Patents

Literature

1838results about How to "The preparation process is simple and controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing low-carbon olefins by one-step conversion of synthetic gas and preparation method thereof

ActiveCN106345514AImprove catalytic performanceImprove connectivityMolecular sieve catalystsSyngasMolecular sieve

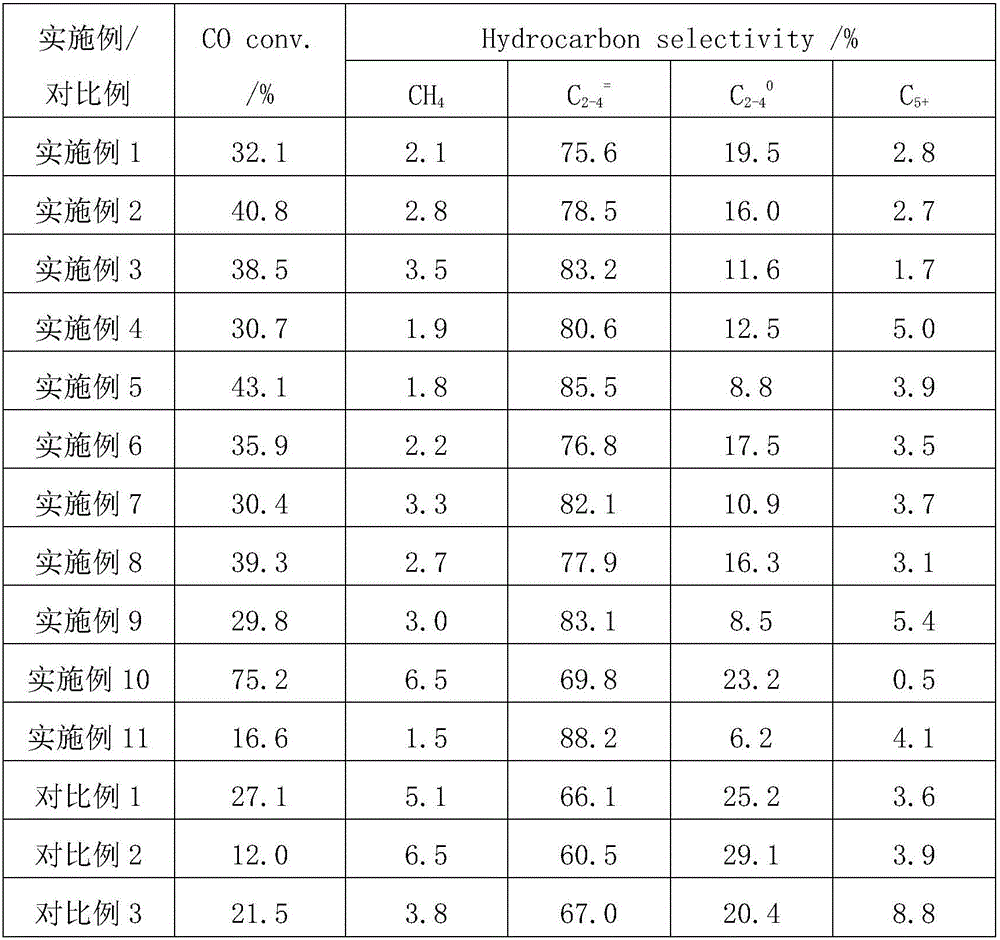

A catalyst for preparing low-carbon olefins by one-step conversion of synthetic gas and a preparation method thereof relate to catalysts; the catalyst is made from 20-60% of a zirconium-based solid solution,30-70% of a double-micropore zeolite molecular sieve and 0.1-10% of metal oxides; the preparation method comprises: adding salt compounds of at least one element from IA, IIIA, VIIB, IB, IIB and the like into deionized water or alcohol to obtain solution A having a mass concentration of 0.1-15%; adding the zirconium-based solid solution into the solution A, heating, drying by distillation, and drying to obtain solid powder; adding the solid powder and the double-micropore zeolite molecular sieve into ethylene glycol, ultrasonically dispersing, and moving a filtered and washed sample to a vacuum drying box, drying at 50-100 DEG C for 2-24 h, calcining in a muffle furnace, and tableting obtained solid sample to obtain the catalyst.

Owner:XIAMEN UNIV

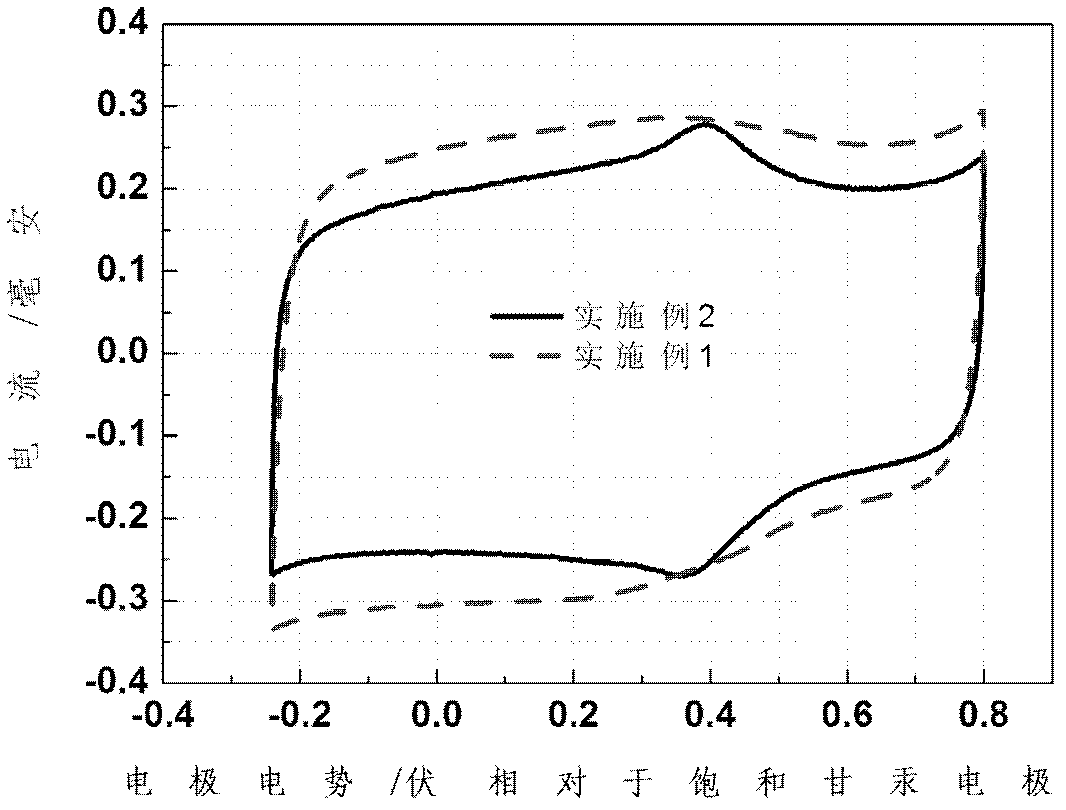

Preparation method of complex lithium negative pole of solid state battery

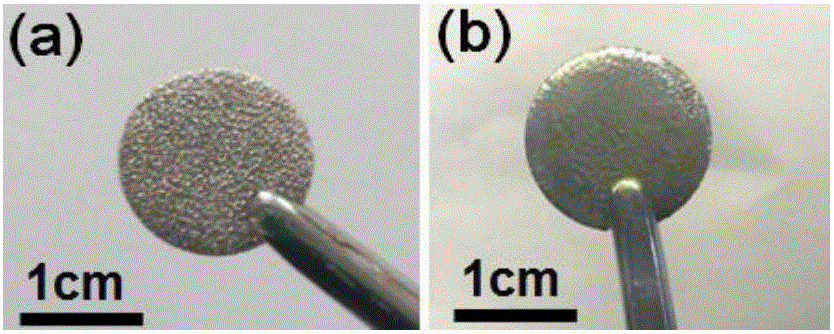

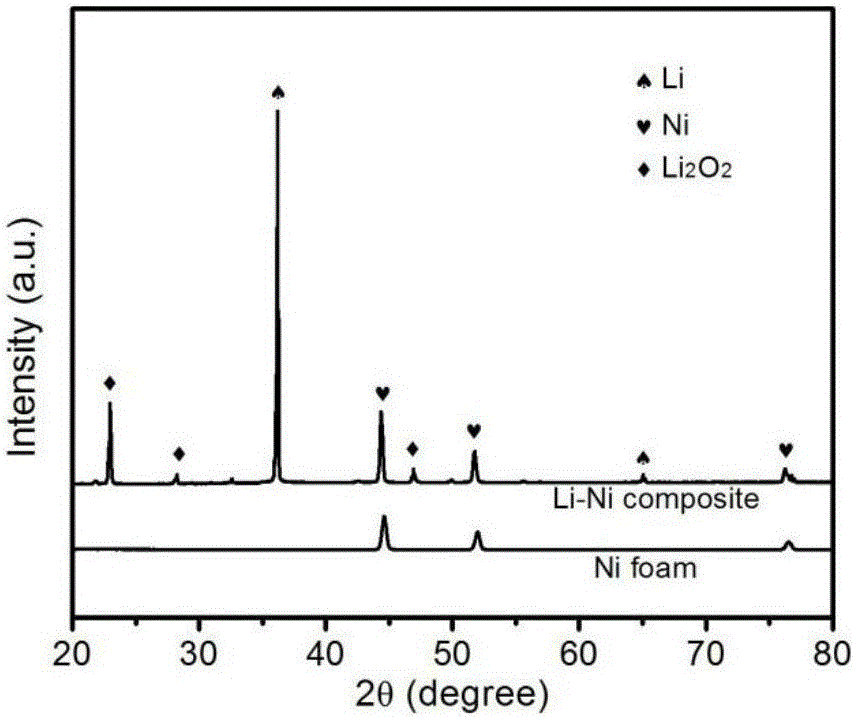

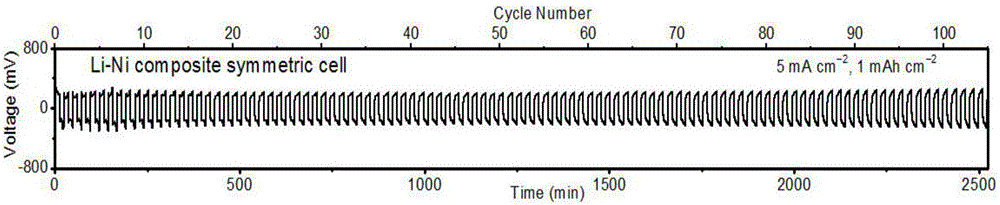

The present invention discloses a preparation method of a complex lithium negative pole of a solid state battery, and belongs to the technical field of electrochemistry and new energy resources. The preparation method mainly comprises the steps: depositing lithium metal on three-dimensional carbon material or foam porous material gaps by using a heat infusing melting method or an electrodeposition method to obtain the complex lithium negative pole, wherein the application of a three-dimensional framework plays two roles, namely, providing adequate space for pre-storing lithium in the preparation process; providing a carrier for receiving metal lithium in a battery circulation process. The complex lithium negative pole can be widely applied in lithium metal batteries such as lithium ion batteries, lithium-air batteries, lithium-sulfur batteries, and solid state batteries. In the assembled symmetric solid state battery, under large electric current density of 5mA cm-2, a stable voltage decay (200mV) can still be kept after circulation for 100 times, in the battery circulation, the growth of lithium dendrites can be inhibited and the pole volume change can be stabilized, and the advantages of being good in circulation stability, and long service life can be realized; in the present invention, a carrier material is rich, and low in price; the process is controlled, the cost is low, and the batch production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

