Patents

Literature

891 results about "Carbon paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon paper (originally carbonic paper) was originally paper coated on one side with a layer of a loosely bound dry ink or pigmented coating, bound with wax, used for making one or more copies simultaneously with the creation of an original document when using a typewriter or a ballpoint pen. The manufacture of carbon paper was formerly the largest consumer of montan wax. In 1954 the Columbia Ribbon & Carbon Manufacturing Company filed a patent for what became known in the trade as solvent carbon paper: the coating was changed from wax-based to polymer-based. The manufacturing process changed from a hot-melt method to a solvent-applied coating or set of coatings. It was then possible to use polyester or other plastic film as a substrate, instead of paper, although the name remained carbon paper.

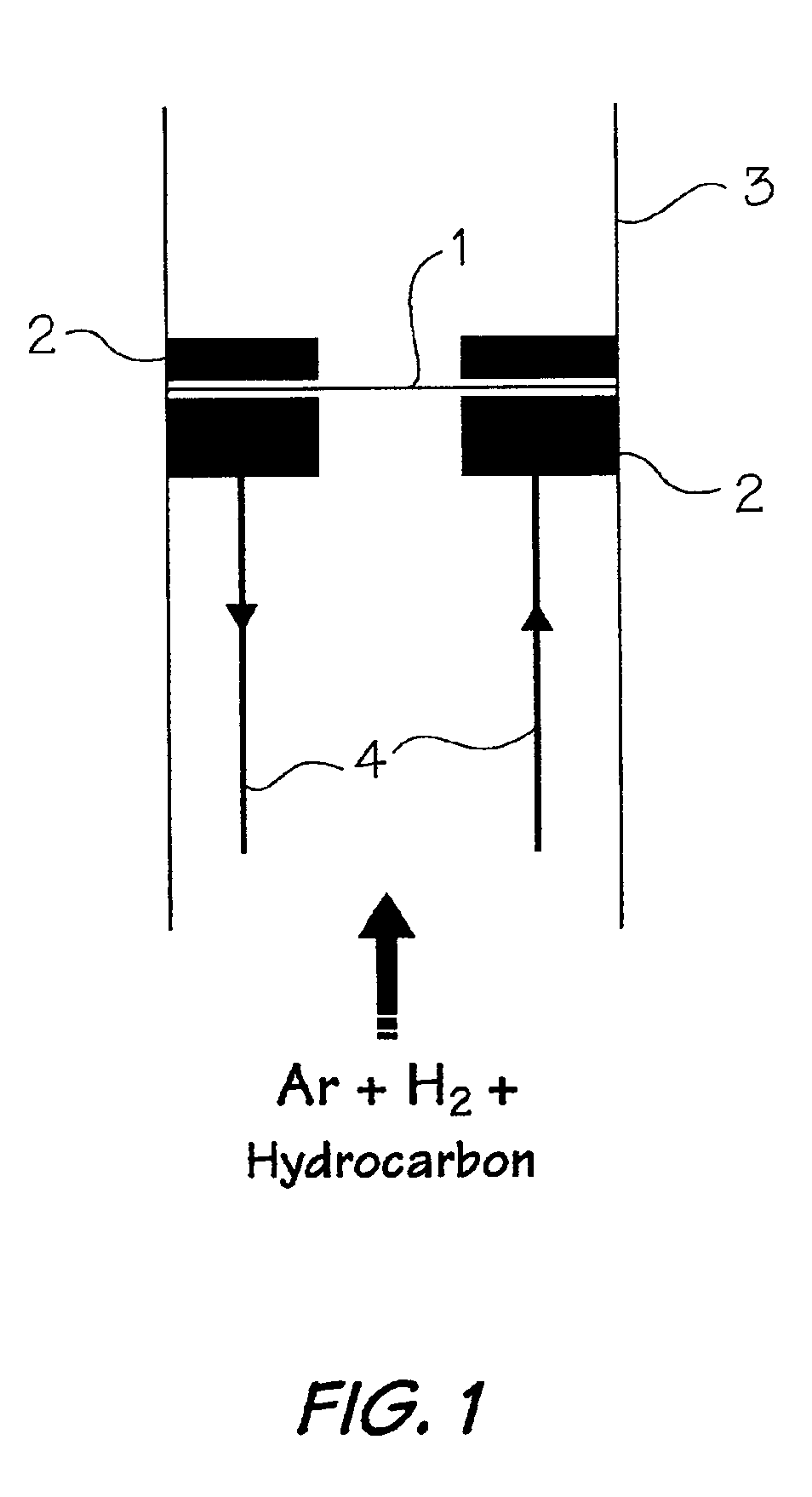

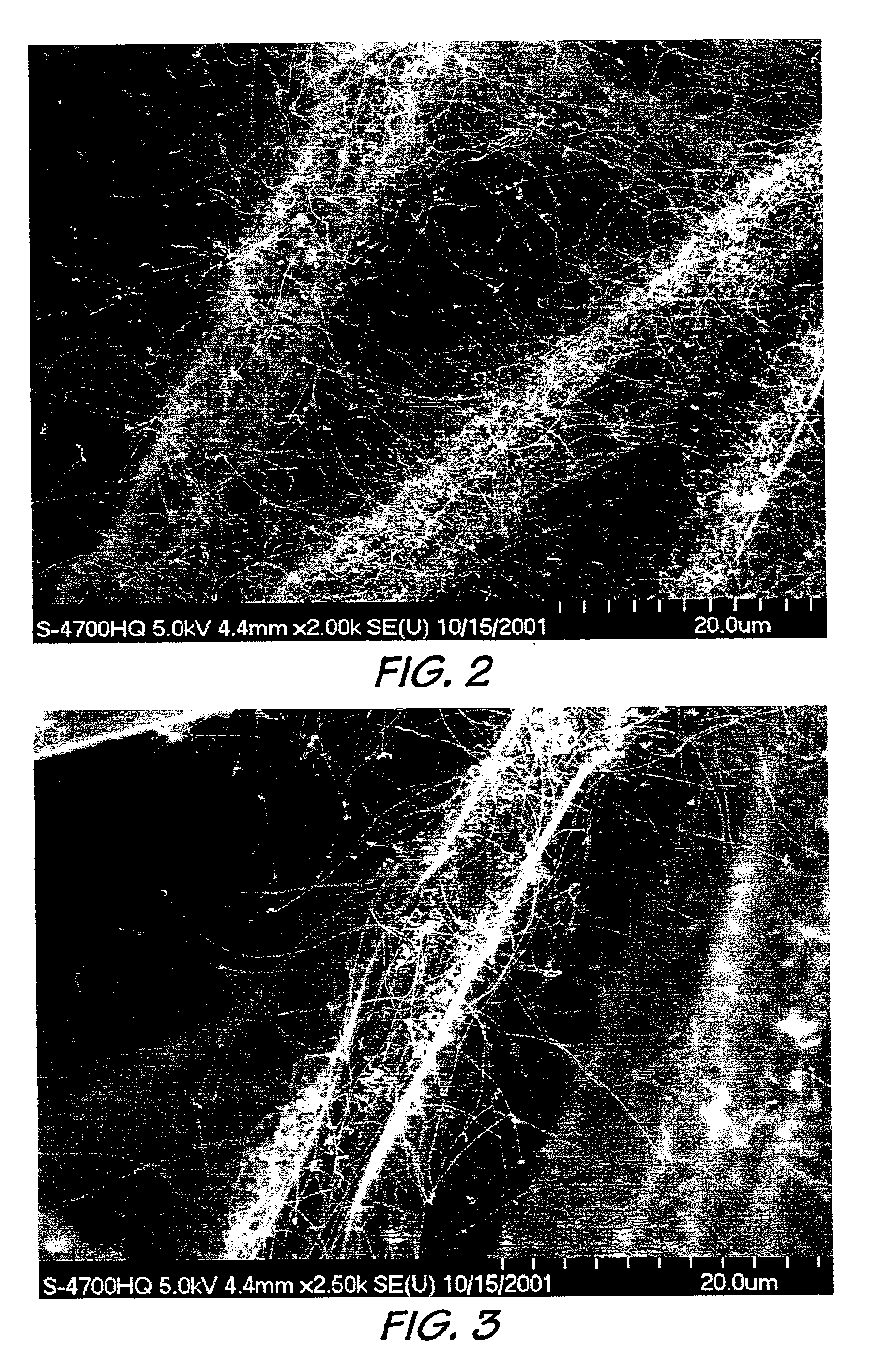

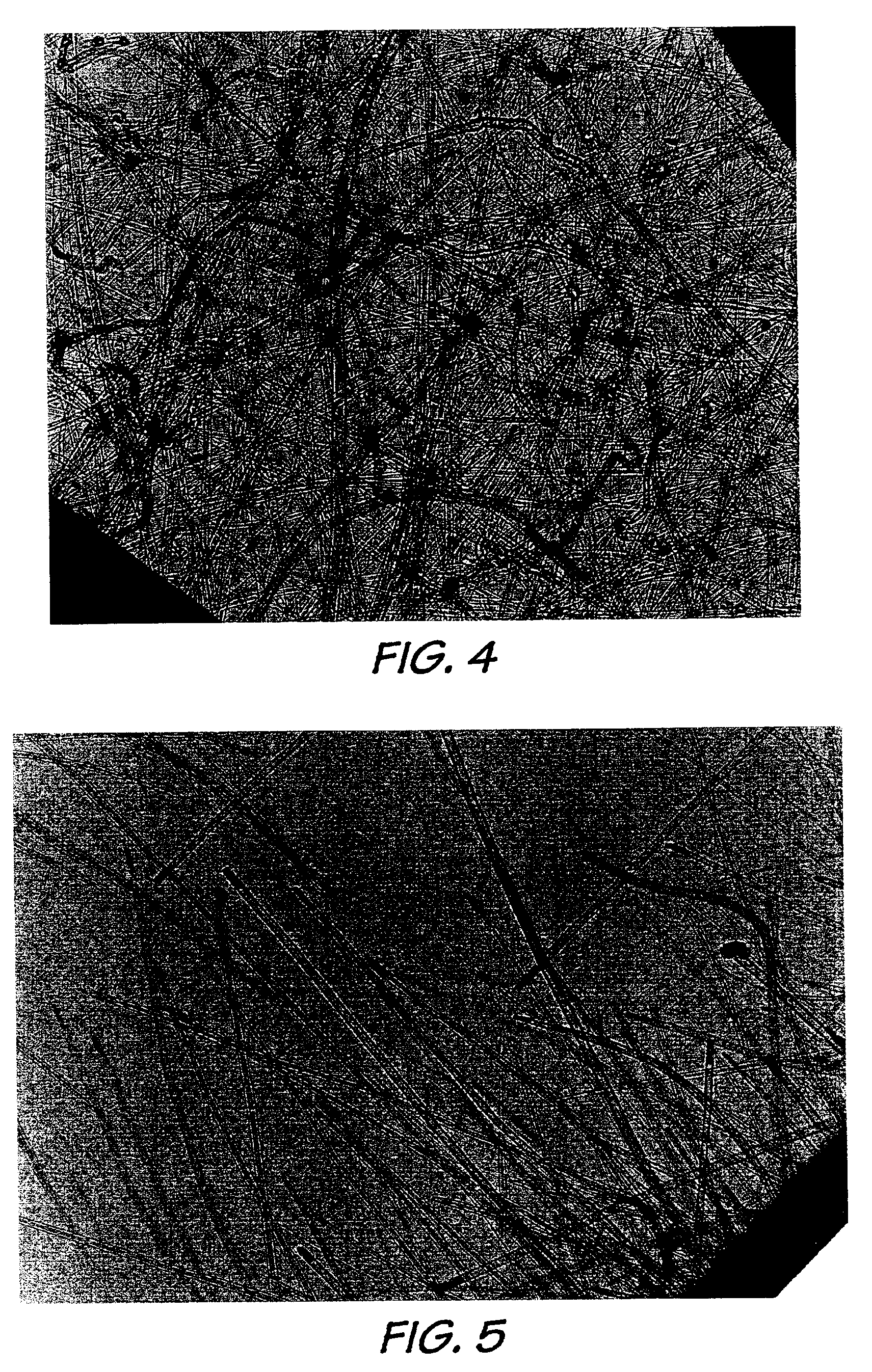

Process for preparing carbon nanotubes

InactiveUS6887451B2Speed up the processMaterial nanotechnologyEnergy inputComposite electrodeSilanes

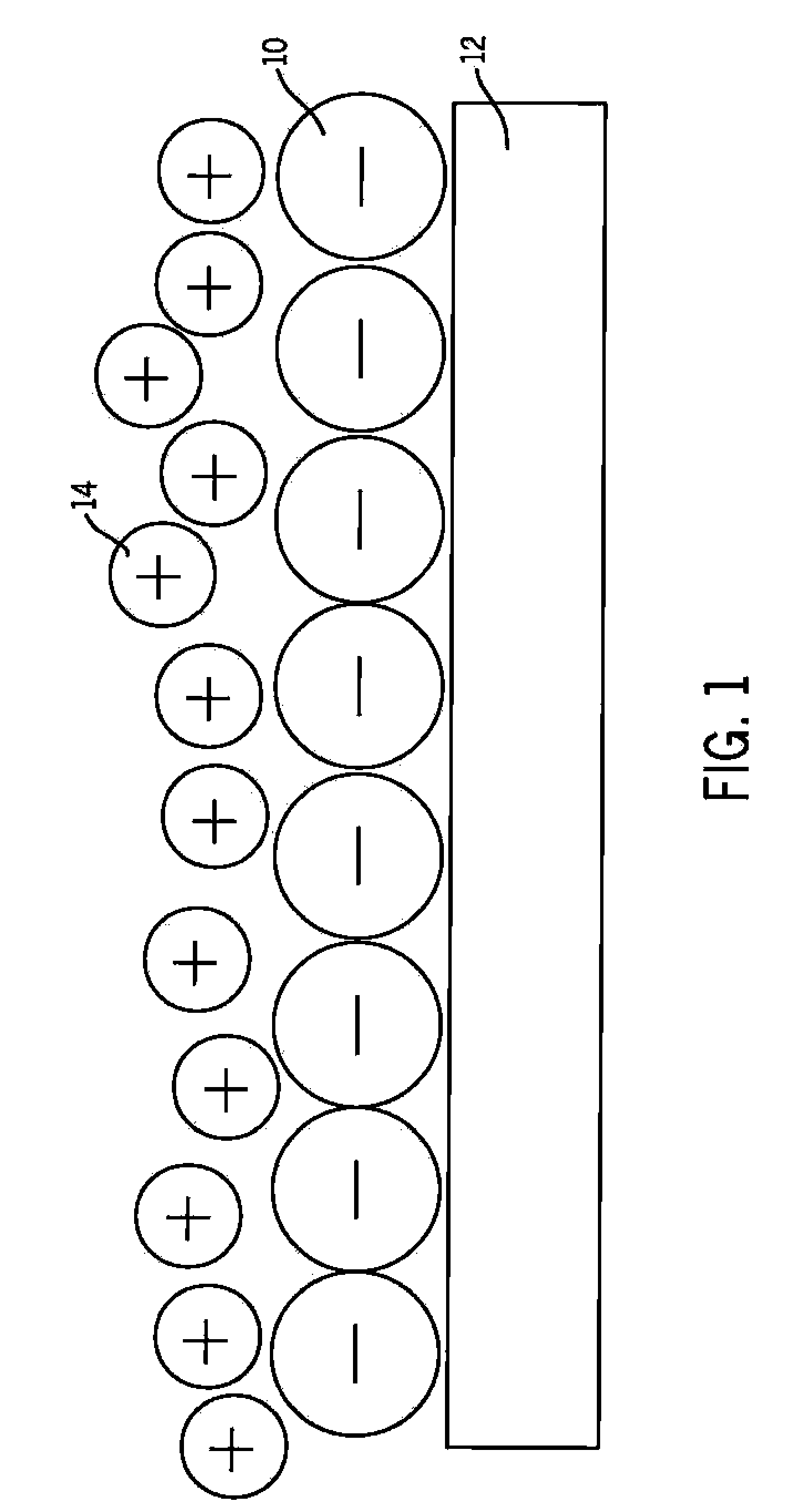

Carbon nanotubes are produced using a silane procedure, in which a substrate such as carbon paper or stainless steel mesh is immersed in a silane solution of a metal catalyst, preferable Co:Ni in a 1:1 ratio; and a feedstock gas containing a carbon source such as ethylene is fed through the substrate and the catalyst deposited thereon while the substrate is heated by applying an electrical current thereto. Thus, a reaction occurs between the catalyst and the gas to yield carbon nanotubes supported on the conductive substrate. These composite electrodes may be used in electrochemistry or in field emitting applications.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

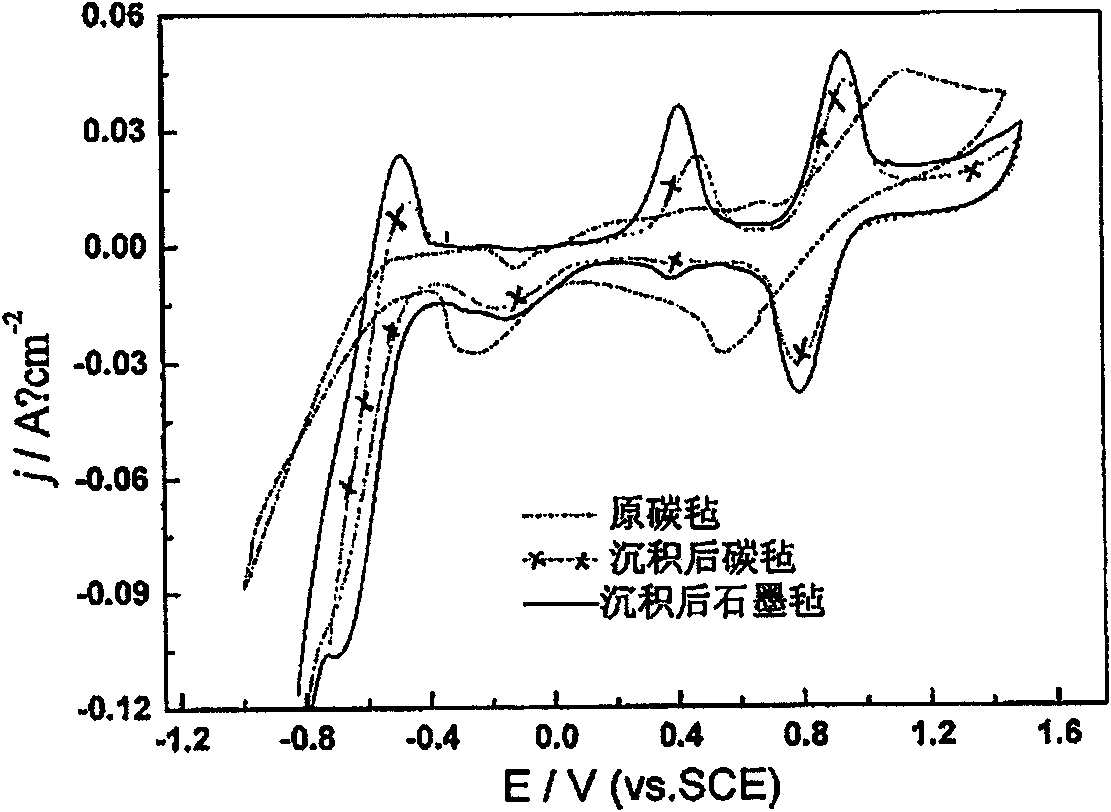

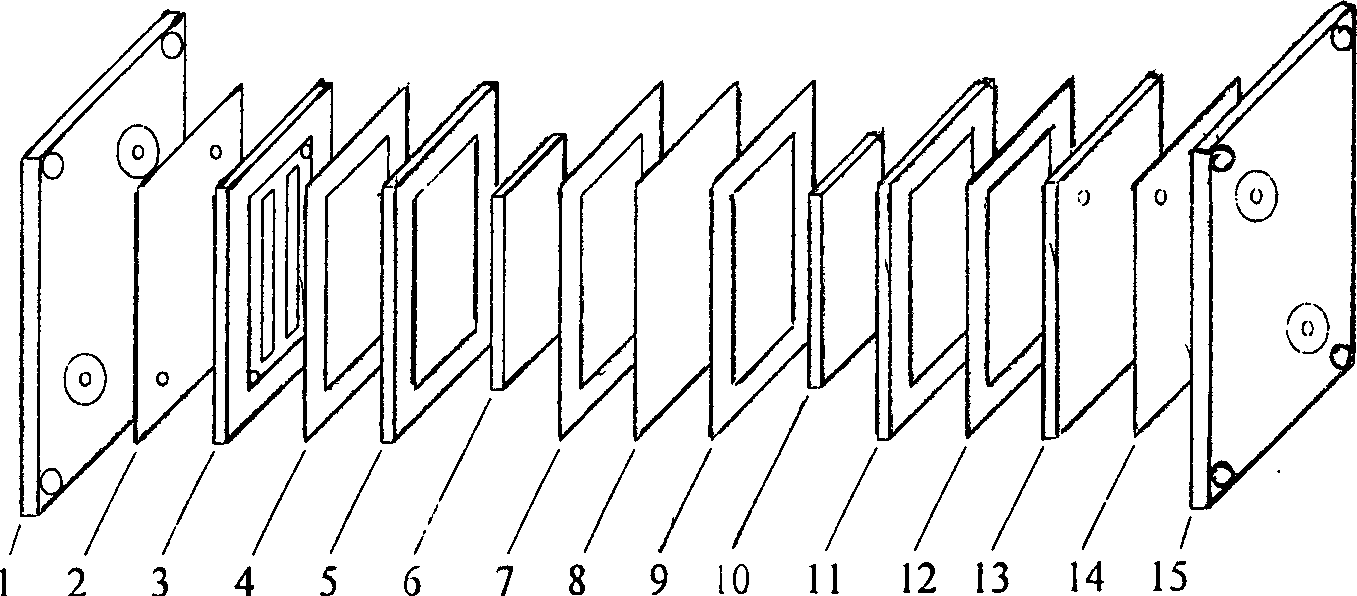

Electrode materials and all-vanadium redox flow battery containing electrode materials

InactiveCN101651201AReduce dosageLow costElectrode manufacturing processesRegenerative fuel cellsCarbon nanotubeRedox

The invention provides an electrode for a vanadium battery, comprising a carbon basal body and a carbon nano-tube layer formed on the surface of the basal body, wherein the carbon basal body is selected from a graphite felt, a carbon felt, a carbon paper and carbon cloth. The invention also provides an all-vanadium redox flow battery containing the electrode. The electrode has improved electrochemical activity and reliable mechanical strength.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG +1

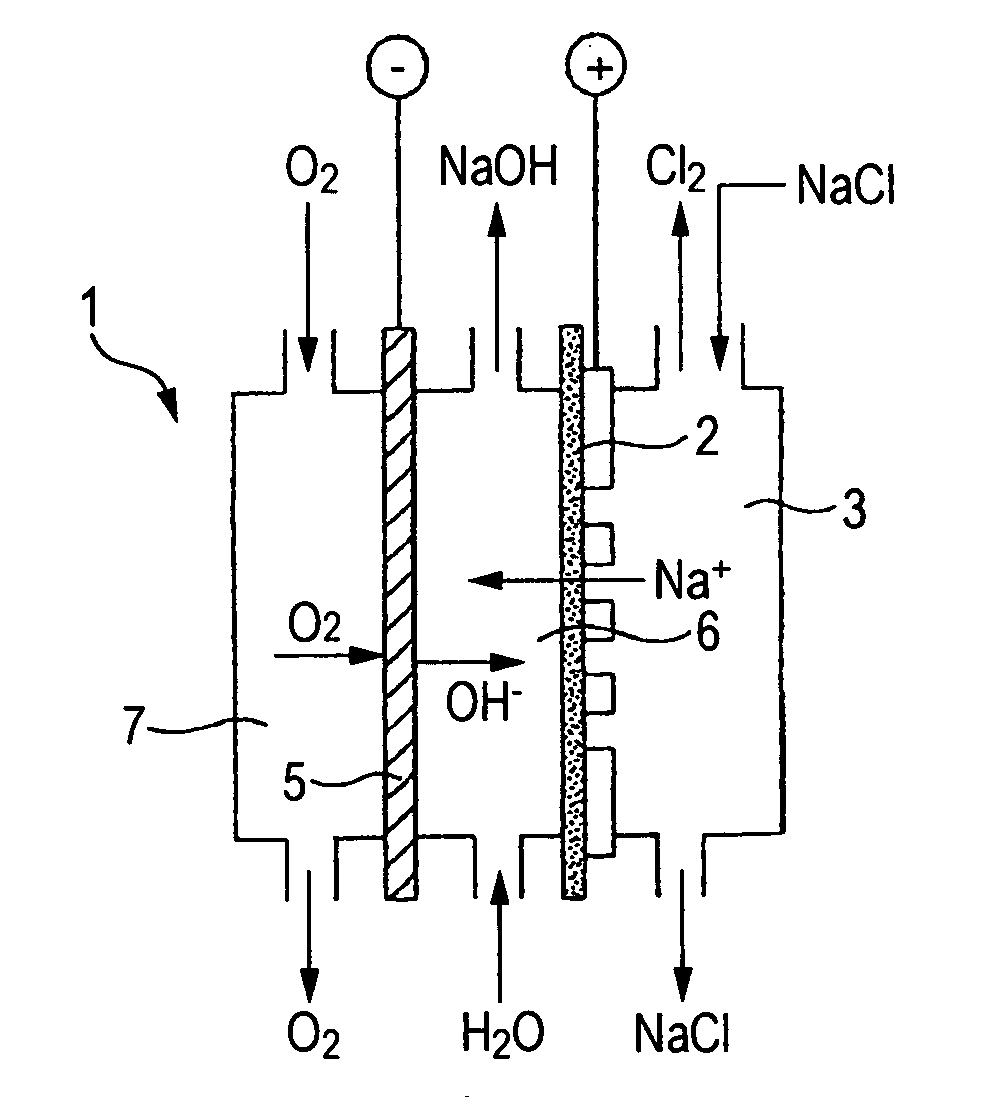

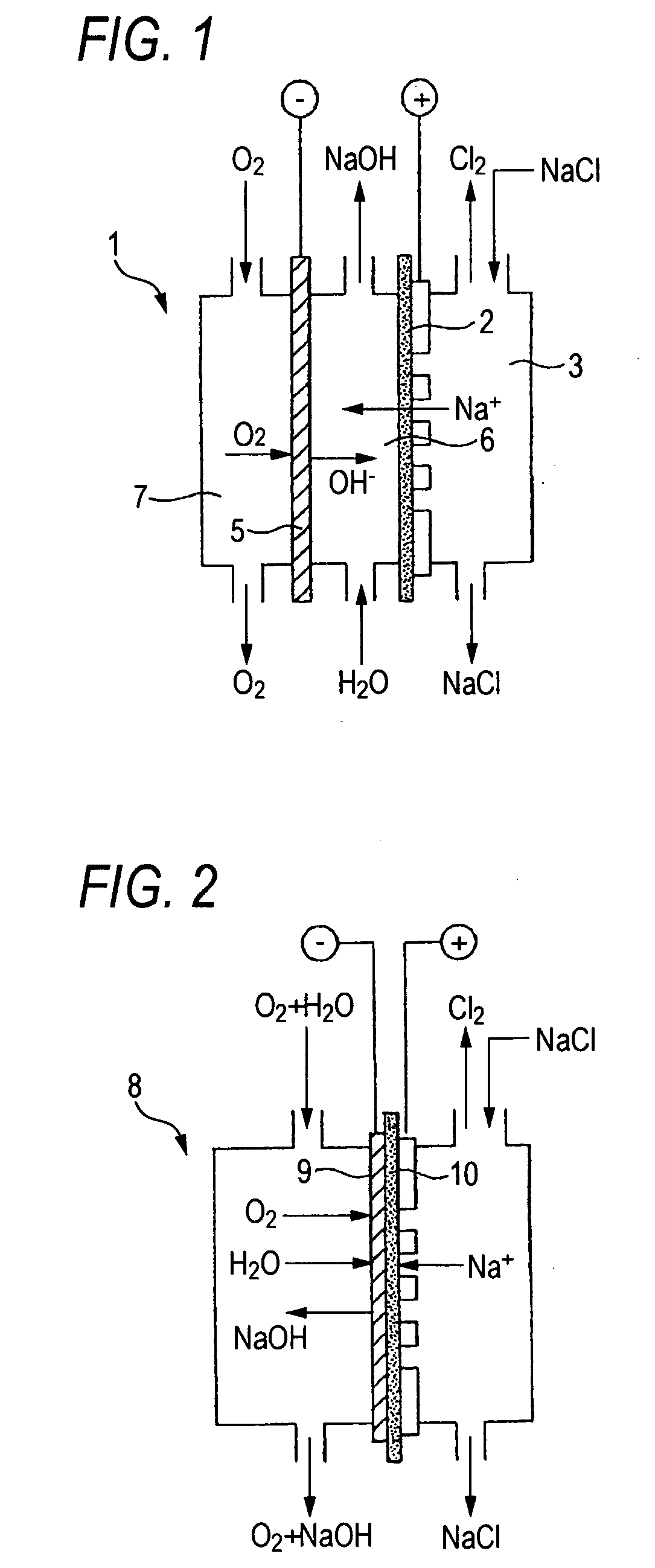

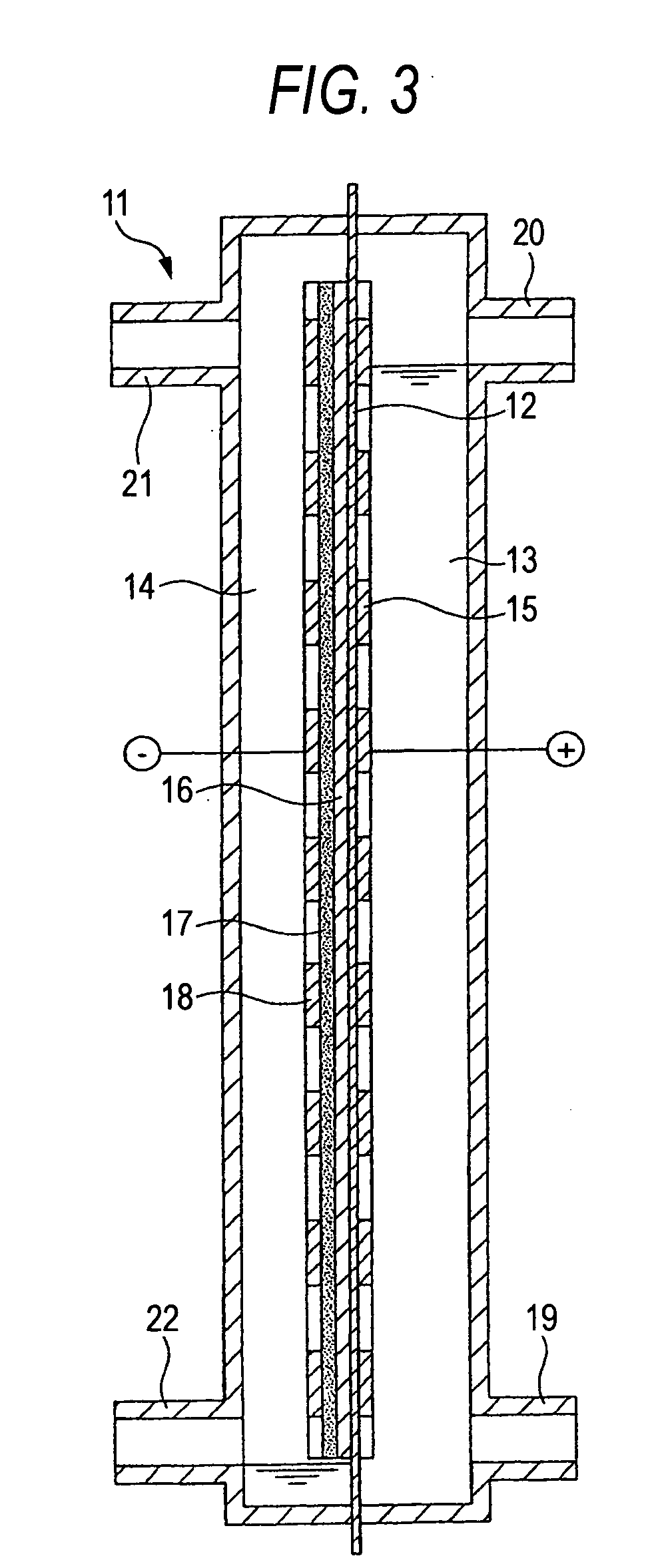

Gas diffusion electrode

InactiveUS20060175195A1High gas diffusionHigh densityMachining electrodesActive material electrodesGas diffusion electrodeNanotechnology

The present invention provides a gas diffusion electrode having: an electrode substrate; and a catalyst layer containing a hydrophilic catalyst and a hydrophobic binder, which is carried on the electrode substrate, wherein the electrode substrate contains at least one carbon material selected from a carbon cloth, a carbon paper, a foamed carbon material, and a sintered carbon material.

