Drive running mechanism of pipeline robot

A pipeline robot and walking mechanism technology, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of small drag force, insufficient obstacle-crossing ability, and poor pipe diameter adaptability, so as to improve transmission efficiency and avoid closed power Streamlined, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

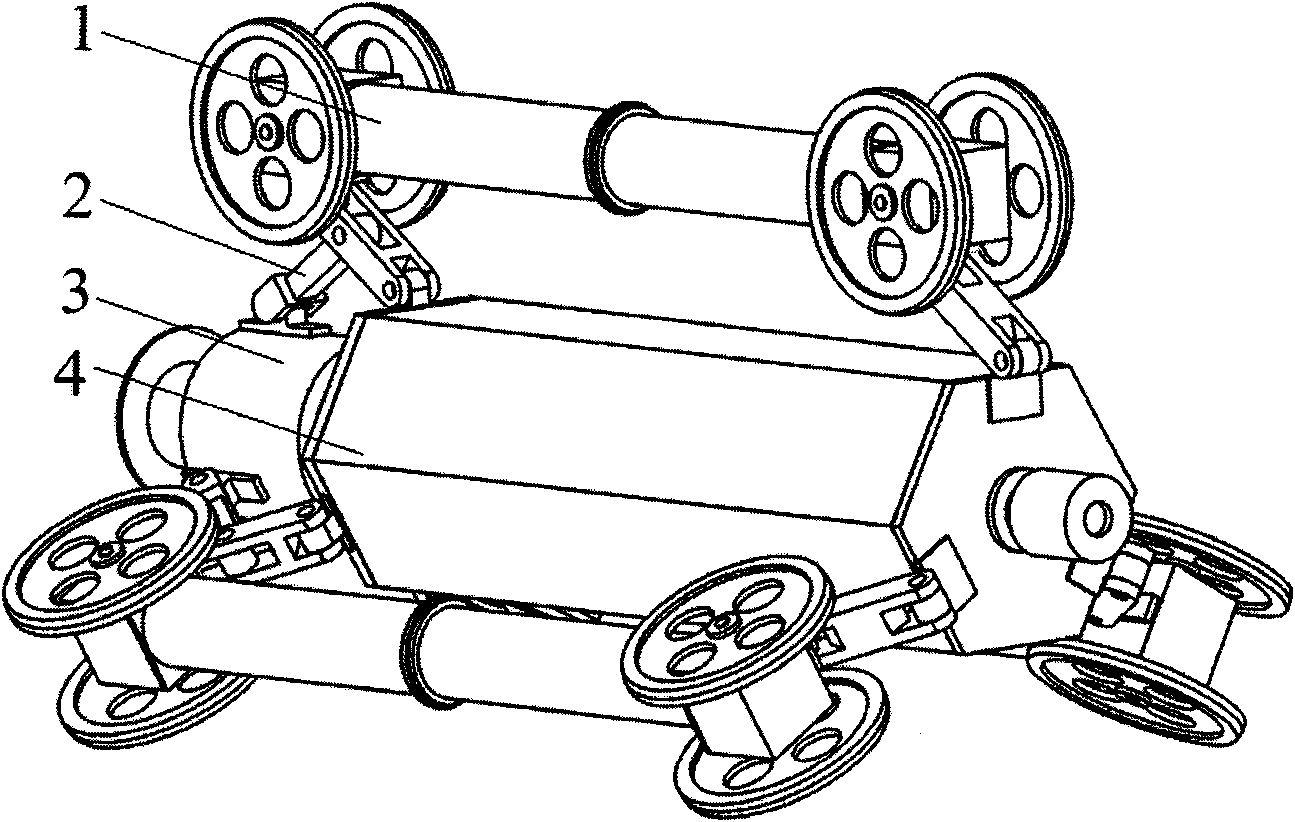

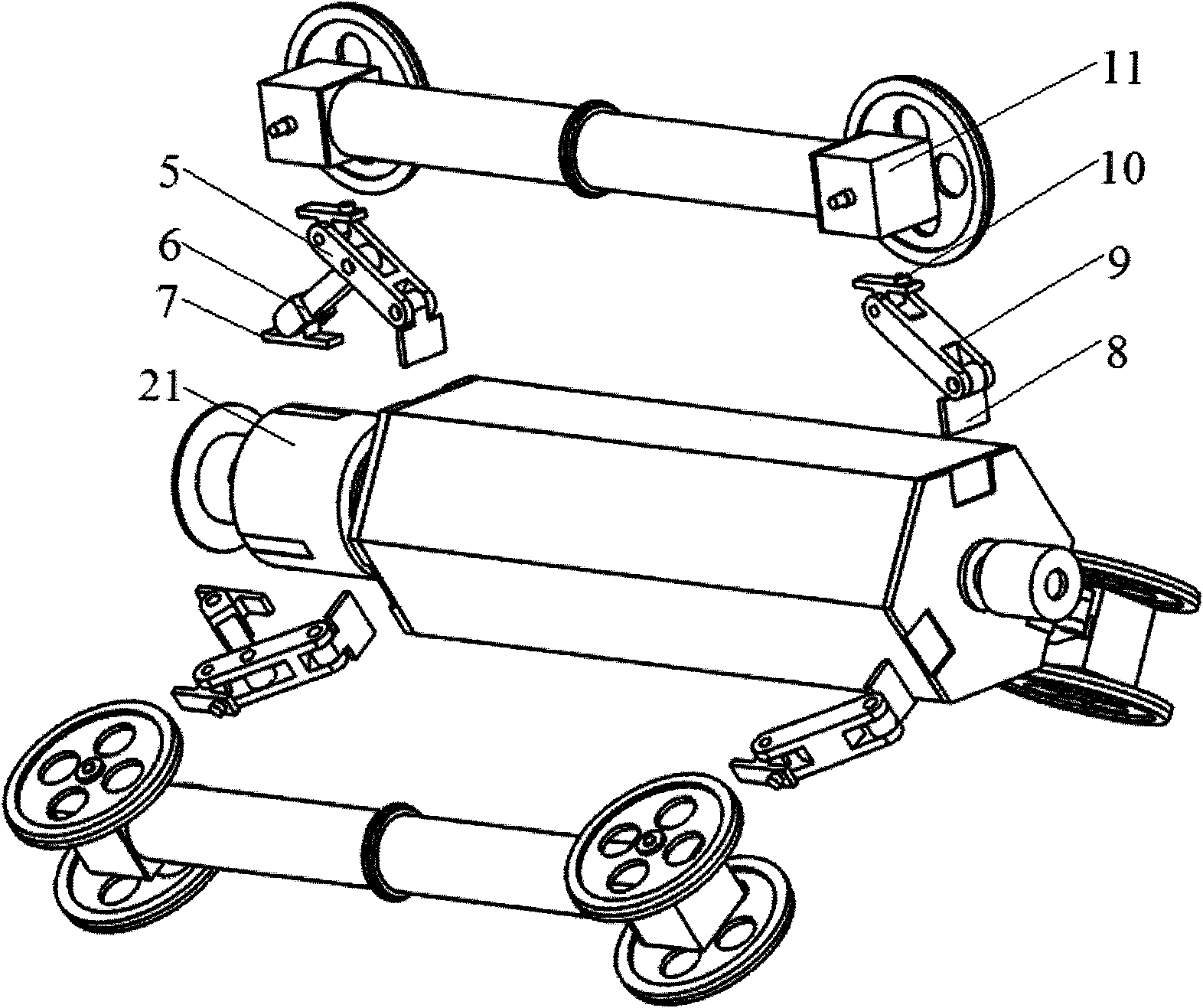

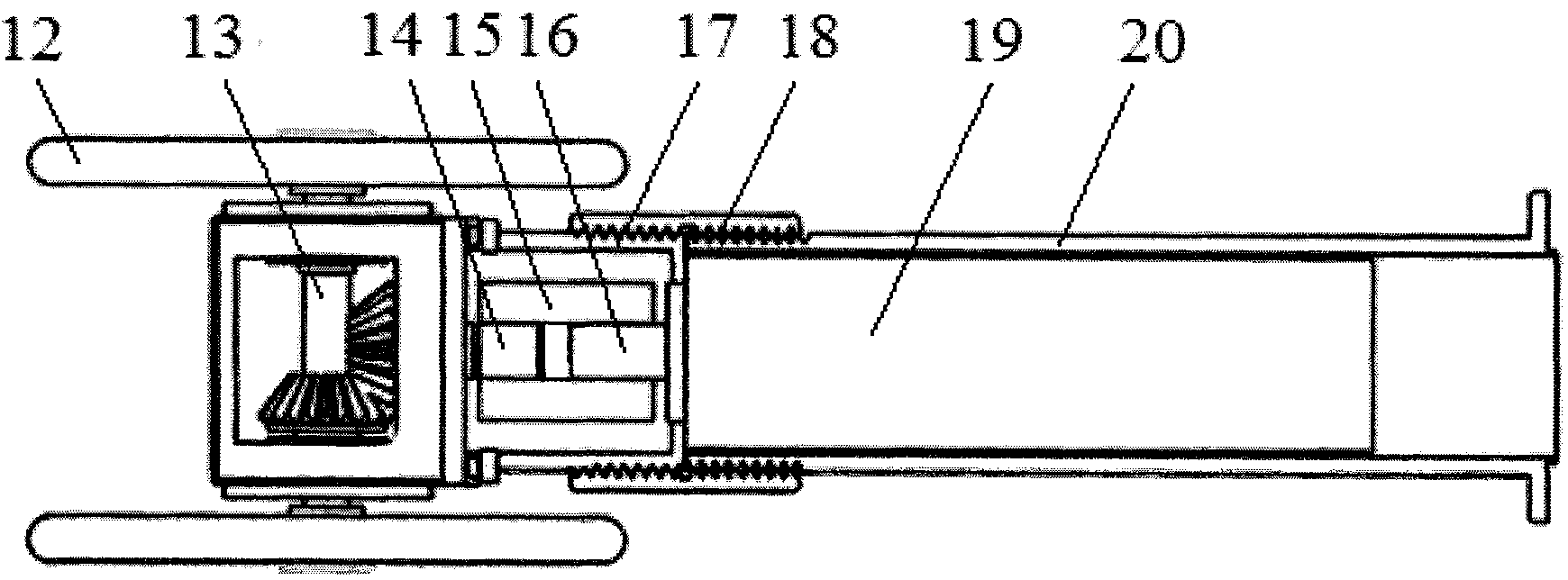

[0021] First of all, in conjunction with the accompanying drawings, an overall description is made of the pipeline robot-driven traveling mechanism of the present invention: figure 1 As shown, this kind of drive traveling mechanism has a main body 4, and an electrical control unit is placed in the main body. The main function of the main body 4 is to connect other parts and install the electrical components of the control system. In addition, combining figure 2 , Figure 5 As shown, the drive traveling mechanism also includes a wheel leg adjustment motor 31 located in the body, and three sets of travel drive units 1 located outside the body, and three sets of front support links 9, rear support links 5 and adjustment The connecting rods 6 are combined to form an elastic wheel leg support unit 2 and a pipe diameter adaptation adjustment unit 3 . In the following, these u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com