Patents

Literature

197results about How to "Avoid violent collisions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

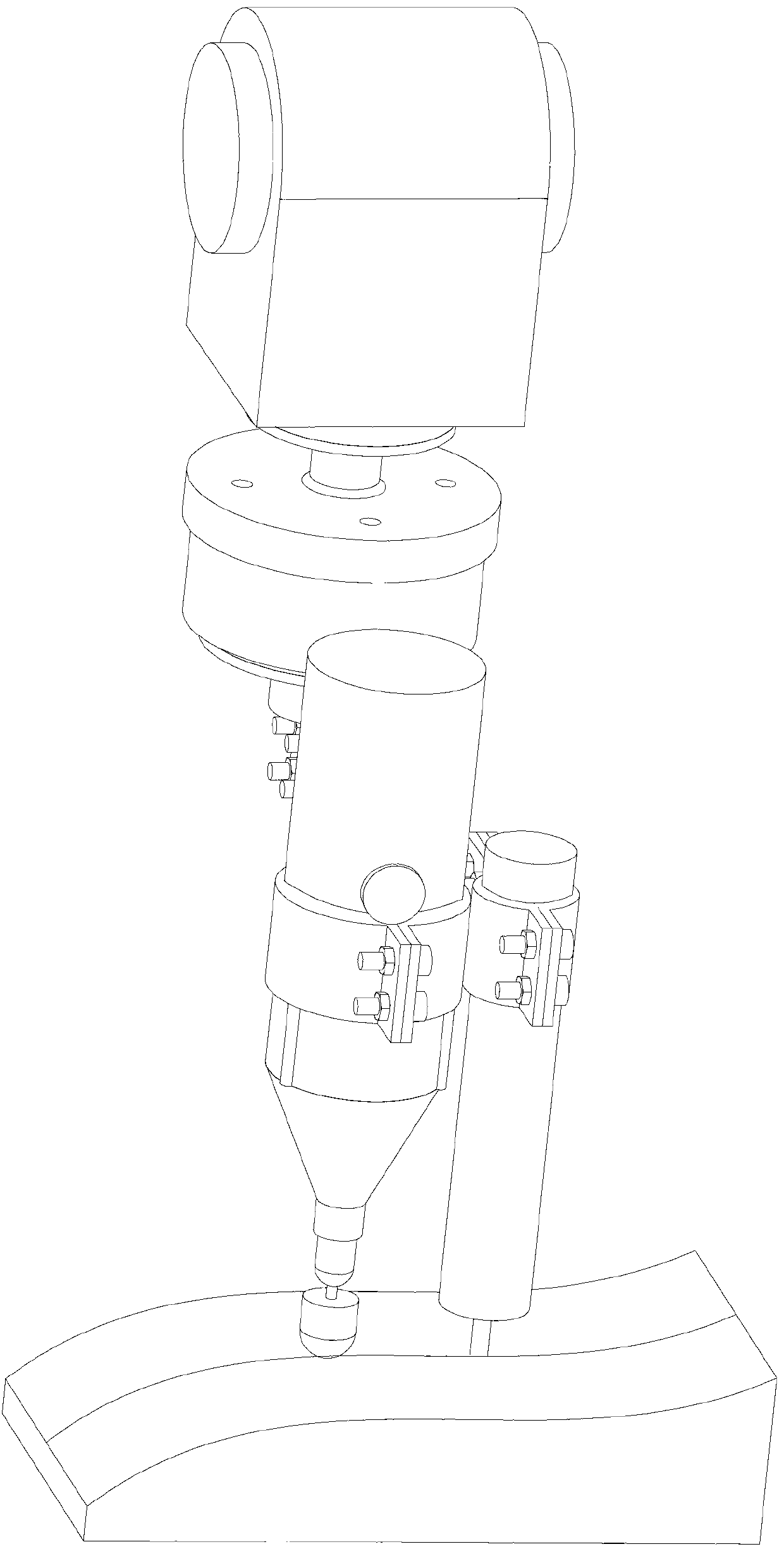

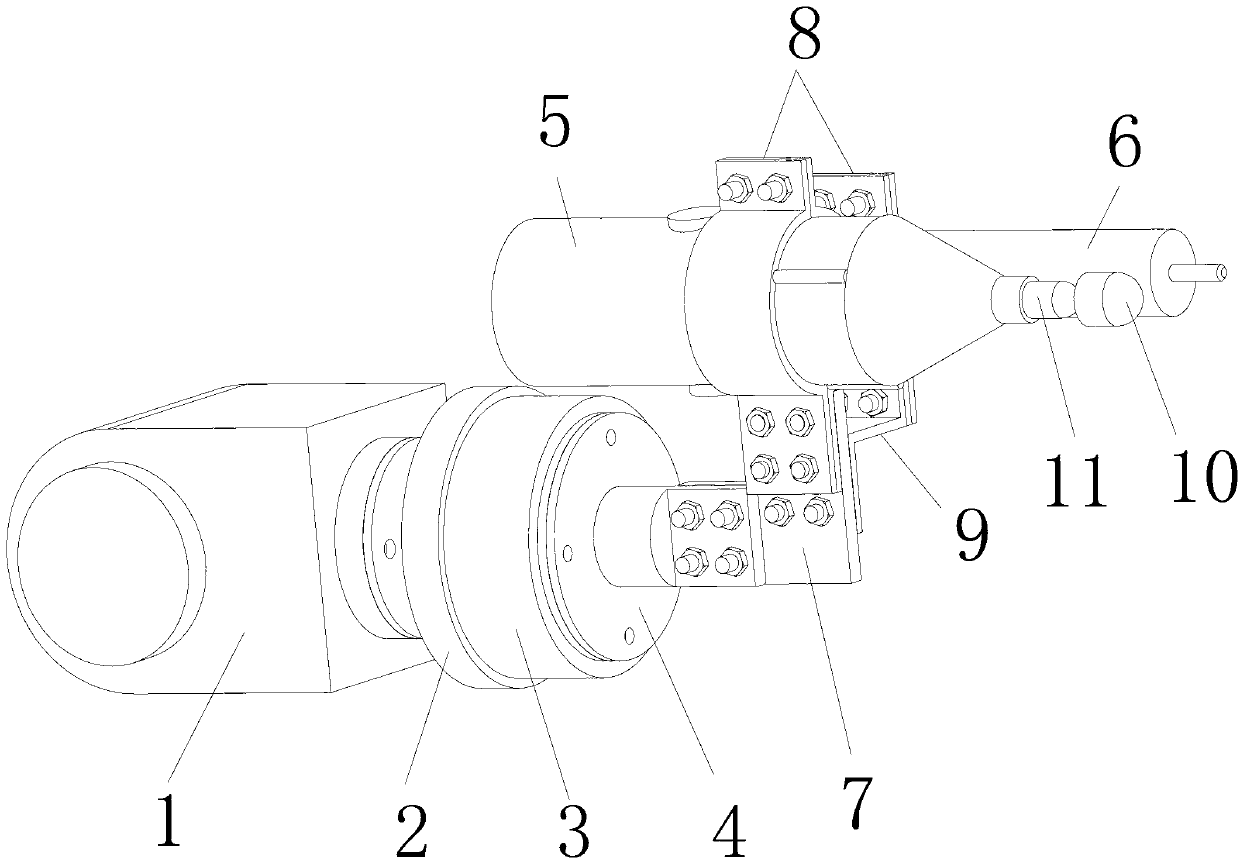

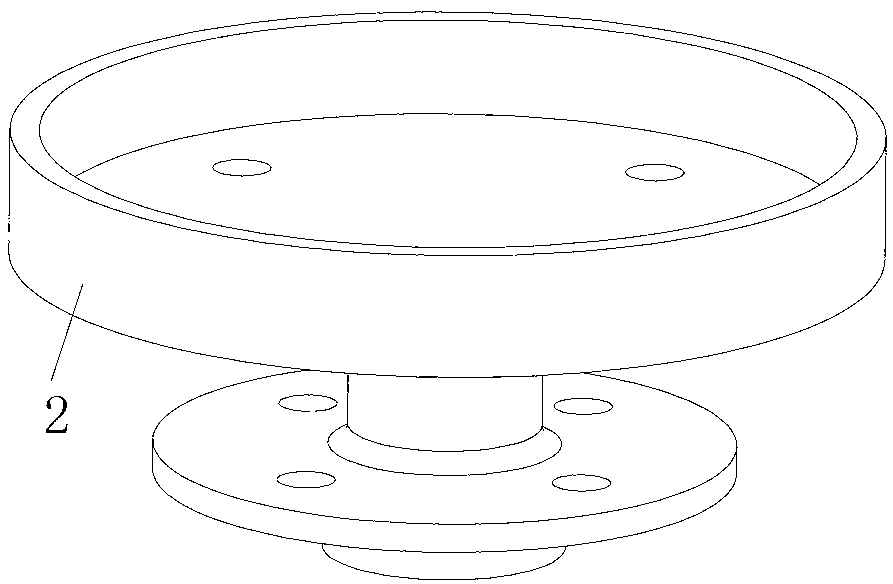

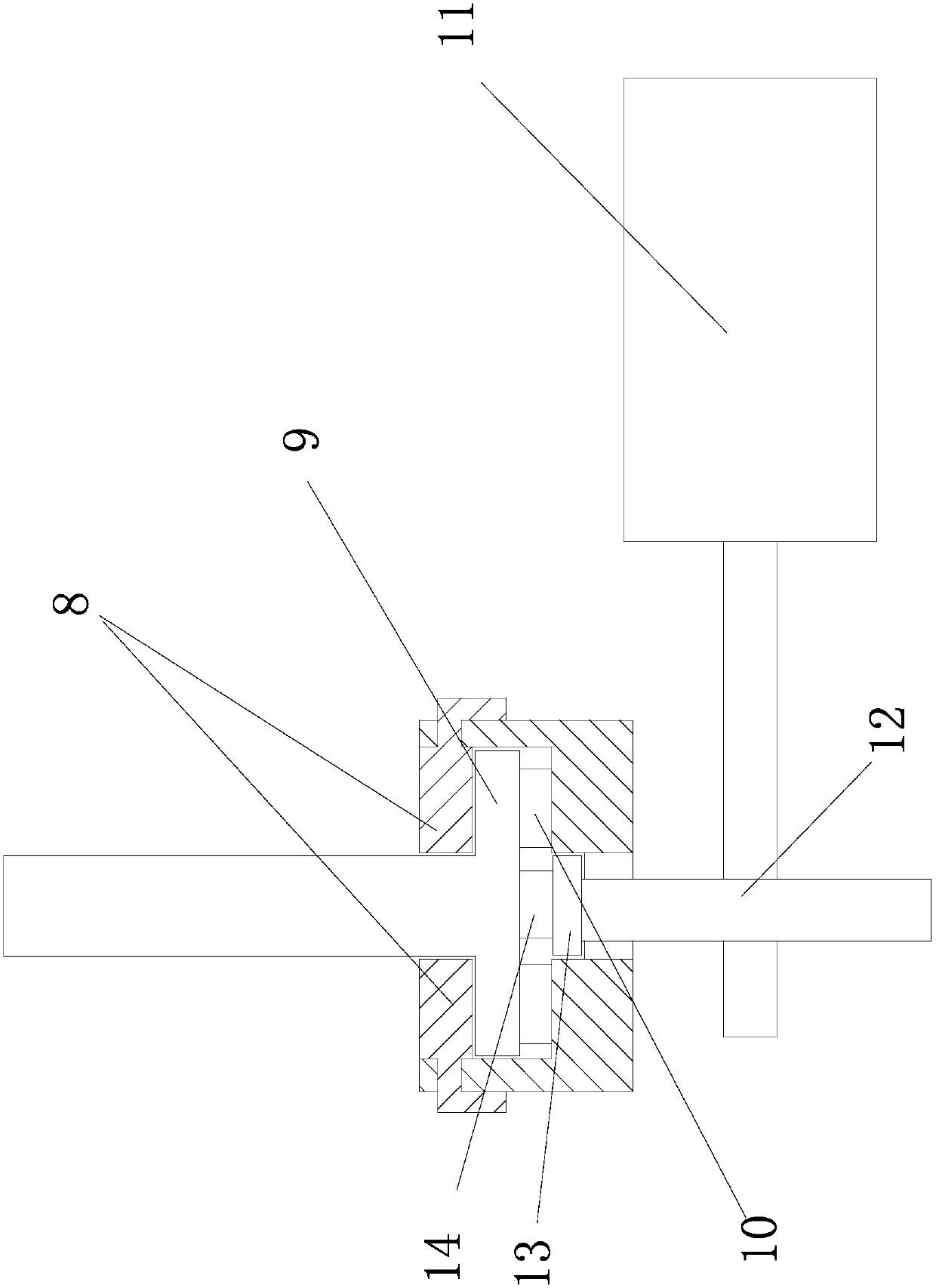

Robot polishing device and polishing method thereof

InactiveCN103009218ADetect force informationSuitable grinding forceGrinding feed controlGrinding machinesSurface plateForce sensor

The invention discloses a robot polishing device, which comprises a robot, a sensor permanent seat, a force sensor, a fixed base, an electric polisher and a displacement sensor, wherein the electric polisher and the displacement sensor are installed on the fixed base; the fixed base is fixedly arranged on the panel of the force sensor; the force sensor is fixedly arranged on the sensor permanent seat; and the sensor permanent seat is fixedly arranged on the tail end of the robot. The invention also discloses a polishing method of the robot polishing device. The robot polishing device disclosed by the invention has the advantages of simple structure, easiness in control and strong generality and can be used for polishing complex curved surfaces, the production efficiency is improved, the cost is lowered, and the processing quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

