A method for preparing nitrogen-doped carbon material containing pure pyridine nitrogen based on chemical vapor deposition

A chemical vapor deposition, nitrogen-doped carbon technology, applied in nanotechnology, electrical components, structural parts, etc. for materials and surface science, which can solve the problems that are not completely convincing, cannot be prepared on a large scale, and have relatively high equipment requirements. Advanced problems, to achieve the effect of suitable for large-scale production, low cost, controllable amount of nitrogen doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

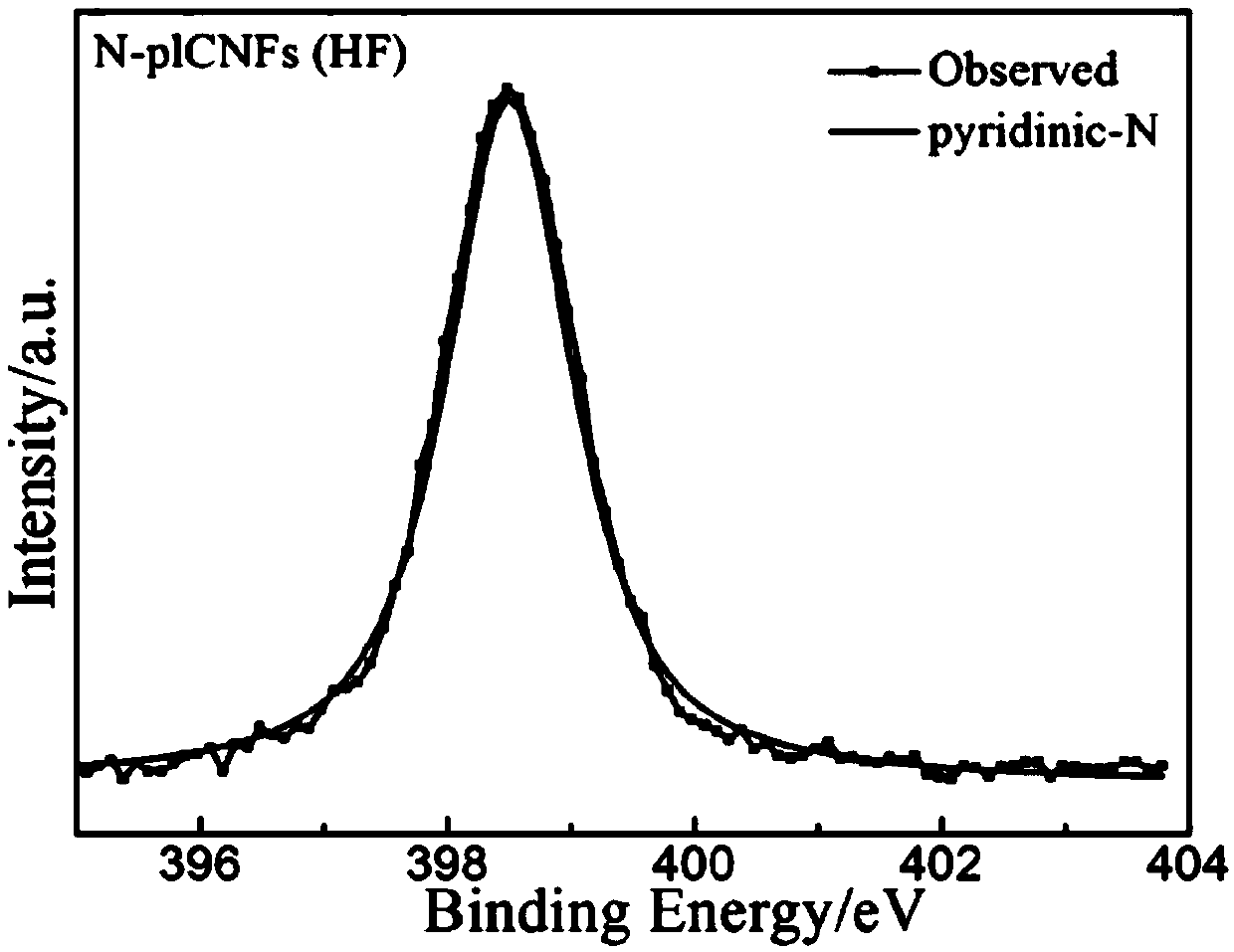

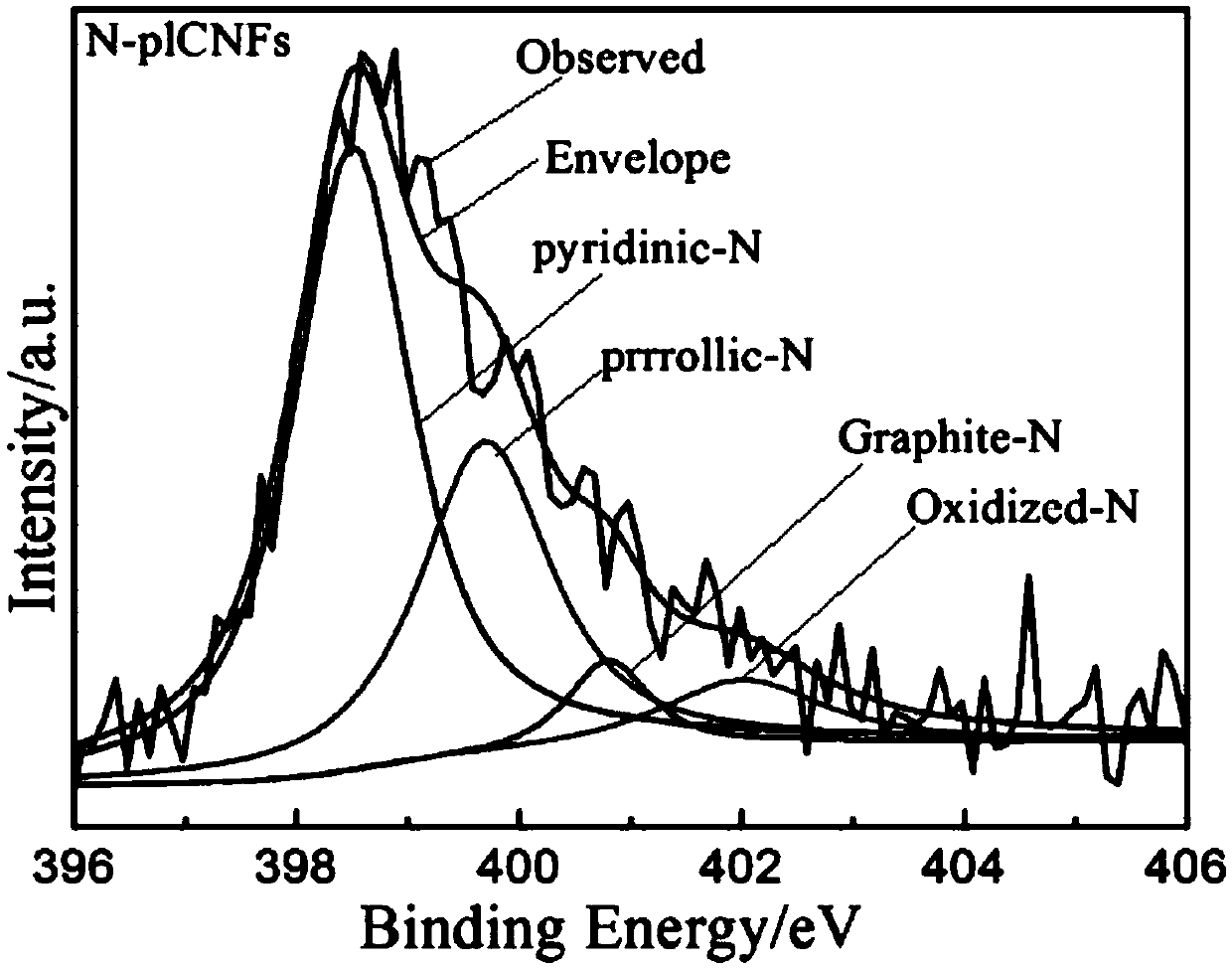

[0034] Based on carbon paper, with 1M HNO 3 After the surface of the carbon paper was roughened for 2 hours, it was washed to neutral and dried at 80°C for 6 hours, and then the dried carbon paper was placed in 6wt.%Ni(NO 3 ) 3 solution for 6 hours, then dried at 80°C for 6 hours after taking it out, and then the surface was loaded with Ni(NO 3 ) 3 The carbon paper is placed in the CVD deposition furnace, under N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 500°C and kept for a period of 4 hours, and N 2 (3L min -1 ,99.9%), after 2h, the reducing gas H 2 (3L min -1 ,99.9%), then in N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 700°C, and at C 3 h 6 with N 2 Mixed atmosphere (C 3 h 6 :3L min -1 ; N 2 :4L min -1 ) for 40min; finally in N 2 (6L min -1 ,99.9%) the protective atmosphere dropped to room temperature. Choose 20mol L -1 The HF was used to "cut" the CNFs for 30 min, washed wi...

Embodiment 2

