Patents

Literature

1951 results about "Nanostructured carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

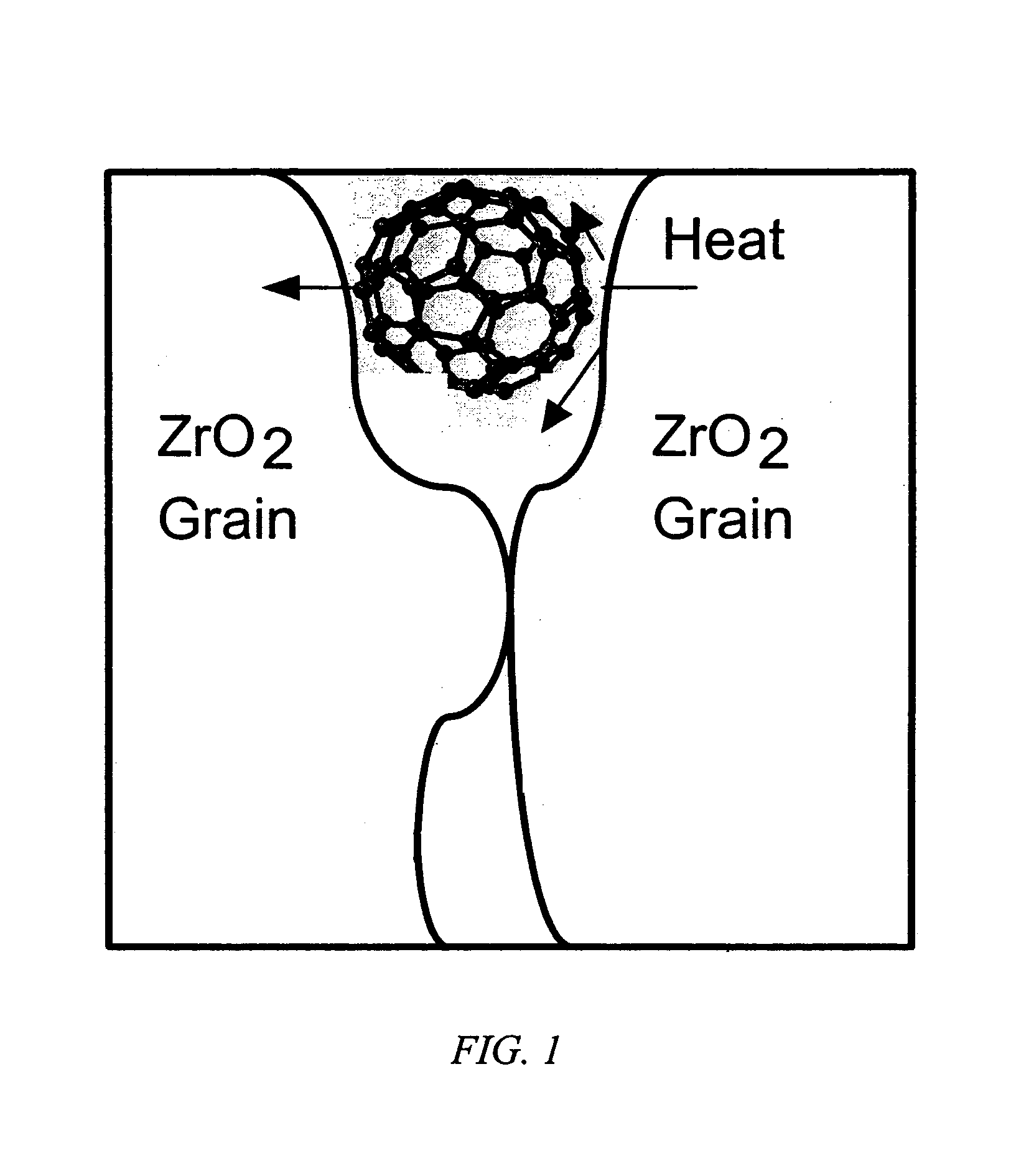

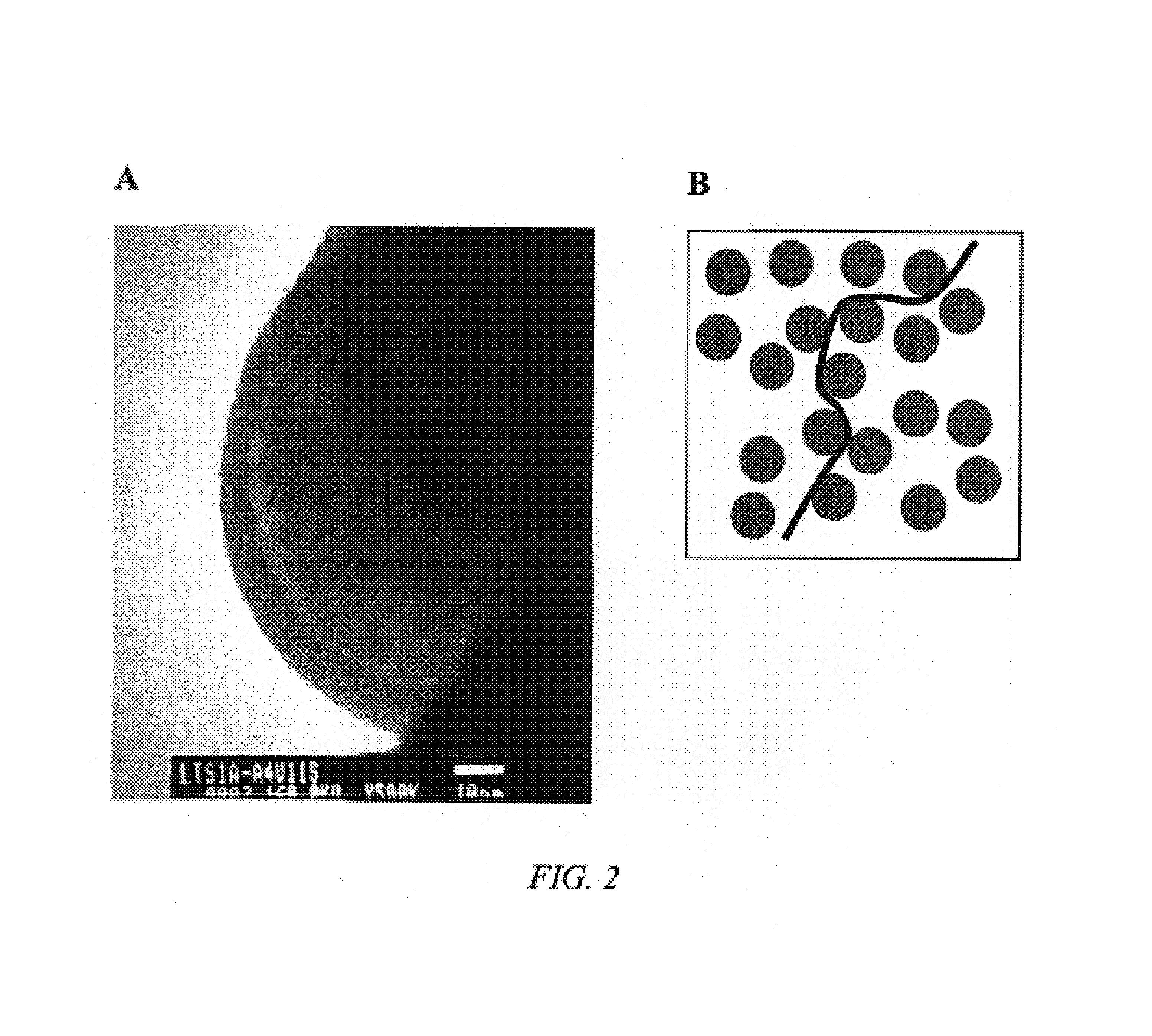

Composite materials containing a nanostructured carbon binder phase and high pressure process for making the same

InactiveUS20050186104A1Simpler and more cost efficient to fabricateHigh strengthMaterial nanotechnologyCarbonsing ragsSufficient timeCarbon Nanoparticles

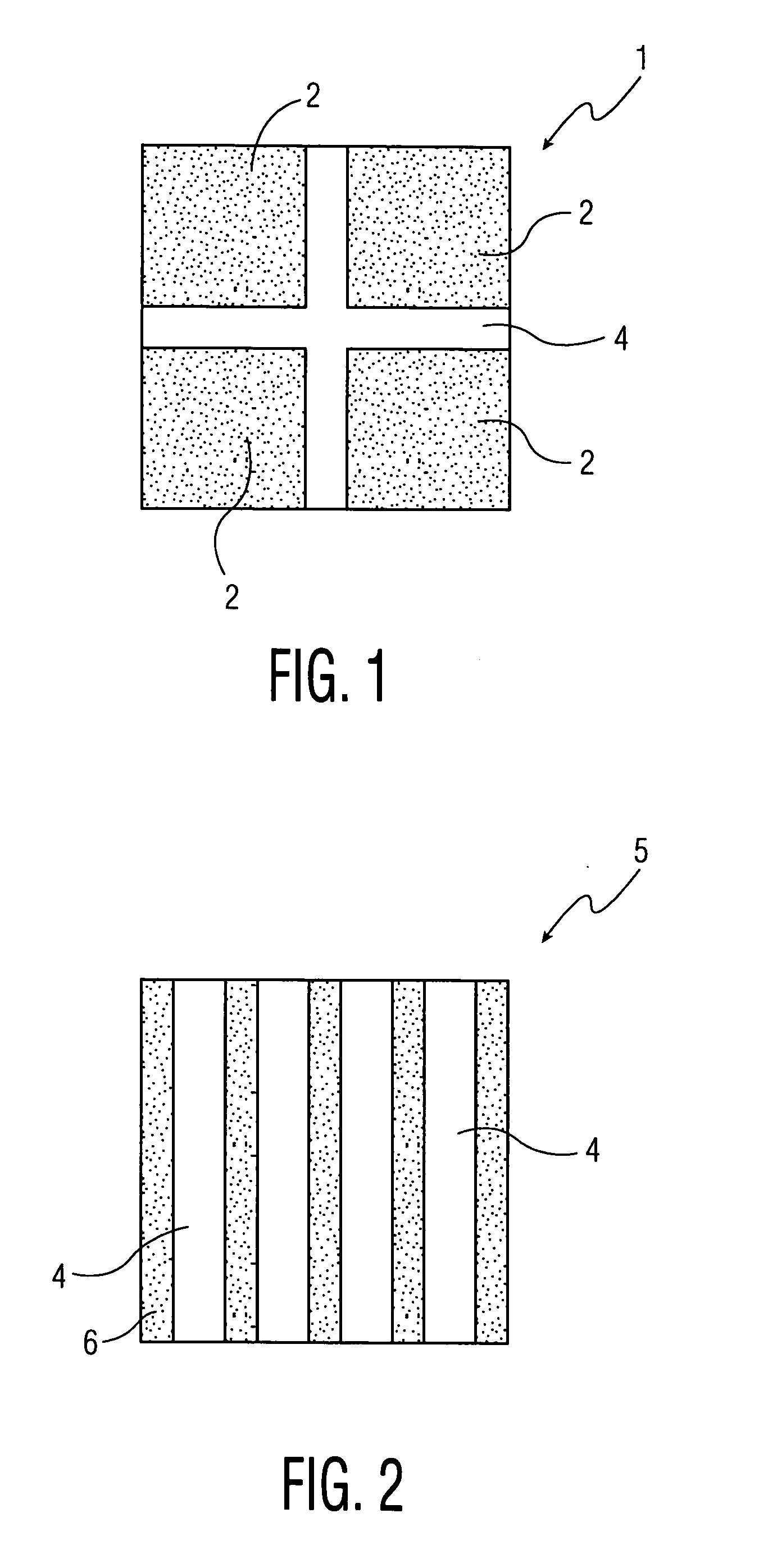

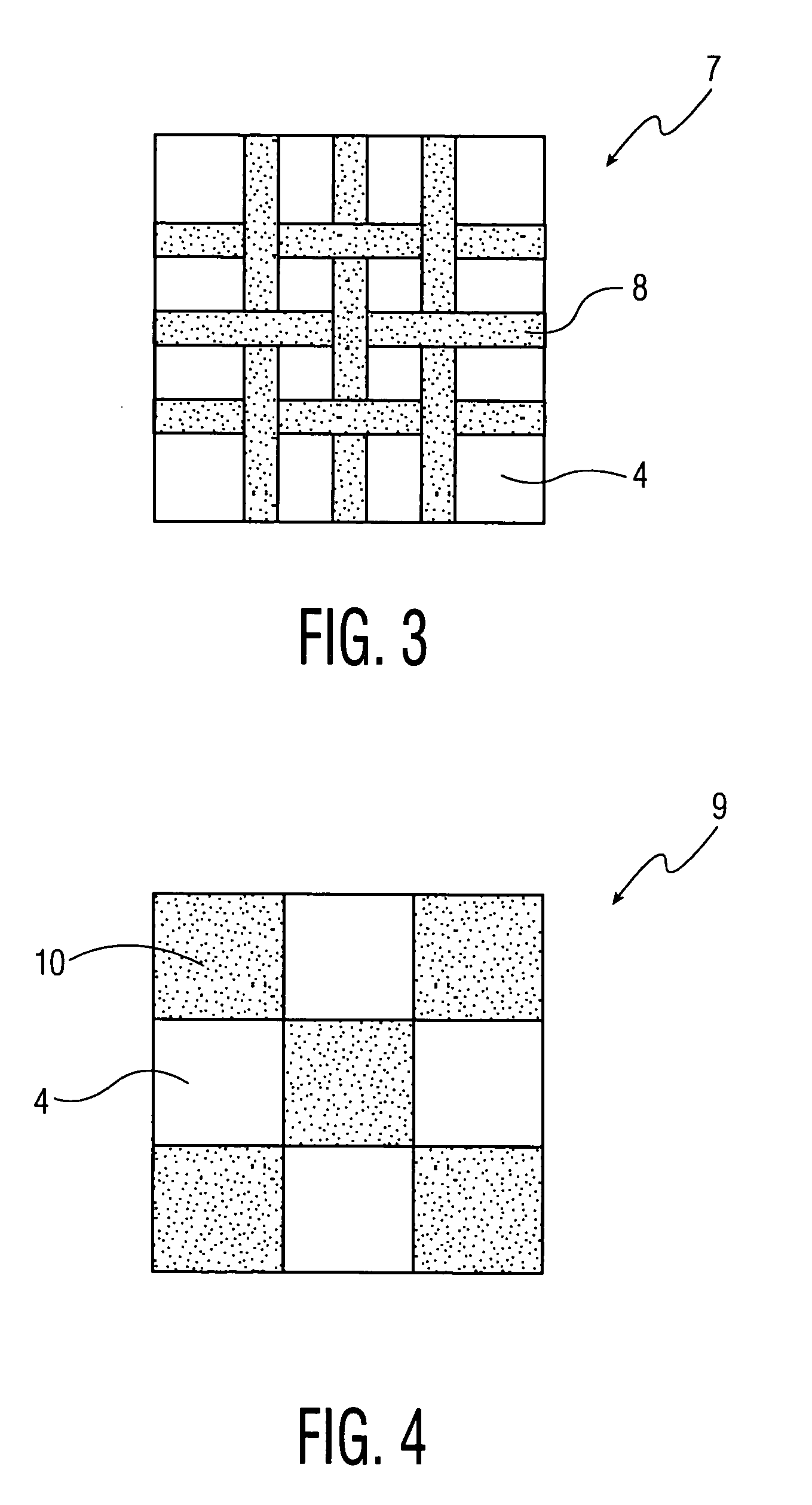

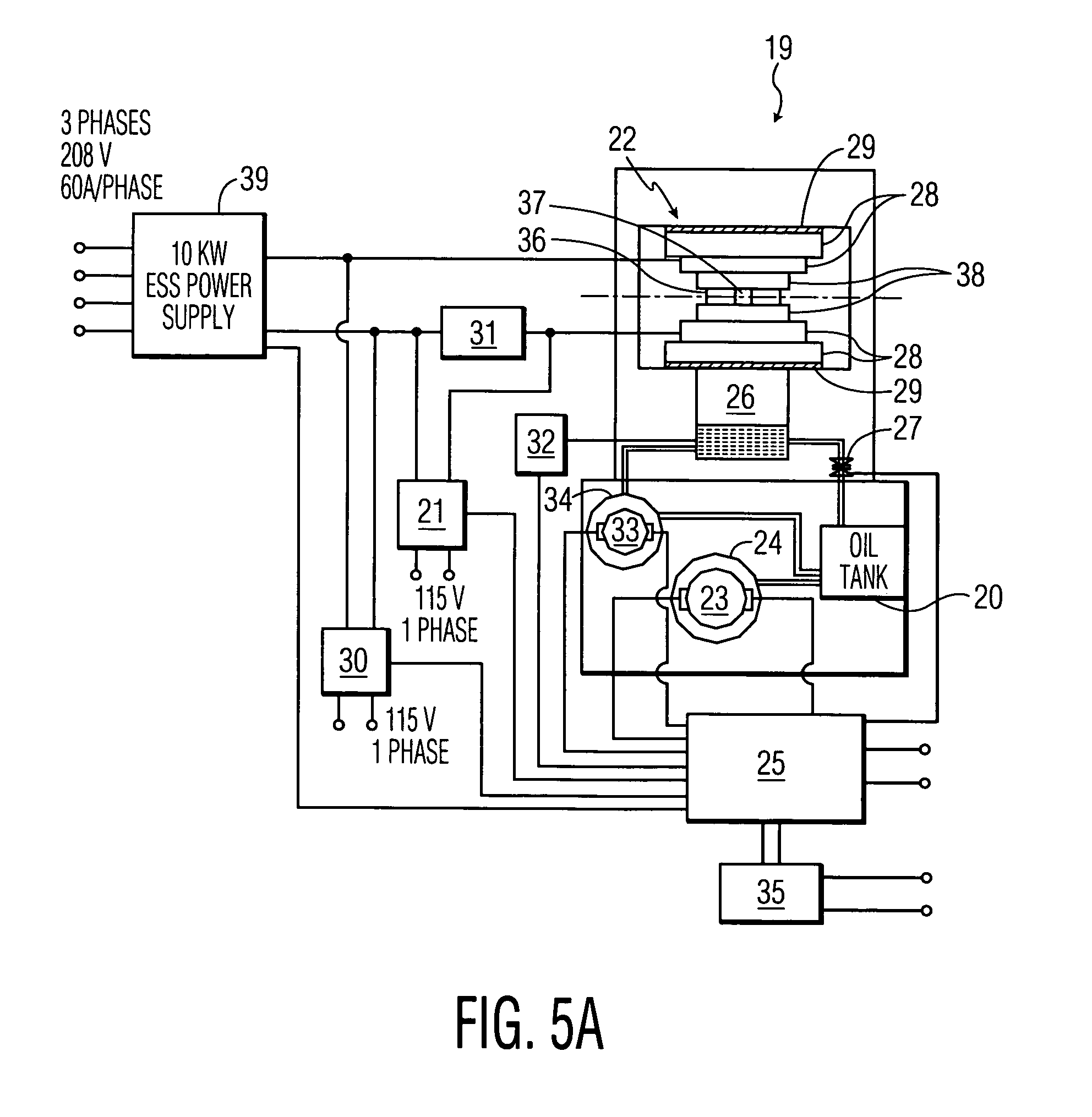

A composite material composed of a matrix phase bonded by a carbon binder phase derived from sintered carbon nanoparticles such as, for example, fullerenes. The present invention further relates to a method of making such composite materials which includes the steps of dispersing a sufficient amount of carbon nanoparticles into a matrix phase, and compressing the carbon nanoparticles-containing matrix phase at a sufficient pressure and temperature over a sufficient time to facilitate the conversion of the carbon nanoparticles into a nanostructured carbon binder phase, thereby yielding the composite material.

Owner:RUTGERS THE STATE UNIV

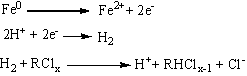

Carbon material loaded nano zero valence metal catalyst and preparation method and application thereof

ActiveCN103191742AGood dispersionImprove stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a carbon material loaded nano zero valence metal catalyst which comprises a nano zero valence metal and a carbon material, wherein the nano zero valence metal is uniformly dispersed in the carbon material; the loading quantity of the nano zero valence metal is 5-15mg / g; the nano zero valence metal is iron, copper, zinc or nickel; and the carbon material is a carbon nano tube, graphene or nano activated carbon. The invention further discloses the preparation and an allocation and application of the catalyst. The nano zero valence metal is loaded to the carbon material, so that the agglomeration of the zero valence metal is prevented, the stability of the catalyst is improved, and the specific surface area of the catalyst is remarkably increased; the catalyst is high efficient, cheap and stable in performance; a chlorine-containing organic pollutant can be rapidly and efficiently absorbed and enriched; and meanwhile the excellent electronic transmission capability of the nano carbon material can greatly accelerate the catalytic degradation speed of the pollutant, so that the pollutant can be more rapidly and effectively removed, so that the carbon material loaded nano zero valence metal catalyst is safe and economical.