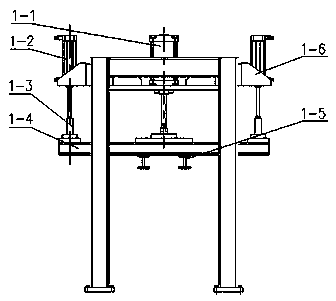

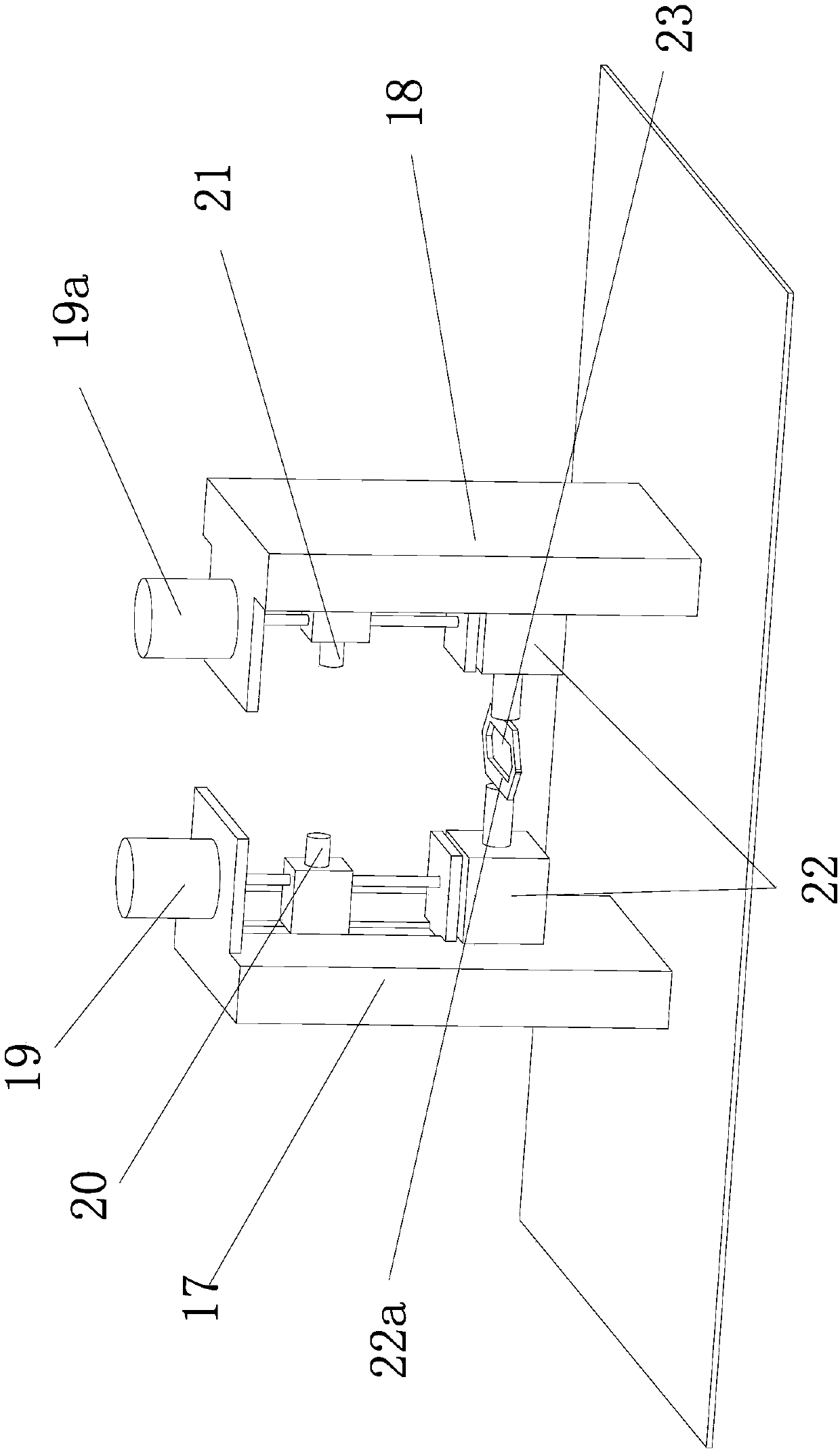

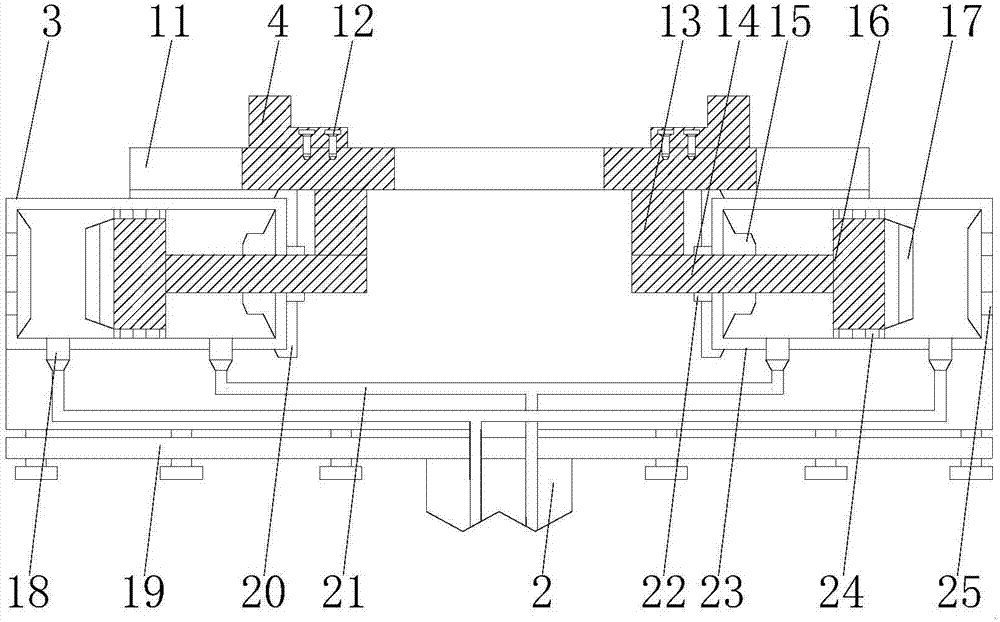

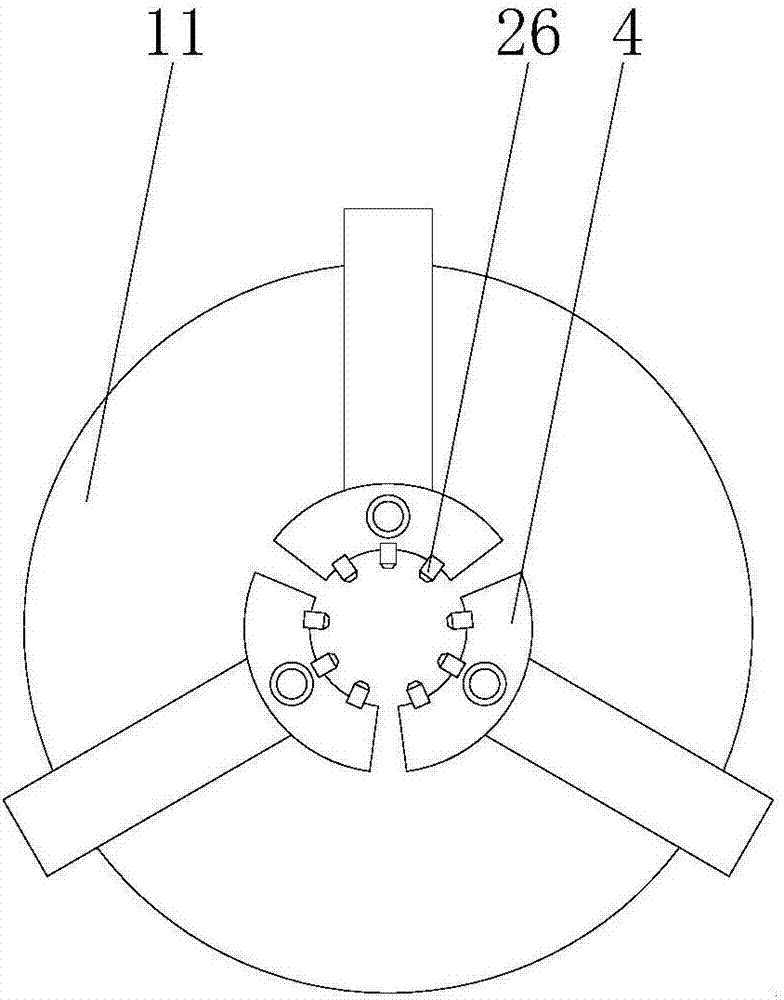

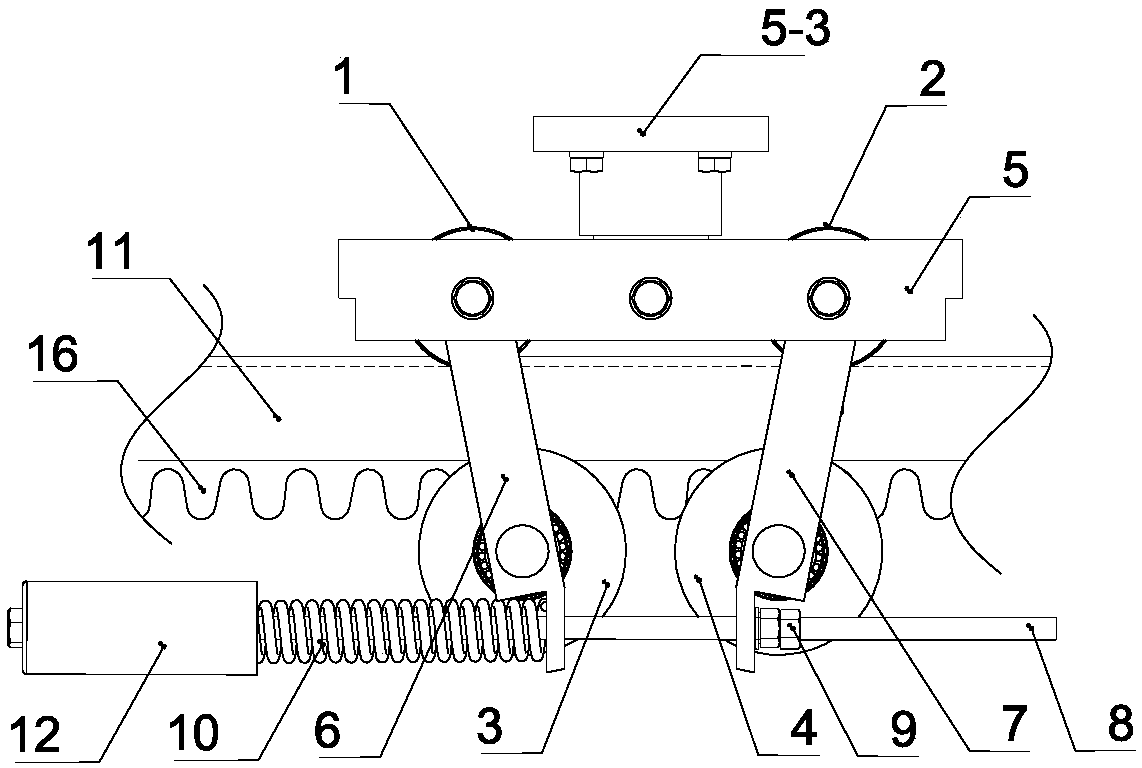

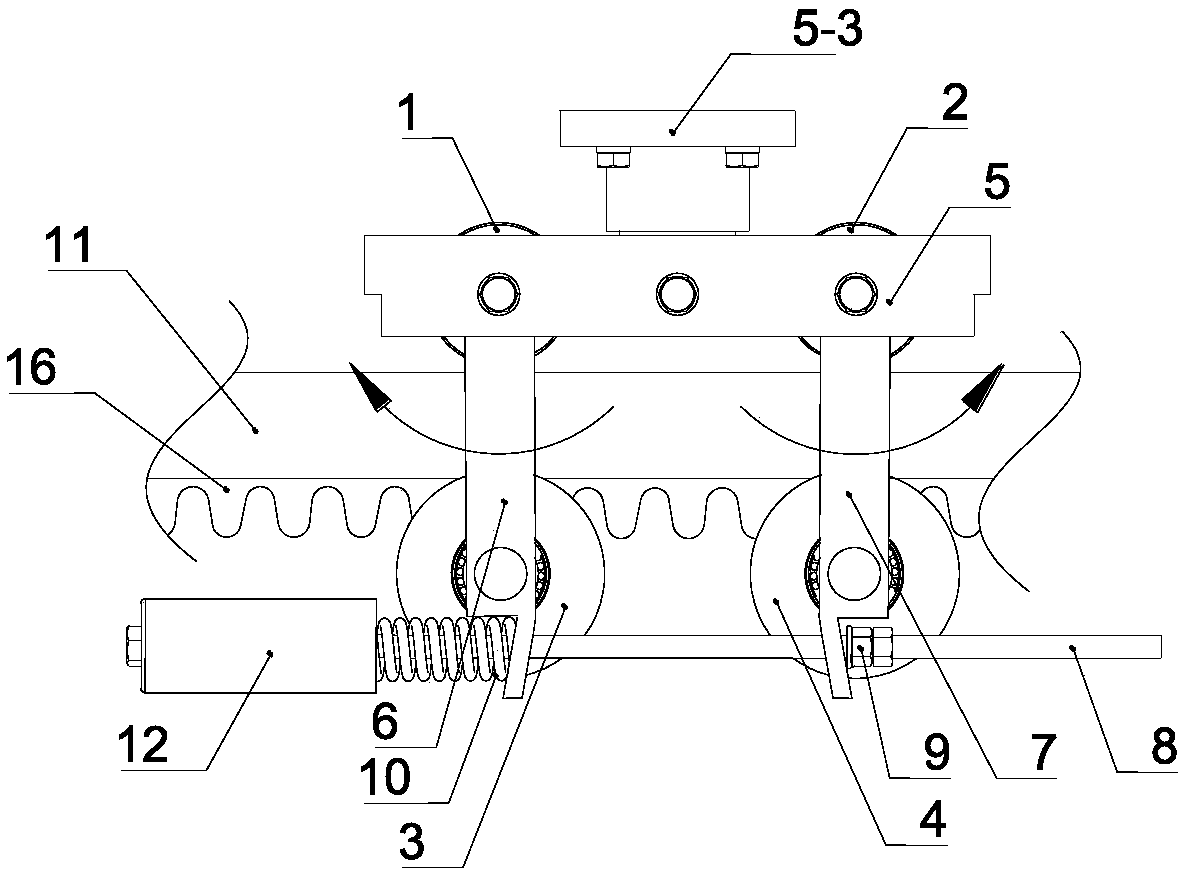

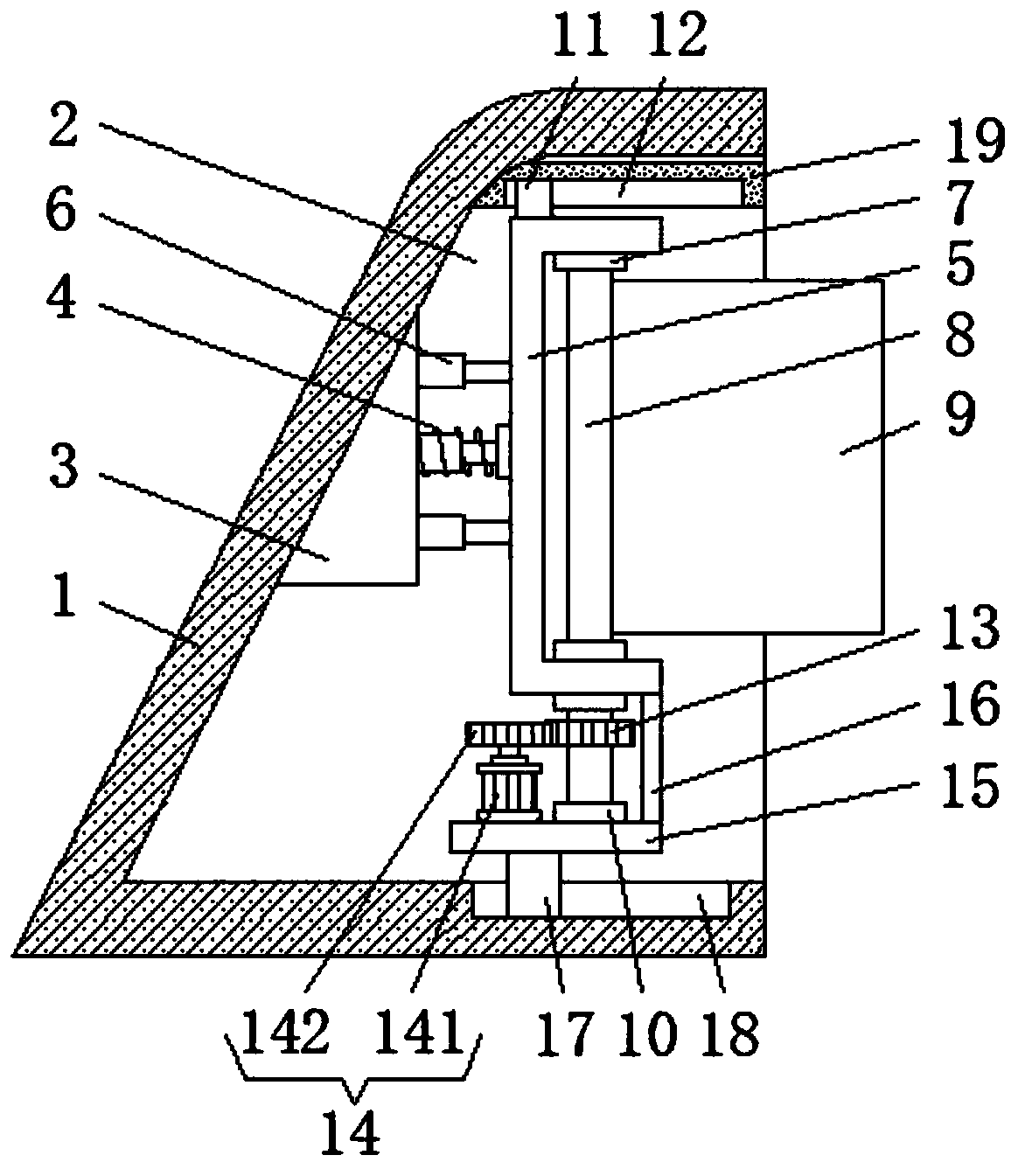

Pressing machine for liner

ActiveCN104028999APrevent slippingAvoid violent collisionsMetal working apparatusControl systemProgrammable logic controller

A pressing machine for a liner comprises a programmable logic controller (PLC) control system, a frame, a clamping mechanism, a plugging mechanism, a feeding mechanism, a pushing mechanism and a pressing mechanism. The clamping mechanism is arranged on the upper portion of the frame. A working platform is arranged on the lower portion of the frame. The plugging mechanism is fixedly arranged on the lower end surface of the working platform and corresponding to a positioning hole of the working platform. The pushing mechanism is arranged on a pressing plate of the clamping mechanism. The pressing plate is provided with a transversal linear slide. The feeding mechanism and the pressing mechanism are matched and respectively connected with the pushing mechanism through a mounting plate. The clamping mechanism, the plugging mechanism, the feeding mechanism, the pushing mechanism and the pressing mechanism are all controlled by the PLC control system. The pressing machine is adaptable to assembling of the liner of an oil pump cylinder body of an engine, and capable of realizing automatic operation, improving working efficiency, reducing labor intensity and improving products quality.

Owner:长城汽车股份有限公司平湖分公司

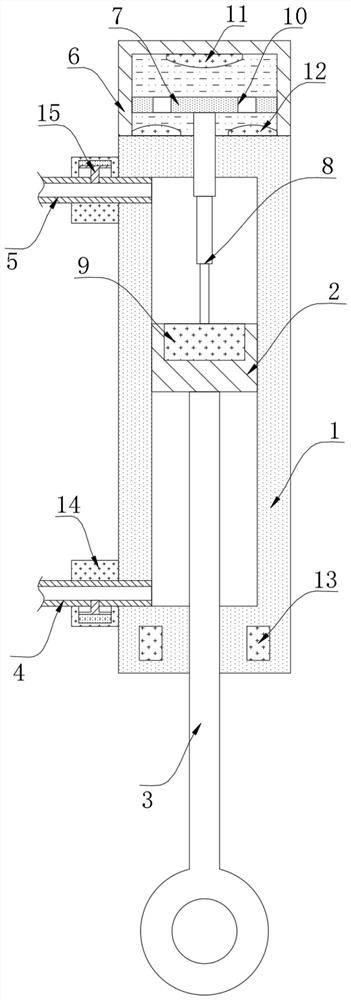

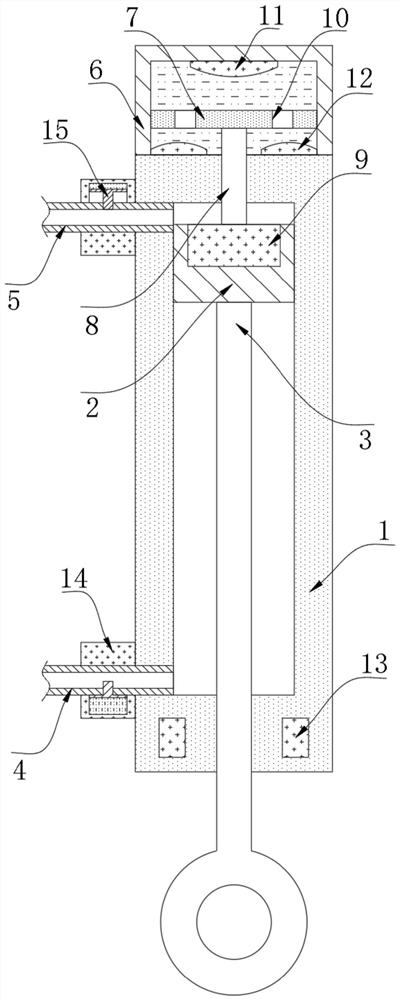

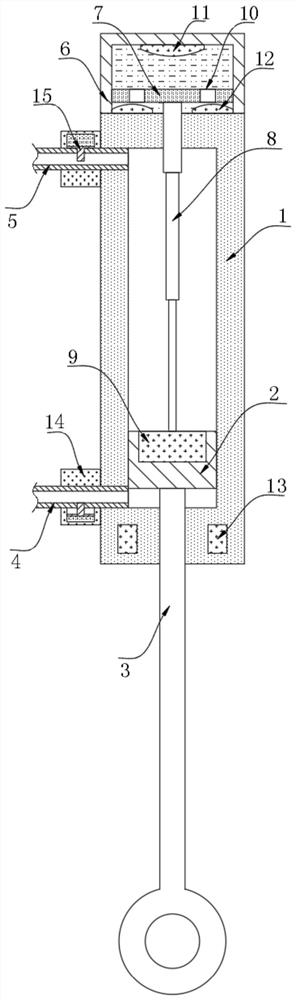

Rotary drilling rig and main winch placing down speed control device thereof

InactiveCN102424336AExtended service lifeImprove machine reliabilityDrilling rodsConstructionsNegative feedbackEngineering

The invention provides a rotary drilling rig and a main winch placing down speed control device thereof, wherein the main winch placing down speed control device comprises a sensor, a controller and a reverse valve device, the sensor is used for sensing the relative distance between a drill rod and a power head buffer device in real time and sending triggering signals when the relative distance equals to the preset distance, the controller is used for sending voltage signals to the reverse valve device after receiving the triggering signals, an oil supply opening of a main pump negative feedback opening is connected with the main pump negative feedback opening through the reverse valve device, and the oil supply opening supplies oil to the main pump negative feedback opening when the reverse valve device receives the voltage signals and the main winch is in the placing down state. The negative feedback pressure of a main pump can be controlled, and the discharge capacity of the main pump is changed, so the main winch placing down speed can be effectively decelerated in the drill rod placing down process, the severe collision between the drill rod and a power head is avoided, the service life of the power head is prolonged, and the whole machine reliability is improved.

Owner:BEIJING SANY HEAVY MASCH CO LTD

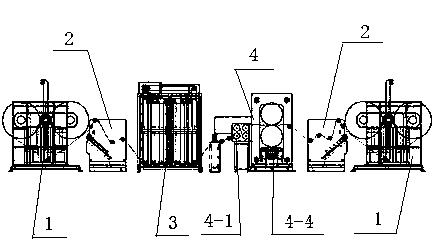

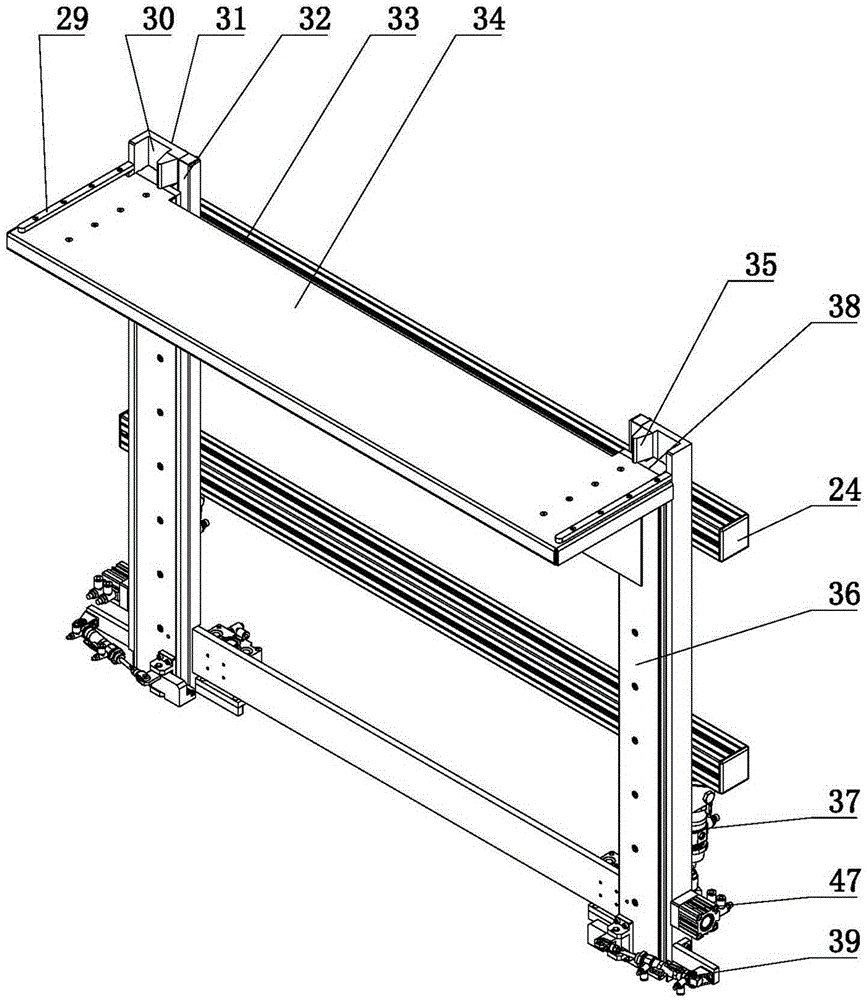

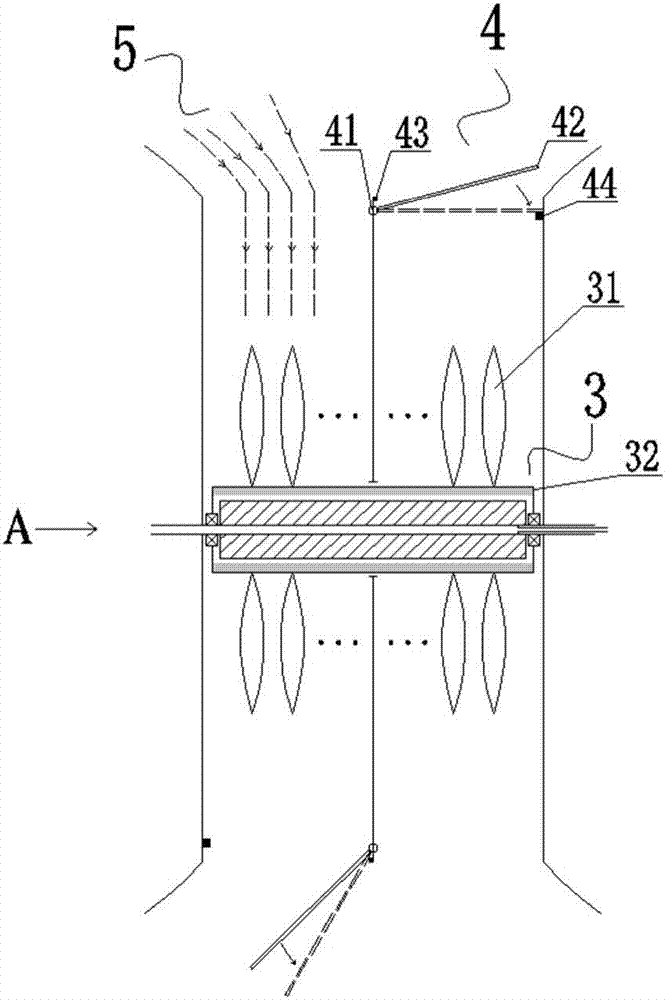

Device used for rolling battery pole piece at high speed

ActiveCN104190708AImprove productivityIncrease productivityElectrode manufacturing processesMetal rolling arrangementsControl systemPole piece

The invention discloses a device used for rolling a battery pole piece at a high speed. The device comprises a control system, two double-station automatic winding and unwinding machines, a band connecting device, a piece storage mechanism and a rolling mechanism. The double-station automatic winding and unwinding machines are arranged at an initial end and a tail end respectively. The band connecting device is arranged on the side face of the output end of a battery pole piece band roll of the double-station automatic winding and unwinding machine arranged at the initial end. The piece storage mechanism and the rolling mechanism are sequentially arranged behind the output end of the band connecting device. The output end of the rolling mechanism is connected with the double-station automatic winding and unwinding machine arranged at the tail end. An automatic roll replacing and band connecting mechanism, the piece storage mechanism and the rolling mechanism are all connected with a control system. According to the device, rolling accuracy can be guaranteed, shutdown is not required in the rolling process, roll replacement and band connection are automatically completed, and therefore automated production is achieved.

Owner:邢台纳科诺尔精轧科技股份有限公司

Live reeves shad transportation method

ActiveCN103891656AAvoid violent collisionsAvoid injuryClimate change adaptationPisciculture and aquariaNarcotic drugsMedicine

The invention discloses a live reeves shad transportation method. The method comprises the specific steps that (1), a transportation tool is prepared; (2), transportation water is prepared; (3), reeves shads are caught; (4), the reeves shads are transported; (5), the reeves shads are bred after reaching the destination. According to the live reeves shad transportation method, no narcotic drug is needed, and the problem that aquatic products are threatened due to the narcotic drug is solved fundamentally; few scars are generated on the body surfaces of the commodity reeves shads, and the quality of the reeves shads is not affected; the transportation survival rate of the commodity reeves shads within 24 hours is 95-100%, and the transportation survival rate of the commodity reeves shads within 48 hours is 85-95%; the method is simple, easy to implement, low in cost and suitable for being popularized.

Owner:中洋鱼天下食品(上海)股份有限公司

Transportation method for live fish and shellfish

InactiveCN104221961AAvoid violent collisionsAvoid rapid deterioration of water qualityClimate change adaptationPisciculture and aquariaSurvival rateScars

The invention discloses a transportation method for live fish and shellfish. The transportation method comprises the following steps that (1) a transportation utensil is prepared; (2) water for transportation is prepared; (3) fishing is performed; (4) transportation is carried out; (5) fish is cultured after the fish reaches the destination. With the adoption of the transportation method, no anesthetic medicine is needed, the problem that aquatic products are threatened due to the usage of the anesthetic medicine is radically solved; scars are seldom caused to the surfaces of the live fish and shellfish, and the quality of the live fish and shellfish is not affected; the survival rate of commodity live fish and shellfish transported in 24 hours can reach 95-100%, and the survival rate in 48 hours can reach 85-95%; the transportation method for the live fish and shellfish is simple and feasible, is lower in cost and suitable for popularization.

