Patents

Literature

1028results about "Shrimp/lobster processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

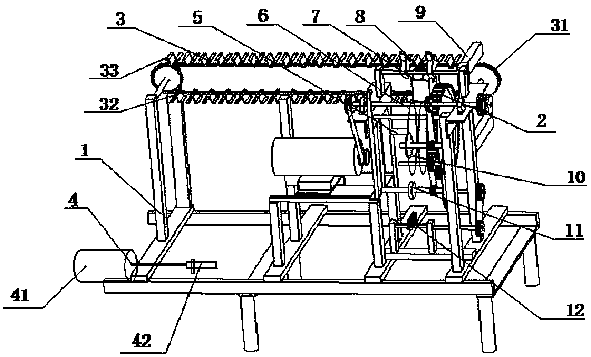

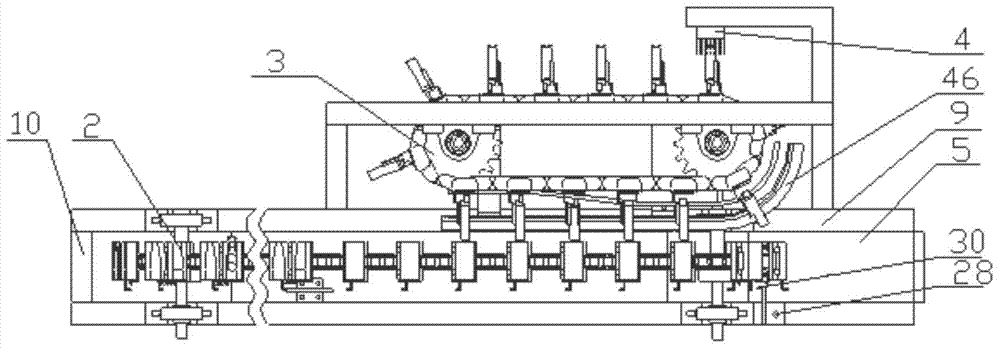

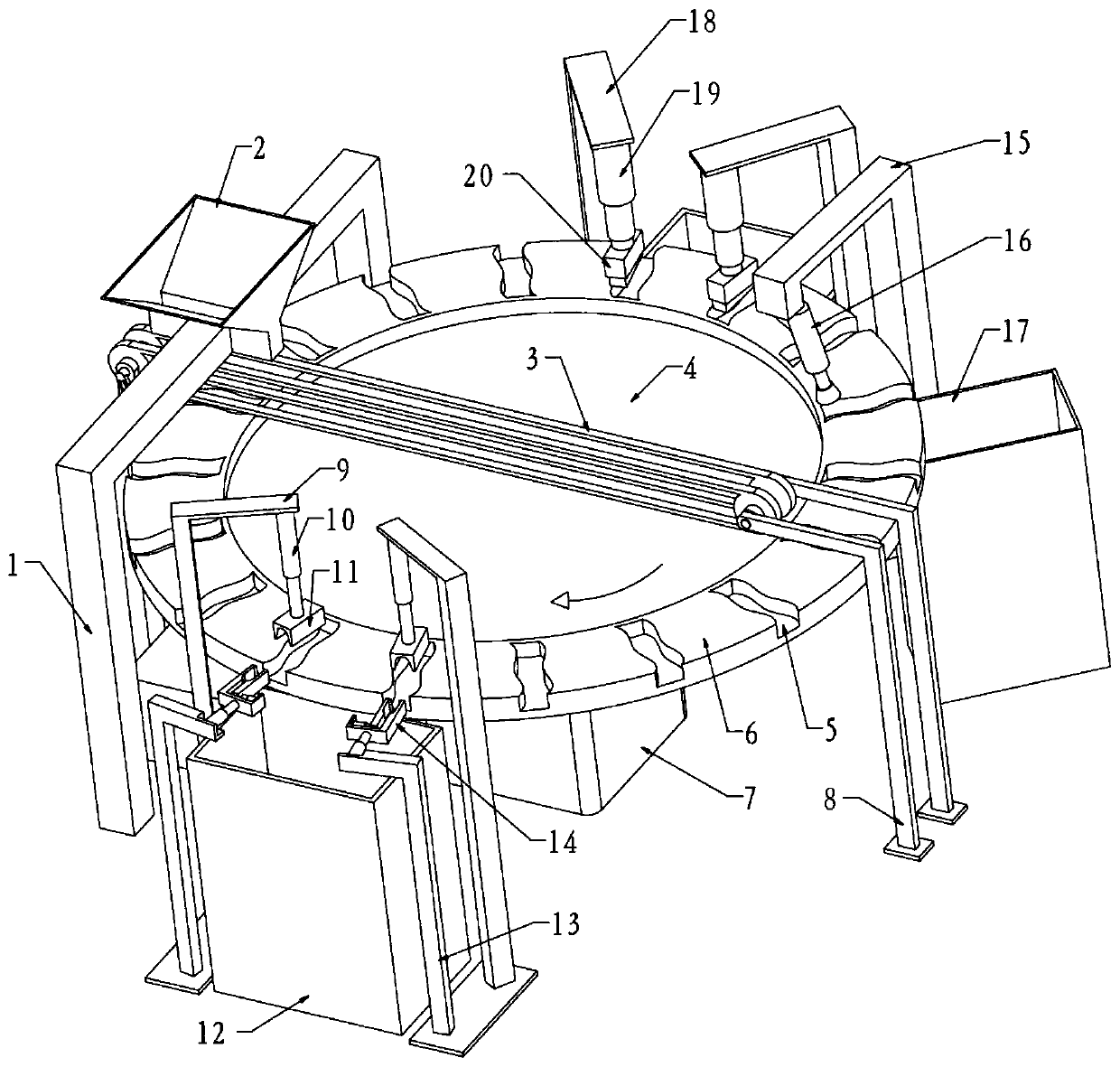

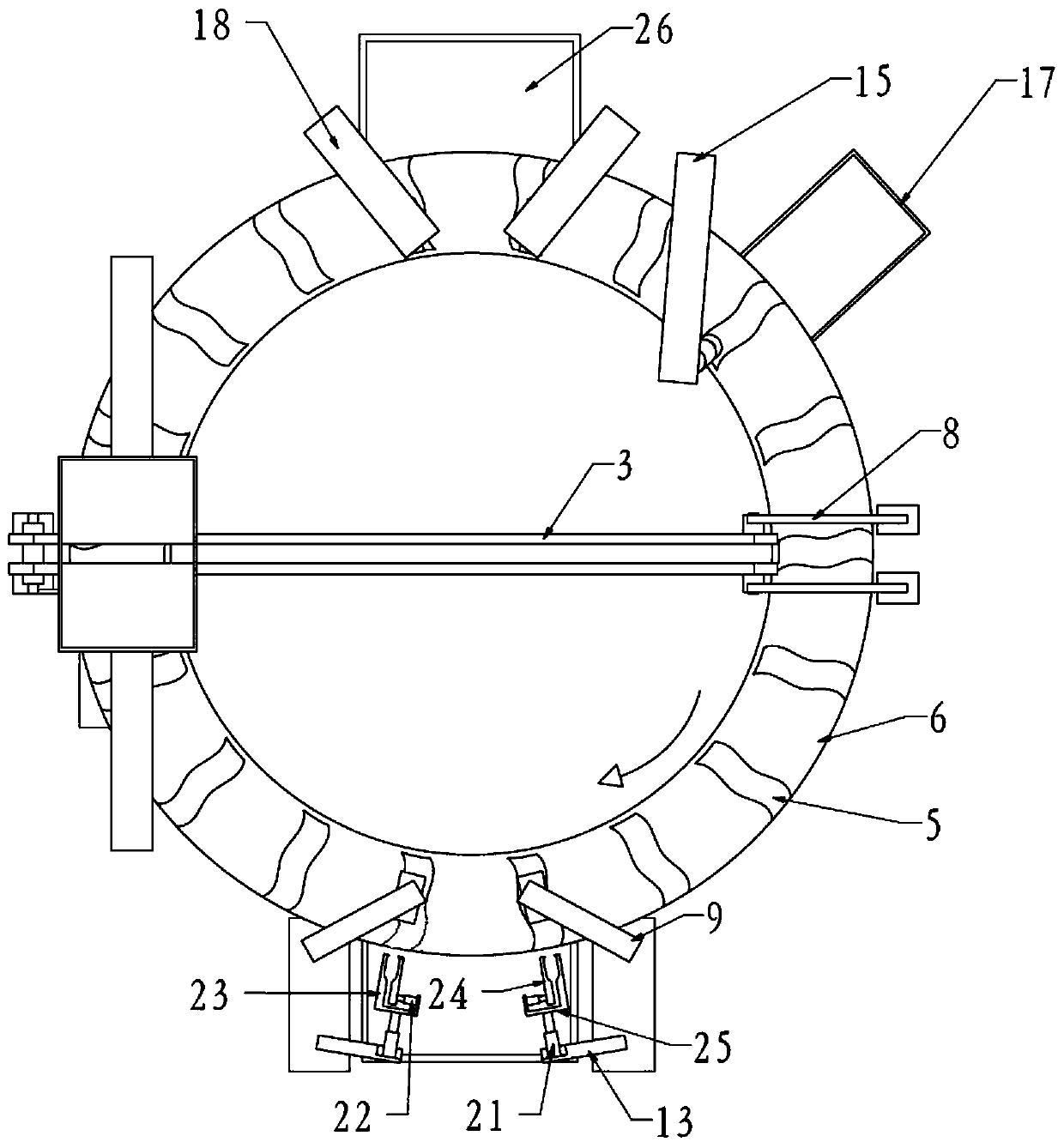

Automatic shrimp peeling machine

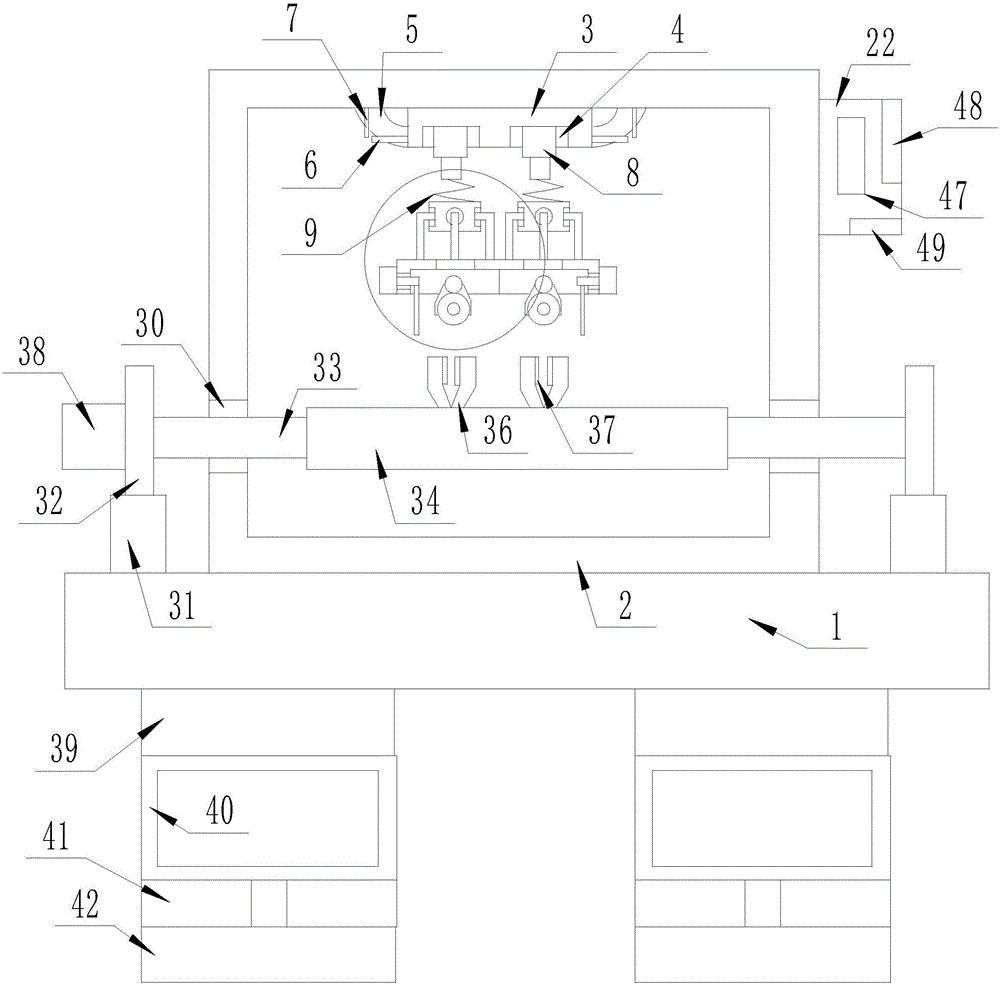

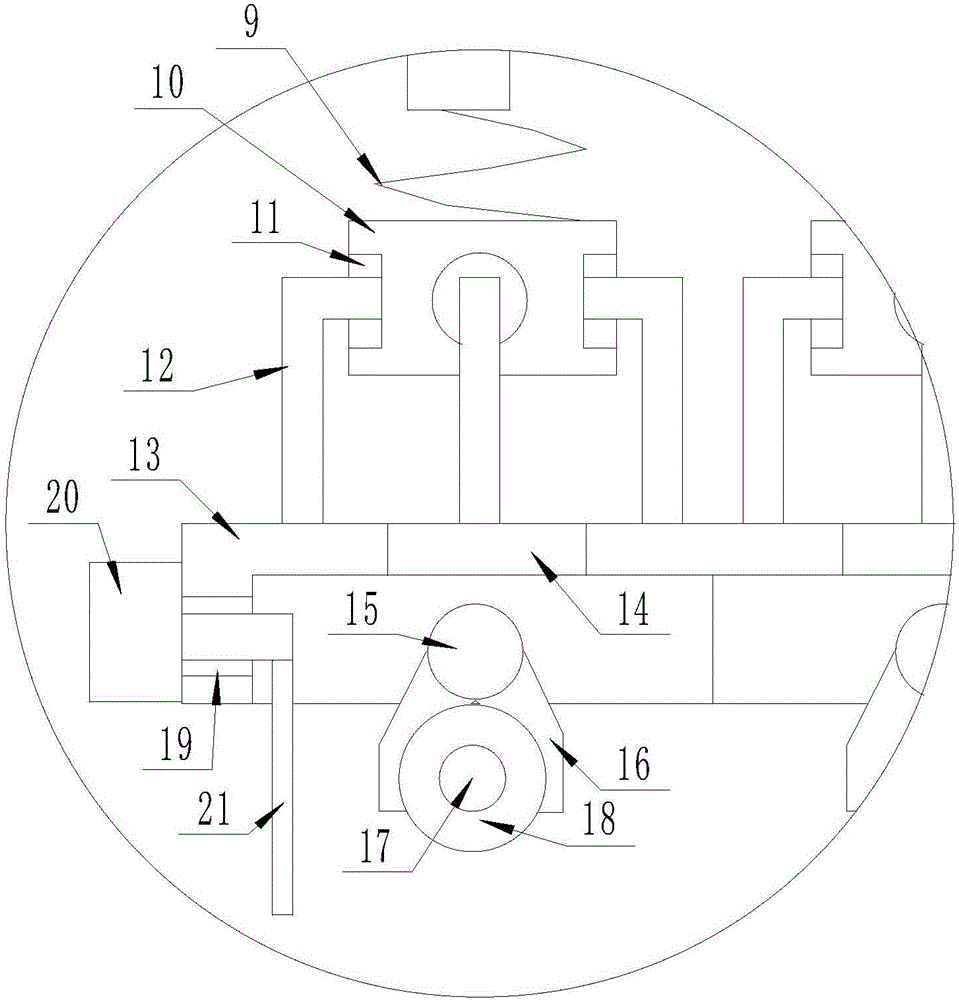

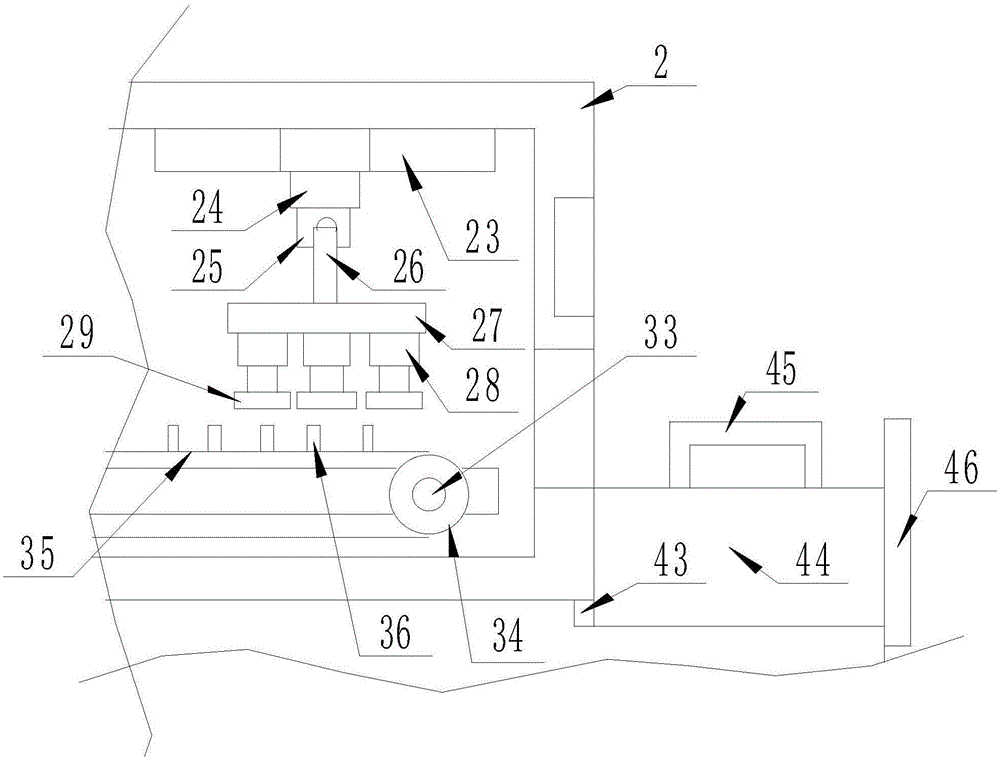

The invention provides an automatic shrimp peeling machine. The automatic shrimp peeling machine is characterized by comprising a frame, a main drive gear, a conveying device, a transmission gear, a cam system and a water spray system which are mounted on the frame, wherein the main drive gear is arranged on a main transmission shaft in a sleeving manner; two corresponding plane cams are further arranged on the main transmission shaft in a sleeving manner; a plurality of large / small jaw clamping devices and final-stage separation devices are arranged around the circumferences of the plane cams; the conveying device, a guide pinch roller device, a blade assembling unit, an intestine-removing brush, an in-vivo long-needle assembling unit and a shrimp shell cleaning brush are sequentially arranged along the working track for mounting the raw material shrimp outside the circumferences of the large / small jaw clamping devices. The automatic shrimp peeling machine disclosed by the invention can eliminate the accumulative error generated in the machine operation process, lower the accumulative error to be minimal, and ensure that the single deheaded shrimp holding position of the circulating jaw in the positioning holding device is correct, so as to enable the working stations of back opening, peeling, and removal of shrimp line to be kept correctly and ensure the peeling quality of the shrimp.

