Patents

Literature

7091 results about "Heating power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

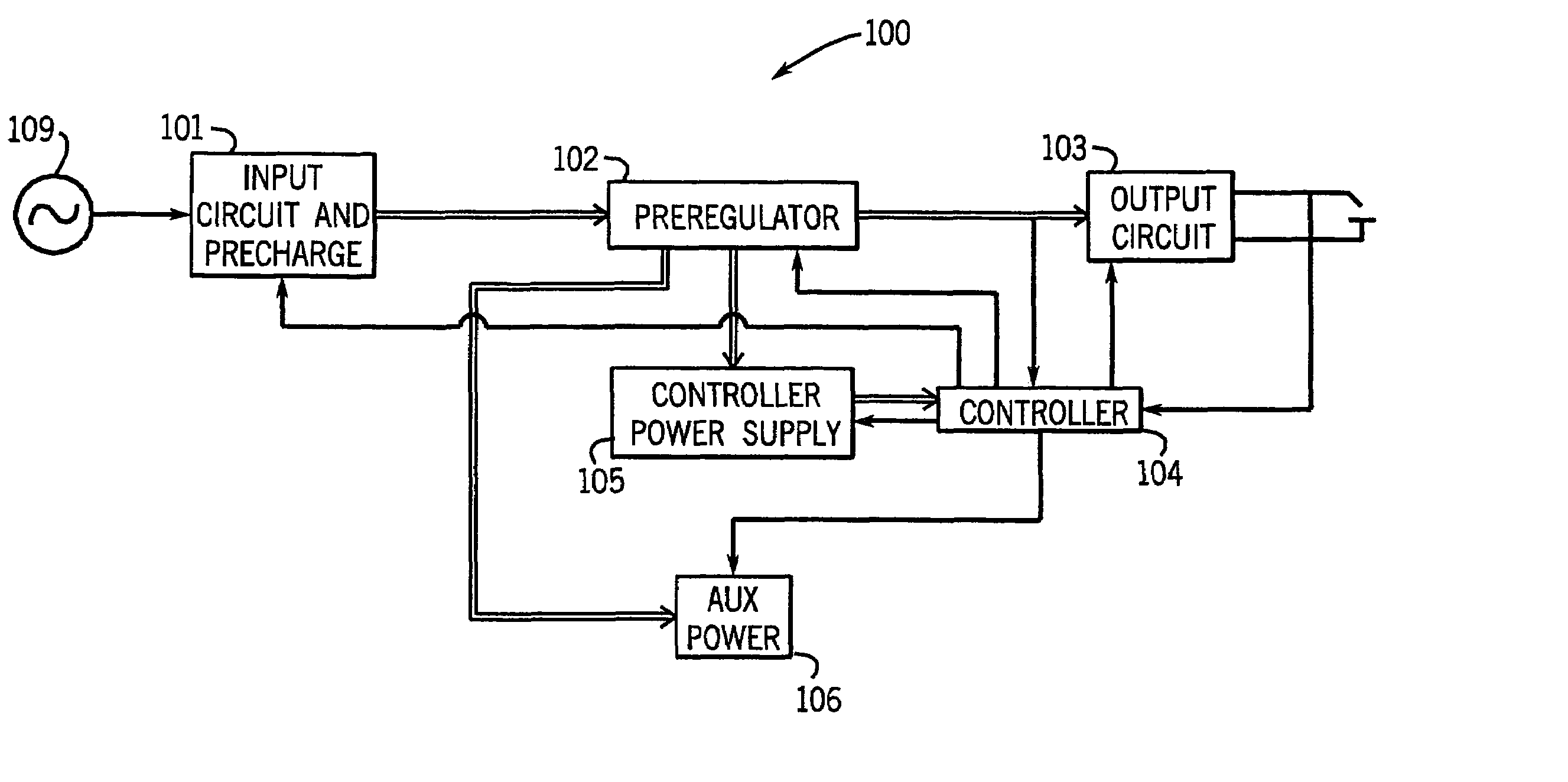

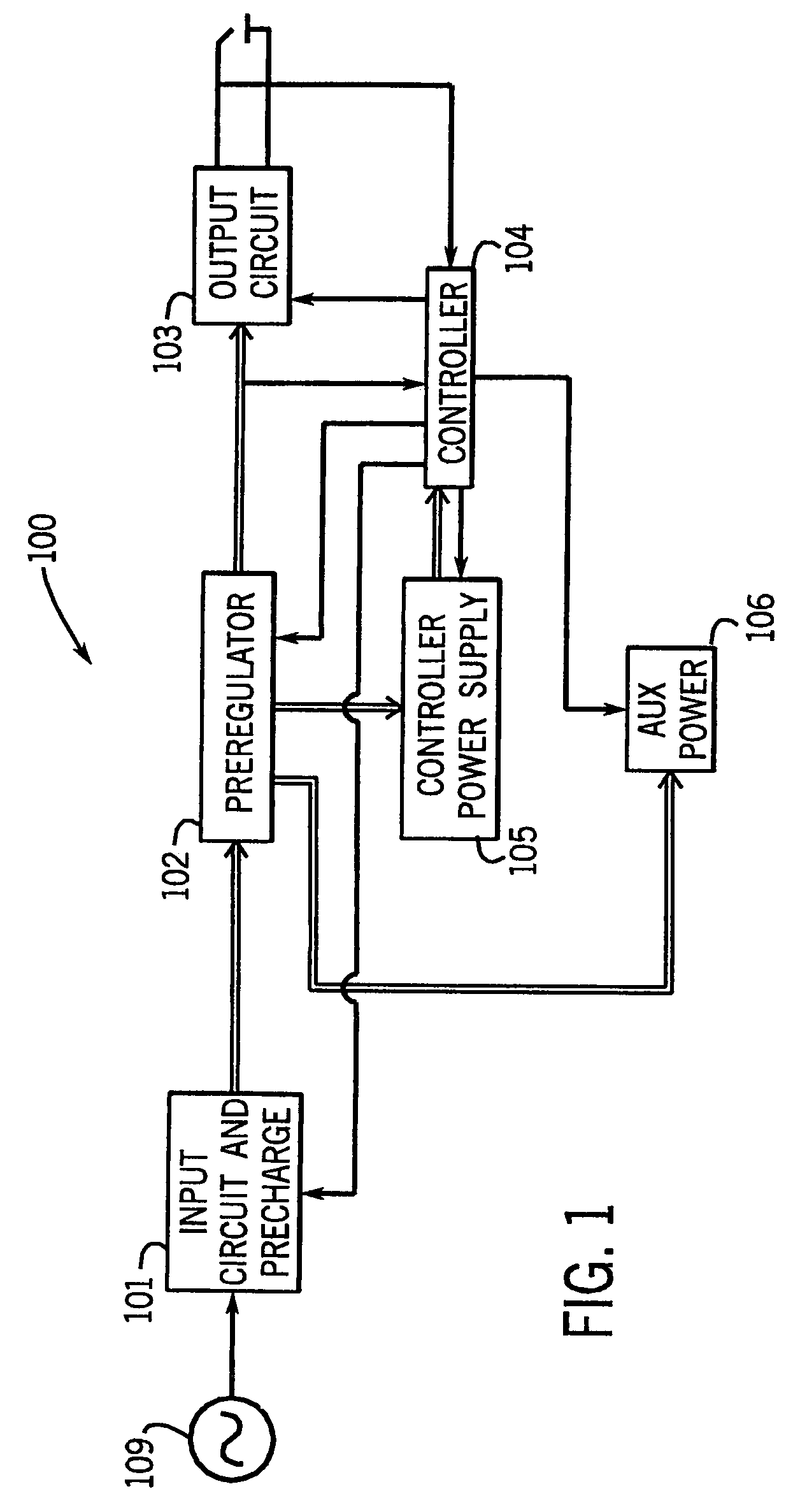

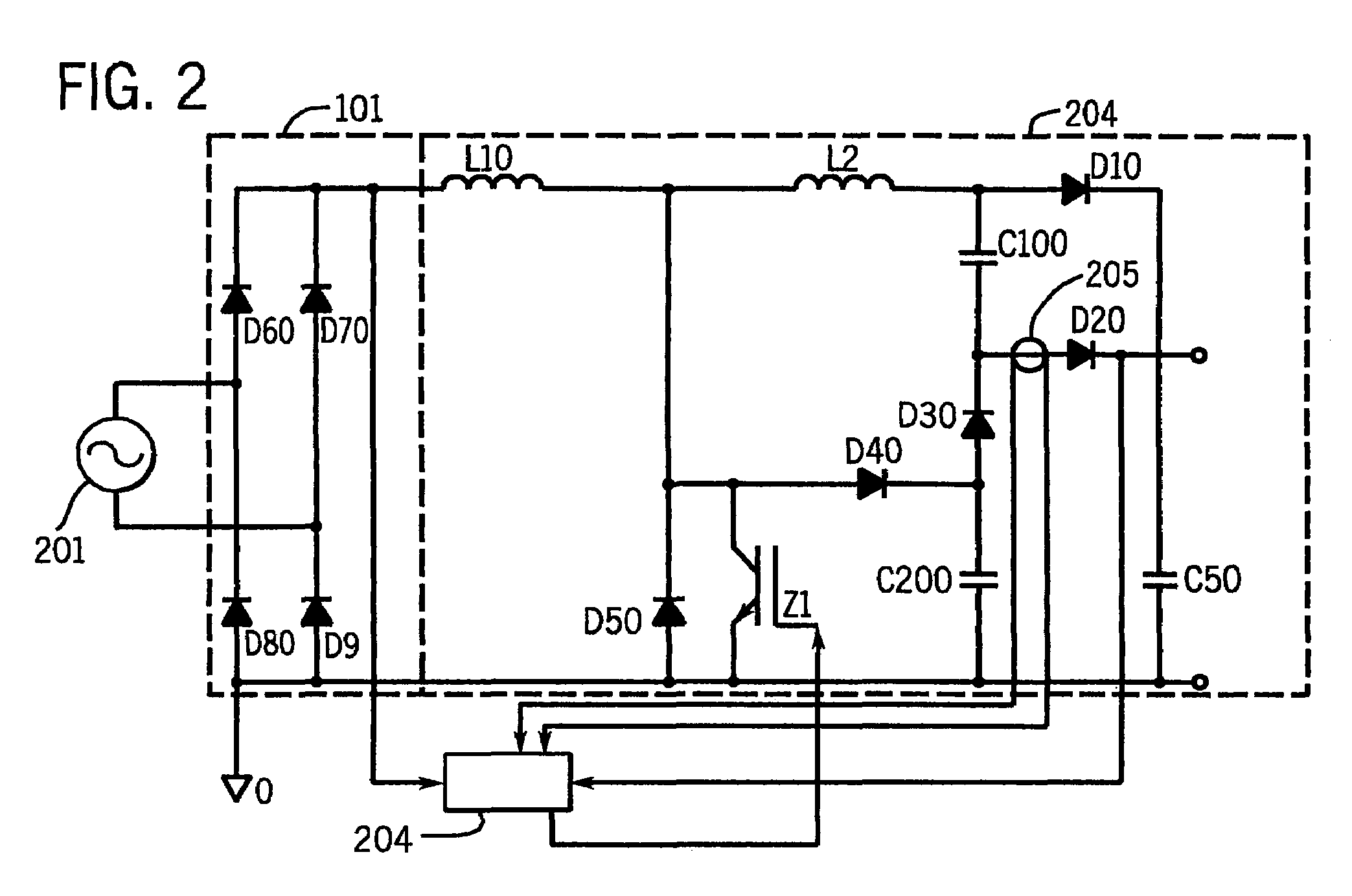

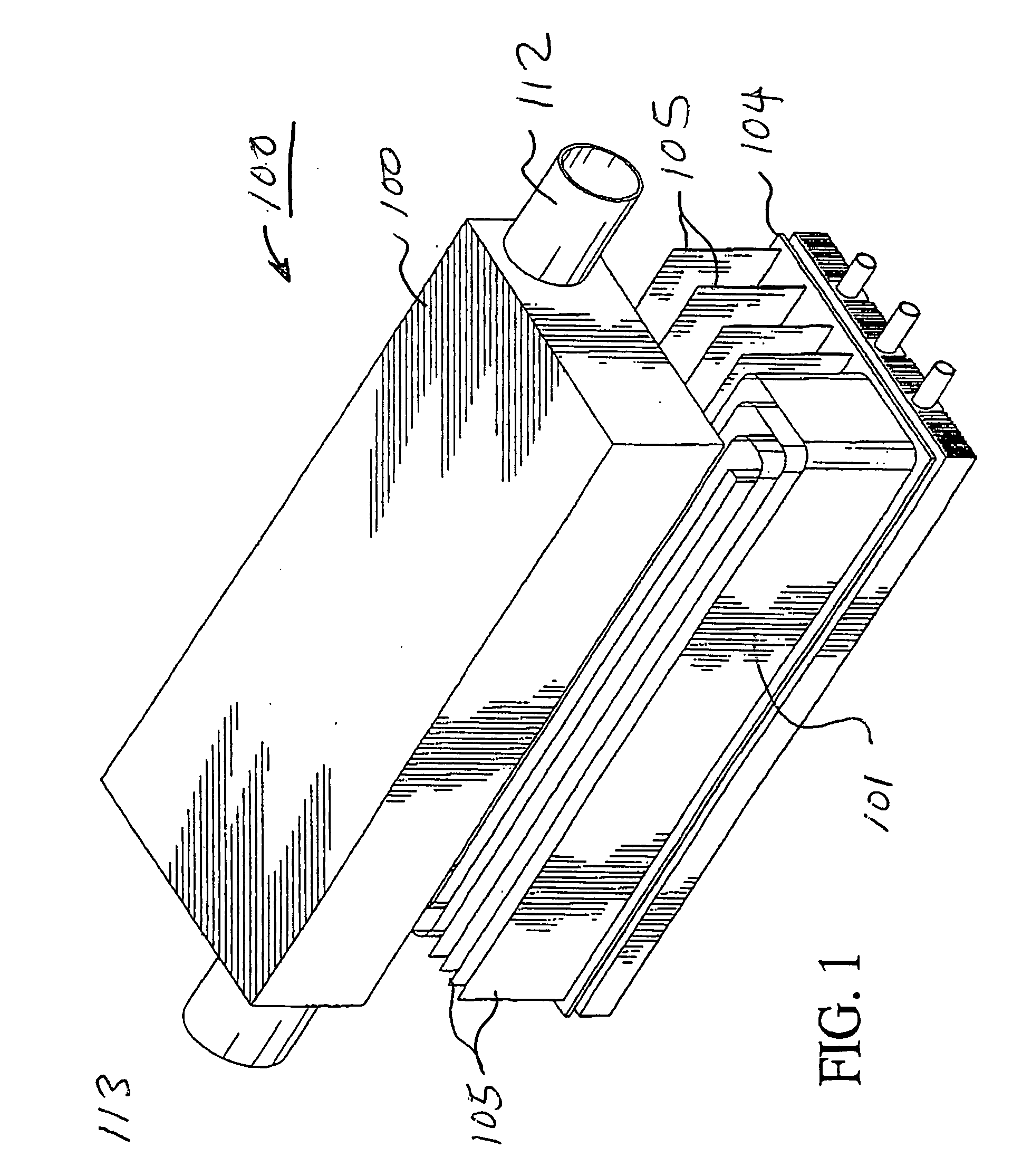

Method and apparatus for receiving a universal input voltage in a welding, plasma or heating power source

A method and apparatus for providing welding type power is disclosed. The power source is capable of receiving any input voltage over a wide range of input voltages and includes an input rectifier that rectifies the ac input into a dc signal. A dc voltage stage converts the dc signal to a desired dc voltage and an inverter inverts the dc signal into a second ac signal. An output transformer receives the second ac signal and provides a third ac signal that has a current magnitude suitable for welding, cutting or induction heating. The welding type current may be rectified and smoothed by an output inductor and an output rectifier. A controller provides control signals to the inverter and a controller power supply can also receive a range of input voltages and provide a control power signal to the controller, and a voltage independent of the input voltage.

Owner:ILLINOIS TOOL WORKS INC

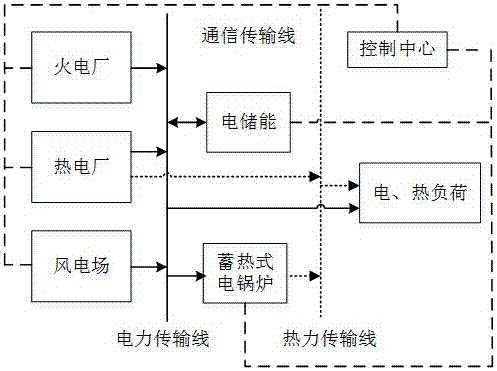

Flow-through mufflers with optional thermo-electric, sound cancellation, and tuning capabilities

InactiveUS20070045044A1Reduce engine fuel consumptionInternal combustion piston enginesThermoelectric device with peltier/seeback effectHeat conductingAcoustic wave

Owner:SULLIVAN JOHN TIMOTHY

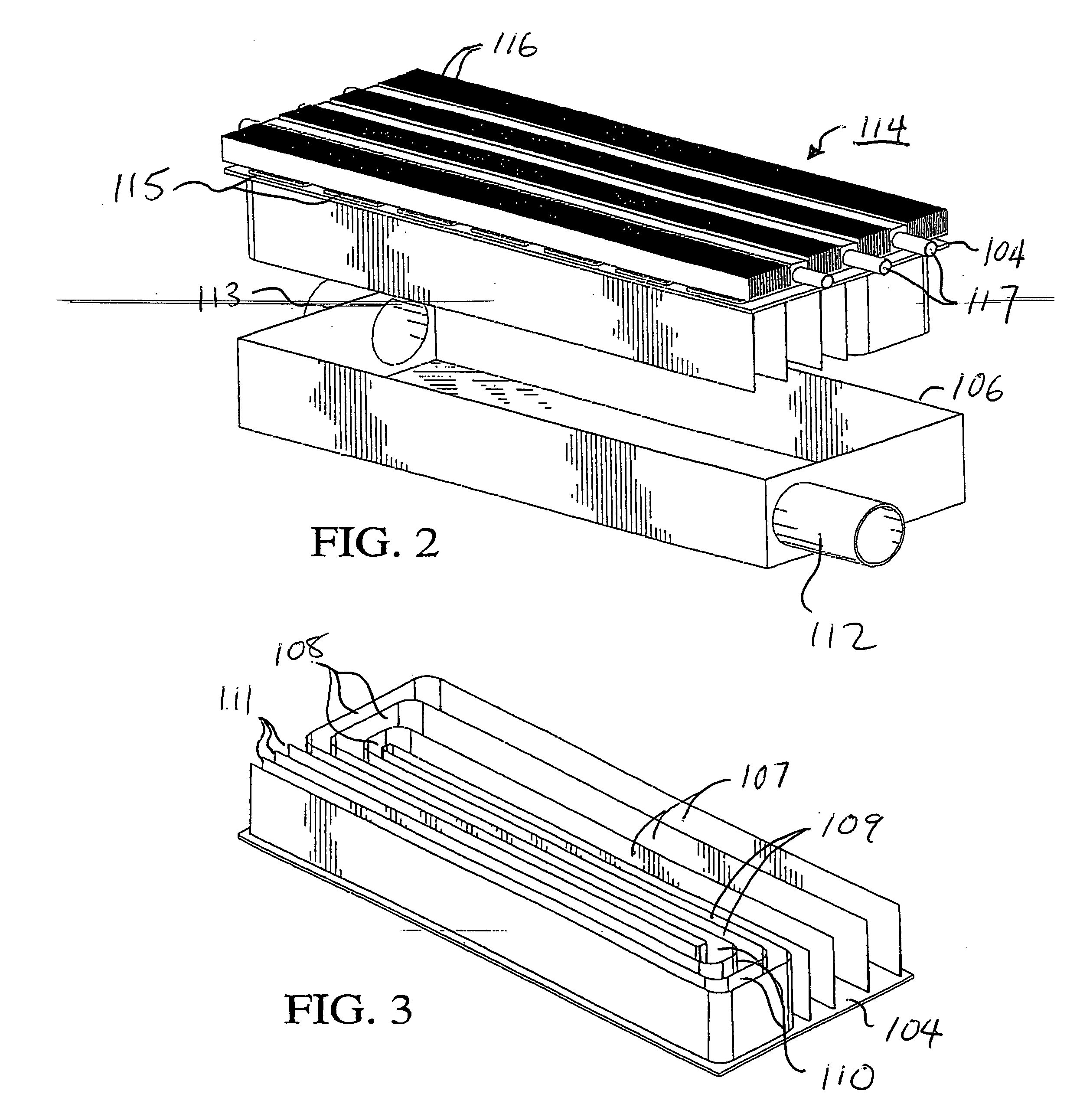

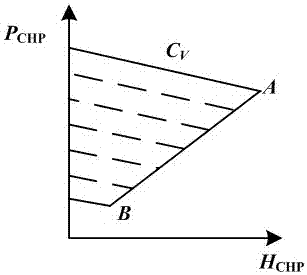

Combined system energy optimization method with consideration of wind power consumption

InactiveCN107508328APromote development and utilizationImprove wind power absorption capacitySingle network parallel feeding arrangementsEnergy storageNew energyElectric power system

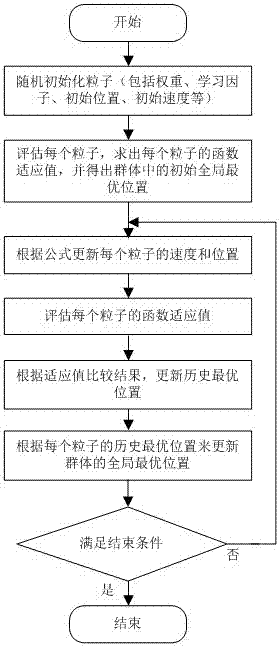

The invention, which belongs to the grid-connected optimization operation field of the new energy, relates to a combined system energy optimization method with consideration of wind power consumption; and thus in order to solve a wind curtailment problem, the combined system energy optimization method uses a cogeneration system based on combined operation of a wind power-electric energy storage-heat accumulating type electric boiler and takes economic optimum as an objective to reduce the wind-curtailment power effectively by increasing the load space. To be specific, the method comprises the following steps: (1), establishing an overall system framework including a conventional thermal power generating unit, a cogeneration unit, a wind turbine generator, an electric energy storage and heat accumulating type electric boiler; (2), carrying out comprehensive modeling of a cogeneration system; (3), establishing an optimal economic objective function; (4), establishing a power and heating power balancing relationship and operational constraints of all units during the operation period of the cogeneration cooperation system; and (5), carrying out optimization for active power outputs of all units. Therefore, development and utilization of the wind power are promoted; and power supply reliability of the power system is improved. The method can be applied to large-scale-wind-power-included provincial companies of all stages and has the broad application prospects.

Owner:NORTHEAST DIANLI UNIVERSITY +2

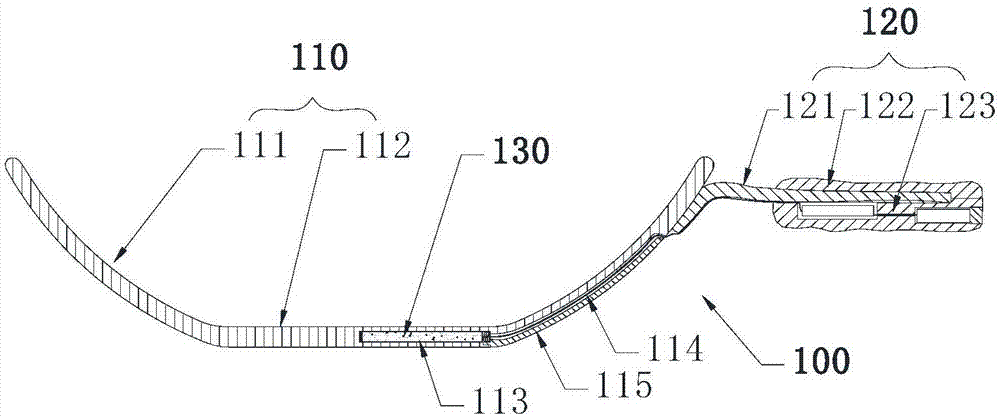

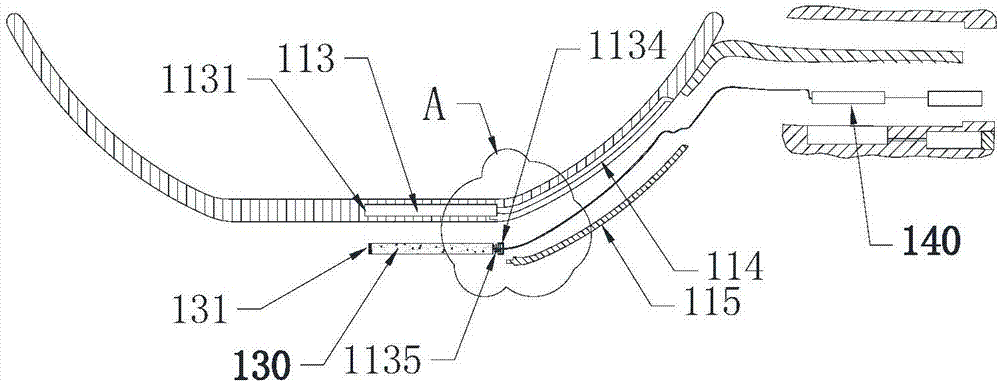

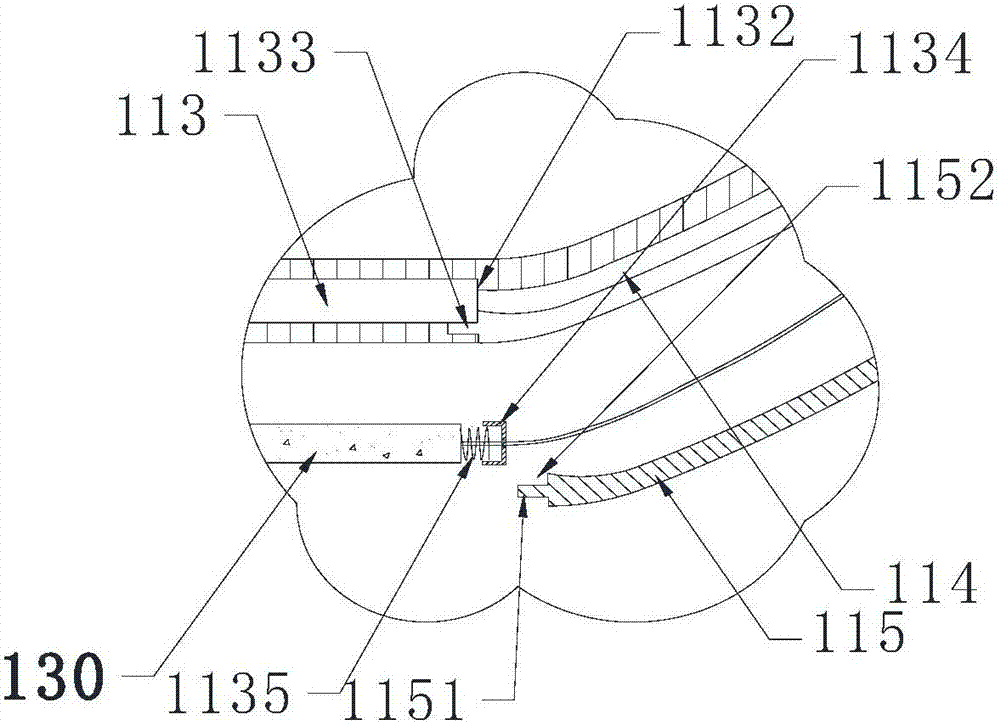

Temperature probe, cooking device and heating control method

InactiveCN106821017AVoid unfamiliarityAvoid overcooked problemsTemperature measurement in household appliancesDomestic articlesWireless transmissionProcess engineering