Owner:DE NORA PERMELEC LTD

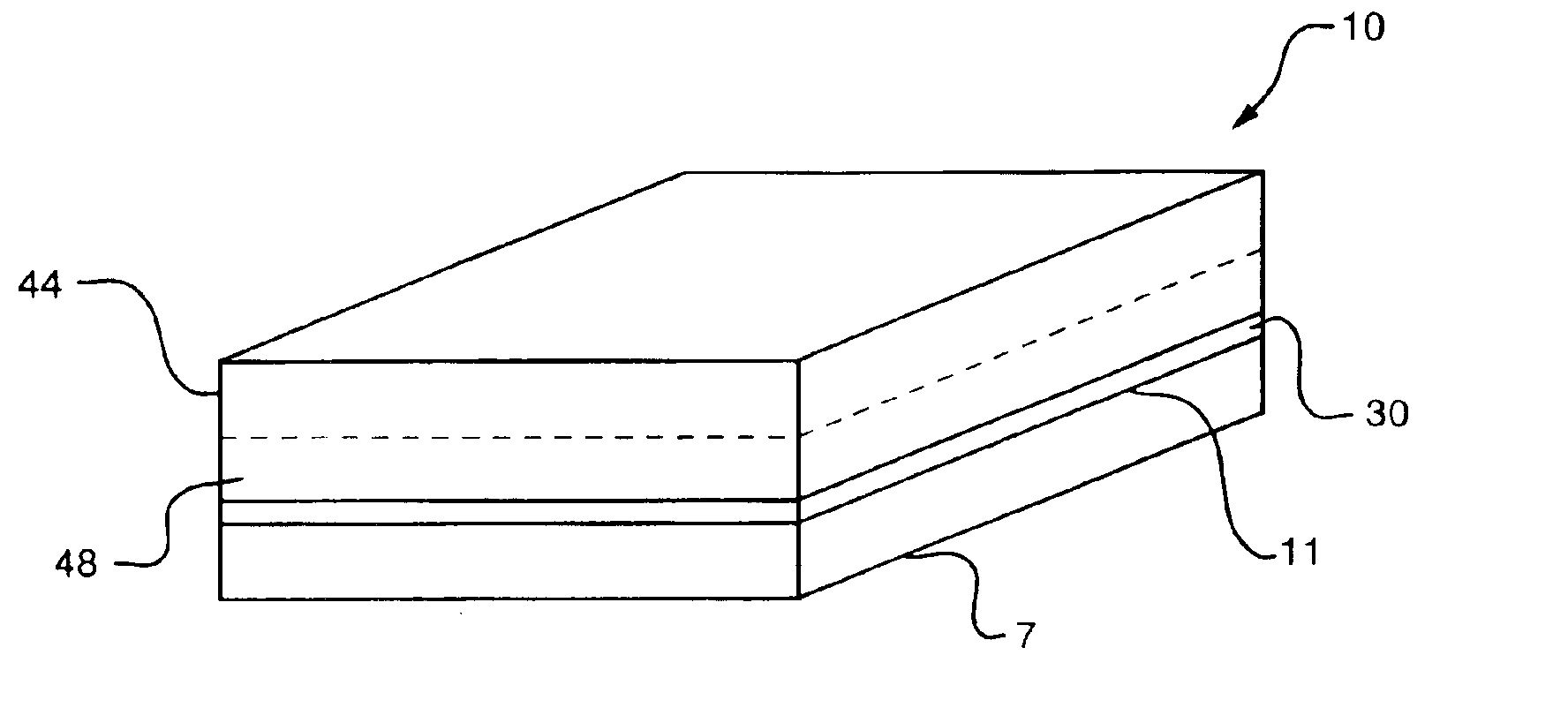

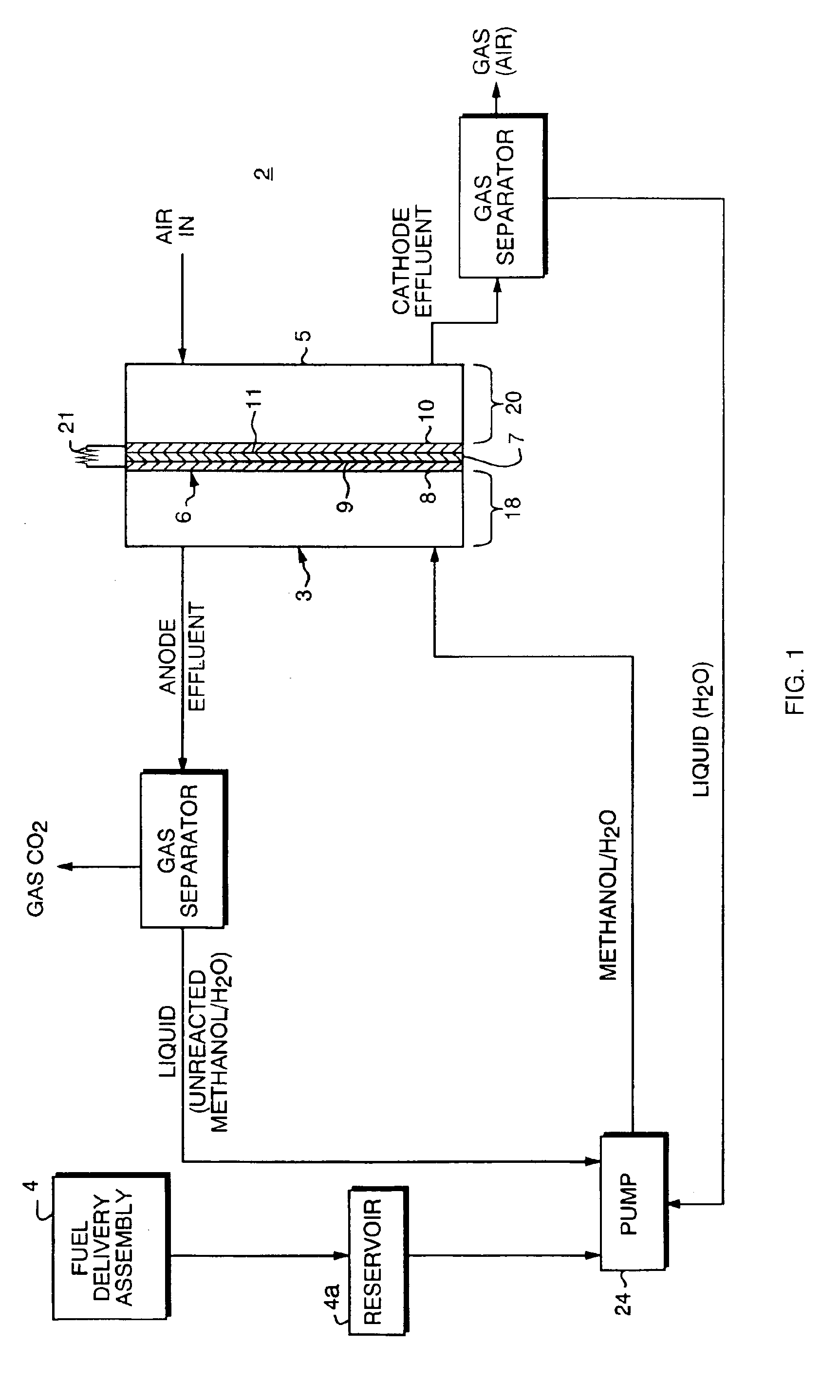

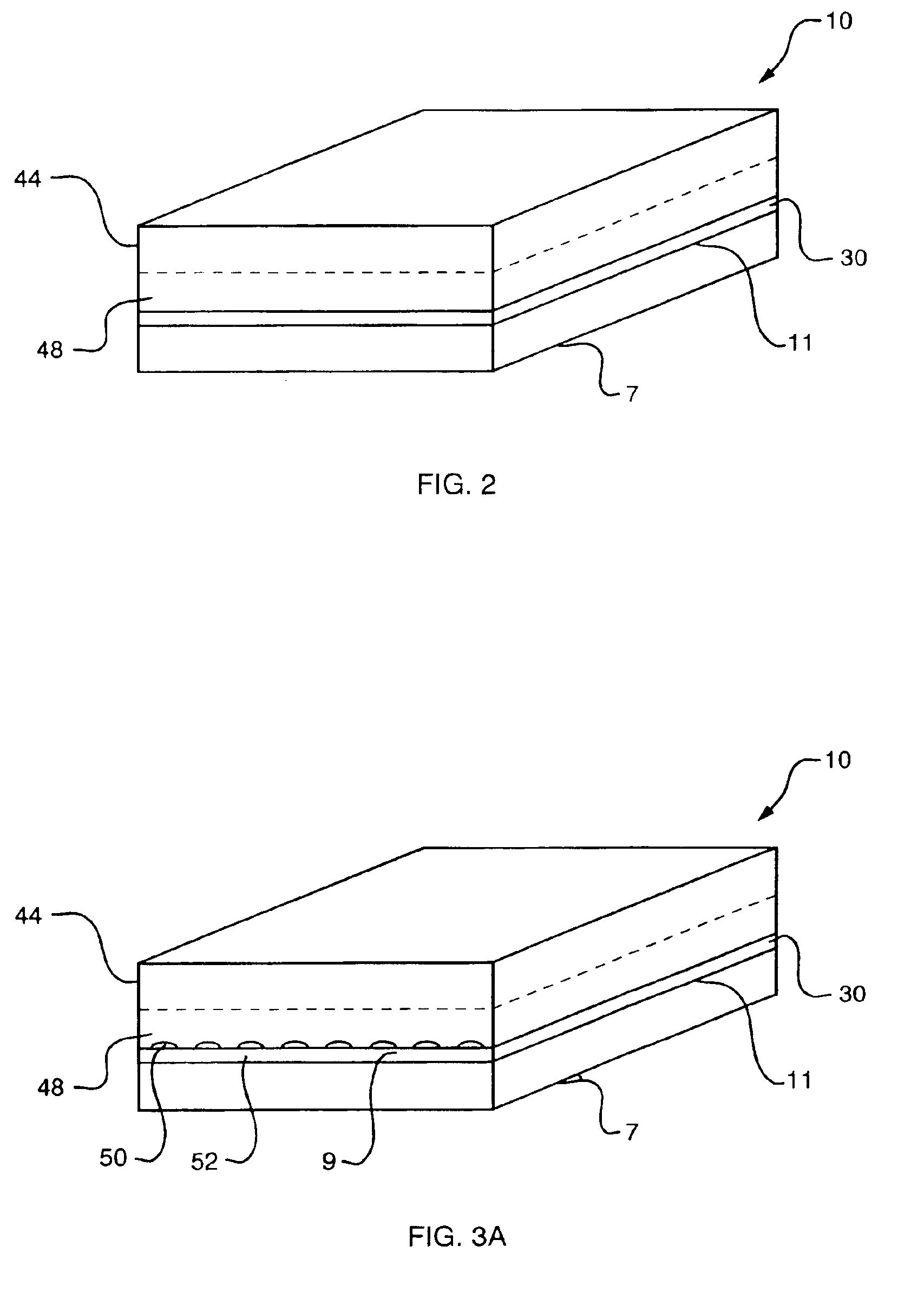

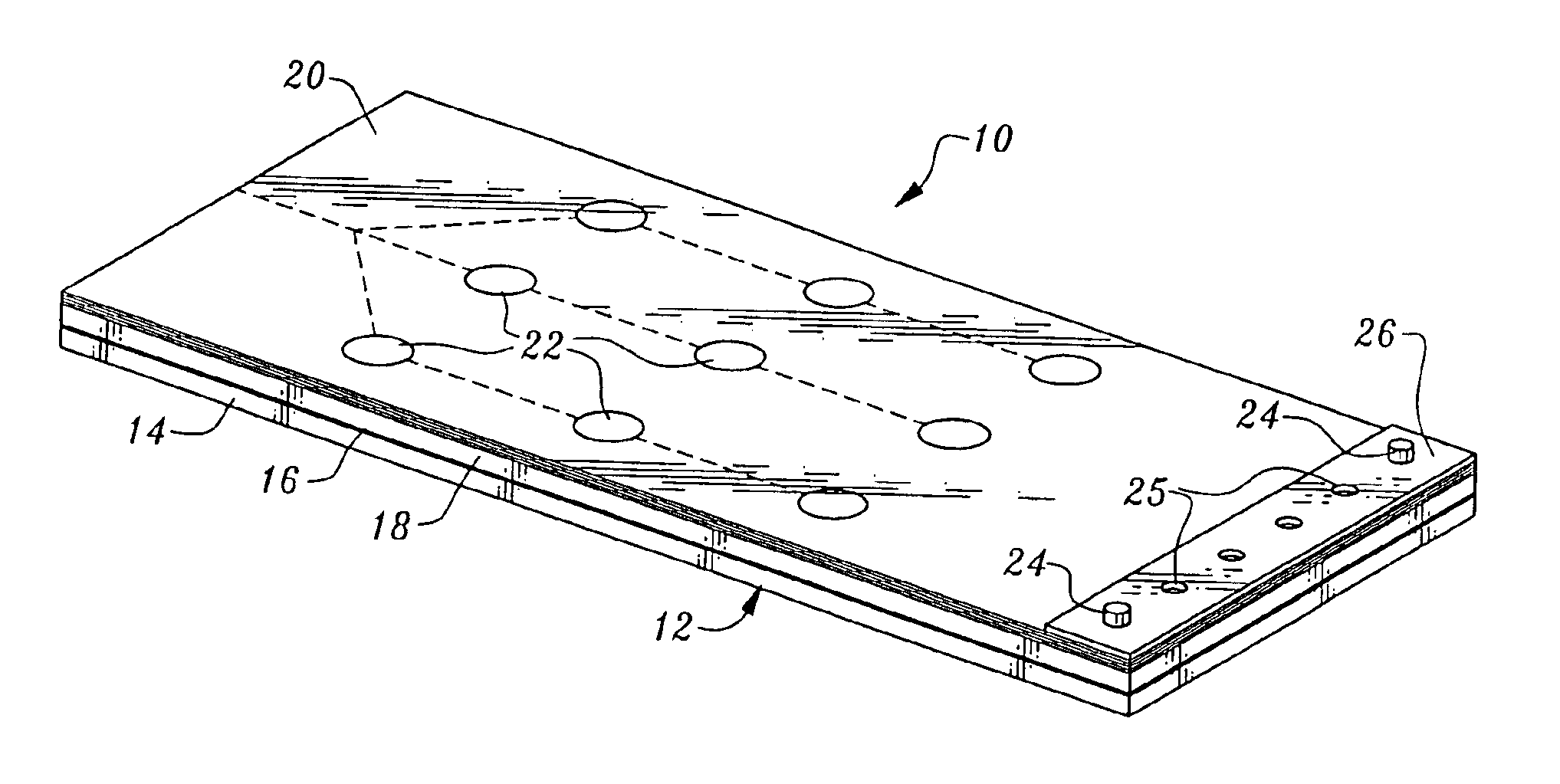

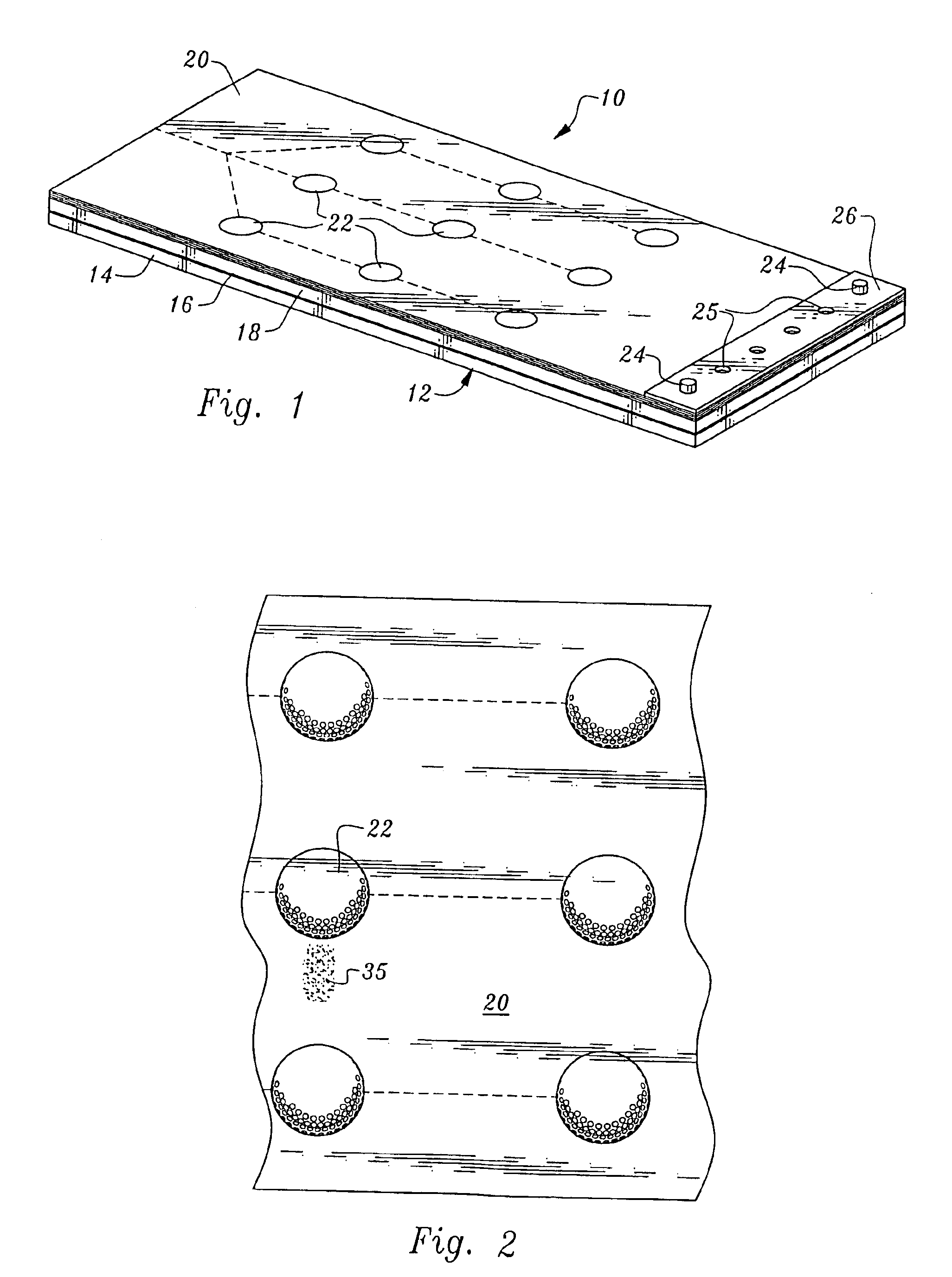

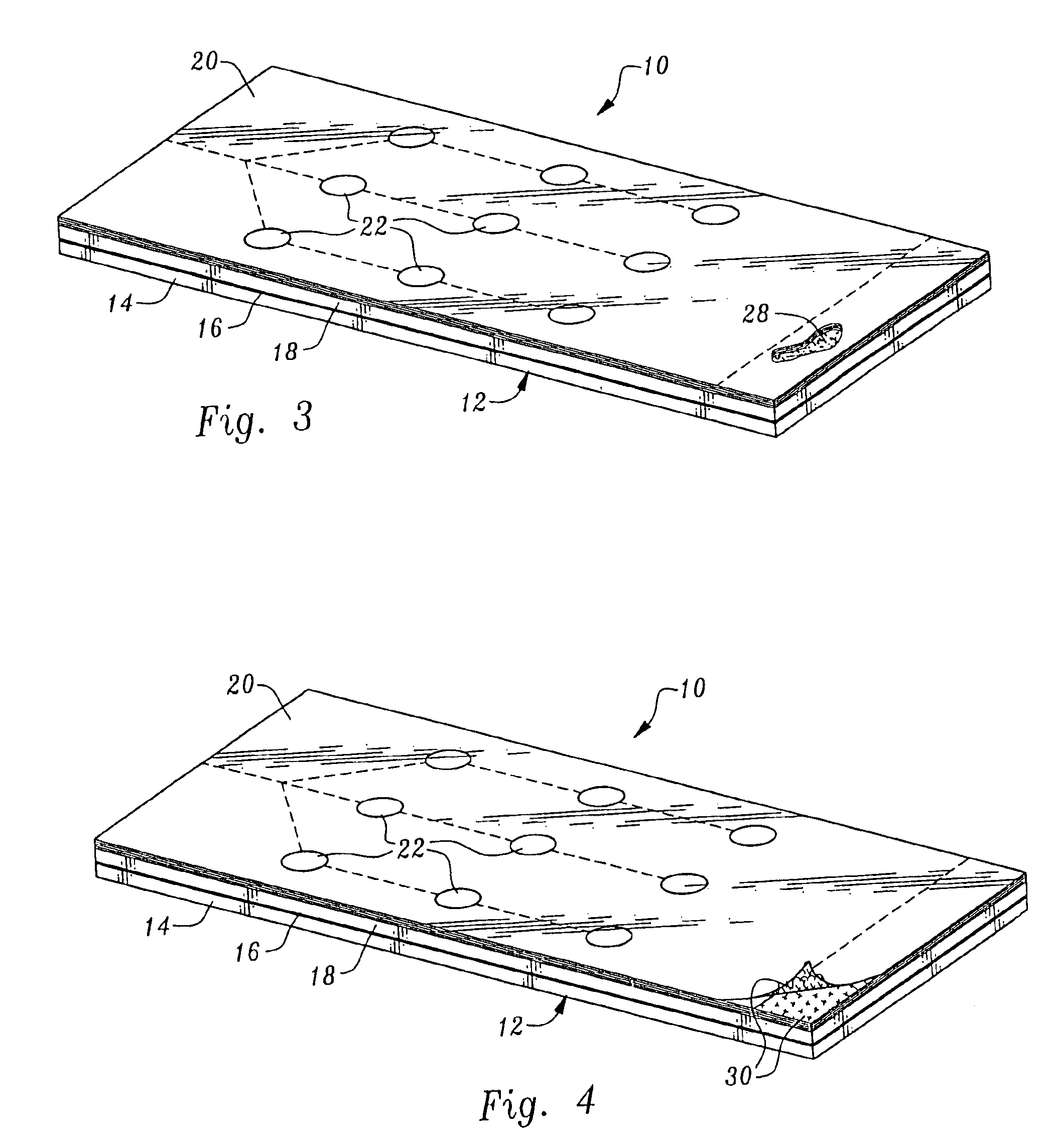

Modified diffusion layer for use in a fuel cell system

InactiveUS6890680B2Improve fuel efficiencyEasy to operateCell electrodesFuel cell auxillariesPreferential flowFuel cells

