Patents

Literature

6458 results about "Nitrogen source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

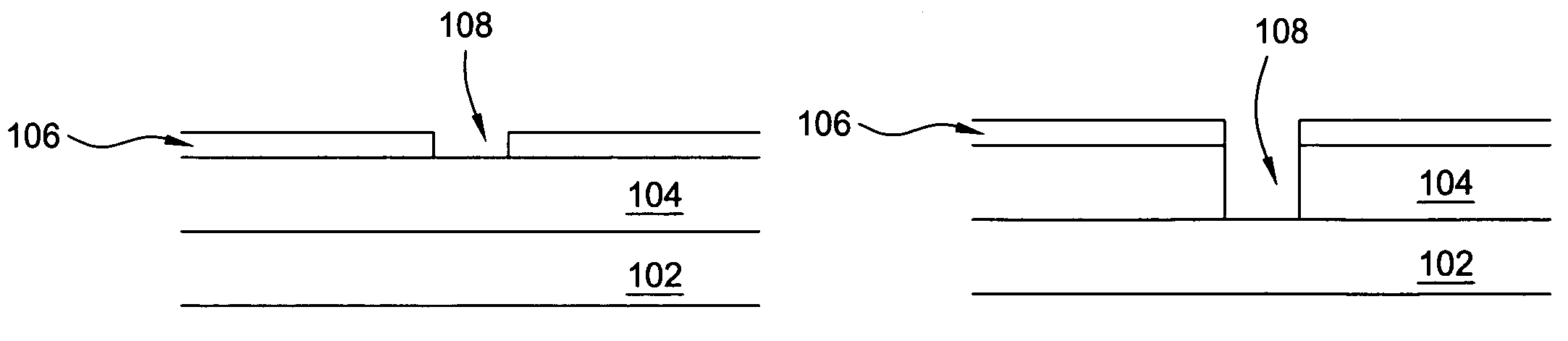

Method of growing nitride semiconductors, nitride semiconductor substrate and nitride semiconductor device

InactiveUS6153010APolycrystalline material growthLaser detailsNitrogen sourceCrystallographic defect

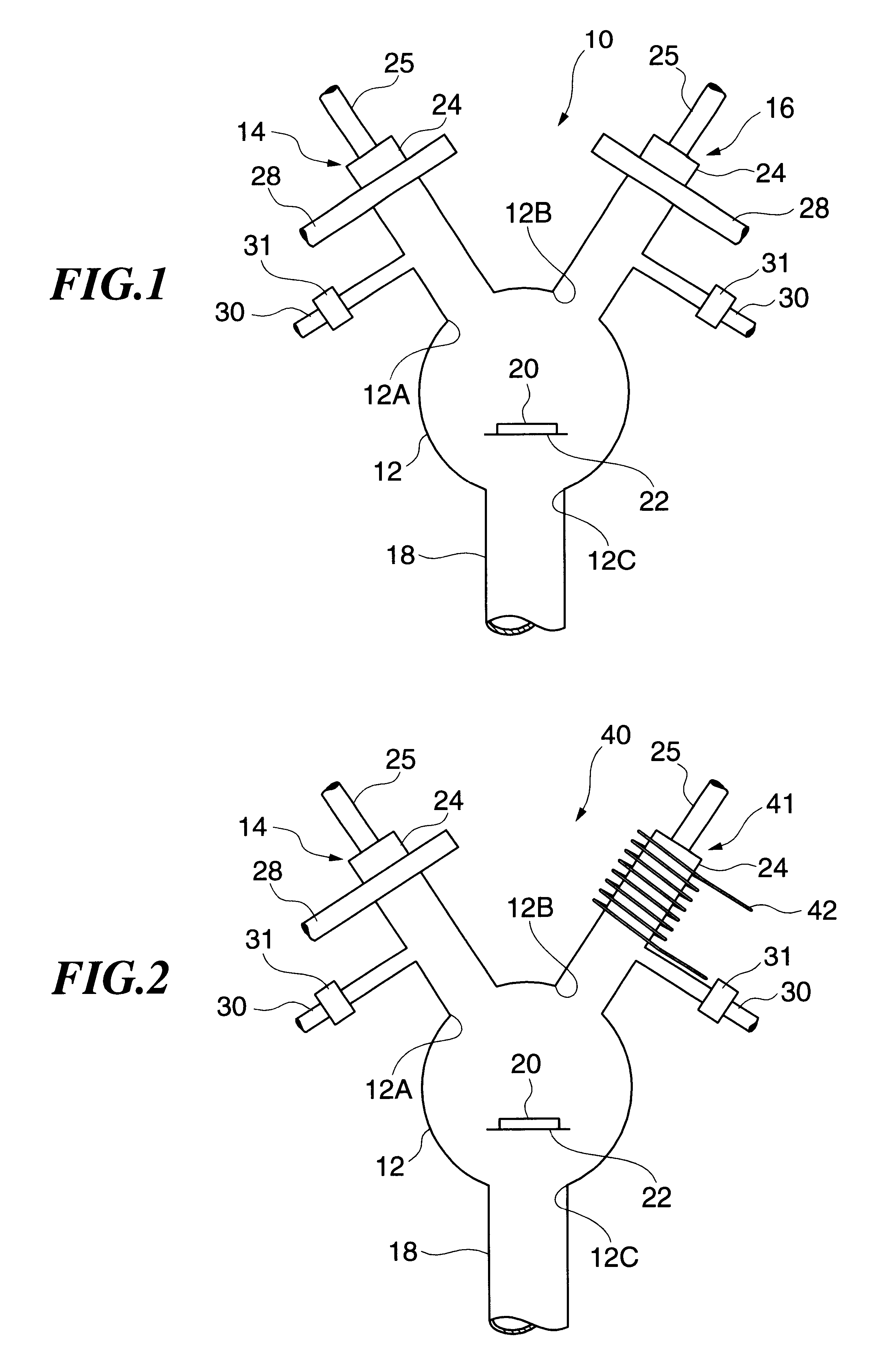

PCT No. PCT / JP98 / 01640 Sec. 371 Date Dec. 9, 1998 Sec. 102(e) Date Dec. 9, 1998 PCT Filed Apr. 9, 1998 PCT Pub. No. WO98 / 47170 PCT Pub. Date Oct. 22, 1998A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

Method for forming introgen-containing oxide thin film using plasma enhanced atomic layer deposition

InactiveUS20040077182A1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateNitrogen source

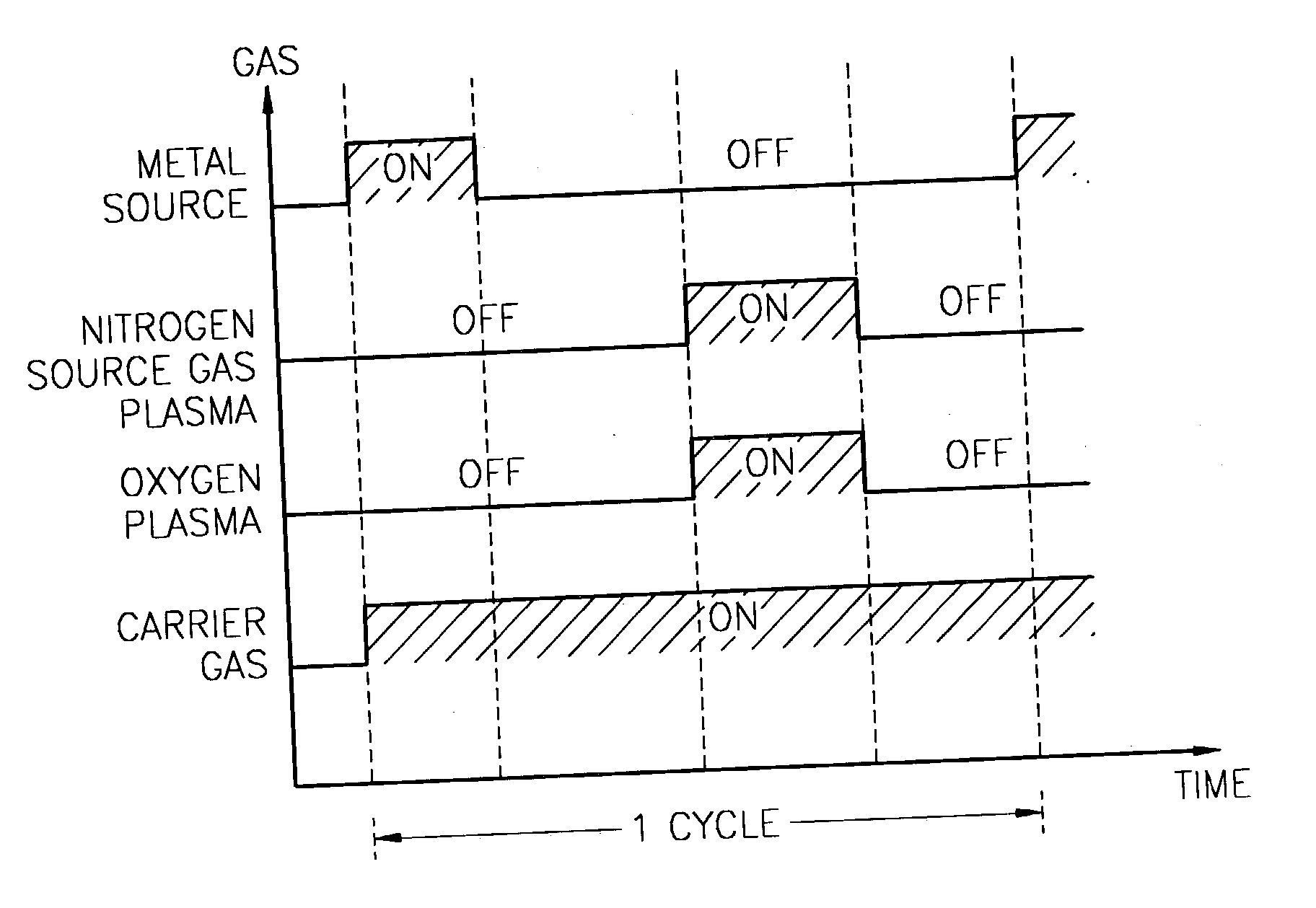

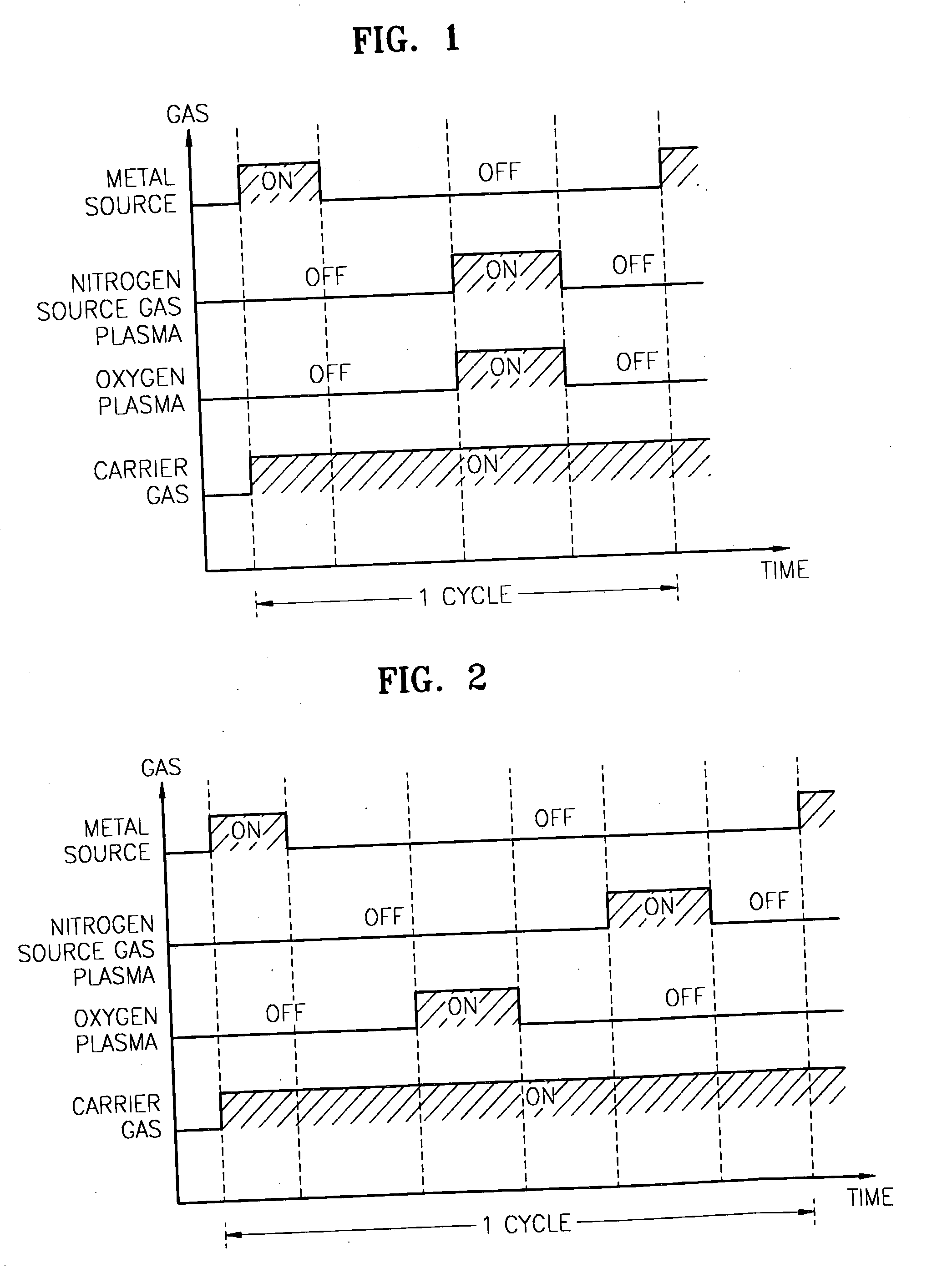

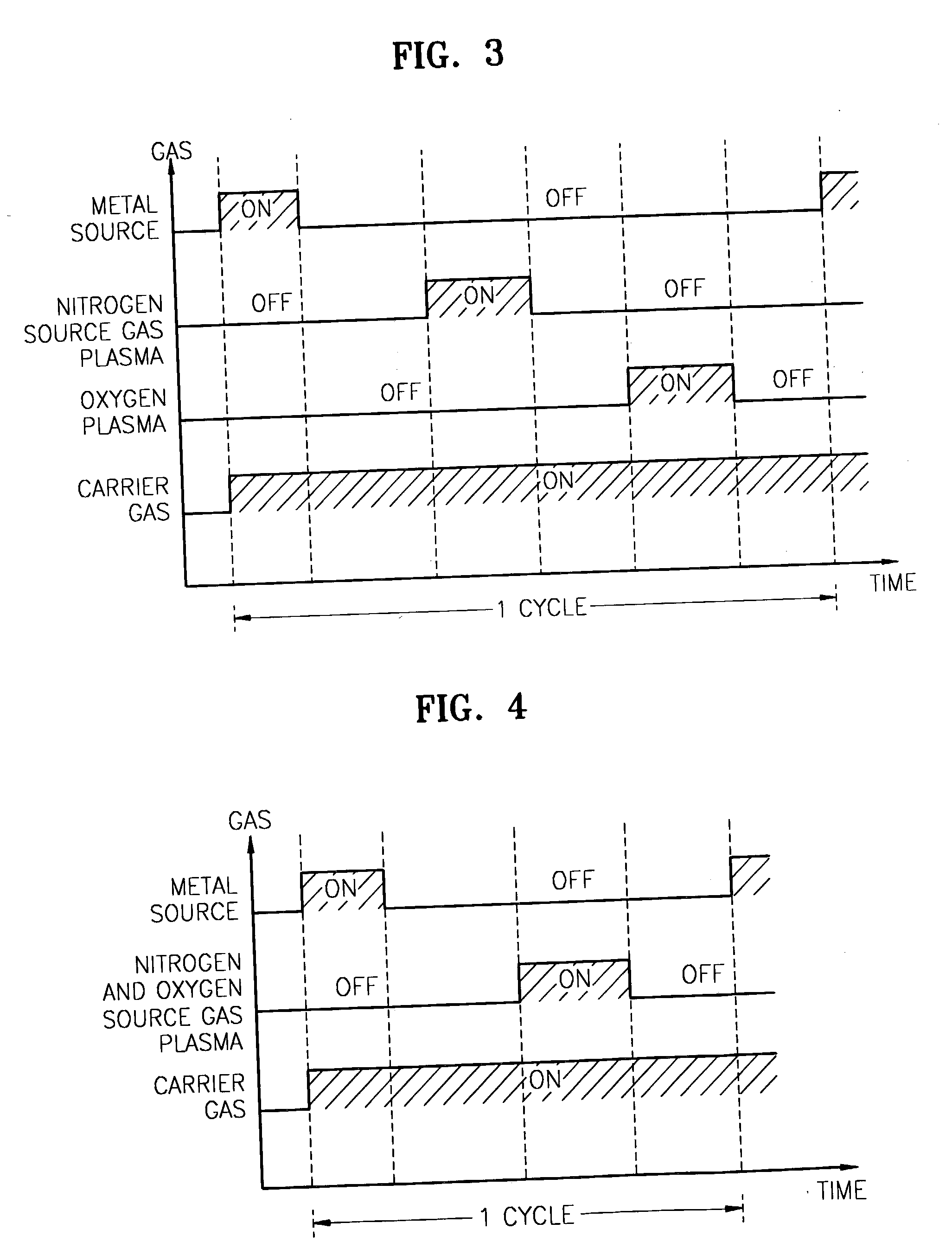

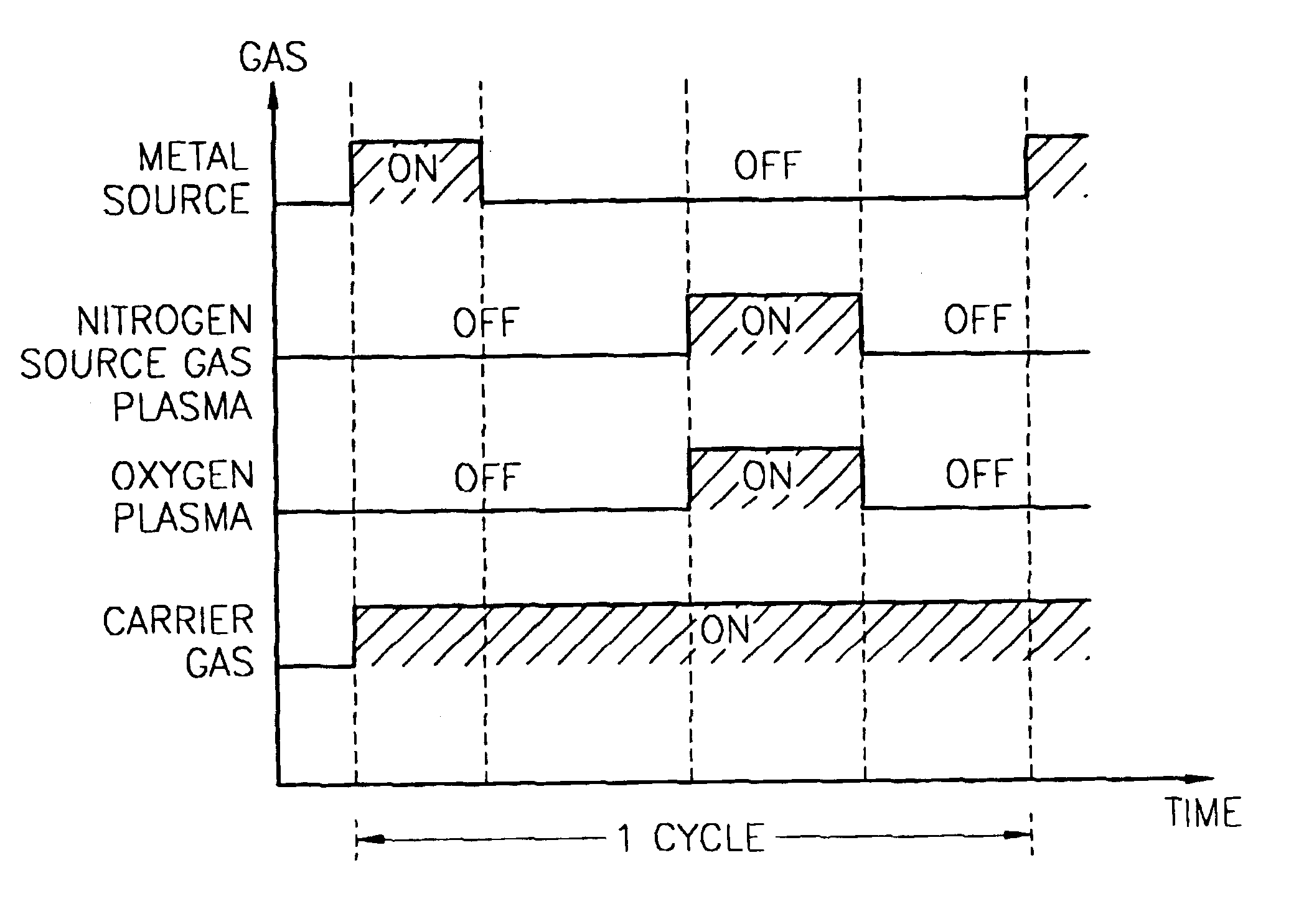

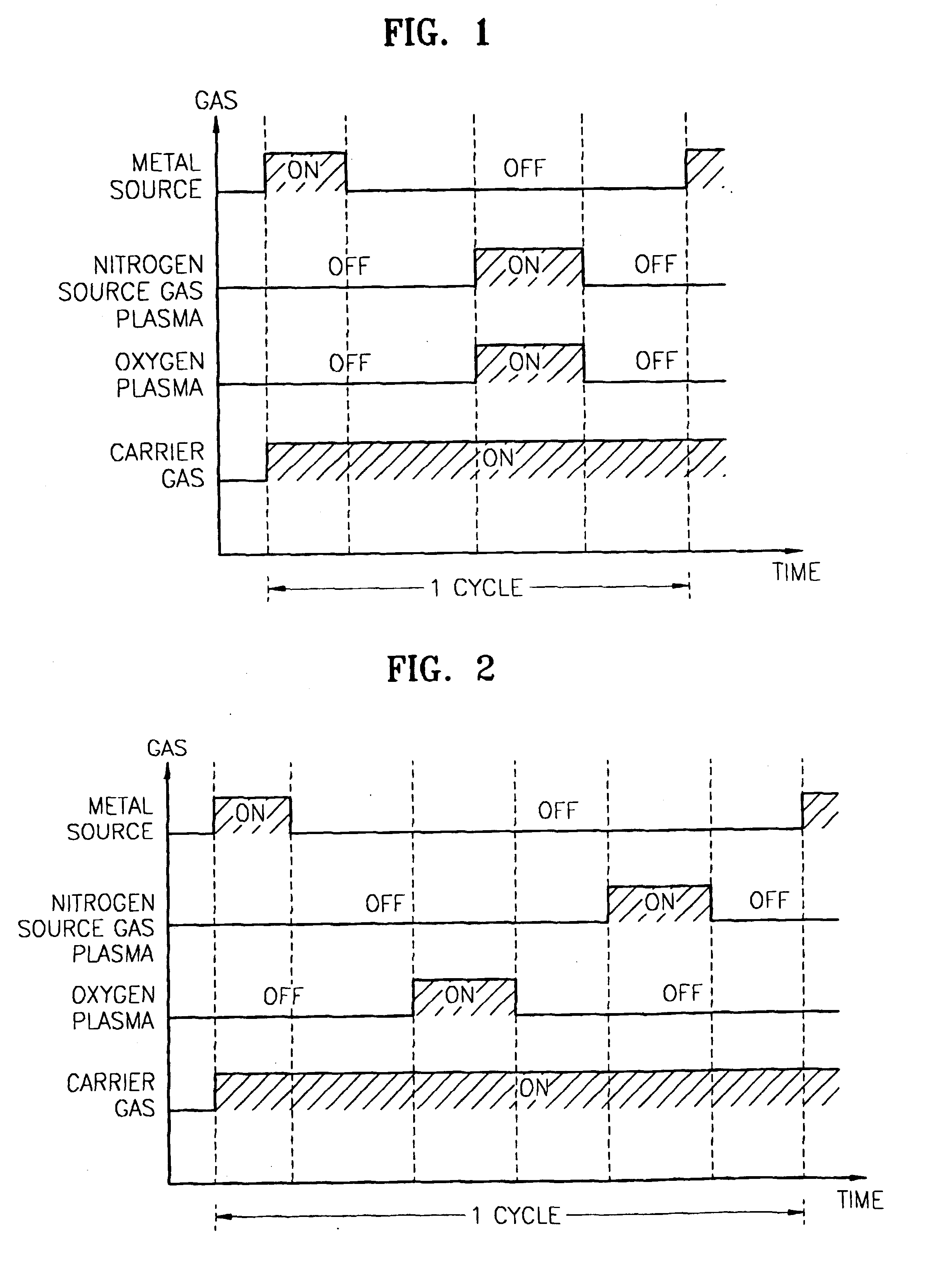

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

Method for forming nitrogen-containing oxide thin film using plasma enhanced atomic layer deposition