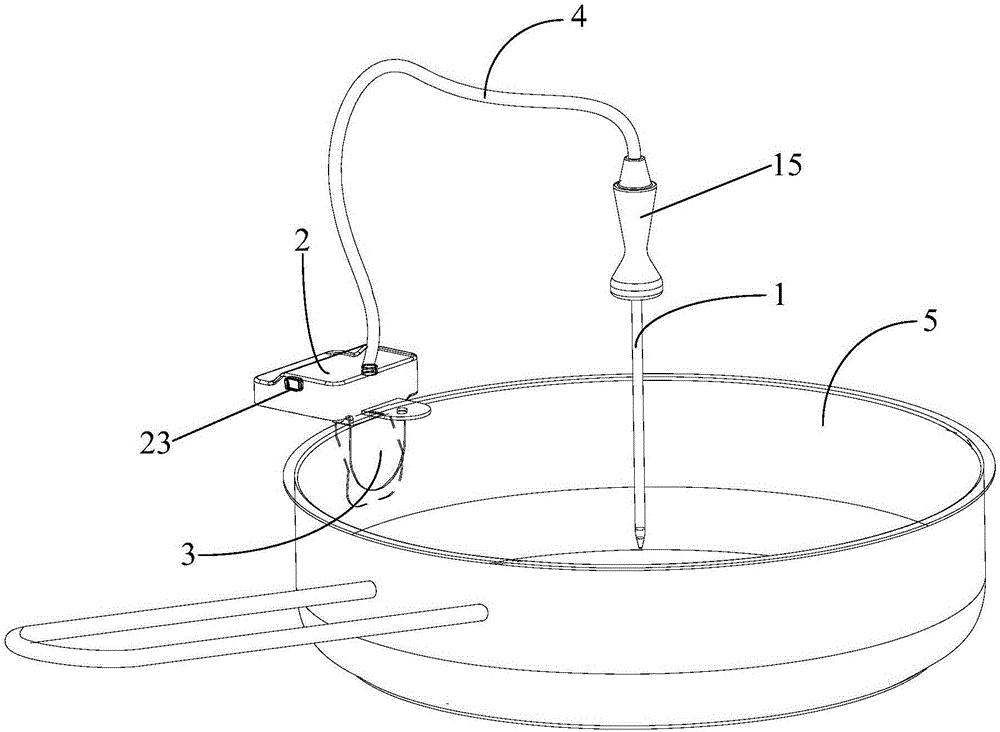

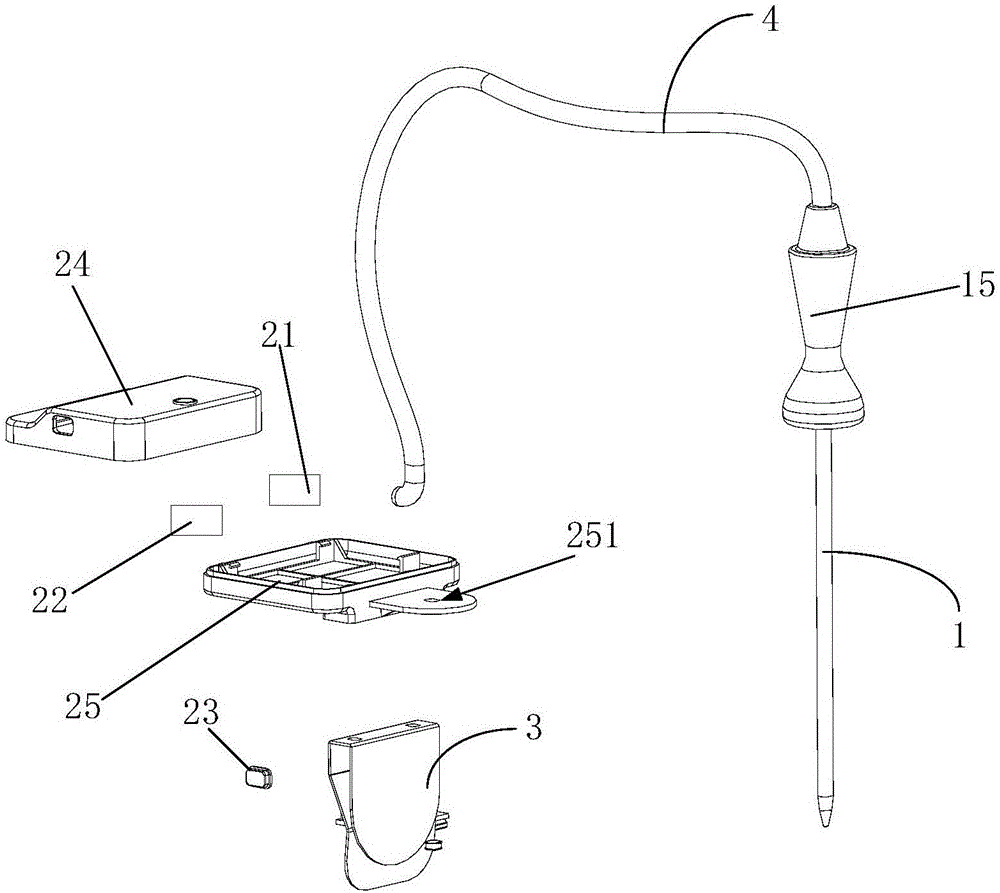

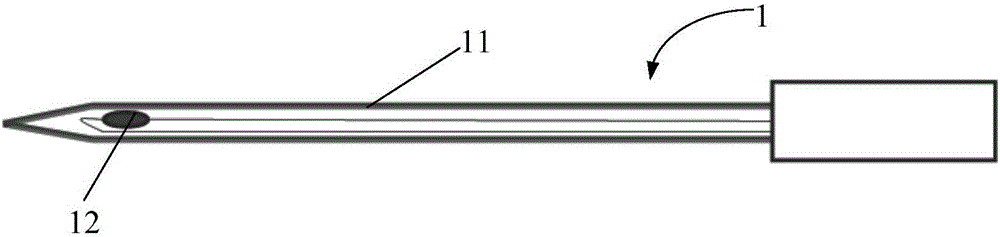

The invention provides a temperature probe, a cooking device and a heating control method. The temperature probe comprises a probe, a hardware box and a clamp, wherein a temperature sensor is arranged in the probe, is inserted into food and / or soup to detect the temperature and wirelessly sends a temperature detection signal to a controller of the cooking device through a probe wireless transmission device, so that the controller judges whether the cooking degree of food and heating firepower are proper according to the temperature detection signal and adjusts the heating power of the heating device to improve the cooking effect if the heating firepower is judged to be improper. The temperature of food and soup is detected by the temperature probe, whether the cooking degree of the food and the heating firepower are proper is judged according to the detected temperature signal, and the judgement mode is more reliable than that according to food color and appearance change. The problem that cooked food is not yet done or overdone due to misjudgment by a user can be effectively solved, and the user can more easily obtain nutritional and delicious food.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

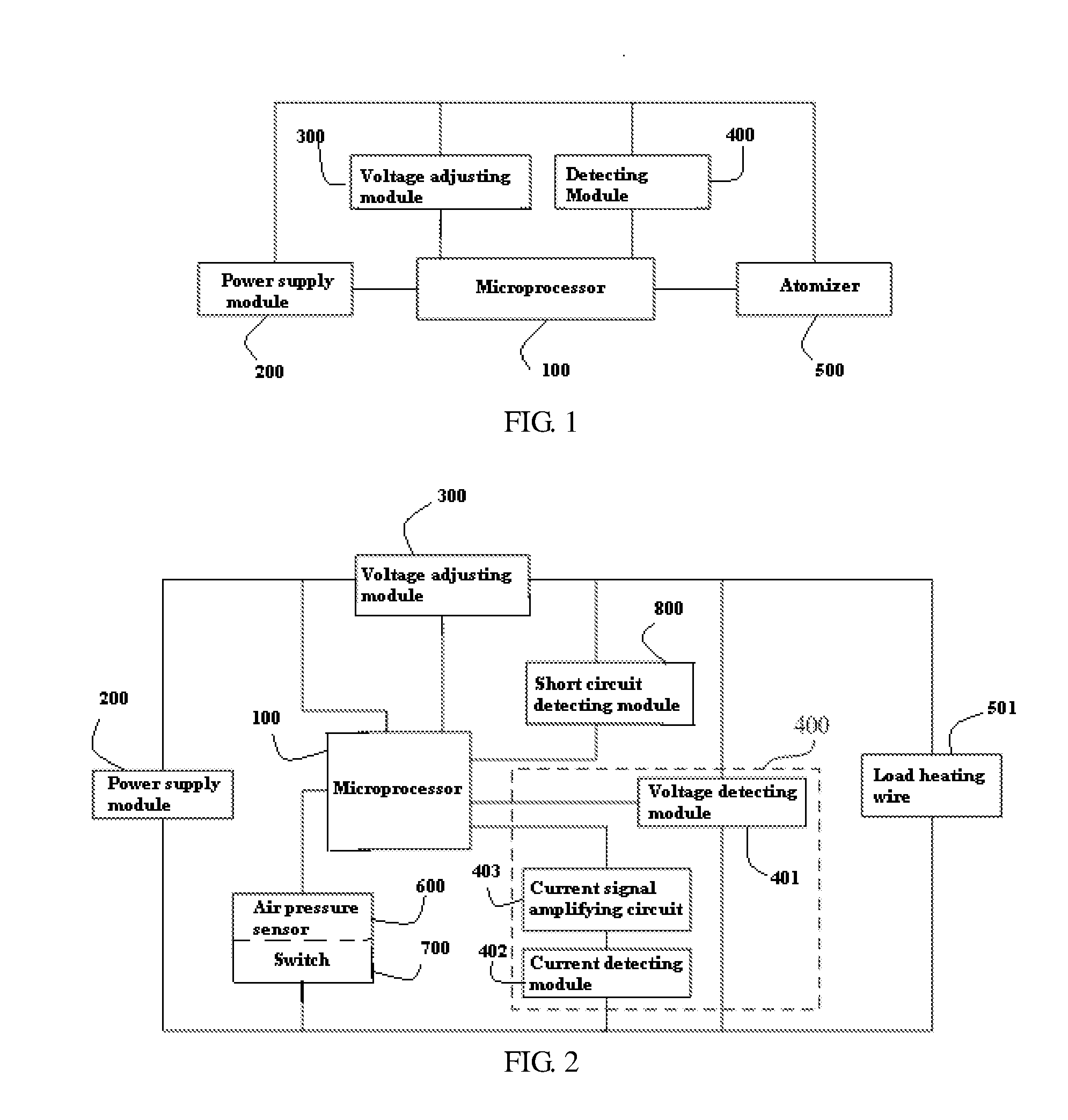

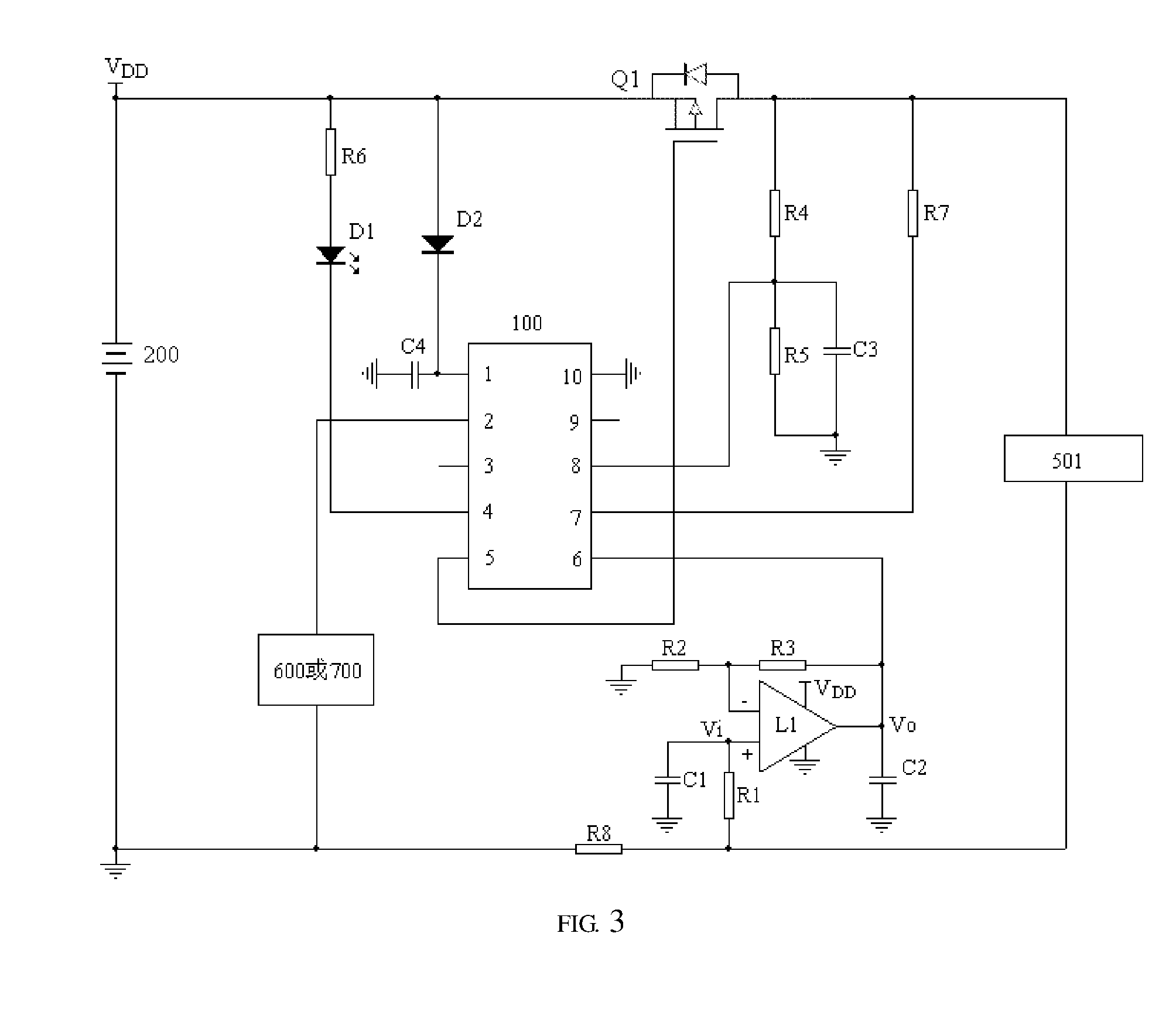

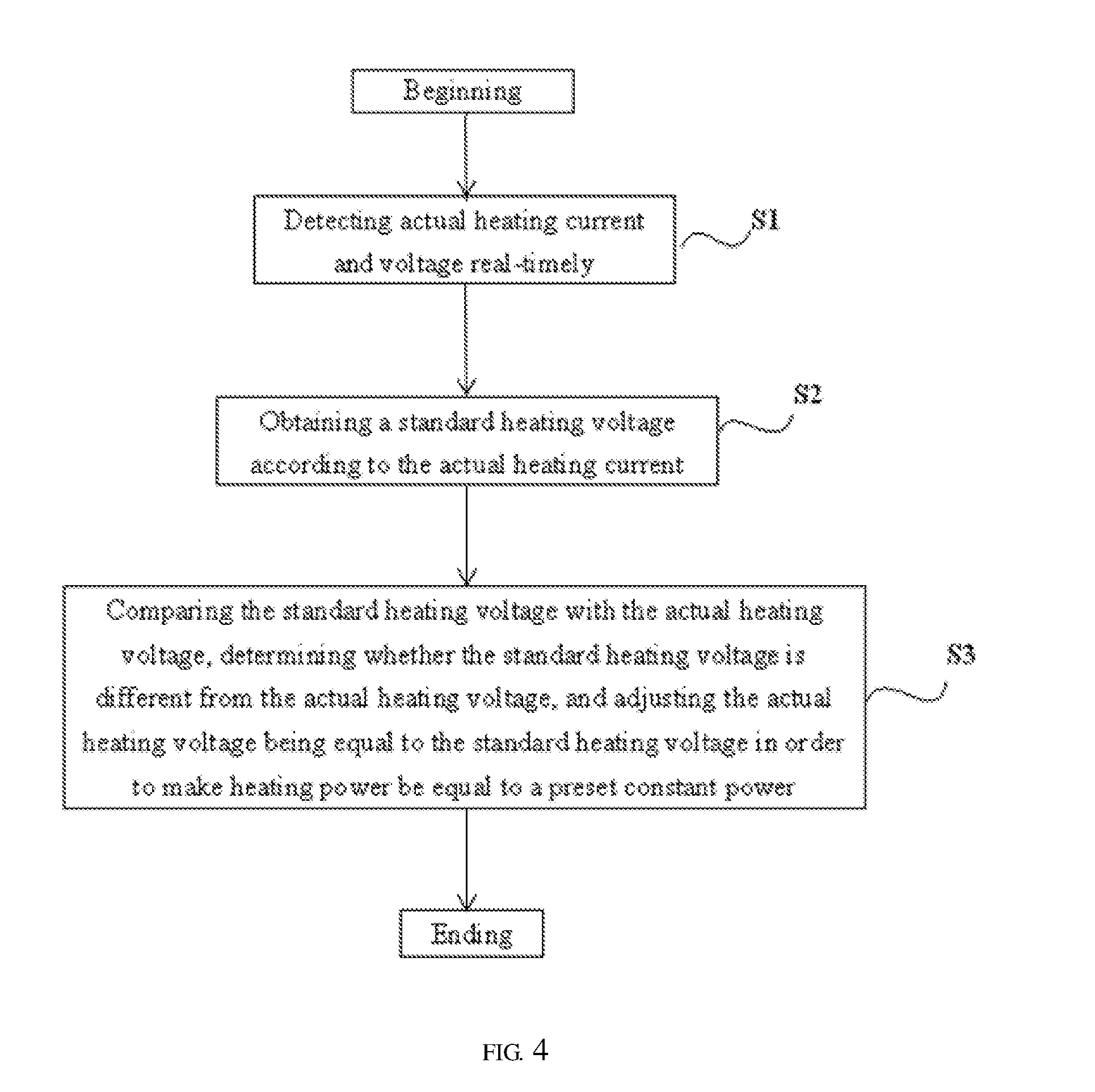

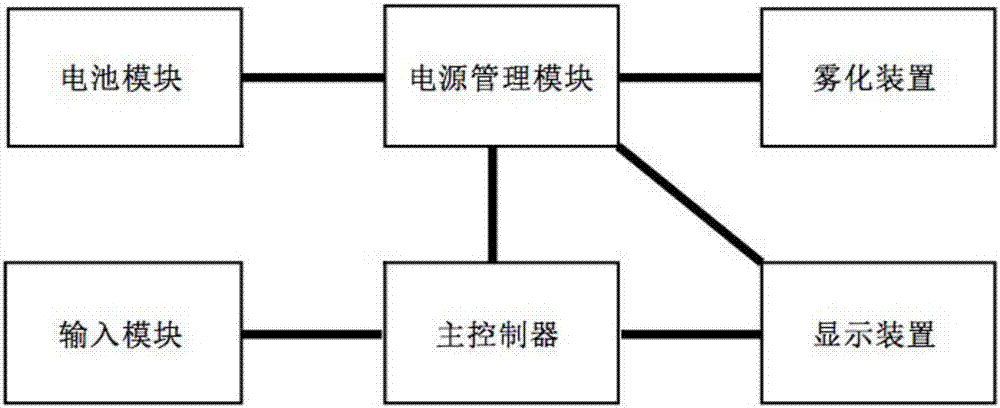

Electronic cigarette and method for supplying constant power therein

InactiveUS20160143359A1Meeting demandMeet needsSteam generation using steam absorptionElectric heatingVoltage regulator moduleConstant power

An electronic cigarette and a method for supplying a constant power therein, the electronic cigarette comprises an atomizer with a heating wire. The electronic cigarette also comprises a power supply module for supplying power to the heating wire to heat the heating wire, and further comprises a microprocessor, a detecting module connected to the microprocessor, and a voltage adjusting module. A preset constant power can supply to the heating wire of the atomizer in the electronic cigarette, so that a consistent heating power can be applied to each of the electronic cigarettes produced in batch production, and smoke amount and flavor of each of the electronic cigarettes are more consistent, thereby better meeting demands of consumers.

Owner:HUIZHOU KIMREE TECH

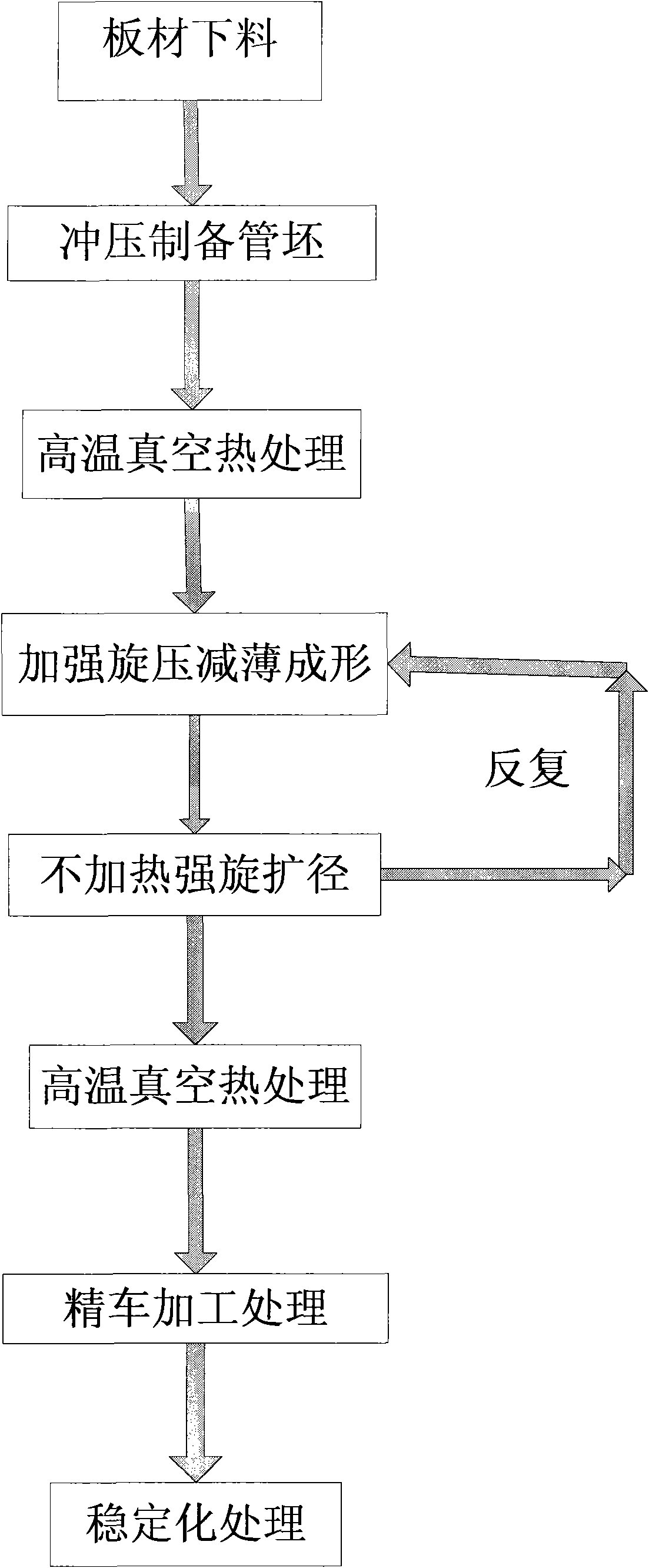

Integral forming method of large size thin-walled titanium alloy cylindrical part without welding line

ActiveCN101579804ASolve UtilizationSolving with longitudinal weldsFurnace typesHeat treatment furnacesThinningLarge size

The invention provides an integral forming method of a large size thin-walled titanium alloy cylindrical part without a welding line. The integral forming method comprises the following steps of: (1) tube blank preparation by stamping; (2) high-temperature vacuum heat treatment; (3) heating power spinning thinning; (4) unheating power spinning diameter expanding; (5) repetitive and alternate conduction of steps (3) and (4) for 2-3 times; (6) high-temperature vacuum heat treatment; (7) finish turning treatment; and (8) stabilizing treatment. The integral forming method prepares the large size thin-walled titanium alloy cylindrical part without the welding line (wall thickness is 1-7mm) which has high precision and high performance by utilizing titanium alloy plates and adopting a composite technique combining a stamping method, a spinning method and a stabilizing treatment method, and solves the problems of low material utilization ratio, having longitudinal welding lines, low precision of tube performance and the like in the forging and roll bending welding forming of the large size titanium alloy thin-walled tubes.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Smart pan

InactiveCN107048976AReduce firepowerAvoid spillingBoiling over preventionWarming devicesAutomatic controlControl signal

The invention belongs to the field of pans, and particularly discloses a smart pan comprising a pan body, a handle, a thermocouple and a pan controller. The thermocouple is assembled to the bottom of the pan body, and the pan controller is disposed within the handle. The pan controller acquires the corresponding cooking program, the cooking program is configured with the set value of the pan temperature associated with time, the measured value of the pan temperature based on thermocouple detection and the set value of the pan temperature obtained from the cooking program are processed to generate a control signal for manipulating a heating unit for heating the smart pan and changing the strength of heating power of the heating unit, the measured value of the pan temperature is enabled to reach the set value of the pan temperature till the cooking program is totally executed by the pan controller, and food cooking is finished. Throughout the cooking process, the smart pan manipulates the heating unit based on the acquired cooking program, the temperature of the smart pan is controlled automatically, food cooking is completed without user participation, and users can make delicious food either with or without cooking skills.

