Patents

Literature

291results about How to "Achieve winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

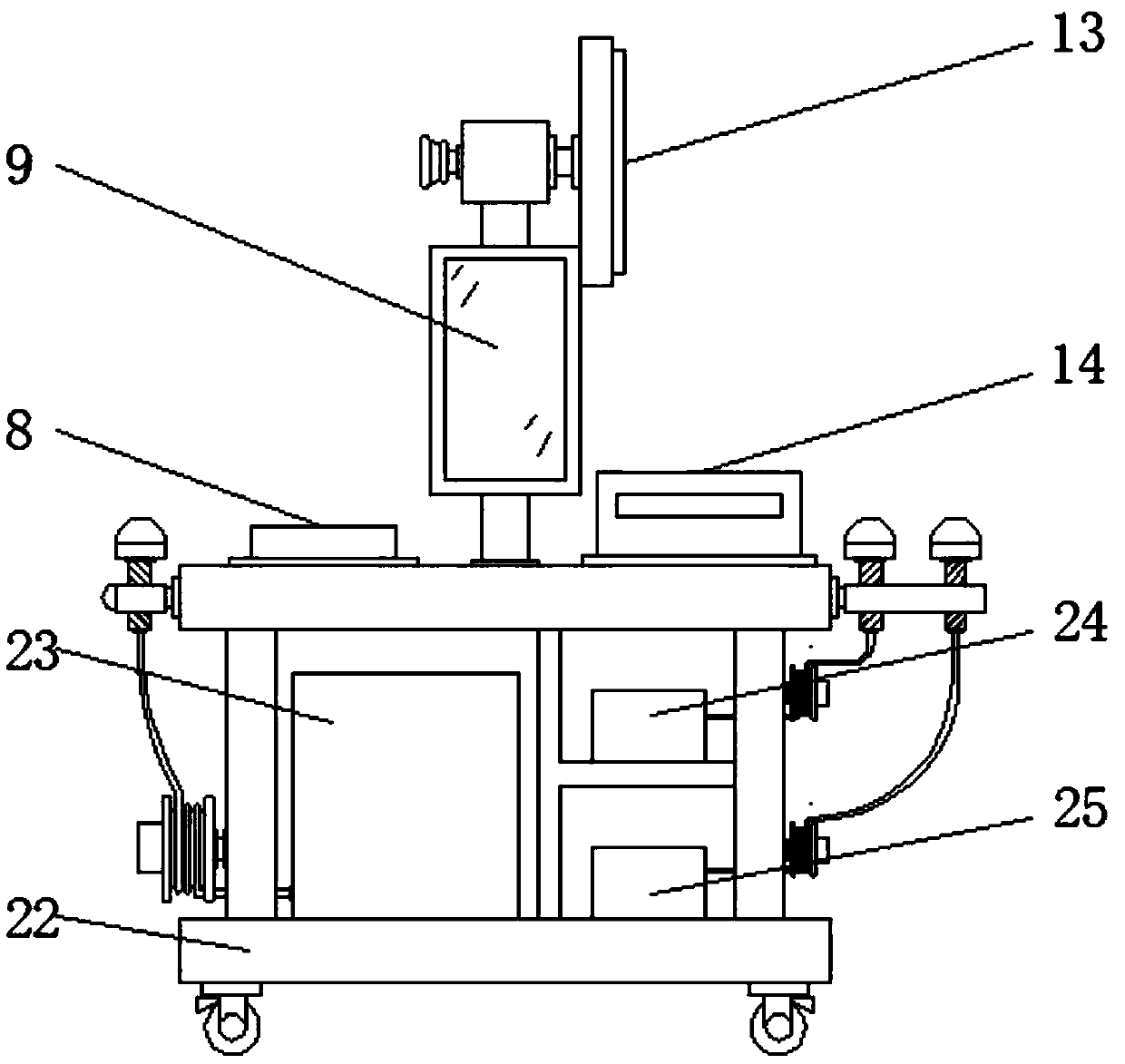

Automatic take-up and pay-off device and take-up and pay-off method for off-board direct-current charger

ActiveCN105752765AEasy accessPrevent tightening and tearingArrangements using take-up reel/drumDrive shaftEngineering

