Patents

Literature

45 results about "Bifluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The bifluoride ion is an inorganic anion with the chemical formula HF⁻₂.

Benign method for etching silicon dioxide

InactiveUS6048406ADecorative surface effectsSemiconductor/solid-state device manufacturingHydrofluoric acidHydrogen

Traditionally, hydrofluoric acid (HF) or buffered bydrofluoric acid (NH4F) is mixed with water to form a etching solution for cleaning silicon dioxide from semiconductor wafer surfaces. An etching solution formed by mixing ammonium hydrogen bifluoride ((NH4)HF2) with water provides a benign alternative for cleaning silicon dioxide.

Owner:TEXAS INSTR INC

Process for production of etching or cleaning fluids

InactiveUS20060178282A1Good storage stabilityEasy to produceDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrogen fluorideHydroxylamine

A method for producing an etching or cleaning solution comprising (1) at least one member selected from the group consisting of fluoride salts and bifluoride salts formed from at least one member selected from the group consisting of ammonia, hydroxylamines, aliphatic amines, aromatic amines, aliphatic quaternary ammoniums and aromatic quaternary ammoniums with hydrofluoric acid; (2) at least one heteroatom-containing organic solvent; and (3) water, the method comprising the steps of: Step 1: mixing an aqueous hydrofluoric acid solution with at least one heteroatom-containing organic solvent, and Step 2: mixing the mixture obtained in Step 1 with at least one member selected from the group consisting of ammonia, hydroxylamines, aliphatic amines, aromatic amines, aliphatic quaternary ammoniums, aromatic quaternary ammoniums, and fluorides thereof.

Owner:DAIKIN IND LTD

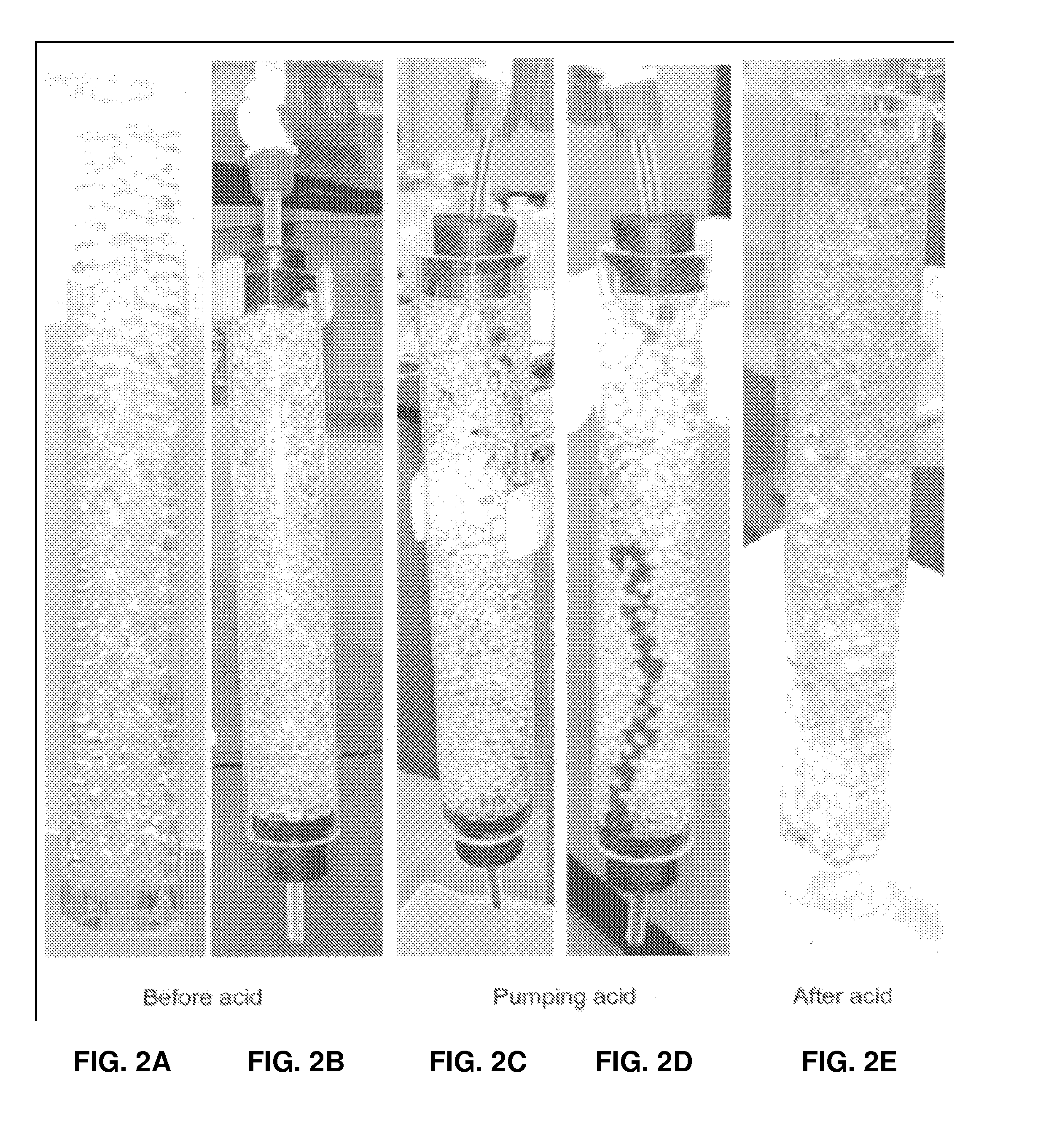

Methods of underground formation consolidation

Unconsolidated formation sand in the near wellbore region may be uniformly consolidated using a system including a sodium silicate solution and a hardener, such as at least one dialkyl ester of a dicarboxylic acid. Subsequently, a low concentration acid, such as hydrofluoric (HF) acid, is pumped through and into the consolidated sand to create channels or passageways to connect the formation hydrocarbons with the wellbore for production of the hydrocarbons through the wellbore. Hydrofluoric acid may be generated in situ by hydrolyzing a substance to hydrofluoric acid where the substance may include ammonium bifluoride, ammonium fluoride, alkali metal fluorides, alkali metal bifluorides, transition metal fluorides, and the like, and mixtures thereof. The acid may instead or additionally include organic acids and other mineral acids.

Owner:SUPERIOR ENERGY SERVICES LLC

Highly selective silicon oxide etching compositions

InactiveUS7192860B2Maximize dehydrationMinimize amide formationDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrofluoric acidSilicon oxide

Silicon oxide etching solutions containing the product of at least one bifluoride source compound dissolved in a solvent consisting of at least one carboxylic acid, and further comprising from about 0.5 to about 3 percent by solution weight of hydrofluoric acid and from about 1 to about 5 percent by solution weight of water, wherein the total concentration of bifluoride source compound is between about 1.25 and about 5.0 moles per kilogram of solvent. Methods for selectively removing silicon oxides and metal silicates from metal surfaces are also disclosed.

Owner:HONEYWELL INT INC

Processes for preparing fluoroarenes from haloarenes

Processes for preparing fluoroarenes are provided. The processes include contacting a compound having an unactivated aryl group with a source of fluoride or bifluoride in the presence of a transition metal a ligand.

Owner:EI DU PONT DE NEMOURS & CO

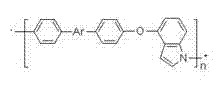

Preparation method of soluble heat-resistant polymer based on benzpyrole skeleton

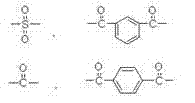

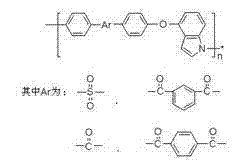

InactiveCN103087316AGood nucleophilic substitution activityImprove solubilitySulfolanePolymer science

The invention relates to a preparation method of a soluble heat-resistant polymer based on a benzpyrole skeleton. The structural general formula of the polymer is shown in the specification. The preparation method comprises the steps of taking aromatic bifluoride of different structures and 4-oxyindole as monomer and N-methyl pyrrolidone as a solvent, and heating under condition of existence of potassium carbonate so as to obtain soluble heat-resistant polymer of different structures based on the benzpyrole skeleton. The polymer prepared by the method has higher glass transition temperature and thermal decomposition temperature, excellent mechanical property, simple operation processes and lower preparation cost, furthermore, the polymer has good dissolving property and can be dissolved in the N-methyl pyrrolidone, N,N-dimethylformamide, N,N-dimethylacetamide, sulfolane, dimethyl sulfoxide and chloroform.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Silicon oxide etching compositions with reduced water content

InactiveUS20030235986A1Semiconductor/solid-state device manufacturingSurface treatment compositionsCarboxylic acidSilicon oxide

Silicon oxide etching solutions consisting essentially of the product of at least one bifluoride source compound dissolved in a solvent consisting of about 90% to 100% by weight of at least one carboxylic acid and 0 to about 10% by weight water, wherein the total concentration of bifluoride source compound is between about 1.25 and about 5.0 moles per kilogram of solvent. Methods for selectively removing silicon oxides and metal silicates from metal surfaces are also disclosed.