Owner:南通宝泰机械科技有限公司

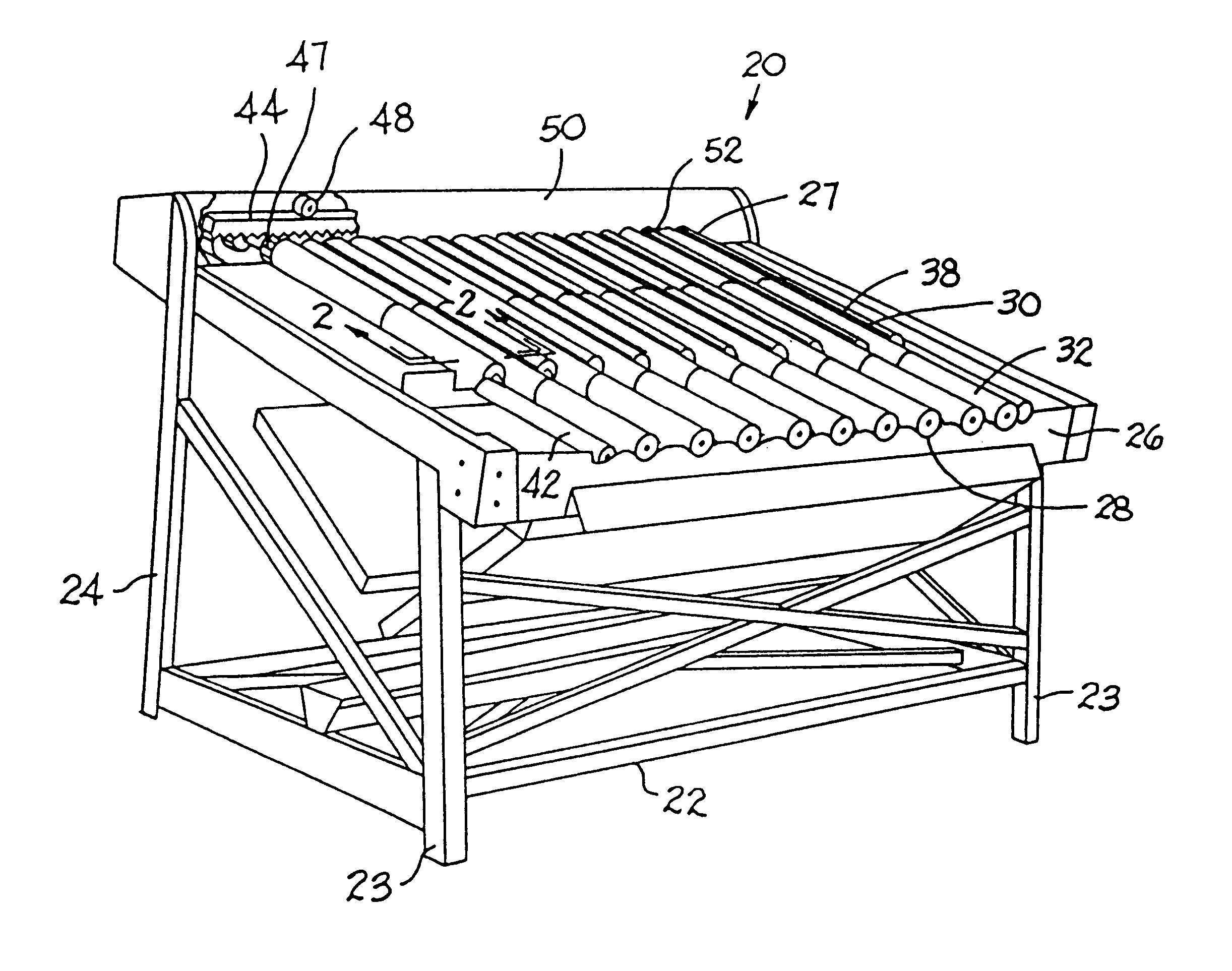

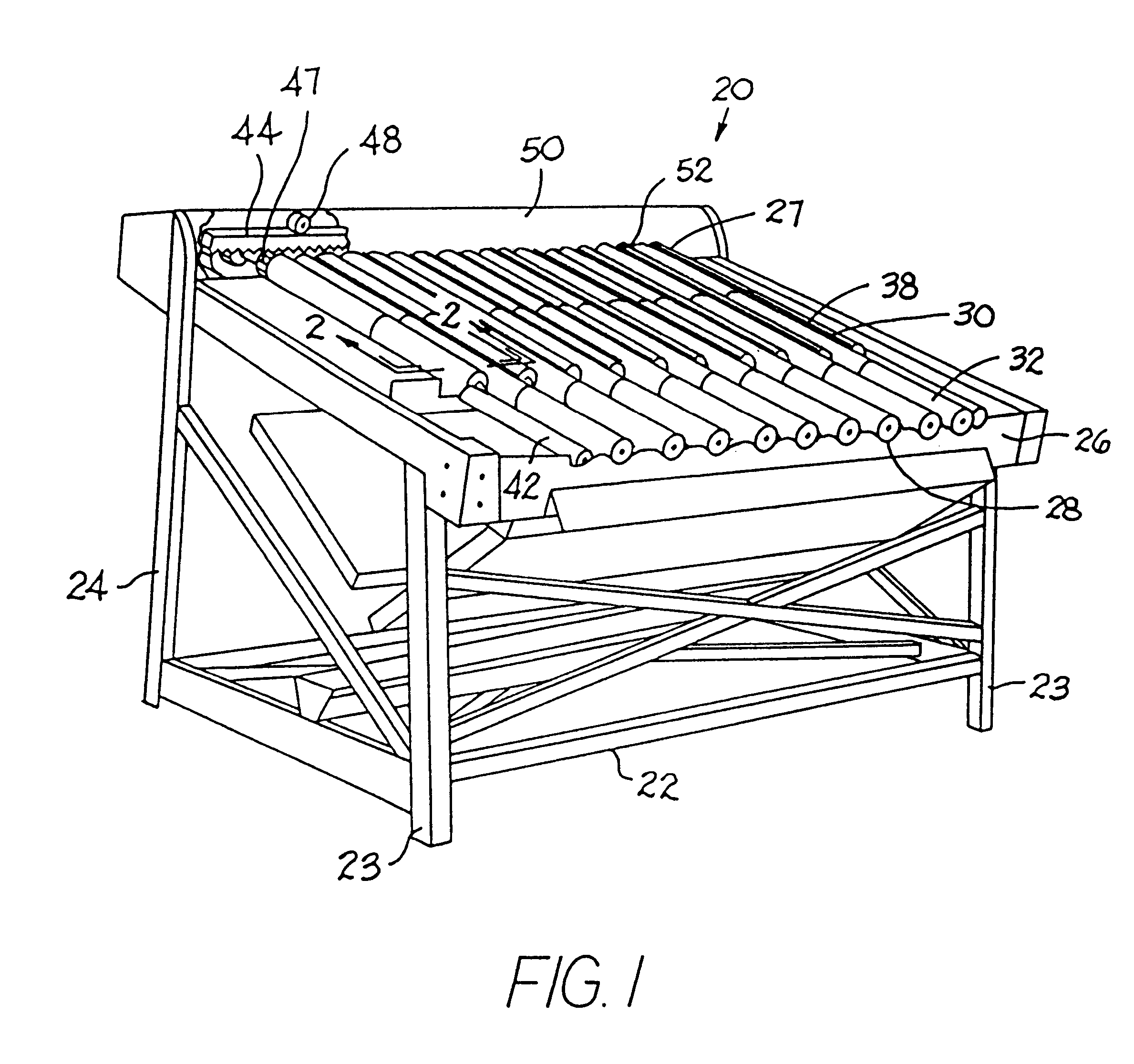

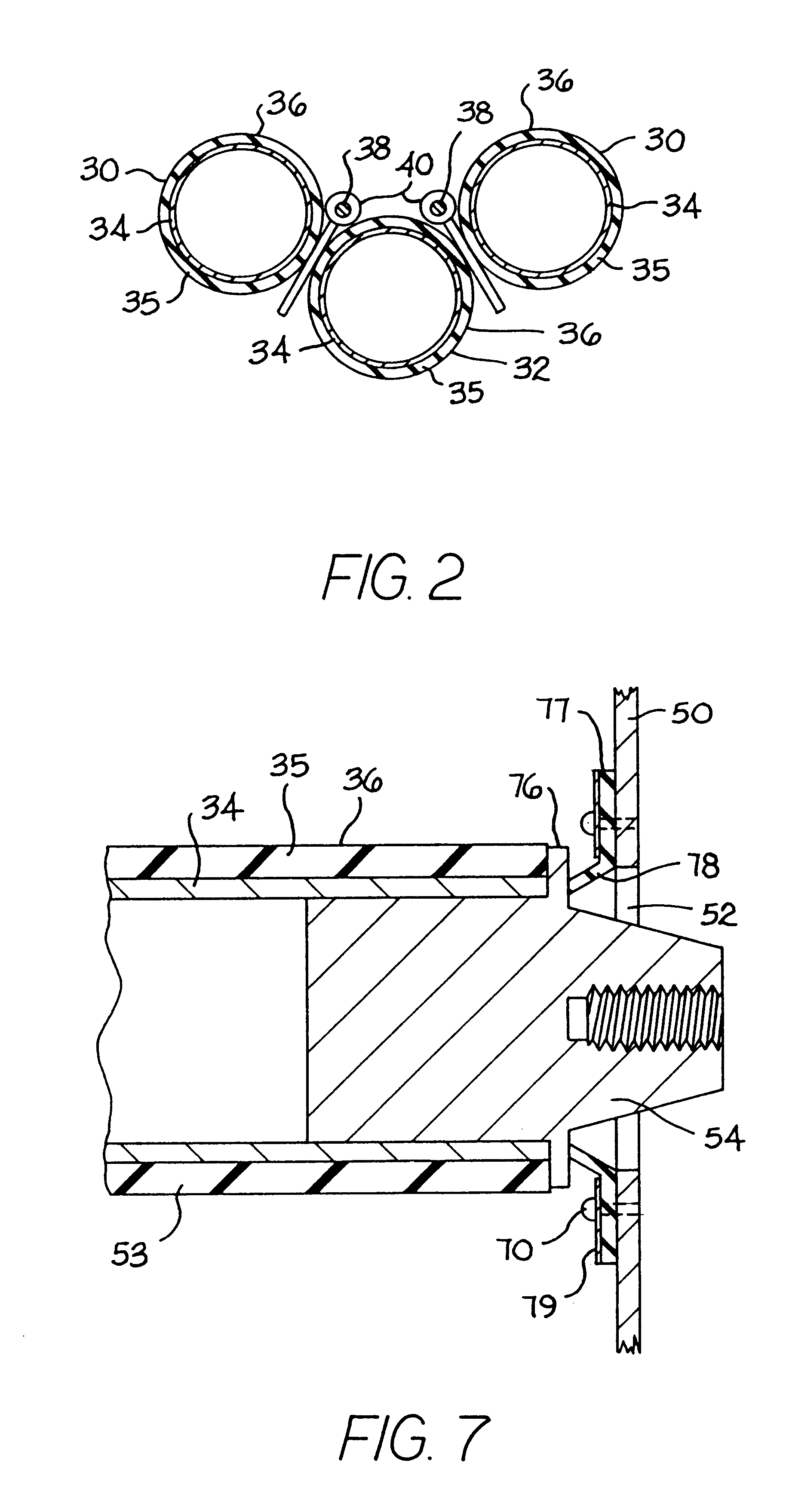

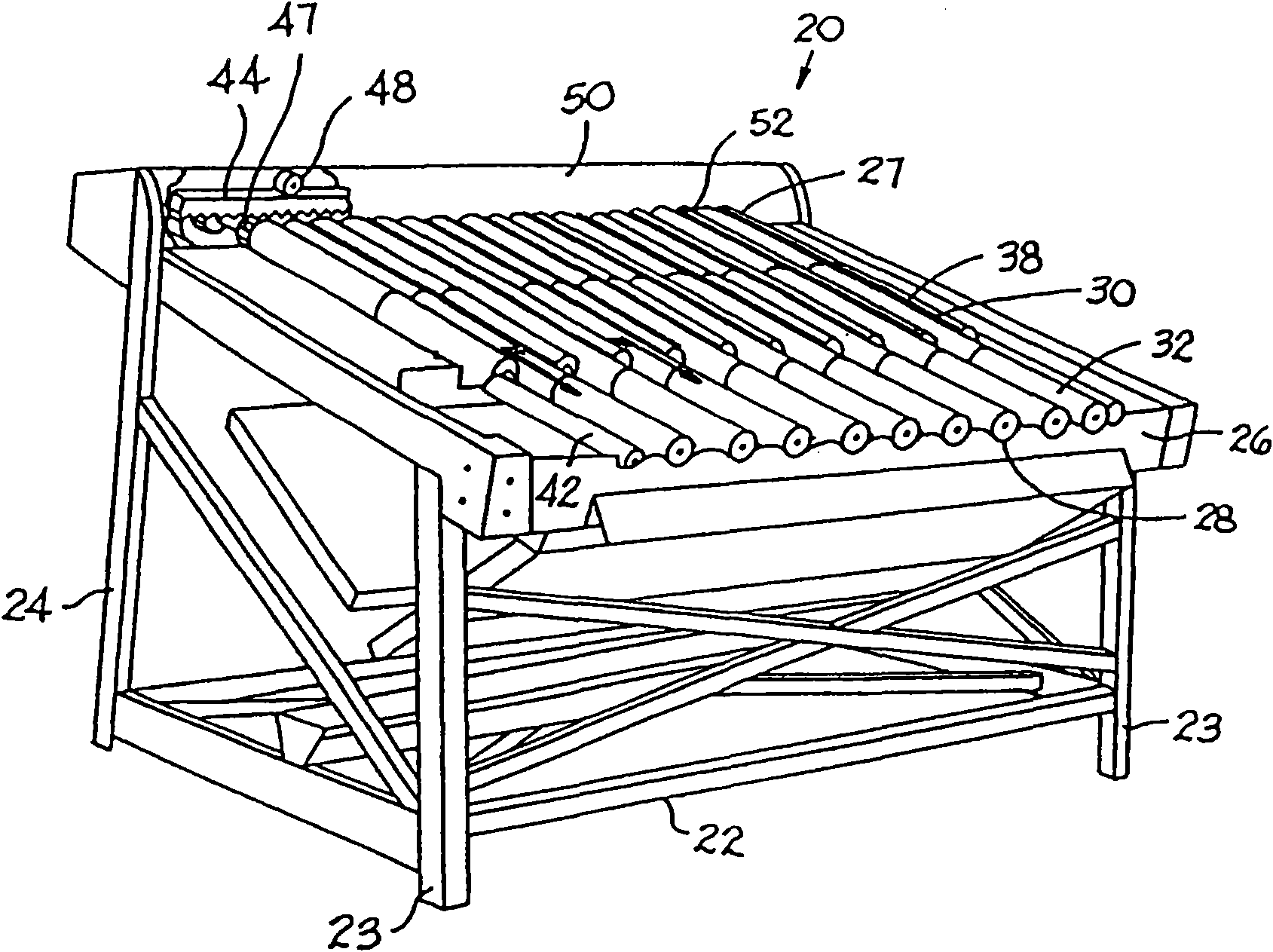

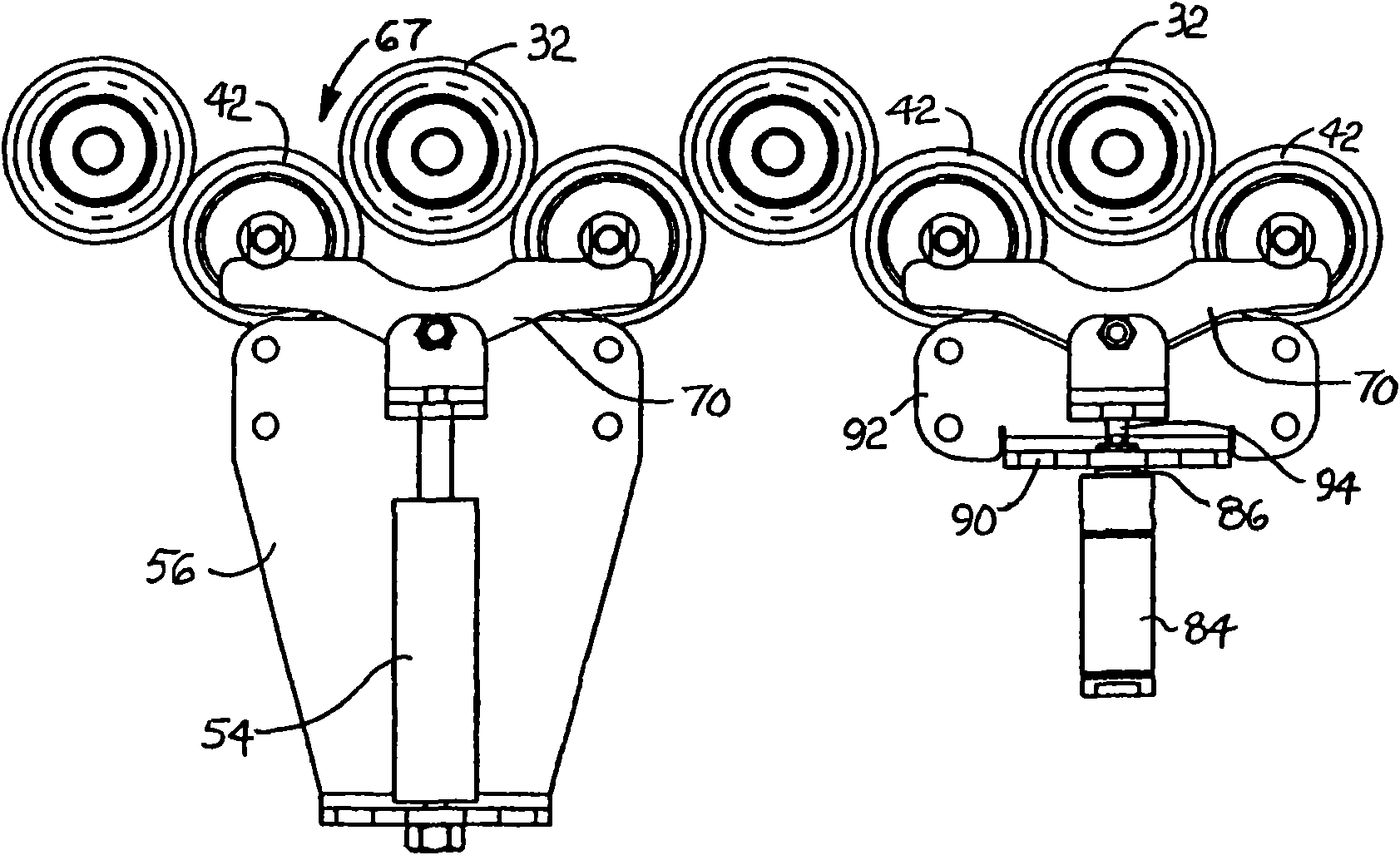

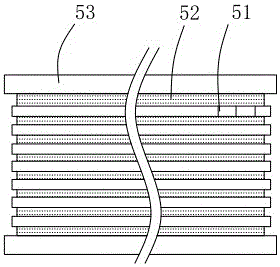

Peeling apparatus with segmented roller assemblies

InactiveUS6248010B1Easy to separateDifferent textureShrimp/lobster processingEngineeringMechanical engineering

Apparatus for peeling shrimp including powered roller assemblies each made up of a peeling roller and a drive member attached by a releasable connection. Roller connection structure at a first end of each roller assembly mates with reciprocal drive connection structure in the drive member. An adjustable element extending through the drive member allows the connection to be released and the roller assembly separated into a roller segment and a drive member segment. In other versions the roller segment can be composed of a series of segments having the same or different peeling surface characteristics in which the individual roller segments are similarly releasably connected.

Owner:THE LAITRAM CORP

Crayfish food as well as preparation method and production equipment thereof

InactiveCN103960697AGood health effectSilky meatWater/sewage treatmentOil/fat bakingVegetable oilAdditive ingredient

Crayfish food comprises ingredients in parts by weight as follows: 100 parts of crayfish, 50 parts of vegetable oil, 10.6-15.2 parts of spice, 0.3-0.5 parts of transglutaminase, 0.3-0.5 parts of nisin, 0.2-0.5 parts of konjac glucomannan, 0.2-0.4 parts of chitosan, 0.4-0.5 parts of lecithin and 0.08-0.16 parts of delta-gluconolactone. According to the crayfish food, crayfish balls are used for preparing instant food, crayfish shells are used for preparing chitosan, and raw materials are sufficiently utilized; transglutaminase in the raw materials prompts crosslinking of crayfish meat protein crosslinking amino acid, tenderness of a product is improved, natural food antiseptics such as nisin and the like meet requirements of people for food health, and at the same time, the guarantee period of the crayfish food is prolonged to 12 months; and defects that crayfish products which can be stored at the normal temperature are less, the guarantee period is short and the like are overcome, and the crayfish food has good market prospect.

Owner:顾炎林

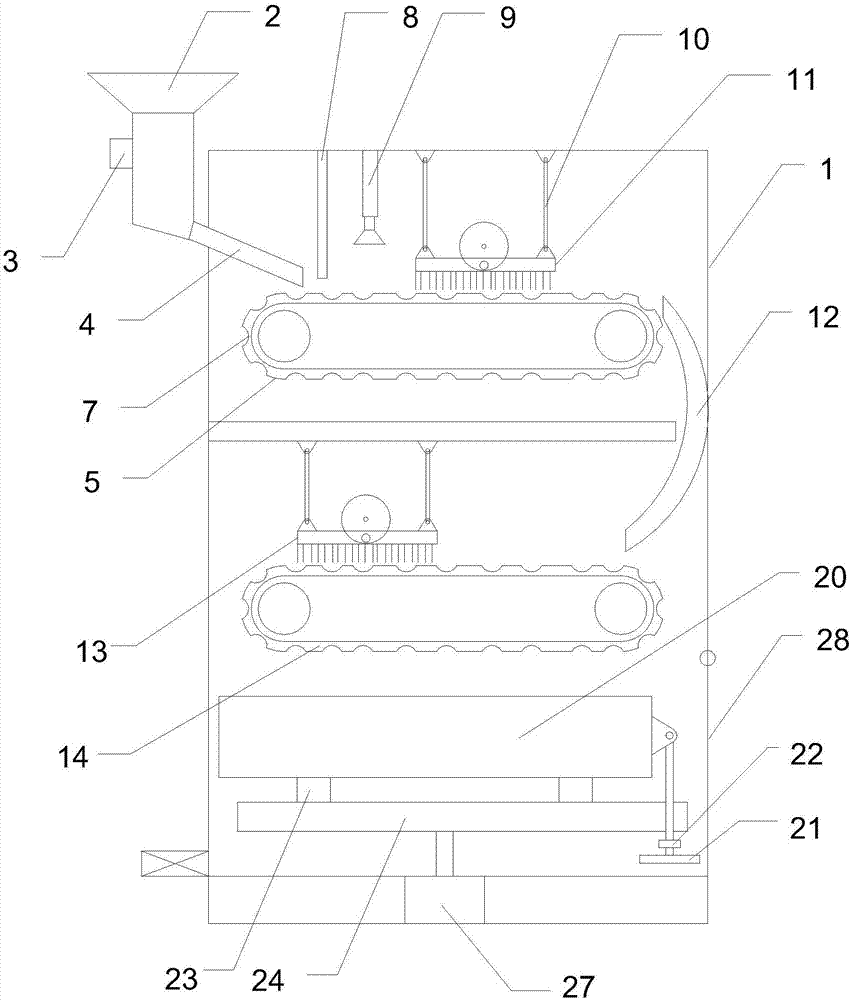

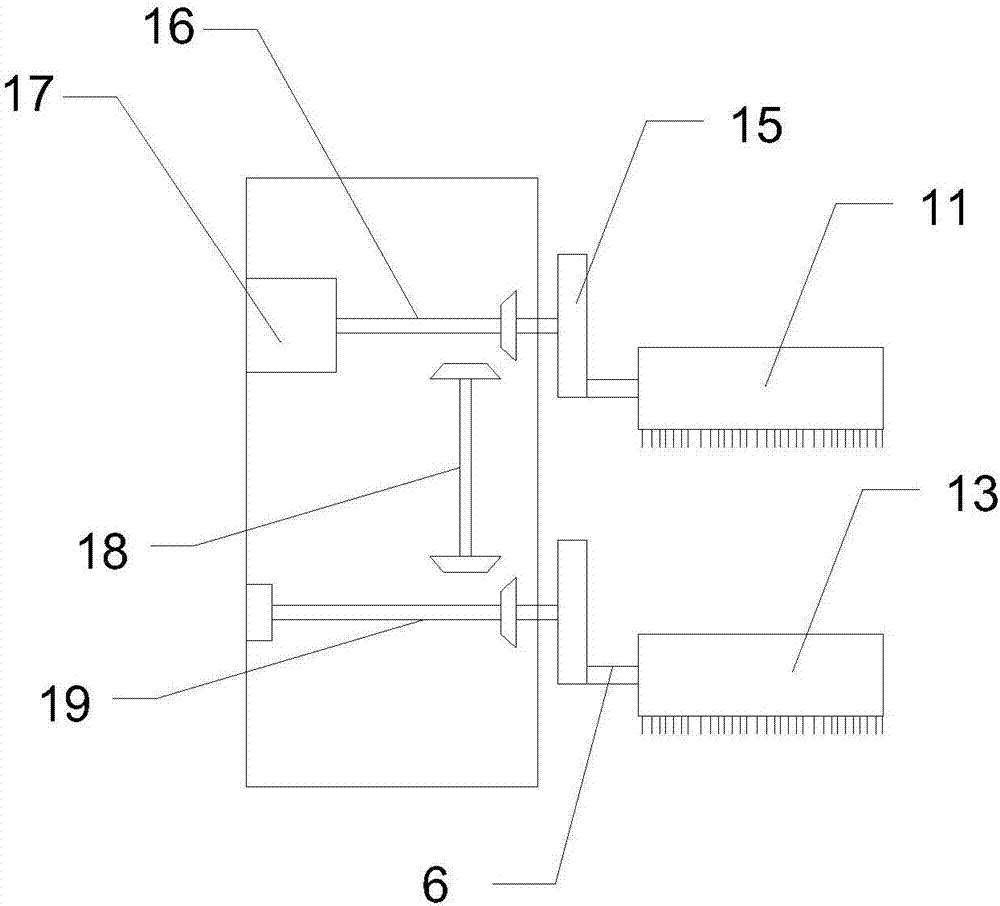

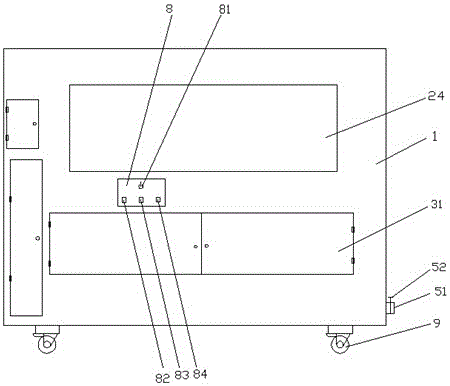

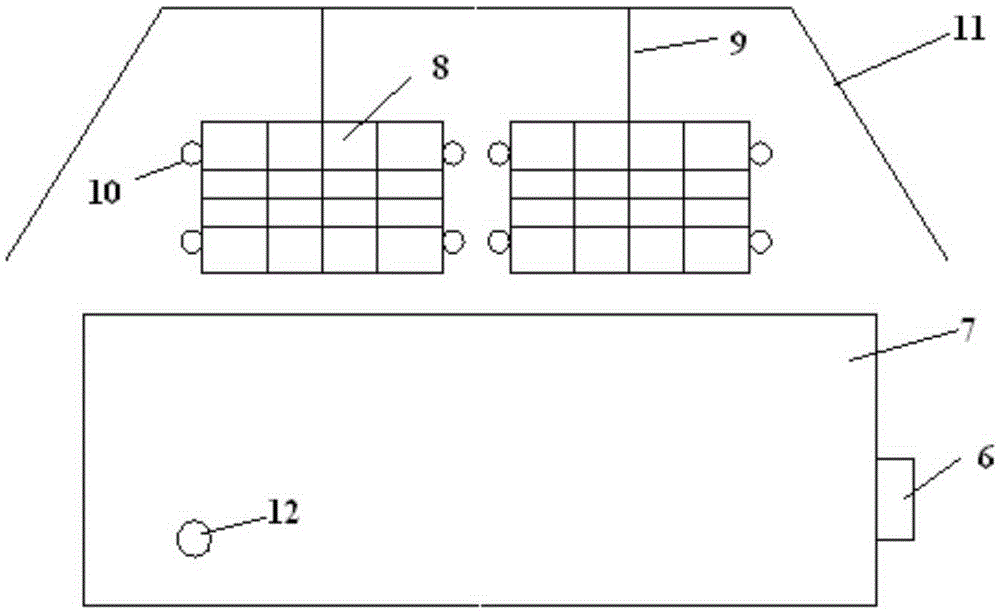

Lobster cleaning machine

ActiveCN108174910AAchieve cleaningImprove cleaning efficiencyShrimp/lobster processingMegasonic cleaningEngineering

The invention discloses a lobster cleaning machine which comprises an engine base, a lobster spreading plate, a cleaning brush, a water spraying device, a driving device, an ultrasonic cleaning vesseland a water supply device, wherein the lobster spreading plate is mounted on the engine base and a brushing tank used for enabling abdomens of lobsters to be exposed downwards runs through the lobster spreading plate; the cleaning brush is mounted at the brushing tank upwards and movably arranged in a horizontal direction; the water spraying device is used for spraying water to the abdomens of lobsters on the lobster spreading plate; the ultrasonic cleaning vessel is arranged on the engine base; and the water supply device is used for supplying water to the water spraying device and the ultrasonic cleaning vessel. According to the technical scheme provided by the invention, the cleaning brush can be driven by the driving device to brush the abdomens of lobsters on the lobster spreading plate, and the lobsters are wholly cleaned by the ultrasonic cleaning vessel, so that a manual cleaning link is reduced. By combining two manners such as cleaning by the cleaning brush and ultrasonic cleaning, the cleaning effect and the cleaning efficiency are greatly increased.