Owner:济南市供排水监测中心

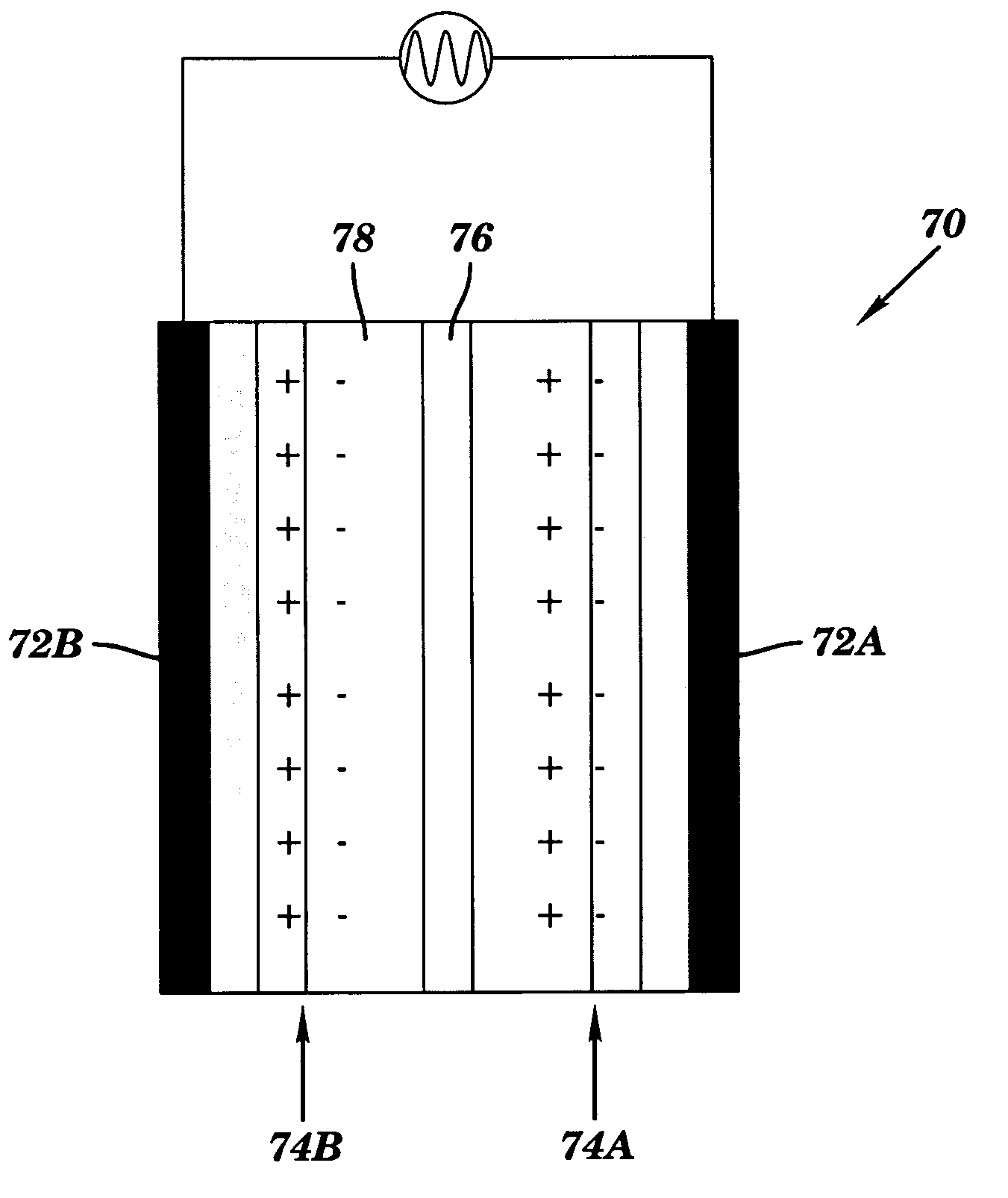

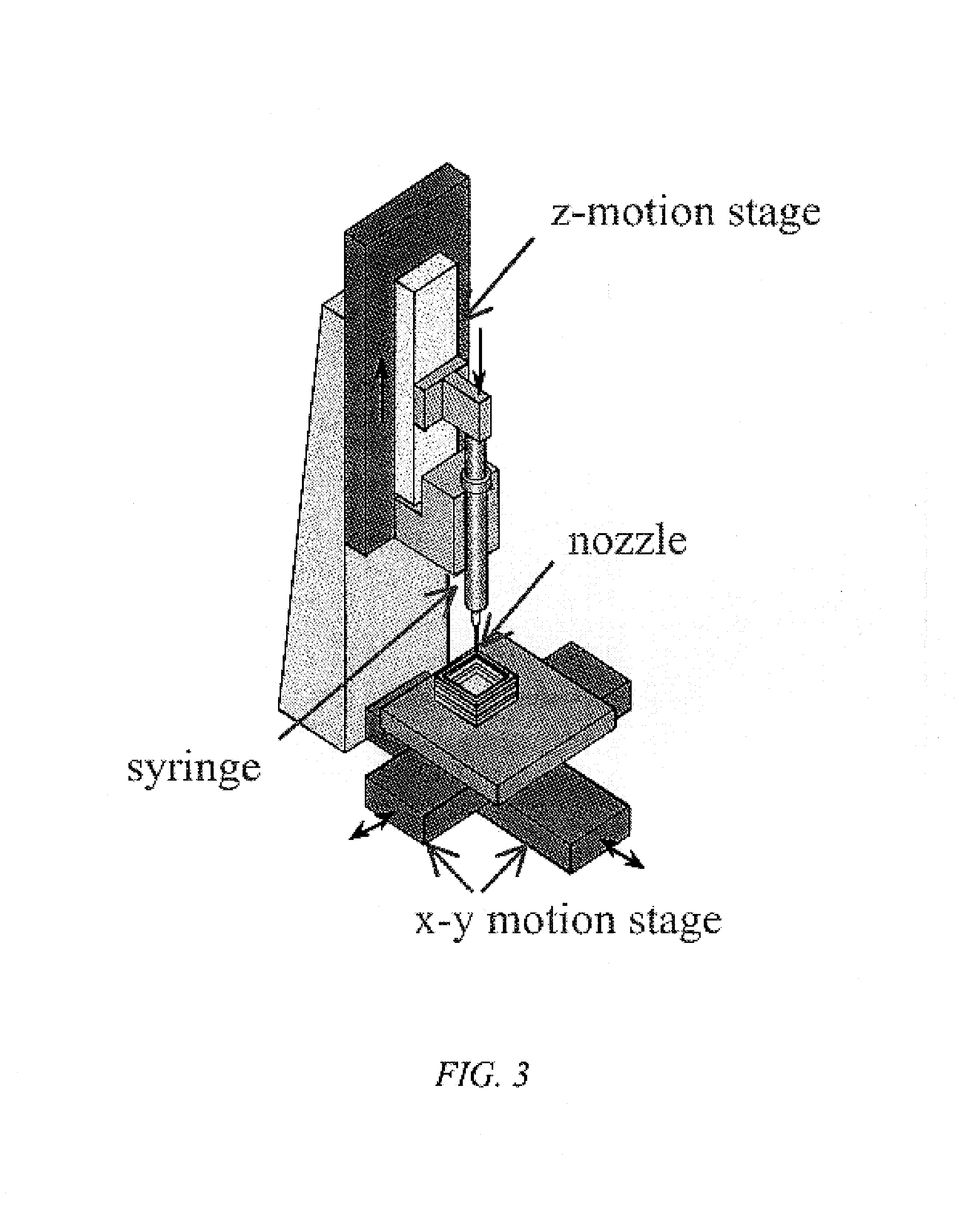

Nano-composite structures, methods of making, and use thereof

ActiveUS20080254362A1Improve electronicImprove ionic transportMaterial nanotechnologyCell electrodesCrystallographyFuel cells

The present invention relates to a nano-composite structure containing nanostructured carbon and nanoparticles. Also disclosed are methods of making the nano-composite structures. The present invention also relates to a lithium ion battery, a capacitor, a supercapacitor, a battery / capacitor, or a fuel cell containing the nano-composite structures of the present invention.

Owner:ROCHESTER INSTITUTE OF TECHNOLOGY

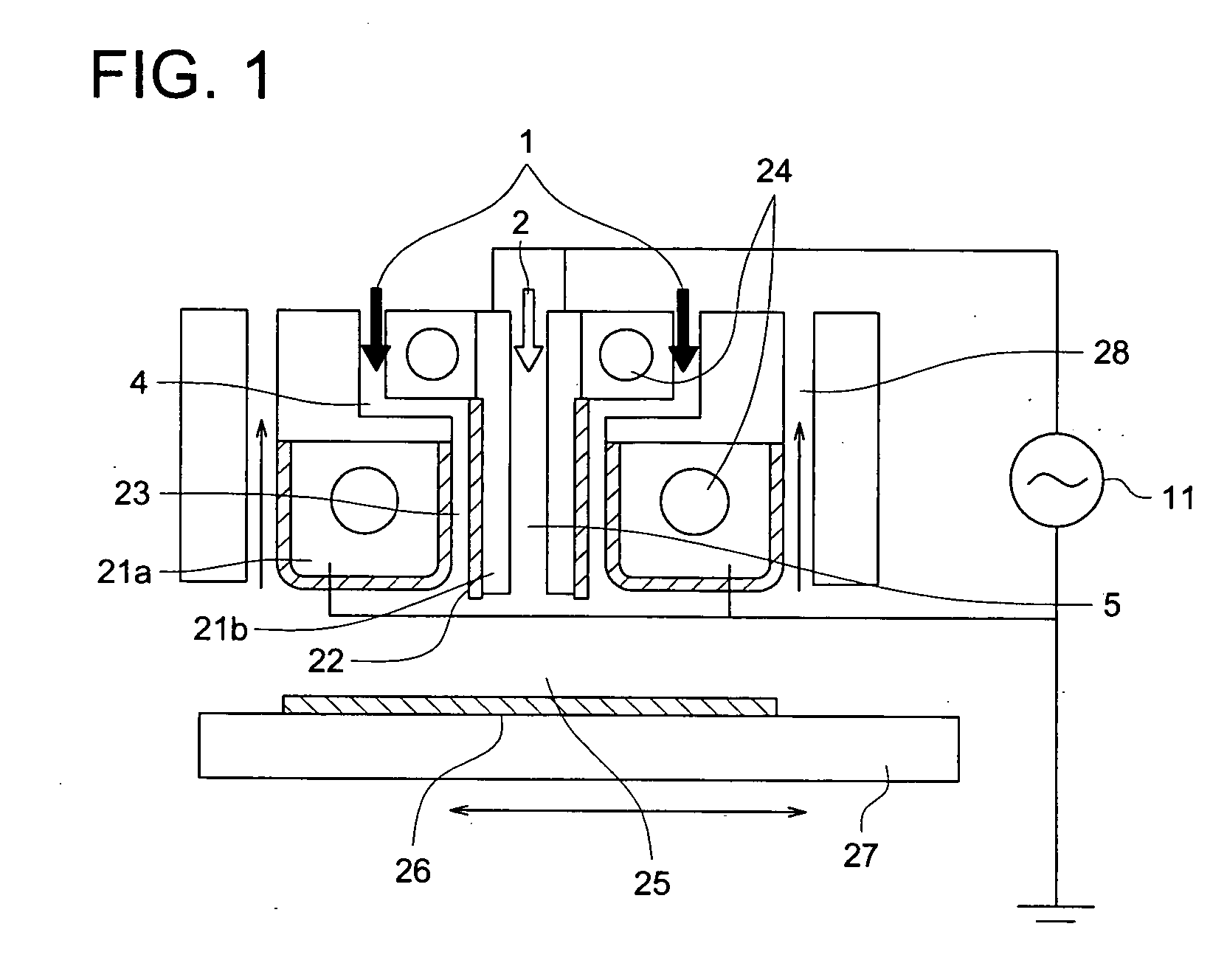

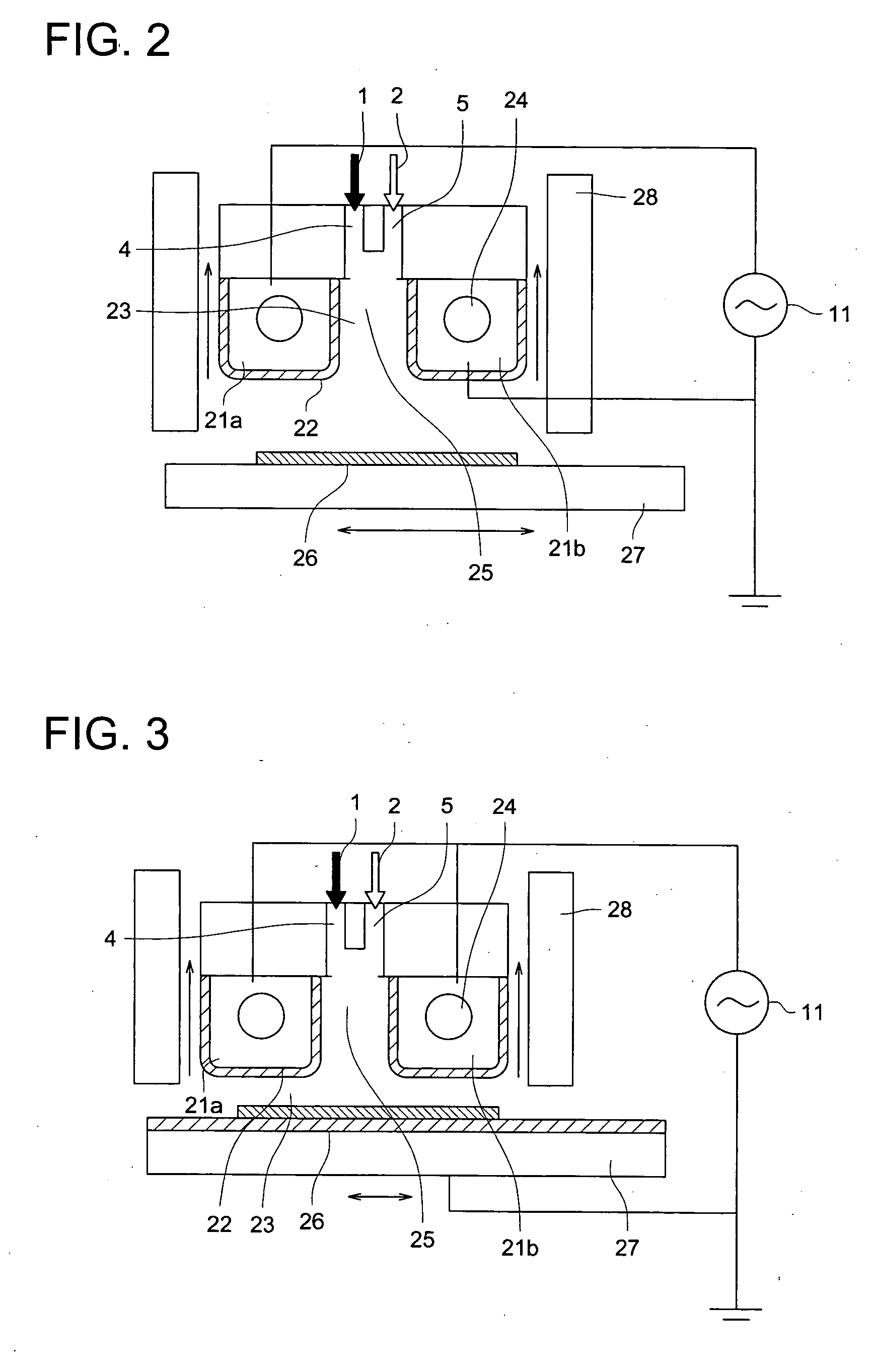

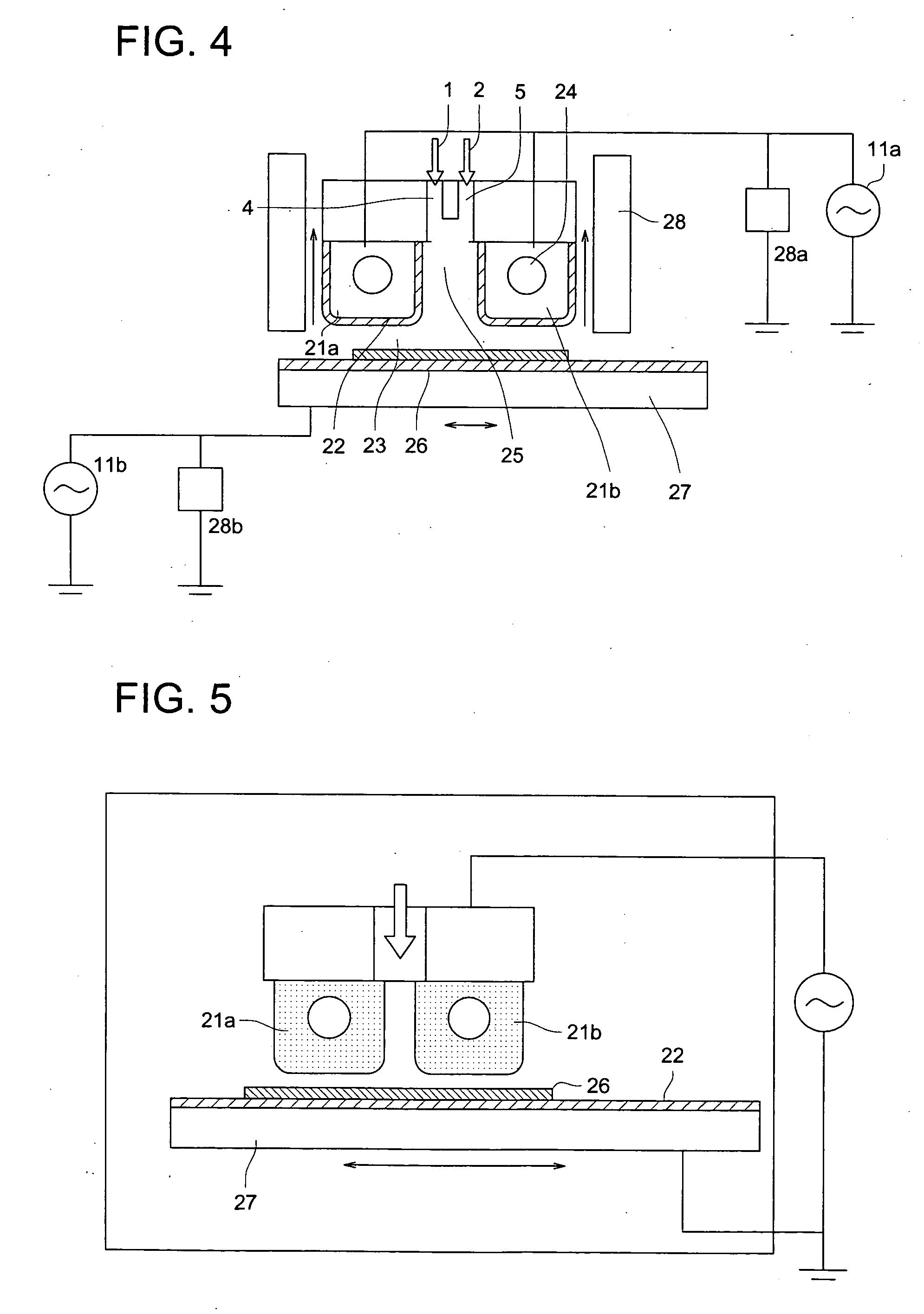

Method for forming nanostructured carbons, nanostructured carbons and a substrate having nanostructured carbons formed thereby

InactiveUS20050106094A1Easy and quick to formMaterial nanotechnologyElectric discharge tubesAtmospheric pressureNanostructured carbon

A method for forming nanostructured carbons comprising the steps of: generating a plasma by supplying at least a discharge gas between opposing electrodes and applying a high-frequency voltage between the electrodes under an approximately atmospheric pressure; existing a material gas for forming the nanostructured carbons with the plasma to generate an activated material gas; and exposing a substrate to the activated material gas.