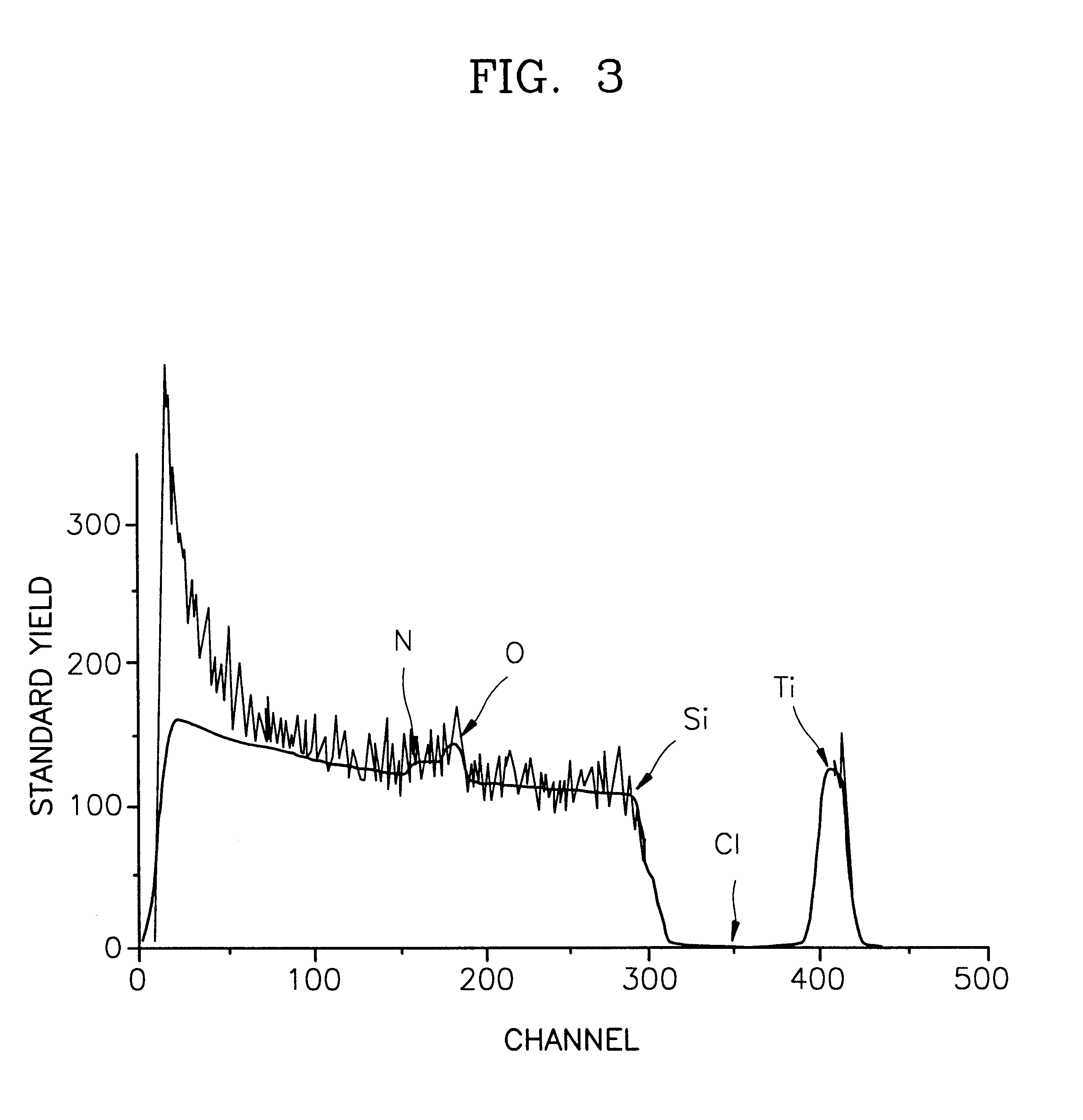

InactiveUS6723642B1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceNitrogen oxide

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

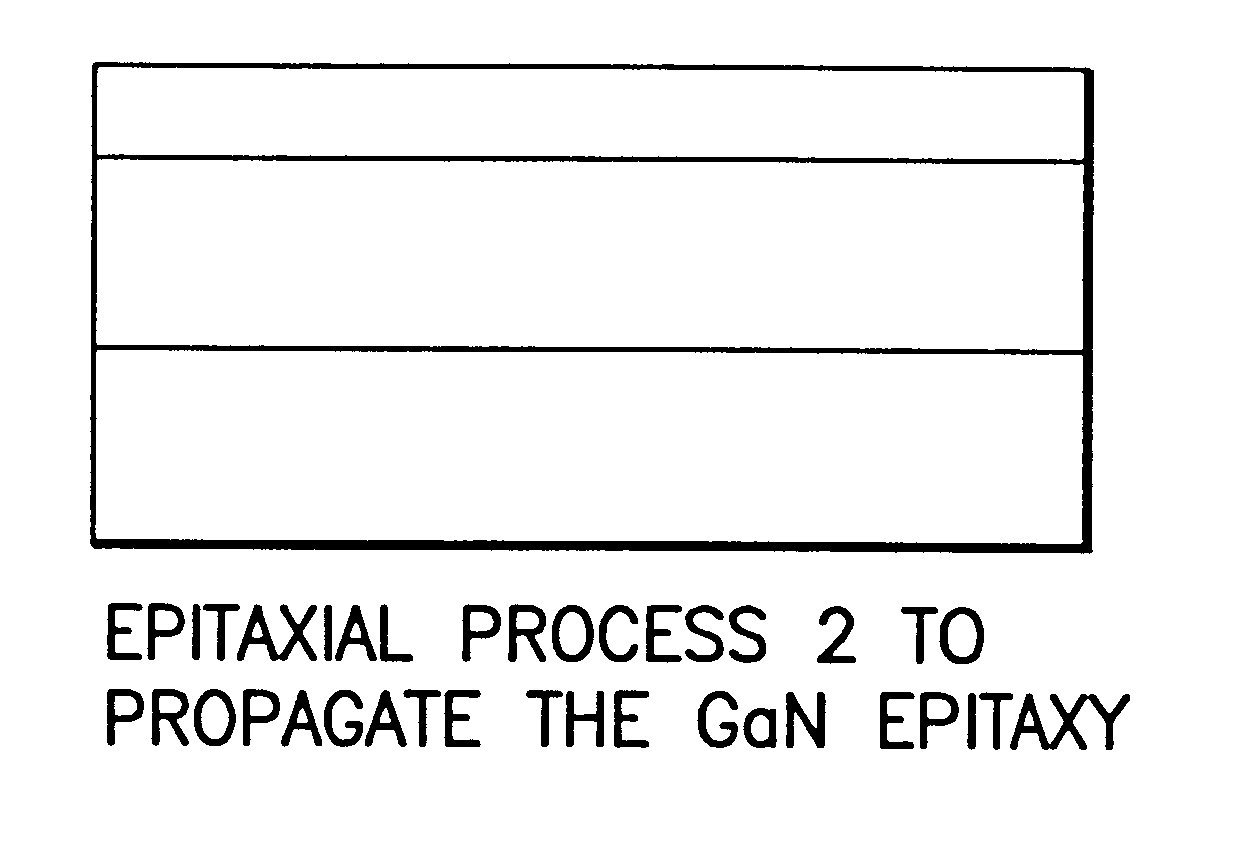

Method for achieving improved epitaxy quality (surface texture and defect density) on free-standing (aluminum, indium, gallium) nitride ((al,in,ga)n) substrates for opto-electronic and electronic devices

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 105, nitrogen source material partial pressure in a range of from about 1 to about 103 torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 500 microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

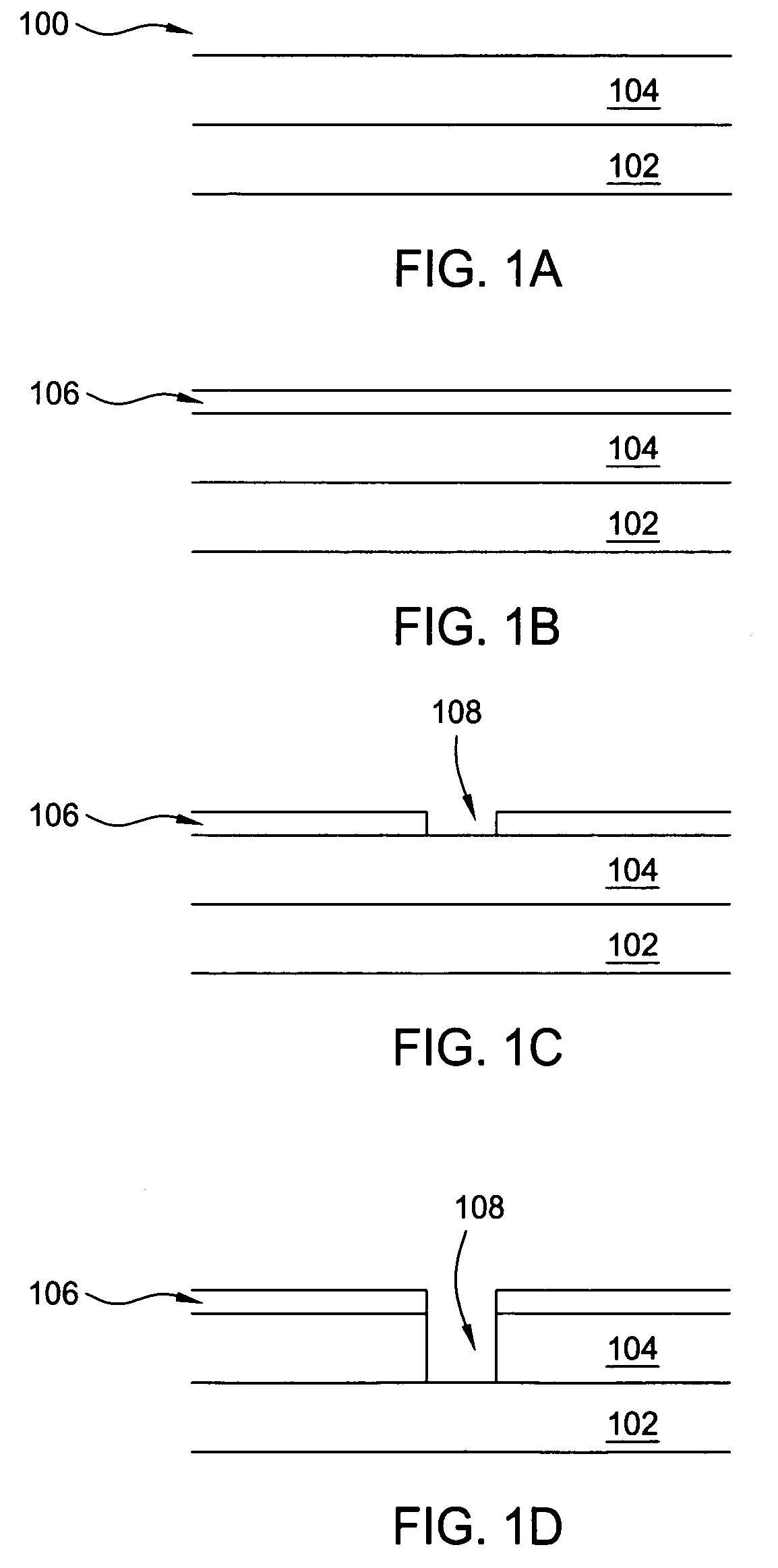

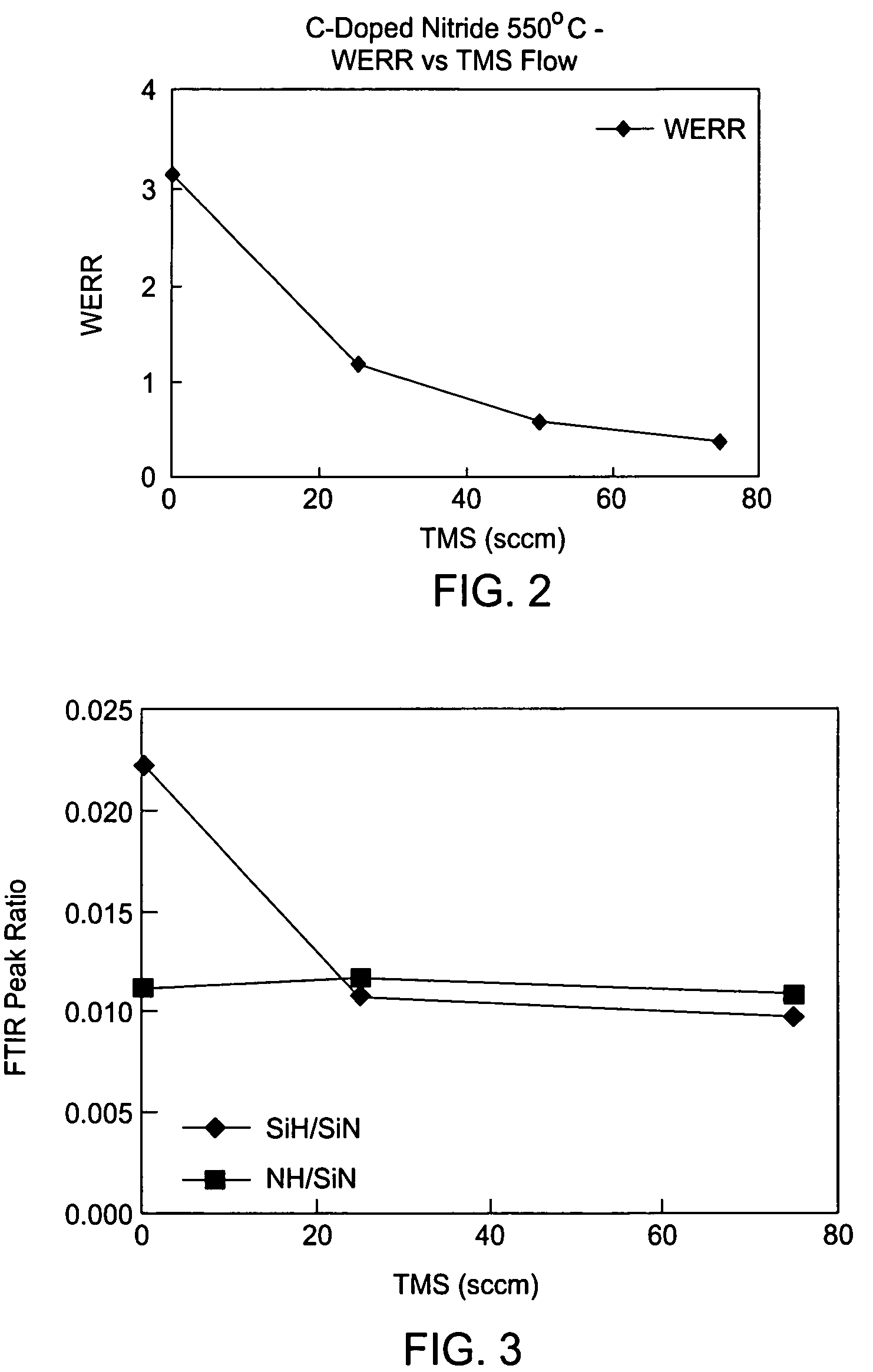

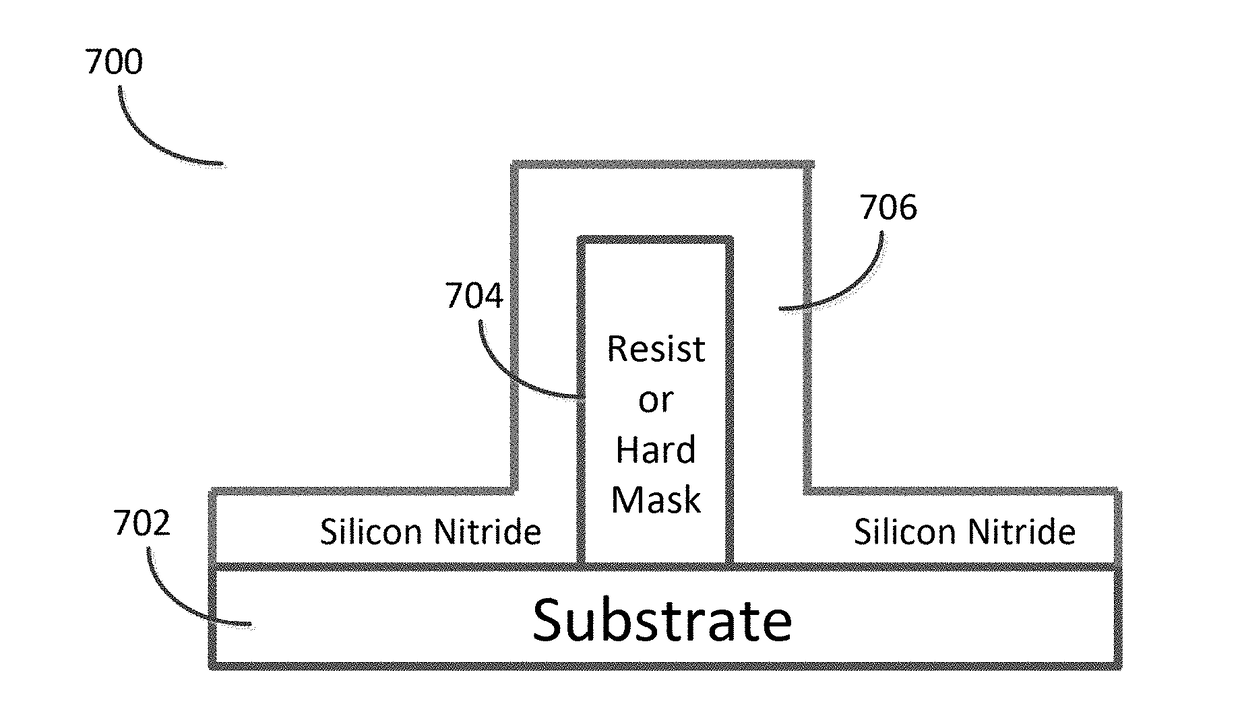

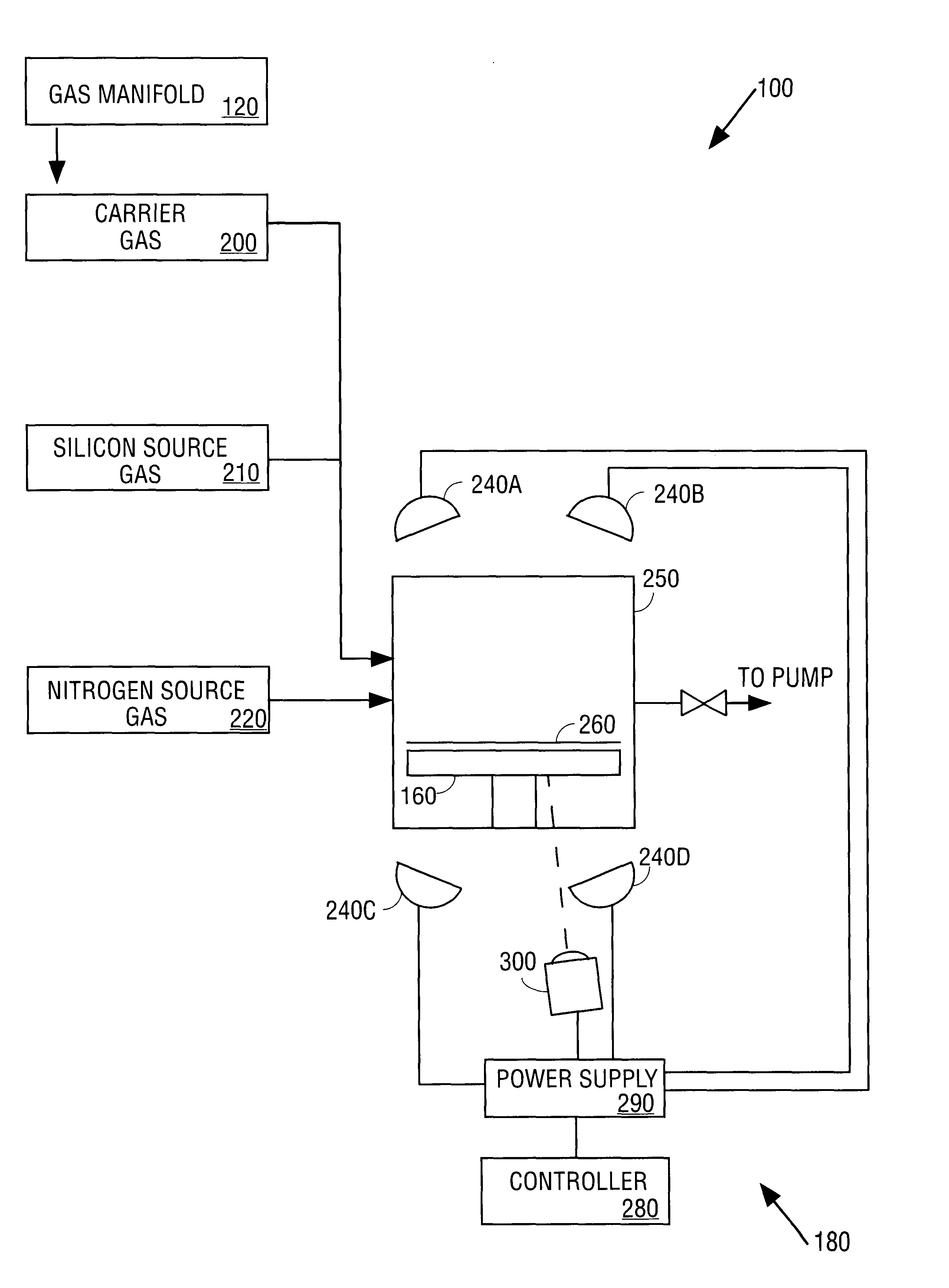

Decreasing the etch rate of silicon nitride by carbon addition

Methods for forming silicon nitride hard masks are provided. The silicon nitride hard masks include carbon-doped silicon nitride layers and undoped silicon nitride layers. Carbon-doped silicon nitride layers that are deposited from a mixture comprising a carbon source compound, a silicon source compound, and a nitrogen source in the presence of RF power are provided. Also provided are methods of UV post-treating silicon nitride layers to provide silicon nitride hard masks. The carbon-doped silicon nitride layers and UV post-treated silicon nitride layers have desirable wet etch rates and dry etch rates for hard mask layers.

