Patents

Literature

184results about How to "Solve stacking problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

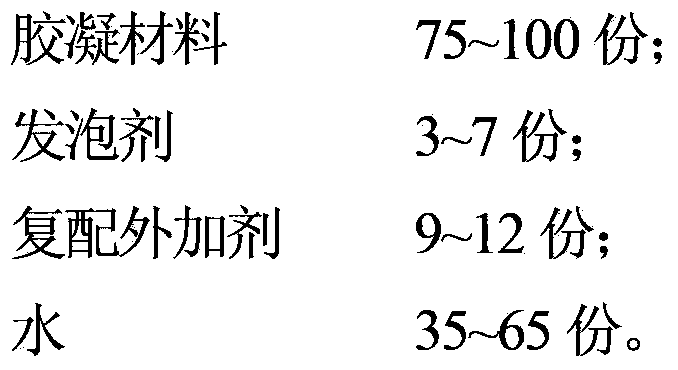

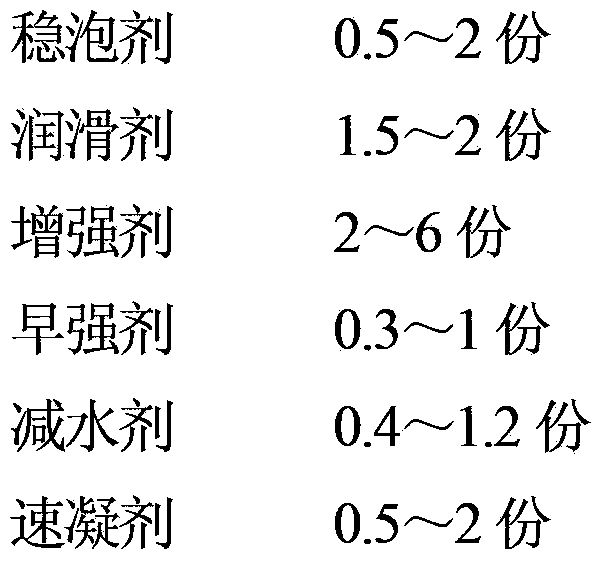

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

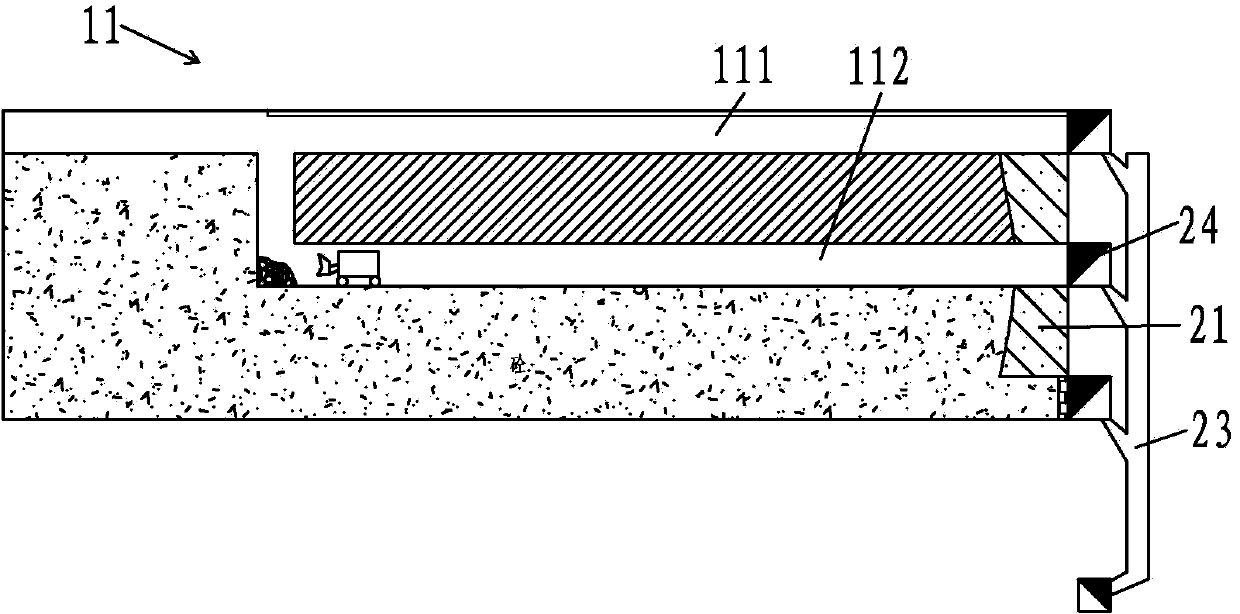

Construction method for precast energy pile

ActiveCN103485332ASolve the loss of densitySolve stacking problemsHeat pumpsBulkheads/pilesPile capArchitectural engineering

A construction method for a precast energy pile is characterized in that a heat transfer tube is embedded into a hollow steel tube, the hollow steel tube replaces a traditional solid reinforcement and serves as a main reinforce ement of the precast pile, and for being connected with the heat transfer pipe in the precast pile, a heat transfer elbow and a heat transfer tube joint are embedded into a precast pile shoe and a precast pile cap. As the heat transfer tube is embedded into the hollow steel tube, the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, effect on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer tube and the main reinforcement are effectively solved. Moreover, the embedded tube is higher in survival rate, a large number of piles are conveniently stacked and safely transported, construction period is short, and underground space and construction cost are saved.

Owner:HOHAI UNIV

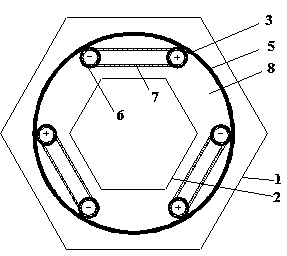

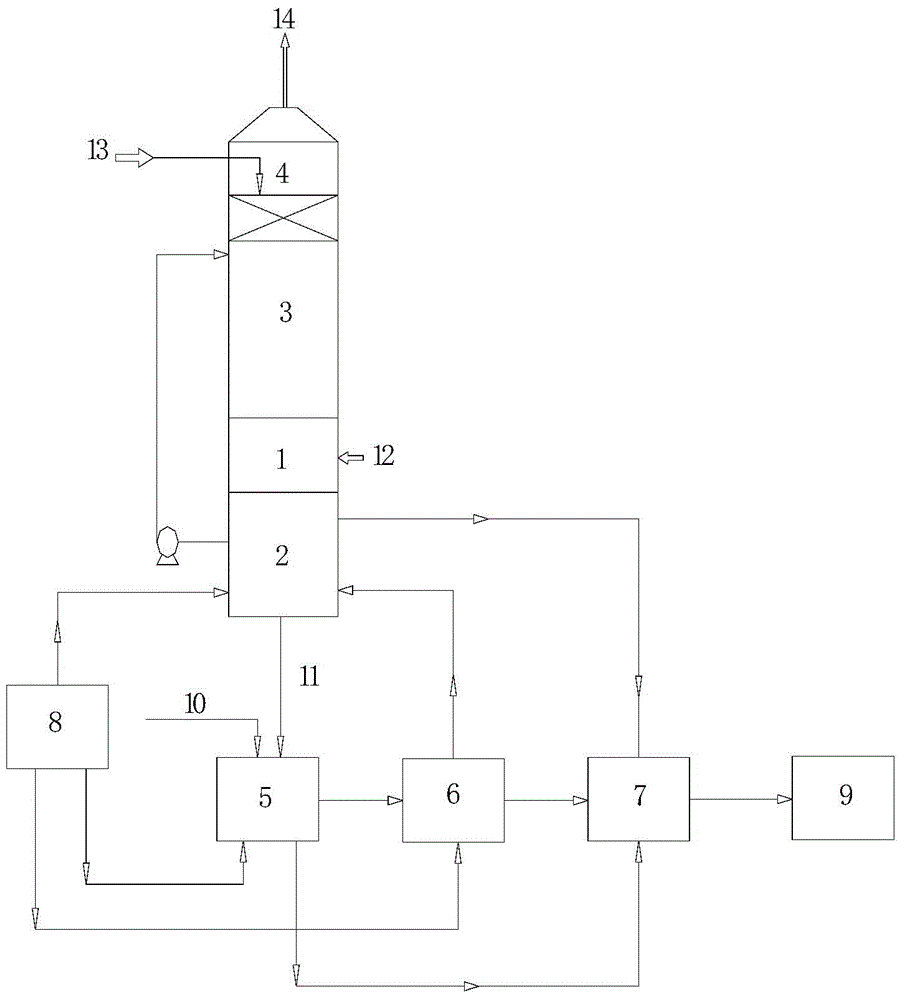

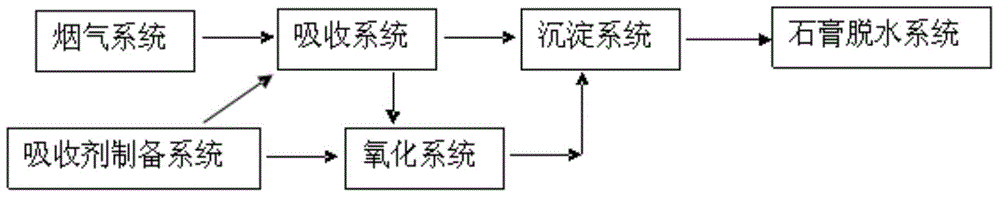

Chemical process wet-method desulphurization technology

InactiveCN105817134AIncrease profitSolve stacking problemsDispersed particle separationSlagIndustrial waste

The invention relates to a chemical process wet-method desulphurization technology. The technology employs alkaline waste residues as a desulfurizer for sulfur-containing flue gas, a desulphurization slurry is oxidized and regenerated outside an absorbing tower, and a dense slag slurry at the bottom of the absorbing tower is timely moved, so that fouling phenomenon is not generated in the absorbing tower. During a whole desulphurization process, only alkaline waste residues are consumed, industrial waste residue stacking and pollution problems can be solved, and a target of waste control by waste can be realized.

