Patents

Literature

123results about "Preparation from carboxylic acid halide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoroalkyl carboxylic acid derivative, method for producing fluorine-containing polymer, and aqueous dispersion of fluorine-containing polymer

ActiveUS20060281946A1Improve efficiencyImprove stabilityPreparation from carboxylic acid halideOrganic compound preparationHydrogen atomAcid derivative

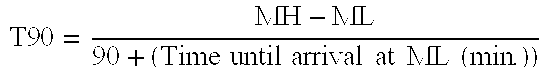

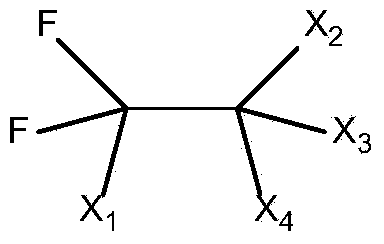

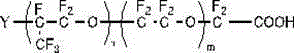

This invention provides a novel compound which can be properly used as a surfactant, a method of producing a fluoropolymer, surfactant and a fluoropolymer aqueous dispersions using the novel compound. This invention is a fluoroalkylcarboxylic acid derivative which is represented by the general formula (i): Rf1(OCH2CF2CF2)n1OCX1X2CF2(Rf2)n2COOM (i) wherein Rf1 represents a straight or branched fluoroalkyl group containing 1 to 20 carbon atoms, which fluoroalkyl group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, Rf2 represents a straight or branched fluoroalkylene group containing 1 to 25 carbon atoms, said fluoroalkylene group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, n1 represents an integer of 0 to 3, n2 represents an integer of 0 or 1, X1 and X2 are the same or different and each represents hydrogen atom or fluorine atom, and M represents NH4 or a monovalent metal element.

Owner:DAIKIN IND LTD

Preparation process of benzoyl chloride

ActiveCN103787874AReduce pollutionSave resourcesPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation process of benzoyl chloride. The preparation process comprises the following steps of synthesis of benzotrichloride: carrying out temperature reaction on methylbenzene and chlorine under the catalytic action of a catalyst to synthetize a crude benzotrichloride product; synthesis of the benzoyl chloride: continuously stirring and heating the crude benzotrichloride product and benzoic acid to prepare a crude benzoyl chloride product after adding the catalyst; refining of the benzoyl chloride: carrying out reduced pressure distillation on the crude benzoyl chloride product to prepare a refined benzoyl chloride product; recovering benzoyl chloride raffinate, adding water to the benzoyl chloride raffinate which is subjected to the reduced pressure distillation, heating and stirring to transform the benzoyl chloride contained in the raffinate into the benzoic acid, cooling, then separating out benzoic acid. The preparation process disclosed by the invention is easy to safe to operate, effectively shortens the reaction time, achieves the purity of the prepared benzoyl chloride by 99.5%, reduces the environmental pollution by recycling residues, saves the resources, reduces the cost, meets the requirements of pharmaceutical chemicals and can carry out massive industrial production.

Owner:YIDU YOUYUAN IND CO LTD

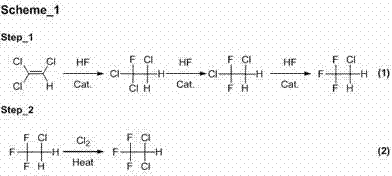

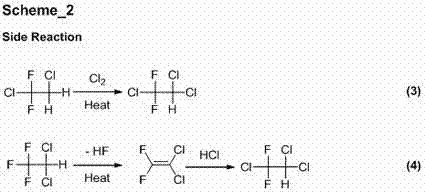

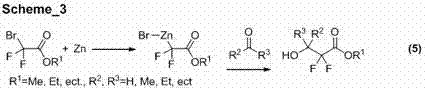

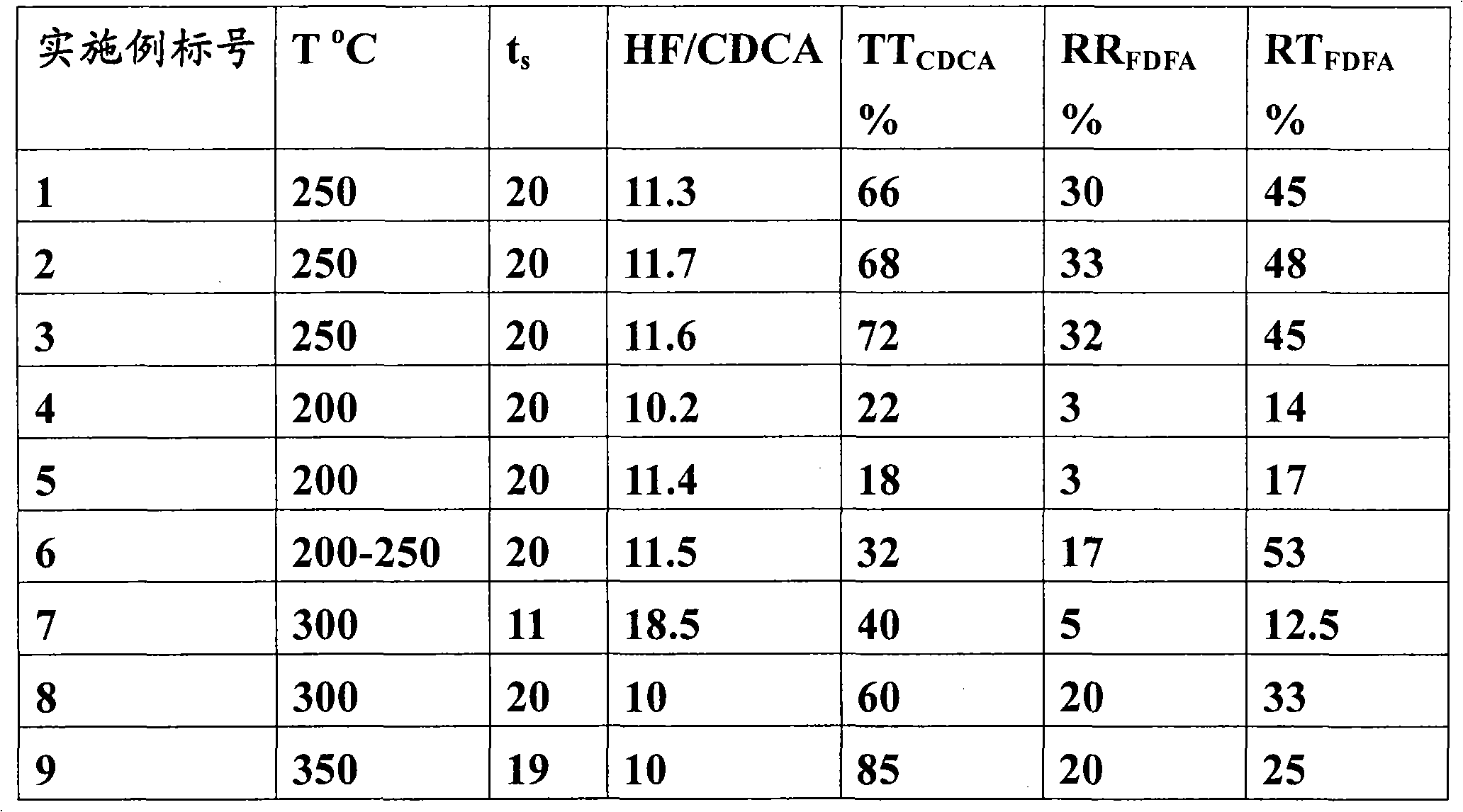

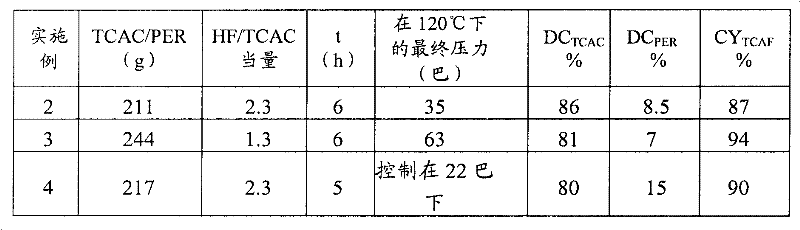

Preparation method of trifluoroacetic acid

InactiveCN103524325ALow costPreparation from carboxylic acid halideHalogenated hydrocarbon preparationCatalytic oxidationTetrachloroethane

