Patents

Literature

2123 results about "Heat transfer tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

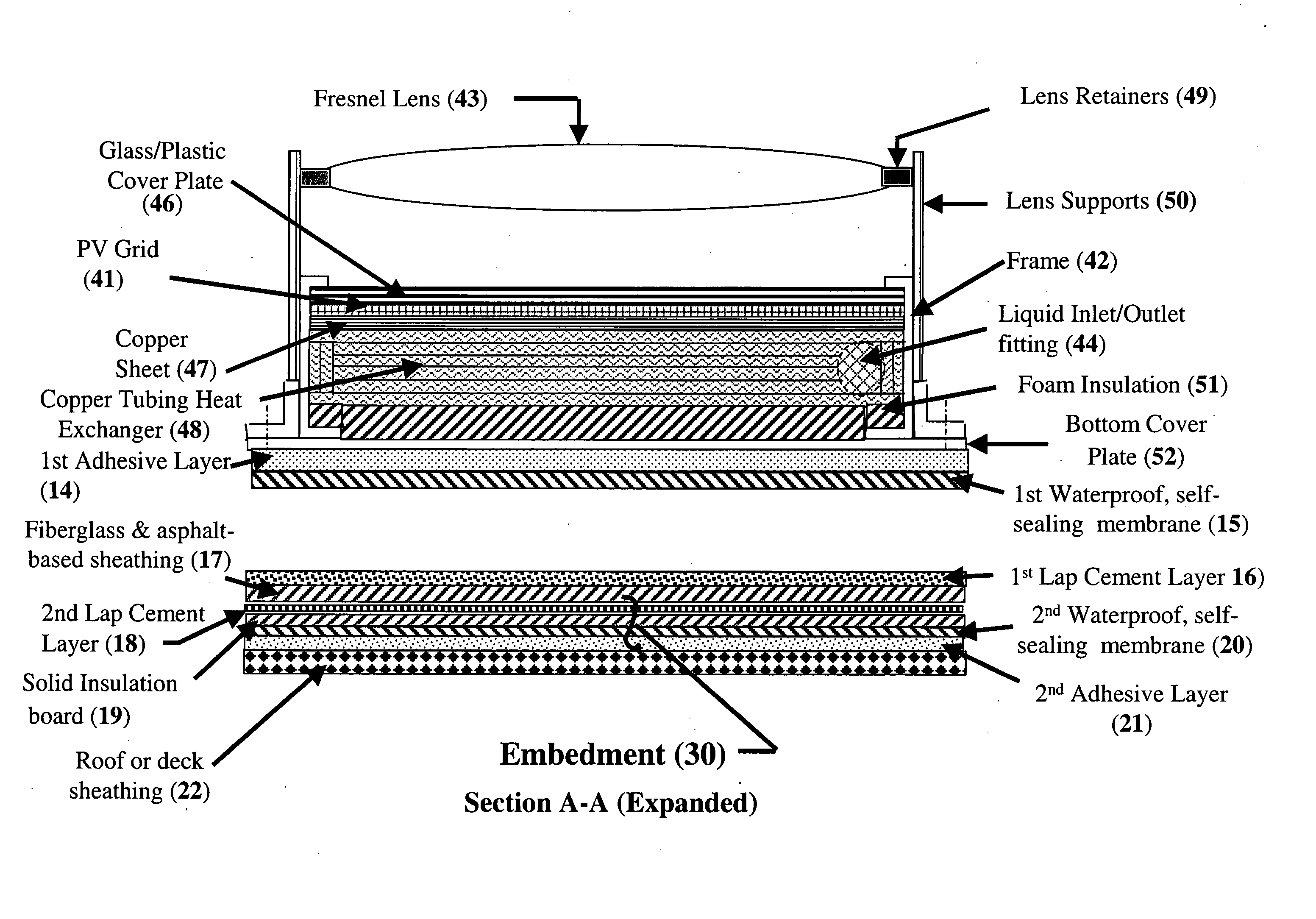

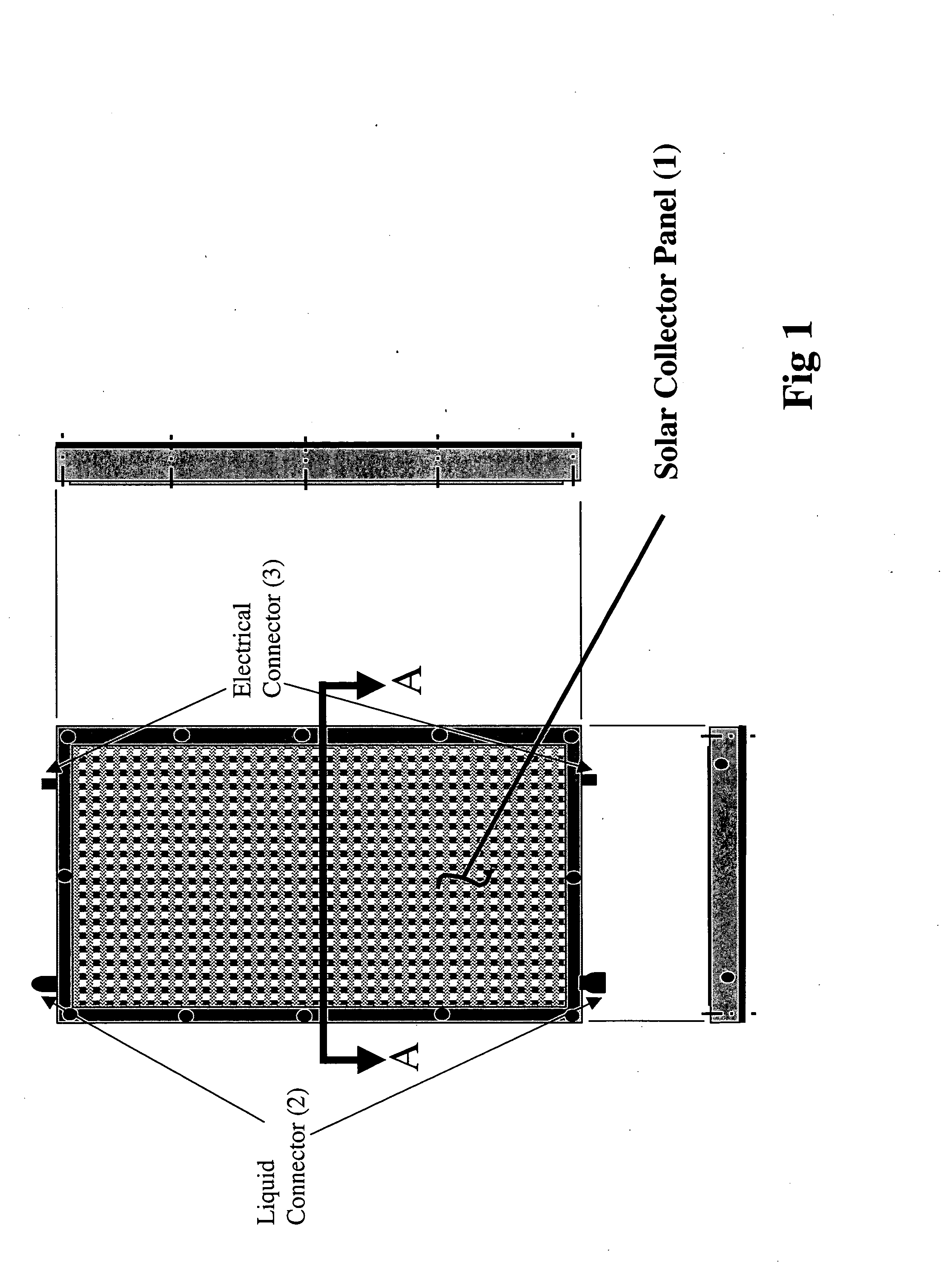

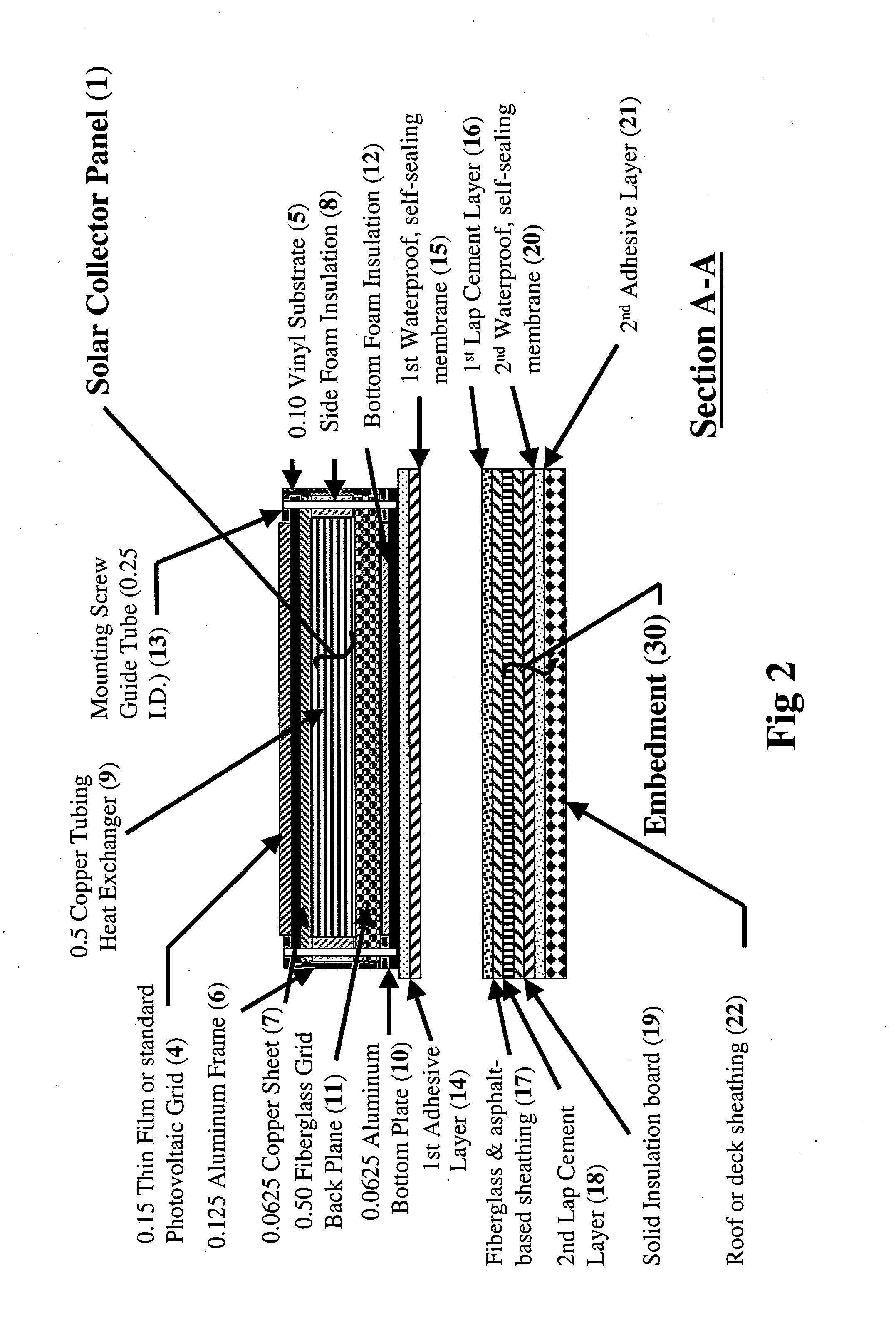

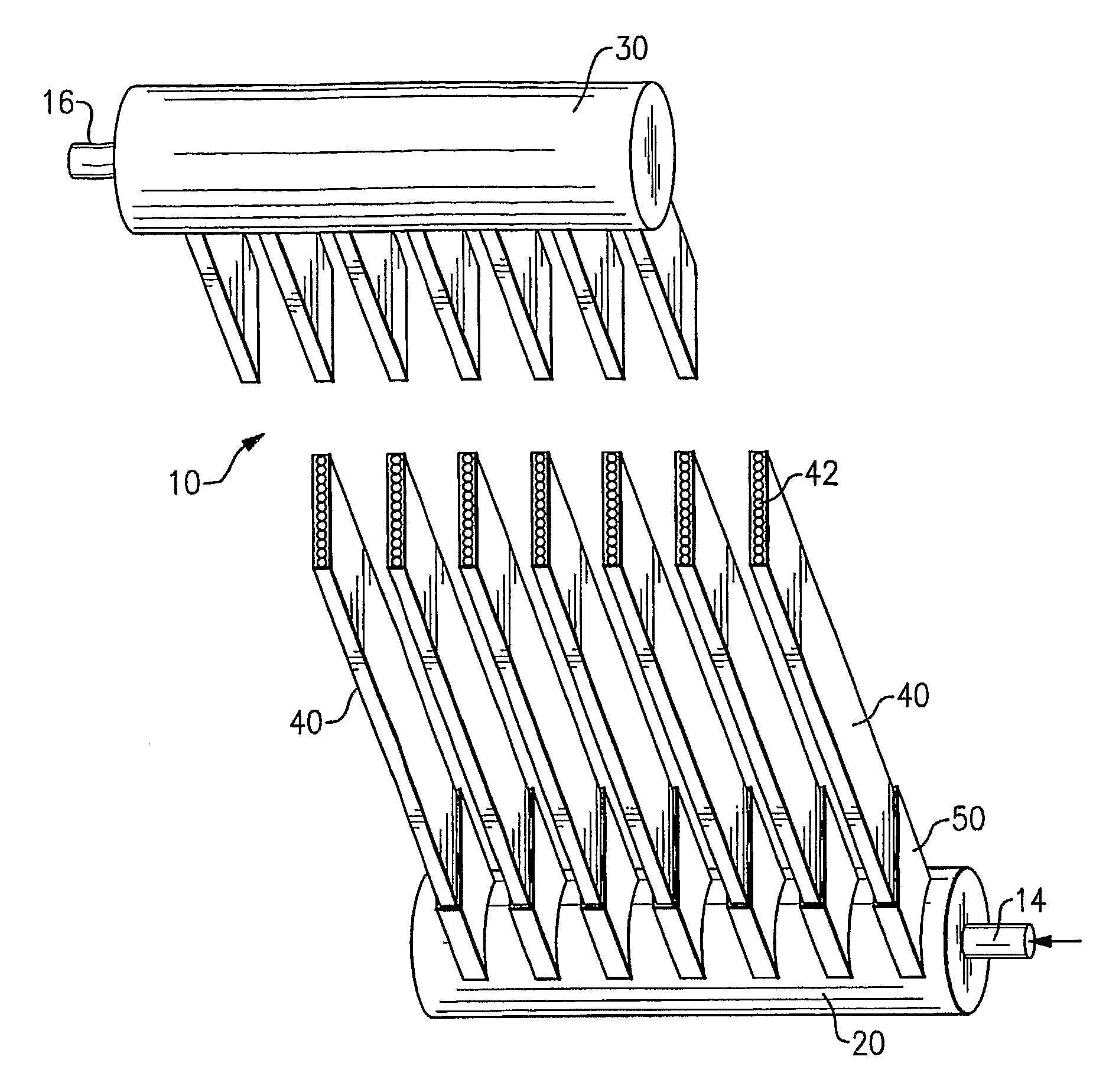

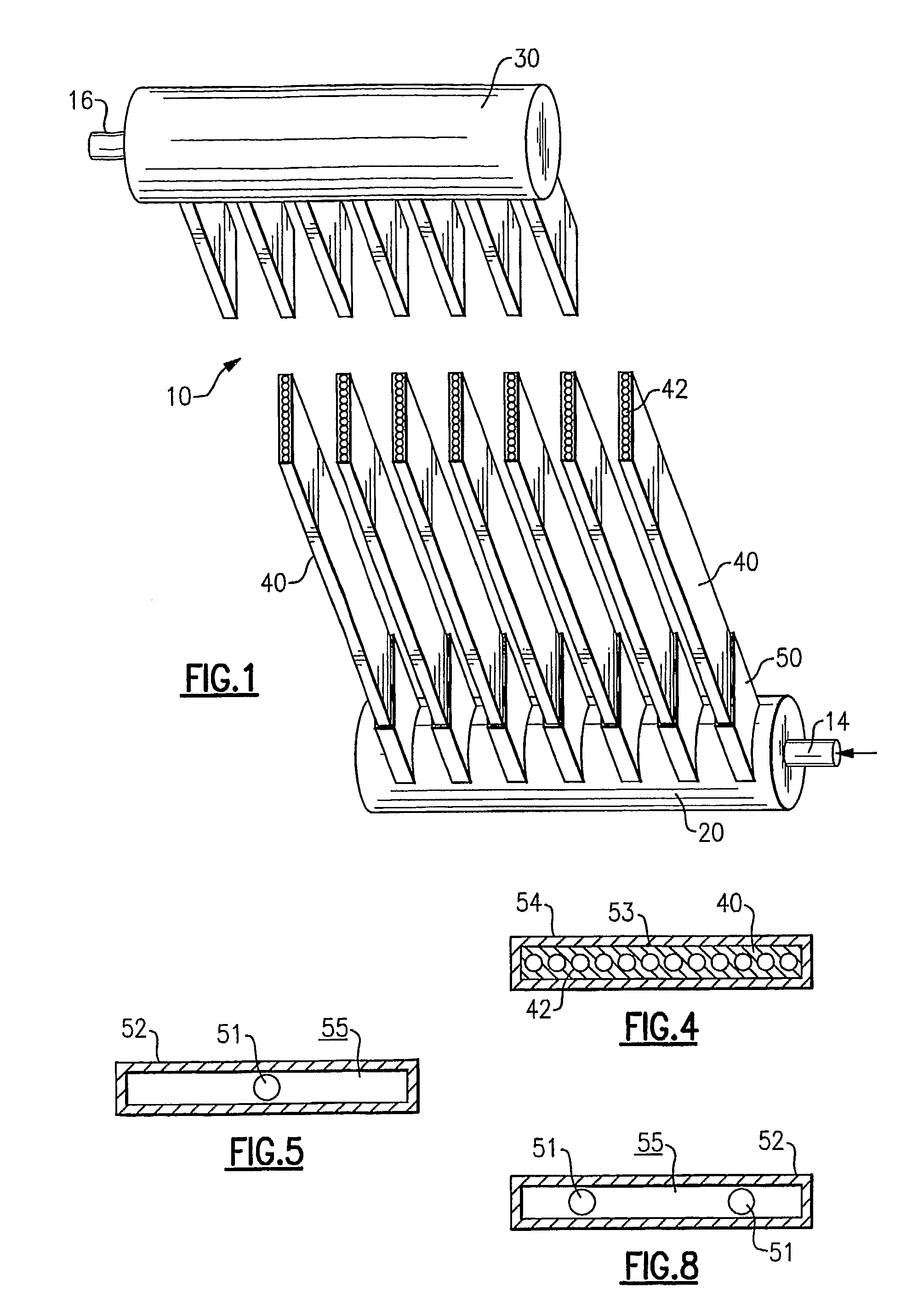

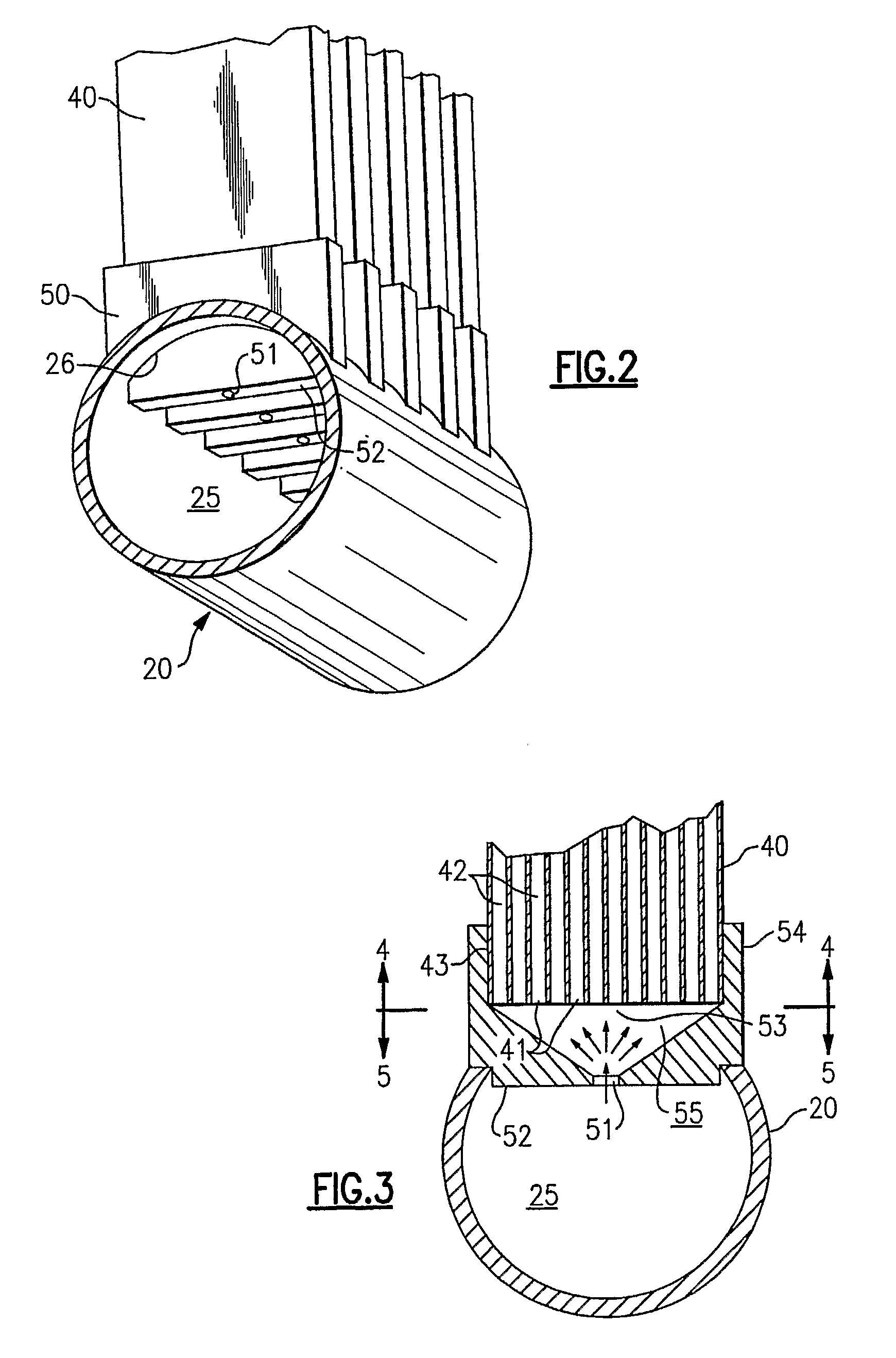

Integrated solar energy roofing construction panel

InactiveUS20050133082A1Reduce installation costsLabor savingSolar heating energySolar heat devicesThermal energyEngineering

A solar assembly comprising two components: a multi-functional solar collecting apparatus and a mounting embedment integrated with building construction material. The mounting embedment component is affixed to a building frame structure using standard construction techniques and receives the multi-functional solar collecting apparatus that is secured with fasteners. The multi-functional solar collecting apparatus converts solar energy to electrical energy using a photovoltaic grid mounted on a copper plate that provides even temperature dispersion across the plate and acts as a thermal radiator when the apparatus is used as a radiant cooler; and a plurality of interconnected heat transfer tubes located within the apparatus enclosure disposed on the plane below the copper plate but conductively coupled to the copper plate for converting the solar energy to thermal energy in a fluid disposed within the heat transfer tubes.

Owner:KONOLD ANNEMARIE HVISTENDAHL +1

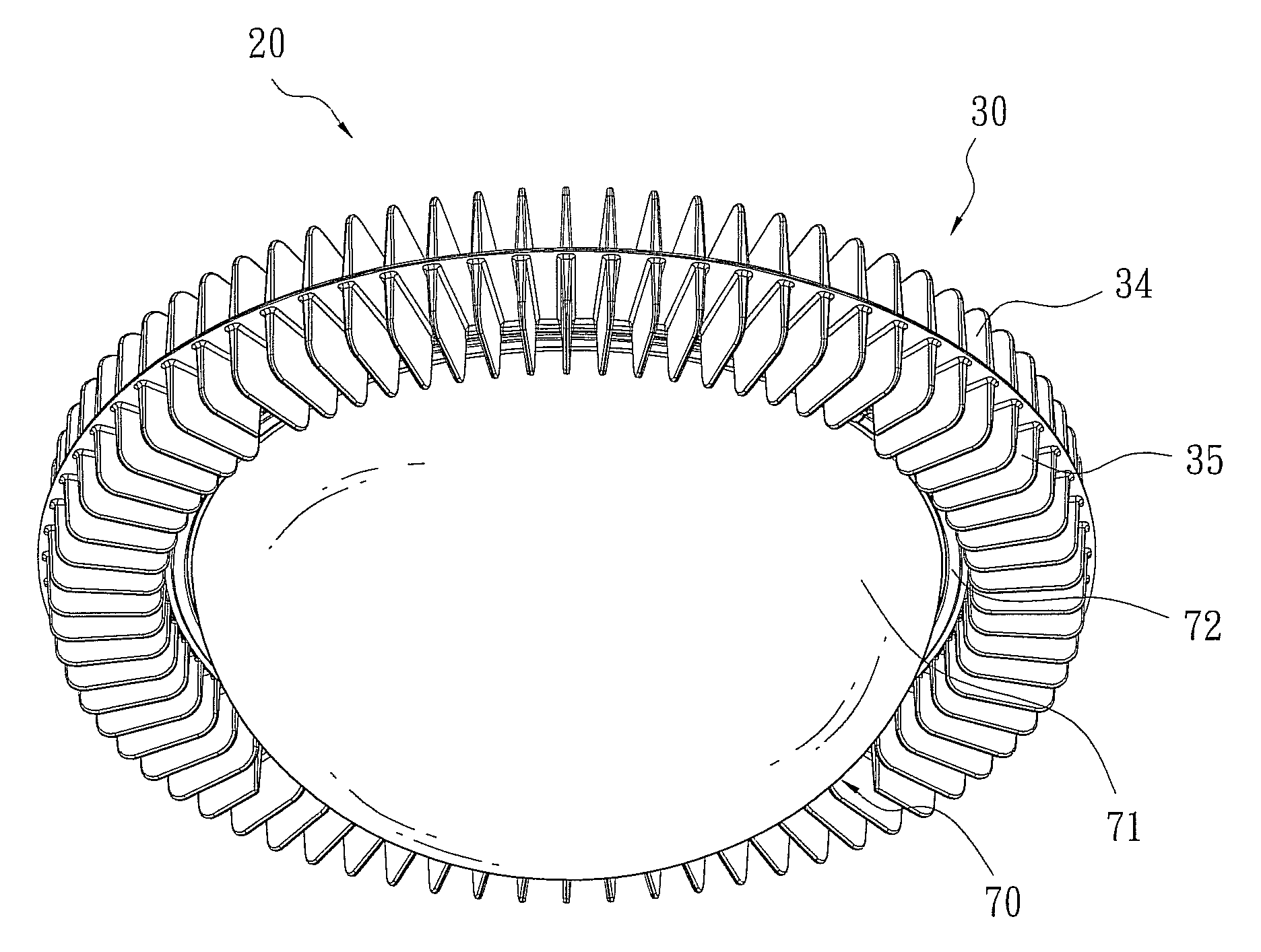

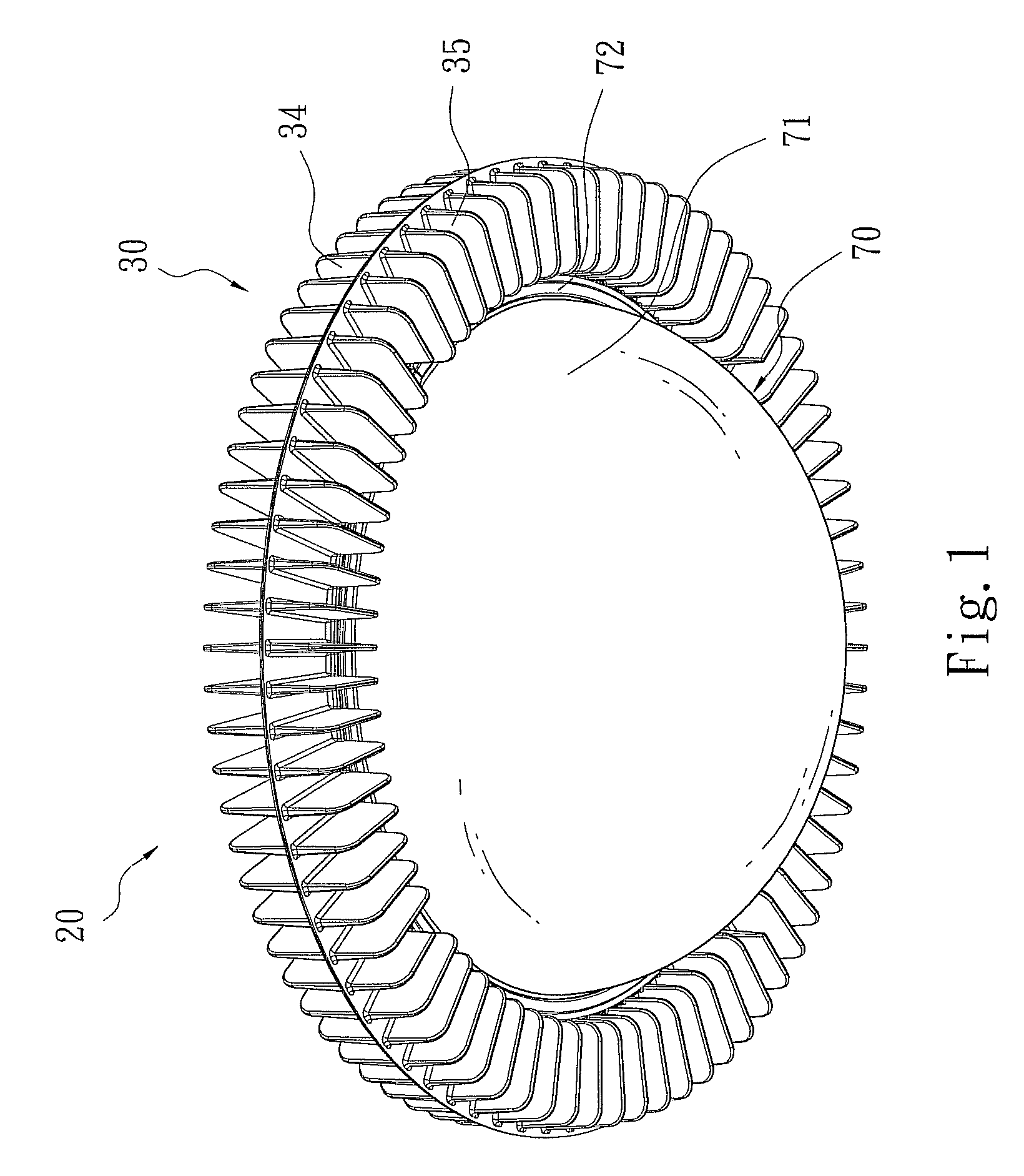

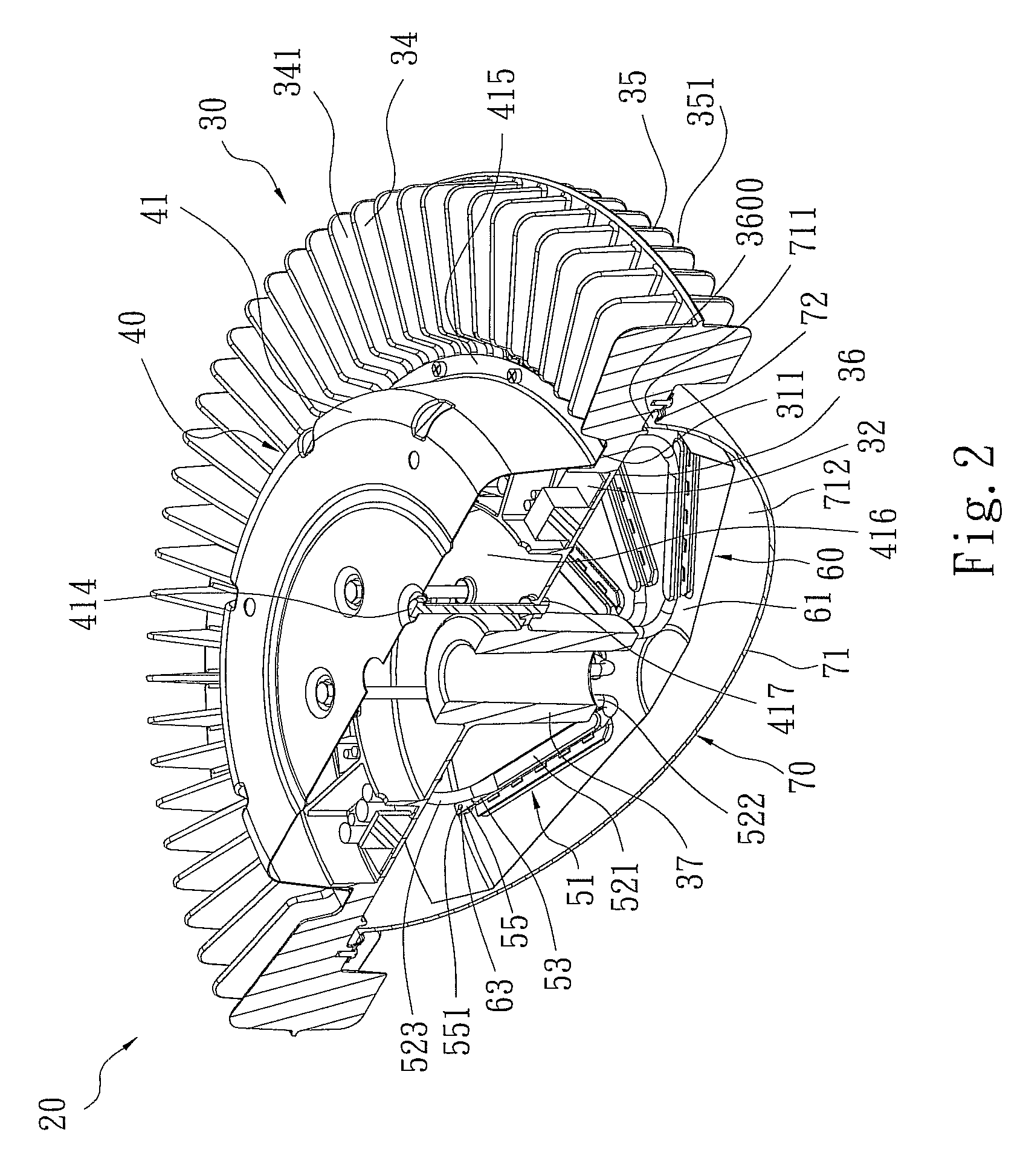

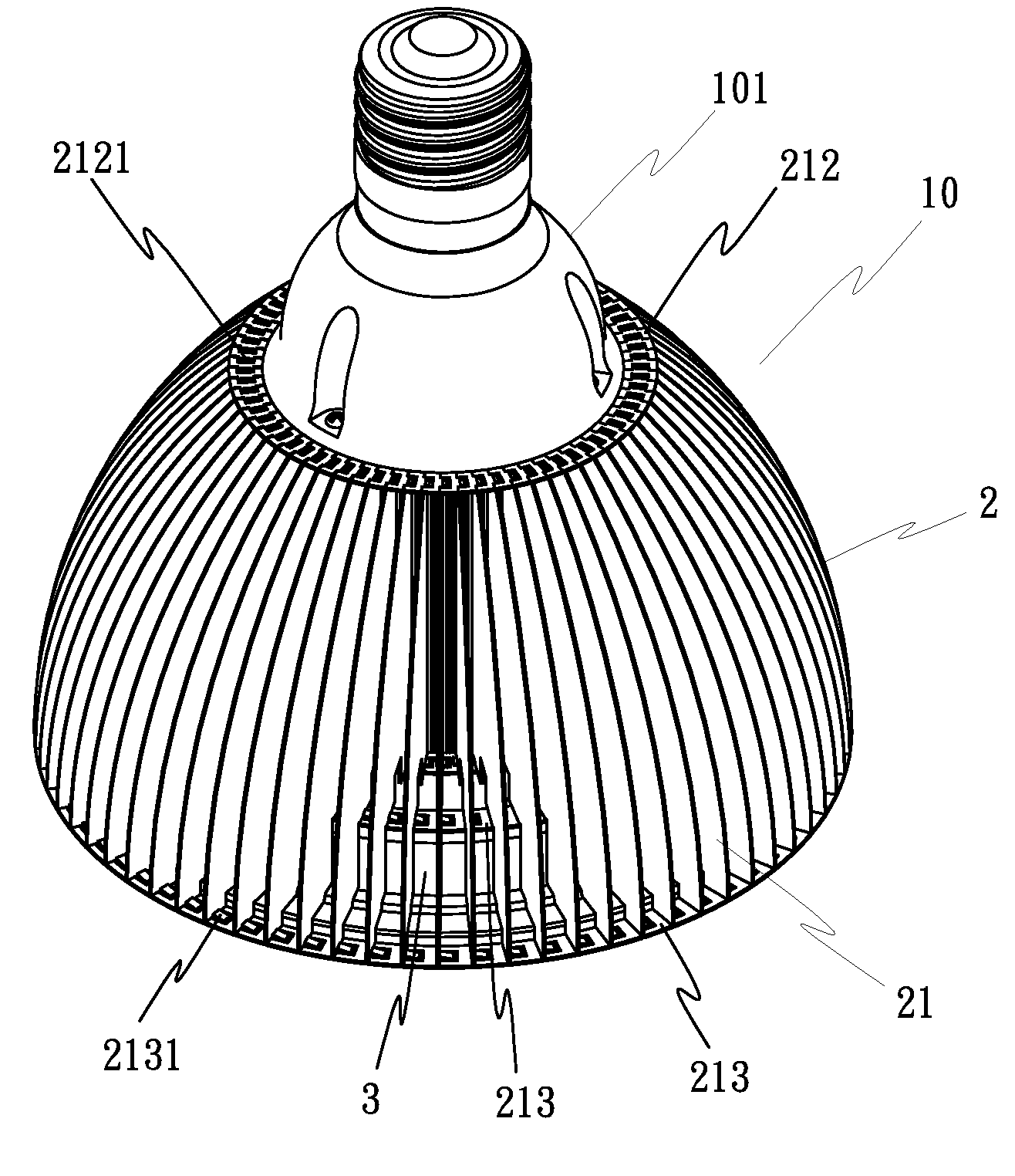

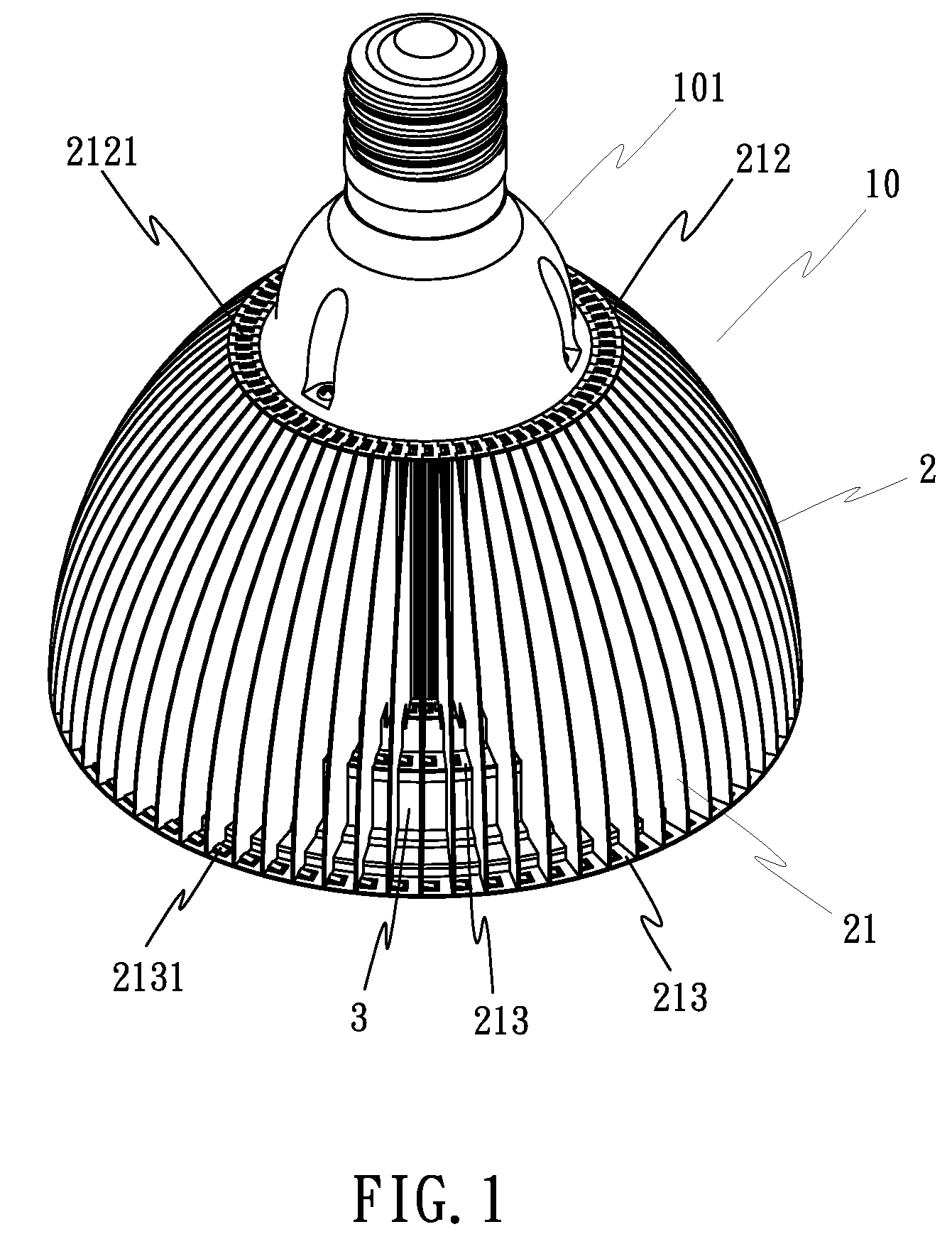

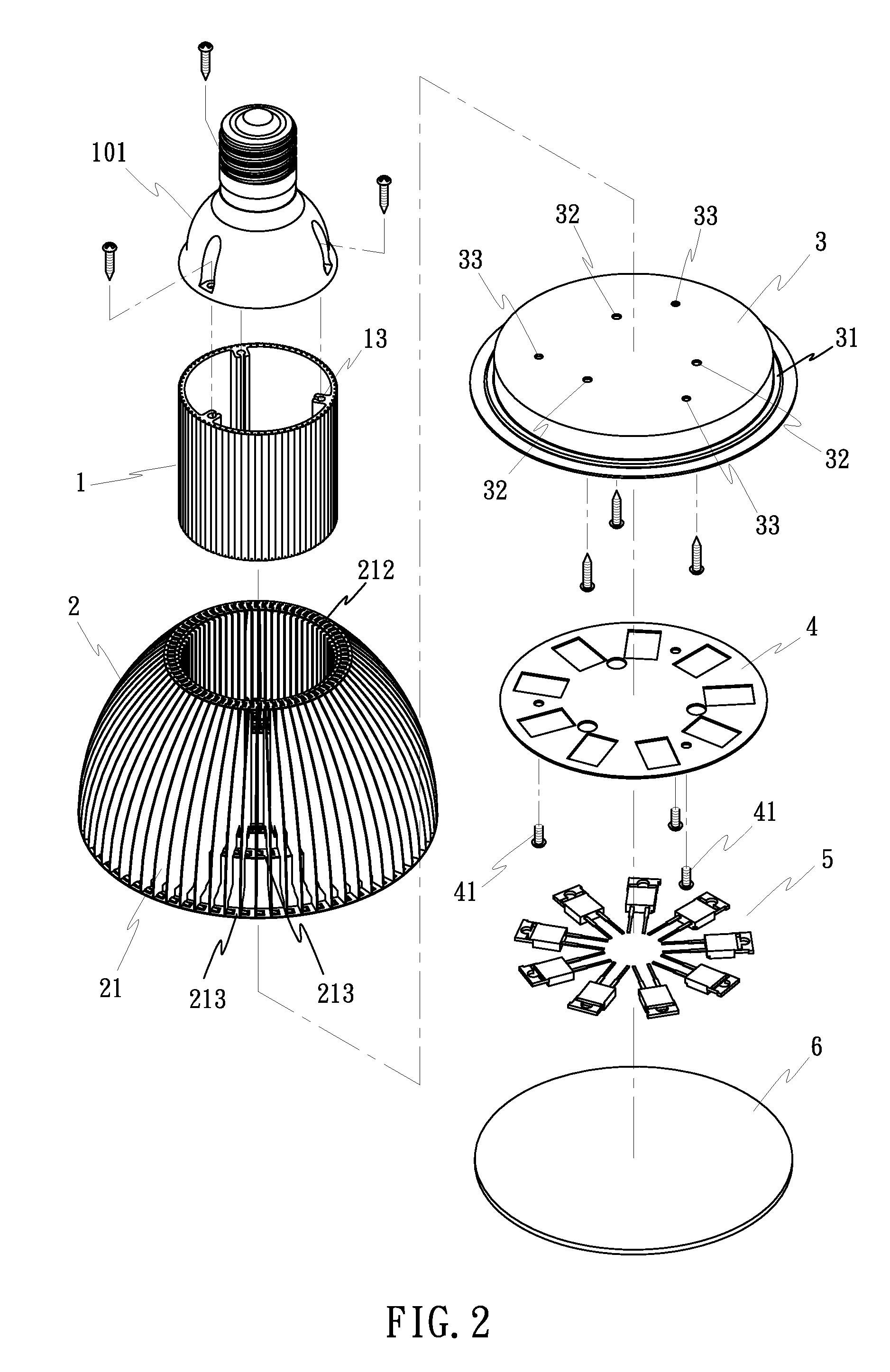

LED lamp

InactiveUS7611264B1Not easy to disperseEffective lightingMechanical apparatusLighting support devicesEngineeringLED lamp

A LED lamp includes a main body surrounded by a fin assembly on the periphery at an upper side and a lower side, a power supply holder located at the upper side and a plurality of LED lamp assemblies located at the lower side. The LED lamp assemblies are encased by a light converging plate which is further encased by a transparent lamp shade fastening to the lower side of the main body. The LED lamp thus formed may be fastened to a ceiling for indoor use through an upper cap of a fastening assembly, or an outdoor electric wire pole through a fastening tray. Each of the LED lamp assemblies has a heat transfer tube to transfer the generated heat to the main body for dispersing through the fin assembly. Thus desired heat dissipation can be accomplished.

