Patents

Literature

86results about "Ammonium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

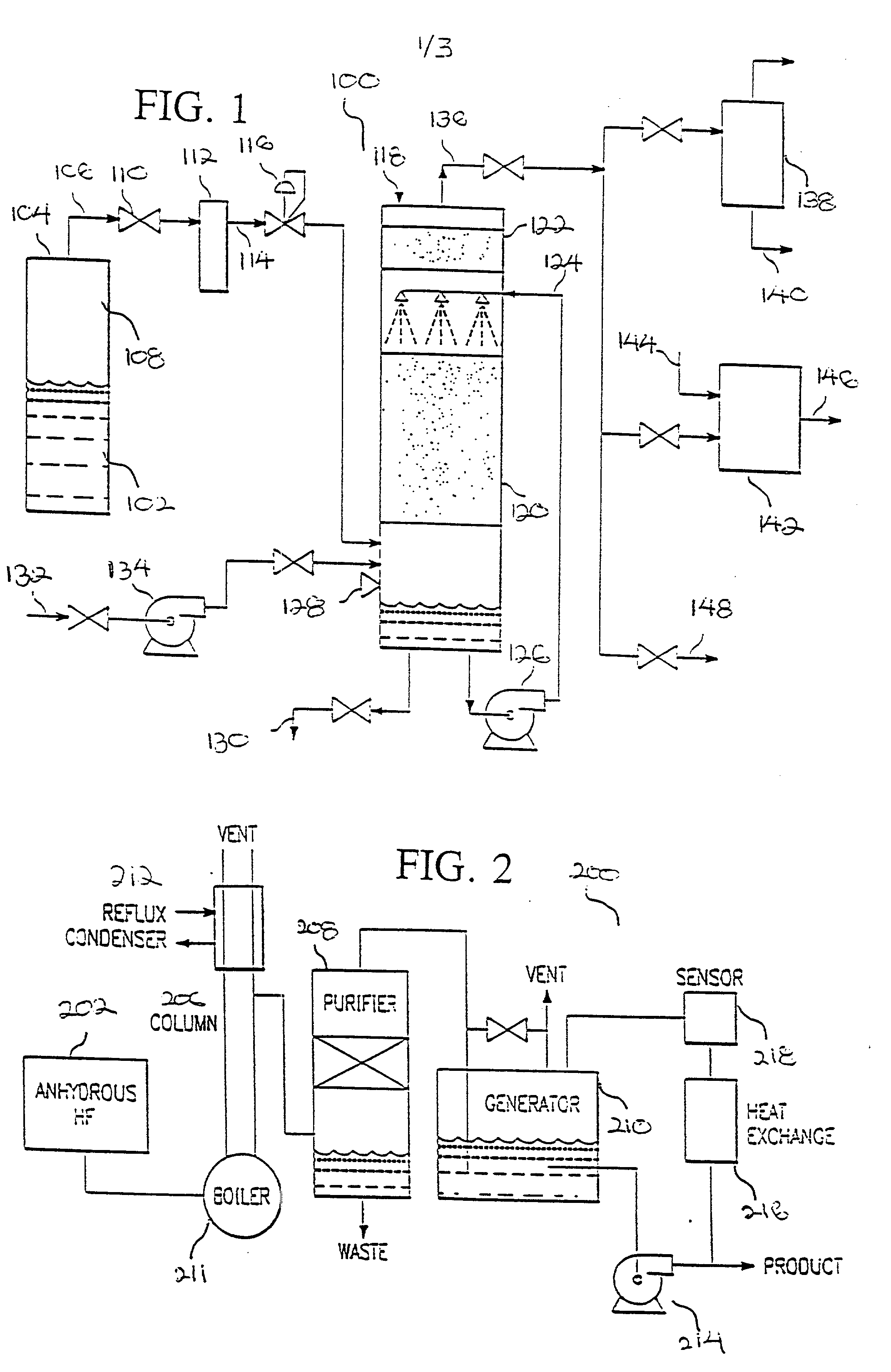

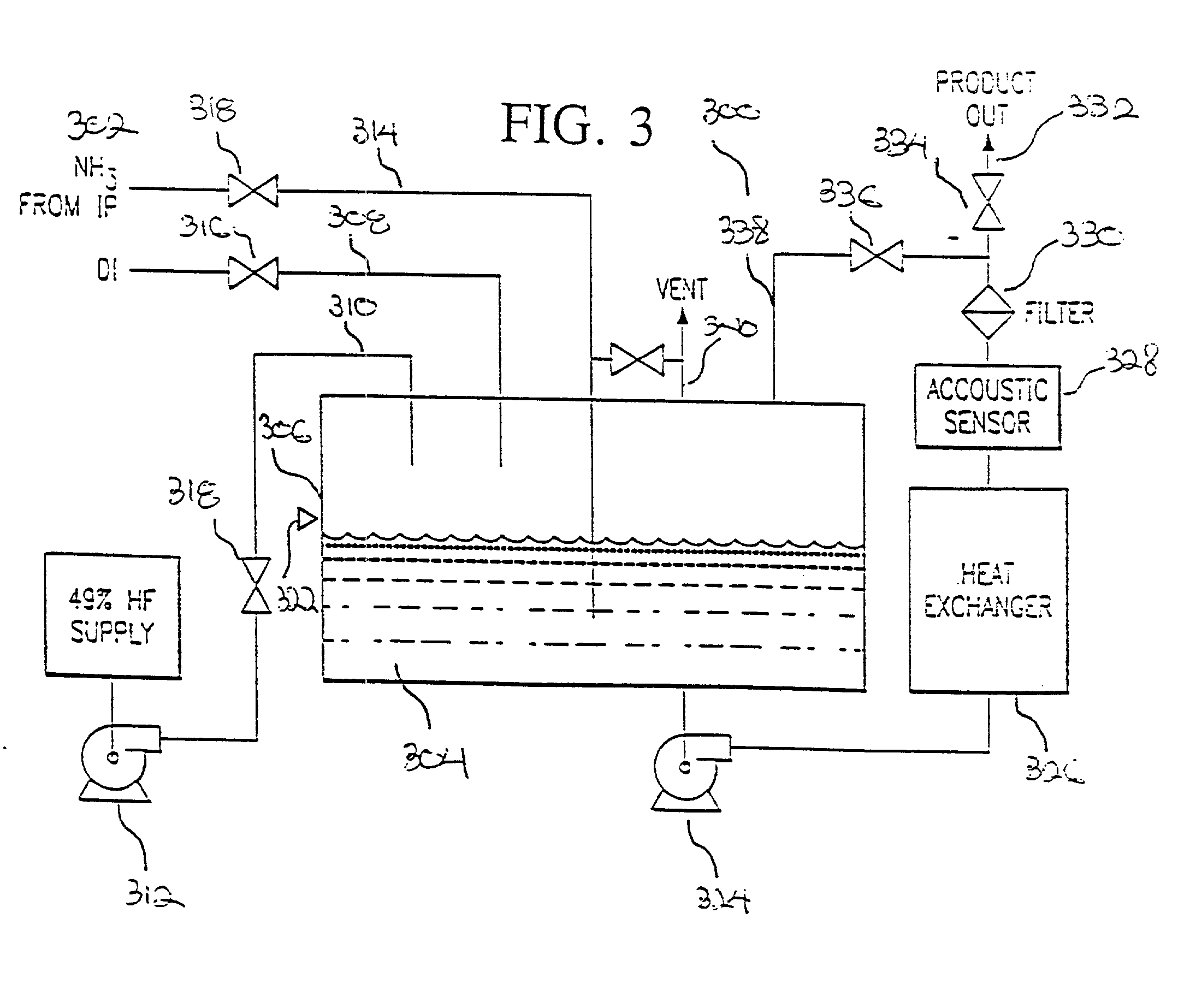

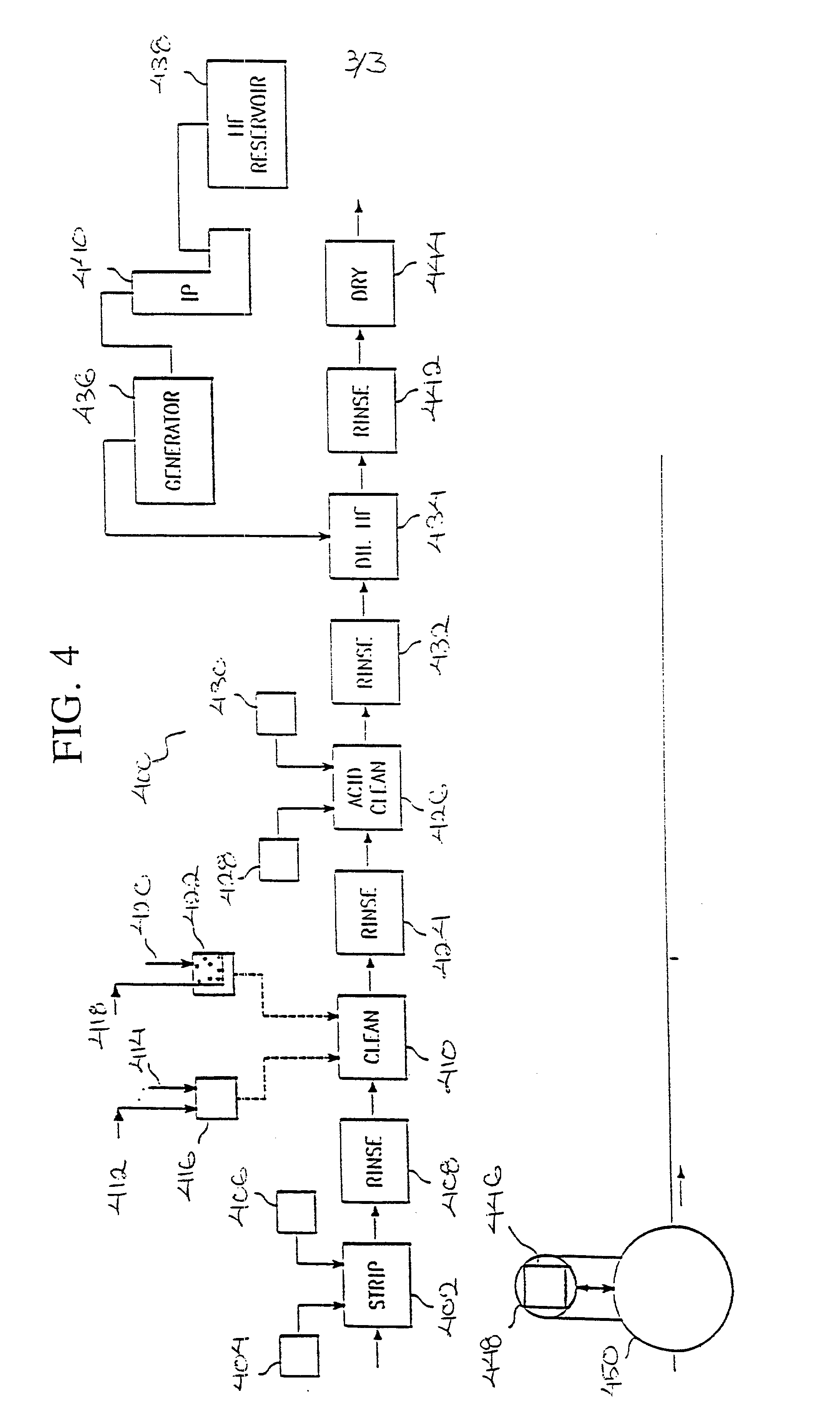

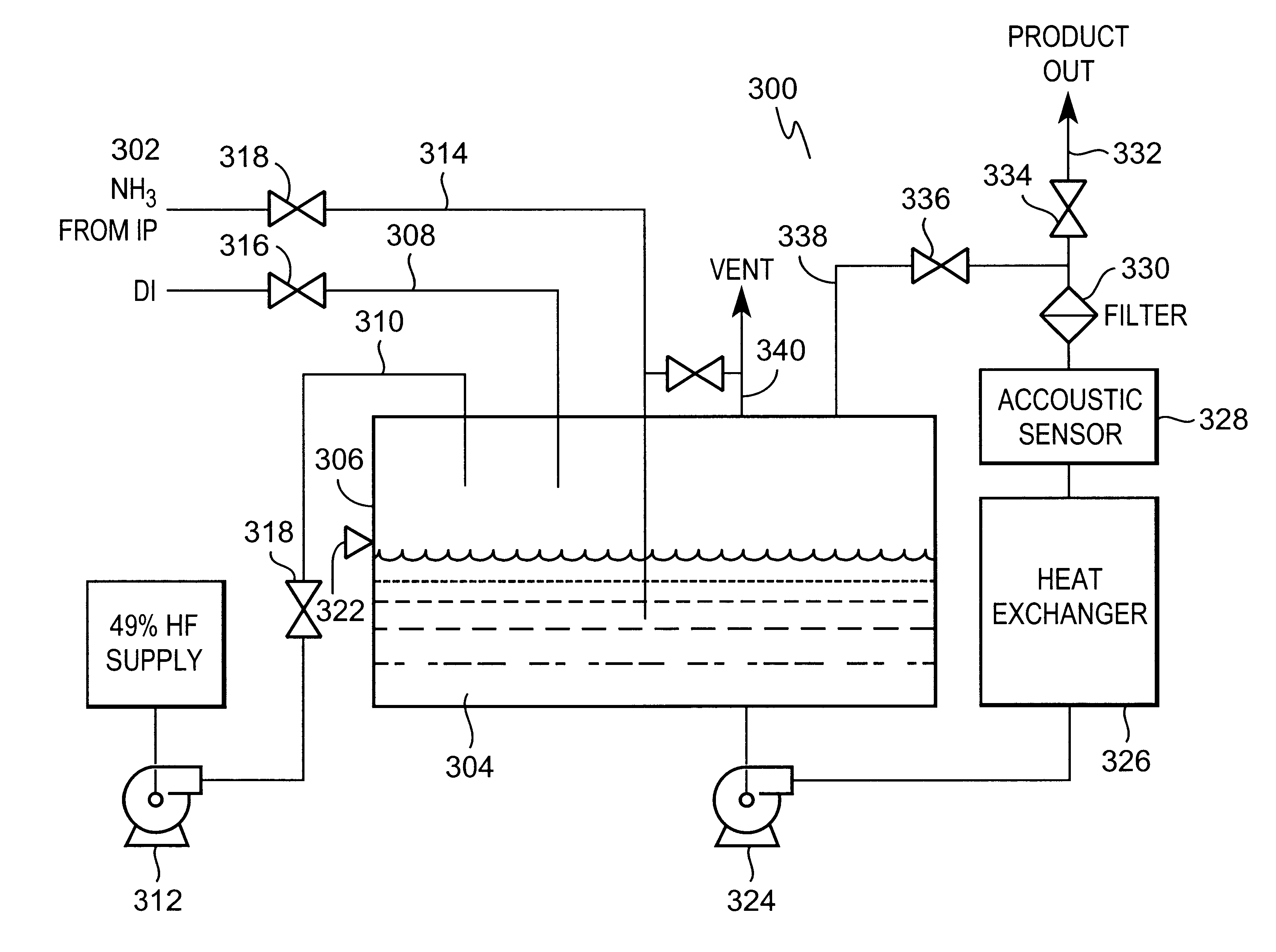

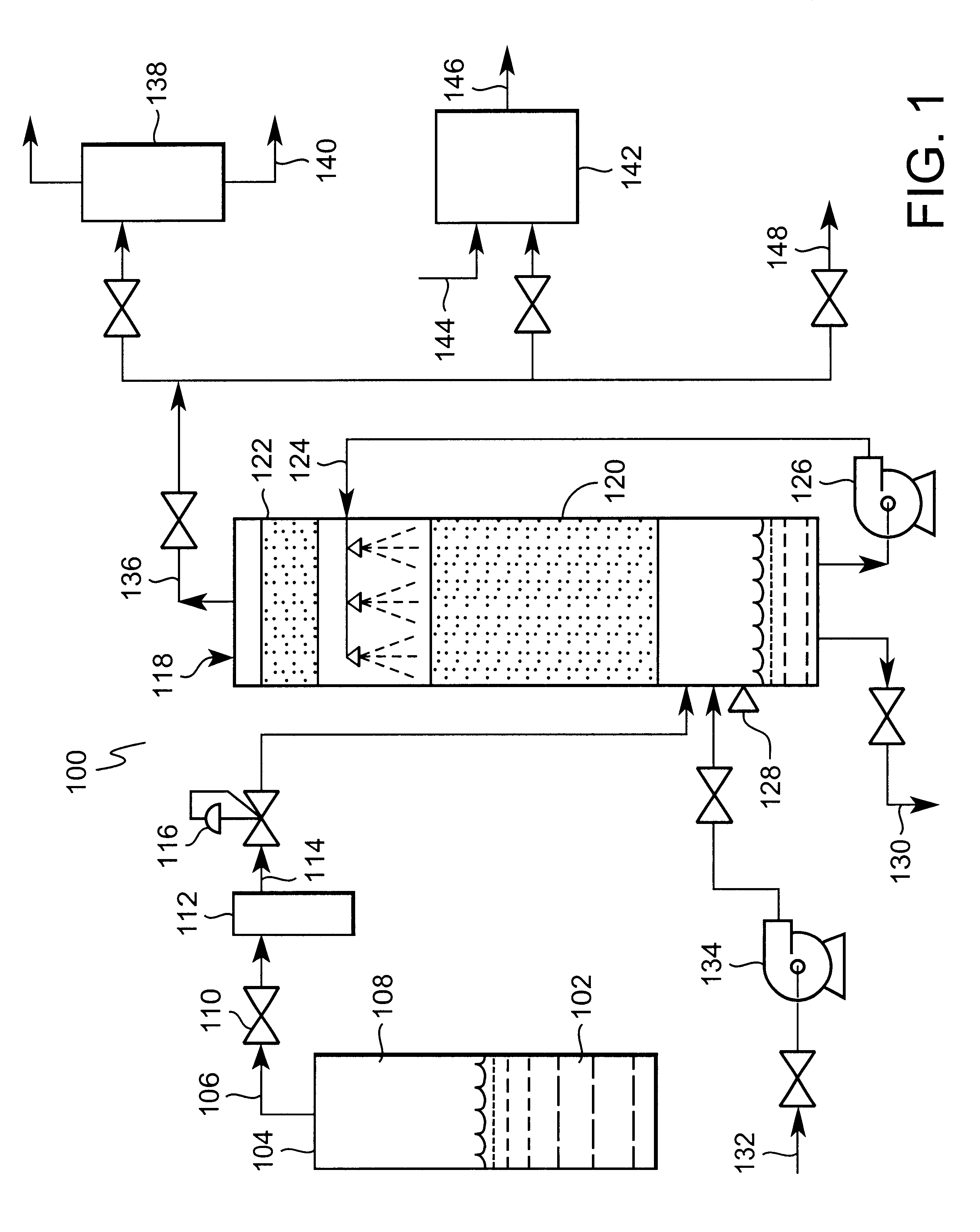

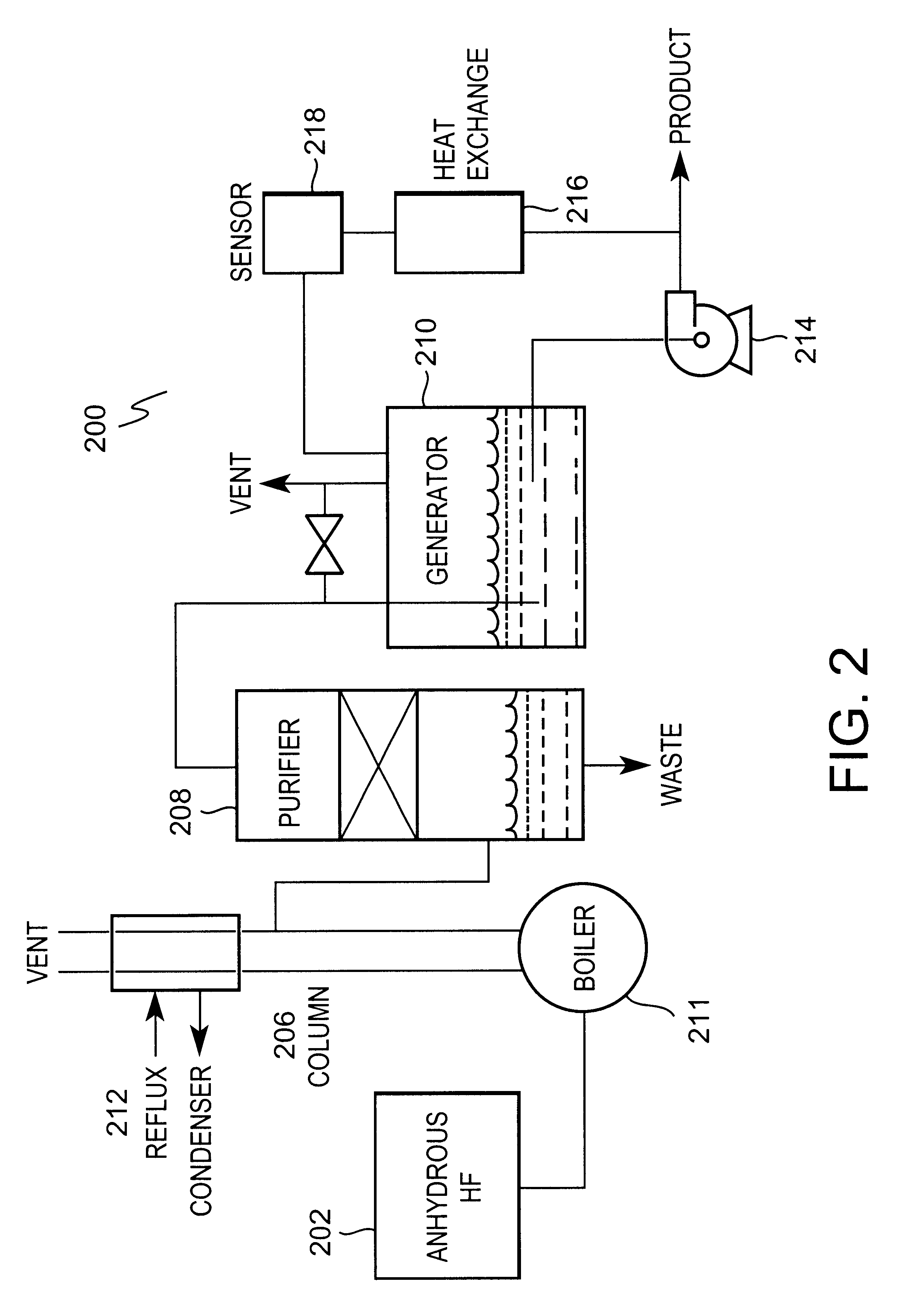

On-site generation of ultra-high-purity buffered-hf and ammonium fluoride

InactiveUS20010051128A1Low impurity contentImprove device characteristicsChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration. The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

On-site generation of ultra-high-purity buffered-HF and ammonium fluoride

InactiveUS6350425B2Reduce processingLow impurity contentChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

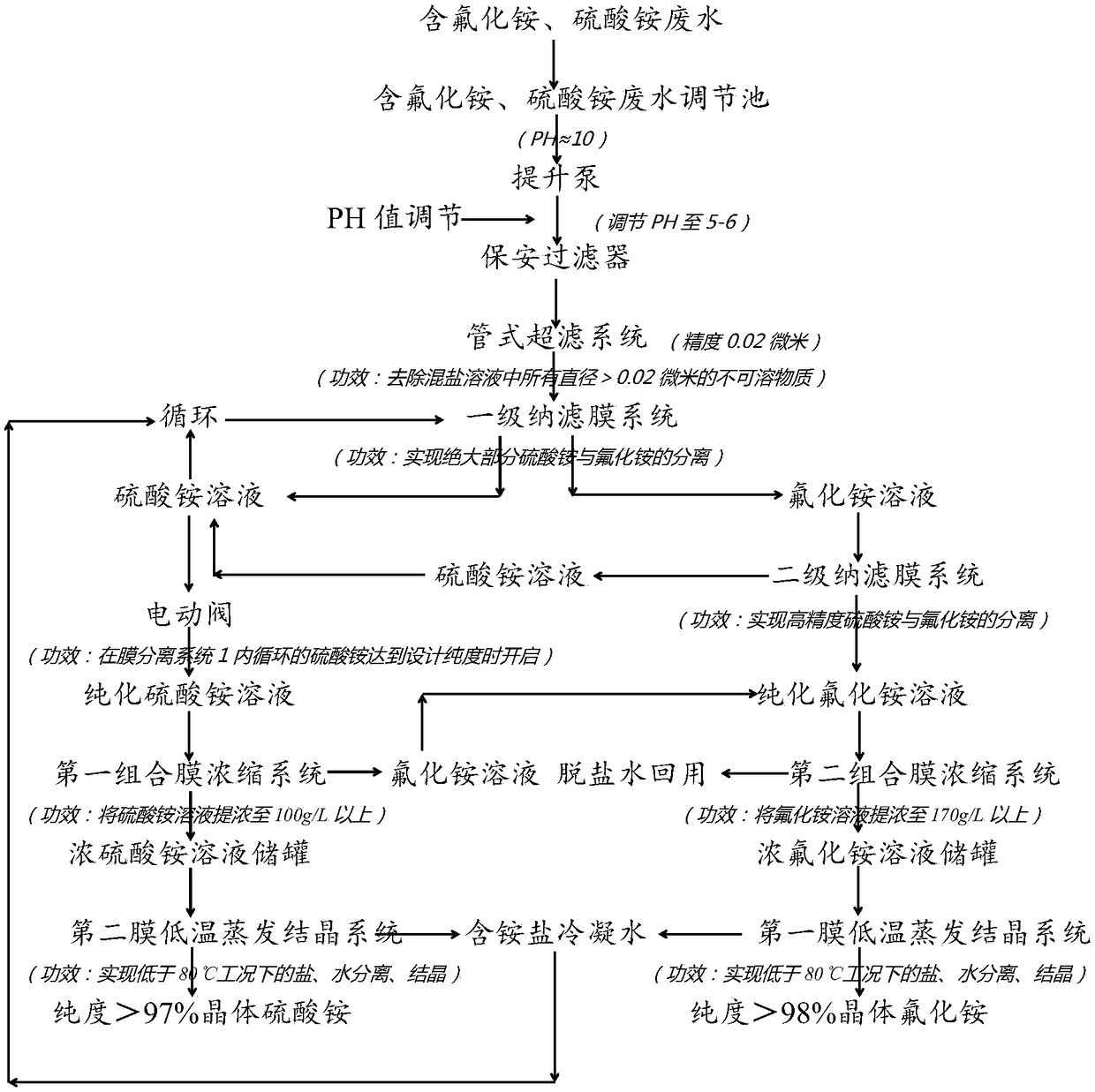

Recycling method for fluorine-containing ammonia-nitrogen-containing wastewater through tantalum-niobium wet-process smelting

The invention discloses a recycling method for fluorine-containing ammonia-nitrogen-containing wastewater through tantalum-niobium wet-process smelting, and relates to the technical field of wastewater recycling. The recycling method comprises the following steps: adding hydrofluoric acid or sulfuric acid into wastewater to regulate the pH value of the wastewater to 5-6, completely converting freeNH3 in the wastewater into