Stripping tool for overhead wire insulating layer

A technology for overhead conductors and insulating layers, which can be used in the direction of dismantling/armoring cable equipment, etc., which can solve the problems of inconvenient use and low operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The new aerial wire insulation stripping tool of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

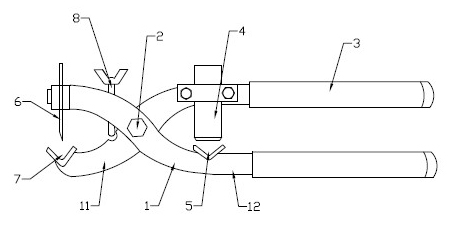

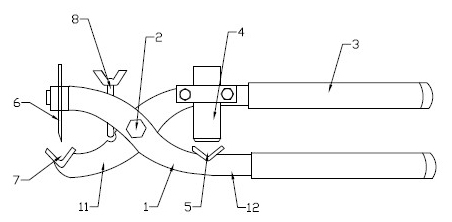

[0008] As can be seen from the figure, the overhead wire insulation layer stripping tool of the present invention includes a pair of long and narrow pliers 1, the front part of the pliers is the pliers head 11, the rear part of the pliers is the pliers handle 12, and the hinge point of the pair of pliers in the middle is The 2 places intersect each other and are hinged, and the rear section of the pliers handle is provided with an insulating handle 3; a section of the pliers handle behind the hinge point 2 is provided with a longitudinal blade 4 whose cutting edge is parallel to the length direction of the pliers body, and the other section of the pliers handle opposite to the longitudinal blade A horizontal rear V-shaped groove 5 is provided on the top; a horizontal blade 6 with a cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com