Patents

Literature

3576 results about "Rolling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling resistance, sometimes called rolling friction or rolling drag, is the force resisting the motion when a body (such as a ball, tire, or wheel) rolls on a surface. It is mainly caused by non-elastic effects; that is, not all the energy needed for deformation (or movement) of the wheel, roadbed, etc. is recovered when the pressure is removed. Two forms of this are hysteresis losses (see below), and permanent (plastic) deformation of the object or the surface (e.g. soil). Another cause of rolling resistance lies in the slippage between the wheel and the surface, which dissipates energy. Note that only the last of these effects involves friction, therefore the name "rolling friction" is to an extent a misnomer.

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

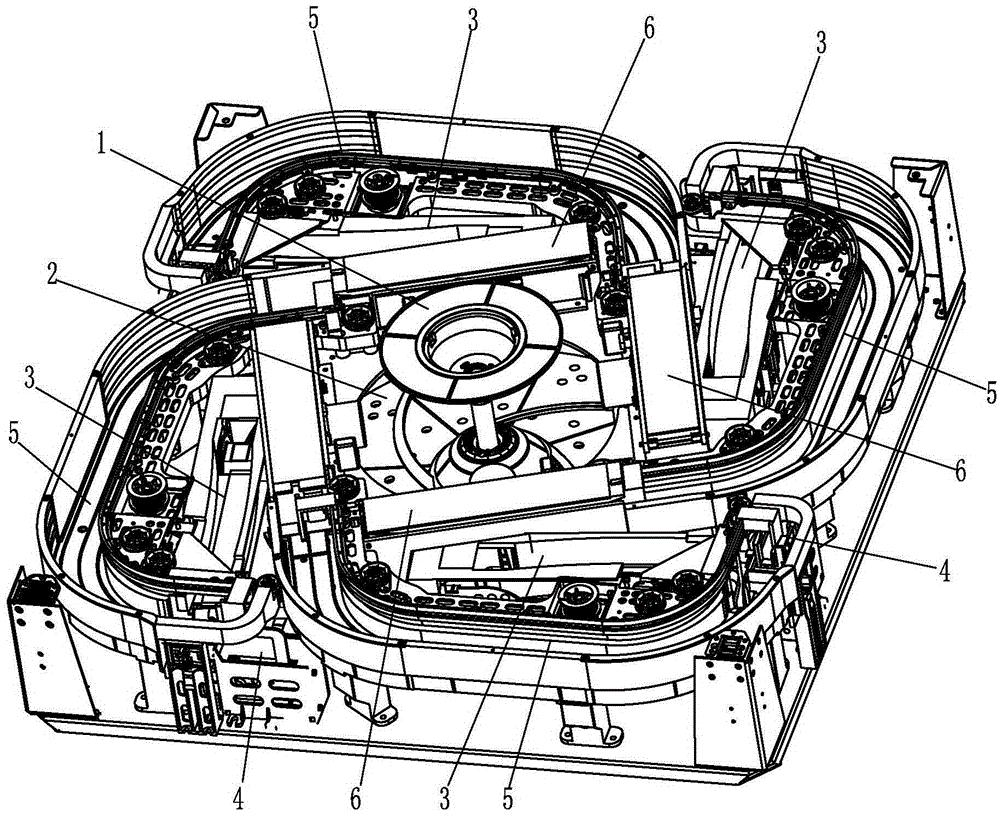

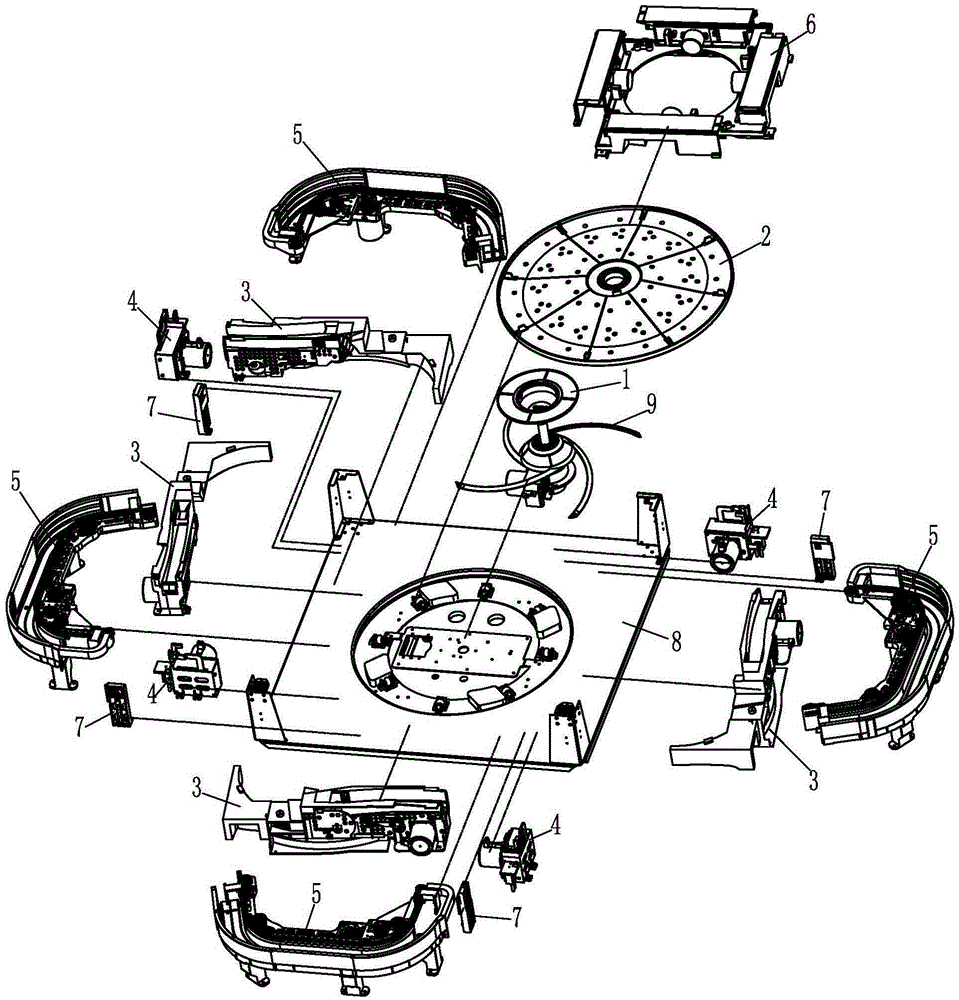

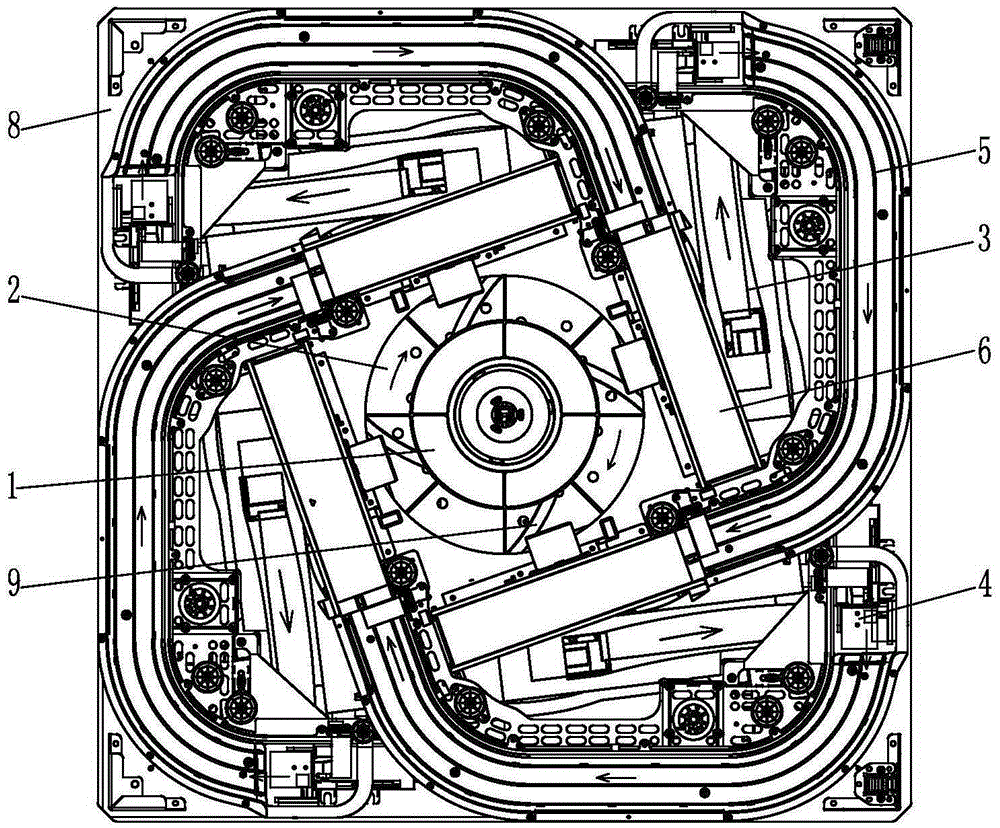

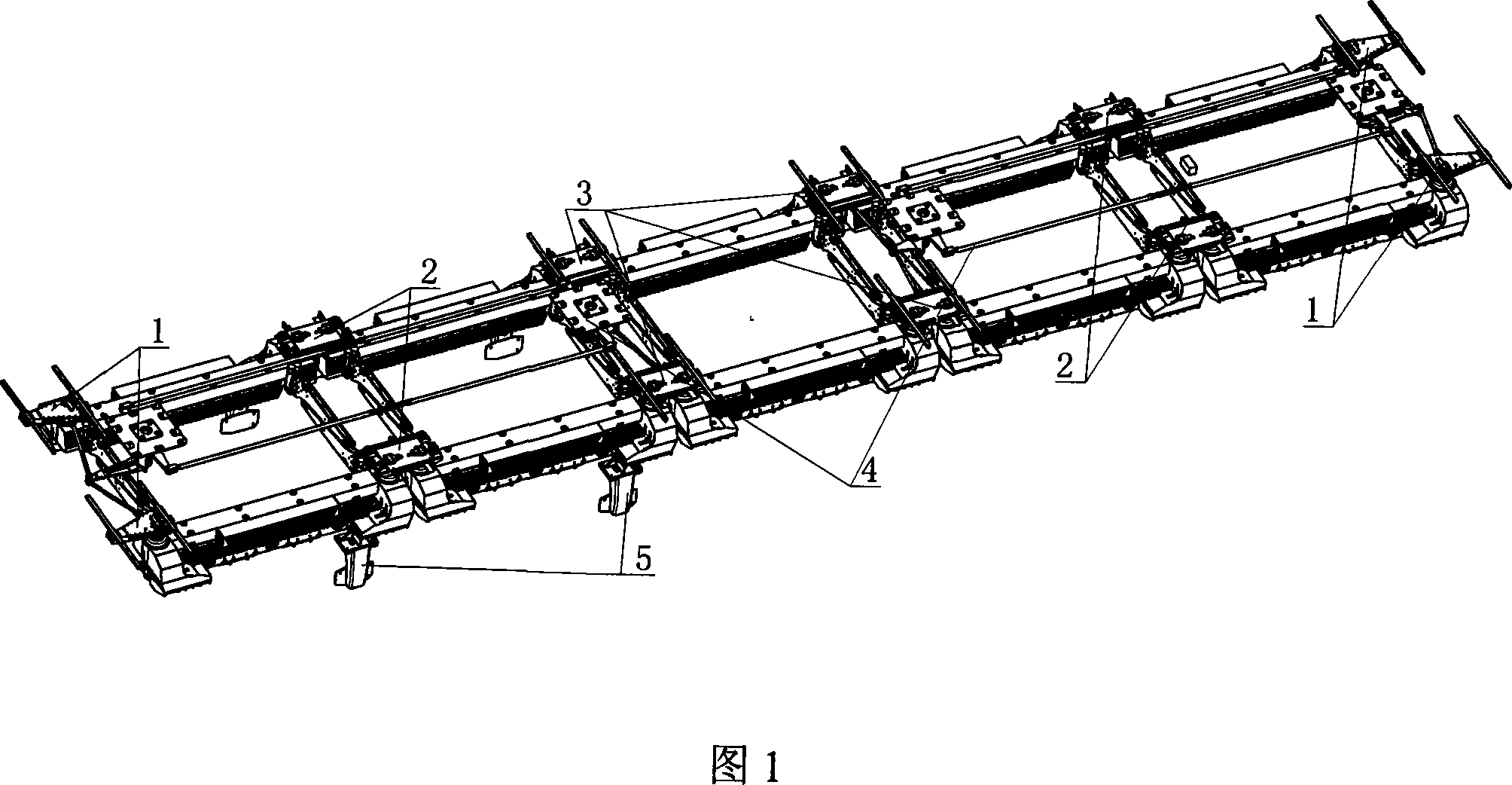

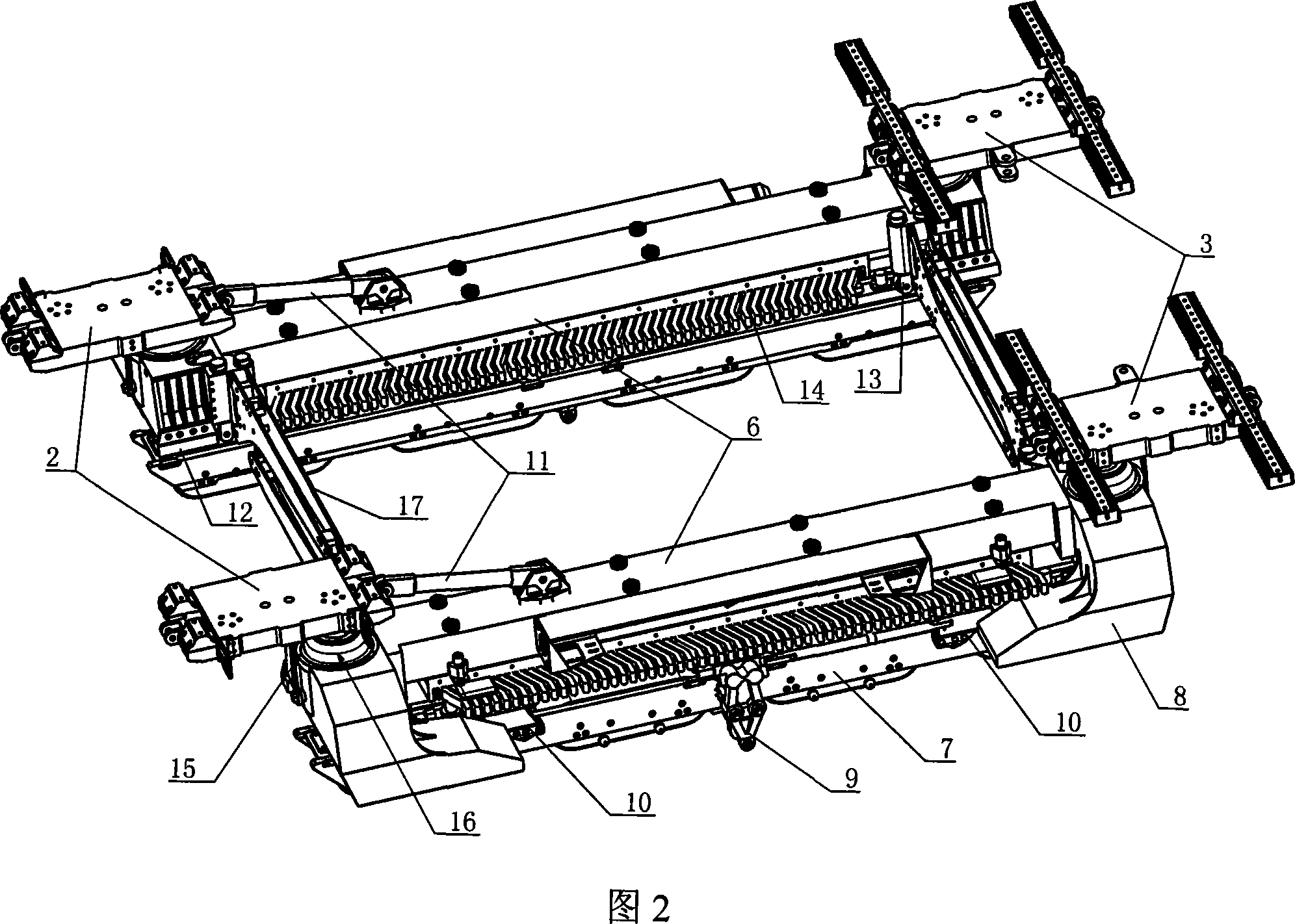

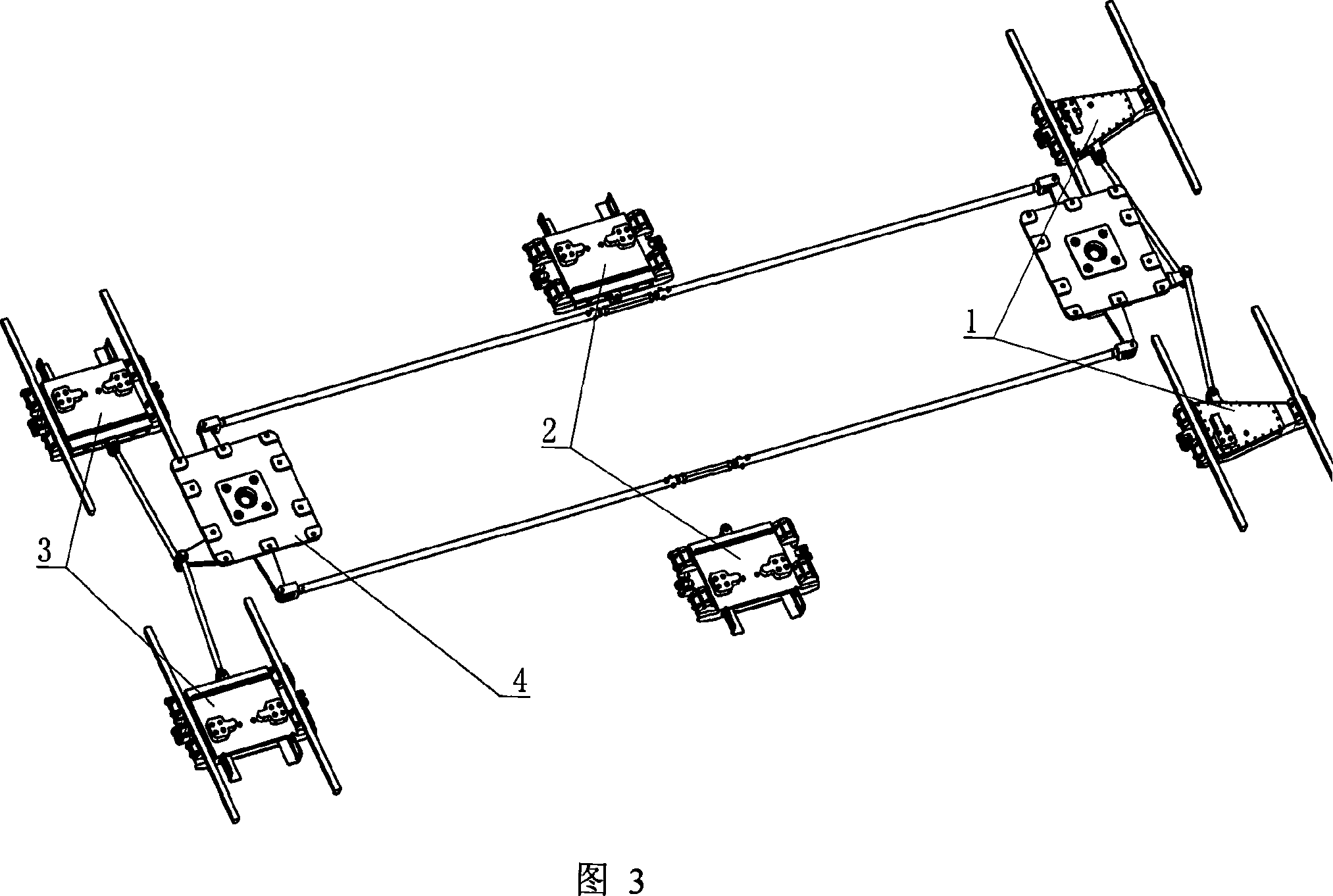

Tile feeding driving mechanisms, tile feeding assemblies and mahjong machine

The invention discloses tile feeding driving mechanisms, tile feeding assemblies and a mahjong machine. Each tile feeding driving mechanism of the mahjong machine comprises a tile feeding support, a tile storage groove, a tile feeding guide rail, a tile feeding pushing head and a steel wire rope, rolling parts are arranged at the position, close to the corresponding tile feeding guide rail and / or the corresponding tile storage groove, of each steel wire rope, each rolling part is installed on the corresponding tile feeding guide rail or the corresponding tile feeding support in a rotatable mode, the part, located in the corresponding tile storage groove, of each steel wire rope are in rolling contact with the multiple rolling parts, and a gap is maintained between the part, located in the corresponding tile storage groove, of each steel wire rope and the corresponding tile feeding guide rail and / or the side wall of the corresponding tile storage groove. According to the scheme, sliding friction of steel wire ropes in the prior art is replaced with rolling friction of the steel wire ropes, friction resistance in the operation process of the steel wire ropes is greatly decreased, and the situation that the service life and operation stability of the steel wire ropes are influenced due to sliding friction contact between the part, located in the corresponding tile storage groove, of each steel wire rope and the corresponding tile feeding guide rail and / or the arc-shaped bent side wall of the corresponding tile storage groove is avoided.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