Owner:WUHAN POLYTECHNIC UNIVERSITY

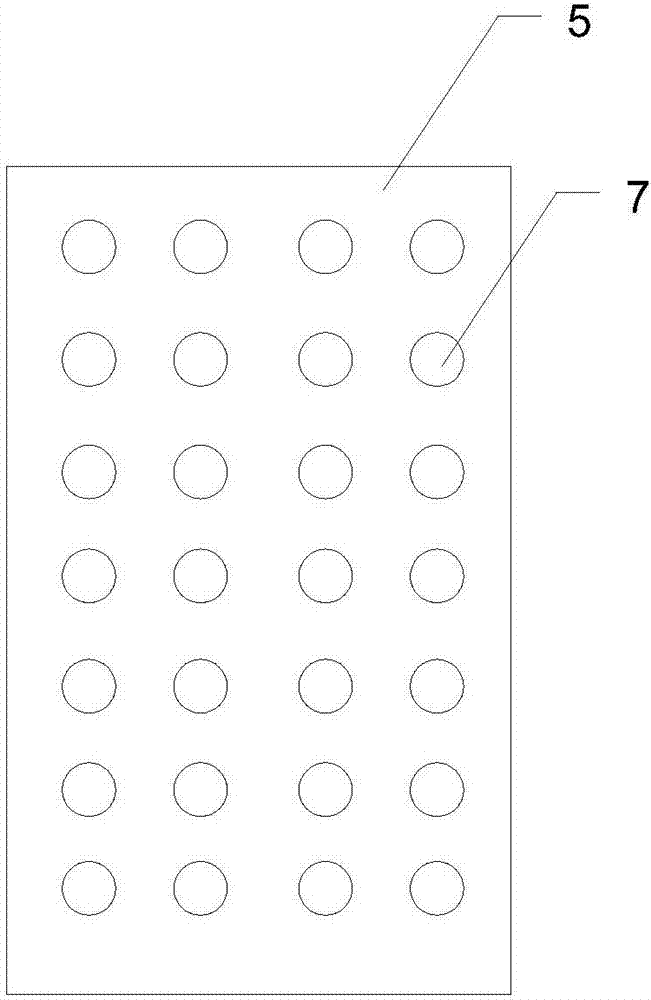

Double-side cleaning device for aquatic products

InactiveCN107006590AFor subsequent scrubbingGuaranteed cleaning effectBivalves processingShrimp/lobster processingAquatic productConveyor belt

A double-sided cleaning device for aquatic products, including a housing, a hopper and a frequency conversion motor; the housing is provided with a first conveyor belt, and the surface of the first conveyor belt is provided with evenly distributed semicircular grooves; the first conveyor belt A baffle is provided above, and a water spray gun is provided on the right side of the baffle; a first brush plate is provided on the right side of the water spray gun; The rotating shaft is connected with a frequency conversion motor; an arc-shaped pipe is arranged on the right side of the first conveyor belt, and a second conveyor belt is arranged under the arc-shaped pipe. The present invention is equipped with a vibrating feeding hopper and a feeding pipeline, so that the aquatic products are evenly spread on the conveyor belt, which is convenient for subsequent brushing. The present invention is equipped with double brushing and conveying devices, so that both sides of the aquatic products are cleaned to ensure cleaning The effect, at the same time has a convenient discharge.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Industrial production of meat using cell culture methods

A meat product containing in vitro produced animal cells in a three dimensional form and a method for producing the meat product.

Owner:GOOD MEAT INC

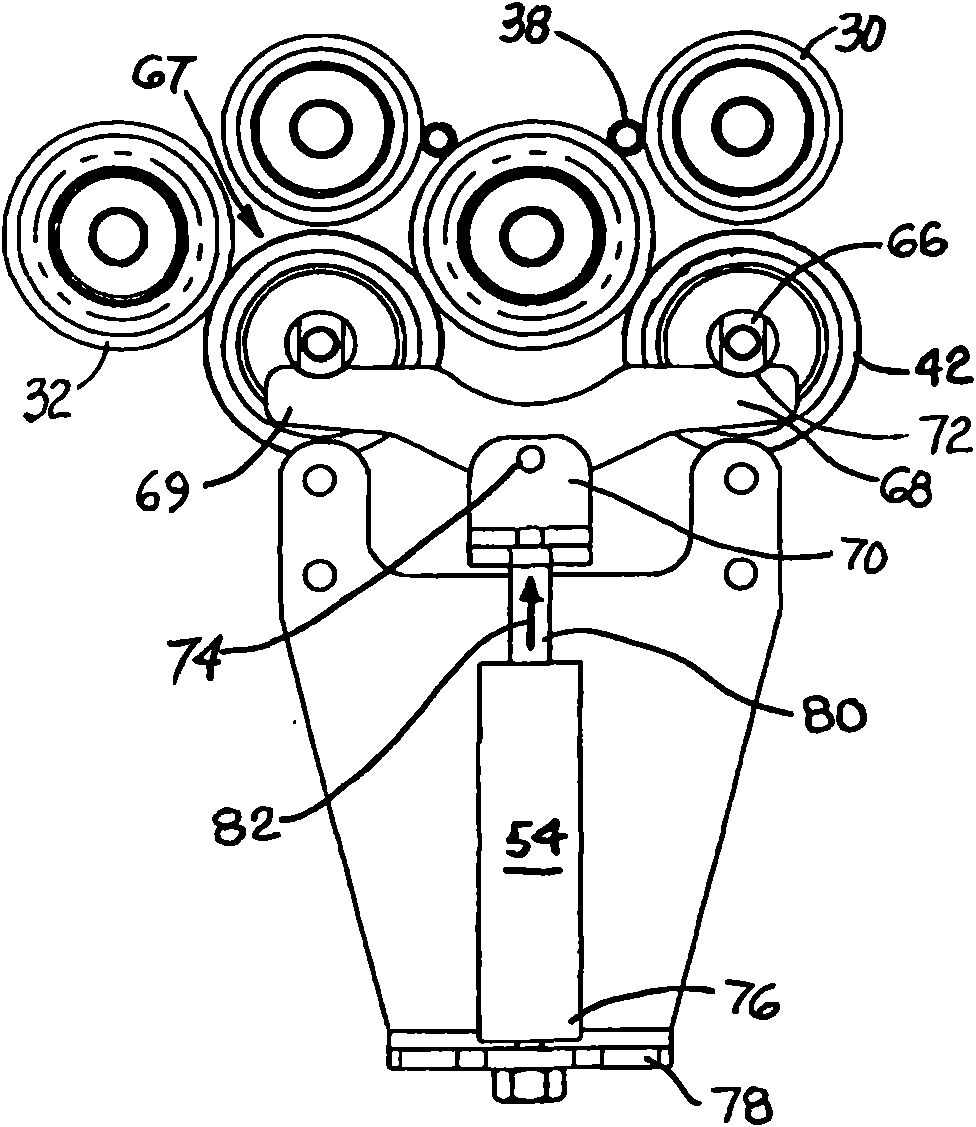

Peeler with self-adjusting rollers

Peeling apparatus and a method for biasing lower idle rollers of a roller-type peeling machine against power rollers to maintain the rollers in contact as the rollers wear. The apparatus includes biasing means, such as a cylinder applying upward pressure against the upper ends of the lower rollers to keep the rollers in constant contact.

Owner:LAITRAM LLC

Protein product and process for preparing injectable protein product

InactiveUS20110244093A1Good moisturizing effectFunction increaseProtein composition from fishFood preparationMuscle tissueFood grade

Moisture is retained in cooked or thawed food by adding to the food an aqueous suspension of animal muscle protein obtained from animal muscle tissue. The aqueous suspension is obtained by mixing comminuted animal muscle tissue with a food grade base to form an aqueous basic solution of animal muscle protein. The basic solution is mixed with a food grade acid to precipitate the protein in an aqueous composition. The precipitated protein then is comminuted to form an aqueous suspension of comminuted animal muscle protein.

Owner:KEMIN PROTEINS LLC

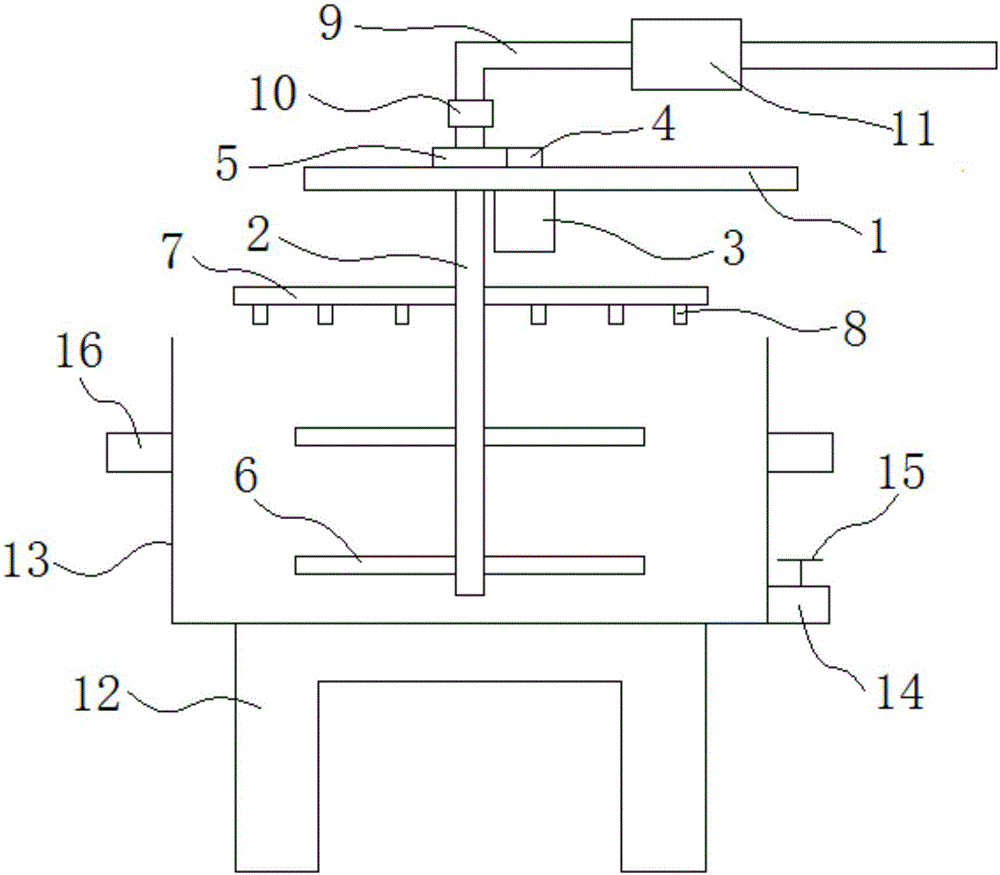

Marine food product cleaning and impurity-removing device

InactiveCN106689323AImprove cleaning efficiencyReduce labor intensityFish washing/descalingBivalves processingDraining tubeEngineering

The invention discloses a marine food product cleaning and impurity-removing device, which comprises a rack, a rotary shaft, stirring rods, a spray pipe, a water inlet pipe, a water pump, a cleaning table, and a cleaning box, wherein the upper part of the rotary shaft is arranged on the rack in a rotatable way; a water inlet cavity with an opening on the upper end is arranged on the upper part of the rotary shaft; at least two layers of stirring rods are arranged on the lower part of the rotary shaft from top to bottom; the spray pipe is arranged on the upper part of the rotary shaft; a pipe cavity of the spray pipe is communicated with the water inlet cavity, and is provided with a plurality of nozzles with downward openings along an axial direction; one end of the water inlet pipe is connected with the upper end of the rotary shaft through a rotating joint; the water pump is connected with the other end of the water inlet pipe; the cleaning table is arranged under the rack; the cleaning box is arranged on the cleaning table in a support way; the stirring rod stretches into the bottom part of the cleaning box; a drainage pipe is arranged on the lower end of the cleaning box; a drainage valve is arranged on the drainage pipe. The marine food product cleaning and impurity-removing device provided by the invention not only can be used for spraying and washing marine food products through the spray pipe, but also can be used for stirring to clean the marine food products through the stirring rod, has high cleaning efficiency on the marine food products, and can be beneficial to effectively reducing the labor intensity.

Owner:防城港市海洋局

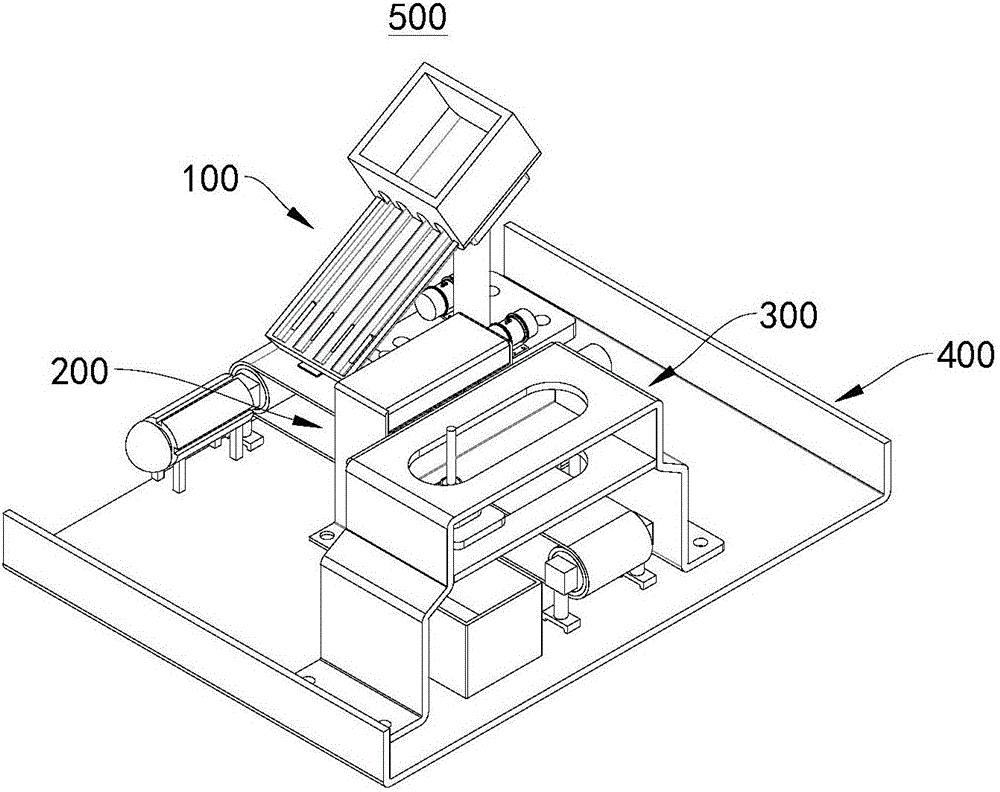

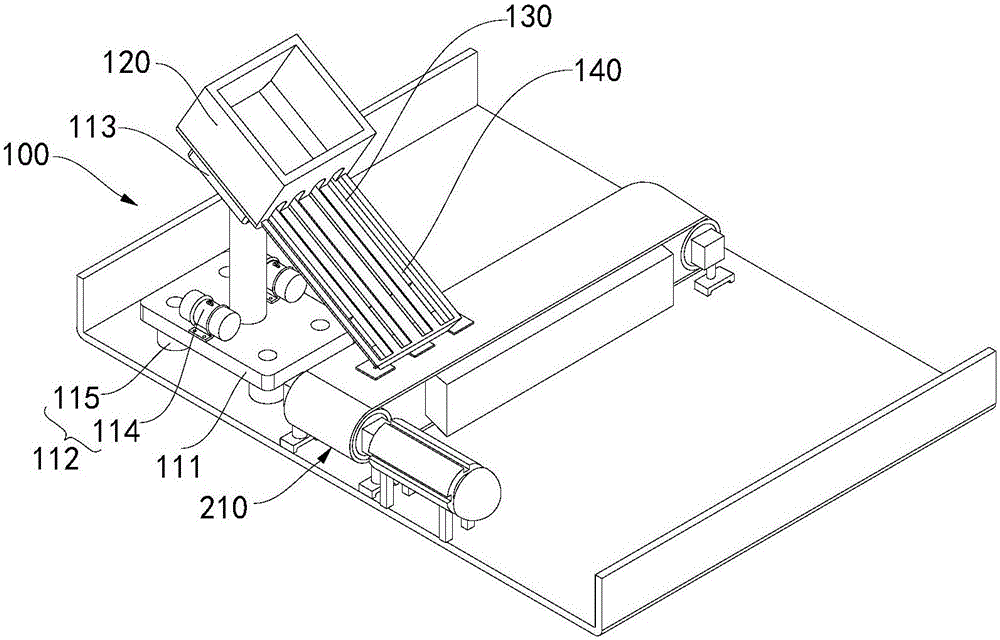

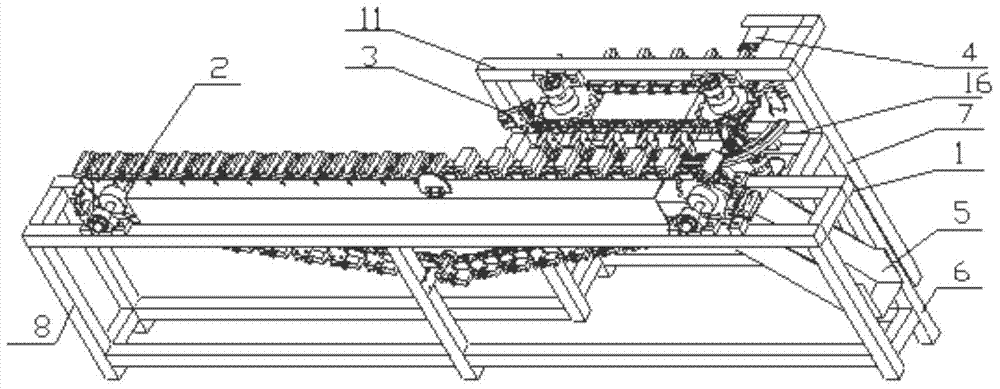

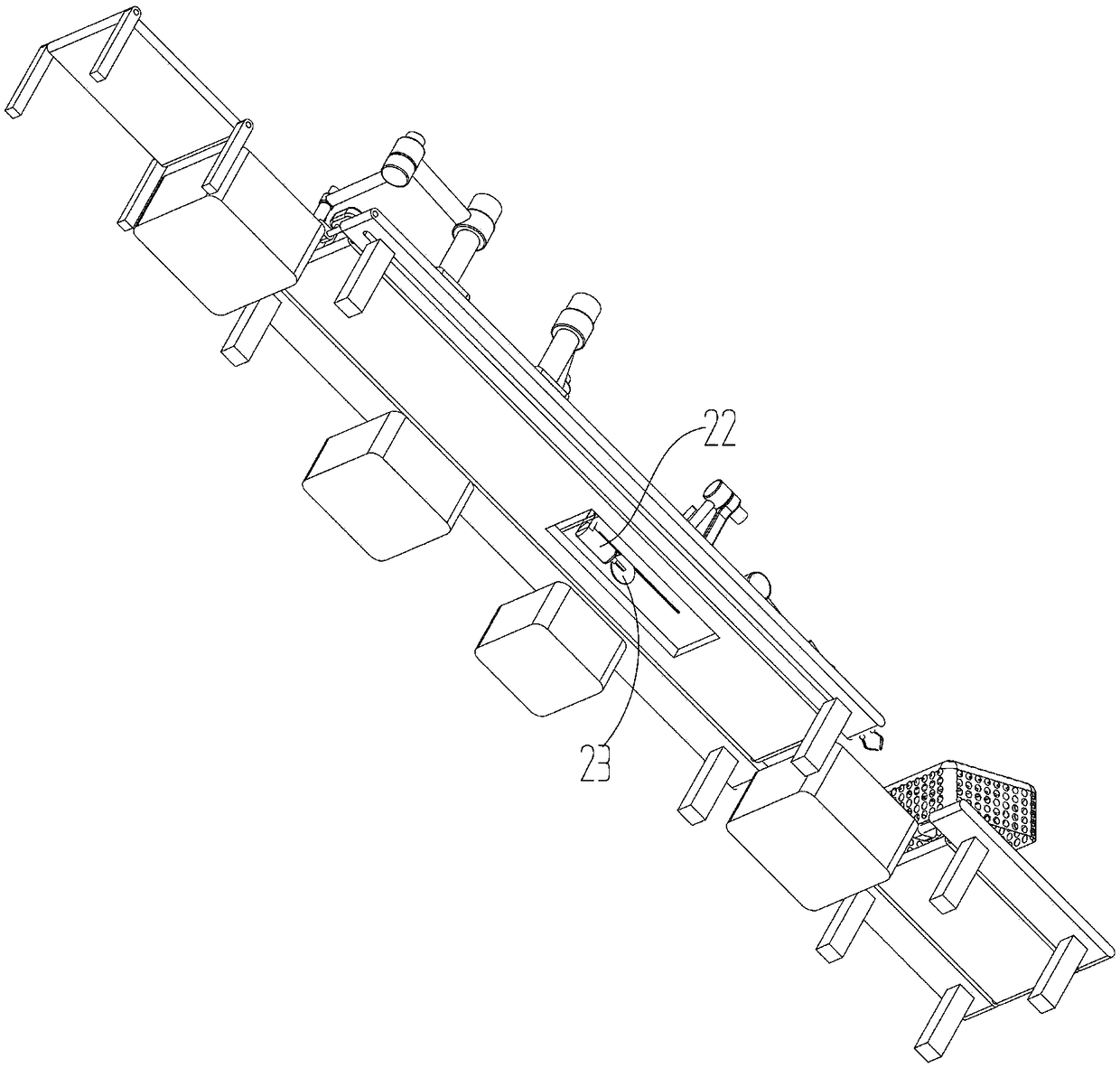

Shrimp sheller and shrimp meat processing system

ActiveCN106417555ALightweight operation structureHigh degree of automationShellfish/bivalves grading/classificationShrimp/lobster processingProduction rateShrimp

The invention relates to a shrimp sheller and a shrimp meat processing system and belongs to the field of shrimp shelling equipment; the shrimp sheller comprises a feeding device, a shelling cutting device, a separating device and a base for mounting the feeding device, the shelling cutting device and the separating device; the feeding device comprises a directional mechanism and a conveying mechanism; the shelling cutting device comprises a tool rest, front and rear cutters, a side cutter and a back cutter, the tool rest is arranged above a conveyer belt, and the front and rear cutters, the side cutter and the back cutter are mounted respectively in the front, middle and rear of the tool rest; the separating device comprises a separating frame, a shrimp pin and a partition, the separating frame is disposed above the tail end of the conveyer belt and is provided with a sliding panel, the partition is horizontally slidably mounted on the sliding panel, and the shrimp pin is vertically slidably mounted at the partition. The shrimp sheller and the shrimp meat processing system allow full-automatic line production, production rate of shrimp eat products is increased, and production cost is reduced.