Owner:陈小洁

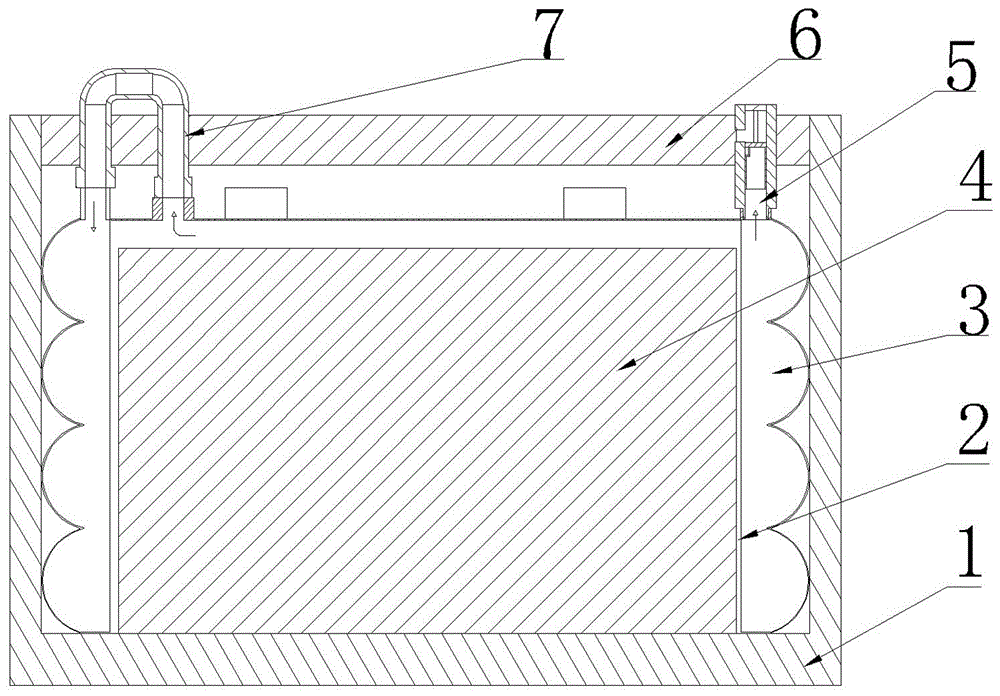

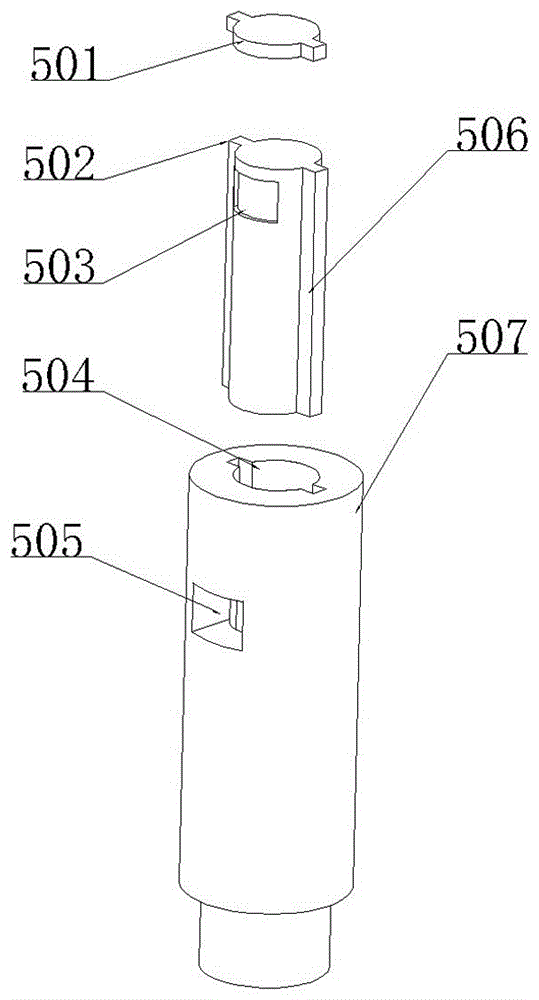

Battery box with shockproof and explosion-proof functions

The invention discloses a battery box with shockproof and explosion-proof functions. The battery box comprises a box body and a box cover which are fixedly connected through buckles, wherein a battery storage cavity is formed in the box body; a battery is arranged in the battery storage cavity; a damping gas bag is further arranged in the box body, positioned between the box body and the battery storage cavity and communicated with a gas guide pipe and a pressure relief pipe; the gas guide pipe is communicated with the battery storage cavity; and the pressure relief pipe penetrates the box body. According to the battery box with the shockproof function, an electrolytic gas generated by the power battery is collected by the damping gas bag in the box body, and the electrolytic gas with large concentration is discharged from the pressure relief pipe, so that on the one hand, a risk of explosion caused when the electrolytic gas is collected to reach a certain concentration is avoided, and on the other hand, the electrolytic gas serves as an expansion gas of the damping gas bag, damages to components band parts in the battery due to shaking of the box body are effectively avoided.

Owner:遵义西南机械设备有限责任公司

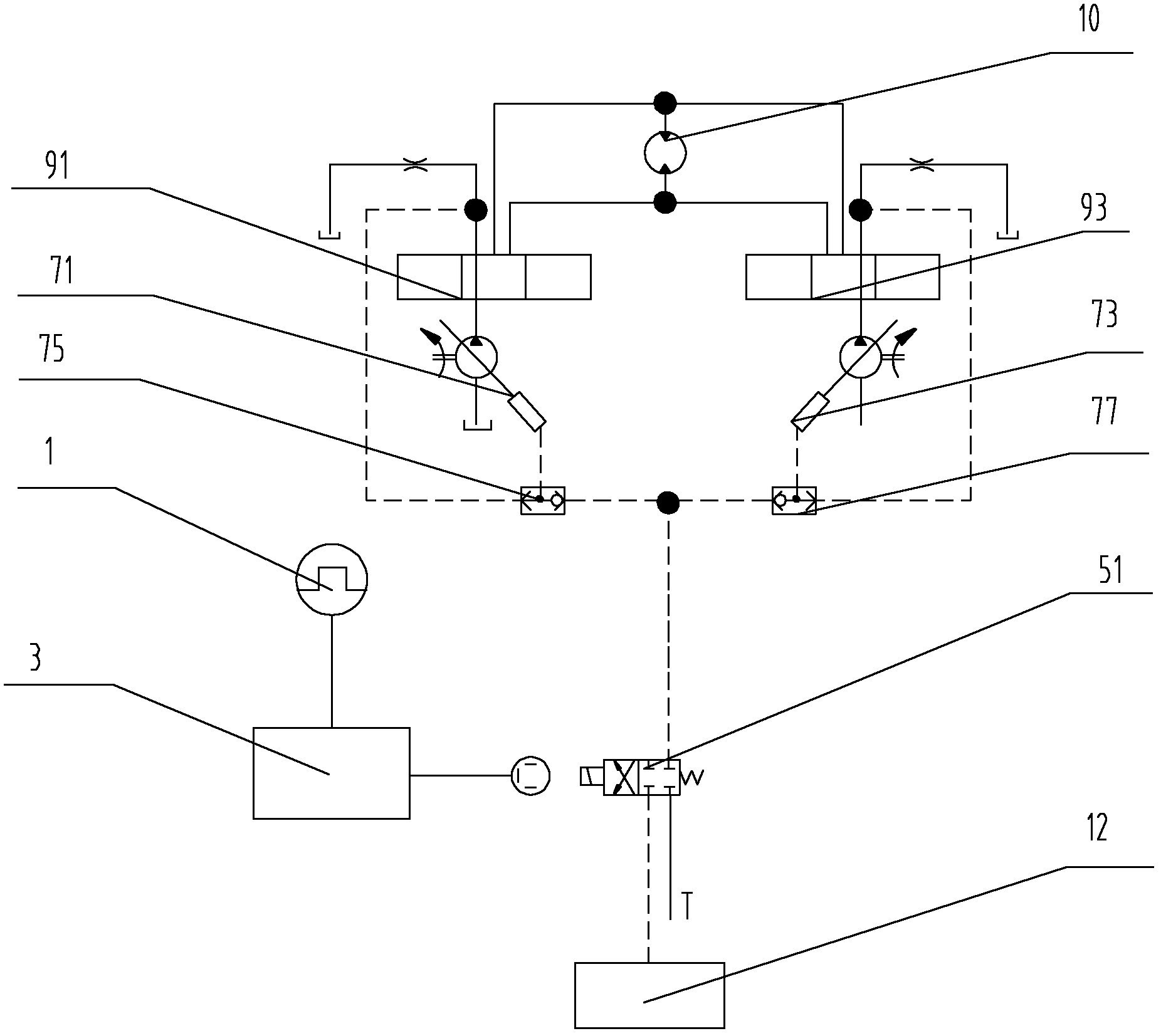

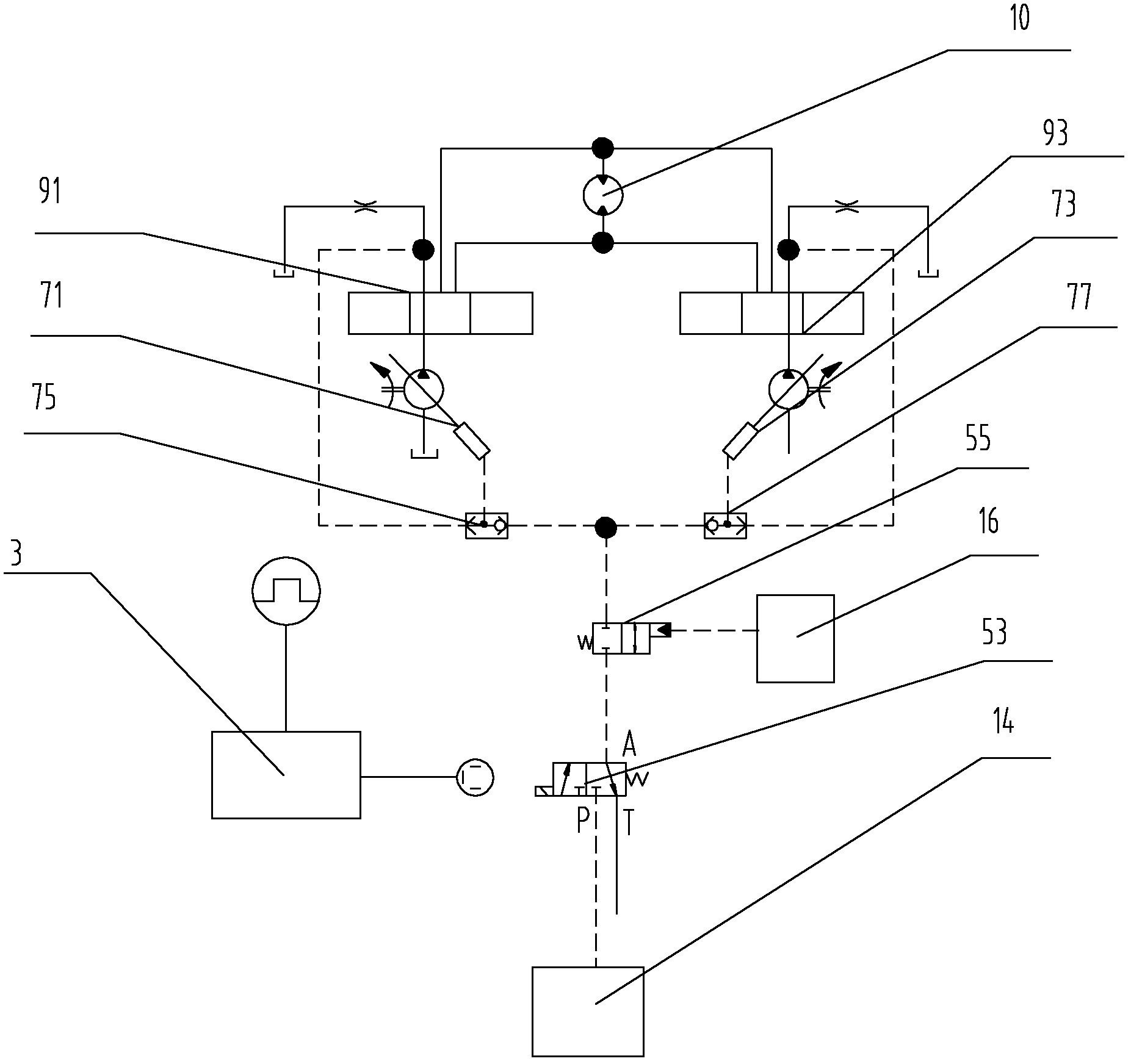

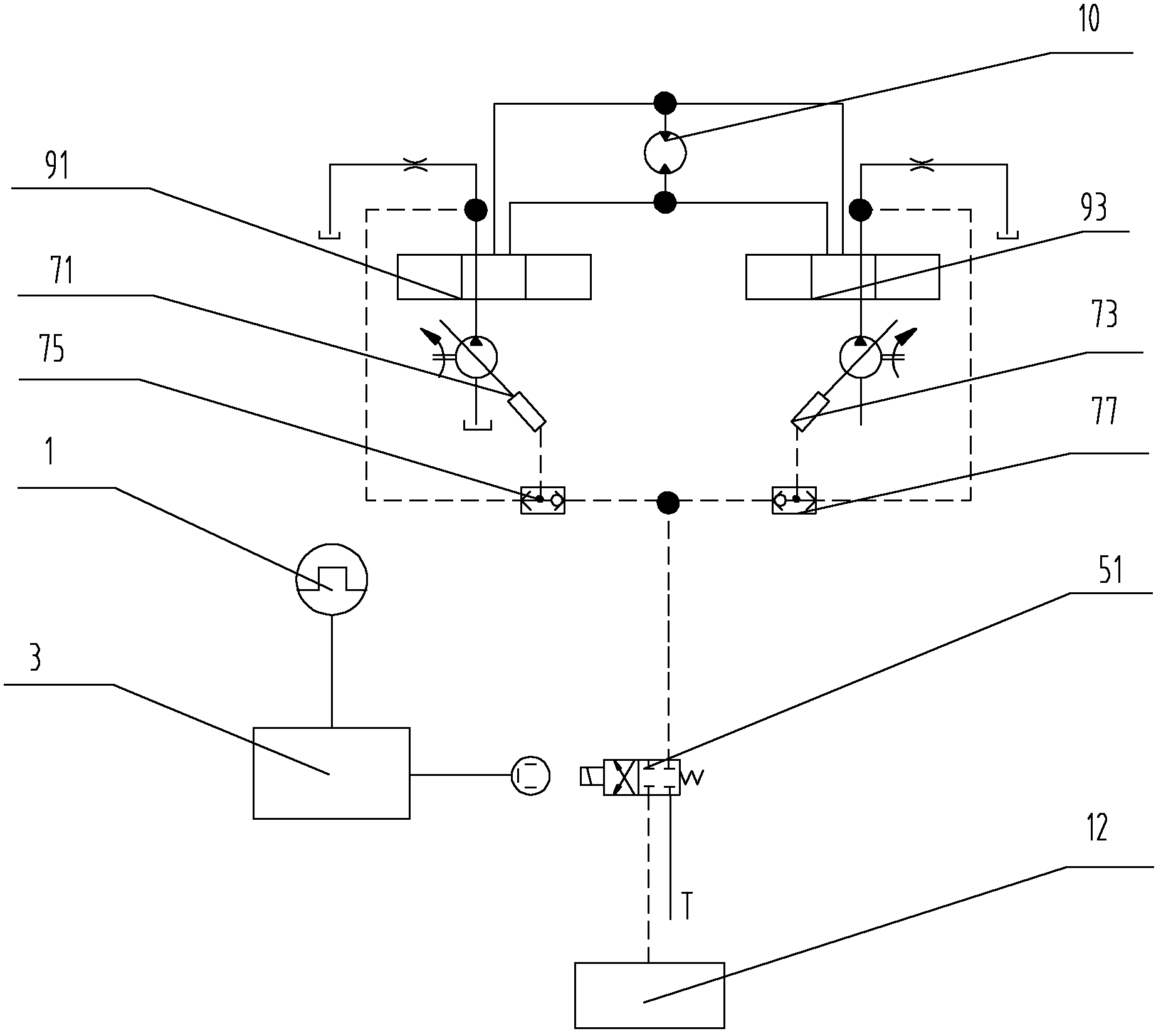

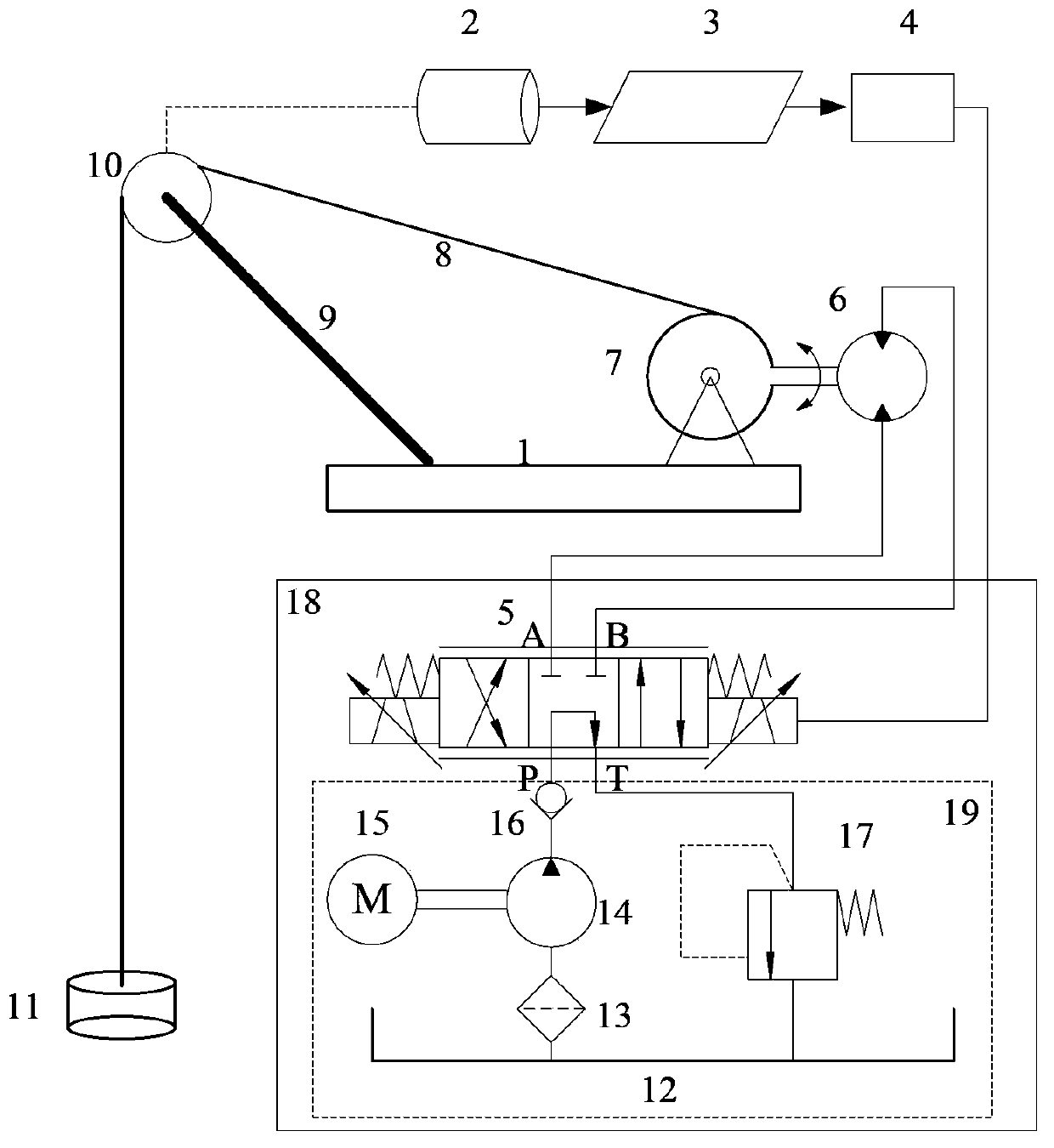

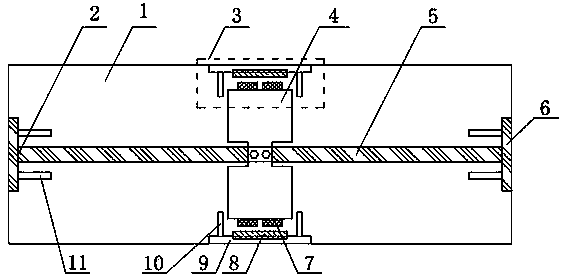

Active heave compensation system of underwater robot

InactiveCN103626068ANo need to increase workspaceLarge working spaceWinding mechanismsActive heave compensationControl cell

The invention relates to an active heave compensation system of an underwater robot. A hydraulic winch is fixedly connected to a deck of a mother ship, an armoured cable is wound on a winding drum of the hydraulic winch, the armoured cable is connected with a combination of a relay and the underwater robot through a fixed pulley, a sensor module is fixedly installed on the fixed pulley and sequentially connected with a signal processing module, a control unit, a hydraulic driving system and the hydraulic winch. An existing hydraulic take-up and pay-off winch can be utilized for the active heave compensation system, additional power equipment does not need to be arranged, and the work space for the deck of the mother ship does not need to be enlarged either. Besides, because the rotation range of the hydraulic winch is wide, the compensation range is wide; meanwhile, violent collision between the underwater robot and the relay is avoided in the releasing or retracting process. Compared with a passive compensation mode of a pneumatic-hydraulic energy accumulator, the active heave compensation system of the underwater robot has the advantages that heave compensation efficiency can be effectively improved, and the active heave compensation system is easy to operate, convenient to obtain in the respect of engineering and capable of being applied to high-precision heave compensation under significant sea conditions.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Sock packer

ActiveCN107776944AAvoid violent collisionsSave productivityLabelling deformable materialsSortingSOCKSBiochemical engineering

The invention provides a sock packer, belongs to the technical field of machinery and solves the technical problems of low efficiency and the like in prior sock packing. The sock packer comprises a rack and is characterized in that a first rail and a second rail which are in closed circulation are fixed on the rack, a first gap is formed between one end of the first rail and one end of the secondrail, a second gap is formed between the other end of the first rail and the other end of the second rail, and the second gap is smaller than the first gap; a first guide groove is formed in the firstrail, a first through hole communicated with the first guide groove is formed in the lower part of the first rail, a second guide groove is formed in the second rail, and a second through hole communicated with the second guide groove is formed in the lower part of the second rail. The sock packer has the advantage that socks are packed automatically and efficiently.