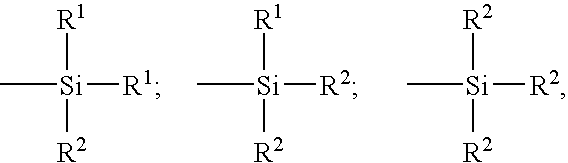

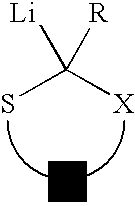

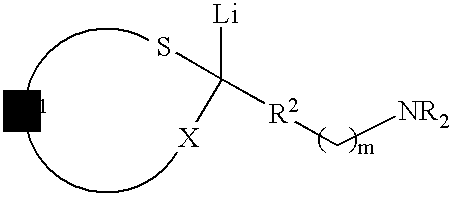

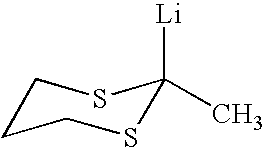

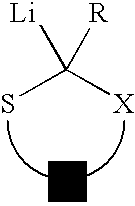

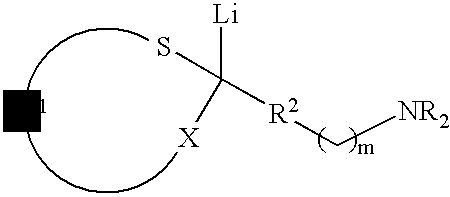

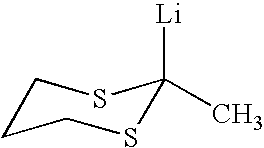

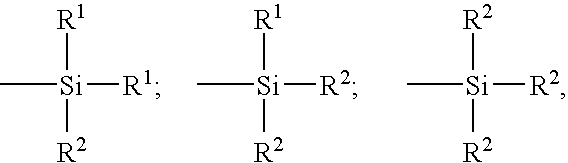

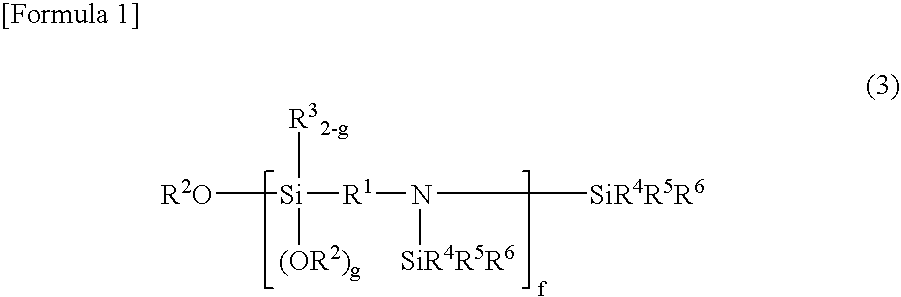

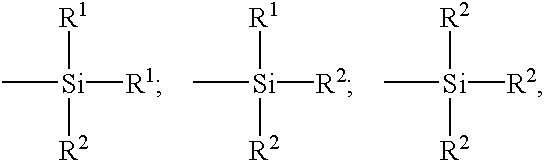

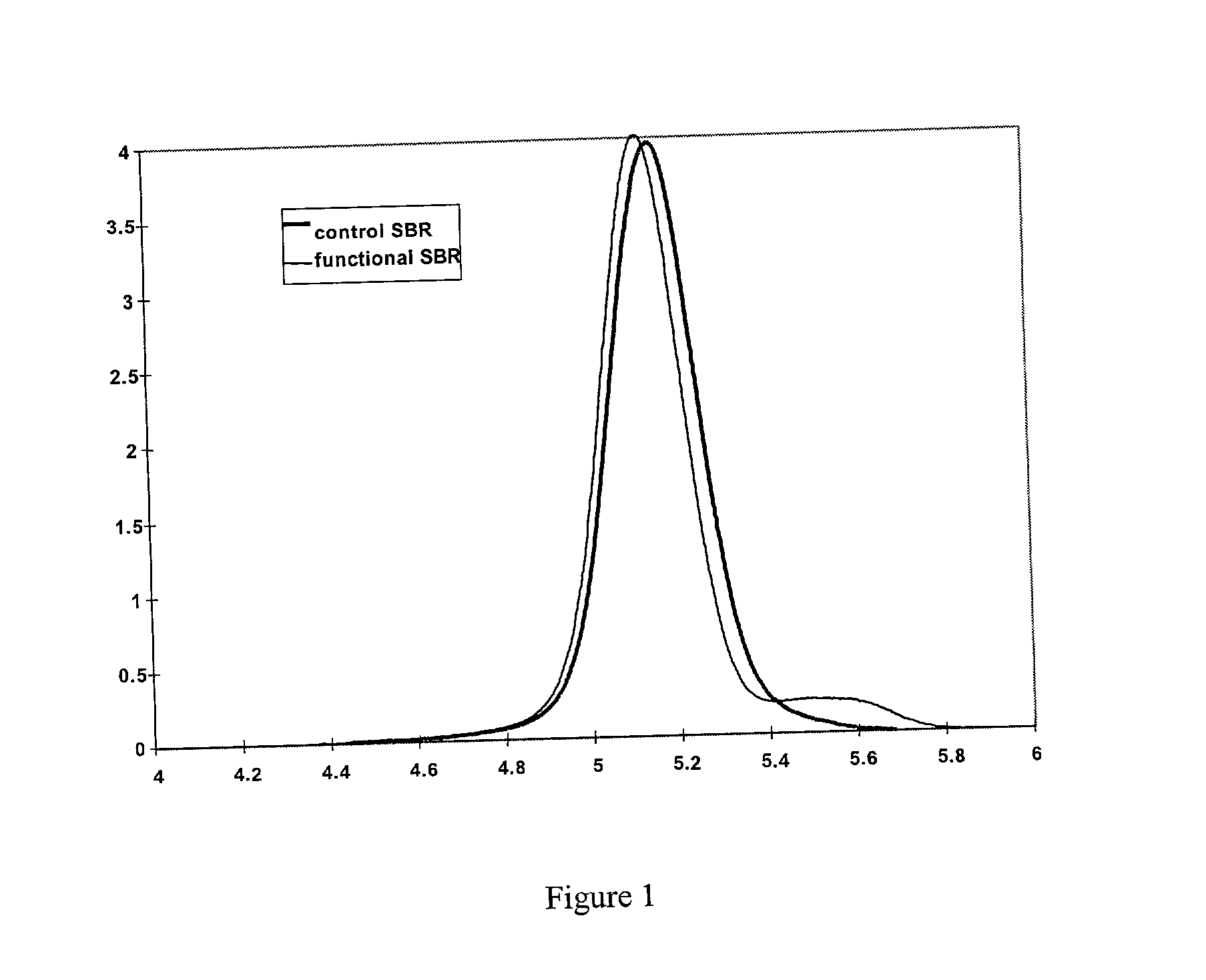

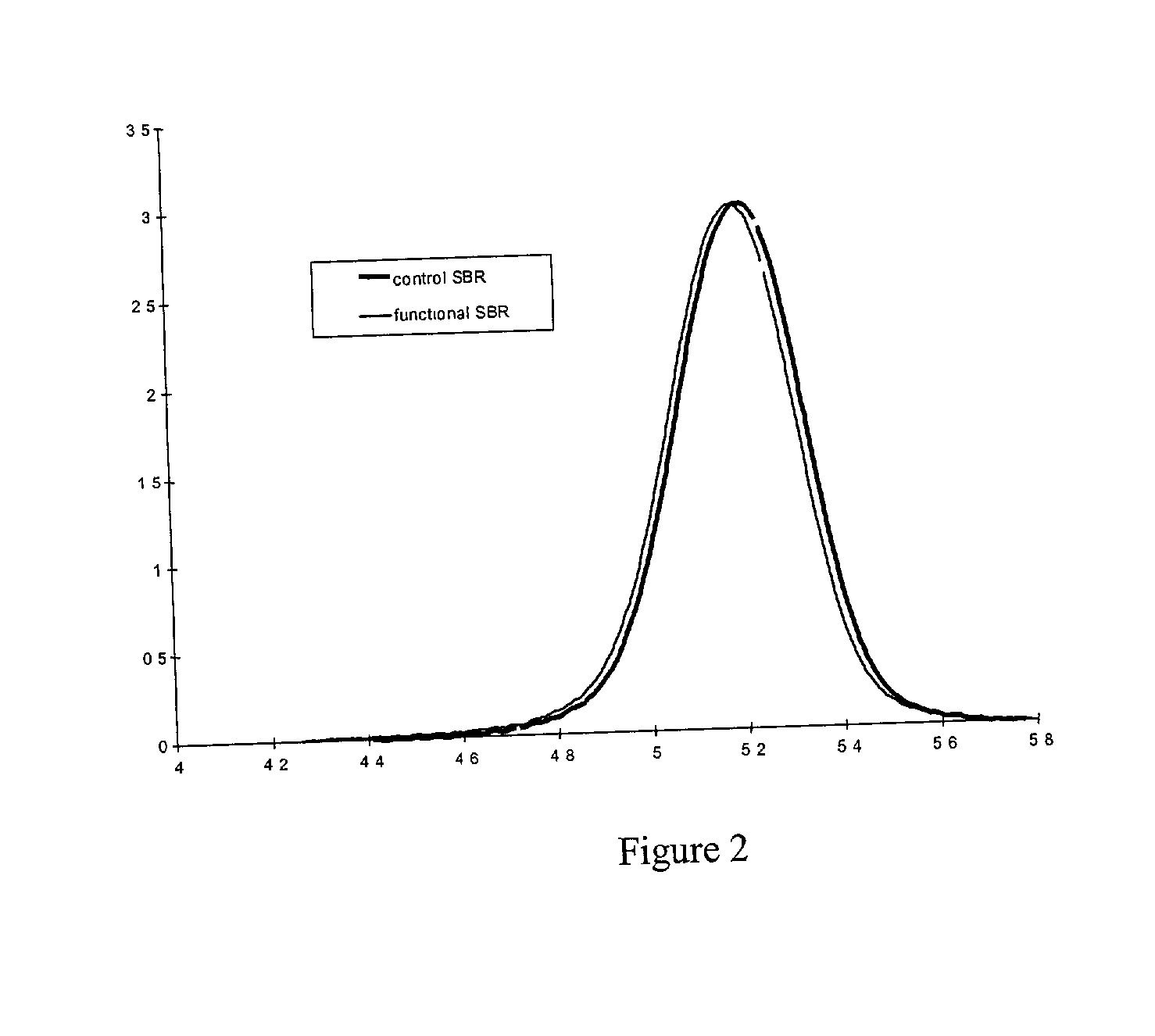

Use of sulfur containing initiators for anionic polymerization of monomers

InactiveUS7153919B2Reduced hysteresis lossSilicon organic compoundsLithium organic compoundsElastomerRolling resistance

An initiator is presented for anionically polymerizing monomers, to provide a functional head group on the polymer. A polymer having a functional head group derived from a sulfur containing anionic initiator, and optionally as additional functional group resulting from the use of a functional terminating reagent, coupling agent or linking agent is also provided. A method is presented for anionically polymerizing monomers comprising the step of polymerizing the monomers with a sulfur containing anionic initiator to provide a functional head group on the polymer. An elastomeric compound, comprising a functional polymer and filler is also described. Also provided is a tire having decreased rolling resistance resulting from a tire component containing a vulcanizable elastomeric compound.