Owner:KONICA MINOLTA INC

Silicon carbon composite negative electrode material for lithium ion battery as well as preparation method and applications of material

ActiveCN102903896AImprove securityImprove cycle performanceCell electrodesCarbon compositesElectrical battery

The invention is applicable to the field of novel materials, and provides a silicon carbon composite negative electrode material for a lithium ion battery, as well as a preparation method and applications of the material. The negative electrode material is of a nuclear-shell-type composite structure, and consists of nano silicon in the core, amorphous carbon at the middle layer and a one-dimensional nano carbon material at the outermost layer, wherein the amorphous carbon at the middle layer forms an elastic loose surface structure, and thus the circulating performance and multiplying performance of silicon are improved; a network structure built by the one-dimensional nano carbon material at the outermost layer not only plays a role in buffering mechanical stress, but also provides a rapid electric conducting channel for active silicon particles, and improves the circulating performance and multiplying performance of silicon further; and meanwhile, a three-dimensional electric-conducting heat-conducting network formed by the one-dimensional nano carbon material can conduct heat generated by a battery during the discharging process to the space around, and the safety performance of the battery is improved. The preparation method of the silicon carbon composite negative electrode material for the lithium ion battery is simple and feasible in process, environment-friendly and energy-saving, low in cost, and easy for industrialization.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Nanosized carbon material-activated carbon composite

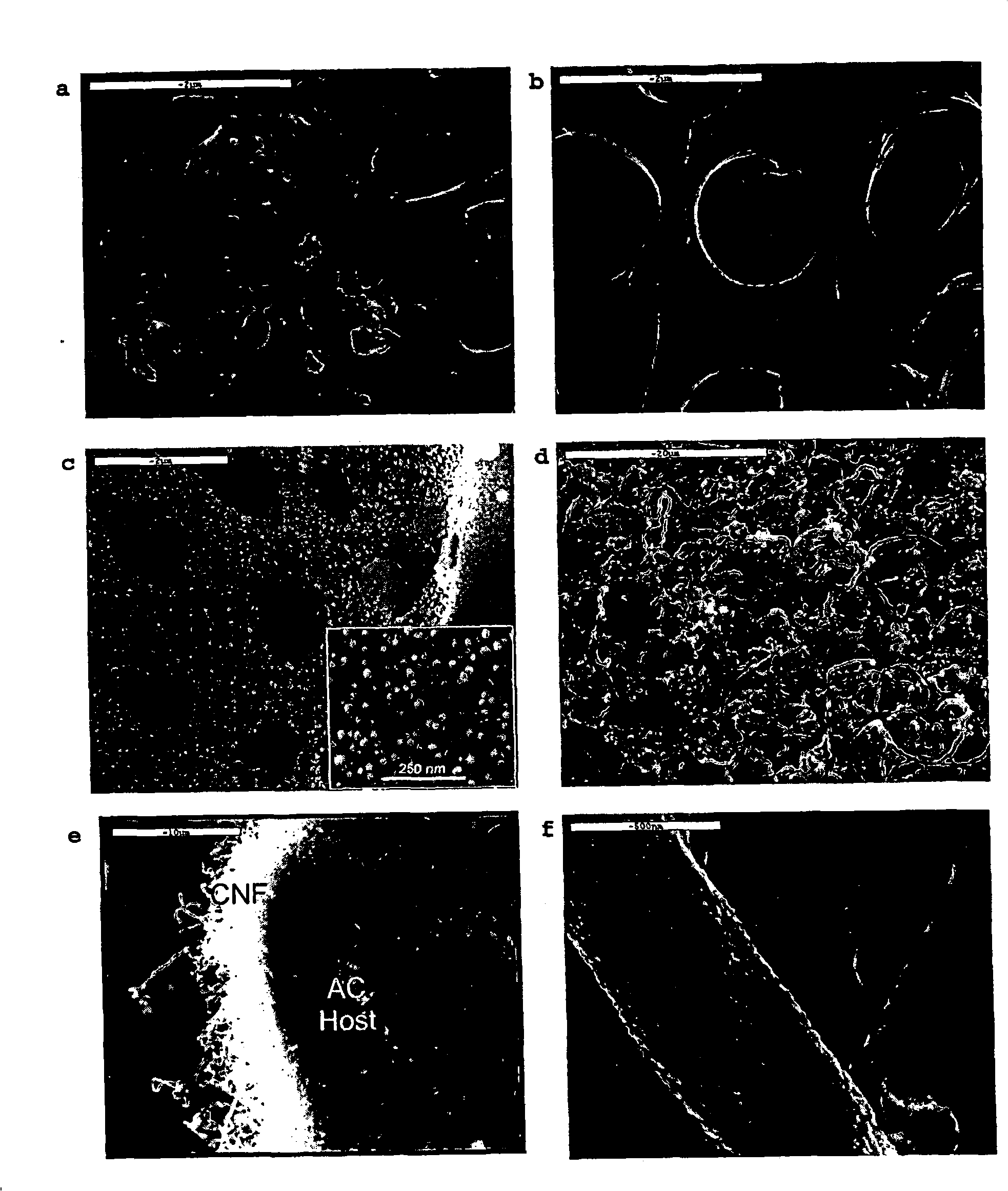

InactiveCN101304945AAvoid disadvantagesMaterial nanotechnologyCarbon compoundsCarbon compositesActivated carbon

The present invention relates to carbon-carbon composite material comprising a carbonaceous carrier and nanosize carbon structures (e.g. CNT or CNF), wherein the nanosize carbon structures are grown on the carbonaceous carrier. The carrier may be porous, as in activated carbon or consists of carbon black particles. In accordance with the invention, nanocarbon growth in the pores of porous carriers can be realized. The process for the manufacture of a this carbon-carbon- composite material comprises the steps of treating a carbonaceous carrier material with a metal -containing catalyst material, said metal being capable of forming nanosize carbon structures, and growing nanosize carbon structures by means of a CVD (chemical vapour deposition) method on the treated carrier in a gas atmosphere comprising a carbon-containing gas, followed by an optional surface modification step. This process allows optimising porosity, hydrodynamical properties and surface chemistry independently from each other, which is particularly beneficial in respect of the use of the composite for water purification. Carbon black-based composites are particularly useful for filler applications.