Owner:李明守

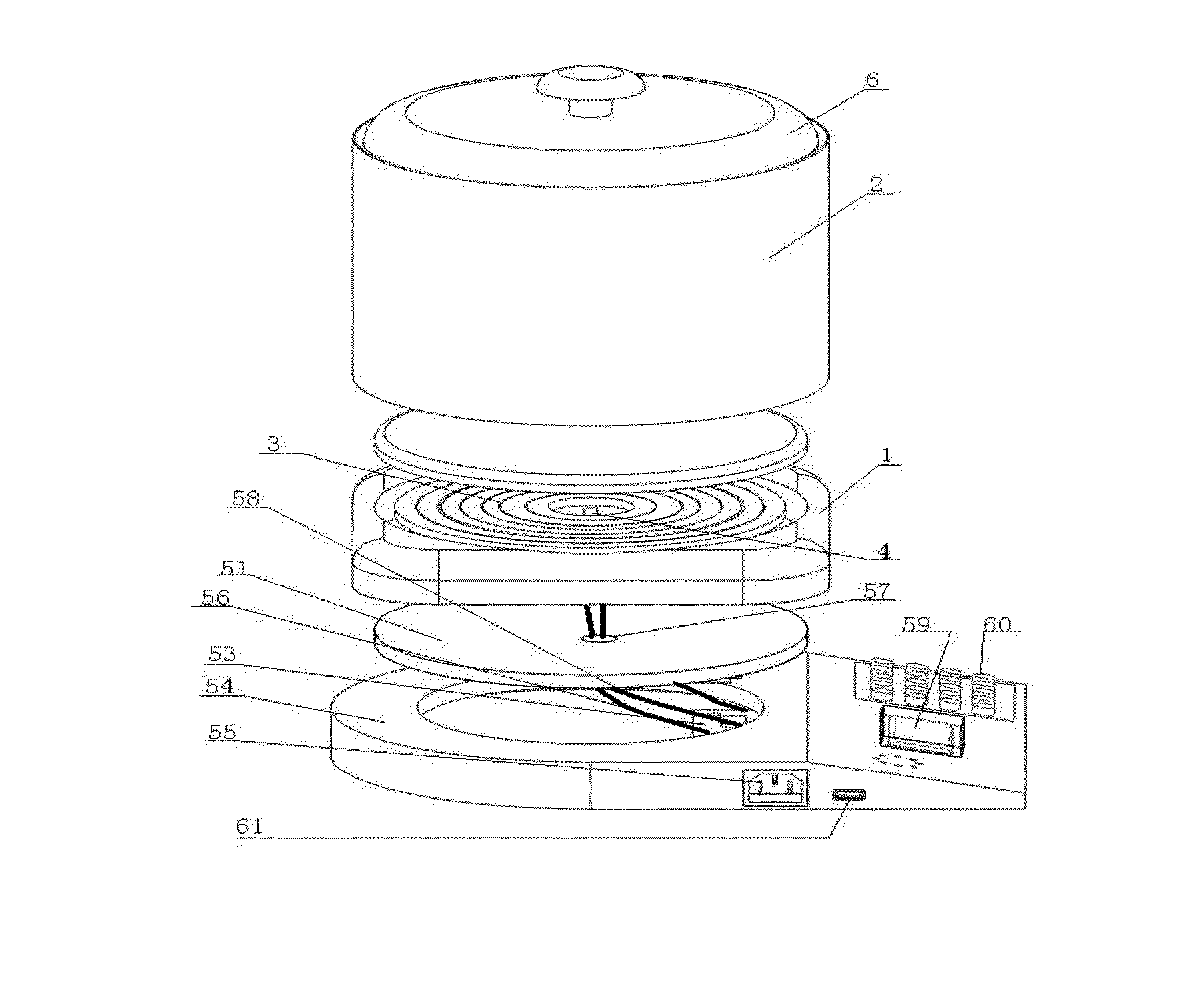

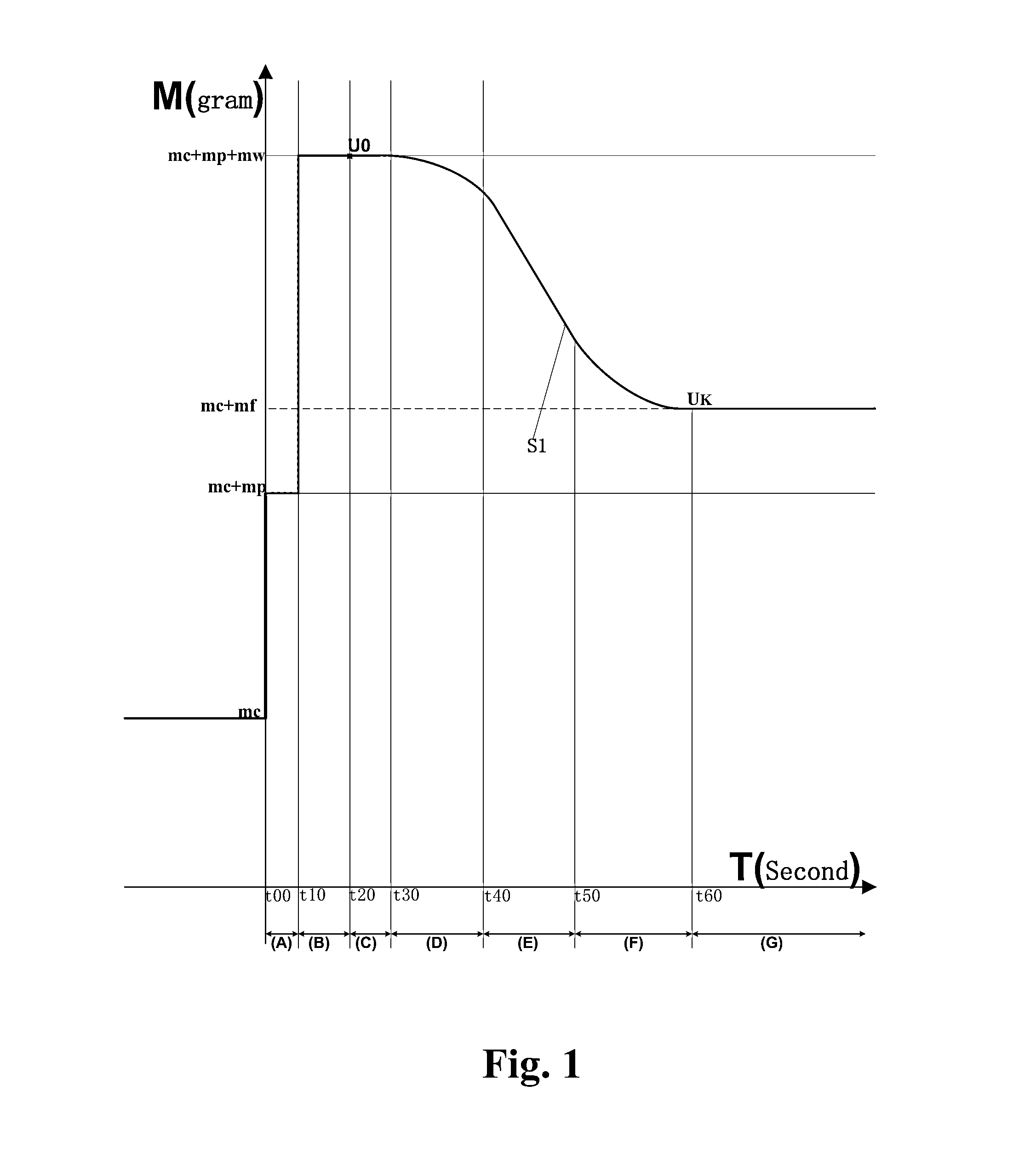

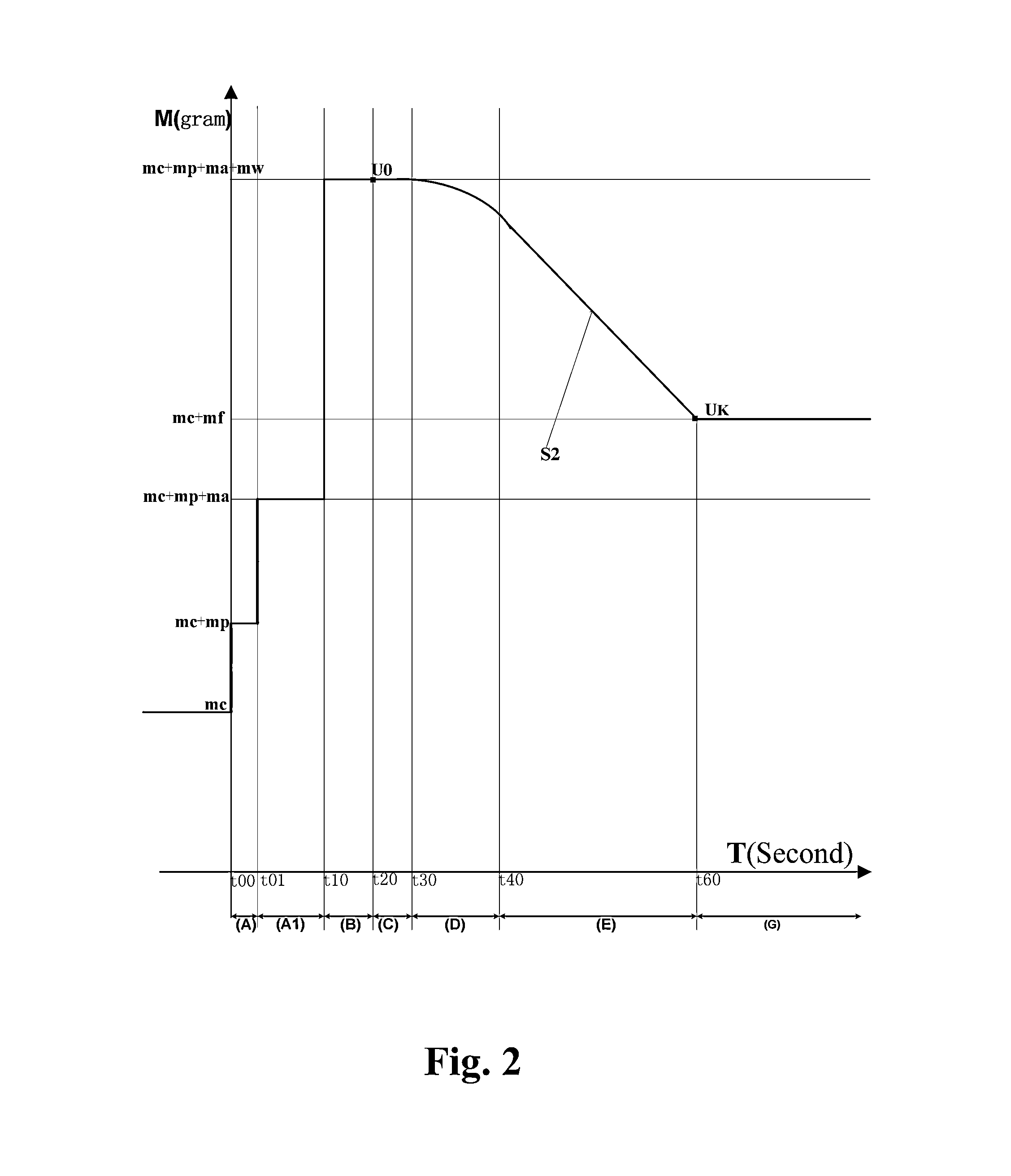

Electric heating cooker with weighing function and weighing control method thereof

ActiveUS9119501B2Increase and decrease valueEasy to controlWeighing apparatus detailsOhmic-resistance heatingCholesterolAdditive ingredient

An electric heating cooker with weighing function and a weighing control method thereof are provided. An electronic scale (5) with weighing function is added under the traditional electric heating cooker and stores cooking experience database and food information database. It solves the problem that users aren't accurate about the amount of water to add for a given weight of ingredient. And experience curve of heating power are designed at different weight points for food such as rice or meat, and also it makes the cooker to intelligently adjust parameters according to the taste feedback of the user so as to be more closer to the user's taste for the cooking next time; additionally it is capable of showing the total and average content of heat quantity, cholesterol, protein, fat, salt and cook oil of various foods in current cooking or if there are unmatched foods.

Owner:DUO AI JIA BEIJING SCI & TECH

Multifunctional pot

InactiveCN105902144ALow costAchieve precise temperature regulationSteam cooking vesselsPressure-cookersElectricityEngineering

The invention provides a multifunctional pot which comprises a heating part and an inner pot, wherein the heating part comprises a main body; a heating body, a temperature measurement assembly and a control panel assembly capable of controlling the heating power of the heating body are arranged on the main body; the control panel assembly is electrically connected with the heating body and the temperature measurement assembly, to receive a temperature signal transmitted by the temperature measurement assembly; the inner pot is placed on the heating body of the main body; the temperature measurement assembly is in contact with the outer side wall of the inner pot, to detect the temperature of the inner pot; an insulation main body connection head is arranged on the main body; a conductive terminal electrically connected with the control panel assembly is arranged in the insulation main body connection head; a temperature measurement device for detecting the temperature in the inner pot is arranged on one side of the inner pot, and can be electrically connected with the conductive terminal on the main body. The multifunctional pot disclosed by the invention can meet various cooking requirements, so that the cost can be lowered for a user.

Owner:ZHEJIANG SHANGCHU COOKER CO LTD

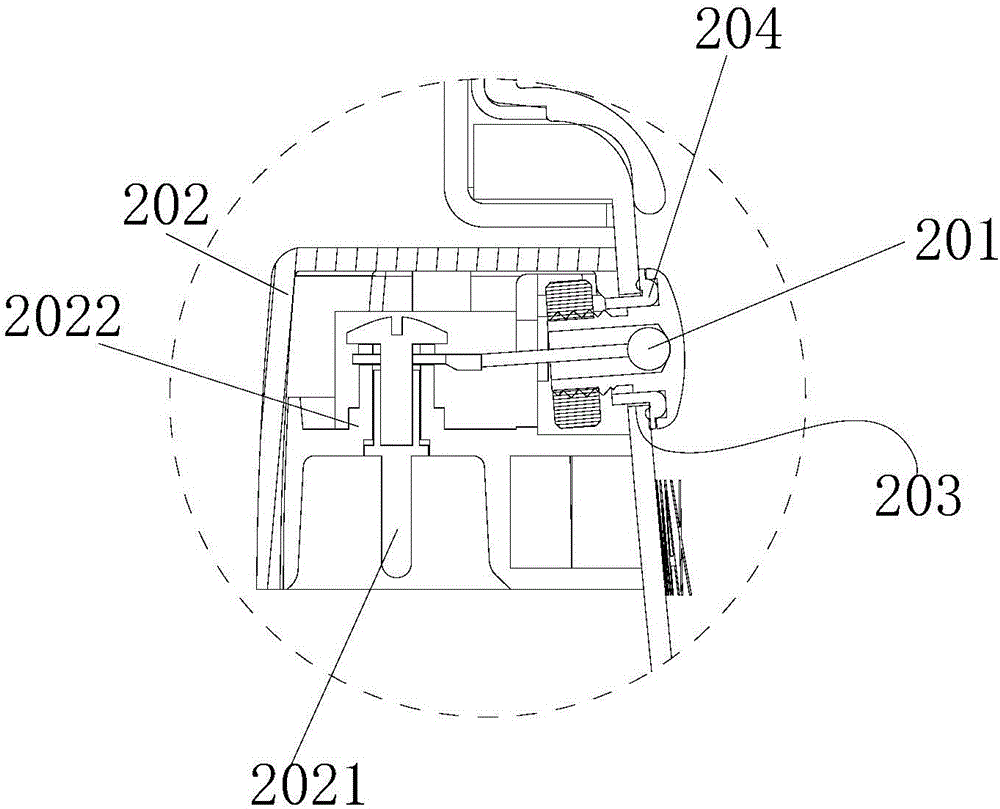

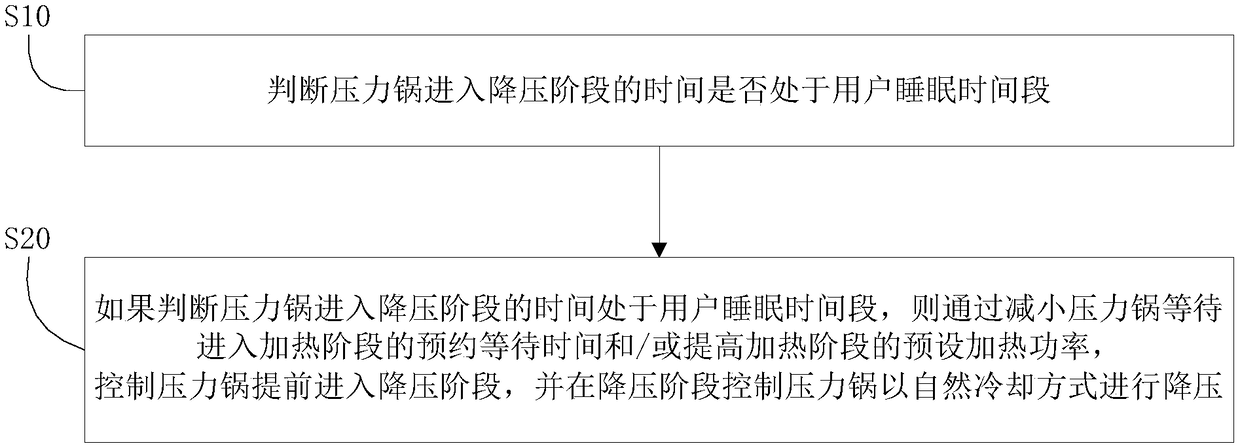

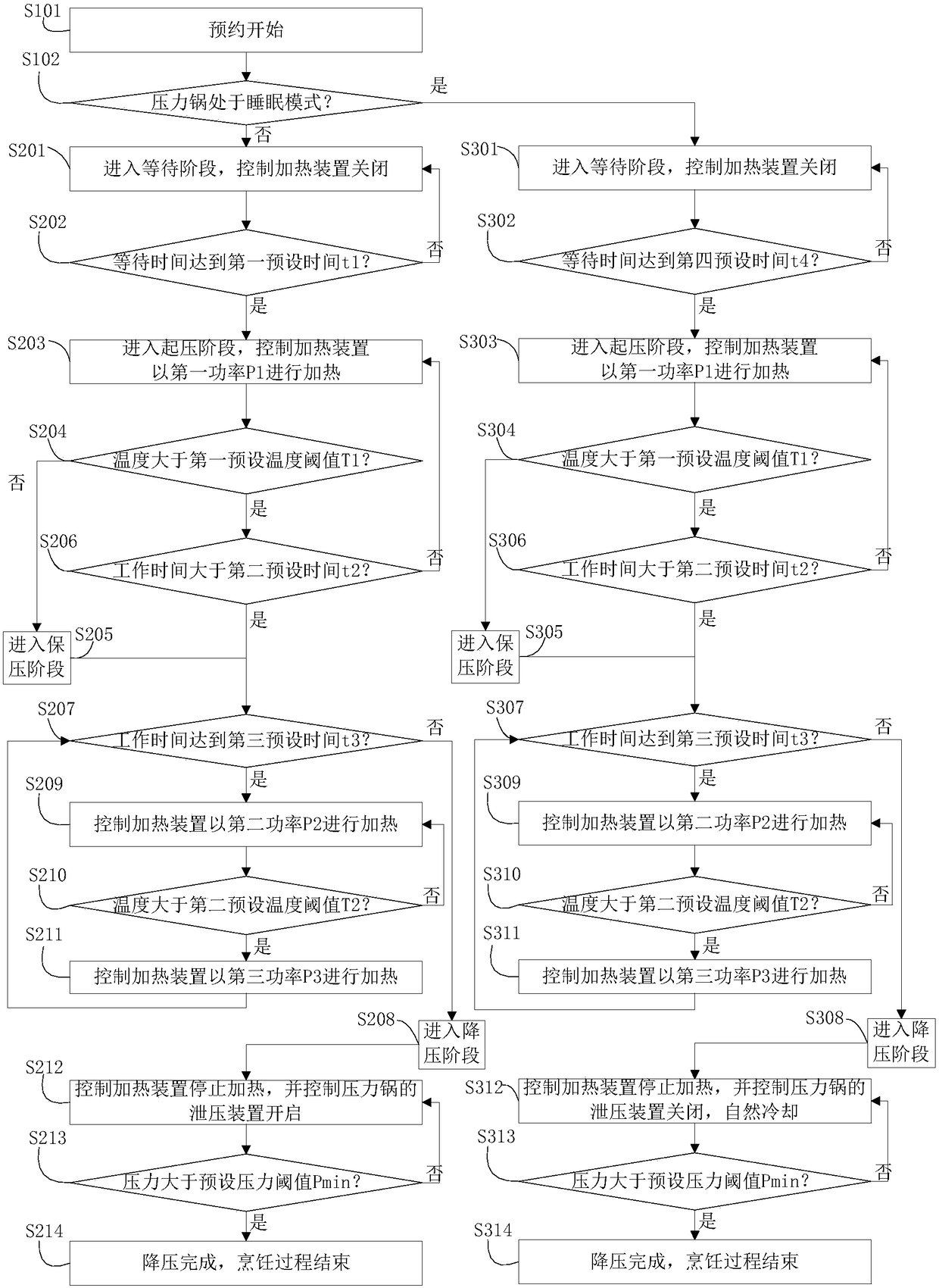

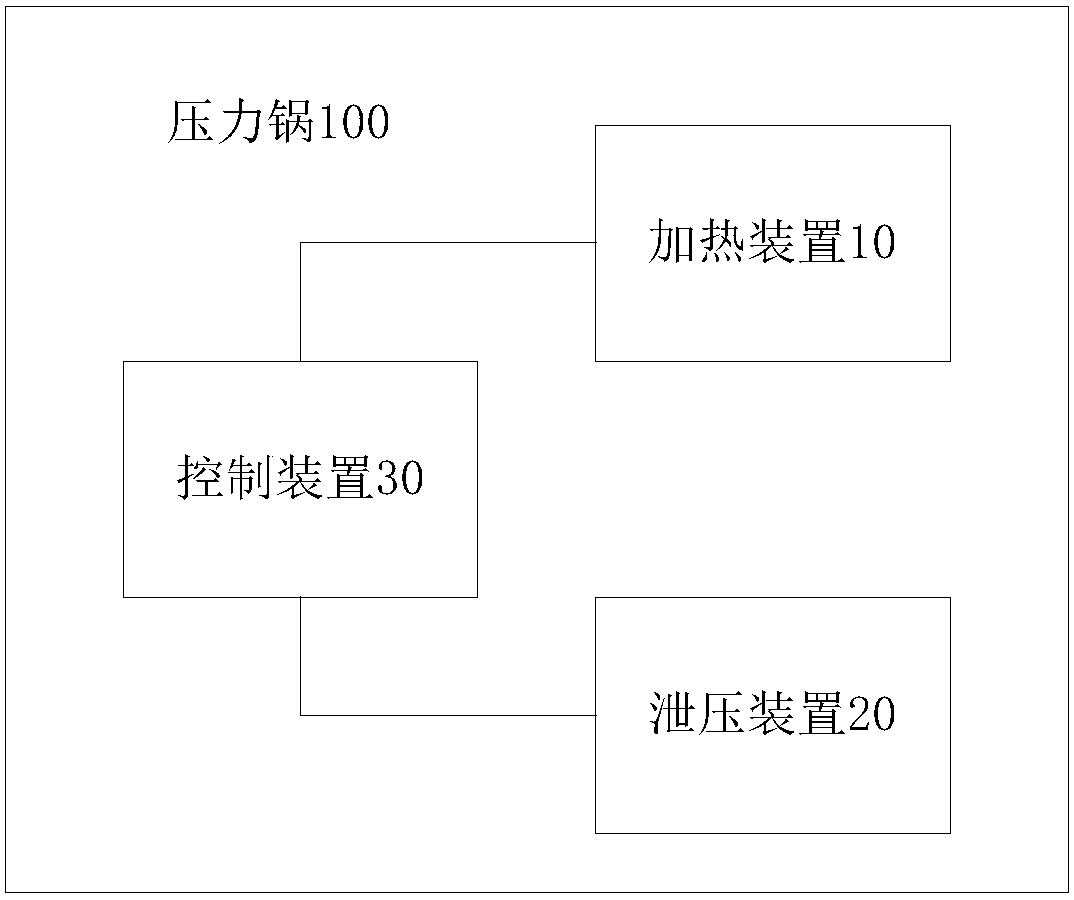

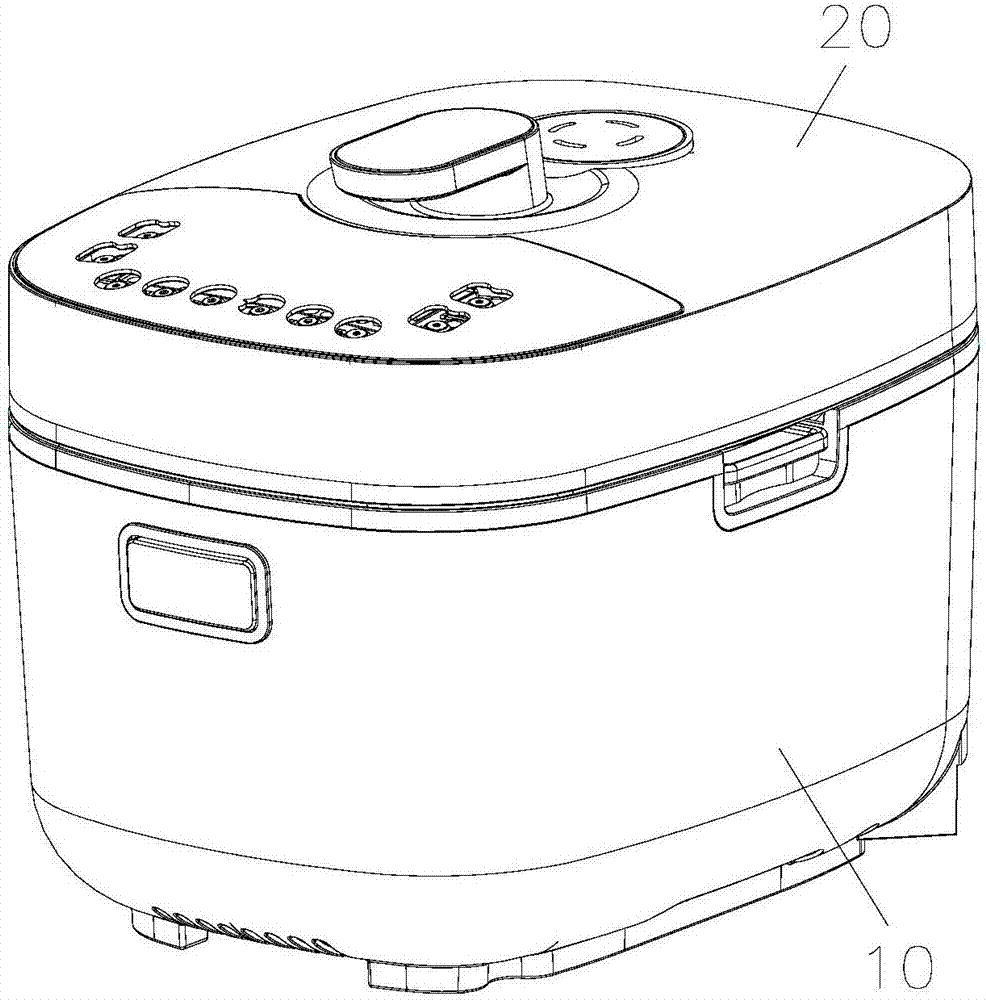

Pressure cooker and control method thereof

The invention discloses a pressure cooker and a control method thereof. The method comprises the steps of judging whether or not the time when the pressure cooker enters a depressurization stage is ata user sleep period; if yes, controlling the pressure cooker to enter the depressurization stage in advance by shortening the appointment waiting time when the pressure cooker waits to enter a heating stage and / or increasing a preset heating power of the heating stage, and controlling the pressure cooker to be depressurized in a natural cooling mode at the depressurization stage; in this way, thedepressurizing sound is effectively prevented from being too large and influencing the sleep of a user when the user is at a sleep period, it can also be ensured that a cover of the pressure cooker is opened quickly when the user is not at a sleep period, accordingly the cooking requirements of different people in different environments are met to the greatest degree, and the user experience is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

