Patents

Literature

15190 results about "Fluorine containing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

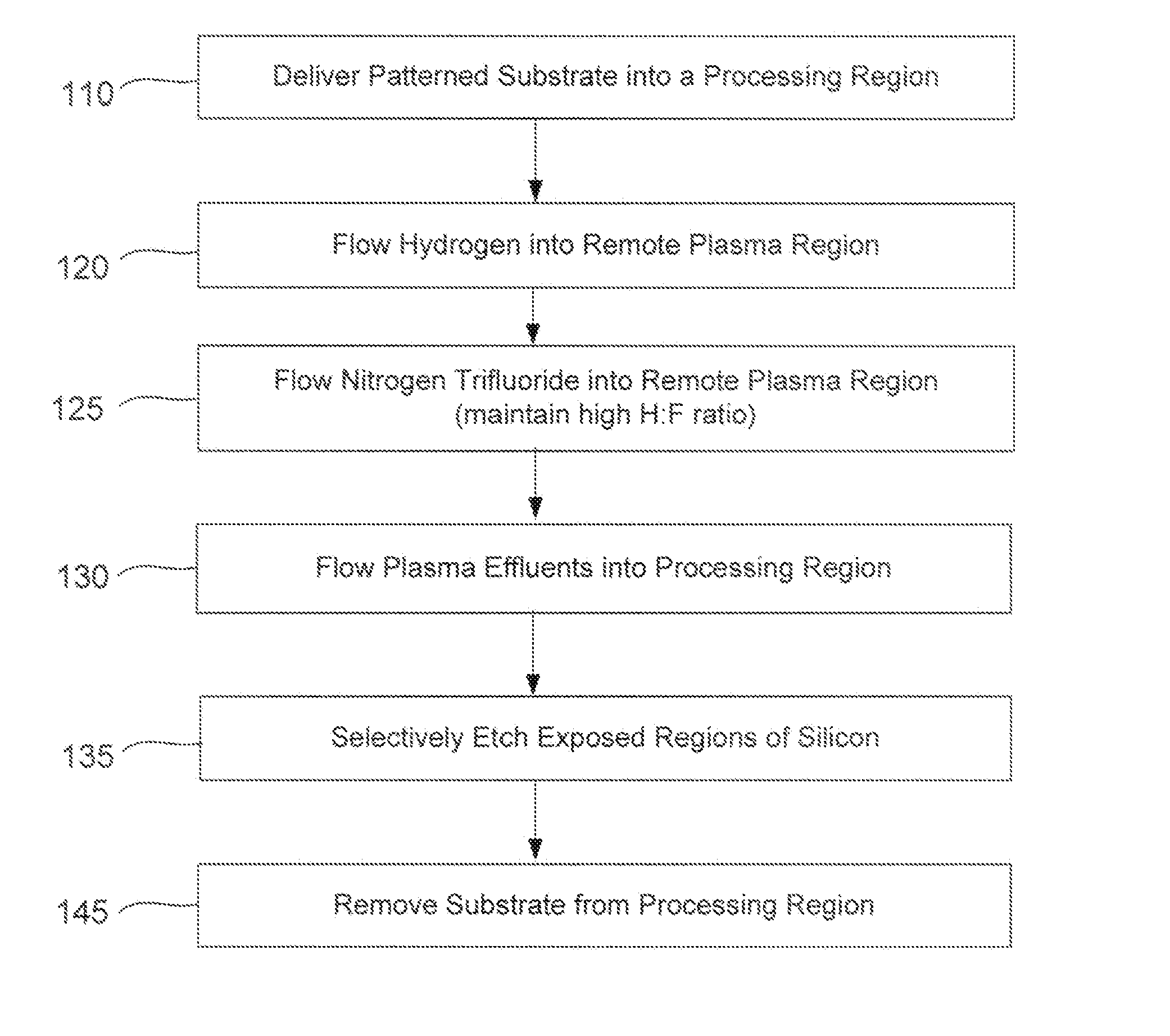

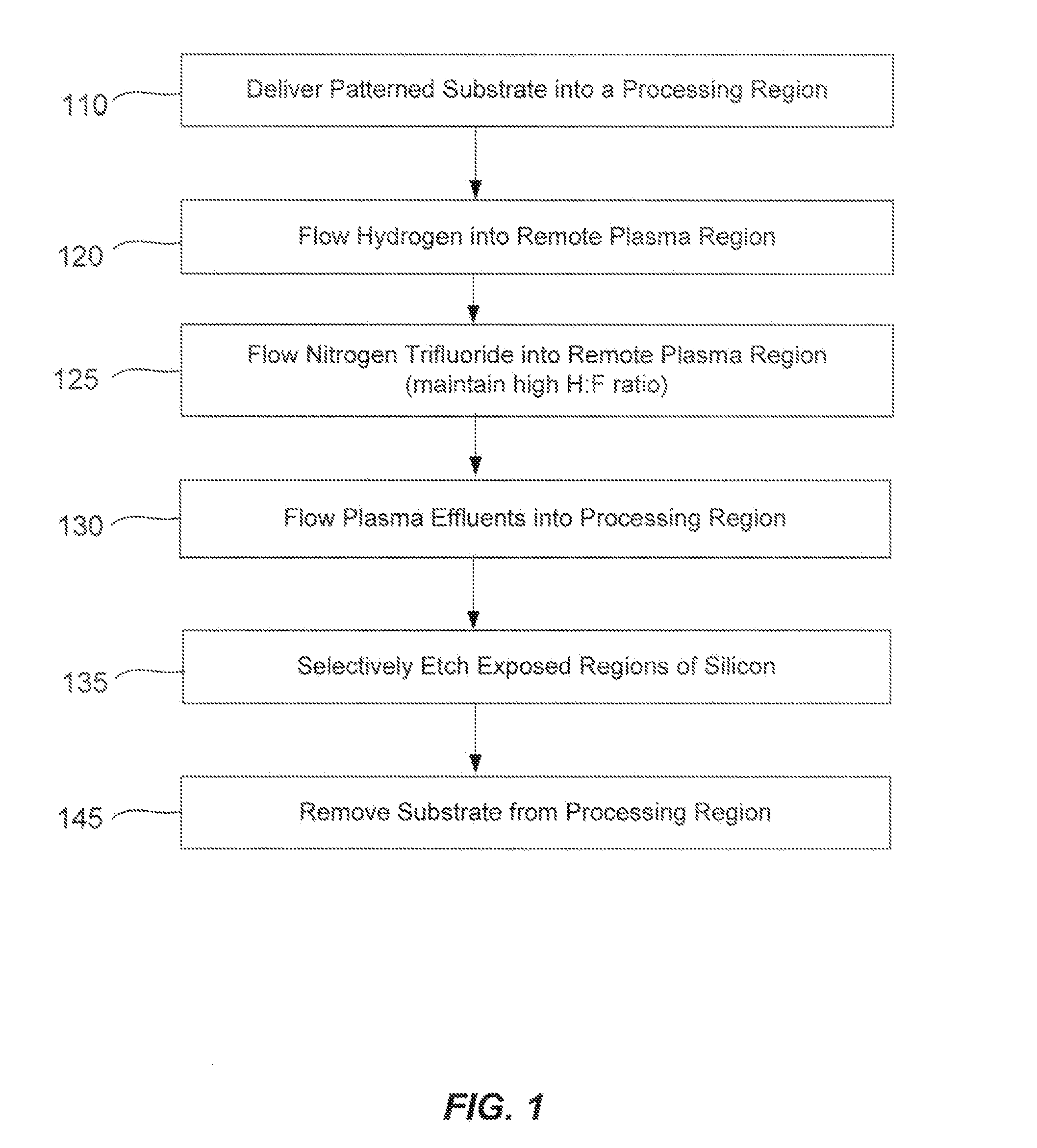

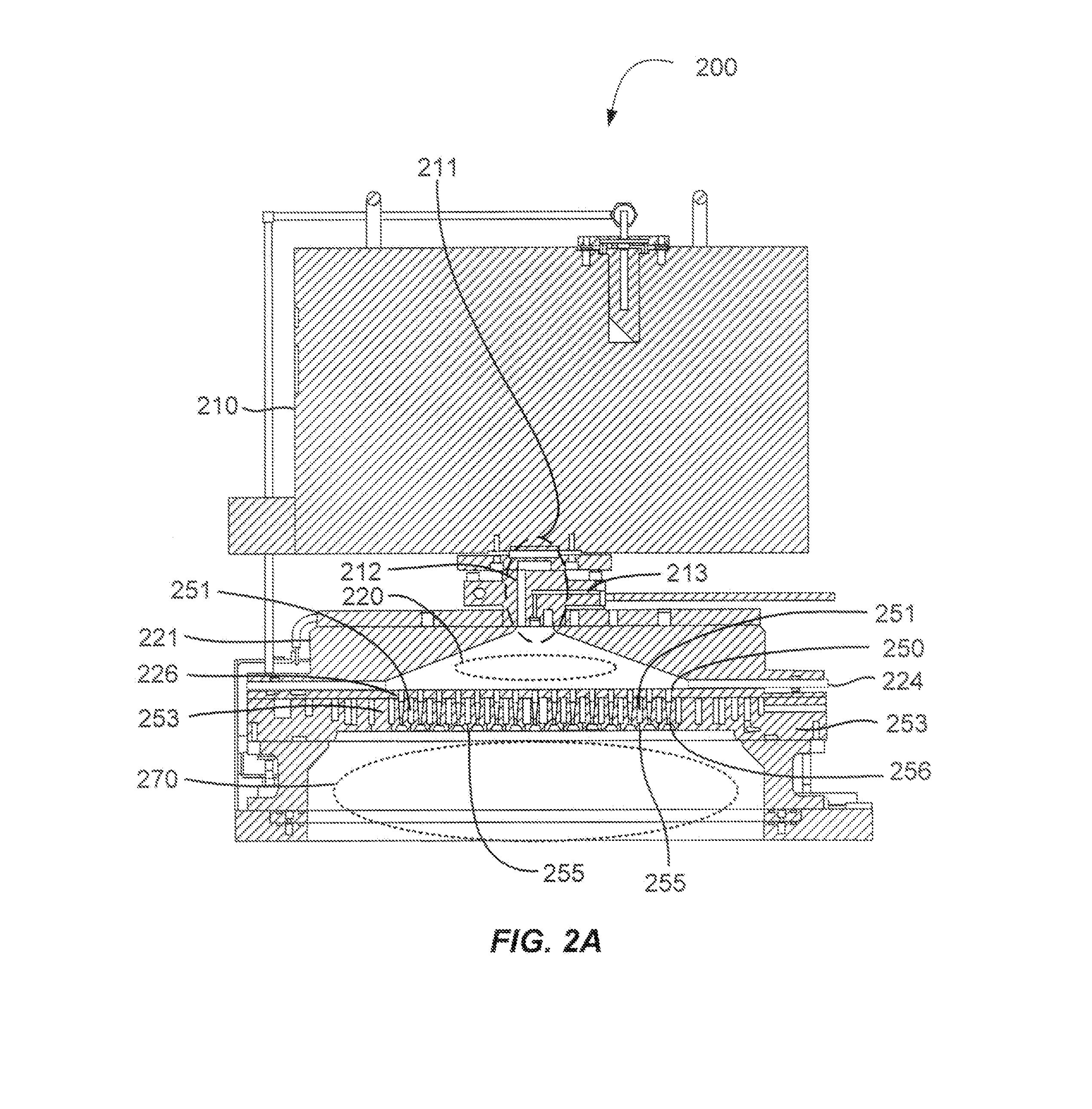

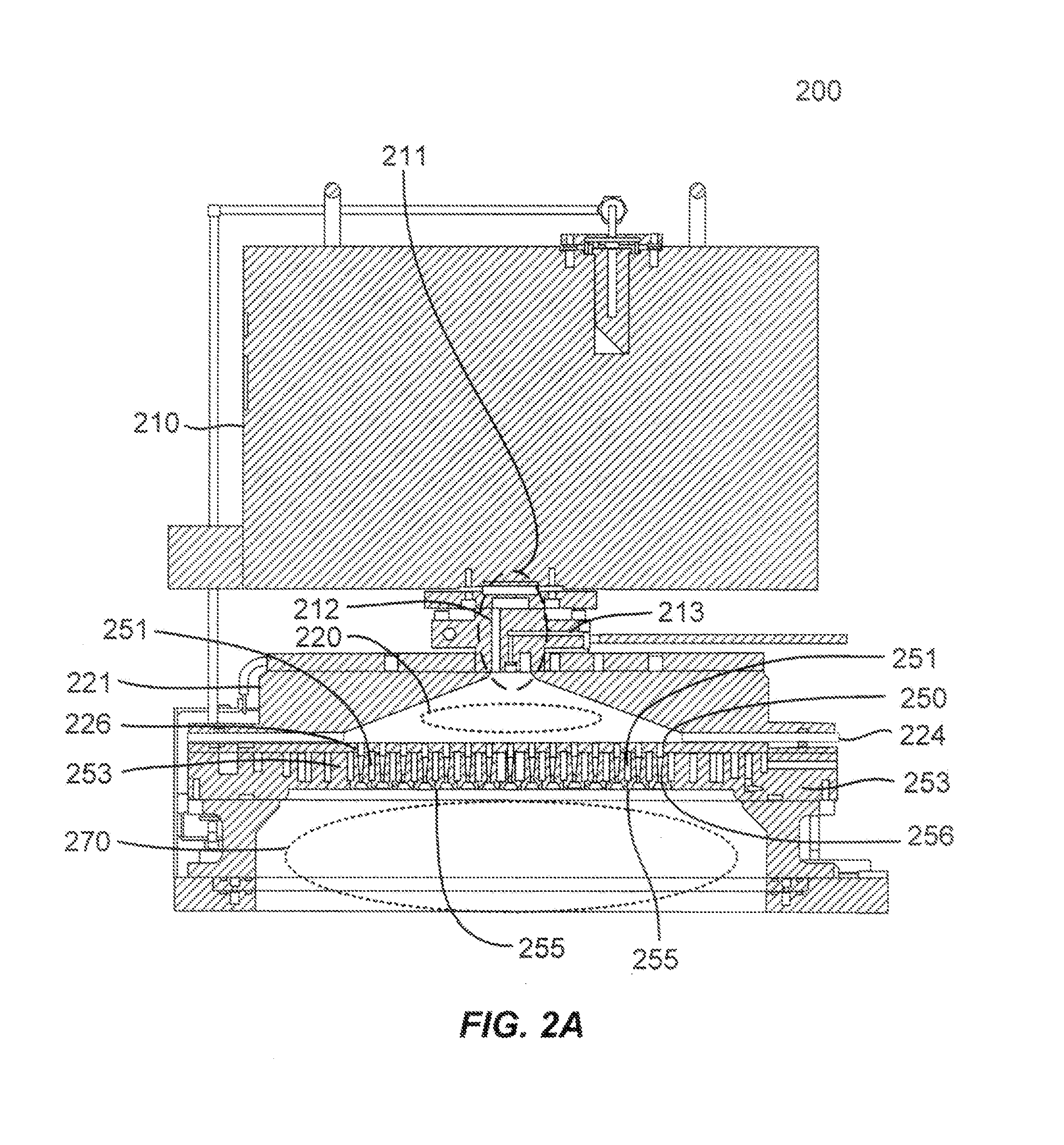

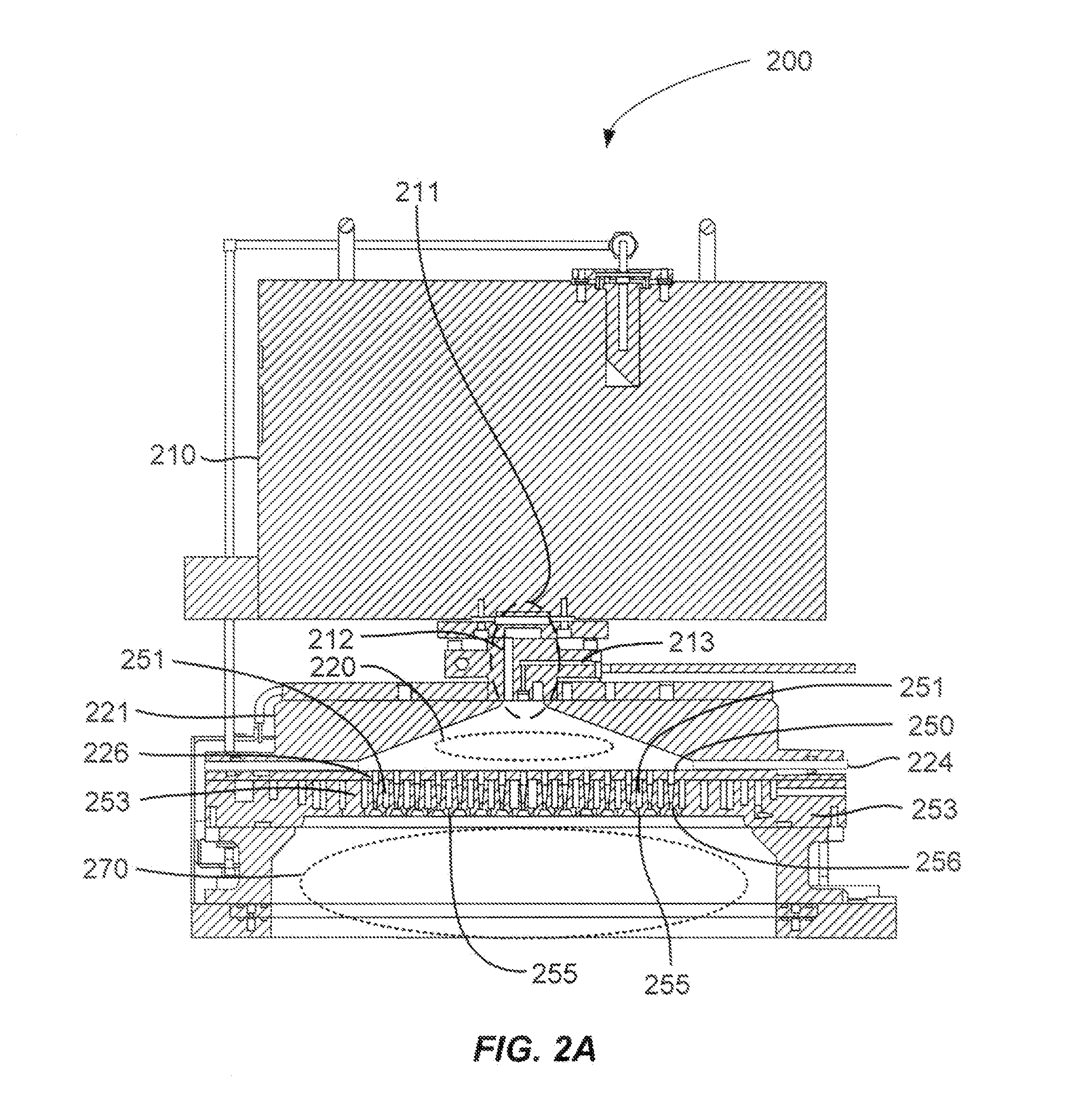

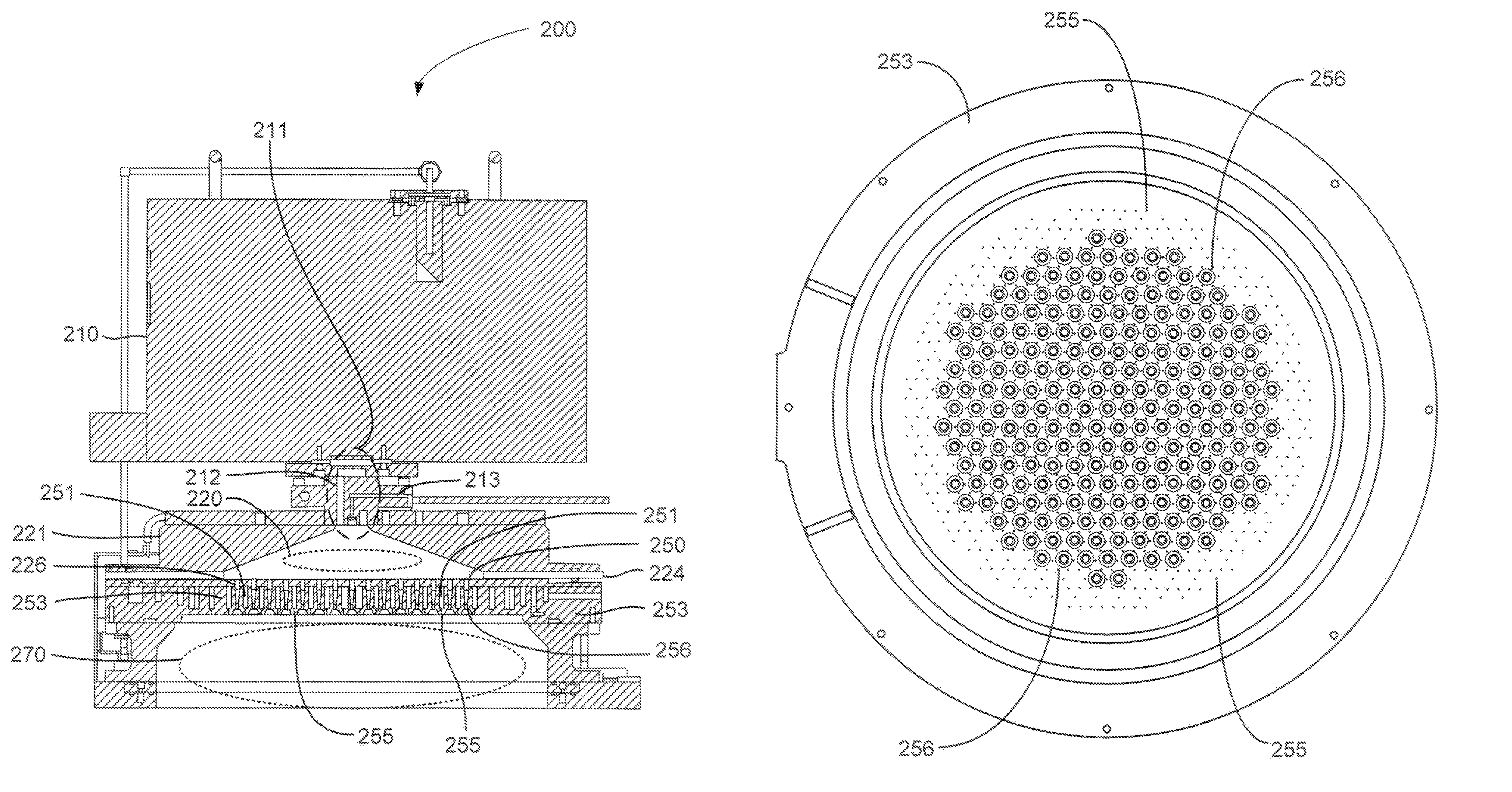

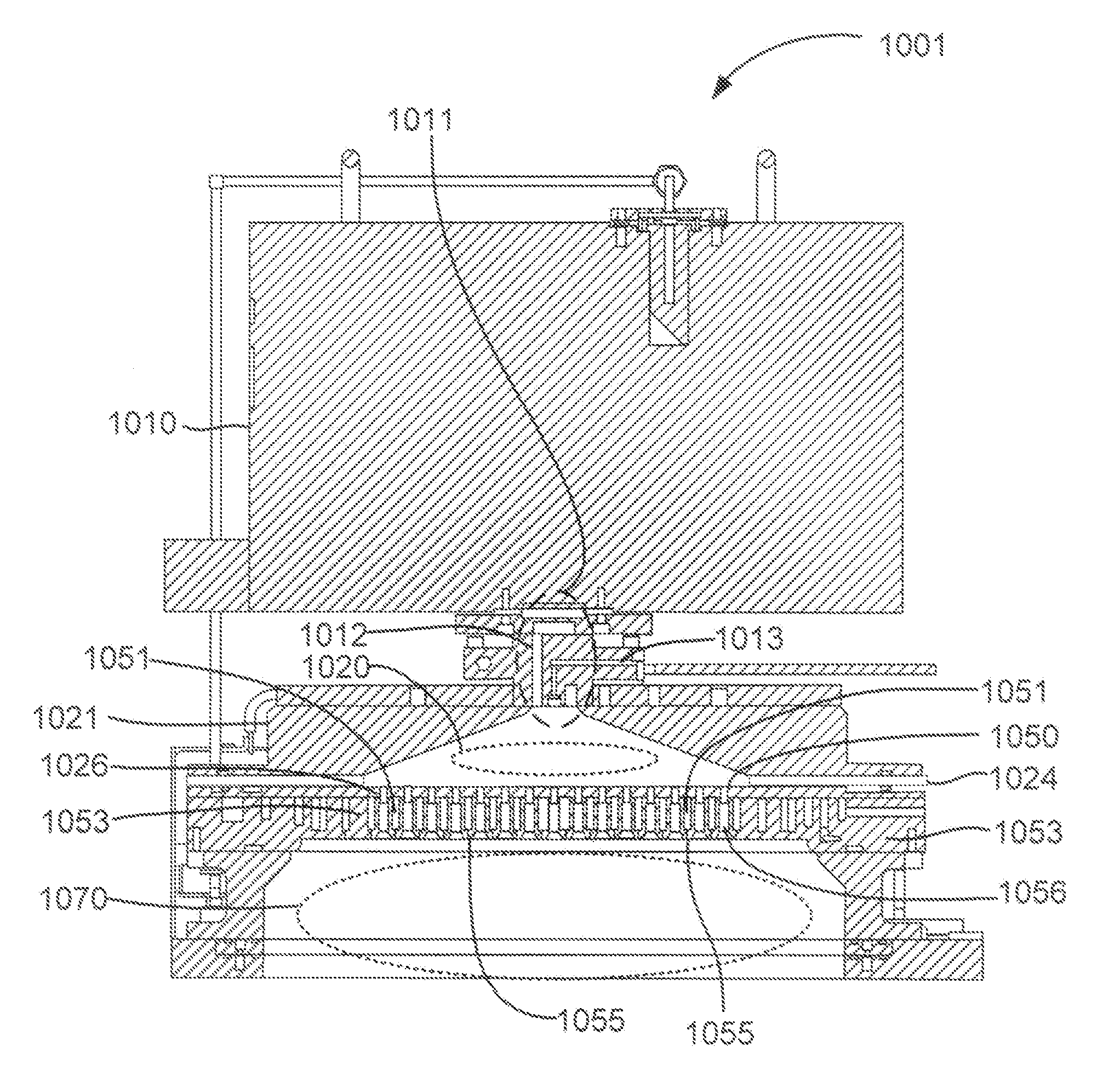

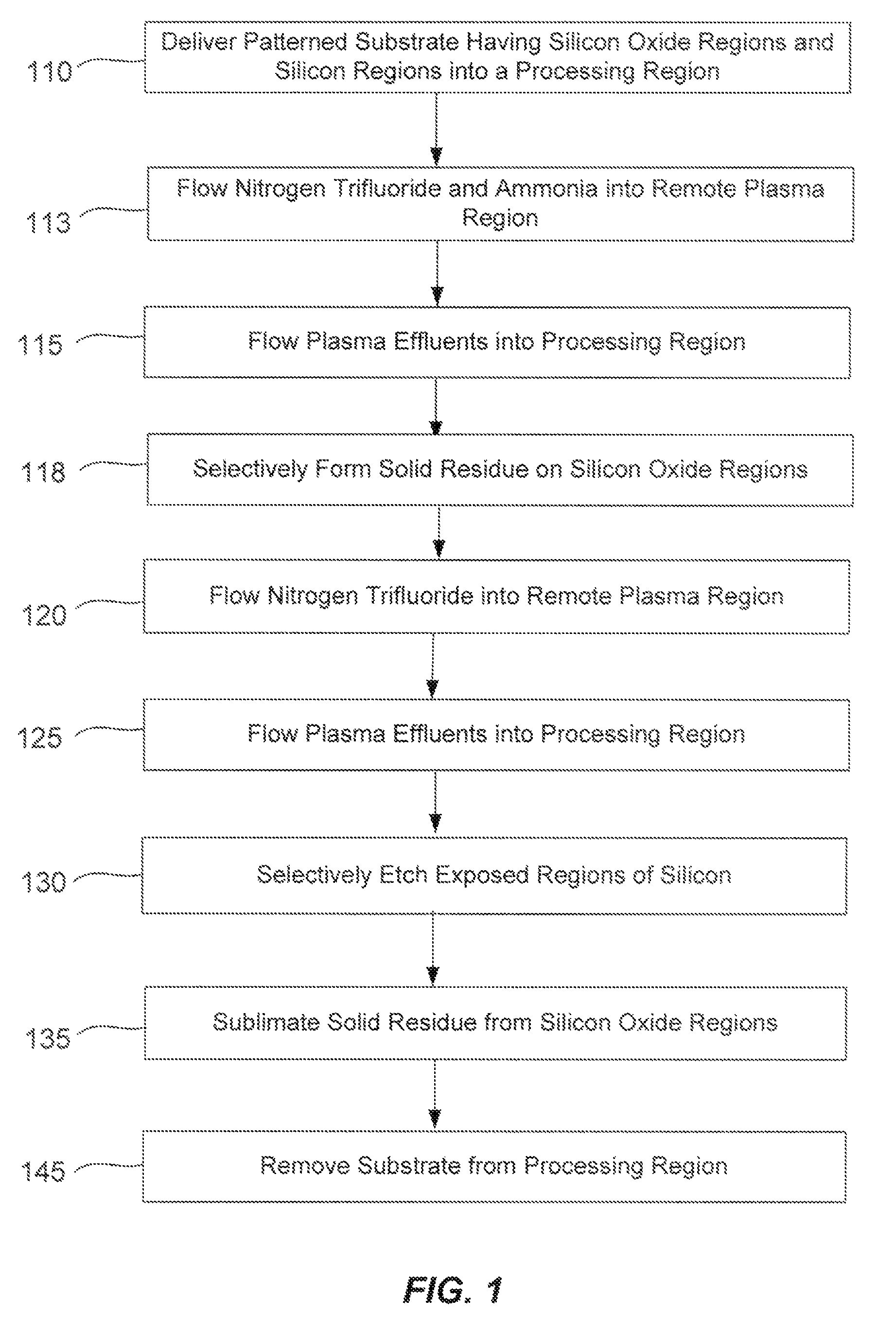

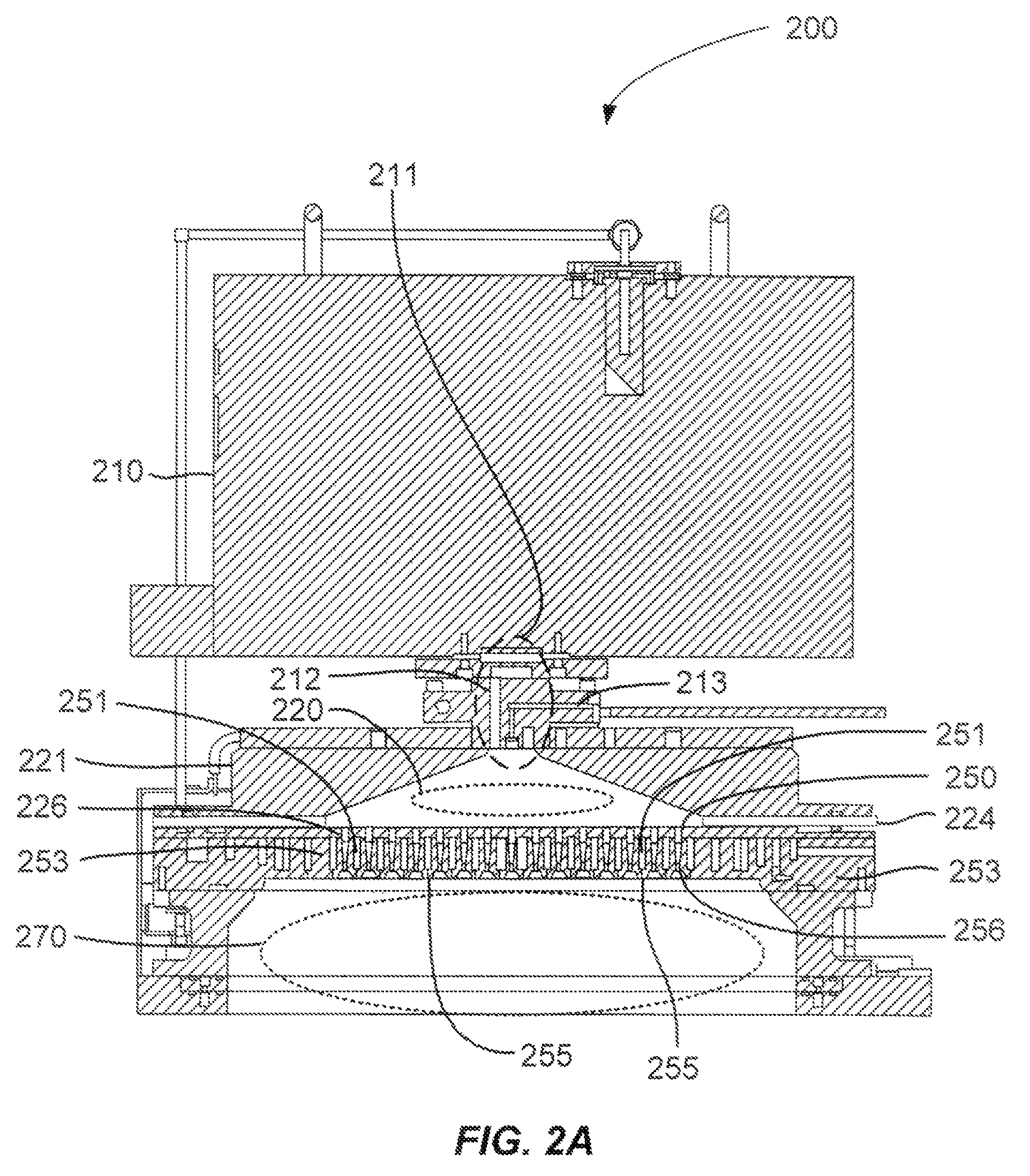

Selective etch of silicon by way of metastable hydrogen termination

ActiveUS20130089988A1Easy to disassembleReduces and substantially eliminates numberElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

Methods of etching exposed silicon on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and a hydrogen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon while very slowly removing other exposed materials. The silicon selectivity results, in part, from a preponderance of hydrogen-containing precursor in the remote plasma which hydrogen terminates surfaces on the patterned heterogeneous structures. A much lower flow of the fluorine-containing precursor progressively substitutes fluorine for hydrogen on the hydrogen-terminated silicon thereby selectively removing silicon from exposed regions of silicon. The methods may be used to selectively remove silicon far faster than silicon oxide, silicon nitride and a variety of metal-containing materials.