Owner:河北衡兴环保设备工程有限公司

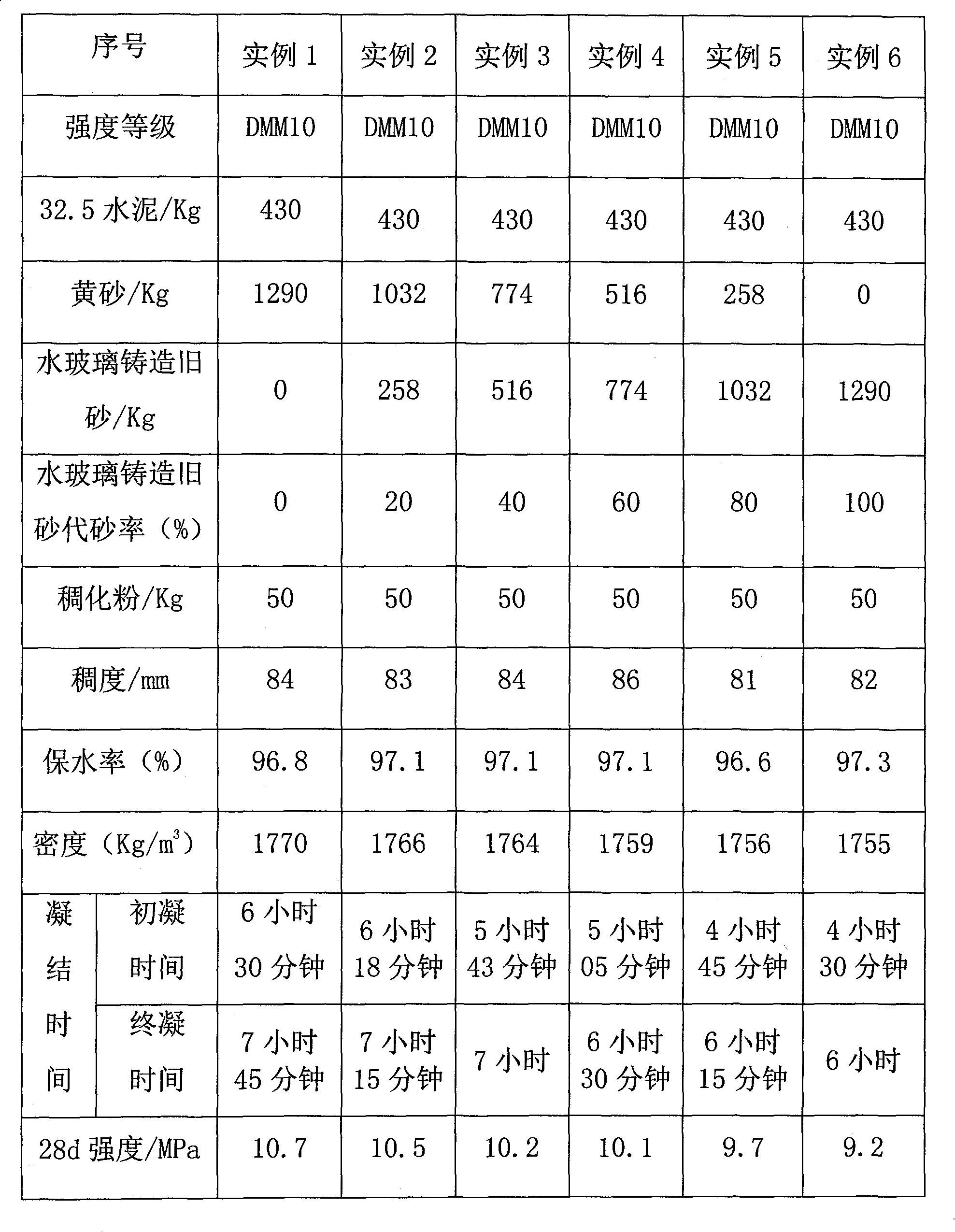

Premixed dry mortar

ActiveCN101838129ASolve stacking problemsLow costSolid waste managementSodium silicateBuilding material

The invention relates to a building material technology, in particular to a concrete premix. A premixed dry mortar is prepared by mainly mixing the components of 12-25 percent of cement, 3-4 percent of pulverized fuel ash, 32-50 percent of yellow sand, 2.7-3.4 percent of mortar thickening powder and 0-0.05 percent of additive. The premixed dry mortar is characterized in that sodium silicate casting used sand is added in the main components. The invention solves the problem of larger consumption of the yellow sand in the traditional premixed dry mortar.

Owner:常州市众华建材科技有限公司 +1

Lightweight water-permeable concrete containing ceramsite

ActiveCN105272067ASolve stacking problemsSolve processingCeramicwareCoal gangueExpanded clay aggregate

The invention relates to lightweight water-permeable concrete containing ceramsite, and belongs to the field of building materials. The concrete is prepared from, by mass (kg / m<3>), 130-150 parts of mixing water, 410-450 parts of cement, 990-1000 parts of the ceramsite and 1.11-1.80 parts of additives, wherein the ceramsite is continuous grading coal gangue ceramsite with the particle sizes ranging from 5 mm to 10 mm, the ceramsite is shaped like a sphere, the stacking density grade of the coal gangue ceramsite ranges from 900 kg / m<3> to 950 kg / m<3>, the close stacking density ranges from 980 kg / m<3> to 1030 kg / m<3>, and the apparent density ranges from 1700 kg / m<3> to 1800 kg<3>. According to the water-permeable concrete, a larger amount of the coal gangue ceramsite which is formed by sintering the byproduct coal gangue raw materials in the coal mining process is used, the water-permeable concrete is excellent in performance, high in permeation coefficient, excellent in strength, low in weight per unit volume and low in price, the requirement of the concrete for natural stone is reduced, and a positive effect on solving solid emissions and atmospheric pollution is achieved.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Method for producing potassium sulphate fertilizer by using phosphogypsum

The invention relates to the technical field of fertilizer production methods, in particular to a method for producing potassium sulphate fertilizer by using phosphogypsum. The method comprises the following steps: fully mixing 20 to 80 percent of the phosphogypsum and 20 to 80 percent of potassium feldspar powder in percentage by weight, and calcining the mixture, wherein the calcination temperature is 800 to 1,800 DEG C, and the calcination time is 2 to 120 minutes. The method has easily-obtained raw materials and low cost; and the whole process flow is smooth, simple, easy and is quite suitable for industrialized production.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

Sludge treatment and recycling method of urban sewage treatment plant

ActiveCN102320854AAvoid disadvantagesSolve the emission problemSludge treatmentCeramicwareMunicipal sewageMaterials science

The invention relates to a sludge treatment and utilization method, in particular to sludge treatment and recycling method of an urban sewage treatment plant. The method is characterized in that the resident domestic sludge of the urban sewage treatment plant is used as a raw material, and is sintered into ceramsite capable of being utilized by people through the steps of drying, stirring, granulating, sintering, breaking, dedusting and screening. By adopting the urban sludge treatment and recycling method, the defect of the urban sludge is overcome; the sludge can be treated without adding other components so that the ceramsite with high quality and high performance can be sintered; and the invention not only solves the problems of discharge and stacking of the urban sludge but also changes the waste into valuable things and ensures that the urban sludge can be continuously utilized by people.

Owner:QINGDAO YI ECO ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing oxide of bimetal and hydrotalcite by using Bayer red mud as raw material

The invention is to mix divalent metal oxide, hydroxide and red mud, then beating, drying and burning to produce divalent metal oxide which is hydrated in carbonate or bicarbonate solution to produce hydrotalcite. Said divalent oxide and hydrotalcite can be used as catalytic agent, catalytic agent carrier, infrared or ultraviolet absorbing and separating material, fire retardant and PVC stabilizer, they have strong adsorption to many harmful and poisonous negative ions.

Owner:ZHEJIANG UNIV

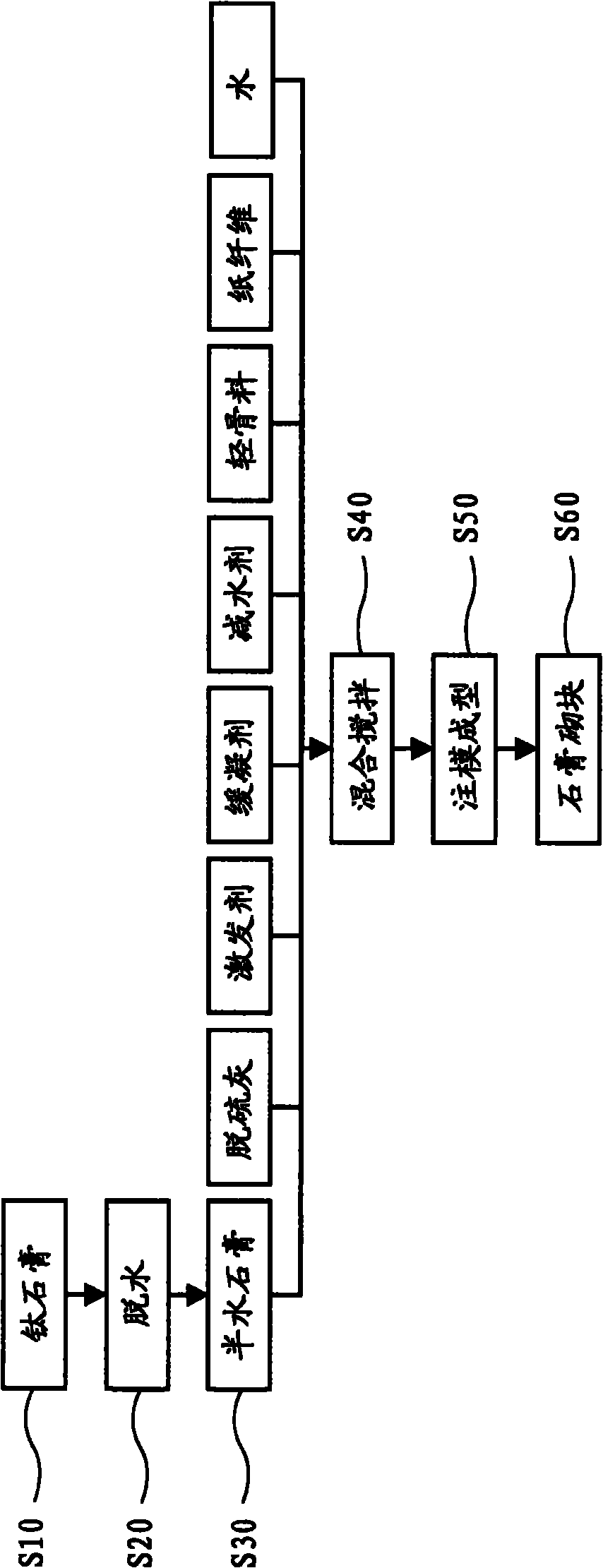

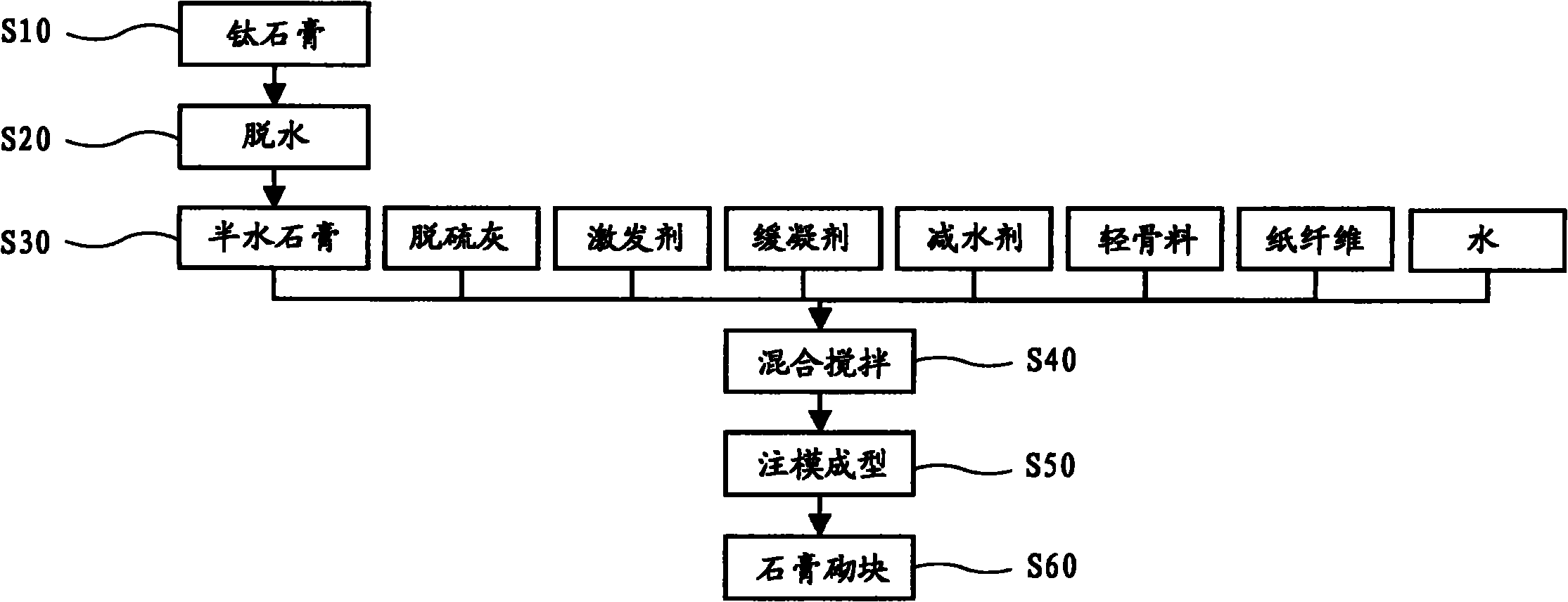

Method for preparing gypsum building block with titanium gypsum

InactiveCN101920520ASolve stacking problemsSolve pollutionSolid waste managementCeramic shaping apparatusSlurryWater reducer

