Transformer substation infrastructure construction anti-toppling device

An anti-dumping and substation technology, applied in the direction of buildings, building types, non-rotational vibration suppression, etc., can solve the problems of increasing labor intensity of staff, reducing work efficiency, wasting resources, etc., to improve fixing and straightening efficiency, and improve work efficiency , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

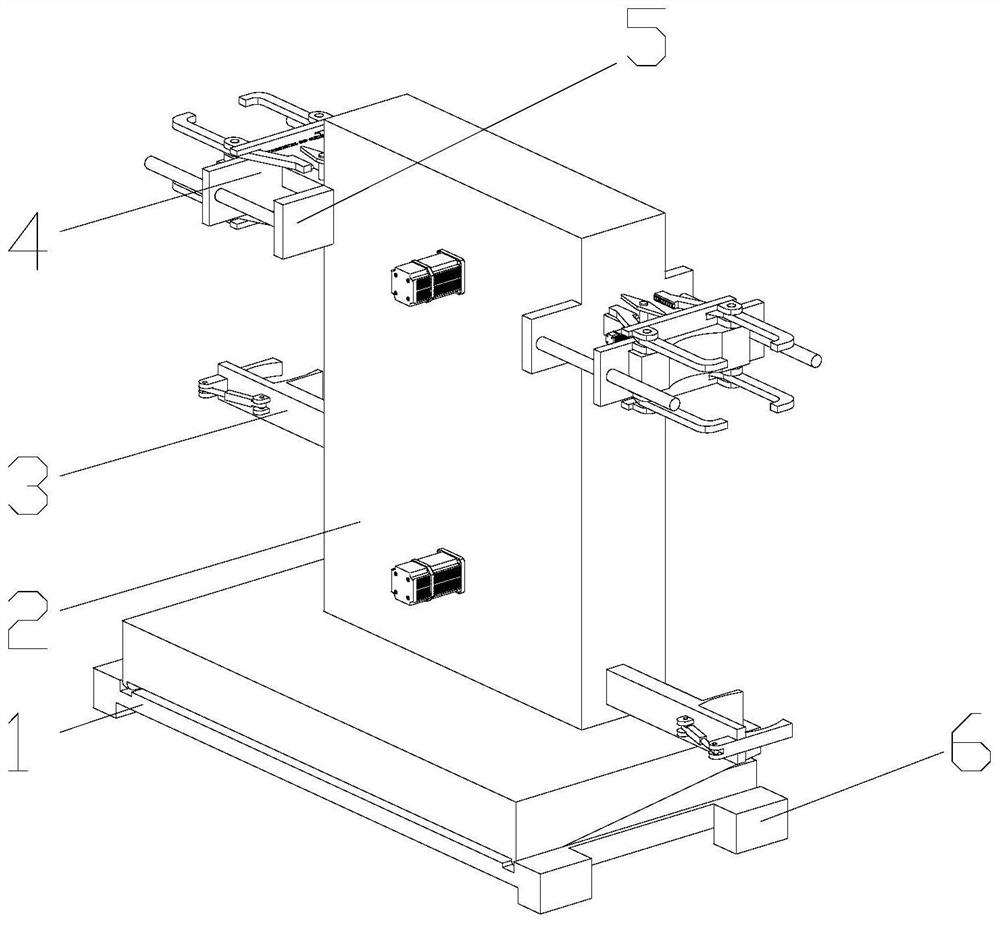

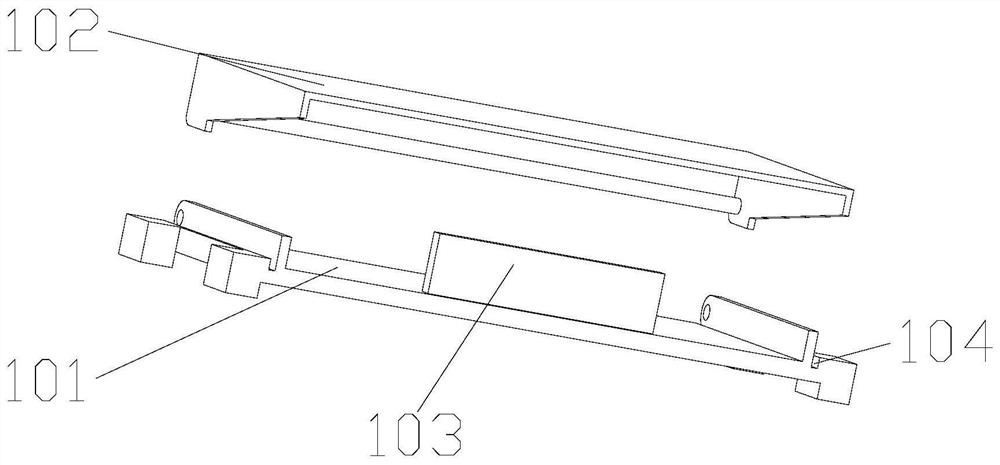

[0041] An anti-dumping device for substation infrastructure construction, comprising a base 1, a fixed frame 2 is installed on the base 1, a first adjustment mechanism 7 and a second adjustment mechanism 8 are installed inside the fixed frame 2, and the first adjustment mechanism 7 The first clamping mechanism 3 is installed, the second adjusting mechanism 8 is installed above the first adjusting mechanism 7, and the second clamping mechanism 4 is installed on the second adjusting mechanism 8, and the base 1 includes a lower support Frame 101, upper support frame 102 and lifting mechanism 103, one end of described upper support frame 102 is rotatably installed on one end of lower support frame 101, and described lifting mechanism 103 is installed on the other end of lower support frame 101 and cooperates with upper support frame 102 .