Owner:APPLIED MATERIALS INC

Plasma-enhanced ald of tantalum nitride films

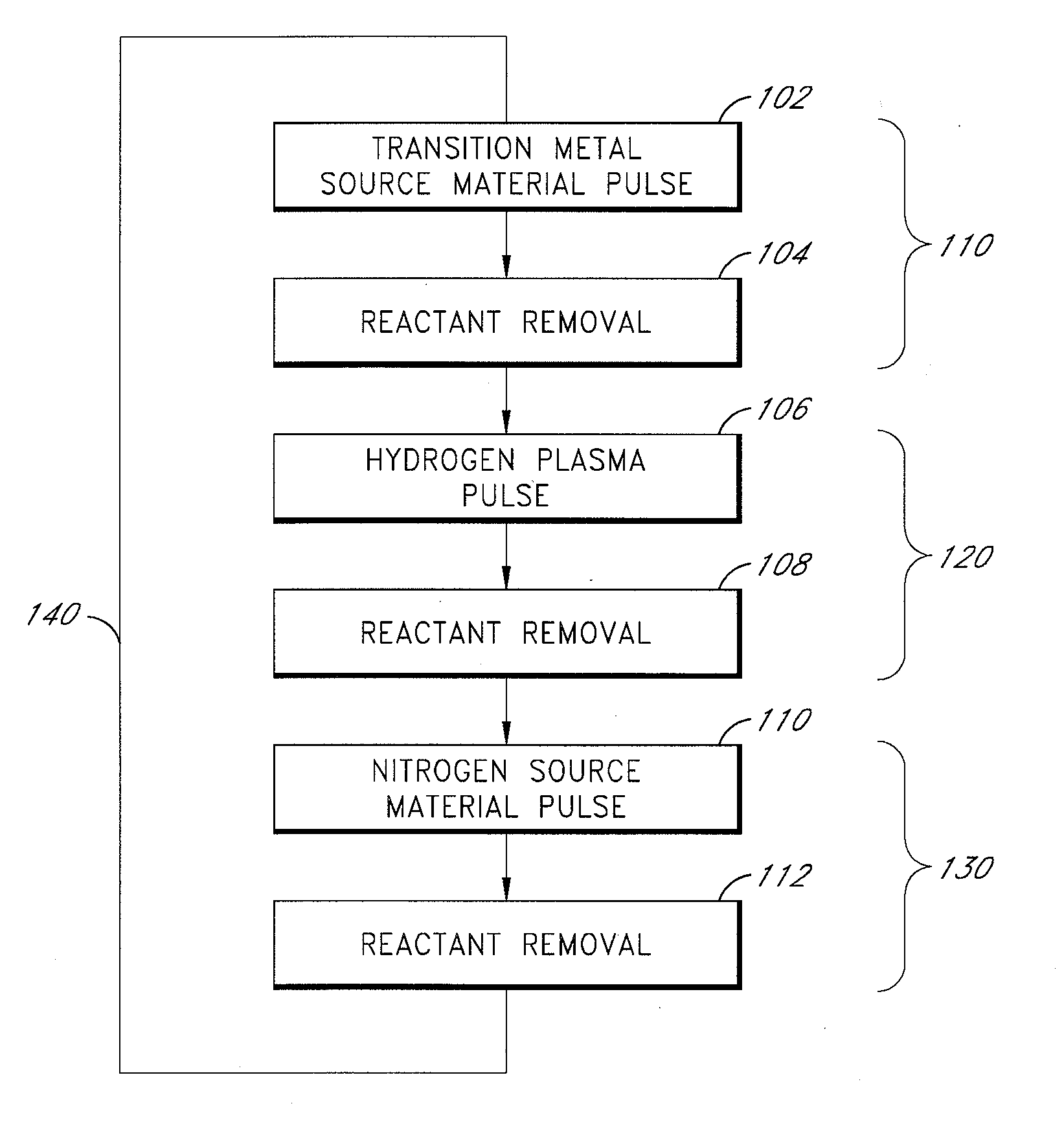

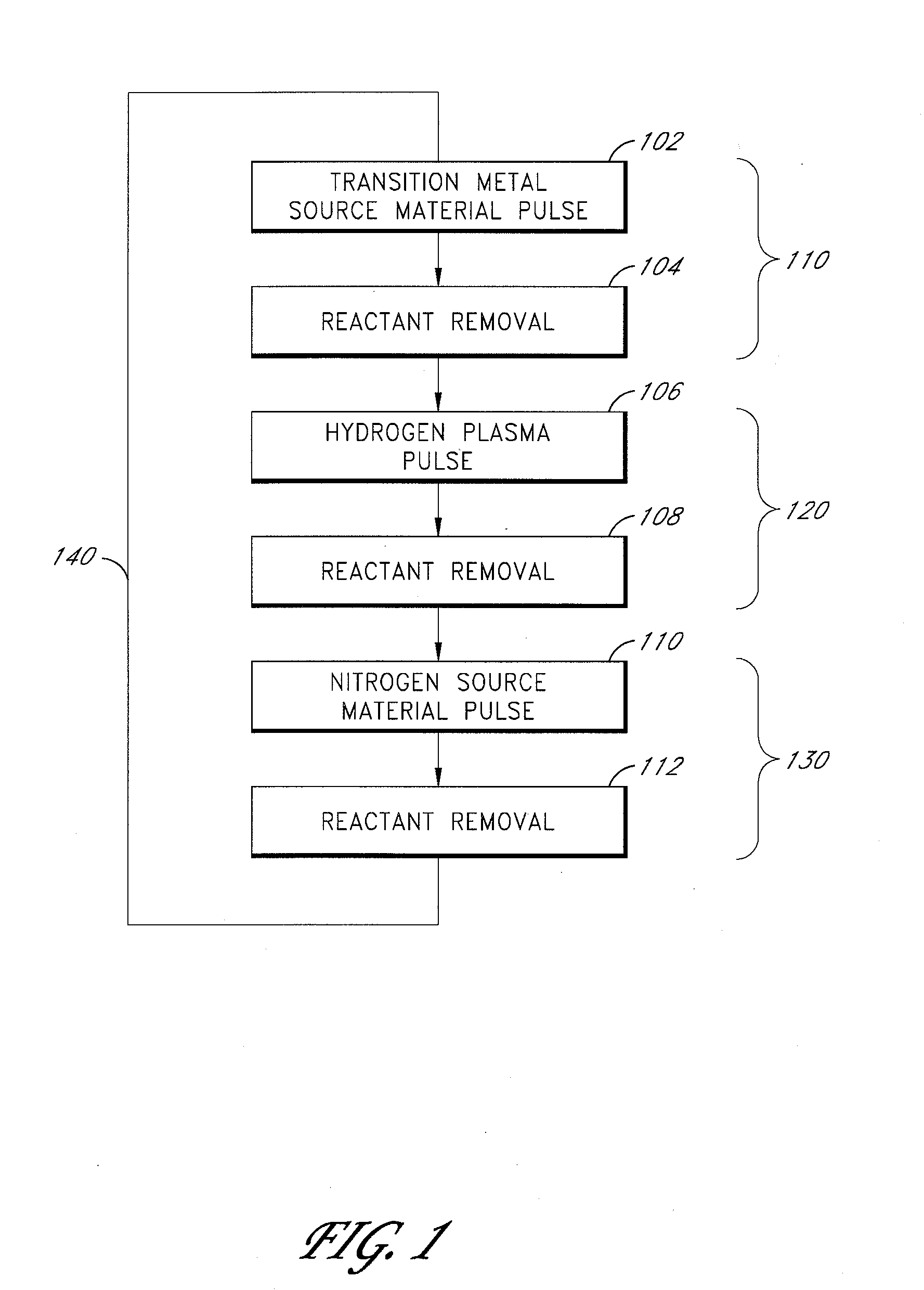

ActiveUS20080182411A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSource material

Methods of controllably producing conductive tantalum nitride films are provided. The methods comprise contacting a substrate in a reaction space with alternating and sequential pulses of a tantalum source material, plasma-excited species of hydrogen and nitrogen source material. The plasma-excited species of hydrogen reduce the oxidation state of tantalum, thereby forming a substantially conductive tantalum nitride film over the substrate. In some embodiments, the plasma-excited species of hydrogen react with and removes halide residues in a deposited metallic film.

Owner:ASM IP HLDG BV

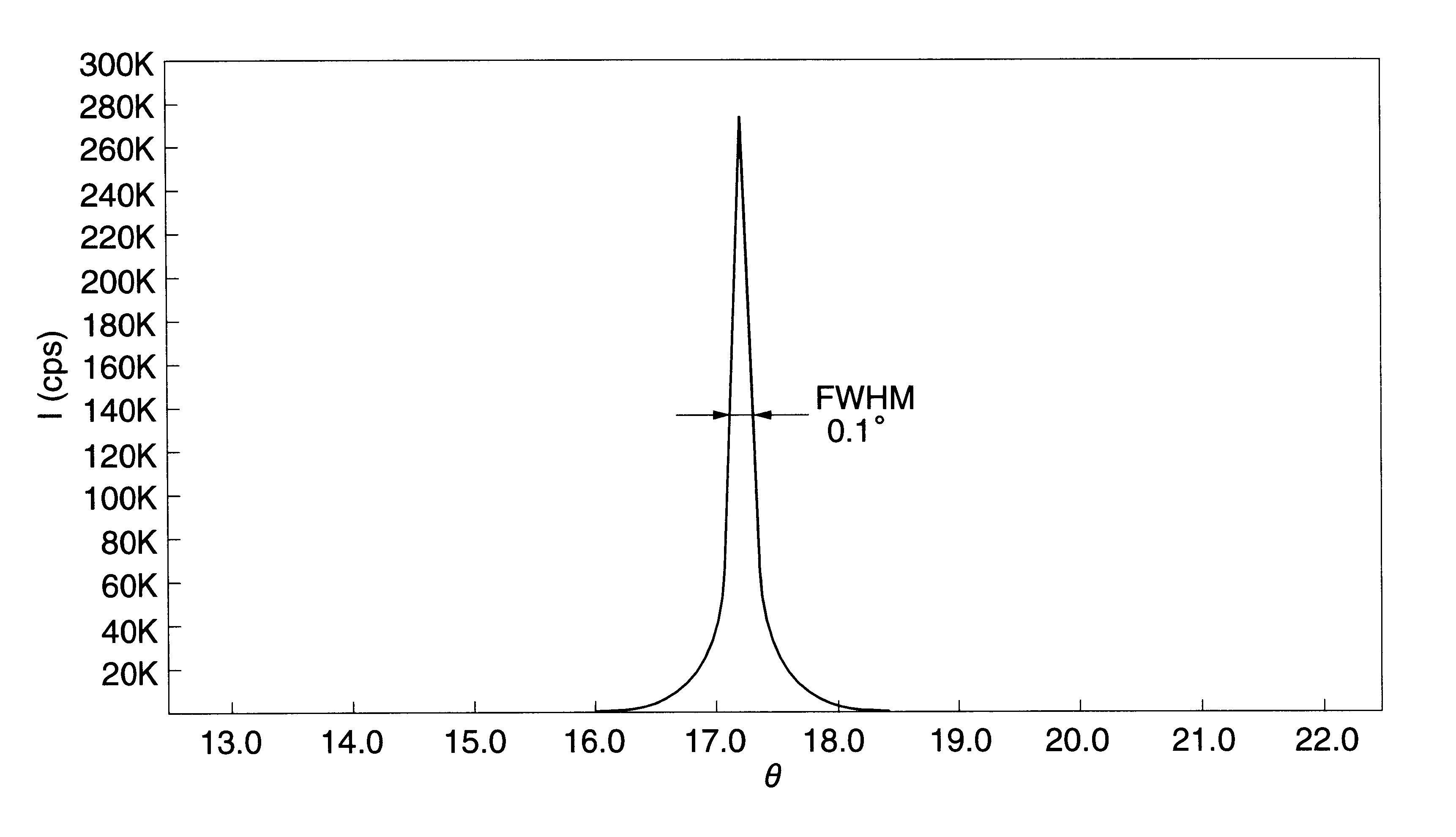

Nitride semiconductor device and method of manufacturing the same

A nitride semiconductor device of high quality and excellent crystallinity and the method of manufacturing the same, wherein a nitride series compound semiconductor having at least an element belonging to the group IIIA and nitrogen is grown directly on a substrate, X-ray diffraction peaks of the nitride series compound semiconductor consist only of the peaks from the C-face of the hexagonal system, and the half width of an X-ray rocking curve at (0002) peak in the C-surface is 0.2 degrees of less, and wherein the method includes a step of introducing an organic metal compound at least containing a group IIIA element and a plasma activated nitrogen source into a reaction vessel to grow a nitride series compound semiconductor on the surface of a substrate, in which the ratio for the amount of the group IIIA element and nitrogen atom supplied (ratio for the number of atoms) is group IIIA element: nitrogen atom=1:50,000 to 1:1,000,000.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS20010034097A1Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsChemical physicsDevice material

