Graphene oxide reinforced composite carbon nanopaper and production method thereof

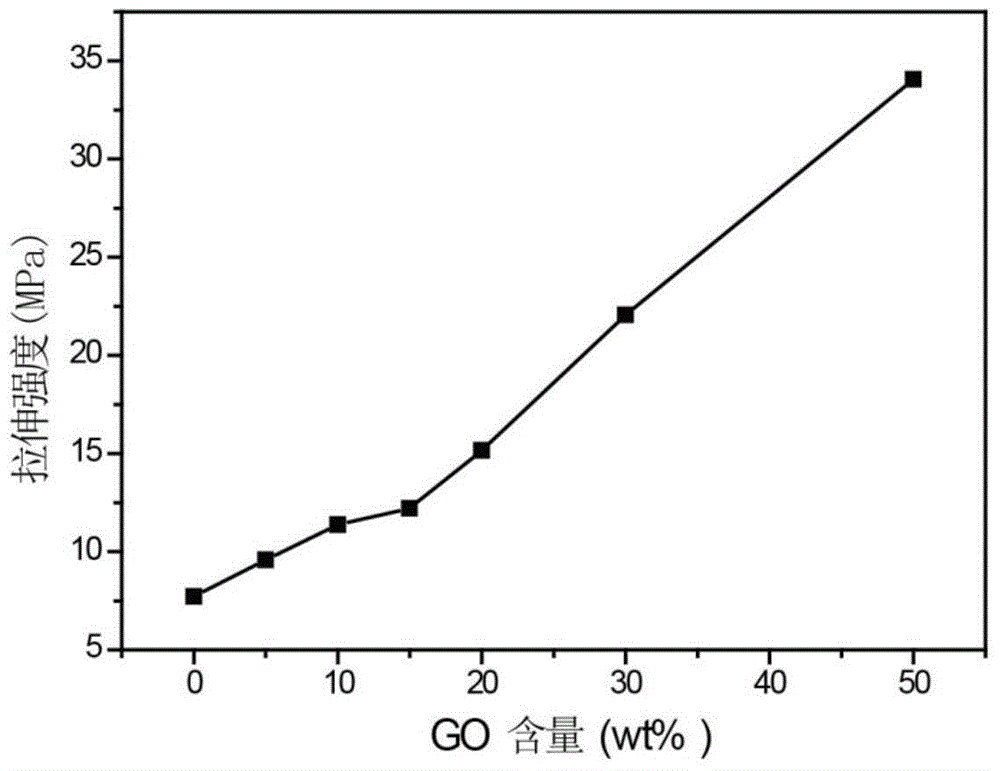

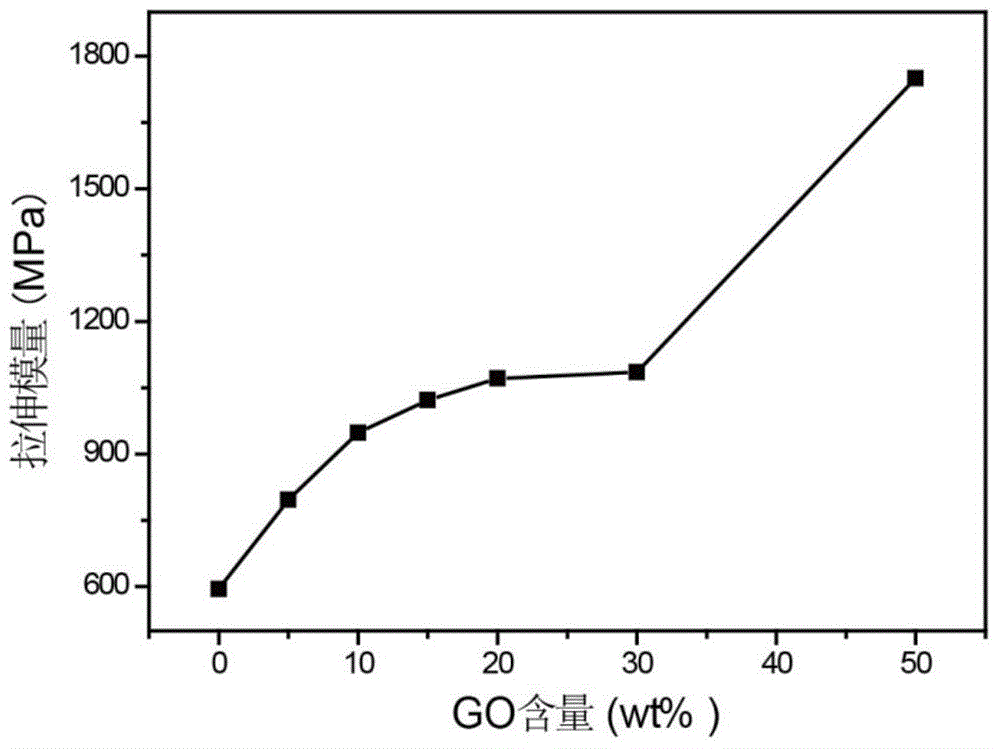

A graphene and nano-carbon technology, applied in the field of nano-carbon material preparation, can solve problems such as poor mechanical strength, and achieve the effects of low cost, easy operation and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