Owner:SUD CHEM IP GMBH & CO KG

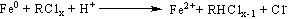

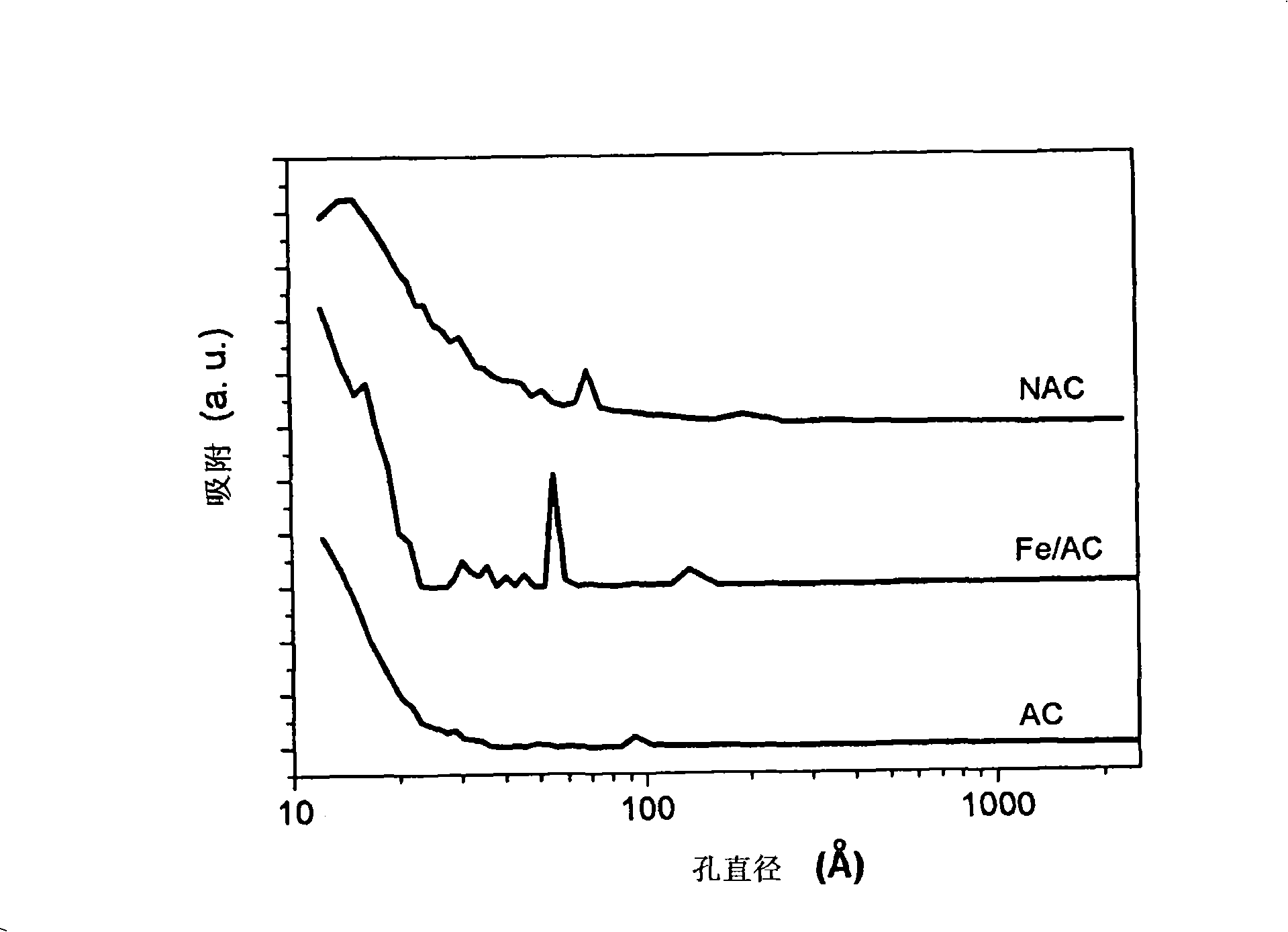

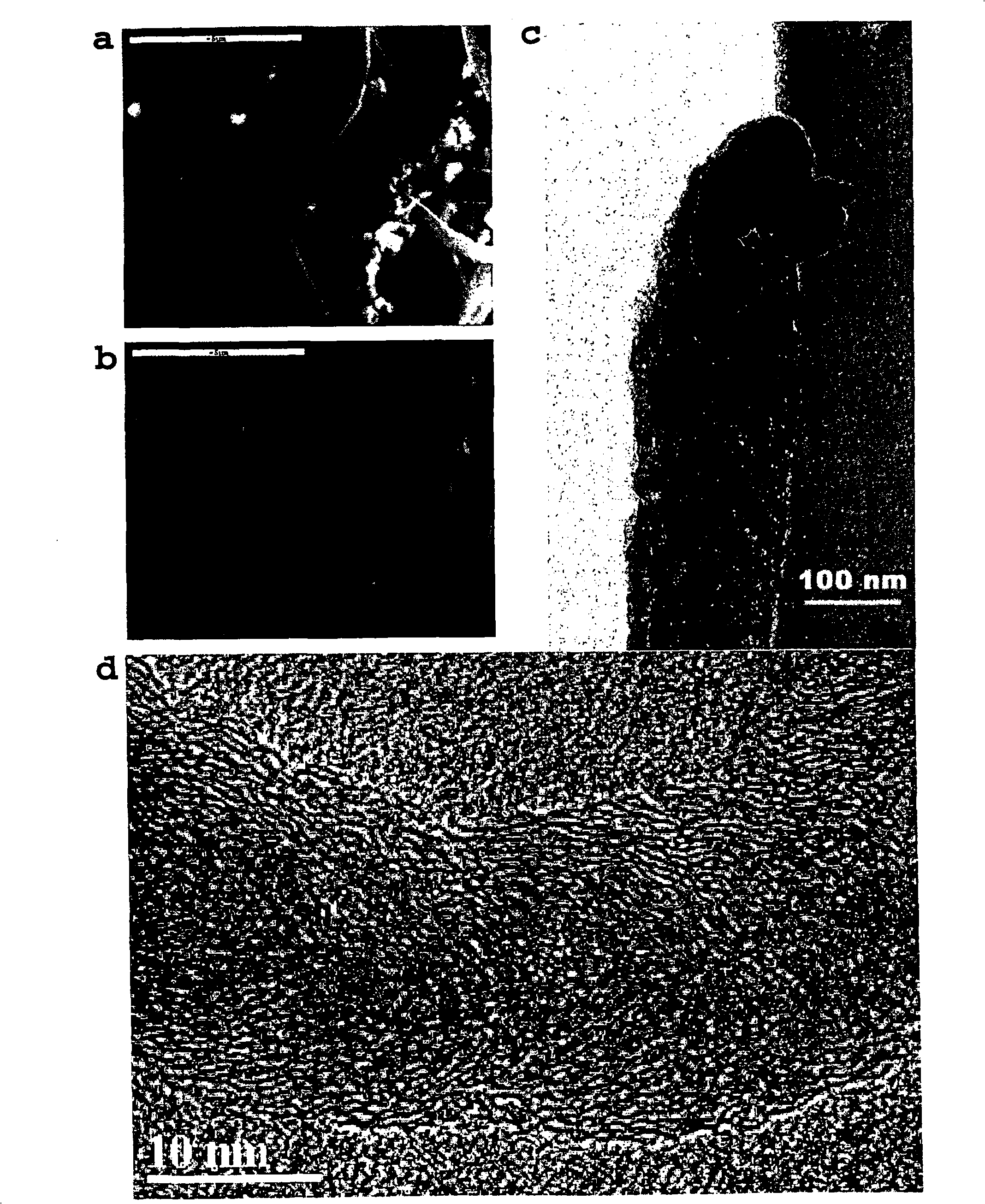

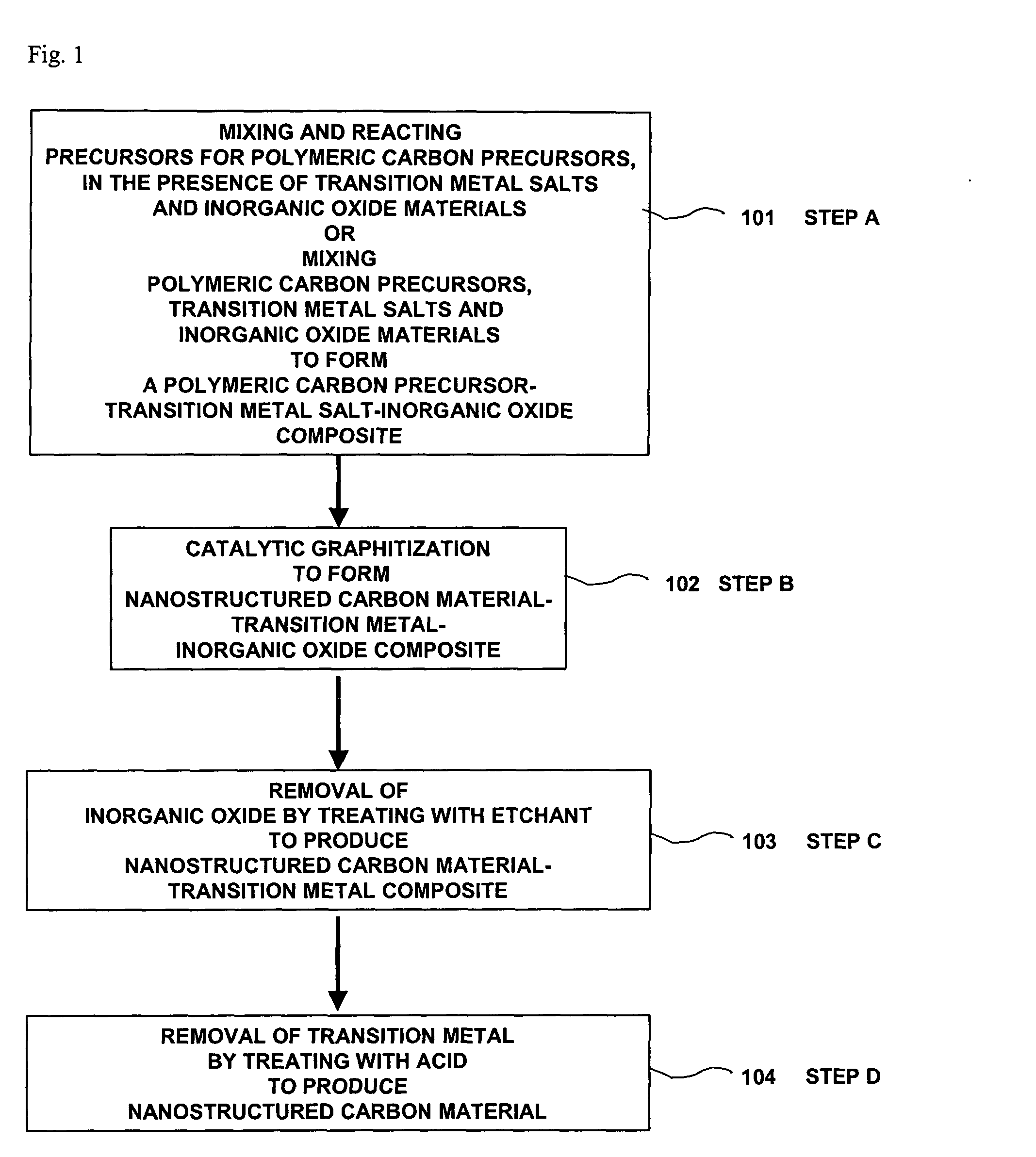

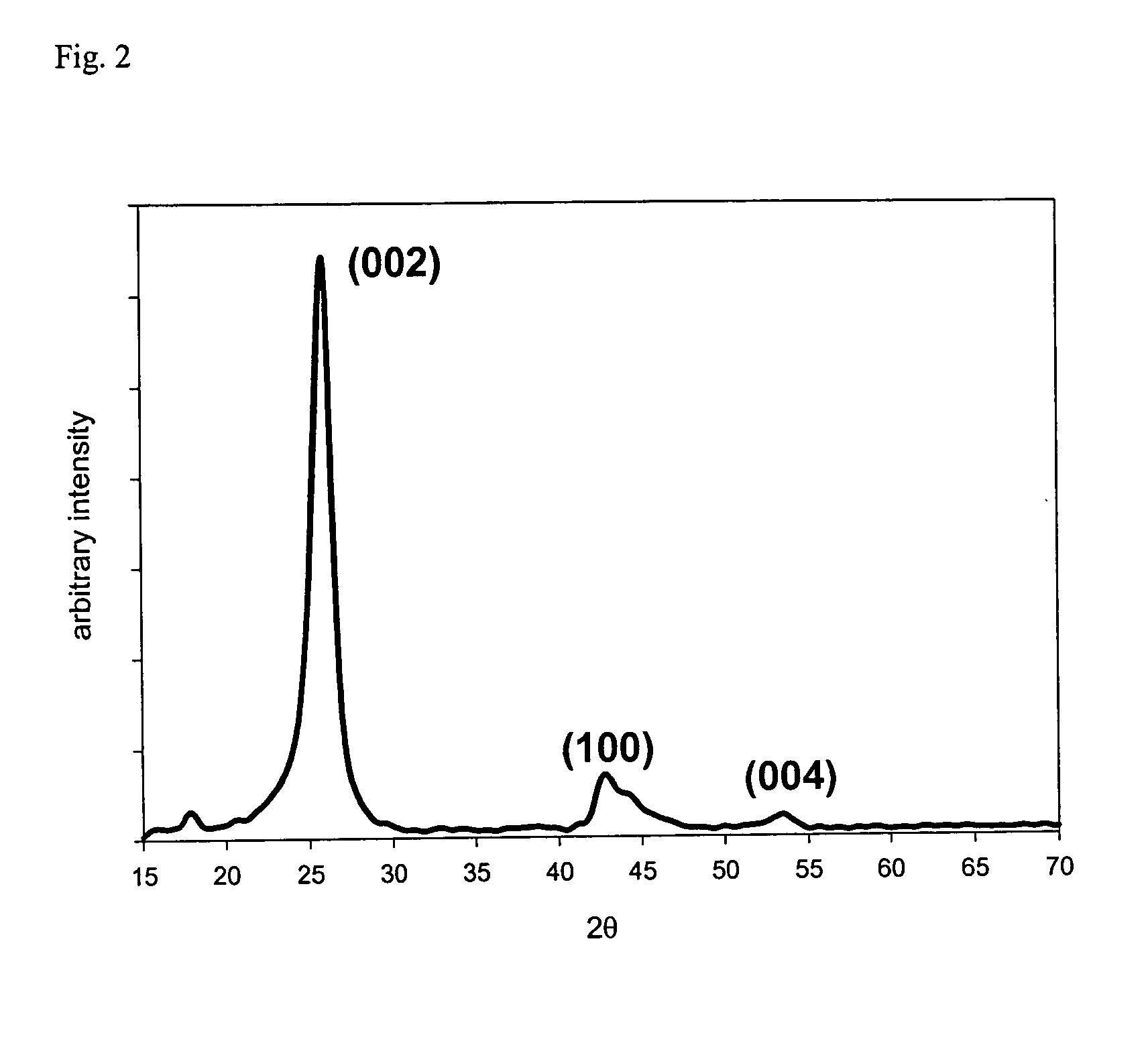

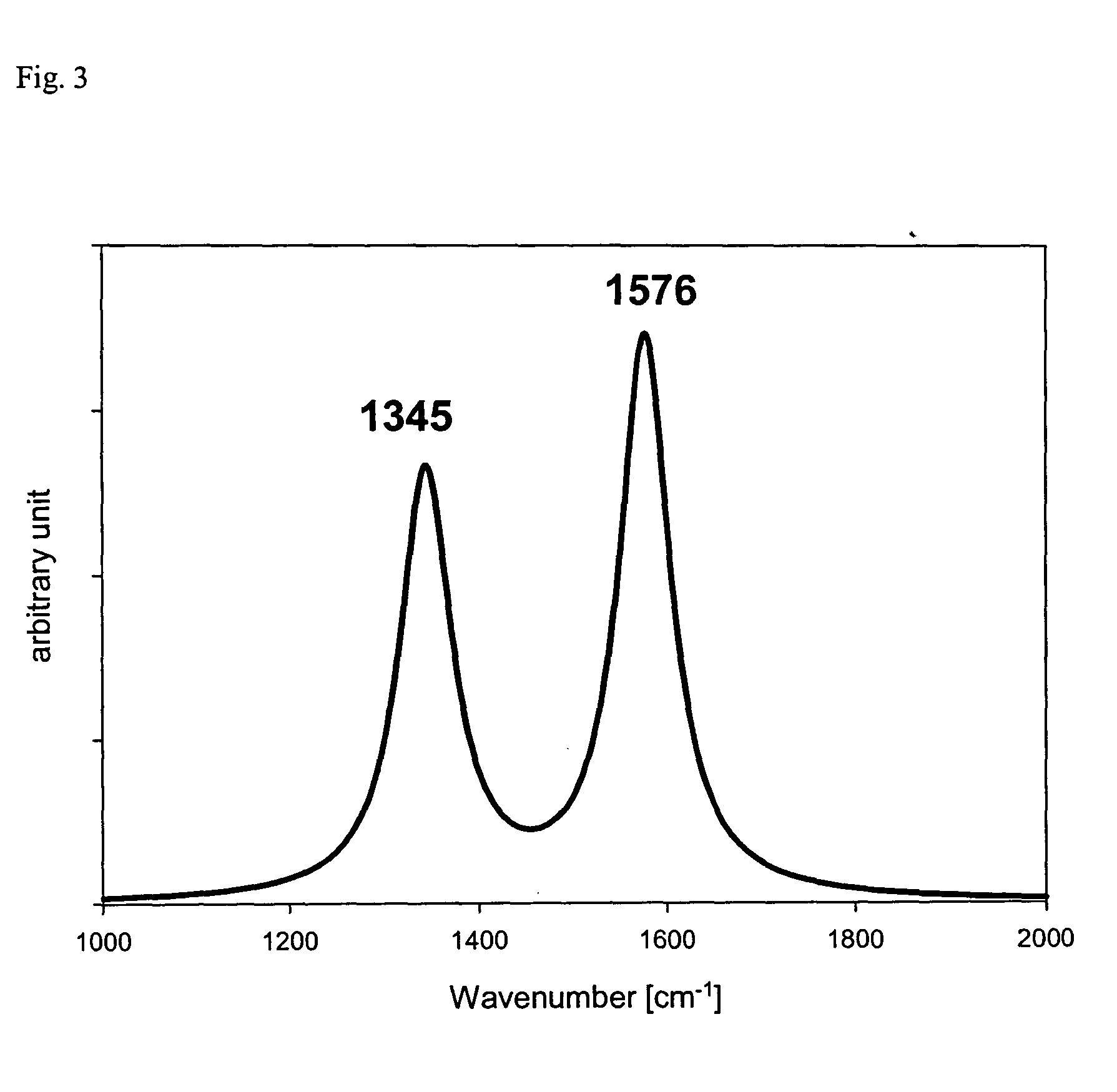

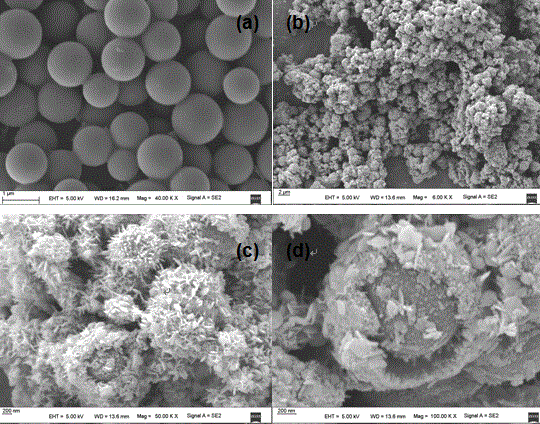

Nanostructured carbon materials having excellent crystallinity and large surface area suitable for fuel cell electrodes and method for synthesizing the same

InactiveUS20050008562A1Excellent graphitic crystallinityIncrease surface areaMaterial nanotechnologyCarbon compoundsCrystallinityNanostructure

A method for synthesizing nanostructured carbon materials having excellent crystallinity and large surface area using inexpensive metal salts and polymeric carbon precursors are disclosed. The synthetic method comprises the formation of nanostructured carbon material—metal—inorganic oxide composite through catalytic graphitization of a polymeric carbon precursor—metal salt—inorganic oxide composite, removal of inorganic oxide using an etchant, and removal of metal through an acid treatment, wherein an inorganic oxide material is added in the reaction mixture in order to increase the surface area of the nanostructured carbon material, and metal salt is used as a graphitization catalyst. The resultant nanostructured carbon materials possess the characteristics of excellent crystallinity and large surface area, where such characteristics are well suited for low temperature fuel cell electrode applications.

Owner:SEOUL NATIONAL UNIVERSITY

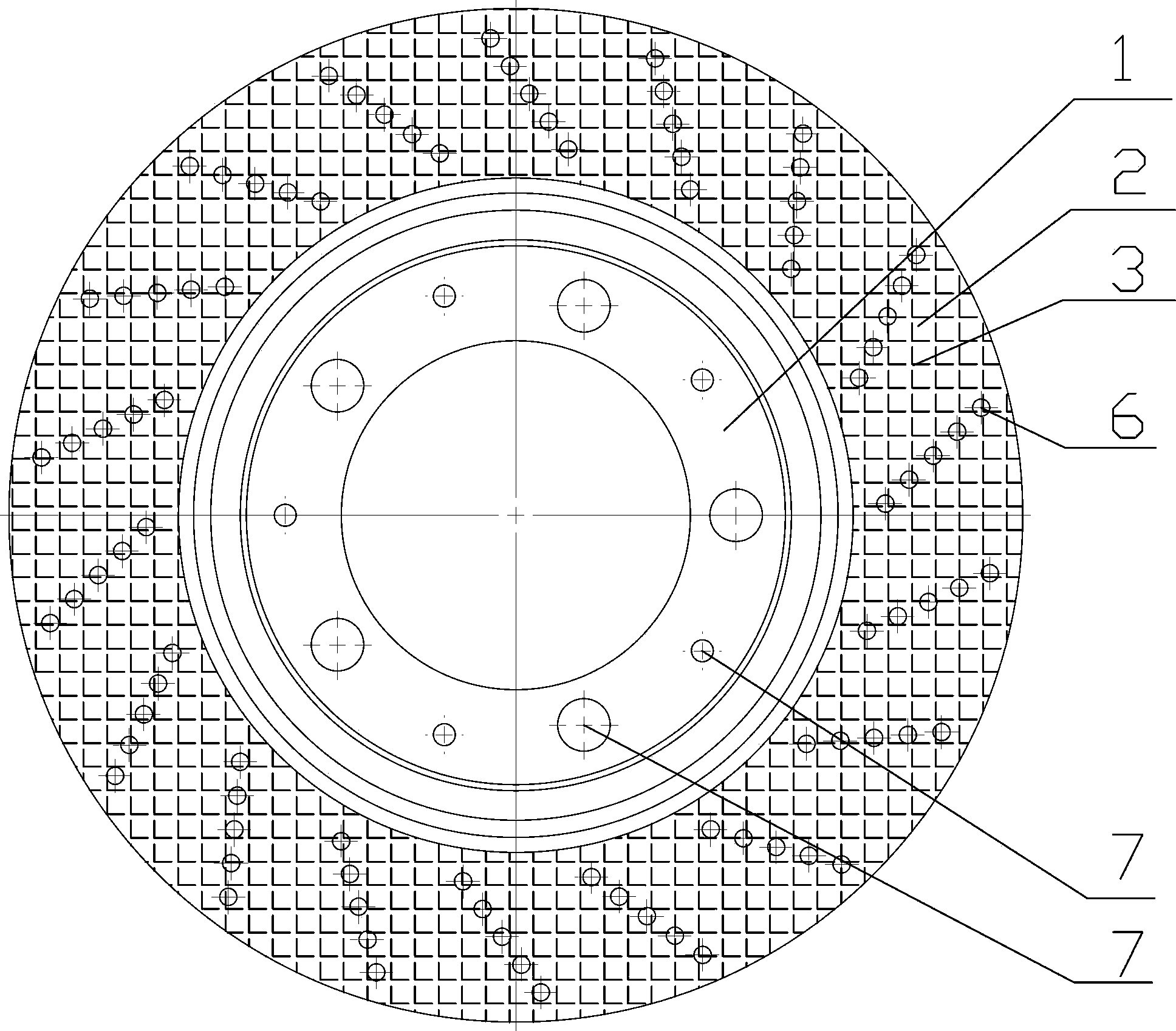

Road vehicle brake disc made of carborundum foamed ceramics/aluminum alloy composite materials and production method of road vehicle brake disc

ActiveCN104235237AReduce weightImprove feeding capacityBraking membersSlack adjustersNanoceramicAlloy composite

The invention discloses a road vehicle brake disc made of carborundum foamed ceramics / aluminum alloy composite materials and a production method of the road vehicle brake disc. The body of the reinforced-aluminum-alloy brake disc with a carborundum foamed ceramics framework is made of reinforced aluminum alloy materials such as aluminum alloy or nano ceramics particles or carbon nano-tubes. The carborundum foamed ceramics framework is integrally casted on two symmetrical friction surfaces of the brake disc, and heat dissipation grooves or air holes can be casted or do not need to be casted on the friction surfaces. A plurality of heat dissipation ribs are casted in the peripheral direction of non-friction surfaces. Mounting holes are formed in the disc body. The production method includes the steps of production of the carborundum foamed ceramics framework, preprocessing of the framework, design and production of a casting mold of the brake disc, lower-pressure casting of the brake disc, heat treatment of the brake disc, precision processing of the brake disc and storage of a finished product. The brake disc is simple in production technology, light in weight, high and stable in friction factor, high in heat conductivity, long in service life and applicable to existing road vehicles.

Owner:SHIJIAZHUANG DONGDA HUITONG NEW MATERIAL CO LTD

Aluminum alloy used for preparing high-strength high-plasticity aluminum matrix composite material and aluminum matrix composite material

The invention discloses an aluminum alloy used for preparing a high-strength high-plasticity aluminum matrix composite material and the aluminum matrix composite material, and belongs to the field of metal matrix composite materials and aluminum alloys. The aluminum alloy comprises chemical components including, by weight percent, 0.3%-0.7% of Si, 0.7%-1.4% of Mg, 0.6%-1.2% of Cu and the balance Al. Ceramic particles such as SiC, Al2O3, B4C, TiC and TiB2 and nanocarbon such as carbon nano tubes and graphene are added into the aluminum alloy to serve as a wild phase, the yield strength of the prepared composite material is obviously improved, and the composite material can reach the level of 2000 series aluminum alloy matrix composite material with the same wild phase content. Meanwhile, the aluminum matrix composite material has the good plasticity, and cold deformation machining can be carried out without cracking. Meanwhile, the natural aging negative effect (parking effect) of the prepared composite material is weak, and the strength of the composite material obtained through manual aging after natural aging can reach the strength value obtained through direct manual aging after quenching.

Owner:中科复材(滨州)新材料有限公司

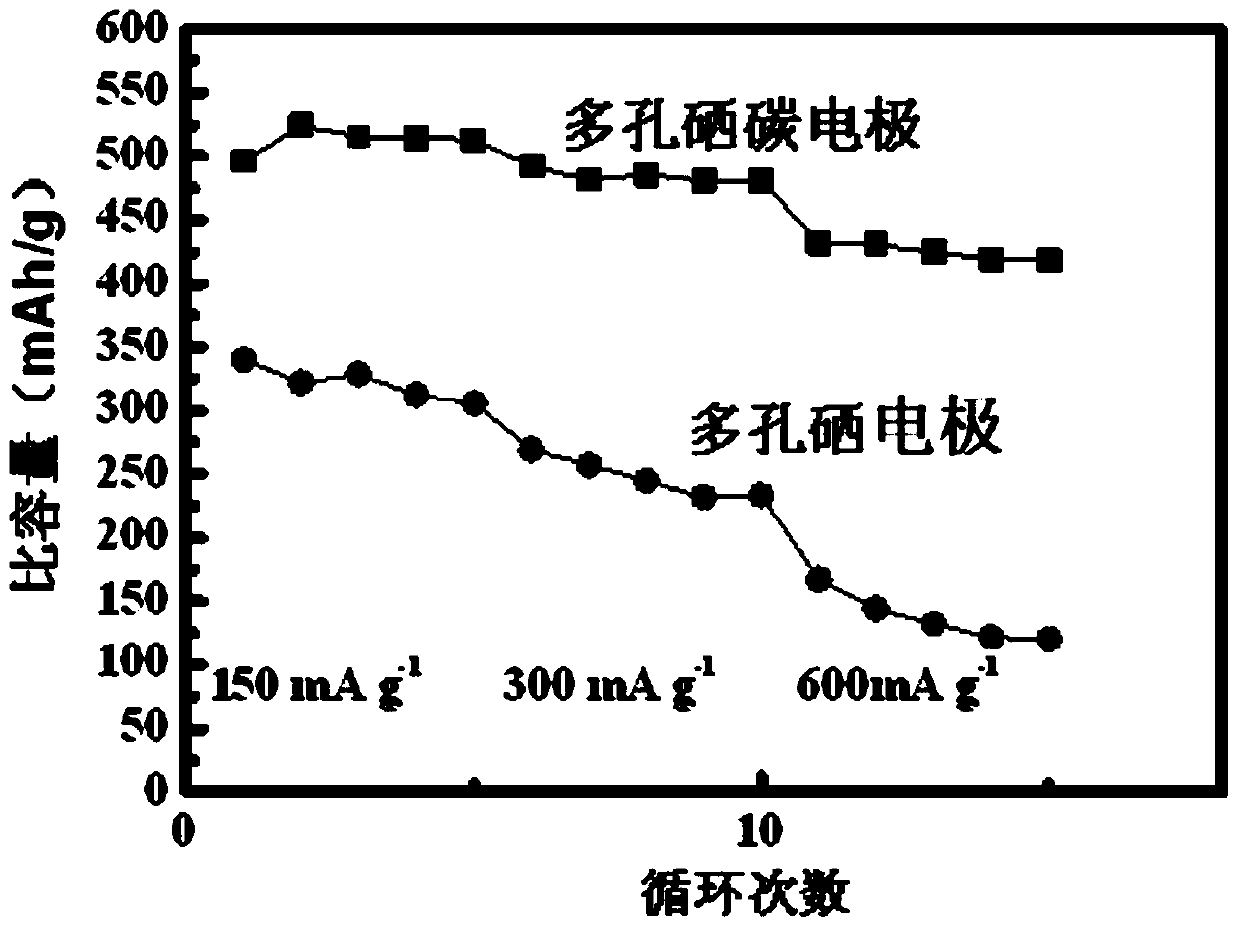

Preparation method of selenium-carbon electrode material with porous structure and application of selenium-carbon electrode material

The invention provides a preparation method of a selenium-carbon electrode material with a porous structure. The preparation method of the selenium-carbon electrode material with the porous structure comprises the following steps: mixing a carbon source, elemental selenium and nano calcium carbonate, adding a mixture into a ball milling tank and carrying out ball milling for 4-78 hours; carrying out heat treatment on the product under an inert atmosphere; cooling and milling; then treating the product in concentrated hydrochloric acid so as to remove nano calcium carbonate; and washing and drying the product, and carrying out heat treatment on the product at 100-500 DEG C under the inert atmosphere to obtain the selenium-carbon electrode material with the porous structure. The preparation method of the selenium-carbon electrode material with the porous structure is simple in process, simple and convenient to operate and low in cost; the prepared selenium-carbon electrode material with the porous structure has good electrochemical performance and excellent rate capability, is safe and reliable, and has a potential of becoming a novel lithium-selenium secondary battery positive electrode.