NH<4+> for being dissolved into the wastewater, performing primary screening on mixed salt wastewater into an ammonium fluoride solution and an ammonium sulfate solution through a primary nanofiltration membrane system, pumping the primarily separated ammonium fluoride solution into a secondary nanofiltration membrane system, removing a little ammonium sulfate in the ammonium fluoride solution, wherein a little ammonium fluoride is contained in the primarily separated ammonium sulfate solution; arranging a fluorine ion concentration online monitor in the primary nanofiltration membrane circulating system until concentration of fluorine ions is lower than a set value; automatically opening an electric regulating valve for discharging the ammonium sulfate solutionwith purity reaching design requirements out of the primary nanofiltration membrane system; and introducing the concentrated ammonium fluoride solution and the concentrated ammonium sulfate solutioninto a low-temperature membrane evaporation and crystallization system, thereby recycling ammonium fluoride crystals and ammonium sulfate crystals.

Owner:肖平

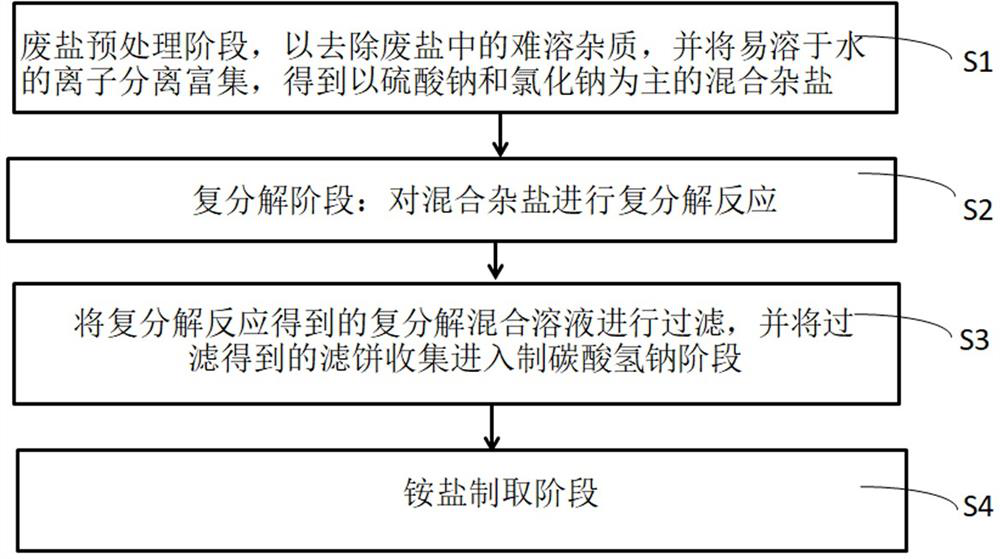

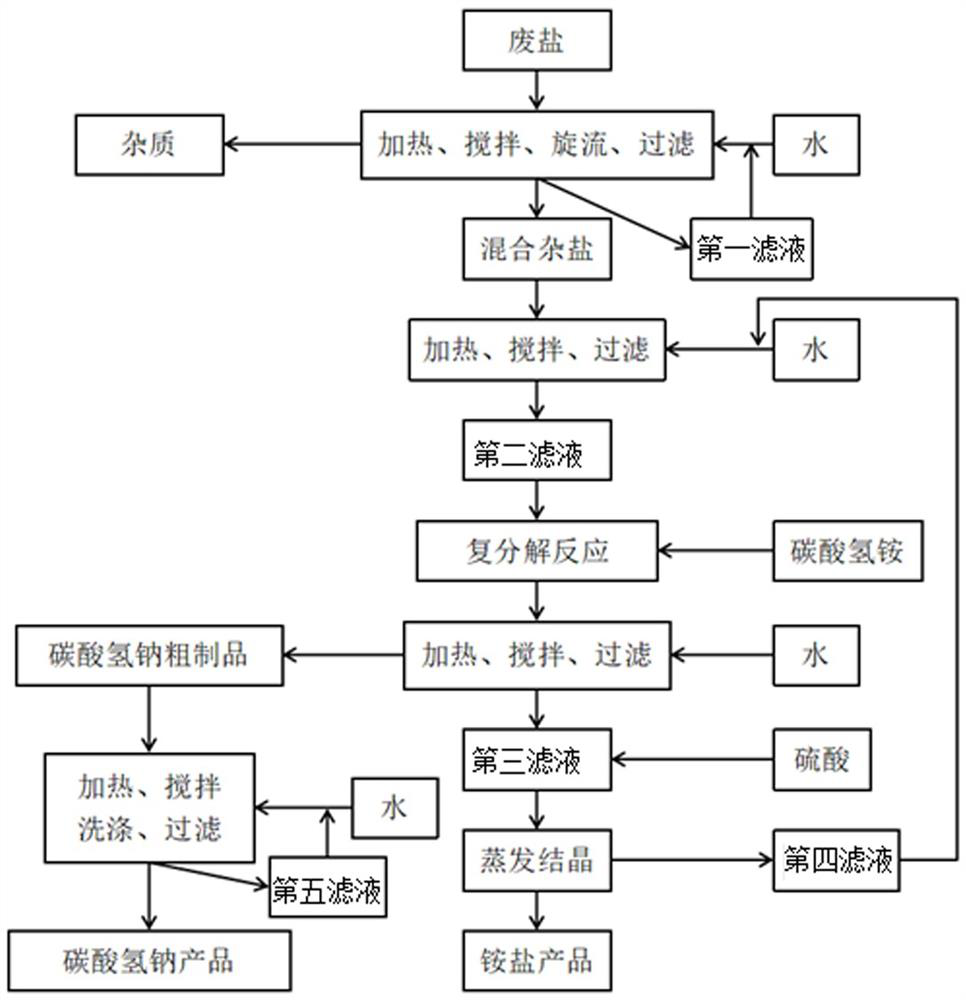

Resourceful treatment method of waste salt

ActiveCN113336246APromote resource utilizationThe method flow is simpleBicarbonate preparationAmmonium fluorideSodium bicarbonateEnvironmental engineering