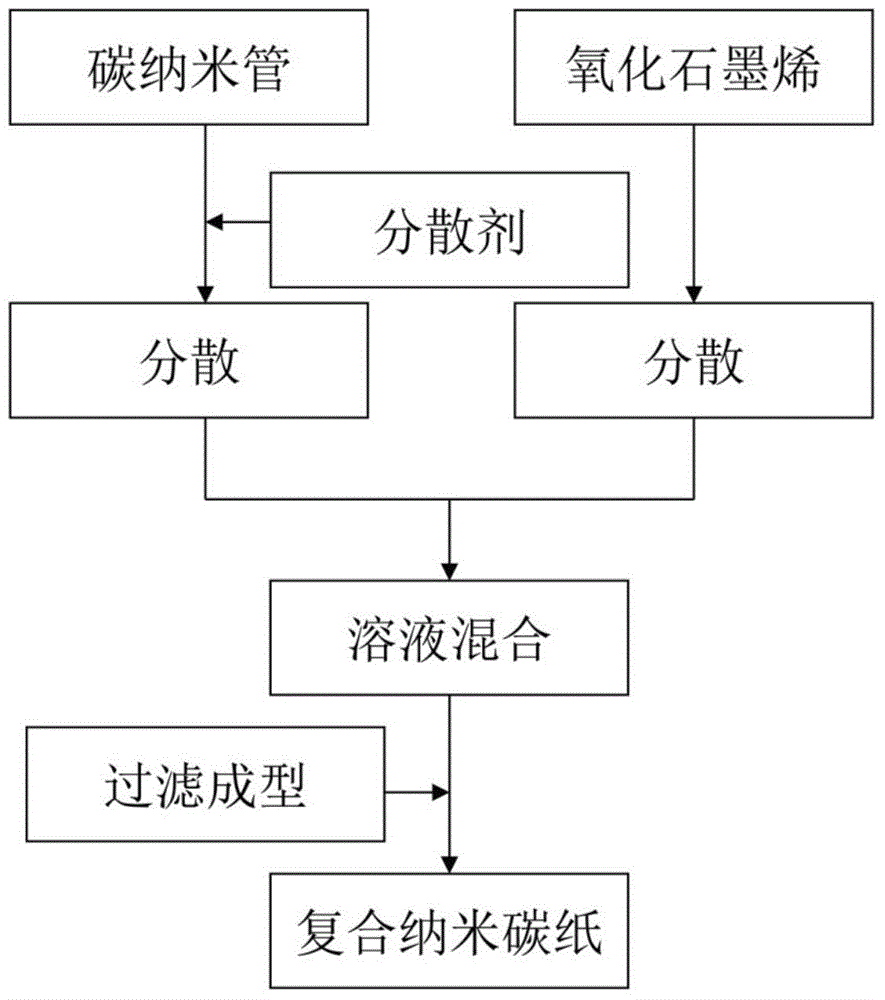

Method used

Image

Examples

Embodiment 1

[0064] Example 1 Weigh 475 mg of carbon nanotubes purified by hydrochloric acid, and disperse them in 1 L of deionized water. The dispersant is polyvinylpyrrolidone, and stir for several minutes with a high-shear mixer until the carbon nanotubes form a slurry-like distribution in the dispersion. Weigh 25 mg of graphene oxide, disperse it in 1L of deionized water, and stir it with a high-shear mixer for several minutes until the graphene oxide forms a slurry-like distribution in the dispersion. Mix the dispersion of carbon nanotubes and the dispersion of graphene oxide, and stir them with a mixer for several minutes to mix them evenly to form a stable dispersion. Spread the cellulose filter paper on the bottom of a Buchner funnel with a diameter of 25 cm, and filter it with a vacuum pump, so that the mixed dispersion of carbon nanotubes and graphene oxide is evenly deposited on the filter paper, and when it is semi-dry, the graphene oxide / carbon nanotubes The composite nanoca...

Embodiment 2

[0065] Example 2 Weighed 450 mg of carbon nanotubes purified by hydrochloric acid, weighed 50 mg of graphene oxide, and prepared composite nanocarbon paper with a graphene oxide content of 10% by the same method as in Example 1. Its cross-sectional structure is as Figure 3b shown.

Embodiment 3

[0066] Example 3 Weighed 425 mg of carbon nanotubes purified by hydrochloric acid, weighed 75 mg of graphene oxide, and prepared composite nanocarbon paper with a graphene oxide content of 15% by the same method as in Example 1. Its structure is as Figure 3c shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com