Owner:SOUTHEAST UNIV

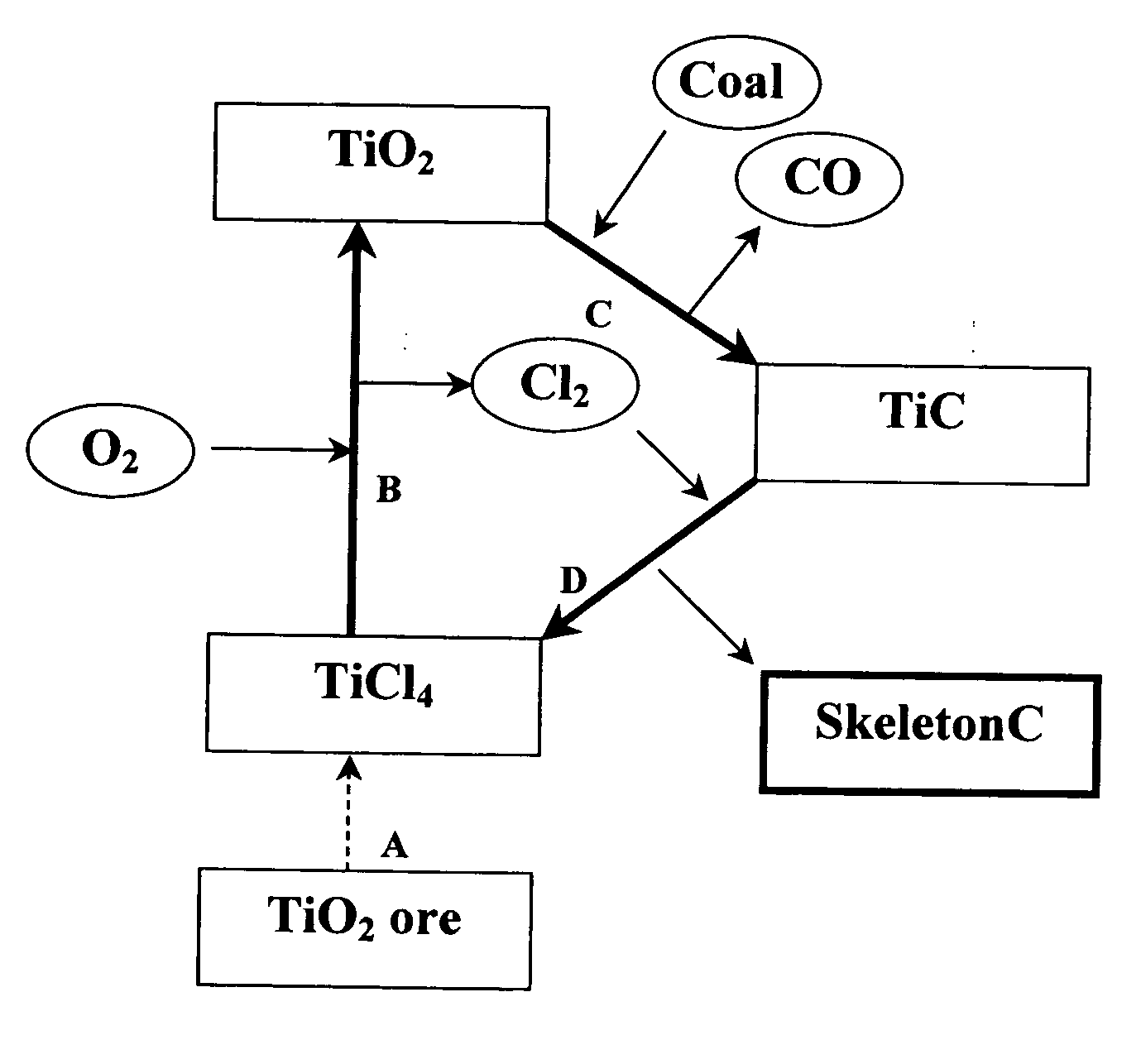

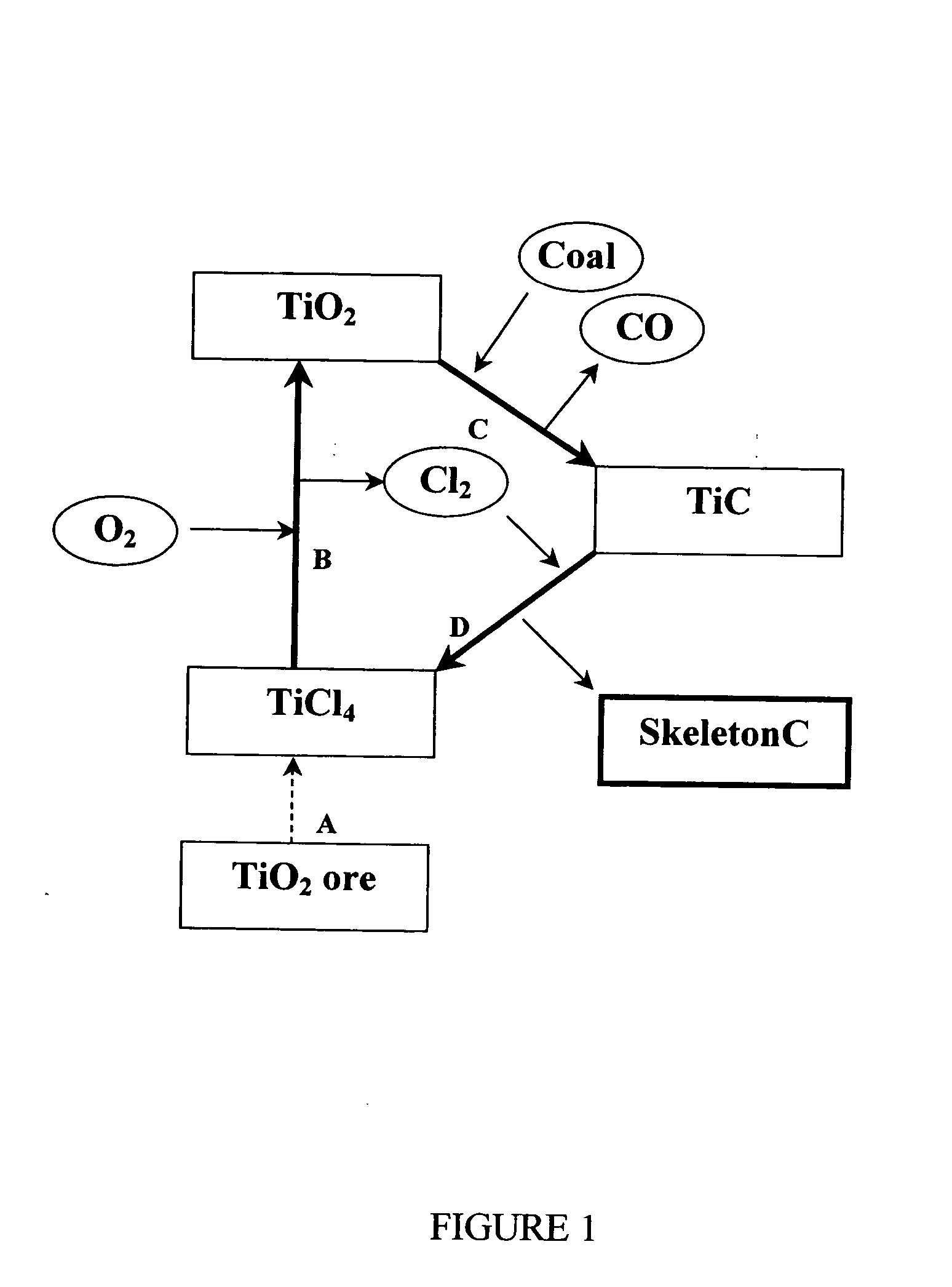

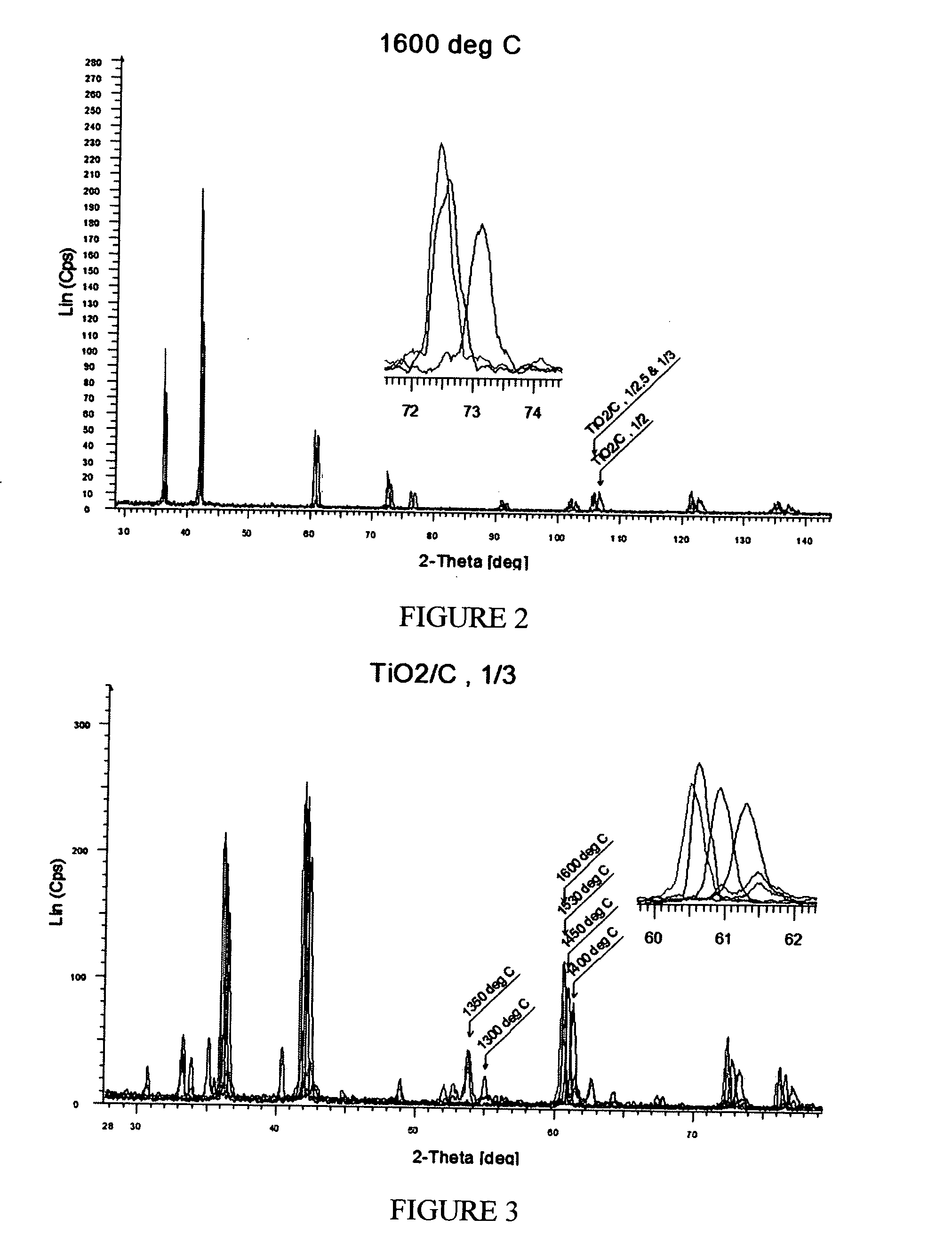

Method for manufacturing the nanoporous skeletonC material

InactiveUS20060251565A1Noticeable economic benefit in productionWaste minimizationTitanium carbideCarbon preparation/purificationMetal chlorideCarbide

A method to produce the nanostructured carbon material comprising the steps of synthesis of metal or metalloid oxide (STAGE B) from respective metal or metalloid chloride, synthesis of metal or metalloid carbide (STAGE C) from respective metal or metalloid oxide and synthesis of metal or metalloid chloride (STAGE D) from the solid product wherein the metal or metalloid carbide in STAGE C is synthesized from the respective metal or metalloid oxide produced in STAGE B.

Owner:CARBON EE OU

Fabrication of reinforced composite material comprising carbon nanotubes, fullerenes, and vapor-grown carbon fibers for thermal barrier materials, structural ceramics, and multifunctional nanocomposite ceramics

InactiveUS7306828B2Low thermal conductivityImproves Structural IntegrityMaterial nanotechnologyPropellersFiberCarbon fibers

Owner:RICE UNIV

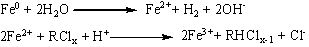

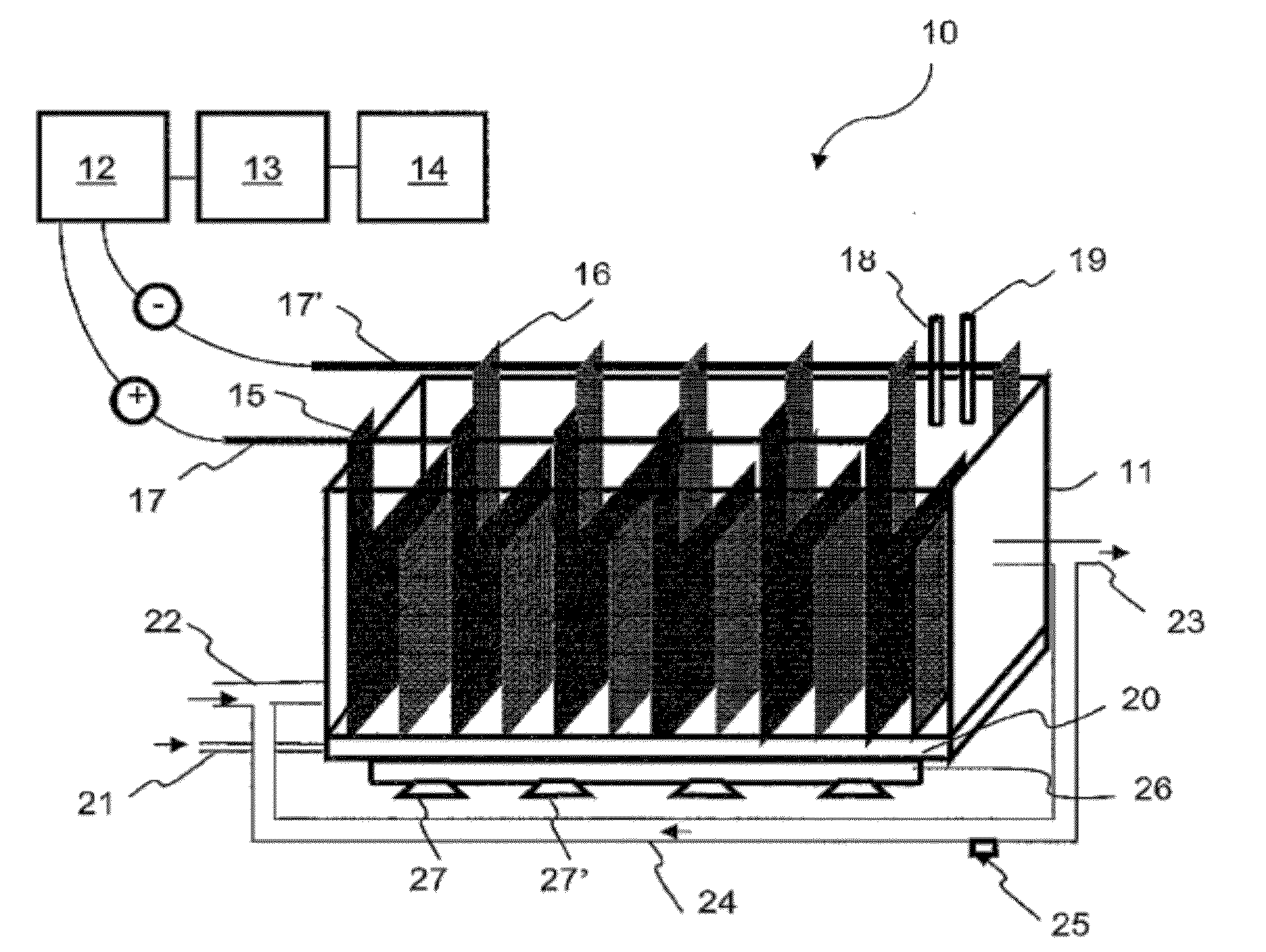

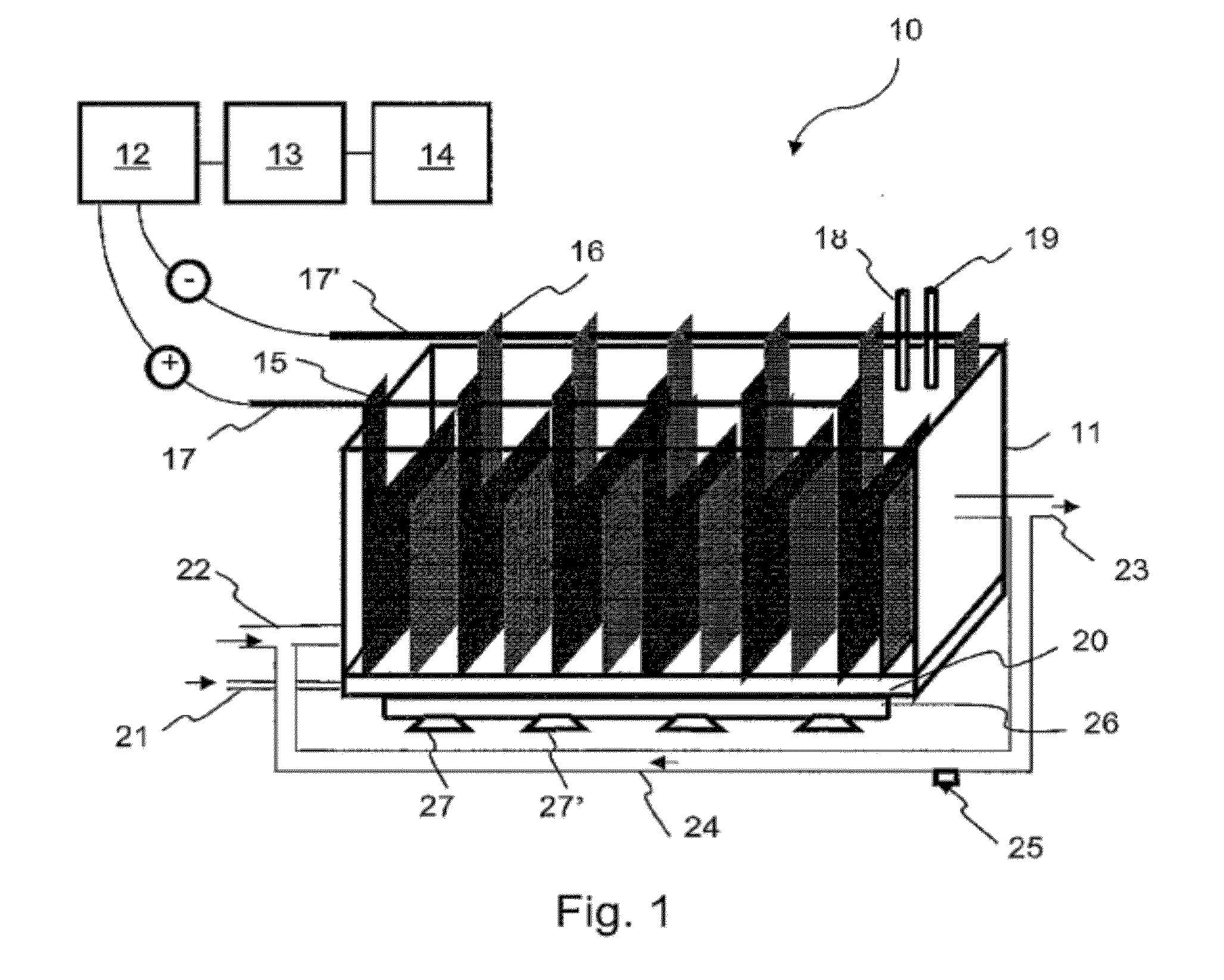

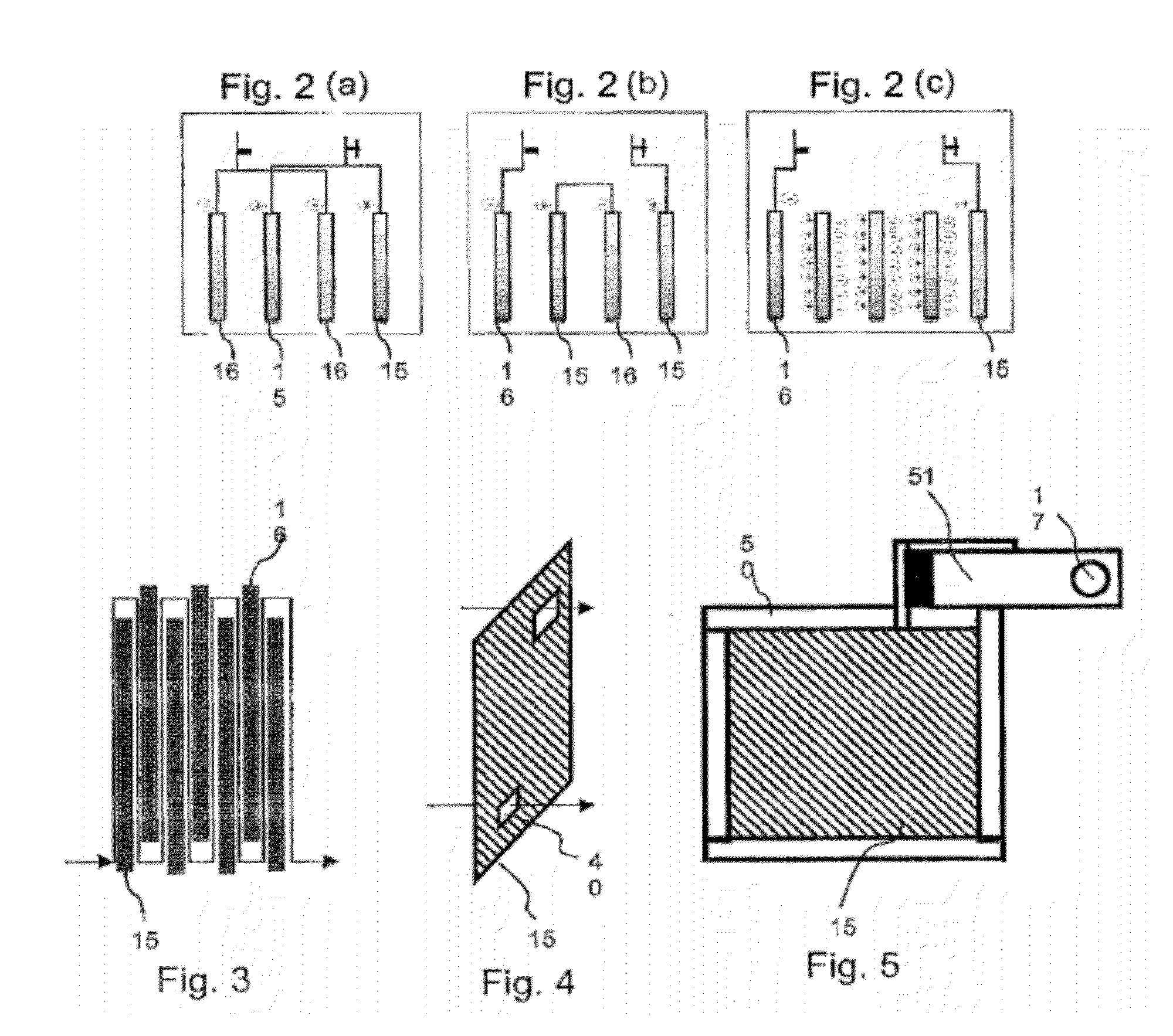

Graphene based electrodes for electrochemical reactions, and electrooxidation process for the removal of contaminants from liquids using said electrodes

