Patents

Literature

9726results about How to "Raw materials are cheap and easy to get" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

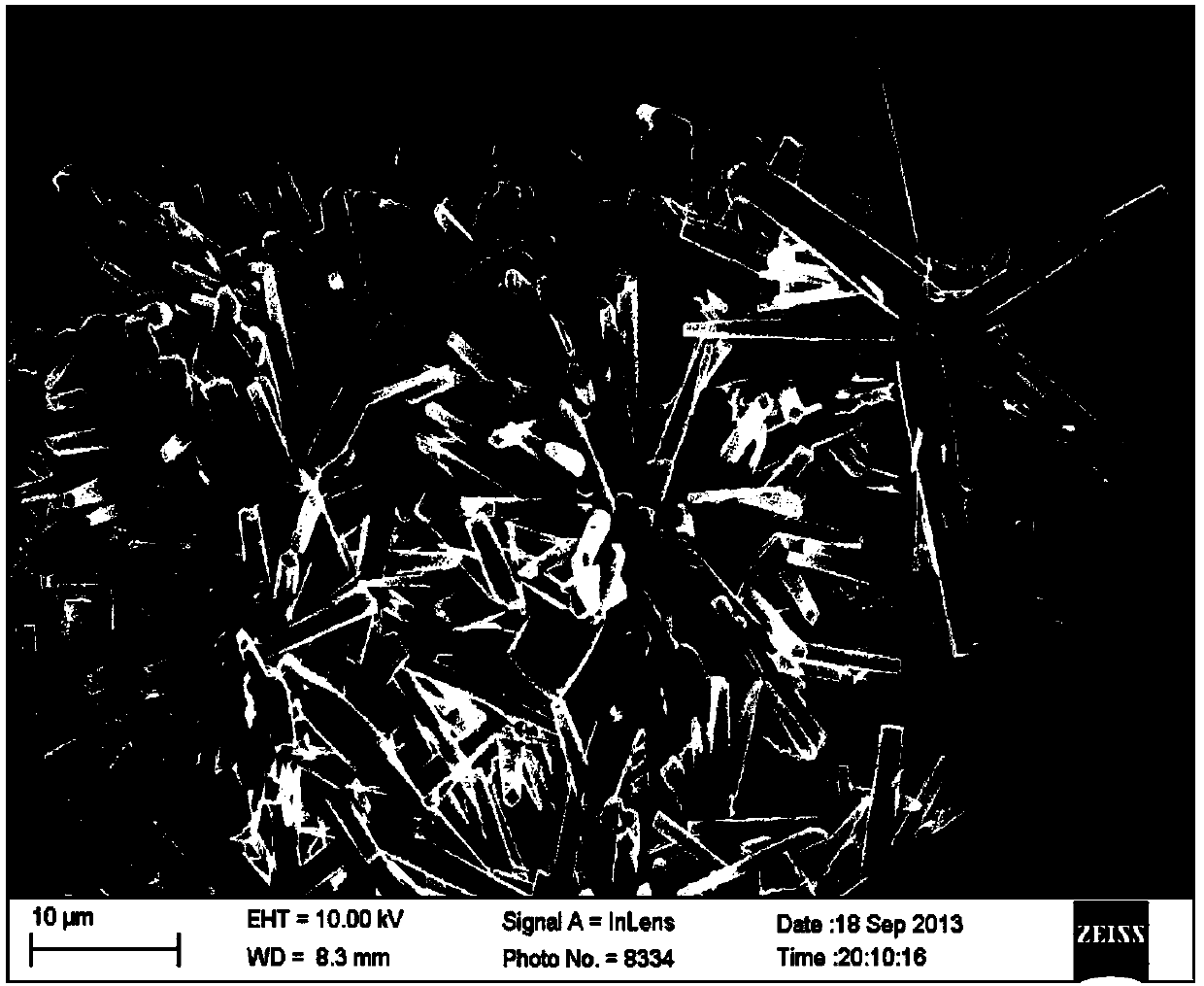

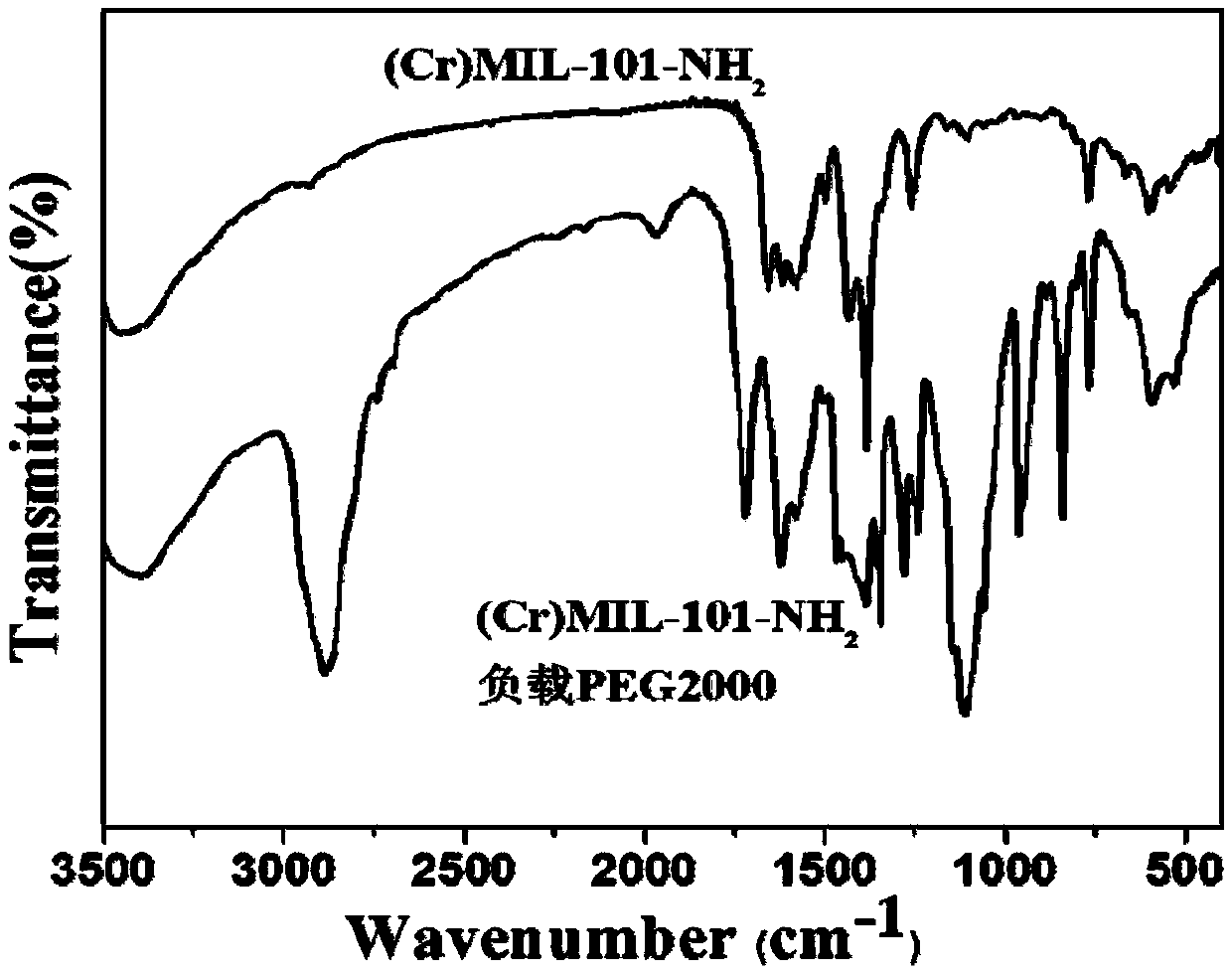

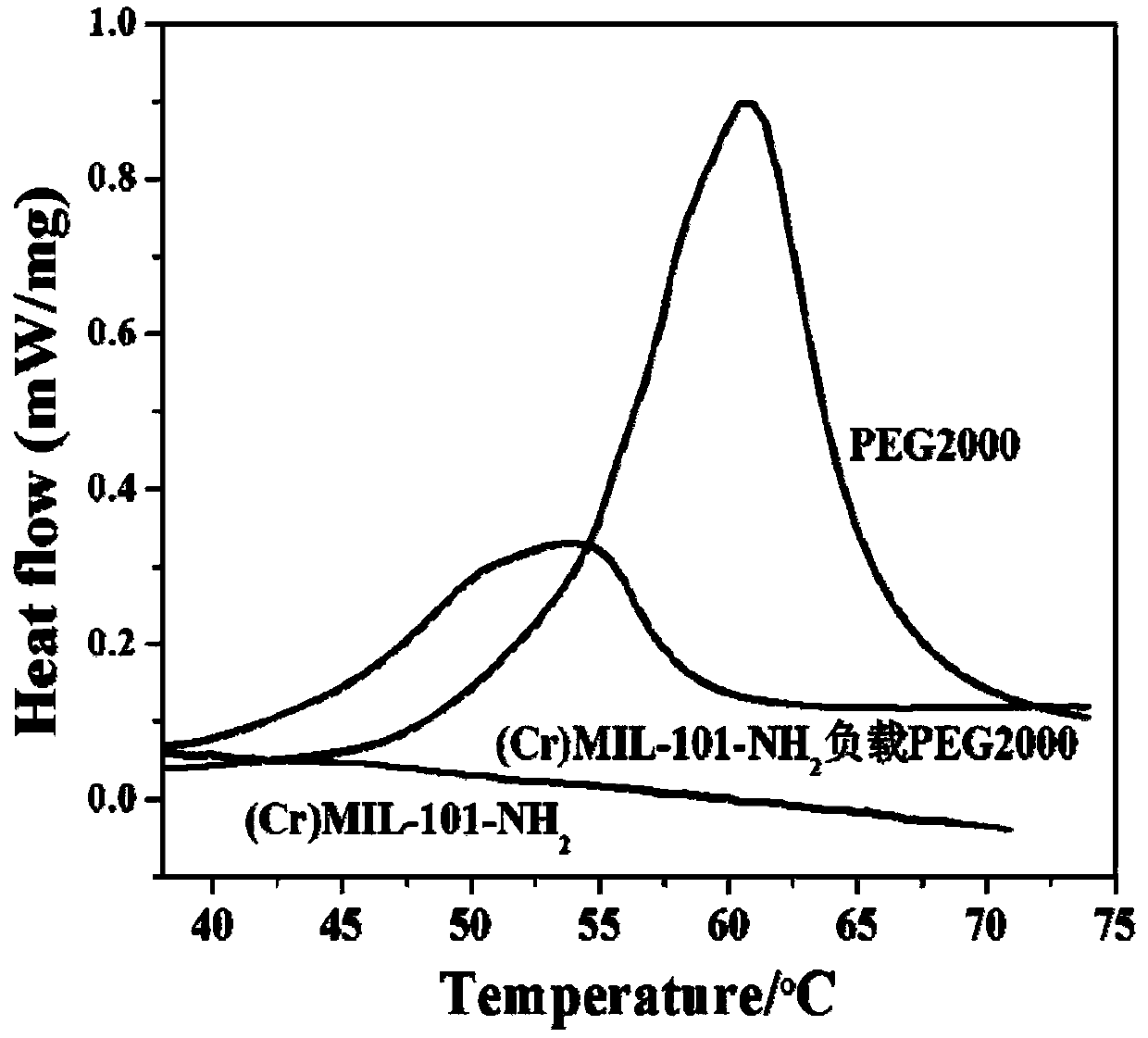

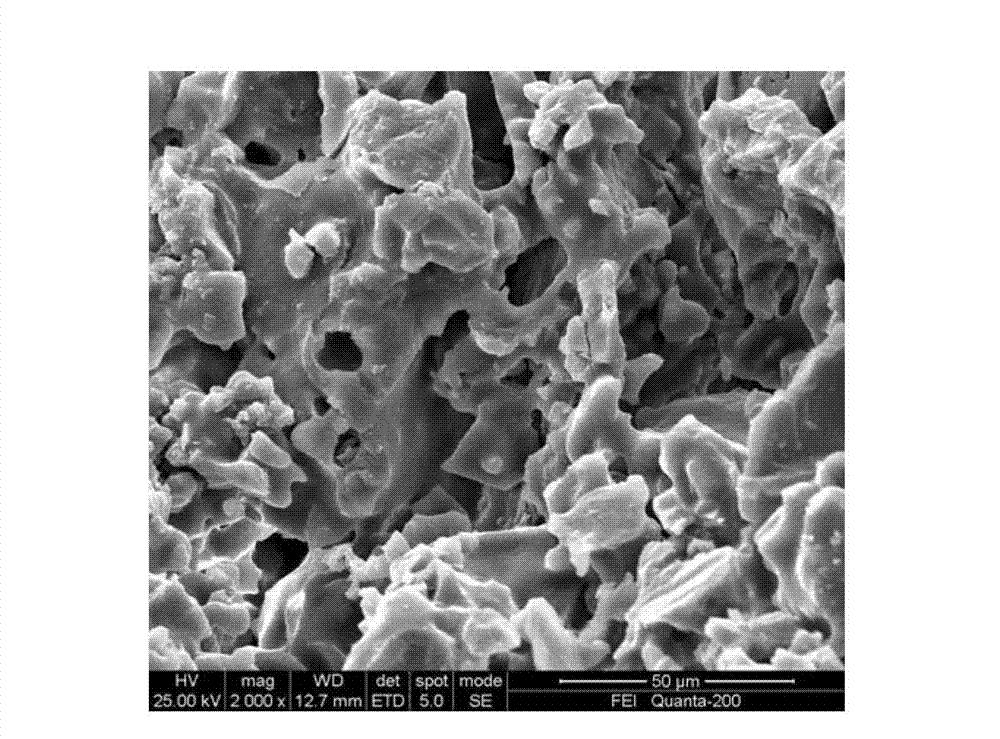

Preparation method of metal organic framework based composite phase-change material

InactiveCN103756646AWide range of choicesPrevent leakage and other issuesProductsReagentsMetal-organic frameworkElectrical polarity

The invention relates to a preparation method of a metal organic framework based composite phase-change material. The method comprises the steps that a metal organic framework material substrate is prepared selectively; hole diameter size design and hole channel polarity regulation and control are performed on the substrate according to the size and the kind of a core material, so that a phase-change core material to be loaded is matched better; the soluble phase-change core material is prepared into a solution; a metal organic framework material is dispersed in the prepared phase-change material solution; a phase-change material is adsorbed by utilizing an extra-large specific surface area and a nano hole channel structure of the metal organic framework material; drying is performed; and then the metal organic framework composite phase-change material with a shaping effect is obtained. According to the method, a novel metal organic framework based composite phase-change material is developed; the prepared metal organic framework based composite phase-change material can effectively avoid leakage and the like, and has the advantages of adjustable nano hole structure and wide core material selection range; the method is simple in technology and mild in reaction condition, and is suitable for scale production; and a raw material is cheap and easy to obtain.