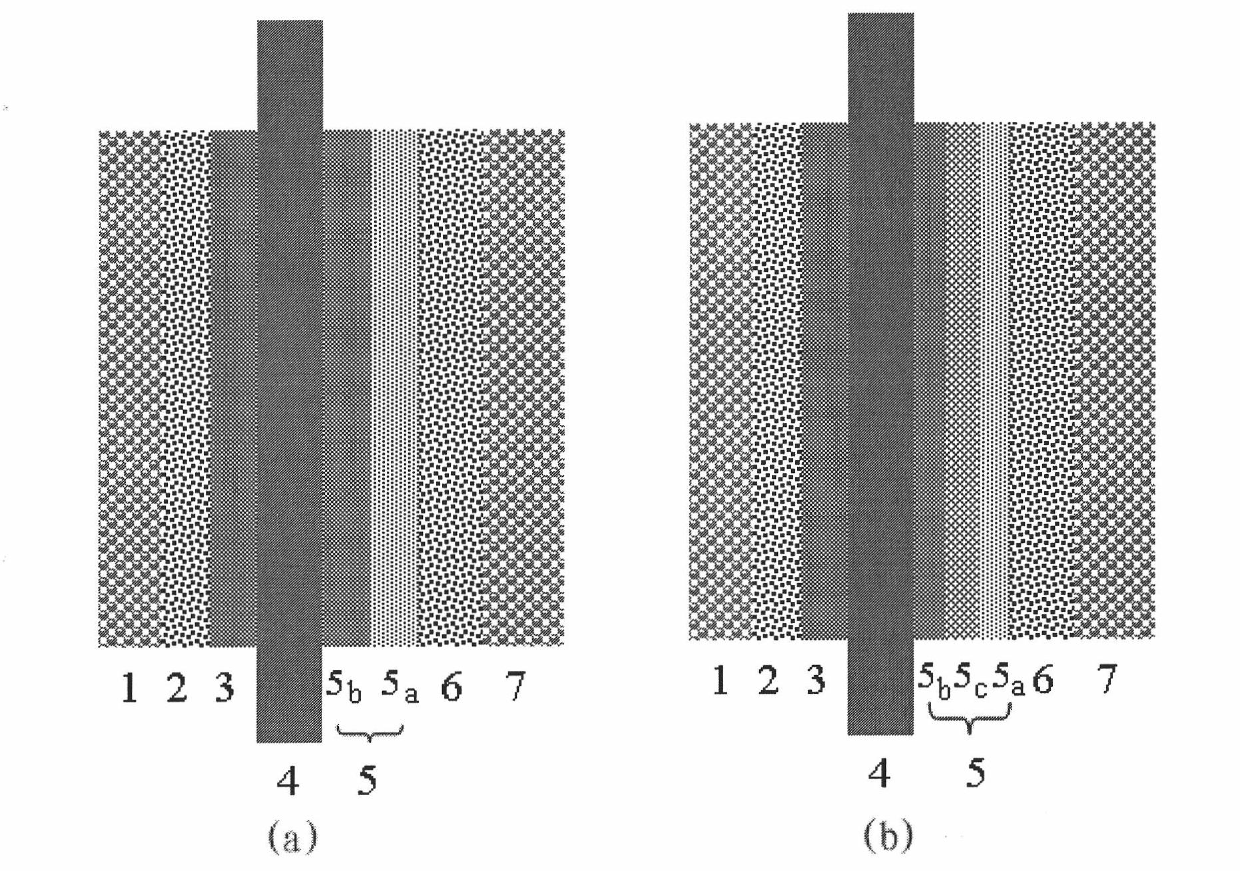

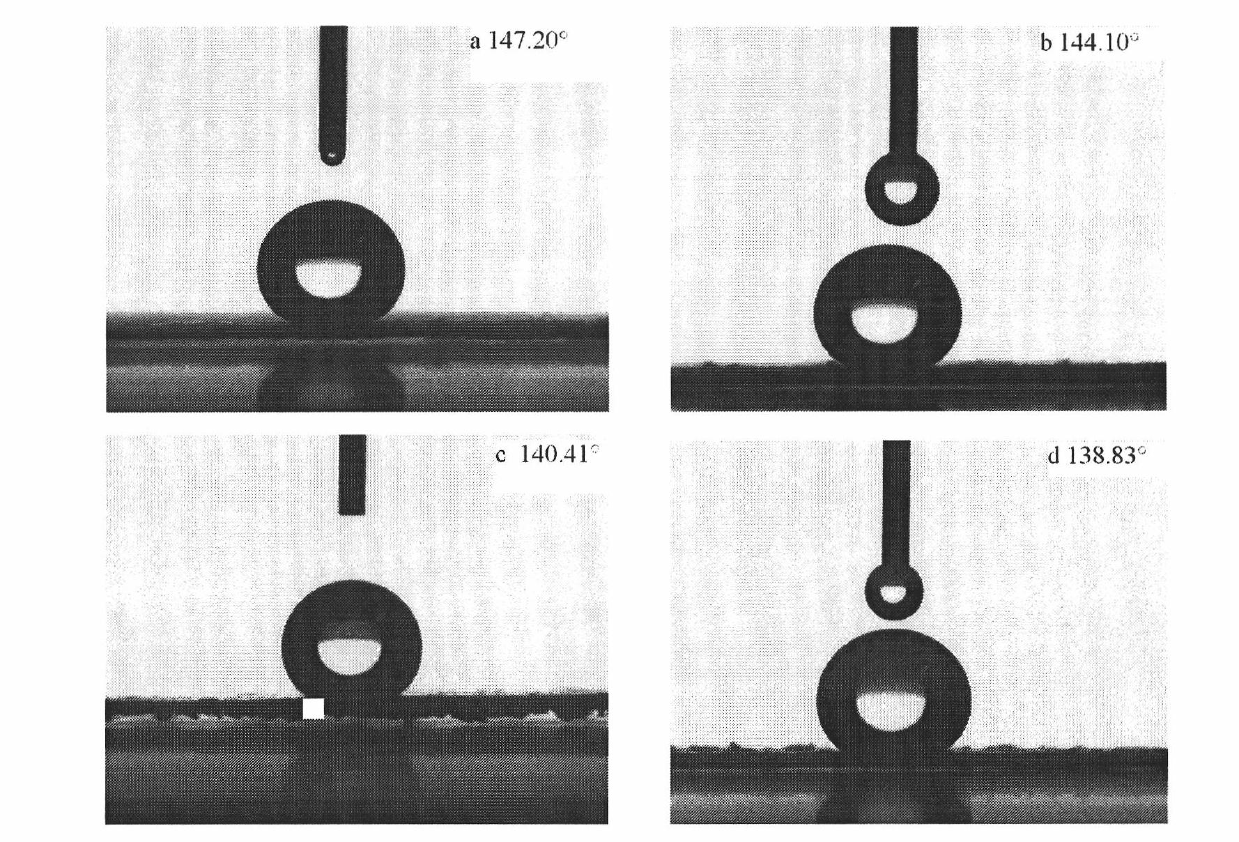

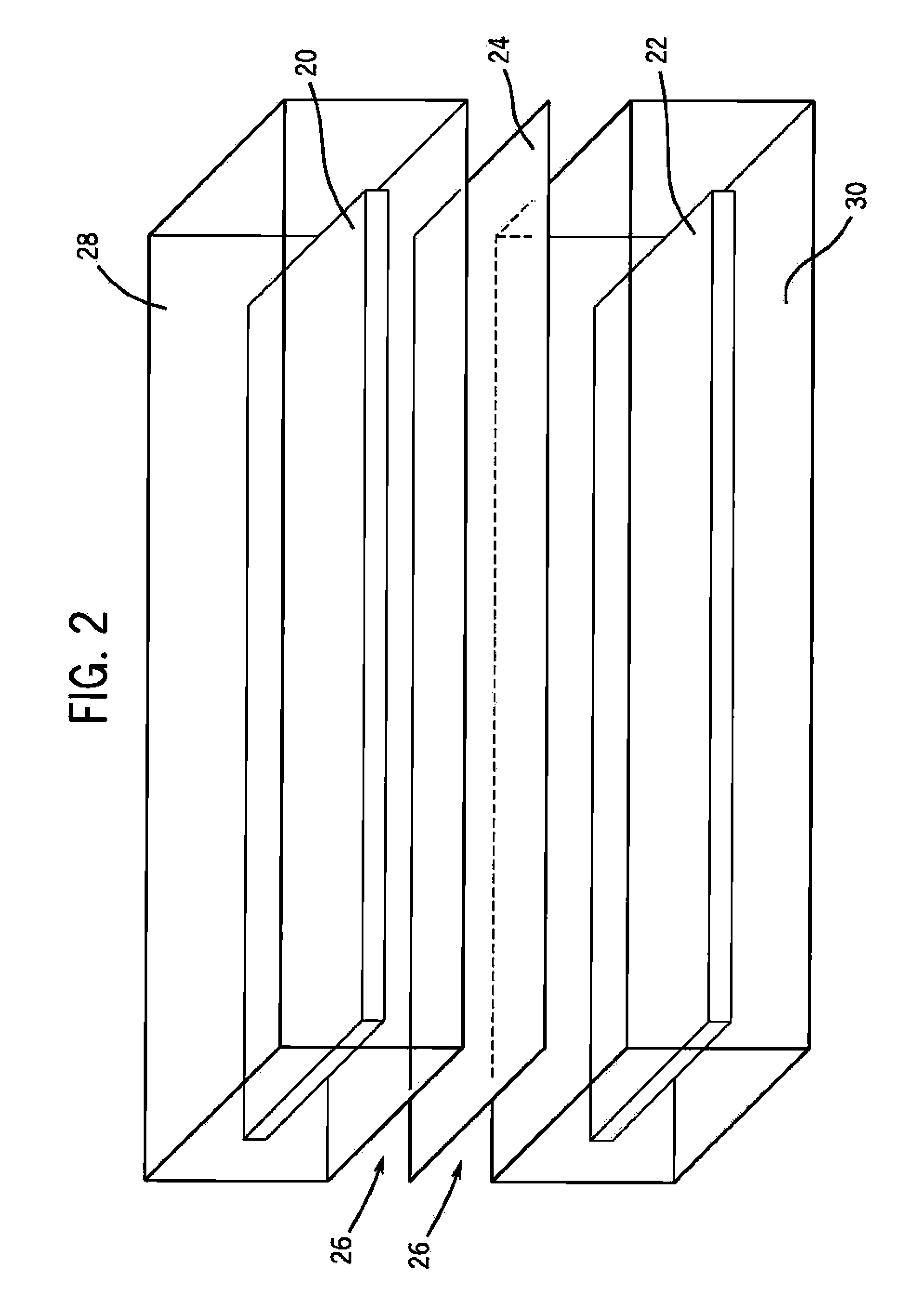

A fuel cell diffusion layer providing a preferential path by which liquid reactants or byproducts may be supplied to or removed from a direct oxidation fuel cell is described. The modified diffusion layer will be typically on the cathode side of the fuel cell and its use is to eliminate or minimize flooding of the cathode diffusion layer area, which is a performance limiting condition in direct methanol fuel cells. In accordance with one embodiment of the invention, the diffusion layer includes a substrate that is coated with a microporous layer. A pattern may be embossed into the diffusion layer, to create preferential flow paths by which water will travel and thereby be removed from the cathode catalyst area. This avoids cathode flooding and avoids build up of potentially destructive pressure by possible cathodic water accumulation. This also provides a means for collecting cathode water for redirection In accordance with another aspect of the invention, the preferential path is established by applying a thicker microporous layer to the carbon cloth or carbon paper and drying it in such a fashion so that when it dries, the surface of the microporous layer cracks to provide the pathways.

Owner:MTI MICROFUEL CELLS

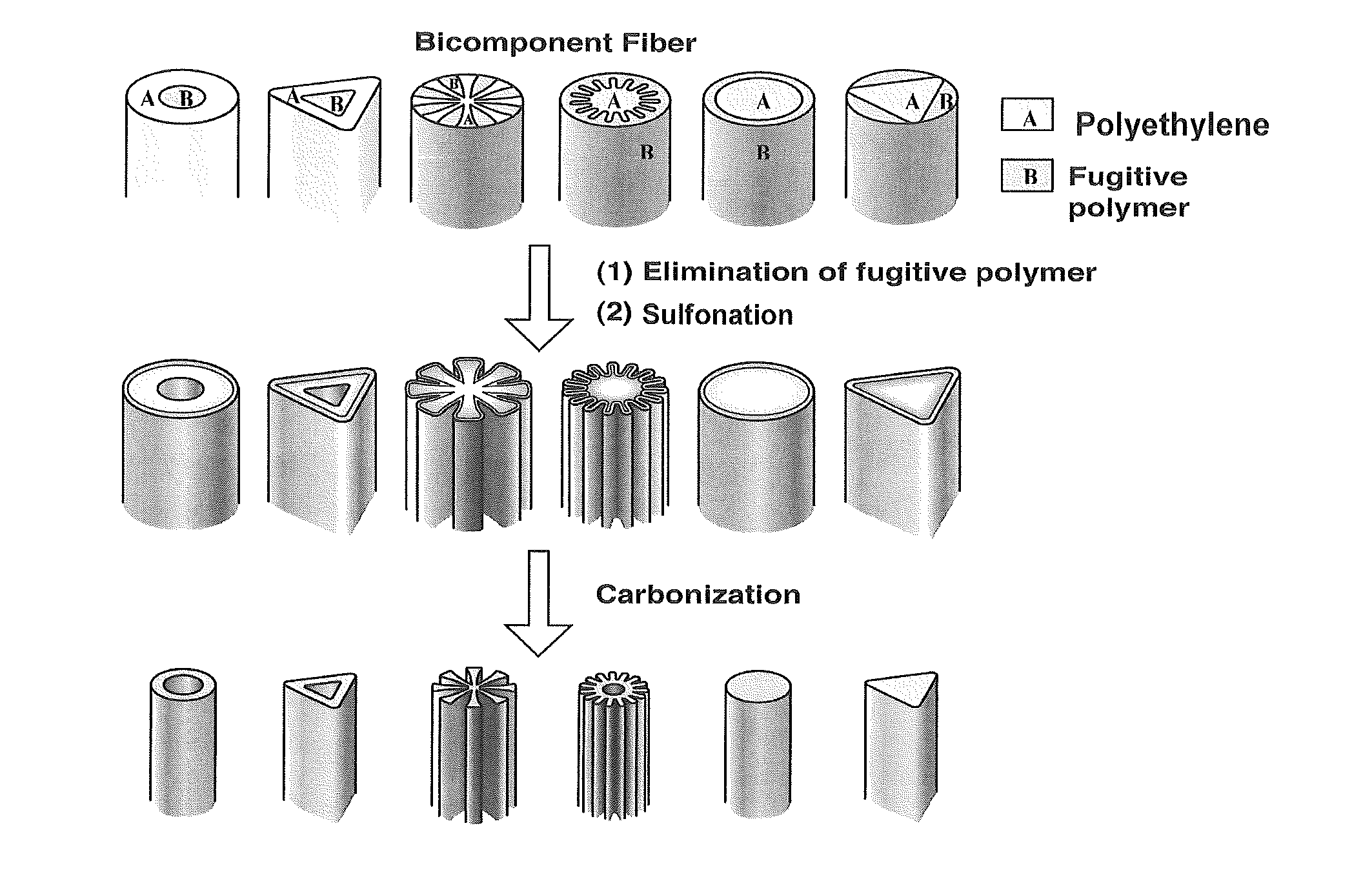

Method for production of carbon nanofiber mat or carbon paper

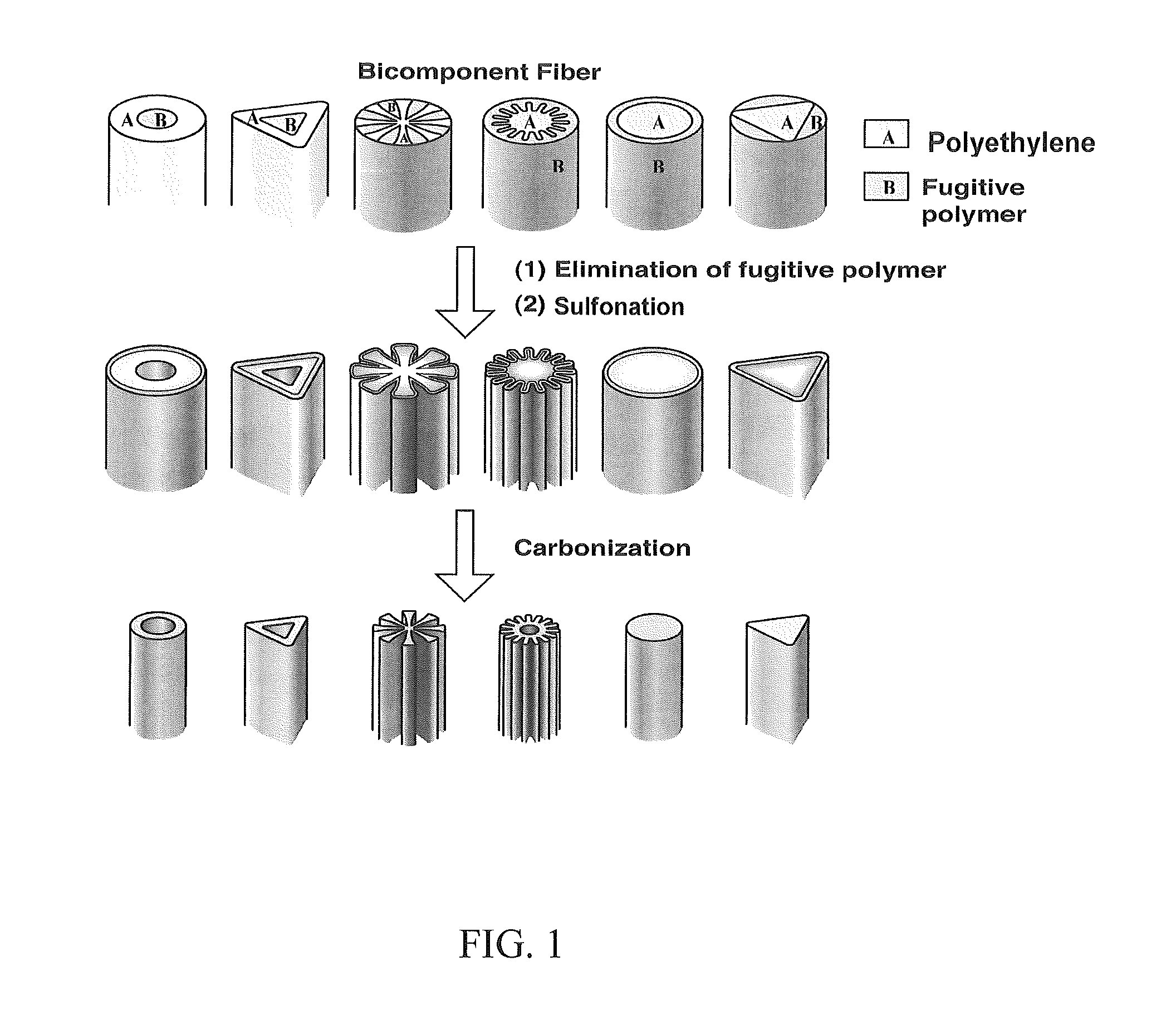

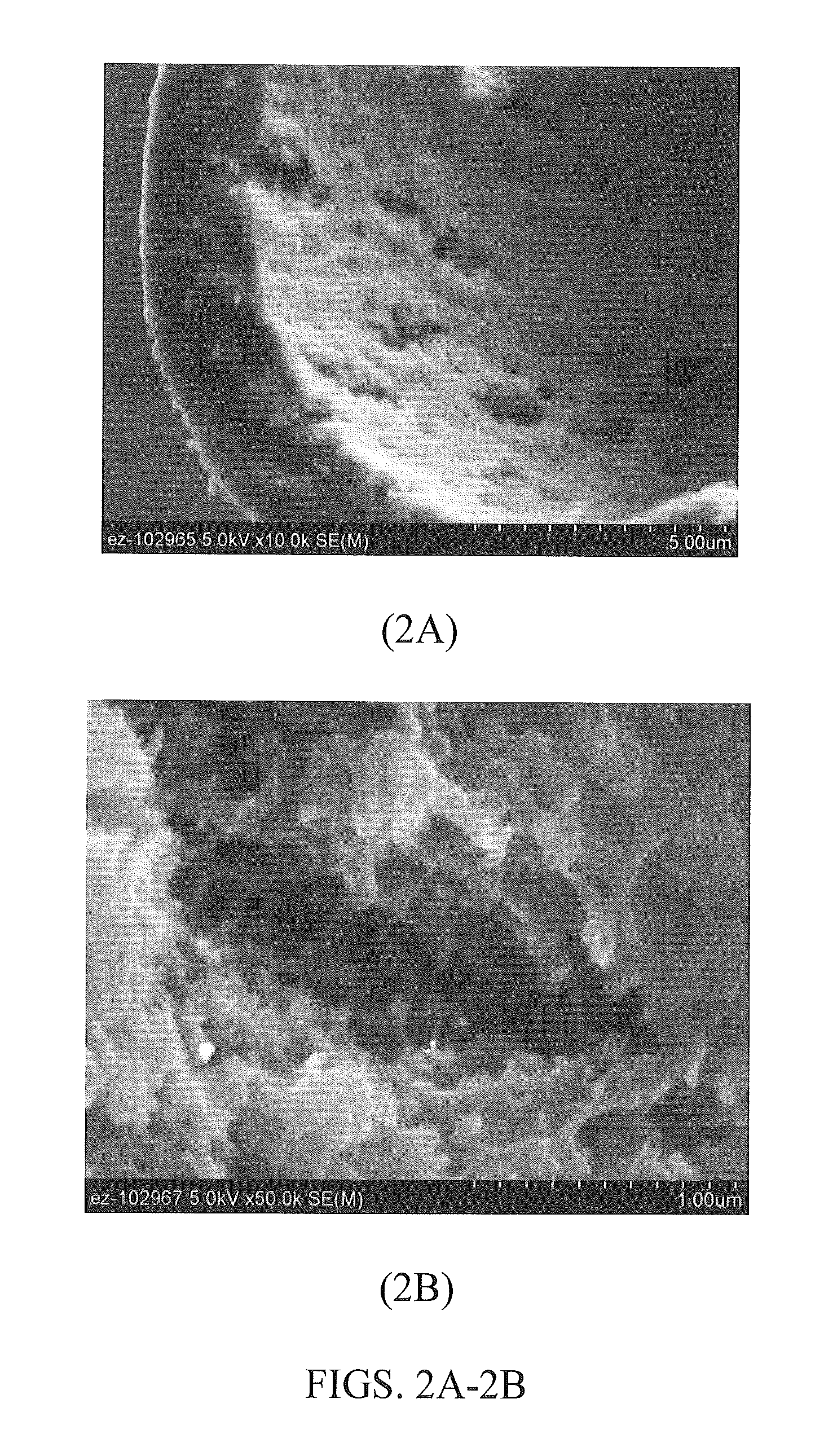

ActiveUS20130214442A1Economical and simpleHighly amenable to scaled up productionSynthetic cellulose/non-cellulose material pulp/paperWoven fabricsFiberPolyolefin

Method for the preparation of a non-woven mat or paper made of carbon fibers, the method comprising carbonizing a non-woven mat or paper preform (precursor) comprised of a plurality of bonded sulfonated polyolefin fibers to produce said non-woven mat or paper made of carbon fibers. The preforms and resulting non-woven mat or paper made of carbon fiber, as well as articles and devices containing them, and methods for their use, are also described.

Owner:UT BATTELLE LLC

Composite nanometer carbon paper and preparation method thereof

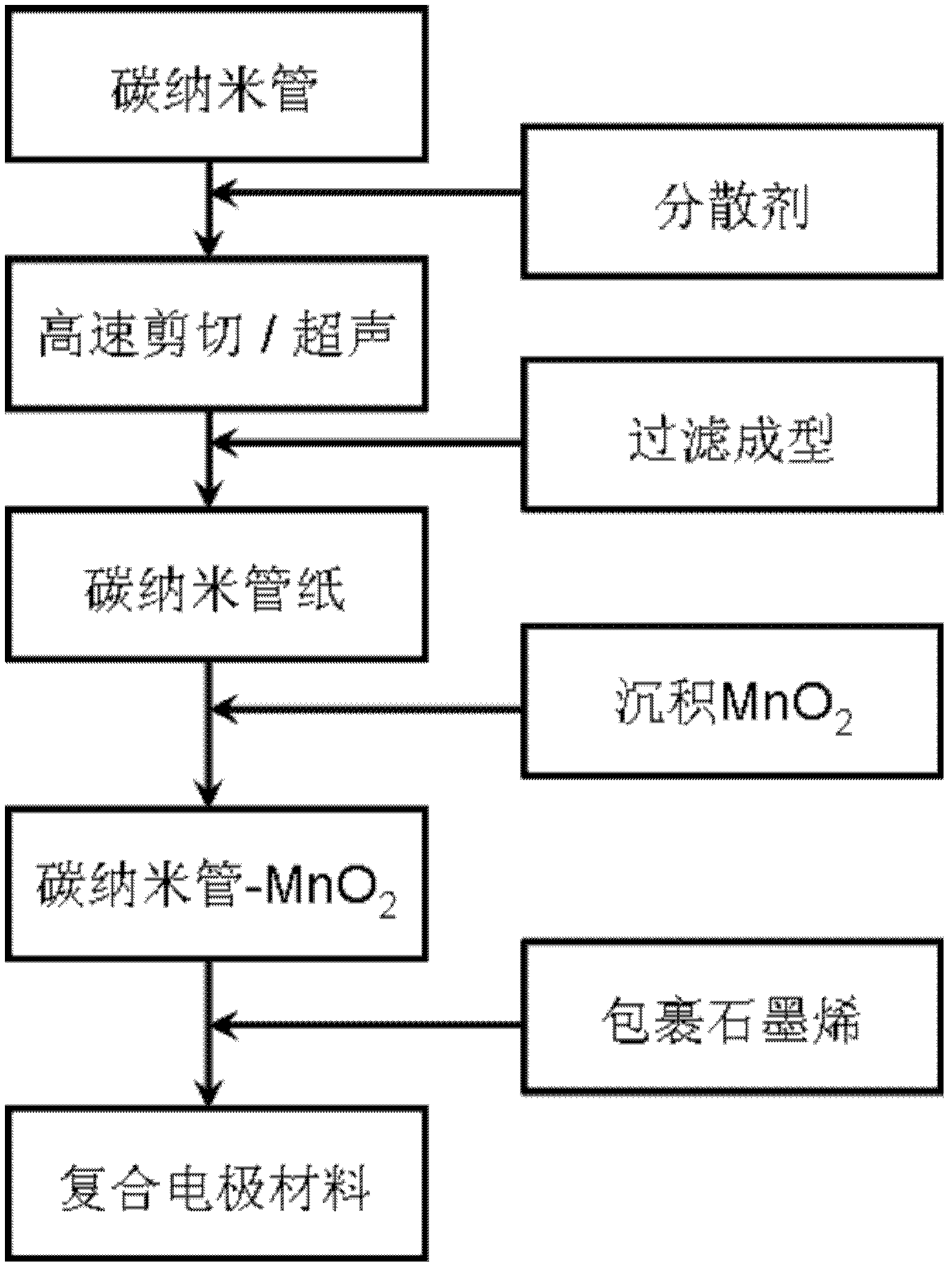

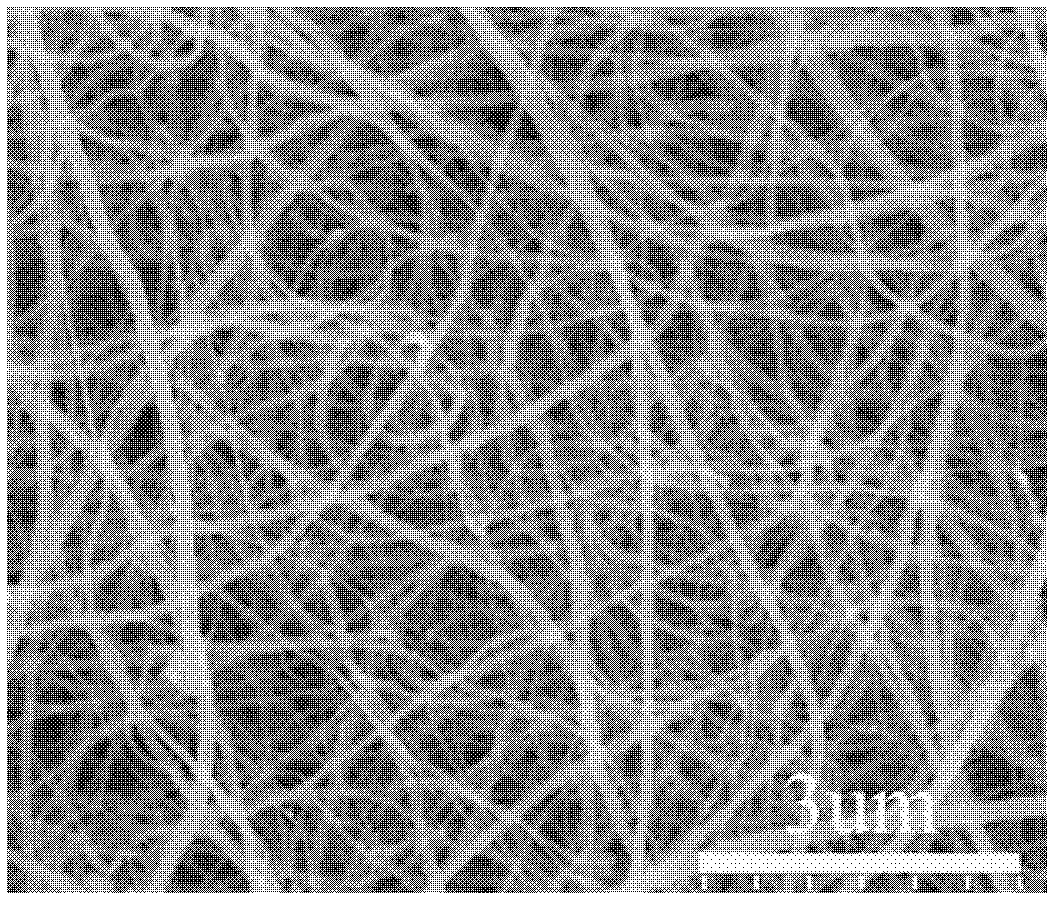

ActiveCN102436934AGood Faraday capacitance characteristicsLarge specific surface areaElectrolytic capacitorsLayered productsNew energyCarbon nanotube

The invention discloses composite nanometer carbon paper and a preparation method thereof. The nanometer carbon paper uses carbon nanometer paper as a framework network, MnO2 metallic oxides are deposited on the surface, the outer layer is covered with grapheme, and the composite nanometer carbon paper belongs to a flexible composite film material. The preparation method of the composite nanometer carbon paper comprises the steps that carbon nanometer tubes are dispersed in a solvent, then, the suction filtering is carried out to obtain carbon nanometer tube paper, next, the carbon nanometer tube paper is used as a carrier for depositing the MnO2 metallic oxides on the surface, and finally, the grapheme is adhered on the product surface to obtain target products. The electrical conductivity, the heavy current charging and discharging capability, the specific capacitance and the cycle life of the composite nanometer carbon paper are respectively and obviously enhanced through being compared with those of the carbon nanometer tube-MnO2, the problems that in the existing super capacitor, the metallic oxides easily fall off from the surface of the carbon nanometer tubes, the electrical conductivity of the metallic oxides is poor, and the like are solved, the composite nanometer carbon paper also has the characteristics of light weight and flexibility of materials and high efficiency, simultaneously, the preparation process is simple, the operation is easy, the controllability is good, and in addition, the cost is low. The composite nanometer carbon paper and the preparation method have wide application prospects in fields of new energy sources, advanced chemical engineering, electronic devices, film preparation and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

