Method for producing cryolite from aluminum electrolysis waste slag

A technology of aluminum electrolysis and cryolite, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of affecting current efficiency, limited scale, high cost of aluminum profiles, etc., and achieve economic benefits, low production costs, and solve stacking problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

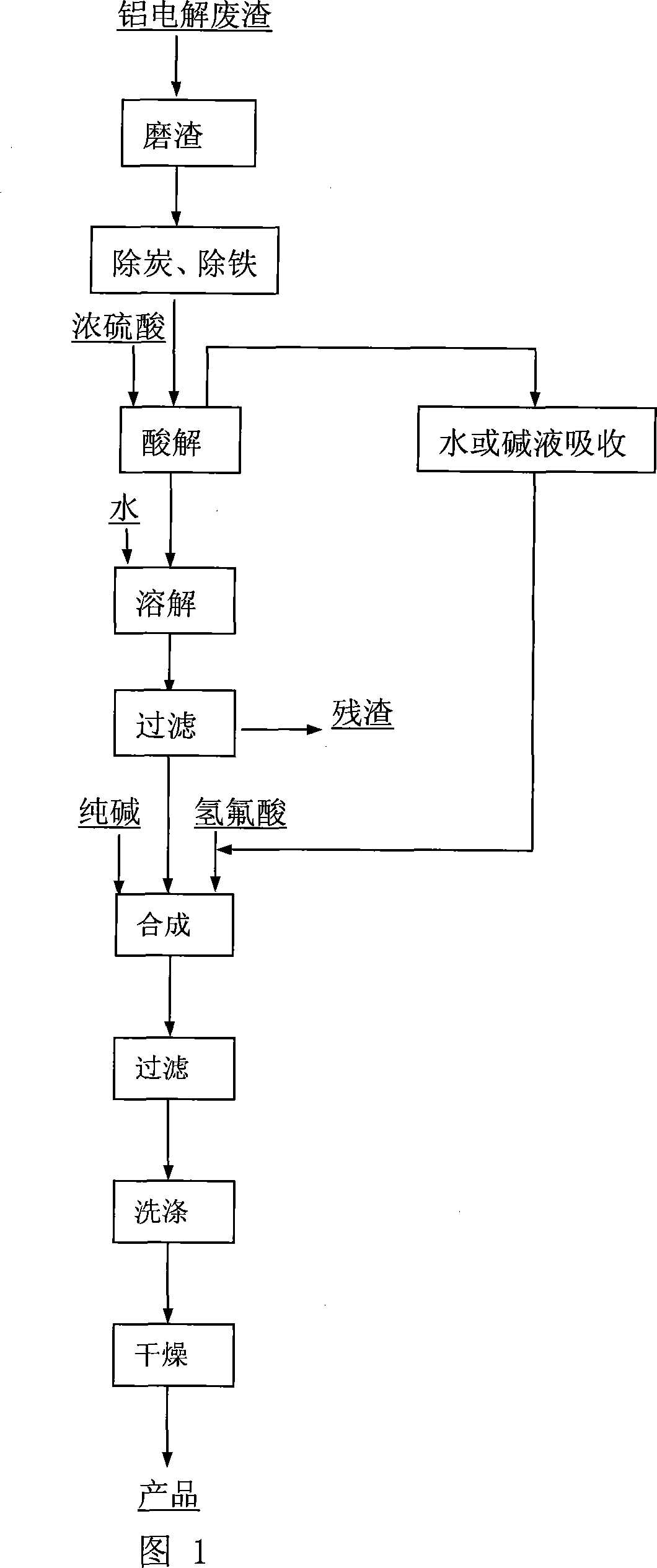

Image

Examples

example 1

[0008] Take 16kg of aluminum electrolysis waste residue, wet or dry grind it to below 60 mesh, after removing carbon and iron, put the treated waste residue into the reactor, add 8kg of concentrated sulfuric acid, start stirring and react at 25°C for 160min, the reaction The hydrogen fluoride gas generated is absorbed with water, and 30kg of water is added to the waste residue after acid hydrolysis, stirred for 2 minutes, and the residue is removed by filtration. The filtrate was put into the reactor, and 20% Na was slowly added under stirring condition. 2 CO 3 3.5kg of solution and 6kg of 30% hydrofluoric acid were reacted at a reaction temperature of 95°C for 1.2h to obtain a cryolite slurry, which was filtered and washed with a disc vacuum filter, and dried by air flow at 140°C to obtain a cryolite product 3.4kg.

Embodiment 2

[0010] Take 16kg of aluminum electrolysis waste residue, wet or dry grind it to below 150 mesh, after removing carbon and iron, put the treated waste residue into the reactor, add 12kg of concentrated sulfuric acid, start stirring and react at 60°C for 90min, the reaction The generated hydrogen fluoride gas was absorbed with NaOH solution, and 60 kg of water was added to the waste residue after acid hydrolysis, stirred for 5 minutes, and the residue was removed by filtration. The filtrate was put into the reactor, and 20% Na was slowly added under stirring condition. 2 CO 3 4.2kg of solution and 5.5kg of 40% hydrofluoric acid were reacted at a reaction temperature of 80°C for 2 hours to obtain a cryolite slurry, which was filtered and washed by a disc vacuum filter, and dried by air flow at 160°C to obtain a cryolite product 4.0kg.

Embodiment 3

[0012] Take 16kg of aluminum electrolysis waste residue, wet or dry grind it to below 200 mesh, after removing carbon and iron, put the treated waste residue into the reactor, add 15kg of concentrated sulfuric acid, start stirring and react at 80°C for 60min, the reaction The hydrogen fluoride gas produced is Na 2 CO 3 After absorbing the solution, add 100kg of water to the waste residue after acid hydrolysis, stir for 10 minutes, and filter to remove the residue. The filtrate was put into the reactor, and 20% Na was slowly added under stirring condition. 2 CO 3 4.6kg of solution and 6kg of 40% hydrofluoric acid were reacted at a reaction temperature of 50°C for 2.5h to obtain cryolite slurry, which was centrifugally filtered and washed by a centrifuge, and dried in a rotary kiln at 200°C to obtain cryolite product 4.4 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com