Owner:LI HONG TECHNOLOGICAL

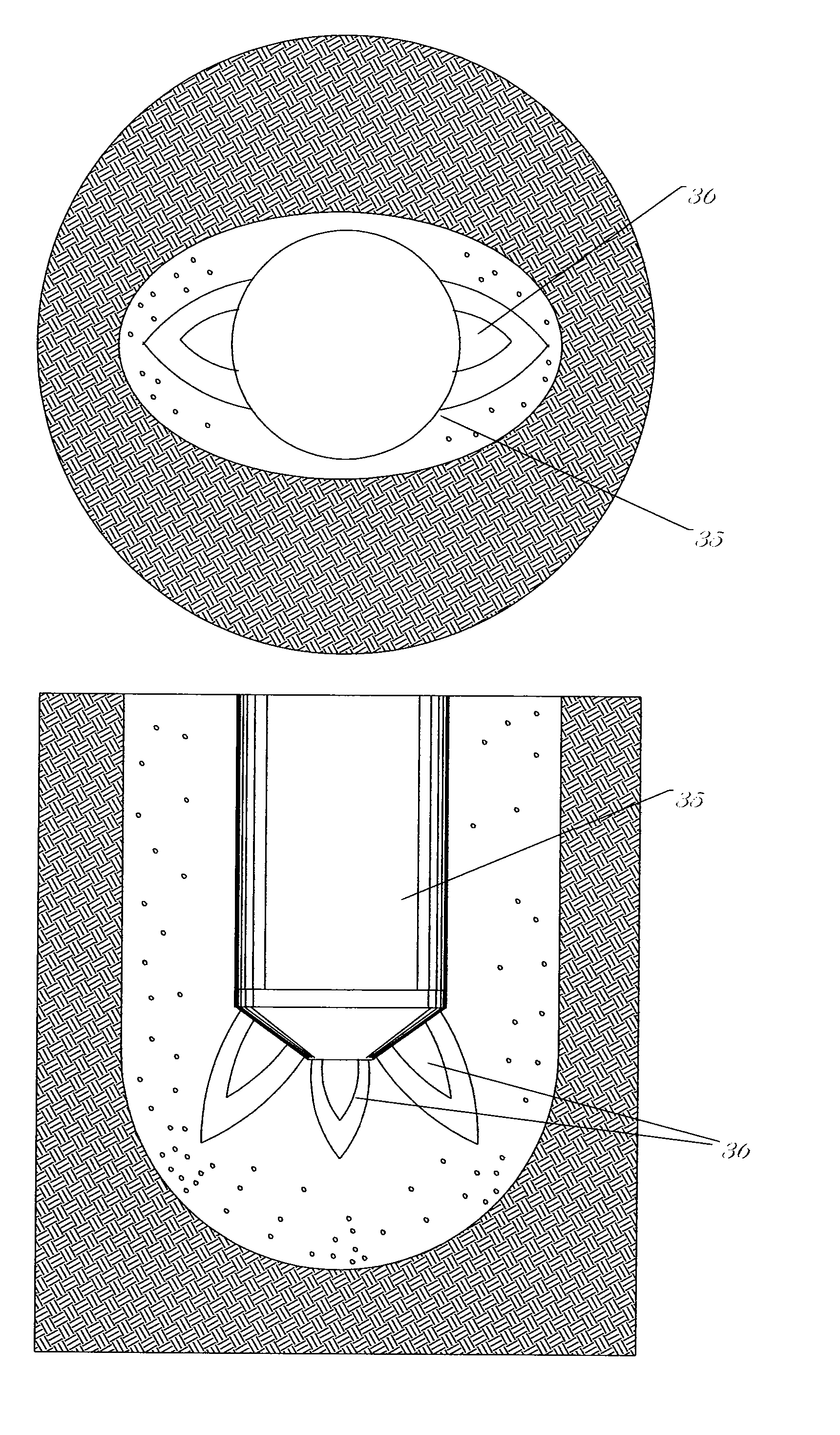

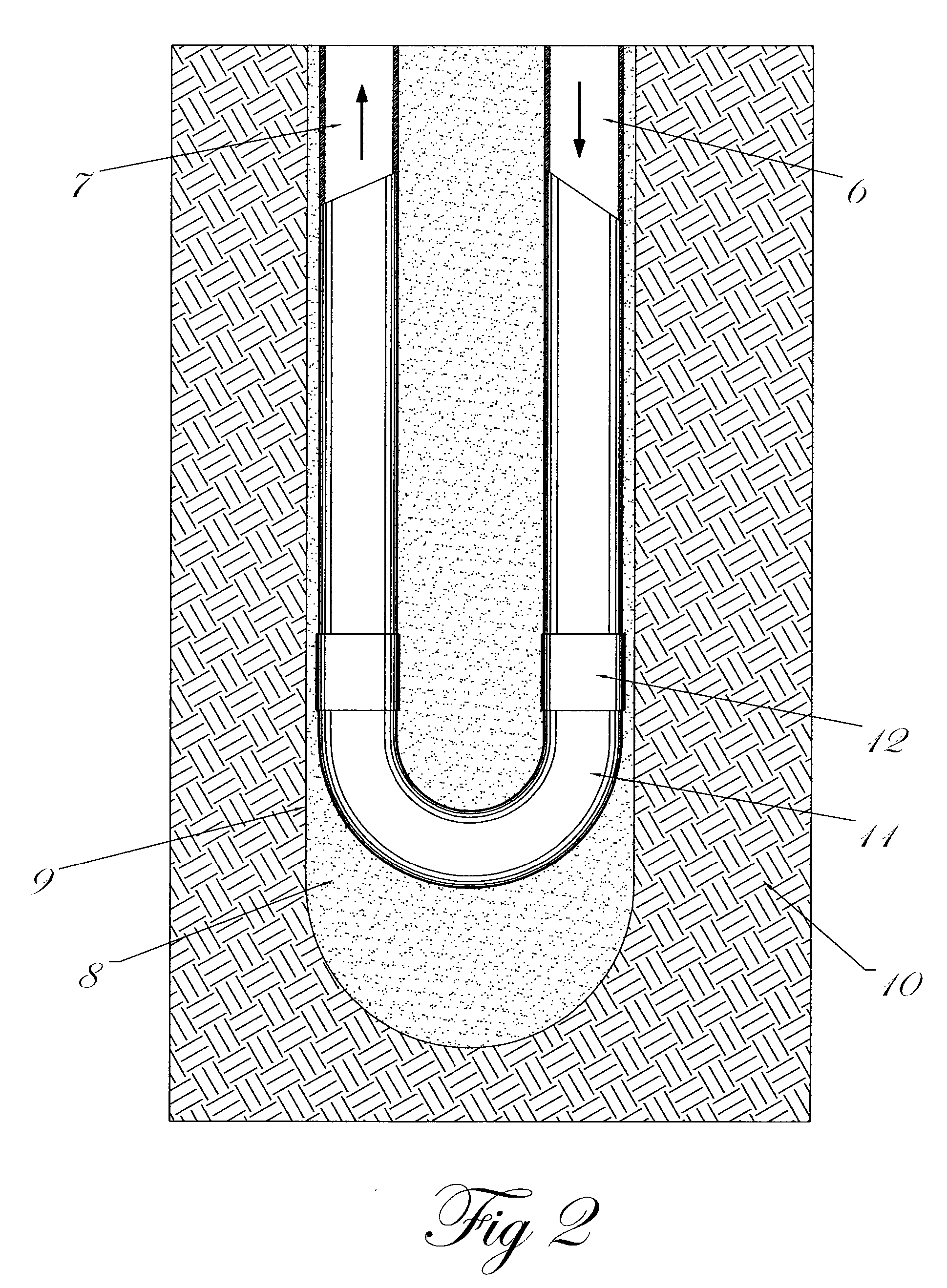

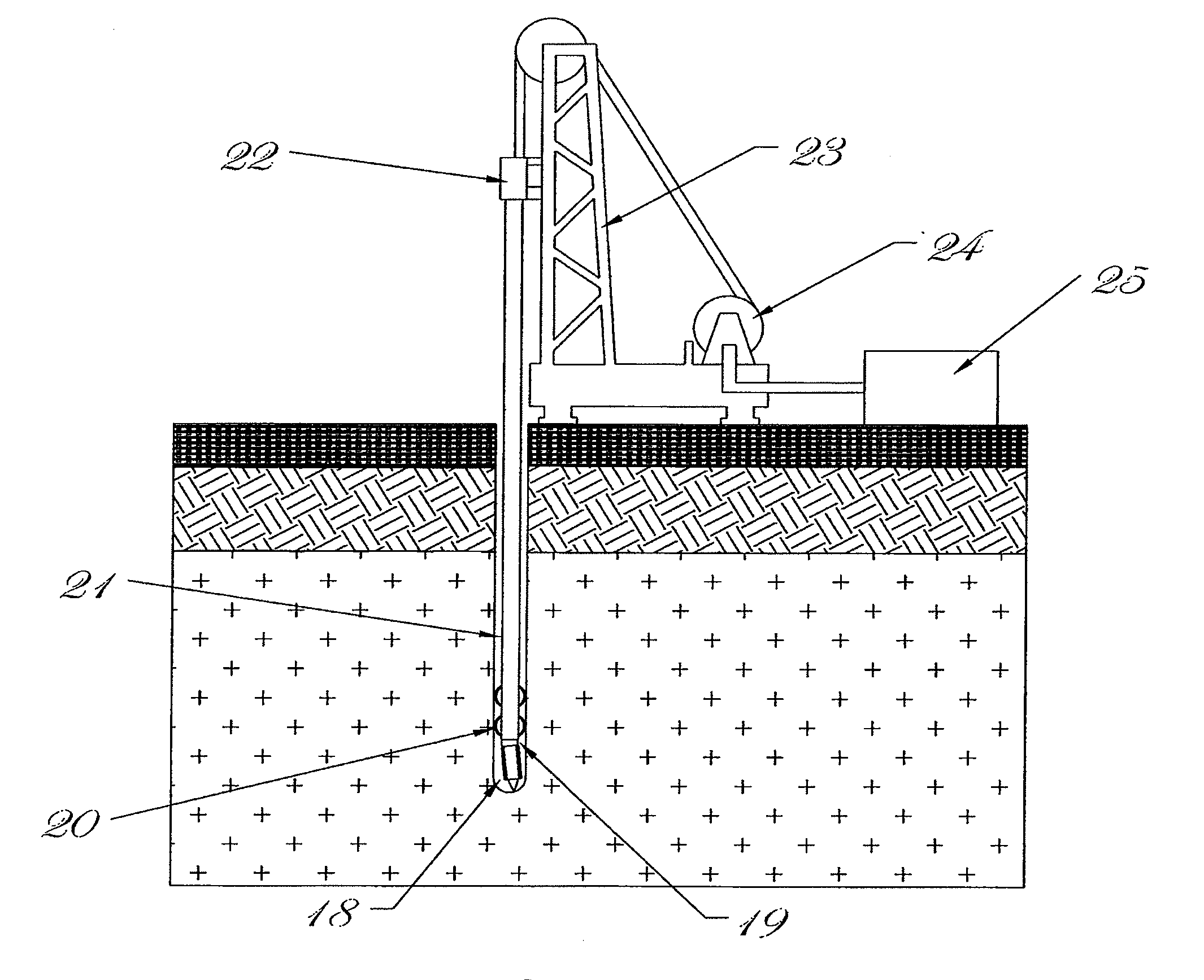

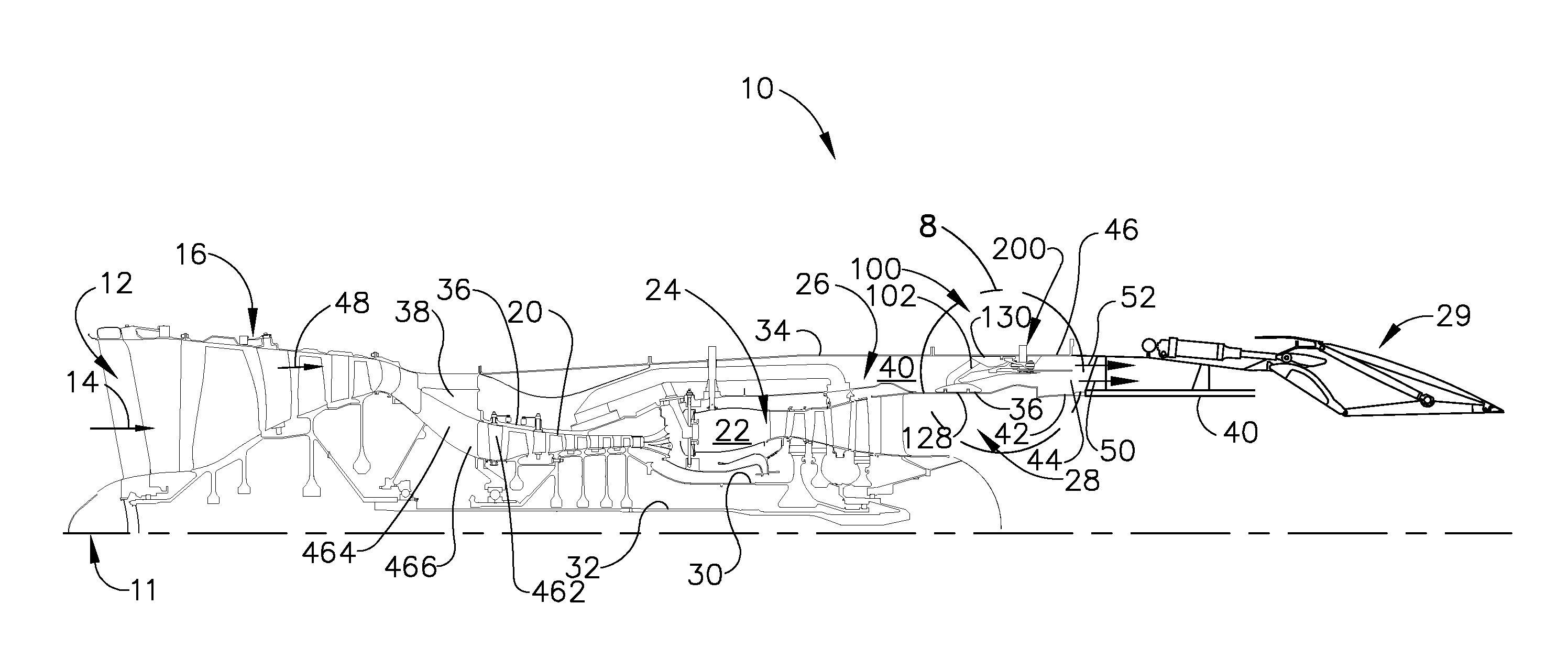

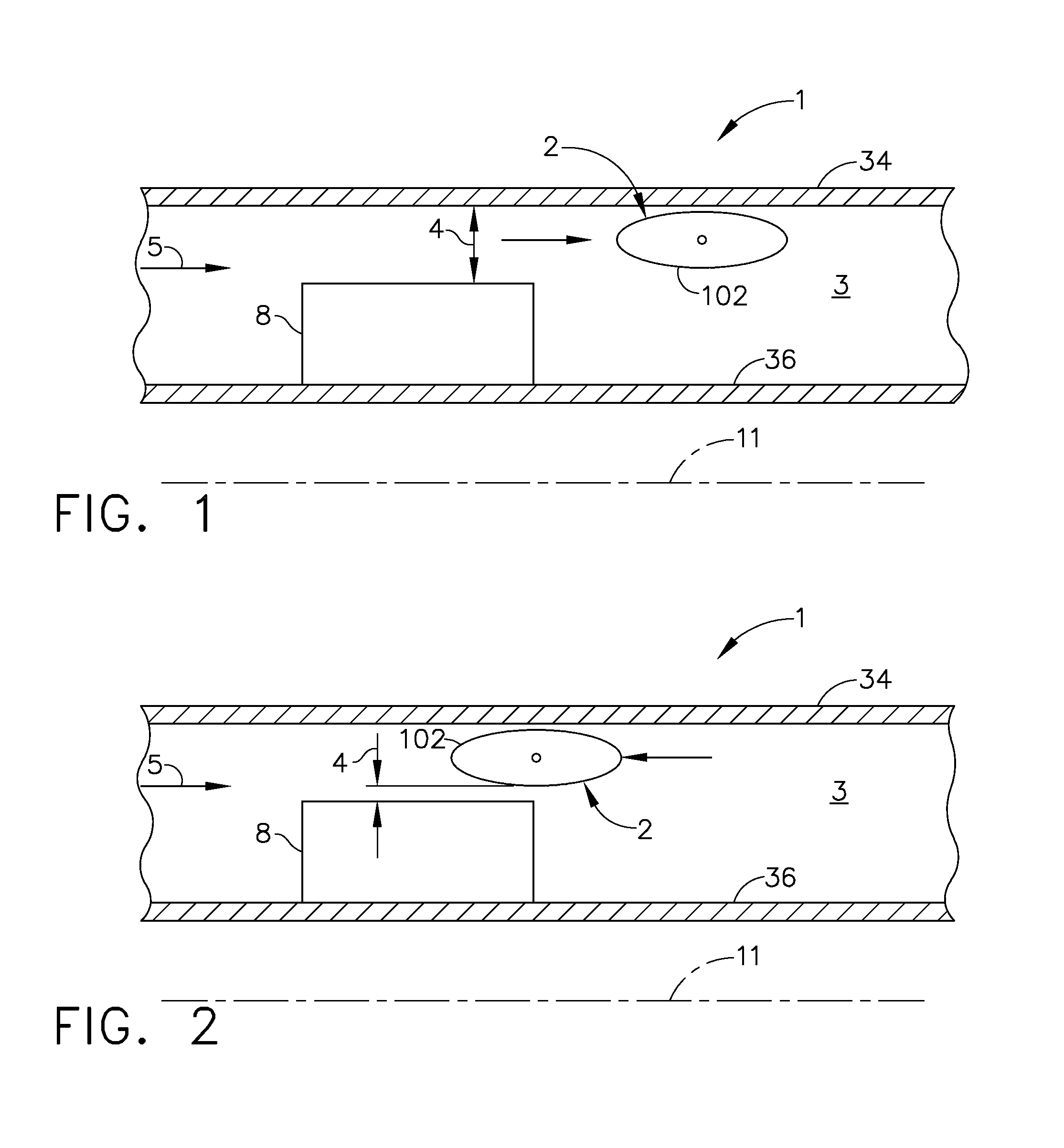

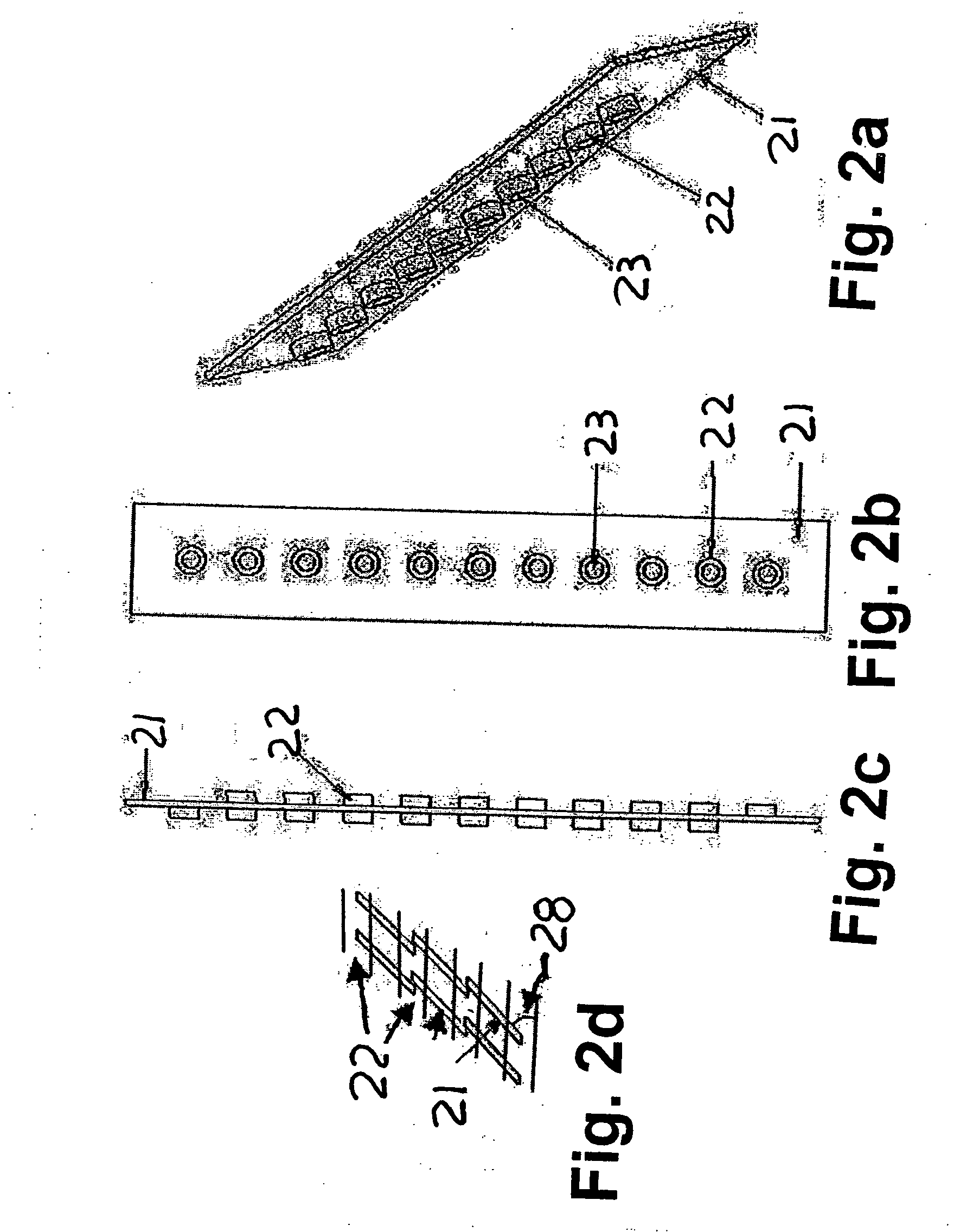

Method and System for Forming a Non-Circular Borehole

InactiveUS20080093125A1Prevent outbreakEasy to installEarth drilling toolsDrill bitsDissolutionGeothermal heat pump

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER DRILLING

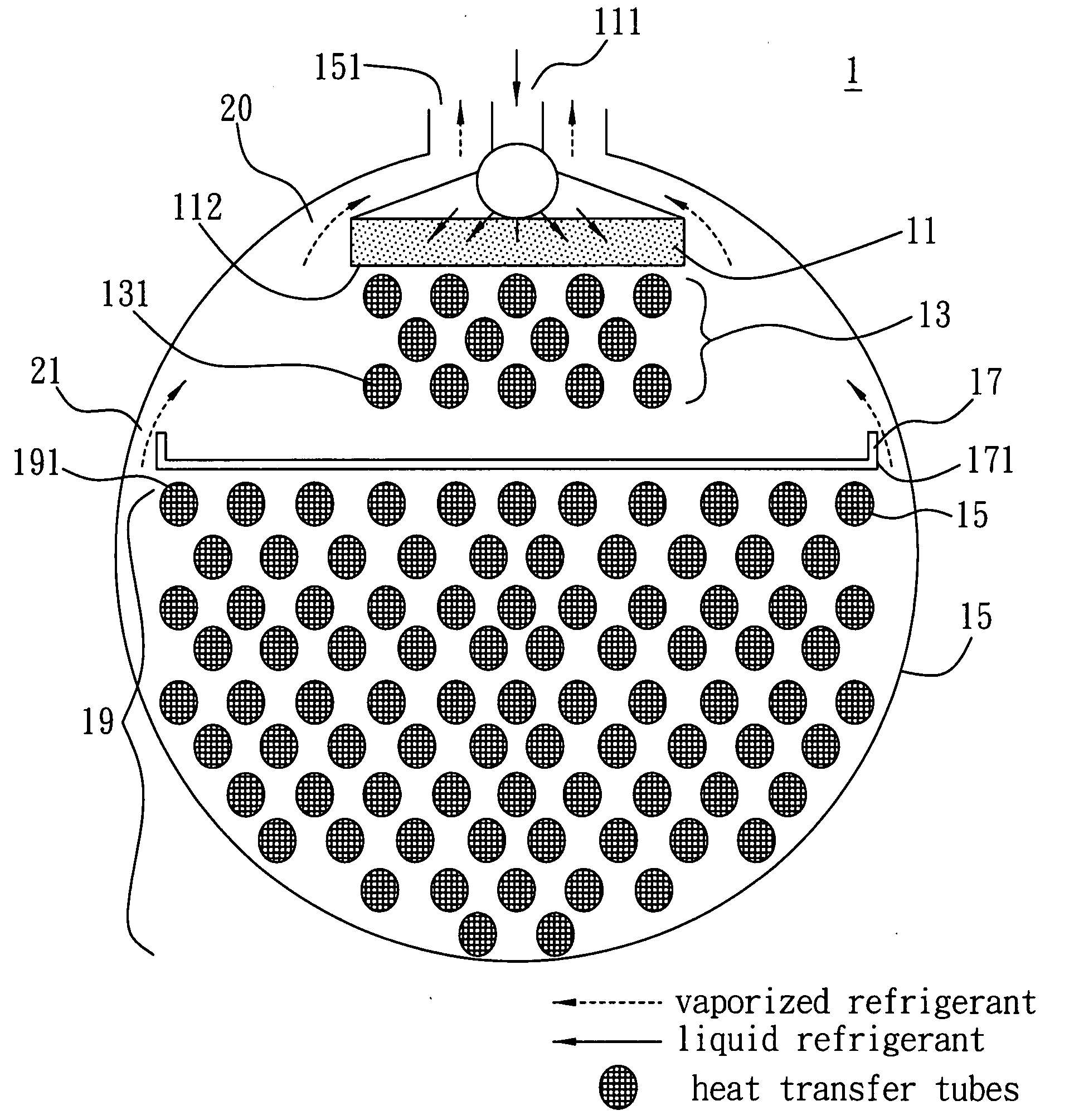

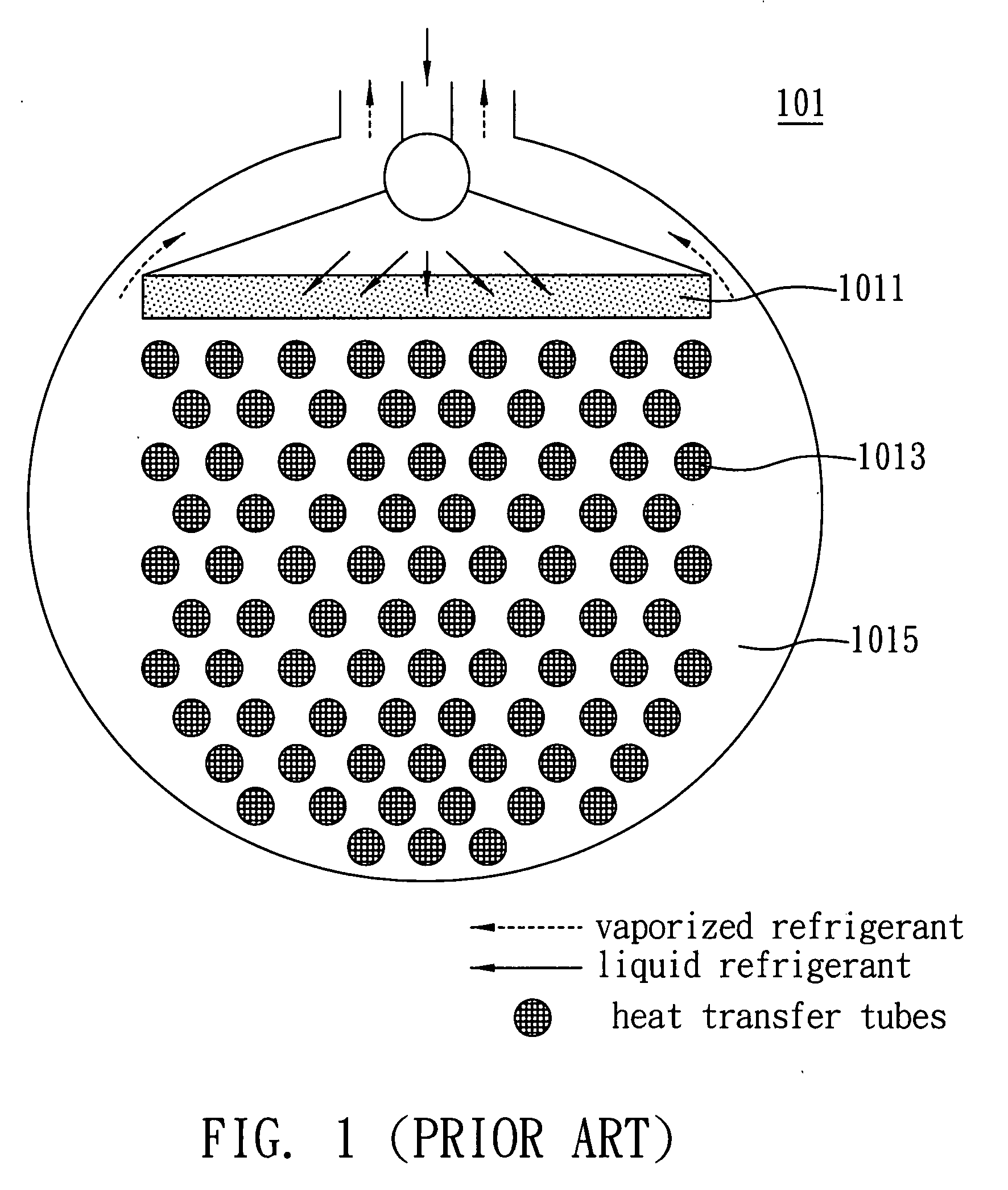

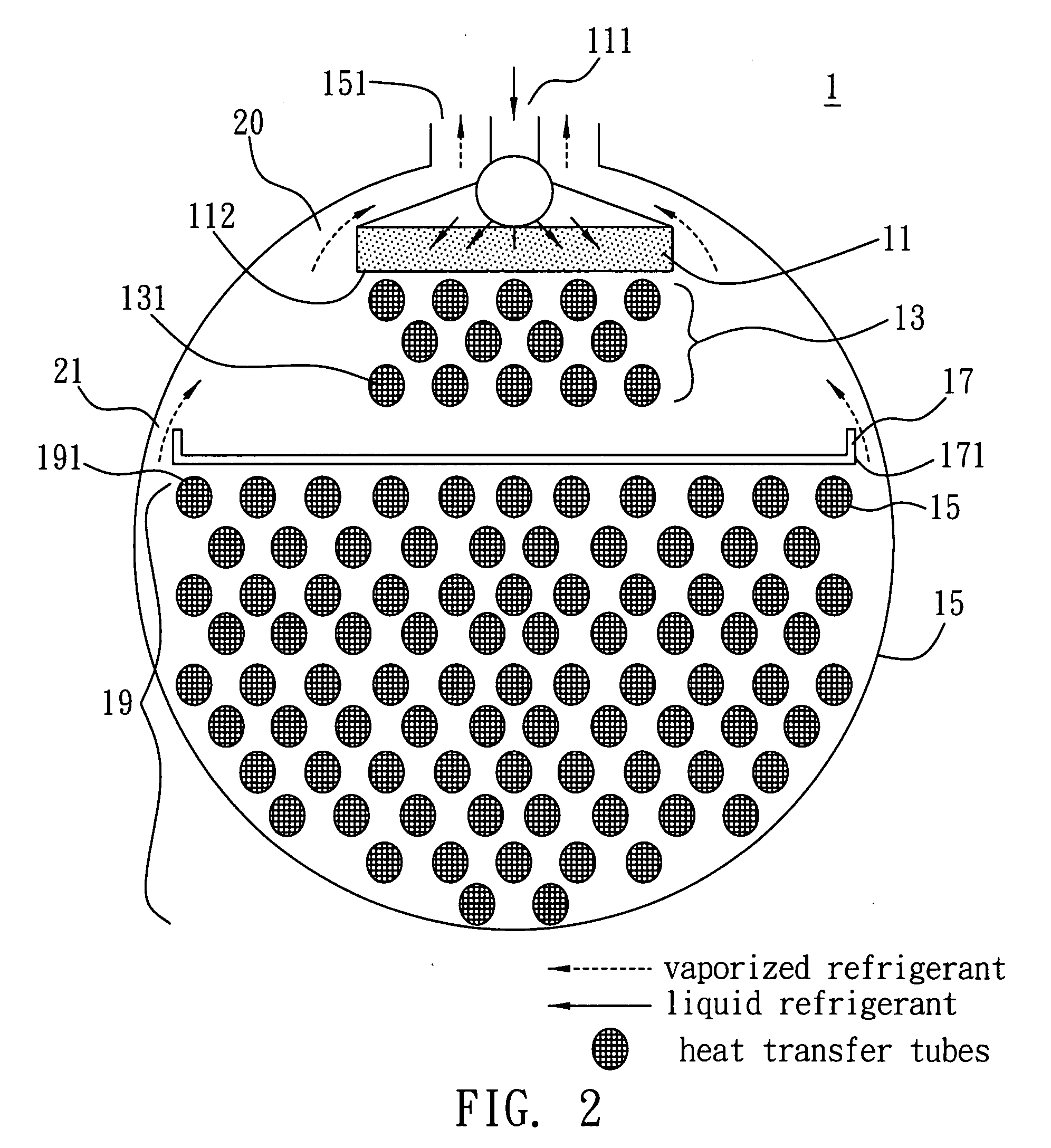

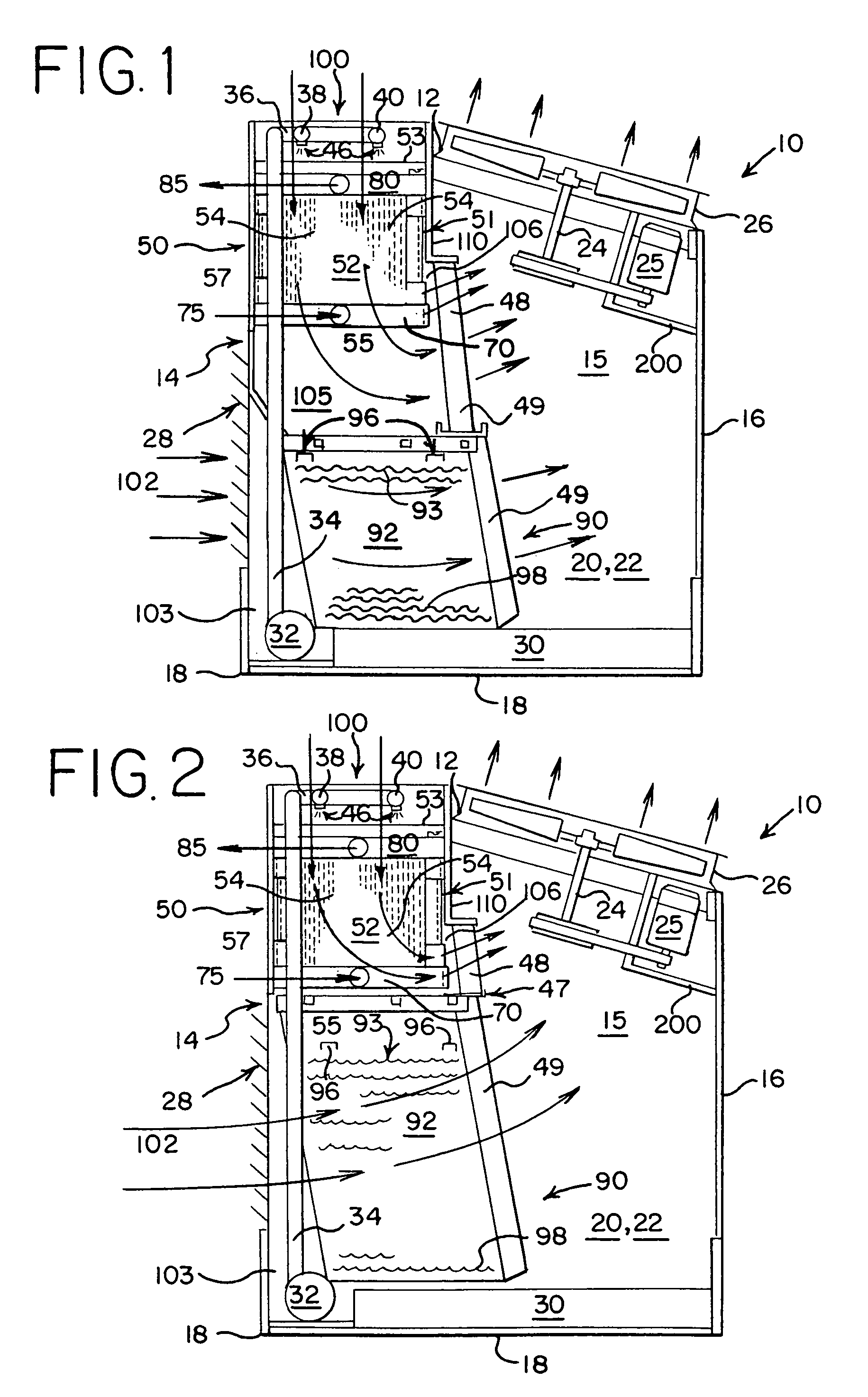

Spray type heat exchange device

InactiveUS20080149311A1Maximize the use of spaceExcessive heat transferMilk preservationEvaporators/condensersInterior spaceEngineering

A spray type heat exchange device includes a spray unit, a first group set of heat transfer tubes, at least a distributing unit and a second group set of heat transfer tubes. The distributing unit redistributes the remaining liquid refrigerant that is sprayed out from the spray unit and flowed through the first group set of heat transfer tubes, and the remaining liquid refrigerant is dropped downwardly to the second group set of heat transfer tubes. By this disclosed method, the inner space of the heat exchange device could be fully utilized to configure and accommodate more heat transfer tubes therein.