[0036] Based on carbon paper, with 1M HNO 3 After the surface of the carbon paper was roughened for 2 hours, it was washed to neutral and dried at 80°C for 6 hours, and then the dried carbon paper was placed in 6wt.%Ni(NO 3 ) 3 solution for 6 hours, then dried at 80°C for 6 hours after taking it out, and then the surface was loaded with Ni(NO 3 ) 3 The carbon paper is placed in the CVD deposition furnace, under N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 350°C and kept for a period of 4 hours, and N was introduced for the first 2 hours of the holding period 2 (3L min -1 ,99.9%), after 2h, the reducing gas H 2 (3L min -1 ,99.9%), then in N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 600°C, and at C 3 h 6 with N 2 Mixed atmosphere (C 3 h 6 :3L min -1 ; N 2 :4L min -1 ) for 40min; finally in N 2 (6L min -1 ,99.9%) the protective atmosphere dropped to room temperature. Choose 20mol L ...

Embodiment 3

[0038] Based on carbon paper, with 1M HNO 3 After the surface of the carbon paper was roughened for 2 hours, it was washed to neutral and dried at 80°C for 6 hours, and then the dried carbon paper was placed in 6wt.%Ni(NO 3 ) 3 solution for 6 hours, then dried at 80°C for 6 hours after taking it out, and then the surface was loaded with Ni(NO 3 ) 3 The carbon paper is placed in the CVD deposition furnace, under N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 600°C and kept for a period of 4 hours, and N was introduced for the first 2 hours of the holding period. 2 (3L min -1 ,99.9%), after 2h, the reducing gas H 2 (3L min -1 ,99.9%), then in N 2 (6L min -1 ,99.9%) under a protective atmosphere, the temperature was raised to 800°C, and at C 3 h 6 with N 2 Mixed atmosphere (C 3 h 6 :3L min -1 ; N 2 :4L min -1 ) for 40min; finally in N 2 (6L min -1 ,99.9%) the protective atmosphere dropped to room temperature. Choose 15mol L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com