Patents

Literature

60results about How to "Convenient righting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

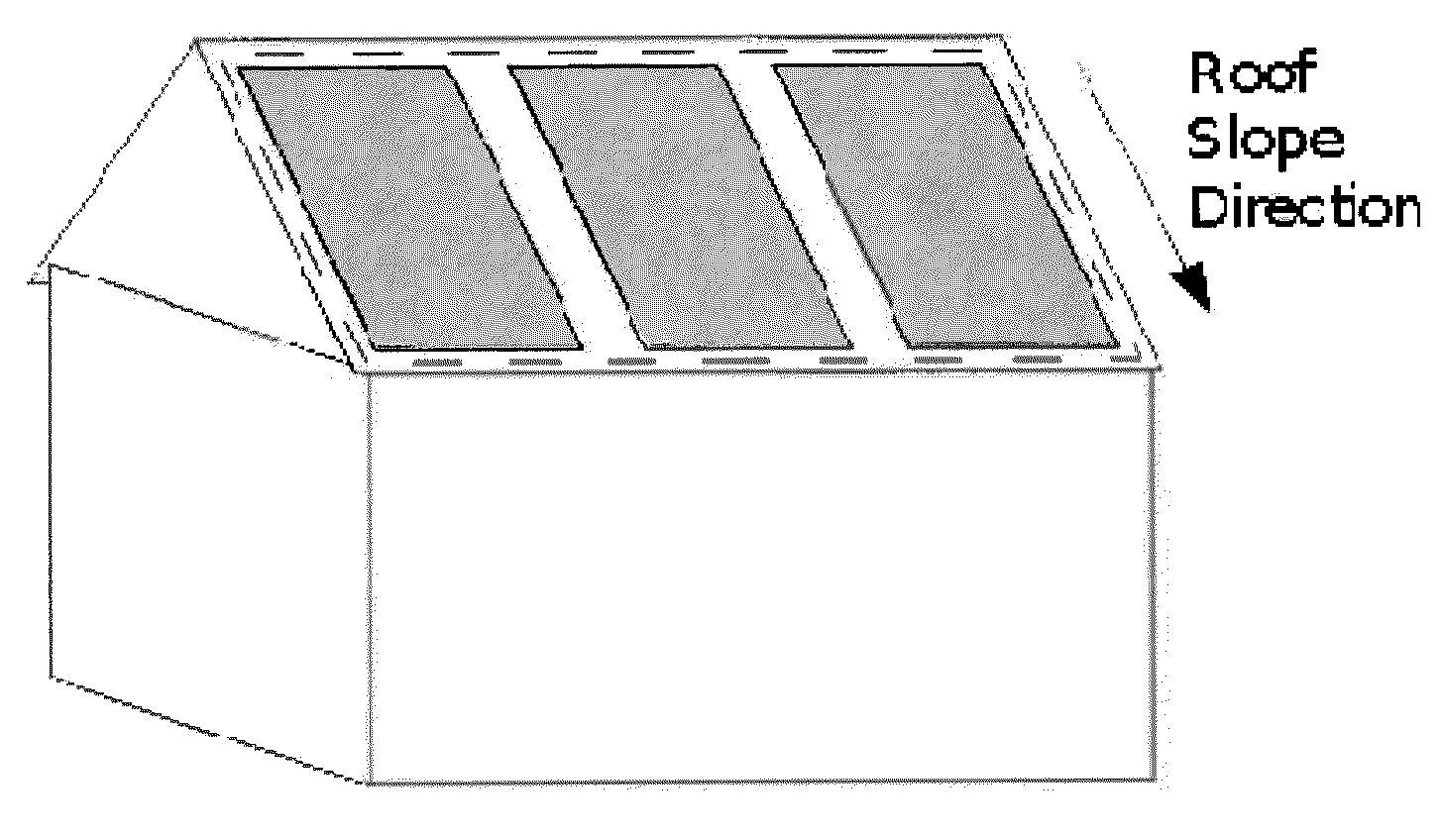

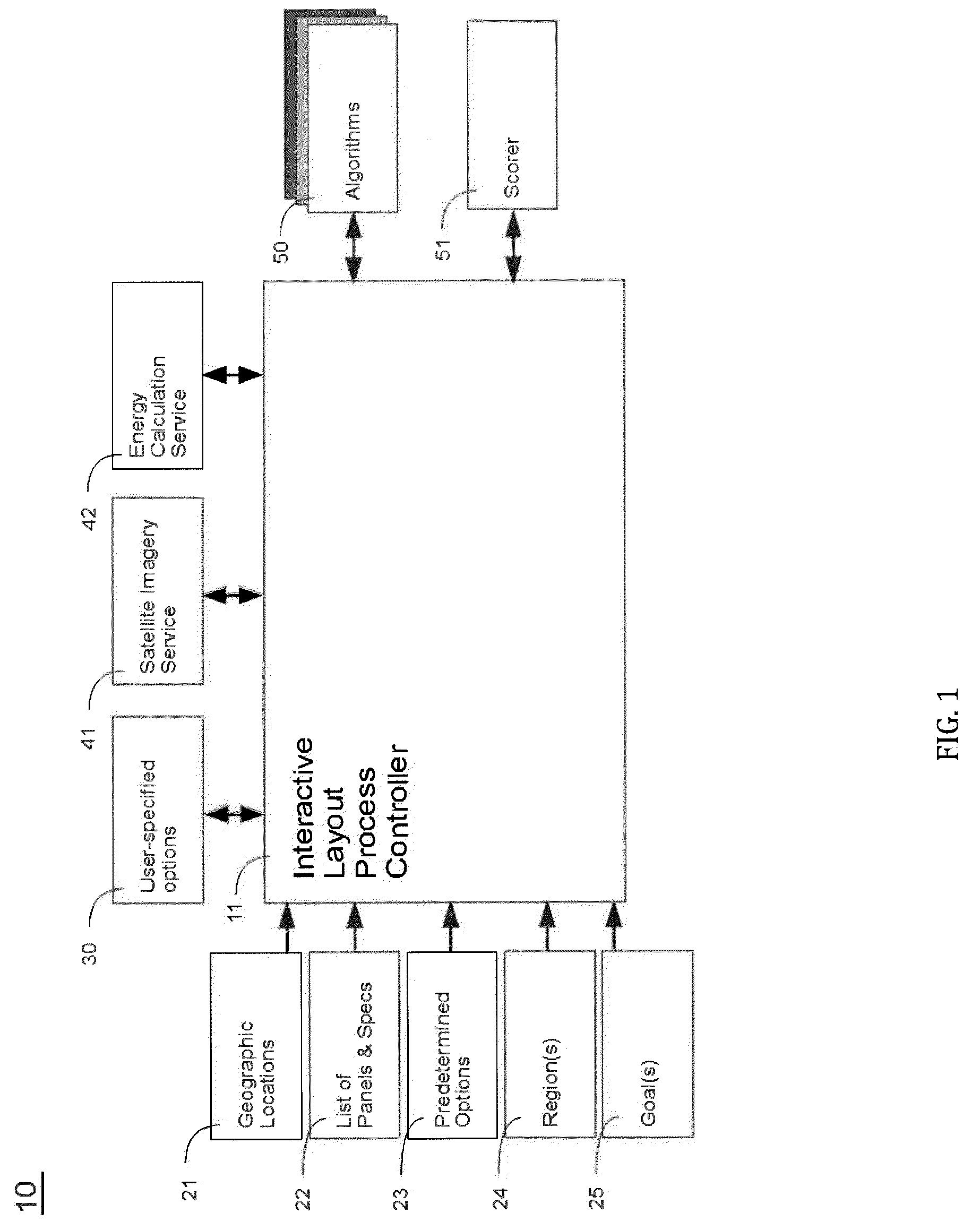

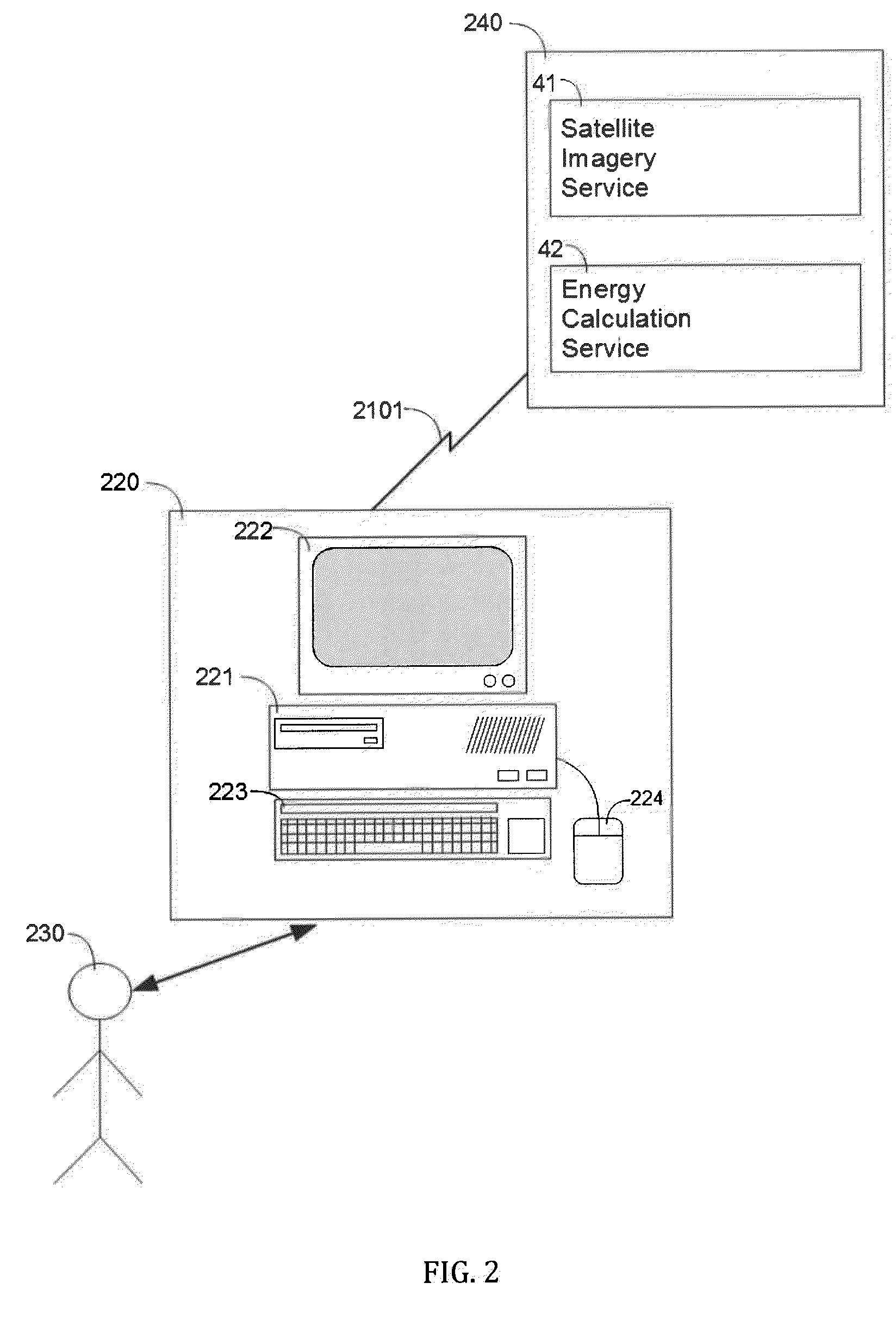

System and Method for Optimized Automated Layout of Solar Panels

InactiveUS20130246010A1Facilitate optimal layoutConvenient rightingPhotovoltaic supportsGeometric CADDeterministic methodGeographic regions

The present invention provides an automated system and method for laying out photovoltaic (PV) solar panels on one or more regions of a roof or ground installation. Automation includes a presentation of optimal comparative layouts, use of different panels (of the same or different manufacturers), and consideration of different energy production characteristics and different layout constraints. Diverse mathematical approaches are used to determine the optimal panel layout for a given geographic region and for particular goals, including, but not limited to, the objective of maximizing the solar production from the designated region(s). The application of two such mathematical algorithms are detailed as parts of an exemplary embodiment: a deterministic edge-aligned approach as well as a nondeterministic approach that employs a genetic evolution simulation.

Owner:MODSOLAR

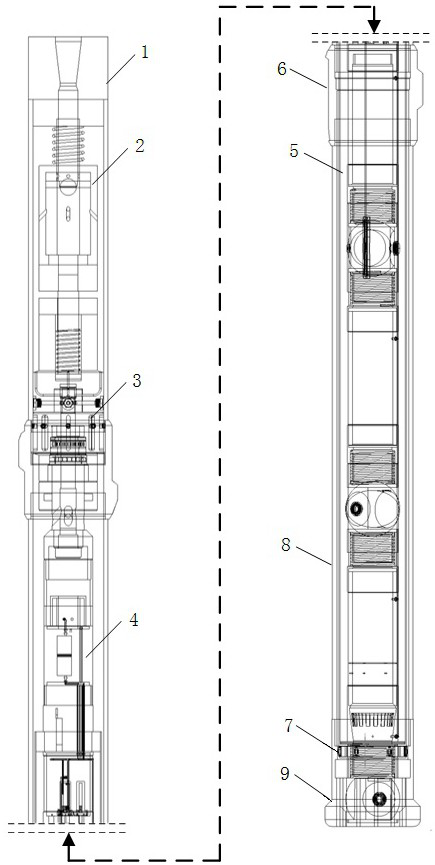

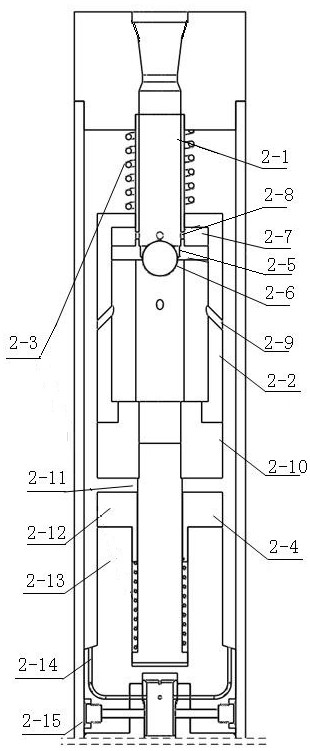

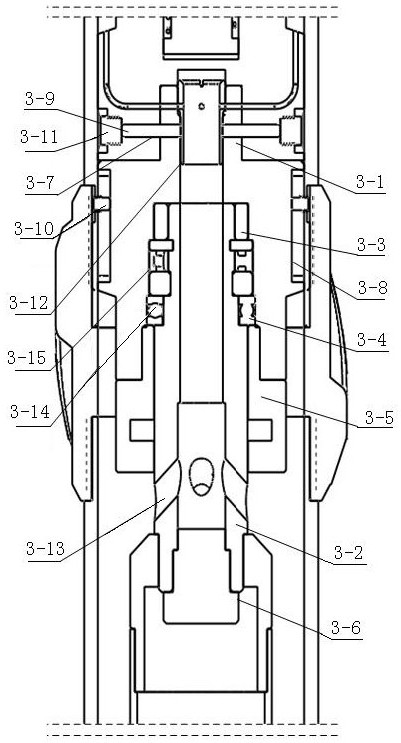

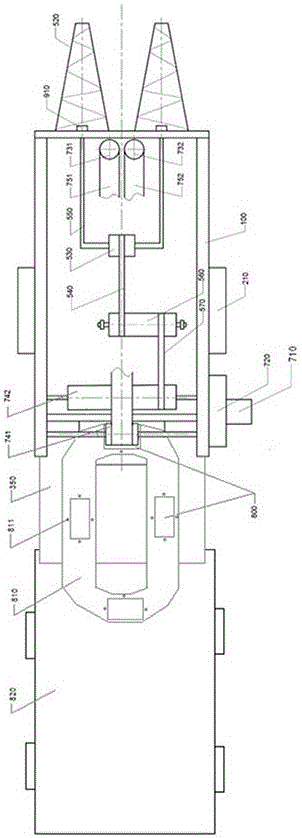

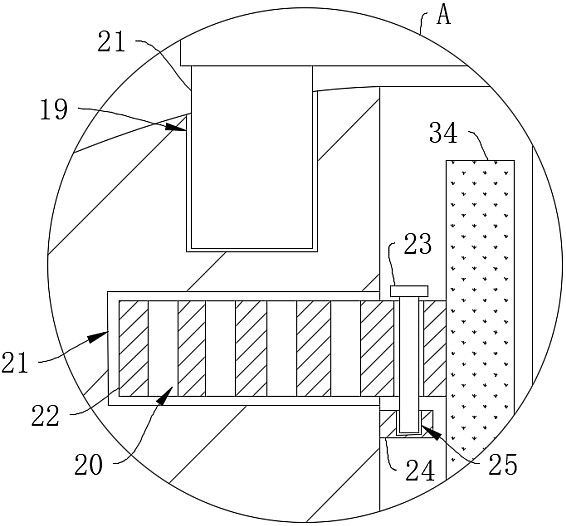

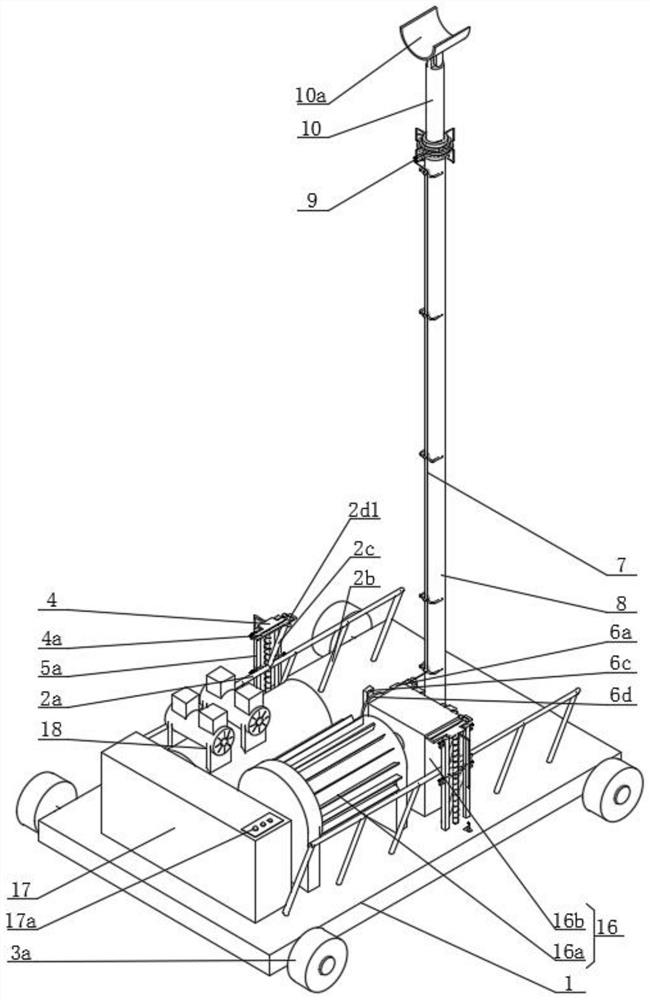

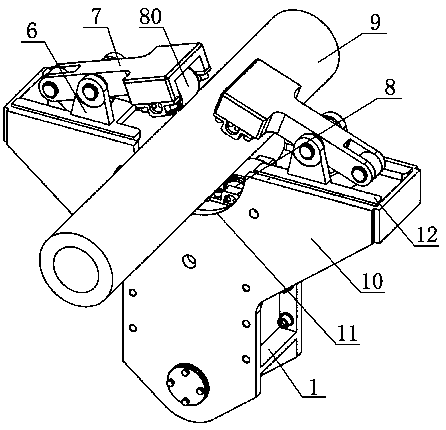

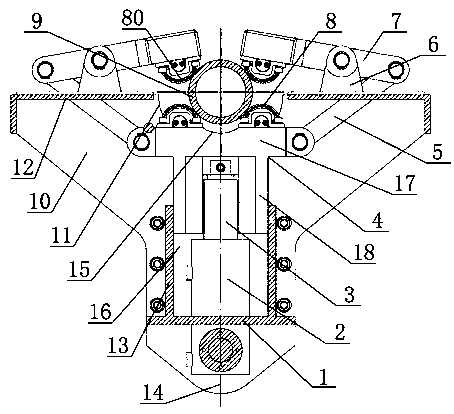

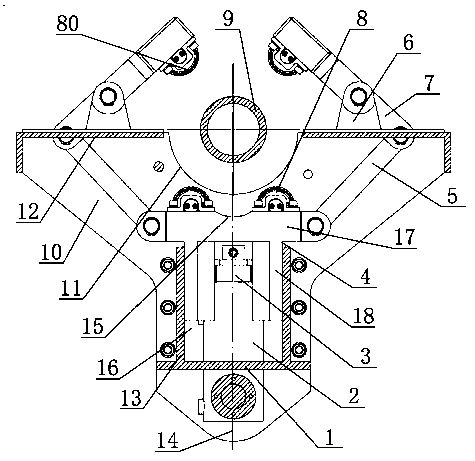

In-situ monitoring fidelity continuous coring tool for horizontal well

ActiveCN112012685AConvenient rightingRealize multi-point continuous coringSurveyConstructionsHorizontal wellsBlocked valves

The invention relates to an in-situ monitoring fidelity continuous coring tool for a horizontal well. The in-situ monitoring fidelity continuous coring tool comprises a safety assembly, a hexagonal differential reverse lifting mechanism, a suspension rotating assembly, an in-situ fidelity intelligent control assembly, a storage inner cylinder assembly, an outer cylinder and a coring drill bit, wherein the safety assembly, an upper outer centralizer, the outer cylinder, a lower outer centralizer and the coring drill bit are fixedly connected in sequence to form an outer cylinder assembly, the hexagonal differential reverse lifting mechanism, the suspension rotating assembly, the in-situ fidelity intelligent control assembly and the storage inner cylinder assembly are fixedly connected in sequence to form an inner cylinder assembly, the inner cylinder assembly is arranged in the outer cylinder assembly, and the inner cylinder assembly is connected to the outer cylinder assembly through the suspension rotating mechanism. After coring is finished, soluble balls are put in, so that the hexagonal differential mechanism is subjected to pressure building reverse lifting to finish core cutting operation; a piston rod of a pneumatic cylinder drives a sliding block valve rod to move to open and close a ball valve, the soluble balls react and dissolve, and multi-point continuous coring operation is completed; and the consistency of the inner cylinder environment and the in-situ environment is recorded, fed back and adjusted through the in-situ fidelity intelligent control assembly.