The invention discloses a resourceful treatment method of waste salt. The method comprises the following steps: S1, a waste salt pretreatment stage: removing insoluble impurities in waste salt, and separating and enriching water-soluble ions to obtain mixed hybrid salt mainly comprising sodium sulfate and sodium chloride; S2, a double decomposition stage: carrying out double decomposition reaction on the mixed hybrid salt; S3, filtering a metathesis mixed solution obtained by the metathesis reaction, and collecting filter cake obtained by filtering to enter a sodium bicarbonate preparation stage; and S4, an ammonium salt preparation stage. The waste salt mainly containing sodium chloride and sodium sulfate is subjected to resourceful treatment, industrial sodium bicarbonate and ammonium salt products are obtained, so that resourceful treatment of the waste salt is greatly improved. The method is simple in process and low in cost, the utilization rate of the waste salt is 84%-89%, the purity of the prepared product sodium bicarbonate is 94%-96%, and the nitrogen content (on a dry basis) in the ammonium salt is greater than or equal to 23.8%.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

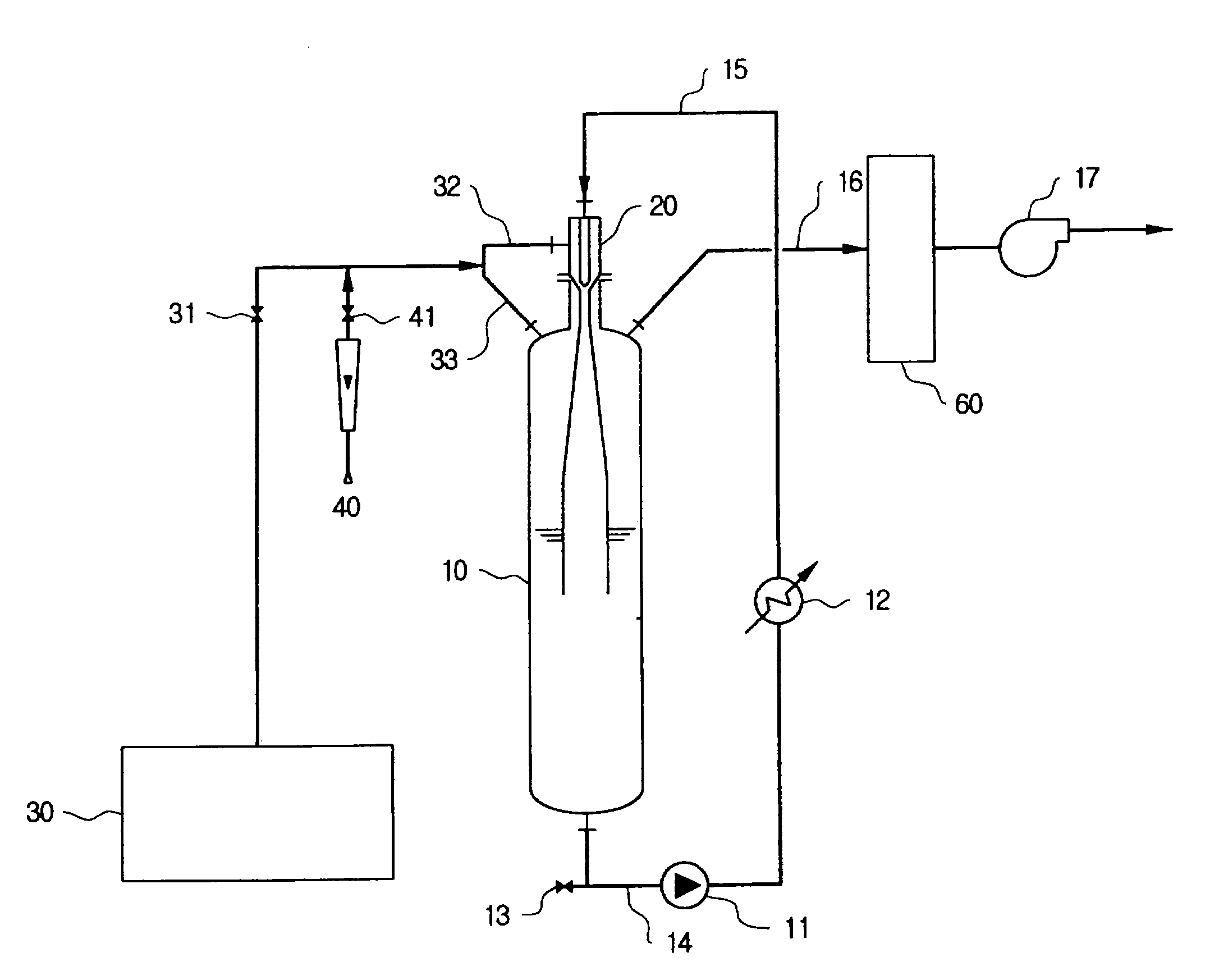

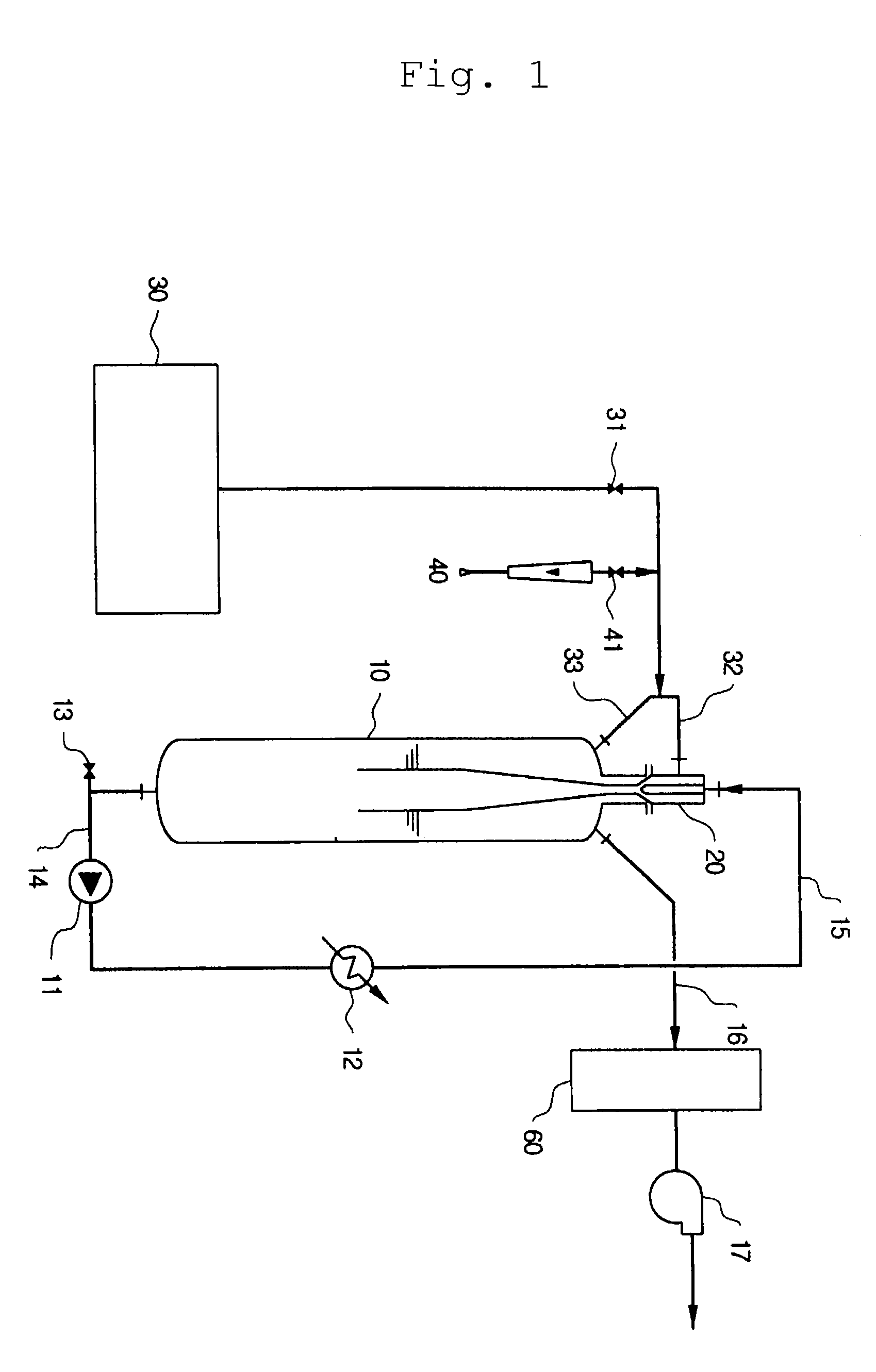

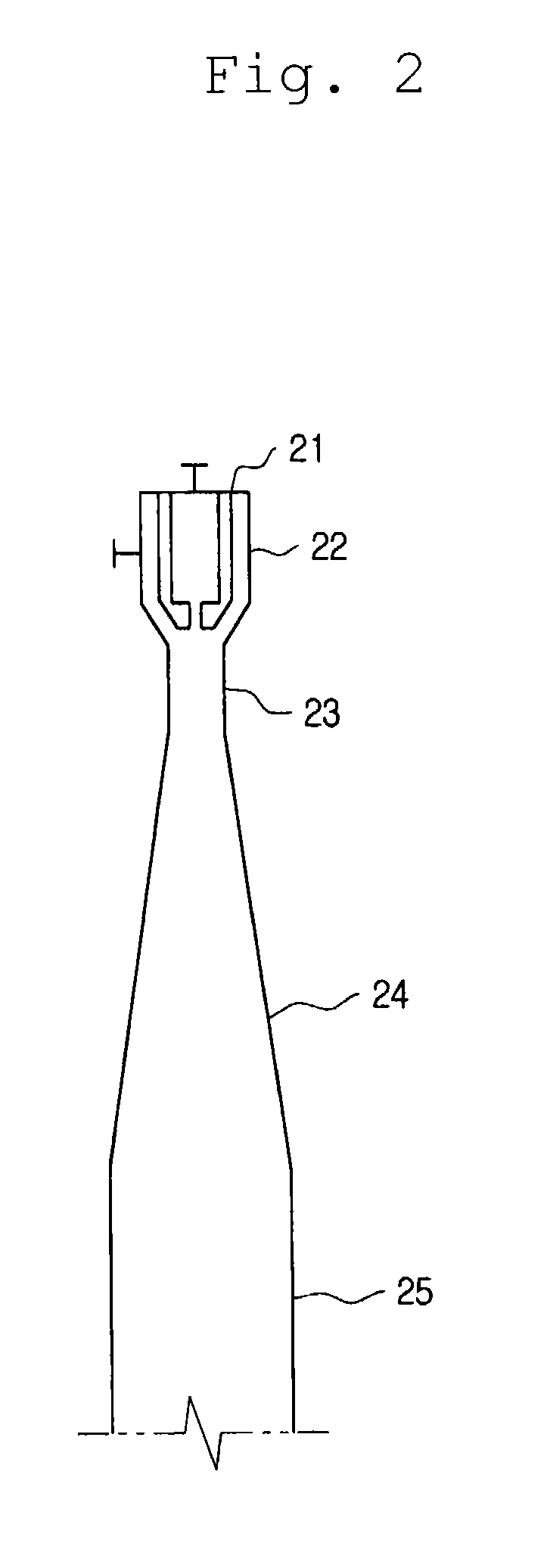

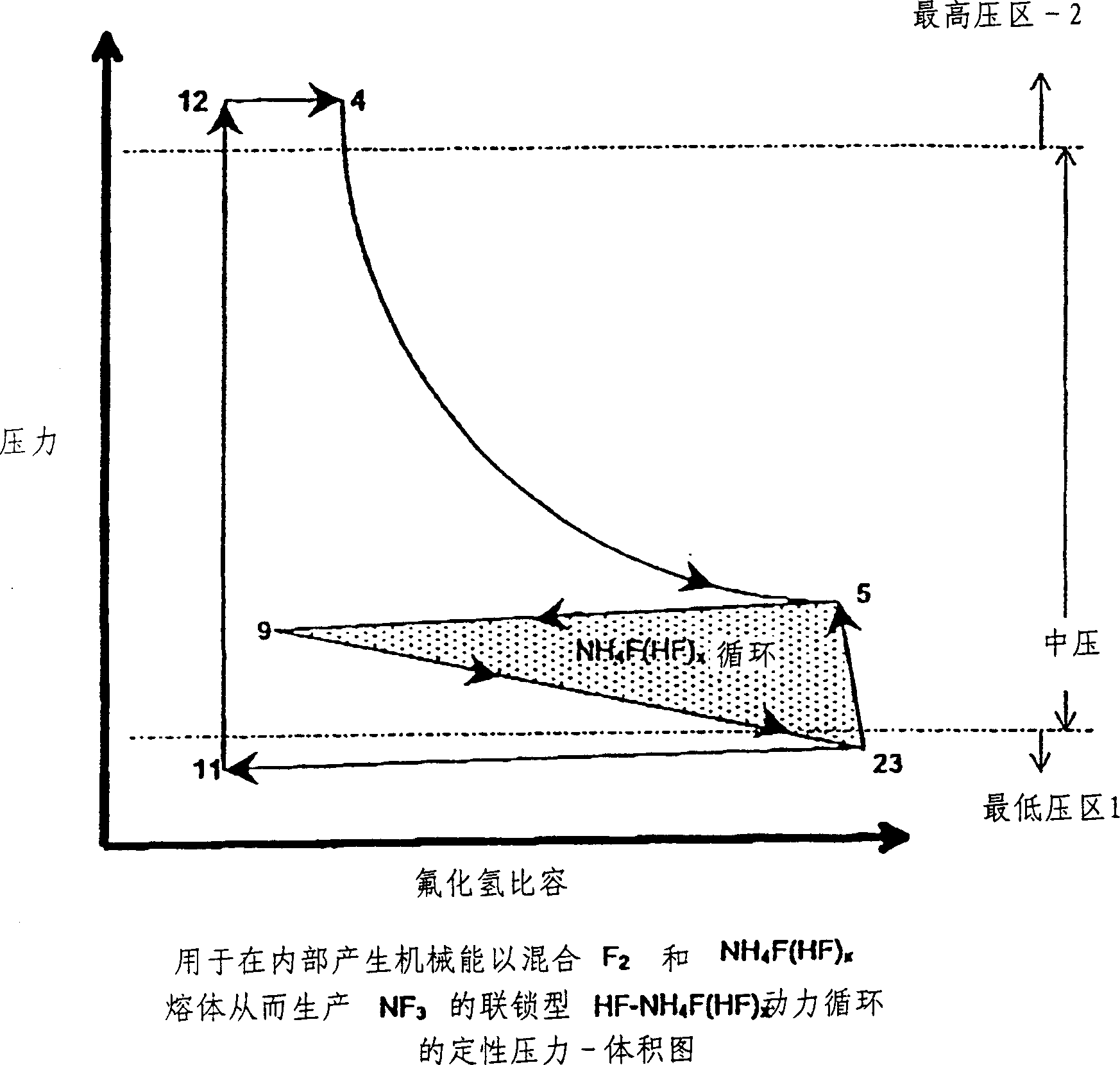

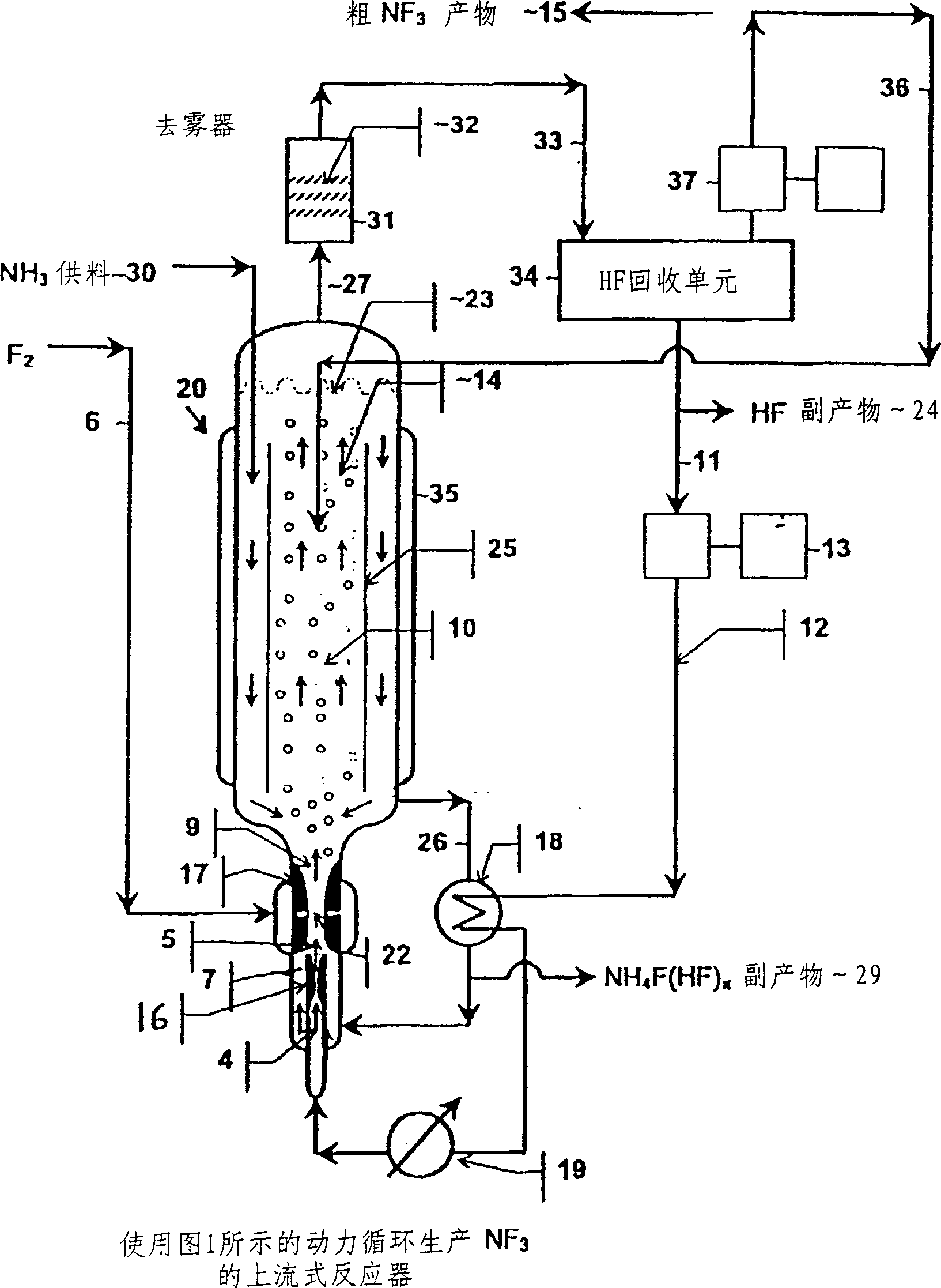

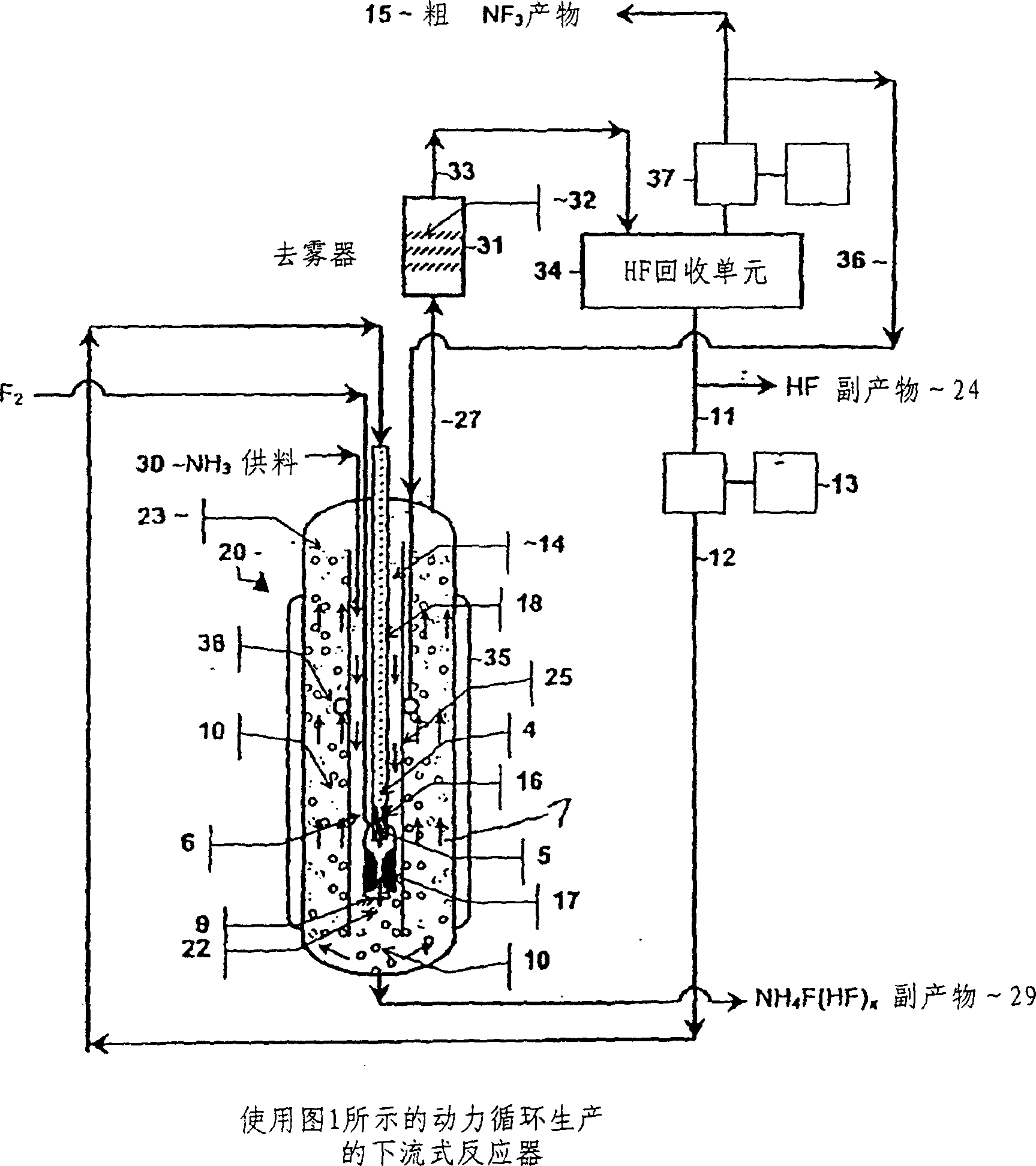

Method for producing nitrogen trifluoride using jet-loop reactors

InactiveUS7083773B2Increasing NF yieldEasy to controlNitrogen-metal/silicon/boron binary compoundsFluorine/hydrogen-fluorideReaction temperatureSide reaction

Nitrogen trifluoride is produced with a high yield by the method comprising forming a fast stream of micro droplets of a fused ammonium fluoride salt by rapidly ejecting the fused ammonium fluoride salt into a reactor through a nozzle while circulating the fused ammonium fluoride salt in the reactor from a lower portion to an upper portion; and contacting micro droplets of the fused ammonium fluoride salt with fluorine gas sucked in the reactor through a suction pipe for fluorine by a negative pressure formed around the nozzle due to an ejection of the fused ammonium fluoride salt, whereby excessive generation and regional accumulation of the heat of reaction are prevented, reducing the reaction temperature by 10˜30° C. compared with those of the existing methods, and a side reaction occurs only to a slight extent according to the lowered reaction temperature.

Owner:KOREA INST OF SCI & TECH

Method for treating electrolytic waste residues and wastewater produced in electrolytic process nitrogen trifluoride production technology

InactiveCN110668629AHigh purityAchieve recyclingWater/sewage treatment by centrifugal separationWater contaminantsHydrogen fluorideProcess engineering

The invention discloses a method for treating electrolytic waste residues and wastewater produced in an electrolytic process nitrogen trifluoride production technology. The method comprises the following steps: (1) neutralizing the electrolytic waste residues and wastewater: adding the electrolytic waste residues and fluorine-containing wastewater generated by cleaning an electrolytic bath into aneutralizing kettle, performing stirring until full dissolving, introducing ammonia water, controlling the reaction temperature to 20-50 DEG C until the pH value of the solution in the reaction kettlereaches 2-5, and stopping the introduction of the ammonia water in order to obtain an aqueous ammonium bifluoride solution; (2) centrifugally separating a nickel-containing byproduct: adding a flocculating agent into the ammonium bifluoride solution to separate out and flocculate