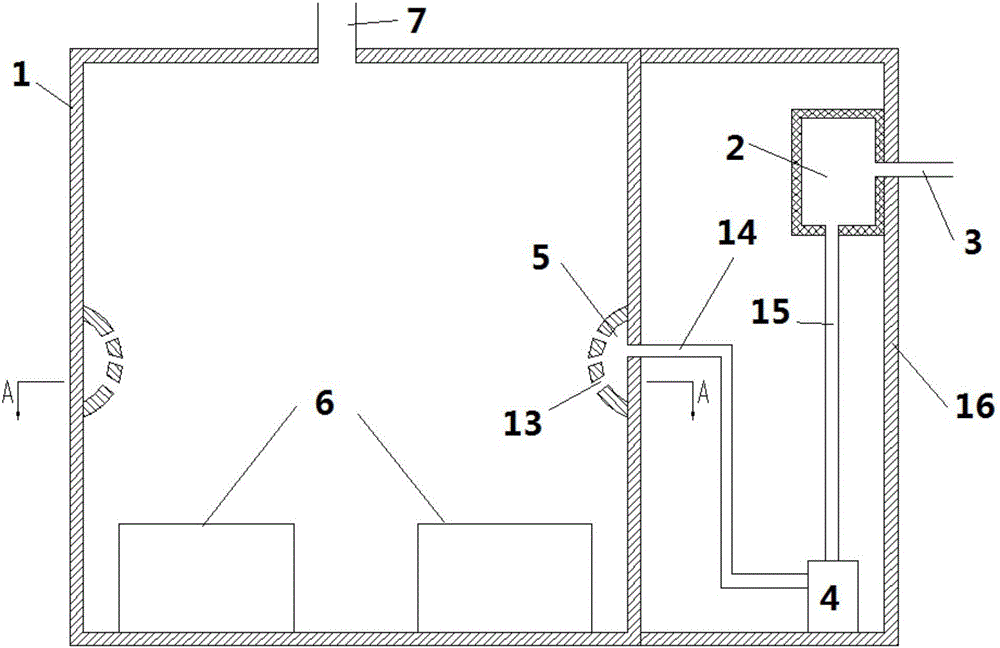

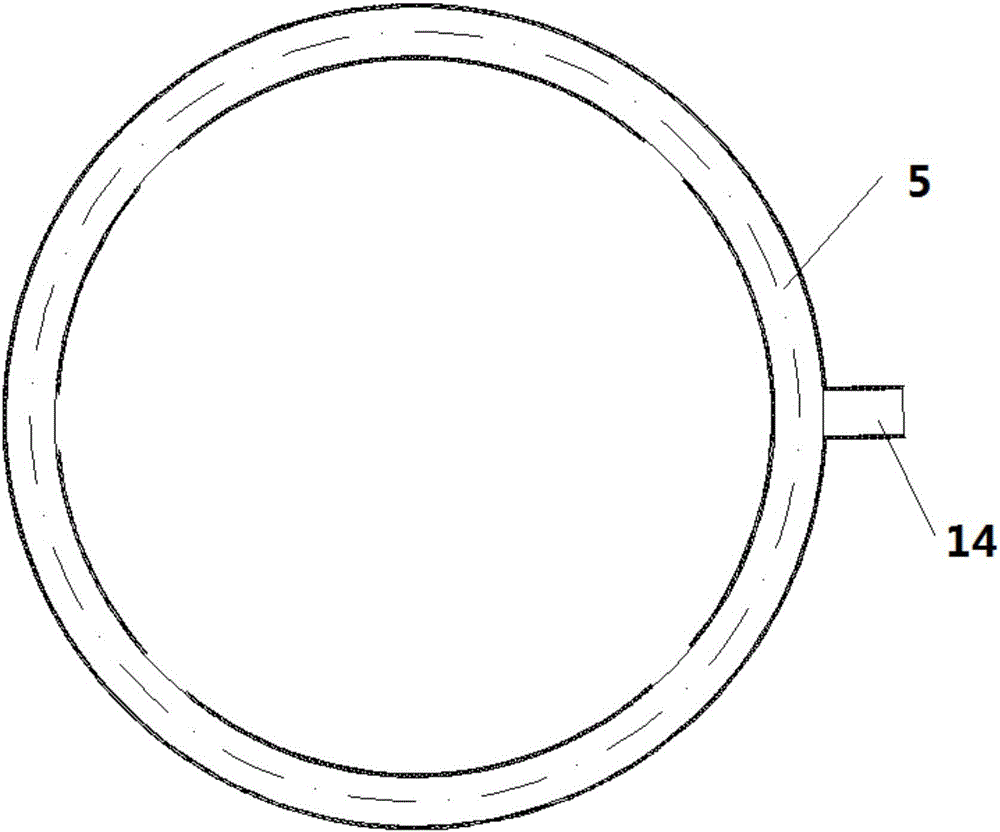

Steam generator with heating power intelligently distributed through mobile phone APP

InactiveCN106402824ARealize automatic allocationImprove intelligenceSteam generation heating methodsBoiler controlData connectionAutomatic control

The invention provides a steam generator which comprises a furnace body, a water tank and a water pump. An electric heating device is arranged in the furnace body. A steam outlet pipeline is arranged on the upper portion of the furnace body. The water tank is provided with an inlet pipe. The electric heating device comprises a left pipe box, a right pipe box and a floating coiled pipe. A first electric heater is arranged in the left pipe box, a second electric heater is arranged in the right pipe box, the first electric heater and the second electric heater are in data connection with a controller, the controller is connected with a cloud server, and the cloud server is connected with a client side. The measured heating power of the first electric heater and that of the second electric heater are transmitted to the cloud server through the controller and then transmitted to the client side through the cloud server, the client side is a mobile phone, an APP is installed in the mobile phone, and a user can select a working mode of automatic control or manual control at the client side. Operation of the steam generator is monitored through the mobile phone APP, and the intelligent control that the steam generator is remotely monitored is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

Electric cooker and porridge-cooking control method thereof

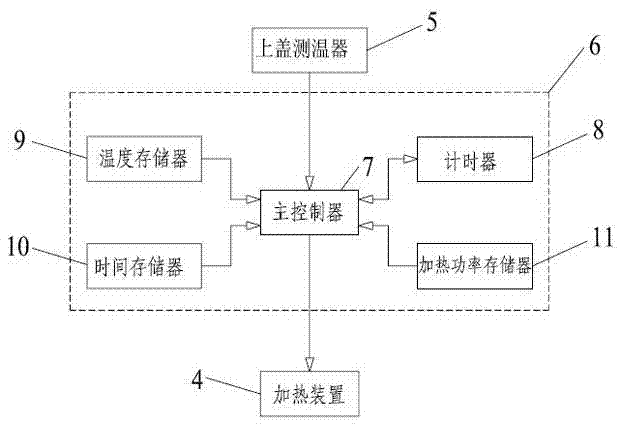

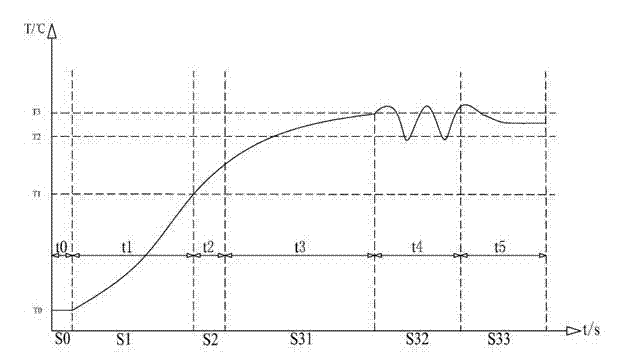

ActiveCN102125385AGuaranteed boiling effectImprove cooking resultsAuxillary controllers with auxillary heating devicesCooking vesselsLow voltageComputer module

The invention relates to an electric cooker and a porridge-cooking control method thereof. In the electric cooker, a temperature memory is preset with a second temperature T2 and a third temperature T3 and T2 is less than or equal to T3; a time memory is preset with a first boiling time t3 and a second boiling time t4; a heating power memory is preset with a second power ratio B, a third power ratio C and a fourth power ratio D corresponding to rice quantity grades; a main controller is provided with a control module; after the electric cooker is used for heating and finishes the first boiling time t3 by the second power ratio B at the boiling stage, a heating device is controlled to heat by the third power ratio C or the fourth power ratio D according to a ratio of an upper cover temperature T to the second temperature T2 and the third temperature T3 until the set second boiling time t4 is met. Heating power is changed according to the upper cover temperature at the boiling stage, so the defect that rice and water are not boiled completely under low voltage or low environmental temperature is overcome, and the porridge-cooking effect is effectively improved.

Owner:MIDEA GRP CO LTD

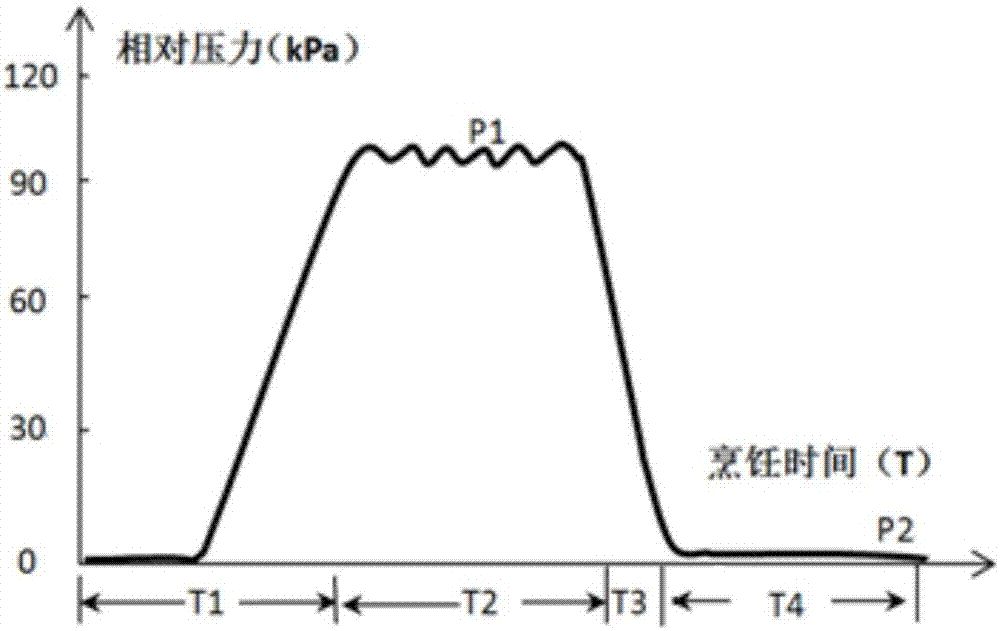

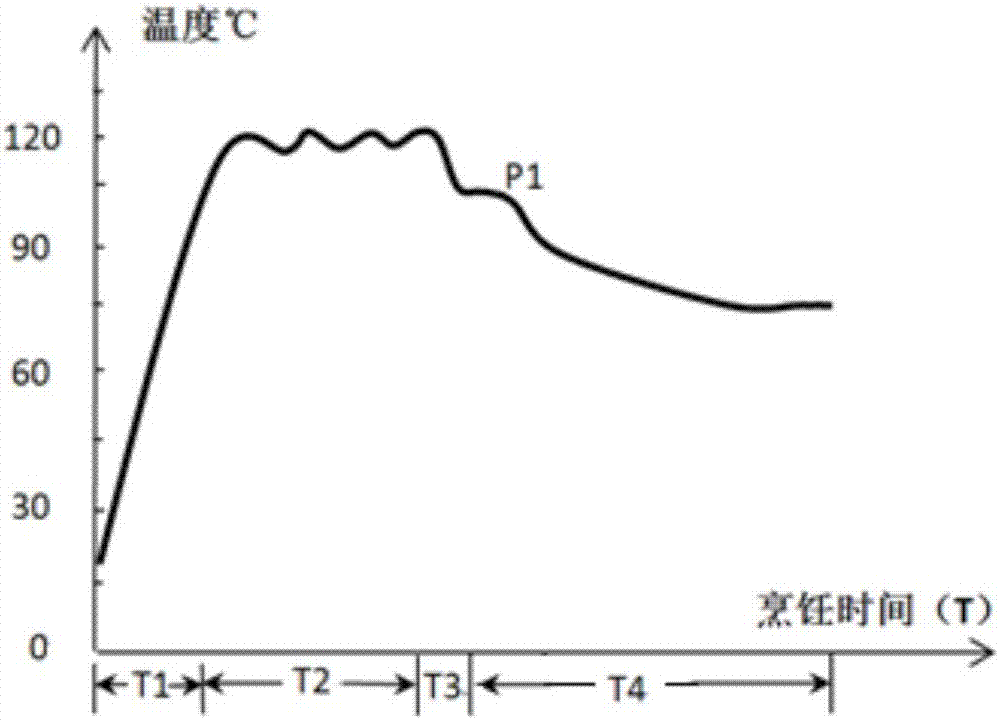

Cooking control method of electric rice cooker

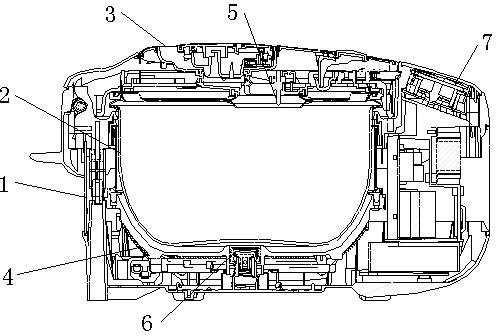

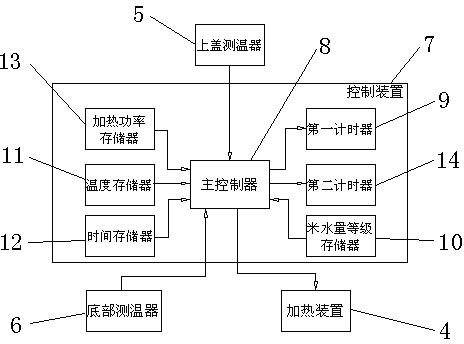

ActiveCN102342737APrevent spillageAvoid bubblingAuxillary controllers with auxillary heating devicesCooking vesselsHeating timeProcess engineering

The invention discloses a cooking control method of an electric rice cooker. The electric rice cooker comprises a cooker body, an inner container arranged in the cooker body, an upper cover, a heating device, a bottom temperature measurer, an upper cover temperature measurer and a control device used for controlling rice cooking work and arranged on the cooker body, wherein the control device comprises a main controller as well as a first timer, a second timer, a rice-water volume level storage, a temperature storage, a time storage and a heating power storage which are respectively connected with the main controller, and a plurality of powers are preset in the heat power storage. A method for controlling the rice cooking of the electric rice cooker by the control device comprises a heating stage, a boiling stage and a cooking stage. The control device controls the heating device to heat until boiling by using gradually reduced powers. In the invention, the gradually reduced powers are adopted for heating unit boiling at the heating stage, and meanwhile, a boiling state is judged according to the bottom temperature, thus, not only is the problem that a small amount of rice is easy to overflow and be ebullient avoided, but also a large amount of rice can be sufficiently heated to reach the boiling state, and the heating time is effectively controlled.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

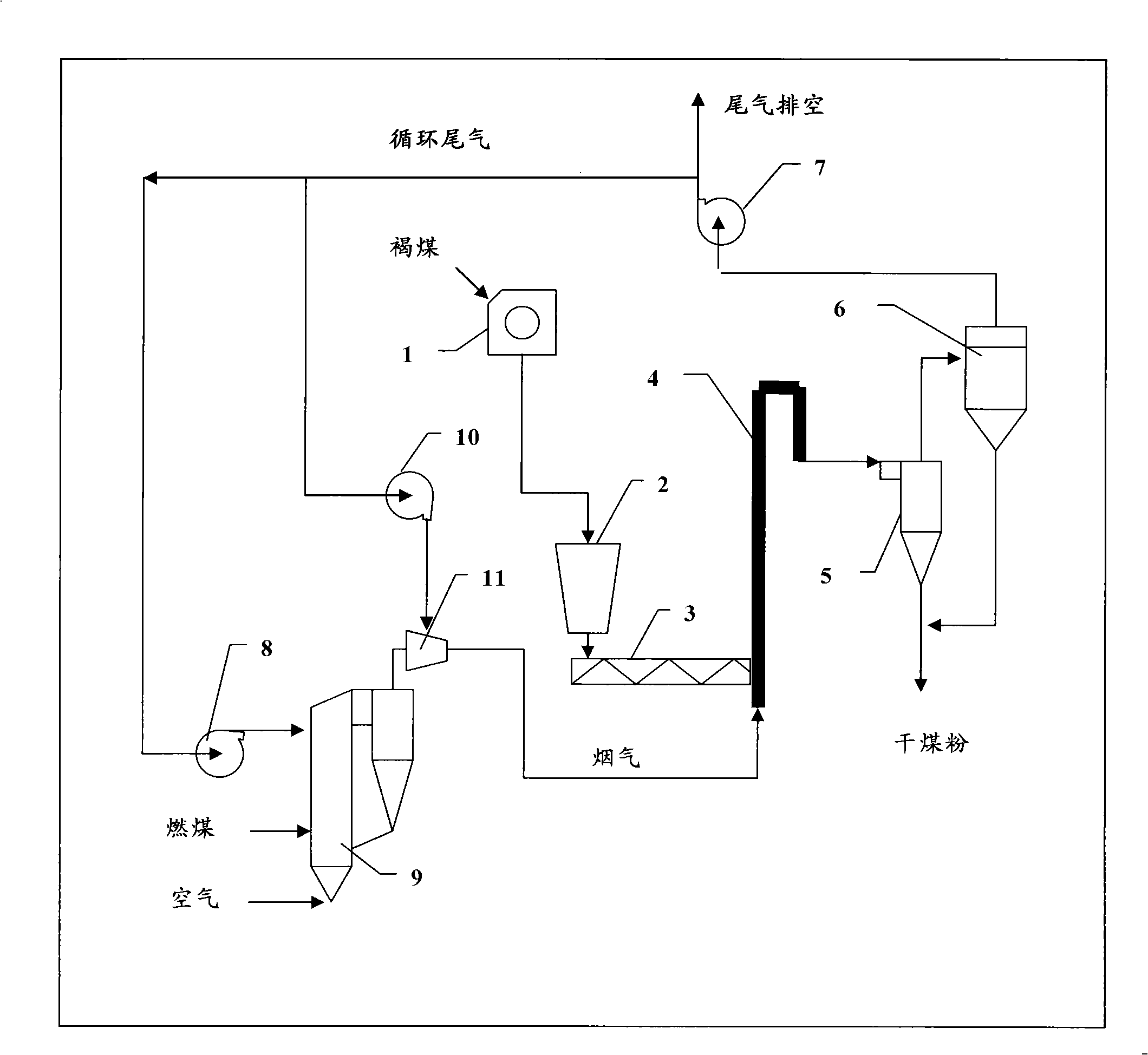

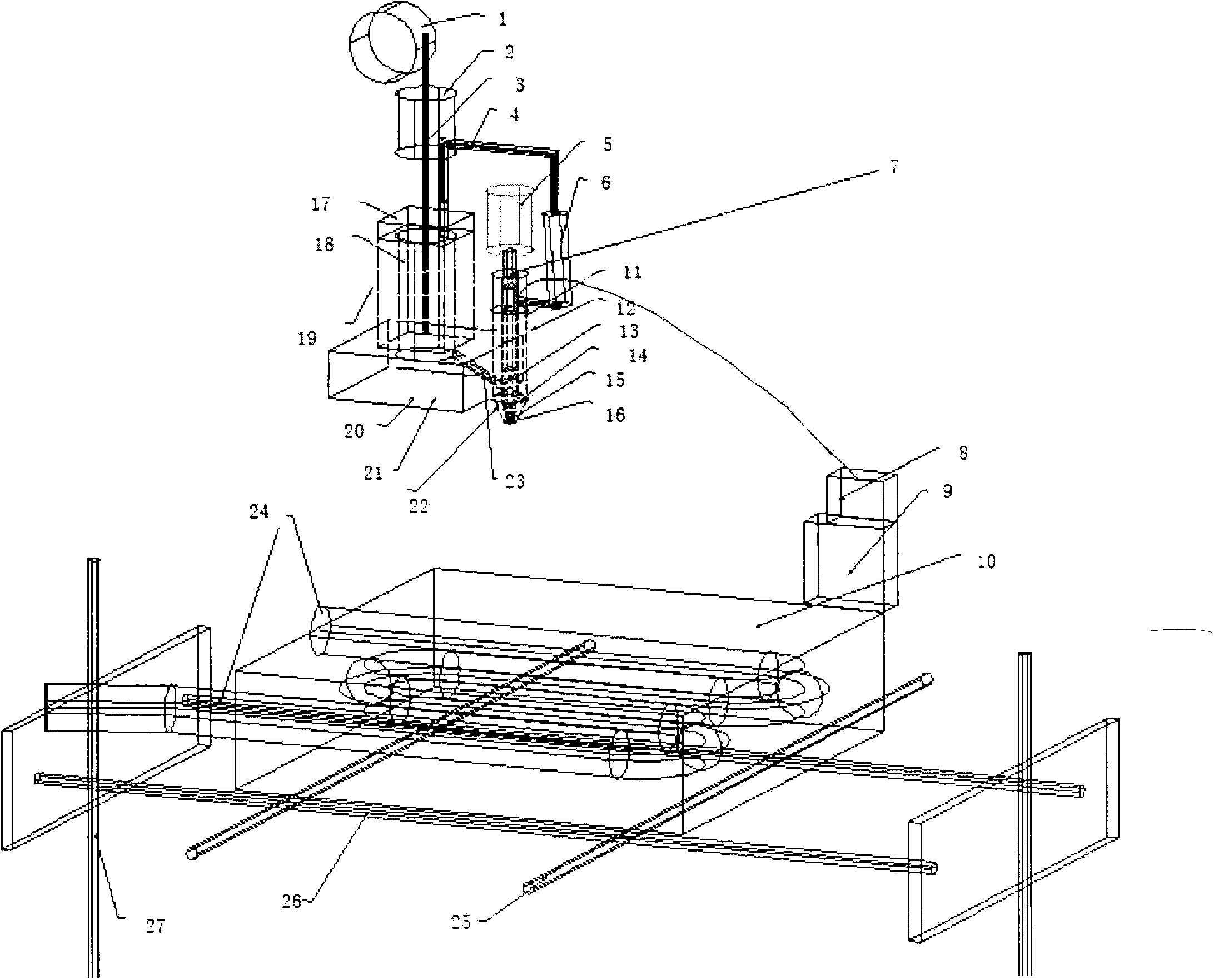

Low rank coal high temperature flue gas drying method and device

The invention relates to a method of high-temperature flue gas drying, which is particularly suitable for drying long flame coal, brown coal or other low rank coal. The coal-fired high-temperature flue gas is used to dry flammable and explosive coal types, such as brown coal in the direct contact method; therefore, the method has less gas exhaust, high thermal efficiency and high drying speed. The internal water content of the dried coal is obviously reduced, and the heating power of the dried coal is greatly increased. The invention also relates to the device using the method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Electric pressure pot

InactiveCN107307730ASolve the problem of poor taste and poor taste effectHigh Flavor Amino Acid ContentPressure-cookersControl systemEngineering

Provided is an electric pressure pot. The electric pressure pot includes a pot body, a pot cover, a cooking control system, a heating device and a pressure adjusting device; the pot body includes an outer pot body and an inner pot body for containing food to be cooked; the pot cover is arranged on the pot body; the cooking control system includes a control panel and a control plate for receiving input information of the control panel; the heating power of the heating device is controlled by the cooking control system, and the maximum heating power of the heating device is 1400 watts or above; by the adoption of the pressure adjusting device, the control panel can select a certain cooking program which includes a high-temperature pressure maintaining stage, and in the high-temperature pressure maintaining stage, the pressure adjusting device controls the pressure inside the inner pot to be in the range from 80 kPa to 110 kPa, so that when cooking ribs, the electric pressure pot can make rib meat separated from rib bone in a preset time duration. By the adoption of the technical scheme, the problems are solved that after electric pressure pots in the prior art are applied, cooked food is poor in mouthfeel and poor in tasty effect.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

