformation ability, and is capable of transforming aromatic hydrocarbons in raw material heavier components into smaller molecules, and distributing the small molecules into naphtha and jet fuel fractions; the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking ability; synergistic effect of the two catalysts is capable of improving quality of hydrocracking products obviously, and especially increasing smoke point of jet fuel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

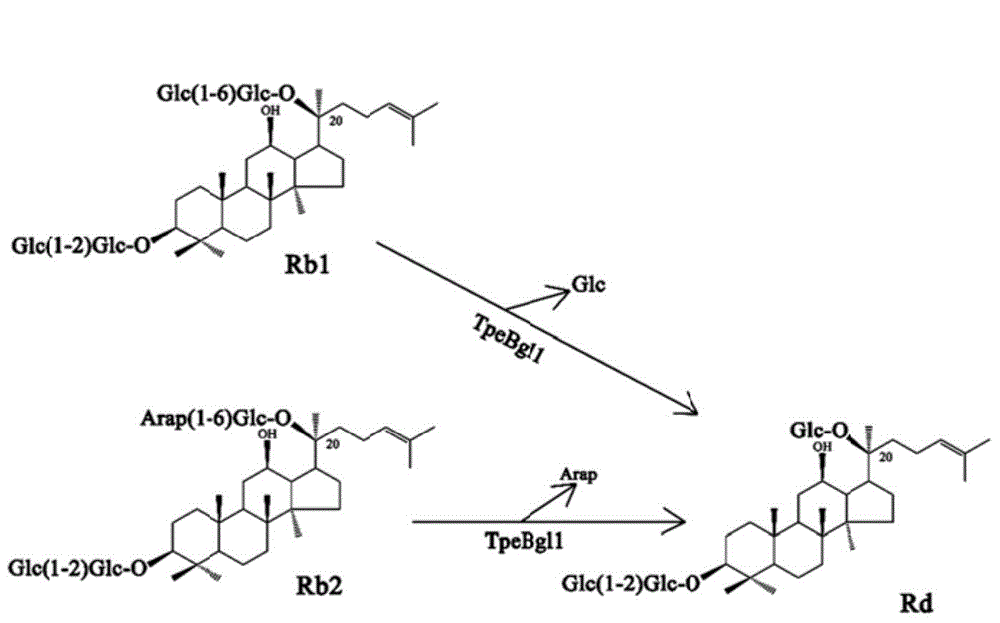

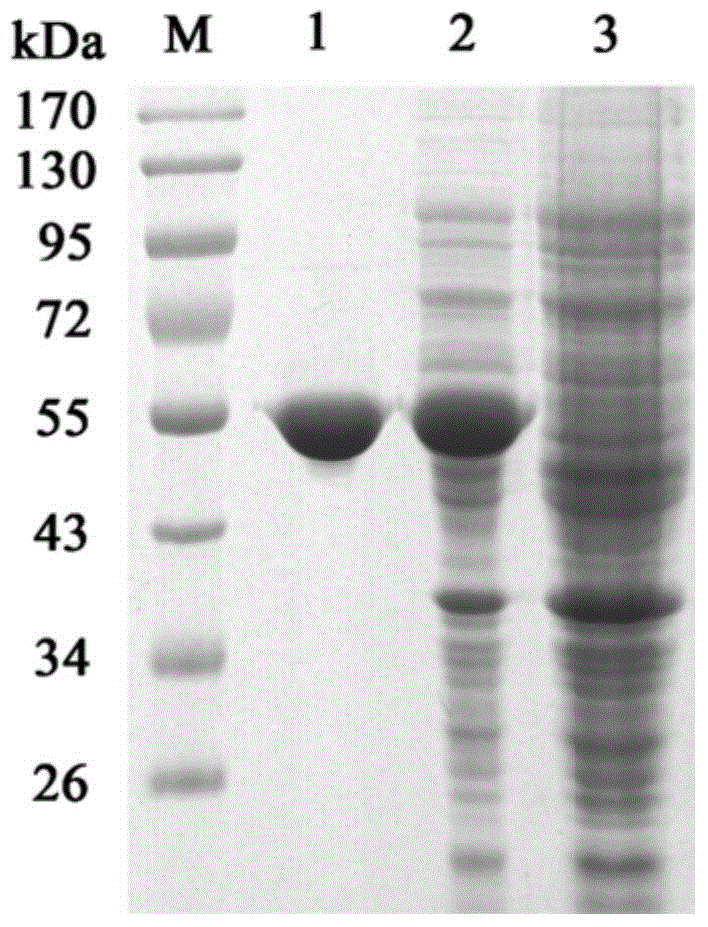

Beta-glucosidase as well as preparation method and application thereof

ActiveCN104611313AGood thermal stabilityStrong conversion abilityFermentationVector-based foreign material introductionAlgluceraseGinsenoside Rb1

The invention provides a beta-glucosidase as well as a preparation method and an application thereof. The amino acid sequence of beta-glucosidase is shown as SEQ ID NO.1. The beta-glucosidase has excellent thermal stability, can resist high temperature, has higher beta-1,6-glucosidic bond hydrolysis capacity as well as higher alpha-1,6-arabinopyranoside bond hydrolysis capacity and has higher transformation capacity for ginsenoside Rb1 and Rb2. After the beta-glucosidase is incubated with the ginsenoside Rb1 and Rb2 for certain period, ginsenoside Rb1 and Rb2 are almost transformed into ginsenoside Rd completely. According to a preparation method of TPEBGL1, high-efficiency expression can be realized without an inducer IPTG (isopropyl beta-D-1-thiogalactopyranoside).

Owner:NANJING FORESTRY UNIV

Two-stage hydrocracking method used for producing high-quality chemical raw materials

ActiveCN103773462AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesMolecular sieveLiquid product

The invention discloses a two-stage hydrocracking method used for producing high-quality chemical raw materials. The two-stage hydrocracking method comprises following steps: (1) raw material oil is mixed with hydrogen, and an obtained mixture is subjected to hydrofinishing reaction; (2) a refining reaction product is subjected to gas-liquid separation; (3) an obtained liquid product and hydrogen are subjected to hydrocracking reaction, and are