The invention discloses a method for preparing a gypsum building block with titanium gypsum. The method comprises the following steps: crushing titanium gypsum to fine powder of which grain size is less than 80mu m, dewatering and drying at 180-220 DEG C; mixing the dried titanium gypsum powder, semidry FGD residues, light-weight aggregate, paper fibre, gypsum booster, retarder and water reducing agent evenly according to a certain ratio, then adding water to stir evenly; pouring the evenly mixed slurry in a standard mould, performing vibro-moulding; and performing natural curing for 2 hours, demoulding, and airing to obtain the gypsum building block. The gypsum building block prepared by the method of the invention is characterized by small volume, low density, high strength and softening coefficient and the like; and the physical performance of the prepared gypsum building block completely meets the national building material industry standard JC / T698-1998. The method for preparing the gypsum building block with titanium gypsum provided by the invention provides a new application way of titanium gypsum and solves the stacking problem of titanium gypsum and the environmental pollution problem.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

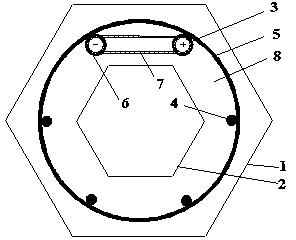

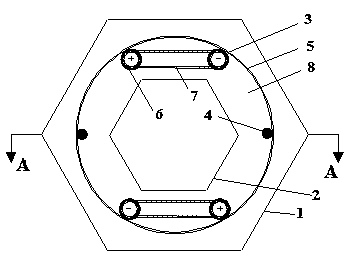

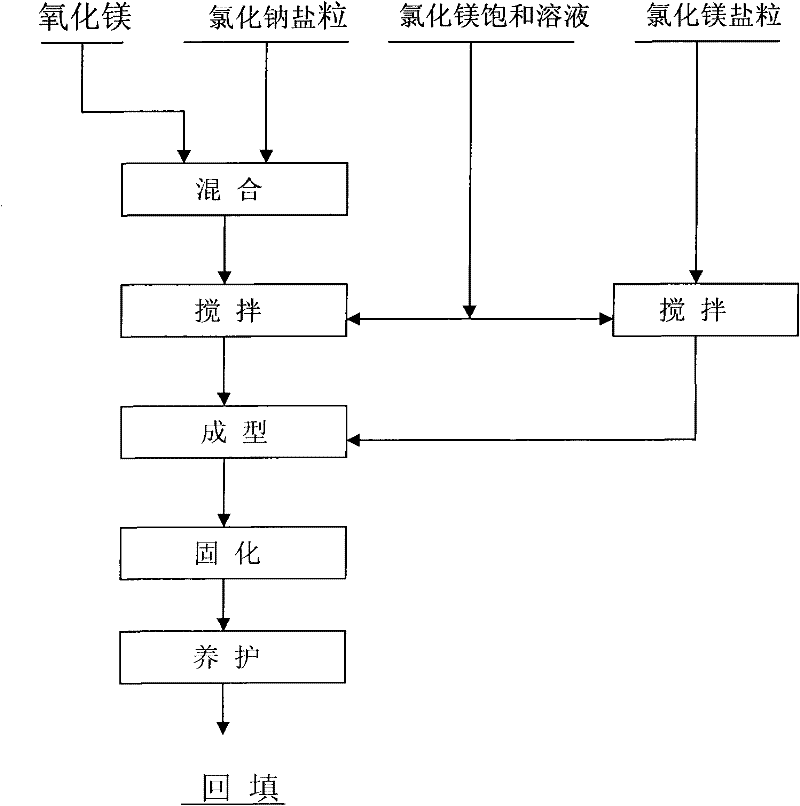

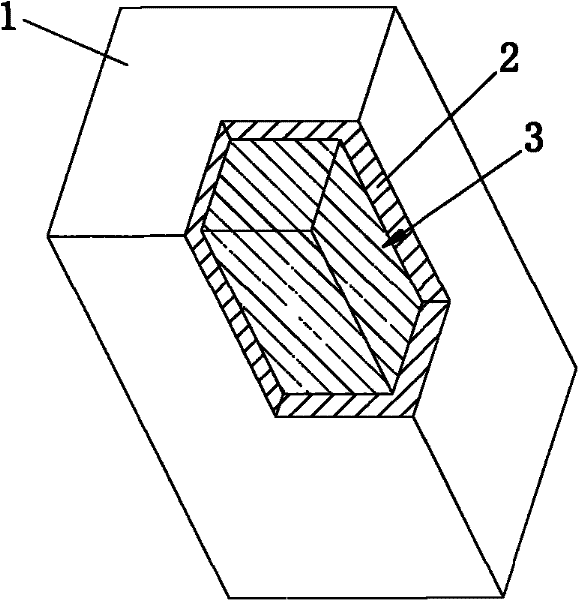

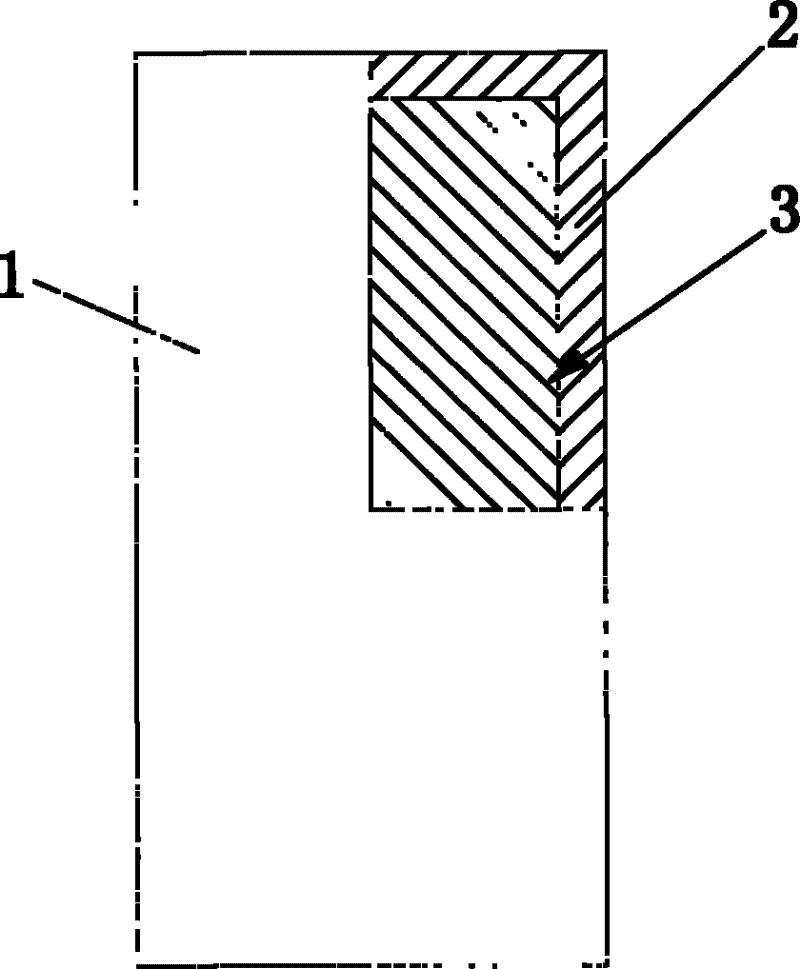

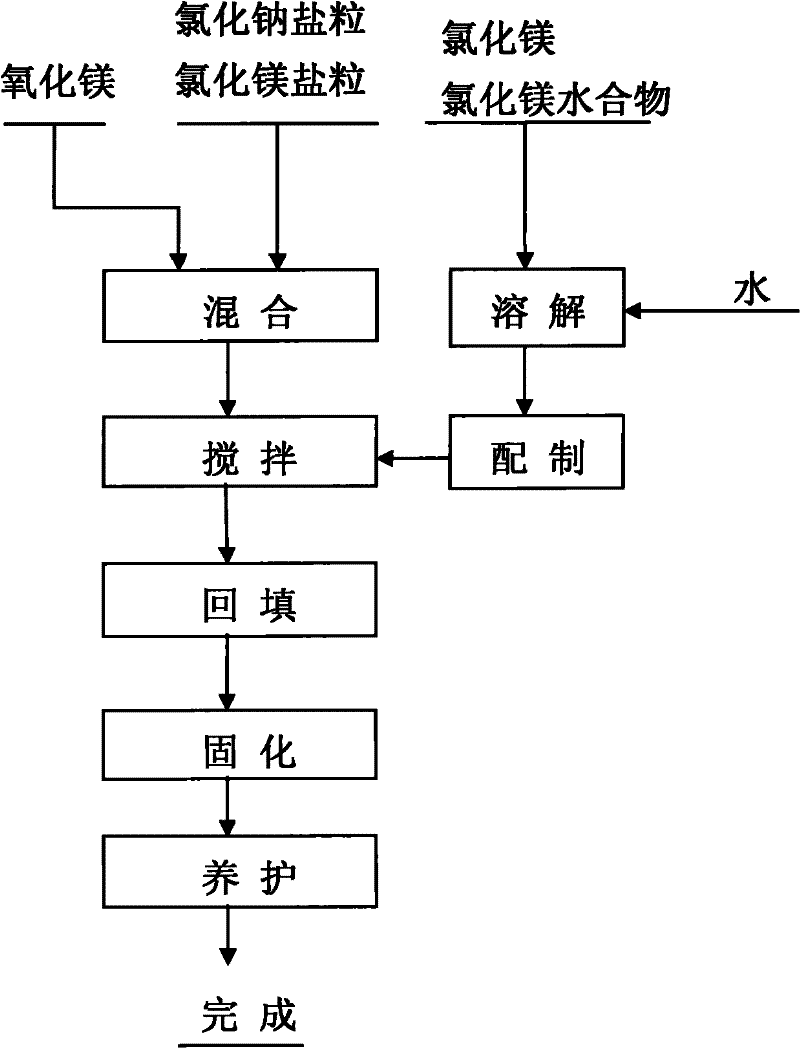

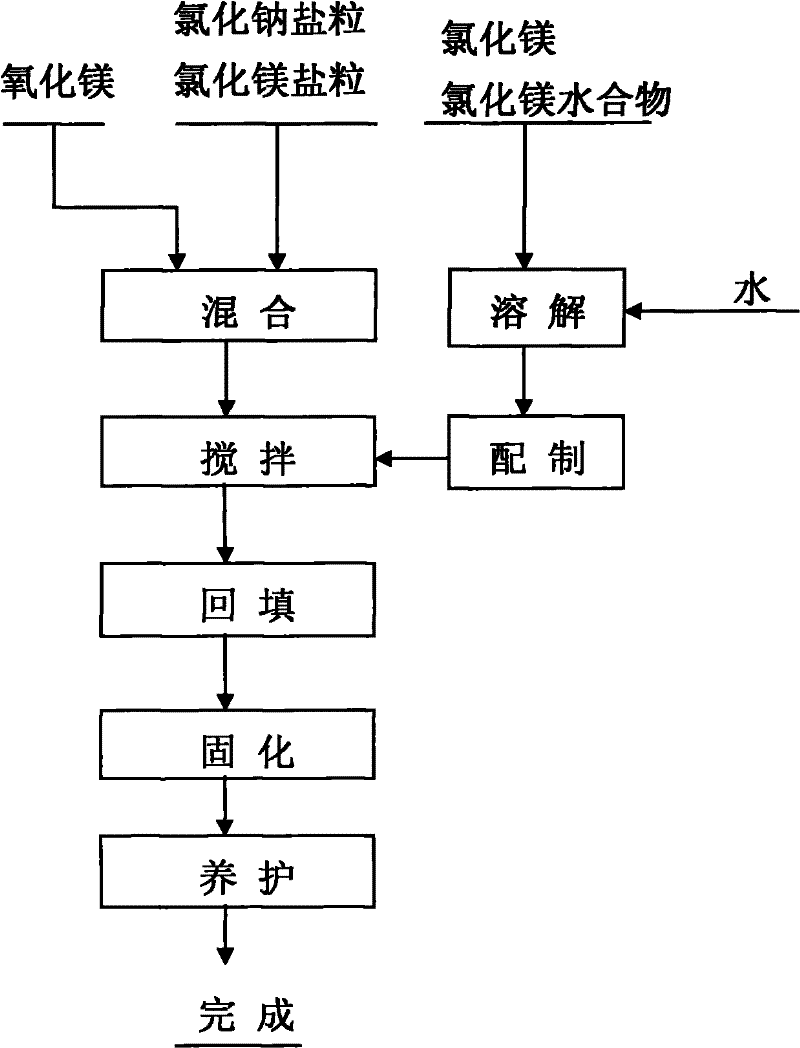

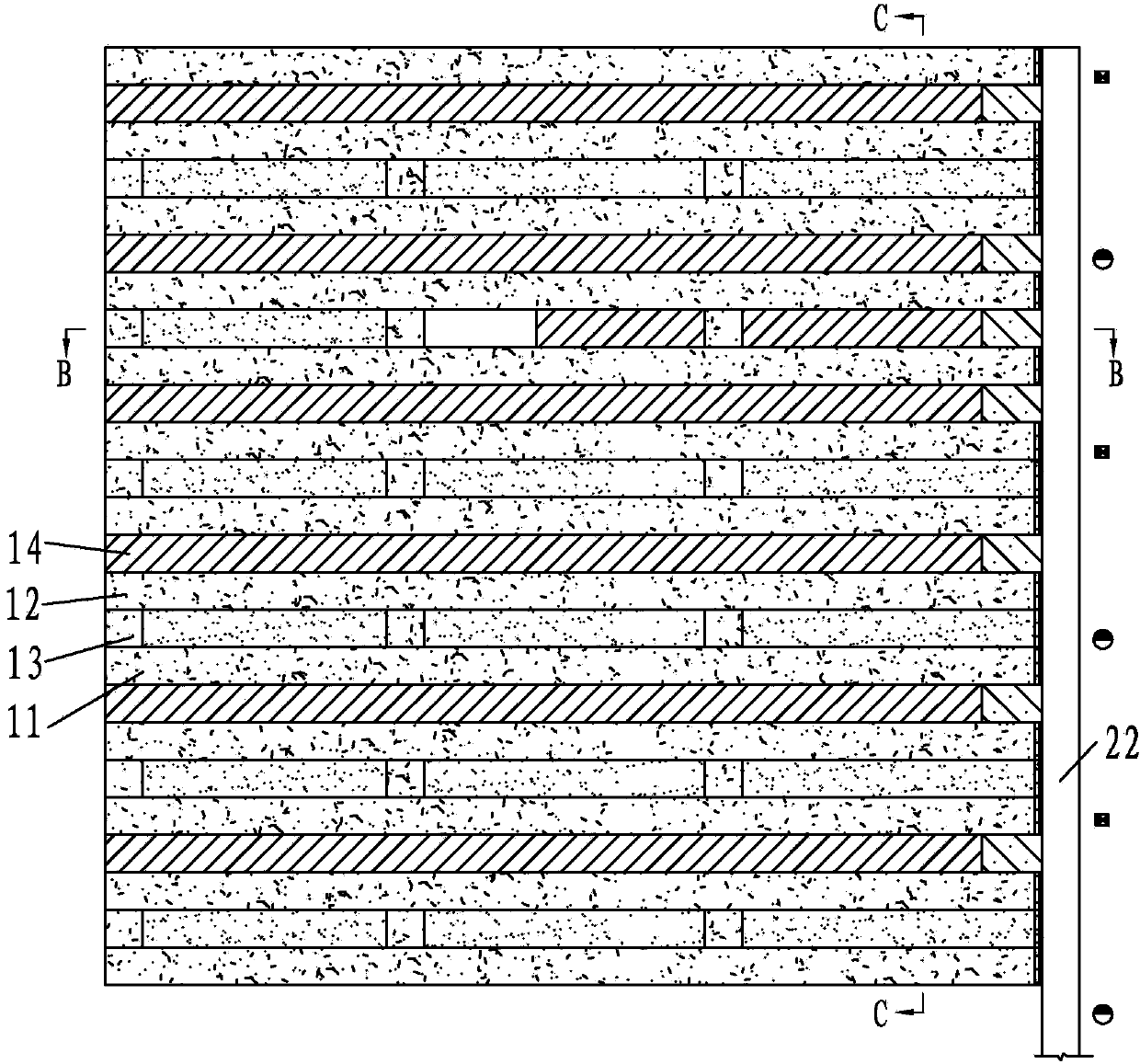

Coagulation salt block for sylvite solid mine backfilling and manufacturing method thereof

The invention relates to a sylvite solid mine backfilling technology, in particular to a manufacturing method of a coagulation salt for sylvite solid mine backfilling. The manufacturing method of the coagulation salt for the sylvite solid mine backfilling comprises the following steps of: mixing and uniformly stirring magnesium oxide, a magnesium chloride saturated solution and sodium chloride salt particles contained in tailings according to the mass ratio of 1.00:(0.80-1.20):(5.00-15.00) to form a first slurry; also mixing and uniformly stirring the magnesium chloride saturated solution and the sodium chloride salt particles according to the mass ratio of 1.00:(8.00-15.00) to form a second slurry; finally pouring the first slurry and the second slurry, carrying out press forming, and then solidifying for 12-24 hours; and conserving under the condition that environmental temperature and humidity is less than 70 percent to prepare a coagulation salt block, wherein the coagulation salt block structurally comprises an outer layer (1) and an inner core (3). The invention has simple manufacturing process, low cost and good social benefit and economic benefit, solves the problems of pollution and stack caused by the tailings on the vegetation of a surrounding environment and realizes the requirements for clean production and environmental protection.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