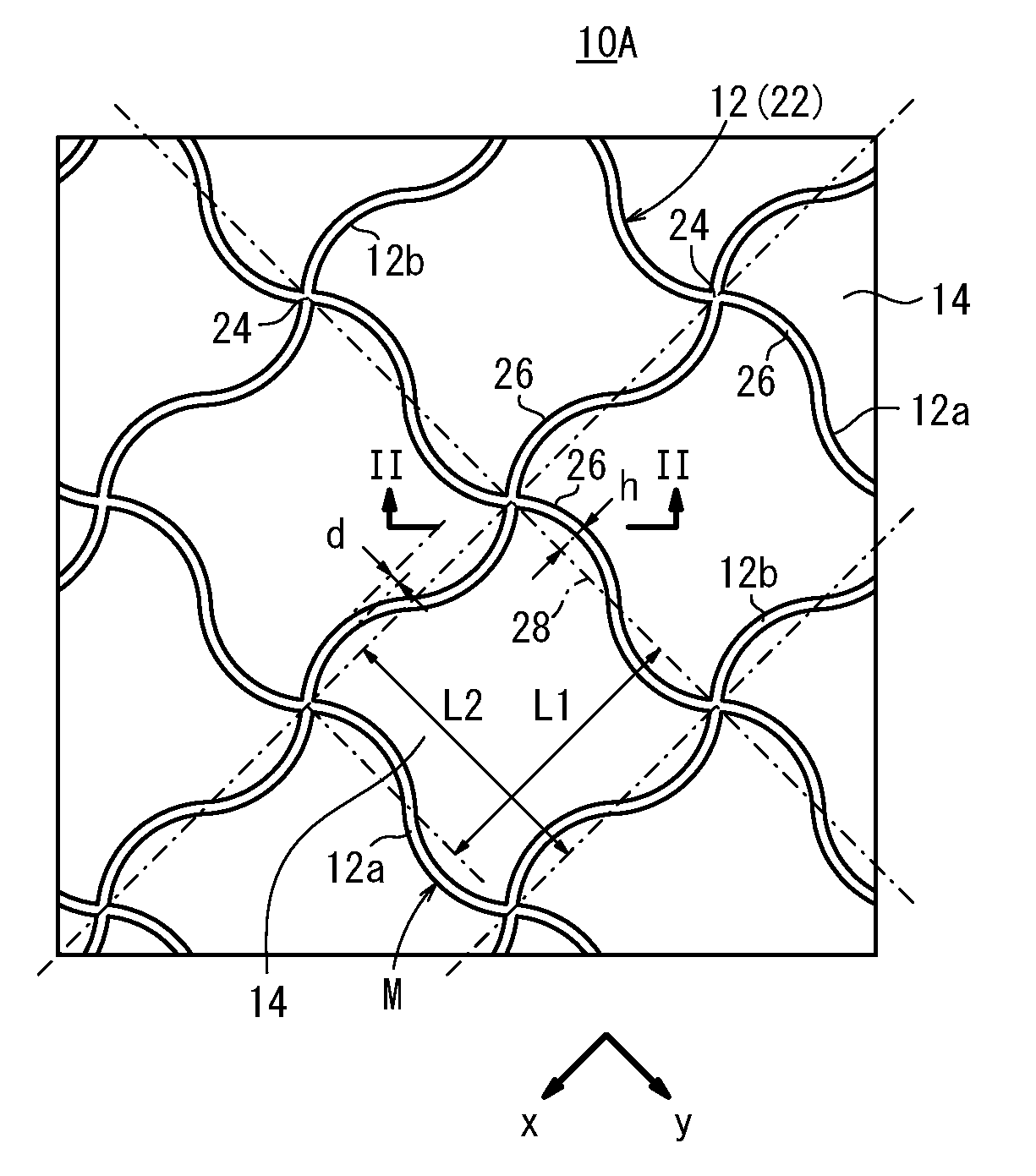

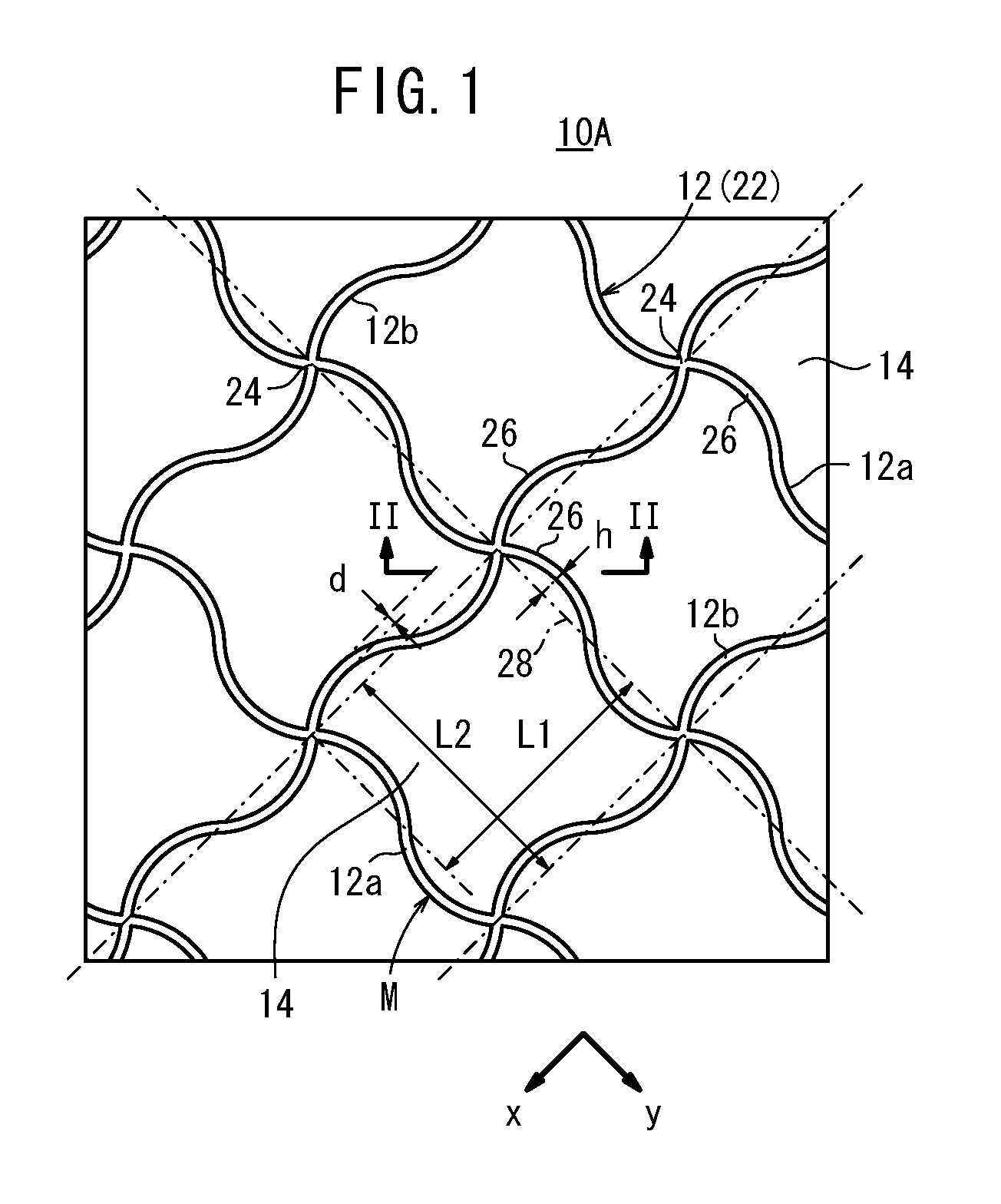

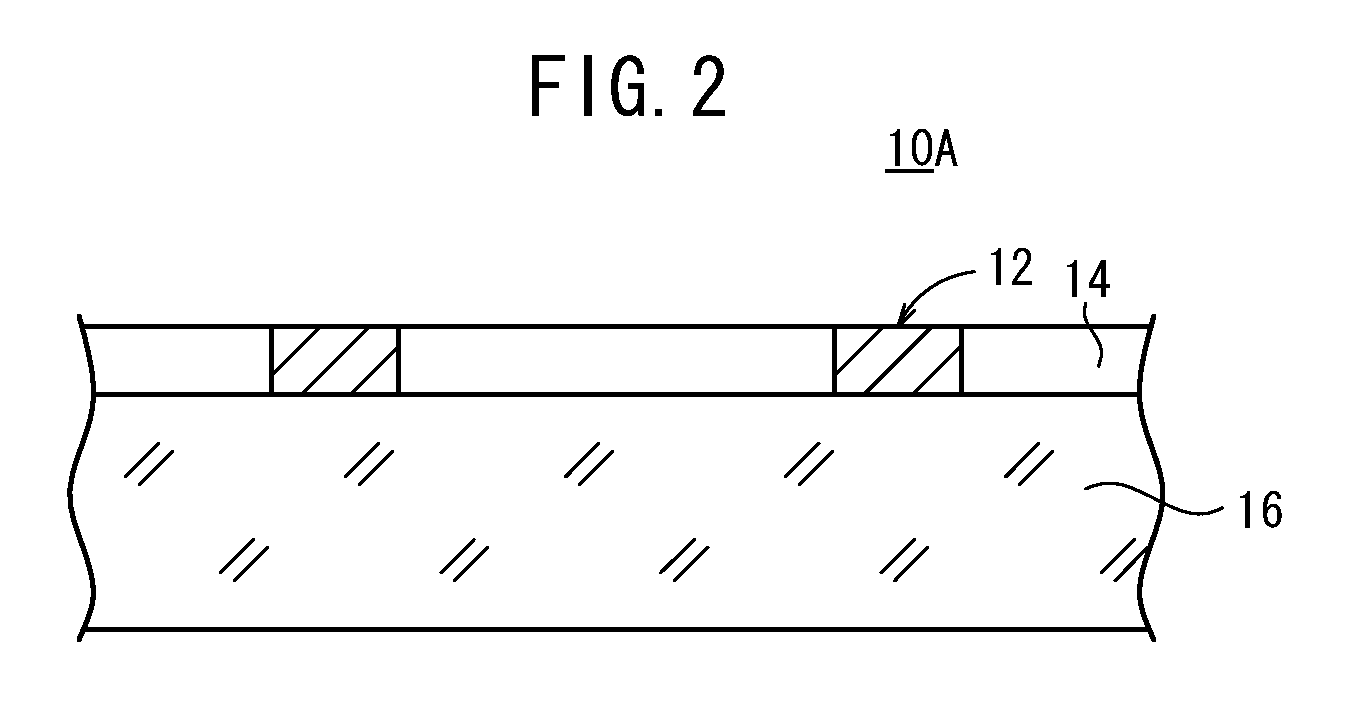

Conductive film, and transparent heating element

ActiveUS20110062146A1High light transmittanceIncrease blockingLayered productsTransparent/reflecting heating arrangementsVisibilityMetal filament

Provided is a conductive film, which is suitably used in a heating element of a transparent property (a transparent heating element) excellent in visibility and a heating power. The conductive portion of a first conductive film includes mesh patterns having multiple intersecting points (intersecting portions), which are constituted of a plurality of first metal filaments and a plurality of second metal filaments, and the conductive portion between the intersecting portions is formed into an undulating shape having at least one curve. The first conductive film is shaped such that the curves are arcuate and two arcs are formed continuously between the intersecting portions, wherein the protrusion-recess directions of the arcs are opposite to each other. Each arc has a center angle of about 90 degrees. Moreover, the conductive portion has a crossing angle of about 90 degrees.

Owner:FUJIFILM CORP

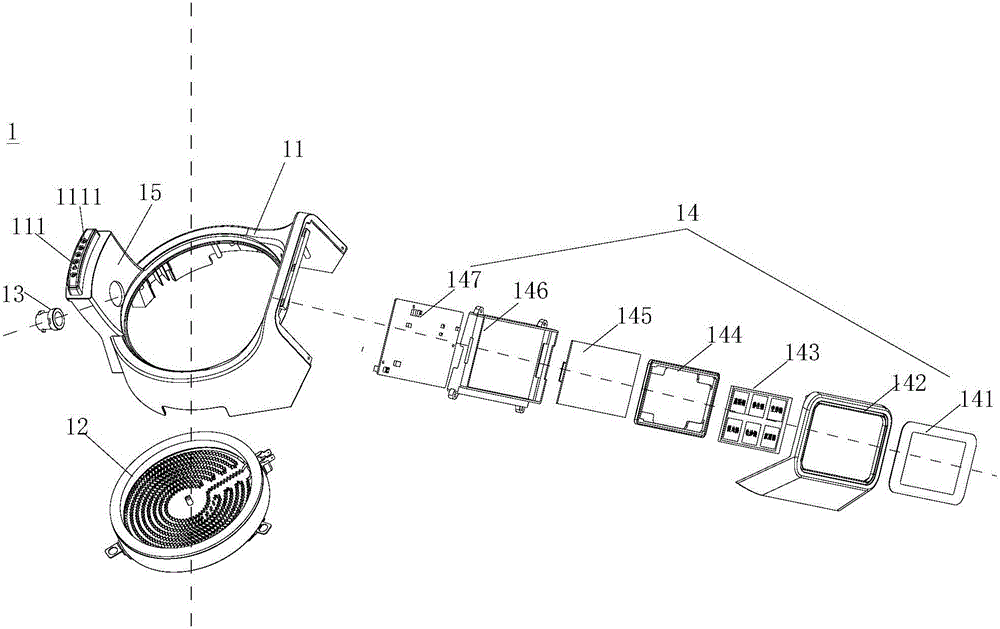

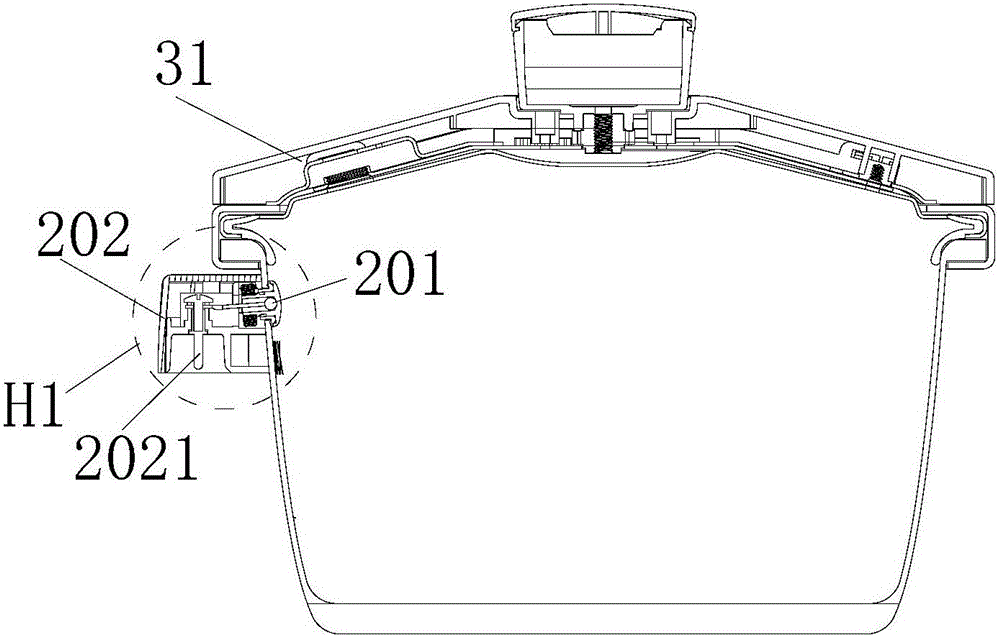

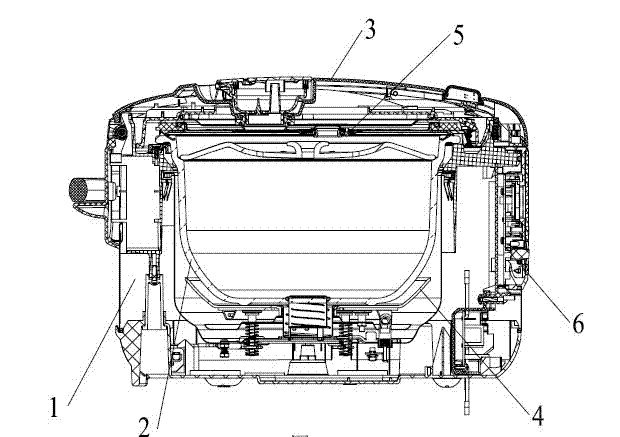

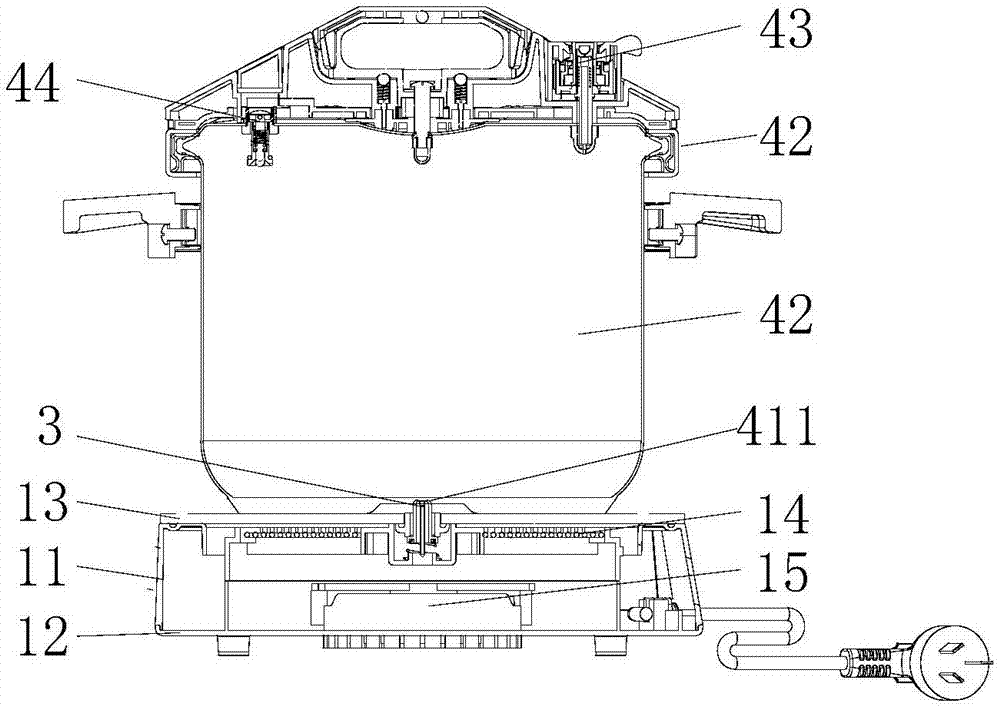

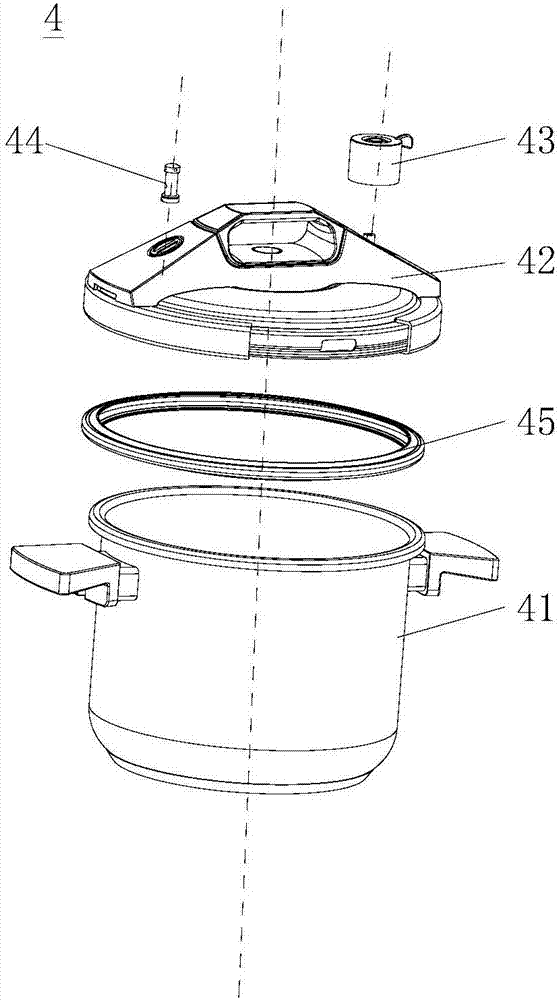

Split type electric pressure cooker

InactiveCN107397431ARegulate internal pressureAvoid disadvantagesPressure-cookersElectricityHome appliance

The invention provides a split type electric pressure cooker. The split type electric pressure cooker comprises a heating bottom disc, a control panel assembly, a thermosensitive temperature-sensing element and a pressure cooker body, wherein the heating bottom disc is provided with a main body and a bottom cover, a microcrystal plate is stored at an upper opening of the main body, a coil disc, a fan and a power panel assembly capable of adjusting the heating power of the coil disc are arranged in an inner cavity of the main body, and the bottom cover and a lower opening of the main body are correspondingly buckled; the control panel assembly is installed on the side wall of the main body, and the power panel assembly is electrically connected with the control panel assembly; the thermosensitive temperature-sensing element can be installed between the microcrystal plate and the coil disc in an extensible mode, the upper end of the thermosensitive temperature-sensing element extrudes out of the upper surface of the microcrystal plate, and the thermosensitive temperature-sensing element is electrically connected with the power panel assembly; and when the pressure cooker is placed on the microcrystal plate of the heating bottom disc, the bottom of the pressure cooker is in contact with the upper end of the thermosensitive temperature-sensing element correspondingly. According to the split type electric pressure cooker, combination work can be achieved, separate using can also be achieved, and the competitiveness of the product in household appliances is improved.