Owner:UNIV OF SCI & TECH BEIJING

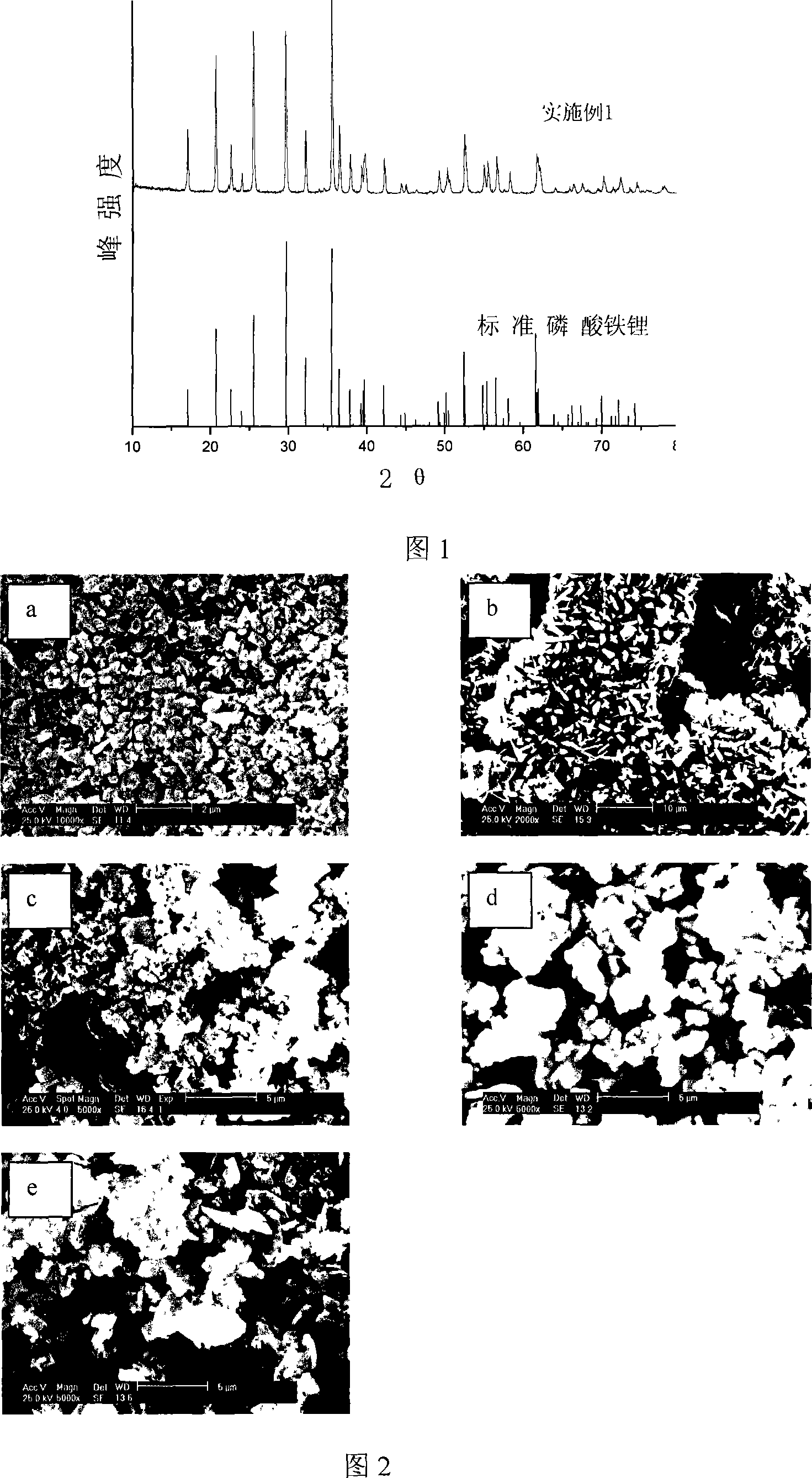

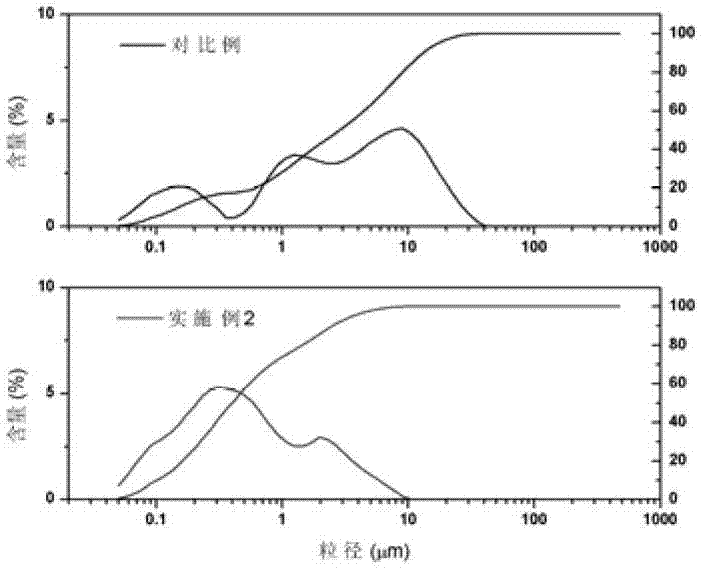

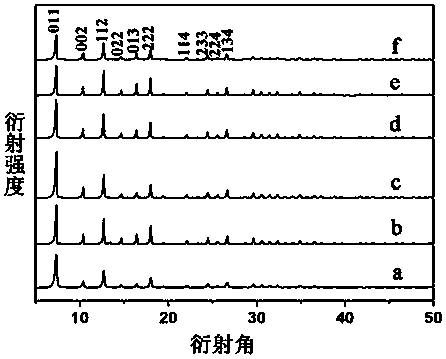

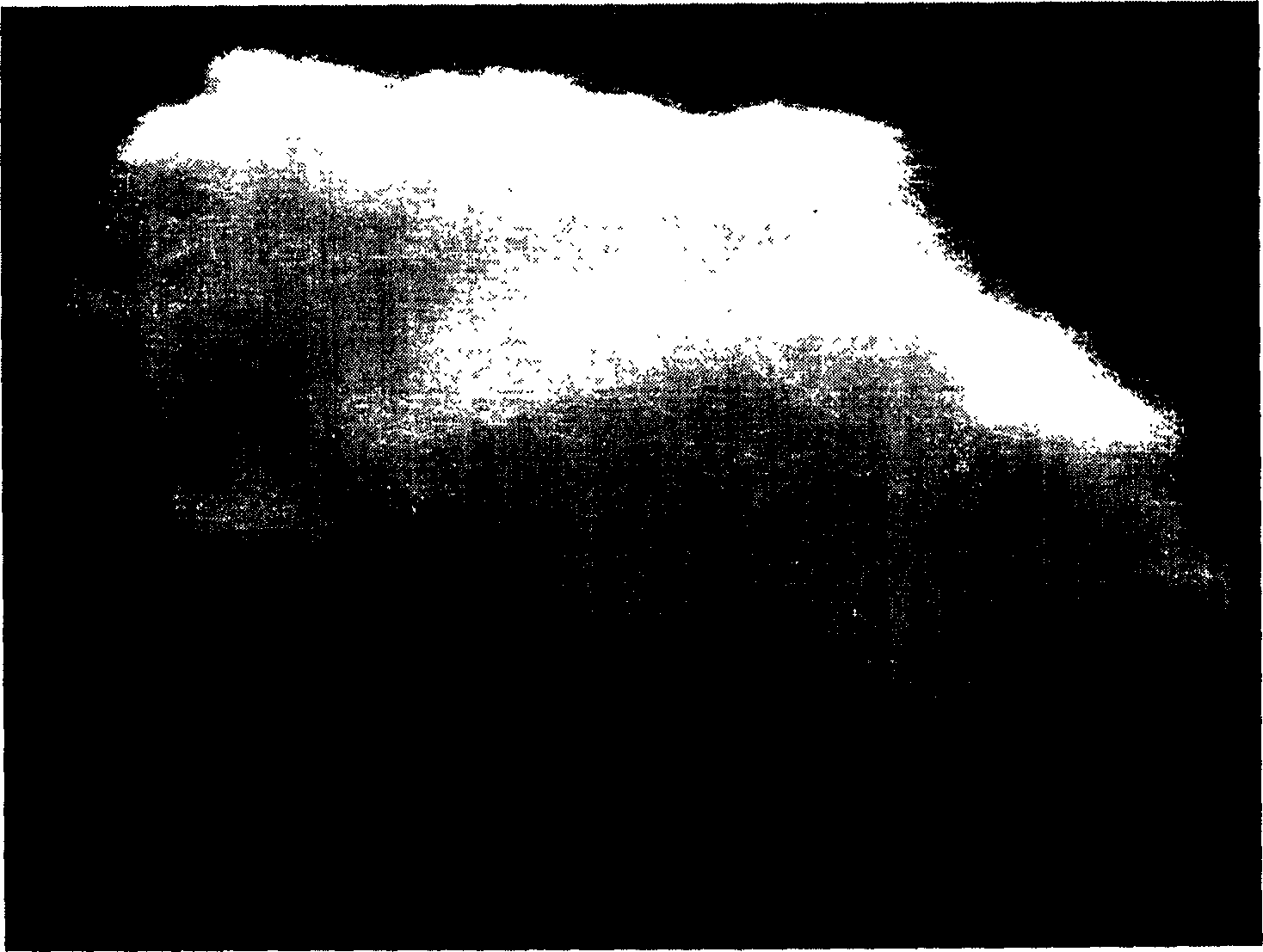

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

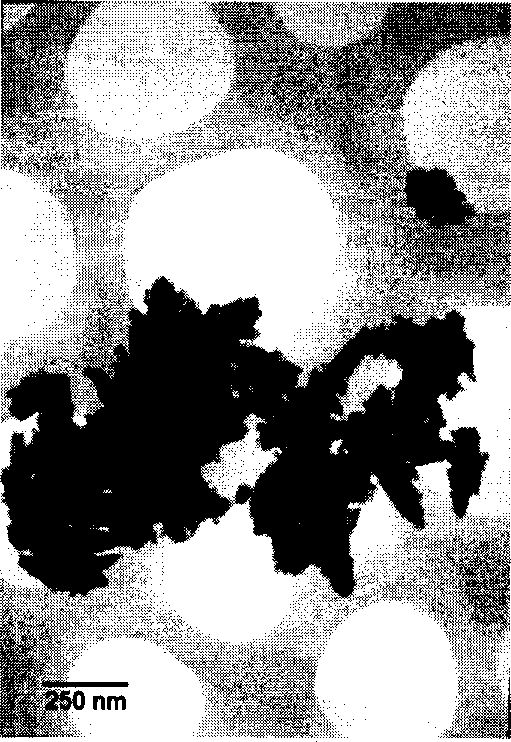

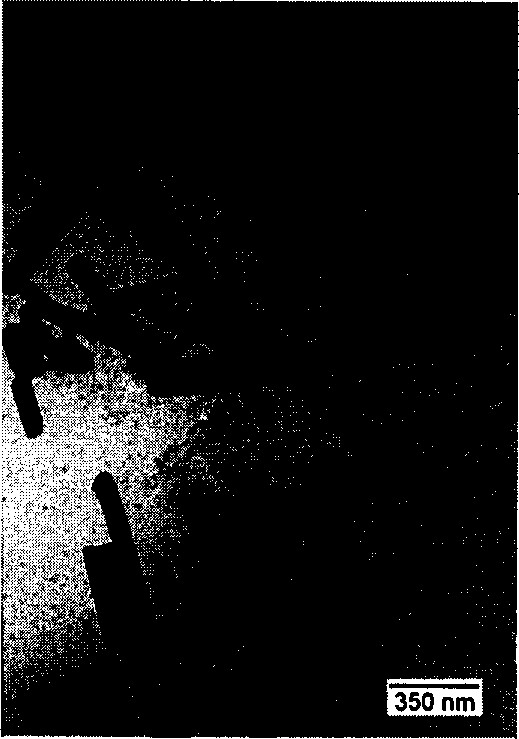

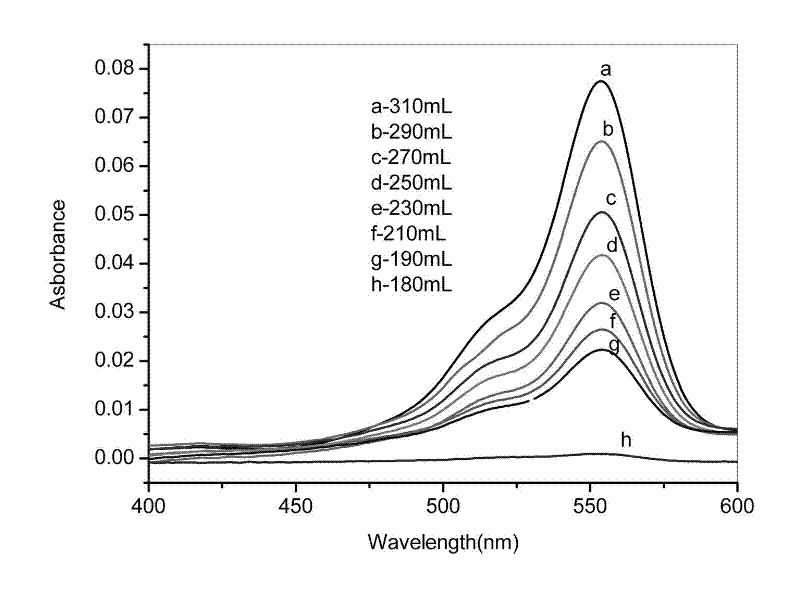

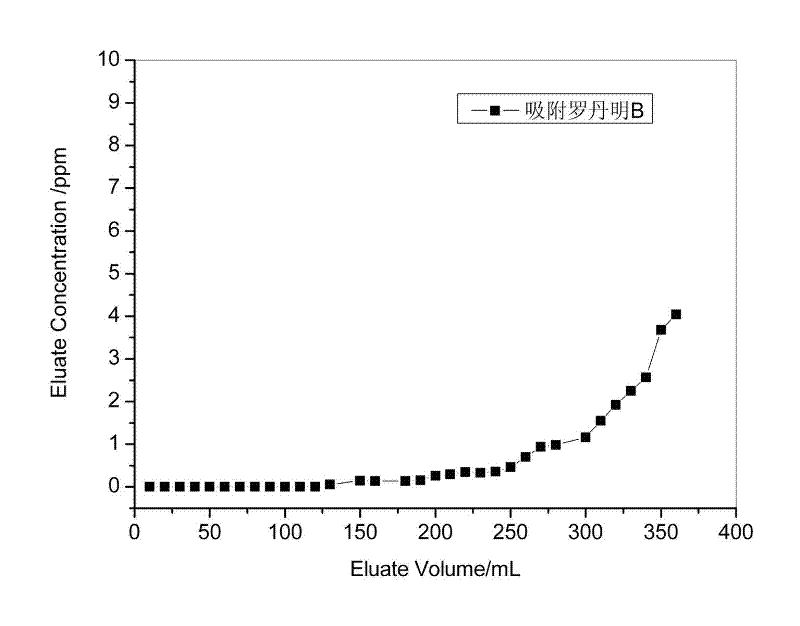

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

Process for preparing n-propanol by hydrogenating glycerol

ActiveCN101054339AHigh selectivityOvercome the disadvantage of low selectivityOrganic compound preparationHydroxy compound preparationChemical industryBiodiesel

The invention provides a method for preparing normal propyl alcohol by glycerol hydrogenation, wherein glycerite or biodiesel byproduct glycerol which is diluted by glycerol or solvent reacting with hydrogen or gaseous mixture containing hydrogen to generatenormal propyl alcohol, which provides a new way for synthesizing normal propyl alcohol. The present invention can enhance activity of glycerol hydrogenation and selectively generates normal propyl alcohol, also can make normal propyl alcohol united generating with 1,2-propanediol, ethandiol, methylic alcohol and ethyl hydrate, thus its product process program is very flexible. The present invention is characterized in that its technological condition is geniality, raw material is cheap and can be obtained easily and the cost of manufacture is low, which belongs to environment friendly green chemical industry technique.

Owner:SHANGHAI HUAYI NEW MATERIAL

Modified silicasol and application thereof in preparing water paint

The invention discloses a modified silica sol and application thereof in preparation of aqueous painting. The inventive modified silica sol is prepared from aqueous silica sol by regulate pH value of raw material to 3-6; charging organosilane with a mass ratio with SiO2 in silica sol of 1:1 - 5:1, water bathing at temperature of 50-80 DEG C., waiting for 0.5-5 hours, vaporizing by-products generated in hydrolysis to obtain transparent sol, which is final product. The modified silica sol has cheap raw material, simple preparation. When used as matrix in preparation of paint, the sol uses only water as solvent, without need of adding any organism such as alcohol. The preparation is simple, economic, environmental protecting. The prepared aqueous paint not only has high decorative, great adhesion and toughness of organic paint, but also has high rigidity, chemical resistance of inorganic paint, which can be used on surface of substrates of metal, glass, wood, plastic and in construction industry.

Owner:DALIAN JIAOTONG UNIVERSITY

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

Composite catalyst for purifying indoor formaldehyde and preparation method of composite catalyst

InactiveCN102198405ASimple preparation processGood dispersionMolecular sieve catalystsDispersed particle separationFiberMolecular sieve

The invention discloses a composite catalyst for purifying indoor formaldehyde and a preparation method of composite catalyst. The catalyst consists of 99 to 90 weight percent of carrier and 1 to 10 weight percent of metal ion doped MnO2 powder, wherein the carrier comprises active carbon powder, active carbon fiber powder or molecular sieve porous superfine particles; and the doped metal ions are silver, copper or zinc ions. The preparation method comprises the following steps of: preparing MnO2 powder by using KMnO4 and MnSO4 as raw materials; adsorbing KMnO4 solution on the carrier under the actions of immersion and adsorption, and reacting the MnSO4 solution serving as a reducing agent with the KMnO4 on the carrier so that the MnO2 powder generated by reaction is directly deposited onthe surface and the interior of the carrier; and soaking the carrier into 0.5 to 2.0 percent of metal ion doped solution, performing rotary evaporation, and drying at the temperature of 100 DEG C to prepare the MnO2 / carrier composite catalyst containing doped ions.