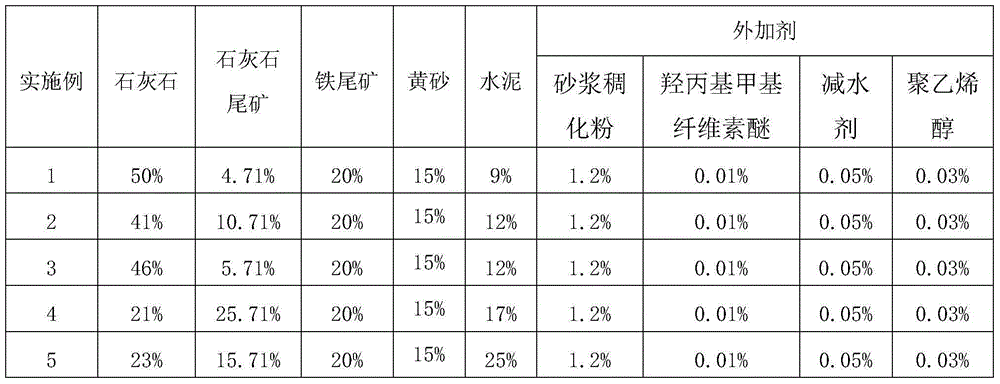

Novel dry-mixed plastering mortar

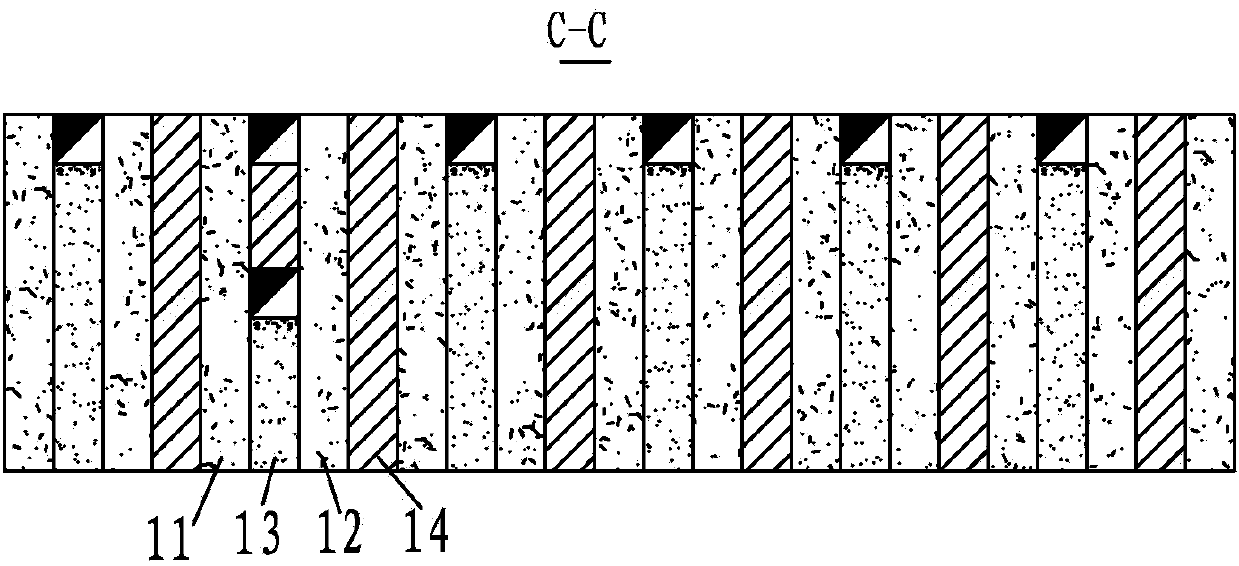

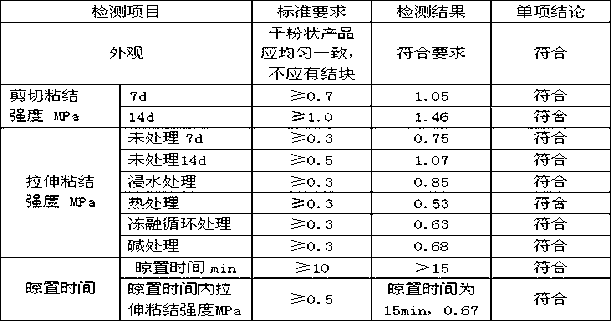

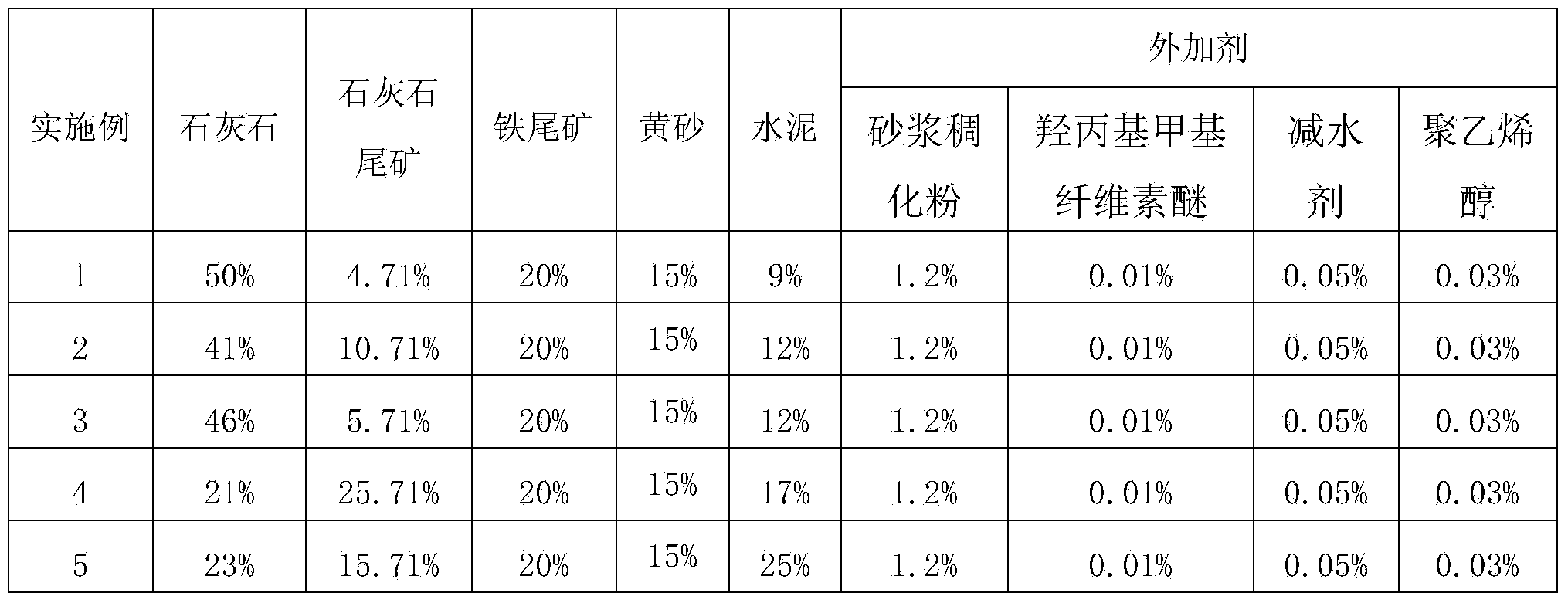

The invention relates to a novel dry-mixed plastering mortar which is composed of the following components in percentage by mass: 20-50% of limestone, 0-30% of limestone tailing, 20% of iron tailing, 15% of yellow sand, 9-25% of cement and the balance of admixture. The admixture is composed of a modifier and a thickener, wherein the modifier is one or mixture of more of cellulose ether, water reducer, air entraining agent, retarder, starch ether and polyvinyl alcohol; and the thickener is mortar thickening powder. The invention effectively utilizes the limestone tailing and iron tailing, solves the problem of placement of the limestone tailing and iron tailing, and avoids the environmental damage of the limestone tailing and iron tailing; the invention lowers the cost of the dry-mixed plastering mortar; and the produced dry-mixed plastering mortar has excellent properties and can effectively substitute natural sand.

Owner:SHAOXING YISHENG MORTAR

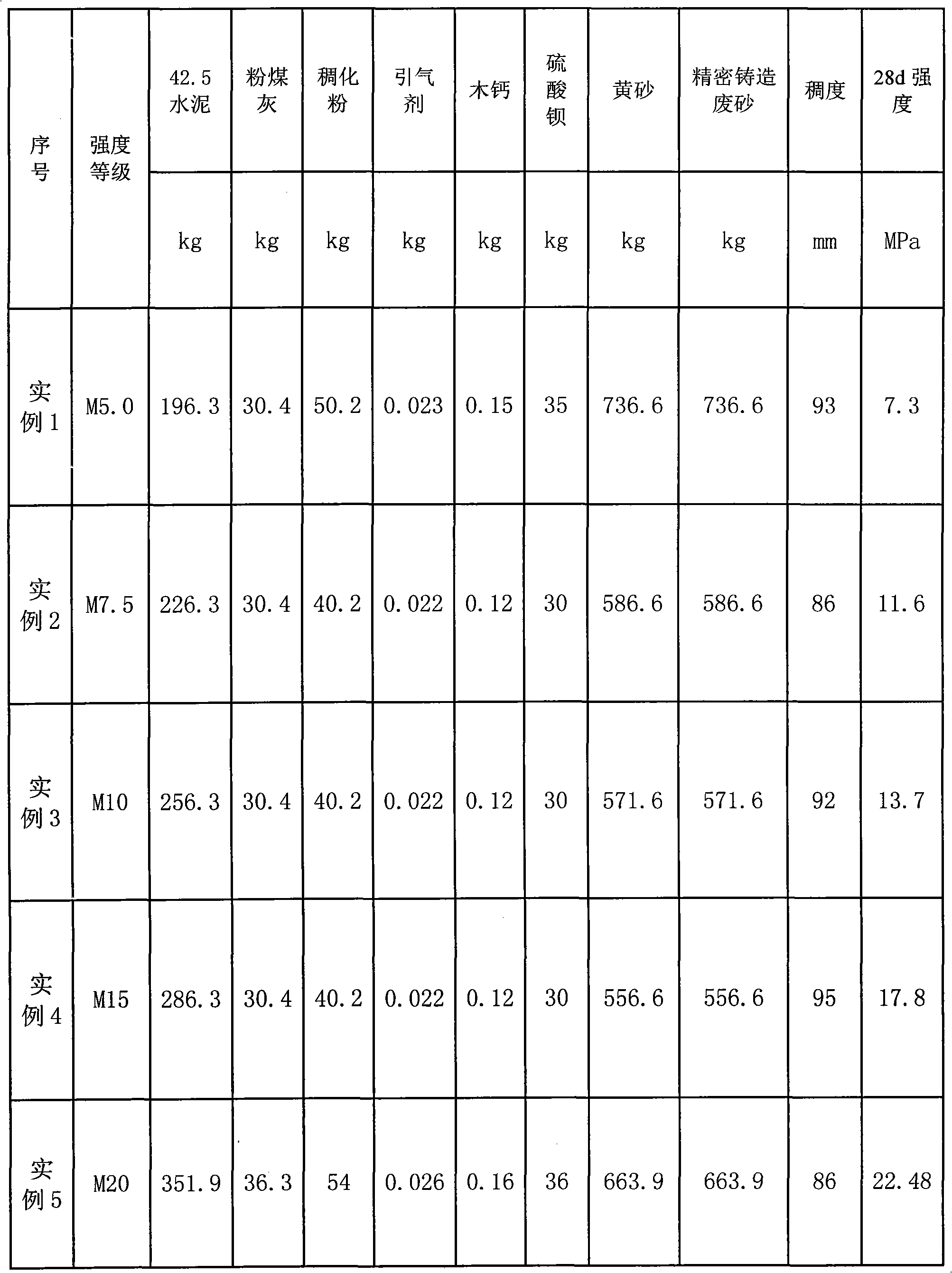

Dry powder mortar

InactiveCN101870571ALow costSolve stacking problemsSolid waste managementPulverized fuel ashPre treatment

The invention relates to the field of building materials, in particular to preparing dry powder mortar by utilizing precision casting waste sand. The dry powder mortar is prepared by mixing 13-35 percent of cement, 3-4 percent of pulverized fuel ash, 30-40 percent of yellow sand, 2.7-3.4 percent of mortar thickening powder, 0.01-4 percent of admixture, and 30-40 percent of precision casting waste sand. In the invention, the dry powder mortar is prepared on the premise of ensuring the same dry powder mortar performance through pretreating the precision casting waste sand by utilizing the precision casting waste sand as an aggregate to replace part of yellow sand. Thus, not only the stacking problem of the precision casting waste sand can be solved but also the cost of the dry powder mortar can be reduced, thereby promoting the popularization of the dry powder mortar and meeting the environmental protection policy for energy saving and emission reduction in China.

Owner:泰州枫叶冶金设备有限公司

Coagulating salt for potassium salt solid mine backfilling and manufacturing method thereof

The invention relates to a coagulating salt for potassium salt solid mine backfilling and a manufacturing method thereof. The manufacturing method comprises the following steps: 1. preparing a magnesium chloride saturated solution; 2. evenly mixing 1.00 part by mass of magnesium oxide, 0.80-1.20 parts by mass of magnesium chloride saturated solution, 1.00-15.00 parts by mass of sodium chloride particle in tailings and 1.00-12.00 parts by mass of magnesium chloride particle in tailings to form a slurry; 3. casting the slurry, and curing to form; and 4. curing at ambient temperature under the humidity of lower than 70% for 6-12 hours to obtain the coagulating salt. By manufacturing the coagulating salt with a certain strength from magnesium oxide and a great deal of tailings containing sodium and magnesium salts, the invention has the advantages of simple manufacturing process, low cost and wide sources of magnesium oxide, can maximally backfill the tailings into the mine, meets the requirement of safety in production, and solves the problem of pollution of tailings for the vegetation in the ambient environment as well as the problem of stacking of the tailings, thereby having favorable social benefit and economic benefit.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Ass bone gel