Owner:HONEYWELL INT INC

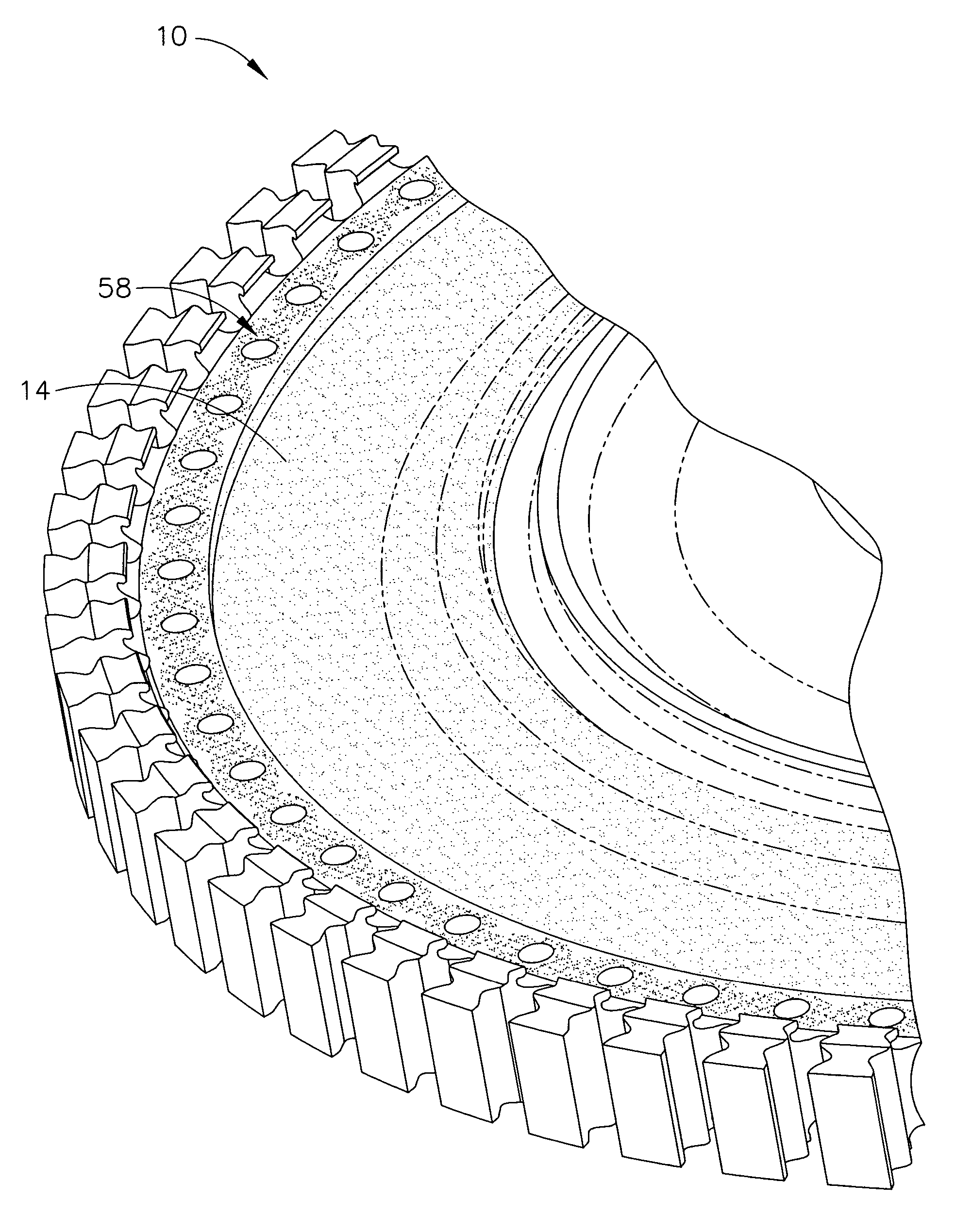

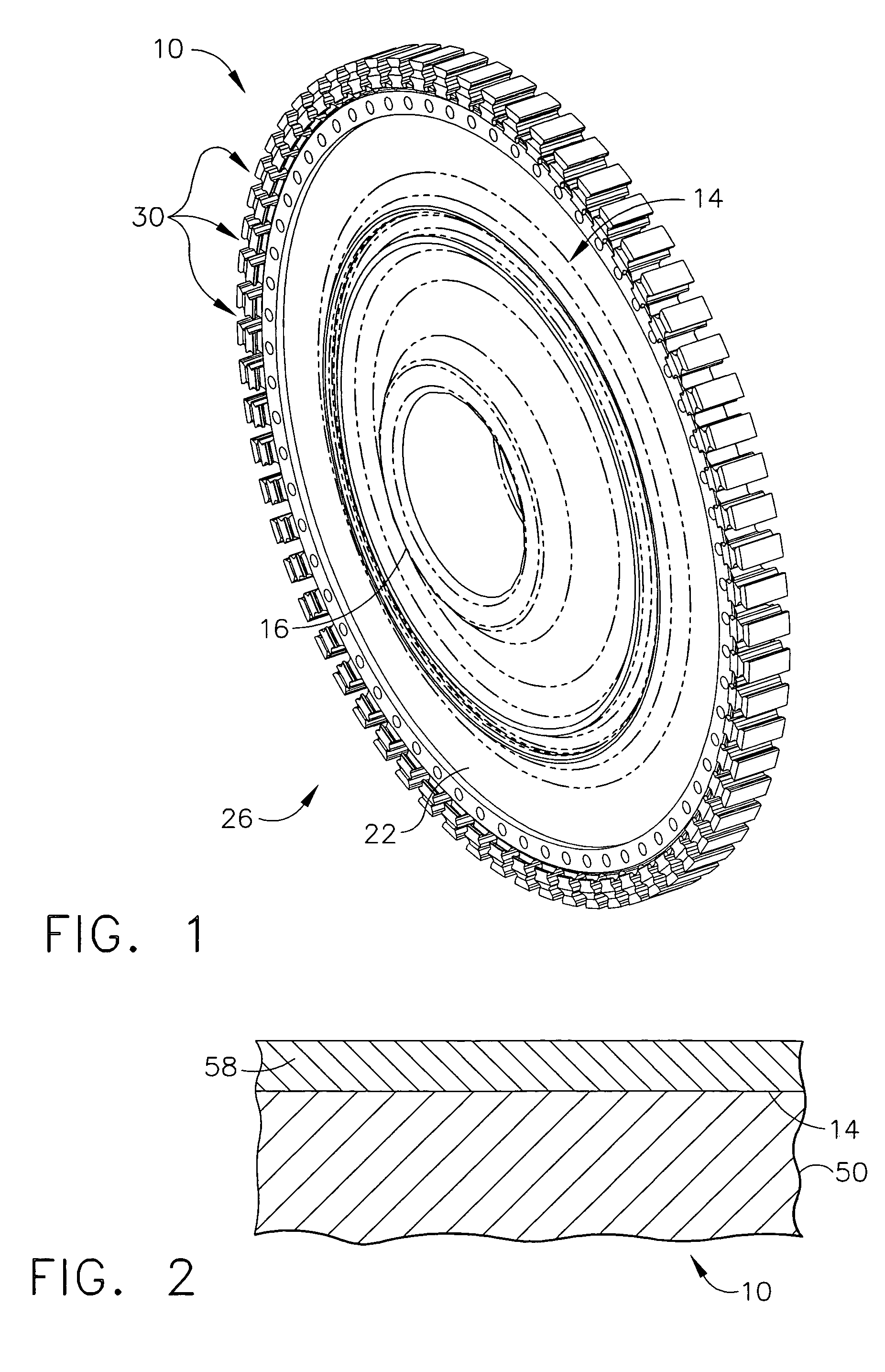

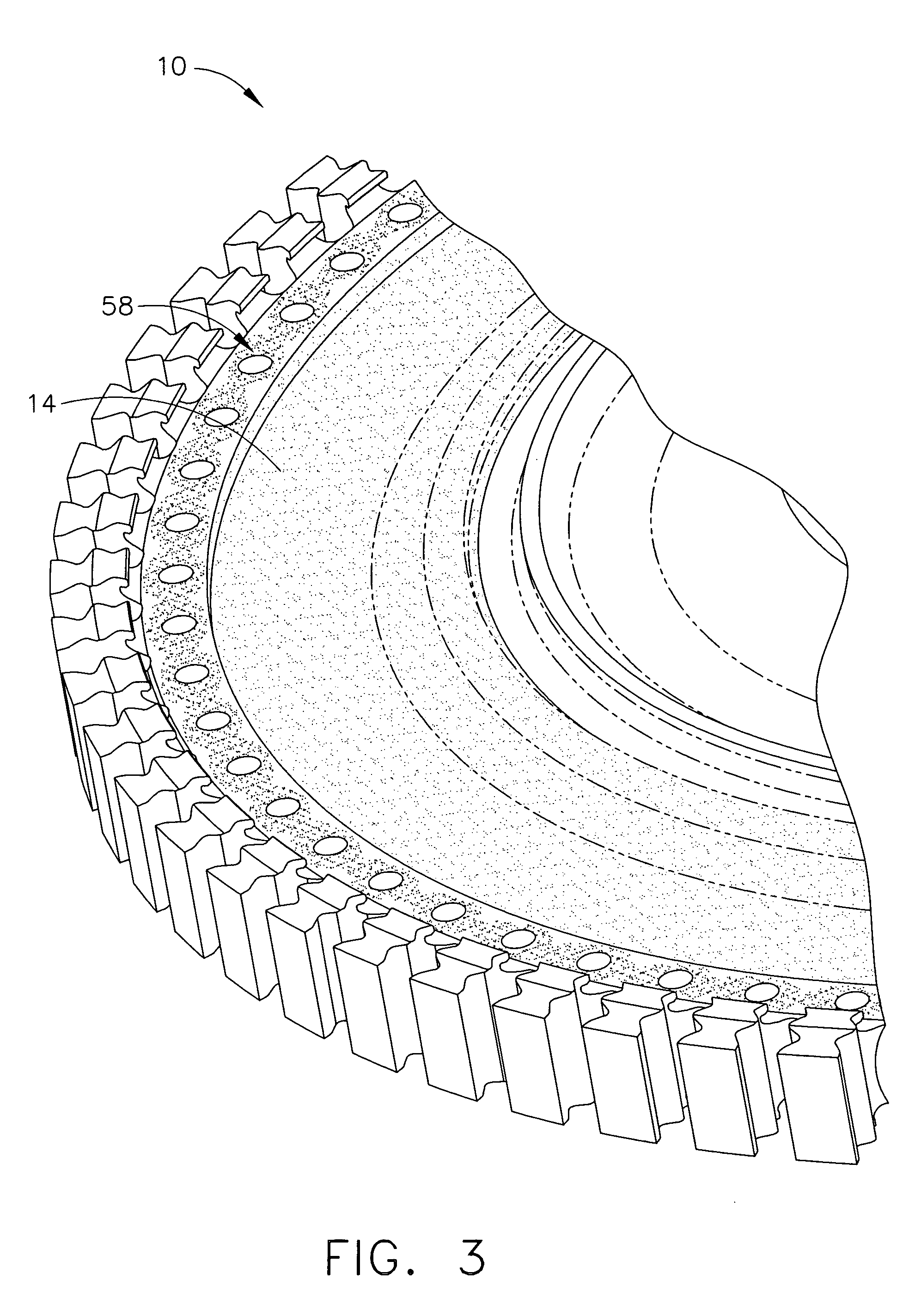

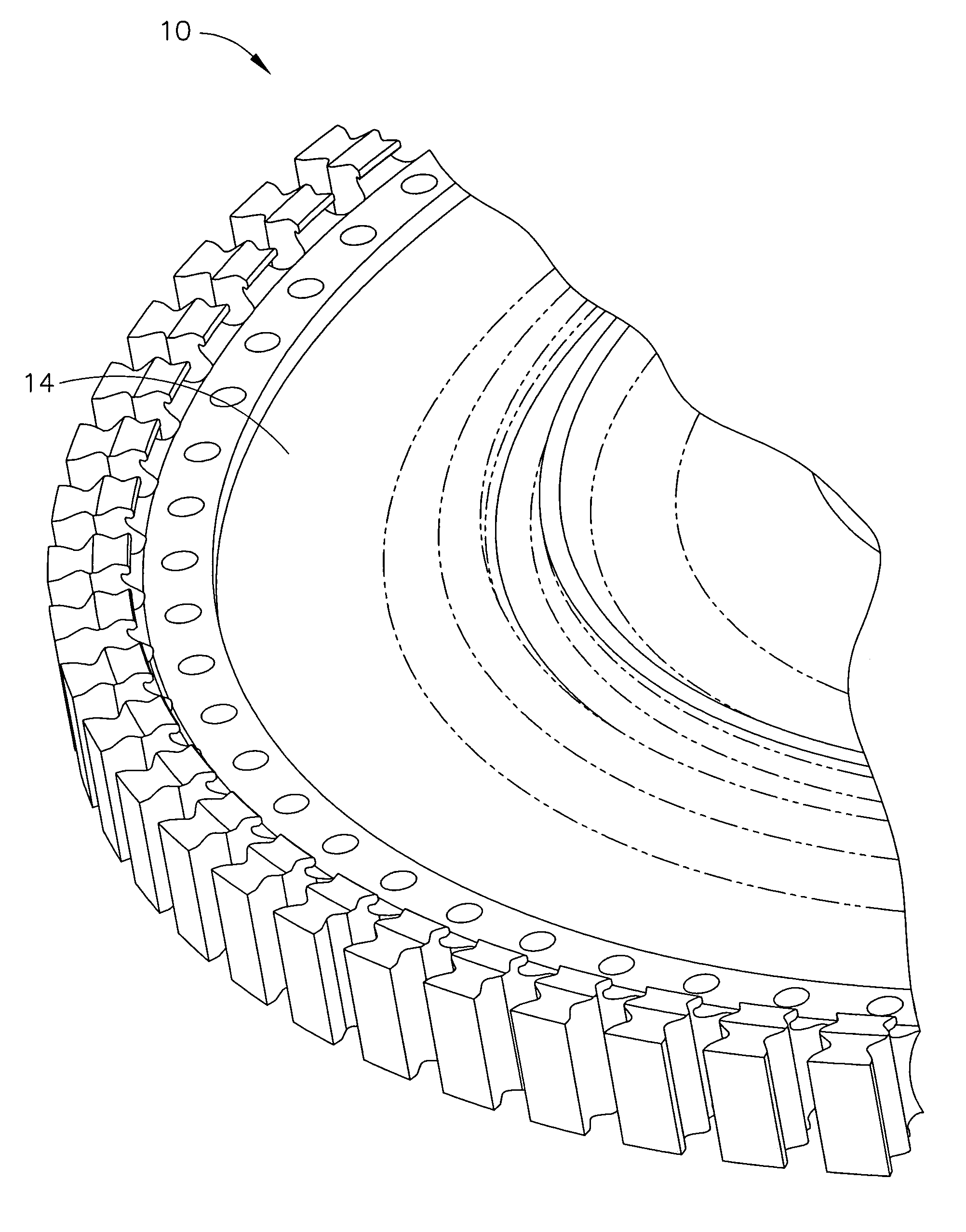

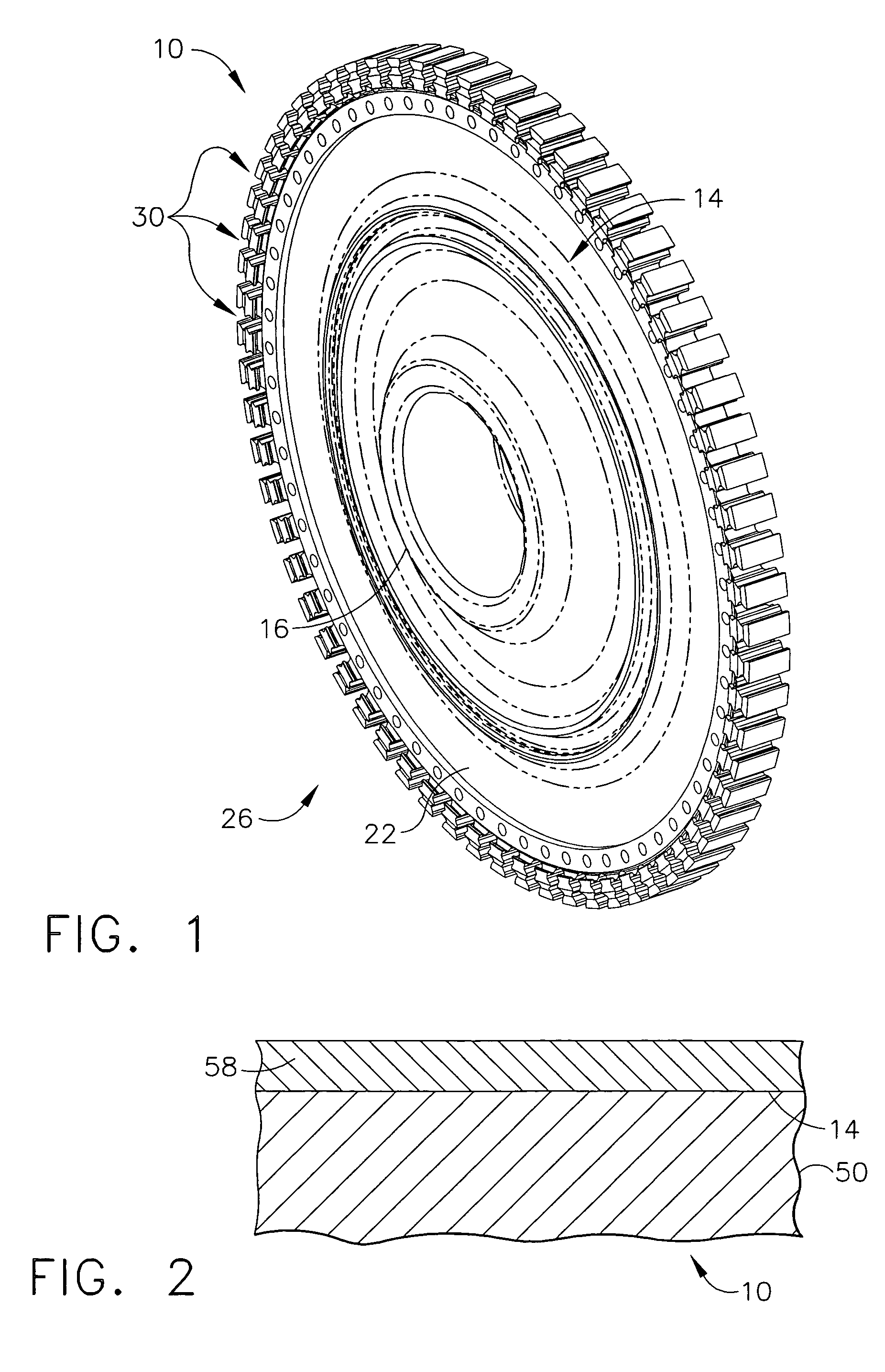

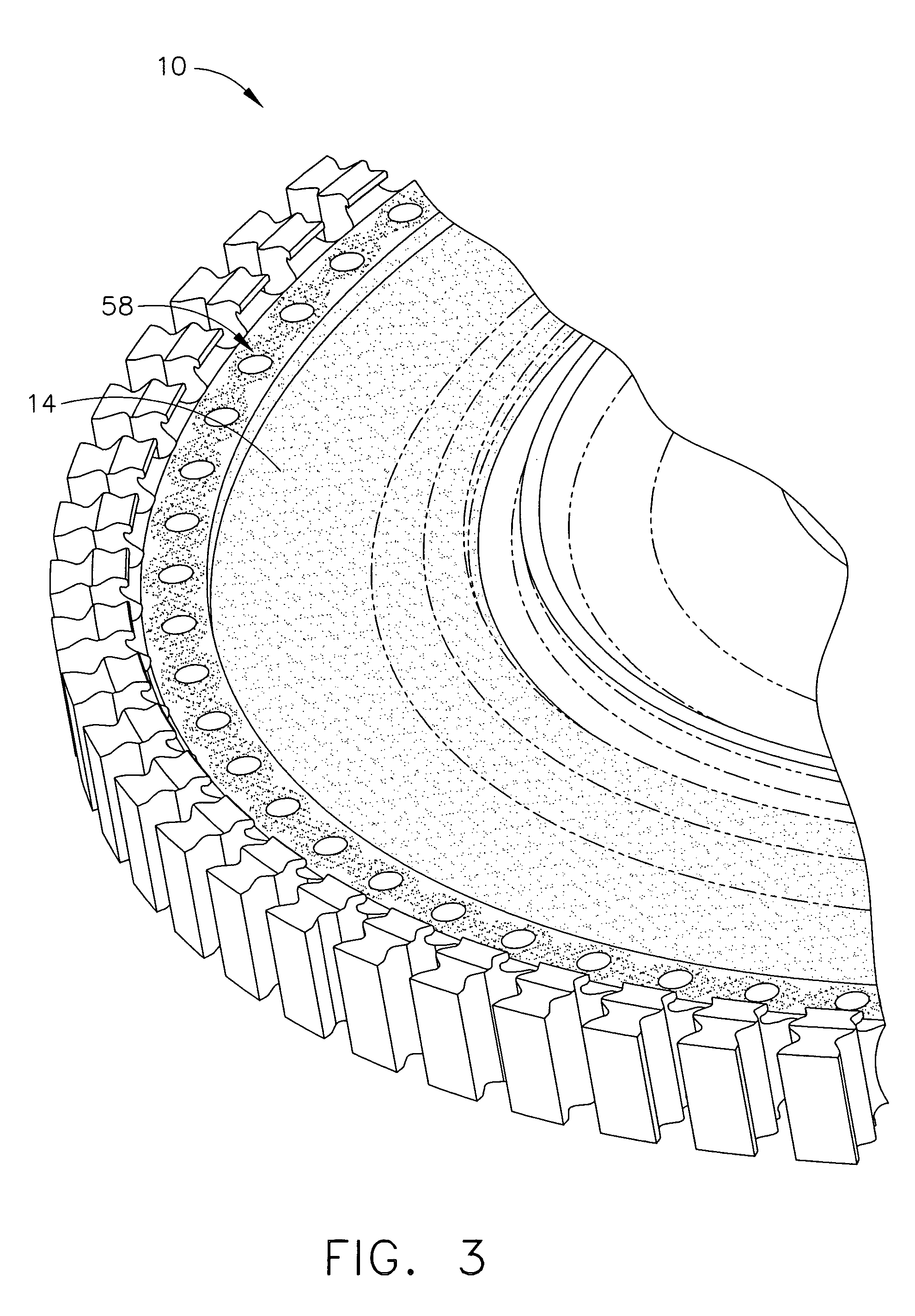

Method for removing engine deposits from turbie components and composition for use in same

ActiveUS20060137724A1Efficient removalHollow article cleaningDetergent mixture composition preparationAcetic acidCobalt

A method and cleaning composition for removing engine deposits from turbine components, in particular turbine disks and turbine shafts. This method comprises the following steps: (a) providing a turbine component having a surface with engine deposits thereon, wherein the turbine component comprises a nickel and / or cobalt-containing base metal; and (b) treating the surface of the turbine component with a cleaning composition to convert the engine deposits thereon to a removable smut without substantially etching the base metal of the turbine component. The cleaning composition comprises an aqueous solution that is substantially free of acetic acid and comprising: a nitrate ion source in an amount, by weight of the nitrate ion, of from about 470 to about 710 grams / liter; and a bifluoride ion source in an amount, by weight of the bifluoride ion, of from about 0.5 to about 15 grams / liter. The smut that is formed can be removed from the surface of the turbine component in a manner that does not substantially alter the surface thereof.