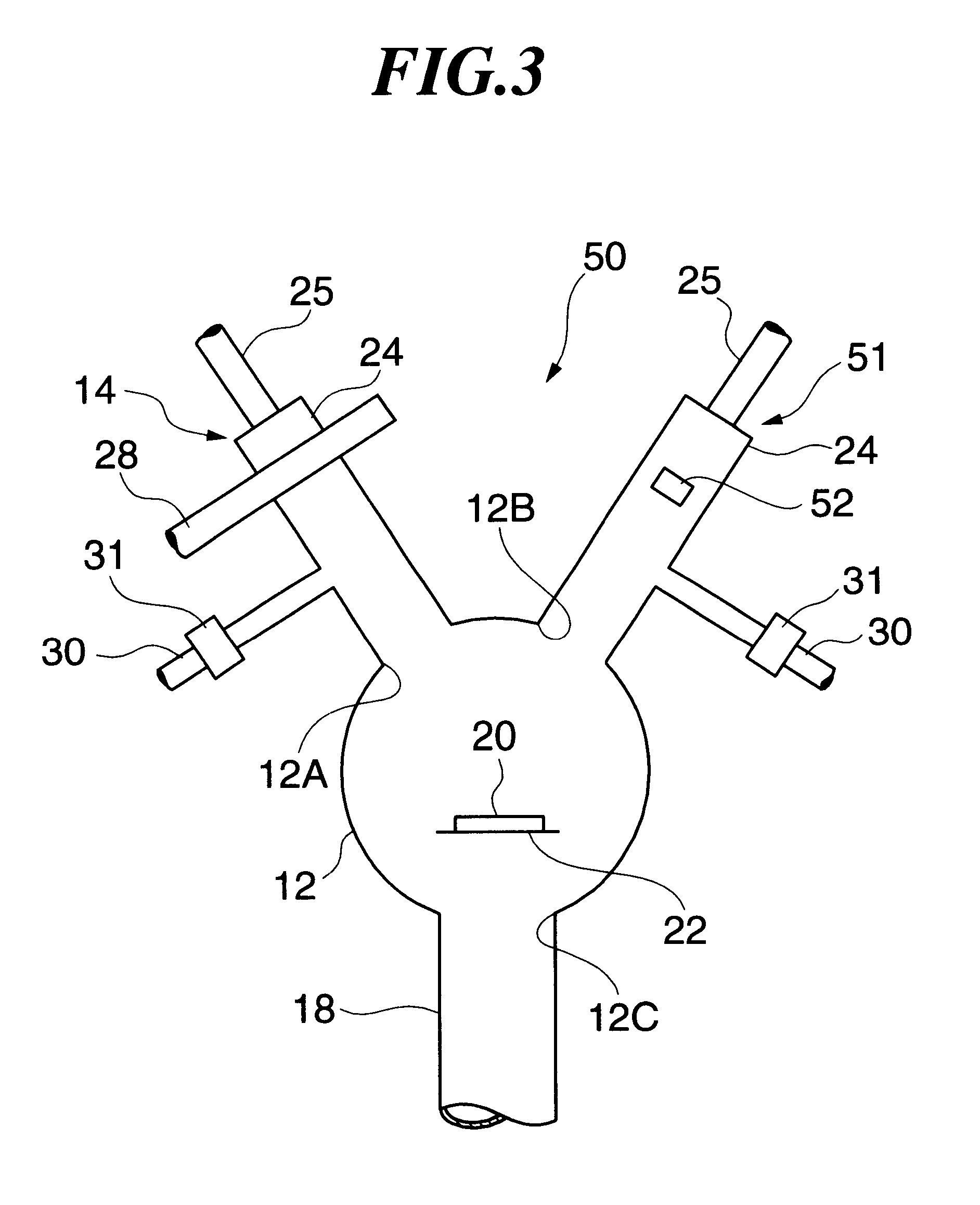

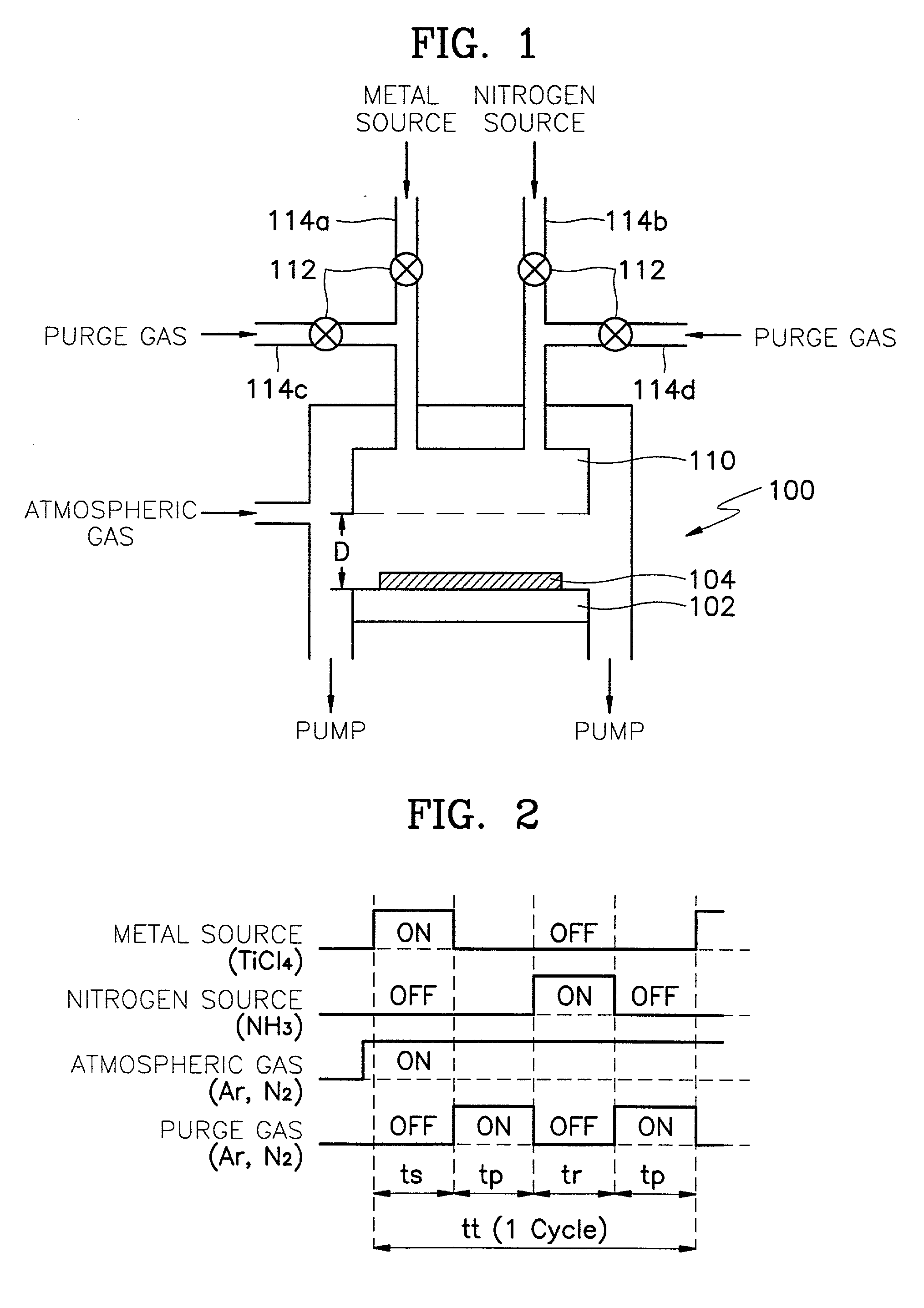

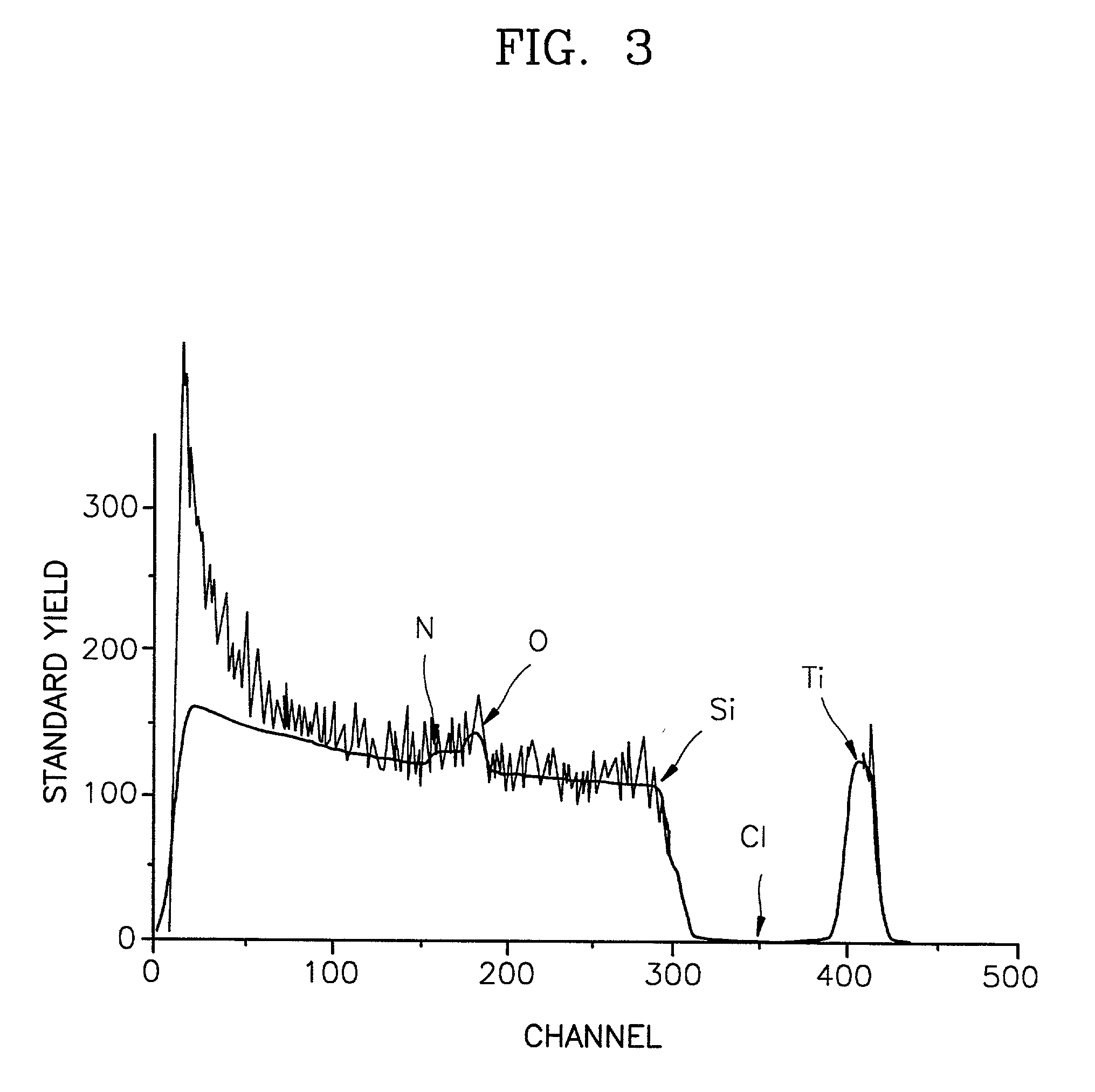

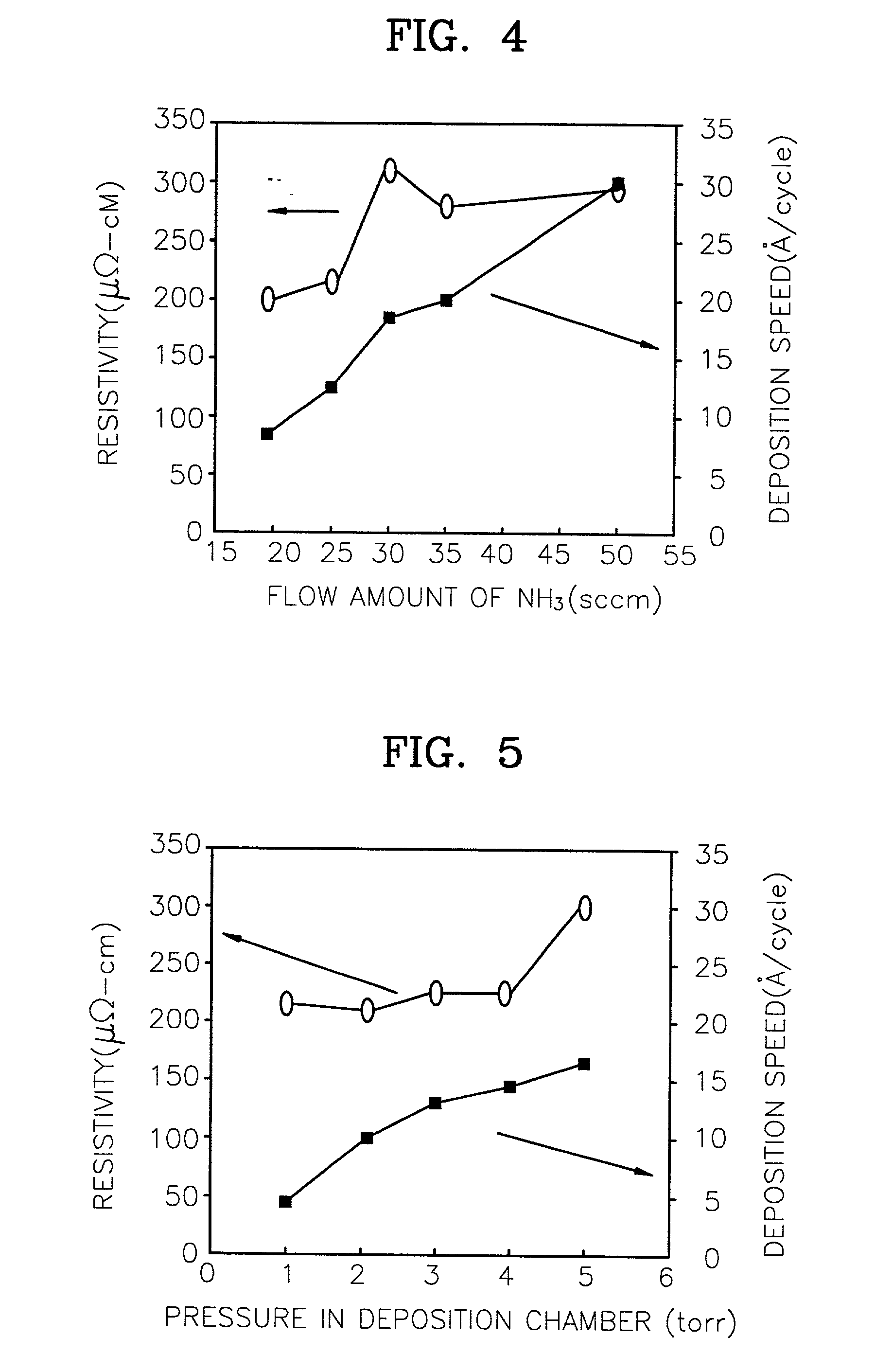

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

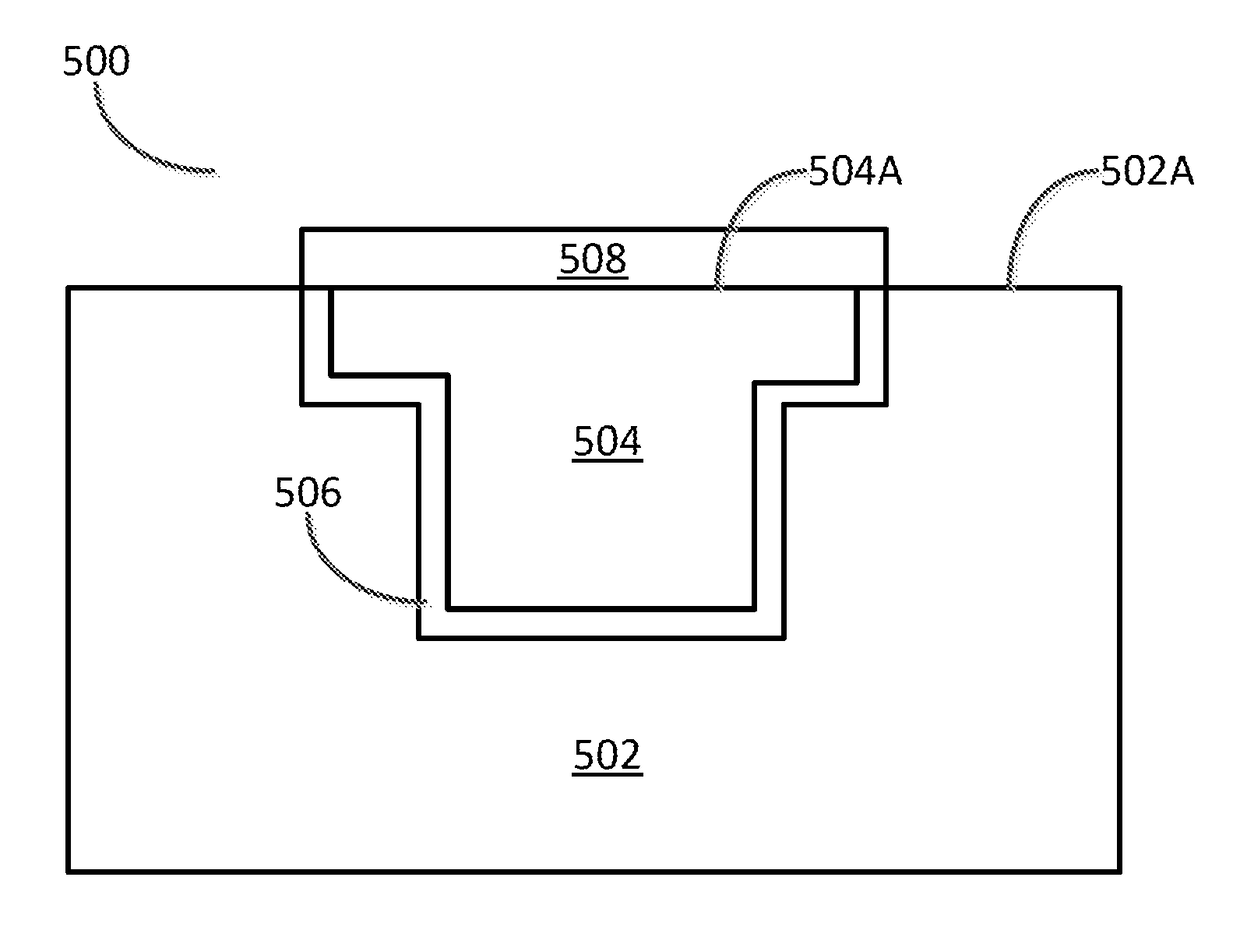

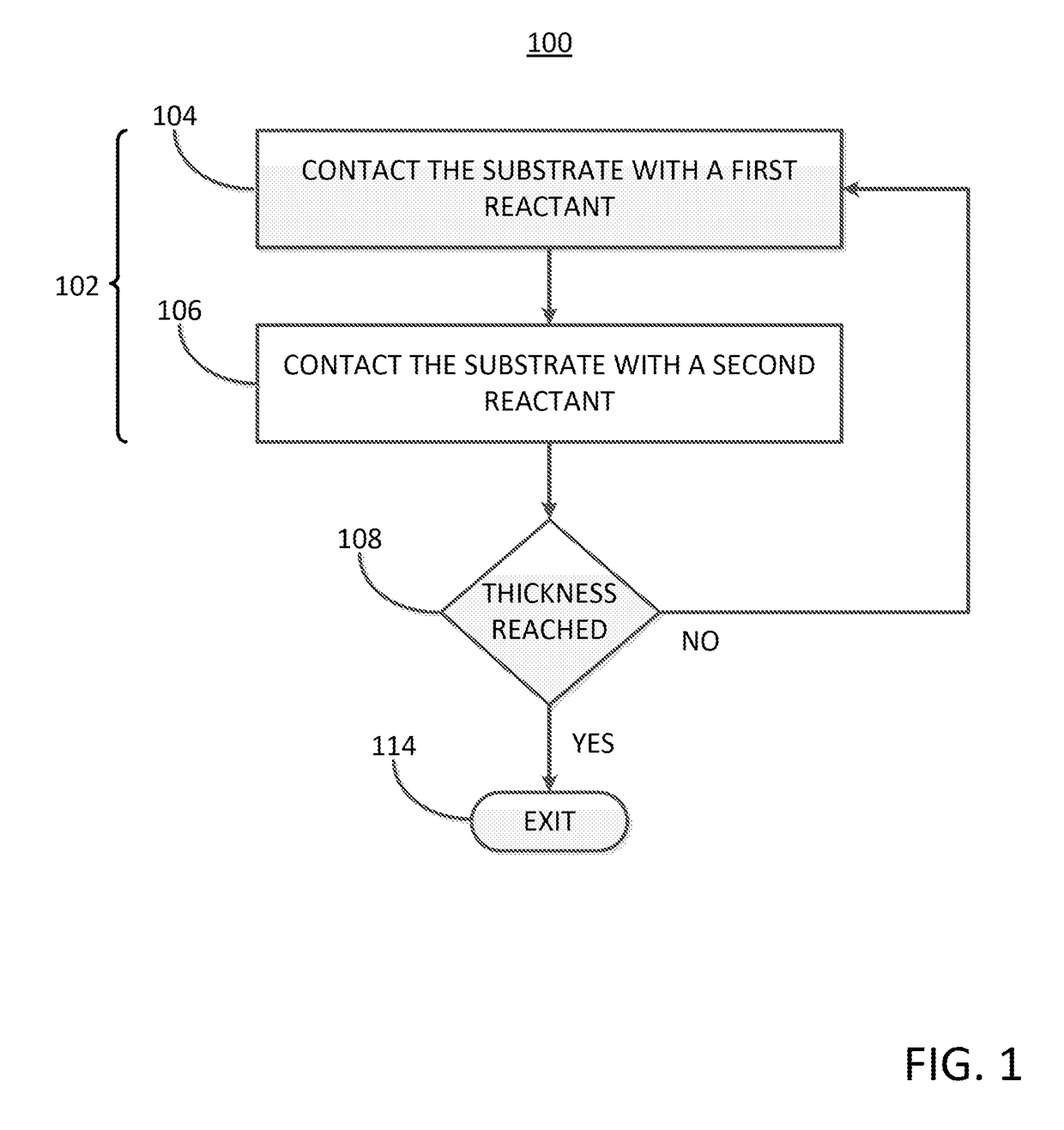

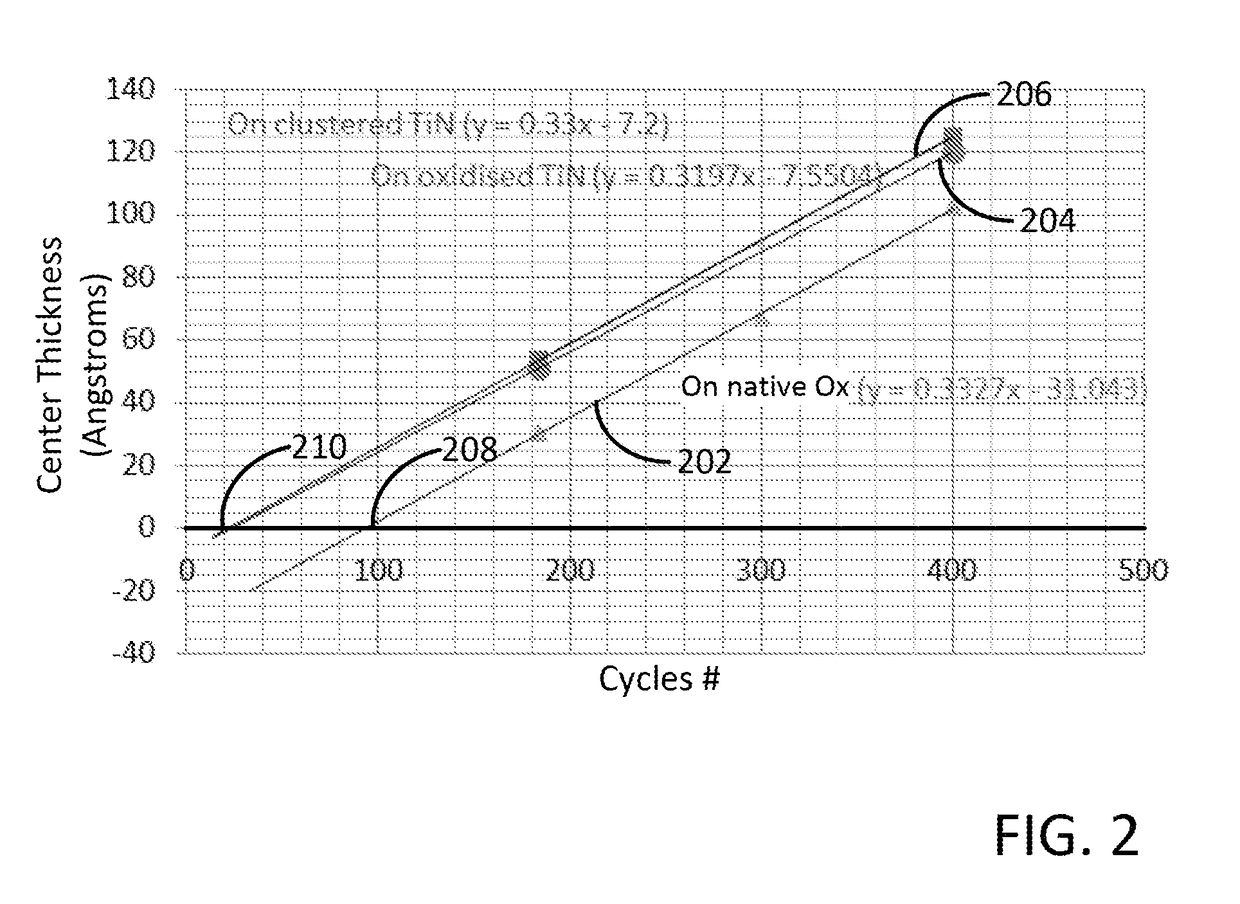

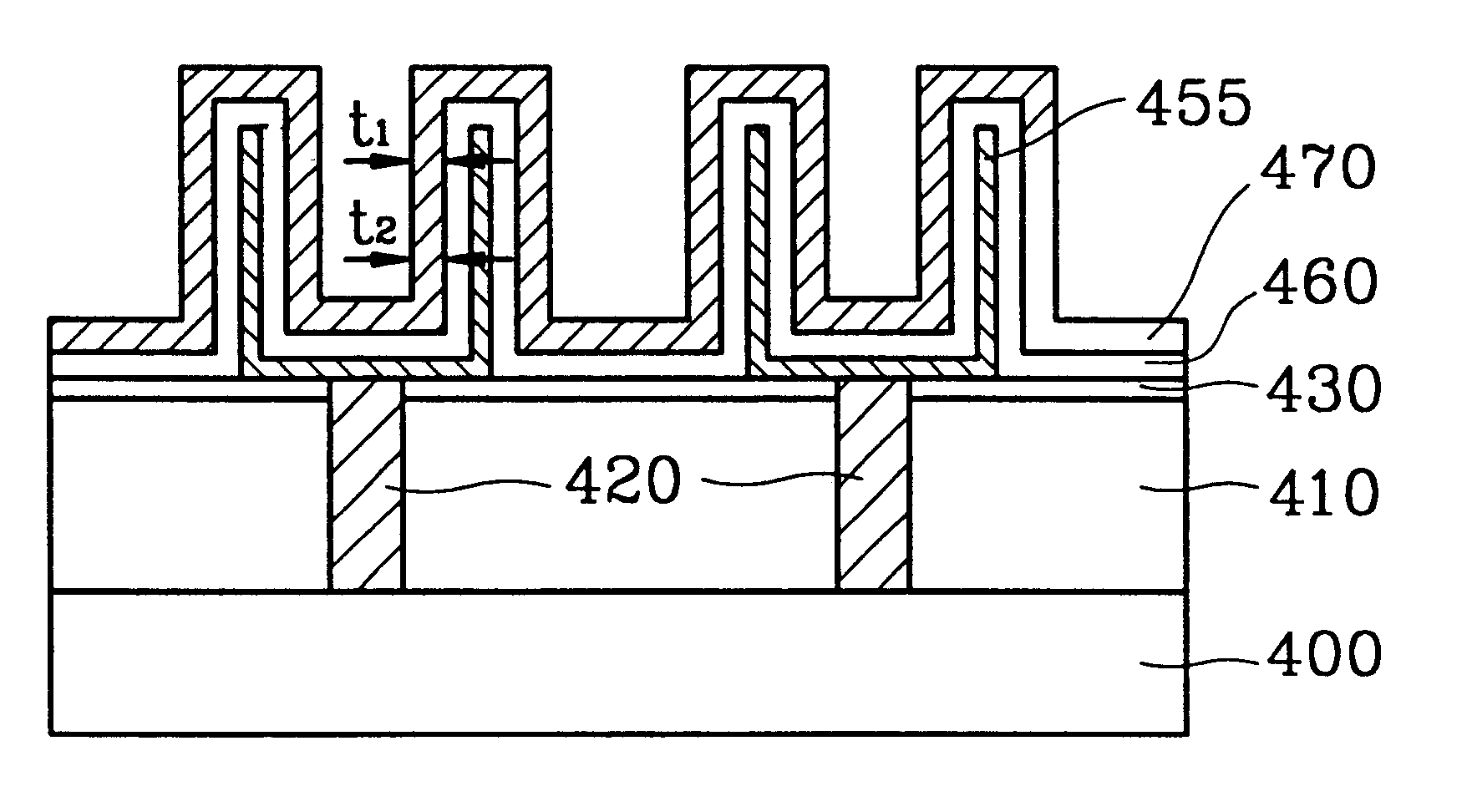

Methods for selectively forming a silicon nitride film on a substrate and related semiconductor device structures

ActiveUS20180323055A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDielectric surfaceNitrogen source

A method for selectively forming a silicon nitride film on a substrate comprising a first metallic surface and a second dielectric surface by a cyclical deposition process is disclosed. The method may comprise contacting the substrate with a first reactant comprising a silicon halide source and contacting the substrate with a second reactant comprising a nitrogen source, wherein the incubation period for the first metallic surface is less than the incubation period for the second dielectric surface. Semiconductor device structures comprising a selective silicon nitride film are also disclosed.

Owner:ASM IP HLDG BV

Methods for forming a silicon nitride film on a substrate and related semiconductor device structures

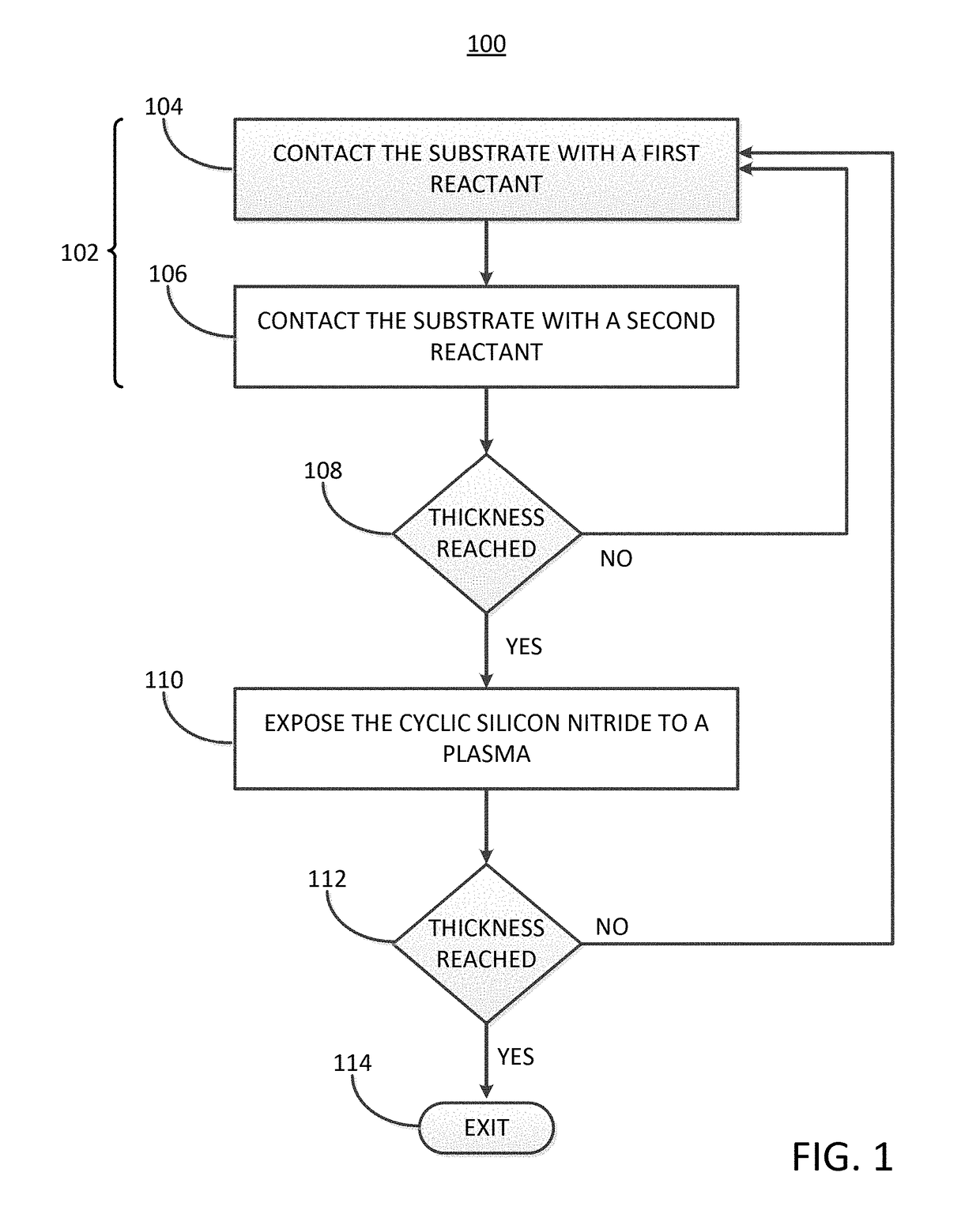

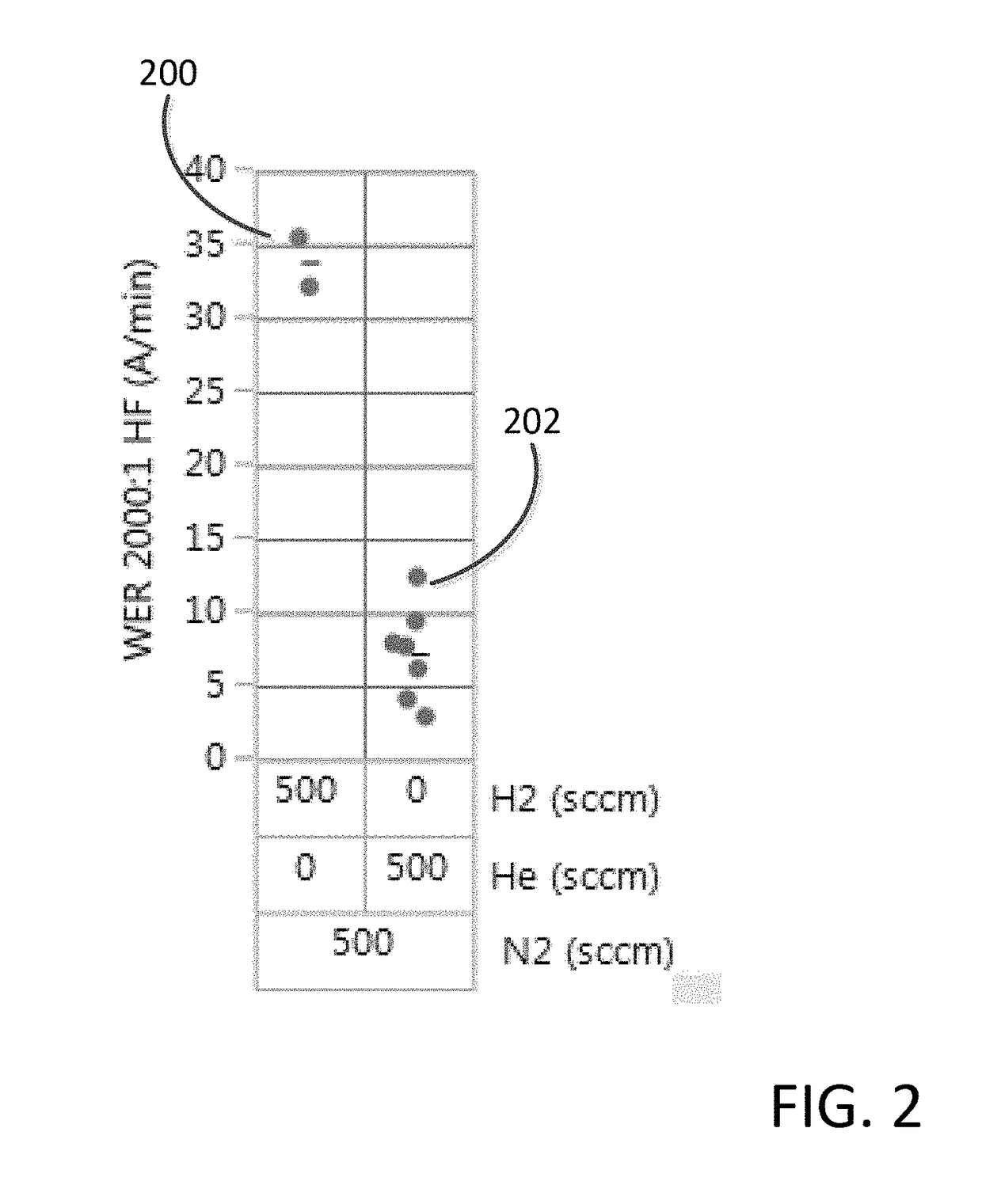

ActiveUS20180323056A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceDeposition process

A method for forming a silicon nitride film on a substrate is disclosed. The method may include; forming a cyclical silicon nitride film on the substrate by a cyclical deposition process, wherein the cyclical deposition process comprises at least one of; contacting the substrate with a first reactant comprising a silicon halide source and contacting the substrate with a second reactant comprising a nitrogen source. The method may also include exposing the cyclical silicon nitride film to a plasma. Semiconductor device structures comprising a silicon nitride film are also disclosed.