the nickel-containing byproduct and form a precipitate, and centrifugally separating the nickel-containing byproduct;(3) performing vacuum concentration: adding the ammonium bifluoride solution into a dehydration kettle, and carrying out evaporative concentrating dehydration under the conditions of -0.086 to -0.096Mpa and 65-75 DEG C until the mass concentration of ammonium bifluoride reaches 60-80%; and (4) performing cooling crystallization, centrifugal separation and drying. The method reduces environmentalpollution, realizes resource recycling and reduces the production cost.

Owner:洛阳昊华气体科技有限公司 +1

Process for producing nitrogen trifluoride and use thereof

InactiveUS20030017098A1Improve securityImprove efficiencyNitrogen-metal/silicon/boron binary compoundsHydrogen fluorideGas phaseOrganic chemistry

Owner:SHOWA DENKO KK

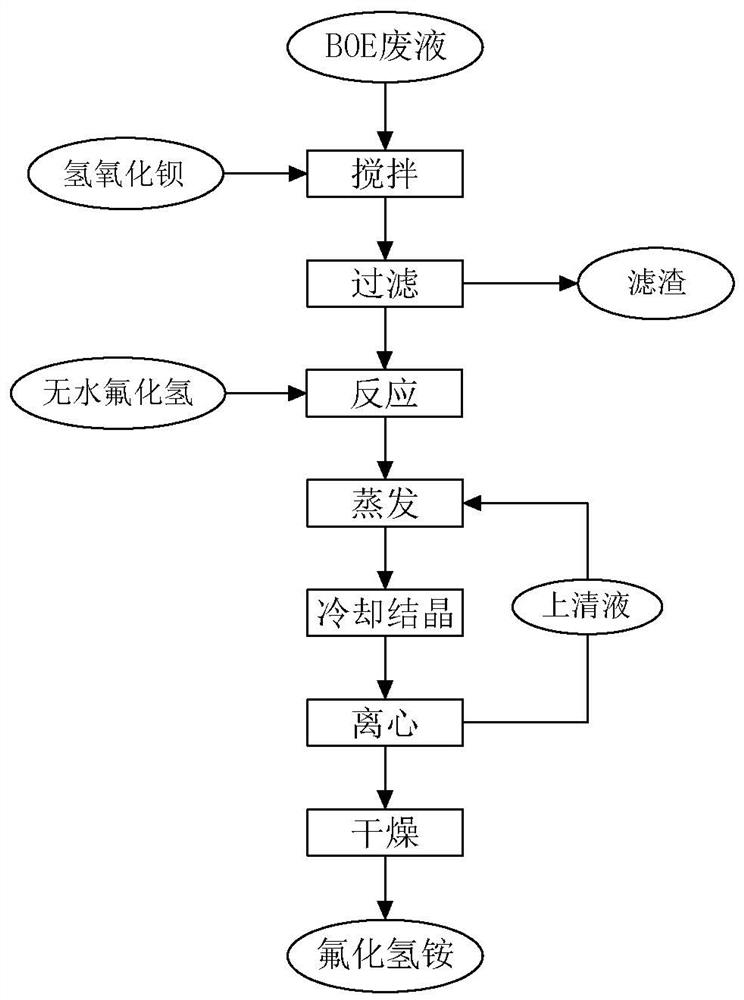

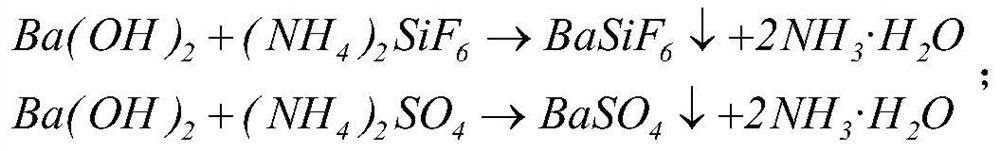

Method for preparing ammonium bifluoride by utilizing BOE waste liquid

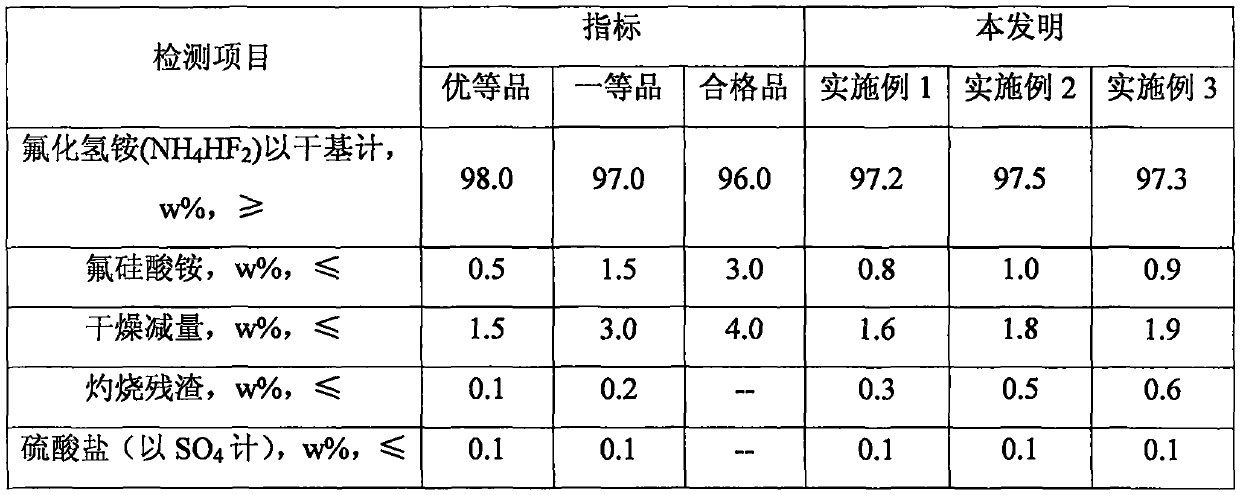

PendingCN112158858AHigh purityReduce moisture contentAmmonium fluorideEnvironmental chemistryAmmonium bifluoride

The invention provides a method for preparing ammonium bifluoride from BOE waste liquid, which can avoid environmental pollution caused by directly discharging the BOE waste liquid by recycling the BOE waste liquid, and the recovered and prepared ammonium bifluoride product has the advantages of high purity, low water content, low investment cost and low production cost. According to the method, BOE waste liquid generated by a semiconductor etching process is used as a raw material, barium hydroxide is used as a precipitator to remove impurities in the waste liquid, then anhydrous hydrogen fluoride is introduced to convert ammonium fluoride into ammonium hydrogen fluoride, and then evaporation, cooling crystallization, centrifugal separation and drying are performed to obtain high-purity ammonium hydrogen fluoride with low water content.

Owner:江苏电科环保有限公司

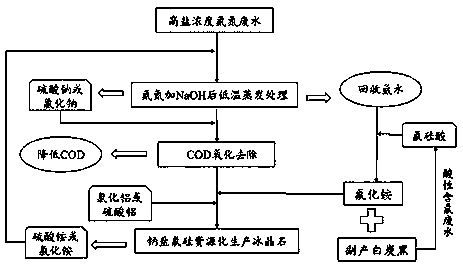

Method for treating high-salt ammonia nitrogen wastewater and comprehensively utilizing fluorine-silicon resources

InactiveCN108862317AReduce salt contentAchieve reuseSilicaWater contaminantsEvaporationHexafluorosilicic acid

The invention relates to a method for treating high-salt ammonia nitrogen wastewater and comprehensively utilizing fluorine-silicon resources. The method is characterized in that high-salt ammonia nitrogen wastewater mainly comprises the following components in percentage by mass: 1) 4%-20% of ammonium chloride or / and ammonium sulfate; 2) 5%-25% of sodium chloride or / and sodium sulfate; the ammonium chloride or / and ammonium sulfate component of the high-salt ammonia nitrogen wastewater is added into sodium hydroxoide, and is subjected to low-temperature evaporation by an ammonia nitrogen treatment system to recycle ammonia water; the recycled ammonia water reacts with hydrofluosilicic acid to generate ammonium fluoride and a byproduct white carbon black; the wastewater subjected to ammonianitrogen treatment reacts with ammonium fluoride, aluminum chloride or aluminum sulfate to obtain cryolite and a byproduct ammonium chloride or ammonium sulfate; and the byproduct ammonium chloride or ammonium sulfate is returned to the ammonia nitrogen treatment system to subject to low-temperature evaporation to recycle ammonia water. The method has the advantages that: ammonia nitrogen and salt in wastewater are sufficiently utilized by fluorine-silicon recycling to produce cryolite, so that content of ammonia nitrogen and salt in high-salt ammonia nitrogen wastewater is remarkably reduced, waste is changed into things of value, and economic benefits are improved.