Owner:GENERAL ELECTRIC CO

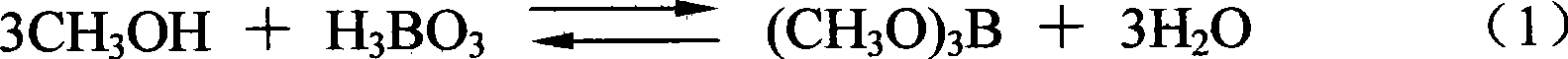

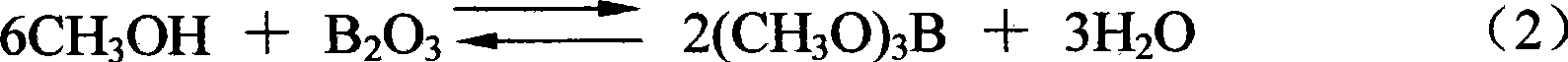

High active no-clean welding flux

InactiveCN101380705ADissolve smoothlyAvoid decompositionWelding/cutting media/materialsSoldering mediaRubidiumSoldering

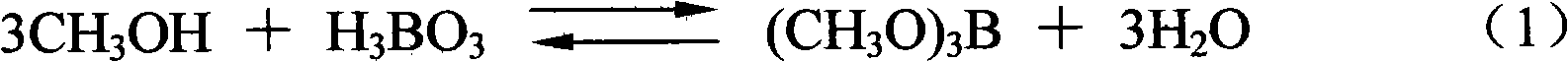

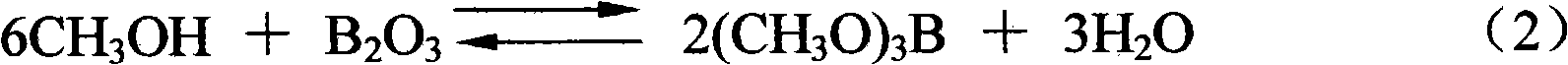

The invention discloses high-activity washing-free scaling powder. According to the weight percentage, the high-activity washing-free scaling powder includes 45.0 to 80.0 percent of trimethyl borate, 0.01 to 10.0 percent of acetone, 0.001 to 1.0 percent of cesium fluoride or rubidium bifluoride, 0.001 to 2.5 percent of aether; and the rest is carbinol. When the scaling powder produced by the invention is matched with the solders like Cu-P series for soldering, the solder has excellent wetting performance and fluidness on a mother plate, can reduce the soldering defects from generating and can improve the intensity of a soldering seam and still has the characteristics of stopping the metal surface in a soldering area from being oxidized and needing not to be washed by acid after soldering.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Processes for preparing fluoroarenes from haloarenes

InactiveUS20060074261A1Organic compound preparationPreparation by halogen halide additionArylDifluoride

Processes for preparing fluoroarenes are provided. The processes include contacting a compound having an unactivated aryl group with a source of fluoride or bifluoride in the presence of a transition metal a ligand.

Owner:EI DU PONT DE NEMOURS & CO

Method for removing engine deposits from turbine components and composition for use in same

ActiveUS7115171B2Efficient removalDetergent mixture composition preparationHollow article cleaningAcetic acidGram

A method and cleaning composition for removing engine deposits from turbine components, in particular turbine disks and turbine shafts. This method comprises the following steps: (a) providing a turbine component having a surface with engine deposits thereon, wherein the turbine component comprises a nickel and / or cobalt-containing base metal; and (b) treating the surface of the turbine component with a cleaning composition to convert the engine deposits thereon to a removable smut without substantially etching the base metal of the turbine component. The cleaning composition comprises an aqueous solution that is substantially free of acetic acid and comprising: a nitrate ion source in an amount, by weight of the nitrate ion, of from about 470 to about 710 grams / liter; and a bifluoride ion source in an amount, by weight of the bifluoride ion, of from about 0.5 to about 15 grams / liter. The smut that is formed can be removed from the surface of the turbine component in a manner that does not substantially alter the surface thereof.

Owner:GENERAL ELECTRIC CO

Producing method of attapulgite double fluorine toothpaste

InactiveCN101224172AQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsLow speedToothpaste

The invention discloses a production method of attapulgite bifluoride toothpaste; the key points of the technical proposal are that: the production method of the attapulgite bifluoride toothpaste includes preparation of materials, low-speed stirring, grinding, high-speed stirring, vacuum degassing and canning into the finished product of the attapulgite bifluoride toothpaste. The attapulgite bifluoride toothpaste is composed of paste attapulgite clay, sodium fluoride, sodium monofluorophosphate, zinc citrate, sodium dodecyl sulfate, titanium white powder, sodium saccharine and deionized water. The attapulgite bifluoride toothpaste can absorb and remove a plurality of offensive smells in the oral cavity, reduce tooth wear, strengthen and regenerate the enamel on the surface of the teeth; the attapulgite bifluoride toothpaste has clean paste body, soft and delicate texture, normal luster and good stability, the paste body is not overflowed to the outside of a pipe mouth, the water is not separated from the invention, the flavor and the luster are normal, and the glass slide has no scratches. The invention is applicable to the production of attapulgite bifluoride toothpaste, Chinese herbal medicine toothpaste and other medicine toothpastes.

Owner:HUAIAN UNIV SCI PARK MANAGEMENT CO LTD

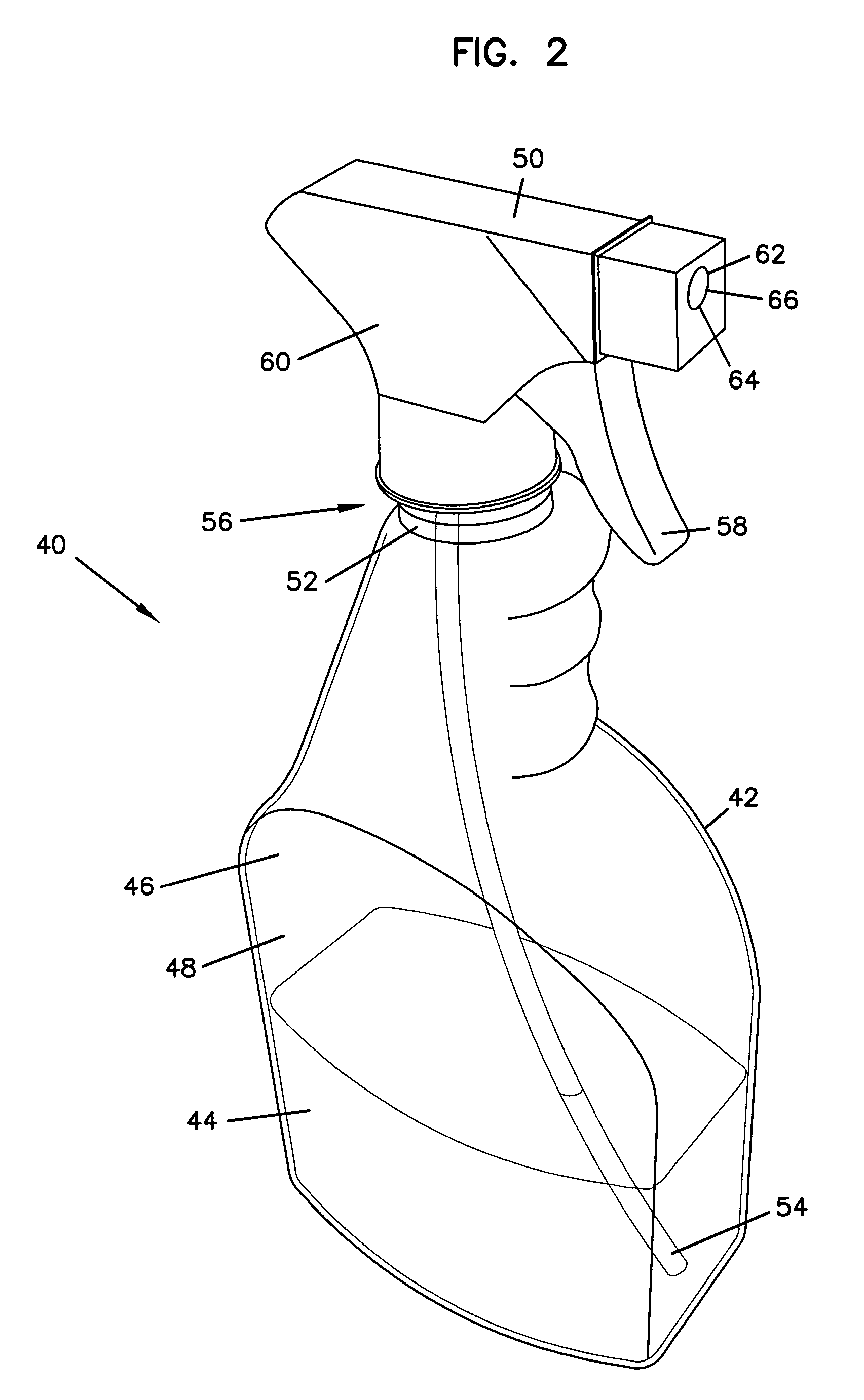

Foam cleaning and brightening composition comprising a sulfate/bisulfate salt mixture

ActiveUS7348302B2Not to damageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsInorganic saltsHydrogen Sulfate

A cleaning composition including a metal bisulfate and metal inorganic salt acid package, and at least one surfactant. The cleaning composition can be a one-step wheel cleaner / brightener. The composition preferably contains no HF, no bifluoride, no oxalic acid, or other poisonous and highly toxic materials commonly found in both industrial and consumer wheel cleaners. Further, the wheel cleaner / brightener composition matches or exceeds the performance of those hazardous formulations and does not damage aluminum wheels even when applied to hot metal. The composition can be a foam composition, provided in a foam dispenser. The foam dispenser includes a container and a mechanical foaming head. The container includes a cleaning composition containing a metal bisulfate and metal sulfate acid package, and at least one surfactant, water, and a foam-boosting solvent.