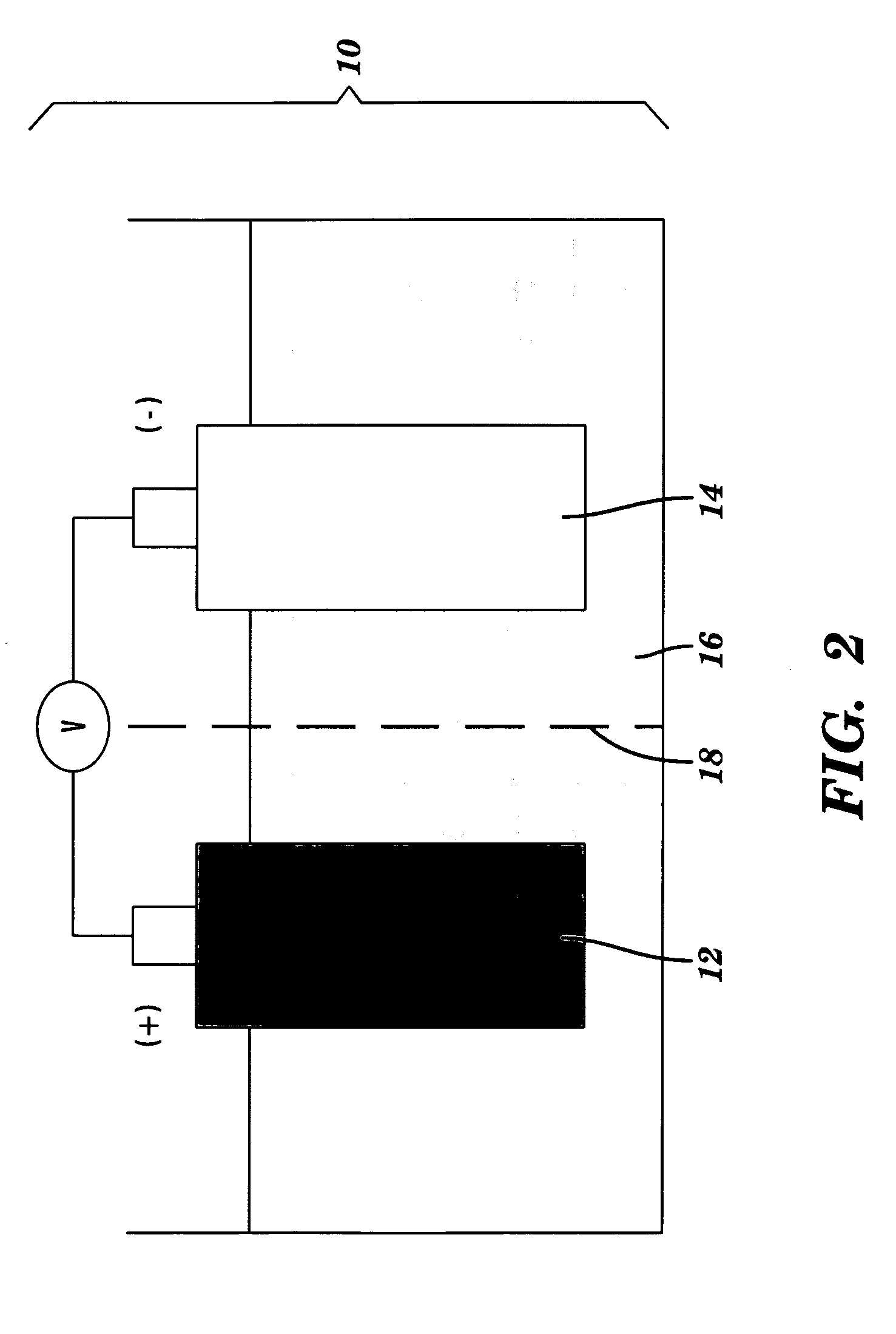

InactiveUS20120031852A1Electrolytic capacitorsConductive materialElectrochemical responseNanostructured carbon

An electrode is described completely made of graphenes or containing high amounts of these compounds in mixture with nanostructured or non-nanostructured carbon-based materials. An electrooxidation process for the removal of contaminants from liquids, and a reactor for performing the process, based on the use of said electrodes, are also described.

Owner:ENVITECH

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

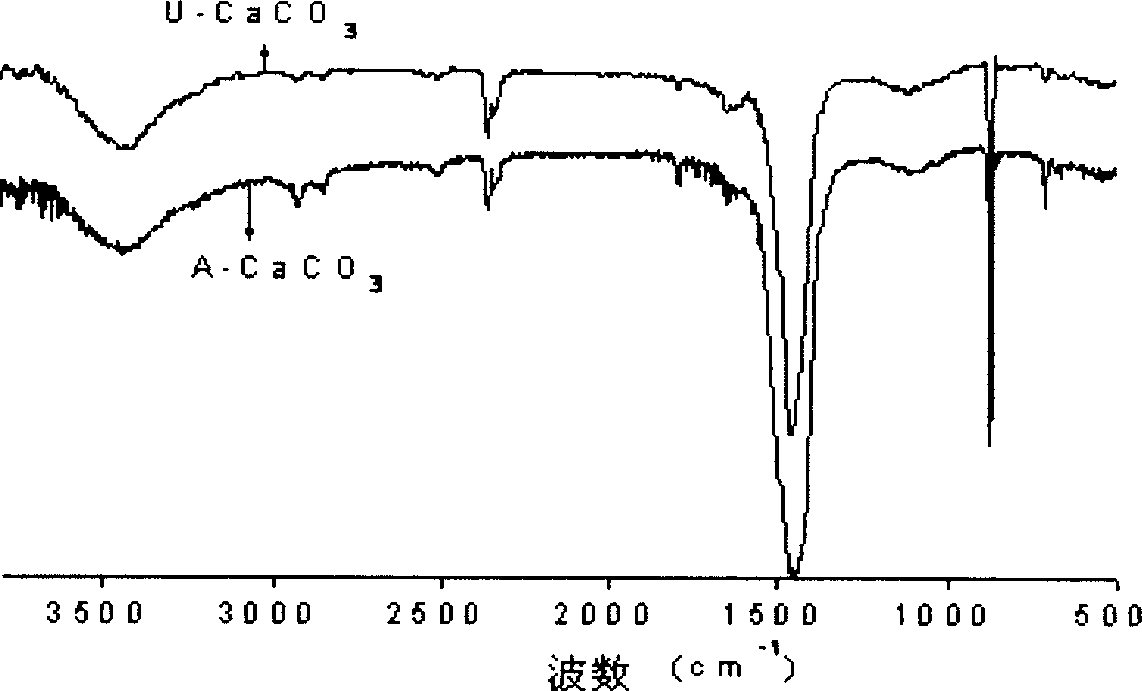

Modified nanometer calcium carbonate and method for making same and uses

InactiveCN1807519AImprove hydrophobicityAct quicklyPigment treatment with non-polymer organic compoundsNanoparticleStearic acid

This invention is related to modified nanocalcium carbonate and method for making same. According to this method, 1-30 lots unsaturated fatty acid and its derivatives were added to 100 weight lots nanocalcium carbonate or stearic acid modified nanocalcium carbonate dry powder or water suspension that contains 100 weight lots nanocalcium carbonate, react for 0. 5-5 hours at the temperature of nomal-130deg C, then modified nanocalcium carbonate is achieved. A zone of unsaturated fatty acid and its derivatives is coated on the product surface, which chemisorbs with nanocalcium carbonate, this buildups the drainability of nanocalcium carbonate surface. So it is easy to diffuse in polymers, and this can reduce reunition of nanoparticle and buildup the interfacial effort and advance the total property of nanocomposite material. Modified nanocalcium carbonate could be used in every polymer manufacturing polymer / inorganic nanocomposite material. It can be used to manufacture all kinds of plastic products, cured rubber, coating, binder, water-proofing material, and so on, and its industry application foreground is very broad.

Owner:SOUTH CHINA UNIV OF TECH

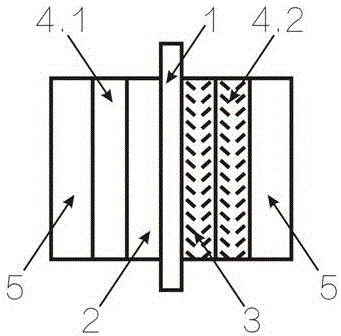

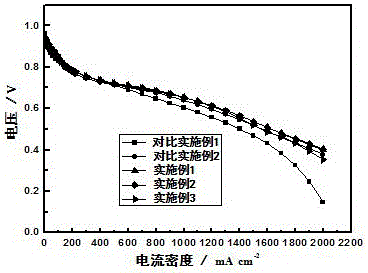

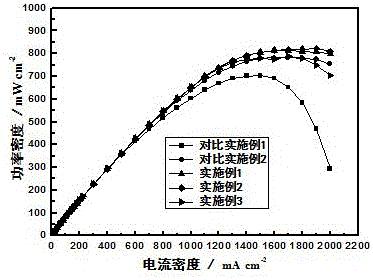

High-power-density membrane electrode for proton exchange membrane fuel cell and preparation method thereof

The invention discloses a high-power-density membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof. According to the method, the thickness of solid electrolyte is reduced, the thickness of a catalyst layer is reduced by using a high-content catalyst, and a nano-carbon tube or carbon fiber is introduced into a cathode catalyst layer and / or gas diffusion layer to improve mass transfer of the catalyst layer and the diffusion layer, so that the power density of a membrane electrode is greatly improved. The preparation method is simple in steps, is practical and feasible and is low in cost, can be used for reducing the thickness of the membrane electrode while improving the performance of the membrane electrode, and is favorable to preparation of high-power-density fuel cells, galvanic piles and systems.

Owner:SOUTH CHINA UNIV OF TECH

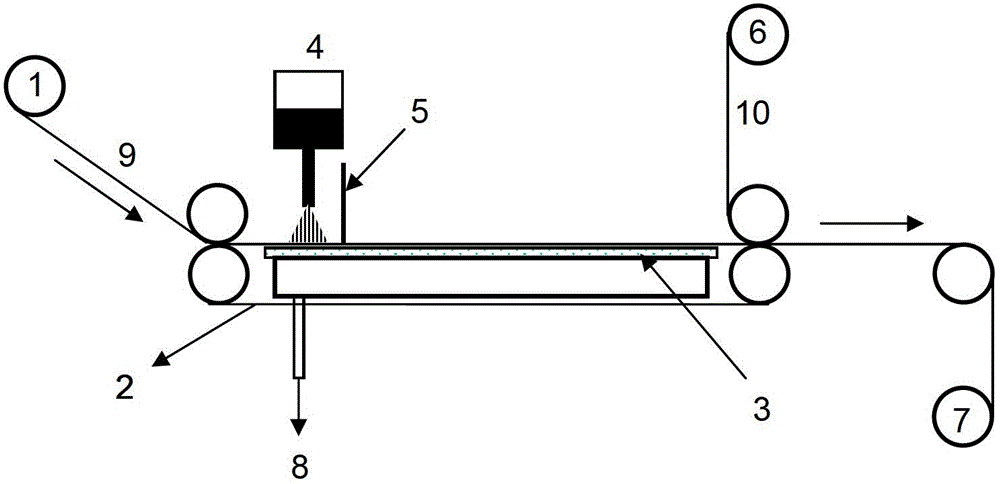

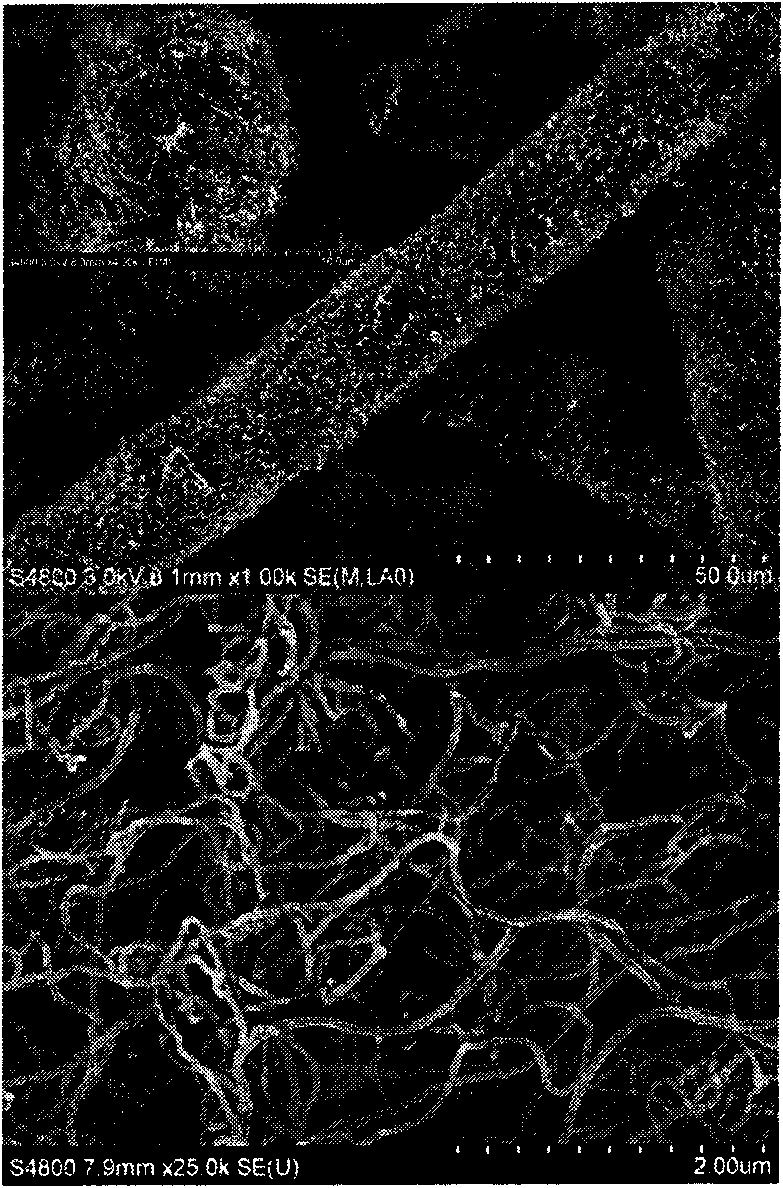

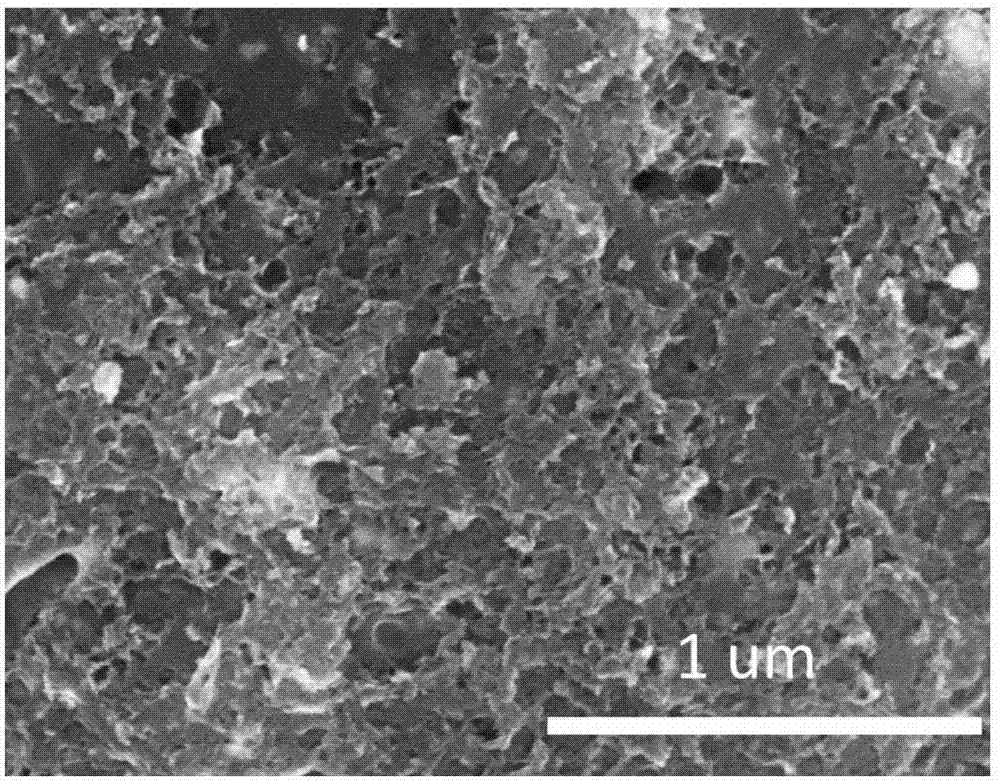

Carbon nanotube/short-fiber composited nano-carbon paper and continuous preparation method thereof

InactiveCN102877367AGuaranteed FeaturesOvercoming the lack of brittlenessSpecial paperPaper/cardboardNanostructured carbonNonwoven fabric

The invention provides a kind of carbon nanotube / short-fiber composited nano-carbon paper and a continuous preparation method thereof. The nano-carbon paper mainly comprises disordered carbon nanotubes and short fibers, and is in a non-woven form. The preparation method of the nano-carbon paper comprises the following steps that: the disordered carbon nanotubes are dispersed in a solvent so as to form a dispersion liquid; then, mixing and dispersing the short fibers so as to form a size; preparing an initial film through vacuum assisted flow-casting film-forming; and then, removing polymers in the initial film through subsequent processing so as to obtain a target product. The composited nano-carbon paper disclosed by the invention integrates the huge specific surface areas, superior conductivity and functional characteristics of the carbon nanotubes and the enhancement effect of the short fibers on the strength and flexibility of the carbon paper, therefore, the composited nano-carbon paper is good in self-supporting property and flexibility; meanwhile, through the direct film-forming implemented by using a flow-casting method, the continuous film-forming of the nano-carbon paper is realized, therefore, the nano-carbon paper has the advantages of high efficiency, rapidness and easy large-scale preparation. The composited nano-carbon paper disclosed by the invention has a wide application prospect in the fields of energy electrodes, catalytic carriers, environmental management, static resistance, electromagnetic shielding, wave-absorbing camouflage, and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