InactiveCN101869308ASolve stacking problemsReduce pollutionFood preparationHigh pressureWaste material

The invention provides ass bone gel, which is prepared from the following raw materials by weight parts according to a method comprising the following work procedures: a. firstly, carrying out coarse crushing on ass bone with cleaned surfaces, then, placing the ass bone into a container, adding water into the container for high-pressure steaming boiling or water decocting boiling, filtering obtained materials, concentrating filter liquor to obtain ass bone gel concentration liquor; and b. adding yellow wine, rock candy and bean oil into the ass bone gel liquor of the work procedure a according to a mixture ratio of ass bone gel concentration liquor / yellow wine / rock candy / bean oil=10 to 200 / 1 to 50 / 1 to 30, and then, preparing the materials into gel blocks by a conventional method. The invention reduces the environment pollution, provides a novel path for the integrated development and utilization of waste materials, changes waste materials into useful materials, and has the advantages of simple process, low cost and easy operation.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

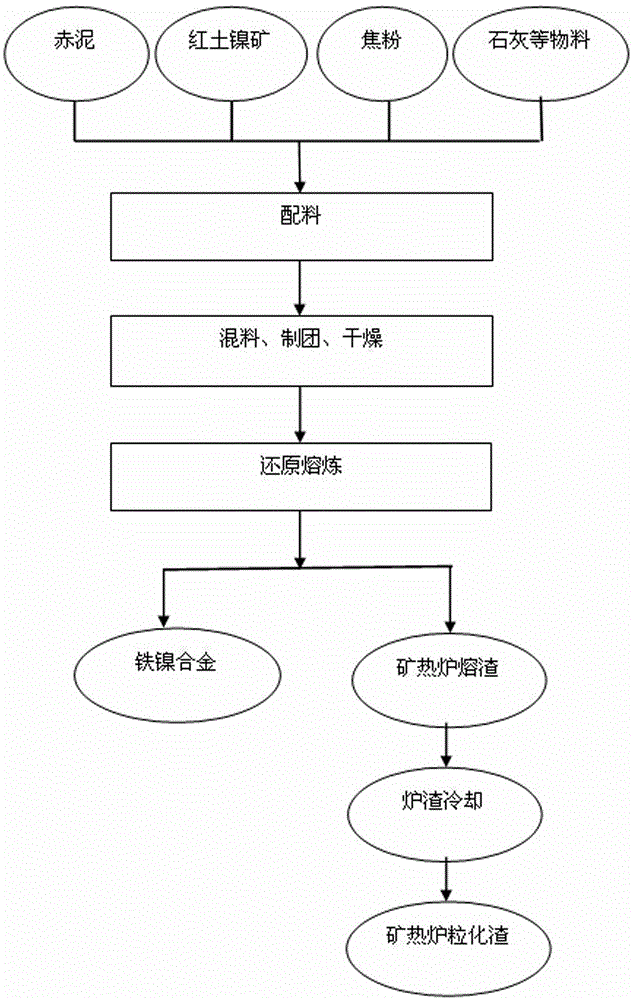

Method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore

ActiveCN106148699AHighlight substantive featuresSignificant progressProcess efficiency improvementRed mudResource utilization

The invention provides a method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore. The method is characterized by comprising the following steps that 1, proportioning is carried out, specifically, raw materials include the red mud, the nickel laterite ore, coke powder and lime; and 2, reduction smelting of a smelting electric furnace is carried out, specifically, clusters formed through the raw materials prepared in the step 1 are conveyed into the smelting electric furnace for reduction smelting, slag and iron separation is completed through slag pre-making, melting and reduction, a furnace slag layer is formed, the furnace slag is discharged out of a slag opening regularly and subjected to water quenching or air-cooling pelletization, and the active smelting electric furnace grain slag is obtained. The smelting electric furnace grain slag prepared through the method can serve as a mixed material applied in the cement production process, the cement performance is improved, the variety and labels of cement products are adjusted, and the production cost is reduced; and meanwhile, the slag can be used for producing a concrete admixture independently or by being combined with other raw concrete admixture materials, and the resource utilization of the ferronickel byproduct active smelting electric furnace grain slag prepared through the red mud and the nickel laterite ore is effectively achieved.