Owner:ECOLAB USA INC

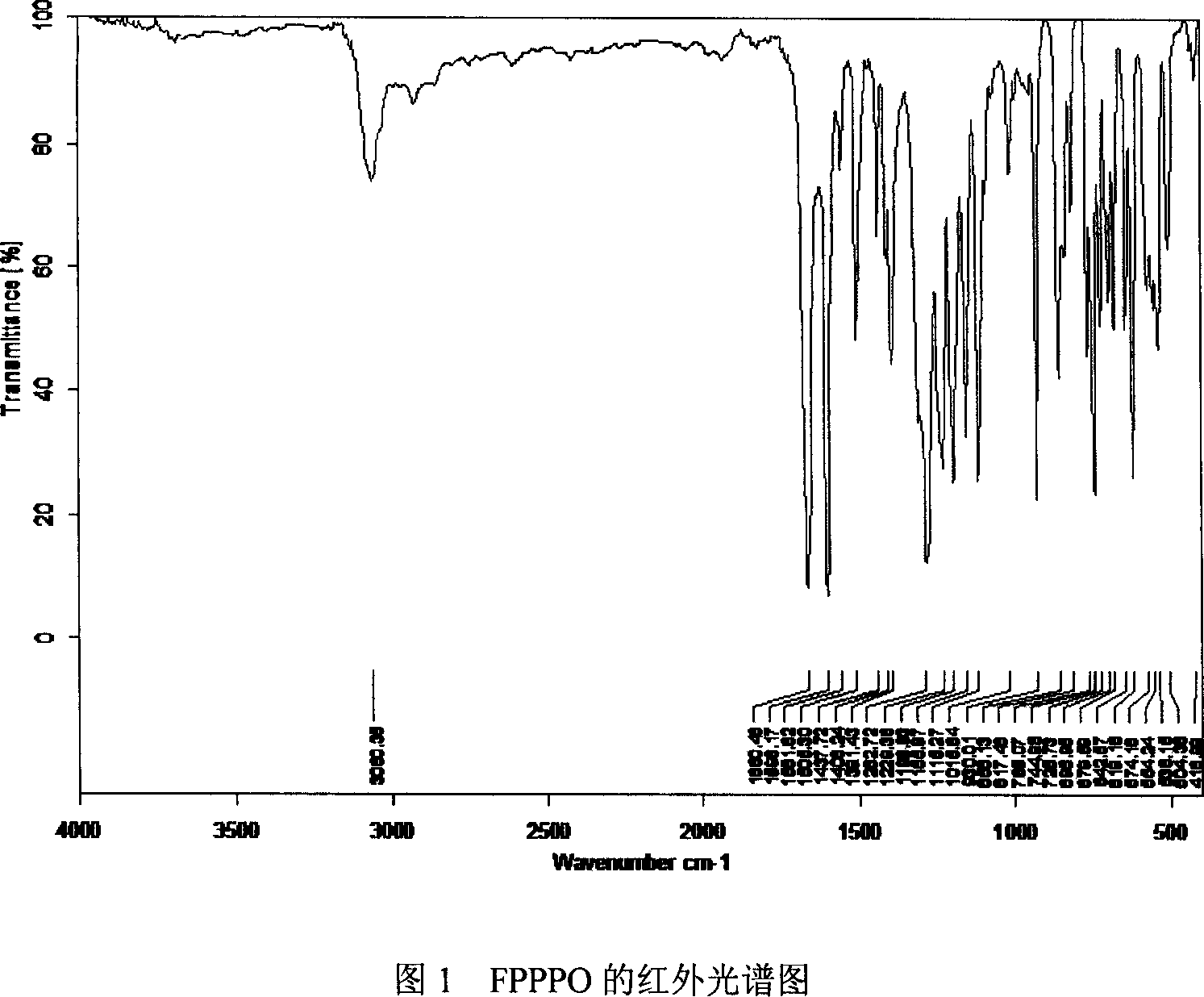

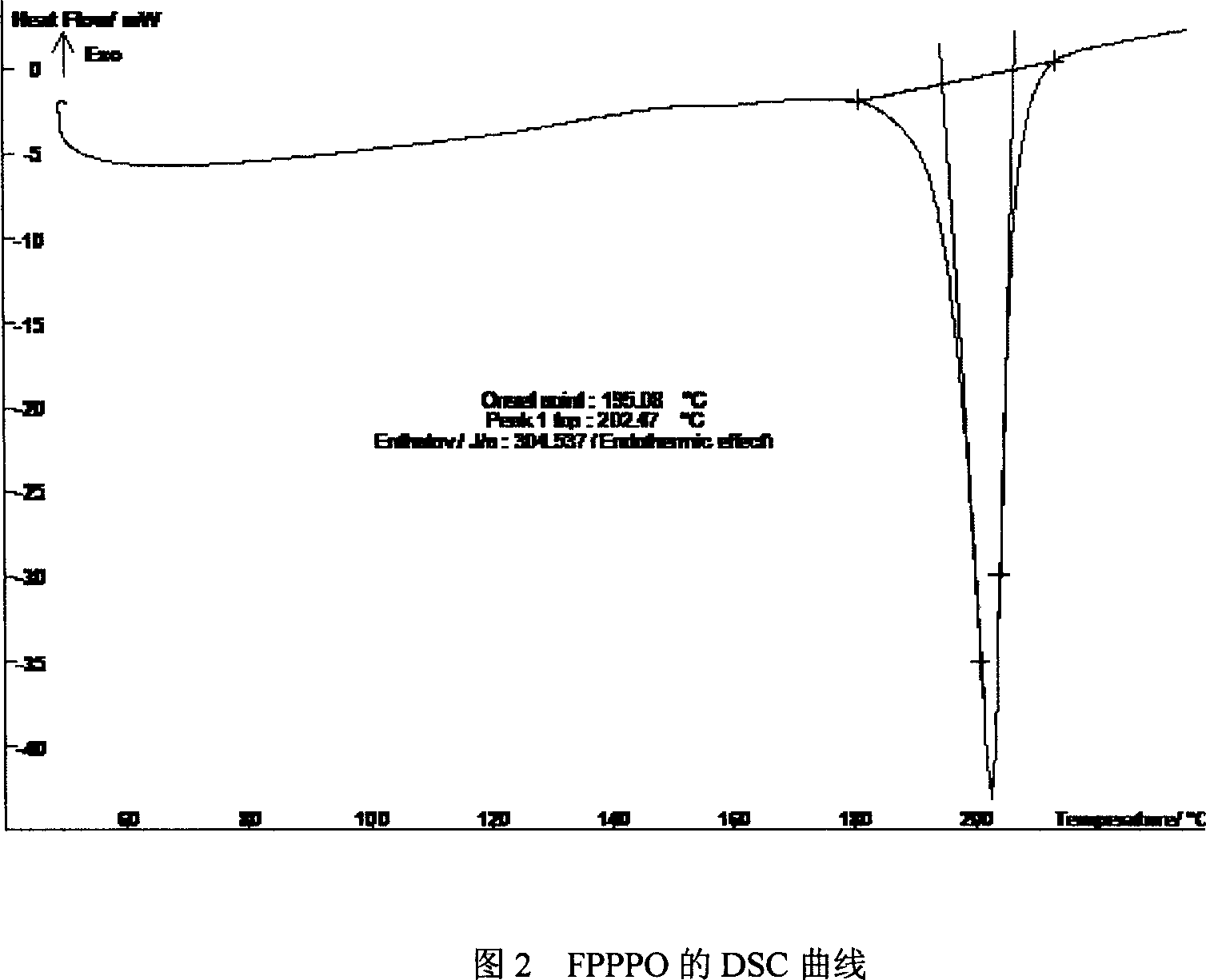

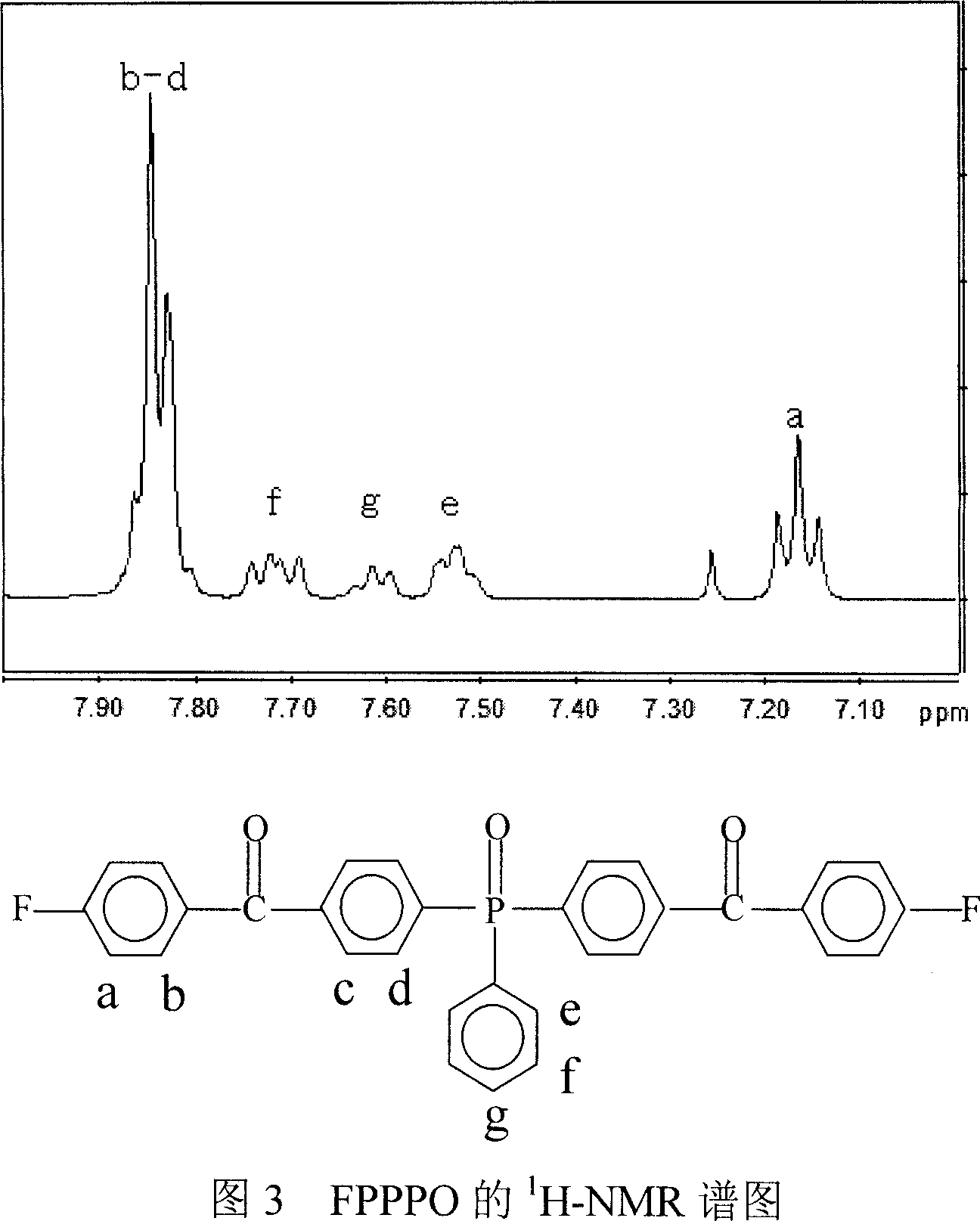

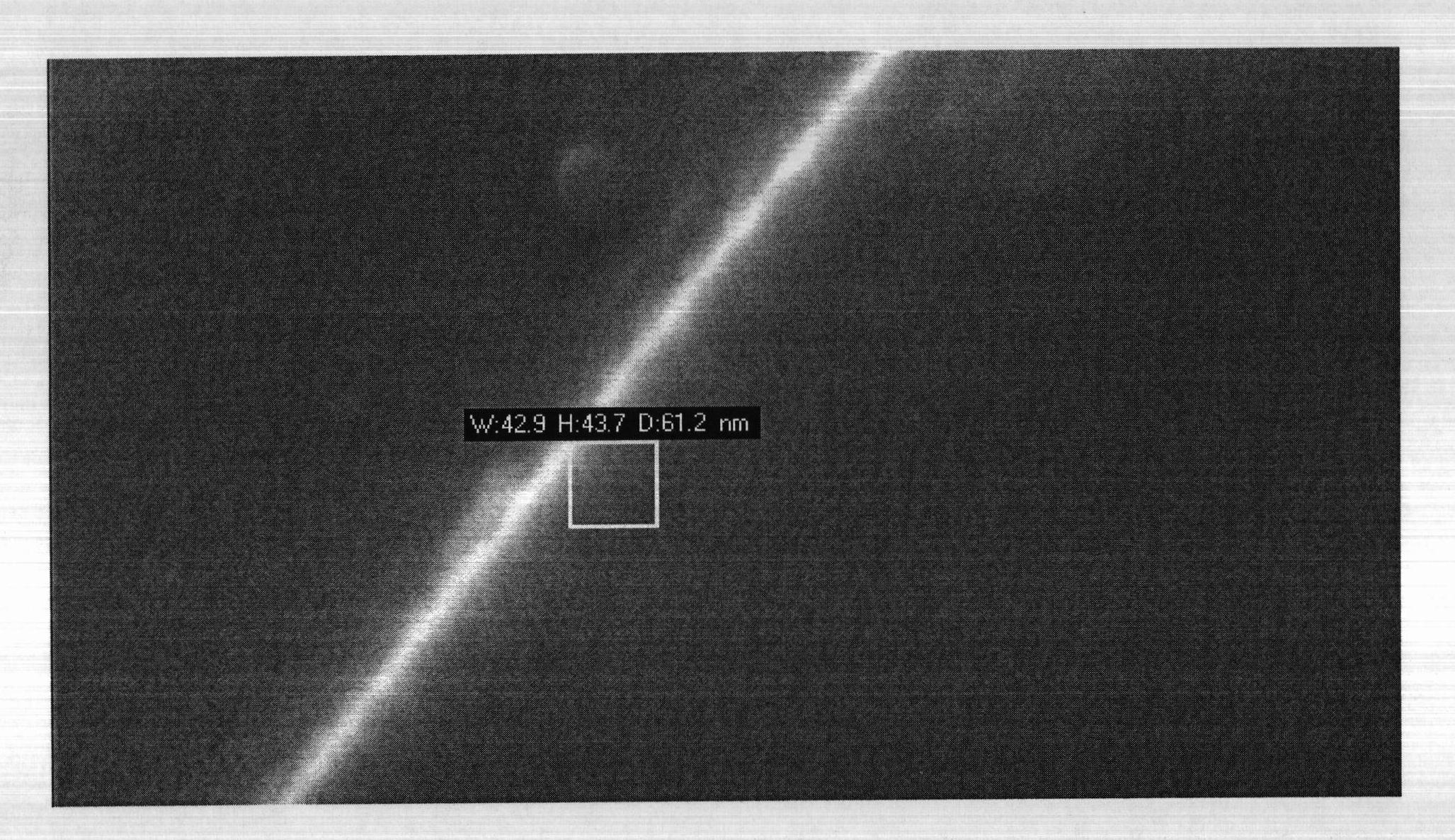

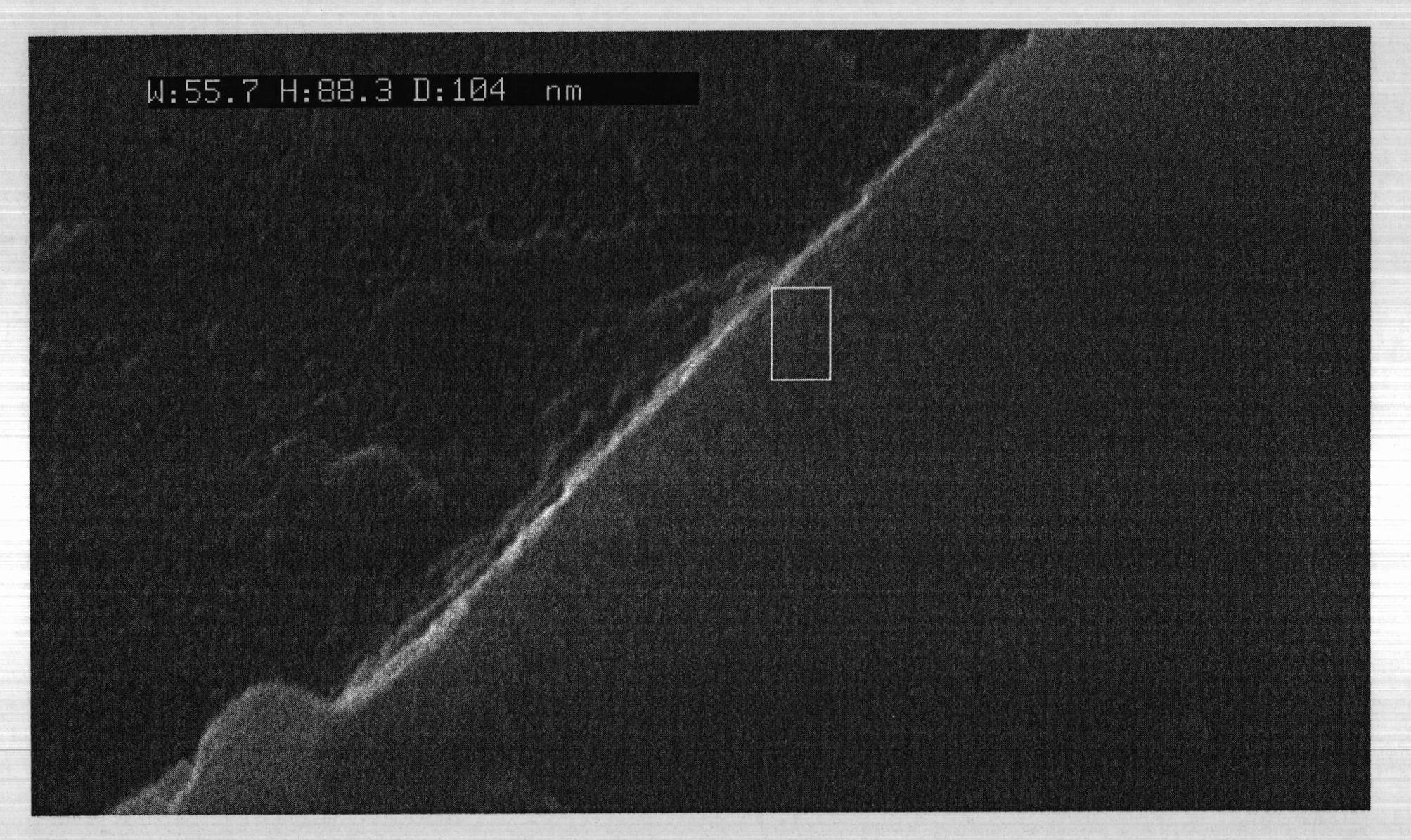

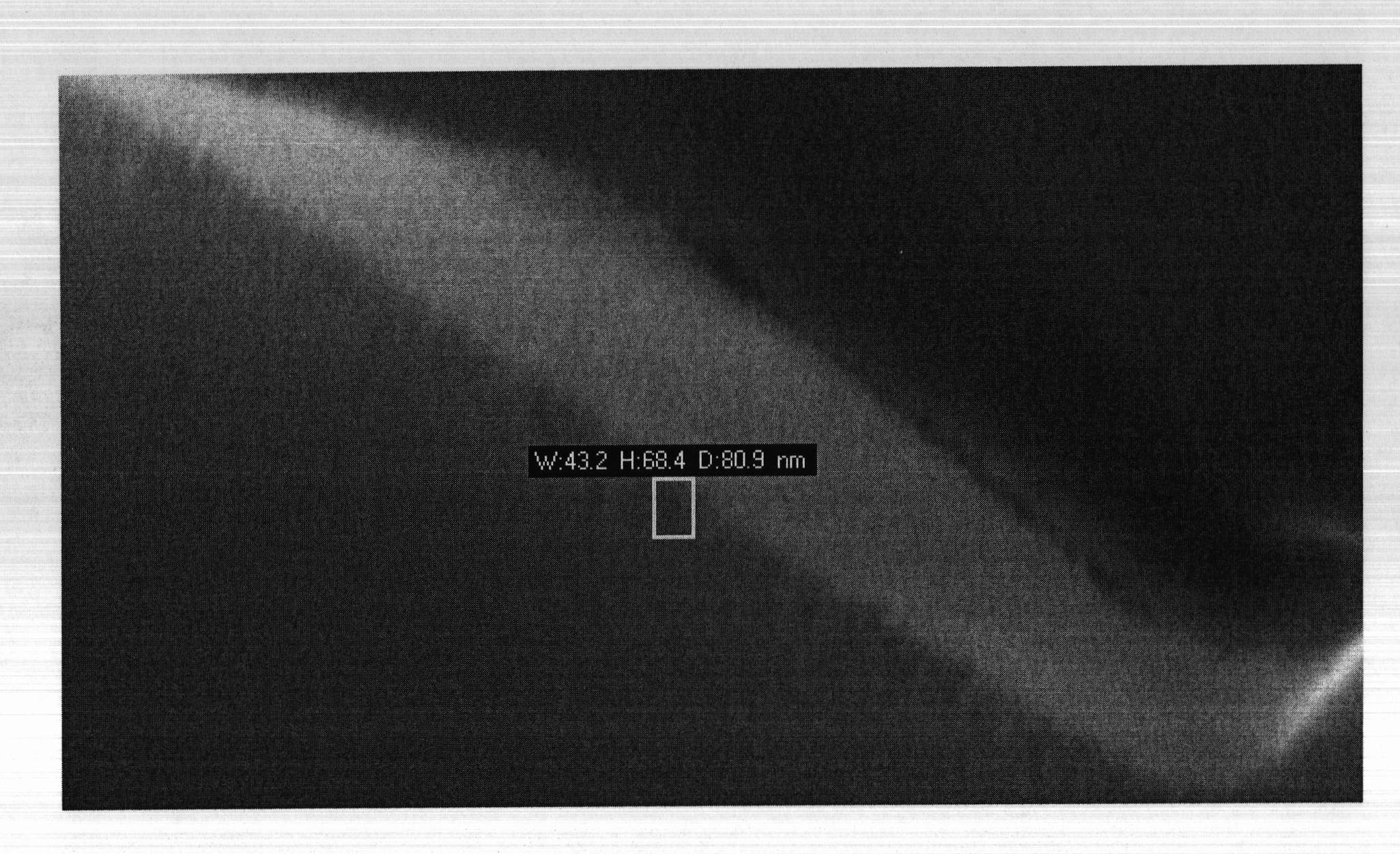

Bi(4-(4-fluorobenzoyl)phenyl)phenyl phosphine oxide monomer and synthetic method thereof

InactiveCN101058587AHigh purityOptimal Synthesis TechnologyGroup 5/15 element organic compoundsPhenacylPtru catalyst

The invention discloses a new aromatic bifluoride monomer with phosphor and compounding and purifying technique with structure as formula (I), which comprises the following steps: affirming the polymer as object product through infrared spectrum and nuclear magnetic resonance; adopting BCPPO and sulfone chloride as raw material; acylating and chlorinating to obtain CPPPO; reacting the CPPPO and fluorobenzene; making anhydrous aluminium trichloride as catalyst to synthesize the FPPPO through Friedel-Crafts reaction.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method of tetrafluoromethane

ActiveCN108863710AShort reaction timeSimple processPreparation by halogen replacementAlkaline earth metalContinuous use

The invention discloses a preparation method of tetrafluoromethane. Waste gas exhausted in the fluoro-hydrocarbon product production process and hydrogen fluoride are proportionally introduced into amicro-channel reactor containing catalysts; reaction is performed for 1 to 30 minutes at the temperature being 150 to 350 DEG C; reaction products are purified to obtain the tetrafluoromethane; the catalyst is prepared from carriers and one kind of materials or a mixture of more than one kind of materials in persulfate, fluoride or bifluoride of alkali metal or alkaline earth metal and oxides or carbonates of titanium, vanadium, chromium, iron, cobalt, nickel, copper and aluminum through roasting; the carriers are one kind of materials or a mixture of more than one kind of materials in activecarbon, molecular sieve, kieselguhr or silicon dioxide. The catalyst can be continuously used; the reaction time is short; the process is simple; safety is realized; the cost is low; the product purity is high and reach 99.99 percent; the technology belongs to a green clean energy-saving environmental-friendly sustainable production technology.

Owner:LINHAI LIMIN CHEM

Anti-dazzle glass frosting powder for windshields

InactiveCN104724939AAdjustable frosting processAdjustable: the invented frosting powder is convenient and quick for the frosting processSodium acetateDiffuse reflection

The invention relates to manufacturing of glass frosting powder, belongs to the field of light industry, and specifically relates to an anti-dazzle glass frosting powder for windshields. A formula of the glass frosting powder is provided and includes the following ingredients: fluorinated ammonia, ammonium bifluoride, magnesium bifluoride, aluminum bifluoride, oxalic acid, sodium acetate, sodium silicate, ammonium fluoroborate, sodium fluoroborate, Al2O3 and SiO2, sodium dodecyl sulfate, cellulose MCC, sodium hexametaphosphate and sodium polypropionate. The above ingredients are crushed according to a weight ratio; the crushed ingredients are uniformly stirred, dried and packaged; and finally, a product obtained is inspected and enters a finished product warehouse. After car windshields or other types of windshields are treated by the use of the glass frosting powder, the effect of diffuse reflection is good, and external bright light is not irritating to eyes when passing through the treated windshields. Thus, traffic accidents are minimized, and life safety factors of people in cars and safety factors of materials in cars are increased.