Owner:BRIDGESTONE CORP

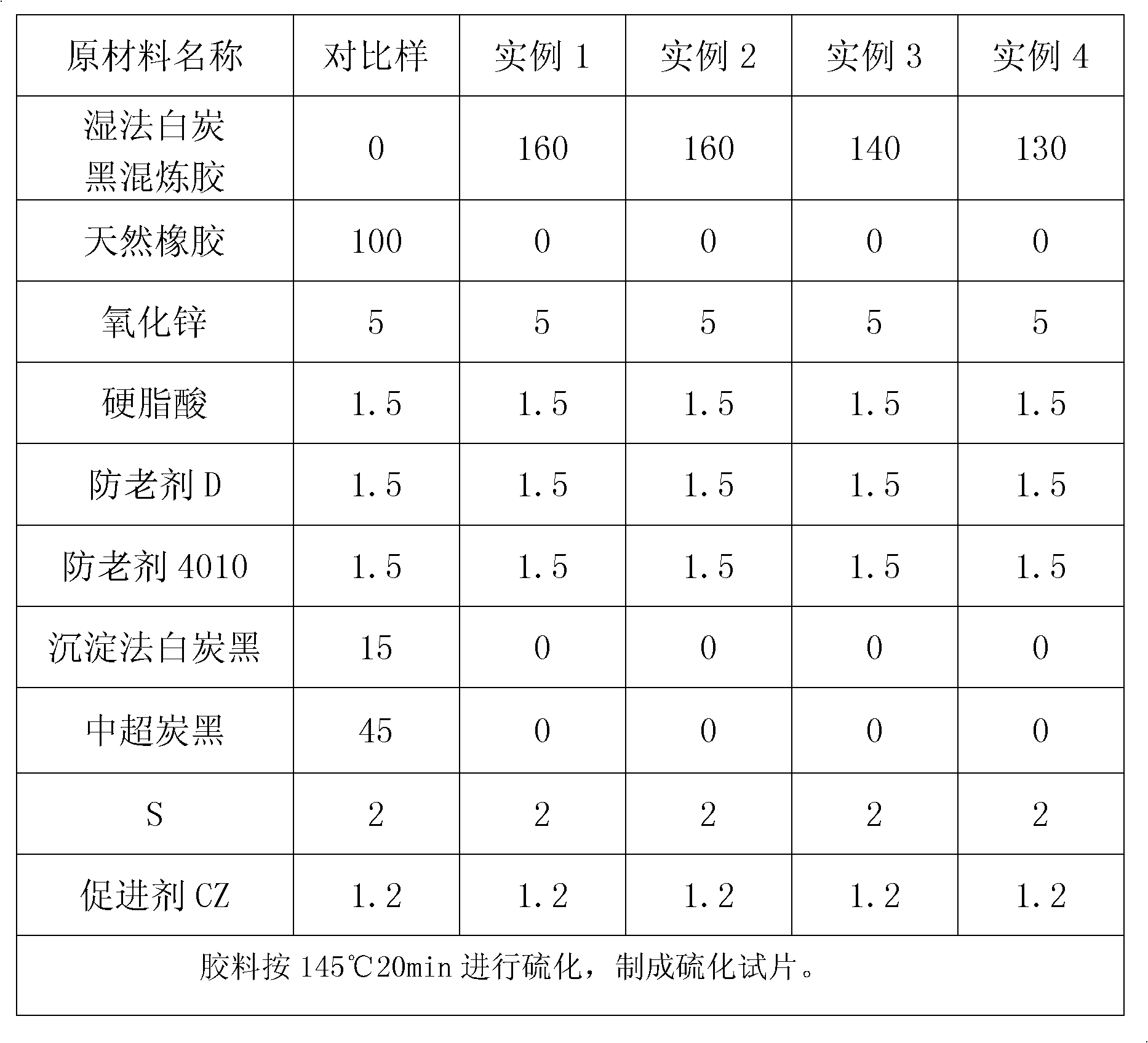

Preparation method of wet process mixed natural rubber material

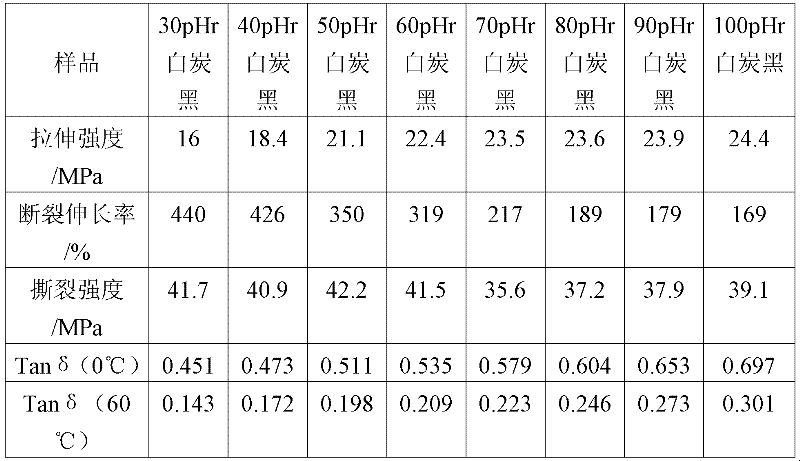

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

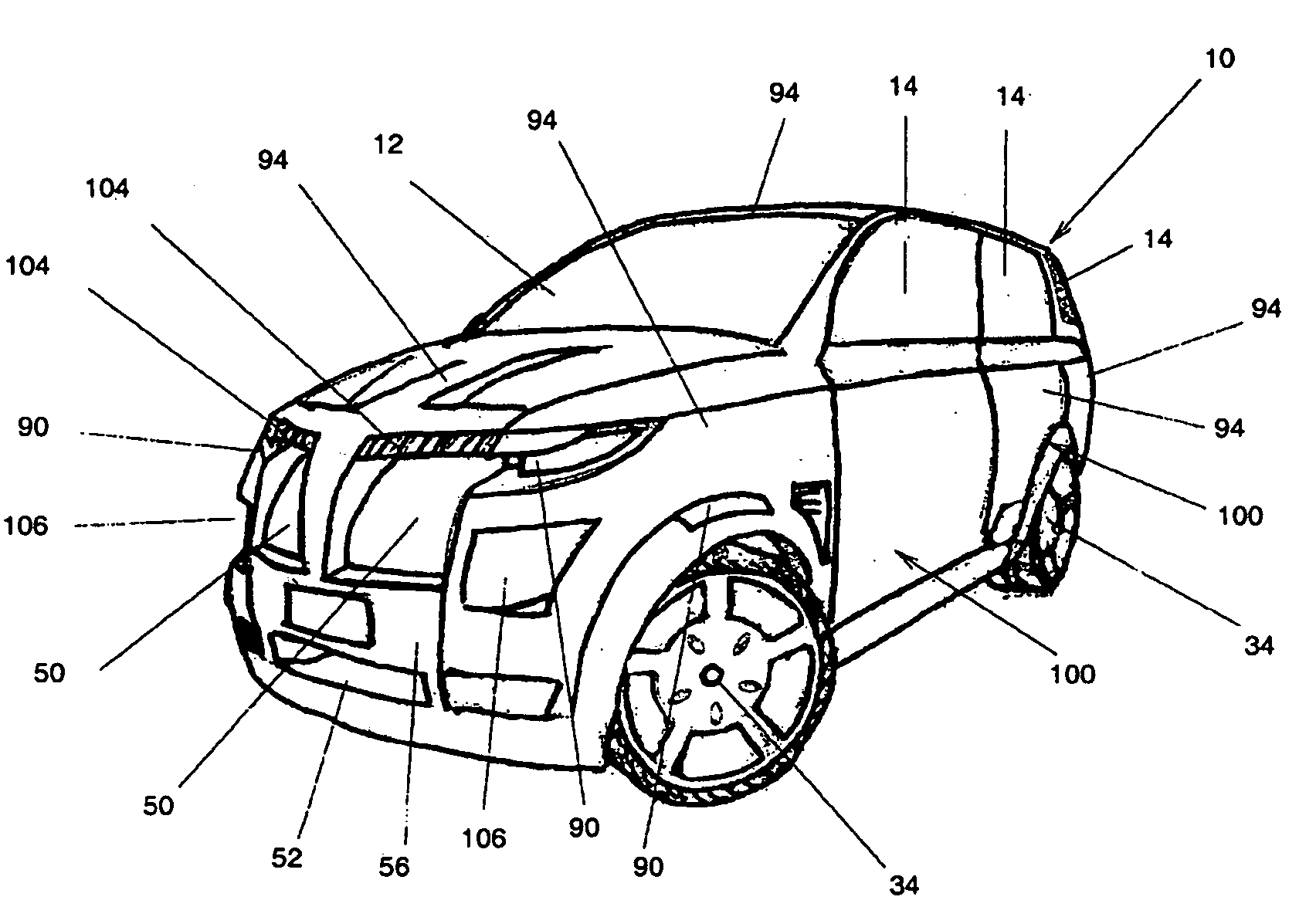

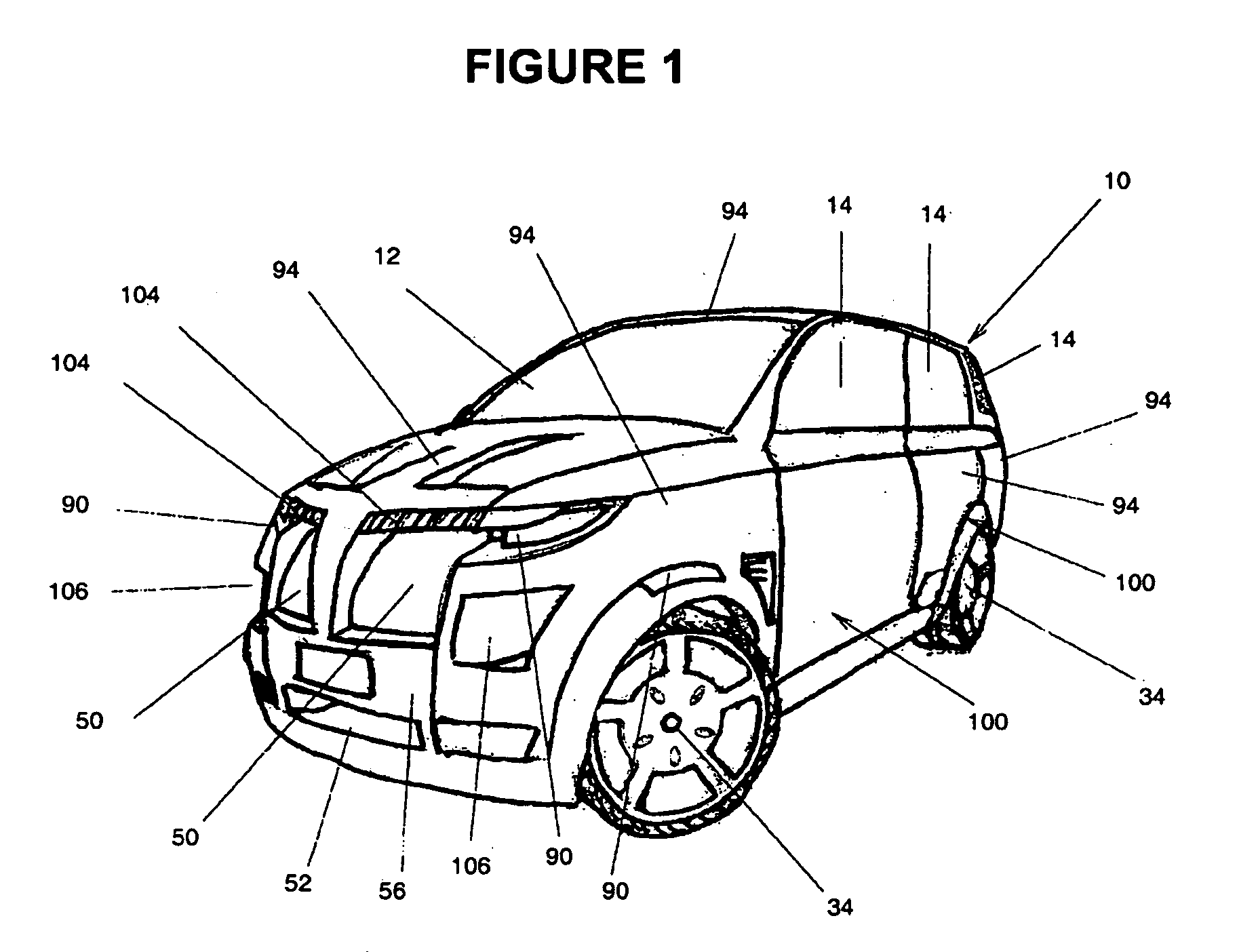

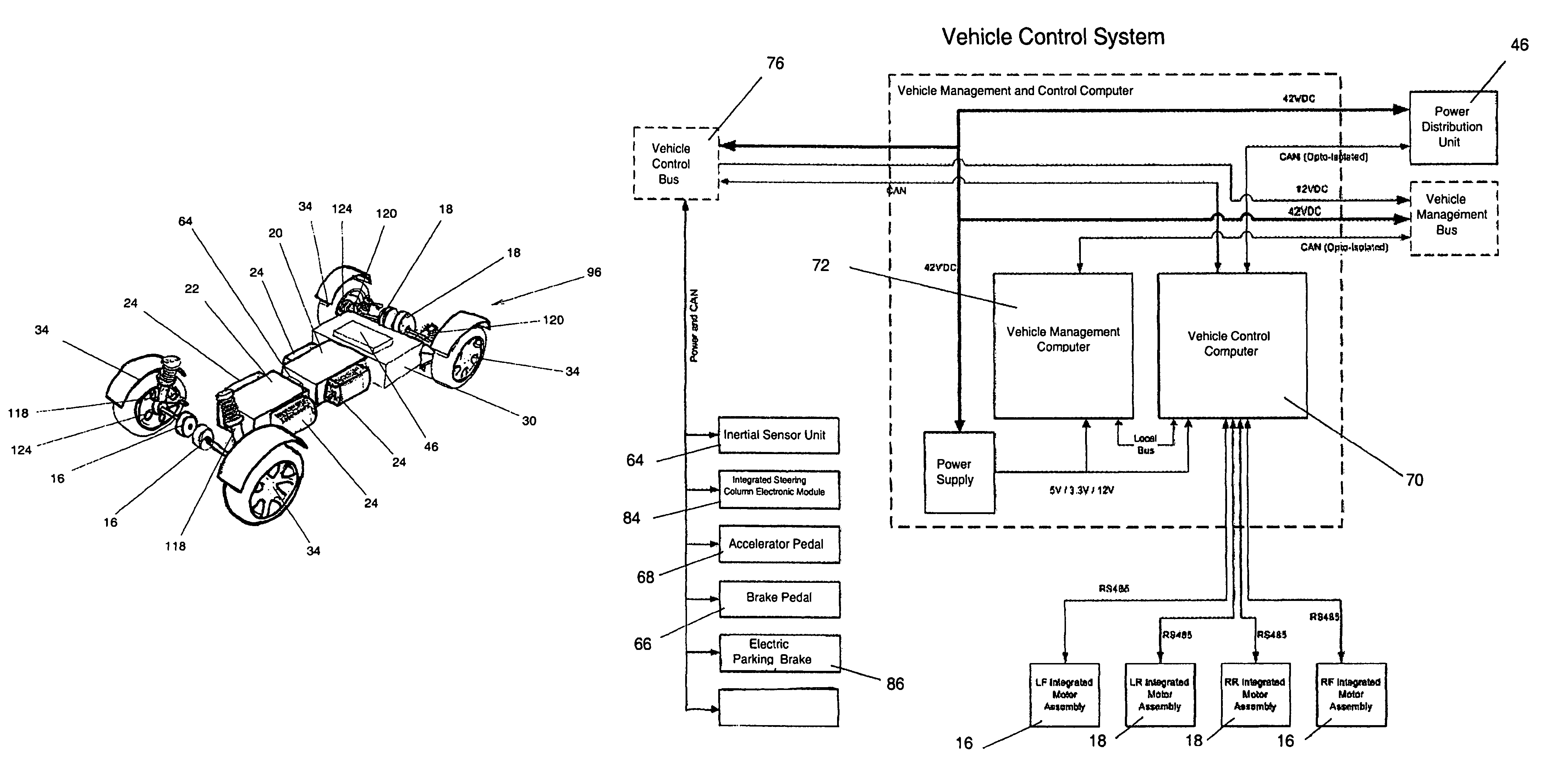

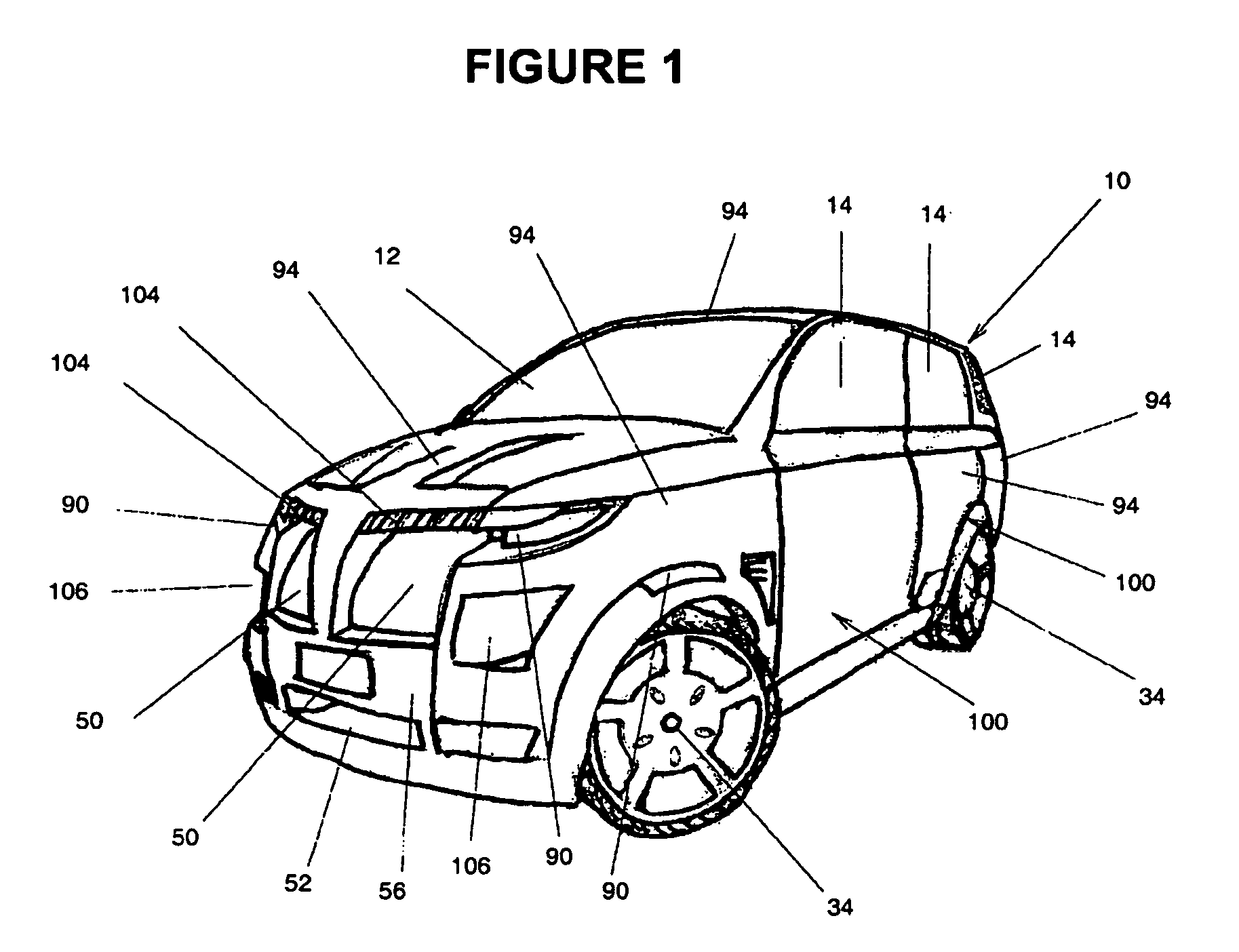

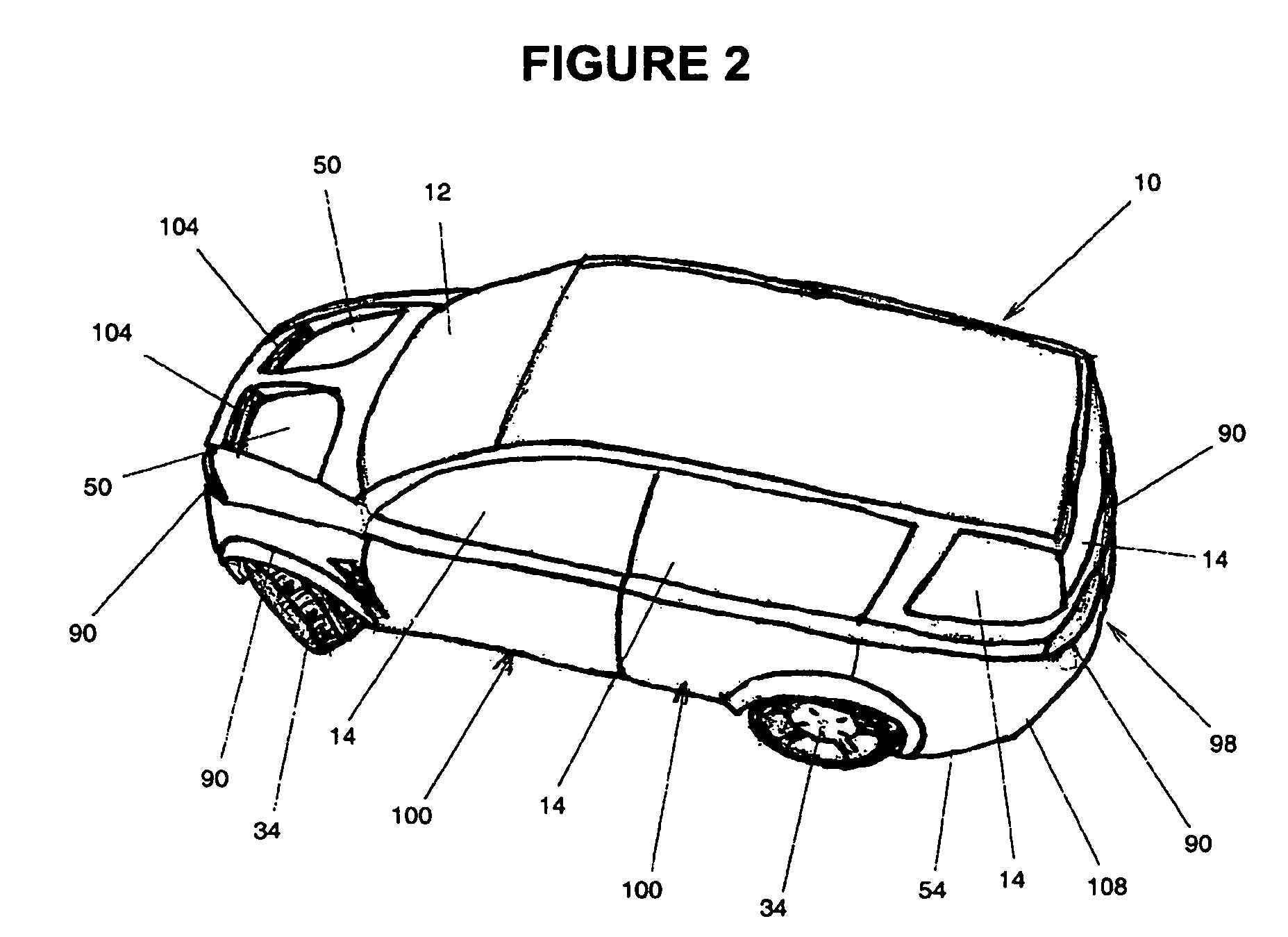

Hybrid electric vehicle

InactiveUS20090145674A1Improve energy efficiencyEasy to operateVehicle seatsDigital data processing detailsRolling resistanceAerodynamic drag

A highly energy efficient automobile that provides payload, safety and performance capacities similar to a comparable vehicle of a given vehicle class. The current invention is ideal for short to medium range urban and suburban driving. The current invention incorporates components in a unique and novel way, in which these components combine to form a system that produces an automobile that reduces overall air pollution while encouraging the commercialization of alternative energy sources. The current invention features an lightweight, low rolling resistance, digitally controlled and direct-drive electric propulsion system. A lightweight spaceframe with a suspension system provides a structure for mounting a low-aerodynamic-drag body system and other components. An intelligent power and thermal management system coupled with a removable auxiliary power module supplies the electrical energy required. While the preferred embodiment is substantially a passenger vehicle, the current invention may be scaled to other land vehicles.

Owner:INT HUMANITIES CENT

Use of sulfur containing initiators for anionic polymerization of monomers

ActiveUS20060030657A1Reduced hysteresis lossSilicon organic compoundsLithium organic compoundsElastomerRolling resistance

An initiator is presented for anionically polymerizing monomers, to provide a functional head group on the polymer. A polymer having a functional head group derived from a sulfur containing anionic initiator, and optionally as additional functional group resulting from the use of a functional terminating reagent, coupling agent or linking agent is also provided. A method is presented for anionically polymerizing monomers comprising the step of polymerizing the monomers with a sulfur containing anionic initiator to provide a functional head group on the polymer. An elastomeric compound, comprising a functional polymer and filler is also described. Also provided is a tire having decreased rolling resistance resulting from a tire component containing a vulcanizable elastomeric compound.