Owner:临沂高新区金蓝领劳务有限公司

Cleaning system for crab-type aquatic products

InactiveCN106615018AImprove qualityAchieve the effect of automatic cleaningPisciculture and aquariaShrimp/lobster processingBristleFree range

The invention relates to a cleaning system for crab-type aquatic products. The cleaning system for the crab-type aquatic products solves the problem of cleaning difficulty of silt adhered to the shell and the legs of the fished crabs which causes affects on sales. The cleaning system for the crab-type aquatic products comprises a crab pool used for free-ranging the crabs; multiple holes are formed at one side of the bottom of the crab pool; a starting end of an conveyor table is arranged at the outer sides of the holes; the direction of the holes are identical to the conveying direction of the conveyor table; a conveyor belt is arranged on the conveyor table; roller brushes are arranged above the conveyor table; spraying pipes which spray water downwards are arranged above the roller brushes; and a crab basin used for containing the cleaned crabs is arranged under the terminal of the conveyor table. The backs and the abdomens of the crabs are respectively cleaned by using the roller brushes and the bristles arranged above the conveyor table, so that the effect of self-cleaning is achieved; thus, the labor intensity is reduced and the qualities of the crab-type aquatic products are improved. The characteristics of the crabs, namely likes to holes and shade, are utilized, so that the holes with shade are arranged at one side of the crab pool; thus, the crabs spontaneously aggregate, and sequentially climb out of the holes to be orderly cleaned.

Owner:ZHEJIANG OCEAN UNIV

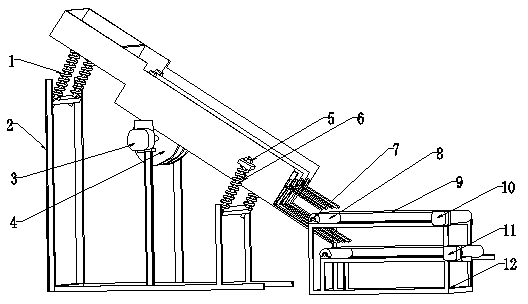

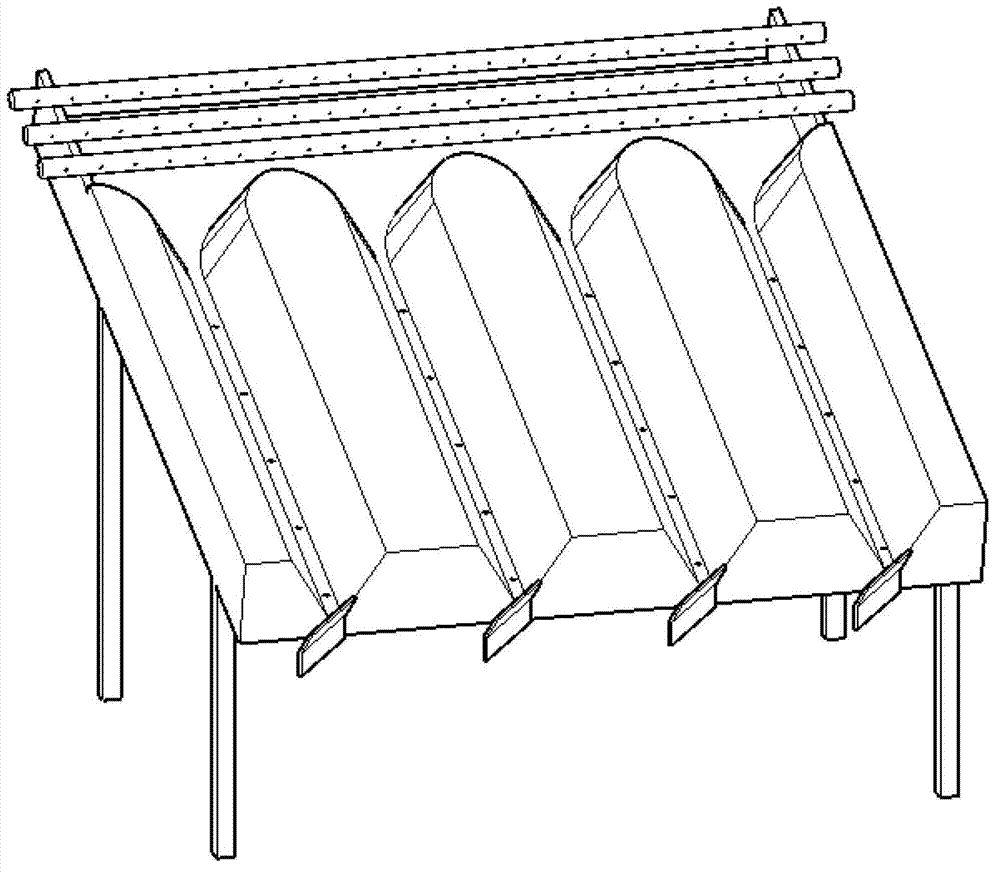

Directional sequencing device for prawns

The invention discloses a directional sequencing device for prawns. The directional sequencing device mainly comprises a rack, an orientation mechanism, a vibration supplying mechanism and a conveying mechanism, wherein a sorting mechanism is aslant arranged on the rack, and comprises a bunker and a plurality of groups of orientation units arranged in parallel. The directional sequencing device completes the directional sequencing of the prawns in an upper sliding groove and a lower sliding groove by fully utilizing the physical characteristic of the prawns, a regular vibration force provided by the vibration supplying mechanism and the gravity of the prawns through arranging a curved surface of a direction selecting slide and a directional slide in the orientation mechanism, and is simple in structure and convenient to operate. The directional sequencing device for the prawns is capable of effectively realizing that the prawns are directionally sequenced and the prawns with same sizes are output, and is used in the field of food machinery.

Owner:HEBEI AGRICULTURAL UNIV.

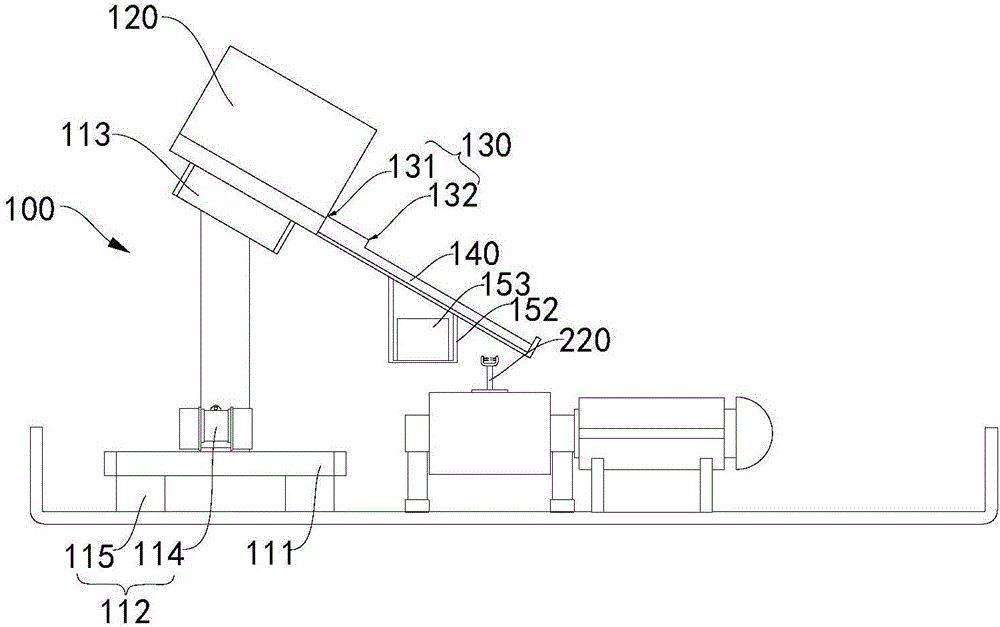

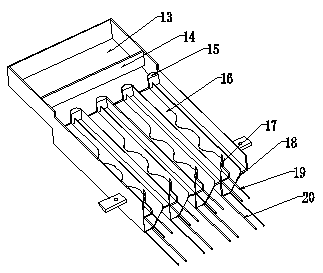

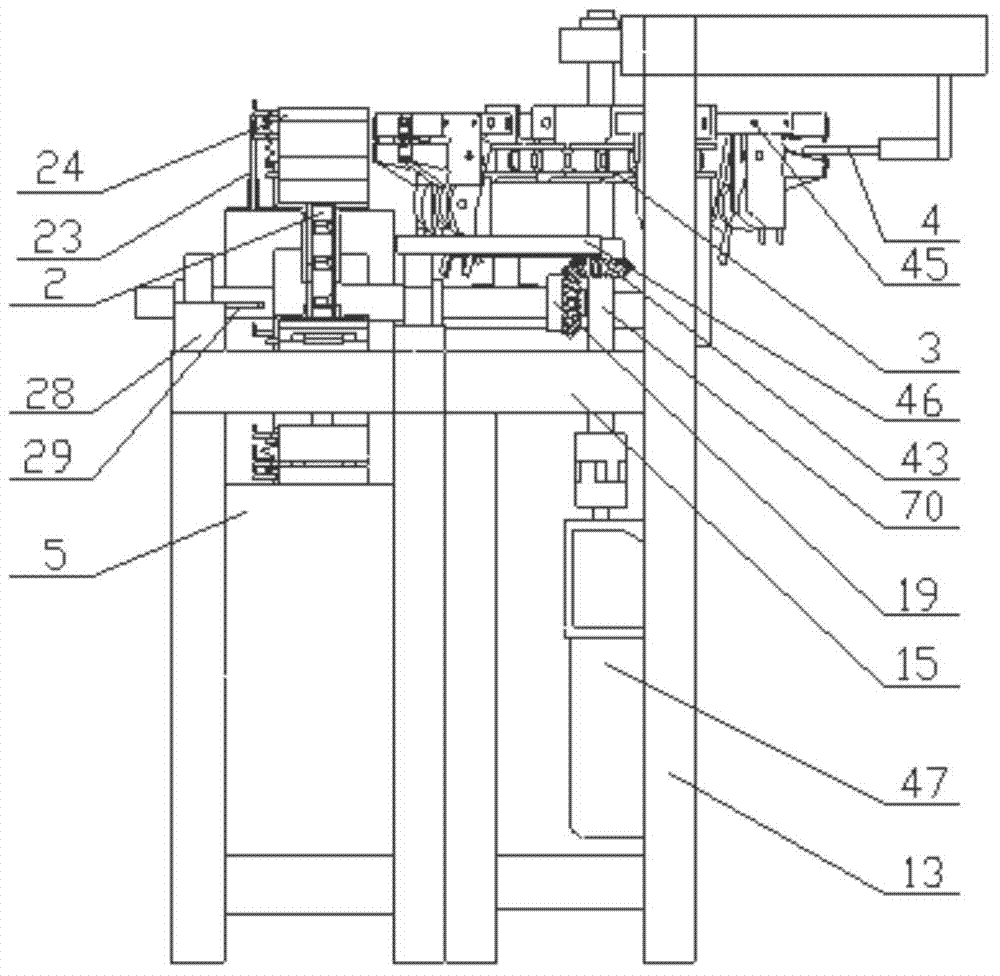

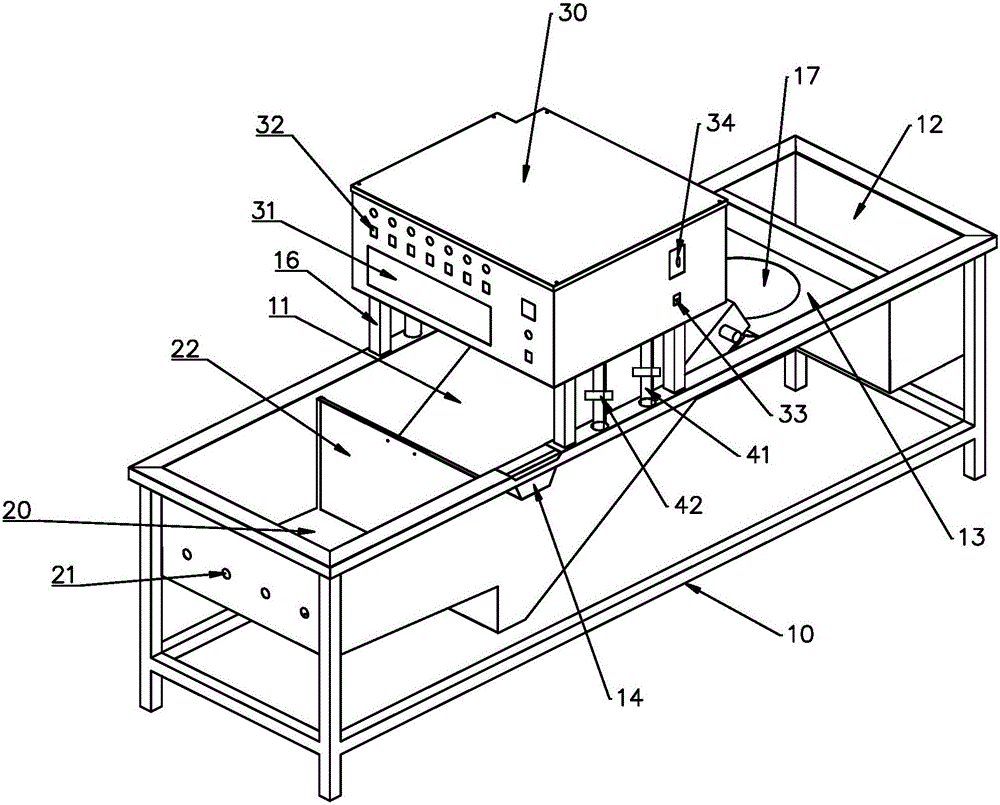

Procambarus clarkia deveining machine

ActiveCN104489049AReduce manufacturing costReduce labor costsShrimp/lobster processingProcambarusShrimp

The invention provides a procambarus clarkia deveining machine which comprises a shrimp tail conveying mechanism, a shrimp intestine removing mechanism, a main stand and a subordinate stand, wherein the shrimp tail conveying mechanism is fixed on the main stand; the shrimp intestine removing mechanism is fixed on the subordinate stand; the shrimp tail conveying mechanism is used for conveying and clamping shrimp tails; and the shrimp intestine removing mechanism is used for shearing tail fans and pulling out shrimp intestines. The deveining machine disclosed by the invention is skillful in structure, and since the shrimp tail conveying mechanism and the shrimp intestine removing mechanism are matched in use, the deveining machine disclosed by the invention can be used for removing the shrimp intestines without damaging the shrimp tails. The deveining machine is high in production efficiency and mechanical degree, and can be used for completely replacing manual labor to remove the shrimp intestines, saving expensive labor cost and greatly reducing the production cost of the shrimp tails; and the deveining machine disclosed by the invention is suitable for the large-scale processing of the procambarus clarkia tails.

Owner:ZHEJIANG UNIV

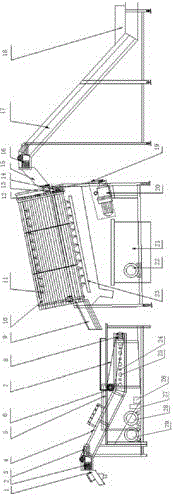

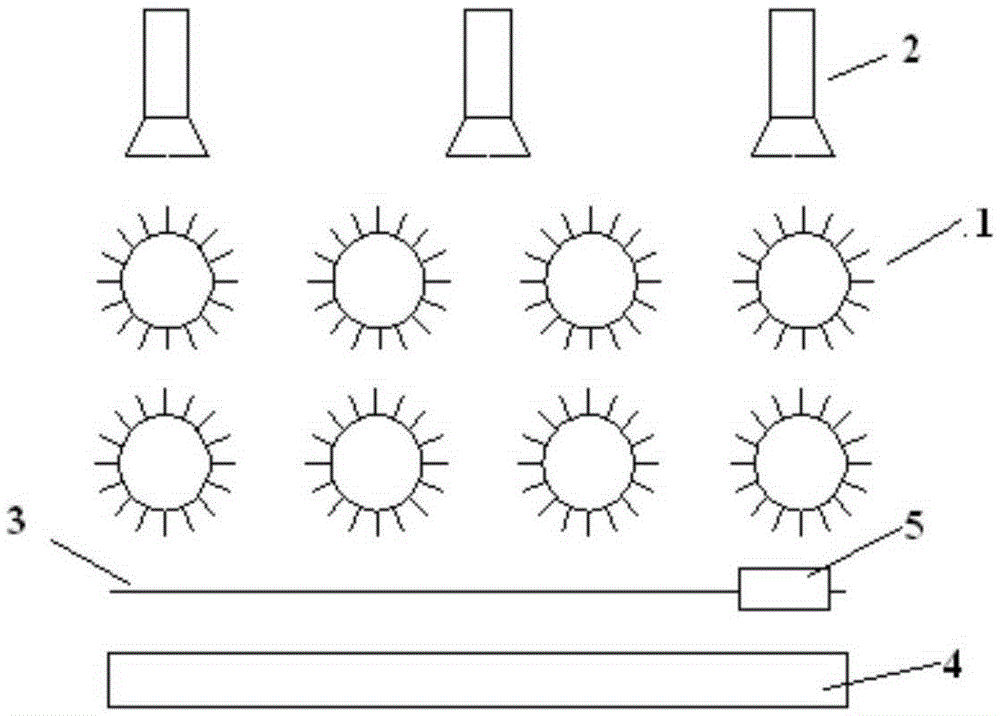

Ultrasonic lobster cleaning machine

InactiveCN105532837AEasy to useLabor savingLiquid spraying apparatusShrimp/lobster processingAir pumpEngineering

The invention discloses an ultrasonic lobster cleaning machine. The machine comprises a lifting and conveying mechanism, a first-level cleaning mechanism and a second-level cleaning mechanism; the lifting and conveying mechanism comprises a second motor, a feeding crawler belt and a buffer bin, and the second motor is in driving connection with the feeding crawler belt; the first-level cleaning mechanism comprises a hexagonal strip sieve and a first water pump, the hexagonal strip sieve is provided with an inner strip sieve nozzle and an outer strip sieve nozzle, and the inner strip sieve nozzle and the outer strip sieve nozzle are connected with a first water pump; the second-level cleaning mechanism comprises a first motor, a conveying crawler belt, a cleaning tank, an ozone machine, an ultrasonic generator and an air pump, the first motor is in driving connection with the conveying crawler belt, the ozone machine and the ultrasonic generator are both located below the cleaning tank, and an ozone output pipe of the ozone machine is connected to a gas nozzle. The ultrasonic lobster cleaning machine comprises the two levels of cleaning mechanisms, the thorough cleaning degree is high, impurities and sticking substances on the surfaces of lobsters can be cleaned, hidden positions of the lobsters such as the gill positions can be cleaned and sterilized, and reliability and environmental protection are achieved.

