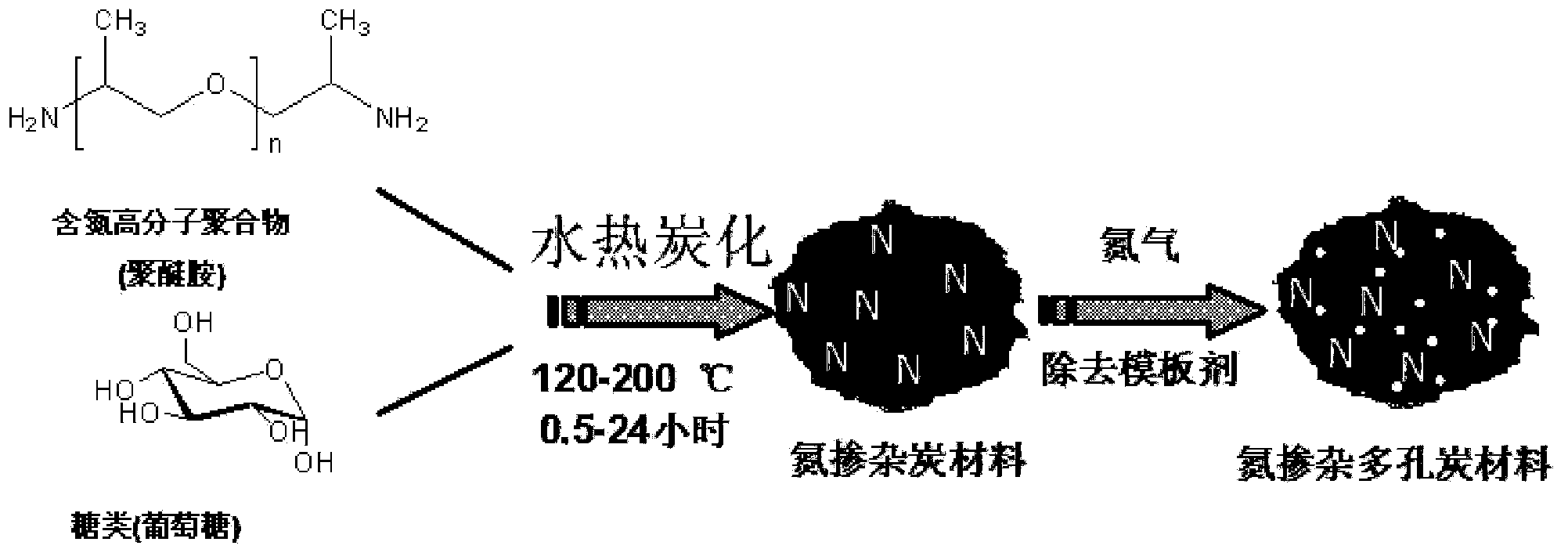

Nitrogen-doped porous carbon material, preparation method and use thereof

A technology of porous carbon and nitrogen doping, applied in separation methods, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of lack of research on surface functional group modification or heteroatom doped materials, focusing on material pore structure, etc. , to achieve the effect of good recycling performance, easy availability of raw materials and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Put 2.00g of glucose into a 25mL tumbler, add 8.0mL of ultrapure water, and stir on a mechanical stirrer; at the same time, take 0.20g of polyetheramine (PEA, the degree of polymerization is 230), add 10.0mL of ultrapure water , stirring on a mechanical stirrer protected from light. After it is completely dissolved, add the glucose solution dropwise into the polyetheramine solution, stir at room temperature in the dark for 15 minutes, then put the flat-bottomed glass containing the mixed solution into the matching polytetrafluoroethylene reactor, and place it in an oven at 180°C , hydrothermal reaction 20h. After the reaction was completed and cooled down to room temperature, it was filtered with suction, and the product obtained by suction filtration was further washed several times with ultrapure water and ethanol, and dried in an oven at 80°C overnight to obtain 0.81 g of gray-brown solid powder.

