Patents

Literature

342results about How to "Mild treatment conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparation of superhydrophobic timber on the basis of sol-gel method

InactiveCN105599077AHas a superhydrophobic surfaceEasy to operateWood treatment detailsPretreated surfacesSilica nanoparticlesSilanes

The present invention pertains to a method for preparation of superhydrophobic timber on the basis of a sol-gel method, and the method is as follows: (1), silica sol synthesis, to be more specific, materials are prepared in the volume ratio of ammonia to anhydrous ethanol to ethyl orthosilicate of 1:15 to 17:1; (2), hydrophobic modification of monodispersed nano silica sol, to be more specific, hexadecyl trimethoxysilane, or triethoxysilane-1H, 1H, 2H, 2H-heptadecafluorodecyl silane is used for hydrophobic modification of the synthesized monodispersed nano silica sol, and the hydrophobic agent promotes mutual aggregation of nanoparticles to promote the formation of aggregates of silica nanoparticles; and (3) timber coating processing, to be more specific, the timber surface is coated with the hydrophobically modified silica sol solution by dipping or spraying process. Contact angles of the processed timber surface and water droplets are greater than 150 degrees, roll angles are less than 10 degrees, and a superhydrophobic film has good resistance to acid and alkali erosion and stability in high-humidity environment. The method is simple in operation, less demanding on equipment, and capable of scale production, and has wide market prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Synchronous aqueous enzymatic ultrasonic extraction for walnut oil and walnut protein peptide

InactiveCN101280327AQuality improvementMild treatment conditionsCheese manufactureVegetable proteins working-upOil phaseDietary fibre

The invention relates to an enzyme method ultrasonic extraction method of walnut oil and walnut protein, which belongs to the food and the functional food field. Water is added into walnut kernel or walnut powder to be grinded into paste, protease or compound protease are added into to be performed hydrolization, and simultaneously ultrasonic processing is performed, then the walnut kernel or walnut powder is agitated to perform enzymatic extraction, and then centrifugal separation oil phase, protein peptide oil water phase and residual solid phase are performed; walnut oil is acquired by refining the obtained oil phase, which meets the requirements of green foods; the protein peptide aqueous solution can be directly used to produce degreased walnut protein nutrient milk, or to prepare walnut antioxidation peptide after performed nanofiltration, which is used in health products, food additives, cosmetics or daily chemical articles, or to produce nutrient condensed milk after being performed low temperature concentrating, or to produce walnut protein nutrition powder after performed spray drying; the solid phase residue is prepared into diet fiber food after being dried and grinded into powder; walnut nutrient protein peptide products can be obtained through performing vacuum concentration and spray drying to walnut protein peptide extracting solution containing nutrient content.