Owner:许云飞

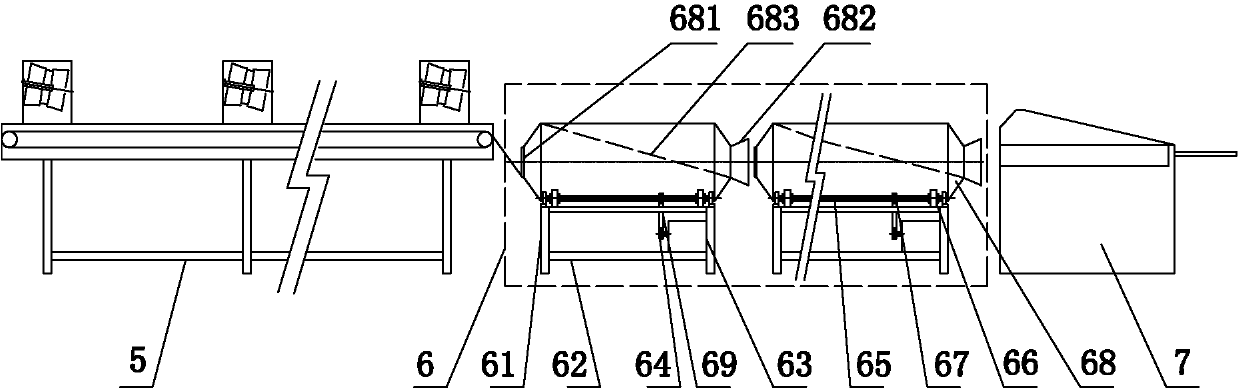

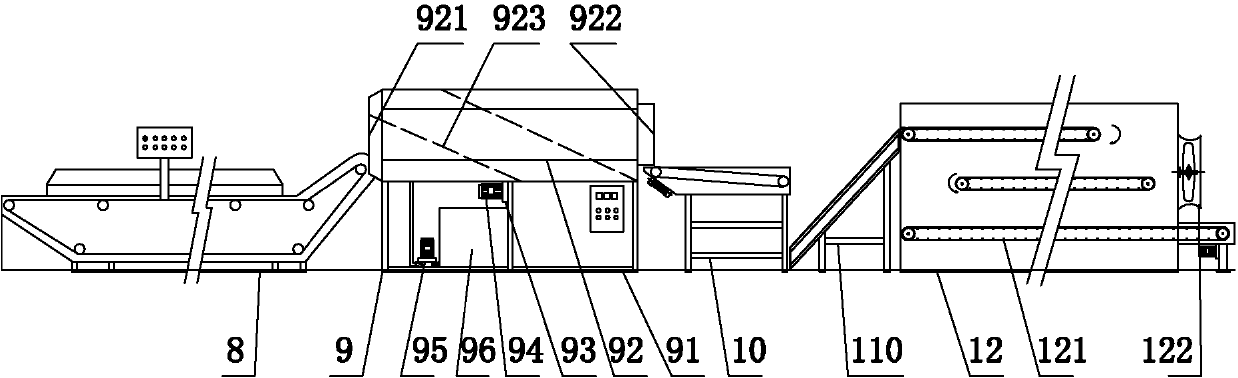

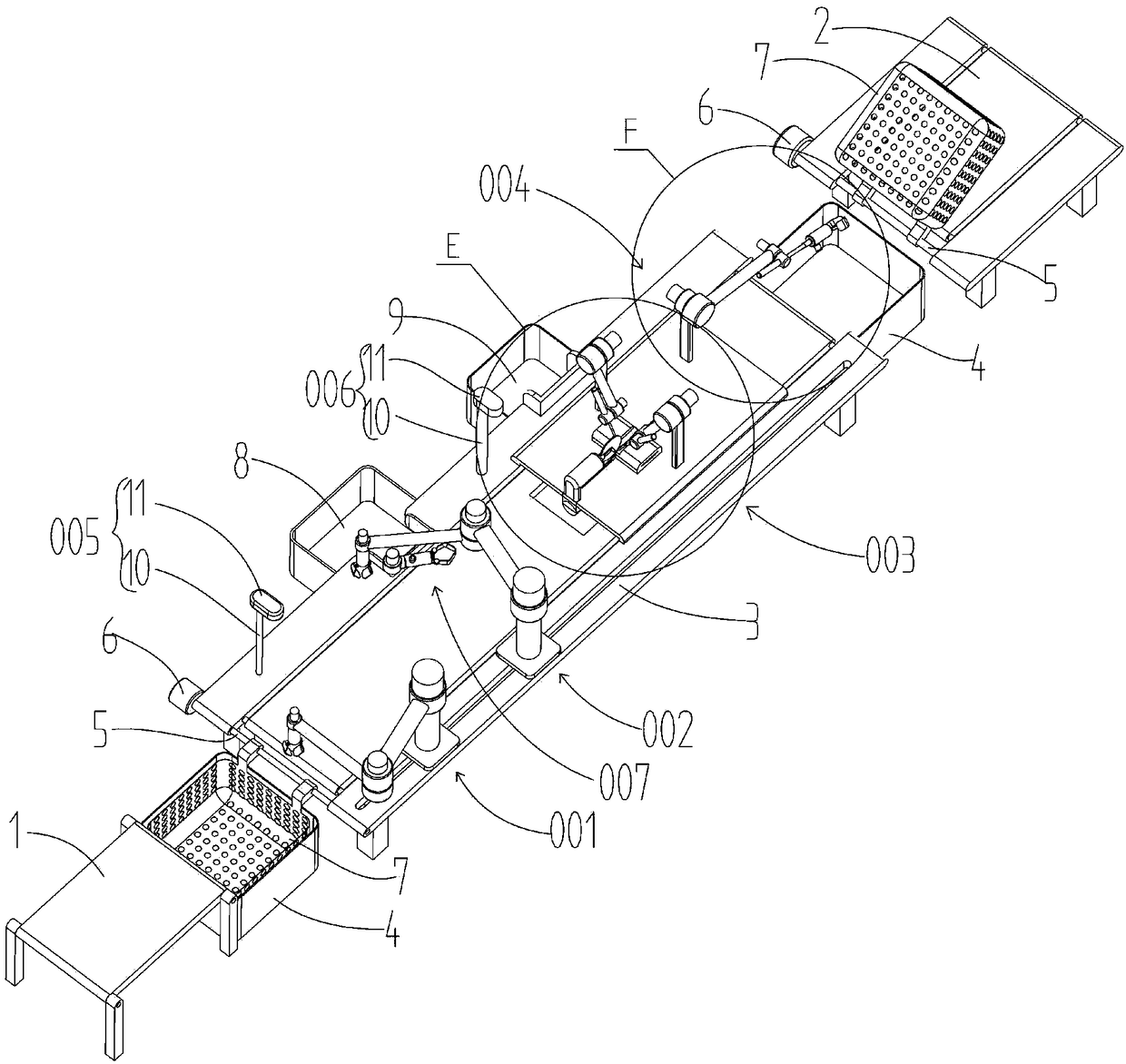

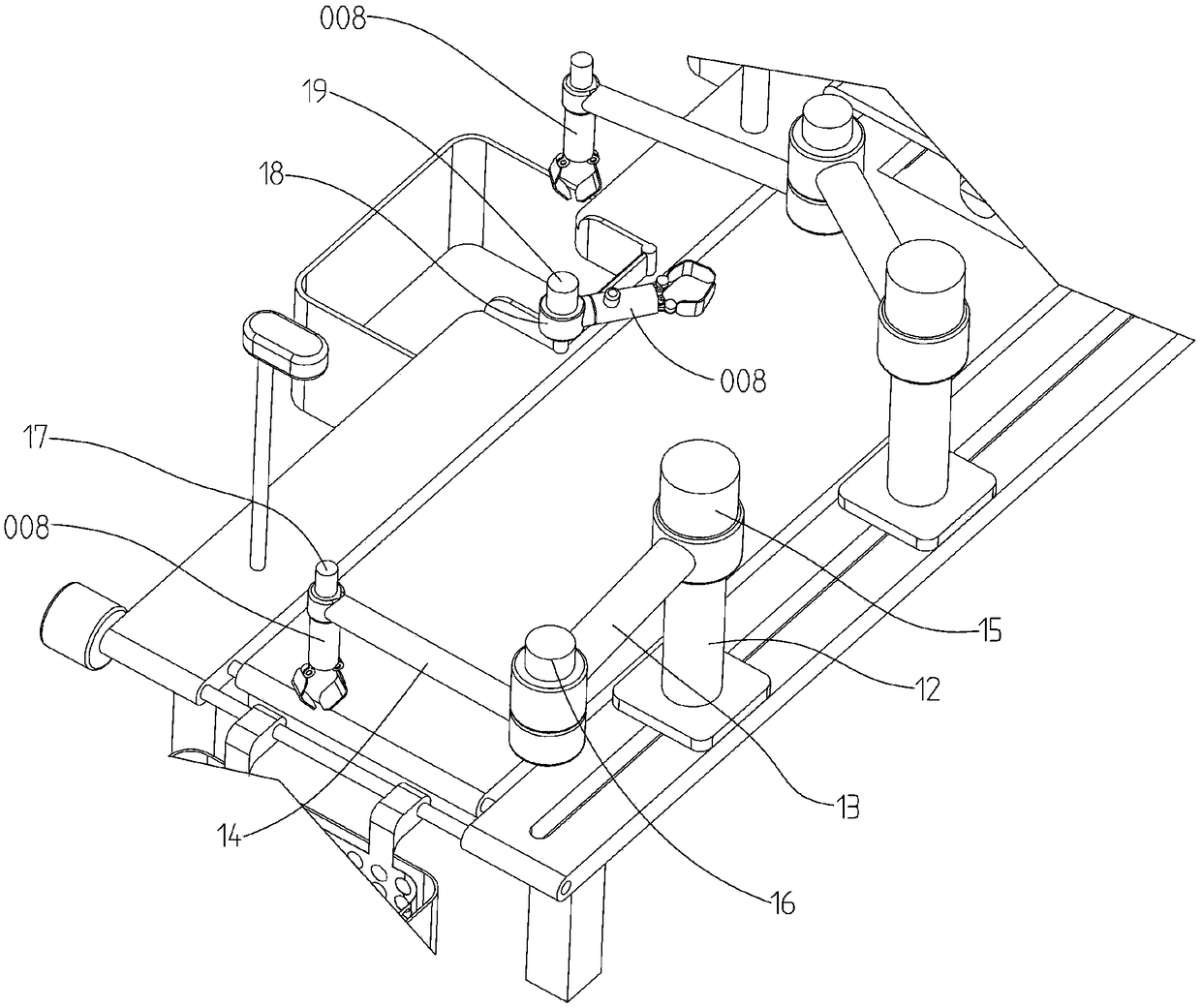

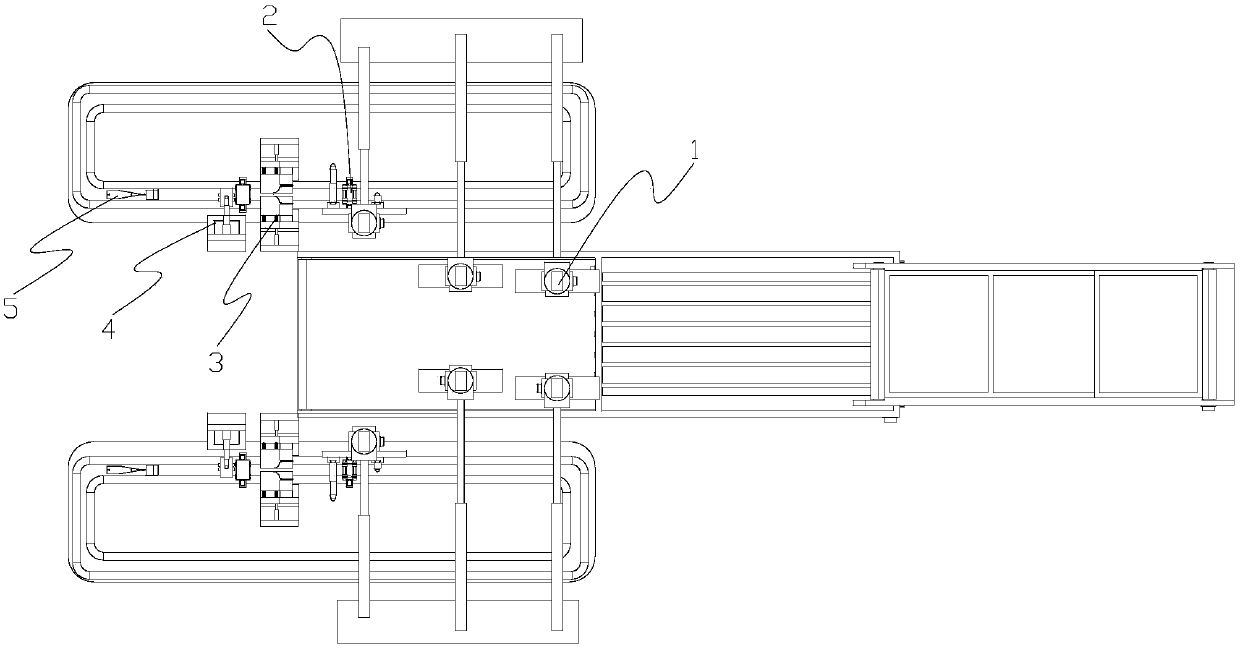

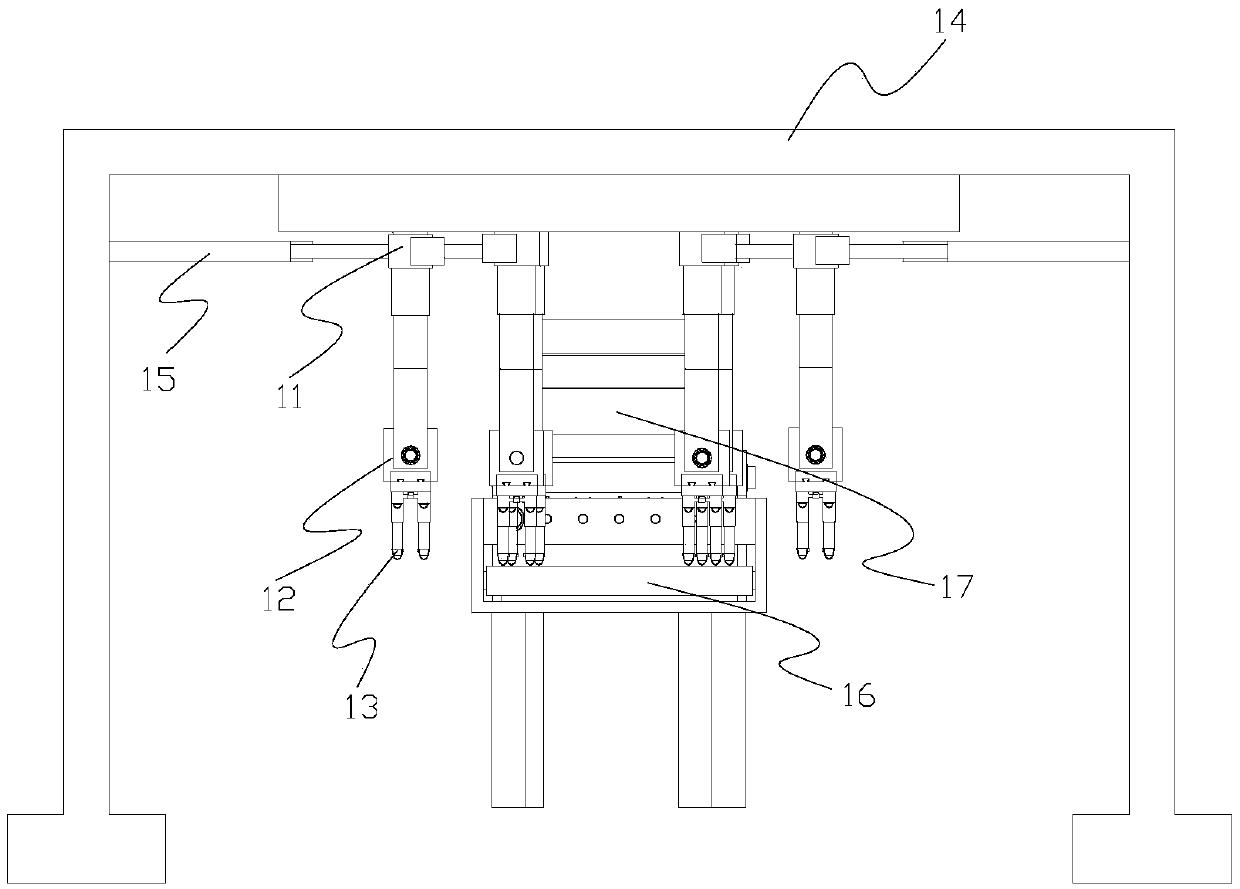

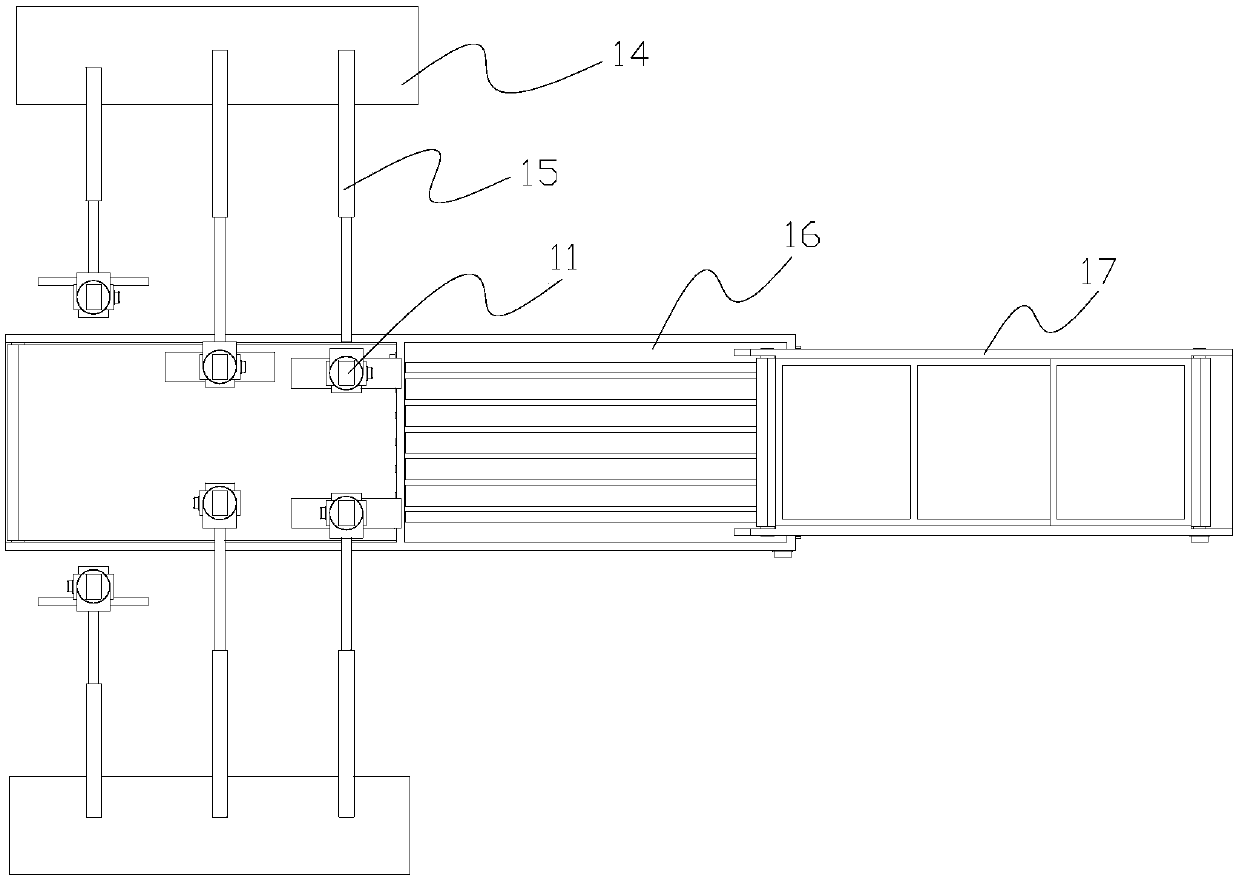

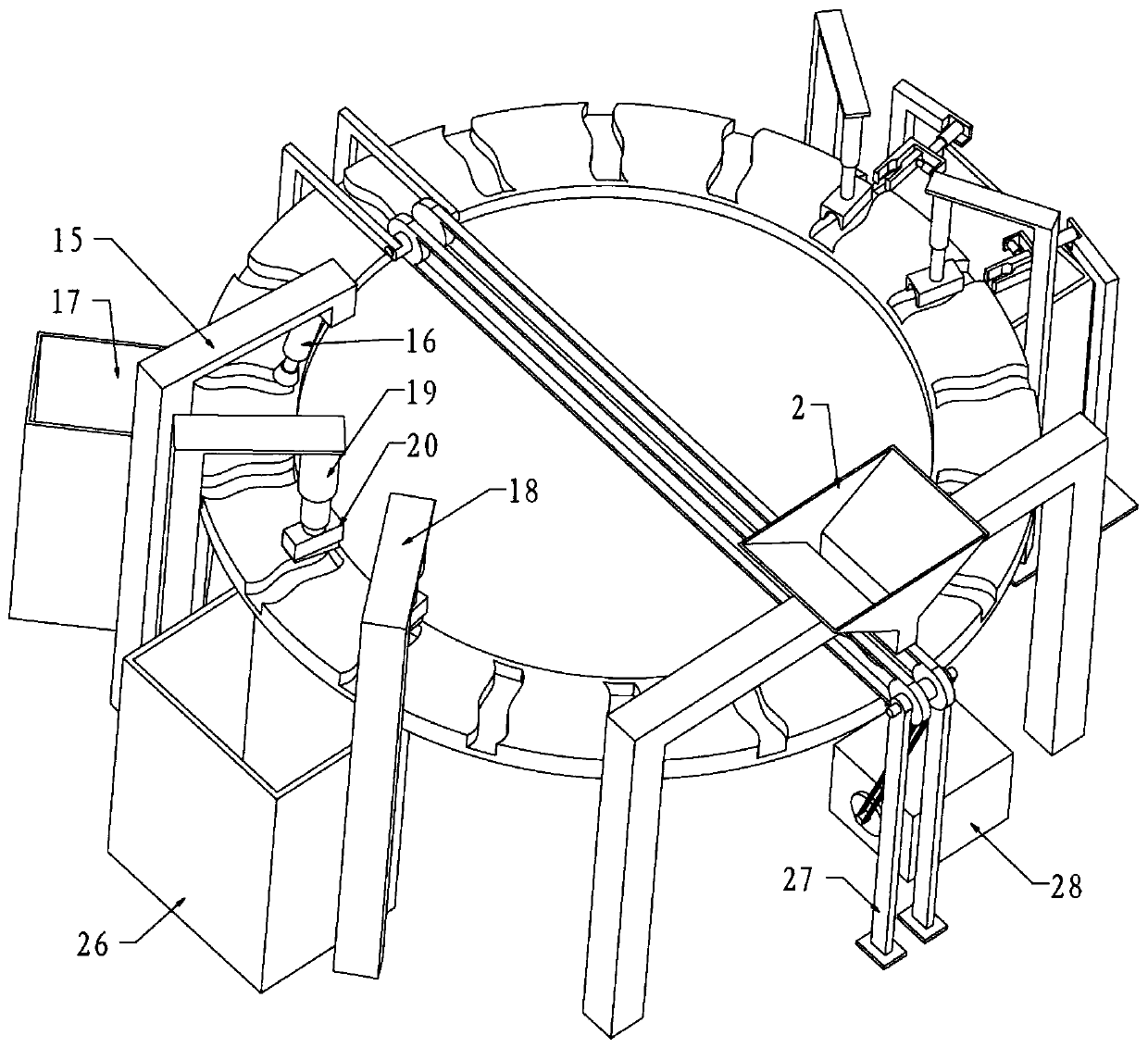

Production line for automatically stripping off shrimp shells

The invention discloses a production line for automatically stripping off shrimp shells. The production line comprises a first conveyor belt, a second conveyor belt and a shrimp stripping operation table. Ultrasonic cleaning ponds are arranged between one end of the shrimp stripping operation table and the first conveyor belt as well as between the other end of the shrimp stripping operation tableand the second conveyor belt respectively; rotary shafts and driving motors are arranged at the end, close to the first conveyor belt, of the shrimp stripping operation table and the end, close to the shrimp stripping operation table, of the second conveyor belt respectively, wherein the driving motors are used for driving the rotary shafts to rotate, and filtering baskets used in cooperation with the ultrasonic cleaning ponds are fixedly installed on the rotary shafts respectively; the shrimp stripping operation table is provided with a head and tail removal mechanical claw module, a shrimpbody taking mechanical claw module, a shrimp shell removing device and a shrimp meat taking mechanical claw module in sequence in the conveying direction of the first conveyor belt; a first visual control module and a second visual control module are installed on the shrimp stripping operation table. The production line for automatically stripping off the shrimp shells can automatically clean shrimps, remove the heads and tails of the shrimps, strip off the shells and clean shrimp meat.

Owner:潜江市湖耕食品有限公司

Industrial production of meat

InactiveUS20060029922A1Increasing of consequenceIncrease the number ofBiocideDead animal preservationBiotechnologyIn vitro

A meat product containing in vitro produced animal cells in a three dimensional form and a method for producing the meat product.

Owner:GOOD MEAT INC

Seafood product washing machine

InactiveCN106064161AEasy to cleanImprove cleaning efficiencyFish washing/descalingBivalves processingWastewaterEngineering

The invention relates to a seafood product washing machine which comprises a base, a washing barrel, washing water guns, a screen frame and a wastewater concentration chamber, wherein the washing water guns are arranged between the screen frame and the washing barrel; a motor accommodating chamber is formed in the case; a screen frame opening-closing door corresponding to the screen frame in position and a drain pipe communicated with the interior of the wastewater concentration chamber are arranged on the case; a drive motor used for driving the washing barrel to rotate is arranged in the motor accommodating chamber; a plurality of material feeding-discharging pipes are uniformly arranged on the washing barrel; a first control valve is arranged on each material feeding-discharging pipe; a plurality of material conveying plates are uniformly distributed on the inner side wall of the washing barrel in a peripheral direction horizontally; a plurality of screen meshes are uniformly formed in the baseplate of the screen frame; two ends of the screen frame are connected to side walls on two sides of the case in a drawable sliding manner. The seafood product washing machine is high in washing efficiency and effect.

