Patents

Literature

2371 results about "Tube diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

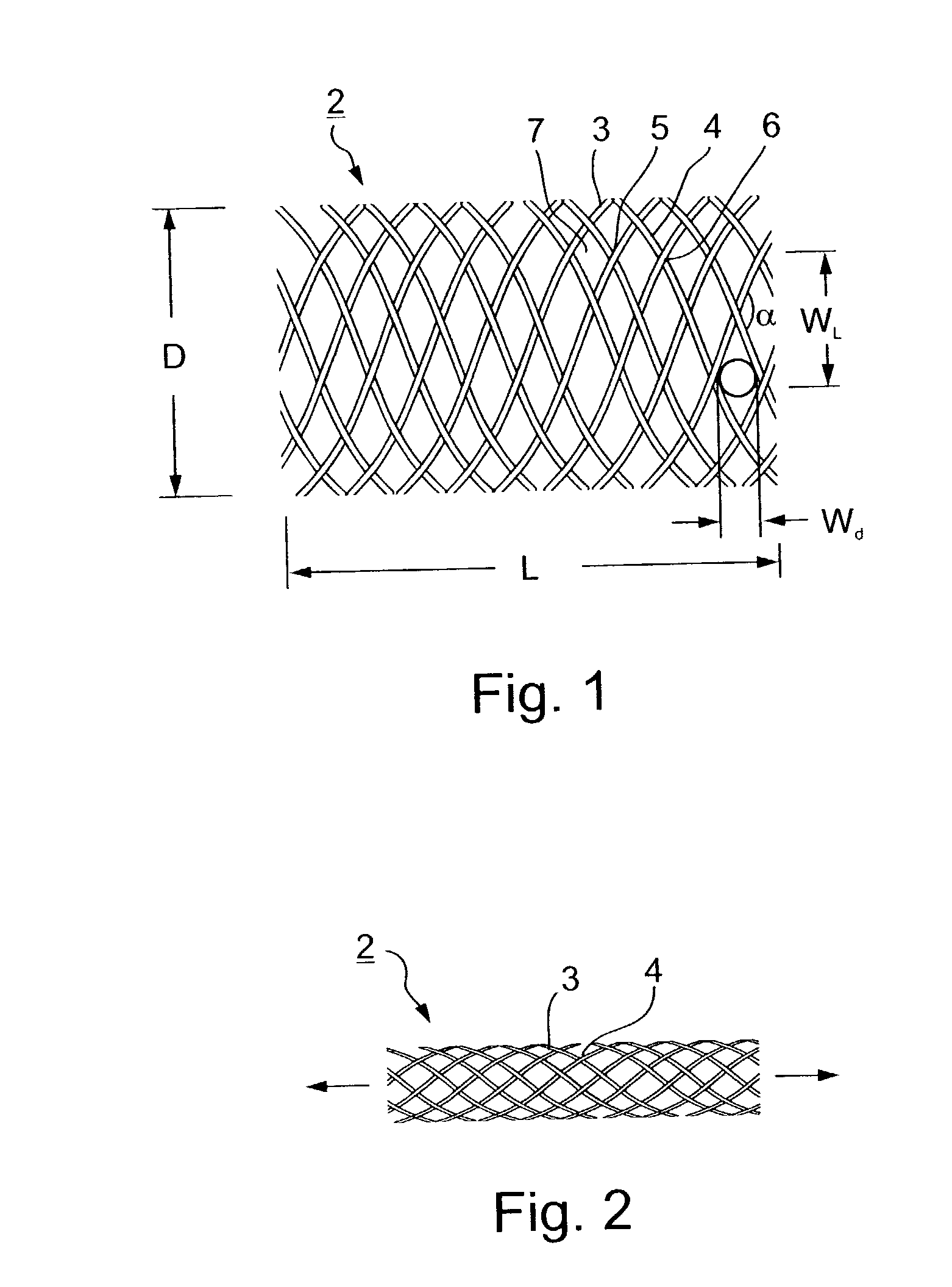

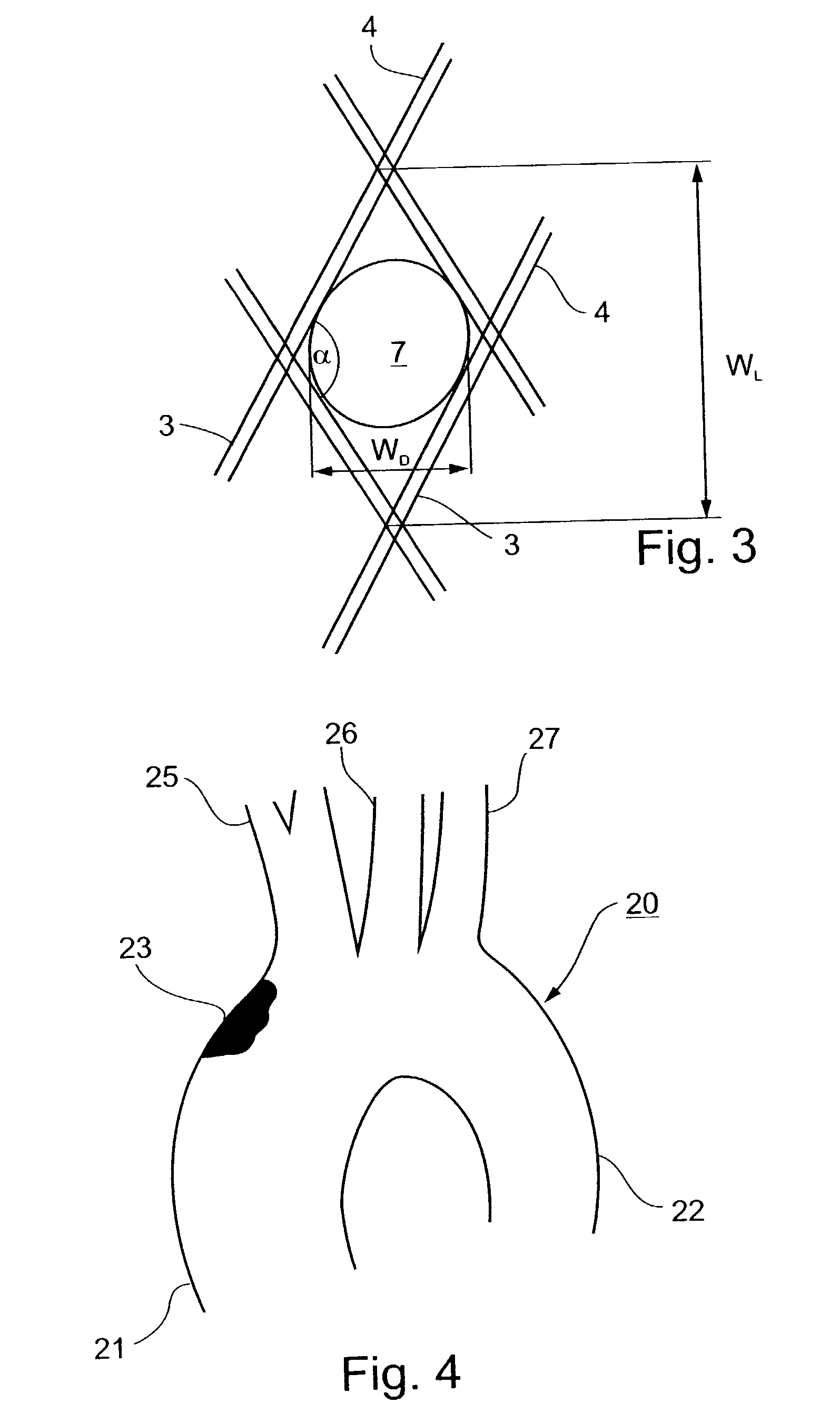

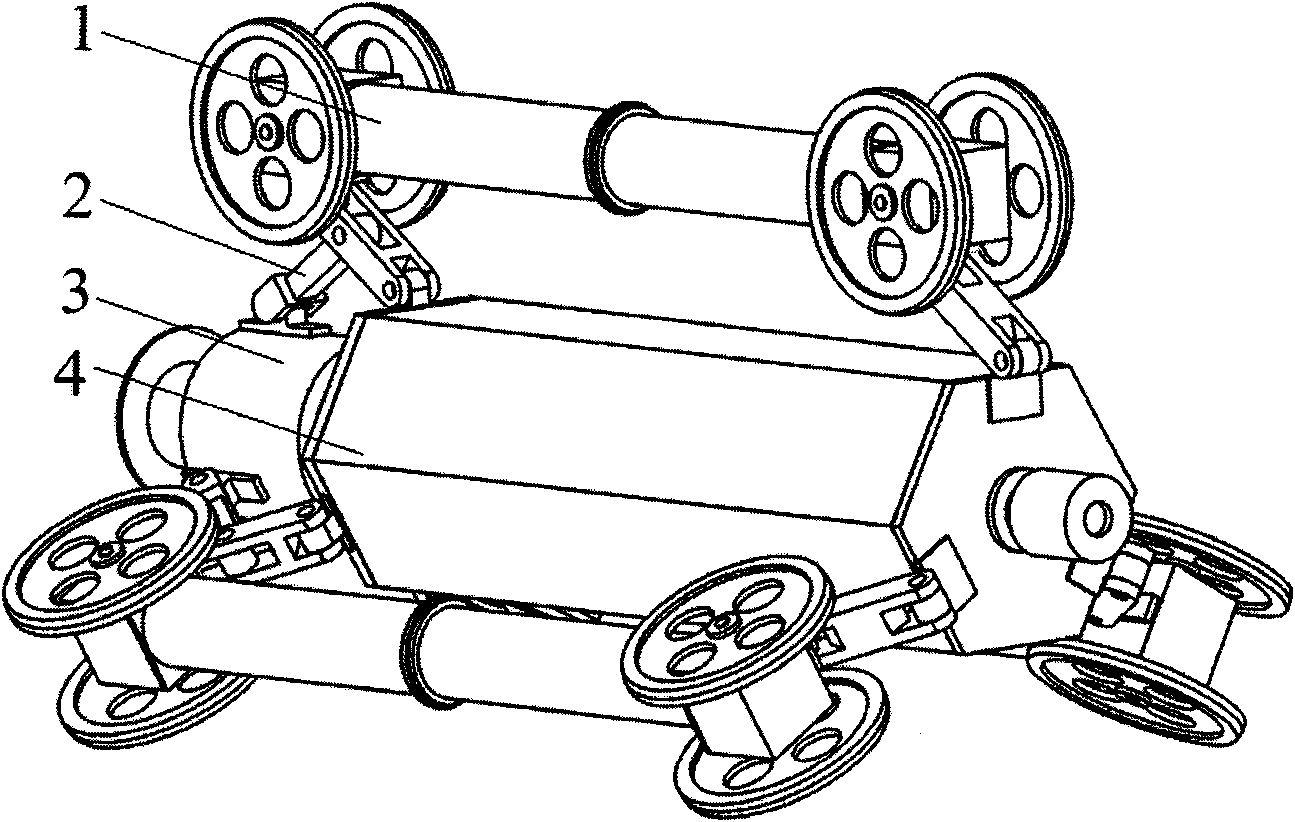

Implantable intraluminal device and method of using same in treating aneurysms

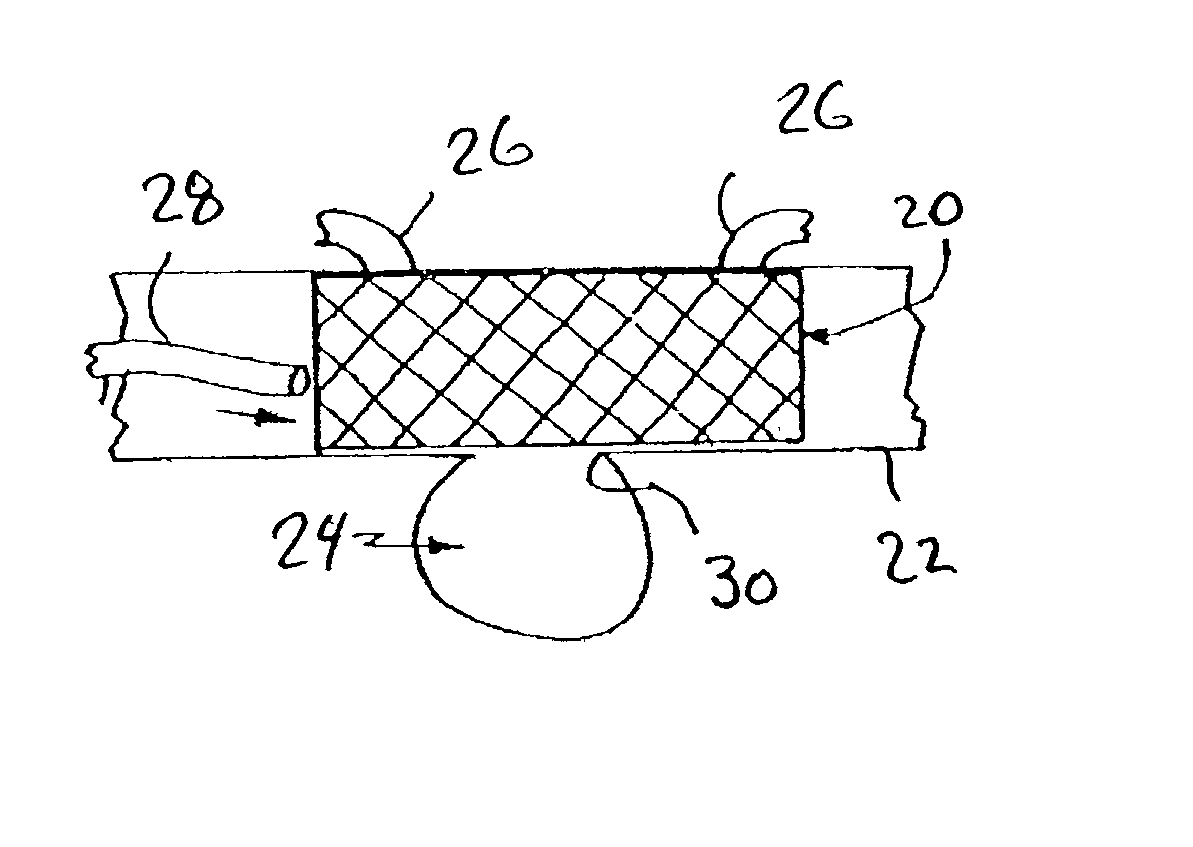

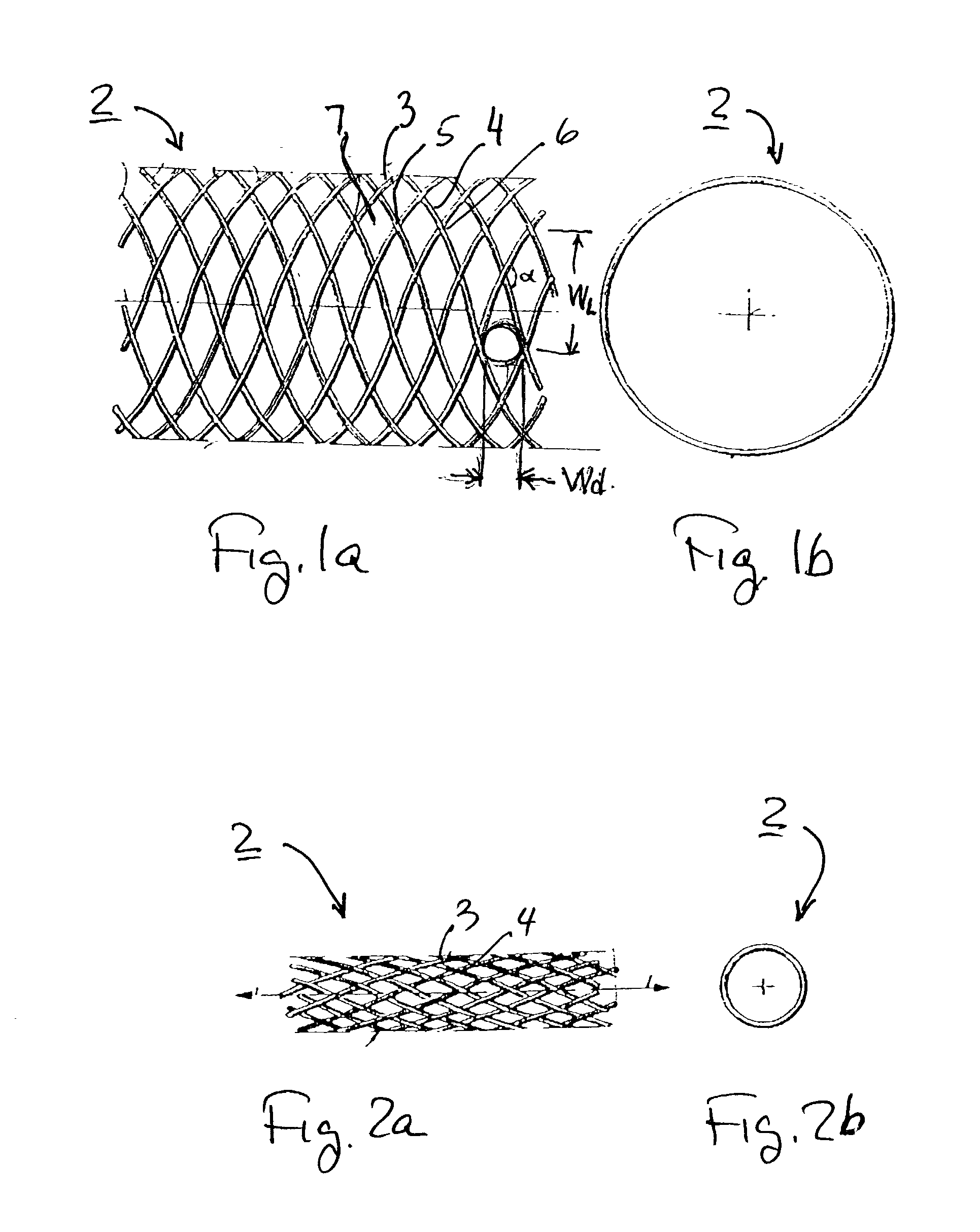

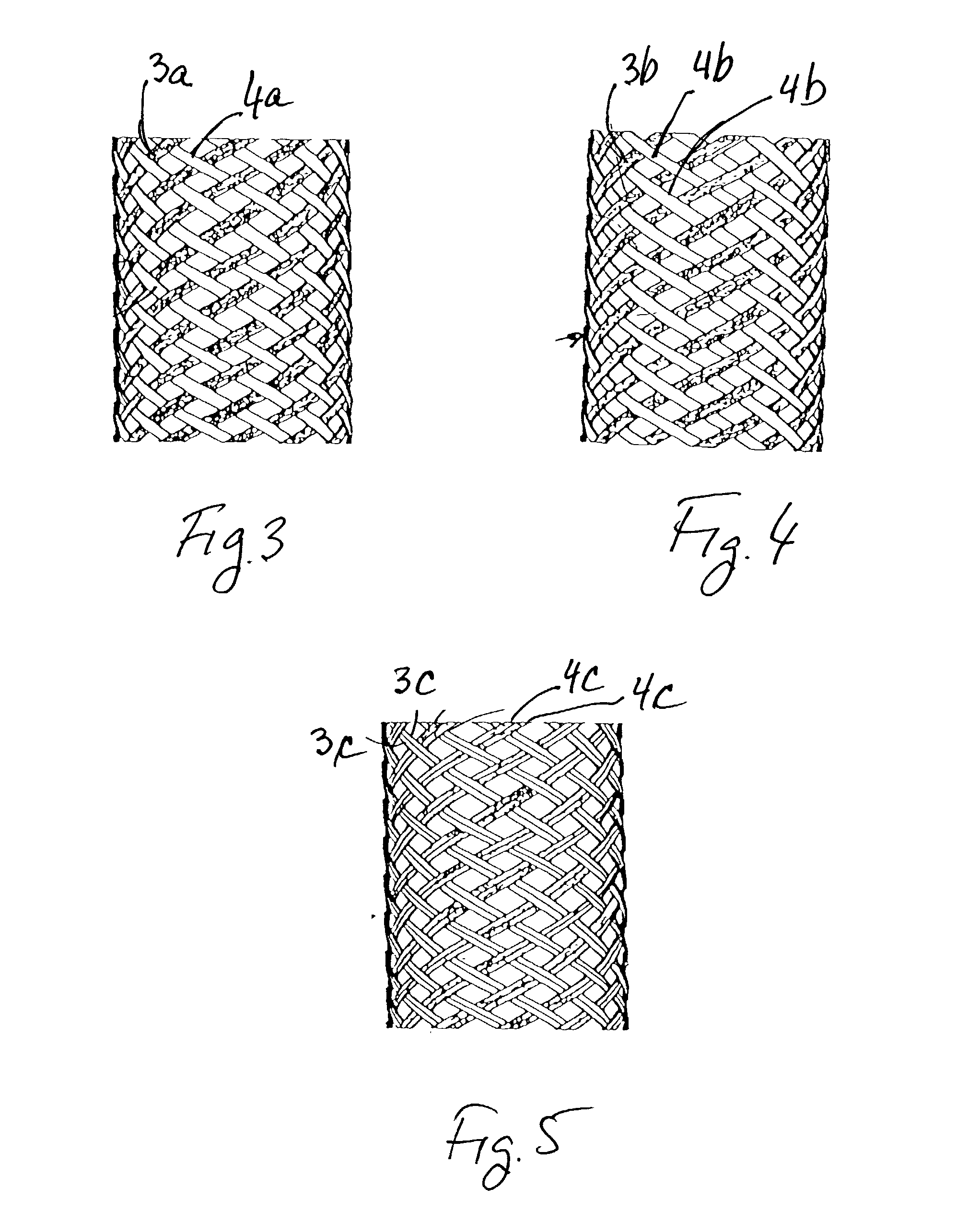

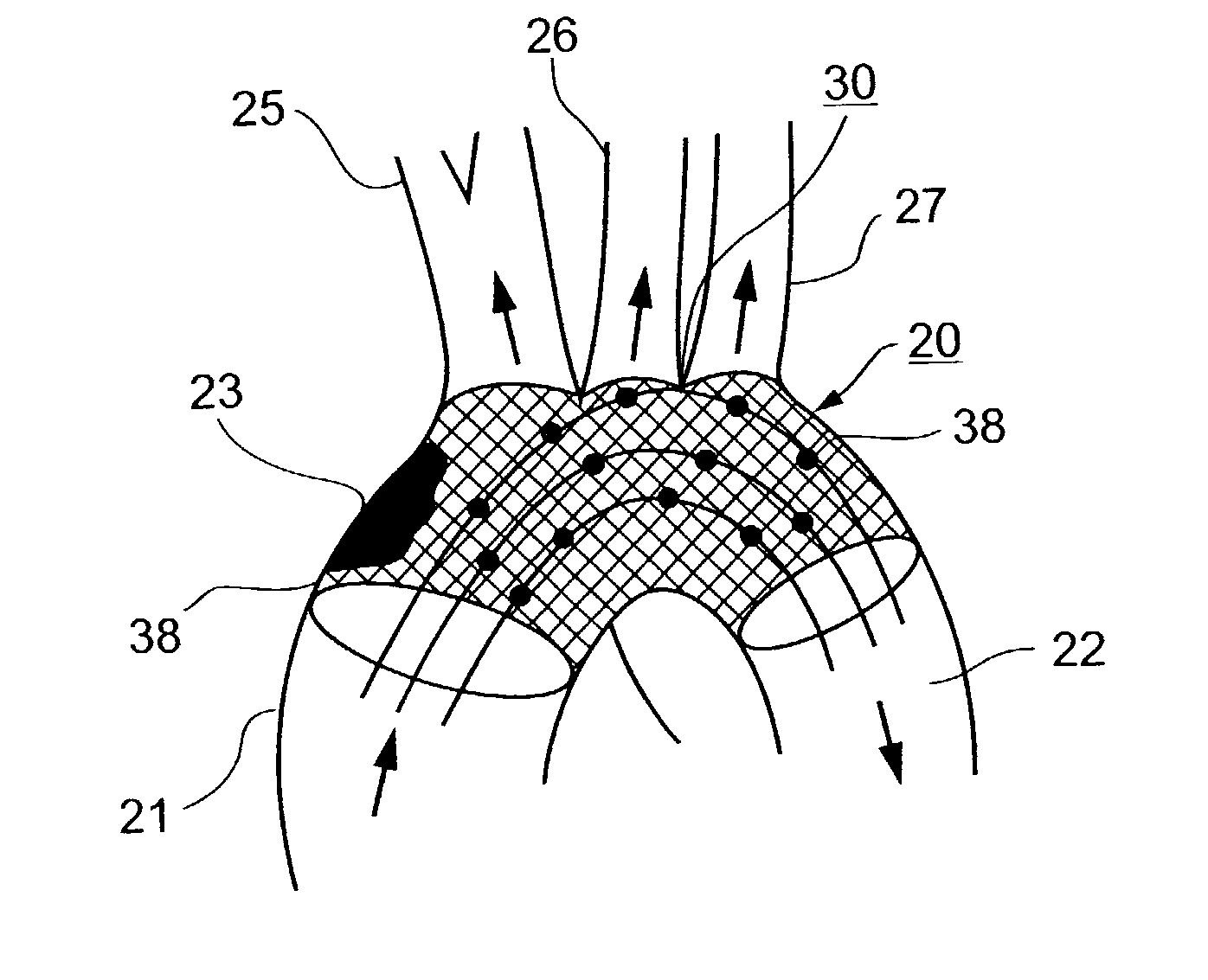

An intraluminal device implantable in a blood vessel having an aneurysm therein in the vicinity of a perforating vessel and / or of a bifurcation leading to a branch vessel. The intraluminal device includes a mesh-like tube of bio-compatible material having an expanded condition in which the tube diameter is slightly larger than the diameter of the blood vessel in which it is to be implanted, and the tube length is sufficient to straddle the aneurysm and to be anchored to the blood vessel on the opposite sides of the aneurysm. The mesh-like tube also has a contracted condition wherein it is sufficiently flexible so as to be easily manipulatable through the blood vessel to straddle the aneurysm. In its expanded condition, the mesh-like tube has a porosity index of 55%-80% such as to reduce the flow of blood through its wall to the aneurysm sufficiently to decrease the possibility of rupture of the aneurysm but not to unduly reduce the blood flow to a perforating or branch vessel to the degree likely to cause significant damage to tissues supplied with blood by such perforating or branch vessel.

Owner:STRYKER CORP

Implantable intraluminal protector device and method of using same for stabilizing atheromas

InactiveUS20030100940A1Process stabilityImprove propertiesStentsBlood vesselsThrombogenicityThrombus

An intraluminal device implantable in a body lumen having an atheroma therein in the vicinity of a side-branch vessel includes a mesh-like tube of bio-compatible material formed with liquid-permeable window openings. The mesh-like tube has an expanded condition in which the tube diameter is slightly larger than the diameter of the body lumen in which it is to be implanted, and the tube length is sufficient to cover the atheroma and the side-branch orifice, and to be anchored to the body lumen around the periphery of the atheroma, and a contracted condition wherein it is sufficiently flexible so as to be easily manipulatable through the body lumen to the site of the atheroma. The mesh-like tube, in its expanded condition, has window openings of a size and distribution such as to structurally stabilize the atheroma and to keep embolic material originating from the atheroma in place on the wall of the body lumen, while diverting embolic material of predetermined size present in the blood flowing through the mesh-like tube from the side-branch orifice, without substantially impeding the blood flow, or increasing the thrombogenitic properties, of the blood flowing into the side-branch orifice.