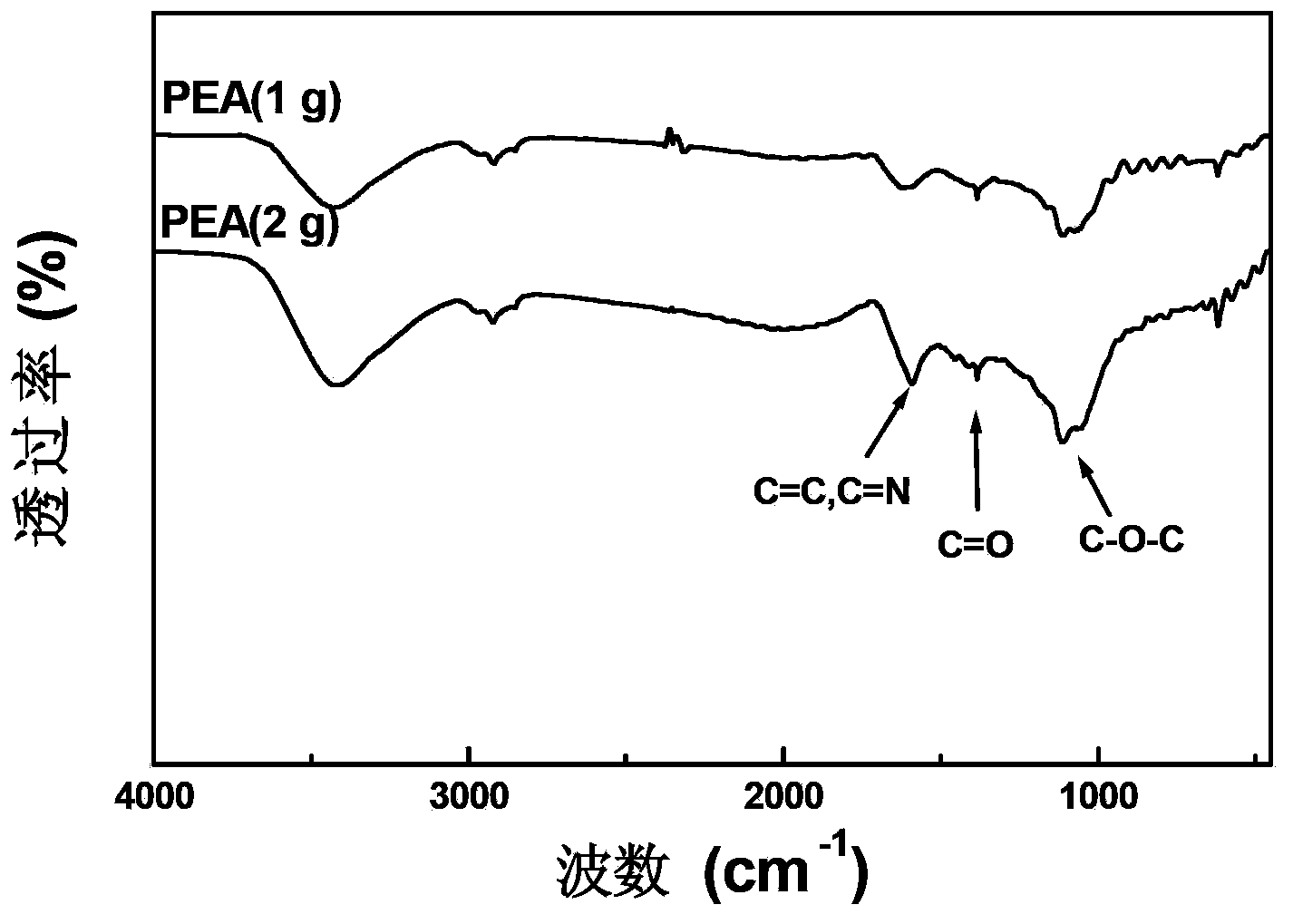

[0056] The form of nitrogen in the obtained carbon material includes...

Embodiment 2

[0058] Put 2.00g of glucose into a 25mL tumbler, add 8.0mL of ultrapure water, and stir on a mechanical stirrer; at the same time, take 0.25g of polyetheramine (PEA, the degree of polymerization is 230), add 10.0mL of ultrapure water , stirring on a mechanical stirrer protected from light. After it is completely dissolved, add the glucose solution dropwise into the polyetheramine solution, stir at room temperature in the dark for 15 minutes, then put the flat-bottomed glass containing the mixed solution into the matching polytetrafluoroethylene reactor, and place it in an oven at 180°C , hydrothermal reaction 20h. After the reaction was completed and cooled down to room temperature, it was filtered with suction, and the product obtained by suction filtration was washed several times with ultrapure water and ethanol, and dried in an oven at 80°C overnight to obtain 0.85 g of beige solid powder.