Owner:王亚龙

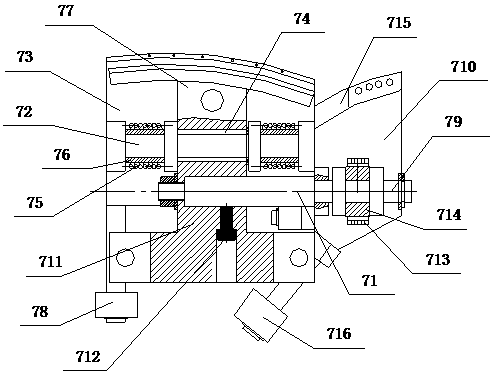

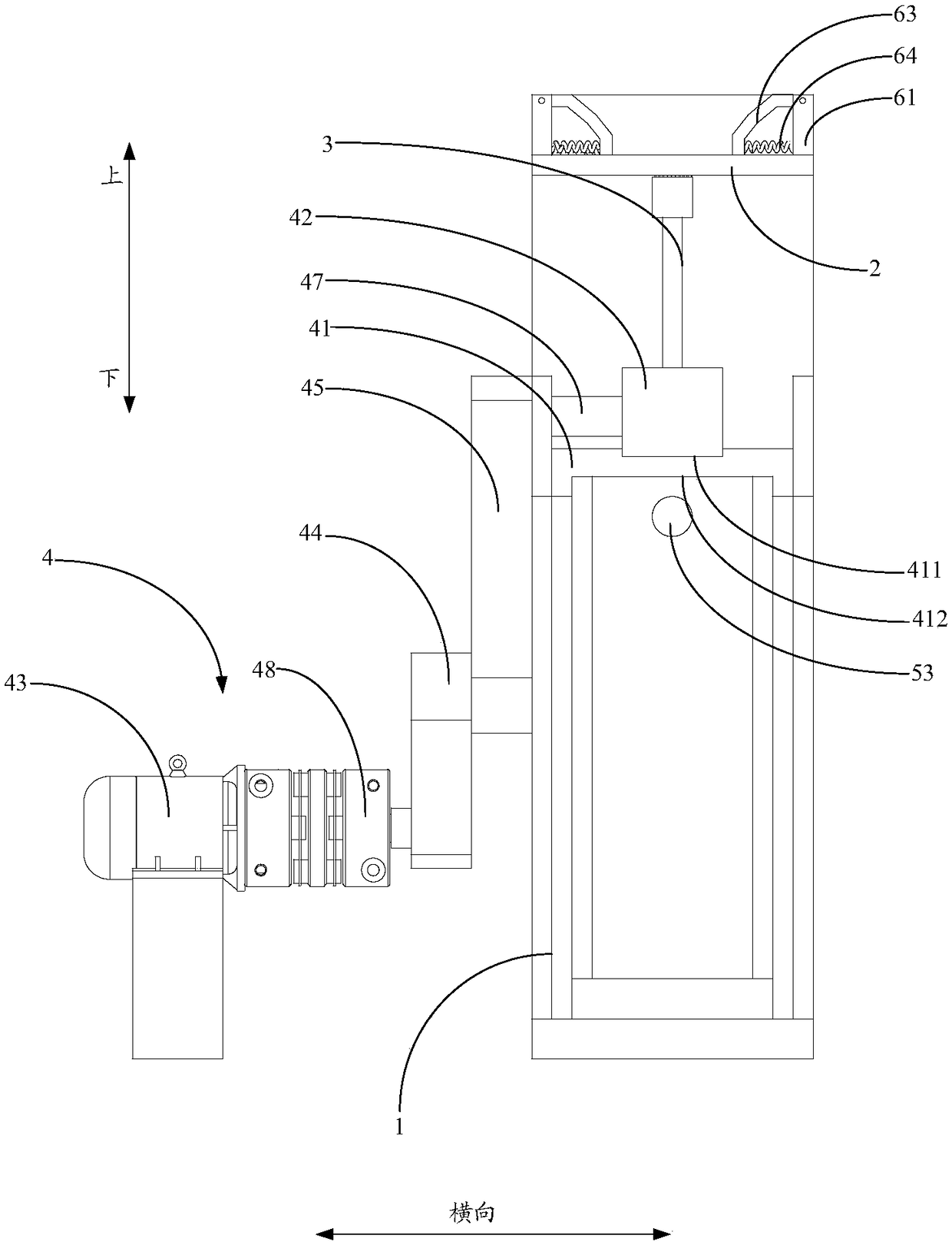

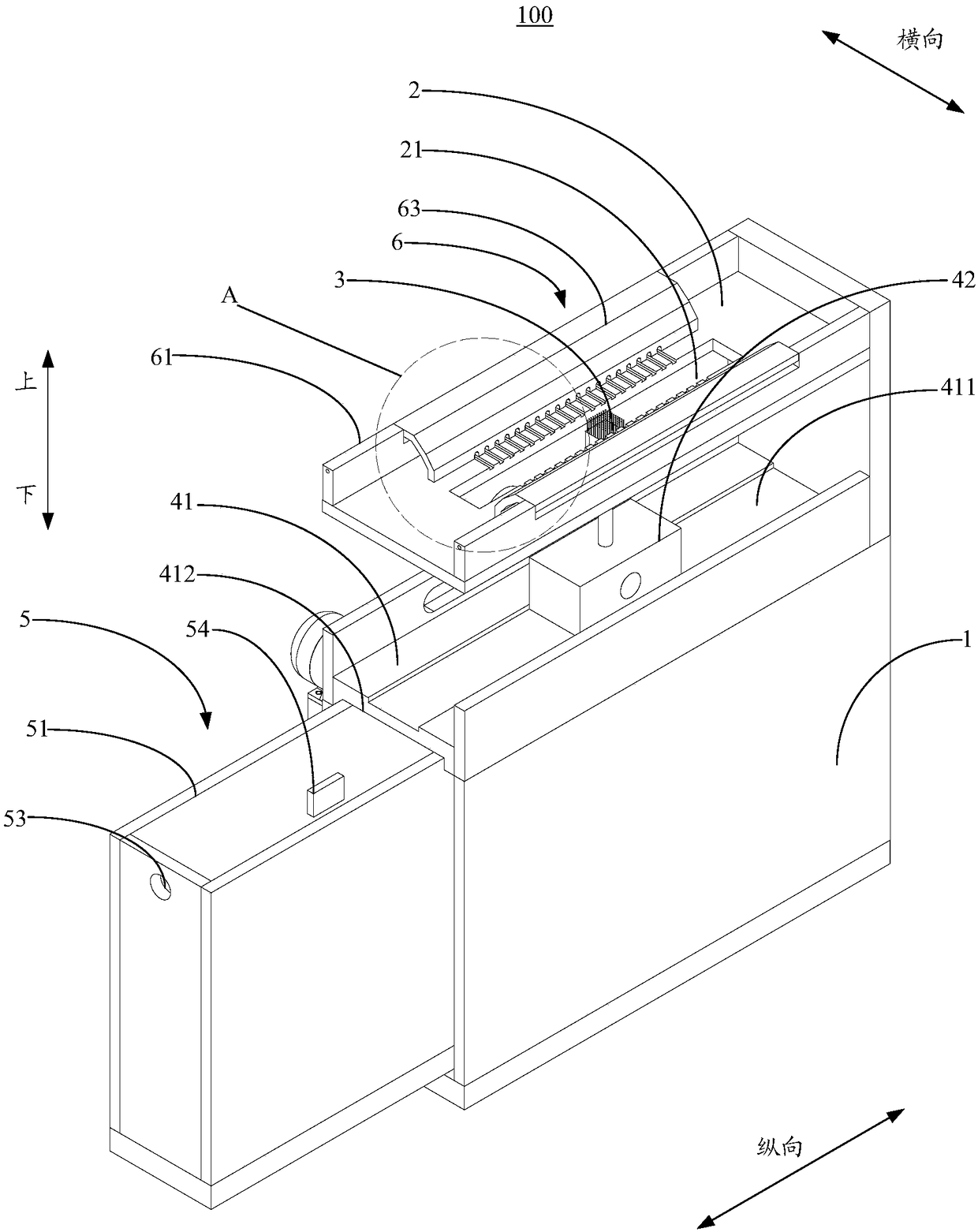

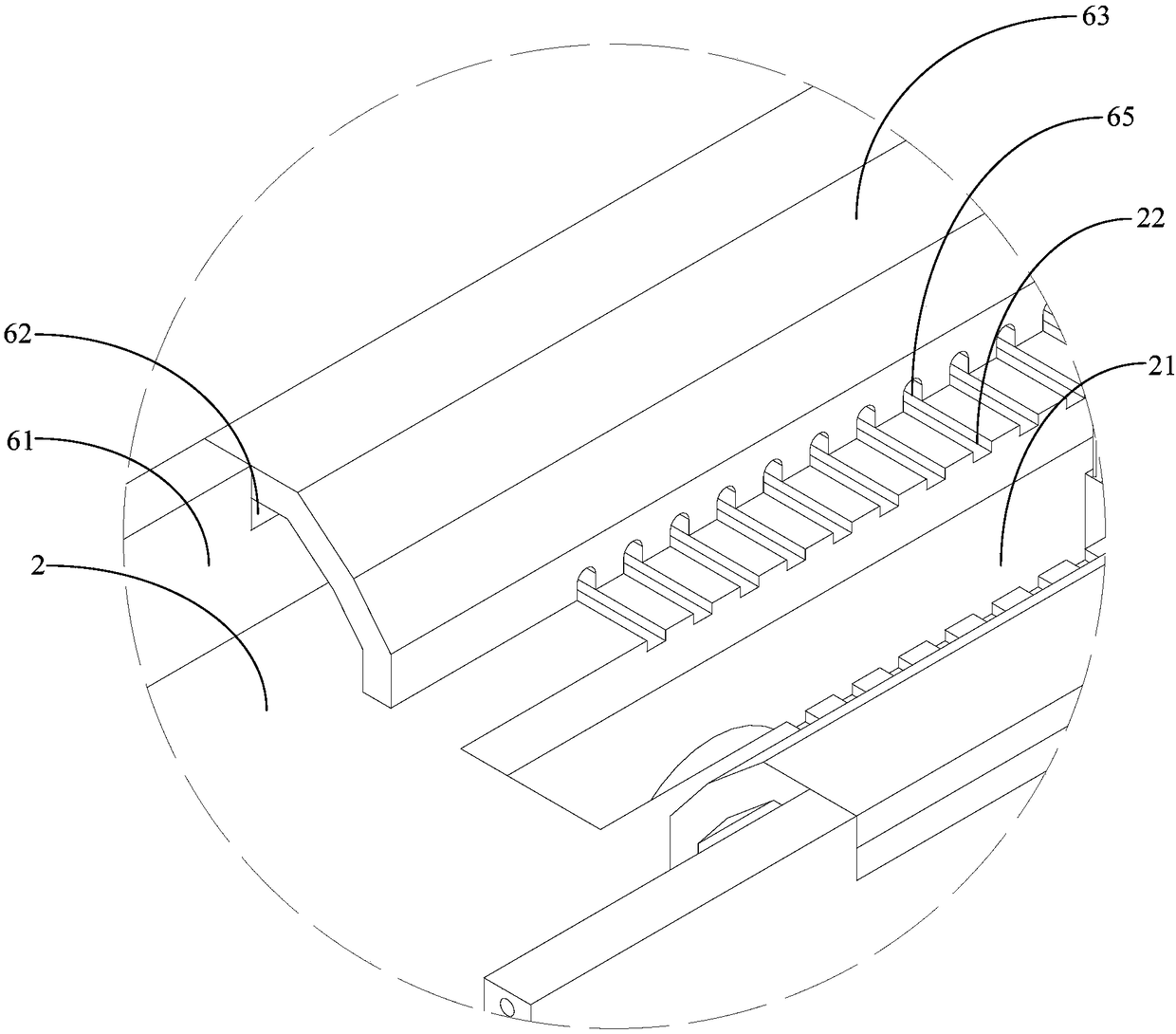

Novel fixing device for automatically stripping off shrimp shells

The invention discloses a novel fixing device for automatically stripping off shrimp shells. The device comprises a rectangular base, wherein the upper surface of the rectangular base is fixedly connected with a rectangular box, a rotating shell removing mechanism is arranged in the rectangular box, a shrimp flesh adsorbing mechanism is arranged on the upper surface in the rectangular box and located on the right side of the rotating shell removing mechanism, a rotating conveying and clamping mechanism is arranged on the lower surface in the rectangular box, a receiving mechanism lapped with the shrimp flesh adsorbing mechanism is arranged on the upper surface of the rectangular base and located on the right side of the rectangular box, a fixing mechanism is arranged on the lower surface of the rectangular base, and a controller is arranged on one side surface of the rectangular box. The device has the benefits of simple structure and high practicability.

Owner:阳江国联海洋食品有限公司

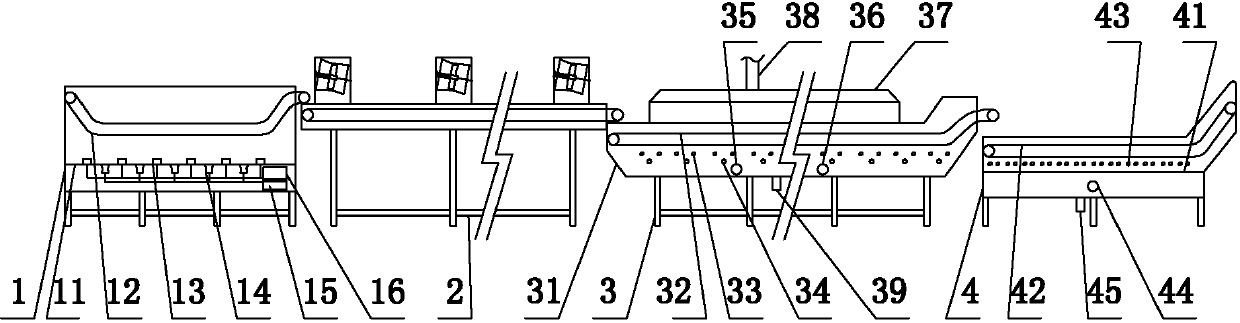

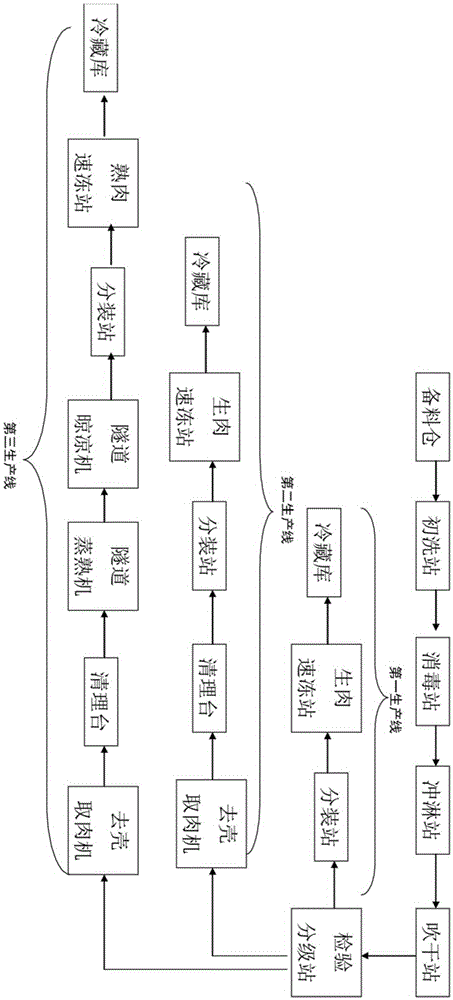

Treatment production line for testacean marine products

ActiveCN105285774AHigh degree of automationGuaranteed processing efficiencyFood preservationShrimp/lobster processingProduction linePre treatment

The invention relates to a treatment production line for testacean marine products. The treatment production line is characterized by comprising a pretreatment production line, a first production line, a second production line and a third production line, wherein according to a processing sequence, the pretreatment production line sequentially comprises a stocking warehouse, a first washing station, a sterilization station, a rinsing station, a blow-drying station and an inspection grading station; according to the processing sequence, the first production line sequentially comprises a subpackaging station, a raw meat quick-freezing station and a refrigerating station; according to the processing sequence, the second production line sequentially comprises a shelling and fleshing machine, a cleaning table, a subpackaging station, a raw meat quick-freezing station and a refrigerating station; according to the processing sequence, the third production line sequentially comprises a shelling and fleshing machine, a cleaning table, a tunnel steaming machine, a tunnel airing machine, a subpackaging station, a cooked meat quick-freezing station and a refrigerating station. The treatment production line for the testacean marine products is simple in structure and high in the degree of automation, and facilitates the mass production of seafood products.