Owner:APPLIED MATERIALS INC

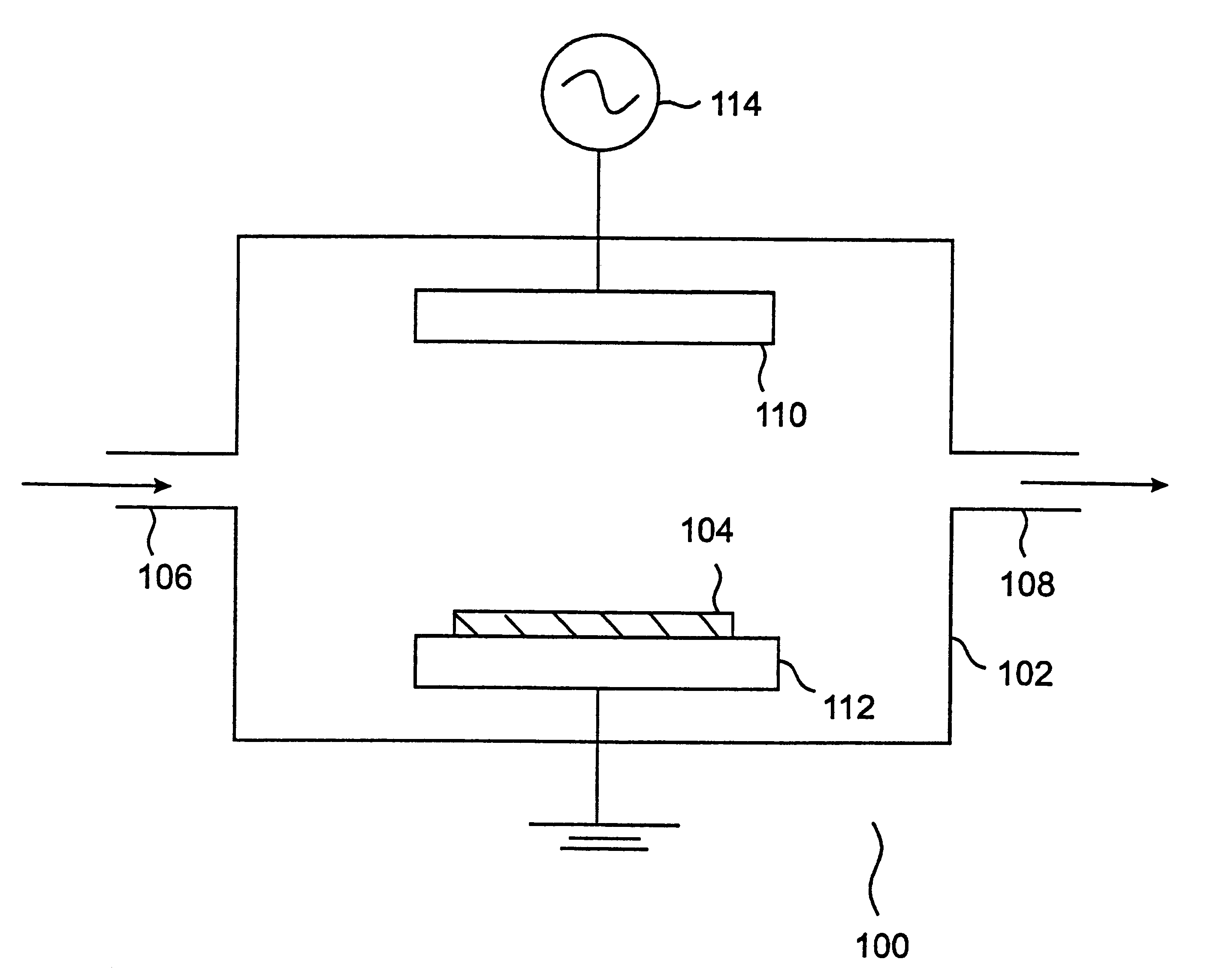

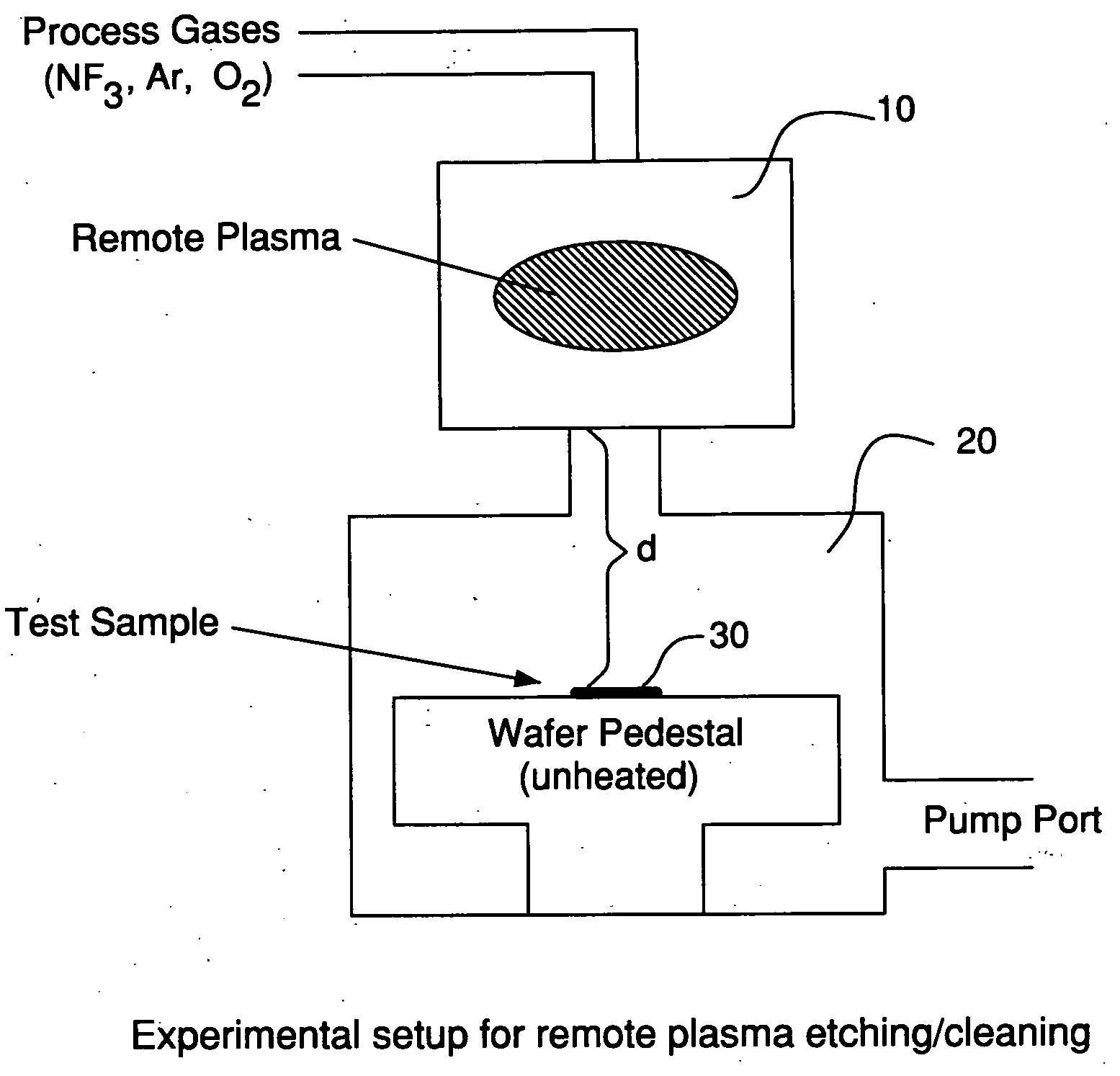

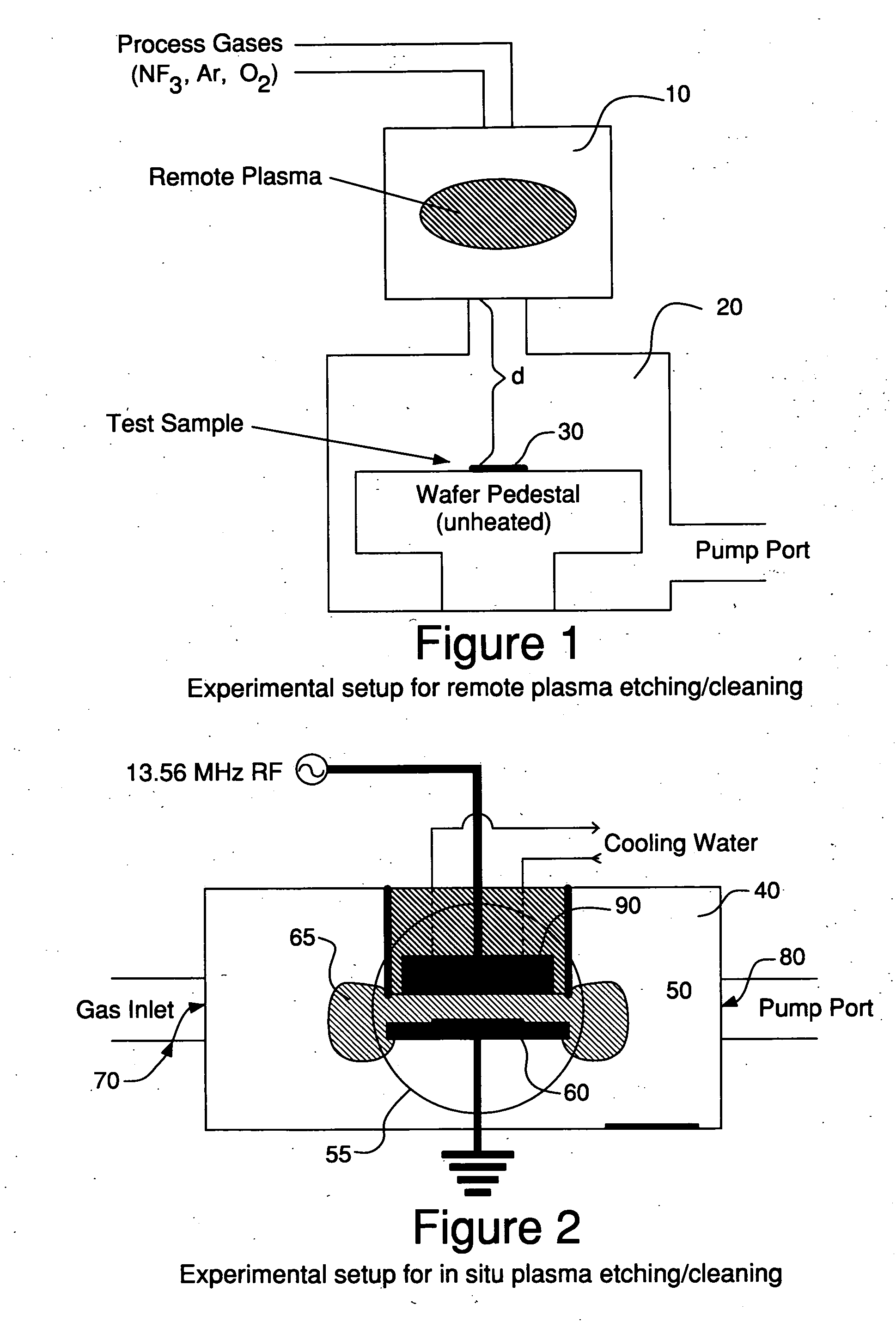

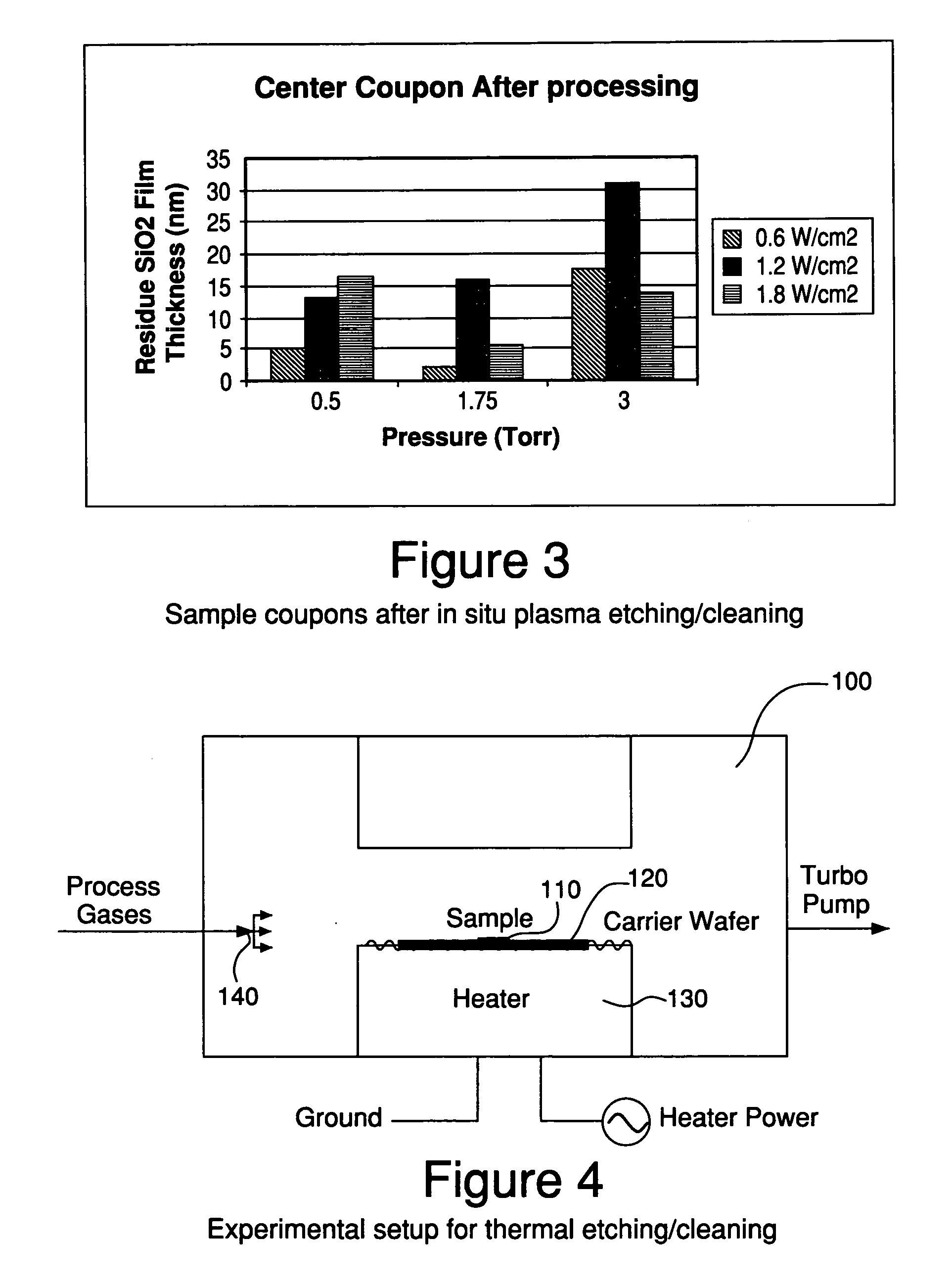

Plasma cleaning and etching methods using non-global-warming compounds

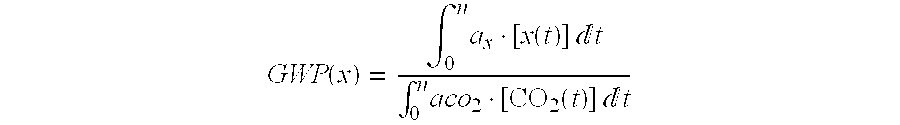

InactiveUS6242359B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrifluoroacetic anhydrideChemical vapor deposition

Provided is a novel method of cleaning a chemical vapor deposition processing chamber having deposits on an inner surface thereof is provided. The process involves forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound, and contacting active species generated in the plasma with the inner surface of the chamber, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. Also provided is a method of etching a layer on a silicon wafer. The method involves the steps of: (a) introducing a silicon wafer into a processing chamber, the silicon wafer comprising a layer to be etched; and (b) forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound. Active species generated in the plasma are contacted with the silicon wafer, thereby etching the layer, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. The chemistries in accordance with the invention provide environmentally benign alternatives to the conventionally used global-warming chemistries for chamber cleaning and semiconductor etching processes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

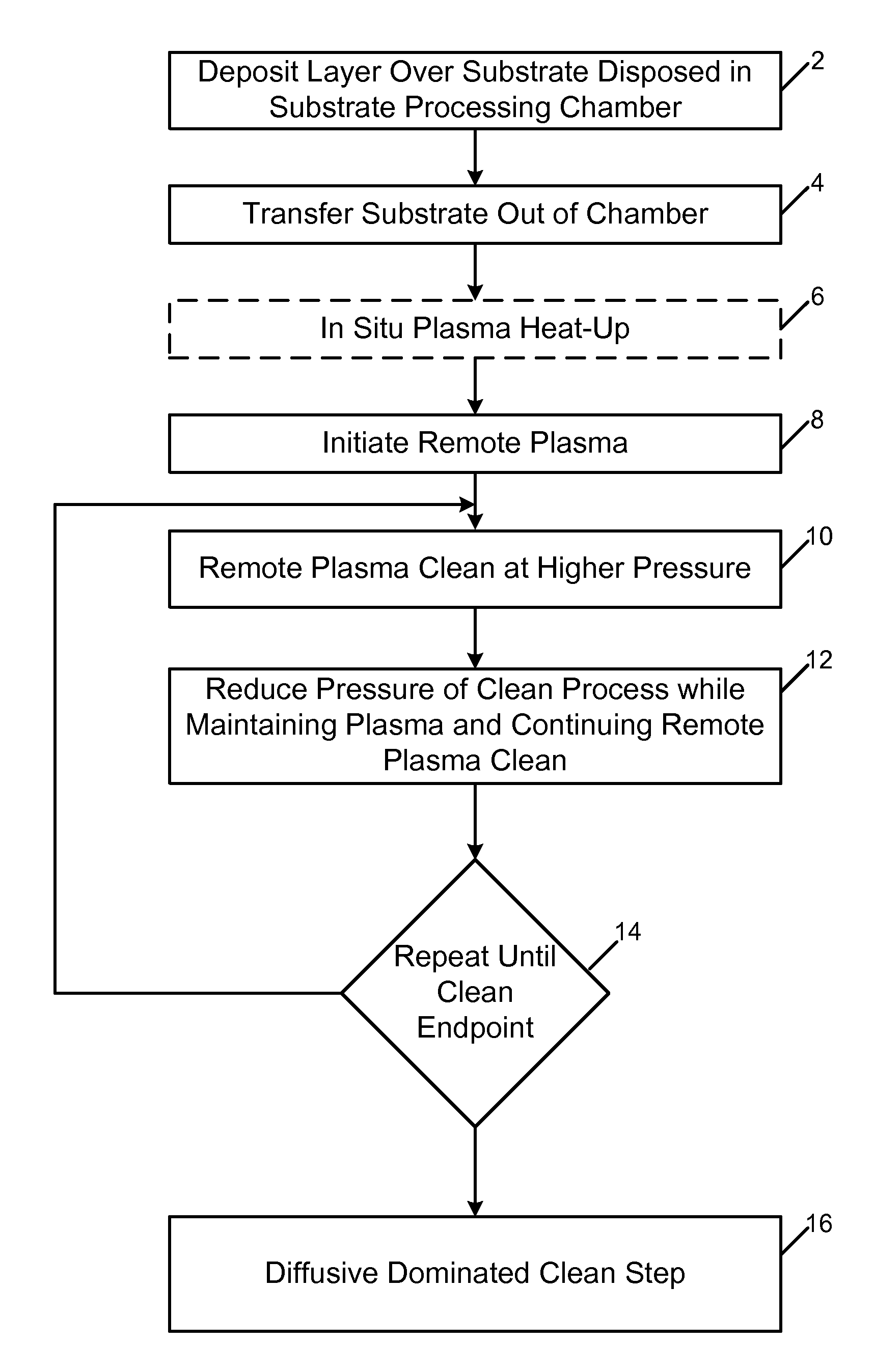

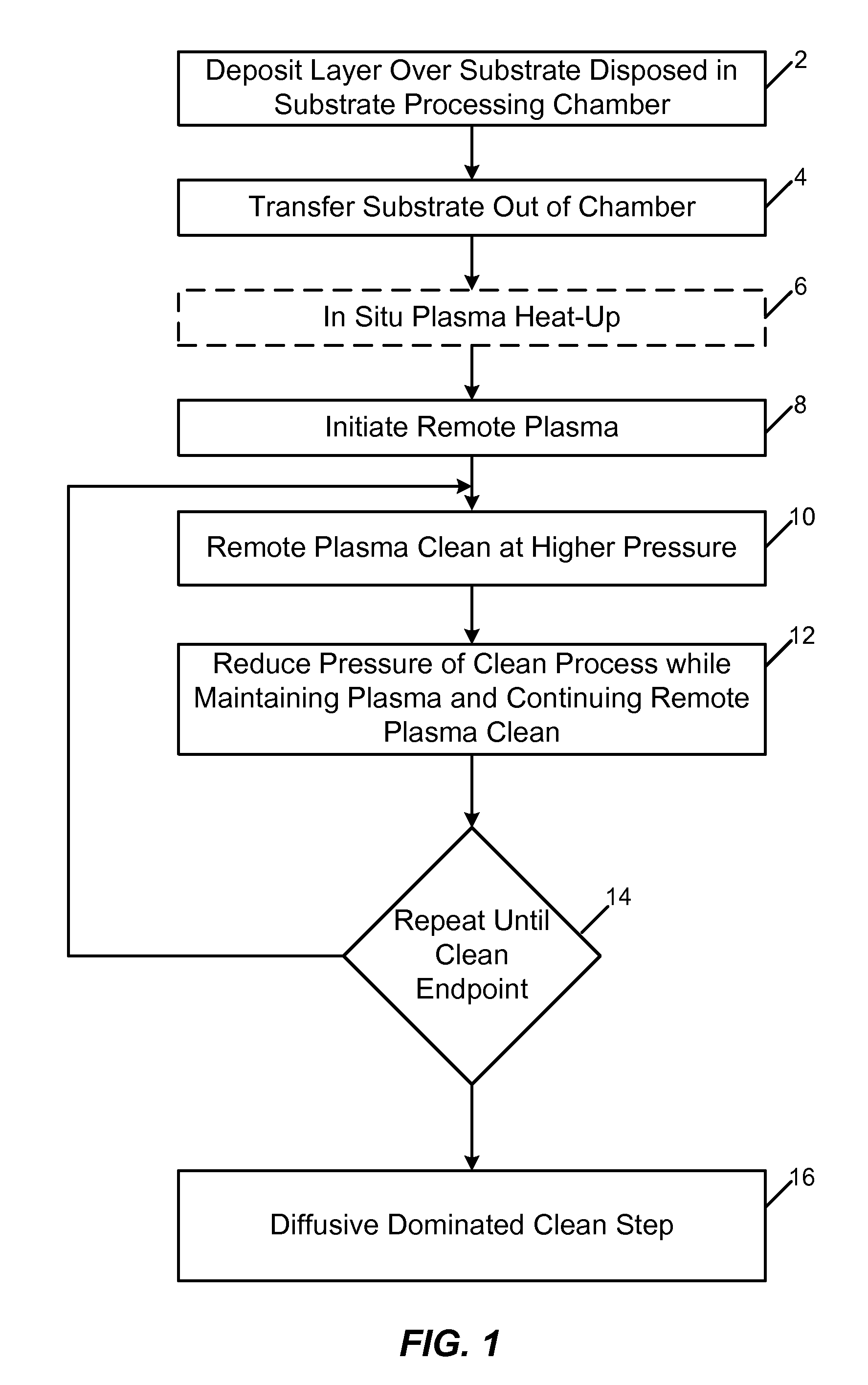

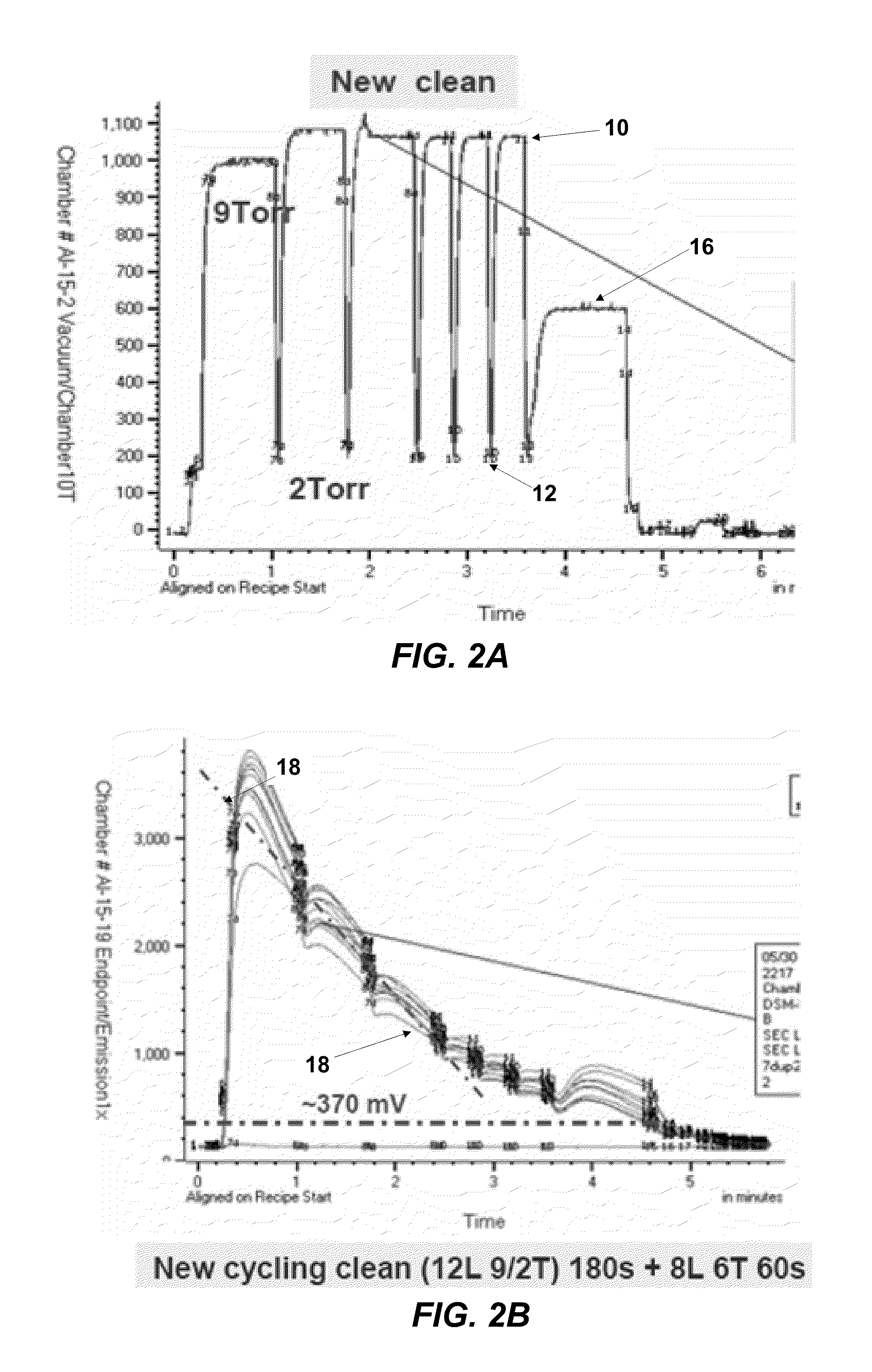

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

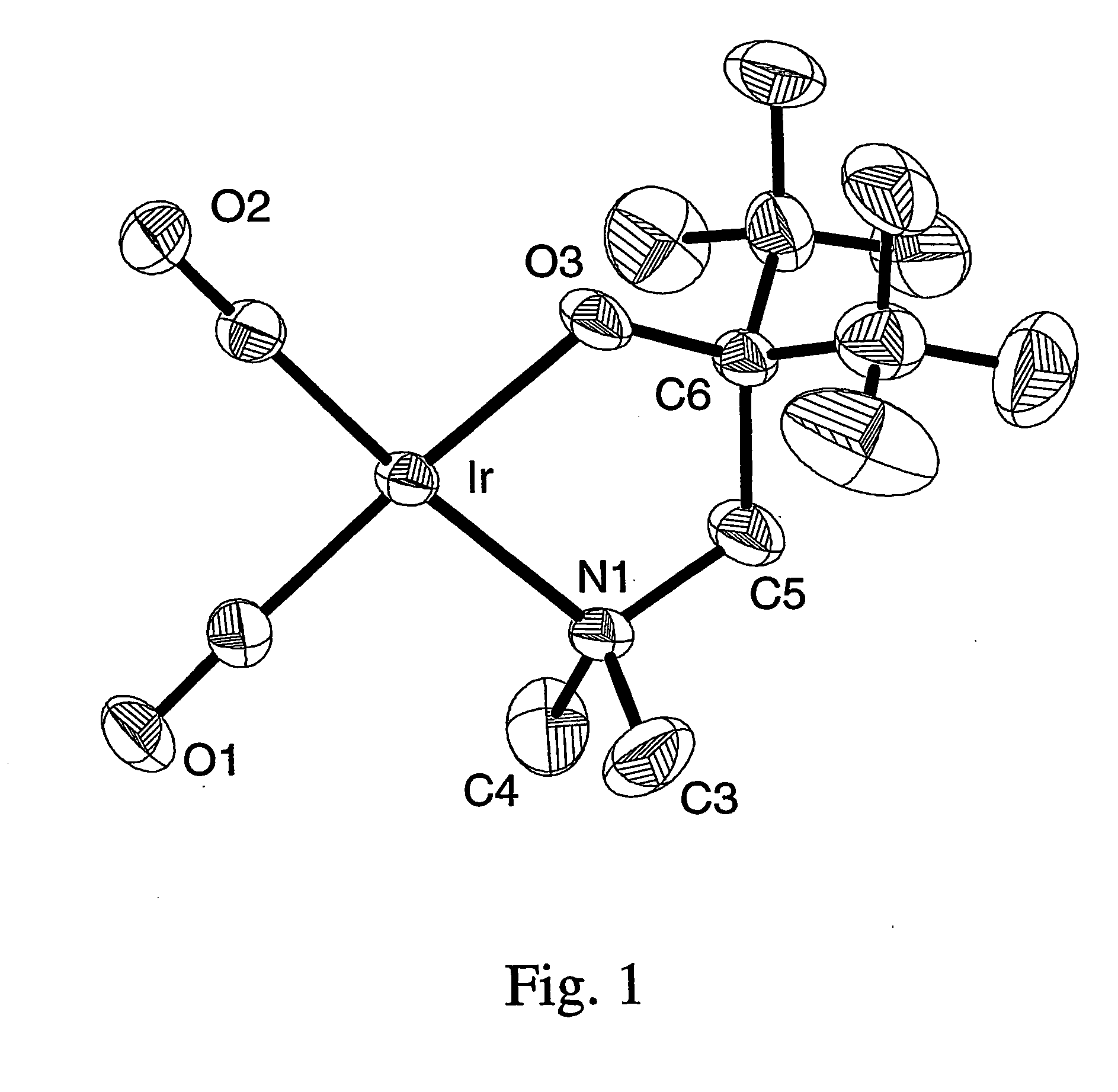

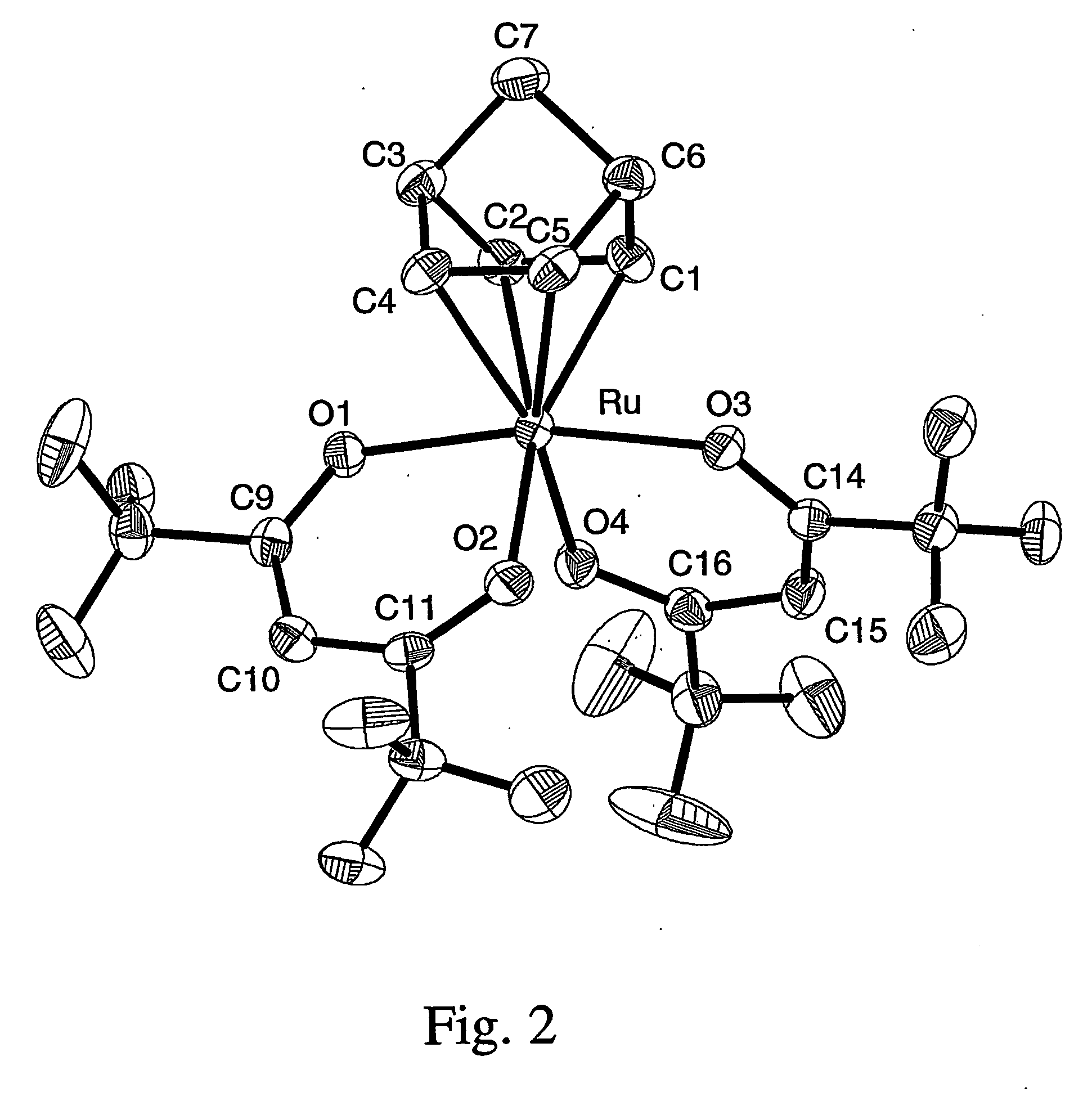

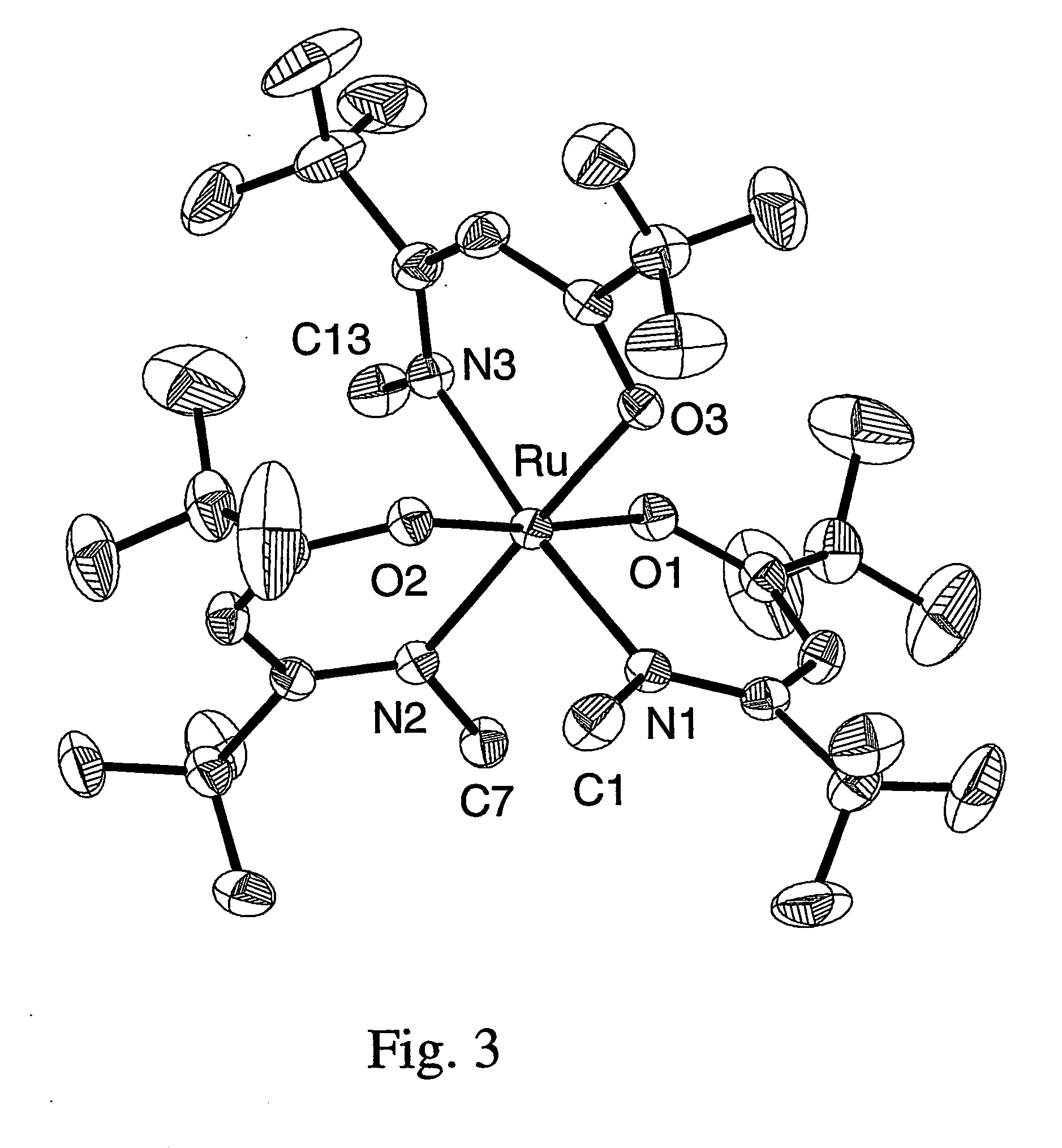

Volatile noble metal organometallic complexes

InactiveUS20050033075A1Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIridiumIodide

A series of noble metal organometallic complexes of the general formula (I): MLaXb(FBC)c, wherein M is a noble metal such as iridium, ruthenium or osmium, and L is a neutral ligand such as carbonyl, alkene or diene; X is an anionic ligand such as chloride, bromide, iodide and trifluoroacetate group; and FBC is a fluorinated bidentate chelate ligand such as beta diketonate, beta-ketoiminate, amino-alcoholate and amino-alcoholate ligand, wherein a is an integer of from zero (0) to three (3), b is an integer of from zero (0) to one (1) and c is an 10 integer of from one (1) to three (3). The resulting noble metal complexes possess enhanced volatility and thermal stability characteristics, and are suitable for chemical vapor deposition(CVD) applications. The corresponding noble metal complex is formed by treatment of the FBC ligand with a less volatile metal halide. Also disclosed are CVD methods for using the noble metal complexes as source reagents for deposition of noble metal-containing films such as Ir, Ru and Os, or even metal oxide film materials IrO2, OsO2 and RuO2.