Owner:WUDU TECH CO LTD

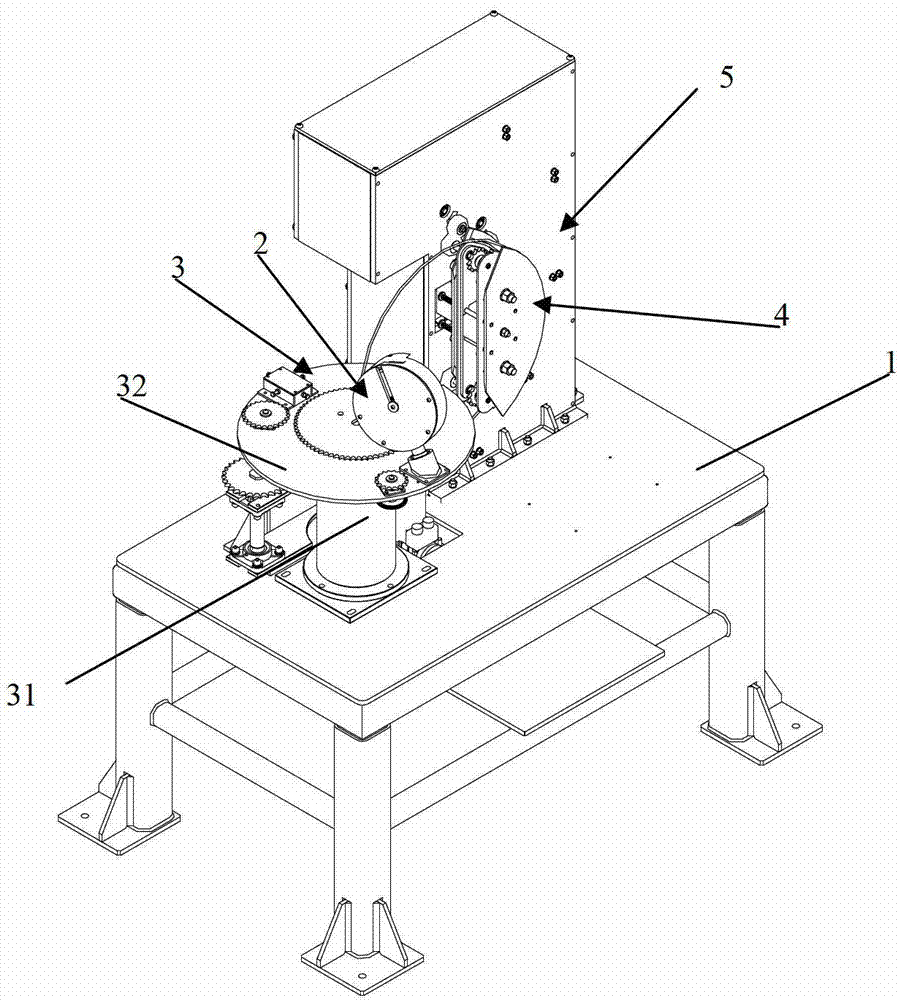

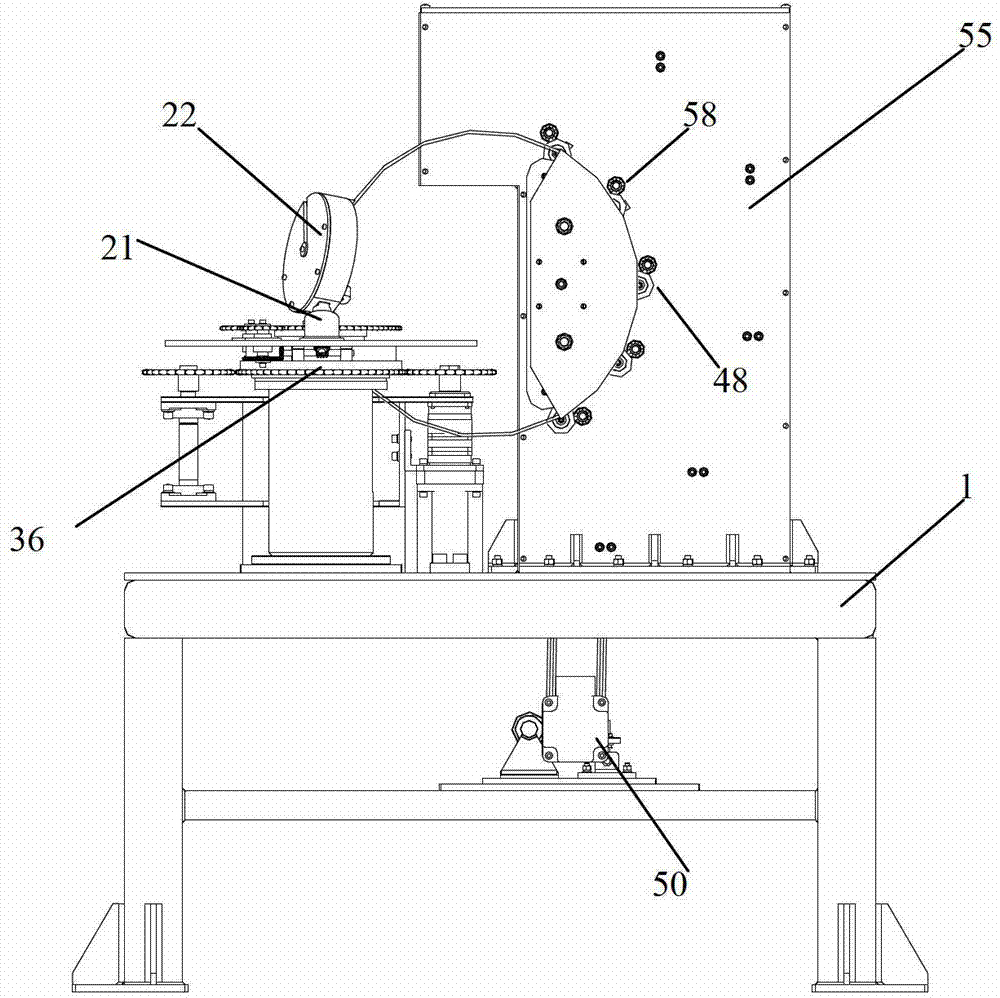

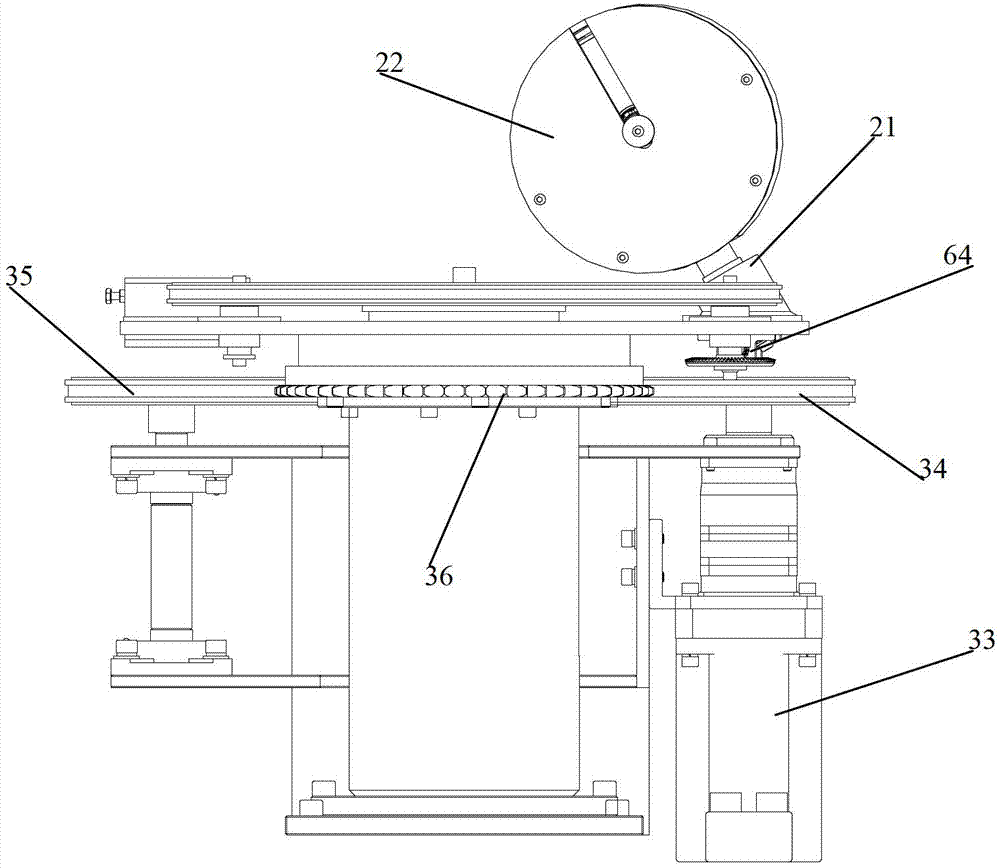

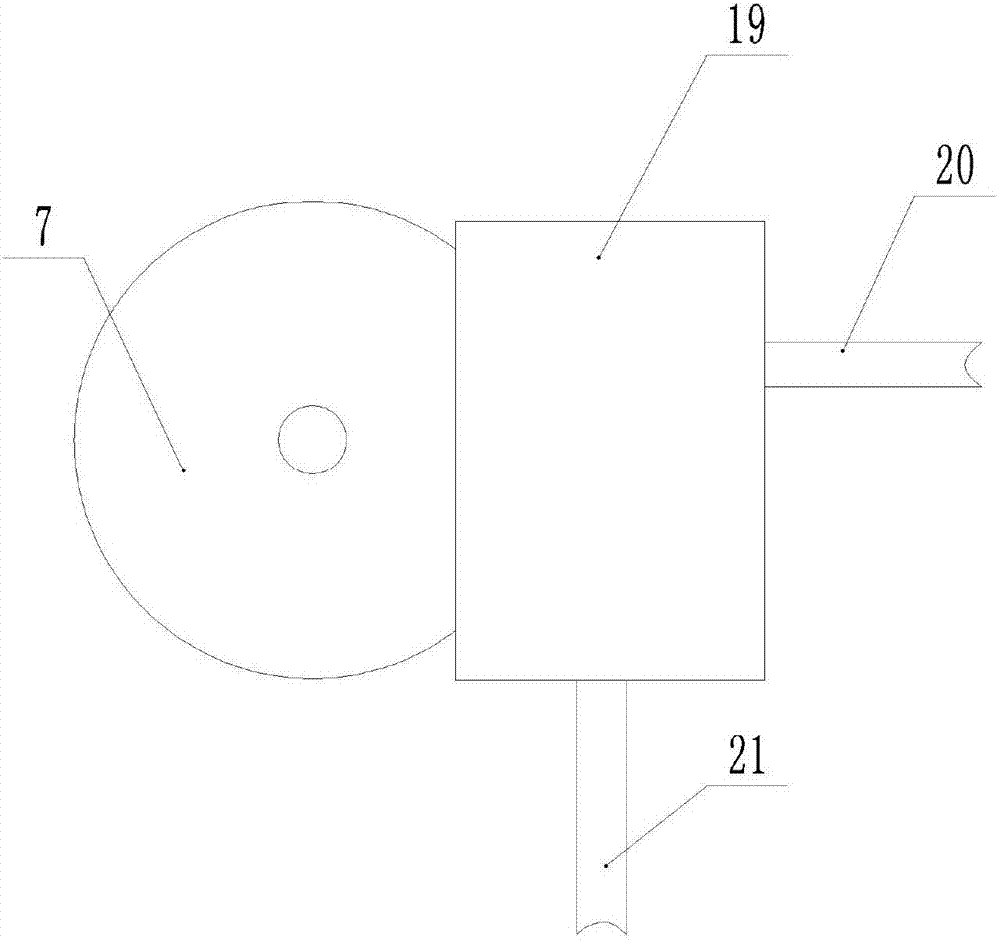

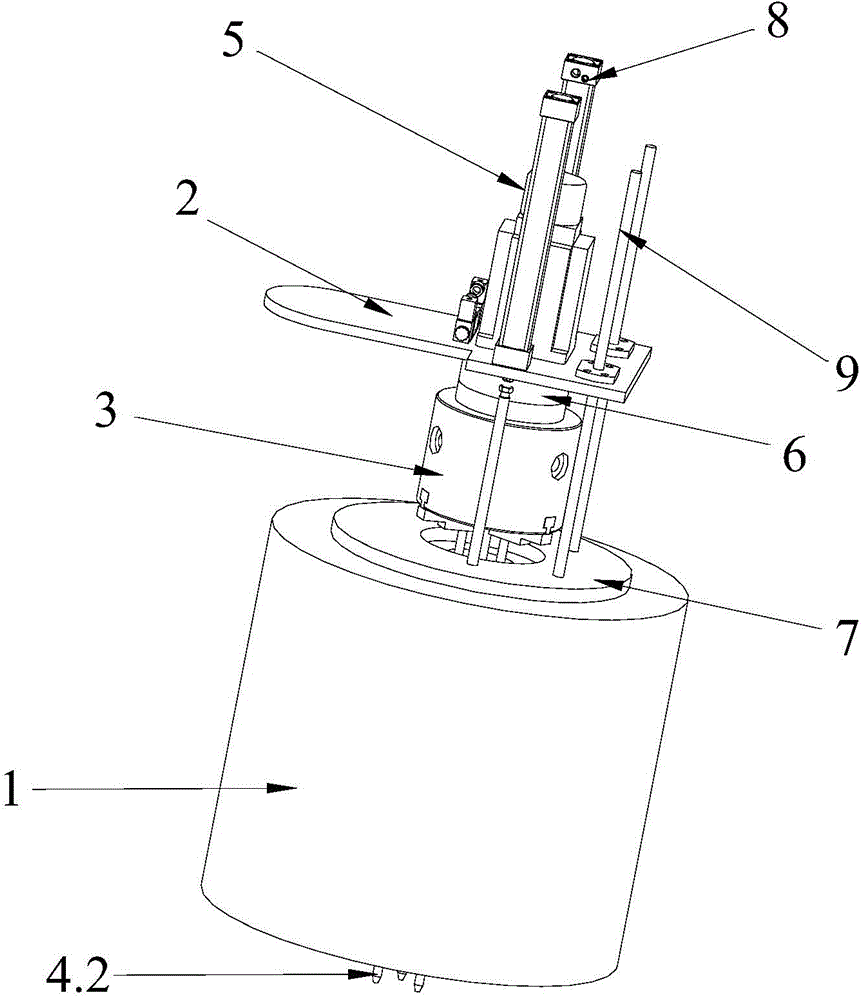

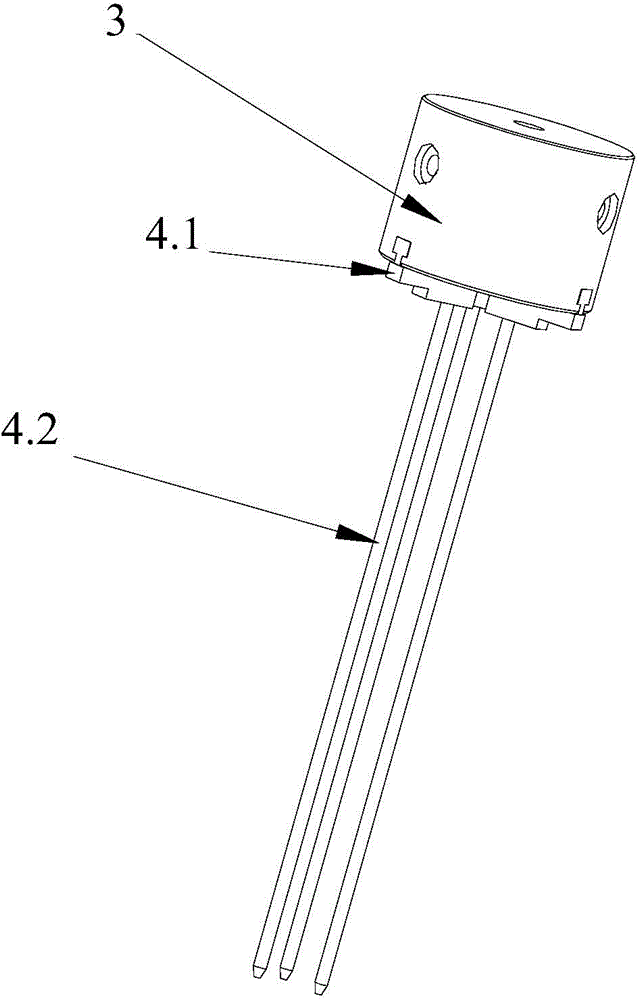

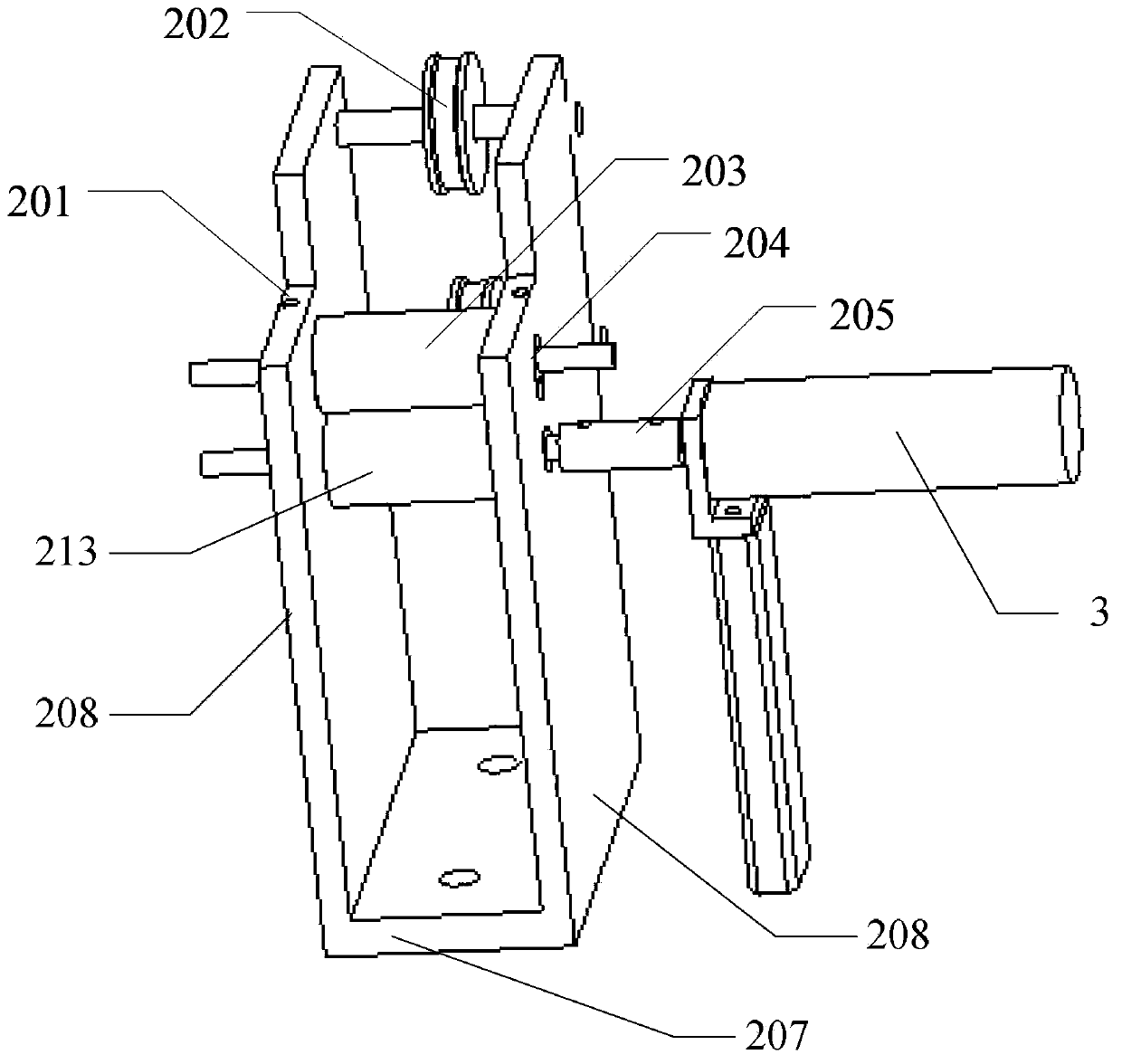

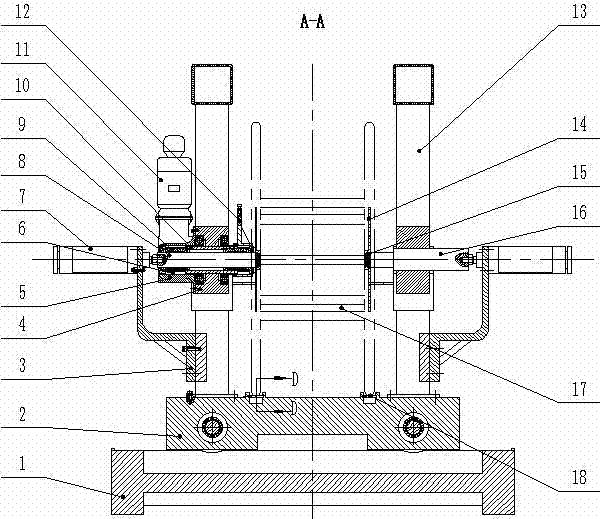

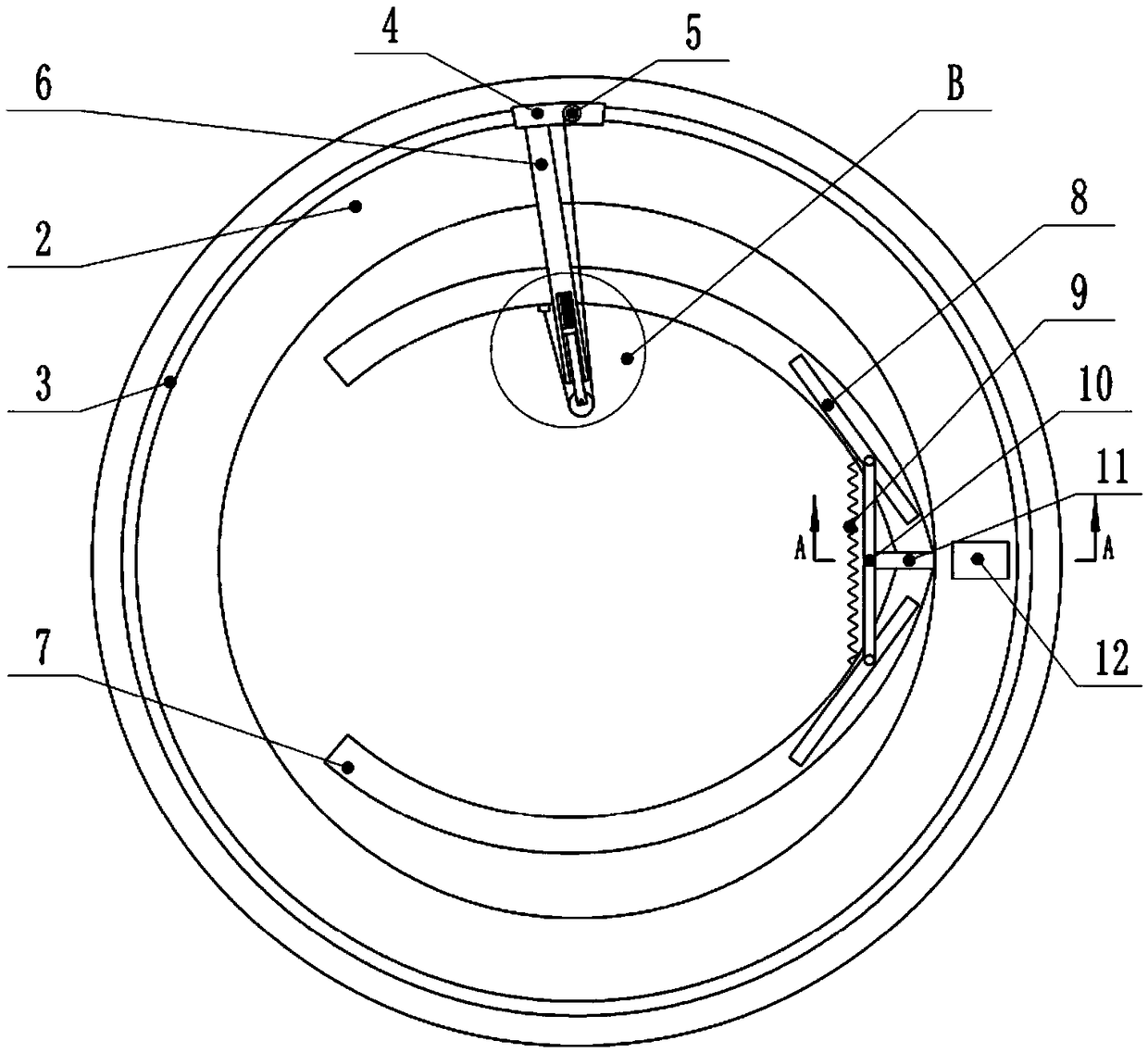

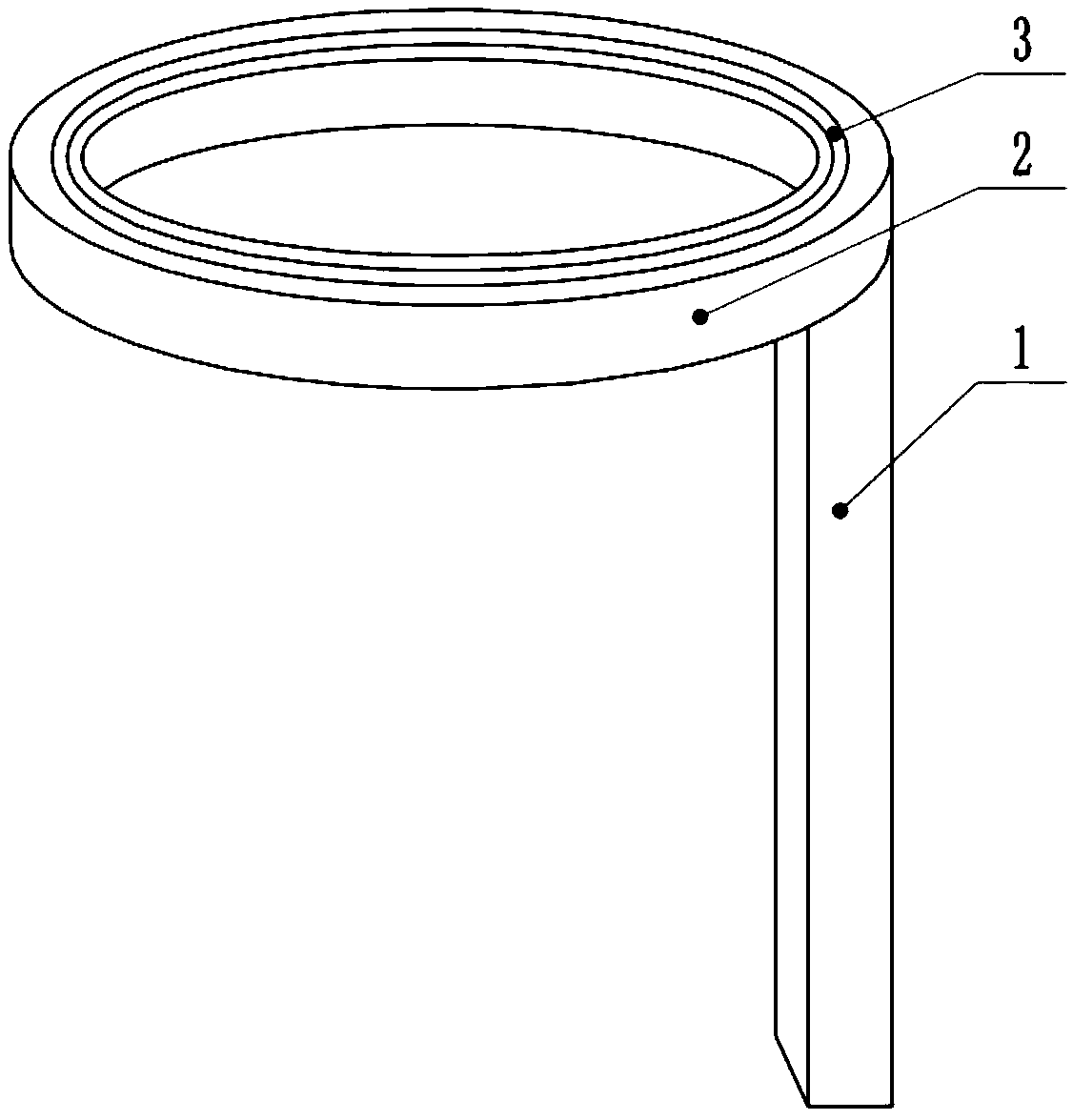

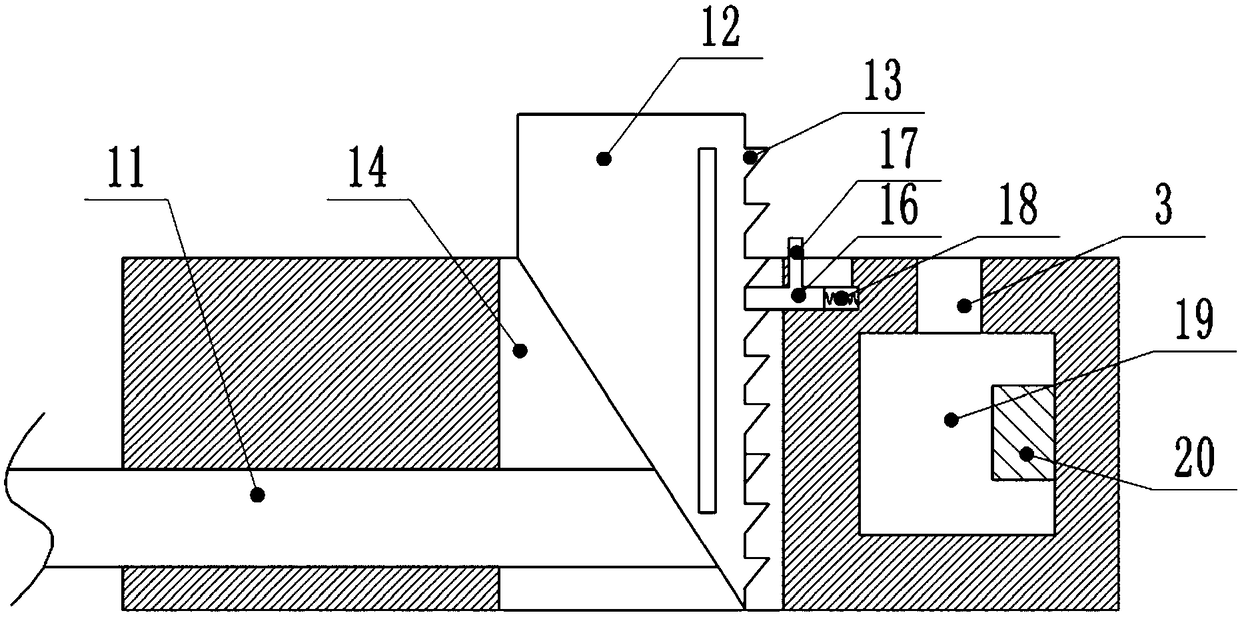

Winding apparatus of bead ring of circular section

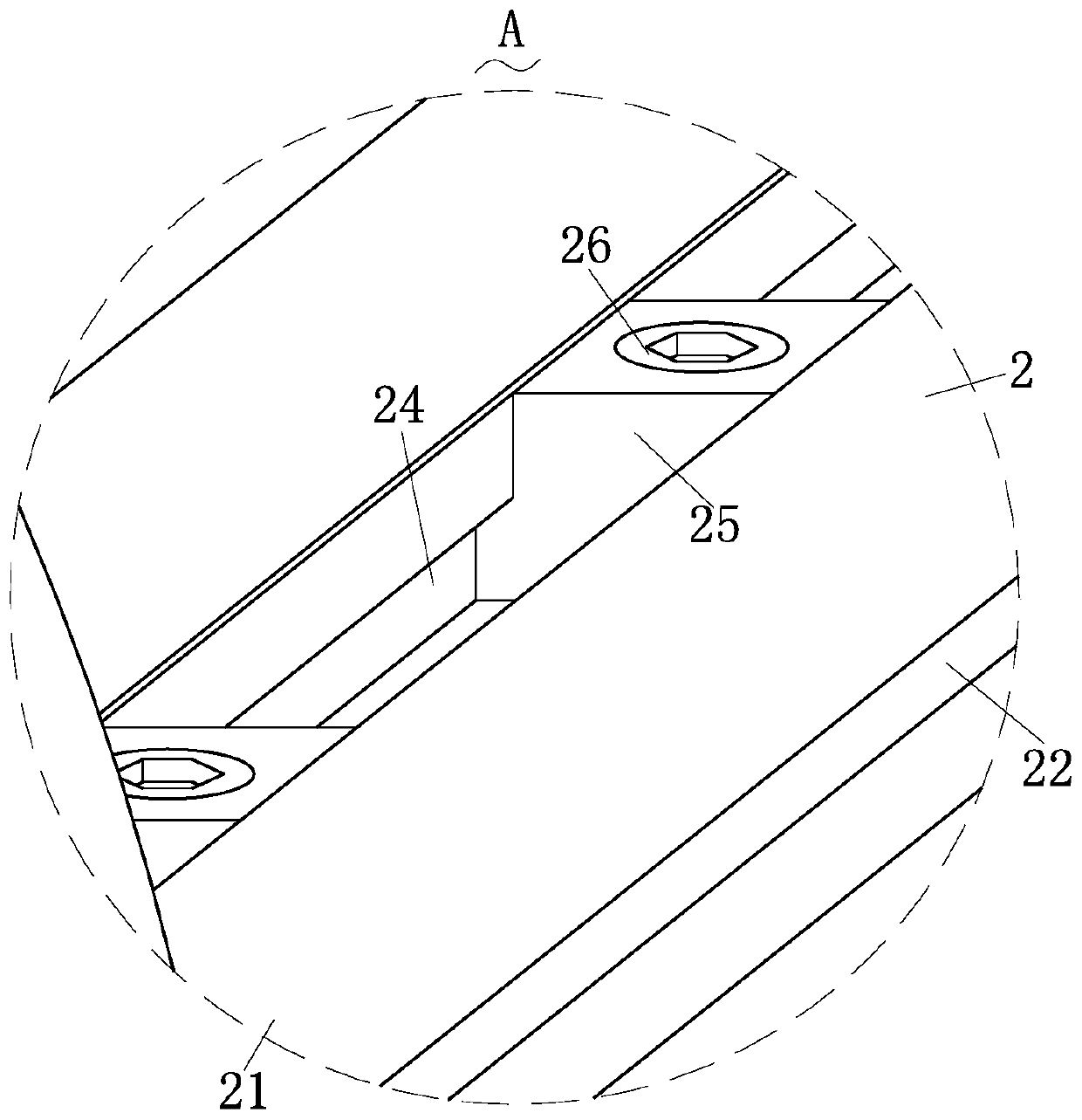

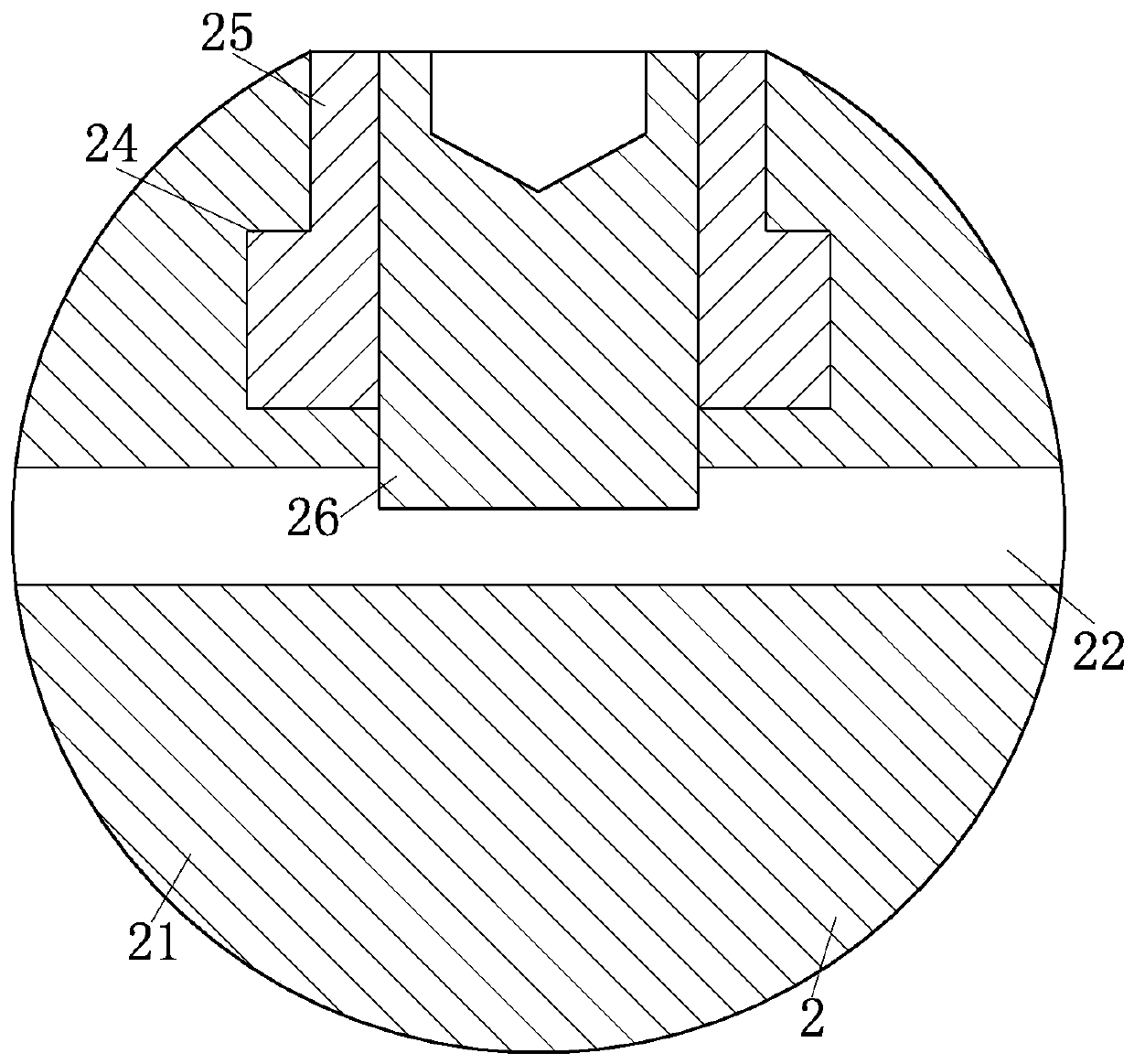

The invention discloses a winding apparatus of a bead ring of a circular section. The winding apparatus of the bead ring of the circular section comprises a stander, a bead ring winding mechanism, a bead ring opening mechanism and a bead ring core clamping mechanism, wherein the bead ring winding mechanism comprises a vertical support post, a disc-shaped horizontal rotation platform which is rotatably arranged at the top of the support post and provided with a slot, and a servo motor capable of driving the horizontal rotation platform to rotate; the bead ring opening mechanism is arranged on the horizontal rotation platform; and the bead ring core clamping mechanism comprises two D-shaped outer support plates, two D-shaped inner clamp plates, a chain and sprocket assembly, the servo motor and a plurality sets of clamping assemblies. According to the winding apparatus of the bead ring provided by the invention, the structure is simple, the control is precise, the servo motor serves as motor input, the chain and the sprocket are taken as a transmission assembly, the bridging is simple, the space requirement is low, and the winding of the bead ring of the circular section can be effectively realized by the rotation of the bead ring core and the rotatable winding of a winding steel wire.

Owner:TIANJIN SAIXIANG TECH

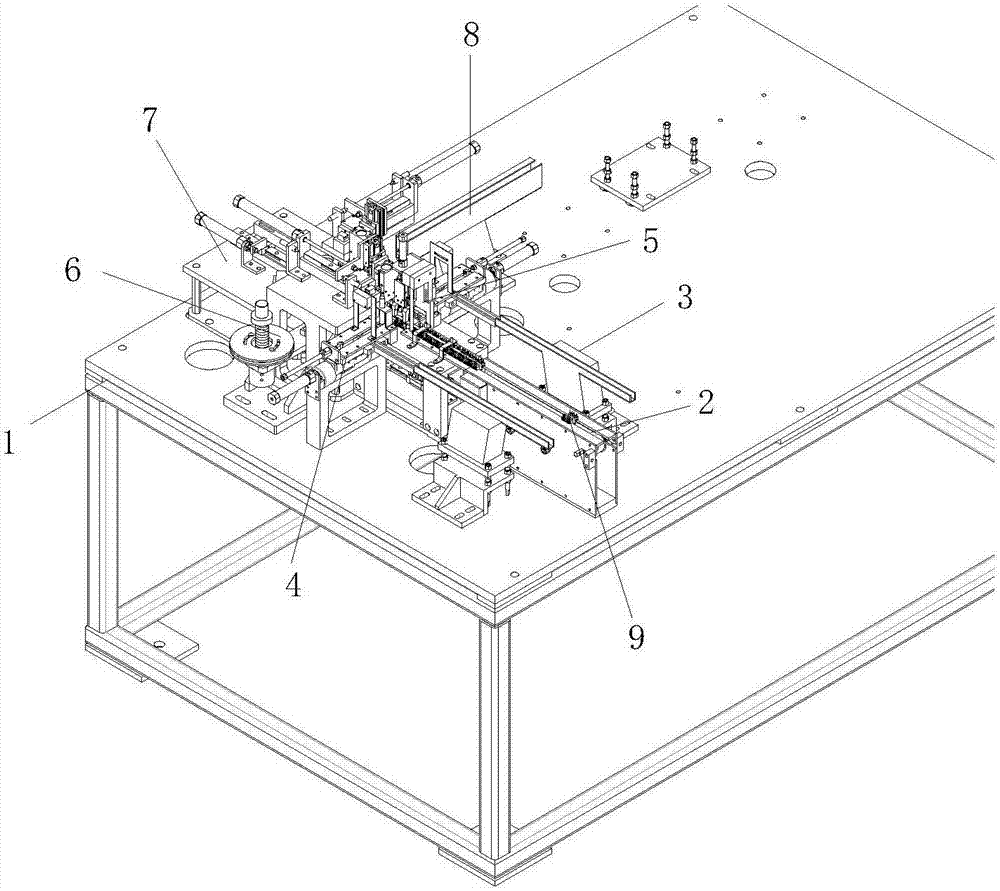

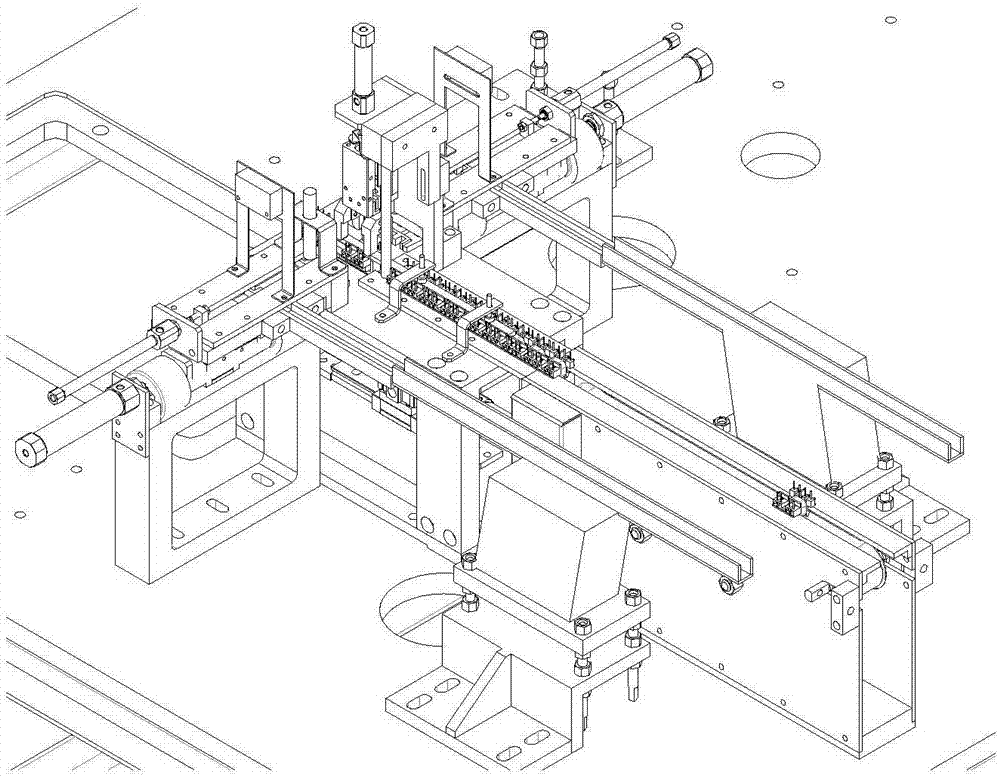

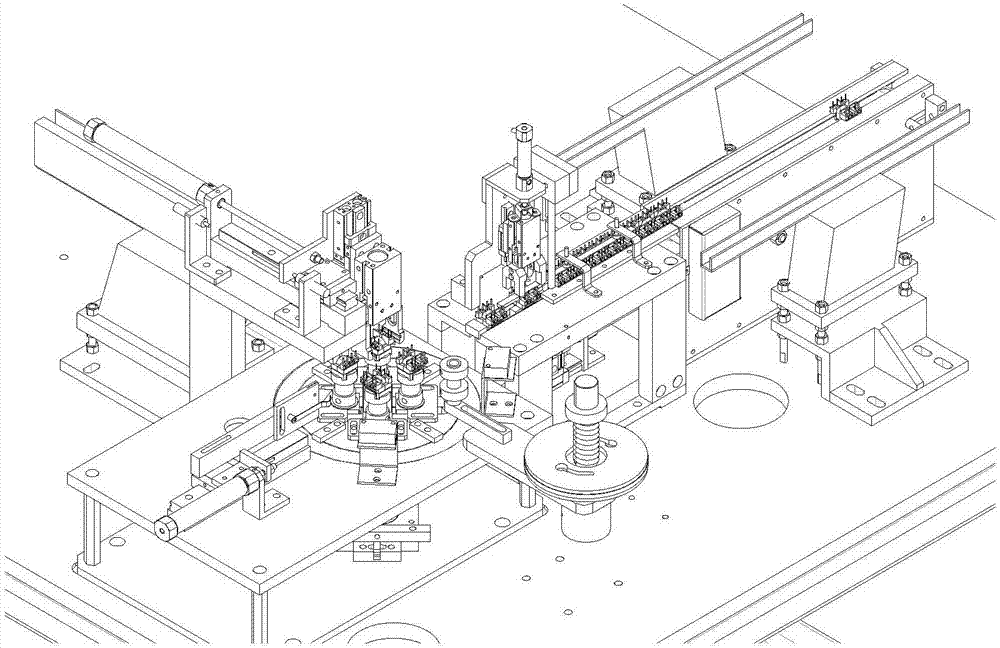

Household electrical appliance product transformer assembly assembling system

ActiveCN106876128AImprove assembly work efficiencyAchieve windingAssembly machinesInductances/transformers/magnets manufactureButt jointAdhesive

The invention discloses a household electrical appliance product transformer assembly assembling system. The household electrical appliance product transformer assembly assembling system includes a rack and a workbench arranged on the rack; a first conveying mechanism, a second conveying mechanism, a third conveying mechanism, an assembly magnetic core inserting positioning mechanism, magnetic core inserting mechanisms, a feeding and grabbing mechanism, an adhesive tape conveying mechanism, a rotation adhesive tape winding mechanism, and a discharging grabbing mechanism are arranged on the workbench, wherein the first conveying mechanism, the second conveying mechanism and the third conveying mechanism are used for conveying a transformer assembly to be assembled; a discharging end of the first conveying mechanism is in butt joint with a feeding end of the assembly magnetic core inserting positioning mechanism; the magnetic core inserting mechanisms are arranged on two sides of the assembly magnetic core inserting positioning mechanism; feeding ends of the magnetic core inserting mechanisms are in butt joint with a discharging end of the second conveying mechanism for conveying a magnetic core; and the feeding and grabbing mechanism is correspondingly arranged on a discharging end of the assembly magnetic core inserting positioning mechanism. The household electrical appliance product transformer assembly assembling system is reasonable in structural design, can achieve rapid inserting and rapid winding of the magnetic core, can achieve continuous assembly production, and can greatly improve the assembly working efficiency.