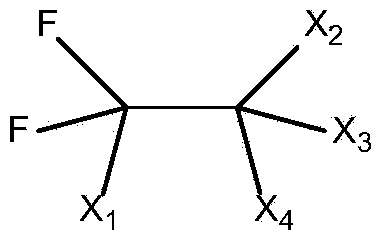

The invention discloses a preparation method of trifluoroacetic acid low in synthesis cost. The preparation method comprises the steps of (1) preparing 1,1-difluoro tetrachloroethane from 1,1-difluoroethane or chloride thereof through ultraviolet catalysis and a chlorine reaction; (2) implementing catalytic oxidation on the 1,1-difluoro tetrachloroethane to obtain 1,1-difluoro-1-chloroacetyl chloride, wherein in the catalytic oxidation, mol ratio of the 1,1-difluoro tetrachloroethane to an oxidizing agent is 1: (2-4), dosage of the catalyst is 0.5-5% of the total weight of an reactant, and reaction temperature is 50-70 DEG C; (3) carrying out hydrogen fluoride (HF) fluoridation on the 1,1-difluoro-1-chloroacetyl chloride under the catalyst to obtain trifluoroacetyl fluoride, wherein mol ratio of the 1,1-difluoro-1-chloroacetyl chloride to the HF is 1: (2-3), reaction temperature is 40-60 DEG C, and the catalyst is either antimony or antimony pentachloride; and (4) hydrolyzing the prepared trifluoroacetyl fluoride to obtain trifluoroacetic acid.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

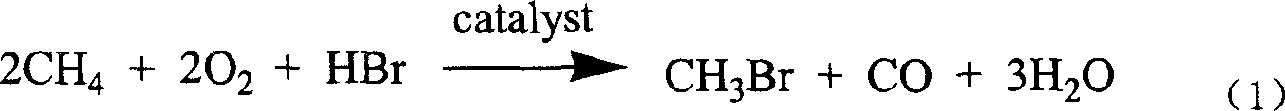

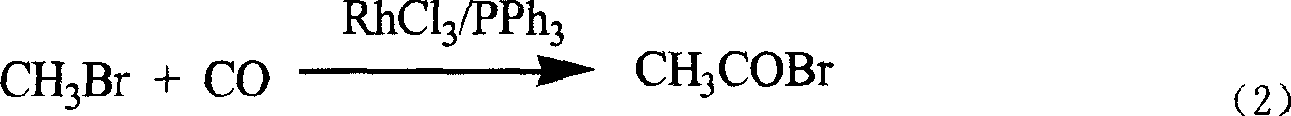

New technological process of synthesizing acetyl bromide, acetic acid, acetate from methane

ActiveCN1724503AEasily hydrolyzedReduces aggravated sedimentationPreparation from carboxylic acid halidesPreparation from carboxylic acid halideSolventOxygen

The invention discloses a novel process for preparing acetyl bromide, acetic acid and acetic ester from methane, which consists of reacting methane, oxygen and aqueous solution of HBr to obtain CH3Br and CO through catalytic reaction, then subjecting CH3Br and CO to carbonation reaction so as to prepare acetyl bromide in organic medium containing catalyst, then directly hydrolyzing the acetyl bromide and a certain amount of water into acetic acid, and reacting acetyl bromide and alcohols to obtain the acetic esters of the corresponding alcohols. The HBr can be regenerated as circular reaction medium and used again for the reaction for preparing CH3Br and CO from methane. The organic medium of the carbonylation reaction contains catalyst such as rhodium (Rh) compound, hydriodate and / or organo-phosphorus ligand, and a certain proportion of solvents.

Owner:MICROVAST POWER SYST CO LTD

Chemical recycling of pla by alcoholysis

ActiveUS20120029228A1Simple processImprove impactPreparation from carboxylic acid halideOrganic compound preparationSolventPolymer

Owner:FUTERRO SA

Method for preparing special fluoroether surfactant

InactiveCN105111351AImprove low temperature resistancePreparation from carboxylic acid halideTransportation and packagingOligomerCarboxylic acid

The invention discloses a method for preparing a special fluoroether surfactant. The method comprises the steps of adding deionized water and a fluoroether oligomer, of which the average molecular weight is 300-1,500, into a hydrolysis reaction kettle according to the weight ratio of about (1: 15) to (3: 1), carrying out stirring heating, maintaining the internal temperature of the kettle to be about 30-200 DEG C, hydrolyzing unstable terminal groups of the fluoroether oligomer into carboxylic acid terminal groups, carrying out reaction for half an hour to 8 hours, then, standing a reaction solution to carry out layering, removing an upper-layer aqueous solution through sucking, adding an approximately equal volume of clean deionized water into the hydrolysis kettle so as to clean reactants, carrying out stirring for about half an hour at normal temperature, then, removing an upper-layer aqueous solution through sucking, repeating the cleaning method for 1-3 times, and discharging the reactant, thereby preparing the fluoroether surfactant containing the carboxylic acid terminal groups.