Owner:黄淼

Electrochemical etching of semiconductors

InactiveCN102623324AGood adhesionImprove reliabilityAnodisationFinal product manufactureElectrochemistrySemiconductor

Semiconductors are electrochemically etched in solutions containing sources of bifluoride and nickel ions. The electrochemical etching may form pores in the surface of the semiconductor in the nanometer range. The etched semiconductor is then nickel plated.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Chemical milling liquid for beryllium material surface chemical milling treatment, and chemical milling treatment method

The invention relates to a chemical milling liquid for beryllium material surface chemical milling treatment. The chemical milling liquid is characterized by being composed of a class-A chemical milling liquid and a class-B chemical milling liquid, wherein the class-A chemical milling liquid is composed of the following ingredients: 200ml of purified water, 3.6g of sodium nitrate, 12g of ammonia bifluoride and 21.6g of chromium trioxide, and the ratio is the use amount of a single sample per surface area of 13cm<2>; the class-B chemical milling liquid is composed of the following ingredients: 1084ml of phosphoric acid, 100g of chromium trioxide and 60ml of sulphuric acid. According to the chemical milling liquid disclosed by the invention, the surface defects of beryllium materials can be greatly and quantitatively removed and the surfaces are enabled to be bright, beautiful and free from any etch pits by using the prepared chemical milling liquids A and B, and chemically milling according to a certain temperature and etching time. The chemical milling liquid disclosed by the invention is especially suitable for being applied to removal of surface damage layers after machining and brightening treatment of product surfaces, of the beryllium materials produced by a powder metallurgy process.

Owner:西北稀有金属材料研究院宁夏有限公司

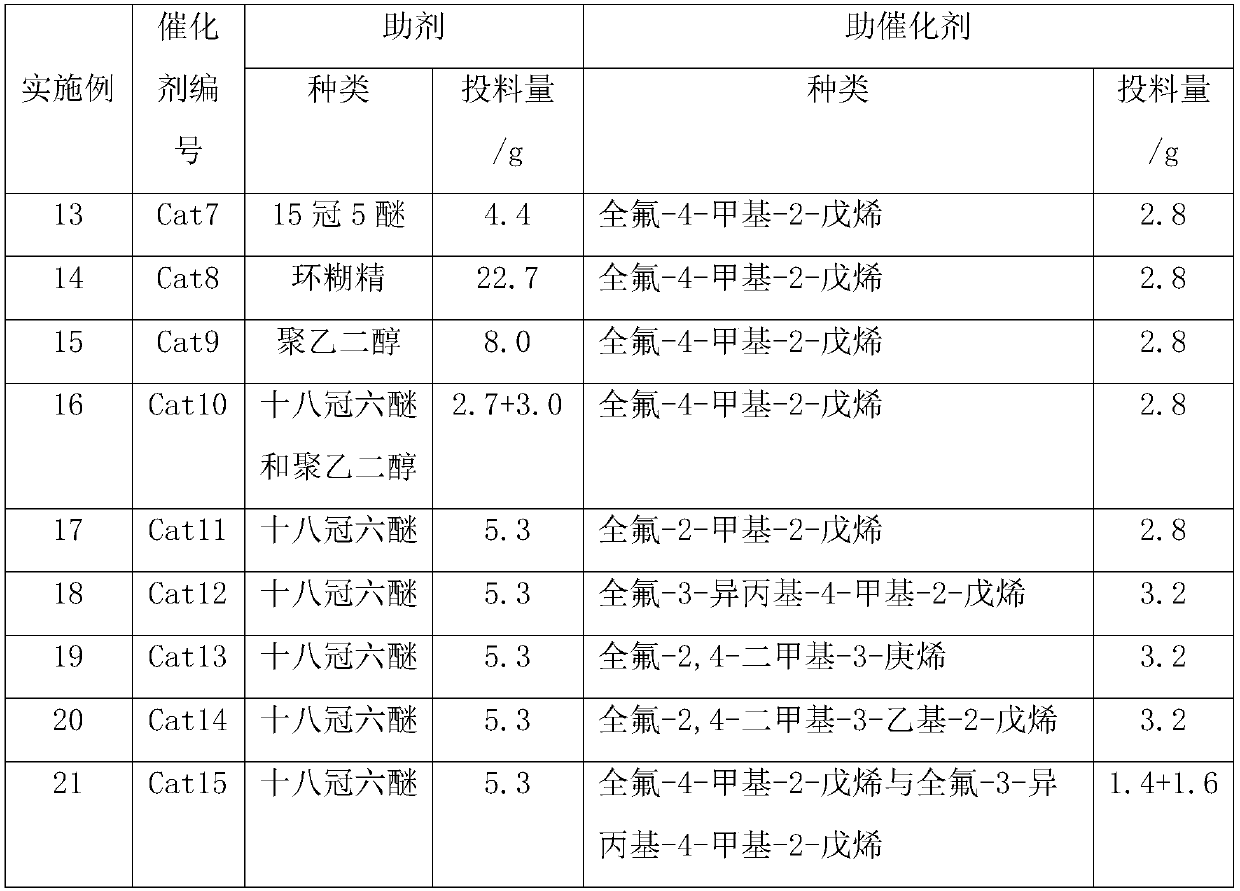

Method of preparing perfluoro-3-methyl-2-butanone

ActiveCN109704935AHigh yieldMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationOrganic solventHexafluoropropylene

The invention discloses a method of preparing perfluoro-3-methyl-2-butanone through a reaction of hexafluoropropylene and trifluoroacetyl fluoride under effect of a liquid-phase catalyst which includes a main catalyst, a cocatalyst, an additive and an organic solvent, wherein the main catalyst is selected from metal fluorides and / or metal bifluorides; the cocatalyst is selected from C6-C9 perfluoroolefines; the additive is selected from crown ether and / or crown ether-like compound; the organic solvent is selected from polar aprotic solvents. The preparation method can achieve one-step reaction, is high in reaction speed, and is high in product yield.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