Owner:浙江预立兴川机器人技术股份有限公司

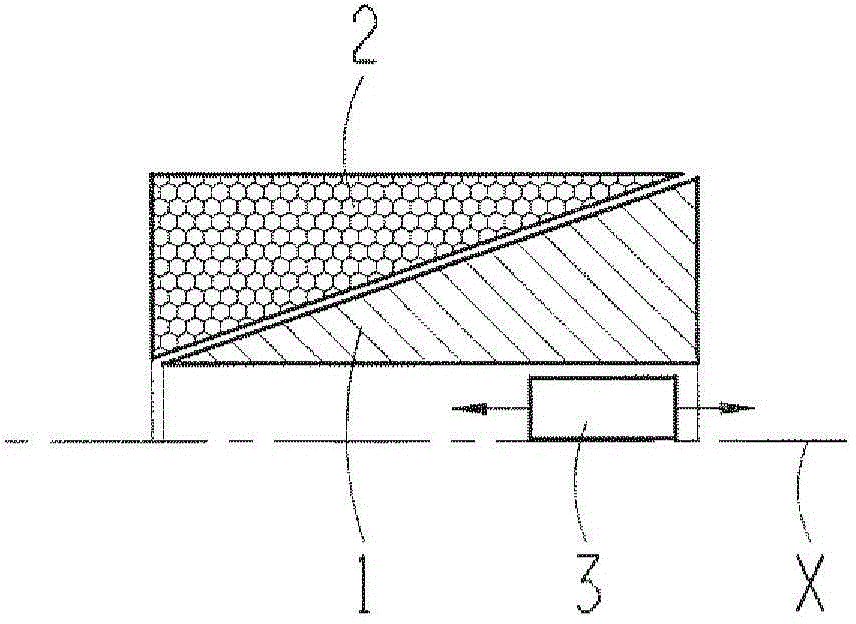

Loose metal litter briquetting machine and processing method

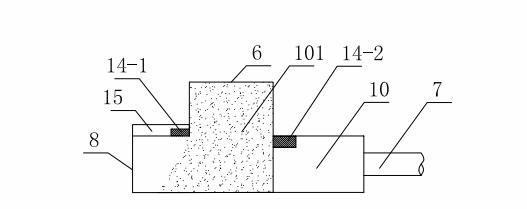

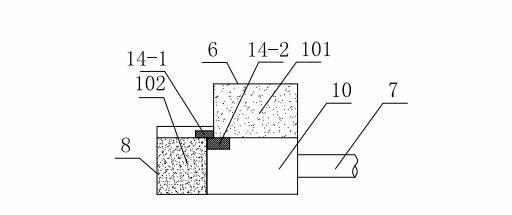

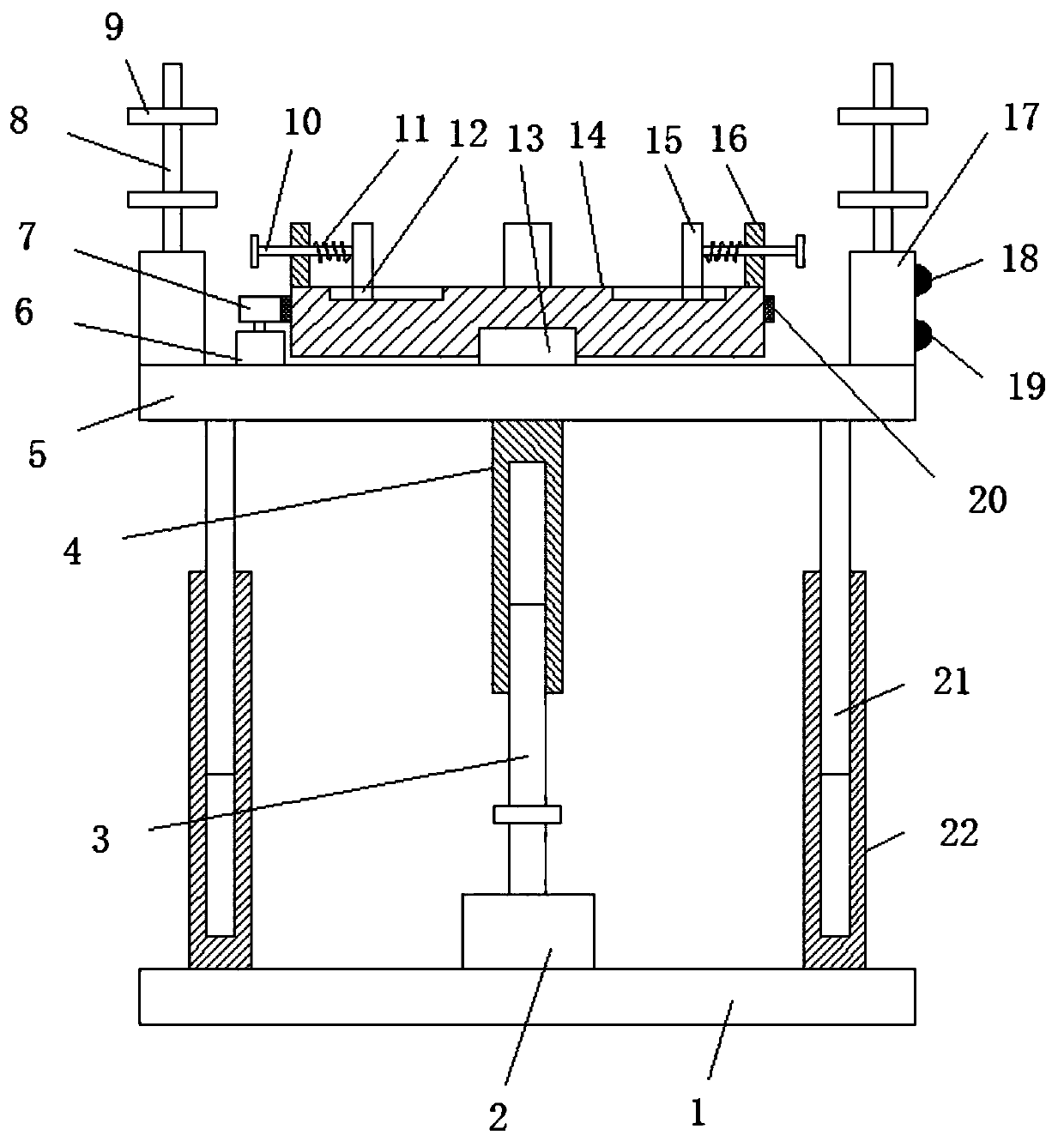

InactiveCN102101364AImprove compression efficiencyImprove work efficiencyPressesHigh densityReciprocating motion

The invention relates to a loose metal litter briquetting machine. A vertical main cylinder is arranged at the top of a stand, a piston of the main cylinder is connected with a punch in up-and-down reciprocating motion in a final pressure swaging bucket, a soleplate for sealing the bucket bottom is arranged at the bottom of the swaging bucket and controlled by a horizontally arranged knife gate cylinder, the middle of the swaging bucket is horizontally provided with a pushing cabin which is in sealed connection and vertical intersection with the swaging bucket; the tail end of the pushing cabin is provided with a pushing head connected with a piston of a pushing cylinder piston, the pushing cabin is provided with an open side which is communicated with the bottom of a feeding hopper, a precompression pushing head is arranged at the other side of the bottom of the feeding hopper and connected with a piston of a precompression cylinder. The precompression cylinder, the pushing cylinder and the main cylinder provided by the invention respectively extrude materials in the three directions of the X axis, the Y axis and the Z axis to effectively improve the compression efficiency of the materials and finally obtain high-density litter cakes while cutting coiled wires and separating litter liquid and have high degree of automation and good economic benefits.