Owner:NORTHEAST GASOLINEEUM UNIV

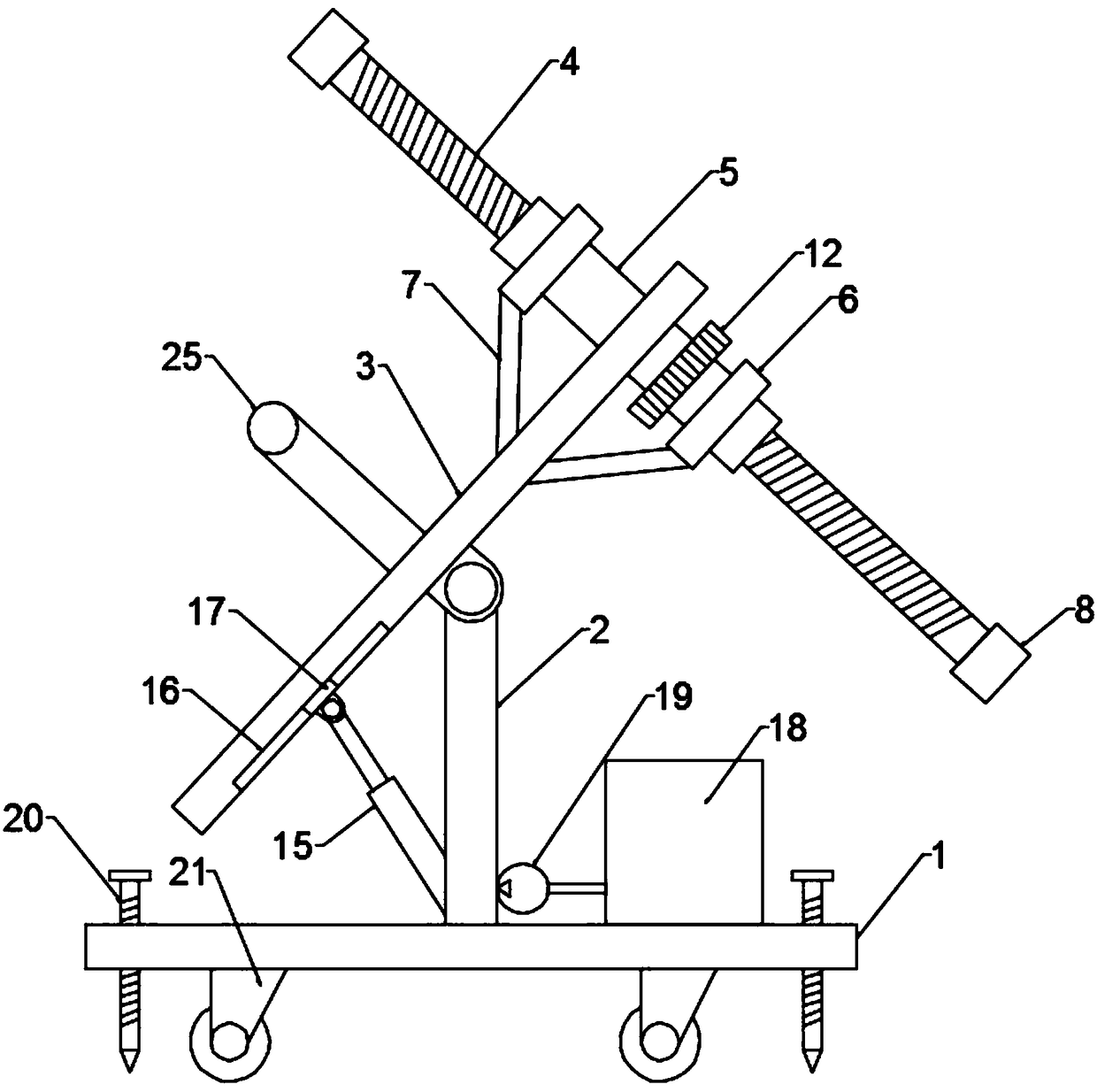

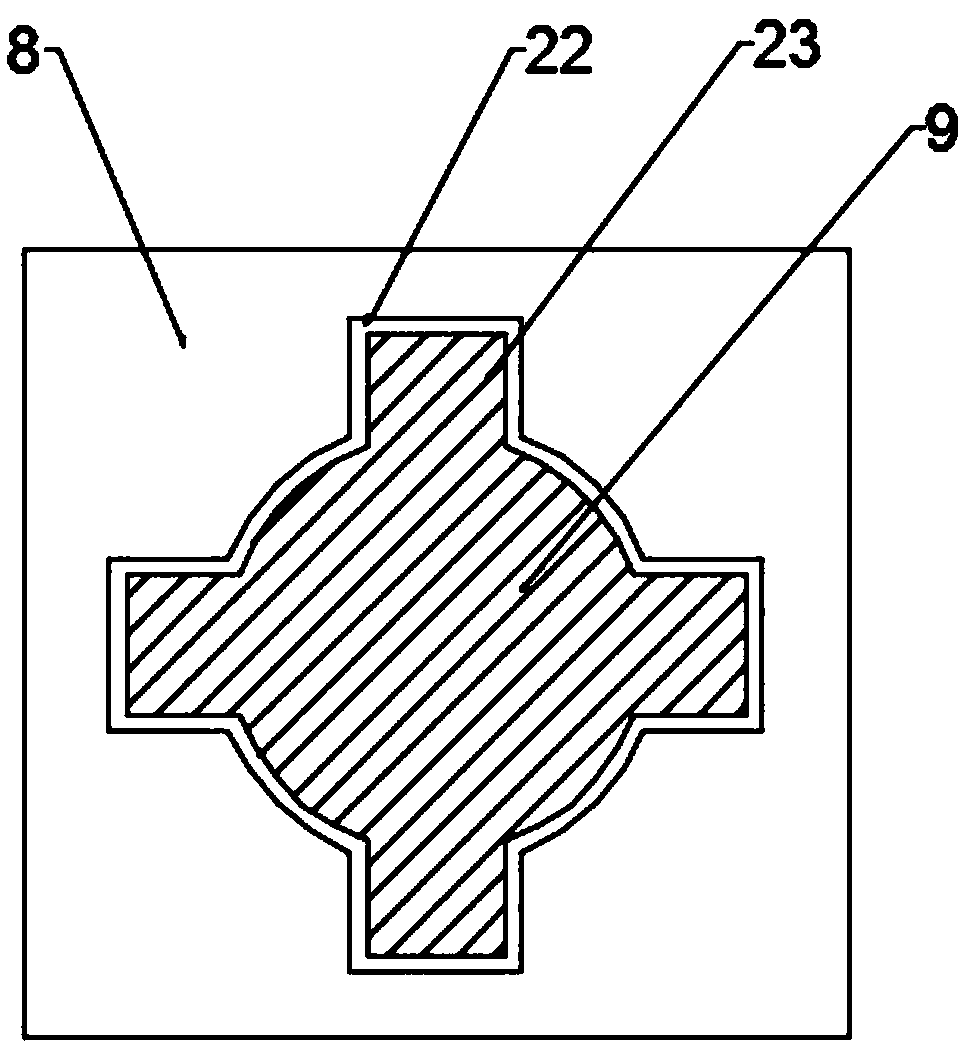

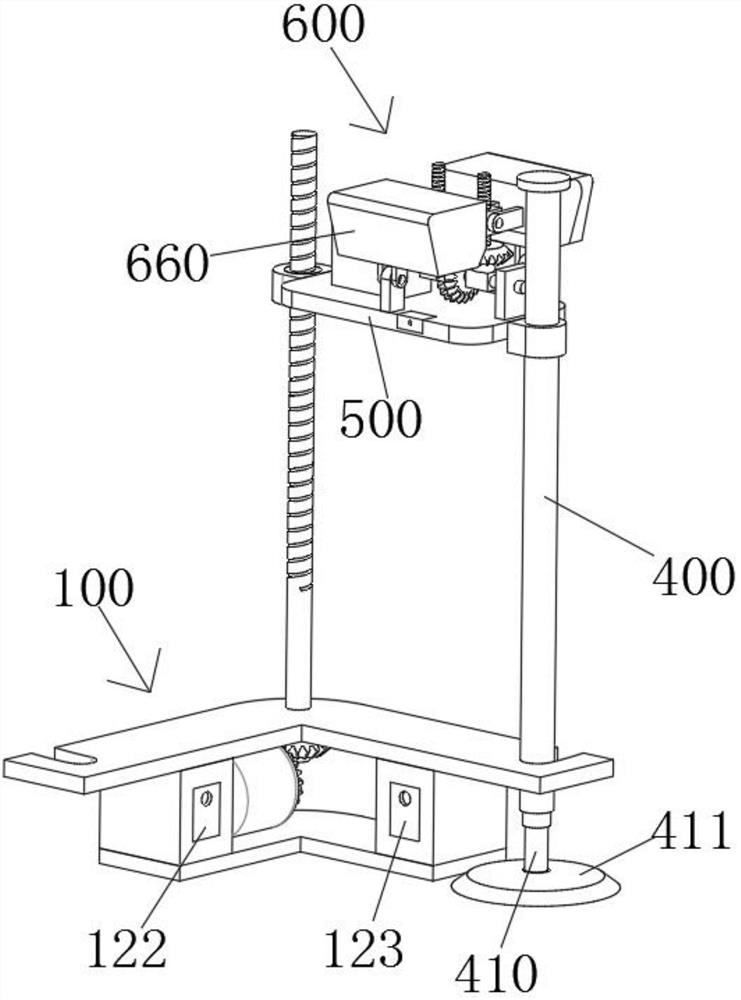

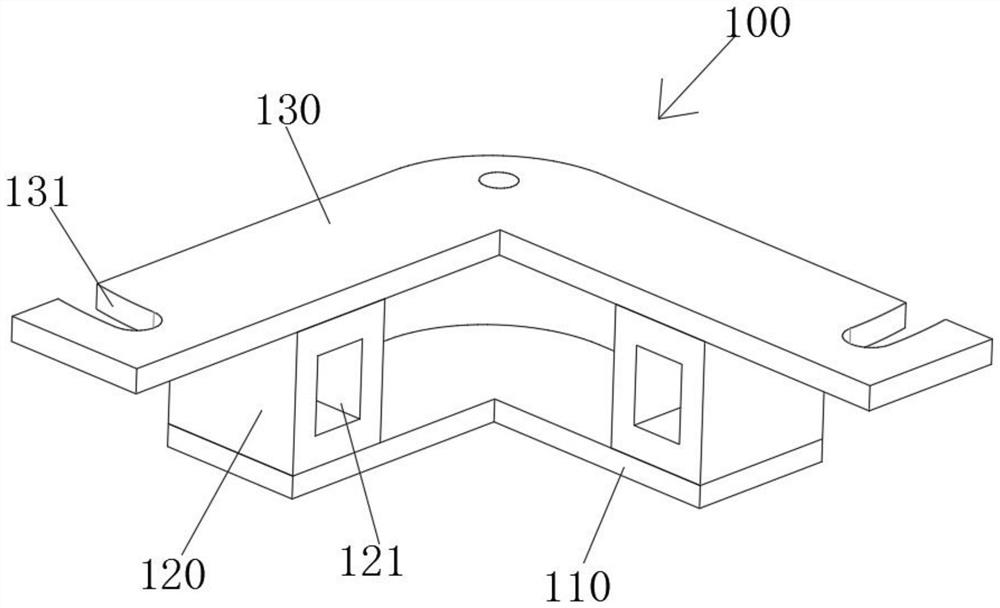

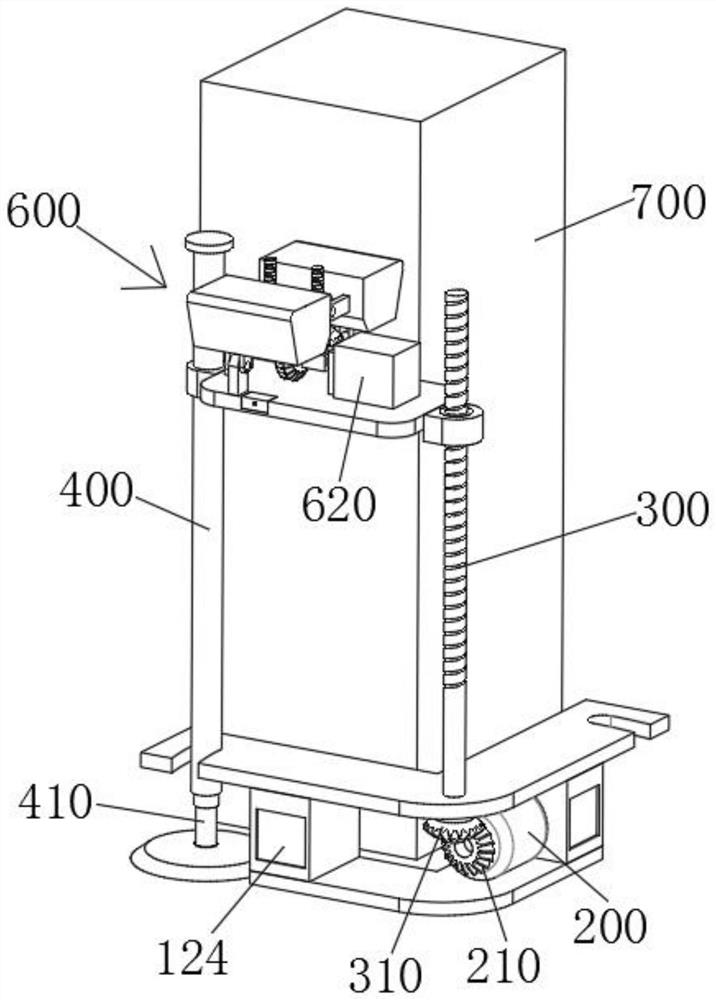

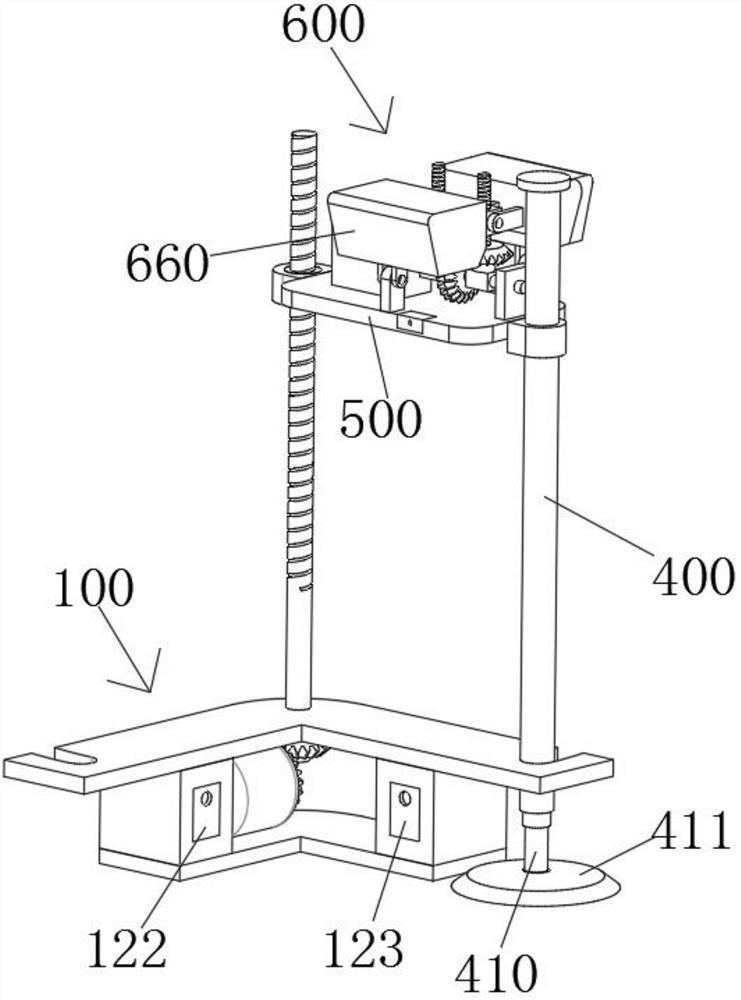

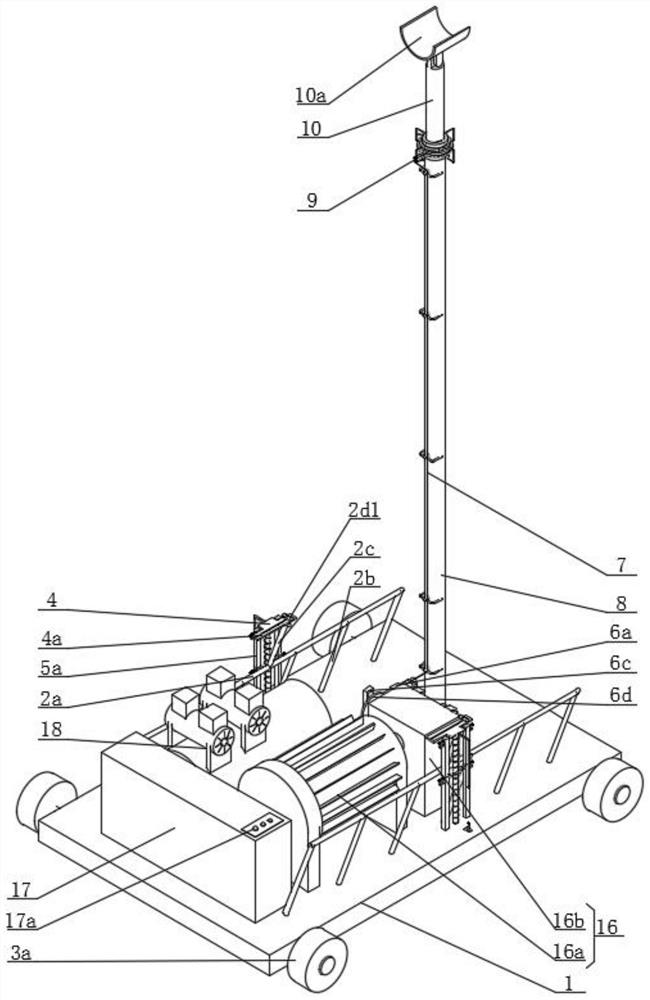

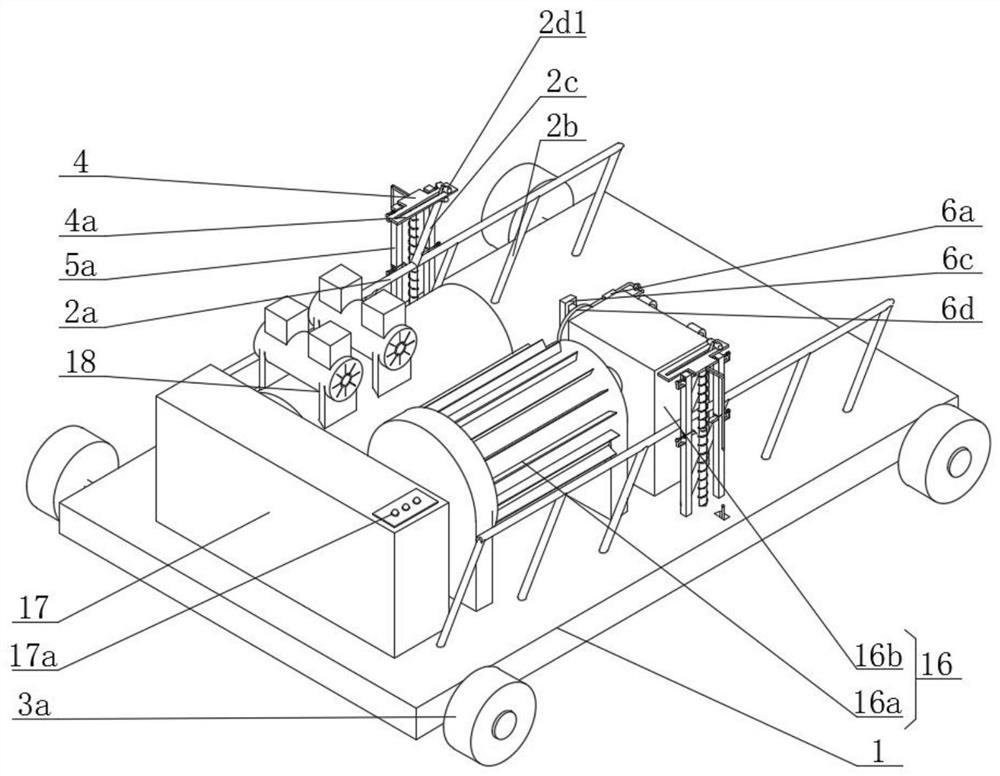

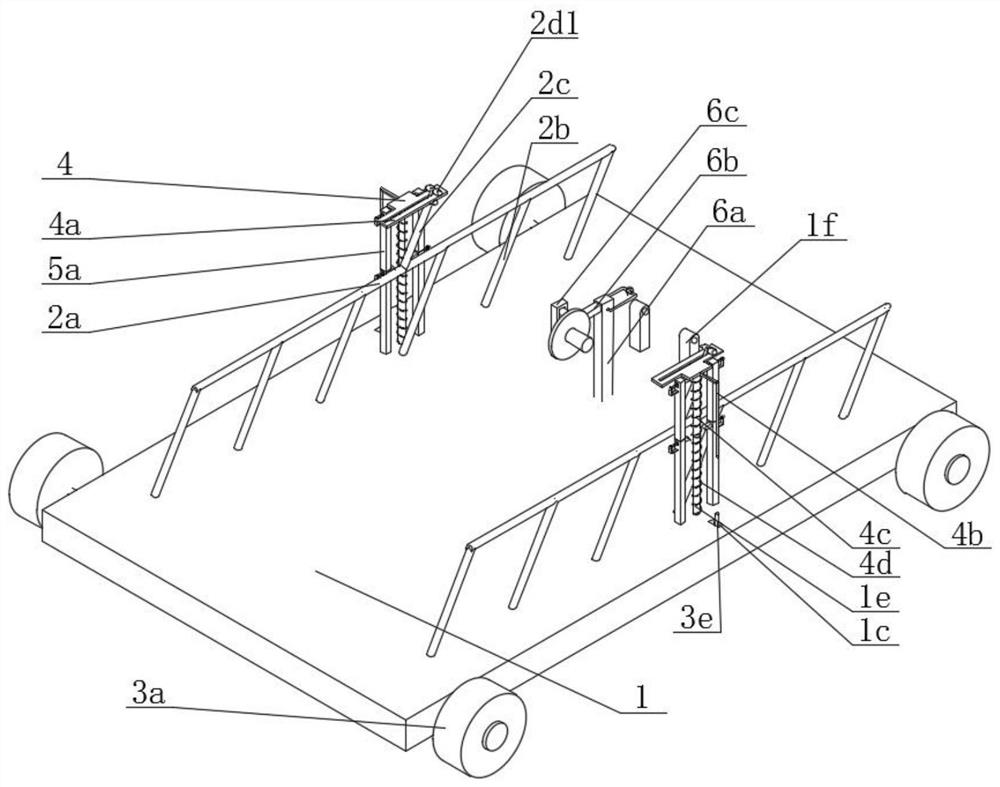

Garden toppled-tree supporting device

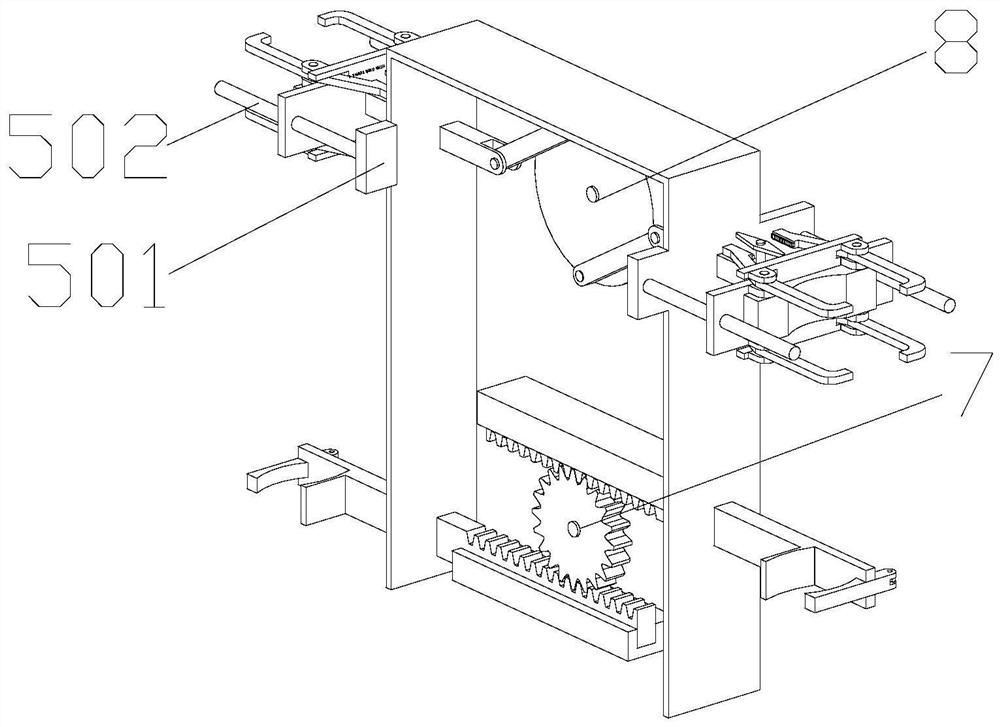

InactiveCN109275489AConvenient rightingHold steadyCultivating equipmentsGear wheelElectric machinery