Owner:SURPASS MEDICAL

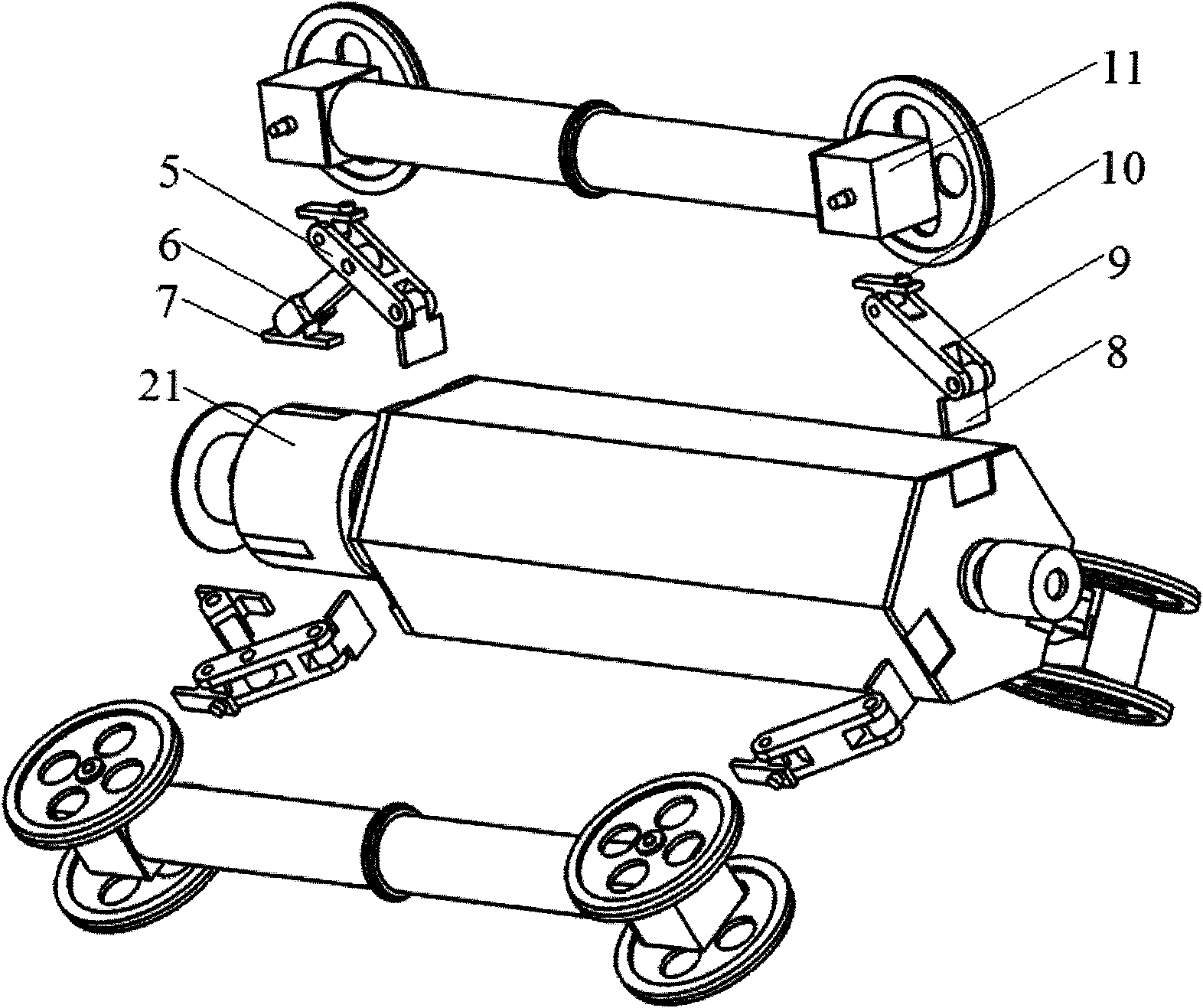

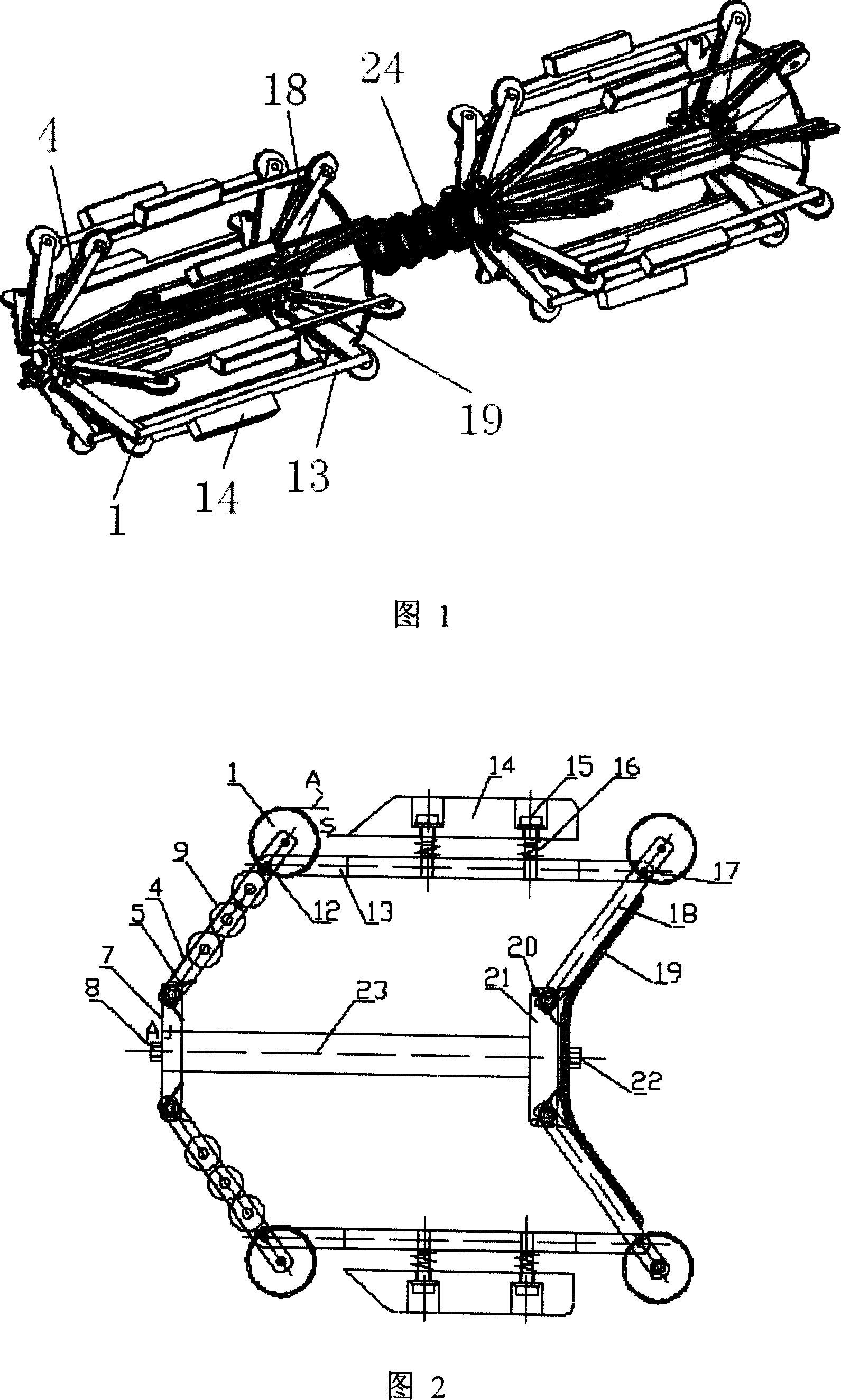

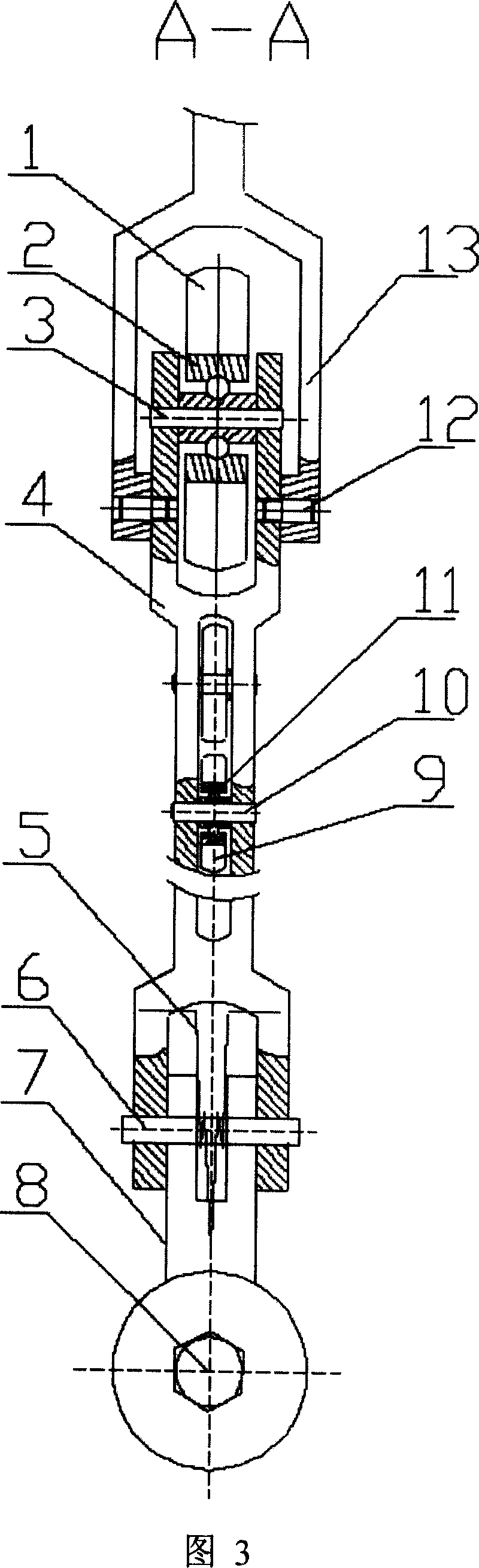

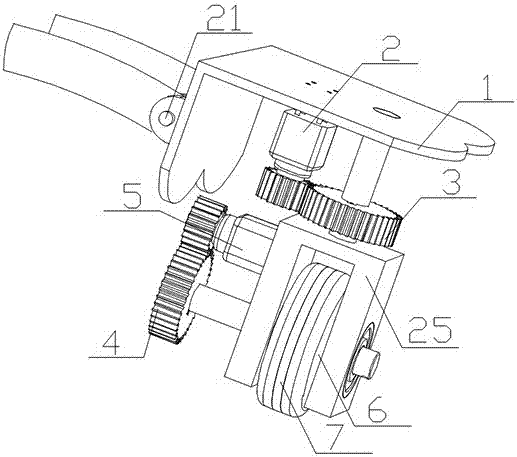

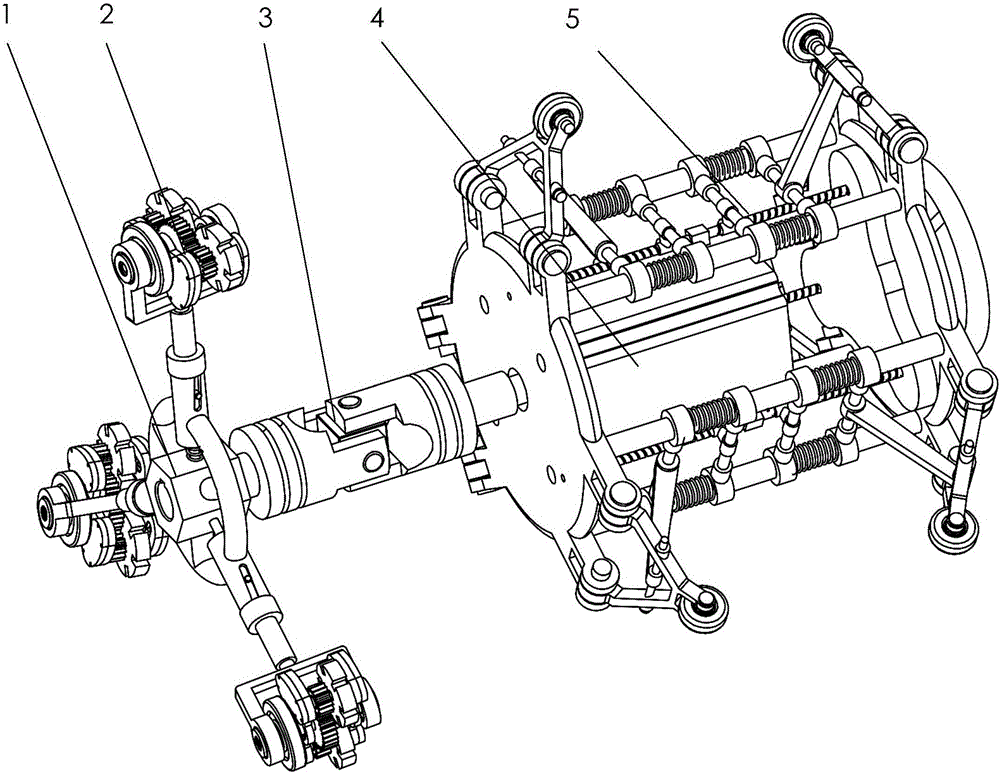

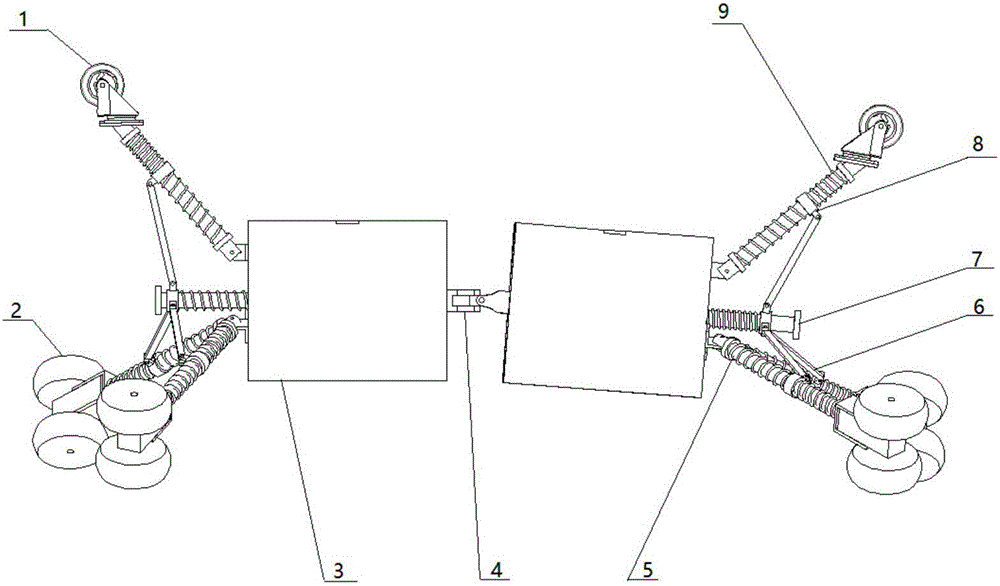

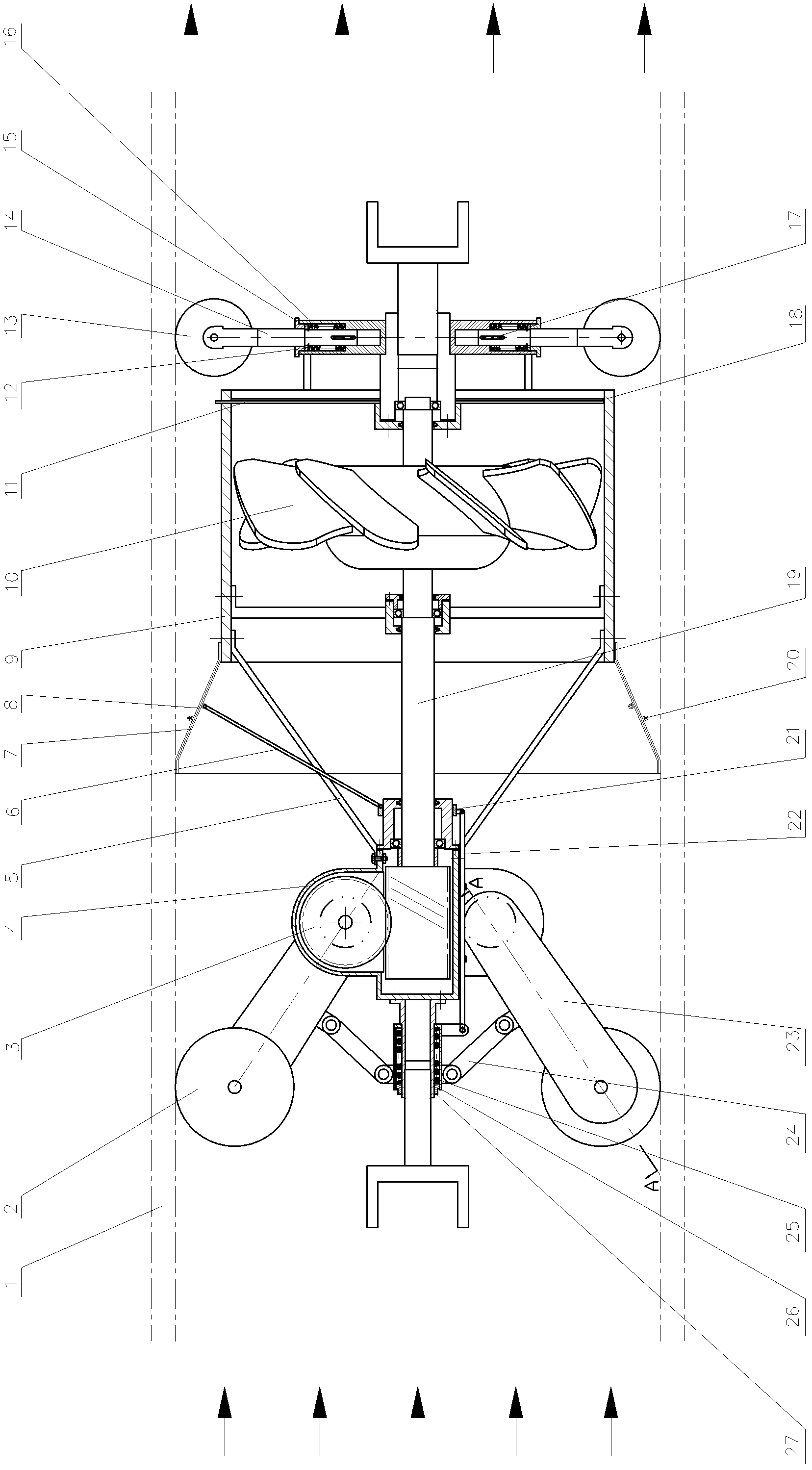

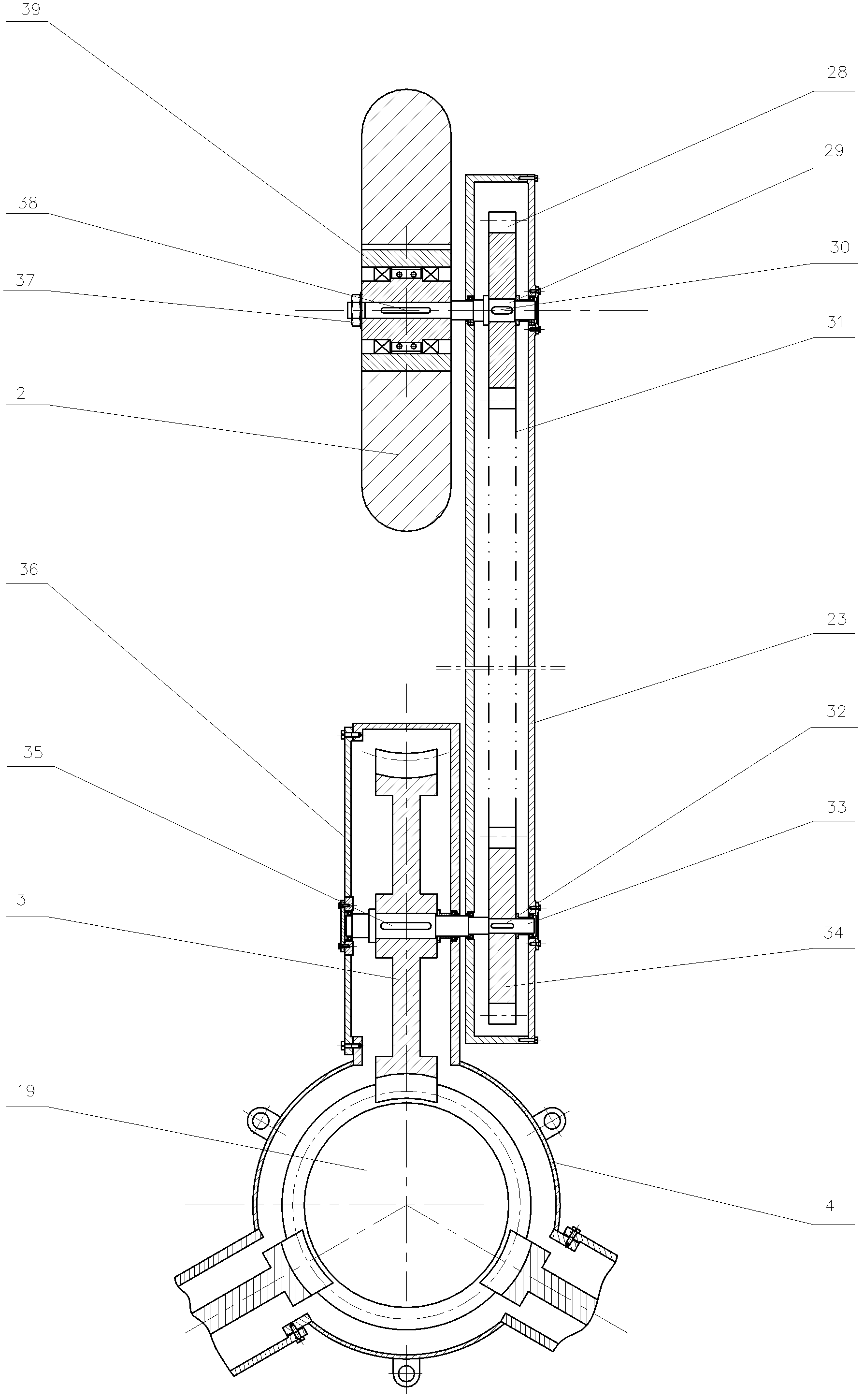

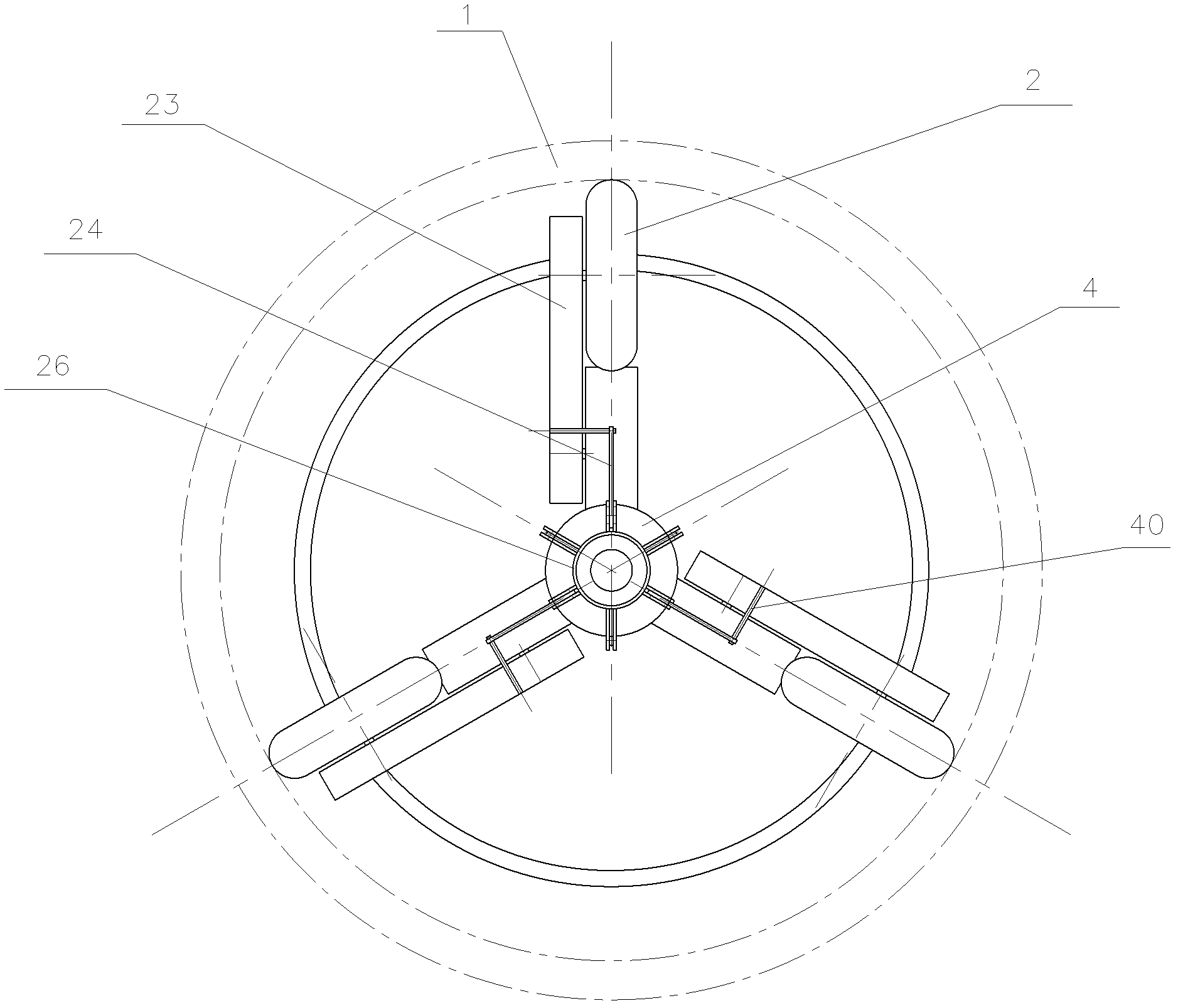

Drive running mechanism of pipeline robot

The invention relates to a drive running mechanism of a pipeline robot, which mainly solves the problems of the existing drive running mechanism of the pipeline robot that the pulling force is smaller, the pipe diameter adaptability is poorer, the ability of surmounting obstacles is insufficient and the like. The invention is characterized in that the drive running mechanism also comprises a wheel leg regulating motor arranged in a body, three running drive units arranged outside the body, three elastic wheel leg support units formed by combining a front support connecting rod, a rear support connecting rod and a regulating connecting rod, and a pipe diameter adaptation adjustment unit; and the body, the front support connecting rod, the rear support connecting rod and running drive units form a parallelogram wheel leg structure; after sensing the pressure from pipe walls, the pipe diameter adaptation adjustment unit regulates the front support connecting rod and the rear support connecting rod so as to adapt to the pipe diameter changes; and each running drive unit is driven by two motors so that larger pulling force can be ensured. The mechanism of the invention has larger pulling force, larger pipe diameter regulating range and better ability of surmounting the obstacles; and compared with the prior art, the mechanism has high transmission efficiency.

