Method for preparing graphene by taking biomass as raw material

A technology of biomass and graphene, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of difficult industrialization and high cost of graphene, and achieve high repeatability and low capital investment , the effect of mitigating post-processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Collect rose petals, clean them, cut them into small pieces, soak them in hydrogen peroxide solution, and stir them at a constant speed of 50r / min for 2 hours. Then the solution was transferred to a high-speed centrifuge, the rotating speed was set to 5000r / min, and the centrifugation time was 10 minutes. After the end, the broken layer was taken out. Under normal temperature and pressure, put the crushed sample into a cell culture dish with a diameter of 15cm, place it at the air inlet, adjust the flow parameters, set the wind speed to 6m / s, and the air volume to 1200m 3 / h, keep the ventilated state for 12 hours. The temperature of the tube furnace was raised to 900° C., and an inert gas protection was introduced and kept for 30 minutes. The dried broken sample was placed in a tube furnace, heated for 3 hours, and after cooling to room temperature, graphene with obvious exfoliation was obtained.

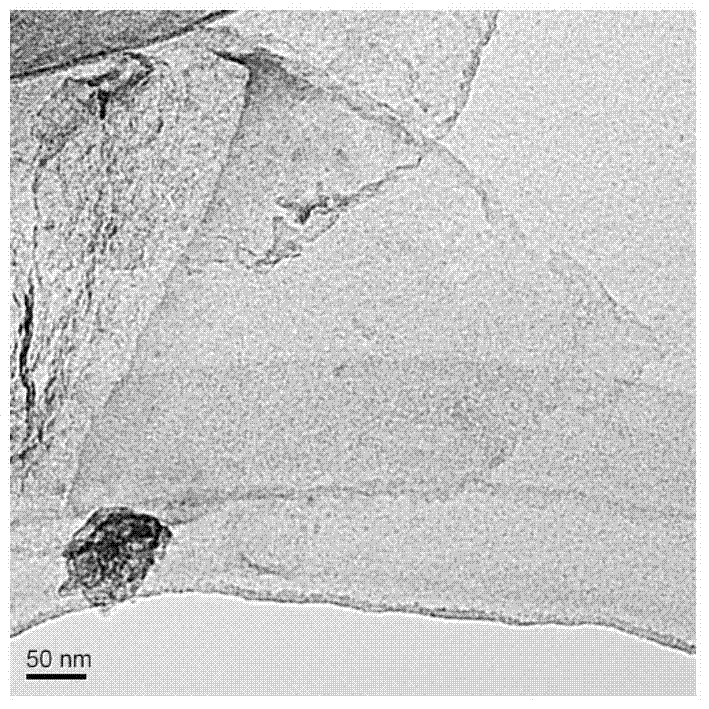

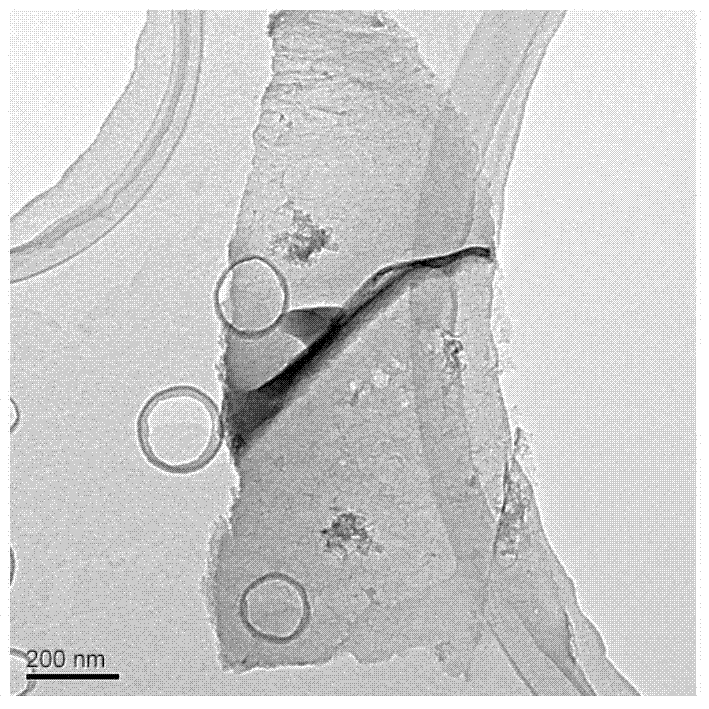

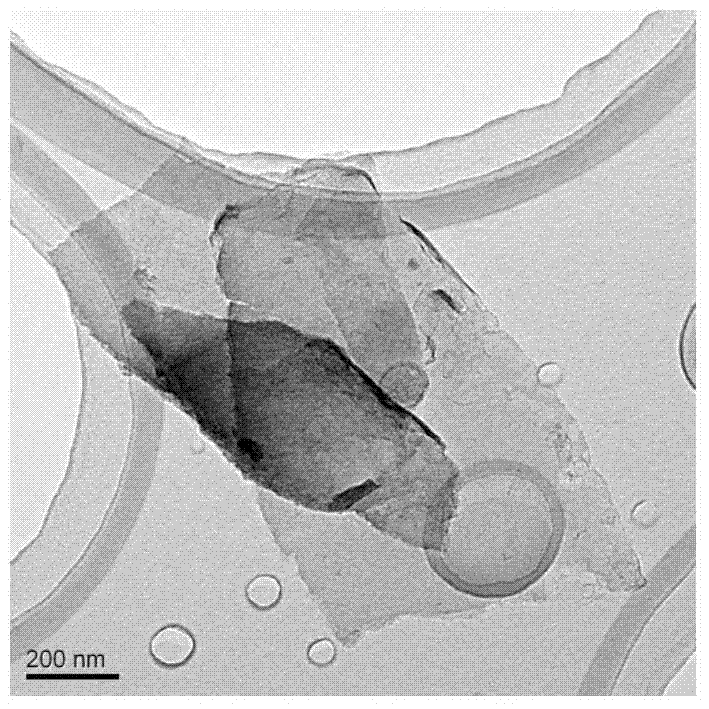

[0029] TEM picture as figure 1 As shown, it shows that the graphite ...

Embodiment 2

[0031] Collect the lotus petals, clean them, cut them into small pieces, soak them in ethanol solution, and stir them at a constant speed of 100r / min for 2 hours. Then the solution was transferred to a high-speed centrifuge, the rotating speed was set to 4000r / min, and the