Owner:江苏梅兰化工有限公司 +2

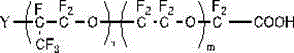

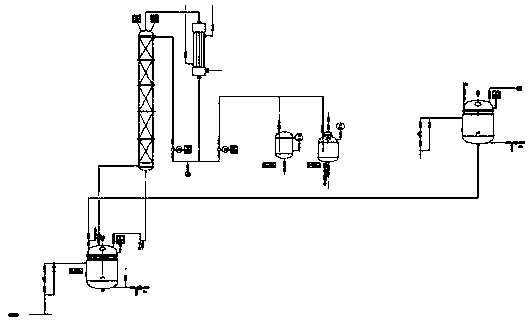

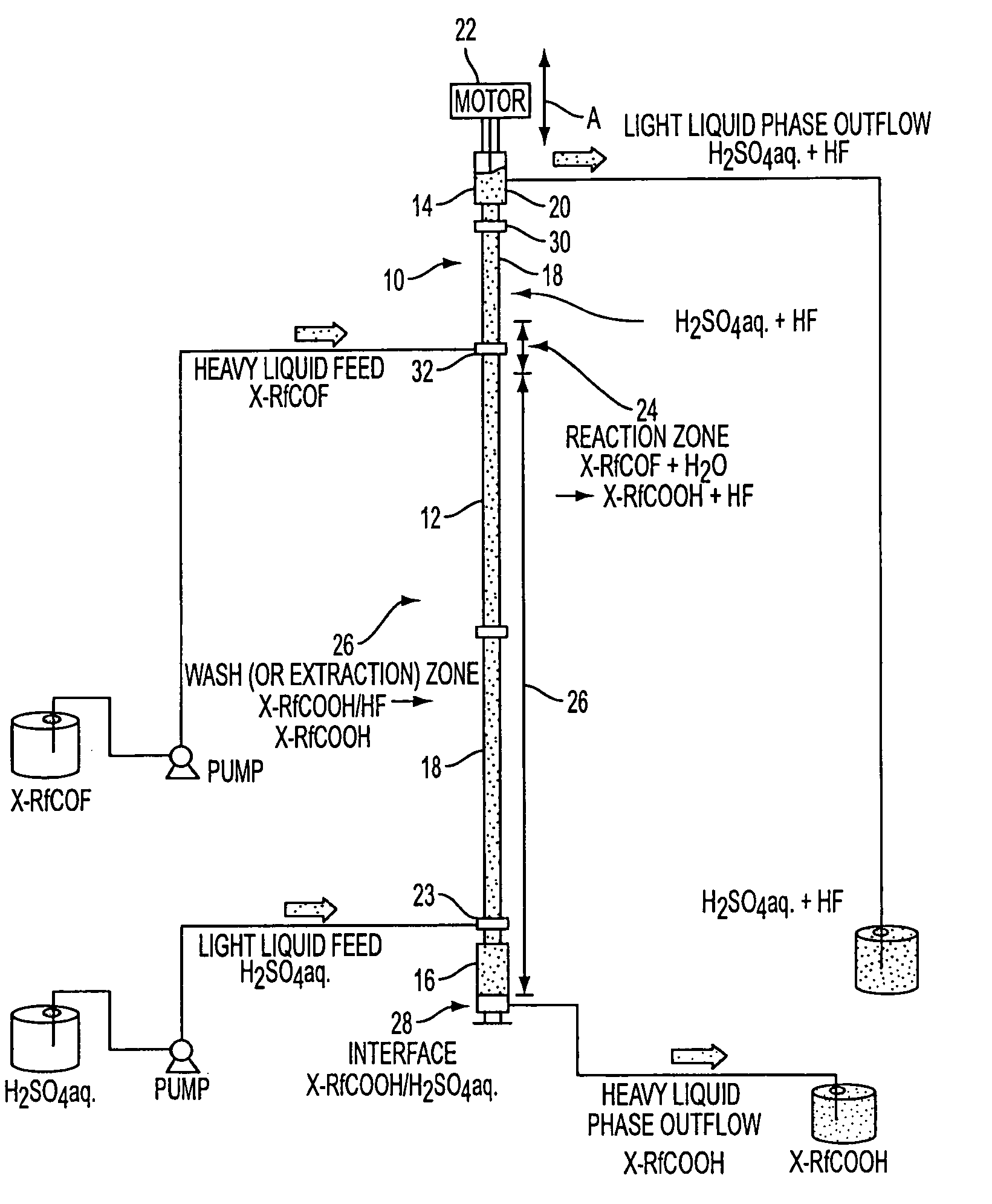

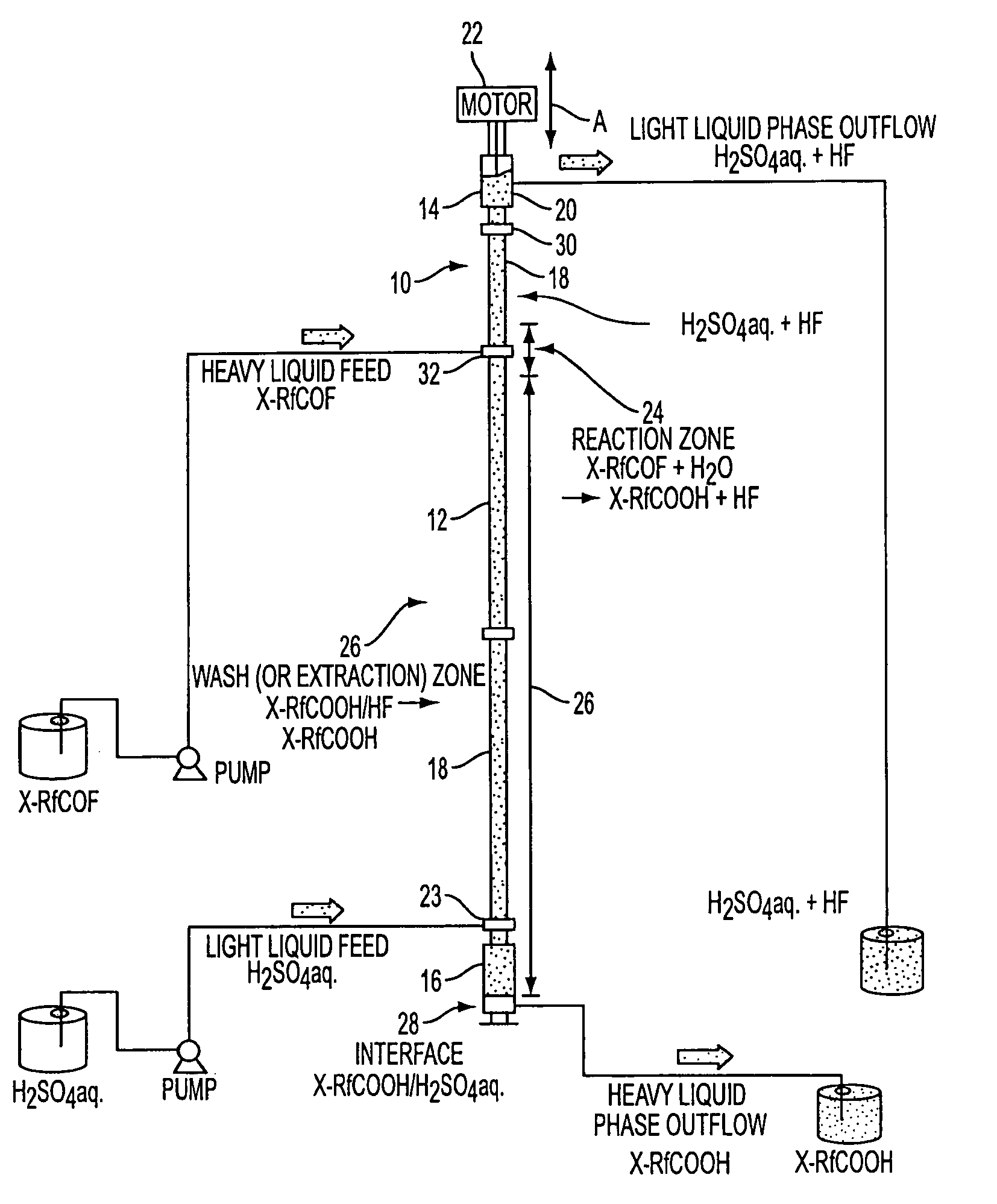

Fluorosurfactant free of perfluorooctanoic acid as well as preparation method and process system of fluorosurfactant

ActiveCN105170018ASolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPeroxide value

The invention discloses a fluorosurfactant free of perfluorooctanoic acid as well as a preparation method and a process system of the fluorosurfactant. The fluorosurfactant is a repeated structure unit which comprises at least one oxoperfluoropropenyl and one or a combination of more of perfluoromethoxyl, a Y group and oxoperfluorovinyl and is provided with a carboxyl group or carboxylate at one end. The fluorosurfactant is a fluoropolymer with the C-O-C ether bond structure as the main structural body; in view of indexes, the fluorosurfactant does not contain perfluorooctanoic acid with a 8-C straight-chain structure or salt of the perfluorooctanoic acid, is easily decomposed in nature and is proved to be harmless to human bodies, the peroxide value is 0.001%-0.1%, the surface tension is 10-30 mN / m, and the fluorosurfactant has an amphiphilic structure of a surfactant.

Owner:成都晨光博达新材料股份有限公司

Fluoroalkyl carboxylic acid derivative, method for producing fluorine-containing polymer, and aqueous dispersion of fluorine-containing polymer

ActiveUS7589234B2Improve efficiencyImprove stabilityPreparation from carboxylic acid halideOrganic compound preparationHydrogen atomAcid derivative

Owner:DAIKIN IND LTD

Preparation method of fluoro-ether carboxylic acid surfactant

InactiveCN103073410ABiodegradableEliminate residuePreparation from carboxylic acid halidePhoto irradiationUltraviolet lights

The invention discloses a preparation method of a fluoro-ether carboxylic acid surfactant. A fluorine-containing olefin monomer, oxygen and a molecular weight regulator are initiated to carry out the photochemical reaction by ultraviolet light to generate fluoro-ether acyl chloride and fluoro-ether acyl fluoride at the temperature of -40 to -80 DEG C, fluoro-ether acyl chloride and fluoro-ether acyl fluoride are hydrolyzed under the radiation of ultraviolet light to generate fluoro-ether carboxylic acid, and the fluoro-ether carboxylic acid is washed and purified to obtain a fluoro-ether carboxylic acid finished product. Through the adoption of the preparation method, the completely nontoxic fluoro-ether carboxylic acid surfactant can be produced, and can serve as a dispersing agent to completely replace perfluoro caprylic acid during the fluorine-containing polymer production process.

Owner:江苏梅兰化工有限公司

Preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and recycling method of waste difluoro trichloroethane

InactiveCN104761446AEnable recyclingIncrease added valuePreparation by hydrogen halide split-offPreparation from carboxylic acid halidesBromoethanePhenol

The invention relates to a preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and a recycling method of waste difluoro trichloroethane. The preparation method comprises the following steps: with waste difluoro trichloroethane produced in the production process of dichlorotrifluoroethane as a raw material, carrying out dehydrochlorination to obtain difluoro dichloroethylene, carrying out addition reaction on difluoro dichloroethylene and bromine to obtain difluoro dichlone dibromoethane; reacting difluoro dichlone dibromoethane with sulfur trioxide to obtain 2-bromo-2,2-difluoroacetyl chloride; and reacting 2-bromo-2,2-difluoroacetyl chloride with alcohol or phenol to obtain 2-bromo-2,2-difluoro acetate series products. According to the preparation method and the recycling method, recycling of waste difluoro trichloroethane is realized; 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate are prepared by a temperature oscillation method, so that the production cost is reduced; and meanwhile, the preparation method is an environment-friendly technique for producing products.

Owner:JIANGXI SUNWAY CHEM CO LTD

Preparation method for special fluoroether oligomer

InactiveCN105111352AImprove surface activityImprove low temperature resistancePreparation from carboxylic acid halideTransportation and packagingAviationOligomer

The invention discloses a preparation method for a special fluoroether oligomer which is obtained by carrying out a photochemical polymerization reaction on a special fluorine-containing monomer mixture. The obtained fluoroether oligomer has many previously unimagined valuable applications. The fluoroether oligomer with the average molecular weight of 300-1500, the viscosity of about 1-20 cPs at 25 DEG C and the acidic value of about 70-100 is suitable for being used as a fluoroether surfactant and further can be used as a perfluoro caprylic acid substituent. The fluoroether oligomer with the average molecular weight over 1500 and the viscosity of about 20-500 cPs at 25 DEG C is further suitable for important applications of being processed as fluoroether oil and high-temperature-resistant lubricating oil and the like. The products or mixture thereof can be further used as an auxiliary for a polymerization process of special fluororubber, particularly low-temperature fluororubber. The low-temperature resistance can reach (-40) DEG C, so that the special fluoroether oligomer can be further accepted in markets of space flight and aviation and automobile industry.