Owner:ZHEJIANG SHANGCHU COOKER CO LTD

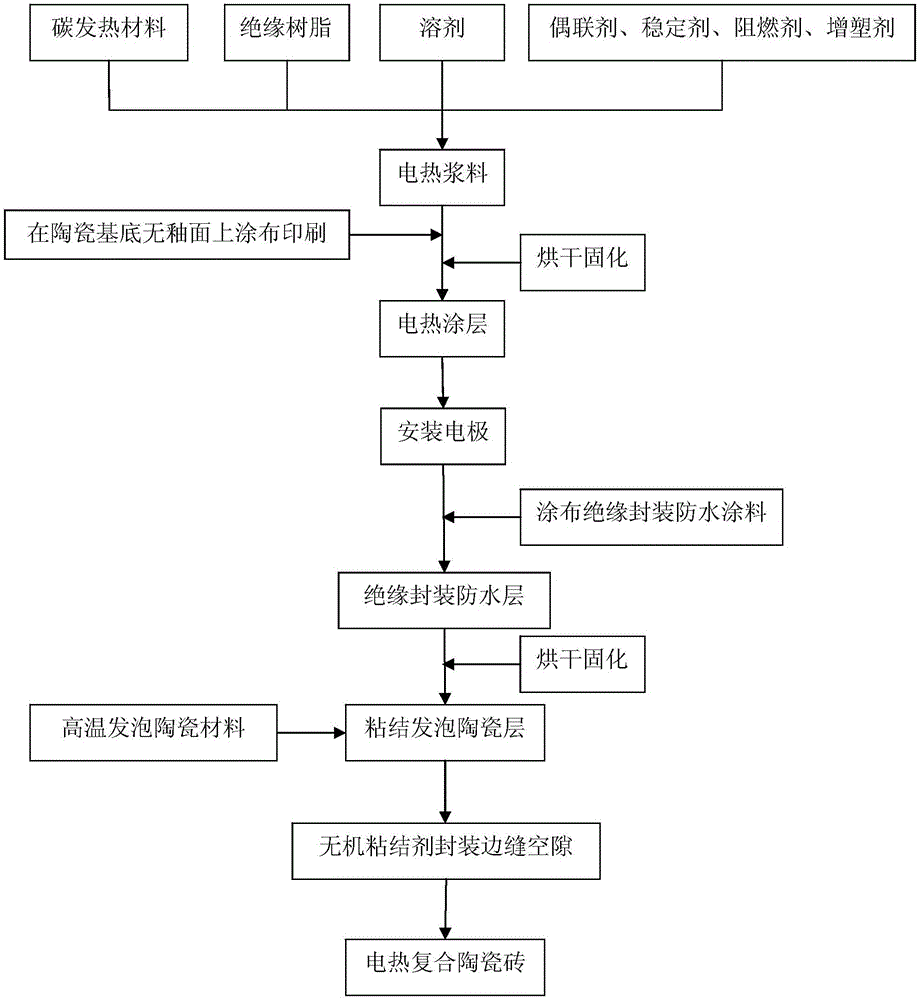

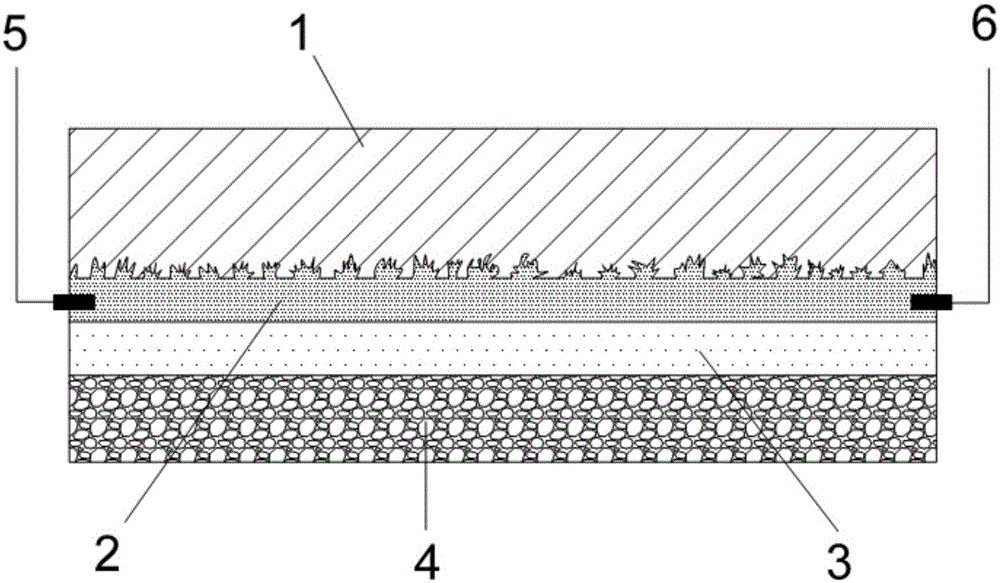

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

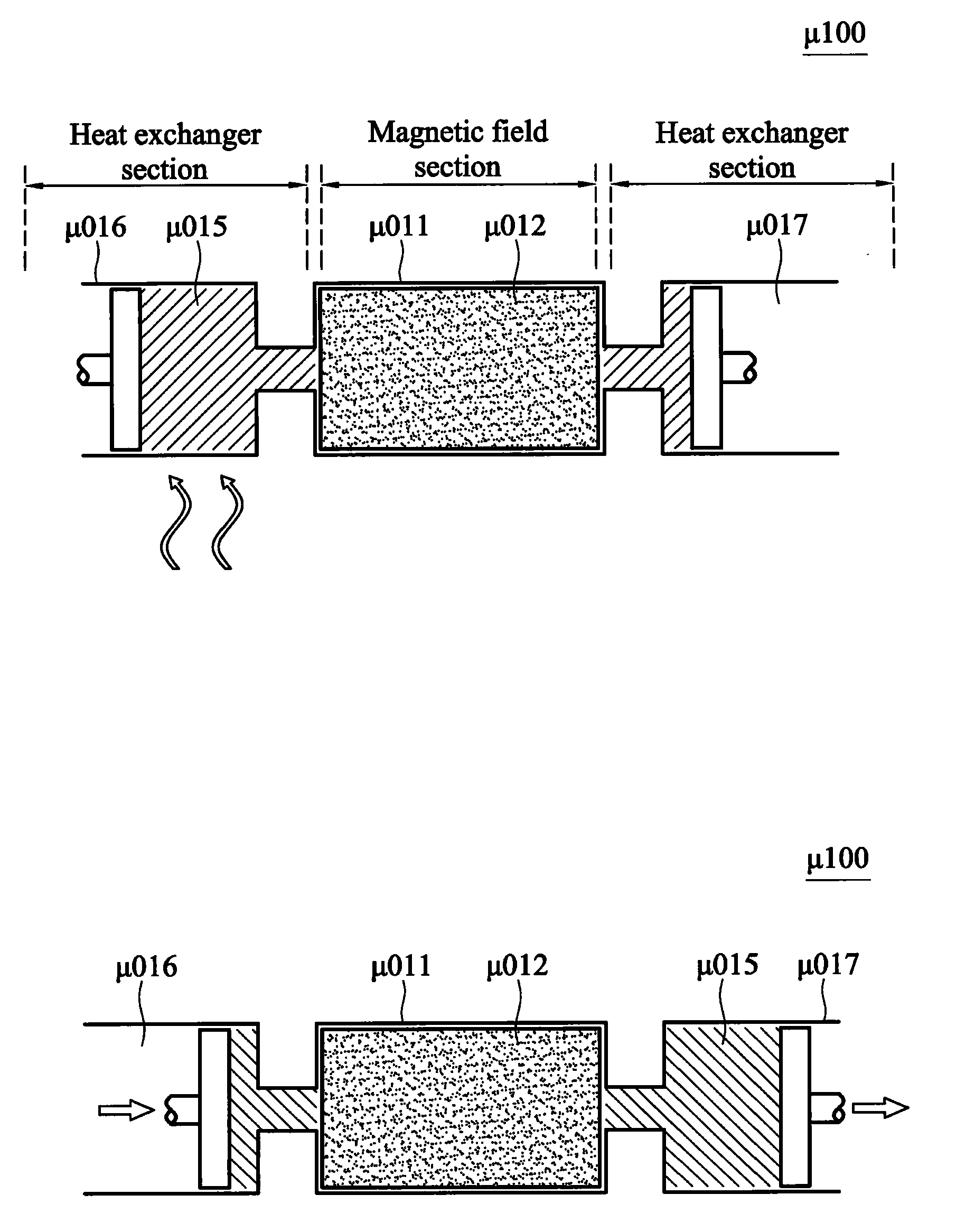

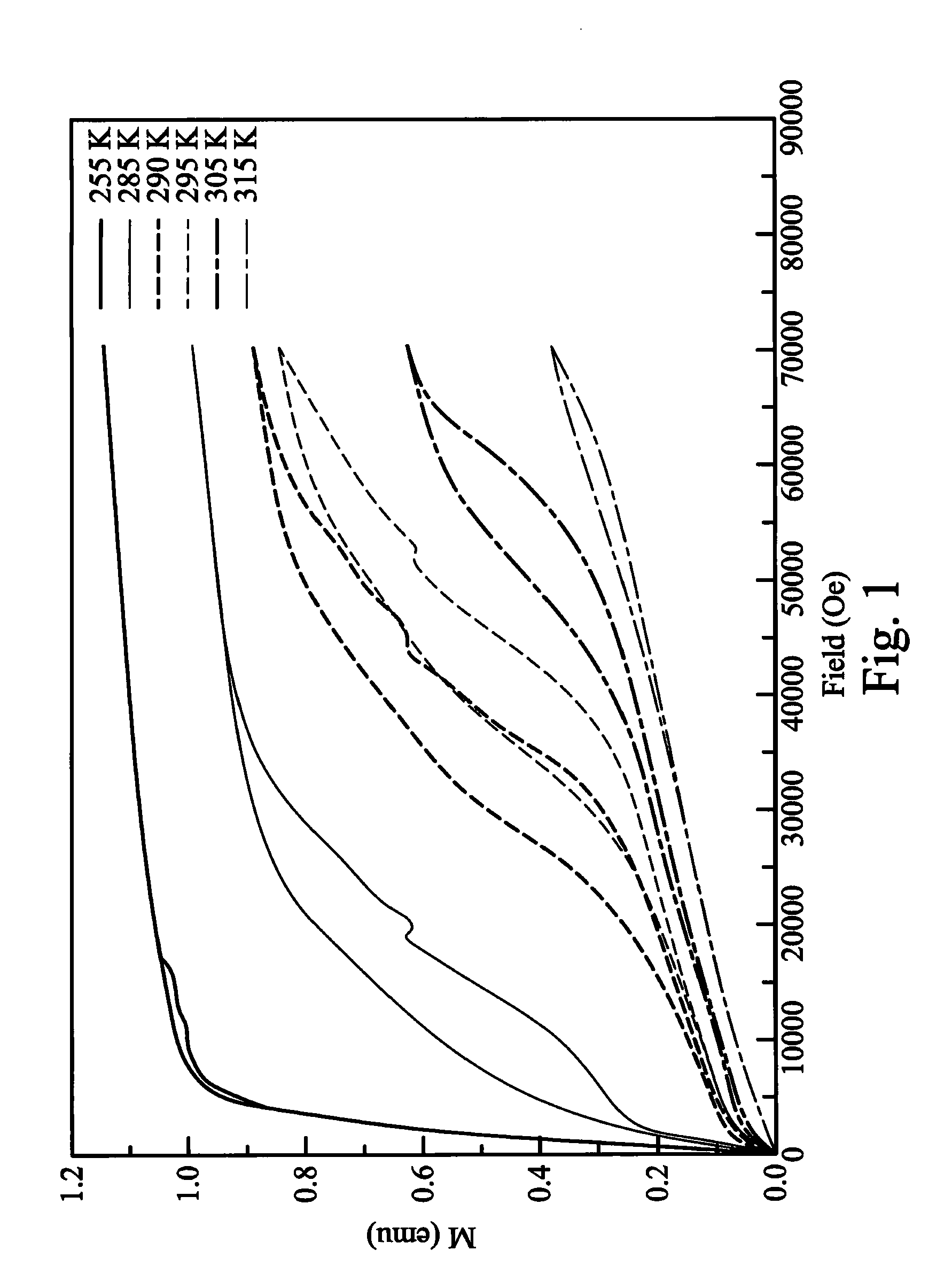

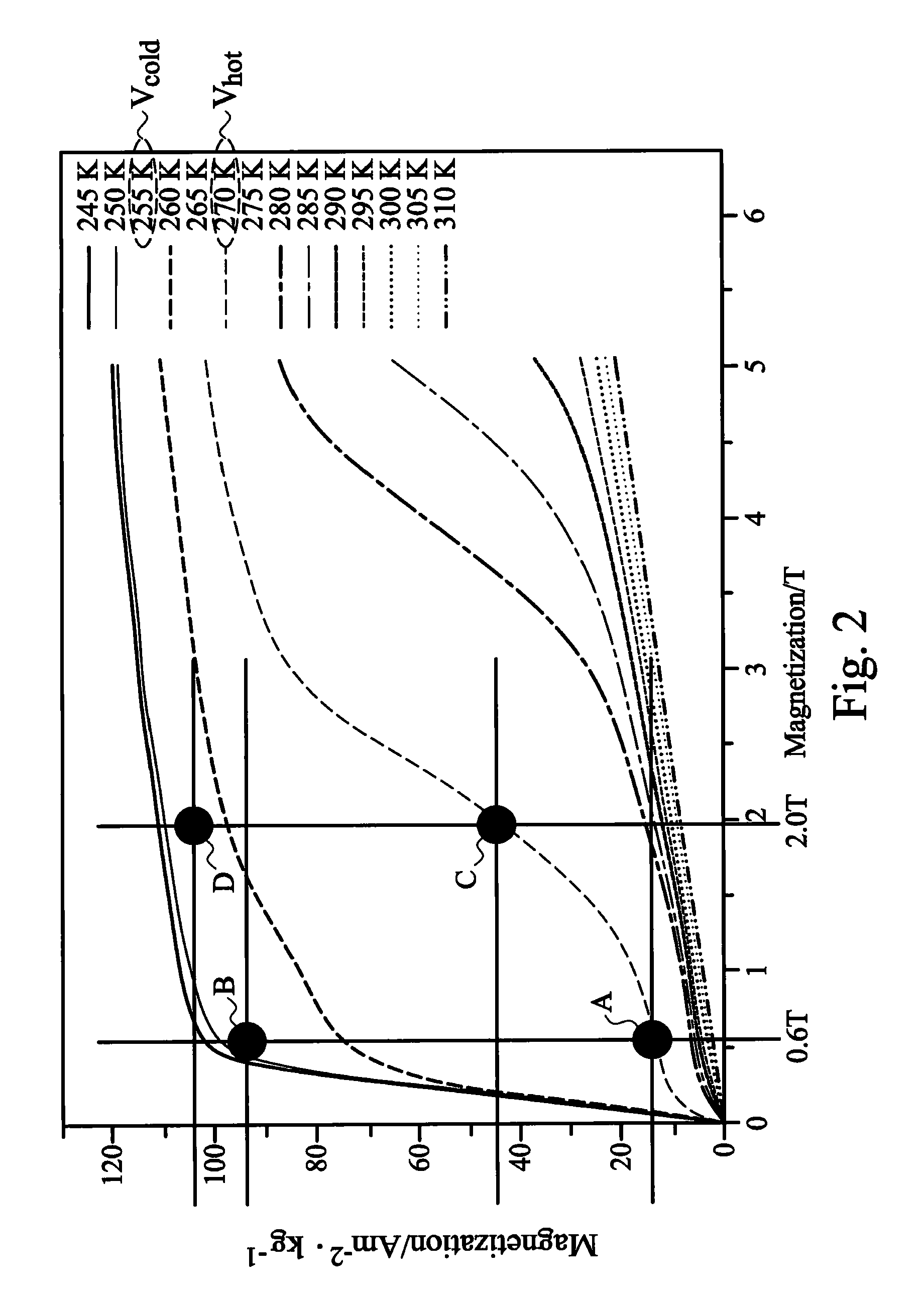

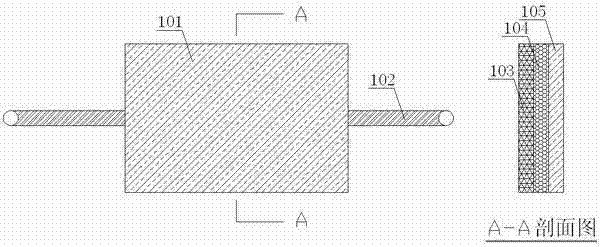

Heat-power conversion magnetism devices

InactiveUS20110062821A1Thermal electric motorRefrigeration machinesTemperature differenceHeating power

Owner:DELTA ELECTRONICS INC

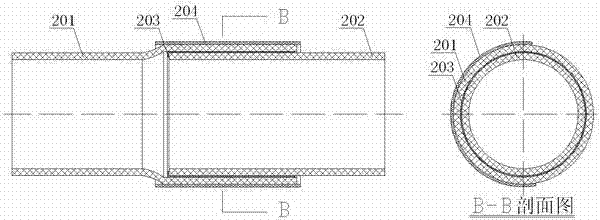

Environment-friendly plastic pipe fusion bonding method

InactiveCN102889446AEasy constructionObvious cost advantagePipe connection arrangementsInduction heating apparatusElectromagnetic pulseEngineering

The invention discloses an environment-friendly plastic pipe fusion bonding method which comprises a magnetic conductivity material net (203) of a plastic pipe fusion bonding material and a portable type electromagnetic heating device. The magnetic conductivity material net (203) is placed in the middle of a flared pipe (201)and a straight cutting pipe (202) of a plastic pipe, and the portable type electromagnetic heating device is spliced on the exterior of the flared pipe (201) of the plastic pipe; the portable type electromagnetic heating device transfers high frequency electromagnetic pulse heating power to act on the magnetic conductivity material net (203) so as to generate vortex to heat, the heat can generate partial fusion with a contact surface of a contacting part, and the fusion splice of the plastic pipe is finished; the portable type electromagnetic heating device drives an electromagnetic heating belt (204), and the heating of the magnetic conductivity material net (203) is finished in step by step; and the fusion splice of the plastic pipe is repeatedly performed for many times, and the splice quality is guaranteed. The plastic pipe fusion bonding method provided by the invention is also suitable for plastic board materials.

Owner:李文忠

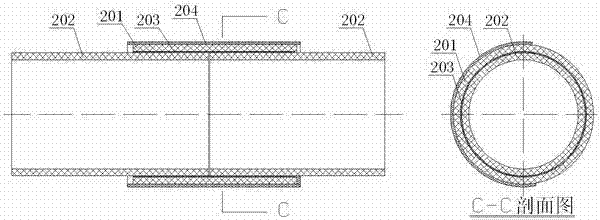

Comprehensive desulphurization technology in coal chemical industry

InactiveCN103418223AHigh recovery rateEmission reductionDispersed particle separationAmmonium sulfatesCombustionTower

The invention discloses a comprehensive desulphurization technology in the coal chemical industry. The comprehensive desulphurization technology comprises the following steps: acidic gas containing hydrogen sulfide and coming from a low-temperature methanol washing device burns to generate mixed gas, and the mixed gas is subjected to two stages of cooling to separate out liquid sulfur for producing solid sulfur; sulphuric mixed gas separated out after cooling is subjected to secondary combustion so that all sulphureous components in the mixed gas are changed into SO2, tail gas generated after combustion and boiler flue gas of a heating power station are fully mixed and enter a desulphurization tower, circulating liquid containing aqua ammonia is used as an absorbent to absorb SO2 in a countercurrent contact way and react to generate ammonium sulfite, and ammonium sulfite is further oxidized to change into ammonium sulfate; desulphurized and purified flue gas is discharged into air through a chimney; ammonium sulfate solution at the bottom of the desulphurization tower enters a circulation tank and is crystallized to form the ammonium sulfate product. The comprehensive desulphurization technology adopts a novel combined desulphurization technology to replace the traditional Klaus Scott or Super Claus technology, and can effectively lower investment, improve recovery rate of sulfur and reduce discharge of sulfur.

Owner:XINWEN MINING GROUP

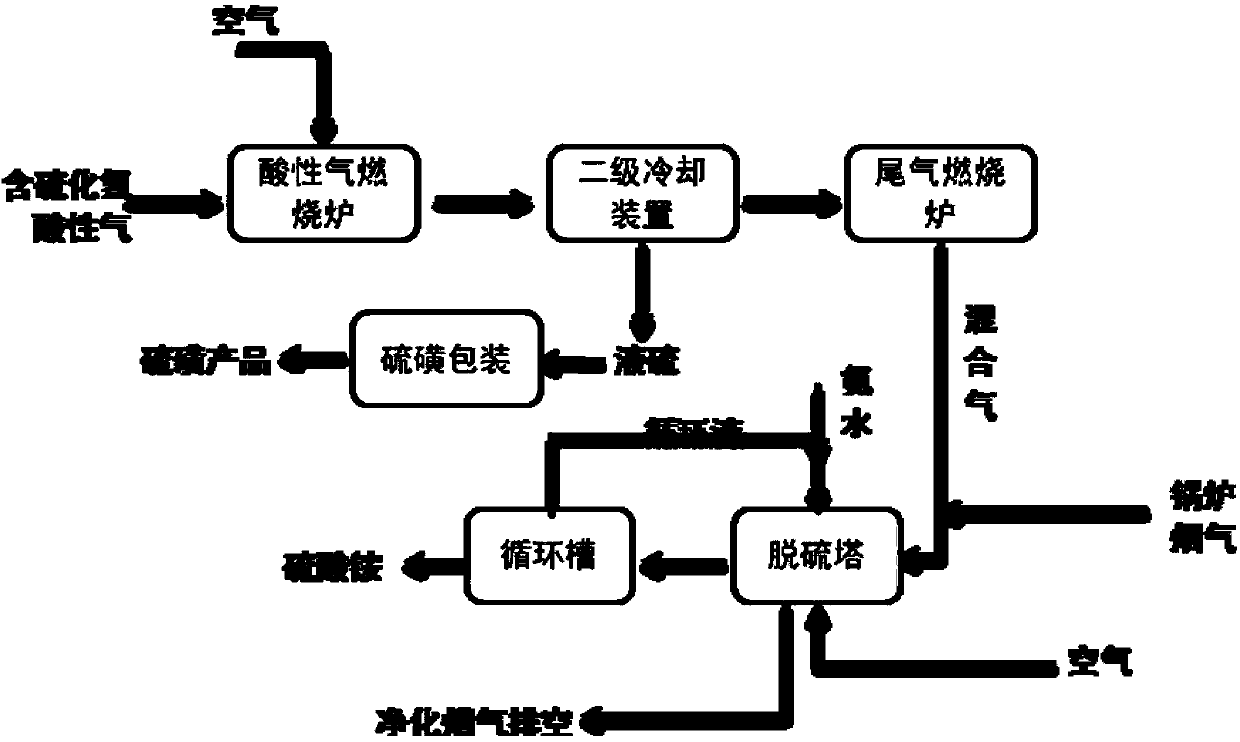

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

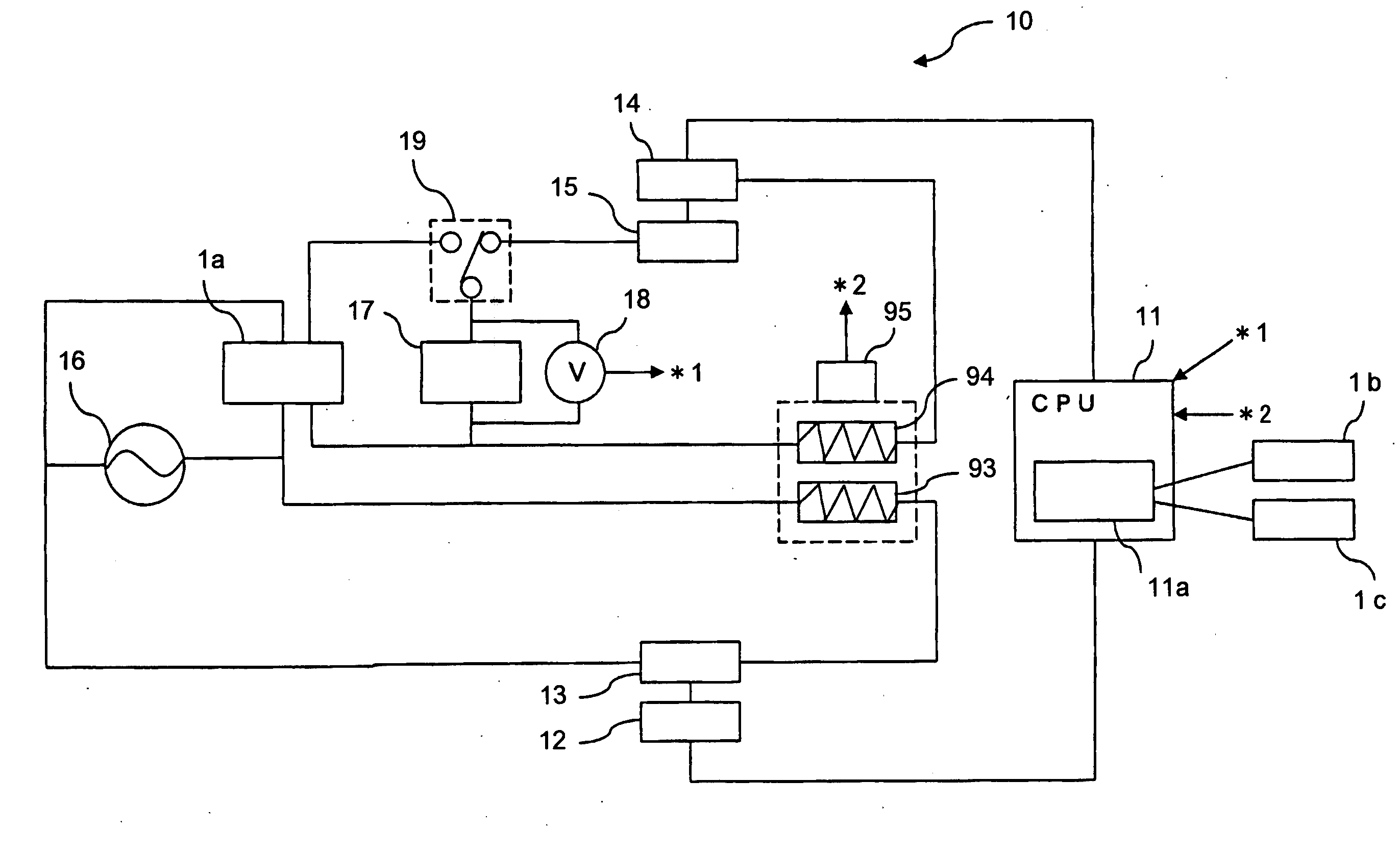

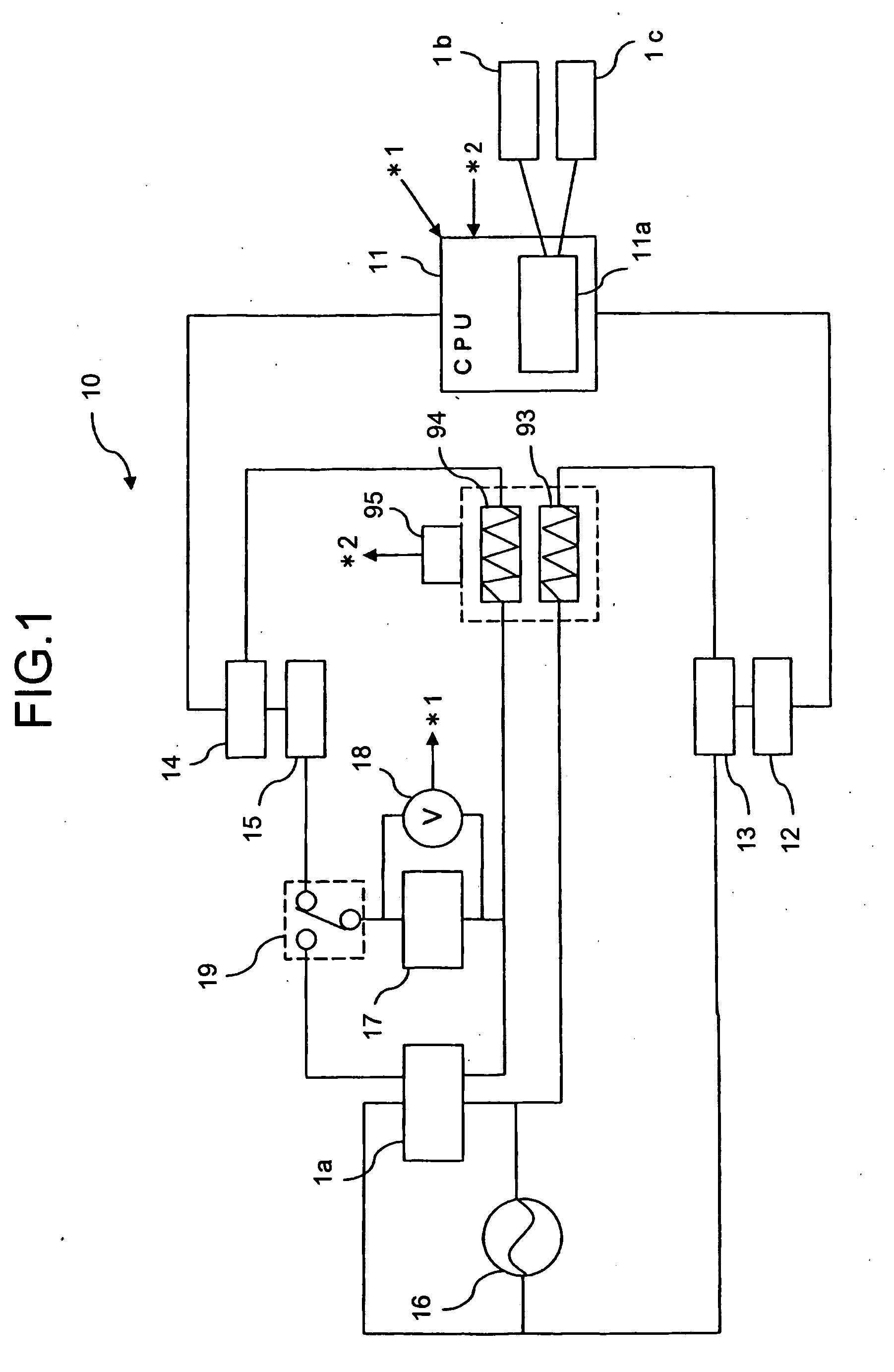

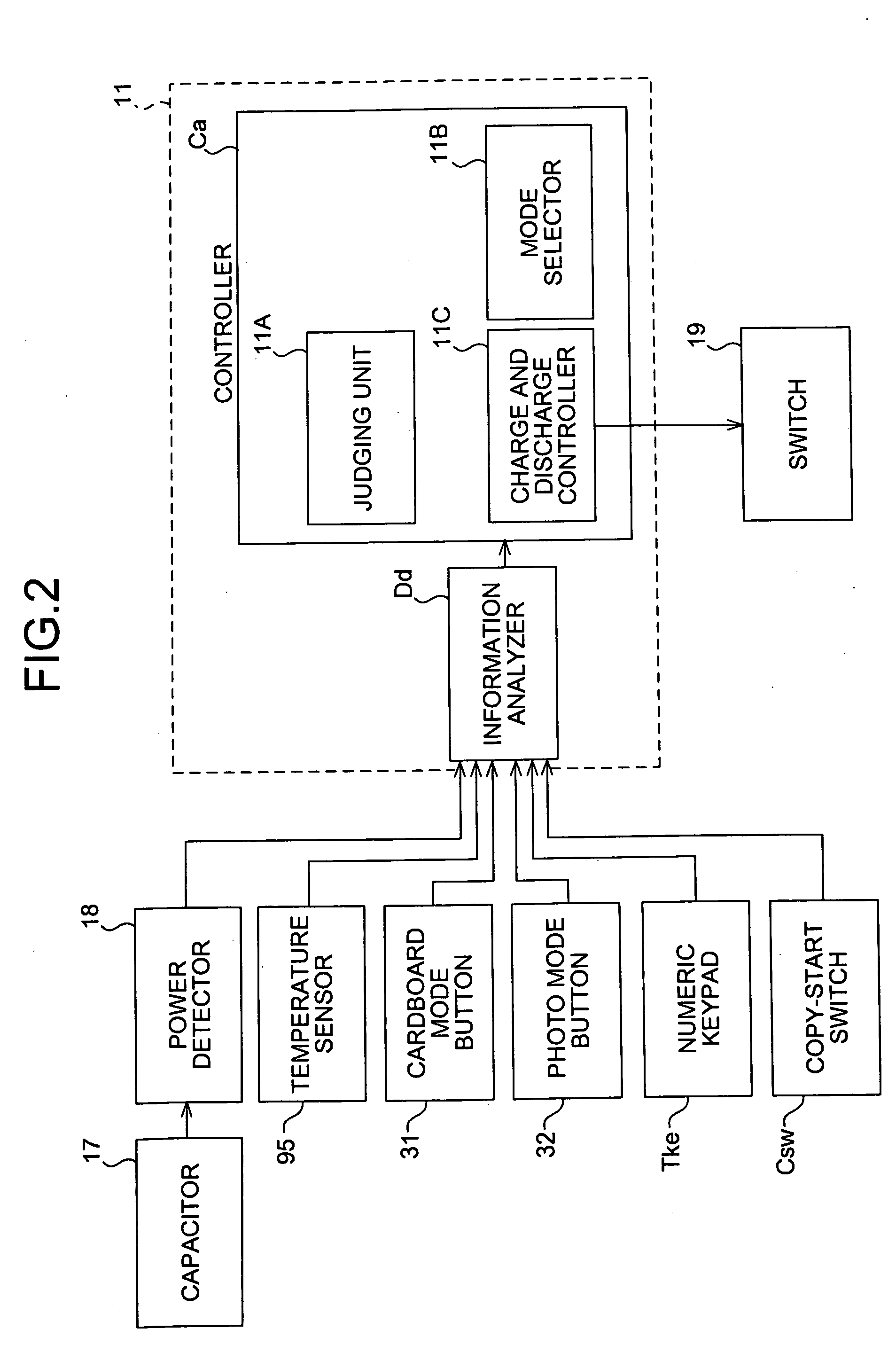

Image forming apparatus

ActiveUS20050175370A1Reduce the number of copiesReduce controlElectrographic process apparatusElectricityCardboard

A fixing member, a power detector, and a controller are included. The fixing member is heated by a heating unit that generates heat when power is supplied by a commercial power and a capacitor. The power detector detects energy of power stored in the capacitor. The controller performs an identical control to reduce number of copies of an image formed (fixed) per minute (CPM) to a predetermined number (40 CPM) in any of three cases in which the energy is less than a threshold for starting electric discharge when a plurality of recording mediums is continuously passed through the fixing member, in which a cardboard paper is continuously passed, and in which an amount of data of an image to be transferred on the recording medium is large.