Owner:IND TECH RES INST

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

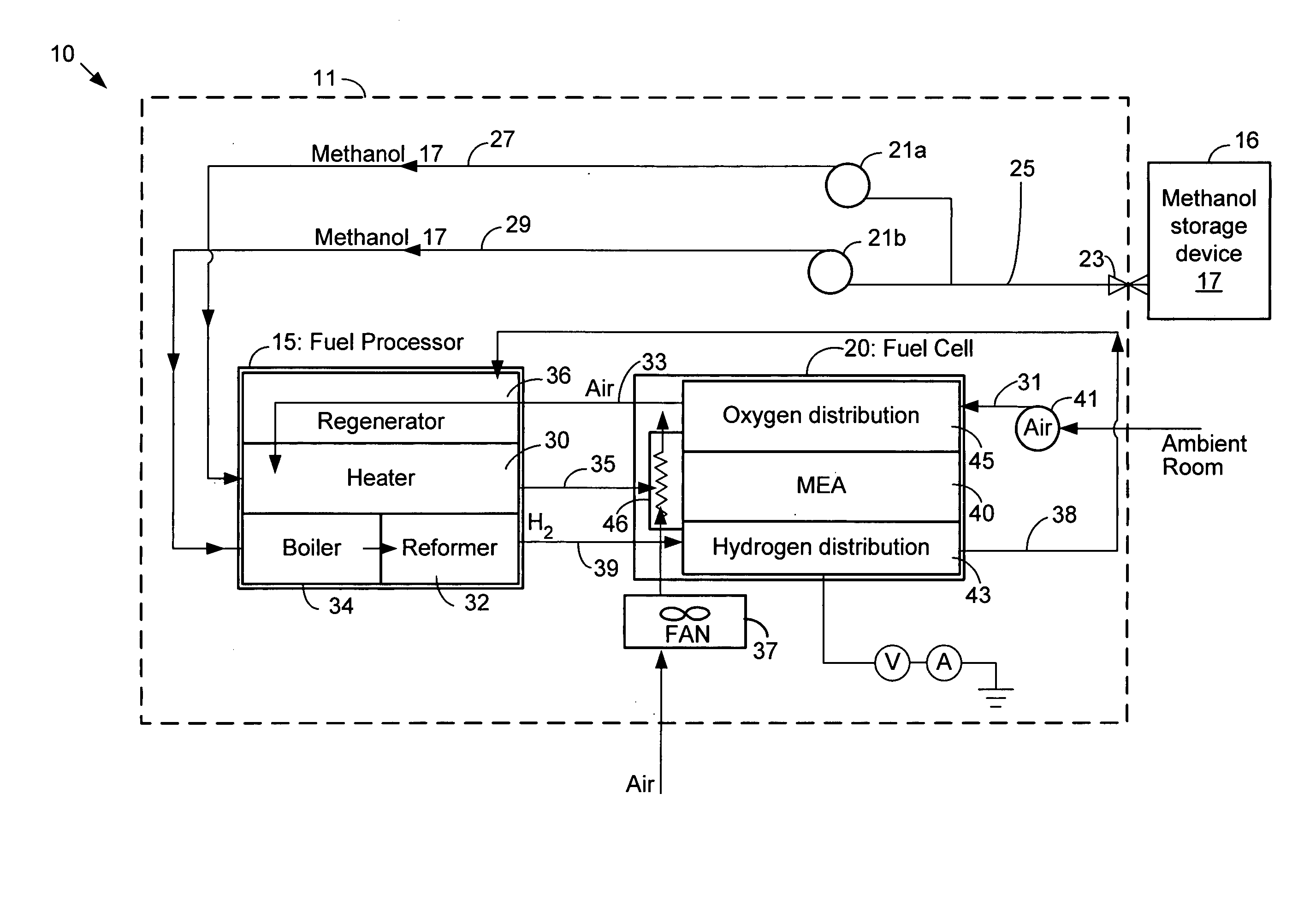

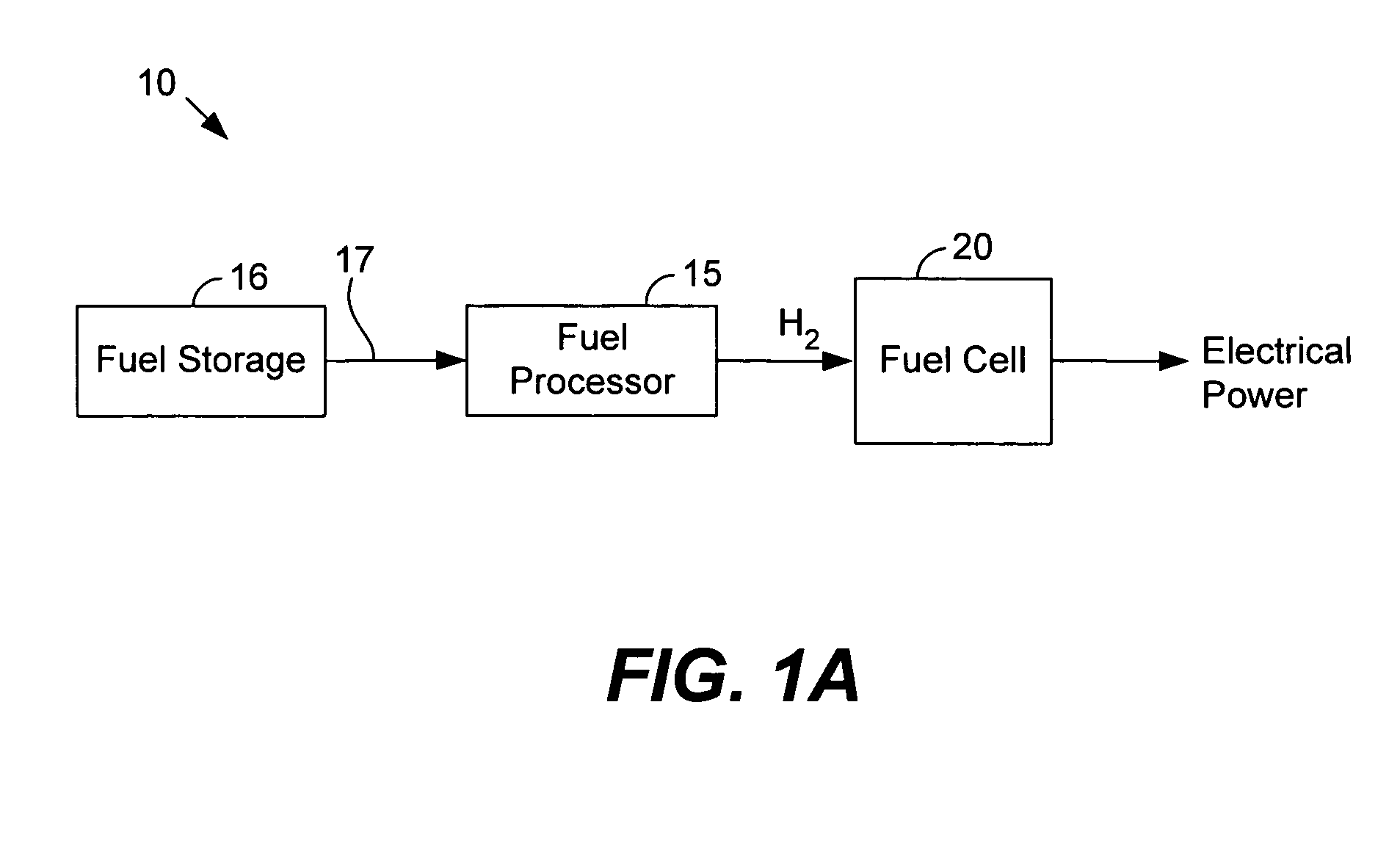

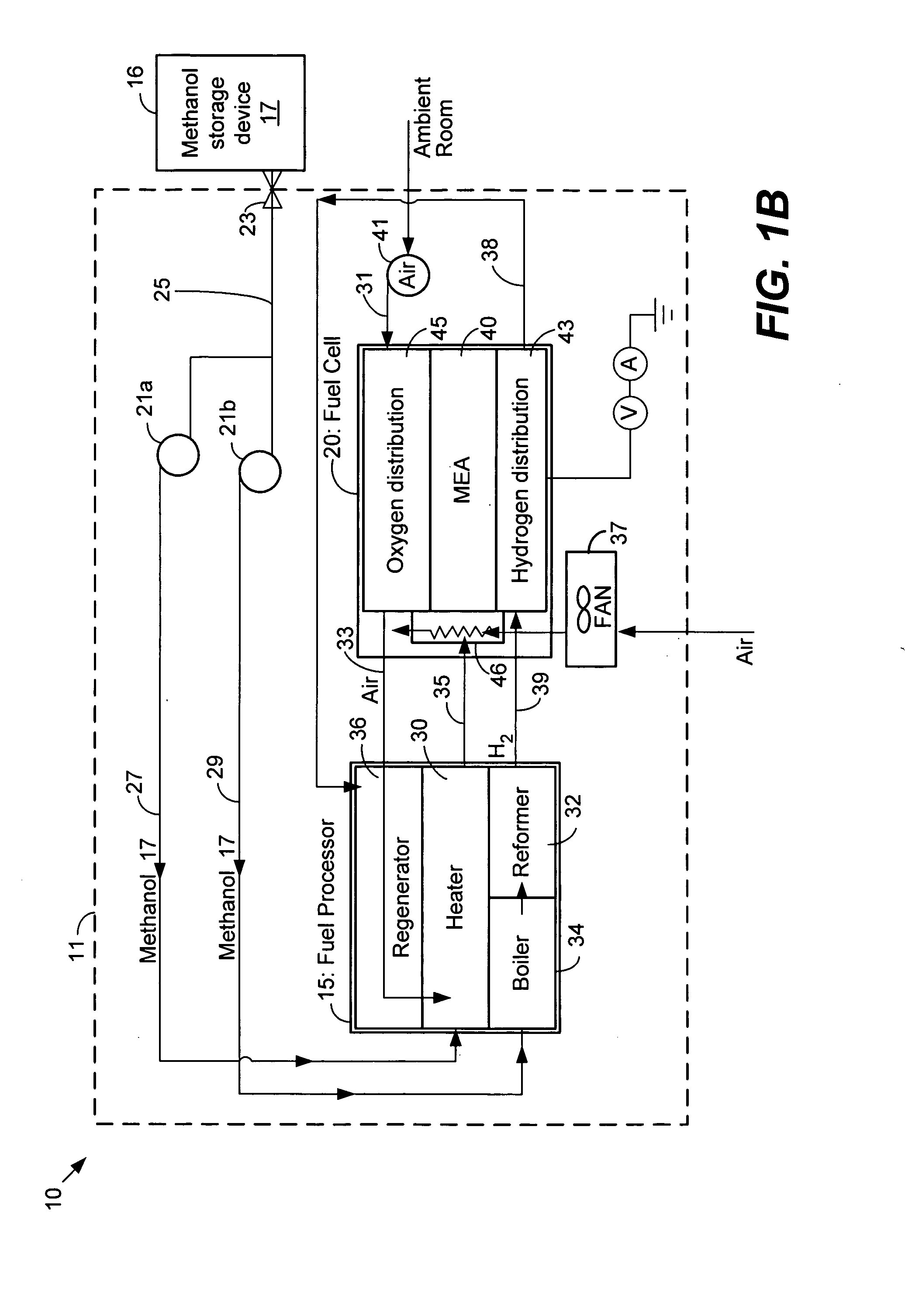

Heat efficient portable fuel cell systems

ActiveUS20060127719A1Reduce heat lossImprove thermal efficiencyHydrogenFuel cells groupingFuel cellsHydrogen

The invention relates to fuel cell systems with improved thermal efficiency. The systems include a fuel cell that generates electrical energy using hydrogen and a fuel processor that produces hydrogen from a fuel. Some heat efficient systems described herein include a thermal catalyst that generates heat when the catalyst interacts with a heating medium. The heat is used to heat the fuel cell. The thermal catalyst may be disposed in, proximity to the fuel cell, or remote from the fuel cell and a heat transfer pipe conducts heat from the catalyst to the fuel cell. Another thermally efficient embodiment uses a recuperator to transfer heat generated in the fuel cell system to incoming fuel. A fuel cell package may also include a multi-layer insulation arrangement to decrease heat loss from the fuel cell and fuel processor, which both typically operate at elevated temperatures.

Owner:ADVENT TECH LLC

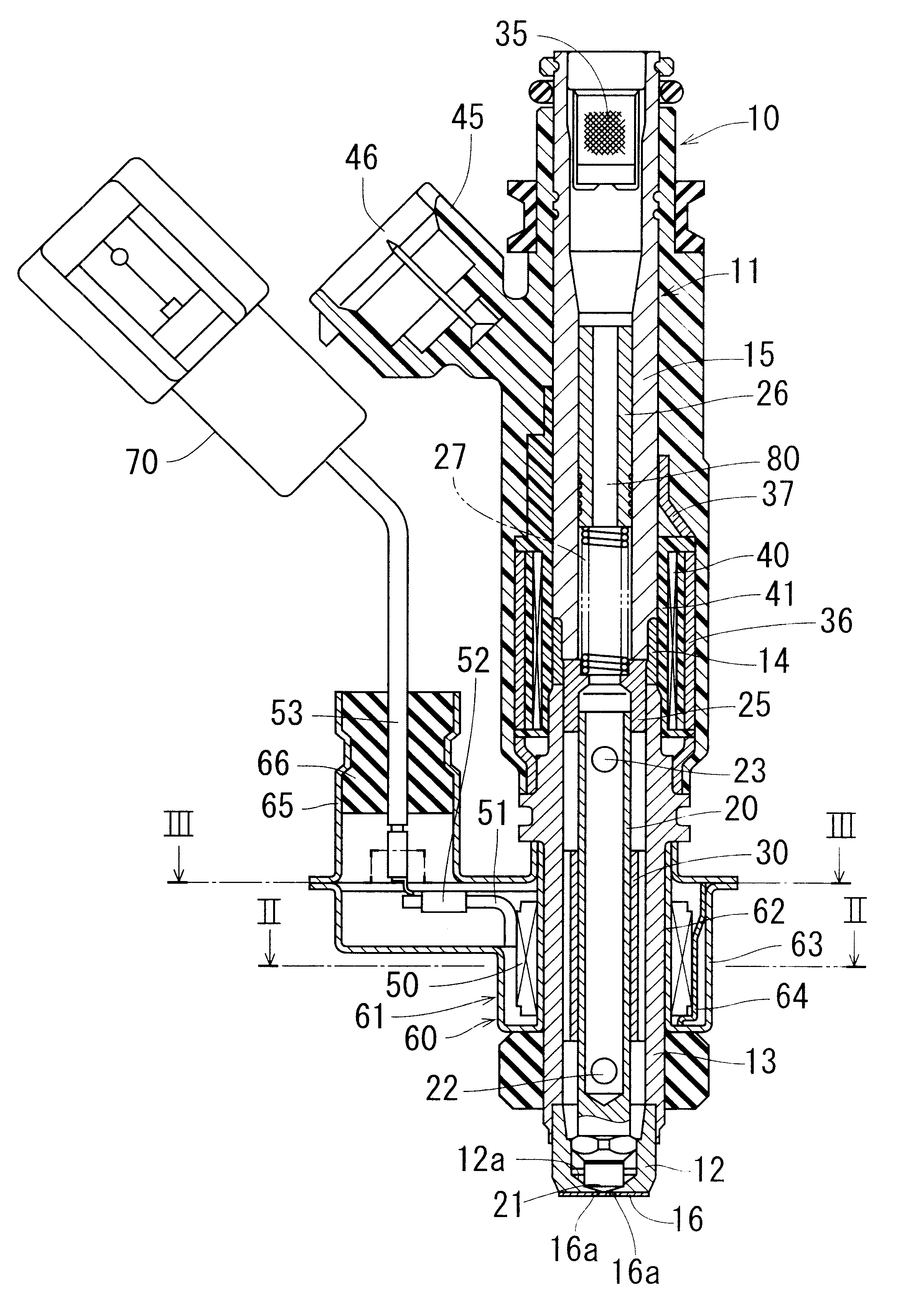

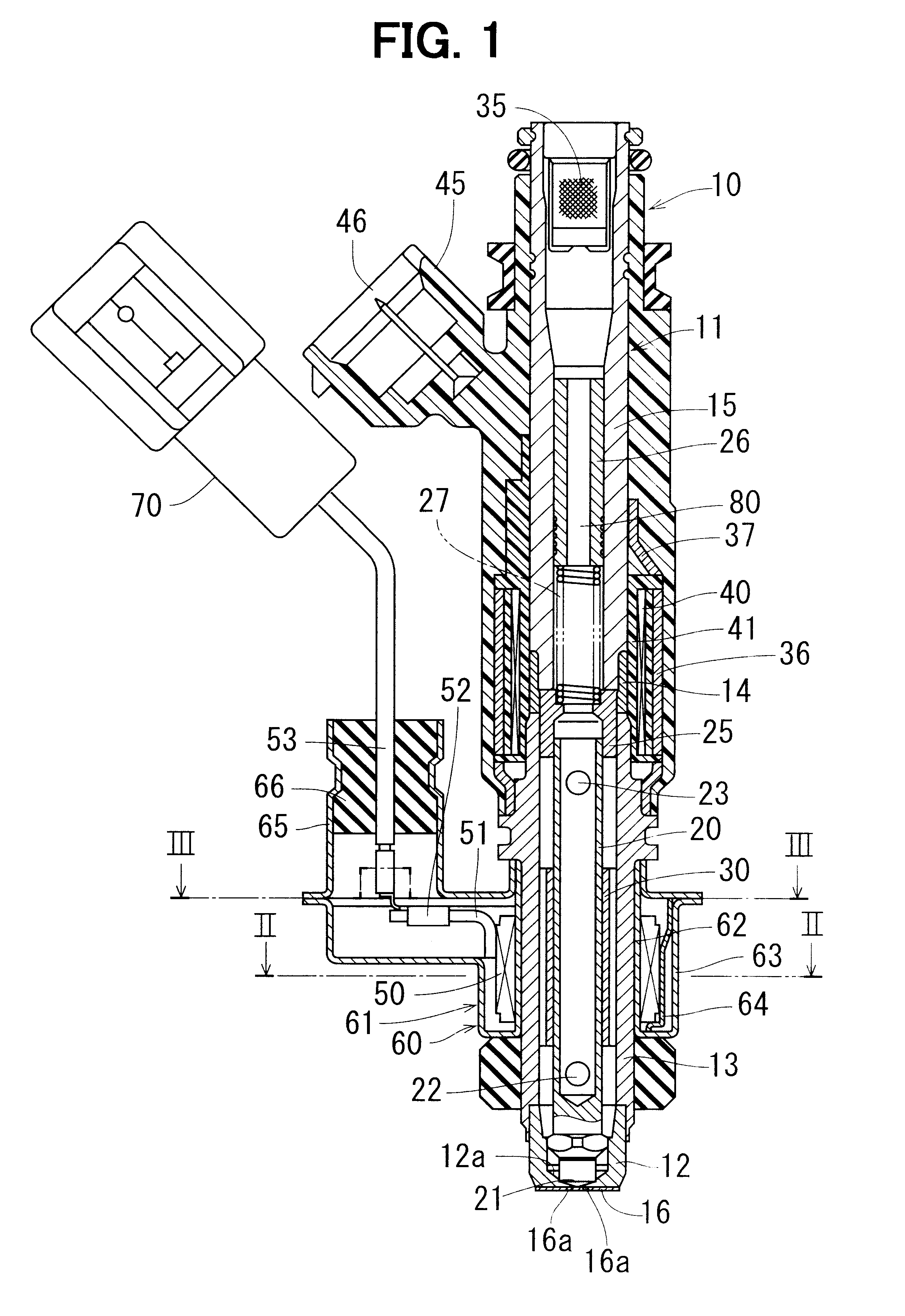

Fuel injection device having heater

InactiveUS6561168B2Liquid fuel feeder/distributionLiquid surface applicatorsEngineeringHeat transfer tube

A nozzle needle has a hollow tubular form having a closed base end. A heat transfer tube is press fitted into a first magnetic portion. The heat transfer tube surrounds an outer peripheral surface of the nozzle needle. A ceramic heater is formed as an integral cylindrical body by sintering a ceramic material together with a heat generating resistive element. A case covers the heater and protects the heater from externally applied water. An inner tube of the case is resiliently engaged with both the heater and the first magnetic portion. Heat of the heater is conducted to the nozzle needle through the inner tube, the first magnetic portion and the heat transfer tube to heat fuel inside the nozzle needle.

Owner:DENSO CORP

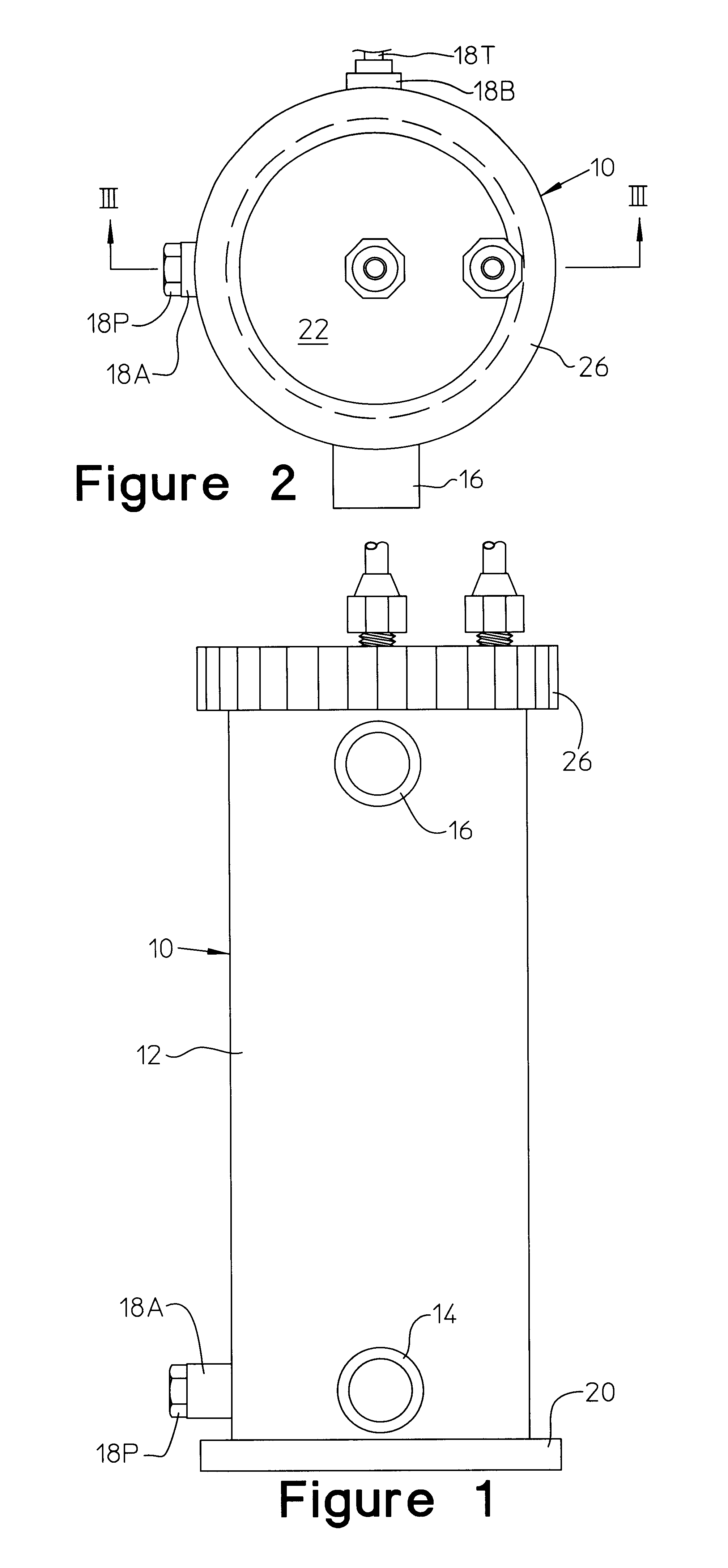

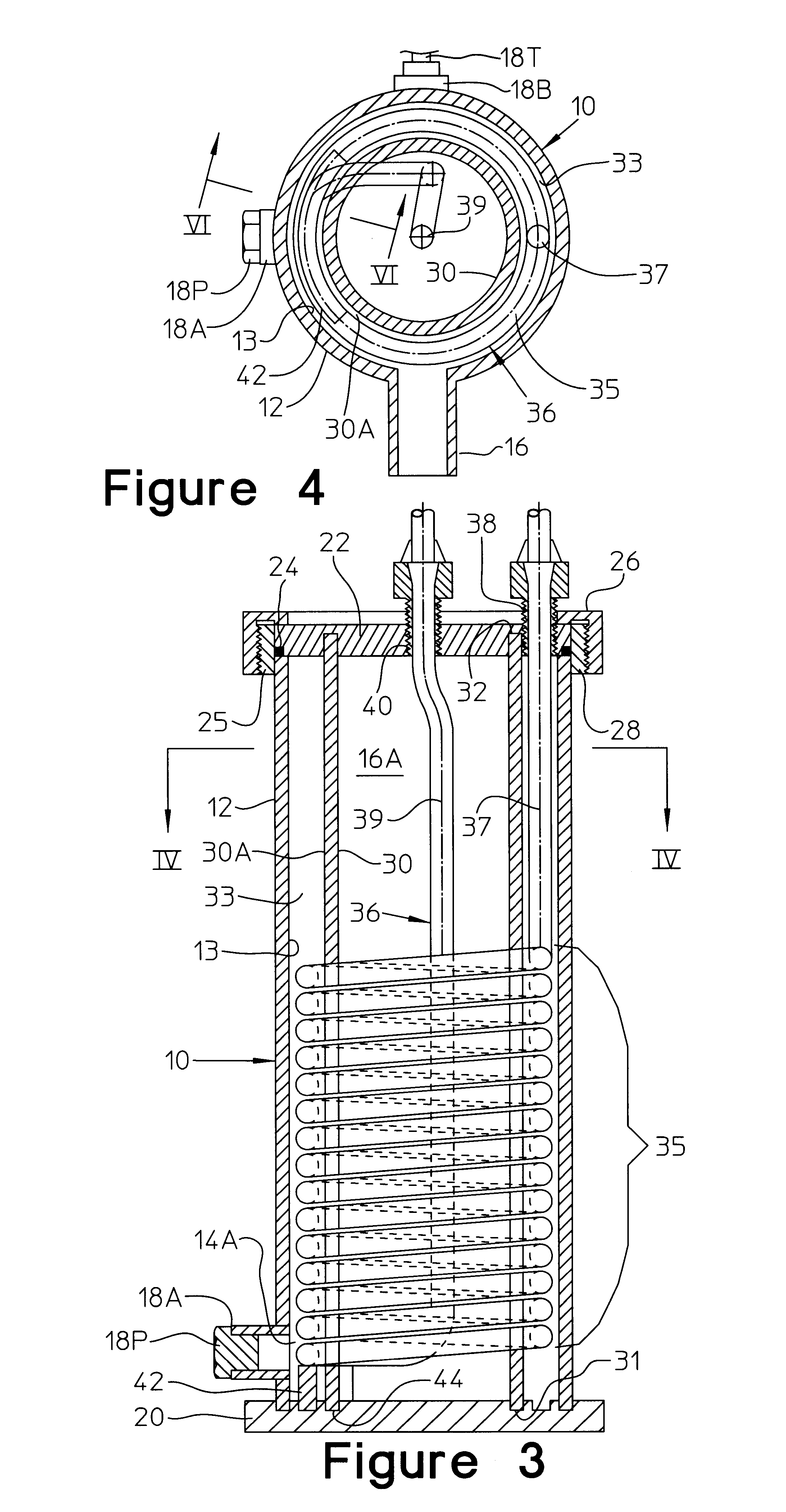

Method and apparatus for optimizing heat transfer in a tube and shell heat exchanger

InactiveUS6293335B1Increased turbulenceMaximize heat transferHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

A tube and shell heat exchanger having a transversely oriented inlet port and a spirally coiled heat transfer tube contained within an arcuate chamber created by an internal baffle in which the water to be conditioned travels along a helical pathway in which the flow has minimized water depth and high turbulence. The tube and shell heat exchanger maximizes heat transfer capability in a relatively easy to assemble design to make feasible the use of a higher cost material for the tubing such as titanium in a wide range of applications.

Owner:AQUACAL

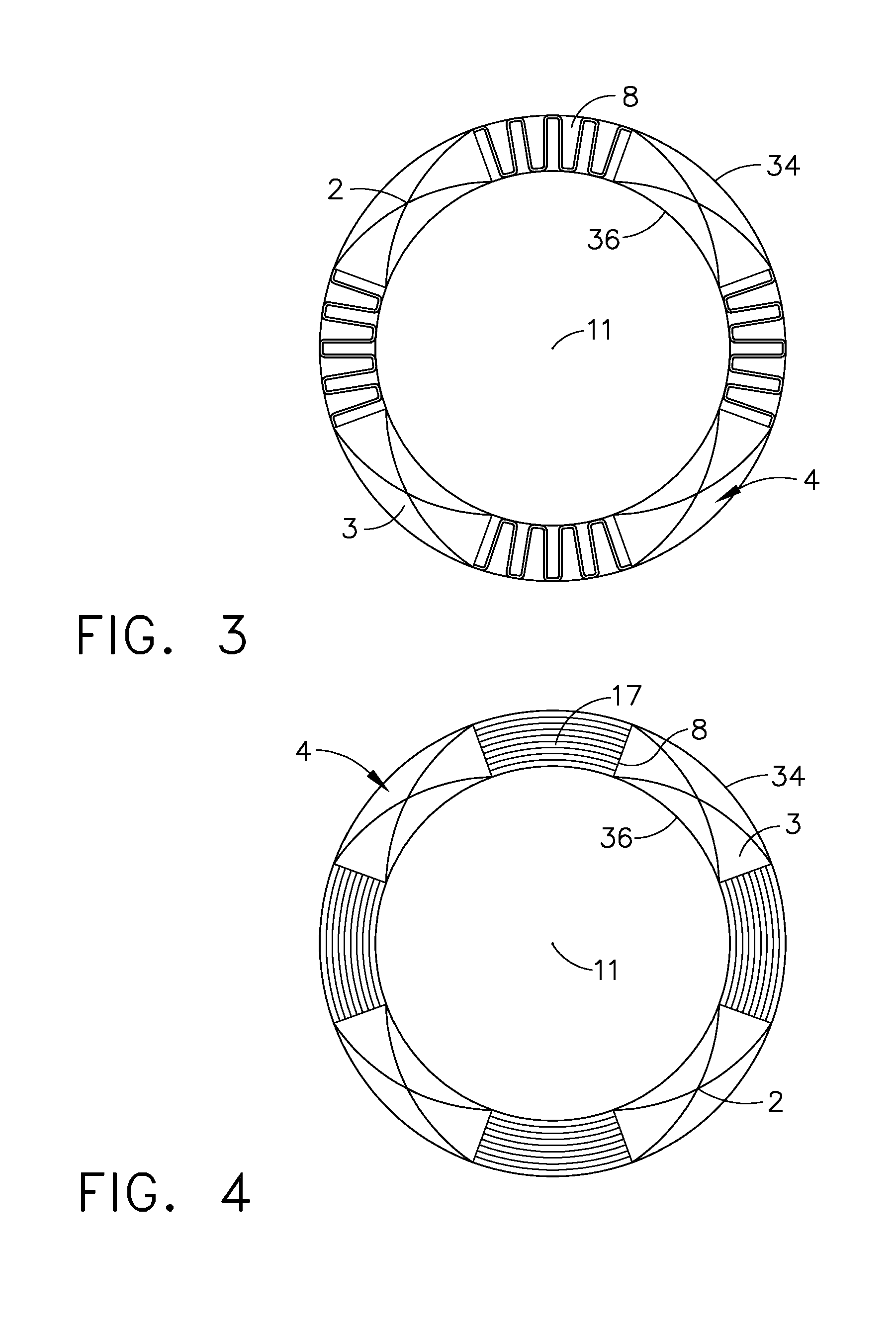

Integrated variable geometry flow restrictor and heat exchanger

ActiveUS20120128467A1Low and reduced performance conflictPump componentsWind motor controlEngineeringAnnular duct

One or more heat exchangers mounted in a duct have heat transfer cooling passages therein and a variable geometry flow restrictor is integral with each of the heat exchangers. An annular slide valve axially translatable within the duct is operable to open and close or vary a variable area between the heat exchangers and one of inner and outer casings bounding the duct. The heat exchangers may be being circumferentially distributed around an annular duct and include radial or circumferentially curved heat transfer tubes or vanes.

Owner:GENERAL ELECTRIC CO

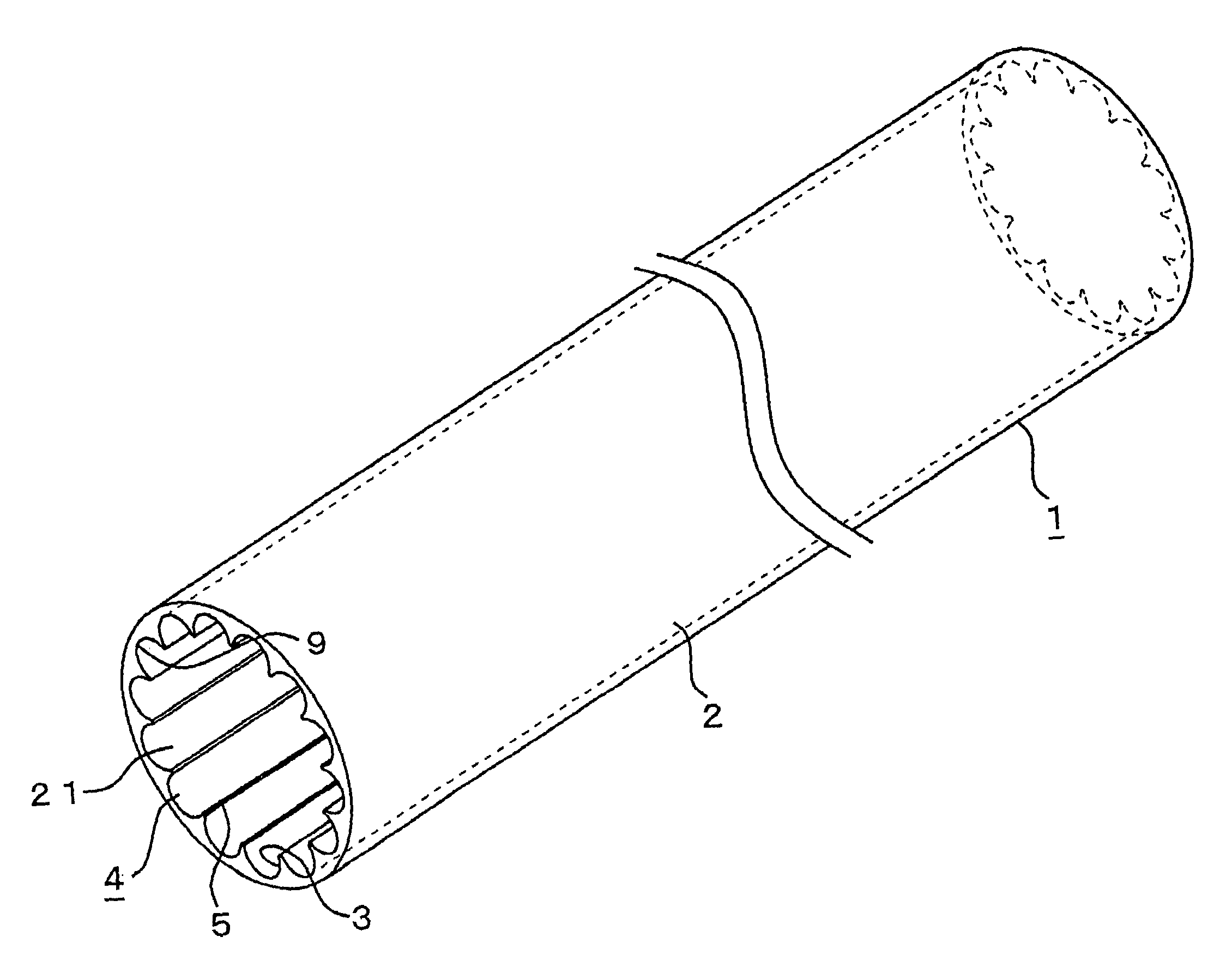

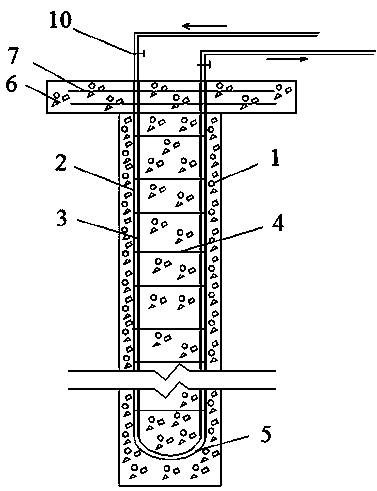

Heat transfer pipe and heat exchange incorporating such heat transfer pipe

InactiveUS7044210B2Facilitate conductionLarge heat exchange surfaceCorrosion preventionHeat exhanger finsPlate heat exchangerHeat transfer efficiency

Soot adhering to the inner surface of a heat transfer pipe can be removed without lowering the heat transfer efficiency that is the inherent object of the heat transfer pipe or without stopping the cooling operation of the heat transfer pipe. Further, this soot removal can be effected when the amount of soot adhering to the inner surface of the heat transfer pipe is small, thus minimizing the soot-caused lowering in the heat transfer efficiency of the heat transfer pipe. A heat transfer pipe (1) wherein the inner peripheral surface of an element pipe (2) through which fluid can flow is formed with longitudinal grooves (4) as recessed grooves (3) of cross-section with a given depth such that the longitudinal grooves are parallel with the pipe axis and circumferentially continuous, and a partition wall (5) of given thickness is formed between the longitudinal grooves (4): and a heat exchanger incorporating this heat transfer pipe (1).