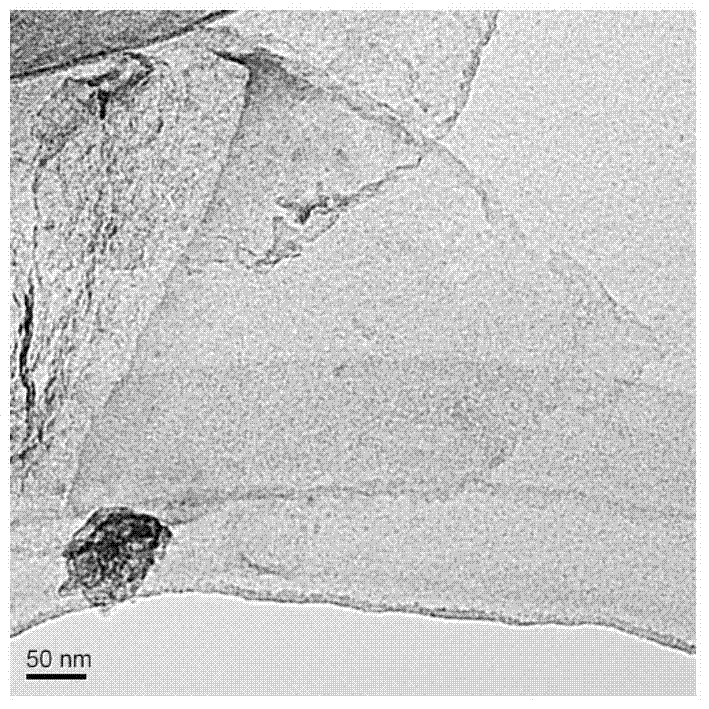

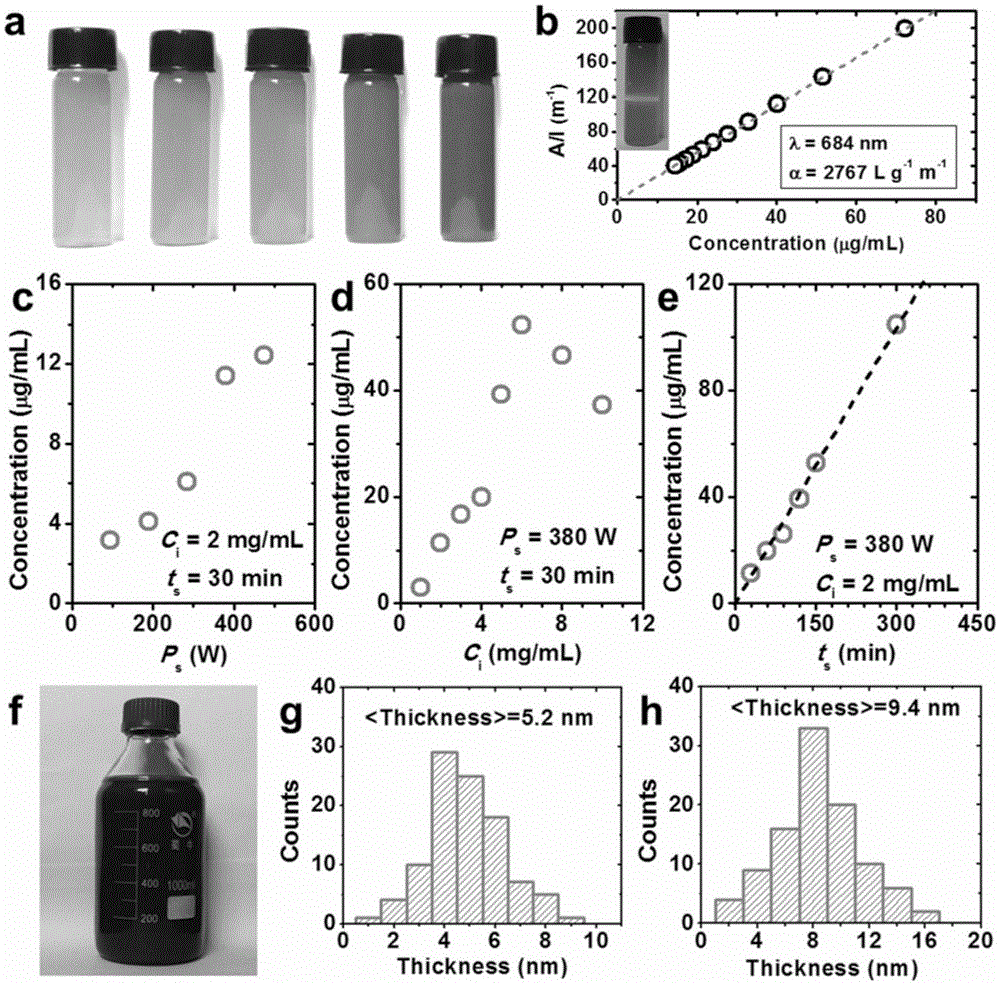

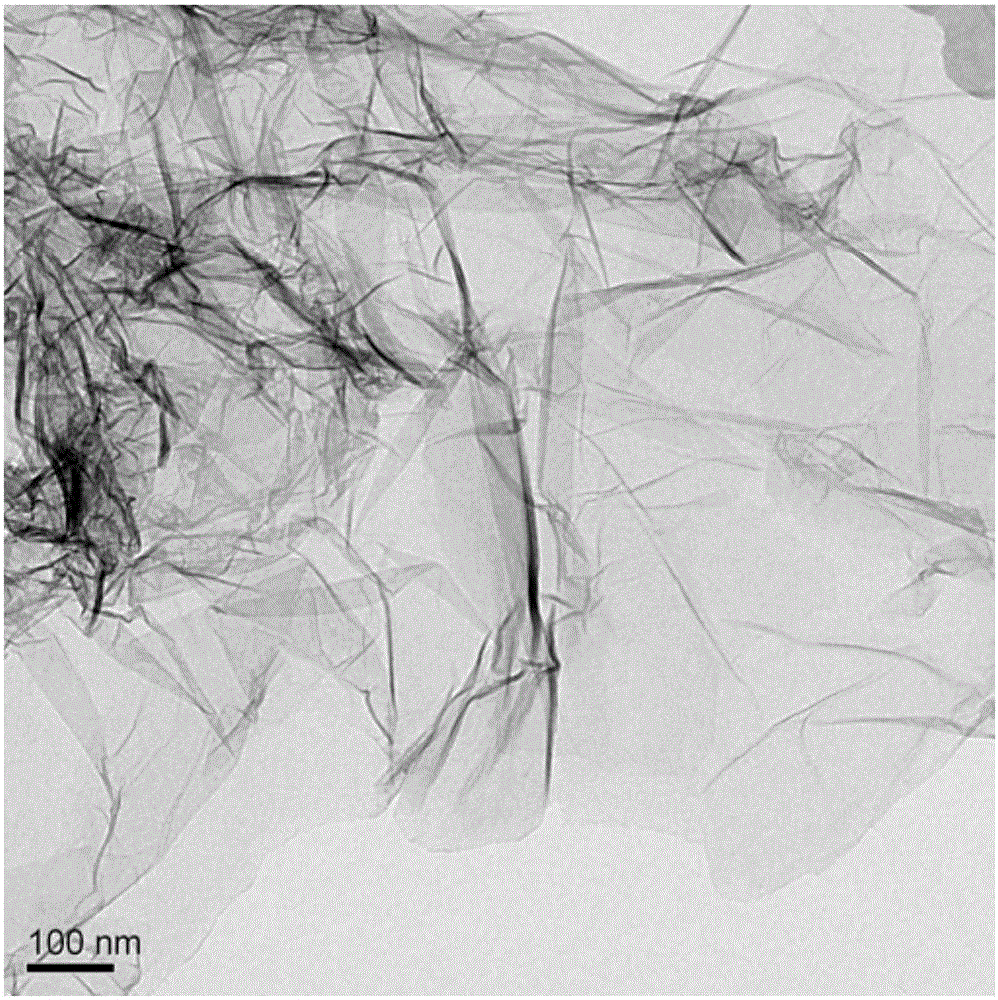

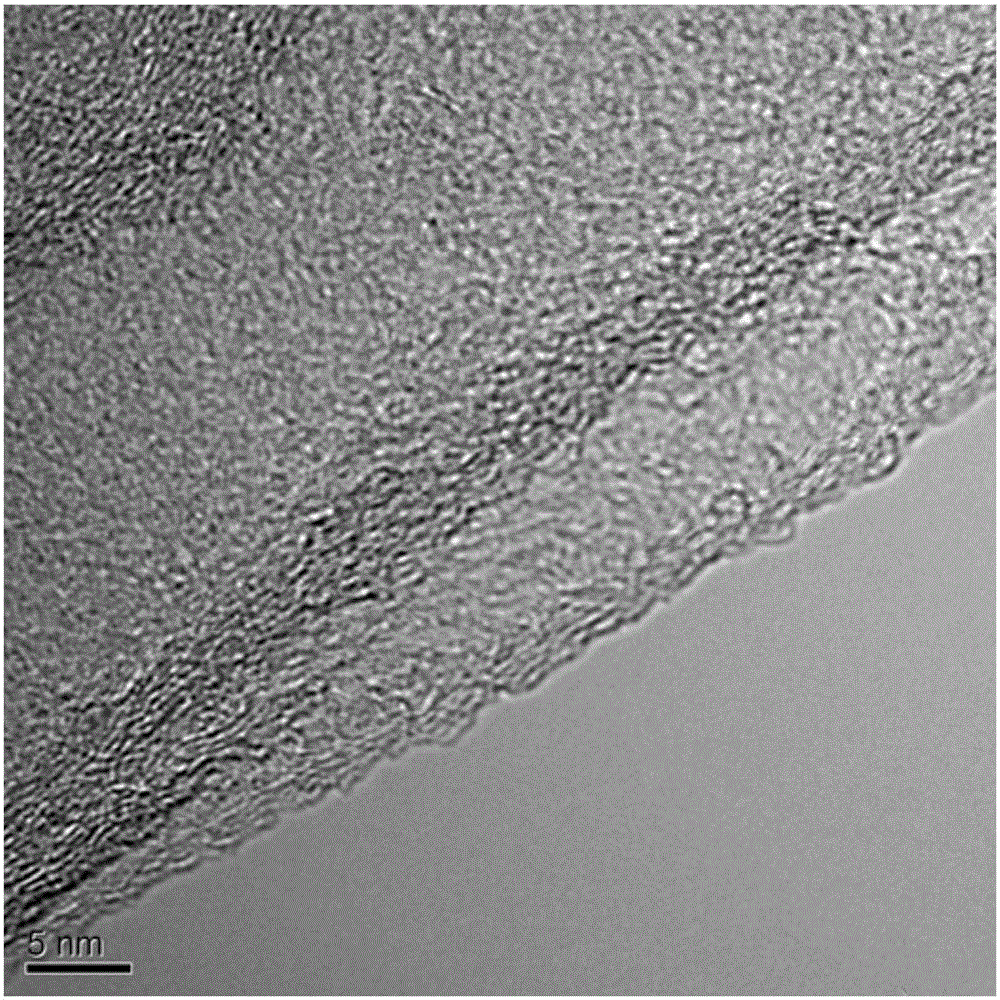

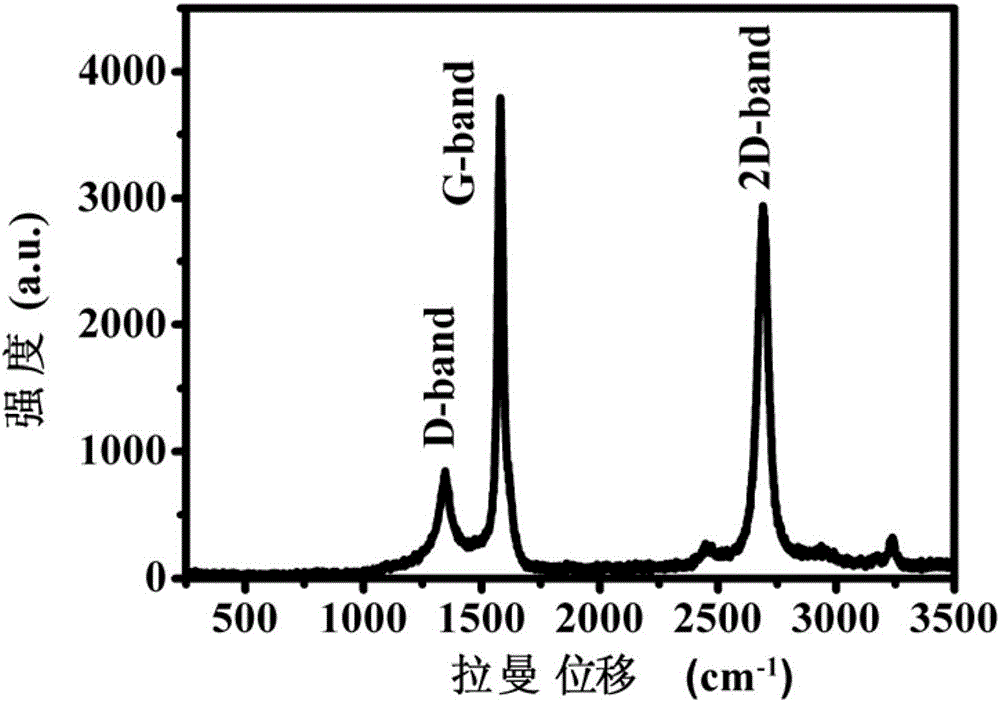

Method for preparing graphene by taking biomass as raw material

InactiveCN104724696AMitigate post-processing issuesEfficient strippingMaterial nanotechnologyOrganic solventCvd graphene

The invention discloses a method for preparing graphene by taking biomass as a raw material. The method comprises the following steps: dipping the biomass in an organic solvent for 1-5 hours, centrifuging, drying, calcining for 1-24 hours at the temperature of 600-1600 DEG C in the presence of inert gas, and cooling, thus obtaining graphene. The method for preparing the graphene by taking the biomass as the raw material has the advantages that cheap and easily available biomass is taken as the raw material, the problem of aftertreatment of dried-up herbaceous plants is effectively solved, and an effective path is provided for high value-added utilization of the herbaceous plants; a preparation technology in each step is controllable and is high in repeatability, the prepared graphene is obvious in exfoliation, and the minimum lamellar thickness is 3nm only; and the method is simple and environmentally friendly, low in capital investment and suitable for large-scale industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

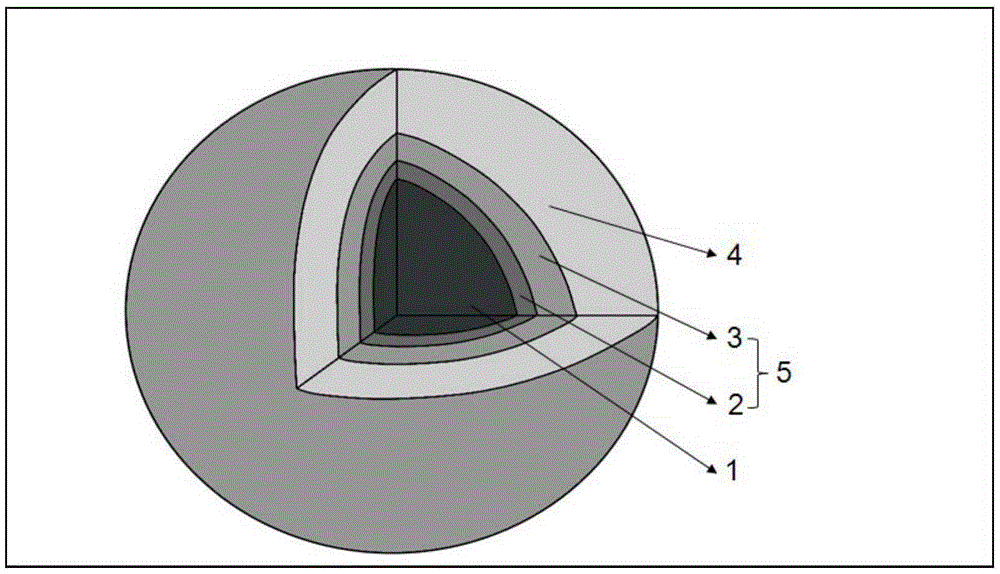

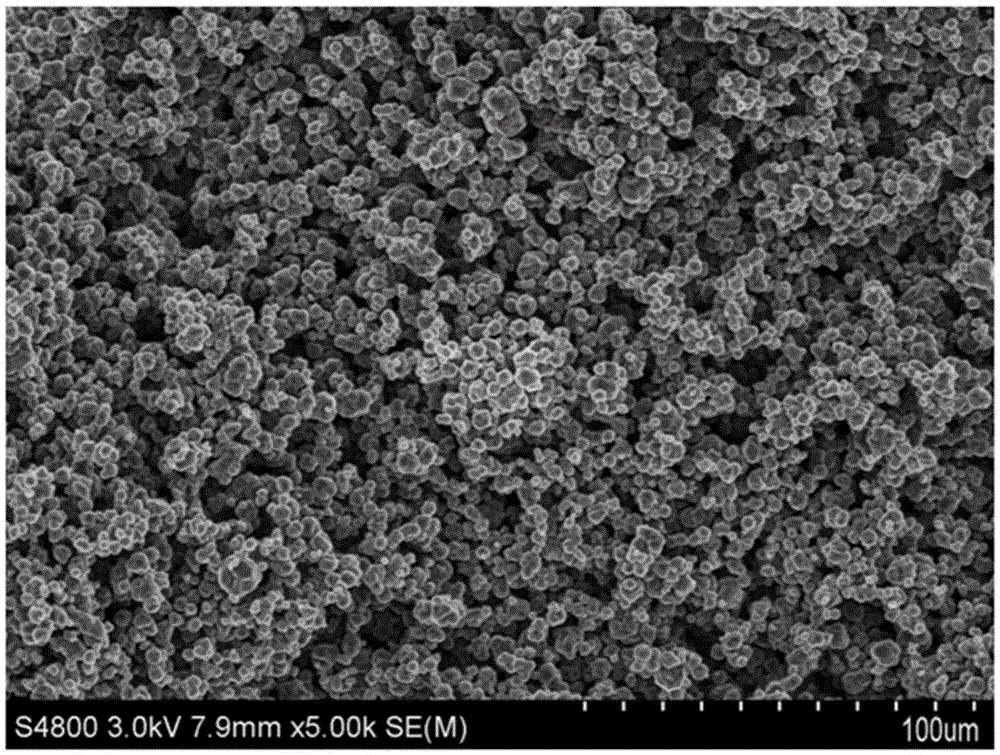

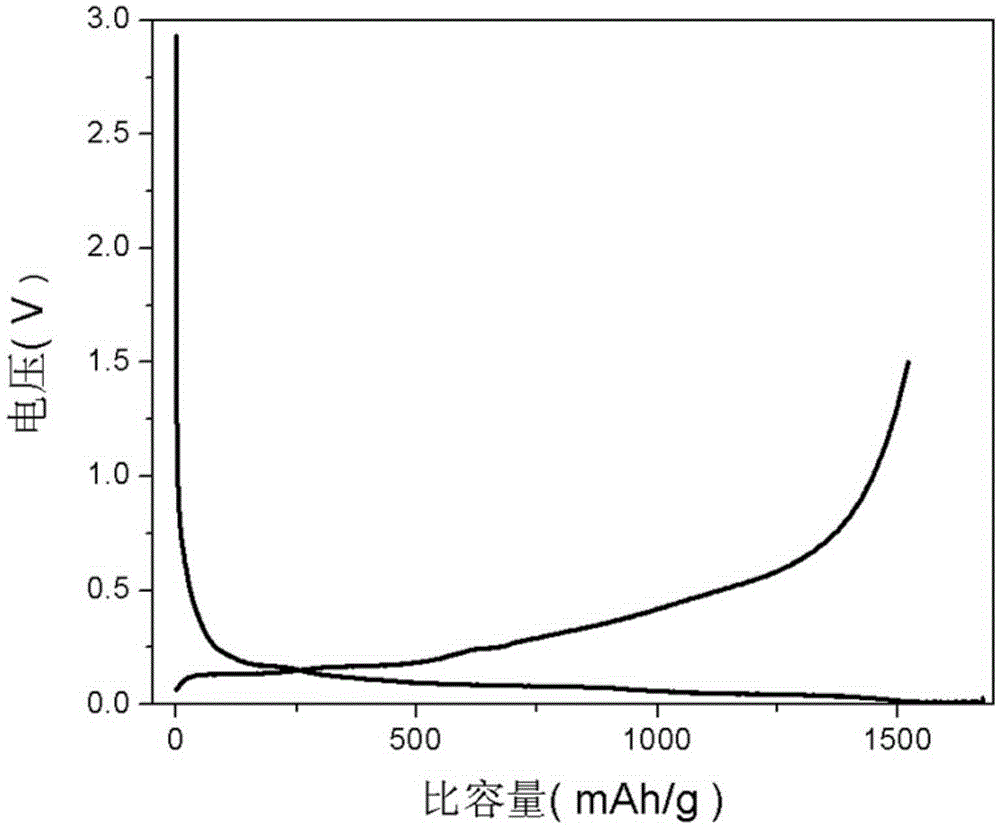

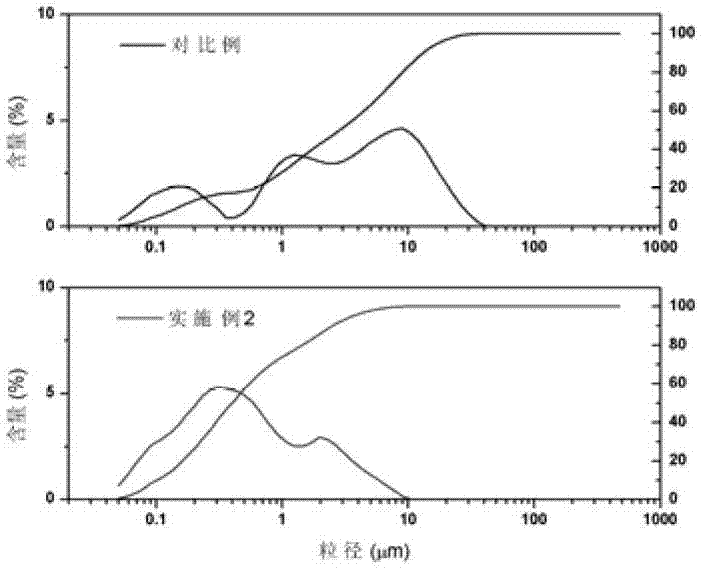

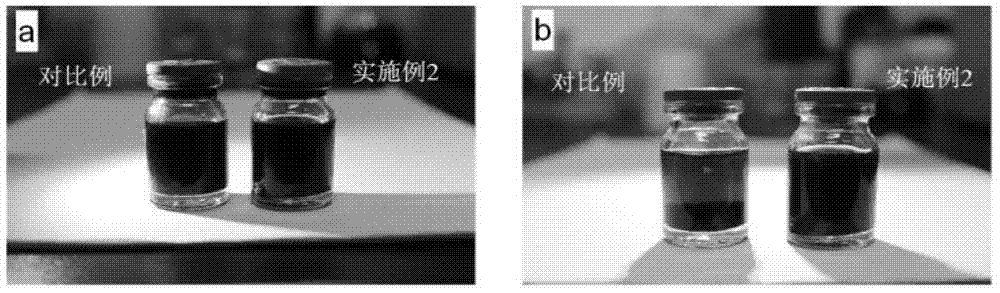

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

PTC graphene heating printing ink, preparation method thereof and heating film prepared from PTC graphene heating printing ink

InactiveCN107446408AImprove securityAchieving self-limiting temperature characteristicsInksHeating element materialsSilver pasteAdhesive

The invention discloses PTC graphene heating printing ink and a preparation method thereof. The PTC graphene heating printing ink is prepared from the following components in percentages by mass: 50% to 70% of a binder, 9% to 21% of a solvent, 1% to 3% of an additive, 10% to 20% of a conductive filler and 5% to 20% of a PTC functional material. The preparation method comprises the following steps: (1) firstly stirring and dispersing the binder, the solvent and the additive for 20 to 30 min, then adding the PTC functional material into stirring equipment for stirring for 8 to 12 min, and finally adding the conductive filler for uniform stirring to obtain a coarse paste; and (2) carrying out four to six times of three-roller grinding on the coarse paste so as to obtain the PTC graphene heating printing ink. The invention also discloses a heating film. The heating film comprises an organic polymer base material film, the PTC graphene heating printing ink, a conductive silver paste, conductive copper foil and an organic polymer adhesive film. The PTC function of the graphene heating film is increased, the potential safety hazard problem of an existing graphene heating film is eliminated, and the practicability is improved.

