Preparation method for carbon nano tube-graphene composite foam

A graphene composite and graphene foam technology is applied in the field of preparation of nano-composite materials, which can solve the problems of insignificant improvement of material hydrophobicity, cumbersome process, low yield and the like, and achieves cheap raw materials, high growth efficiency, and easy raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

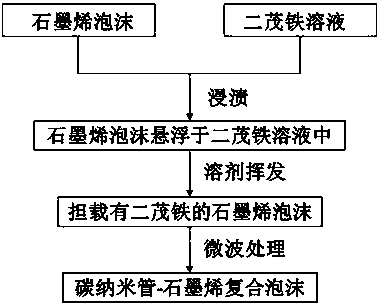

Method used

Image

Examples

Embodiment 1

[0034] 0.6 g of ferrocene was ultrasonically dispersed in 40 mL of acetone to obtain a solution of ferrocene in acetone with a concentration of 15 mg / mL. Put the graphene foam prepared by ethylenediamine-assisted reduction into the acetone solution of the above-mentioned ferrocene. The impregnated graphene foam was taken out, placed at room temperature to dry naturally, and after the acetone volatilized completely, the graphene foam loaded with ferrocene was obtained. The graphene foam loaded with ferrocene is placed in a microwave reactor, and the air in the reactor is replaced by argon gas. The microwave reactor was opened, and microwave irradiation treatment was carried out. The power of the microwave reactor was 800 W, and the treatment time was 1 min to obtain carbon nanotube-graphene composite foam. Thermogravimetric analysis showed that the content of carbon nanotubes in the syntactic foam was 32 wt%. figure 2 Shown is a digital photograph of the resulting syntactic ...

Embodiment 2

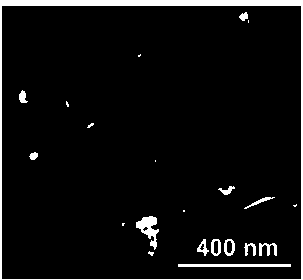

[0036] 0.75 g of ferrocene was ultrasonically dispersed in 50 mL of acetone to obtain a solution of ferrocene in acetone with a concentration of 15 mg / mL. Put the graphene foam prepared by ethylenediamine-assisted reduction into the acetone solution of the above-mentioned ferrocene. The impregnated graphene foam was taken out, placed at room temperature to dry naturally, and after the acetone volatilized completely, the graphene foam loaded with ferrocene was obtained. The graphene foam loaded with ferrocene is placed in a microwave reactor, and the air in the reactor is replaced by argon gas. The microwave reactor was opened for microwave irradiation treatment. The power of the microwave reactor was 800 W and the treatment time was 5 s to obtain carbon nanotube-graphene composite foam. Thermogravimetric analysis showed that the content of carbon nanotubes in the composite was 8 wt%. Figure 5 Shown is a scanning electron micrograph of the obtained composite foam, from which...

Embodiment 3

[0038] 0.6 g of ferrocene was ultrasonically dispersed in 30 mL of gasoline to obtain a ferrocene gasoline solution with a concentration of 20 mg / mL. Put the graphene foam prepared by ascorbic acid-assisted reduction into the above ferrocene solution. The impregnated graphene foam was taken out, placed at room temperature to dry naturally, and after the gasoline was completely volatilized, a graphene foam loaded with ferrocene was obtained. The ferrocene-loaded graphene foam is placed in a microwave reactor, and the air in the reactor is replaced by nitrogen gas. The microwave reactor was opened for microwave irradiation treatment. The power of the microwave reactor was 800 W and the treatment time was 30 s to obtain carbon nanotube-graphene composite foam. The content of carbon nanotubes in the composite is 42 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com