Owner:HUNAN UNIV OF TECH

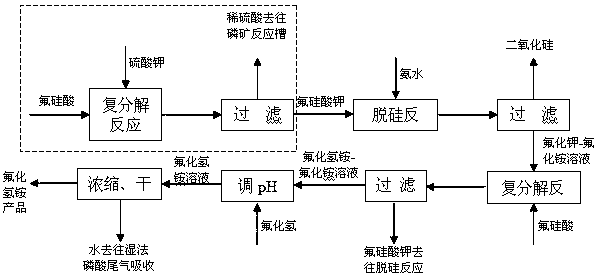

Method for preparing ammonium hydrogen fluoride by circularly treating fluosilicic acid through sylvite

ActiveCN108439365AReduce usageReduce production energy consumptionSilicaCarbon preparation/purificationChemical industryPotassium fluoride

The invention discloses a method for preparing ammonium hydrogen fluoride by circularly treating fluosilicic acid through sylvite, and belongs to the technical field of phosphorus chemical industry. The method comprises the following steps: reacting potassium fluosilicate with ammonia water, after reaction is finished, carrying out solid-liquid separation to obtain a potassium fluoride-ammonium fluoride solution and a silicon dioxide filter cake, and preparing white carbon black from the silicon dioxide filter cake; reacting the potassium fluoride-ammonium fluoride solution with the fluosilicic acid, after reaction is finished, carrying out solid-liquid separation to obtain an ammonium hydrogen fluoride-ammonium fluoride solution and potassium fluosilicate, and returning the potassium fluosilicate into step (1) as a raw material; and feeding hydrogen fluoride in the ammonium hydrogen fluoride-ammonium fluoride solution to enable ammonium fluoride to be completely converted into ammonium hydrogen fluoride so as to obtain an ammonium hydrogen fluoride solution, and carrying out concentration and drying to obtain ammonium hydrogen fluoride. The method has the economic value that the ammonium hydrogen fluoride and the white carbon black which have high value can be obtained simultaneously, and fluorosilicone resources are comprehensively and effectively utilized.

Owner:HUBEI XIANGYUN GROUP CHEM

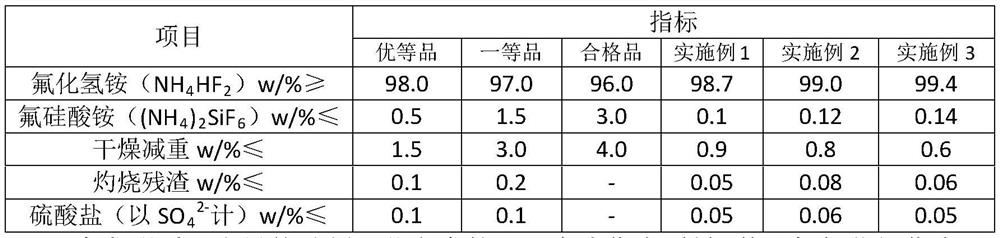

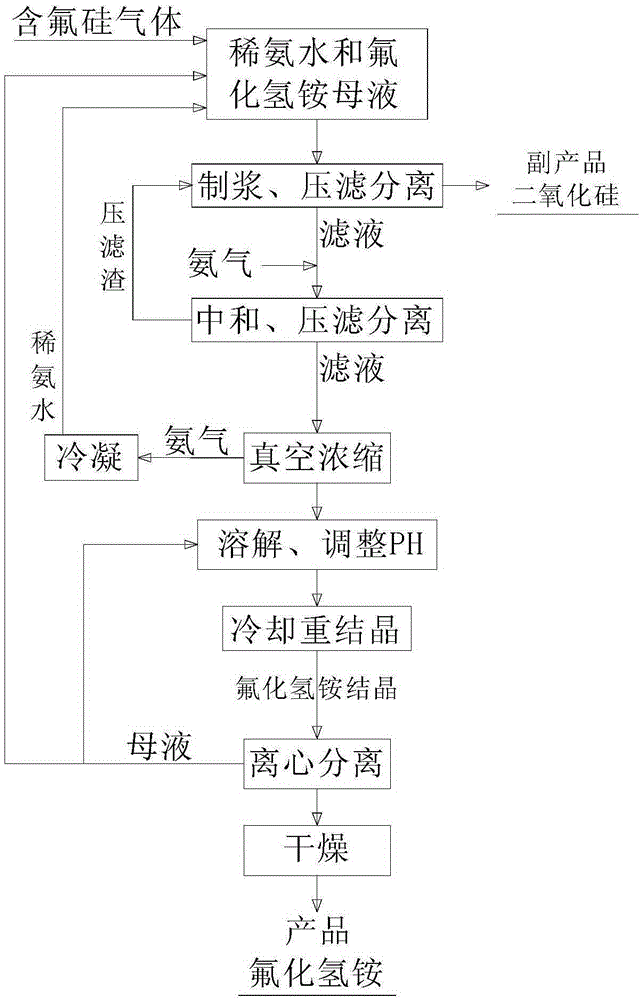

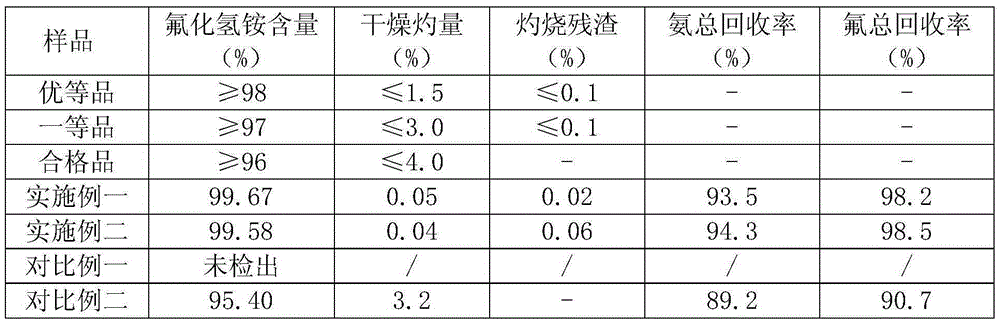

Preparation method of ammonium bifluoride

The invention discloses a preparation method of ammonium bifluoride. The method comprises steps as follows: a, dilute ammonia water and ammonium bifluoride mother liquor are mixed to adsorb gas containing fluorine and silicon, and a mixed solution is obtained; b, the mixed solution and filter-press residues obtained in Step d are mixed for slurry making and filter-press separation, and a filtrate and a silica by-product are obtained; c, ammonia is introduced into the filtrate; d, slurry is subjected to filter-press separation, and an ammonium fluoride filtrate and filter-press residues are obtained; e, the ammonium fluoride filtrate is subjected to vacuum concentration; f, concentrated slurry is dissolved, the pH value of the solution is adjusted with hydrogen fluoride, and cooling crystallization is performed; g, ammonium bifluoride crystals are filtered, separated and dried, and the ammonium bifluoride product is obtained. With the adoption of the method, the utilization rate of fluorine and ammonia is increased, the gas containing fluorine and silicon is changed into the ammonium bifluoride product with the high economic value in the phosphoric acid production process, the production cost is low, the economic benefit is significant, meanwhile, the purity and other indexes of the product meet the requirement for superior products, and the method is suitable to be popularized and applied in the field.

Owner:GUIZHOU CHANHEN CHEM CO LTD

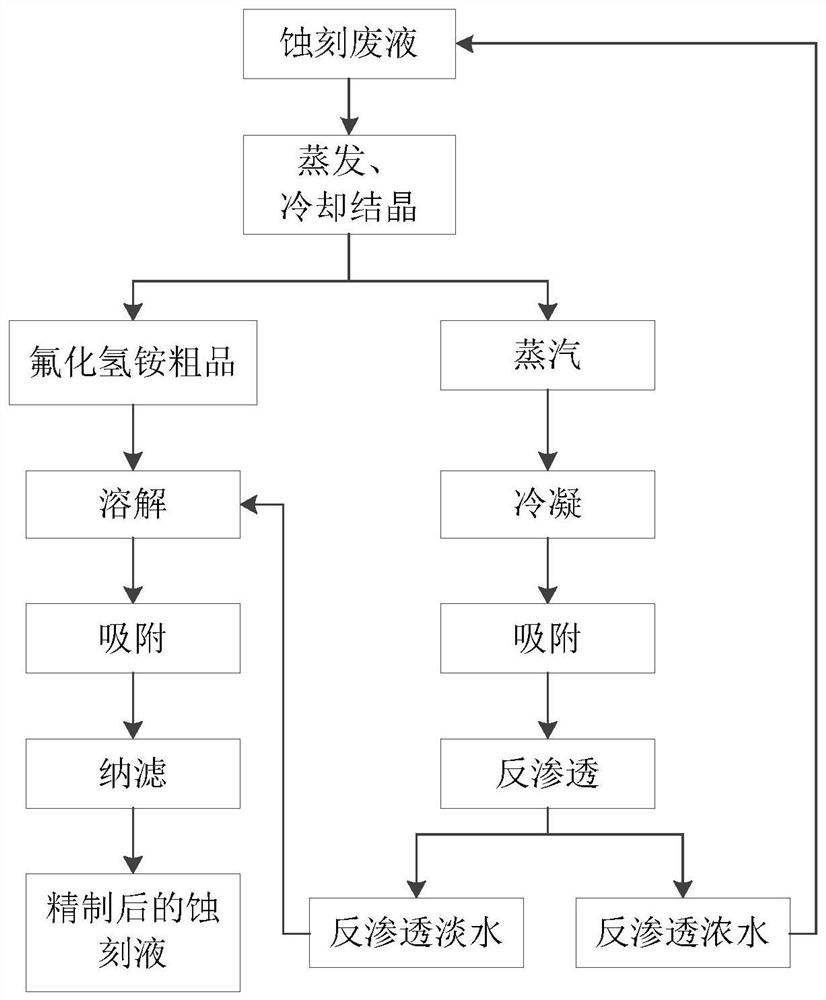

Method for refining and purifying etching waste liquid

ActiveCN113045089AImprove use valueRealize processingMultistage water/sewage treatmentNature of treatment waterHydrogen fluorideReverse osmosis

The invention provides a method for refining and purifying waste etching liquid. The method comprises the following steps: sequentially evaporating, cooling and crystallizing waste liquid generated by an etching process to obtain a crude ammonium bifluoride product and steam; dissolving the crude ammonium bifluoride product again, then performing adsorption, subjecting the adsorbed solution to nanofiltration, and conducting refining so as to obtain a refined etching solution; and condensing the steam to obtain a condensate, adsorbing the condensate, and performing reverse osmosis to obtain reverse osmosis concentrated water and reverse osmosis fresh water. According to the method, evaporation and cooling crystallization treatment are conducted on the etching waste liquid, preliminary purification is carried out to obtain a crude ammonium bifluoride product, and then the crude ammonium bifluoride product is dissolved and then subjected to adsorption and nanofiltration treatment for refining so as to obtain electronic-grade-purity ammonium bifluoride; steam in the evaporation stage is separated and purified through condensation, adsorption and reverse osmosis treatment, so comprehensive treatment of the etching waste liquid is integrally achieved; and the method is simple in process, low in raw material price and operation cost and wide in application range.

Owner:盛隆资源再生(无锡)有限公司

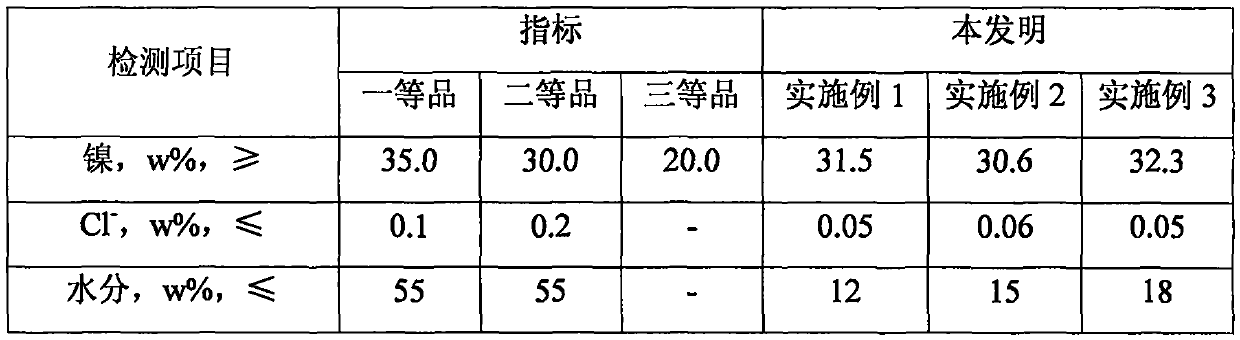

Treatment method of fluorine-containing nickel slag generated in nitrogen trifluoride preparation process

ActiveCN112645396AImprove solubilityEasy to operateIron oxides/hydroxidesNickel halidesFerric hydroxideSlag

The invention relates to a treatment method of fluorine-containing nickel slag generated in a nitrogen trifluoride preparation process, and belongs to the technical field of harmless treatment of nickel-containing hazardous wastes. The method comprises the following steps: (1) crushing the fluorine-containing nickel slag into solid powder; (2) dissolving the fluorine-containing nickel slag solid powder by using a hydrofluoric acid solution, performing stirring at 30-60 DEG C, and adding an oxidizing substance in the stirring dissolution process until the fluorine-containing nickel slag is completely dissolved to obtain a mixed solution a; (3) adjusting the pH value of the mixed solution a to 3.5-4.5 by using ammonia water, and performing filtering to obtain ferric hydroxide precipitate and a mixed solution b; and (4) continuing to adjust the pH value of the mixed solution b to 6.5-7.5 with the ammonia water, performing filtering to obtain nickel fluoride and a mixed solution c, heating and concentrating the mixed solution c, and performing cooling crystallizing to obtain ammonium fluoride and a mixed solution d. The method realizes recovery and cyclic utilization of nickel metal resources and ammonium fluoride, and can significantly reduce the production cost of nitrogen trifluoride.

Owner:PERIC SPECIAL GASES CO LTD

Method for recovering ammonium fluoride from ammonium fluoride wastewater

InactiveCN111410210ALower evaporation temperatureAvoid secondary pollutionAmmonium fluorideWastewaterAmmonium fluoride

The invention discloses a method for recovering ammonium fluoride from ammonium fluoride wastewater, which comprises the following steps: S1, adding hydrofluoric acid into the ammonium fluoride wastewater, regulating the pH value of the wastewater to 5-6, converting NH3 in the wastewater into ammonium fluoride salt, and dissolving the ammonium fluoride salt in the wastewater; and S2, pumping the ammonium fluoride waste water with the pH adjusted into an evaporator, keeping the interior of the evaporator in a vacuum environment, carrying out reduced-pressure constant-temperature evaporation onthe ammonium fluoride waste water in the evaporator at the evaporation temperature of 50-70 DEG C for 1-5 hours, continuously separating out crystallized ammonium fluoride in the evaporation process,and recycling the generated condensate water. According to the method for recycling the ammonium fluoride from the ammonium fluoride wastewater, solid waste pollutants cannot be generated in the recycling process, secondary pollution is avoided, the evaporation temperature of the evaporator is low, the evaporation cost is greatly reduced, the ammonium fluoride is recycled, condensate water is recycled, resources are reutilized, and extra economic benefits are generated.