Owner:TIANJIN POLYTECHNIC UNIV

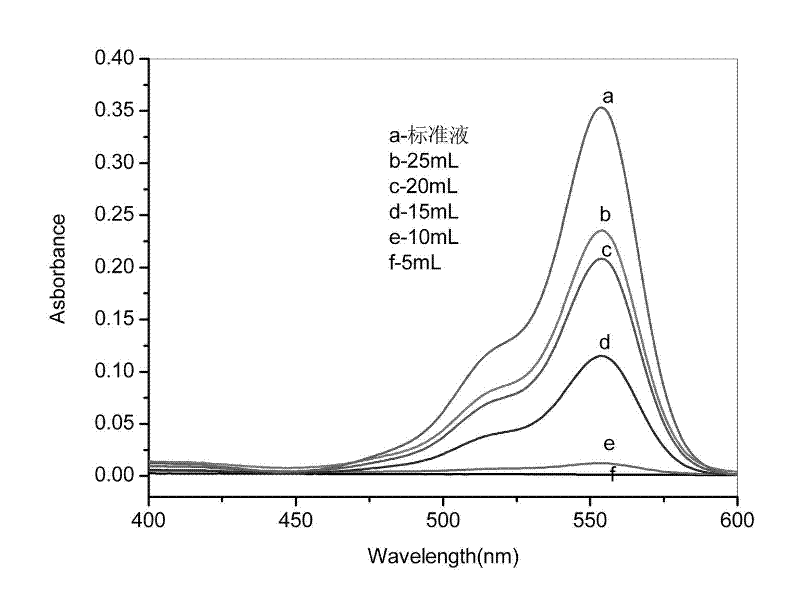

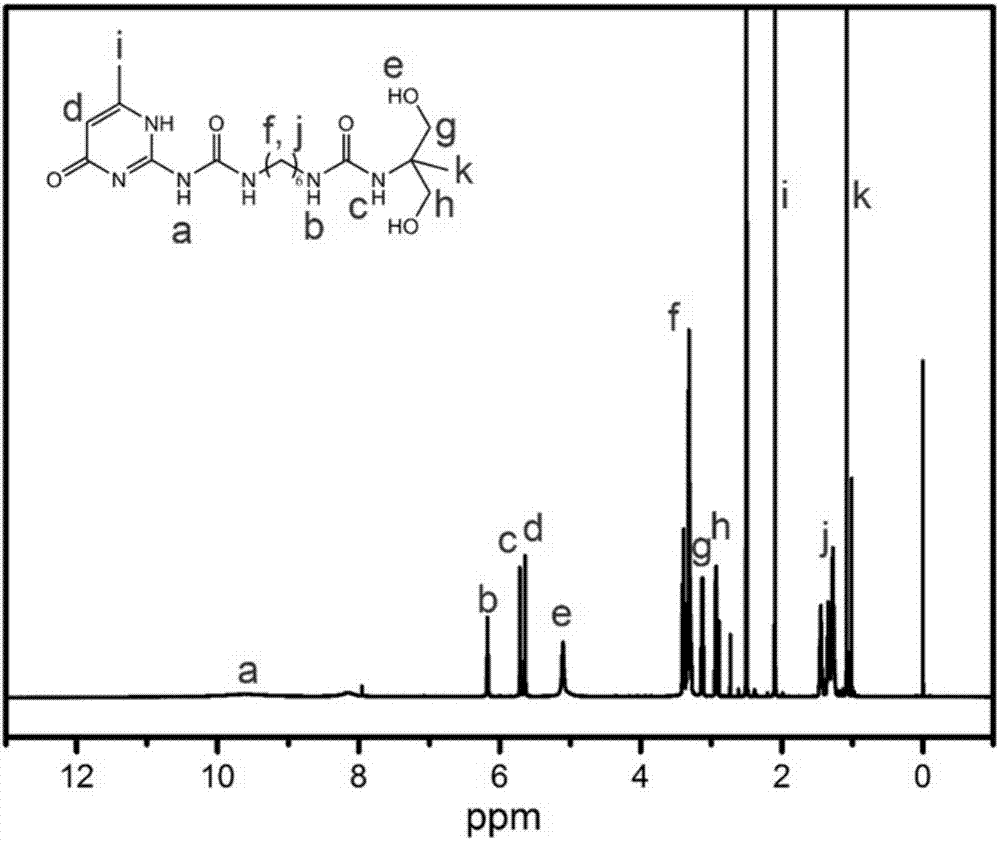

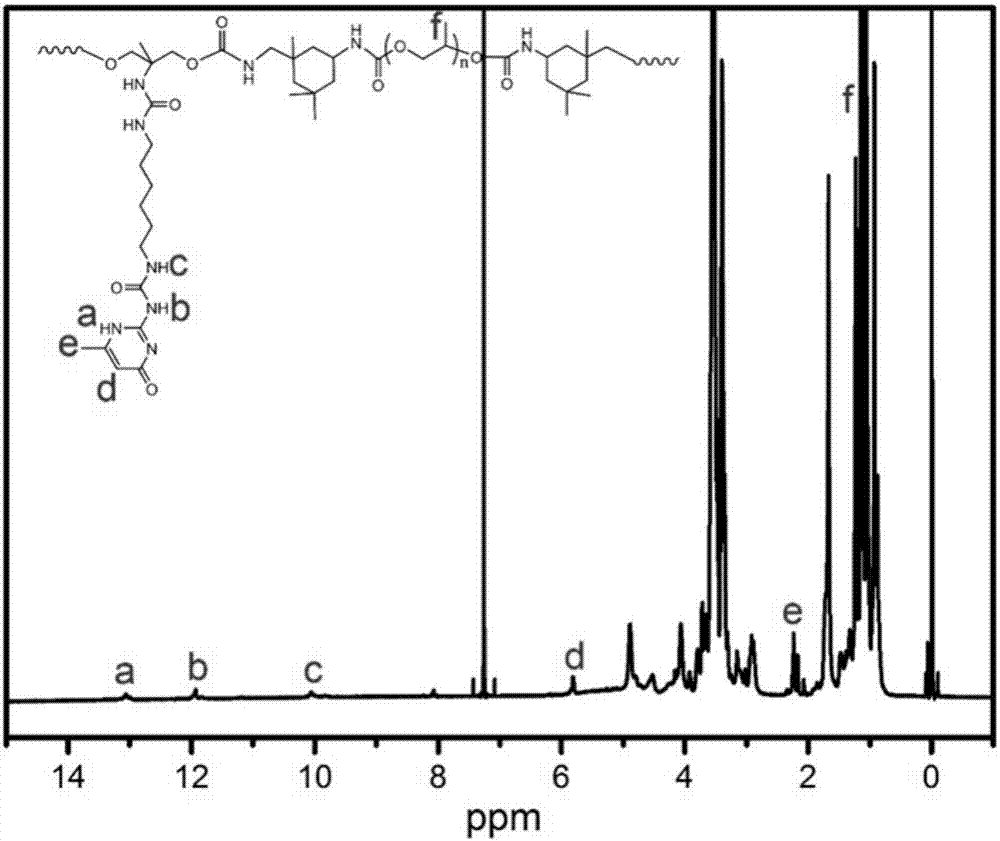

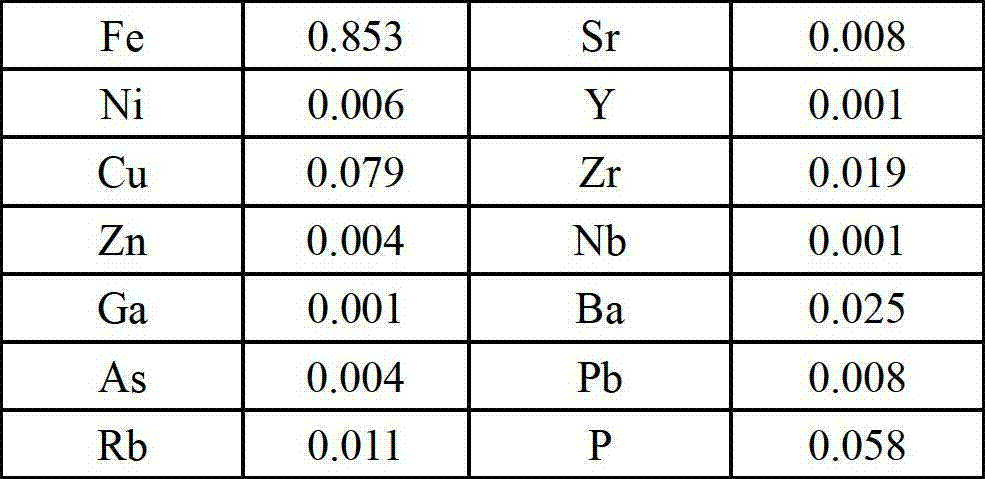

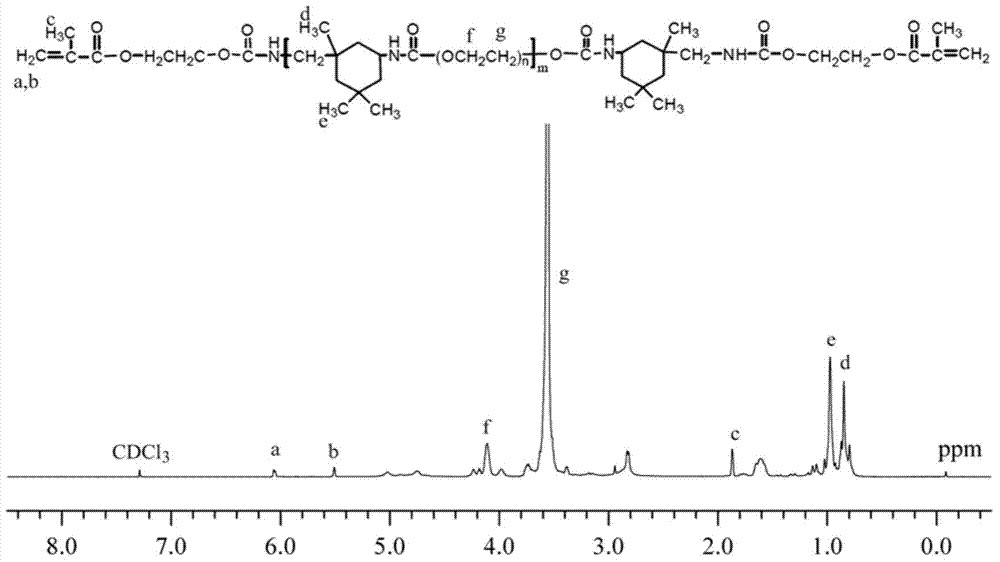

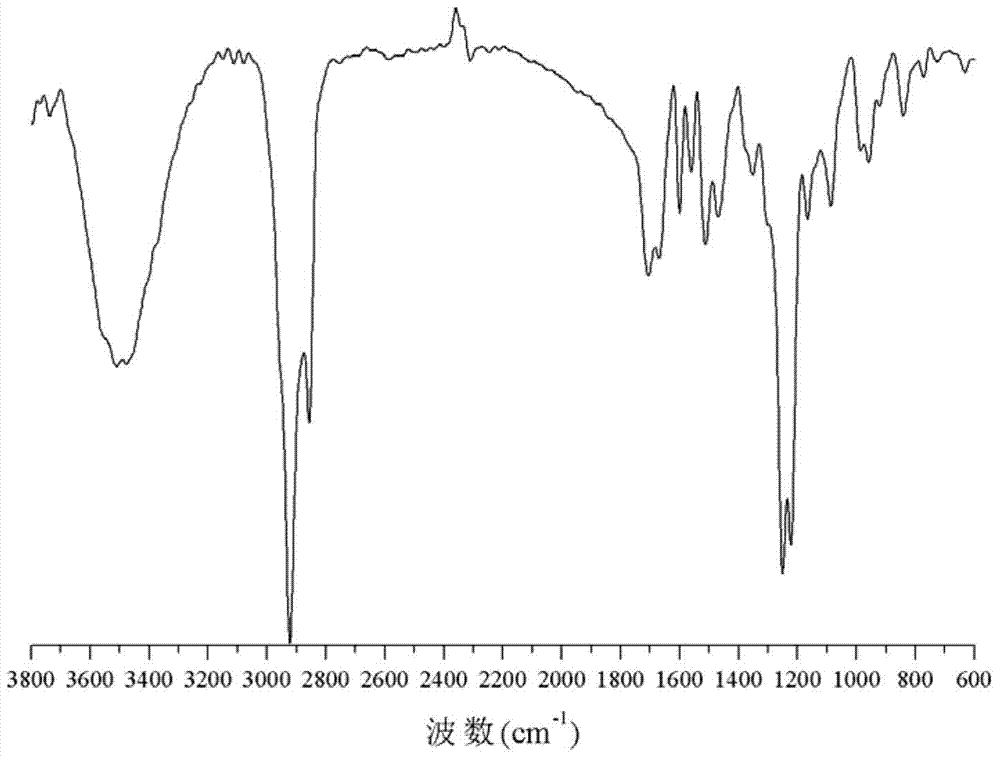

Self-healing polymer material and preparation method thereof

The invention discloses a self-healing polymer material and a preparation method thereof. The self-healing polymer material comprises at least one polyurethane polymer prepared by random copolymerization reaction of a low polymer dihydric alcohol, a chain extender and a first diisocyanate, wherein the chain extender comprises at least one multiple hydrogen bond chain extender. The invention further provides a preparation method of the self-healing polymer material. The method comprises the following steps: preparing a ureido pyrimidone type end-capping reagent or chain extender, and preparing the low-temperature rapid self-healing polymer material containing quadruple hydrogen bond groups on side chains and end groups by utilizing the random copolymerization reaction of the low polymer diglycol, the chain extender and the first diisocyanate. Compared with the traditional self-healing material, the self-healing material disclosed by the invention can realize repeated self-healing at the same position at a low temperature without adding a repair agent to the damaged part, and the self-healing polymer material is high in healing ability, excellent in mechanical property, excellent in material film-forming property and transparency, simple in process and low in cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

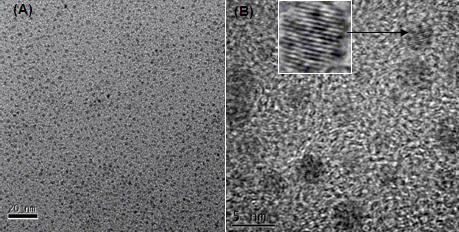

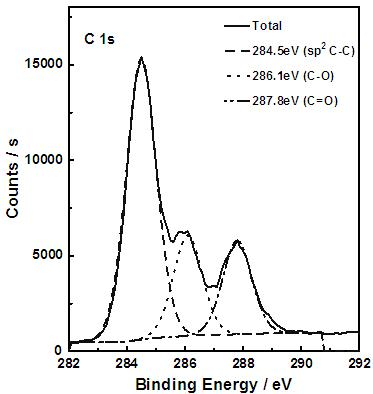

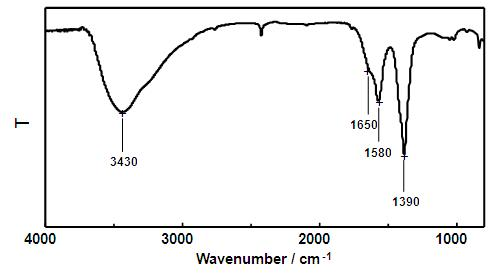

Method for extracting carbon quantum dots from activated carbon

ActiveCN101973541AUniform particle sizeImprove photoelectric performanceNanostructure manufactureLuminescent compositionsActivated charcoal powderCarboxyl radical

The invention provides a method for extracting carbon quantum dots from activated carbon, which comprises the following steps of: adding dry activated carbon powder to salpeter solution and stirring for backflow; performing reduced pressure distillation for evaporating suspension obtained by backflow to dryness; dispersing obtained black solids in water, and neutralizing obtained solution with sodium hydroxide; and finally, centrifugating neutralized black suspension for removing precipitation, separating supernatant fluid by using an ultrafiltration centrifugal tube or an ultrafiltration membrane, collecting filtrate, and drying the filtrate to obtain carbon quantum dots. The method uses cheap and available activated carbon as carbon sources, and can obtain a large number of carbon quantum dots by simple chemical oxidation process and simple subsequent processes of evaporation, saturation, centrifugation and ultrafiltration. The carbon quantum dots are graphite structure nanocrystals with the grain diameter of 3 to 5 nm, the surfaces of which have a large amount of hydroxide radicals. The carbon quantum dots have good fluorescence and electrochemiluminescence.

