Shrimp sheller and shrimp meat processing system

A shrimp machine and shrimp peeling technology, applied in shrimp/lobster processing, processing crustaceans, crustacean/bivalve grading/classification, etc., can solve the problem of manual peeling labor intensity, affecting product freshness and quality , the product is susceptible to bacterial contamination and other problems, to achieve the effect of eliminating the need for shelling work, the equipment operation structure is light, and the degree of automation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

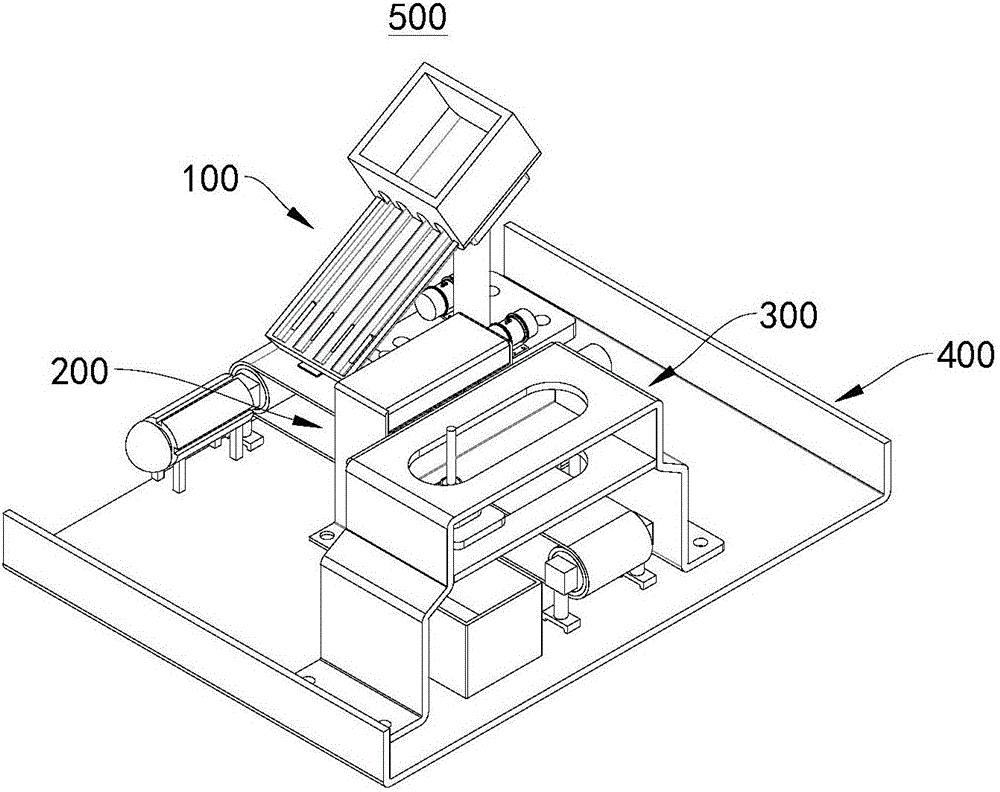

[0045] see figure 1 The shrimp peeling machine 500 shown in the embodiment of the present invention includes a feeding device 100 , a shrimp peeling and cutting device 200 , a separating device 300 and a base 400 . The feeding device 100 , the shrimp peeling and cutting device 200 and the separating device 300 are installed on the base 400 respectively.