Owner:DEYANG CARBONENE TECH

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

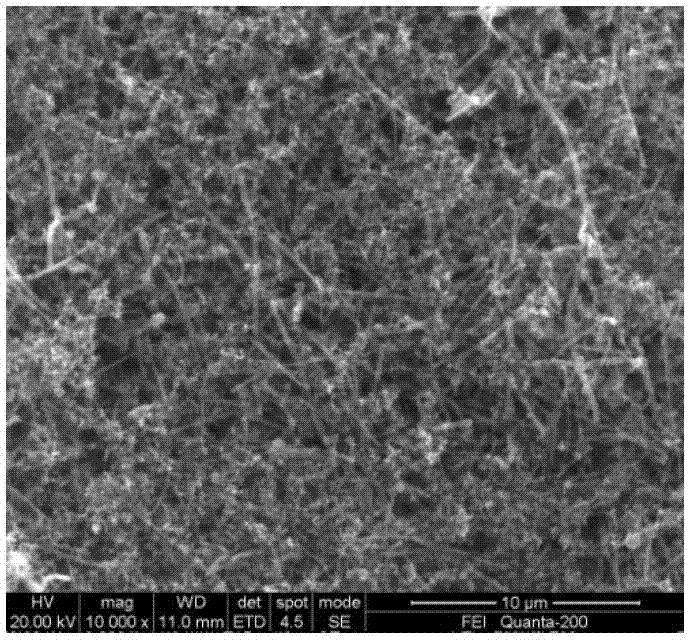

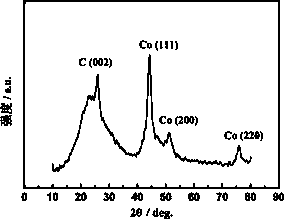

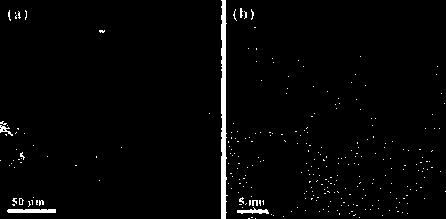

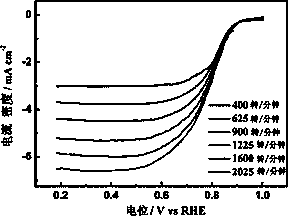

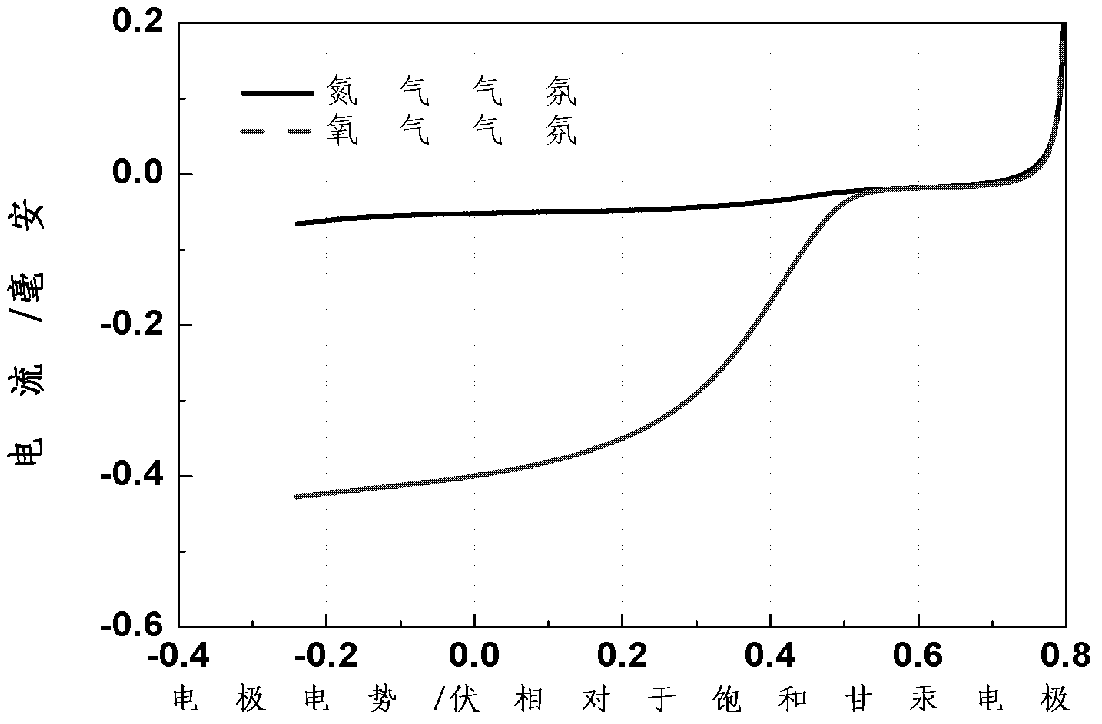

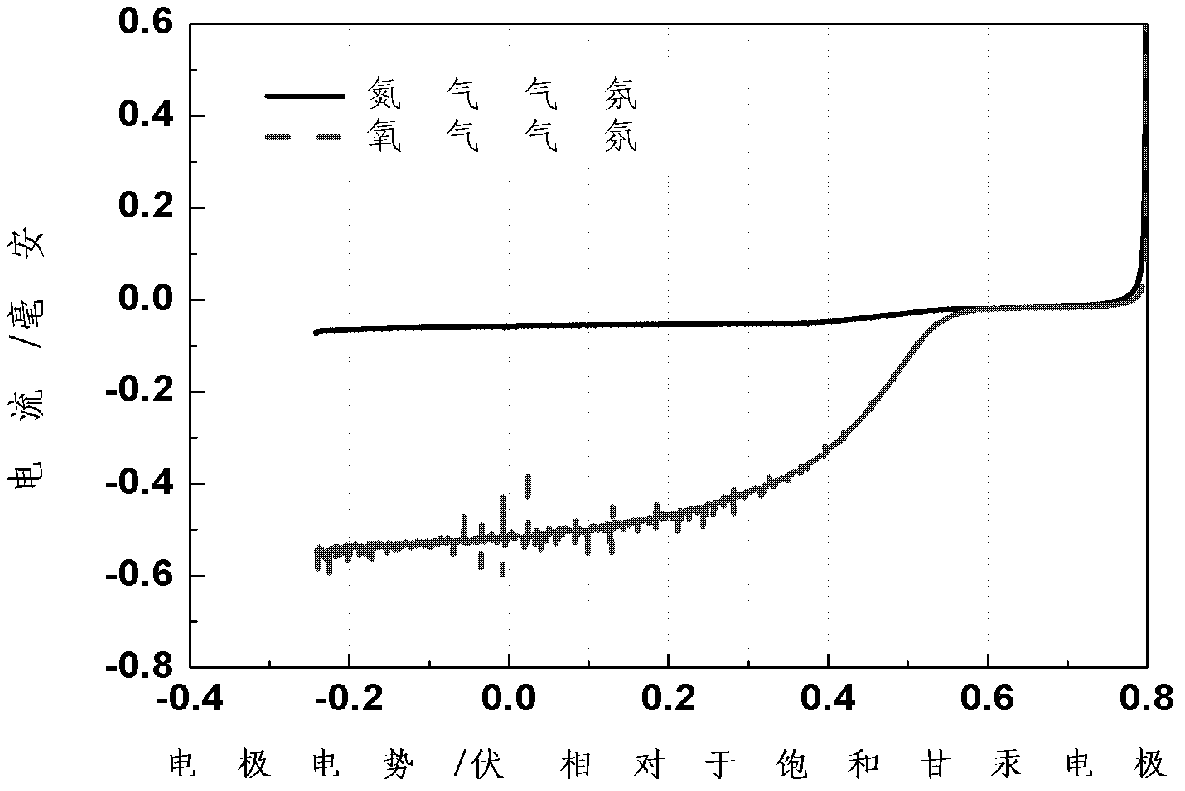

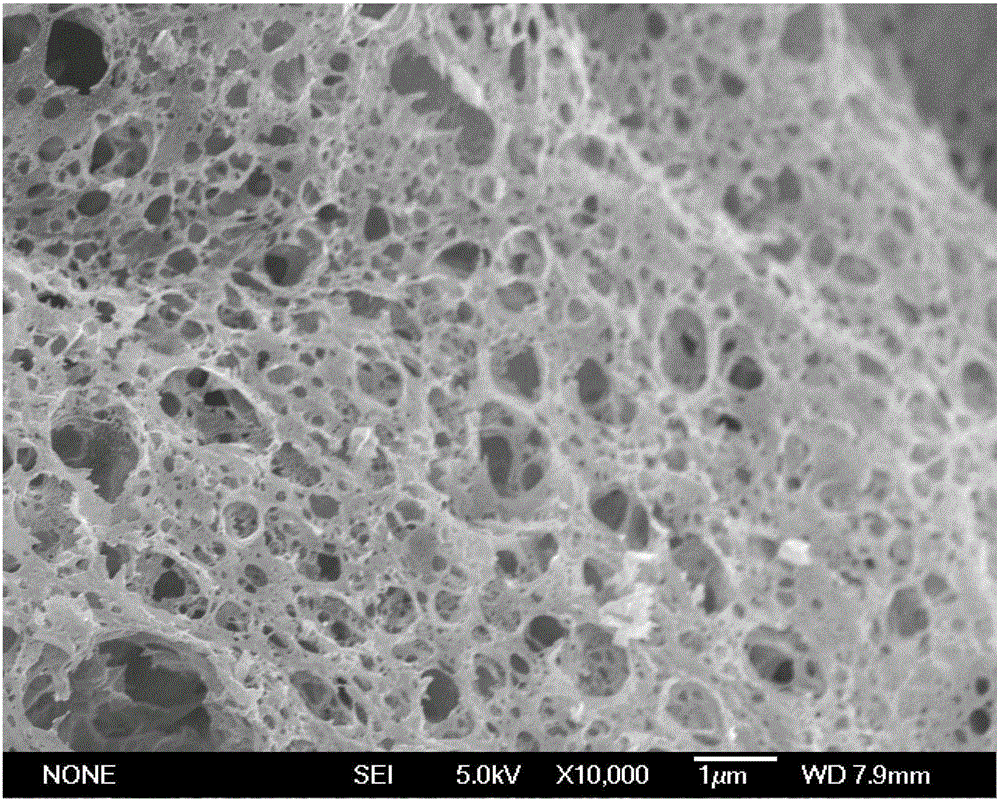

Porous nano composite material for fuel cell oxygen reduction catalyst

InactiveCN103811775AImprove cycle stabilityEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsPorous carbonOxygen

The invention discloses a porous nano composite material for a fuel cell oxygen reduction catalyst, and is an M-N-C porous nano composite material, wherein M in M-N-C refers to base metal ferrum, cobalt or nickel, N refers to nitrogen, and C refers to carbon; small-particle-size metal nano particles are uniformly dispersed and embedded in a nitrogen-doped porous carbon carrier material; the base metal nano particles have the particle size range being 5-100nm; the mass percentage of nitrogen contained in the porous carbon carrier is 3-7%. The porous nano composite material for the fuel cell oxygen reduction catalyst, which is provided by the invention, has the advantages that because of the in-situ nitrogen doping of a carbon substrate, the implant of base metal nano particles in uniform distribution and the formation of the porous structure with high specific area, the catalytic oxygen reduction capability of the porous nano composite material is improved obviously, and the cycle stability of the material is improved; a precursor prepared by the composite material is low in cost, is easy to prepare, is controlled easily in the preparation process, is simple to operate, and facilitates industrial large-scale production.

Owner:NANKAI UNIV

Vegetable oil polyol preparation method by using continuous method

ActiveCN103274930AThe preparation process is simple and easy to controlImprove securityOrganic compound preparationCarboxylic acid esters preparationOrganic acidResidence time

The invention discloses a vegetable oil polyol preparation method by using a continuous method. The vegetable oil polyol preparation method comprises the following steps: firstly mixing oxydol and organic acid, adding a catalyst and a stabilizing agent, simultaneously pumping vegetable oil and mixed solution into a micro-channel modular reactor, maintaining reaction residence time for 5-18 min, performing reaction at normal pressure with the temperature of 65-130 DEG C, still standing a reaction product for liquid separation, collecting oil phase to be washed to neutral by using a Na2CO3 solution, and then performing liquid separation and rotary evaporation to obtain the vegetable oil polyol. The vegetable oil polyol preparation method provided by the invention can be operated continuously, and in the process, two steps of epoxidation and ring-opening are integrated into one step, so that the preparation process is simple, easy to control, high in safety, short in reaction time, low in energy consumption and low in pollution, can weaken side reaction, further has the characteristics of simple production device, easiness in assembly and disassembly, and convenience in carrying and moving, can be adjusted by simply increasing or decreasing the number of micro-channels for regulation, and can avoid 'amplification effect' generated in similar industrial production.

Owner:NANJING UNIV OF TECH

Method for preparing porous tantalum medical implant material through three-dimensional printing forming

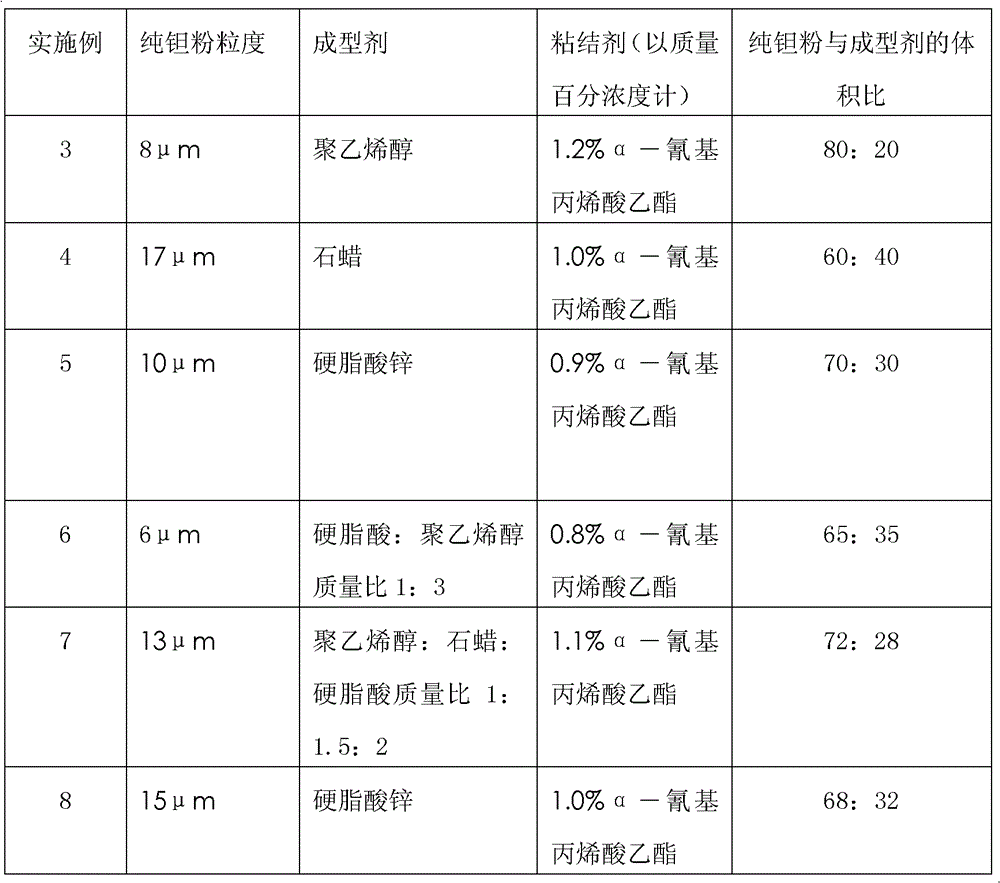

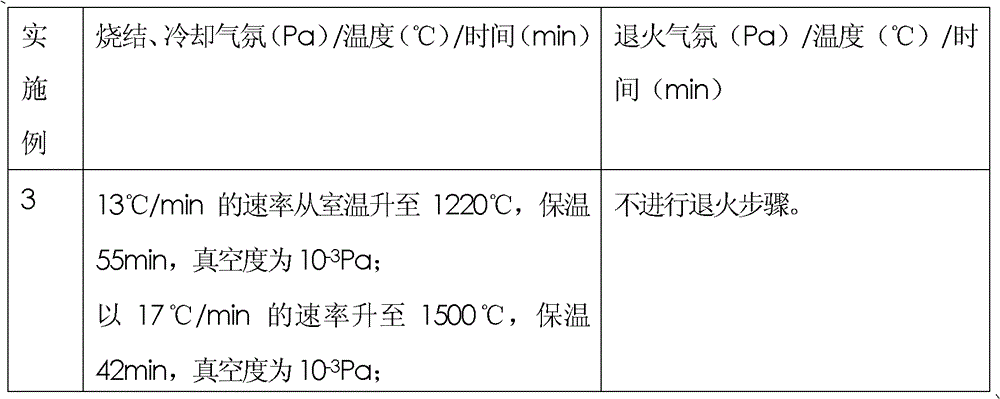

ActiveCN102796909AFast molding speedHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyPorous tantalumBone tissue

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps of: feeding mixed tantalum power formed by mixing pure tantalum powder and a forming agent into a printing platform of a three-dimensional printer, and rolling and paving; spraying an adhesion agent by a printing head of the three-dimensional printer to adhere the mixed tantalum powder so as to form a two-dimensional plane; descending a working table 80 to 100 mu m, and processing the next layer; accumulating and forming layer by layer; removing the tantalum powder particles which are not adhered to obtain an initially formed sample; and performing aftertreatment such as degreasing, vacuum sintering, cooling and the like to obtain the porous tantalum medical implant material, wherein the volume ratio of the pure tantalum powder to the forming agent is (60-80):(20-40), and the adhesion agent is 1 mass percent alpha-cyanoacrylate adhesive. The pores of the porous tantalum medical implant material prepared by the method are completely communicated in a three-dimensional mode; the porous tantalum medical implant material prepared by the method is high in biocompatibility; and meanwhile, the mechanical property of the porous tantalum medical implant material prepared by the method is consistent with that of loading bone tissues of a human body.

Owner:CHONGQING RUNZE PHARM CO LTD

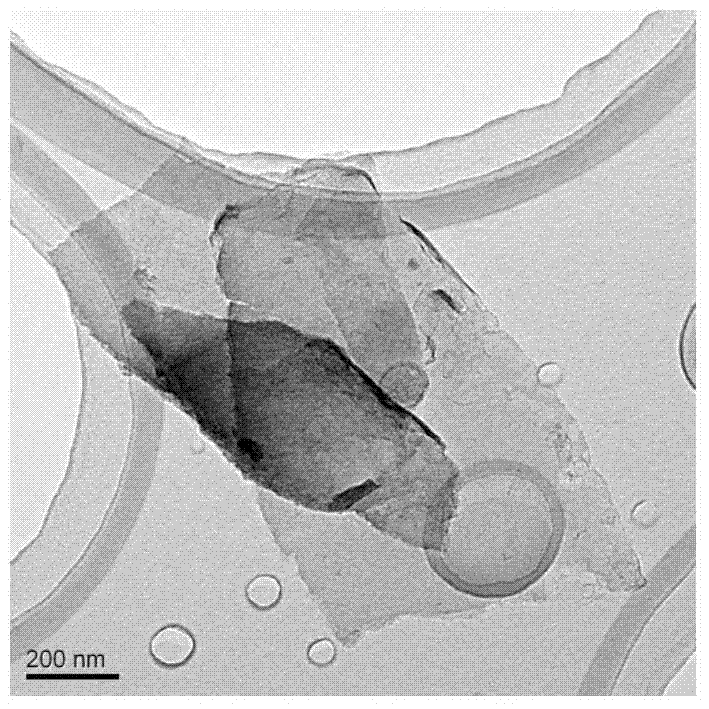

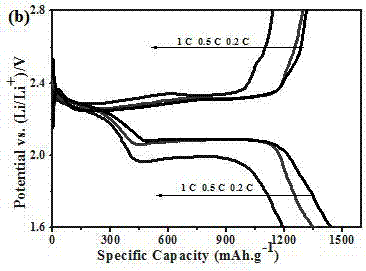

Hollow silicon-based composite material, preparation method and lithium ion battery comprising composite material

ActiveCN106129411AHigh strengthSmall volume expansionCell electrodesSecondary cellsLithium electrodeThermal treatment

The invention relates to a hollow silicon-based composite material, a preparation method and a lithium ion battery. The hollow silicon-based composite material disclosed by the invention comprises hollow cavities, a carbon-silicon composite layer and a cladding carbon layer in sequence from inside to outside, wherein the carbon-silicon composite layer comprises a secondary particle silicon layer and a deposited carbon layer. The preparation method comprises the following steps: firstly bonding silicon oxide and / or silicon on the surface of graphite uniformly, then removing the graphite through oxidizing heat treatment to obtain a hollow structure, then obtaining nanometer silicon through reduction by using a reducing agent, obtaining hollow particles consisting of the hollow cavities and the secondary particle silicon layer, then carrying out in-situ cladding on the surface of the secondary particle silicon layer, and then finally carrying out cladding of the cladding carbon layer to obtain the hollow silicon-based composite material. The battery prepared by using the composite material as an anode material has high cycle performance and rate capability, the first-time reversible capacity is more than 1453.2 mAh / g, the first-time coulomb efficiency is more than 87.8%, and the hundred-time cycle capacity retention ratio is more than 95.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