Owner:DAQING GASOLINEEUM INST

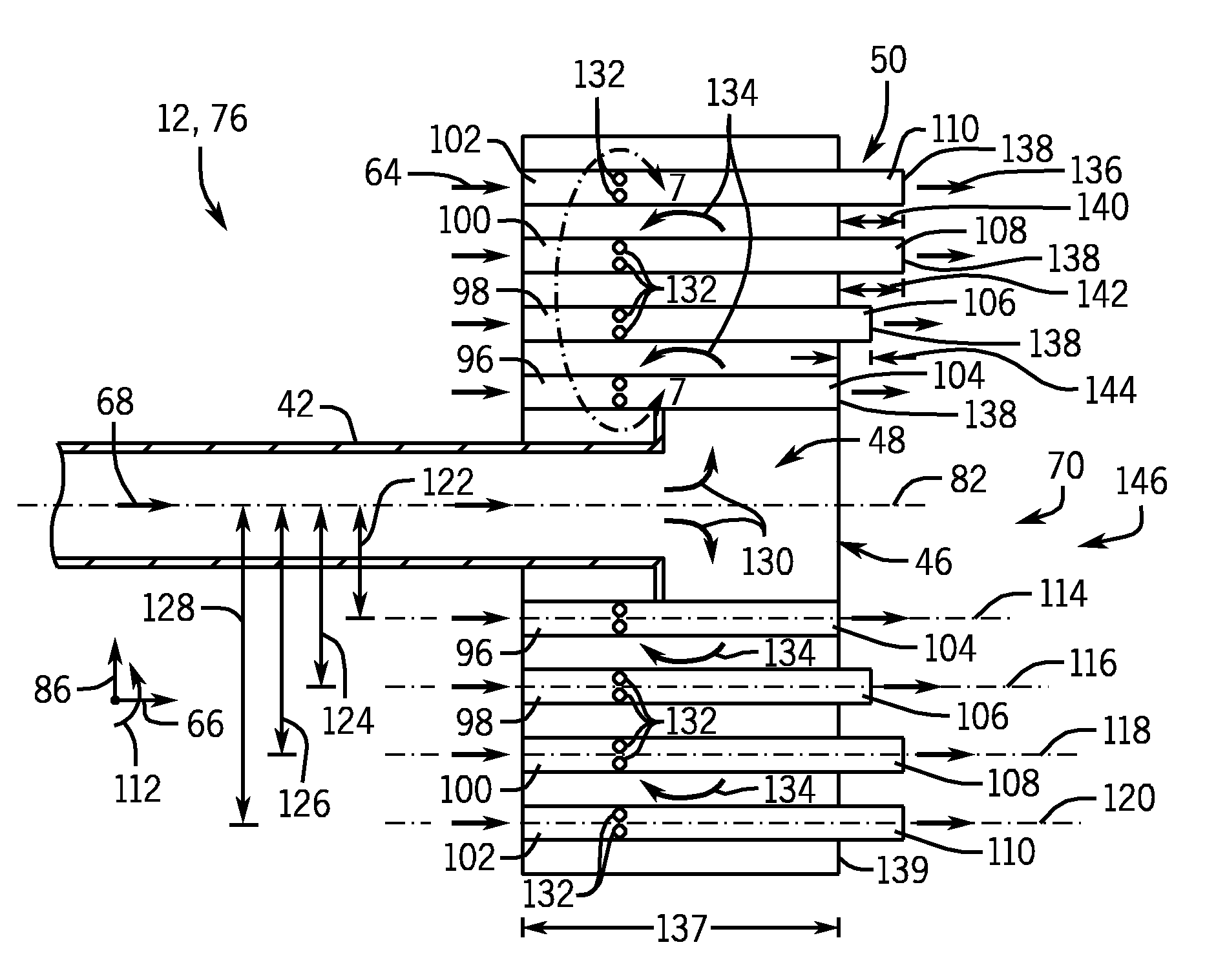

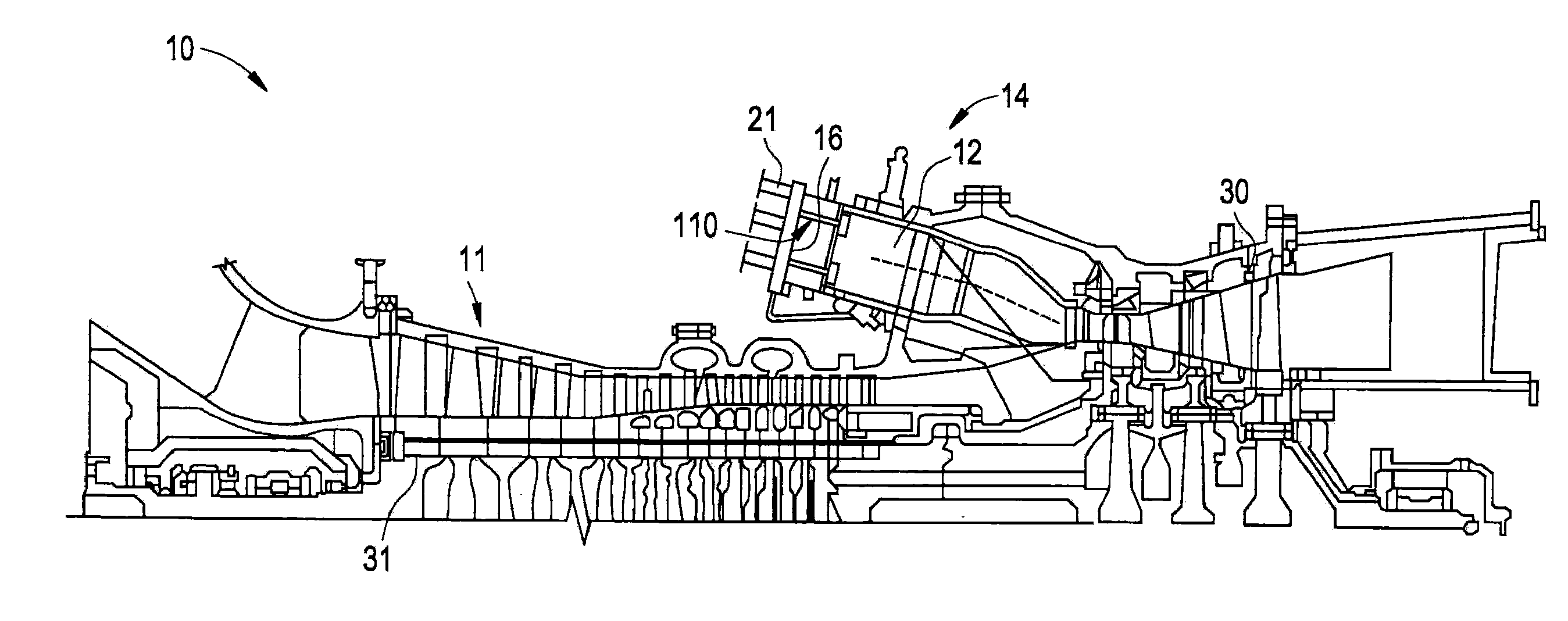

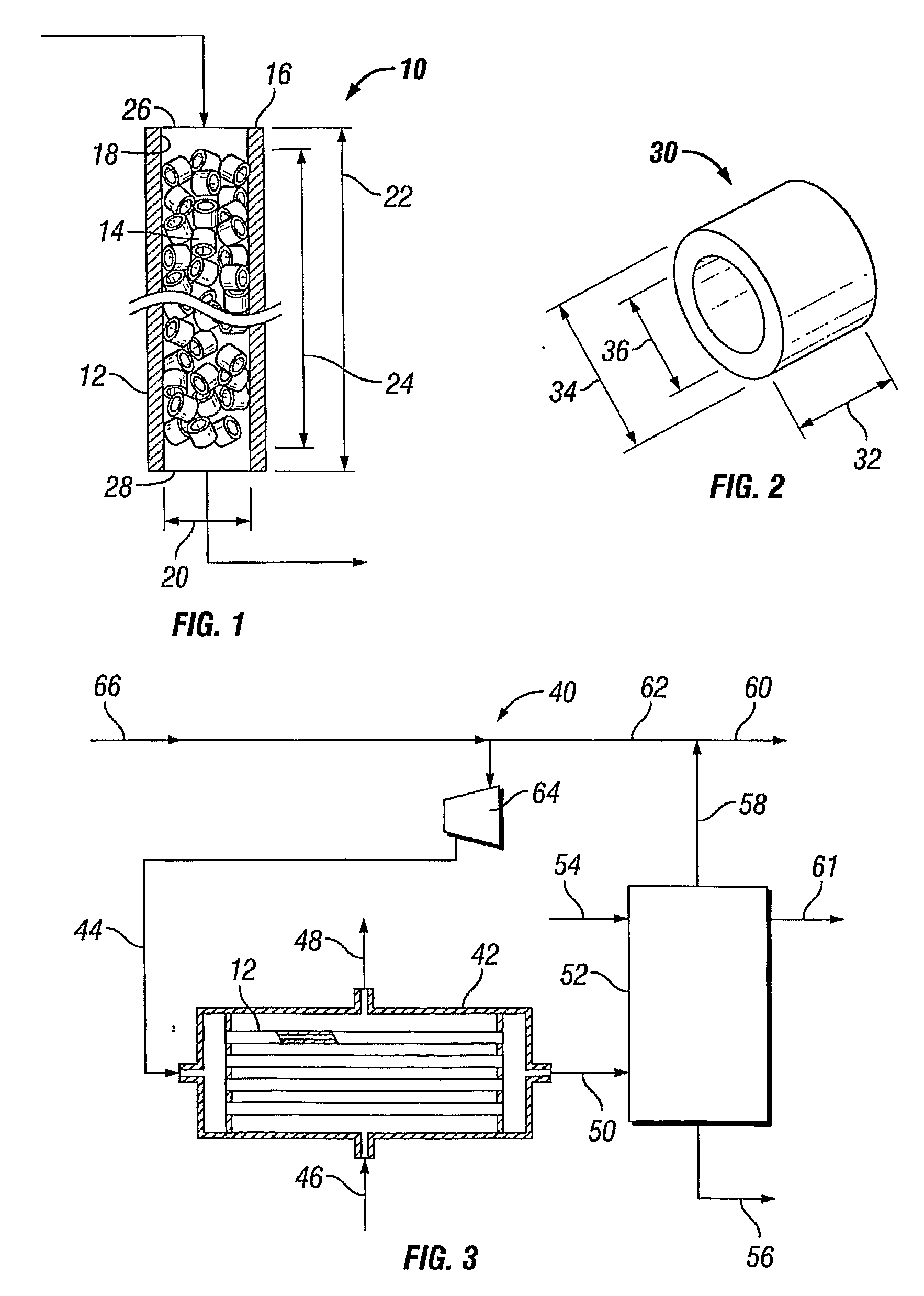

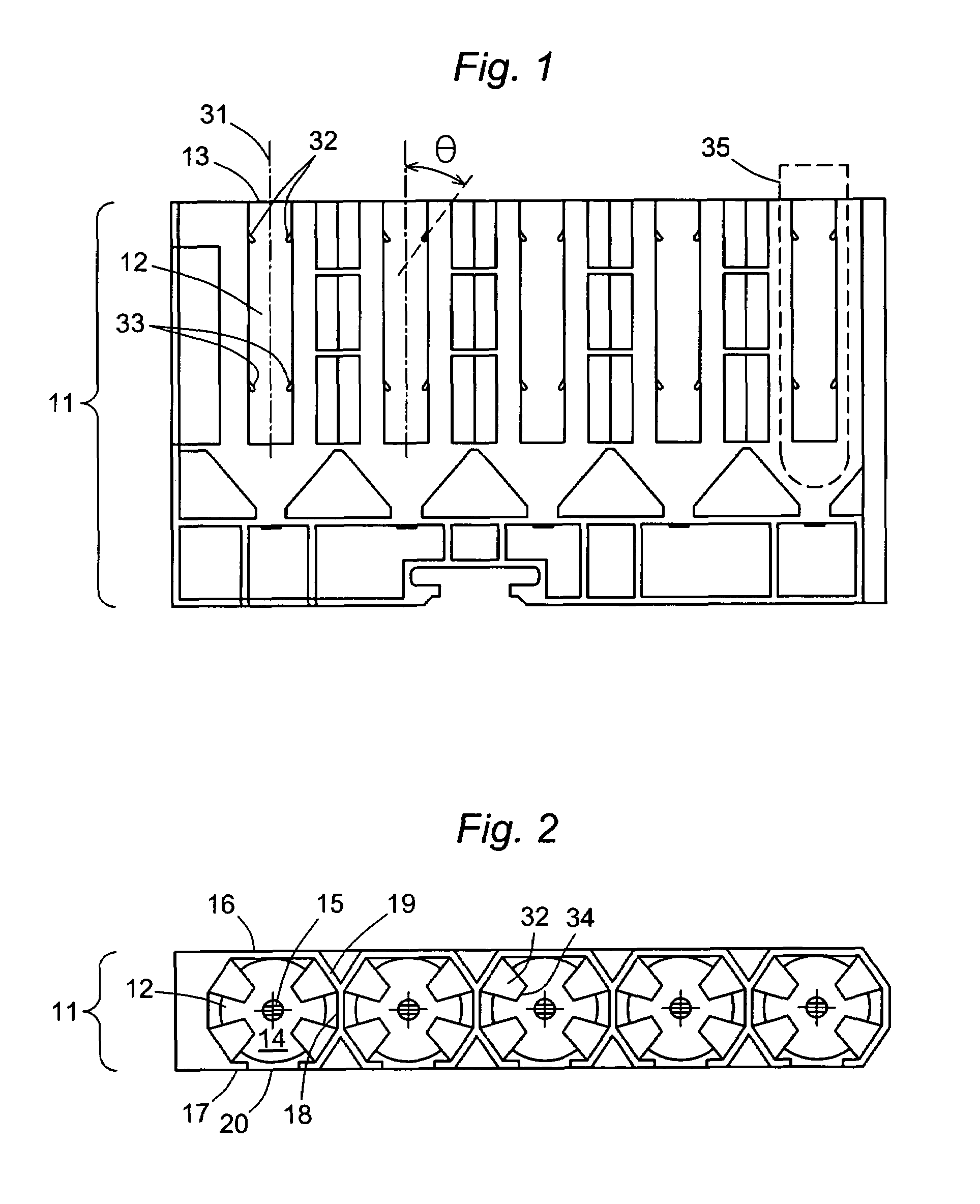

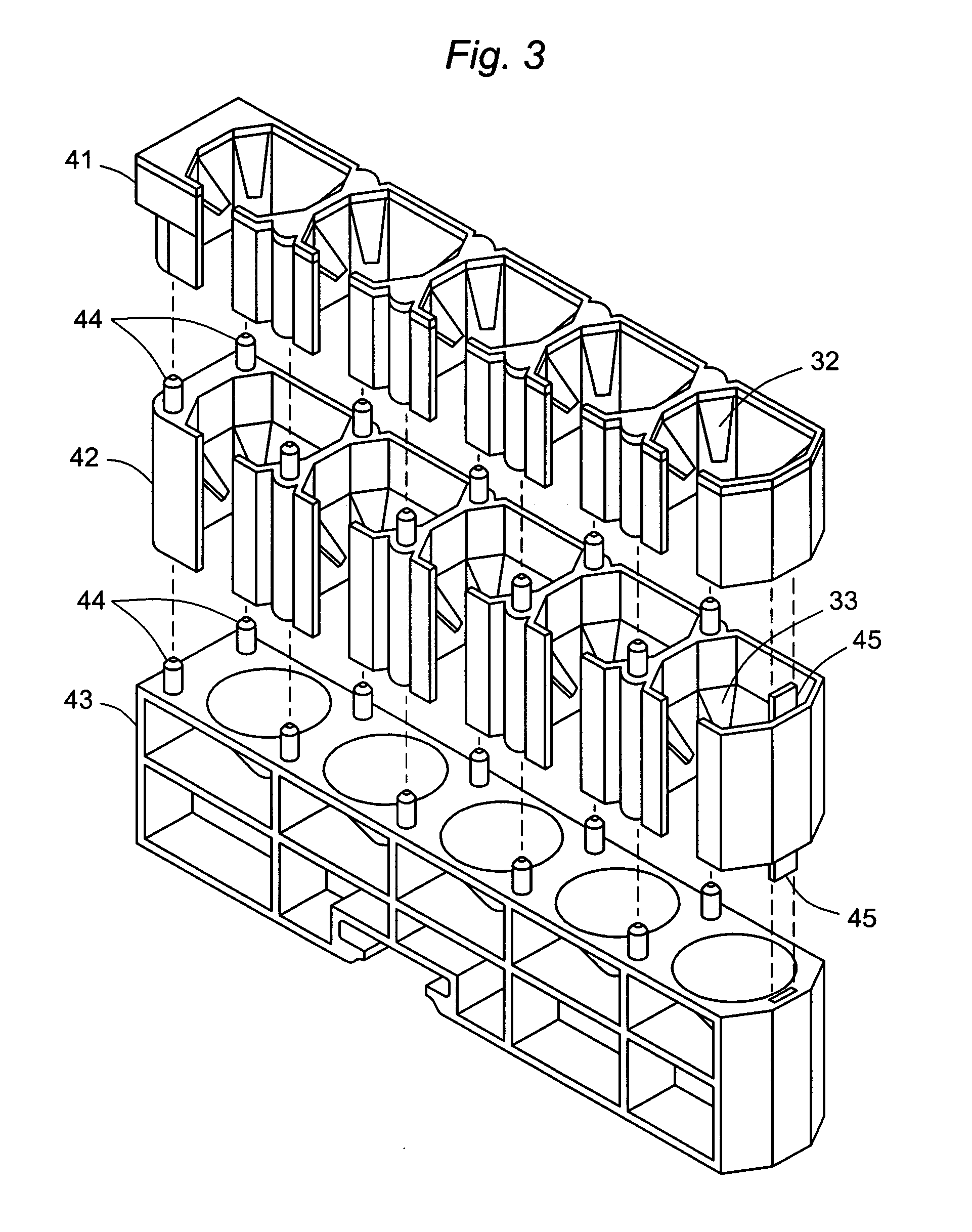

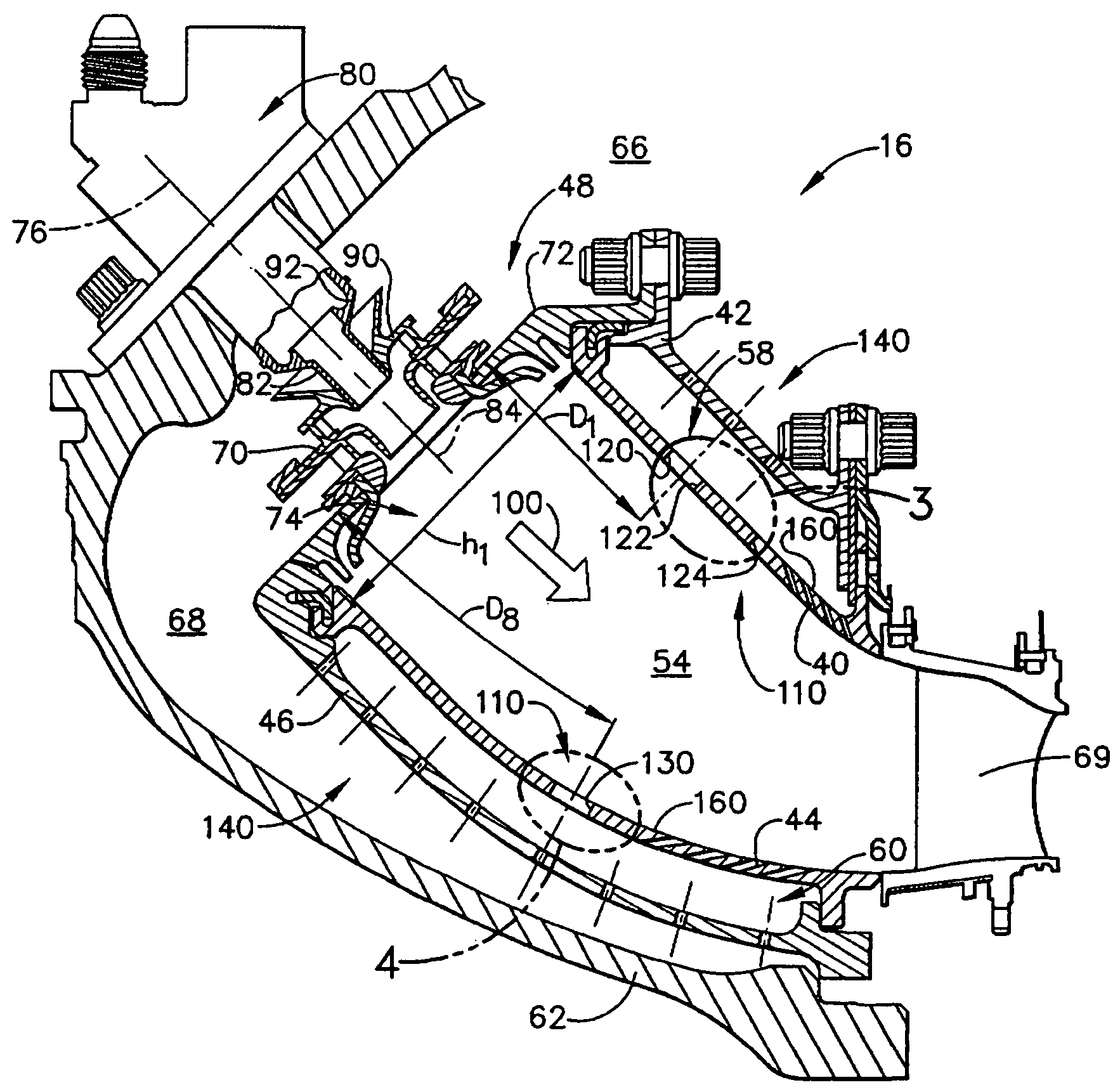

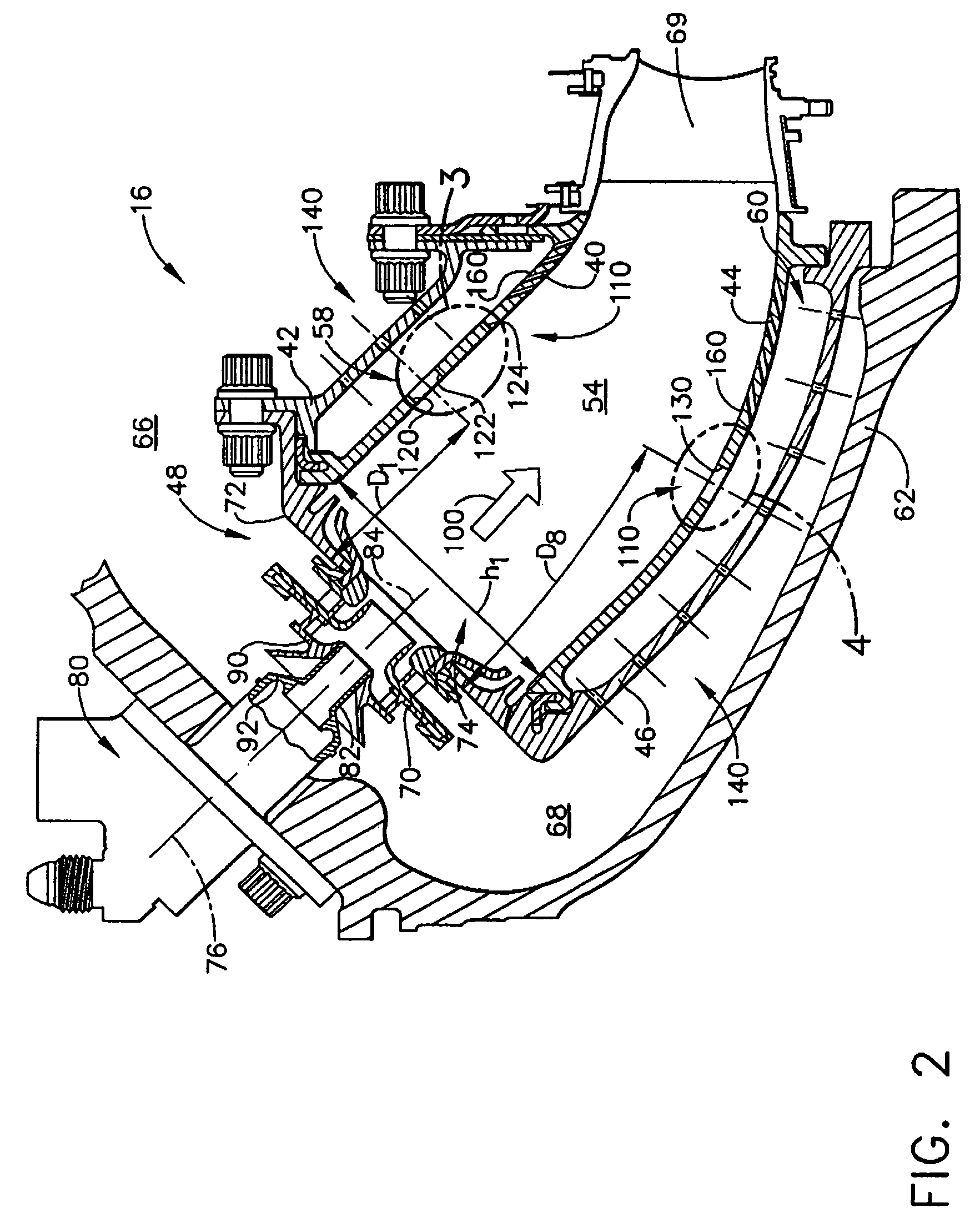

System for flow control in multi-tube fuel nozzle

InactiveUS20120180487A1Turbine/propulsion fuel supply systemsContinuous combustion chamberControl systemTube diameter

A system includes a multi-tube fuel nozzle. The multi-tube fuel nozzle includes a fuel conduit, a fuel chamber coupled to the fuel conduit, and multiple tubes concentrically arranged in multiple rows about a central axis of the multi-tube fuel nozzle and extending through the fuel chamber to a downstream end portion of the multi-tube fuel nozzle. The multiple tubes include fluids flow and different flow control features including at least one of different fuel / air premixing ratios, different tube diameters, or different outlet distances relative to the downstream end portion.

Owner:GENERAL ELECTRIC CO

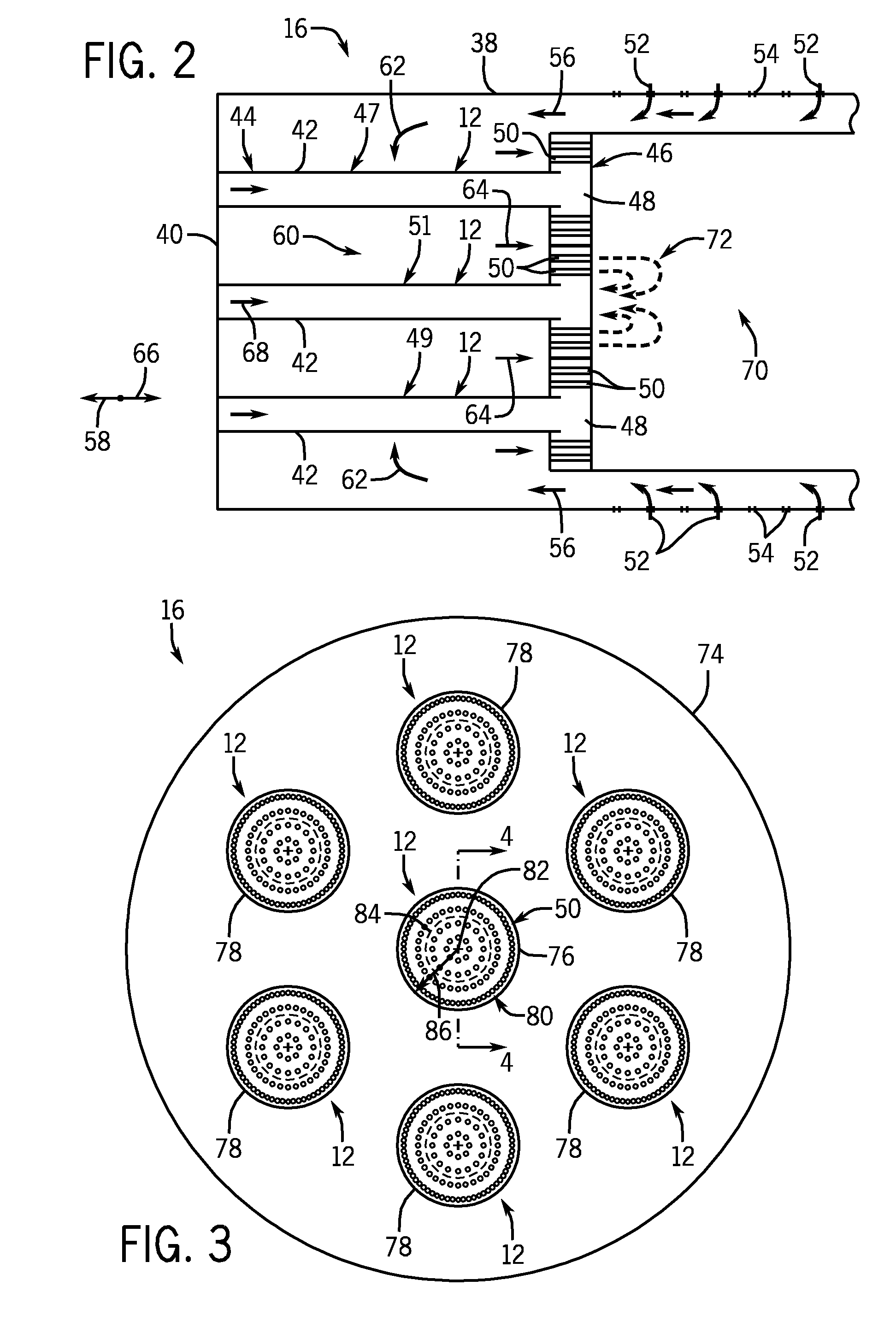

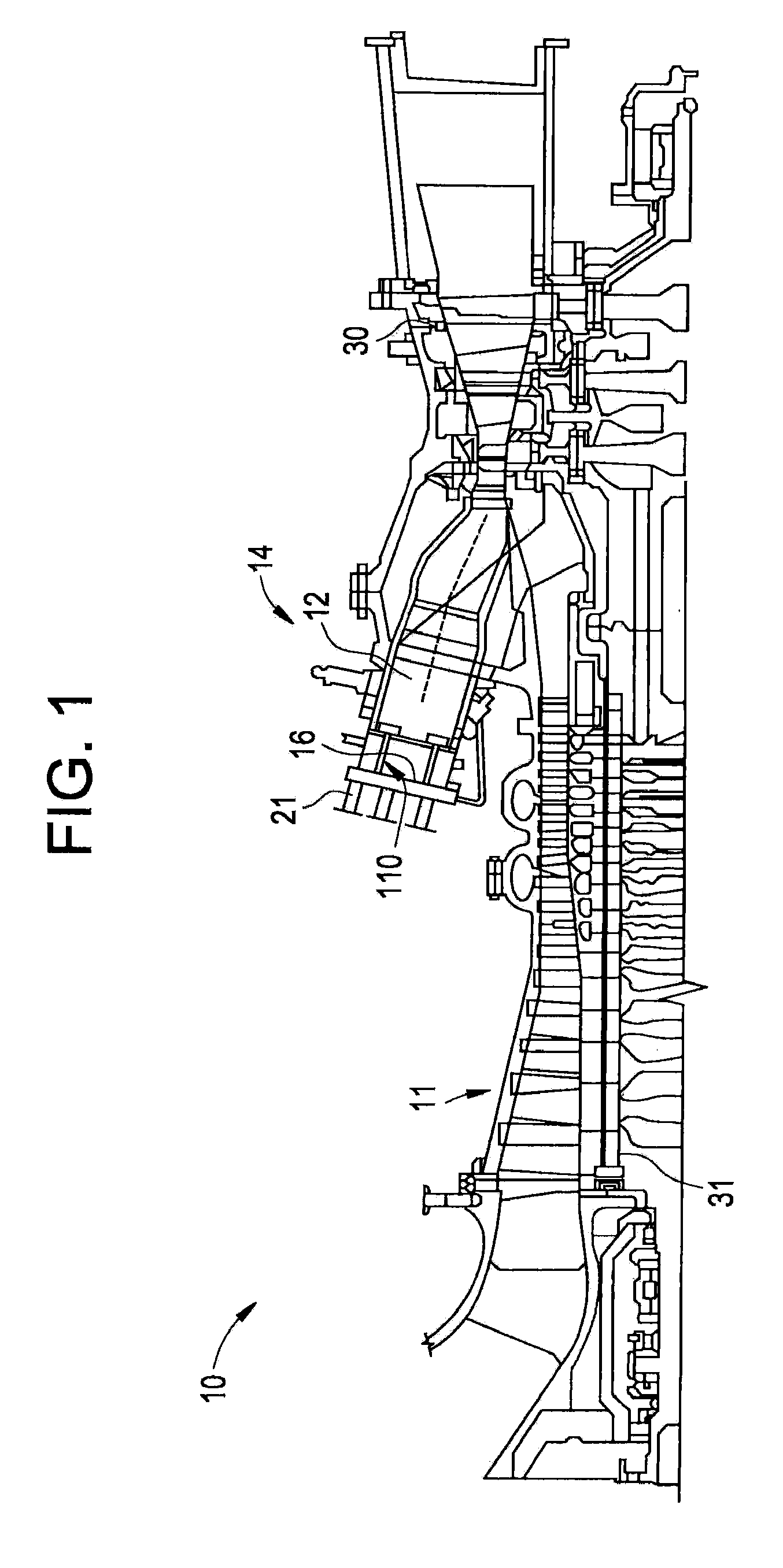

Premixed direct injection nozzle

ActiveUS20100192581A1Air mix wellReduce burnBurnersContinuous combustion chamberEngineeringGas turbines

A fuel / air mixing tube for use in a fuel / air mixing tube bundle is provided. The fuel / air mixing tube includes an outer tube wall extending axially along a tube axis between an inlet end and an exit end, the outer tube wall having a thickness extending between an inner tube surface having a inner diameter and an outer tube surface having an outer tube diameter. The tube further includes at least one fuel injection hole having a fuel injection hole diameter extending through the outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GENERAL ELECTRIC CO

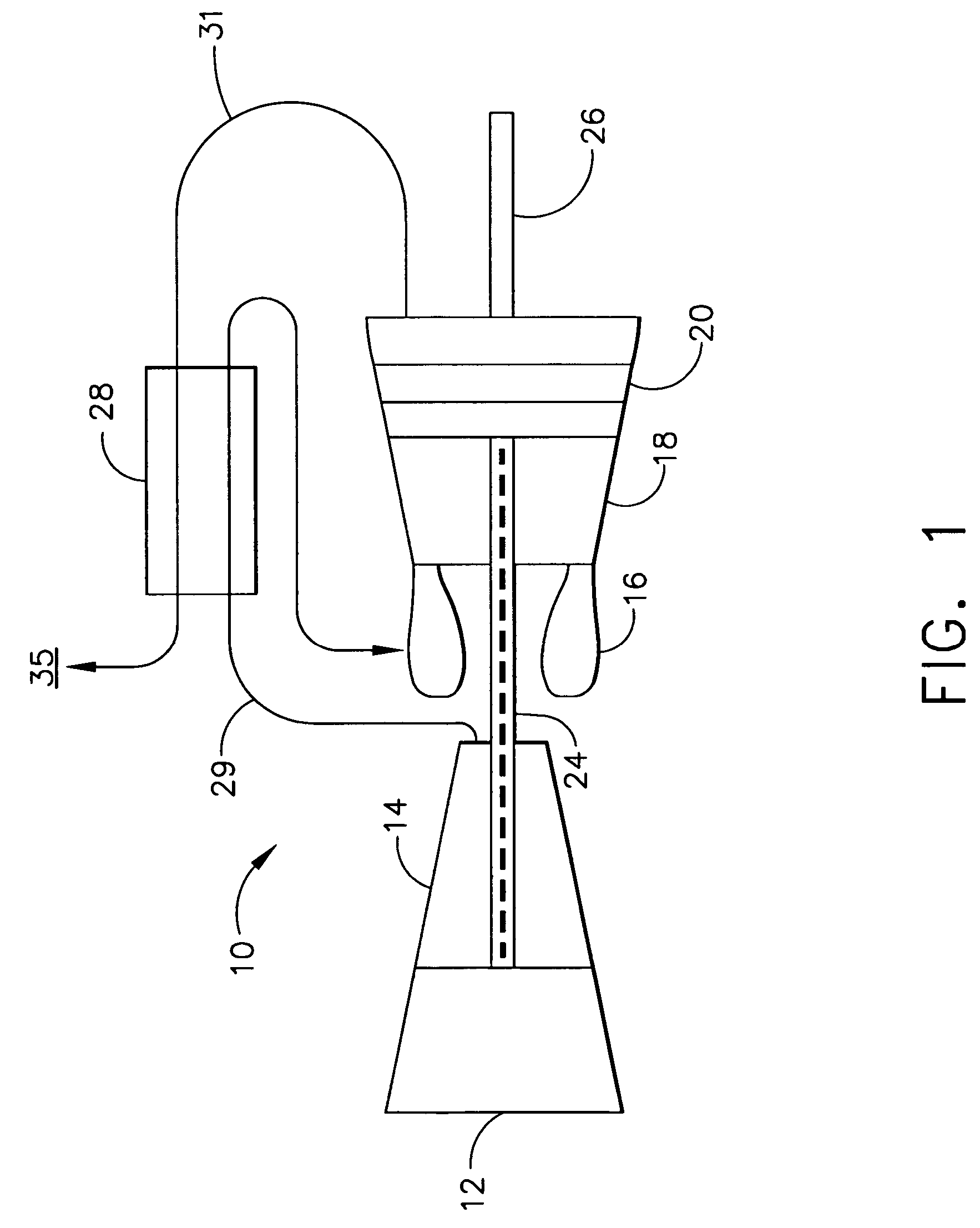

Reactor System and Process for the Manufacture of Ethylene Oxide

A reactor system for the epoxidation of ethylene, which reactor system comprises an elongated tube having an internal tube diameter of more than 40 mm, wherein contained is a catalyst bed of catalyst particles comprising silver and a promoter component deposited on a carrier, which promoter component comprises an element selected from rhenium, tungsten, molybdenum and chromium; a process for the epoxidation of ethylene comprising reacting ethylene with oxygen in the presence of the catalyst bed contained in the reactor system; and a method of preparing ethylene glycol, an ethylene glycol ether or an ethanol amine comprising obtaining ethylene oxide by the process for the epoxidation of ethylene, and converting the ethylene oxide into ethylene glycol, the ethylene glycol ether, or the ethanol amine. Preferably, the internal tube diameter is at least 45 mm.