Owner:GUANGXI UNIV

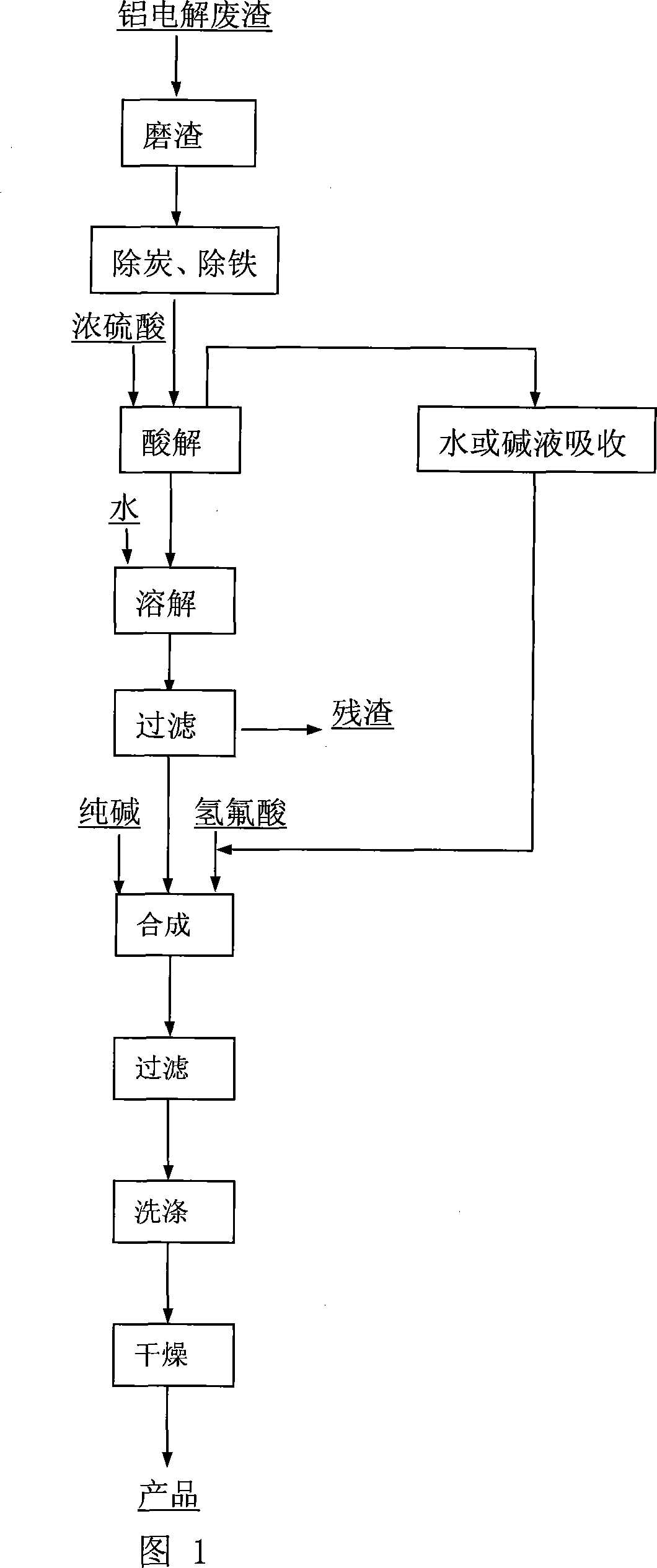

Method for producing cryolite from aluminum electrolysis waste slag

InactiveCN101239731ASolve stacking problemsReduce manufacturing costAluminium fluoridesHydrofluoric acidHydrogen fluoride

The present invention provides a method of cryolite by aluminum electrolysis waste residue, aluminium electrolysis waste residue is milled below 60-200 mesh, removing carbon, iron in waste residue, adding concentrated sulphuric acid, reacting 30-180 min under the temperature 20-90 Celsius, the prepared Hydrogen fluoride gas is absorbed by water or lye. Adding 1-20 times water of waste quality after completing, mixing 2-20 min, filtering, adding 10%-30% sodium carbonate solution or solid sodium carbonate, 10%-50% hydrofluoric acid in filtering liquid. Under the mixing condition, ice crystal stone slurry is obtained by reaction 1-3 hours under the temperature 20-95 Celsius, ice crystal stone product is obtained by filtering, washing, drying. The invention can utilize waste slag generated in aluminium electrolysis course, and has lower cost, hydrogen fluoride gas generated in the waste treating process produces ice crystal stone product for recycling use after being absorbed by water or lye.

Owner:CENT SOUTH UNIV

Production of acqueous talc from brine

Production of hydrotalcite by salt-making bittern is carried out by mixing bittern, bauxite acid dissolving or basic dissolving pulp with red mud, crystallizing, washing, and drying to obtain hydrotalcite. It can be used as catalyst and catalyst carrier in chemical field, as infrared or ultraviolet absorbing material in functional material field,etc., and sewage treatment and pollution prevention. It achieves simple process and low cost.

Owner:ZHEJIANG UNIV

Novel self-thermal-insulation sintered bricks containing building wastes and production method of novel self-thermal-insulation sintered bricks

InactiveCN106116514ALow costStable performanceCeramic materials productionClaywaresThermal insulationScrap

The invention relates to novel self-thermal-insulation sintered bricks containing building wastes and a production method of the novel self-thermal-insulation sintered bricks. The self-thermal-insulation sintered bricks comprise, by weight, 20-50 parts of building wastes, 30-65 parts of project waste soil and 20-50 parts of coal cinder. The novel self-thermal-insulation sintered bricks have the advantages that the bricks produced by living and production wastes are low in cost, environment problems and the problem of waste stacking are solved, the self-thermal-insulation sintered bricks conform to the standards of GB26538-2011 Sintered Thermal-insulation Bricks and Thermal-insulation Building Blocks, and the bricks are stable in performance, good in thermal insulation effect, high in yield, good in market value and worthy of wide-range popularization.

Owner:福鼎市利民城市建筑垃圾处理有限公司

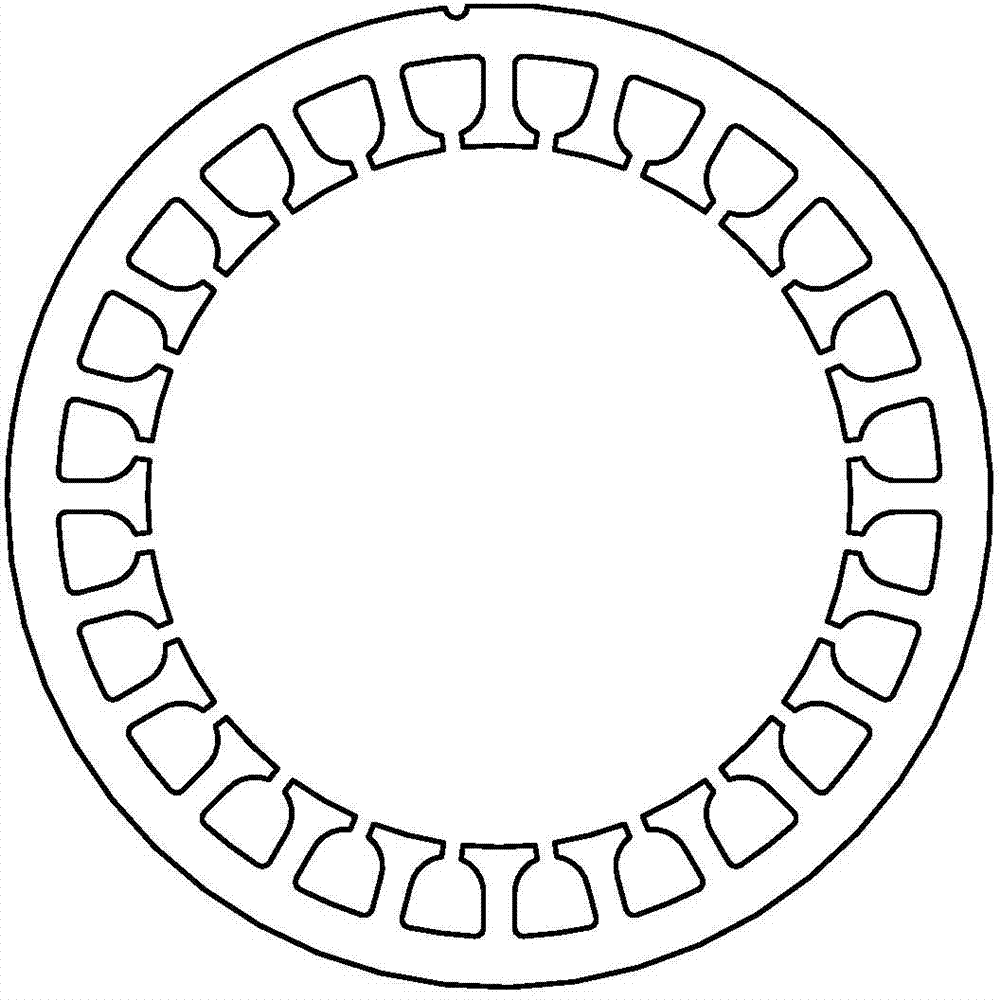

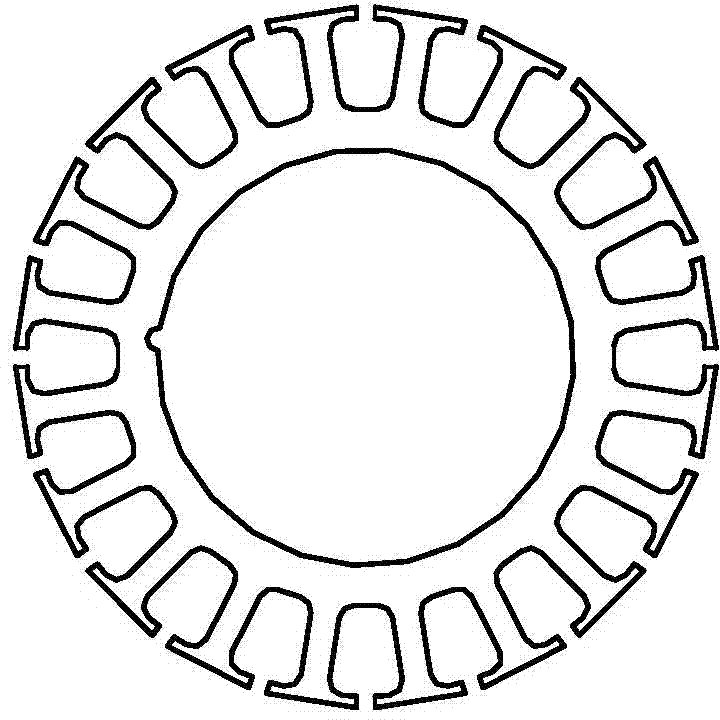

Motor iron core manufacturing method

ActiveCN104734431AImprove electrical accuracyImprove product qualification rateManufacturing stator/rotor bodiesElectrophoresisCoolant