Owner:全椒县瑞祥工艺品有限公司

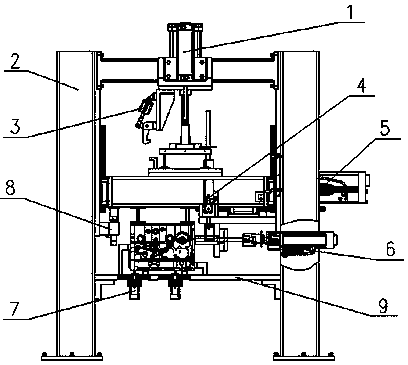

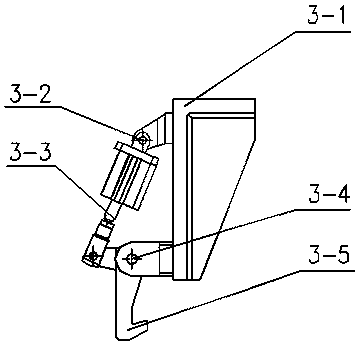

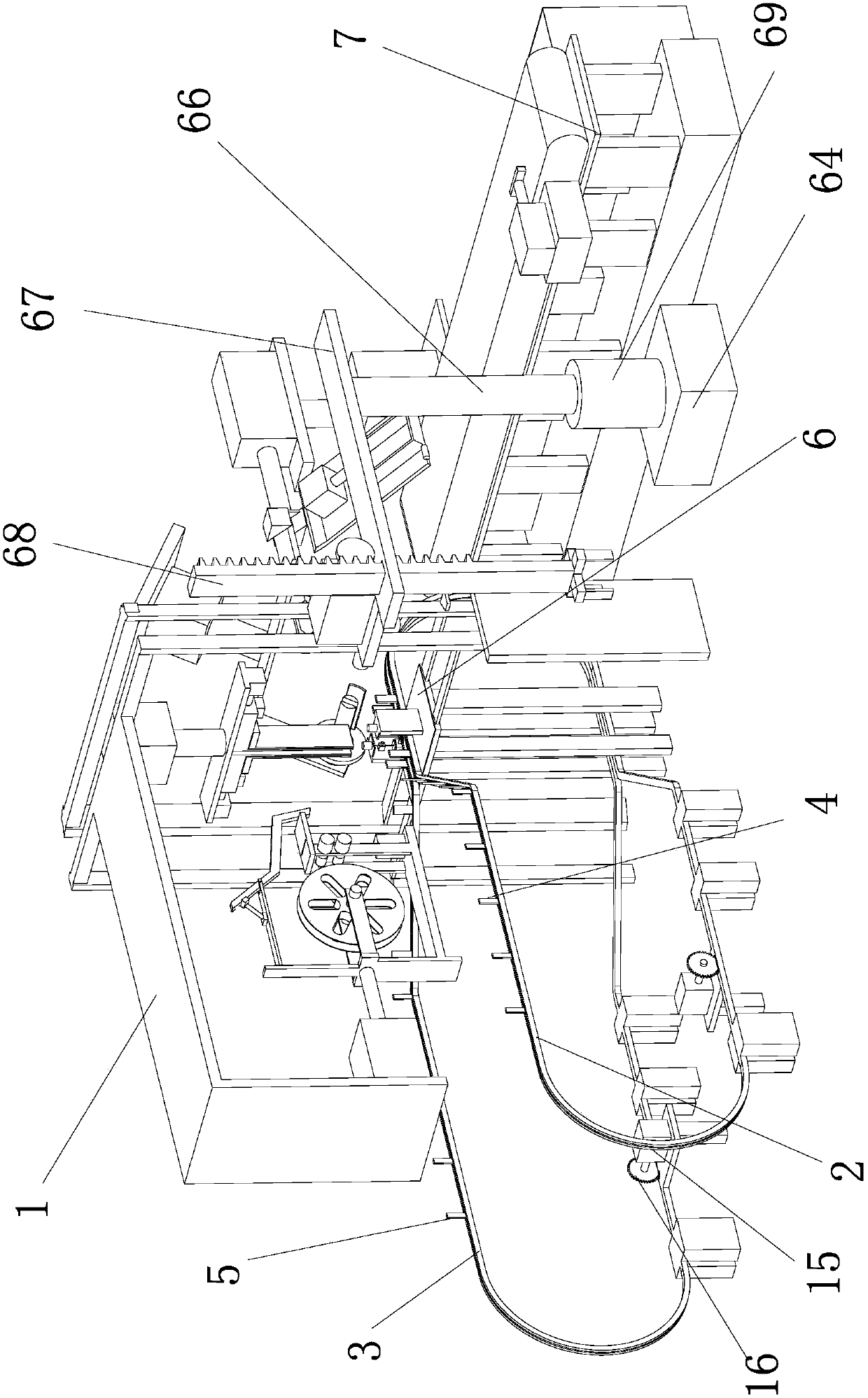

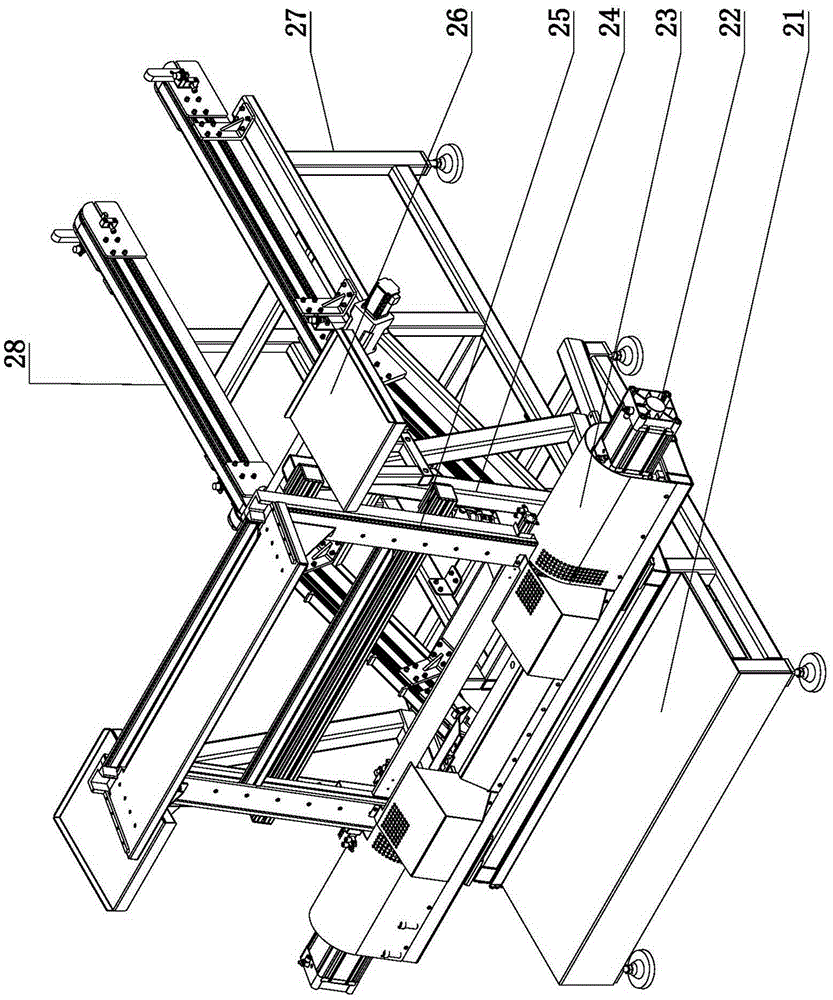

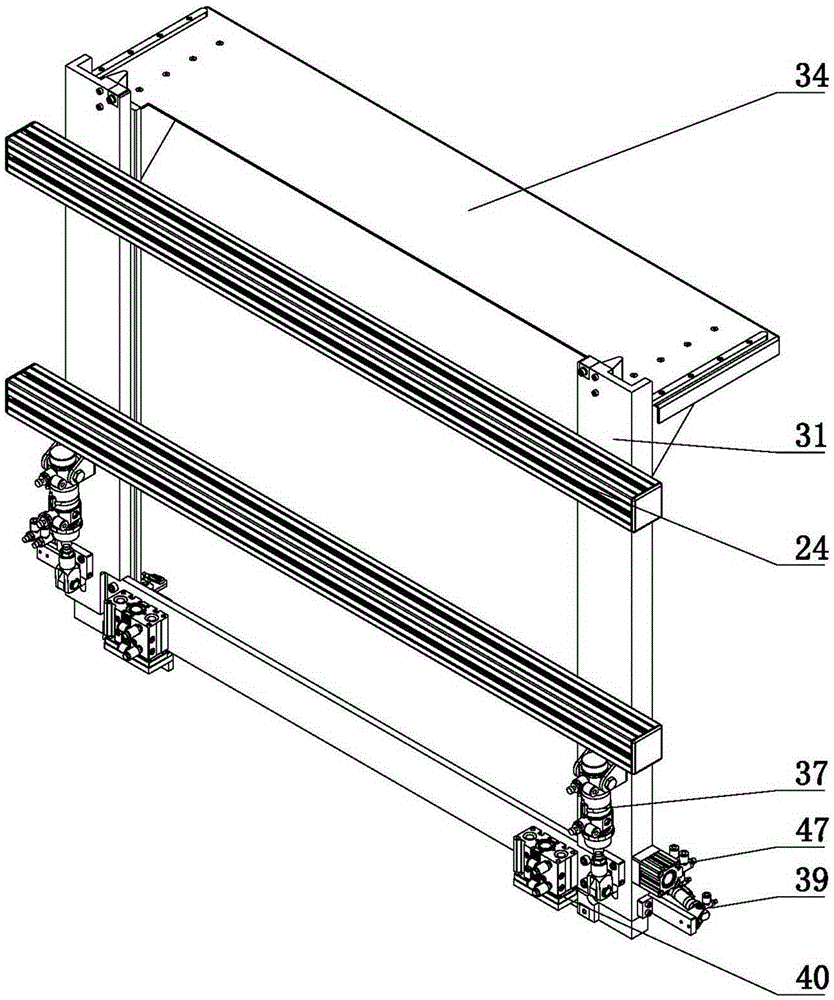

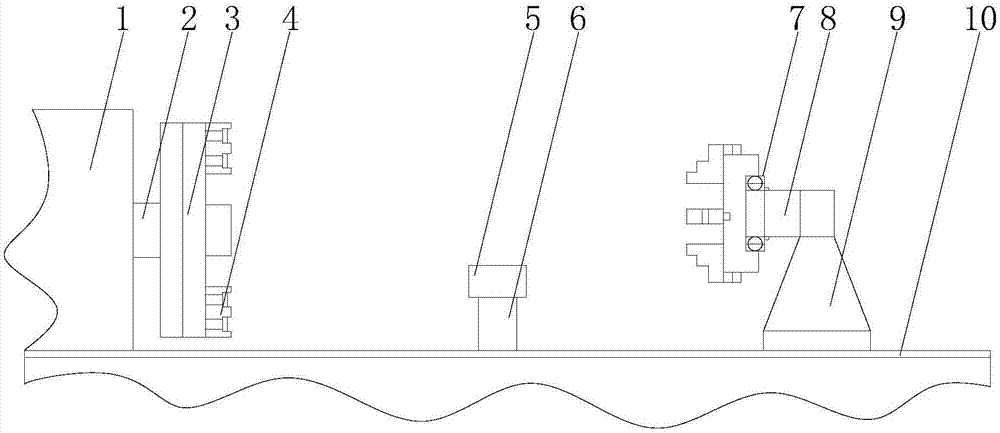

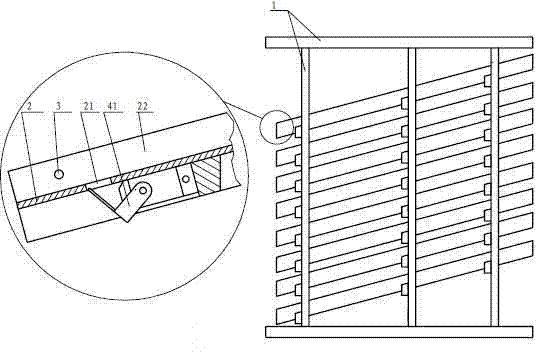

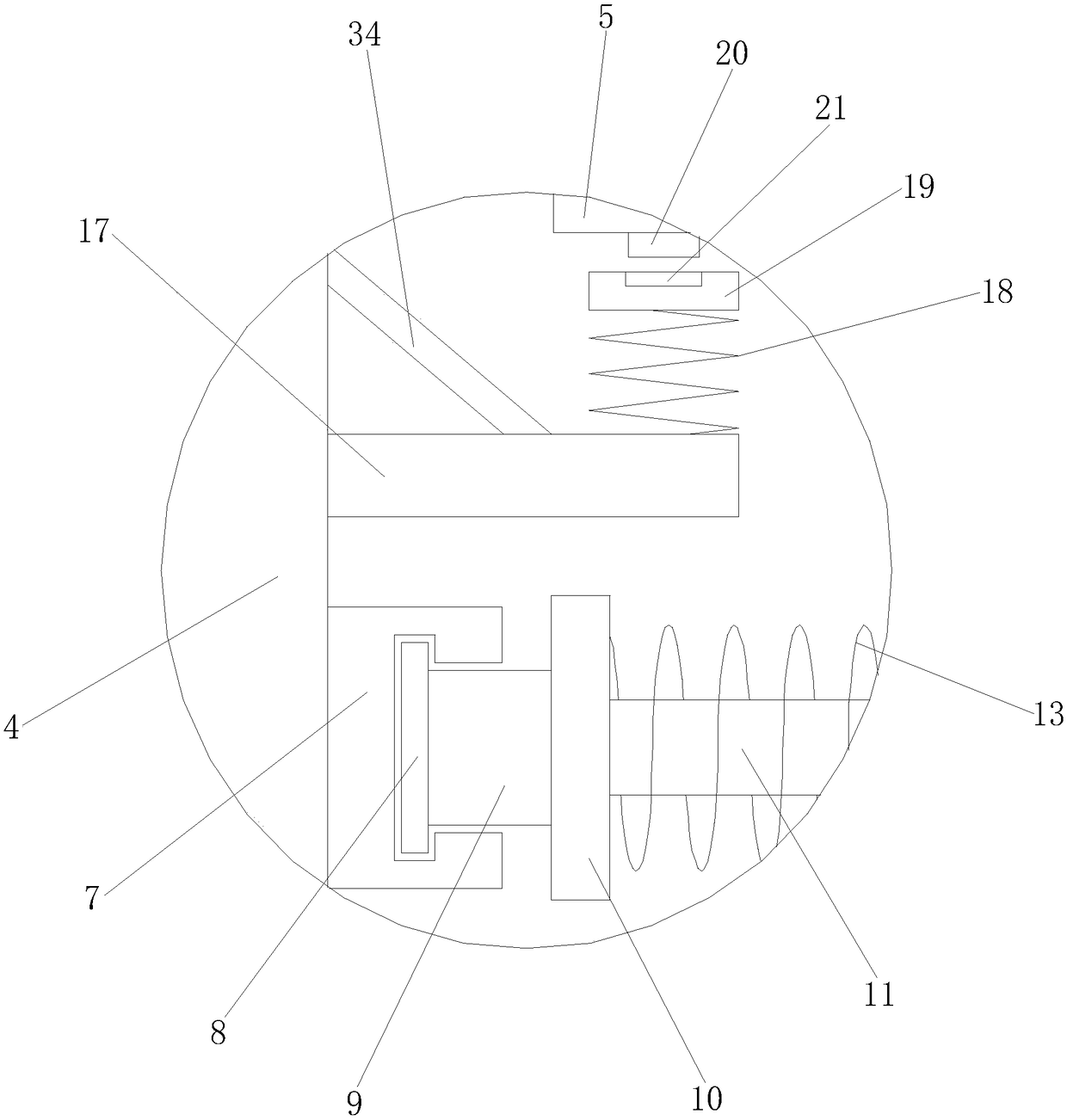

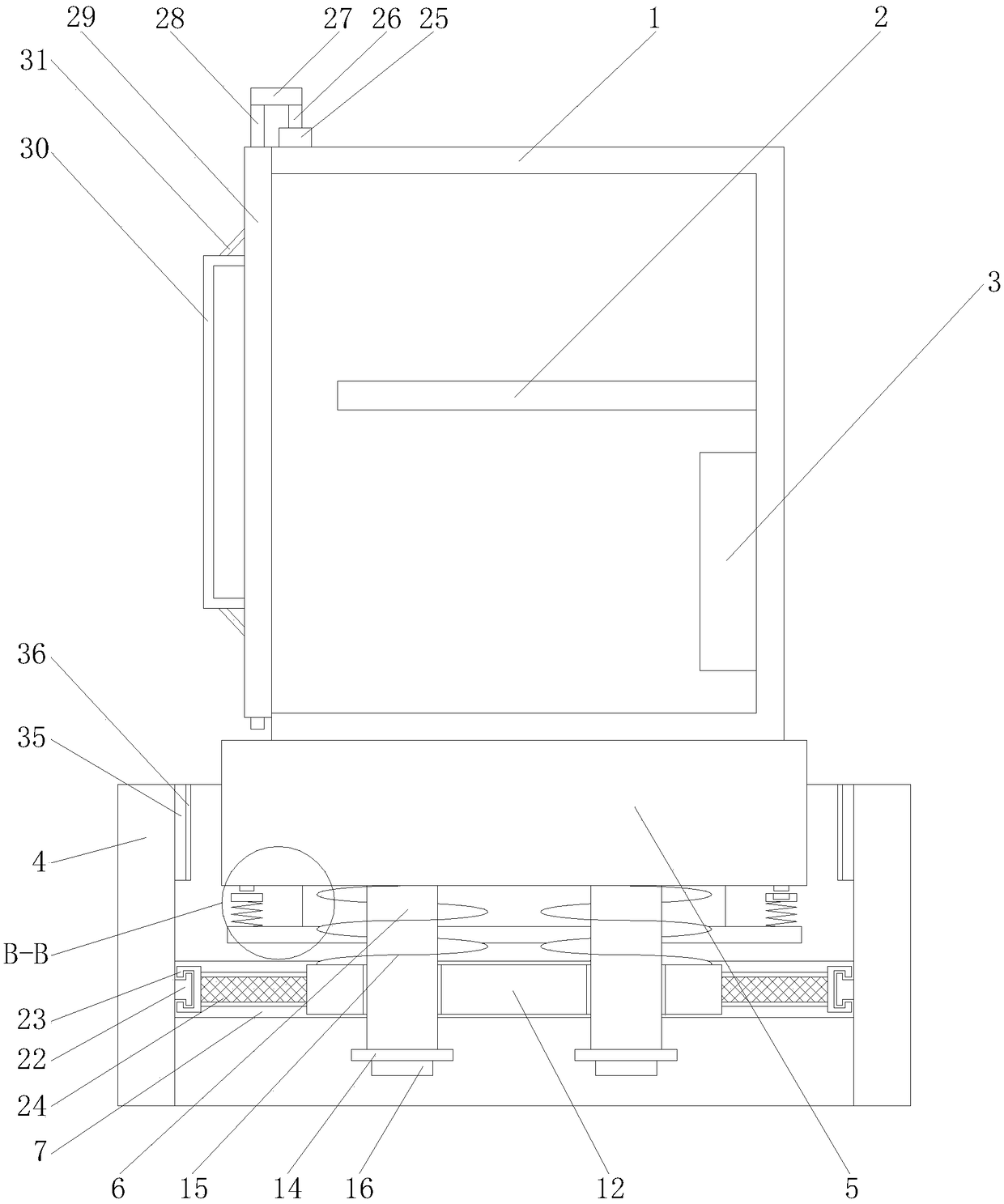

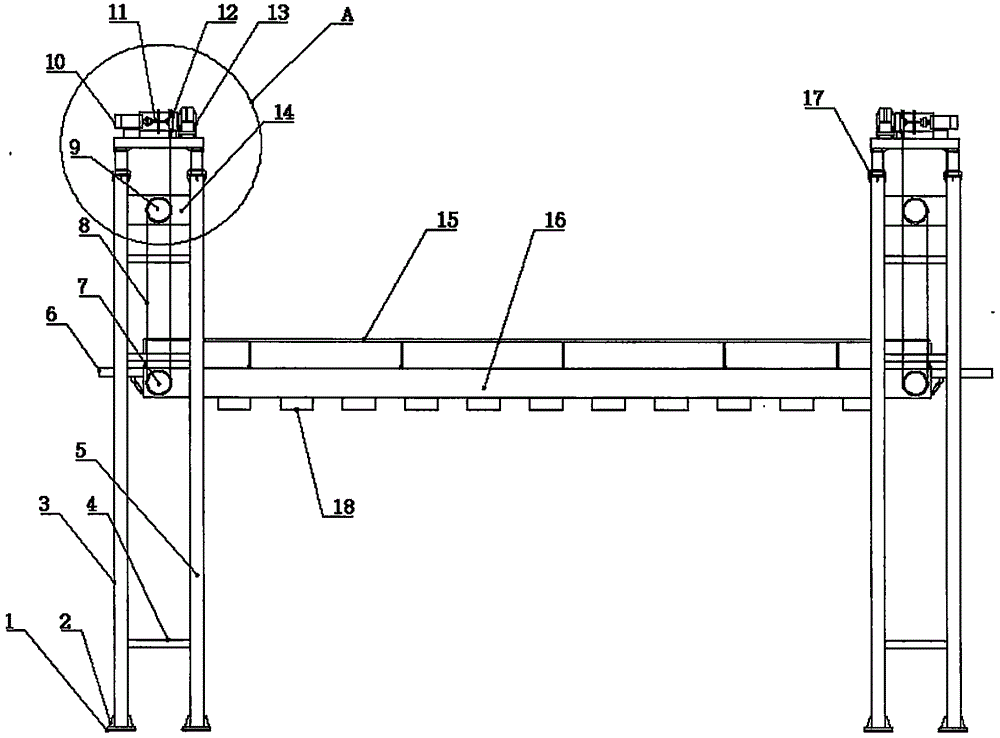

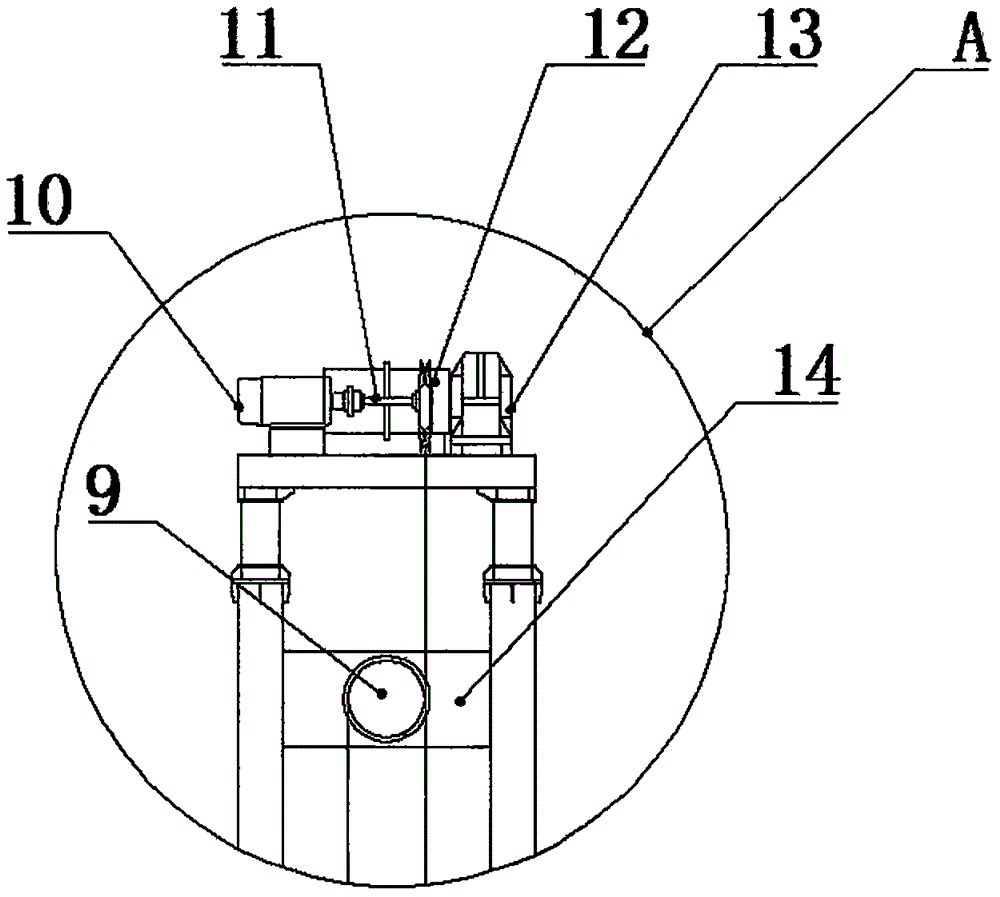

Automatic mounting machine for aluminum profile border corners

ActiveCN105345440ARealize automatic feedingSave human effortMetal working apparatusStructural engineeringMachine

The invention relates to the technical field of automated production equipment of aluminum profiles, in particular to an automatic mounting machine for aluminum profile border corners. The automatic mounting machine for the aluminum profile border corners saves manpower, improves the production efficiency and improves product quality. The automatic mounting machine for the aluminum profile border corners is characterized in that a feeding device comprises a rack, wherein two bin stand columns are arranged on the rack; a loading plate is arranged between upper ends of the two bin stand columns; a border discharging trough is formed between the two bin stand columns and on the loading plate, and border slides are arranged on the bin stand columns and correspond to the border discharging trough; corner slides are arranged on the bin stand columns and correspond to two ends of the loading plate, and a corner discharging trough is formed in the loading plate and correspond to the corner slides; a border unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding border slide; a corner unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding corner slide; a corner pressing mechanism corresponds to the lower ends of the bin stand columns.