Owner:KUNMING UNIV OF SCI & TECH

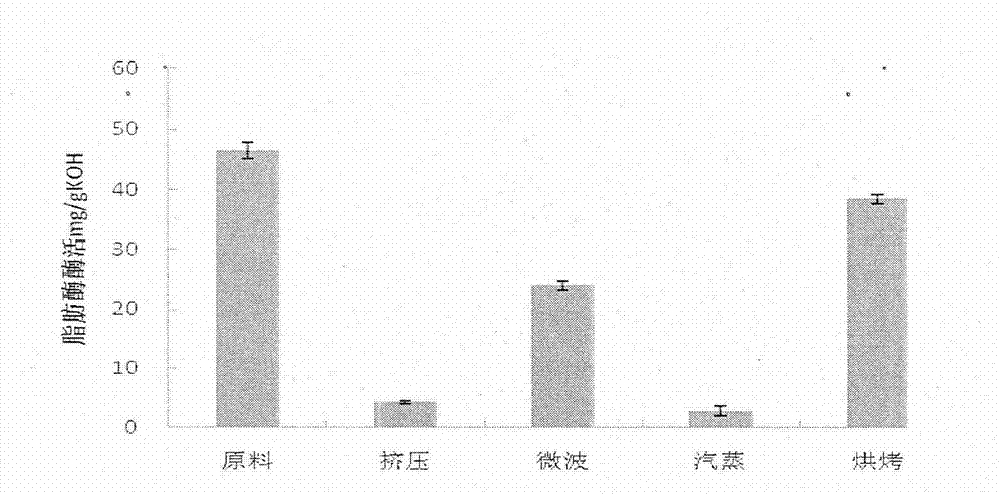

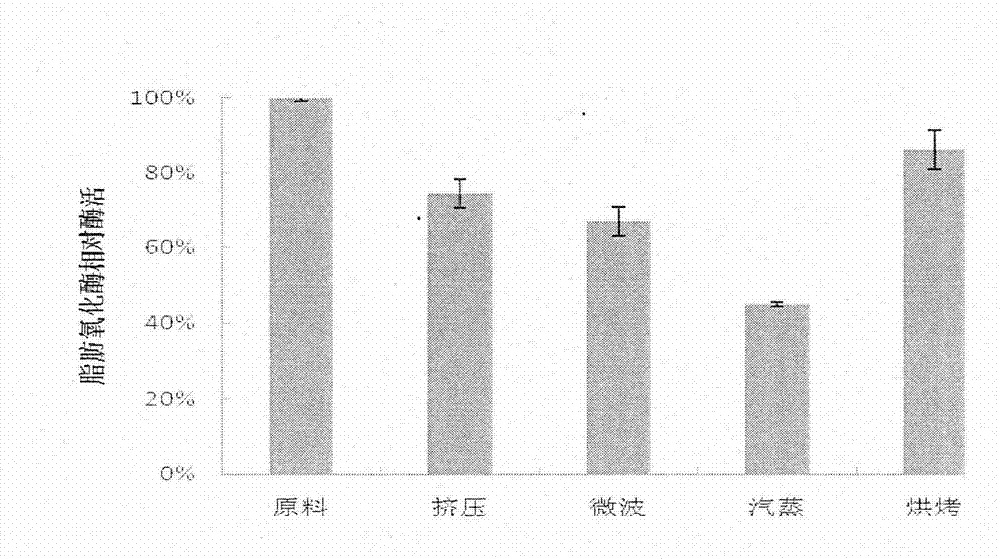

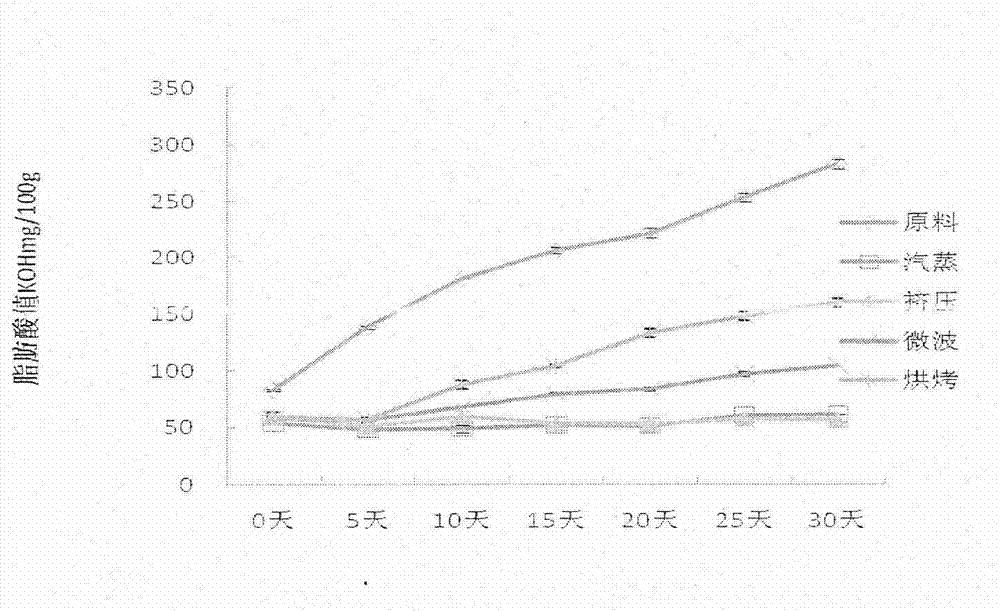

Method for stabilizing wheat bran specially used for whole wheat flour

InactiveCN102805292ASolve the problem of poor storage stabilityInactivated lipaseFood preparationOrganolepticWholemeal flour

The invention discloses a method for stabilizing the wheat bran specially used for the whole wheat flour, which is mainly characterized in that: the wheat bran is treated by steam and dried by the ultraviolet microwave so that the wheat bran is stabilized. Due to the adoption of the method, the activity of the lipase and the lipoxygenase in the wheat bran can be reduced significantly, and the storage stability of the wheat bran can be improved significantly. In addition, the treated wheat bran has little difference from the non-stabilized wheat bran in colour and organoleptic quality, the content of total phenols in the treated wheat bran is increased slightly, and the antioxidant activity of the treated wheat bran is improved obviously. The method is simple and practical, has an obvious effect and effectively solves a series of problems of the existing method for stabilizing the wheat bran that the equipment has high cost, the operation process is burdensome and complicated, the wheat bran has poor storage stability, the colour of the stabilized wheat bran is dark, the efficacy and the activity are lost, and the stabilized wheat bran is not suitable for producing the whole wheat flour, thereby creating the conditions for producing the high-quality whole wheat flour with long shelf life.