Owner:BRIDGESTONE CORP

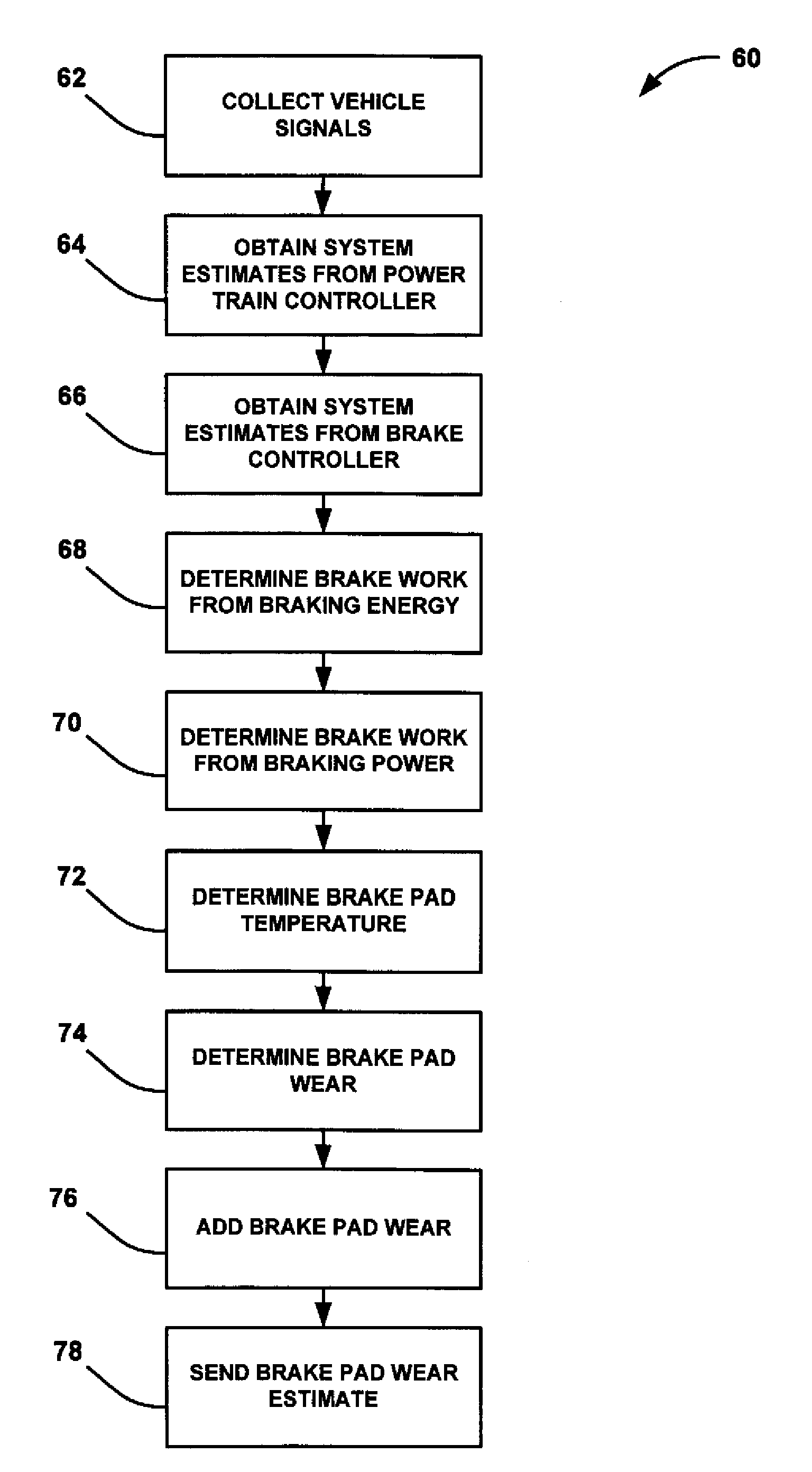

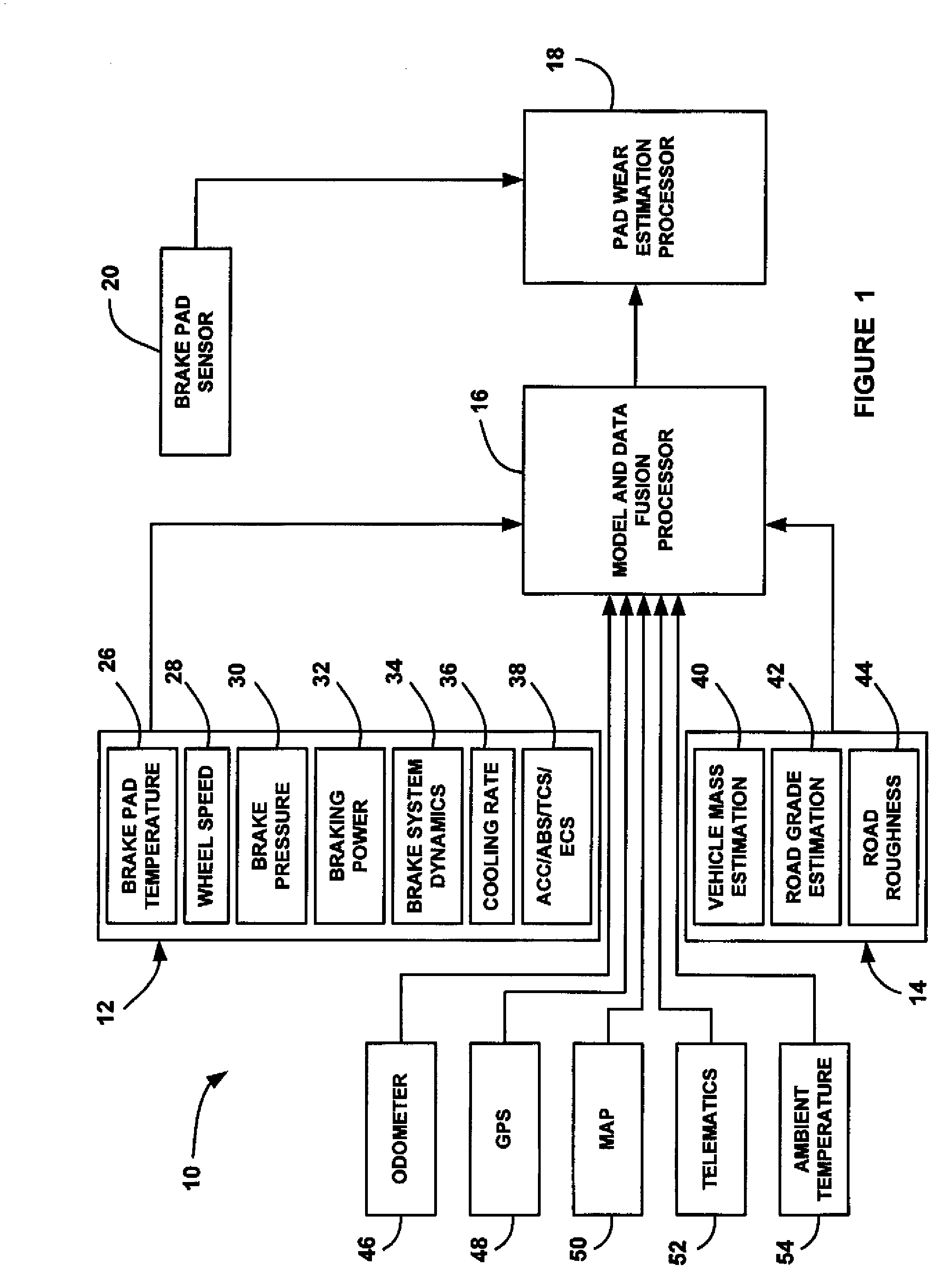

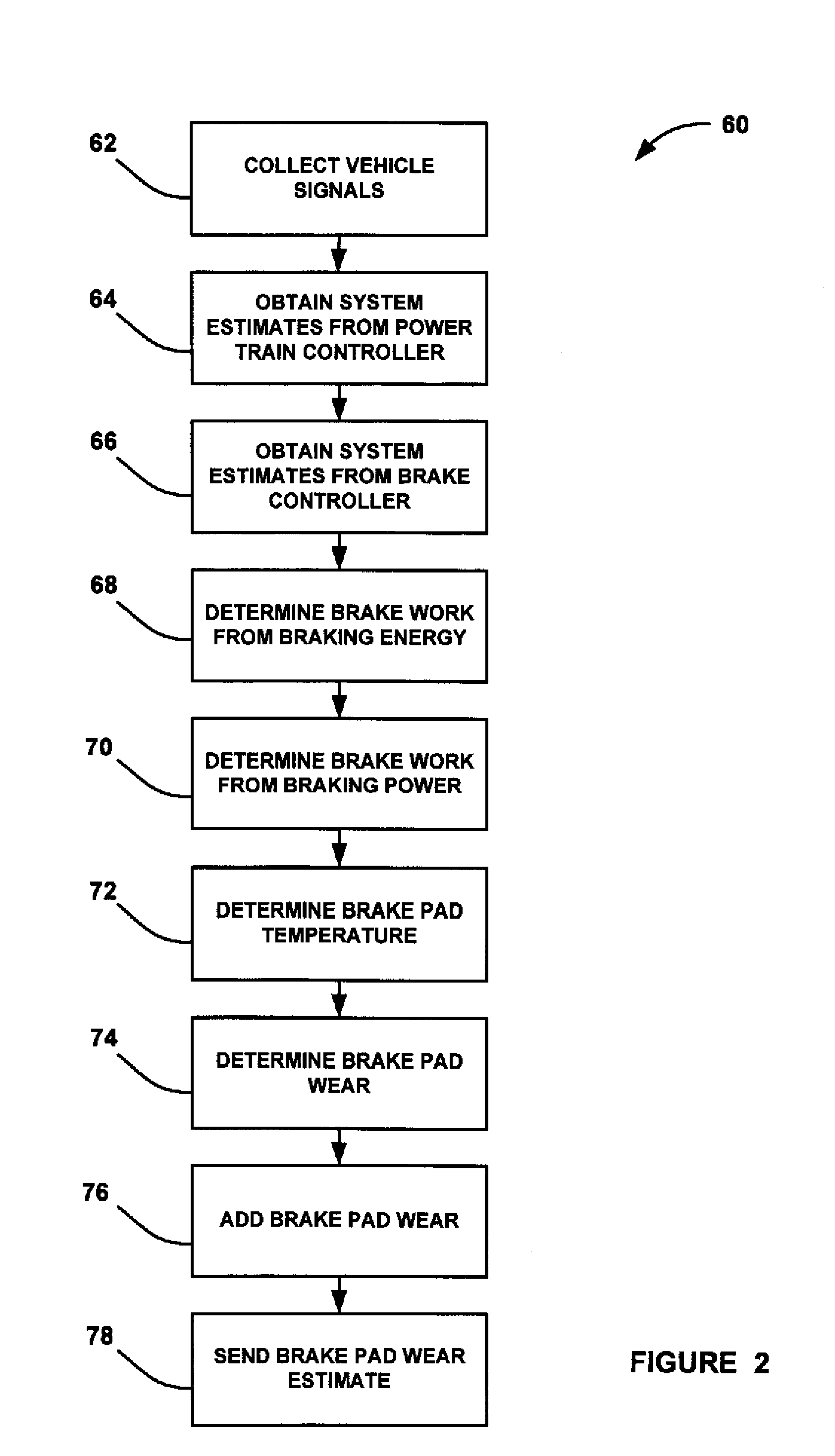

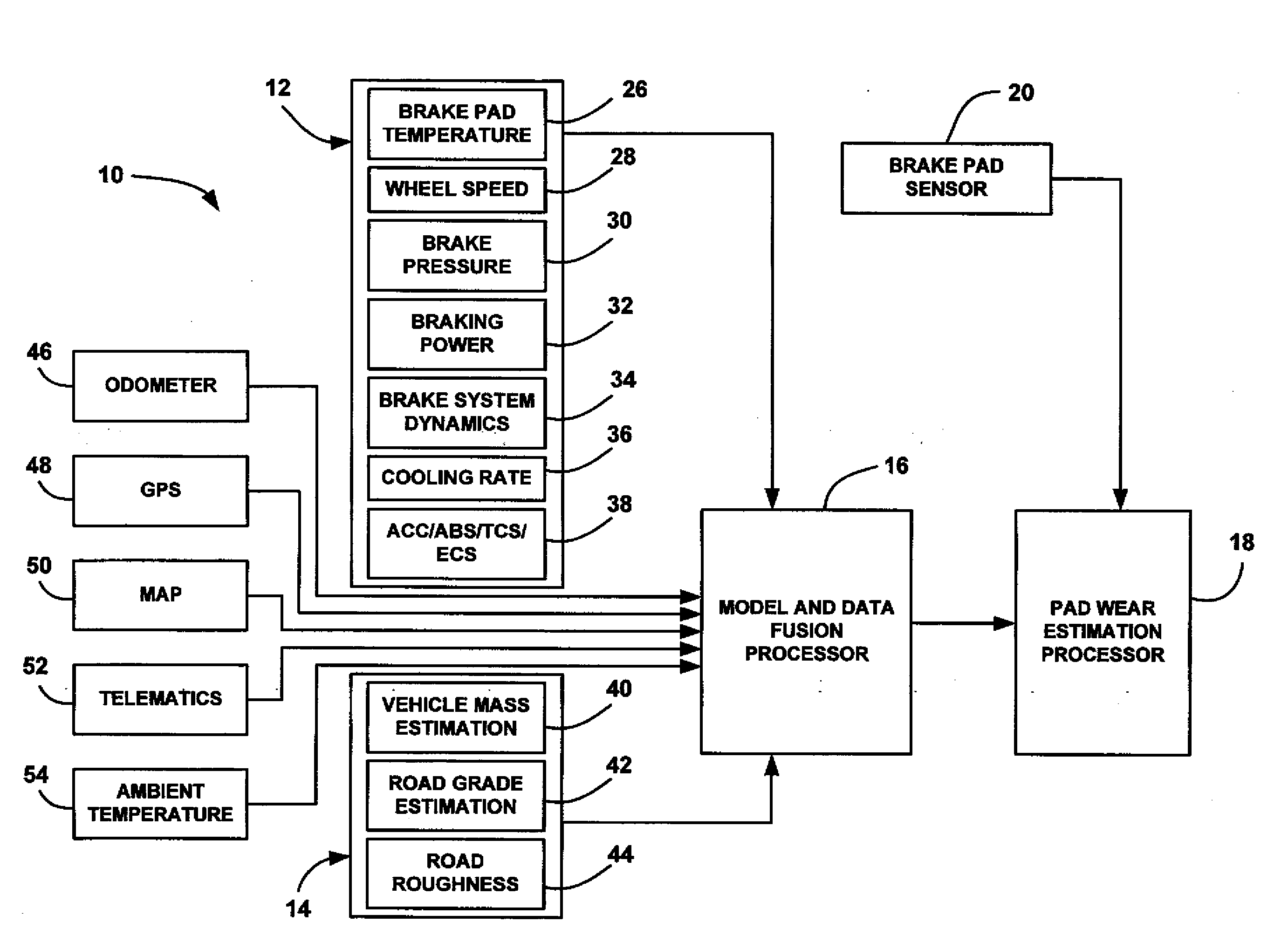

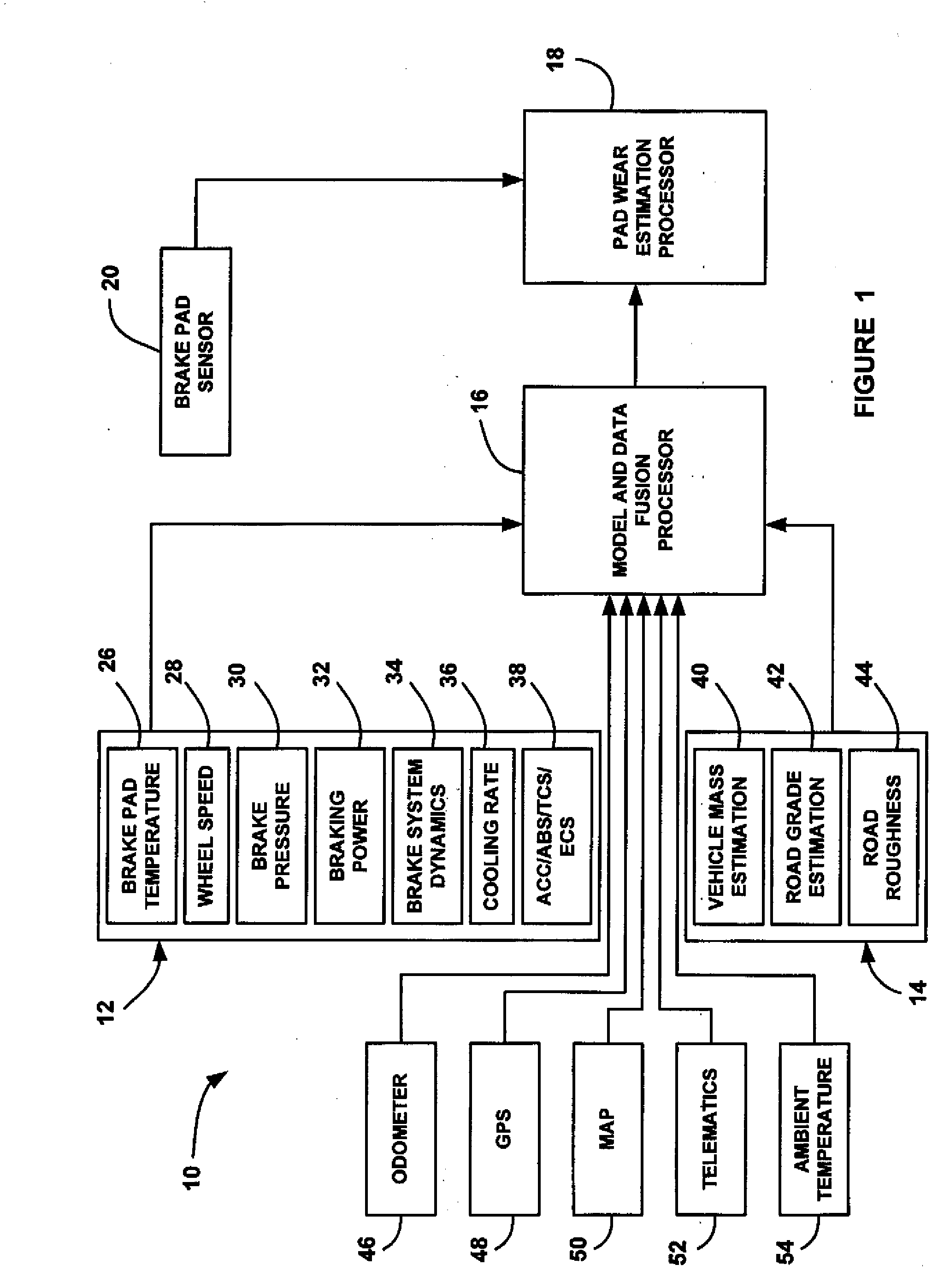

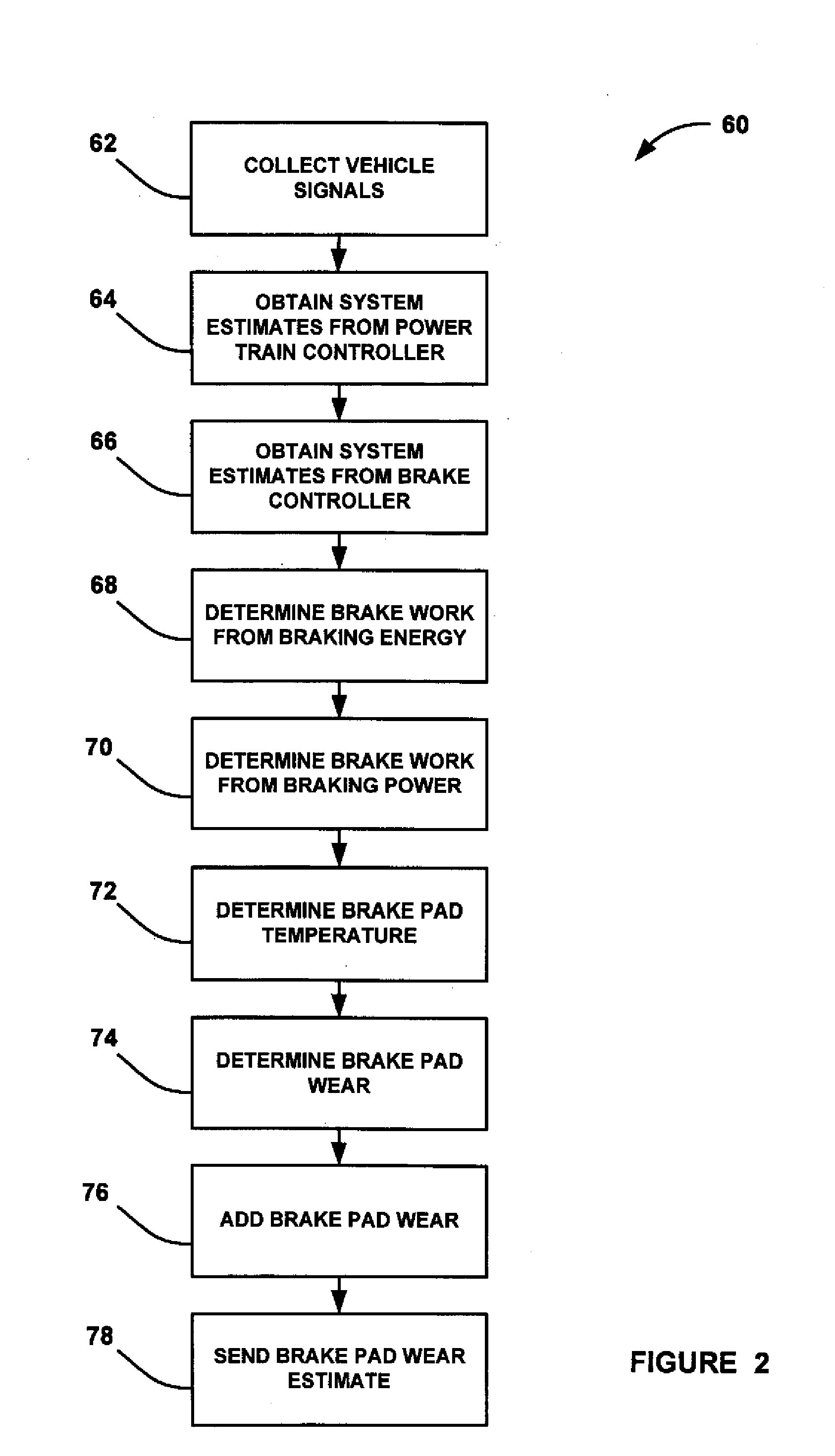

Brake pad prognosis system

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

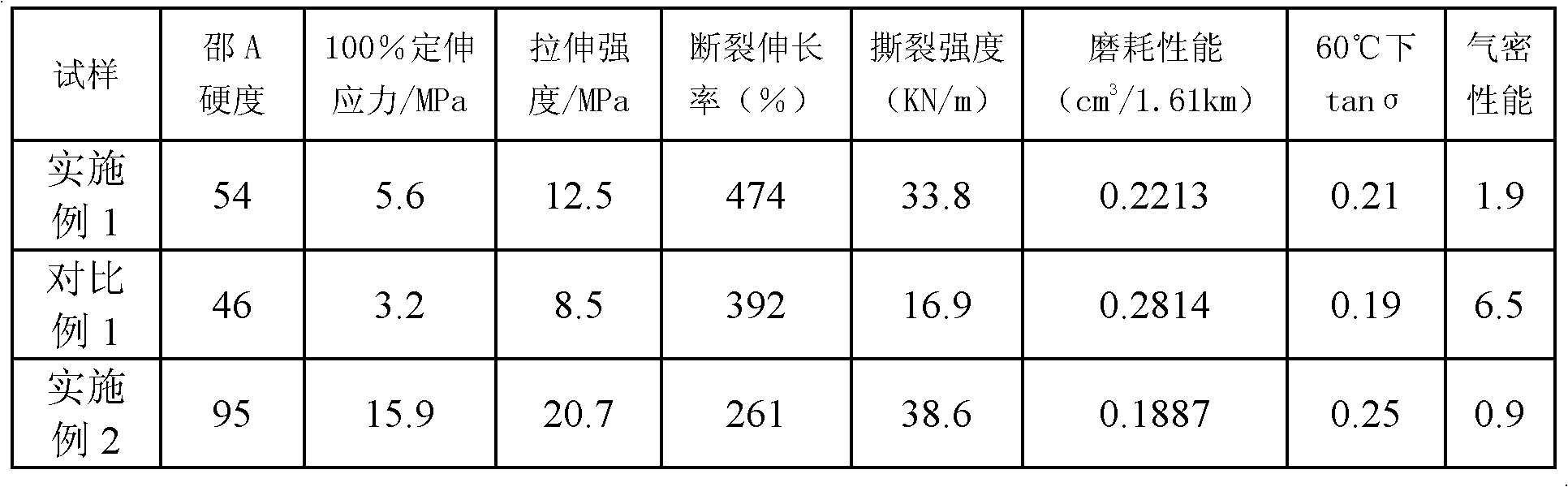

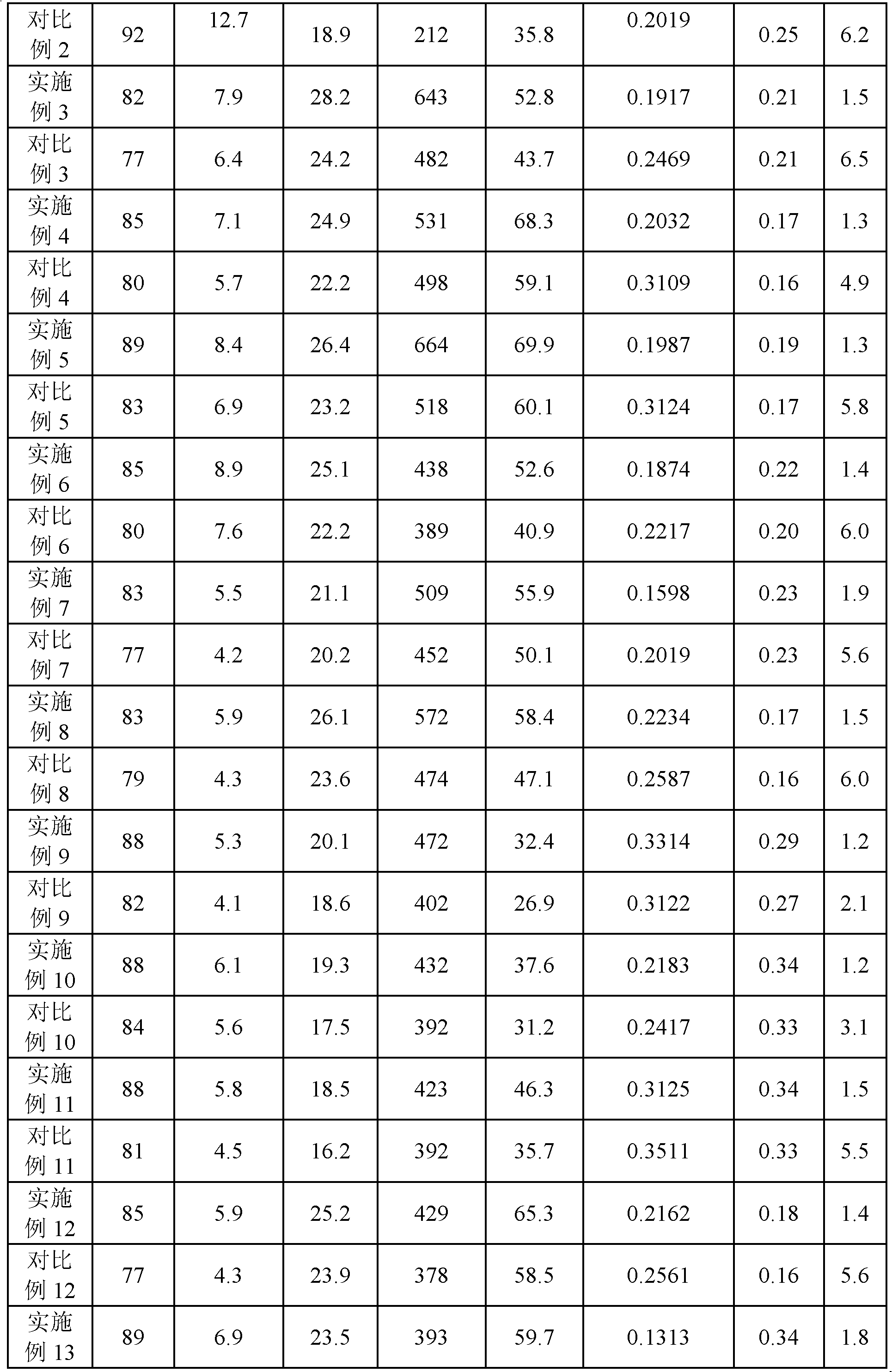

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

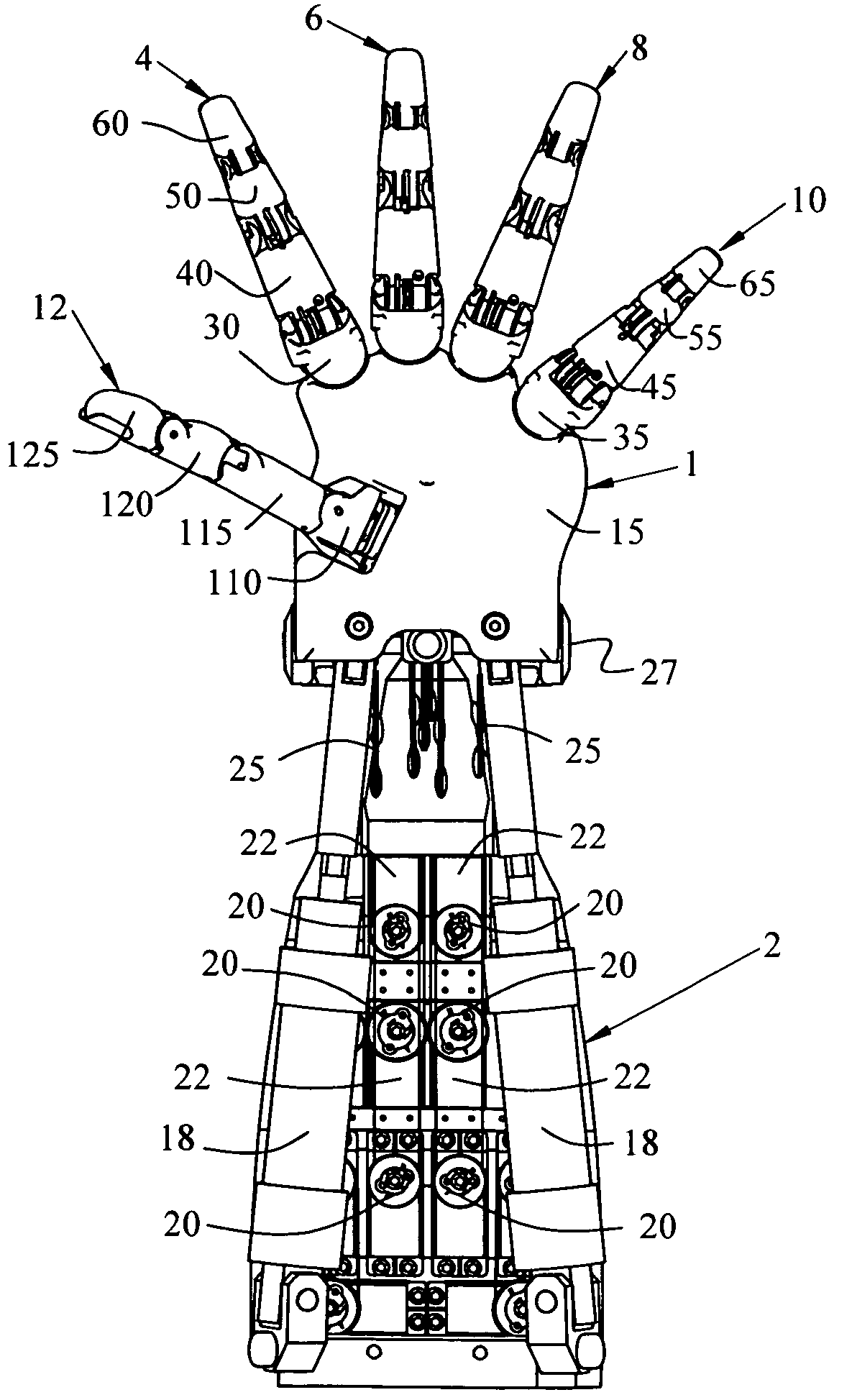

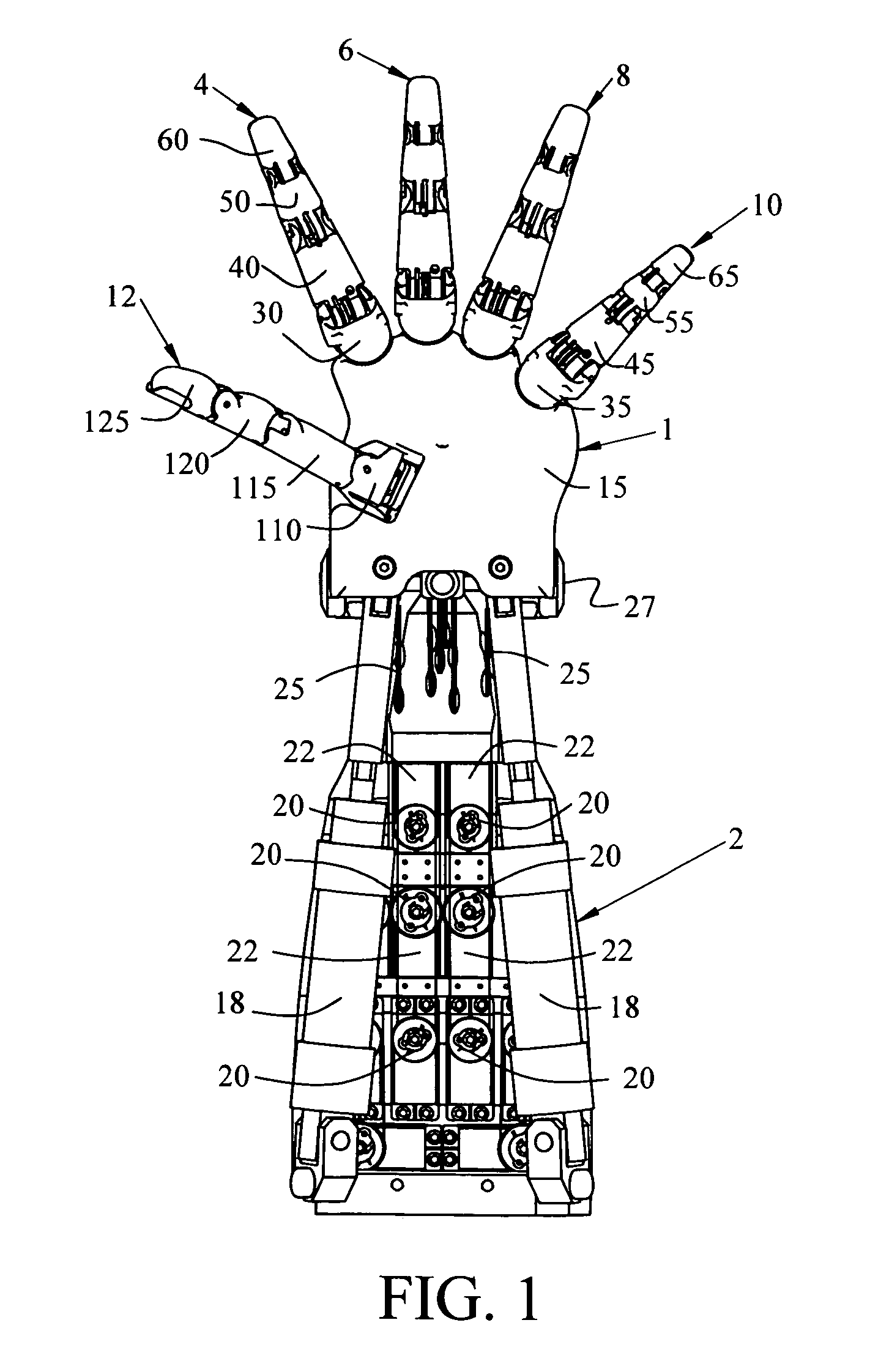

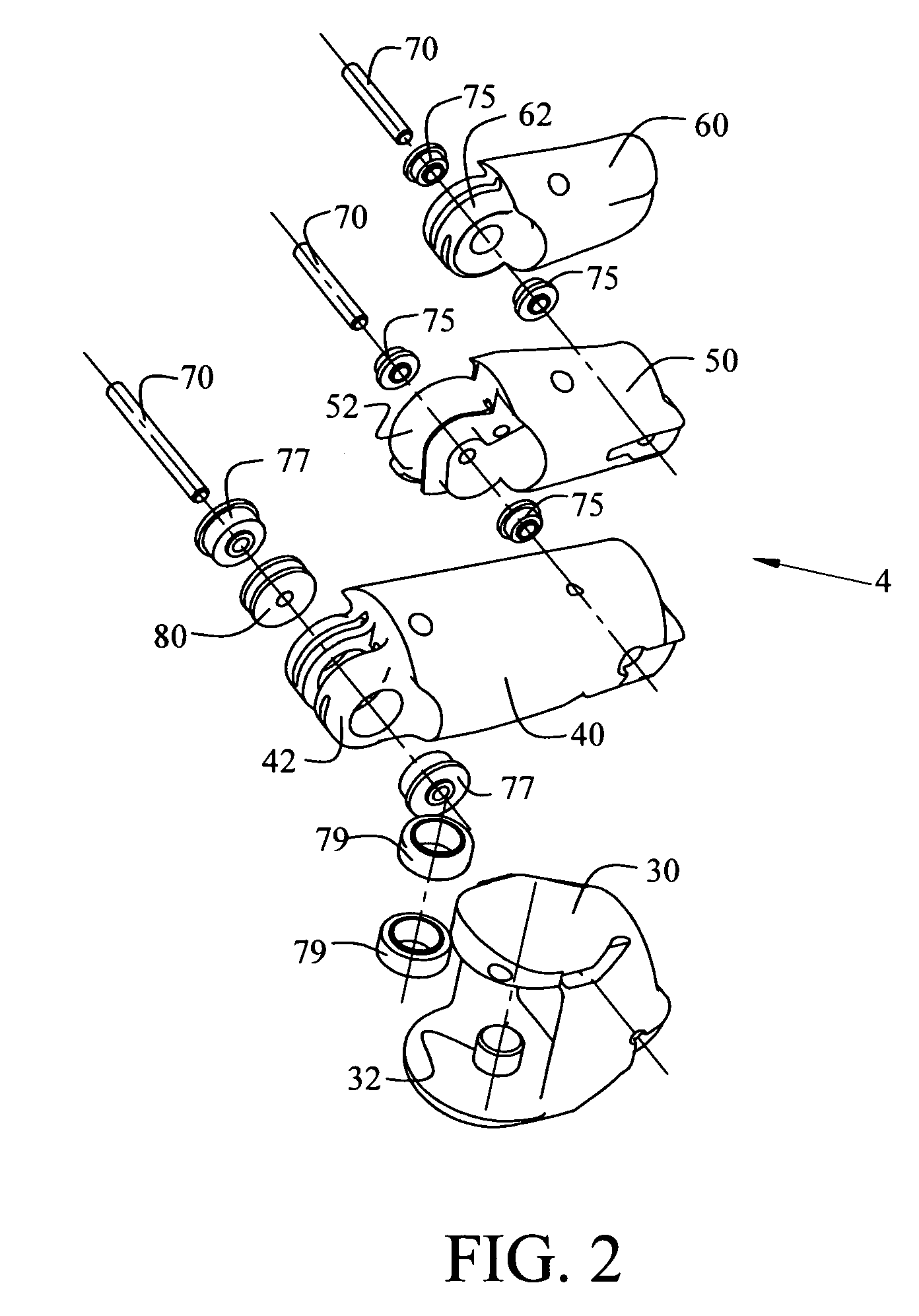

Robotic hand and arm apparatus

ActiveUS7296835B2Low costEasy to assembleProgramme-controlled manipulatorGripping headsRolling resistanceRobotic arm

A robotic hand and arm where the fingers are driven by rotational motors with drums, and pulled with cables using rolling friction. The hand extends into a robotic arm through a wrist wherein the wrist is controlled by pneumatic cylinders. Each finger preferably is provided with four manufactured parts and a single pulley. The thumb is provided with three pulleys for independent distal movement. Cables wraps around or over pulleys, eliminating tight bends. A glove is provided about the robotic hand which provides a compressive, liquid resistant membrane.