The invention provides a motor iron core manufacturing method. The manufacturing method is characterized by comprising the following steps that 1, iron core punching sheets are machined and formed according to outline dimensions; 2, the iron core punching sheets are subjected to magnetic performance treatment; 3, electro-coating is conducted; 4, semi-curing treatment is conducted; 5, stack mounting is conducted; 6, complete curing treatment is conducted. According to the manufacturing method, the iron core punching sheets are subjected to electro-coating; electrophoresis paint is subjected to semi-curing treatment based on the character that the electrophoresis paint can be semi-cured; after the punching sheets are stacked, the electrophoresis paint is completely cured, and punching sheets are bonded firmly after curing is finished. By means of the manufacturing method, the problem existing when motor iron cores are stacked in coolant media is solved, the possible influence of adhesive application and machining stress on the motor performance is avoided, the electric accuracy of a rotary transformer is improved, and the qualified rate of products is increased by 50% or more.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

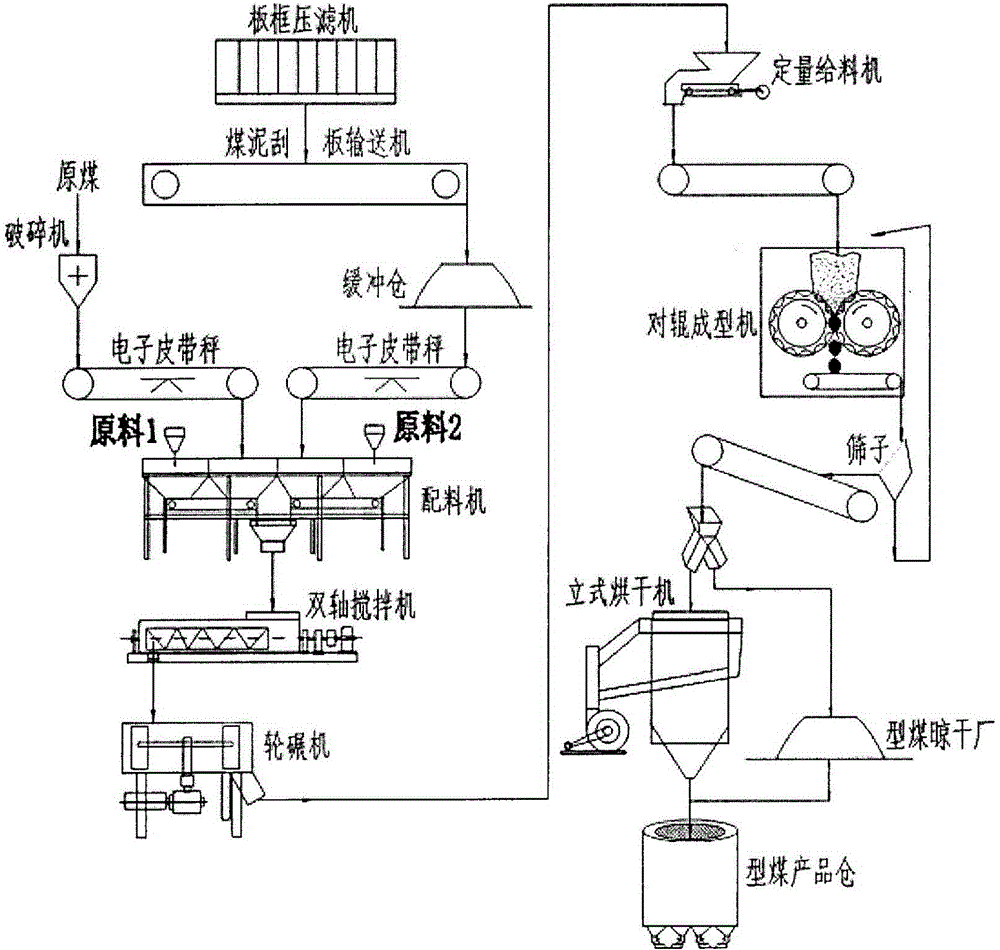

Process of directly forming and utilizing coal slime of coal cleaning plant

The invention discloses a process of directly forming and utilizing coal slime of a coal cleaning plant. The process comprises the following steps: directly transporting the coal slime from a filter-pressing workshop of the coal cleaning plant to a dosing machine; adding a certain amount of raw coal and an adhesive in percentage by mass; adopting a double-roller forming machine or a screw extruder to form after stirring and uniformly mixing. According to the process disclosed by the invention, the filter-pressing coal slime is not needed to be dried, and can be directly transported to a forming site, so that the coal slime is prevented from occupying land and being polluted. The forming process is simple, a briquette coal product is good in mechanical strength, so that the calorific value of the coal slime briquette coal can be adjusted by matching with the raw coal, and therefore, the use requirements of different users are satisfied. The process disclosed by the invention can be used for effectively solving the problems that the coal slime of the coal cleaning plant is in excess of demand, occupies land, and is polluted.

Owner:HENAN POLYTECHNIC UNIV

Pillar pre-isolation sublevel stick-filling mining method and ore body therefor

InactiveCN103590832ALarge amount of oreIncrease productivityUnderground miningSurface miningEngineering

The invention discloses a pillar pre-isolation sublevel stick-filling mining method and an ore body therefor. The pillar pre-isolation sublevel stick-filling mining method comprises the following steps of 1, dividing the whole mining area into multiple zones, dividing each one of the zones into a step-I stick chamber, a step-III stick pillar, a step-II stick chamber and a step-IV stick pillar orderly arranged along an ore growth direction, and 2, orderly carrying out stoping on the step-I stick chamber, the step-II stick chamber, the step-III stick pillar and the step-IV stick pillar, wherein the same-step stick stopes in all the zones are stoped simultaneously. The pillar pre-isolation sublevel stick-filling mining method has the advantages of low mining cost and high production efficiency.

Owner:SHANDONG SHENGDA MINING

Preparation method of light-weighted autoclaved unburned block

ActiveCN101804659ALow densityHigh strengthCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention relates to a preparation method of a light-weighted autoclaved unburned block, which relates to the integrated utilization of a solid waste. Aerated concrete block waste is crushed into aggregate; dry FGD is mixed with the aggregate, added with water during the stirring and formed, to prepare an adobe; and the adobe is sent into steam to be cured, to prepare the light-weighted autoclaved unburned block. The preparation method of the light-weighted autoclaved unburned block has small finished product density, high strength and lighter weight, realizes the 'zero emission' of the dry FGD in a dry desulfurization process, solves the problem of enterprise product waste piling of the aerated concrete block, and reduces piling sites; the compressive strength and the flexural strength of the unburned block exceed the standard of a national autoclaved lime sand brick superior product; the weight of the produced autoclaved unburned block is 20 percent less than that of the traditional clay brick and autoclaved sand-lime brick on the basis of reaching all strength standards of the traditional red brick; no secondary pollution is produced, and the integrated utilization of resources is realized; and the process is simple, and the investment and treatment cost is low. The preparation method of the light-weighted autoclaved unburned block is universal.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

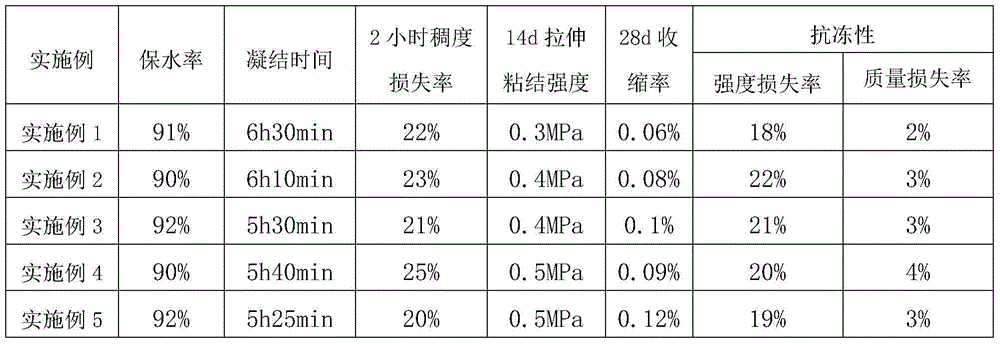

Interface mortar for autoclaved aerated concrete

InactiveCN103102127ALow costAvoid destructionSolid waste managementAutoclaved aerated concreteMaterials science

The invention discloses interface mortar for autoclaved aerated concrete. The interface mortar consists of the following components in percentage by mass: 42% of cement, 28.1-44.96% of yellow sand, 11.24-28.1% of tailing iron sand, and 1.8% of additive. With the adoption of the interface mortar for autoclaved aerated concrete disclosed by the invention, the tailing iron sand replaces a part of yellow sand as aggregate to prepare the interface mortar for autoclaved aerated concrete under the premise of ensuring the same property of the interface mortar for the autoclaved aerated concrete, thus not only the stacking problem of the tailing iron sand is solved, but also the cost of the interface mortar for the autoclaved aerated concrete is reduced; and meanwhile, the environment damage caused by the tailing iron sand is avoided as well.

Owner:SHAOXING YISHENG MORTAR

Heat-preservation and energy-saving bricks made from Taihu silt and preparation method for bricks

InactiveCN105016709ASolve cleanupSolve stacking problemsCeramic materials productionClaywaresBrickShock resistance

The invention discloses heat-preservation and energy-saving bricks made from Taihu silt. The bricks comprise the following raw materials in percentage by weight: 25 to 45 percent of Taihu silt, 1 to 20 percent of illite, 1 to 15 percent of kaolin, 10 to 20 percent of waste clinker, 1 to 10 percent of quartz, 5 to 20 percent of feldspar, 1 to 5 percent of a dry-blend and 3 to 8 percent of water. The preparation method for the heat-preservation and energy-saving bricks comprises the following steps of preparing the Taihu silt; weighing the raw materials in percentage by weight, and rolling and kneading the raw materials into uniform clay strips; performing vacuum extrusion forming to obtain wet blanks, wherein the forming pressure is 2.0 to 4.0MPa; drying the wet blanks for 2 to 4 hours at 100 to 200 DEG C to obtain dried blank bodies; firing the dried blank bodies for 3 to 20 hours at firing temperature of 1,000 to 1,200 DEG C to obtain heat-preservation and energy-saving brick finished products. According to the heat-preservation and energy-saving bricks, the Taihu silt is effectively cleaned and stacked, and the fired products have the characteristics of heat preservation, waterproofness, shock resistance, durability and the like.

Owner:宜兴市浦发陶瓷厂

Aluminium-silicon carbide-carbon refractory material

The alumina-silicon carbide-carbon refractory material includes alumina, silicon carbide and graphite on the carrier of bauxite, brown corundum and white corundum. The present invention features that waste furnace lining is crushed and impurity eliminated to obtain recovered material, which is used to replace partial new material of bauxite, brown corundum and white corundum. The added amount of the recovered material is based on the total alumina content in the refractory material not more than 30 %, and the recovered material has grain size up to 8 mm and water content not higher than 0.5 %. The present invention solves the technological problem of using partial waste alumina-silicon carbide-carbon brick to replace new material while ensuring the normal campaign life.