Owner:USUI KOKUSAI SANGYO KAISHA LTD

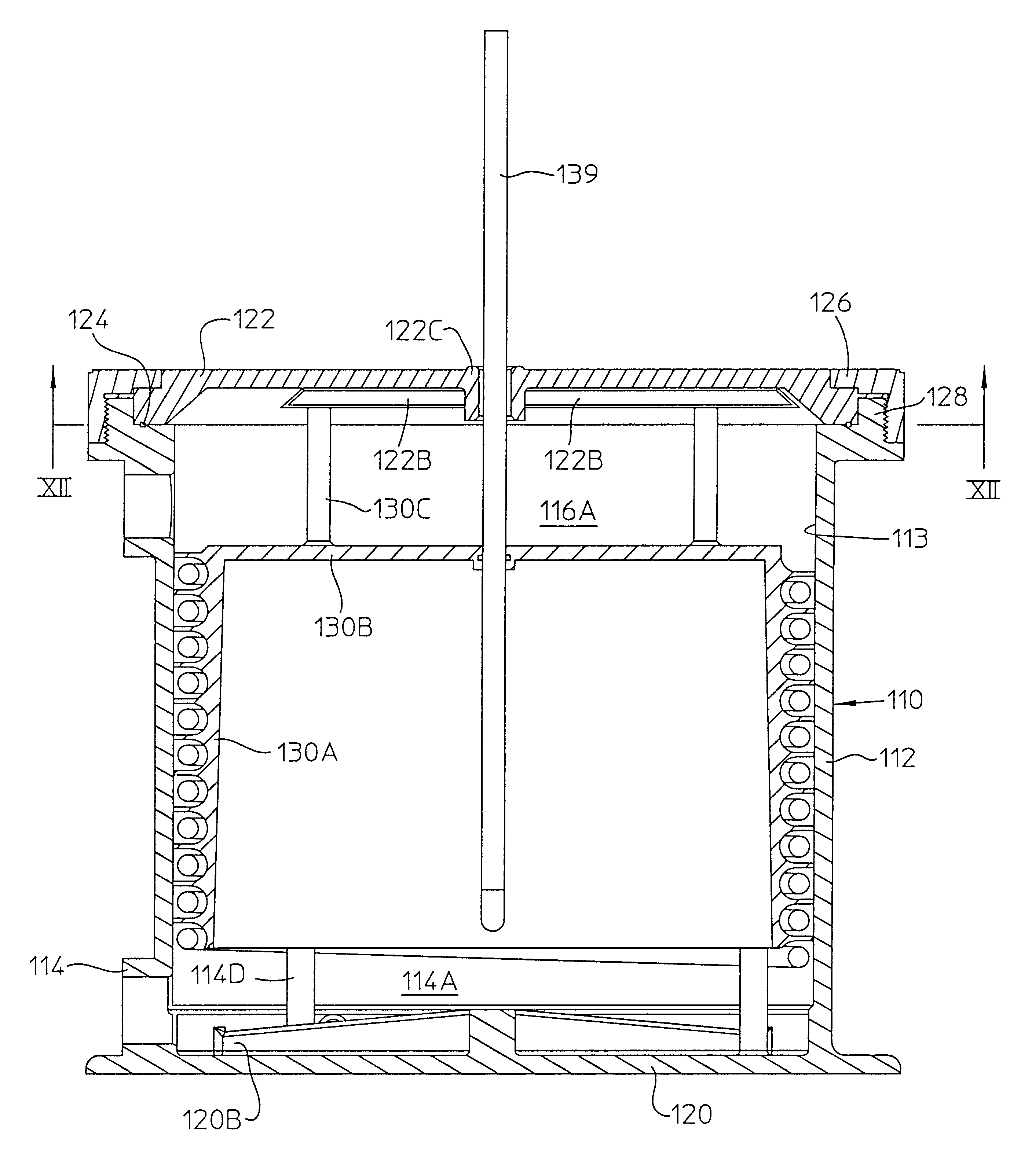

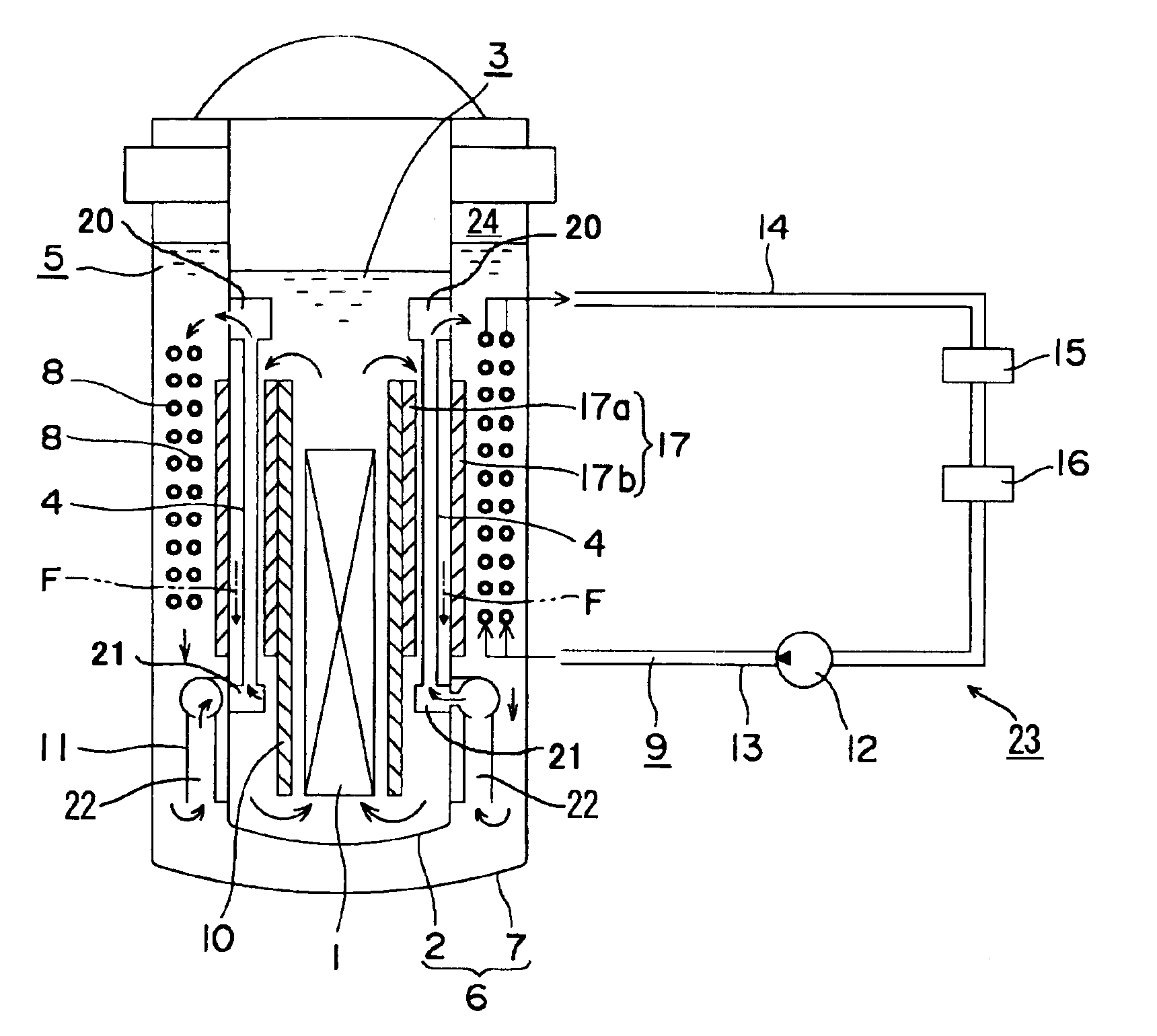

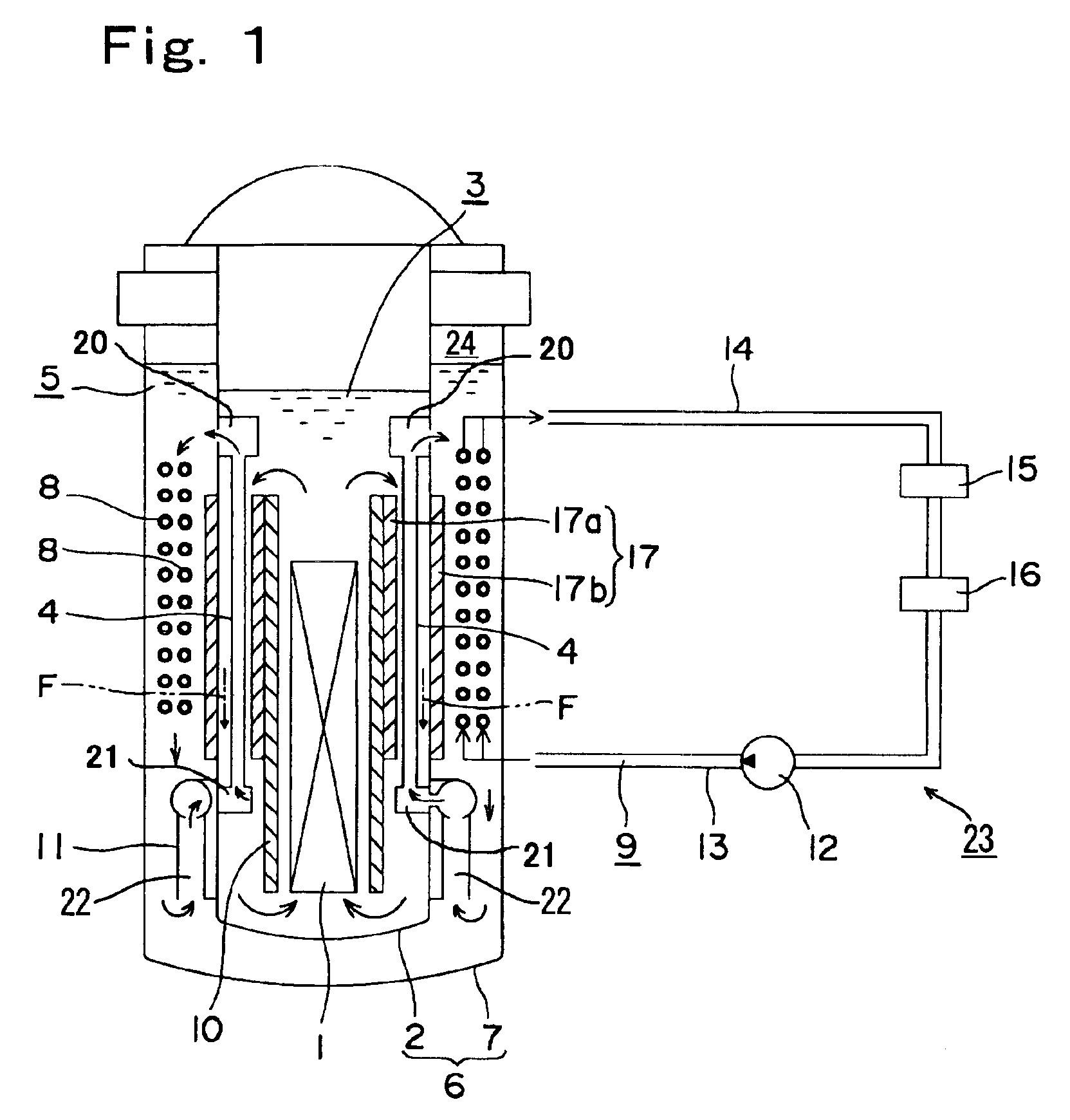

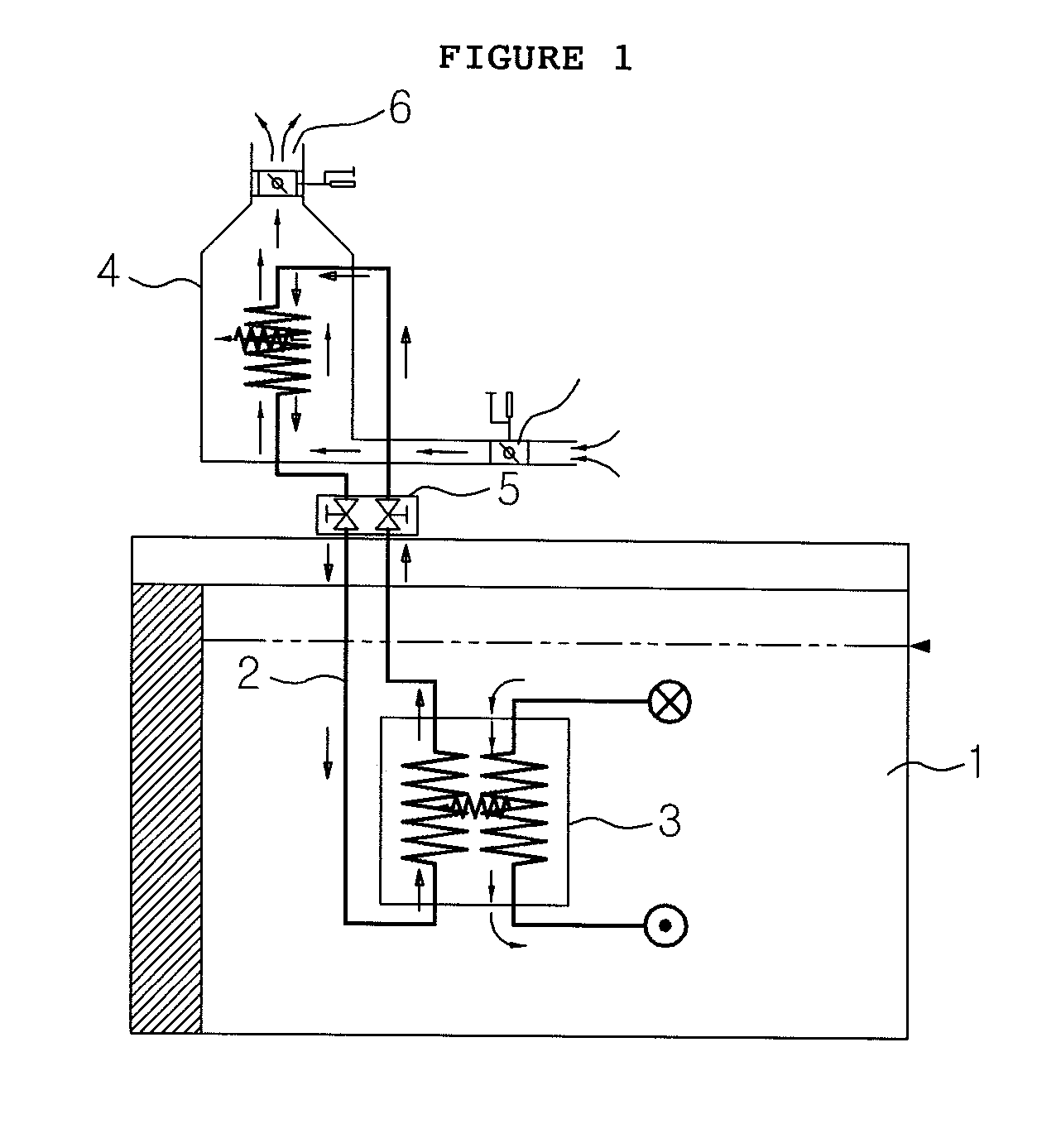

Nuclear reactor

InactiveUS6944255B2Small sizeReduce manufacturing costIntegral reactorsNuclear energy generationNuclear reactorHeat transfer tube

A nuclear reactor in which a secondary or tertiary coolant system of a nuclear steam supply system is simplified, comprising: a reactor vessel (2) which integrates a reactor core (1); a first coolant (3) which is stored in the reactor vessel (2) and heated by the reactor core (1) to convect; a first heat transfer tube (4) which is arranged in the reactor vessel (2) and comes into contact with the first coolant (3); and a second coolant (5) which is supplied from the outside of the reactor vessel (2) to the first heat transfer tube (4), cools the first coolant (3) and led to the outside of the reactor vessel (2).

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

Heat Exchanger with Fluid Expansion in Header

InactiveUS20080092587A1Reduce inequalityMechanical apparatusCompression machines with non-reversible cycleEngineeringMechanical engineering

A heat exchanger includes a plurality of flat, multi-channel heat exchange tubes extending between spaced headers. Each heat exchange tube has a plurality of flow channels extending longitudinally in parallel relationship from its inlet end to its outlet end. A plurality of connectors are positioned between the inlet header and the heat transfer tubes such that the connector inlet ends are in fluid flow communication with the header through a relatively small cross-sectional flow area openings and the connector outlet ends are adapted to receive the inlet end of a heat exchanger tube. The connector defines a fluid flow pathway from the relatively small cross-sectional flow area opening in the inlet end of the connector to an outlet opening in the outlet end of the connector that opens to the flow channels of the heat exchange tube received in the outlet end of the connector.

Owner:CARRIER CORP

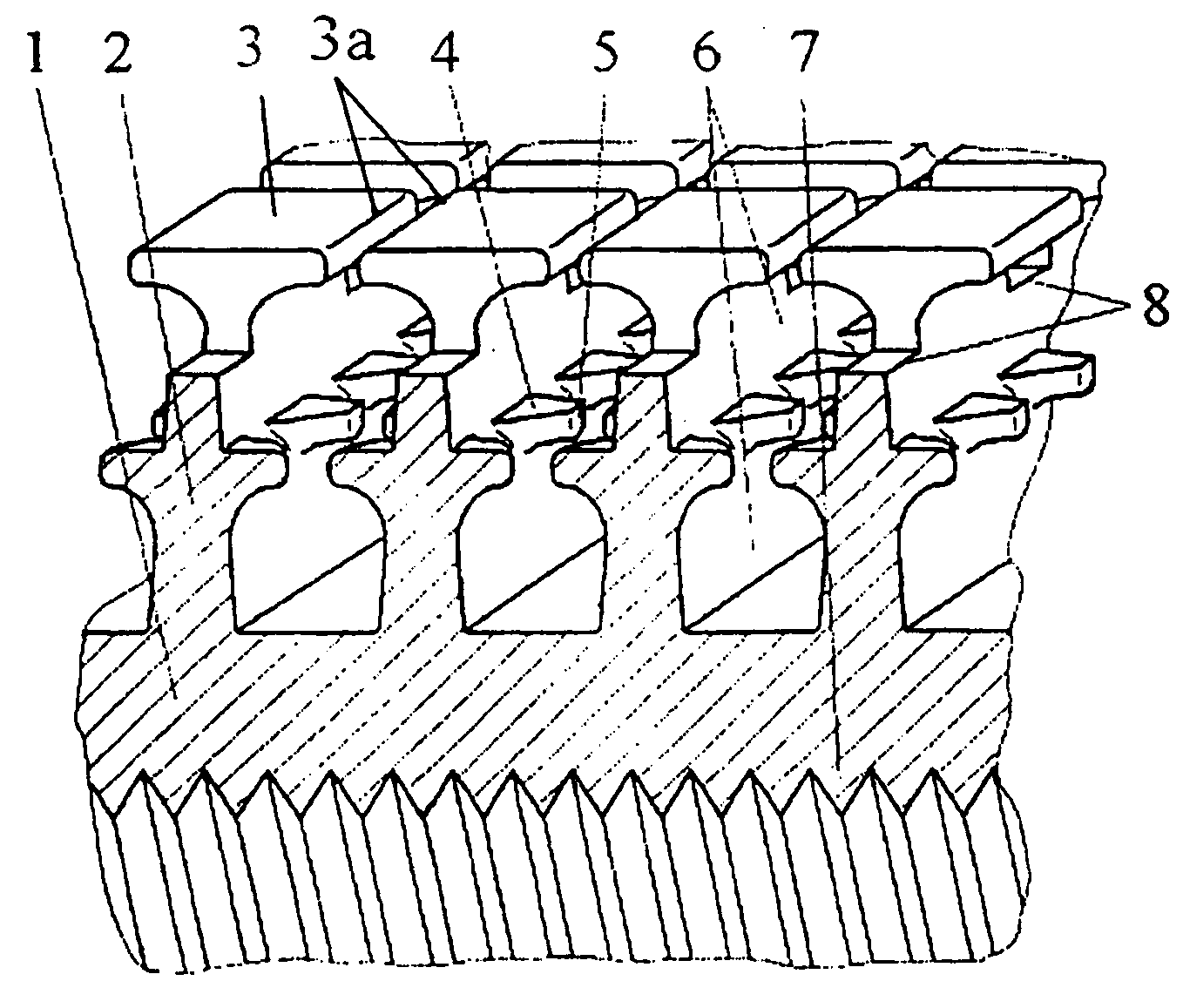

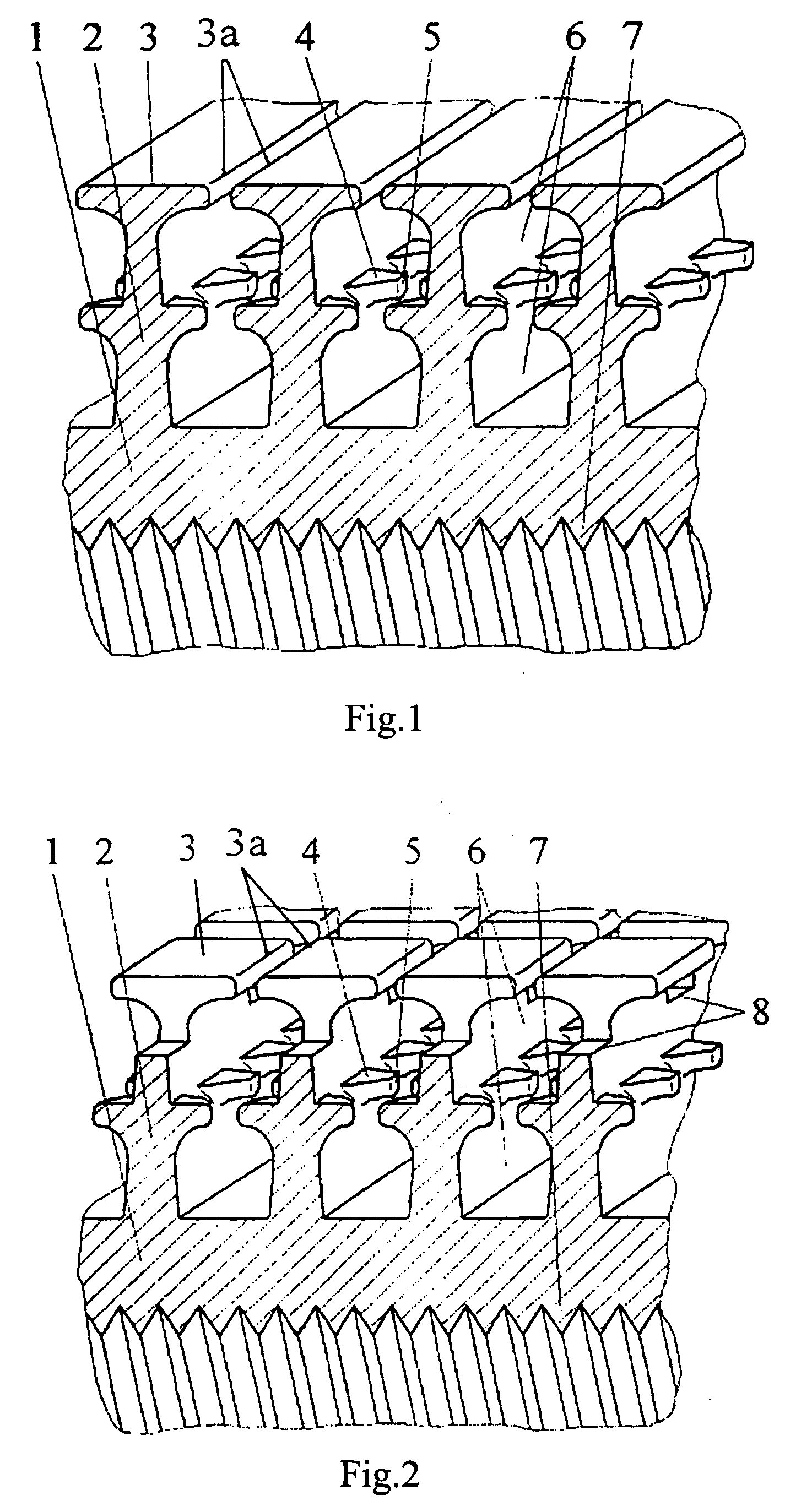

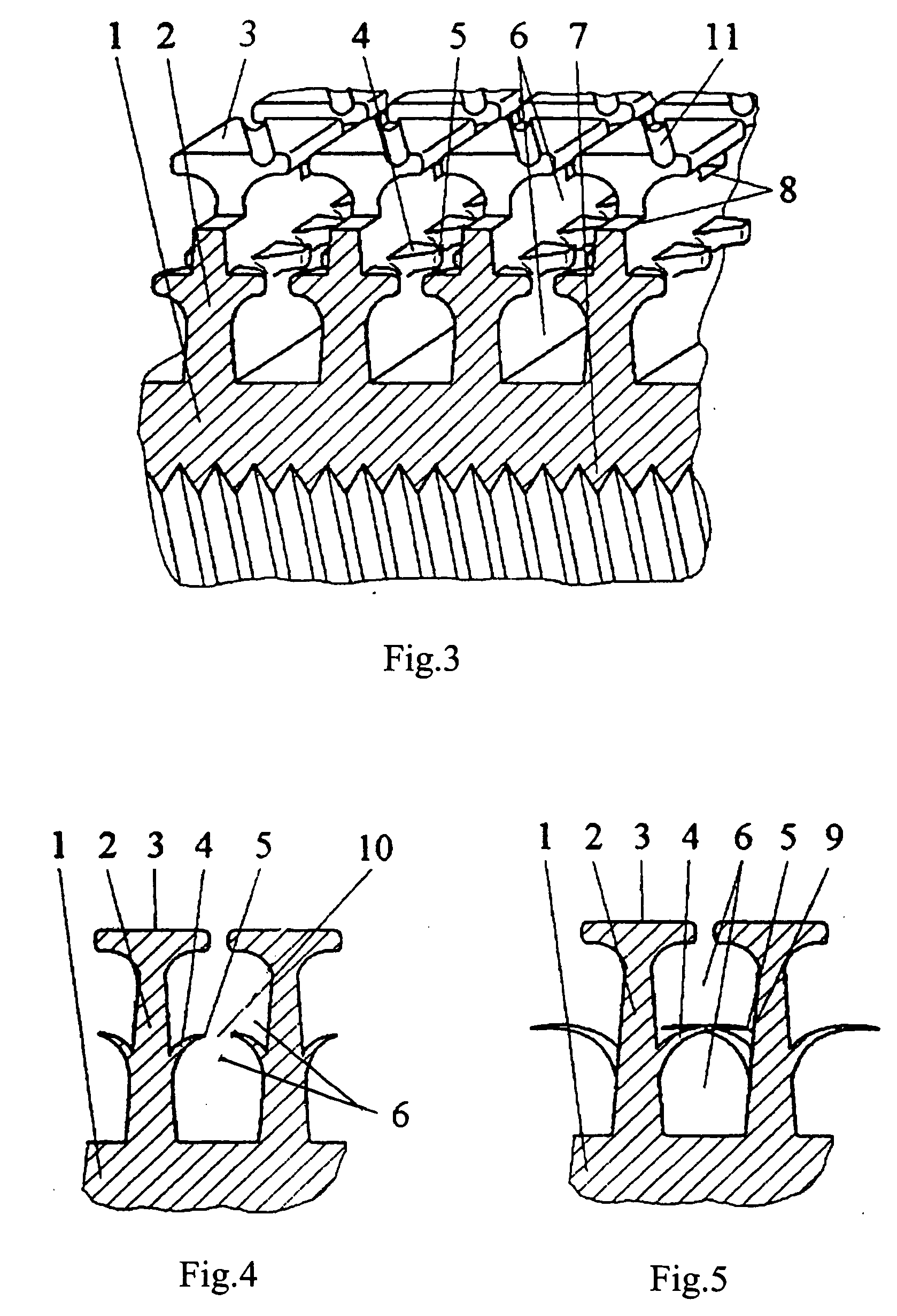

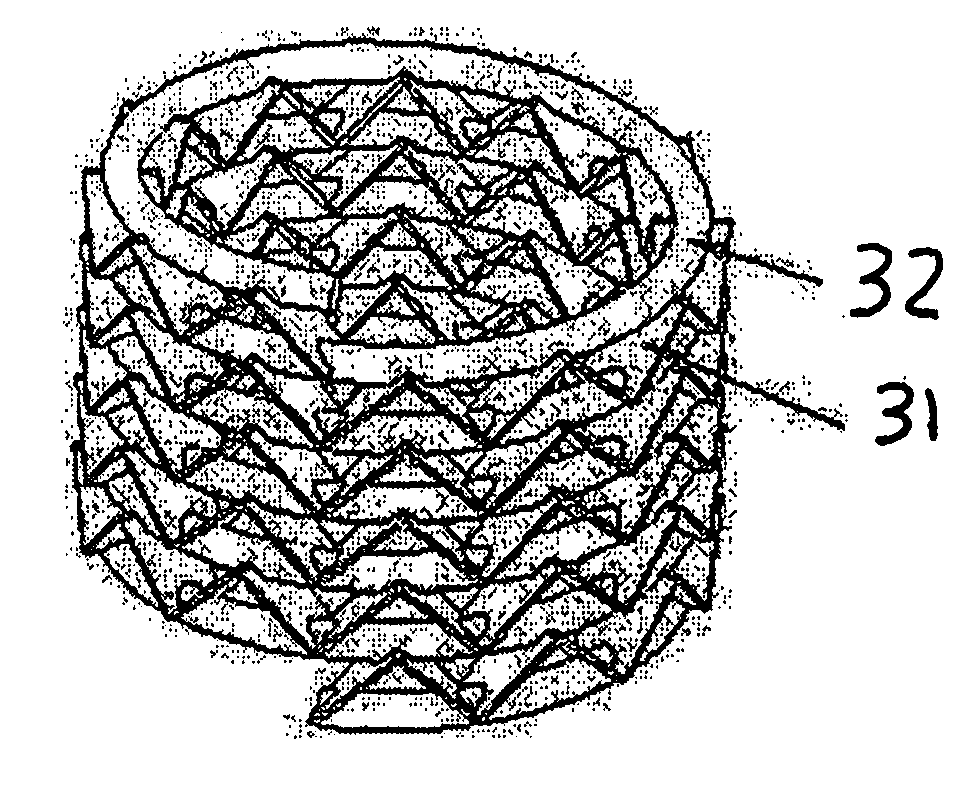

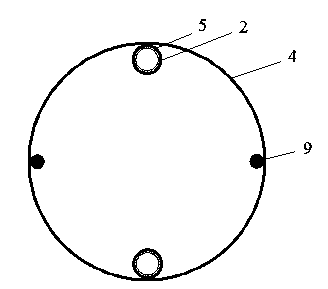

Heat transfer tubes for evaporators

ActiveUS20070034361A1Improve boiling heat transfer coefficient heat transferWeight of transfer being reducedCorrosion preventionIndirect heat exchangersEngineeringAir conditioning

The present invention discloses heat transfer tubes for evaporators in air conditioning and refrigeration systems, comprising: a tube body (1); outer fins (2) extending on an outer wall surface of the tube body (1) and having outer fin walls opposite to the outer fin walls of the adjacent outer fins; channels (6) located between the adjacent fins (2) so as to constitute channel chambers; fin top platforms (3) on respective tops of the outer fins (2), the fin top platforms (3) including fin top edges (3a) extending from both sides of the fin top platforms (3) so that the channel chambers take a form of a cavity structure as a whole; channel chamber openings constituted by gaps between the adjacent fin top edges (3a) of the fin top platforms (3) of the outer fins; and lateral fins (4) arranged on portions or substantially middle portions of the outer fin walls of the outer fins (2) in a height direction of the outer fins (2) and at intervals in an spreading direction of the outer fins (2), so that the cavity structure is formed into a double cavity structure. The heat transfer tube of the present application can achieve the technical effect of producing an excellent boiling heat transfer coefficient and enhancing the boiling heat transfer as well as saving material and reducing the weight of the tube body.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

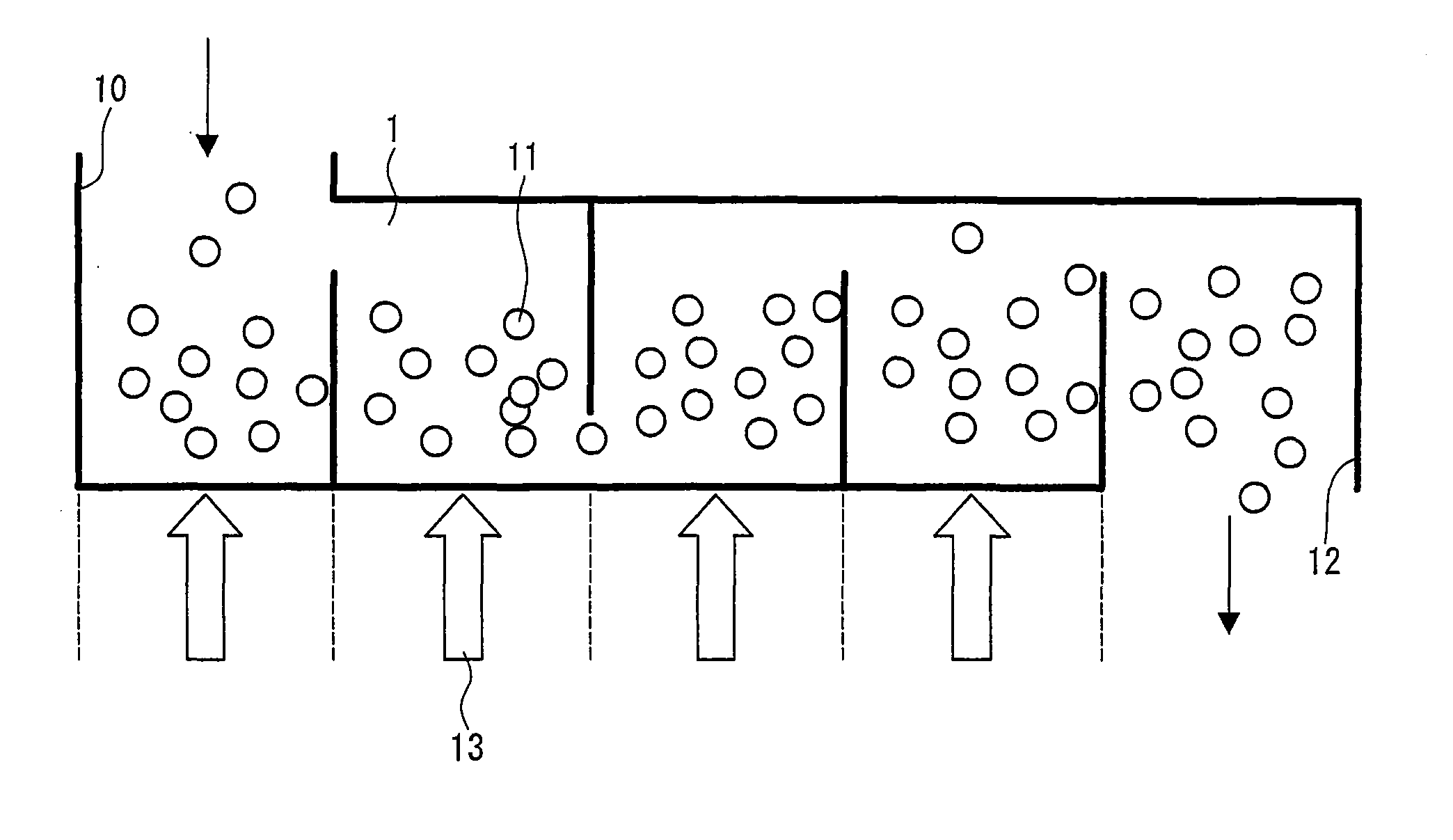

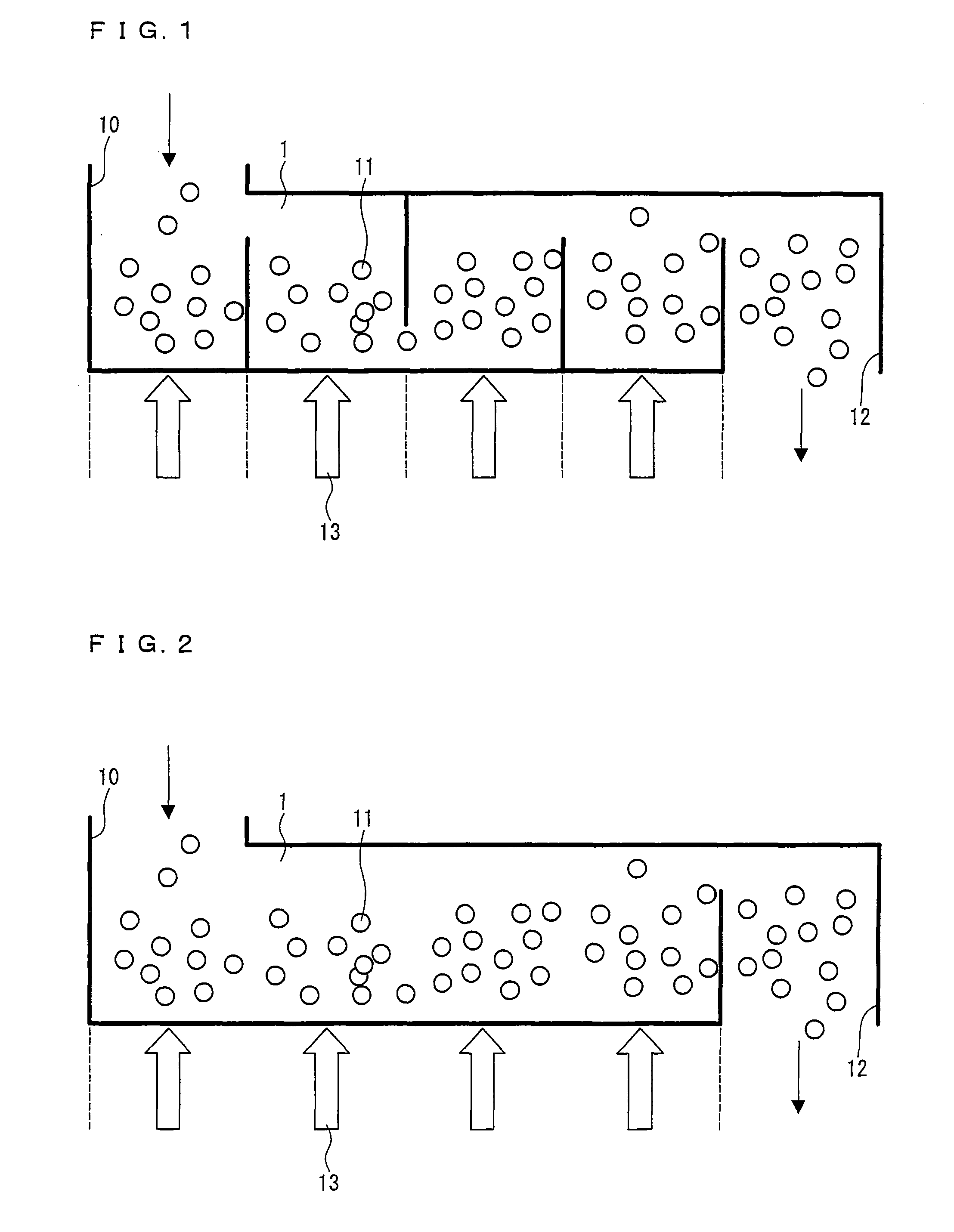

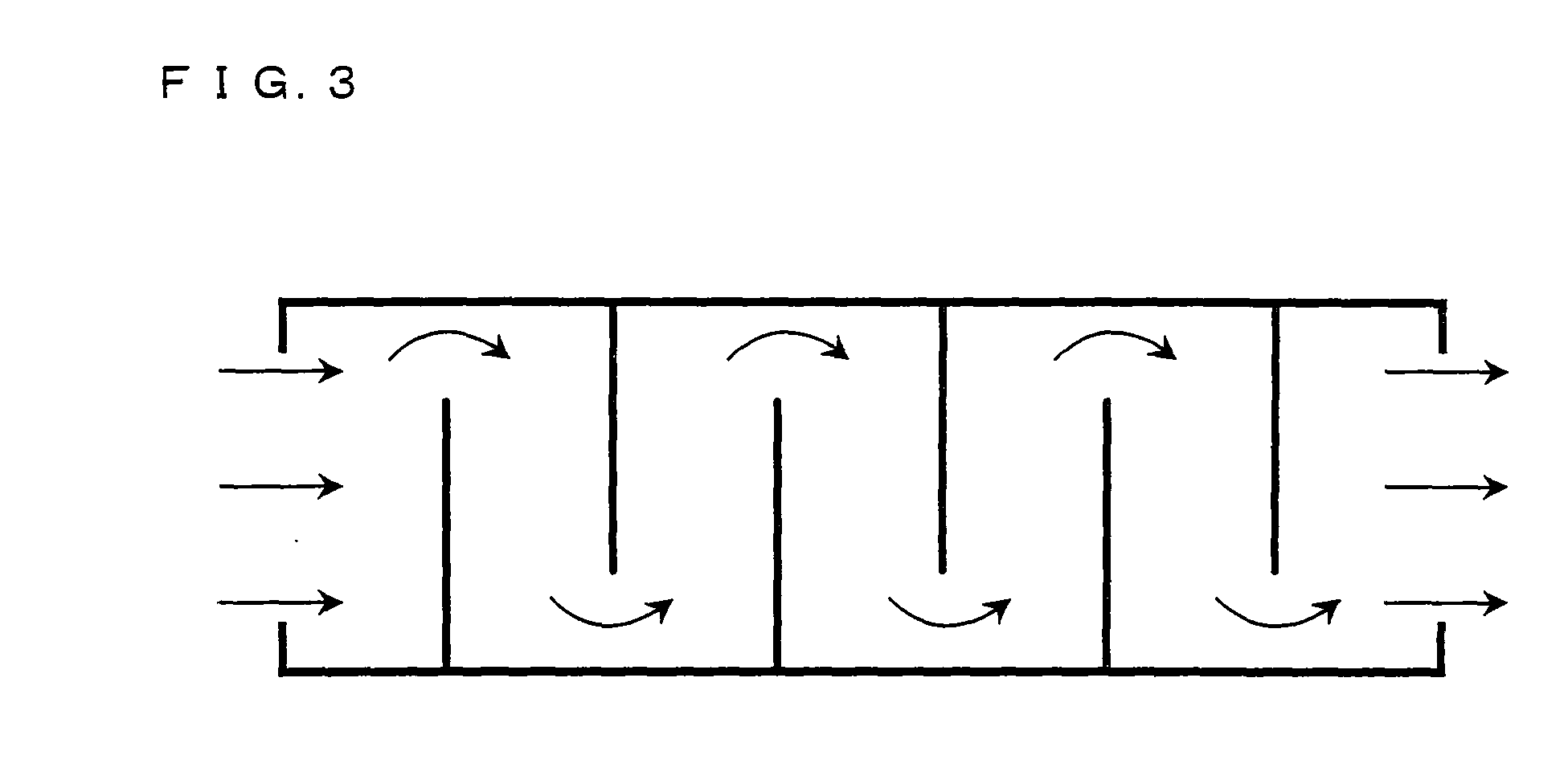

Process for producing water-absorbing resin

ActiveUS20100249320A1Low costImprove productivityDrying solid materials with heatHearth type furnacesParticulatesProduction rate

Drying is performed in a continuous fluidized bed having at least two drying rooms. Drying is performed after pulverization is performed between drying in a first drying room and drying in a second or subsequent room. Drying is performed in a continuous fluidized bed whose fluidized bed contains a heat transfer tube. The second or subsequent drying room has a higher drying temperature than the first drying room. Drying is performed with the drying temperature of the first drying room falling within a range of not less than 80° C. to not more than 200° C. and with the drying temperature of the second or subsequent drying room falling within a range of not less than 100° C. to not more than 220° C. Further, a method for producing a water absorbent resin includes: a sequence of the steps of: (1) polymerizing a monomer aqueous solution; (2) drying a hydrogel polymer obtained in the step (1); (3) performing particle size control by either pulverizing or pulverizing and classifying a dry polymer obtained in the step (2); and (5) performing surface crosslinking on water absorbent resin powder whose particle size has been controlled in the step (3), the method further including the step (4) of performing second heat drying on the water absorbent resin powder whose particle size has been controlled in the step (3), the step (4) preceding the step (5). Further, the water absorbent resin has a moisture content (defined by a loss on drying performed for three hours at 180° C.) of 0 wt % to 3 wt % before it is supplied to the step (5). (This makes it possible to provide a method for producing a water absorbent resin which method makes it possible to obtain a particulate water absorbent resin of excellent properties at low cost with high productivity.