Owner:ASM IP HLDG BV

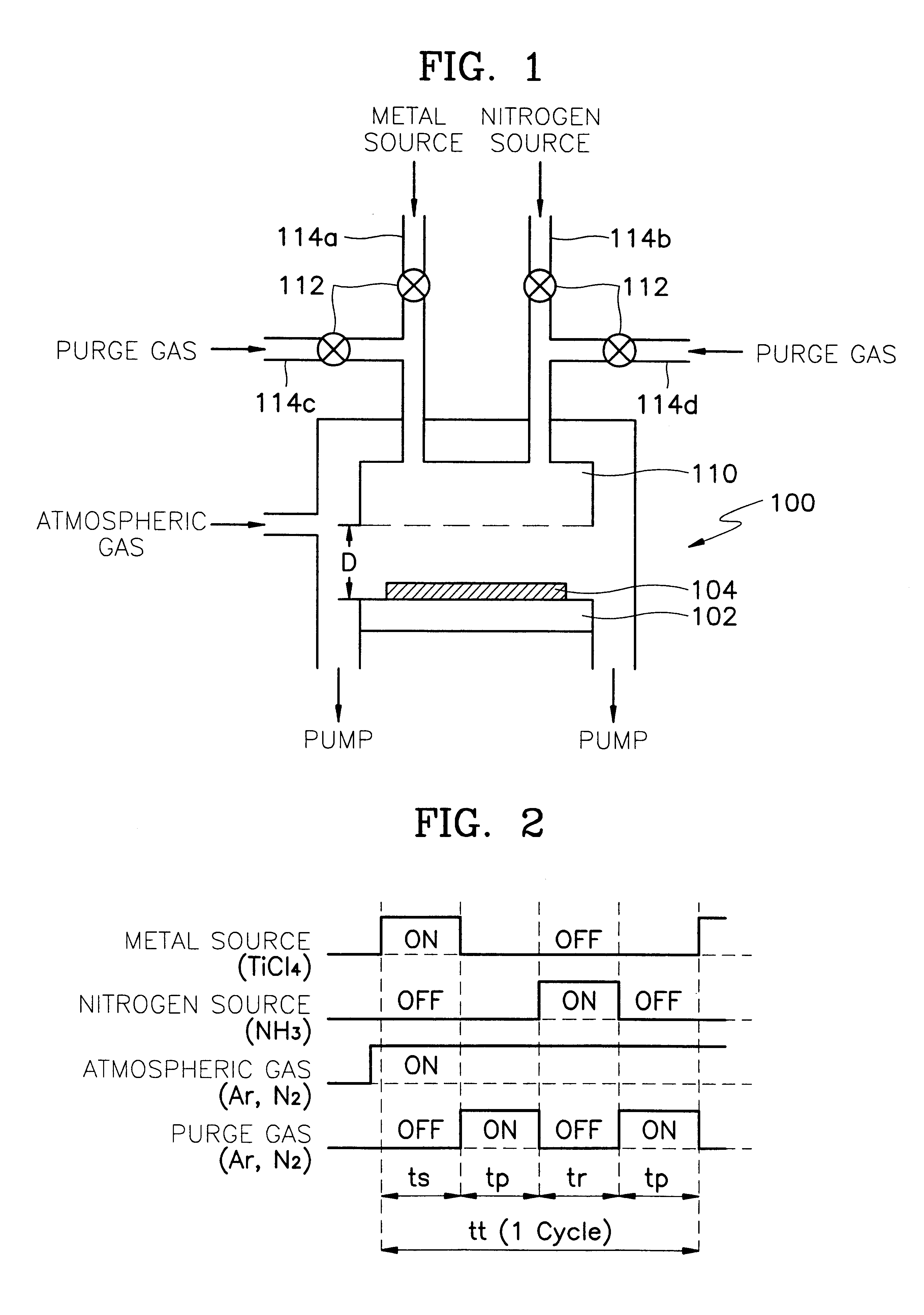

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS6348376B2Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsDevice materialNitrogen source

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

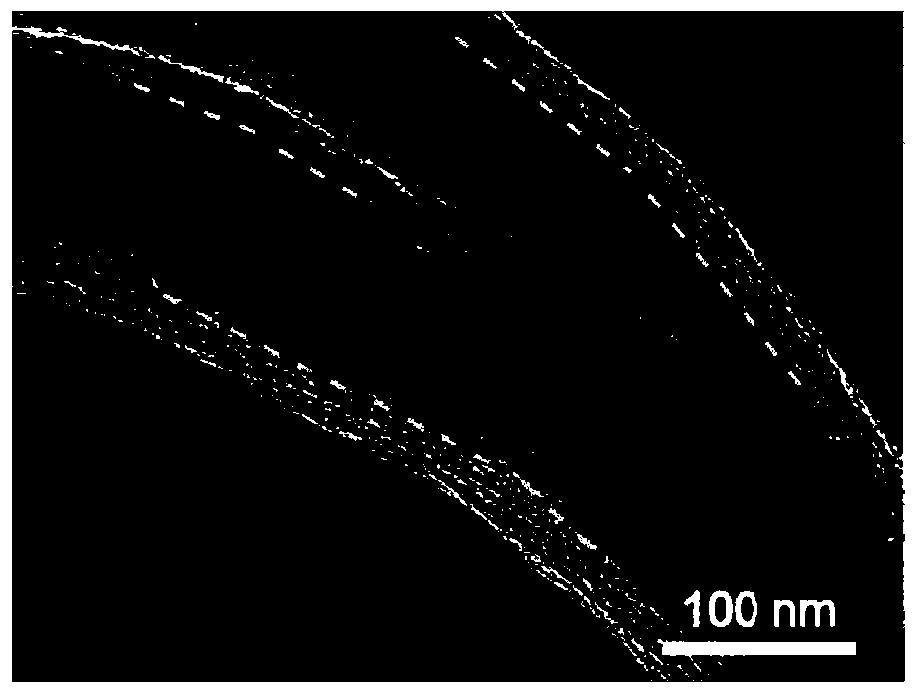

Nitride nanowires and method of producing such

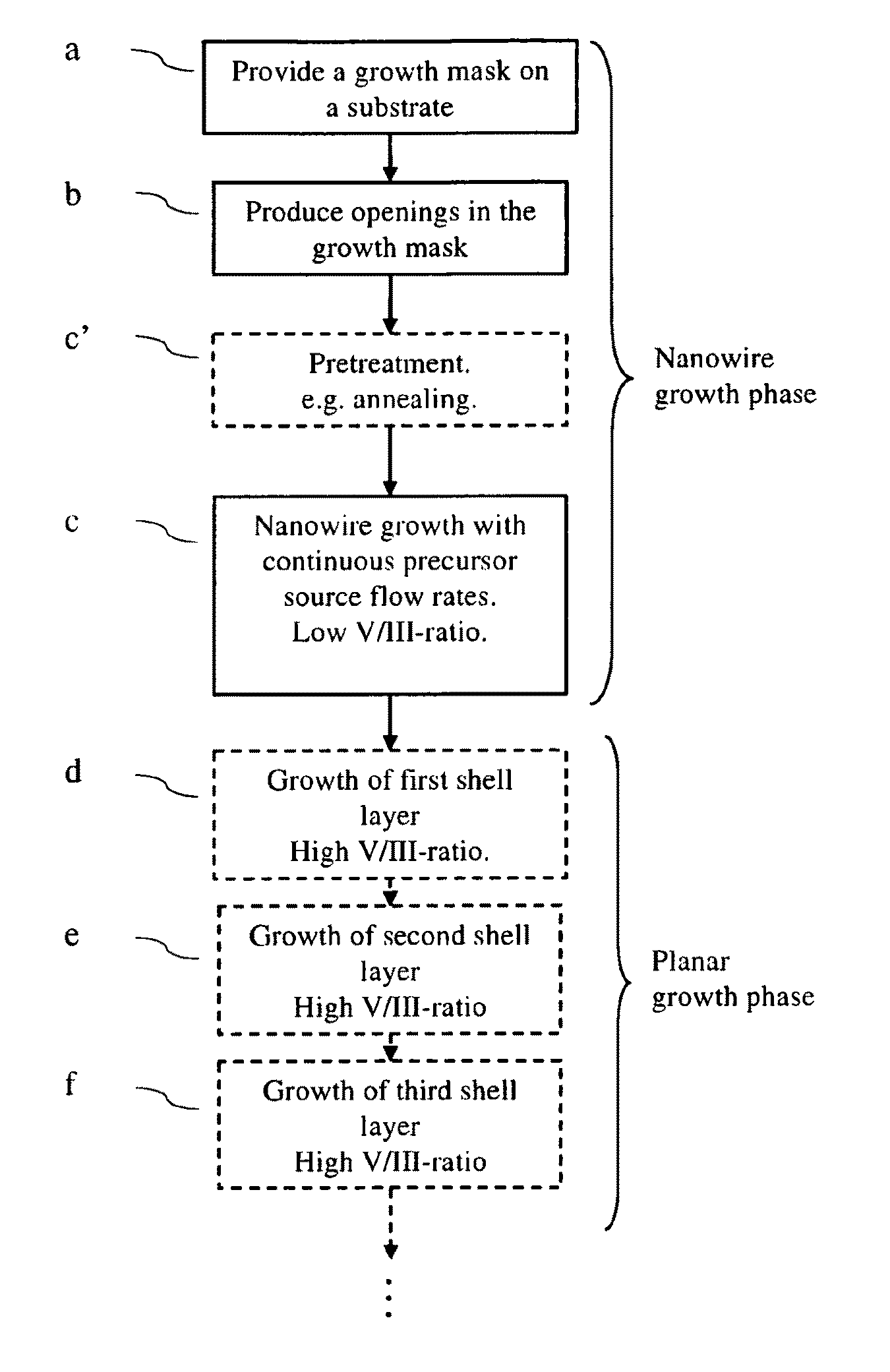

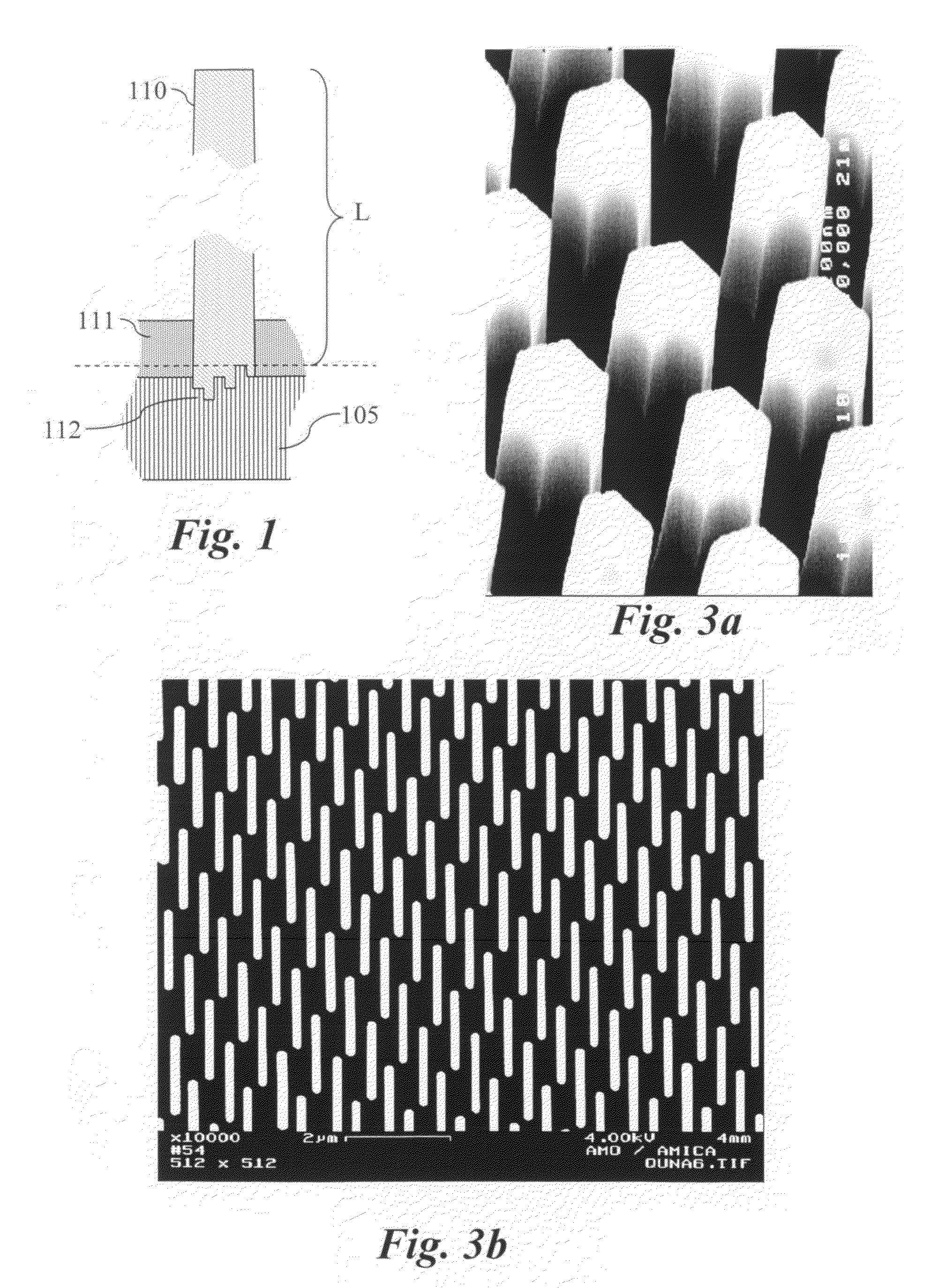

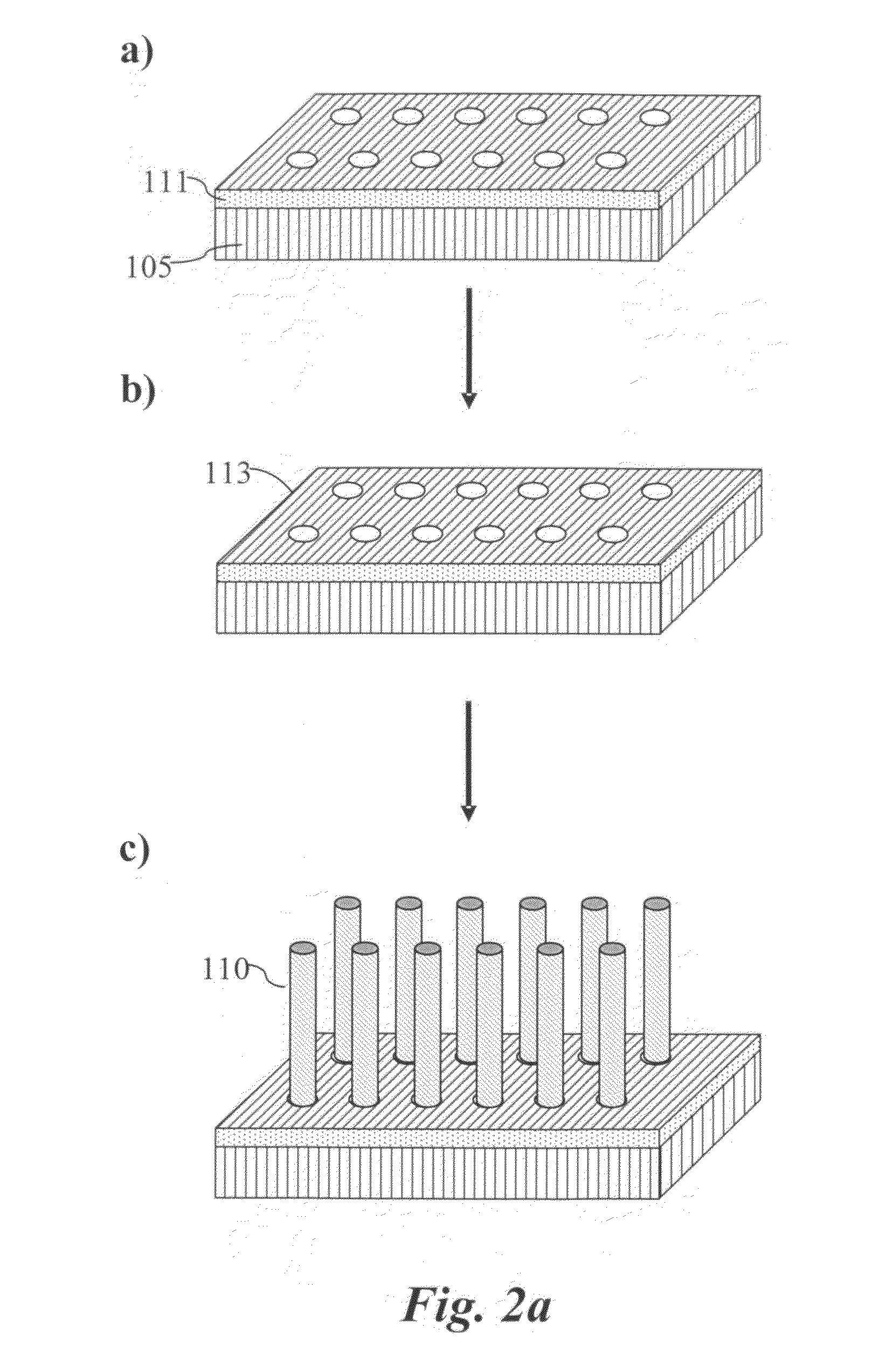

ActiveUS7829443B2Low fraction of defect nanowiresIncrease probabilityPolycrystalline material growthIndividual molecule manipulationNanowireNitrogen source

The present invention relates to the growing of nitride semiconductors, applicable for a multitude of semiconductor devices such as diodes, LEDs and transistors. According to the method of the invention nitride semiconductor nanowires are grown utilizing a CVD based selective area growth technique. A nitrogen source and a metal-organic source are present during the nanowire growth step and at least the nitrogen source flow rate is continuous during the nanowire growth step. The V / III-ratio utilized in the inventive method is significantly lower than the V / III-ratios commonly associated with the growth of nitride based semiconductor.

Owner:QUNANO

III-V Nitride homoepitaxial material of improved MOVPE epitaxial quality (surface texture and defect density) formed on free-standing (Al,In,Ga)N substrates, and opto-electronic and electronic devices comprising same

InactiveUS20030213964A1Improve material qualityReduce dislocation densityPolycrystalline material growthAfter-treatment detailsCelsius DegreeSource material

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer of improved epitaxial quality deposited on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 10<5>, nitrogen source material partial pressure in a range of from about 1 to about 10<3 >torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 10<2 >microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

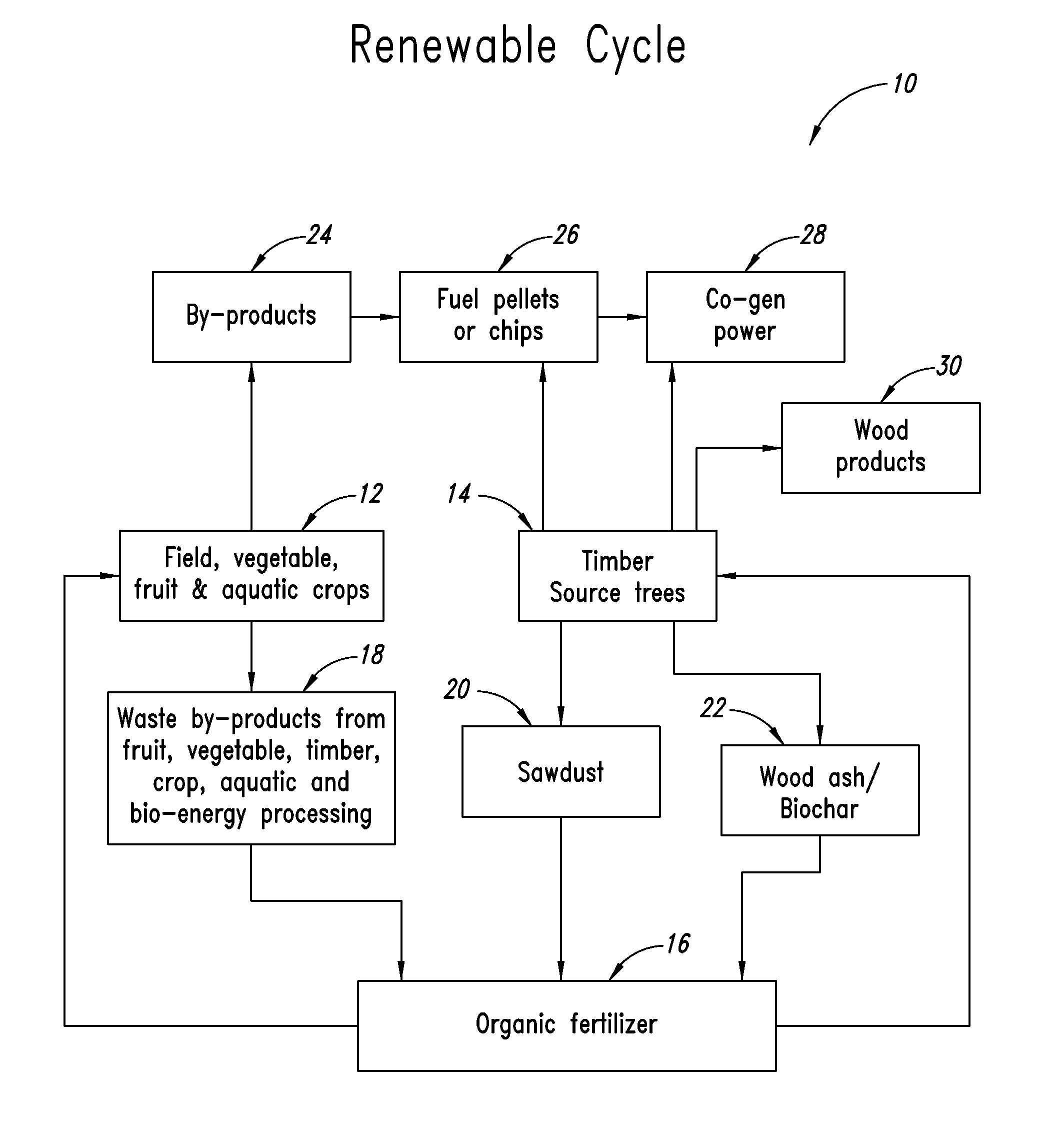

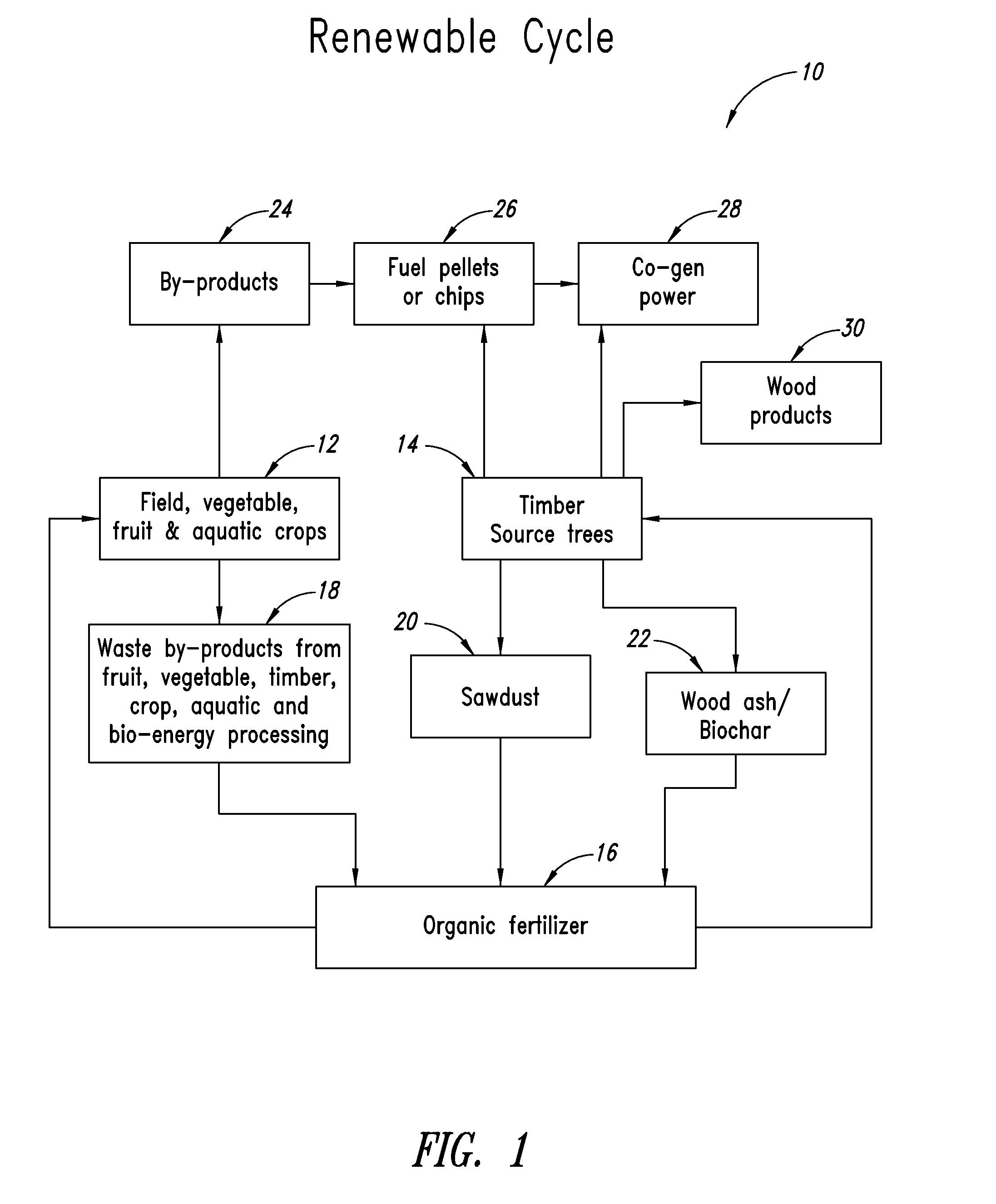

Organic soil treatment compound and method of making and using

InactiveUS20110023566A1Promote plant growthImprove scalabilityClimate change adaptationBioloigcal waste fertilisersParticulatesSoil treatment

A composition is provided that includes particulates from wood, chaff, hulls, crop compost, biochar, or waste residue, wood or crop ash and biochar, and a nitrogen source from waste residue from gasification processes, food processing waste water or other residual by-products of forest, aquatic, food or feed processing. Ideally, all of the components are environmentally friendly, from natural products, and free of manufactured chemicals.

