F rail vehicle running mechanism

A traveling mechanism and vehicle technology, which is applied to vehicle components, electric vehicles, electric traction and other directions, can solve the problems of high-speed maglev vehicles, heavy weight, high-speed maglev vehicle running mechanisms that cannot meet track requirements, and high manufacturing costs, and achieves low noise and high performance. Stable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

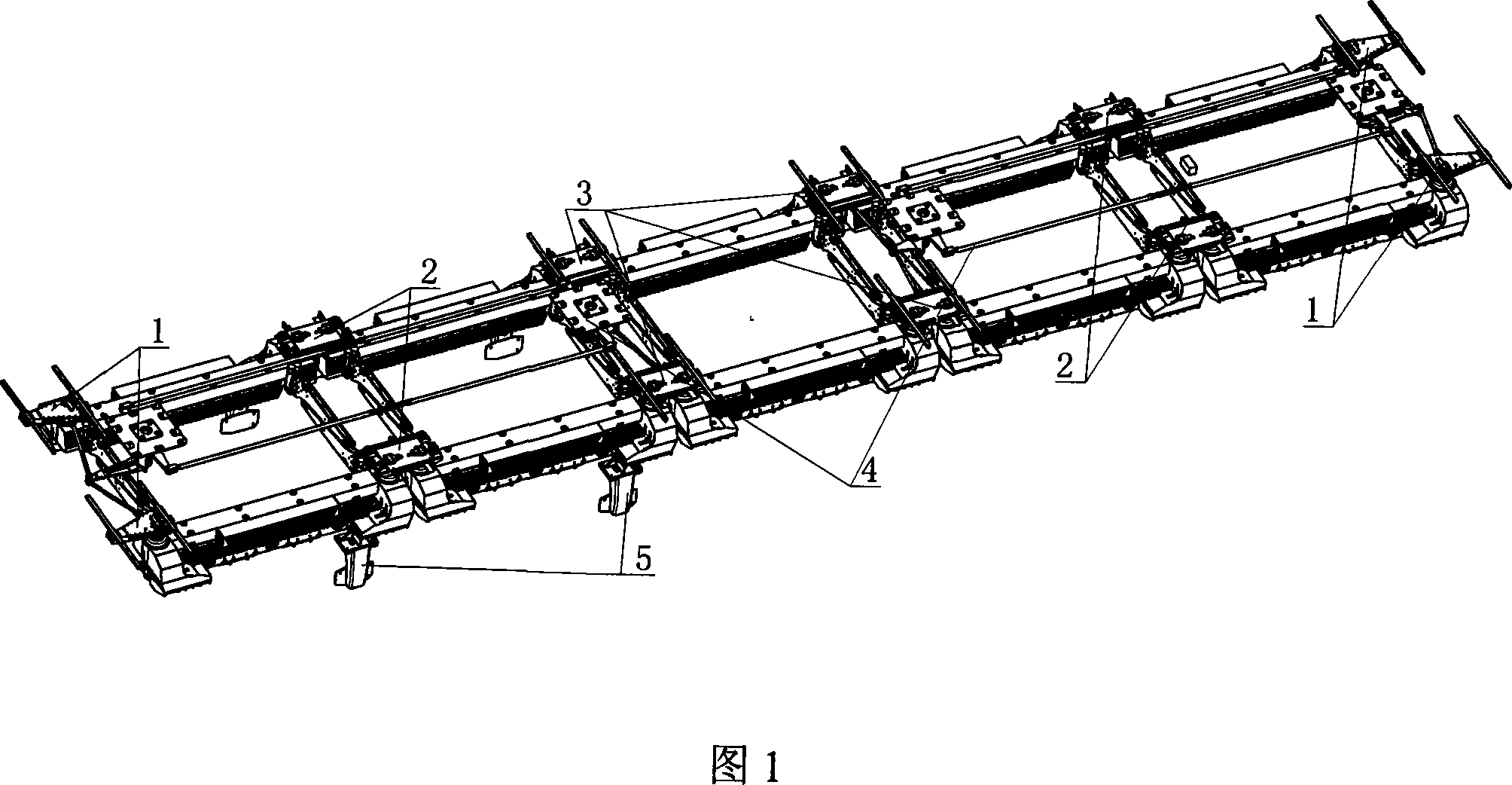

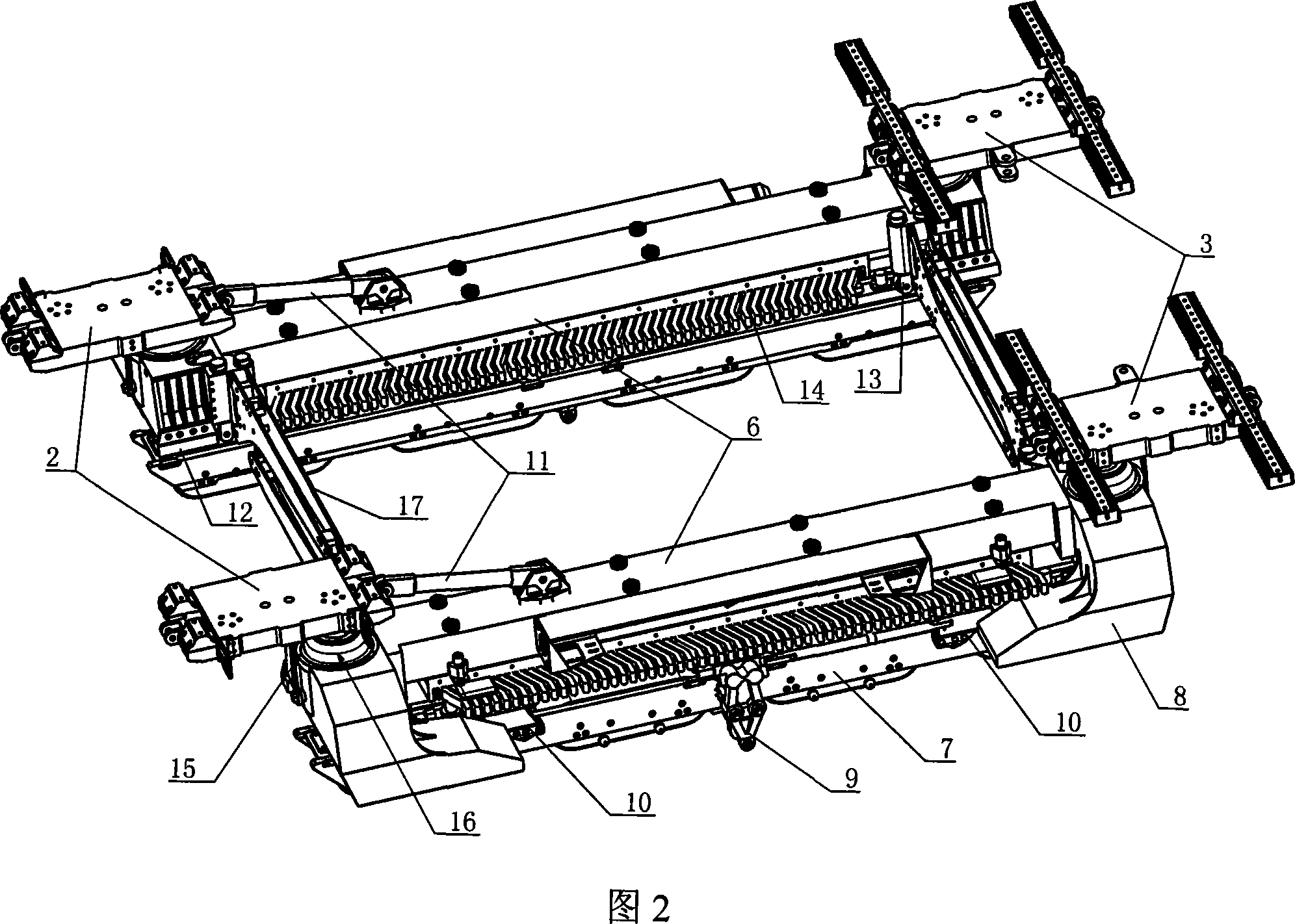