Owner:JIANGYIN RUIFENG HYDRAULIC MACHINE CO LTD

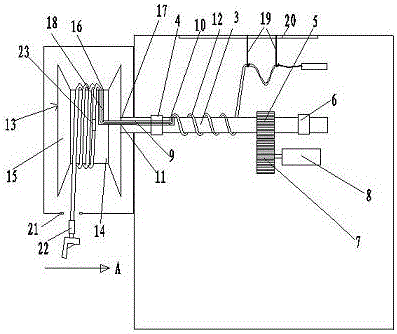

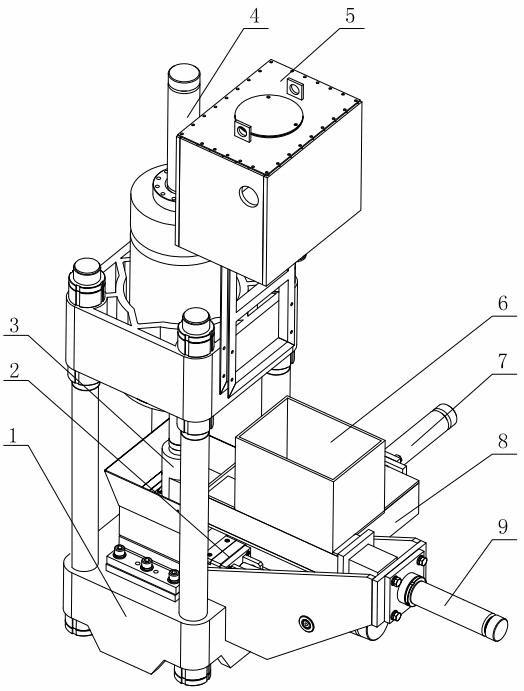

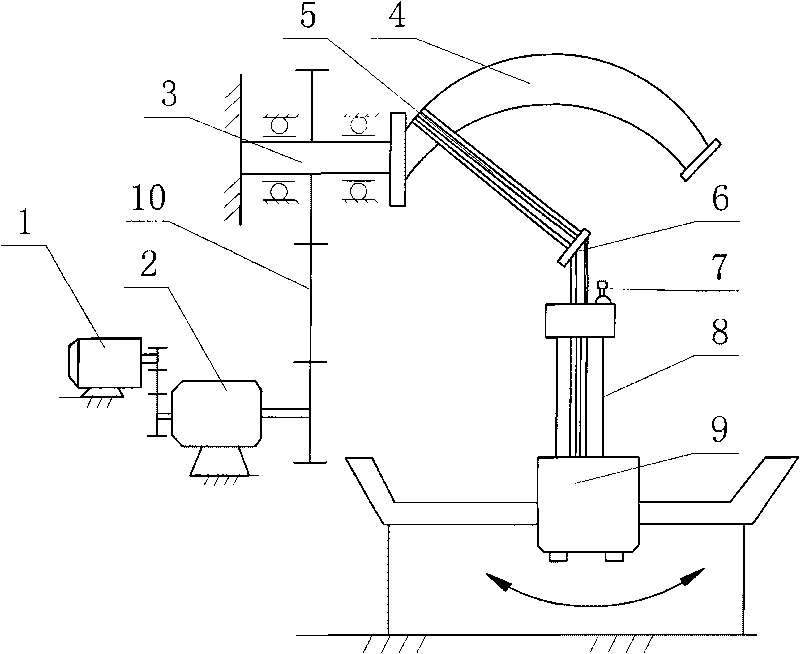

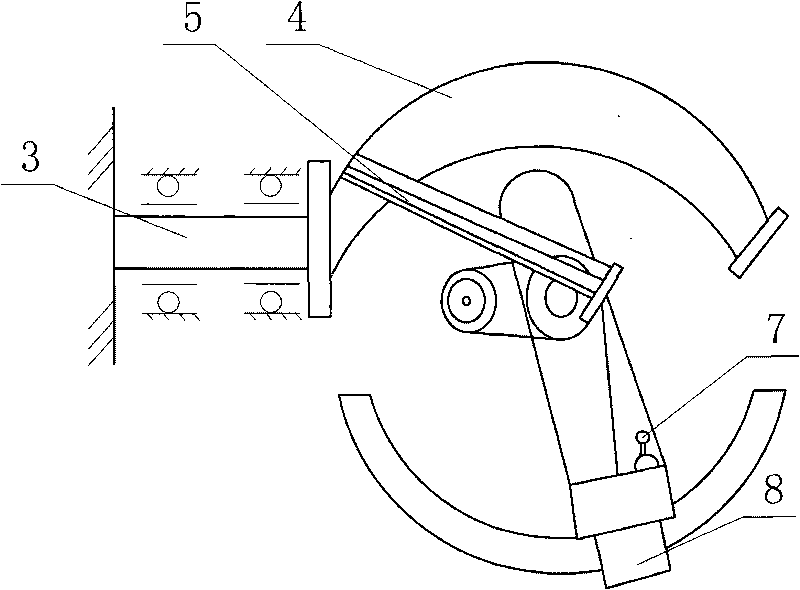

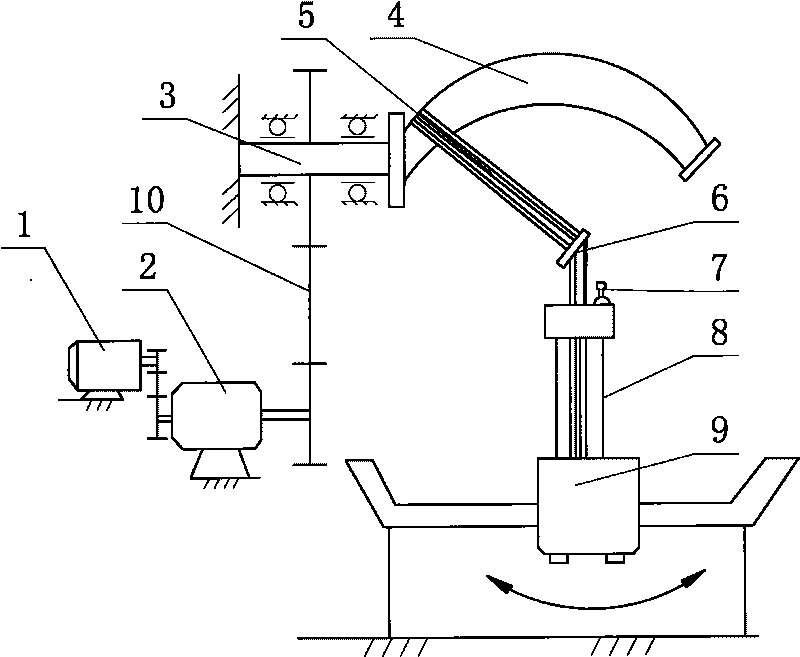

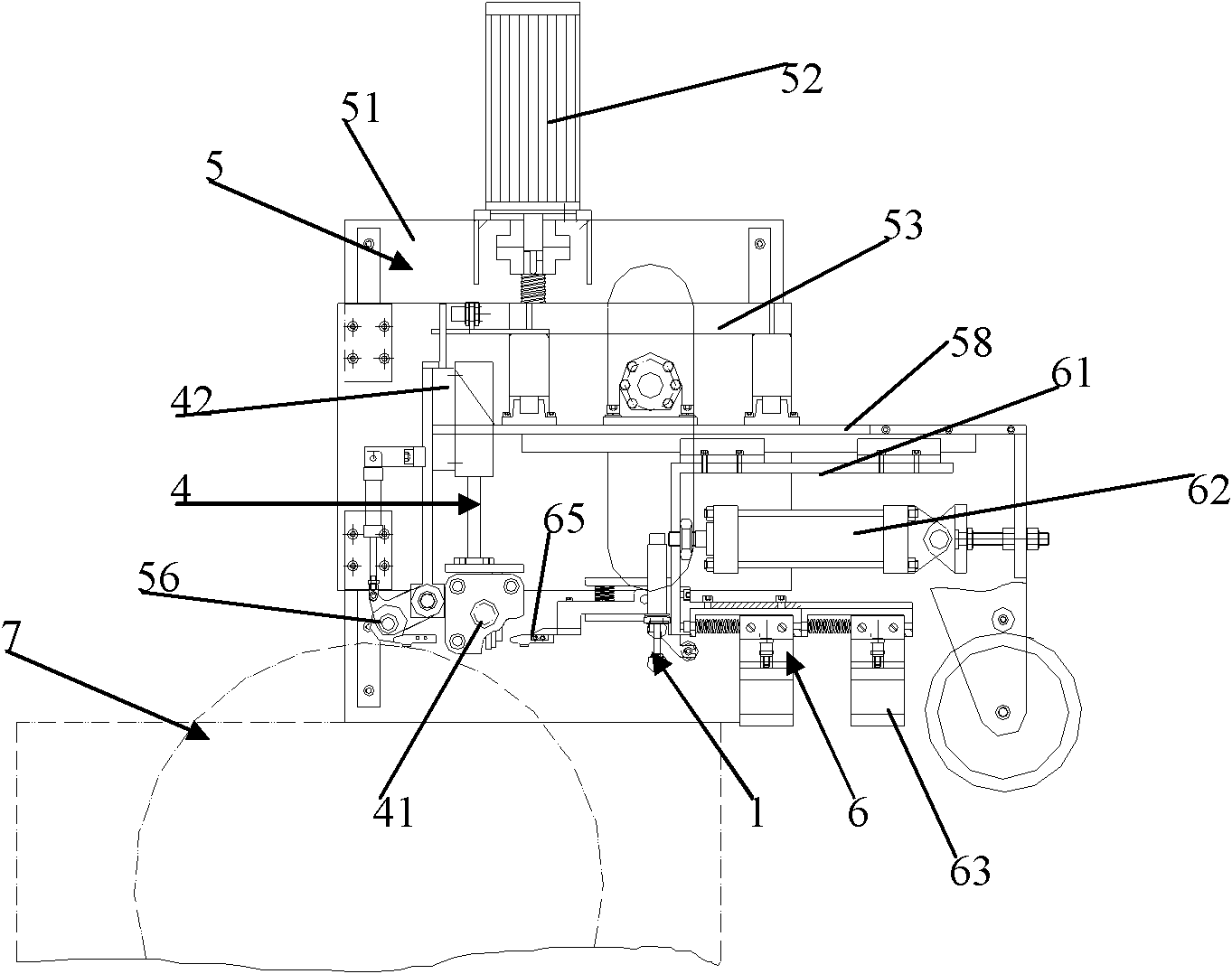

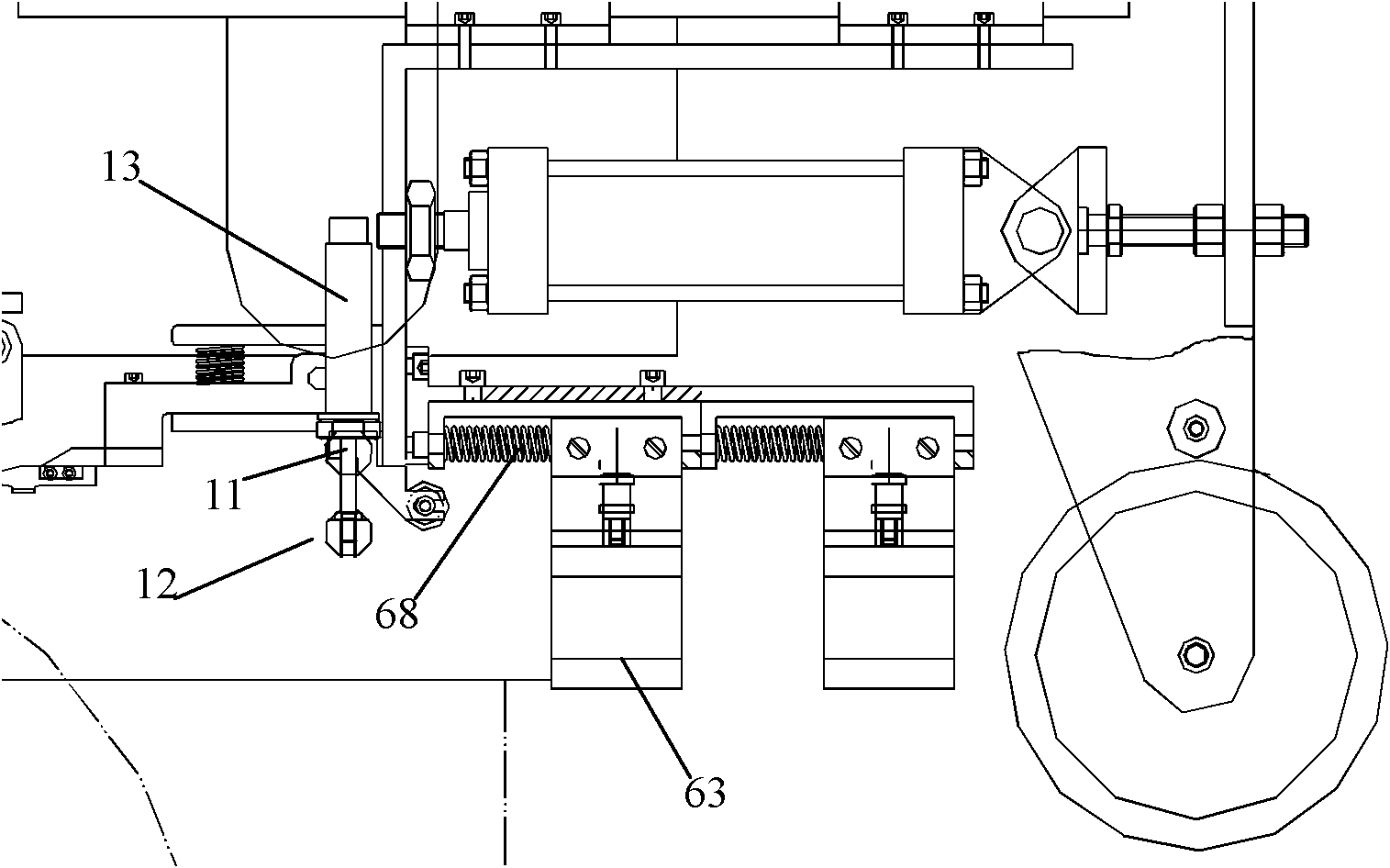

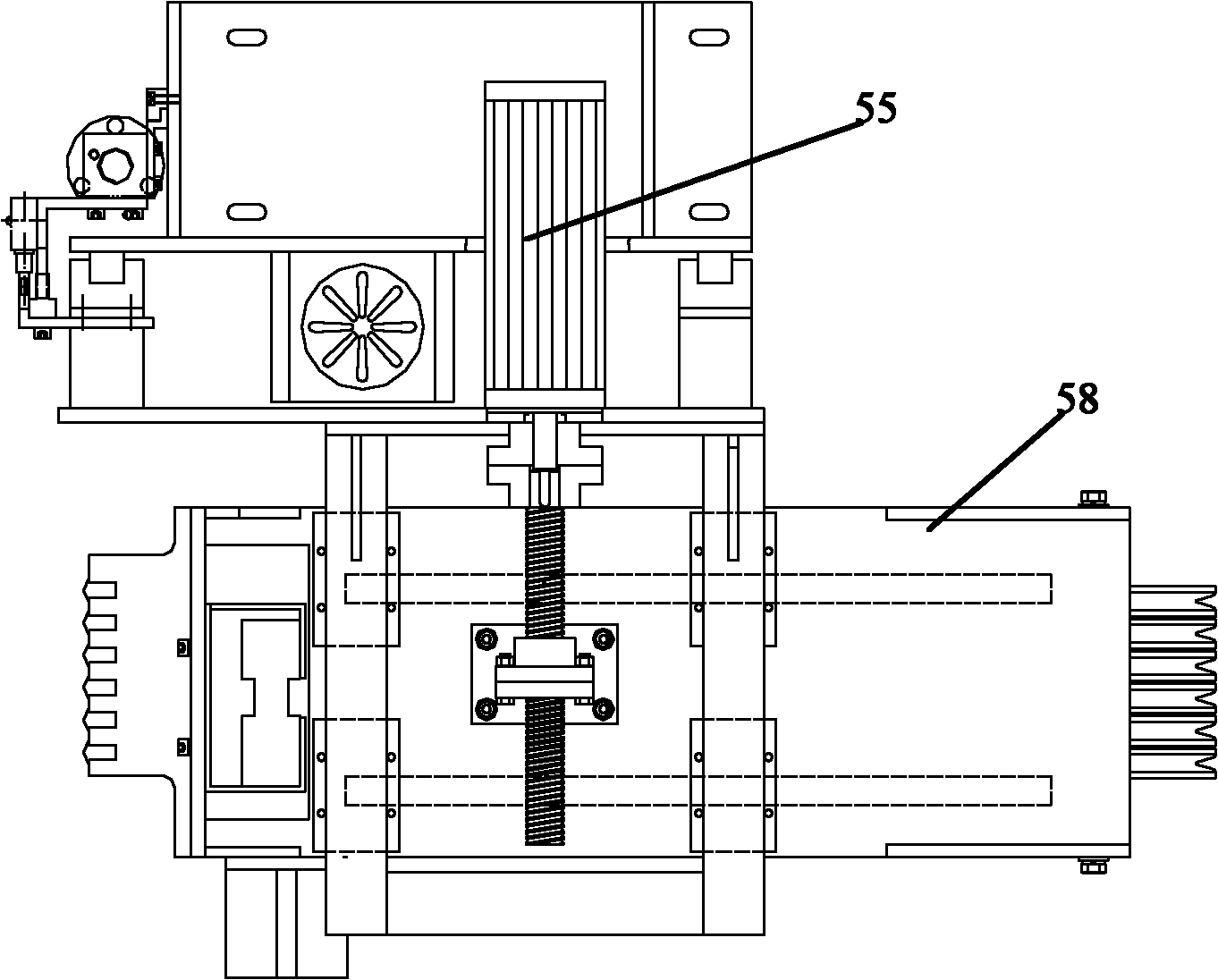

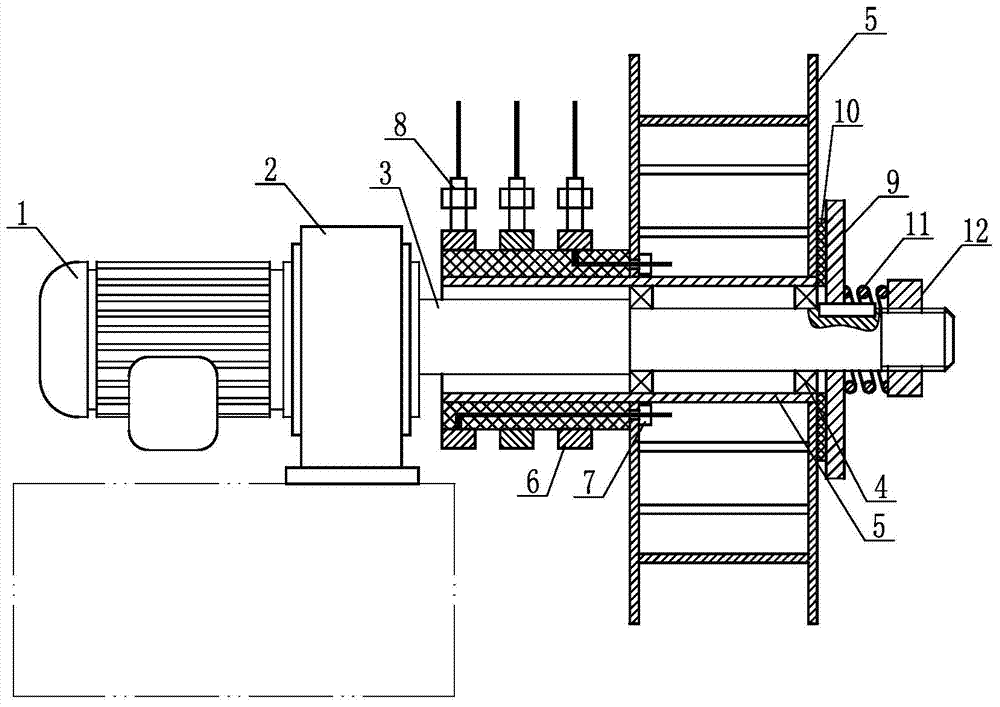

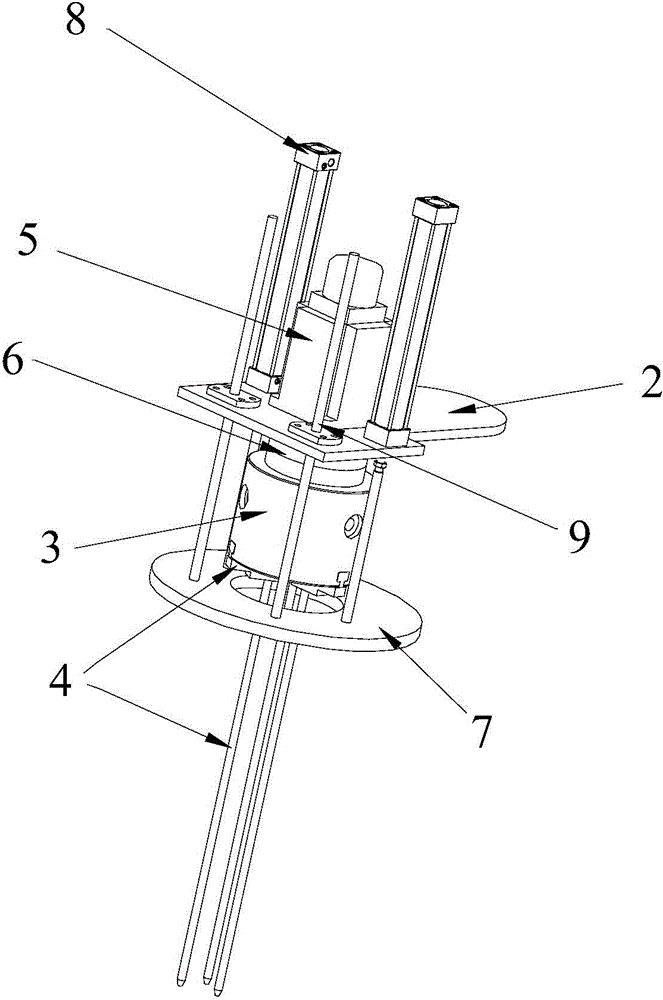

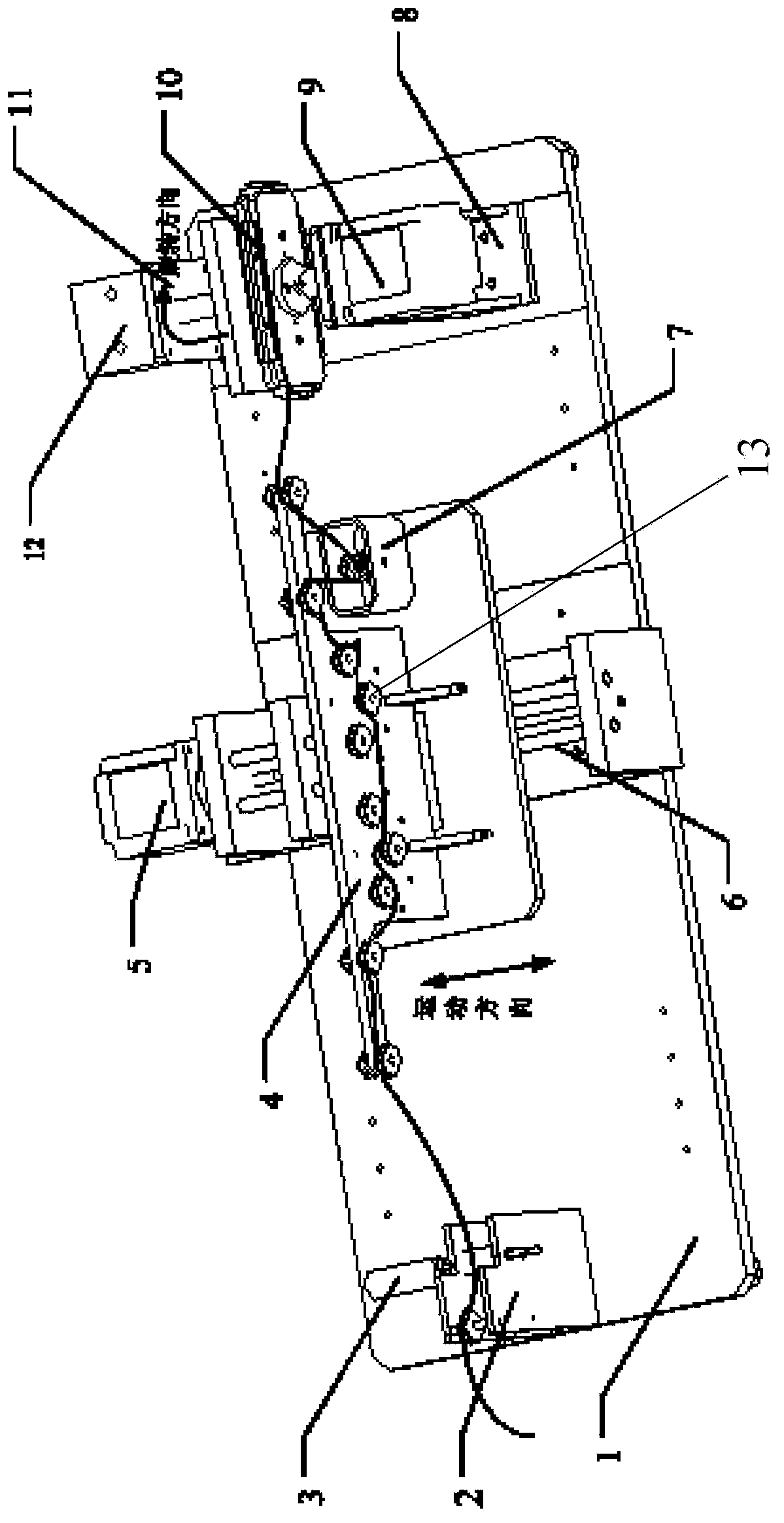

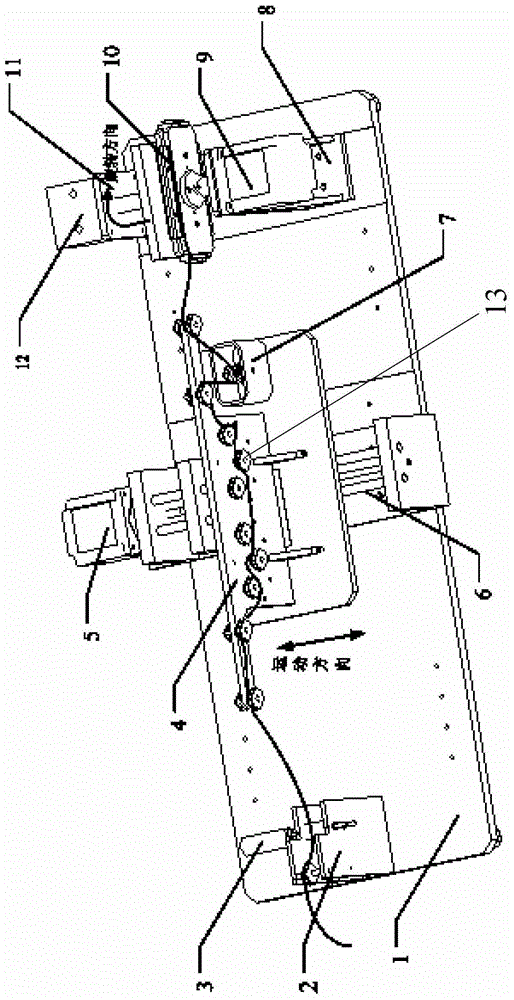

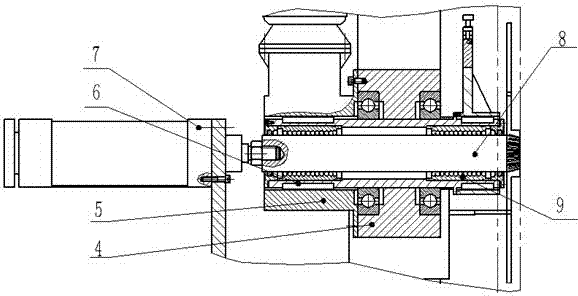

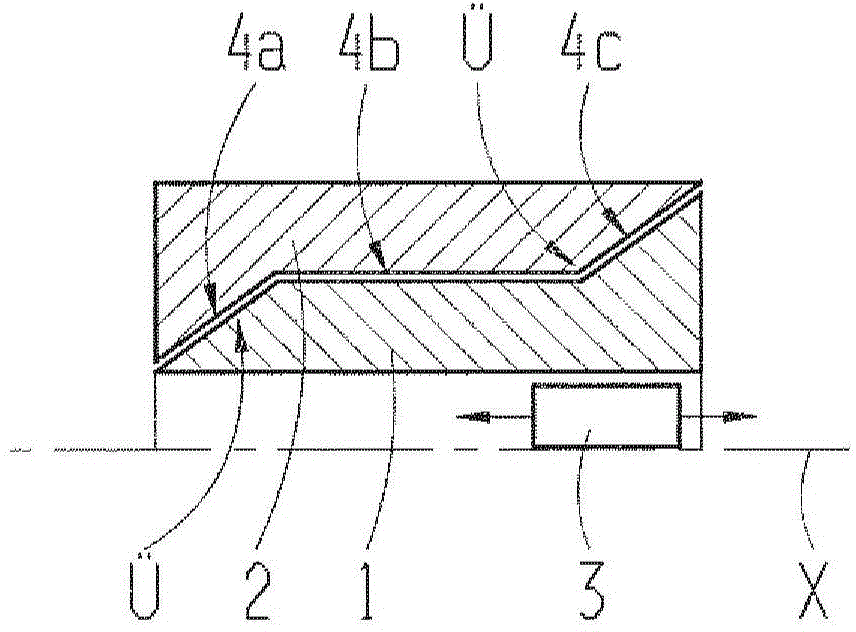

Composite material elbow winding machine control mechanism and winding method thereof

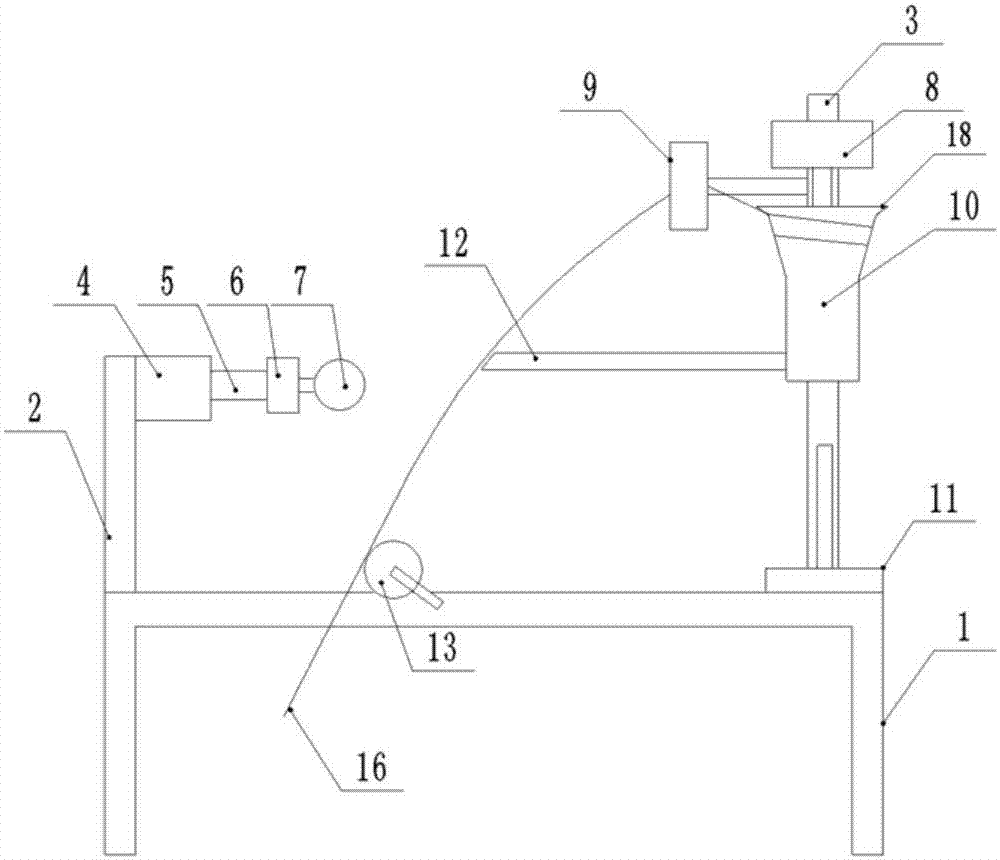

InactiveCN101758621AAchieve windingRealize industrializationTubular articlesWinding machineThree-phase

The invention relates to a composite material elbow winding machine control mechanism and a winding method thereof. The existing multi-shaft winding machine not only has very complicated mechanical structure and locus planning, but also is high in manufacturing cost, thus limiting the industrialized application. The composite material elbow winding machine control mechanism comprises a main shaft three-phase asynchronous machine (1) which is connected with a main shaft (3) by a main shaft speed reducer (2); the main shaft corresponds to a connecting bending pipe core model (4) which corresponds to composite material (5) wound with impregnating resin; the composite material is wound on a wire guide head (6) which is driven by a winding trolley (8) provided with an operation handle (7); and the winding trolley is connected with a glue dipping groove. The invention is used for winding a composite material elbow.

Owner:HARBIN UNIV OF SCI & TECH

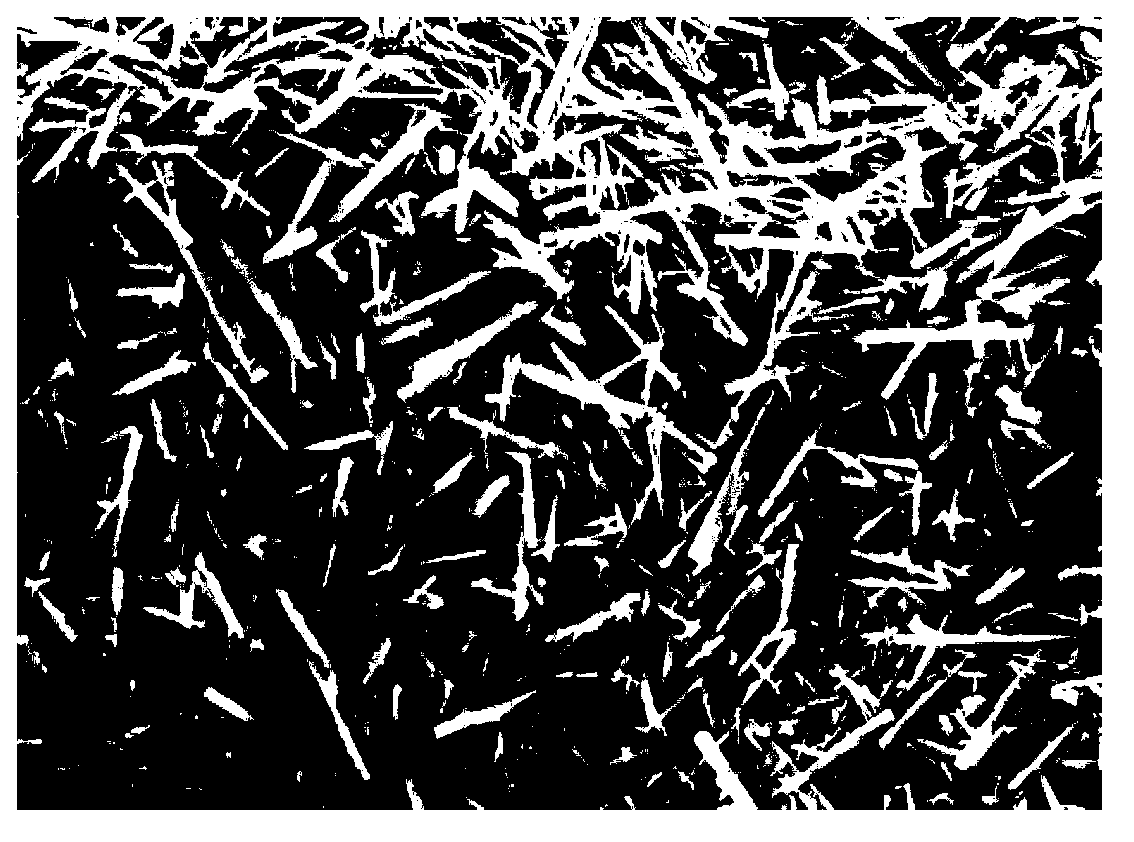

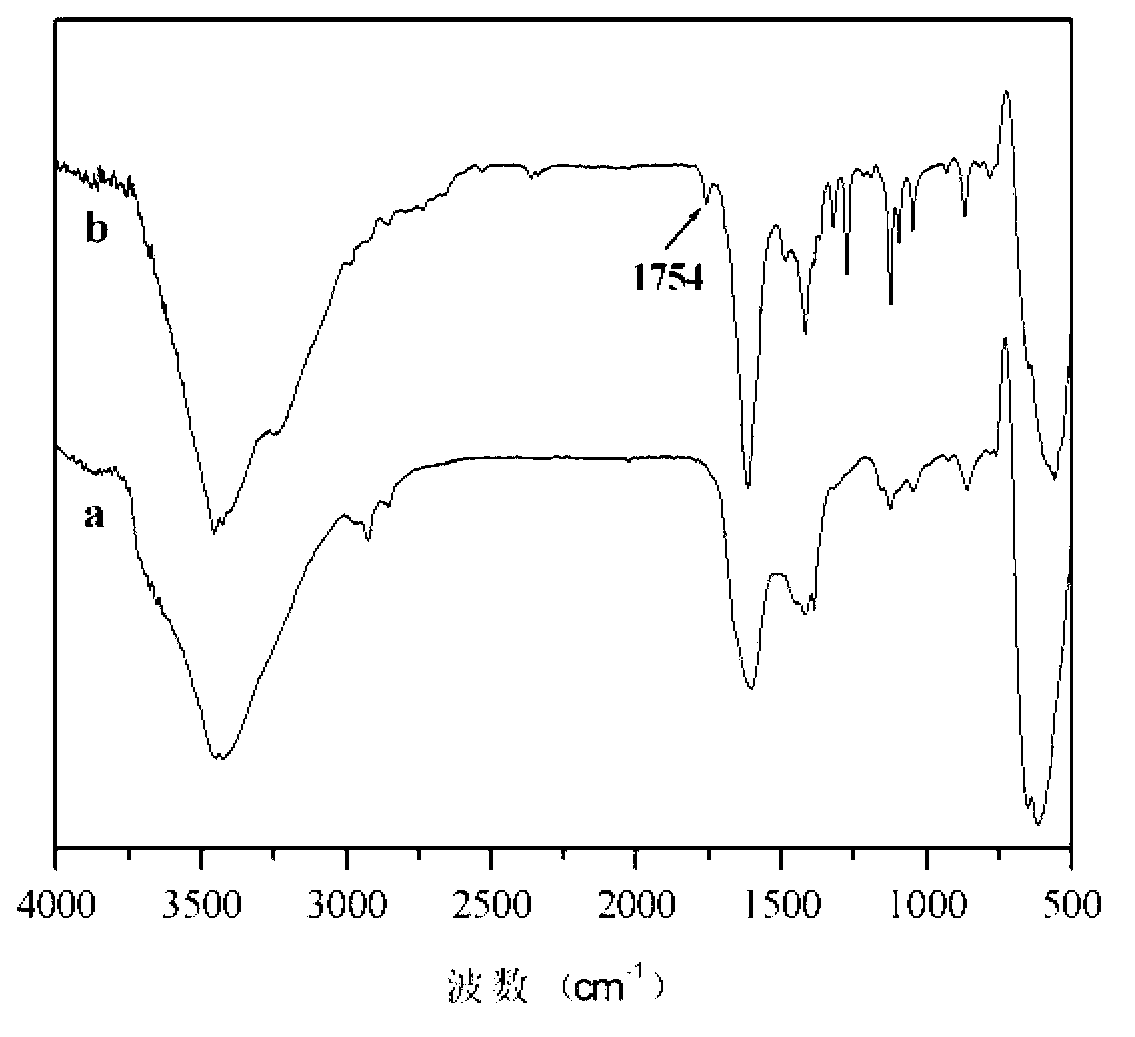

Magnesium oxide whisker/biodegradable polyester composite material and its preparation method and application thereof

ActiveCN103319866AImprove the interface binding forceImprove mechanical strength and modulusProsthesisIn situ polymerizationMagnesium

The invention discloses a magnesium oxide whisker / biodegradable polyester composite material and its preparation method and an application thereof. The composite material contains 0.1-60 wt% of magnesium oxide whisker and 40-99.9 wt% of biodegradable polyester. The magnesium oxide whisker / biodegradable polyester composite material provided by the invention has excellent mechanical properties, good biocompatibility and bone healing-promoting capability. Alkalinity of the magnesium oxide whisker also can regulate and control degradation rate of the biodegradable polyester, neutralize its acidic degradation products and reduce inflammatory response. The magnesium oxide whisker / biodegradable polyester composite material is a novel bone tissue repair material with an excellent osteogenic activity. The preparation method is a solution blended process or a melt blending method by using the magnesium oxide whisker and the biodegradable polyester as raw materials, or an in situ polymerization method by using the magnesium oxide whisker and a cyclic ester monomer as raw materials. According to the invention, preparation cost of the composite material is low; the preparation method is simple; condition is mild; and the preparation method is easy for industrial production.