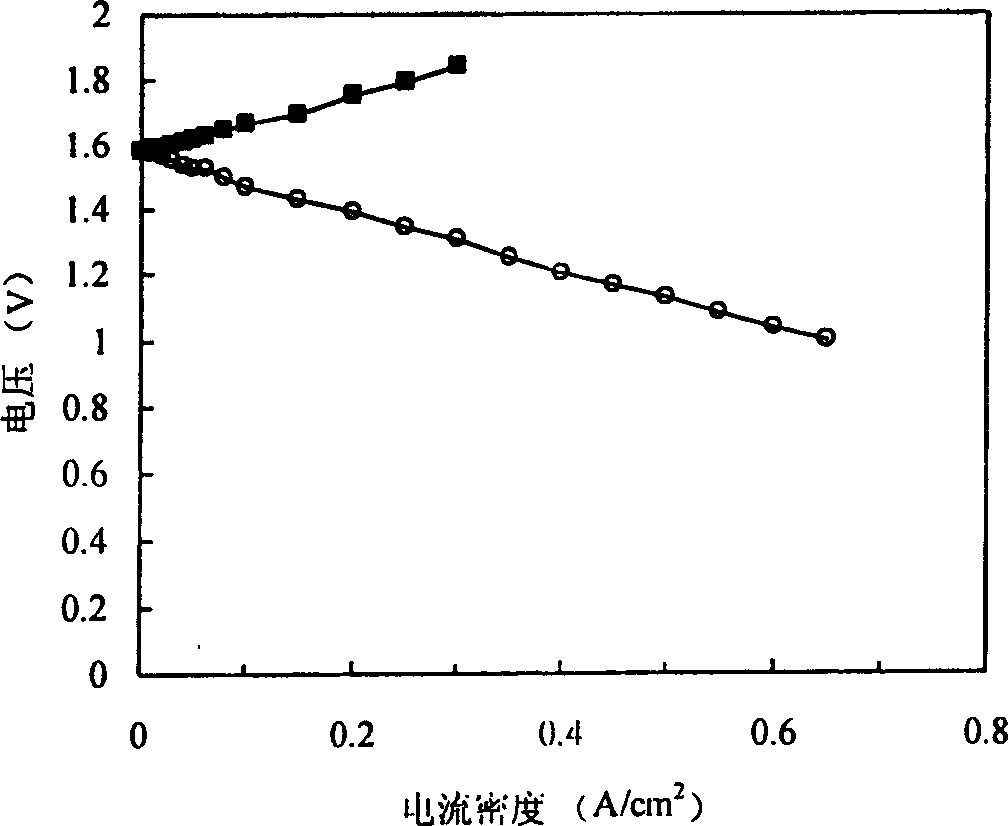

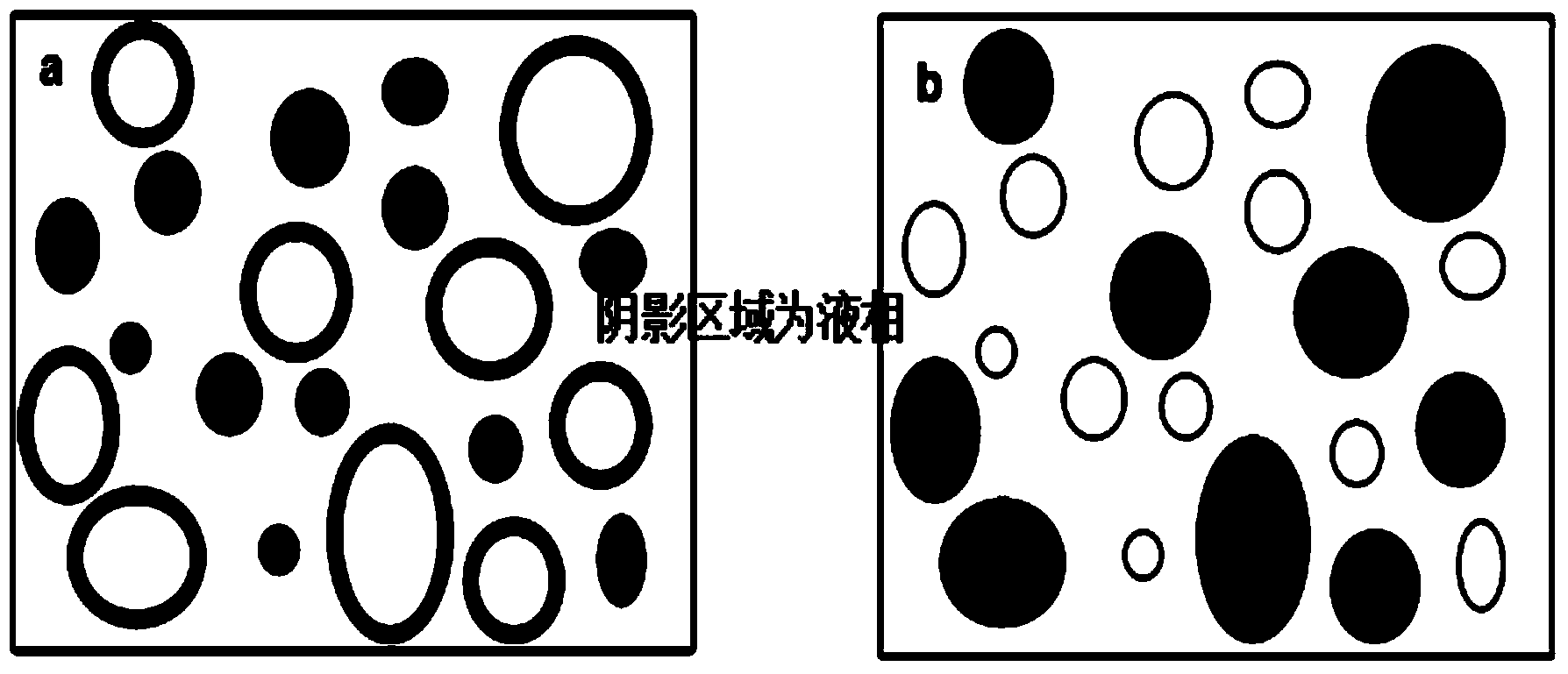

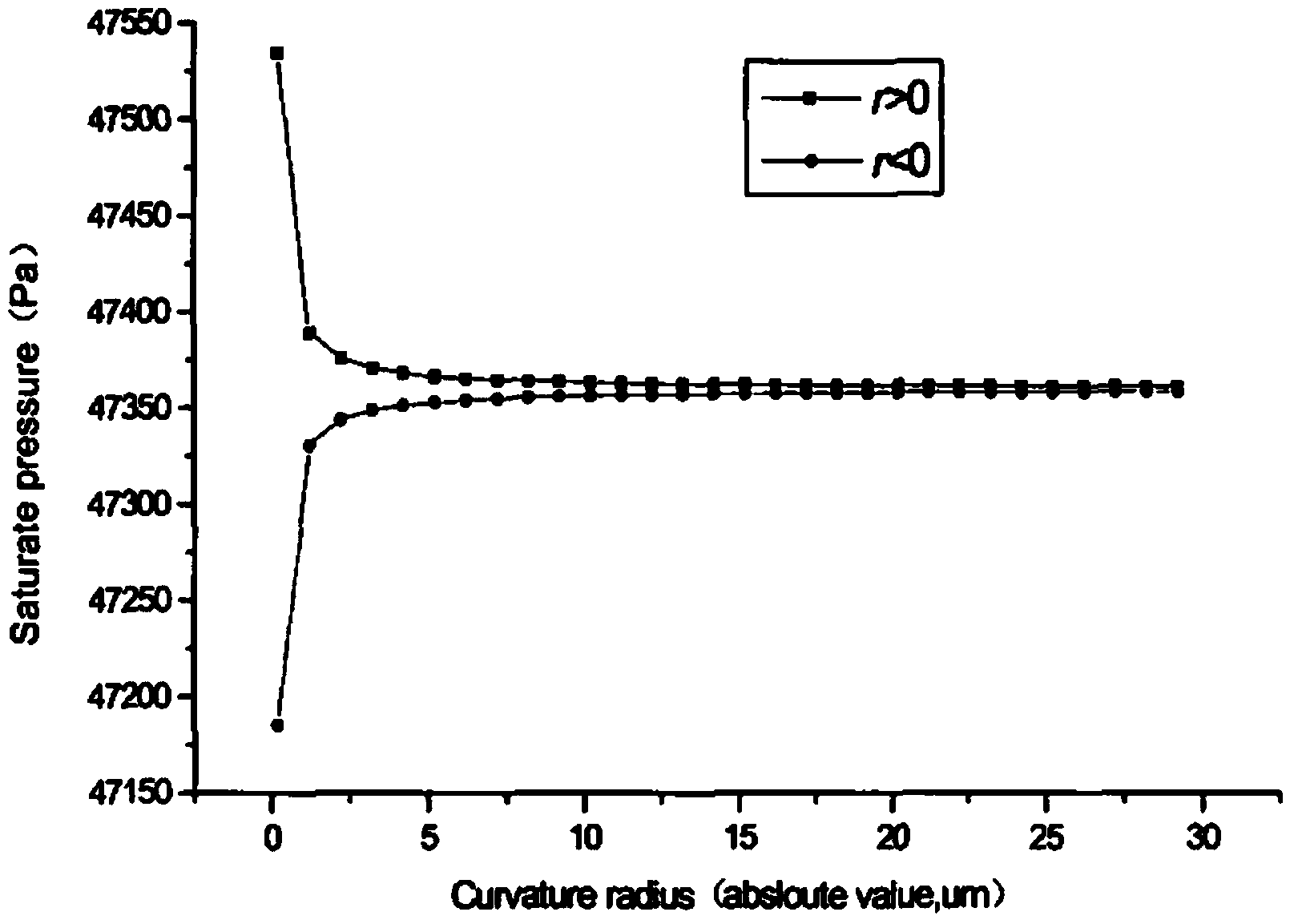

Method for preparing double-microporous layers for improving performance of fuel batteries

The invention provides a method for preparing double-microporous layers for improving the performance of fuel batteries. The method is characterized by comprising steps of preparing first slurry with uniform components from high-conductivity materials, pore forming agents, hydrophobic agents and dispersion liquid by means of stirring; coating the prepared first slurry on carbon paper or carbon cloth by means of screen printing to form a first coating layer; spraying second slurry with a preset thickness on the surface of the carbon paper or carbon cloth to form a second spraying layer; carrying out heat treatment to form loose, porous, hydrophilic and hydrophobic gas reaction channels. The carbon paper or carbon cloth is subjected to hydrophobic treatment before the first slurry is coated. The second slurry comprises high-conductivity materials, hydrophobic agents and dispersion liquid. The method has the advantages that operation procedures are simple, the method has low requirements on equipment, the pore diameters and the porosity of the double-microporous layers are sequentially reduced from the surface of the carbon paper to the surfaces of microporous layers, the double-microporous layers are high in flatness, damage to proton exchange membranes can be reduced, the service lives of membrane electrode assemblies can be prolonged, and the electric performance can be improved.

Owner:SUNRISE POWER CO LTD

Expansion graphite base compound material dual-pole board and its making method

InactiveCN101101994AAccelerated corrosionImprove antioxidant capacityCell electrodesFinal product manufactureEmulsionProton

The invention is concerned with double plate of the proton exchange film fuel battery and it's making method. It is to have the two layers of the expansion graphite material and the mesosphere carbon cloth or carbon paper put in the double plate module with the gas flow field for molding; All of the molding materials dip inside the emulsion or solution of the thermoplastic resin with the solid content 10-50wt%; the expansion graphite material is the graphite in helminthes state.

Owner:WUHAN UNIV OF TECH

Composite conductive paper of carbon fiber

InactiveCN101003956AHigh porosityImprove conductivityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The present invention discloses a composite conductive carbon fiber paper. Its preparation process includes the following steps: using acrylonitrile carbon fiber and other carbon material as raw material, adopting polyphenylamine, conventional polyvinyl alcohol and water-soluble phenolic resin and mixing them, and using their mixture as adhesive, the polyphenylamine is conductive high-molecular polymer; mixing sodium alginate and conventional dispersing agent; adopting wet-process paper-making technique to make paper; vacuum drying the obtained carbon paper, then using Teflon emulsion whose concentration is 5%-20% to make treatment; finally, introducing nitrogen gas and making carbonization, carbonization temperature is higher than 1000 deg.C, so as to obtain the invented composite conductive carbon fiber paper. Said composite conductive carbon fiber paper mainly is used in fuel cell field.

Owner:DONGHUA UNIV

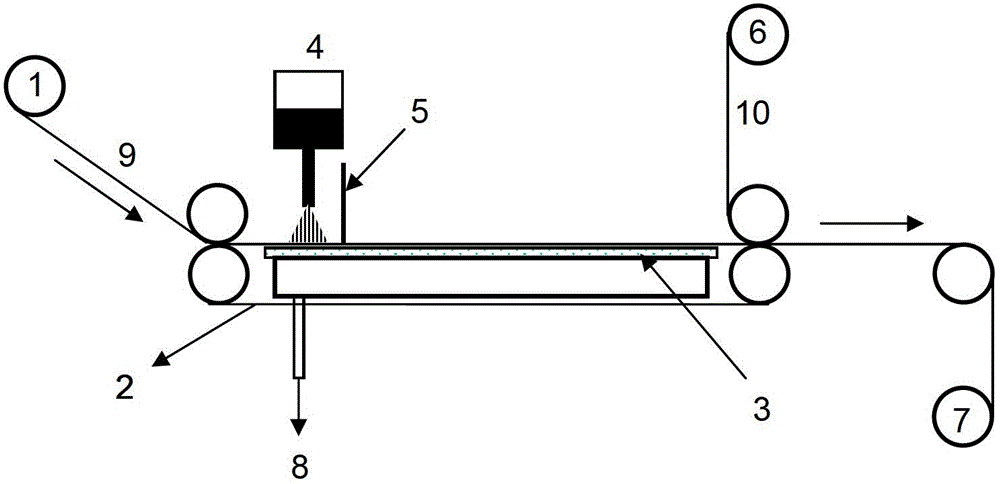

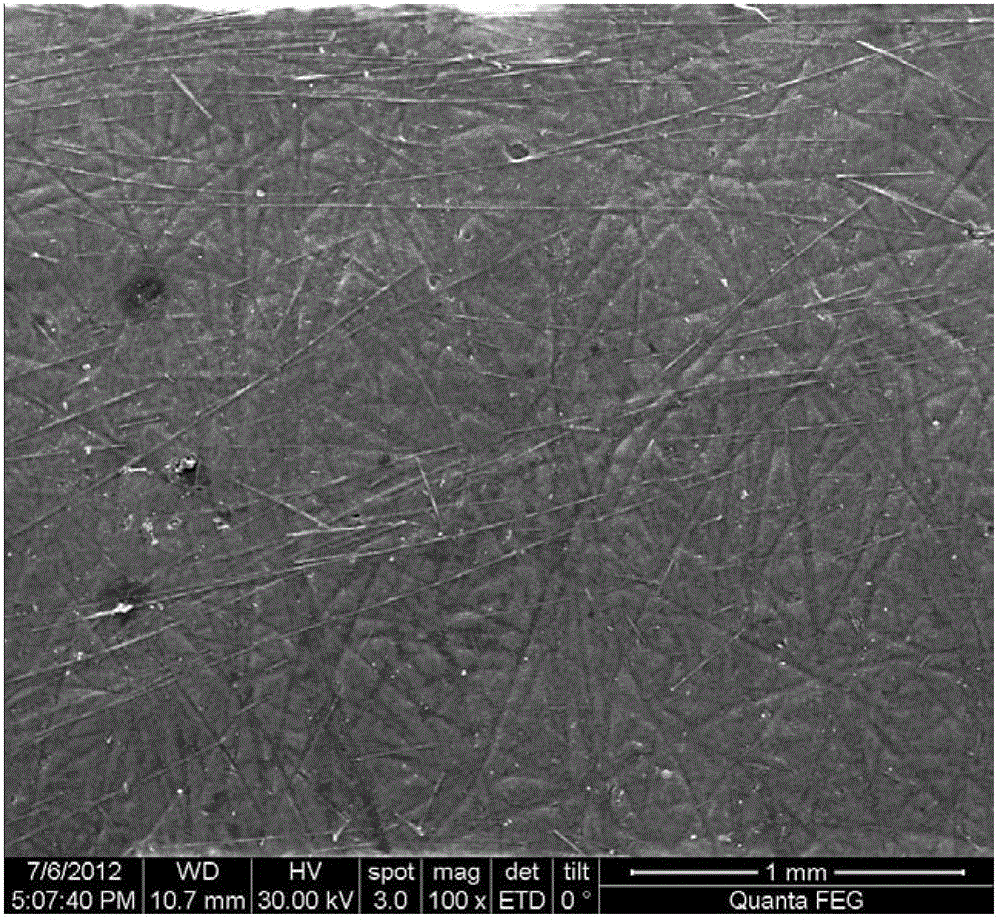

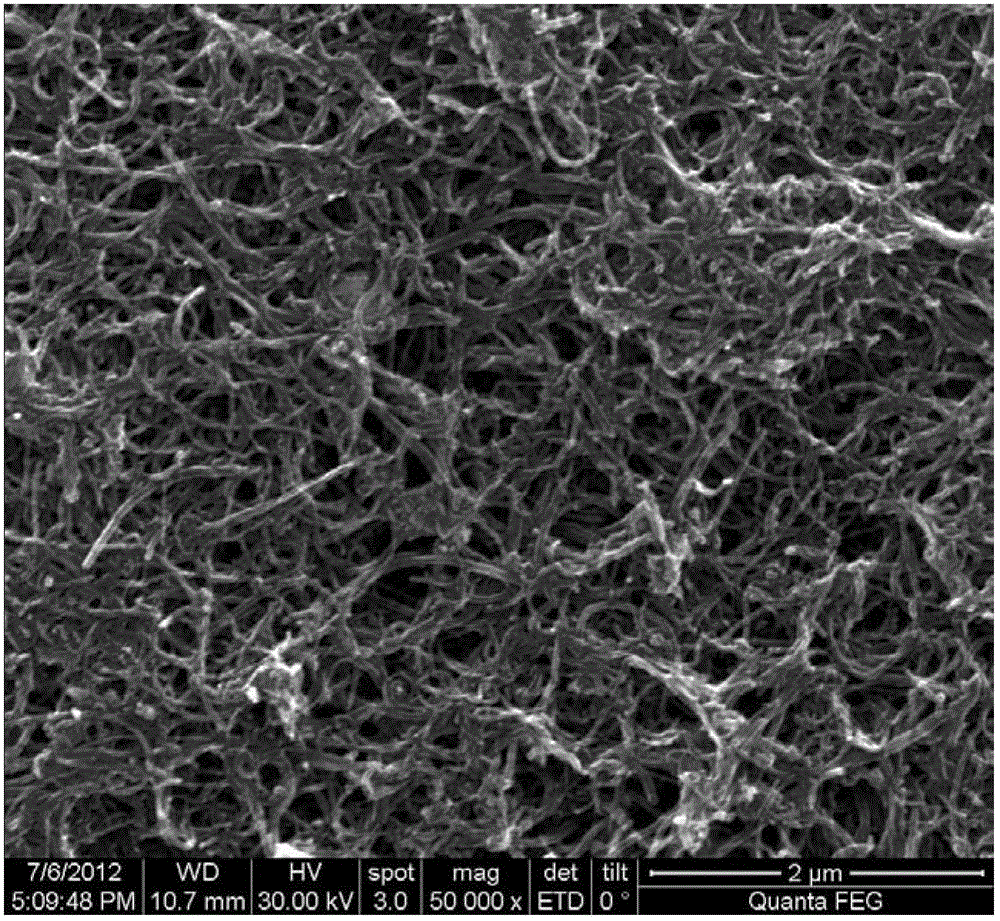

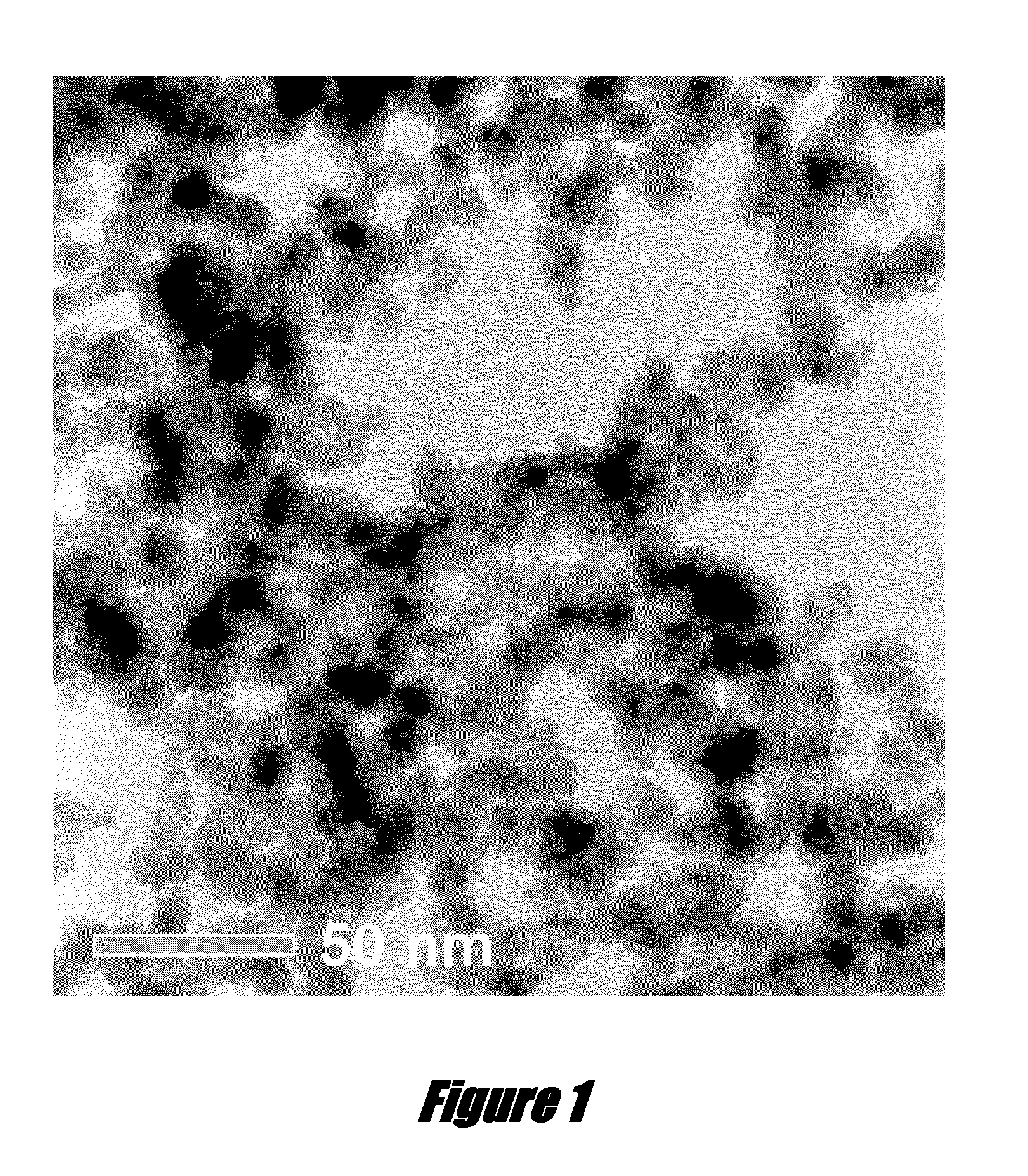

Carbon nanotube/short-fiber composited nano-carbon paper and continuous preparation method thereof

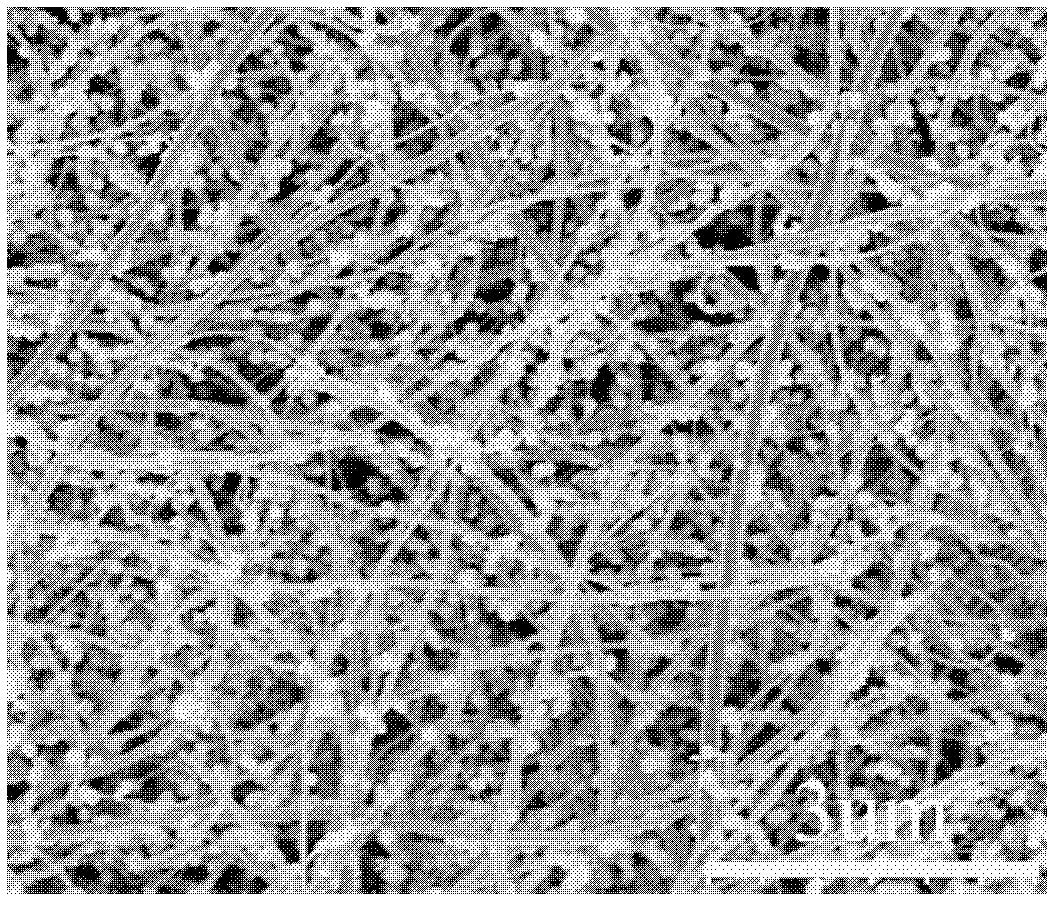

InactiveCN102877367AGuaranteed FeaturesOvercoming the lack of brittlenessSpecial paperPaper/cardboardNanostructured carbonNonwoven fabric

The invention provides a kind of carbon nanotube / short-fiber composited nano-carbon paper and a continuous preparation method thereof. The nano-carbon paper mainly comprises disordered carbon nanotubes and short fibers, and is in a non-woven form. The preparation method of the nano-carbon paper comprises the following steps that: the disordered carbon nanotubes are dispersed in a solvent so as to form a dispersion liquid; then, mixing and dispersing the short fibers so as to form a size; preparing an initial film through vacuum assisted flow-casting film-forming; and then, removing polymers in the initial film through subsequent processing so as to obtain a target product. The composited nano-carbon paper disclosed by the invention integrates the huge specific surface areas, superior conductivity and functional characteristics of the carbon nanotubes and the enhancement effect of the short fibers on the strength and flexibility of the carbon paper, therefore, the composited nano-carbon paper is good in self-supporting property and flexibility; meanwhile, through the direct film-forming implemented by using a flow-casting method, the continuous film-forming of the nano-carbon paper is realized, therefore, the nano-carbon paper has the advantages of high efficiency, rapidness and easy large-scale preparation. The composited nano-carbon paper disclosed by the invention has a wide application prospect in the fields of energy electrodes, catalytic carriers, environmental management, static resistance, electromagnetic shielding, wave-absorbing camouflage, and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