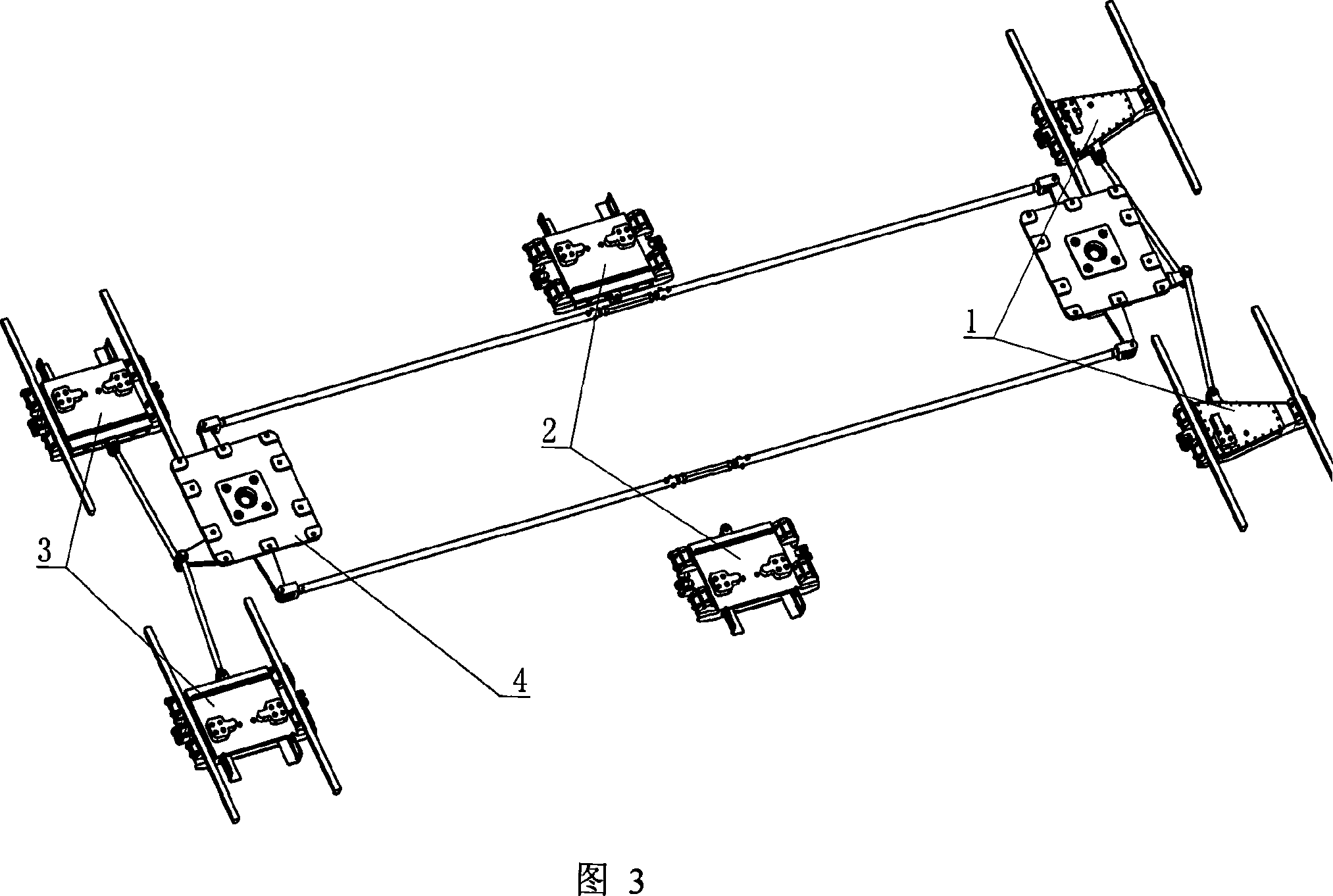

[0018] Fig. 1 has described an embodiment of the traveling mechanism that a section of vehicle is equipped with five suspended walking frames. Among them, the floating walking frame module frame composed of four support arms 8, two longitudinal beams 6 and two sets of anti-rolling devices is equipped with a suspension electromagnet 7, a traction motor 14, a lateral stopper 10, a braking device 9, and a traction rod 11. Anti-rolling device 17, emergency rescue wheel 13, skid device 12 and air spring device 16. The emergency rescue wheel 13 and the skid device 12 are installed on the bracket arms 8, and the two bracket arms 8 in the longitudinal direction are connected with the suspension electromagnet 7. Lateral stop 10 and braking device 9 are installed on the levitation electromagnet 7. The linear motor is connected on the longitudinal beam 6 through the vertical adjustment bolts on the longitudinal beam 6 . The sliding table device is connected to the air spring device 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com