Owner:SHELL OIL CO

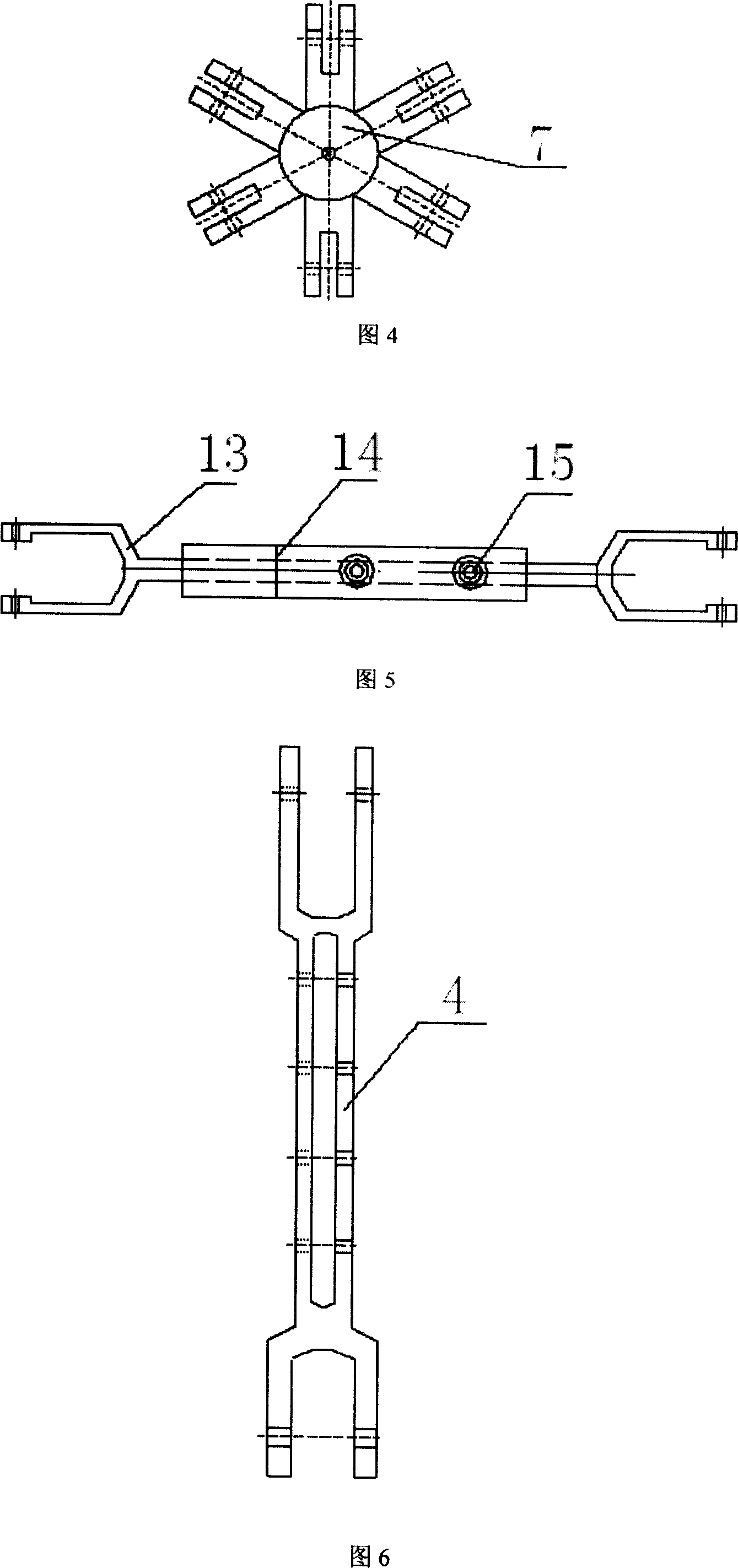

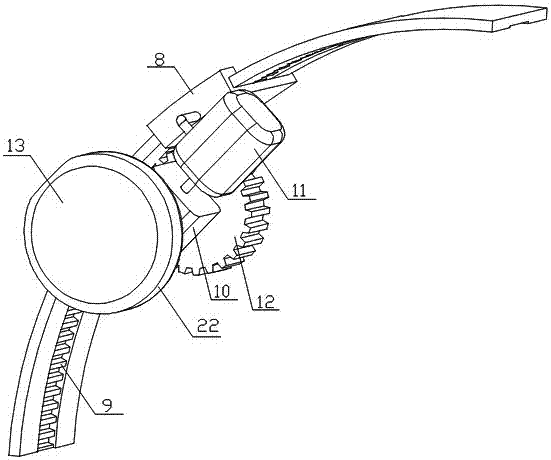

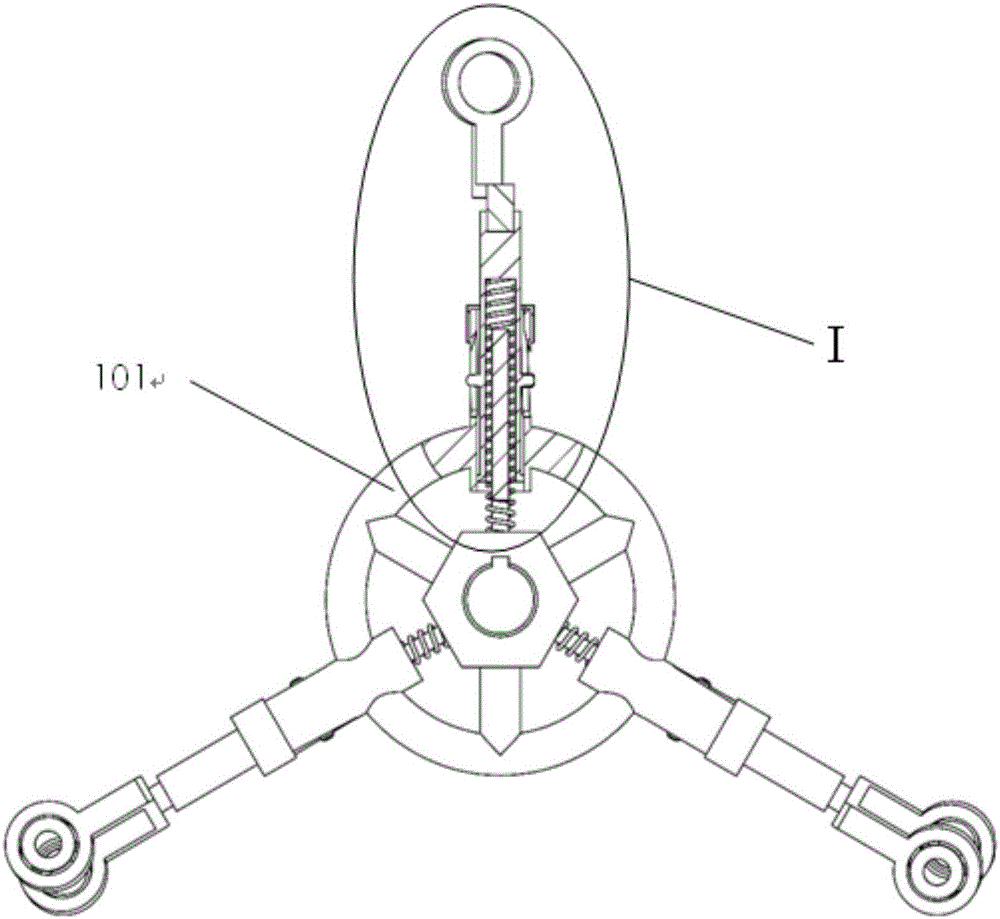

Diameter changeable pipeline cleaning robot having parallel four-bar mechanism

ActiveCN1962091AImprove passabilityImprove reliabilityHollow article cleaningManipulatorSpring forceEngineering

The invention relates to a diameter-variable tube washing robot with parallel four-rod device, wherein it is formed by several same tube washing devices, that connected by flexible springs; each unit is formed by support, flexible panel and washing head; the support is formed by several parallel four-rod devices around the central axle; via torsion spring, the parallel four-rod device will open, and the rolling wheel on the swing rod will contact the inner wall of tube, to support the whole tube washing device; when meeting obstacle, the four-rod device will overcome torsion spring to contract; the washing head is mounted on the connecting rod of four-rod device, to contact the inner wall of tube via spring; the flexible panel on the back swing rod can block the inner fluid, to generate pushing force, and move the support forwards. The invention can avoid additive powder and clean any tubes.

Owner:溧阳常大技术转移中心有限公司

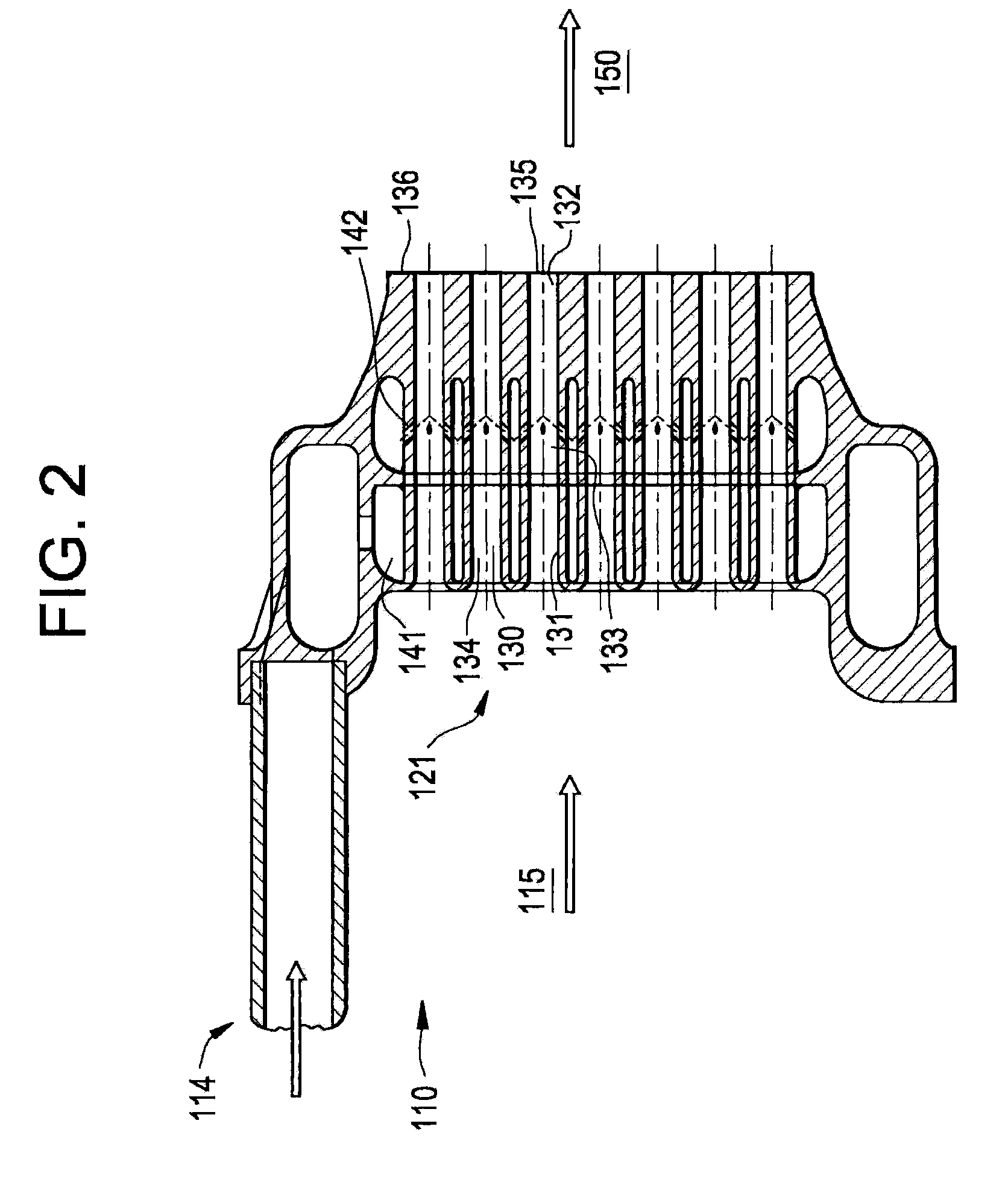

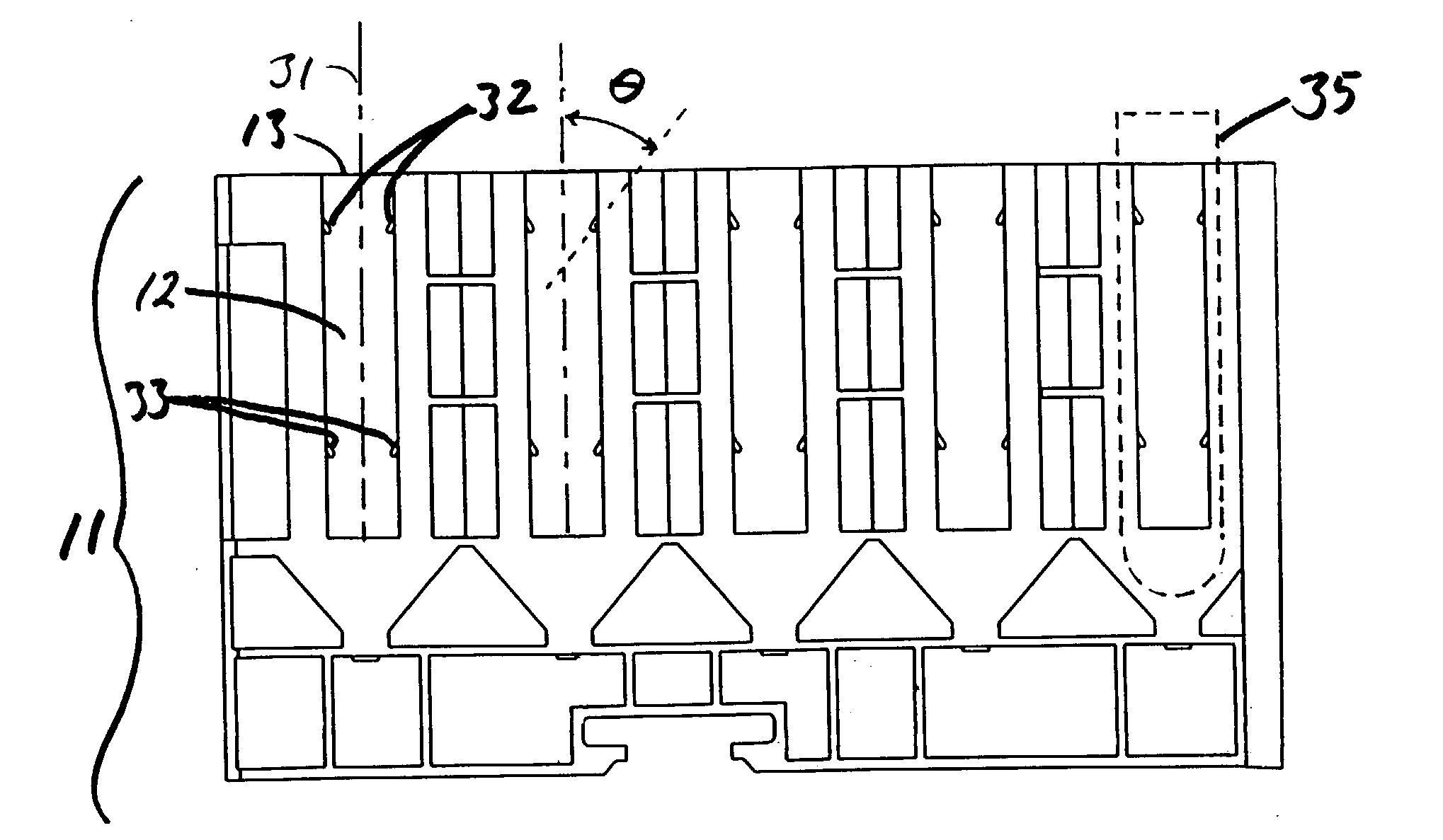

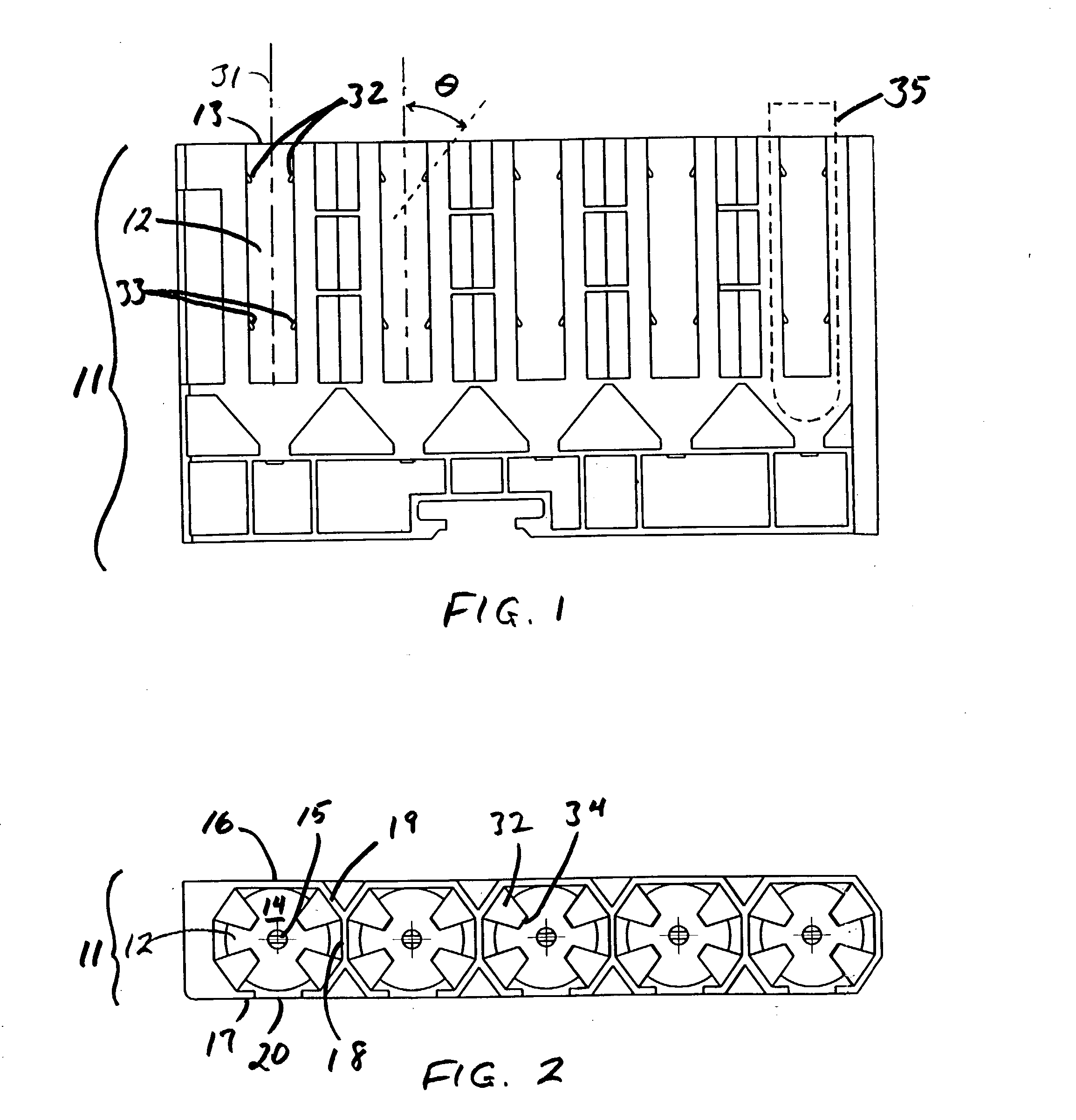

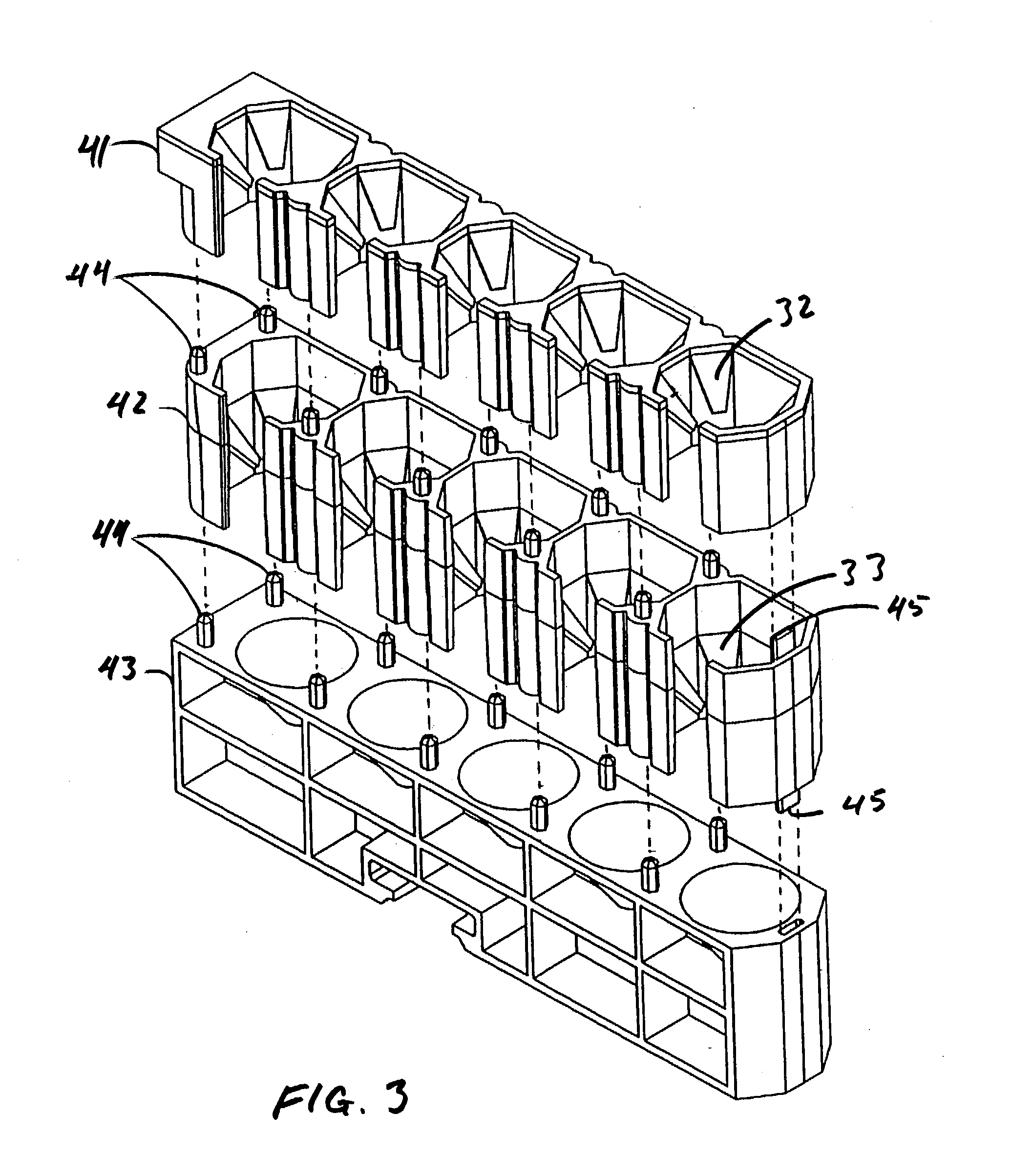

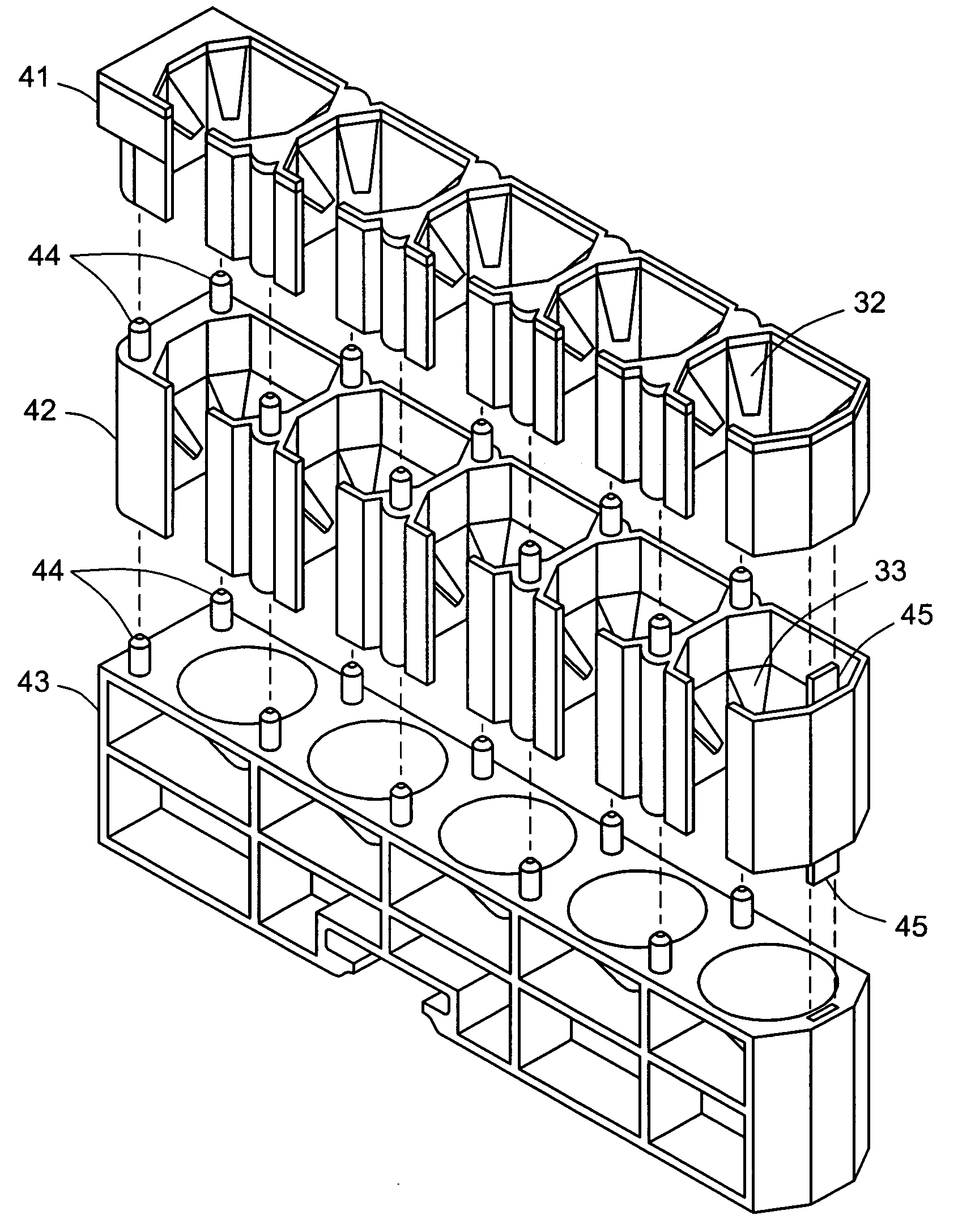

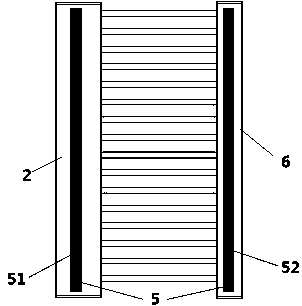

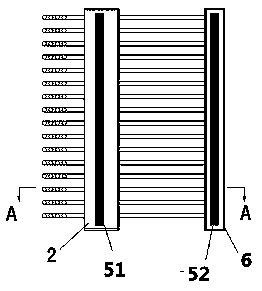

Tube rack accommodating a range of tube diameters

A tube rack for holding and transporting sample tubes or other liquids in an automated analyzer is built to accommodate tubes of different sizes in a stable aligned configuration, the rack containing a row of parallel open-top tube chambers, each chamber containing two sets of resilient tabs integrally molded with the chamber walls and at different heights in the chamber.