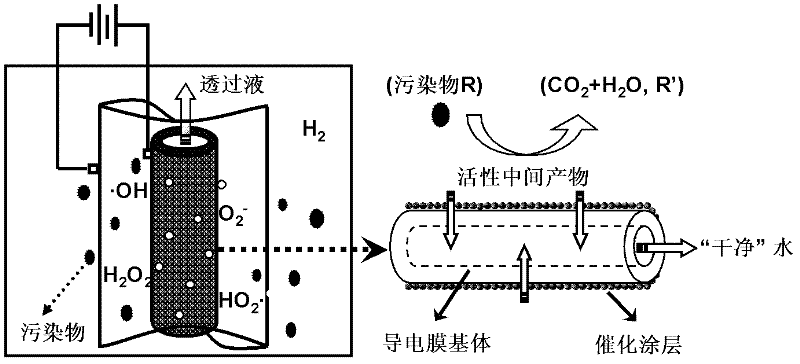

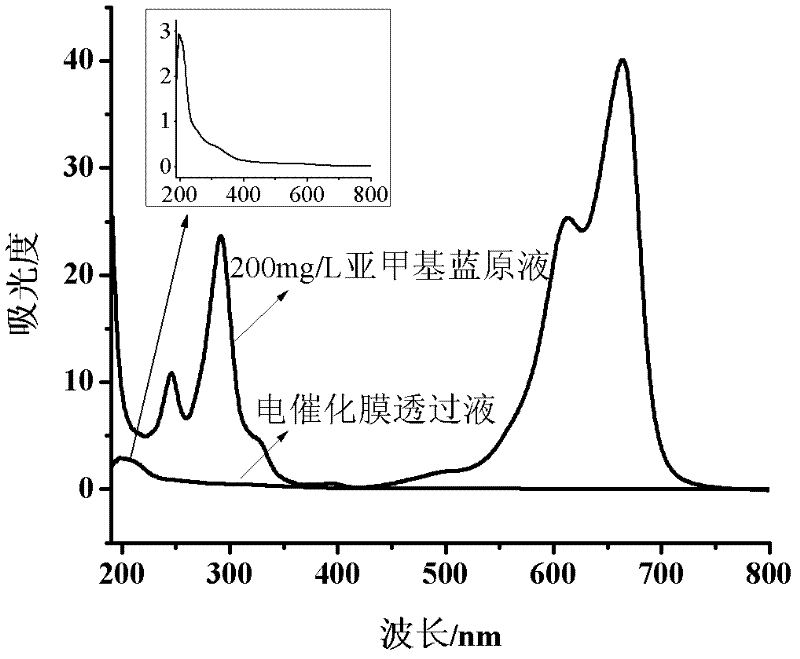

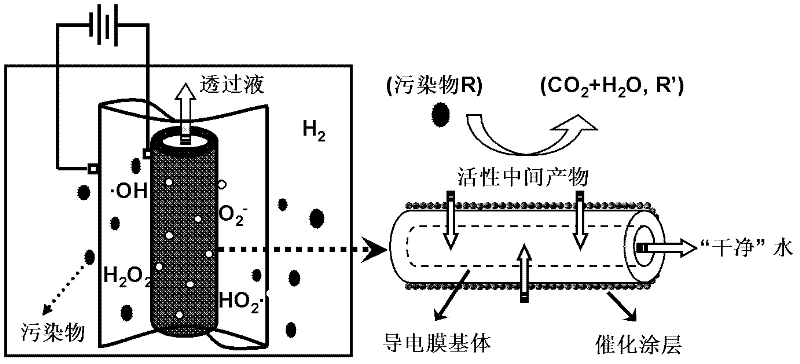

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

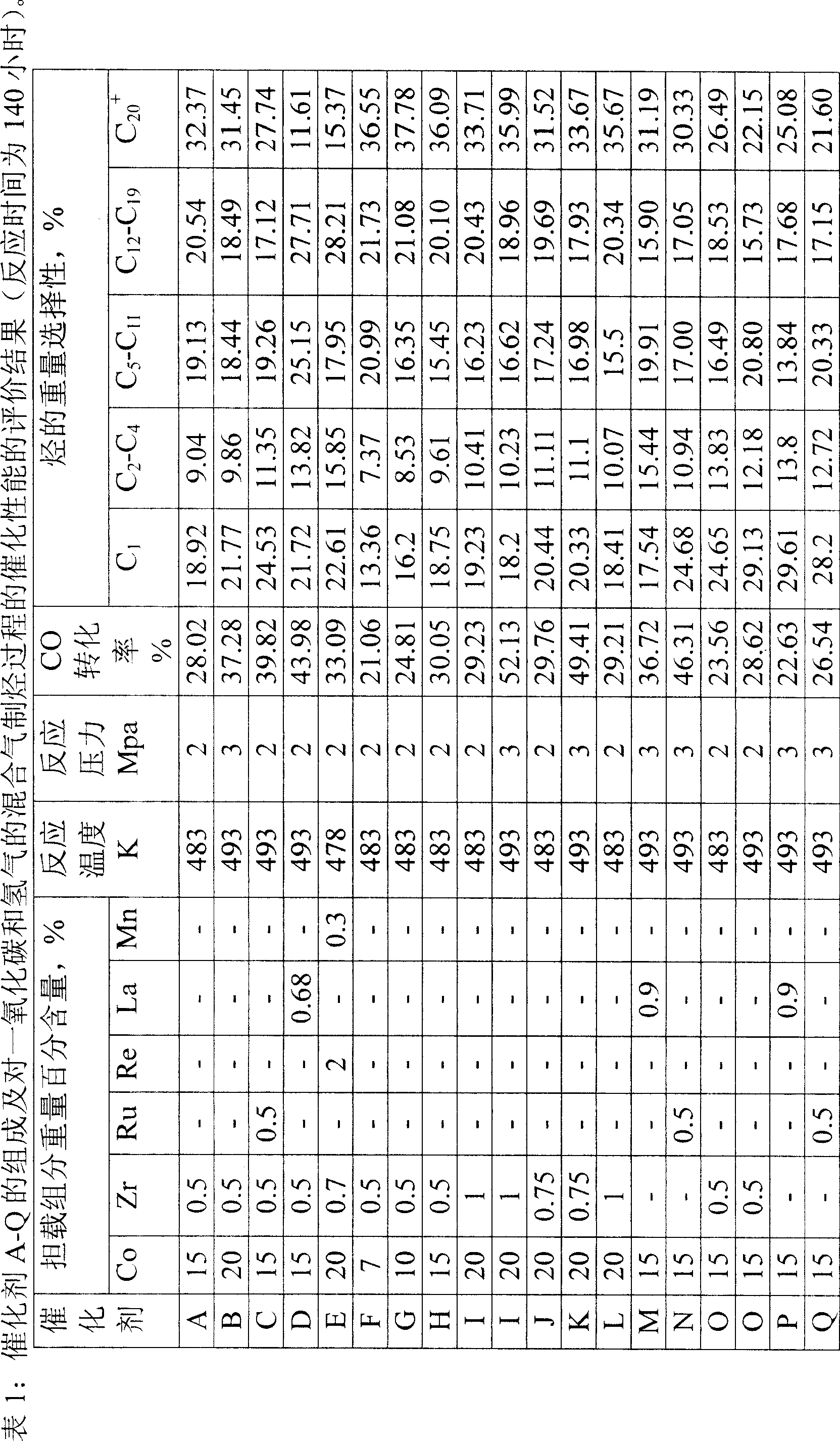

Method for preparing catalyst and application thereof

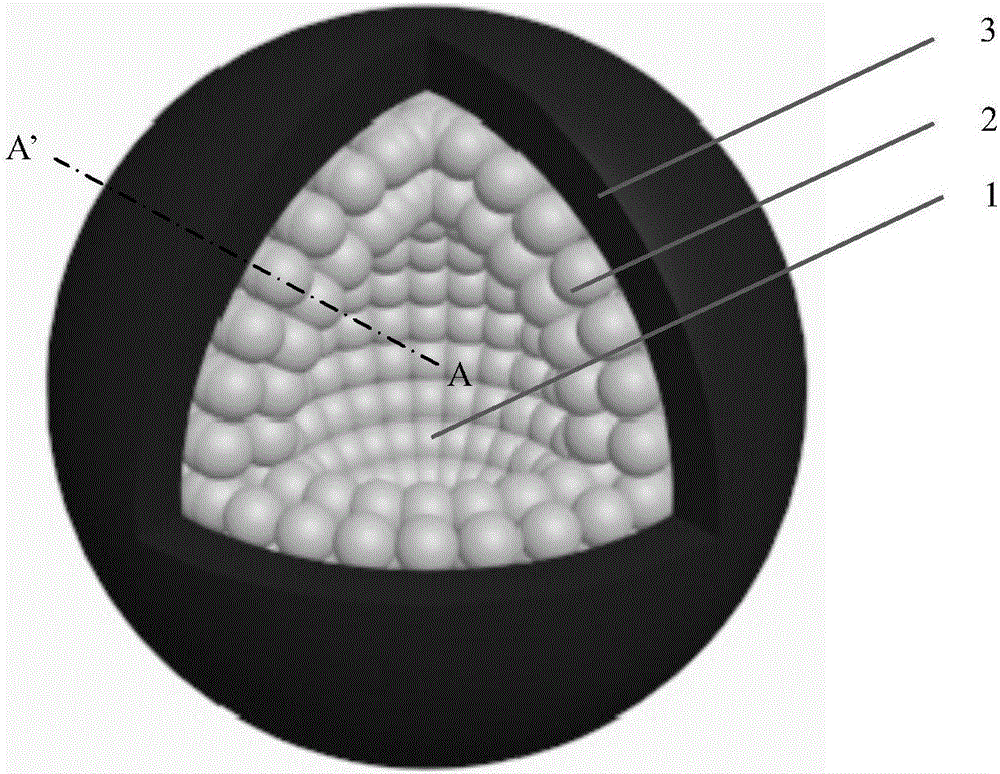

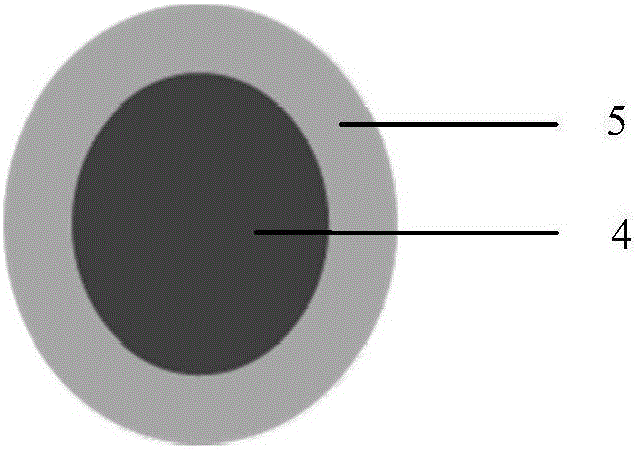

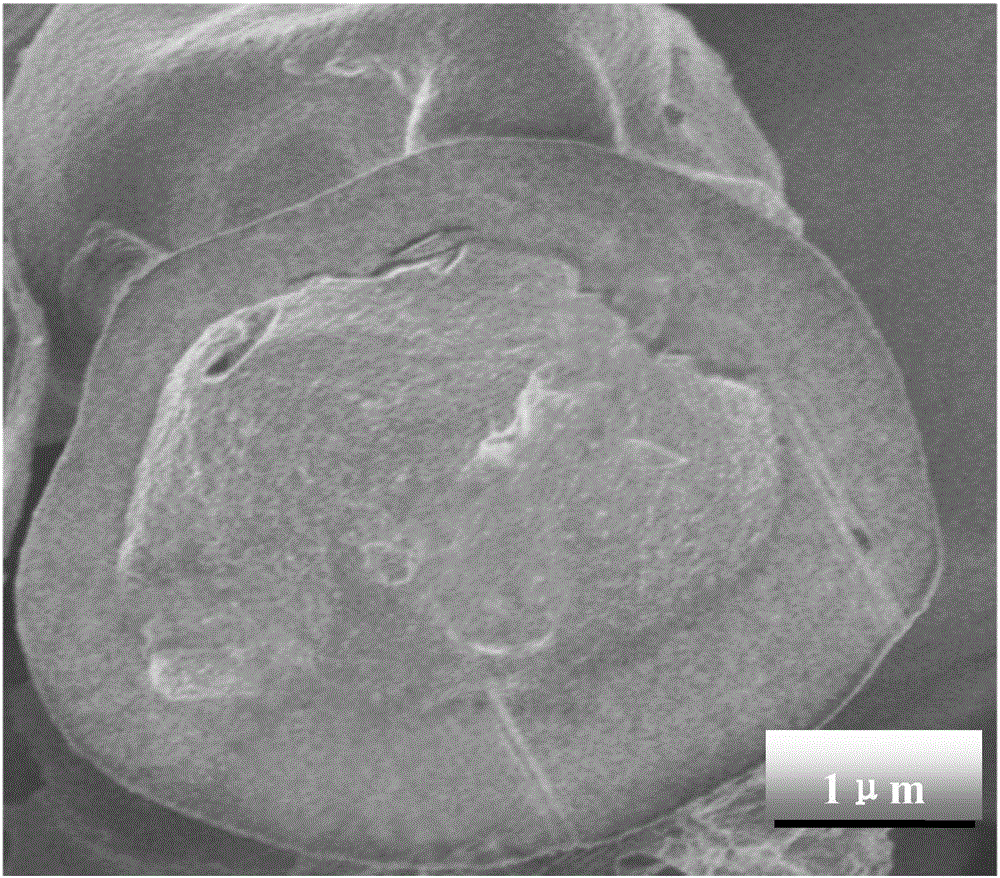

ActiveCN101143325AEasy to manufactureEasy to operateCatalyst carriersHydrocarbon from carbon oxidesHydrogenActive component

The invention provides a catalyst preparation method. The procedure is that:1} a solution containing soluble compounds with loaded components is prepared; 2} the solution produced in procedure 1 is sprayed on a rolling carrier or a carrier preloading one or a plurality of components and the carrier is heated in the process of spraying; 3) the product produced in procedure 2 is dried or roasted; 4) the procedures 2 and 3 are repeated. The active components of the catalyst prepared in the method of the invention contain group eight elements. When the catalyst preparation method of the invention is applied in the hydrocarbon preparation procedure from mixed gas of carbon monoxide and hydrogen, the active components of the catalyst prepared contain group eight elements. The invention provides a better shell catalyst preparation technique, which solve the problem of internal diffusion in certain chemical conversion procedures. The catalyst can be applied in hydrocarbon preparation reaction of gas mixture of carbon monoxide and hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

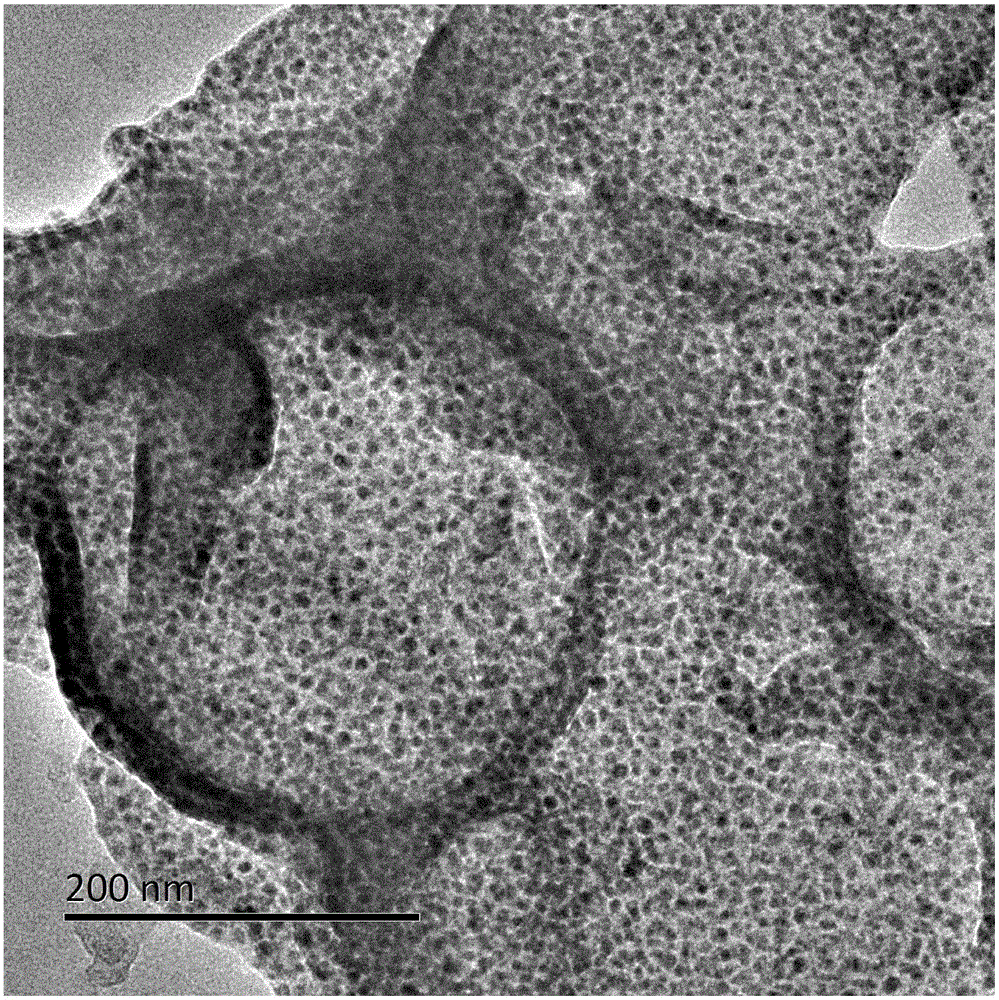

Nitrogen-doped nano carbon electrocatalyst for fuel cell, and preparation and application of nitrogen-doped nano carbon electrocatalyst

ActiveCN103041827AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsCell electrodesCarbonizationOxygen

The invention relates to a nitrogen-doped nano carbon electrocatalyst for a fuel cell, and preparation and application of the nitrogen-doped nano carbon electrocatalyst. The electrocatalyst is prepared by adopting the steps of: with phenylamine as a reaction precursor, mixing the phenylamine, a surfactant and a soluble transition metal salt and then polymerizing under acidic and high-oxidization conditions, carrying out high-temperature carbonization on the polymer under the protection of an inert gas and / or ammonia atmosphere after drying, and finally carrying out acid treatment. The preparation method of the electrocatalyst is simply and easily controlled, and the mass production is easily realized. The nitrogen-doped nano carbon electrocatalyst has better oxygen reduction catalytic activity, stability and selectivity in an acidic medium fuel cell compared with Pt / C, and has higher catalytic activity and stability in an alkaline medium fuel cell compared with commercialized Pt / C. In addition, the nitrogen-doped nano carbon electrocatalyst also has the advantages of low cost and high anti-poisoning property, and is capable of replacing platinum to be used as a fuel cell oxygen reduction electrocatalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