Owner:YINGKOU JINCHEN MACHINERY

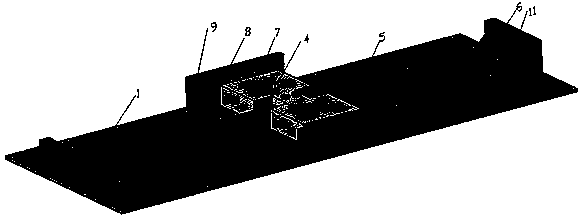

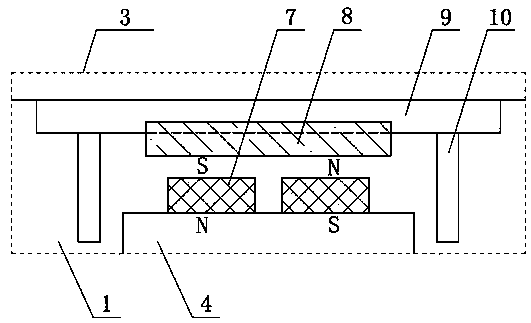

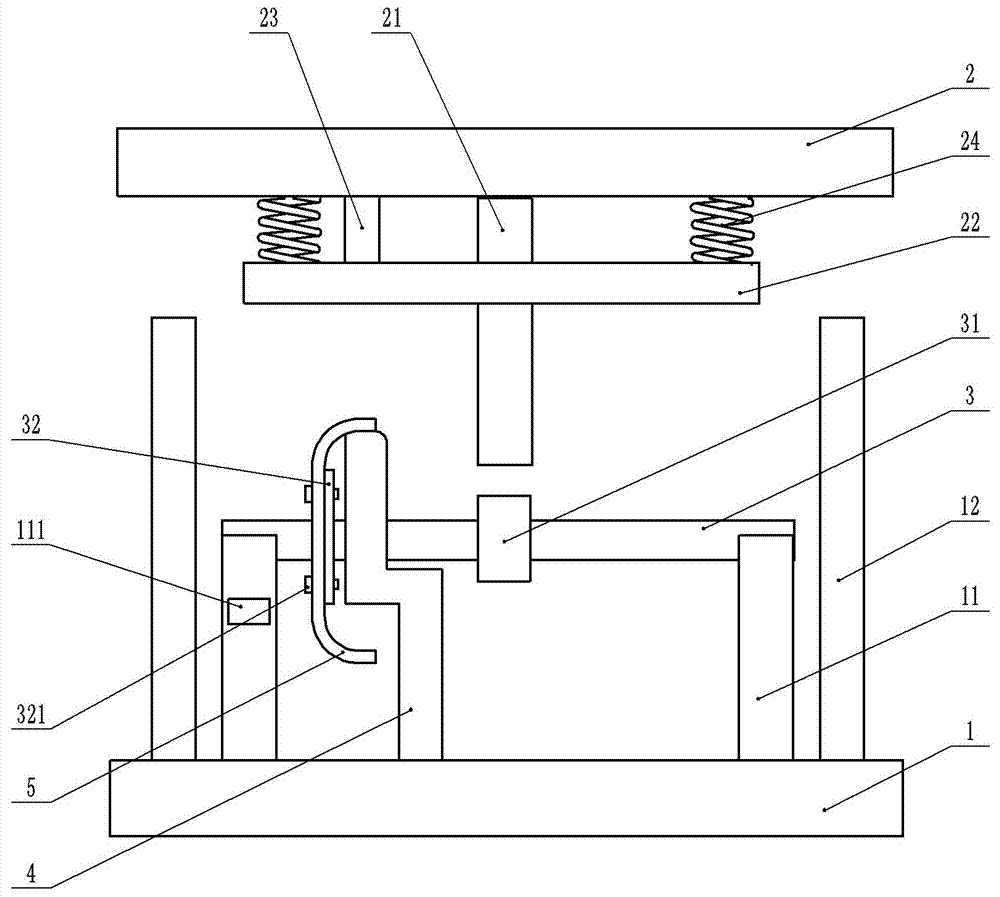

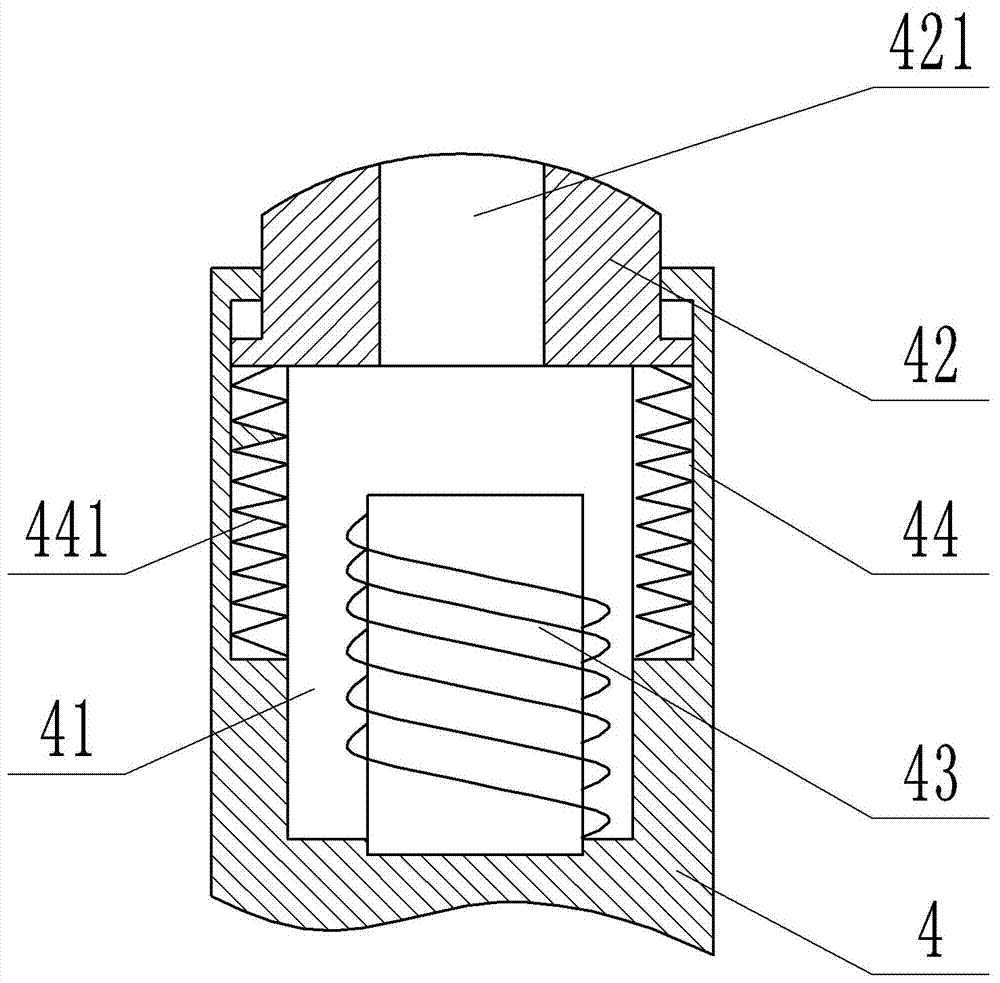

Tuned mass damper for controlling vertical high-frequency vibration of floor slabs and manufacturing method thereof

The invention discloses a tuned mass damper for controlling vertical high-frequency vibration of floor slabs and a manufacturing method thereof. The tuned mass damper mainly comprises a gantry rigid frame, a weight and damping units; the gantry rigid frame is composed of pillars and a horizontal steel beam; the weight fixed on the horizontal steel beam is driven by vertical bending deformation of the horizontal steel beam to linearly reciprocate in the vertical direction; the weight is in a variable section form, thus the weight is centrally stressed on the horizontal steel beam, and height of the weight is reduced; eddy current damping units are used as damping elements, including two sets, used to keep balanced lateral stress; the whole damper is mounted inside a floor slab through a bottom steel plate, and partial rigidity of the floor slab is enhanced by the bottom steel plate. The tuned mass damper and the manufacturing method thereof have the advantages that high frequency required by the tuned massage damper for use in damping vertical vibration of floor slabs of industrial workshops is achieved, height of the damper is effectively reduced, and embedding the damper into the floor slab is facilitated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

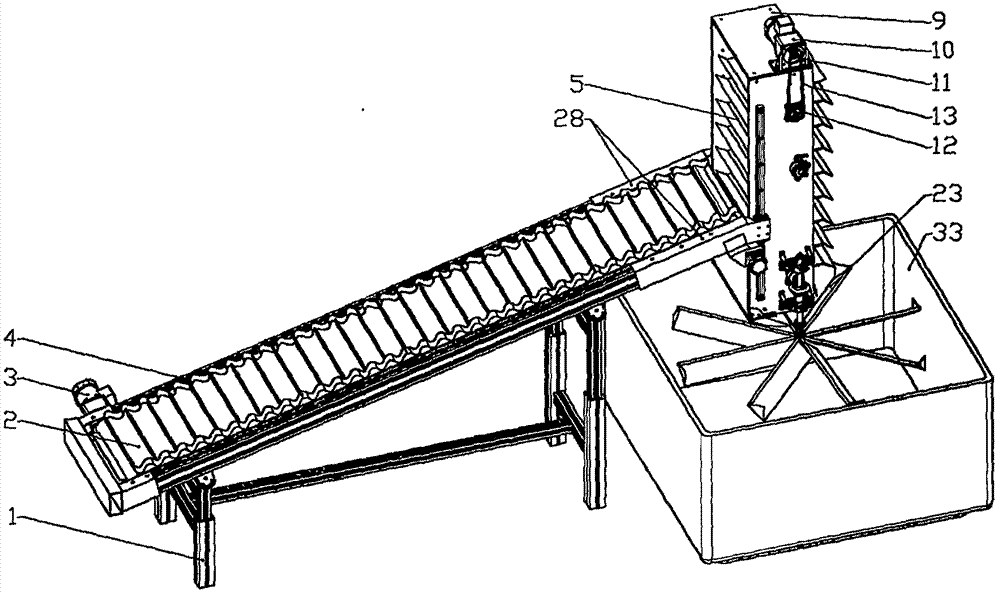

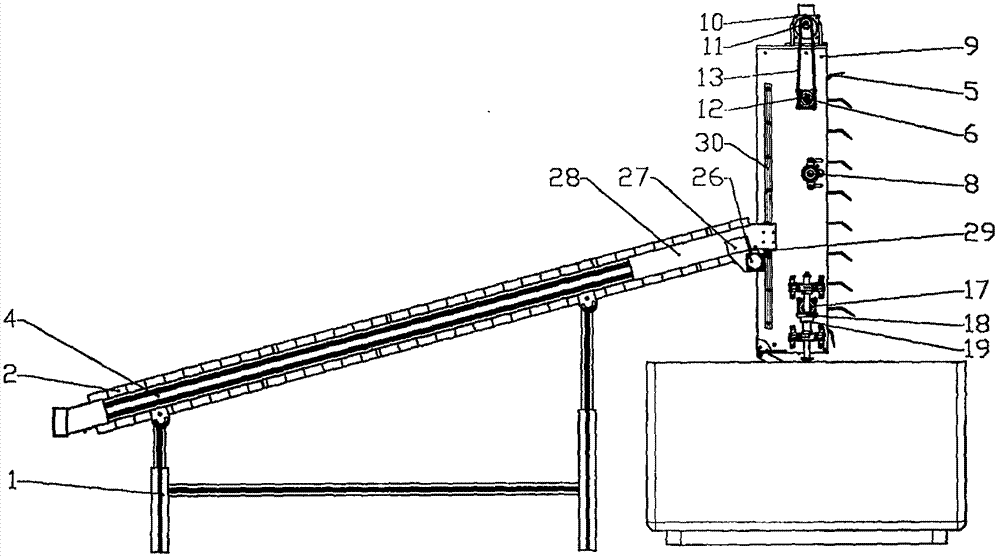

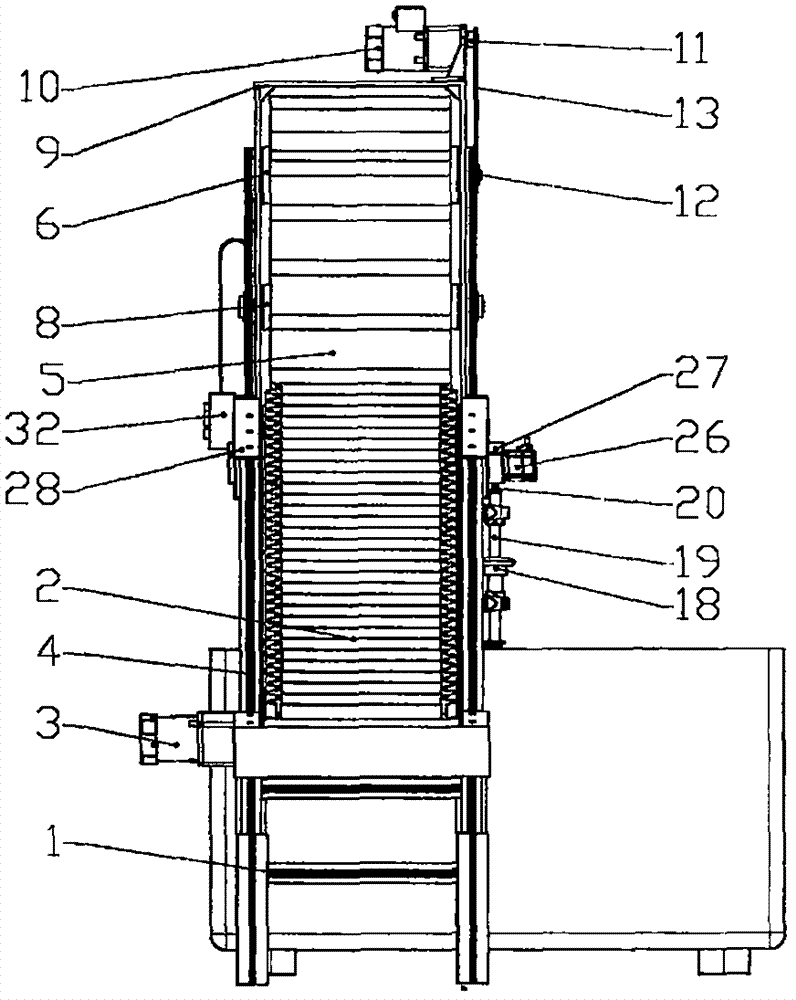

Fruit boxing device

InactiveCN107416264AStable transmissionAvoid violent collisionsPackaging automatic controlPackaging fruits/vegetablesEngineeringControl system

The invention discloses a fruit boxing device which mainly comprises a supporting frame, a main conveying mechanism, a vertical conveying mechanism, a rotating mechanism, a lifting mechanism and a fruit box. The supporting frame achieves a supporting effect, the main conveying mechanism is fixed to the supporting frame and conveys fruits to the boxing device, the vertical conveying mechanism is installed at the tail end of the main conveying mechanism, the rotating mechanism is installed on the side face of the vertical conveying mechanism, the lifting mechanism is installed on the main conveying mechanism and the vertical conveying mechanism, and the fruit box is placed under the rotating mechanism. The fruit boxing device is characterized in that with the fruit boxing process carried out, the fruit stacking height is changed, the vertical conveying mechanism can be lifted by the certain height under the effect of a control system and the lifting mechanism, fruit boxing continuity is ensured, violent collision is prevented from being caused when fruits are conveyed into the box, and the purposes that the boxing efficiency is improved and the fruit damage rate is lowered are achieved.

Owner:NORTHWEST A & F UNIV

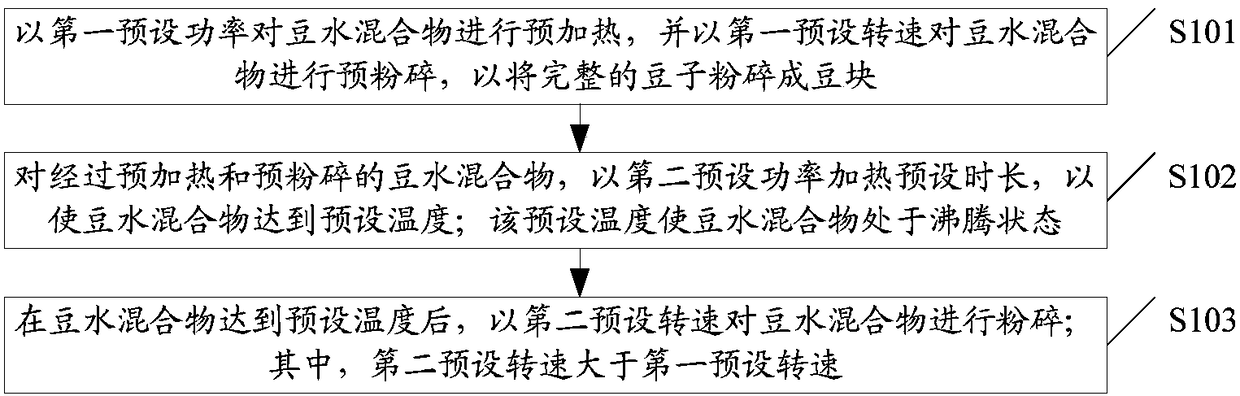

Soybean milk preparation method of soybean milk machine

ActiveCN108514346ALow powerImprove work performanceWarming devicesMilk substitutesSlurryWork Performances

The embodiment of the invention discloses a soybean milk preparation method of a soybean milk machine. The soybean milk preparation method of the soybean milk machine includes the steps that first preset power is used for preheating a bean and water mixture, the bean and water mixture is preliminarily smashed at first preset rotation speed, and therefore integrated beans are smashed into bean blocks; a second preset power is adopted to heat the preheated and pre-smashed bean and water mixture for preset time to make the bean and water mixture reach a preset temperature, wherein the preset temperature makes the bean and water mixture in a boiling state; after the bean and water mixture reaches the preset temperature, the bean and water mixture is smashed at second preset rotation speed, wherein the second preset rotation speed is greater than the first preset rotation speed. By the adoption of the soybean milk preparation method of the soybean milk machine, before a subsequent smashingprocess starts, the bean blocks in soybean milk are in a suspension state under heat convection and cannot sink to the bottom of a cup, therefore, loads generated when a motor sucks materials up are reduced, the power of the motor is reduced, the working performance of the motor is improved, and the service life of the motor is ensured; noise of bean milk beating is reduced to the maximum degree,and the user experience is improved.

Owner:JOYOUNG CO LTD

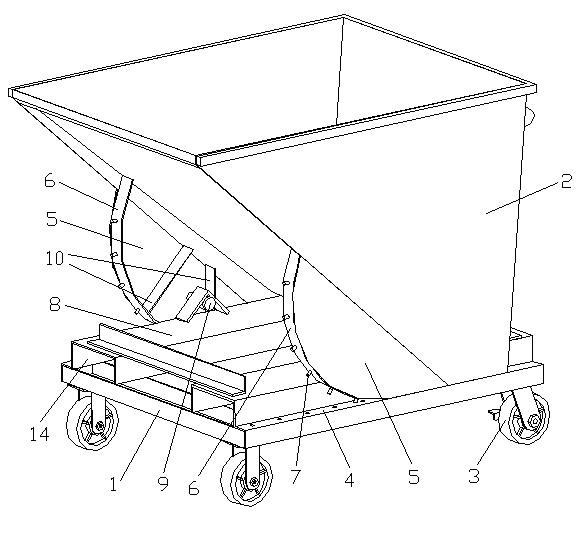

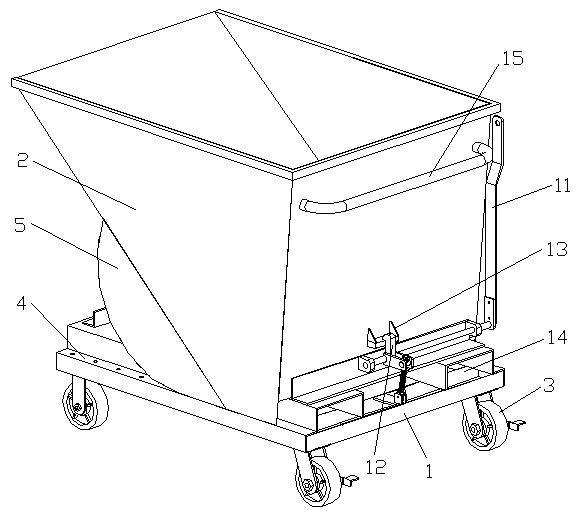

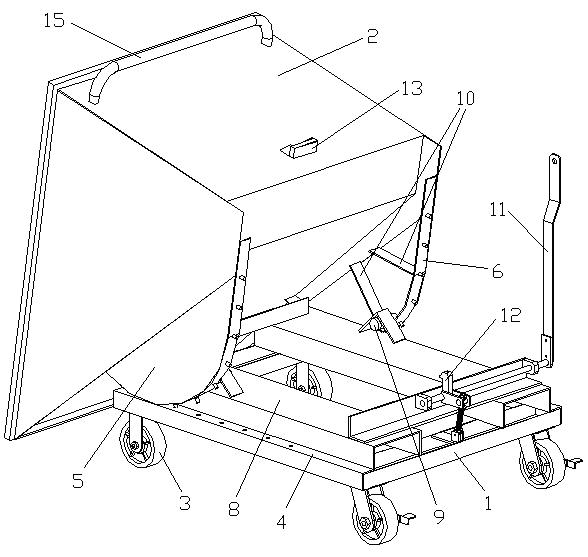

Rolling disc self-discharging type scrap iron vehicle

InactiveCN102464179AEase the turning speedAvoid violent collisionsRefuse vehiclesBuffer stripEngineering

The invention provides a rolling disc self-discharging type scrap iron vehicle, relates to the technical field of scrap iron vehicles, and aims to prolong the service life. The rolling disc self-discharging type scrap iron vehicle comprises a chassis with wheels and a moveable box body, wherein a left linear buffer guide rail and a right liner buffer guide rail which extend forwards and backwards are fixedly arranged at the upper end of the chassis; a plurality of buffer holes are formed in each buffer guide rail along the axis of the buffer guide rail; a left buffer board and a right buffer board are fixedly arranged at the bottom of the box body; the bottom edge of each buffer board is an arc-shaped edge with the arc center facing the box body; an arc-shaped buffer strip is fixedly arranged on each buffer board along the bottom edge of the buffer board; the arc-shaped buffer strips on the bottom edges of the two buffer boards are propped against the rail surfaces of the two buffer guide rails; and a plurality of semi-spherical bumps are formed on the arc-shaped buffer strips on the bottom edges of the two buffer boards, and the quantity and the positions of the semi-spherical bumps correspond to those of the buffer holes in the two buffer guide rails one to one. The scrap iron vehicle can effectively avoid unexpected discharging and has long service life.