Owner:BIO RAD LAB INC

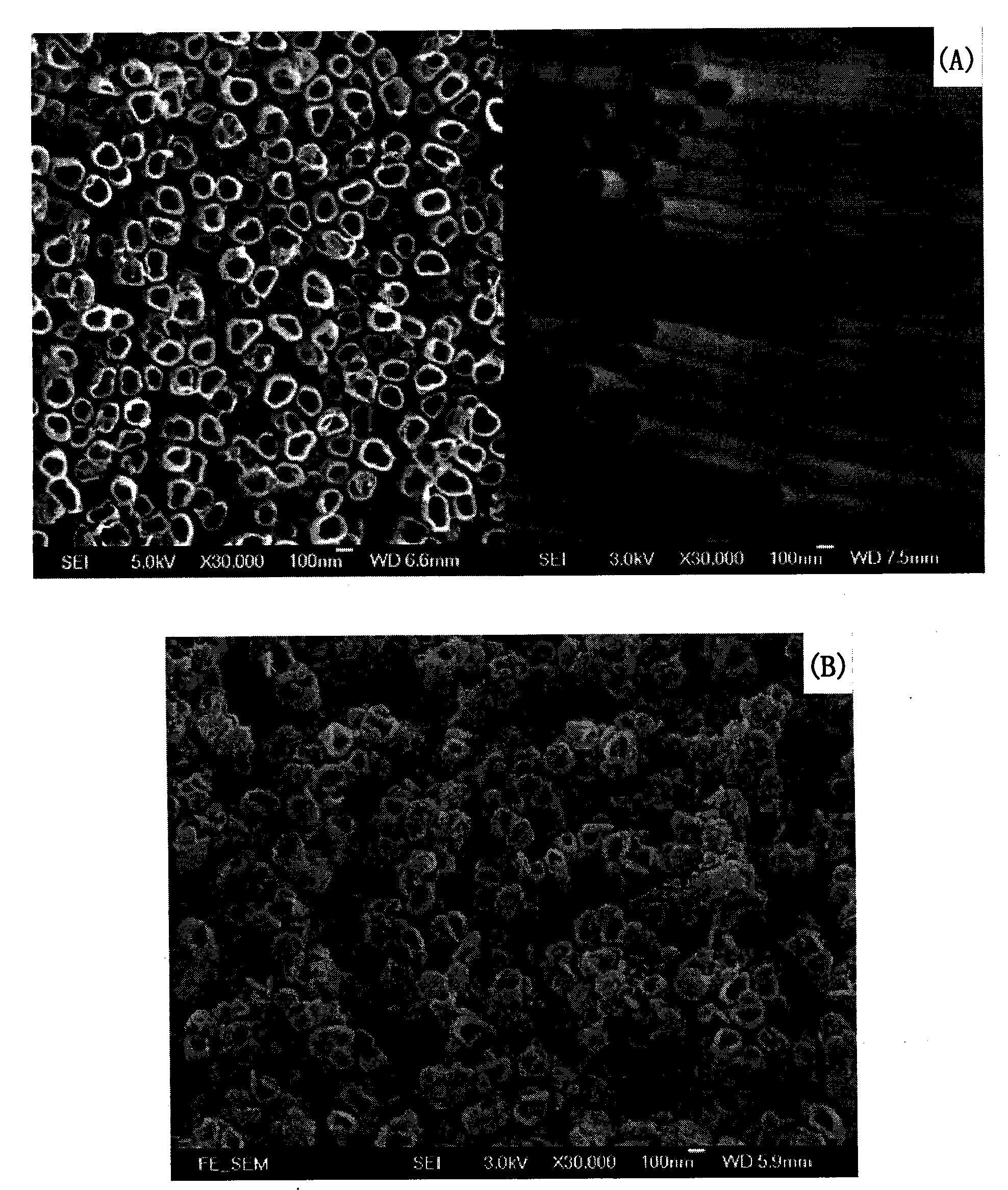

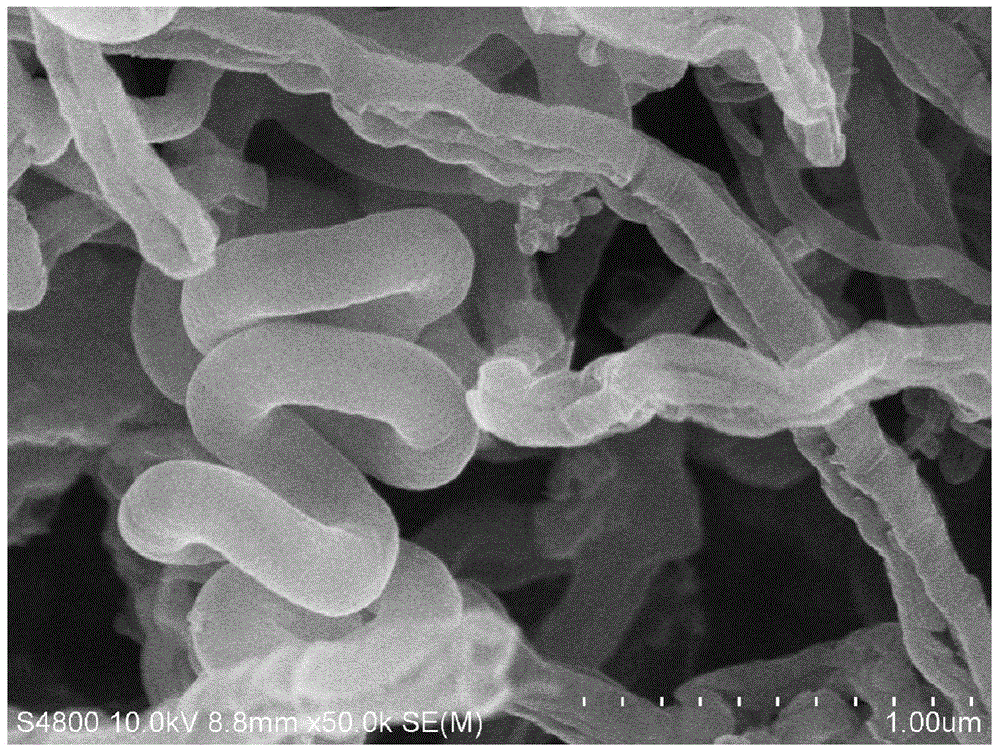

Method for preparing porous titanium dioxide nanotube array

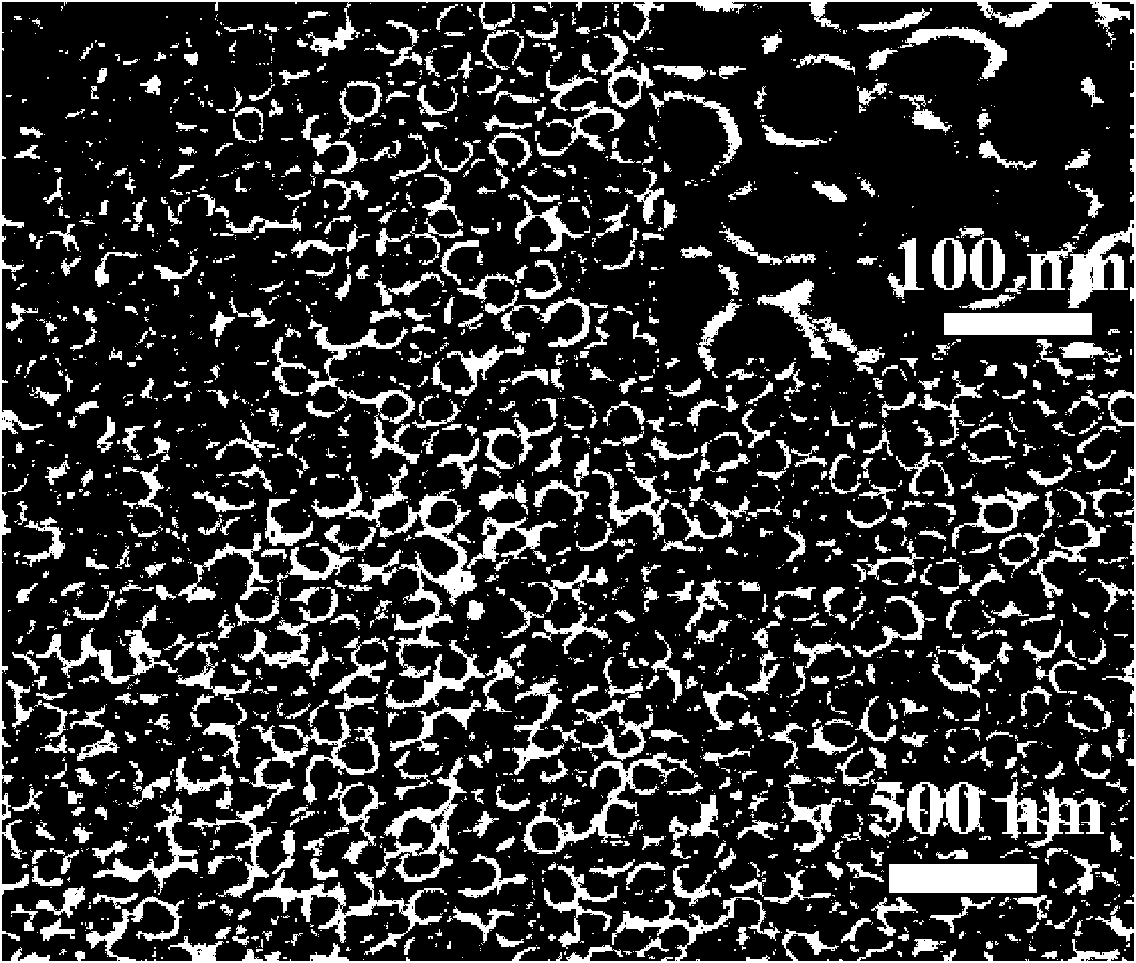

InactiveCN101748463AControllable growthEffective peelingPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium oxide

The invention relates to a method for preparing an ordered porous anodic titanium dioxide nanotube array. The method can prepare an ultra-large area defect-free titanium dioxide nanotube array film, the surface layer is the porous shape like an anodic aluminum oxide template, and the lower layer is a nanotube ordered array, thereby overcoming the common problems of easy lodging and aggregation of tubes in the prior art of preparing the anodic titanium dioxide nanotube array and simultaneously solving the problems that the prepared nanotube array film has more surface defect corrosion pits and the sediment blocks tube mouths. The nanotube array can realize the controllable growth by controlling the preparation conditions and the process and obtain the ordered array films with different tube diameters, different wall thicknesses and different tube lengths. The diameter range of the nanotubes is 20-200nm, the wall thickness range is 5-30nm, and the length range of the titanium dioxide tubes is 100nm-1mm. The invention particularly relates to a technology which can effectively and completely strip the titanium dioxide array film, effectively strip a titanium substrate from the TiO2 nanotube array and obtain the different sizes of porous nanotube array self-support films.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Tube rack accommodating a range of tube diameters

A tube rack for holding and transporting sample tubes or other liquids in an automated analyzer is built to accommodate tubes of different sizes in a stable aligned configuration, the rack containing a row of parallel open-top tube chambers, each chamber containing two sets of resilient tabs integrally molded with the chamber walls and at different heights in the chamber.

Owner:BIO RAD LAB INC

Heat exchanger assembly capable of automatically controlling heating power of left tube box and right tube box

InactiveCN108800990AImprove heating efficiencySimple structureSafety devices for heat exchange apparatusStorage heatersAutomatic controlEngineering

The invention provides a heat exchanger assembly. The heat exchanger assembly comprises a left tube box, a right tube box and a heat exchange tube, wherein the heat exchange tube communicates with theleft tube box and the right tube box; electric heating devices are arranged in the left tube box and / or the right tube box; the left tube box, the right tube box and the heat exchange tube are filled with heating fluid to form a heating fluid closed cycle; the tube diameter of the left tube box is larger than that of the right tube box; and the tube diameter of the left tube box is 3-5 times ofthe tube diameter of the right tube box. Aiming at the deficiencies in the prior art, the immersed heat exchanger assembly is provided, the heating power is controlled to reach the best, and energy resources are saved.

Owner:ZHONGBEI UNIV

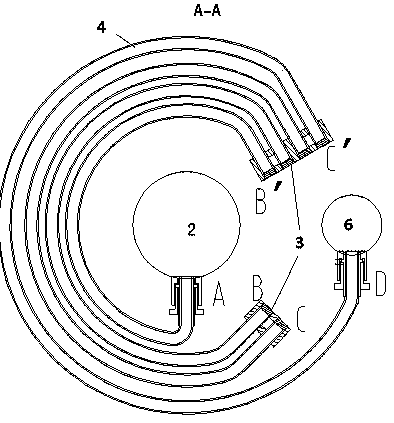

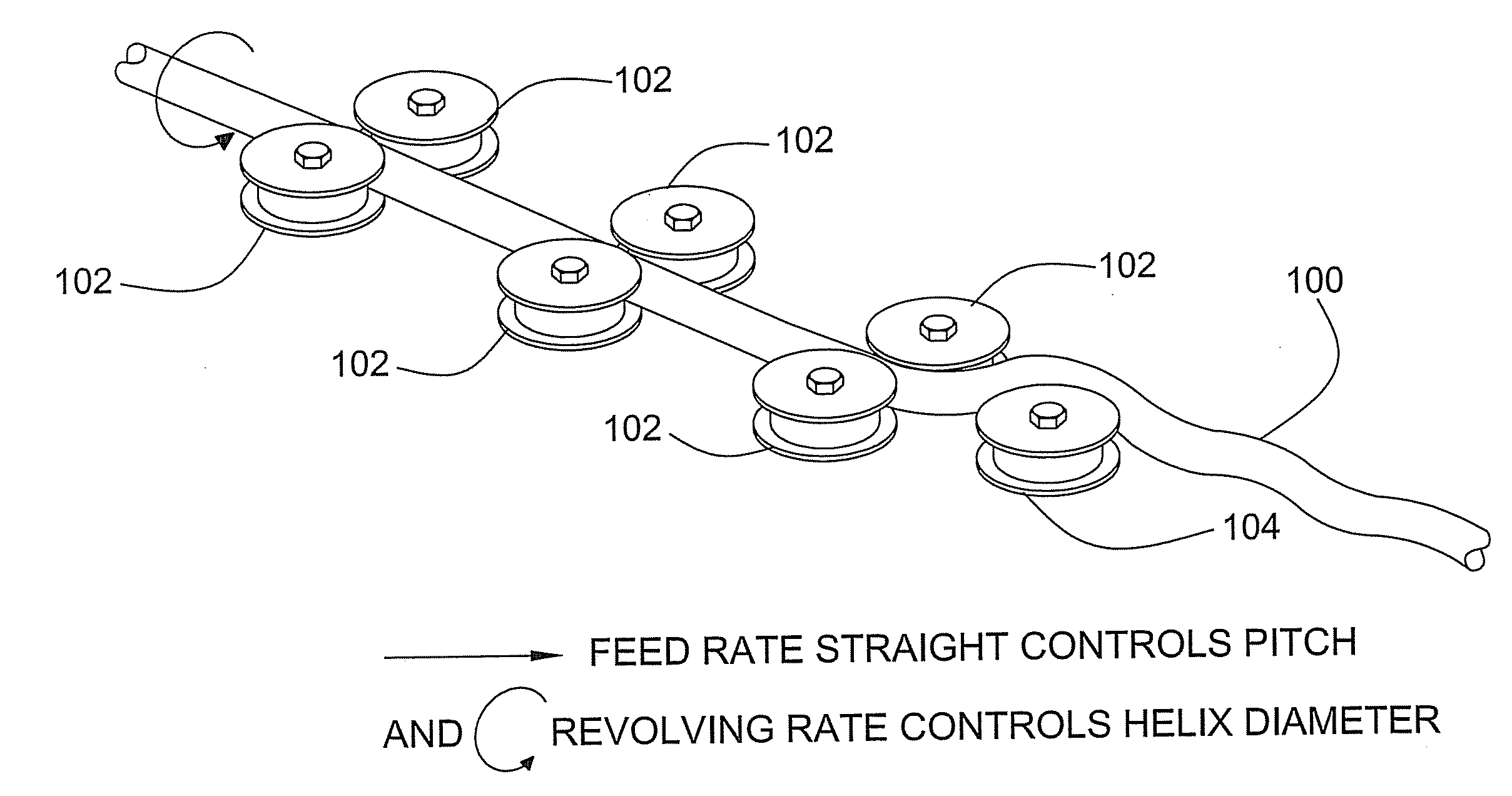

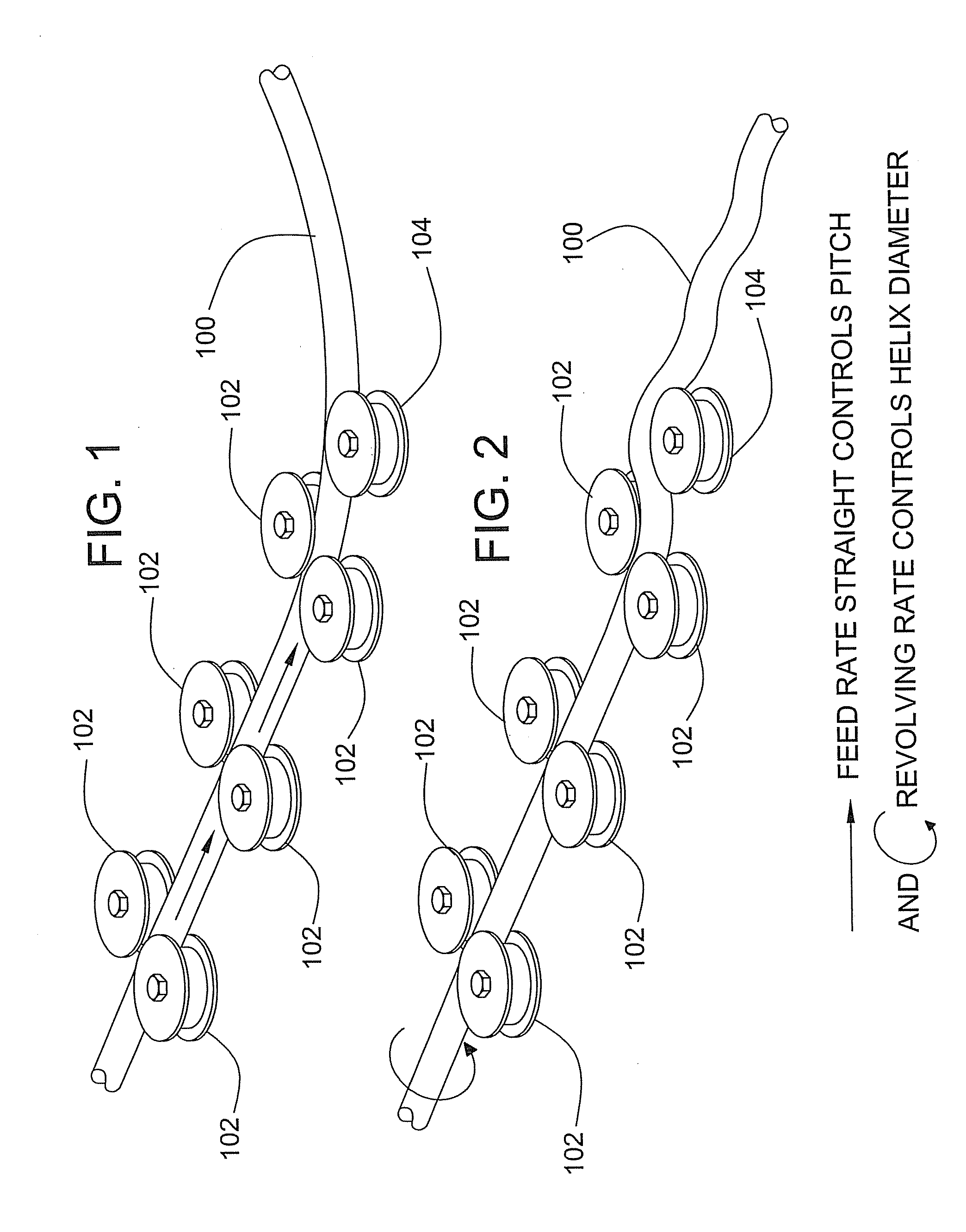

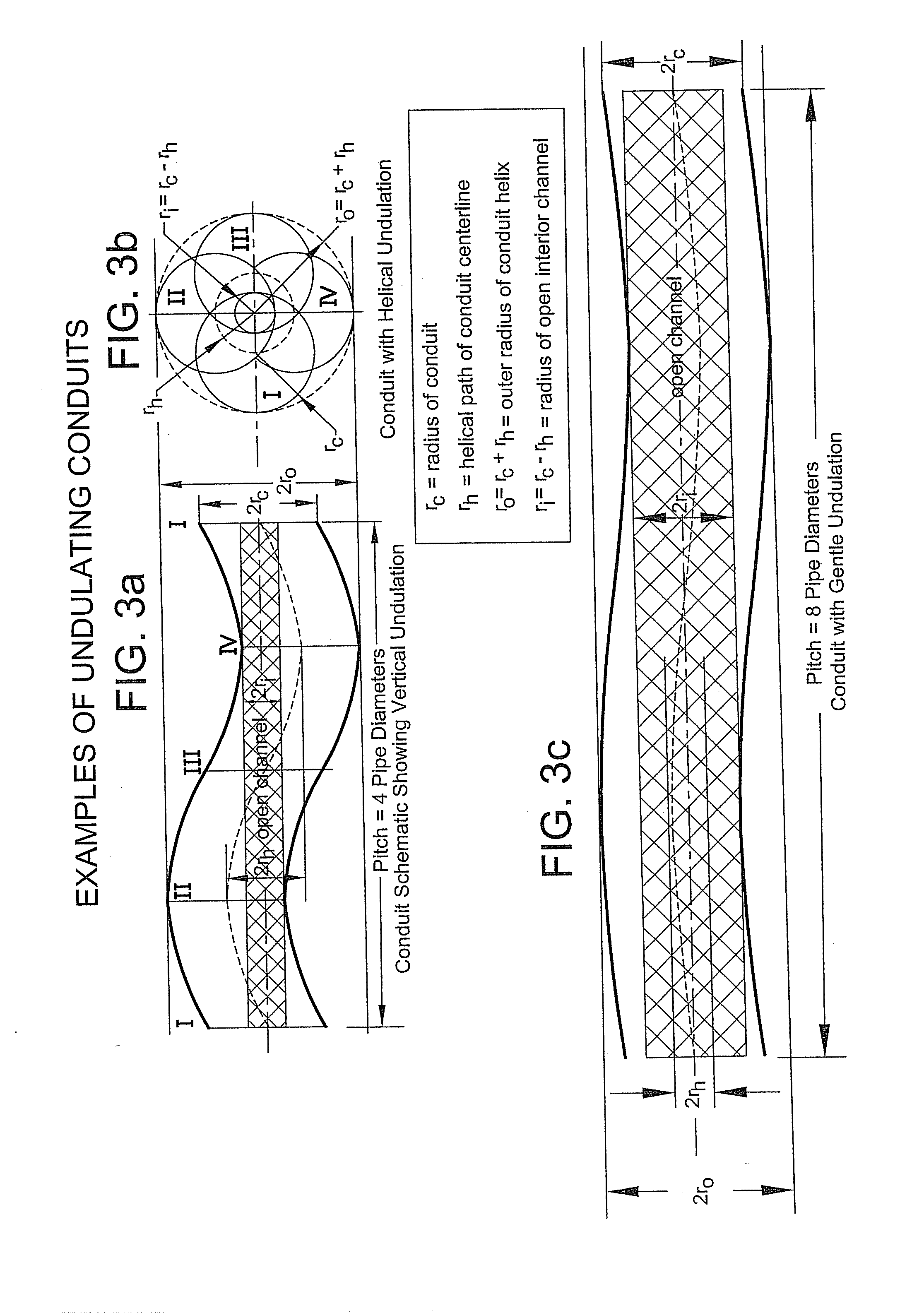

Method and apparatus for forming undulating conduit

Method and apparatus for forming conduit or pipe of various sizes into undulating, helical pipe by feeding a length of conduit at a controlled rate through a bending mechanism while also continuously rotating the pipe at a controlled rate so that bending occurs in multiple axis directions and the diameter of the helical path of the conduit centerline of the coil is less than the conduit diameter, the pitch is greater than the pipe diameter, and a straight open channel is retained through the pipe coil.