Owner:NIPPON SHOKUBAI CO LTD

Finned helicoidal heat exchanger

InactiveUS20070125528A1Additional exchangeHigh densityStationary conduit assembliesStationary tubular conduit assembliesWorking fluidEngineering

Heat exchanger having a plurality of heat transfer tubes arranged substantially in the shape of a helicoidal tube with the individual coils running parallel to one another, and a plurality of fins secured to the external surfaces of the heat transfer tubes and arranged perpendicular to the tube to extend outwardly therefrom. The first working fluid flows inside the heat transfer tubes, and air flows through a passage defined between the adjacent fins and at right angles to the axis of each heat transfer tube. The blower is placed co-axial with the helicoid's axis to further enhance the heat exchange.

Owner:FAKHERI AHMAD

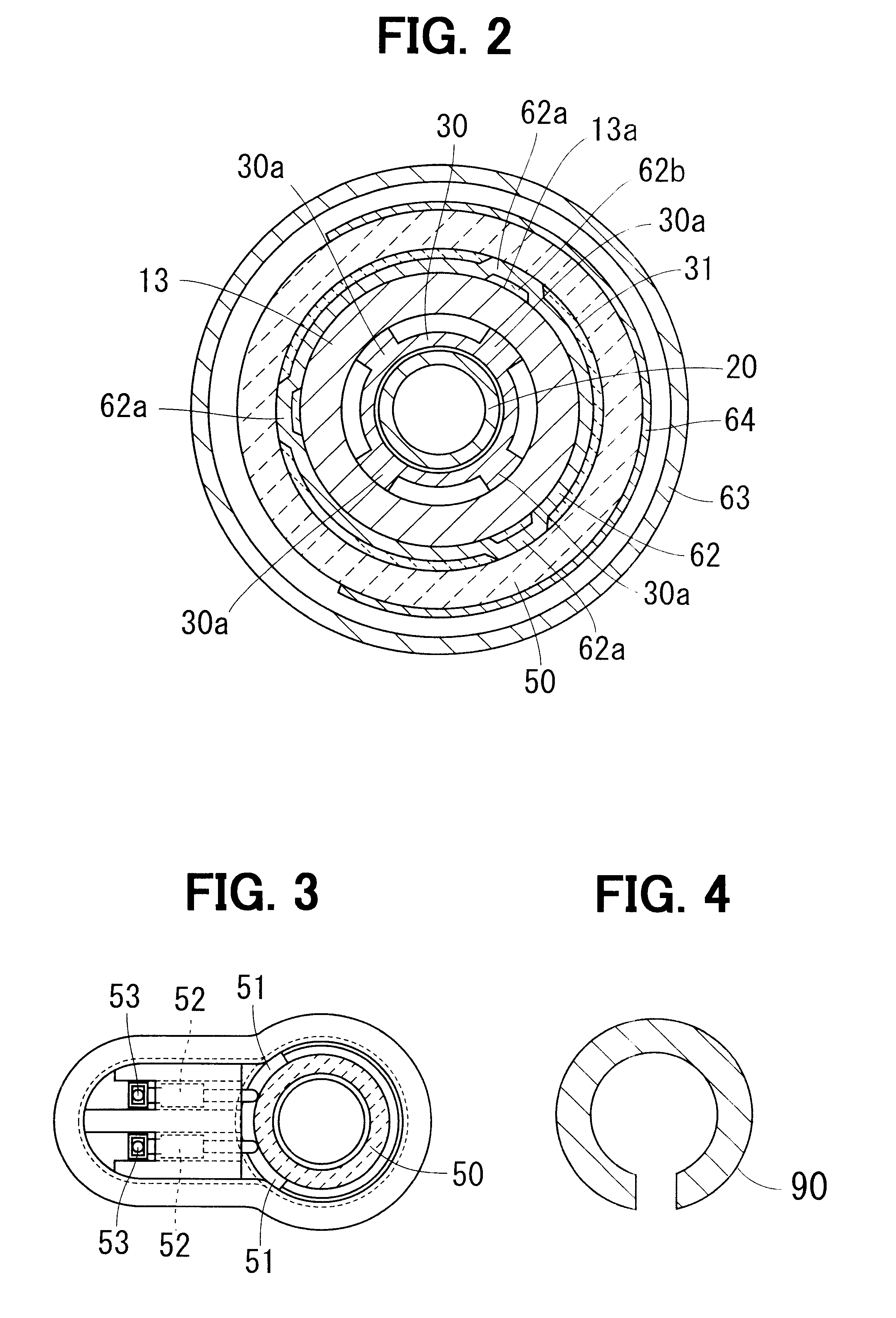

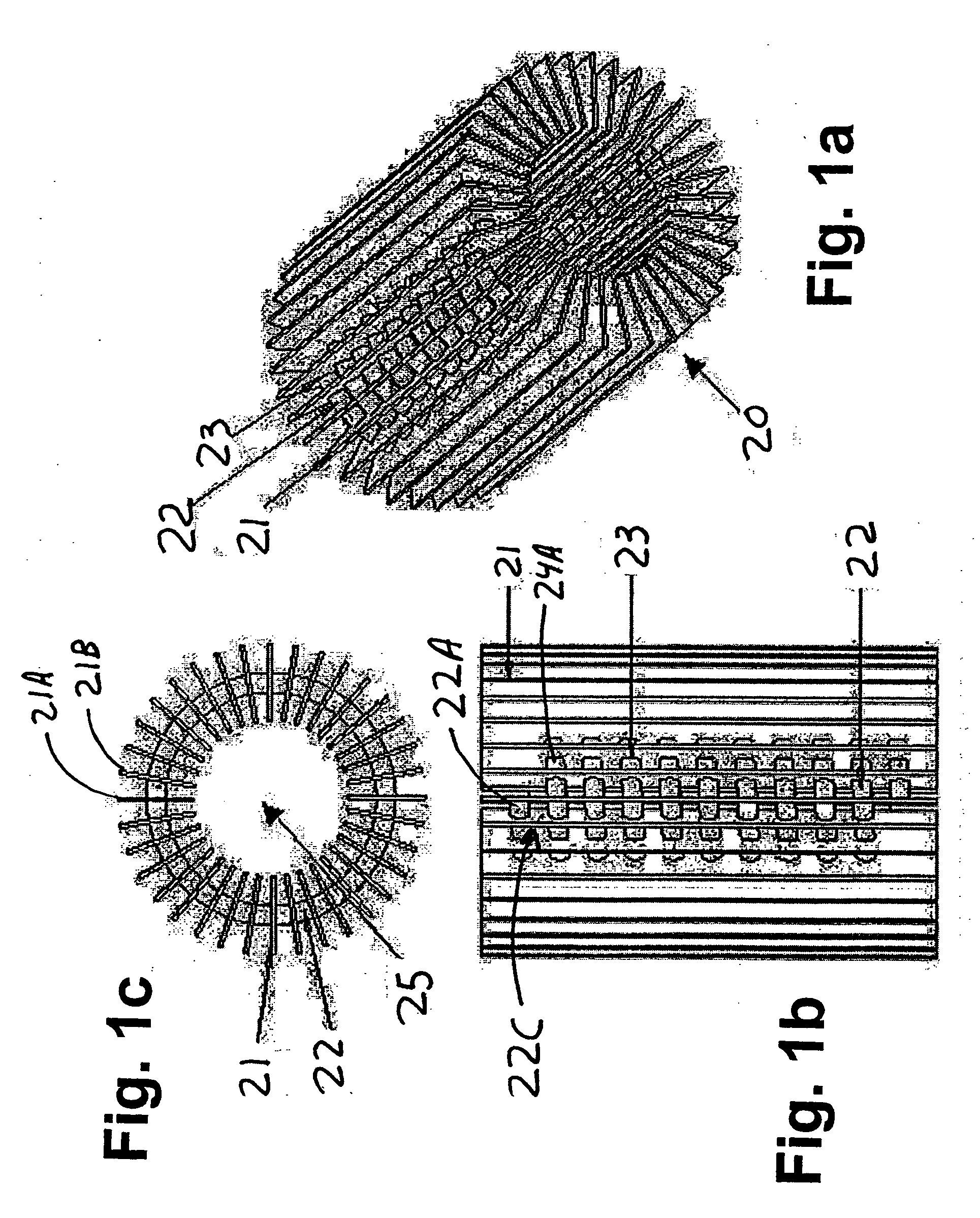

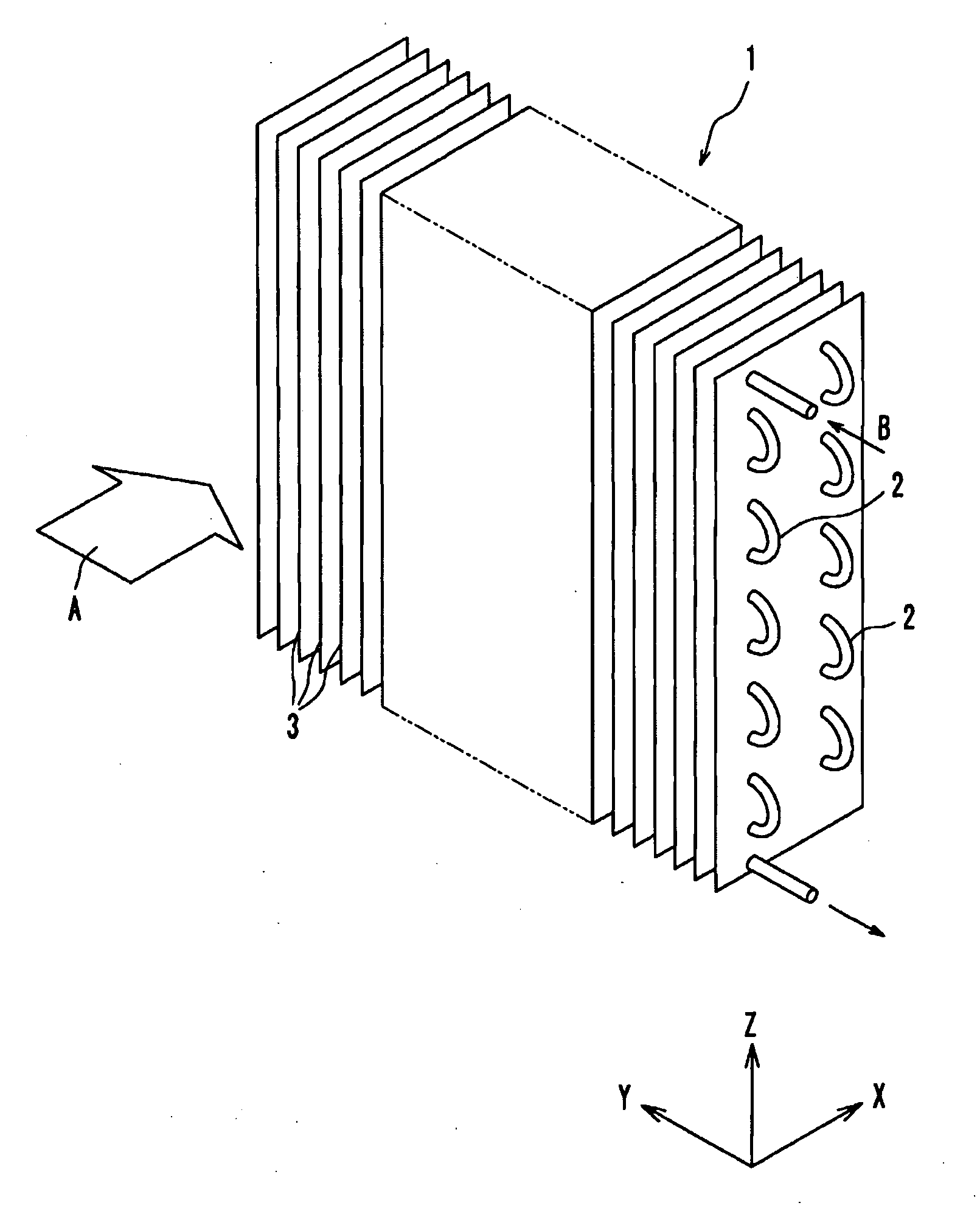

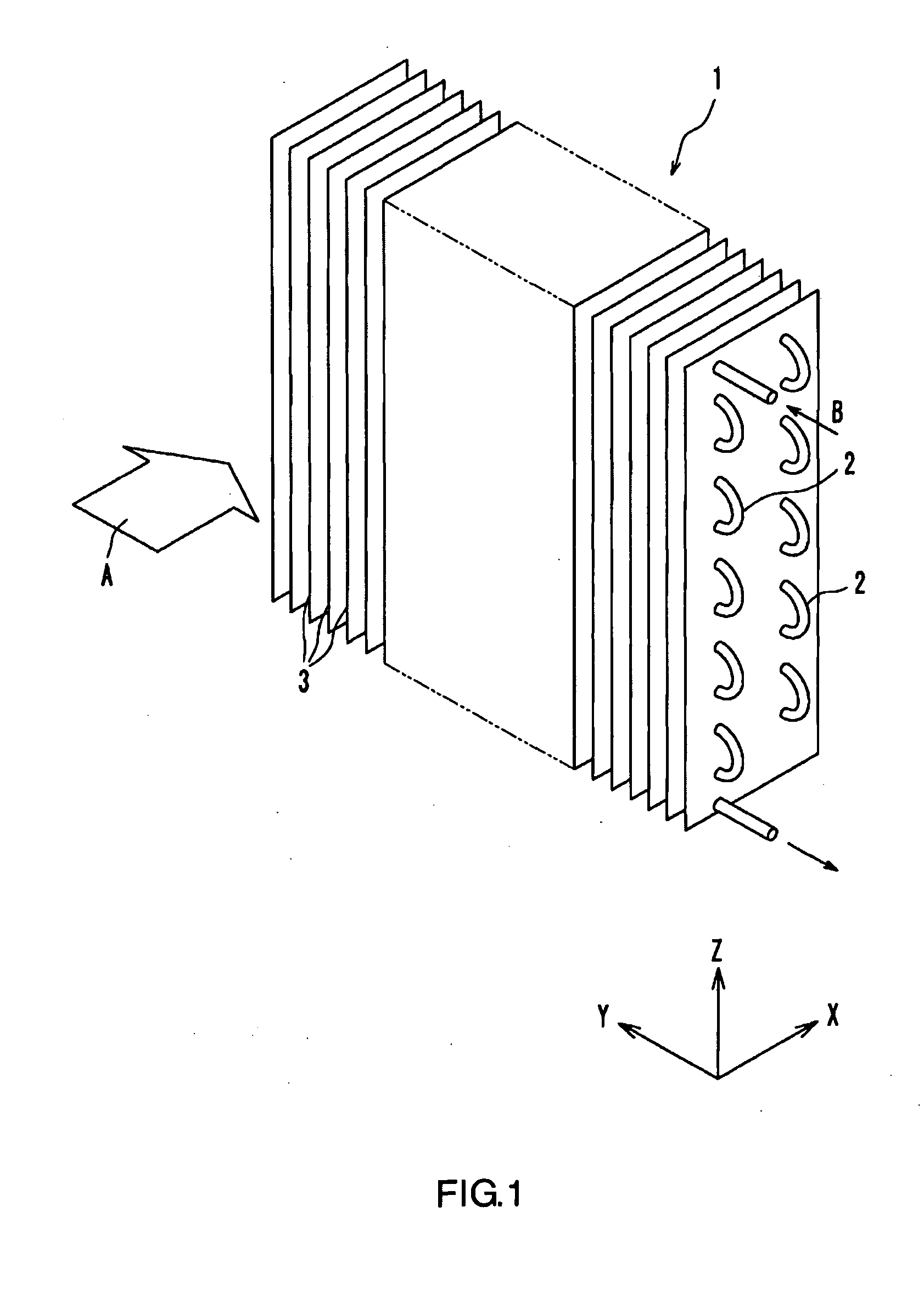

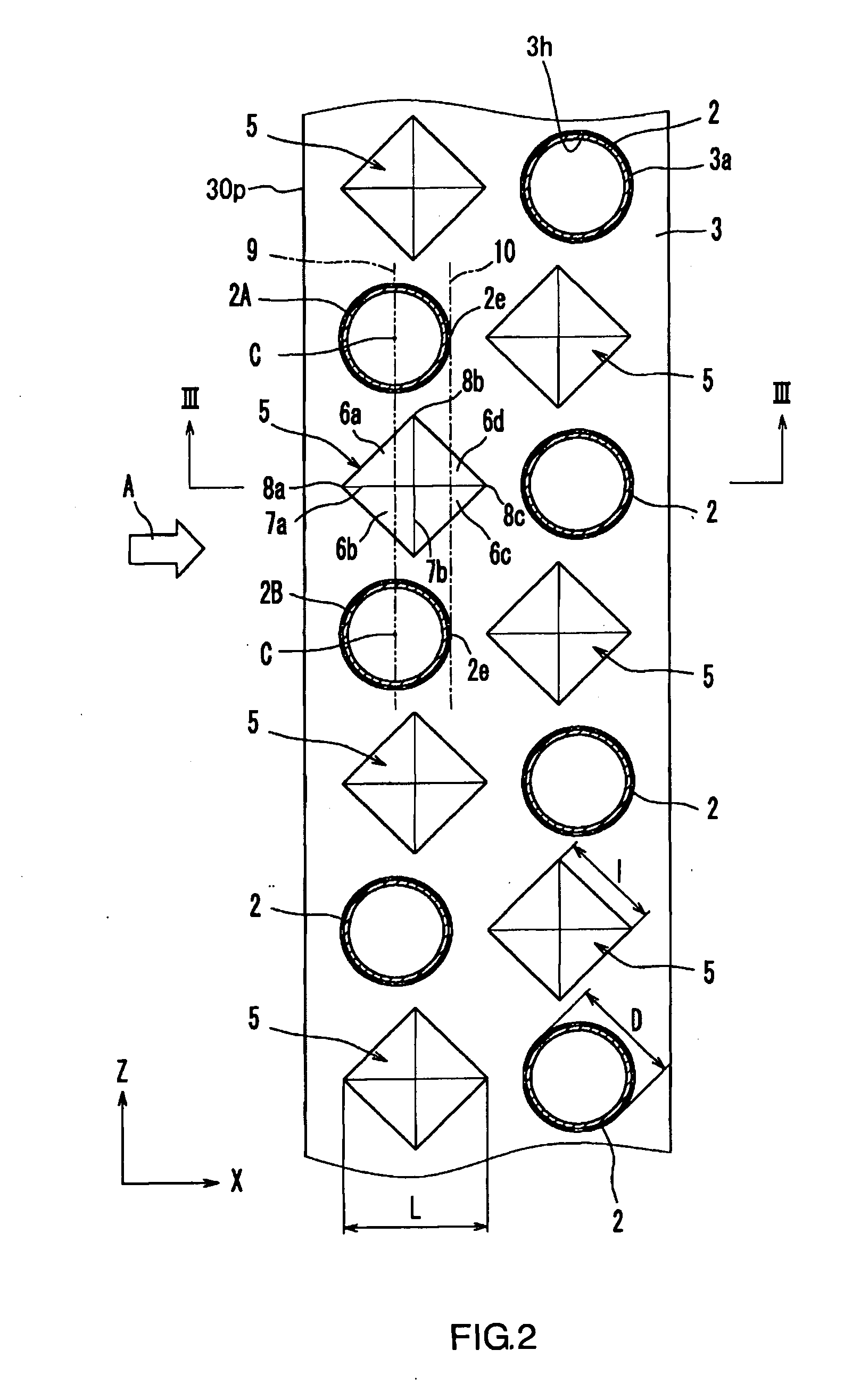

Fin-tube heat exchanger, fin for heat exchanger, and heat pump apparatus

InactiveUS20090199585A1Small surface areaImprove heat transfer performanceStationary conduit assembliesCompression machines with reversible cycleEngineeringHeat transfer tube

A fin-tube heat exchanger 1 includes a plurality of fins 3 arrayed spaced apart from and parallel to each other so as to form gaps for allowing a first fluid to flow therethrough, and a plurality of heat transfer tubes 2 penetrating the plurality of fins 3 and for allowing a second fluid to flow therethrough. The plurality of heat transfer tubes 2 includes first heat transfer tubes 2A and second heat transfer tubes 2B arranged in a predetermined row direction that intersects the flow direction of the first fluid. The fins 3 have protrusions 5 each disposed between a first heat transfer tube 2A and a second heat transfer tube 2B, for guiding the first fluid toward the first heat transfer tube 2A side and the second heat transfer tube 2B side. The equivalent diameter of the protrusion 5, as viewed in the axis direction of the heat transfer tubes 2, is equal to or greater than the outer diameter of the heat transfer tubes 2.

Owner:PANASONIC CORP

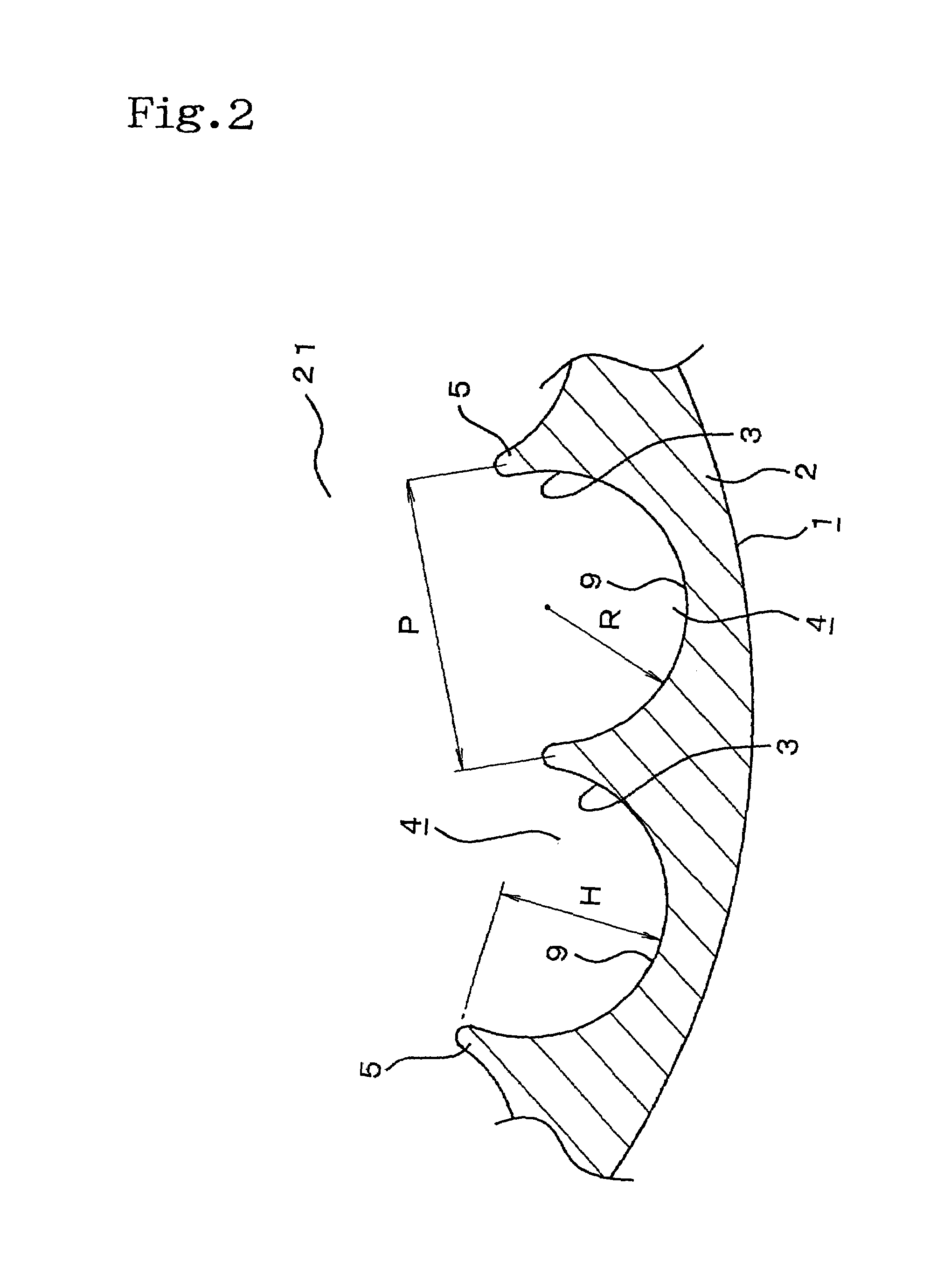

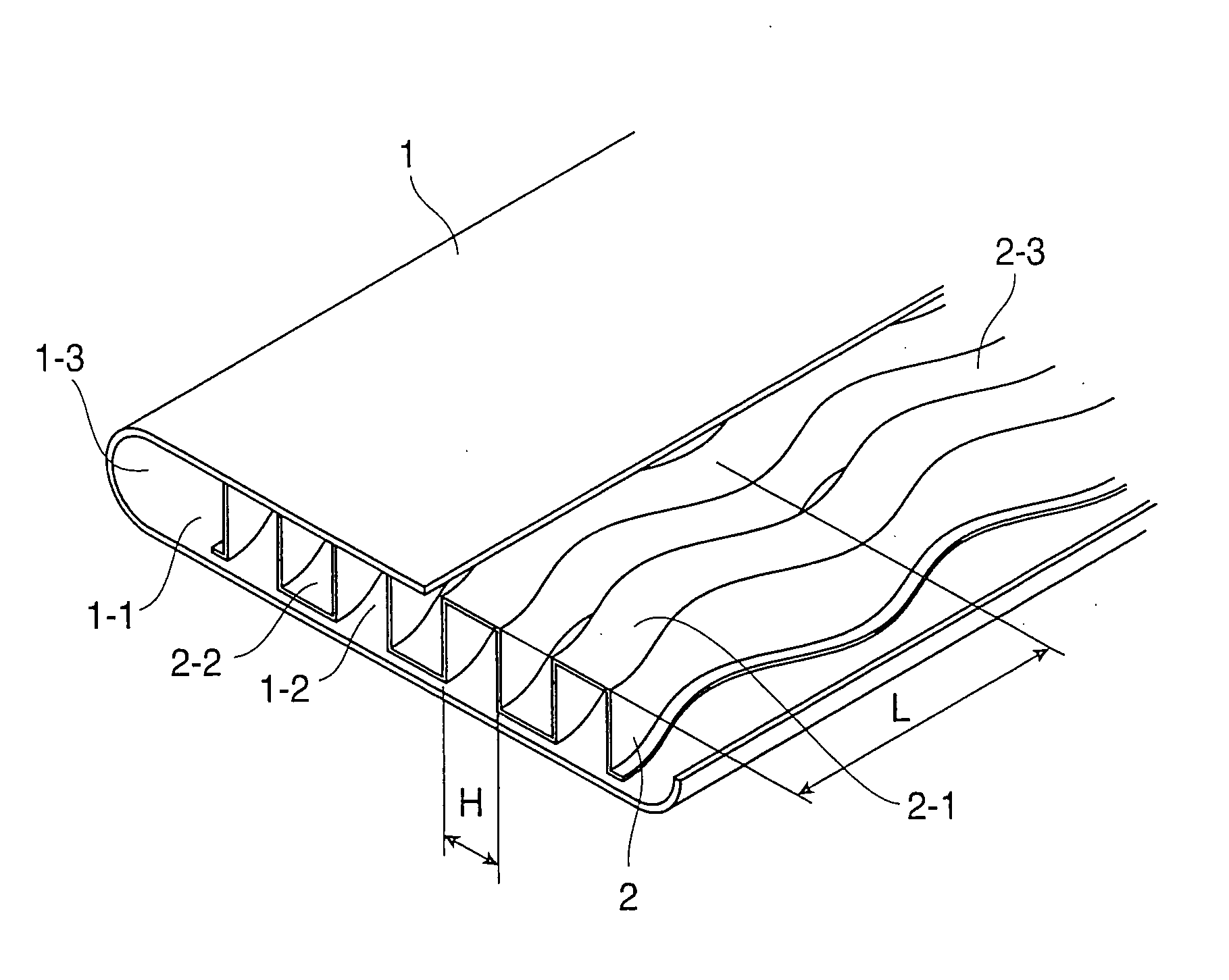

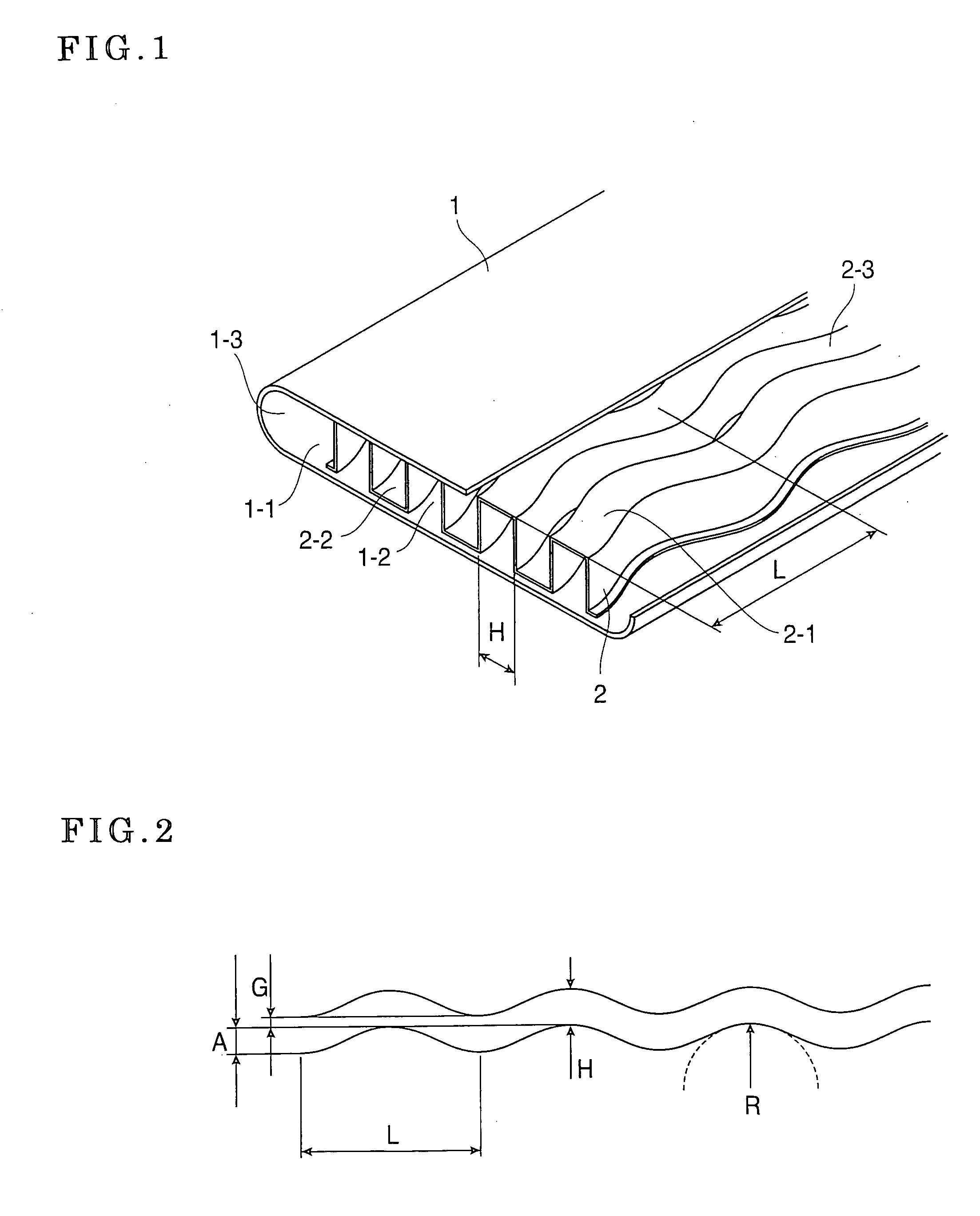

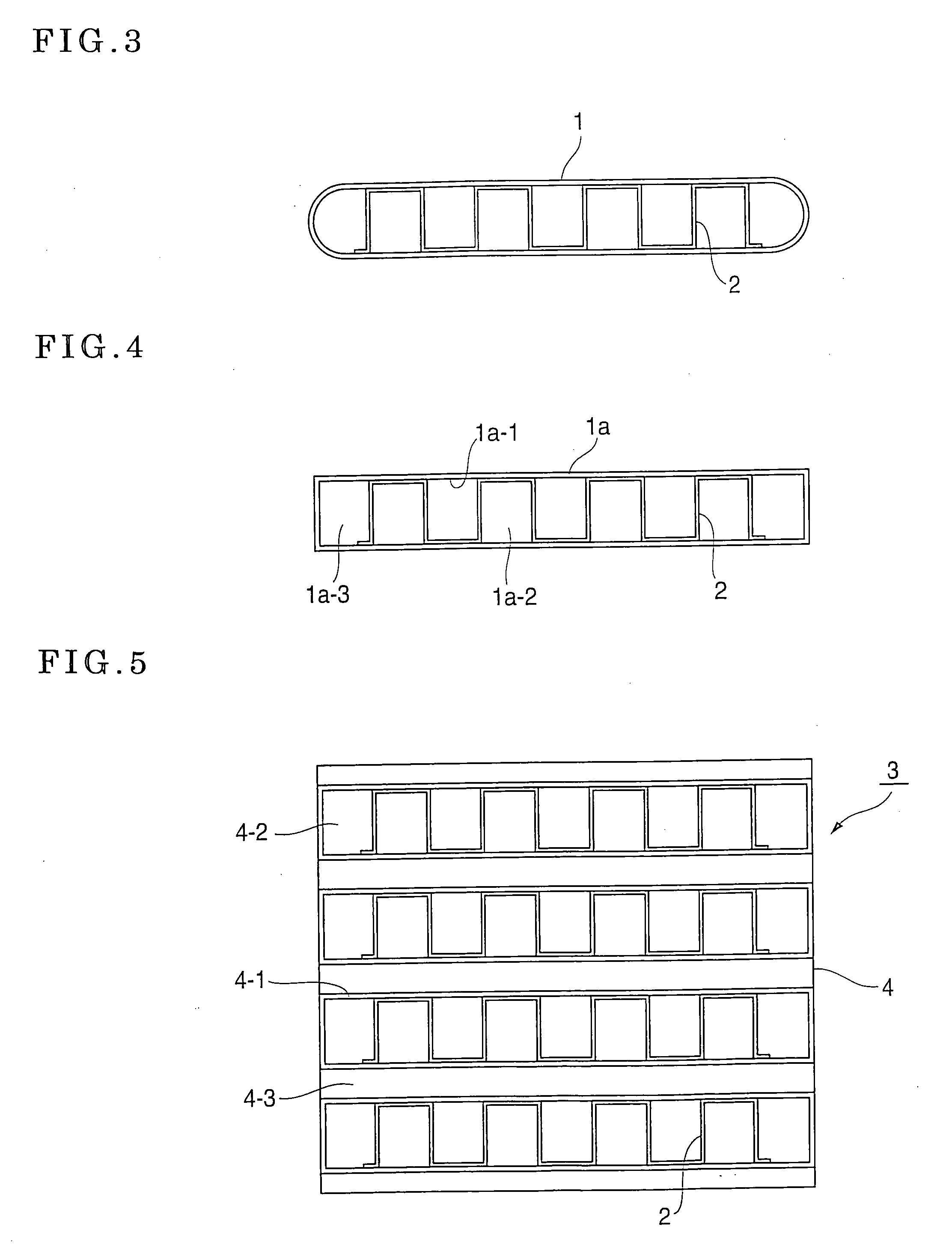

Heat exchanger tube

InactiveUS20070056721A1Improve cooling effectImprove heat transfer performanceRecuperative heat exchangersExhaust gas recirculationWave shapeEngineering

A heat exchanger tube has an inner peripheral surface serving as an exhaust gas flow path with a flat cross-sectional shape. A thin structure is incorporated in the heat exchanger tube and has a substantially rectangular channel-shaped waveform in cross section. The corrugated fin structure has a curved surface forming waveform meandering with a predetermined wavelength in the lengthwise direction. The wave width of the channel-shaped waveform is H, the wavelength of the waveform meandering in the lengthwise direction is L and the amplitude of the waveform meandering in the lengthwise direction is A. The heat exchanger tube is formed so that H / L is set at 0.17 to 0.20 and the ration (G / H) of a gap G determined by H-A to H is set at −0.21 to 0.19.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Heat sink module

ActiveUS20100126697A1Dissipate quicklyHeat dissipation fastPoint-like light sourceElongate light sourcesEngineeringHeat sink

A heat sink module includes a heat transfer tube, a plurality of radiation fins respectively riveted to locating grooves around the periphery of the heat transfer tube, and a heat transfer panel fastened to the bottom side of the heat transfer tube and the radiation fin set and kept in contact with a heat source, such as a CPU or a light emitting unit of a LED lamp for transferring heat from the heat source to the radiation fins for quick dissipation.