Owner:NATIONAL TSING HUA UNIVERSITY +1

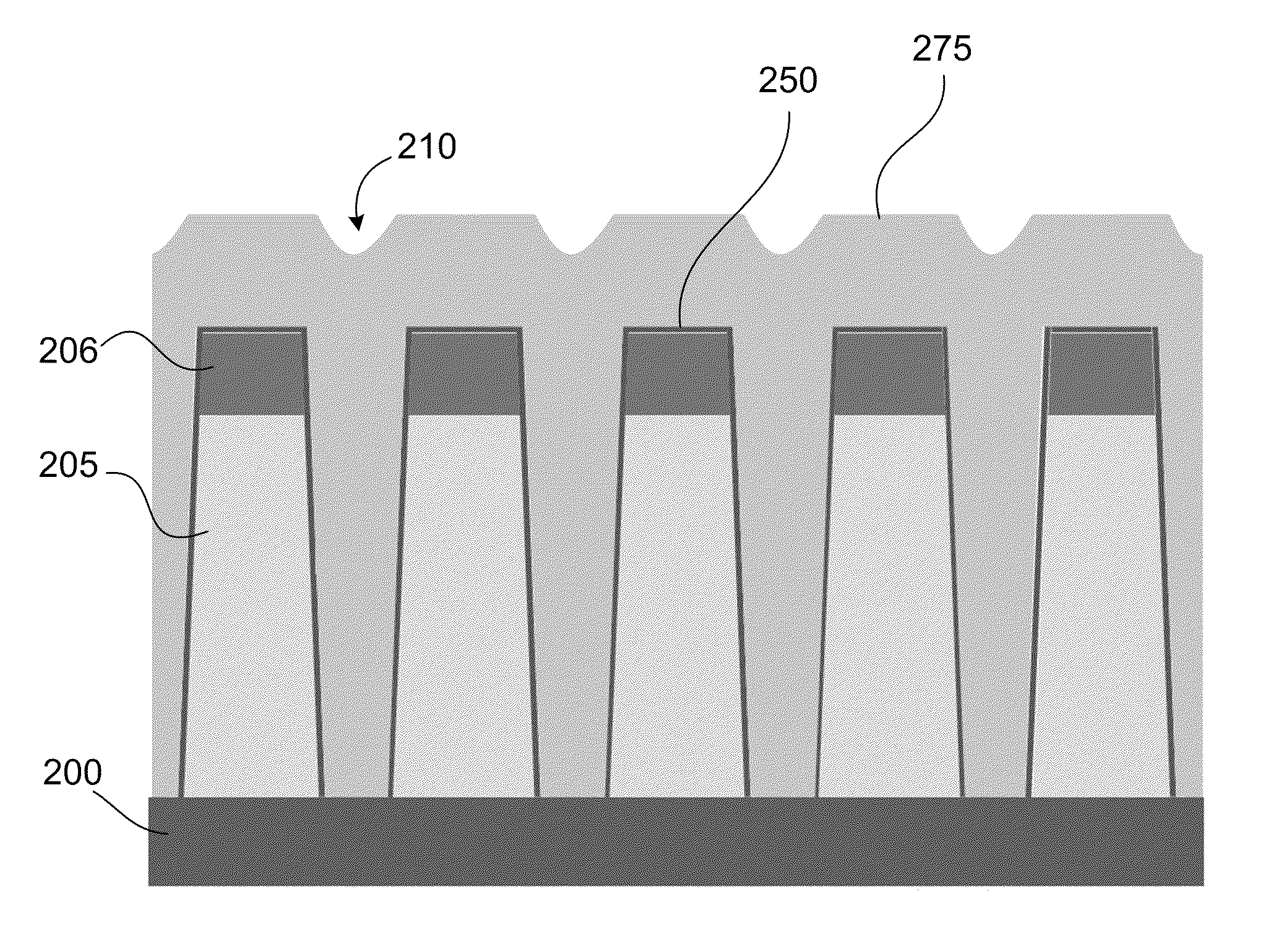

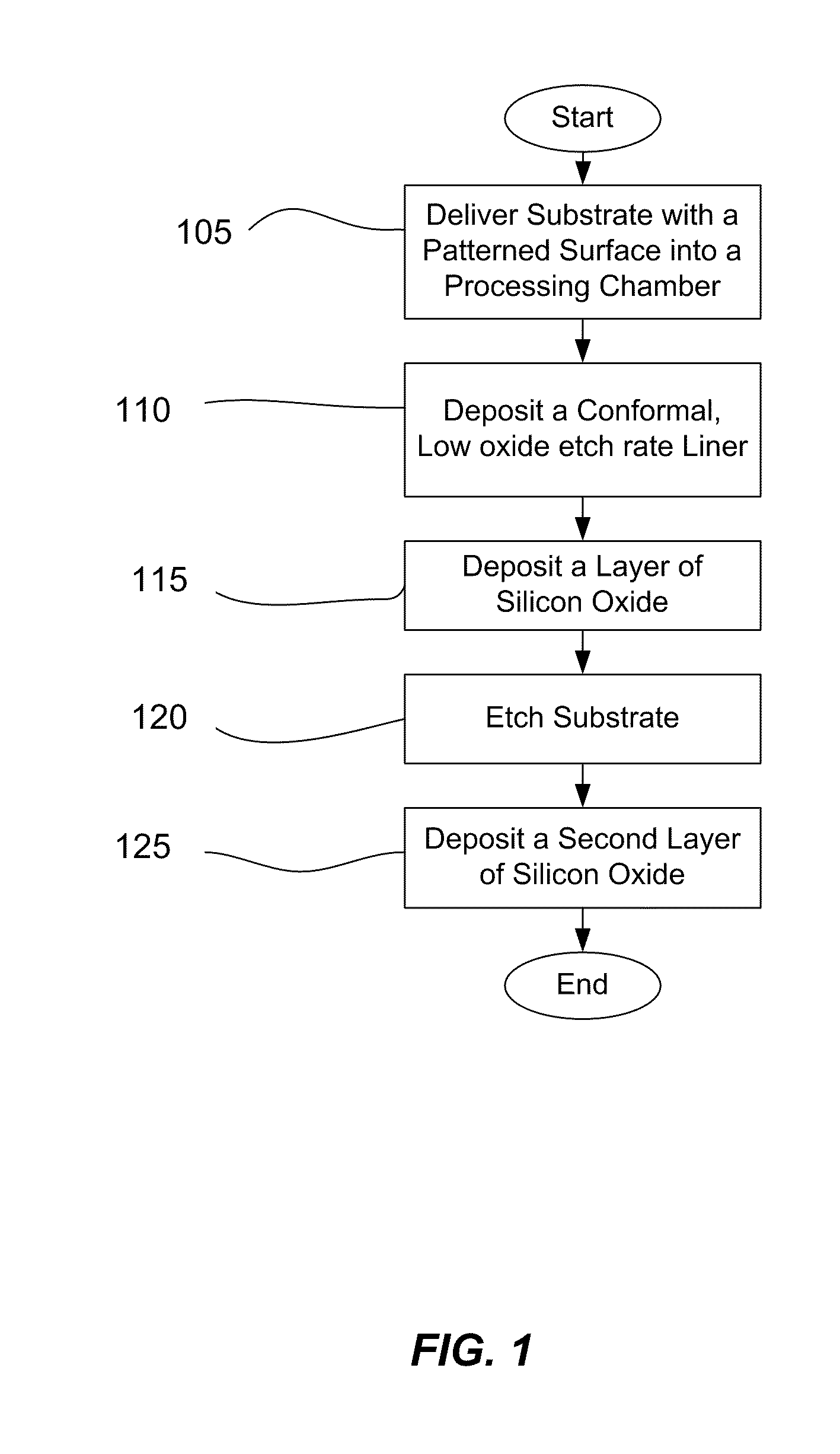

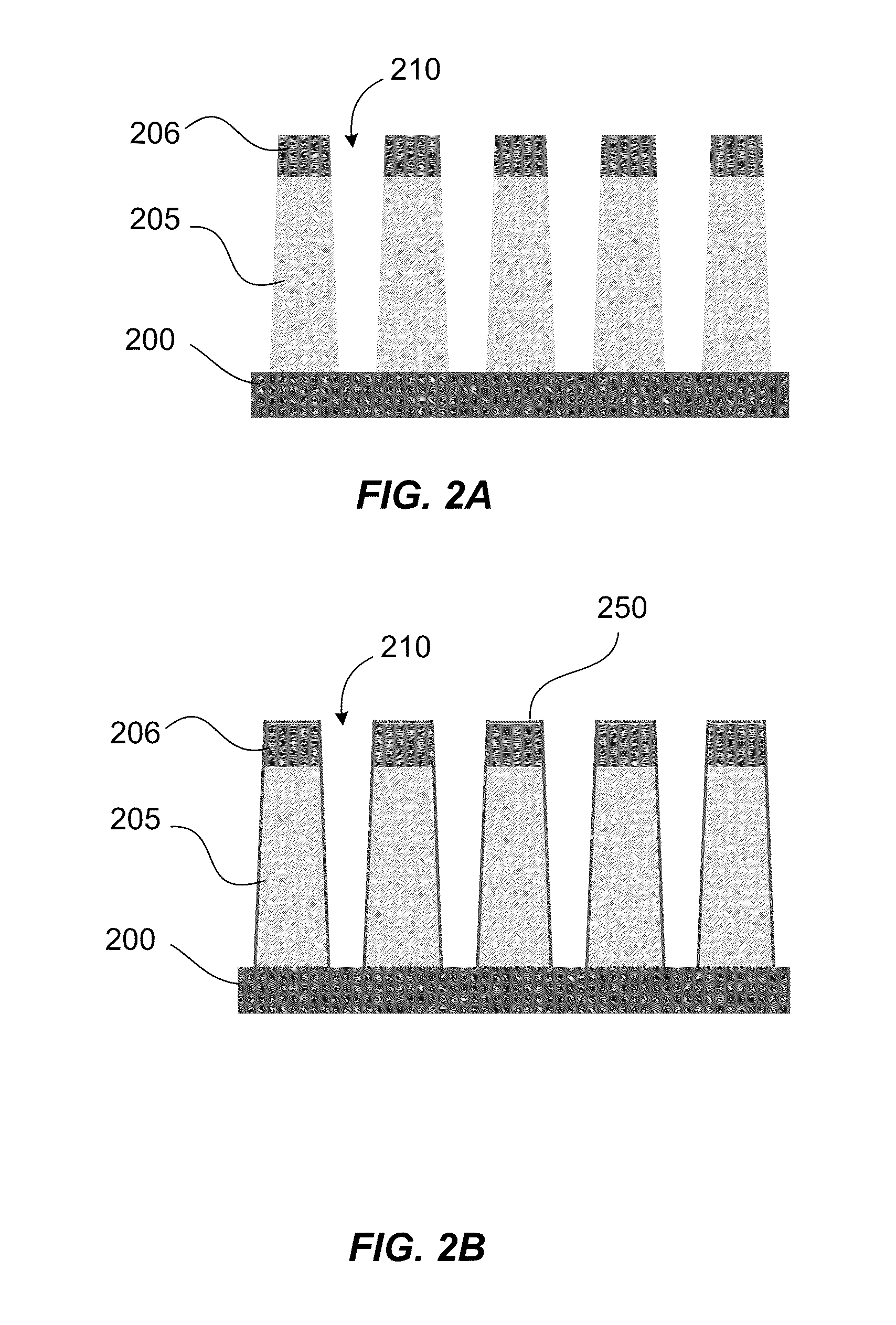

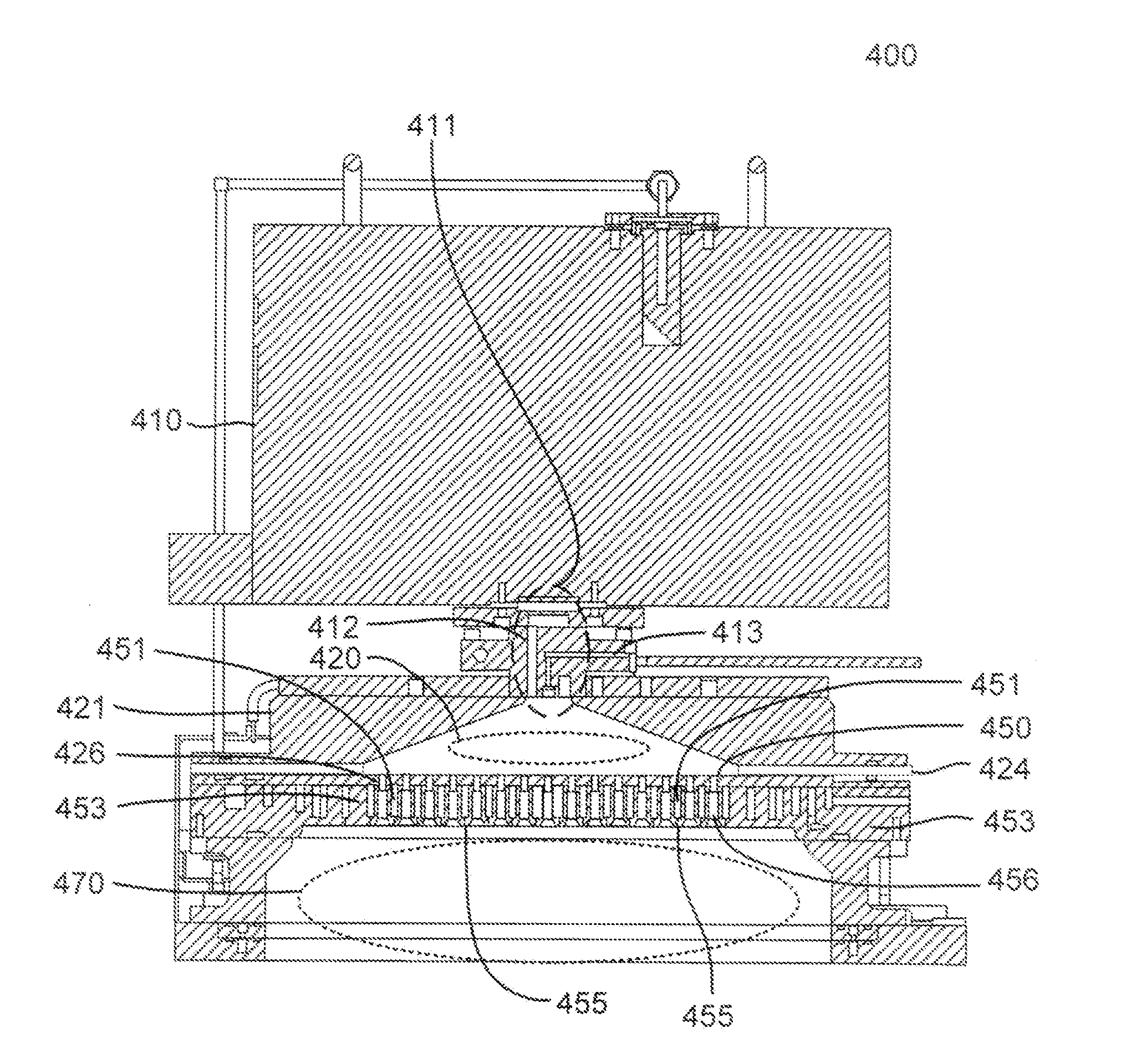

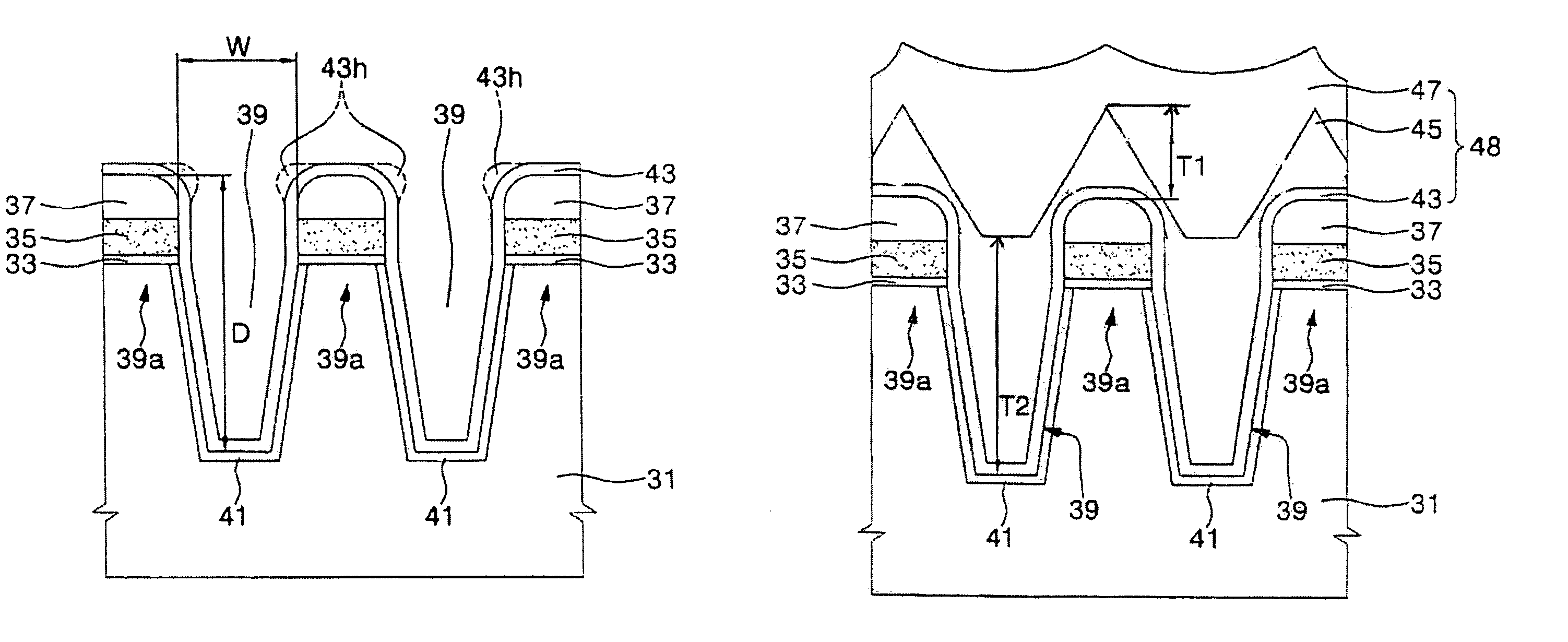

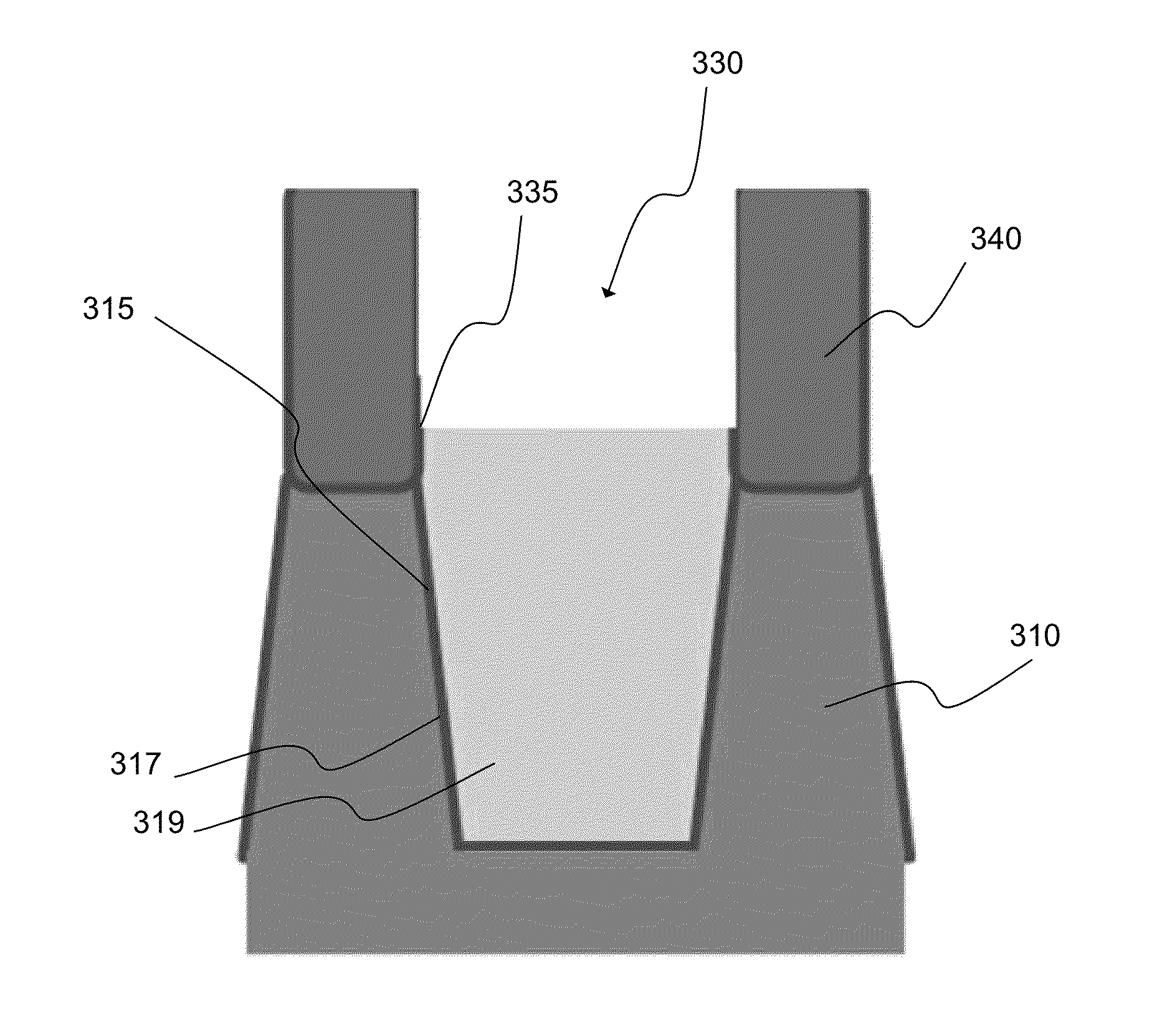

Gapfill improvement with low etch rate dielectric liners

A method of filling a trench is described and includes depositing a dielectric liner with a high ratio of silicon oxide to dielectric liner etch rate in fluorine-containing etch chemistries. Silicon oxide is deposited within the trench and etched to reopen or widen a gap near the top of the trench. The dielectric liner protects the underlying substrate during the etch process so the gap can be made wider. Silicon oxide is deposited within the trench again to substantially fill the trench.