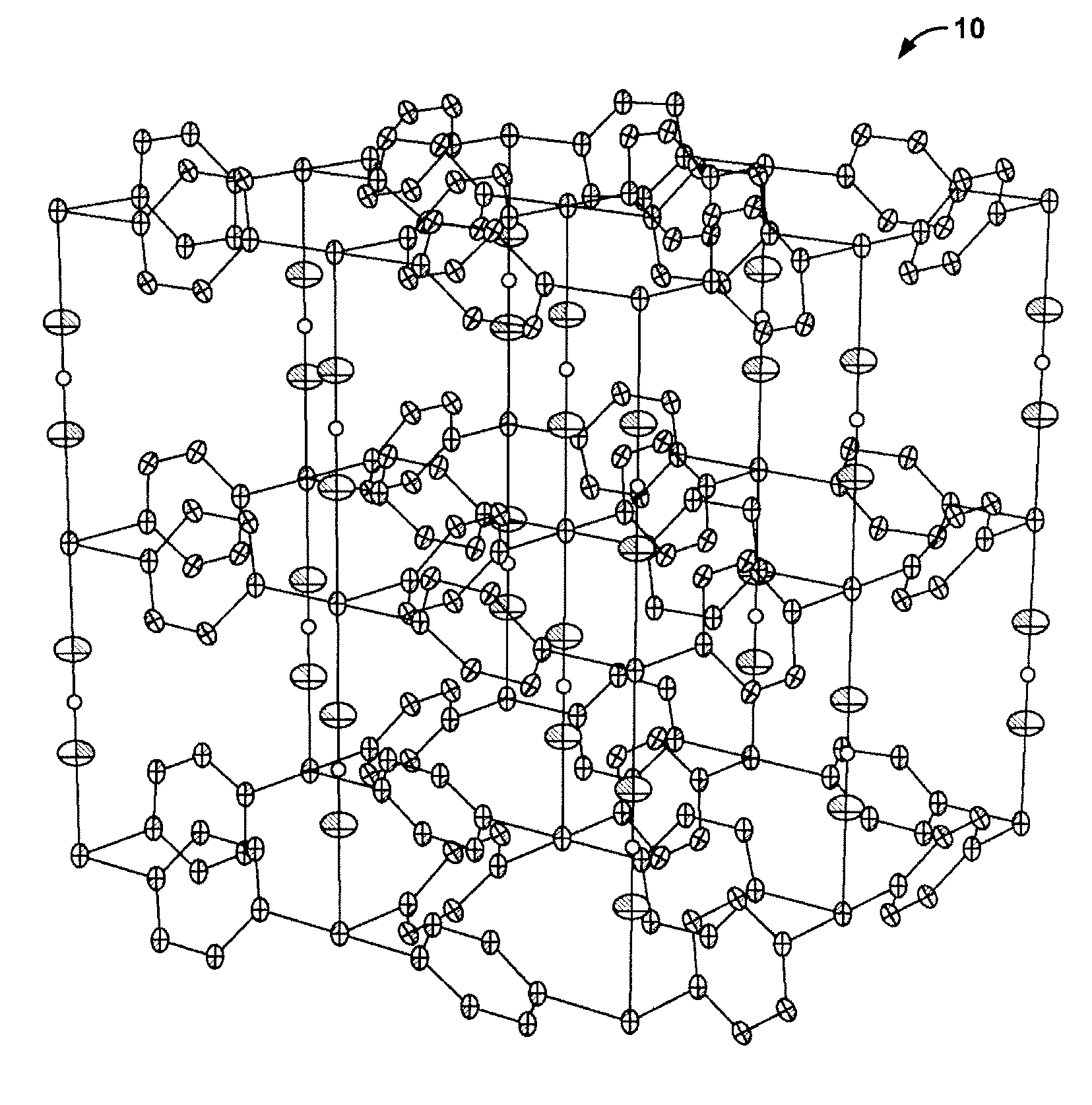

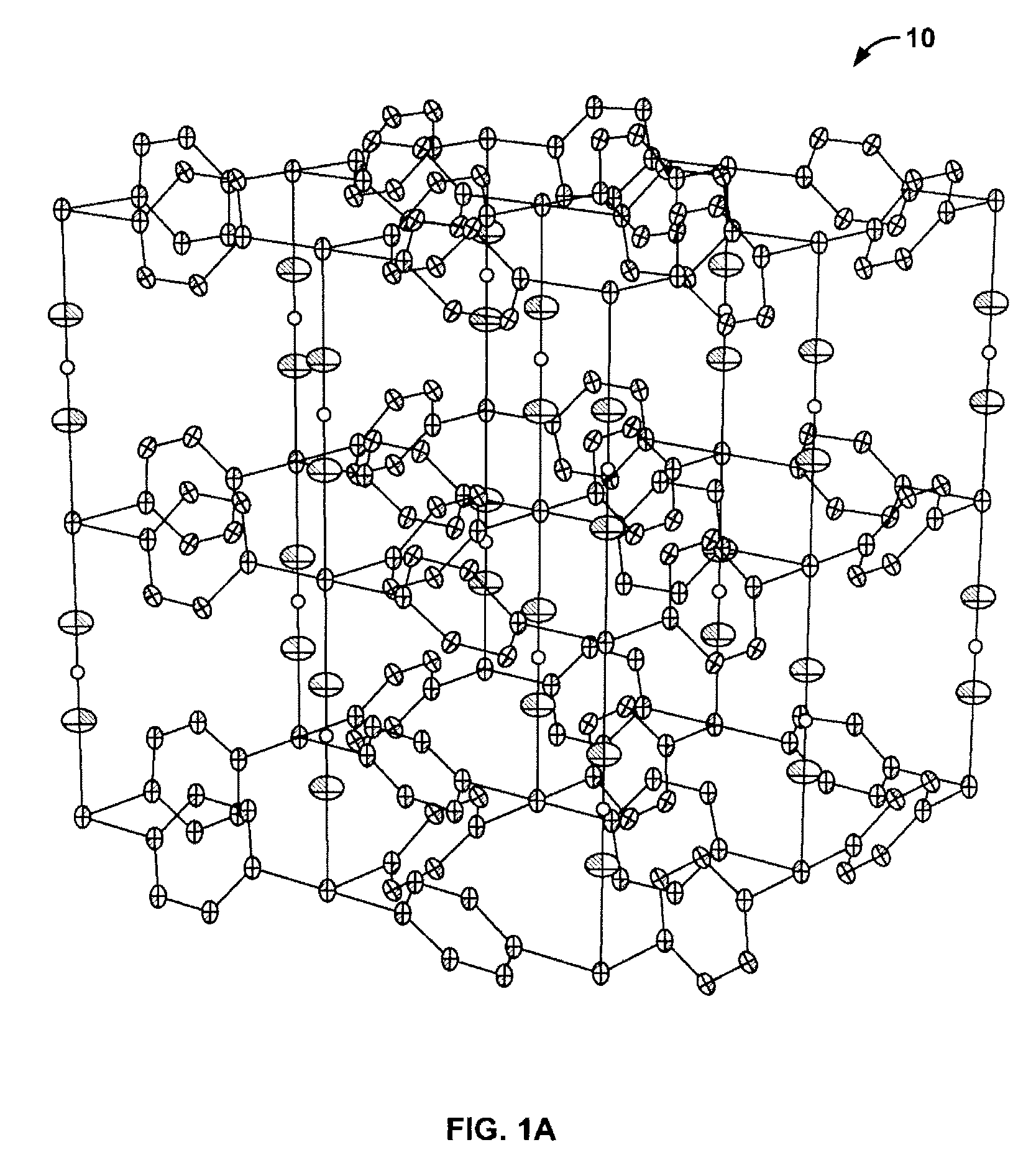

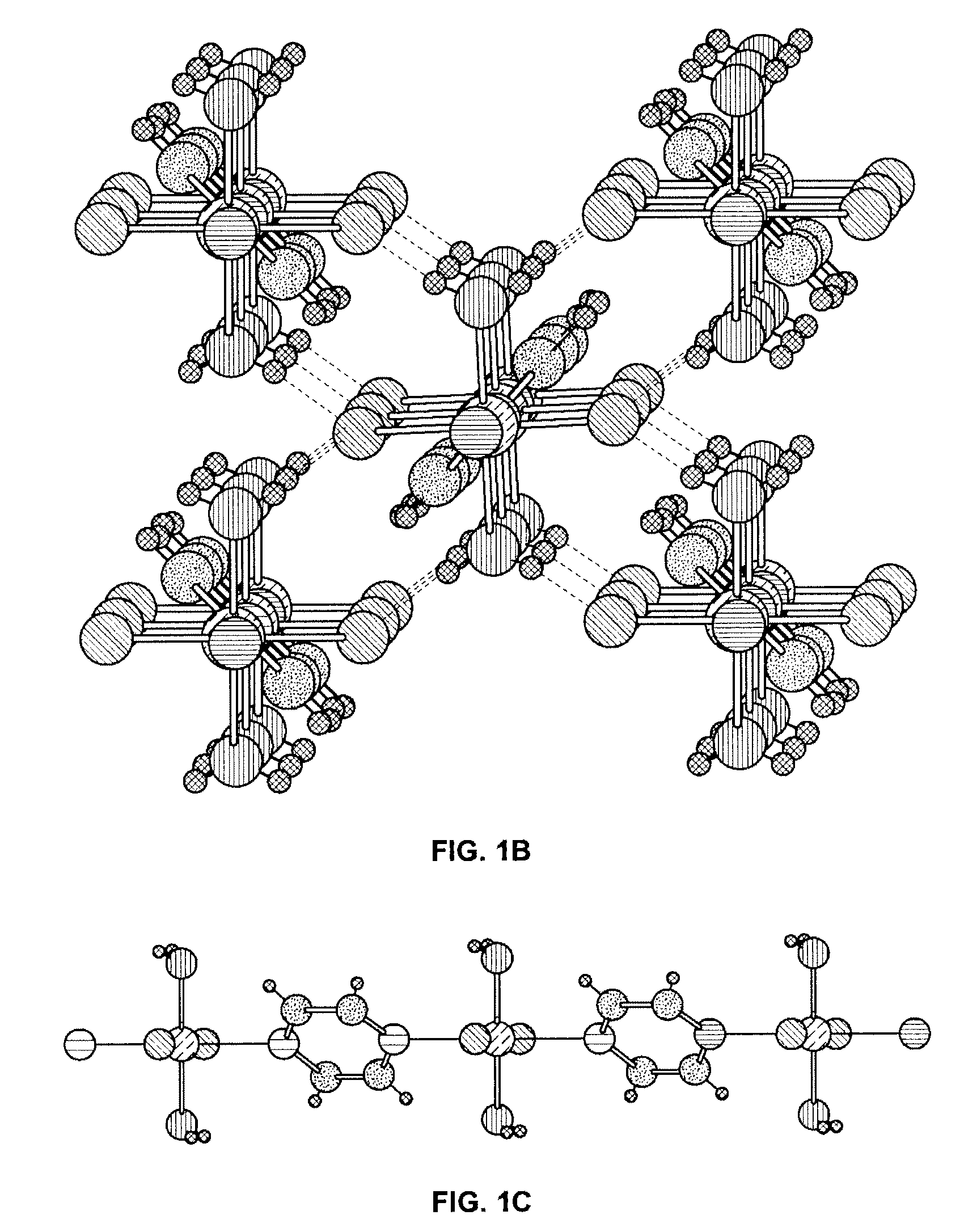

Magnetic coupling through strong hydrogen bonds

A composition of matter for a polymeric material for magnetic coupling through strong hydrogen bonds. A hydrogen bound structural directing entity, such as the bifluoride ion, HF2−, or coordination polymers incorporating strong OH...F type interactions can be used to manufacture organic polymers which allow, via strong hydrogen bonds, the bridging across polymeric magnetic layers to couple spin-polarized electrons to the conduction band, in order to enable control of the electron spin state for spintronic applications.