Owner:ECOTRAC ORGANICS

Atomic layer deposition methods

InactiveUS7077902B2Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrogen sourceNitride

An aluminum-containing material deposition method includes depositing a first precursor on a substrate in the substantial absence of a second precursor. The first precursor can contain a chelate of Al(NR1R2)x(NR3(CH2)zNR4R5)y or Al(NR1R2)x(NR3(CH2)zOR4)y; where x is 0, 1, or 2; y is 3−x; z is an integer 2 to 8; and R1 to R5 are independently selected from among hydrocarbyl groups containing 1 to 10 carbon atoms with silicon optionally substituted for one or more carbon atoms. The method includes depositing the second precursor on the first deposited precursor, the second precursor containing a nitrogen source or an oxidant. A deposition product of the first and second precursors includes at least one of an aluminum nitride or an aluminum oxide. The deposition method can be atomic layer deposition where the first and second precursors are chemisorbed or reacted as monolayers. The first precursor can further be non-pyrophoric.

Owner:MICRON TECH INC

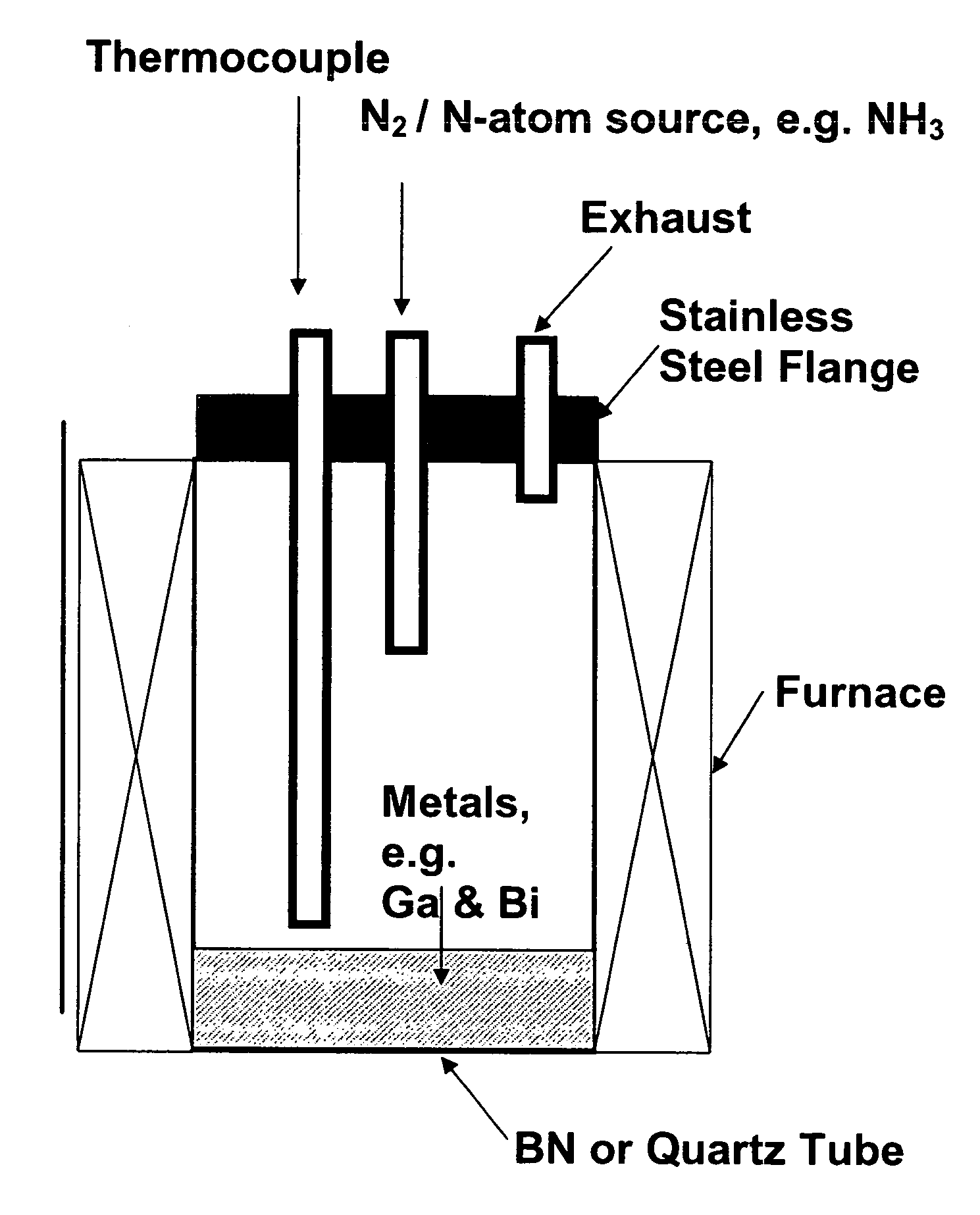

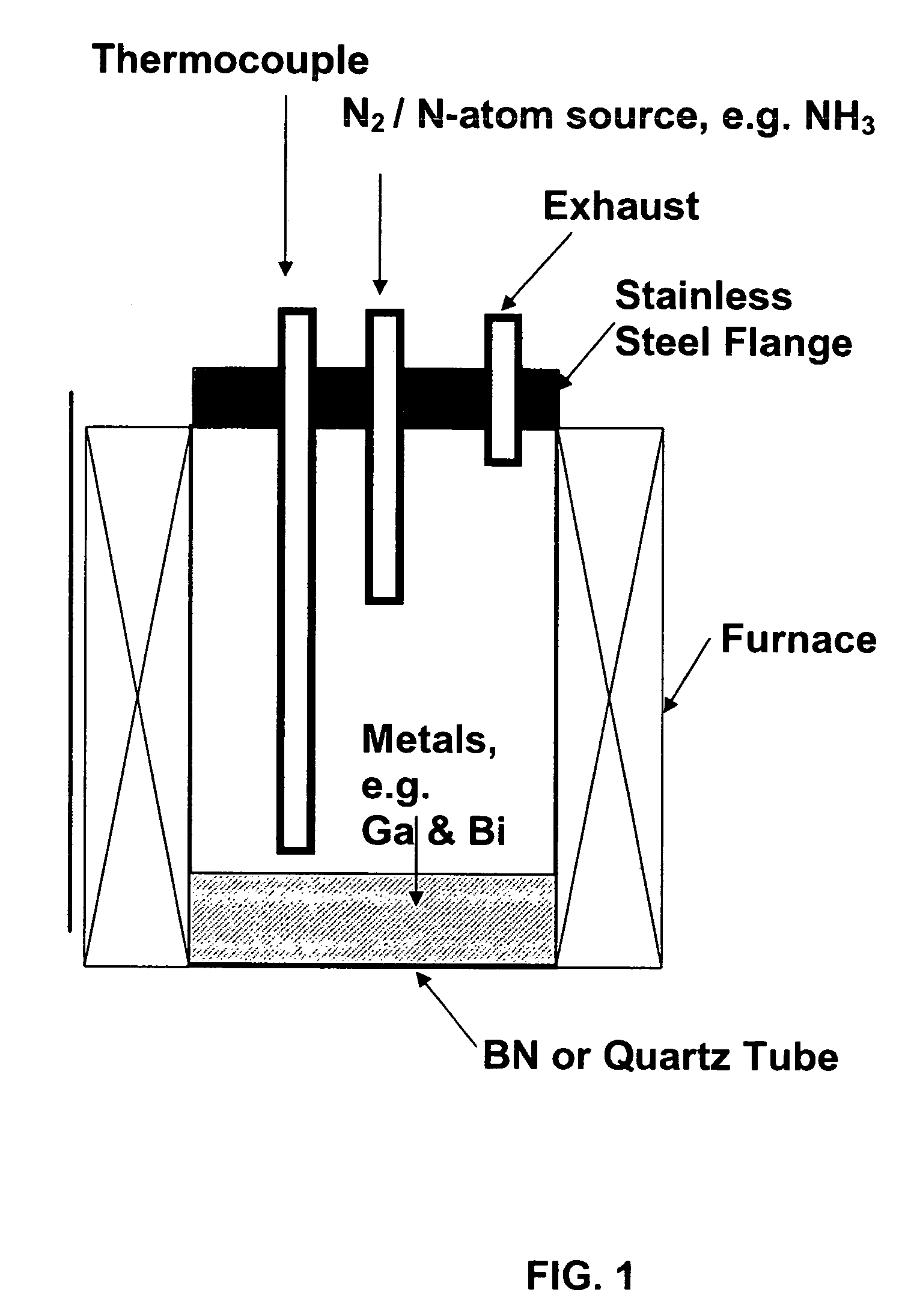

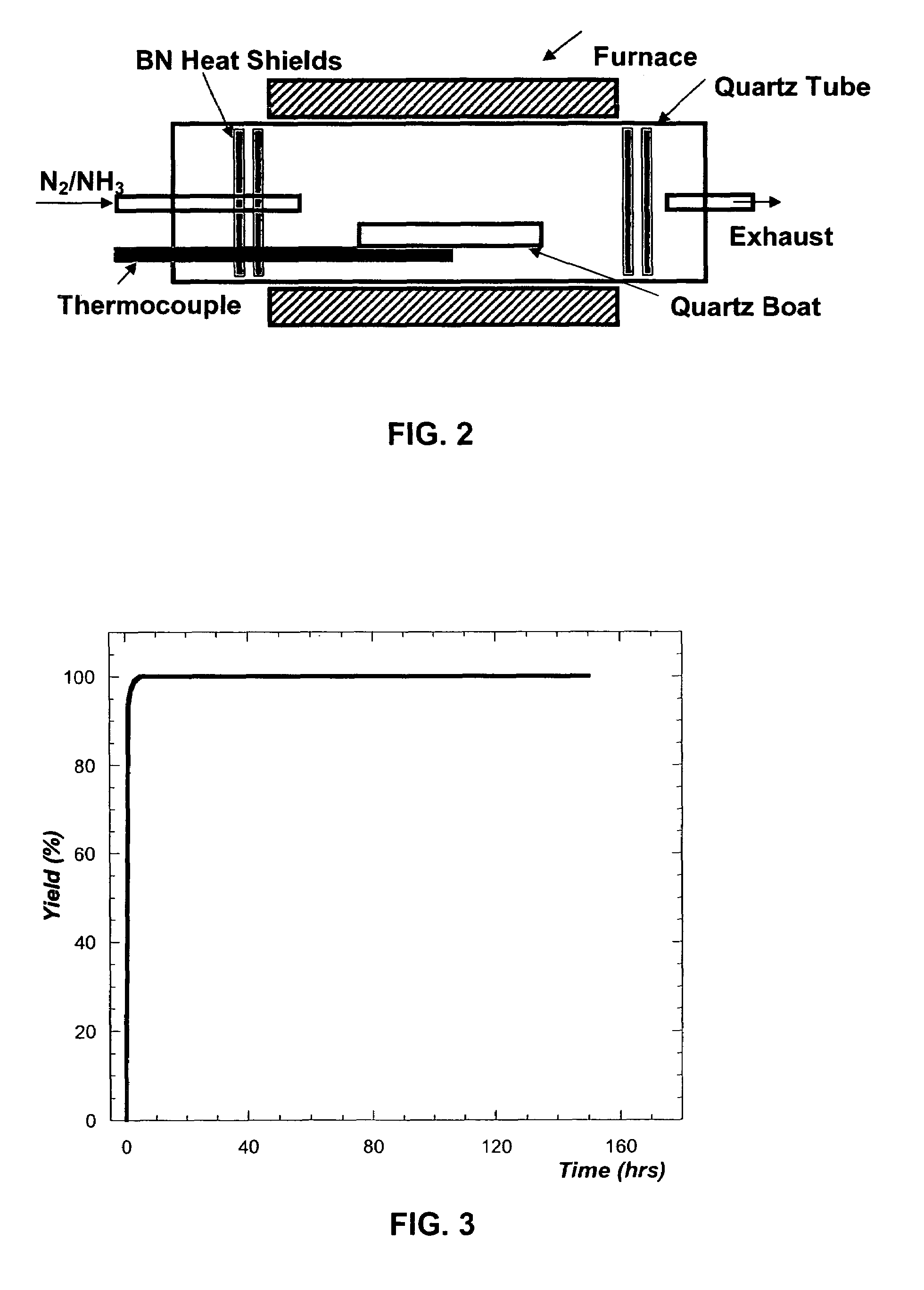

Method of making Group III nitrides

InactiveUS7381391B2High purityShort reaction timePolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsOptical propertyGlow Discharge Mass Spectrometry

The present invention provides compositions and a novel high-yielding process for preparing high purity Group III nitrides. The process involves heating a Group III metal and a catalytic amount of a metal wetting agent in the presence of a nitrogen source. Group III metals can be stoichiometrically converted into high purity Group III nitride powders in a short period of time. The process can provide multi-gram quantities of high purity Group III nitrides in relatively short reaction times. Detailed characterizations of GaN powder were preformed and are reported herein, including morphology and structure by SEM and XRD, optical properties by cathodoluminescence (CL), and Raman spectra to determine the quality of the GaN particles. The purity of GaN powder was found to be greater than 99.9% pure, as analyzed by Glow Discharge Mass Spectrometry (GDMS). Green, yellow, and red light emission can be obtained from doped GaN powders.

Owner:CORNELL RES FOUNDATION INC

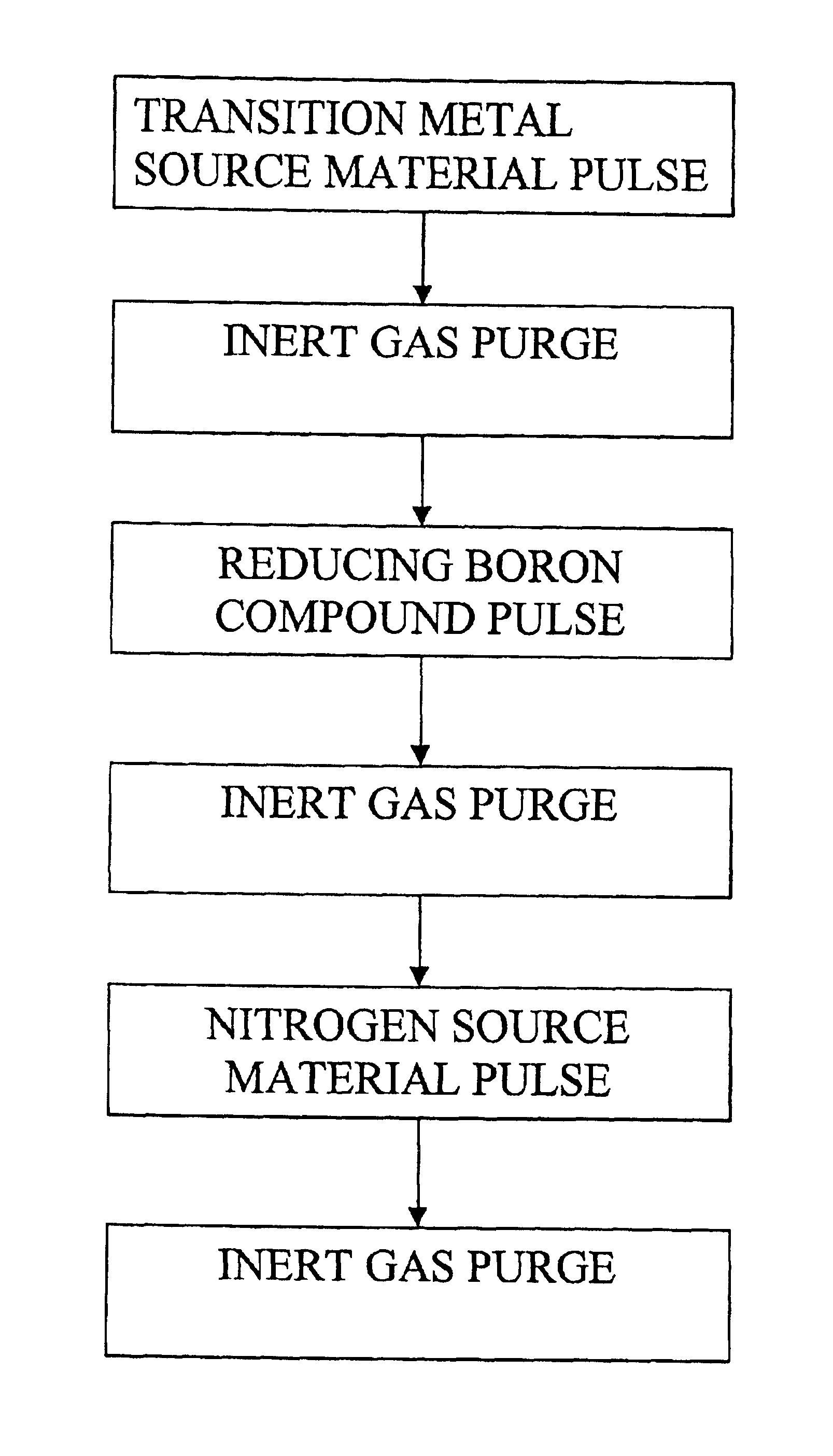

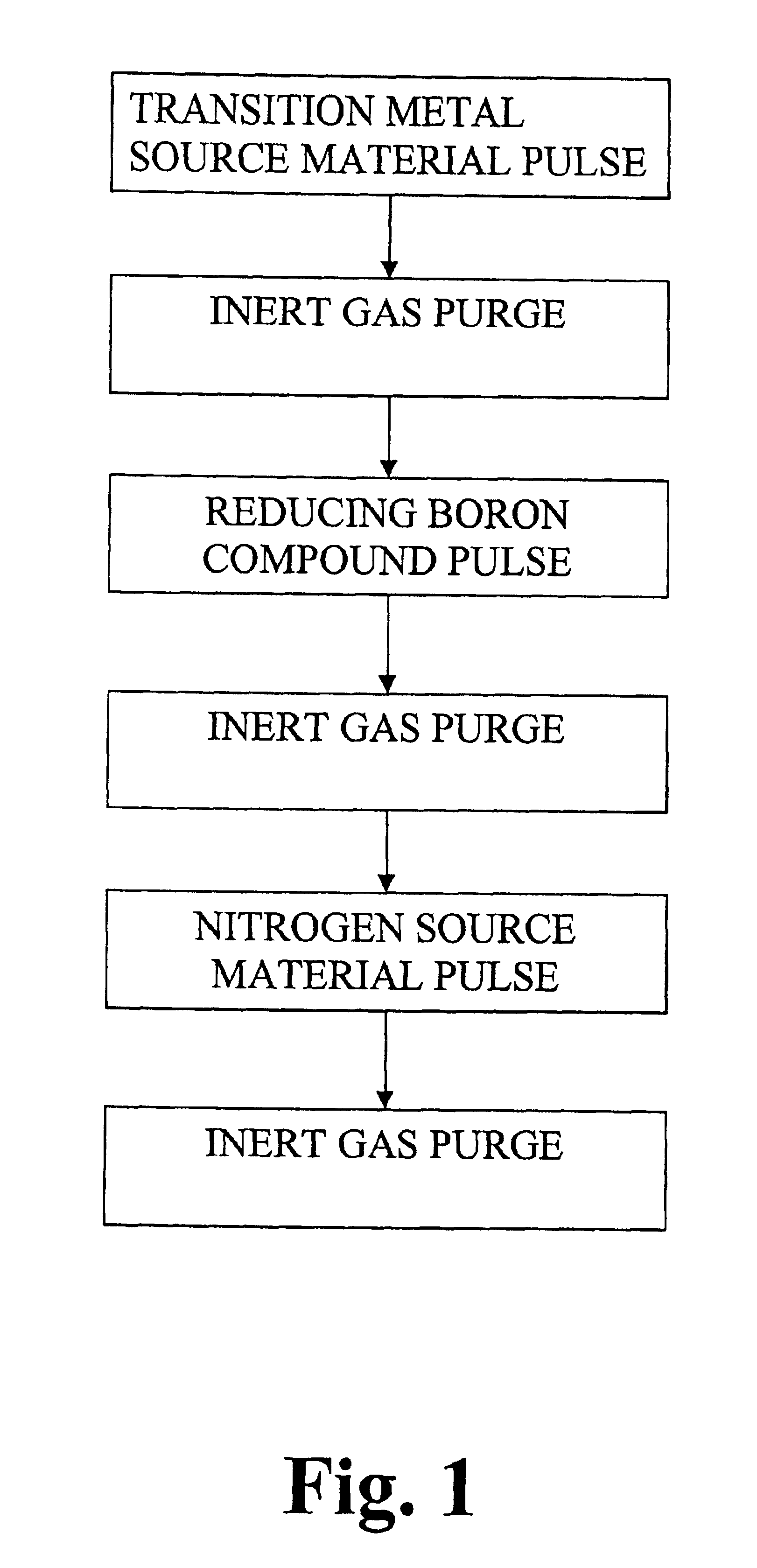

Method of depositing transition metal nitride thin films

InactiveUS6863727B1Low resistivityEasy to disassemblePolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseSource material

This invention concerns a method for depositing transition metal nitride thin films by an Atomic Layer Deposition (ALD) type process. According to the method vapor-phase pulse of a source material, a reducing agent capable of reducing metal source material, and a nitrogen source material capable of reacting with the reduced metal source material are alternately and sequentially fed into a reaction space and contacted with the substrate. According to the invention as the reducing agent is used a boron compound which is capable of forming gaseous reaction byproducts when reacting with the metal source material.

Owner:ASM INTERNATIONAL

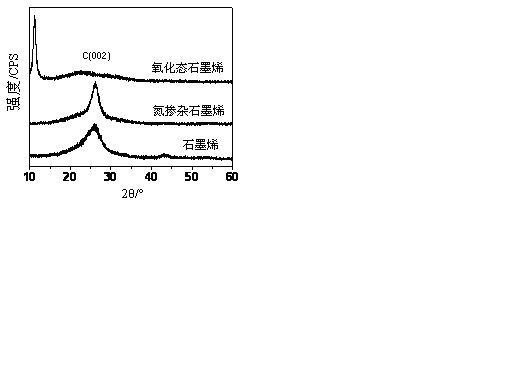

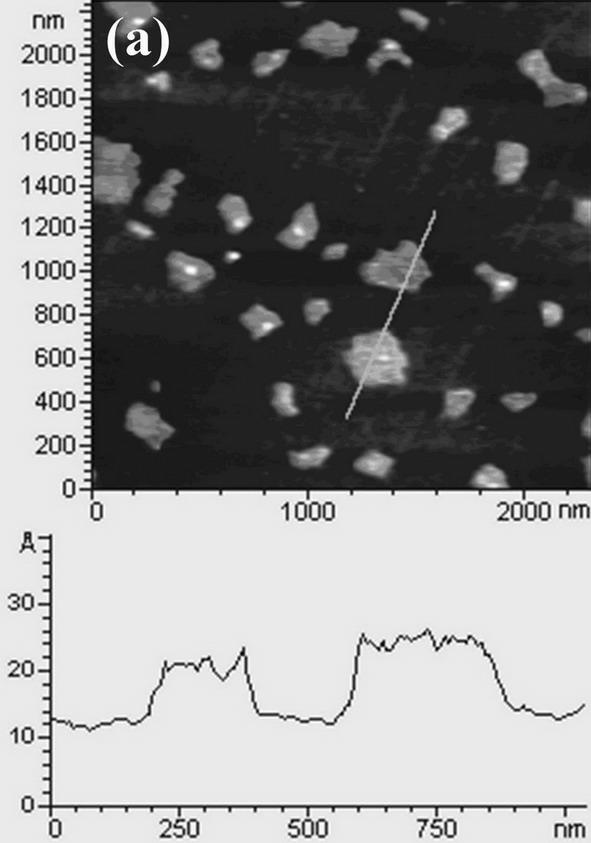

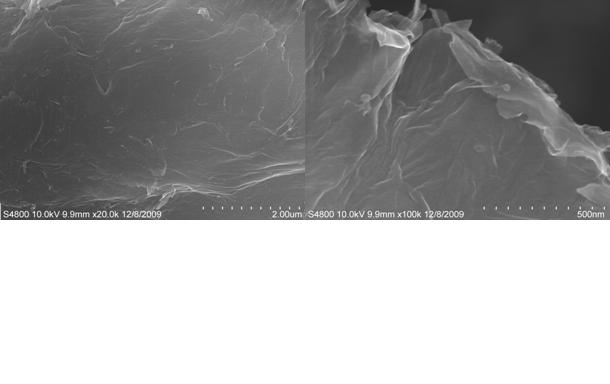

Method for preparing nitrogen-doped graphene

The invention relates to a method for preparing nitrogen-doped graphene, in particular to a novel simple, convenient and scale method for preparing nitrogen-doped graphene at high temperature under the protection of inert gas by taking melamine as a nitrogen source. In the method, graphene oxide and the melamine are taken as raw materials, wherein the melamine is taken as the nitrogen source and the graphene oxide is taken as a carbon source; high temperature annealing is carried out in the atmosphere of inert gas, and the reduction of the graphene oxide and the nitrogen doping of graphene are realized; and by controlling reaction conditions such as temperature, time, the ratio of the raw materials and the like, graphene products with different nitrogen doping ratios can be prepared. The preparation method is simple and practicable; catalysts are not needed; the reaction process is easy to control; special requirements on equipment do not exist; the cost is low; and the method is easy to promote and use.

