Soybean milk preparation method of soybean milk machine

A soybean milk machine and pulping technology, which is applied to dairy products, milk substitutes, heating devices, etc., can solve the problems of high motor load, loud beating noise, and sinking to the bottom of the cup, so as to ensure service life, reduce beating noise, The effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

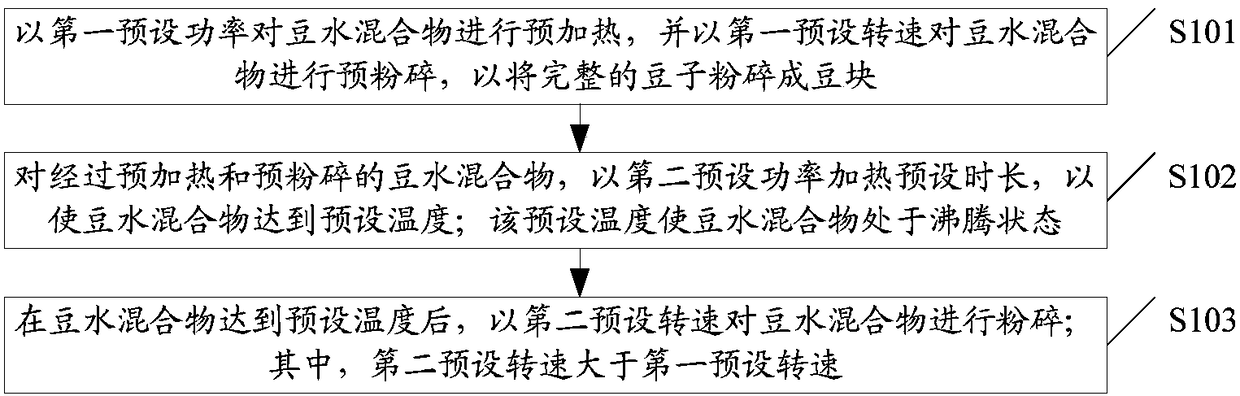

Method used

Image

Examples

Embodiment 2

[0050] In this embodiment, on the basis of the first embodiment, the value ranges of the first preset rotation speed and the second preset rotation speed are further limited.

[0051] Optionally, the first preset rotation speed satisfies: 3000rpm-8000rpm; the second preset rotation speed satisfies: greater than 8000rpm.

[0052] In the embodiment of the present invention, the limited first preset rotation speed, that is, the low rotation speed M1 is kept in the range of 3000rpm-8000rpm, which can produce a certain pre-crushing effect, and at the same time avoid the material and soybean milk machine due to excessive motor rotation speed. The smashing cup (usually a steel cup) violently collides, thereby reducing the sound produced by the material hitting the crushing cup.

[0053] In the embodiment of the present invention, the limited second preset rotation speed, that is, the high rotation speed M2 is kept greater than 8000rpm, which can ensure the pulping efficiency and crus...

Embodiment 3

[0055] This embodiment further limits the value ranges of the preset temperature, the preset duration and the second preset power on the basis of any of the above embodiments.

[0056] Optionally, the preset temperature satisfies: 98-100°C;

[0057] The second preset power meets: 1 / 4-1 / 2 of the rated heating power;

[0058] The preset duration satisfies: greater than 30 seconds.

[0059] In the embodiment of the present invention, the preset temperature satisfies: 98-100°C, which can ensure that the slurry will be in a boiling state, so that materials such as beans are in a suspended state under the action of thermal convection.

[0060] In the embodiment of the present invention, the second preset power is related to the maximum heating power of the heating tube of the soybean milk machine during the heating process. Generally, the second preset power should not be greater than 1 / 2 of the maximum heating power, nor should it be less than the maximum heating power 1 / 4 of the...

Embodiment 4

[0064] On the basis of any of the foregoing embodiments, this embodiment provides an adjustment scheme for the preset duration and the second preset power.

[0065] Optionally, the method may further include: adjusting the preset duration and / or the second preset power along with changes in the number of consecutive pulping times of the soymilk machine.

[0066] In the embodiment of the present invention, after the defoaming waiting process ends, during the heating process with the second preset power for the preset duration, the second preset power and heating duration of the heating tube (that is, the preset duration) It can be adjusted according to the number of continuous pulping pots of the soybean milk machine.

[0067] Optionally, adjusting the preset duration and / or the second preset power as the number of consecutive pulping times of the soymilk machine changes may include:

[0068] Every time the number of continuous pulping times increases, the preset duration decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com