Owner:RICOH KK

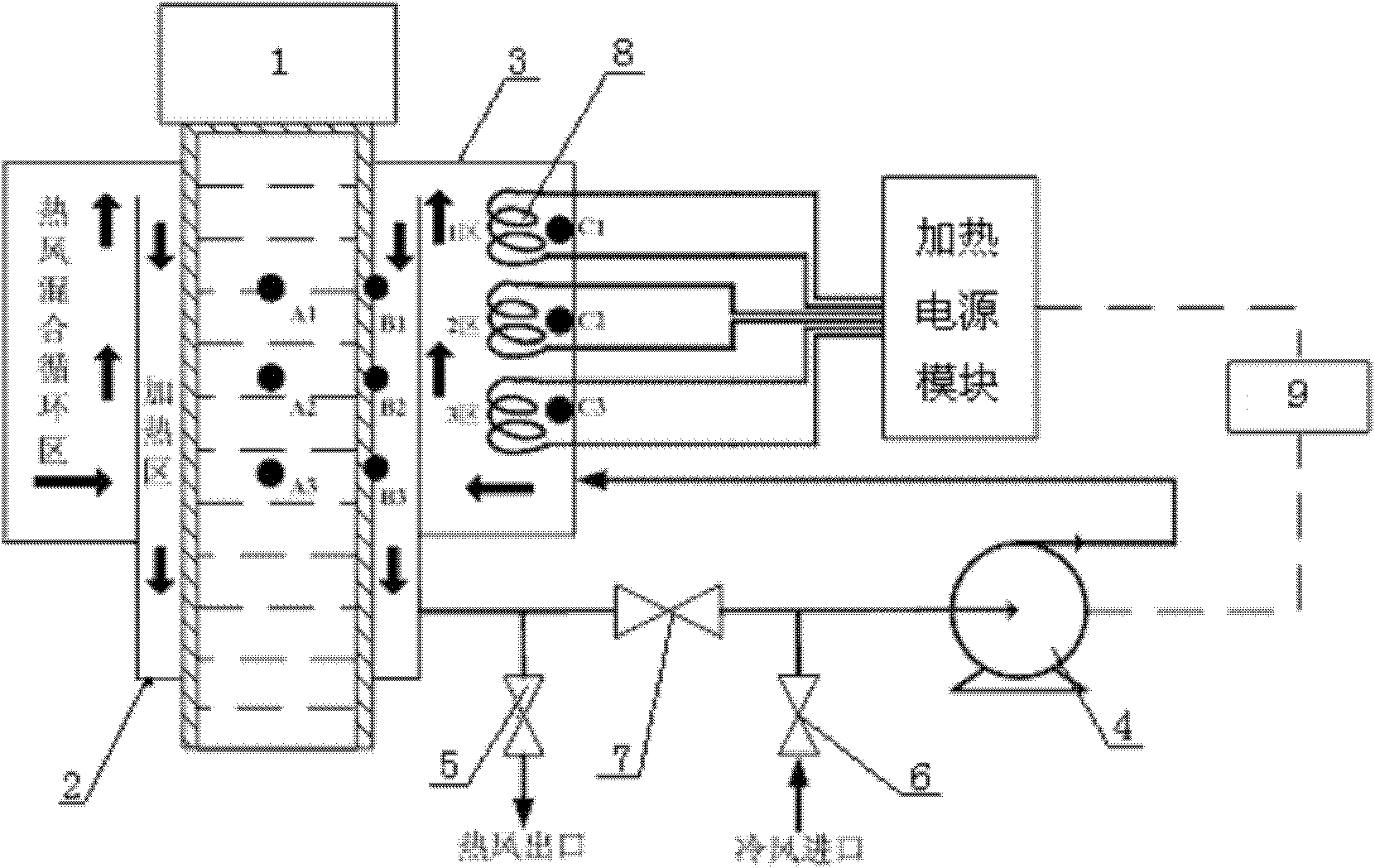

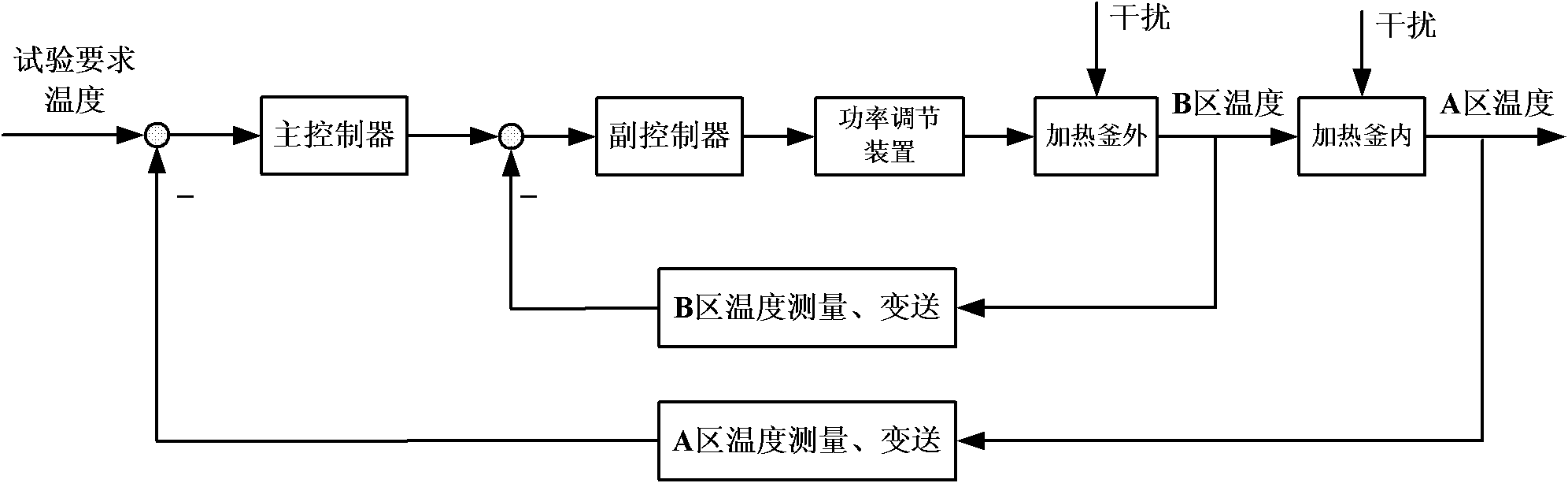

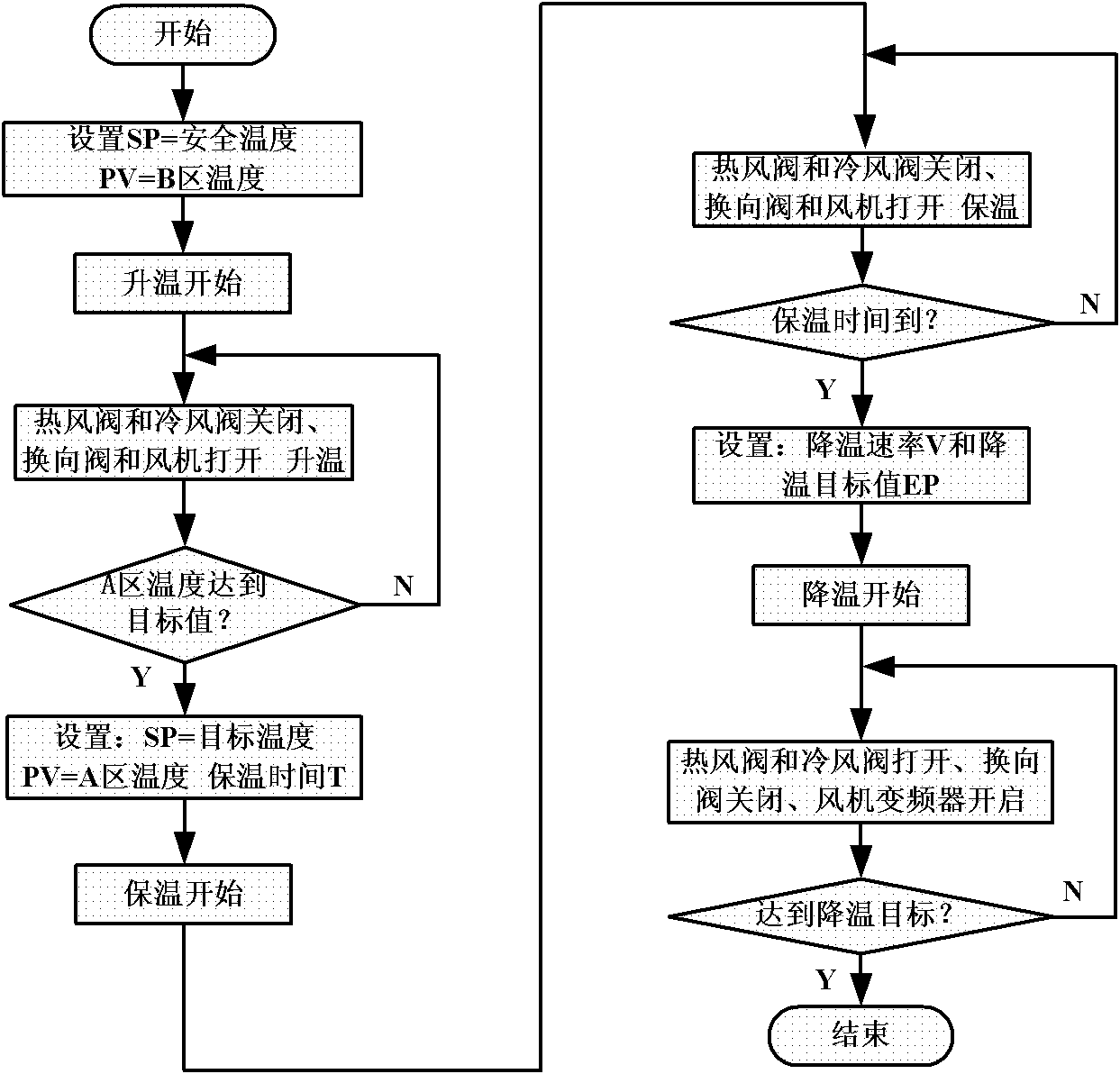

Temperature cascade PID (Proportion Integration Differentiation) control system of high-temperature high-pressure testing device and control method thereof

InactiveCN101866190AGuaranteed sealing temperatureTemperatue controlControllers with particular characteristicsTemperature controlProportion integration differentiation

The invention relates to a temperature cascade PID (Proportion Integration Differentiation) control system of a high-temperature high-pressure testing device and a control method thereof. A high-temperature autoclave for test is used for simulating the temperature, the pressure and other parameters of a stratum environment and carrying out detection test on performances of an instrument working in an environment similar to the stratum environment. The temperature cascade PID control system comprises a hot air mixed heating module, a heating power supply module, a fan circulating module and a temperature measurement and control module; a heating area of the hot air mixed heating module is divided into three temperature measurement areas, i.e. a target temperature measurement area, a safetytemperature measurement area and a hearth temperature measurement area; the target temperature of which an output signal is transmitted to an inner ring auxiliary control PID control circuit after operated and processed through an outer ring main control PID control circuit is compared with a safety temperature for operation processing, and the output signal is amended by a temperature control coefficient and converted into a simulation control signal which is output to a power adjusting device for adjusting the output power of the heating power supply. Three temperature control areas in the invention realize the accurate control on the test temperature in the autoclave by using a cascade control method according to the requirement of a process curve of raising, preserving and reducing the temperature.

Owner:XIAN ELECTRIC FURNACE INST

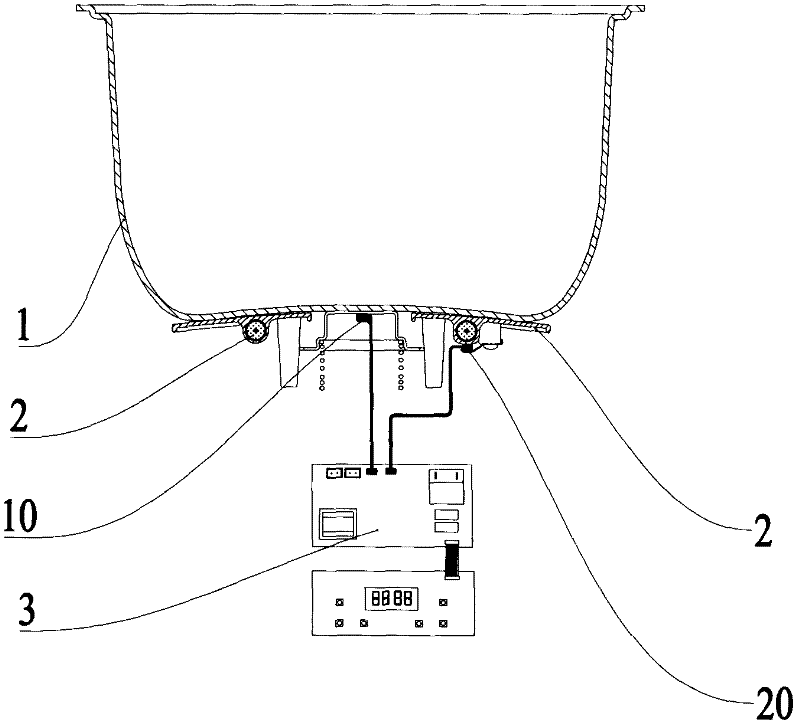

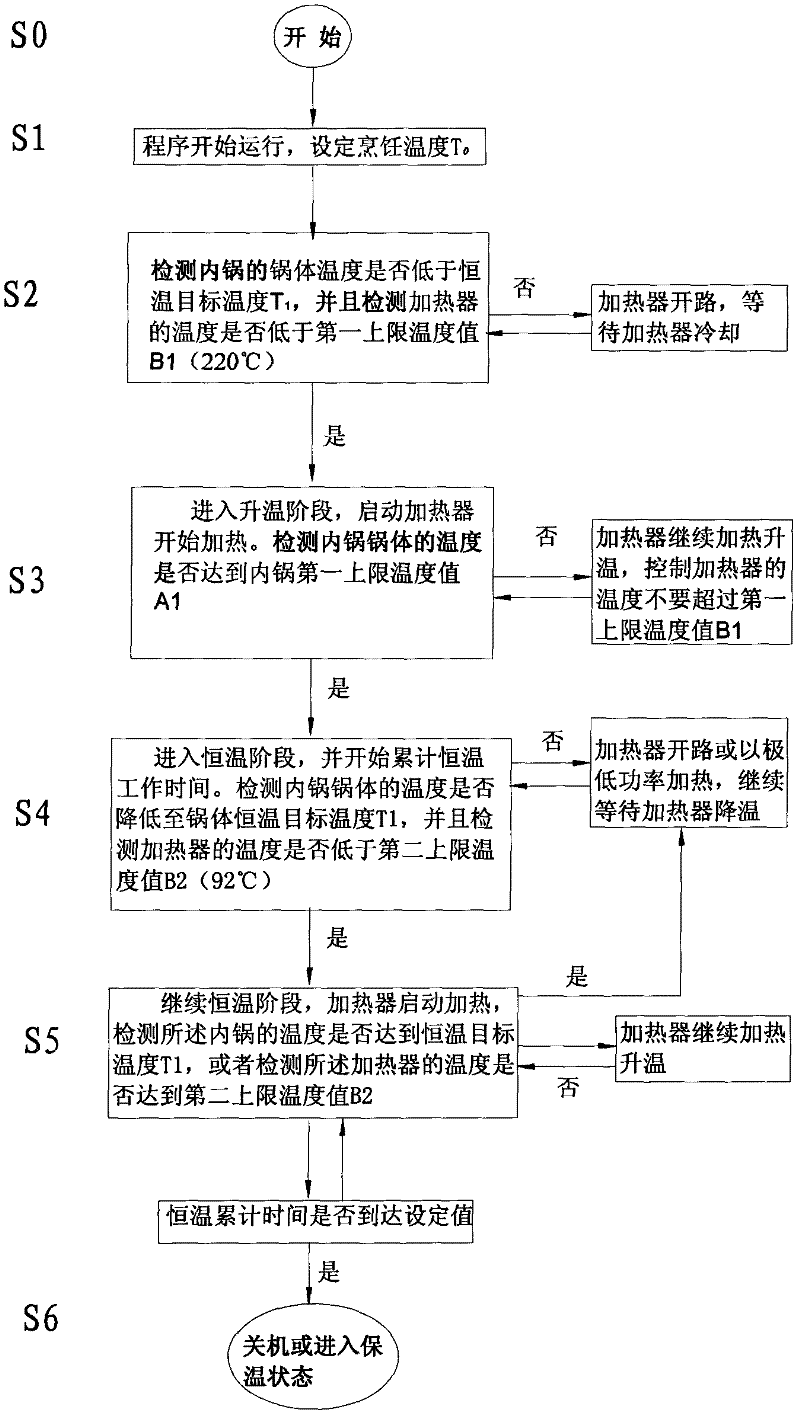

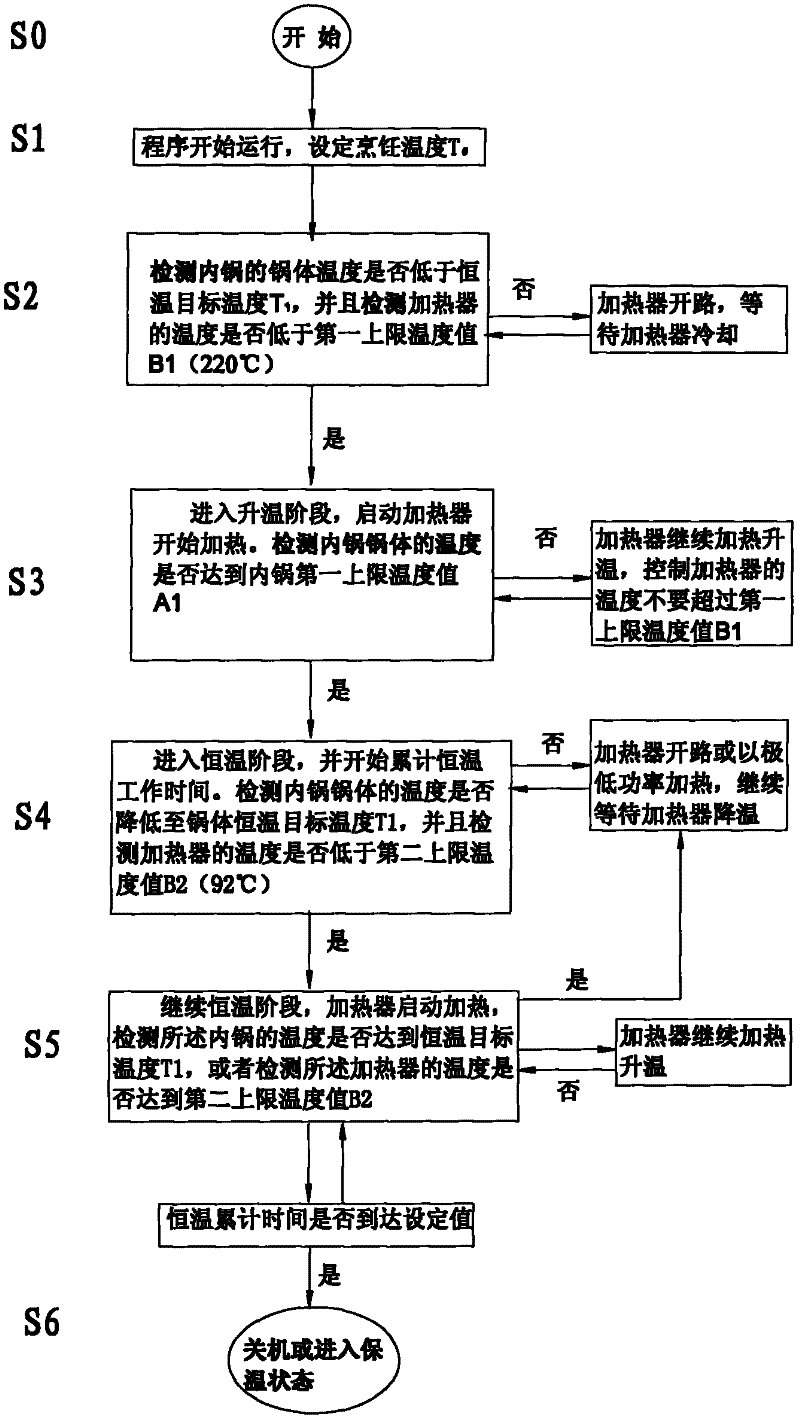

Temperature control method of electric heating kitchenware

ActiveCN102389254ACooking vesselsTemperature control using electric meansTemperature controlEngineering

The invention discloses a temperature control method of electric heating kitchenware, which comprises the following steps of: starting a heater and coming to a heating temperature rise period, when the temperature of an inner pot reaches first upper limit temperature value A1 of the inner pot or the temperature of the heater reaches first upper limit temperature value B1 of the heater, driving the heater by a controller to reduce heating power or stopping heating, and making the heater come to a constant temperature heating period; when the temperature of the inner pot is reduced to constant temperature target temperature T1 and the temperature of the heater is lower than second upper limit temperature value B2 of the heater, driving the heater by the controller to increase heating power; and when the temperature of the inner pot is increased to constant temperature target temperature T1 or the temperature of the heater reaches second upper limit temperature value B2, driving the heater by the controller to reduce heating power or stopping heating. In this way, the temperature control method not only realizes simple control structure and smaller consumed electric power, but also makes food cooking temperature T0 remain unchanged substantially. Due to the above characteristics, the temperature control method can be applied to the electric heating kitchenware such as general electric rice cooker, soup pot, oven and the like.

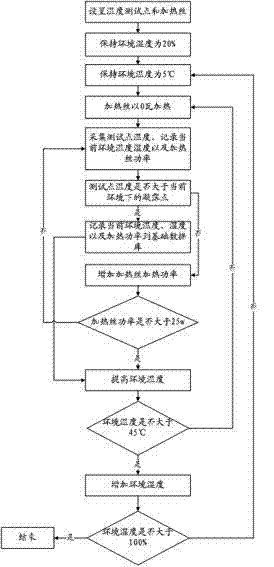

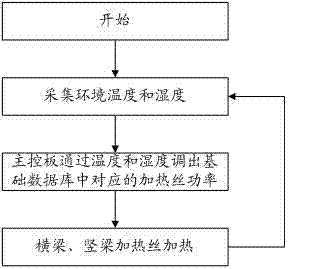

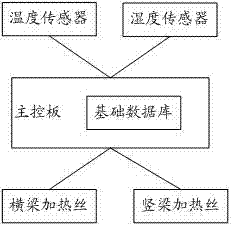

Method and system for preventing condensation

ActiveCN102192631AReduce energy consumptionLighting and heating apparatusDefrostingControl powerProcess engineering

The invention relates to a method and a system for preventing condensation, wherein the heating power of a heater strip and the corresponding temperature and humidity information are stored into a foundation database to construct a condensation-prevention foundation database; the method for preventing condensation comprises the following steps: setting up the foundation database of temperature, humidity and heating power, and controlling the heater strip to heat at the corresponding power according to the control power in the foundation database corresponding with the specific temperature andhumidity; and the system for preventing condensation comprises a temperature sensor, a humidity sensor, a heating device and a master control board, wherein the master control board is provided with the foundation database. Thus, at the specific temperature and humidity, the heater strip works at the control power corresponding with the temperature and humidity at the same time in the foundation database, the energy consumption can be reduced effectively, and the working efficiency can be improved.