Owner:NANJING UNIV

Nitrogen, phosphorus and sulphur doping or co-doping carbon dot and batch controllable preparing method and application thereof

InactiveCN104987863ASimple processShort synthesis timeNanoopticsFluorescence/phosphorescenceAir atmosphereSilica gel

The invention provides a nitrogen, phosphorus and sulphur doping or co-doping carbon dot and a batch controllable preparing method and application thereof. The method comprises the steps that a carbon source, a nitrogen source, a phosphorus source and a sulphur source are evenly mixed, and a mixture is obtained, wherein the molar ratio of C to N to P to S in the mixture is 1 to 0-0.8 to 0-0.4 to 0-0.4, and the contents of N, P and S are prevented from being zero at the same time; in the air, the mixture is heated to be fused, the reaction is carried out for 3 min to 60 min, natural cooling is carried out till the indoor temperature is reached, a reaction product is separated by a silicagel column, raw materials which do not react are removed, and the nitrogen, phosphorus and sulphur doping or co-doping carbon dot is obtained. According to the method, the technology is simple, the compound time is short, batch producing can be achieved, the doping amount can be adjusted and controlled accurately, the fluorescence color of the prepared carbon dot ranges from blue to green, the application can be achieved on bioluminescence marking and cell imaging aspects, and the good economic benefit and the application prospect are achieved.

Owner:XI AN JIAOTONG UNIV

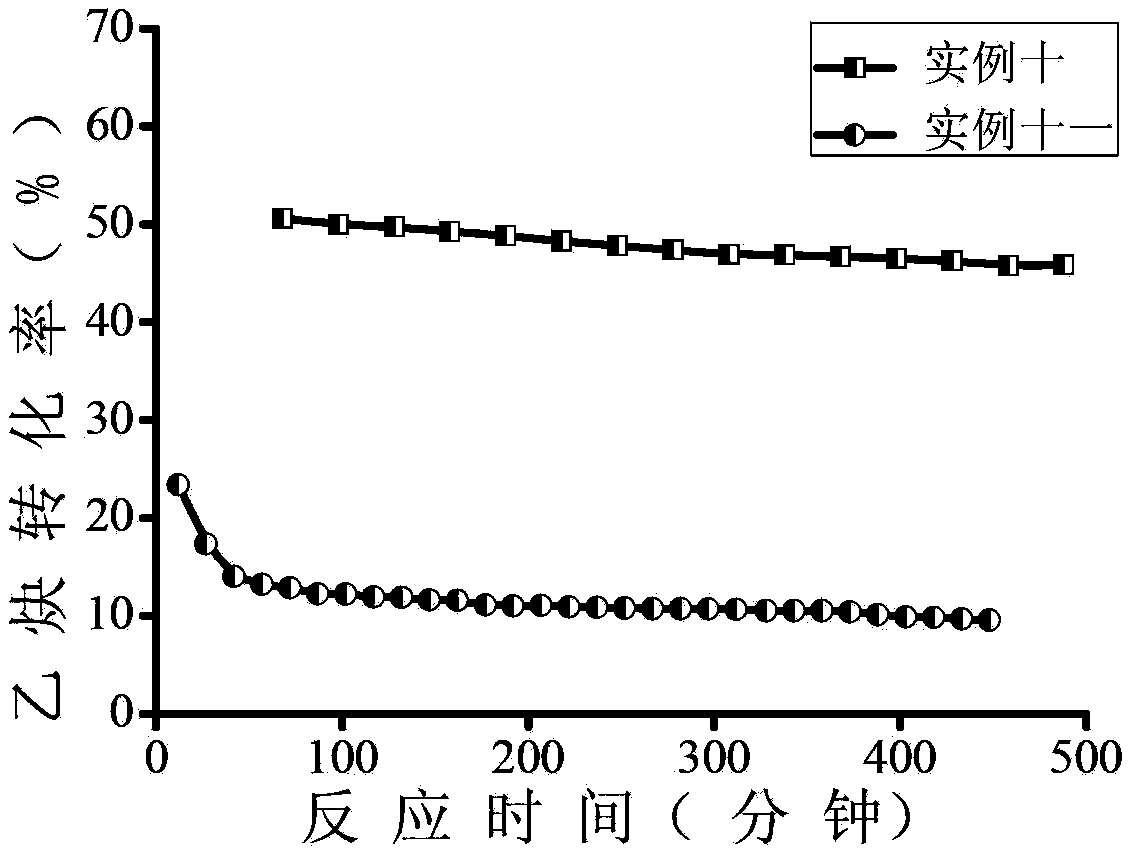

Preparing method for nitrogen-doped porous carbon material, catalyst comprising material and application of material

ActiveCN104689857AGood dispersionHigh bonding strengthCatalyst carriersOrganic compound preparationDispersityIn situ doping

The invention relates to a novel preparing method for an in-situ nitrogen-doped porous carbon material, the application of the in-situ nitrogen-doped porous carbon material serving as a carrier of a load type catalyst, the load type catalyst comprising the in-situ nitrogen-doped porous carbon material, and the application of the load type catalyst in the water phase alcohol condensation reaction. Cheap micromolecule nitrogen substances serve as a nitrogen source of the in-situ nitrogen-doped porous carbon material, nitrogen atom in-situ doping is achieved in the carbon material preparing process, the doping content of the in-situ nitrogen-doped porous carbon material is controllable, the in-situ nitrogen-doped porous carbon material is distributed evenly, the dispersity of metal in the carrier and the combining strength with the carrier can be improved through doping of nitrogen atoms, and therefore the catalytic activity of the nitrogen-doped porous carbon material can be improved, and the service life of the nitrogen-doped porous carbon material can be prolonged.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Novel edible fungus culture medium and preparation method thereof

InactiveCN102617240APrevent evaporationImprove breathabilityFertilizer mixturesCelluloseAdditive ingredient

The invention discloses a novel edible fungus culture medium and a preparation method thereof. The novel edible fungus culture medium comprises 70-85% of main material, 15-20% of auxiliary material, 3-5% of additive material and 0.1-0.8% of absorbent resin, wherein the main material comprises sawdust, straws, corncobs, and cottonseed hull; the auxiliary material comprises bran, rice bran and maize meal; and the additive material comprises land plaster, slaked lime, calcium superphosphate, white sugar and urea. The preparation method disclosed by the invention comprises the following steps of: reasonably selecting raw materials in the ratio of nutrient ingredients according to the nutritional requirements of different kinds of edible fungi to prepare the culture medium, and adding the absorbent resin synthesized by the biological materials. The permeability and the water retaining capacity of the culture medium are greatly enhanced, and the accumulation of the various nutrient elements and the slow releasing capacity to the nutrient elements are enhanced; meanwhile, the properties of the cellulose and the protein of the absorbent resin provide the nutrition in the aspect of carbon source or nitrogen source so as to ensure the sufficient supplement of the required raw materials of the fungi; and by adopting the novel edible fungus culture medium disclosed by the invention, the output of a single bag is enhanced by 25%-35%, and the fungus output time is advanced by 4-6 days.

Owner:SUIHUA UNIV

Nitrogen doped carbon material loaded catalyst

InactiveCN103381369AGood dispersionImprove adsorption capacityCatalyst carriersPreparation by halogen halide additionPotassiumNitrogen source

Belonging to the technical field of catalysts, the invention discloses a nitrogen doped carbon material loaded catalyst. The carbon material can realize nitrogen doping by means of nitrogen containing precursor chemical coupling and other surface modification methods, also a nitrogen source and a carbon source can be introduced simultaneously at high temperature for in situ synthesis of a nitrogen doped carbon material, and then a simple substance or compound of one or more of gold, copper, manganese, potassium or bismuth can be loaded on the nitrogen doped carbon material. The nitrogen doped carbon material loaded mercury-free catalyst involved in the invention has activity and stability obviously superior to those of ordinary carbon material loaded catalysts. Under certain reaction conditions, the activity of the nitrogen doped carbon material loaded catalyst is superior to that of ordinary carbon material loaded catalysts by over 10%. The carbon material and the catalyst disclosed in the invention are green and non-toxic, and have good environmental benefits. The process involved in the invention is simple, economical and feasible.

Owner:TSINGHUA UNIV +1

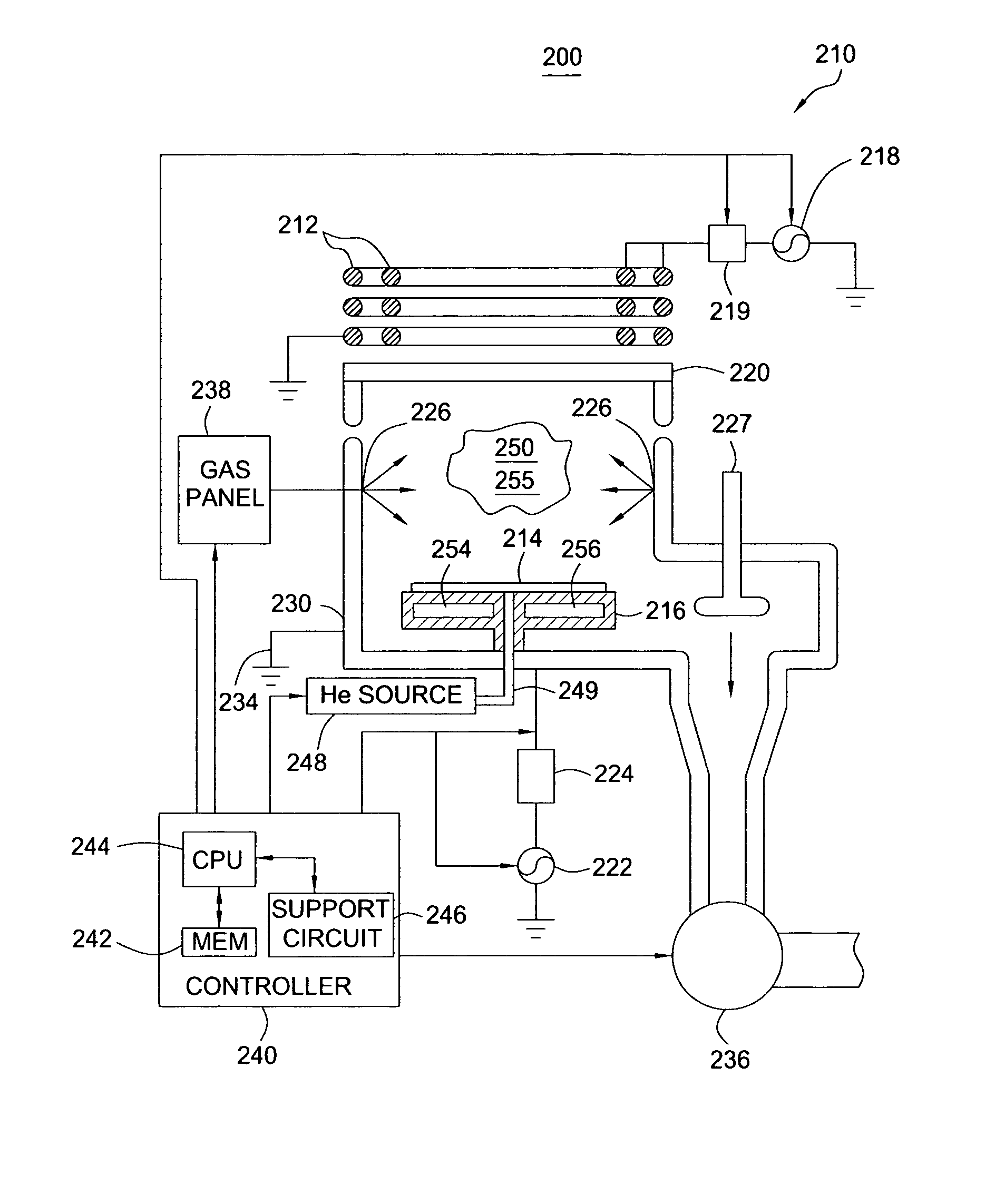

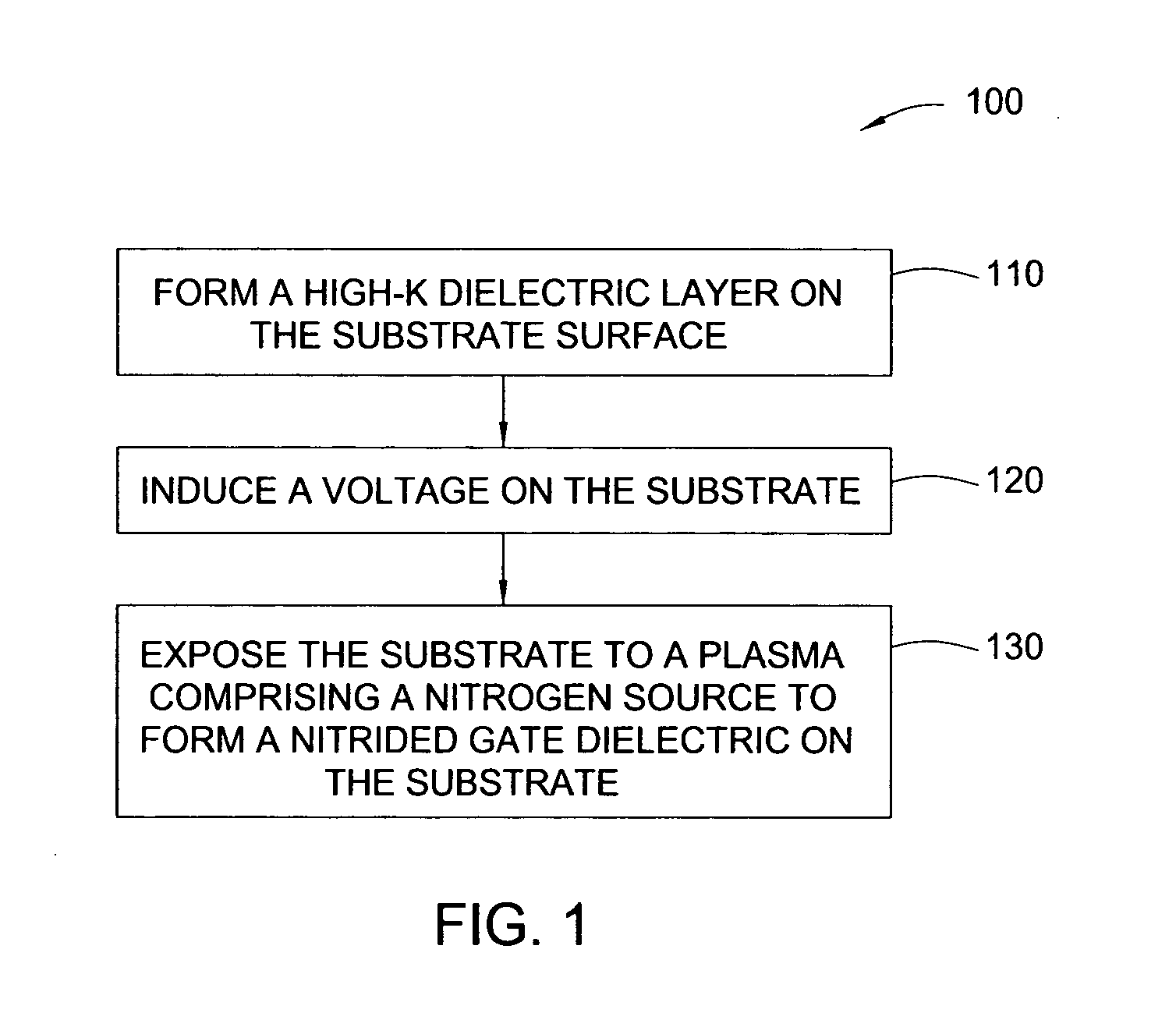

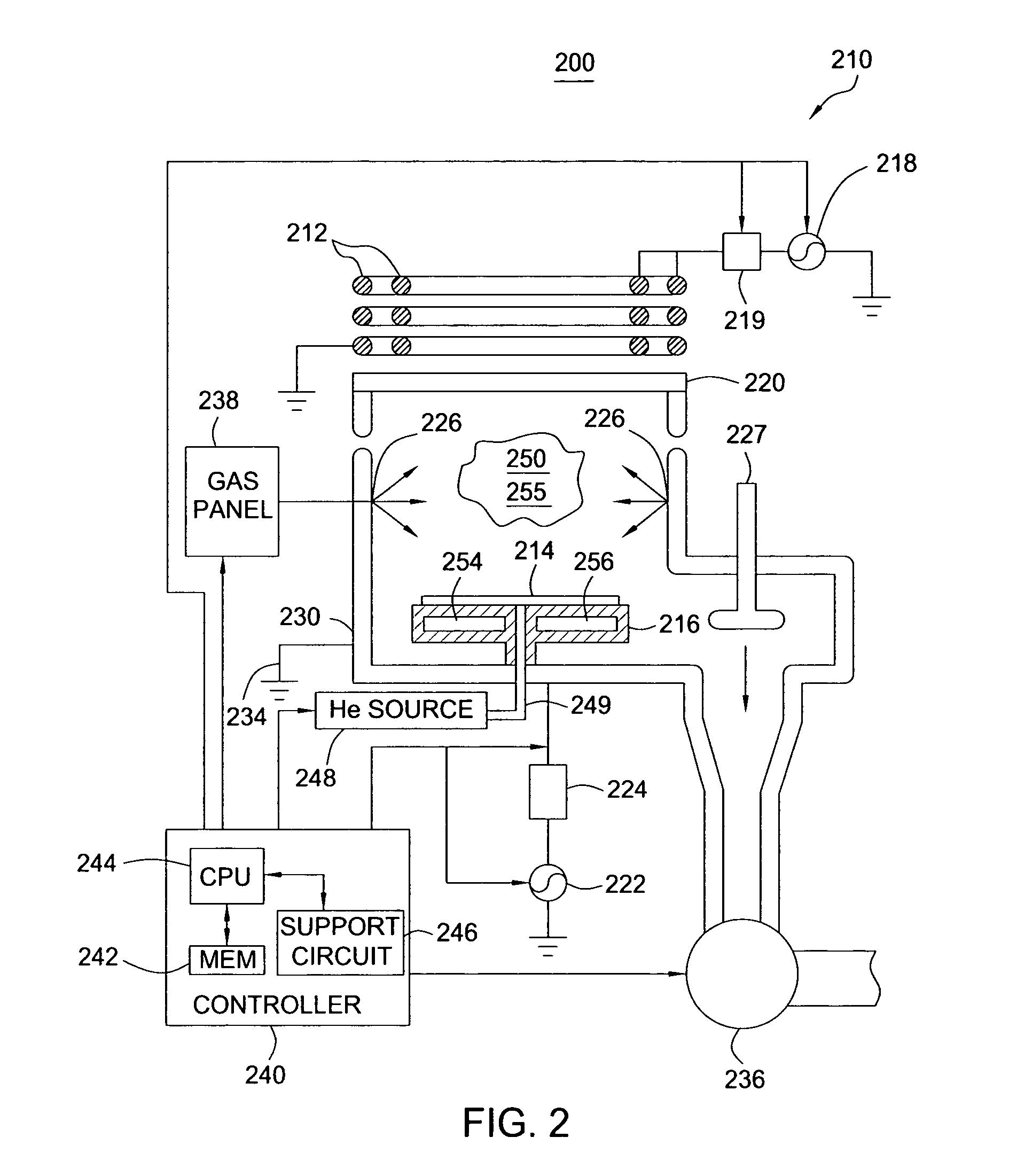

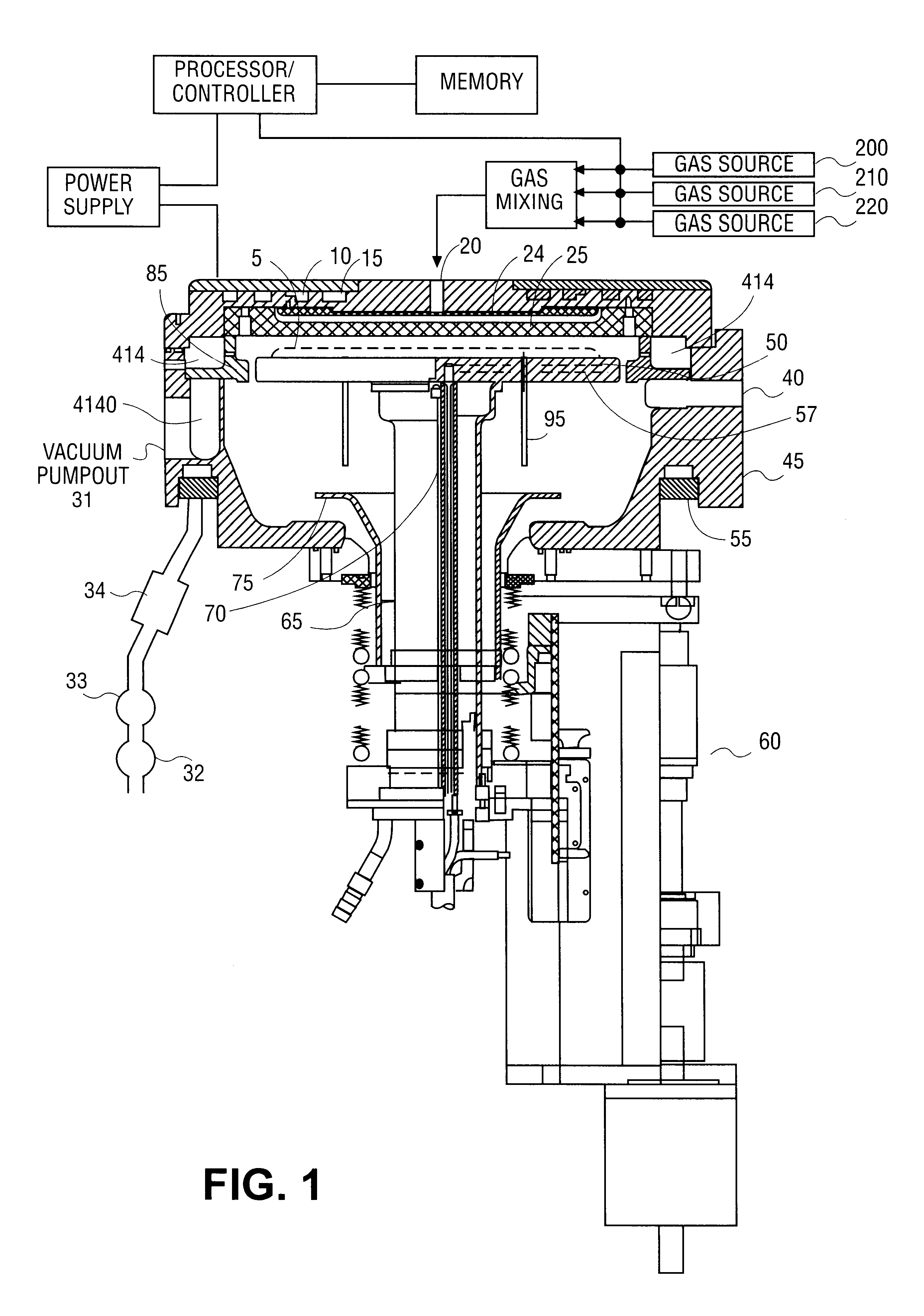

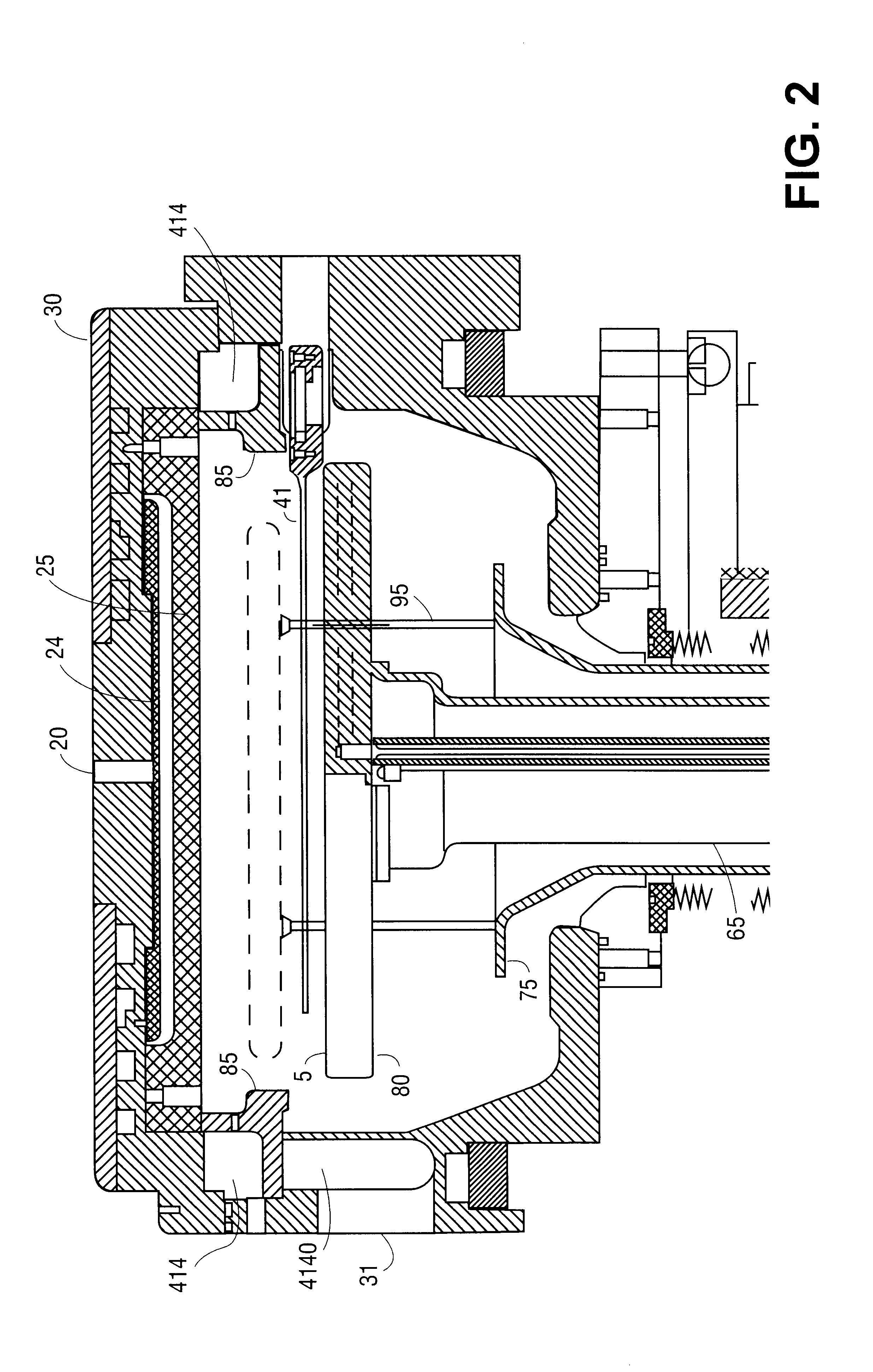

Nitrogen profile engineering in HI-K nitridation for device performance enhancement and reliability improvement

InactiveUS20070049043A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricPerformance enhancement

A method and apparatus for forming a nitrided gate dielectric. The method comprises incorporating nitrogen into a dielectric film using a plasma nitridation process to form a nitrided gate dielectric. The first step involves providing a substrate comprising a gate dielectric film. The second step involves inducing a voltage on the substrate. Finally, the substrate is exposed to a plasma comprising a nitrogen source while maintaining the voltage to form a nitrided gate dielectric on the substrate. In one embodiment, the voltage is induced on the substrate by applying a voltage to an electrostatic chuck supporting the substrate. In another embodiment, the voltage is induced on the substrate by applying a DC bias voltage to an electrode positioned adjacent the substrate.