Owner:UCHICAGO ARGONNE LLC

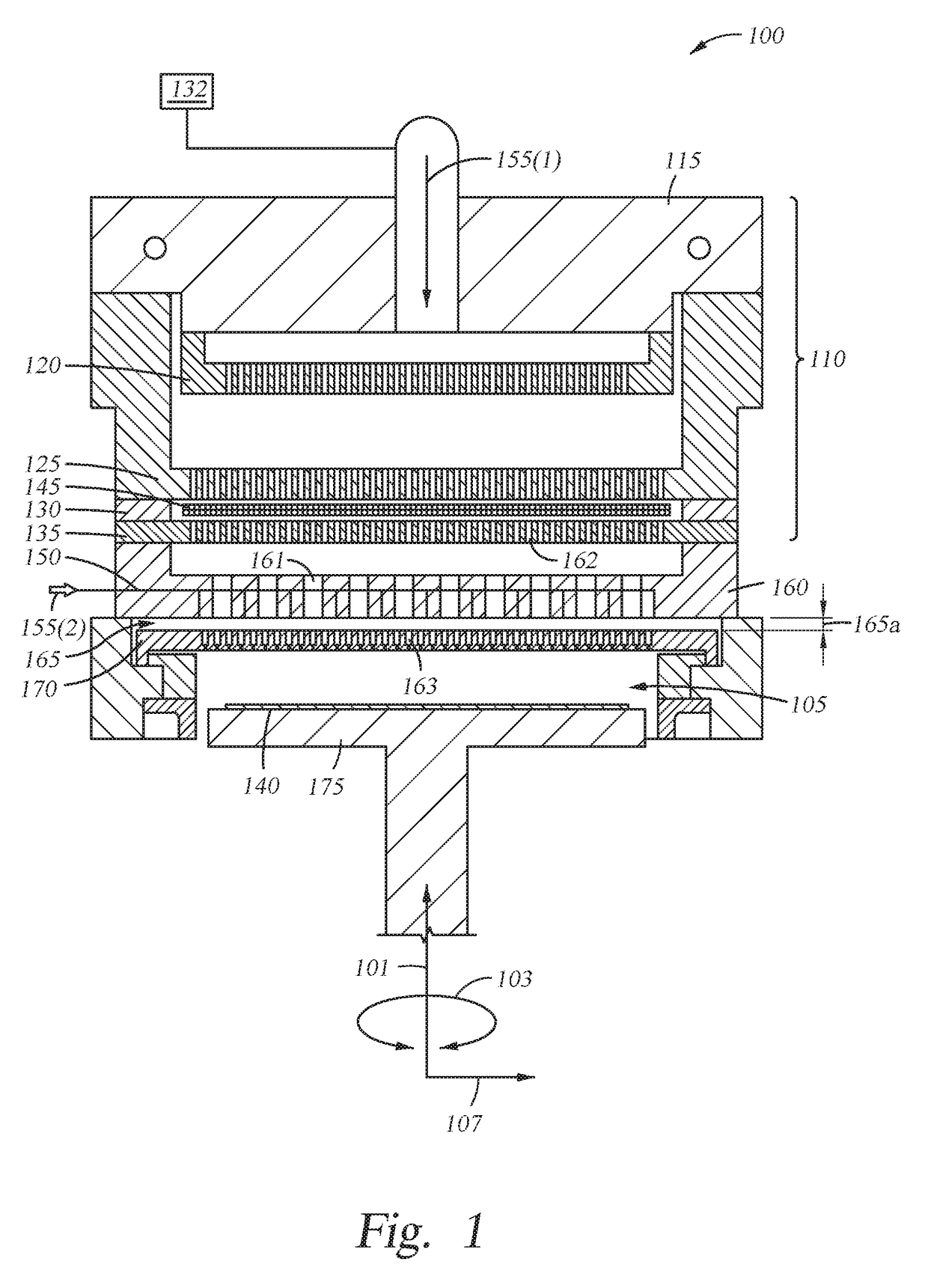

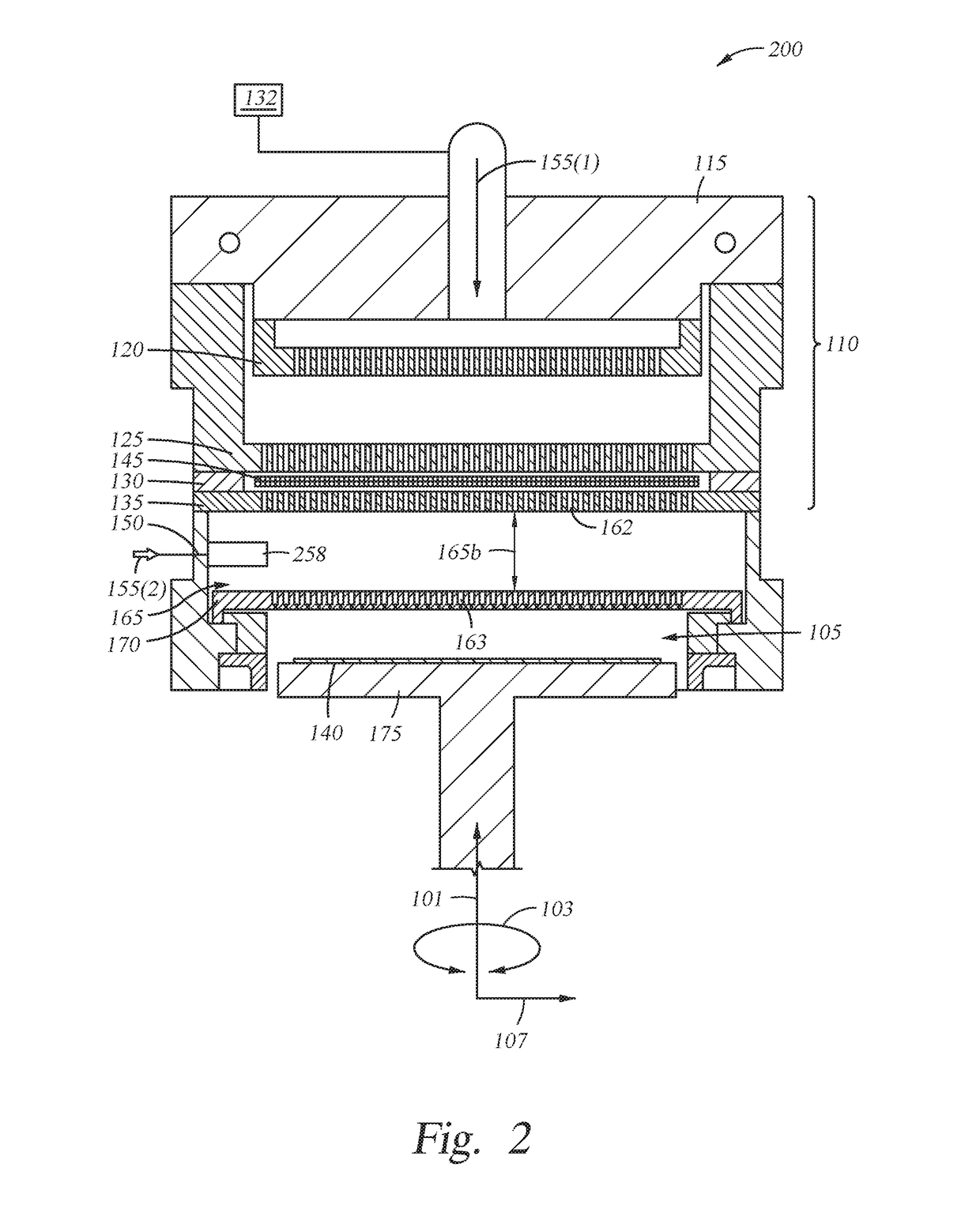

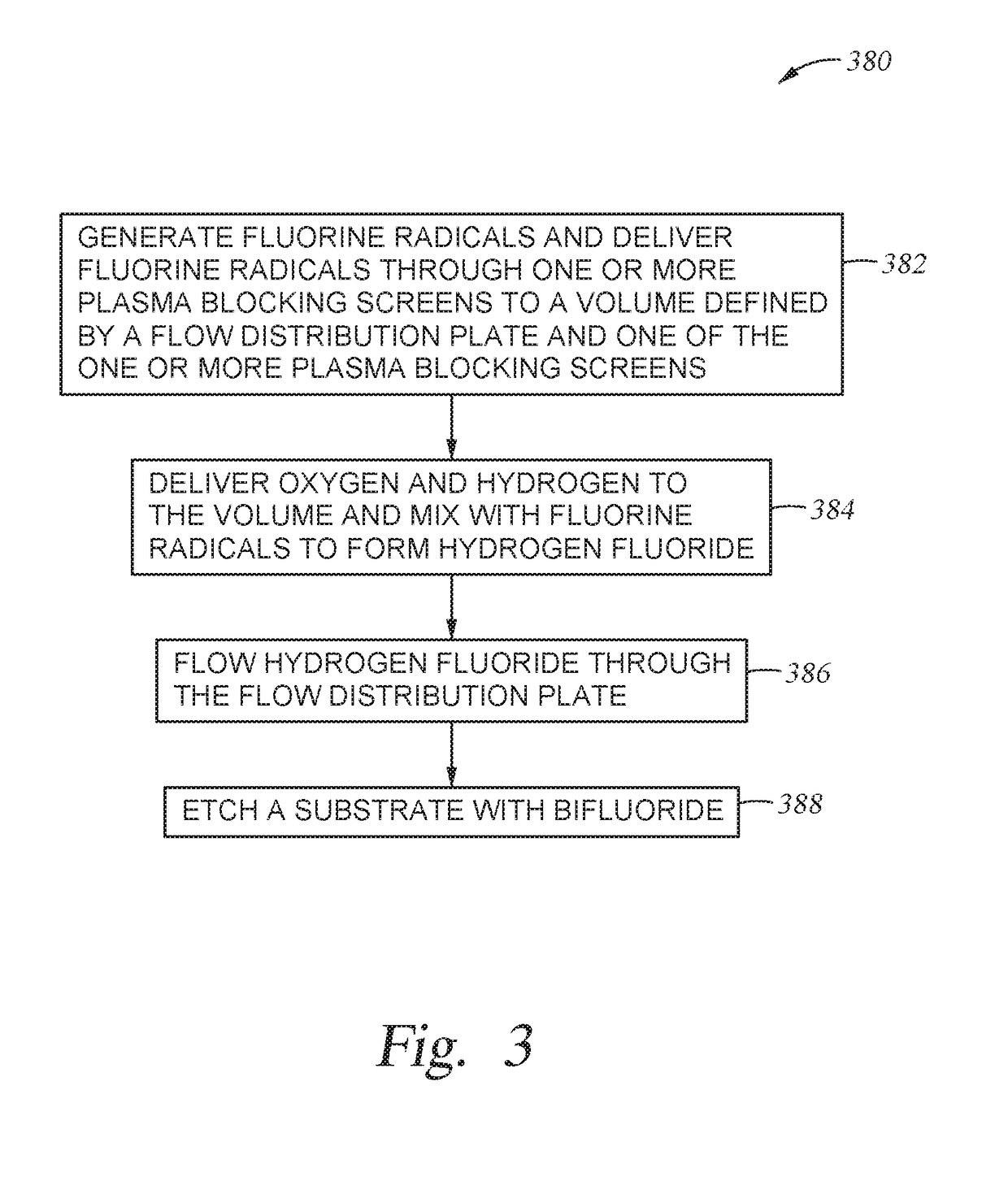

Flow distribution plate for surface fluorine reduction

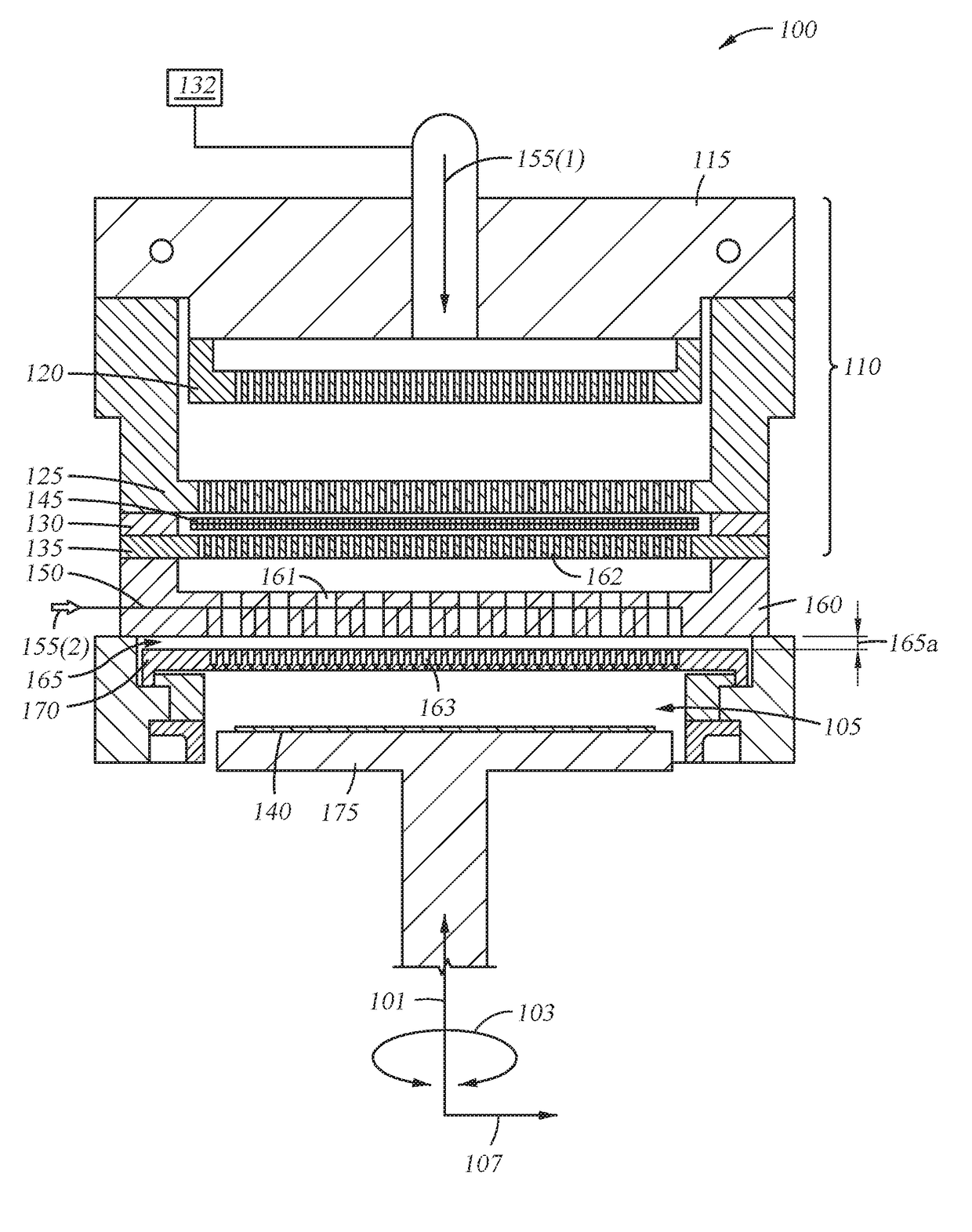

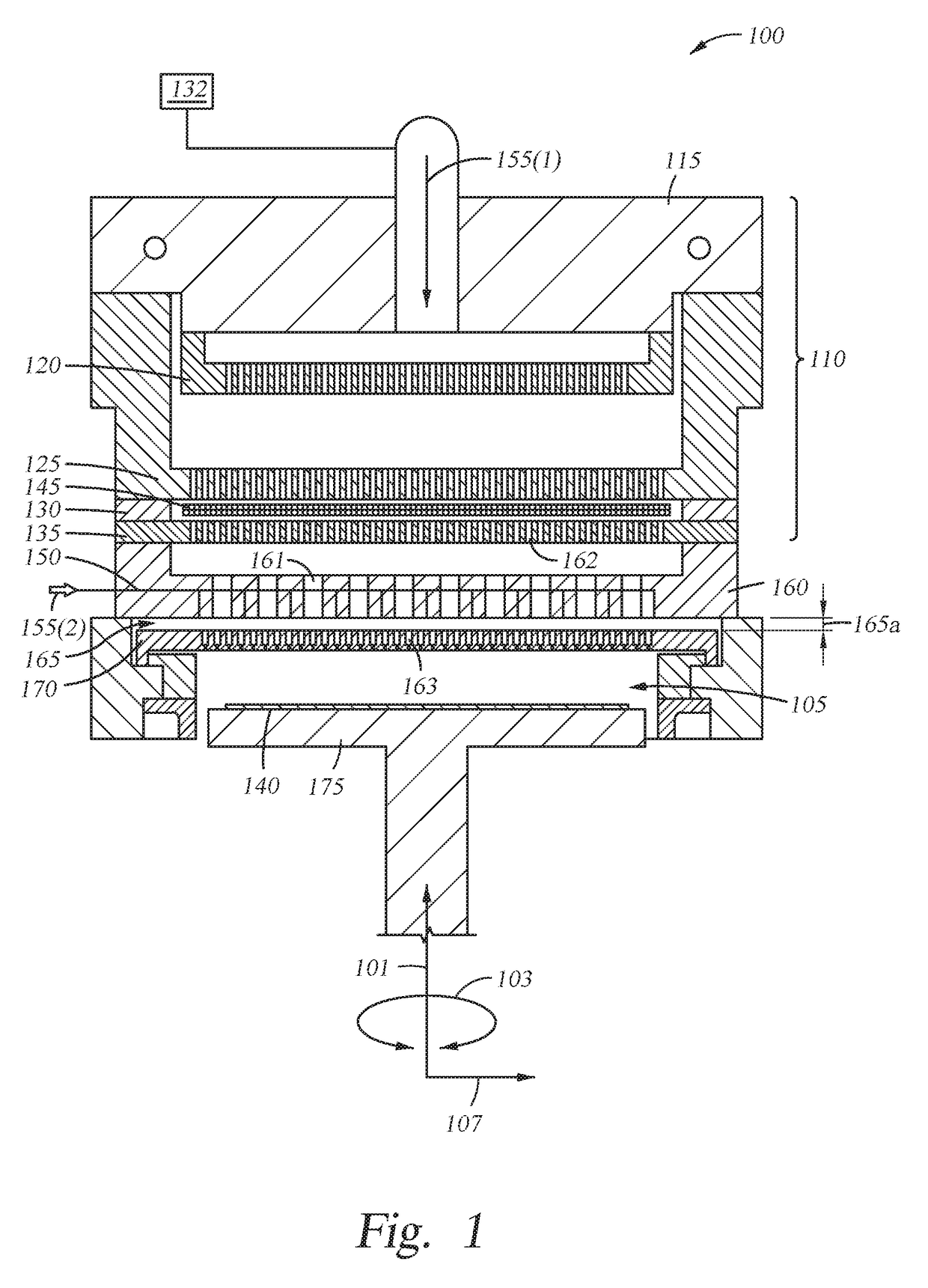

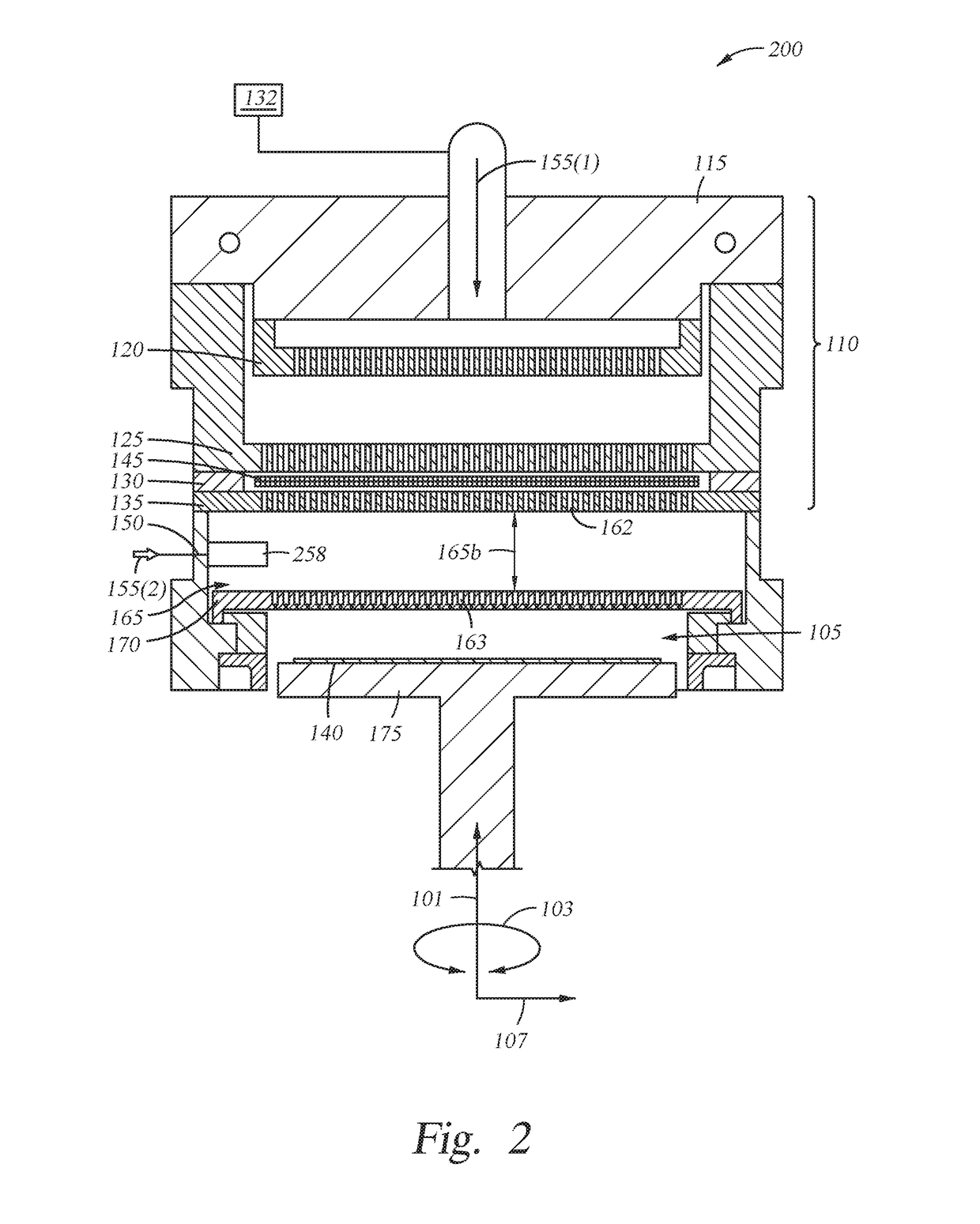

ActiveUS20170229309A1Reduce fluorine contentElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogen fluorideProcess systems

A method and apparatus for processing a semiconductor substrate are described herein. A process system described herein includes a plasma source and a flow distribution plate. A method described herein includes generating fluorine radicals or ions, delivering the fluorine radicals or ions through one or more plasma blocking screens to a volume defined by the flow distribution plate and one of one or more plasma blocking screens, delivering oxygen and hydrogen to the volume, mixing the oxygen and hydrogen with fluorine radicals or ions to form hydrogen fluoride, flowing hydrogen fluoride through the flow distribution plate, and etching a substrate using bifluoride. The concentration of fluorine radicals or ions on the surface of the substrate is reduced to less than about two percent.