Owner:吴丹花

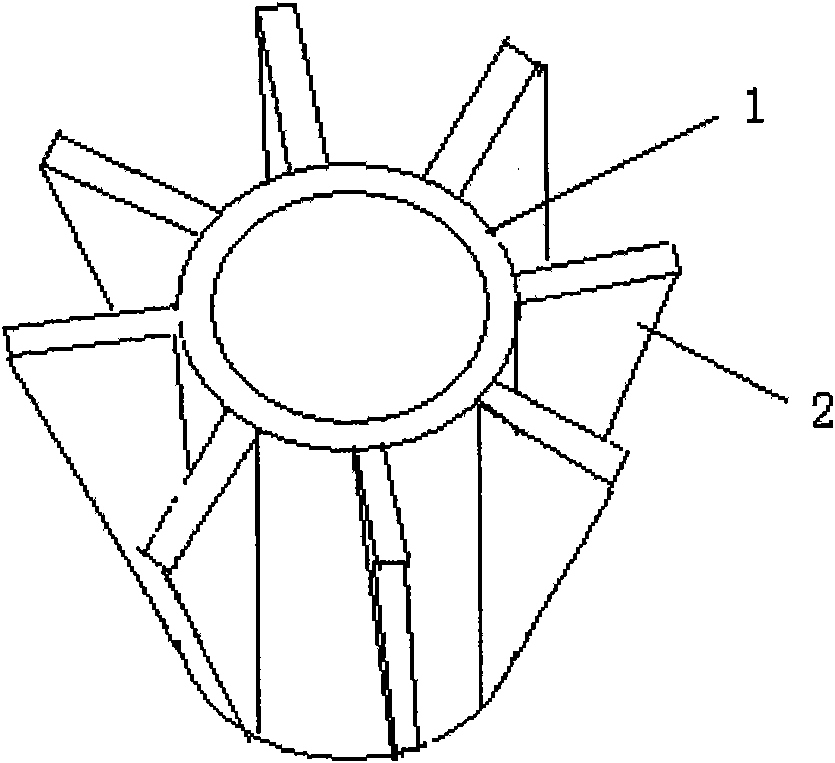

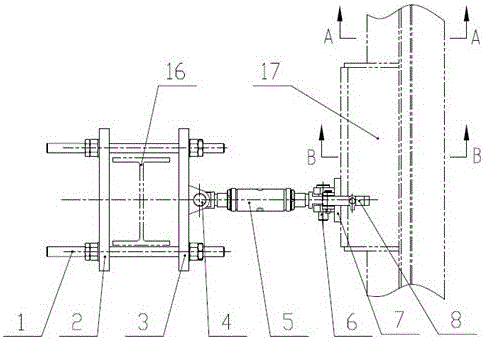

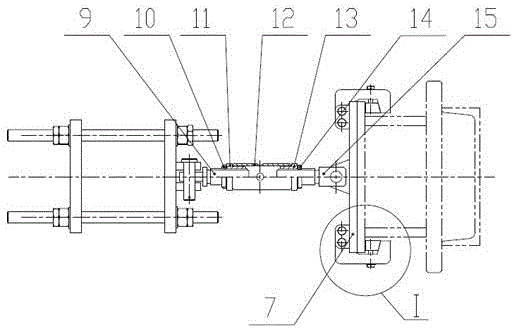

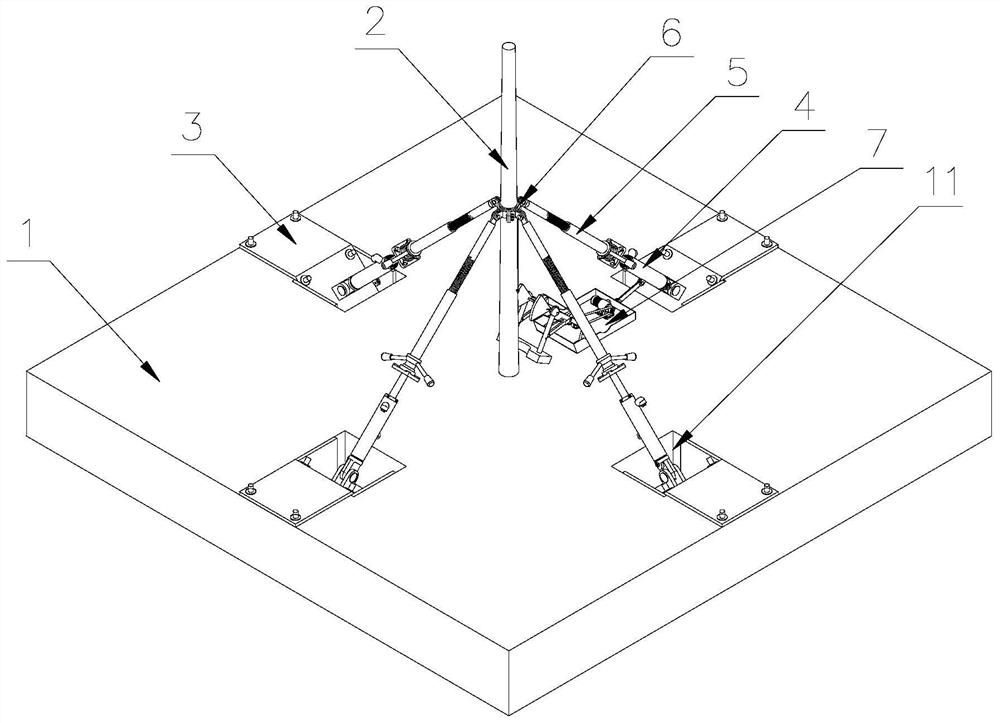

Erection device

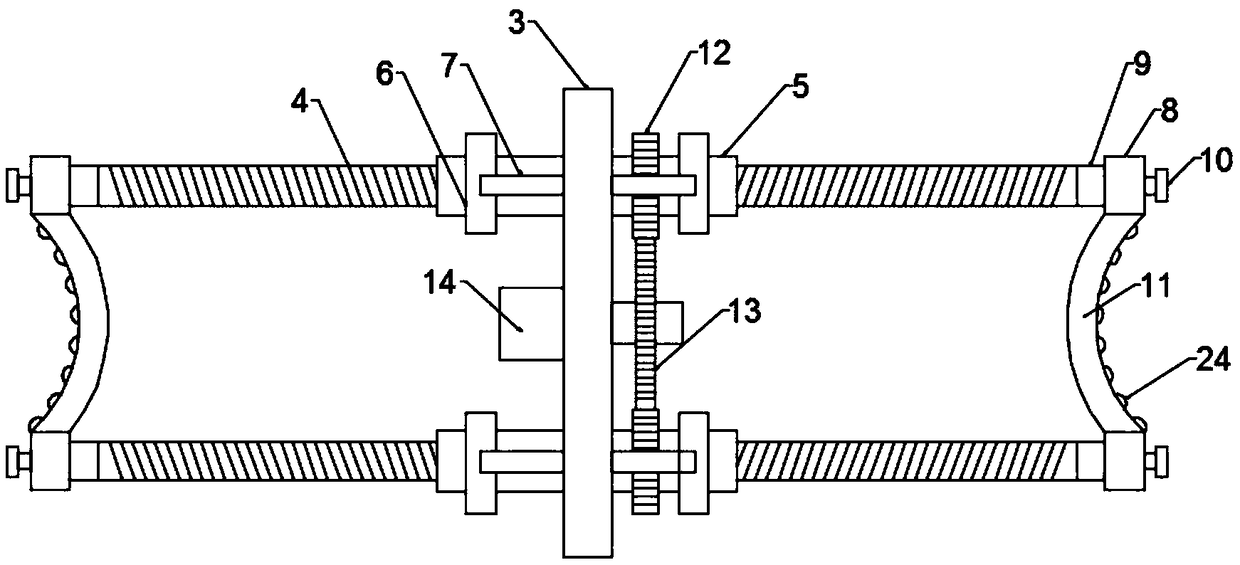

ActiveCN101586451AIncrease lateral stiffnessGood for vertical mud entryDrilling rodsDrilling casingsRight triangleEngineering

The invention relates to an erection device, comprising a circular sleeve and identical right triangle reinforcement plates, the same right-angle sides of the reinforcement plates are uniformly welded on the outer wall of the sleeve at intervals along the sleeve shaft, a riser pipe penetrates through and is welded on the sleeve, the non-welding right-angle sides of the reinforcement plates are aligned with the end plane of the sleeve. The erection device has simple structure and good guidance quality, thorough solving the problem that the riser pipe under the mud line is easy to incline and bend in the offshore piling process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

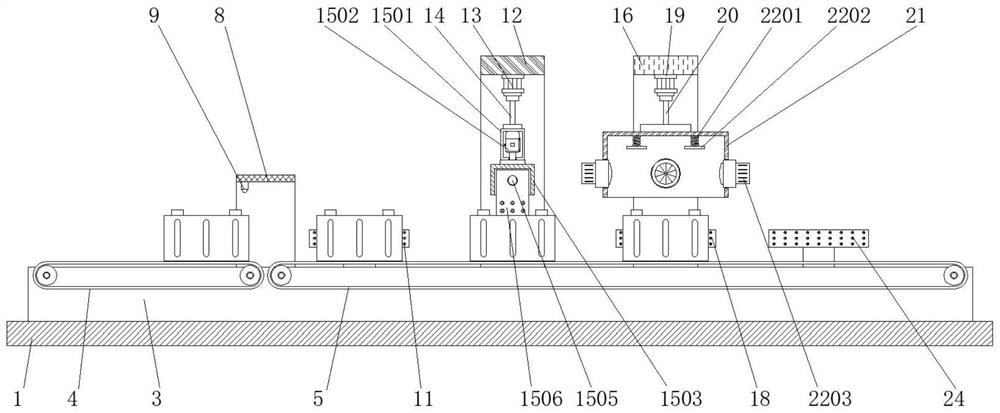

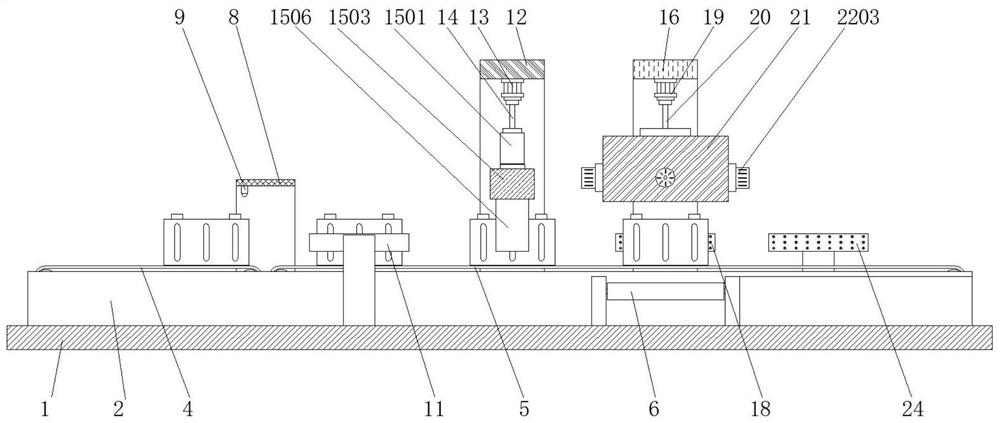

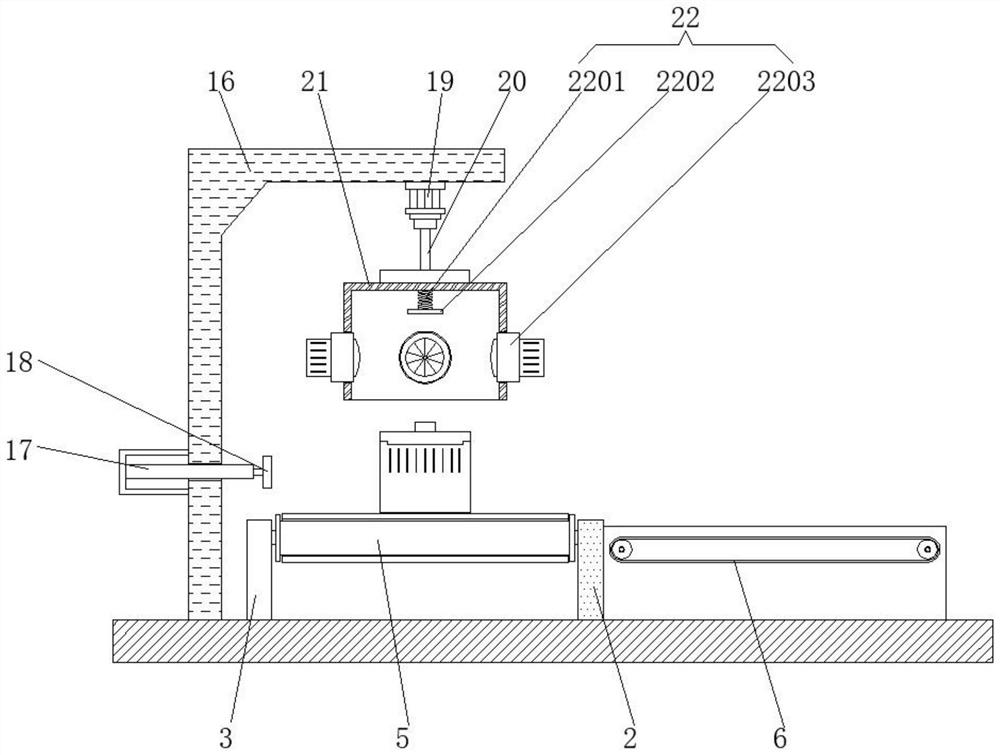

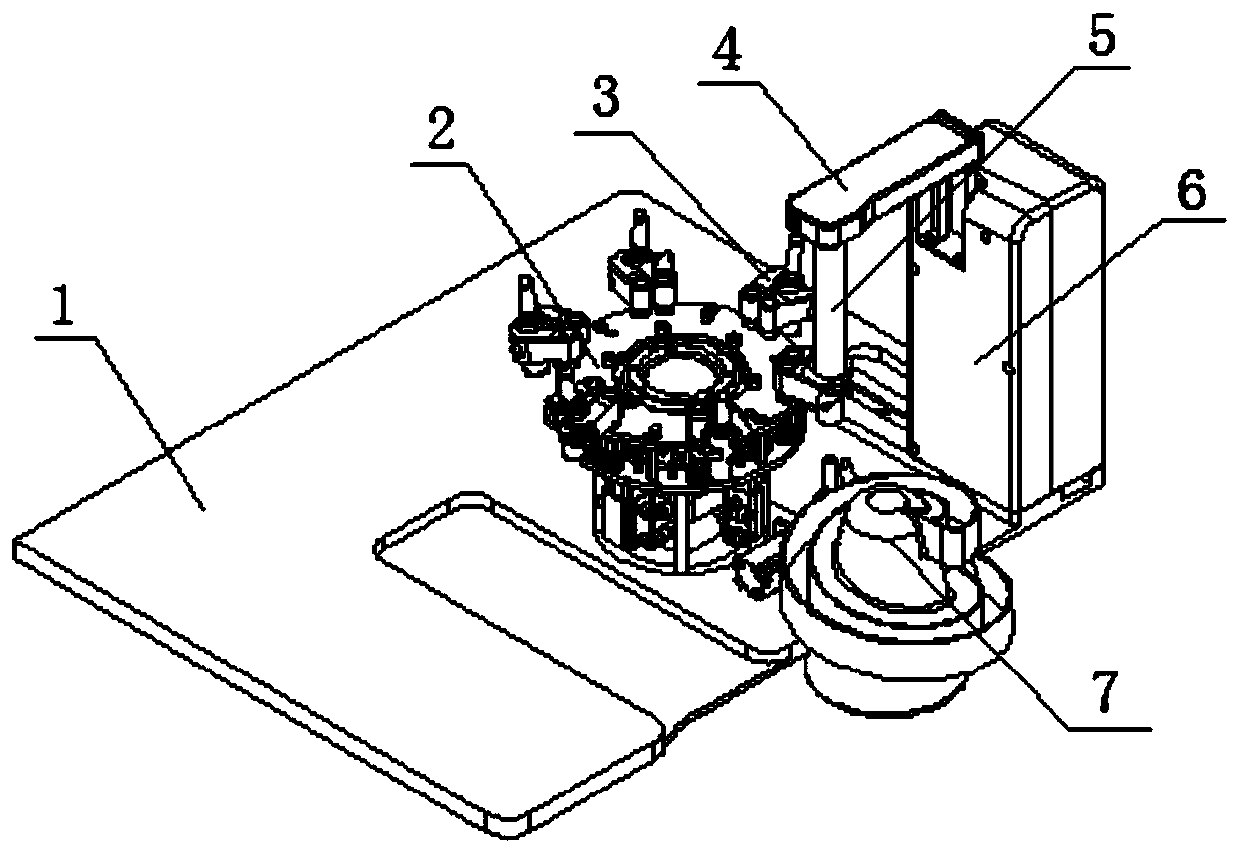

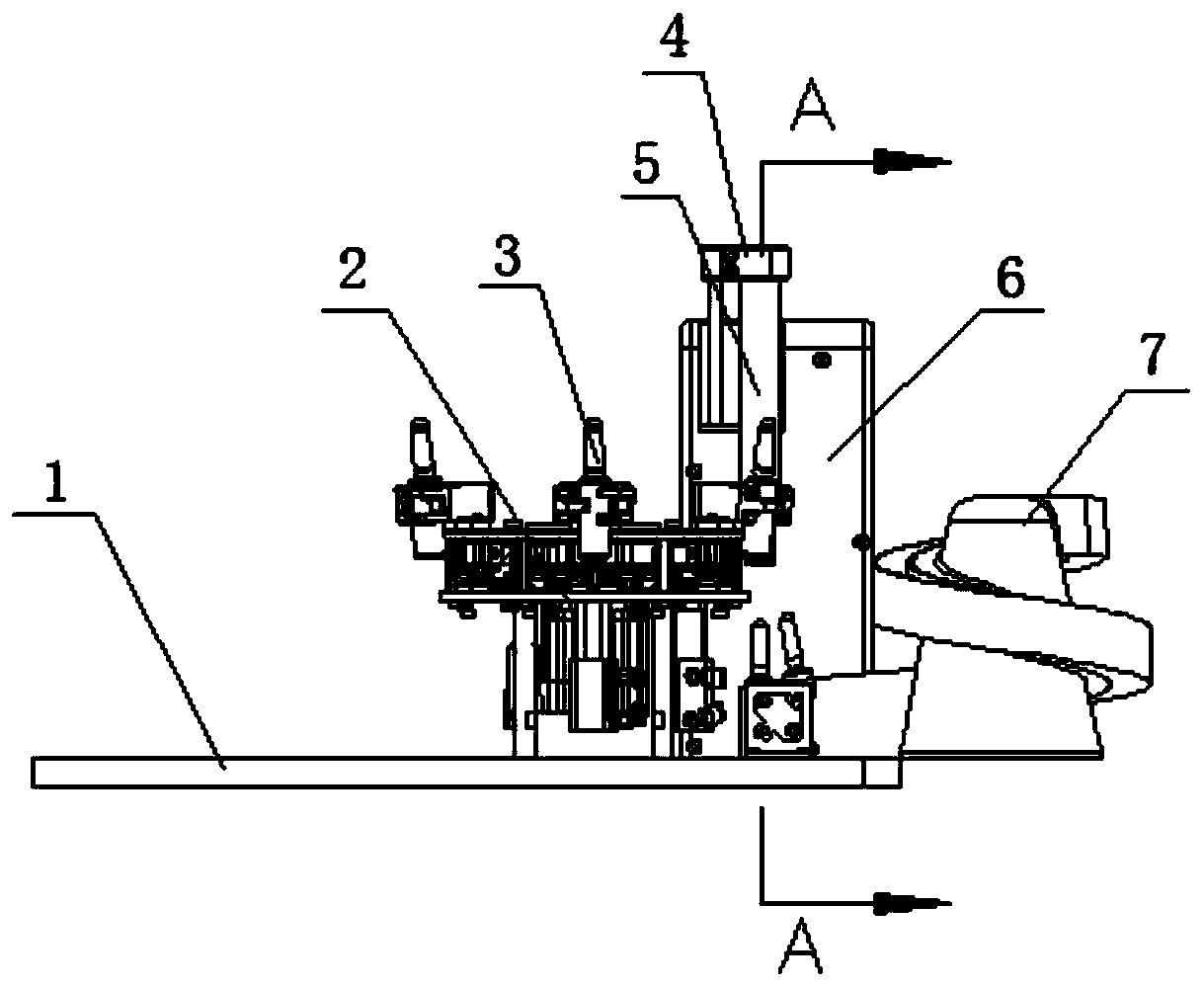

Detection device for lithium battery processing

PendingCN112474439AHigh automation of operationReduce labor intensitySortingConveyor partsStructural engineeringElectrical and Electronics engineering

The invention discloses a detection device for lithium battery processing. The detection device comprises a base, a second support, an orientation adjusting mechanism, a third support, a detection mechanism and a third electric telescopic rod, the second support is located at the right side of a first electric telescopic rod at the rear side, and the orientation adjusting mechanism is connected with the bottom of a first piston rod; and the third support is located at the right side of the second support, a second hydraulic cylinder is fixed to the inner top of the third support, the detectionmechanism is arranged on a cover frame, the third electric telescopic rod is located at the right side of the third support, and the front end of the third electric telescopic rod is connected with asecond push plate. According to the detection device for lithium battery processing, after a lithium battery moves to the position under the cover frame, the cover frame moves downwards and is placedat the outer side of the lithium battery in a covering manner, at the moment, electrode plates can abut against the positive electrode and the negative electrode of the lithium battery under the action of compression springs, and the voltage of the lithium battery can be detected by using an external control device in a matched manner; and meanwhile, a detection probe can detect the damage condition of the surface of the lithium battery.