Owner:FUZHOU UNIV

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

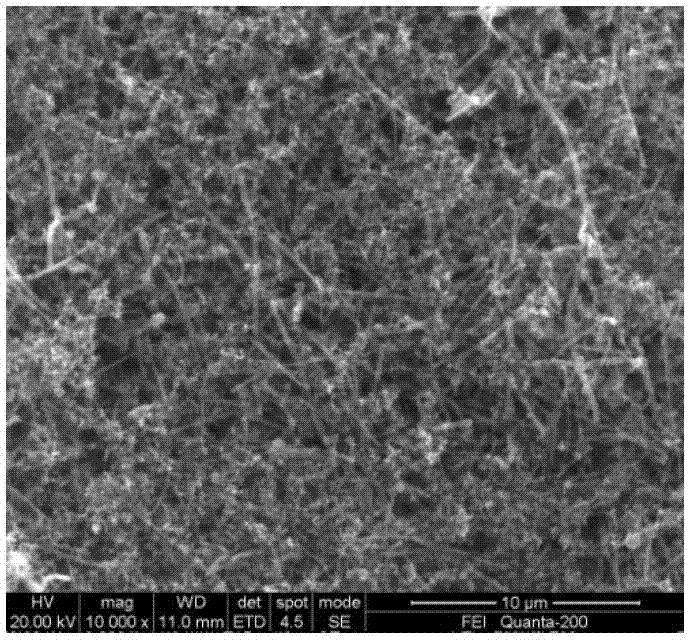

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

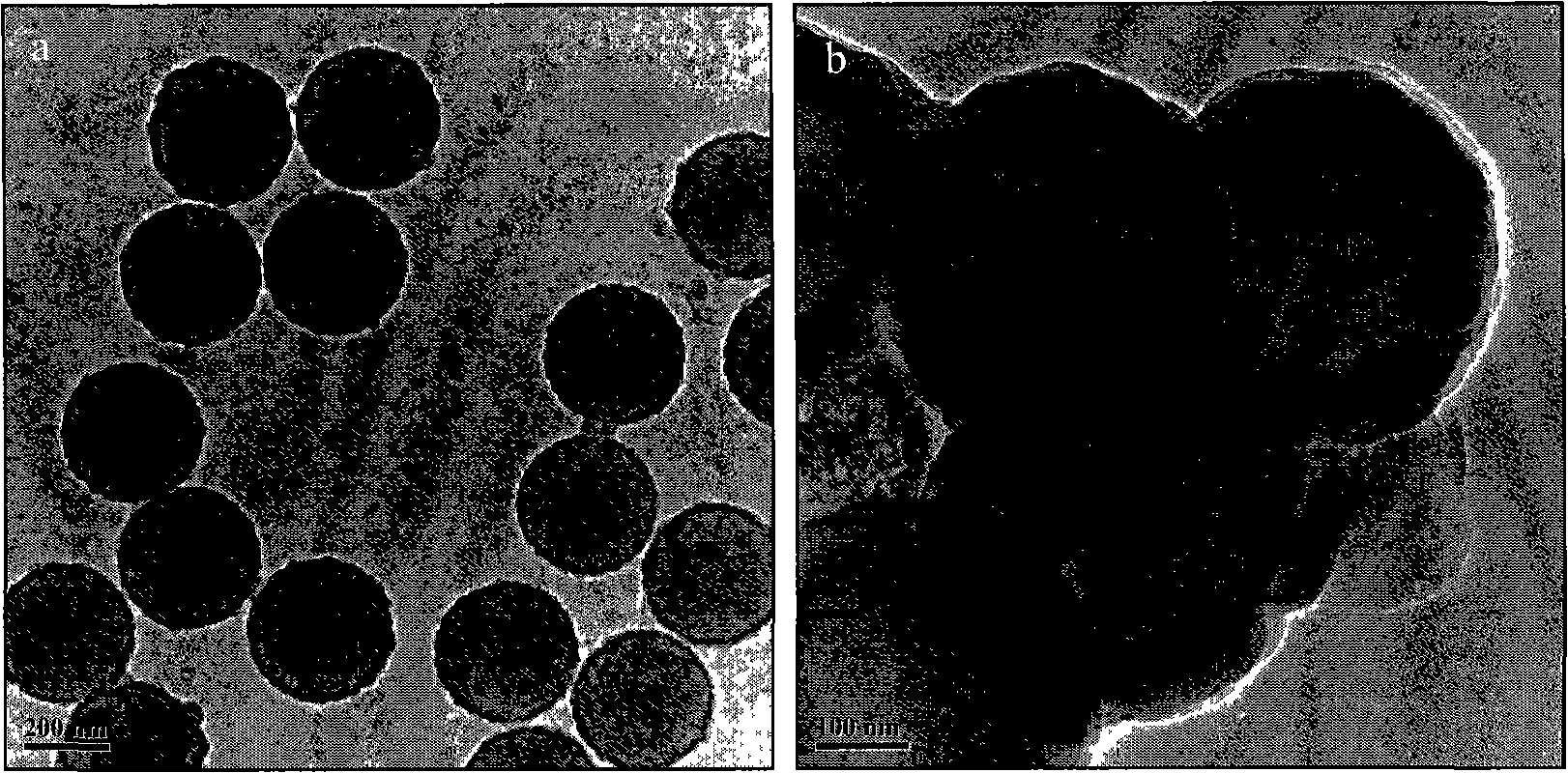

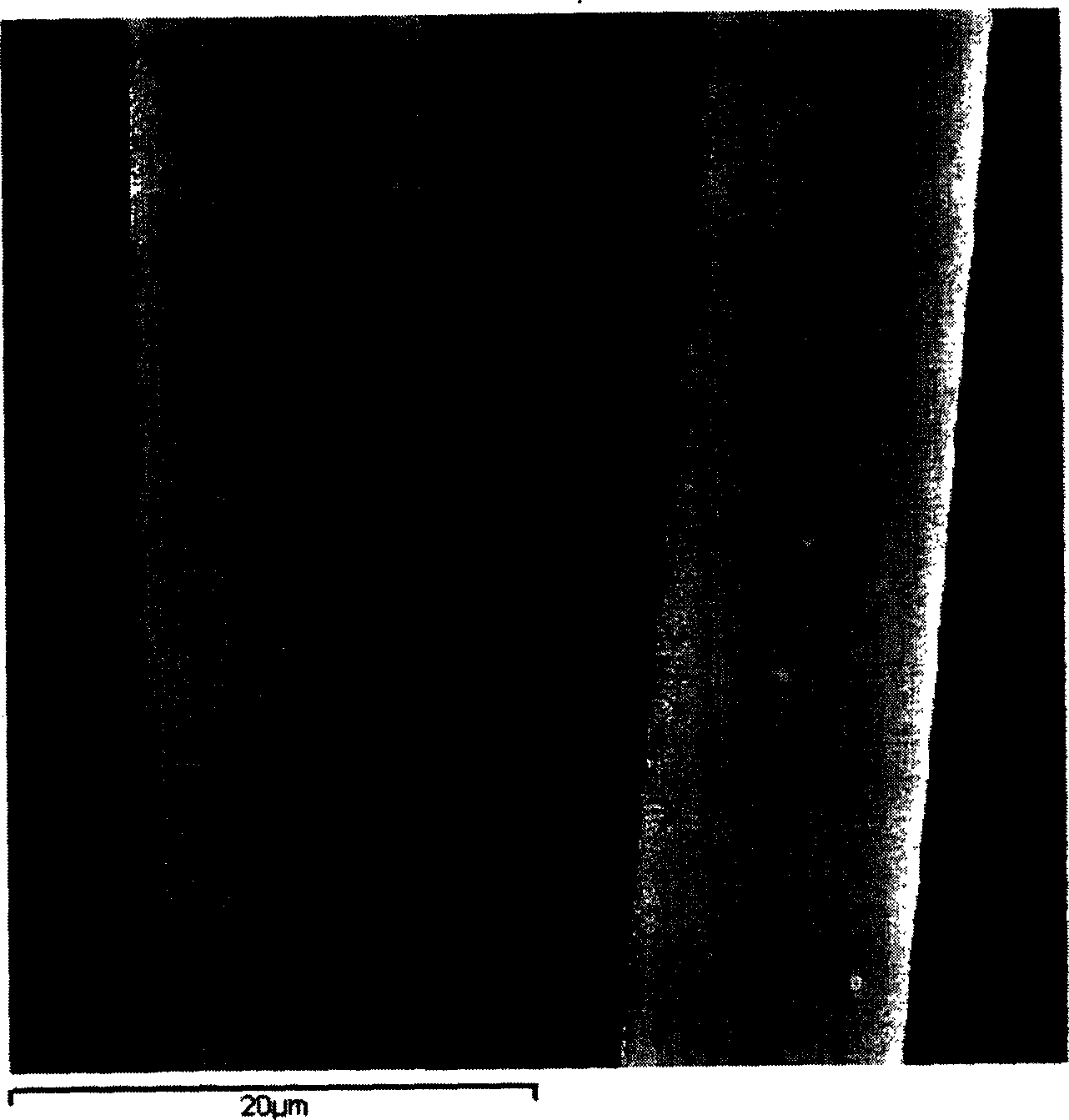

Method for regulating ZIF-8 crystal morphology by utilizing surfactant

InactiveCN107722046ARaw materials are cheap and easy to getLow costOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesCrystal morphologyRhombic dodecahedron

The invention provides a method for regulating ZIF-8 crystal morphology by utilizing a surfactant and belongs to the technical field of synthesis of porous materials. The method disclosed by the invention is mainly characterized in that the morphology and size of the ZIF-8 crystal are controlled by adding a certain amount of a surfactant. The specific preparation method comprises the following steps: respectively dissolving a zinc salt, a surfactant and dimethyl imidazole into a certain amount of water, stirring to enable the components to be fully dissolved, and preparing a solution; mixing adimethyl imidazole solution and a surfactant solution, fully stirring, finally adding a zinc salt solution, and mixing and stirring for 10 minutes; then transferring the mixed solution into a high temperature reactor, and reacting at a constant temperature for several hours; cooling, centrifuging, washing and drying, thereby obtaining the ZIF-8 crystal. The ZIF-8 crystal prepared by the method has excellent crystallinity and has five morphologies such as rhombic dodecahedron, cube, sheet, interpenetration twin and rod. The invention provides a novel method for controlling the morphology and size of MOFs materials.

Owner:NANJING UNIV OF TECH

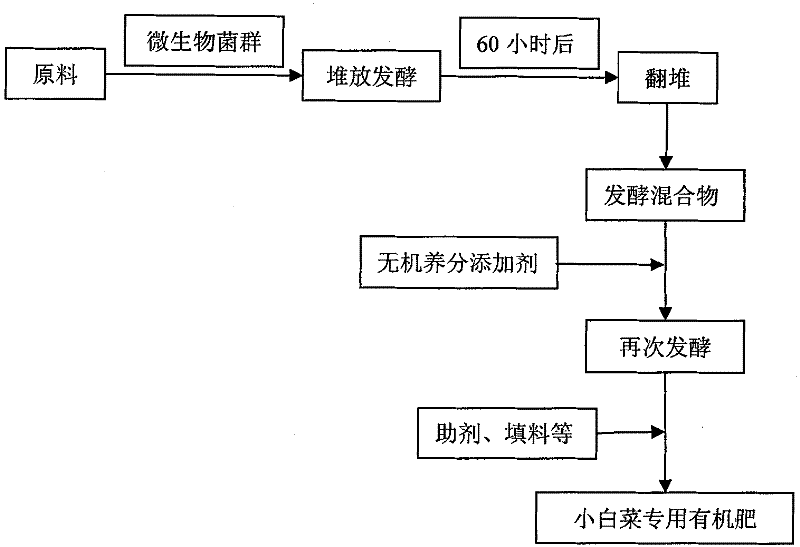

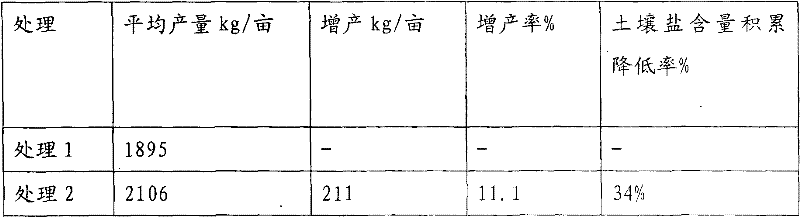

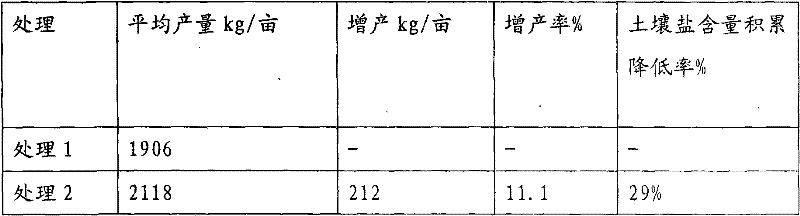

Pakchoi organic composite fertilizer

ActiveCN102351596AReasonable ratioFully absorb and utilizeBio-organic fraction processingOrganic fertiliser preparationSoil typeEffective microorganism

The invention relates to pakchoi organic composite fertilizer. The pakchoi organic composite fertilizer is characterized in that medium and trace elements needed by multiple plants are mixed with inorganic fertilizer and organic fertilizer; and simultaneously, auxiliary agents capable of improving an absorption and utilization rate for a plant and increasing fertilizer slow-release performances and effective microorganisms are added into the mixture to be prepared into specialized composite fertilizer particles through proper fermentation and processing. The pakchoi organic composite fertilizer has the advantages that scopes of suitable regions and soil types are wide; base fertilizer one-step application can be realized in fertilizer application and topdressing can be carried out later according to needs; pakchoi growth needs are satisfies; and effects of yield increase and harvest increase are realized.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

Alcohol-based biological fuel oil for boiler and preparation method thereof

InactiveCN101948702ALow costRaw materials are cheap and easy to getBiofuelsLiquid carbonaceous fuelsBiodieselAlcohol

The invention provides a biodiesel-based alcoholic fuel oil, which consists of the following substances in percentage by mass: 20 to 50 percent of refined biodiesel, 40 to 80 percent of industrial methanol and 5 to 30 percent of additive, wherein the additive comprises 5 to 20 percent of solvent aid, 1 to 15 percent of cosurfactant, 0.2 to 2 percent of stabilizer and 0.1 to 1 percent of corrosion inhibitor. A preparation method comprises the following steps of: mixing the substances in percentage by mass, and stirring the mixture uniformly at normal temperature to obtain the fuel oil. The fuel oil has the advantages of low cost, high heat value and stable performance; the preparation method has the advantages of simple process, convenience and safety of use and good adaptability to the boiler; and compared with diesel oil, the fuel oil is economic and energy-saving, has low environmental pollution, is regenerative energy, and can be used as commercial oil for great popularization and use.

Owner:KUNMING UNIV OF SCI & TECH

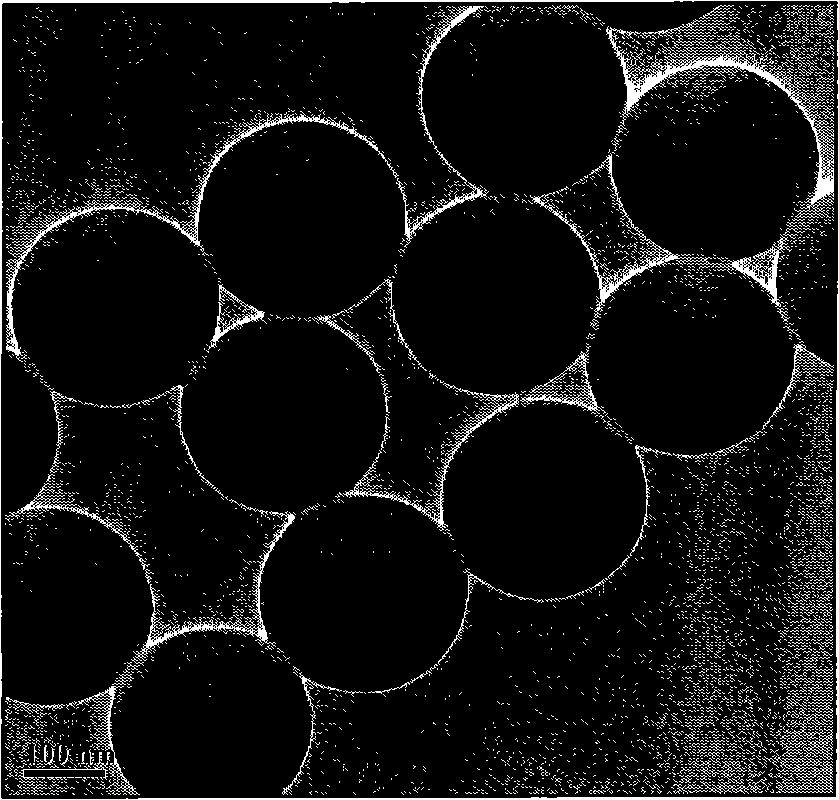

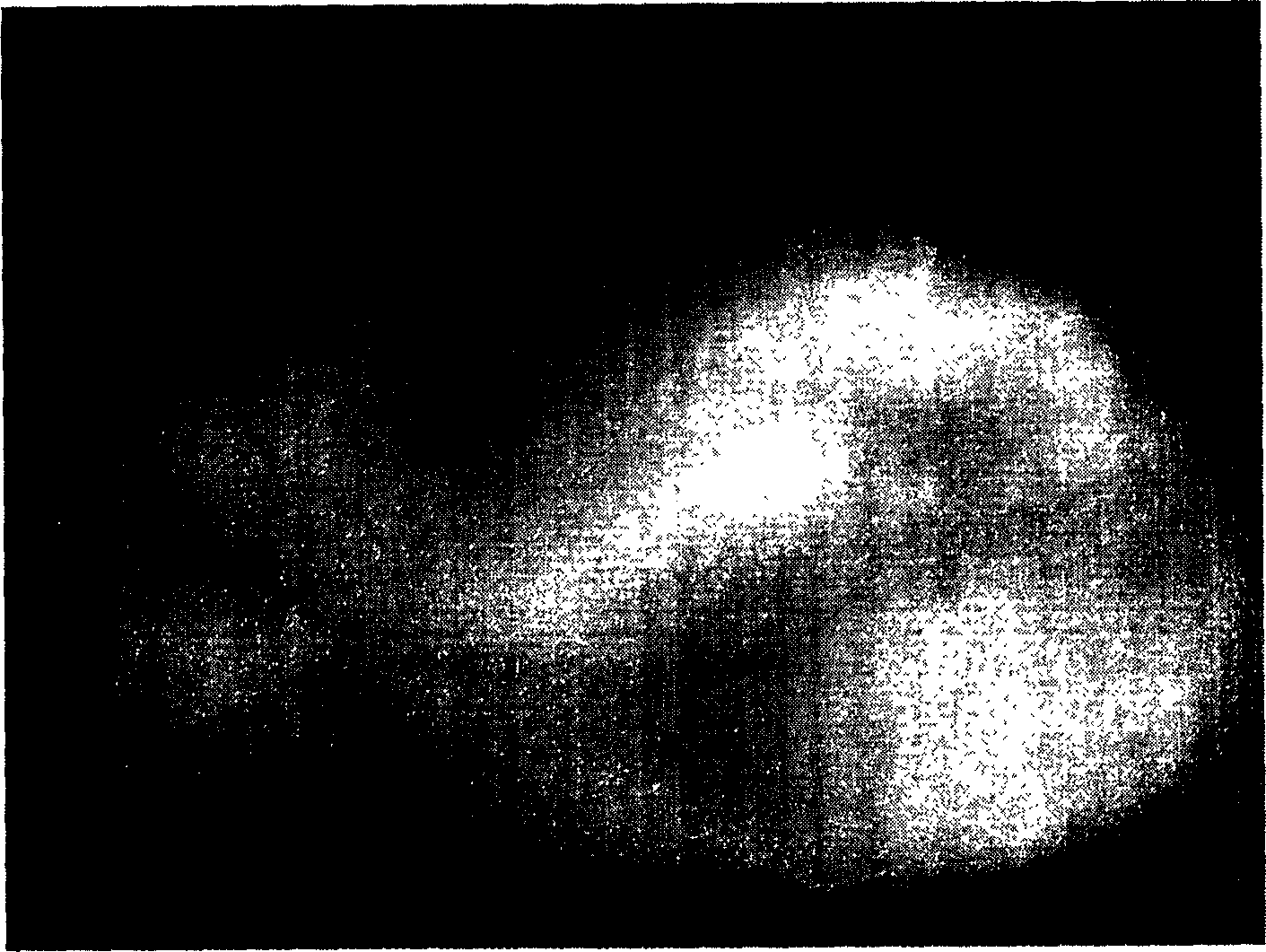

Sol-gel method for preparing earth silicon/titanic oxide hollow microballoon

InactiveCN101274246AFlexible production processRaw materials are cheap and easy to getMicroballoon preparationMicrocapsule preparationPolystyrene microsphereSol-gel

The invention provides a method for preparing an SiO2 / TiO2 hollow microsphere by a sol-gel method. The method is mainly characterized in that cation polystyrene microsphere (PS) is used as a formwork; ethyl silicate and butyl titanate are respectively used as raw material and diluted ammonia is taken as regulator of pH value; a multi-layer organic-inorganic hybrid composite microsphere is obtained by the sol-gel reaction under the temperature of 70-80 DEG C. Formwork particle of the obtained deposition is removed by a calcining process to obtain the SiO2 / TiO2 hollow microsphere. By changing the consistency of reactant, content of surfactant and calcining temperature, the SiO2 / TiO2 hollow microsphere with different spherical shell thickness, density and grain size can be obtained. The hollow microsphere prepared by the method has high photo-catalytic activity, overcomes the shortage that existing preparation method of hollow microsphere can only prepare single shell layer microsphere; the multi-layer hollow microsphere can be prepared, the technique is simple, the cost is low and the preparation method of the invention is suitable for industrialized production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Zirconium oxide fabrics prepared from organic polyzirconium fore spinning solution by silk process

InactiveCN1584155AGood effectRaw materials are cheap and easy to getInorganic material artificial filamentsFuranSolvent