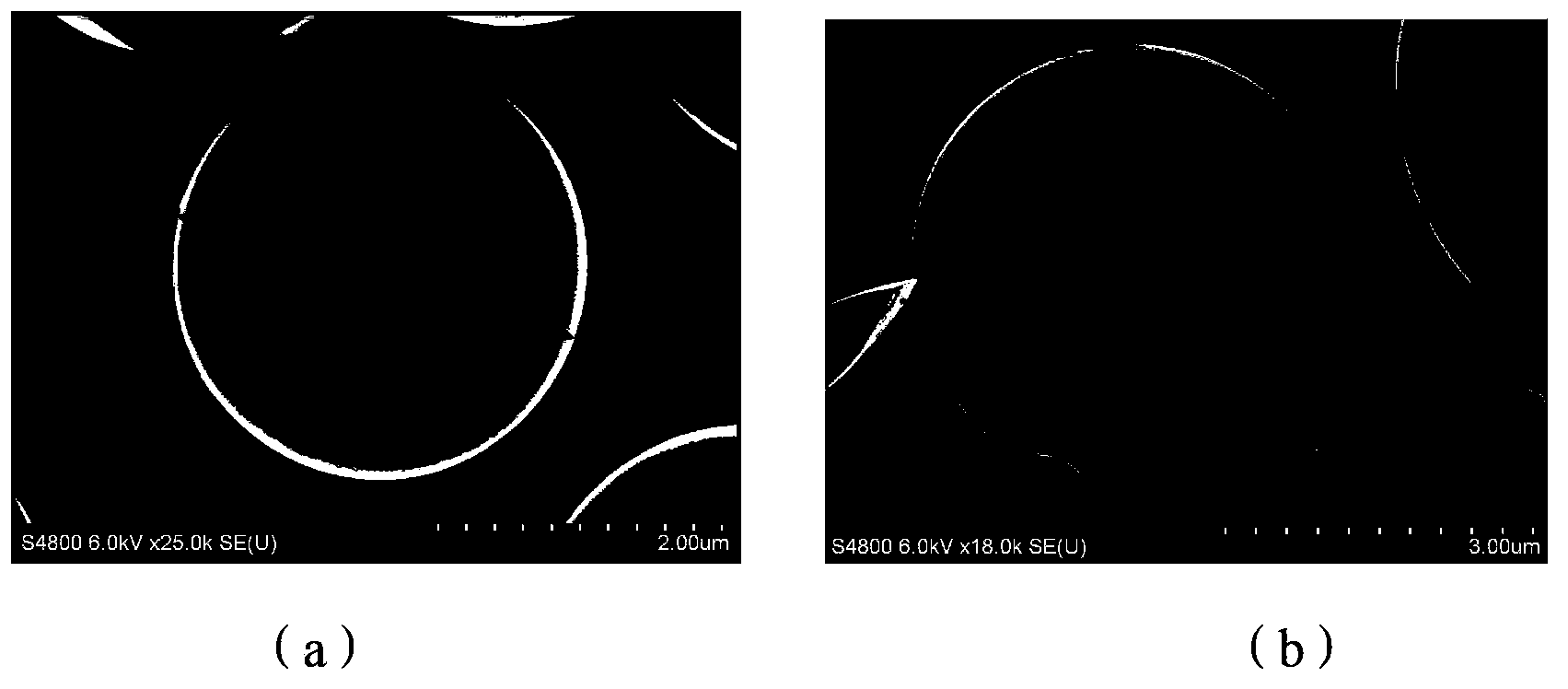

[0059] Take 0.50g of the obtained solid powder into a quartz boat, put it into a ...

Embodiment 3

[0062] Put 2.00g of glucose into a 25mL tumbler, add 8.0mL of ultrapure water, and stir on a mechanical stirrer; at the same time, take 0.50g of polyetheramine (PEA, the degree of polymerization is 230), add 10.0mL of ultrapure water , stirring on a mechanical stirrer protected from light. After it is completely dissolved, add the glucose solution dropwise into the polyetheramine solution, stir at room temperature in the dark for 15 minutes, and then put the flat-bottomed glass containing the mixed solution into the matching polytetrafluoroethylene reaction kettle. Thermal reaction 20h. After the reaction was completed and cooled down to room temperature, it was filtered with suction, and the product obtained by suction filtration was further washed several times with ultrapure water and ethanol, and then dried in an oven at 80°C overnight to obtain 0.80 g of beige solid powder.

[0063] Take 0.50g of the obtained solid powder into a quartz boat, put it into a tube furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com