Owner:ANYBOTS 2 0

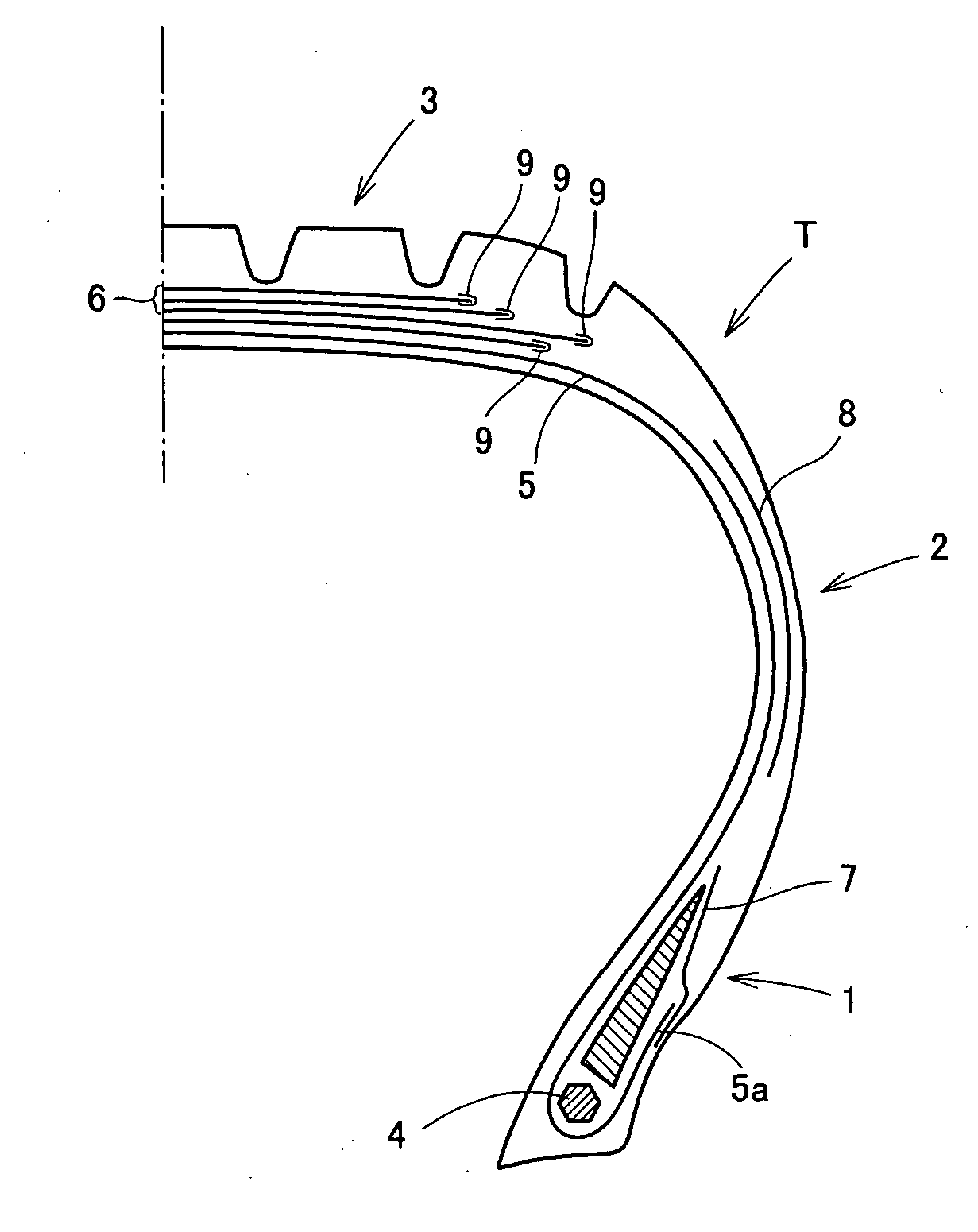

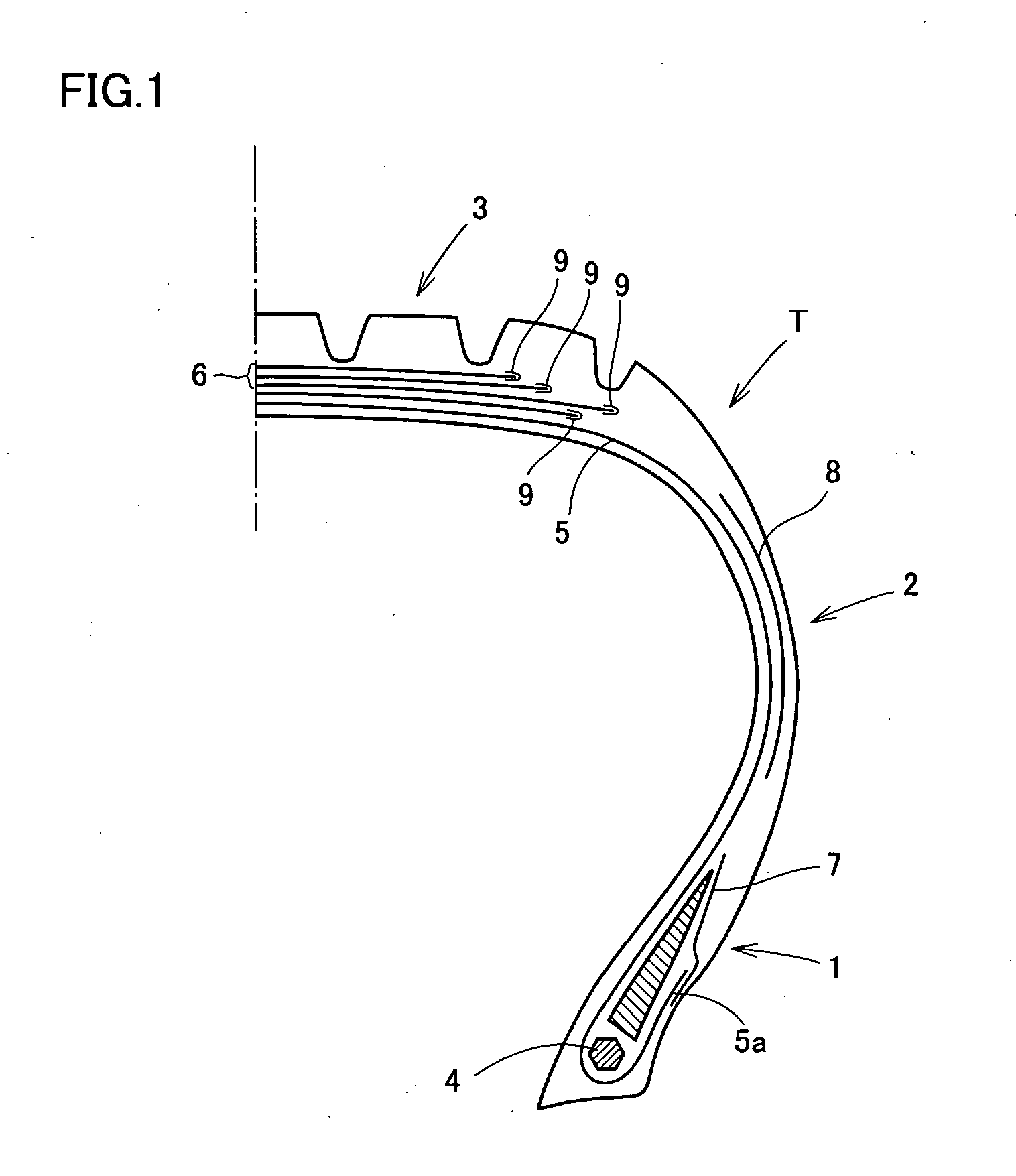

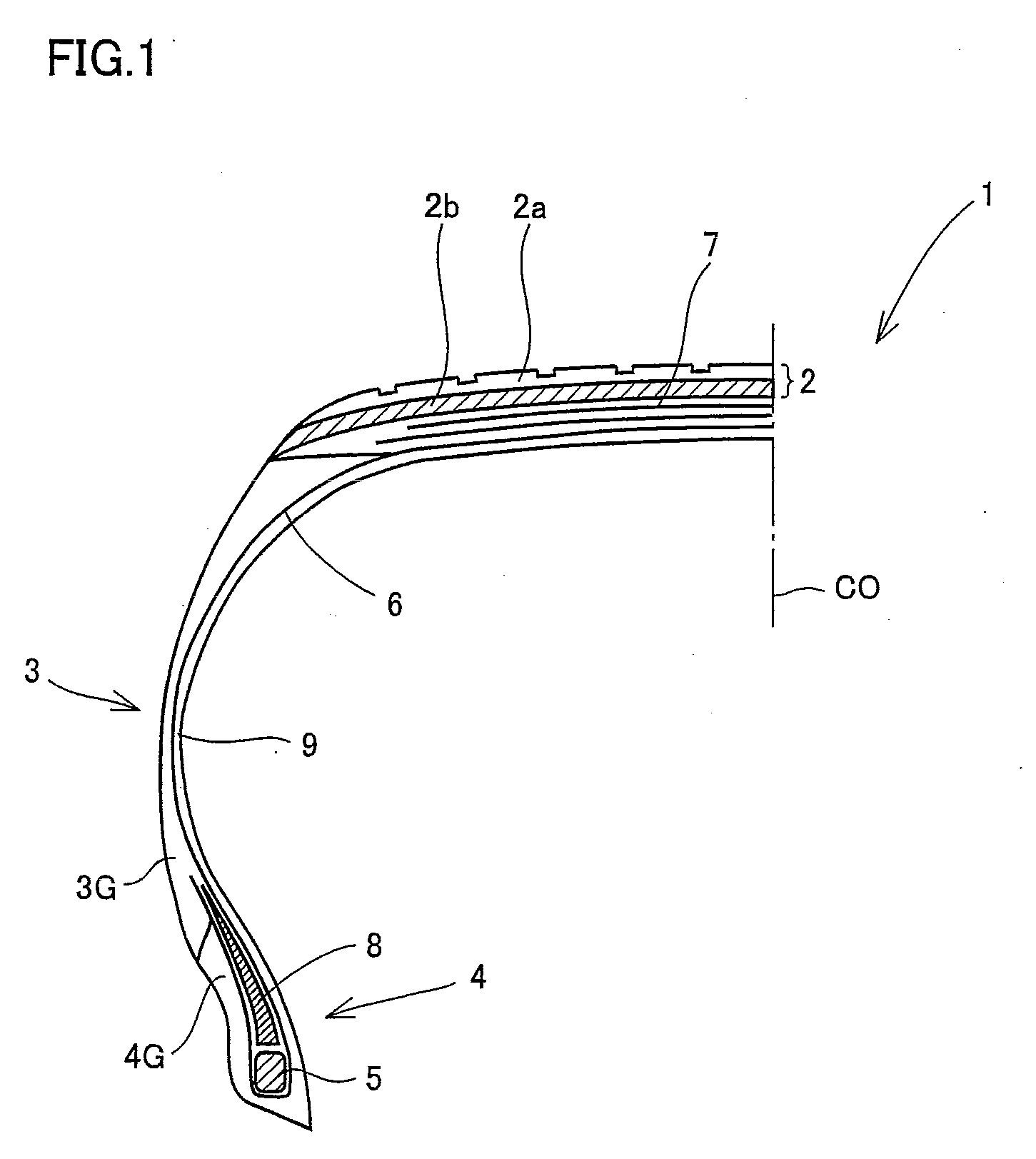

Pneumatic tire and method of producing the same

InactiveUS20060102269A1Increased durabilityReduce rolling resistanceSpecial tyresPneumatic tyre reinforcementsRolling resistanceCobalt salt

There is provided a pneumatic tire capable of achieving both reduced rolling resistance and enhanced durability and a method of producing the same. The pneumatic tire includes a reinforcement layer, formed of a steel cord coated with coating rubber, including at least one of a carcass, a bead reinforcement layer, a side reinforcement layer and a belt, with said coating rubber formed of a rubber compound containing 100 parts by mass of diene rubber, 30 to 80 parts by mass of silica having a nitrogen surface area of at least 70 m2 / g and at most 150 m2 / g, 1 to 15 parts by mass of a silane coupling agent, and organic acid cobalt salt. Preferably the steel cord has a cut edge of a breaker coated with an edge strip of rubber.

Owner:SUMITOMO RUBBER IND LTD

Silane-modified white carbon black-carbon black composite filling and preparation method thereof

ActiveCN101798473AImprove glue burn resistanceGood processing characteristicsPigment treatment with organosilicon compoundsRolling resistanceGas phase

The invention discloses a silane-modified white carbon black-carbon black composite filling and a preparation method thereof. The method is characterized in comprising the following steps of: (1) adding white carbon black which is prepared by means of precipitation and white carbon black which is prepared by means of gas phase into a high-speed mixer according to the weight ratio of 3:1-3:2, slowly and evenly adding silane polysulfide in a spraying way, and gradually heating up at 100-120 DEG C to promote the surface modification reaction to be thoroughly performed; and (2) adding carbon black and mixing for 60-180min according to the weight ratio of the carbon black to the white carbon black which is prepared by means of gas phase and the white carbon black which is prepared by means of precipitation of 1:5-1:10 under the condition of continuous stirring and temperature persevering, and cooling by means of temperature reducing to obtain the silane-modified white carbon black-carbon black composite filling. The silane-modified white carbon black-carbon black composite filling which is prepared by the method improves the dispersibility of the white carbon black which is prepared by means of gas phase in rubber, reduces the charging time of a production field, obviously improves the operation environment, is used for the prescription of a tread rubber of a tire, can obviously reduce the rolling resistance of the tire, and saves the gasoline.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

Rubber composition based on carbon black having silica fixed to its surface and on diene polymer functionalized or modified with silanol functions

A rubber composition of improved hysteretic and physical properties which make it suitable for forming a tire tread, notably a tire tread of reduced rolling resistance, the rubber composition including carbon black having silica fixed to its surface as the majority portion of reinforcing filler and at least one functionalized diene polymer having at the end of its chain a silanol function or a polysiloxane block including a silanol end or a diene polymer modified along its chain by silanol functions.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