Owner:APPLIED MATERIALS INC

High active no-clean welding flux

InactiveCN101380705BDissolve smoothlyAvoid decompositionWelding/cutting media/materialsSoldering mediaRubidiumSoldering

The invention discloses high-activity washing-free scaling powder. According to the weight percentage, the high-activity washing-free scaling powder includes 45.0 to 80.0 percent of trimethyl borate, 0.01 to 10.0 percent of acetone, 0.001 to 1.0 percent of cesium fluoride or rubidium bifluoride, 0.001 to 2.5 percent of aether; and the rest is carbinol. When the scaling powder produced by the invention is matched with the solders like Cu-P series for soldering, the solder has excellent wetting performance and fluidness on a mother plate, can reduce the soldering defects from generating and canimprove the intensity of a soldering seam and still has the characteristics of stopping the metal surface in a soldering area from being oxidized and needing not to be washed by acid after soldering.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Anti-bacterial and heat-resistant rubber seal ring for instruments and apparatus

InactiveCN107033476AImprove antibacterial propertiesLong antibacterial timeSodium BentoniteFatty acid

The invention discloses an anti-bacterial and heat-resistant rubber seal ring for instruments and apparatus. The rubber seal ring comprises raw materials in parts by weight as follows: 20-40 parts of brominated butyl rubber, 5-15 parts of bifluoride rubber, 5-15 parts of fluororubber, 1-2 parts of zinc oxide, 0.5-1 part of magnesium oxide, 0.5-1 part of fatty acid, 1 part of sulfur, 5-15 parts of modified diatomite, 5-15 parts of white carbon black, 2-8 parts of fly ash, 1-4 parts of carbon nano tubes, 2-5 parts of bentonite, 1-3 parts of a silane coupling agent KH-540, 0.2-0.6 parts of chlorinated paraffin, 1-2 parts of chloro-methoxy methyl oleate, 0.2-0.6 parts of butyl oleate, 1-2 parts of dioctyl phthalate, 0.1-0.5 parts of diethylene glycol dibenzoate, 1-2 parts of a calcium-zinc composite stabilizer, 1-2 parts of an anti-aging agent H and 1-2 parts of phosphite ester. The rubber seal ring is good in anti-bacterial effect, excellent in mechanical performance, good in toughness and quite good in aging resistance and heat resistance.

Owner:芜湖地心引力运动科技有限公司

Method for reducing ammonium fluorosilicate in ammonium bifluoride

The invention discloses a method for reducing ammonium fluorosilicate in ammonium bifluoride. The method comprises the steps as follows: fluorosilicic acid is subjected to an ammoniation reaction anda silicon dioxide-containing ammonium fluoride mixed solution is obtained, wherein the mass concentration of ammonium fluoride is 20%-35%, the mass concentration of silicon dioxide is 2%-15%, and thePH value is 8.0-10; the ammonium fluoride mixed solution in step (1) is filtered by a filter press, most silicon dioxide is removed, a filtrate enters a filtrate tank and left to stand and clarified for 1-3 h, most silicon dioxide settles to the bottom, and the upper layer is a clear ammonium fluoride liquid; the upper clear ammonium fluoride liquid in step (2) is finely filtered again by micropores with the diameter being 3-10 micron, and a wet filter cake returns to a feeding chute of the filter press; a refined filtrate enters a concentrated raw material chute to be left to stand and clarified for 1-3 h, an upper clear ammonium fluoride liquid enters a concentration system, conventional concentration, acid addition, crystallization and centrifugal separation are performed later, and anammonium bifluoride product is obtained. The method can effectively reduce ammonium fluorosilicate in ammonium bifluoride, has low energy consumption, introduces no other impurities and avoids waste emission.

Owner:贵州瓮福蓝天氟化工股份有限公司

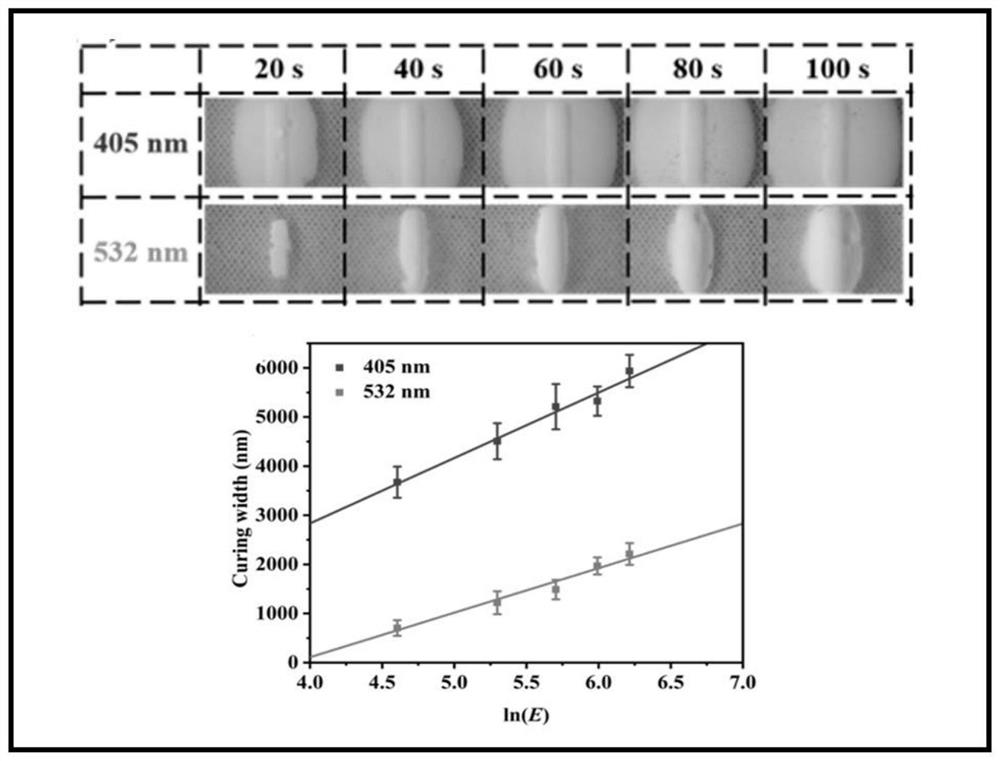

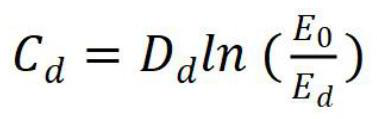

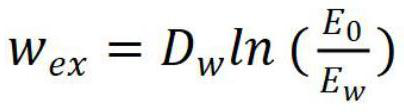

3D printing photosensitive material taking green light as photocuring light source and 3D printer thereof

InactiveCN113895031AImprove curing depthHigh refractive indexAdditive manufacturing apparatusCeramic shaping apparatus3d printComputer printing

The invention discloses a 3D printing photosensitive material taking green light as a photocuring light source. The 3D printing photosensitive material at least comprises a green light photo-initiation system, the green light photo-initiation system is a Norrish I type photosensitizer and a Norrish II type photosensitizer which have light absorption and initiation capability in a green light wavelength range, and the system comprises a curcumin compound / onium salt system, a boron bifluoride curcumin compound / onium salt system, a ferrocene-contained conjugated indandione compound / onium salt / N-methyl pyrrolidone system, a benzal ketone compound / onium salt system and a benzal ketone compound / amine system. The 3D printing photosensitive material has the beneficial effects that on one hand, through the principles that the longer the wavelength is, the lower the light refractive index is, and the longer the wavelength is, the stronger the light penetrability is, the curing depth of the 3D printing material can be remarkably improved, and the problem of interlayer cracking is avoided, especially for the 3D printing material with the high refractive index, such as 3D printing photosensitive ceramic slurry; and on the other hand, through the principle that the longer the wavelength is, the lower the light refractive index is, the curing width of the 3D printing material can be remarkably reduced, and the curing and printing precision can be improved, especially for the 3D printing material with the high refractive index, such as 3D printing photosensitive ceramic slurry.

Owner:SUN YAT SEN UNIV

Grass lawn herbicide and its preparing method

The present invention relates to a lawn weedicide and its preparation method. The composition of said lawn weedicide includes (by wt%) 1-50% of alpha-bifluoropropanoic acid, 1-20% of fenchlorazole, 5-10% of synergistic agent and the rest is adjuvant. Its preparation method includes the following steps: synthesizing monofluoride, synthesizing bifluoride, dissolving three kinds of isomer compounds in acetylacetone, separating to obtain alpha-bifluroropropanoic acid solution, mixing alpha-bifluoropropanoic acid, fenchlorazole, bromoxynil and adjuvant, stirring them uniformly so as to obtain the invented weedicide.

Owner:张伟兴

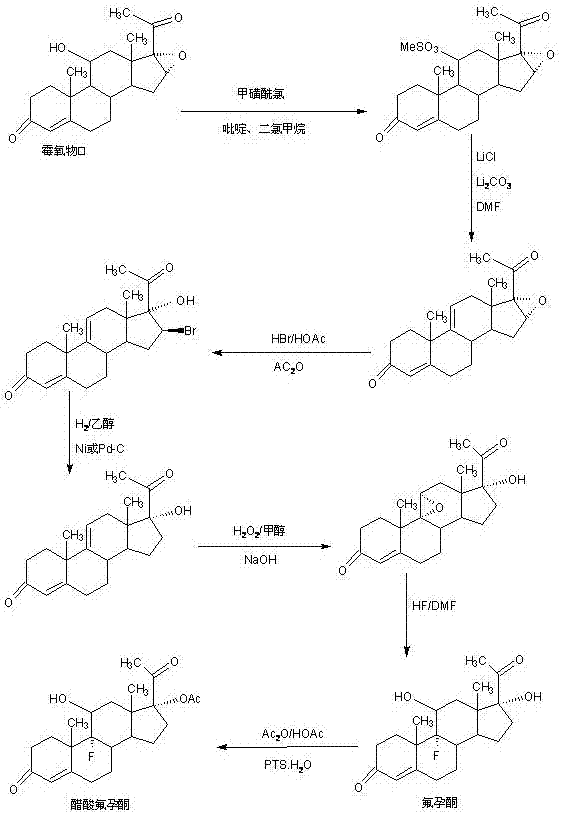

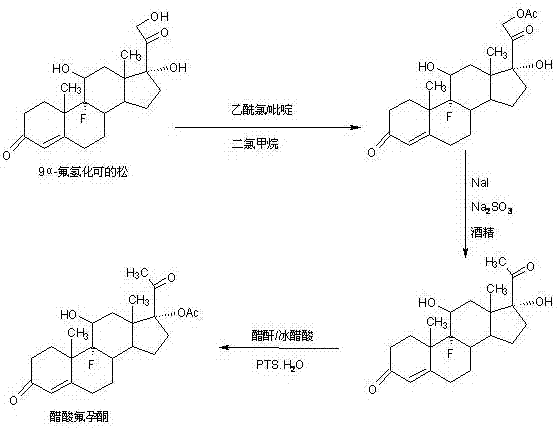

Preparation method of flurogestone acetate

InactiveCN107365341AWide variety of sourcesShort synthetic routeSteroidsAcetic anhydrideSodium iodide

The invention discloses a preparation method of flurogestone acetate. The preparation method comprises the following steps: using 9a-cortisone bifluoride as a raw material, dissolving 9a-cortisone bifluoride into an organic solvent, and reacting with acyl chloride under the existence of an acid-binding agent to obtain a 9a-cortisone bifluoride-21-O-ester; then reacting the ester with sodium iodide and a sulfur-containing reducing agent in the organic solvent for deesterification, and synthesizing flugestone; and finally reacting the flugestone with acetylchloride or acetic anhydride in the organic solvent, and synthesizing flurogestone acetate. According to the preparation method, 9a-cortisone bifluoride is used as the raw material, flurogestone acetate is synthesized through three-step reaction of 21-site esterification, then reduction and de-esterification and finally 17-site ethyl esterification, and compared with a traditional synthetic method for using a mold removal object acquired through diosgenin processing as a raw material, the preparation method has the advantages such as wide raw material source, short synthetic route, simple, convenient and environmentally-friendly process, few invested equipment and high product yield, and the production cost in the method is reduced by 25% to 30% as compared with a traditional method; and a solvent used in the production can be recycled and circularly used, and is easy for industrial production.

Owner:HUNAN KEREY BIOTECH

Flow distribution plate for surface fluorine reduction

ActiveUS10204795B2Reduce fluorine contentElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogen fluorideProcess systems

Owner:APPLIED MATERIALS INC

Process for production of etching or cleaning fluids

InactiveCN1759472AEasy to adjustDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrofluoric acidOrganic solvent

Owner:DAIKIN IND LTD

Anti-dazzle glass frosting powder for windshields

InactiveCN104724941AAdjustable frosting processAdjustable: the invented frosting powder is convenient and quick for the frosting processSodium acetateDiffuse reflection

The invention relates to manufacturing of glass frosting powder, belongs to the field of light industry, and specifically relates to an anti-dazzle glass frosting powder for windshields. A formula of the glass frosting powder is provided and includes the following ingredients: fluorinated ammonia, ammonium bifluoride, magnesium bifluoride, aluminum bifluoride, oxalic acid, sodium acetate, sodium silicate, ammonium fluoroborate, sodium fluoroborate, Al2O3 and SiO2, sodium dodecyl sulfate, cellulose MCC, sodium hexametaphosphate and sodium polypropionate. The above ingredients are crushed according to a weight ratio; the crushed ingredients are uniformly stirred, dried and packaged; and finally, a product obtained is inspected and enters a finished product warehouse. After car windshields or other types of windshields are treated by the use of the glass frosting powder, the effect of diffuse reflection is good, and external bright light is not irritating to eyes when passing through the treated windshields. Thus, traffic accidents are minimized, and life safety factors of people in cars and safety factors of materials in cars are increased.

Owner:黄淼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com