A small-size fragrant-flowered garlic harvester

A harvester and leek technology, which is applied in the field of agricultural machinery, can solve the problems of no safety protection device around the cutting disc, manual supplementary cutting, hidden safety hazards, etc., and achieves the advantages of light equipment operation structure, high degree of automation, and avoiding the problem of missed cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

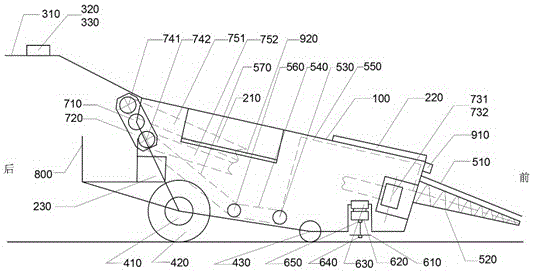

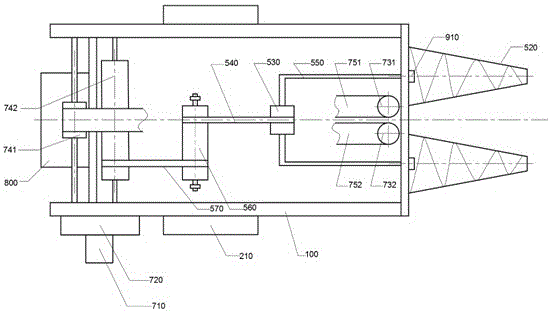

[0031] figure 1 , 2 Shown is an embodiment of the small leek harvester of the present invention, including a main body, a power supply system, a control system, a walking mechanism, a gathering mechanism, a harvesting mechanism, a conveying mechanism, a collection mechanism, and a lighting system; the main body of the leek harvester is a self-propelled Walk frame 100; described power supply system comprises storage battery 210, solar power generation device 220; Described control system comprises: handrail 310, operation switch 320, control unit 330; Described walking mechanism comprises: wheel hub motor 410, rear drive wheel 420, Front roller 430; the gathering mechanism includes: gathering plate 510, spiral gatherer 520, spiral gatherer driving roller shaft 530, cylindrical belt 540, flexible shaft 550, intermediate roller shaft 560, cylindrical belt 570; the harvesting mechanism Including cutterhead 610, cutterhead drive motor 620, cutterhead lifting device 630, ranging se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com