Owner:江苏超聚新能源科技有限公司

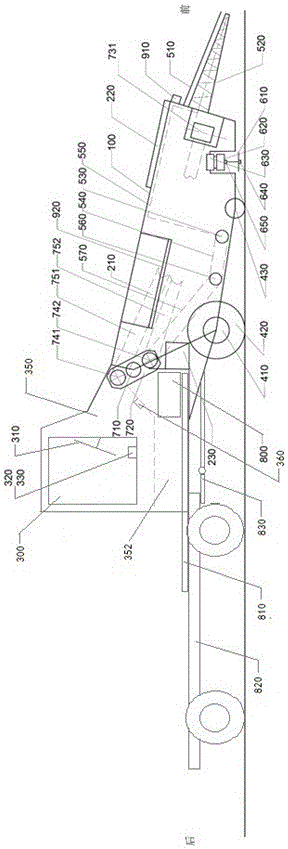

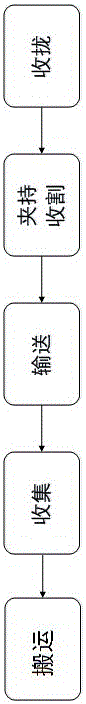

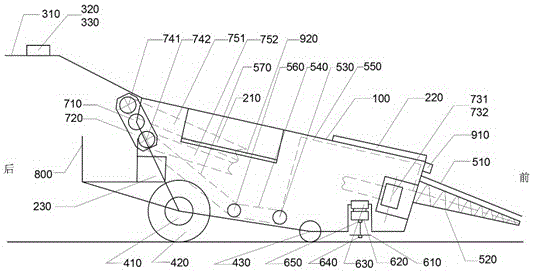

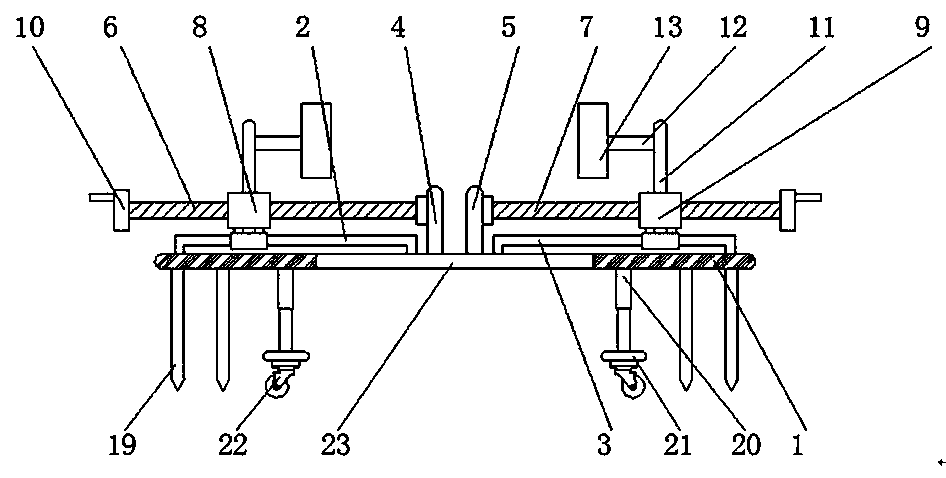

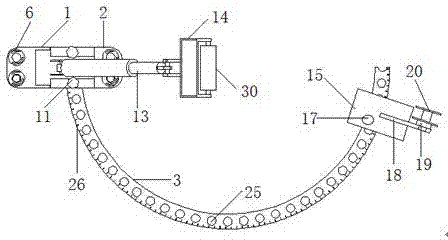

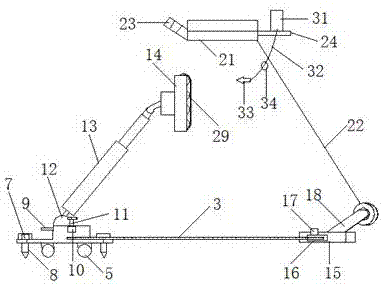

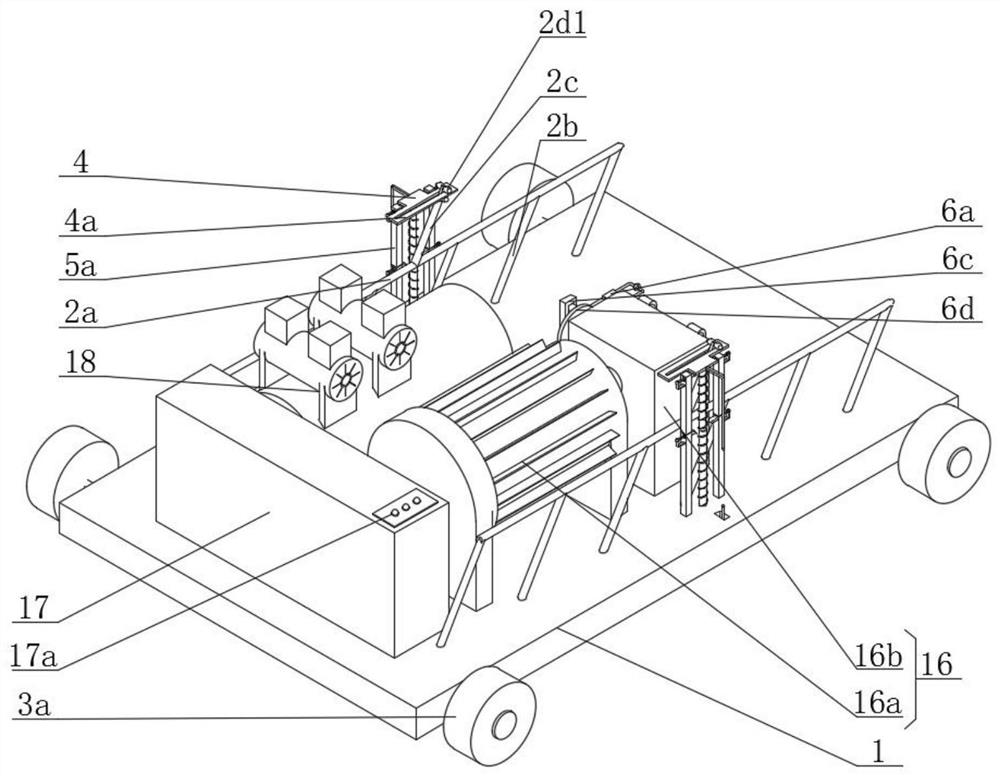

Automatic Chinese chive harvester

InactiveCN106134629ALightweight operation structureHigh degree of automationMowersRenewable energy machinesVideo monitoringChinese Chive

The invention discloses an automatic Chinese chive harvester. The automatic Chinese chive harvester comprises a Chinese chive harvester body, a cockpit, a flat car, a power supply system, a walking mechanism, a drawing-in mechanism, a harvesting mechanism, a conveying mechanism, a collecting mechanism and a lighting system. The Chinese chive harvester body is a self-propelled rack. The cockpit is arranged on the rear of the Chinese chive harvester body in a connected mode and comprises a cab and a control system. The control system comprises a rudder, an operating switch, a control unit and a video monitoring unit. The flat car is arranged on the rear of the cockpit and connected with the Chinese chive harvester body through a movable buffer rod. An upper roll shaft at the rear end and a lower roll shaft at the rear end are driven by a conveying motor installed at the right rear end of the self-propelled rack and a speed reducer attached to the conveying motor respectively, and therefore conveying belts are driven to achieve Chinese chive conveyance. The automatic Chinese chive harvester is easy to operate and learn, light in structure, high in automation degree, capable of achieving stepless speed adjustment, single-person operation and self-propelling and good in working reliability.

Owner:盐城市新明悦机械制造有限公司

Antineoplastic vascular embolic agent and its preparing process

The invention discloses an antineoplastic vascular embolic agent and its preparing process which consists of using asparagus root for extraction to obtain fine extract powder, charging iodine containing solution. The preparing method provided by the invention can effectively preserve the active constituents in the medicinal materials and simplify preparing traditional Chinese medicinal preparations.

Owner:SHUGUANG HOSPITAL AFFILIATED WITH SHANGHAI UNIV OF T C M

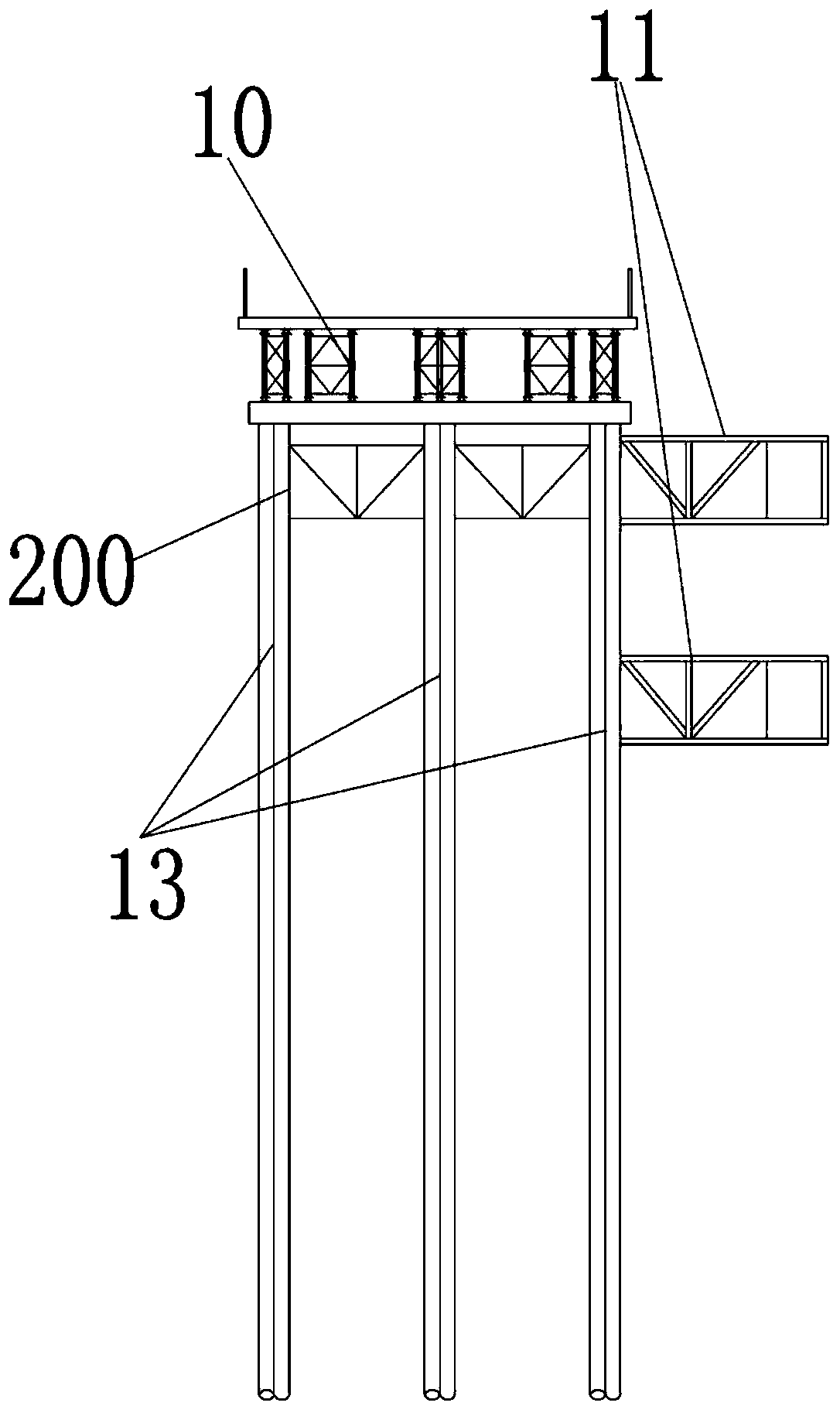

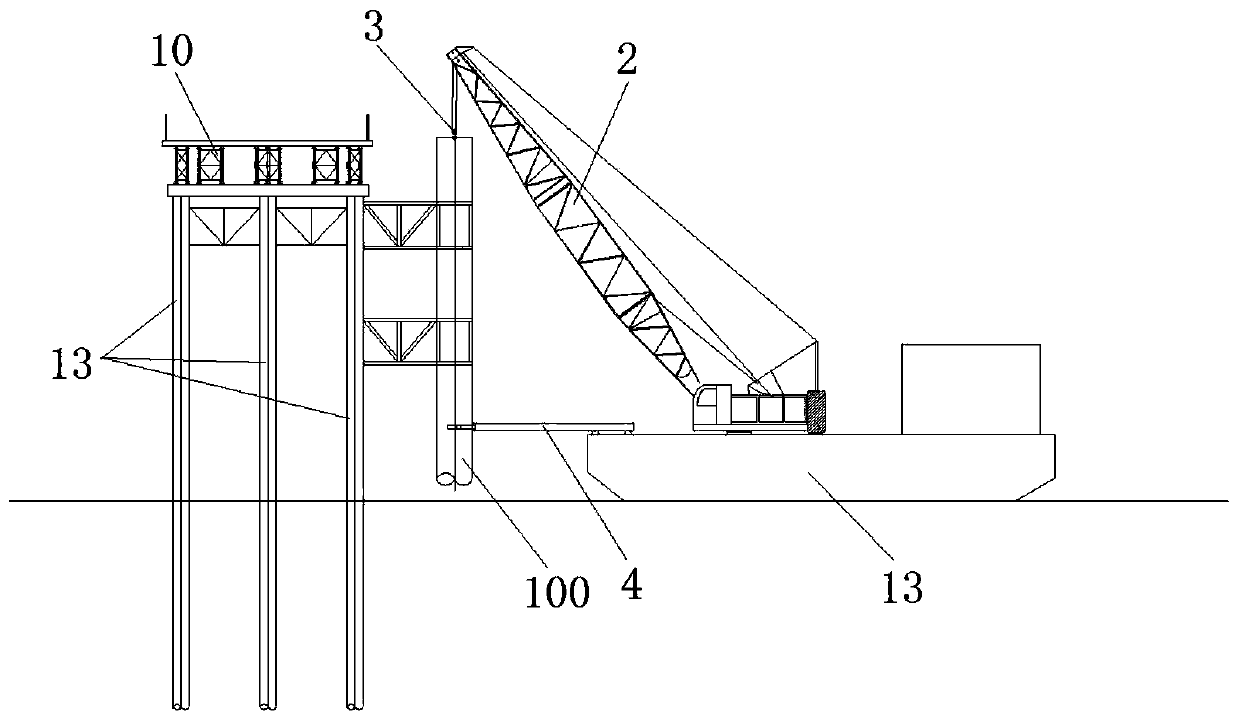

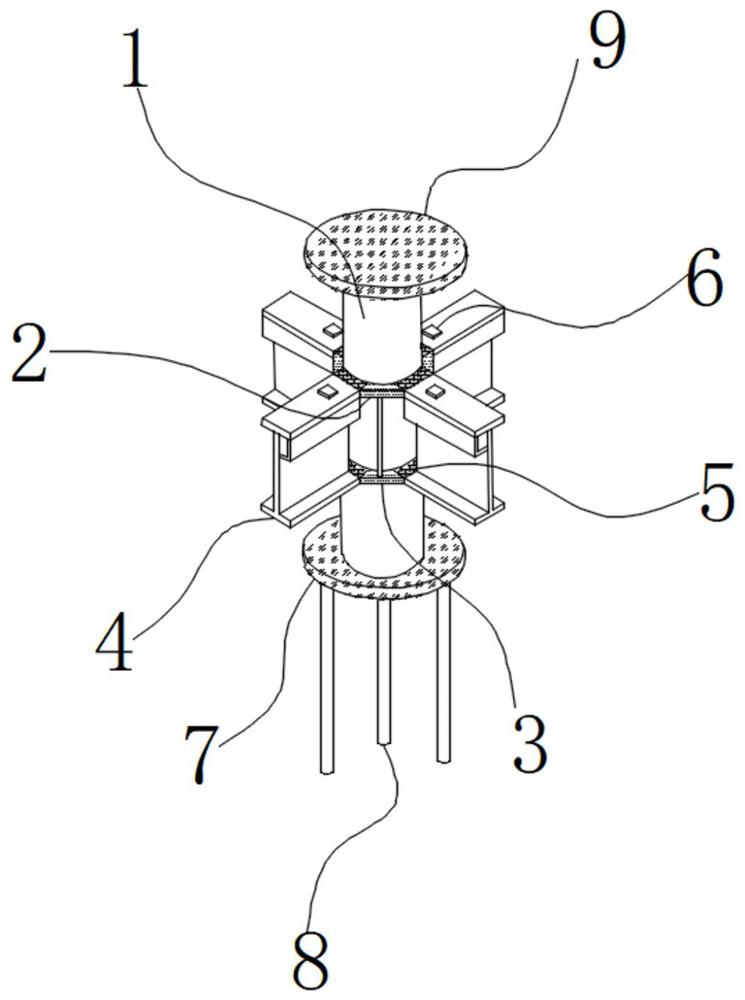

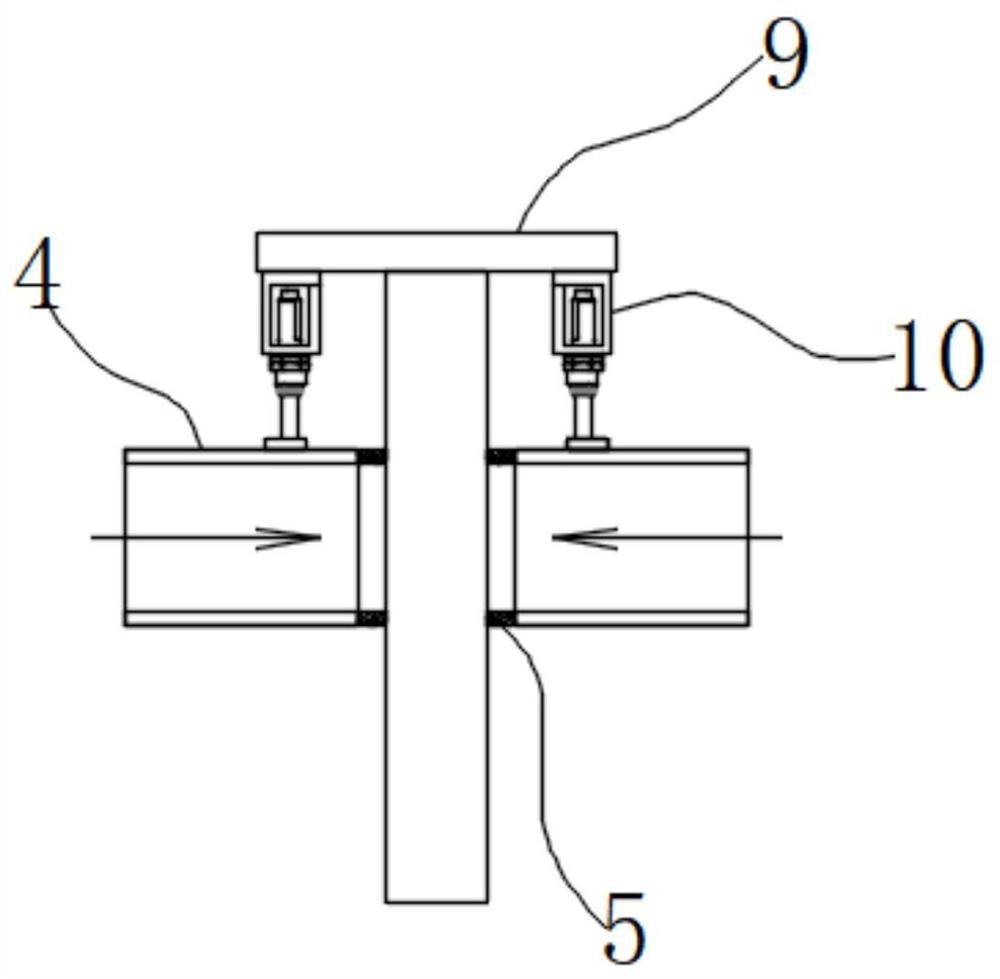

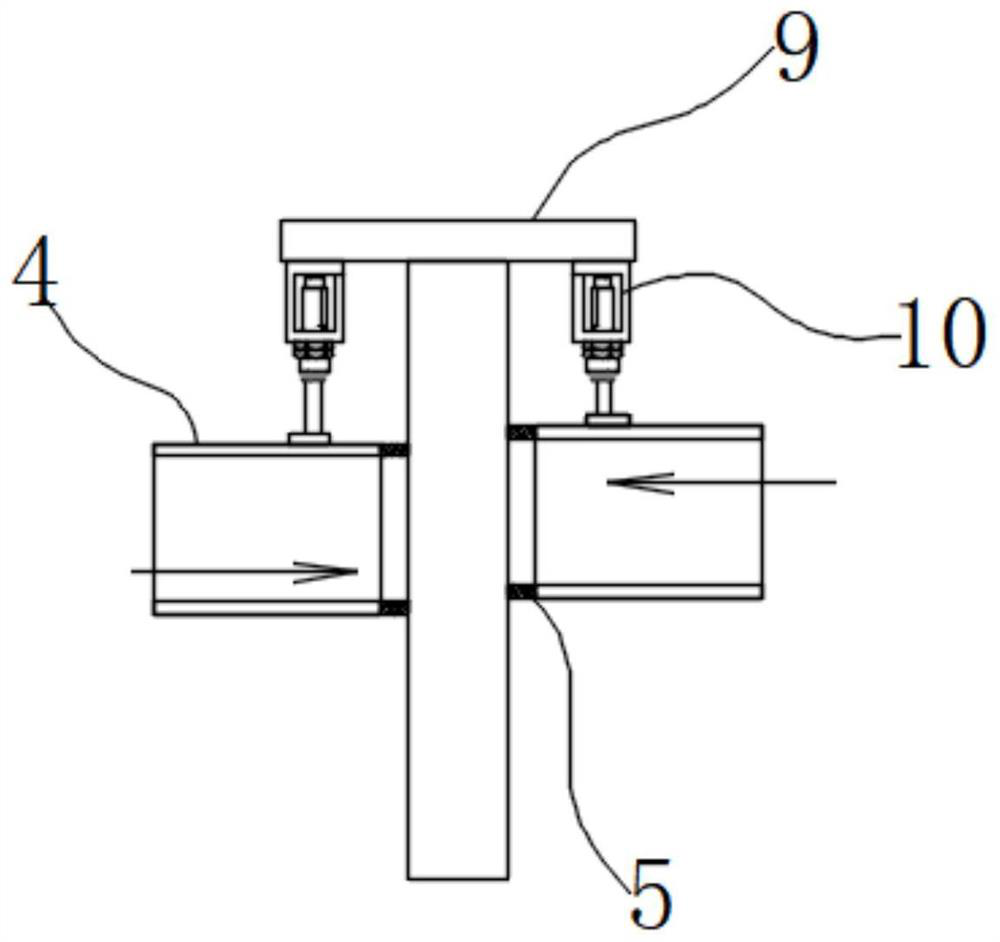

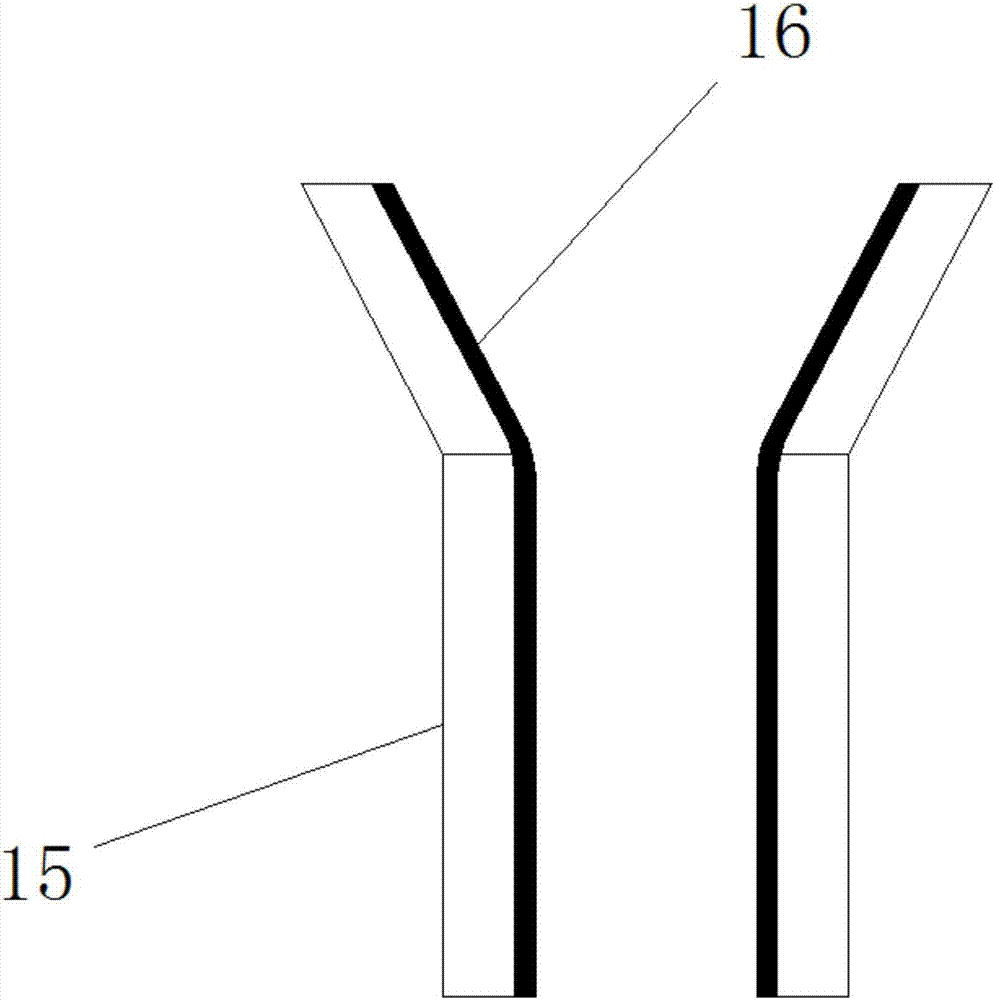

Steel protective cylinder guiding and installing method and pile foundation construction platform and floating crane ship

PendingCN110777789APrevent dumpingEasy lateral entryCranesBulkheads/pilesMarine engineeringStructural engineering

The invention relates to a steel protective cylinder guiding and installing method and a pile foundation construction platform and a floating crane ship. When a steel protective cylinder is lifted andconveyed to a corresponding fixed positioning rack by the floating crane ship, the steel protective cylinder in a vertical hoisting posture is transversely fed into a fixed fork-shaped head by the floating crane ship, the fixed fork-shaped head and a movable fork-shaped head which are staggered in the up-and-down direction cooperate to form a constraint on the radial direction of the steel protective cylinder, thus the steel protective cylinder is constrained and positioned at the preset steel protective cylinder installation position, the steel protective cylinder is guided into the riverbedby the fixed fork-shaped head and the movable fork-shaped head, and the guide installation of the steel protective cylinder is realized. According to the steel protective cylinder guiding and installing method, radial constraint is achieved through mutual cooperation of the fixed fork-shaped head and the movable fork-shaped head, the end part of the fixed fork-shaped head is open, so that the steel protective cylinder is convenient to transversely enter, the steel protective cylinder does not need to be lowered from the high position, the safety performance is improved, the installation difficulty is reduced, the end part of the movable fork-shaped head is open so that the steel protective cylinder can be conveniently withdrawn from the movable fork-shaped head, and the assembly efficiency is improved.