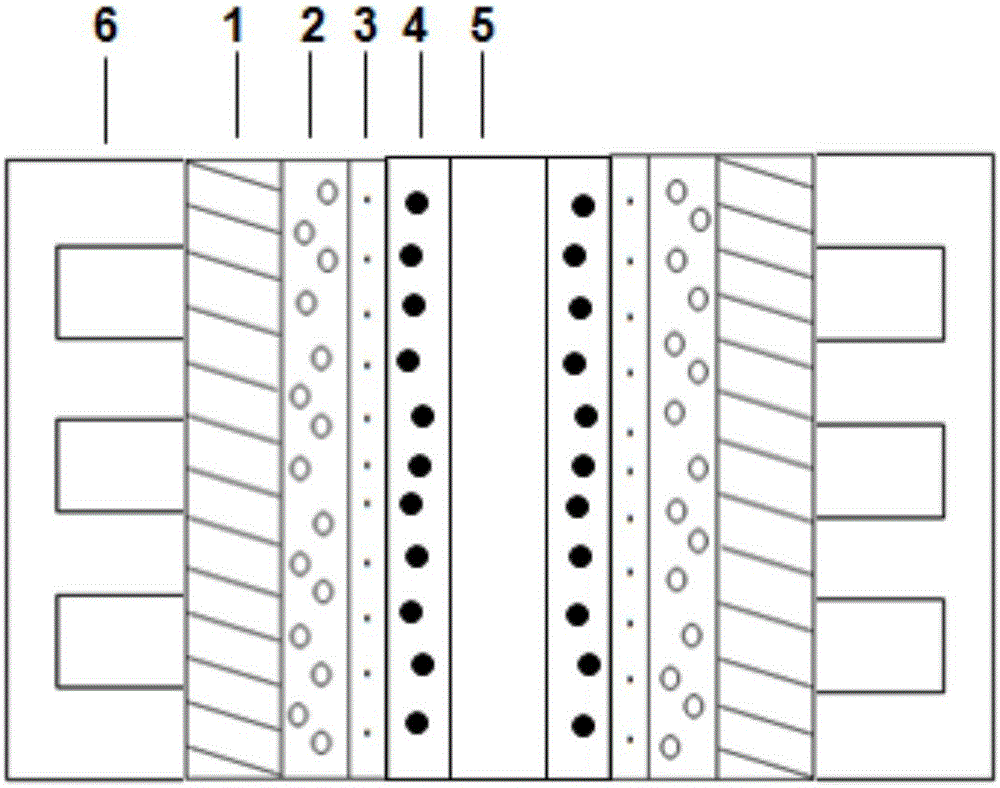

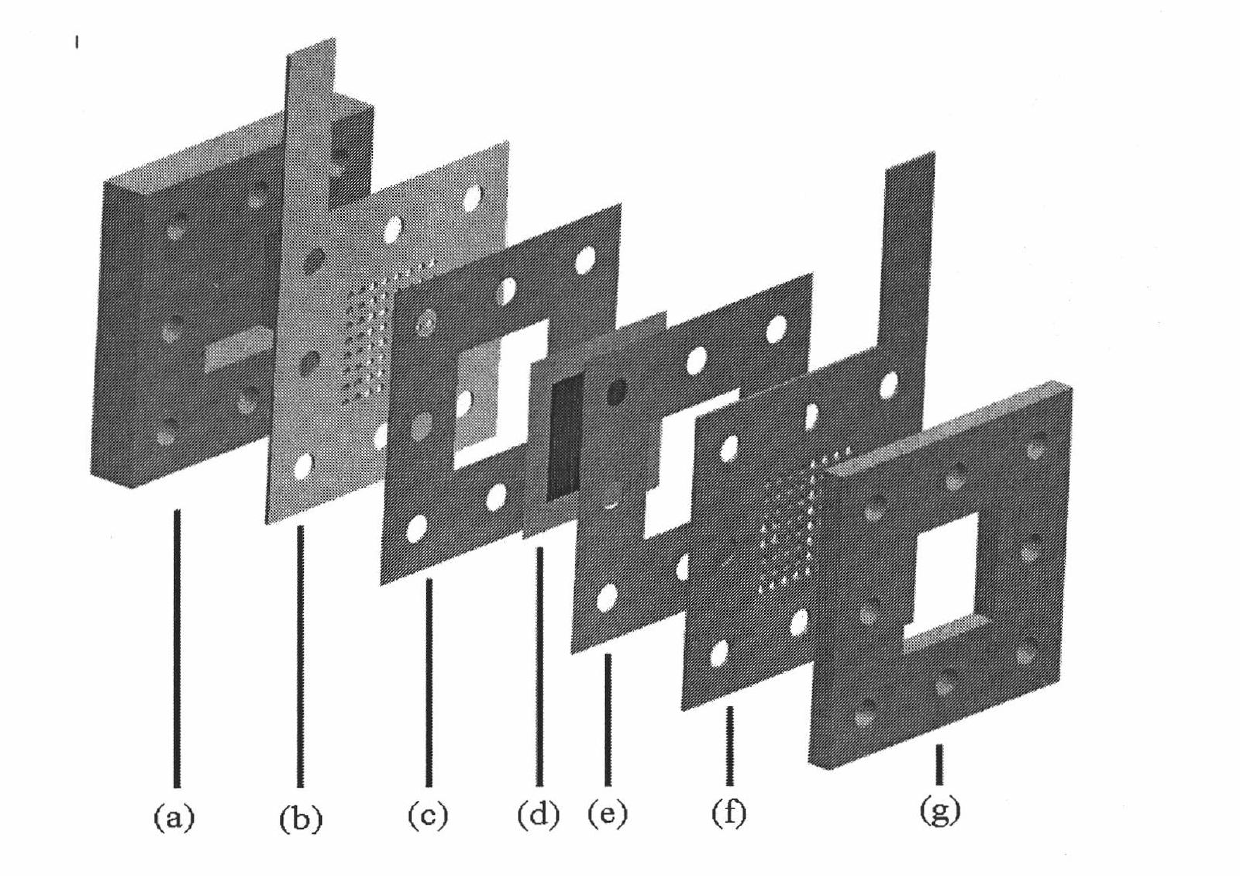

Structure of direct alcohol fuel cell membrane electrode aggregate and preparation method thereof

InactiveCN102005582AImprove transmission efficiencyImprove utilization efficiencyCell electrodesAlcohol fuelCell membrane

The invention relates to a structure of a direct alcohol fuel cell membrane electrode aggregate. The membrane aggregate sequentially comprises a support layer, an anode micropore layer, an anode catalysis layer, a Nafion film, cathode catalysis layers, a cathode micropore layer and a cathode support layer. The structure is characterized in that the cathode catalysis layers are in hydrophobic and graded distribution, i.e. dual layers, three layers or multiple layers of prepared cathode catalysis layers the hydrophobicity of which is gradually changed; and a preparation method of the membrane aggregate comprises the following steps of: with carbon paper or carbon cloth as the support layer, coating a micropore dispersion layer formed by various carbon materials and a polytetrafluoroethylenebinder according to the requirements; then coating slurry formed by a precious metal-based catalyzer, Nafion resin and the like; and carrying out hot pressing on an anode and a cathode and the Nafionfilm through a proper hot treatment step and the like under certain conditions to obtain MEA (Mono Etobaccool Amine). Because the cathode catalysis layer structure in the hydrophobic and graded distribution improves the mass transfer of cathode oxygen and the catalyzer use ratio, the power density and the discharging stability are improved.

Owner:上海新微科技集团有限公司

Compositions of nanometal particles containing a metal or alloy and platinum particles for use in fuel cells

Owner:QUANTUMSPHERE

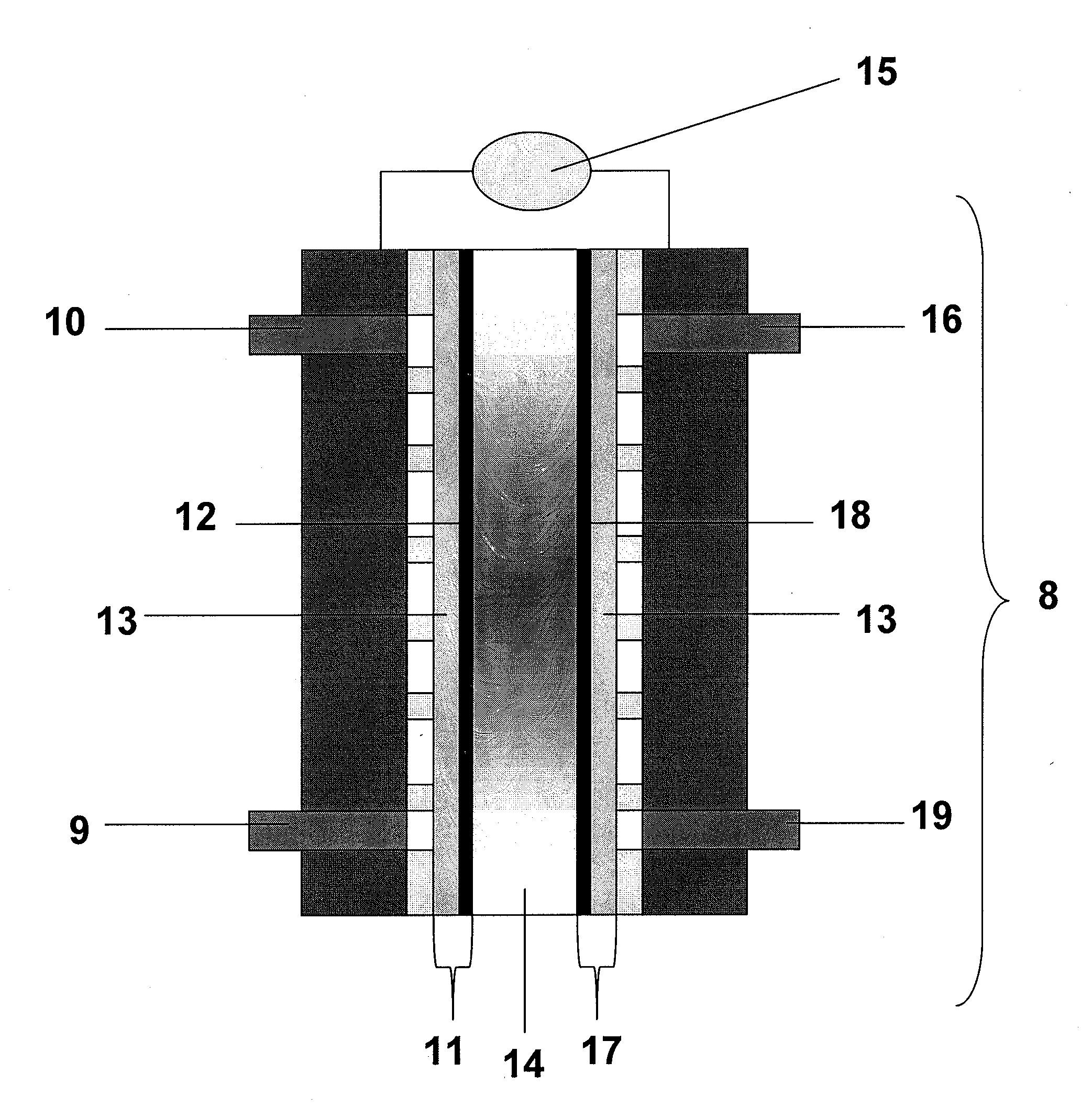

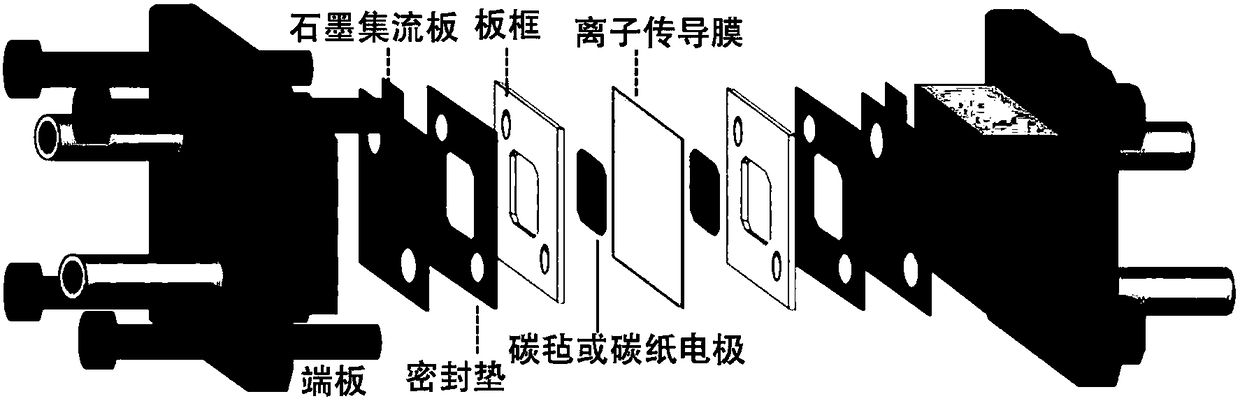

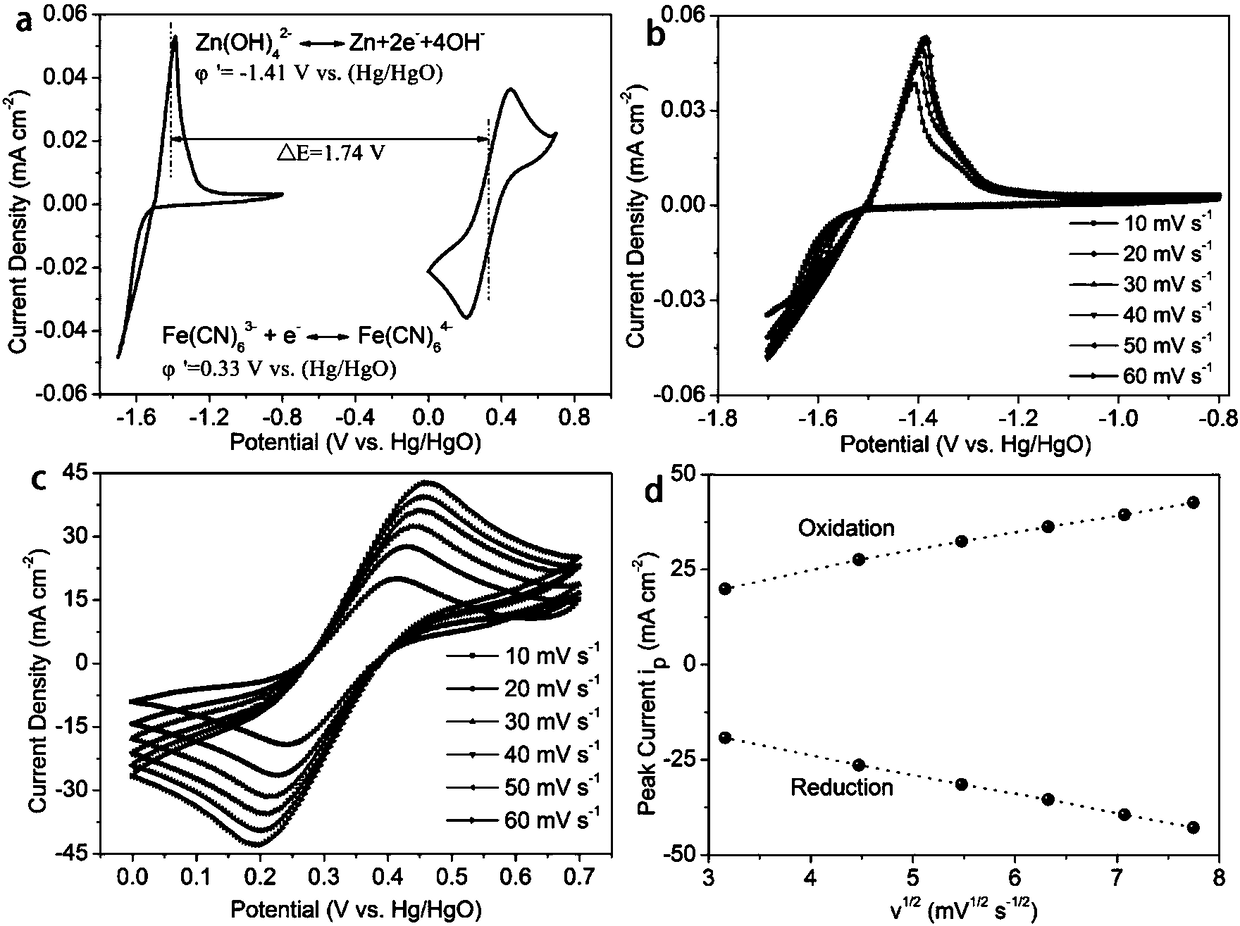

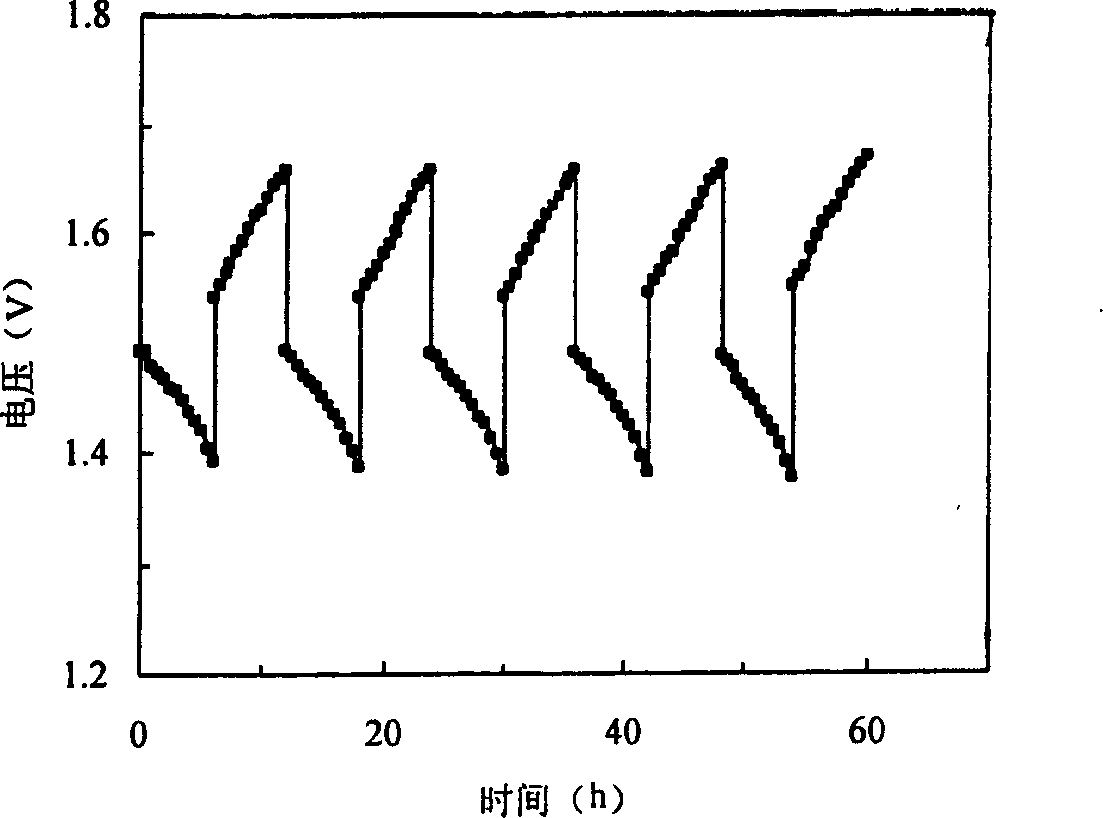

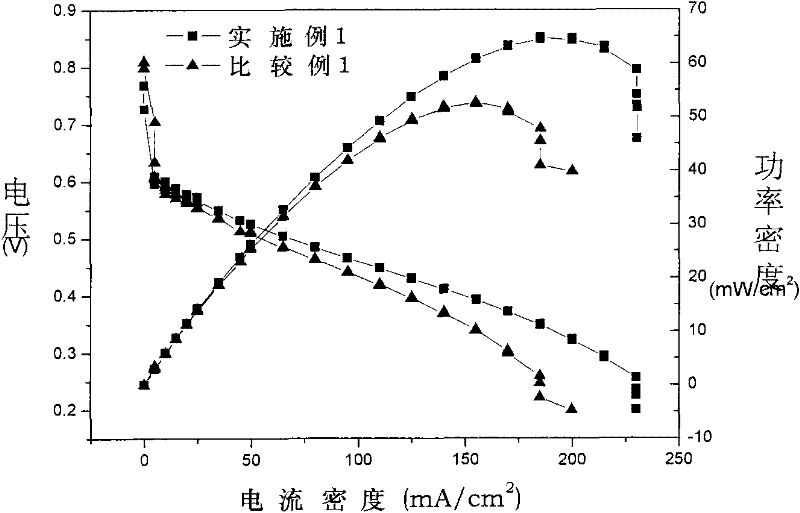

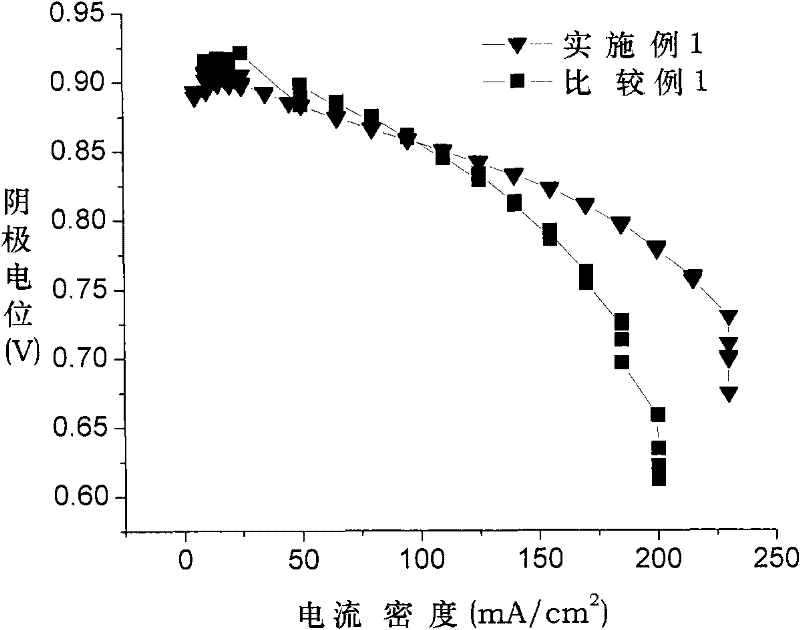

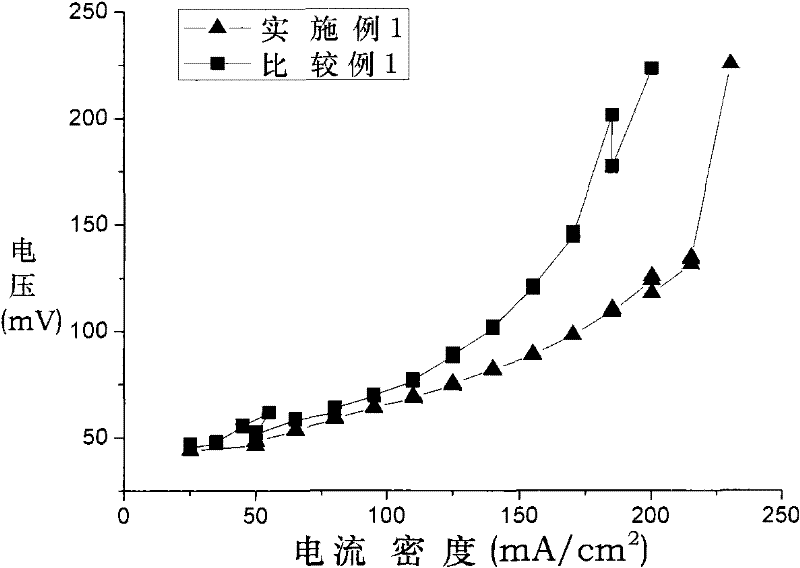

Alkaline zinc-iron flow battery

InactiveCN108461784ARich reservesLow costCell electrodesRegenerative fuel cellsHigh energyCarbon felt

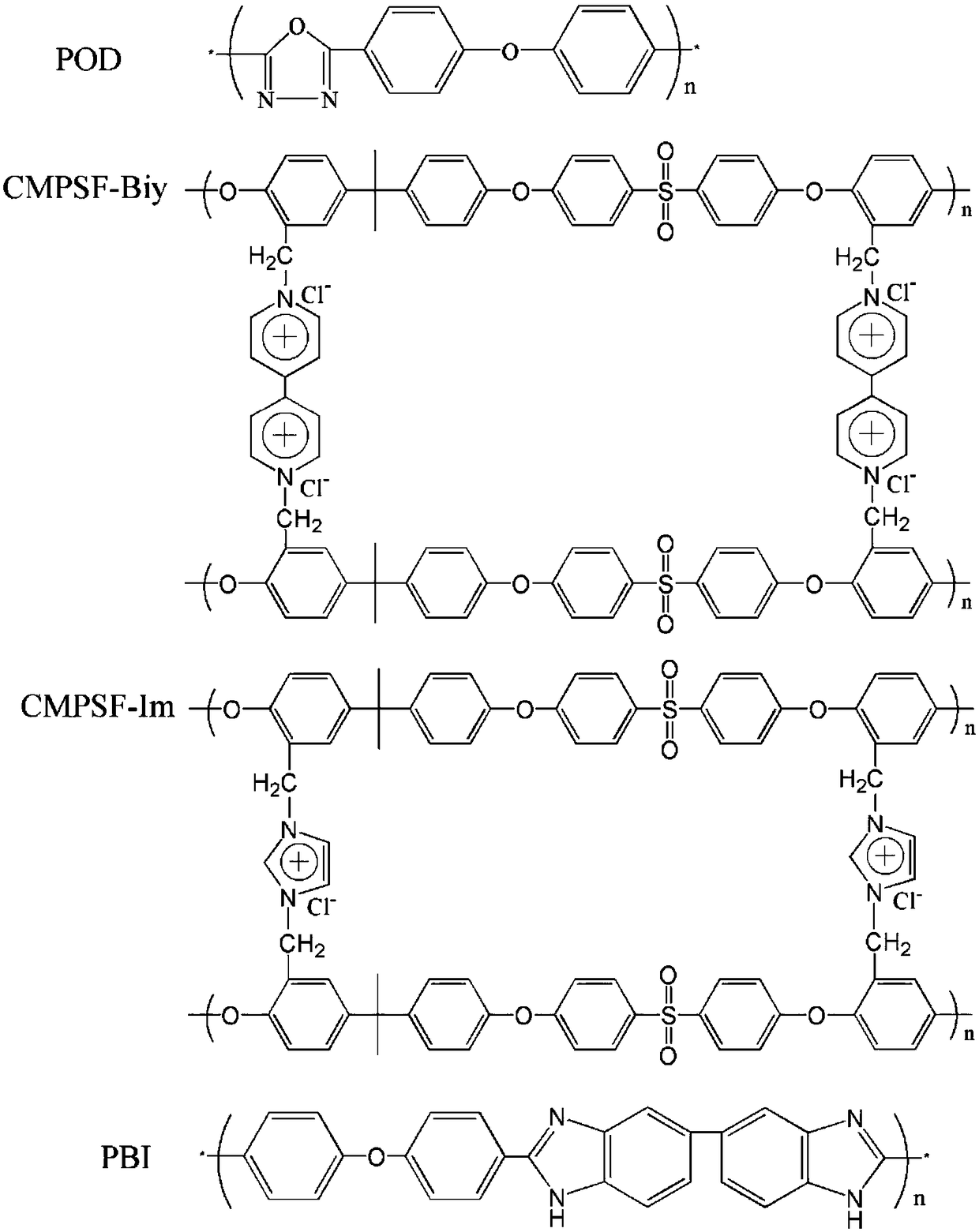

The invention relates to an alkaline zinc-iron flow battery, wherein an ion conduction membrane is prepared from an aromatic polymer containing nitrogen heterocycle, electrodes are carbon felt or carbon paper, a positive electrode electrolytic solution is the mixed aqueous solution of ferrocyanide and strong alkali, a negative electrode electrolytic solution is the mixed aqueous solution of a zincsalt or / and a zinc oxide and strong alkali, the concentrations of the strong alkalis in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-10 mol / L, and the concentrations of the active substances in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-3 mol / L. According to the present invention, a class of the alkaline zinc-iron flow batteries with characteristics of high energy density, high power density and long service life are provided, wherein the performance of the batteries is comparable to or superior to the current mature all-vanadium flow batteries, and the batteries have good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing fuel battery gas diffusion layer

InactiveCN101022164AStable structureUniform pore size distributionCell electrodesFuel cellsDistilled water

This invention relates to a preparation method for fuel cell gas diffusion layers, which mixes carbon black powder, distilled water and dispersant according to the following proportion: the volume of dispersant is 5-30wt% that of carbon black, the volume of carbon black powder is 1-20wt% that of the entire system, the size of carbon black is 30-1000nm, then adds PTFE or PVDF latex of 10-60% concentration in said carbon black dispersed system uniformly by supersonics, mechanical high speed cutting or mixing for 0.5-3hours, and the content of PTFE or PVDF is 10-50wt% that of the carbon black, and puts carbon paper or cloth in the system to dip for 0.5-15min to take out and dry it and puts it in a dry box to be dried for 5-60min under 45-150deg.C to get carbon paper or cloth carried with carbon black and PTFE or PVDF.