Owner:杭州创培信息科技有限公司

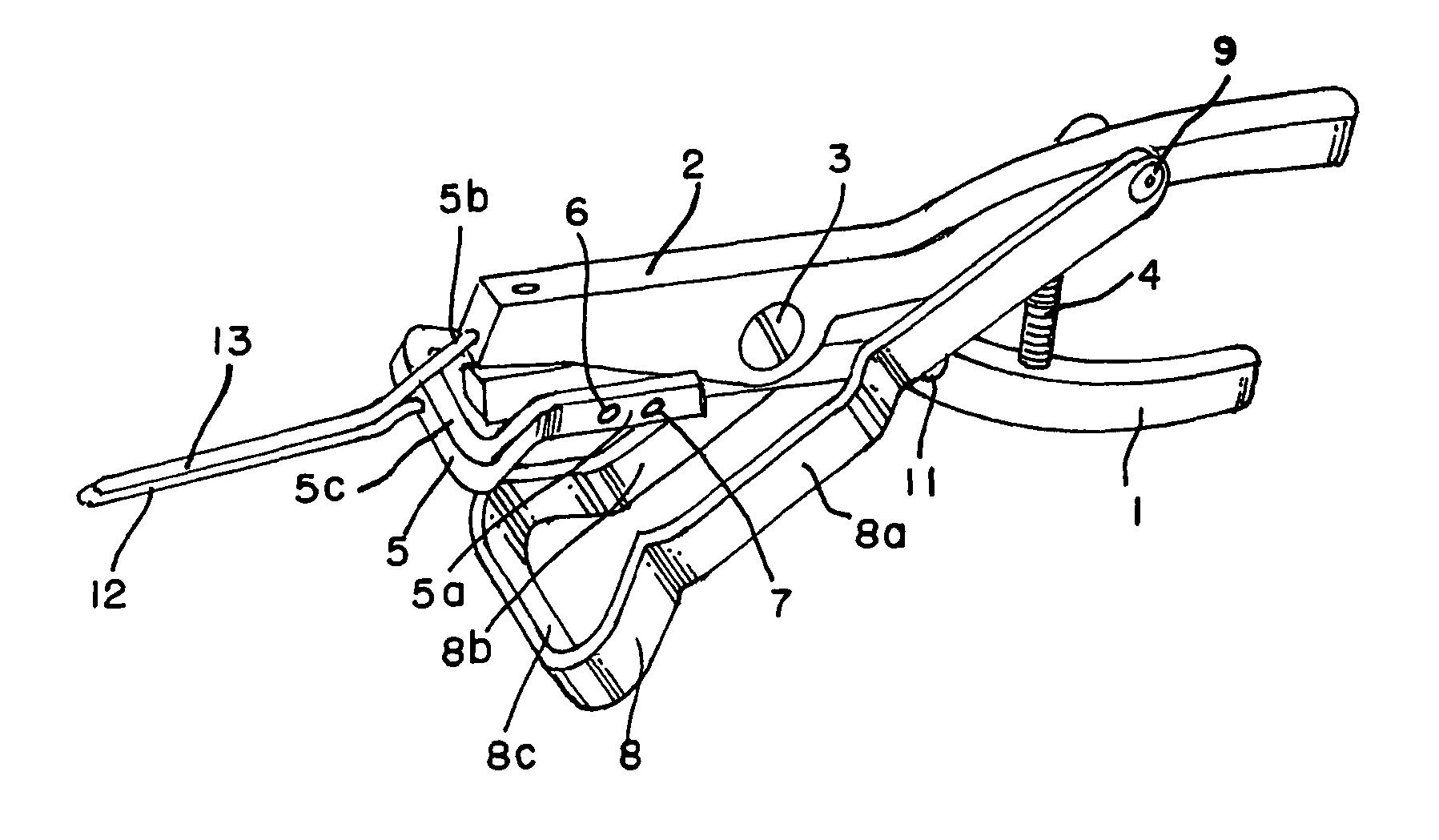

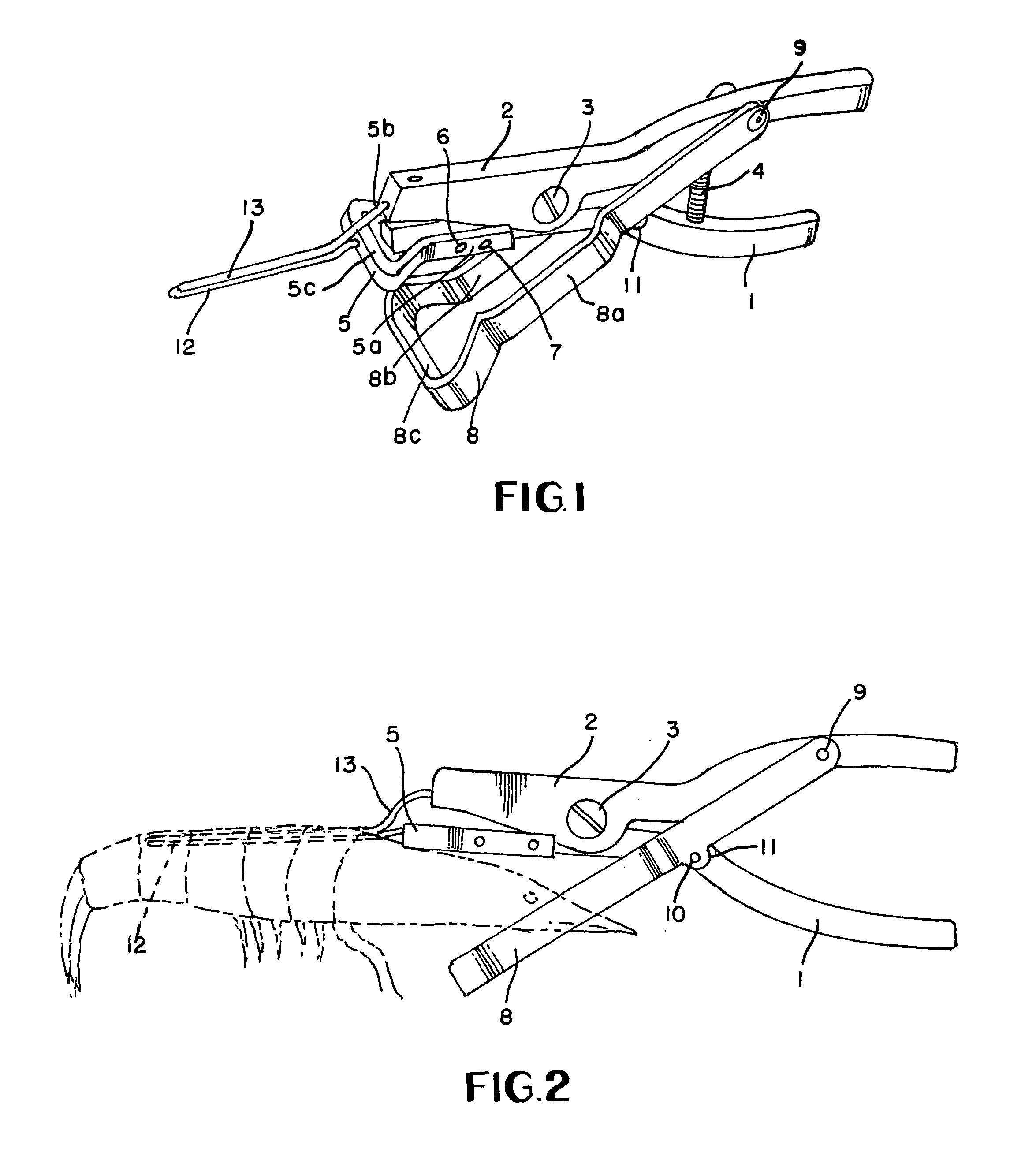

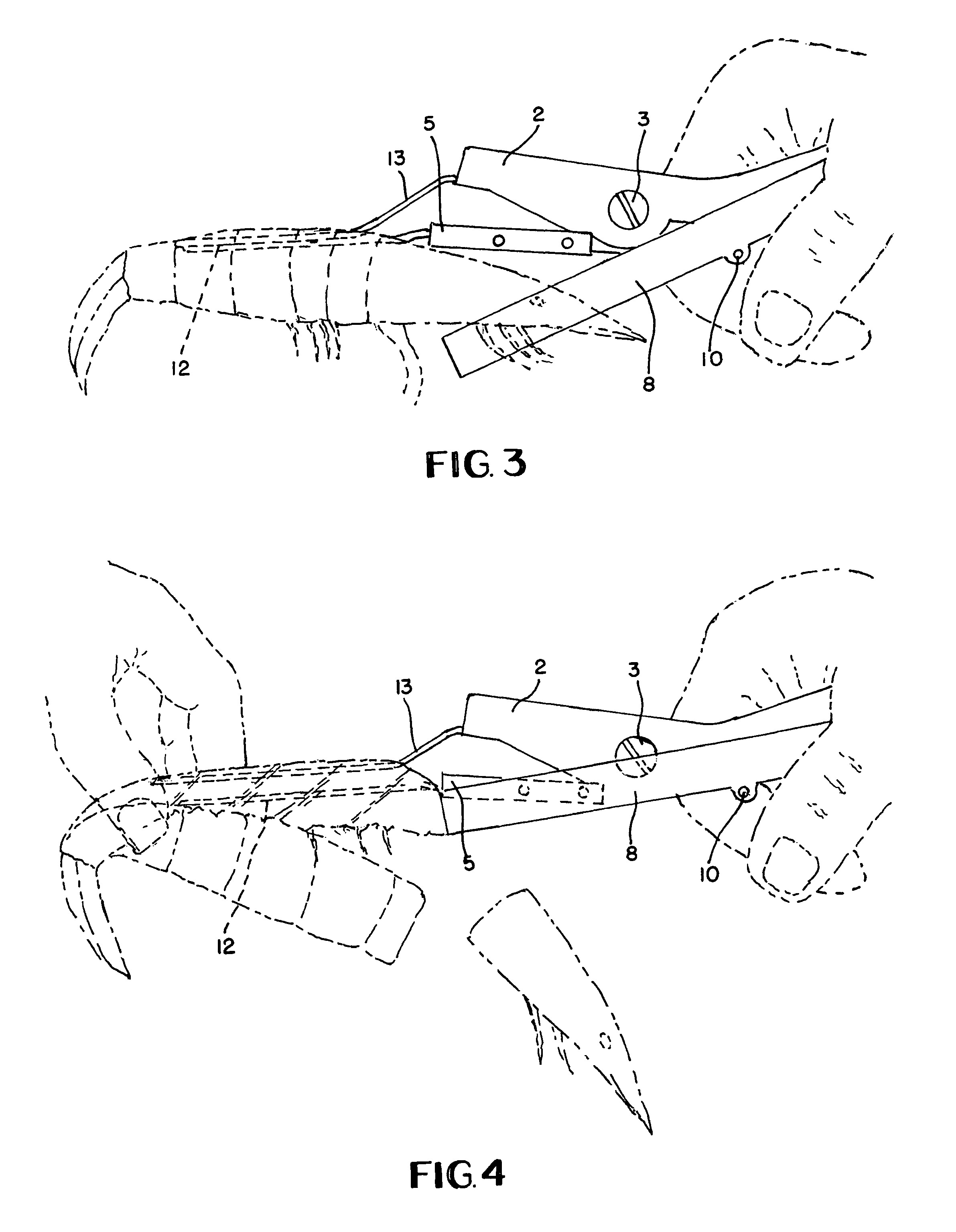

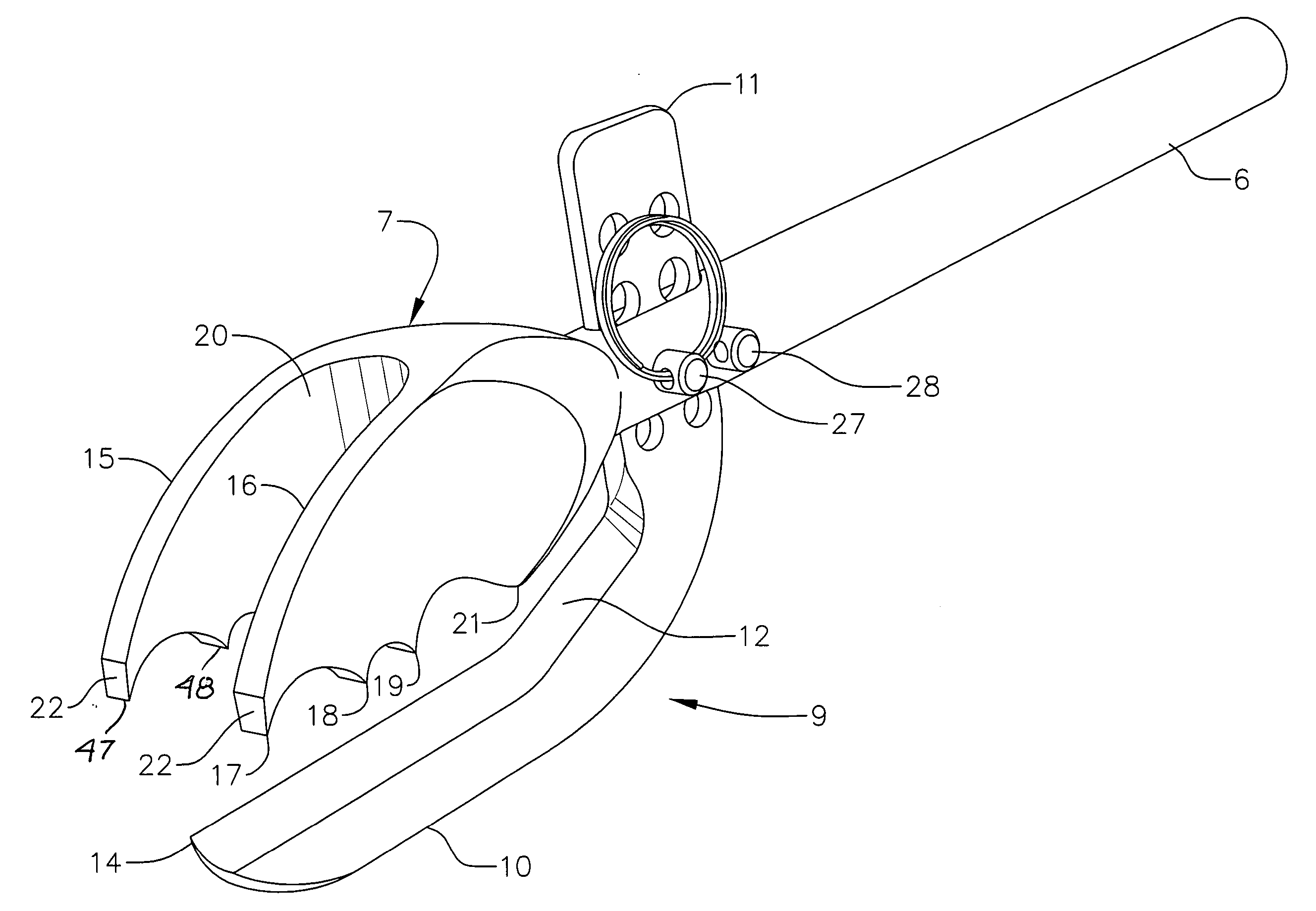

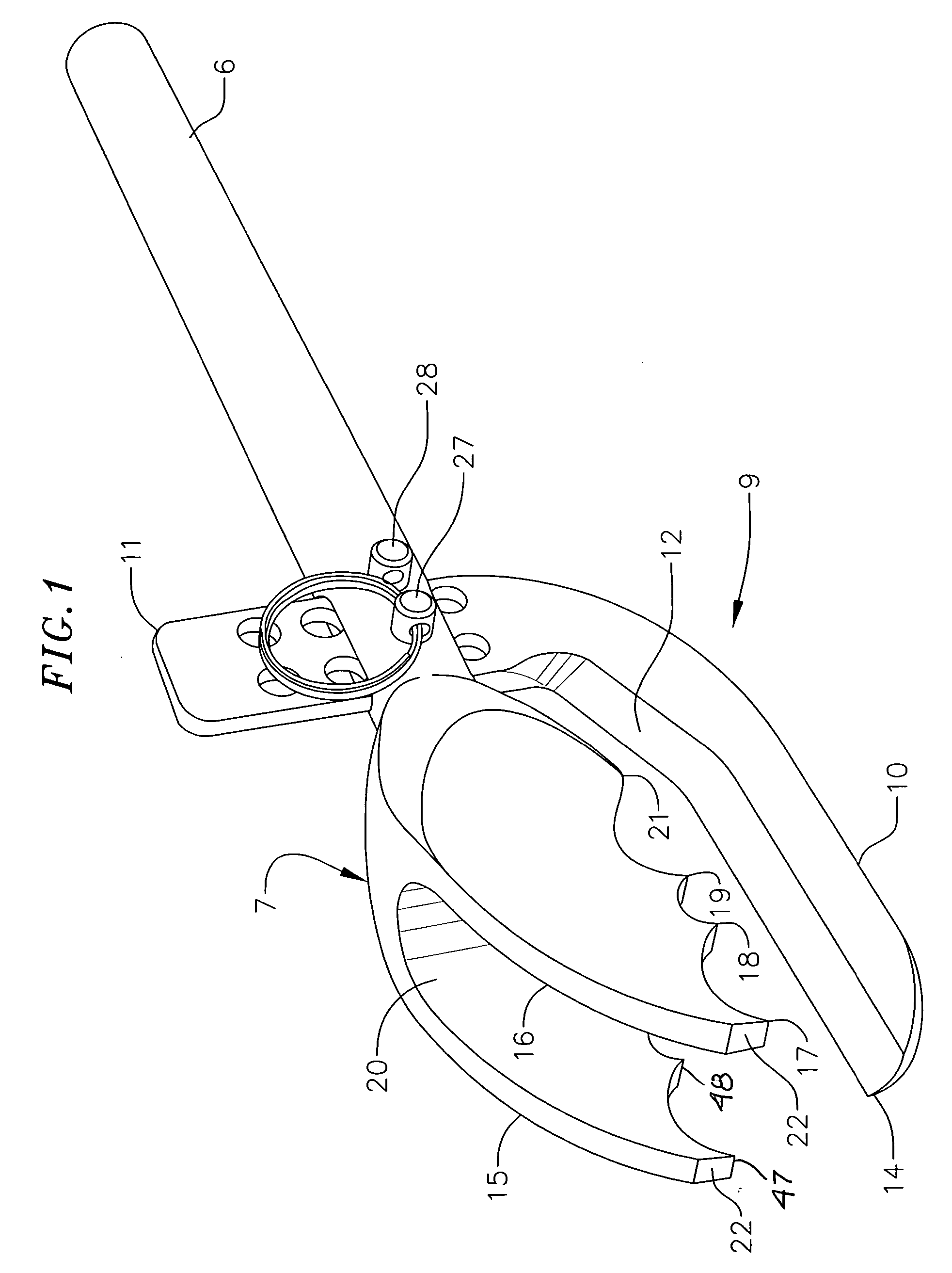

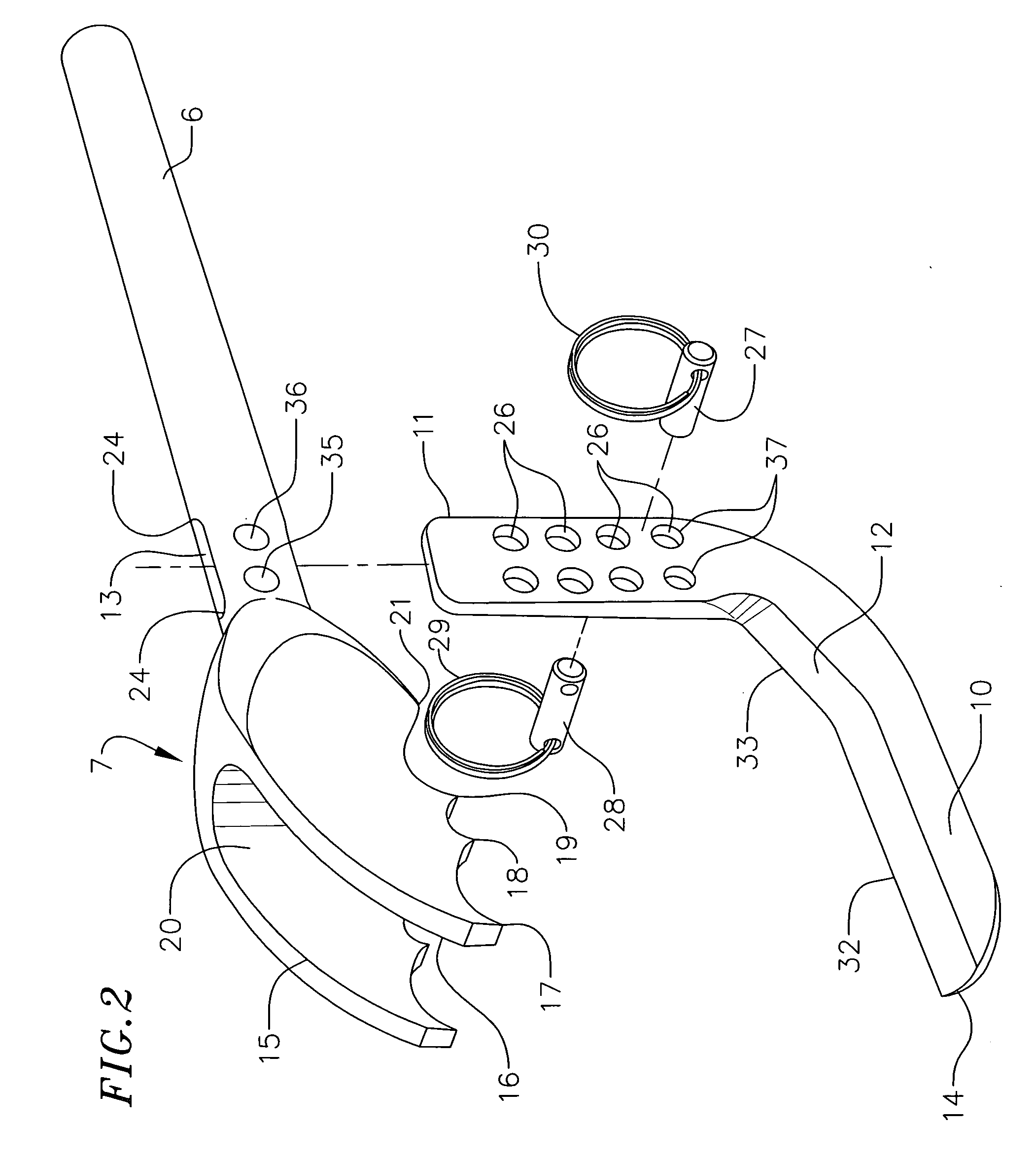

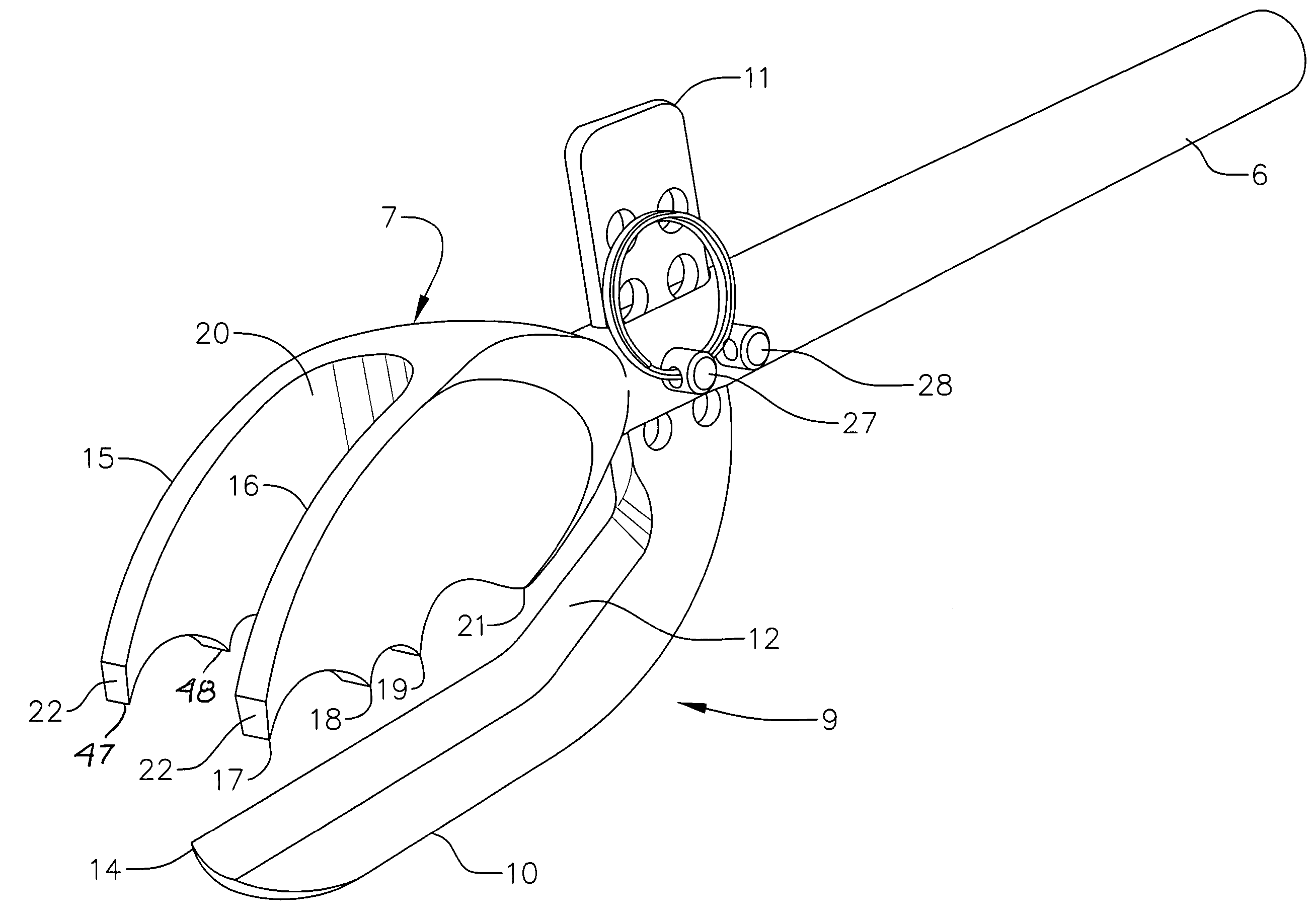

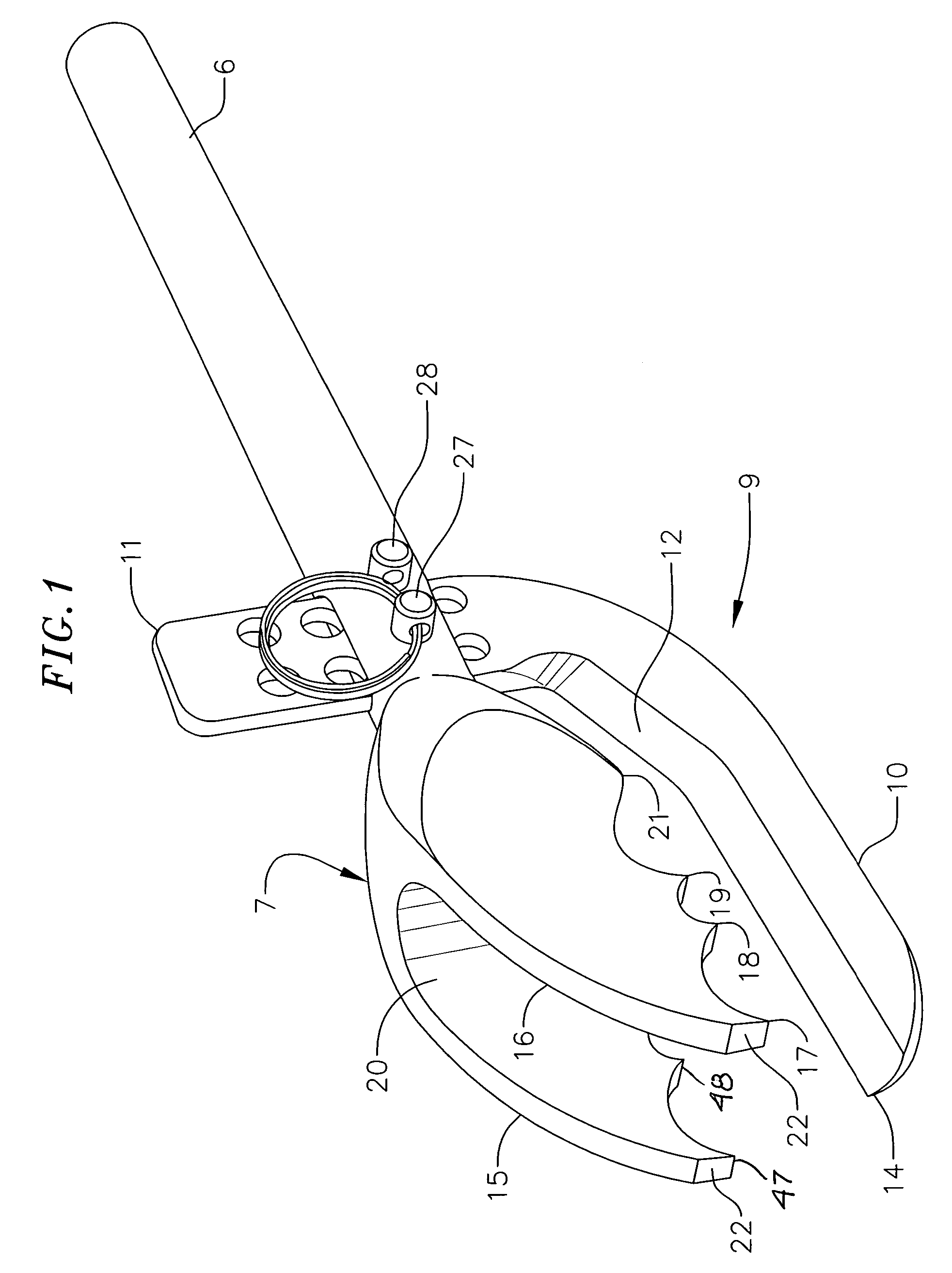

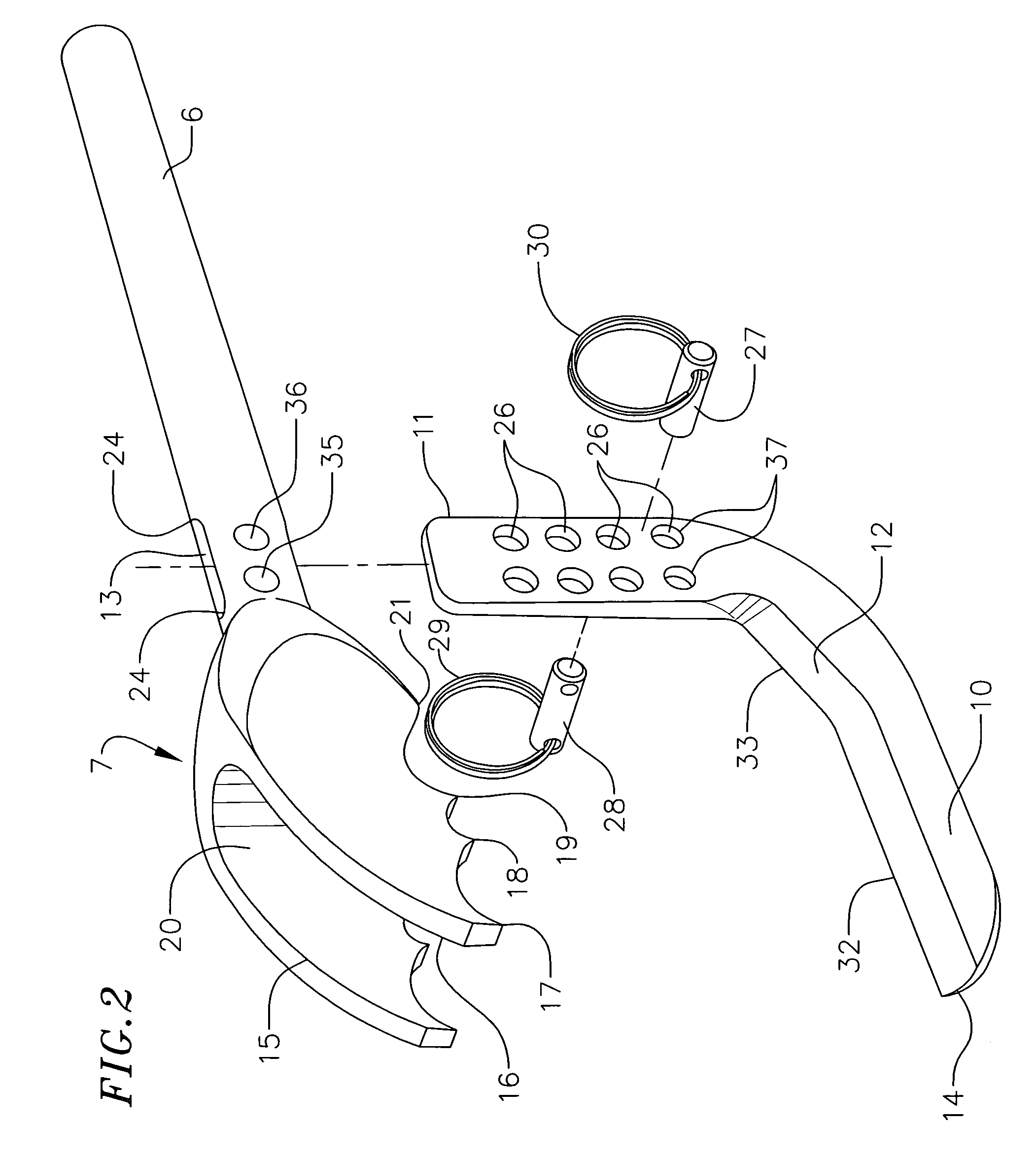

Shrimp peeling, deveining and head removal tool

A shrimp peeling, deveining and head removal tool including a pair of handles pivoted together and urged apart by a compression spring, an upper blade attached to lower handle and a lower blade pivoted to both handles with the ends of the blades of substantially of the same configuration and disposed in close proximity one within the other when the handles are compressed, and a pair of tines extending, respectively, from the upper handle and the upper blade and being in contact substantially the entire length thereof when the handles are not compressed.