Owner:HAIER GRP CORP +1

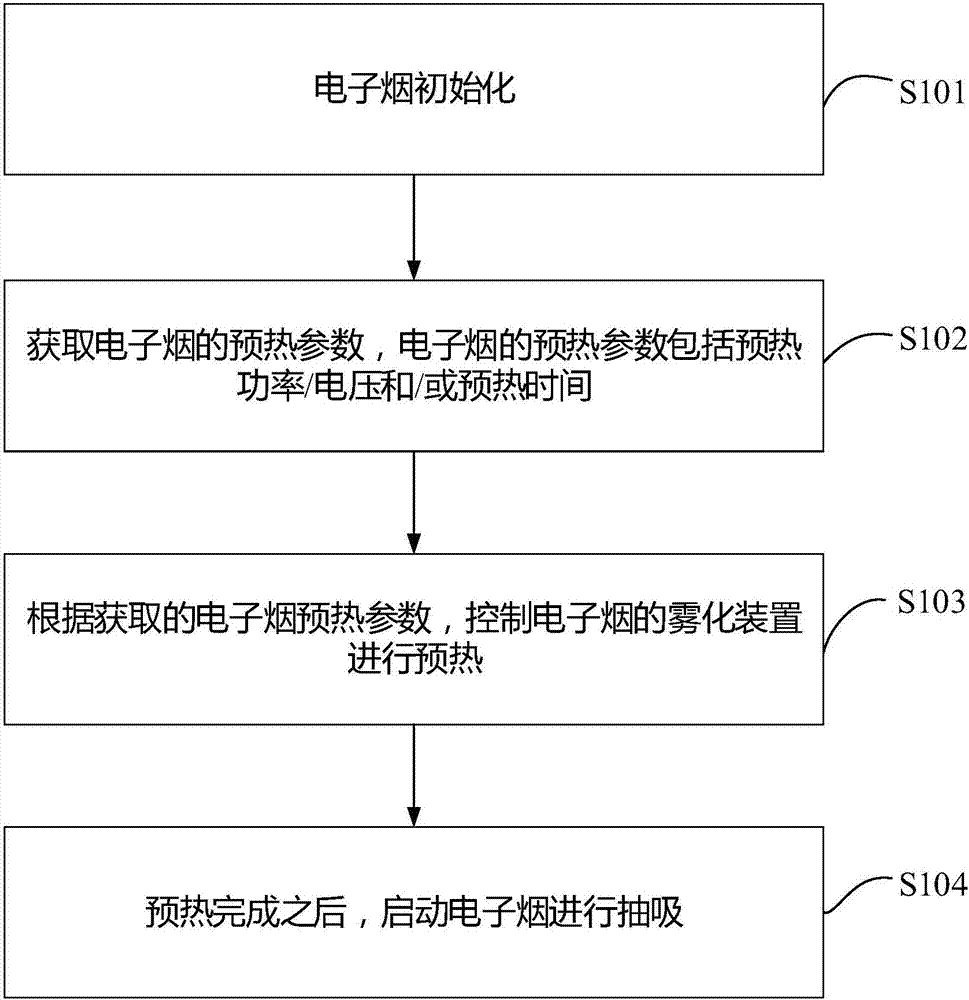

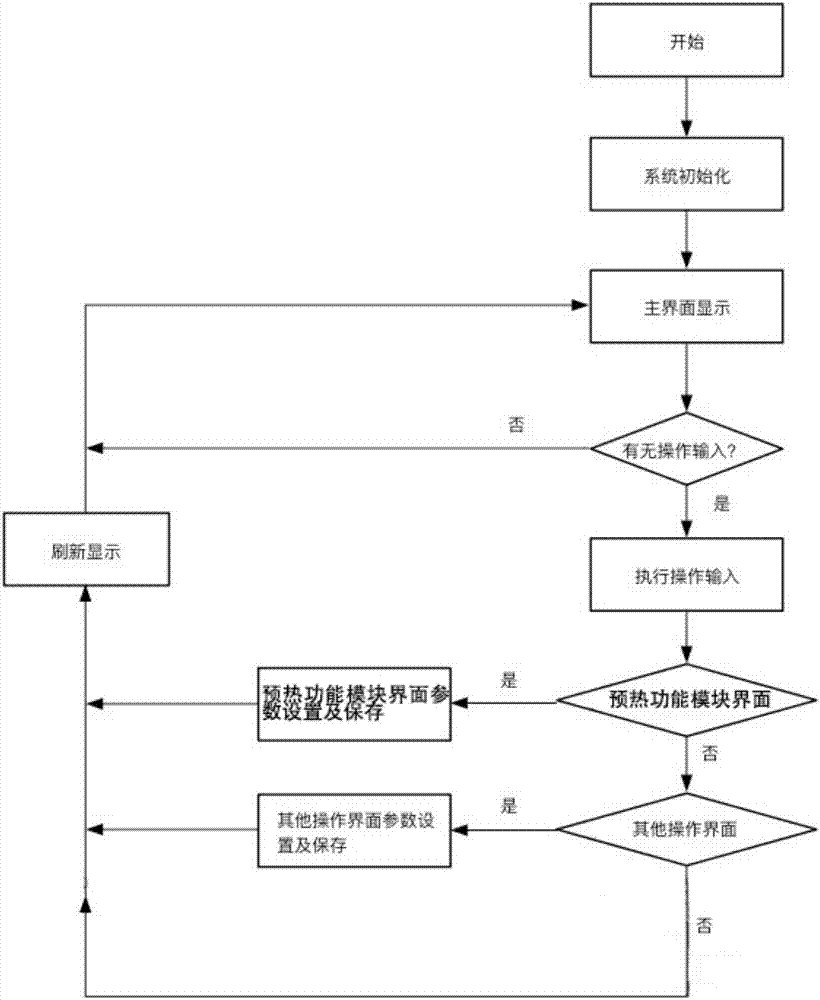

Electronic cigarette and pre-heating method of electronic cigarette

InactiveCN107156915AStrong sense of experienceComputer controlTobacco devicesHeating timeControl electronics

The invention discloses an electronic cigarette and a pre-heating method of the electronic cigarette. The method comprises the following steps: initializing the electronic cigarette; acquiring and / or calling pre-heating parameters of the electronic cigarette; controlling an atomizing device of the electronic cigarette to implement pre-heating in accordance with the acquired or called electronic cigarette pre-heating parameters; and starting electronic cigarette smoking. According to the electronic cigarette and the pre-heating method of the electronic cigarette provided by the invention, by setting the pre-heating parameters of the electronic cigarette and by controlling the atomizing device of the electronic cigarette to implement pre-heating, pre-heating power and pre-heating time of the electronic cigarette become controllable, so that user's experience feeling is enhanced.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

Three-dimensional (3D) metal printer

InactiveCN103551572AAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsLiquid metal

The invention discloses a three-dimensional (3D) metal printer. A printing head integrating a ceramic melting furnace and a liquid metal ejector is a key technology for the 3D metal printer. The printing head is made of high temperature resistant ceramic or graphite material, a water cooling eddy current coil is installed on an outer layer, the melting furnace is filled with inert gas to protect liquid metal, and the ejector is a reciprocating type plunger pump. The water cooling eddy current coil is electrified with high-frequency current, and heating power can be adjusted through a high-frequency controller according to factors such as material types, model requirements and processing speeds. The inert gas keeps a certain pressure while protecting the molten metal, flow of the liquid metal is facilitated, and metal residue in the plunger pump and the melting furnace is removed by means of gas simultaneously during shutdown. Besides application to the 3D metal printer, the printing head can also be used for devices for die-cast molding and injection molding of metal material and the like.

Owner:王璐瑶

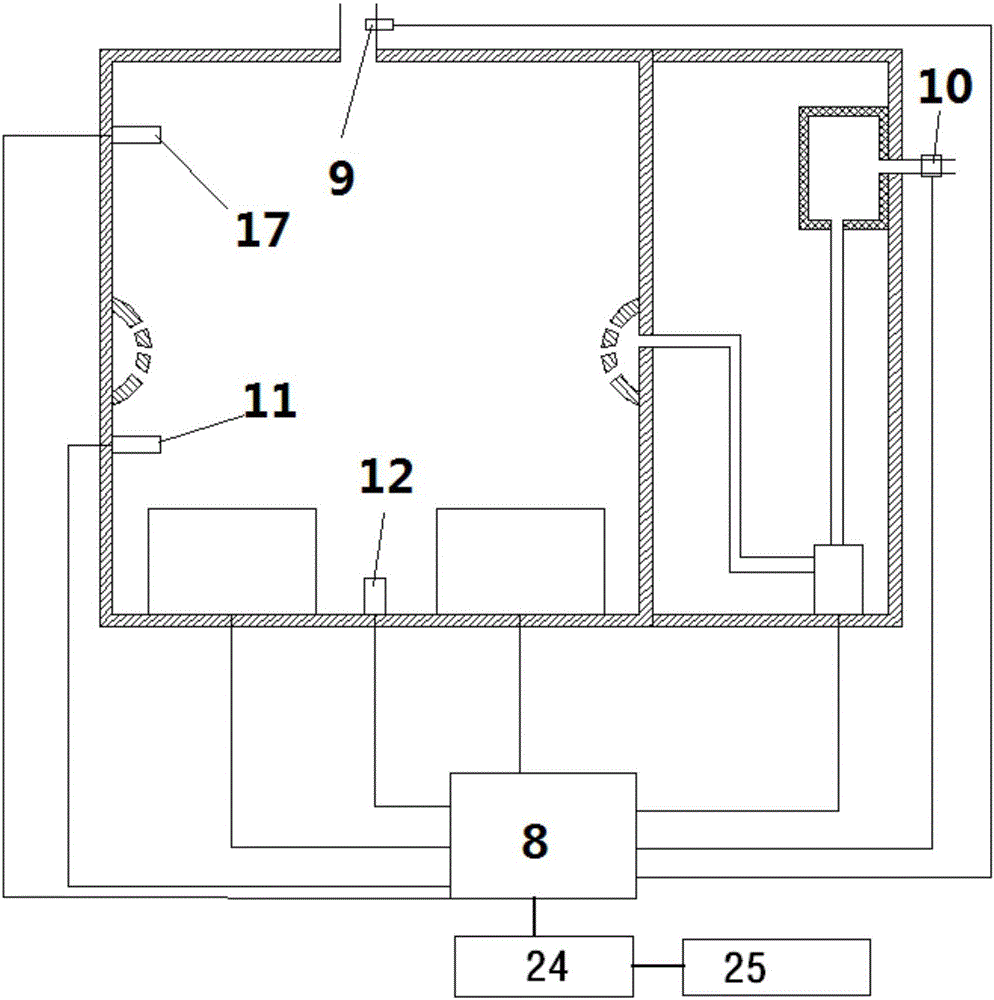

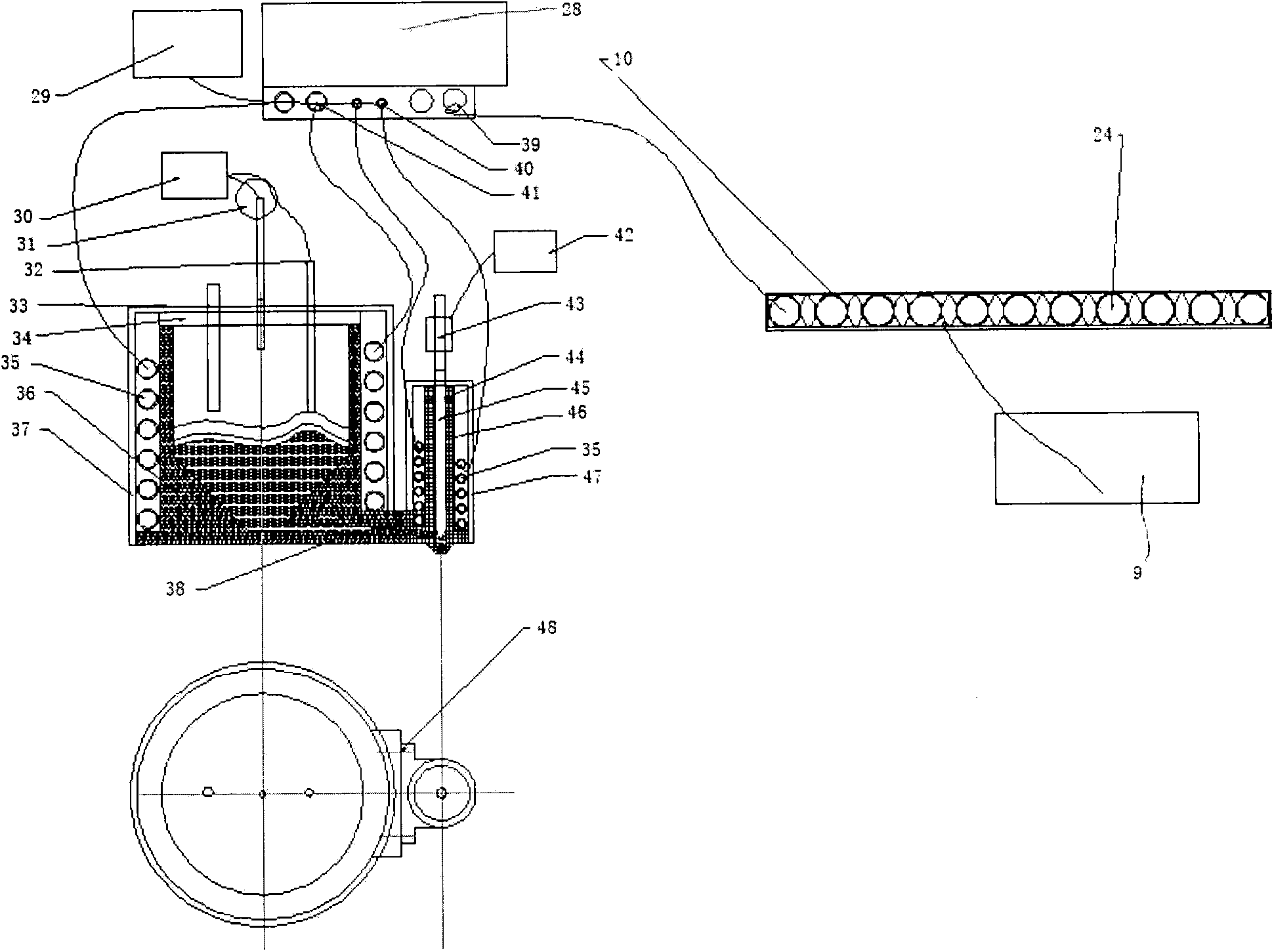

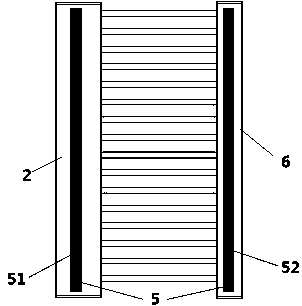

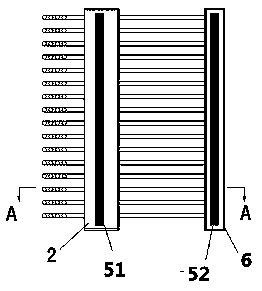

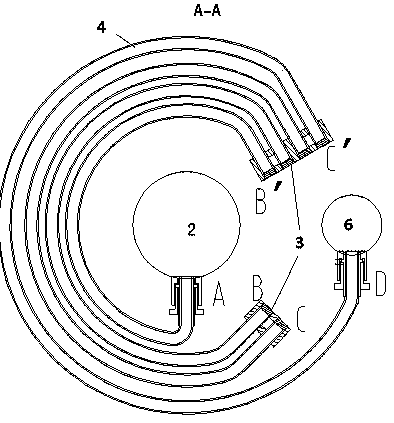

Heat exchanger assembly capable of automatically controlling heating power of left tube box and right tube box

InactiveCN108800990AImprove heating efficiencySimple structureSafety devices for heat exchange apparatusStorage heatersAutomatic controlEngineering

The invention provides a heat exchanger assembly. The heat exchanger assembly comprises a left tube box, a right tube box and a heat exchange tube, wherein the heat exchange tube communicates with theleft tube box and the right tube box; electric heating devices are arranged in the left tube box and / or the right tube box; the left tube box, the right tube box and the heat exchange tube are filled with heating fluid to form a heating fluid closed cycle; the tube diameter of the left tube box is larger than that of the right tube box; and the tube diameter of the left tube box is 3-5 times ofthe tube diameter of the right tube box. Aiming at the deficiencies in the prior art, the immersed heat exchanger assembly is provided, the heating power is controlled to reach the best, and energy resources are saved.

Owner:ZHONGBEI UNIV

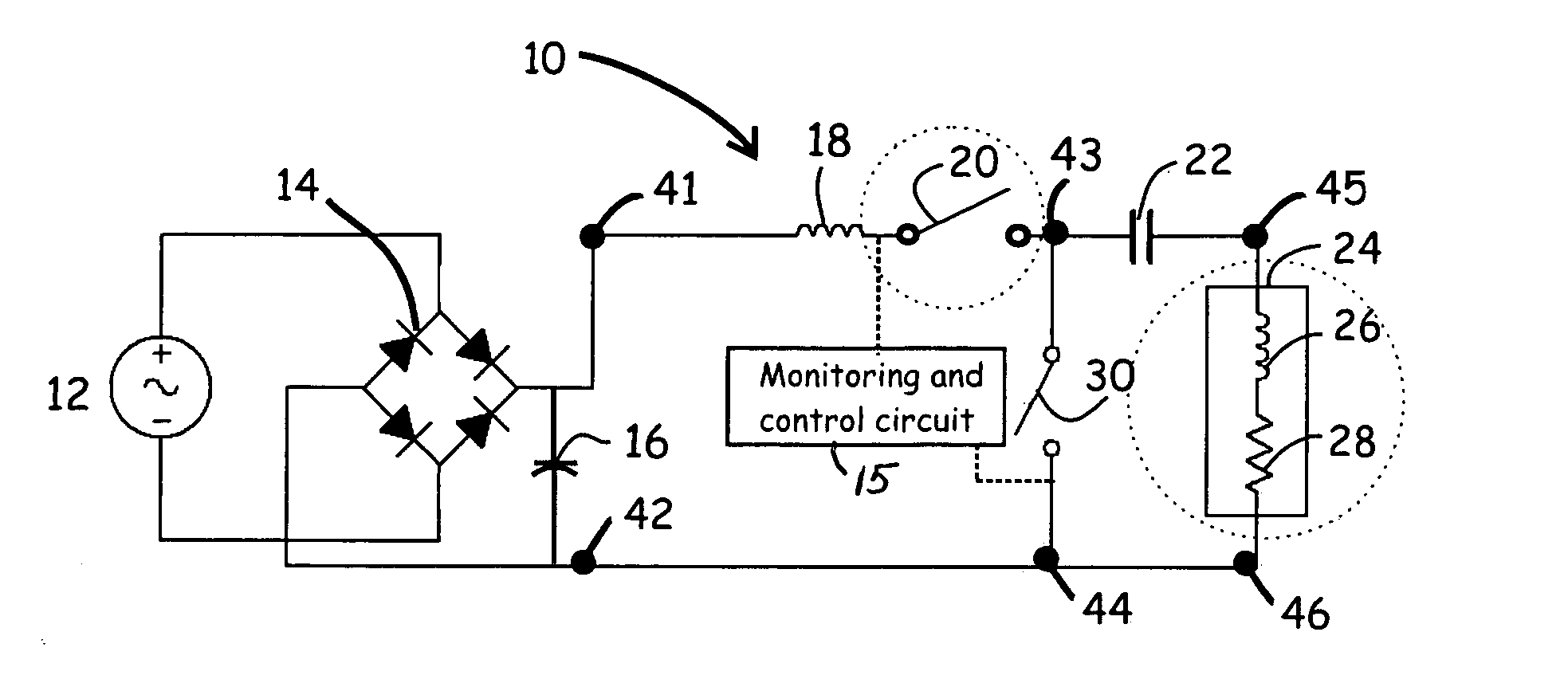

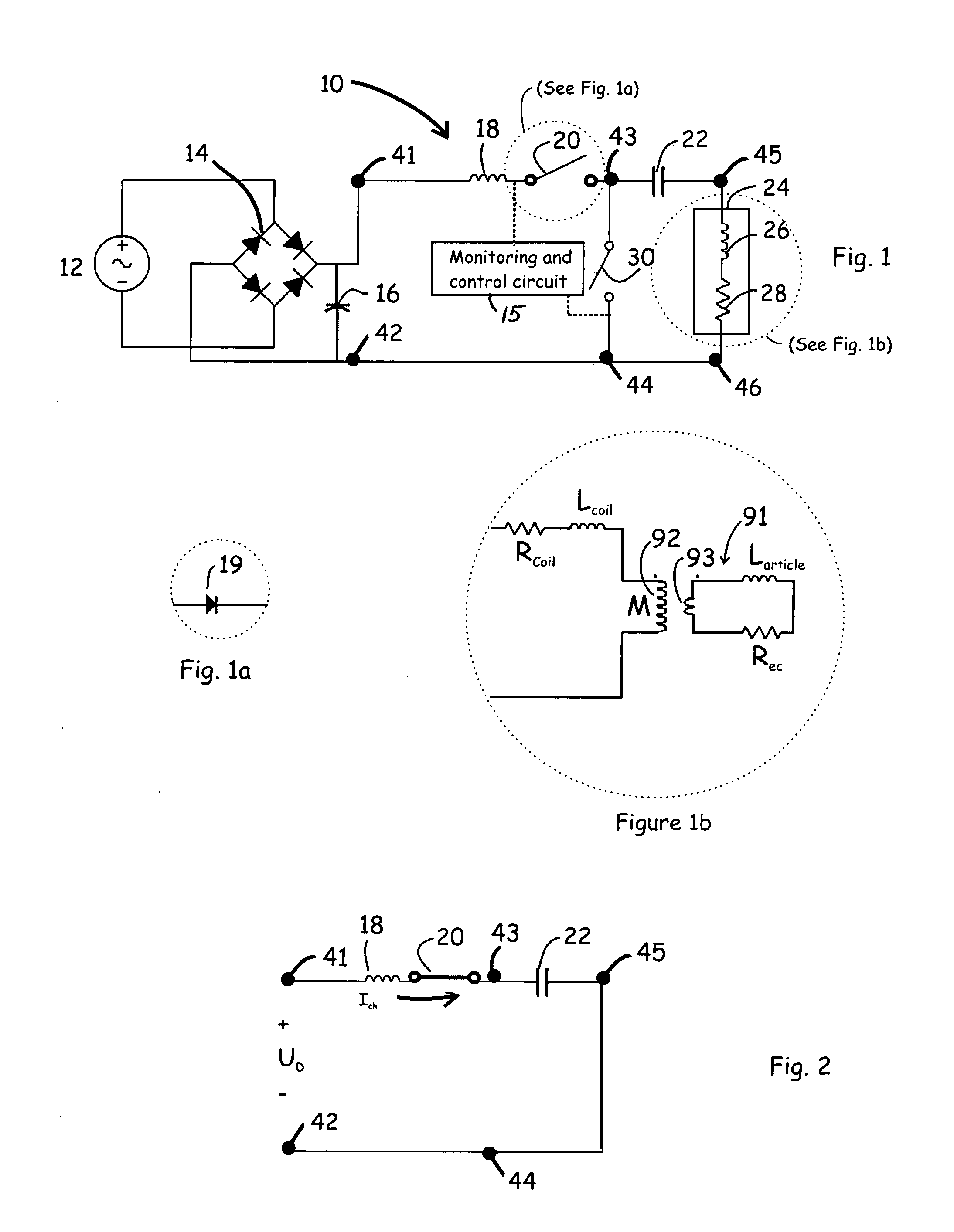

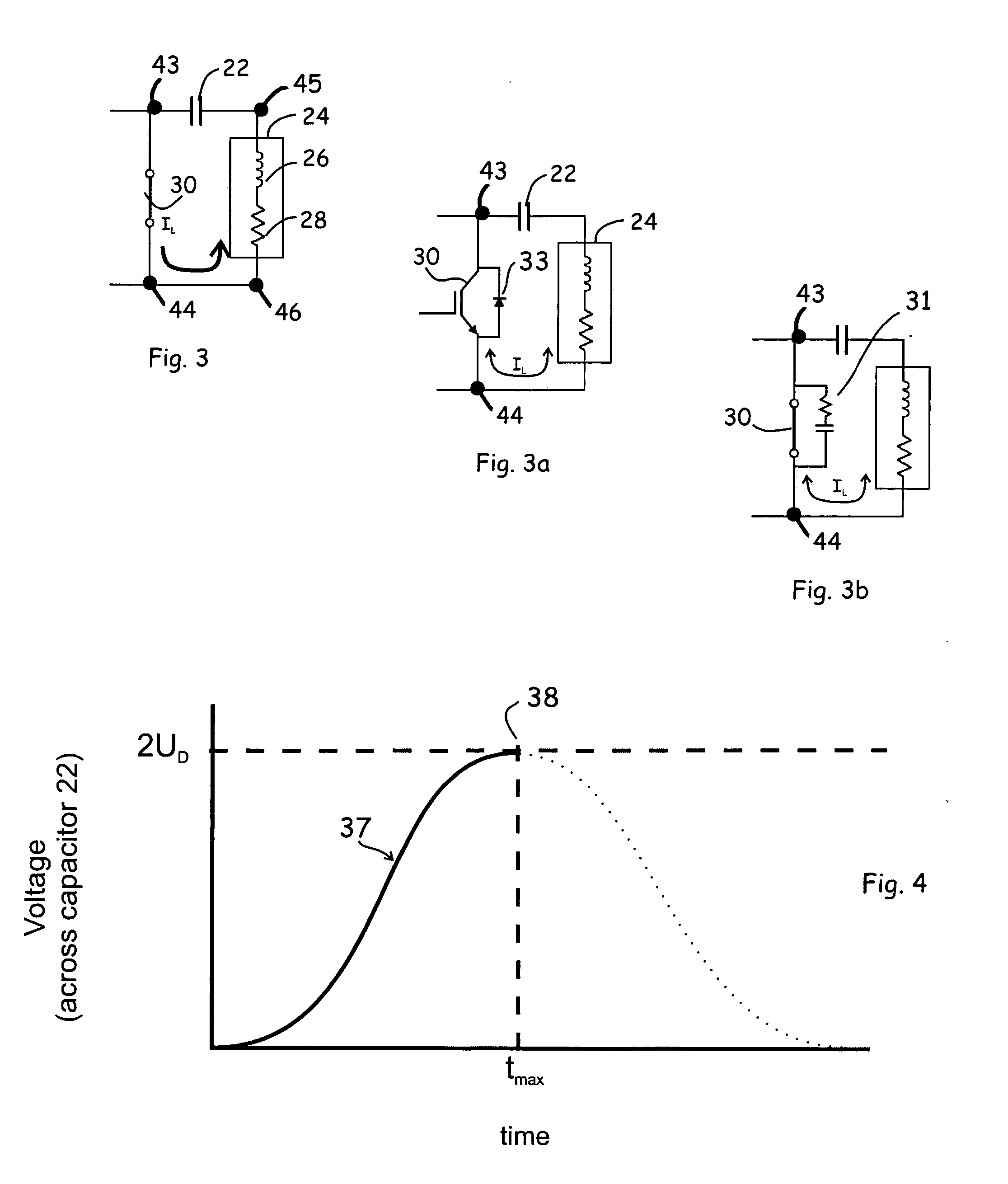

Method and apparatus for providing harmonic inductive power

InactiveUS20060076338A1Improve power transmissionBioreactor/fermenter combinationsBiological substance pretreatmentsLoad circuitEngineering

Method and apparatus for providing harmonic inductive power, and more particularly for delivering current pulses providing a desired amount of pulse energy in high frequency harmonics to a load circuit for inductive heating of an article. By controlling the shape and / or frequency of such current pulses, the apparatus and method can be used to enhance the rate, intensity and / or power of inductive heating delivered by the heater coil and / or to enhance the lifetime or reduce the cost and complexity of an inductive heating power supply. Of particular significance, the apparatus and method may be used to significantly increase the power inductively delivered to a ferromagnetic or other inductively heated load, without requiring an increase of current in the heater coil. This enables new heating applications, and in some known applications, decreases the energy consumption or cooling requirements and / or increase the lifetime of the heater coil.

Owner:OPTITHERM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com