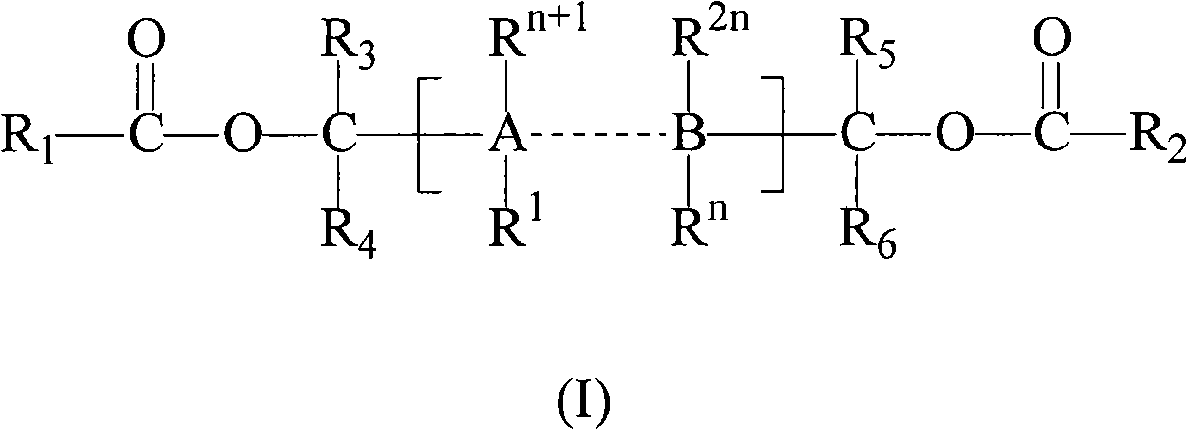

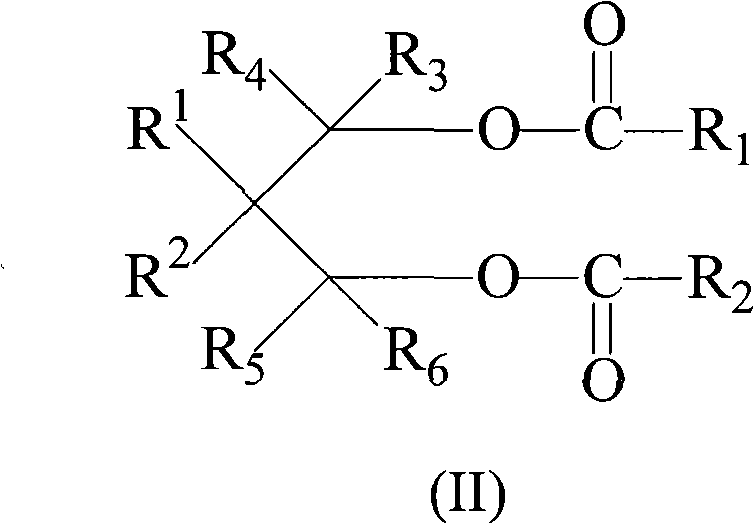

Catalyst component used for propene polymerization and catalyst

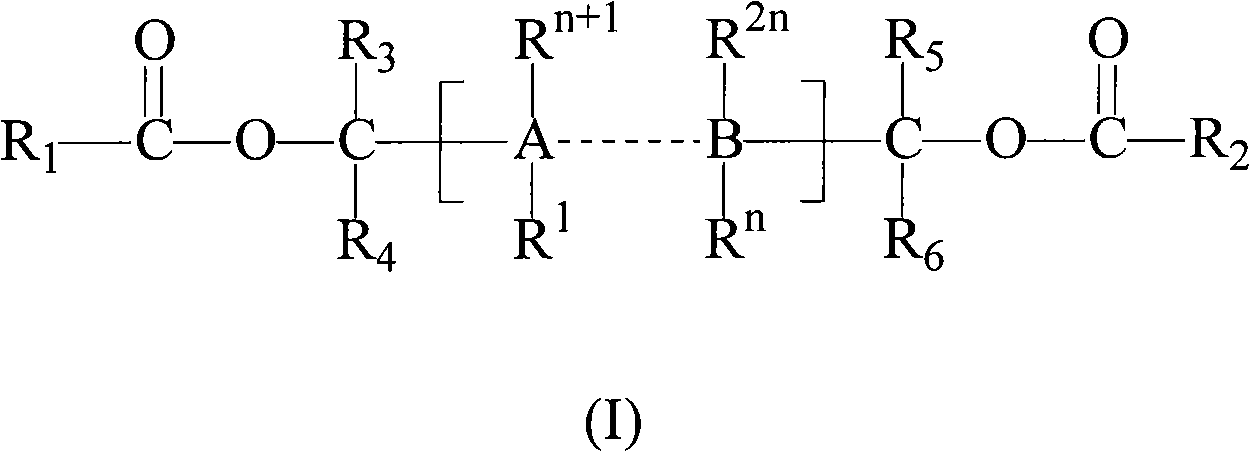

ActiveCN101643519AThe preparation process is simple and controllableExciting polymerization activityOlefin polymerizationTitanium

The invention provides a catalyst used for olefin polymerization, particularly propene polymerization. A titanium-containing catalyst component A selects a polyol ester compound with a special structure as an auxiliary precipitator, simultaneously a polyol ester compound or a binary aromatic carboxylate compound taken as an electron doner is matched for application, the conventionally used auxiliary precipitator, namely a compound phthalic anhydride is saved, a reaction step of dissolving the auxiliary precipitator is saved, and the complexity of synthesizing the catalyst component is reduced,so that the catalyst preparing process is more easily controlled, the prepared catalyst shows exciting polymerization activity and stereospecificity when used for the propene polymerization, and thepolymer has less fine powder content and wide molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

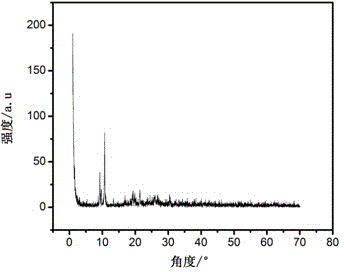

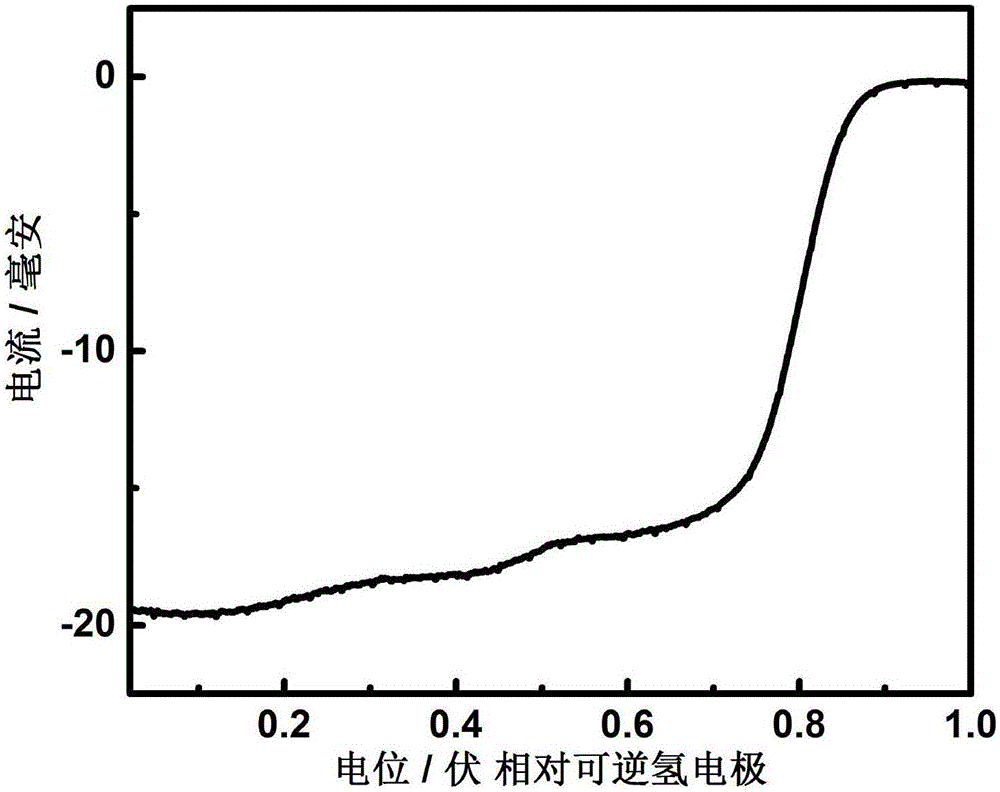

Preparation of layered metal organic framework material nano-array water oxidation electrocatalyst using LDH as template

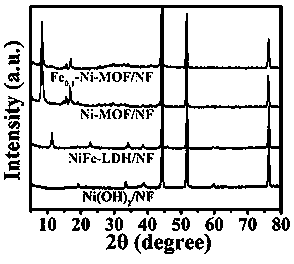

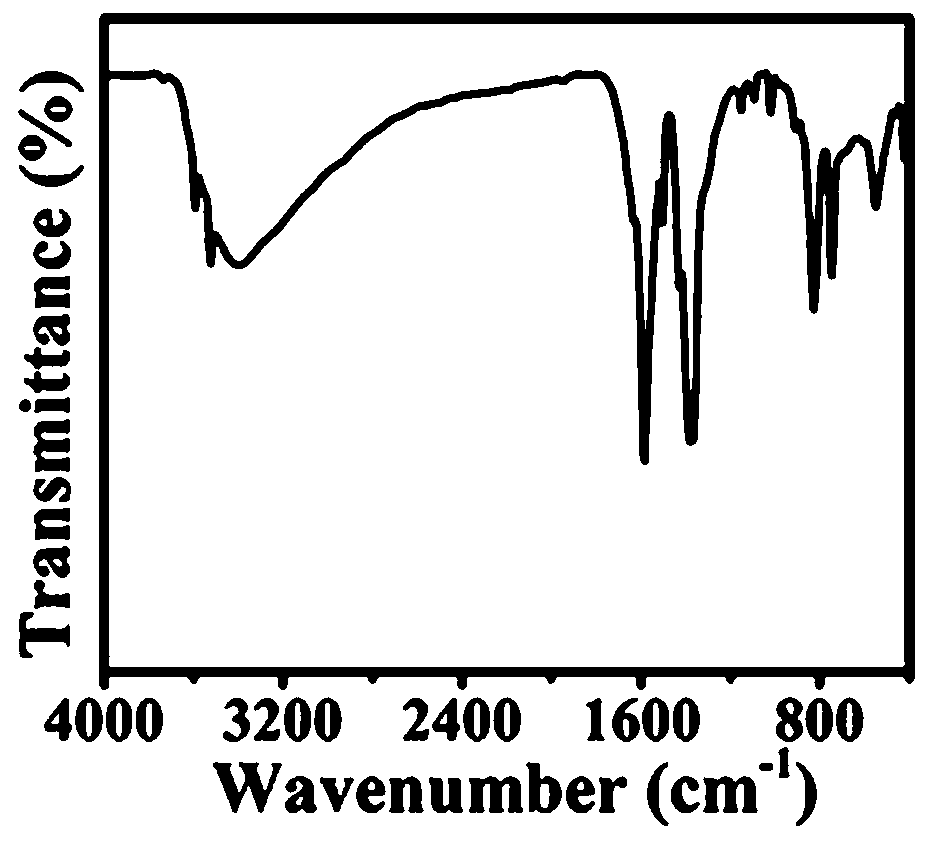

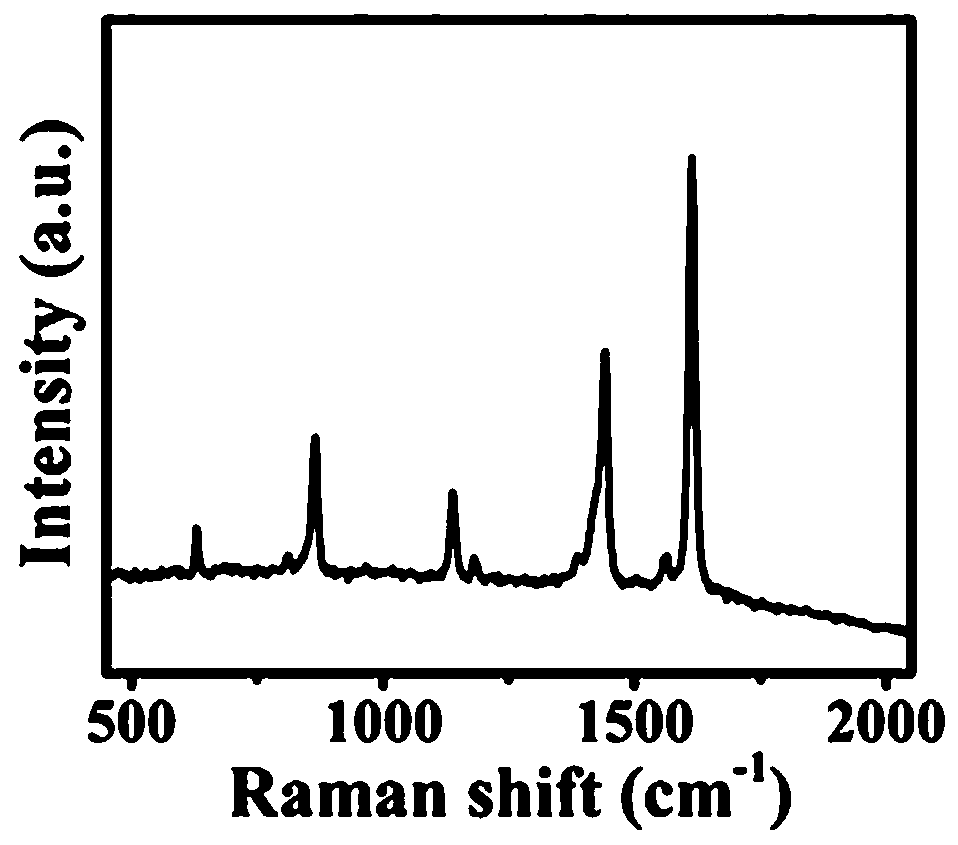

InactiveCN109652822AThe preparation process is simple and controllableMild reaction conditionsElectrode shape/formsMetal-organic frameworkRegular array

The invention discloses a preparation method of a three-dimensional layered structure Fe-doped Ni-MOF nano-array (Fe0.1-Ni-MOF / NF) which is grown in situ on foamed nickel and has high regular array. Nickel foam is used as a conductive substrate. The NiFe-LDH nano-array (NiFe-LDH / NF) firstly grows by a hydrothermal method, and then terephthalic acid is used as an organic ligand to convert a NiFe-LDH / NF precursor template to Fe0.1-Ni-MOF / NF by a solvothermal method, and the product is used as an electrocatalyst for water oxidation reaction. The electrocatalyst shows excellent catalytic activity(eta 100mA cm-2=263mV) in 1M KOH electrolyte, which is much better than undoped Ni-MOF / NF material (eta 100mA cm-2=298mV). The invention fully utilizes the doping introduction impurity level to regulate the electronic configuration and induce the synergy effect between metals, and the highly regularly arranged layered structure nano-array reduces the series resistance, exposes more active sites and promotes the diffusion of electrolytes and evolved gases. A novel energy-transduction material with high electrocatalytic activity, good cycle stability, durability and low cost is constructed.

Owner:SICHUAN UNIV

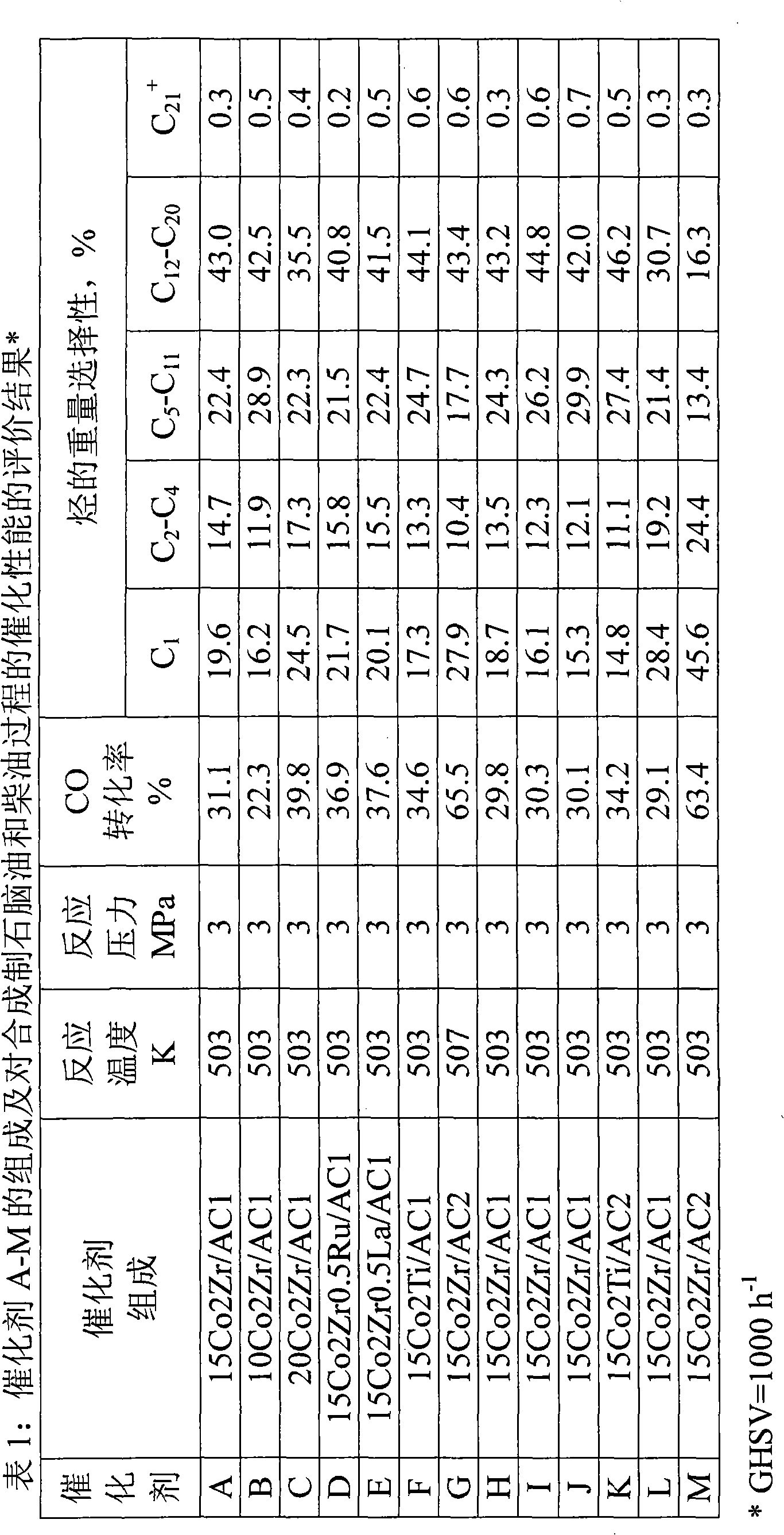

Lamella catalyst for preparing petroleum naphtha and diesel oil, preparation method and application thereof

ActiveCN101318133AEasy to manufactureEasy to operateLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNaphtha

The invention relates to a shell catalyst used for preparing naphtha and diesel oil, which takes active carbon loaded with 5-35 percent of active component and 0.01-5 percent of auxiliary components by weight as a carrier; wherein, the active component is cobalt and the auxiliary components can be one or a plurality of La, Ce, Zr, Cr, Ti, V, B, Mn, Re, K, Pt, Ru, Mg, Ba and Ca. The preparation method of the catalyst comprises: a) preparing the solution containing soluble compounds of the loaded component; b) spraying the solution prepared in the step a) on the rolling carrier; c) drying or roasting the catalyst prepared in the step b) in inert gases. The invention can easily prepare eggshell type catalyst, which has the advantages of simple operation, uniform shell, easily controlled preparation process and good repeatability, thus being easy for large-scale production. Furthermore, the obtained catalyst has great service effect in overcoming the diffusion control problem in the chemical conversion process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

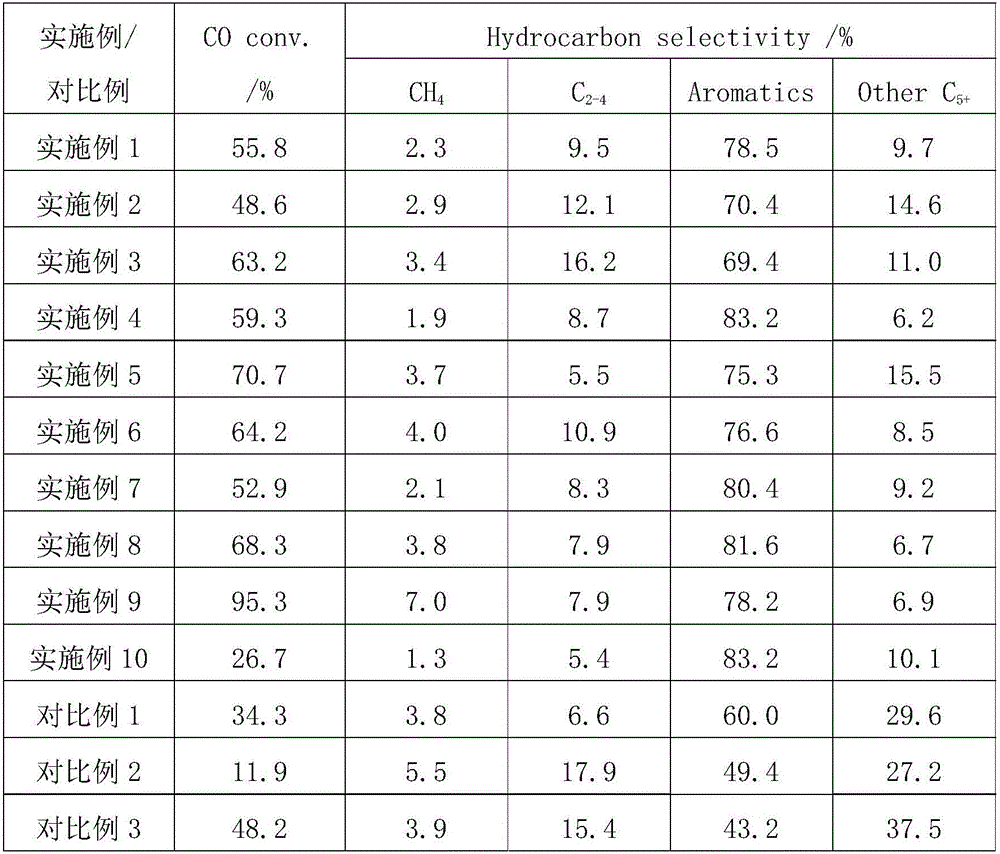

Catalyst for preparing arene from synthesis gas through one-step conversion and preparation method of catalyst

ActiveCN106215972AImprove catalytic performanceHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to catalysts, in particular to a catalyst for preparing arene from synthesis gas through one-step conversion and a preparation method of the catalyst. The catalyst is prepared from, by mass, 30%-70% of zirconium-containing perovskite, 30%-60% of multistage porous zeolite molecular sieve and 0.1%-10% of oxide additive. The preparation method comprises the steps that 1, a salt compound of at least one of IA, IIA, VB, VIB, VIIB, IIB and IVA family elements and rare earth elements is weighed according to the components of the catalyst and added into water or alcohol to be prepared into a solution A; the multistage porous zeolite molecular sieve is weighed and added into the solution A, suction filtration, washing and filter cake drying are carried out to obtain solid powder, then the solid power and the zirconium-containing perovskite are mixed, ground and calcined, hydrogen or mixed gas of hydrogen and inert gases is introduced, heating is carried out for reduction, the reduced solid sample is tablet molded, and the catalyst is prepared.