Owner:SHANGHAI POWERWAY LOGISTICS EQUIP

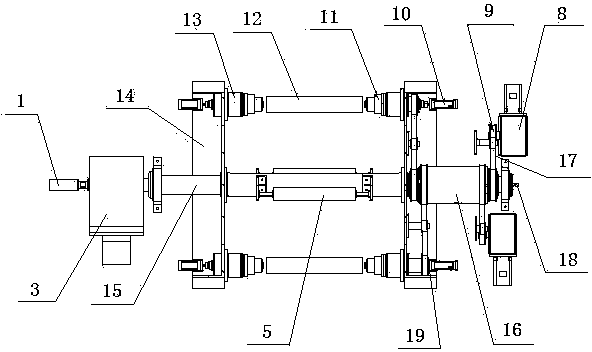

Automatic tool clamp of machine tool shaft pipe fittings

InactiveCN107138999AAvoid deformationAvoid violent collisionsTailstocks/centresLarge fixed membersHydraulic cylinderPipe fitting

The invention discloses an automatic tooling fixture for machine tool shaft pipe fittings, which includes a machine tool, a concave support table, a tailstock and a second guide rail. The connecting plate is fixedly connected, and the right side of the chuck body is equipped with a claw with a clamping nail inside, the bottom end of the concave support table is installed with a hydraulic rod that is slidingly connected with the first guide rail, and the upper end of the tailstock The connecting rod and the inner ring of the bearing are fixedly connected, the slider inside the second guide rail is fixedly connected with one end of the piston rod through a fixed block, and the piston is fixed on the inner wall of the chuck body through a positioning block A sealing ring is installed between the cylinder blocks. The invention adopts the hydraulic cylinder to drive the claws to clamp the shaft pipe fittings, so that the positioning and clamping process is quick, and at the same time, a chuck is also arranged on the tailstock, which avoids the need to process the inner hole on the parts when clamping the shaft pipe fittings, saving working hours.

Owner:十堰市神针工贸有限公司

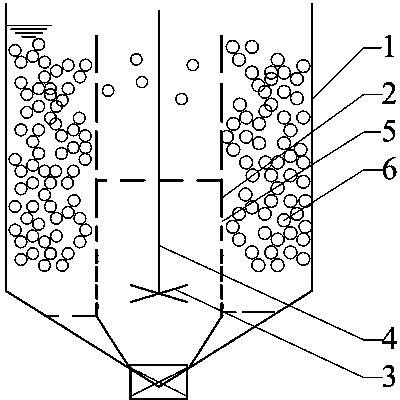

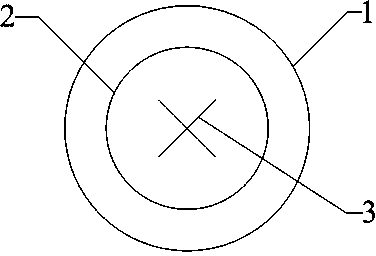

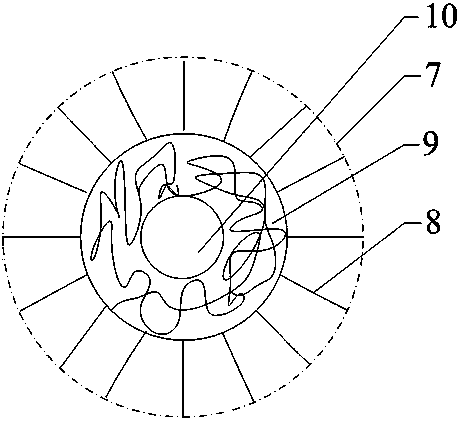

Reactor for realizing suspension of biofilm carriers under low aeration quantity

ActiveCN103508555AAvoid accumulationAvoid violent collisionsTreatment using aerobic processesSustainable biological treatmentMaterial consumptionEngineering

The invention relates to a reactor for realizing suspension of biofilm carriers under low aeration quantity. The reactor comprises a vertical cylindrical shell, wherein a vertical hollow cylinder is coaxially arranged in the shell, and a stirring paddle is mounted in the hollow cylinder; a plurality of through holes are formed on the wall of the hollow cylinder; the bottom end of the hollow cylinder is fixedly connected with the bottom end of the shell; and the biofilm carriers are filled in a circular space between the hollow cylinder and the shell. According to the unique structure design of the reactor and the control to the rotating speed of the stirring paddle, the biofilm carriers in the reactor can be ensured always in the suspension state under the low aeration quantity, and excellent fluidization character is maintained, so that the partial nitrification advantages are stably kept, the advantages are created for simultaneous nitrification and denitrification, and the aeration energy consumption and the carbon source material consumption in the denitrification phase are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

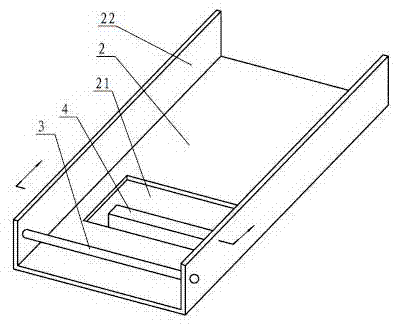

Storage cargo outlet method for storage rack and storage rack

InactiveCN102398756AIncrease the speed of warehouse deliverySimple structureStorage devicesEngineeringStructural engineering

The invention relates to a storage cargo outlet method for a storage rack, which is characterized in that a storage plate for storing cargos is inclined so that the surface of the storage plate becomes an inclined surface, the bottom of the inclined surface is provided with a position limiting element used for preventing the cargos from downwards sliding, the cargos are placed on the inclined storage plate, and the cargos are arranged at the inclined surface above the position limiting element one by one, when the cargo delivery is needed, the cargos to be outlet tightly leaning on the position limiting element are firstly lifted, in addition, the cargos are higher than the position limiting element, the cargos exceed the position limiting element under the gravity effect of the cargos above the inclined surface and slide out of the storage plate in inclined arrangement, and the subsequent cargos slide to the position limiting element and are blocked on the storage plate in inclined arrangement by the position limiting element. The storage rack comprises a support frame, wherein the storage plate is connected onto the support frame and is in inclined arrangement, the position limiting element is arranged on the storage plate and is positioned at the downstream part of the storage plate in the inclined arrangement, a through hole is arranged on the storage plate and is adjacent to the position limiting element, and a lifting mechanism is arranged under the through hole.

Owner:JIANGSU XUNJIE HARNESS TECH

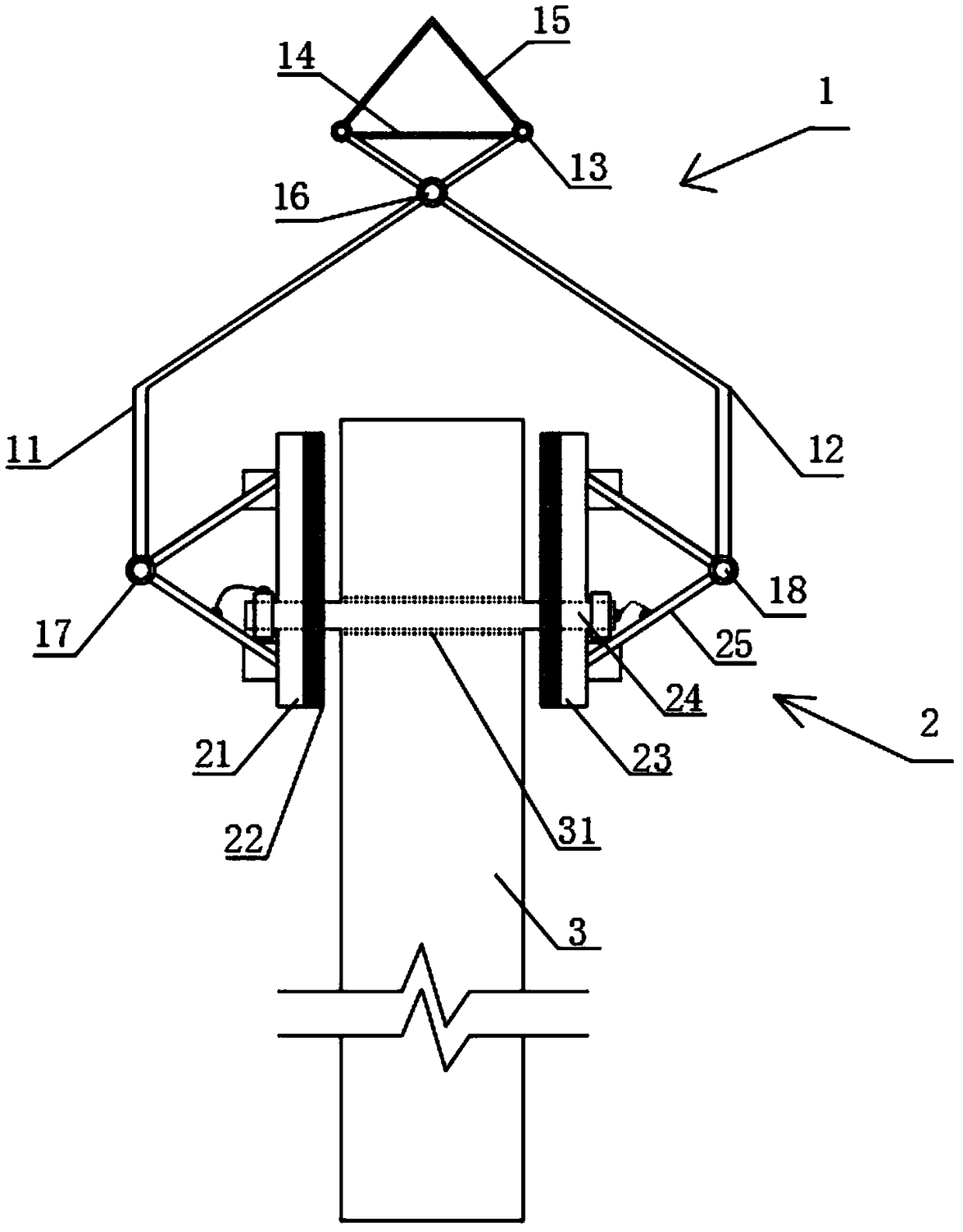

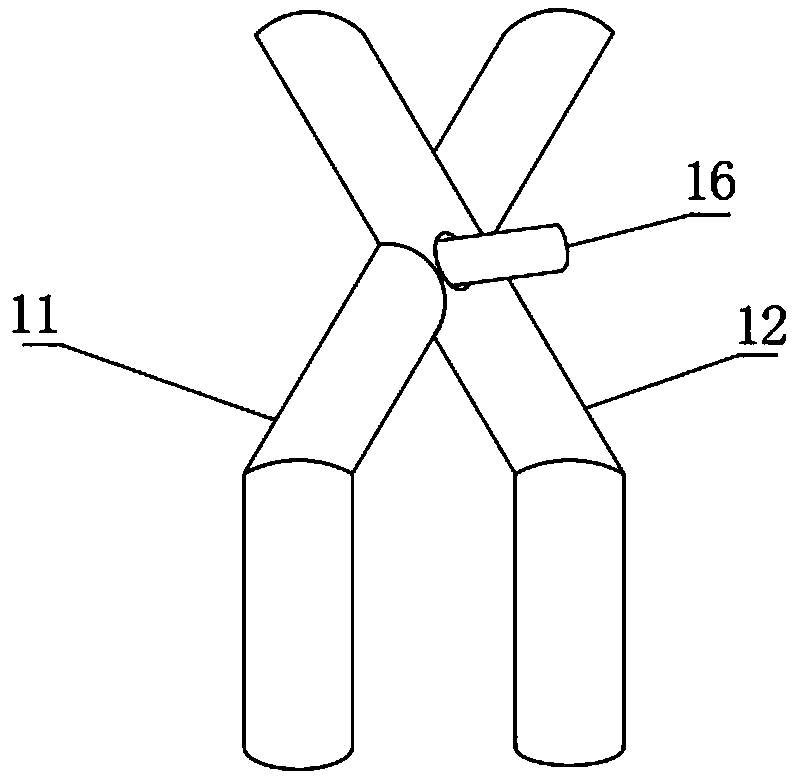

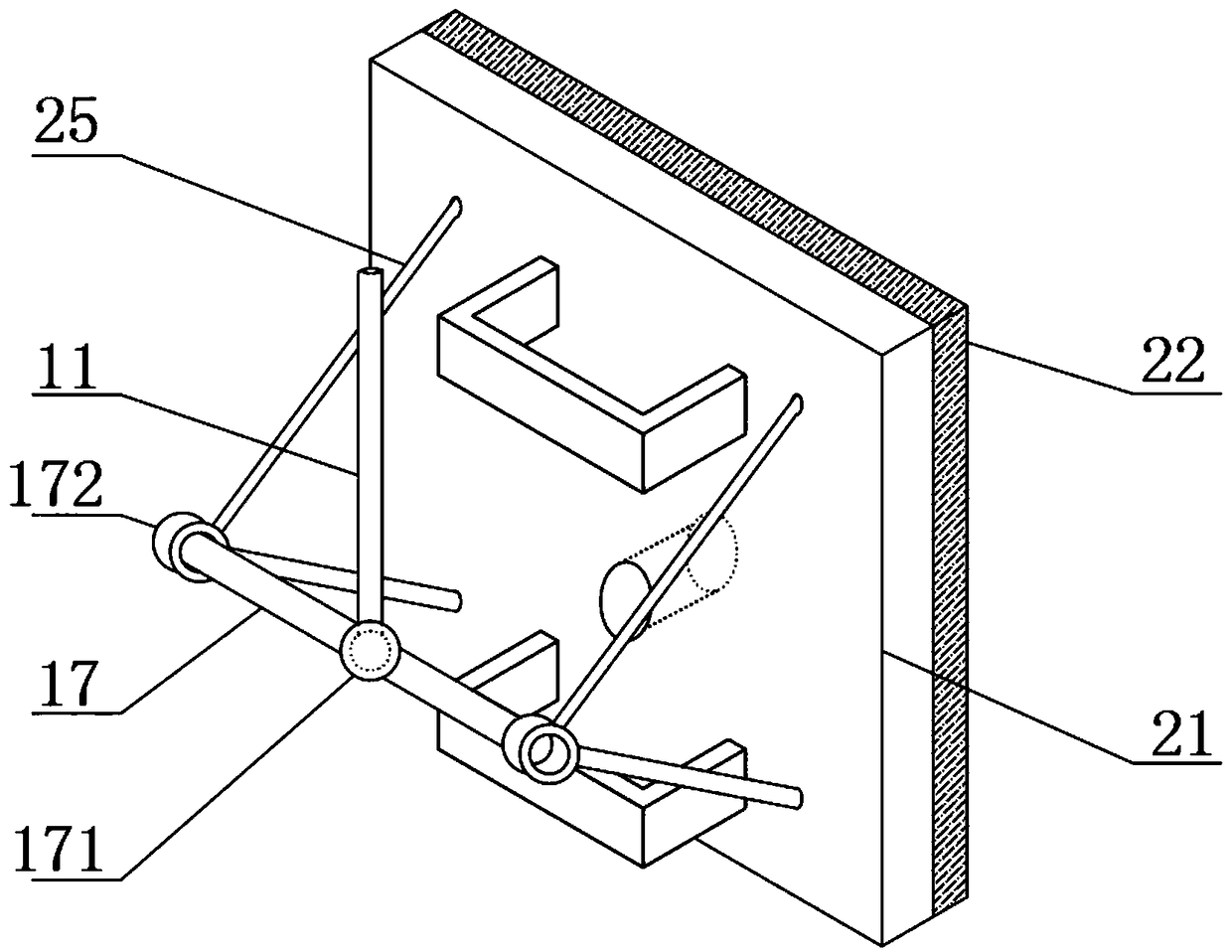

Hoisting device and hoisting method for prefabricated panel

PendingCN109205463AImprove safety and reliabilityMeet the use requirementsLoad-engaging elementsEngineeringWall plate

The invention relates to the technical field of building construction, particular to a hoisting device and hoisting method for a prefabricated panel. The hoisting device comprises a hoisting portion for hoisting the prefabricated panel and a clamp portion for fixing the position of the prefabricated panel, wherein the clamp portion is connected with the lower end of the hoisting portion and is provided with an anchor bolt arranged in the penetrating a hoisting hole that is formed in the prefabricated panel. When the prefabricated panel is hoisted by using the hoisting device, the prefabricatedpanel is placed in the clamp portion at first, the hoisting anchor bolt is inserted into the hoisting hole, and the prefabricated panel is fixed onto the hoisting device; a combination of the clamp portion and the hoisting anchor bolt replaces hoisting rings for the prefabricated panel, so safety and reliability during hoisting are improved, and usage requirements of prefabricated panels with different thicknesses and different bore diameters on the hoisting device are met; and in use of the hoisting device, presetting of hoisting rings on prefabricated panel is not needed, so materials are saved.

Owner:HEFEI UNIV OF TECH

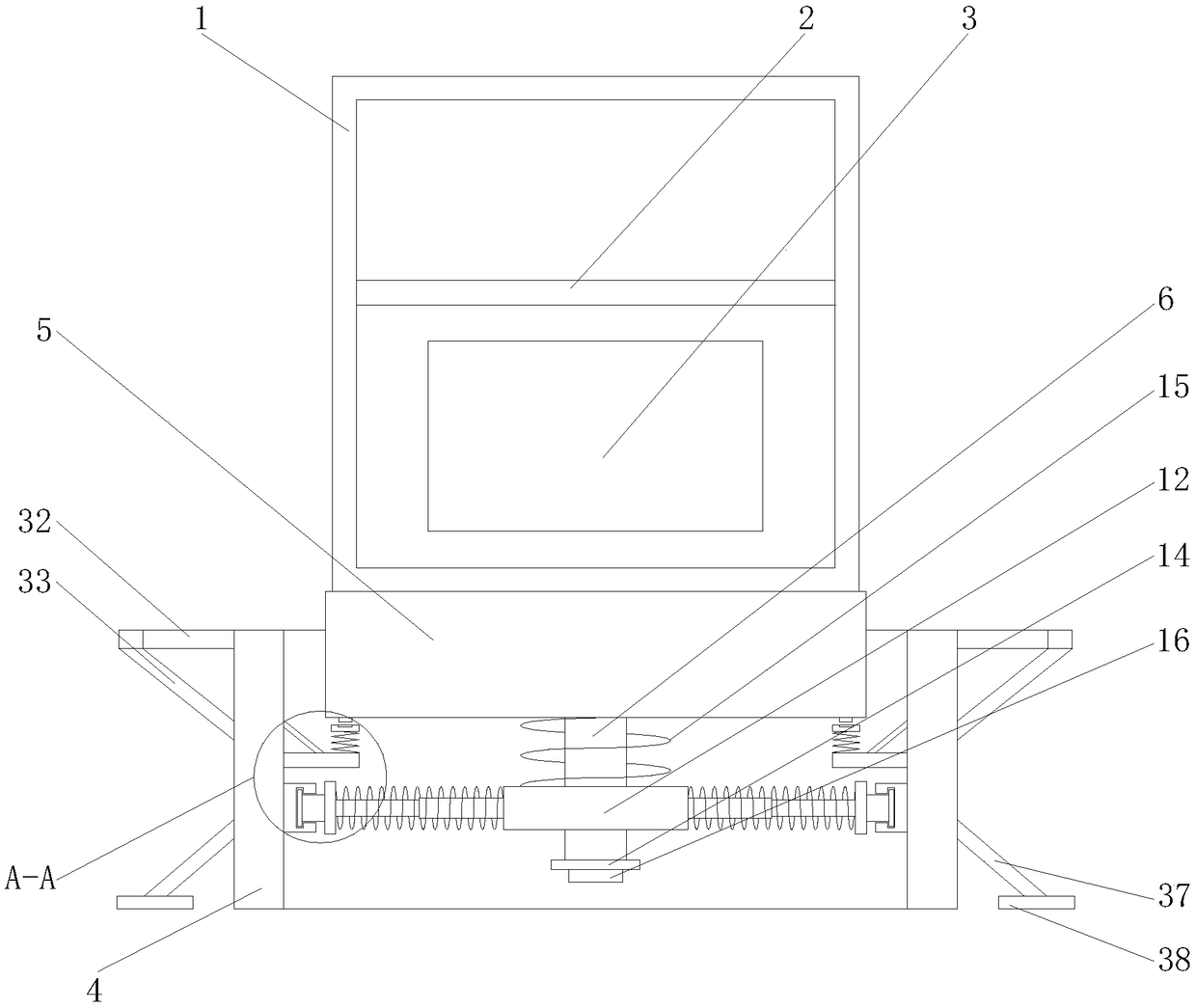

High-voltage distribution cabinet with good shock absorption effect

ActiveCN109256705AImprove shock absorptionAvoid damageSubstation/switching arrangement casingsAnti-seismic devicesEngineeringSlide plate

The invention discloses a high-voltage distribution cabinet with good shock absorbing effect, comprises a cabinet body, a partition plate is fixedly connected to the inner wall of the cabinet body, aninstrument mounting plate is fixedly connected to the back surface of the cabinet body and is positioned below the partition plate, a protective shell is arranged below the cabinet body, a movable block is fixedly connected to the bottom of the cabinet body, and the bottom of the movable block penetrates the protective shell and extends to the inside thereof. protective shell is arrange, a movingblock, a limit chute block, a sliding plate, a Spring retaining plate, a telescopic bar, a movable plate, a transverse spring, a limit baffle, a first vertical spring, the top block, the support plate, the second vertical spring, the support block, the striking block, the striking groove, the slide rail, the sliding block and the elastic belt are arranged so that better shock absorption effect ofthe high-voltage distribution cabinet is acquired. the damage of the distribution cabinet itself and the internal apparatus of the distribution cabinet is avoided, the unnecessary economic damage isprevented, the occurrence of the safety accident is lowered, and great convenience to a user is brought.