Owner:江苏梅兰化工有限公司 +2

Method for preparing difluoroacetic acid and salts thereof

InactiveCN101977885APreparation from carboxylic acid halideCarboxylic acid halides preparationHydrofluoric acidDifluoroacetic acid

The invention relates to a method for preparing difluoroacetic acid and the salts thereof. The invention also relates to the preparation of difluoroacetyl fluoride used as an intermediate product in the preparation of difluoroacetic acid. The method for preparing difluoroacetic acid according to the invention is characterised in that the same comprises the step of preparing difluoroacetyl fluoride by reacting dichloroacetyl chloride with hydrofluoric acid in a gaseous phase and in the presence of a chromium-based catalyst, followed by the step of hydrolysing the difluoroacetyl fluoride thus obtained.

Owner:RHODIA OPERATIONS SAS

Preparation method of perfluoroheptanoic acid

ActiveCN106831388ALimited useReduce energy consumptionPreparation from carboxylic acid halidePerfluoroheptanoic acidMedicinal chemistry

The invention relates to the technical field of fluorochemical preparation, particularly a preparation method of perfluoroheptanoic acid. The method comprises the following steps: oxidizing dodecafluoroheptanol to obtain dodecafluoroheptanoic acid, carrying out reaction on the dodecafluoroheptanoic acid and thionyl chloride to obtain dodecafluoroheptanoyl chloride, carrying out fluorination on the dodecafluoroheptanoyl chloride to obtain perfluoroheptanoyl chloride, and hydrolyzing to obtain the perfluoroheptanoic acid. The technical process of preparing perfluoroheptanoic acid from dodecafluoroheptanol has the advantages of low energy consumption, no pollution and high yield (up to 75% or above), is easy to operate, and has higher competitive edges than the existing perfluoroheptanoic acid production technique.

Owner:济南齐氟新材料技术有限公司

Production of carboxylic acids or carboxylic acid esters

ActiveUS7432390B2Reduce fluorine contentReduce contentPreparation from carboxylic acid halidesPreparation from carboxylic acid halideAlcoholFluoride

In the production of carboxylic acid or carboxylic acid ester, a reaction product containing the carboxylic acid or carboxylic acid ester which has been produced by the reaction of an olefin, carbon monoxide, and water or an alcohol in the presence of HF is heat-treated in the presence of an acid catalyst and an acid adsorbent. By the heat treatment, the contamination of the carboxylic acid or carboxylic acid ester with HF and / or fluorine compounds such as acyl fluorides can be prevented, to enable the stable production of a high quality and high purity carboxylic acid or carboxylic acid ester without causing troubles such as corrosion of apparatus.

Owner:MITSUBISHI GAS CHEM CO INC

Process for preparing bromodifluoacetic acid compounds

InactiveCN1392133APreparation from carboxylic acid halidePreparation from carboxylic acid halidesOleumAlcohol

The invention relates to a method for preparing bromodifluoroacetic compounds which comprises converting a 1,1-diflouro-1,2-dibromodihaloethane with oleum having 50-70% SO3 to a bromodifluoroacetyl halide (bromide or chloride) and then in reacting the latter directly with either an alcohol, or with water.

