Current collector carbon coated aluminum foil and its preparation method

A current collector and carbon-coated technology, which is used in the current collector carbon-coated aluminum foil and its preparation, the preparation of current collectors, and the field of lithium ion batteries, which can solve the problem that the unity of bonding strength and low internal resistance, low impedance and good adhesion cannot be achieved. It is difficult to popularize and use on a large scale, etc., to achieve good adhesion and conductivity, overcome bonding strength, low internal resistance, and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Get the dispersant polyethylene oxide ether of 1 weight part and the organic solvent vinylene carbonate of 500 weight parts and mix 10 minutes under the high-speed dispersing device, add the acetylene black of 10 weight parts after polyethylene oxide ether dissolves completely , the primary particle size is 140nm, disperse at high speed for 40 minutes, then add 2 parts by weight of VGCF, stir for 20 minutes, and finally add 20 parts by weight of sodium polyacrylate adhesive and stir for 10 minutes to make a conductive carbon composite slurry coated on aluminum foil On, the coating thickness is 8 μm. Dry in a vacuum oven at 110°C for 10 hours.

Embodiment 2

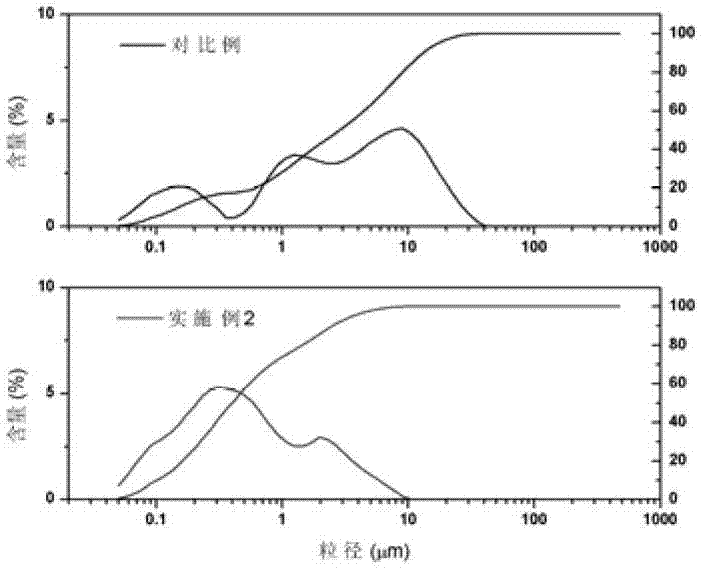

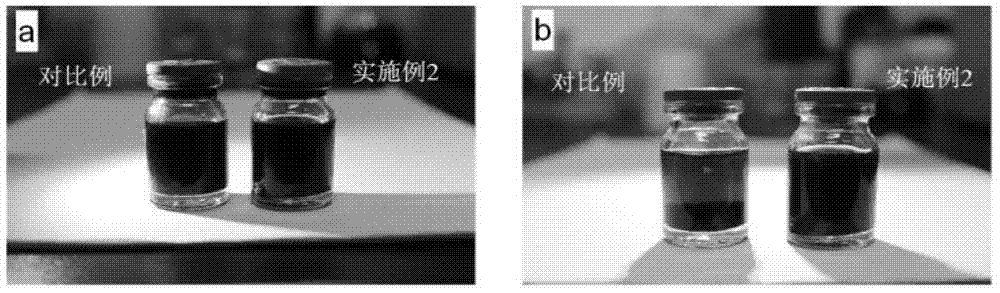

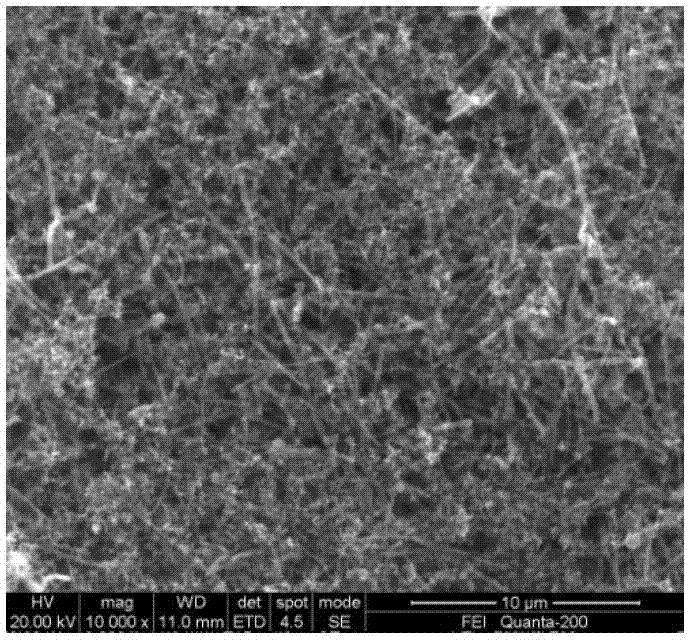

[0042] Get 2 parts by weight of the dispersant polyacrylic acid and 500 parts by weight of the organic solvent N-methylpyrrolidone and mix them under a high-speed dispersing device for 10 minutes. After the polyacrylic acid is completely dissolved, add 15 parts by weight of Super P. The primary particle size is 40nm. Disperse at high speed for 40 minutes, then add 3 parts by weight of VGCF, stir for 20 minutes, and finally add 20 parts by weight of sodium polyacrylate adhesive and stir for 10 minutes to make a conductive carbon composite slurry and coat it on aluminum foil with a coating thickness of 10 μm . Dry in a vacuum oven at 110°C for 10 hours.

Embodiment 3

[0044] Get the dispersant polyethylene glycol octyl phenyl ether of 2 weight parts and the organic solvent propylene carbonate of 500 weight parts and mix 8 minutes under the high-speed dispersing device, add 20 after polyethylene glycol octyl phenyl ether dissolves completely Parts by weight of SP-Li, with a primary particle size of 80nm, dispersed at high speed for 40 minutes, then added 4 parts by weight of CNT, stirred for 20 minutes, and finally added 20 parts by weight of polyvinylidene fluoride adhesive and stirred for 10 minutes to make conductive carbon The composite slurry was coated on aluminum foil with a coating thickness of 15 μm. Dry in a vacuum oven at 110°C for 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com