Owner:NANJING UNIV

Gas diffusion layer for proton exchange membrane fuel cells and preparation method thereof

ActiveCN101771155ALow electrical resistanceImprove electronic conductivityCell electrodesFinal product manufactureFiberCarbon fibers

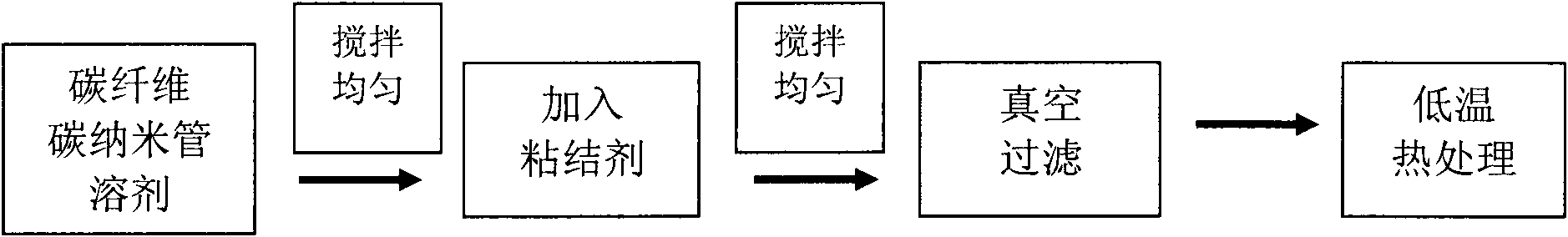

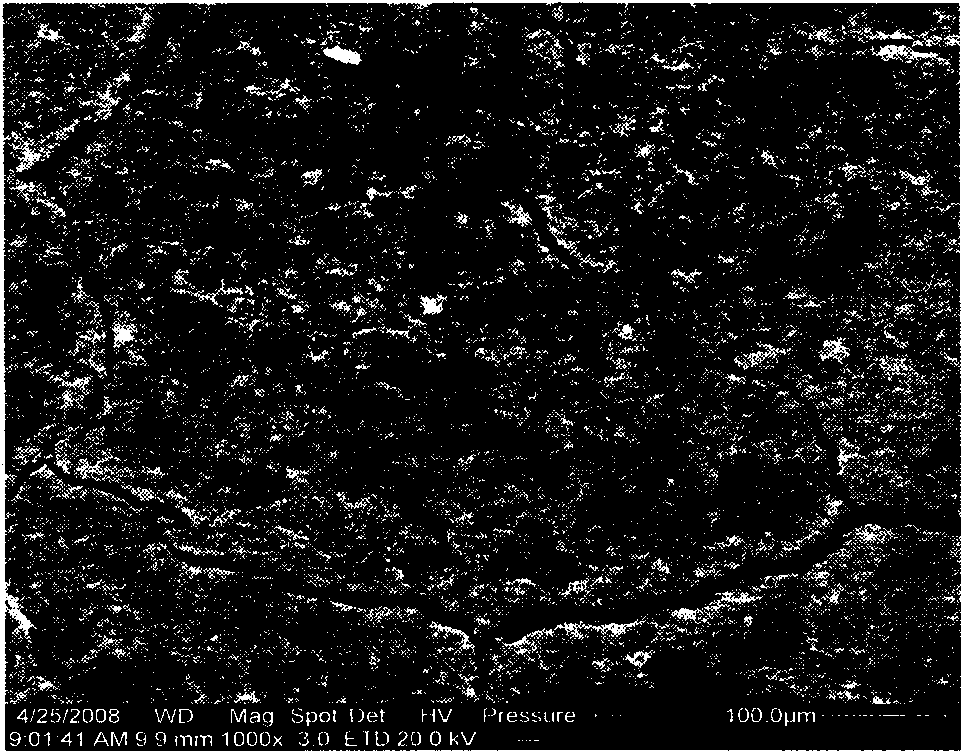

The invention relates to a gas diffusion layer for proton exchange membrane fuel cells; the gas diffusion layer is composed of a carbon nano tube, a carbon fiber and a binder and can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells; the preparation process is as follows: a certain amount of the carbon fiber and the carbon nano tube are weighted according to the proportion and are dispersed uniformly in the solvent; and then a certain amount of the binder is added in the mixture and is mixed uniformly to form slurry; and then the slurry is poured into a filter to carry out vacuumizing filtration, so as to obtain a wet type gas diffusion layer; finally, the prepared wet type gas diffusion layer is placed in a calcining furnace for carrying out heat treatment. The gas diffusion layer in the invention has good electrical conductivity and mass transfer property, can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells, so as to avoid complex treatment process when commodity carbon paper is used; the gas diffusion layer prepared by the method has the advantages of low raw material price, easily-obtaining raw material, simple technology process and controllable thickness / shape, thereby being suitable for mass production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

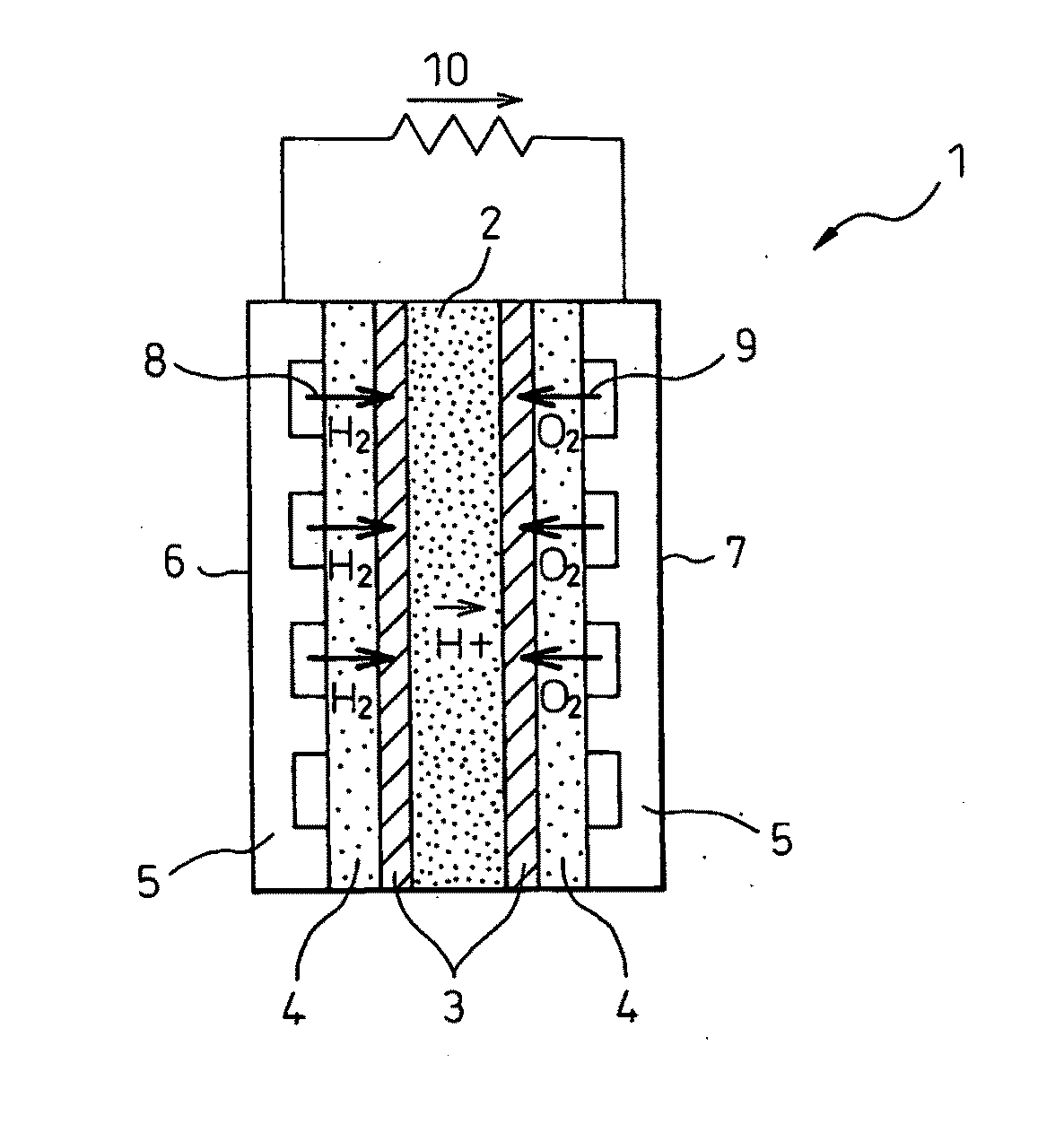

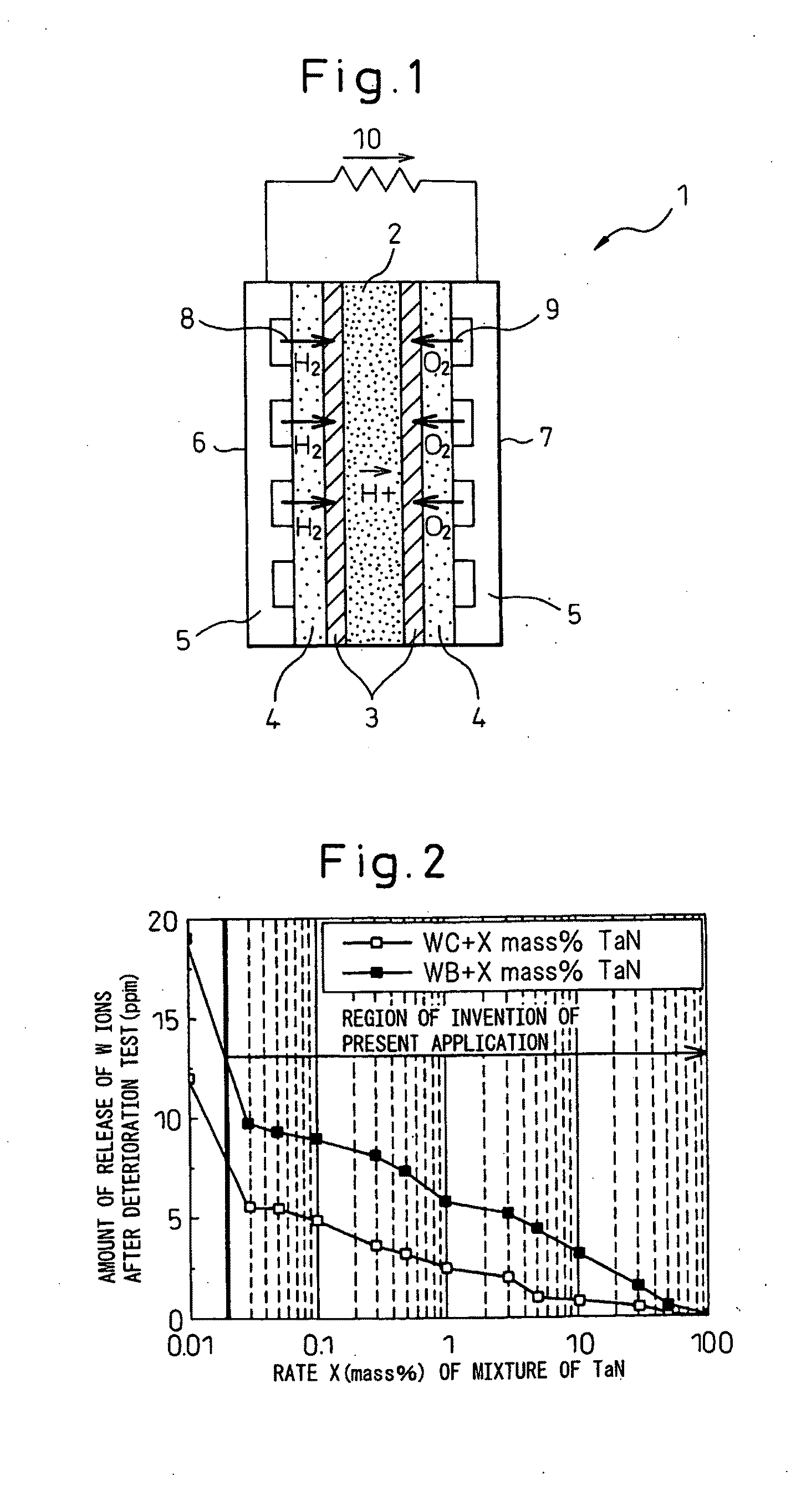

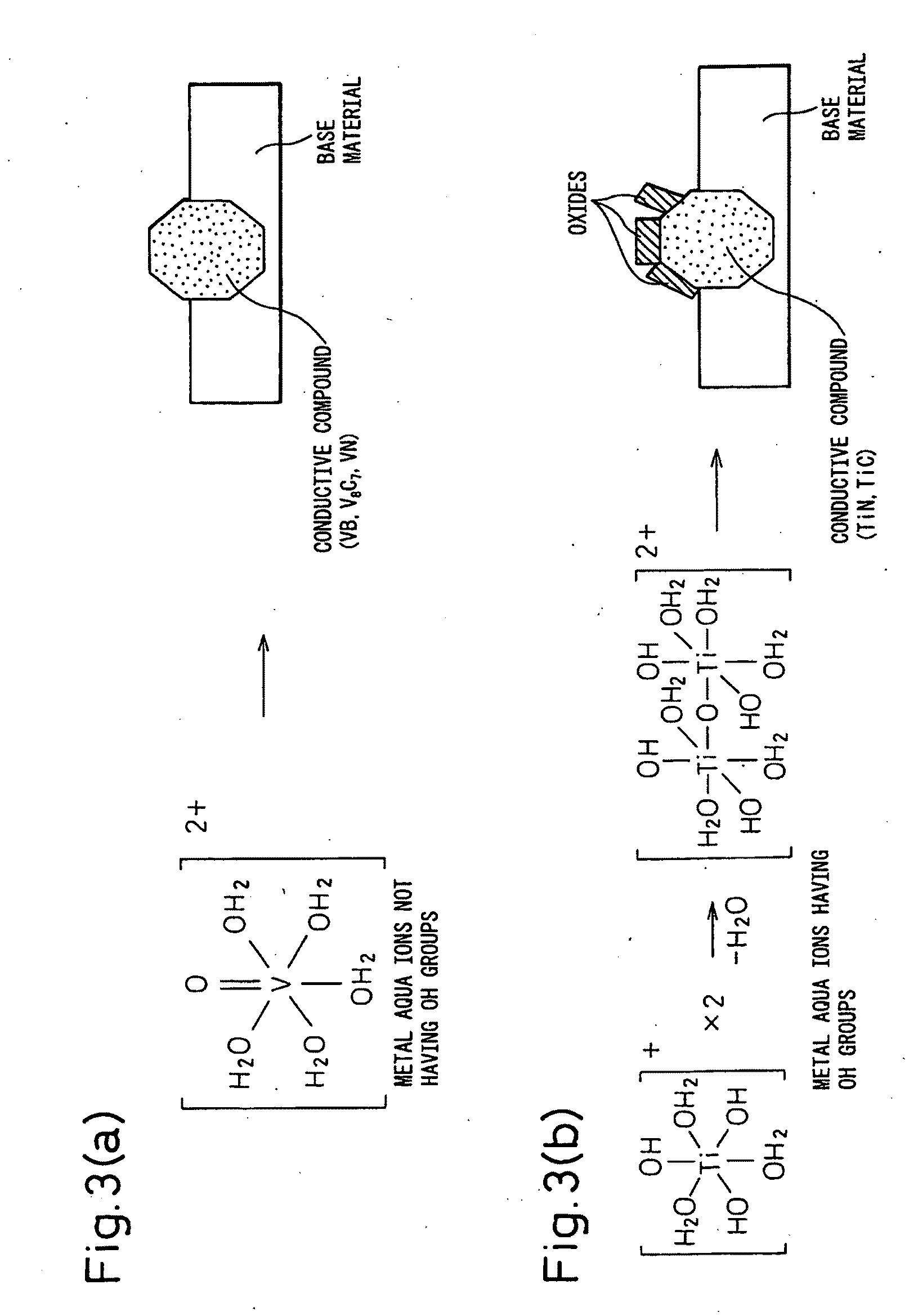

Stainless Steel, Titanium, or Titanium Alloy Solid Polymer Fuel Cell Separator and Its Method of Produciton and Method of Evaluation of Warp and Twist of Separator

ActiveUS20090226785A1Little dropLow costTransportation and packagingFinal product manufactureTitanium alloyContact resistance

The present invention releases a method of producing a metal separator for a solid polymer fuel cell by stainless steel, titanium, or titanium alloy during which securing lower cost and mass producibility by using a material having a high workability to form a complicated shape by a high productivity, then using an inexpensive blast process to drive a conductive substance into the surface of the metal separator member, that is, provides a stainless steel, titanium, or titanium alloy solid polymer fuel cell separator comprised of stainless steel, titanium, or titanium alloy in the surface of which a low ion release conductive substance is buried, having an arithmetic mean roughness (Ra) of the separator surface of 0.5 to 5.0 μm, having a 10-point mean roughness (Rz) of 3 to 20 μm, having an average spacing of surface relief shapes (Sm) of 300 μm or less, having values of a warp rate and twist rate of a separator of 0.1 or less, and having a contact resistance value with respect to carbon paper of 15 mΩcm2 or less at a surface pressure of 1 MPa.

Owner:SINTOKOGIO LTD

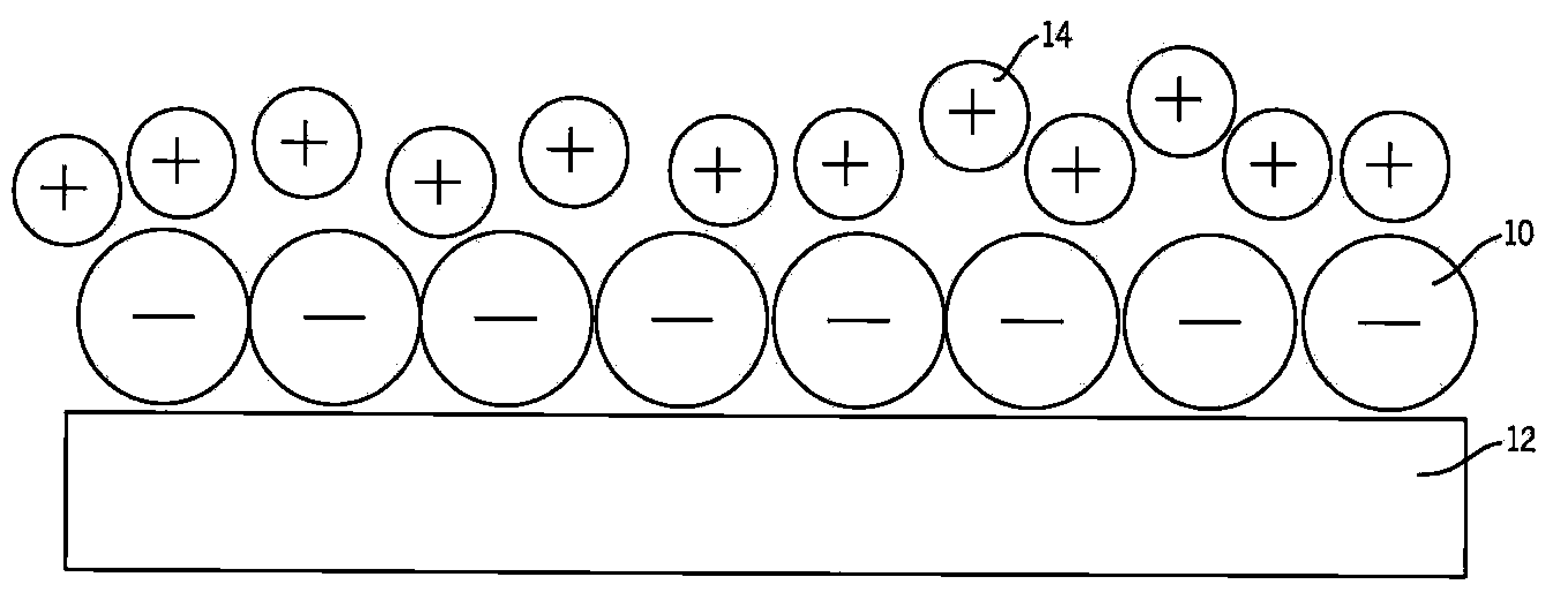

Nanoporous Insulating oxide Electrolyte Membrane Ultracapacitor, Button Cell, Stacked Cell and Coiled Cell and Methods of Manufacture and use Thereof

A nanoporous insulating oxide composite electrode and ultracapacitor device, method of manufacture and method of use thereof. The composite electrode being constructed from a conductive backing electrode and an composite layer. Preferably, the ultracapacitor device is configured in a stacked, coiled or button cell configurations and includes composite electrodes. The composite layer being substantially free of mixed oxidation states and nanoporous and having a median pore diameter of 0.5-500 nanometers and average surface area of 300-600 m2 / g. The composite layer made from a stable sol-gel suspension containing particles of the insulating oxide, the median primary particle diameter being 1-50 nanometers. Preferably, the insulating oxide is Al2O3, MgAl2O4, SiO2 or TiO2. Preferably, the backing electrode is carbon paper sputter-coated with a film of Au.

Owner:WISCONSIN ALUMNI RES FOUND

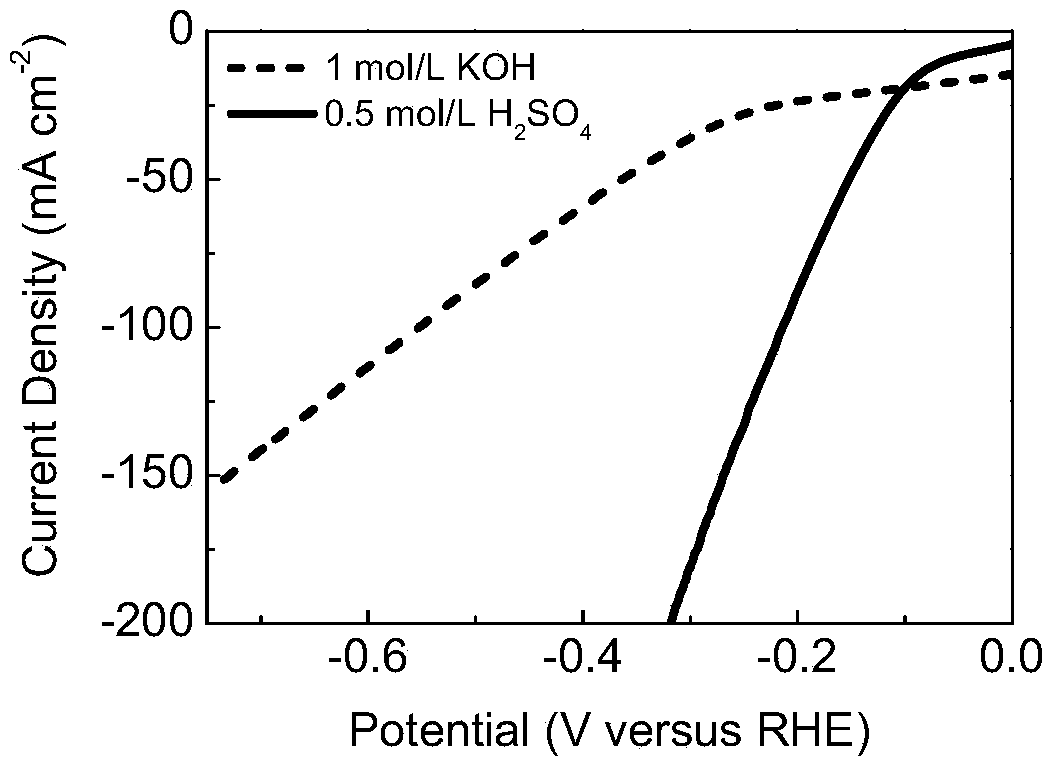

Preparation method of catalyst material for hydrogen production by virtue of electrolysis of water

InactiveCN104190443AReduced catalytic efficiencyLow costPhysical/chemical process catalystsElectrolysis componentsSolventSolvothermal reaction

The invention relates to a preparation method of a catalyst material for hydrogen production by virtue of electrolysis of water. The preparation method comprises the steps of soaking graphite carbon nanostructure-graphene composite carbon paper in a precursor solution of molybdenum and sulfur, carrying out a hydrothermal reaction or a solvothermal reaction, and then repeatedly washing to obtain a molybdenum sulfide and graphite carbon nanostructure-graphene composite carbon paper material, namely the catalyst material. Compared with the prior art, the catalyst material can be directly used as a catalytic electrode material for hydrogen production by virtue of electrolysis of water without glassy carbon electrode coating treatment; the preparation method is green and safe, simple in process and low in raw material cost, can realize large-scale continuous production and has wide application prospect in the field of hydrogen production by virtue of electrolysis of water.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method and product of cobalt manganese sulfide electrocatalyst

InactiveCN107855128ARaw materials are cheap and easy to getEasy to preparePhysical/chemical process catalystsElectrodesVulcanizationOxygen

The invention relates to a cobalt manganese sulfide electrocatalyst and a preparation method thereof. The preparation method comprises the following steps that 1, cobalt salt, manganese salt and ureaare weighed, the weighed cobalt salt, manganese salt and urea are dissolved in water, stirring is conducted, and evenly mixed solution is obtained; 2, the solution and carrier are placed into a reactor together to undergo a hydrothermal reaction, and supported cobalt manganese carbonate is obtained; 3, the supported cobalt manganese carbonate is put into aqueous solution containing vulcanizing agent to undergo a vulcanization reaction, and supported cobalt manganese sulfide is obtained. The cobalt manganese sulfide electrocatalyst and the preparation method have the following advantages that the adopted raw materials are cheap and easy to obtain, the preparation method is simple, operation is easy and convenient, and the cost is low; the manganese element is introduced into cobalt, binarycobalt manganese sulfide is prepared, meanwhile carbon paper, carbon cloth, foam nickel, foam copper, titanium mesh or stainless steel mesh are combined and used as substrate, the two-in-one structureof catalyst and electrode is directly formed, testing is convenient, and the catalyst is endowed with excellent electrochemical catalysis hydrogen evolution or oxygen evolution performance by means of the synergistic effect of cobalt manganese sulfide and the substrate.

Owner:JIANGHAN UNIVERSITY

Divot practice mat

A golf or divot practice mat, comprising a base element and a mark retaining surface operably secured or mounted to the base element. The mark retaining surface may be a no carbon required paper, carbon paper, or wax containing surface, and has one or more simulated golf balls imprinted thereon. The mark retaining surface may be secured to the base element by dowels, adhesives, hook and loop fastening material, or other fastening mechanism. A mark is left on the mark retaining surface from contact with the golf club head, which instantly records and characteristics a golf swing, position, and angle of contact with the simulated golf ball.

Owner:TIFFIN COMPANY INC THE

Method for producing electrode of sodium polysulfide/bromine novel energy storage cell

InactiveCN1474470AHigh mechanical strengthImprove conductivityCell electrodesSodium polysulfideChemistry

An electrode process method for multiple Na / Br sulfide type energy storage battery is to mix carbon loading transition metal catalyst and perfluorinated sulfonic acid resin uniformly to be coated on the supporting carbon paper or felts as the negative pole, and mix carbon loading Pt catalyst and perfluorinated sulfonic acid resin evenly to be coated on carbon paper or felts as the positive pole. The inverted electrodes have rather high mechanical strength, good conductance.