Owner:JINAN UNIVERSITY

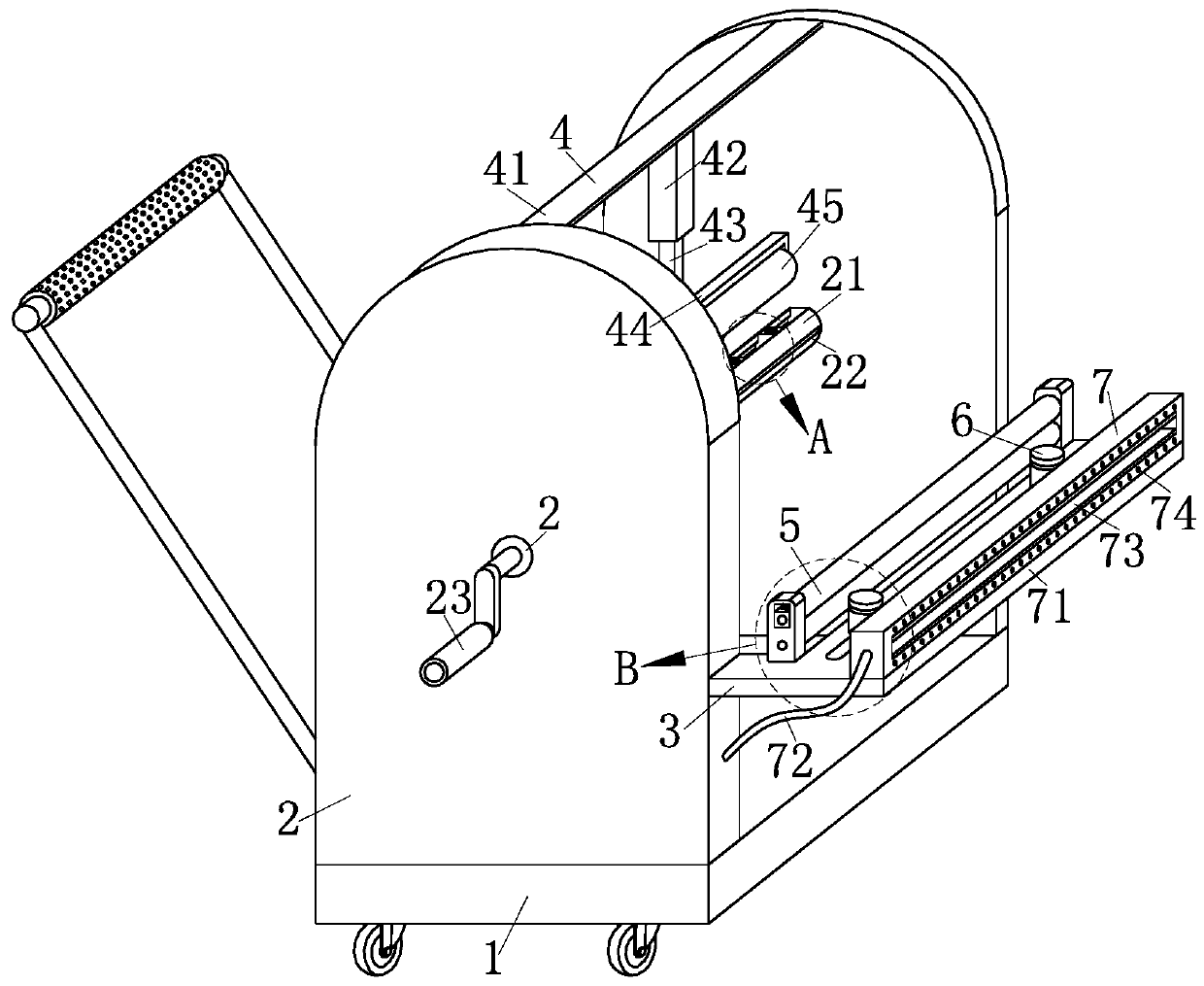

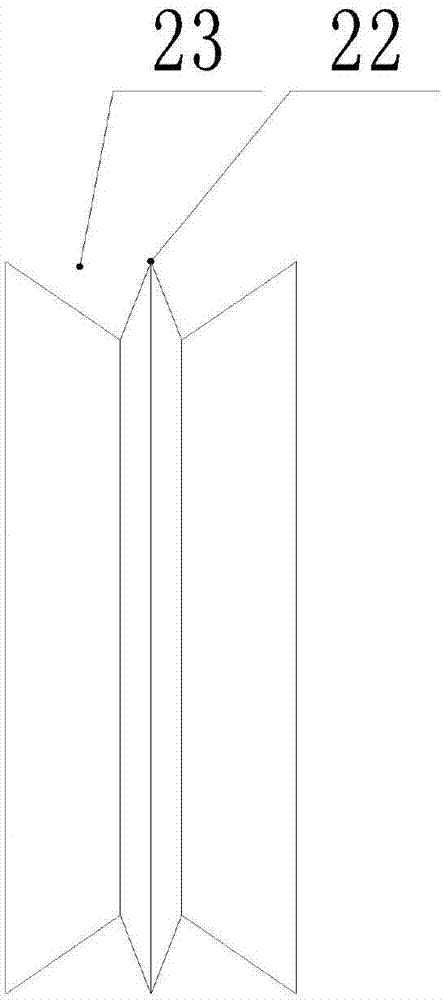

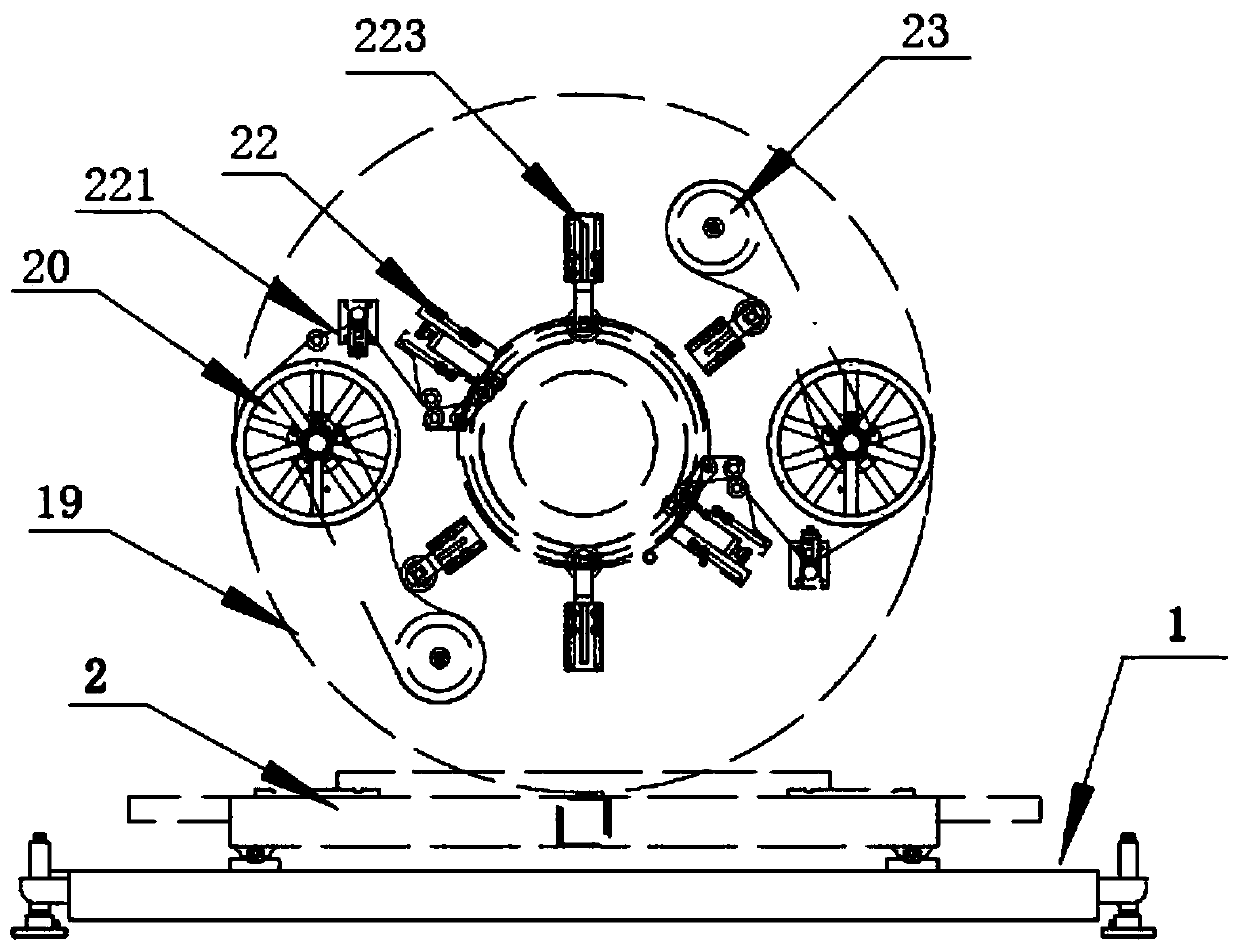

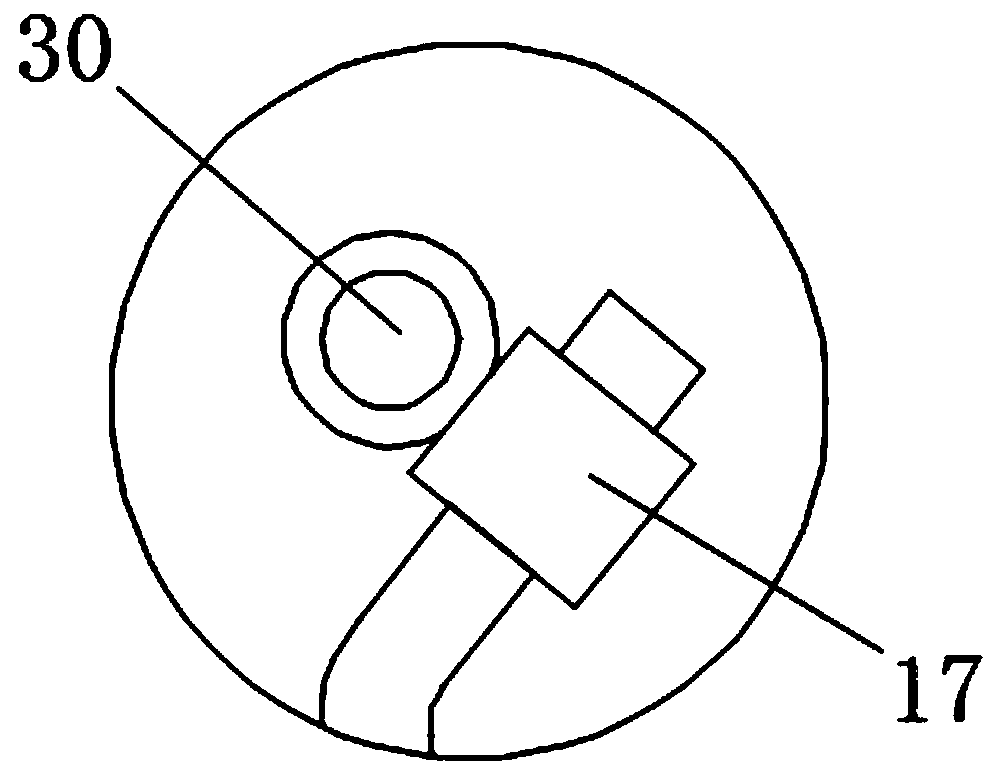

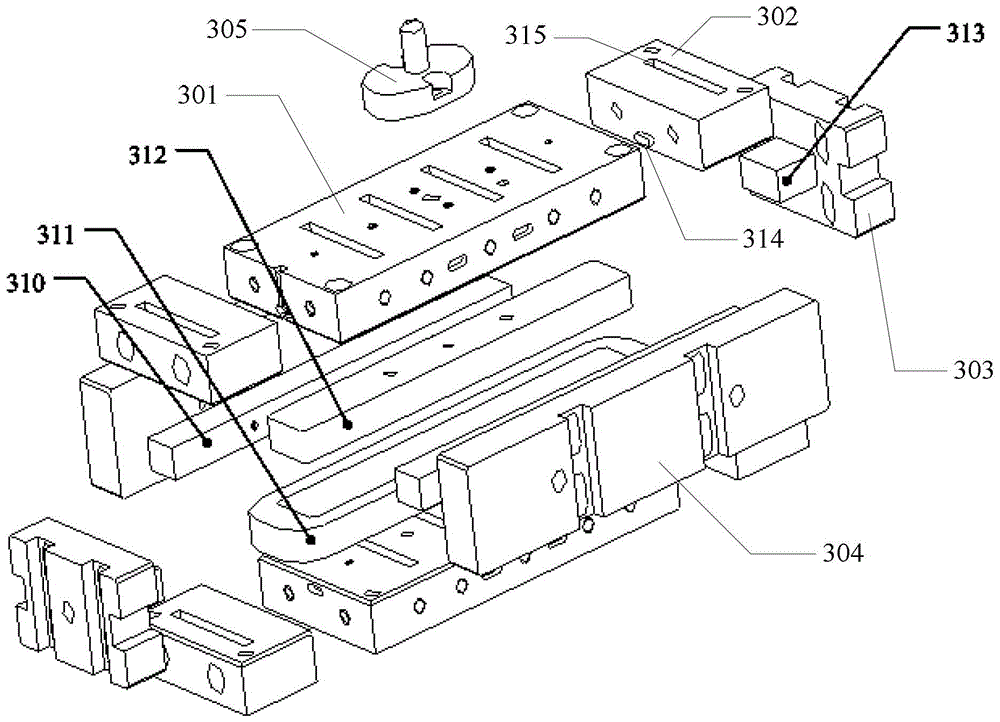

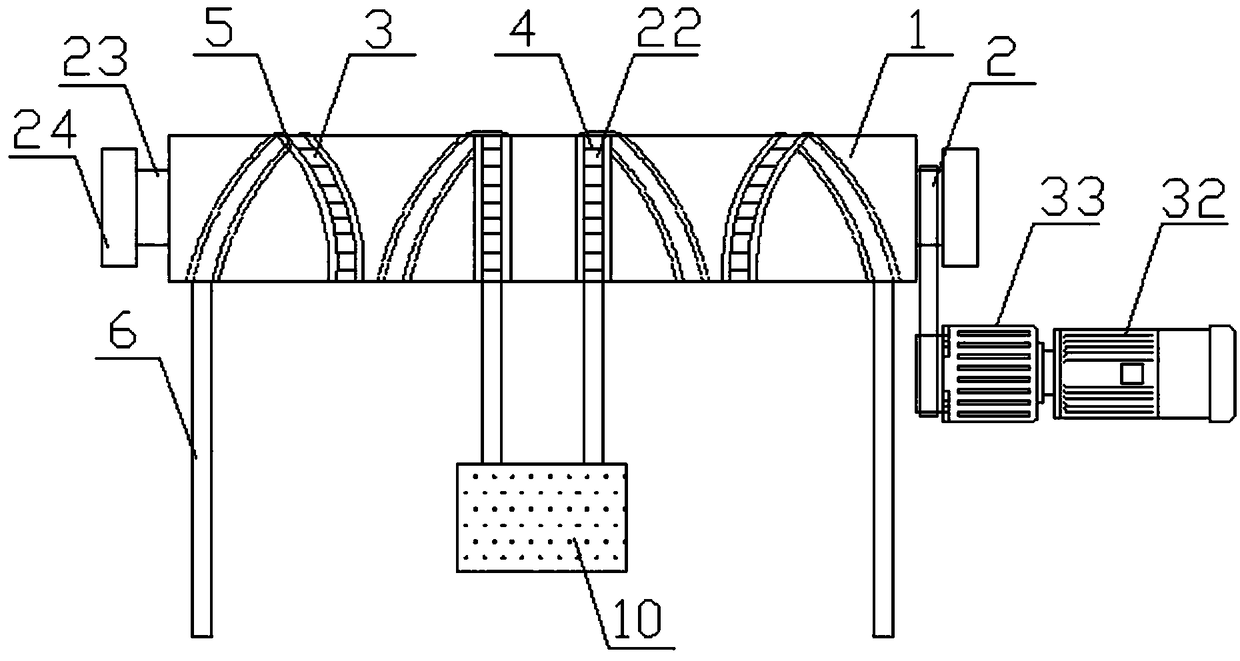

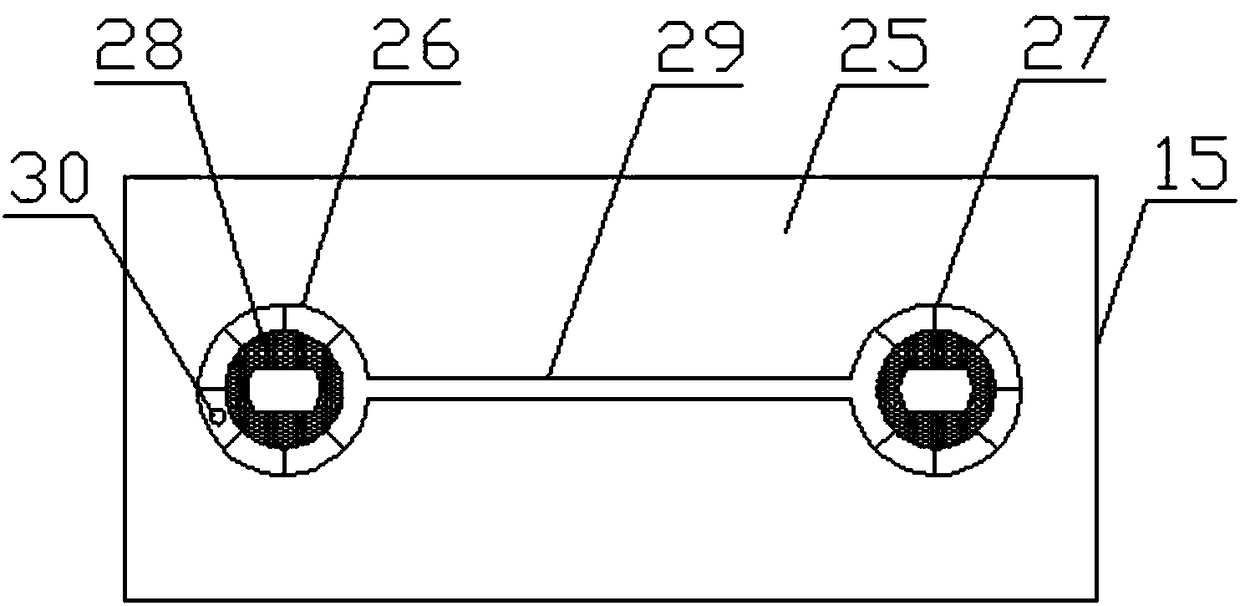

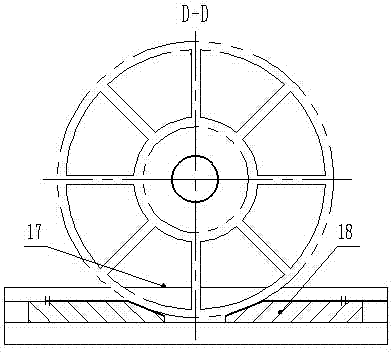

Radial tire bead ring winding machine with six stations

The invention discloses a radial tire bead ring winding machine with six stations, comprising a wire arraying device, a wire feeding device, a wire cutting device and a winding device, wherein the winding device comprises a stand, a sliding shaft driving motor, a sliding shaft, a main shaft, a main shaft driving motor and a speed reducer; a main connecting disk is installed on the main shaft; a plurality of fixed linear rails in an outward radiating form from the center are uniformly distributed on the end face of the main connecting disk; an umbrella stand seat is installed on a sliding block of the linear rail; a hexagonal pyramid-shaped movable umbrella stand is arranged fixedly at the end part of the sliding shaft; a winding module is detachably and fixedly arranged on the umbrella stand seat; and a plurality of wire winding grooves are uniformly distributed along the circumference direction of a cambered surface on the winding module. According to the radial tire bead ring winding machine with six stations disclosed by the invention, six wire winding grooves are arranged on the winding module, thus the bead rings can be wound in the six stations simultaneously, the production efficiency is improved by at least more than 50% compared with two-ring and four-ring winding, bead rings with different diameters can be effectively wound by controlling the positions of the movable umbrella stand and the umbrella stand seat, and the diameter range of the bead rings is 13-25cun.

Owner:TIANJIN SAIXIANG TECH

Temporary winding device with cleaning function and used for gauze production and machining

InactiveCN110626838AGood cleaning effectGuaranteed cleanlinessCleaning using toolsCleaning using gasesMachiningBlow out

The invention relates to the field of gauze production and machining devices, and specifically relates to a temporary winding device with a cleaning function and used for gauze production and machining. The temporary winding device with the cleaning function and used for gauze production and machining comprises a bottom plate, a winding structure, a fixed plate, a compression structure, a flatly-laying structure, a guide structure, a cleaning structure and a side plate. The winding structure is capable of synchronously driving the cleaning structure to work during working, so that a better cleaning effect of the cleaning structure can be achieved; two oppositely-arranged brush plates are fixed into a cleaning sleeve, and cleaning working can be carried out on a gauze being wound, so that impurities on the surface of the gauze can be cleaned, and then the cleanliness of the wound gauze can be ensured; gas blowing holes communicate with the interior of a gas storage groove separately, and therefore, gas in the gas storage groove is blown out via the gas blowing holes, so that ash blowing cleaning working can be carried out before the gauze enters the two brush plates, and then the cleanliness of the wound gauze can be ensured.

Owner:LIXIN FUYA GAUZE CO LTD

Waste cable recovery device

InactiveCN107979032AEasy to scrape awayEnable mobilityApparatus for removing/armouring cablesCopper wireEngineering

The invention belongs to the technical field of cable waste treatment equipment and particularly discloses a waste cable recovery device. The waste cable recovery device comprises a rack, wherein a support rod is arranged at one end of the rack and a bracket is arranged at the other end of the rack; an air cylinder is arranged at the upper end of the support rod; a first motor is arranged on a telescopic pole of the air cylinder; a cutter knife is arranged on an output shaft of the first motor; a second motor and a guide roller are arranged at the upper end of the bracket; a winding roller isarranged on the output shaft of the second motor; the upper end of the winding roller is in an inverted cone form; a horizontal guide hole is formed in the guide roller; a wire spool opposite to the winding roller is arranged on the rack; a horizontal scraper is arranged in the middle of the bracket; and a wire feeding roller in rotational connection is arranged in the middle of the rack. The waste cable recovery device is mainly used for recovering copper wires in waste cables and wires, so that the problem that the recovery efficiency is reduced due to the fact that the peeled copper wires cannot be automatically wound and collected in the recovery process is solved.

Owner:宁波得晴电器科技有限公司

Safe retracting device of cable

The invention discloses a safe retracting device of a cable. The safe retracting device comprises a driving device and a driving shaft, wherein the driving shaft is rotatably sleeved with a wind-up roller; an electric slip ring is arranged on one end of the wind-up roller; the electric slip ring is connected with a connection terminal which is connected with the cable on the wind-up roller; a carbon brush is arranged corresponding to the electric slip ring, connected with the external cable and fixedly mounted; a friction clutch is arranged between the driving shaft and the wind-up roller; when the cable is wound up, the driving device drives the driving shaft to rotate, and if the friction force of the friction clutch is larger than traction force and weight of the cable, the driving shaft drives the wind-up roller to turn through the friction clutch, in order to enable the wind-up roller to automatically wind up; when the cable is paid off, the wind-up roller is continuously located at the wind-up state, but the traction force and the weight of the cable are larger than the friction force of the friction clutch, and the wind-up roller is pulled by the traction force of the cable and located at the reverse turning state, thus the cable is passively paid off by the wind-up roller. In the working process, the safe retracting device keeps the cable at a certain tension, thereby preventing the cable from tying knot, twisting and being torn down. The safe retracting device is safe and convenient to use.

Owner:潍坊金丝达环境工程股份有限公司

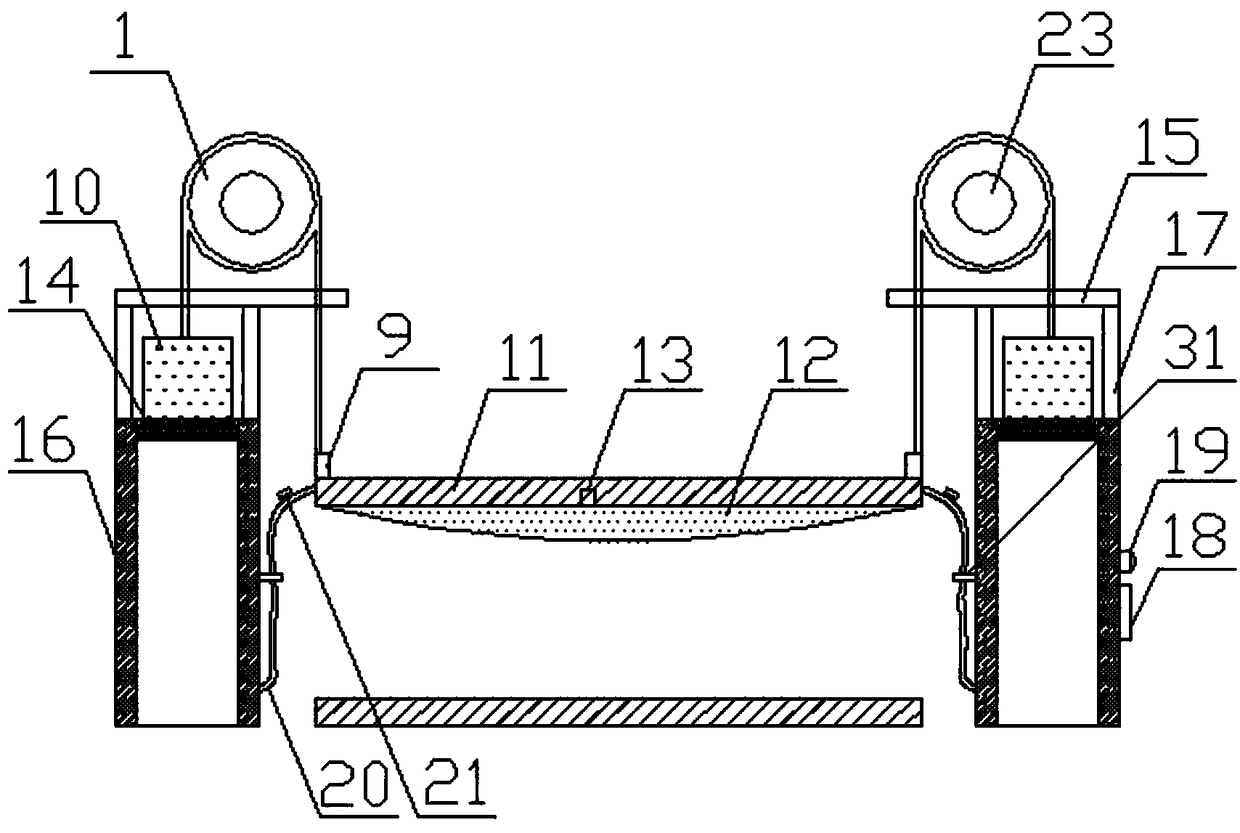

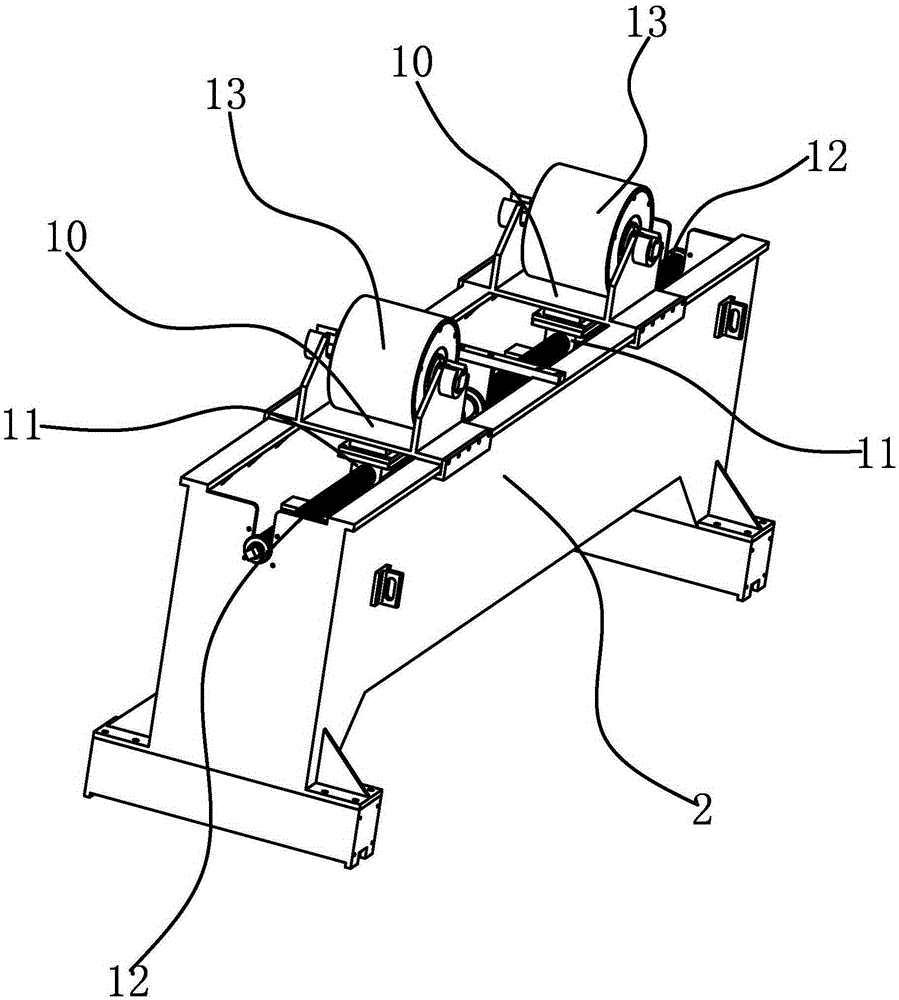

Uninterrupted steel wire winding device for production of PE reinforced composite pipe

The invention relates to the field of plastic processing, and discloses an uninterrupted steel wire winding device for production of a PE reinforced composite pipe. The uninterrupted steel wire winding device comprises a base, two sliding rails are welded to the top of the base, sliding blocks are slidably connected into the two sliding rails correspondingly, a sliding trolley is welded between the two sliding blocks, a traction block is welded to the bottom of the sliding trolley, a screw hole corresponding to a lead screw is formed in the right side of the traction block, a fixing block is welded to the right side of the top of the base, and a motor is mounted on the right side of the fixing block. According to the uninterrupted steel wire winding device for production of the PE reinforced composite pipe, uninterrupted winding is achieved, in this way, a fault of a steel wire wound around the PE pipe is prevented, the production efficiency of the PE pipe is improved, the scrap rate is decreased, and the production cost is saved.

Owner:JIANGSU COCON TECH

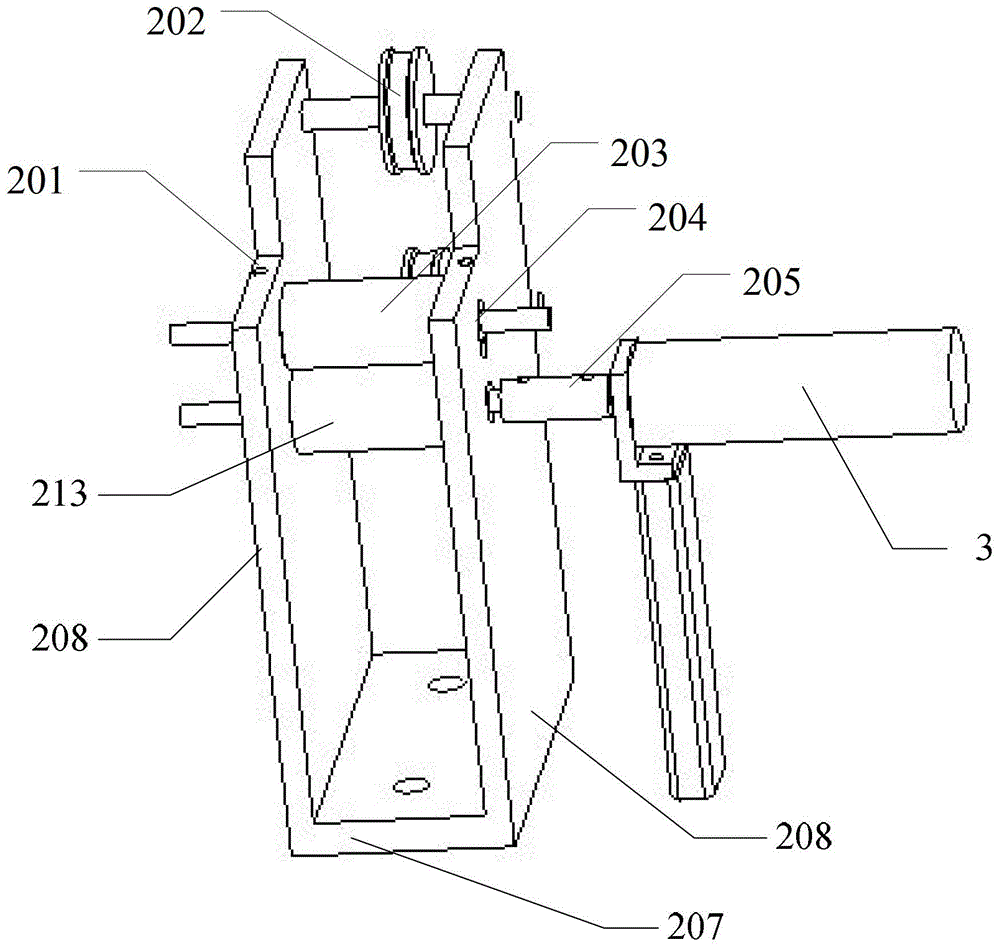

Robot gripper for roll material

InactiveCN104828610AAchieve windingRealize fully automatic windingProgramme-controlled manipulatorFilament handlingEngineeringConductor Coil

The invention provides a robot gripper for a roll material. The gripper is mounted at the movable end of a robot, and is used for fixing a roll material shaft to wind the material. The robot gripper comprises a connecting plate connected with the movable end of the robot, a fixing device for supporting the inner cavity of the roll material shaft so as to fix the roll material shaft and a driving device for driving the fixing device to rotate; the driving device is arranged on the connecting plate and is connected with the fixing device, so that the fixing device is driven to rotate so as to wind the material. The robot gripper for the roll material provided by the invention is simple in structure, high in universality and high in flexibility, multidirectional and multi-angle full-automatic winding and coil discharging can be realized, manual intervention and assist are not needed, and thus the efficiency and quality of material winding are effectively improved.

Owner:广东泰格威机器人科技有限公司

Spinning device facilitating automatic thread winding

The invention discloses a spinning device facilitating automatic thread winding. The spinning device comprises a left support and a second rotary shaft. The right end of the left support is connectedwith a first supporting plate. Supporting shafts are fixed to the upper end of the first supporting plate. The upper end of each spinning bobbin is connected with an upper shell. The middle end of theleft support is provided with a first threading hole. A horizontal support is internally provided with a second threading hole. The upper end of a right support is fixedly provided with a second supporting plate. The outer surfaces of clamping blocks are connected with connecting plates. The upper ends of the connecting plates are connected with first rotary shafts. The rear portions of the firstrotary shafts are connected with winding reels. A second rotary shaft is located in the winding reels. The outer surface of the left end of the esc rotary shaft is connected with a second fixed sleeve. The spinning bobbins and the winding reels of the spinning device facilitating automatic thread winding are convenient to assemble and disassemble. The spinning device facilitating automatic threadwinding is uniform in thread winding, high in working efficiency, capable of winding multiple coils of threads simultaneously and automated in the whole process.