[0042] Wherein, the lifting mechanism 103 can drive the upper support frame 102 to rotate around one end of the upper support frame 102, which...

Embodiment 2

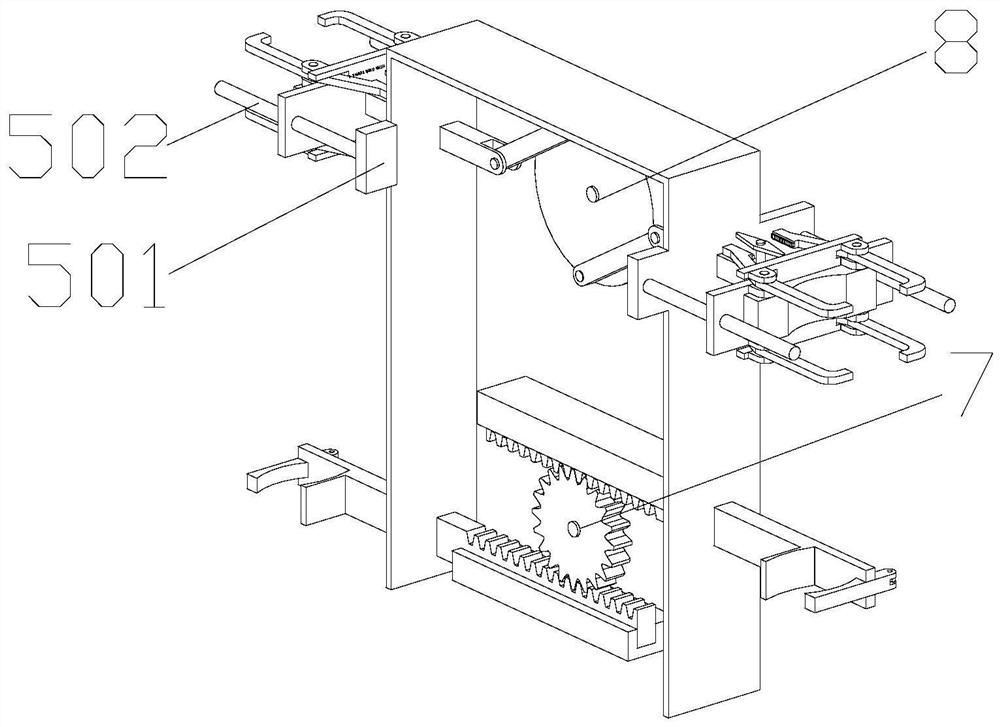

[0054] The difference with Embodiment 1 is that a guide mechanism 5 is also provided on the fixed frame 2, and the guide mechanism 5 is provided with two, and the two guide mechanisms 5 correspond to the two second clamping mechanisms 4, and the guide mechanism 5 includes a mounting block 501 and a guide rod 502, the mounting block 501 is provided with two, and the two mounting blocks 501 are symmetrically installed on both sides of the fixed frame 2, the guide rod 502 is installed on the guide rod 502, and the guide rod 502 is matched with the guide hole 402 on the support plate 403. On the one hand, the guide mechanism 5 guides the second clamping mechanism 4 to ensure that the second clamping mechanism 4 can clamp the pole smoothly, and the other is convenient for supporting the second clamping mechanism 4. The clamping mechanism 4 ensures the normal operation of the second clamping mechanism 4 .

Embodiment 3

[0056] The difference from Embodiment 1 and Embodiment 2 is that a leveling mechanism 6 is installed at the four corners of the fixed plate, and the leveling mechanism 6 includes a fixed shell 604 and a first motor 608, and one side of the fixed shell 604 is fixed Installed on the fixed plate, a first connector 601, a second connector 602, a first support rod 603, an adjustment plate 605, a sleeve 607 and a threaded rod 606 are arranged inside the fixed shell 604, and the first connector 601 and the middle part of the second connecting piece 602 are hinged together, one end of the first connecting piece 601 is rotatably mounted on the top of the fixed shell 604, and the sleeve 607 is rotatably mounted on the other end of the first connecting piece 601, and the sleeve 607 Covered on the threaded rod 606 and threaded with the threaded rod 606, the upper half of the threaded rod 606 is provided with threads, the lower half is a smooth round rod, and one end of the first support ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com