Owner:APPLIED MATERIALS INC

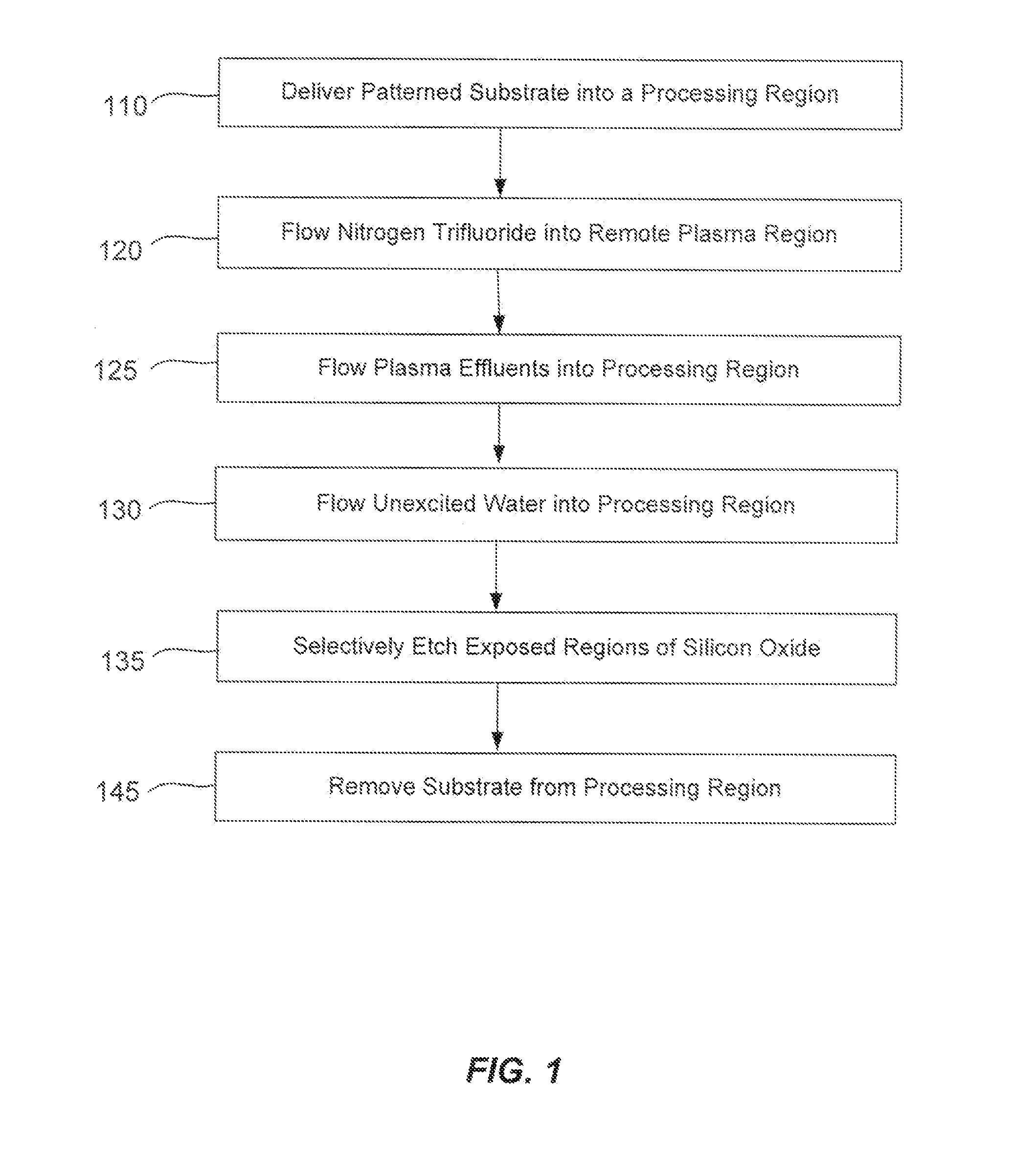

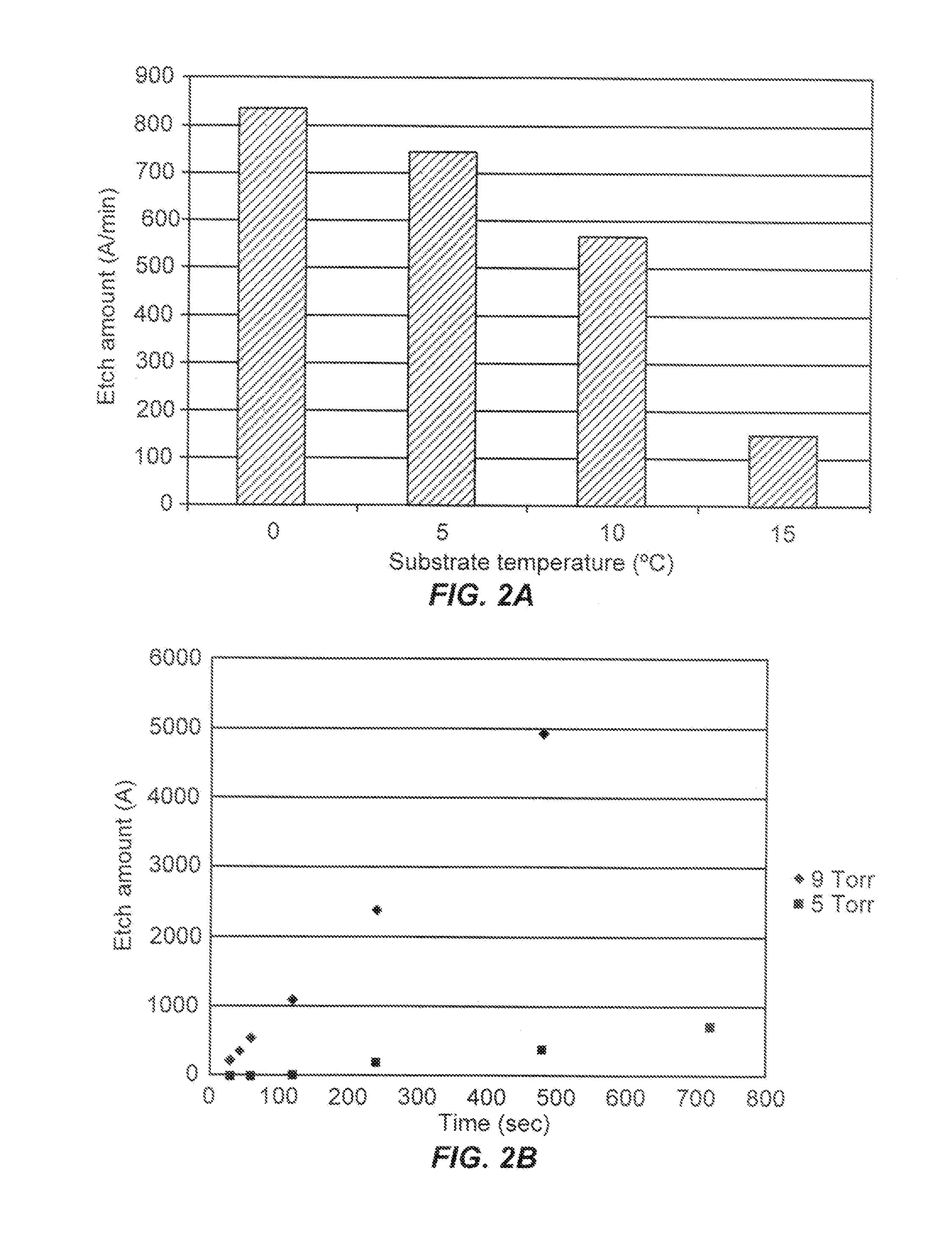

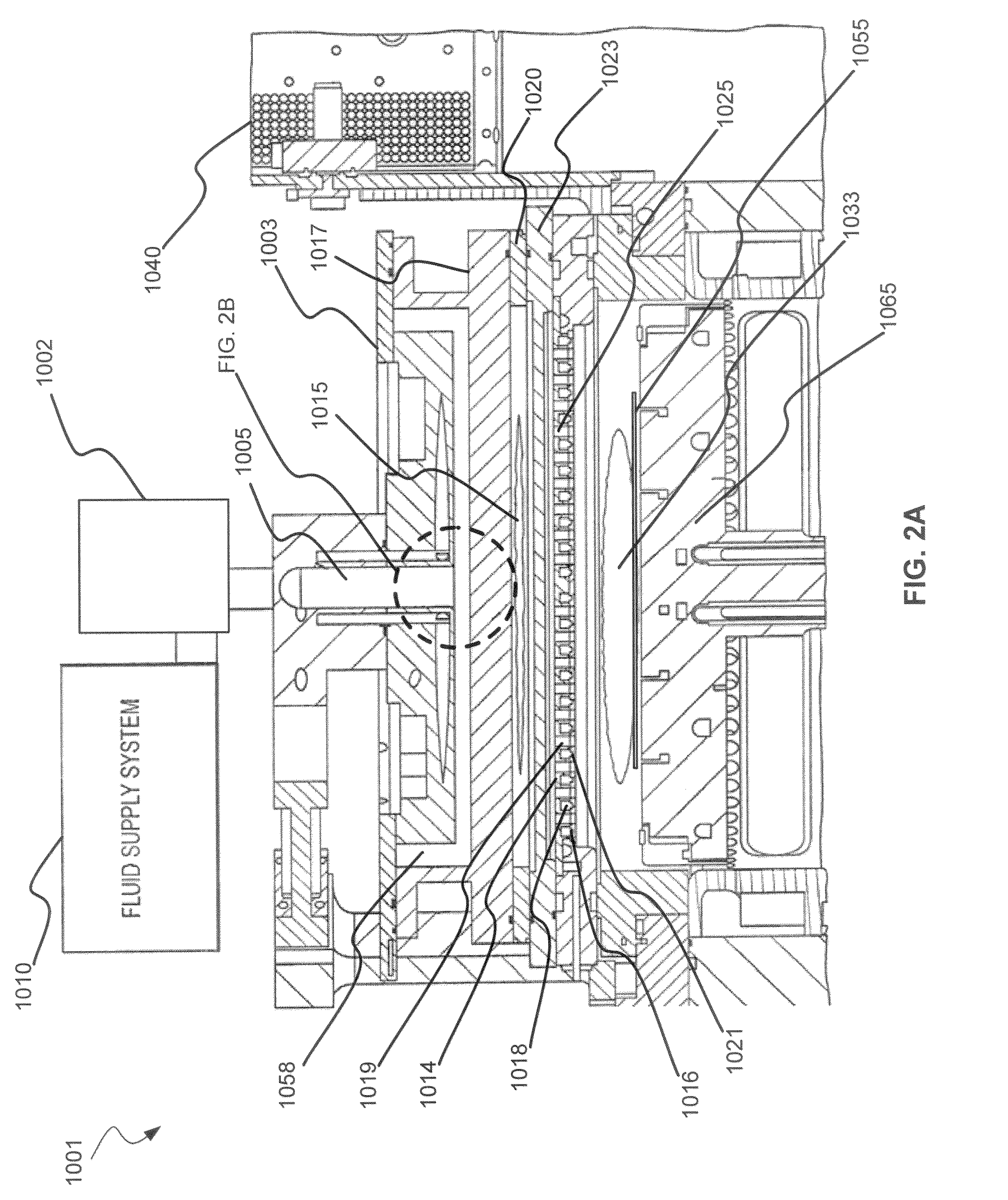

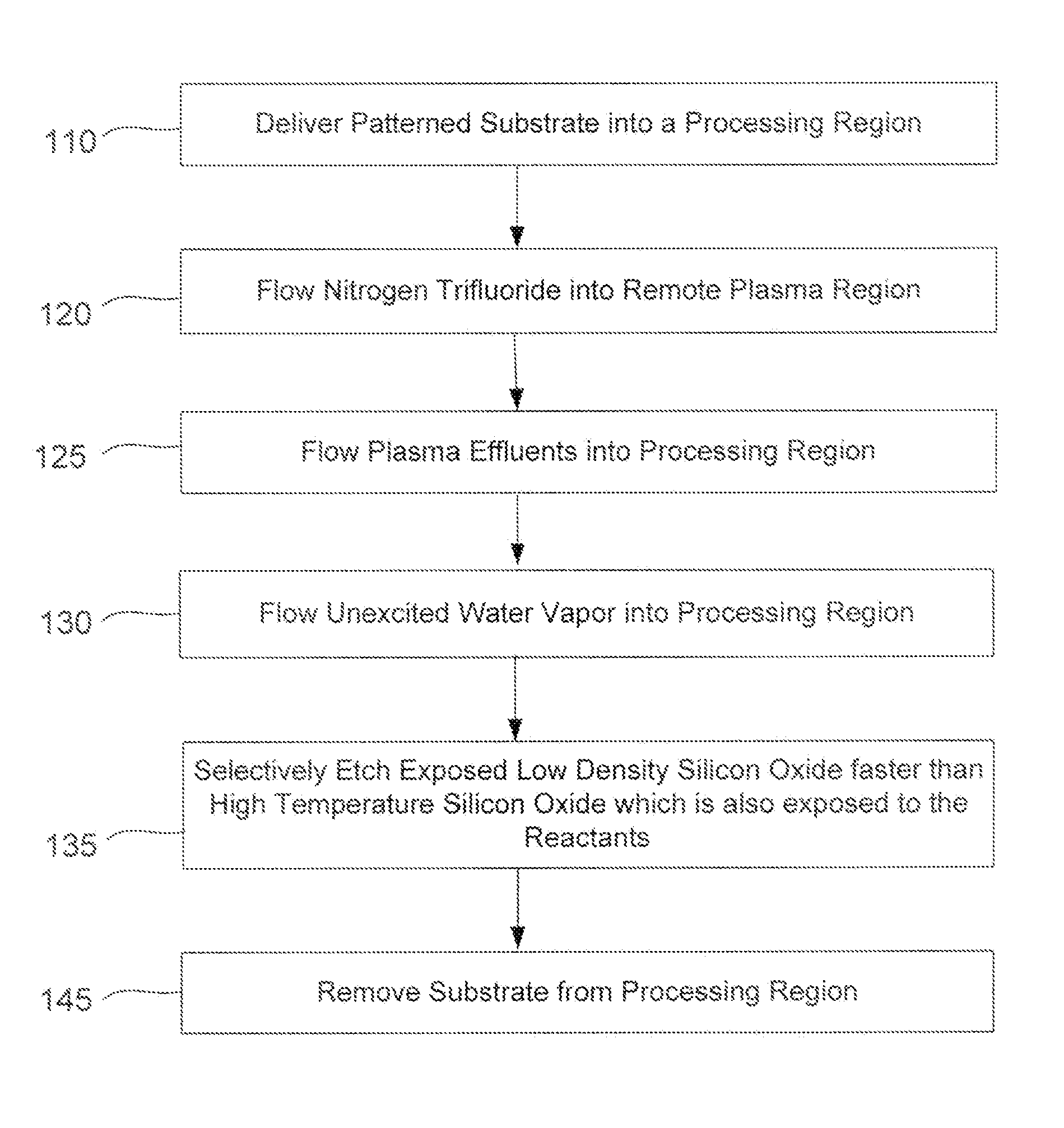

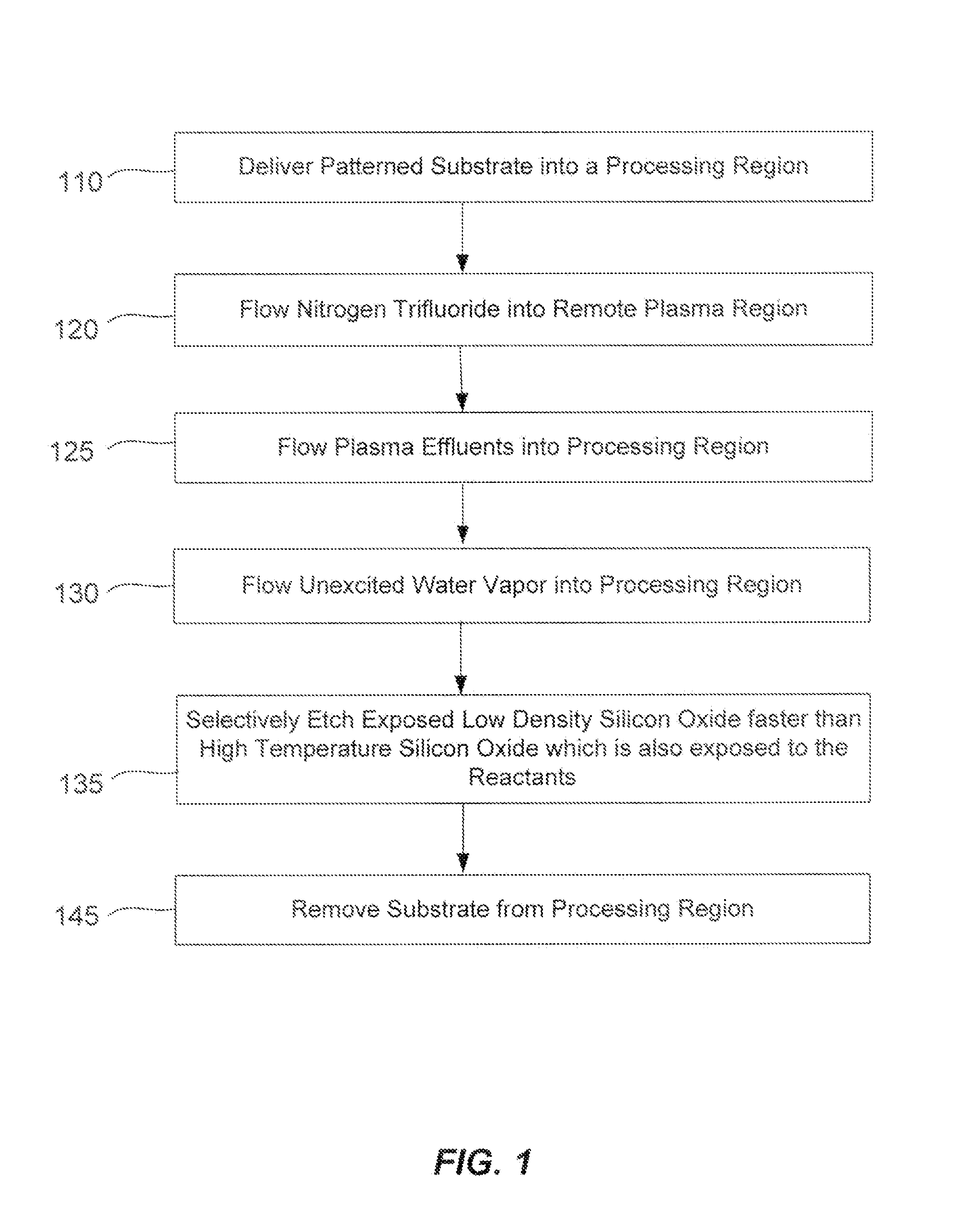

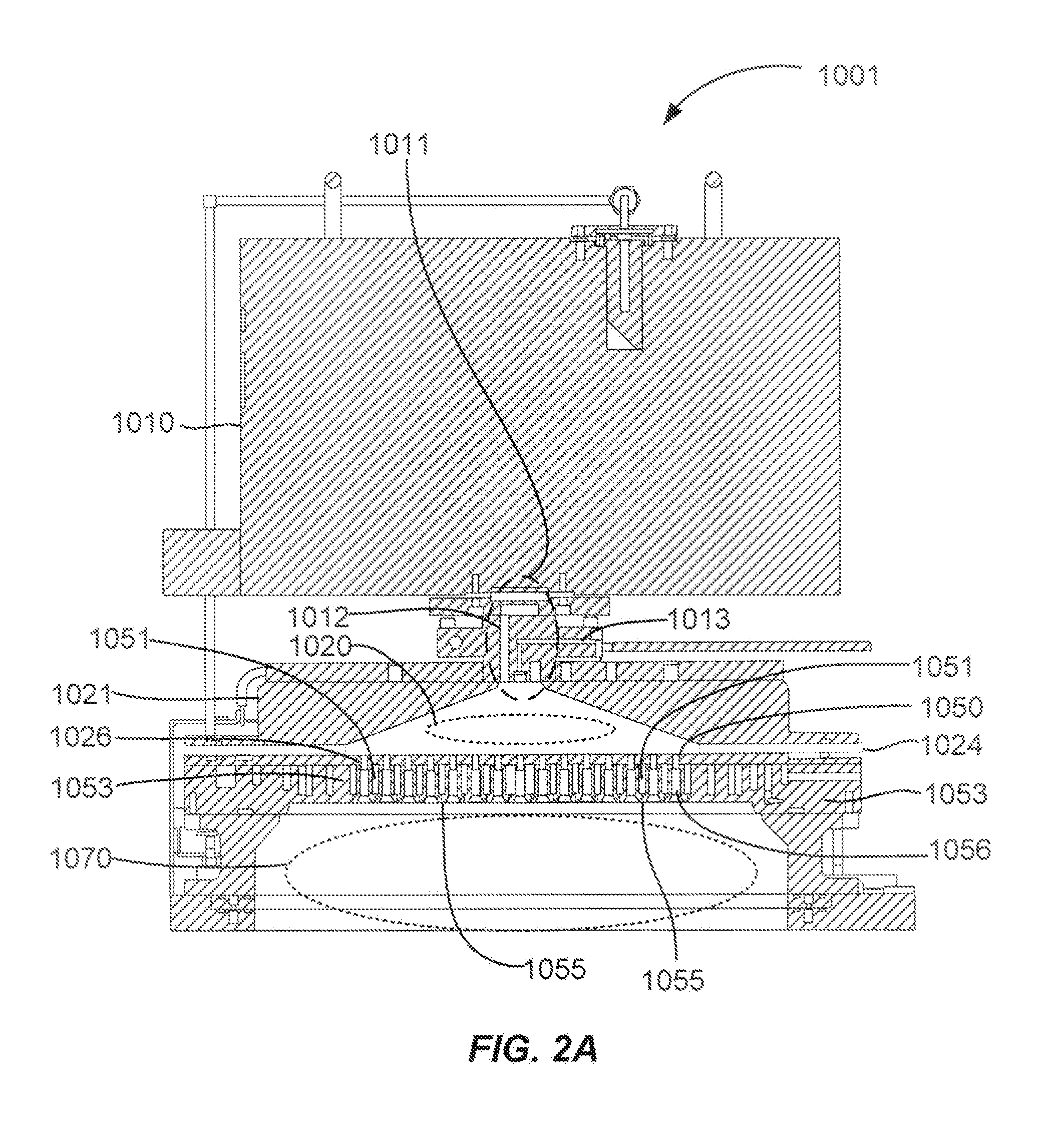

Remotely-excited fluorine and water vapor etch

ActiveUS20120211462A1Small overall deformationElectric discharge tubesDecorative surface effectsChemical reactionRemote plasma

A method of etching exposed silicon oxide on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents combine with water vapor. The chemical reaction resulting from the combination produces reactants which etch the patterned heterogeneous structures to produce, in embodiments, a thin residual structure exhibiting little deformation. The methods may be used to conformally trim silicon oxide while removing little or no silicon, polysilicon, silicon nitride, titanium or titanium nitride. In an exemplary embodiment, the etch processes described herein have been found to remove mold oxide around a thin cylindrical conducting structure without causing the cylindrical structure to significantly deform.

Owner:APPLIED MATERIALS INC

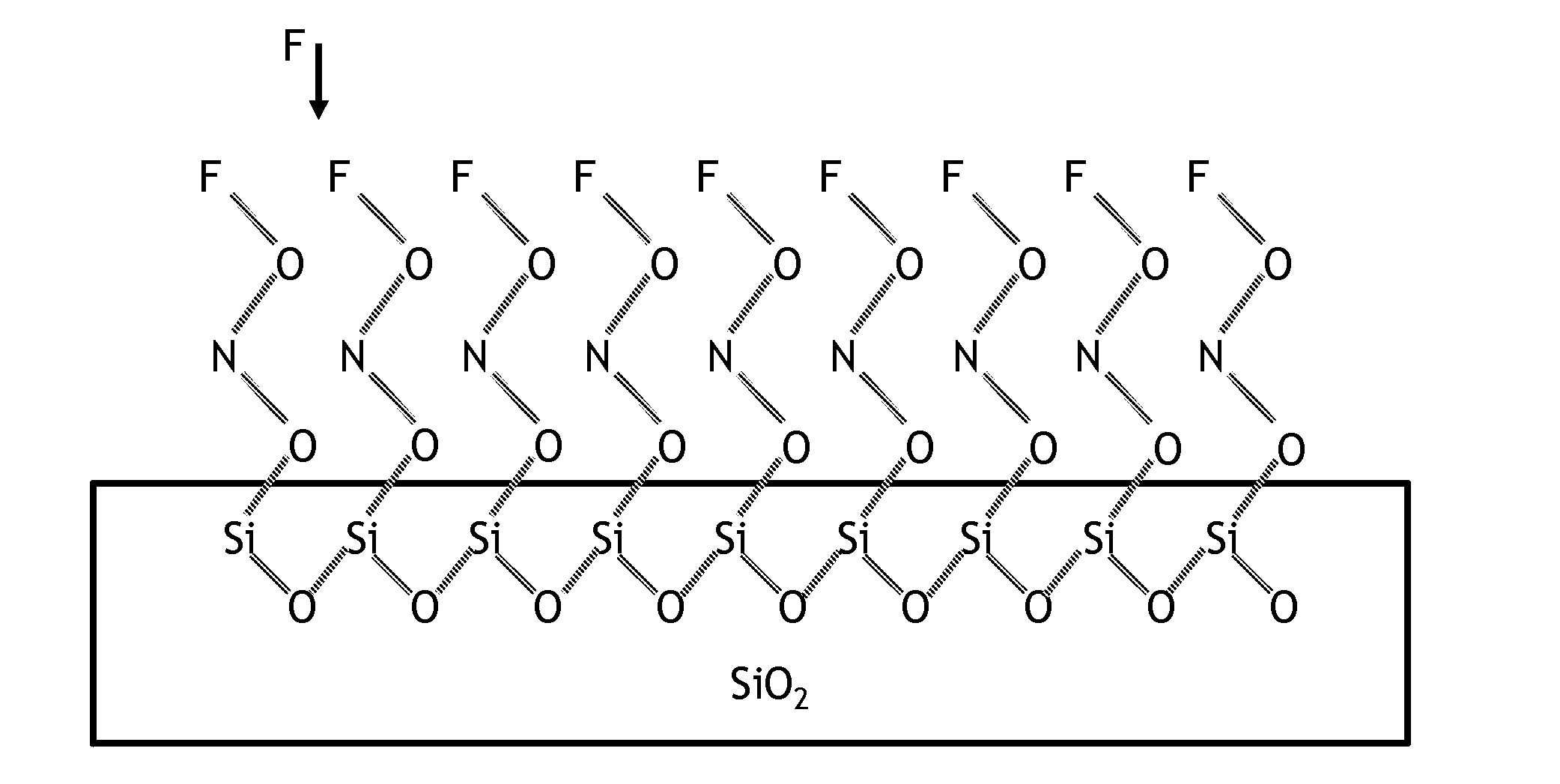

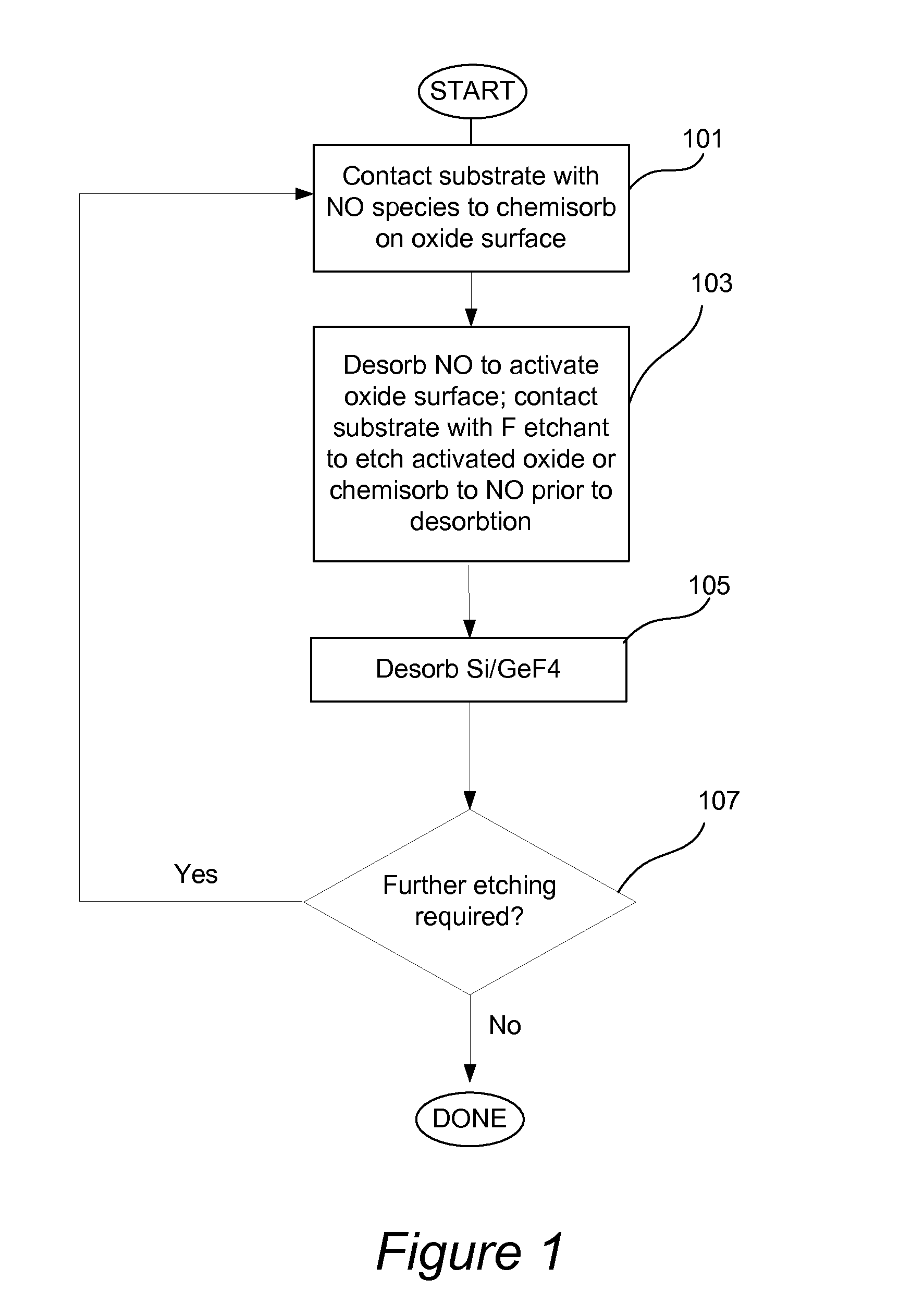

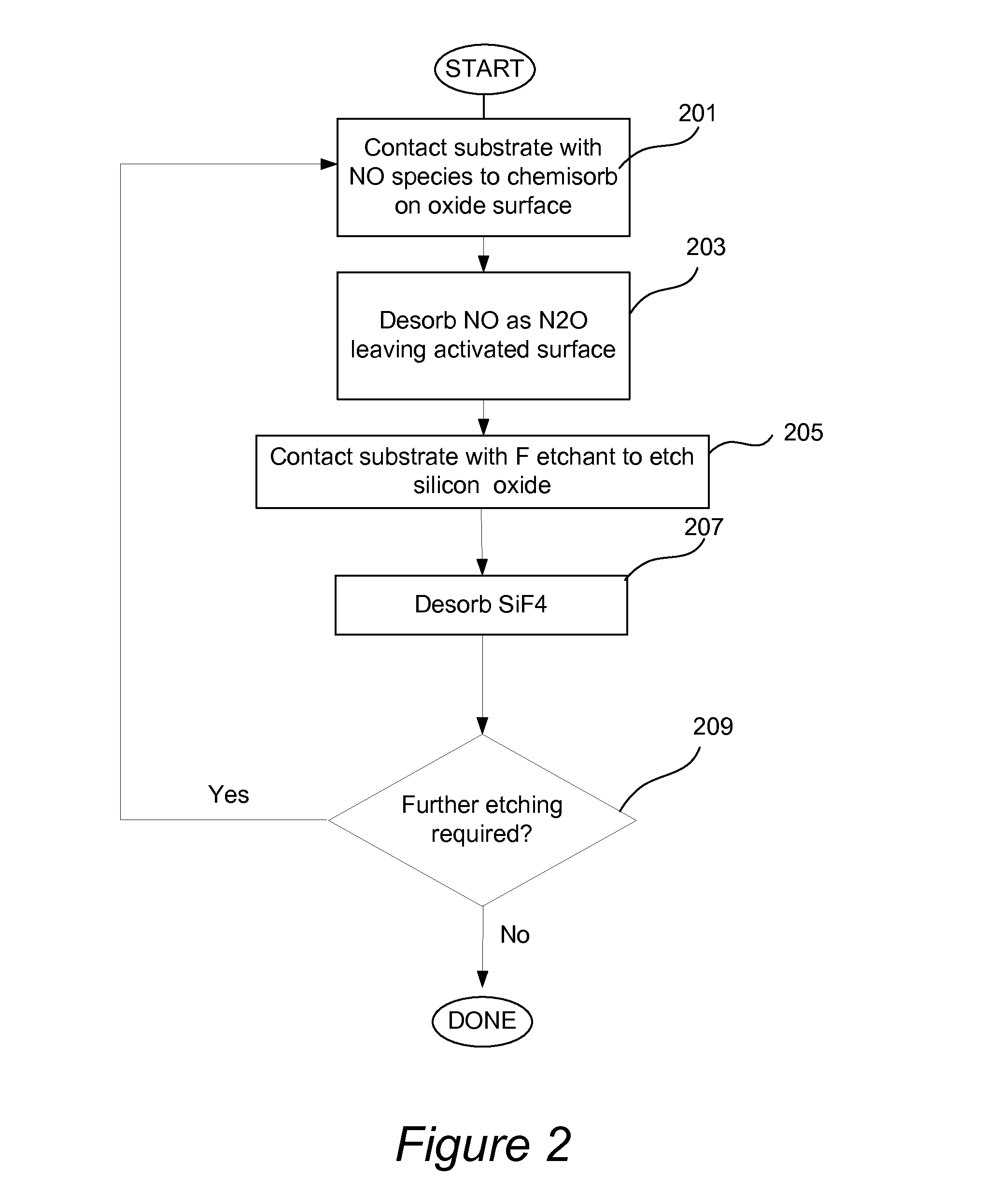

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS20160196969A1Electric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

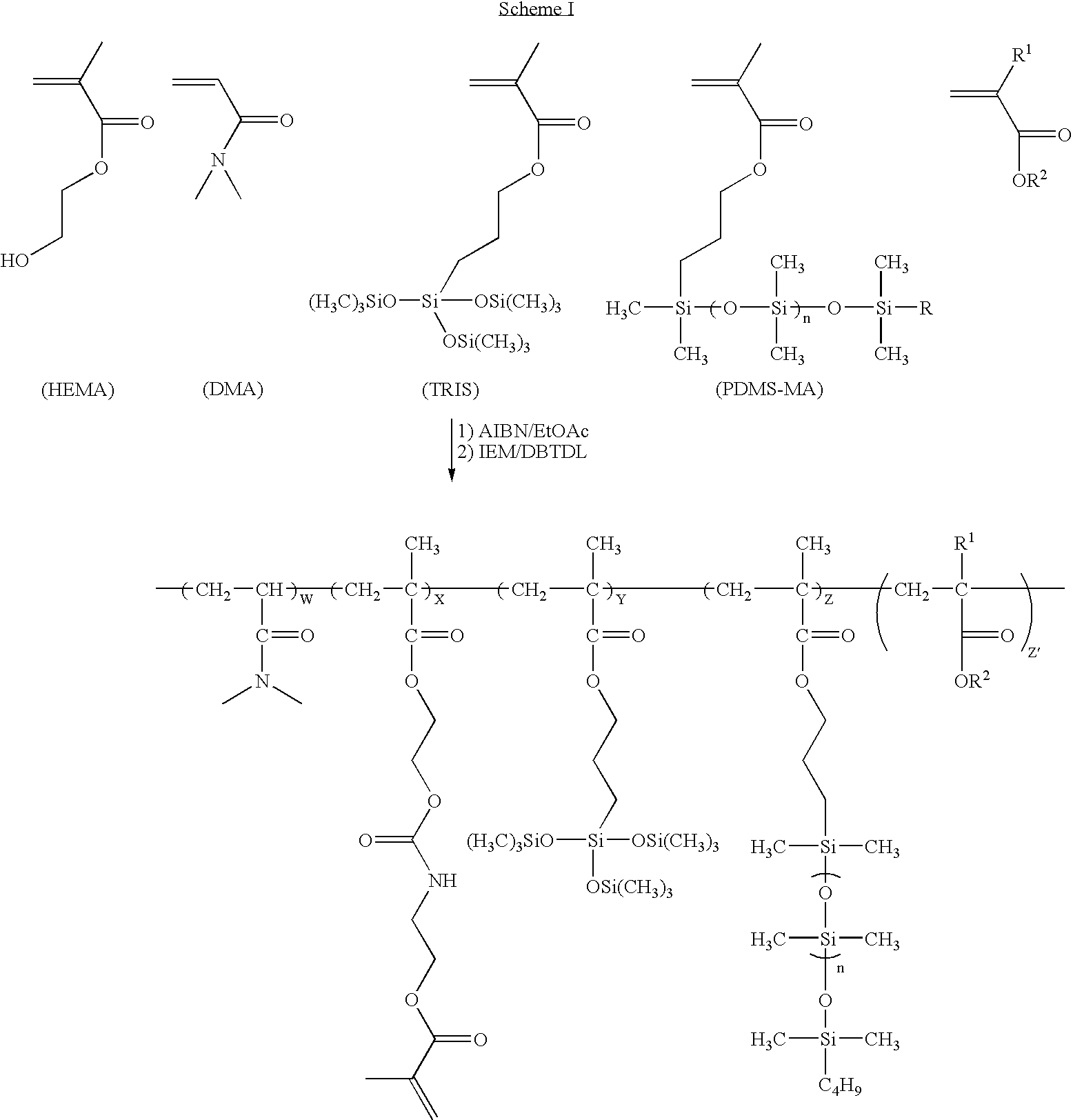

Actinically curable silicone hydrogel copolymers and uses thereof

The present invention provides inks and methods for making colored silicone hydrogel contact lenses. The ink of the invention comprises an actinically-curable binder copolymer comprising fluorine-containing segments and is characterized by having capability to be cured actinically or thermally to form a colored film on a molding surface of a mold or a silicone hydrogel contact lens and by having an increased durability in a solvated state in a silicone-hydrogel lens formulation in relation to a control colored film obtained from a control ink including an actinically-curable fluorine-free binder copolymer. The invention also provides methods for making colored silicone hydrogel contact lenses based on print-on-mold processes for producing colored contact lenses.

Owner:ALCON INC

Removal of transition metal ternary and/or quaternary barrier materials from a substrate

InactiveUS20050112901A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCompound (substance)Quaternary compound

A process for the selective removal of a substance from a substrate for etching and / or cleaning applications is disclosed herein. In one embodiment, there is provided a process for removing a substance from a substrate comprising: providing the substrate having the substance deposited thereupon wherein the substance comprises a transition metal ternary compound, a transition metal quaternary compound, and combinations thereof; reacting the substance with a process gas comprising a fluorine-containing gas and optionally an additive gas to form a volatile product; and removing the volatile product from the substrate to thereby remove the substance from the substrate.

Owner:VERSUM MATERIALS US LLC

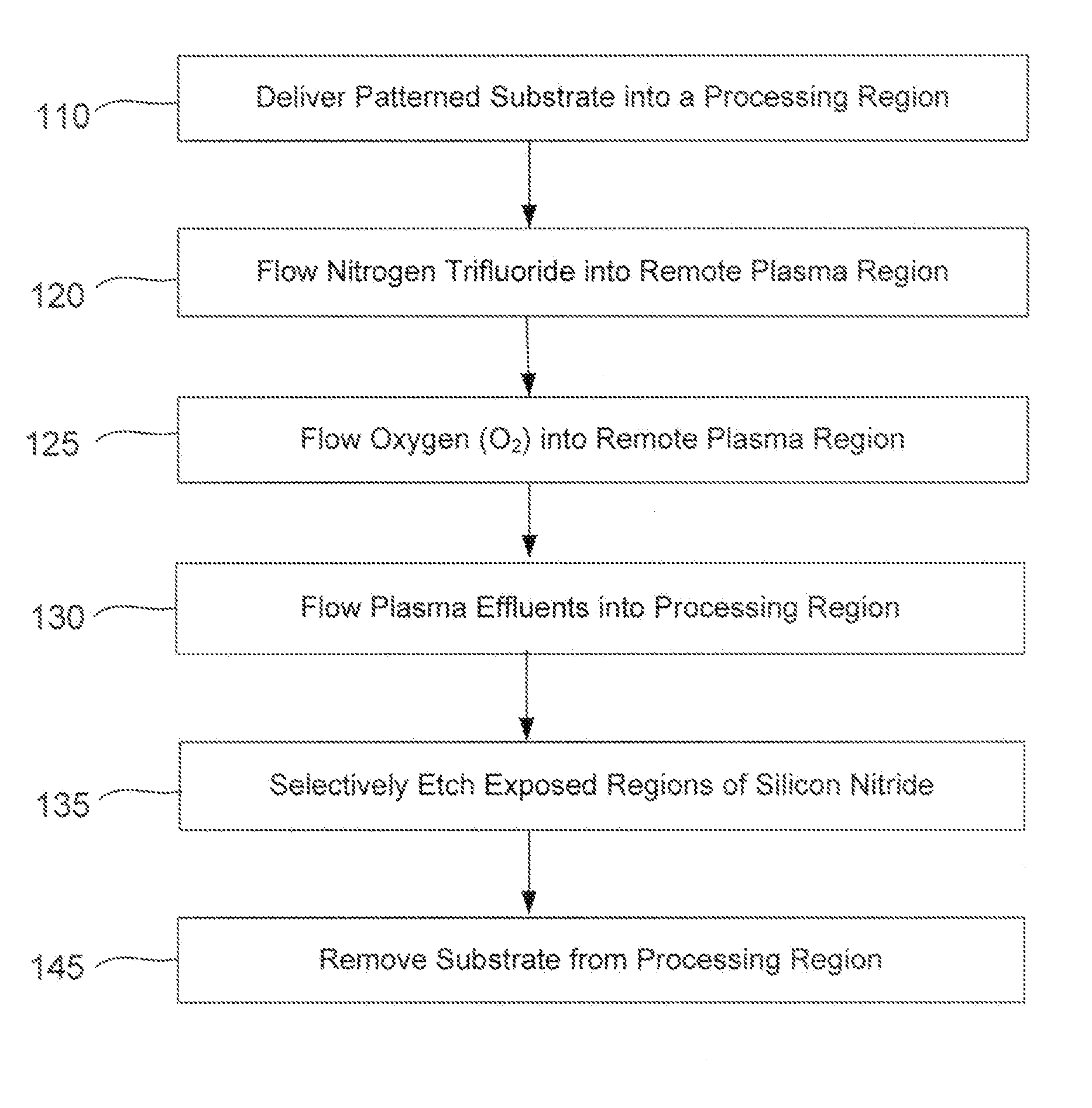

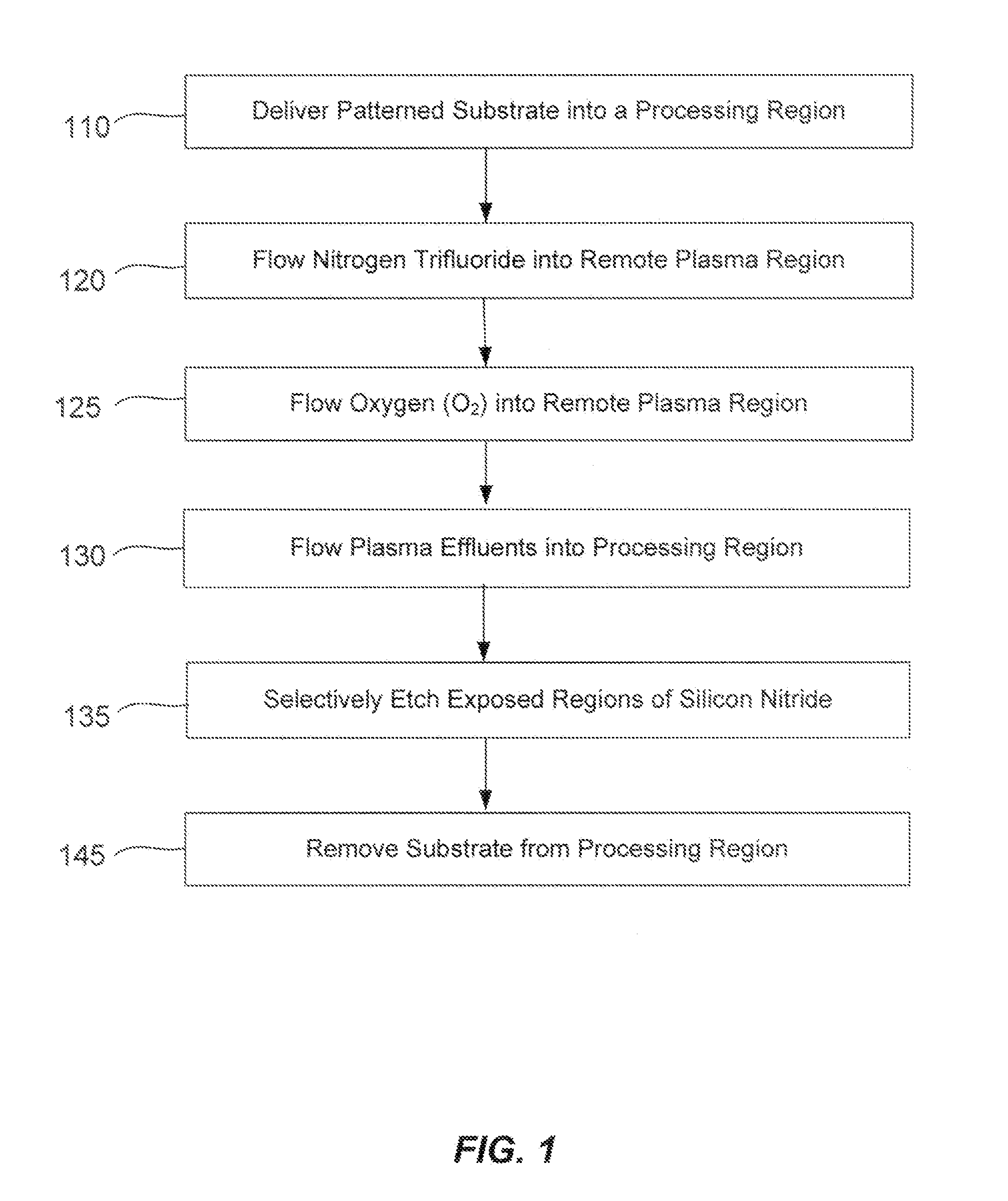

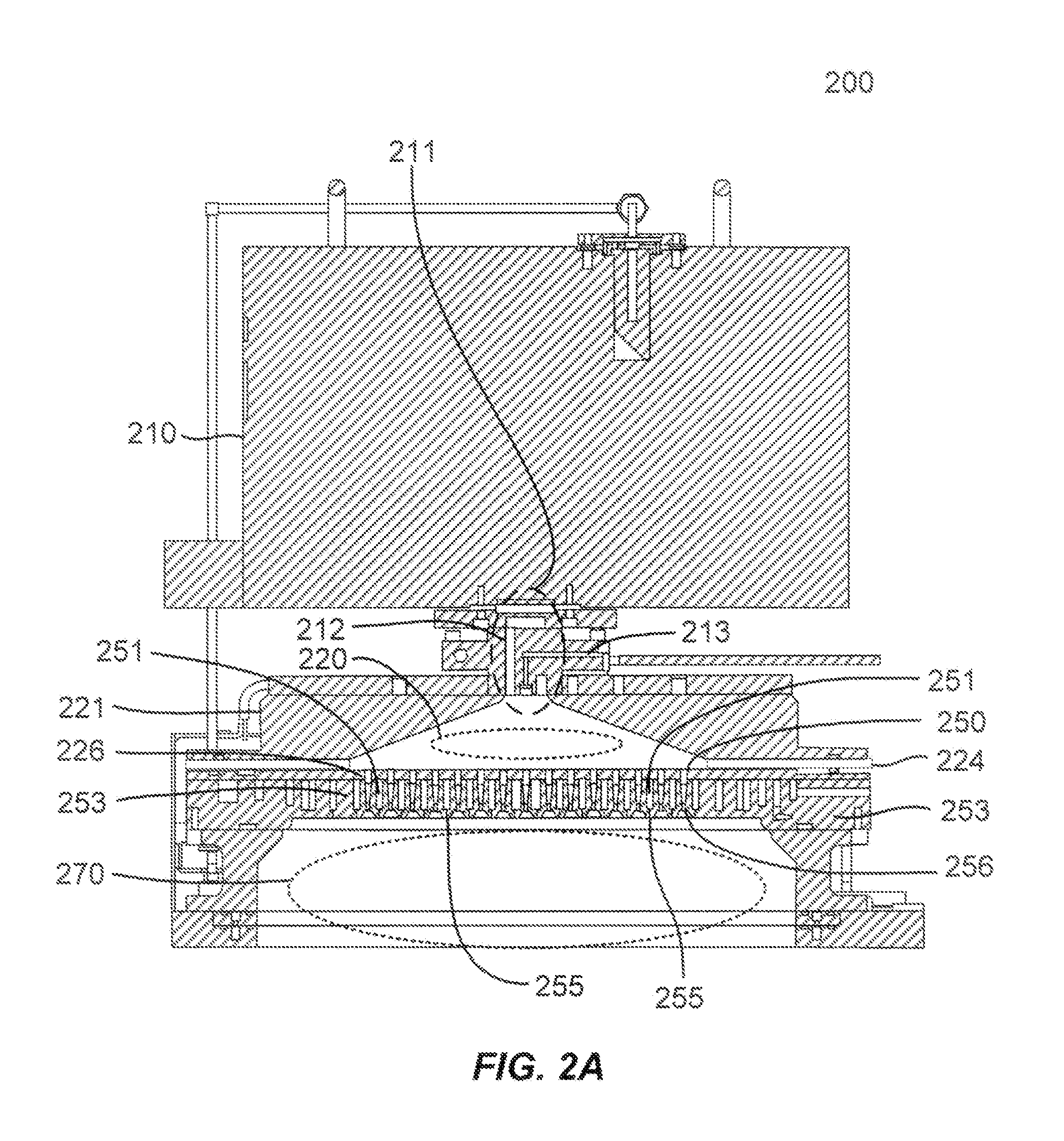

Dry-etch for silicon-and-nitrogen-containing films

InactiveUS20130045605A1Reduces and substantially eliminates numberMaterial removalElectric discharge tubesSemiconductor/solid-state device manufacturingHeterojunctionRemote plasma