Owner:嘉兴市大众丝绸印花有限责任公司

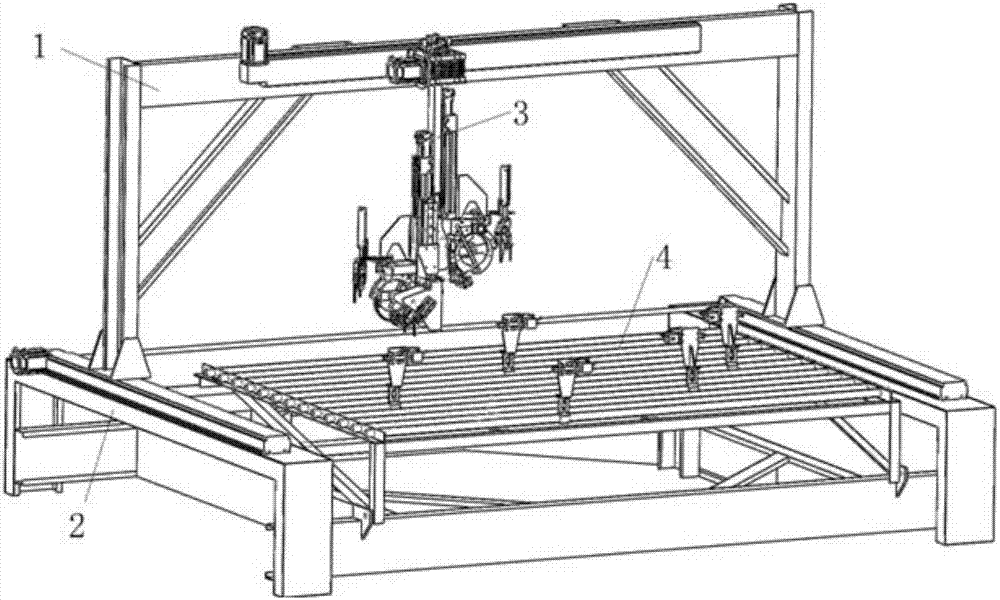

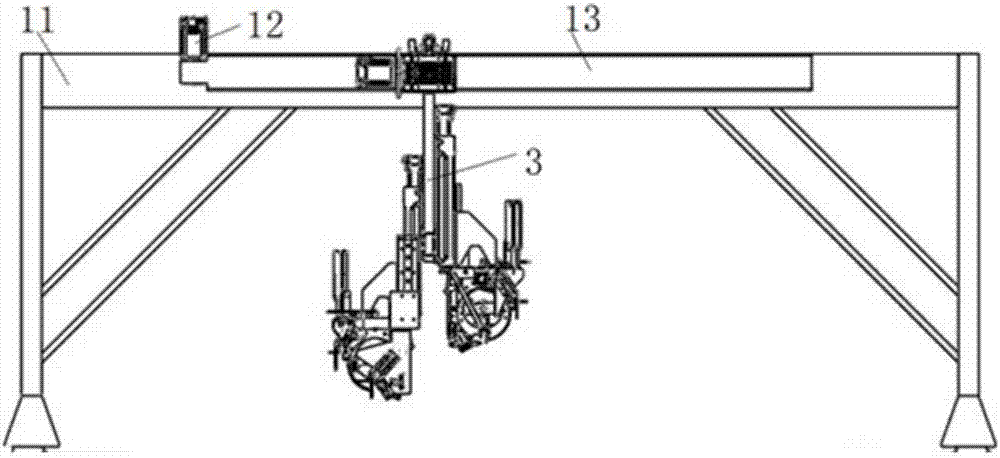

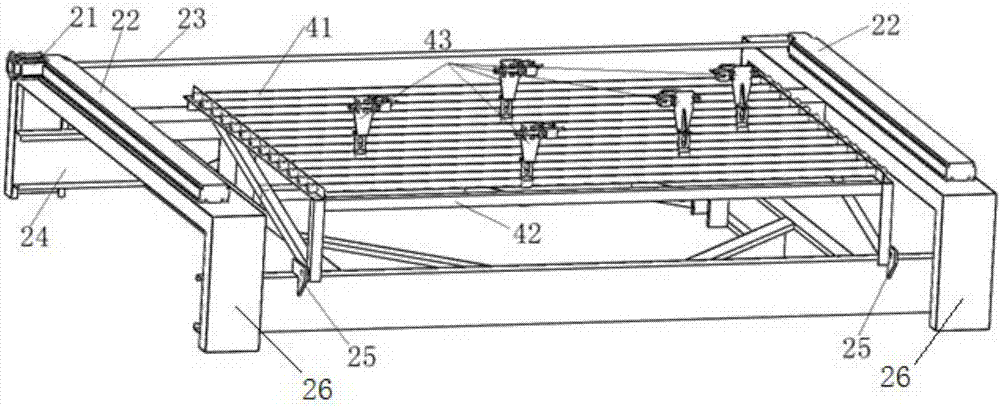

Fully automatic wire harness winding machine

ActiveCN107123482AIncrease the level of automationReduce spendingManufacturing wire harnessesWinding machineEngineering

The invention discloses a fully automatic wire harness winding machine. The fully automatic wire harness winding machine comprises a portal frame, an equipment base, a tape winding mechanism and work tables, the equipment base is provided with the portal frame moving along the y-axis direction of a longitudinal synchronous belt module, the equipment base is also provided with a work tables on a plurality of self-provided wire harness ends, a belt winding mechanism moving along the x-axis direction of a transverse synchronous belt module is arranged on a beam of the portal frame above the work table, wherein the tape winding mechanism moves along the z-axis direction of a screw rod module and comprises a winding mechanism, a wire harness mechanism and a wire smoothing mechanism, and a tape cutting device is arranged on the winding mechanism. The winding mechanism moves in the x-axis, y-axis and z-axis directions, and performs wrapping, encrypted or fixed-point winding work on the wire harness. The fully automatic wire harness winding machine can finish the automatic tape winding of multi-branch wire harness, the enterprise automation level is greatly improved and the labor cost expenditure is reduced.

Owner:SHANGHAI INST OF TECH +1

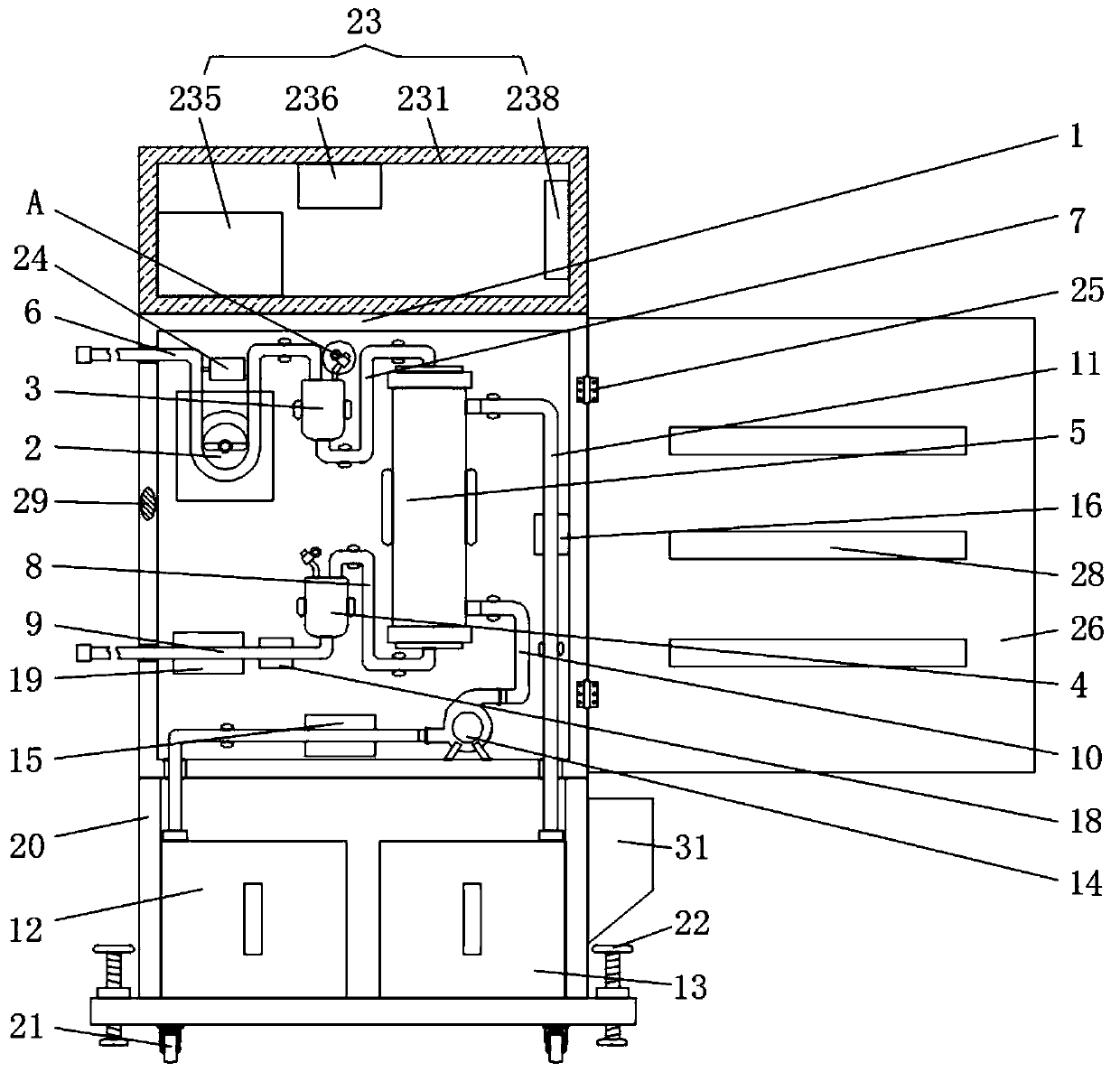

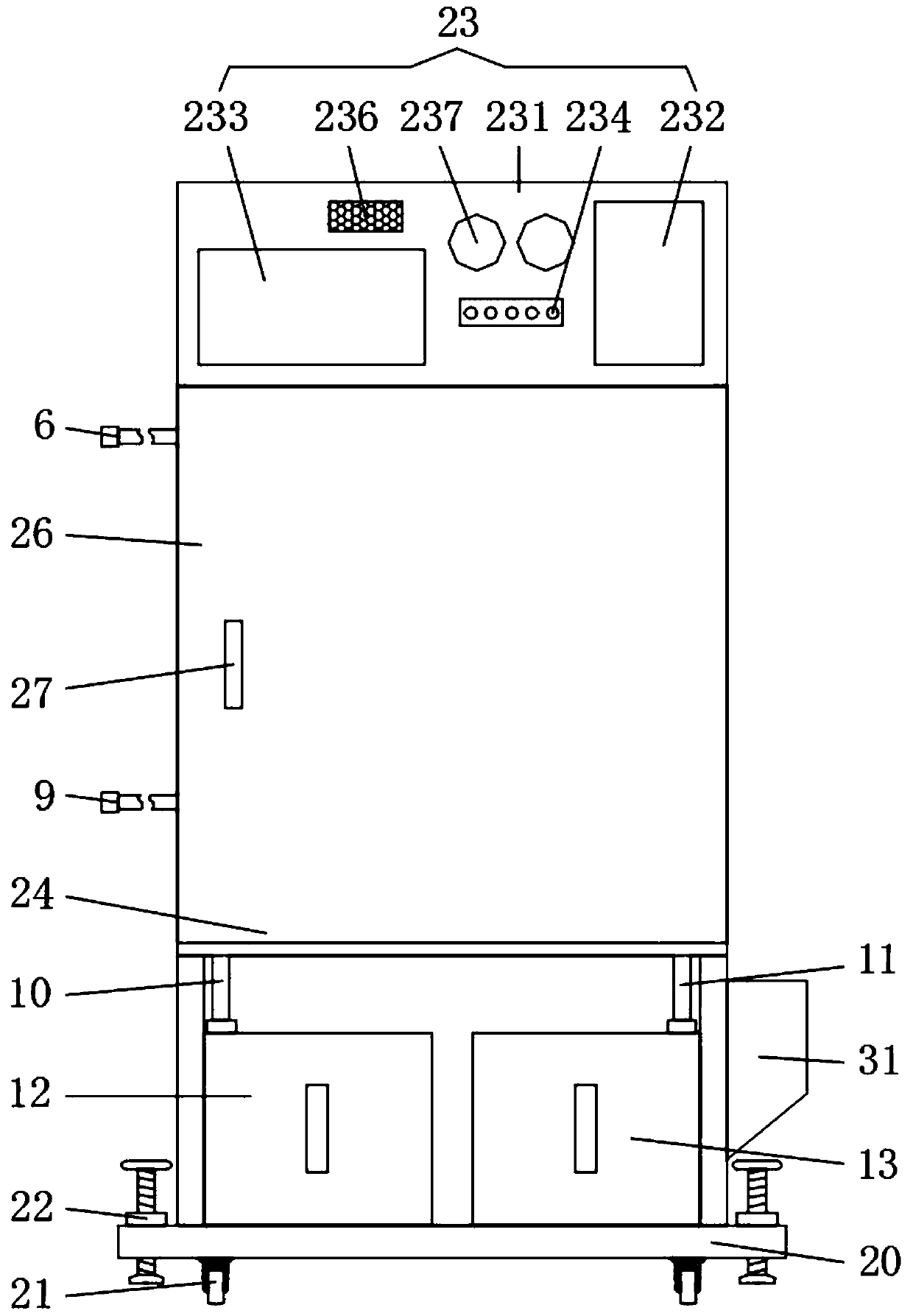

Hemodialysis device for hematology department

InactiveCN109663160AEnsure blood circulationEasy to install and disassembleOther blood circulation devicesDialysis systemsHematology departmentDialysis fluid

The invention discloses a hemodialysis device for the hematology department and relates to the technical field of medical instruments. The hemodialysis device comprises a frame, wherein the surface ofthe frame is separately provided with a blood pump, an arterial jug, a venous jug and a dialyzer, a liquid inlet pipe is arranged in the blood pump, one side of the liquid inlet pipe is communicatedwith the upper portion of the arterial jug, the bottom of the arterial jug is communicated with the top of the dialyzer through a first hose, and the bottom of the dialyzer is communicated with the top of the venous jug through a second hose; the bottom of the venous jug is communicated with a liquid outlet pipe, and a dialysate inlet and dialysate outlet of the dialyzer are communicated with a dialysate liquid inlet pipe and a dialysate liquid outlet pipe respectively. The hemodialysis device for the hematology department solves the problems that hemodialysis devices applied at present comprise a lot of dialysis pipes and are complicated to operate, the dialysis pipes are mostly exposed, patients are likely to be uncomfortable if the external temperature is low when blood is returned to the bodies of the patients, and meanwhile, since medical personnel need to wipe the hemodialysis device bodies for disinfection, the work load of the medical personnel is large.

Owner:韩东

Cable winding device

The invention discloses a cable winding device which comprises a bracket, a winding rod, a guide component and a driving component, wherein a thread hole is formed in the bracket; the winding rod is provided with a rotating thread matched with the thread hole; the winding rod is arranged in the thread hole through the rotating thread, so that the winding rod can move relative to the bracket along the axial direction of the winding rod when winding a cable; the guide component is arranged on the bracket to limit side movement of the cable when the cable is wound; the driving component is connected with the winding rod and is used for driving the winding rod to rotate. According to the cable winding device, the driving component is used for driving the winding rod to wind the cable, so that the efficiency is higher; manual winding by a laboratory technician is not needed; fatigue of the laboratory technician and superposition of the cable which are caused by the manual winding are avoided.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

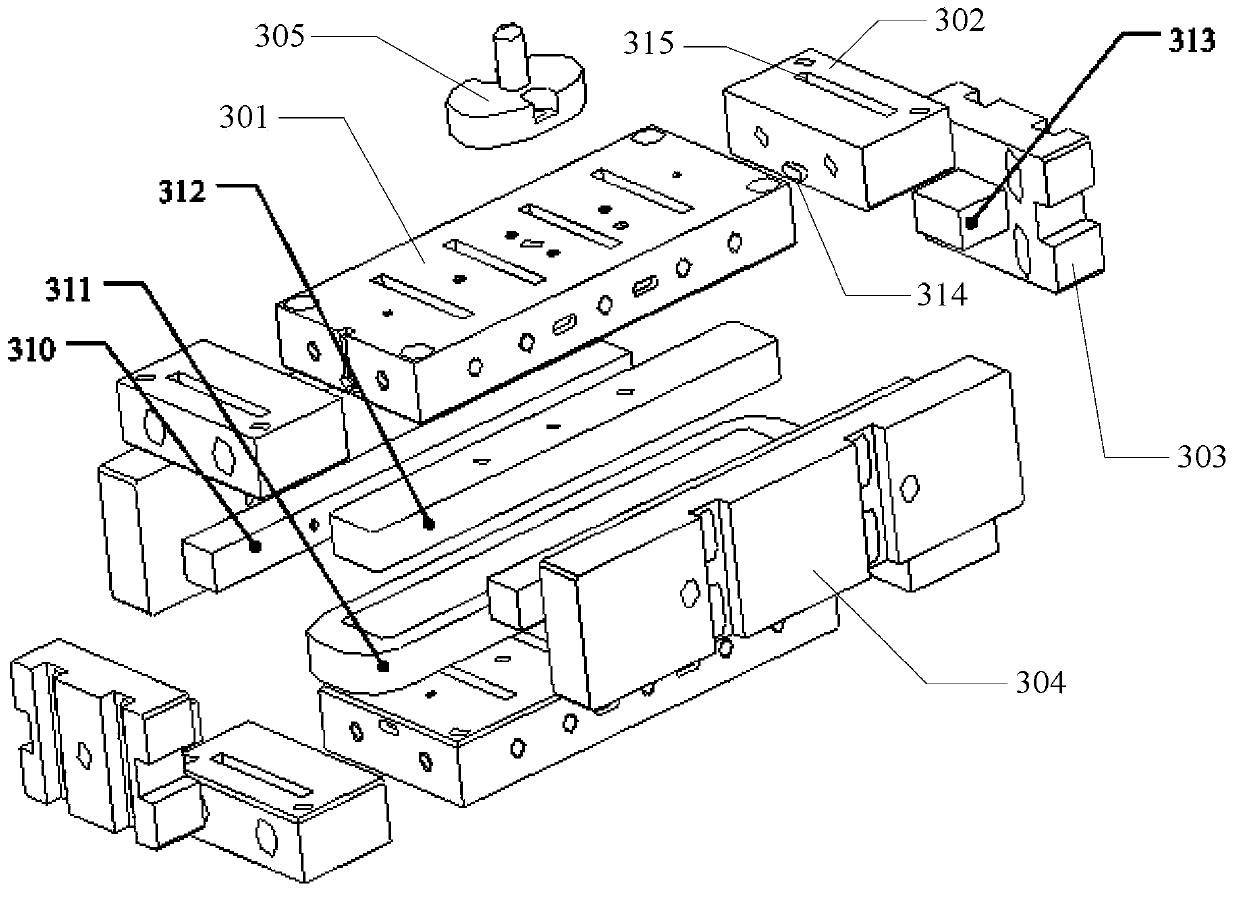

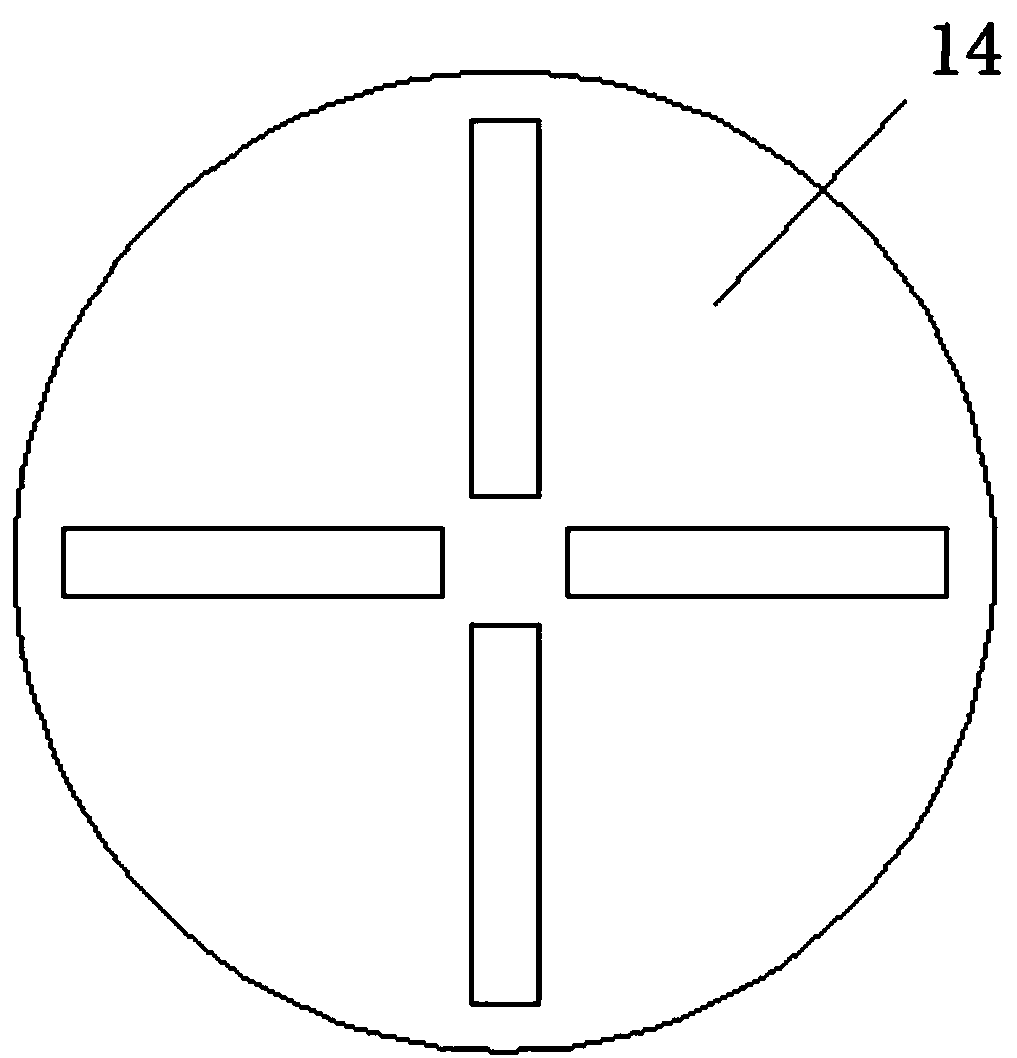

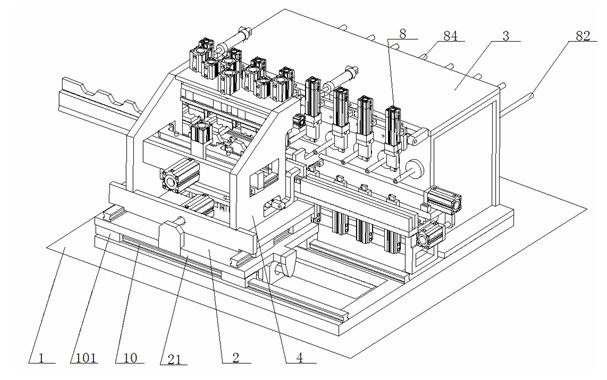

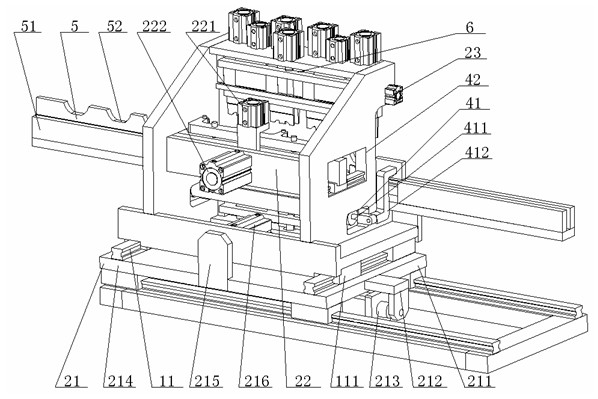

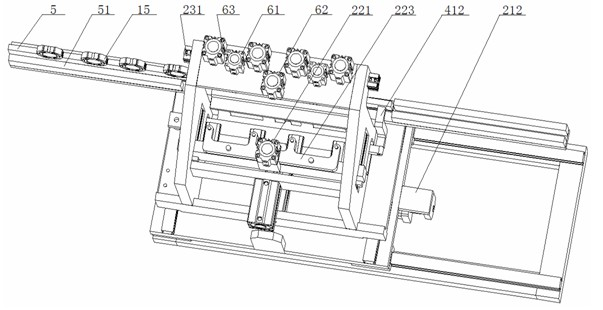

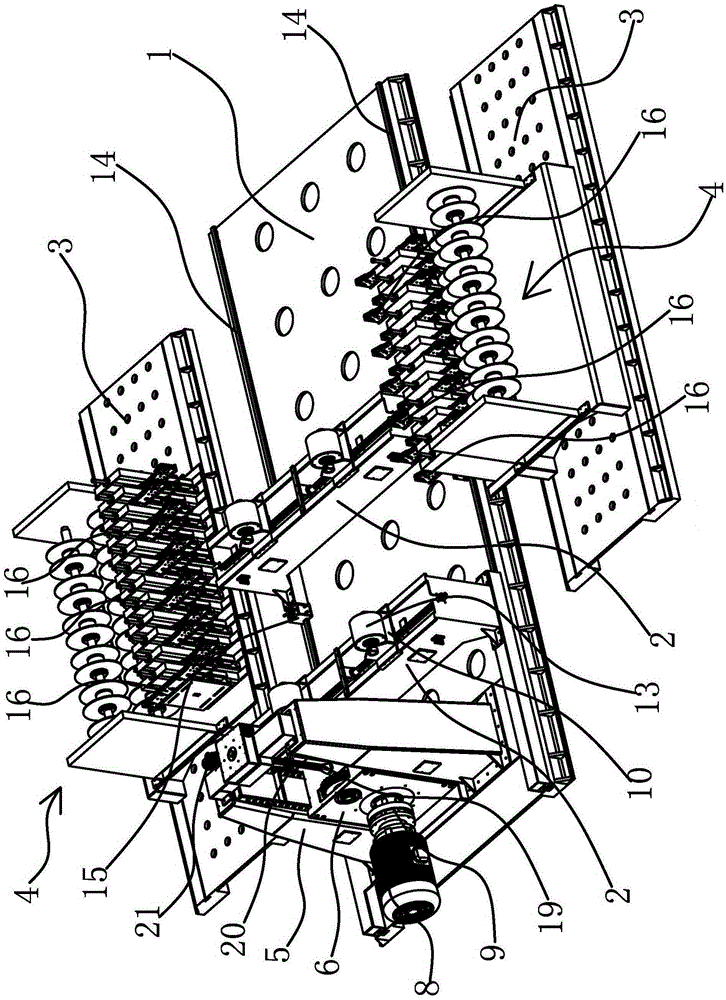

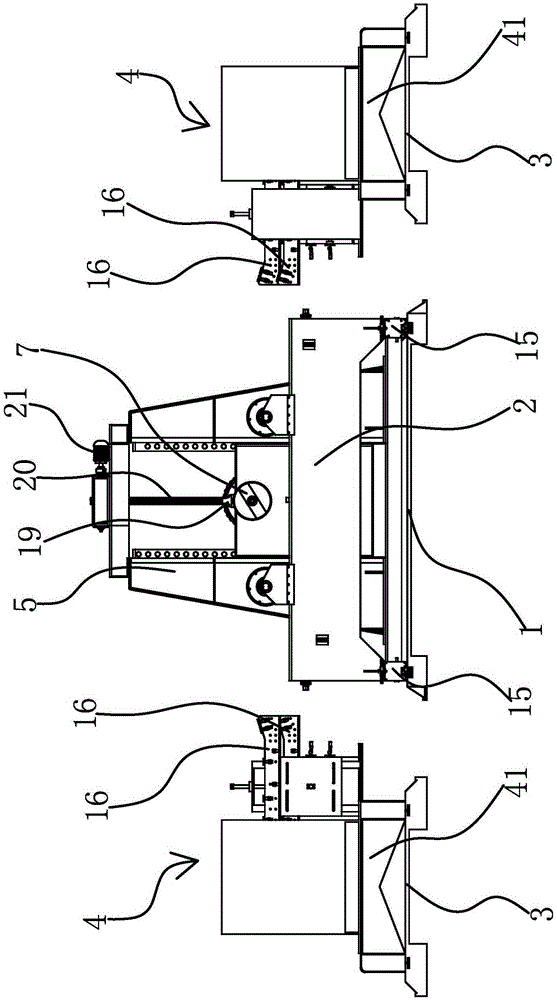

Linear and planar motor coil winding device and method

ActiveCN104184276AWinding is accurate and effectiveControl the speed of deliveryManufacturing dynamo-electric machinesEngineeringMotor drive

The invention provides a linear and planar motor coil winding device for winding flat or circular varnished wires. The winding device comprises a wire-pressing device, a wire-passing mechanism and a winding mechanism. The wire-passing mechanism comprises a wire-passing panel and a wire-passing wheel array. The winding mechanism comprises a winding mould and a winding motor. The wire-passing wheel array is arranged on the surface of a wire-passing panel. The varnished wires are delivered to the wire-passing wheel array through the wire-pressing device; and the varnished wires are further delivered to the winding mould through the wire-passing wheel array. The winding motor drives the winding mould to rotate. The varnished wires are wound on the winding mould through the rotation of the winding mould. Through the arrangement of the wire-pressing device and the wire-passing mechanism, pretightening force is provided for the varnished wires, and thus the transmission speed of the varnished wires can be better controlled; and meanwhile, the winding motor is used to drive the winding mould to rotate so as to realize the winding of the varnished wires, and thus the defects of pure manual operation in the prior art are prevented.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Wiring harness tightening device

InactiveCN101656388AAchieve windingHigh degree of automationLine/current collector detailsManufacturing efficiencyStator

The invention belongs to electrical machine equipment, and in particular relates to a wiring harness tightening device, which is used for a stator lead on a wiring terminal crimping machine. The device is characterized in that a base plate is provided with a support which supports and fixes a vertical moving cylinder; a piston rod of the vertical moving cylinder is connected with a bearing inner core; the bearing inner core is provided with a bearing which is connected a bearing sleeve; the base plate is provided with two support riser plates; each of the support riser plates is provided witha wiring harness tightening teleflex through the bearing; a pull rod spindle is sleeved in the wiring harness tightening teleflex; one end of the pull rod spindle is provided with a fixed head of a connecting plate, while the other end is fixedly connected with the bearing sleeve; and the fixed head of the connecting plate is provided with a wiring harness tightening mechanism. The device has theadvantages of high automation degree, strong reliability of welding or sleeving of the wiring terminal, high manufacturing efficiency and long service life.