contacted with a catalyst I and a catalyst II successively, wherein molecular sieve content of the catalyst I and molecular sieve content of the catalyst II are different; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain a plurality of hydrocracking products. The molecular sieve content of the hydrocracking catalyst I is higher, acid center of the hydrocracking catalyst I matches hydrogenation center, and the hydrocracking catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw material oil into smaller molecules so as to distribute in heavy petroleum fractions. The two hydrocracking catalysts with different molecular sieve contents are combined, so that aromatic hydrocarbon potential content of heavy naphtha is increased, and tail oil BMCI value is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst containing nanometer rare-earth oxide and method of preparing the same

InactiveCN101138740AImprove distributionReduce olefin contentCatalytic crackingMolecular sieve catalystsMicrosphereRare earth

The present invention relates to a cracking catalyst comprising a nano rare earth oxide and a preparation method of the catalyst. The present invention is characterized in that a compound consisting of a rare earth Y molecular sieve (15-50 weight percent), a silica and / or aluminum bonding agent (10-30 weight percent, the nano rare earth oxide (0.5-20 weight percent), a natural inorganic packing substance (10-60 weight percent), and other active components (0-10 weight percent) is molded into the microsphere cracking catalyst after the spray drying. The rare earth content is 0-30 weight percent calculated based on the rare earth oxide, and the select content of the rare earth is 1-10 weight percent. The cracking catalyst is characterized in that the catalyst is provided with the excellent heavy oil conversion capability and promotes the hydrothermal stability, so the catalyst is more suitable for the long-period use on a cracking catalysis device under the highly rigor renewal condition; the catalyst improves the product distribution and reduces the alkene content and the sulfur content of the catalytically cracked gasoline.

Owner:北京盛大京泰化学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com