Owner:HUANGHE ENG BUREAU HENAN

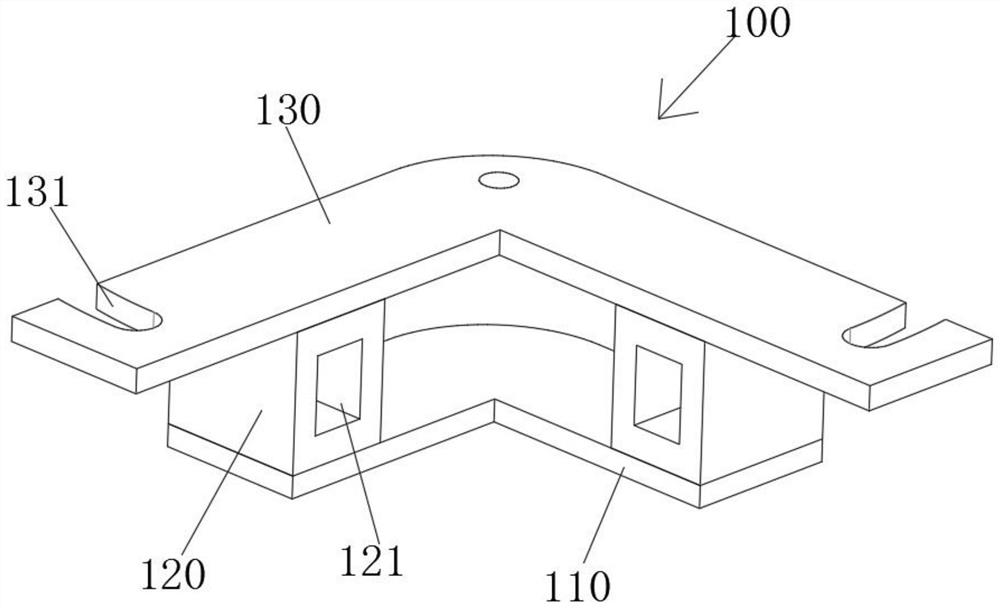

Fabricated intelligent frame node with damping particles and construction method

ActiveCN113653076AReduce the degree of extrusion damageConvenient rightingExcavationsBulkheads/pilesEngineeringStructural engineering

Owner:NAT INST OF NATURAL HAZARDS MINISTRY OF EMERGENCY MANAGEMENT OF CHINA

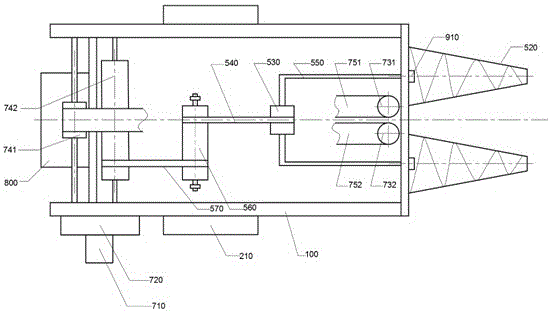

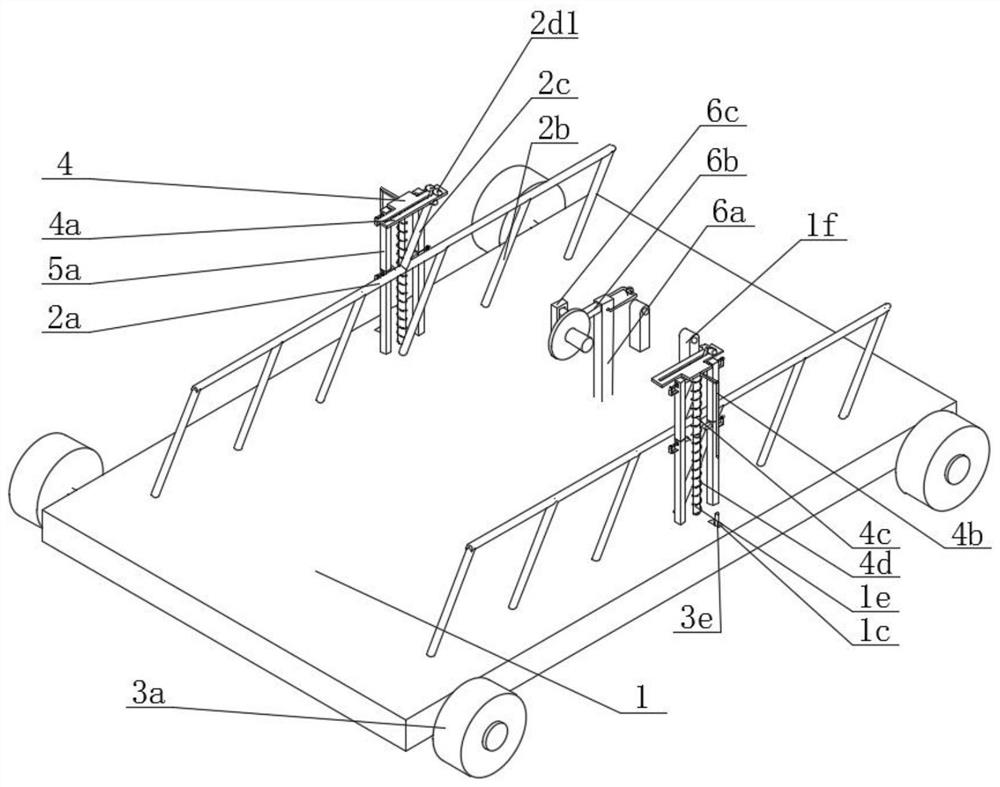

A small-size fragrant-flowered garlic harvester

InactiveCN106068911ALightweight operation structureHigh degree of automationHarvestersRenewable energy machinesDrive wheelMotor drive

The invention provides a small-size fragrant-flowered garlic harvester comprising a fragrant-flowered garlic harvester body, a power supply system, a control system, a walking mechanism, a closing mechanism, a harvesting mechanism, a conveying mechanism, a collection mechanism and a lighting system. The body employs accumulators for power supply and employs a solar power generation device and a small-size generator unit as auxiliary power sources; with a hub motor driving a rear drive wheel, self-walking and stepless speed regulation can be realized; via the different-direction rotation of spiral closing devices, fragrant-flowered garlic can be centralized and guided; a conveying motor installed on the right rear end of the self-walking frame and a speed reducer attached thereto drive a rear end upper roll shaft and a rear end lower roll shaft, so that conveying belts are driven to convey fragrant-flowered garlic. The operation of the small-size fragrant-flowered garlic harvester is simple and easy to learn; the small-size fragrant-flowered garlic harvester is light in structure and high in degree of automation, realizes stepless speed regulation, single-man operation and self-walking, and is great in work reliability.

Owner:盐城市新明悦机械制造有限公司

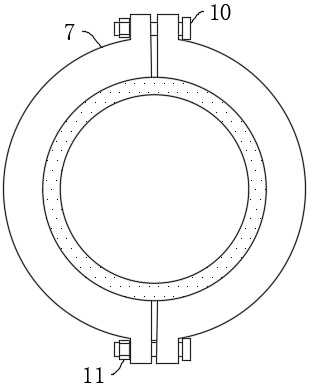

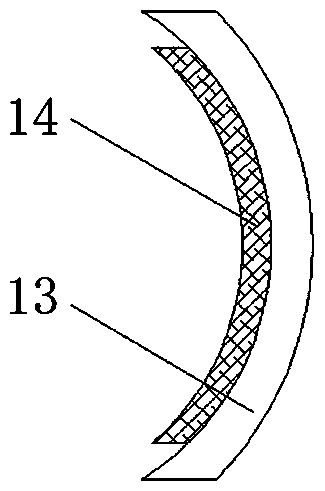

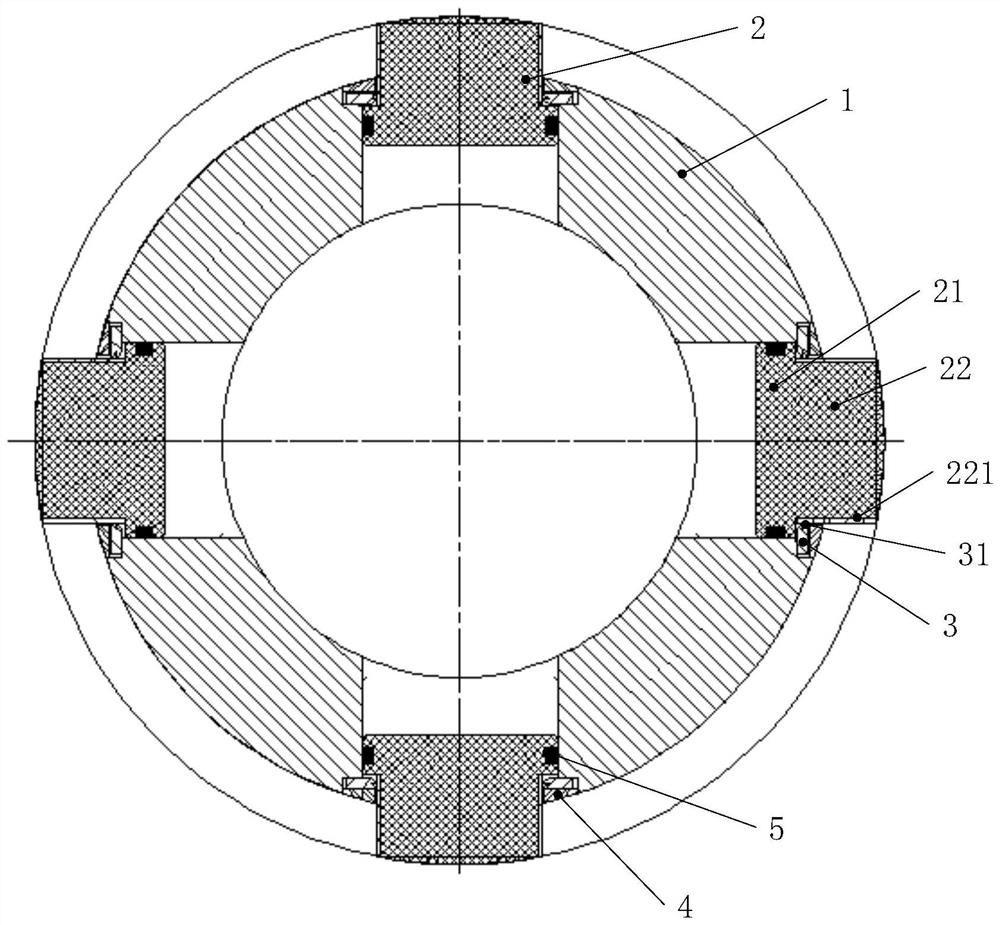

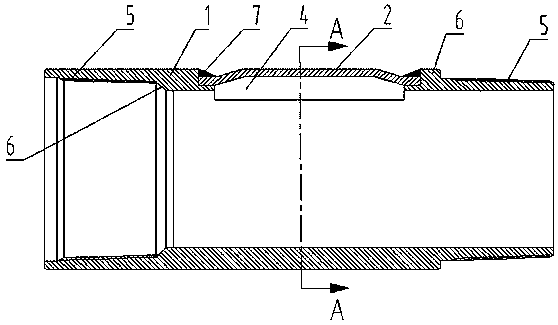

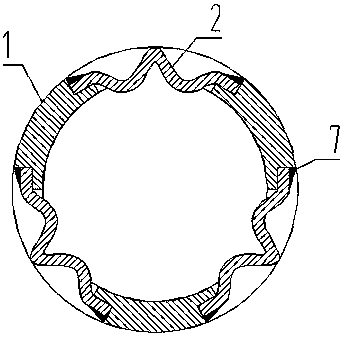

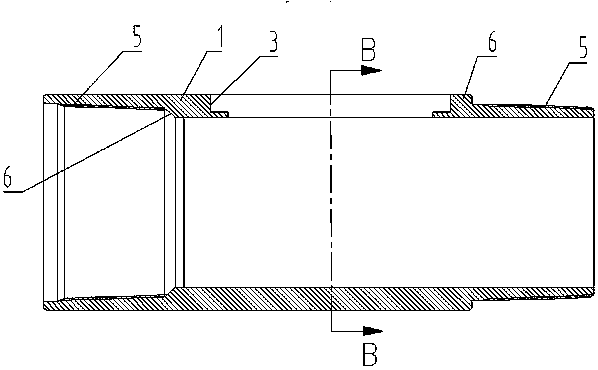

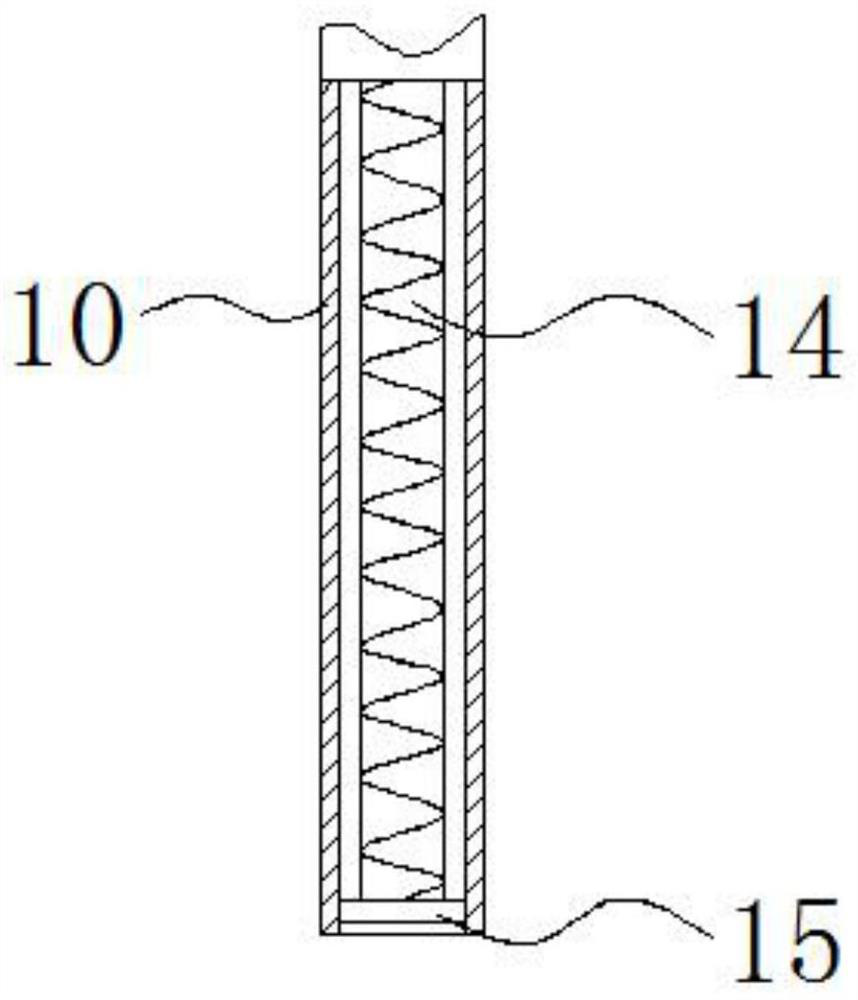

Anti-deformation elastic casing centralizer

ActiveCN112012671APlay a supporting roleAvoid deformationDrilling rodsDrilling casingsStructural engineeringMechanical engineering

Owner:胜利油田固邦石油装备有限责任公司

Centering adjusting device for top-drive guide rail

InactiveCN105822236AConvenient rightingRestraint torsionDrilling rodsDrilling casingsEngineeringMechanical engineering

Owner:GANSU LANPEC TECH +2

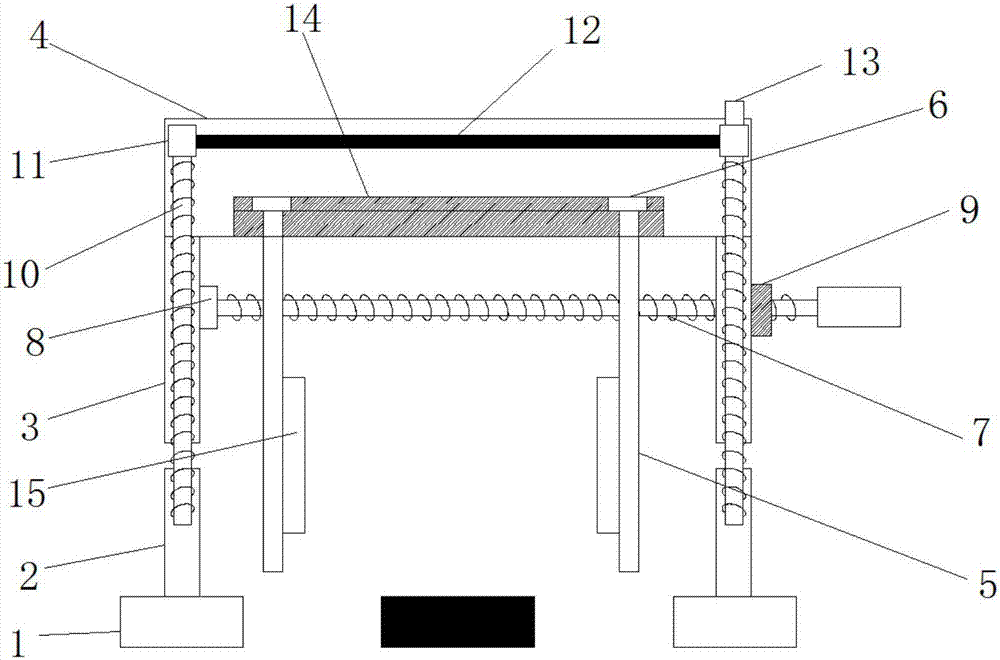

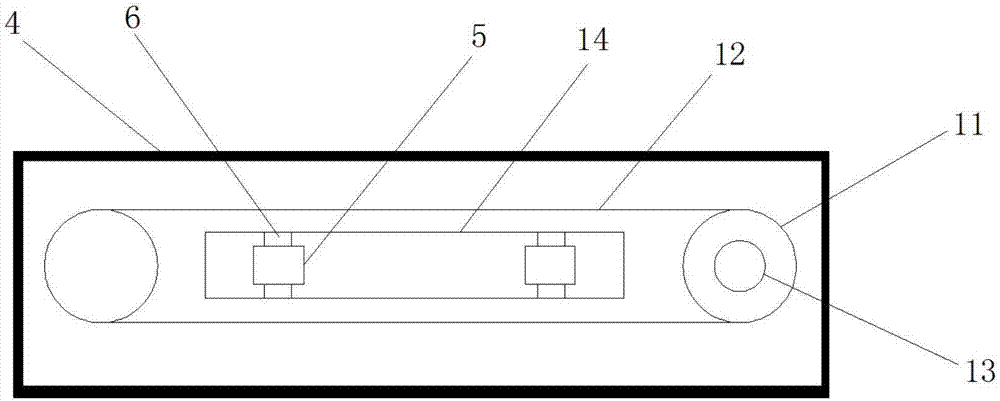

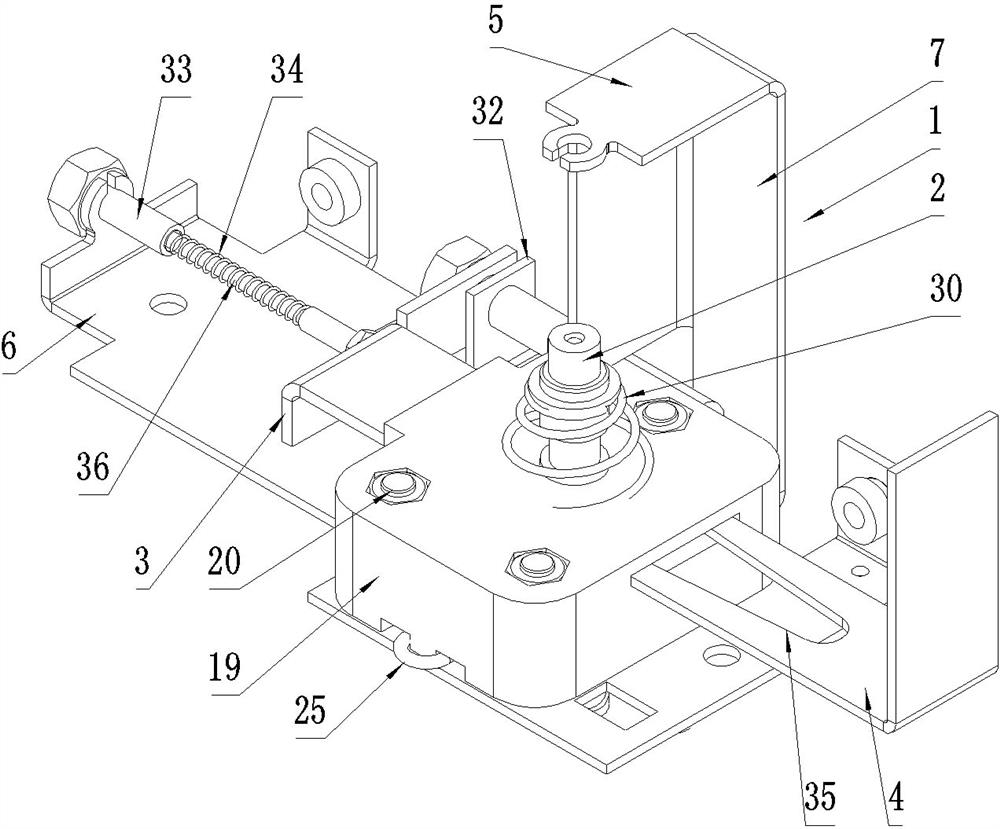

Ceramic wine bottle righting device on production line

InactiveCN107215644AConvenient rightingEasy height adjustmentConveyorsConveyor partsProduction lineWine bottle

The invention discloses a centering device for ceramic wine bottles on a production line, which comprises two bases symmetrically arranged on both sides of the conveyor belt, the upper ends of the two bases are fixed with a first bracket, and a There is a second bracket, and the upper ends of the two second brackets are jointly provided with a placing plate, and a lifting mechanism and a moving mechanism are arranged in the placing plate, and two symmetrical belt pulleys are arranged in the described placing plate, and the two placed Belts are provided on opposite sides of the belt pulleys, and a hand wheel is provided on one of the pulley pulleys, and the hand wheel runs through the placement plate and extends above it. The invention has a simple structure, can adjust the height of the ceramic wine bottle centering device, is convenient for matching ceramic wine bottles of different heights, and can also correct the ceramic wine bottles on the production line, which is convenient for reducing labor intensity and improving production efficiency, and does not require workers to work all the time. work and save costs.