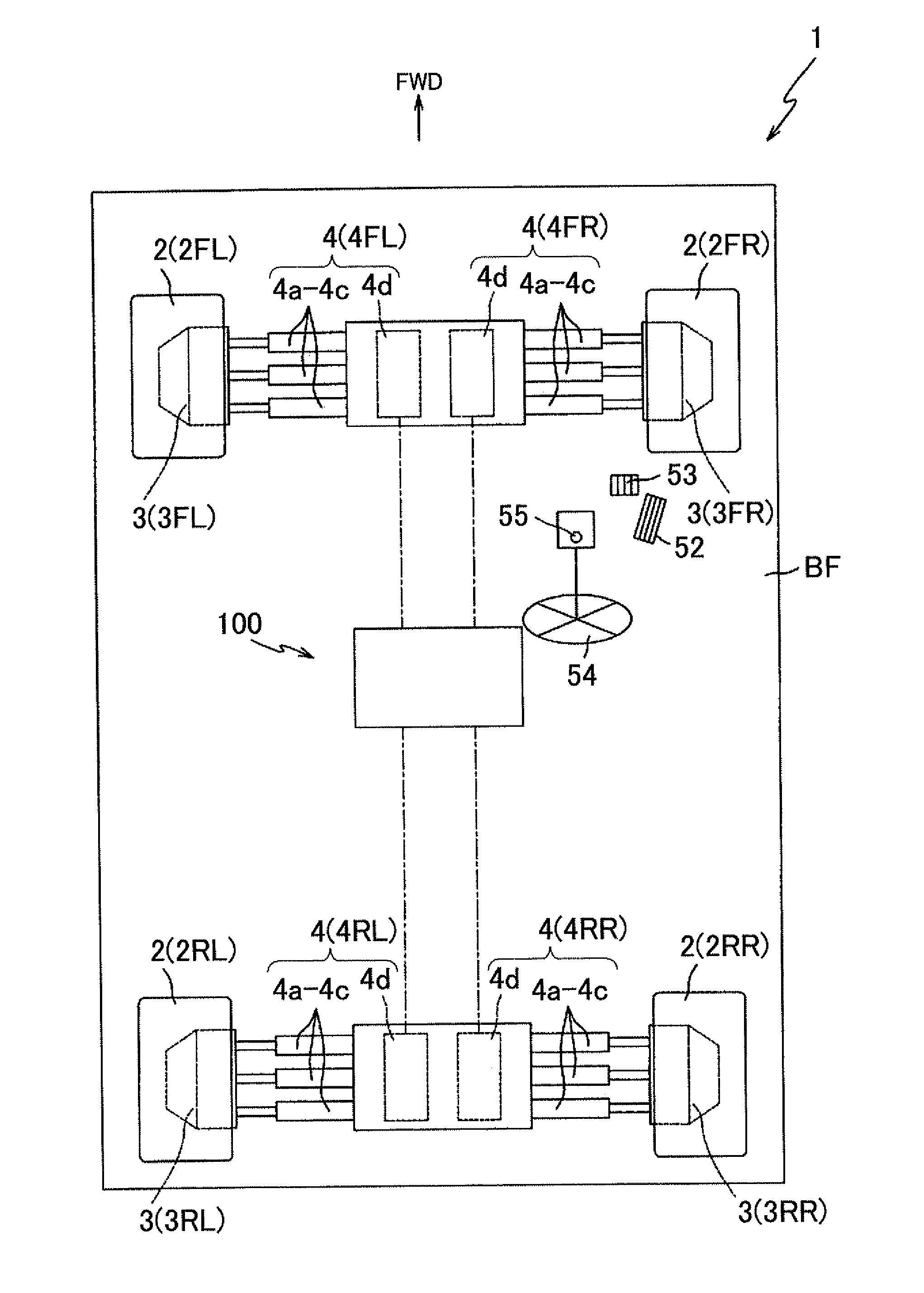

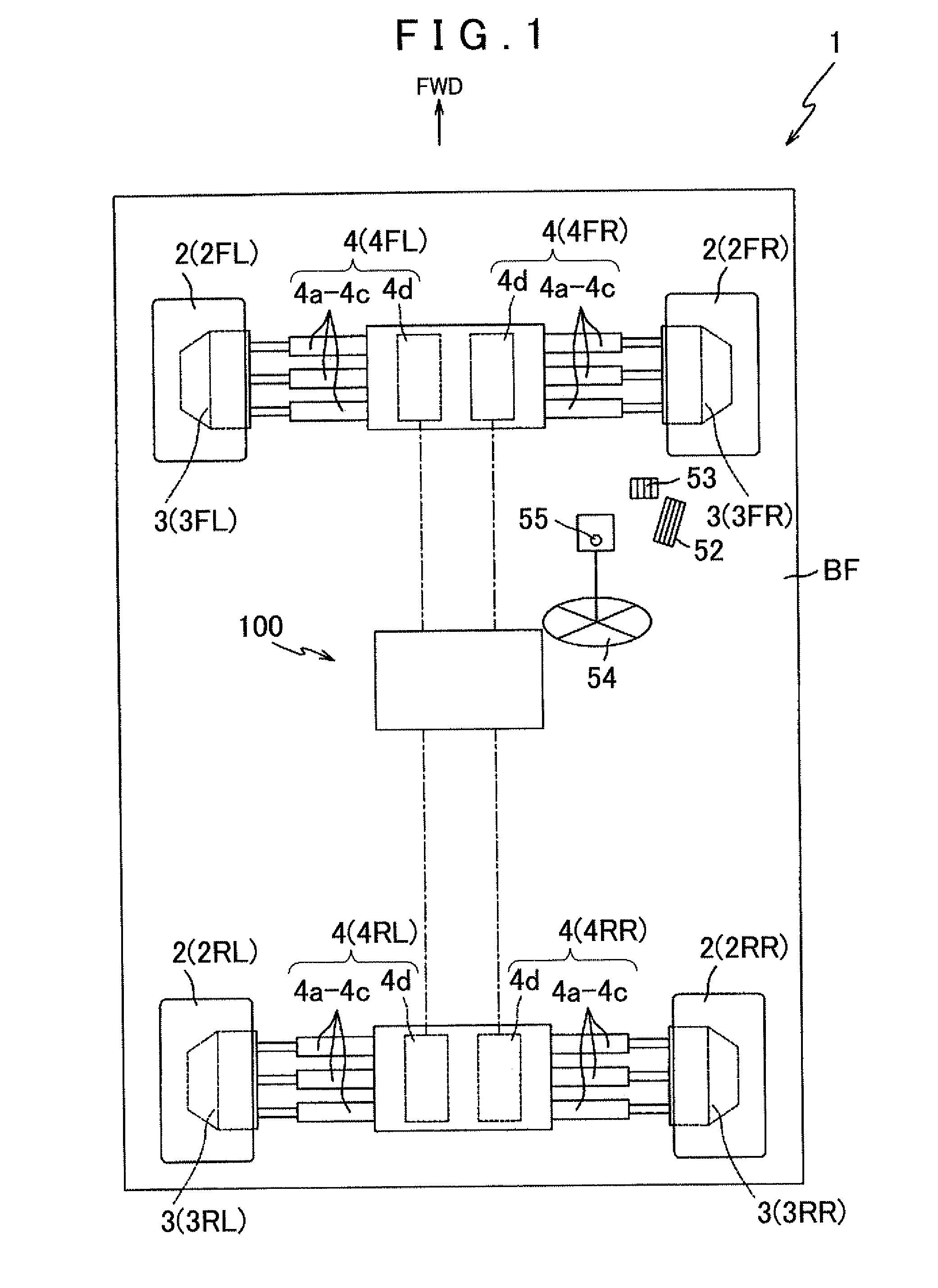

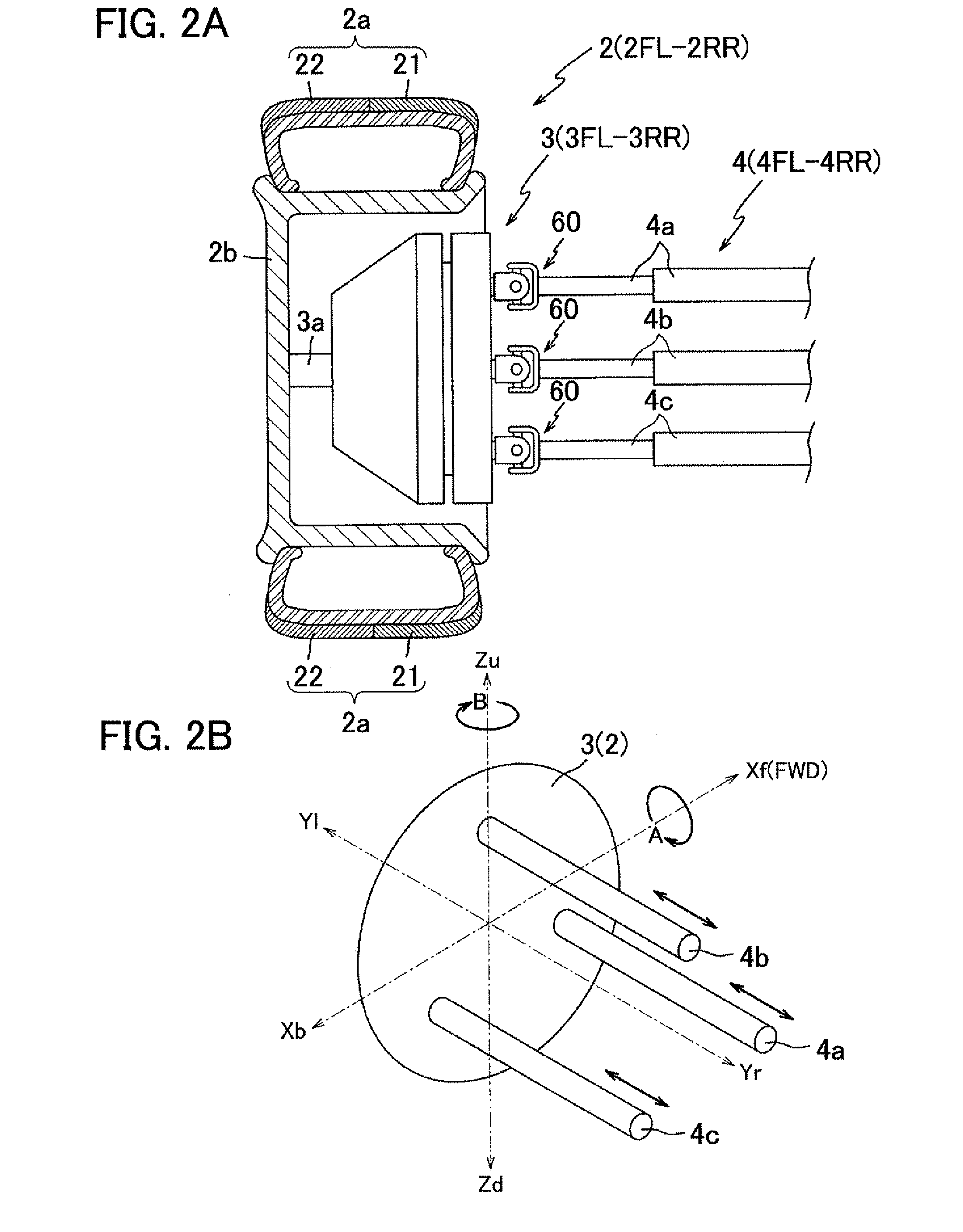

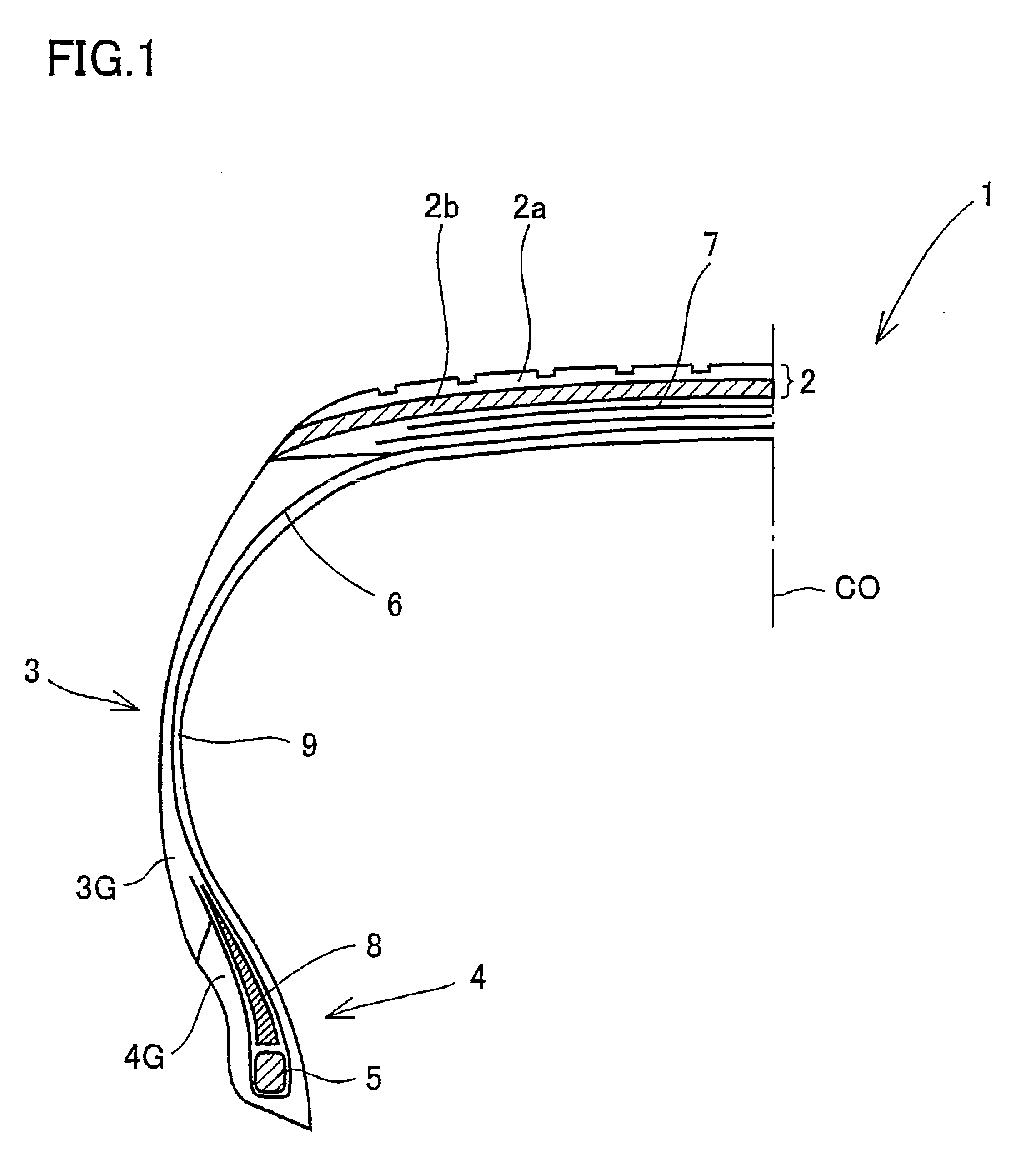

Camber angle controlling device

InactiveUS20100217491A1Improve gripIncrease clamping forceDigital data processing detailsSpecial tyresRolling resistanceCamber angle

A camber angle applying device is controlled to adjust the camber angle of wheels to a predetermined value. Therefore, the characteristics (or a high gripping property) of a high gripping force and the characteristic (or a low rolling resistance) of a small rolling resistance can be separately used as the performance of the wheels. By utilizing the high gripping property of the wheels, therefore, a vehicle is enabled to reduce its energy consumption, while retaining its running characteristics (such as a turning performance, an accelerating performance or a braking performance), by utilizing the rolling resistance of the wheels. Moreover, the camber angle applying device is controlled to reduce the rolling resistance of the wheels, so that the energy loss to occur in the wheels during running can be reduced to further reduce the energy consumption of the vehicle.

Owner:EQUOS RES

Vulcanized rubber composition, pneumatic tire and the process of producing the same

InactiveUS8022136B2Improve featuresReduce energy lossSpecial tyresPneumatic tyre reinforcementsPolymer scienceRolling resistance

By using a vulcanized rubber composition containing a rubber component composed of at least any one of a natural rubber, a modified natural rubber and a synthetic rubber, and chemically modified microfibril cellulose, it is possible to provide a vulcanized rubber composition that is environmentally conscious and that exhibits excellent rupture characteristics and a low energy loss, and a pneumatic tire that is excellent in rolling resistance property, steering stability and durability.

Owner:SUMITOMO RUBBER IND LTD +1

Hybrid electric vehicle

InactiveUS7854282B2Highly energy efficient operationIncrease demandDigital data processing detailsPlural diverse prime-mover propulsion mountingAerodynamic dragRolling resistance

Owner:INT HUMANITIES CENT

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

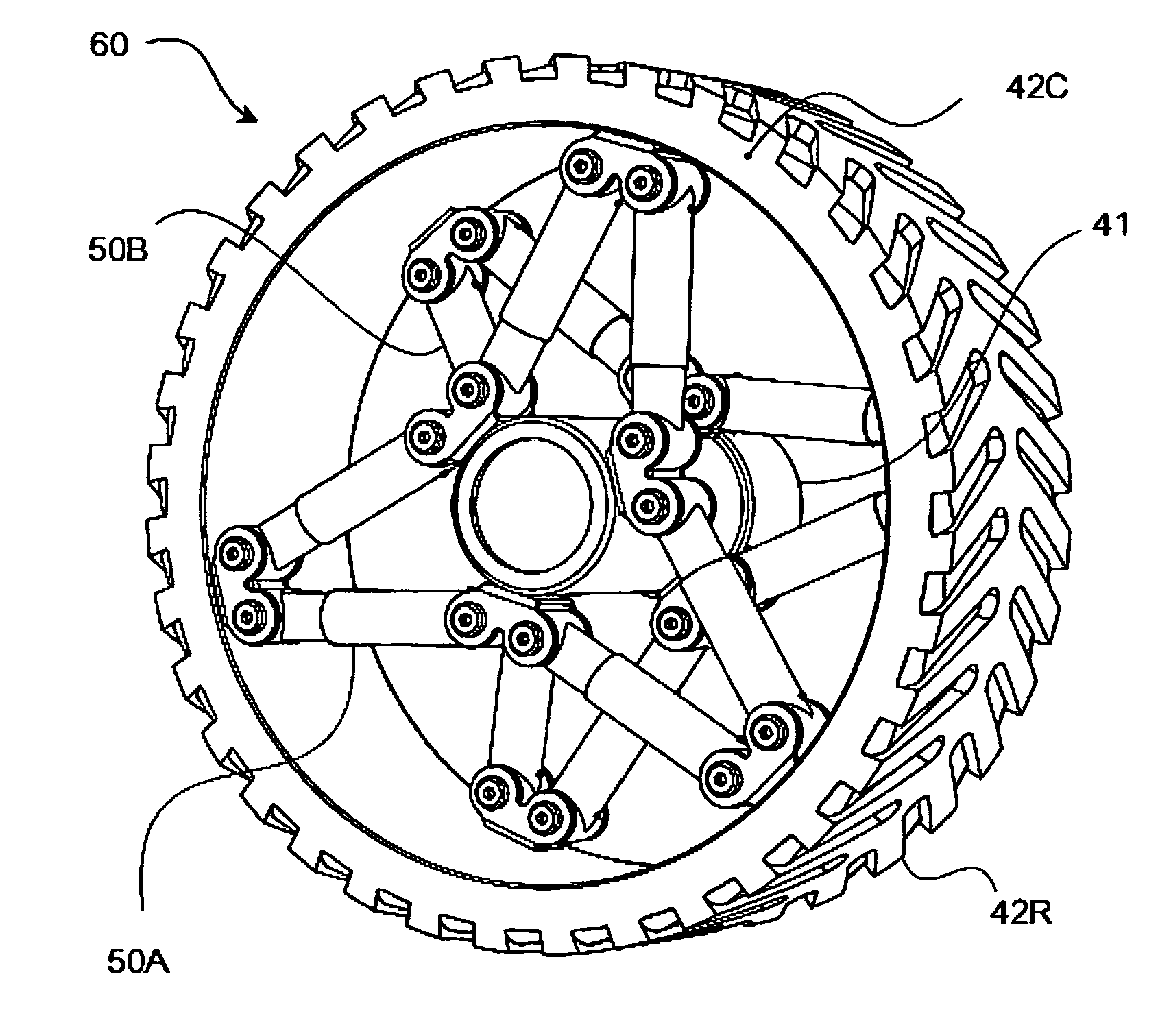

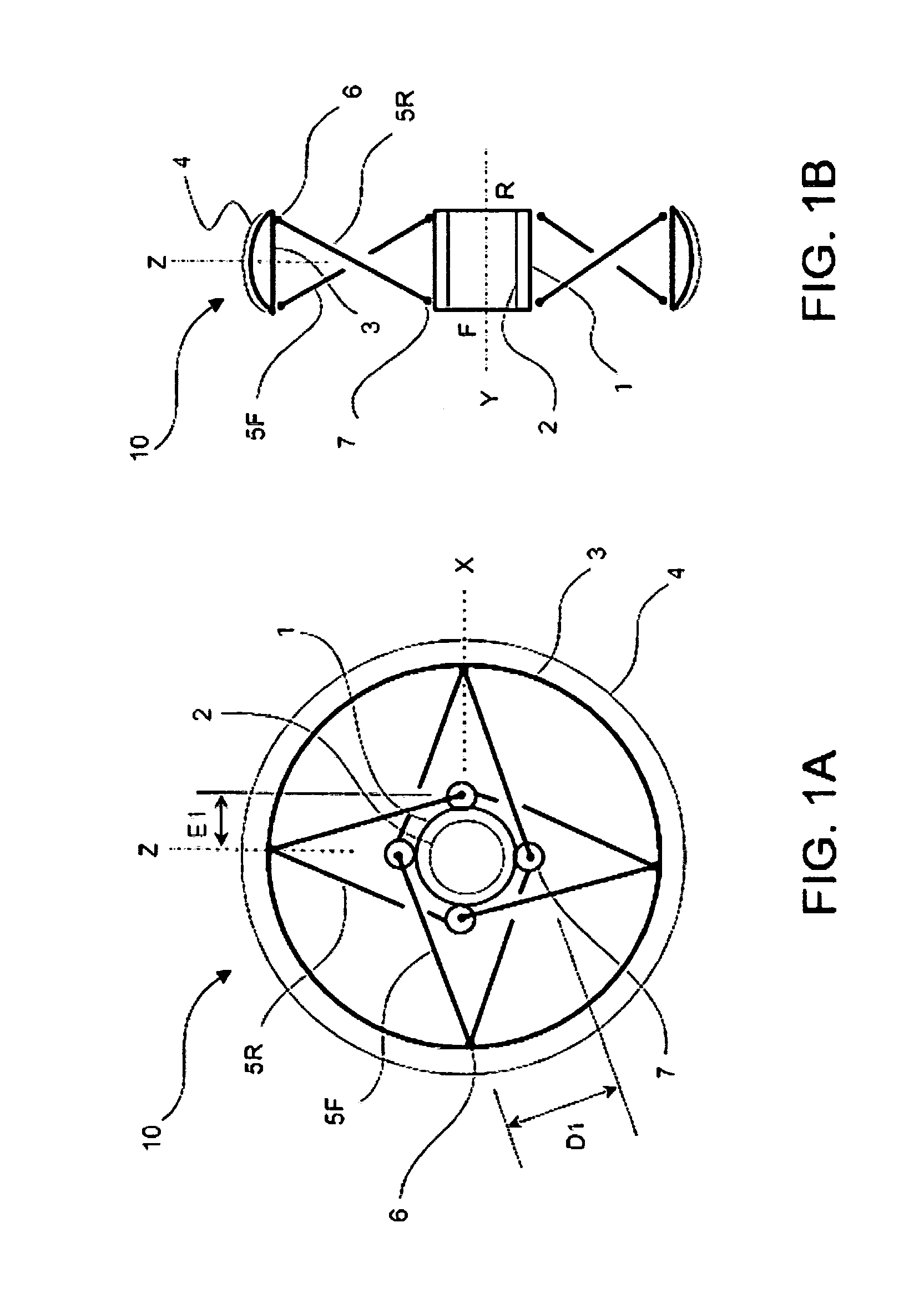

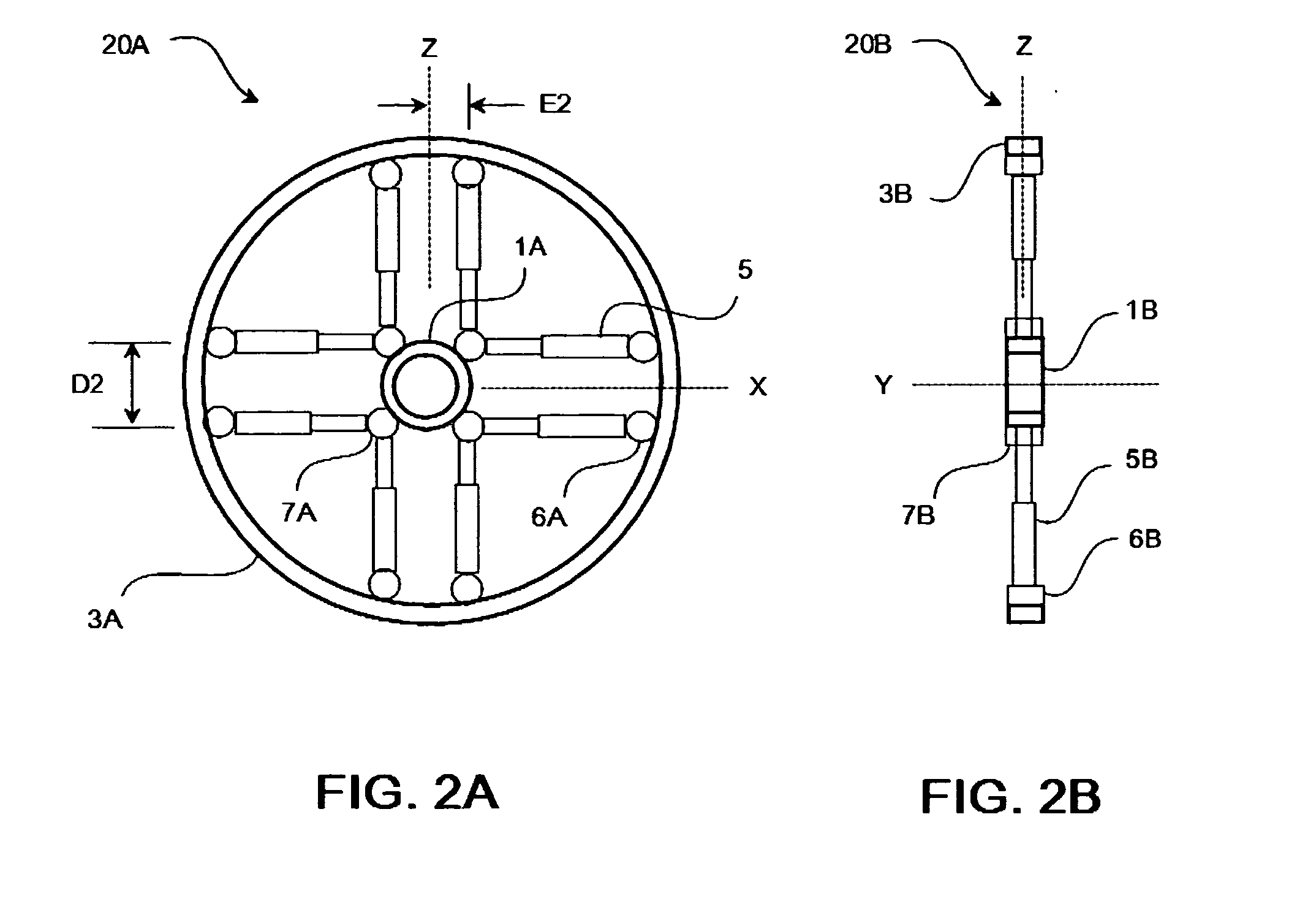

Shweel

InactiveUS20130340902A1Quiet and comfortable rideReduce rolling resistanceHigh resiliency wheelsMetalworkingRolling resistance

Shock-absorbers used as wheel-spokes between wheel-hub and rigid rim, which may be lined with threaded rubber or having gripping features otherwise. It reduces rolling resistance, saving fuel. It improves drivability. The compliance of the shocks is commensurate with that of a comparable inflated tire, but optimized passively or actively circumferentially, vertically and laterally. Rubber-bushing or spoke-inclination enhances driving stability. Giant field assembled mining-truck-wheels may be produced and deployed and field-assembled quickly by common metalworking shops at fractional cost and weight. It is environmentally friendly, for hardly using or not using rubber. The gas or liquid of the shock spokes may be interconnected and cooled. Soft and hard driving may be controlled manually or by computer on the fly. It is suitable for applications ranging from bicycle wheels to aircraft landing gears. It is fireproof, bulletproof, airless and silent. It cannot bounce or skid at jumpstart or braking and on ice.