Owner:XIAMEN UNIV

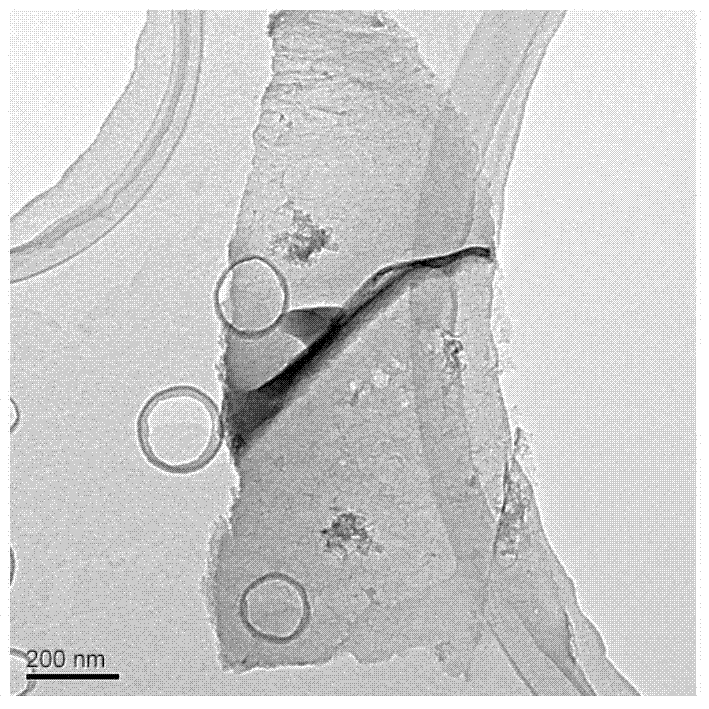

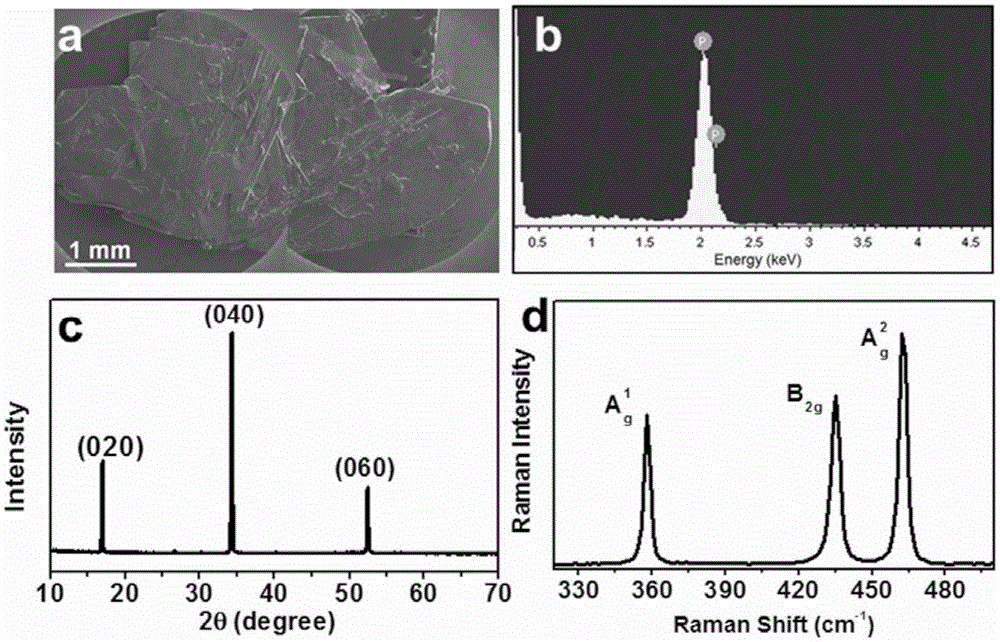

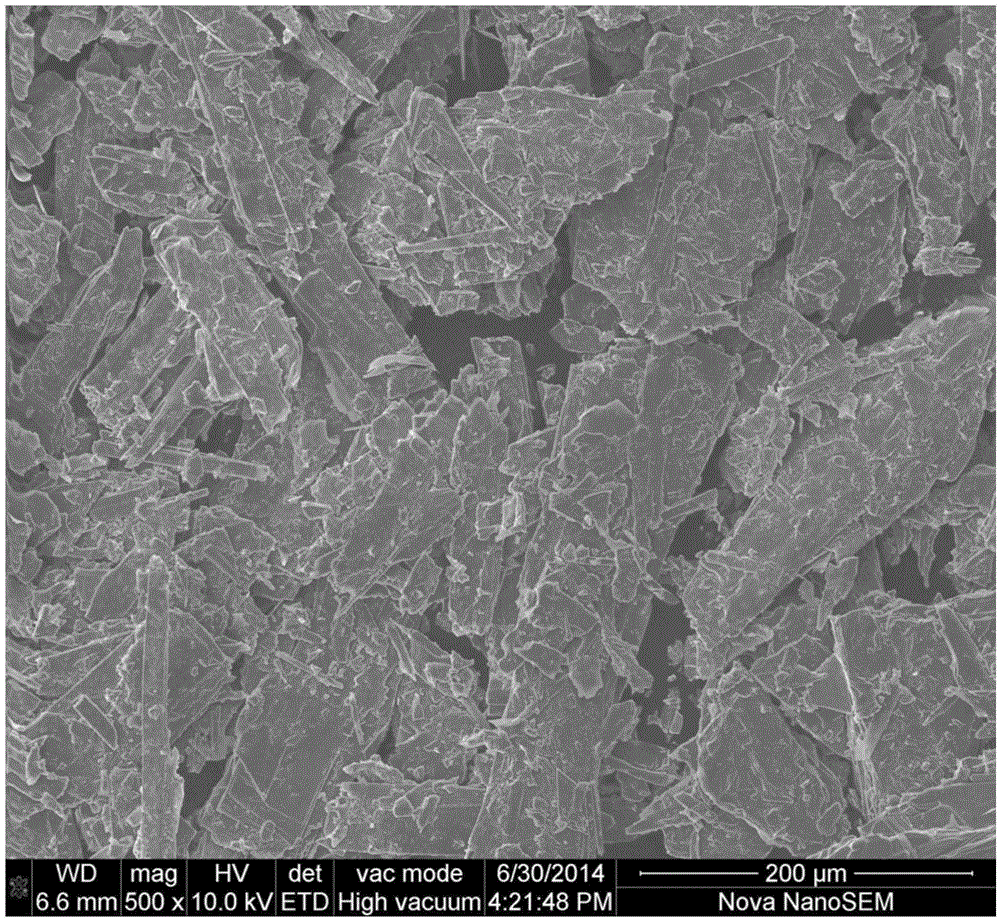

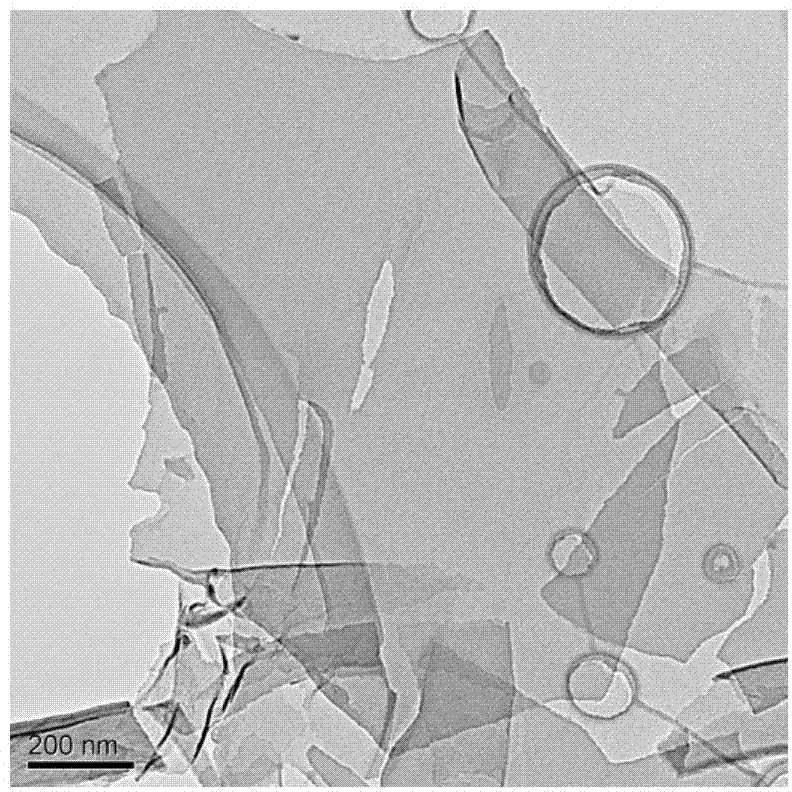

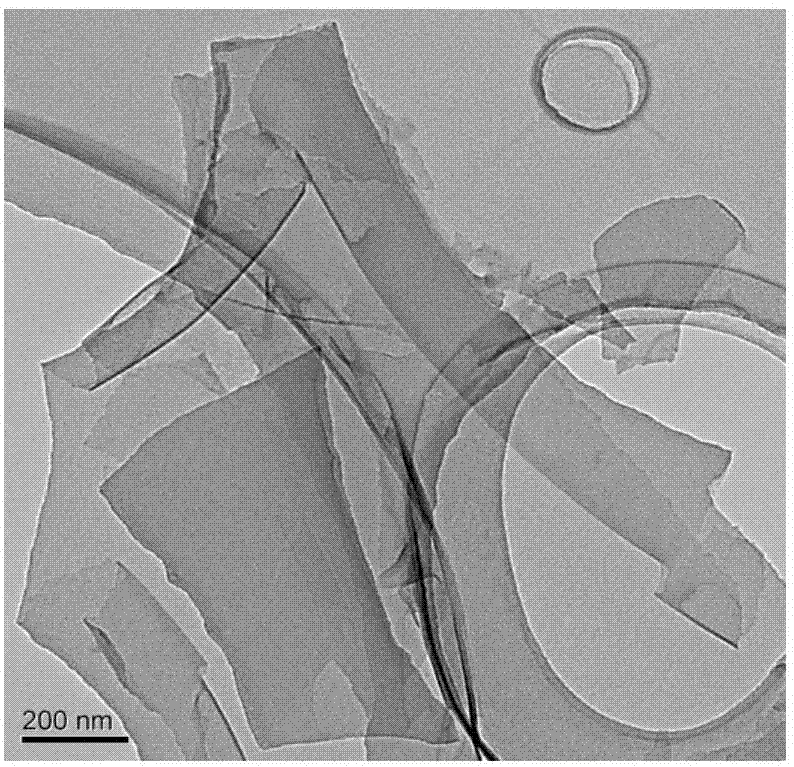

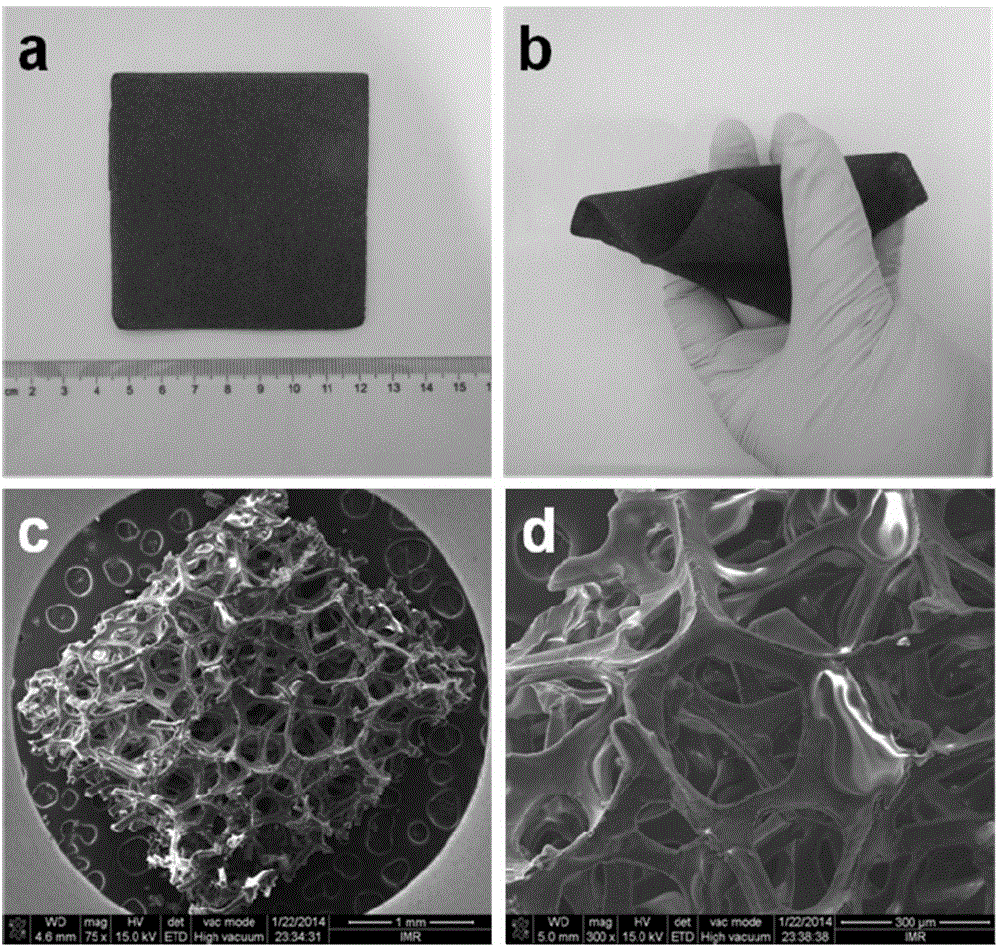

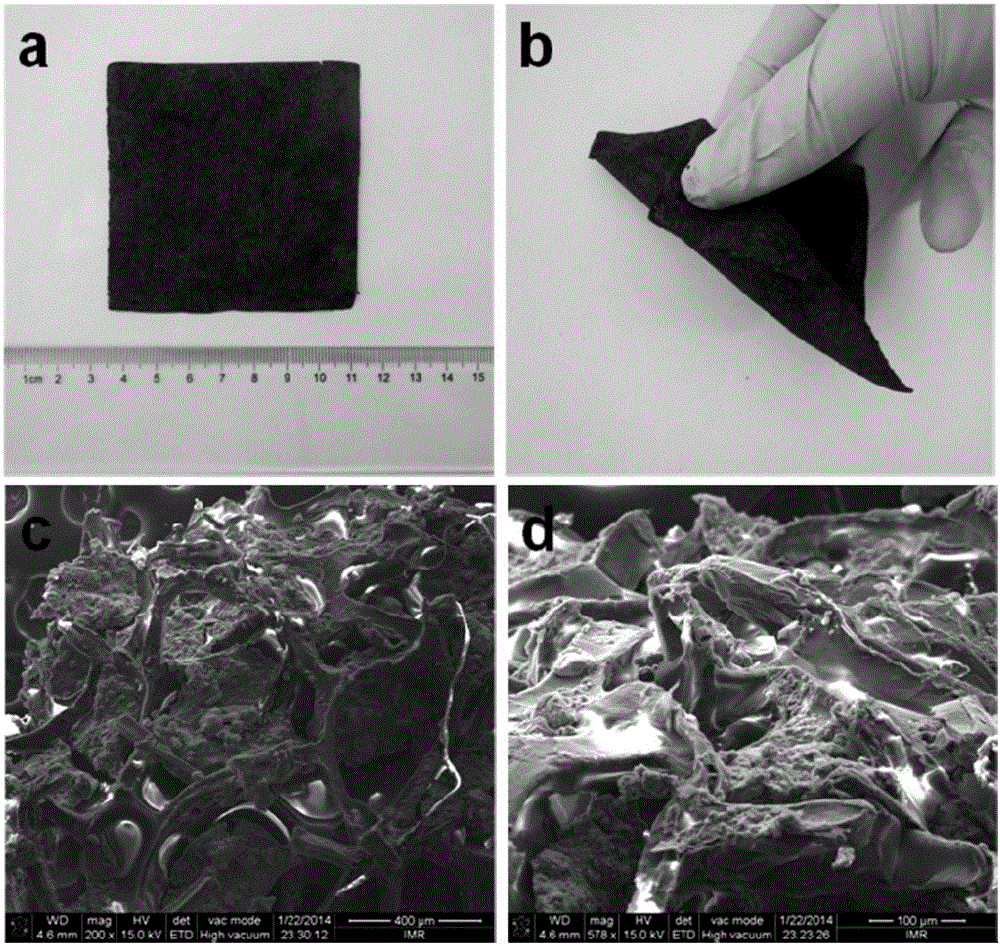

Flexible lithium ion battery black phosphorus nanosheet-graphene composite film anode, and preparation thereof

ActiveCN106711408AHigh puritySmall sizeSecondary cellsNon-aqueous electrolyte accumulator electrodesComposite filmFiltration

The invention belongs to the field of electrochemistry battery, and more specifically relates to a black phosphorus nanosheet-graphene composite film anode used for flexible lithium ion batteries, and a preparation method thereof. According to the preparation method, high purity and large scale black phosphorus blocks are synthesized via mineral substance assistant vapor transporting method with high efficiency; a large amount of clean and high quality black phosphorus sheets are prepared in water via ultrasound treatment; the clean and high quality black phosphorus sheets and high conductive graphene nanosheets prepared via intercalation stripping method are subjected to mixing ultrasonic dispersion; and flexible high-strength laminated composite film is prepared via vacuum filtration. The preparation process of the flexible high-strength laminated composite film is simple and controllable; large scale low cost preparation can be realized; black phosphorus nanosheets are high in capacity, graphene is high in electrical conductivity, and the black phosphorus nanosheets and graphene both possess two-dimensional structures high in flexibility and strength, so that problems the black phosphorus is poor in electrical conductivity and stability are solved, lithium ion battery capacity, cycling stability, and entire energy density are increased, and lithium ion battery electrode integrated flexible design is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

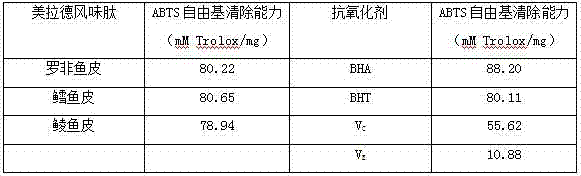

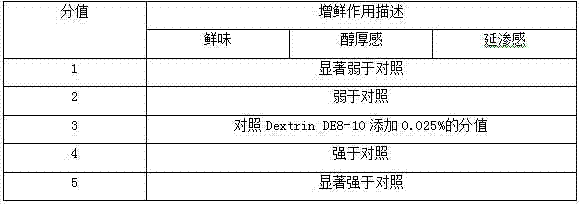

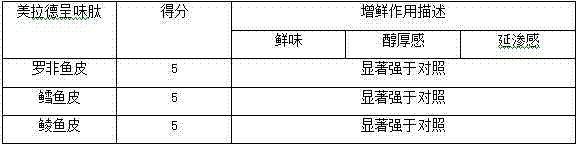

Anti-oxygenation maillard flavor peptides and method for preparing same

InactiveCN102228218ASignificant freshening effectImprove antioxidant capacityFood preparationBiotechnologyMaillard reaction

The invention discloses anti-oxygenation maillard flavor peptides and a method for preparing the same. The anti-oxygenation maillard flavor peptides are prepared by using fish skin, which is waste from the processing of various fishes as a raw material and by the steps of pre-treatment, controlled enzymolysis, ultrafiltration, maillard reaction, ultrafiltration, drying and the like. The molecularweight range of the prepared maillard flavor peptides is between 1,000 and 5,000Da and the peptide content in the maillard flavor peptides is more than or equal to 90 percent. Tests indicates that the maillard flavor peptides prepared by the method can obviously improve delicate flavor, plumpness and delayed permeation property; simultaneously, the maillard flavor peptides are high in anti-oxygenation, and the oxidation resisting activity of the maillard flavor peptides is equal to commercial edible antioxidants; and the maillard flavor peptides not only obviously improve the delicate flavor,but also contain health-care ingredients, and is a novel natural and healthy flavor-development base material for flavorings.