Owner:XIAMEN STARMEM TECH

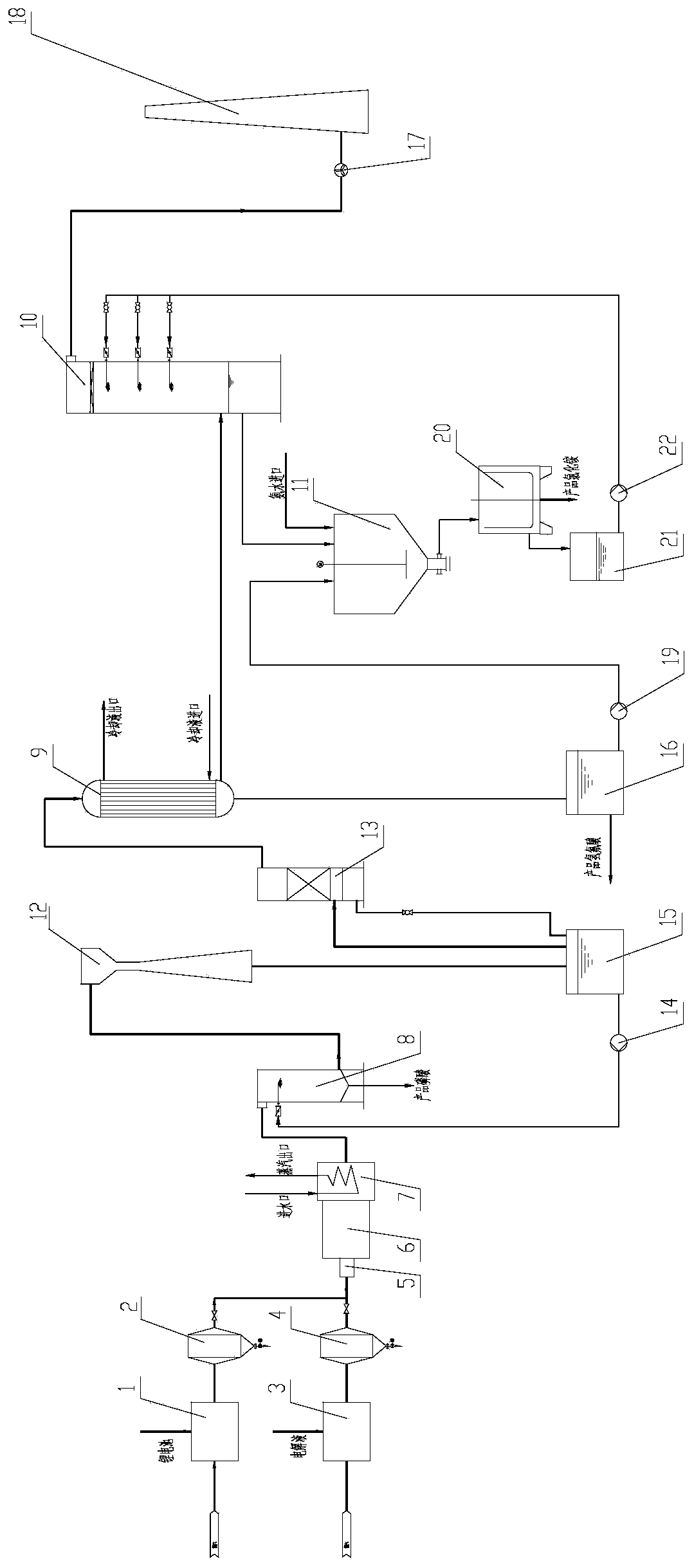

Method for producing electronic-grade ammonium fluoride water solution

ActiveCN102557076AEasy dischargeQuality improvementAmmonium fluorideHydrofluoric acidAqueous solution

The invention relates to a method for producing electronic-grade ammonium fluoride water solution. The method comprises the steps of taking industrial liquid ammonia as a raw material, heating the raw material to release ammonia; adsorbing and removing organic gas impurity in the ammonia by using active carbon; obtaining high-purity ammonia by deoxidizing adsorption; absorbing the high-purity ammonia by high-purity hydrofluoric acid, and then obtaining the electronic product grade ammonium fluoride water solution. The obtained electronic-grade ammonium fluoride water solution has high purity and stable quality, and can be directly used for producing electronic products. The method of the invention for producing electronic-grade ammonium fluoride water solution has a simple operation, and is suitable for continuously large-scale production.

Owner:SHANGAI HUAYI MICROELECTRONICS MATERIAL +1

Method for reducing ammonium fluorosilicate in ammonium fluoride

InactiveCN109384248ABring into nothingNo emissionsAmmonium fluorideAmmonium fluorosilicateFilter press

The invention discloses a method for reducing ammonium fluorosilicate in ammonium fluoride. The method comprises the steps as follows: fluosilicic acid is subjected to an amination reaction to producean ammonium fluoride mixed solution containing silicon dioxide, wherein the mass concentration of ammonium fluoride is 20%-35%, the mass concentration of silicon dioxide is 2%-15%, and the PH value is 8.0-10; the ammonium fluoride mixed solution is filtered by a filter press, most silicon dioxide is removed, and an ammonium fluoride solution containing a little silicon dioxide is obtained; the ammonium fluoride solution containing a little silicon dioxide is left to stand and clarified in a filtrate tank for 1-3 h, most silicon dioxide settles to the bottom, an upper clear ammonium fluoride liquid is subjected to refined filtration by micropores with the diameter being 3-10 micron again, and a wet filter cake returns to a feeding tank of the filter press; a filtrate enters a concentratedraw material tank to be left to stand and clarified for 1-3 h, an upper clear ammonium fluoride liquid is taken to enter a concentration system, conventional concentration, ammonia introduction, crystallization and centrifugal separation are performed later and an ammonium fluoride product is obtained. The method can effectively reduce ammonium fluorosilicate in ammonium fluoride and is low in energy consumption and environmentally friendly.

Owner:贵州瓮福蓝天氟化工股份有限公司

Method and system for purifying waste gas generated in lithium battery recovery and recovering resources

PendingCN111544972AAchieve separationHigh economic valueDispersed particle filtrationHydrogen fluorideO-Phosphoric AcidCombustion chamber

The invention discloses a system for purifying waste gas generated in lithium battery recovery and recovering resources. The system comprises a pyrolysis device, a second dust removal device, a gas mixer, a combustion chamber and a boiler, which are connected in sequence; a splitting device, a first dust removal device and a gas mixer are sequentially communicated; and a hydration tower, a first-stage phosphoric acid catcher, an acid mixing tank, a second-stage phosphoric acid catcher, a hydrofluoric acid recovery tower and a purification tower are sequentially communicated. The invention alsodiscloses a method for purifying waste gas generated in lithium battery recovery and recovering resources. The method has the advantages that the separation and purification of P2O5 and HF are realized, the combustion energy of carbonic ester organic matters is utilized, and byproducts such as phosphoric acid, hydrofluoric acid or ammonium fluoride are extracted in a grading manner, so that the treatment difficulty of wastewater and waste residues is greatly reduced, and the method is environment-friendly. In addition, due to the fact that byproducts are high in market value at present, the environment-friendly project has good economic benefits in operation, and resources are saved.

Owner:YONKER ENVIRONMENTAL PROTECTION

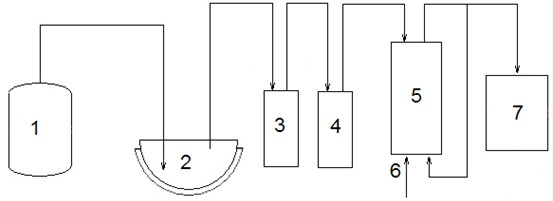

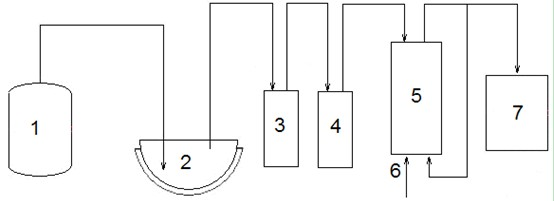

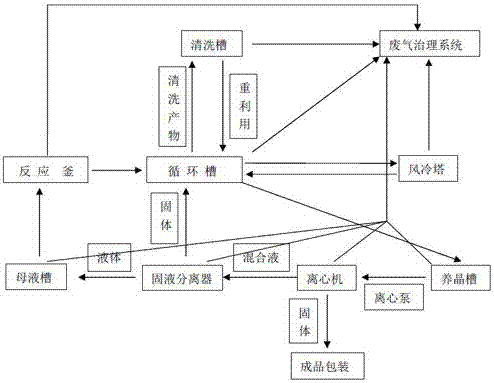

Ammonium bifluoride mother solution cooling system

The invention relates to the technical field of production of ammonium bifluoride and in particular relates to an ammonium bifluoride mother solution cooling system. The ammonium bifluoride mother solution cooling system comprises a circulating groove, an air cooling tower, crystal growing grooves, a solid-liquid separator and a mother solution groove, wherein the bottom part of the air cooling tower is communicated with an inlet of the circulating groove; the bottom of the circulating groove is communicated with the upper end of the air cooling tower and the upper ends of the plurality of crystal growing grooves through a first centrifugal pump respectively; the bottoms of the plurality of crystal growing grooves are communicated with a centrifugal machine through a second centrifugal pump; the centrifugal machine is connected with the solid-liquid separator; a liquid outlet of the solid-liquid separator is connected with the mother solution groove; a solid outlet of the solid-liquidseparator is connected with the circulating groove. The ammonium bifluoride mother solution cooling system has the advantages of high cooling efficiency and good cooling effect; zero emission of wasteliquid and waste dreg can be realized in a cooling process and waste gas is discharged after reaching the standards.

Owner:浙江朗泰环境工程有限公司

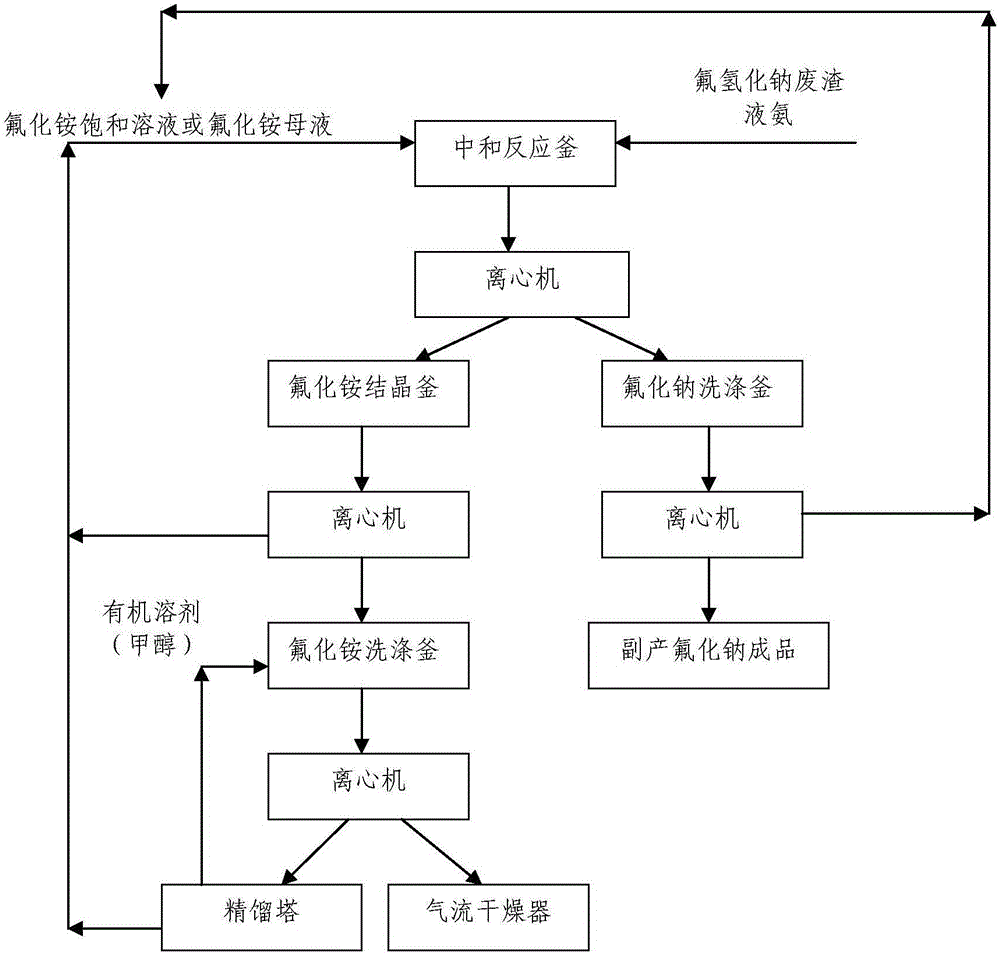

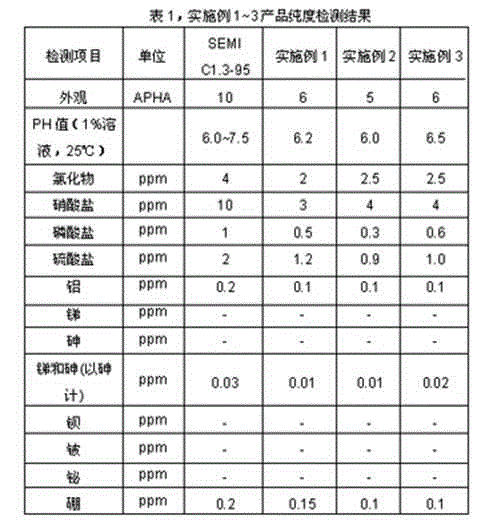

Method for producing high-purity ammonium fluoride by utilizing sodium hydride waste residues

ActiveCN106673015AImprove conversion rateImprove methodAlkali metal fluoridesAmmonium fluorideFiltrationSolvent

The invention discloses a method for producing high-purity ammonium fluoride by utilizing sodium hydride waste residues. The method is characterized in that sodium hydride waste residues for producing 2-chlorine-6-fluorotoluene or a similar product and ammonia are taken as raw materials for reaction; the high-purity ammonium fluoride is prepared through the steps of neutral reaction, suction filtration for impurity removal, cooling crystallization, solvent leaching, air flow drying and the like, and meanwhile, by-product sodium fluoride is prepared. The method has the characteristics of being high in reaction speed, controllable in reaction conditions, low in production energy consumption, good in ammonium fluoride quality (the purity is more than or equal to 98.0 percent, and silicate is less than 0.01 percent) and high in raw material conversion rate; no ammonium fluoride evaporative crystallization device is required, so that production equipment is simple.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Method for producing electronic-grade ammonium fluoride water solution

The present invention relates to a method for producing of electronic grade aqueous ammonium fluoride solution. The industrial grade liquid ammonia is used as the raw material, when it is heated, the ammonia gas will be released. The organic gas impurities in the ammonia gas are removed by activated charcoal, and the oxygen is removed by deoxidizer, and then the high-purity ammonia gas is gotten. The high-purity hydrofluoric acid absorbs and reacts with the high-purity ammonia gas to obtain the electronic grade aqueous ammonium fluoride solution. The product has high-purity and stable quality, and it can be used in producing of electronic products directly. The method for producing of electronic grade ammonium aqueous fluoride solution provided by the present invention is suitable for continuous production on a large scale because of its simple operation.

Owner:SHANGAI HUAYI MICROELECTRONICS MATERIAL +1

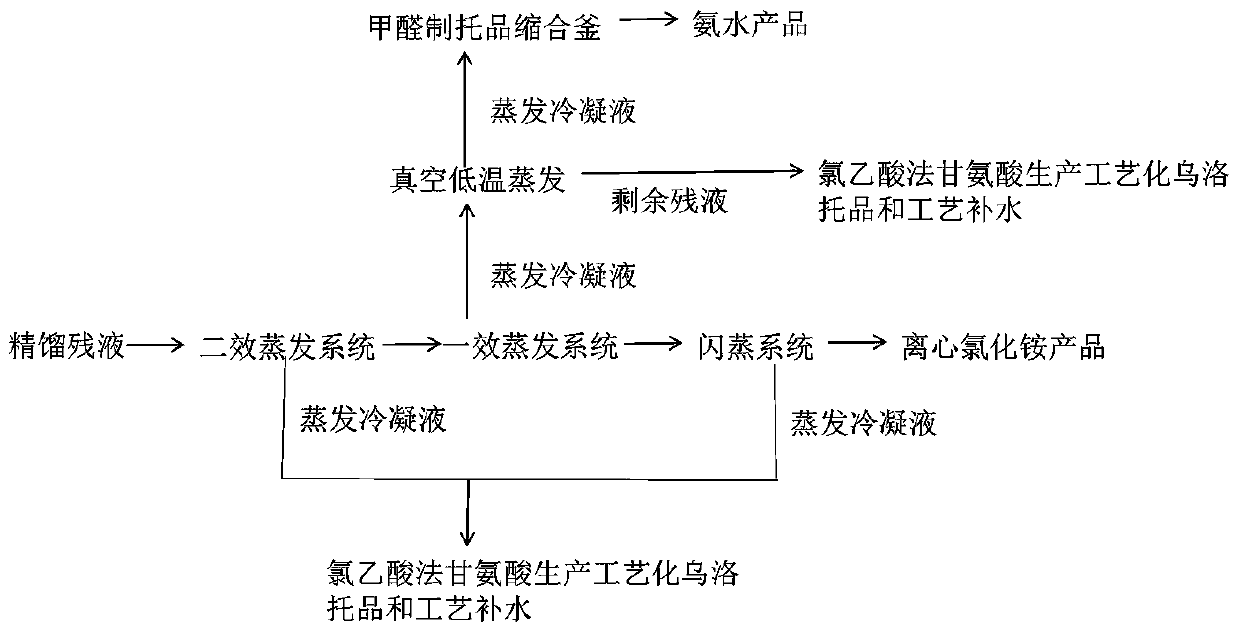

Cleaning treatment method for ammonium chloride production wastewater

ActiveCN109651182AReduce processing costsSimple processOrganic compound preparationChemical industryAmmonia productionEvaporation

The invention relates to a cleaning treatment method for ammonium chloride production wastewater. The method comprises the specific steps that during the separation and purification process of ammonium chloride, residual liquid after rectification of methanol passes through a two-effect evaporation system, a first-effect evaporation system and a decompression flashing system, and a high-ammonia nitrogen and COD content condensed water obtained from the two-effect evaporation system and the decompression flashing system is directly reused in a chloroacetic acid method glycine production process. The water obtained by the first-effect evaporation system is treated by a vacuum low-temperature evaporation system, the obtained low-ammonia nitrogen condensed water is used as a raw material for industrial grade ammonia production, and the residual liquid is directly reused in the chloroacetic acid method glycine production process. The method has small investment in equipment, the evaporationcondensed water treatment is harmless, and the method is energy-saving and environmentally friendly, and is suitable for the chloroacetic acid method glycine production process.