Owner:CHONGQING YONGHENG BOTAO TECH

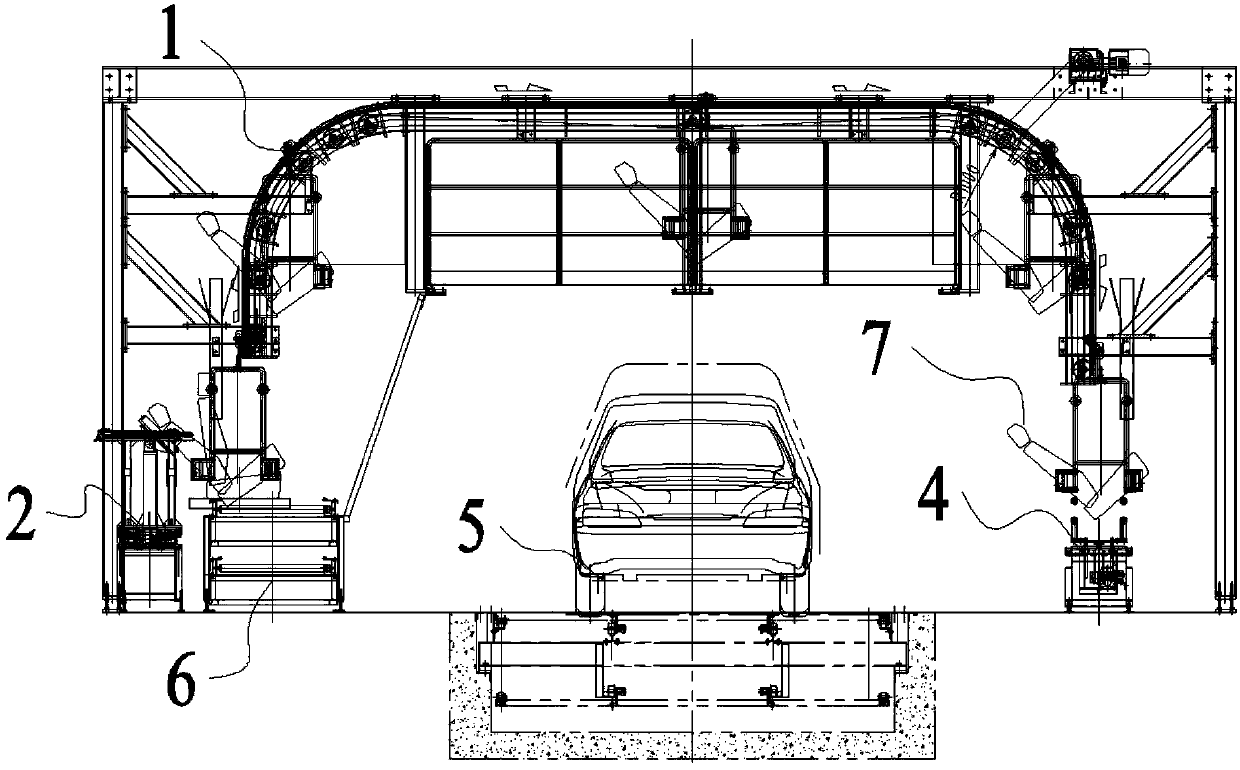

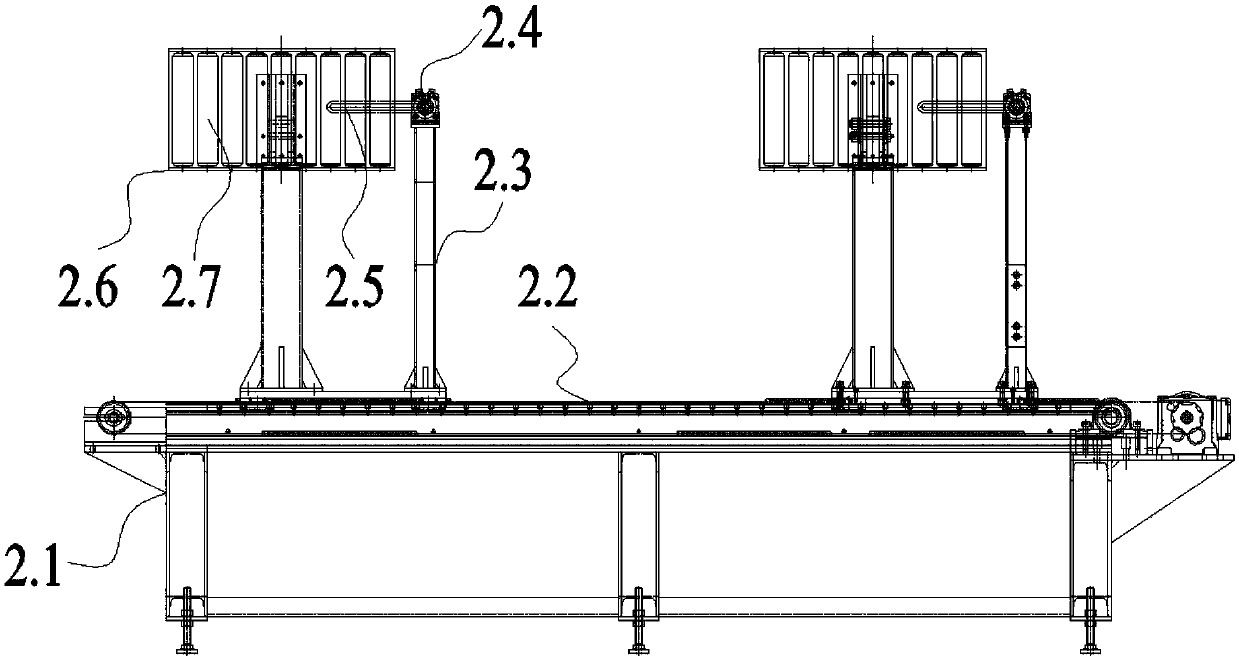

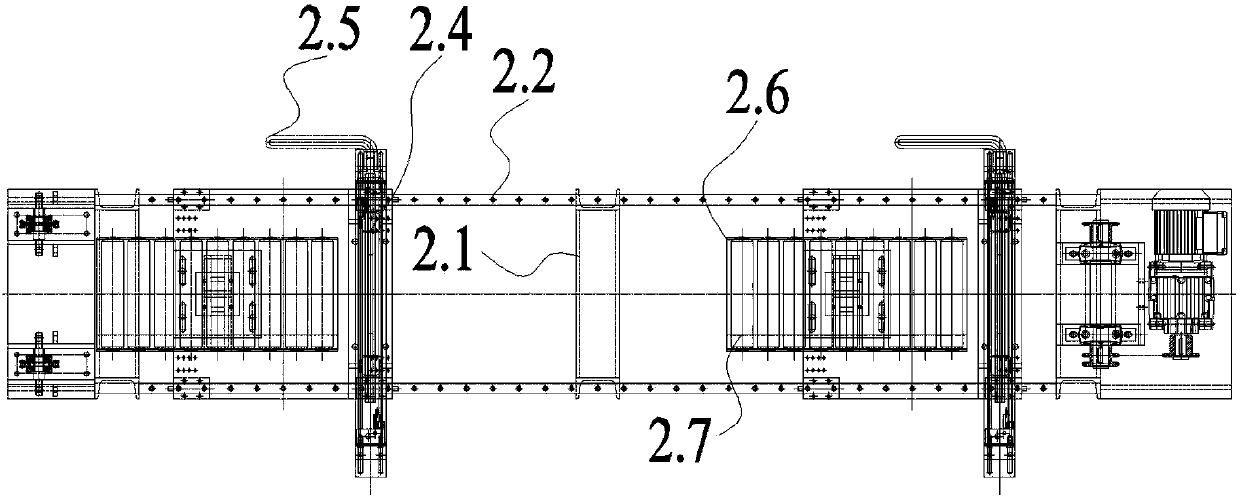

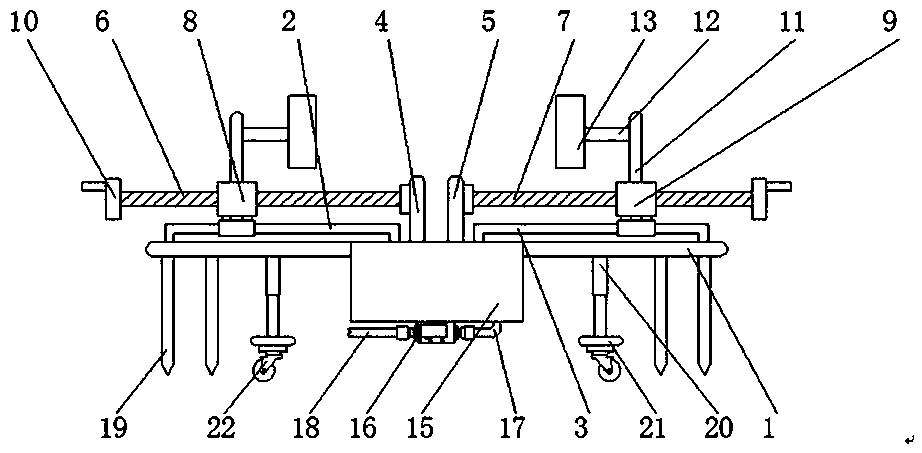

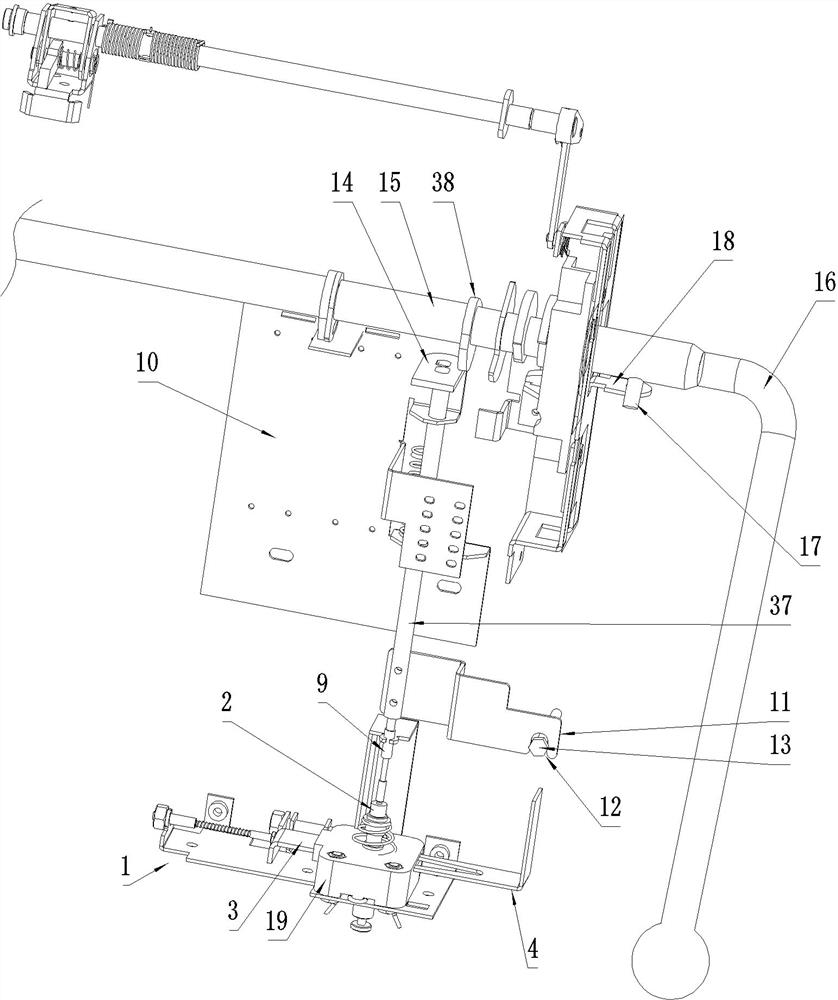

Automatic line-cross device for seats

ActiveCN108016992AAvoid scratchesIntegrity guaranteedLifting devicesTrolley cranesEngineeringAssembly line

The invention relates to the technical field of automobile assembly devices, in particular to an automatic line-cross device for seats. The automatic line-cross device comprises a transplanter used for shifting the seats to the transverse second side from the transverse first side of an assembly line; a turnover device located on the transverse first side of the assembly line and used for pullingdown the upright seats on a seat conveyor line and enabling the upright seats to vertically rotate and offset for an angle; and a righting device located on the transverse second side of the assemblyline and used for righting the seats in the inclined deflection state; the transplanter comprises transportation tracks across the assembly line, and seat slings slidably connected to the transportation tracks; and the turnover device and the righting device are arranged below the two transverse ends of the transportation tracks separately. The automatic line-cross device provided by the inventionis simple in structure, and easy to operate, and the transfer of the seats can be achieved efficiently; the structure weight on the assembly line is reduced, and the assembly efficiency of bodies isimproved; and the automatic line-cross device has extremely high promotion value.

Owner:DONGFENG MOTOR CORP HUBEI

Righting device for Chinese yew planting

The invention discloses a righting device for Chinese yew planting. The device comprises a transverse plate, wherein two sides of the top of the transverse plate are fixedly connected with a first sliding rail and a second sliding rail respectively, a first vertical plate and a second vertical plate are fixedly connected to the two sides of the top of the transverse plate and located between the first sliding rail and a second sliding rail respectively, one side of the first vertical plate is rotationally connected with a first threaded rod through a bearing, one side of the second vertical plate is rotationally connected with a second threaded rod through a bearing, the outer surface of the first threaded rod is in threaded connection with a first sliding block, and the bottom of the first sliding block is slidably connected with the outer surface of the first sliding rail. The invention relates to the technical field of Chinese yew planting. The righting device for Chinese yew planting has the advantages that Chinese yew can be clamped and fixed well, so that the Chinese yew can be well righted during planting, manual righting is not needed, the burden on a planter is reduced, Chinese yew planting is ensured faster and better, and the planting efficiency is improved.

Owner:湖北天华林药有限公司

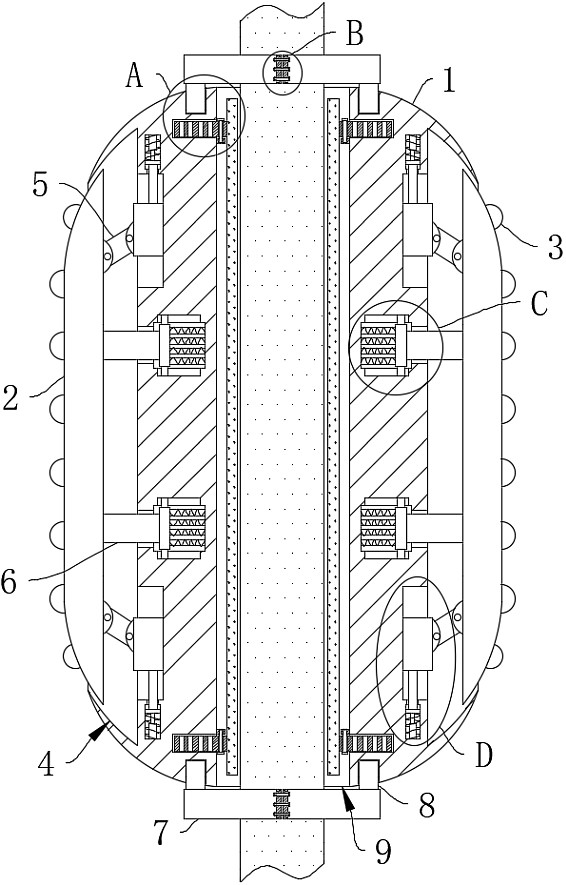

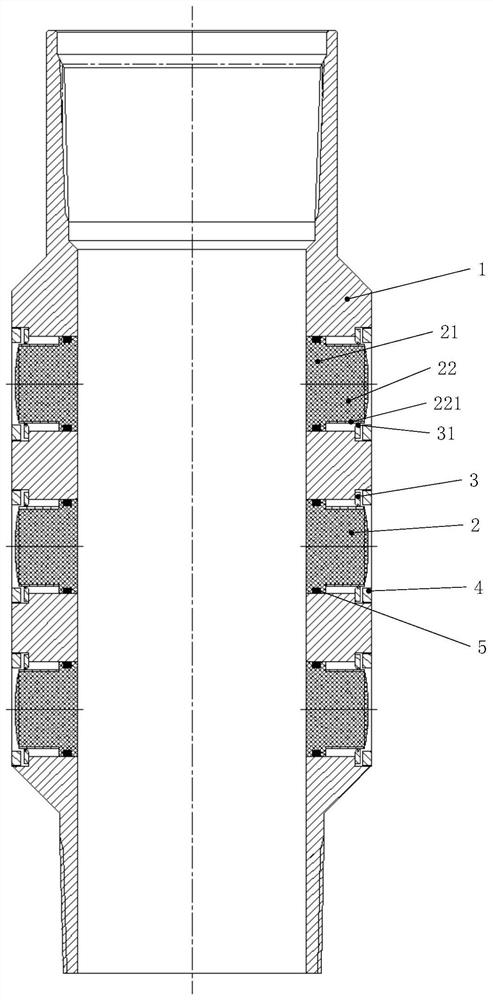

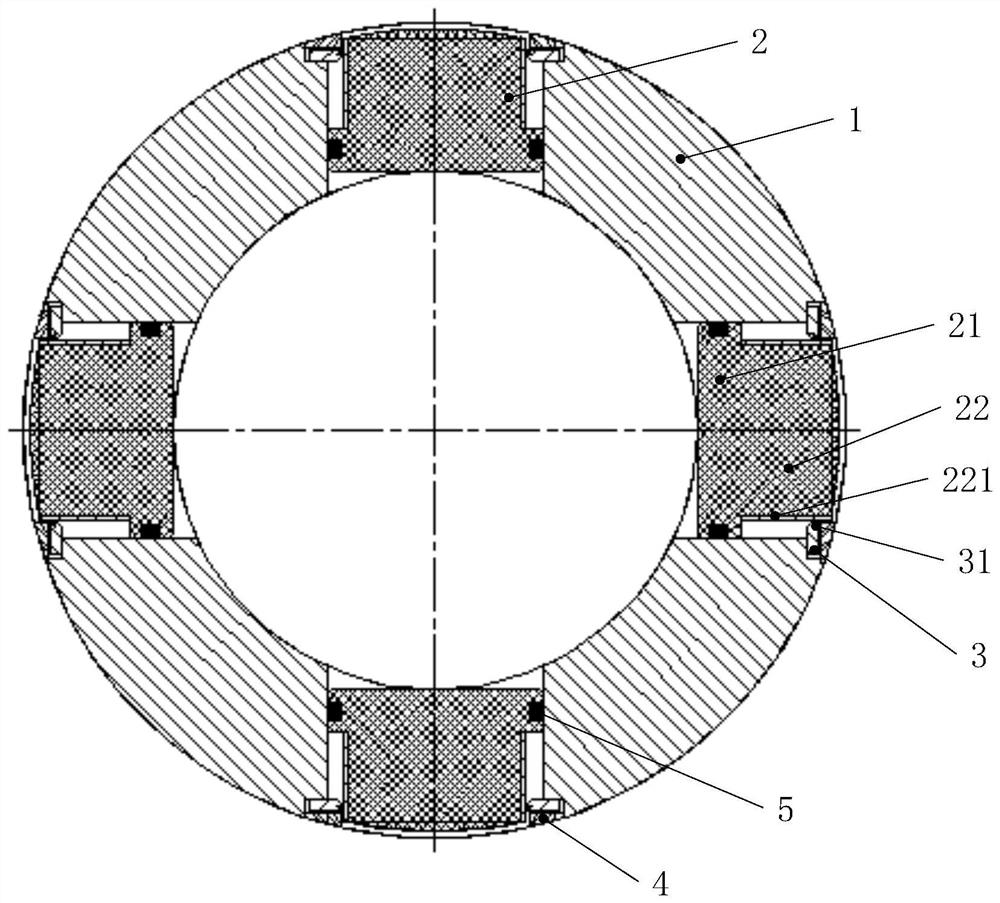

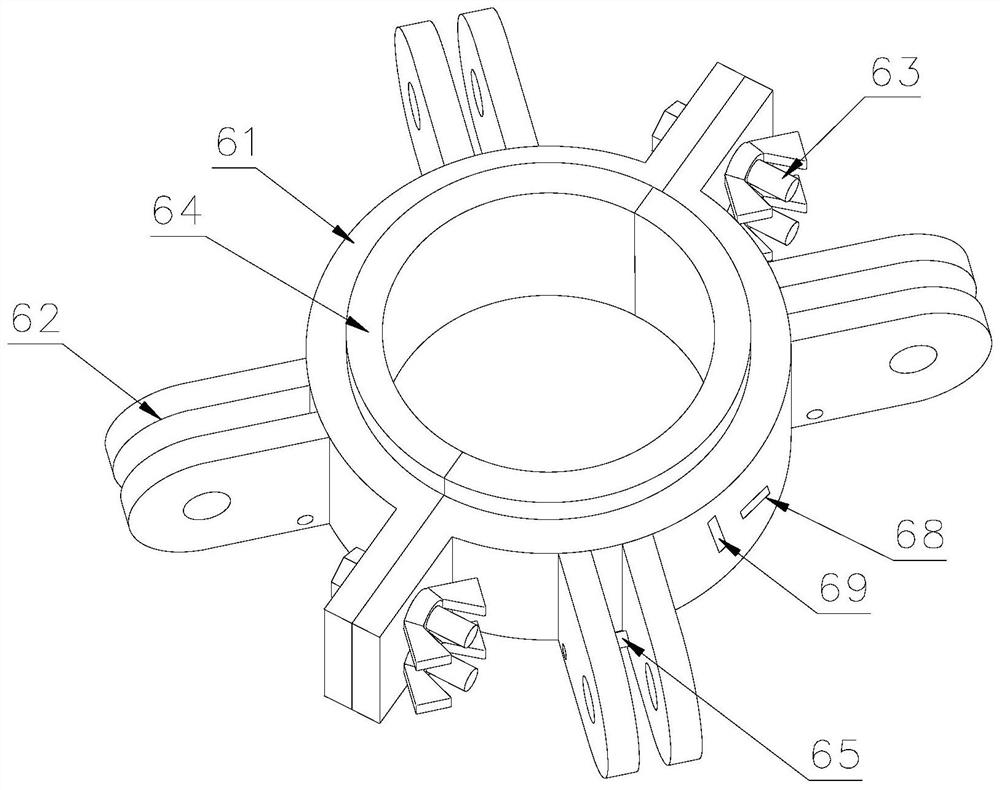

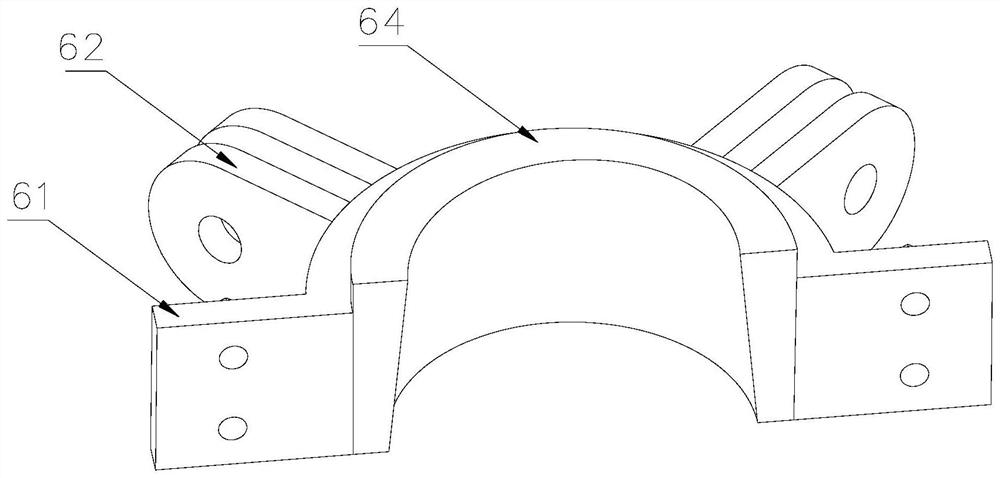

Casing centralizer and casing installation method

PendingCN112780196AConvenient rightingRighting the realizationDrilling rodsDrilling casingsHorizontal wellsMechanical engineering

The invention provides a casing centralizer and a casing installation method, and belongs to the technical field of oil extraction equipment. According to the casing centralizer, the casing centralizer is arranged on a casing in a sleeve mode, a main body of the casing centralizer is provided with multiple movable centralizing blocks, in a lowering process of the casing, the centralizing blocks are fixed in a through holes of the main body, so that the outer diameter of the casing centralizer is smaller, the possibility that friction is generated between the casing centralizer and a well wall is small, lowering of the casing is facilitated, after the casing is lowered in place, the centralizing blocks can move outwards under the action of external force, so that the end parts of the clamping sections of the centralizing blocks abut against the well wall outside the casing, and centralizing of the casing is achieved. The casing centralizer is more suitable for a horizontal well or a large-displacement well, the casing lowering process is easy, and the risk in the casing lowering process is reduced.

Owner:PETROCHINA CO LTD

Ornamental tree and shrub efficient centering device capable of preventing damage

InactiveCN107567947ARealize side pullImprove the righting effectFertiliser distributersCultivating equipmentsFertilizerCast iron

The invention discloses an ornamental tree and shrub efficient centering device capable of preventing damage. The device comprises a fixing base, a movable plate, a movable frame and a fixing belt, wherein the two sides of the lower portion of the fixing base stretch out to form a rectangular solid cast iron structure for positioning a ribbed plate, the movable plate is arranged above the fixing base and is in sliding fit with the fixing base through a sliding groove, an arc groove structure is formed in the middle of the movable frame, the movable frame is in sliding fit with a steering wheelthrough an arc groove, the fixing belt is flat nylon tape with the width larger than 5 cm, and the fixing belt is arranged over the center of the steering wheel. A take-up reel and an anti-inversiondevice can stably tension the fixing belt through a steel wire rope, the fixing belt is wound around the upper end of an ornamental tree and shrub, yawing force is applied to the ornamental tree and shrub, a fertilization frame is used for adding fertilizer and auxin to the ornamental tree and shrub, self-centering of the ornamental tree and shrub is promoted, and the damage caused by external force application is reduced.