Owner:APPLIED MATERIALS INC

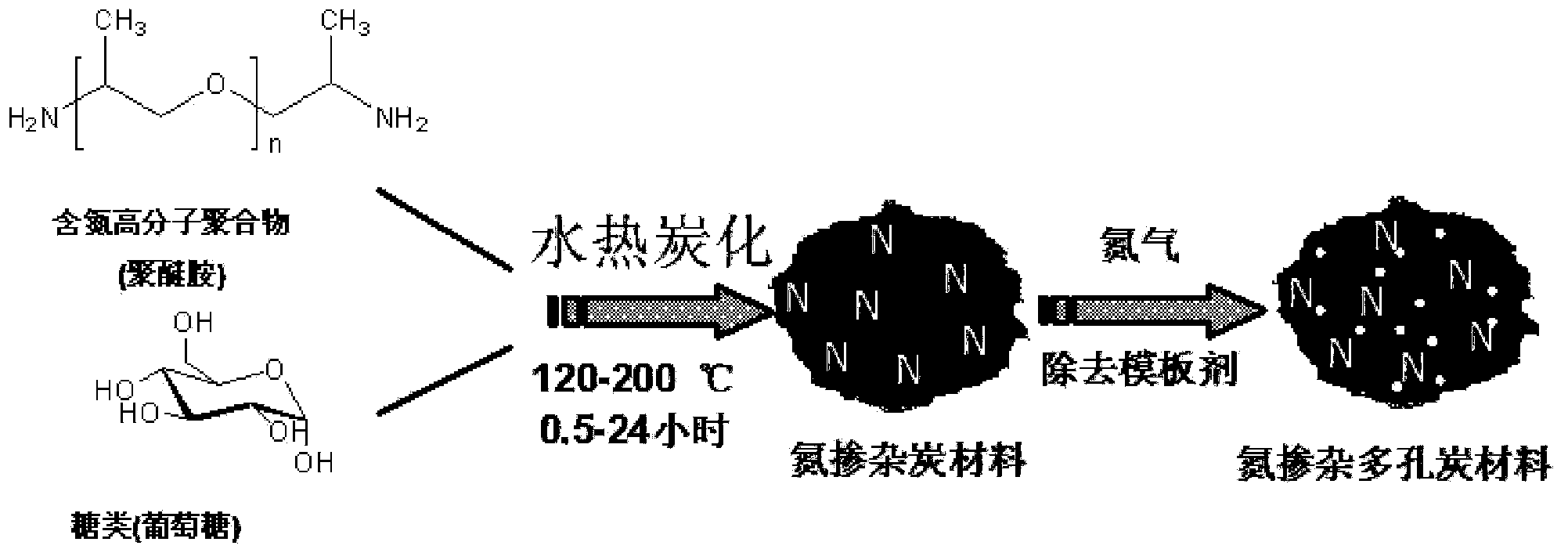

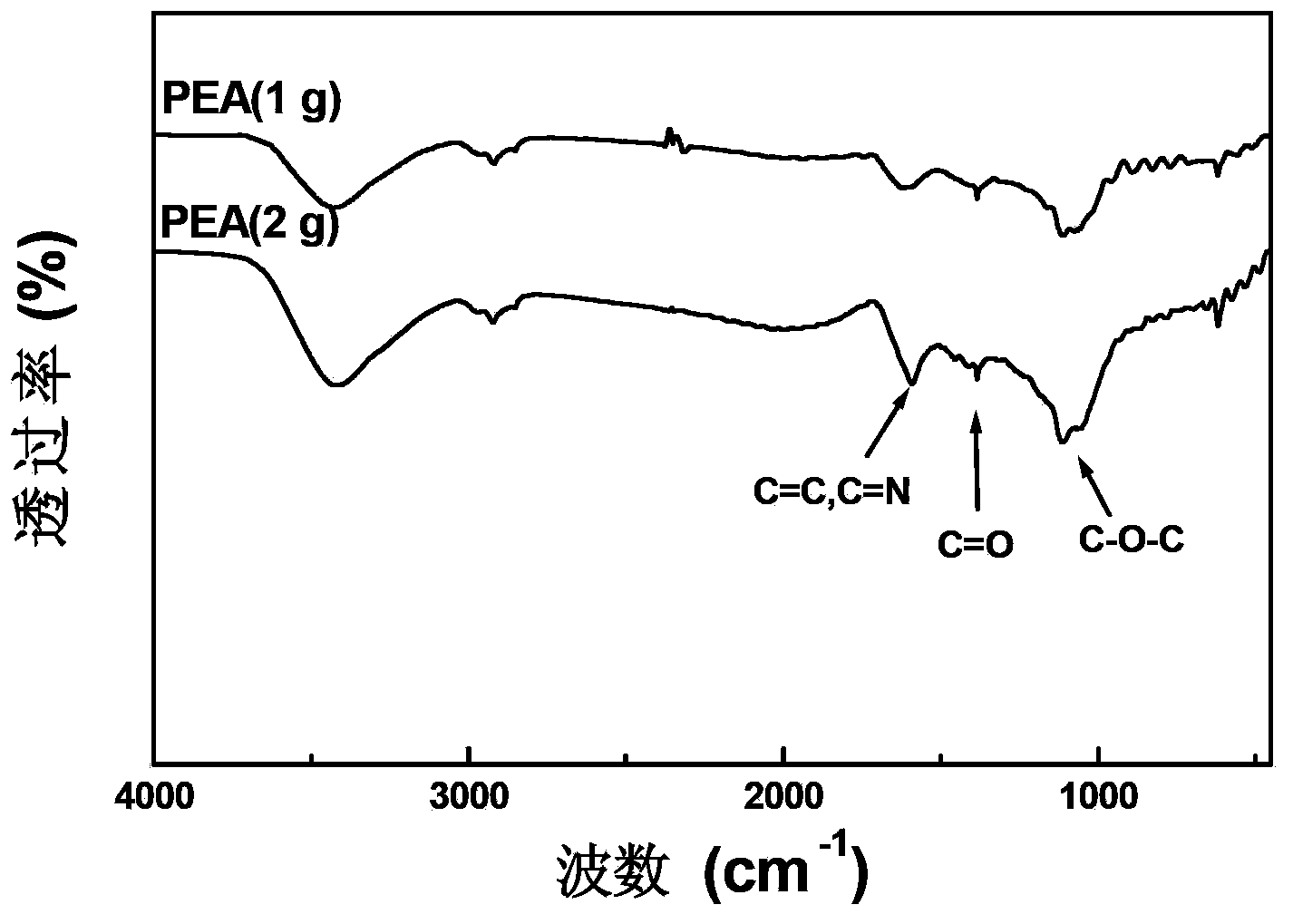

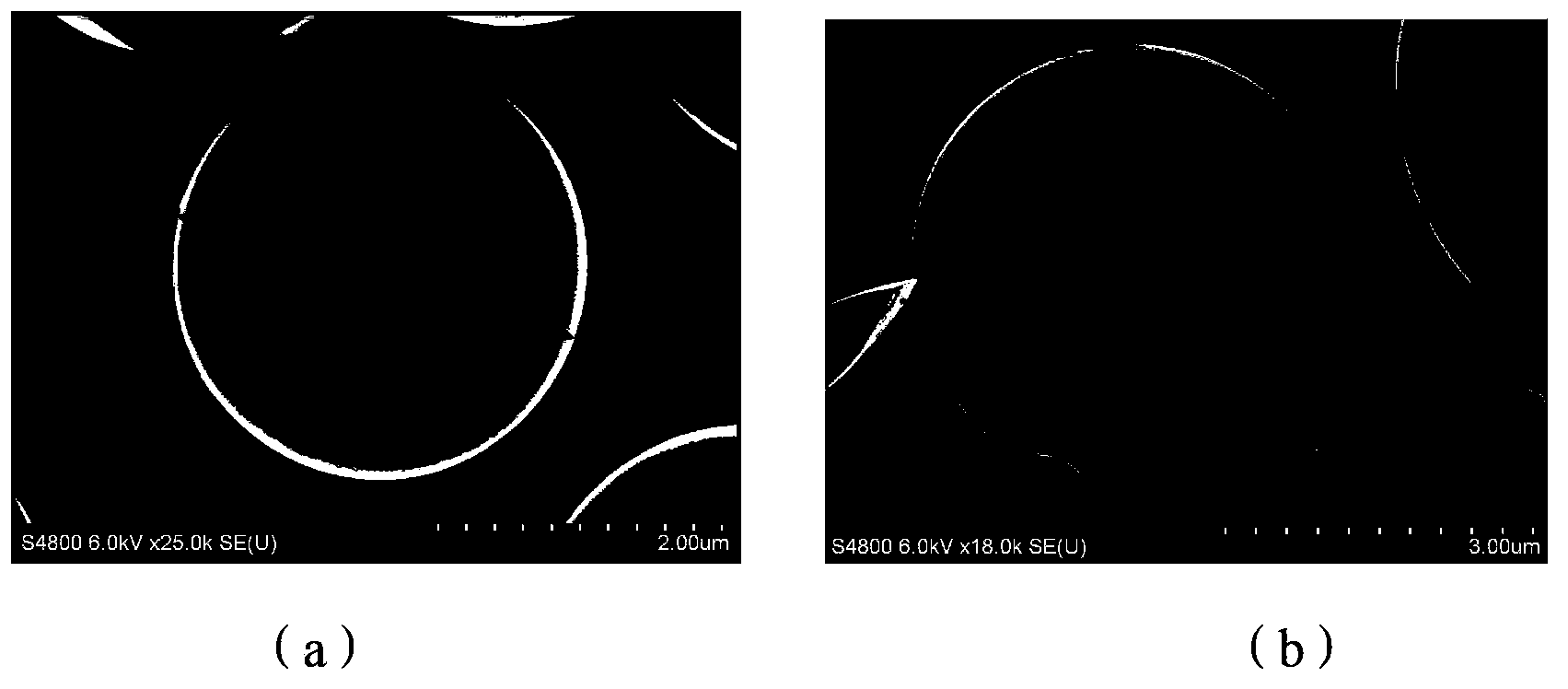

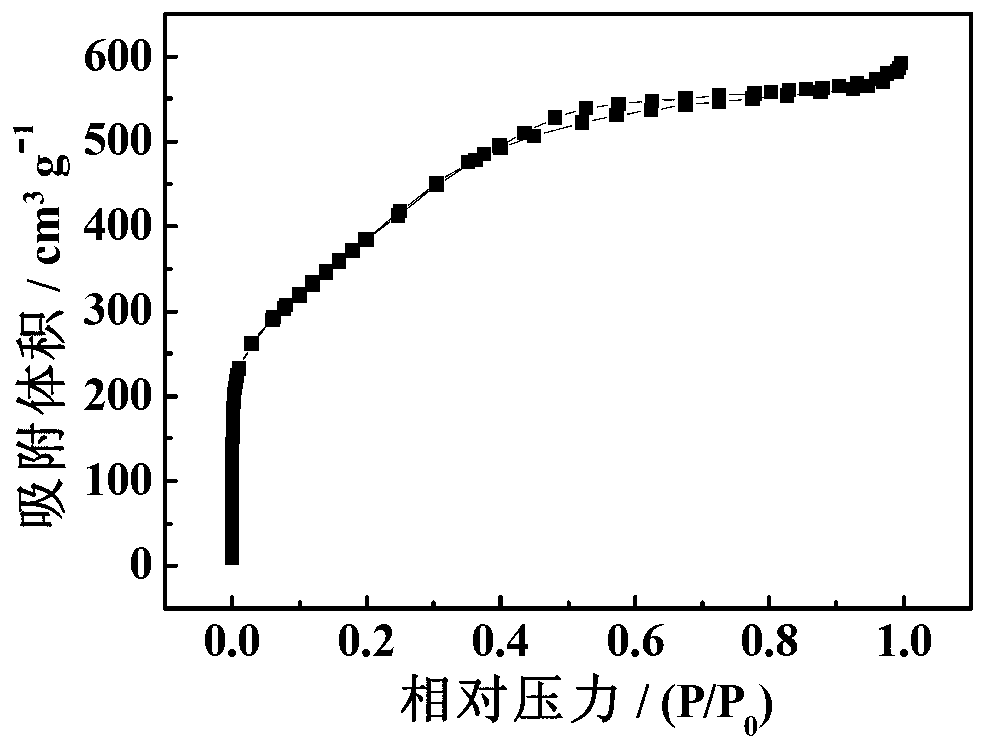

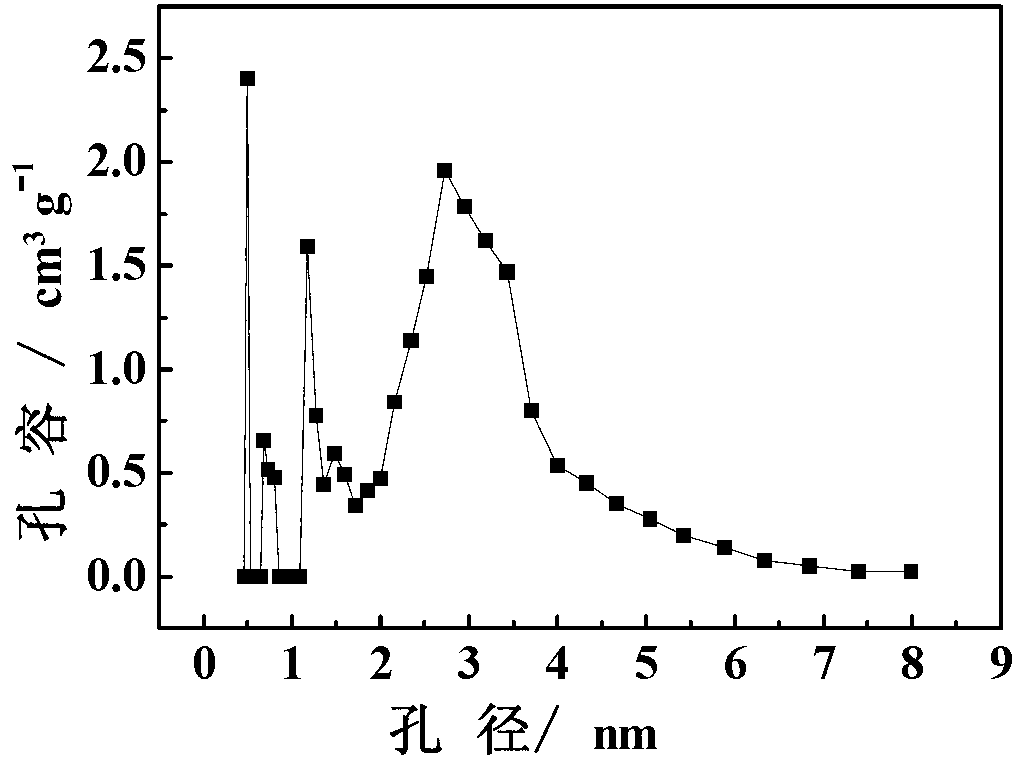

Nitrogen-doped porous carbon material, preparation method and use thereof

ActiveCN103406096AHigh nitrogen dopingLarge specific surface areaOther chemical processesDispersed particle separationMaterials preparationPorous carbon

The present invention discloses a nitrogen-doped porous carbon material preparation method, which comprises: adopting nitrogen-containing macromolecule as a template agent and a nitrogen source, adopting a biomass derivative as a carbon source, carrying out a hydrothermal carbonization reaction under a hydrothermal condition, and removing the template agent to obtain the nitrogen-doped porous carbon material. The present invention further provides a class of nitrogen-doped porous carbon materials prepared by using the method. The material obtained through the preparation method has characteristics of high nitrogen content and relatively high specific surface area. Experiment results show that the nitrogen-doped porous carbon materials provide excellent absorption performances for hydrogen and carbon dioxide. In addition, due to presence of the nitrogen-containing group, the porous material of the present invention can be expected to be used for catalysis, gas storage, molecule separation, clean energy carriers, super capacitors and other fields.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Sphingomonas strain and application thereof in water treatment

InactiveCN102168054APromote degradationReduce concentrationBacteriaMicroorganism based processesIndustrial waste waterWater source

The invention belongs to the technical fields of environmental engineering and bioengineering and particularly relates to a sphingomonas strain and applications thereof in the aspects of shortcut nitrification-denitrification of nitrogen-containing industrial waste water and domestic sewage and treatment of a polluted water source. The sphingomonas strain is separated from a Taihu water in China,is a local strain and has high safety; and the strain can be grown in a basic medium, wherein in the basic medium, CO2 is used as a carbon source and energy or CO2 and an organism are used as a mixedcarbon source and energy, and ammonia nitrogen or nitrate nitrogen is used as a nitrogen source. The bacterium liquid, the dormancy cell and the immobilized strain of the sphingomonas can decompose ammonia nitrogen into nitrite nitrogen and simultaneously can decompose the ammonia nitrogen into nitrogen, can be used as denitrification microorganism for converting the ammonia nitrogen into the nitrite nitrogen and the nitrogen, thereby achieving the shortcut nitrification-denitrification. The strain can rapidly decompose the ammonia nitrogen and is suitable for treating the nitrogen-containingindustrial waste water and domestic sewage as well as polluted water source.

Owner:NANJING UNIV

Method for preparing bacillus subtilis lipopeptid biosurfactant

InactiveCN101838621AThe fermentation process is simple to operateEfficient productionBacteriaMicroorganism based processesBacterial strainGuar gum

The invention relates to a method for preparing a bacillus subtilis lipopeptid biosurfactant, which is characterized in that the adopted bacterial strain is efficient lipopeptid producing strain bacillus subtilis BIT09S1,BIT09S2 and BIT09A2, and the lipopeptid biosurfactant is prepared by taking cheap molasses, pulse flour, konjac gum finemeal, guar gum and gum breaking liquid of modified guar gum as carbon sources for the culture medium; adding other nitrogen sources, phosphorus sources, inorganic salt components and nutrient elements into the culture medium; and carrying out fermentation, separation and purification. The raw materials used for producing lipopeptid by the method are easily obtained and can be enormously purchased. The crude extract of the obtained lipopeptid biosurfactant Surfactin can be used in various drilling and production processes such as oil-gas field fracturing, acidizing, de-plugging, controlling and water shut-off, oily water treatment, environment renovation and the like, and the biosurfactant has wide prospect.

Owner:DALIAN BITEOMICS INC

Special diet and foodstuffs formula containing small peptide for tumor patient

ActiveCN101496579AImprove the immunityImprove nutritional statusAntineoplastic agentsFood preparationNutritional statusWarm water

The invention provides a formulation for a special prandial food, which contains short peptides and is provided for tumor sufferers to eat. The food uses food-originated short peptides as raw materials which are added with extracts of medical-edible Chinese herbal medicines such as champignons, dried orange peels, Chinese wolfberry, yams, tuckahoes, rhizoma polygonati, and the like, and compound complex formulation. With the food formulation, powdered or granular foods can be prepared and are dissolved with warm water to eat. The food prepared according to the formulation is easy to dissolve, can be absorbed and utilized quickly, provides a high quality nitrogen source for organisms, supplements various vitamins and minerals necessary for a human body, can correct the negative nitrogen balance of the tumor sufferers, improve the nutritional status of the tumor sufferers, and can play a role in improving organism immunity and suppressing and resisting cancers through the combined action of various factors such as bioactive components, the functional oligosaccharides, and the like in the food-originated short peptides and the extracts of the medical-edible Chinese herbal medicines, thus the food is suitable for the tumor sufferers, particularly for cancer patients who receive radiation therapy and chemotherapy to eat.

Owner:GUANGDONG SINO NUTRI-FOOD BIOLOGICAL TECH CO LTD

Nitrogen-doped porous carbon and preparation method thereof

ActiveCN103265008AWide range of choicesEasy to operateCarbon preparation/purificationPorous carbonCarbonization

The invention relates to a preparation method of nitrogen-doped porous carbon, and in particular relates to a method for preparing doped porous carbon by taking a heavy organism as a carbon source, belonging to the technical field of carbon material preparation. The method comprises the following steps of: firstly, conducting a reaction between a nitrogen source and formaldehyde to generate a prepolymer; then, mixing the prepolymer with a template and the carbon source, and reacting at certain temperature; and finally, curing and carbonizing a crosslinking product to obtain nitrogen-doped porous carbon. The method provided by the invention can obtain nitrogen-doped porous carbon with different pore structures and nitrogen contents through multiple ways such as control on the nitrogen source type, temperature control, control on the mass ratio of a carbon source to a nitrogen source, control on the dosage of a template agent and the like. By adopting a chemical polymerization blending carbonization method, the method effectively controls the loss of nitrogen in a thermal treatment process and improves the utilization rate of the nitrogen source; the selection range of the raw material is wide; and the method is easy to operate and easily realizes large-scale preparation while providing a new way for efficiently utilizing heavy organic matters.

Owner:DALIAN UNIV OF TECH

Method of forming a silicon nitride layer on a substrate

InactiveUS6645884B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorNitrogen source

The invention provides methods and apparatuses of forming a silicon nitride layer on a semiconductor wafer. A semiconductor wafer is located on a susceptor within a semiconductor processing chamber. A carrier gas, a nitrogen source gas, and a silicon source gas are introduced into the semiconductor processing chamber and a semiconductor wafer is exposed to the mixture of gases at a pressure in the chamber in the range of approximately 100 to 500 Torr.

Owner:APPLIED MATERIALS INC

Composite material of nitrogen-doped porous carbon-wrapped carbon nano tube as well as preparation method and application of material

ActiveCN103706388AEasy to prepareEconomical method of preparationMaterial nanotechnologyPhysical/chemical process catalystsCarbon layerPorous carbon

The invention relates to a composite material of a nitrogen-doped porous carbon-wrapped carbon nano tube as well as a preparation method and an application of the composite material. The preparation method comprises the following steps: dispersing the carbon nano tube in water, adding a carbon source to obtain a reaction system, subsequently performing hydrothermal reaction, performing thermal treatment on the carbon nano tube wrapped with a carbon layer on the surface, and a nitrogen source at the high temperature so as to obtain the composite material of the nitrogen-doped porous carbon-wrapped carbon nano tube. According to the preparation method, the carbon source is polymerized under a hydrothermal reaction condition so as to obtain the carbon layer, the outer surface of the carbon nano tube is wrapped with the carbon layer, subsequently the carbon layer is carbonized and decomposed to generate a porous structure under high temperature treatment, and at the same time, the gasified nitrogen source is diffused to the carbon layer through ducts to be subjected to in-situ doping. The composite material provided by the invention can be used as a cathode oxidation reduction catalyst of a fuel battery, is excellent in catalysis, and is high in oxidation activity when being compared with other nitrogen-doped materials reported in documents. The preparation method provided by the invention is simple and economic in process, convenient to operate and easy to achieve the large-scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com