Owner:UNDULTEC

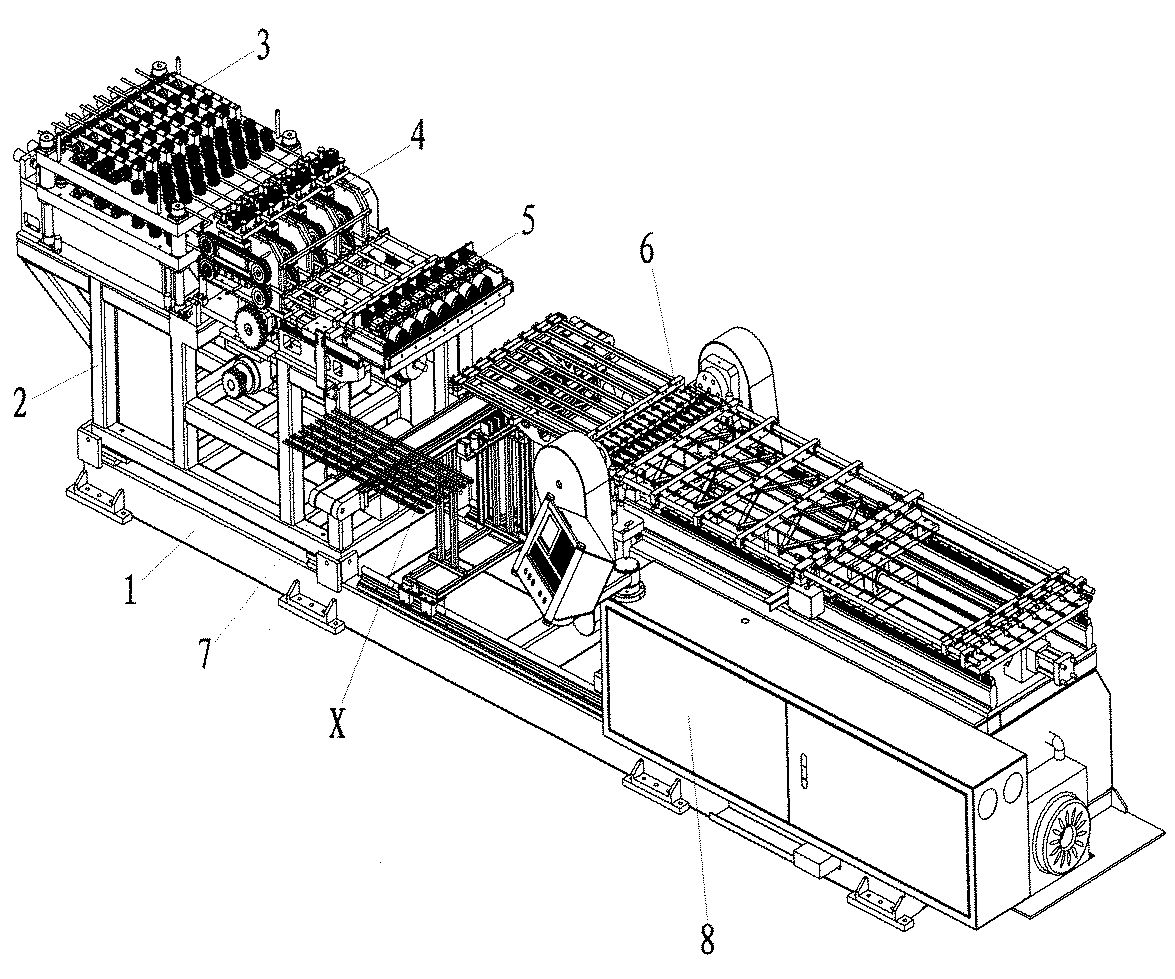

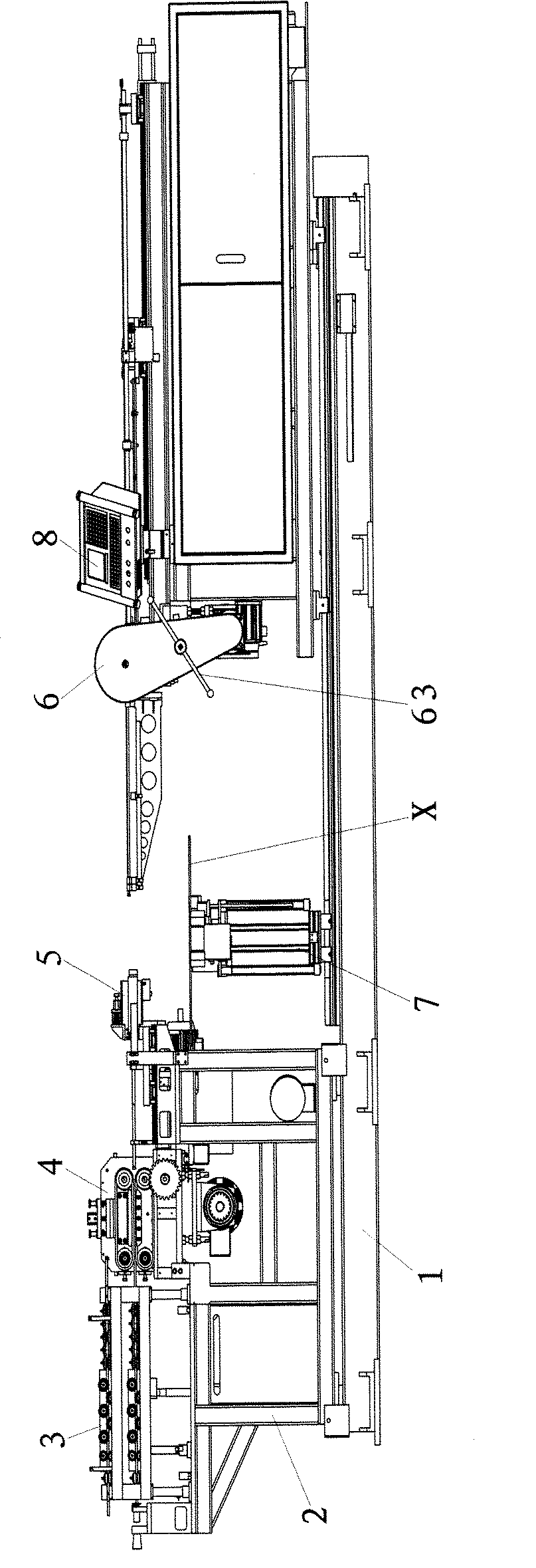

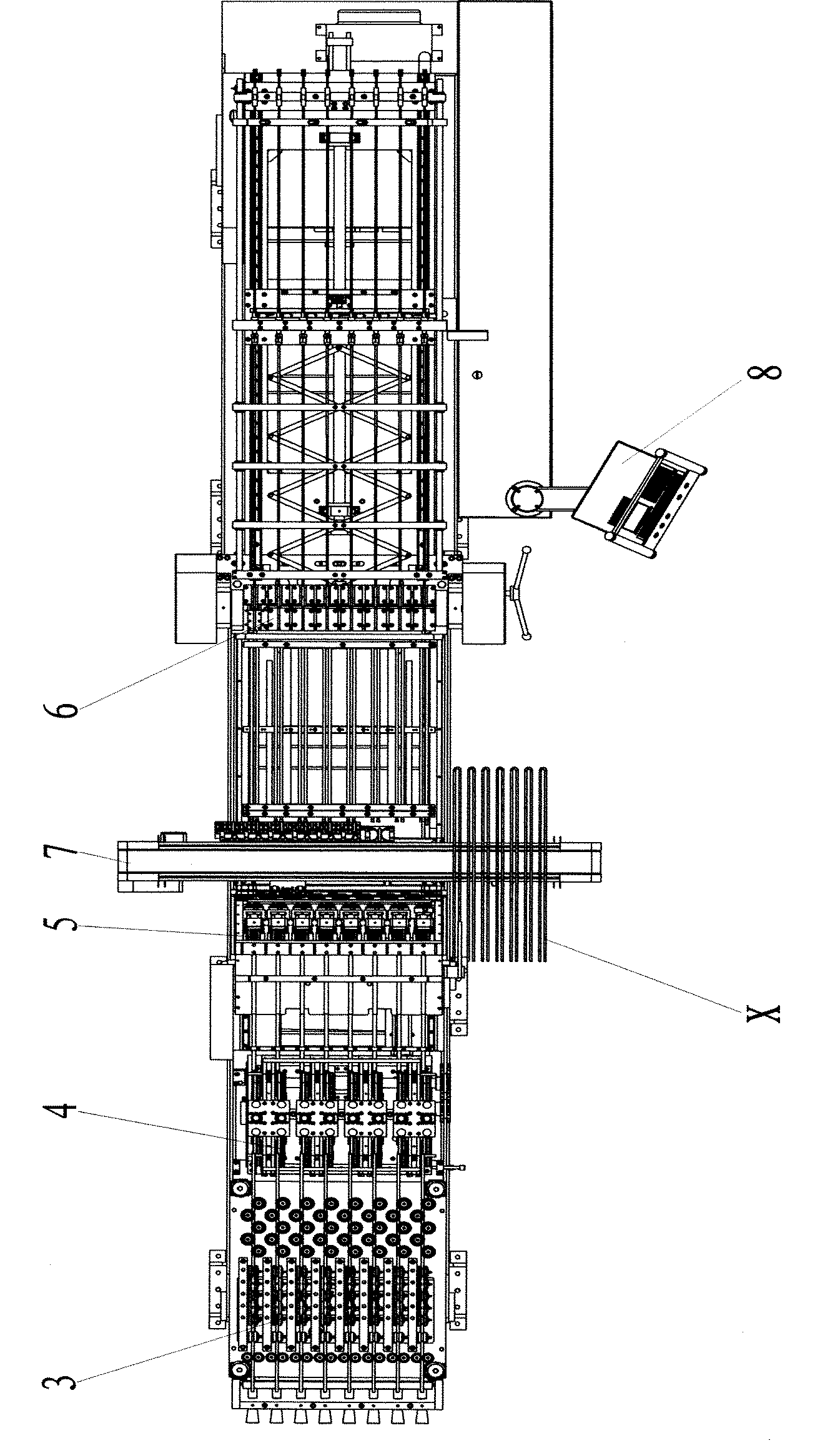

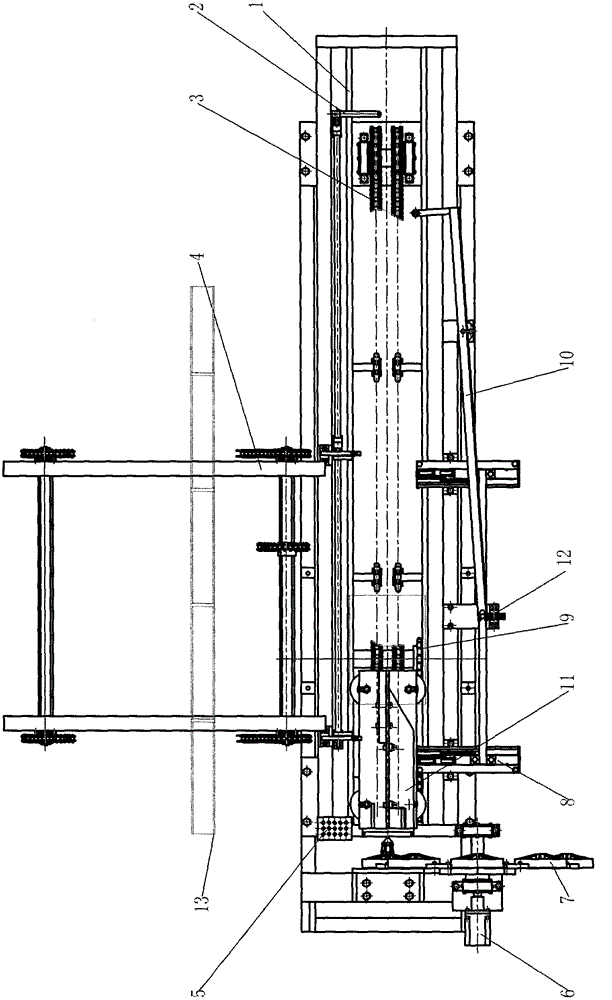

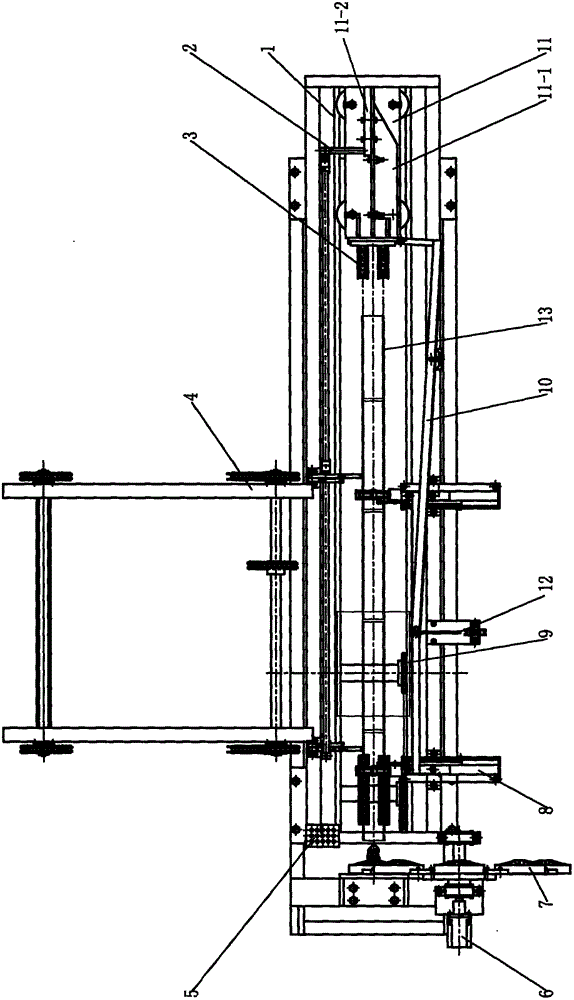

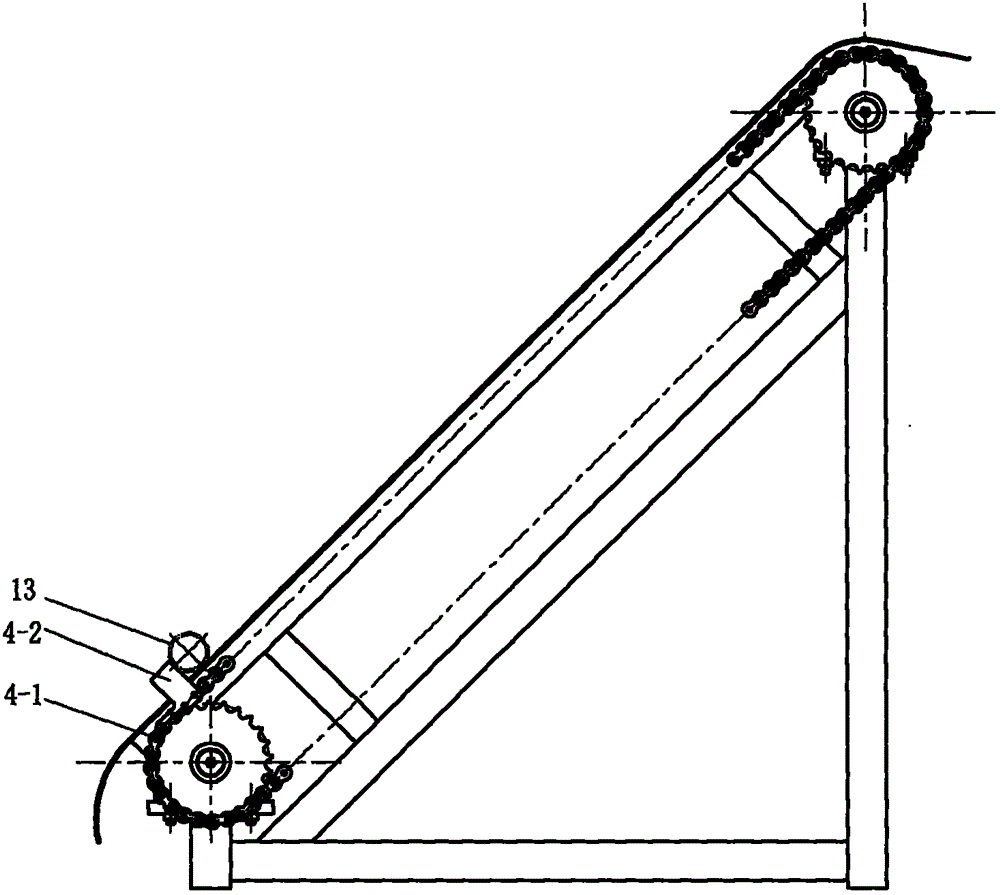

Long U-shaped tube bender

ActiveCN102139301ASimple structurePrecise positioningShaping toolsMetal-working feeding devicesPipe fittingEngineering

The invention relates to a long U-shaped tube bender, in particular to the long U-shaped tube bender capable of processing two tubes in different pipe diameters. The long U-shaped tube bender comprises a base, a stand, a rounding and straightening device, a feeding device, a cutting device, a feeding path, a bending device, a receiving device and a controller, wherein the rounding and straightening device comprises two sets of rounding and straightening mechanisms; the stand is provided with a position switching mechanism for adjusting positions of the two sets of rounding and straightening mechanisms; the feeding device comprises two kinds of feeding channels for conveying pipe fittings in different pipe diameters; a position switching part for adjusting the positions of the two feeding channels is arranged on the stand; the bending device comprises two kinds of bending channels for bending pipe fittings in different pipe diameters; and a bending bracket is arranged on the stand and is provided with a position switching part for adjusting the positions of the two bending channels. The long U-shaped tube bender has a simple and reasonable structure, is accurately positioned, is convenient to operate and easy for manufacture. On the basis of no dismount and replacement of main parts, the long U-shaped tube bender can be used for processing the pipes in different pipe diameters and has wide processing range.

Owner:OMS MASCH CO LTD

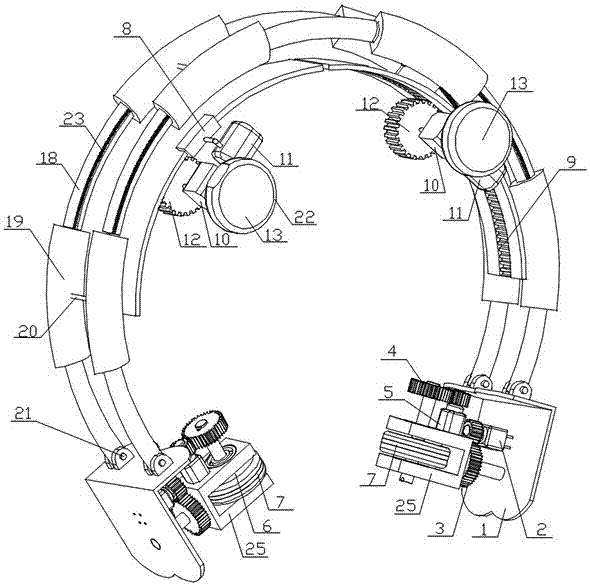

Opening type circular-pipe crawling detection device

ActiveCN107064297AIncrease the number ofEnsure comprehensivenessAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsMotor driveDrive wheel

The invention relates to an opening type circular-pipe crawling detection device. The opening type circular-pipe crawling detection device comprises a driving mechanism, a track clamping mechanism and a detecting mechanism, wherein the track clamping mechanism is opening-ring-shaped, the two ends of the track clamping mechanism are respectively provided with a set of driving mechanism, and the detecting mechanism is fixed at the inner side of the track clamping mechanism; the track clamping mechanism is a circumferential and telescopic articulated structure formed by connecting rings and sleeve rings which are arranged at intervals, and the connecting rings extend into the adjacent sleeve rings and are connected with the sleeve rings by connecting ring racks; an inner rack track of the detecting mechanism is a blocking type track and is provided with a sliding clamping seat; the sliding clamping seat is in sliding connection with the inner rack track; a detecting motor drives a driving wheel which is meshed with the inner rack track; and an ultrasonic wheel type probe is arranged at the outer side of the inner rack track. The opening type circular-pipe crawling detection device has the advantages that the detection range can be changed in a freely-telescopic manner, and the quantity of the connecting rings and the quantity of the sleeve rings can be increased according to the need so as to adapt to different pipe diameters, and the pipeline can be detected comprehensively.

Owner:NORTHEAST GASOLINEEUM UNIV

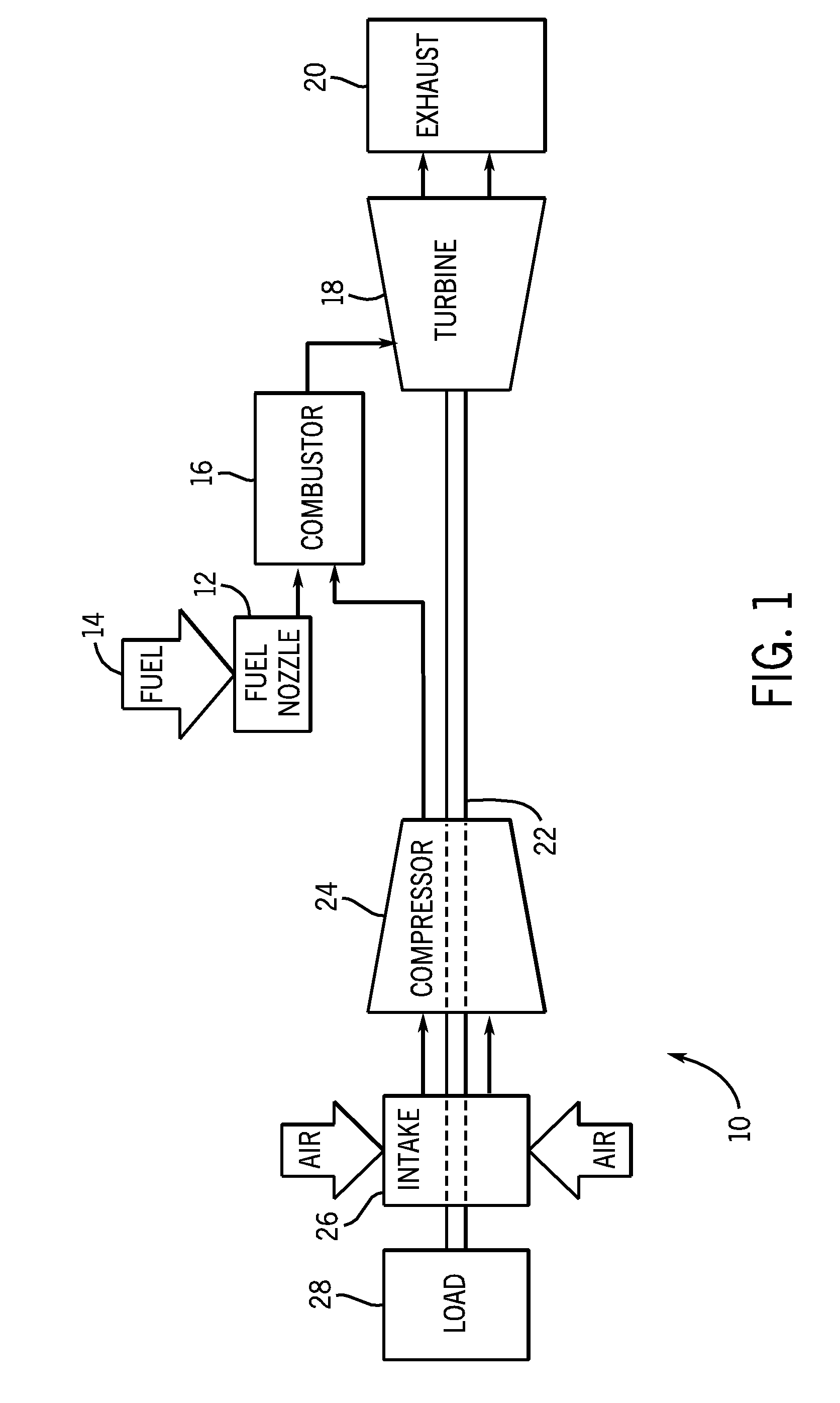

Methods and apparatus for cooling turbine engine combustor exit temperatures

InactiveUS7036316B2Continuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

Owner:GENERAL ELECTRIC CO

Spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters

ActiveCN106239284AGrinding muchLow costGrinding carriagesRevolution surface grinding machinesDrive wheelPipe fitting

The invention relates to a spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters, and belongs to the field of pipeline robots. A hub assembly and a cross-axis universal joint are mounted in a spline fit manner, three driving wheel grinding assemblies are arranged, two ends of drive shafts of the assemblies and a drive shaft support in the hub assembly are mounted in a matched manner through bearings, a motor and control and power assembly is mounted on a direction keeping mechanism, and a motor shaft of the assembly and the cross-axis universal joint are mounted in a spline fit manner. The spiral angles of the grinding assemblies relative to the cross section of a pipe fitting are adjusted in a self-adaptation manner, and therefore the aim that the position with the small pipe diameter and many impurities is ground much, and the position with the large pipe diameter and few impurities is ground little is achieved, the robot can be matched with multiple different-size grinding assemblies for use, the aim that one robot has multiple purposes is achieved, and the cost can be saved to a certain degree.

Owner:JILIN UNIV

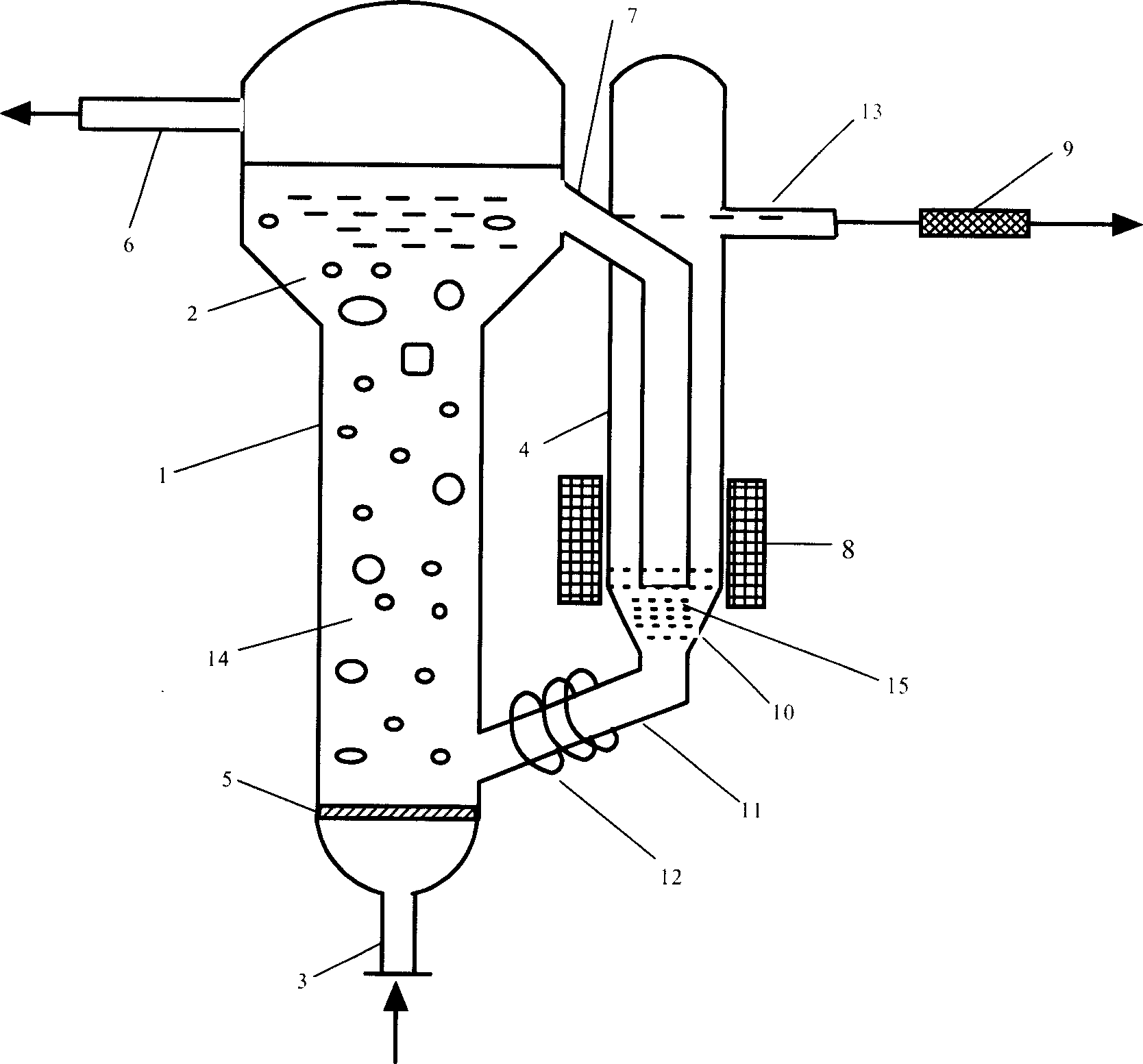

Slurry ¿Cbed reaction unit and method of use thereof

ActiveCN101116803AImprove space utilizationSave spaceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSeparation technologyProduct gas

A slurry bed reaction equipment and method of using the same is provided, wherein the equipment comprises an ascending tube reactor 1 and a settling tube 4; the lower part of the ascending tube reactor 1 is a reacting region 14, while the upper part of the ascending tube reactor is a settling region 2 with tube diameter enlarged; the top of the settling region 2 is provided with an exhaust port 6; the bottom of the ascending tube is provided with a feed port 3 and a gas distributor 5; a pipeline 7 is used for connecting the settling region 2 with the settling tube 4, of which the opening position is arranged at the inside of the settling tube 4; the lower part of the settling tube 4 is a magnetic separation region 15, of which the lower end is communicated with the lower end of the ascending tube reactor 1 through a conical spout 10 and a reflux pipe 11; the upper part of the settling tube 4 is provided with a liquid discharging hole 13. The space utilization ratio of the reactor is improved by adopting the equipment and the separation method of the present invention; meanwhile, the separation technology combining settling, magnetic separation and filtering are adopted, making the separation part small in equipment volume, high in efficiency and space saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

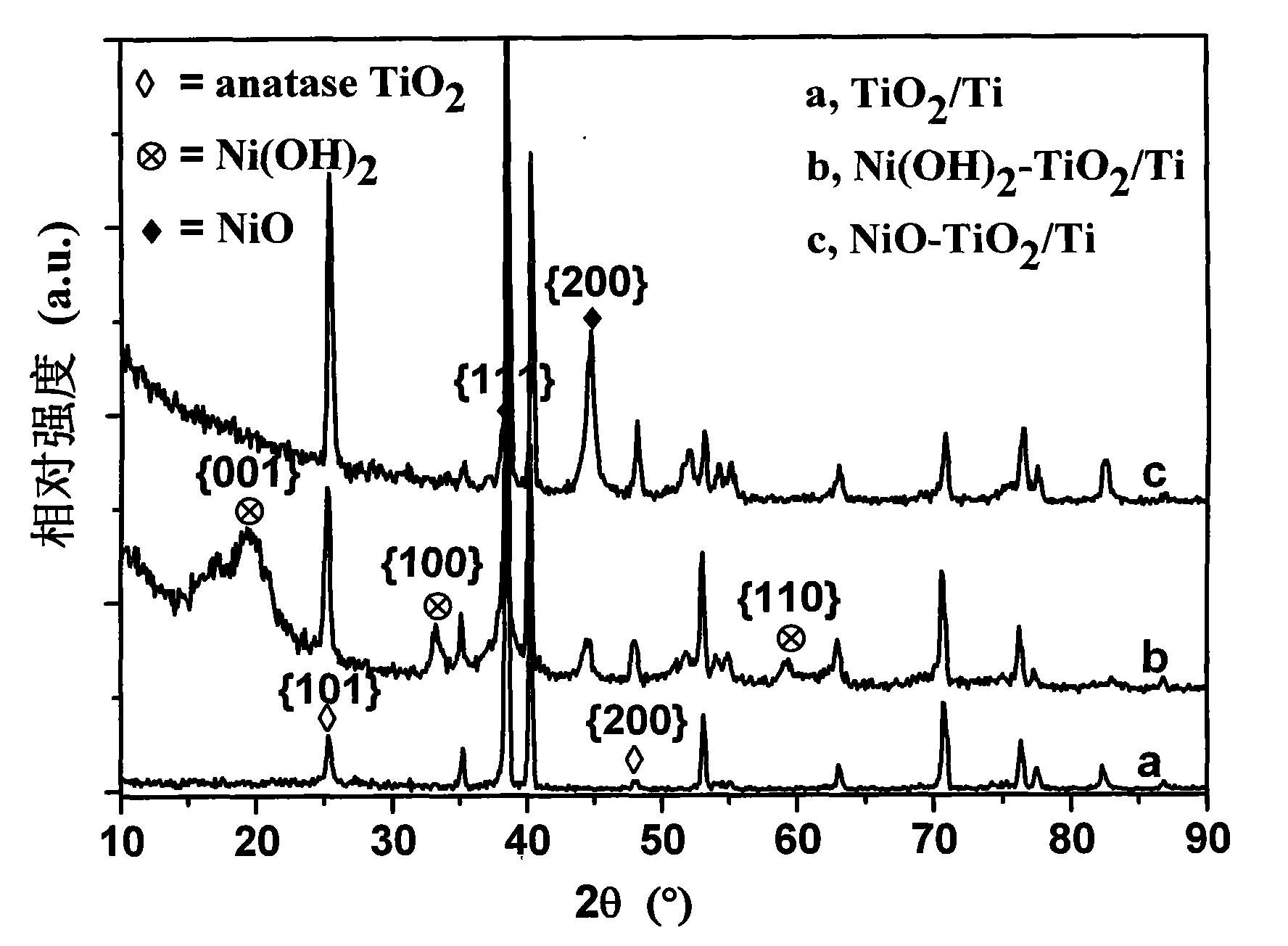

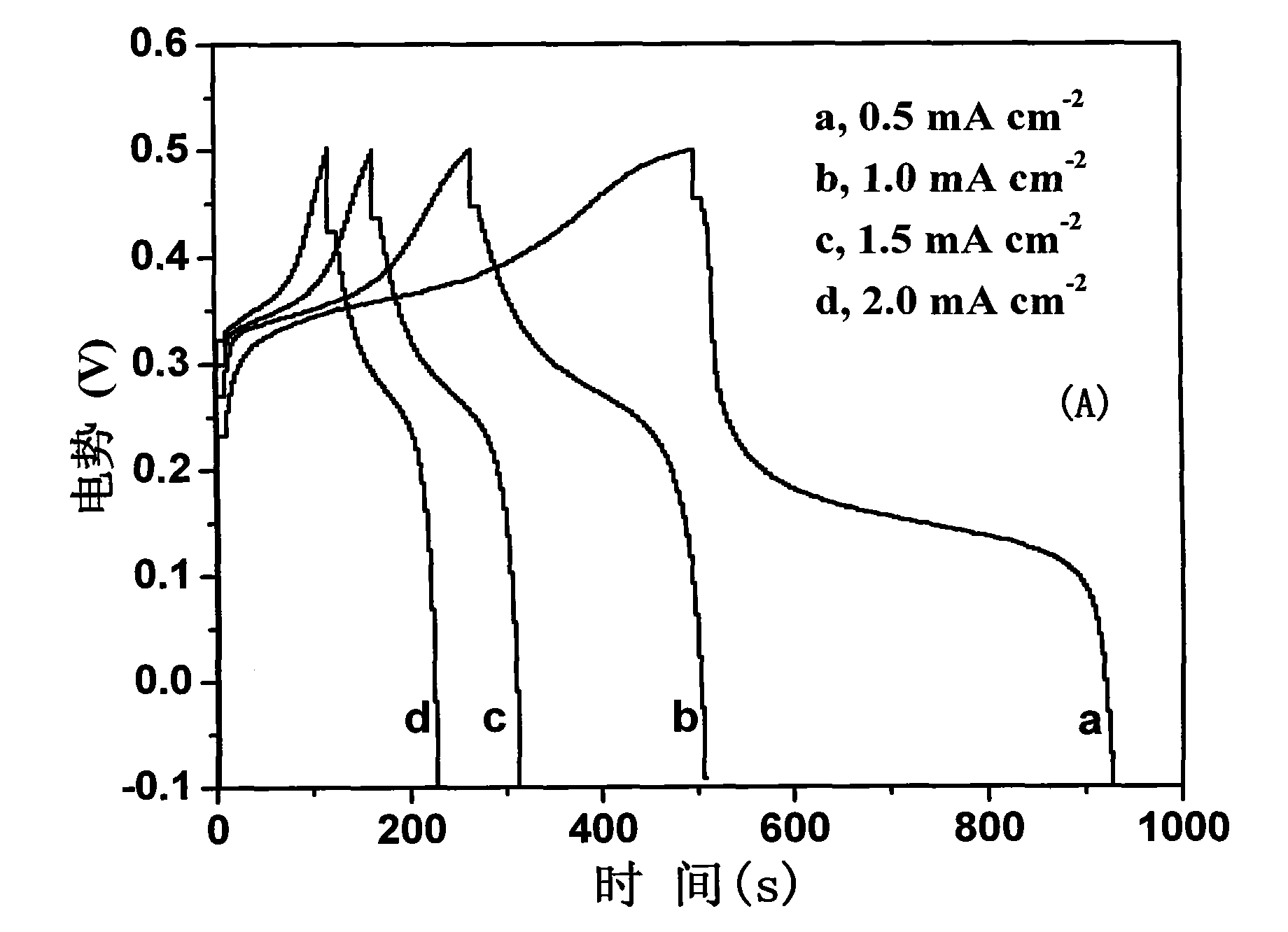

Ordered nano-tube array structure electrode material, preparation method and stored energy application

InactiveCN101625930AImprove energy storage efficiencyHigh capacity densityIndividual molecule manipulationCapacitor electrodesOxide coatingMaterials science

The invention relates to a preparation method for electrode material of a super capacitor of an ordered nano-tube array structure. A titanium-base titanium dioxide nano-tube is used as a carrier of the electrode; metallic oxide with electrochemical activity is loaded on the tube wall surface of the nano-tube; functional electrode material of the nano-tube array structure is built, wherein the tube diameter of the nano-tube is 50-200nm, the wall thickness is 10-20nm and the length is 0.2-50 mu m. The preparation method is as follows: firstly, adopting the titanium-base titanium dioxide electrode carrier of the ordered nano-tube array structure prepared by a self-template anodic oxidation reaction synthetic method; then, taking the titanium-base titanium dioxide electrode carrier of the ordered nano-tube array structure as a working electrode and transition metal ion or noble metal ion water solution as working electrolyte, carrying out electro reduction-electro oxidation reaction by circulation, synthesizing a metallic oxide coating layer on the wall surface of the nano-meter tube in situ, and preparing electrode material with the electrochemical activity. The electrode material of the ordered nano-tube array structure is used as the stored energy application of the electrode of the super capacitor.

