Automatic Chinese chive harvester

A technology for harvesters and leeks, which is applied to harvesters, cutters, agricultural machinery and equipment, etc., can solve the problems of no safety protection device around the cutter head, high labor intensity, manual re-cutting, etc. Prolong the working time and reduce the effect of downtime and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

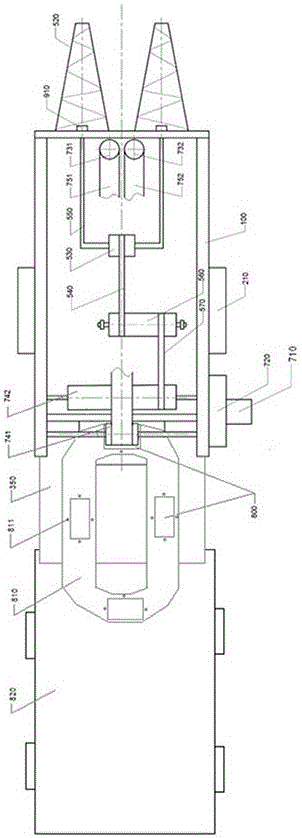

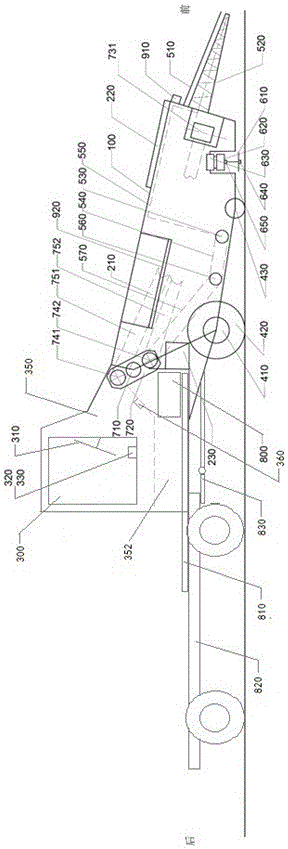

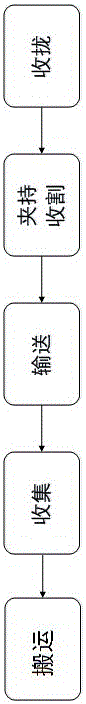

[0034] As shown in the figure, it is an embodiment of the automatic leek harvester of the present invention, including the main body of the leek harvester, the cockpit, the flatbed, the power supply system, the walking mechanism, the gathering mechanism, the harvesting mechanism, the conveying mechanism, the collecting mechanism, and the lighting system; The main body of the leek harvester is a self-propelled frame 100; the cockpit 350 is connected and arranged at the rear of the main body of the leek harvester, and the cockpit includes a cockpit 300 and a control system, and the control system includes: a rudder 310, an operating switch 320, the control unit 330, the video monitoring unit 360; the flatbed car 820 is arranged at the rear of the cockpit, and is connected to the main body of the leek harvester through a movable buffer bar 830; the power supply system includes a storage battery 210 and a solar power generation device 220; The running mechanism includes: hub motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com