Owner:ATOFINA

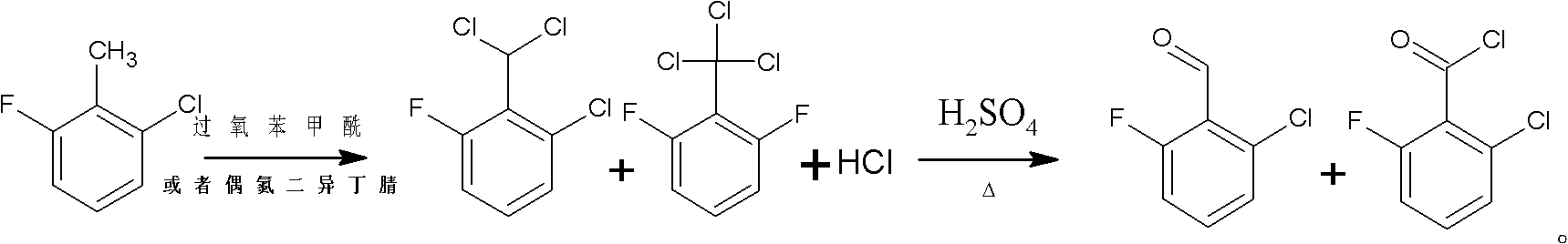

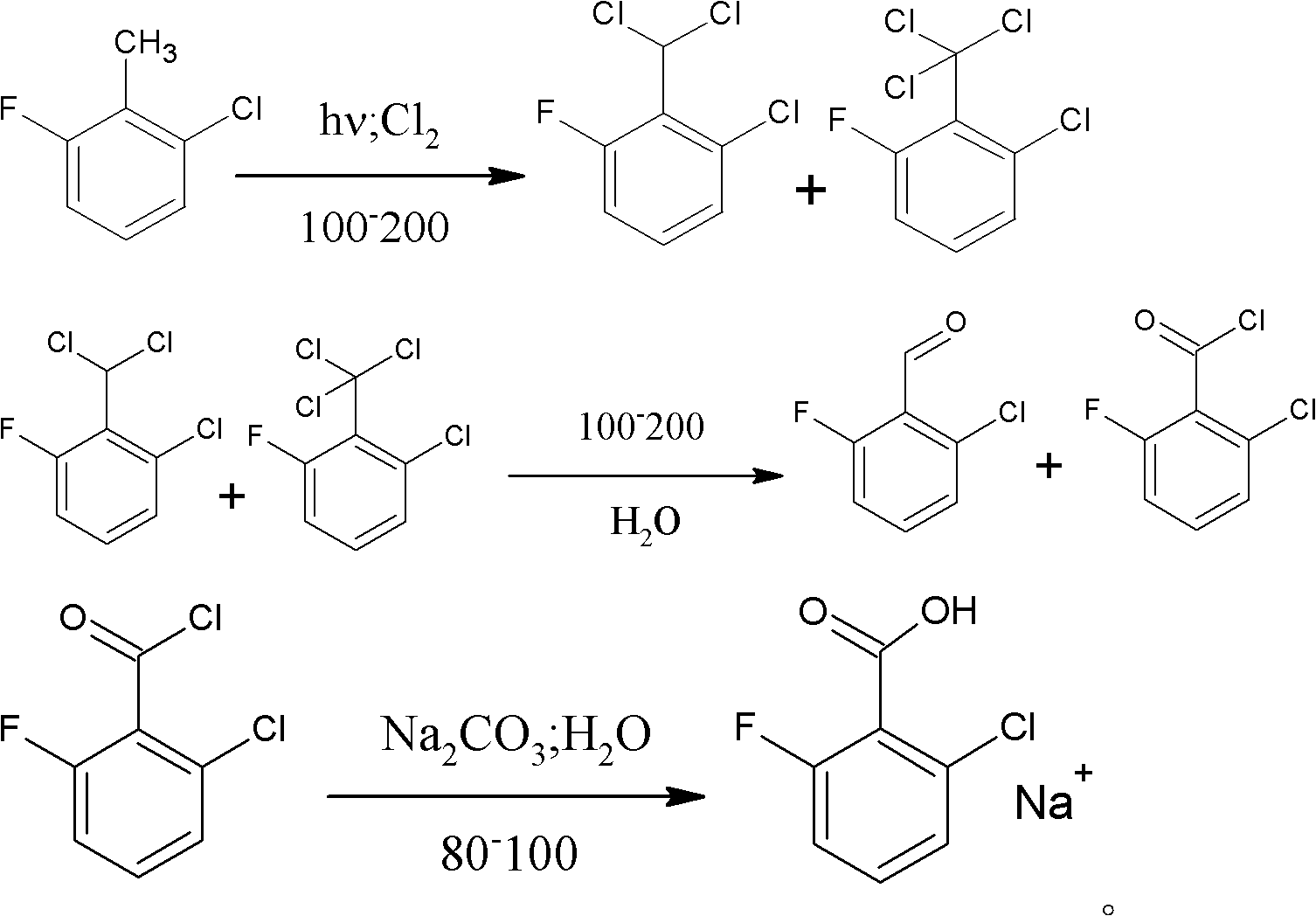

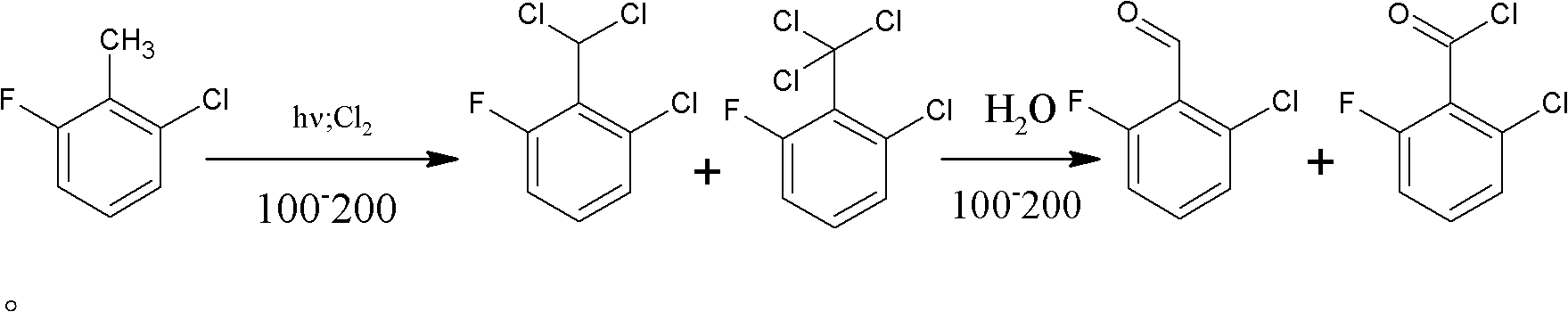

Method for preparing 2-chloro-6-fluorobenzaldehyde

ActiveCN102617312AImprove qualityAvoid demandingPreparation from carboxylic acid halideCarbonyl compound preparation by hydrolysisDistillationChloride

The invention relates to a method for preparing 2-chloro-6-fluorobenzaldehyde, and belongs to the technical field of organic synthesis. The method for preparing 2-chloro-6-fluorobenzaldehyde comprises the following steps of: performing chlorination on 2-chloro-6-fluorotoluene under illumination to obtain 2-chloro-6-fluorobenzyl chloride, 2-chloro-6-difluorobenzyl chloride, and 2-chloro-6-trifluorobenzyl chloride; when the content of 2-chloro-6-fluorobenzyl chloride is less than 0.5 percent, adding ferric solid superacid, dripping water at the temperature of between 100 and 200 DEG C, and preserving heat for 4+ / -5 hours; and adding alkali liquor, stirring to ensure that a liquid phase is layered, and performing reduced pressure distillation or rectification and purification on an organic phase which is obtained after the liquid phase is layered to obtain 2-chloro-6-fluorobenzaldehyde.

Owner:江苏万隆化学有限公司

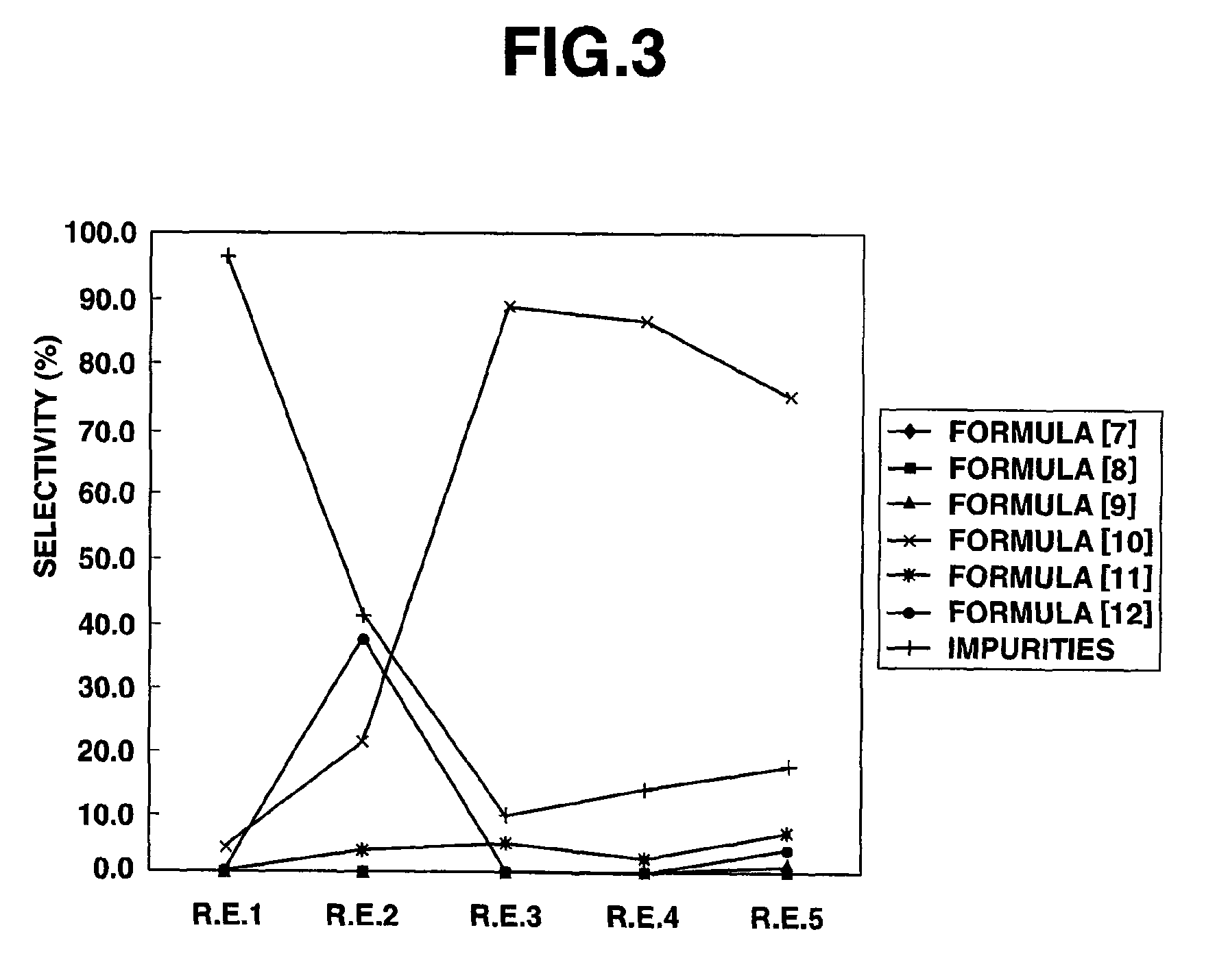

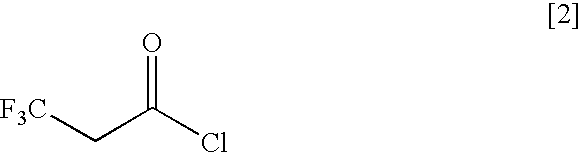

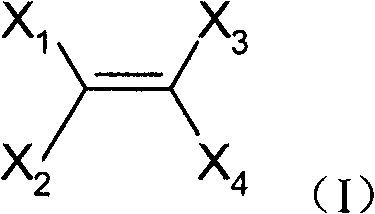

Method for producing 3,3,3-trifluoropropionyl chloride

InactiveUS7754927B2High selectivitySuppress generationPreparation from carboxylic acid halideOrganic compound preparationChlorideSulfuryl chloride

Owner:CENT GLASS CO LTD

Treatment method of perfluoroalkyl acyl fluoride waste

ActiveCN103086865AEmission reductionMild treatment conditionsPreparation from carboxylic acid halideHalogenated hydrocarbon separation/purificationOil phaseTherapeutic effect

The invention discloses a treatment method of perfluoroalkyl acyl fluoride waste. The method comprises the following steps of: first, adding aqueous alkali to the perfluoroalkyl acyl fluoride waste, adjusting the pH value to 7-8, standing and separating to obtain a water phase and an oil phase; then, separating and purifying the water phase to obtain perfluorocarboxylate; and finally, separating and purifying the oil phase to obtain inertial fluorocarbon. The perfluoroalkyl acyl fluoride waste is treated in grades in the following steps of: adding aqueous alkali to separate the perfluoroalkyl acyl fluoride waste into the water and oil phases, and respectively separating and purifying the water and oil phases; and obtaining high purity perfluorocarboxylate after separation and purification of the water phase and obtaining high purity inertial fluorocarbon after separation and purification of the oil phase. The treatment condition is mild and the treatment effect is good.