Owner:SOUTHEAST UNIV

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

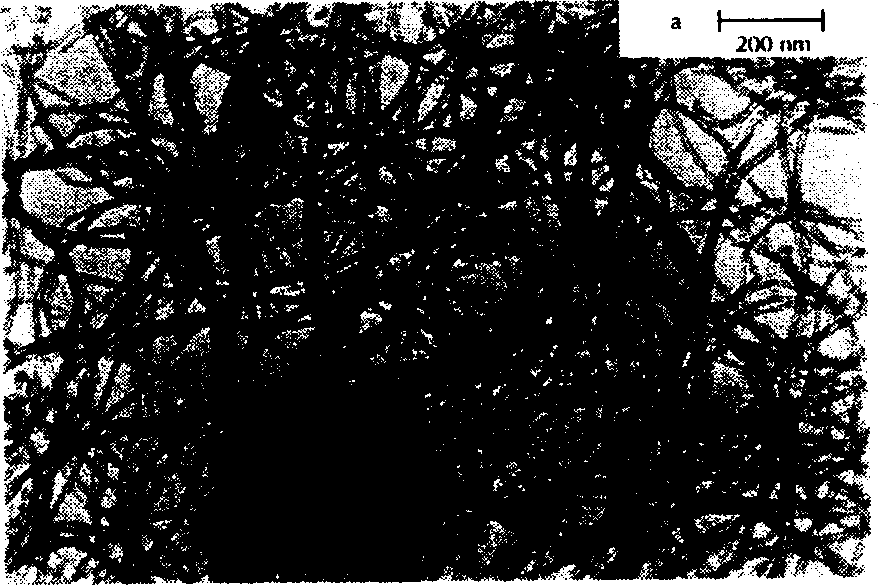

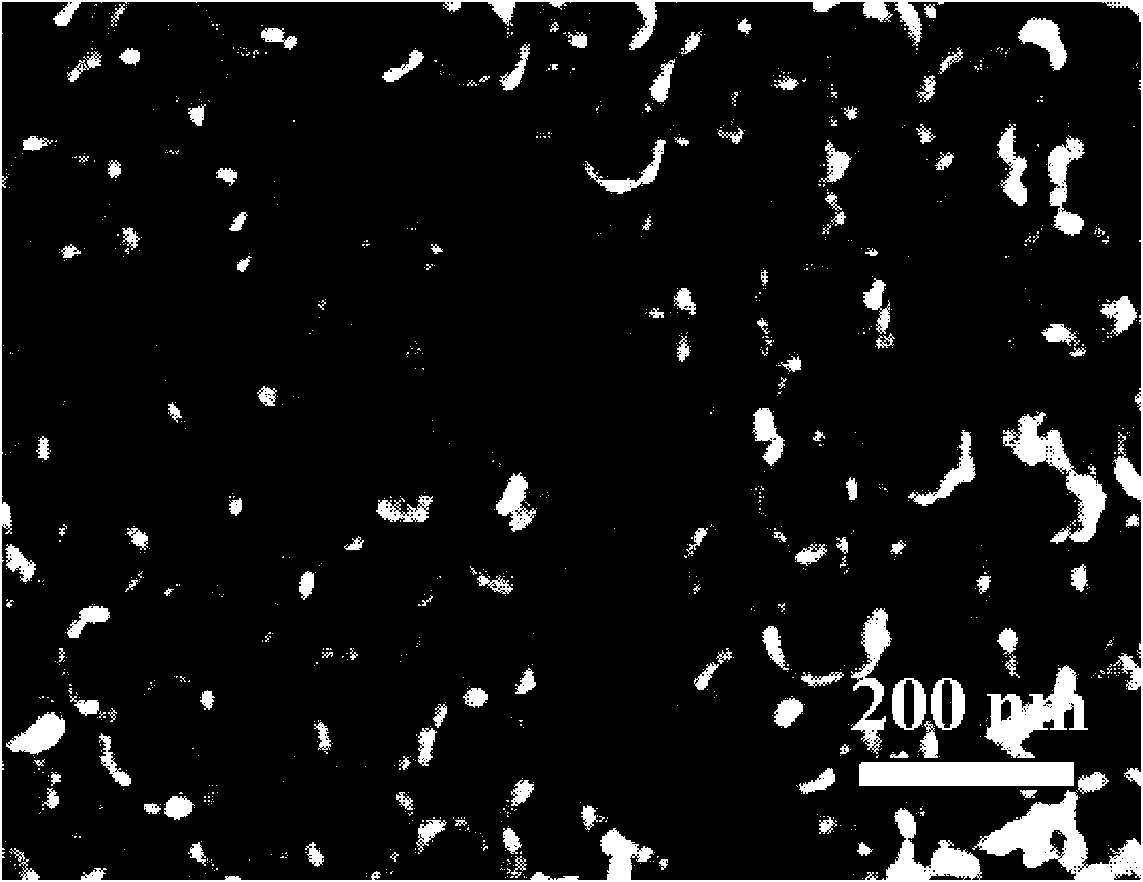

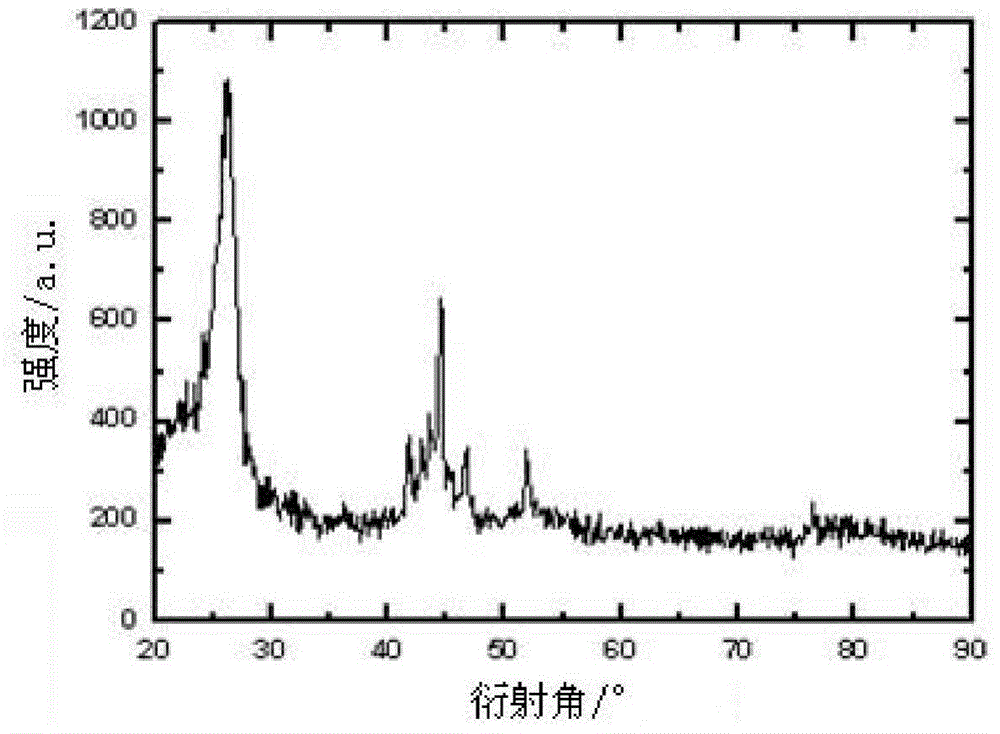

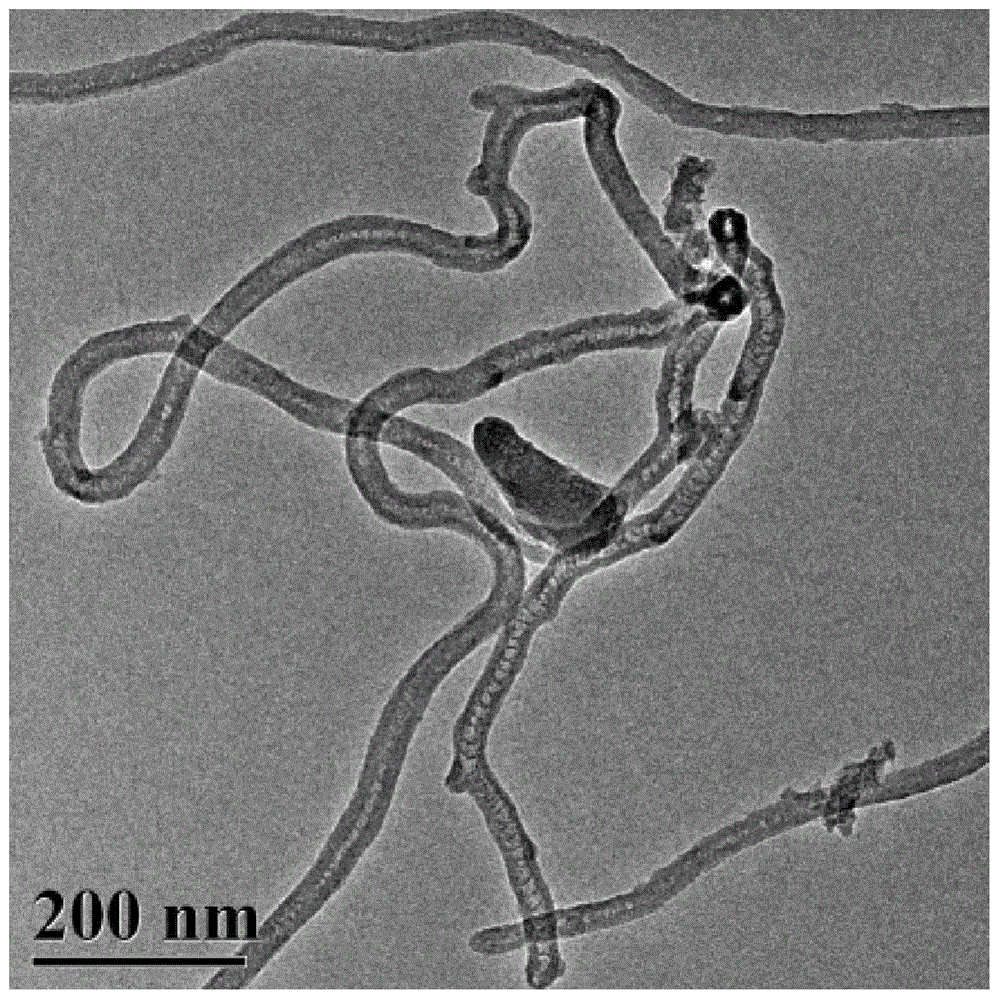

Catalyst for preparing carbon nanotube and its prepn

The catalyst for preparing carbon nanotube has perovskite or perovskite-like structure. Under heating condition, the catalyst is reduced with hydrogen to produce hydroxide of RE or alkali earth element. During its preparation, salt or oxide of corresponding element is used as main material, and one or several of citric acid, tartaric acid, glycin and EDTA is used as complexing agent and burning agent to prepare the catalyst via gel burning synthesis process in water or ethanol solution. If necessary, ammonia or ammonium compound as pore creating agent may be added in the preparation process to increase the specific surface area of the catalyst. The catalyst makes the prepared carbon nanotube possess even homogeneous tube diameter and even high yield.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes

InactiveCN102463272AIncrease productivityShort labor intensityExtrusion control devicesAlloyMaterials science

The invention relates to a short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes, belonging to the technical field of processing non-ferrous metal material tubes, mainly comprising the following steps that: (1) centrifugal casting technology is carried out to prepare nickel-based alloy tube billets, wherein, the ratio of outer diameters and inner diameters of the tube billets is 0.4-0.6; (2) the hot extrusion temperature of nickel-based alloy tubes is 1000-1250 DEG C, and the extrusion ratio is 5-16; (3) LG / LD and other series of cold pilger mills or drawing machines are used for carrying out multi-pass cold processing to reduce the tube diameter and reduce the wall thickness, so as to obtain thin-wall tubes; and (4) intermediate annealing, final annealing and final tube straightening are carried out. The method has the advantages of short flow, low labor intensity, laborsaving shaping, low cost, and high production efficiency. The prepared minor-caliber nickel-based alloy thin-wall tubes have high additional values. The method is suitable for large scale production, and has remarkable economic benefits and social benefits.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

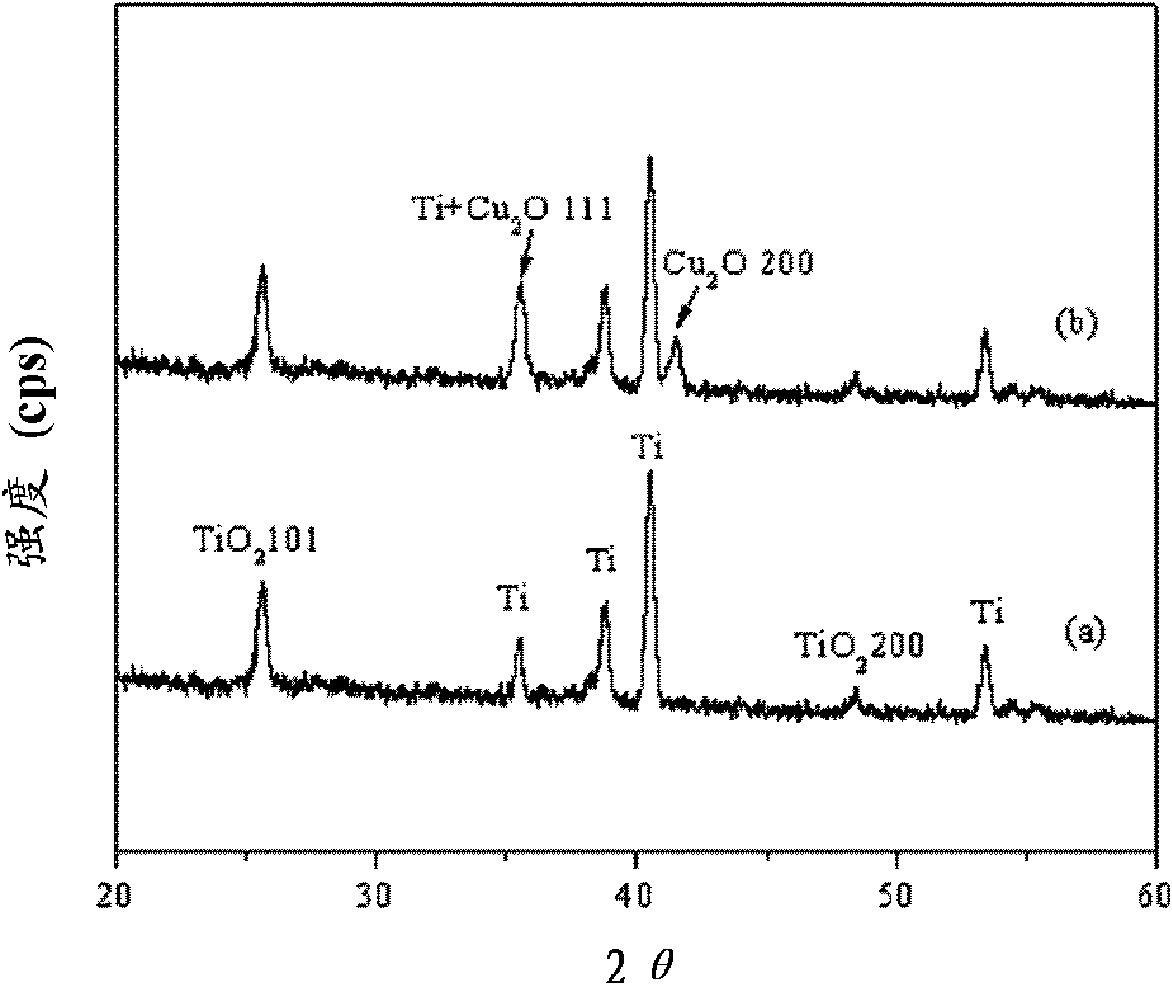

Preparation method of visible-light activated cuprous oxide/titanium dioxide nano-composite photocatalyst and applications thereof

InactiveCN101537354ASimple processLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationLight response

Owner:DALIAN UNIV OF TECH

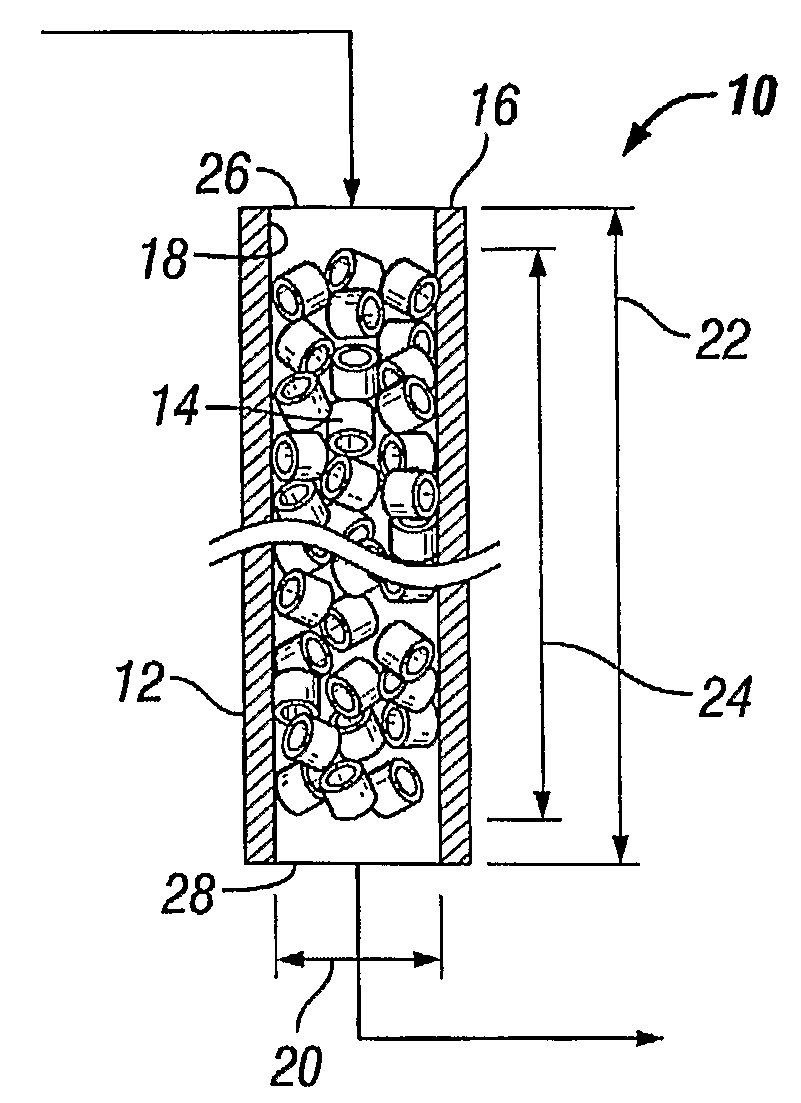

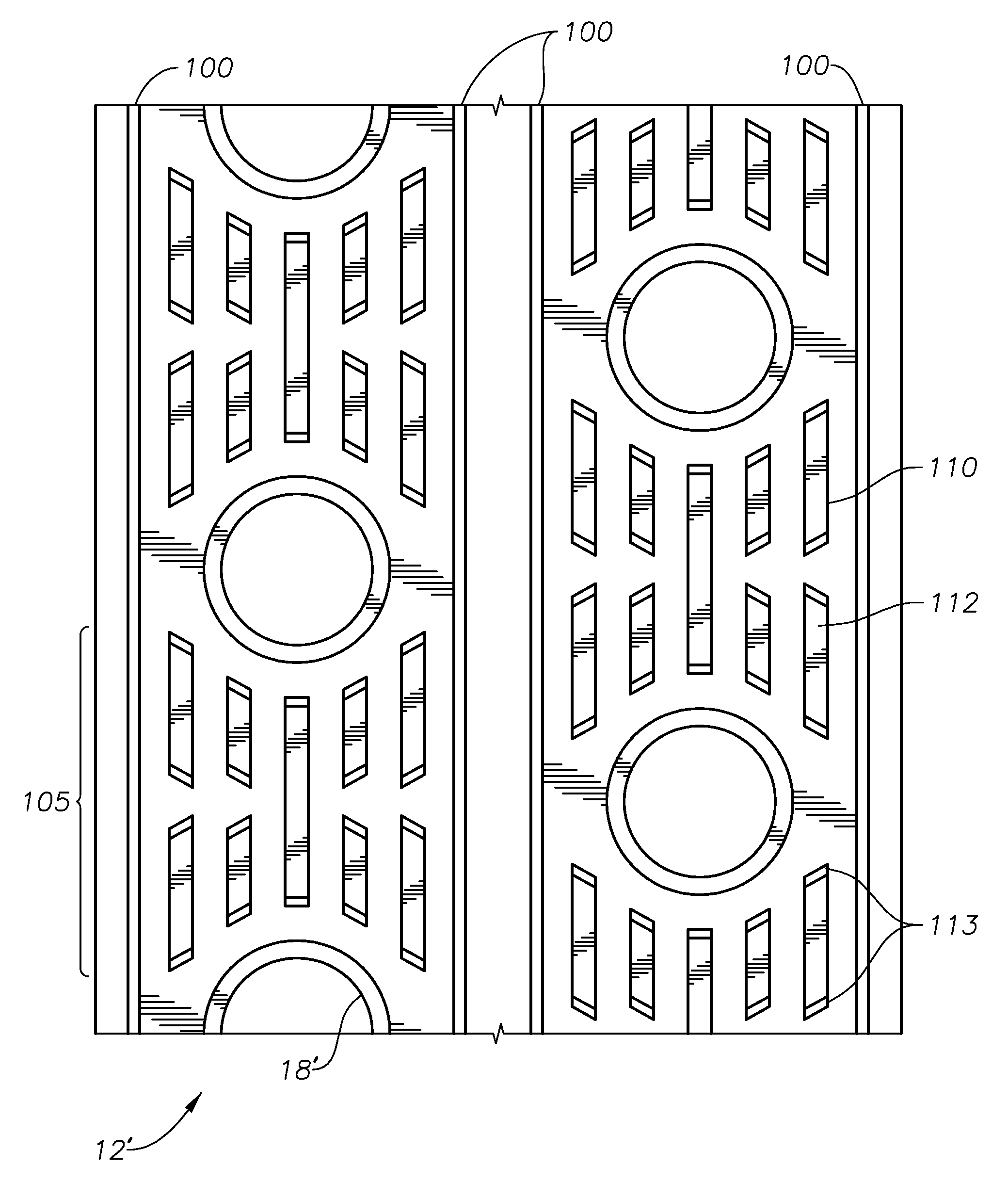

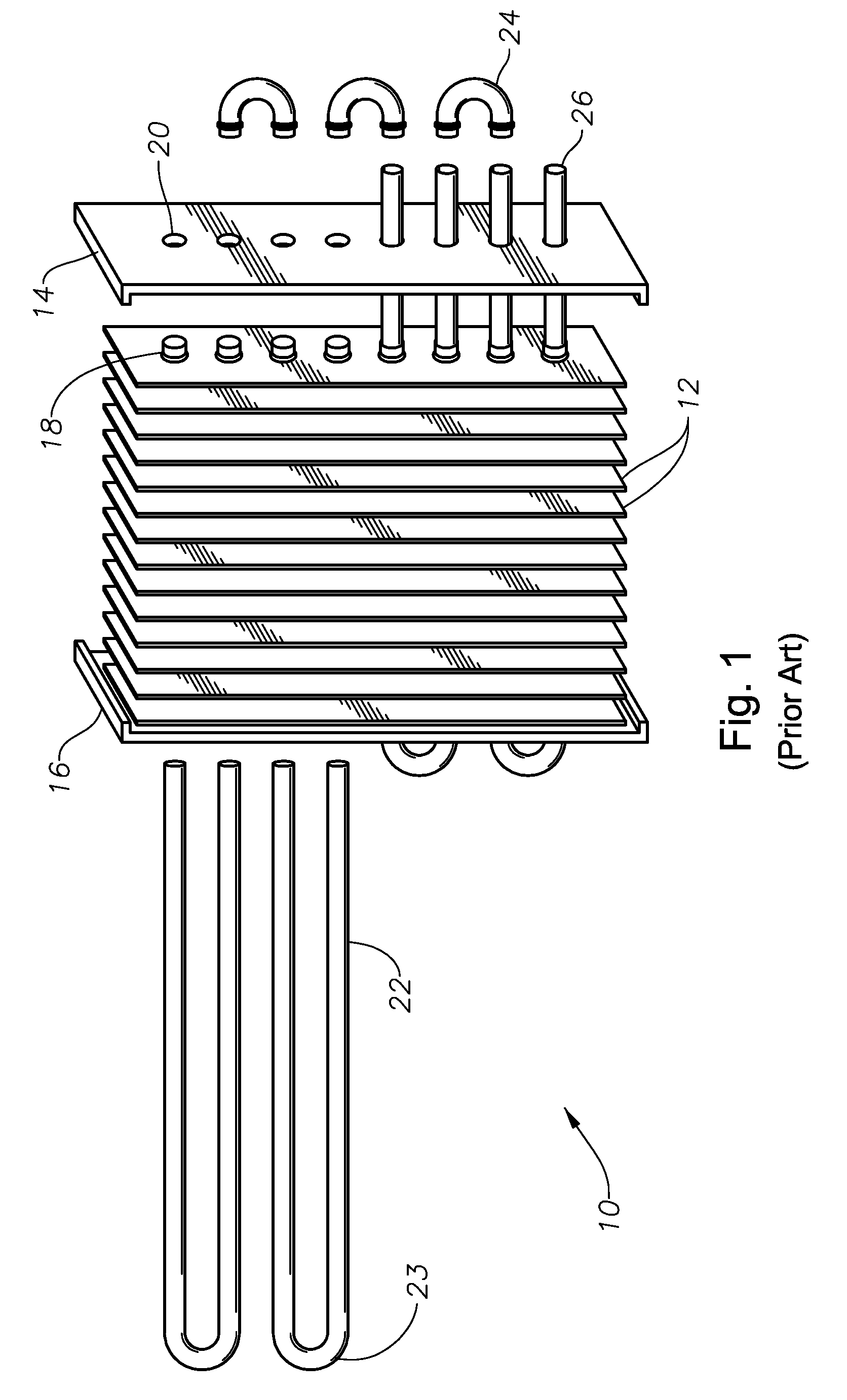

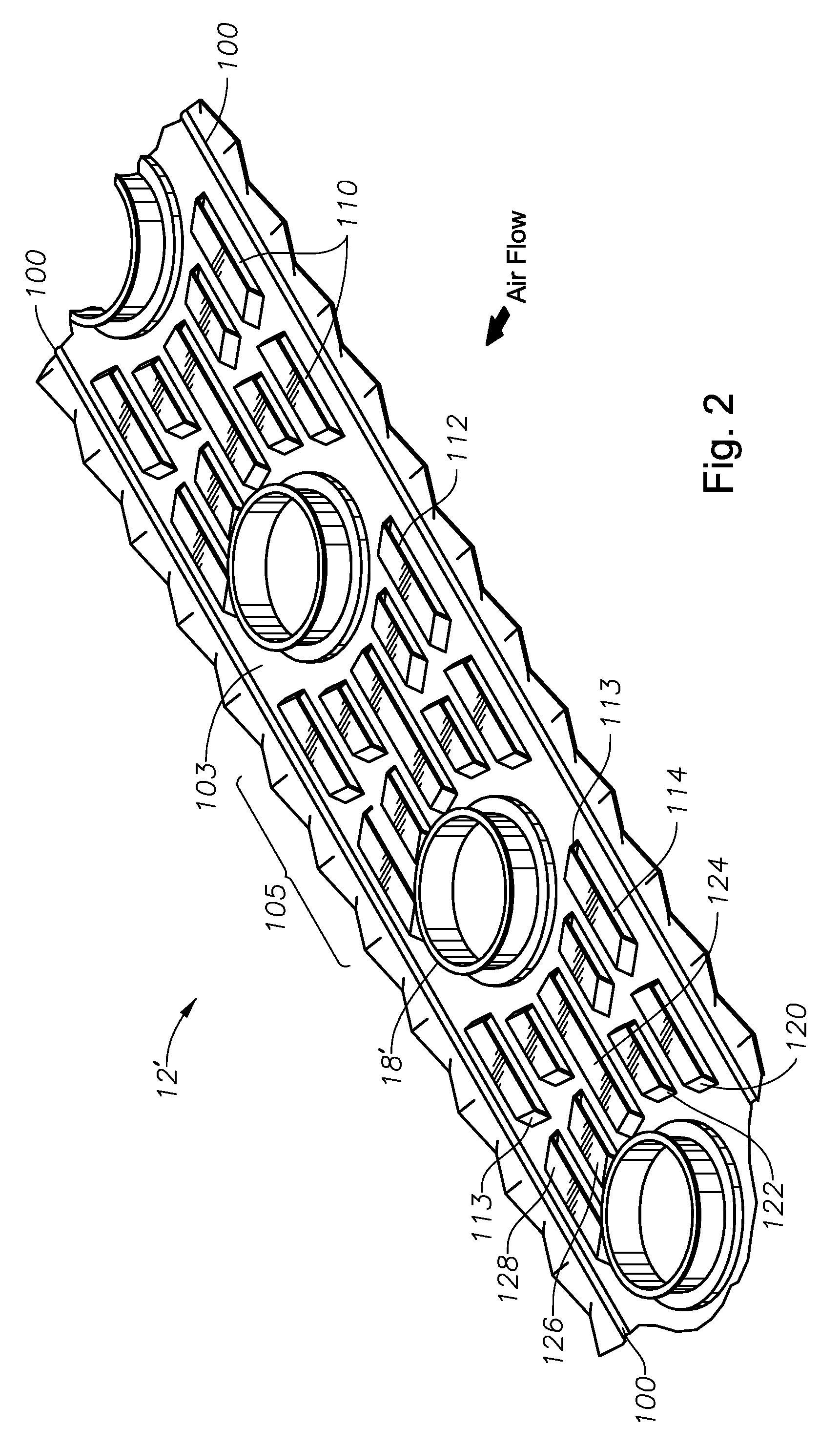

Method for Manufacturing Tube and Fin Heat Exchanger with Reduced Tube Diameter and Optimized Fin Produced Thereby

InactiveUS20090308585A1Increase stiffnessImprove rigidityHeat exhanger finsStationary conduit assembliesEngineeringImproved method

An improved method for manufacturing tube and fin heat exchangers that, according to a preferred embodiment, includes a process for increasing the stiffness and rigidity of heat exchanger fins. Stiffer fins have a greater tendency to maintain proper alignment within a stack of fins, which aids in lacing long stacks of fins with small (e.g., 5 mm) diameter tubing. Preferably, fin stiffness is increased by forming a plurality of longitudinal ribs within the fin during the fin stamping process. More preferably still, two ribs for each longitudinal row of collared holes are provided. The preferred embodiment also includes a slotted heat exchanger fin that is dimensioned and arranged for optimized thermodynamic performance when used with small diameter tubing, thus reducing the space required for a given heat exchanger system.

Owner:GOODMAN GLOBAL INC

Method for preparing titanium dioxide nano tube array on titanium-substrate material surface

InactiveCN101191248AEasy to controlSimple and fast operationSurface reaction electrolytic coatingAir atmosphereTio2 nanotube

The invention discloses a method by which titanium dioxide nanometer tube array layer is prepared on surface of titanium base material, wherein the titanium base materials undergo the surface pretreatment and receive the electrochemistry anodic oxidation treatment in the electrolyte containing the HF acid, the components of the mixed electrolyte are that the ammonium dihydrogen phosphate is 1 to 3mol / L and the hydrofluoric acid is 0.2 to 0.4mol / L, as a result, the amorphous form titanium dioxide nanometer tube surface structure is achieved; the subsequent heat treatment condition is that under air atmosphere, the rate of temperature rise is 3 DEG C / min, the heat is preserved for 3 hours at the temperature of 450 DEG C, the anatase titanium dioxide nanometer tube array layer is achieved after being cooled in the furnace to the room temperature. The electrolyte system prepared based on the method of the invention can control the balance of oxidation and the corrosion within a relatively long time, thereby preferably realizing the control on the shape of the titanium dioxide nanometer tube. The invention has the advantages of easy operation, low cost and orientated and order distribution of the prepared titanium dioxide nanometer tube array; moreover, the amorphous form titanium dioxide nanometer tube is generated normal to the direction of the base; the tube diameter is 80 to 100nm, the wall thickness is 18 to 21nm, the tube length is 0.7 to 2.0um, thereby the specific surface area is large.