centrifugation time was 10 minutes. After the end, the broken layer was taken out. Under normal temperature and pressure, put the crushed sample into a cell culture dish with a diameter of 15cm, place it at the air inlet, adjust the flow parameters, set the wind speed to 6m / s, and the air volume to 1500m 3 / h, keep the ventilated state for 12 hours. The temperature of the tube furnace was raised to 1000° C., and an inert gas protection was introduced and kept for 30 minutes. The dried broken sample was placed in a tube furnace, heated for 2 hours, and after cooling to room temperature, graphene with obvious exfoliation was obtained.

[0032] TEM image with figure 1 Similarly, graphite flakes were effectiv...

Embodiment 3

[0034] Collect peach blossom petals, clean them, cut them into small pieces, soak them in hydrogen peroxide solution, and stir them at a constant speed of 60r / min for 3 hours. Then the solution was transferred to a high-speed centrifuge, the rotating speed was set to 3000r / min, and the centrifugation time was 10 minutes. After the end, the broken layer was taken out. Under normal temperature and pressure, put the crushed sample into a cell culture dish with a diameter of 15cm, place it at the air inlet, adjust the flow parameters, set the wind speed to 6m / s, and the air volume to 1600m 3 / h, keep the ventilated state for 12 hours. The temperature of the tube furnace was raised to 1100° C., and an inert gas protection was introduced and kept for 30 minutes. The dried crushed sample was placed in a tube furnace, heated for 1 hour, and cooled to room temperature to obtain graphene with obvious exfoliation.

[0035] TEM image with figure 1 Similarly, graphite flakes were effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com