Owner:GOODMAN DANNY

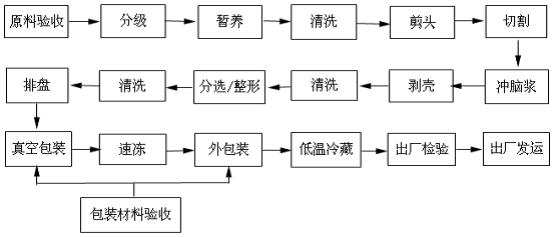

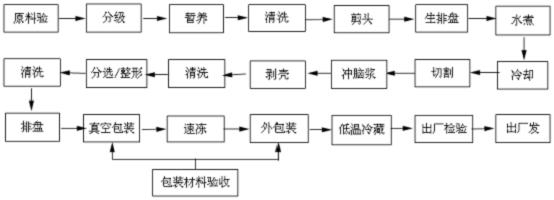

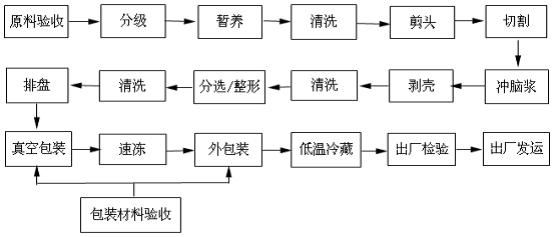

Processing method of frozen live sushi shrimps

InactiveCN102028266AGuaranteed activityGuaranteed nutritional valueClimate change adaptationFood preservationQuality levelShrimp

The invention relates to a processing method of frozen live sushi shrimps, which belongs to the technical field of processing of aquatic products. The processing flow of the method comprises the following steps of: inspecting and receiving raw materials; grading; holding; cleaning; cutting shrimp heads; cutting; flushing brains; husking; cleaning; sorting / reshaping; cleaning; arranging on disks; performing vacuum packing; freezing quickly; externally packaging; performing metal detection; storing at low temperature; performing delivery inspection; and delivering. In the method, disk arranging, water boiling and cooling technical steps can be added between head cutting and cutting technical steps, so that boiled sushi shrimps can be obtained. The frozen live sushi shrimps processed by the method have pure flavor and high nutrition value and are convenient to eat. Due to the adoption of the method, the nutrition value and quality level of a product can be enhanced remarkably, the product has high technical advancement and core competitiveness, and enterprise performance and industrial technical level are enhanced greatly.

Owner:雷州市运源水产品有限公司

Method for preparing shrimp paste by using low-value shrimp and shrimp offal

ActiveCN104256479AReduce pollutionGuaranteed naturalAcidic food ingredientsShrimp/lobster processingMaillard reactionHydrolysate

The invention relates to a method for preparing shrimp paste by using low-value shrimp and shrimp offal. The method comprises the following steps of washing the low-value shrimp; removing impurities; grinding; adding water for homogenizing; carrying out autolysis; adding protease to carry out enzymolysis; adding reducing sugar and amino acids to carry out a Maillard reaction by using a enzymatic hydrolysate as a base material; cooling a reaction liquid to a room temperature; adding shrimp flavor substances; and regulating to obtain the shrimp paste. The shrimp flavor substances are obtained by using shrimp offal such as shrimp heads and shrimp shells as raw materials and extracting by using supercritical carbon dioxide extraction technology. The method prepares the shrimp paste by using the low-value shrimp and shrimp offal, effectively reduces source waste and environment pollution, has significant social importance and considerable economic benefits, and guarantees that the sources of the raw materials are natural, nutritional and safe. In cooperative with a modern technology, a natural and healthy seasoning item with realistic fragrance and thick shrimp flavor can be produced by the method, thereby solving the defects existing in present products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

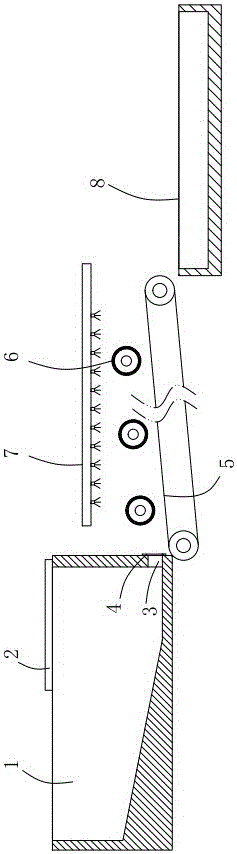

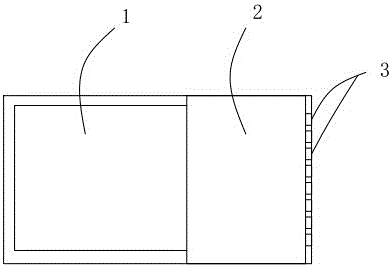

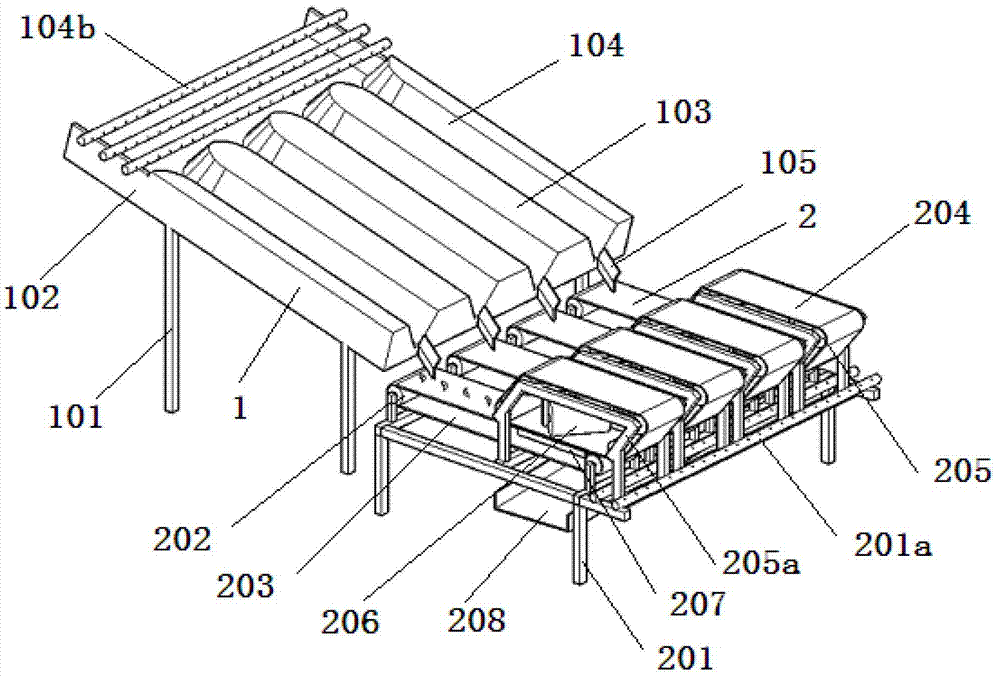

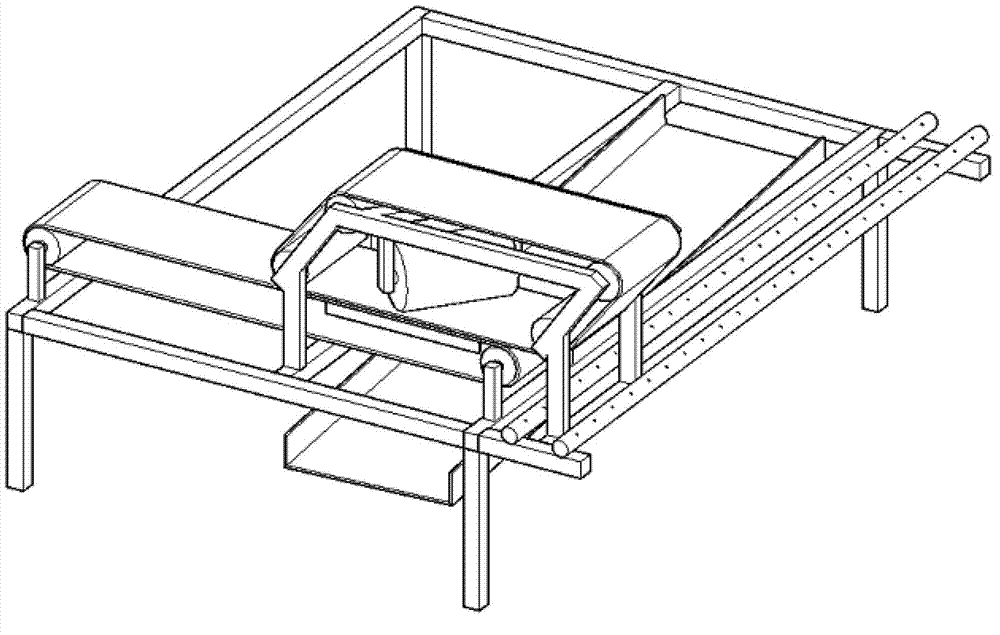

Shrimp unshelling device

The invention relates to a shrimp unshelling device which comprises a chute feeding mechanism (1) and a shell-meat separation mechanism (2). The chute feeding mechanism (1) and the shell-meat separation mechanism (2) are connected together. According to the invention, a shrimp shell can be rapidly stripped from a shrimp body; shrimp meat obtained after the shell-meat separation is carried out by the device is of a shelled shrimp shape and the appearance of the shrimp meat is kept complete; the shrimp unshelling device can be used for processing the complete-shaped shrimp meat of antarctic krill; and the integral shrimp unshelling device has simple structure and low price and is convenient to install on an ocean fishing ship.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Animal dressing tool

InactiveUS20050227601A1Easy to useSecure attachmentSplitting instrumentsShrimp/lobster processingEngineeringKnife blades

A bladed lever for cutting through or splitting animal bones having a head, a handle and a knife with the head having two sides with a row of teeth at the bottom of each side to grip the bone to be cut or split and the knife having a blade positioned below and between the two sides of the head at a distance to permit the bone to be split to fit between the teeth of the head and the blade of the knife.

Owner:WHETSTONE GREGORY JACK +1

Processing method of soft baked prawn

InactiveCN101396135AImprove convenienceNo nutrient lossMeat/fish preservation by heatingShrimp/lobster processingPrawnHigh heat

The invention relates to a processing method of a soft-roasted prawn. The method comprises the following steps: live prawns or frozen whole prawns or headless prawns which are not polluted, and have no abnormality and even size are taken as raw materials, deshelled, cleaned, cleared, prickled, roasted at high temperature for sterilization and packaged for sealing, and an instant soft-roasted prawn is obtained after mild secondary sterilization. The method is simple and feasible, and the prawn product processed has no nutrition loss, has natural color and beautiful appearance, and can be eaten after being opened, thus improving the edible convenience of prawns. The instant product can be stored for six months to one year at normal temperature, and is easy for storage and circulation. The taste of the instant product can meet the requirements of people with different ages and in different regions, and the soft-roasted prawn is safe in eating and is suitable for travel and leisure.

Owner:SHANDONG HOMEY AQUATIC DEV +1

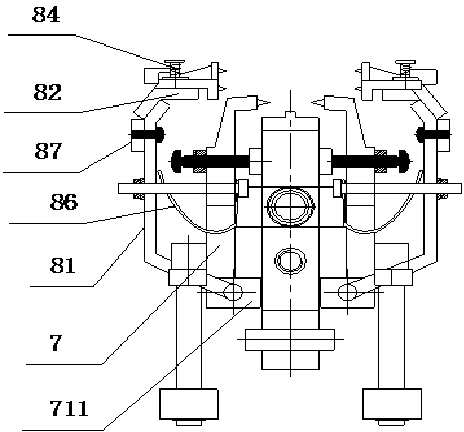

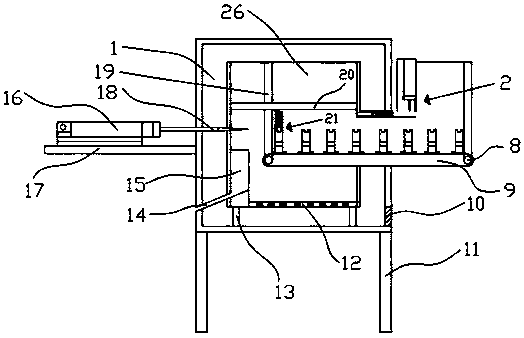

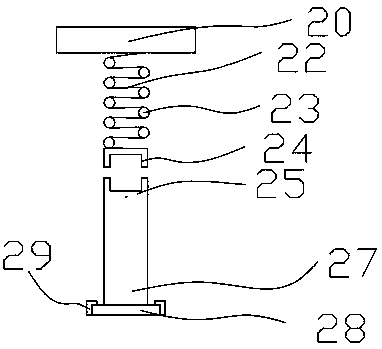

Automatic flesh taking equipment for crayfishes

ActiveCN108029739ARealize automatic clamp removalEfficient and high-quality processingShrimp/lobster processingCrayfishBiomedical engineering

The invention discloses automatic flesh taking equipment for crayfishes. The automatic flesh taking equipment comprises a crayfish expending device, a crayfish transporting device, a crayfish claw removing device, a crayfish head and tail removing device and a crayfish intestine removing and meat taking device, wherein the crayfish expending device can be used for straightening and expending crayfishes in a curling state; the crayfish transporting device can be used for clamping expended crayfishes on the crayfish expending device and transporting the crayfishes to the crayfish claw removing device, the crayfish head and tail removing device and the crayfish intestine removing and meat taking device; the crayfish claw removing device can realize automatic claw removal of the crayfishes; the crayfish head and tail removing device can realize automatic head and tail removal of the crayfishes; the crayfish intestine removing and meat taking device can be used for automatically separatingcrayfish intestine lines and crayfish meat in crayfish trunks. By use of the automatic flesh taking equipment for the crayfishes, disclosed by the invention, the crayfishes can be efficiently treatedat high quality.

Owner:ZHEJIANG RONGXIN BIOTECH CO LTD

Shrimp shelling device

The invention discloses a shrimp shelling device, and belongs to the technical field of shrimp processing. The shrimp shelling device comprises a housing, wherein supporting feet are arranged under the housing; a separation box is arranged in the housing; a collecting box is arranged at the lower part on the left side of the separation box; a discharge pipeline is arranged in the collecting box; propping bars are arranged under the separation box; a head removing device is arranged above the outer part of the right side of the housing; a conveying device is arranged in the housing; a clampingdevice is movably connected to the conveying device; and an air cylinder is arranged on the outer part of the left side of the housing. The shrimp shelling device is high in shelling efficiency; shrimps cannot be contaminated during shelling, so that the freshness of the shrimp meat is guaranteed; and shrimp head removal, separation and conveyance are integrated, so that the shrimp shelling deviceis practical and convenient, and has good market prospect.

Owner:金华市鸿讯机械工程技术有限公司

Animal dressing tool

InactiveUS7198562B2Easy to useSecure attachmentSplitting instrumentsShrimp/lobster processingKnife bladesBiomedical engineering

A bladed lever for cutting through or splitting animal bones having a head, a handle and a knife with the head having two sides with a row of teeth at the bottom of each side to grip the bone to be cut or split and the knife having a blade positioned below and between the two sides of the head at a distance to permit the bone to be split to fit between the teeth of the head and the blade of the knife.

Owner:WHETSTONE GREGORY JACK +1

Crayfish shell removing device

PendingCN111011465AImprove convenienceSmall space requirementShrimp/lobster processingShrimpEngineering

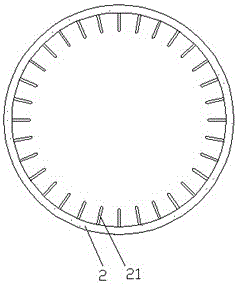

The invention discloses a crayfish shell removing device, and belongs to the field of crayfish processing devices. The crayfish shell removing device comprises a rotating disc, a boss is arranged on the rotating disc, grooves are formed in the boss in an annular array, and a conveying belt is arranged above the rotating disc; a clamping device is movably arranged above the boss, the clamping device is connected to a piston rod of a first air cylinder, and the first air cylinder is installed on a third support; a head removing device is movably arranged on the outer side of the boss, the head removing device is connected to a piston rod of a third air cylinder, and the third air cylinder is installed on a fourth support; an extrusion device is movably arranged above the boss, the extrusiondevice is connected to a piston rod of a second air cylinder, and the second air cylinder is installed on a sixth support; an air spraying pipe is arranged above the boss and installed on a fifth support. According to the crayfish shell removing device, shrimp heads and shrimp lines can be synchronously removed, the rotating disc type annular integrated design is adopted, the space requirement ofa workshop is reduced, meanwhile, overall management and operation are facilitated, and the production efficiency is further improved.

Owner:国联(益阳)食品有限公司

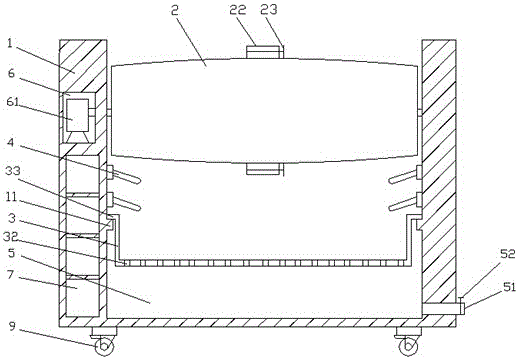

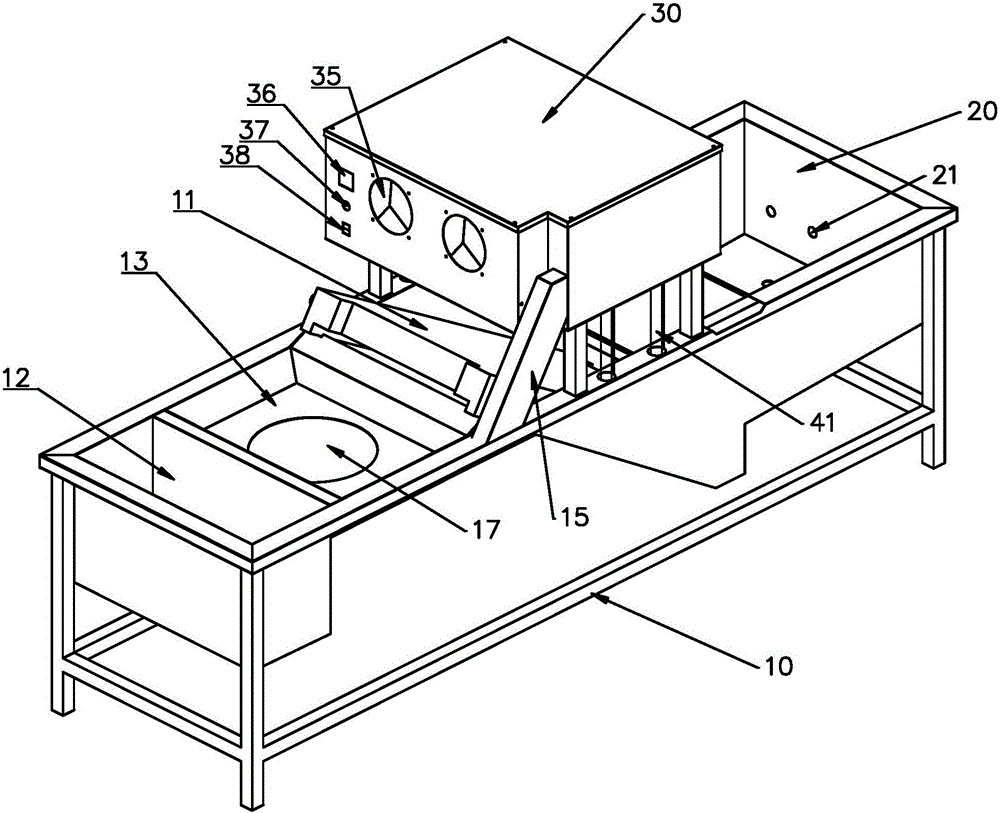

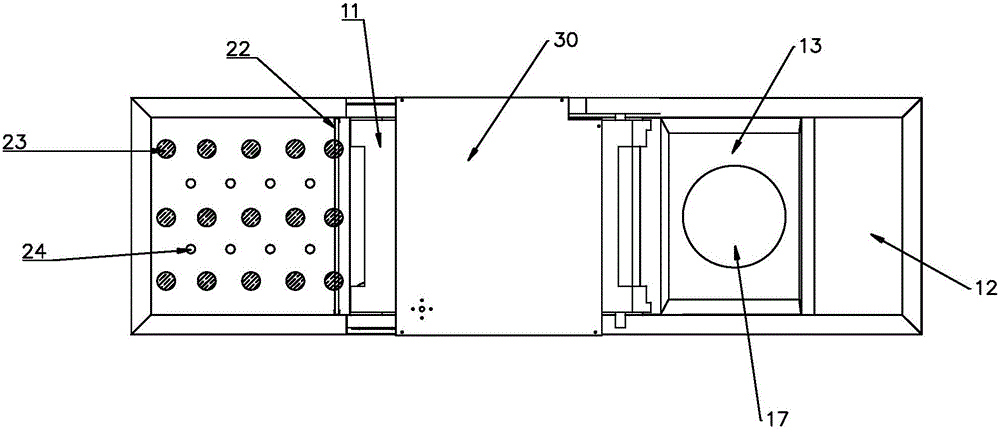

Ultrasonic integral crawfish washing machine

InactiveCN105901109AAvoid staleAvoid problems such as necrosisShrimp/lobster processingPulp and paper industryCrayfish

The invention provides an ultrasonic integral crawfish washing machine, and relates to food processing devices, which is used for integrating crawfish washing and boiling. The ultrasonic integral crawfish washing machine comprises a machine frame, a conveying belt, a water overflow opening, a crawfish washing tank and a control tank, wherein the crawfish washing tank is connected with one end of the conveying belt; one end, connected with the crawfish washing tank, of the conveying belt is the first end, and the other end of the conveying belt is the final end; an ultrasonic oscillator is arranged at the bottom end of the crawfish washing tank, and a crawfish discharging gate is arranged between the crawfish washing tank and the first end of the conveying belt; a processing table is arranged on the machine frame, one end of the processing table is connected with the final end of the conveying belt, and the other end of the processing table is connected with a crawfish cooling tank. The ultrasonic integral crawfish washing machine has the advantages that the common methods of artificial crawfish washing and crawfish washing by crawfish washing powder are replaced by ultrasonic crawfish washing type, and the health and high-efficiency effects are realized; by arranging the cooking and processing places, the washed crayfish can be directly sent into a cooking device; the device is miniature, the handling is easy, the integral design is realized, the cost is lower, and the device can be used as a movable stand.

Owner:东莞市优之净环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com