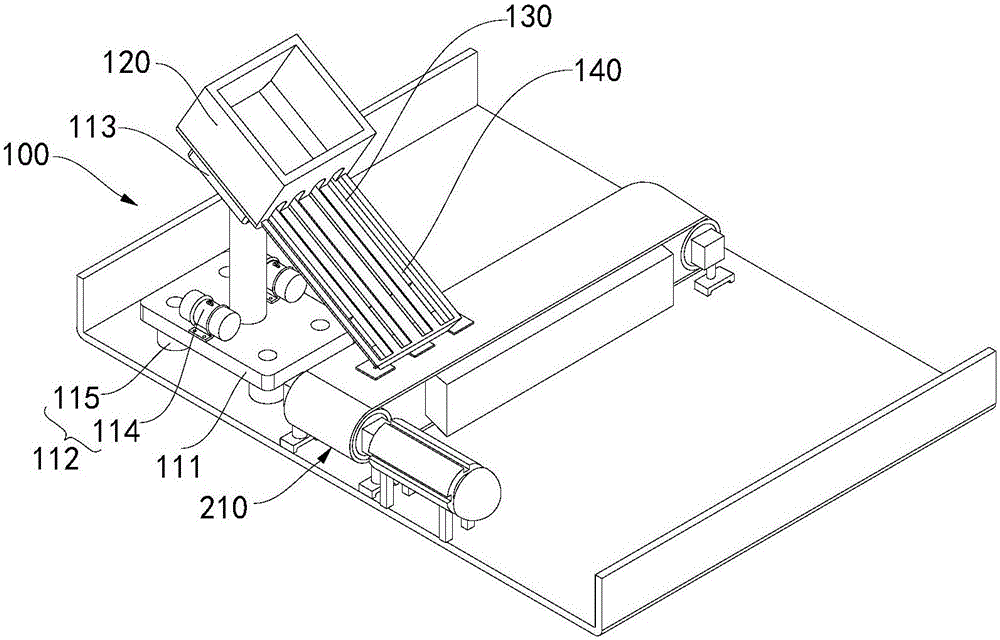

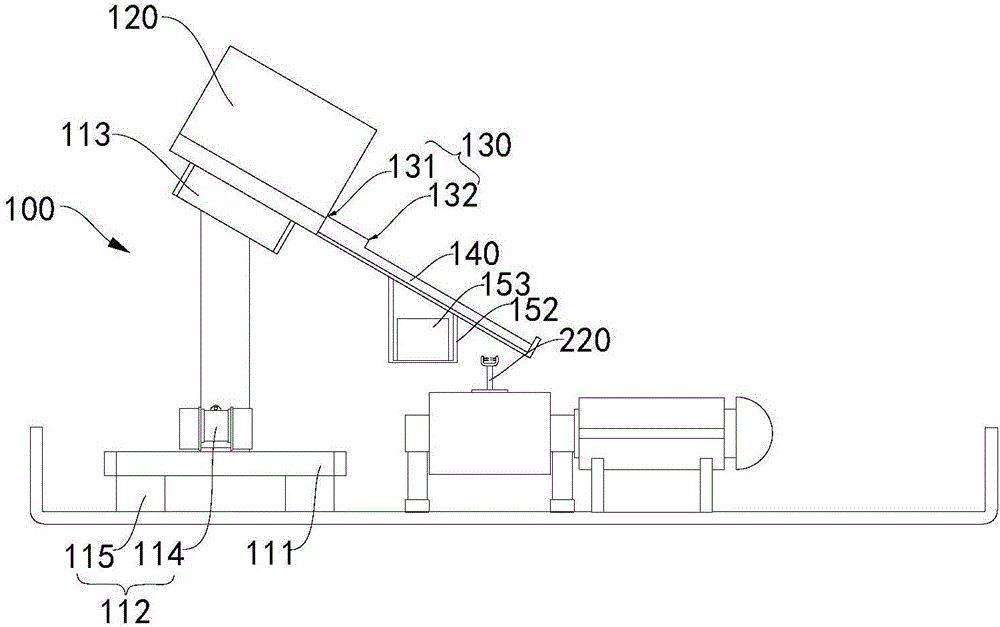

[0046] see figure 2 , the feeding device 100 , the orientation mechanism and the delivery mechanism 210 provided in this embodiment. The output port 141 of the orientation mechanism is disposed above the starting end of the transmission mechanism 210 . The conveyor belt 211 of the transmission mechanism 210 is provided with a clamping mechanism 220 , and the opening of the clamping mechanism 220 is opposite to the output port 141 .

[0047] The orientation mechanism includes an orientation frame 111 , a vibration mechanism 112 and an orientation plate 113 . The orientation frame 111 is used for installing the vibration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com