Owner:YUEQING WENBAO ELECTRONICS ELECTRICAL

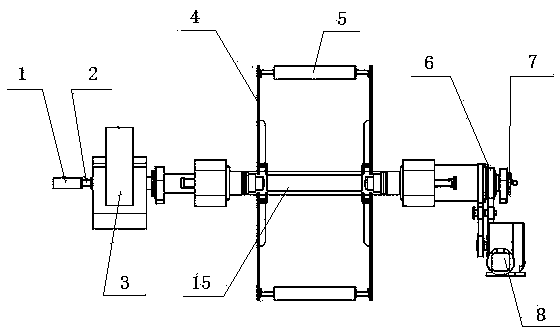

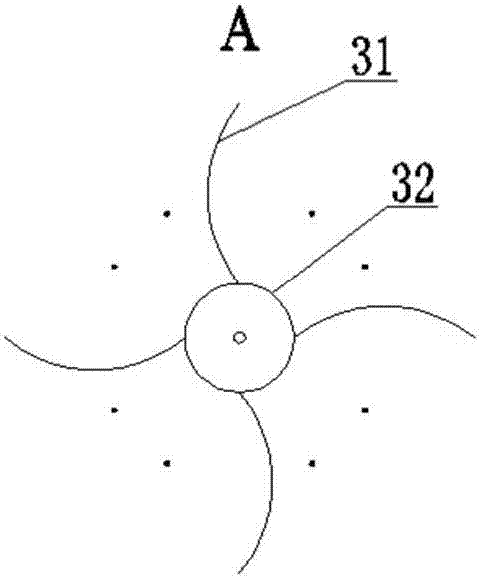

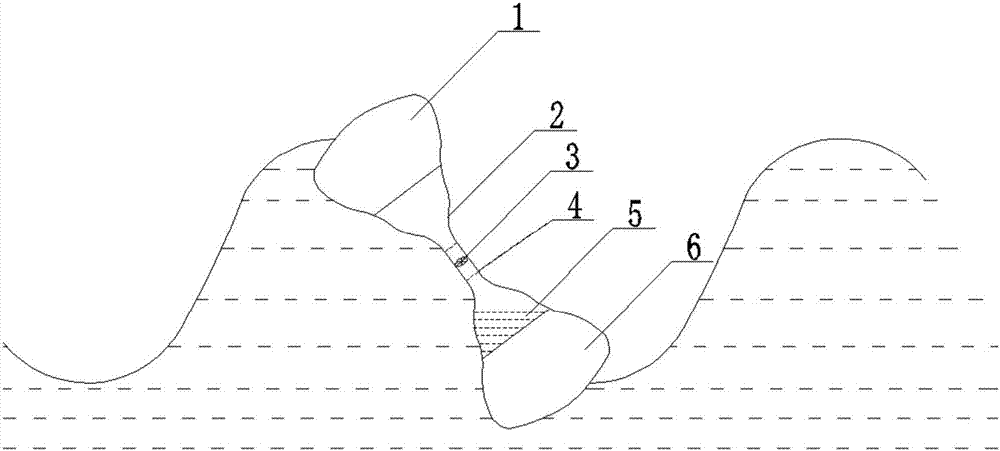

Mechanical-electrical-hydraulic integrated full-sealed wave energy power generating device

PendingCN107100783AImprove power generation efficiencyOvercoming violent collisionsHydro energy generationMachines/enginesMass distributionElectric energy

The invention discloses a mechanical-electrical-hydraulic integrated full-sealed wave energy power generating device. A first floating body and a second floating body are fixedly arranged at the two ends of a sealed flow tube, so that the first floating body and the second floating body support the whole wave energy power generating device to float on the sea; an energy extracting unit, a stream guiding mechanism and a fluid medium are arranged in the sealed flow tube, the device swings in a reciprocating manner under the action of waves, and the fluid medium flows in the sealed flow tube in a reciprocating manner through the energy extracting unit, so that the fluid medium absorbs wave energy and transfers the wave energy to the energy extracting unit for generating power; and an electric generator in the energy extracting unit rotates in one direction all the time by means of the flow guiding mechanism to complete the wave energy power generating process. According to the mechanical-electrical-hydraulic integrated full-sealed wave energy power generating device, fluid, machine and electric power integrated design is adopted, the interior is completely isolated from sea water, the structure is simple, few moving parts exist, and moveless sealing is achieved; by means of internal and external shape design, mass distribution design and culvert tube flow channel design, reliable, efficient and stable wave power generation can be achieved.

Owner:ZHEJIANG UNIV

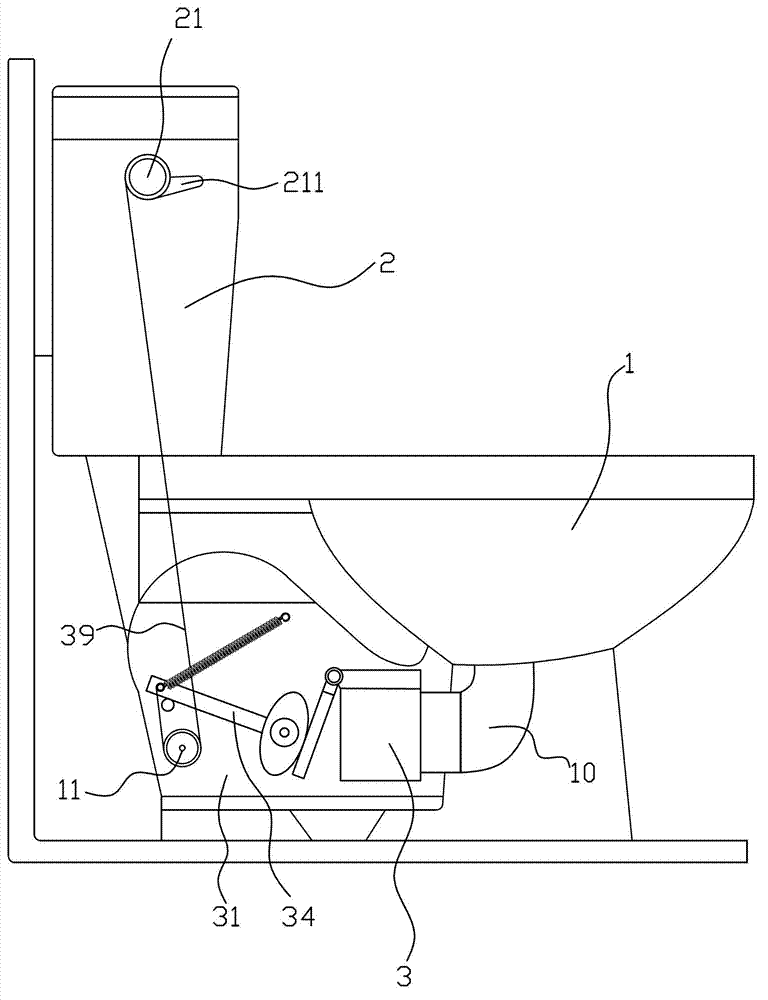

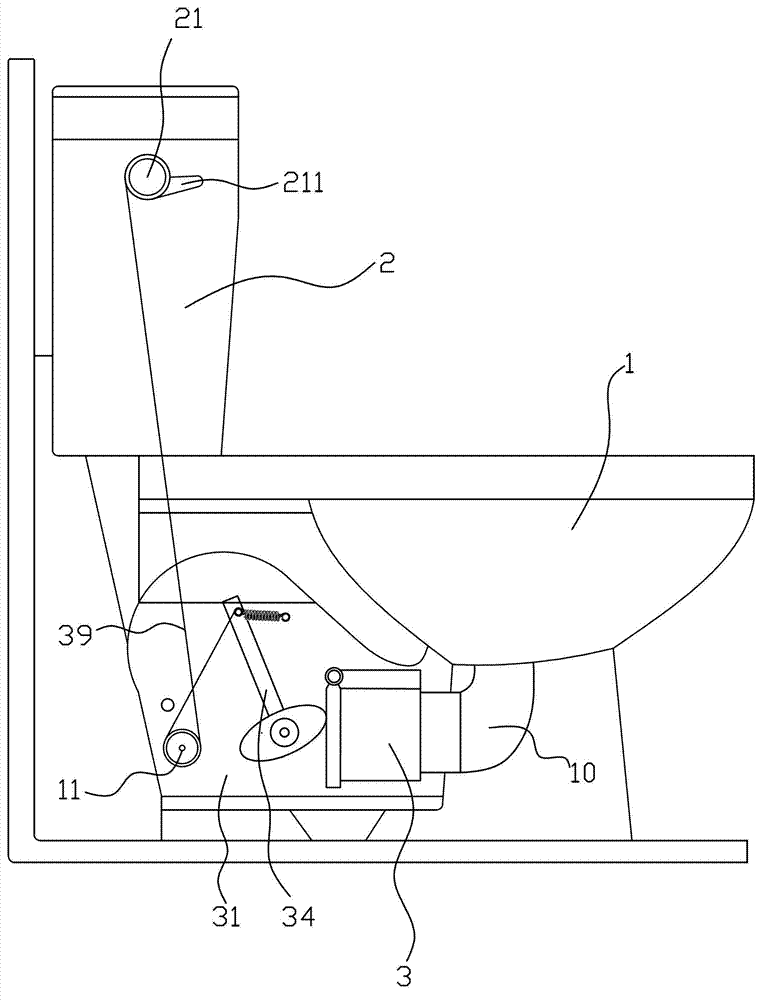

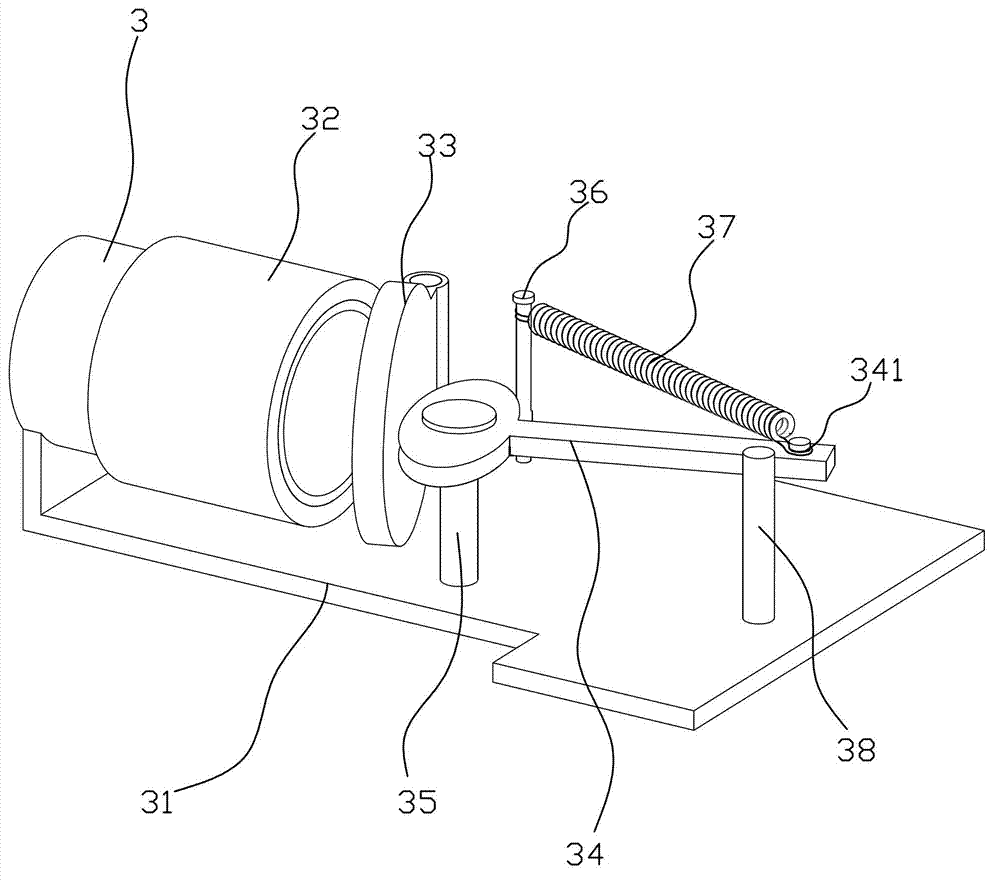

Lever valve closestool

InactiveCN102966163AThe principle is simpleStable structureWater closetsFlushing devicesWater savingSewage

The invention discloses a lever valve closestool. The lever valve closestool comprises a closestool body and a water storage bucket, wherein a sewage outlet is arranged at the lower part of the closestool body; and a lever valve for sewage disposal is mounted at the sewage outlet in a matched way. The lever valve closestool has the advantages of stable structure, simple principle, convenience for use, water saving and the like.

Owner:广东慧信环保有限公司

Buffering hydraulic oil cylinder

ActiveCN112324744AExtended service lifeReduce collisionFluid-pressure actuatorsHydraulic ramEngineering

The invention discloses a buffer hydraulic oil cylinder. The hydraulic oil cylinder comprises a cylinder body, a piston is connected to the inner wall of the cylinder body in a sealed and sliding manner, a pull rod penetrating through the cylinder body is fixed to the side wall of the piston, a contraction pipe and an extension pipe are inserted into the side wall of the cylinder body in a penetrating manner, and a buffer box is fixed to the outer wall of the cylinder body. A push plate is connected to the inner wall of the buffer box in a sealed and sliding manner, a telescopic rod is fixed to the side wall of the push plate, and a magnetic block is fixed to the side wall of the piston. The buffer hydraulic oil cylinder has the advantages that magnetorheological fluid is arranged in the buffer box, the magnetic block is arranged on the piston, and when the piston gets close to the buffer box at a high speed, magnetic force acts on the magnetorheological fluid, so that the fluidity ofthe magnetorheological fluid is reduced, the movement of the push plate is limited, the movement of the piston is limited, and furthermore, the piston does not violently collide with the inner wall ofthe cylinder body, a buffering effect is achieved on movement of the piston, and the service life of the cylinder body and the service life of the piston are prolonged.

Owner:常德市富斯特液压油缸有限公司

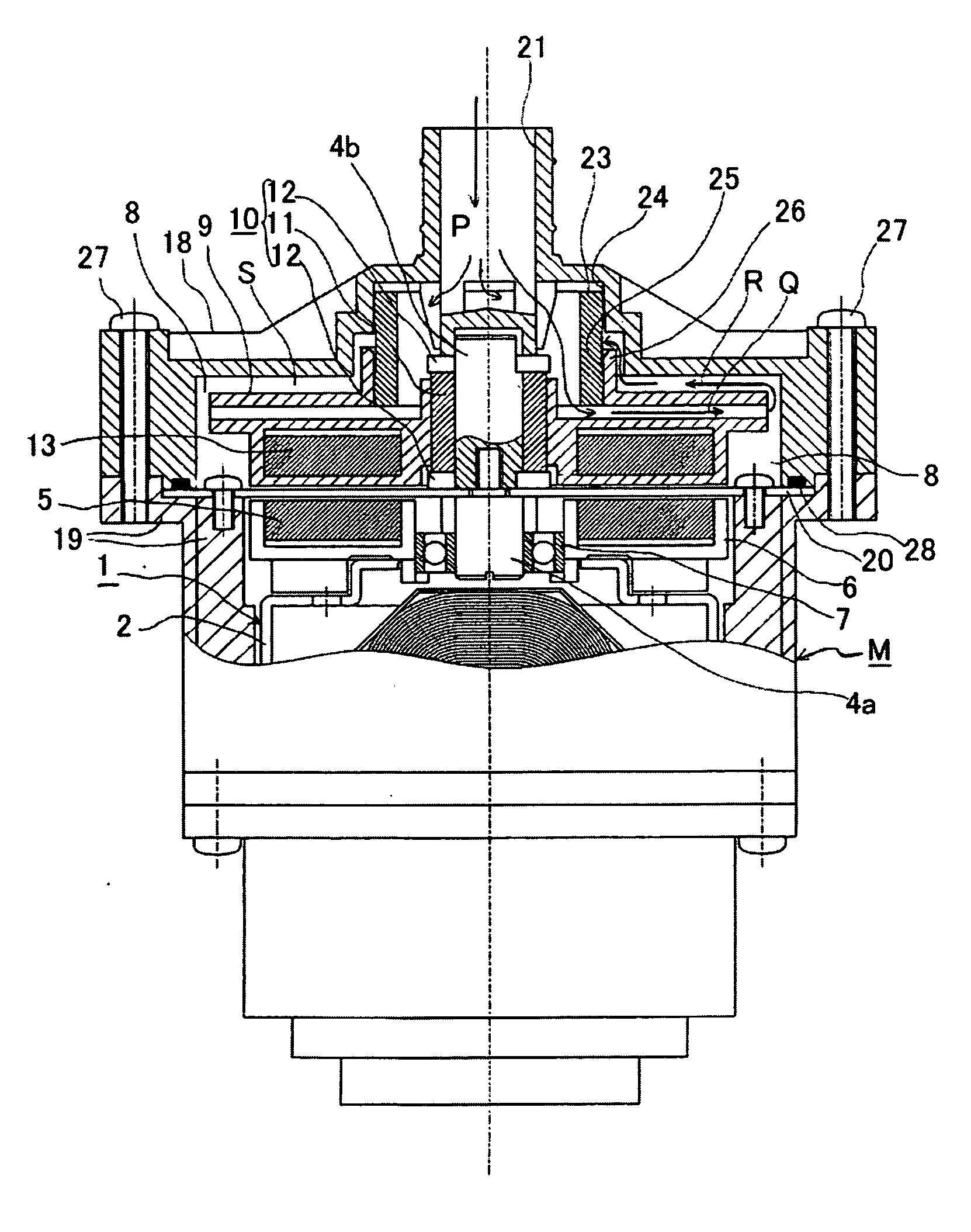

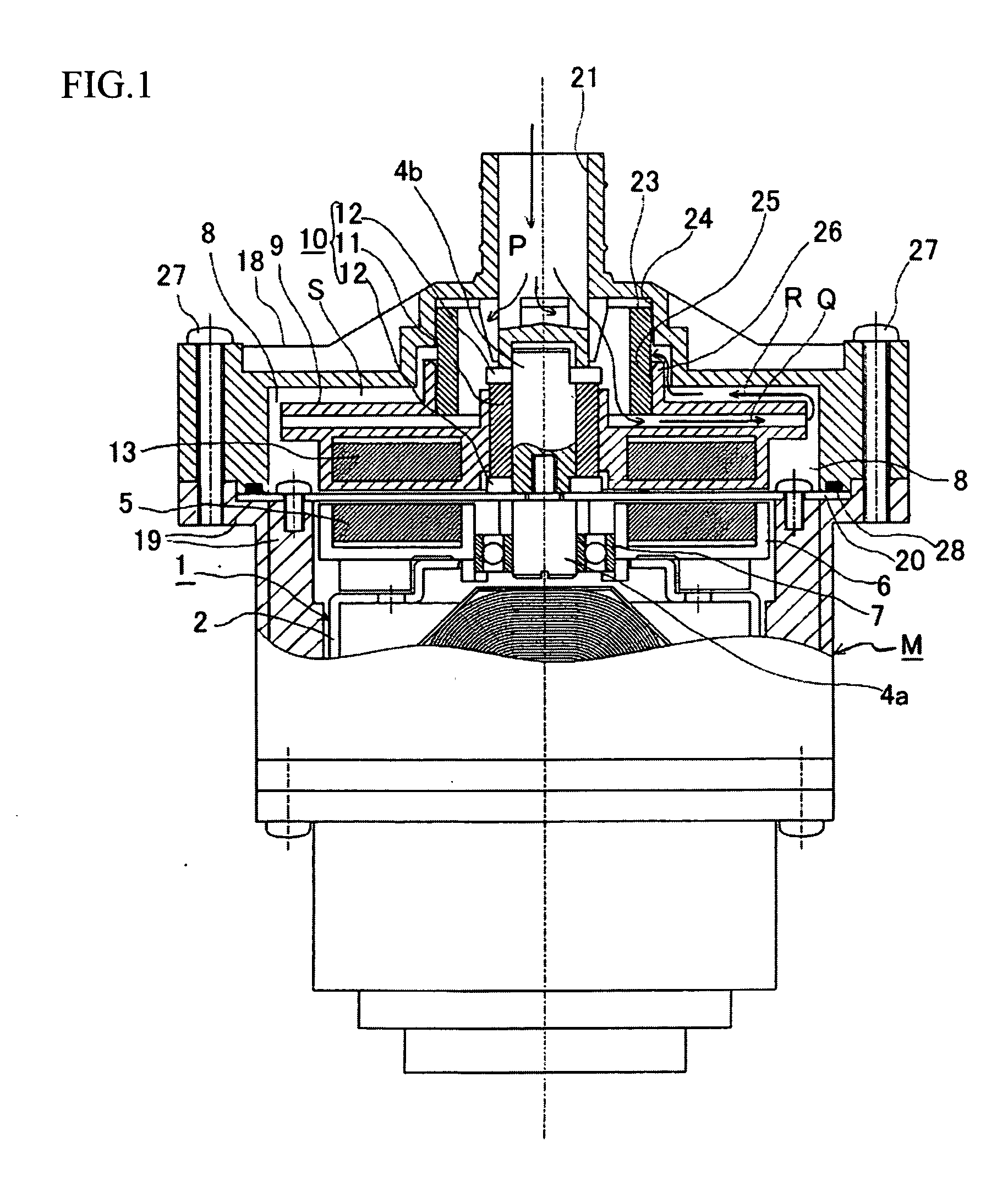

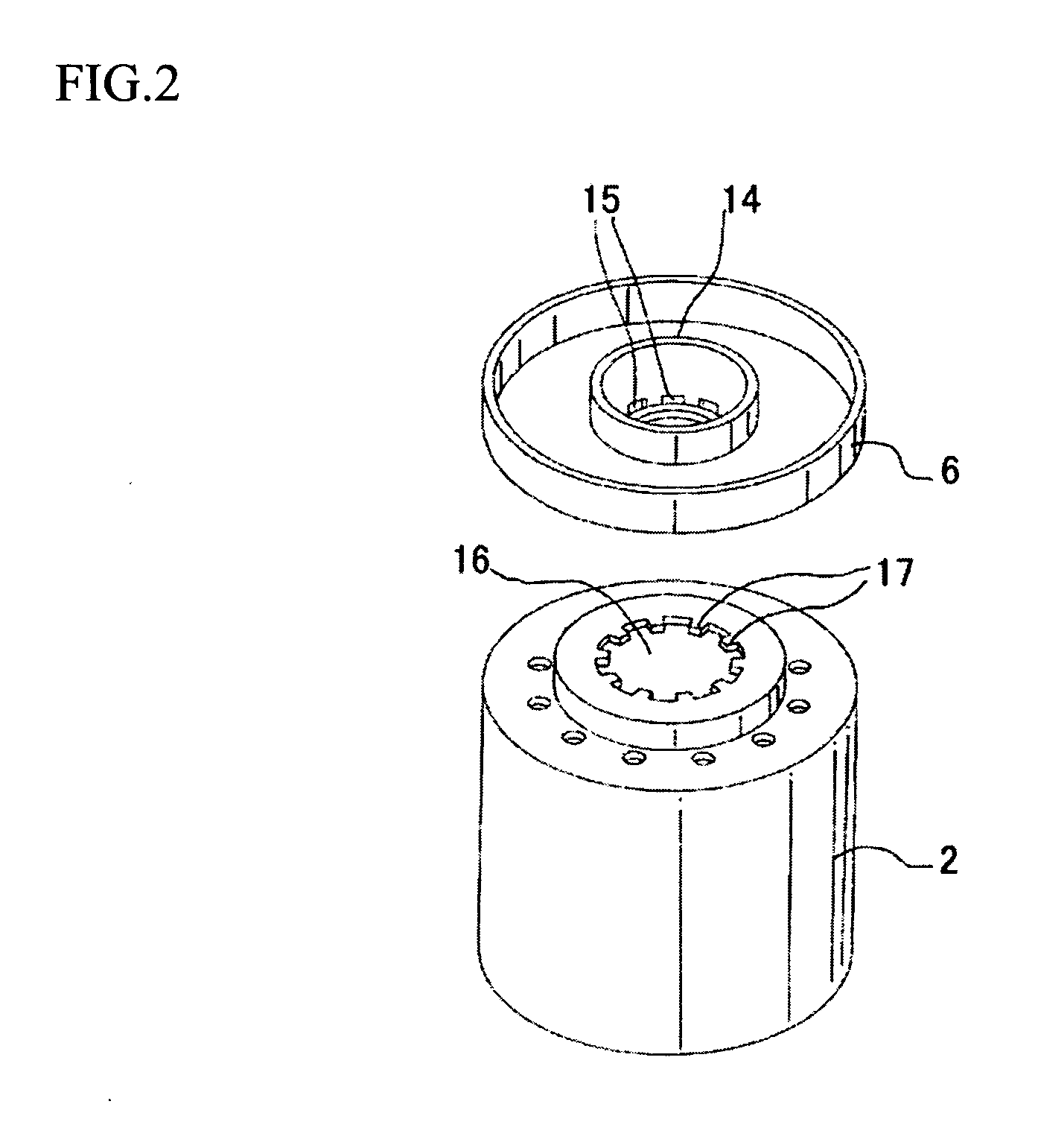

Pump Driving Apparatus

InactiveUS20090155066A1Prevent collisionImprove pump efficiencyPump componentsStatorsImpellerBackflow

A pump driving apparatus that can suppress backflow of a liquid in a pump chamber and improve pump efficiency is provided.A guide tube 23 is provided coaxially with an output shaft 4 of a motor M inside a pump chamber 8, and the ends in the axial direction of the guide tube 23 are fitted into and make sliding contact with a case inner wall surface that forms the pump chamber 8 and a shaft core-side inner wall surface 25 of an impeller 9 enclosed inside the pump chamber 8.