Owner:DALIAN RONGKE POWER

Cathode diffusion layer for proton exchange membrane fuel cell, preparation and application thereof

ActiveCN102479960AImprove mass transfer effectImprove battery performanceCell electrodesProton exchange membrane fuel cellDiffusion layer

The invention relates to a cathode diffusion layer for proton exchange membrane fuel cell, preparation and application thereof. The diffusion layer uses carbon paper or carbon cloth with a single surface treated with hydrophobic treatment as a supporting layer, and a surface treated with hydrophobic treatment of the supporting layer is provided with a micropore layer; the micropore layer comprises oxygen storage material powder, powdered carbon and PTFE, wherein a usage amount of the oxygen storage material powder is 5-10 wt% of powdered carbon, and a usage amount of the PTFE is 0.6-1.6 times of the weight of the powdered carbon. The diffusion layer of the invention has good gas mass transfer performance and can enhance discharging property of a cell under condition of self-breathing or low air intake when used as a cathode diffusion layer of a proton exchange membrane fuel cell. Meanwhile, the diffusion layer prepared by the method has advantages of cheap, easily available and various oxygen storage material and simple preparation technology, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

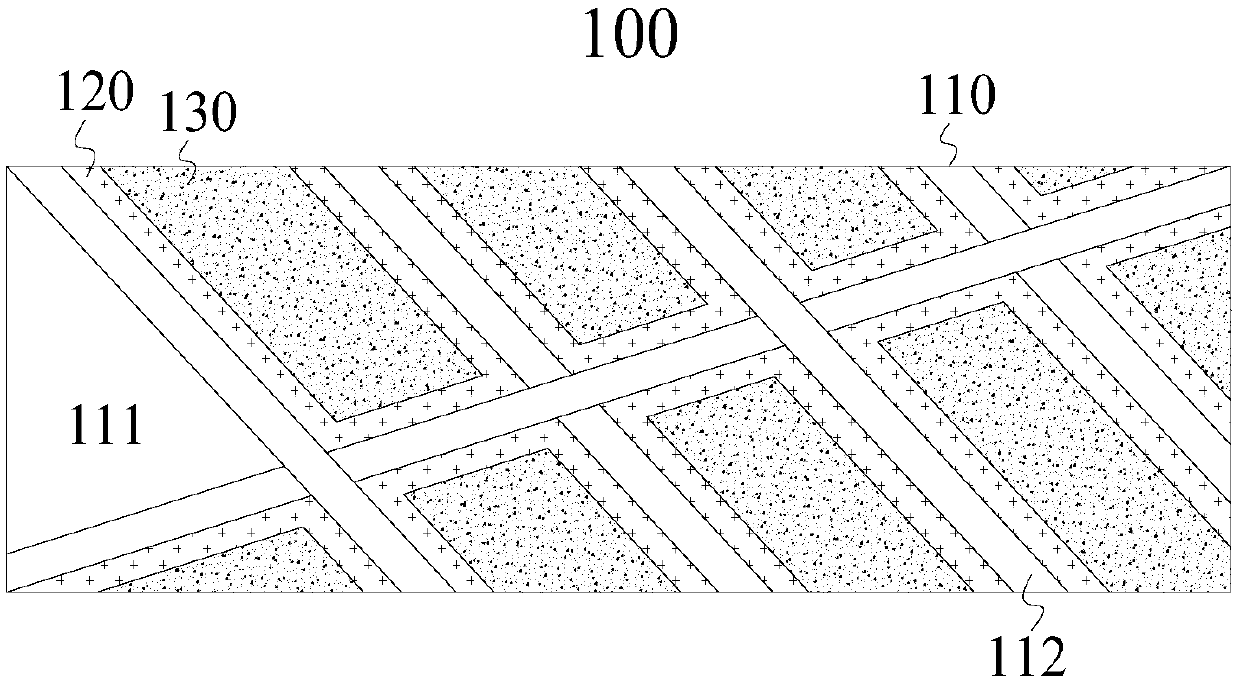

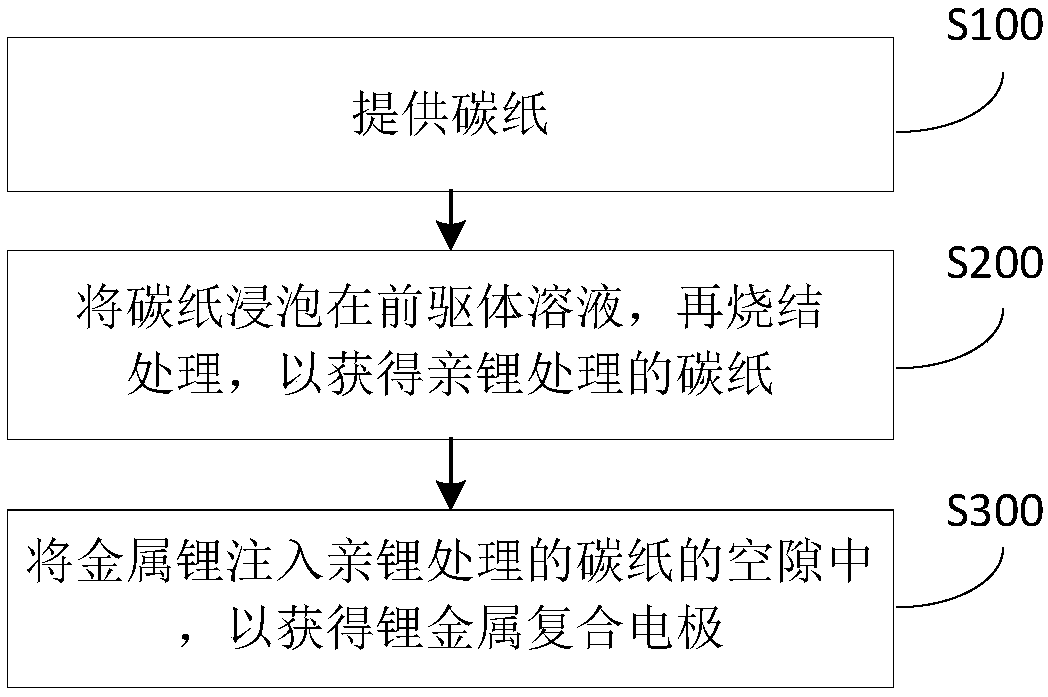

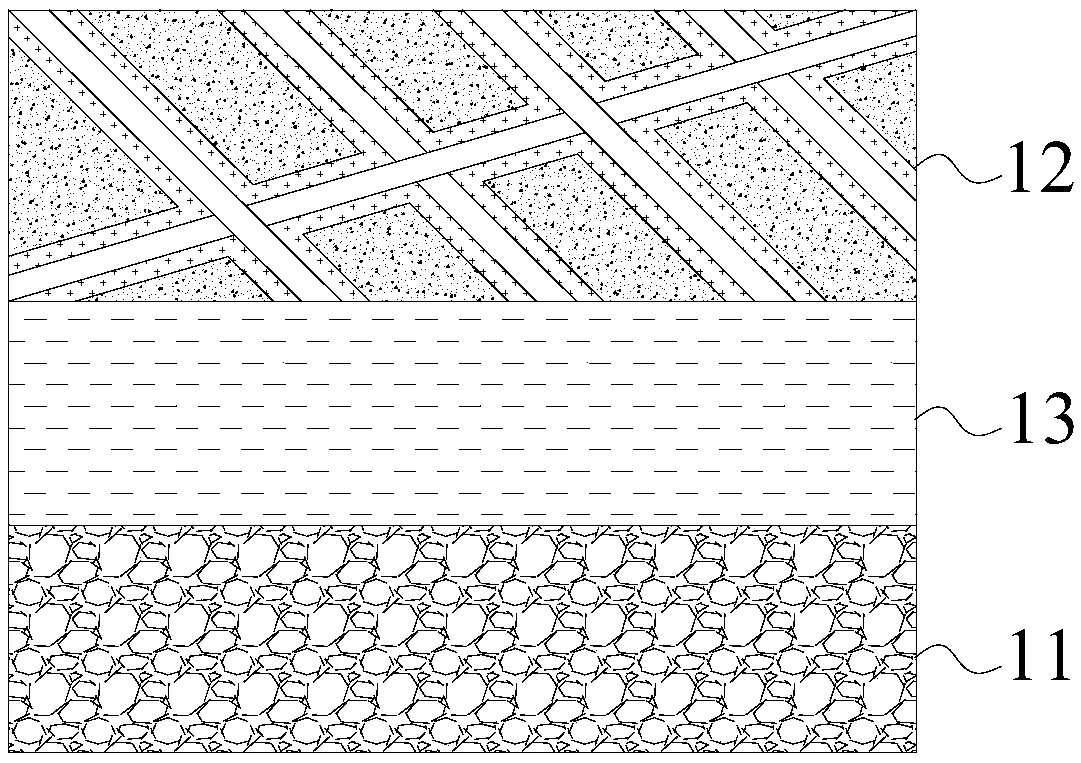

Lithium metal composite electrode, preparation method thereof and lithium ion battery

InactiveCN109546141AImprove cycle coulombic efficiencyStable energy densityElectrode carriers/collectorsSecondary cellsCharge dischargeSodium-ion battery

The invention provides a lithium metal composite electrode, a preparation method thereof and a lithium ion battery. The lithium metal composite electrode includes: a carbon paper, a lithium affinity layer covering the surface of gaps on the carbon paper; and a lithium metal filled in the gaps of the carbon paper. The invention provides a lithium metal composite electrode. The supporting structureis made of multi-gap carbon paper. The surface of the gaps of the carbon paper is coated with the lithium affinity layer, so that the surface lithium affinity performance of the supporting structure can be provided, and the nucleation overpotential of the metal lithium is reduced. The lithium metal can be effectively induced to uniformly nucleate on the carbon paper in the charging and dischargingprocess. Further, the generation of lithium dendrites in the charging and discharging process is reduced. Moreover, lithium metal is uniformly distributed in the gaps of the carbon paper, so that theproblem of volume expansion of the carbon paper in the charge-discharge process can be obviously reduced. The carbon paper with a three-dimensional multi-gap structure has a relatively high specificsurface area, so that the effective contact area of the lithium metal is increased, and the specific capacity of the lithium metal composite electrode is further improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

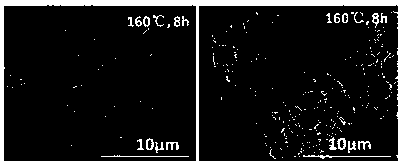

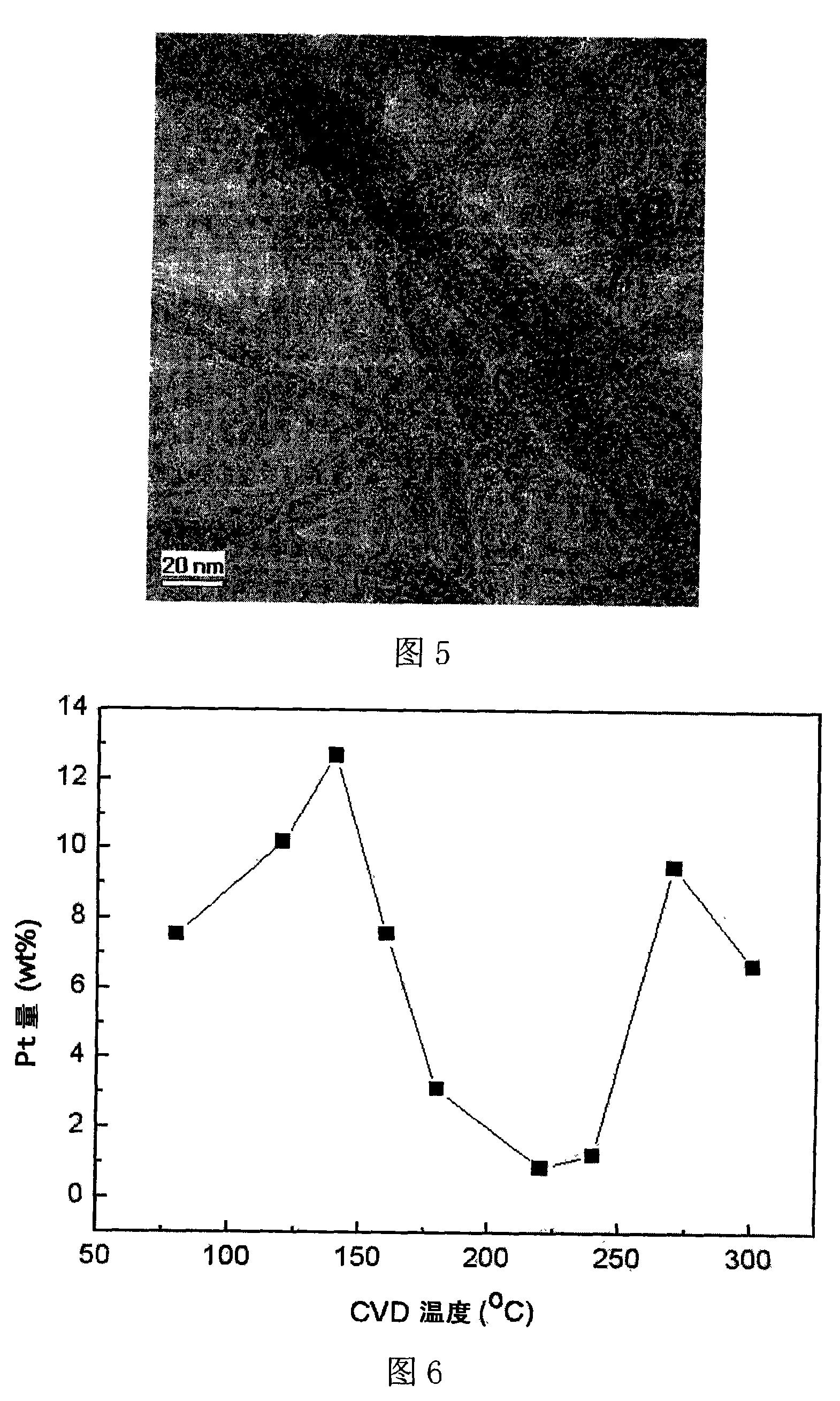

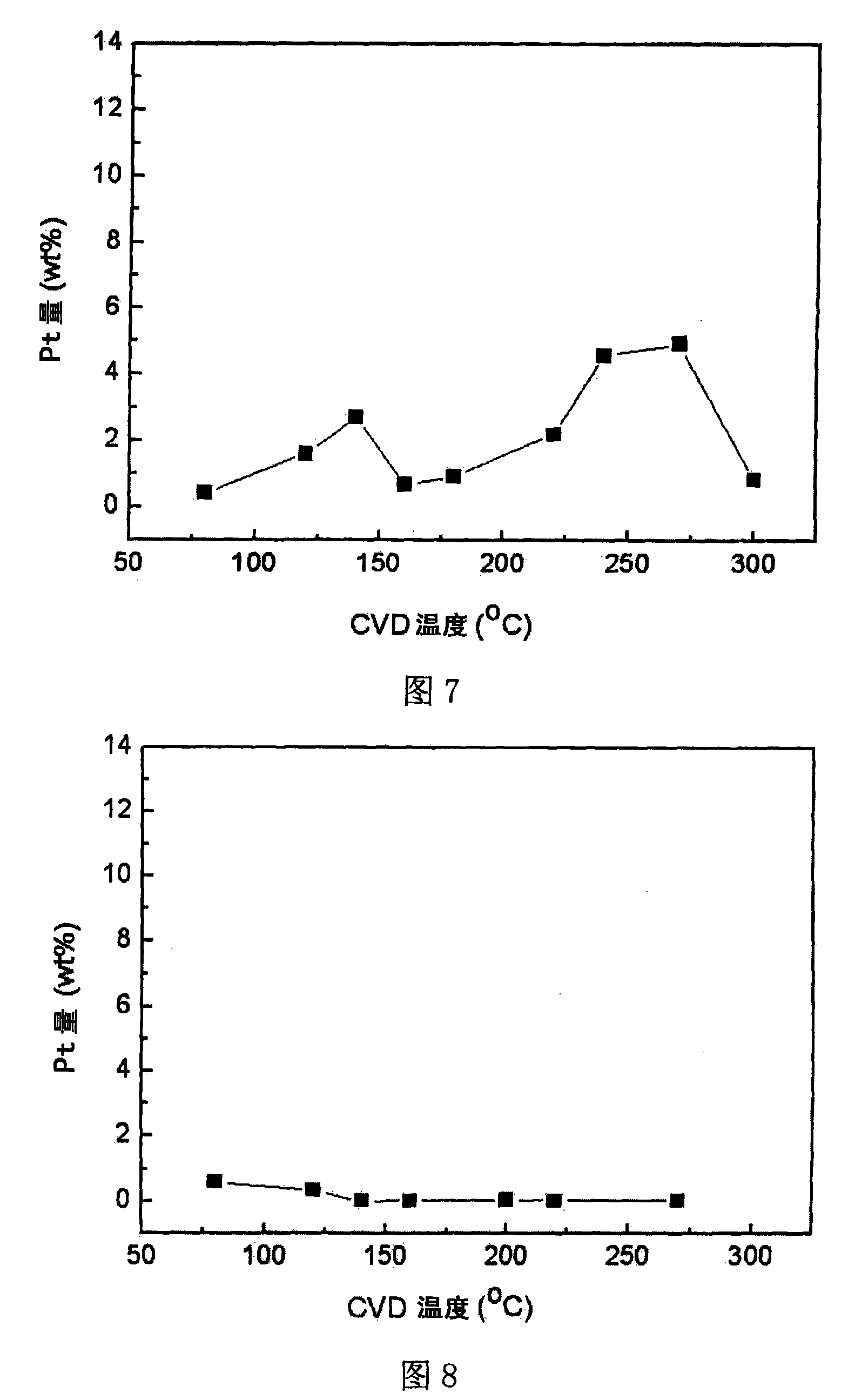

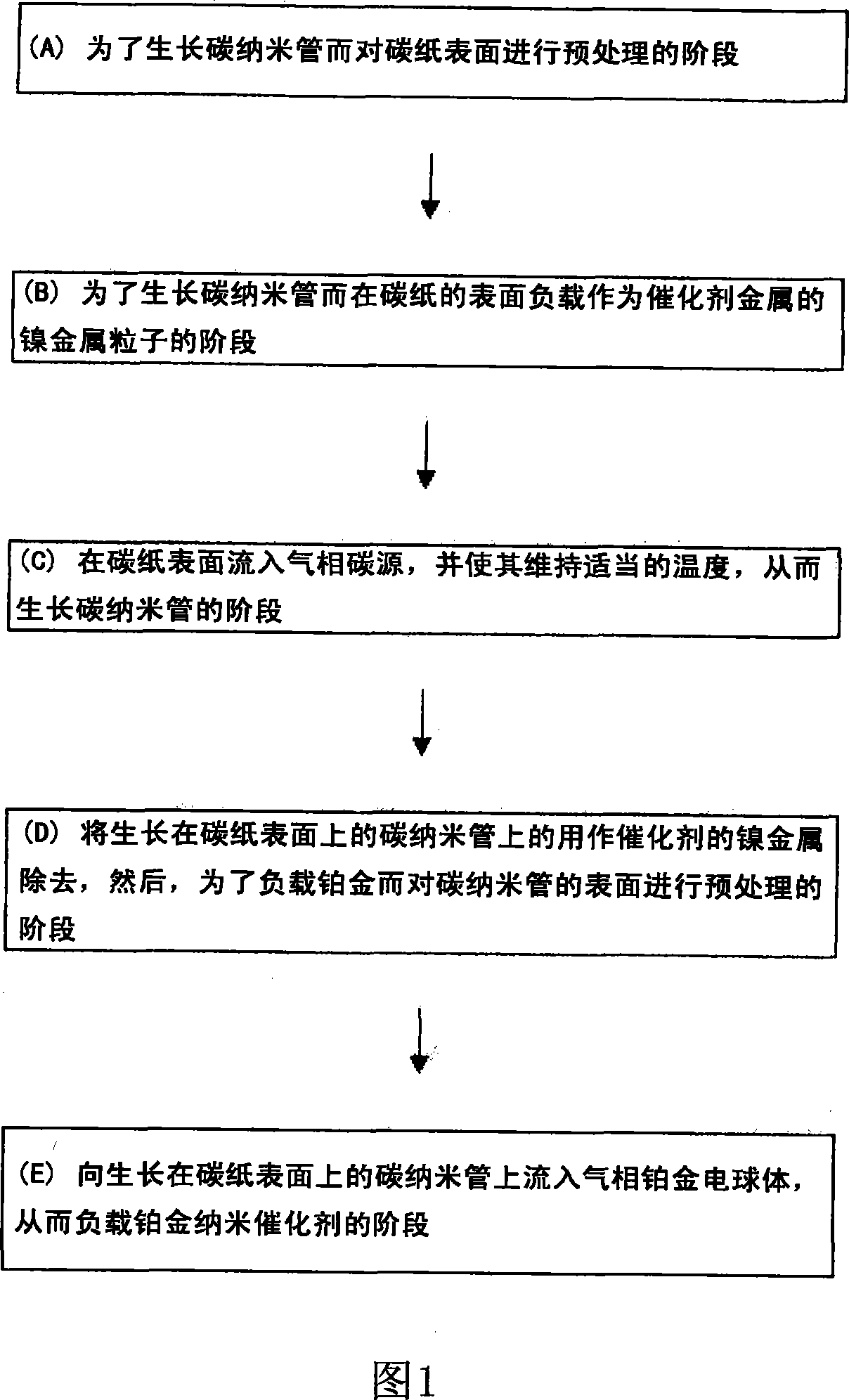

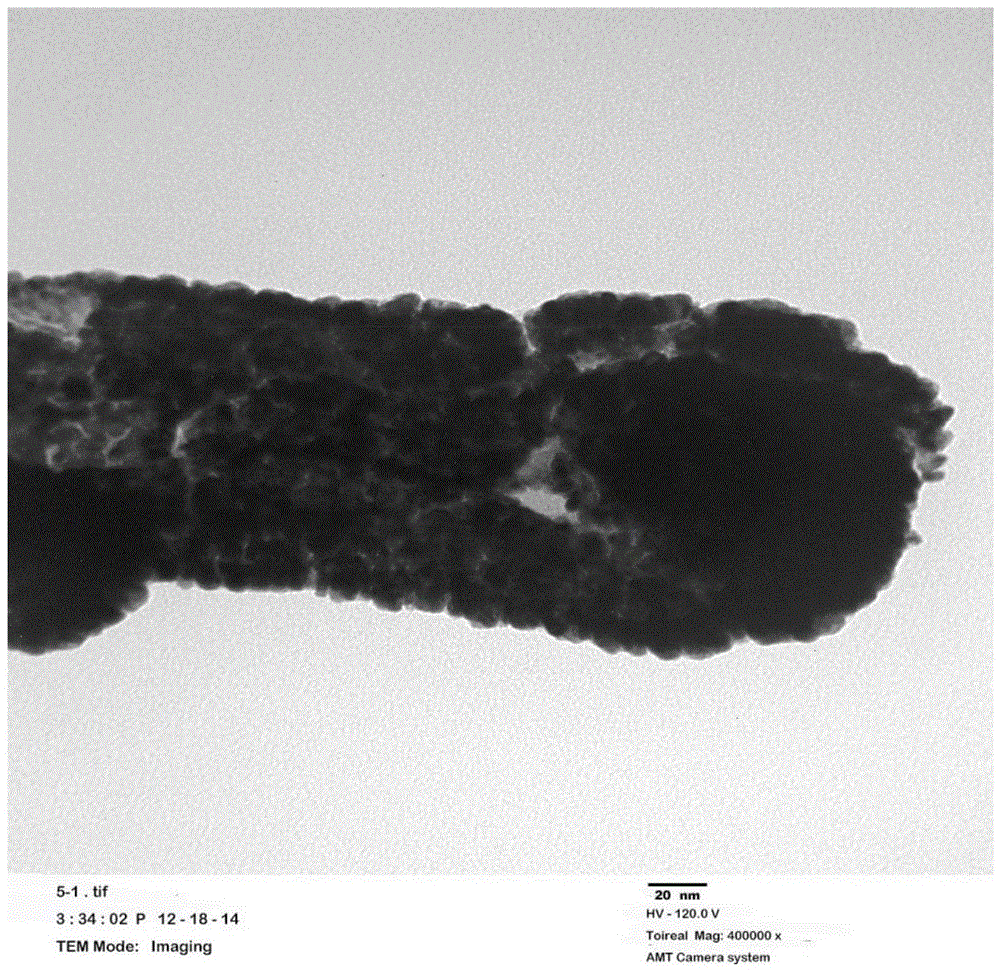

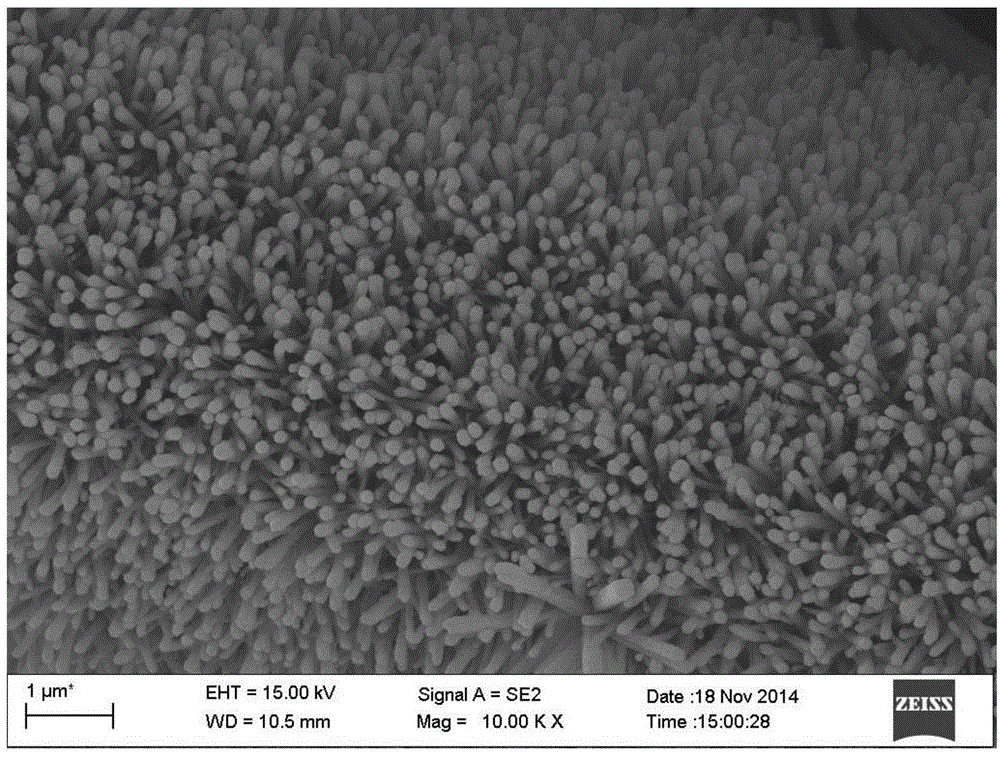

Carbon nano tube electrode formed by directly growing carbon nano tube on surface of carbon paper and supporting platinum-based nano catalyst on carbon nano tube using CVD method and manufacturing met

A platinum-based nano catalyst supported carbon nano tube electrode and a manufacturing method thereof, more particularly to a manufacturing method of a carbon nano tube electrode and a carbon nano tube electrode supported with the platinum-based catalyst by growing the carbon nano tube on the surface of the carbon paper and using a CVD method on the surface of the carbon nano tube. By growing the carbon nano tube directly, the broad surface area and excellent electric conductivity of the carbon nano tube can be utilized maximally, and especially, the nano catalyst particles with minute sizes on the surface of the carbon nano tube by using the CVD method as a supporting method of the platinum-based catalyst on the surface of the carbon nano tube, the amount of the platinum can be minimized and still shows an efficient catalyst effect and by improving the catalyst activity by increasing the distribution, so academic and industrial application in the future is highly expected.

Owner:KOREA INST OF ENERGY RES

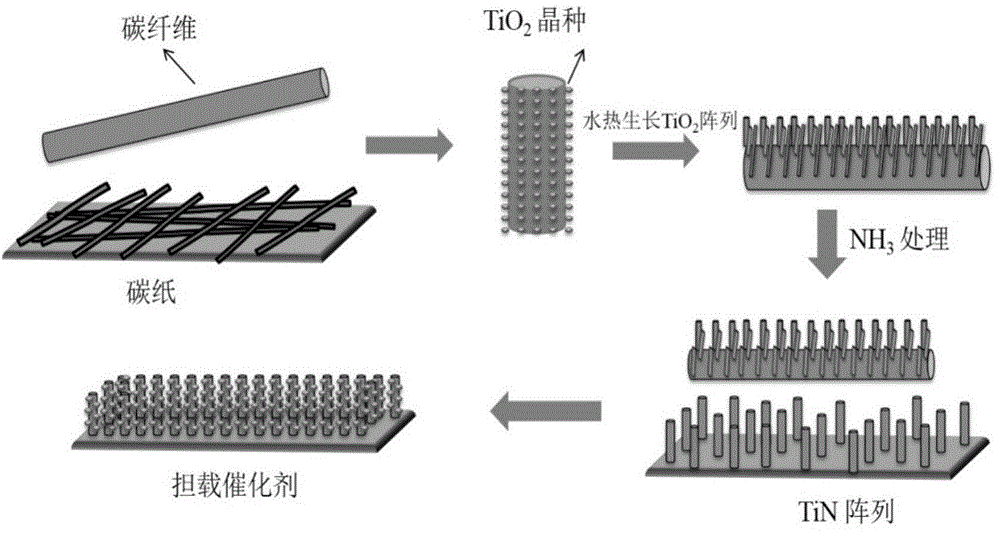

Preparation method for ordered ultra-thin catalyst layer, catalyst layer and application

ActiveCN106159285AIncrease the reaction areaIncrease profitCell electrodesElectrical conductorProton

The invention relates to a preparation method for an ordered ultra-thin electrode of a proton exchange membrane fuel cell. The preparation method comprises the steps of preparing an ordered electrode structure and establishing an ultra-thin catalyst layer; a process of impregnating and annealing is carried out on a carbon paper to obtain TiO<2> seed crystals; then a TiO<2> nanorod is grown through a hydrothermal method; a TiN ordered array is prepared through NH<3> etching; and the array is loaded with a catalyst to establish the ordered ultra-thin catalyst layer without containing a proton conductor (such as Nafion). The established ordered ultra-thin catalyst layer can be used for the proton exchange membrane fuel cell, other fuel cells and electrochemical devices.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