Owner:KEMENY ZOLTAN A

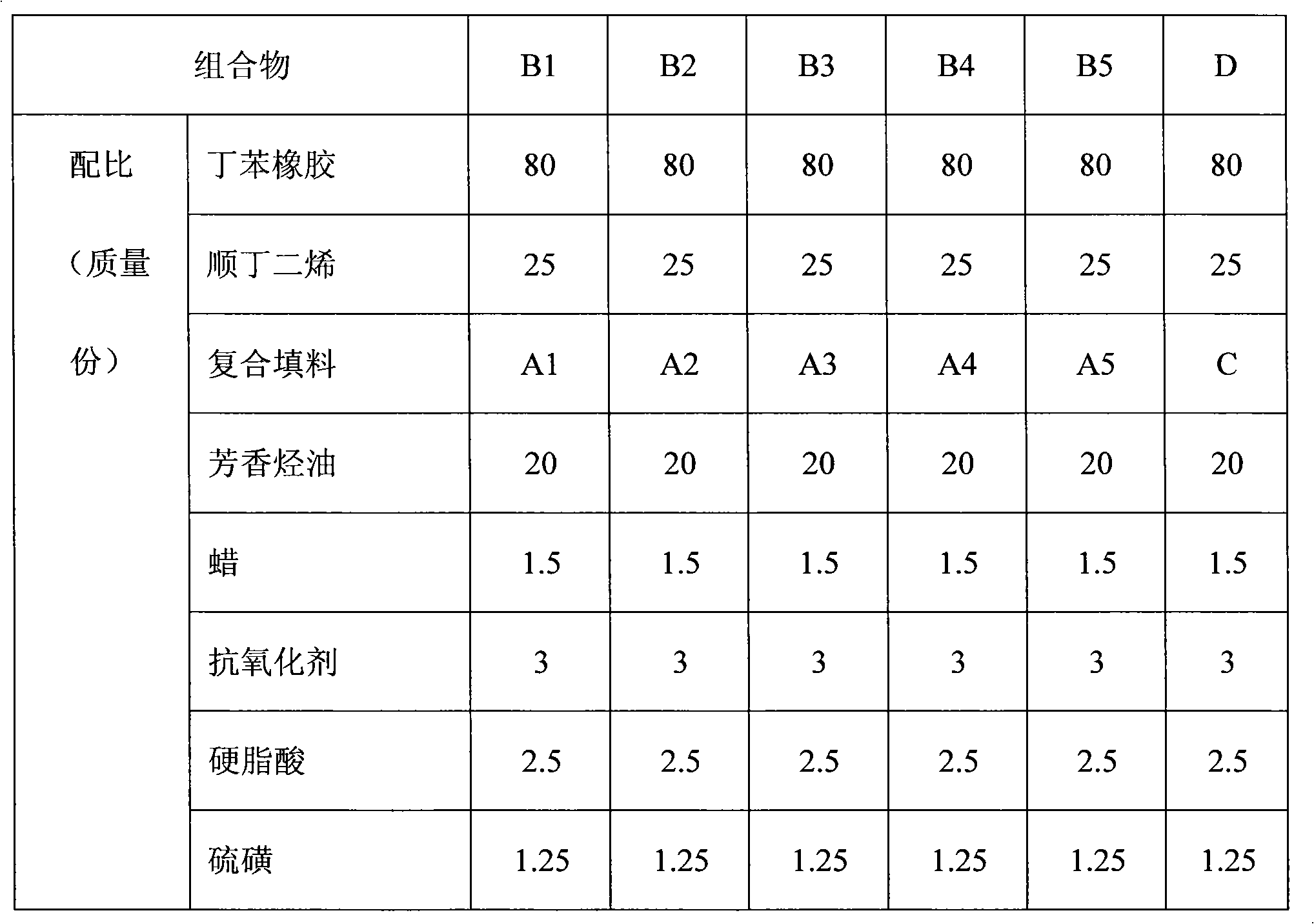

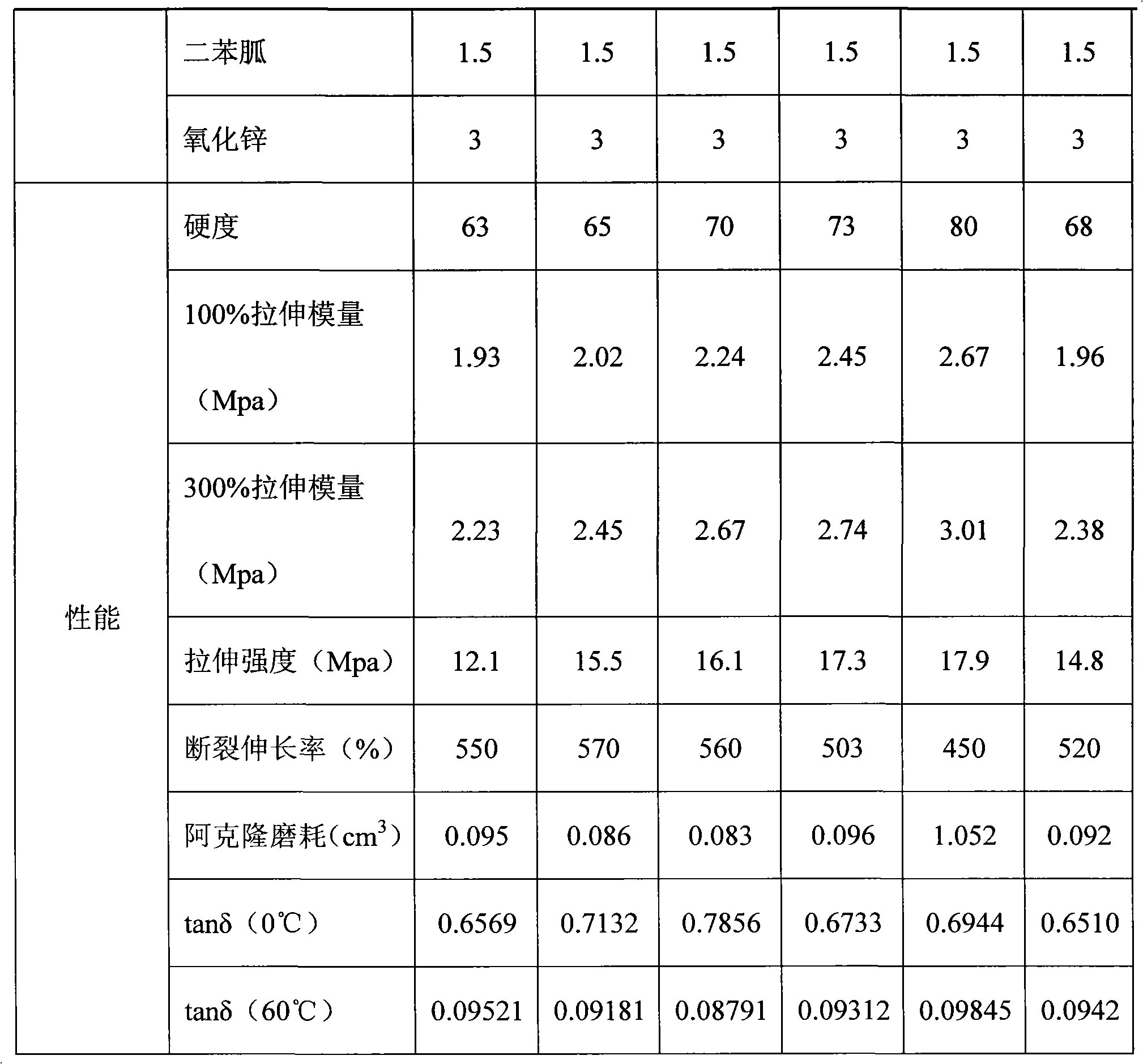

Preparation method of white carbon black modified styrene-butadiene rubber facing green tires and product thereof

ActiveCN102558627AEvenly dispersedImprove mechanical propertiesSpecial tyresRolling resistance optimizationFlocculationHydrogen

The invention provides a preparation method of white carbon black modified styrene-butadiene rubber facing green tires and a product thereof. White carbon black is used in the technical field of styrene-butadiene rubber modification, so as to provide guidance to the application of the white carbon black modified styrene-butadiene rubber in the tire industry. The styrene-butadiene rubber is characterized in that the styrene-butadiene rubber contains white carbon black of which the weight percentage to dry styrene-butadiene rubber latex is 30 percent to 100 percent. The preparation method comprises the steps that firstly, the white carbon black is mixed with water to obtain a white carbon black-water suspension; afterwards, the white carbon black-water suspension is subject to surface treatment, so as to enable the surface of the white carbon black to be organized; the pH (potential of hydrogen) value of the suspension is adjusted to be 9 to 12; and finally, the suspension is evenly mixed with the styrene-butadiene rubber latex to obtain liquid styrene-butadiene rubber sizing to which the white carbon black is added, and then the modified styrene-butadiene rubber containing the white carbon black is prepared by adopting an emulsion blending and flocculation process. The white carbon black modified styrene-butadiene rubber prepared by adopting the preparation method has the advantages that the white carbon black is evenly distributed in the styrene-butadiene rubber, and compared with pure styrene-butadiene rubber, the mechanical performance, the wet-skid resistant performanceand the rolling resistance of the white carbon black modified styrene-butadiene rubber are remarkably improved.

Owner:BEIJING UNIV OF CHEM TECH

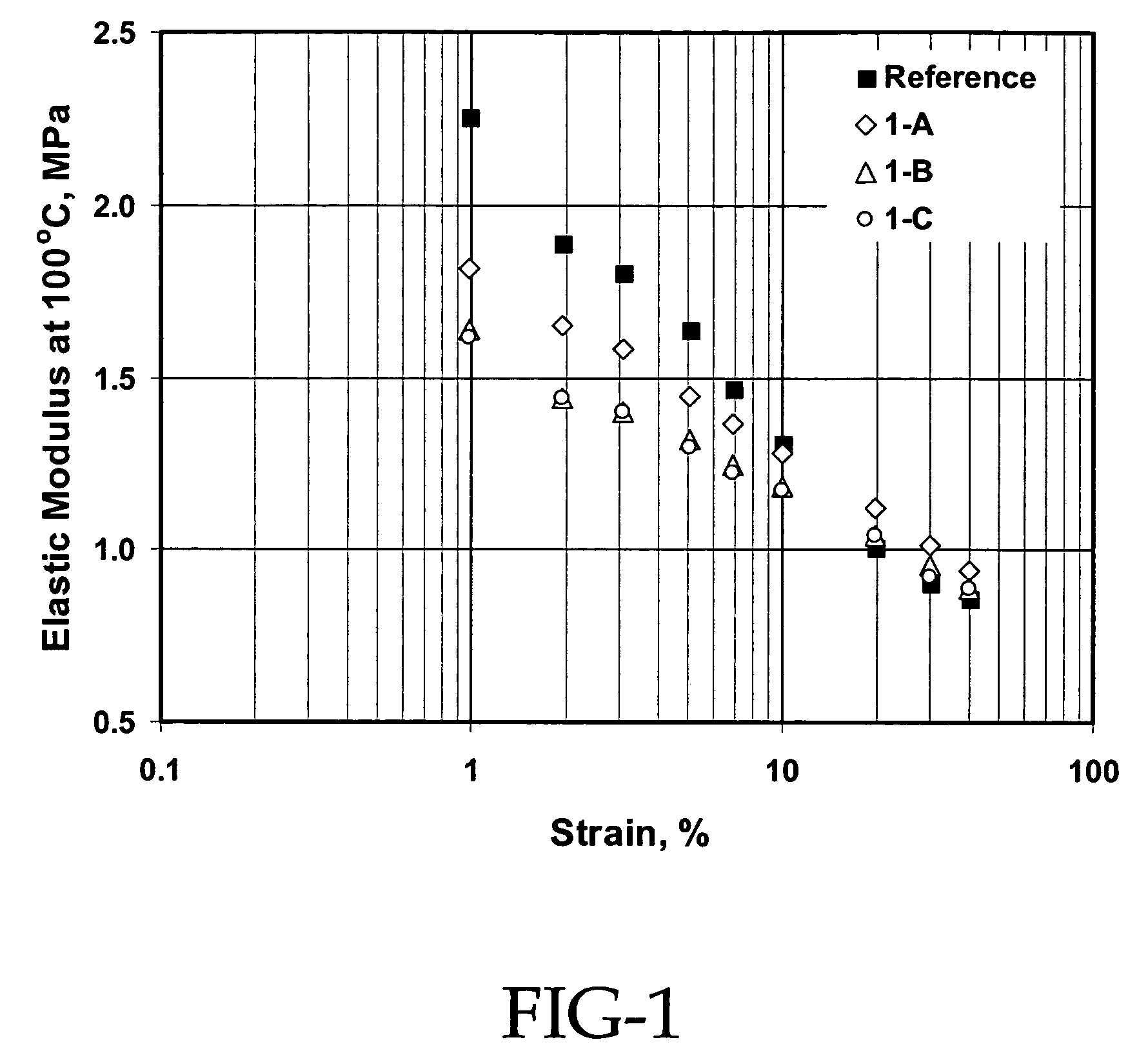

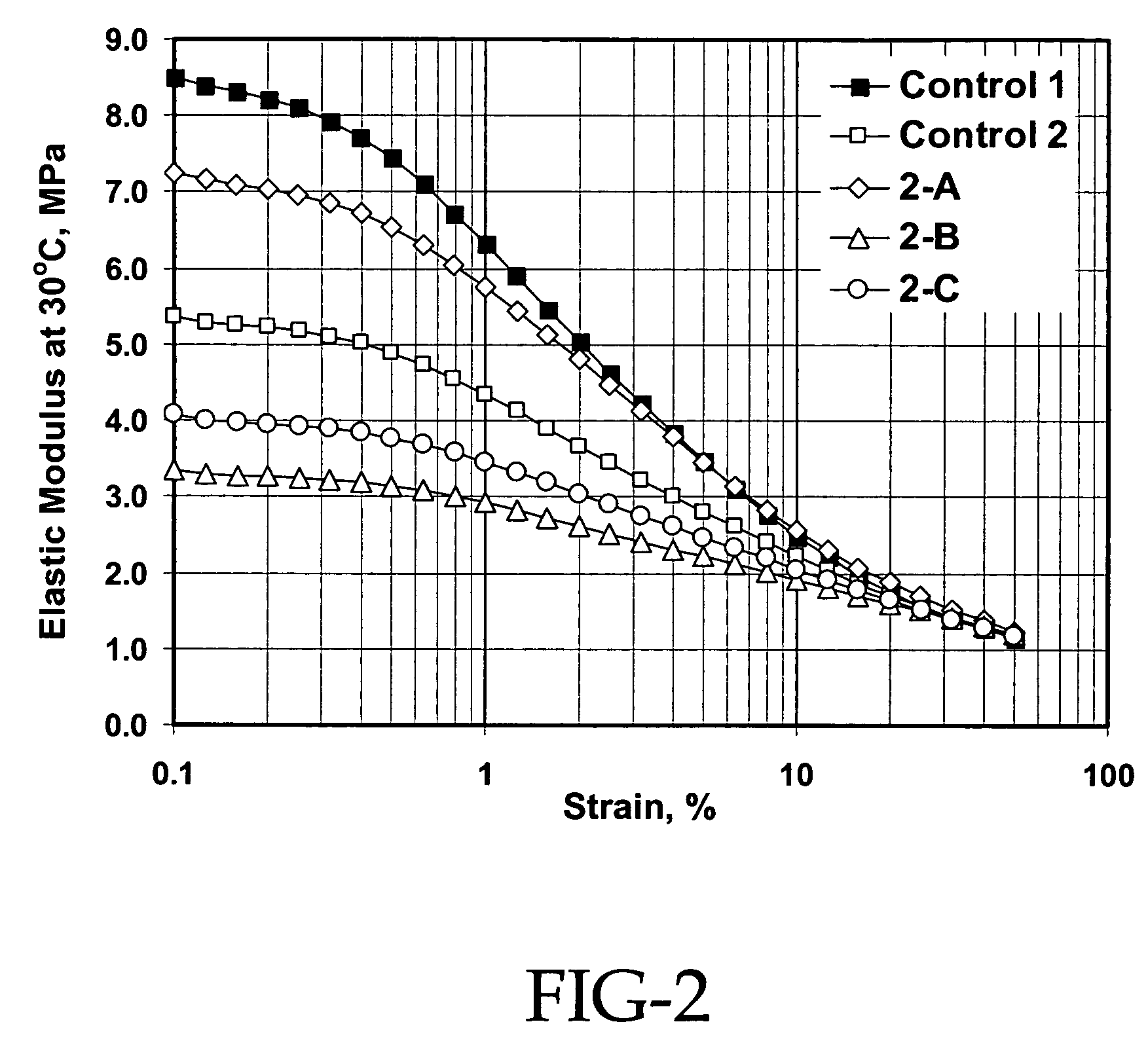

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Brake Pad Prognosis System

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

F rail vehicle running mechanism

InactiveCN101062662AGuaranteed SuspensionStable deliveryElectric propulsionHydraulic cylinderRolling resistance

The F track running structure has its suspension running frame made of two parallel vertical beam and anti side rolling module, through four corners installed support arm linked to form the rectangular suspension running frame module, suspension electromagnetic iron connected with support arm at both sides vertically, each has emergency rescue wheel supported by the hydraulic cylinder, sliding platform connected through the steel cable and the support arm with inner side having forcing guide device through the installation base, combining several assembled suspension running frame modules together. It ensures the train follow F track all the time through air spring, side rolling resistance, horizontal block device, forced guide device to realize the movement decoupling. It reduces the vibration from the track and the system itself, applies to all kinds of specified geometrical torque and unsmoothness, greatly reduced in vehicle noise. It has flexible line selection, low in noise, low in cost, applicable for running between stations.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method for preparing graphene oxide/white carbon black/rubber nanocomposite material

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite material is described. The prepared graphene oxide / white carbon black / rubber nanocomposite material contains nanoscale graphene oxide and white carbon black that are highly dispersed. The nanocomposite material has a relatively high modulus, excellent wear resistance and tear resistance, a relatively low rolling resistance, and at the same time has a low air-permeability and excellent self-healing capability.

Owner:BEIJING UNIV OF CHEM TECH

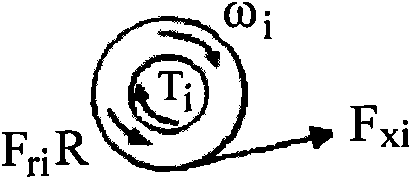

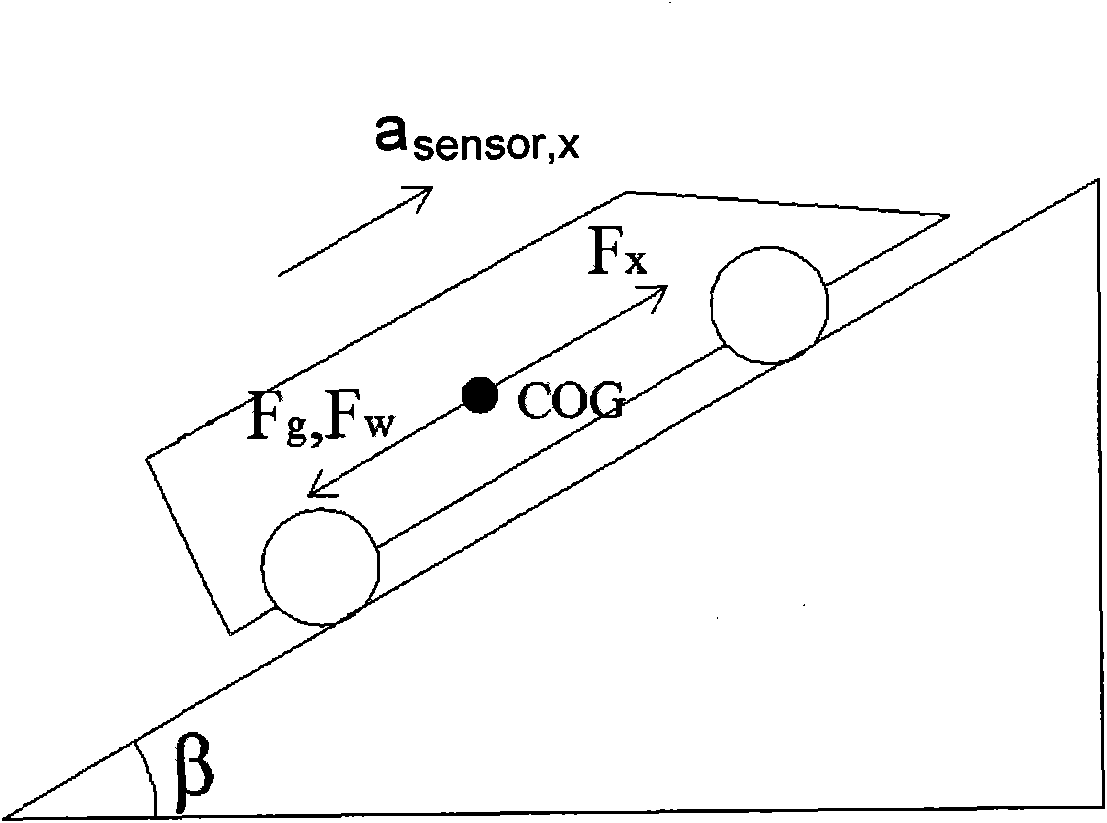

Vehicle mass identification method and device

ActiveCN102486400AEasy to use in real timeAccurate signalSpecial purpose weighing apparatusAerodynamic dragRolling resistance

The invention provides a vehicle mass identification method and a device. The vehicle mass identification method comprises the following steps of: acquiring wheel rotating speed and driving torque of a vehicle during running; acquiring a longitudinal acceleration value of the running vehicle; constructing a longitudinal kinetic equation of the vehicle; and on the basis of the longitudinal kinetic equation, setting a roughly estimated vehicle mass by taking the wheel rotating speed, the driving torque and the longitudinal acceleration value of the running vehicle as measurement input parameters and taking a sum of rolling resistance and air resistance as a variable, and identifying the mass of the vehicle through a recursive least square method with a plurality of forgetting factors.