Owner:KUNMING UNIV OF SCI & TECH

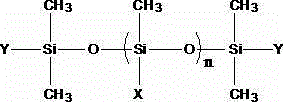

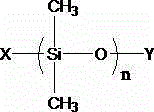

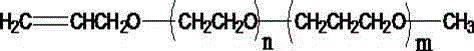

Preparation method of defoaming agent for waterborne system

ActiveCN105148571AActive ingredient reductionReduce manufacturing costCoatingsFoam dispersion/preventionAdjuvantNitrogen gas

The invention relates to a preparation method of a defoaming agent for a waterborne system. The preparation method of the defoaming agent for the waterborne system comprises the following steps: a) adding silicon oil, gaseous silicon dioxide and catalyst into a reaction container according to proportions, and preparing silicon cream under an agitating condition protected by nitrogen; b) adding hydrogen-containing silicon oil and allyl polyether into the reaction container, agitating under the protection of nitrogen, increasing temperature and adding an initiator for reaction to obtain polyether modified organic silicon; c) jading the silicon cream obtained in step a), the polyether modified organic silicon obtained in step b) and an emulsifier into the reaction container, adding water for emulsification under a high-speed agitating condition, and adding a thickening agent to regulate viscosity to obtain a product. The defoaming agent prepared by adopting the preparation method provided by the invention has the advantages that the active components are low, the manufacturing cost is low and the environmental friendliness is better; the emulsification is stable, the compatibility in the waterborne system is good, the defoaming agent is easy to disperse, the surface tension is low, the defoaming speed is quick, the foam inhibiting time is long, the thermal resistance, shear resistance and acid and alkali resistance thereof are good, and the defoaming agent can adapt to various places; the defoaming agent can be separately used and can also be jointly used with other adjuvants, the stability is good, the phenomenon of oil floating due to demulsification does not occur, no sediment is produced and shrinkage cavities during coating are not caused; and the defoaming agent is also very effective to non-waterborne systems.

Owner:KITO CHEM CO LTD

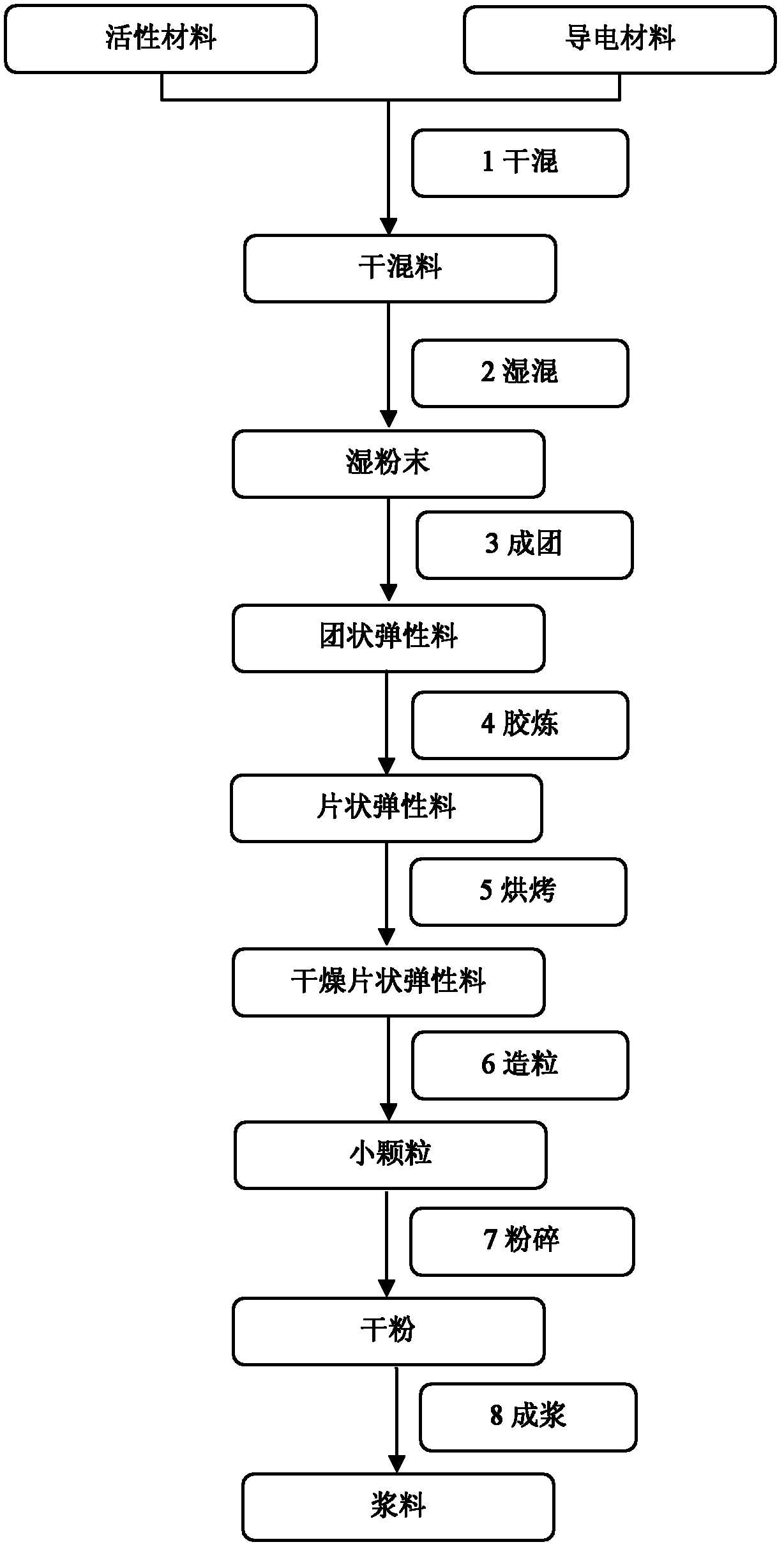

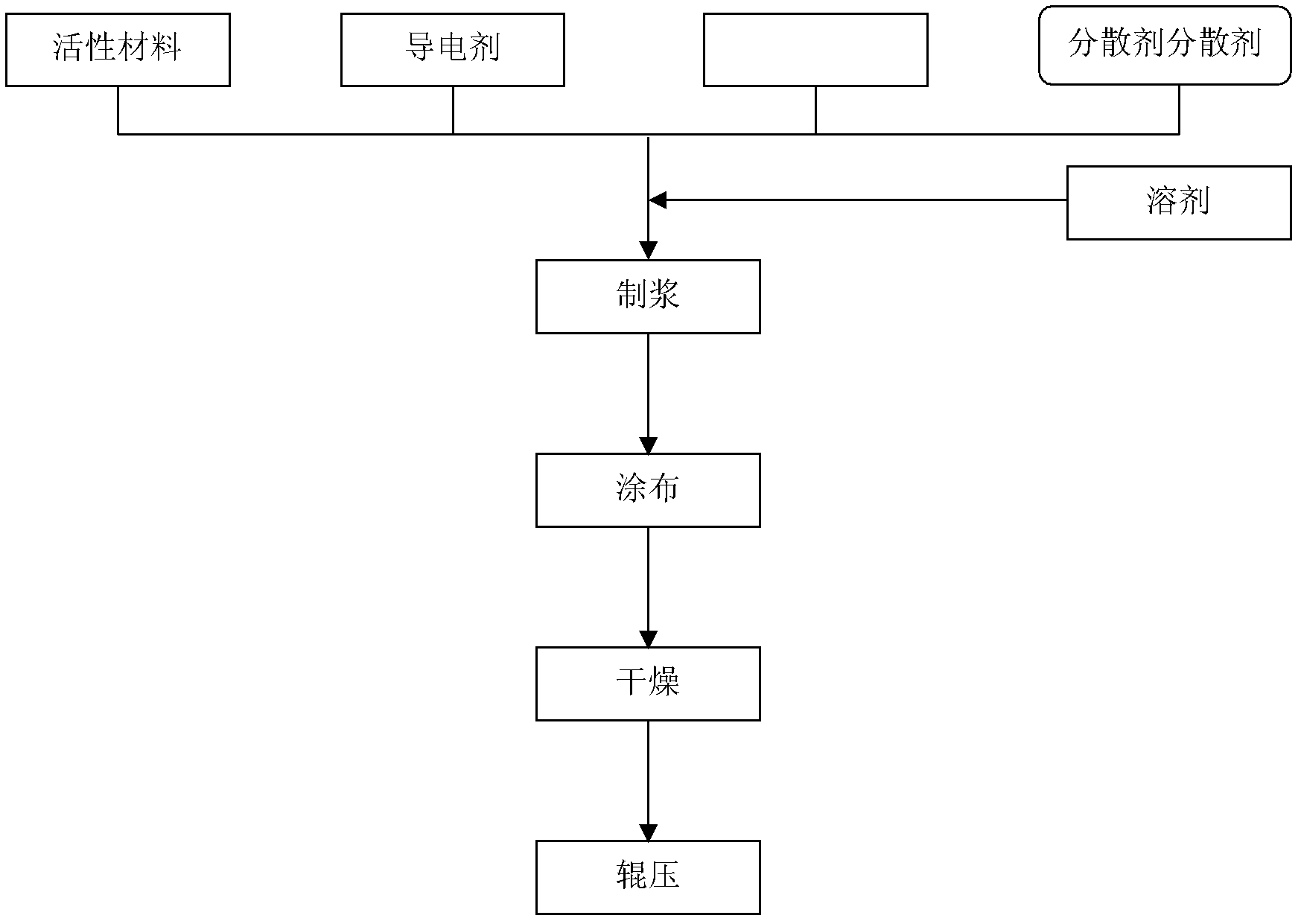

Electrode of supercapacitor, preparation method of electrode and preparation method of slurry of electrode

ActiveCN102637531AHigh solid contentGood dispersionProtecting/adjusting hybrid/EDL capacitorElectrolytic capacitorsInternal resistanceAdhesive

The invention provides a preparation method of slurry for an electrode of a supercapacitor, the electrode of the supercapacitor and a preparation method of the electrode of the supercapacitor. A eight-stage slurry preparation process is adopted in the preparation method of the slurry, and the preparation method of the slurry comprises the following steps of: I, dry mixing; II, wet mixing; III, lumping; IV, rubber mixing; V, roasting; VI, pelleting; VII, smashing; and VIII, slurry forming. The preparation method of the slurry can be used for increasing the solid content of the slurry, reducing the using amount of an adhesive, improving the dispersing effect of the slurry, realizing the quantitative control for the slurry preparation process and achieving better process stability and consistency. The electrode prepared by using the slurry has the advantages that the strength of the electrode is enhanced, the internal resistance of the electrode is reduced, the electrochemical stability and the structural stability of the electrode are improved, the reliability of the supercapacitor with the electrode is improved, and the service life of the supercapacitor is prolonged.

Owner:TIG TECH CO LTD

Method for high yield preparation of graphene by using biologic carbon source material

The invention discloses a method for the high yield preparation of graphene by using a biologic carbon source material. The method comprises the following steps: carrying out microwave treatment on the biologic carbon source material, adding to an acid solution, dipping for 1-24h, washing with water, and drying to obtain a preprocessed biologic carbon source material; and mixing the preprocessed biologic carbon source material with a catalyst, calcining at 600-1600DEG C in the presence of a protection gas for 1-2h, and cooling to obtain graphene, wherein the catalyst is at least one of platinum, palladium, rhodium and iron. The method for the high yield preparation of graphene by using the biologic carbon source material uses cellulose or lignin as a raw material, so the production cost is greatly reduced, and the large-scale industrial production of graphene is realized; and graphene prepared through the method has a lamellar thickness of 2-5nm, and the yield and the purity of graphene are improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

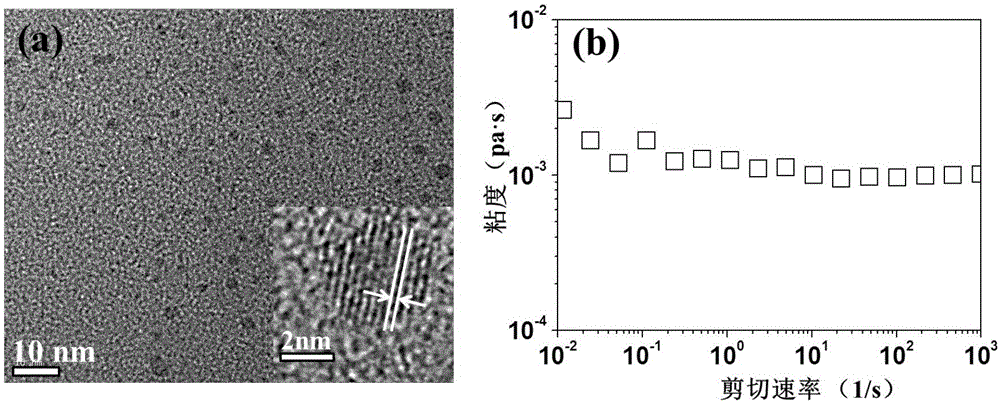

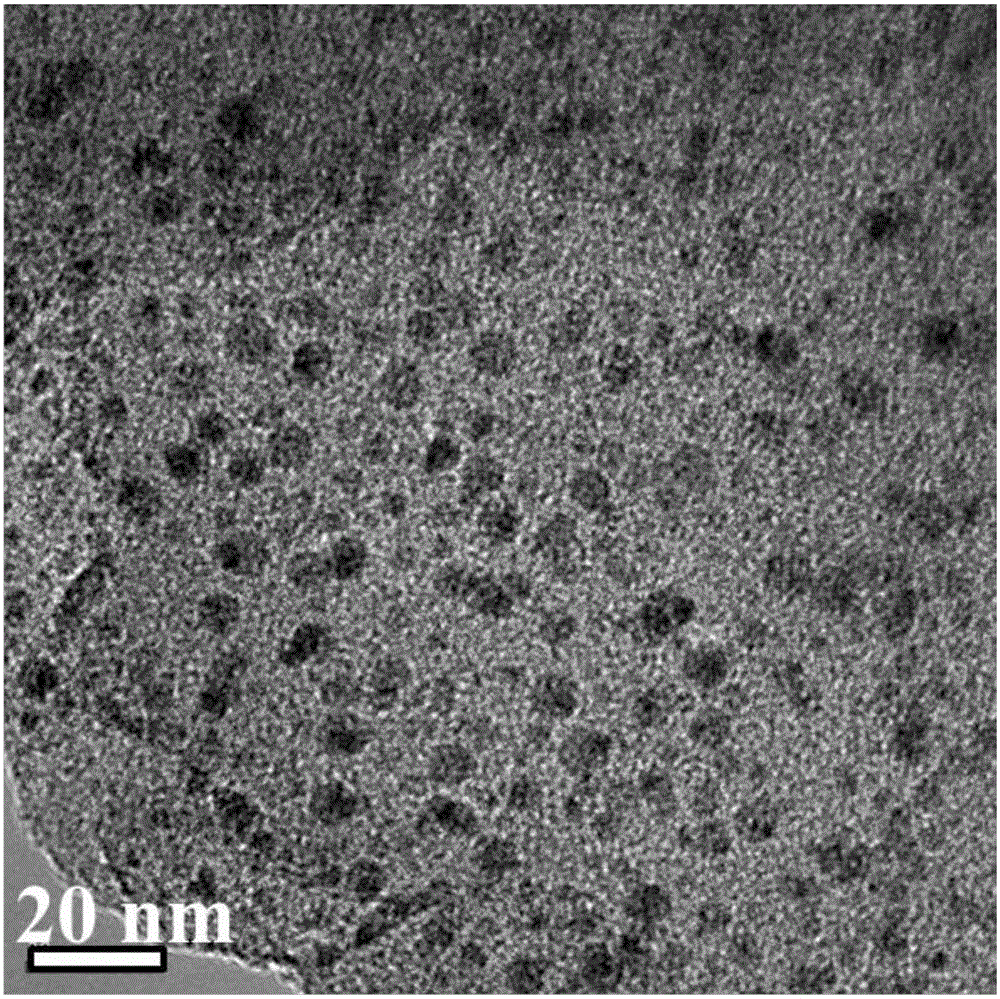

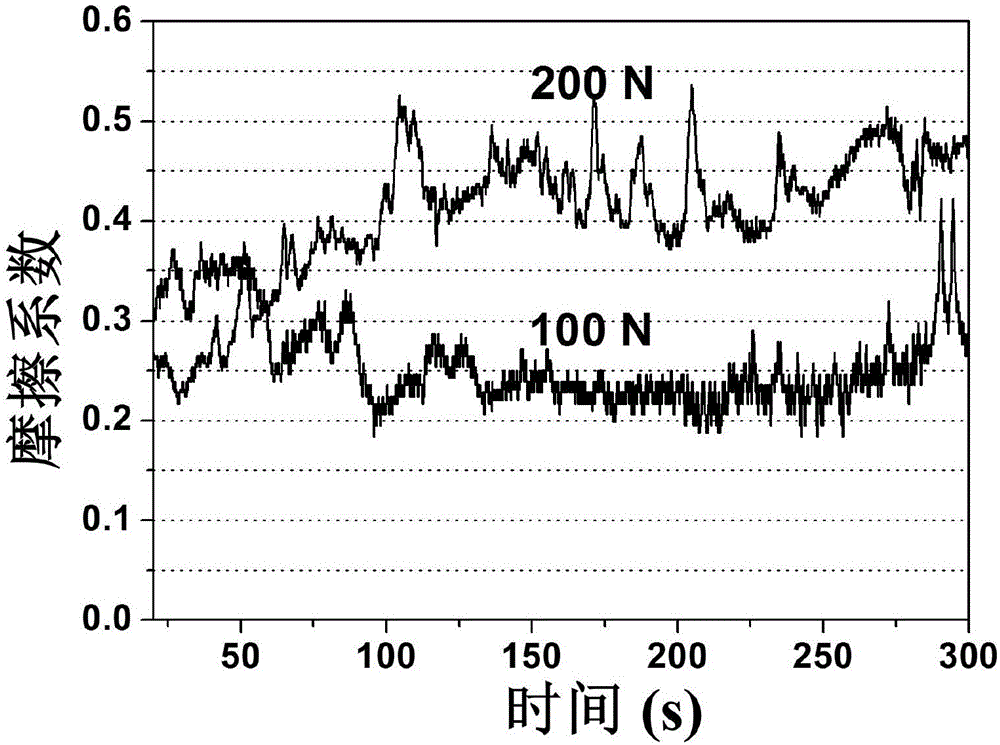

Water-based lubricant based on two-dimensional material nanosheets/carbon quantum dots and preparation method of water-based lubricant

InactiveCN106520354AReduce coefficient of frictionImprove adaptabilityLubricant compositionWater basedMaterials preparation

The invention belongs to the technical field of nano lubricant material preparation and relates to a water-based lubricant based on two-dimensional material nanosheets / carbon quantum dots and a preparation method of the water-based lubricant. Carbon quantum dot powder is first prepared, then the prepared carbon quantum dot powder is added into ultra-pure water, and ultrasonic treatment is conducted for 10 min to obtain a carbon quantum dot aqueous solution; then, two-dimensional material nanosheets are added into the carbon quantum dot aqueous solution for ultrasonic treatment to prepare the water-based lubricant based on the two-dimensional material nanosheets / carbon quantum dots, wherein the water-based lubricant comprises, by mass, 0.01-15% of the carbon quantum dots, 0.001-0.1% of the two-dimensional material nanosheets and the balance ultra-pure water. The lubricant is simple and controllable in preparation process, low in cost, environmentally friendly, clean and free of toxin, large-scale production is easy, and the prepared water-based lubricant is extremely low in friction coefficient and good in adaptability with friction pairs, and does not corrode common carbon steel.