A method of etching exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-nitrogen-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-nitrogen-containing material from the exposed silicon-and-nitrogen-containing material regions while very slowly removing other exposed materials. The silicon-and-nitrogen-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-nitrogen-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

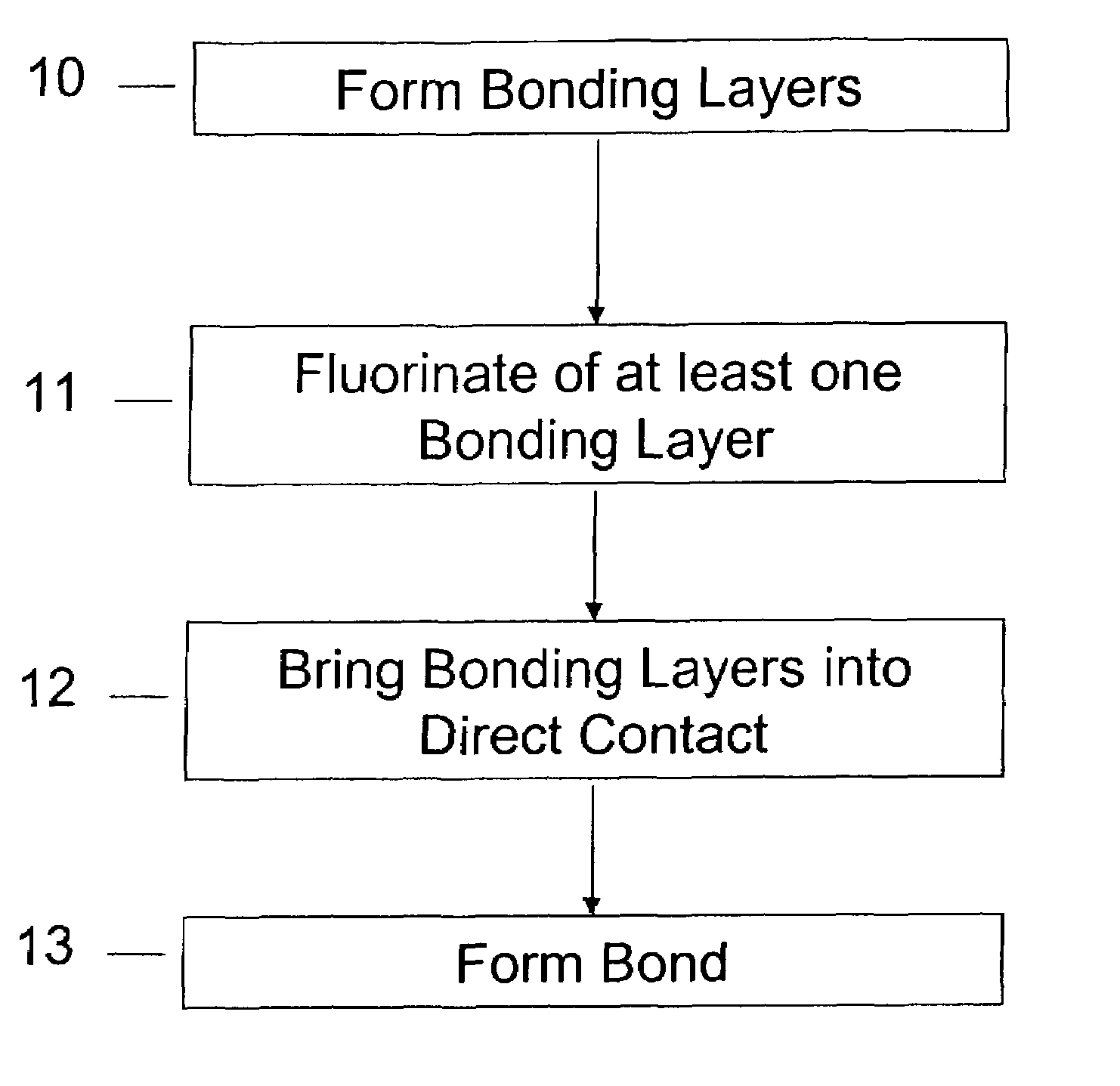

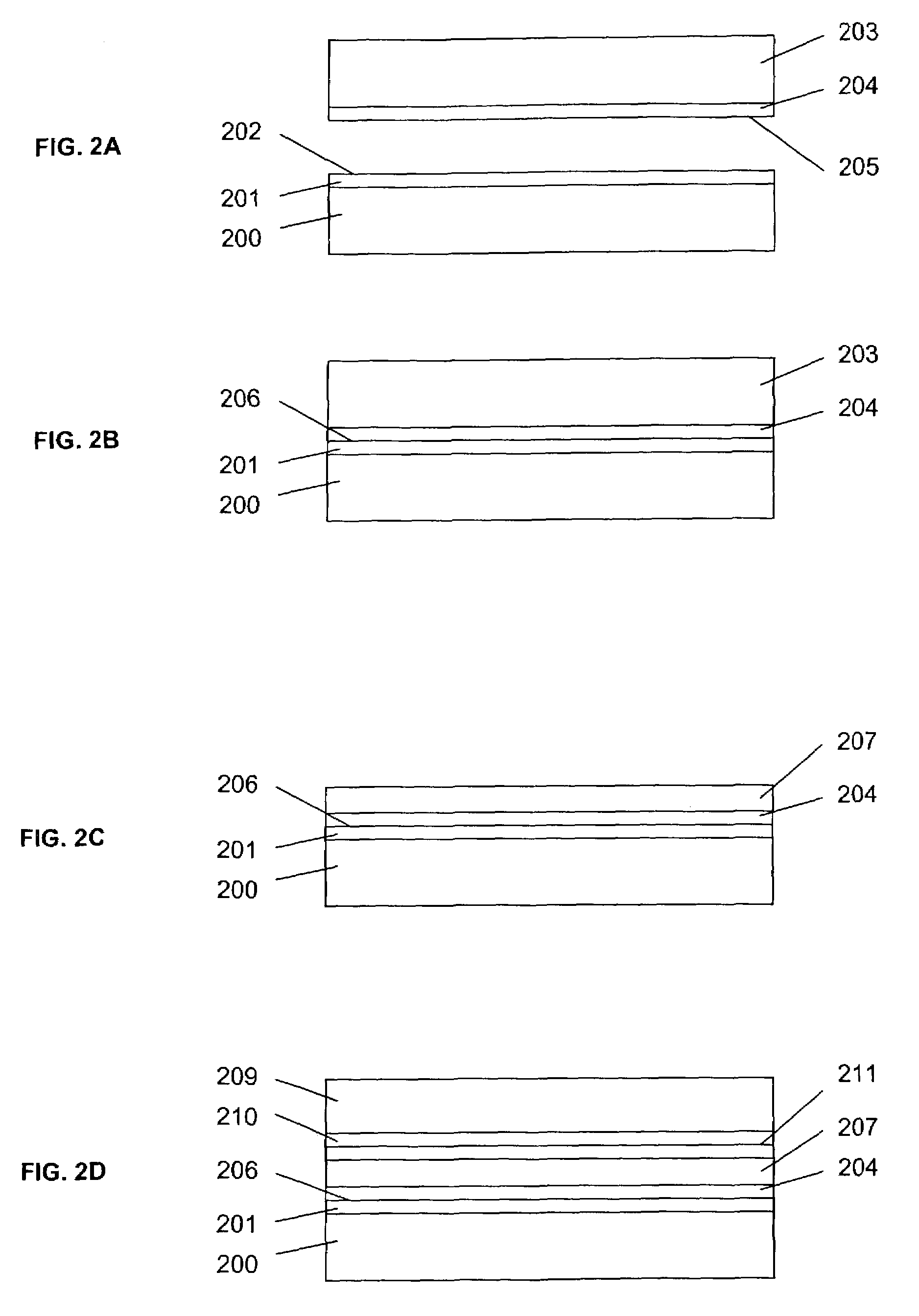

Method of room temperature covalent bonding

InactiveUS7109092B2High densityLow densityLayered productsDecorative surface effectsRoom temperatureFluorine containing

A method of bonding includes using a bonding layer having a fluorinated oxide. Fluorine may be introduced into the bonding layer by exposure to a fluorine-containing solution, vapor or gas or by implantation. The bonding layer may also be formed using a method where fluorine is introduced into the layer during its formation. The surface of the bonding layer is terminated with a desired species, preferably an NH2 species. This may be accomplished by exposing the bonding layer to an NH4OH solution. High bonding strength is obtained at room temperature. The method may also include bonding two bonding layers together and creating a fluorine distribution having a peak in the vicinity of the interface between the bonding layers. One of the bonding layers may include two oxide layers formed on each other. The fluorine concentration may also have a second peak at the interface between the two oxide layers.

Owner:INVENSAS BONDING TECH INC

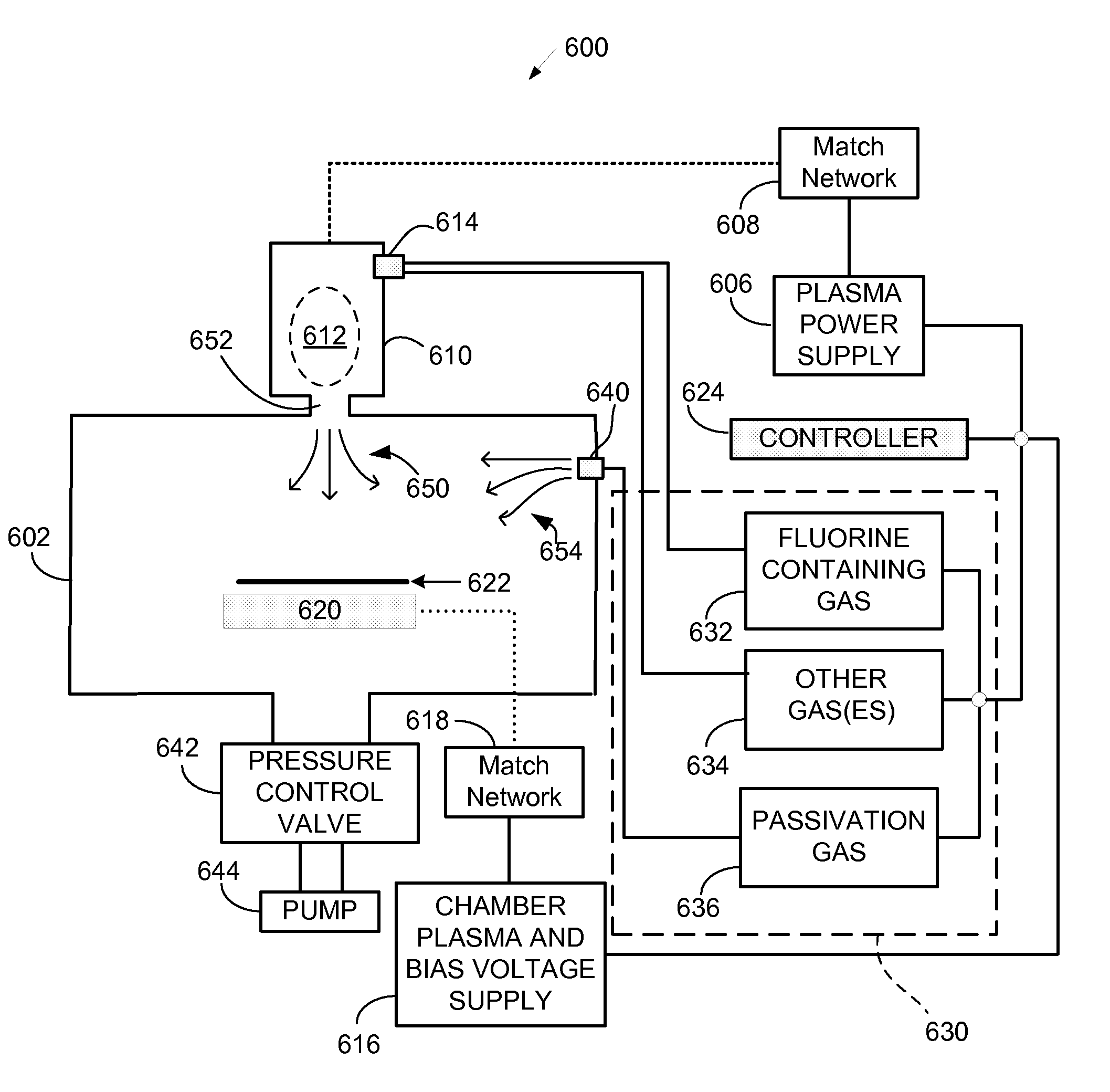

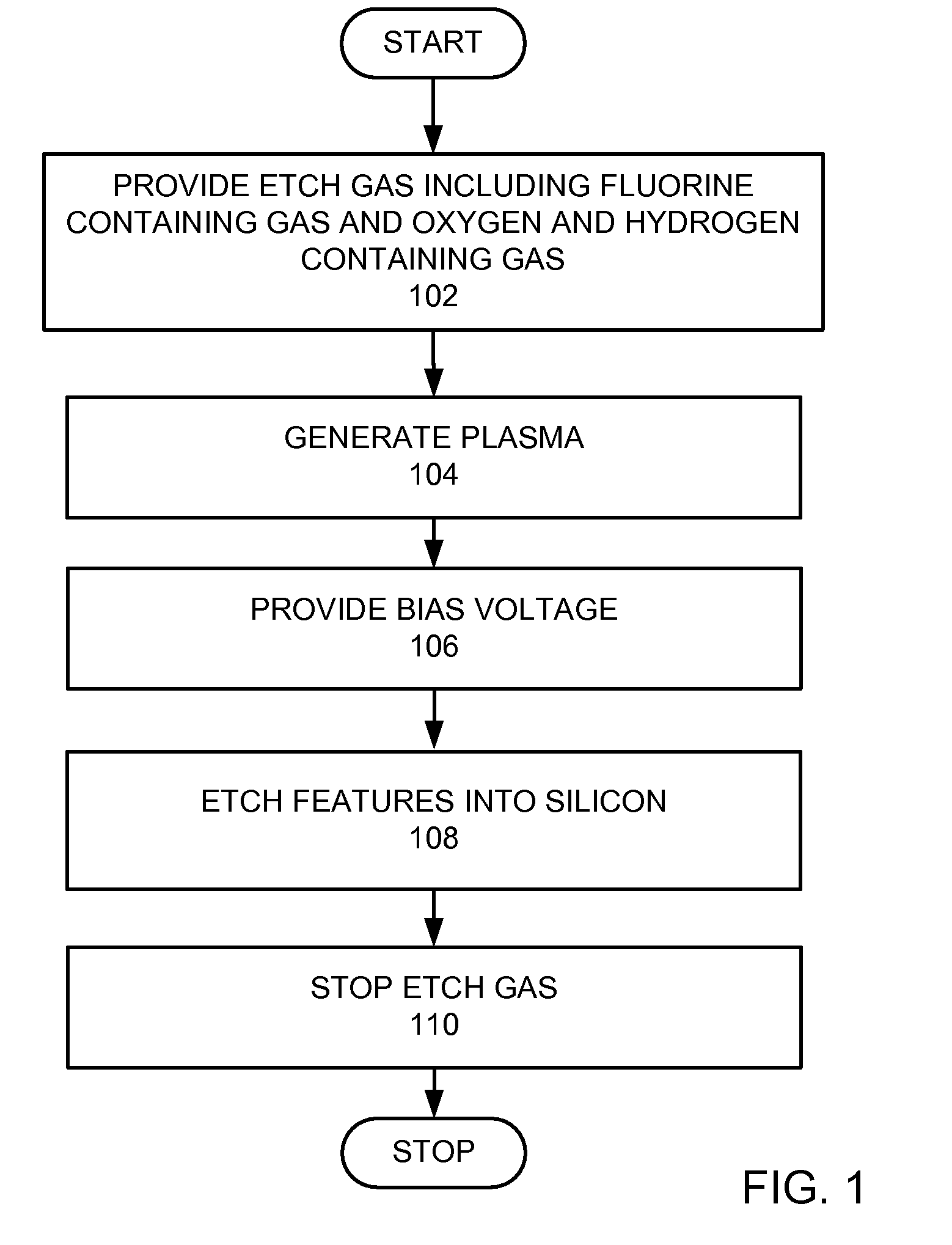

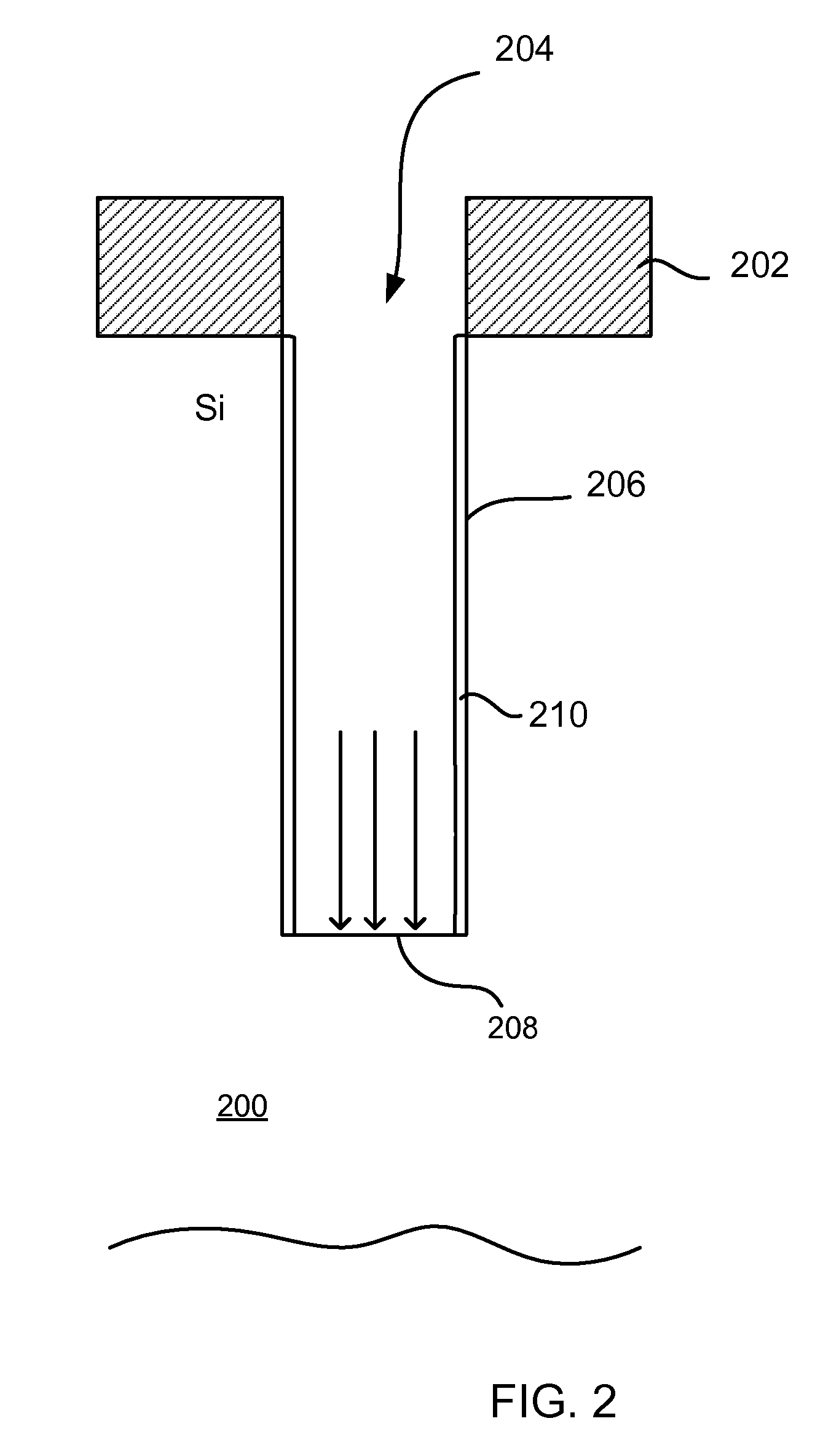

Silicon etch with passivation using plasma enhanced oxidation

A method and apparatus for etching a silicon layer through a patterned mask formed thereon are provided. The silicon layer is placed in an etch chamber. An etch gas comprising a fluorine containing gas and an oxygen and hydrogen containing gas is provided into the etch chamber. A plasma is generated from the etch gas and features are etched into the silicon layer using the plasma. The etch gas is then stopped. The plasma may contain OH radicals.

Owner:LAM RES CORP

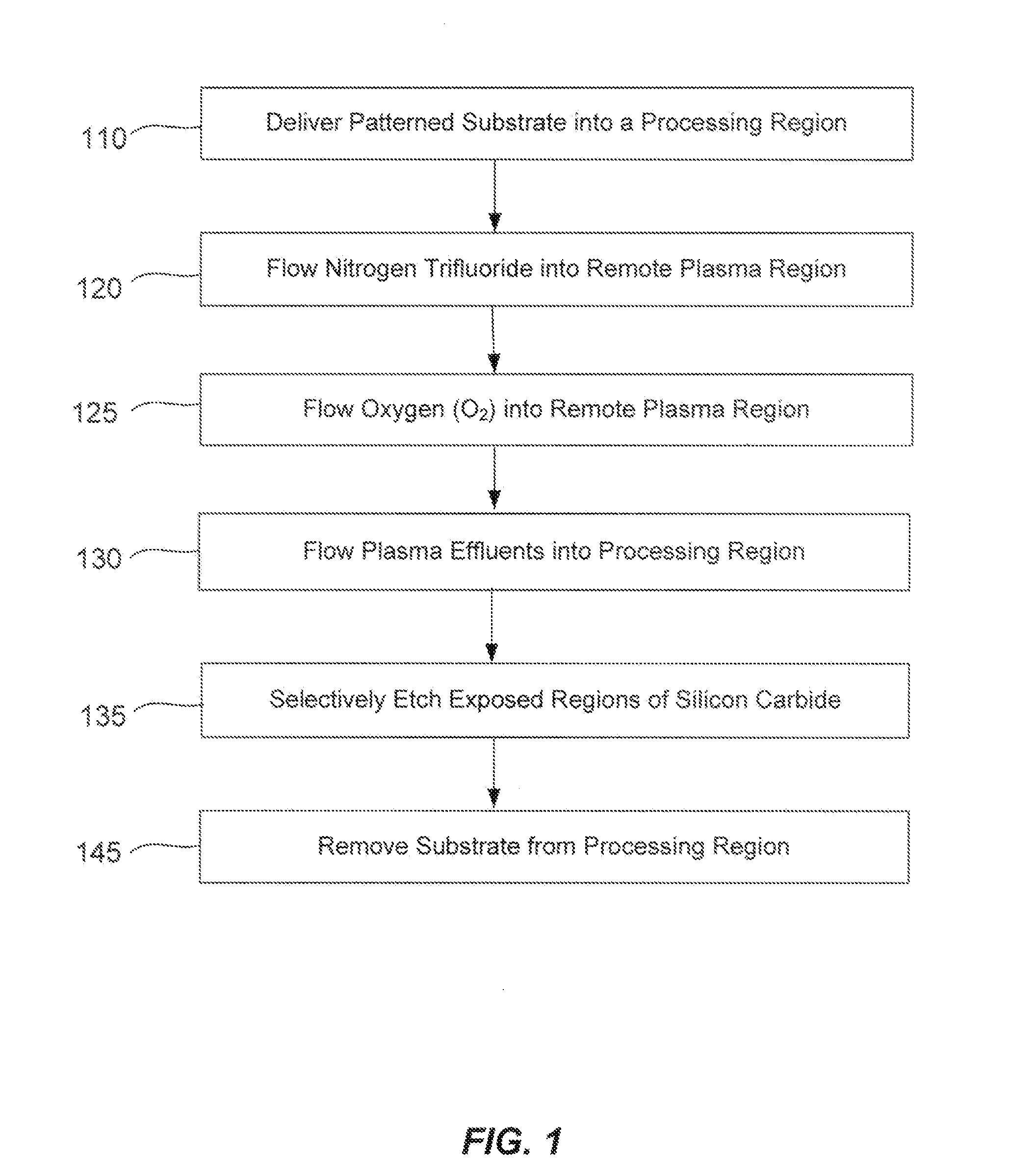

Dry-etch for silicon-and-carbon-containing films

InactiveUS20130034968A1Reduces and substantially eliminates numberMaterial removalSemiconductor/solid-state device manufacturingRemote plasmaSilicon oxide

A method of etching exposed silicon-and-carbon-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-carbon-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-carbon-containing material from the exposed silicon-and-carbon-containing material regions while very slowly removing other exposed materials. The silicon-and-carbon-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-carbon-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

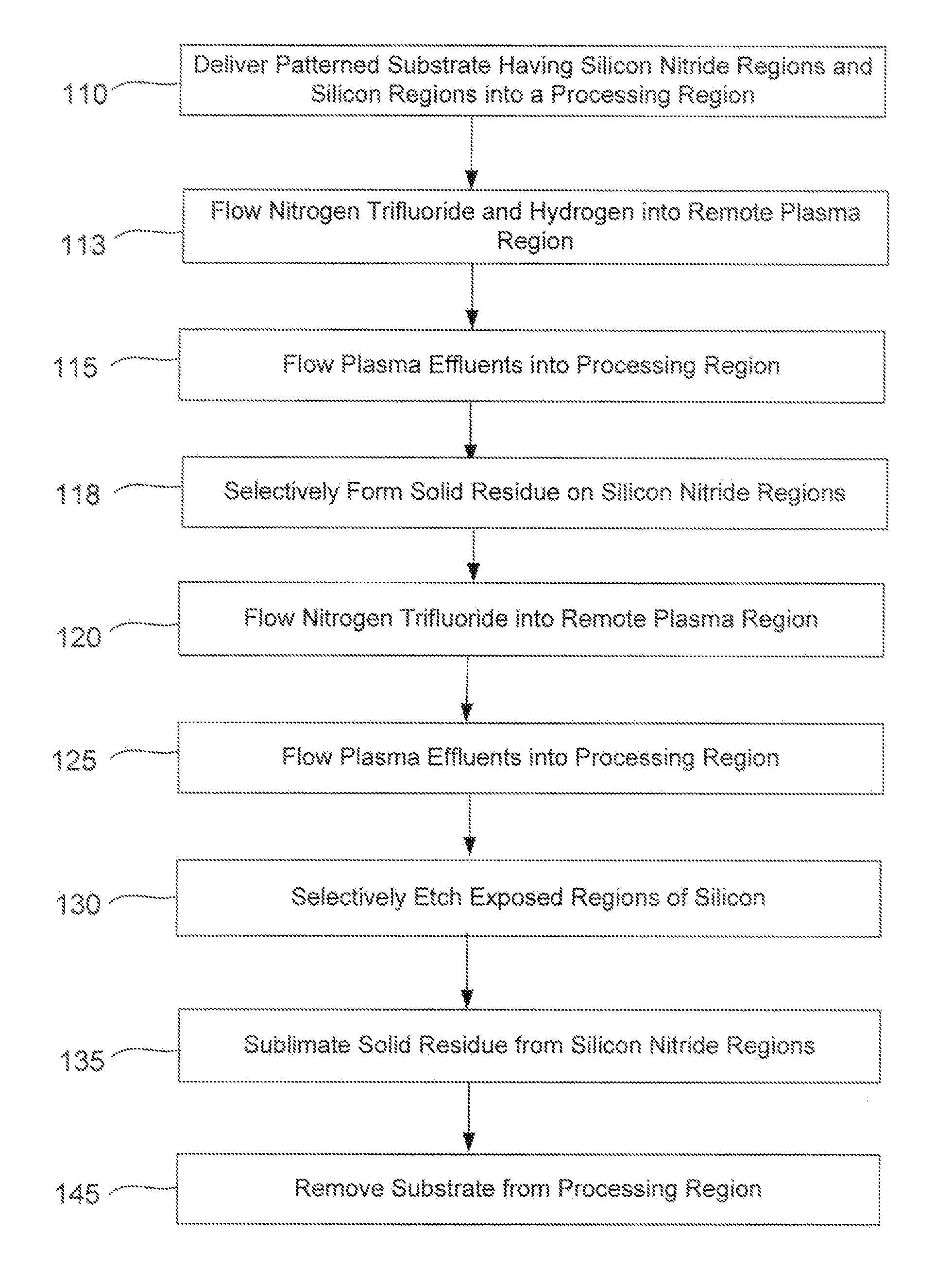

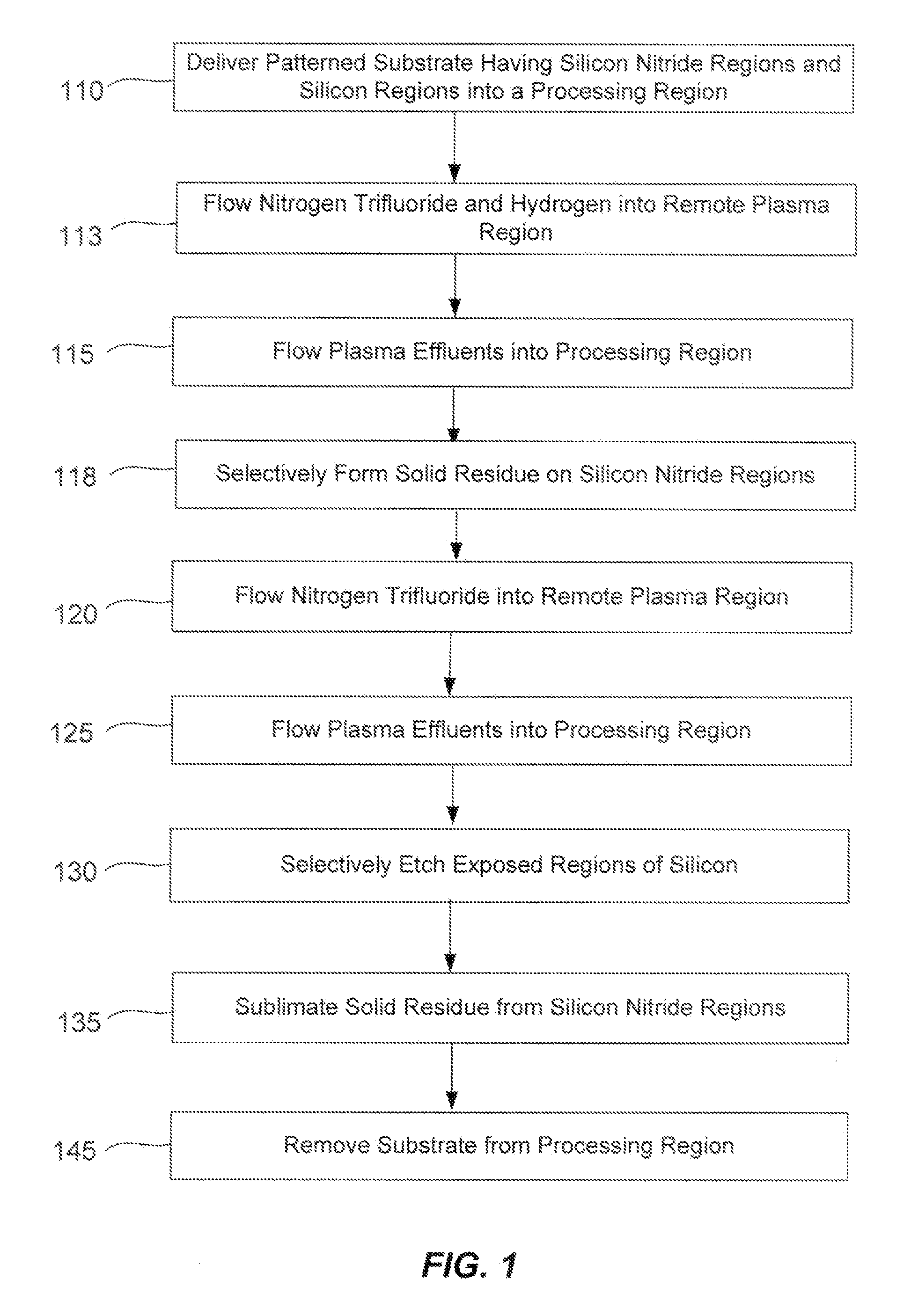

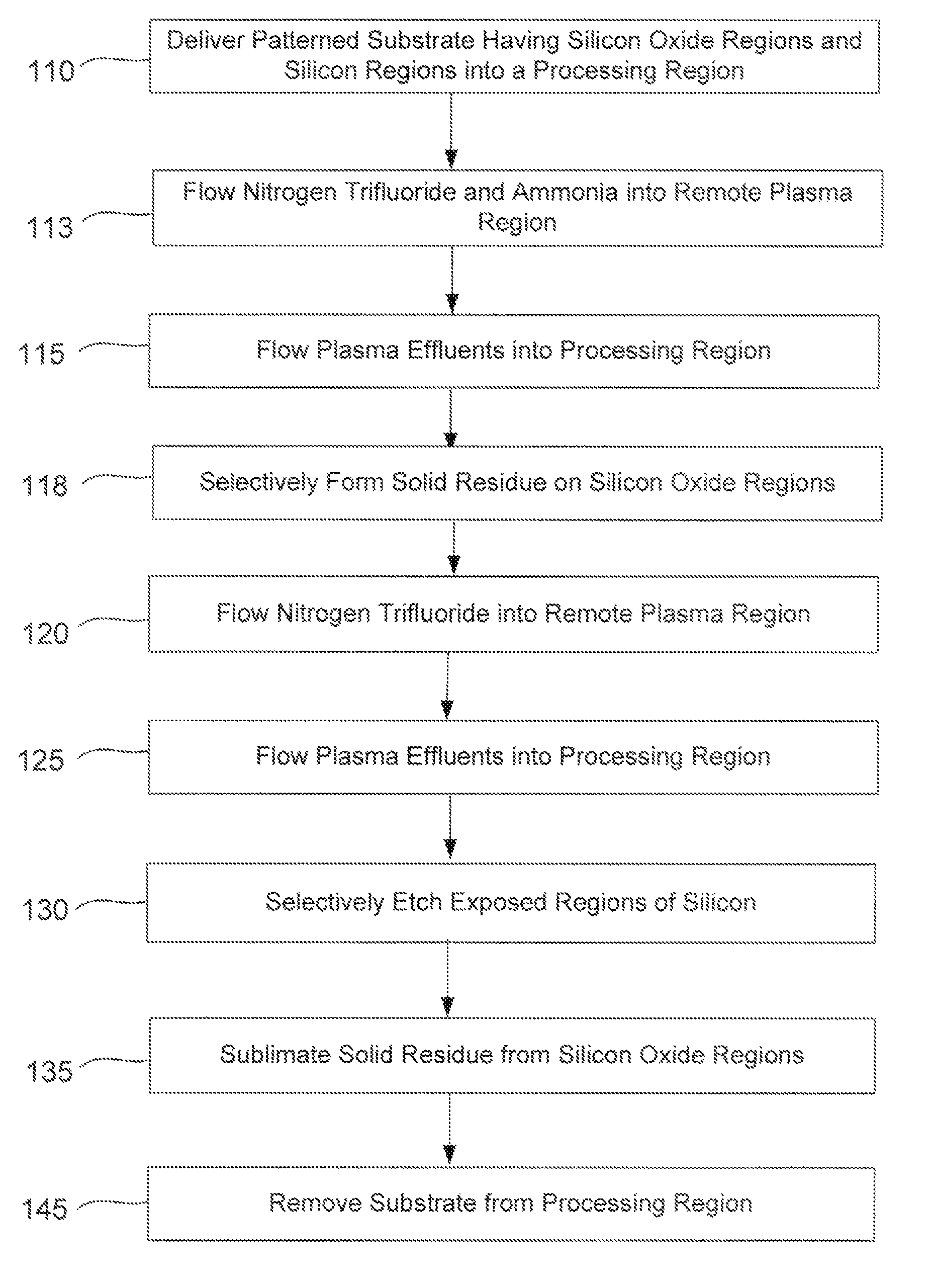

Selective suppression of dry-etch rate of materials containing both silicon and nitrogen

InactiveUS20130059440A1Inhibit etch rateImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

A method of suppressing the etch rate for exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. The etch selectivity of silicon relative to silicon nitride and other silicon-and-nitrogen-containing material is increased using the method. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-nitrogen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including nitrogen trifluoride and hydrogen (H2). The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