Owner:ZHEJIANG UNIV +1

Method for preparing a halogenocetyl fluoride and the derivatives thereof

InactiveCN102471207APreparation from carboxylic acid halideOrganic compound preparationHydrofluoric acidTrifluoroacetic acid

The present invention relates to a method for preparing a halogenocetyl fluoride and the derivatives thereof. The inventive method for preparing a halogenocetyl fluoride acid is characterised in that said method includes: a step of preparing a halogenoacetyl halide by photo-oxidation of a halogenoethylene compound in conditions such that the transformation rate of the halogenoethylene compound into halogenoacetyl halide is no higher than 80 %, producing a reaction mixture essentially including halogenoacetyl halide and the excess halogenoethylene compound; a step of partial fluorination of the mixture obtained by reacting the latter with hydrofluoric acid suitable for obtaining a mixture of halogenoacetyl fluoride and the excess halogenoethylene compound; a step of separating the halogenoacetyl fluoride and the excess halogenoethylene compound. The invention can be used, specifically, for preparing the trichloroacetyl fluoride used as an intermediate species in the production of trifluoroacetic acid.

Owner:RHODIA OPERATIONS SAS

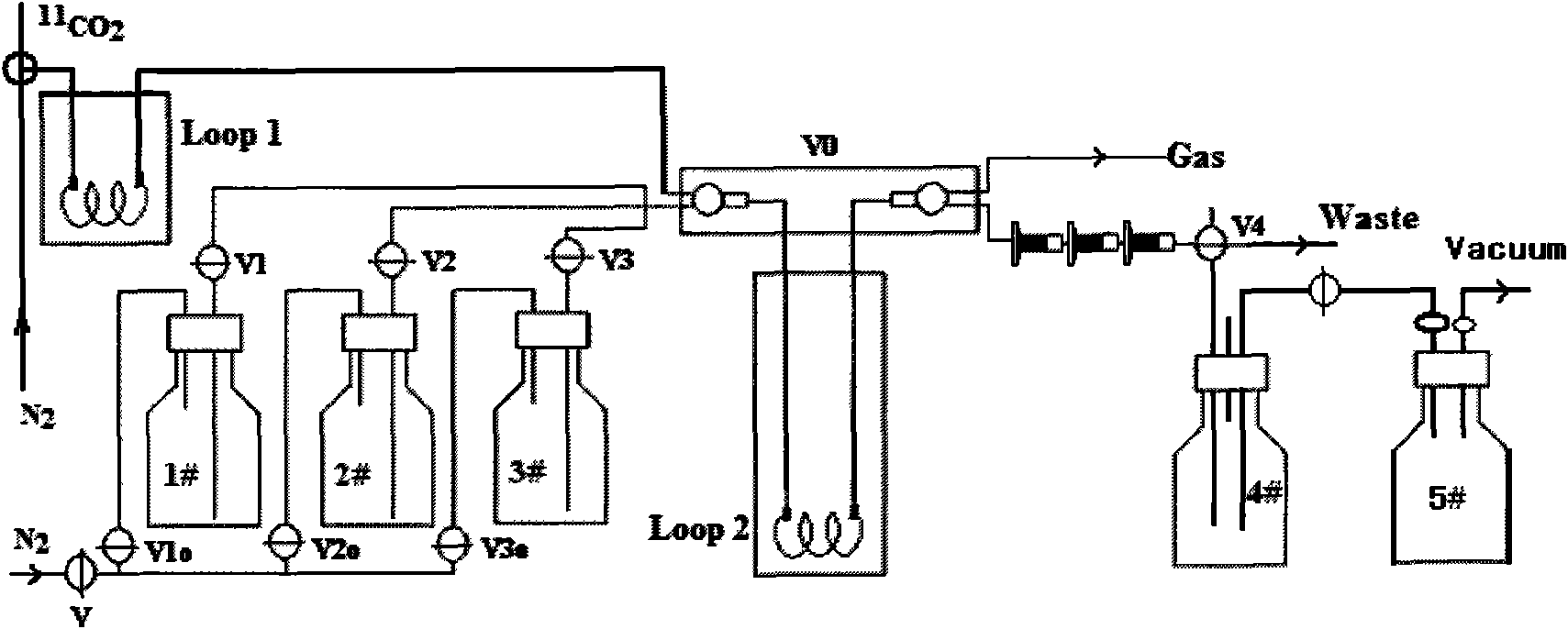

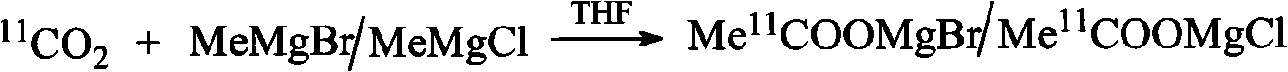

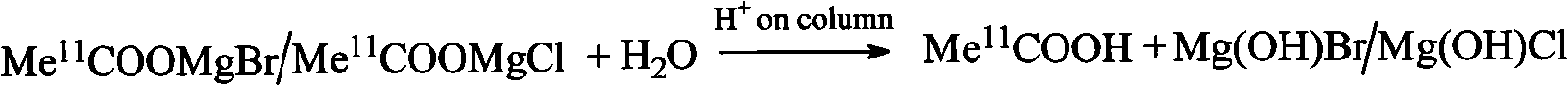

C-acetate preparation method

InactiveCN101597228AReduce manufacturing costPreparation from carboxylic acid halideRadioactive preparation carriersBromineChloride

An C-acetate preparation method comprises the following steps: adopting methyl magnesium bromide or methyl magnesium chloride as precursor, reacting the precursor with CO2 in a Loop to prepare an intermediate C-acetyl bromine or magnesium chloride adduct; without adopting purification process, injecting N2 and removing tetrahydrofuran (THF), adding water in the mixture, injecting the mixture through integral small columns (C18 small column, SEP-PAK TSCX small column and SEP-PAK TIX small column) in turn for isolation and purification where the intermediate C-acetyl bromine or magnesium chloride hydrolyzes, filtrating by aseptic filter membrane, neutralizing by alkaline solution and obtaining C-AC parenteral solution. The preparation method of the invention has the advantages of the realization of column hydrolysis and purification, fully automatic synthesis, short synthesis time, high radiochemical yield, high radiochemical purity and low production cost.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

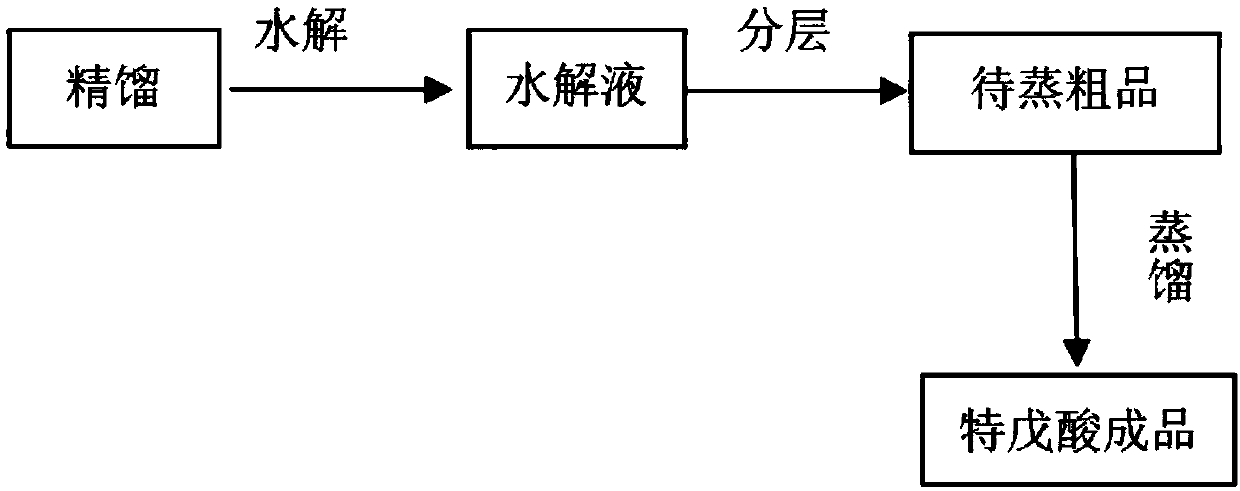

Method for recycling trimethylacetic acid from pivaloyl chloride rectification raffinate

PendingCN107721841AIncrease profitReduce pressure on environmental protectionPreparation from carboxylic acid halidePreparation from carboxylic acid anhydridesPhosphorous acidRaffinate

The invention provides a method for recycling trimethylacetic acid from pivaloyl chloride rectification raffinate. According to the technical scheme, the method has the experiment ideas that components and contents of pivaloyl chloride rectification raffinate are analyzed firstly on the basis of experiment means, on the basis, procedures such as hydrolysis, layering and rectification are confirmedaccording to chemical properties of pivaloyl chloride and trimethylacetic anhydride, and trimethylacetic acid is recycled. Specifically, the method comprises the following steps: firstly, adding a certain amount of pivaloyl chloride rectification raffinate, controlling specific temperature and pressure, adding a proper amount of water for hydrolysis reactions for multiple times to sequentially convert pivaloyl chloride and trimethylacetic anhydride into trimethylacetic acid, leaving to stand to layer water-containing phosphorous acid and a crude trimethylacetic acid product, feeding back thecrude trimethylacetic acid product to a trimethylacetic acid rectification procedure, and performing decoloring refining. By adopting the method provided by the invention, more than 90% of the pivaloyl chloride rectification raffinate can be converted into trimethylacetic acid, so that the utilization rates of raw materials are increased, the wastes are reduced, the environment protection burden of companies is alleviated, and meanwhile the production cost of products is effectively reduced.