The manufacture method of a kind of zirconia fibre cotton relates to the field of resistance of fire fibre material. We compose van-style acetamide acetone zirconium polymer according to chloridze zirconia, acetamide acetone and three-ethylamine. We use methanol as the dilute impregnant, we mix round them to let hloridize zirconia, acetamide acetone and three-ethylamine react at 40-20 deg.C, and we can receive poly-acetamide acetone zirconium van-substance. Four-hydrogen furan filtrate and remove the outgrowth hydrochloric three-ethylamine. The offspring dissolve in the filature liquid made of methanol. After centrifugal swing, we can receive van-substance fibre. After we do special hear treatment, the zirconia fibre cotton we receive has the characteristic of good filature ability, high content of zirconium, equality andclarity and jarles capability. It can be used as industrial stove, roomage fusion stove, atomic energy reactor and the high temperature heat insulation material used in aviation and military. The material of the invention cost low, the method is easy, the impregnant can be recycled, the preparation of fibre cost low.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

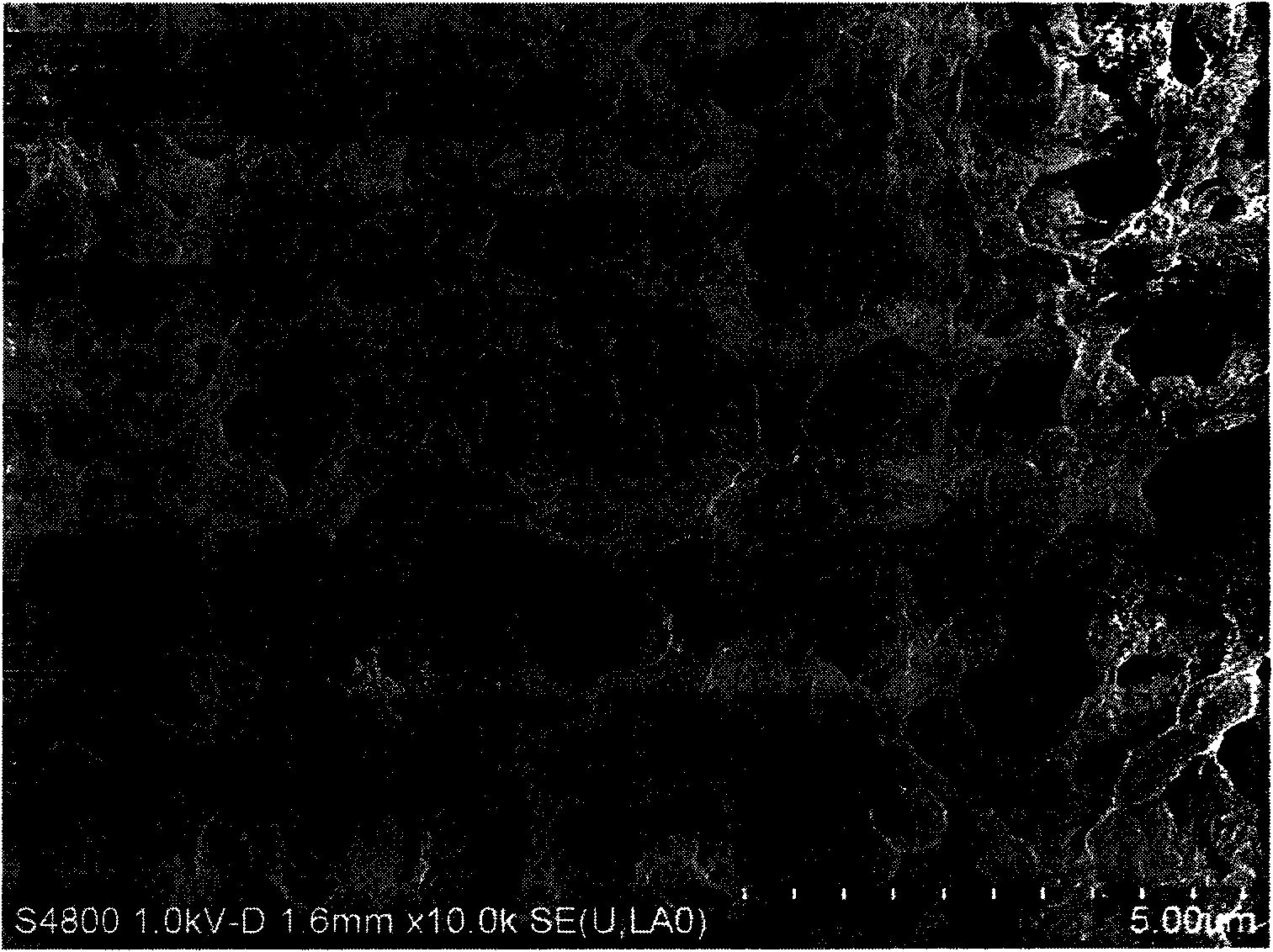

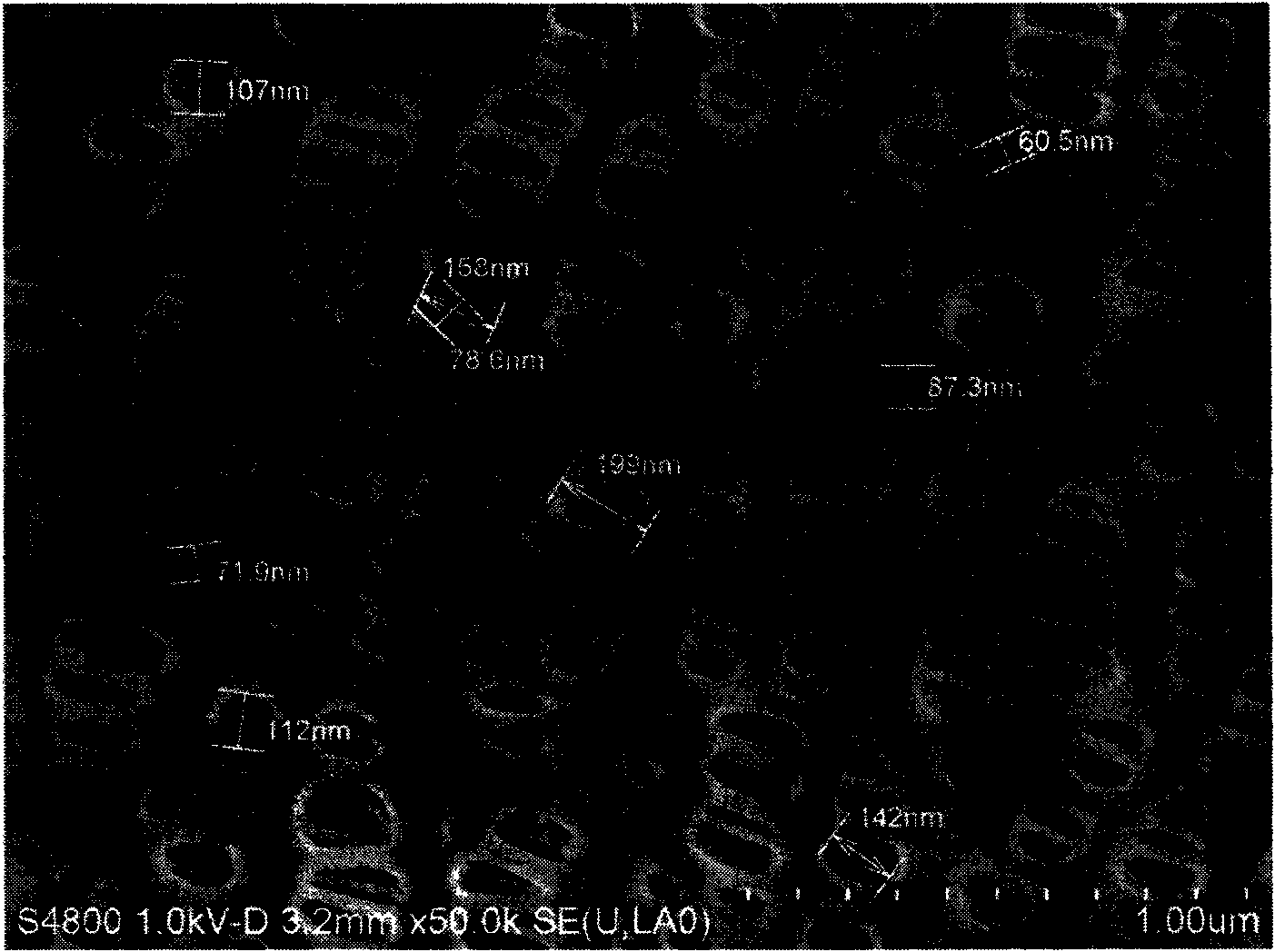

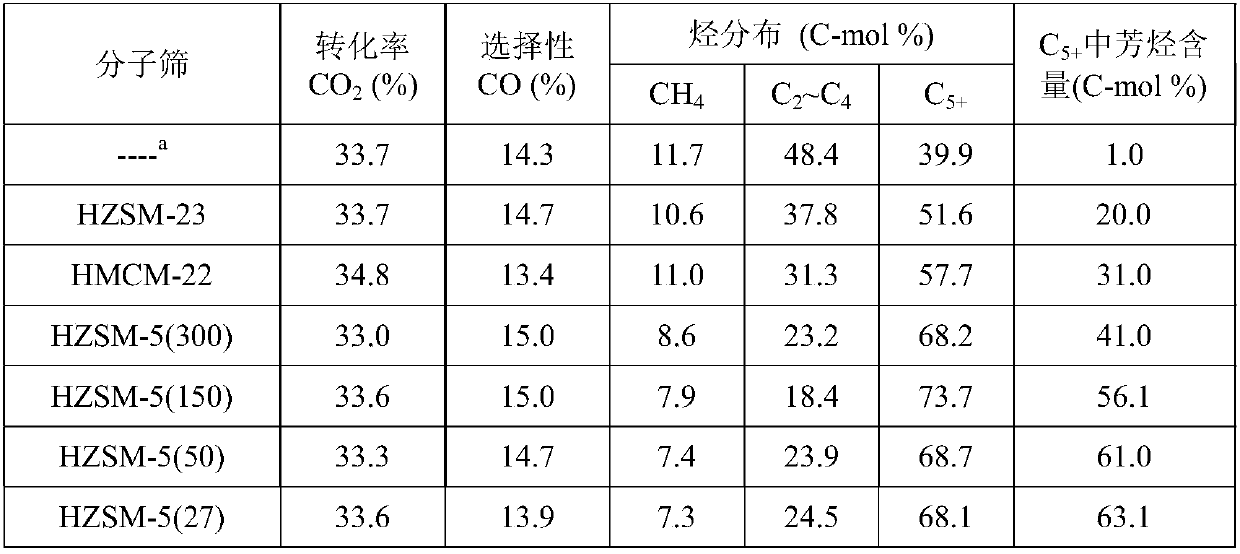

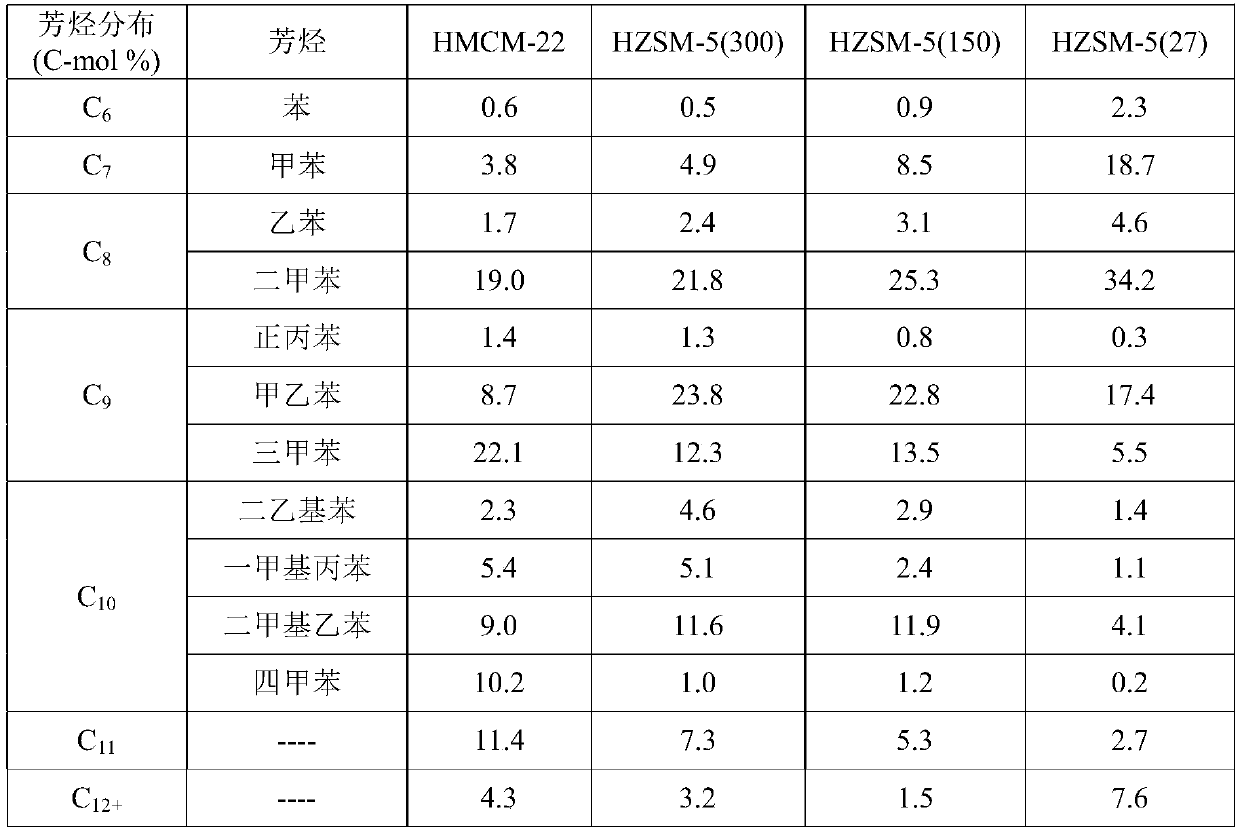

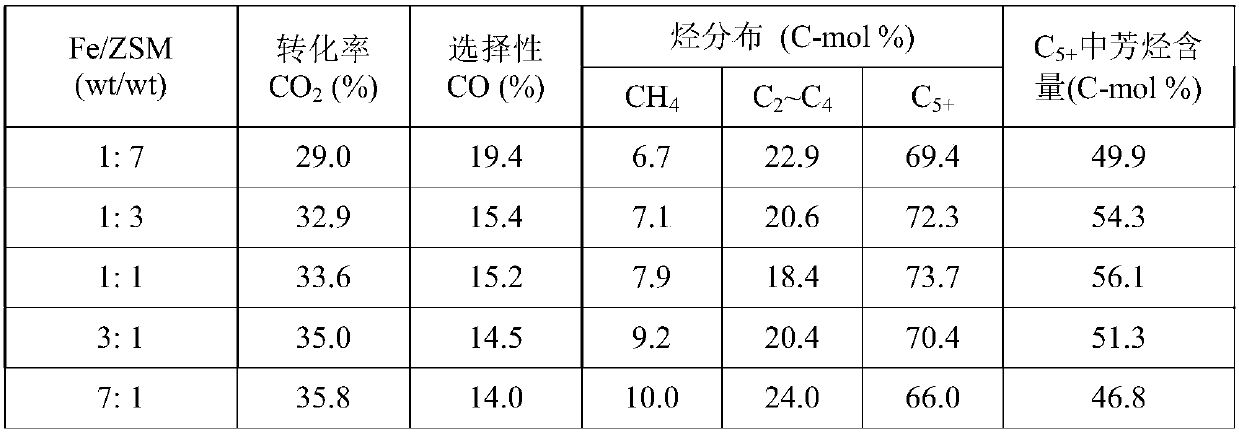

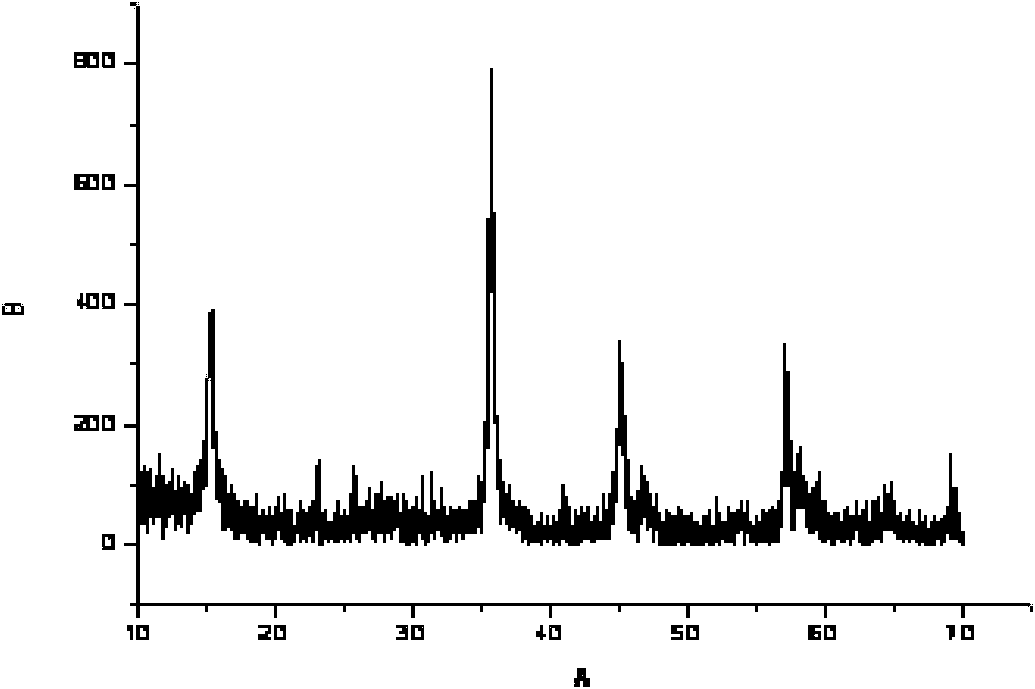

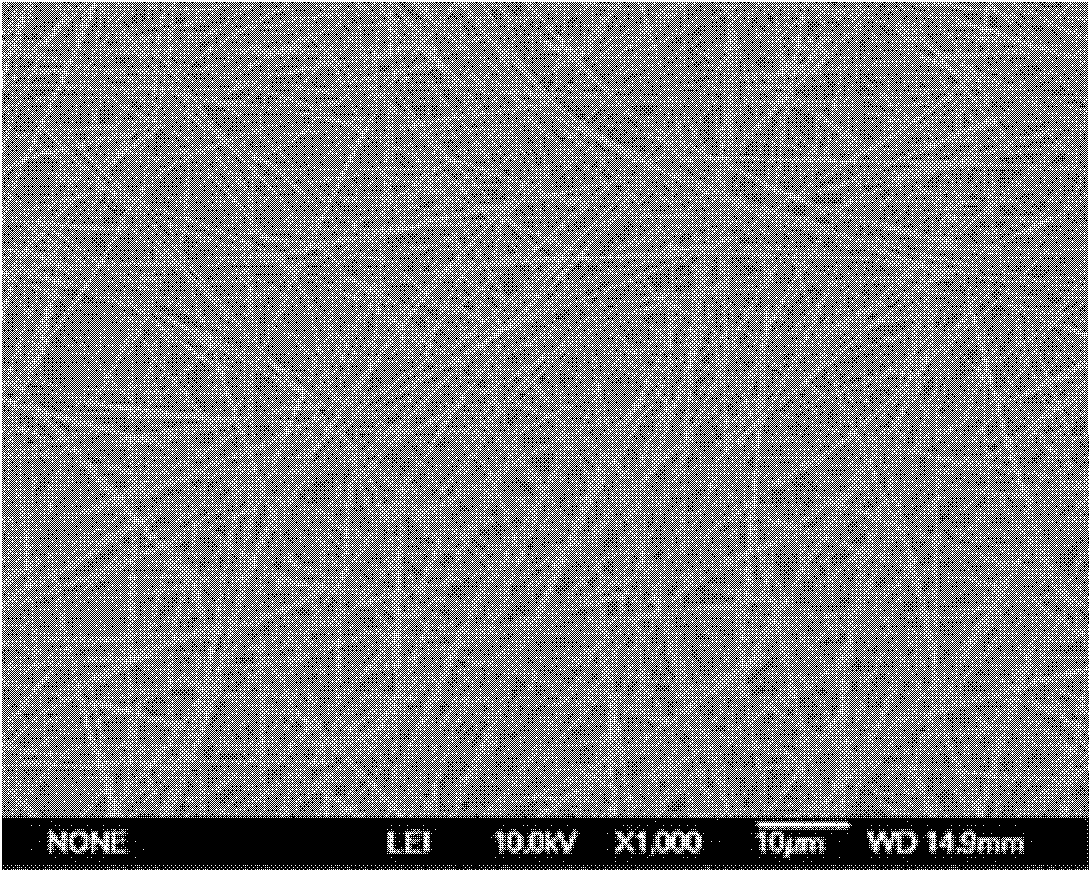

Method for preparing aromatic hydrocarbons through hydrogenation of carbon dioxide

ActiveCN107840778AEasy to prepareRaw materials are cheap and easy to getHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveCarbon dioxide production

The invention provides a method for preparing aromatic hydrocarbons through hydrogenation of carbon dioxide. A gas mixture composed of carbon dioxide and hydrogen is directly converted under the catalysis of a multifunctional composite catalyst under the reaction conditions of a temperature of 250 to 450 DEG C, a pressure of 0.01 to 10.0 MPa, space velocity of 500 to 50000 mL / (h.g<cat>) and a H<2> / CO<2> mol ratio of 0.5 to 8.0 so as to produce the aromatic hydrocarbons. The composite catalyst is prepared by mixing a first component with a second component, wherein the first component is a Fe-based catalyst for preparation of low-carbon olefins through hydrogenation of carbon dioxide, and the second component is one or more than two selected from a group consisting of molecular sieves modified or unmodified by metals and mainly exerting aromatization effect on olefins. According to the method, the one-way CO2 conversion rate can reach 33% or above; the selectivity of hydrocarbon products can be controlled to be 80% or above; the content of methane in hydrocarbon products is lower than 8%; the content of C<5+> hydrocarbons is higher than 65%; and the aromatic hydrocarbons account for63% or more of the C<5+> hydrocarbons. The method opens up a novel route for production of aromatic hydrocarbons from carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for preparing vanadium disulphide nano powder

InactiveCN102010004AHigh purityLow costNanotechnologyVanadium compoundsHigh volume manufacturingCentrifugation