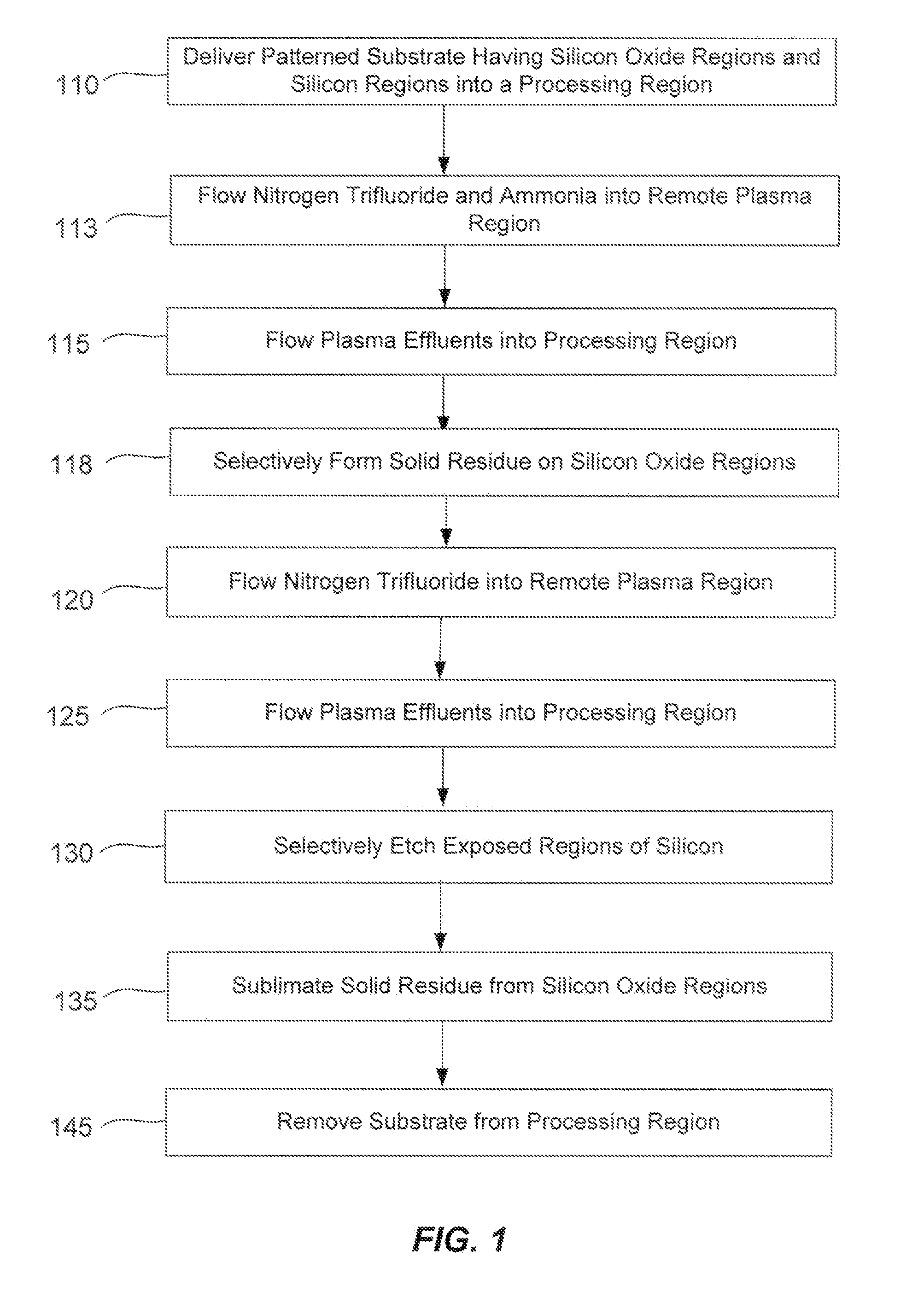

Selective suppression of dry-etch rate of materials containing both silicon and oxygen

InactiveUS20130052827A1Inhibit etch rateHigh selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

A method of suppressing the etch rate for exposed silicon-and-oxygen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. Examples of materials whose selectivity is increased using this technique include silicon nitride and silicon. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-oxygen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including a nitrogen-containing precursor and a hydrogen-containing precursor. The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

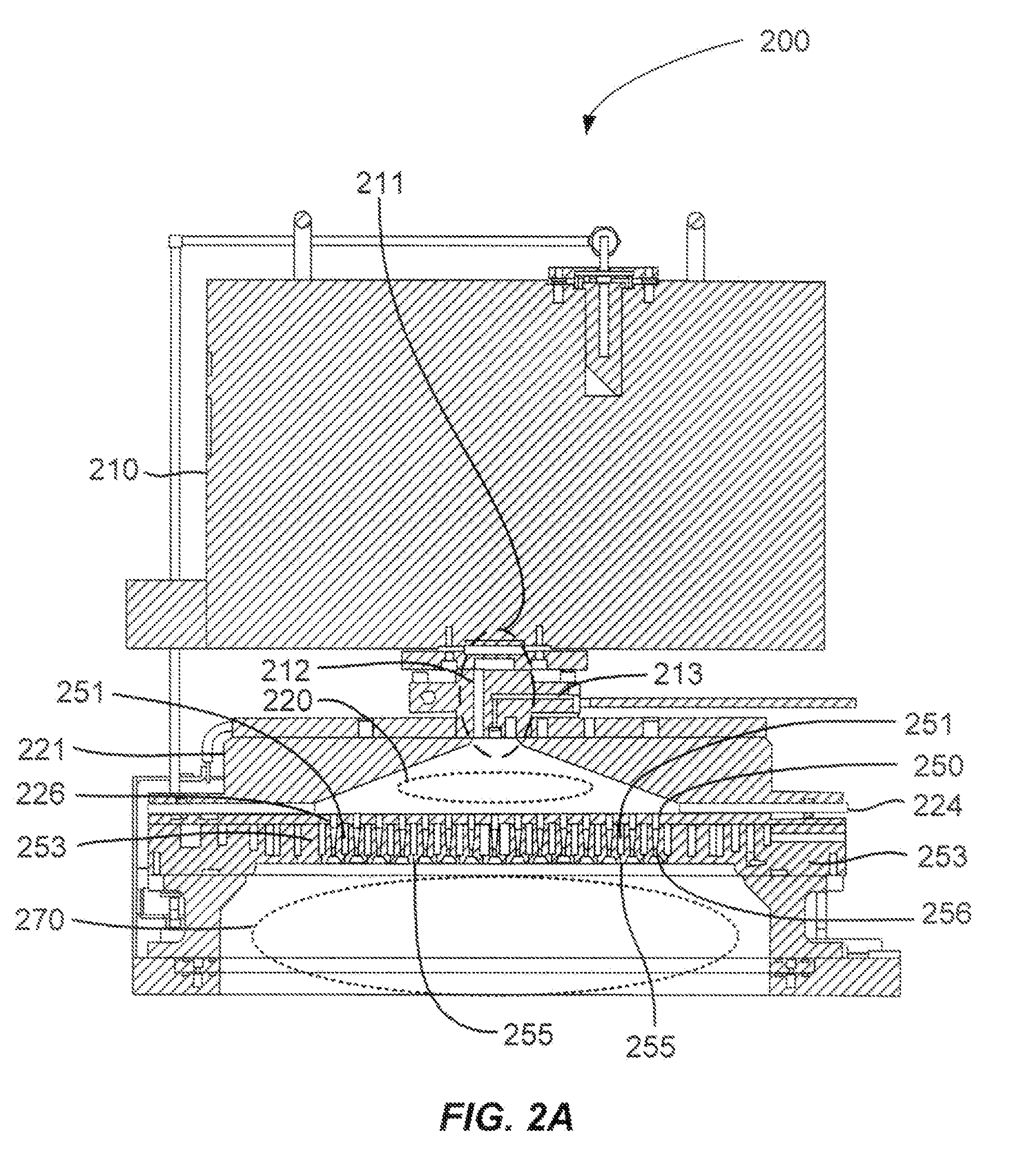

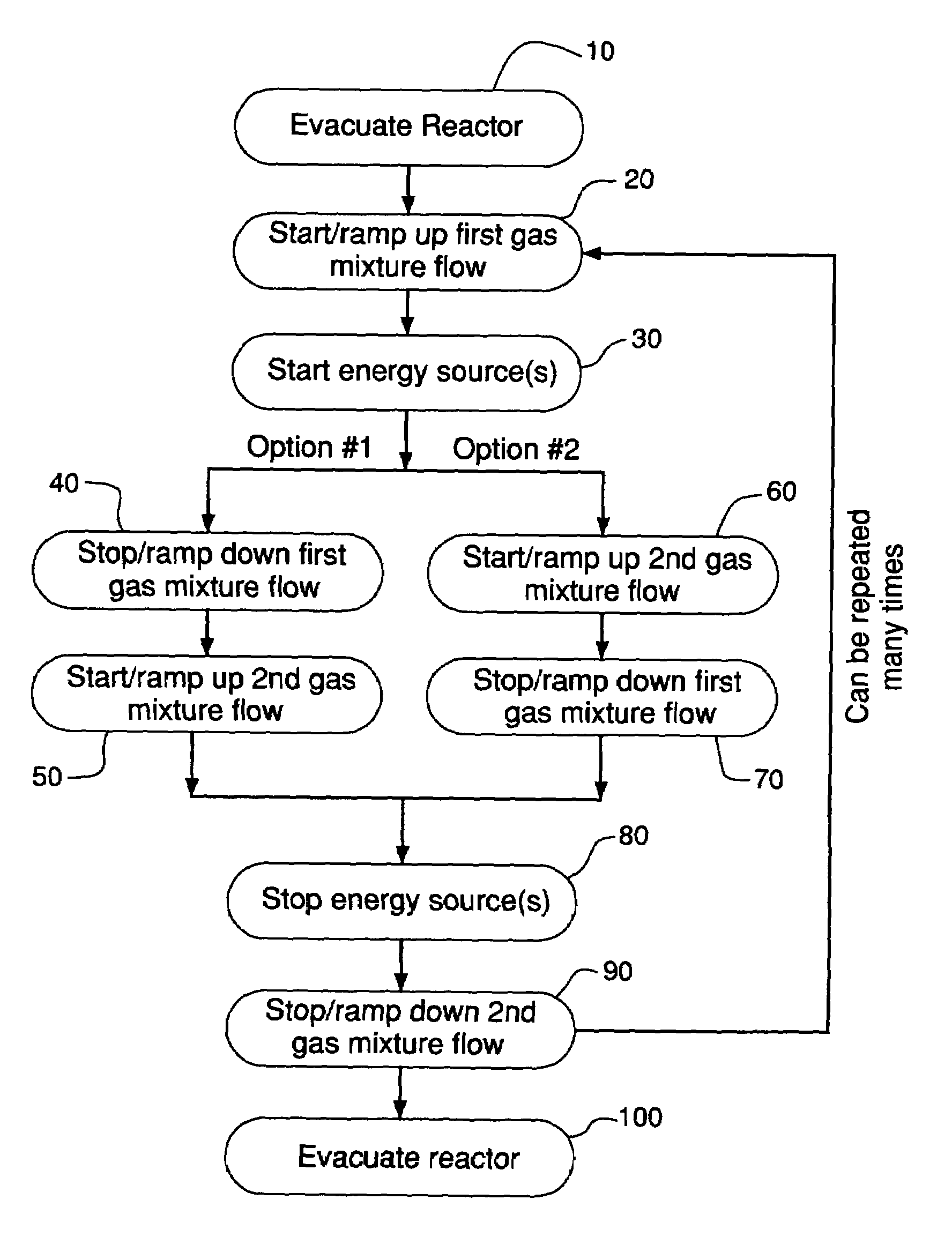

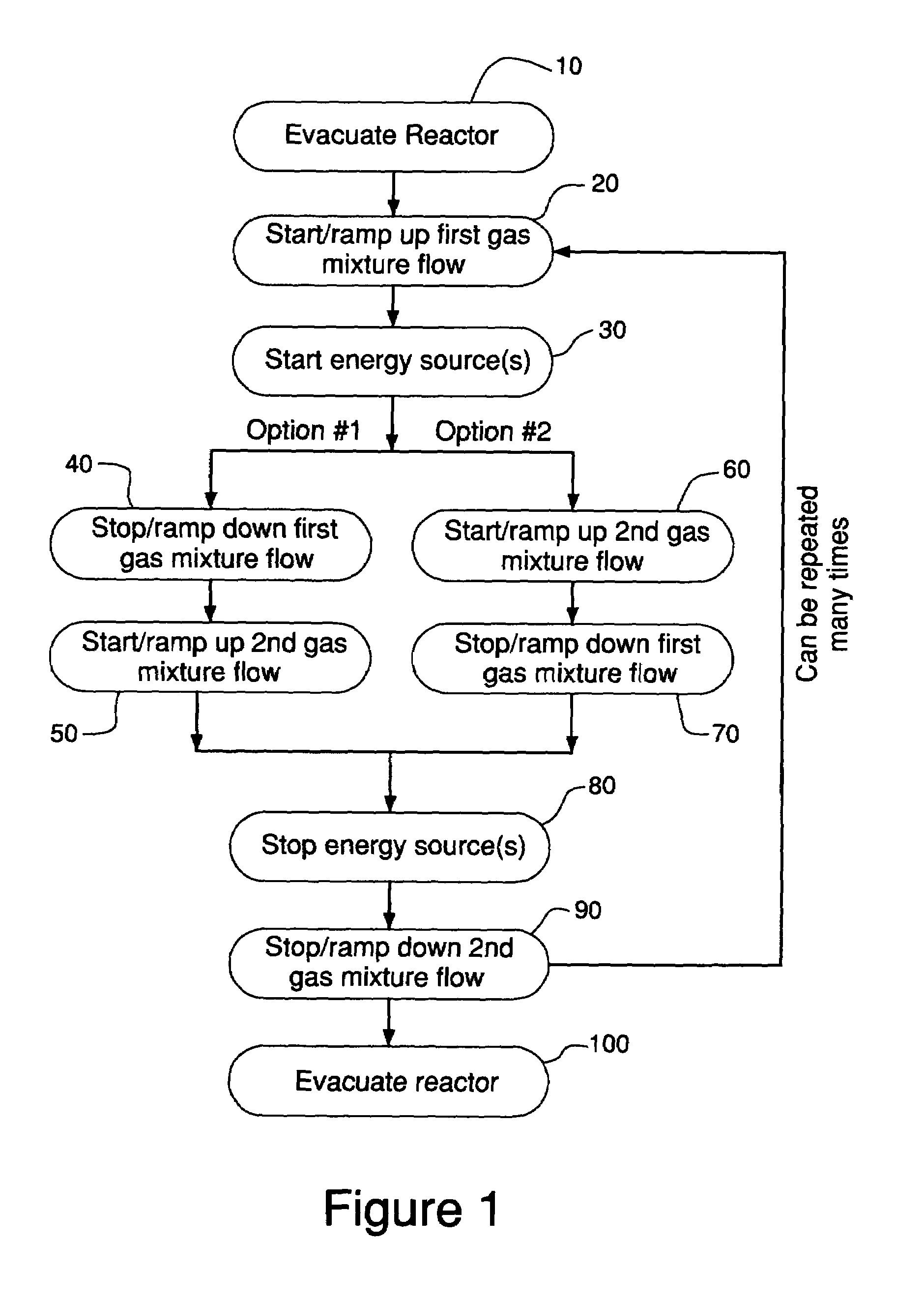

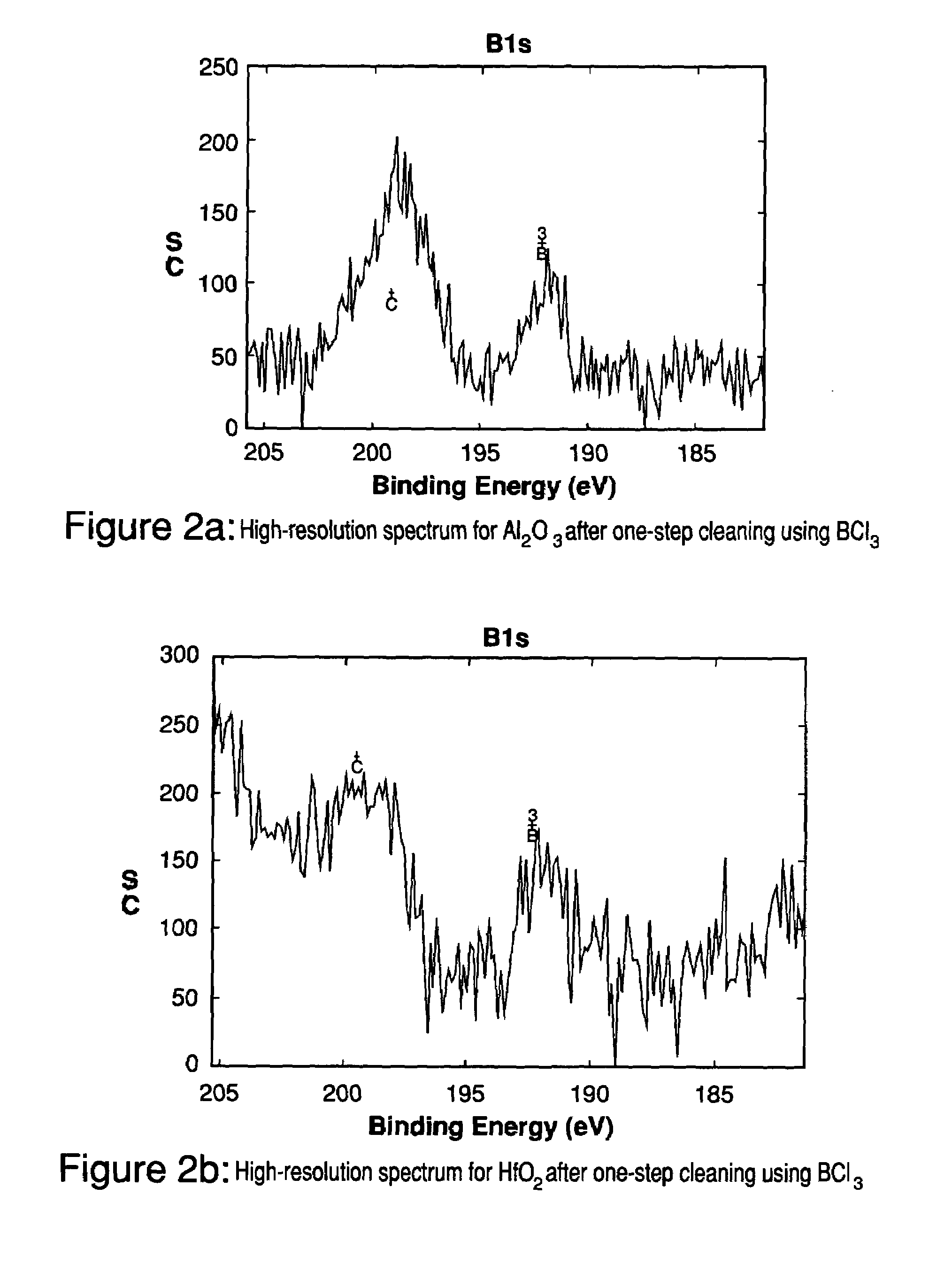

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

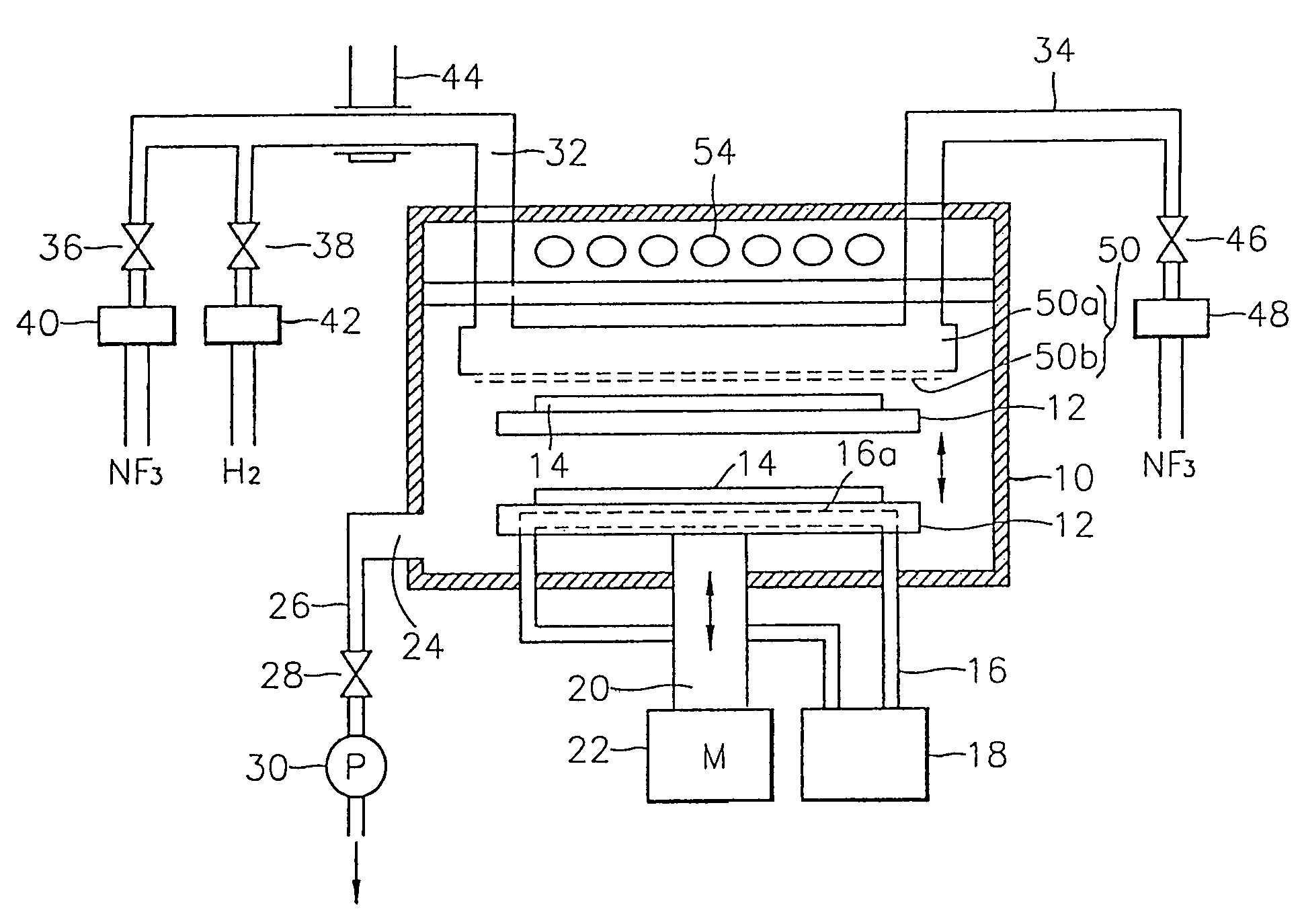

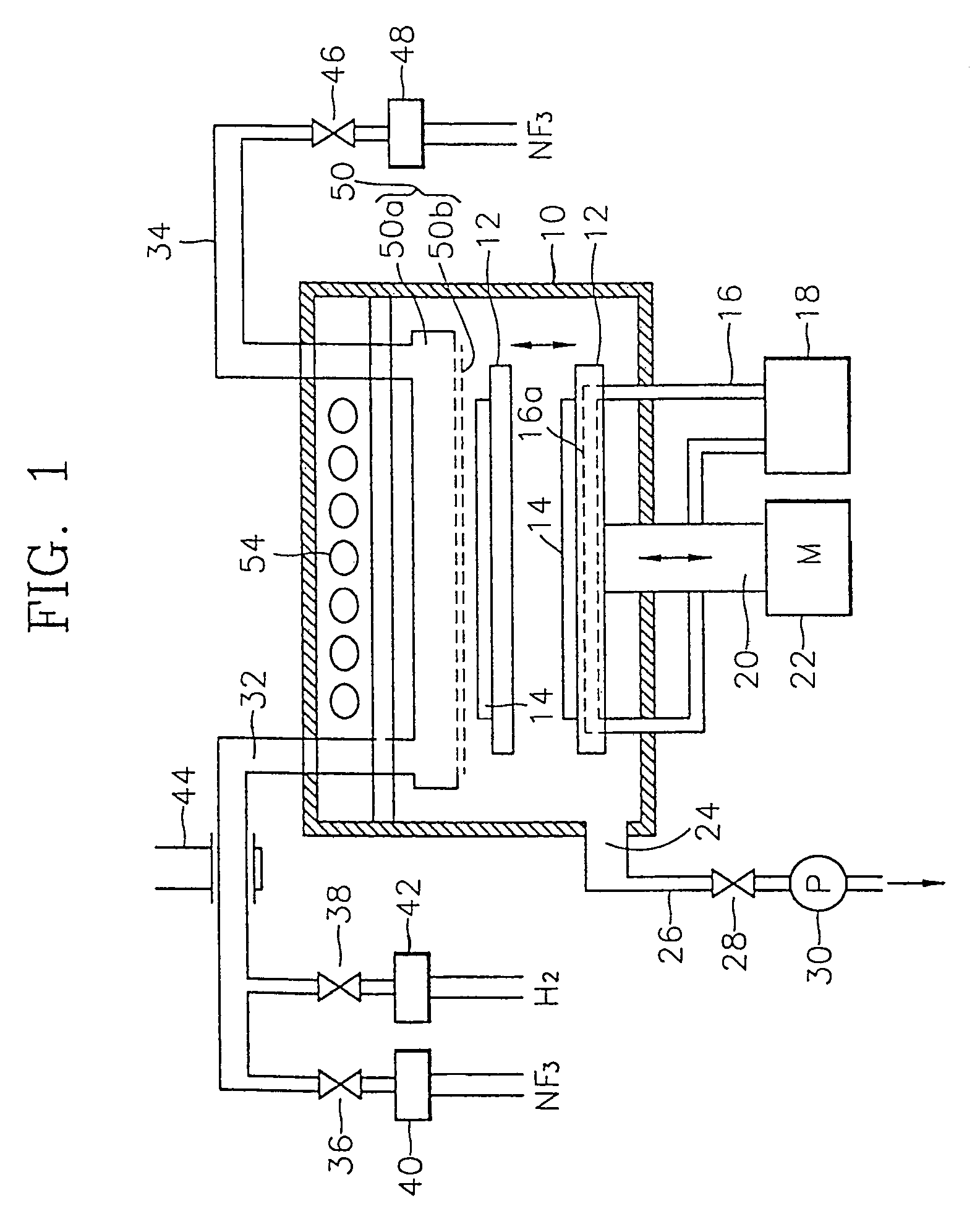

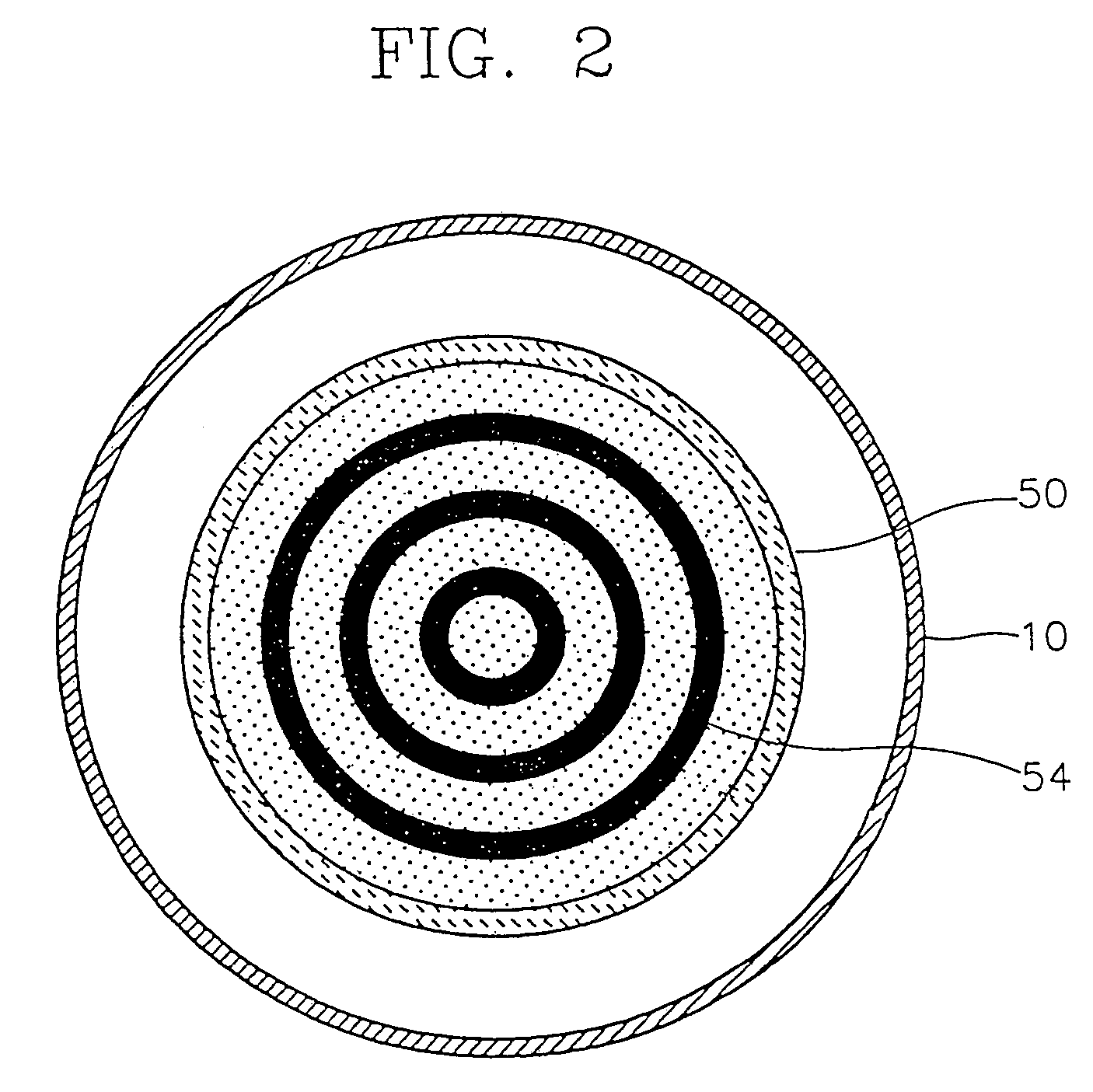

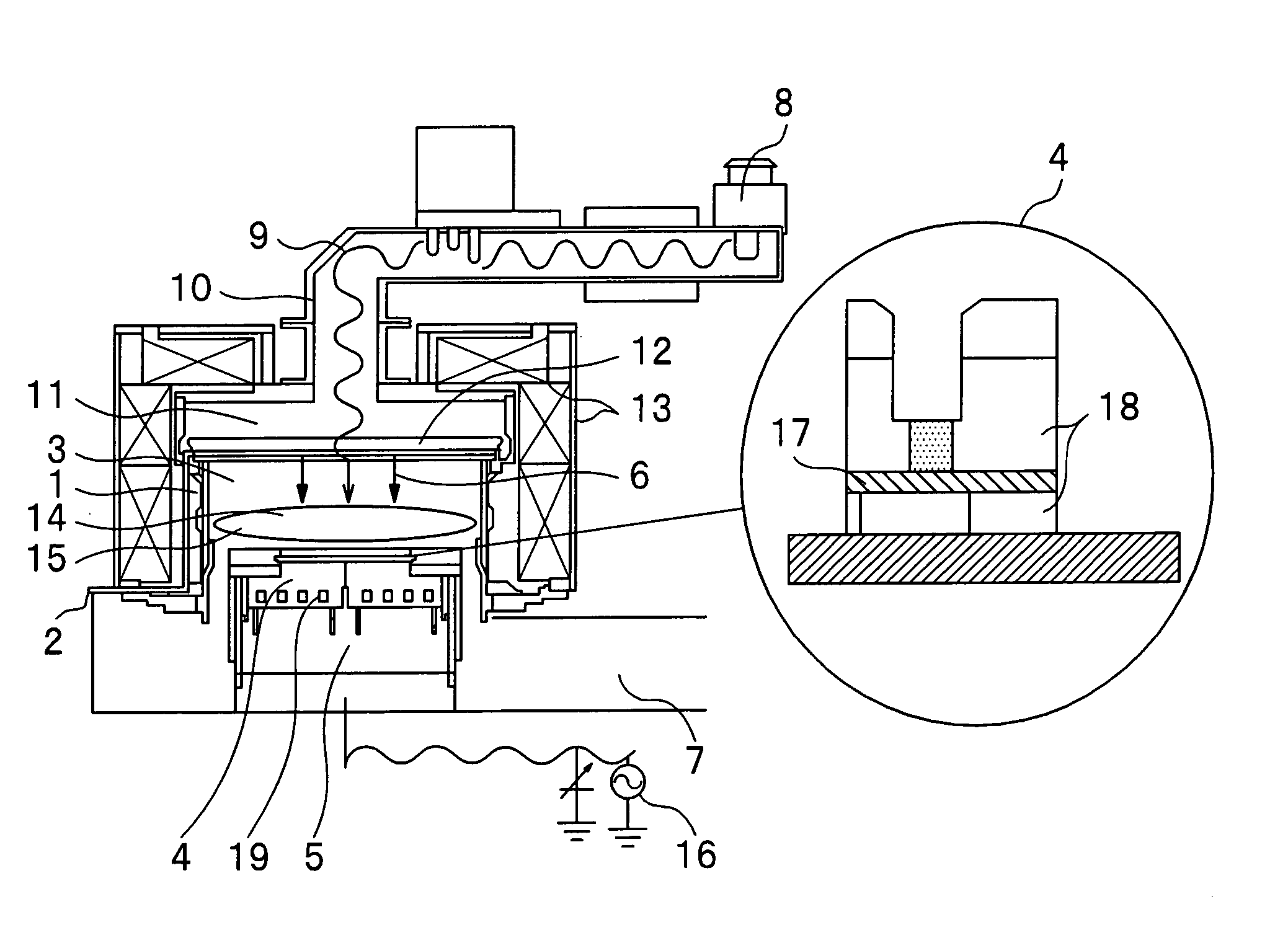

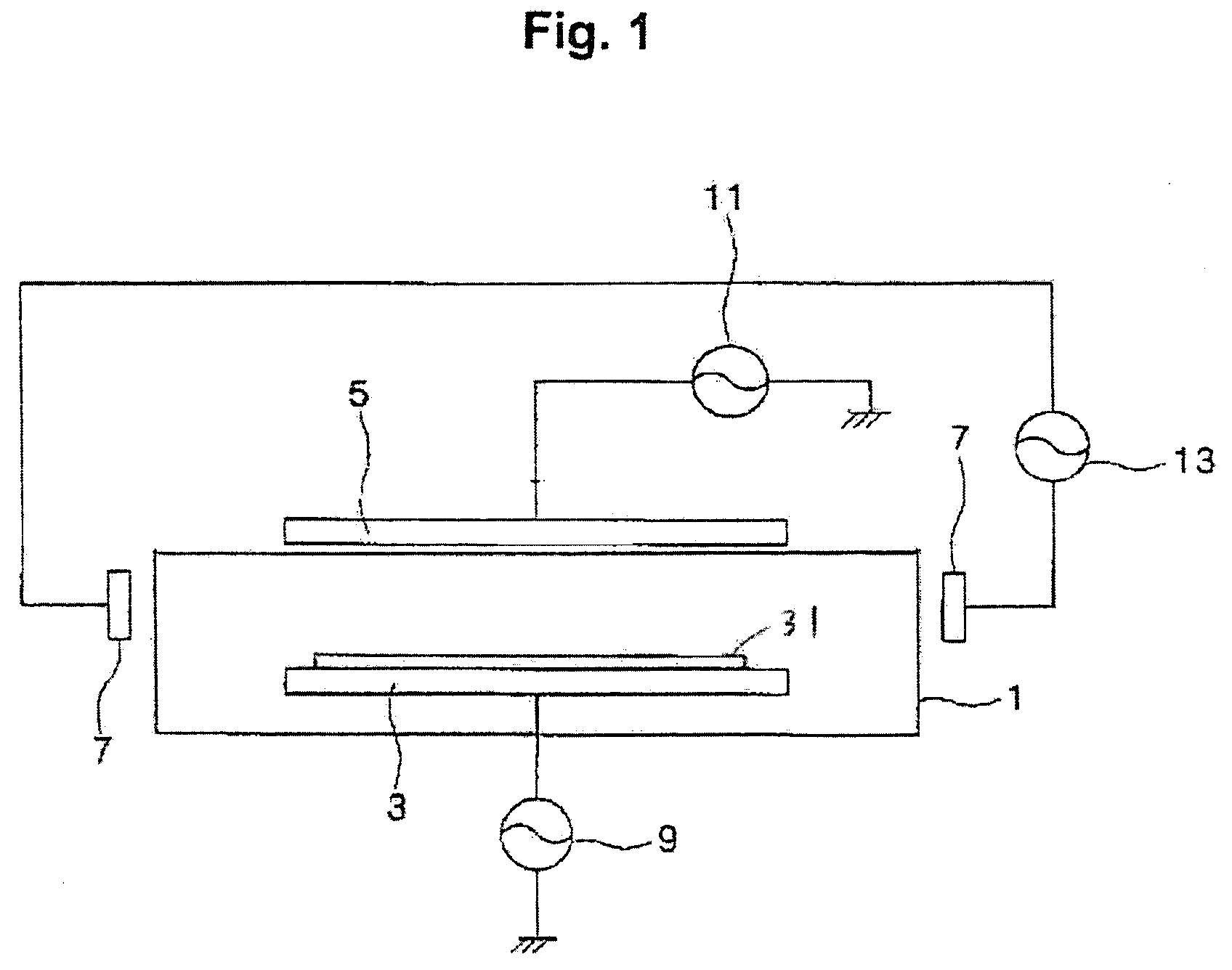

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS7488688B2High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