Owner:山东民基新材料科技有限公司

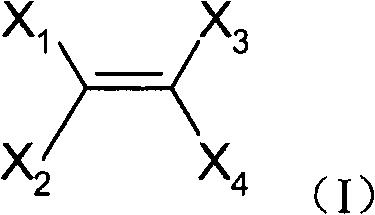

Hydrofluoroethers having at least one hydrogenated -OCFX'CH3 end group wherein X'=F, CF3 and their preparation process

InactiveUS20070106092A1Preparation from carboxylic acid halideOrganic compound preparationHydrogenEnd-group

Hydrofluoroethers of formula: T-CFX′—O—Rf—CFX-T′ (II) wherein: T=CH3; X, X′, equal to or different from each other, are selected between F, CF3; T′=F, Cl, H, C1—C3 perfluoroalkyl, CH3, CH20H, COC1, CHO, CO2H; Rf is a perfluoroalkylene or a perfluoropolyoxyalkylene and respective preparation process by reduction with hydrogen in the presence of a platinum catalyst supported on metal fluorides of the corresponding compounds with at least one —COCl end group.

Owner:SOLVAY SOLEXIS

Method for comprehensively utilizing byproducts produced in HFPO (hexafluoropropylene oxide) preparation based on oxygen oxidation method

PendingCN109678700AReduce investmentEasy to operatePreparation from carboxylic acid halideTransportation and packagingCarbonyl fluorideHexafluoropropylene

The invention belongs to the field of fluorine chemical and particularly relates to a method for comprehensively utilizing byproducts produced in HFPO (hexafluoropropylene oxide) preparation based onan oxygen oxidation method. The method comprises following steps: 1), oxygen and hexafluoropropylene are taken as raw materials, and HFPO is prepared under the action of a fluoride solvent, and the fluoride solvent is recycled; 2), when content of the byproducts in the recycled fluoride solvent is lower than 40wt%, ultraviolet irradiation is performed every 10-30 h; 3), when content of the byproducts is higher than or equal to 40wt%, water is added to the fluoride solvent, and a carboxylic acid product is obtained. On one hand, an important chemical intermediate carbonyl fluoride in the fluorine chemical can be obtained, on the other hand, the byproducts can be converted into a perfluoro surfactant or fluorine-containing fluid for further application, and therefore, the byproducts producedin the HFPO preparation process based on the oxygen oxidation method are comprehensively utilized.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