Owner:YG K R & D

Transport vehicle lifting platform

InactiveCN105947931AImprove securityImprove stabilitySafety devices for lifting equipmentsLifting framesDrive shaftEngineering

The invention relates to a transport vehicle lifting platform. The transport vehicle lifting platform comprises a base. A lifting table is arranged between two first supporting columns on the outer sides. A clamping rail plate is arranged between the lifting table and the first supporting columns and wraps and buckles the first supporting columns. A guard bar is arranged on the upper side of the lifting table. Buffering blocks are evenly arranged on the lower side of the lifting table. Movable pulleys are arranged on the left side and the right side of the lifting table. The movable pulleys are connected with conveying belts in a winding manner. Drive motors are arranged on cross supports at the top ends. The right sides of the drive motors are connected with transmission shafts. Lifting devices are arranged on the right sides of the transmission shafts and arranged on fixing frames. The lower ends of the lifting devices are connected with the conveying belts. A fixing plate is arranged on the upper side of the part between each first supporting column and a corresponding second supporting column and provided with a fixed pulley, the conveying belts pass through the fixed pulleys in a winding manner, and limiting devices are arranged on the upper sides of the first supporting columns and the second supporting columns. In a word, the transport vehicle lifting platform has the beneficial effects of being wide in application range, convenient and fast to use, high in safety and rapid in lifting.

Owner:徐玉中

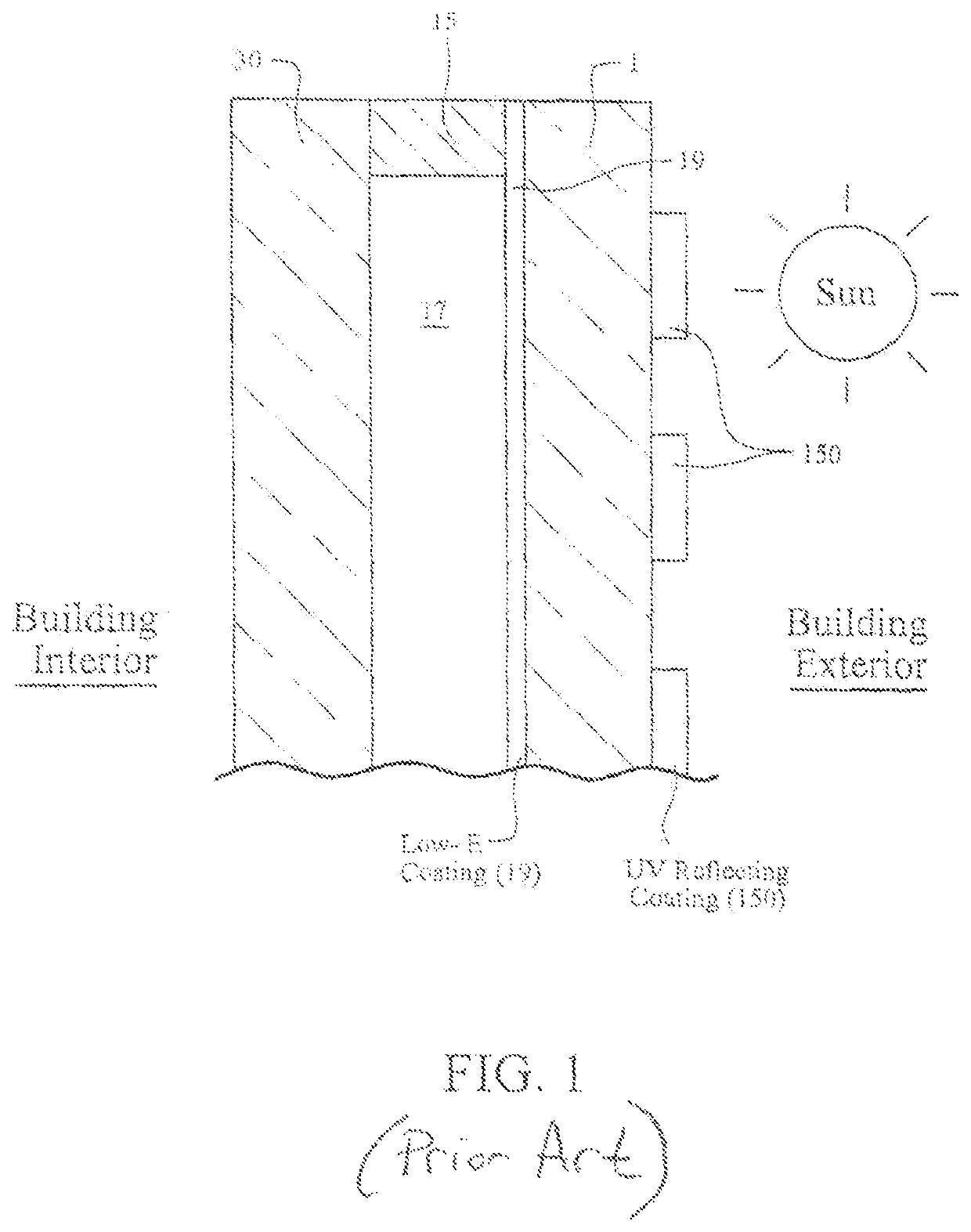

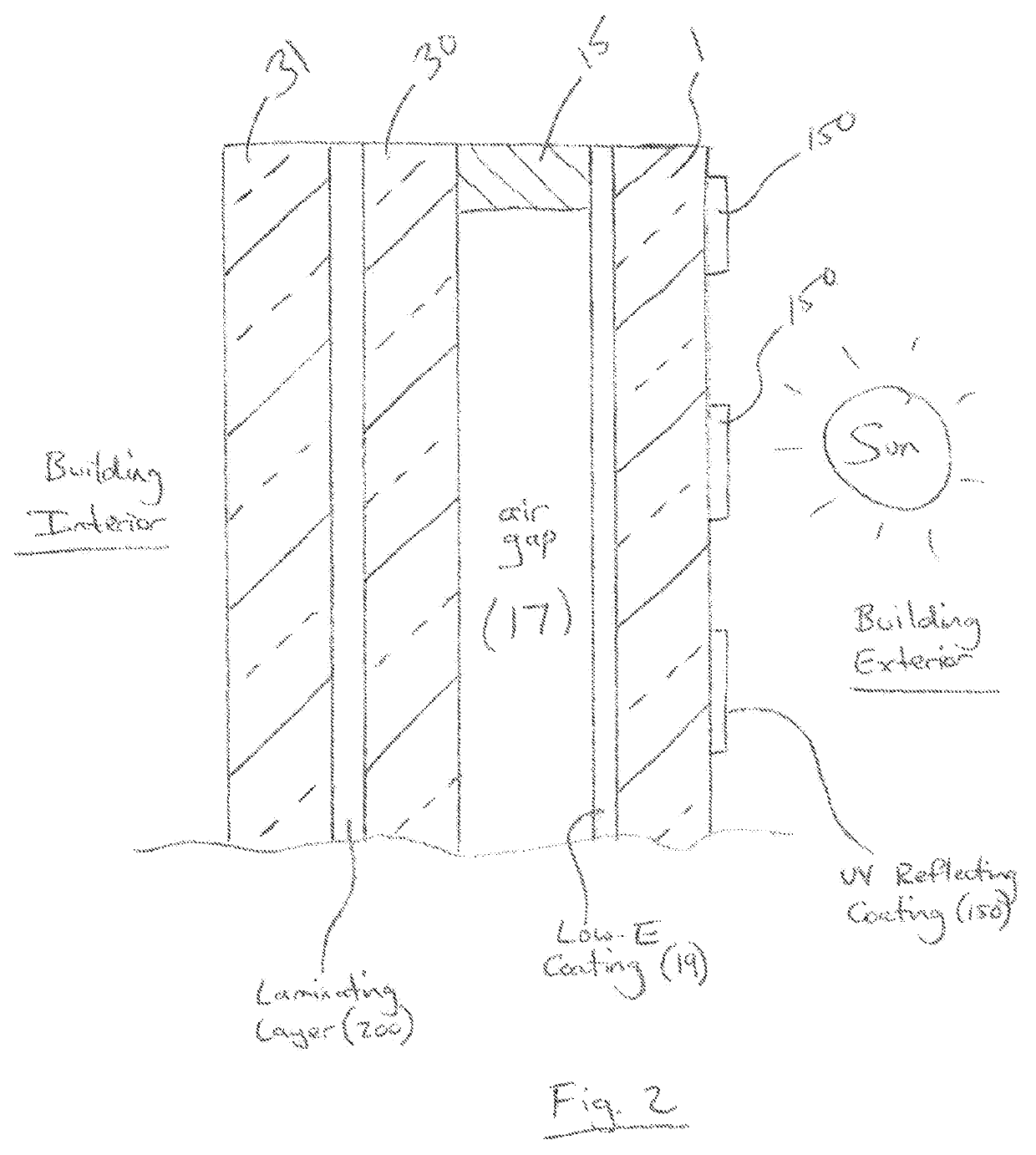

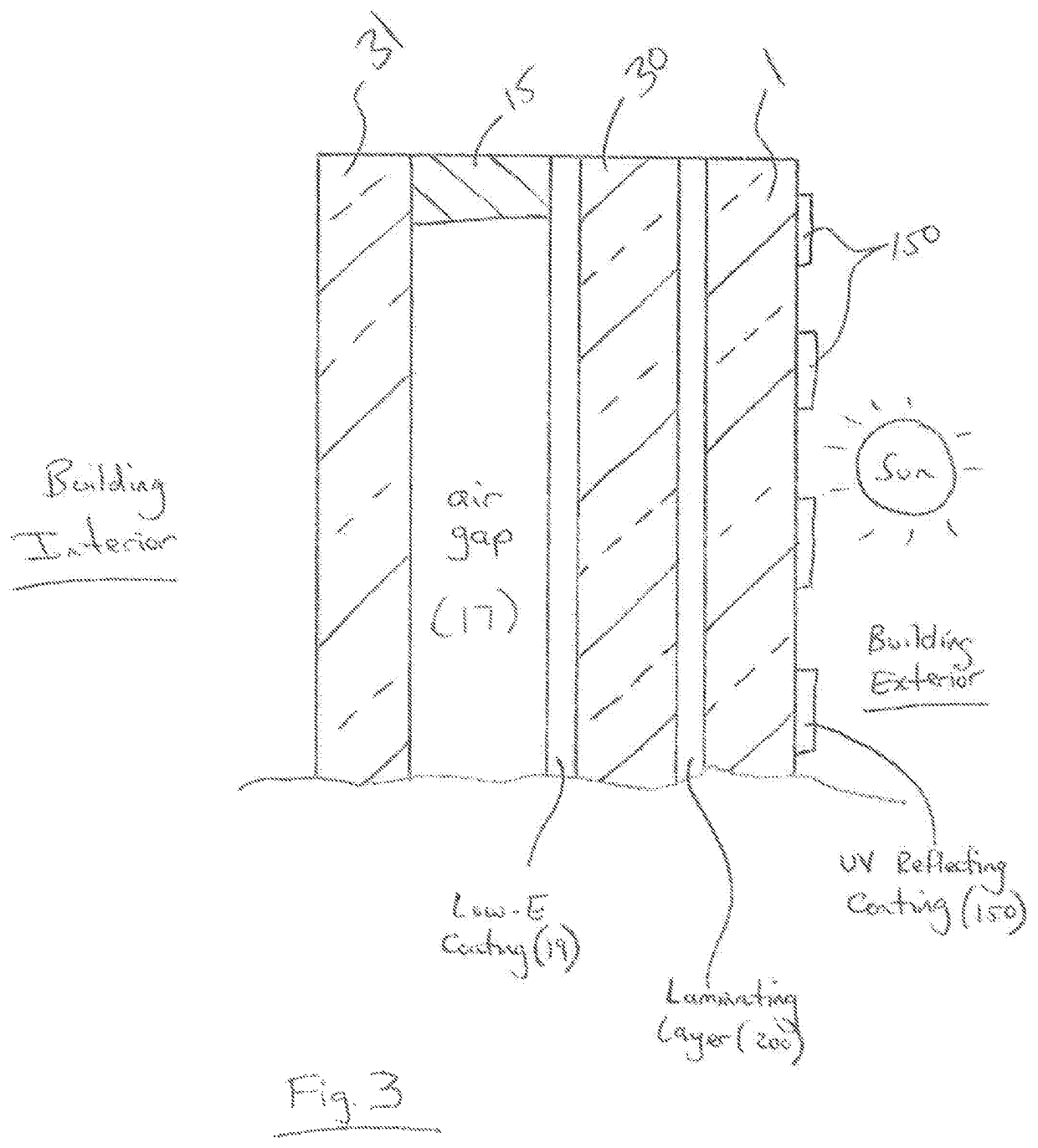

Window unit having UV reflecting coating with high contrast ratio at large viewing angles for reducing bird collisions

ActiveUS11092726B1Reducing bird collisionEasy to seeGlass/slag layered productsAnimal repellantsEngineeringMaterials science

A window unit is designed to prevent or reduce bird collisions therewith. The window unit may include first and second substrates (e.g., glass substrates) spaced apart from one another, wherein at least one of the substrates supports an ultraviolet (UV) reflecting coating for reflecting UV radiation so that birds are capable of more easily seeing the window. The UV reflecting coating is preferably patterned so that it is not provided across the entirety of the window unit. By making the window more visible to birds, bird collisions and bird deaths can be reduced. The UV reflecting coating is designed to have high UV reflectance across a large range of viewing angles.

Owner:GUARDIAN GLASS LLC +1

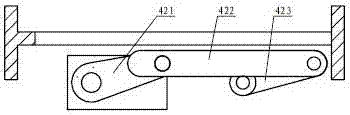

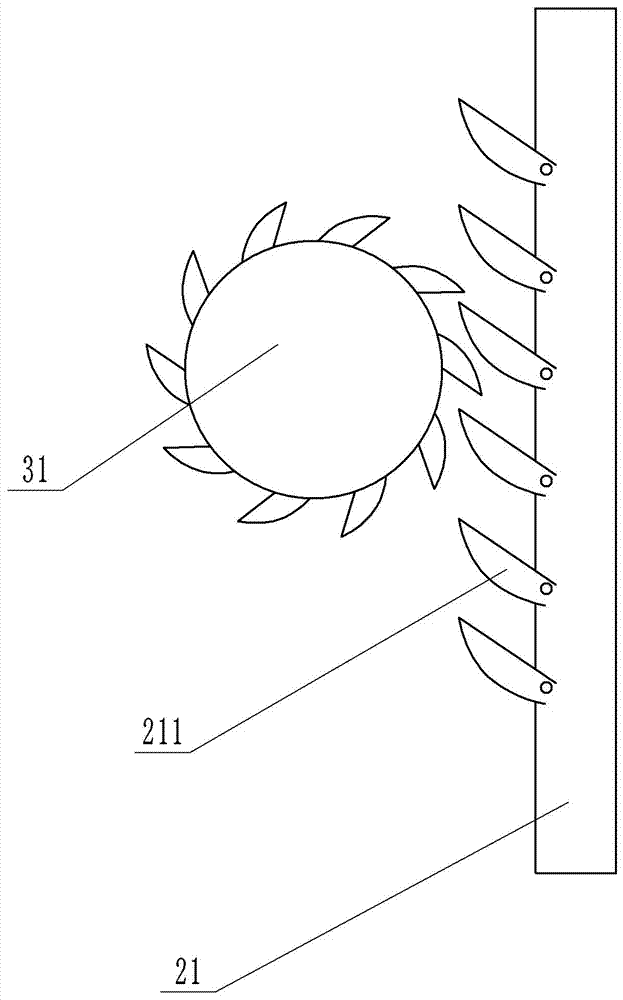

Anti-shake travelling mechanism for monorail conveyor

The invention discloses an anti-shake travelling mechanism for a monorail conveyor. The anti-shake travelling mechanism is characterized by comprising a first load-bearing wheel and a second load-bearing wheel which are arranged above a monorail, a first anti-roll wheel and a second anti-roll wheel which are arranged below the monorail, a fixation frame, a first rotating arm used for mounting thefirst anti-roll wheel, a second rotating arm used for mounting a second anti-roll wheel and an elastic buffering mechanism arranged between the first rotating arm and the second rotating arm, whereinthe upper ends of the first rotating arm and the second rotating arm are connected with the fixation frame by virtue of hinges; and the elastic buffering mechanism comprises a locking rod, a locking block arranged at one end of the locking rod and a buffer spring arranged at the other end of the locking rod, wherein one end of the buffer spring props against one end of the locking rod, the other end props against the first rotating arm, and elastic force of the buffer spring enables the first anti-roll wheel and the second anti-roll wheel to be fit on the monorail. The travelling mechanism disclosed by the invention can overcome violent shake of the monorail conveyor, so that a fruit conveying process of the whole monorail conveying mechanism is smoother and safer.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Spoke air hole machining die

ActiveCN106964688AGuaranteed uniformityReduce labor intensityPerforating toolsInterference fitPunching

The invention belongs to the technical field of punching machining and particularly discloses a spoke air hole machining die. The spoke air hole machining die comprises an upper die and a lower die. The upper die comprises an upper die plate, a transmission rod and a punch. Pawls are hinged to the transmission rod. The lower die comprises a lower die plate, a rack, a rotating shaft and a punching block. The rotating shaft is rotationally connected to the rack, and the rotating shaft is in interference fit with the rack. A positioning plate and a ratchet wheel are fixed to the rotating shaft. A through hole matched with a spoke bolt hole is formed in the positioning plate. A cavity and a sliding groove communicating with the cavity are formed in the upper portion of the punching block. A magnet protruding block is connected to the sliding groove in a sliding manner, a punching hole is formed in the magnet protruding block, and a coil located below the magnet protruding block is arranged in the punching block. A controller and a speed sensor are installed on the rack, and the speed sensor and the coil are electrically connected with the controller. The spoke air hole machining die is adopted for machining a spoke air hole, after hole punching is completed, a spoke can be driven to rotate, punching continuity is ensured, and in addition, friction between the spoke and the magnet protruding block in the spoke rotating process can be avoided.

Owner:重庆鼎汉巅宏汽车零部件有限公司

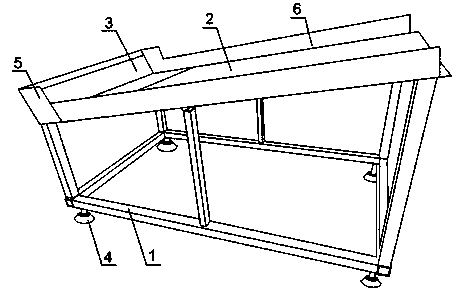

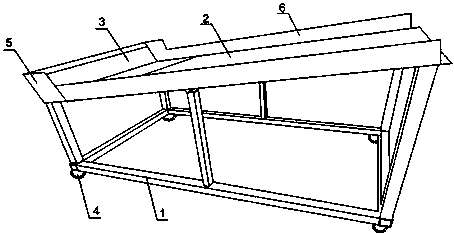

Simple conveying mechanism for silencing barrel

The invention discloses a simple conveying mechanism for a silencing barrel. The simple conveying mechanism comprises a support frame, a conveying plate, a baffle plate, a plurality of damping foot-pads and rubber cushions, wherein the conveying plate is connected with the baffle plate; the conveying plate and the baffle plate are both arranged on the support frame; the damping foot-pads are uniformly distributed at the bottom of the support frame; and the rubber cushions are arranged at the bottom of the conveying plate and on the baffle plate. The conveying plate arranged on the support frame forms a certain angle with a horizontal direction, and a silencing barrel which is subjected to a curling process is placed at the top end of the conveying plate, slides to the bottom end of the conveying plate under the action of dead-weight, and is collected by a worker being responsible for a detection procedure. On the conveying plate, the silencing barrel slides downwards at a higher speed, and is blocked by the baffle plate after sliding to the bottom end, greater mutual acting force is generated between a silencer and the baffle plate, and the rubber cushions arranged at the baffle plate and the bottom of the conveying plate can play roles in buffering, so that the impact of the silencing barrel on the baffle plate is reduced, and the service life of equipment is prolonged.

Owner:CHENGDU LINGCHUAN SPECIAL IND

Simple conveying mechanism

The invention discloses a simple conveying mechanism. The simple conveying mechanism comprises a supporting frame, a conveying board, a baffle and a plurality of universal wheels, wherein the conveying board is connected with the baffle, both the conveying board and the baffle are arranged on the supporting frame, the universal wheels are evenly distributed on the bottom of the supporting frame, and a spring is arranged at the position where the conveying board is connected with the supporting frame. The simple conveying mechanism further comprises a rubber pad which is arranged on the bottom of the conveying board and on the baffle. A certain angle is formed between the conveying board arranged on the supporting frame and the horizontal direction. A noise reduction barrel is placed at the top end of the conveying board after hemming is carried out on the noise reduction barrel, the noise reduction barrel slides downwards to the bottom end of the conveying board under the self-gravity of the noise reduction barrel, and finally the noise reduction barrel is collected by a worker responsible for detection. According to the simple conveying mechanism, when the noise reduction barrel collides with the baffle, acting force applied to the baffle can be further buffered by the universal wheels arranged on the bottom of the supporting frame and the spring arranged between the supporting frame and the conveying board, the supporting frame is prevented from swinging seriously, and then the internal structure of the noise reduction barrel is prevented from being damaged to a certain degree.

Owner:CHENGDU LINGCHUAN SPECIAL IND

A rudder that quickly turns an aircraft around

ActiveCN109018305AHeading controlGuaranteed normal flightAircraft stabilisationWithout power ampliicationFlight directionGear wheel

The invention discloses a rudder for rapidly turning the flight direction of an aircraft, the invention relates to the technical field of rudder, The left side of the inner wall of the cavity is fixedly connected with the left side of the placing block, the right side of the placing block is overlapped with the left side of the U-shaped plate through a buffer, and the left side of the U-shaped plate is fixedly connected with the right side of the placing block through two electric pushrods. The vertical tail comprises a vertical tail, a right side of which is provided with a cavity, and the left side of the cavity is fixedly connected with the left side of the placing block through a buffer. The rudder that quickly turns the plane 's flight direction, Through the electric push rod, Place blocks, U-plates, shaft, first bearing, The second bearing, the motor, the first gear and the second gear are matched, so that the heading of the aircraft can be controlled, the rotational amplitude ofthe moving wing surface can be enlarged, the contact area with the airflow can be enlarged, sufficient torque can be generated, the heading of the aircraft can be controlled conveniently, and the normal flight of the aircraft can be ensured to a certain extent.

Owner:晨龙飞机(荆门)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com