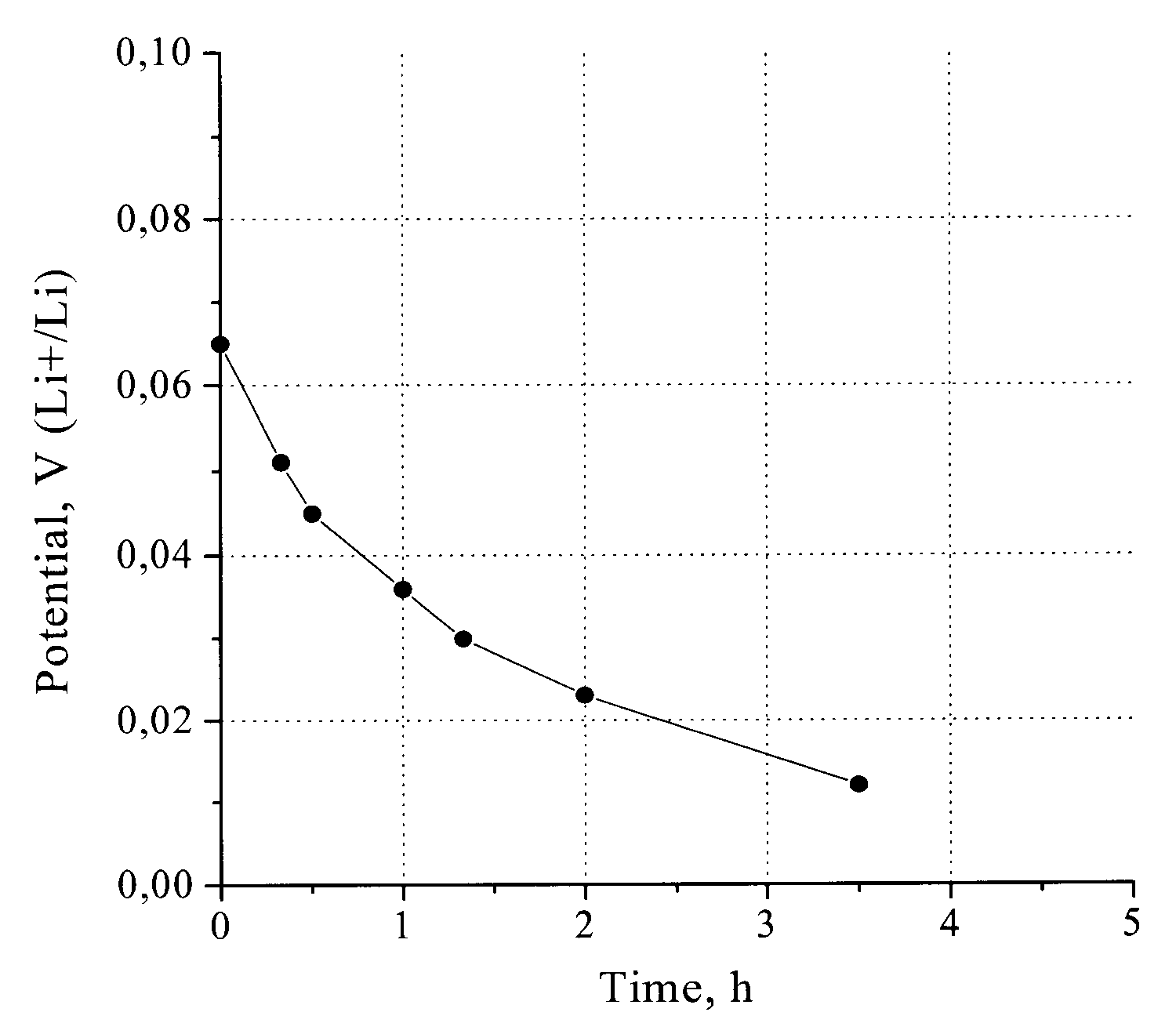

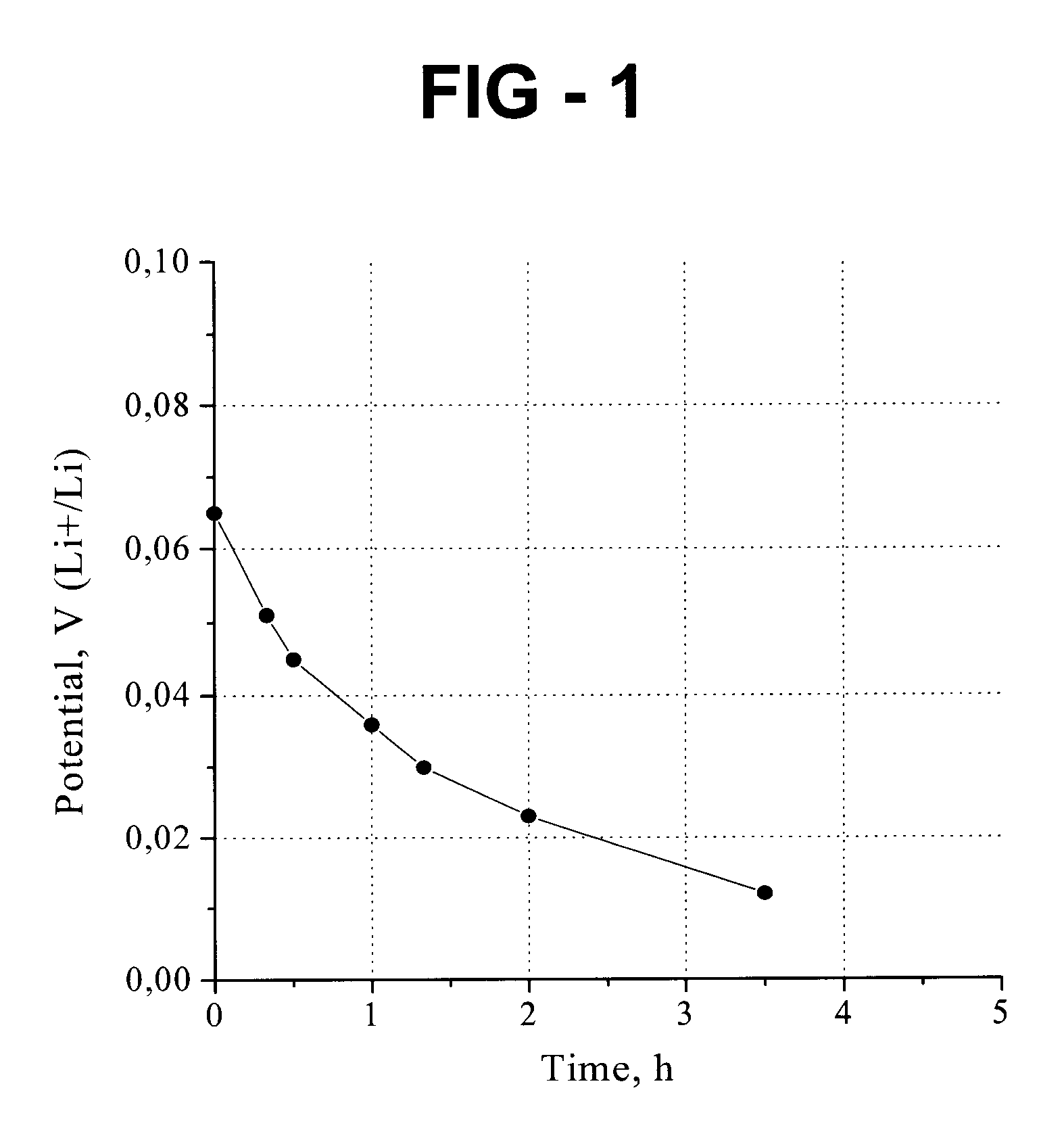

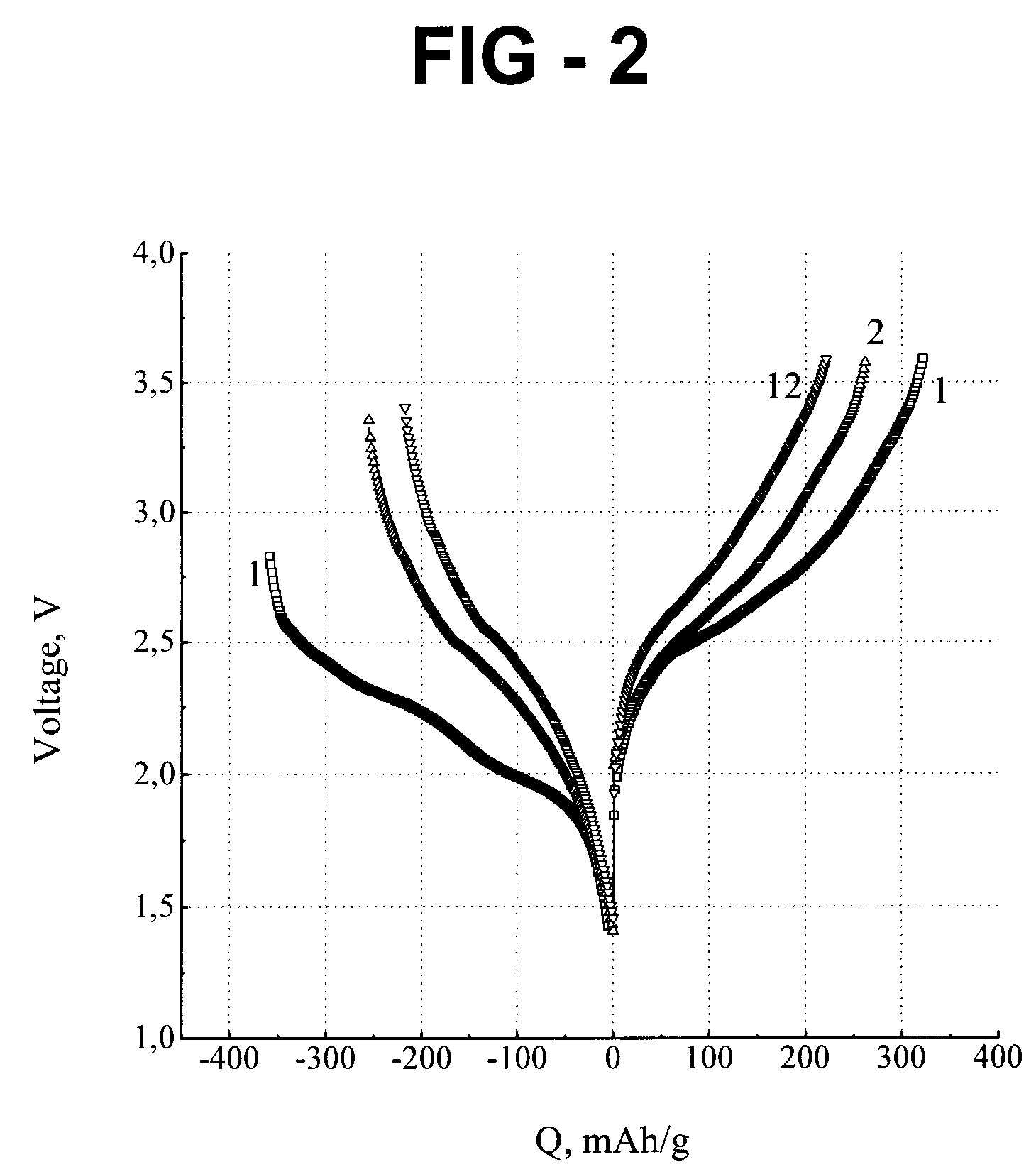

Lithium-ion secondary battery cell, electrode for the battery cell, and method of making the same

InactiveUS20090148773A1Improve cycle lifeIncrease energy densityElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesLithium metalLithium-ion battery

An electrode, e.g. a negative electrode, for a lithium-ion battery cell is made from a carbonaceous material, such as a carbon paper, which is lithiated by direct contact with a piece of lithium metal in an atmosphere comprising carbon dioxide (CO2) gas. A method of making the electrode comprises the step of contacting tightly the carbonaceous material with the piece of lithium metal in the atmosphere. The method further comprises the step of storing the carbonaceous material and the piece of lithium metal in the atmosphere, and optionally, in an electrolyte, for a period of time sufficient to completely lithiate the carbonaceous material. A lithium-ion battery cell comprises the negative electrode, a positive electrode comprising oxides of a transition metal, and a non-aqueous electrolyte.

Owner:ENERDEL

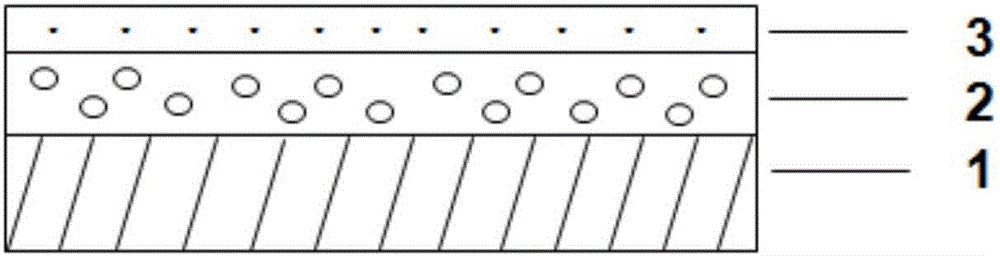

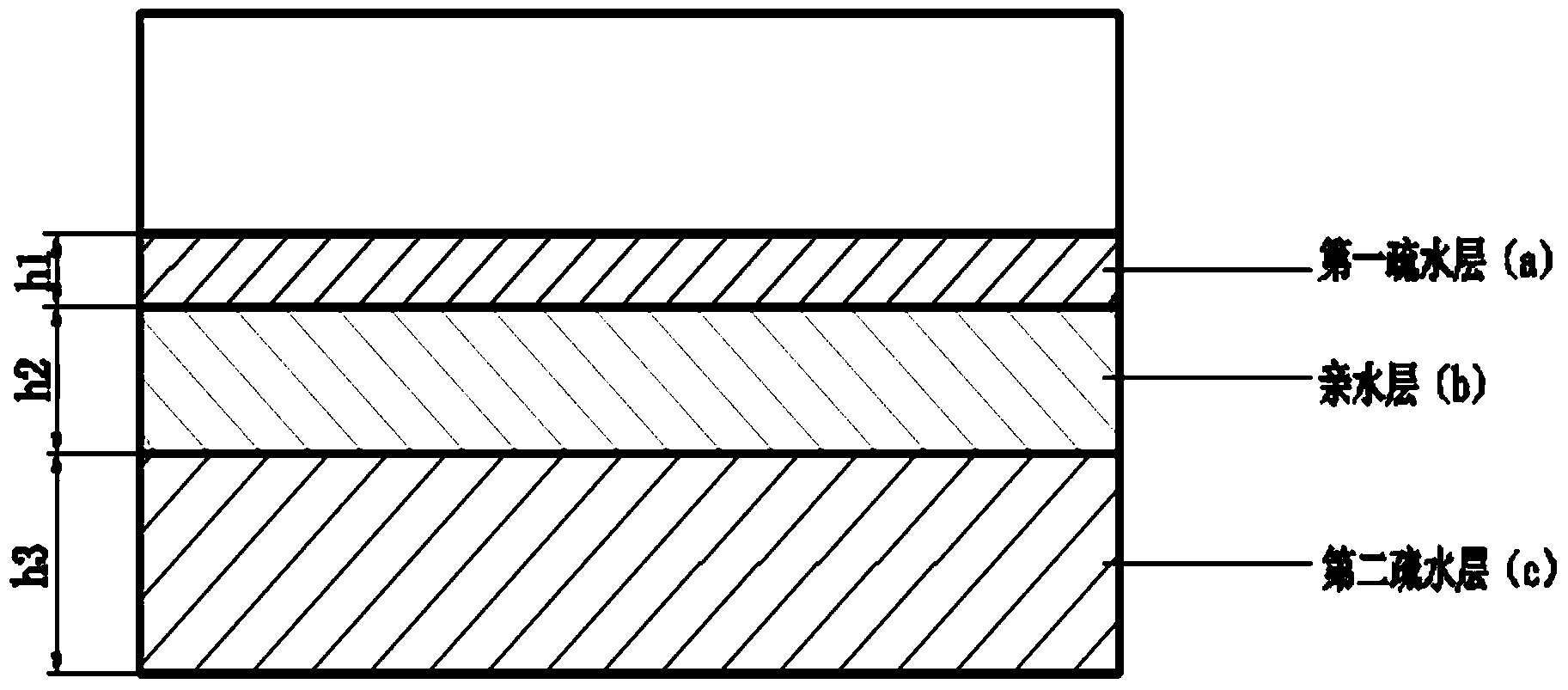

Gas diffusion layer with water retaining property for fuel cell, preparation method of gas diffusion layer, membrane electrode assembly and application

ActiveCN103956505AImprove water retentionReduce volatilityCell electrodesFuel cell detailsFuel cellsLiquid water

The invention relates to a gas diffusion layer with water retaining property for a fuel cell, a preparation method of the gas diffusion layer, a membrane electrode assembly and application. The gas diffusion layer comprises a carbon paper base and a micro-porous layer, wherein the micro-porous layer is formed by a first hydrophobic layer closely adjacent to the carbon paper base, a hydrophilic layer and a second hydrophobic layer closely adjacent to a catalyst layer by overlaying in sequence, the thickness h2 of the hydrophilic layer is 1.5-2.5 times of the thickness h1 of the first hydrophobic layer, and the thickness h3 of the second hydrophobic layer is 2.5-3.5 times of the thickness h1 of the first hydrophobic layer. The gas diffusion layer can achieve good water retaining property, so as to reduce volatilization amount of liquid water and enable the membrane to be kept in a hydration status under a low-humidity condition; the membrane electrode prepared by the gas diffusion layer can be used for a self-humidifying pile, and is particularly used for the cathode side of an air cooling pile to improve the self-humidifying effect.

Owner:武汉理工新能源有限公司

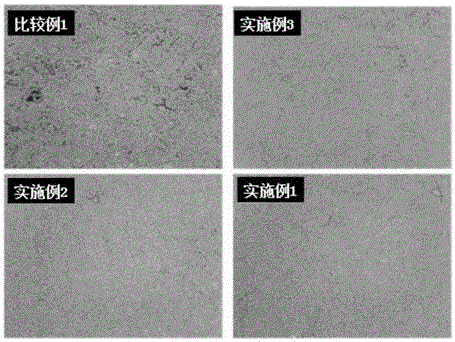

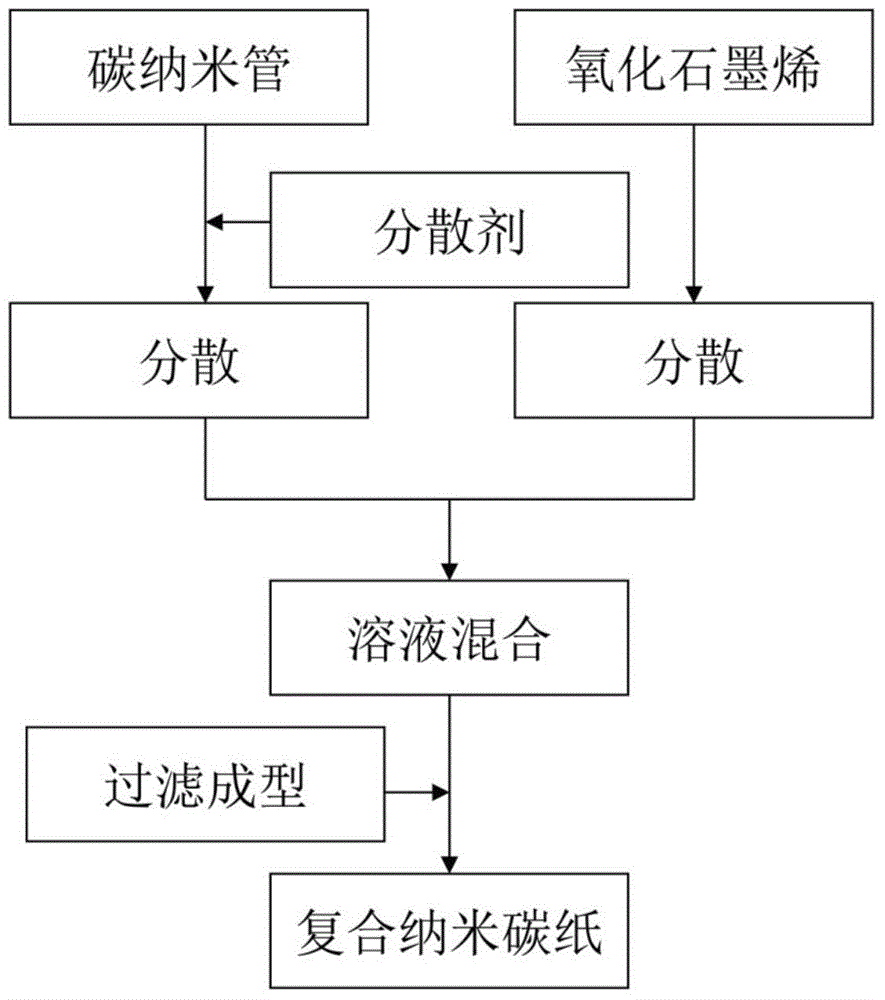

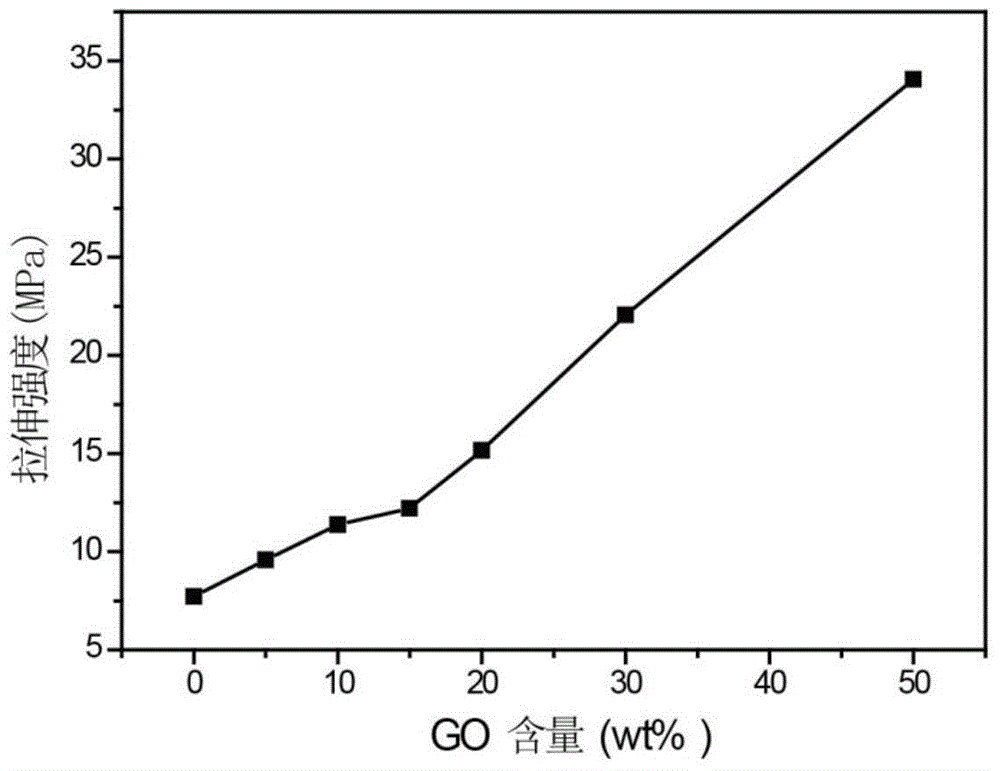

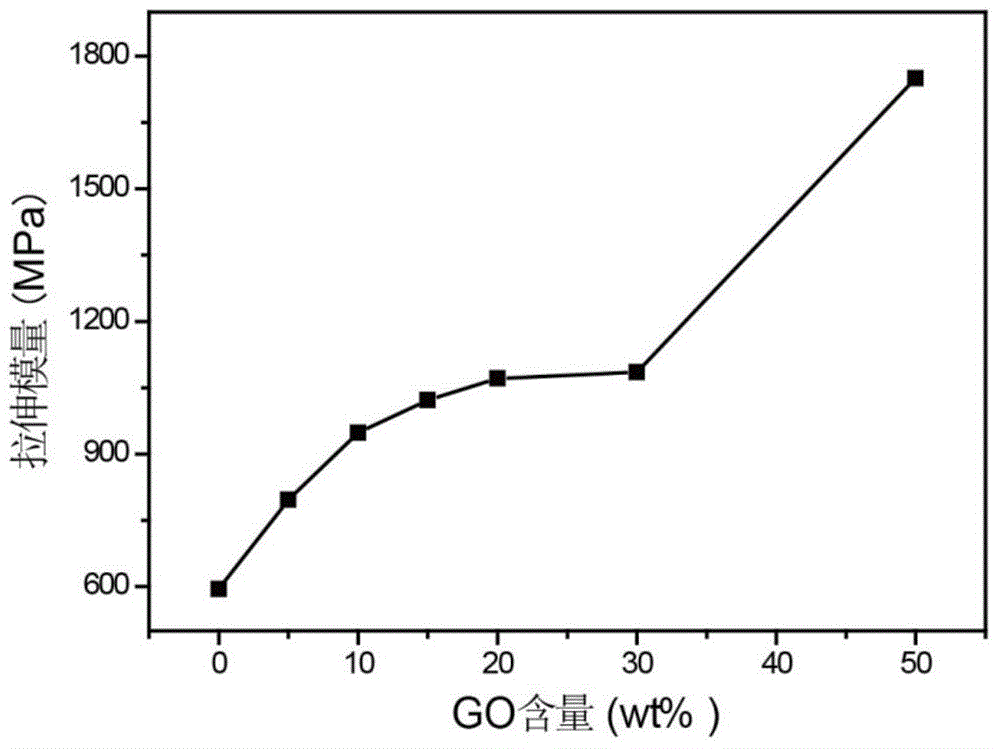

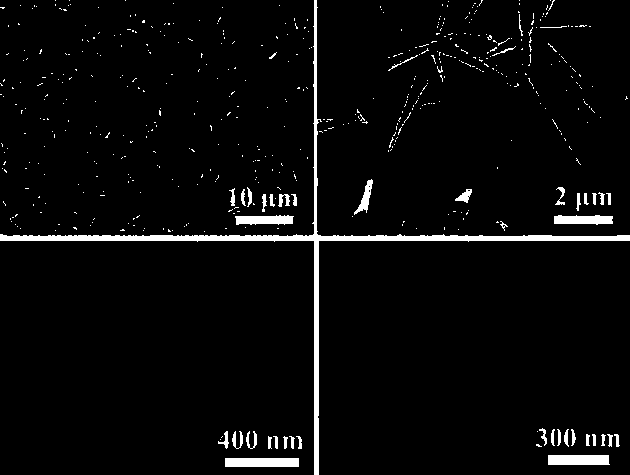

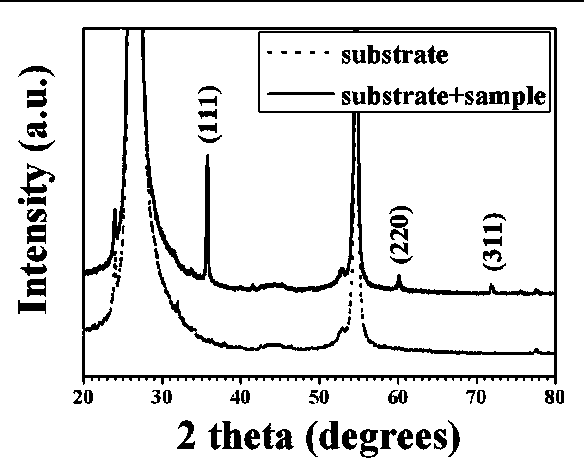

Graphene oxide reinforced composite carbon nanopaper and production method thereof

ActiveCN104627977ARegulated contentSolve the problem of poor mechanical strength of paperCarbon nanotubeNanostructured carbon

The invention discloses a graphene oxide reinforced composite carbon nanopaper and a production method thereof. The above carbon paper includes: a carbon nanotube substrate including a skeleton network mainly formed by carbon nanotubes; and at least an enhanced network for connecting the carbon nanotubes in the skeleton network, wherein the enhanced network is mainly formed by graphene oxide dispersed in the skeleton network. The production method comprises the following steps: uniformly mixing a carbon nanotube dispersion with a graphite oxide graphene dispersion filtering to form a film, and peeling the formed film from a substrate filter film in order to obtain a target product. The composite carbon nanopaper has greatly improved mechanical properties, has no apparent loss of the excellent electrical conductivity or thermal conductivity, fully solves the problem of poor mechanical strength of present carbon tube nanopaper, and has the characteristics of electrical conduction, thermal conduction, light weight, flexibility and high efficiency. The production method has the advantages of simplicity, easy operation, good controllability, low cost and wide application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Electrode production of fuel battery membrane with proton exchange membrane

ActiveCN1713424AIncrease contactTightly boundCell electrodesFinal product manufacturePtru catalystNafion

The method includes following steps: 1) the carbon paper or carbon fabric is dipped in PTFE latex, and then dried to get conduction base; 2) the VXCÊ72 carbon black or acetylene black is mixed with PTFE latex to form synthetic size that is coated on the conducting base; after drying, forms a gas diffusion layer; 3) prepares catalyst slurry; 4) the catalyst slurry is coated on the diffused layer; after hot pressing, it is cooled at the condition of keeping pressure, and the gas diffusion electrode is formed; 5) the Nafion film is set between two gas diffusion electrodes with catalysis layer; after hot pressing, it is cooled at the condition of keeping pressure.

Owner:BYD CO LTD

Method for improving emission stability of high-temperature electrons of SiC field emission cathode materials

ActiveCN103928276AAchieve preparationExcellent high temperature electron emission stabilityMaterial nanotechnologyCold cathode manufactureNanowireBall mill

Provided is a method for improving emission stability of high-temperature electrons of SiC field emission cathode materials. The method comprises the following specific steps that 1) heat preservation is carried out on organic precursor polyborosilazane in an atmosphere sintering furnace for 30 min at the temperature of 260 DEG C for thermo crosslinking curing, and then the organic precursor polyborosilazane is smashed through a ball mill; 2) carbon paper is adopted as a substrate, the carbon paper is arranged in 0.05 mol / L Co(NO3)2 ethanol solutions with the purity of 99 percent for immersion treatment, and the carbon paper is taken out and naturally aired for standby application; 3) smashed powder is arranged at the bottom of a graphite crucible, the carbon paper after the immersion treatment is arranged at the top of the graphite crucible, and the powder and the carbon paper are placed in an atmosphere protecting furnace together; 4) the powder is heated to 1550 DEG C from the indoor temperature at the speed of 25 DEG C / min under protection of Ar atmosphere with the purity of 99.9 percent; 5) the temperature is reduced to 1100 DEG C from 1550 DEG C at the speed of 15 DEG C / min; 6) the powder is cooled to the indoor temperature along with the furnace, and in-situ B doped SiC nanowires are manufactured; 7) the SiC nanowires are applied to a field emission cathode for electron emission performance detection and analysis. Through B-site doping, the emission stability of the high-temperature electrons of the SiC field emissioncathode materials is effectively improved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com