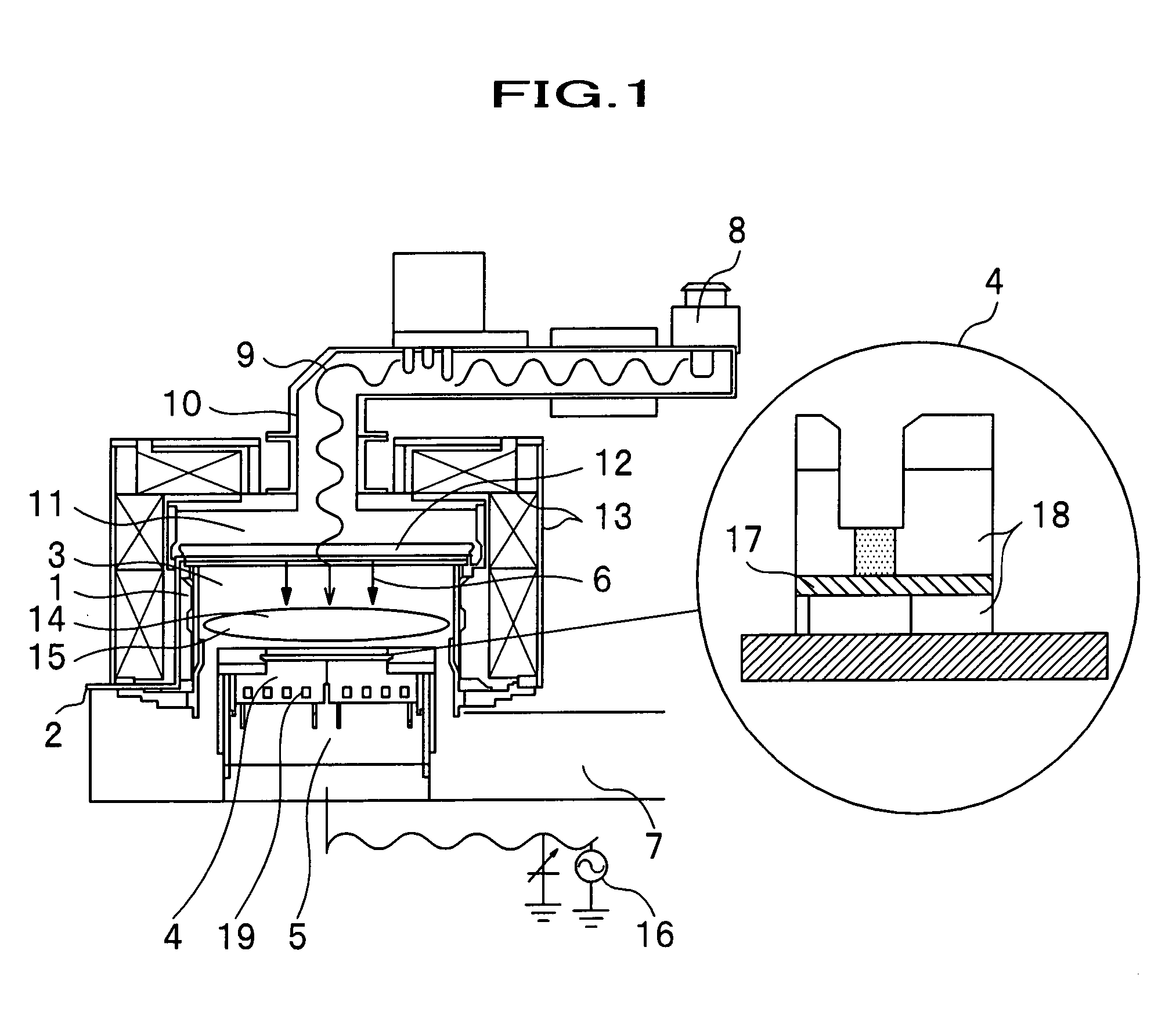

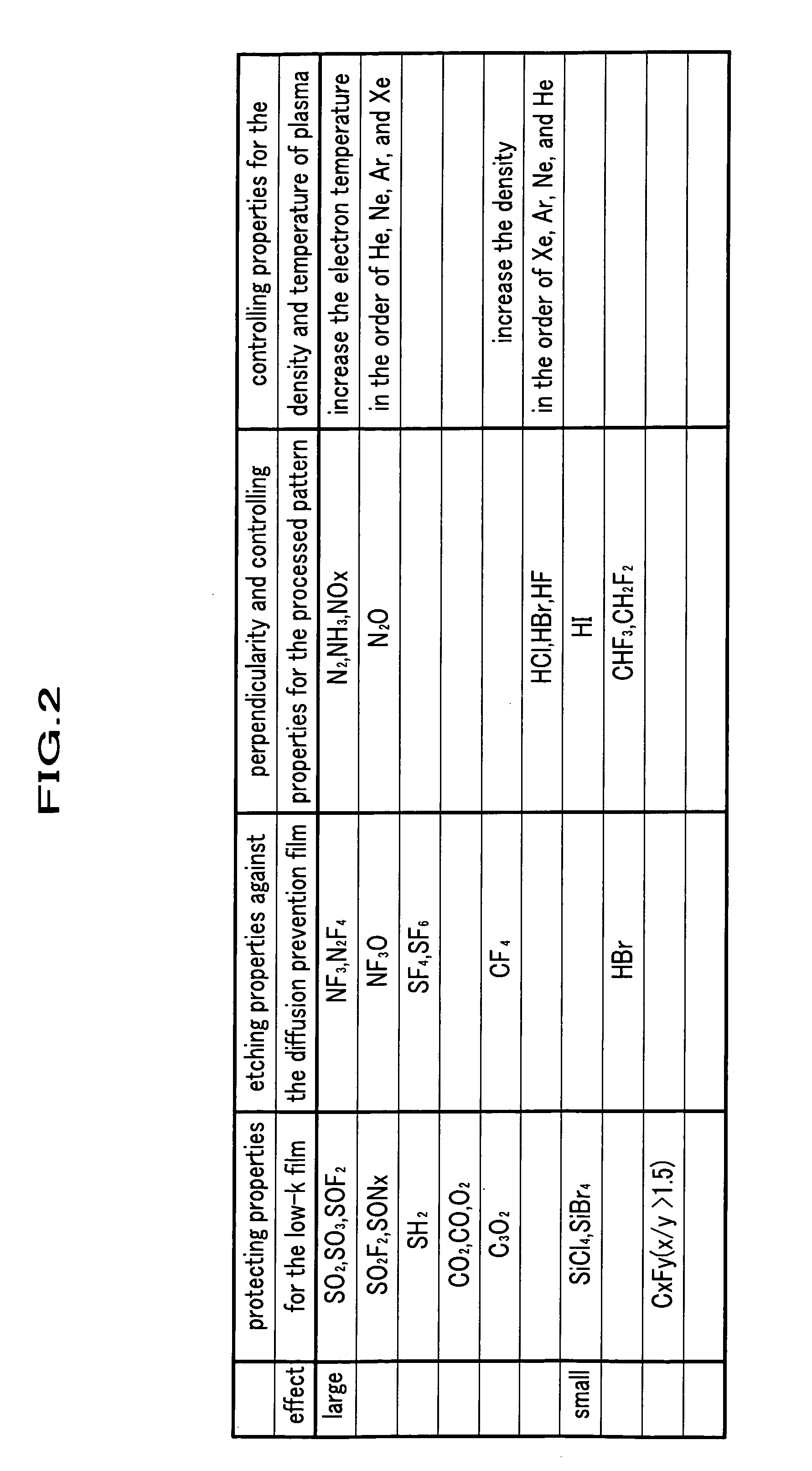

LSI device etching method and apparatus thereof

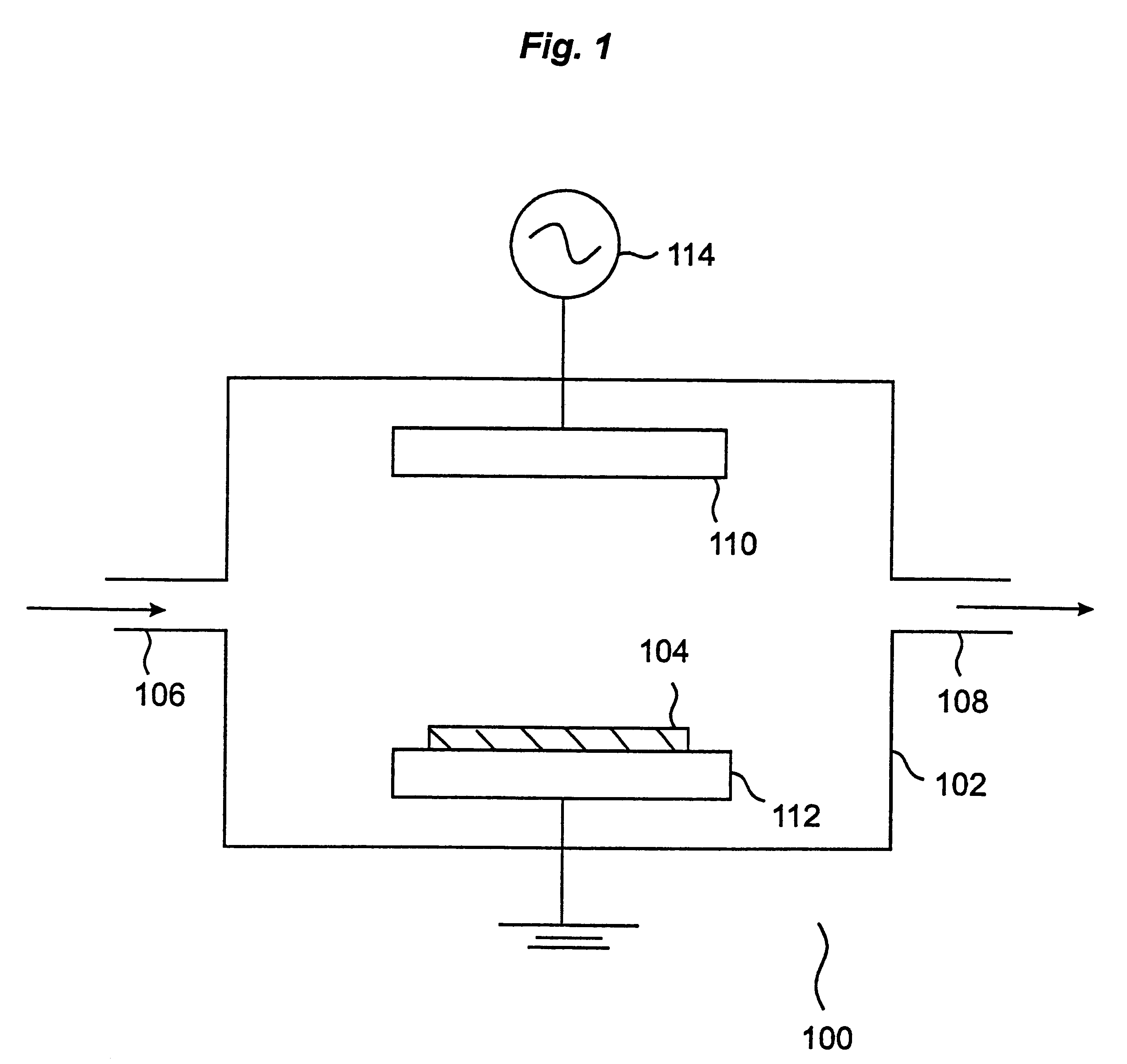

InactiveUS20050026431A1Realize processingImprove the protective effectSemiconductor/solid-state device manufacturingInterconnectionRadio frequency

An apparatus for performing a plasma-etching of a LSI device including a Cu interconnection, a low-k film, and a diffusion prevention film has a treatment chamber, into which an etching gas is introduced, and a support table which is equipped with electrodes and on which said LSI device is placed. In this apparatus, the etching gasses are turned into plasma by supplying radio frequency power to electrodes provided within the treatment chamber, so that the LSI device is etched with ions of the plasma. In this apparatus, a sulfur-containing gas and a fluorine-containing gas are mixed to the etching gasses, so that the diffusion prevention film is selectively etched against the low-k film.

Owner:HITACHI HIGH-TECH CORP

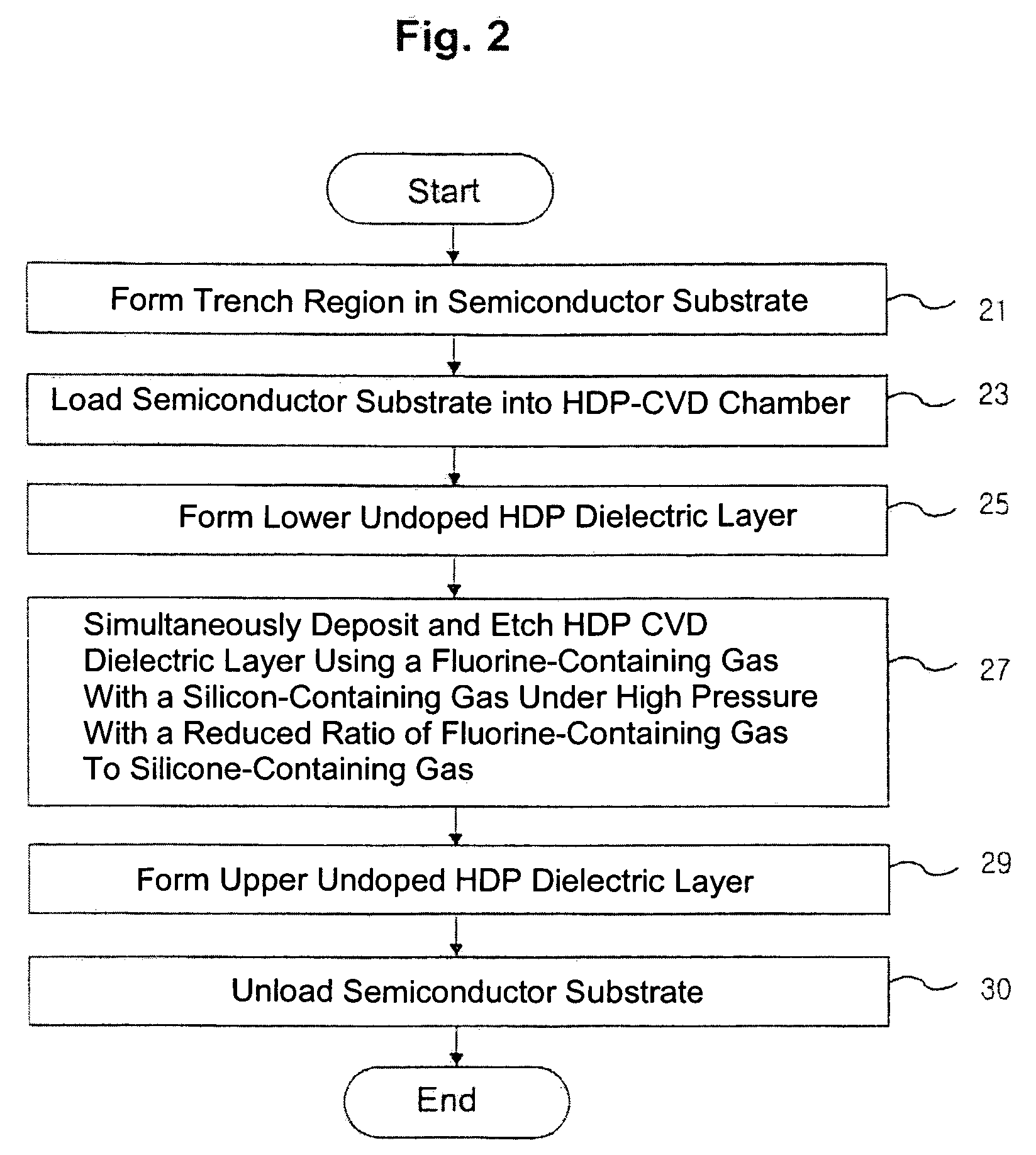

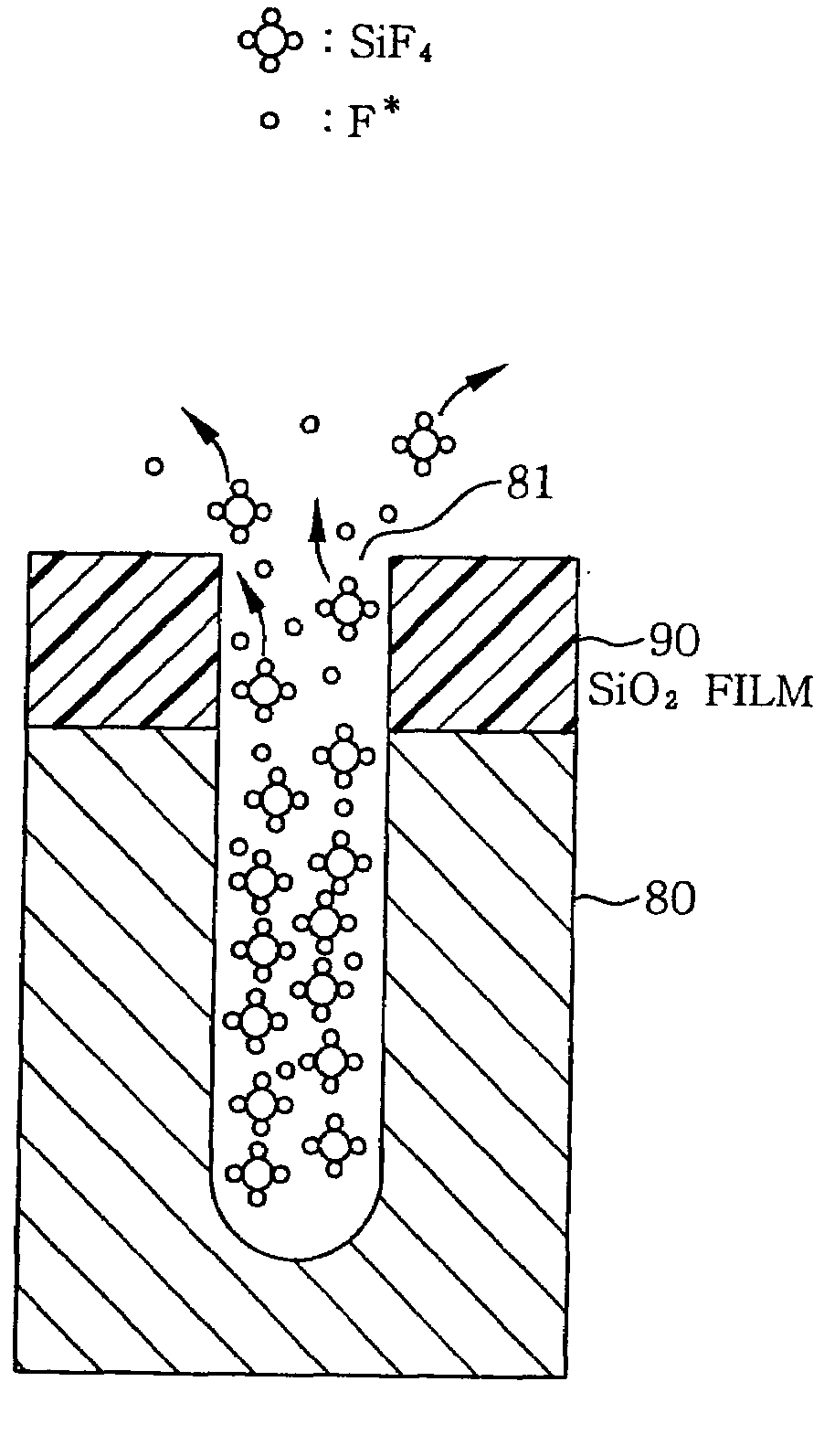

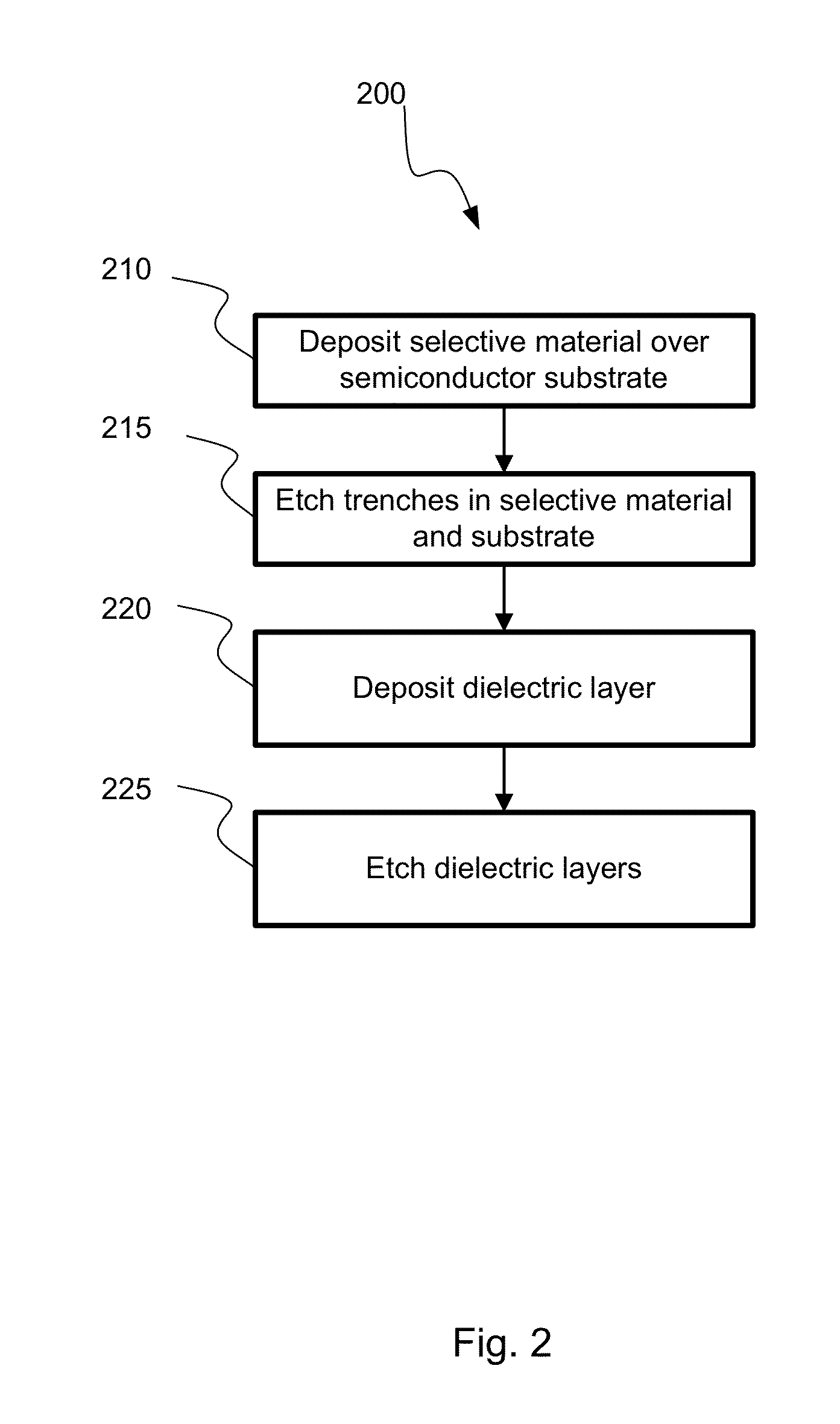

High-density plasma (HDP) chemical vapor deposition (CVD) methods and methods of fabricating semiconductor devices employing the same

InactiveUS7183214B2Reduce amountStrong Gap Filling CapabilitySemiconductor/solid-state device manufacturingPackaging toiletriesGas phaseDevice material

In one embodiment, a semiconductor substrate is placed into a process chamber. A gas mixture including a silicon-containing gas, a fluorine-containing gas, an inert gas, and an oxygen gas is introduced into the chamber at a pressure range of from about 30 mTorr to about 90 mTorr. During this time, deposition and etching processes are concurrently performed using a plasma to form a high-density plasma (HDP) insulating layer on the semiconductor substrate. A ratio of deposition to etching is from about 3:1 to about 10:1. A ratio of a flow rate of the fluorine-containing gas to a flow rate of the silicon-containing gas is less than about 0.9.

Owner:SAMSUNG ELECTRONICS CO LTD

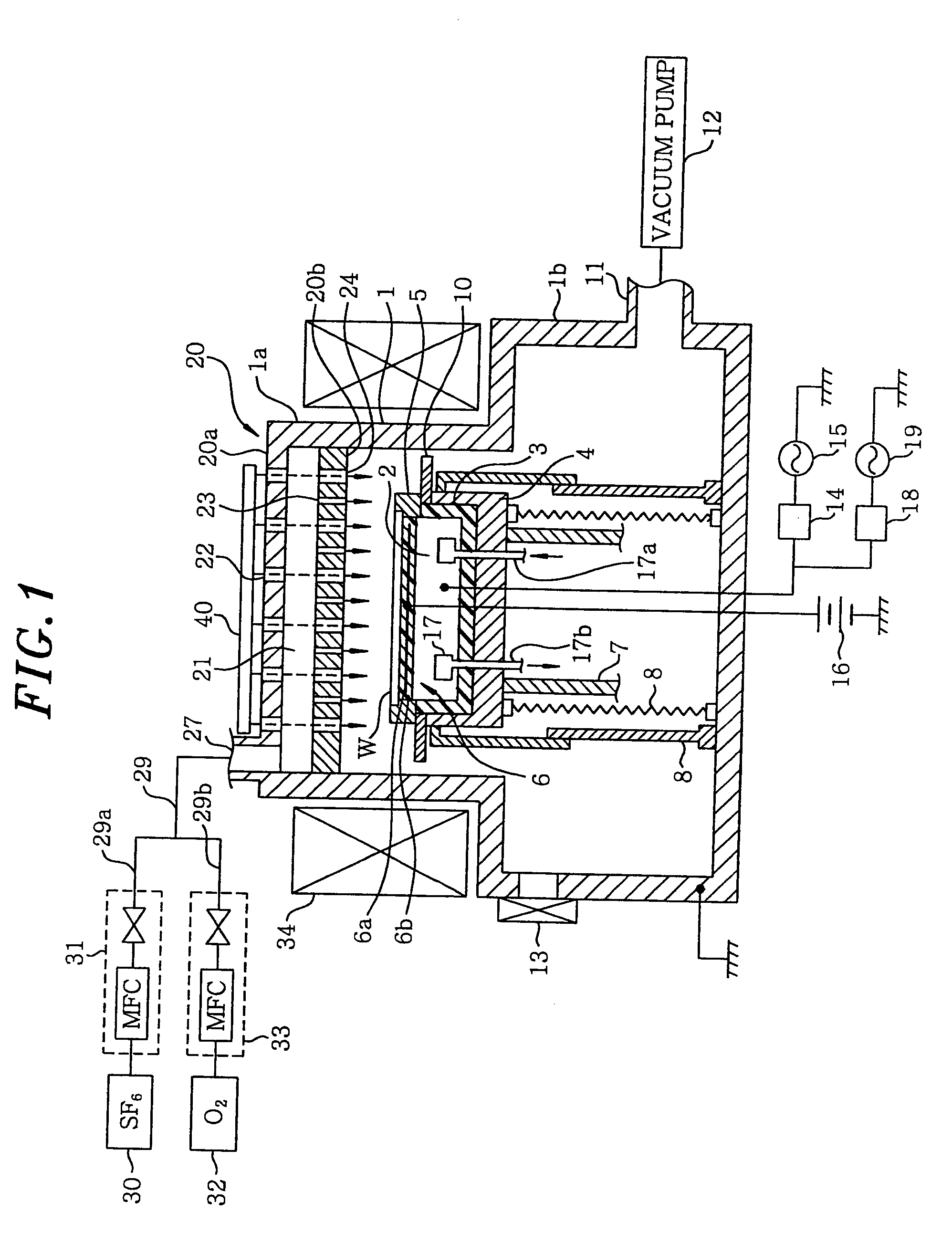

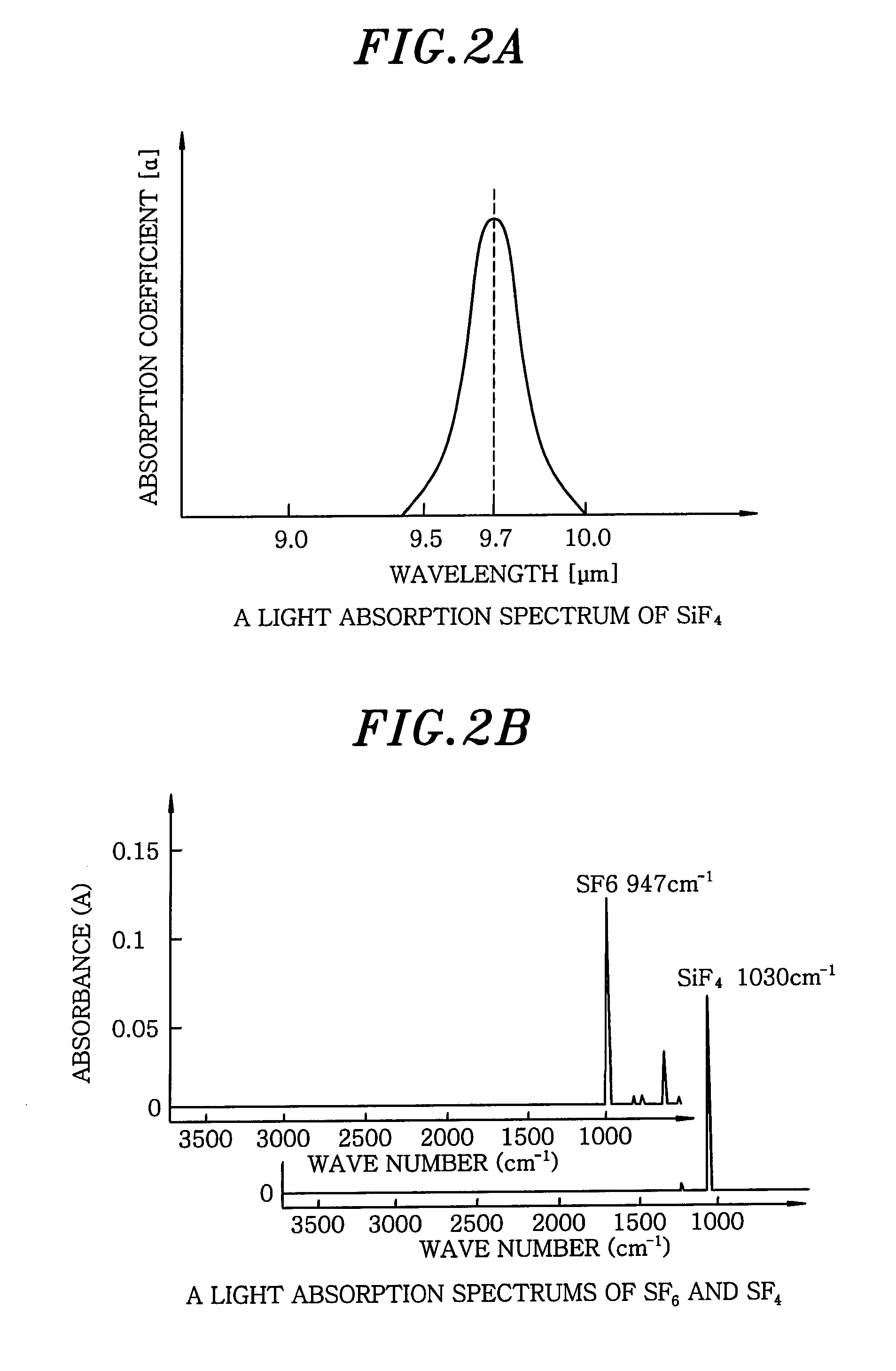

Plasma etching method and apparatus therefor

InactiveUS20090045167A1Increase chanceIncrease etch rateElectric discharge tubesVacuum gauge using ionisation effectsPeak intensityFluorine containing

A fluorine-containing compound gas, e.g., SF6 gas, is converted into a plasma and a silicon portion of an object to be processed is etched by the plasma. At the same time, using a light source having a peak intensity of light in a wavelength range of light absorption of a reaction product, e.g., SiF4, for which, to be more precise, ranges from 9 μm to 10 μm, the light is irradiated onto a surface of an object to be processed from the light source. The SiF4 molecules absorb the light, become activated and gain kinetic energy to be used in gaining an easy escape from a hole. As a consequence, an amount (a partial pressure) of fluorine radicals (F*) used as an etchant is increased and an etching rate of a silicon is increased.

Owner:TOKYO ELECTRON LTD

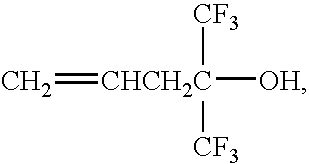

Photoresists, polymers and processes for microlithography

InactiveUS6849377B2Improve balanceHigh transparencyOrganic chemistryPhotosensitive materialsResistChemical compound

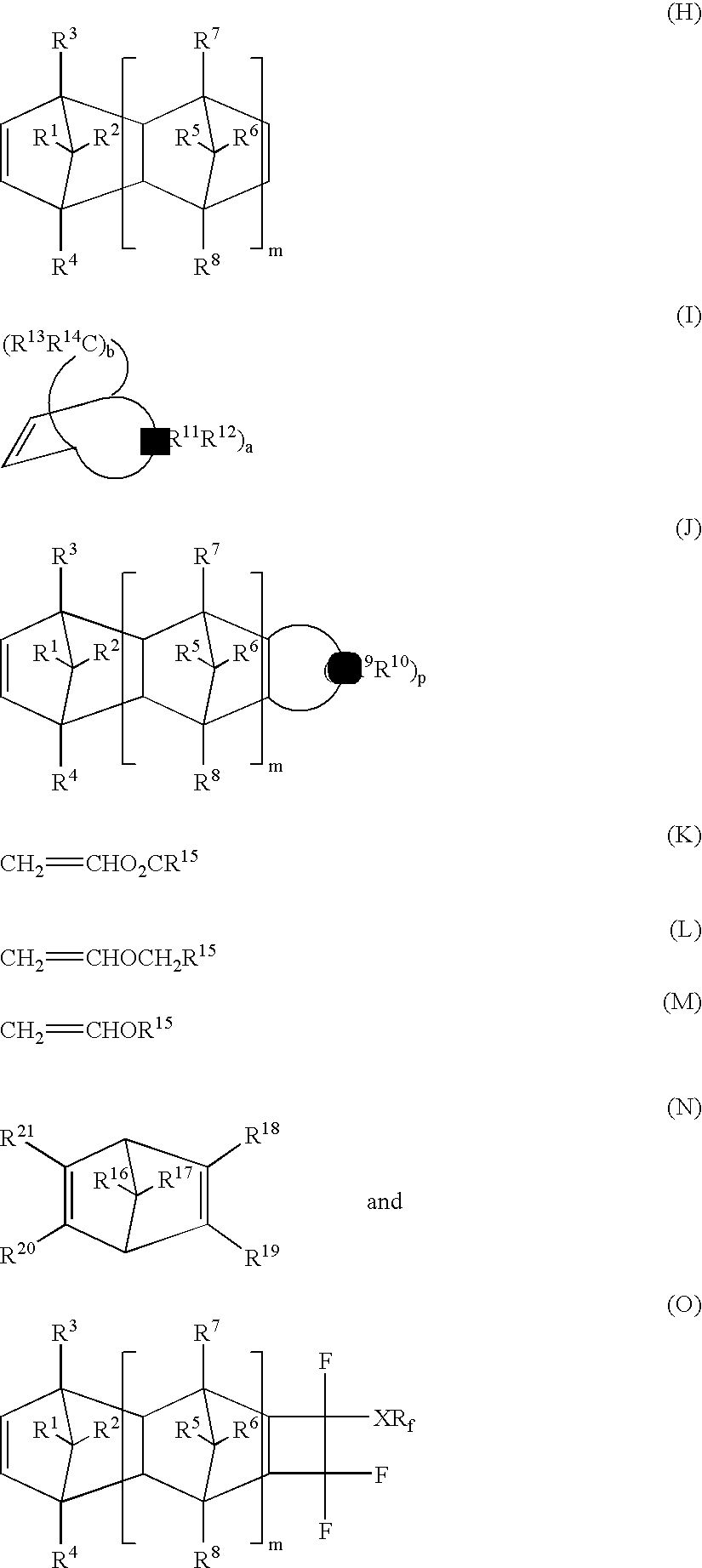

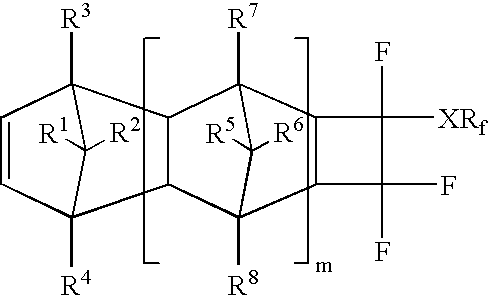

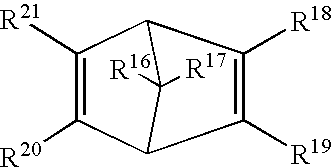

Photoresists and associated processes for microlithography in the extreme, far, and near UV are disclosed. The photoresists in some embodiments comprise (a) a fluorine-containing copolymer derived from at least one polycyclic ethylenically unsaturated compound and at least one compound having at least one fluorine atom covalently attached to an ethylenically unsaturated carbon atom; and (b) at least one photoactive component. In other embodiments, the photoresists comprise a fluorine-containing copolymer derived from at least one polycyclic ethylenically unsaturated compound having at least one atom or group covalently attached to a carbon atom contained within a ring structure and separated from each ethylenically unsaturated carbon atom of the ethylenically unsaturated compound by at least one covalently attached carbon atom, wherein the atom or group is selected from the group consisting of fluorine perfluoroalkyl and perfluoroalkoxy.