Owner:HUANG TSUNG HSIEN

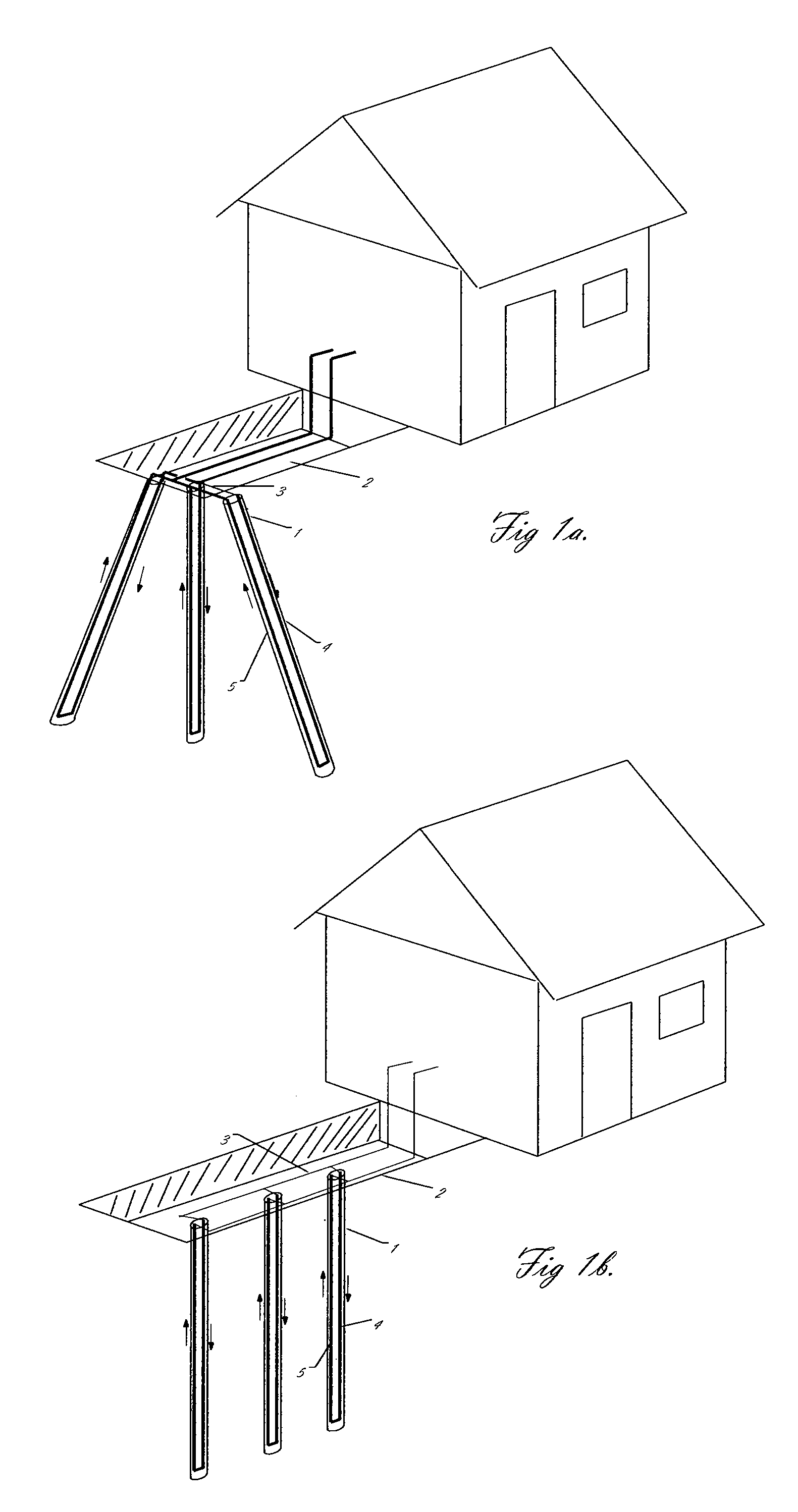

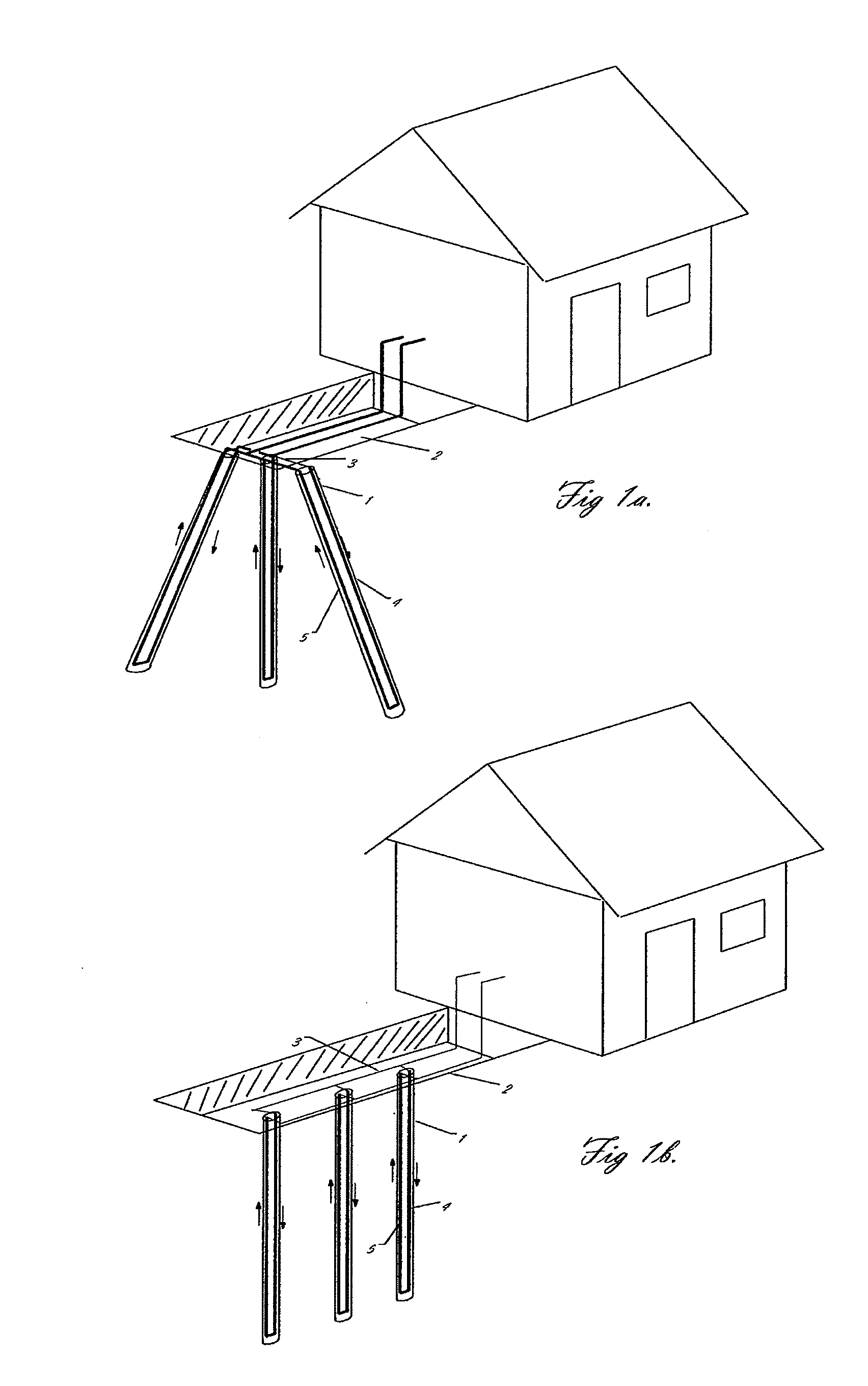

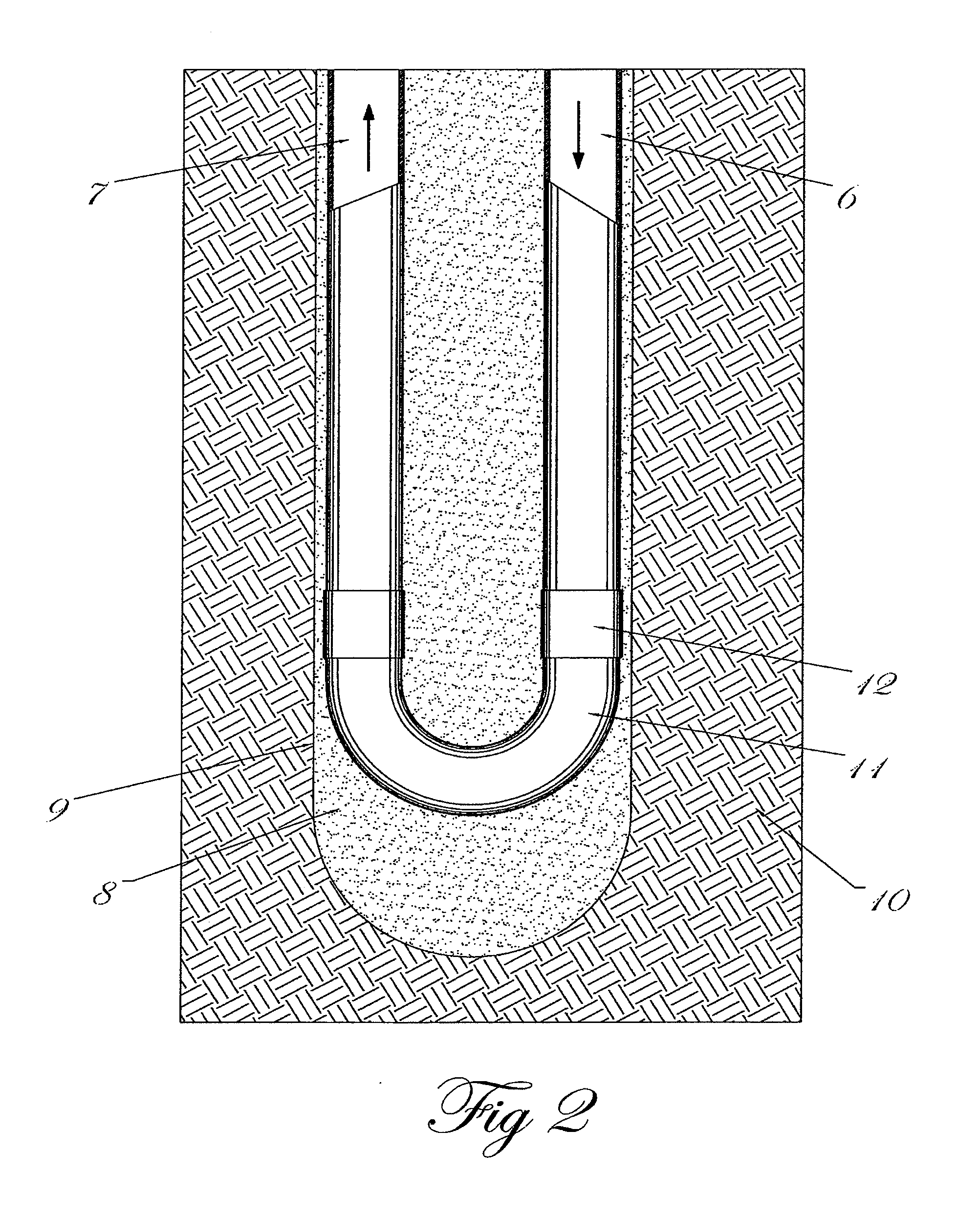

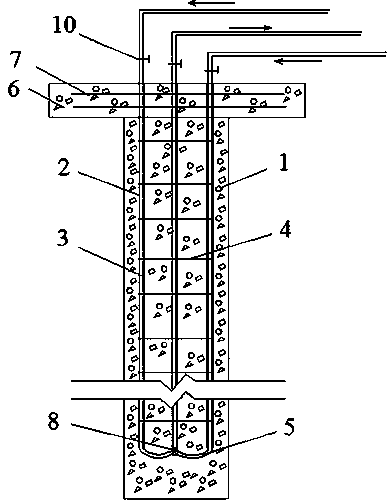

Construction method for precast energy pile

ActiveCN103485332ASolve the loss of densitySolve stacking problemsHeat pumpsBulkheads/pilesPile capArchitectural engineering

A construction method for a precast energy pile is characterized in that a heat transfer tube is embedded into a hollow steel tube, the hollow steel tube replaces a traditional solid reinforcement and serves as a main reinforce ement of the precast pile, and for being connected with the heat transfer pipe in the precast pile, a heat transfer elbow and a heat transfer tube joint are embedded into a precast pile shoe and a precast pile cap. As the heat transfer tube is embedded into the hollow steel tube, the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, effect on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer tube and the main reinforcement are effectively solved. Moreover, the embedded tube is higher in survival rate, a large number of piles are conveniently stacked and safely transported, construction period is short, and underground space and construction cost are saved.

Owner:HOHAI UNIV

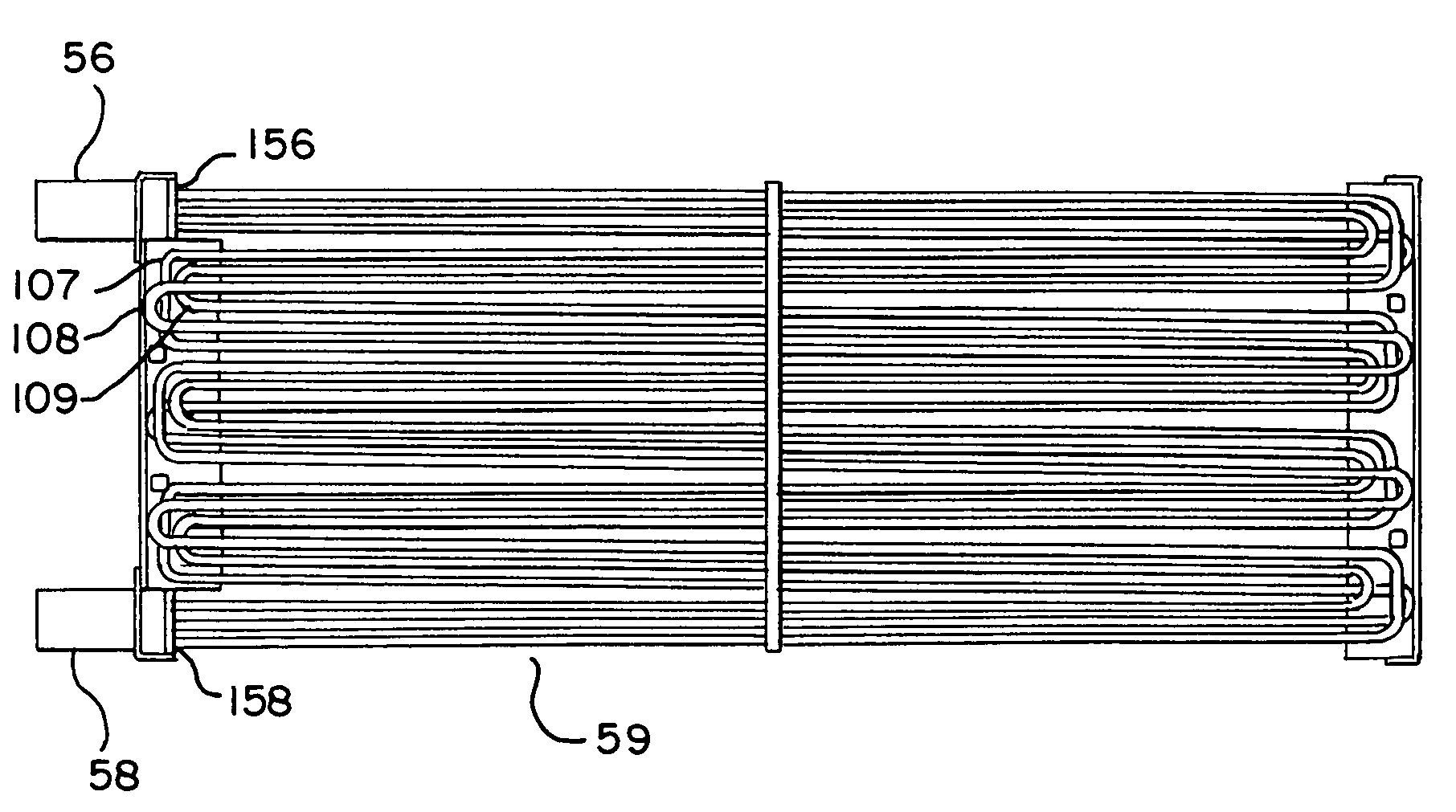

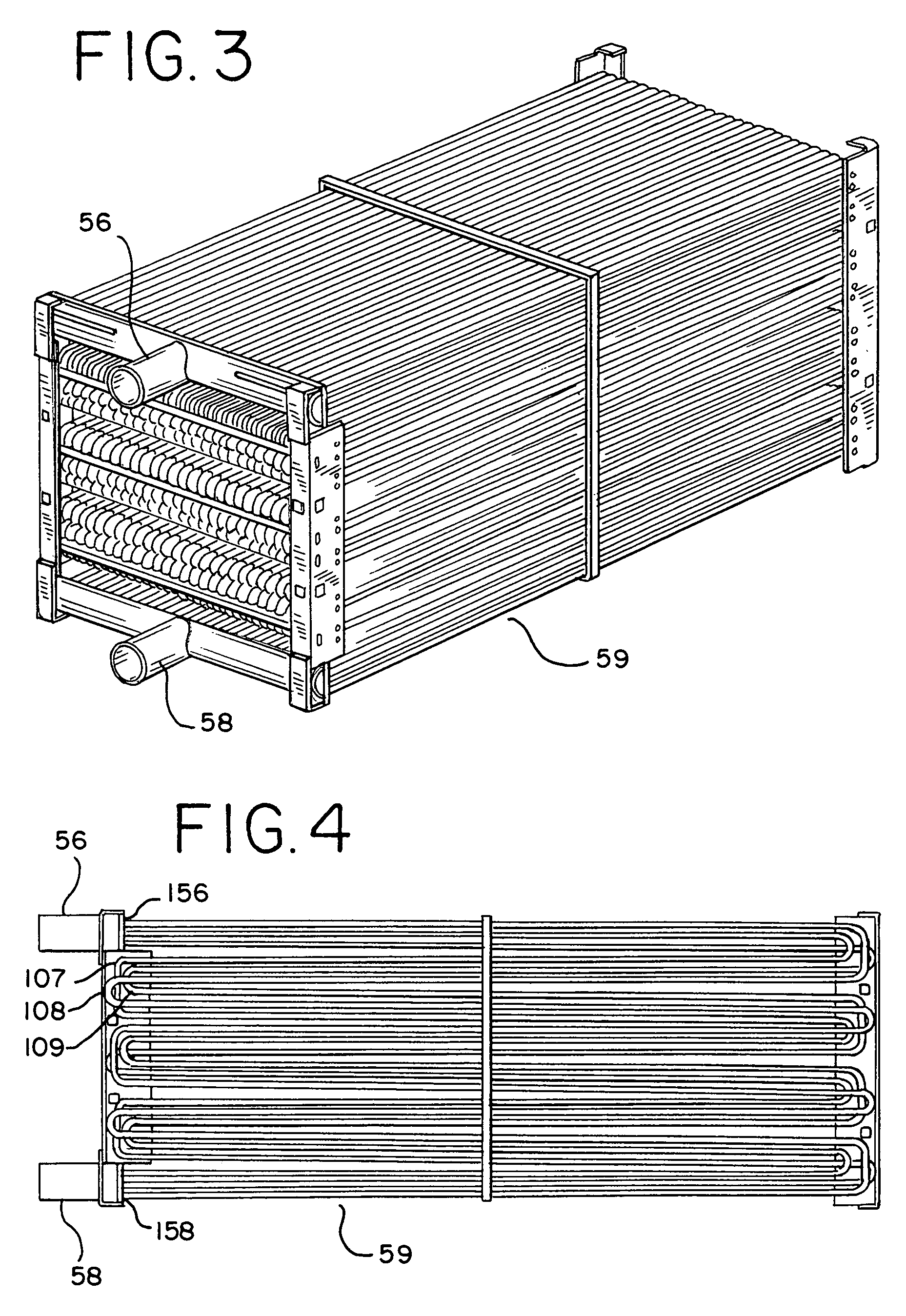

Heat transfer tube assembly with serpentine circuits

ActiveUS7779898B2Efficient heat transferLower overall pressure dropEfficient regulation technologiesStationary conduit assembliesCooling towerClosed loop

A method and apparatus are provided for cooling fluids entering a closed circuit cooling tower. A triple circuit assembly is used to cool the fluid in the closed loop. The triple circuit assembly design allows a heat transfer tube bundle to maintain a relatively low pressure drop, but without simultaneously lowering thermal performance to a significant degree as compared to traditional double serpentine or QUAD serpentine designs.

Owner:BALTIMORE AIRCOIL CO INC

Construction method for embedding pipe in ground source heat pump pouring pile reinforcement cage

ActiveCN103383018AReduce load capacityImprove compactnessPipe laying and repairHeat pumpsHeat transmissionArchitectural engineering

The invention discloses a construction method for embedding a pipe in a ground source heat pump pouring pile reinforcement cage. A steel pipe is used for substituting for a solid reinforcing steel bar as the main rib of a pouring pile reinforcement cage, and a heat transmission pipe is embedded in the steel pipe, as a result, problems caused by binding and embedding the heat transmission pipe and the reinforcement cage, including mutual interference, high probability of corrosion of a reinforcing steel bar, effect on overall bearing capacity of a pile foundation and the like, are solved. Compared with the traditional way of binding and embedding the heat transmission pipe and the reinforcement cage, the construction method is higher in survival rate of embedded pipe, compactedness of concrete is high, and embedment of the heat transmission pipe surely does not lower the overall bearing capacity of the pile foundation; compared with another traditional way of drilling and pipe embedding, the construction method greatly shortens construction period and saves underground space and engineering cost. The construction method is simple in construction process, strong in operability, convenient for quality control, and remarkable in economic benefit and heat transmission effect.

Owner:HOHAI UNIV

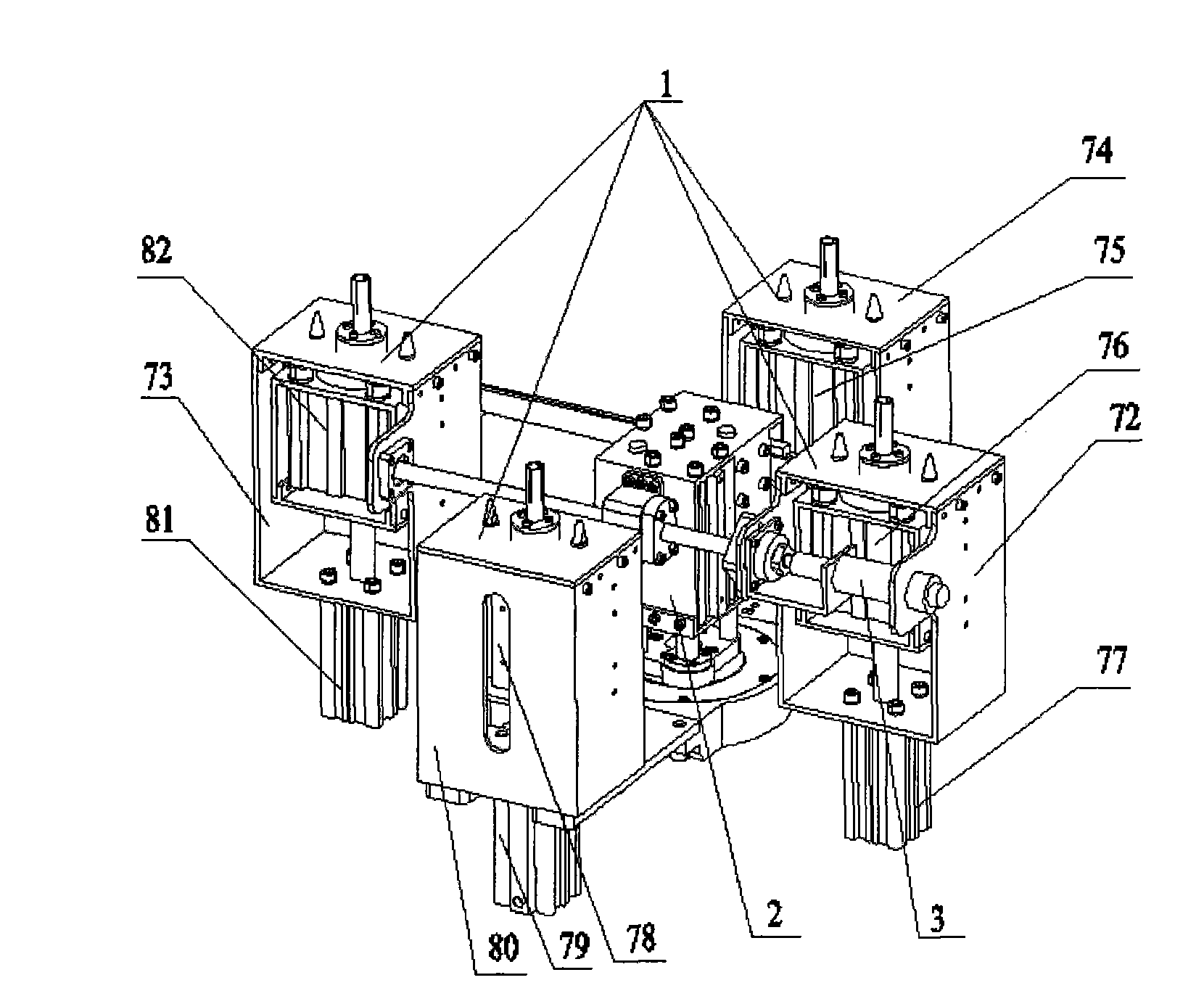

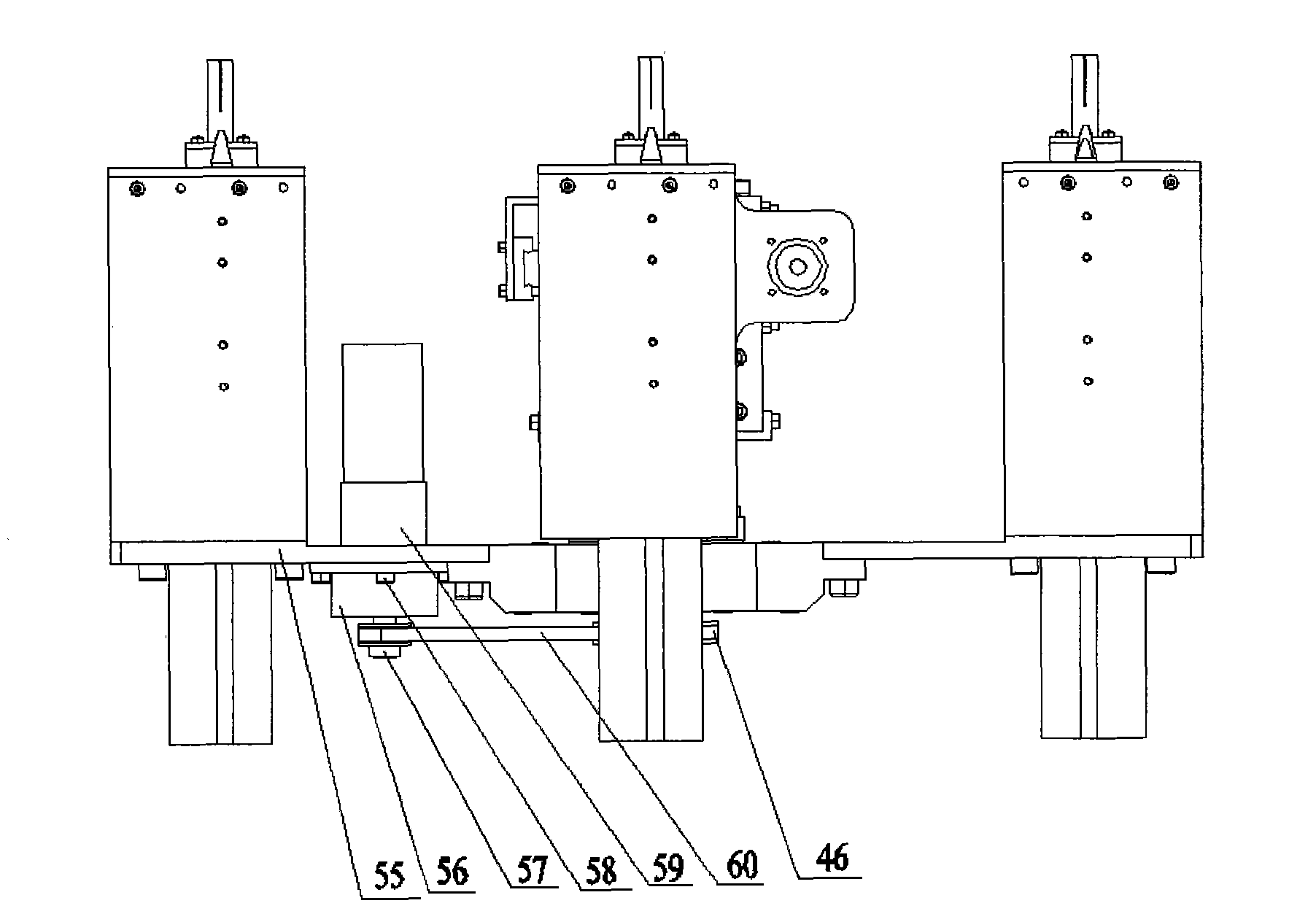

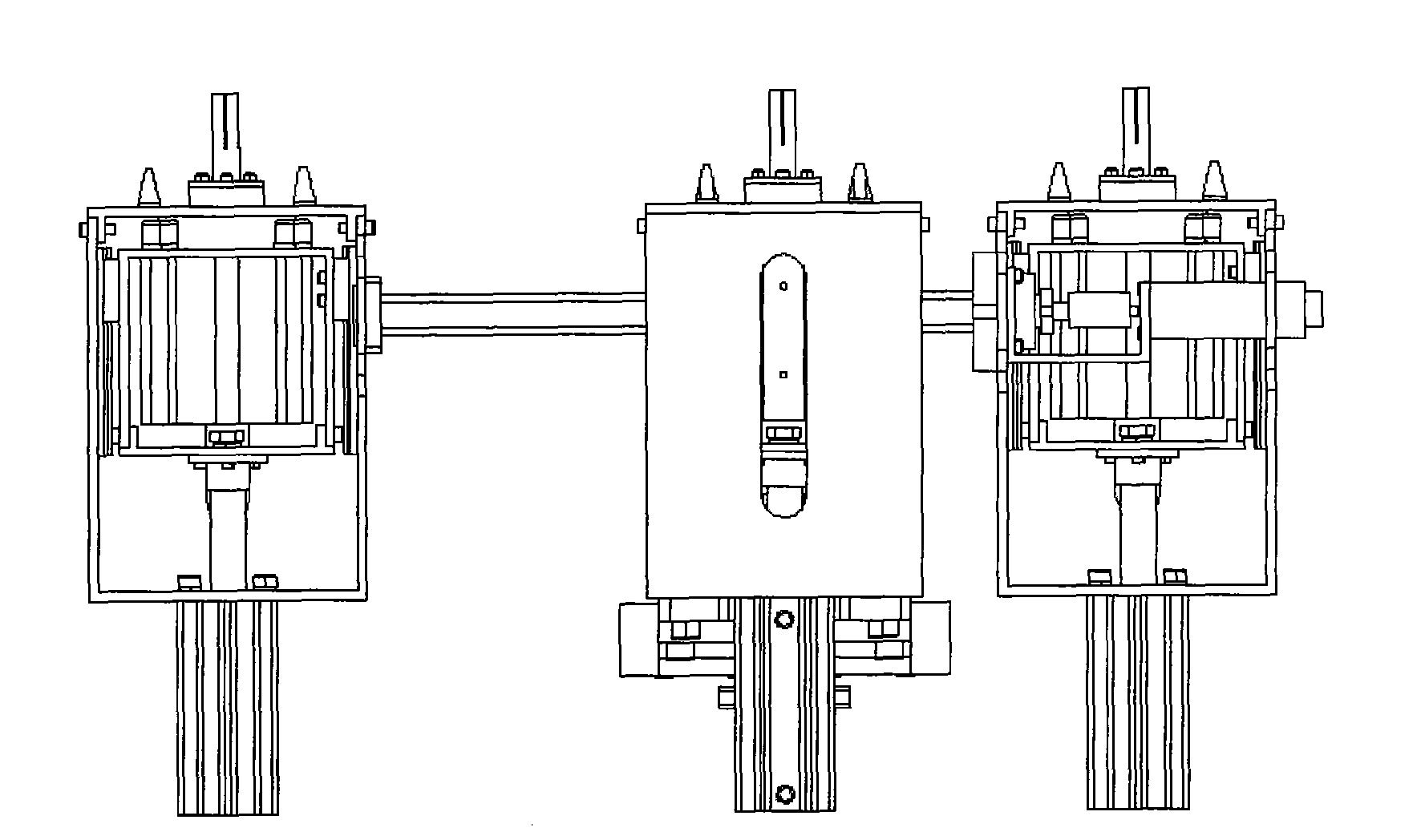

Robot for overhauling primary side of steam generator of nuclear power plant

InactiveCN101667465AReduce volumeReduce weightNuclear energy generationNuclear monitoringNuclear powerGas cylinder

The invention provides a robot for overhauling the primary side of a steam generator of a nuclear power plant, comprising a substrate unit, a rotating unit and a sliding unit. Each modularizing unit is internally provided with two gas cylinders capable of generating two lifting motions with different functions, wherein one pair of modularizing units can simultaneously provide loading spaces for adetecting device. When in use, a pneumatic self-locking expansion mechanism of a pair of modularizing units extends into a heat transfer pipe and is expanded, and a static friction force generated with the inner wall is used for supporting the total weight of the robot; the rotating unit is driven by one servomotor and two gas cylinders for respectively generating two motions of rotation and lifting; and the sliding unit converts the rotation motion of the servomotor into a rectilinear motion by a ball screw shaft and drives the modularizing unit to move on a tube plate hole. The invention isconvenient to be installed through a manhole of the steam generator so as to largely improve the overhauling efficiency, and can realize the fast replacement of operating apparatus for the eddy current inspection, the ultrasonic testing, the tube blockage detection, the water chamber surface condition detection and the like of the heat transfer tube.