Owner:HUBEI TAISHENG CHEM

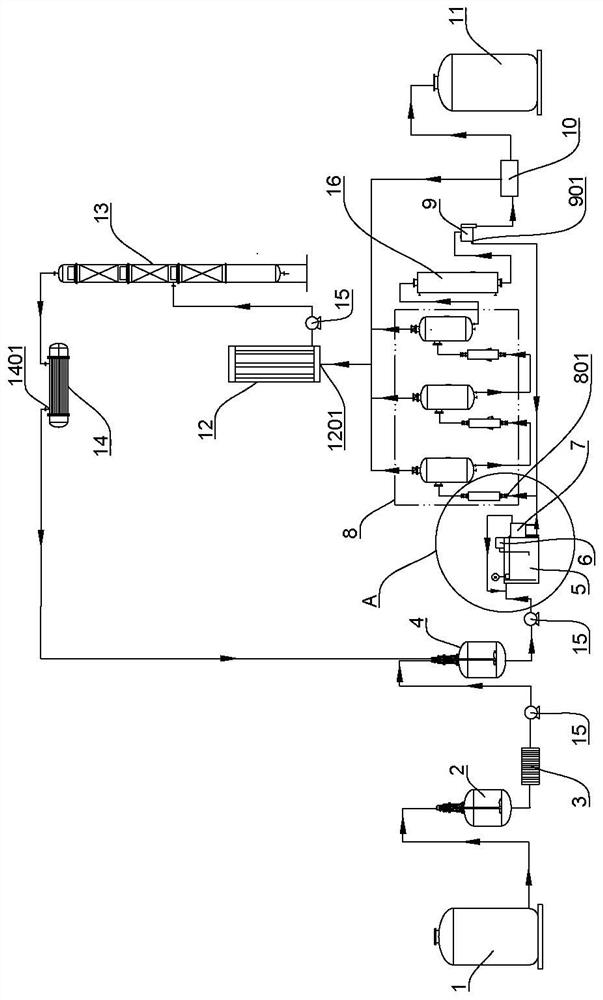

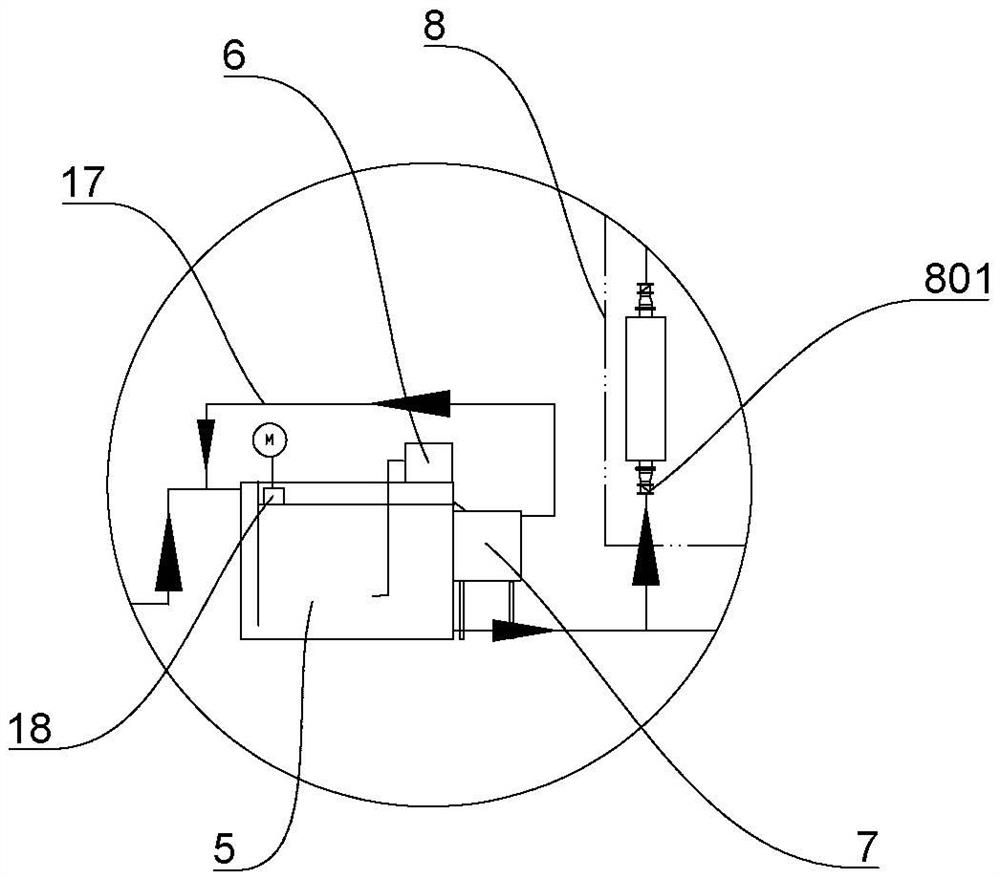

System for preparing ammonium bifluoride by utilizing BOE waste liquid

PendingCN112028371AHigh purityReduce moisture contentWater/sewage treatment by centrifugal separationWater/sewage treatment bu osmosis/dialysisHydrogen fluorideLiquid storage tank

The invention provides a system for preparing ammonium bifluoride by utilizing BOE waste liquid, the system not only can avoid environmental pollution caused by directly discharging the BOE waste liquid, but also can recover and prepare an ammonium bifluoride product with high purity, low moisture content, low investment cost and low production cost, and can reduce the discharge of hydrogen fluoride gas. The system comprises a BOE waste liquid storage tank, a first reaction kettle, a filtering device, a second reaction kettle, a triple-effect evaporator, a cooling crystallizer, a continuous centrifuge, a drying device and an ammonium bifluoride storage tank which are connected in sequence, a supernatant outlet of the continuous centrifuge is communicated with an inlet of the triple-effectevaporator, and the triple-effect evaporator and the drying device are connected with the inlet end of a membrane adsorption system, and the outlet end of the membrane adsorption system is communicated with the second reaction kettle.

Owner:江苏电科环保有限公司

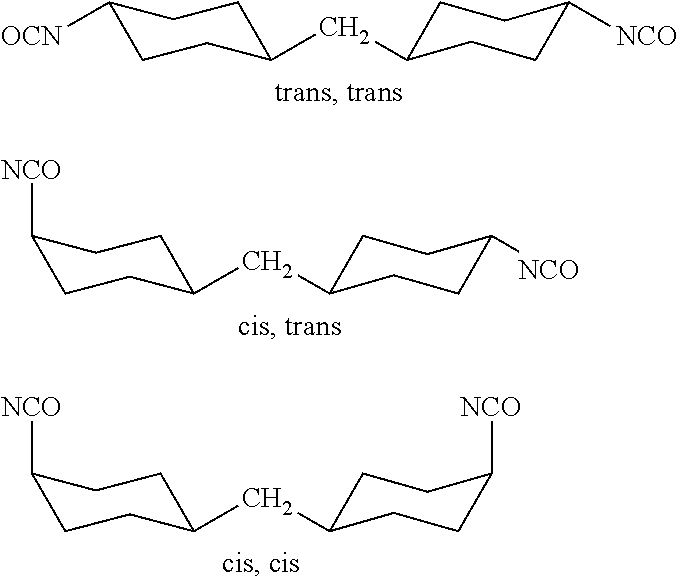

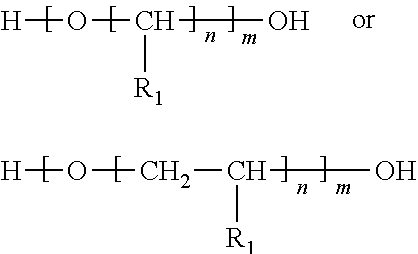

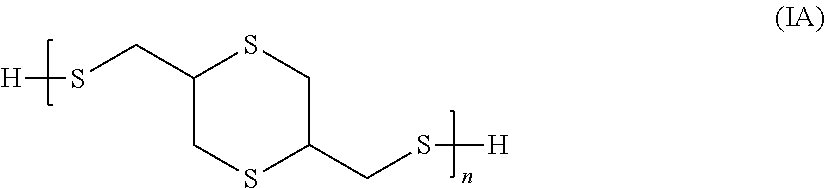

Composition for Preparing Molded Polymeric Article

The present invention is directed to an organic polymerizable composition for producing a molded polymeric article. The composition includes a mold release agent of ionic fluoride and / or ionic fluoride precursor present in an amount sufficient to effect at least partial demolding of the polymeric article from a mold. Molded articles also are provided.

Owner:PPG IND OHIO INC

Production process for preparing low-silicon ammonium bifluoride by taking fluosilicic acid as raw material

The invention discloses a production process for preparing low-silicon ammonium bifluoride by using fluosilicic acid as a raw material, which comprises the following steps: by using a fluosilicic acidsolution as a raw material, carrying out ammoniation desilicication and filtration to obtain an ammonium fluoride primary solution; and then adding a desilicication agent into the ammonium fluoride primary solution to carry out secondary desilicication, and then filtering, concentrating and crystallizing to obtain an ammonium hydrogen fluoride product. The content of fluosilicic acid radicals inthe ammonium bifluoride product is lower than 0.2%, and the application value of the byproduct fluosilicic acid is greatly improved.

Owner:承德莹科精细化工股份有限公司

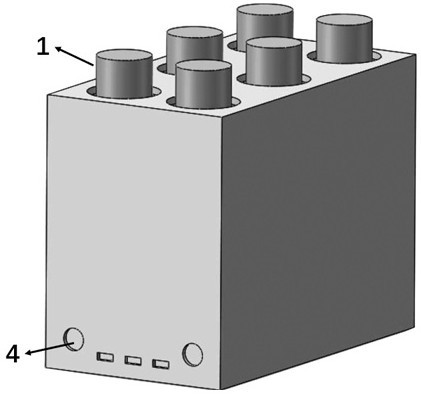

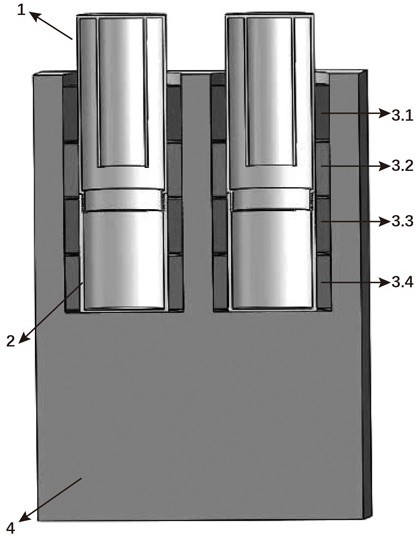

Reagent purification device and method for purifying ammonium bifluoride or ammonium fluoride by using same

ActiveCN112090106ARealize automatic purificationThe principle is simpleSublimationAmmonium fluorideHydrogen fluorideIn situ crystallization

The invention belongs to the field of analysis and detection, and particularly relates to a reagent purification device and a method for purifying ammonium bifluoride or ammonium fluoride by using thesame, the reagent purification device enables NH4HF2 or NH4F steam to be crystallized in situ at different positions of a reagent collection bottle in an integral heating and step-by-step cooling manner. The purification device is of a vertical full-closed structure, temperature and time parameters can be designed in advance through programs, and automatic purification is achieved. The equipmentprinciple is simple, multiple units can be combined for use, a large number of NH4HF2 or NH4F reagents are purified at a time, and high efficiency, simplicity and convenience are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

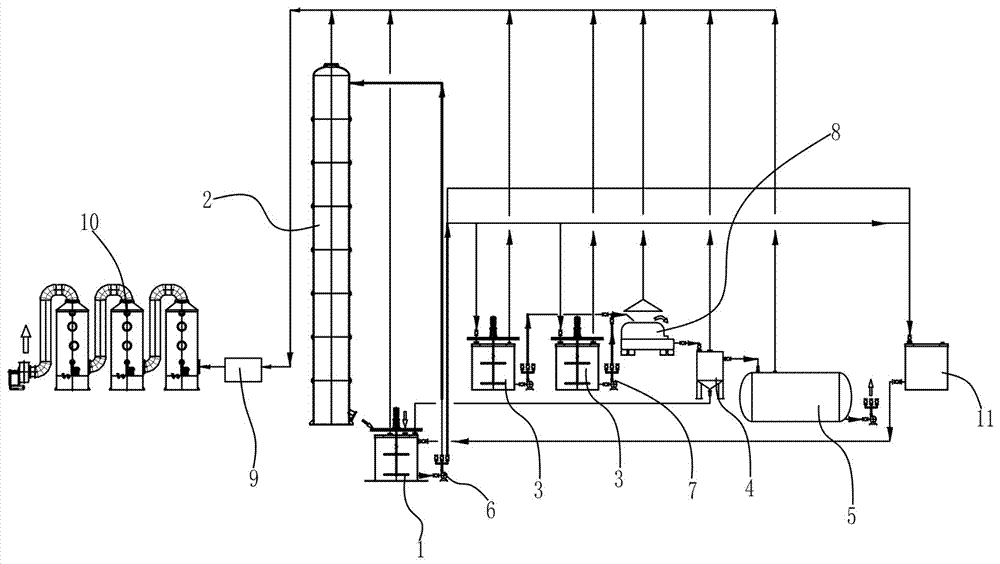

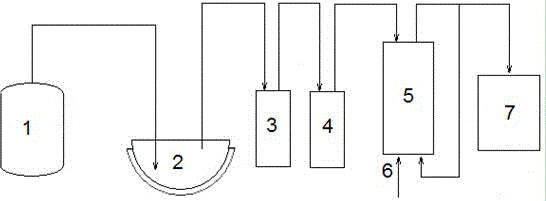

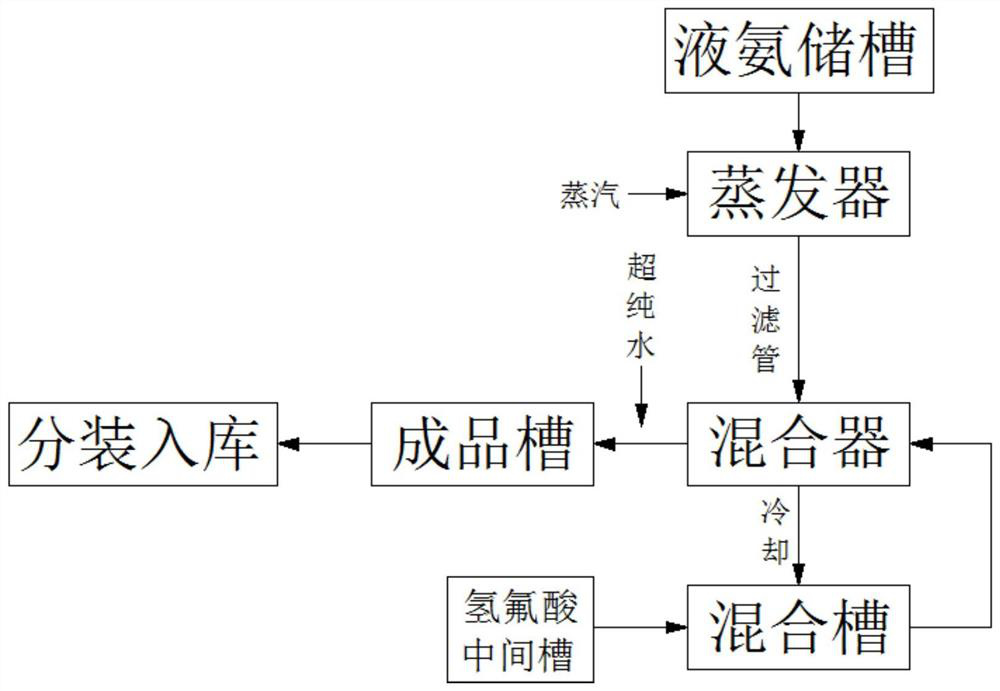

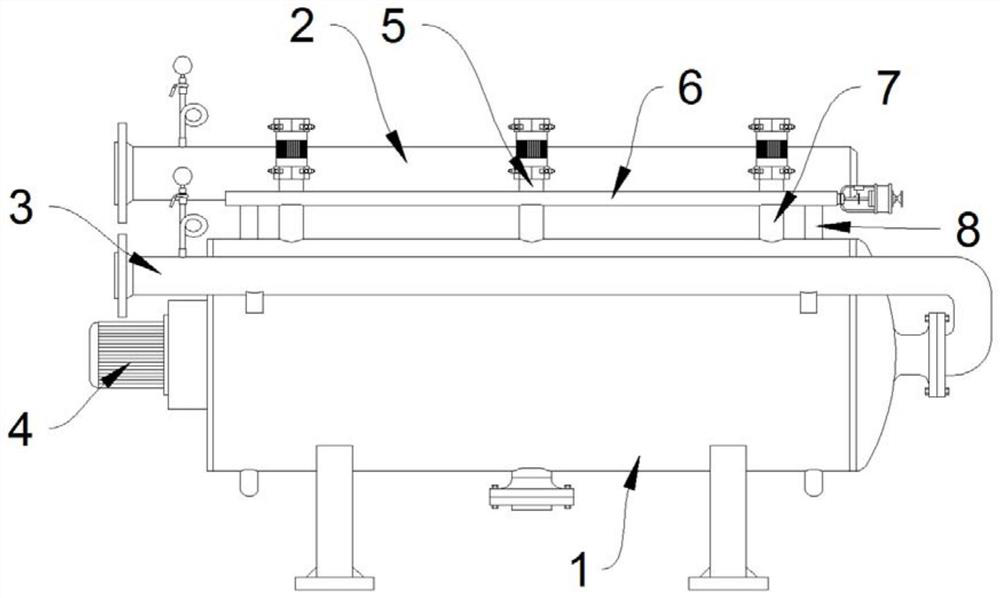

Preparation system and process of electronic-grade ammonia fluoride

ActiveCN112058199ARealize quantitative productionHelps quantify productionChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesProcess engineeringFluoride

