Method for treating electrolytic waste residues and wastewater produced in electrolytic process nitrogen trifluoride production technology

A treatment method, nitrogen trifluoride technology, applied in water/sewage treatment, improvement of process efficiency, chemical instruments and methods, etc., to achieve recovery and comprehensive utilization, high purity, significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

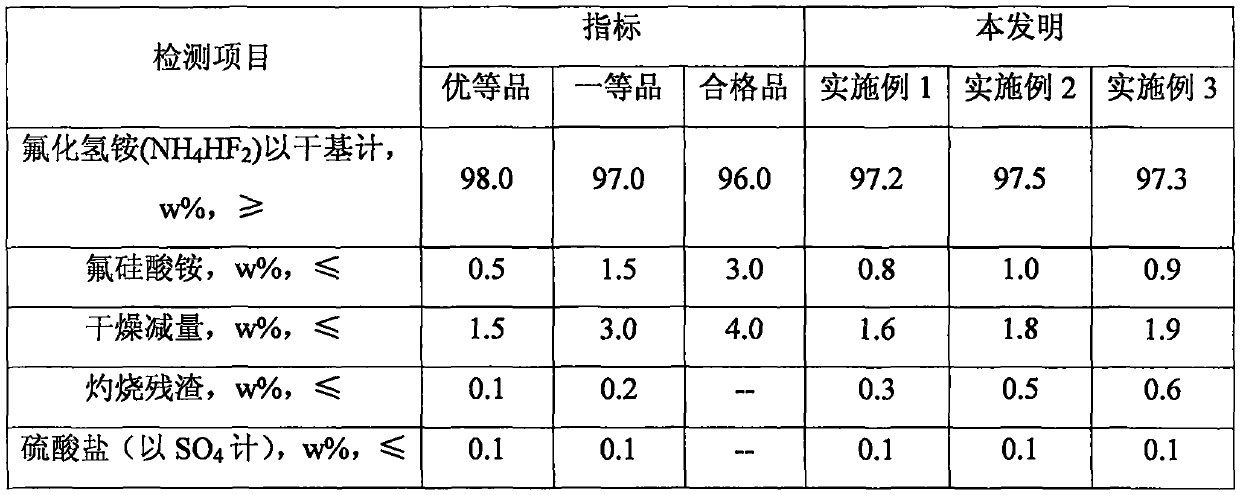

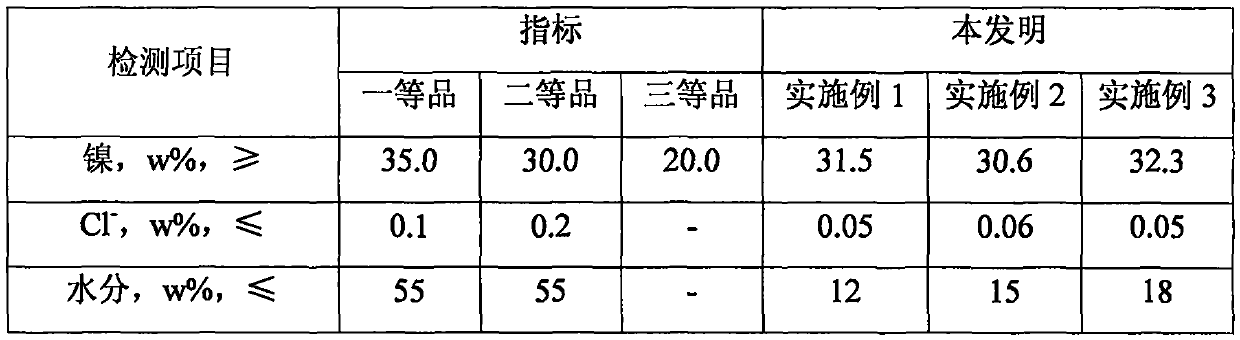

Embodiment 1

[0019] Add 300kg of electrolytic waste residue and 1 ton of fluorine-containing waste water produced during the dismantling of the electrolytic cell into the neutralization kettle, stir until fully dissolved, feed ammonia water with a mass concentration of 20% to 25%, and control the reaction temperature at 35°C 45° C., until the pH value of the reaction kettle solution reaches 3, stop feeding ammonia water to obtain an ammonium bifluoride solution with a mass concentration of 18%. Add 10 g of polyferric chloride to the ammonium bifluoride solution to precipitate nickel-containing by-products, flocculate and form precipitates, and centrifuge to separate nickel-containing by-products.

[0020] Mix the obtained ammonium bifluoride solution with a mass concentration of 18% and the crystallized ammonium bifluoride mother liquor, add it to a vacuum dehydration kettle, and conduct evaporation, concentration and dehydration under the conditions of -0.086~-0.096MPa, 65~75°C until the ...

Embodiment 2

[0024] Add 400kg of electrolytic waste slag and 1 ton of fluorine-containing wastewater generated during the dismantling process into the neutralization reactor, stir until fully dissolved, feed ammonia water with a mass concentration of 20% to 25%, and control the reaction temperature at 40°C 50 DEG C, until the pH value of the reactor solution reaches 2, stop feeding ammonia water to obtain a 22% ammonium bifluoride solution with a mass concentration. Add 10 g of iron polysilicate to the ammonium bifluoride solution to precipitate, flocculate and form precipitates by-products containing nickel, and centrifuge to separate the by-products containing nickel.

[0025] Mix the obtained ammonium bifluoride solution with a mass concentration of 22% and the crystallized ammonium bifluoride mother liquor, add it to a vacuum dehydration kettle, and conduct evaporation, concentration and dehydration under the conditions of -0.086~-0.096MPa, 65~75°C until the ammonium bifluoride The co...

Embodiment 3

[0029] Add 500kg of electrolytic waste slag and 1 ton of fluorine-containing waste water produced during the dismantling process into the neutralization reactor, stir until fully dissolved, feed ammonia water with a mass concentration of 20% to 25%, and control the reaction temperature at 20°C 35° C., until the pH value of the reaction kettle solution reaches 4, stop feeding ammonia water to obtain an ammonium bifluoride solution with a mass concentration of 26%. Add 10 g of polyferric sulfate to the ammonium bifluoride solution to precipitate nickel-containing by-products, flocculate and form precipitates, and centrifuge to separate nickel-containing by-products.

[0030] Mix the obtained ammonium bifluoride solution with a mass concentration of 26% and the crystallized ammonium bifluoride mother liquor, add it to a vacuum dehydration kettle, and conduct evaporation, concentration and dehydration under the conditions of -0.086~-0.096MPa, 65~75°C until the ammonium bifluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com