Owner:SOUTHWEST JIAOTONG UNIV

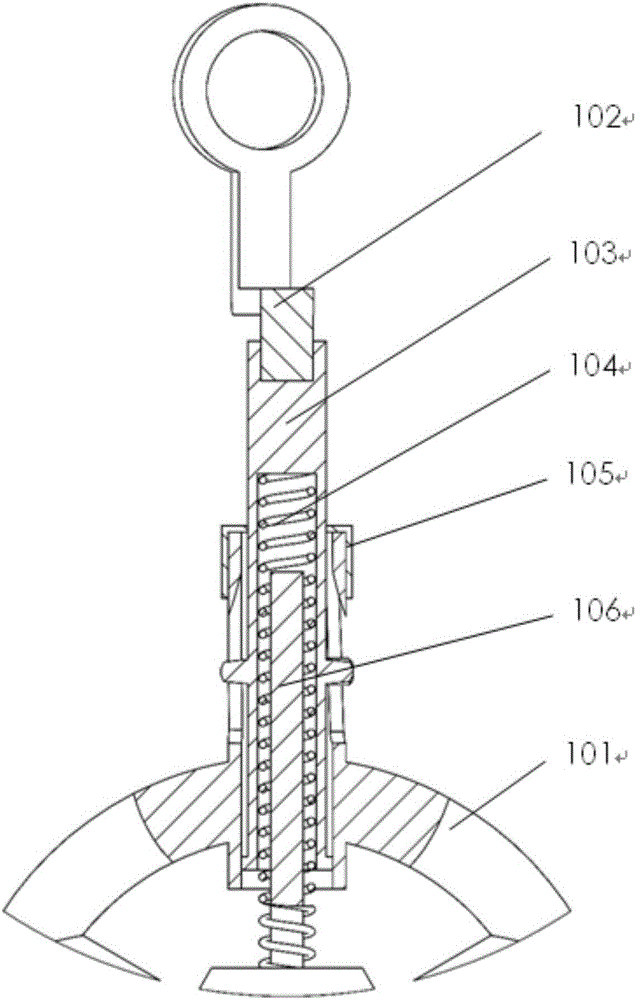

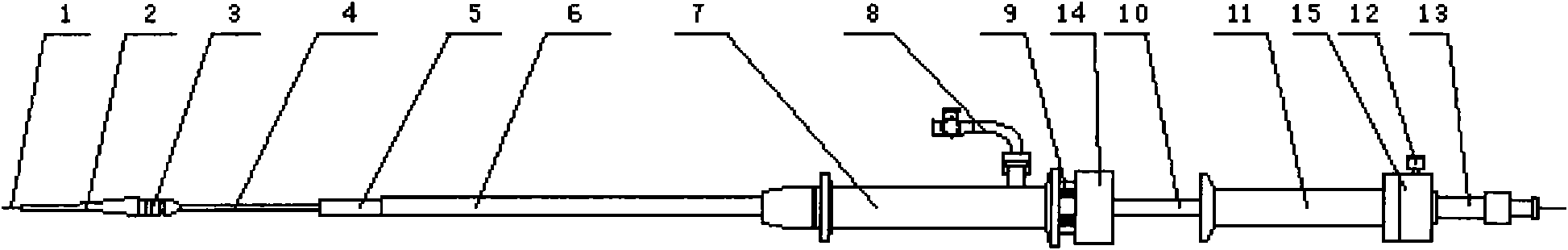

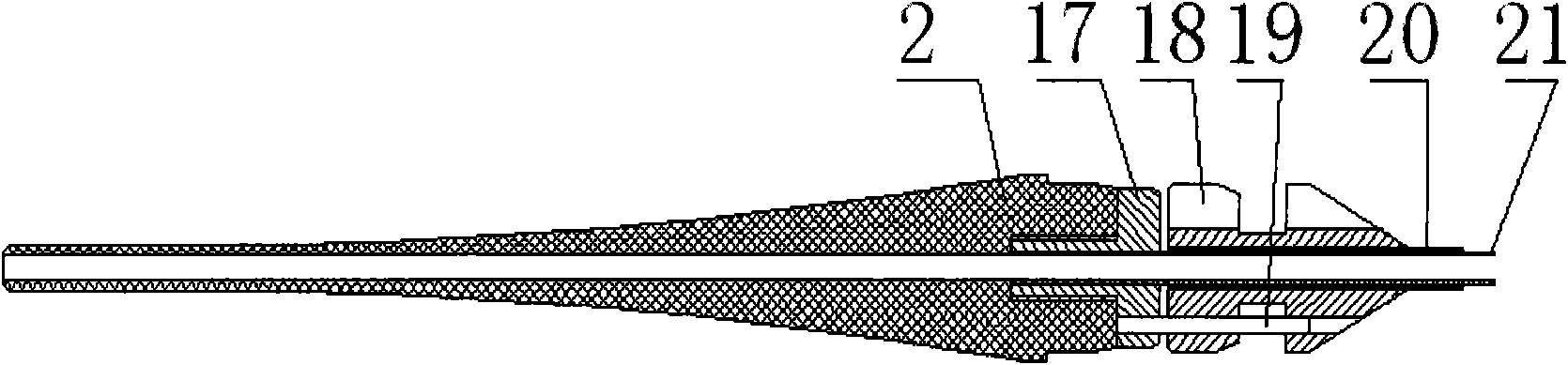

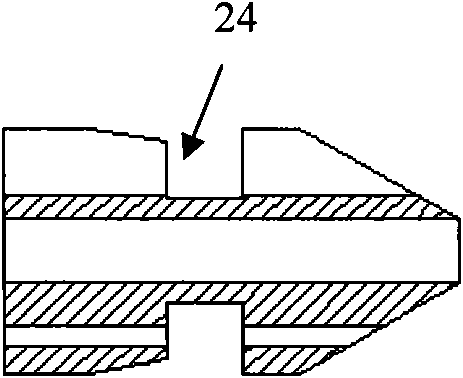

Novel great vascular stent delivery system

ActiveCN102038565ACompact structureAvoid the disadvantages of inaccurate placement of displacementStentsProsthesisInjury causeMedical device

The invention belongs to the field of medical devices, and in particular to a great vascular stent delivery system capable of realizing a front-end back release function. The great vascular stent delivery system is composed of a locating guide head, a back release mechanism, a core tube, a middle tube, a sheath tube, a big handle, a small handle and a push rod which are sequentially arranged fromfront to back. The whole system has the advantage of simple mechanism, is convenient in operation and safe in use and is capable of effectively avoiding the phenomena of release in advance and failure in release; and meanwhile the stainless steel core tube is locally engraved into a spring, thus achieving the purposes of reducing core tube diameter and system size, greatly improving flexibility of the far end of the system, and reducing vascular injury caused by the system during the delivery process.

Owner:北京有卓正联医疗科技有限公司

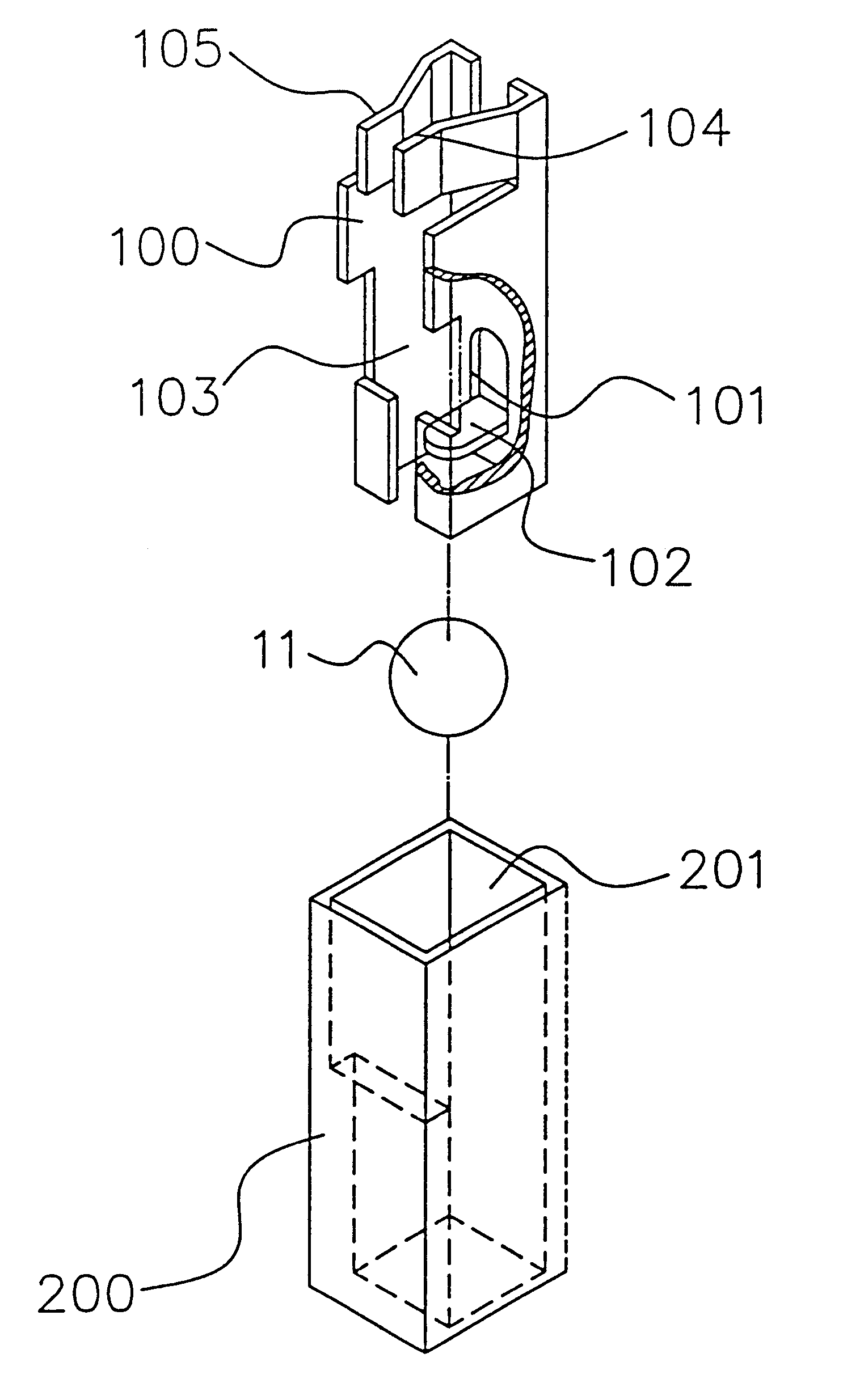

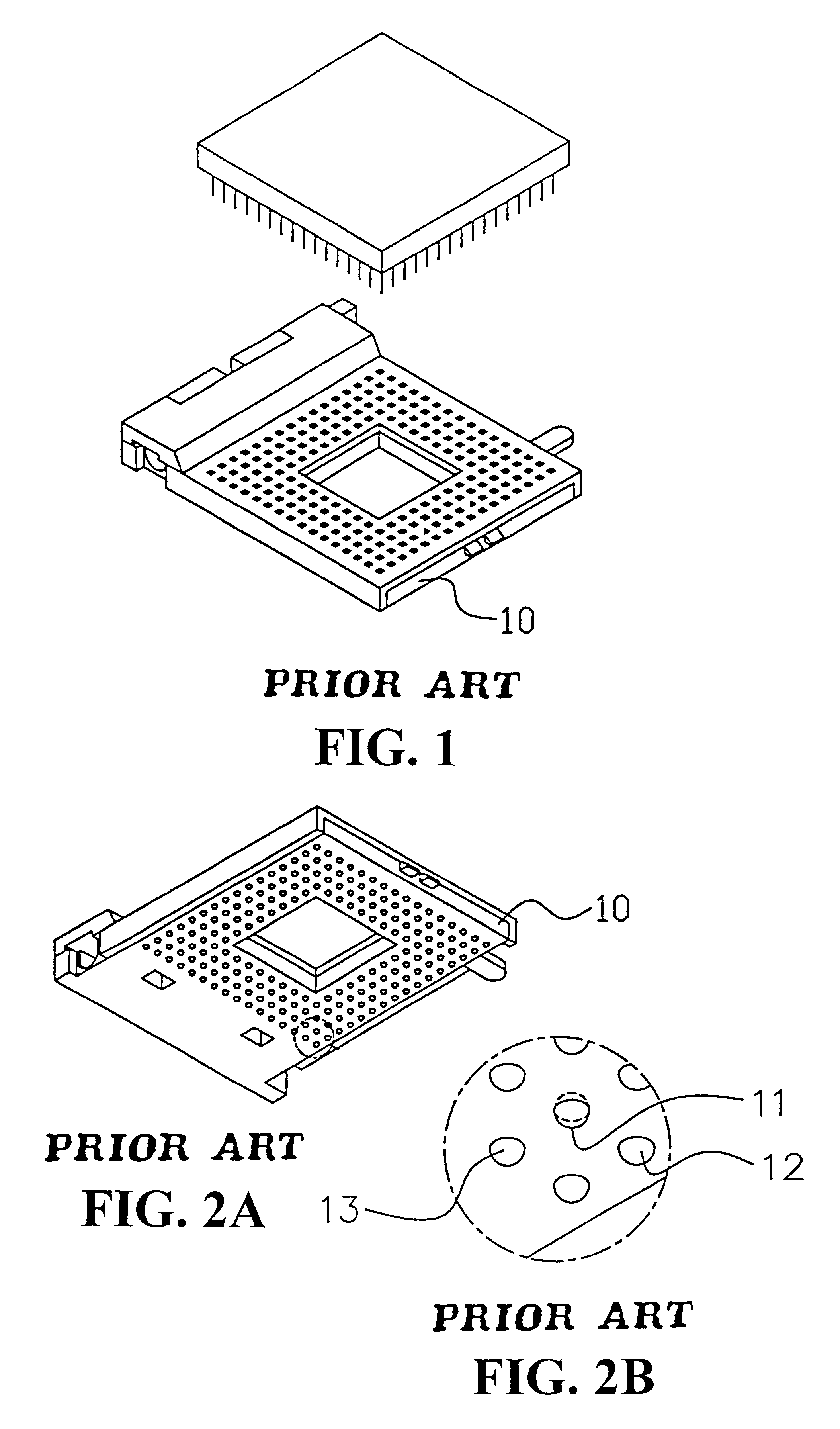

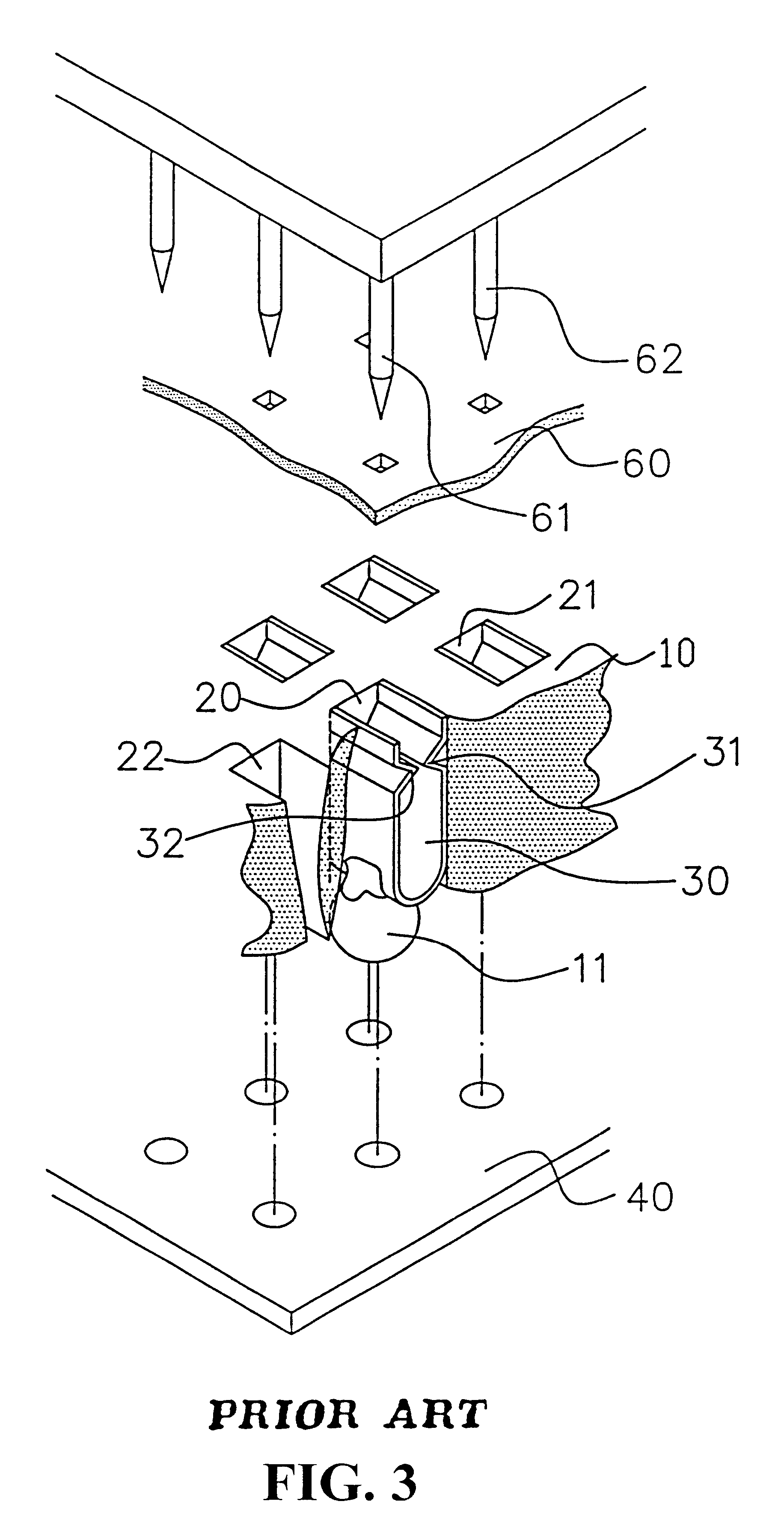

Structure of a ball grid array IC socket connection with solder ball

InactiveUS6530788B1Closely connectedSimple structureSoldered/welded conductive connectionsCoupling contact membersSolder ballEngineering

A Ball Grid Array IC Socket connection with solder ball is characterized in that the conductive plate is formed from bendable, flexible conductive thin plate surrounded to form slotted cylindrical tube for the insertion and clipping of IC pins. The slotted cylindrical tube is in the form of square shape, wherein the size of the tube diameter can tightly clip the ball wall of a solder ball, such that the tube opening mounted with the solder ball provides a tight connection. On the other end of the slotted cylindrical tube, remote from the end inserted with IC pins, at a position about half the height of the solder ball, an arc-shaped slit is provided so that a blocking plate is joined to the wall of the tube, and the blocking plate touches the top portion of the solder ball.

Owner:LOTES

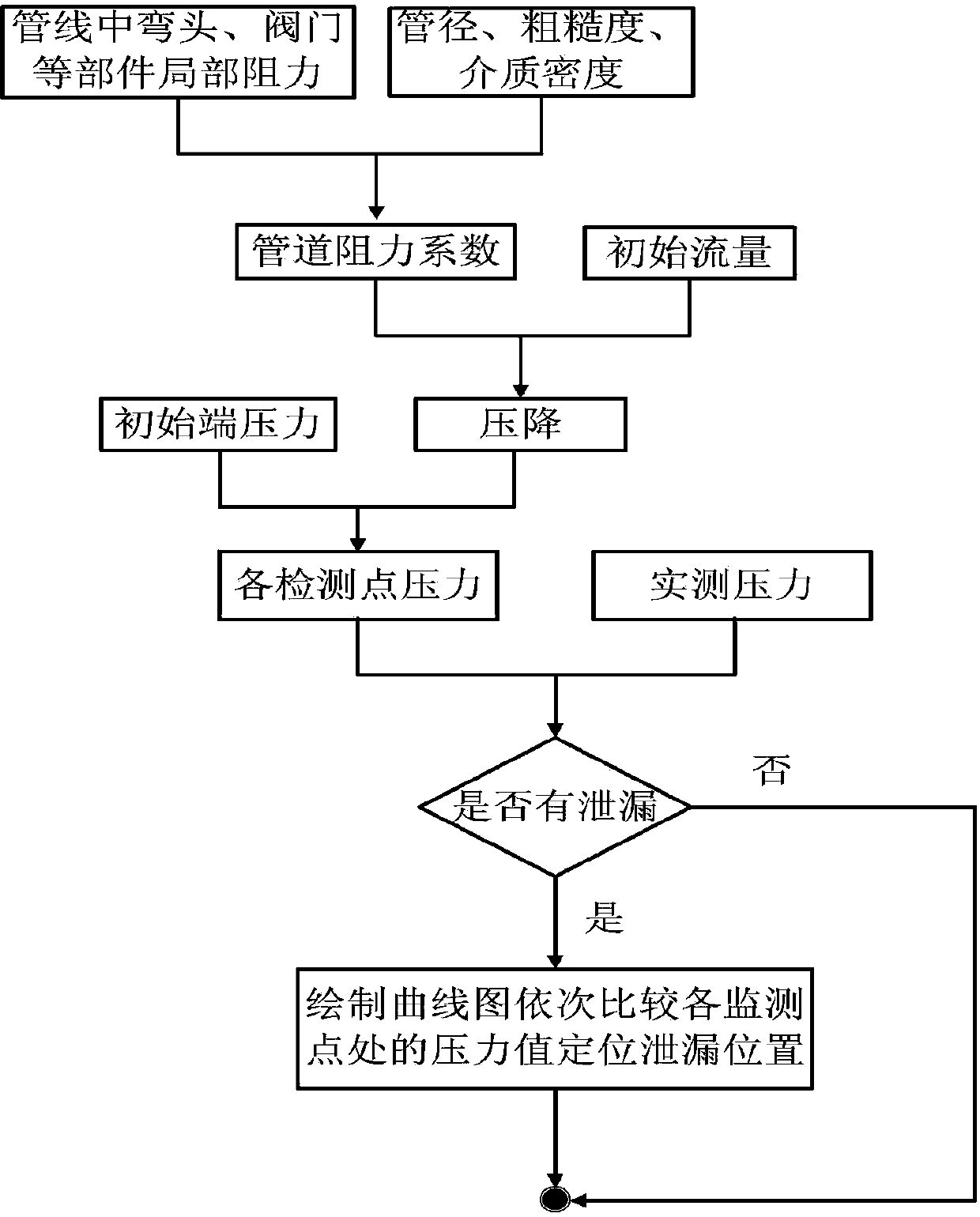

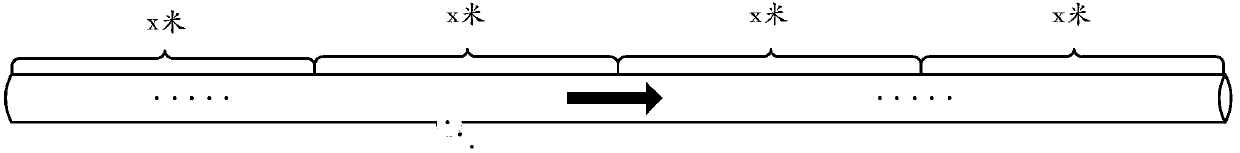

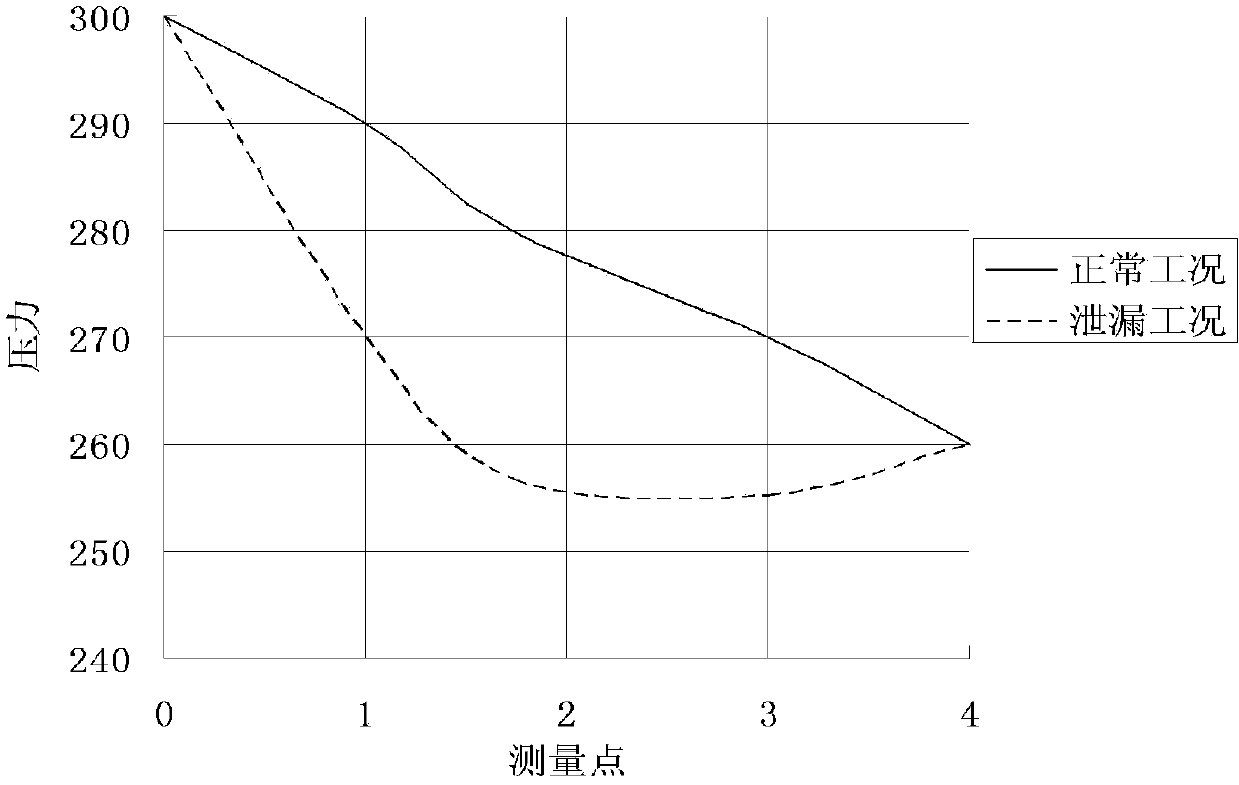

Pipeline leakage detection method based on pipeline pressure data

InactiveCN104180166AOvercome operational complexityOvercome defects such as unsatisfactory prediction resultsPipeline systemsStream flowStructural engineering

The invention provides a pipeline leakage detection method based on pipeline pressure data. According to the method, firstly, the resistance factor of each part of pipeline is calculated according to the pipeline pipe diameter, the roughness degree, the medium density and the local resistance of parts such as elbows in the pipeline; then, the pressure drop of each part is worked out according to the initial flow rate, and the pressure value of each detection point is calculated through being combined with the pressure of the initial end; finally, a theoretical value is subjected to comparison analysis with the actual measured value, so that the pipeline leakage condition is obtained, and the position of a leakage point is positioned. The method provided by the invention has the advantages that the factors, such as the pipe diameter, the roughness degree and the local resistance of various components, for reflecting the concrete conditions of the pipeline in the whole pipeline are fully considered, whether the existing pipeline leaks or not can be effectively judged, and the prediction precision is higher.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

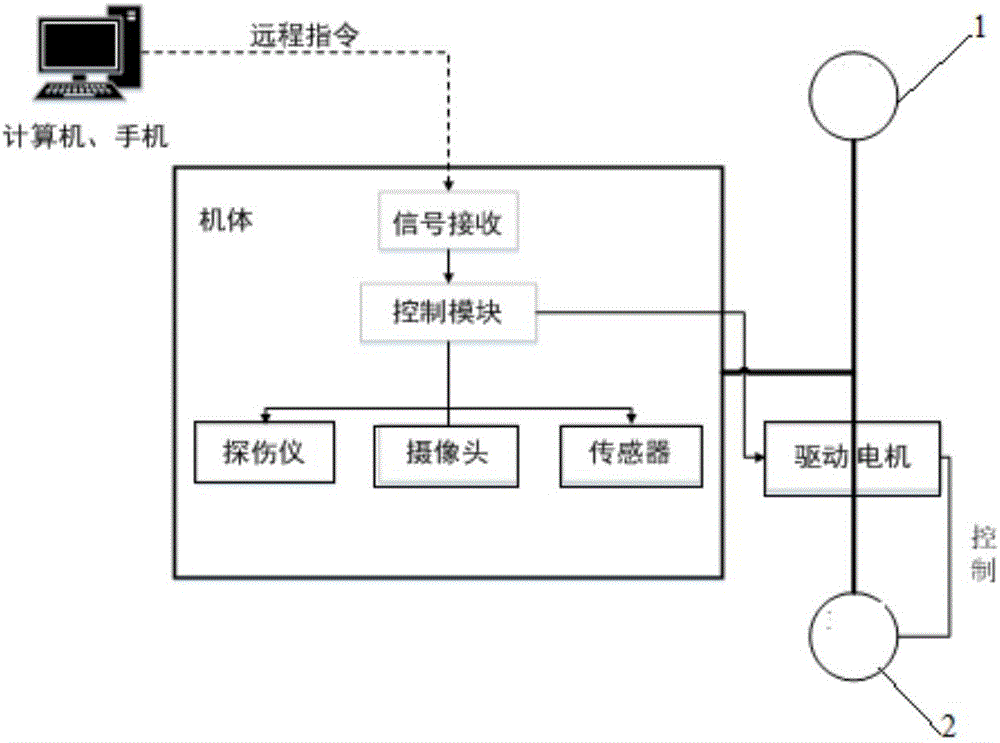

Intelligent pipe inner wall walking robot

The invention discloses an intelligent pipe inner wall walking robot. The intelligent pipe inner wall walking robot comprises two machine bodies; the two machine bodies are connected through an universal joint; walking mechanisms and extension leg structures are respectively mounted at two unconnected ends of the machine bodies; in the working process, a WIFI module is remotely connected to control driving wheels; motors drive the driving wheels; the driving wheels drive the machine bodies to move in pipes; under the condition of meeting with curves, the rotating speeds of two driving wheel motors are adjusted, and the rotating speeds of the two wheels are asynchronous to realize curving; when the pipes suddenly change the diameters, the adaption to the pipe diameters is realized through extension mechanisms, specifically, the pressure is applied to the driving wheels and driven wheels by pipe walls, so that three machine legs are inwards gathered, and meanwhile, slide sleeves are driven to compress springs; and after normal pipe diameters are recovered, the springs push the slide sleeves to drive outward expansion of the machine legs so as to adapt to new pipe diameters. The intelligent pipe inner wall walking robot has the characteristics of simple structure, convenience and practicability.

Owner:XI'AN PETROLEUM UNIVERSITY

Foam metal-carbon nanotube composite material, and preparation method and application thereof

ActiveCN104868134AEasy to control shapeCatalyst composition free regulationMaterial nanotechnologyCell electrodesDispersityChemical plating

The invention belongs to the technical field of nano materials, and discloses a foam metal-carbon nanotube composite material, and a preparation method and application thereof. The preparation method comprises the steps of pretreating a polyurethane sponge substrate, then putting the pretreated polyurethane sponge substrate in a chemical plating solution containing metallic elements to perform a chemical plating reaction, and drying the obtained product to obtain a foam metal catalyst with the polyurethane sponge substrate; then putting the foam metal catalyst in a tube furnace, heating the furnace to 500-550 DEG C, and feeding hydrogen for 0.5-2 hours; heating the furnace up to 600-800 DEG C, feeding an acetylene mixed gas to be used as a carbon source, and growing carbon nano material on the surface of the foam metal catalyst through chemical vapor deposition so as to obtain the foam metal-carbon nanotube composite material. According to the preparation method provided by the invention, carbon nanofibers or carbon nanotubes grow in-situ on the surface of a transition metal catalyst, so that the combination at the metal / carbon interface is tight, the carbon nanofibers or carbon nanotubes have good dispersity, and the tube diameters are controllable and uniform.

Owner:SOUTH CHINA UNIV OF TECH

Fluid-driven self-adaption pipeline crawler

The invention discloses a fluid-driven self-adaption pipeline crawler comprising a reducing adapting mechanism, a driving travelling mechanism, a driven travelling mechanism, an umbrella-shaped water stopping wing mechanism and a flow divider valve structure. The fluid-driven self-adaption pipeline crawler is characterized in that the fluid drive is used as the main driving form while the driving wheel drive supplements, so that the moving speed is uniform. The reducing mechanism can effectively adjust and adapt automatically according to the change of the diameter of a pipe, and can change the opening degree of an umbrella-shaped water stopping wing by a transmitting mechanism. An impeller is arranged on an inlet of a flow guide pipe, the impeller rotates when a fluid flows through, and the power is transmitted to a driving wheel by a principal shaft. The pipeline crawler is driven by fluid without additional energy source, the resistance caused by drawing a cable is avoided, the on-line work requirement of ultra-long distance can be satisfied, the situation with larger pipe diameter change can be adapted, the moving speed of the device is stable due to double drives of fluid pressure difference and driving wheel; in addition, the pipeline crawler further has the following advantages of high adaption to the inner wall condition of the pipeline, simple structure, high efficiency, convenience in manufacturing, low cost, and on the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com