Owner:ROBERT BOSCH GMBH

Rubber composition for tire tread and pneumatic tire using the same

InactiveUS20050209390A1Excellent abrasion resistanceEasy to processOther chemical processesSpecial tyresRolling resistanceEngineering

Owner:SUMITOMO RUBBER IND LTD

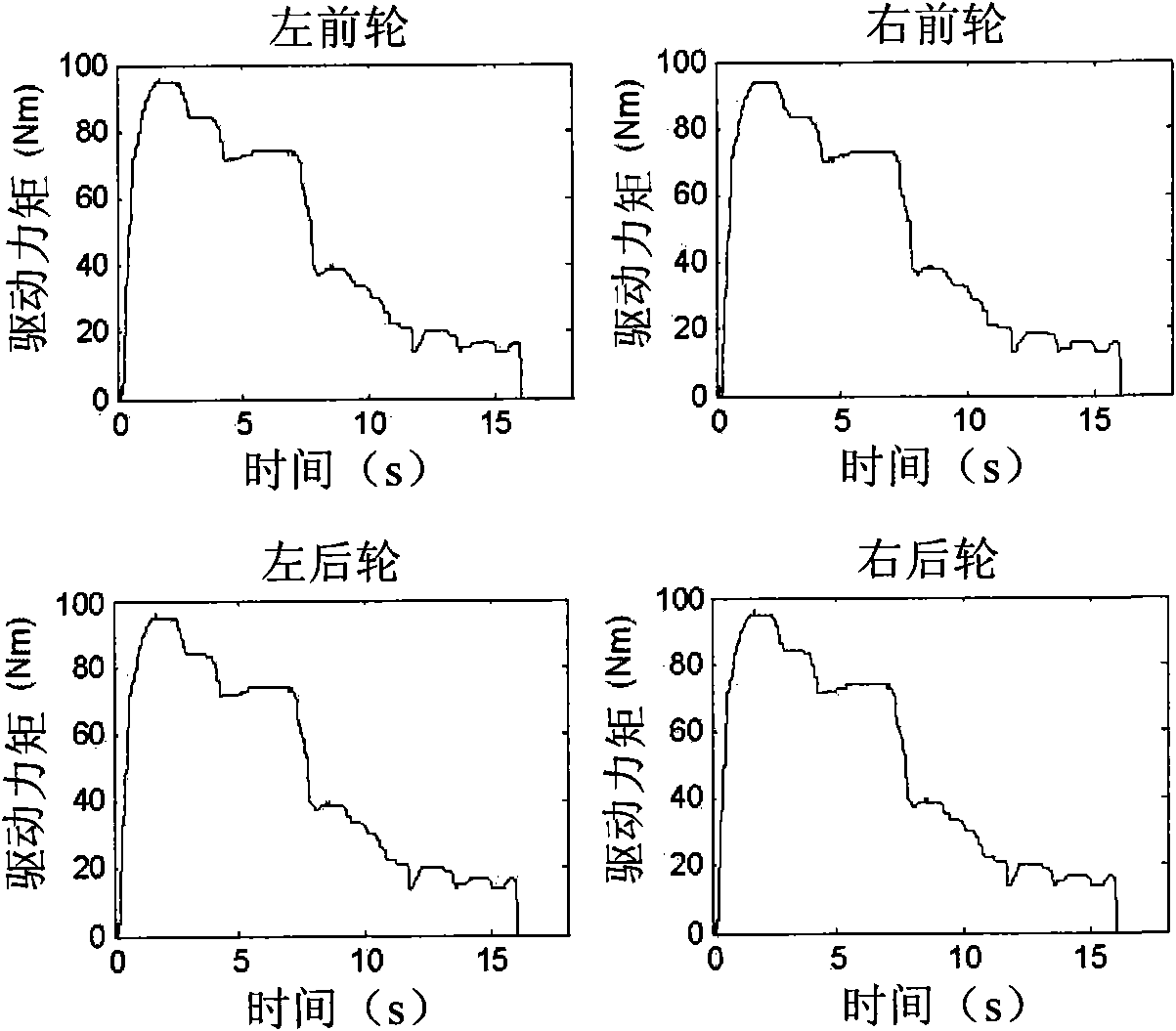

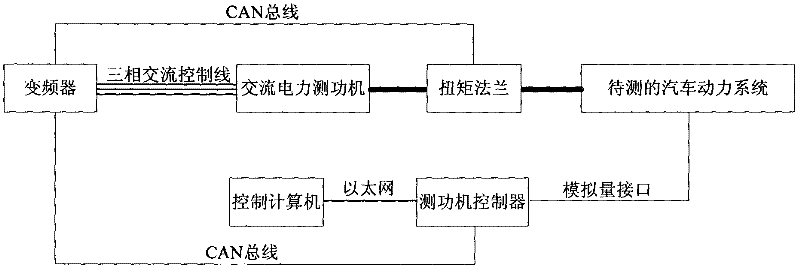

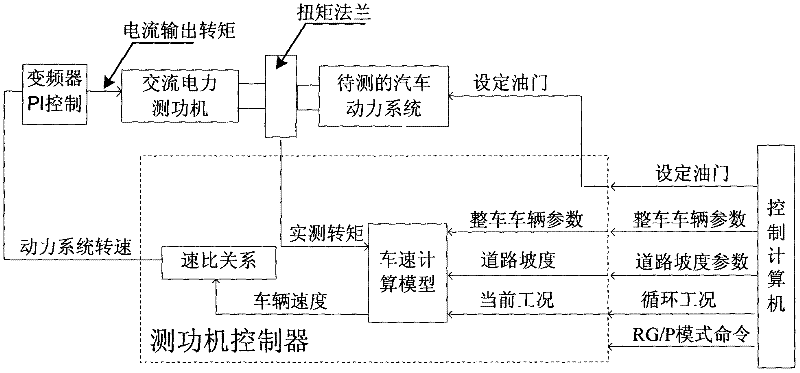

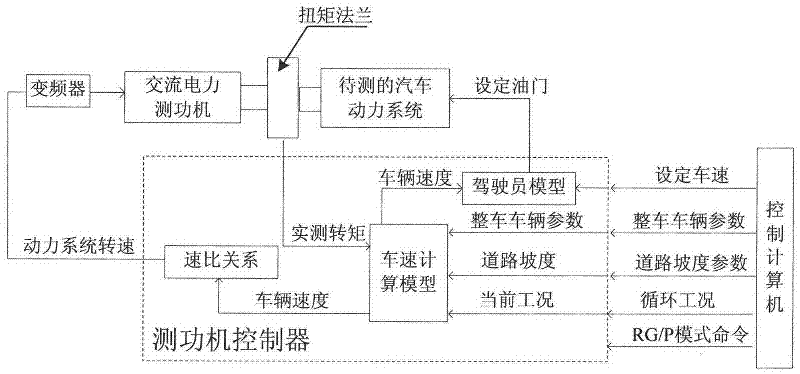

Dynamic load simulating device and method for automobile power system test

InactiveCN102305715AAvoid Differential ValuesImprove dynamic stabilityMachine gearing/transmission testingEngine testingRolling resistanceDynamometer

The invention relates to a dynamic load simulating device and a dynamic load simulating method for an automobile power system test, and belongs to the technical field of vehicle power system tests. The dynamic load simulating device comprises a control computer, a dynamometer controller, a frequency converter, an alternating current (AC) power dynamometer and a torque flange with a controller. A virtual automobile model-based control algorithm is adopted, a virtual automobile model is driven by an actual measurement torque, and the simulation of the rolling resistance, wind resistance and the inertia resistance of a vehicle is realized under the conditions of not calculating angular acceleration of the dynamometer. The dynamic load simulating device and the dynamic load simulating method have high stability and high simulation precision, are favorable for shortening the development cycle of an automobile power system and providing convenient test environment for the development of the power system. A process that the vehicle acceleration is acquired by differentiating the rotation speed of the automobile power system is avoided in the calculation process, and a phenomenon that accurate differential values are difficult to acquire due to relatively large noise caused by the process of differentiating the rotation speed is prevented.

Owner:TSINGHUA UNIV

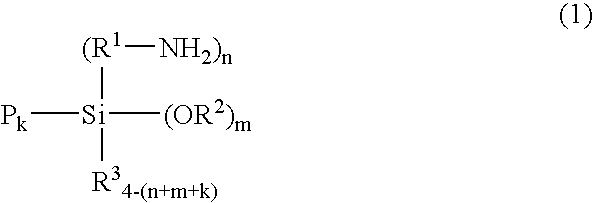

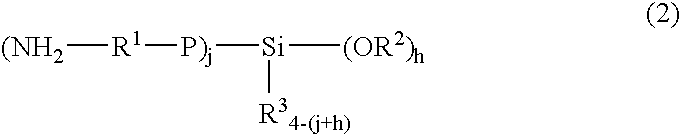

Rubber composition

ActiveUS20070185267A1Easy to processReduce rolling resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

There is obtained a rubber composition excellent in processability of unvulcanized compounded rubber, excellent in wear resistance and wet skid resistance of vulcanized rubber, low in rolling resistance, and suitable for tire applications, particularly for tire tread applications in which importance is given to low fuel consumption and safety. A rubber composition mainly comprising (I) 0.5 to 35% by weight of a conjugated diene-based (co)polymer rubber having an amino group and an alkoxysilyl group on a polymer chain and having a weight average molecular weight of 1,000 to 90,000, and (II) 99.5 to 65% by weight of a conjugated diene-based (co)polymer rubber having a weight average molecular weight of 100,000 to 2,000,000 (with the proviso that (I)+(II)=100% by weight).

Owner:JSR CORPORATIOON

Rubber composition usable as a tire tread

InactiveUS20020183436A1Improved hysteresis propertiesReduce rolling resistanceSpecial tyresTyre tread bands/patternsElastomerCross-link

The present invention relates to a cross-linkable or cross-linked rubber composition having improved hysteresis properties in the cross-linked state which is useful for constituting a tire tread, to a process for preparation of such a cross-linkable composition, to a tread of this type and to a tire having reduced rolling resistance. The rubber composition according to the invention is based on: an elastomeric matrix comprising at least one diene elastomer which comprises a carboxylic acid function at one or at each of its two chain ends, and a reinforcing filler comprising a reinforcing inorganic filler, wherein said diene elastomer has a molecular weight which is greater than 80,000 g / mol, and it is present in a majority quantity in said elastomeric matrix.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

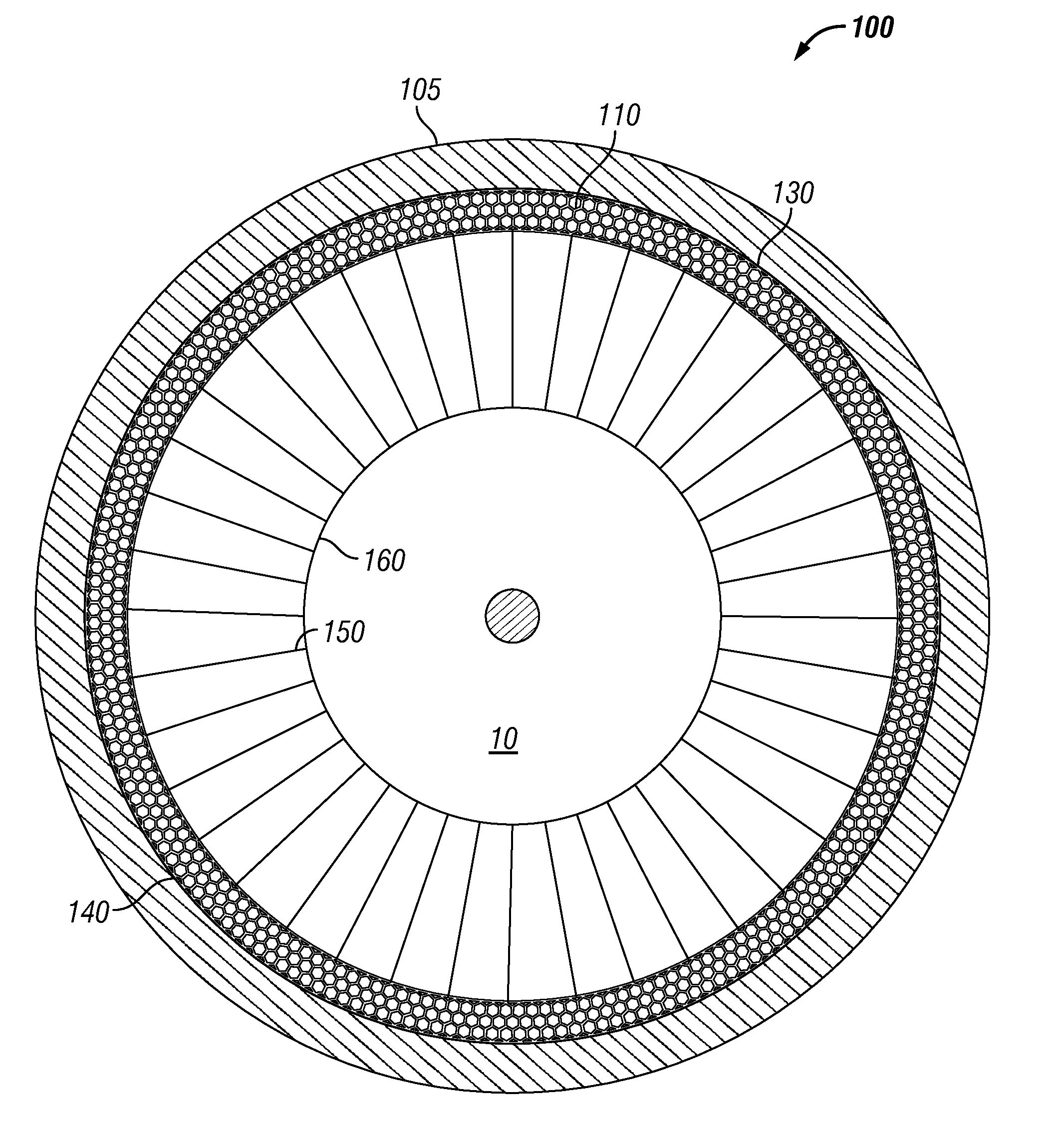

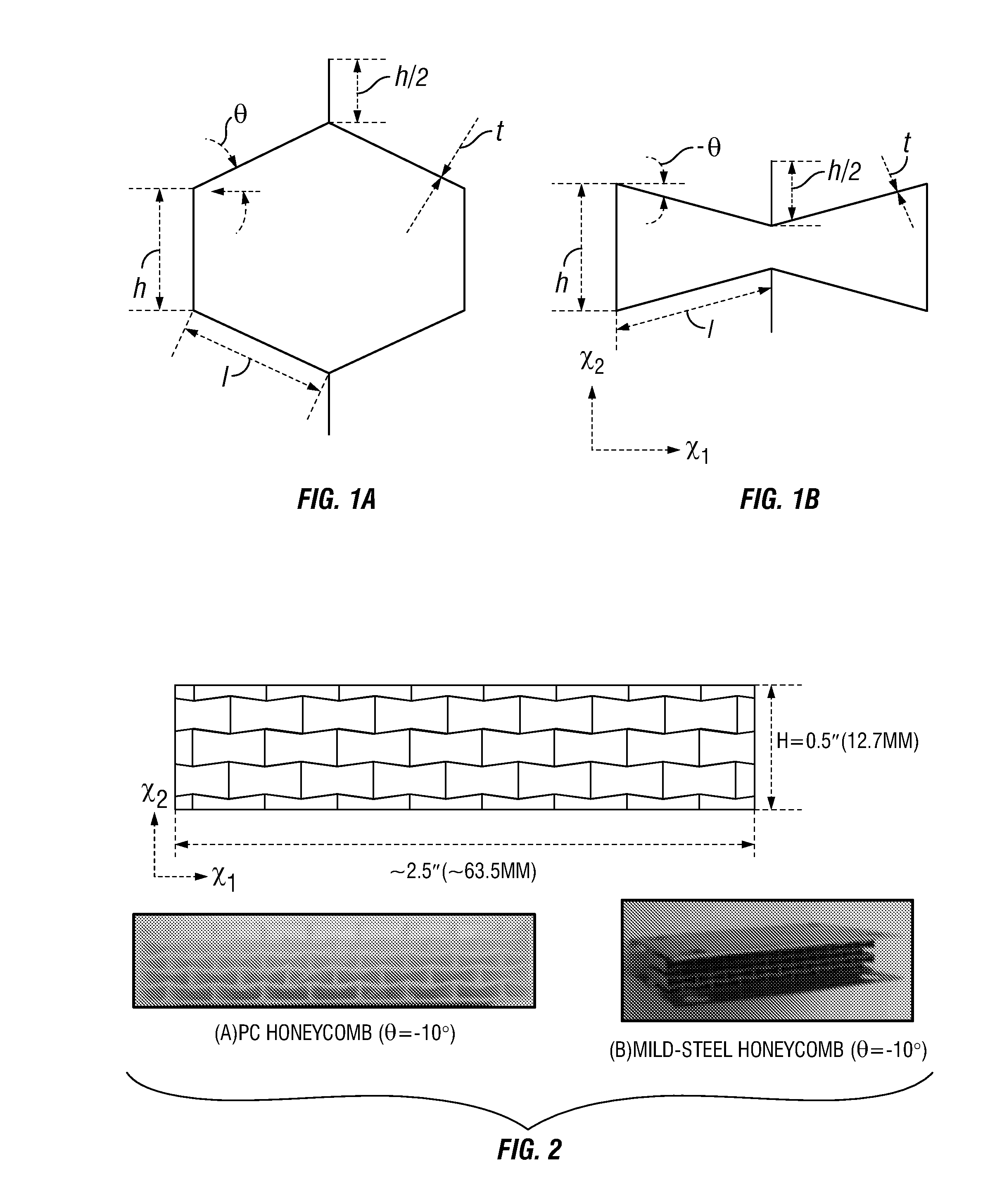

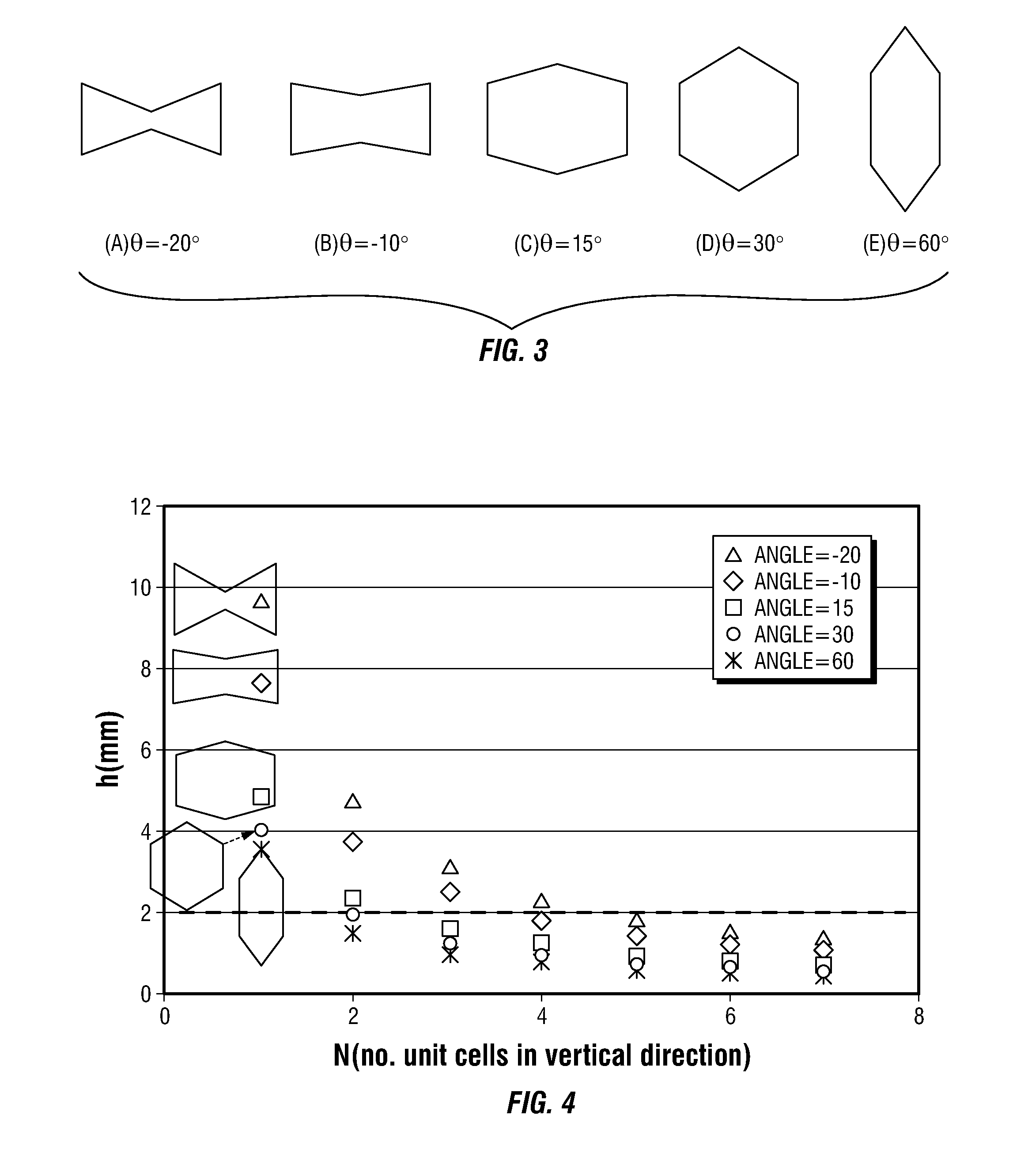

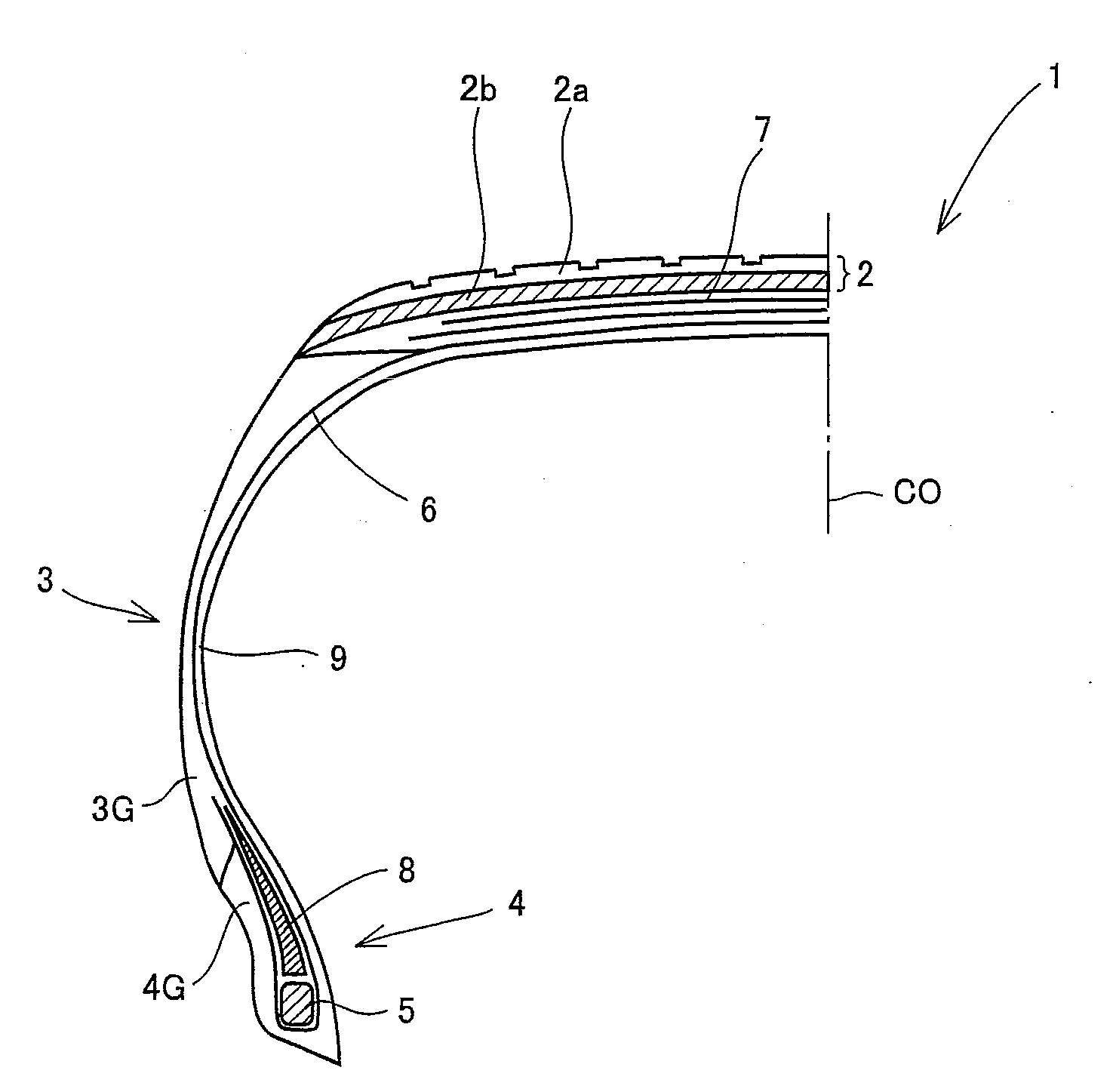

Honeycomb structures for high shear flexure

The present invention provides an improved shear band for use in non-pneumatic tires, pneumatic tires, and other technologies. The improved shear band is uniquely constructed of honeycomb shaped units that can replace the elastomeric continuum materials such as natural or synthetic rubber or polyurethane that are typically used. In particular, honeycomb structures made of high modulus materials such as metals or polycarbonates are used that provide the desired shear strains and shear modulus when subjected to stress. When used in tire construction, improvements in rolling resistance can be obtained because of less mass being deformed and reduced hysteresis provided by these materials. The resulting mass of the shear band is greatly reduced if using low density materials. Higher density materials can be used (such as metals) without increasing mass while utilizing their characteristic low energy loss.

Owner:MICHELIN NORTH AMERICA

Vulcanized rubber composition, pneumatic tire and the process of producing the same

ActiveUS20100076118A1Improve featuresReduce energy lossSpecial tyresTyre tread bands/patternsPolymer scienceRolling resistance

By using a vulcanized rubber composition containing a rubber component composed of at least any one of a natural rubber, a modified natural rubber and a synthetic rubber, and chemically modified microfibril cellulose, it is possible to provide a vulcanized rubber composition that is environmentally conscious and that exhibits excellent rupture characteristics and a low energy loss, and a pneumatic tire that is excellent in rolling resistance property, steering stability and durability.

Owner:SUMITOMO RUBBER IND LTD +1

Grafting modification method for solution-polymerized styrene-butadiene rubber with low gel rate

The invention relates to a preparation method of polar solution-polymerized styrene-butadiene rubber with low gel rate. The method involves grafting polar monomers on solution-polymerized styrene-butadiene rubber by means of free radical solution method, so as to change the polarity and further improve the interface bonding force of styrene-butadiene rubber and carbon black or white carbon black, so that the wet-skid resistance, wear resistance and dynamic mechanical property of vulcanized rubber are improved and the rolling resistance is reduced. The polar monomers used comprise maleic anhydride, acrylic acid, acrylamide, N-vinyl pyrrolidone and the like. The grafting rate of modified styrene-butadiene rubber is 1-5% and the gel rate is 1-3%; and the rubber polarity changes obviously.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com