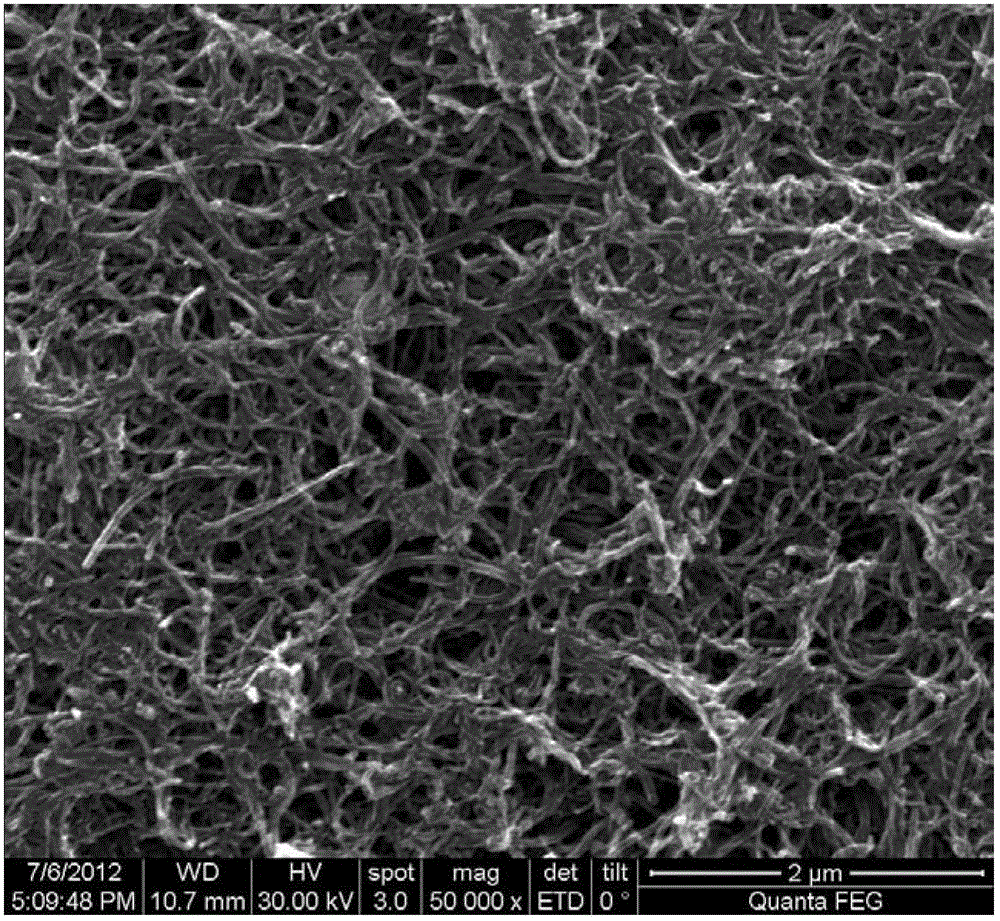

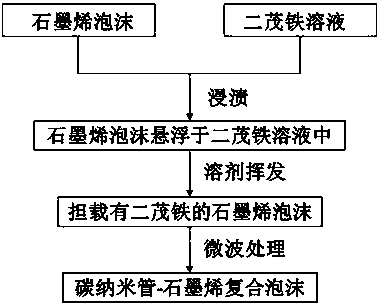

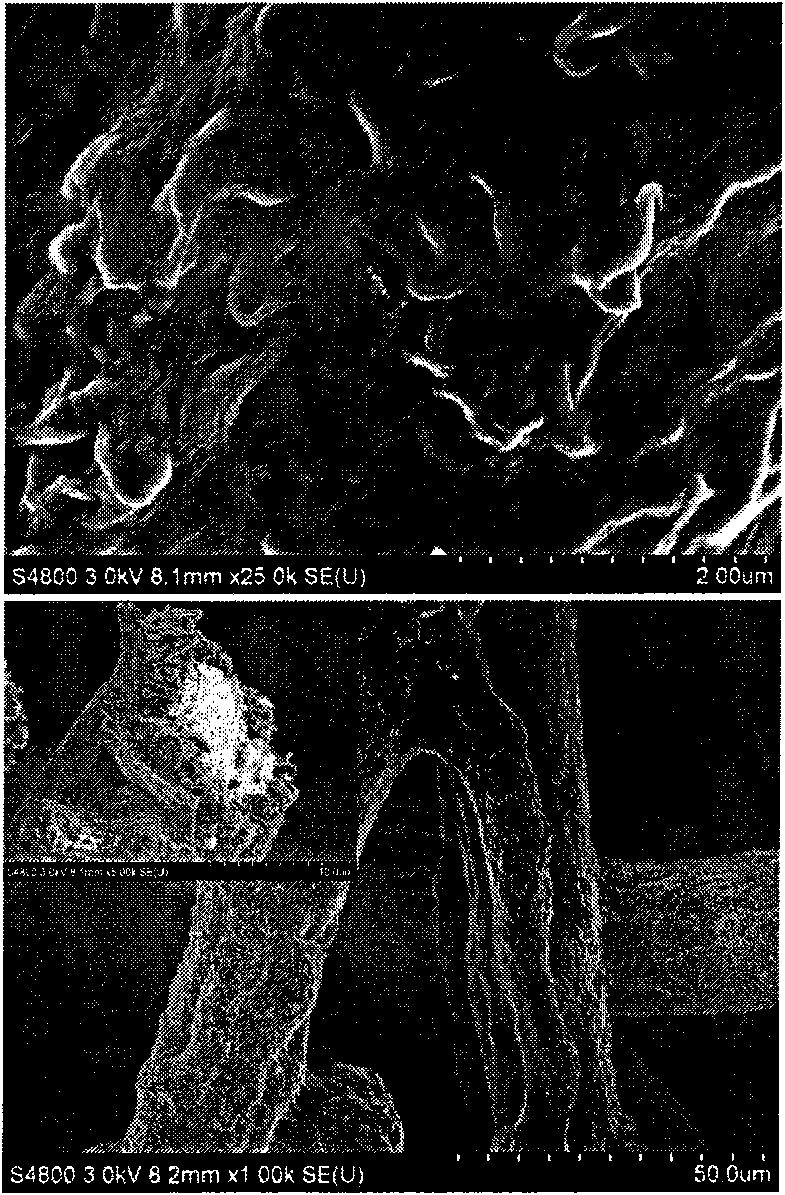

Preparation method for carbon nano tube-graphene composite foam

InactiveCN103738953ASimple processRaw materials are cheap and easy to getMaterial nanotechnologyCarbon compoundsPtru catalystNanotube

The invention belongs to a preparation method of a nano composite material and particularly relates to the field of a microwave preparation method for a grapheme-based composite material. A preparation method for carbon nano tube-graphene composite foam comprises the following steps: firstly, loading ferrocene on graphene foam; and then carrying out microwave treatment on the graphene foam loaded with the ferrocene and decomposing the ferrocene on the graphene foam by a high temperature which is instantly generated, so as to generate a catalyst and a carbon source to realize carbon nano tube in-situ growth and obtain the carbon nano tube-graphene composite foam. A carbon nano tube in the composite material vertically and epitaxially grows on the surface of a hole wall of the graphene foam; the super-hydrophobic and super-lipophilic surface chemical characteristics are represented; the preparation method has a wide application prospect in the aspects of adsorption, oil-water separation and the like; the method has the characteristics that operation is simple and convenient, cost is low, and industrial production is easily realized, and is an important preparation method for nano carbon materials.

Owner:DALIAN UNIV OF TECH

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

Preparation method of manganese dioxide/ carbon microspheres composite material and application of composite material serving as supercapacitor electrode material

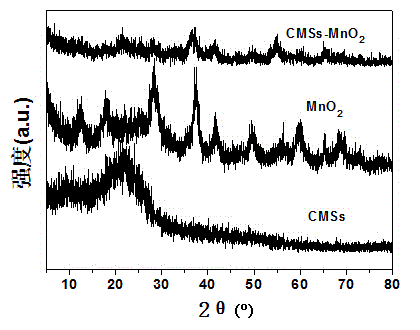

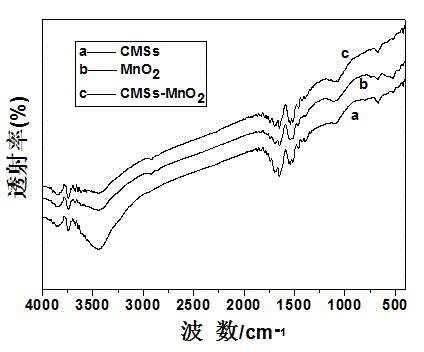

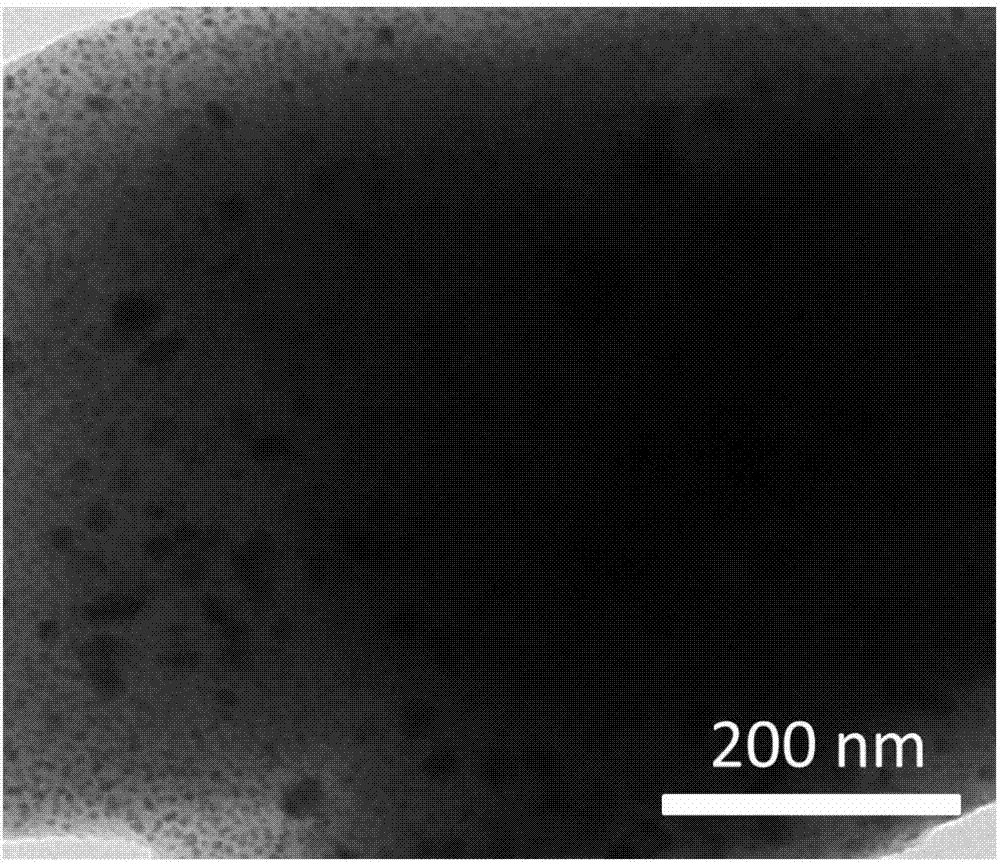

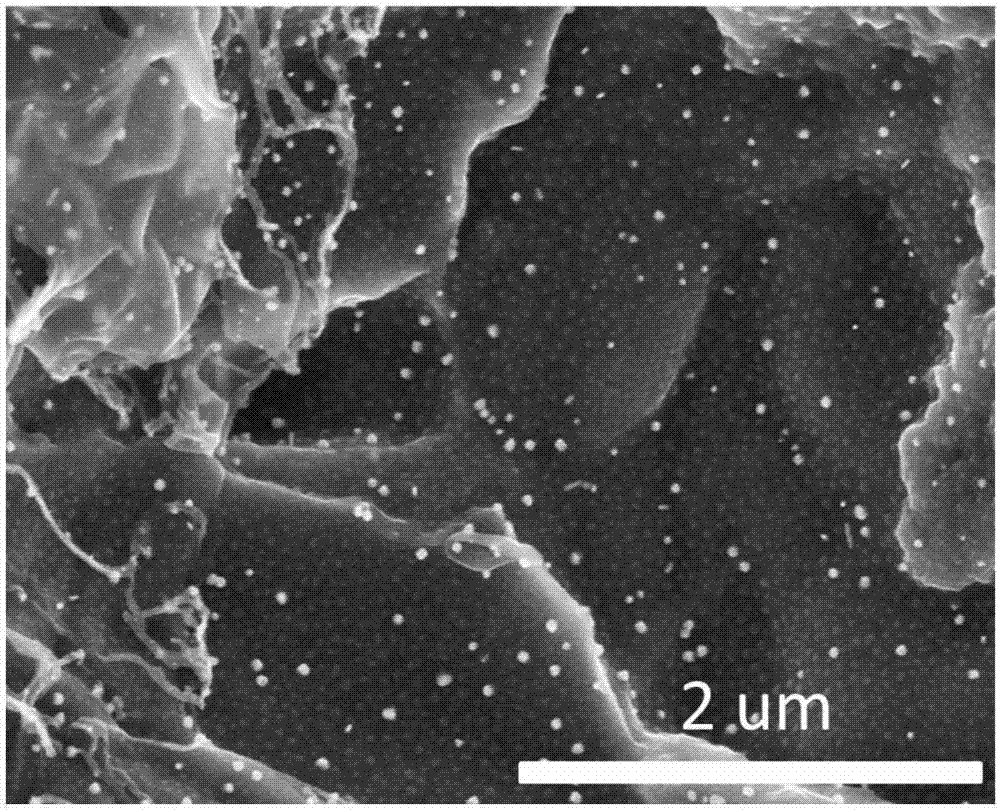

InactiveCN104409225AEasy to makeEfficient processHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMicrosphere

The invention discloses a manganese dioxide / carbon microspheres (MnO2 / CMSs) composite material used as a supercapacitor electrode material, and belongs to the technical field of composite materials. The MnO2 / CMSs composite material is obtained by a preparation method including taking glucose as an initial raw material, obtaining the carbon microspheres according to a hydrothermal method and compositing the carbon microspheres with the manganese dioxide according to an in-situ self-assembly method. Electrochemical property tests show that the prepared MnO2 / CMSs composite material can achieve a synergistic effect of properties of the carbon microspheres and the manganese dioxide, has excellent properties which a single electrode does not have, and demonstrates high electrochemical capacitor behaviors, excellent rate capability and high cycling stability, thereby being capable of serving as the supercapacitor electrode material. Moreover, the composite material is simple in preparation process, stable in technology, easy to operate, reliable in quality and low in cost, and can meet basic requirements of commercialization when serving as the supercapacitor electrode material.

Owner:NORTHWEST NORMAL UNIVERSITY

Concrete with functions of crack resistance and infiltration resistance

InactiveCN104386959AReduce porosityImprove pore structureSolid waste managementCrack resistanceDiethylenetriamine

The invention discloses concrete with the functions of crack resistance and infiltration resistance. The concrete comprises the following raw materials in part by weight: 70-100 parts of cement, 400-500 parts of macadam, 50-70 parts of river sand, 40-50 parts of fly ash, 30-60 parts of mine residues, 5-20 parts of coal slack, 20-50 parts of basalt fibers, 5-15 parts of polypropylene fibers, 5-20 parts of glass fibers, 6-13 parts of expanded perlite, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nano calcium carbonate, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zinc stearate, 2-5 parts of zinc borate, 3-7 parts of sodium citrate, 0.5-1.4 parts of acetyl tributyl citrate, 0.7-1.3 parts of diethylenetriamine, 3-10 parts of a water reducing agent, and 80-100 parts of water. The concrete disclosed by the invention has the advantages of good crack resistance, excellent infiltration resistance and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

Preparation and application for paper-making process reconstituted tobacco sizing agent coated with calcium carbonate

InactiveCN104705775AImprove performanceRealize the function of reducing focus and harmTobacco preparationFiberProcess engineering

The invention relates to a method and application for a paper-making process reconstituted tobacco sizing agent coated with calcium carbonate. The method comprises the steps that wood pulp fibers, tobacco stem fibers and fragment fibers are used for preparing a sizing agent, then, the sizing agent is soaked into a soluble carbonate solution for 0.5 h to 3 h, and then water is removed through centrifuge dripping; the sizing agent fiber with no water is added into a soluble calcium salt with the calcium ion concentration ranging from 1 mol / L to 3 mol / L, the concentration of the sizing agent is controlled to range from 3% to 10%, and a reaction is performed at room temperature for 3 min to 5 min; in the sizing agent solution, citric acid with the mass concentration ranging from 0.01% to 0.03% is added as a crystal form control agent, and CO2 is led into the solution at the temperature ranging from 20 DEG C to 35 DEG C for a reaction for 0.5 h to 1 h until the pH value of the solution ranges from 7.0 to 7.5, so that a certain amount of nano calcium carbonate coats the surface of paper-making process reconstituted tobacco, and centrifuge dripping is carried out to obtain the paper-making process reconstituted tobacco sizing agent coated with calcium carbonate. The method has the advantages of being easy to implement, high in efficiency and high in application value.

Owner:CHINA TOBACCO YUNNAN IND

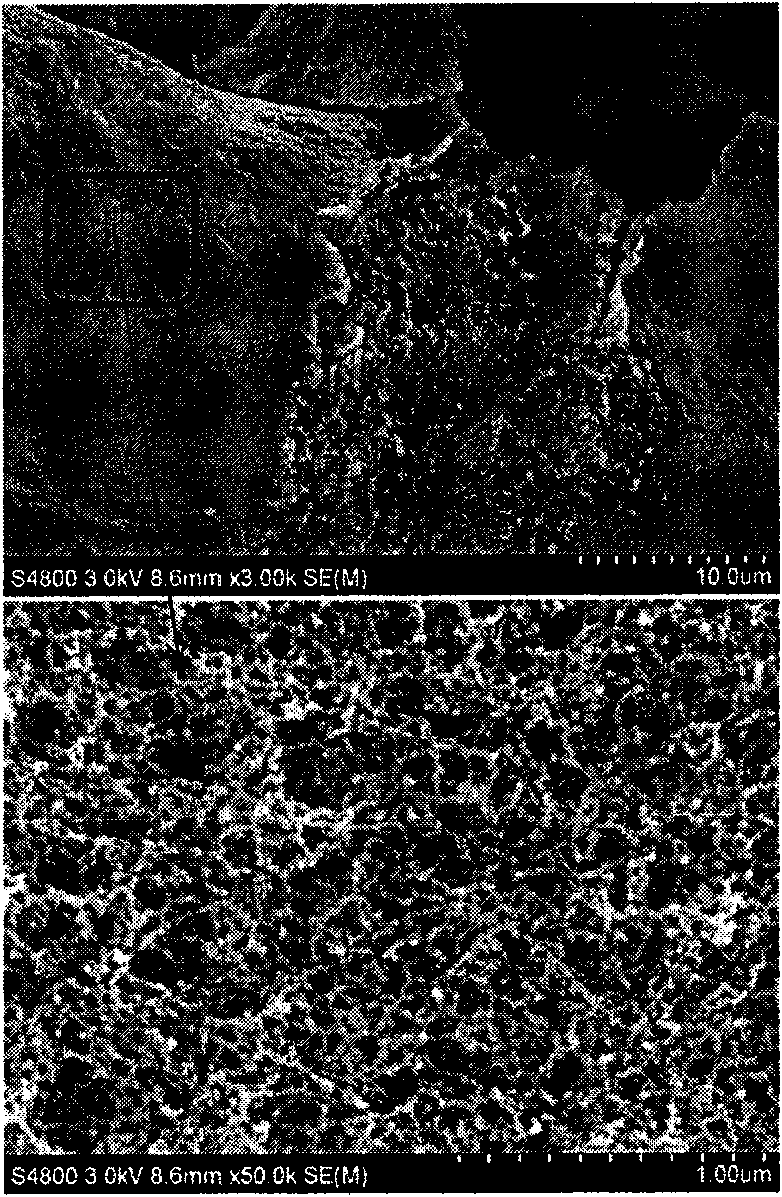

Method for preparation of nitrogen doped porous nano carbon material with biomass as carbon source by gel process

ActiveCN106914265ARich pore structureStrong adsorption capacityMaterial nanotechnologyCatalyst carriersBiomassChemistry

The invention discloses a method for preparation of a nitrogen doped porous nano carbon material with biomass as the carbon source by gel process and application thereof. The method includes: selecting soybean residue or soybean as the carbon source, using a transition metal salt as the coagulant, and making soaked, grinded and boiled soybean milk solidify to form tofu gel; and conducting vacuum freeze drying, and performing high temperature carbonization and activation under an inert atmosphere, thus obtaining the transition metal embedded nitrogen doped porous carbon nano material. The preparation method provided by the invention has the advantages of simple process operation, low cost and easy realization of large-scale commercial production. The nitrogen doped porous nano carbon material prepared by the method has a high degree of graphitization, large mechanical strength and high conductivity, is embedded with metal nanoparticles, and can be applied to supercapacitors, lithium-ion batteries, catalysis, adsorption and other fields.

Owner:NANJING NORMAL UNIVERSITY

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

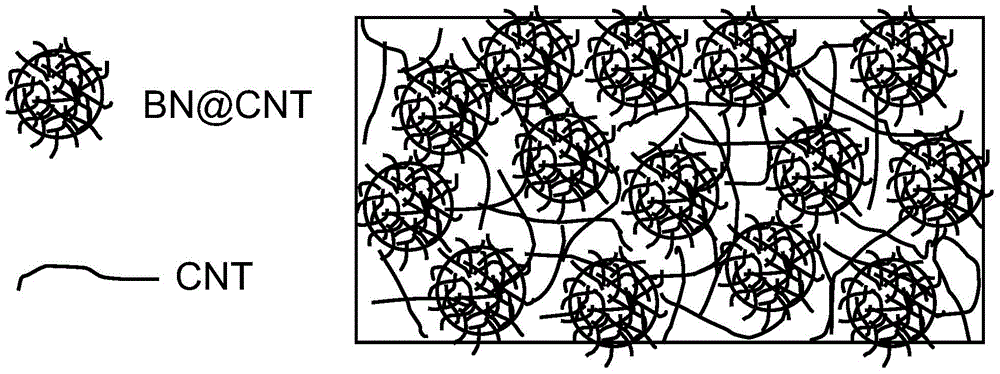

Aqueous heat dissipation coating and preparation method thereof

ActiveCN104804618AImprove cooling effectHigh thermal conductivityEpoxy resin coatingsBoron nitrideSlurry

The invention discloses an aqueous heat dissipation coating and a preparation method thereof. The aqueous heat dissipation coating comprises an aqueous dispersoid containing a base resin, nanometer carbon material-coated boron nitride composite powder and optional auxiliary materials. The composite powder comprises boron nitride and a boron nitride-coating nanometer carbon material. The preparation method comprises carrying out grinding dispersion on the aqueous dispersoid containing a base resin and the optional auxiliary materials to obtain dispersive slurry, at least adding slowly the composite powder into the dispersive slurry, carrying out high speed stirring and carrying out standing defoaming. The nanometer carbon material-coated boron nitride composite powder is used as a coating filler so that excellent thermal conductivity of the nanometer carbon material and boron nitride and conductive infrared radiation characteristics of the nanometer carbon material are fully utilized, interface thermal resistance of the nanometer carbon material and boron nitride is reduced, and the coating has the advantages of high thermal conductivity, high infrared radiation rate, construction convenience, safety, environmental friendliness and wide application prospect.