Owner:LONGKOU ZHONGJI ELECTRICAL MACHINERY

Logistics packing device

InactiveCN107745836AEasy to operateAchieve windingWrapping with article rotationLogistics managementEngineering

Owner:CHENG DU XIN AO GUAN MEDICAL EQUIP

Linear and planar motor coil winding apparatus and method

ActiveCN104184276BControl the speed of deliveryEasy to limitManufacturing dynamo-electric machinesMotor driveEngineering

The invention provides a linear and planar motor coil winding device for winding flat or circular varnished wires. The winding device comprises a wire-pressing device, a wire-passing mechanism and a winding mechanism. The wire-passing mechanism comprises a wire-passing panel and a wire-passing wheel array. The winding mechanism comprises a winding mould and a winding motor. The wire-passing wheel array is arranged on the surface of a wire-passing panel. The varnished wires are delivered to the wire-passing wheel array through the wire-pressing device; and the varnished wires are further delivered to the winding mould through the wire-passing wheel array. The winding motor drives the winding mould to rotate. The varnished wires are wound on the winding mould through the rotation of the winding mould. Through the arrangement of the wire-pressing device and the wire-passing mechanism, pretightening force is provided for the varnished wires, and thus the transmission speed of the varnished wires can be better controlled; and meanwhile, the winding motor is used to drive the winding mould to rotate so as to realize the winding of the varnished wires, and thus the defects of pure manual operation in the prior art are prevented.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

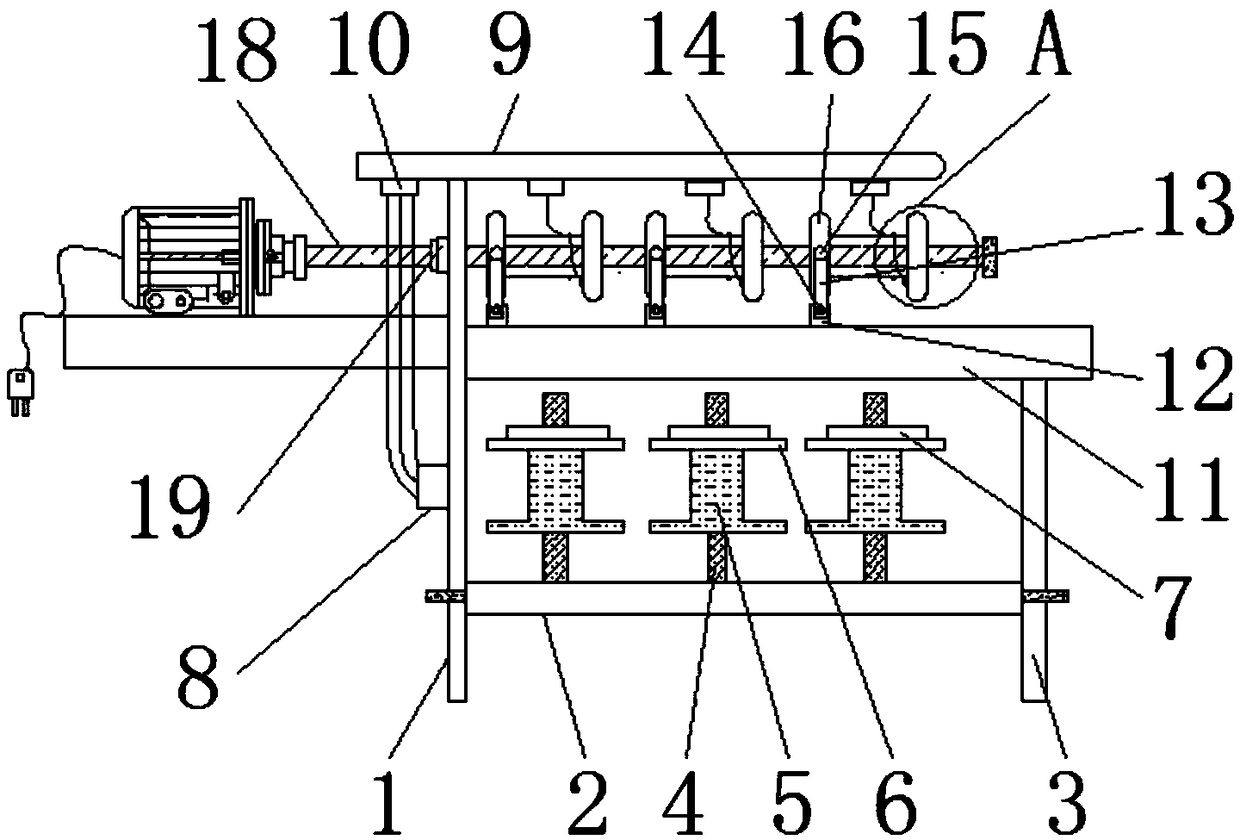

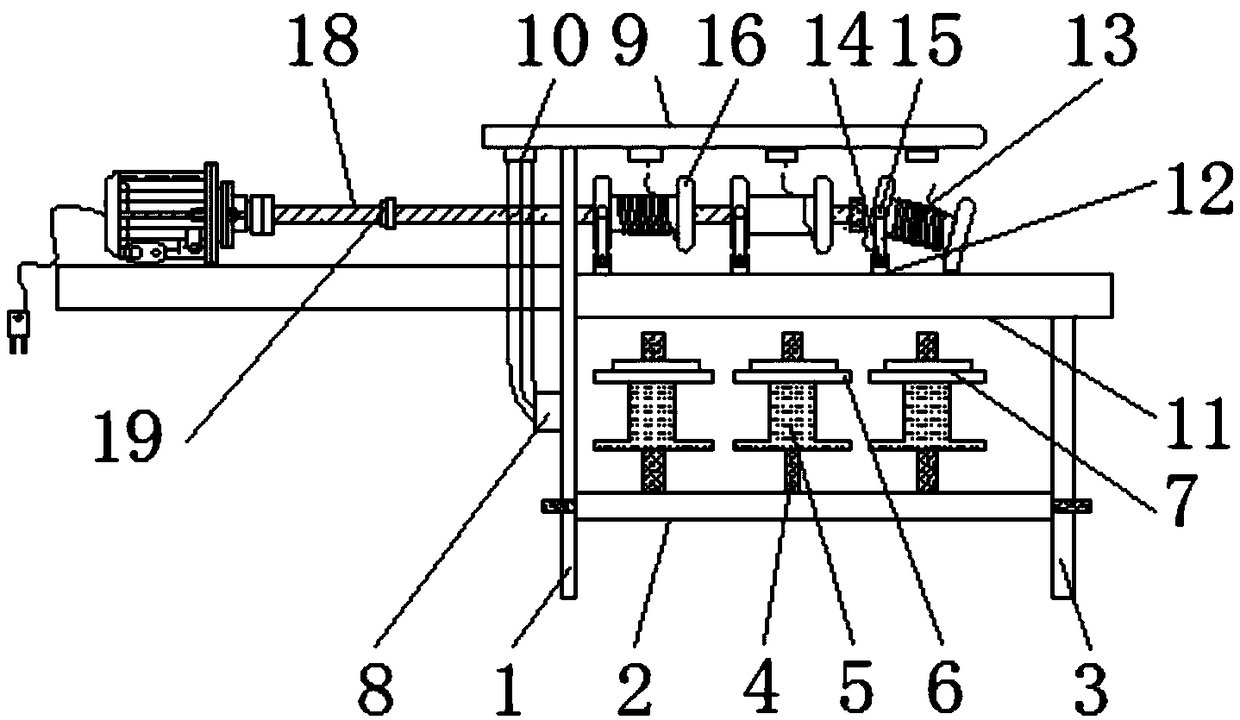

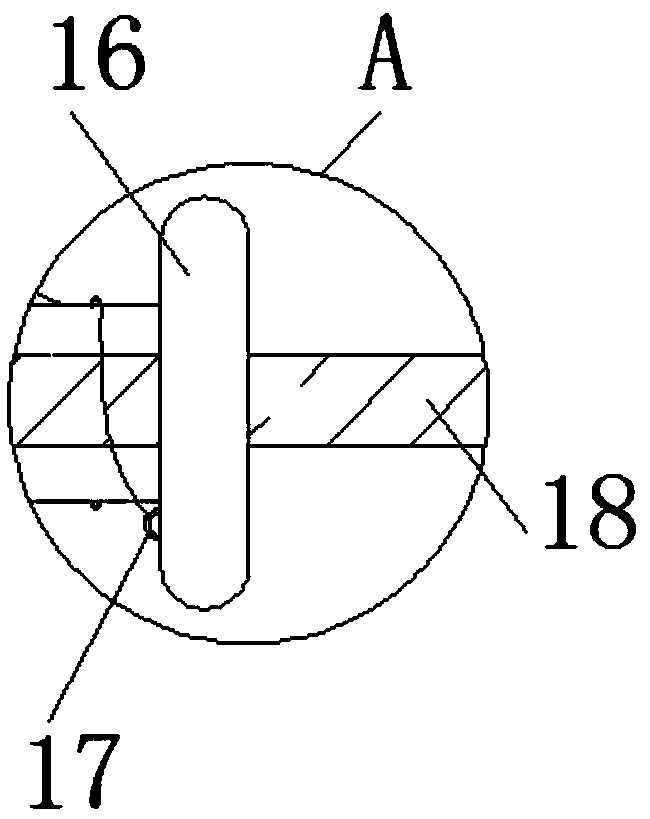

Full-automatic multi-station double-wire diameter winding machine and using method thereof

InactiveCN102104300AAchieve windingImprove efficiencyManufacturing dynamo-electric machinesWinding machineEngineering

The invention discloses a full-automatic multi-station double-wire diameter winding machine. The full-automatic multi-station double-wire diameter winding machine comprises a base, a stator fixing and moving device, and a stator winding and trimming device, wherein the stator fixing and moving device comprises a sliding mechanical frame, a stator locking strip, a stator fixing part and a first line mode assembly hand; the stator winding and trimming device comprises a drive chassis, a winding rod, a second line mode assembly hand and a trimming part; and the winding rod comprises a primary-winding winding rod and a secondary-winding winding rod around which different wire-diameter windings are wound. The using method of the machine comprises a preorder preparation process, a stator chip fixing process, a line mode assembly process, a primary winding process, a primary trimming process, a secondary winding process, a secondary trimming process, a line mode demolishing process and a stator chip collection process which are performed fully automatically in turn. The design not only can realize the winding of a plurality of windings with different wire diameters and high production efficiency, but also is convenient to use and maintain and has small working space.

Owner:DONGGUAN CAIBEI ELECTRICAL EQUIP TECH

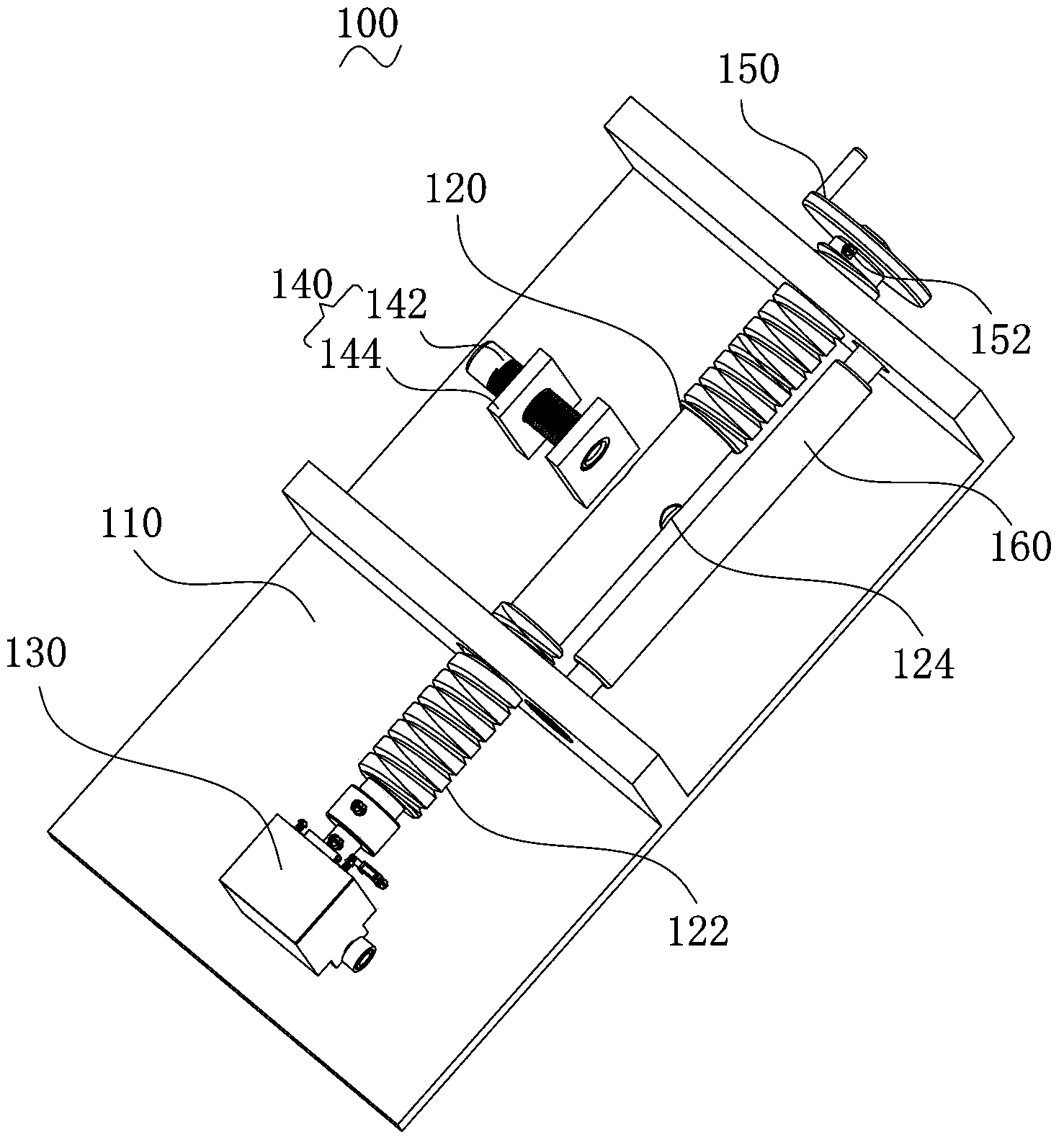

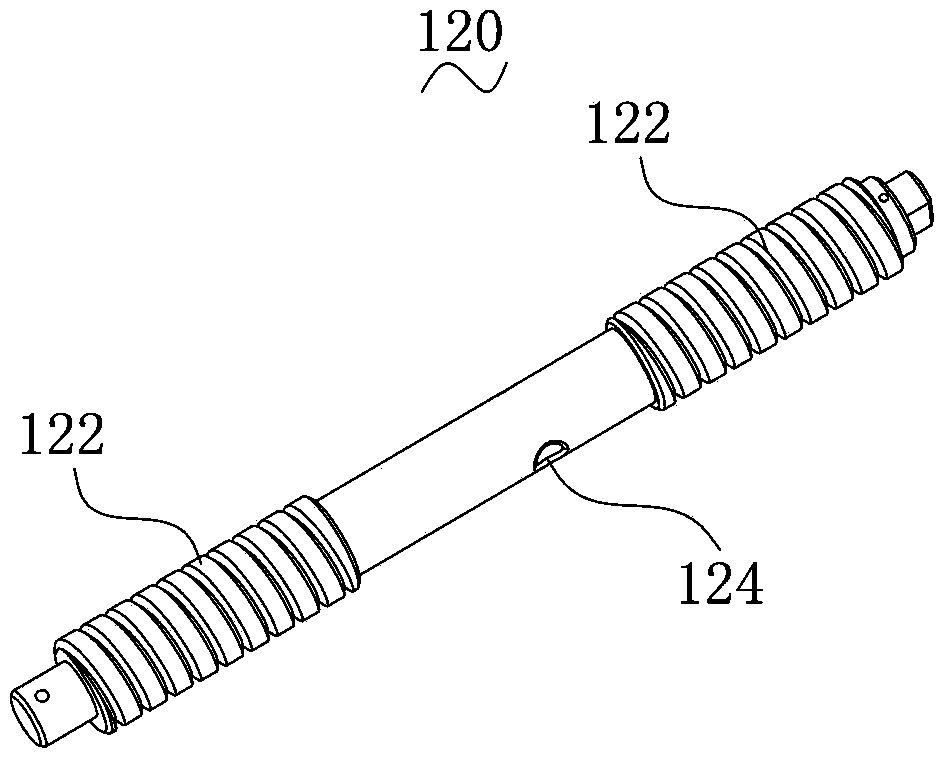

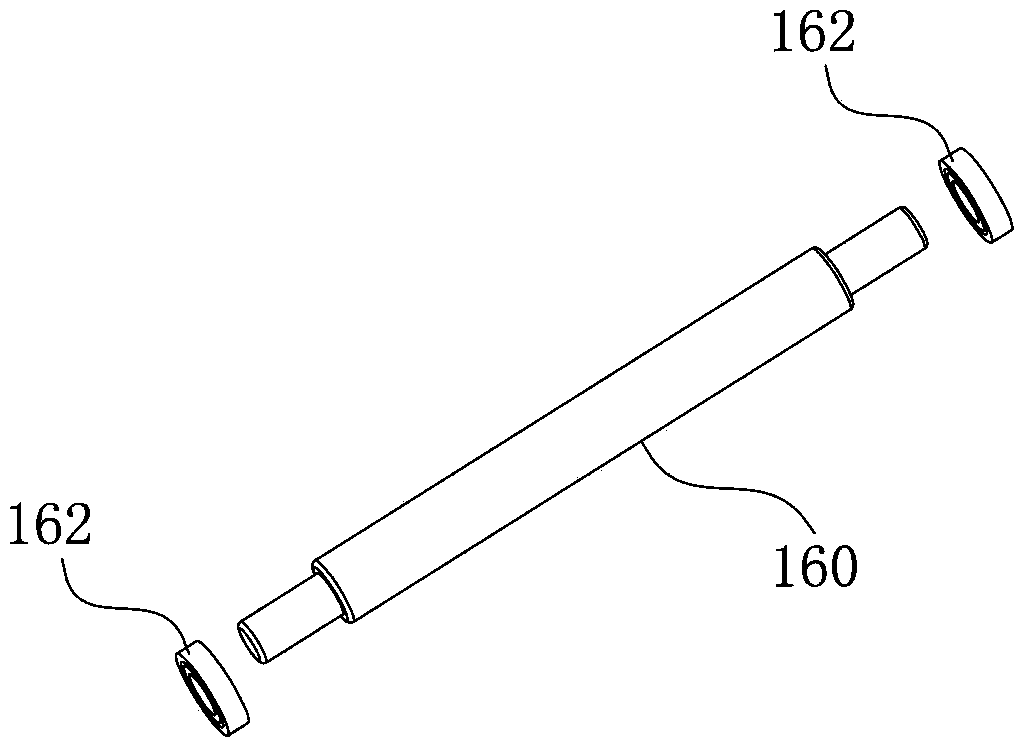

Transmission system for intelligent parking equipment

The invention discloses a transmission system for intelligent parking equipment. The transmission system comprises a rotating roller, a driving device is arranged on one side of the rotating roller, and a spiral guiding rail and a linear guiding rail are arranged on the rotating roller. Baffles are arranged on the two sides of the linear guiding rail and the spiral guiding rail correspondingly, chains are arranged in the linear guiding rail and the spiral guiding rail correspondingly, and the chains comprise chain sections. According to the transmission system for the intelligent parking equipment, the chains are guided through the baffles in winding, the chains smoothly move in the linear guiding rail and the spiral guiding rail through arrangement of balls, the chains on the two sides can be wound and tightened in a centralized mode, a vehicle-carrying plate is lifted, and the stability of vehicle carrying is high; additionally, when the rotating roller rotates to drive the vehicle-carrying plate to be lifted, a counter weight drives the chains to move downwards, and a plug head discharges gas in a roller body into an air bag through an air inlet pipe; and through arrangement ofan electromagnetic valve, when the vehicle-carrying plate falls, the protection effect can be achieved on a vehicle at the bottom, the buffering effect can be achieved for a vehicle at the top, and the whole transmission system is high in safety performance and stable in conveying.

Owner:ANHUI LOCKU INTELLIGENT PARKING EQUIP

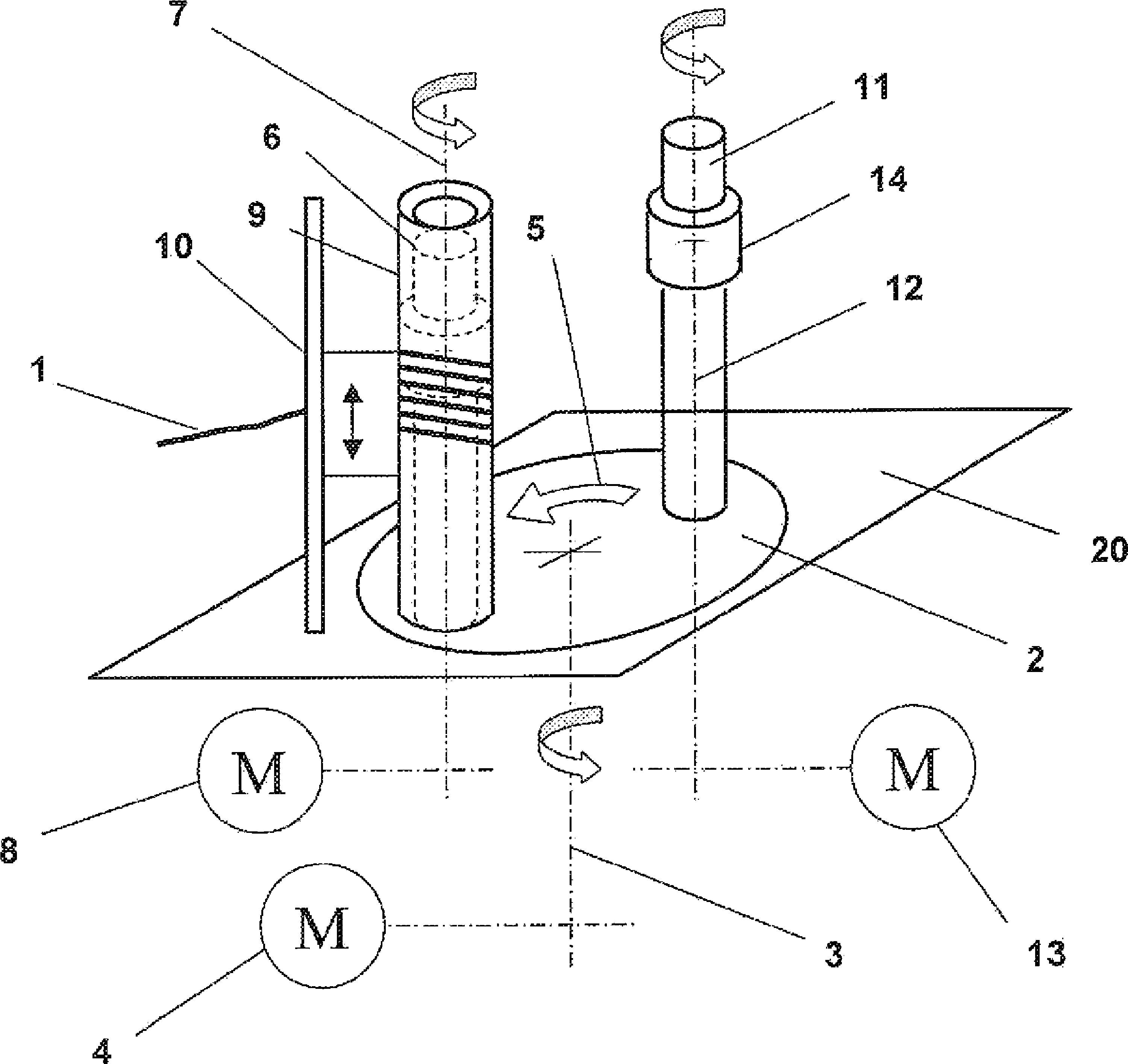

Bobbin-winding machine

InactiveCN103648941ACompatibleFull concentric operationFilament handlingContinuous wound-up machinesWinding machineBobbin

The invention relates to an apparatus and a method for winding roving (1) onto bobbin tubes (9) by way of a turret winding head. The turret winding head comprises a turret base plate (2) having a first spindle (6) and a second spindle (11) for receiving the bobbin tubes, said spindles being held in the turret base plate and having a longitudinal axis (7, 12). The turret base plate (2) and the spindles (6, 11) are each provided with a separate drive (4, 8, 13). The longitudinal axes (7, 12) of the spindles (6, 11) are oriented in the vertical direction.