Owner:杨桂华

Self-adaptive casing centralizer and righting method

PendingCN110566138AEasy to operateConvenient rightingDrilling rodsSealing/packingWell cementingSelf adaptive

The invention discloses a self-adaptive casing centralizer and a righting method. The self-adaptive casing centralizer comprises a body. A plurality of self-adaptive expansion assemblies capable of being automatically expanded by pressure to automatically adapt to the diameter of a well to right and fix a casing are arranged on the body. Each self-adaptive expansion assembly comprises a bellows arranged in a stepped through-hole slot. The cross section of each bellows is in a wavy shape. The self-adaptive casing centralizer is simple in whole structure and convenient to operate and can adapt to different well diameters, the casing is effectively righted and fixed, and the well cementing quality is improved; the overall outer diameter of the body of the self-adaptive casing centralizer is smaller than the well diameter of a wellbore when the body of the self-adaptive casing centralizer is in an initial state, the centralizer can smoothly enter the well, the risk of encountering resistance is reduced, the well wall is not damaged, the bellows can uniformly expand, the supporting force is improved, the casing is effectively righted, and the centering degree of a casing column is increased; and after centering of the casing is completed, the wellbore annular clearance is uniform, the well cementing quality can be effectively improved, and the whole construction is easy and convenient.

Owner:潍坊市宇宏石油机械有限公司

Inclined telegraph pole centralizing device

The invention relates to an inclined telegraph pole centralizing device. The inclined telegraph pole centralizing device comprises a chassis, a traction wire driving device, a traction wire, a supporting pipe, a telescopic rod driving device and a screw rod. The traction wire driving device is arranged on the chassis, the supporting pipe is hinged to the chassis, the screw rod is inserted into thesupporting pipe, and a telegraph pole top plate is hinged to the tail end of the screw rod. The telescopic rod driving device is arranged at the tail end of the supporting pipe, and the traction wiredriving device drives the telescopic rod driving device to rotate through the traction wire and controls the screw rod to stretch out and draw back. The inclined telegraph pole centralizing device islight and convenient to move, small in occupied area and capable of conveniently centralizing an inclined telegraph pole in various environments.

Owner:JUNAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

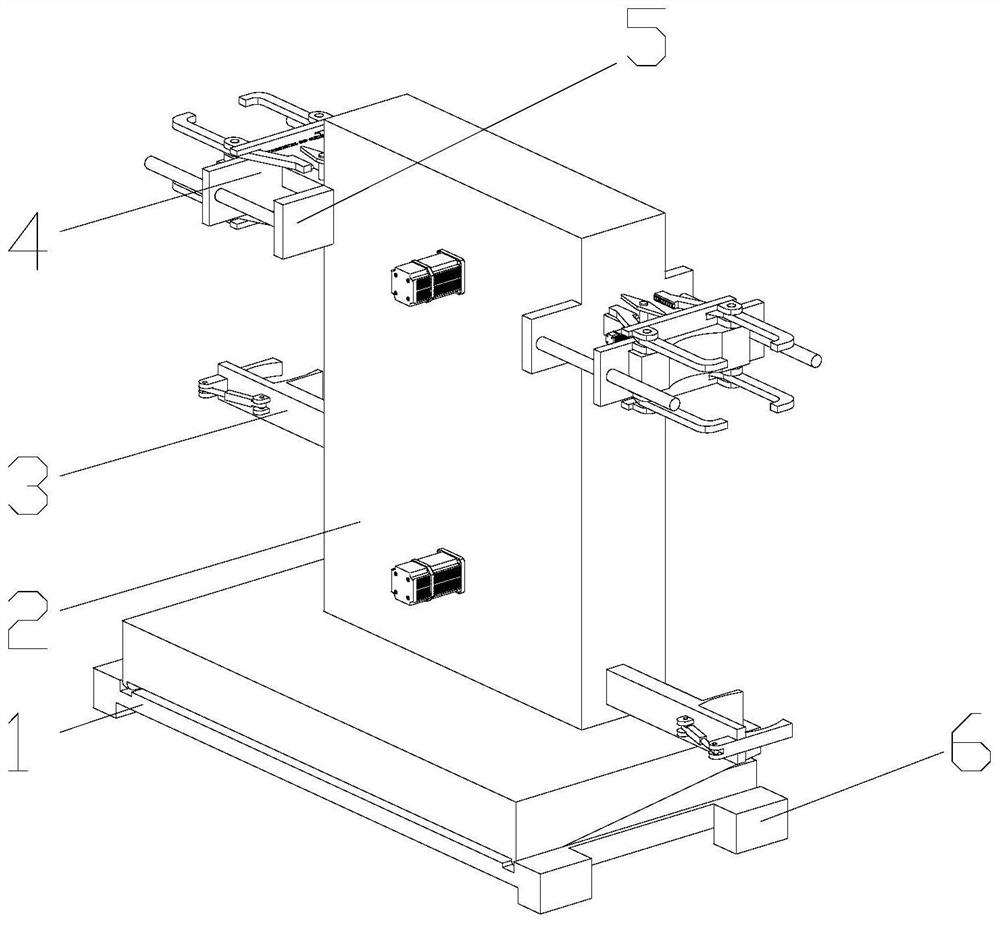

Transformer substation infrastructure construction anti-toppling device

ActiveCN113585857AAchieve fixationGuaranteed verticalityNon-rotating vibration suppressionTowersTransformerControl theory

The invention discloses a transformer substation infrastructure construction anti-toppling device. The transformer substation infrastructure construction anti-toppling device comprises a base, a fixing frame is installed on the base, a first adjusting mechanism and a second adjusting mechanism are installed in the fixing frame, and a first clamping mechanism is installed on the first adjusting mechanism. Two electric poles can be fixed and straightened at the same time, the base is used for supporting the device on the one hand, and the purpose of straightening the electric poles on the other hand can be achieved; the perpendicularity of the fixing frame on the base and the ground can be adjusted through a lifting mechanism on the base, and therefore it is guaranteed that the inclination of the fixing frame and the inclination of the electric poles are kept consistent; and first fastening mechanisms and second fastening mechanisms on the fixing frame are conveniently fixed to the electric poles, the fixing and righting efficiency is greatly improved, the second fastening mechanisms are matched with the second adjusting mechanism, the electric poles can be fixed and righted, the perpendicularity of the electric poles and the ground is guaranteed, the electric poles are prevented from inclining in the installation process of a transformer substation, the working efficiency is greatly improved, and the working quality is ensured.

Owner:国网山东省电力公司建设公司 +2

Electric pole straightening device for electric power engineering construction

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +3

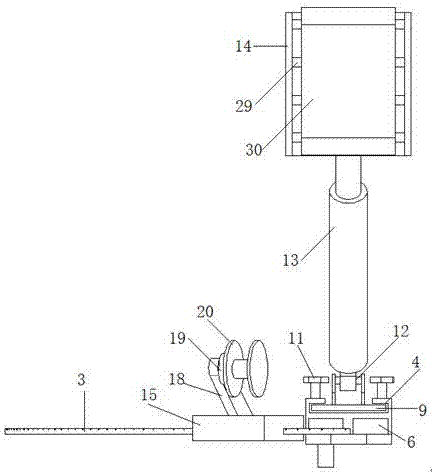

Drill rod centralizer

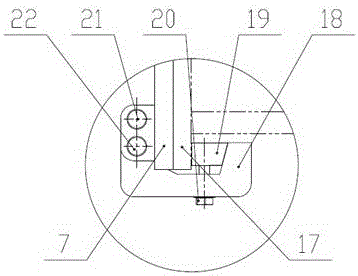

PendingCN111287675AFast releaseQuick loading and unloadingDrilling rodsDrilling casingsClassical mechanicsEngineering

The invention discloses a drill rod centralizer. The drill rod centralizer comprises a lower supporting structure and an upper supporting structure, wherein the lower supporting structure is composedof a plurality of lower rolling wheels arranged on the top face of a support, and the upper supporting structure is composed of a plurality of upper rolling wheels arranged at the end of a swing rod,the middle of the swing rod rotates around a supporting seat, and the other end of the swing rod is hinged to the two sides of the support through a connecting rod; and a lifting driving mechanism isarranged at the bottom of the support. According to the drill rod centralizer, the connecting rod and the swing rod are driven by the lifting driving mechanism to move progressively, so that the drillrod centralizer is applicable to drill rods of various different sizes, namely, the drill rod centralizer is not only applicable to the drill rods of conventional sizes, but also applicable to the drill rods of infrequently-used or non-standard sizes, thus being wide in application range; and moreover, when the drill rods of different specifications are replaced, the drill rods can be replaced only through driving the connecting rod and the swing rod to loosen the drill rods through an oil cylinder, disassembling and assembling are not needed, the disassembling and assembling time is saved, and labor cost is reduced.

Owner:无锡市安曼工程机械有限公司

Interlocking device of grounding switch and front lower door in switch cabinet and switch cabinet

ActiveCN112509835ASolve the problem of openingEasy to pushEarthing arrangementsSubstation/switching arrangement casingsControl theoryMechanical engineering

The invention relates to an interlocking device of a grounding switch and a front lower door in a switch cabinet and the switch cabinet. The interlocking device comprises a limiting rod ejector rod and a clamping plate pushing piece; the limiting rod ejector rod has an upward movement trend under the action of a corresponding elastic structure; the limiting rod ejector rod is provided with a blocking position and a receding position in the moving stroke, and the blocking position corresponds to the upper end of the moving stroke of the limiting rod ejector rod and is used for blocking the vertical limiting rod on the switch cabinet from moving downwards; a limiting groove is formed in the outer circumferential face of the limiting rod ejector rod, an ejector rod bayonet is formed in the side, close to the limiting rod ejector rod, of an ejector rod clamping plate, and the ejector rod bayonet is used for being clamped into the limiting groove to limit downward movement of the limiting rod ejector rod when the limiting rod ejector rod is located at the blocking position; and the clamping plate pushing piece is used for pushing the ejector rod clamping plate under the driving of the front lower door when the front lower door is closed, so that the limitation of the ejector rod bayonet in the ejector rod clamping plate on the limiting rod ejector rod is relieved. According to the scheme, the problem that in the prior art, when the front lower door of the switch cabinet is not closed, the grounding switch can still be switched off is solved.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

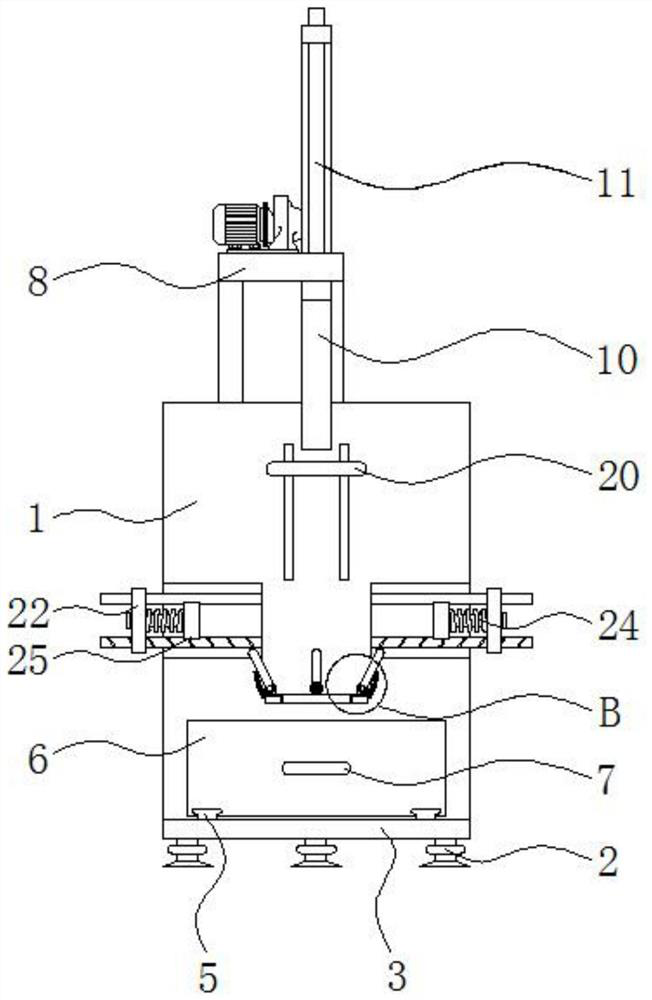

Pineapple core removing machine with positioning structure and convenient to fix

PendingCN112641105AConvenient rightingAvoid damageFruit stoningElectric machineryStructural engineering

The invention relates to a pineapple core removing machine with a positioning structure and convenient to fix. The pineapple core removing machine comprises an equipment shell and an upper fixing ring, wherein the lower end of the equipment shell is connected with a sucker supporting leg; the upper end of an extending plate is connected with a collecting box through a sliding rail; a bracket is fixed at the upper end of the equipment shell; a lower pressing rod and a positioning rod sequentially penetrate through the interior of the bracket from front to back; a first motor is mounted at the upper end of the bracket; one side of the first motor is connected with a rack through a first gear; a first spring is connected to the interior of the lower pressing rod; the lower end of the first spring is connected with a pushing block; and a multi-section hydraulic cylinder, a sliding rod and a bearing are sequentially arranged in the equipment shell from top to bottom. The pineapple core removing machine with the positioning structure and convenient to fix has the beneficial effects that pineapples are primarily fixed through an upper ring and a lower ring, and then the pineapples are fixed through clamping blocks, so that the pineapples do not need to be held by hands for core removing, and the situation that the pineapples are deviated to cause failure of pineapple core removing can be prevented.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

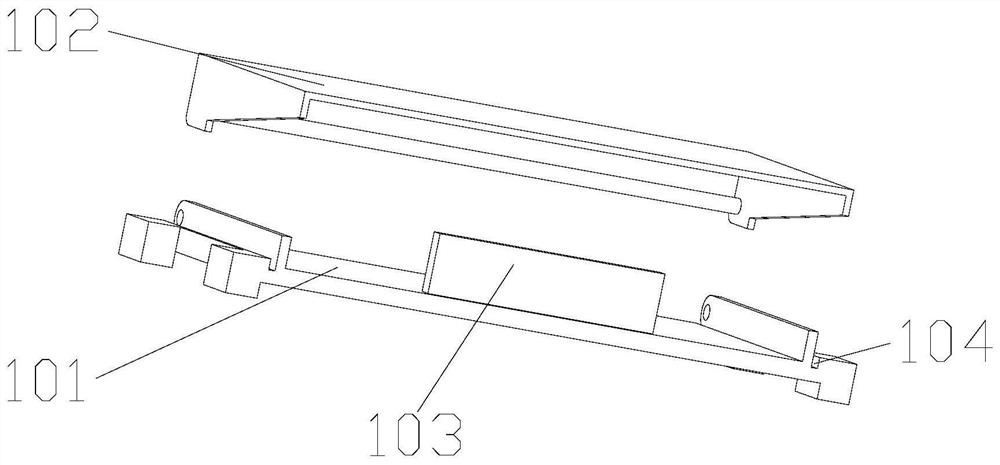

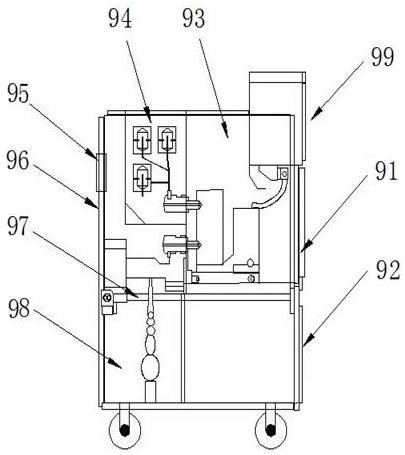

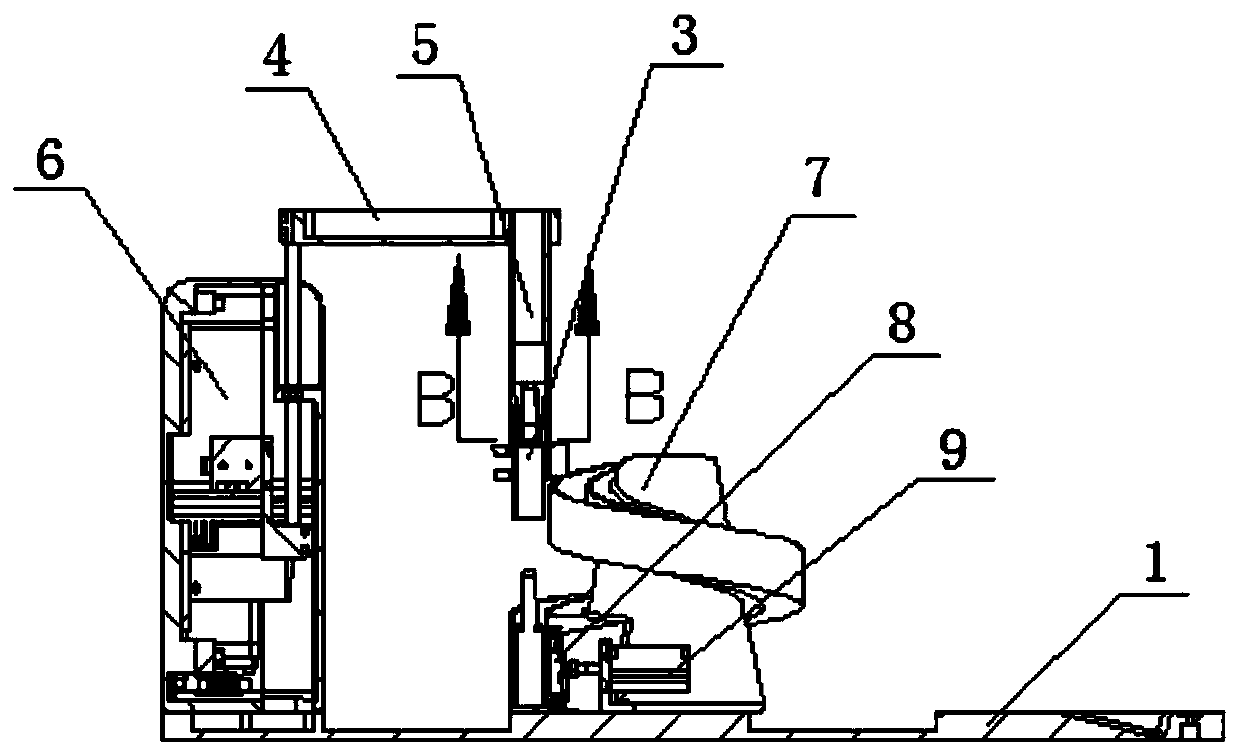

Bottle feeding device of aqueous solution dispensing machine

PendingCN111137480AConvenient rightingEasy to grab materialLiquid materialLiquid bottlingEngineeringBottle

The invention discloses a bottle feeding device of an aqueous solution dispensing machine. The bottle feeding device comprises an equipment base, wherein a rotary bottle feeding mechanism for conveying ampoule bottles, a grabbing mechanism for grabbing the ampoule bottles in the rotary bottle feeding mechanism and conveying the ampoule bottles, and a rotary disc for clamping the ampoule bottles onthe grabbing mechanism and rotatably conveying the ampoule bottles are arranged on the equipment base. The ampoule bottles are spirally sorted and intermittently shielded, so that more ampoule bottles are accommodated in a narrow space, and therefore, automatic sorting and low-cost feeding are realized; a baffle plate is convenient for righting the ampoule bottles, so that the ampoule bottles areconveniently grabbed and crushed; the ampoule bottles are elastically clamped by a connecting arm, so that the ampoule bottles are not damaged due to mechanical clamping, and therefore, the dispensing cost is reduced, and the bottle feeding device is suitable for ampoule bottles of different diameters; a ball screw linear driver can control any needed position of the ampoule bottles in a stroke,and follow-up station changes are not needed, so that the structure of a follow-up station can be simplified; and the rotary disc is adopted for feeding, so that feeding continuity is guaranteed, andintegral streamlined feeding is realized.