The invention provides a method for preparing vanadium disulphide nano powder. The method comprises the following steps: a) sulphur source is added into a hydrothermal device filled with a vanadium source aqueous solution; b) the obtained mixed solution be subjected to is kept at the temperature of 40-300 DEG C; and c) after reaction is completed, natural cooling is carried out, and the product is washed and collected by centrifugation, thus obtaining the vanadium disulphide nano powder. In the invention, the vanadium disulphide nano powder is prepared by hydrothermal synthesis at lower temperature, the vanadium source and the sulphur source react according to the reaction principle of oxidoreduction, fixing of quadrivalence of vanadium is realized, no large-scale equipment and extreme conditions are required, raw materials are cheap and easily available, the cost is low, the process is simple, the yield is high, the purity of the prepared vanadium disulphide nano powder is high, the system is clean, and mass production is easy to realize.

Owner:UNIV OF SCI & TECH OF CHINA

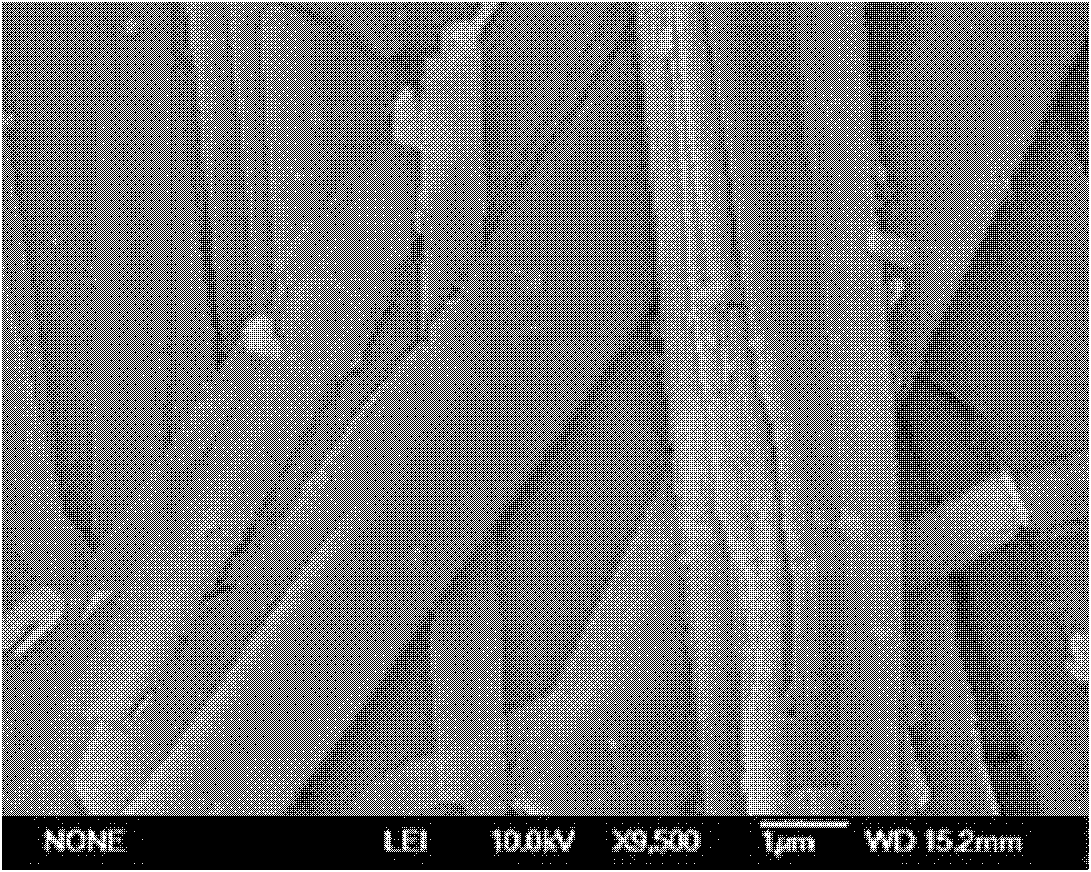

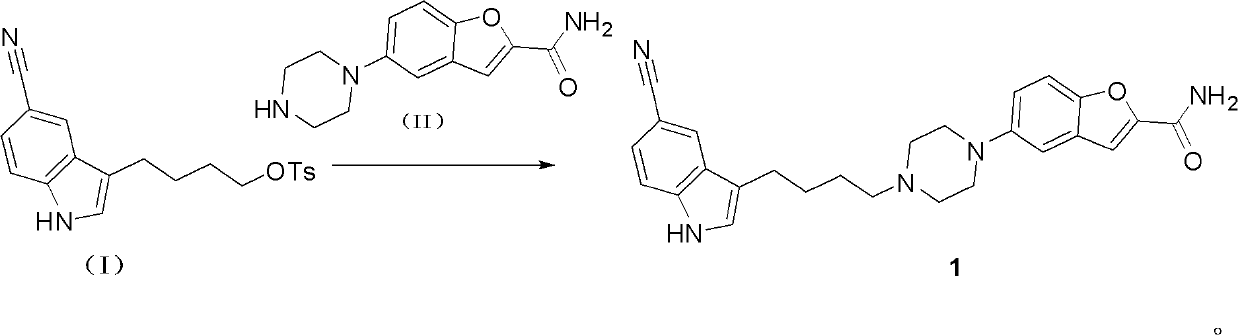

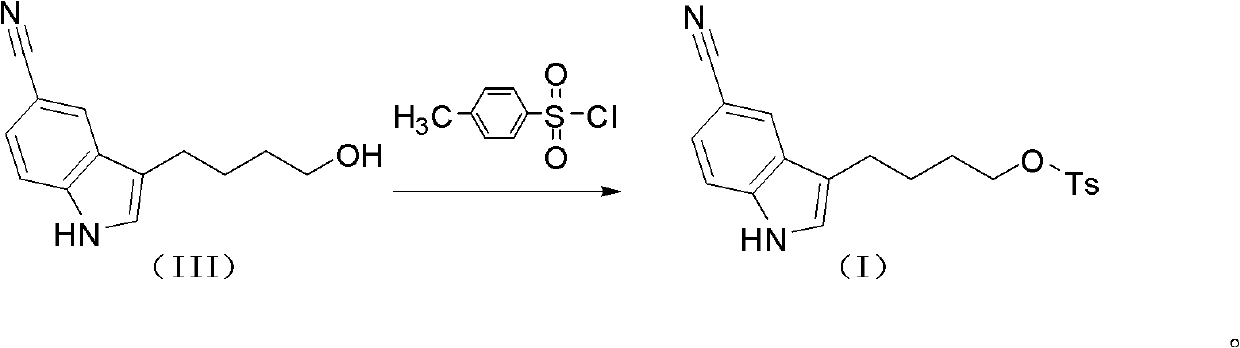

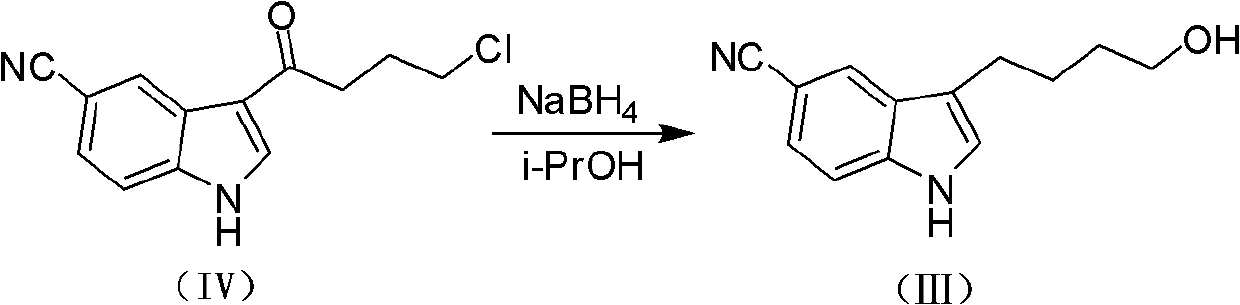

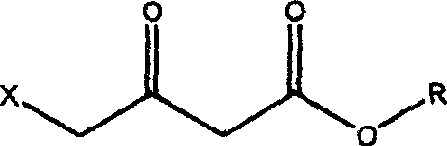

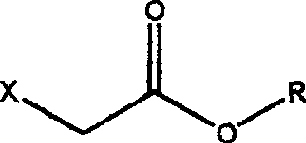

Preparation method of vilazodone or its hydrochloride

The invention discloses a preparation method of vilazodone or its hydrochloride, which comprises the following steps: the compound of formula (I) is mixed with the compound of formula (II) 5-(1 -piperazinyl)-benzofuran-2-formamide reaction, then collect vilazodone shown in formula 1 from the reaction product; Gained vilazodone 1 is in a solvent, and hydrochloric acid is salified to prepare formula (A ) shown vilazodone hydrochloride. The present invention overcomes the defects and deficiencies in the existing preparation methods of vilazodone and its intermediates, is more suitable for the large-scale industrial preparation of vilazodone hydrochloride, has obvious creativity, and has a relatively large positive progress effect and practical application value. The reaction formula is as follows:

Owner:SHANGHAI INST OF PHARMA IND

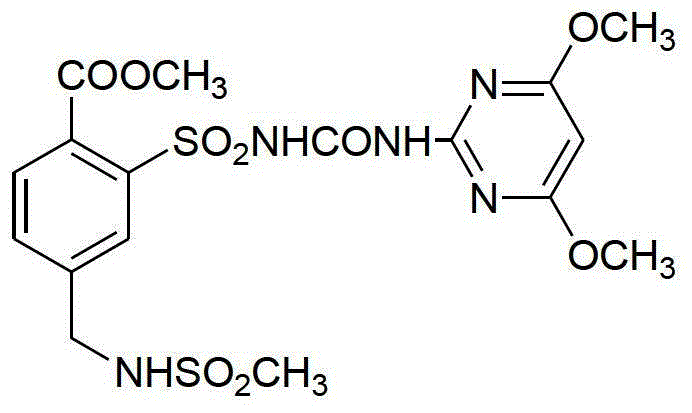

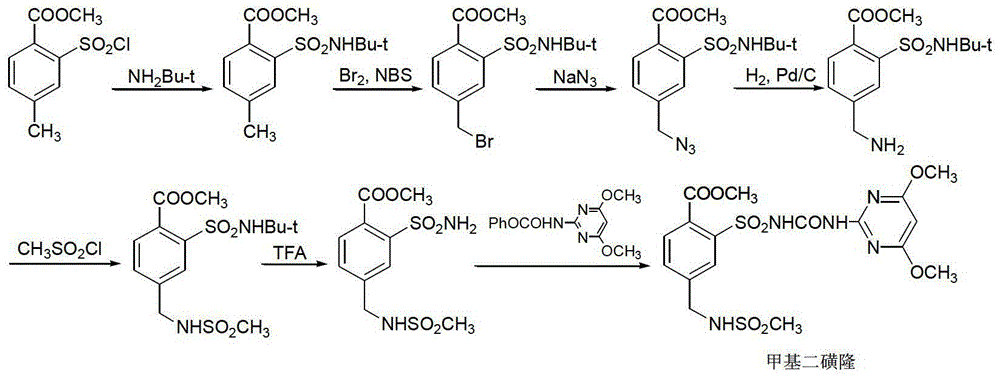

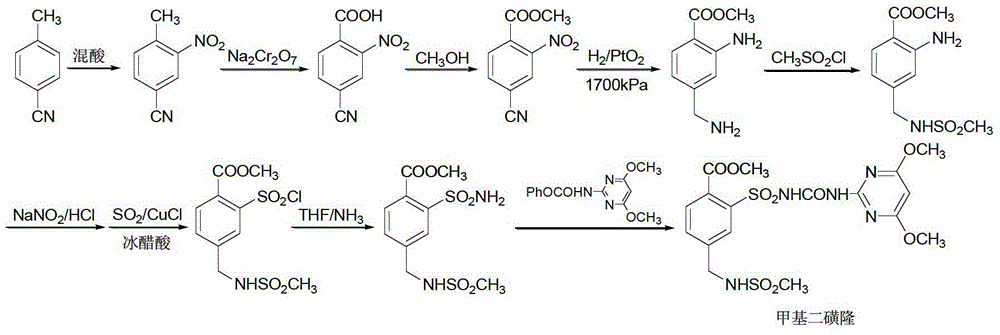

Mesosulfuron-methyl synthetic method

ActiveCN103333120ARaw materials are cheap and easy to getEasy to operateOrganic chemistryMesosulfuron-methylChloride

The invention discloses a mesosulfuron-methyl synthetic method. The mesosulfuron-methyl synthetic method is characterized in that mesosulfuron-methyl is prepared from raw materials such as paratoluic acid by adopting the seven steps of chlorosulfonation-ammonolysis, oxidation, dehydration, reduction, alcoholysis, methyl sulfone chloride acylation and condensation. The mesosulfuron-methyl synthetic method provided by the invention has the advantages of being low in cost of the raw materials, easy in availability of the raw materials, simple in operation and mild in conditions, having low requirements on equipment, high yield and strong practicability and being suitable for industrial production.