Owner:HARBIN ENG UNIV

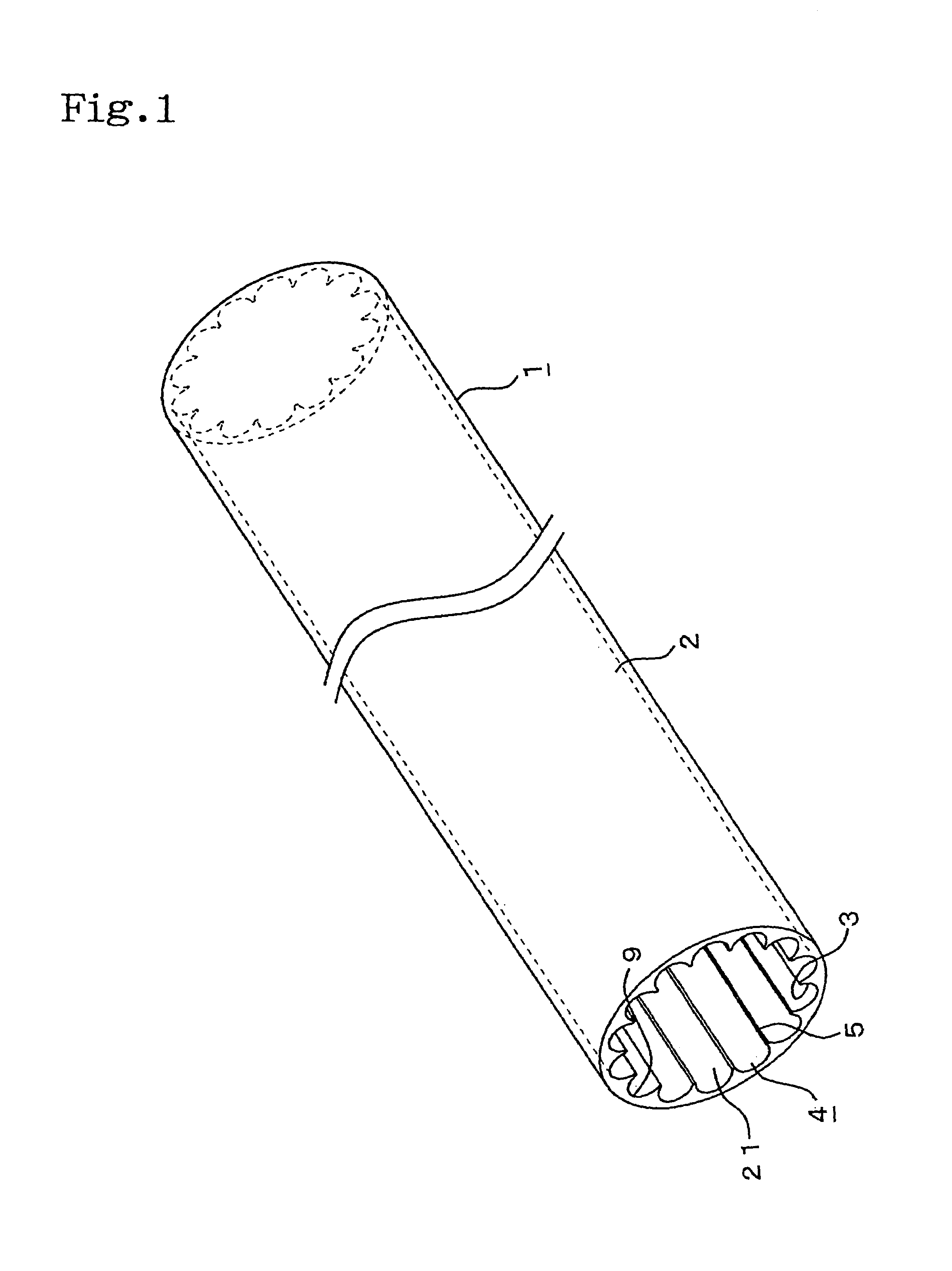

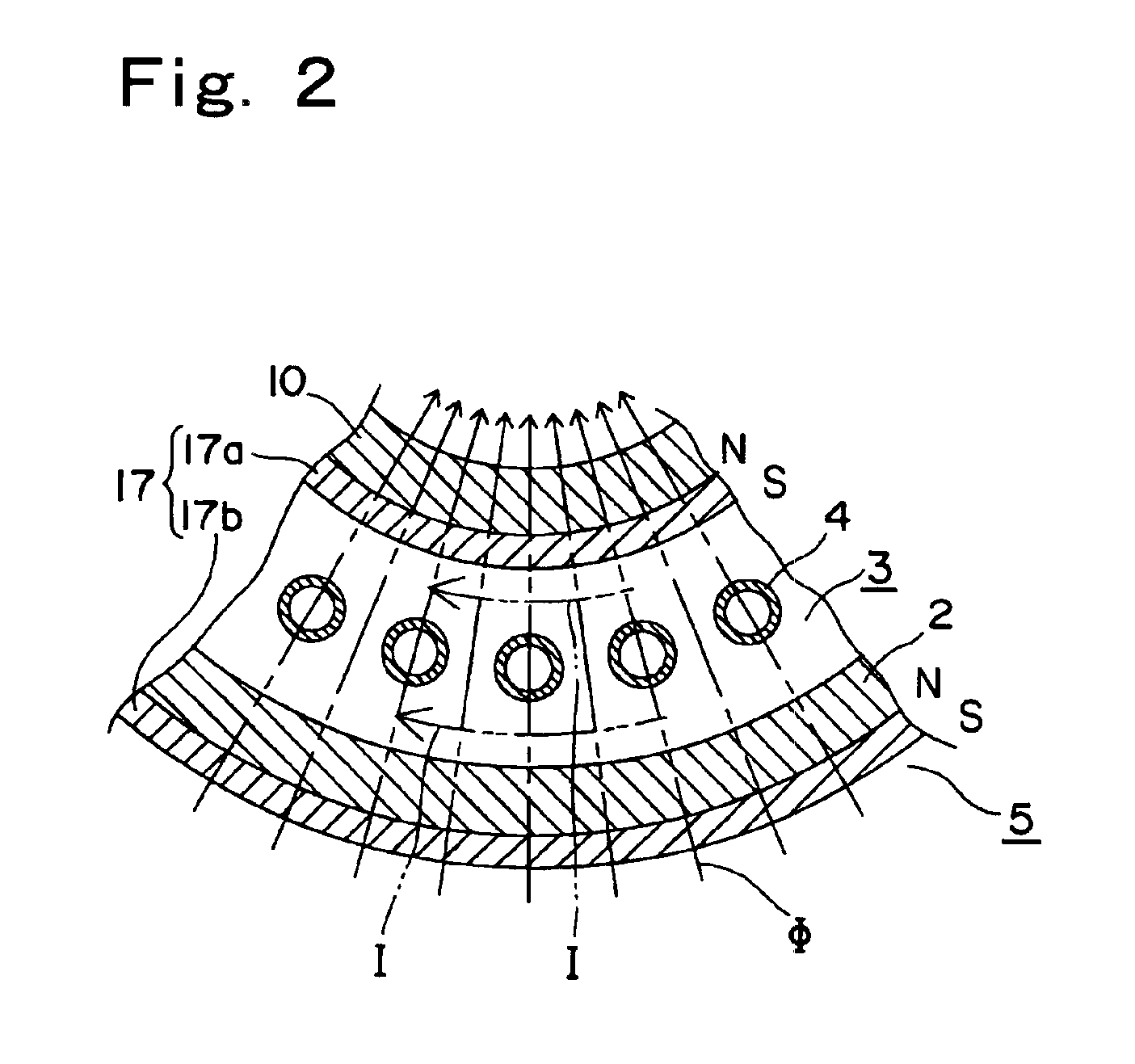

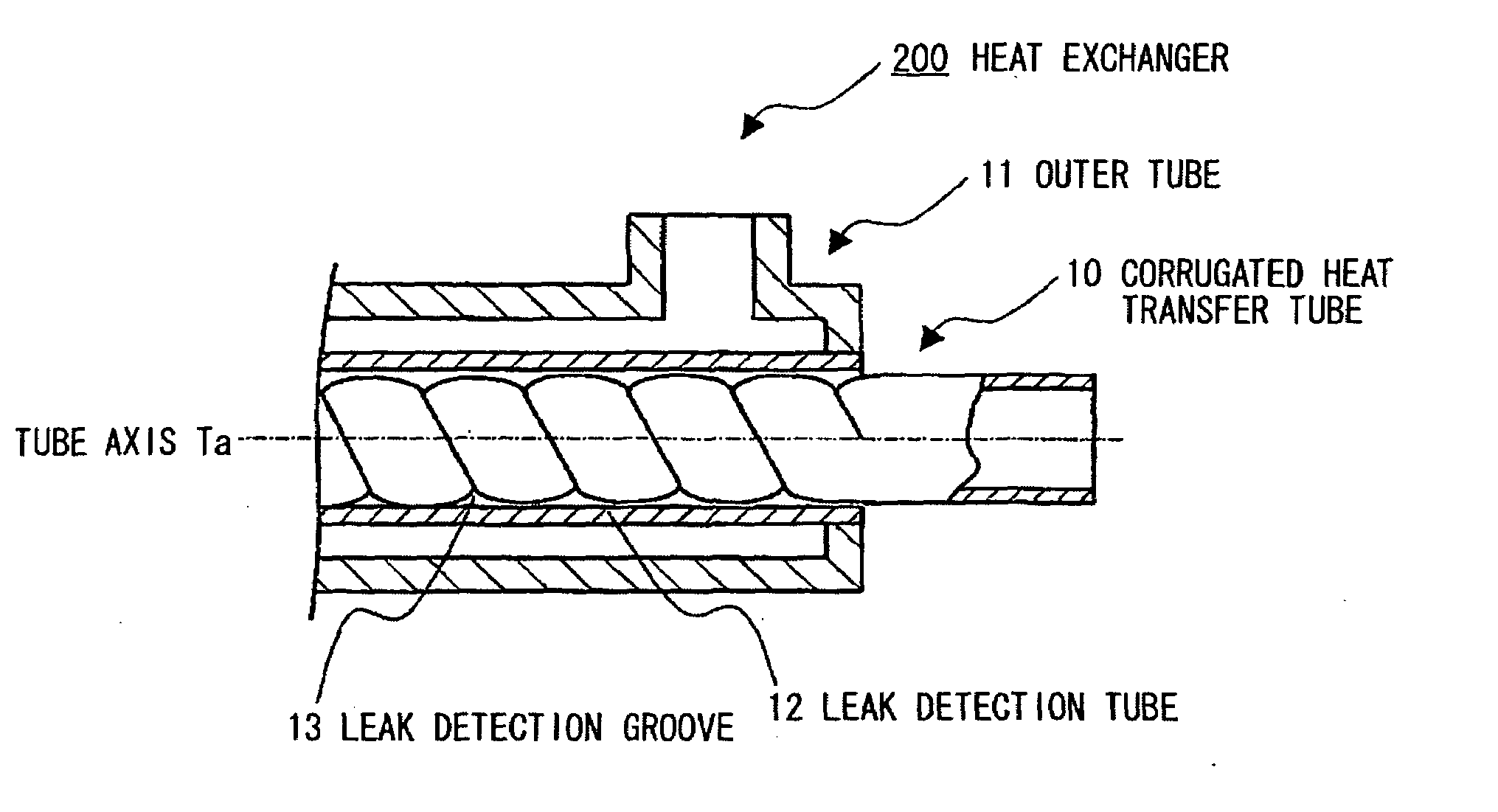

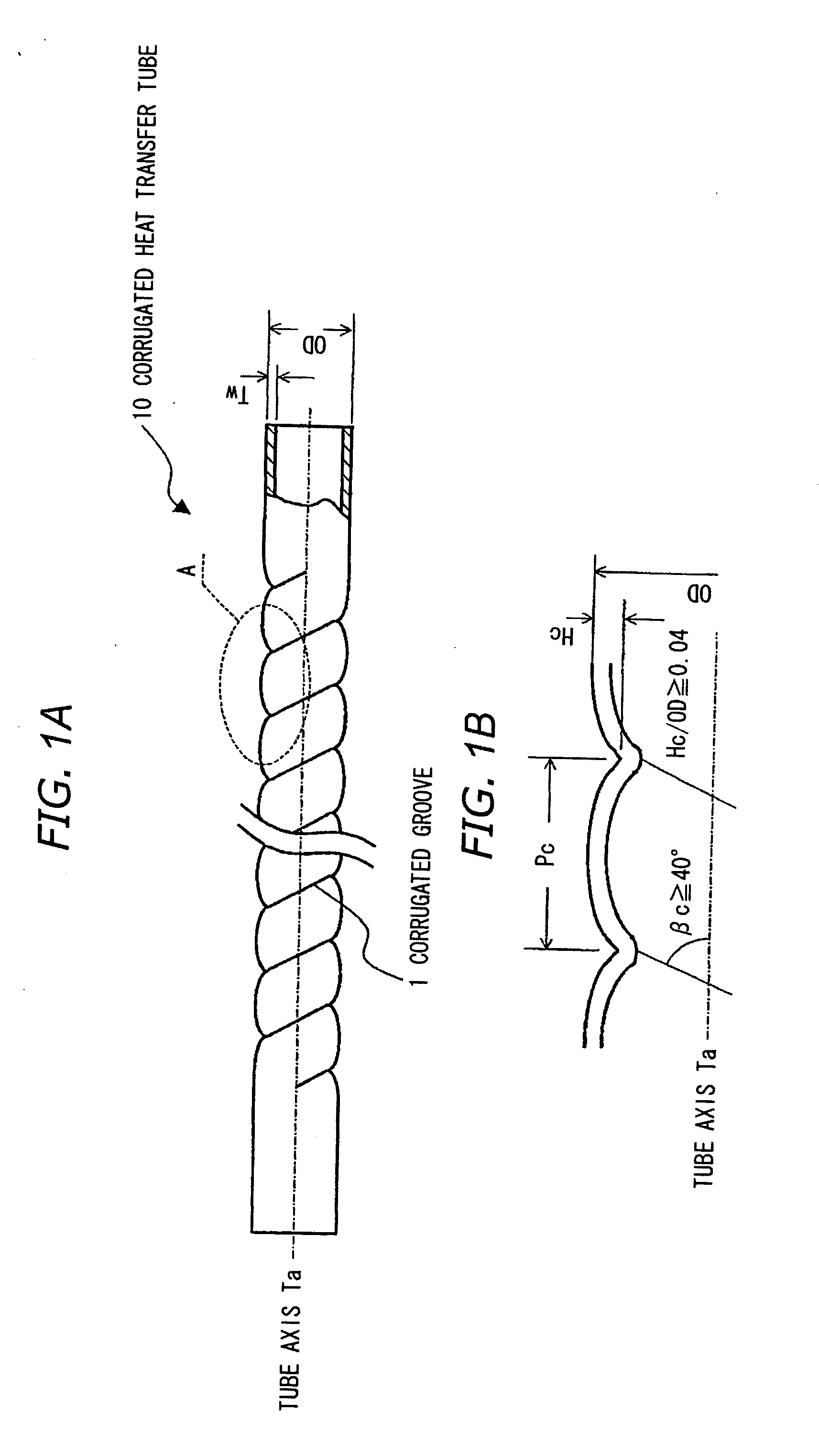

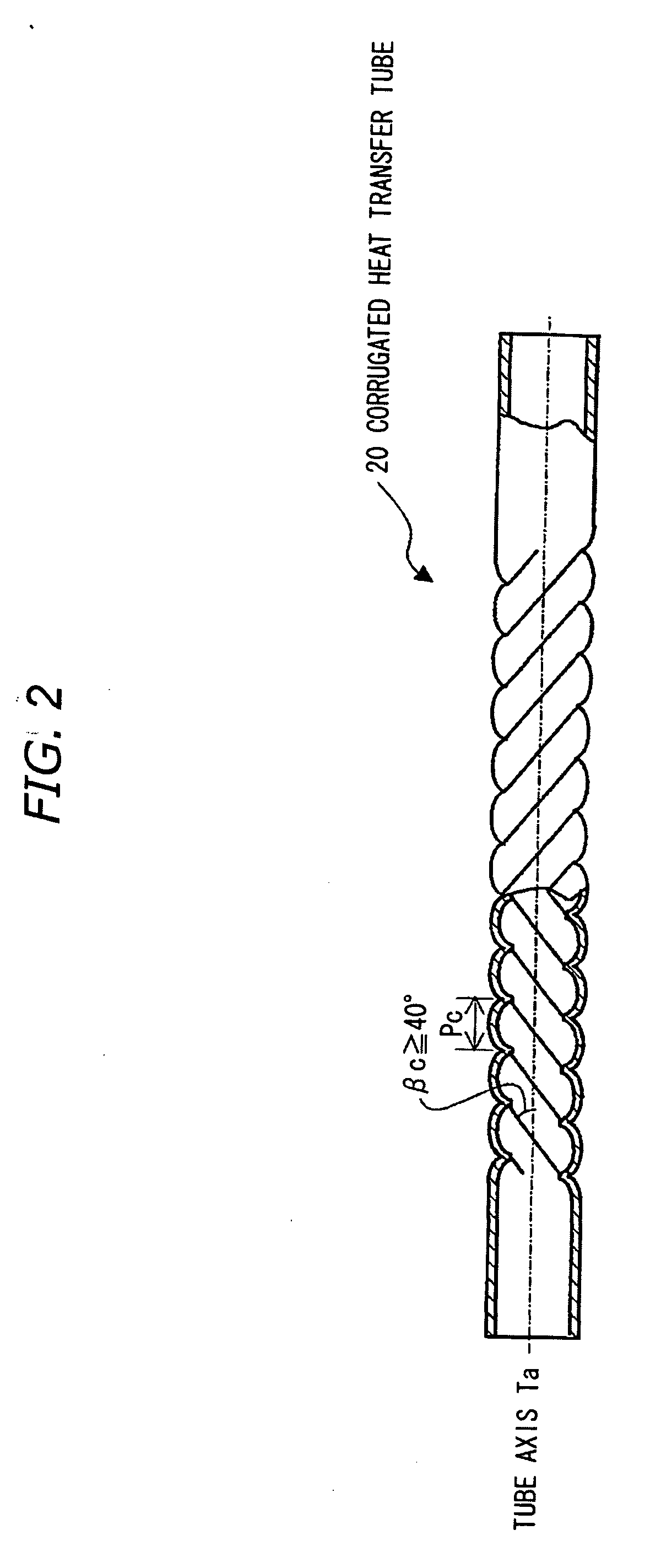

Heat transfer tube and heat exchanger using same

InactiveUS20070187067A1Improve heat transfer performanceImprove performanceHeat exhanger sealing arrangementStationary tubular conduit assembliesPlate heat exchangerEngineering

A heat transfer tube is formed with a corrugated water tube to be used in a heat exchanger, and satisfying 0.04≦Hc / OD, where Hc is the corrugated groove depth of the corrugated tube and OD is the corrugation outside diameter thereof.

Owner:HITACHI CABLE

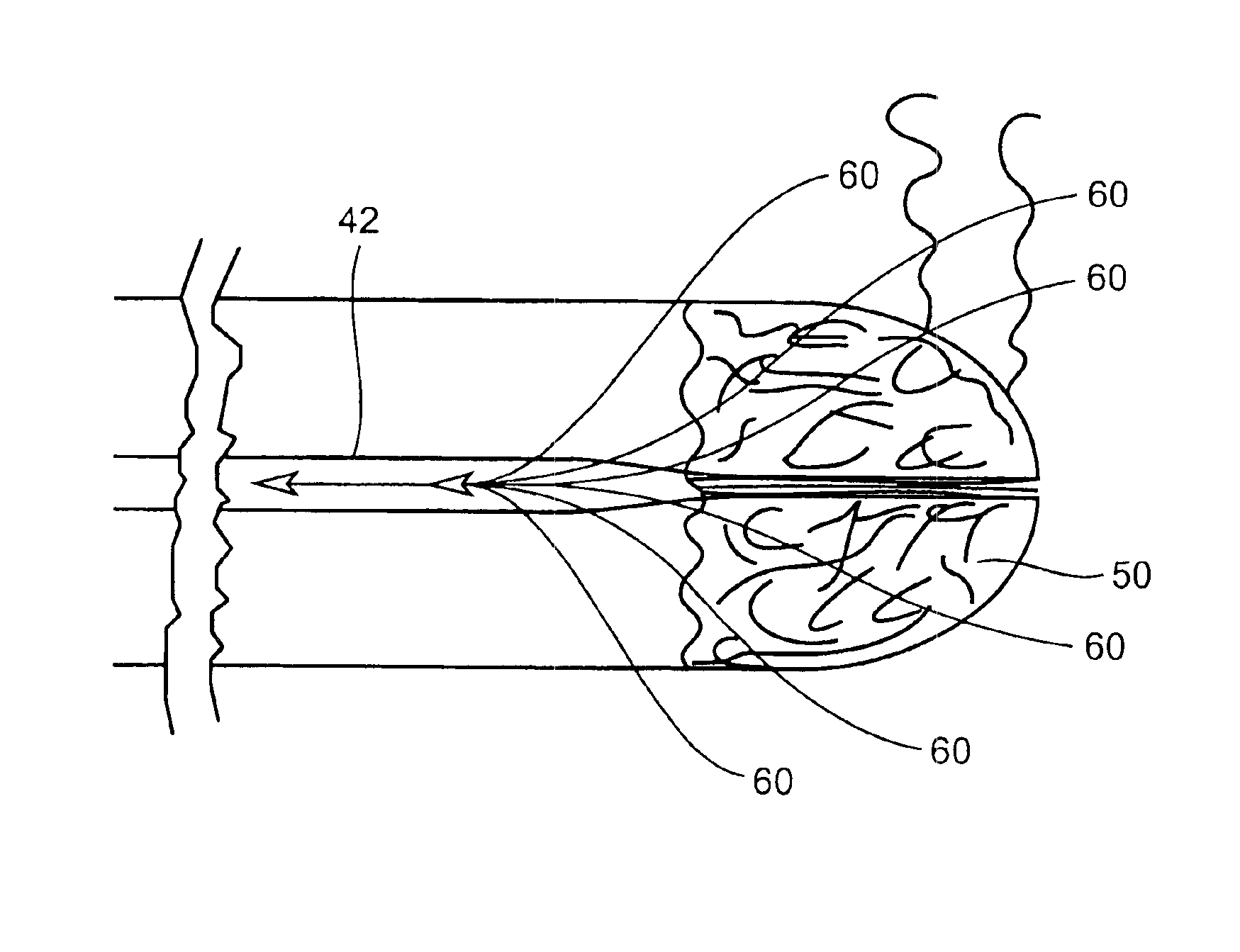

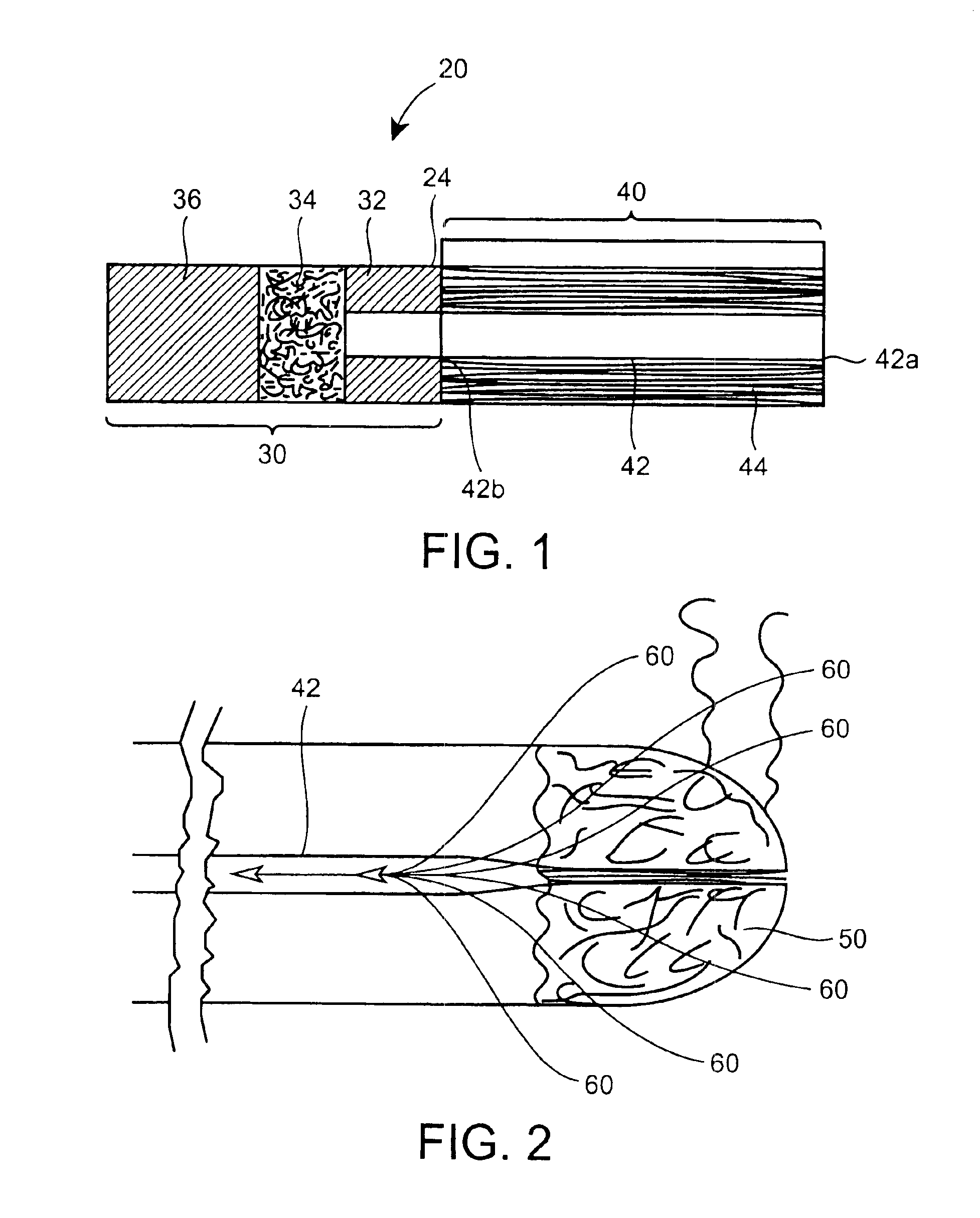

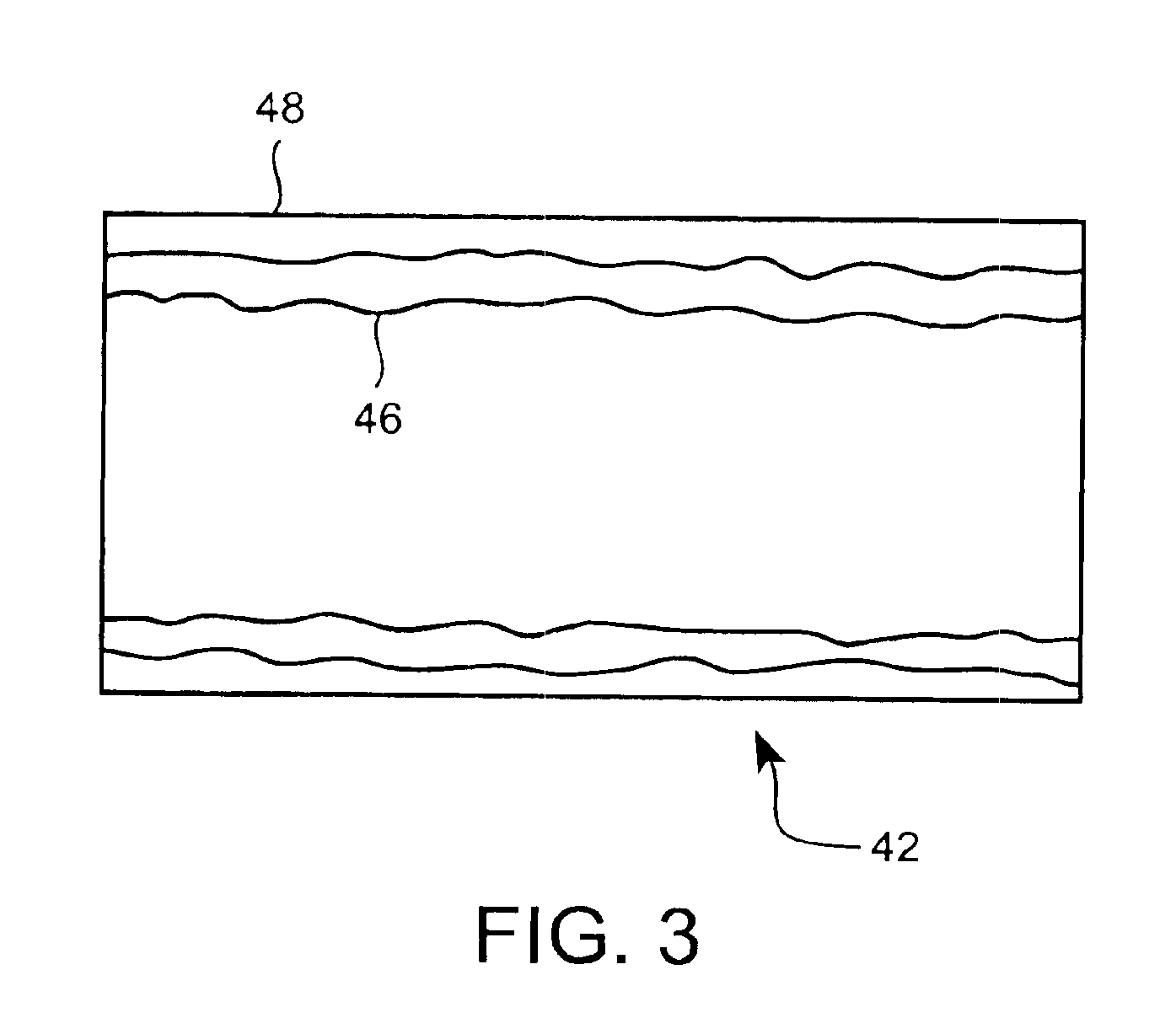

Cigarette having porous heat transfer tube

InactiveUS6883523B2Pressure dropLarge heat energyTobacco preparationCigar manufactureThermal energyEngineering

A smoking article includes a cylinder of smoking material, a filter attached to the cylinder of smoking material, and a tube of preferably porous and / or perforated material adapted to collapse at an open end upon exposure to thermal energy and preferably extending from one end portion of the smoking material to the junction of the filter and the cylinder of smoking material. Thermal energy generated by a burning portion of the tobacco filler material within the cylinder of smoking material is transferred by convection through the open portion of the tube after the end portion of the tube has collapsed closed by the heat from the burning portion of the tobacco.

Owner:PHILIP MORRIS USA INC

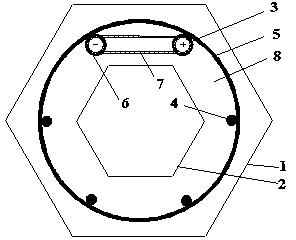

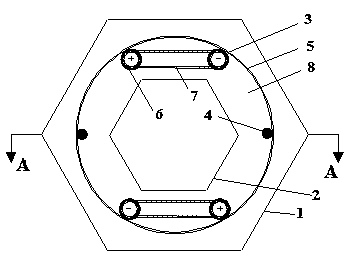

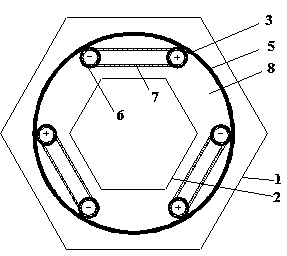

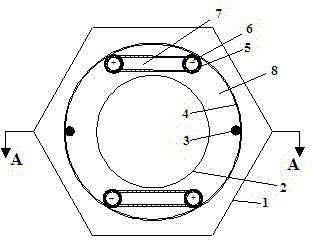

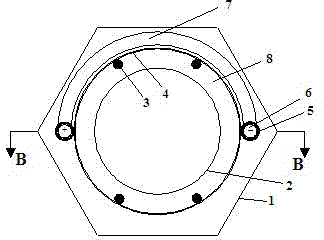

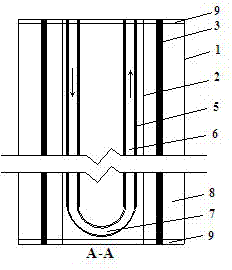

Prefabricated hexagonal energy pile and manufacturing method thereof

ActiveCN103498470AGuaranteed force characteristicsGuaranteed StrengthHeat pumpsOther heat production devicesPre stressArchitectural engineering

The invention discloses a prefabricated hexagonal energy pile and a manufacturing method of the prefabricated hexagonal energy pile. Solid steel bars are used as pre-stressed main reinforcements of the prefabricated pile, hollow steel pipes are used as constructional main reinforcements of the prefabricated pile, and heat transfer pipes are embedded in the hollow steel pipes; the exterior of a pile body where the heat transfer pipes are embedded is in the shape of a hexagon, and the interior of the pile body where the heat transfer pipes are embedded is in the shape of a circle; the heat transfer pipes are connected by heat transfer elbows to form U-shaped loops at the bottom of the prefabricated pile; the heat transfer pipes are arranged at sharp corner positions where the wall thickness is large, namely, the six corners of the hexagon. The heat transfer pipes are embedded in the hollow steel pipes, and therefore the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, influences on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer pipes and the main reinforcements are effectively solved; besides, the survival rate of the embedded pipes is higher, a large number of pile bodies can be conveniently stacked and safely transported, a construction period is short, underground space is saved, and construction cost is lowered.

Owner:HOHAI UNIV

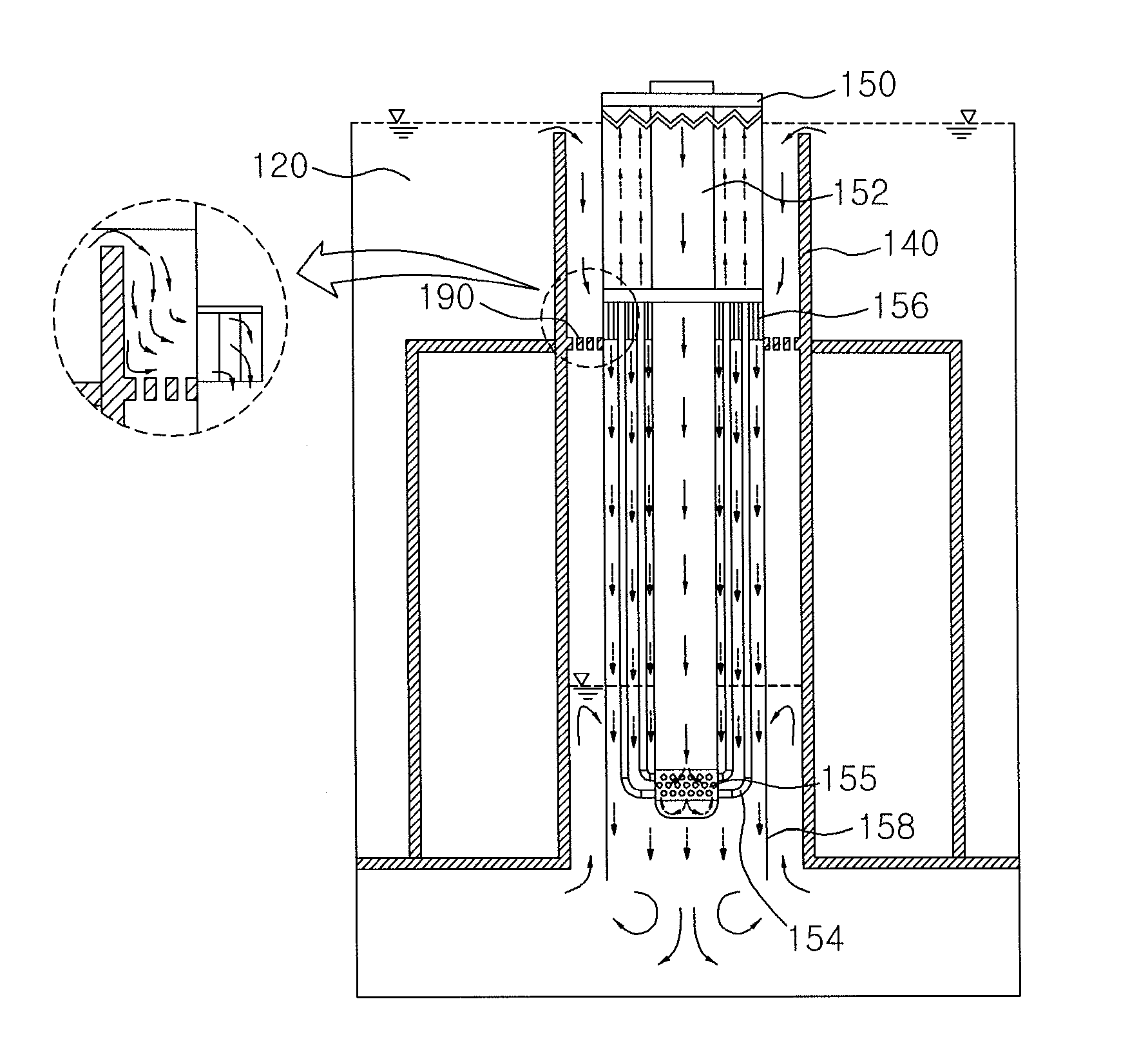

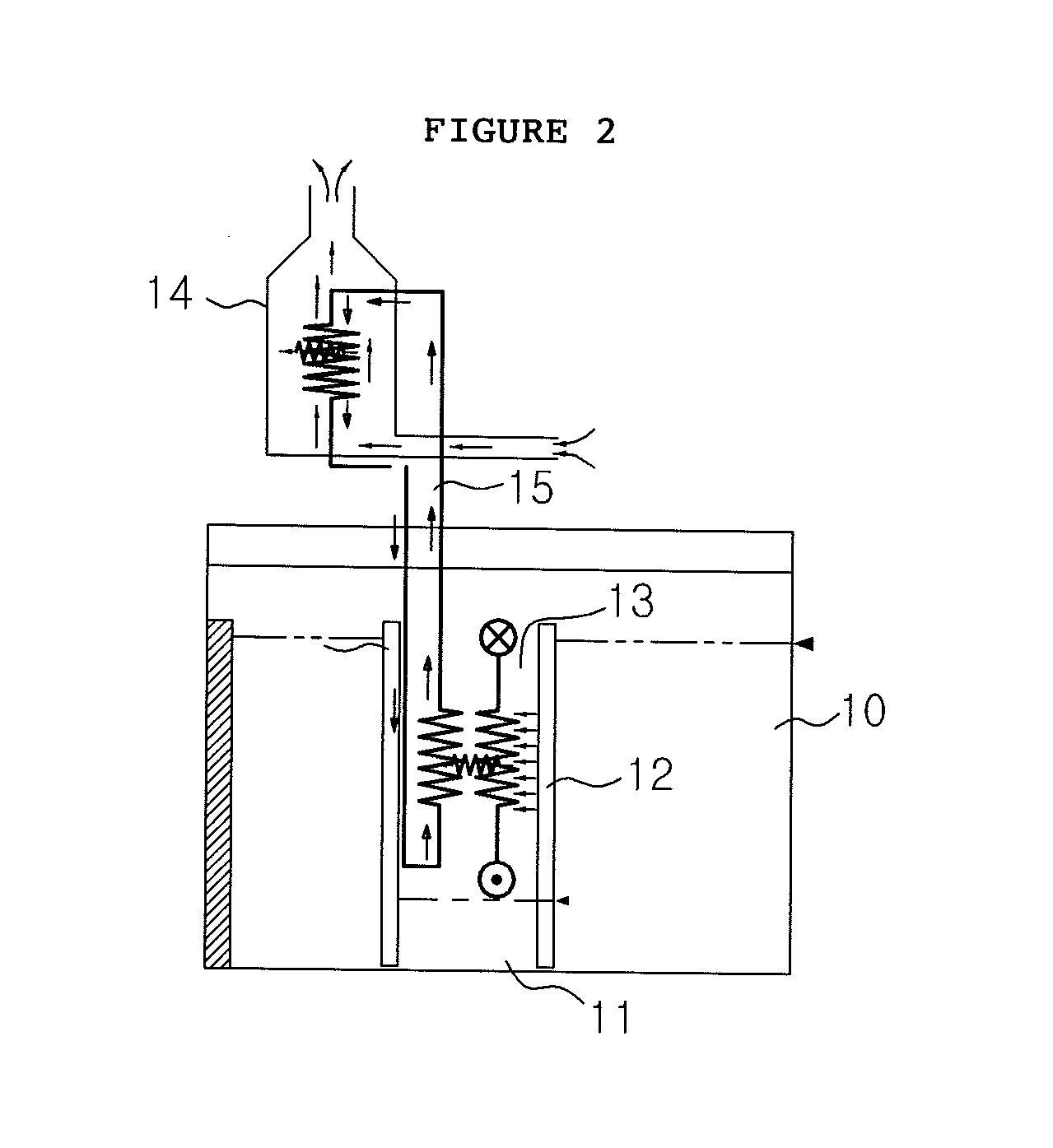

Fully passive decay heat removal system for sodium-cooled fast reactors that utilizes partially immersed decay heat exchanger

ActiveUS20100177860A1Reduced operational reliabilityImprove business performanceNuclear energy generationFast fission reactorsIntermediate heat exchangerSodium-cooled fast reactor

Disclosed herein is a fully passive decay heat removal system utilizing a partially immersed heat exchanger, the system comprising: a hot pool; an intermediate heat exchanger which heat-exchanges with the sodium of the hot pool; a cold pool; a support barrel extending vertically through the boundary between the hot pool and the cold pool; a sodium-sodium decay heat exchanger received in the support barrel; a sodium-air heat exchanger provided at a position higher than the sodium-sodium decay heat exchanger; an intermediate sodium loop connecting the sodium-sodium decay heat exchanger with the sodium-air heat exchanger; and a primary pump, wherein a portion of the effective heat transfer tube of the sodium-sodium decay heat exchanger is immersed in the cold pool, particularly in a normal operating state, and the surface of the lower end of a shroud for the sodium-sodium decay heat exchanger, the lower end being immersed in the sodium of the cold pool, has perforated holes.