Owner:QINGDAO UNIV +1

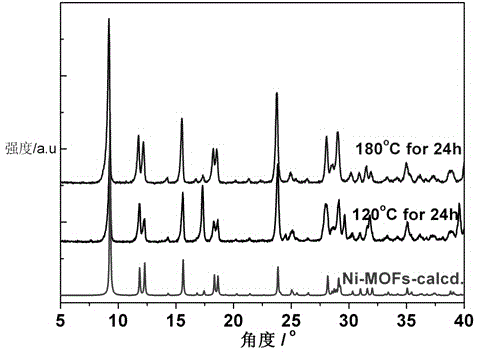

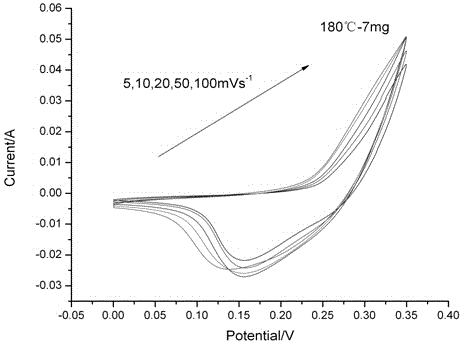

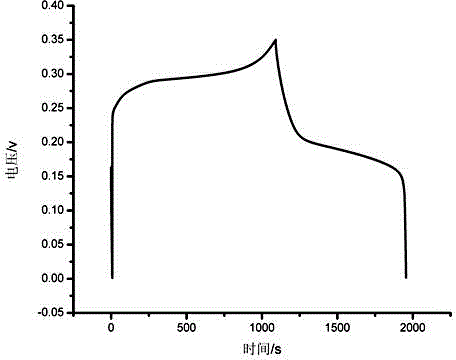

Preparation method of Ni-MOF electrode material

InactiveCN104979104AImprove electrochemical performanceExcellent specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceAlcohol

Disclosed in the invention is a preparation method of a Ni-MOF electrode material. A nicdel nitrate aqueous solution with the total concentration of 0.0075 to 0.43mol / l is added into a PTA / DMF solution with the total concentration of 0.005 to 0.03 mol / l, wherein the adding speed is 2 to 5ml / min and the volume ration of the nicdel nitrate aqueous solution to the terephthalic acid solution is 1.5-3 :1; after dissolution stirring of 1 to 2 hours, a precursor solution is obtained; solvothermal reaction is carried out on the precursor solution for 12 to 48 hours in a hydro-thermal kettle with the temperature of 120 to 200 DEG C, centrifugal washing and filtering are carried out on an obtained green precipitate respectively by DMF and absolute ethyl alcohol, and drying is carried out under the temperature of 80 DEG C, thereby obtaining a Ni-MOF electrode material. According to the preparation method, the specific capacitance of the material can be up to 1500F / g; after 3000-times charging and discharging circulation, 90% of specific capacitance still can be kept. The method is simple and can be controlled easily; the conditions are mild; and the production cost is low.

Owner:SHANGHAI INST OF TECH

Method for preparing graphene from agriculture and forestry waste biomass as carbon source

The invention belongs to the technical field of graphene preparation, and discloses a method for preparing graphene by using agricultural and forestry waste biomass as a carbon source. The method specifically includes the following steps: (1) Take the pulverized agricultural and forestry waste biomass, add it to a reaction kettle filled with water, undergo a hydrothermal reaction, cool to room temperature after the reaction, and then filter, wash, and dry to obtain a solid biochar; (2) mix the alkali with the biochar obtained in step (1), grind it sufficiently to make it evenly mixed, and heat and calcinate in the presence of protective gas; (3) use acid to prepare the sample after calcining in step (2) Soaking in liquid to remove by-products in the reaction, and then filtering, washing the obtained solid with water until the washing liquid is neutral, and then drying to obtain few-layer graphene. The method has the advantages of simple process, high yield, mild reaction conditions, simple required instruments and equipment, no pollution to the environment, using agricultural and forestry waste biomass as raw materials, greatly reducing production costs, and easy to realize industrial production.

Owner:SOUTH CHINA AGRI UNIV

Flexible high-sulfur load self-repairing cathode structure for lithium-sulfur battery and preparation method of flexible high-sulfur load self-repairing cathode structure

ActiveCN105098143AEasy to makeThe preparation process is simple and controllableNon-aqueous electrolyte accumulator electrodesSulfurLithium–sulfur battery

The invention discloses a flexible high-sulfur load self-repairing cathode structure for a lithium-sulfur battery and a preparation method of the flexible high-sulfur load self-repairing cathode structure, and belongs to the field of electrochemical batteries. The lithium-sulfur battery cathode structure disclosed by the invention is composed of graphene / high-molecular polymer flexible foam and a carbon / sulfur active material layer, wherein the active material is sulfur; and the graphene / high-molecular polymer flexible foam provides strength and a self-repairing function. The flexible high-sulfur load self-repairing cathode structure has the characteristics that a multicomponent integrated design of the lithium-sulfur battery is realized; the electrochemical property is ensured; meanwhile, the content of sulfur is increased; high active material surface density of the battery is realized; the obtained lithium-sulfur battery has the advantages of high specific capacity and high specific energy density, and simultaneously has flexibility and self-healing characteristics; the preparation process of the flexible high-sulfur load self-repairing cathode structure is simple and easy to control; large-scale and low-cost preparation can be realized; and the application value is wide.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Spherical lithium-enriched anode material with gradient concentration and preparation method thereof

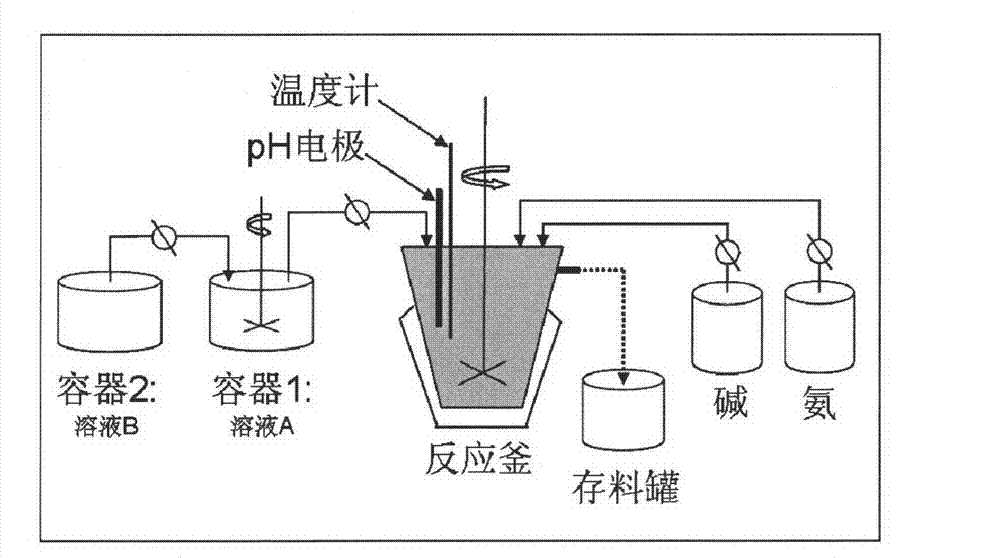

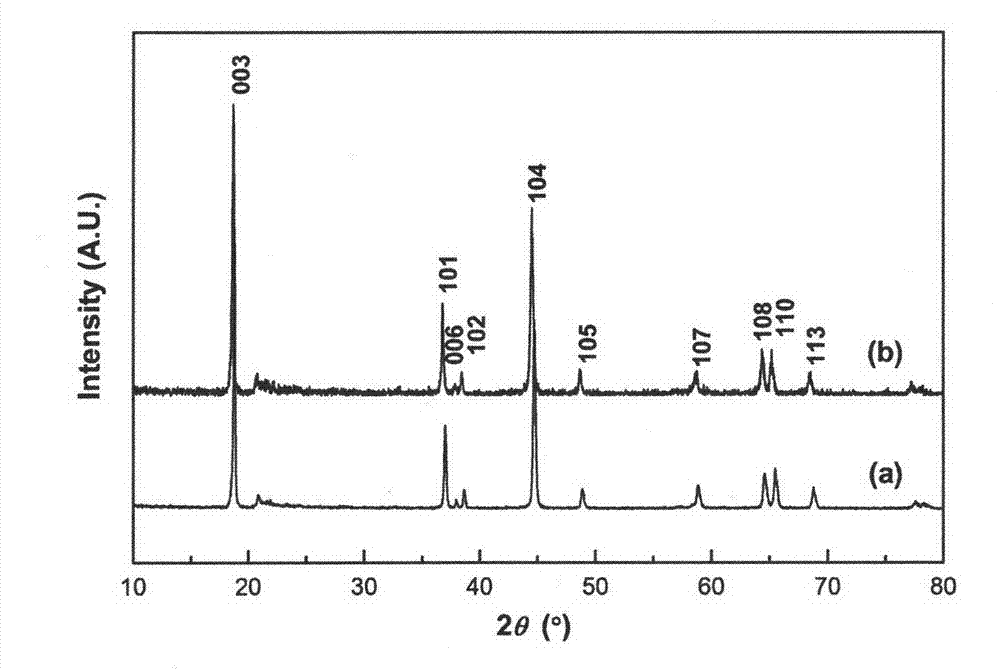

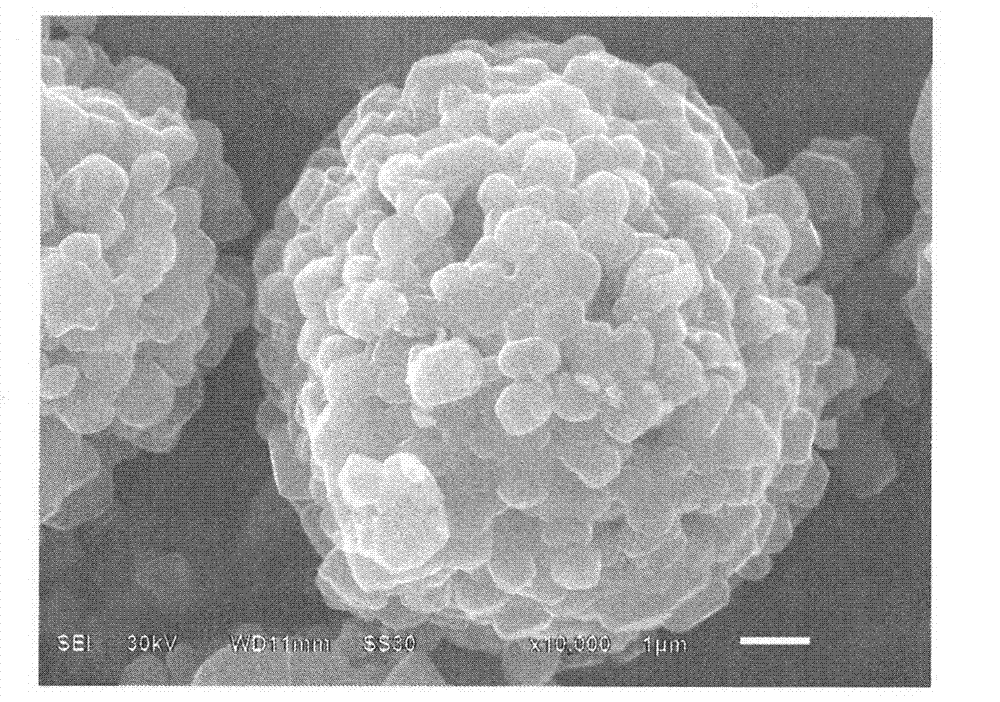

The invention discloses a preparation method of a spherical lithium-enriched anode material with gradient concentration. The invention has the technical effects as follows: a controlled crystallization coprecipitation method is adopted to prepare the spherical lithium-enriched anode material with the gradient concentration, the Mc concentration of the spherical lithium-enriched anode material gradually increases from cores of spherical particles to surface layers, and the concentrations of Ni and Co gradually decrease from the cores of the spherical particles to the surface layers. The spherical lithium-enriched anode material not only has the characteristic of high specific capacity of the lithium-enriched anode material, but also acquires more excellent cyclic life and thermal stability through gradient Mn concentration, and can meet the requirements of electric vehicles and other fields for the service of motive power supply. The preparation method is simple in preparation process, easy to control, low in raw material cost and friendly to environment, can be applied to large-scale industrialization, and has a good application prospect.

Owner:XIANGTAN UNIV

Graphene / Fe-MOFs composite material and preparation method thereof

InactiveCN104538200AImprove electrochemical performanceHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorTerephthalic acid

The invention discloses a graphene / Fe-MOFs composite material and a preparation method thereof. Adding oxidized graphene, FeCl3 and terephthalic acid into N, N-dimethyl formamide according to the corresponding ratio of 1-15 g : 100 g: 200 g : 150 ml, ultrasonically dissolving the mixture at a power of 600 W for 1 h, and then controlling the temperature to be at 150 degrees to conduct hydrothermal reduction reaction for 15 h; conducting suction filtration on the obtained reaction liquid, conducting repeated washing and suction filtration on the filter cake with N, N-dimethyl formamide till the filter does not contain incompletely reacted oxidized graphene, FeCl3 and terephthalic acid, controlling the temperature to be at 80 degrees to conduct drying, and then the graphene / Fe-MOFs composite material with good electro-chemical performance is obtained and can be used for super capacitor electrode materials. The graphene / Fe-MOFs composite material is simple and controllable in preparation technology, mild in conditions, low in production cost and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

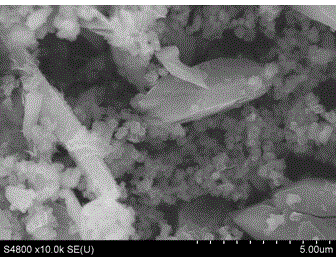

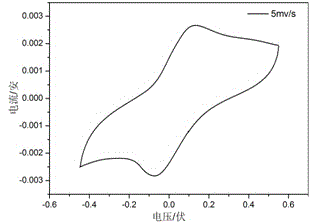

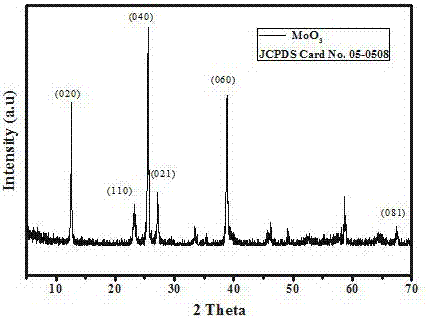

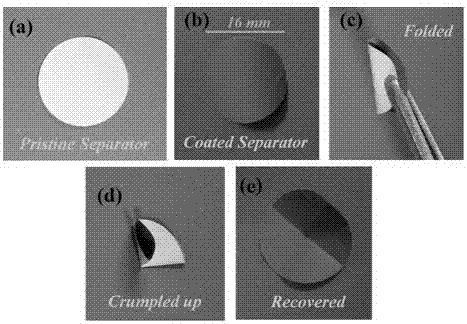

Modified diaphragm for lithium-sulfur battery, preparation method thereof and lithium-sulfur battery with diaphragm

InactiveCN107359303AWide variety of sourcesLow costMaterial nanotechnologyCell electrodesInorganic particleSulfur

The invention belongs to the technical field of energy materials, and specifically relates to a modified diaphragm for a lithium-sulfur battery, a preparation method of the modified diaphragm and the lithium-sulfur battery with the diaphragm; the diaphragm adopts a diaphragm body of a commercial battery as a skeleton, and a decorative coating is coated on one side of the diaphragm body; and the decorative coating consists of nanometer inorganic particles containing molybdenum element, a conductive agent and a binder. Through the diaphragm for the commercial battery and the nanometer inorganic particles containing molybdenum element as raw material and a proportional relation among the raw materials, the composite diaphragm for the lithium-sulfur battery is formed through a simple technology, the technology is simple and controllable, a complex and energy-consuming sulfur-filling process is not needed, the raw materials are wide in sources, the cost is low, and the technology is beneficial for large-scale implementation. The lithium-sulfur assembled in the invention is high in capacity and good in cycle performance, and the preparation technology is simple and controllable, economical and environmentally-friendly, and is applicable for large-scale production.

Owner:UNIV OF JINAN

Nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and preparation method thereof

ActiveCN105879895ASimple processGood repeatabilityMaterial nanotechnologyPhysical/chemical process catalystsMetal oxide nanoparticlesPorous carbon

The invention relates to nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and a preparation method thereof. The catalyst is made by embedding metal and metal oxide nanoparticles into nitrogen-doped porous carbon nanosheets or supporting them to the surfaces of the nitrogen-doped porous carbon nanosheets; the preparation method comprises: 1), synthesizing a polymerizable ionic liquid monomer; 2), reacting the obtained ionic liquid with a metal salt precursor, and drying to obtain an intermediate product, solid powder; 3), placing the obtained solid powder in a magnetic boat, placing in a tubular furnace fitted with a quartz tube, charging an inertial gas at a certain flow rate, heating to 600-1000 DEG, holding the temperature for 0.5-5 h, and naturally cooling to room temperature to obtain the catalyst. The poly-ionic liquid is used as the precursor, metal supporting capacity is high, the cost is low, oxygen reduction and oxygen evolution catalytic activity is high, the prepared product has stable performance, and the preparation method is simple and is easy to scale up and industrially apply.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com