Owner:JIANGSU REPONT PESTICIDE FACTORY

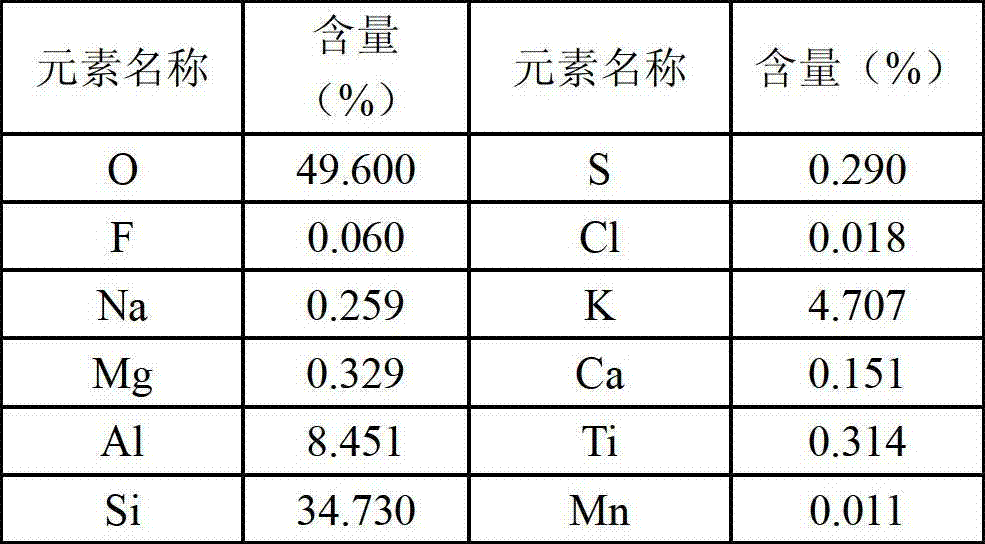

Copper mine tailing slag porous ceramic material and preparation method thereof

A copper mine tailing slag porous ceramic material comprises copper mine tailing slag, a pore-foaming agent, an adhesion agent and a fluxing agent. A preparation method comprises the steps of using the copper mine tailing slag as aggregate, adding the pore-foaming agent, the adhesion agent, the fluxing agent and water to be stirred evenly, using a mold to perform compression molding to obtain a blank, controlling the temperature and sintering through a high-temperature procedure after drying, and obtaining porous ceramics. Raw materials used by the copper mine tailing slag porous ceramic material are cheap and easy to obtain, the compression strength of the porous ceramic material can be remarkably improved and can reach to 5-25 MPa only by adding the copper mine tailing slag and a small amount of additives, and the apparent porosity can reach to 40%-65%. A large amount of beneficiation tailing slag can be utilized effectively, the environmental pollution is reduced, wastes are turned into wealth, and the prepared porous ceramic material can be used as an excellent adsorbing material and a filter material. The technical process is simple, the utilization amount of the copper mine tailing slag is large, secondary pollution is not caused, the porous ceramic material is high in compression strength and porosity, and the resource utilization of the copper mine tailing slag is achieved. The copper mine tailing slag porous ceramic material is suitable for industrial production.

Owner:CENT SOUTH UNIV

High-resilience self-repair high-polymer aquagel and preparation method thereof

The invention discloses a high-resilience self-repair high-polymer aquagel and a preparation method thereof. The high-resilience self-repair high-polymer aquagel is prepared from the following raw materials in parts by mass: 15-20 parts of polyisocyanate, 40-75 parts of hydrophilic polyester polyol or hydrophilic polyether glycol, 1-5 parts of acrylate monomer, 10-15 parts of acrylamide monomer, 0.5-2 parts of chain extender, 1-3 parts of surfactant, 0.1-1 part of alkyl acrylate monomer and 0.5-2 parts of catalyst. The preparation method comprises the following steps: preparing an acrylate-monomer-terminated hydrophilic polyurethane high-polymer monomer self-assembly and an alkyl acrylate micelle; and carrying out radical copolymerization with acrylamide monomer under the photoinitiation action. The obtained self-repair high-polymer aquagel can complete self repair on self damage without any repair agent or specific environment, and has excellent resilience and physical and mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of diatomite ceramic particles or ceramic plates

InactiveCN102093033AIncrease contentImprove adsorption capacityClaywaresExpanded clay aggregateVegetable fibers

The invention relates to a preparation method of diatomite ceramic particles or diatomite ceramic plates. The preparation method of the diatomite ceramic particles comprises the following steps: grinding diatomite, adding cosolvent, mineral powder and vegetable fiber powder to mix evenly and grind; and adding water to mix, shaking to obtain diatomite ceramic particles, and roasting to obtain the finished diatomite ceramic particles. The preparation method of the ceramic plates comprises the following steps: using evenly mixed powder to perform dry pressing with a pressure forming machine, or using mud with the water content of 15-25wt% to perform extrusion forming; and roasting to obtain the diatomite ceramic plates. The formed and dried diatomite ceramic plates or diatomite ceramic particles are soaked in slurry prepared from anatase titanium dioxide nanometer powder or metatitanic acid powder and then dried and roasted to obtain diatomite ceramic particles or diatomite ceramic plates with photochemical activity. In the invention, the low temperature sintering method is adopted to prepare the diatomite diatomite ceramic plates and ceramic particles which have high diatomite content and good adsorption property and water resistance and can be combined with various functional components on the surface. The diatomite ceramic products in the invention are convenient to use and have simple production technology and cheap and easy available raw materials.

Owner:JILIN UNIV +1

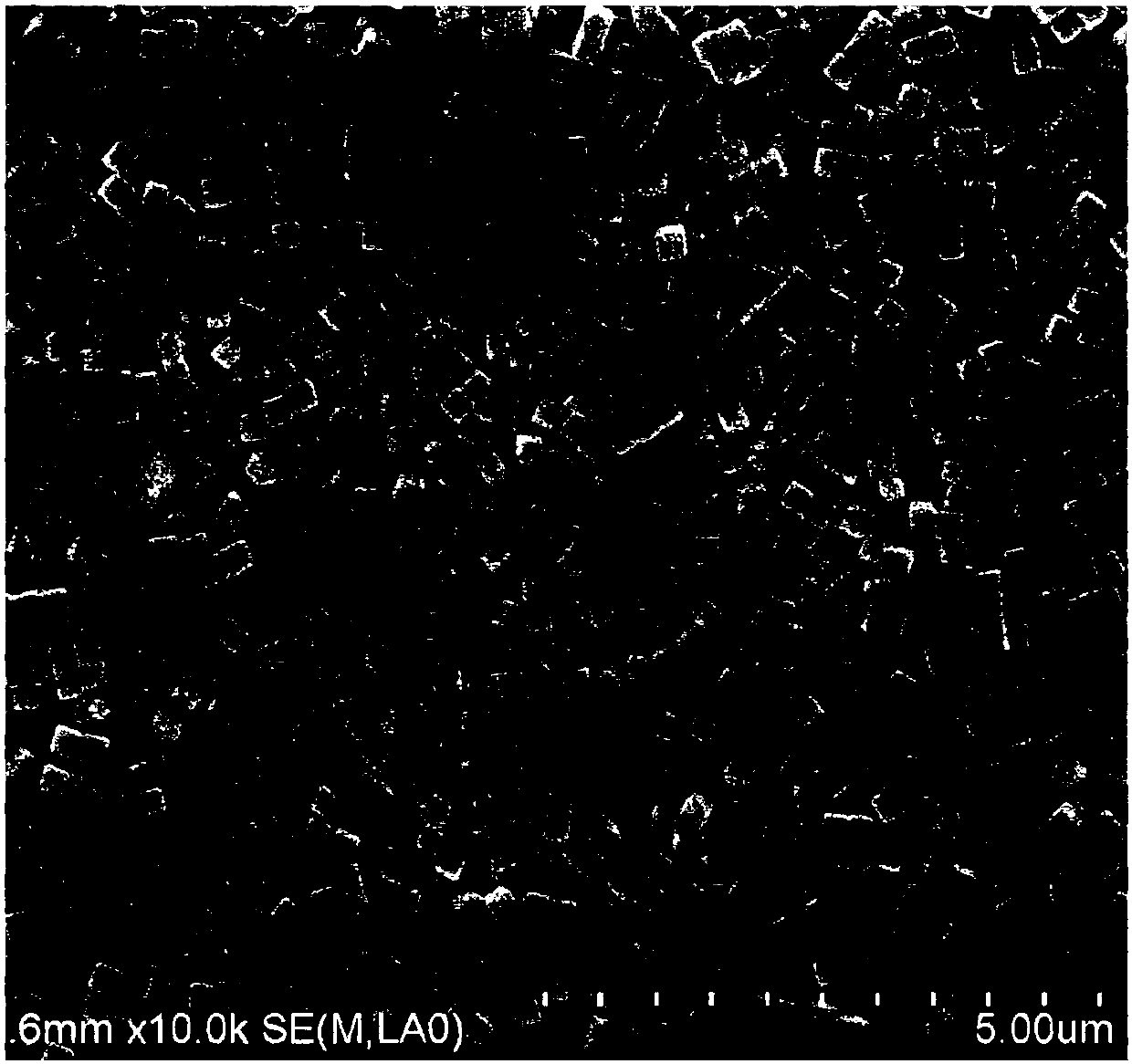

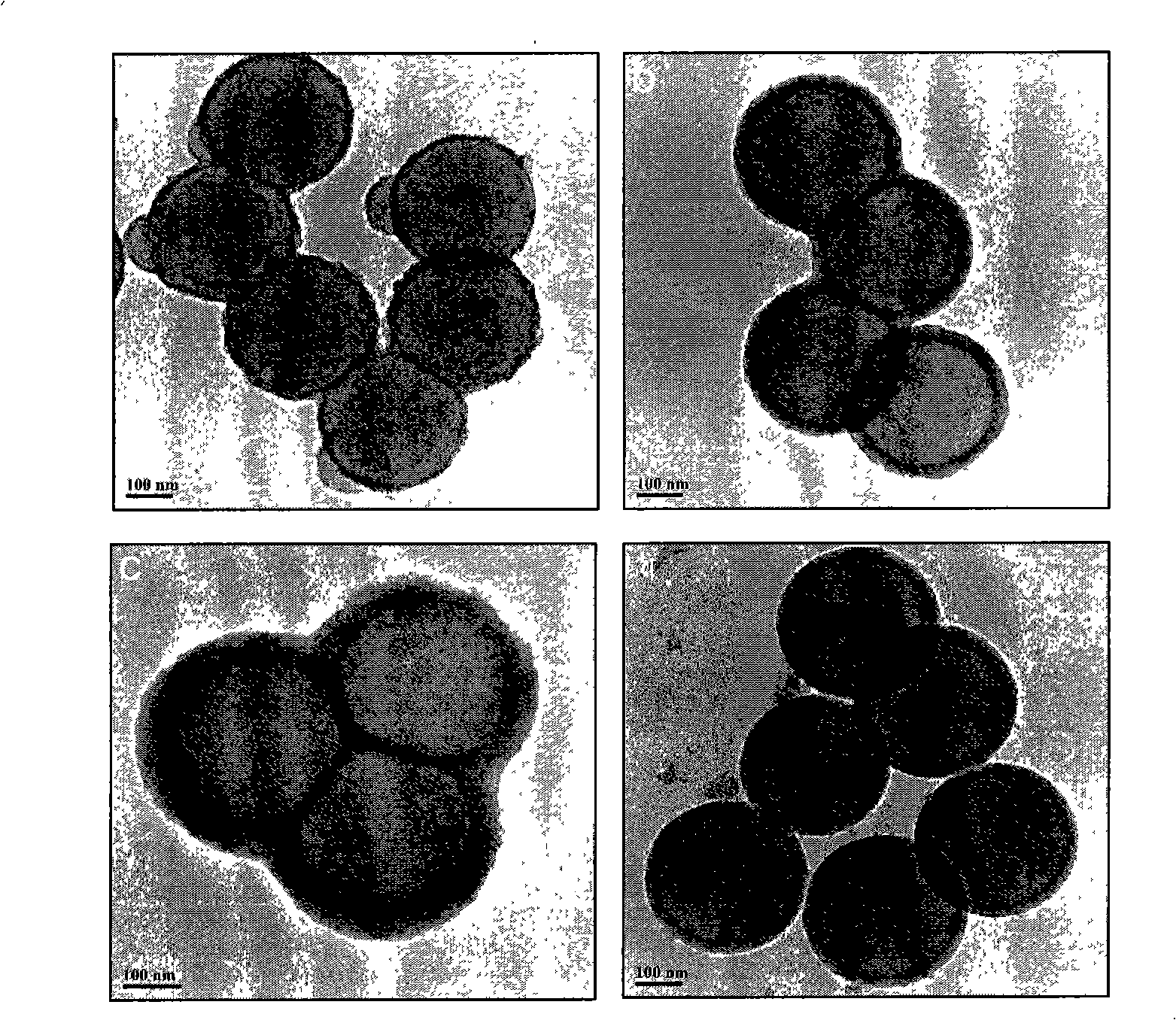

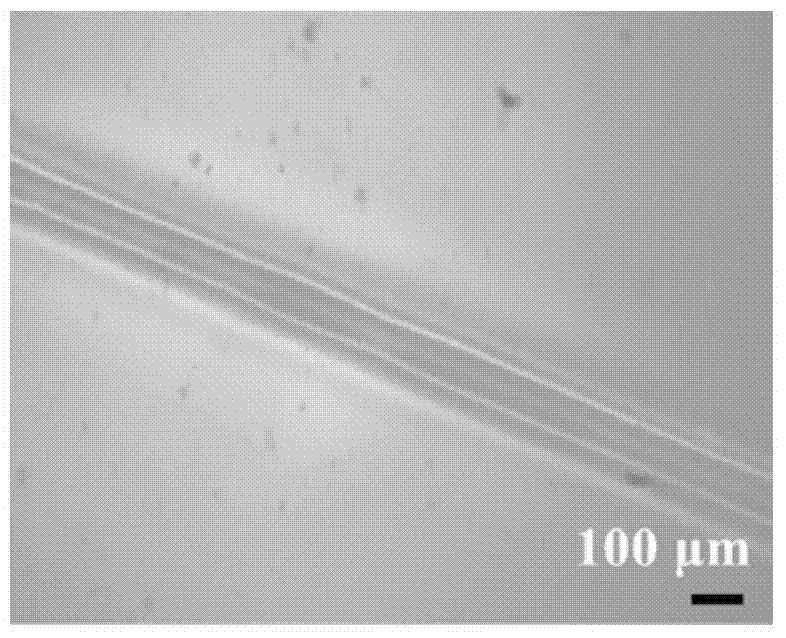

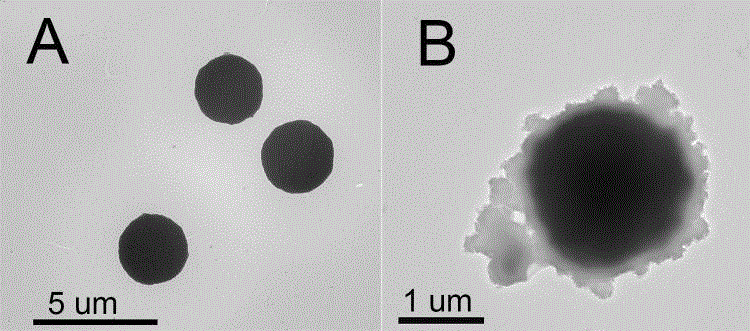

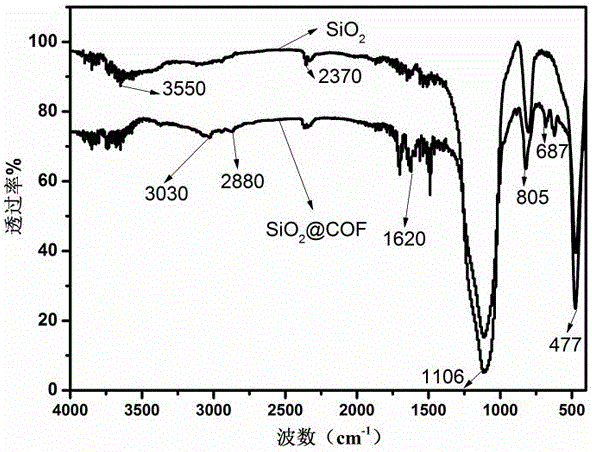

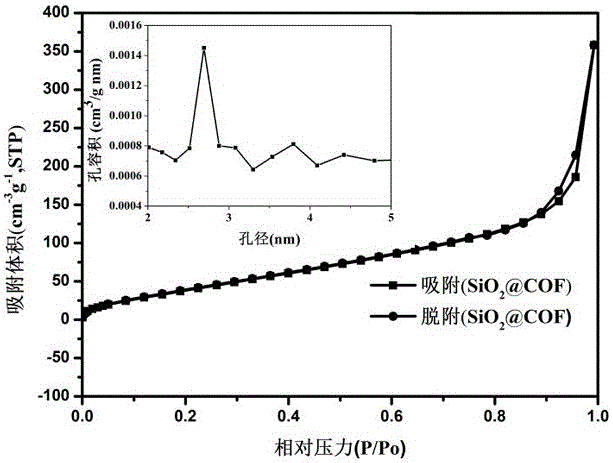

Preparation method of covalent organic framework composite microspheres with core-shell structures

InactiveCN107175053AMild preparation conditionsRaw materials are cheap and easy to getOther chemical processesDispersed particle separationMicrosphereSolid phase extraction

The invention relates to a preparation method of covalent organic framework composite microspheres with core-shell structures. The method comprises the following steps: dissolving silicon dioxide microspheres, a first construction element and a second construction element in an organic solvent; and after adding a catalyst, rapidly synthesizing into the composite microspheres with core-shell structures at a certain temperature. In a preparation process, reaction conditions are gentle, the method is simple, and the yield is high; the prepared covalent organic framework composite microspheres have the advantages of good core-shell morphology, high specific surface area, ordered pore structures, good mechanical stability, thermal stability, chemical stability and the like, if the microspheres are used as a chromatographic stationary phase, the chromatographic mass transfer resistance can be reduced effectively, the theoretical plate height is improved, and finally, column efficiency and degree of separation are improved; and if the microspheres are used as solid-phase extracting filler, the enrichment effect can be improved remarkably. The covalent organic framework composite microspheres with core-shell structures have good application prospects in the aspect of separation and enrichment of small organic molecules.