Owner:WUXI ANZHIZHUO MEDICAL ROBOT CO LTD

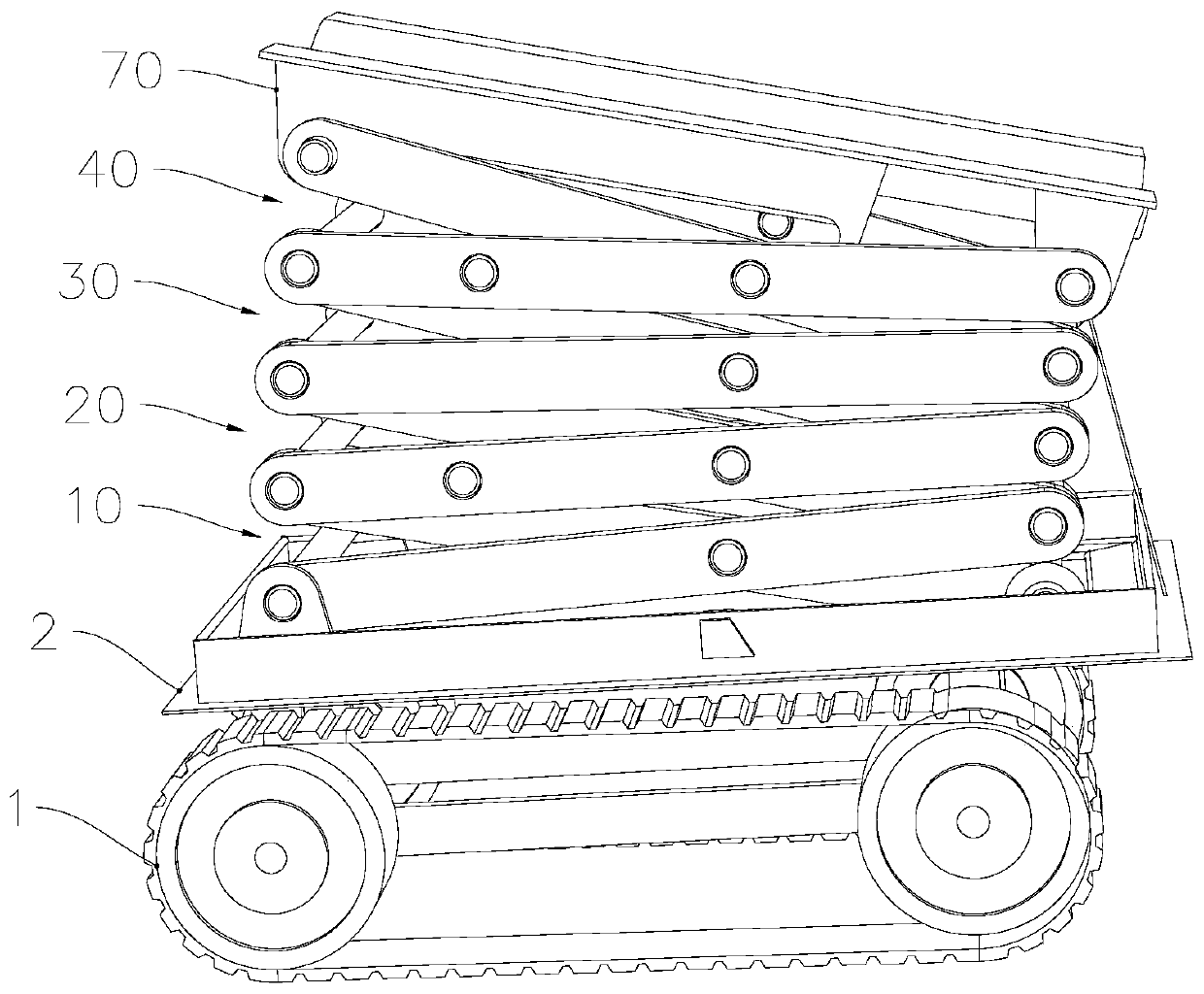

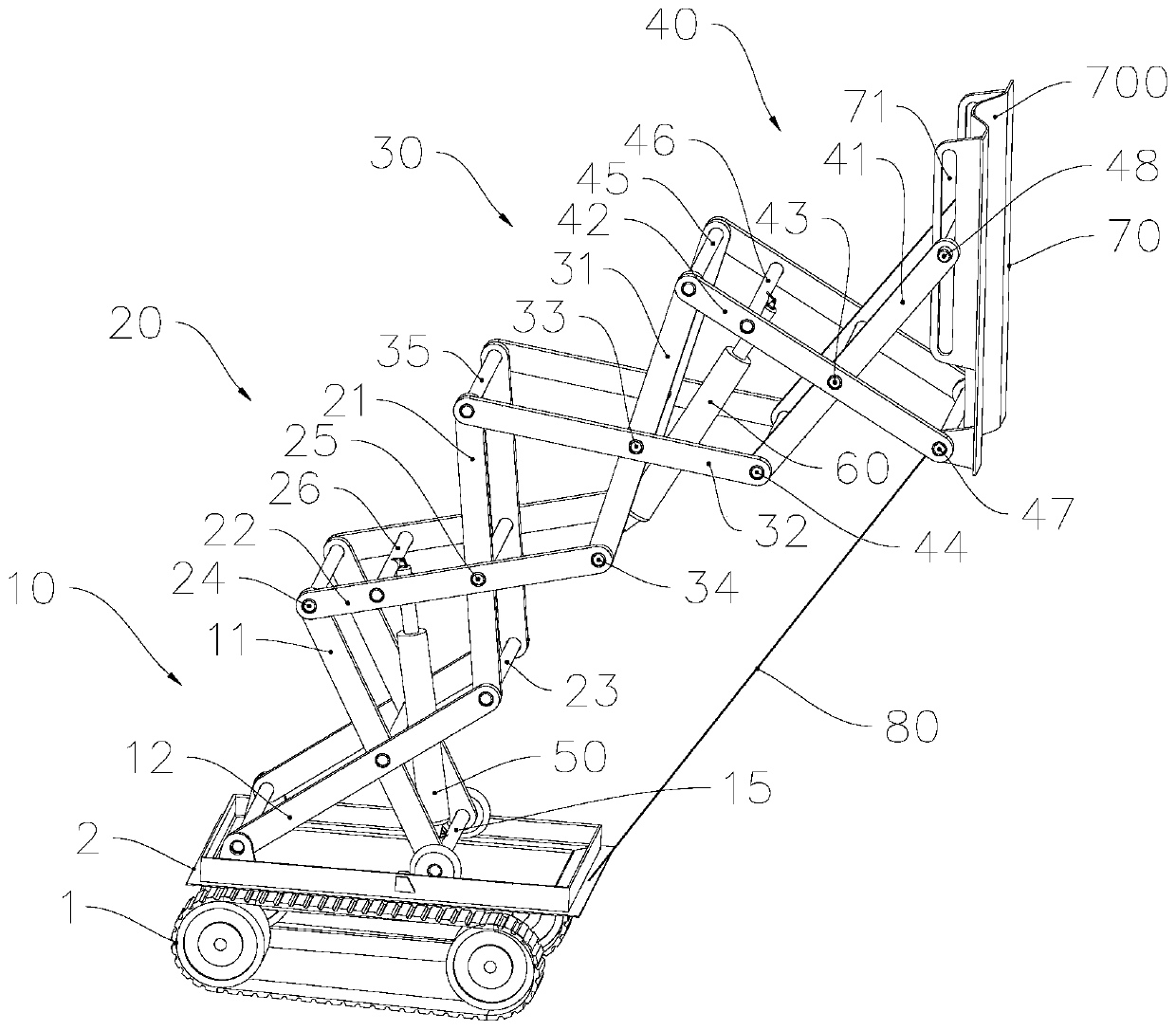

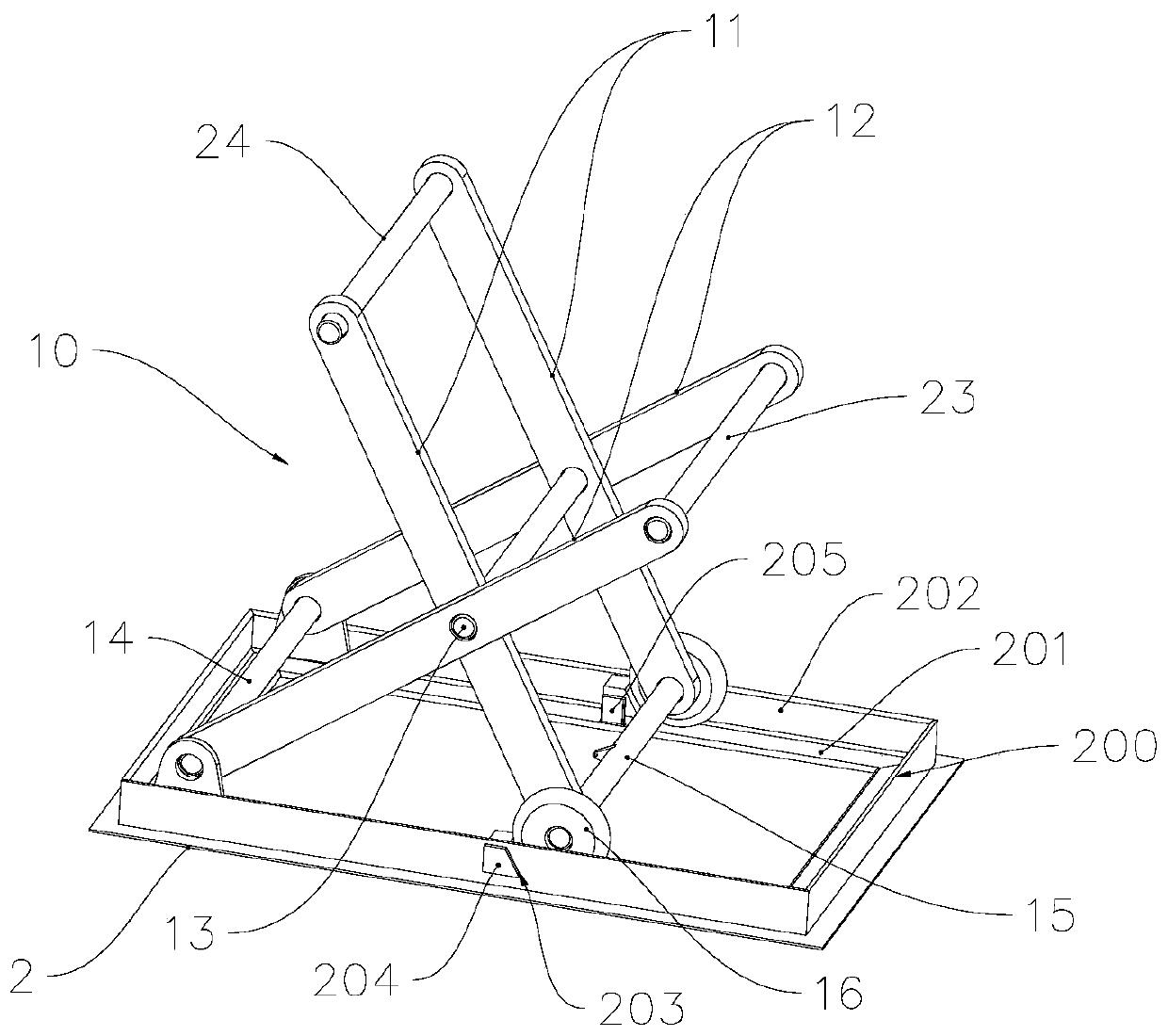

Lifting device and application thereof

PendingCN110194427AConvenient rightingReduce work intensitySafety devices for lifting equipmentsEngineeringElectrical and Electronics engineering

Owner:GUANGDONG INST OF SCI & TECH

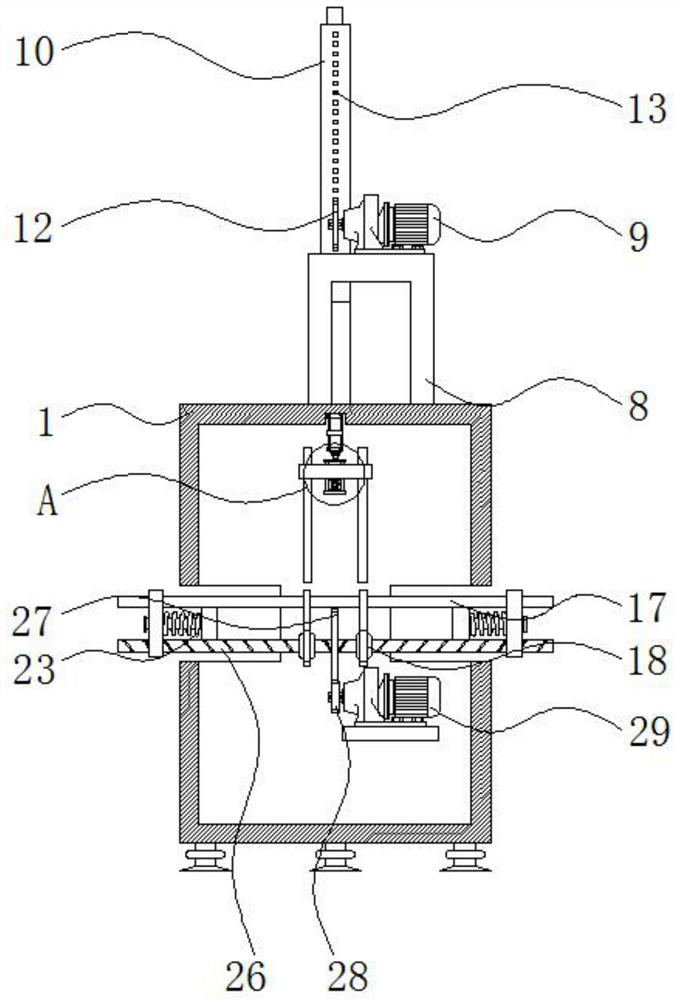

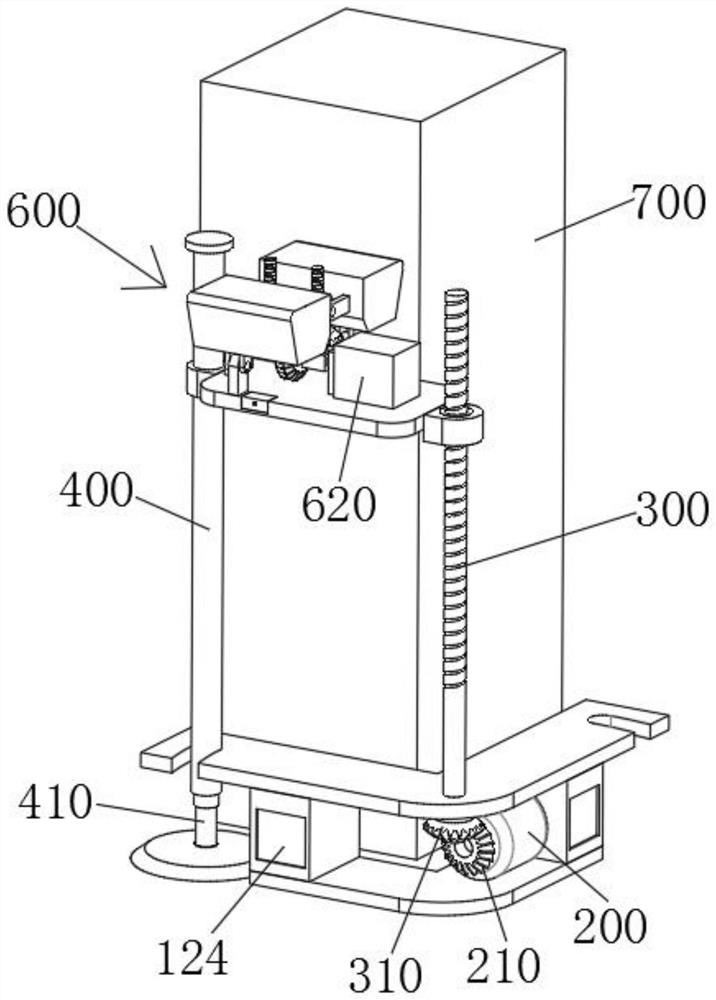

Intelligent fabricated fine adjusting device for constructional engineering

ActiveCN113090045AConvenient rightingAvoid installationBuilding material handlingGear wheelElectric machinery

The invention relates to the technical field of constructional engineering, in particular to an intelligent fabricated fine adjusting device for constructional engineering. The intelligent fabricated fine adjusting device comprises a base, a first motor is fixedly connected into the base, a first gear is fixedly connected to the output end of the first motor, a first threaded rod is rotationally connected to the middle of the top face of the base, a guide rod is movably clamped to one end of the top face of the base, a bearing plate is arranged between the first threaded rod and the guide rod, and a boosting mechanism is fixedly connected to the top face of the bearing plate. According to the intelligent fabricated fine adjusting device for the constructional engineering, a first square sleeve on a second threaded rod moves upwards through rotation of a fourth gear, the second threaded rod and the fourth gear gradually deflect in the direction of a special-shaped extrusion block in the corresponding position, the protruding part of the special-shaped extrusion block gradually pushes a prefabricated column, fine adjustment is achieved, and the righting effect of the prefabricated column can be improved; and in addition, by observing the deflection condition of the special-shaped extrusion block away from the prefabricated column, the degree that the special-shaped extrusion block in contact with the prefabricated column extrudes the prefabricated column is visually known.

Owner:刘序鹏

An assembly fine adjustment device for intelligent construction engineering

ActiveCN113090045BConvenient rightingAvoid installationBuilding material handlingGear wheelArchitectural engineering

The present invention relates to the technical field of construction engineering, in particular to an intelligent construction engineering fine assembly adjustment device, comprising a base, a motor 1 is fixedly connected to the inside of the base, and a gear 1 is fixedly connected to the output end of the motor 1, The middle part of the top surface of the base is rotatably connected with a threaded rod one, and one end of the top surface of the base is movably clamped with a guide rod, and a receiving plate is arranged between the threaded rod one and the guide rod, and the top surface of the receiving plate The fixed connection has a booster mechanism. In the present invention, through the rotation of gear 4, the square sleeve 1 on the threaded rod 2 moves upward, and the threaded rod 2 and gear 4 gradually deflect toward the direction of the special-shaped extrusion block at the corresponding position, so that the protruding part of the special-shaped extrusion block gradually pushes the prefabricated Column, to achieve fine adjustment, is conducive to improving the effect of prefabricated column centralization, in addition, by observing the deflection of the special-shaped extrusion block away from the precast column, intuitively understand the degree of extrusion of the precast column by the special-shaped extrusion block in contact with the prefabricated column.

Owner:刘序鹏

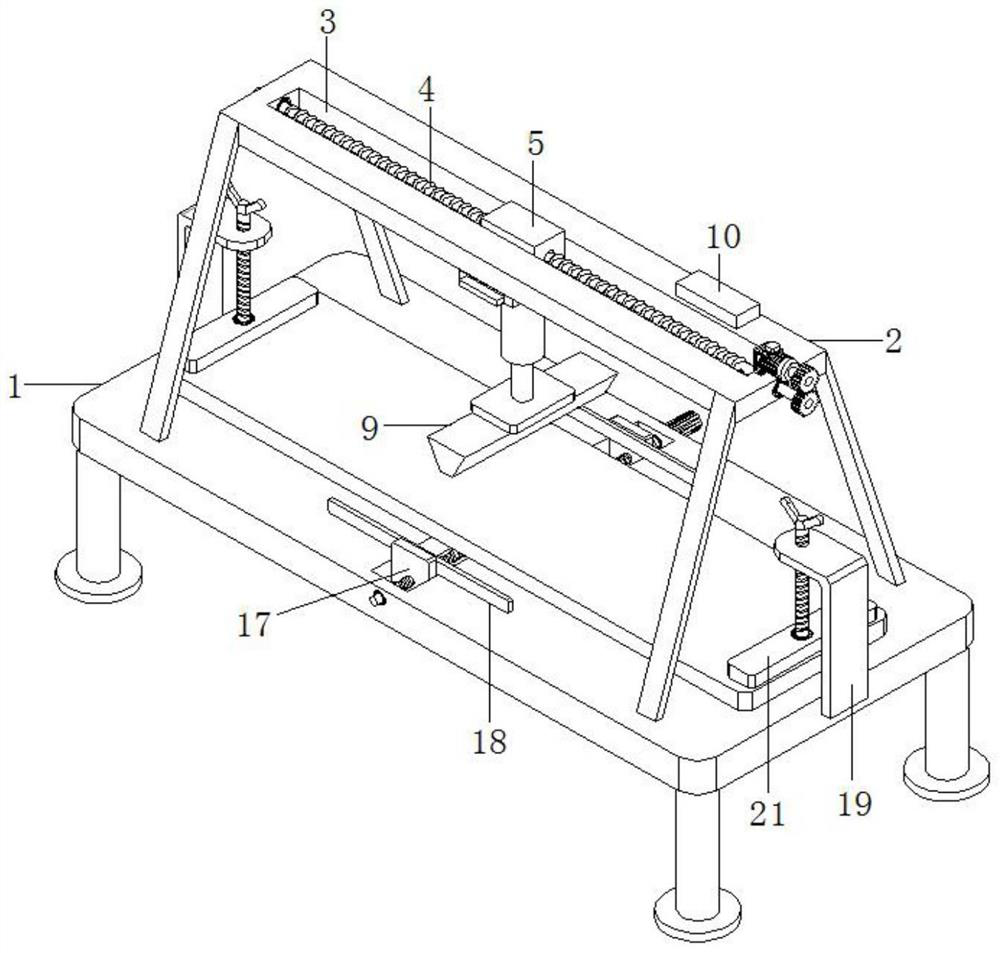

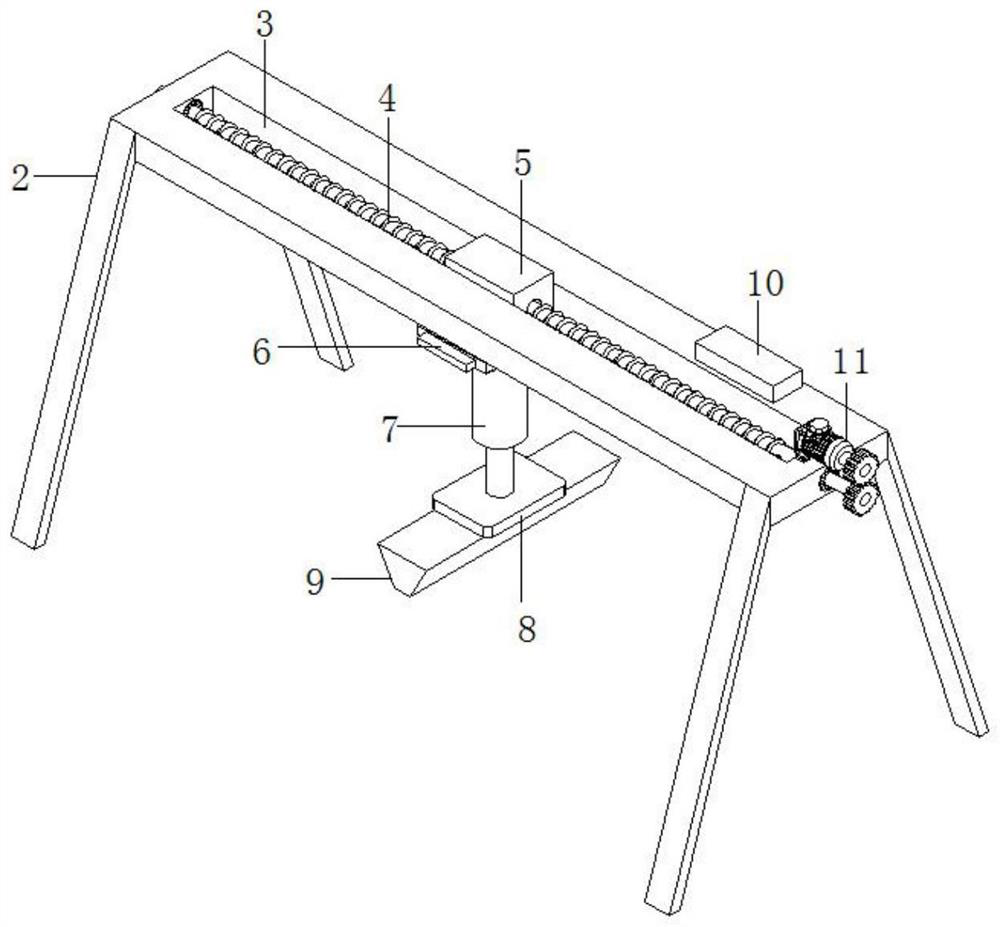

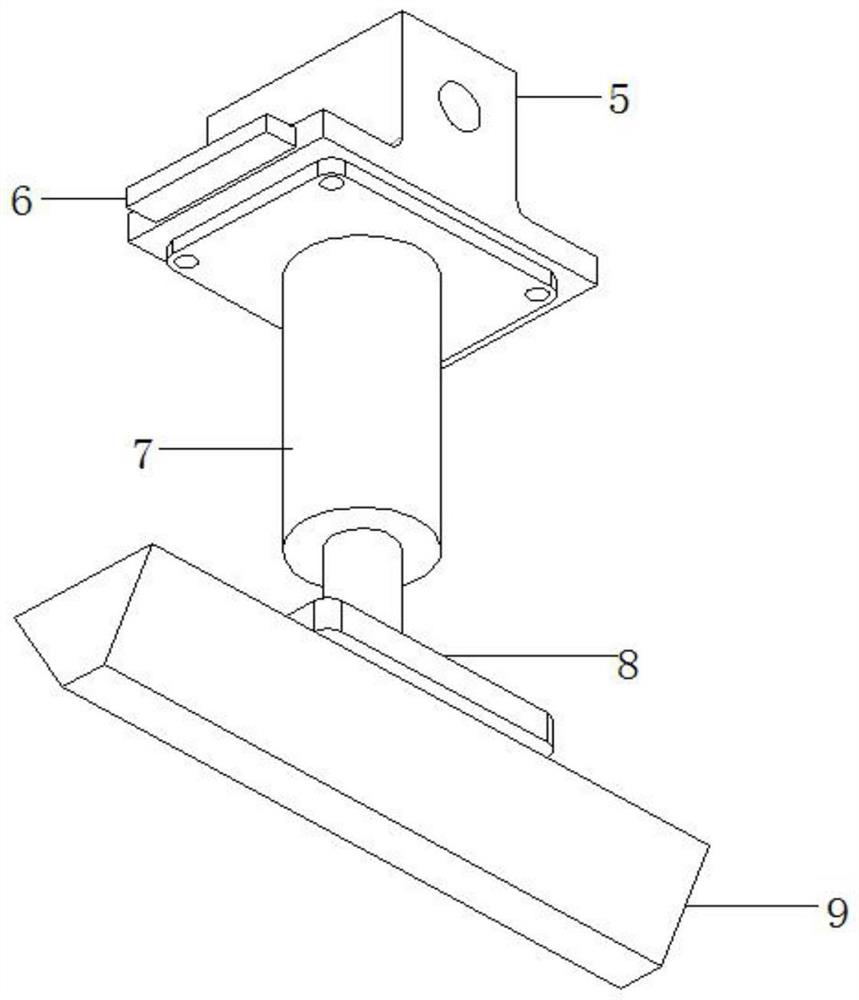

Line pressing machine for corrugated carton production

PendingCN114872378AImprove crimping efficiencyAvoid warpingPaper-makingBox making operationsPackaging industryManufacturing engineering

The invention belongs to the technical field of packaging industry, and particularly relates to a corrugated carton production line pressing machine which comprises a machining table, a rack is fixed to the outer wall of the top of the machining table, and an adjusting mechanism is arranged on the rack. The adjusting mechanism comprises a sliding way formed in the top of the rack, a lead screw rotationally installed in the sliding way, a T-shaped sliding block connected to the middle of the lead screw in a threaded mode, an infrared sensor installed on the T-shaped sliding block, a pressing assembly and a control assembly, and two edge warping preventing mechanisms and a righting mechanism are arranged on the machining table. The adjusting mechanism is arranged, through accurate control of an infrared sensor and a microprocessor, the horizontal position of the line pressing cutter can be accurately adjusted, and therefore the line pressing efficiency of the line pressing machine is improved; through cooperative use of the righting mechanism and the two edge warping prevention mechanisms, righting is facilitated, the two edges of the wire pressing machine are pressed tightly after righting is completed, the edge warping condition is prevented, and therefore the wire pressing quality of the whole wire pressing machine can be improved.

Owner:固丽纸业(上海)有限公司

A tilting utility pole straightening device

The invention relates to a straightening device for an inclined electric pole, which comprises a chassis, a traction wire drive device, a traction wire, a support pipe, a telescopic rod drive device and a screw rod. The traction line driving device is arranged on the chassis, the support tube is hinged to the chassis, the screw is inserted inside the support tube, and the end of the screw is hinged to the top plate of the utility pole. The telescopic rod driving device is arranged at the end of the support pipe, and the traction wire driving device drives the telescopic rod driving device to rotate through the traction wire, and controls the expansion and contraction of the screw rod. The invention is easy to move, occupies a small area, and is convenient for straightening inclined utility poles in various environments.

Owner:JUNAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com