The invention discloses a preparation system and process of an electronic-grade ammonia fluoride. The preparation system mainly comprises a mixing tank, an evaporator, a mixer and a finished product tank; one side of the mixing tank is connected with a hydrofluoric acid intermediate tank; one side of the evaporator is connected with a liquid ammonia storage tank; the mixer is connected with the evaporator through a filter pipe; a circulating pipe group is connected between the mixer and the mixing tank; and the finished product tank is connected with the mixer. The preparation system providedby the invention is simple in structural composition; complex procedures are orderly and simply materialized, so that complexity is decreased; the systematization of an electronic-grade ammonium fluoride production process is realized, and quantitative production of enterprises under relatively economic conditions is facilitated; and the preparation process provided by the invention is operated onthe basis of adopting the basic support of the main body of the above main structure, so that the whole process is ordered and clear, electronic-grade ammonium fluoride finished products can be prepared in batches, and the advantages of relatively economical cost and relatively high production efficiency can be achieved.

Owner:福建天甫电子材料有限公司

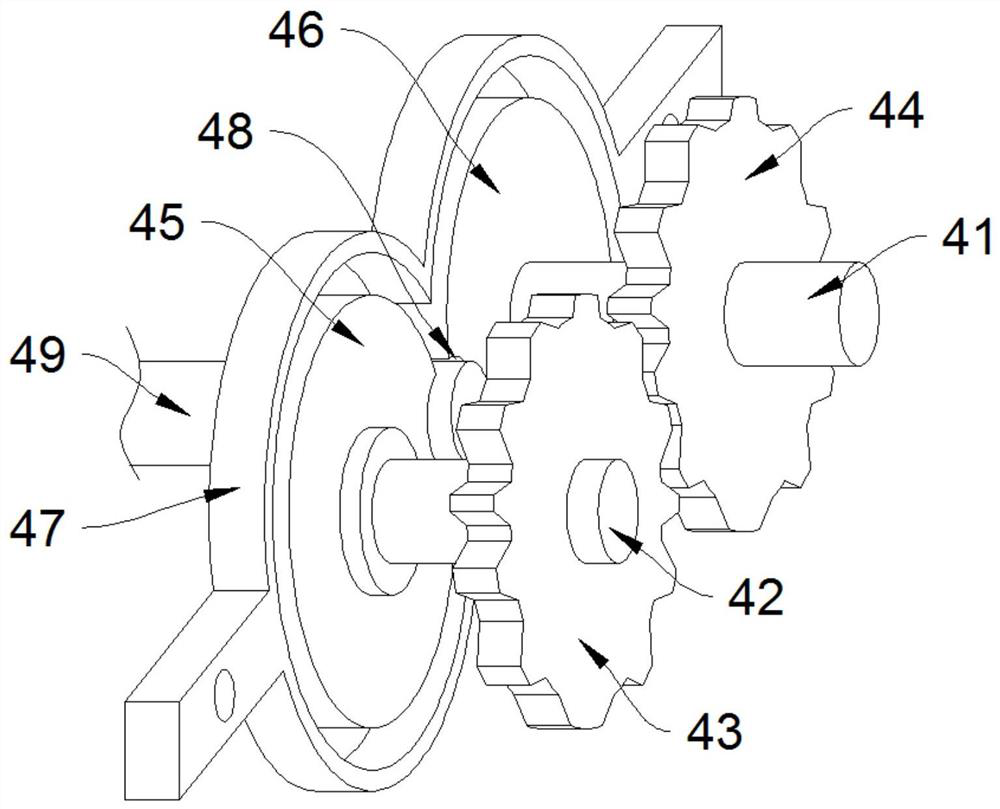

Method and apparatus for producing nitrogen trifluoride

InactiveCN1449992ALiquid-gas reaction as foam/aerosol/bubblesFlow mixersHydrogen fluorideMechanical energy

Owner:BOC GRP INC

Process for extracting silicon fertilizer from fluorite waste liquid

The invention provides a process for extracting a silicon fertilizer from fluorite waste liquid. The process comprises the following steps: heating and concentrating the fluorite waste liquid at 100-150 DEG C, so as to obtain mixed gas and a mixed solid; grinding the mixed solid, and sieving by virtue of a 200-mesh sieve, so as to obtain mixed solid powder; carrying out cyclone separation on the mixed solid powder, so as to obtain a silicon-containing mixture; and carrying out magnetic separation on the silicon-containing mixture, so as to obtain the silicon fertilizer finished product. The method has the beneficial effects that elements such as potassium, sodium, silicon and fluorine in the fluorite waste liquid can be adequately utilized, so that the production cost of fluorite is lowered; meanwhile, the environmental pollution caused by direct emission of the fluorite waste liquid is avoided; the method is simple, feasible and suitable for large-scale application.

Owner:河南绿能环保科技有限公司

Method for reducing ammonium fluorosilicate in ammonium bifluoride

The invention discloses a method for reducing ammonium fluorosilicate in ammonium bifluoride. The method comprises the steps as follows: fluorosilicic acid is subjected to an ammoniation reaction anda silicon dioxide-containing ammonium fluoride mixed solution is obtained, wherein the mass concentration of ammonium fluoride is 20%-35%, the mass concentration of silicon dioxide is 2%-15%, and thePH value is 8.0-10; the ammonium fluoride mixed solution in step (1) is filtered by a filter press, most silicon dioxide is removed, a filtrate enters a filtrate tank and left to stand and clarified for 1-3 h, most silicon dioxide settles to the bottom, and the upper layer is a clear ammonium fluoride liquid; the upper clear ammonium fluoride liquid in step (2) is finely filtered again by micropores with the diameter being 3-10 micron, and a wet filter cake returns to a feeding chute of the filter press; a refined filtrate enters a concentrated raw material chute to be left to stand and clarified for 1-3 h, an upper clear ammonium fluoride liquid enters a concentration system, conventional concentration, acid addition, crystallization and centrifugal separation are performed later, and anammonium bifluoride product is obtained. The method can effectively reduce ammonium fluorosilicate in ammonium bifluoride, has low energy consumption, introduces no other impurities and avoids waste emission.

Owner:贵州瓮福蓝天氟化工股份有限公司

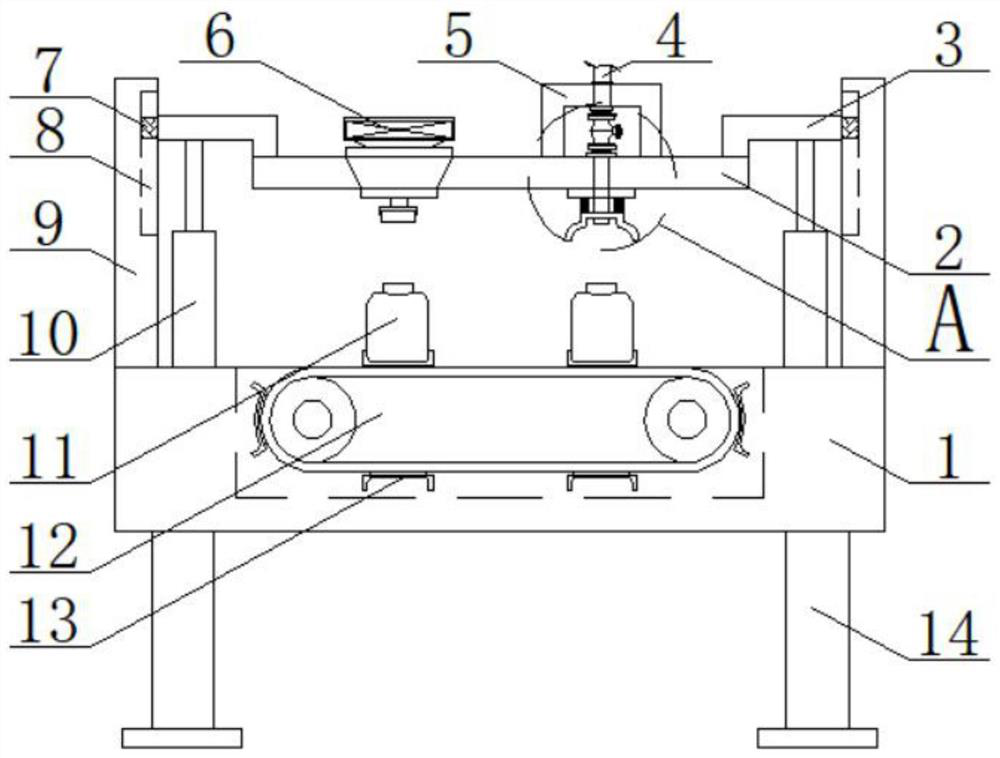

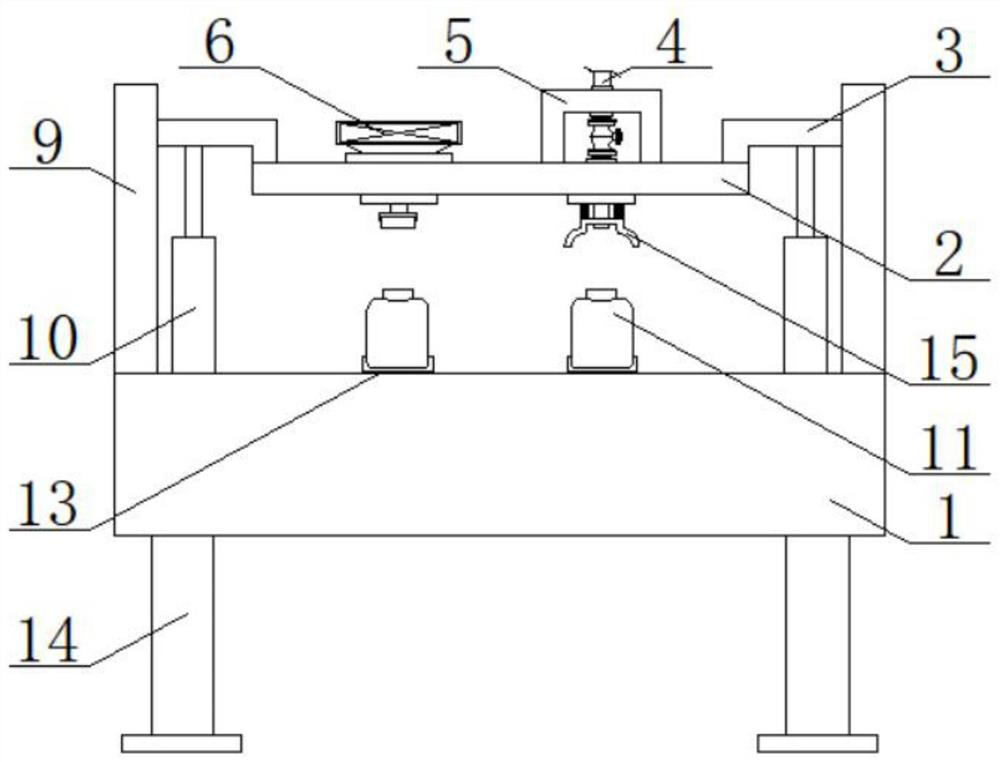

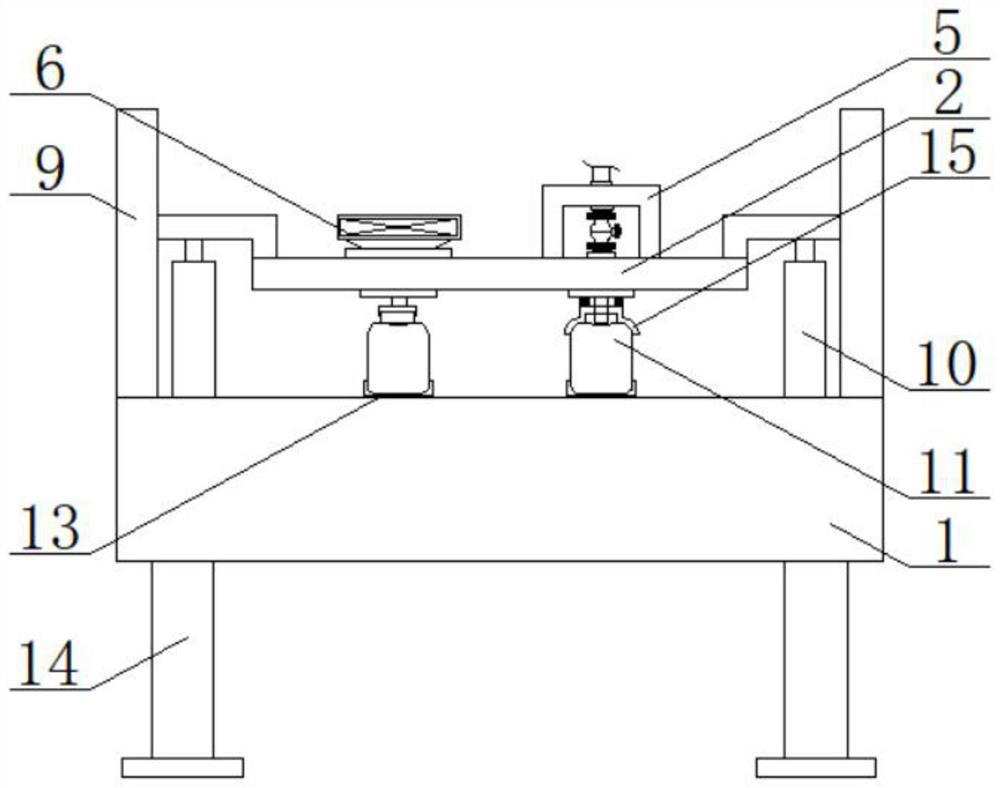

Device and process for producing byproducts ammonium bifluoride and potassium fluoride from NF3 production

InactiveCN112897486APrevent floatingReduce pollutionAlkali metal fluoridesNickel sulfatesHydrogen fluoridePotassium fluoride

The invention discloses a device and process for producing byproducts ammonium bifluoride and potassium fluoride from NF3 production, and the device comprises a workbench; a groove is formed in the middle of the upper end of the workbench, a conveying mechanism is arranged in the groove, electric push rods are fixed to the two sides of the upper end of the workbench, lifting blocks are fixed to one ends of the two electric push rods, a lifting plate is fixed to one ends of the two lifting blocks together, and a mounting frame is fixed to one side of the upper end of the lifting plate. The invention further provides a process for producing ammonium bifluoride and potassium fluoride as byproducts in NF3 production. Filling and installation of the bottle cap can be achieved through intermittent movement of the bottle body, the labor cost is effectively saved, dust is prevented from flying out, the production efficiency is improved, hazardous waste containing nickel and fluorine can be eliminated and converted into by-products, environmental pollution is reduced, and the method can convert the original hazardous wastes needing to be treated into byproducts, and has certain economic benefits.

Owner:PERIC SPECIAL GASES CO LTD

Popular searches

Semiconductor/solid-state device manufacturing Ammonia preparation/separation Waste water treatment from metallurgical process Ammonium sulfates Water/sewage treatment by neutralisation Water/sewage treatment by heating Water treatment multistage treatments Nitrogen trifluoride Process efficiency improvement Nitrogen and non-metal compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com