Owner:EI DU PONT DE NEMOURS & CO

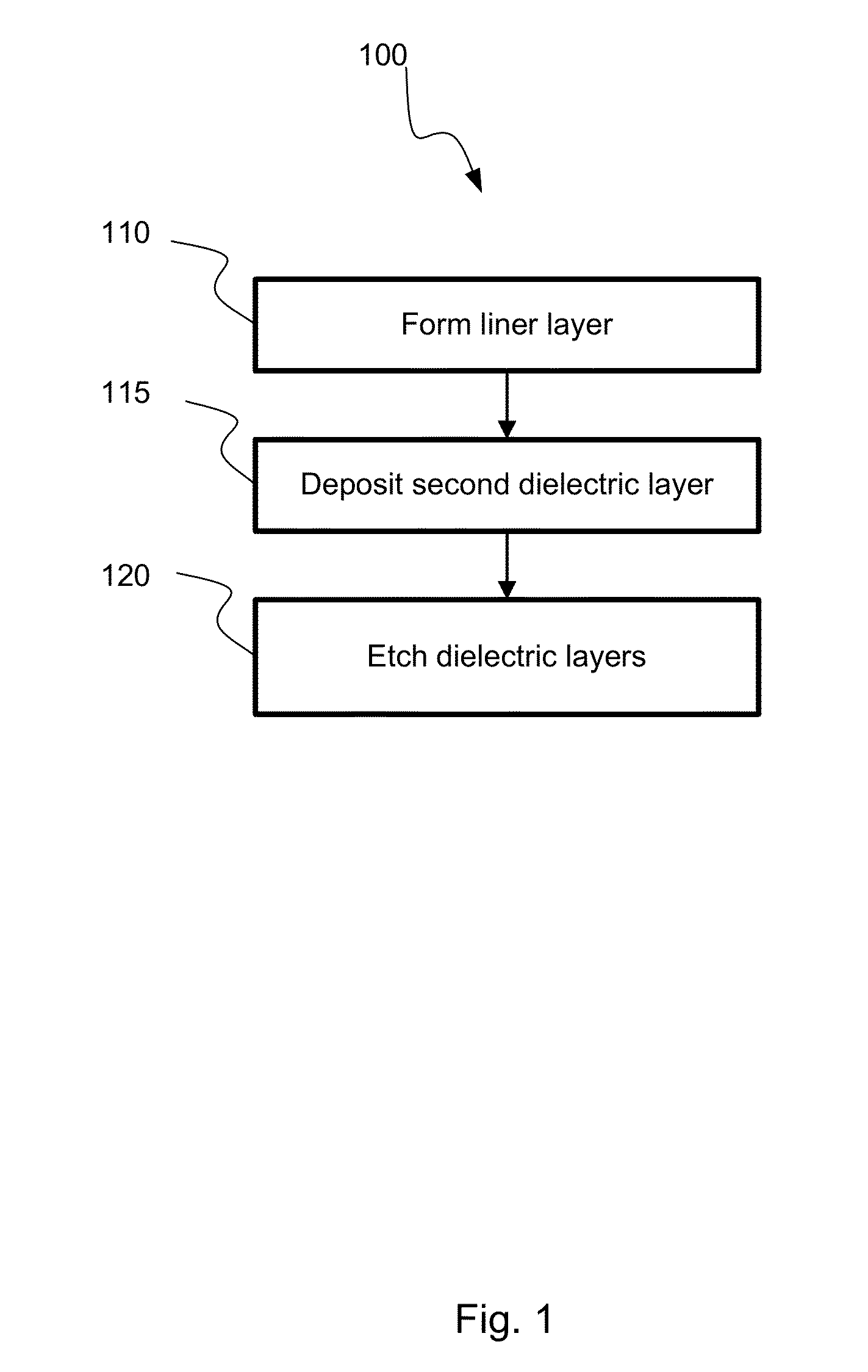

Intrench profile

ActiveUS20130260533A1Uniform profileSemiconductor/solid-state device manufacturingHydrogenFluorine containing

A method of etching a recess in a semiconductor substrate is described. The method may include forming a dielectric liner layer in a trench of the substrate where the liner layer has a first density. The method may also include depositing a second dielectric layer at least partially in the trench on the liner layer. The second dielectric layer may initially be flowable following the deposition, and have a second density that is less than the first density of the liner. The method may further include exposing the substrate to a dry etchant, where the etchant removes a portion of the first liner layer and the second dielectric layer to form a recess, where the dry etchant includes a fluorine-containing compound and molecular hydrogen, and where the etch rate ratio for removing the first dielectric liner layer to removing the second dielectric layer is about 1:1.2 to about 1:1.

Owner:APPLIED MATERIALS INC

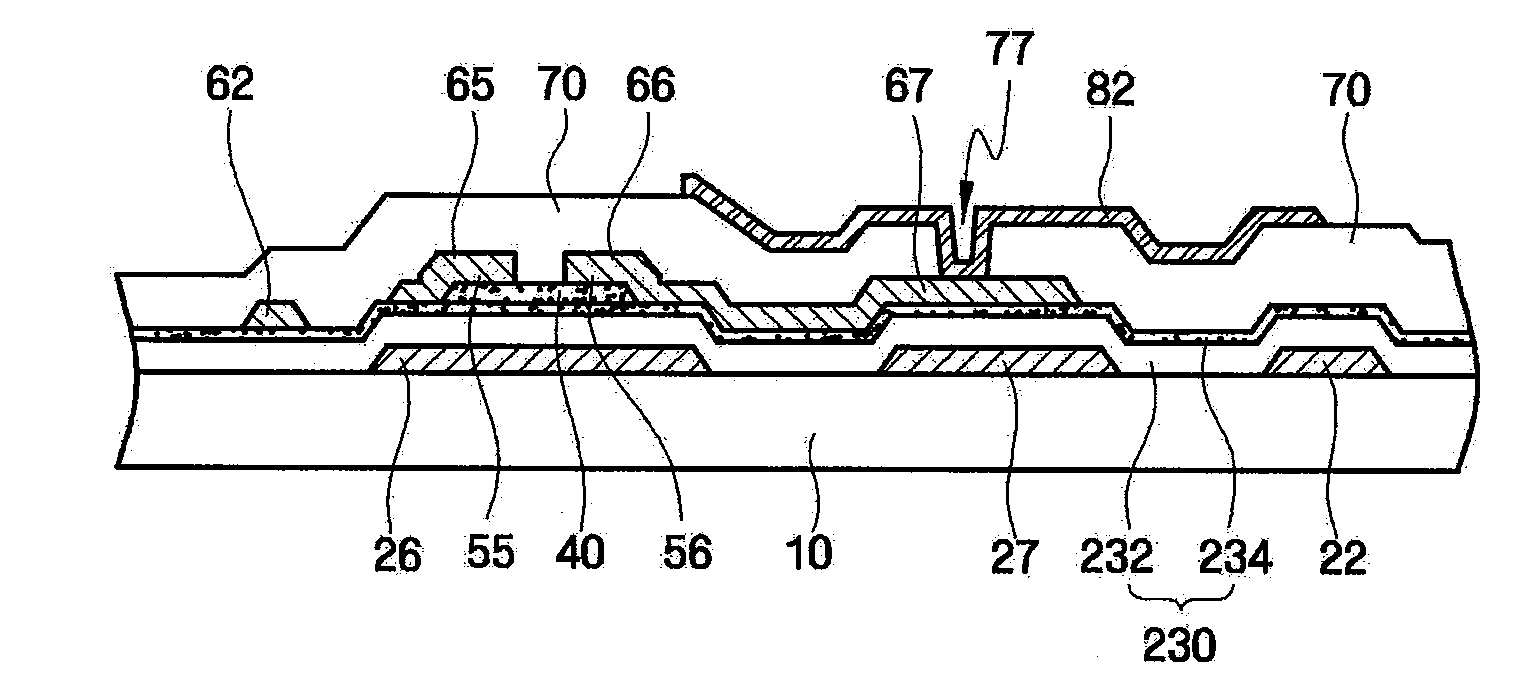

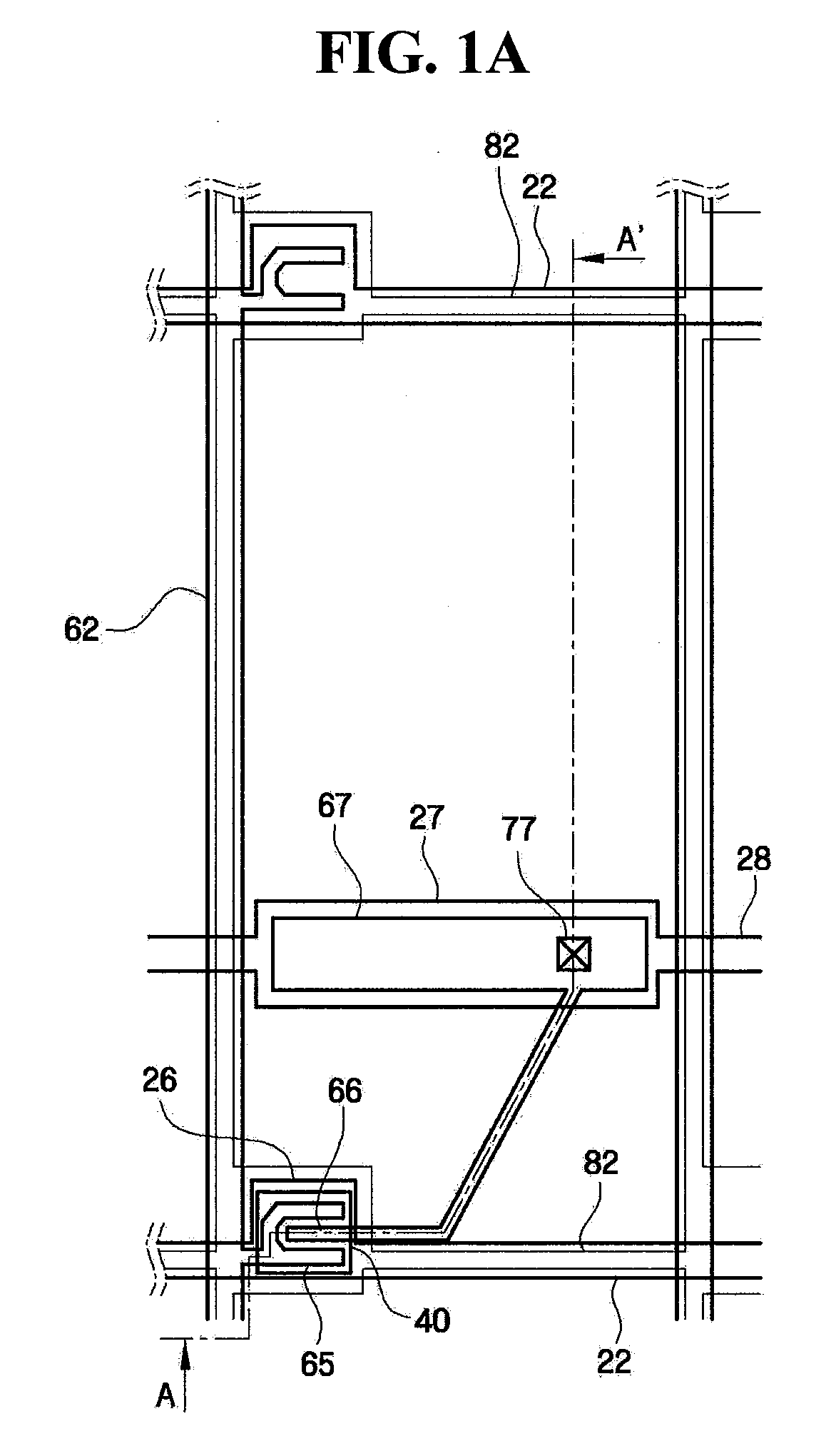

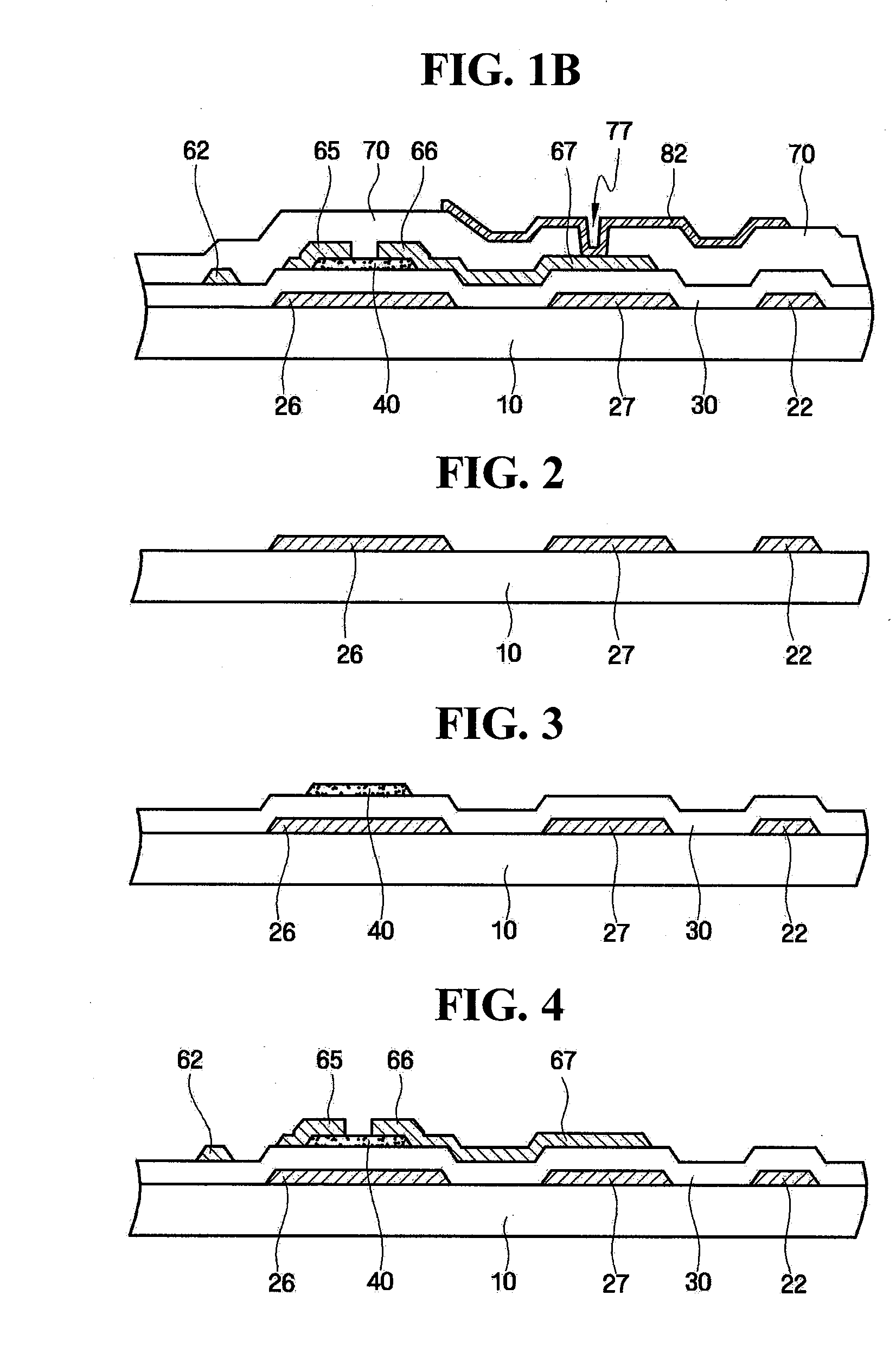

Thin film transistor array substrate having improved electrical characteristics and method of manufacturing the same

ActiveUS20090184315A1Increase charge mobilityUniform electrical characteristicsTransistorSolid-state devicesDisplay deviceFluorine containing

A thin film transistor array substrate, which can have high mobility of charge and can achieve uniform electrical characteristics for wide display devices, and a method of manufacturing the thin film transistor array substrate, are provided. The thin film transistor array substrate includes an oxide semiconductor layer having a channel and formed on an insulating substrate, a gate electrode overlapping the oxide semiconductor layer, a gate insulating film disposed between the oxide semiconductor layer and the gate electrode, and a passivation film formed on the oxide semiconductor layer and the gate electrode. At least one of the gate insulating film and the passivation film contains fluorine-containing silicon.

Owner:SAMSUNG DISPLAY CO LTD

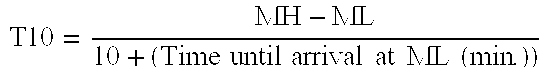

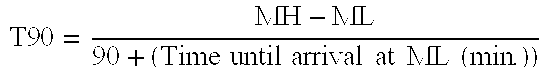

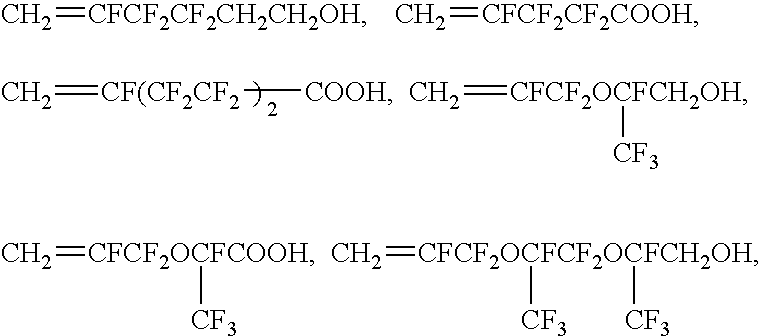

Fluoroalkyl carboxylic acid derivative, method for producing fluorine-containing polymer, and aqueous dispersion of fluorine-containing polymer

ActiveUS20060281946A1Improve efficiencyImprove stabilityPreparation from carboxylic acid halideOrganic compound preparationHydrogen atomAcid derivative

This invention provides a novel compound which can be properly used as a surfactant, a method of producing a fluoropolymer, surfactant and a fluoropolymer aqueous dispersions using the novel compound. This invention is a fluoroalkylcarboxylic acid derivative which is represented by the general formula (i): Rf1(OCH2CF2CF2)n1OCX1X2CF2(Rf2)n2COOM (i) wherein Rf1 represents a straight or branched fluoroalkyl group containing 1 to 20 carbon atoms, which fluoroalkyl group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, Rf2 represents a straight or branched fluoroalkylene group containing 1 to 25 carbon atoms, said fluoroalkylene group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, n1 represents an integer of 0 to 3, n2 represents an integer of 0 or 1, X1 and X2 are the same or different and each represents hydrogen atom or fluorine atom, and M represents NH4 or a monovalent metal element.

Owner:DAIKIN IND LTD

Thin coating film comprising fluorine-containing polymer and method of forming same

InactiveUS6794027B1High propertyLowering transparencySynthetic resin layered productsPretreated surfacesHeat resistanceFluorine containing

To provide the method of forming the thin coating film of fluorine-containing polymer having heat resistance and non-sticking property by adhering directly to a substrate without lowering characteristics such as reflection and light transmission which the substrate has. The thin coating film is a film which comprises a continuous layer of fluorine-containing polymer formed by adhering directly to the substrate and has a thickness of less than 3 mum, wherein the fluorine-containing polymer in the coating film has a hydrophilic functional group and a crystalline melting point of not less than 200° C.

Owner:DAIKIN IND LTD

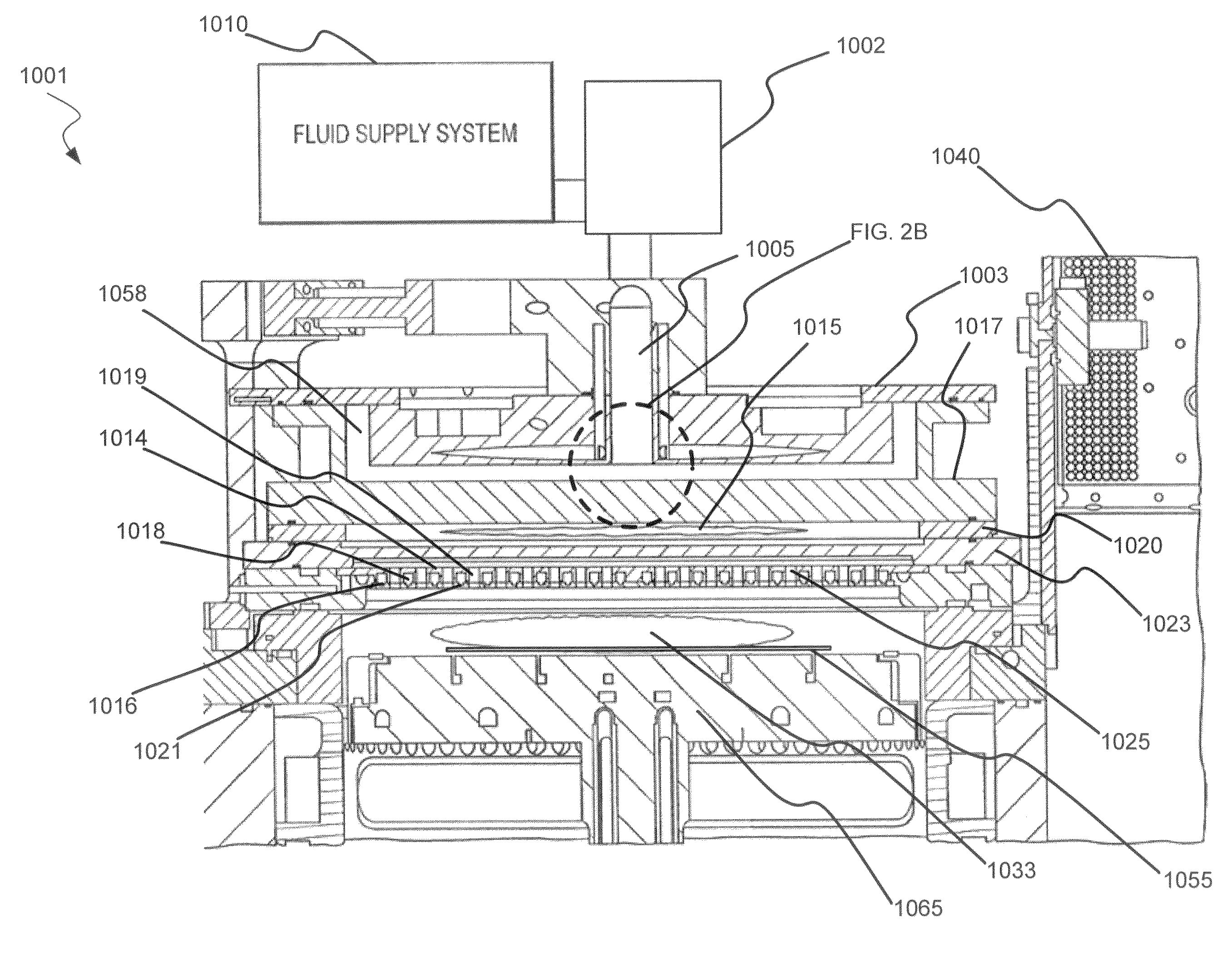

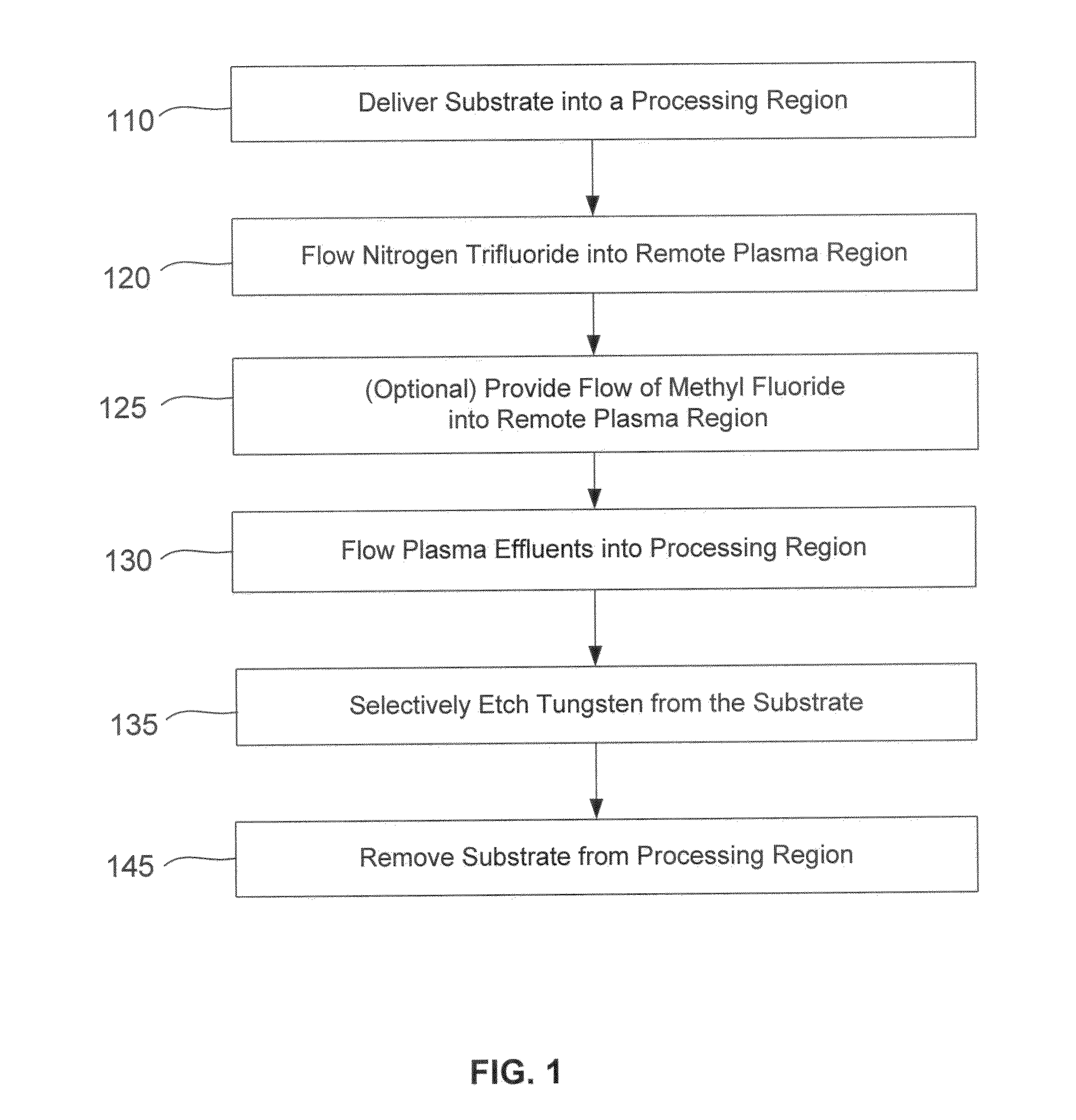

Dry-etch for selective tungsten removal

Methods of selectively etching tungsten relative to silicon-containing films (e.g. silicon oxide, silicon carbon nitride and (poly)silicon) as well as tungsten oxide are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten. The plasma effluents react with exposed surfaces and selectively remove tungsten while very slowly removing other exposed materials. Sequential and simultaneous methods are included to remove thin tungsten oxide which may, for example, result from exposure to the atmosphere.

Owner:APPLIED MATERIALS INC

Differential silicon oxide etch

ActiveUS20140080309A1Low densityDensityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHigh density

A method of etching exposed silicon oxide on patterned heterogeneous structures is described and includes a gas phase etch created from a remote plasma etch. The remote plasma excites a fluorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents combine with water vapor. Reactants thereby produced etch the patterned heterogeneous structures to remove two separate regions of differing silicon oxide at different etch rates. The methods may be used to remove low density silicon oxide while removing less high density silicon oxide.

Owner:APPLIED MATERIALS INC

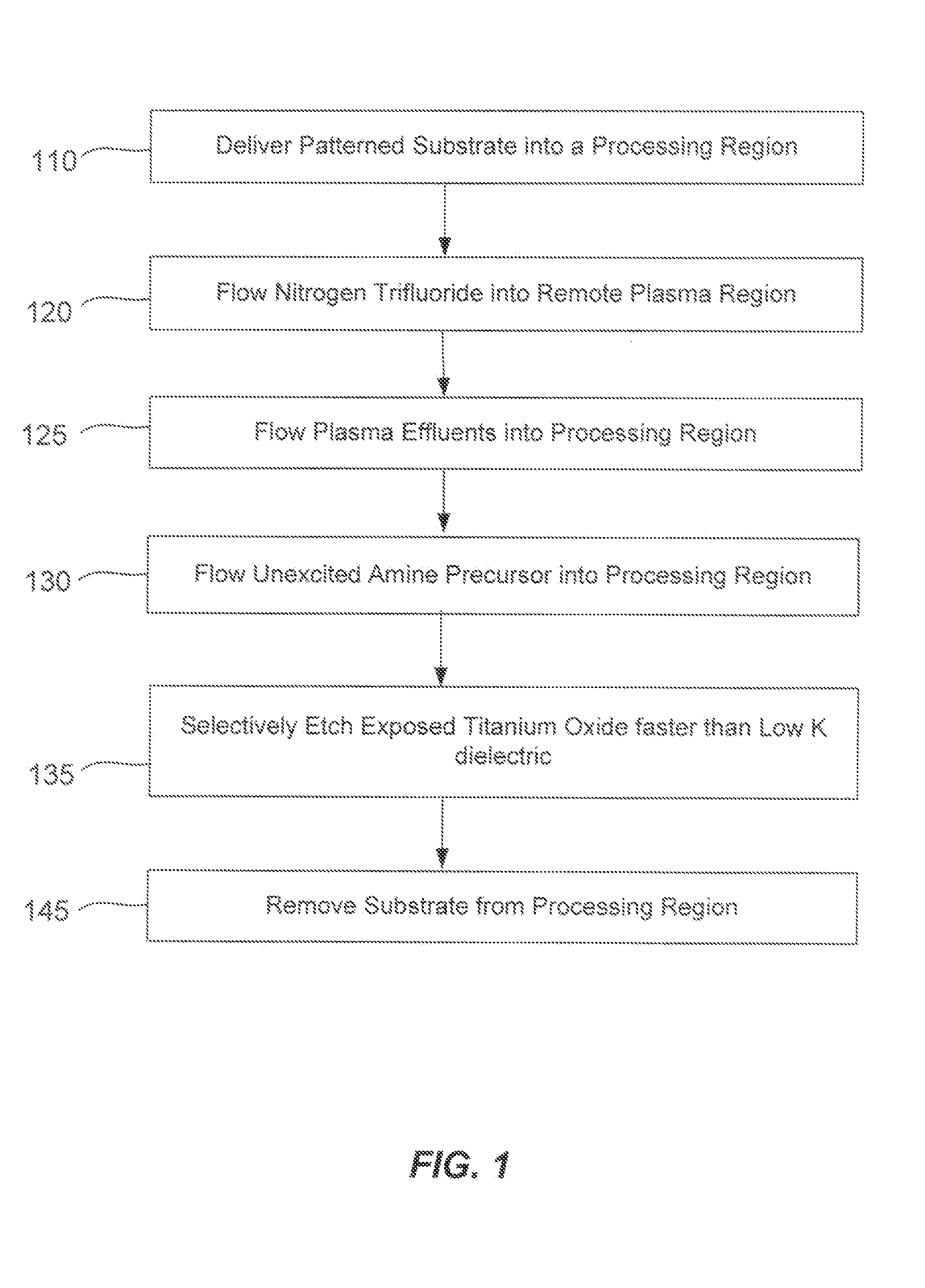

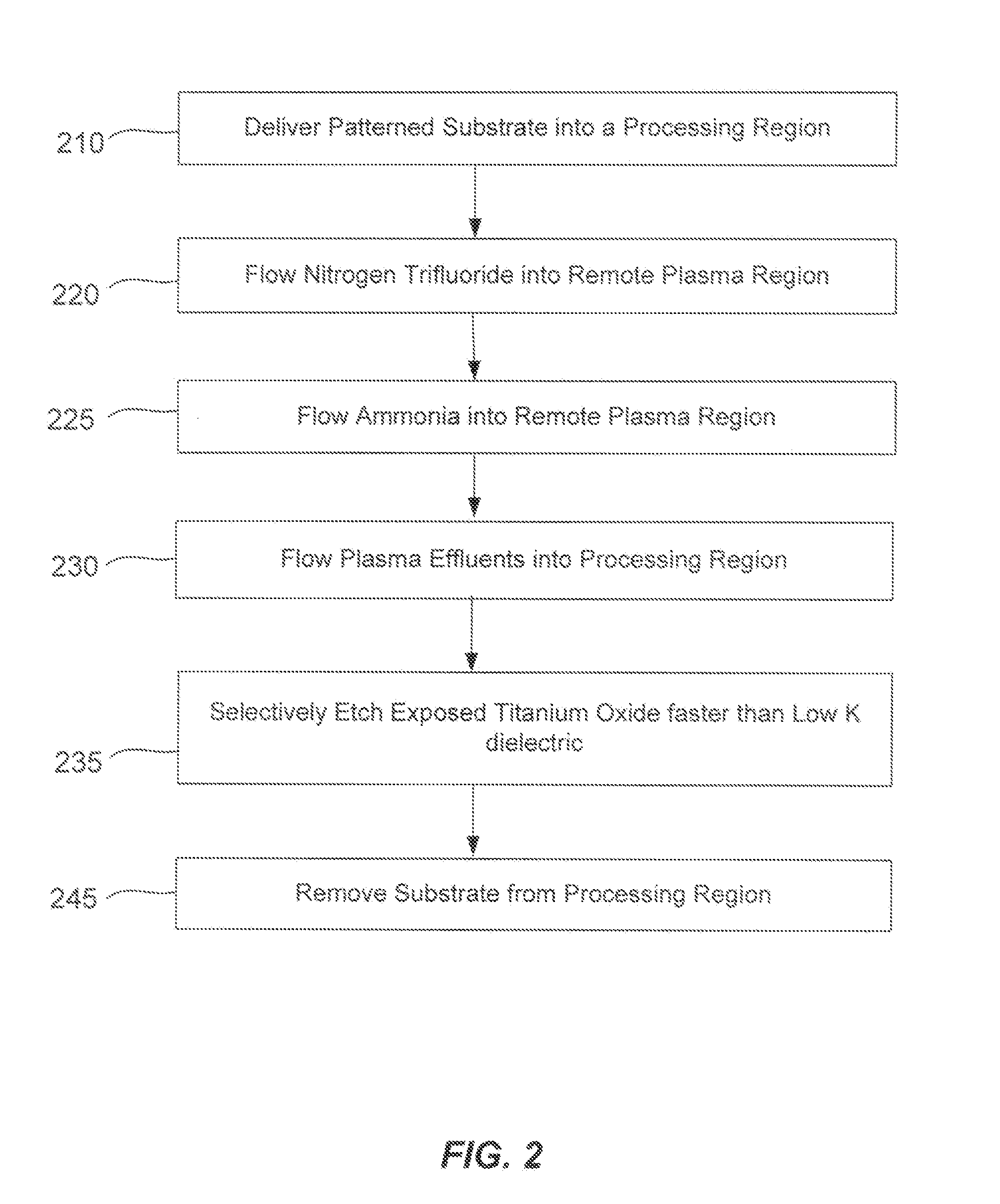

Non-local plasma oxide etch

ActiveUS20140166617A1High titanium oxide selectivityElectric discharge tubesDecorative surface effectsRemote plasmaHydrogen

A method of etching exposed titanium oxide on heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor. Plasma effluents from the remote plasma are flawed into a substrate processing region where the plasma effluents may combine with a nitrogen-containing precursor such as an amine (N:) containing precursor. Reactants thereby produced etch, the patterned heterogeneous structures with high titanium oxide selectivity while the substrate is at elevated temperature. Titanium oxide etch may alternatively involve supplying a fluorine-containing precursor and a source of nitrogen-and-hydrogen-containing precursor to the remote plasma. The methods may be used to remove titanium oxide while removing little or no low-K dielectric, polysilicon, silicon nitride or titanium nitride.

Owner:APPLIED MATERIALS INC

Selective suppression of dry-etch rate of materials containing both silicon and oxygen

A method of suppressing the etch rate for exposed silicon-and-oxygen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. Examples of materials whose selectivity is increased using this technique include silicon nitride and silicon. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-oxygen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including a nitrogen-containing precursor and a hydrogen-containing precursor. The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com