Owner:KOREA ATOMIC ENERGY RES INST +1

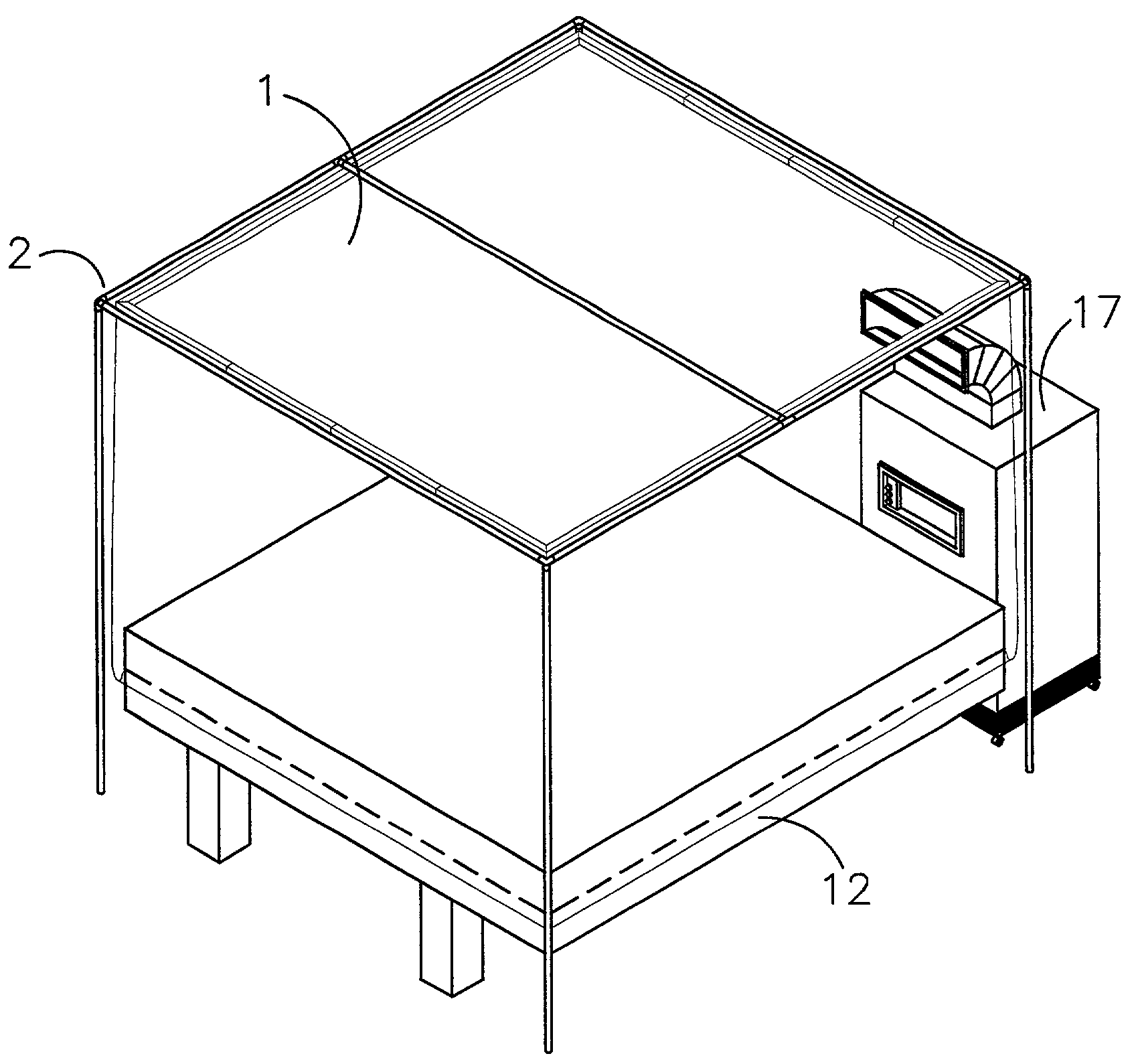

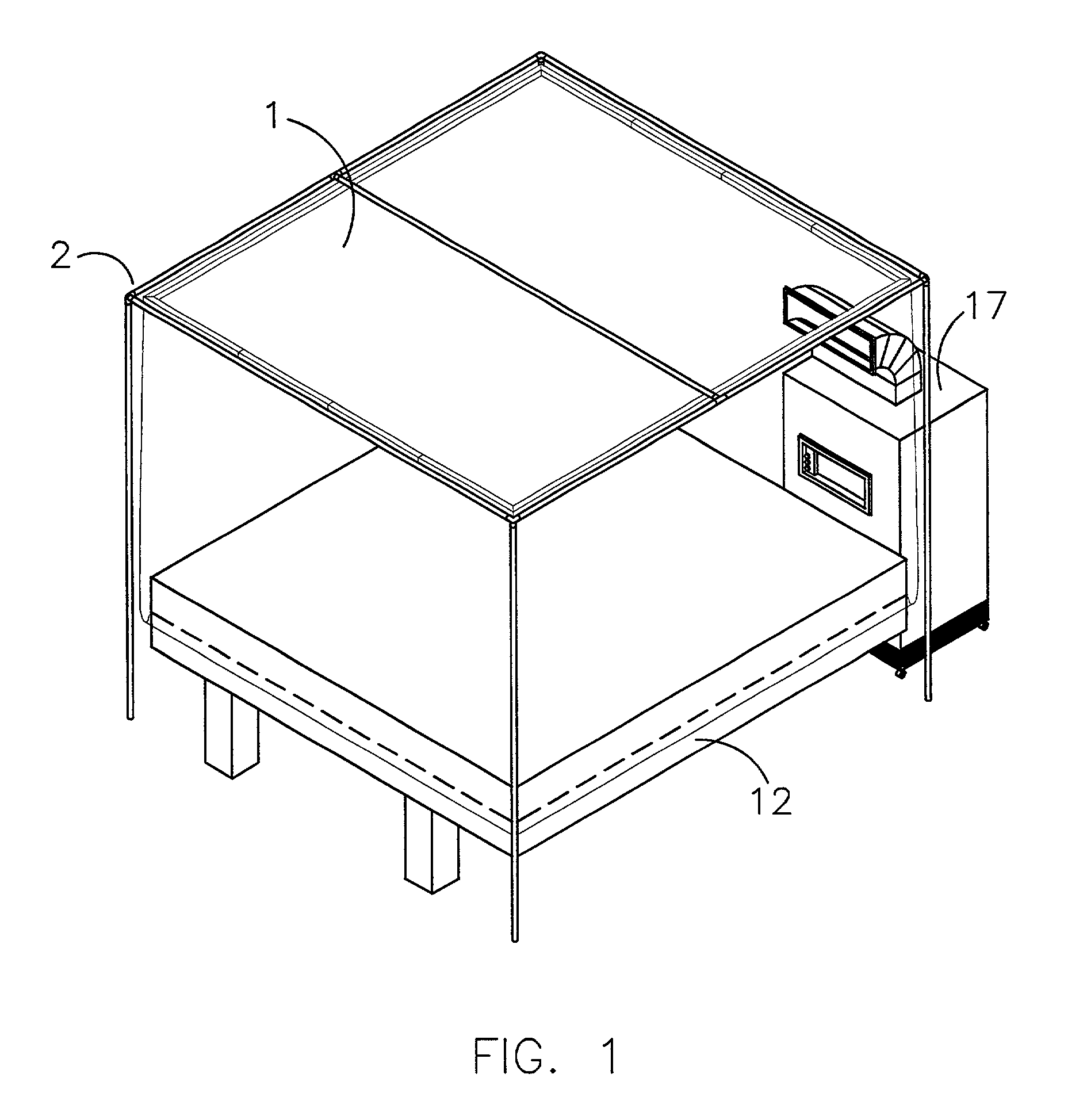

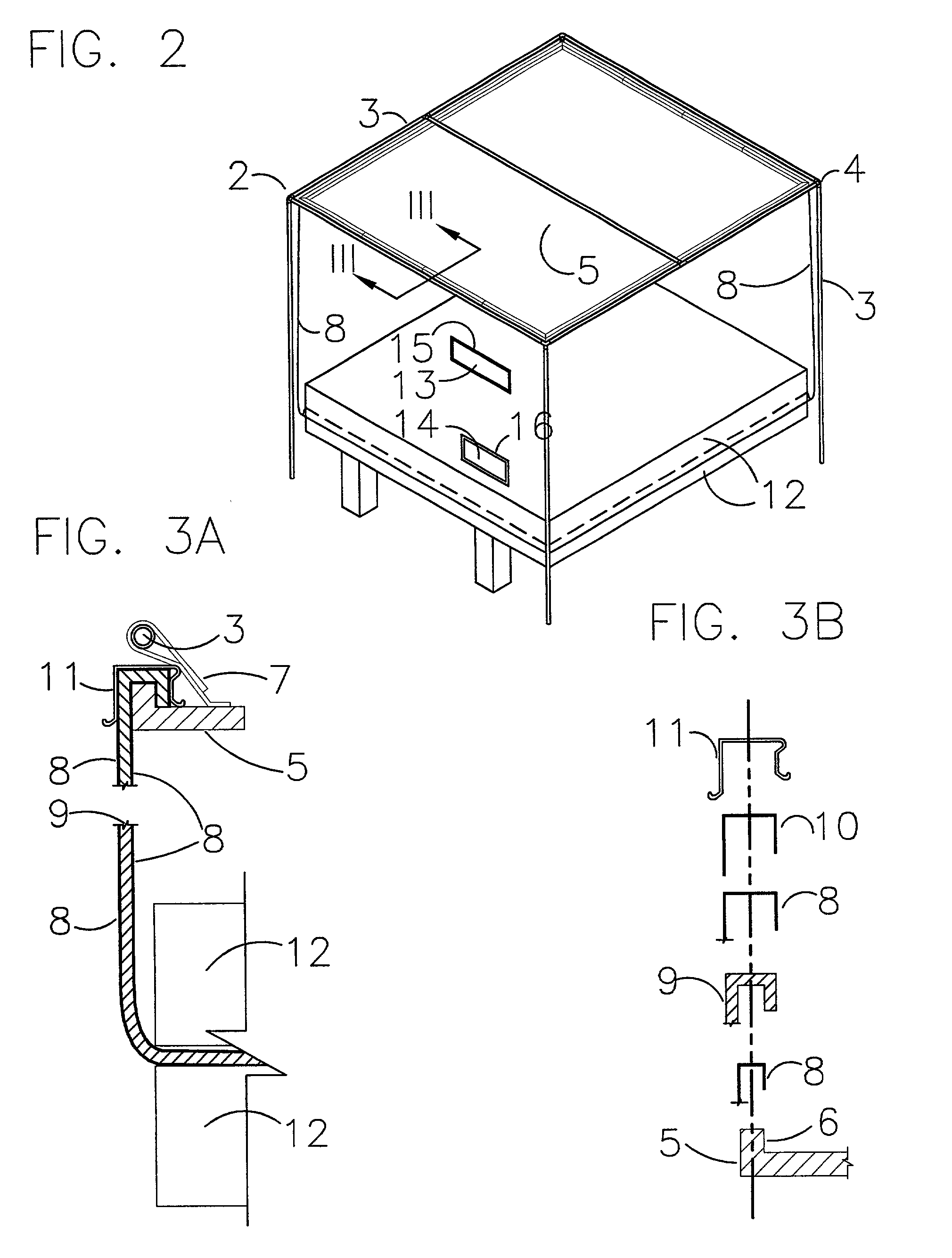

Self-contained air-conditioned enclosure

InactiveUS20020121101A1Lower initial costLighting and heating apparatusHeating and ventilation casings/coversFresh airEngineering

A Self-Contained Air-Conditioned Enclosure; comprises of an Enclosure (1), connected through plurality of openings (13,14) to air ducts (20,21) of an Air-conditioning Unit (17). The Enclosure has a Roof (5), and sidewalls assembled with plurality of Wall Sheets (8) interspaced with Spacer Strips (9) to enhance thermal resistance of the sidewalls. The bottom of the sidewall is inserted under the structure that forms the floor to create an isolated enclosure. The Air-conditioning Unit (17) supplies the Enclosure through the Supply Air Duct (21) and withdraws air through Exit Air Duct (20). Part of the withdrawn air is reconditioned and supplied to the enclosure; the other part is replaced by fresh air. Energy is conserved from the replaced air in Heat Transfer Duct (37) and transferred to fresh air in Fresh Air Chamber (36). Unit efficiency is improved by mixing the exhausted withdrawn air in the Compressor Chamber (31) and exhausted by the Exhaust Air Duct (28). Flow of fresh air is controlled through the Air Damper (39) and Control Knob (38).

Owner:JEBARAJ ASIR IYADURAI

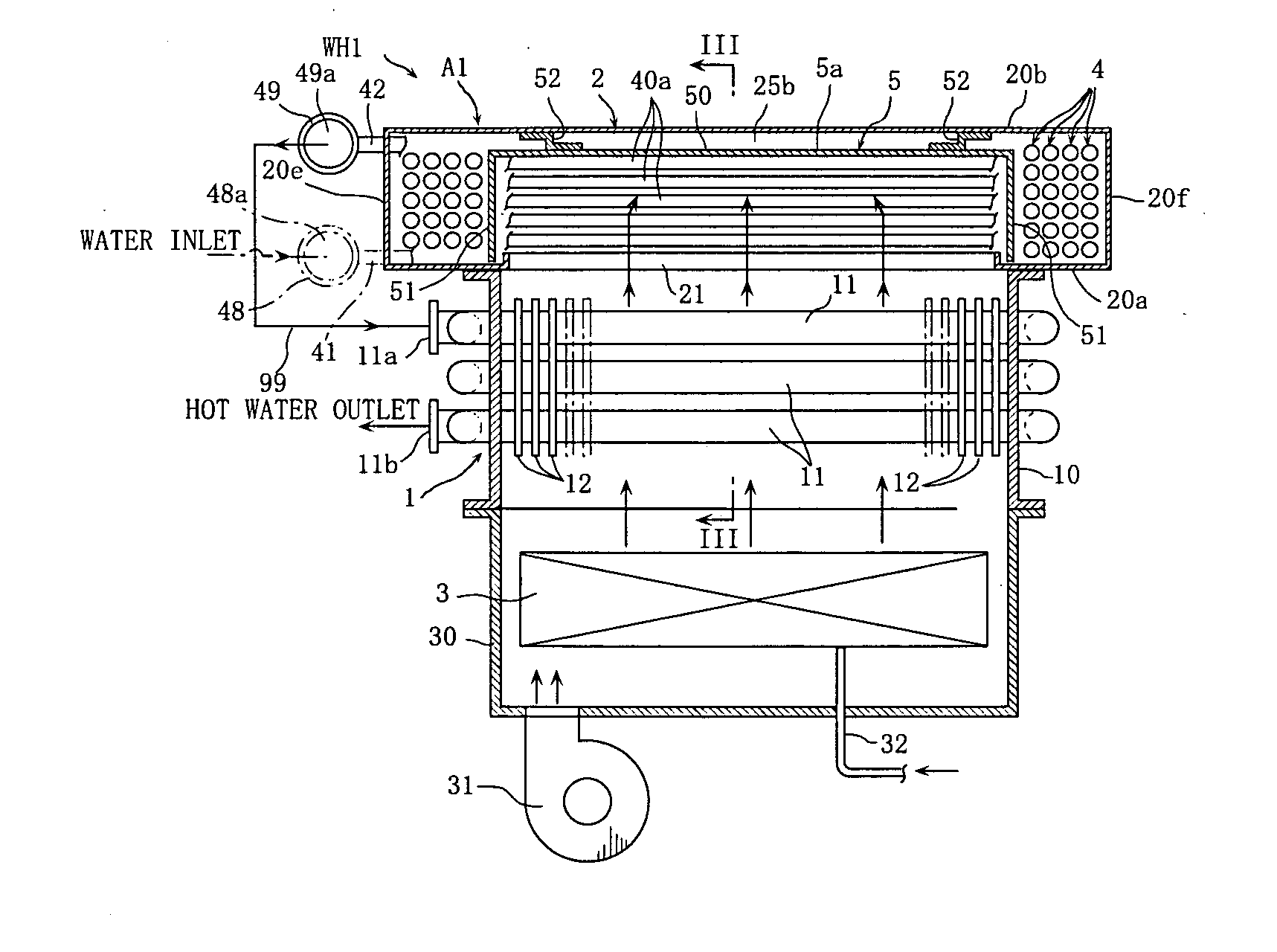

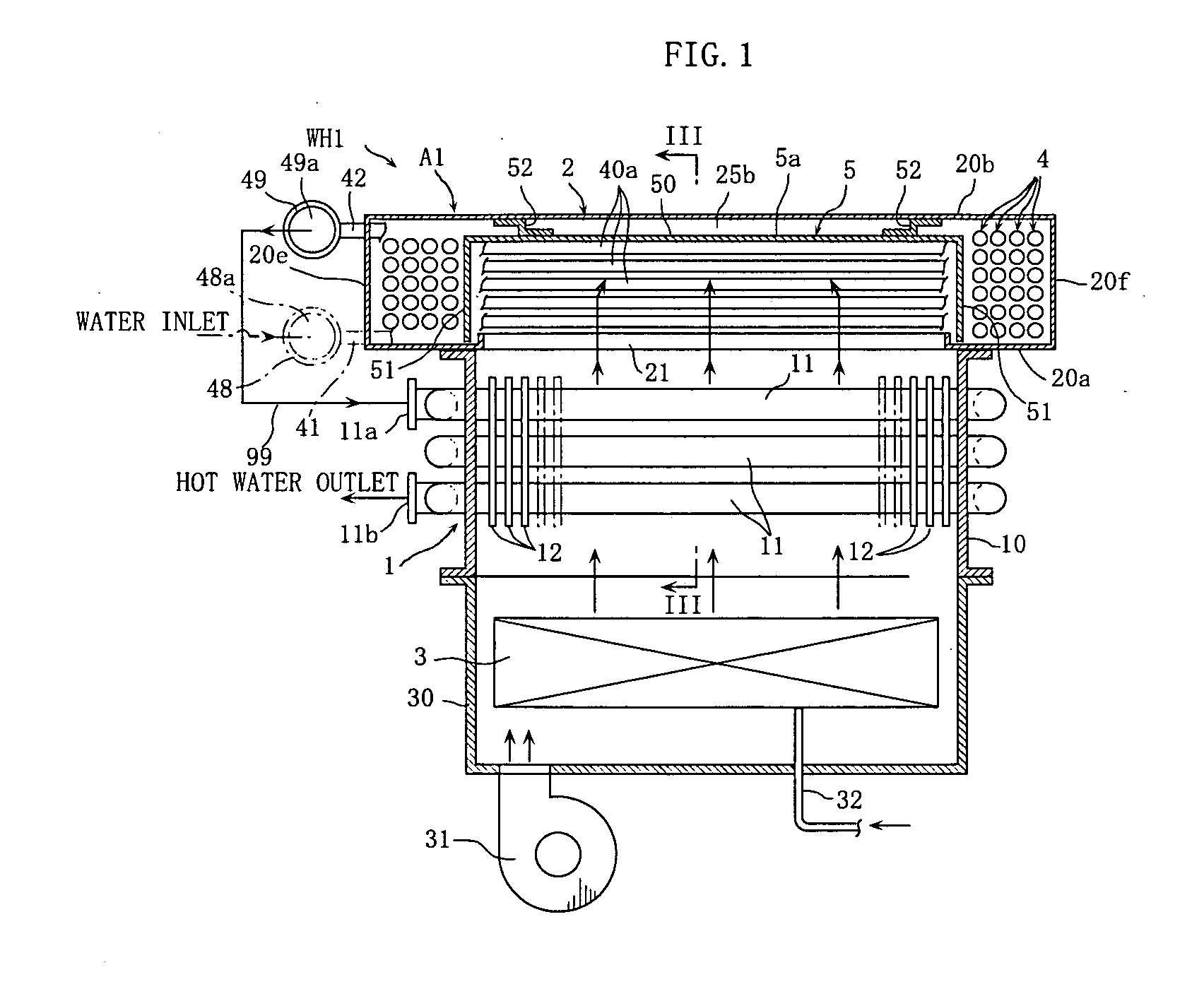

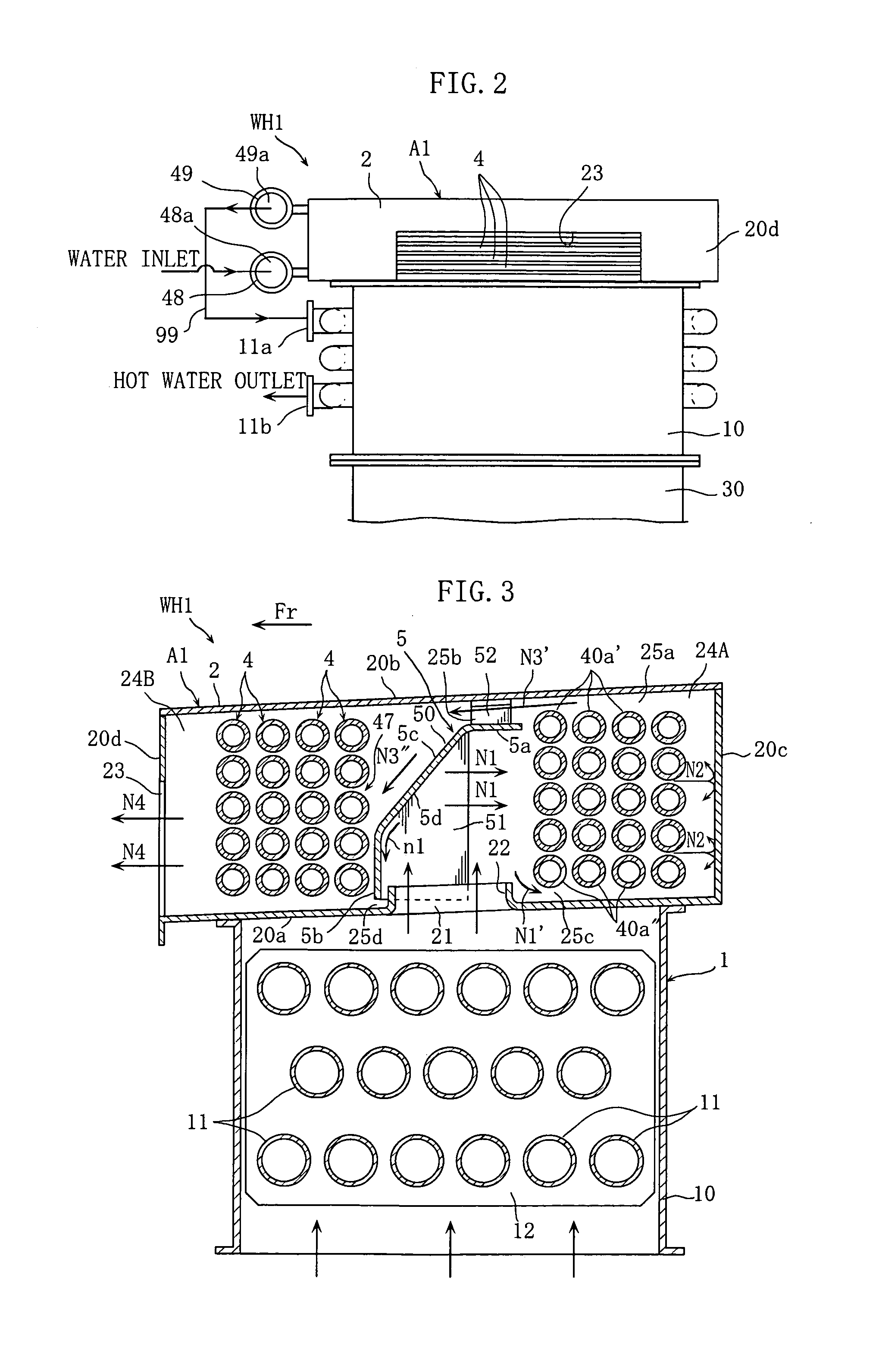

Heat exchanger and water heater incorporating the same

InactiveUS20110155079A1Avoid flowEnergy efficient heating/coolingSpace heating and ventilation detailsPlate heat exchangerEngineering

A heat exchanger A1 includes: a case 2 surrounding a heat transfer tube 4; and a guide member 5 for guiding heating gas entering the case 2 through an intake vent 21 to a first space region 24A and then to a second space region 24B, the guide member 5, together with a wall portion 20b, defining therebetween a gap 25b in communication with a gap 25a between the wall portion 20b and the heat transfer tube 4 for allowing part of the heating gas having been guided to the first space region 24A to proceed into the second space region 24B through the gaps 25a and 25b. This arrangement performs efficient heat recovery from the heating gas by effectively utilizing the entire heat transfer tube 4 while alleviating a problem that the case 2 is partially heated to elevated temperatures.

Owner:NORITZ CORP

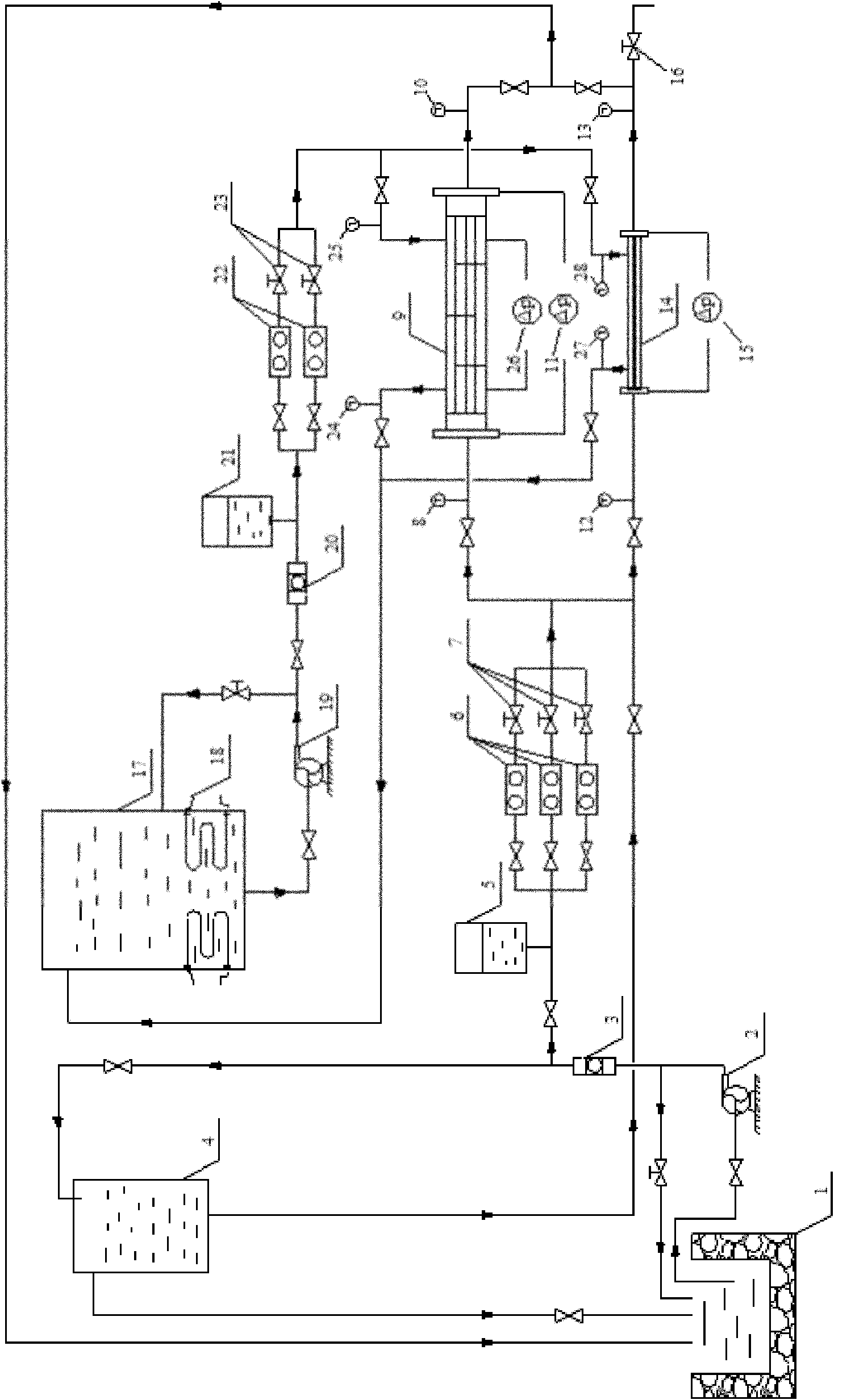

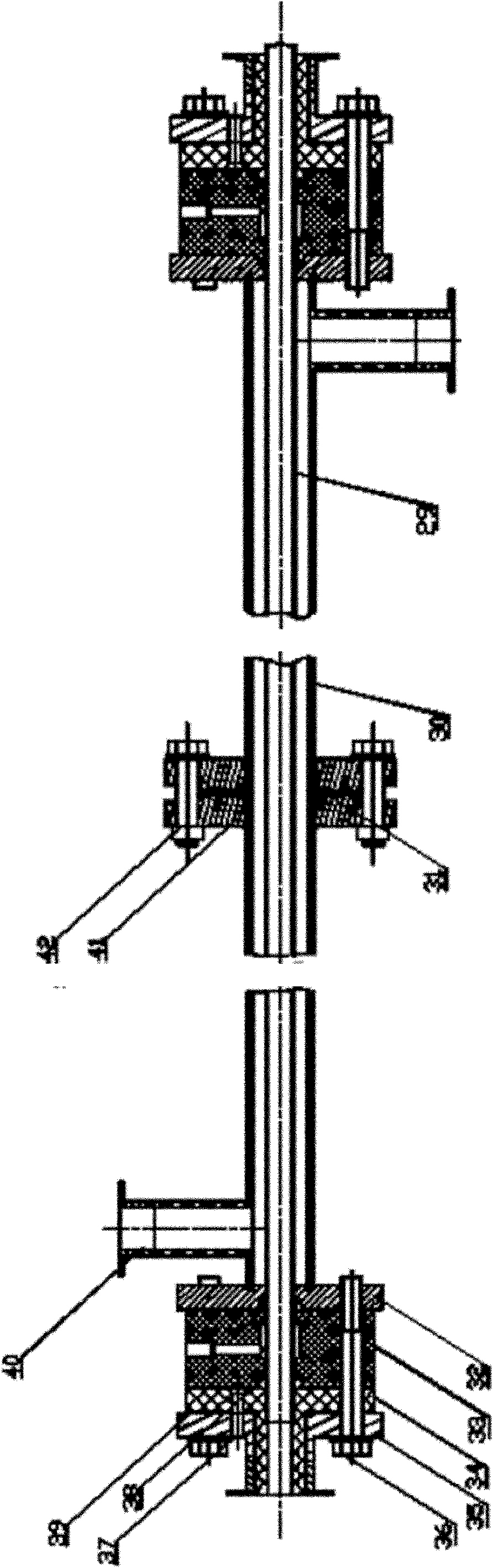

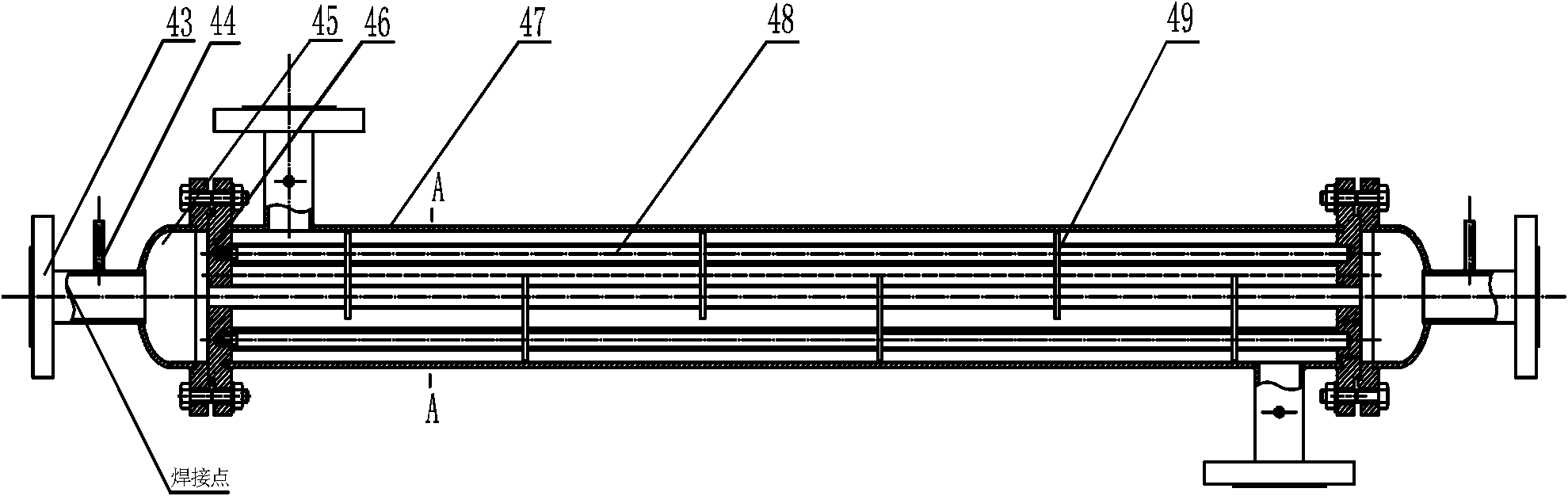

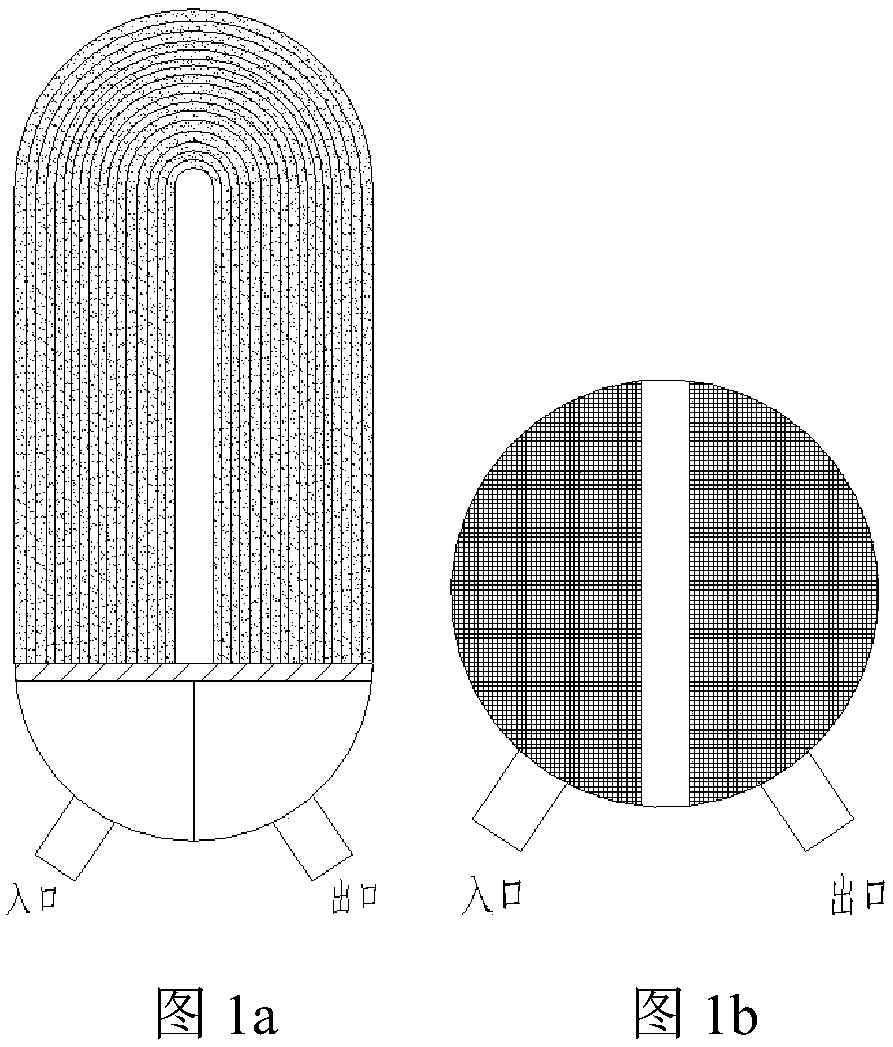

Multifunctional wide flow single-phase convective heat exchange test device

InactiveCN102081060ASimple designWide test processMaterial heat developmentHeat transfer tubeSingle phase

The invention discloses a multifunctional wide flow single-phase convective heat exchange test device. The device comprises the following four parts: a circulating water system, an electric heating system, a measurement system and an experimental section. The circulating water system consists of two parts, namely a hot water circulating system and a cold water circulating system; the electric heating system mainly consists of an electric heater and a corresponding control system; the measurement system comprises a temperature measurement system, a flow measurement system, a pressure difference measurement system and a corresponding data acquisition system; and the experimental section is formed by connecting a tubular heat exchanger and a tube bundle heat exchanger in parallel. The device has a simple structure, and is flexile and convenient to operate; the adopted equipment is small in volume, small in number and high in measurement precision; and single-phase convective heat exchange and flow resistance test of a heat transfer pipe and the tube bundle heat exchanger are integrated, and the heat transfer properties and flow resistance properties of the heat transfer pipes of different shapes and different geometric dimensions and the heat exchangers of different pipe arrangement modes can be tested and researched within wide reynolds number ranges of a laminar area, a transition area and a turbulence area.

Owner:HARBIN ENG UNIV

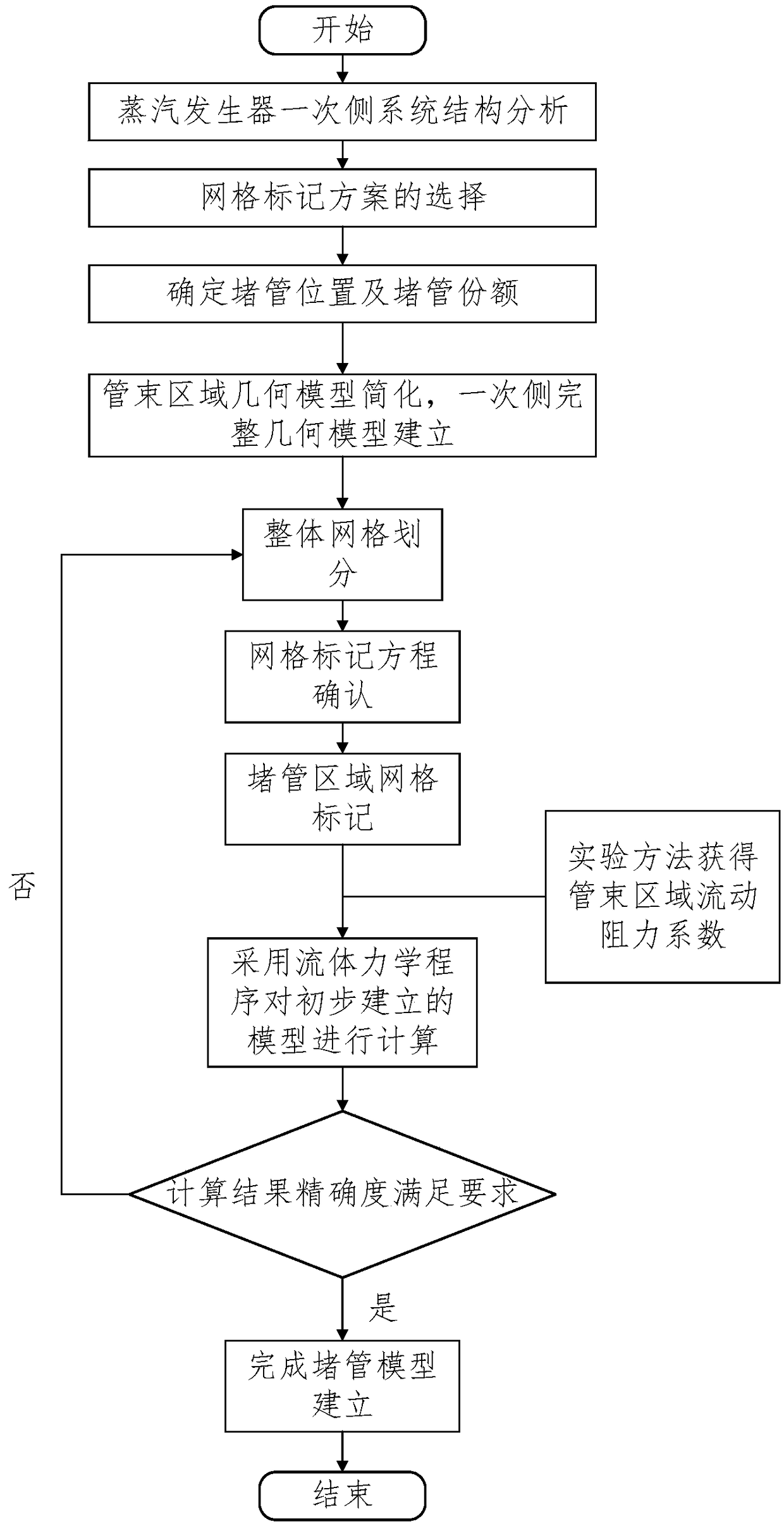

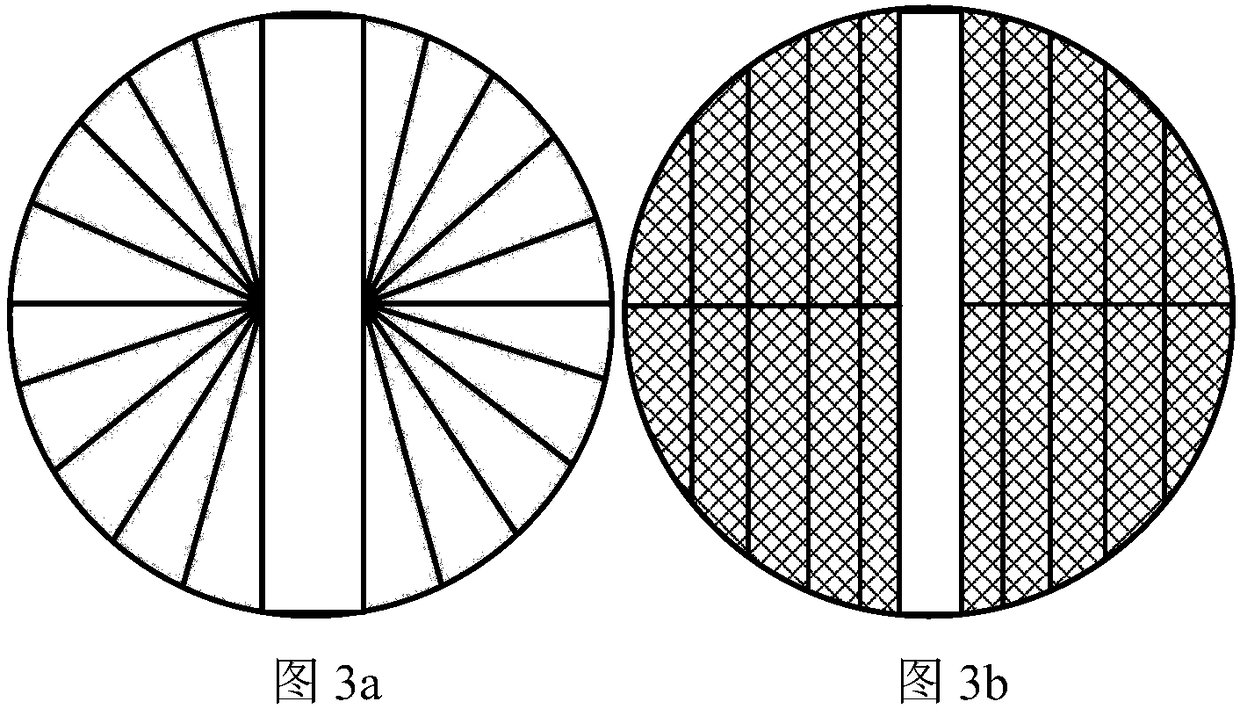

Method for establishing blocking condition models of heat transfer tubes of vapor generators in nuclear power plants

ActiveCN108170924AChange changeChange heat transferGeometric CADSpecial data processing applicationsNODALNuclear power

The invention discloses a method for rapidly establishing three-dimensional fine thermos-hydraulic calculation models for primary side systems of large-scale natural circulation vapor generators in nuclear power plants under certain heat transfer tube blocking accident conditions. The method comprises the following steps of: 1, carrying out complete primary side hydraulic analysis on a vapor generator so as to analyze a flow distribution law at a tube plate; 2, selecting a tube blocking scheme according to a result of the last step; 3, determining a tube blocking share and a tube blocking position; 4, carrying out geometric simplification and overall geometric modeling on a plurality of heat transfer tubes in the real vapor generator; 5, dividing preliminary calculation nodes; 6, establishing a tube blocking equation to tracing marked control areas, and carrying out calculation domain grid marking on the control areas by adoption of a network marking method so as to realize a tube blocking function; and 7, carrying out blocking condition calculation by adoption of a preliminarily established model and analyzing the precision of the result, and if a requirement is satisfied, considering that the modeling is completed, and otherwise, returning to the step 5 to encrypt the calculation nodes until the model satisfies the calculation precision requirement.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com