Owner:FUZHOU UNIV

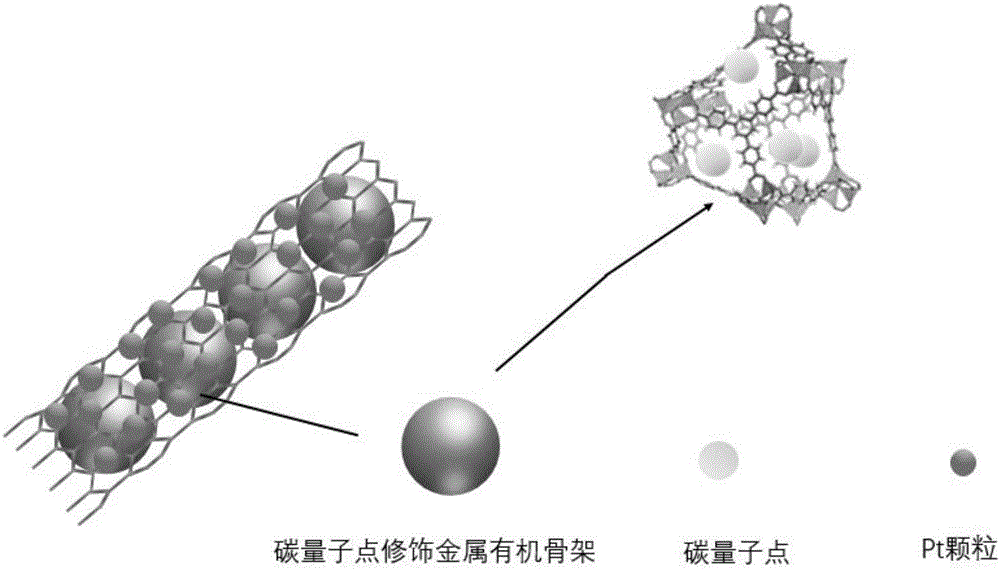

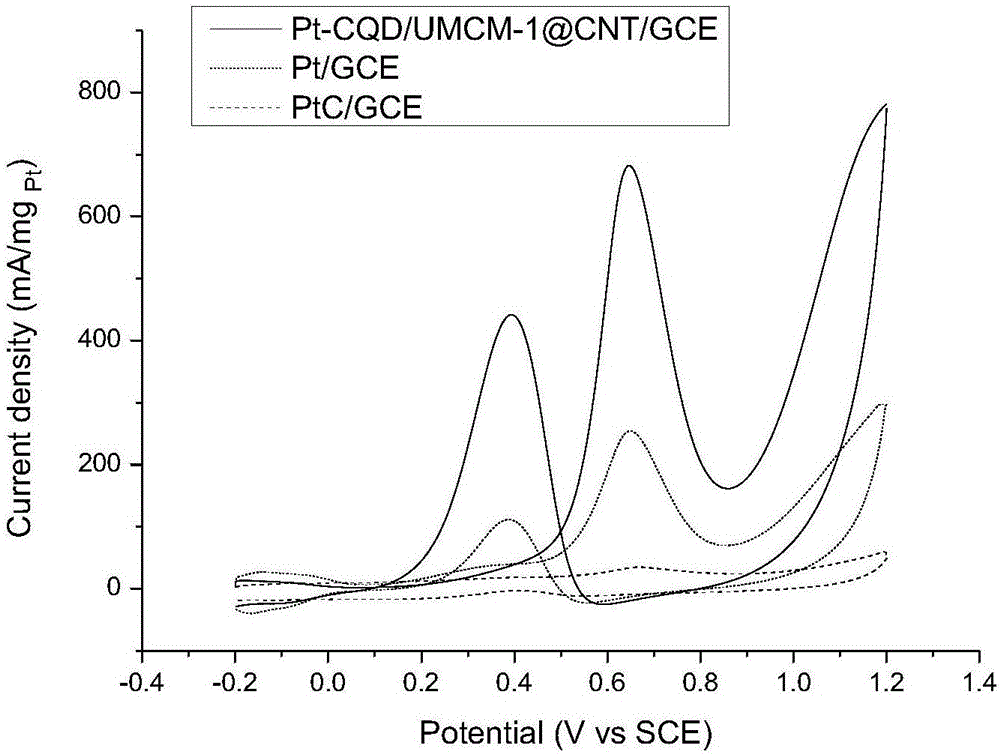

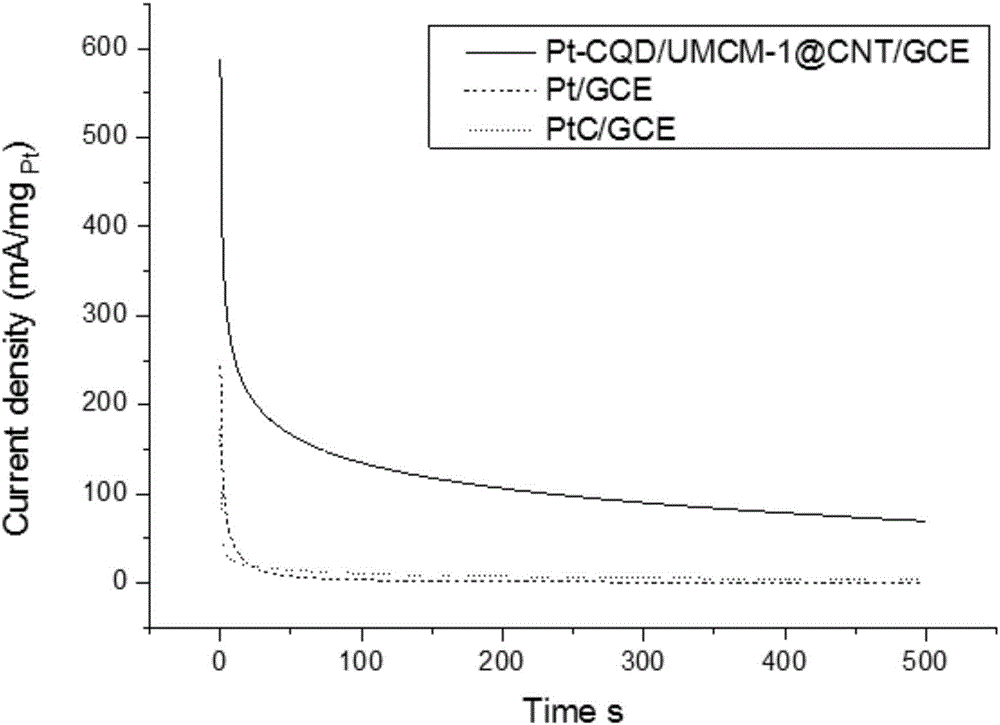

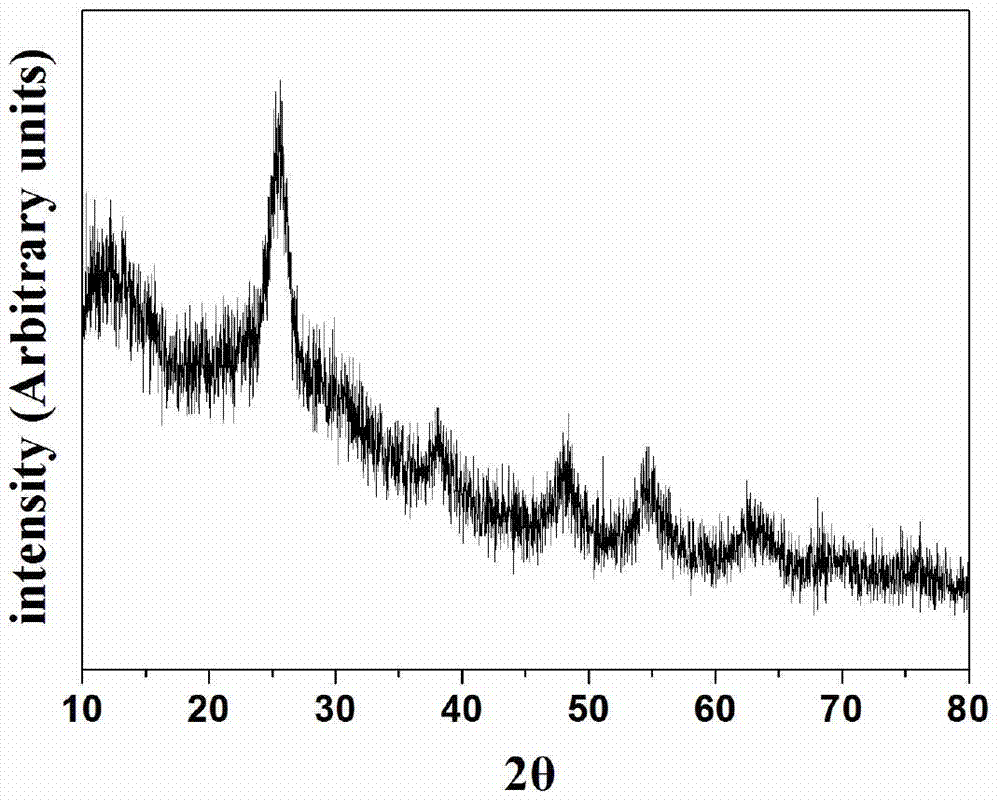

Preparation of carbon nanotube material embedded with quantum-dot modified metal organic framework

The invention provides preparation of a carbon nanotube material embedded with a quantum-dot modified metal organic framework. The preparation comprises the following steps of firstly, adding a certain amount of powder quantum dots to a formed metal organic framework precursor solvent so that the quantum dots of which the diameters are matched with the sizes of pore passages are embedded into the pore passages of the formed metal organic framework; secondly, uniformly mixing the obtained quantum-dot modified metal organic framework and melamine powder, and performing high-temperature processing to obtain a composite material (QD / UMCM-1@CNT) in a carbon nanotube embedded with the quantum-dot modified metal organic framework; and finally, enabling Pt to be loaded on a surface of the composite material carbon nanotube (Pt / QD / UMCM-1@CNT) by microwave radiation heating to be used as a positive electrode catalyst of a methanol fuel cell. Compared with a traditional hydrothermal method for synthesis of the carbon nanotube, the quantum-dot modified metal organic framework obtained by high-temperature processing is embedded into the composite material in the carbon nanotube, the structural aspects such as the length and the diameter of the carbon nanotube are more consistent, and a catalyst substrate with a unified structure is easier to form.

Owner:QINGDAO UNIV

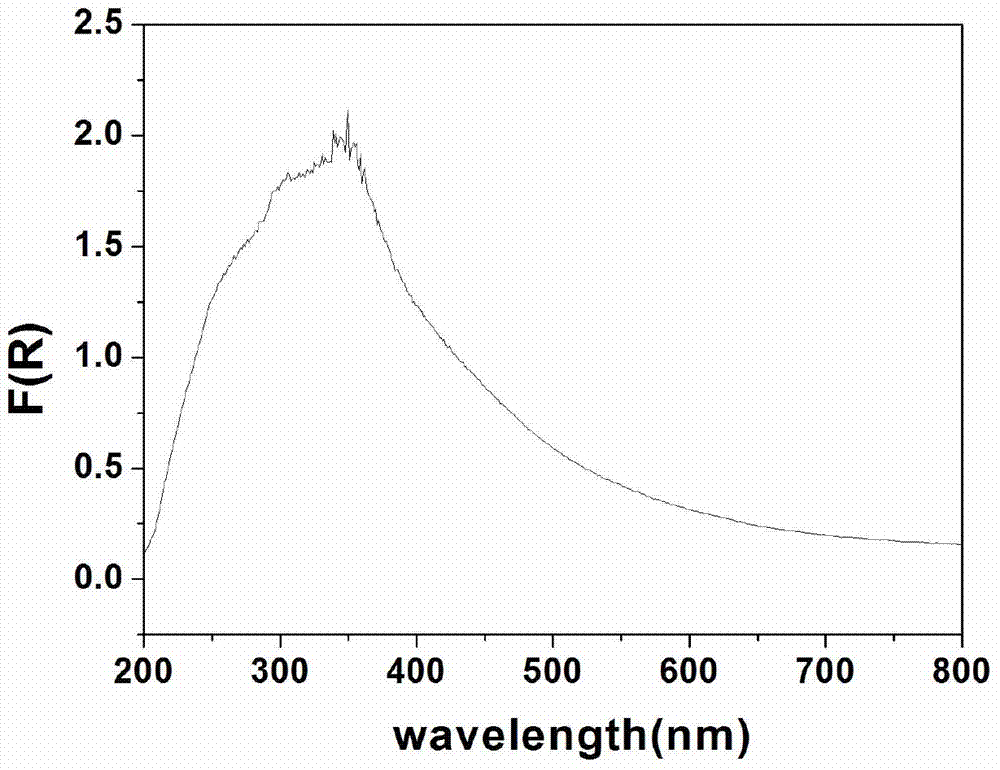

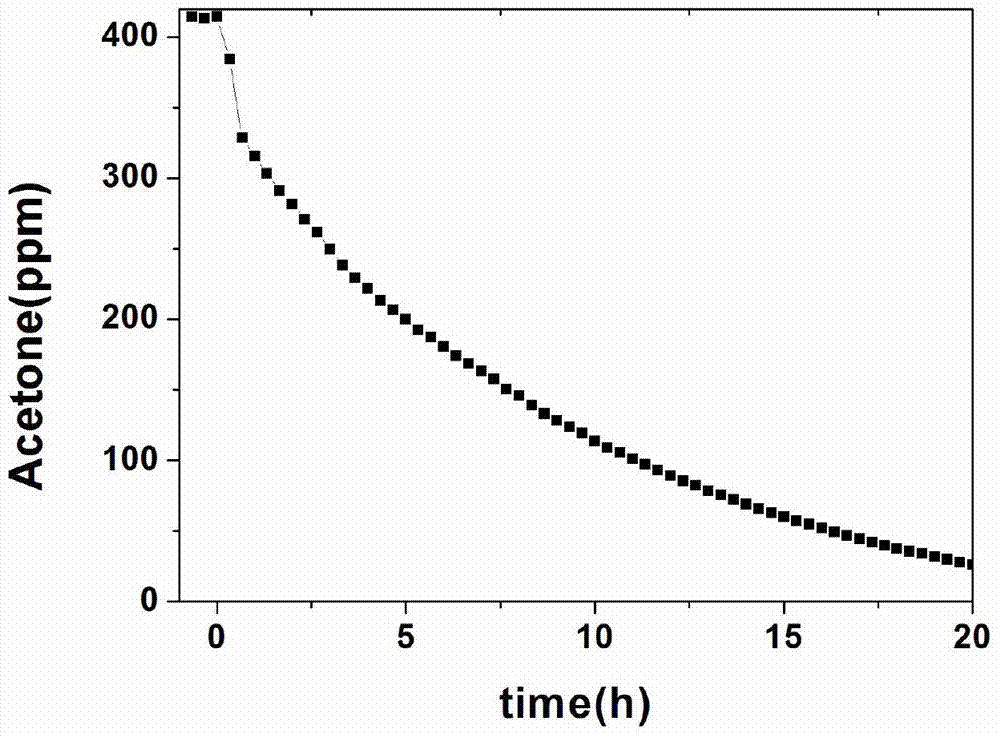

Preparation method and applications of biomass modified TiO2 visible light photocatalyst

ActiveCN103920479AEasy to controlLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationAlcoholWastewater

The invention discloses a biomass modified TiO2 visible light photocatalyst. A preparation method of the biomass modified TiO2 visible light photocatalyst comprises the following steps: hydrolyzing titanium alkoxide to obtain sol, adding biomass in the sol and stirring, drying the sol to obtain gel, and calcining the gel. According to the preparation method, the reaction conditions are moderate and easy to control, raw materials are easily available, the synthesis process is simple, industrialized production is achieved easily, the prepared biomass modified TiO2 visible light photocatalyst has the performance of photocatalytically degrading organic substances by visible light and can be used for photocatalytically treating organic pollutants in air, soil and wastewater.

Owner:FUJIAN NORMAL UNIV

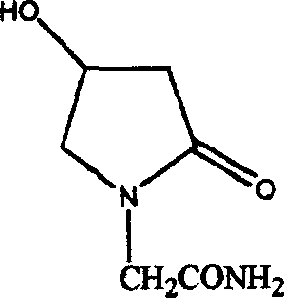

Method of preparing 4-hydroxy pyrrolidone-2-acetamine

InactiveCN1513836ARaw materials are cheap and easy to getLow costOrganic chemistryAcetic acidAlkaline earth metal

A process for preparing 4-hydroxypyrrolidone-2-acetylamine used as brain function improver includes reacting between 4-haloacetoacetic acid derivative and the azide of alkali metal or alkali-earth metal to obtain 4-azoacetoacetic acid derivative, hydrogenating, cyclizing, and ammoniating. Its advantages are high quality and output rate of product, and low cost.

Owner:SUZHOU HOPE TECH

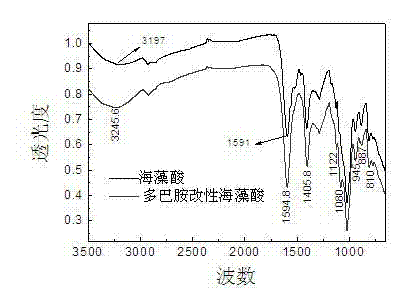

Preparation method of polydopamine modified alginic acid microspheres

InactiveCN102964610AImprove mechanical propertiesGood anti-swelling performanceMicroballoon preparationMicrocapsule preparationMicrosphereN-Hydroxysuccinimide

The invention discloses a preparation method of polydopamine modified alginic acid microspheres, which comprises the following steps of: under the protection of nitrogen, grafting dopamine to alginic acid by use of N-hydroxysuccinimide and 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride; polymerizing the synthesized dopamine modified alginic acid under the slight alkaline condition to obtain a polydopamine modified alginic acid solution; dropwise adding the polydopamine modified alginic acid solution into a CaCl2 solution by a syringe; and aging to obtain polydopamine modified alginic acid microspheres. The method disclosed by the invention is simple in process, and the prepared modified alginic acid microspheres have higher swelling resistance and good mechanical properties.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com