Owner:MASCHINENFABRIK RIETER AG

Automatic ground rail type steel wire rope winding machine without lifting device

InactiveCN104773606AThe overall structure is simpleReduce the incidence of complete machine failureFilament handlingWinding machineEngineering

Owner:UNIV OF JINAN

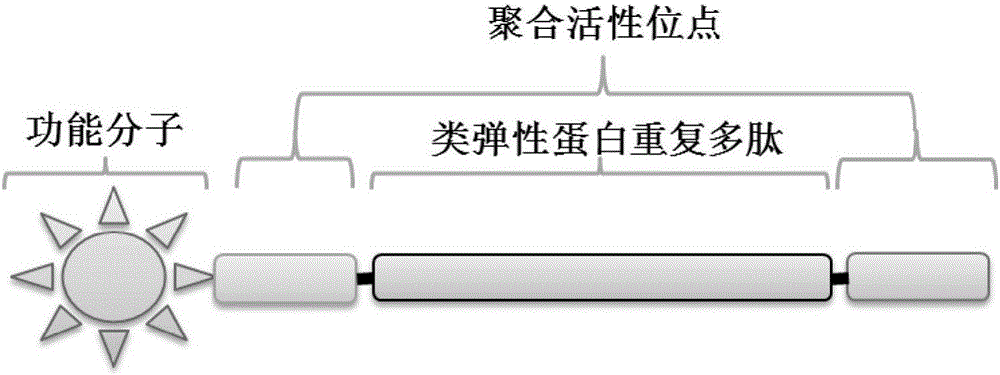

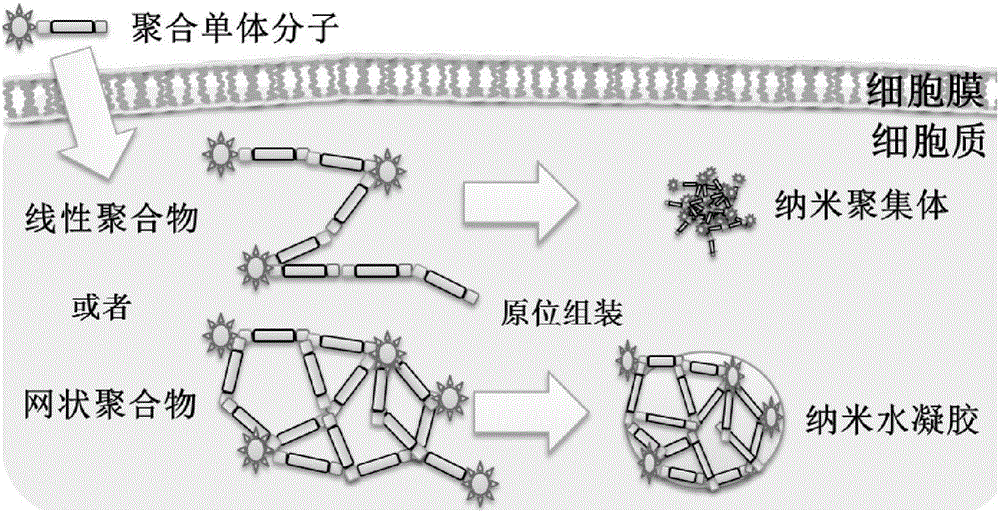

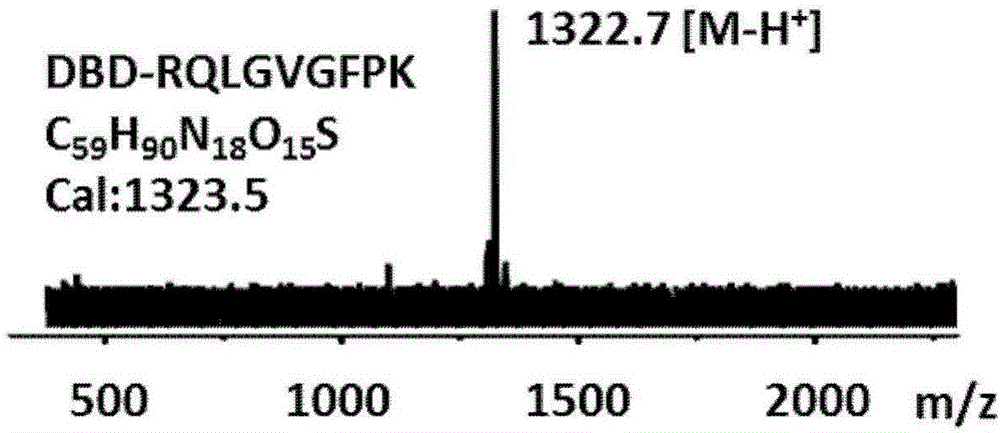

Polypeptide monomer molecule based on intracellular enzyme catalyzed polymerization and application thereof in construction of nano materials

ActiveCN106084003AAchieve distortionAchieve windingPeptide preparation methodsMacromolecular non-active ingredientsNano structuringGlutamine

The invention relates to a polypeptide monomer molecule based on intracellular enzyme catalyzed polymerization and application thereof in construction of nano materials especially elastin-like nano materials. The polypeptide monomer molecule is composed of a functional molecule, a polymerization active site and elastin-like repeat polypeptide, and can efficiently polymerize under the catalysis of transglutaminase, the formed polymer has temperature sensitive characteristic, and by changing the polypeptide sequence of monomer molecules, and the three-dimensional structure, conversion temperature, pore size and other parameters of the polymer can be adjusted. The polymer can achieve in situ controllable synthesis in living cells, and form a nano structure. The preparation method of the nano material can realize real-time in-situ imaging or high retention rate drug delivery in living cells, and has good application prospects.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

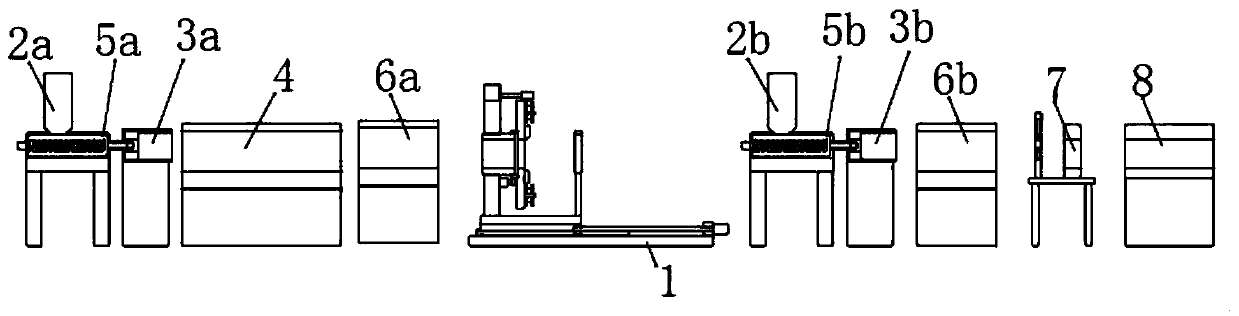

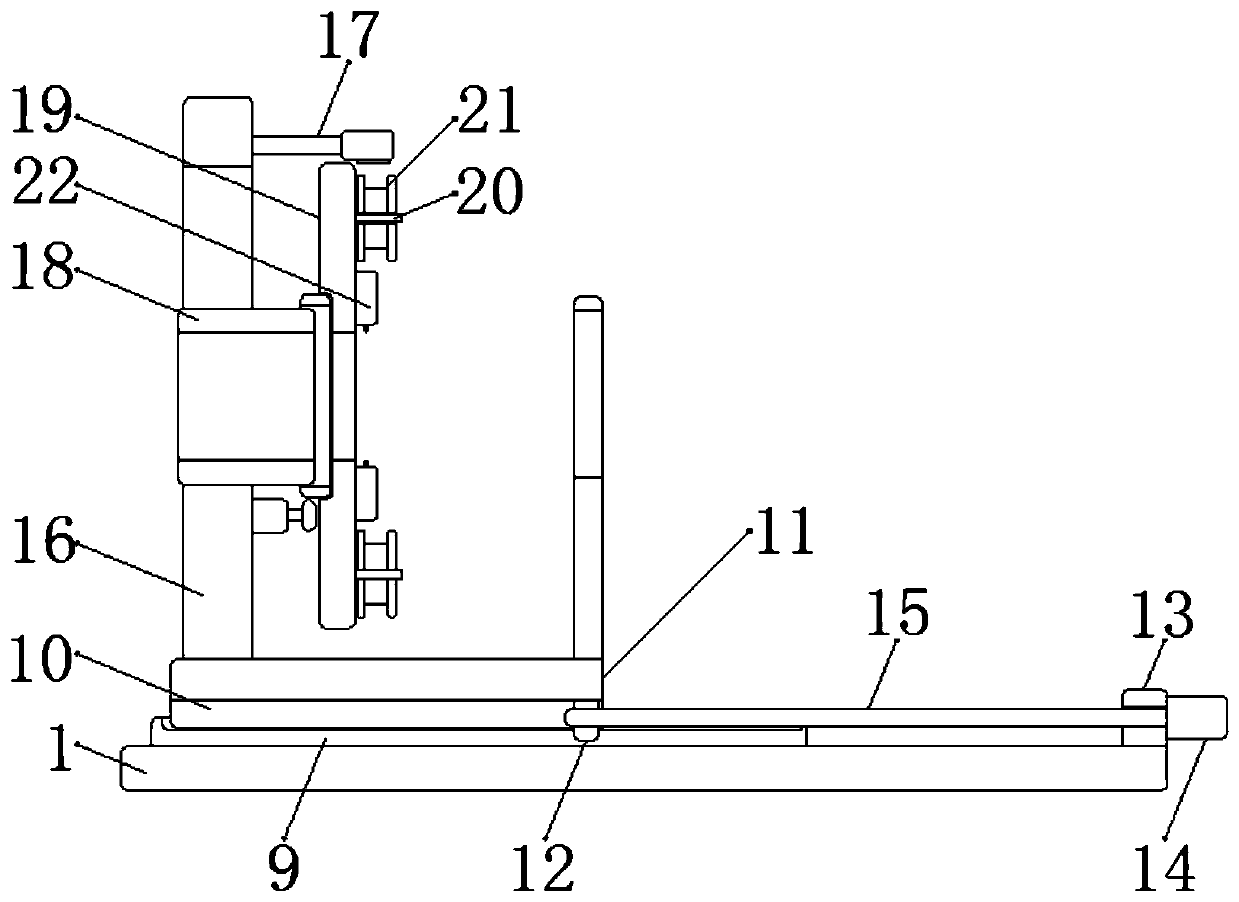

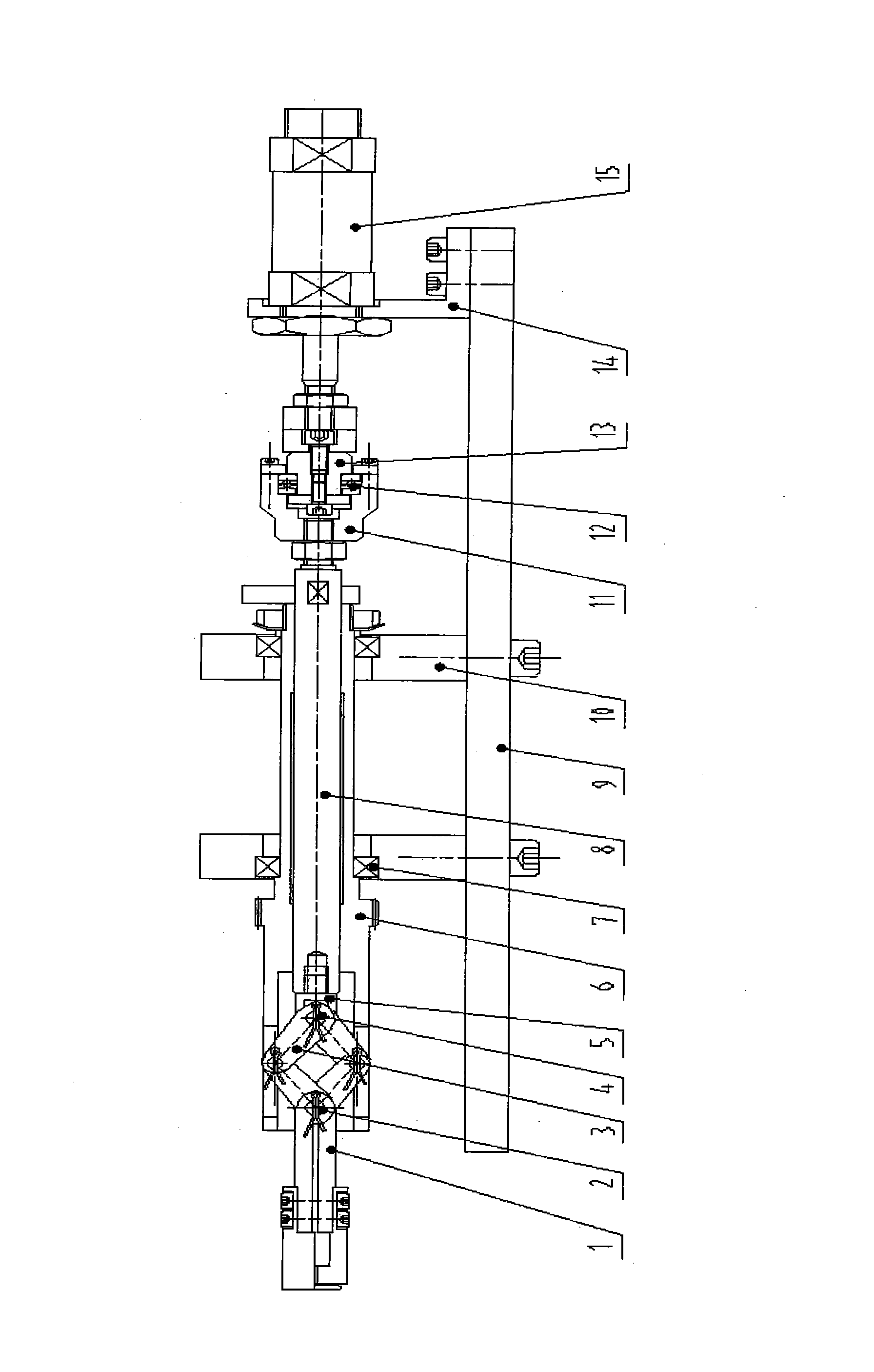

Automatic pipe winder of winding type heat exchanger

ActiveCN105290258AAchieve windingControl volumeMetal-working feeding devicesHeat exchange apparatusPlate heat exchangerMachining

The invention provides an automatic pipe winder of a winding type heat exchanger and belongs to the technical field of machining equipment. The automatic pipe winder of the winding type heat exchanger solves the problem that an existing automatic pipe winder of the winding type heat exchanger is low in production efficiency. The automatic pipe winder of the winding type heat exchanger comprises a main guide rail bottom plate which is provided with at least two supporting bases in the length direction, and the supporting bases are used for supporting core tubes; the two sides of the main guide rail bottom plate are both provided with feeding guide rail bottom plates; each feeding guide rail bottom plate is provided with an automatic correcting pipe conveying mechanism; the automatic correcting pipe conveying mechanisms are located on the sides of the supporting bases and can be aligned with the core tubes located on the supporting bases; and the feeding guide rail bottom plates are further provided with travelling driving mechanisms capable of driving the automatic correcting pipe conveying mechanisms to slide along the feeding guide rail bottom plates. The automatic pipe winder of the winding type heat exchanger can wind a plurality of heat transfer pipes in a multi-layer manner.

Owner:杭州量创科技咨询有限公司

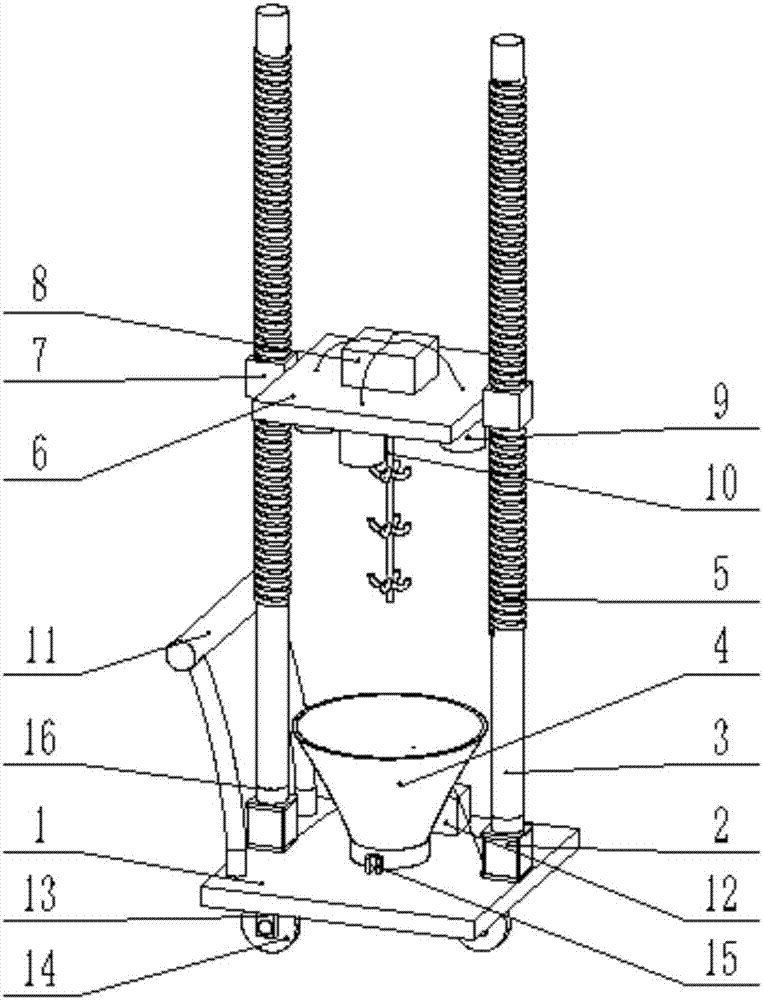

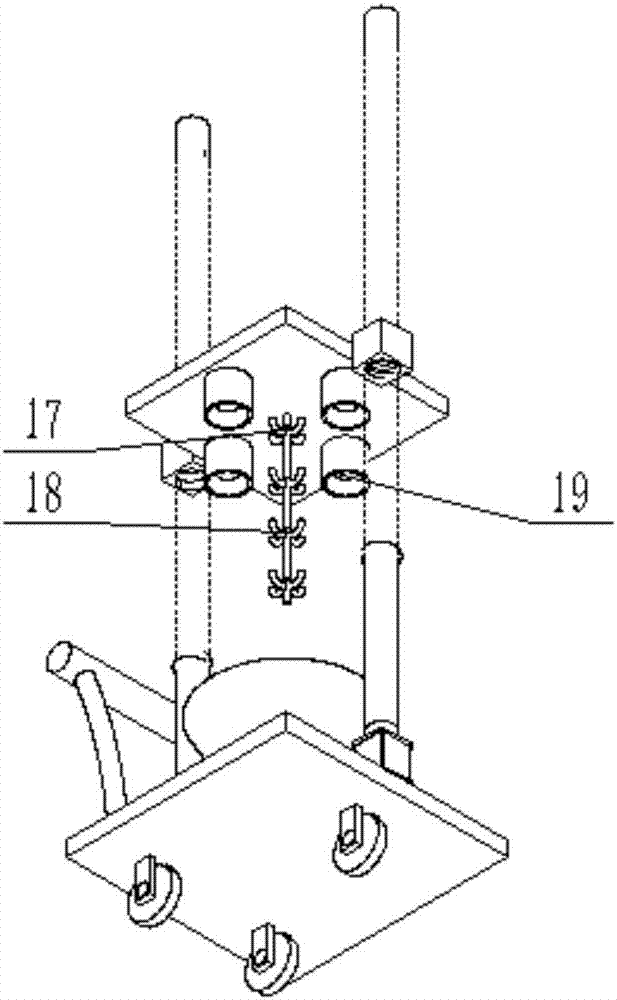

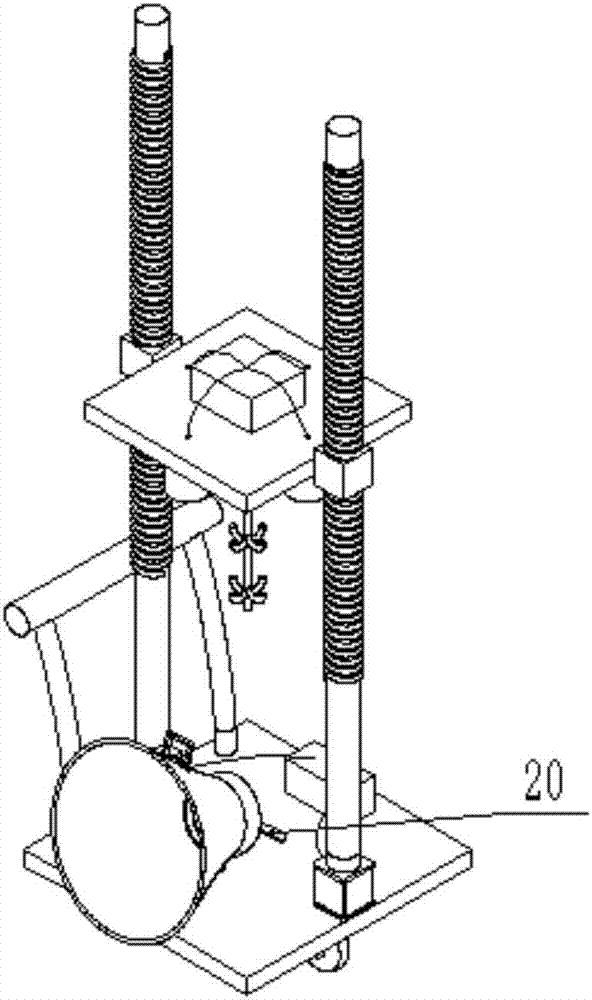

Firecracker firing and recovering device

ActiveCN106895748APrevent the phenomenon that cannot be ignitedAggregation is achievedFirecrackersFirecrackerFireworks

The invention discloses a firecracker firing and recovering device, and belongs to the field of firework and firecracker firing equipment. A firing barrel is arranged at the upper end of a bottom plate; a light concentration disc is arranged at the lower end in the firing barrel; two stepping motors are mounted on two sides of the firing barrel at the upper end of the bottom plate; an output shaft of each stepping motor is connected with an upright column; outside threads are formed in the circumference of each upright column; a connecting block sleeves the outside threads of each upright column and is fixedly connected with a lifting plate; the lower end of the lifting plate is fixedly connected with a hanging device; an incandescent lamp is mounted at the lower end of the lifting plate; and a lampshade is mounted at the periphery of the incandescent lamp; the upper end of the lifting plate is fixedly connected with a battery box which supplies power for the incandescent lamp; and a control cabinet is arranged on the bottom plate and is connected with the stepping motors. The firecracker firing and recovering device fires a firecracker by generating heat through light concentration and has the recovering function to firecracker skin generated after the firecracker is fired.

Owner:牟浩语

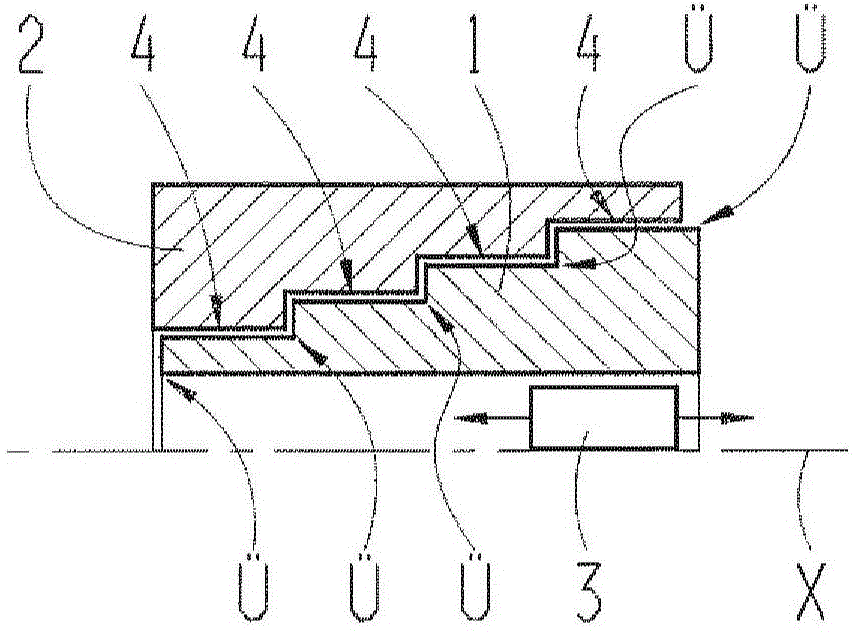

Coil arrangement having two coils

InactiveCN104903684AReduce gapImprove fill factorConverting sensor output electrically/magneticallyCoils manufactureElectricityPosition sensor

The invention relates to a coil arrangement, in particular for a position sensor, having a first coil (1) and a second coil (2) which are electrically connected to one another and are arranged in a substantially coaxial manner with respect to one another, wherein the first coil (1) has a winding density that increases in the longitudinal direction (X) of the coil arrangement, whereas the second coil (2) has a winding density which decreases in the longitudinal direction (X) of the coil arrangement. The invention also relates to a position sensor having such a coil arrangement and to a method for producing such a coil arrangement.

Owner:ZF FRIEDRICHSHAFEN AG

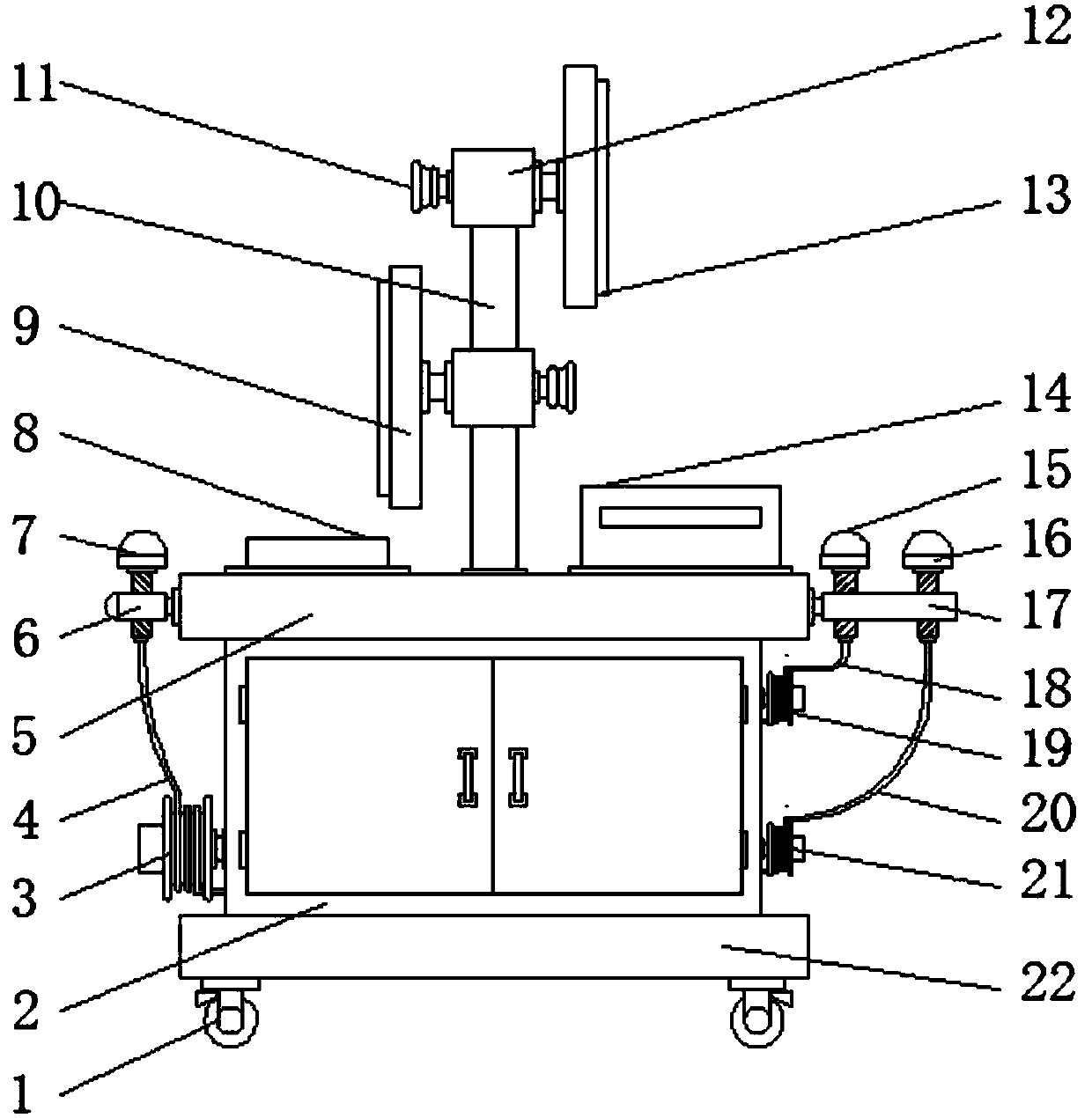

Comprehensive inspection instrument for obstetrics and gynecology department

InactiveCN107890368AAvoid running back and forthReduce workloadSurgical furnitureOrgan movement/changes detectionObstetric historyBlood pressure

The invention discloses a comprehensive inspection instrument for obstetrics and gynecology department. The comprehensive inspection instrument comprises a base plate, a tank body and a worktable, wherein the tank body is fixed in the center of the top of the base plate, the worktable is mounted at the top of the tank body, an upright pillar is mounted in the center of the top of the worktable through a bolt, and a main display screen and an auxiliary display screen are respectively movably mounted on the upright pillar through movable casing pipes; and an ultrasonic B inspection instrument, afetal heart inspection instrument and a blood pressure inspection instrument are uniformly mounted in the tank body and are respectively electrically connected with a master controller through leads.According to the comprehensive inspection instrument, the main display screen and the auxiliary display screen are respectively movably mounted on the upright pillar through the movable casing pipes,so that a pregnant woman can timely know the body condition during the inspection; and meanwhile, the angles of the main display screen and the auxiliary display screen can be adjusted, and the position of the main display screen and the auxiliary display screen can be adjusted according to different requirements in the use process, so that the pregnant woman can obtain an optimal view angle, andthe use of the comprehensive inspection instrument is convenient.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

High-efficiency grafting method for torreya grandis

InactiveCN108617307AImprove survival rateRealize automatic fasteningGraftingCultivating equipmentsForest industryHigh survival rate

The invention belongs to the technical field of forestry planting, and specifically discloses a high-efficiency grafting method for torreya grandis. The method comprises the following steps: (1) performing preparation: selecting seedlings of 2-3-year-old torreya grandis at late February to late March, and cutting off parts located 5-10 cm above rhizomes of the seedlings of the torreya grandis to obtain a rootstock; and cutting 1-1.5-year-old tender branches from an excellent-quality mother tree as scions, wherein a length of each scion is 6-10 cm; (2) treating the rootstock: performing vertically-downward chopping from the middle part of a cross section of the rootstock by using a cleft grafting knife, wherein a length of a chopped opening is 4-5 cm; (3) treating the scions: reserving 6-8leaves of the top of each scion, removing the rest, and cutting the lower part of each scion into a wedge shape; (4) binding up the scions: inserting the scions into the chopped openings of the rootstock, fastening the scions and the rootstock by using a clamping binding device, and performing winding by using a film; and (5) performing management after grafting: performing fertilization on grafted seedlings every 3-4 days, applying a long-acting insecticide and bactericide, and building a sunshade shed with light transmittance of 20%-30%. The method disclosed by the invention has high efficiency of grafting, and the grafted torreya grandis has a higher survival rate.

Owner:GUIZHOU WUCHUAN WANNIANFENG AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com