Automatic pipe winder of winding type heat exchanger

A heat exchanger, winding technology, applied in the field of automatic tube winding machines, can solve the problems of low production efficiency, inability to meet the simultaneous winding of multiple heat transfer tubes, etc., and achieve the effects of easy layout, compact structure and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

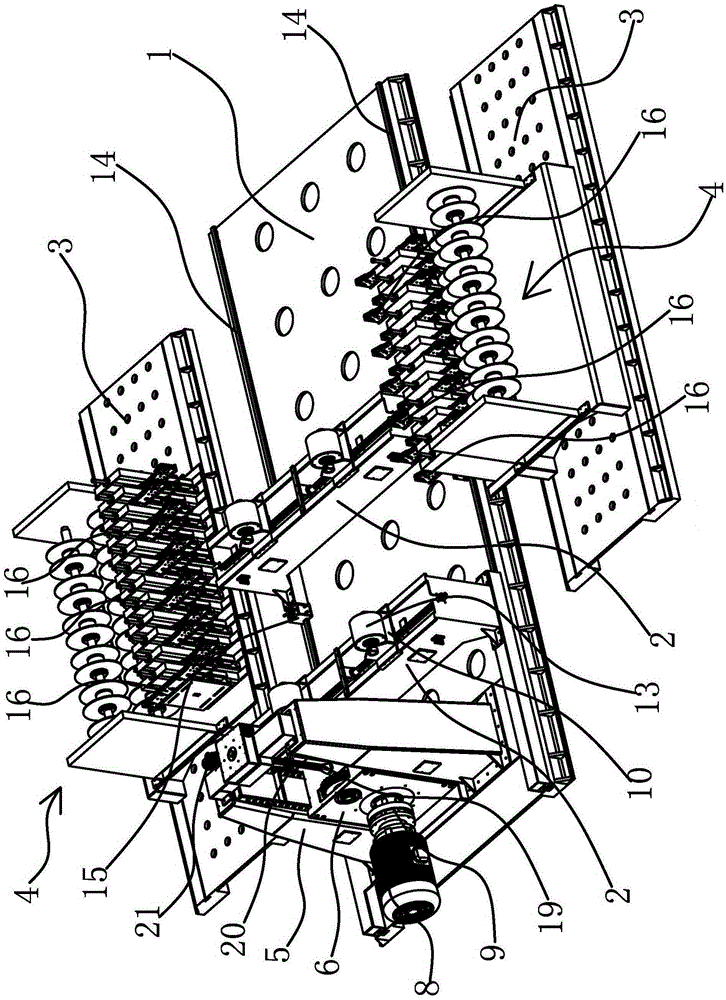

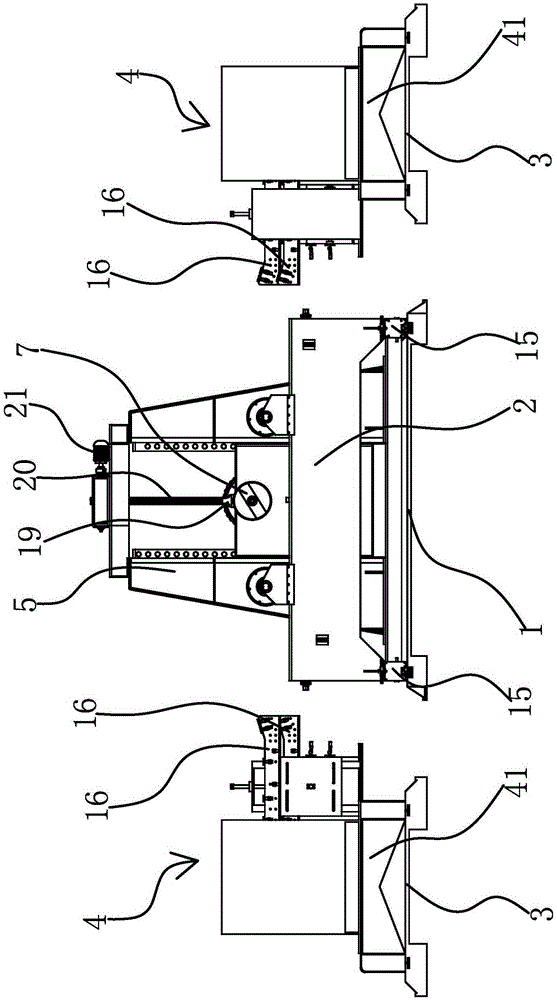

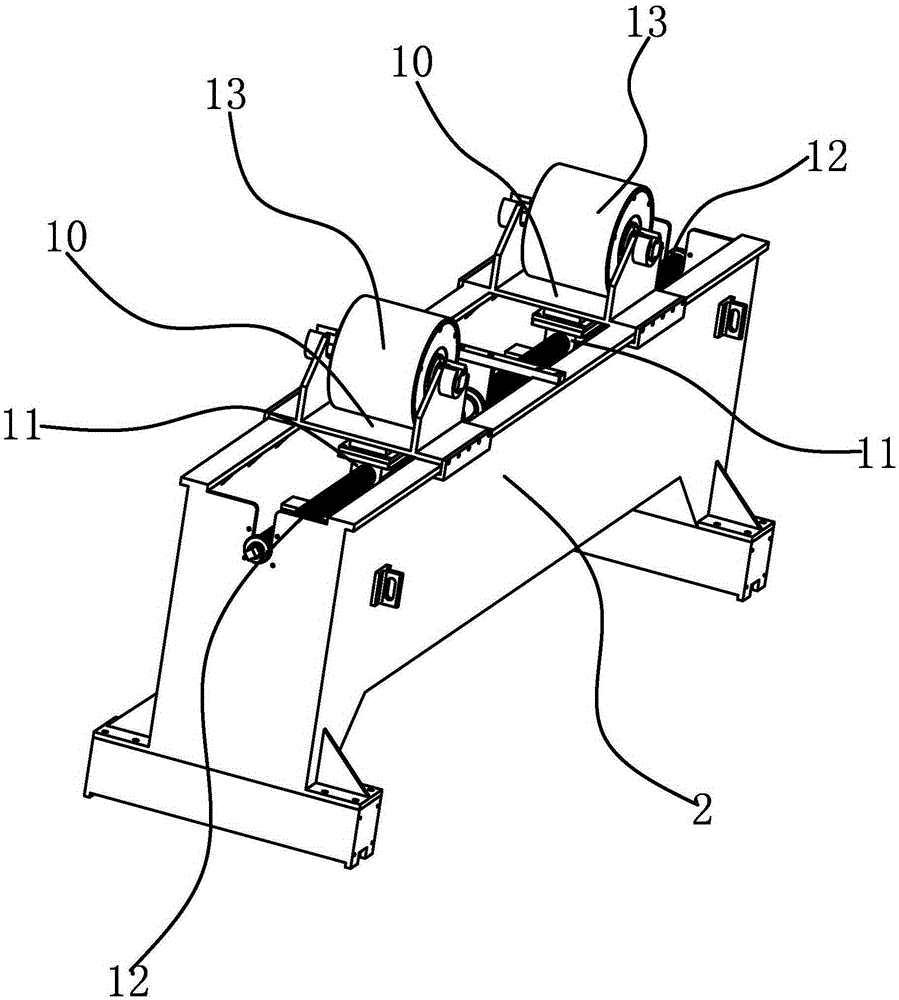

[0035] The automatic pipe winding machine of the winding heat exchanger includes a main guide rail bottom plate 1, a support seat 2, a feeding guide rail bottom plate 3, a self-correcting pipe feeding mechanism 4 and a traveling drive mechanism.

[0036] Specifically, as figure 1 and figure 2 As shown, a guide rail 14 is provided on the main rail bottom plate 1, and the two support seats 2 are slidably connected to the main rail bottom plate 1 along the length direction of the main rail bottom plate 1 through the guide rails 14, and a compression block is arranged between the support seat 2 and the guide rail 14. 15. Such as Figure 4 As shown, the pressing block 15 includes two oppositely arranged L-shaped pressing plates 151 and a top panel 152 at the top of the pressing plates 151. The bottom of the pressing plate 151 has an outstretched abutting portion 153 for abutting against The portion 153 can abut against the bottom surface of the guide rail 14 , and the top panel...

Embodiment 2

[0050] The technical solution in this embodiment is basically the same as that in the first embodiment, the difference is that in this embodiment, the support seat 2 is fixed on the main rail bottom plate 1 .

Embodiment 3

[0052] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the self-correcting tube feeding mechanism 4 includes a base 41 and a plurality of self-correcting tubes fixed on the base 41 The base 41 of the unit 16 is also provided with storage tanks 42 corresponding to the same number and positions of the self-correcting tube delivery unit 16 one-to-one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com