Wiring harness tightening device

A wire harness and clamping mechanism technology, applied in the direction of line/collector components, electrical components, circuits, etc., can solve the problems of poor product consistency and low production efficiency, and achieve high production efficiency, long service life and strong reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

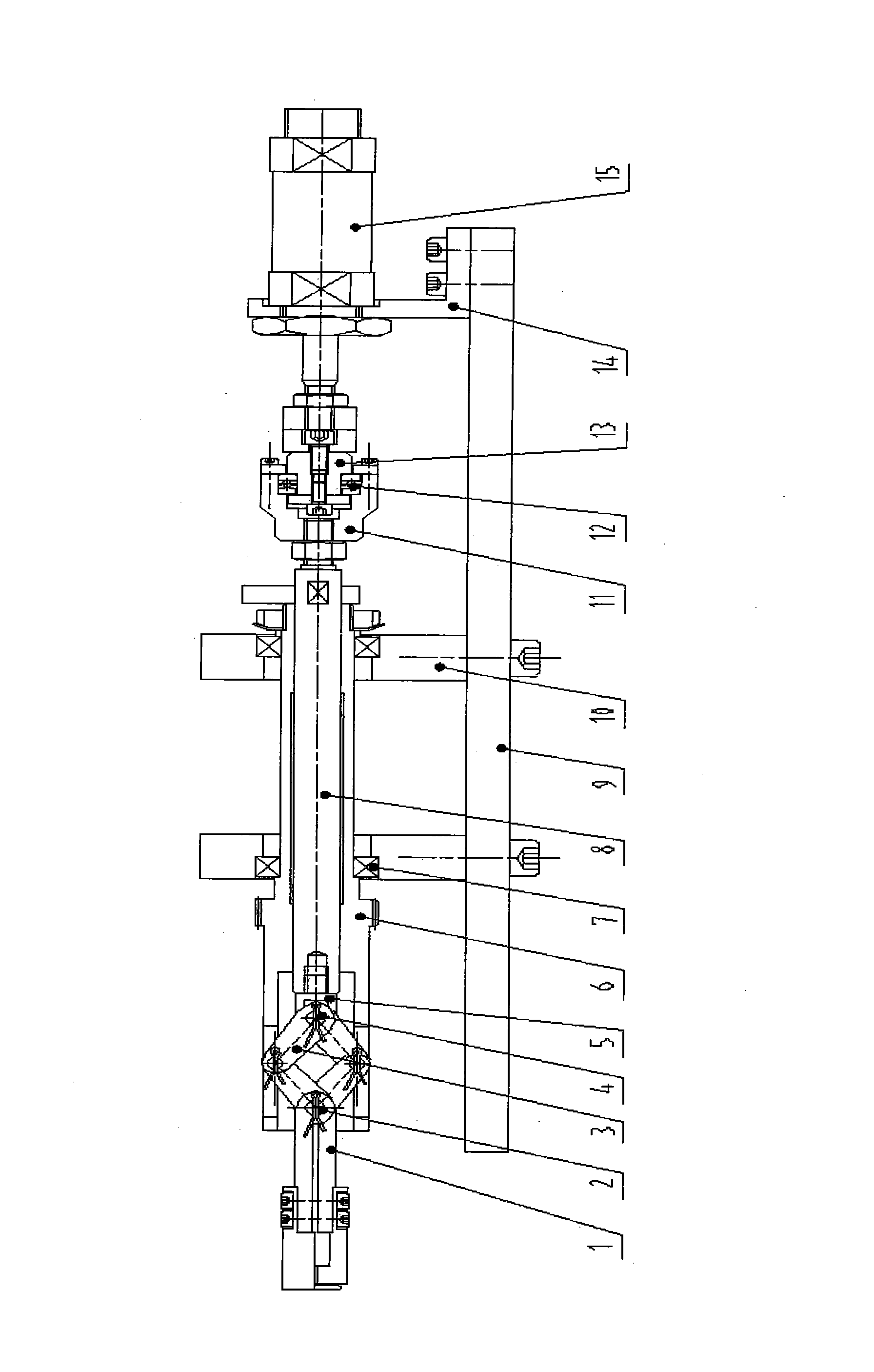

[0009] Refer to attached picture. A wire harness tightening device, a base plate 9 is provided with a support 14 to support and fix a longitudinally moving cylinder 15, the piston rod of the longitudinally moving cylinder 15 is connected with a bearing inner core 13, and the bearing inner core 13 is provided with a bearing 12 connected to a bearing outer shell 11; the base plate 9 There are two support vertical plates 10 on the support vertical plate 10, and the wire harness tightening sleeve 6 is installed on the support vertical plate 10 through the bearing 7. The wire harness tightening sleeve 6 is equipped with a tie rod mandrel 8; one end of the tie rod mandrel 8 is provided with a connecting plate fixing head 5, The other end is fixedly connected with the bearing jacket 11; the connecting plate fixing head 5 is provided with a wire harness clamping mechanism. The wire harness clamping mechanism is provided with a front support shaft 2 on the wire harness tightening sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com