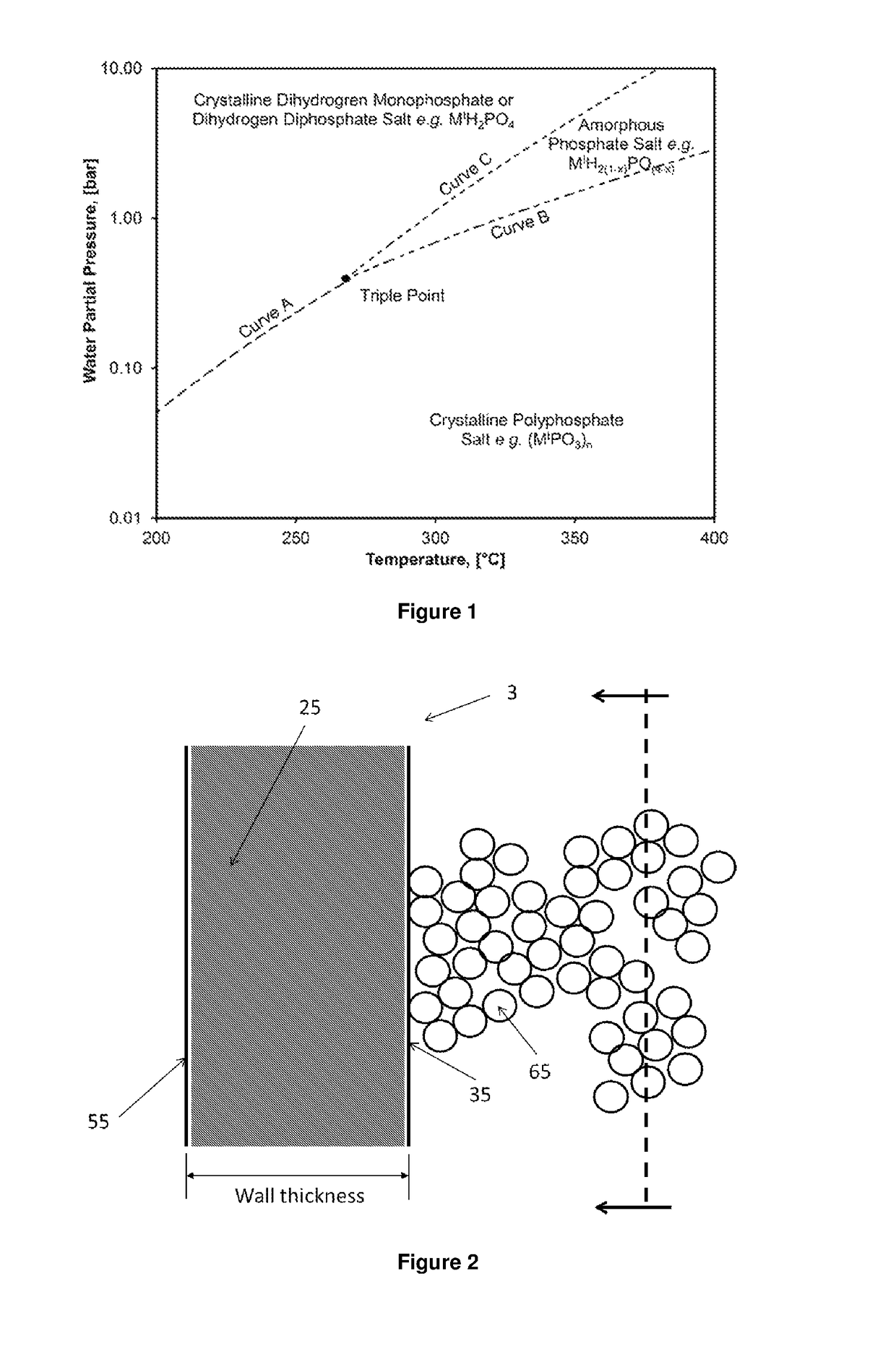

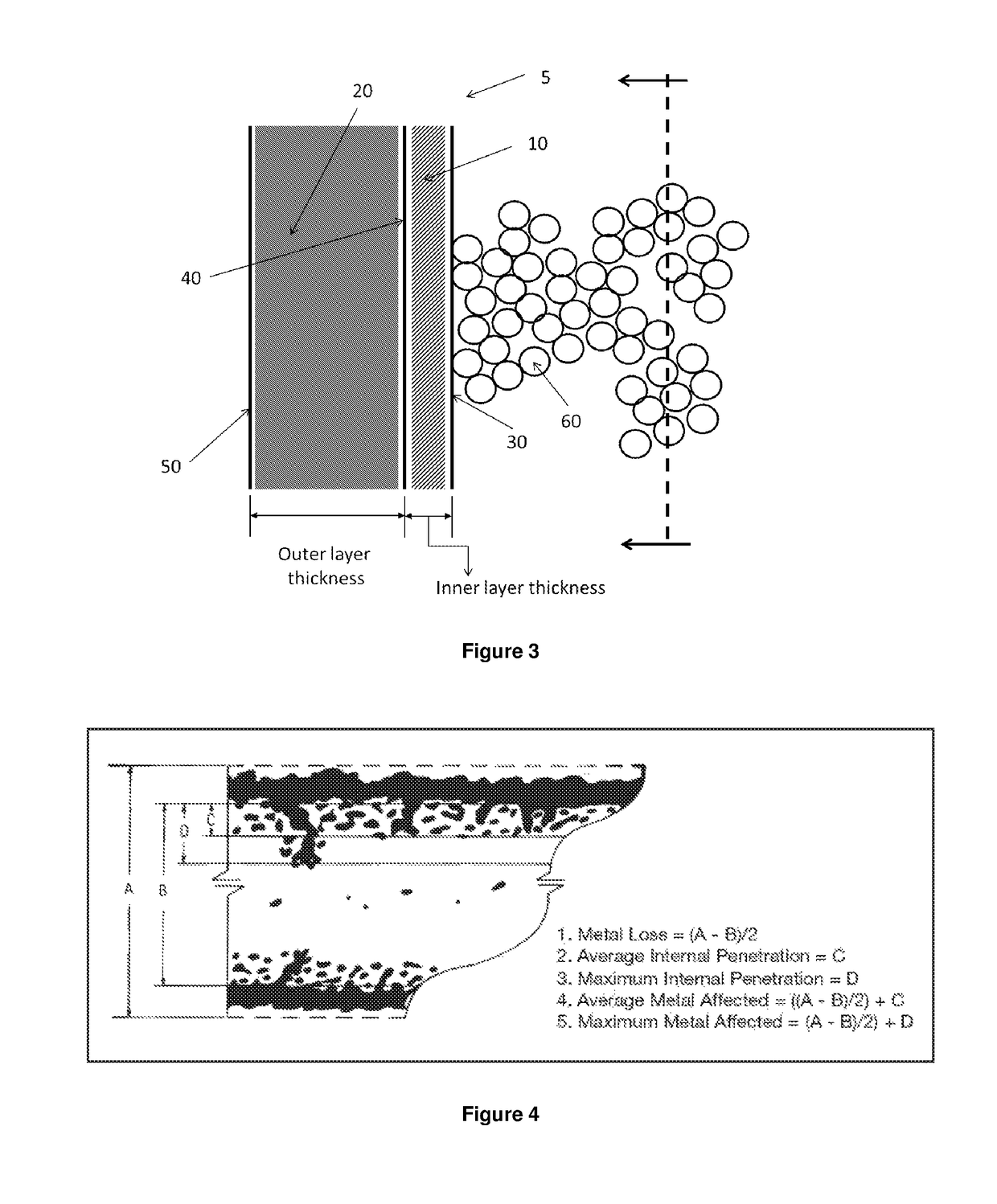

Method of making acrylic acid from hydroxypropionic acid

ActiveUS9890102B1Physical/chemical process catalystsPreparation from carboxylic acid halide3-Hydroxypropionic acidAcid derivative

Methods for making acrylic acid, acrylic acid derivatives, or mixtures thereof by contacting a stream containing hydroxypropionic acid, hydroxypropionic acid derivatives, or mixtures thereof with either an active catalyst containing an amorphous and partially-dehydrated phosphate salt or a precursor catalyst containing a crystalline phosphate salt in a reactor with a low corrosion rate are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Catalyst for production of unsaturated aldehyde and unsaturated carboxylic acid, and process for its production

ActiveUS7262148B2High activityImprove performancePreparation from carboxylic acid halideOrganic compound preparationGas phaseCatalytic oxidation

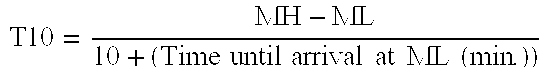

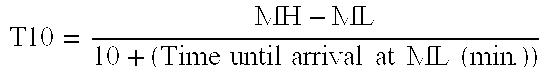

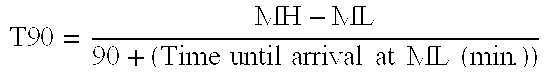

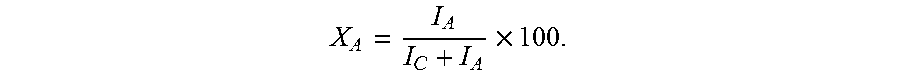

A catalyst for producing from an olefin the corresponding unsaturated aldehyde and unsaturated carboxylic acid in good yield, and a process for its production, are presented.It is a composite oxide catalyst containing at least molybdenum, bismuth and iron, to be used at the time of gas phase catalytic oxidation of an olefin with a molecular oxygen-containing gas to produce the corresponding unsaturated aldehyde and unsaturated carboxylic acid, wherein the loss on drying of the contained moisture, as represented by the following formula (1) (wherein W1 represents the weight when the catalyst is heated for two hours at 110±5° C., and W2 represents the weight of the catalyst prior to such heating), is at most 0.5 wt %:Loss on drying=(W2−W1) / W2×100. (1)

Owner:MITSUBISHI CHEM CORP

Production of carboxylic acids or carboxylic acid esters

ActiveUS20060205970A1Reduce fluorine contentReduce contentPreparation from carboxylic acid halidesPreparation from carboxylic acid halideAlcoholAcyl group

In the production of carboxylic acid or carboxylic acid ester, a reaction product containing the carboxylic acid or carboxylic acid ester which has been produced by the reaction of an olefin, carbon monoxide, and water or an alcohol in the presence of HF is heat-treated in the presence of an acid catalyst and an acid adsorbent. By the heat treatment, the contamination of the carboxylic acid or carboxylic acid ester with HF and / or fluorine compounds such as acyl fluorides can be prevented, to enable the stable production of a high quality and high purity carboxylic acid or carboxylic acid ester without causing troubles such as corrosion of apparatus.

Owner:MITSUBISHI GAS CHEM CO INC

Preparation method of perfluoro caprylic acid

InactiveCN100999456AIncrease productionQuality improvementPreparation from carboxylic acid halideElectrolysisDistillation

This invention relates to a perfluorooctanoic acid preparation method, belong to fluorine chemicals technology field. It takes electrolysis fluorine hydride and octanoyl chlorine electrolyte as materials, the main ingredients is perfluorooctanoic acid fluoride. First use liquid alkali to alkaline hydrolyze electrolyte containing perfluorooctanoic acid fluorine, isolate part of sodium fluoride and the main byproduct of fluorocarbon, obtain perfluorooctanoic acid solution of sodium, then use sulfate for acidification, gain perfluorooctanoic acid. Through organic and water phase separation to remove some of the residual hydrogen fluoride, the organic phase by means of distillation purification, to obtain perfluorooctanoic acid products. The invention can improve the yield of perfluorooctanoic acid products while enhancing straight chain content.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Process for preparing fluorocarboxylic acids

InactiveUS7253315B2Minimize releaseReduce lossesPreparation from carboxylic acid halideCarboxylic acid halides preparationHydrogen fluorideHydrofluoric acid

Owner:THE CHEMOURS CO FC LLC +1

Fluorine-containing polymer for photoresist, top anti-reflection film composition containing fluorine-containing polymer and application of fluorine-containing polymer in photoresist

ActiveCN112034683AEasy to produceLow raw material costPreparation from carboxylic acid halidePhotosensitive materials for photomechanical apparatusPolymer scienceFluoropolymer

The invention relates to a fluorine-containing polymer for photoresist, a top anti-reflection film composition containing the fluorine-containing polymer and application of the fluorine-containing polymer in the photoresist. The structural formula of the fluorine-containing polymer for the photoresist is CF2(CF3)CF2-[O-CF(CF3)CF2]n-O-CF(CF3)COO-R, wherein n is in a range of 1-8, and R is one or more selected from the group consisting of H, NH4 or other similar structures. On the basis of the weight of the whole polymer, the content a of a polymer component with n of no more than 1 is 0-12%; the content b of a polymer component with n of 2 is 55-80%; the content c of a polymer component with n of 3 is 15-30%; the content d of a polymer component with n of 4 is 0-15%; the content e of a polymer component with n of no less than 5 is 0-8%, wherein the sum of b and c is no less than 80%; and a, d and e are equal to 0 at the same time, or any one of a, d and e is equal to 0, or a, d and e are not equal to 0 at the same time. By controlling the content distribution of the polymer components with different molecular weights in the fluorine-containing polymer, the fluorine-containing polymer meeting specific composition requirements is obtained; and the fluorine-containing polymer is easy to degrade, low in toxicity and friendly to environment and can be used for preparing a top anti-reflection film with a low refractive index.

Owner:GANSU HUALONG SEMICON MATERIAL TECH CO LTD

Popular searches

Mixing Carboxylic acid salt preparation Chemical/physical processes Carboxylic compound separation/purification Carboxylic acid esters preparation Plastic recycling Preparation from carboxylic acid esters/lactones Solid waste disposal Preparation by halogen addition Preparation by carbon monoxide or formate reaction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com