Owner:上海盛江特种耐火材料有限公司 +1

Novel dry-mixed plastering mortar

The invention relates to a novel dry-mixed plastering mortar which is composed of the following components in percentage by mass: 20-50% of limestone, 0-30% of limestone tailing, 20% of iron tailing, 15% of yellow sand, 9-25% of cement and the balance of admixture. The admixture is composed of a modifier and a thickener, wherein the modifier is one or mixture of more of cellulose ether, water reducer, air entraining agent, retarder, starch ether and polyvinyl alcohol; and the thickener is mortar thickening powder. The invention effectively utilizes the limestone tailing and iron tailing, solves the problem of placement of the limestone tailing and iron tailing, and avoids the environmental damage of the limestone tailing and iron tailing; the invention lowers the cost of the dry-mixed plastering mortar; and the produced dry-mixed plastering mortar has excellent properties and can effectively substitute natural sand.

Owner:SHAOXING YISHENG MORTAR

Preparation method of sintered water permeable brick

InactiveCN103332924AEfficient use ofSolve stacking problemsCeramicwareClaywaresEcological environmentBrick

The invention discloses a preparation method of a sintered water permeable brick. The method comprises the following steps of: pre-processing raw materials, drying, crushing and pelleting, adding caking powder to manufacture mixed powder, compression moulding, and finally sintering, wherein the main raw material is sludge in Taihu Lake, and the pre-processing comprises the following steps of: a, excavating the sludge in Taihu Lake, drying and crushing the sludge, sieving in a 40-mesh sieve; b, sufficiently mixing 50-10wt% of sludge in Taihu Lake, 0-30wt% of bauxite, 0-20wt% of lithium feldspar in proportion, adding water, manufacturing the uniformly mixed pug with water content of 10-20wt%, pelleting by using a pelleting machine, wherein the granularity is 4-24 meshes; c, after moulding the particle, drying and then sintering, wherein the sintering temperature is 850-1200 DEG C, and the sintering time is 180min. By specially pre-processing the sludge in Taihu Lake, the subsequent pressing and high-temperature sintering can be performed to manufacture the water permeable brick, the water permeable brick is high in strength, and high in water permeable speed; and the dual purposes of recycling the sludge in Taihu Lake and improving the urban ecological environment is realized.

Owner:JIANGSU CN ECO MATERIALS CO LTD

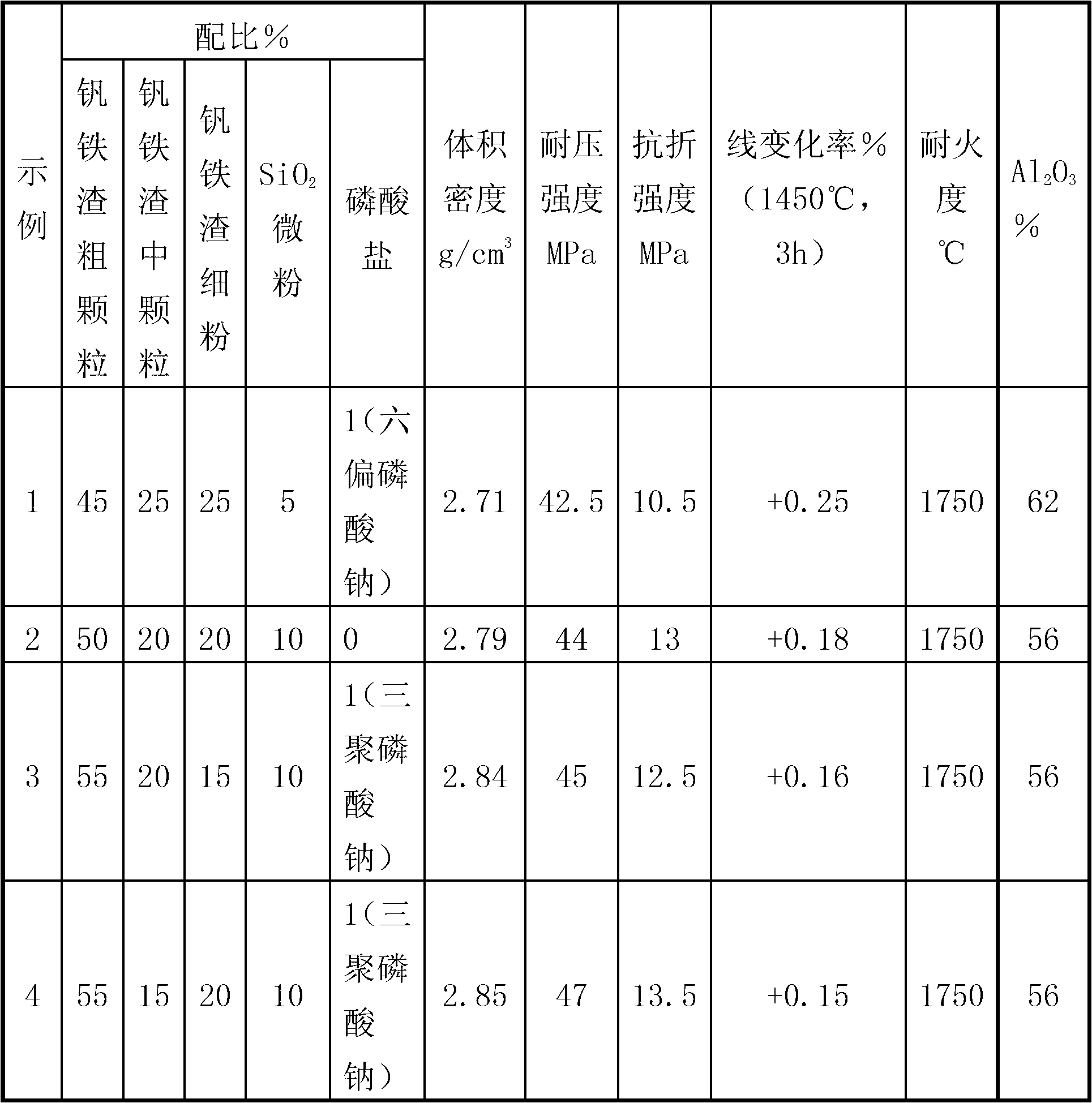

Baking-free fireproofing brick and preparation method thereof

The invention discloses a baking-free fireproofing brick. The baking-free fireproofing brick comprises the following components in percentage by weight: 90-95% of vanadium iron slag, 5-10% of SiO2 micropowder and the balance of of phosphate, wherein the total mass of the vanadium iron slag and SiO2 are 100 parts; and the mass of phosphate is 0-14% of the total mass of the SiO2 micropowder. The invention also discloses a method of preparing the baking-free fireproofing brick. The method comprises the following steps of: A, preparing the vanadium iron slag, the SiO2 micropowder and the phosphate according to a predetermined proportion; B, adding water in the prepared materials and uniformly mixing, and performing compression moulding to obtain a brick blank; and C, after curing the brick blank at a temperature of 18-25 DEG C and a moisture condition of 85%-95%, and drying, thereby obtaining the baking-free fireproofing brick. The method provides a novel path of comprehensively using the vanadium iron slag, solves the problems of stacking and pollution of the vanadium iron, effectively uses waste slag resources, and is energy-saving and environment-friendly.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

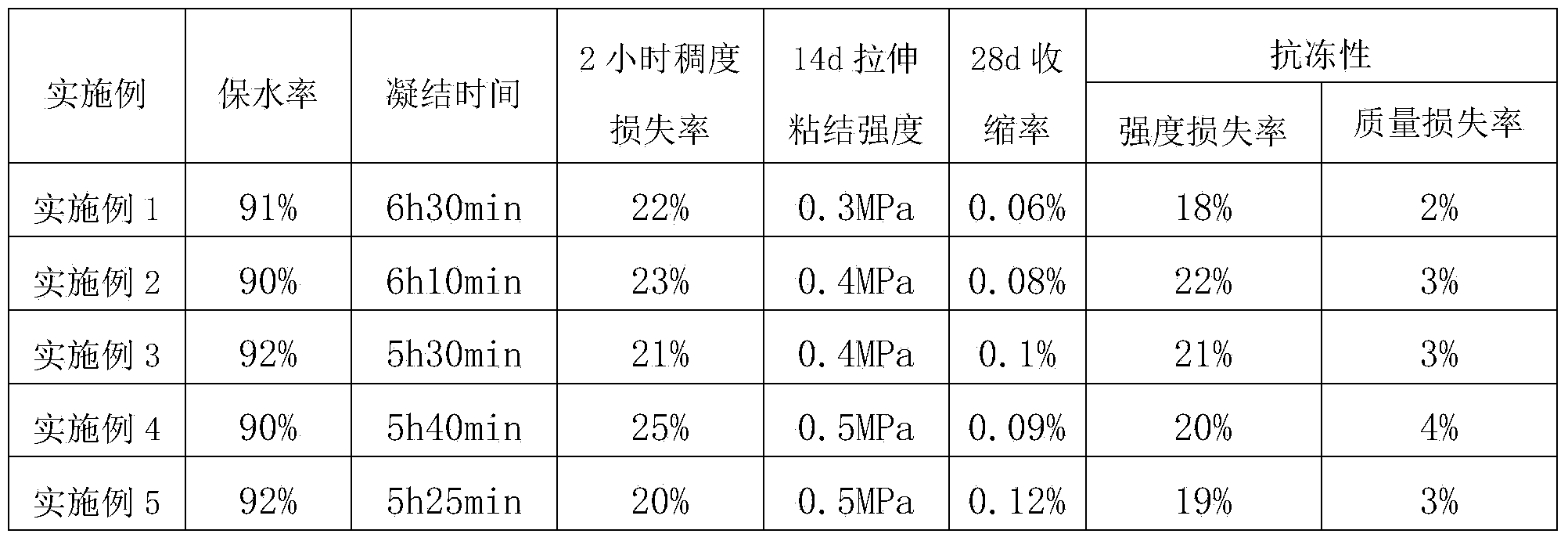

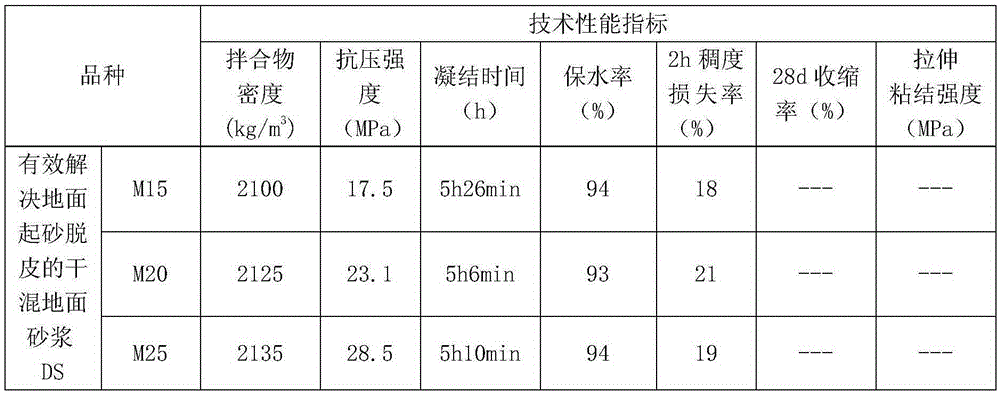

Dry mixed ground mortar for effectively solving dusting and peeling of ground and preparation method for dry mixed ground mortar

The present invention relates to the technical field of premixing mortar, particularly dry mixed ground mortar for effectively solving dusting and peeling of a ground. The mortar comprises the following components in percentage by mass: 40%-60% of limestone rock machine-made sand, 20%-30% of yellow sand, 3%-7% of coal ash, 15%-21% of cement and the balance of an additive, wherein the additive is a modifying agent and a thickening agent; the modifying agent is one of or a mixture of cellulose ether, an air entraining agent or a water reducing agent.

Owner:浙江兆山建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com