Owner:芜湖海泰科新材料有限公司

Nanometer composite silicon brick and preparation method thereof

The invention relates to a nano-sized composite silica brick and a production method thereof. The invention is characterized in that: raw materials and binder of the silica brick are as follows: silica granules and fine powders, waste silica brick granules, calcium carbonate nanoparticles, iron oxide nanoparticles, silicon dioxide nanoparticles, fluorite powders, lime and sulfite pulp wastes. The production method is based on the existing production process of the silica brick, and introduces compound nanopowders in optimal proportions in the production process of the silica brick after high-efficiency dispersion, to produce nano-sized composite silica bricks. With the addition of nanopowders, the performance of silica brick is significantly improved, and manifested as follows: 1) the particle size fraction is more reasonable, the accumulation is compact and the texture is uniform; 2) the slurry has good plasticity and moldability and the production efficiency is improved; 3) the burning temperature is decreased to 20 DEG C, thus realizing energy conservation and discharge reduction; 4) the tridymite is superior in crystallization conversion and has low content of quartz residues; 5) the number of closed pores is increased, the number of opened pores are reduced, the porosity is reduced, and the strength and refractoriness under load are increased; and 6) the final product has good appearance, smooth end surface and good bonding property, and the rate of qualified products is increased.

Owner:ZHENGZHOU UNIV +1

Method of producing nanometer silicon carbide material

InactiveUS20040202599A1Simpler and cheap for producingCheap methodMaterial nanotechnologySilicon carbideElectron sourceNanowire

This invention relates to a method for preparing nanometer SiC material using nanometer-grade or micron-grade commercial SiC with different shapes, sizes as raw material. The raw materials and catalysts are put into heating device, which is pumped beforehand. Inert gas is let into the heating device as protective gas. The materials and catalysts then will be heated to temperature of 1300~2000° C., and the temperature preserved for a certain period. The nanorod or nanowire produced can be used in the research and development for SiC photoelectric devices, especially for nanometer photoelectric devices and field emission electron sources. This method features simple operation, low cost, and high yield.

Owner:XU NINGSHENG +3

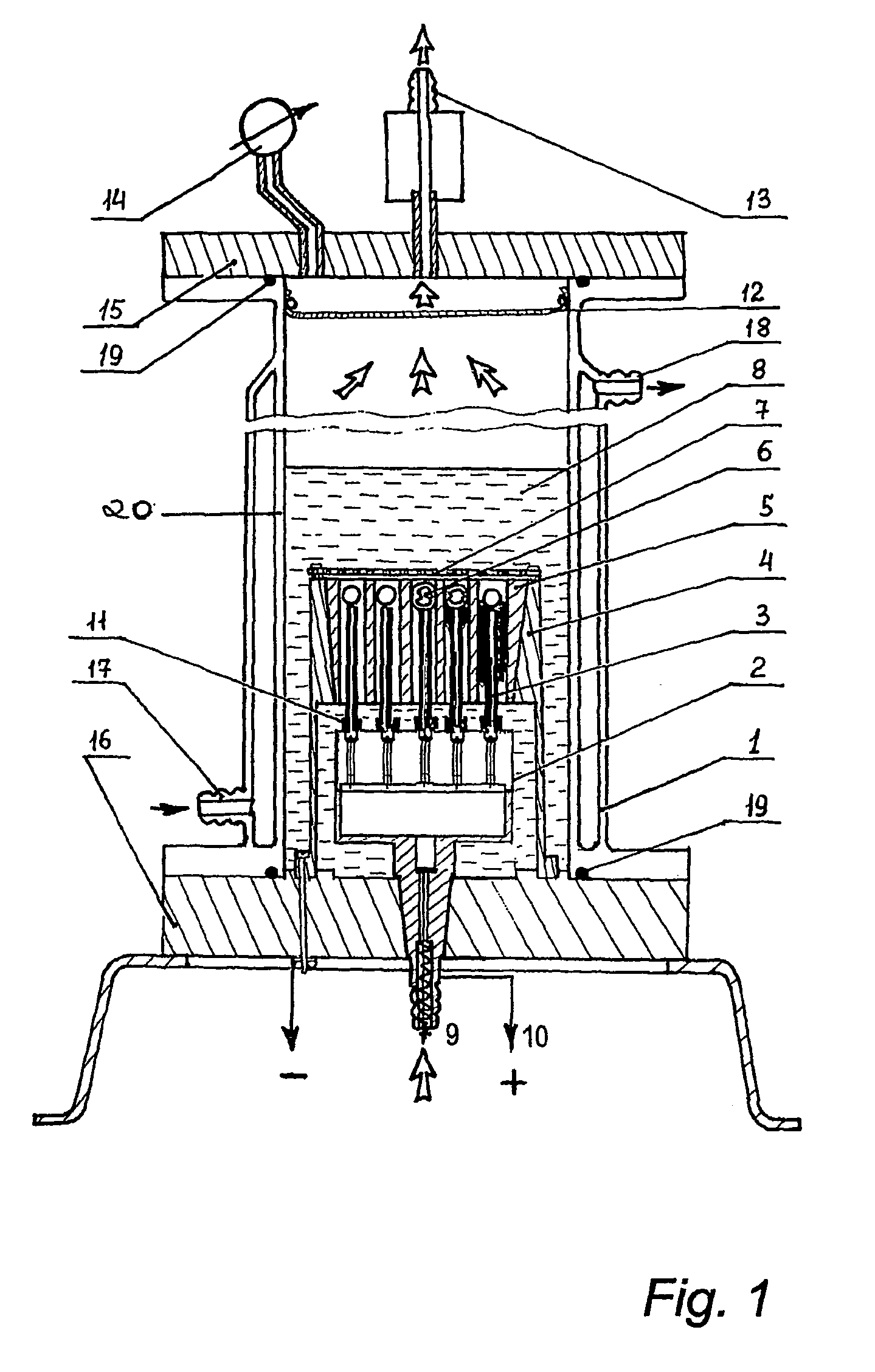

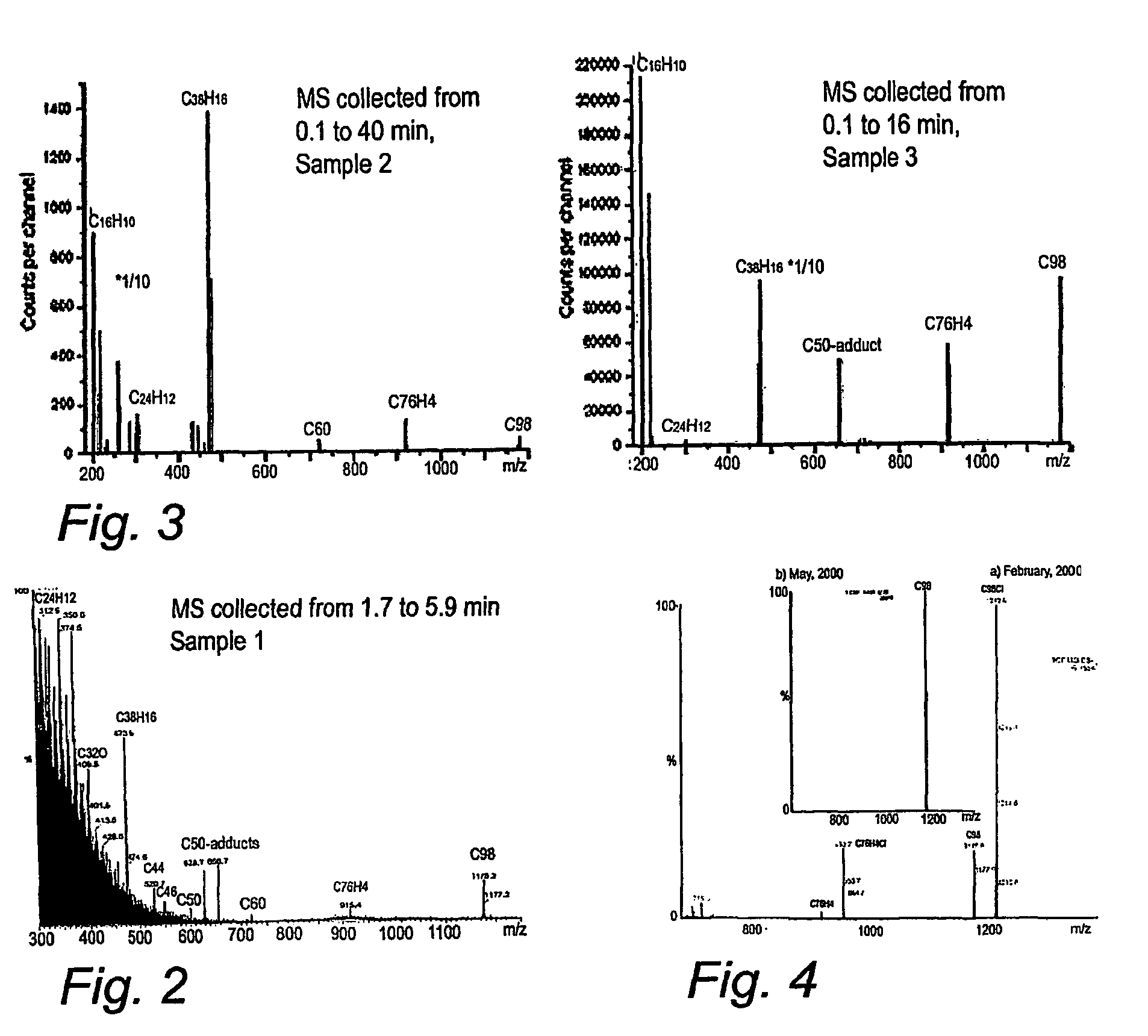

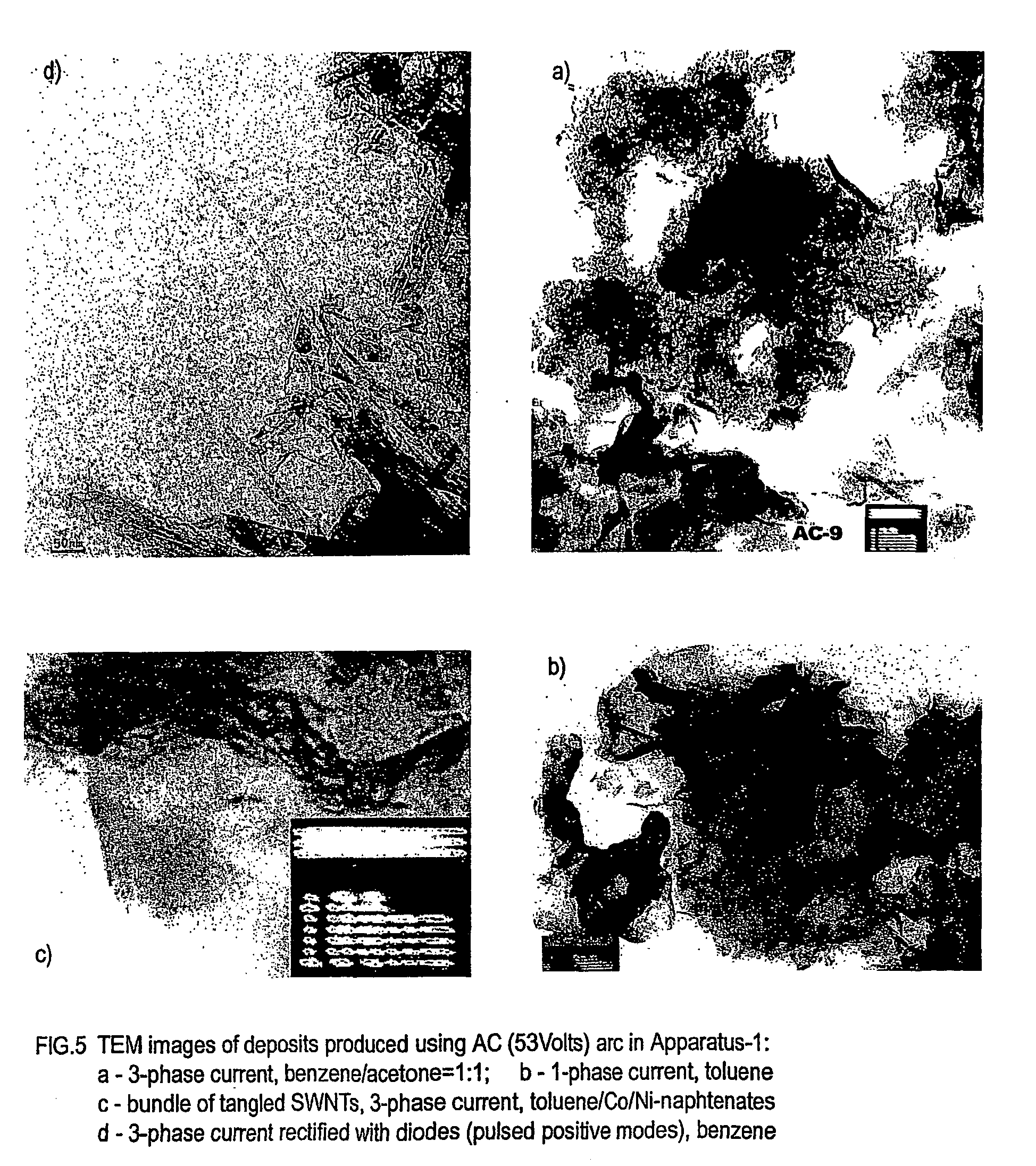

Apparatus and method for nanoparticle and nanotube production and use therefor for gas storage

InactiveUS20040258604A1Avoid saturationIncrease productionMaterial nanotechnologyHydrogenNanoparti clesNanotube

There is provided a method for the enhanced production of fullerenes, nanotubes and nanoparticles. The method relies upon the provision of a hydrocarbon liquid which is converted by a suitable energy source to a synthesis gas such as acetone, ethylene, methane or carbon monoxide, the synthesis gas(es) forming the precursors need for fullerene, nanotube or nanoparticle production. The nanotubes formed by the method described are in general terms shorter and wider than conventionally produced nanotubes. An improved apparatus for production of the fullerenes and nanocarbons is also disclosed wherein a moveable contactor is attached to a first electrode with a sealable chamber, and is spaced from the second electrode such that an electric arc can pass between them.

Owner:ROSSETER HLDG

Nitrogen-doped carbon nano-tube array and graphene hybrid and preparation method thereof

ActiveCN103407982AUniversalConvenient researchMaterial nanotechnologyGrapheneMaterials preparationHigh density

The present invention discloses a nitrogen-doped carbon nano-tube array and graphene hybrid and a preparation method, and belongs to the technical field of carbon material preparation. The hybrid comprises a nitrogen-doped carbon nano-tube array and graphene, wherein the end portion of the carbon nano-tube array is directly and effectively connected with the graphene sheets. The preparation method comprises: adopting a high density catalyst particle loaded material having a microscopic flat surface as a catalyst, and adopting chemical vapor deposition to grow a nitrogen-doped carbon nano-tube array and graphene on the surface of the catalyst, wherein the nitrogen-doped carbon nano-tube array and the graphene are directly and effectively connected to form a three-dimensional structure. With the present invention, types of multifunction specialty nanometer carbon materials are enriched, assembly of nanometer carbon materials from bottom to top and from low-dimension to three-dimension is achieved, and a moving bed, a fluidized bed and the like can be adopted to achieve engineering magnification and scalization production so as to easily promote researches, supplies and practical applications of the nitrogen-doped carbon nano-tube array and graphene hybrid.

Owner:TSINGHUA UNIV

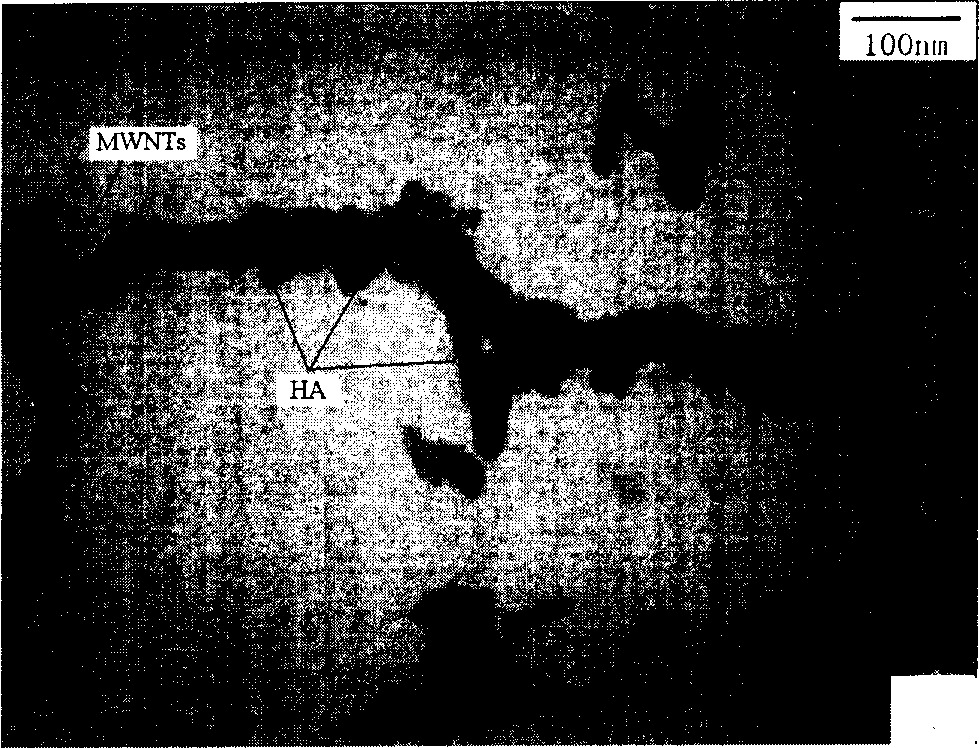

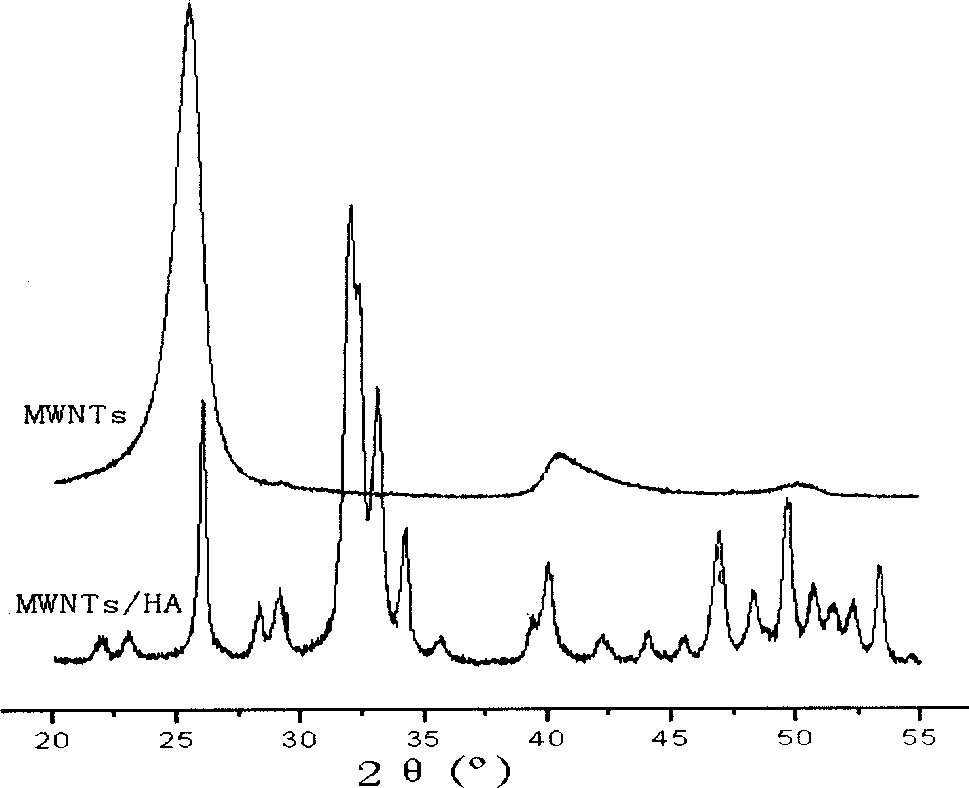

Hybridized fiber contg. high molecular material, carbon material and hydroxy apatite and its prepn. method

InactiveCN1831219AAverage particle size optimizationGood orientationFilament/thread formingMonocomponent polyesters artificial filamentPorosityApatite

The invention relates to a macromolecule material / carbon material / hydroxyapatite hybridization fiber and the manufacture method. It includes the following steps: compounding carbon material / hydroxyapatite nm particle, making electric spinning suspension liquid, adopting electric spinning technology to make macromolecule material / carbon material / hydroxyapatite hybridization fiber and the carbon material and hydroxyapatite existing as nm compounding particle. The hybridization fiber has 3D multi-hole, and the porosity could be 30-99%, and the fiber diameter could be 20nm-2um. The invention has the excellent mechanical properties and good biocompatibility.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com