Owner:JIANGNAN UNIV

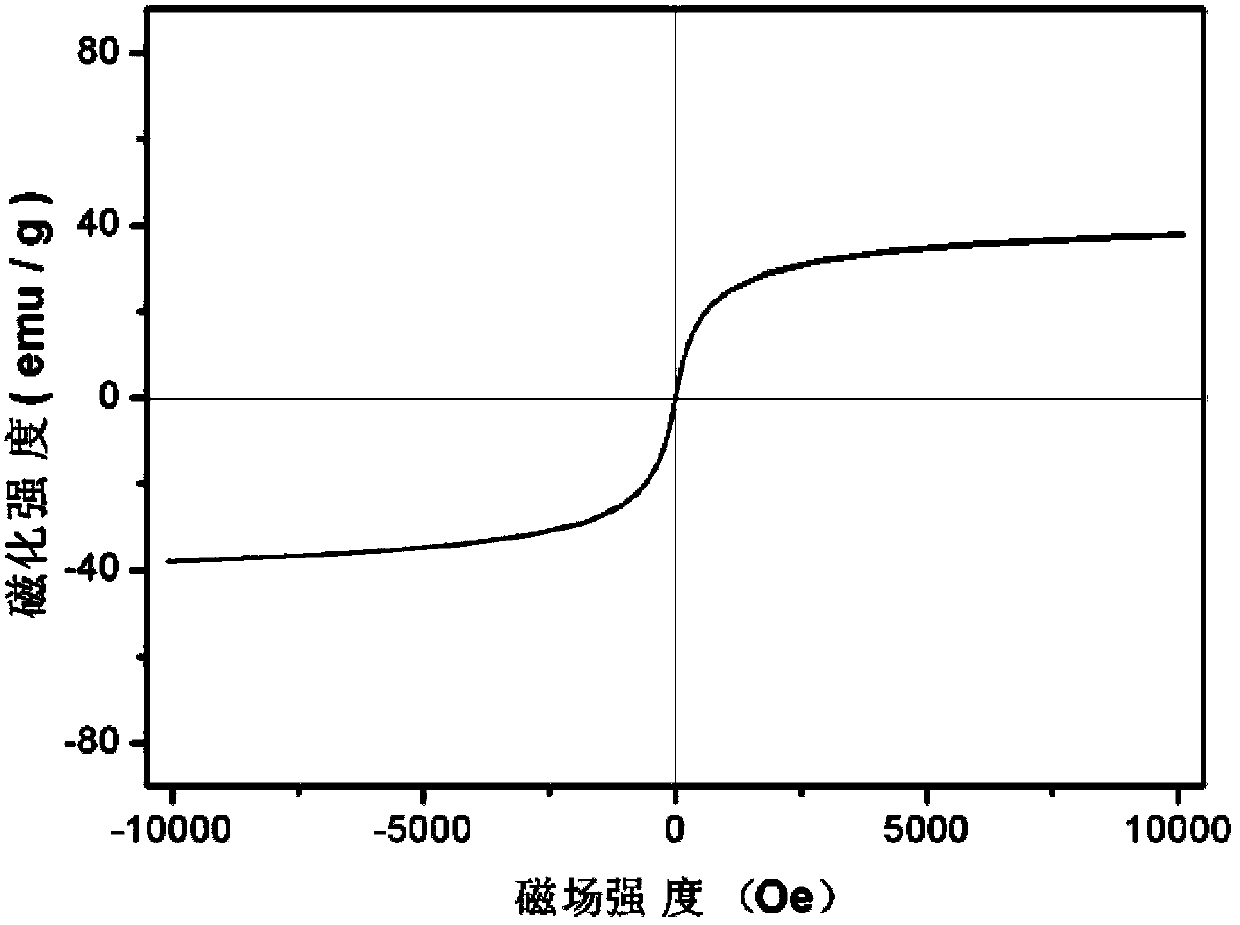

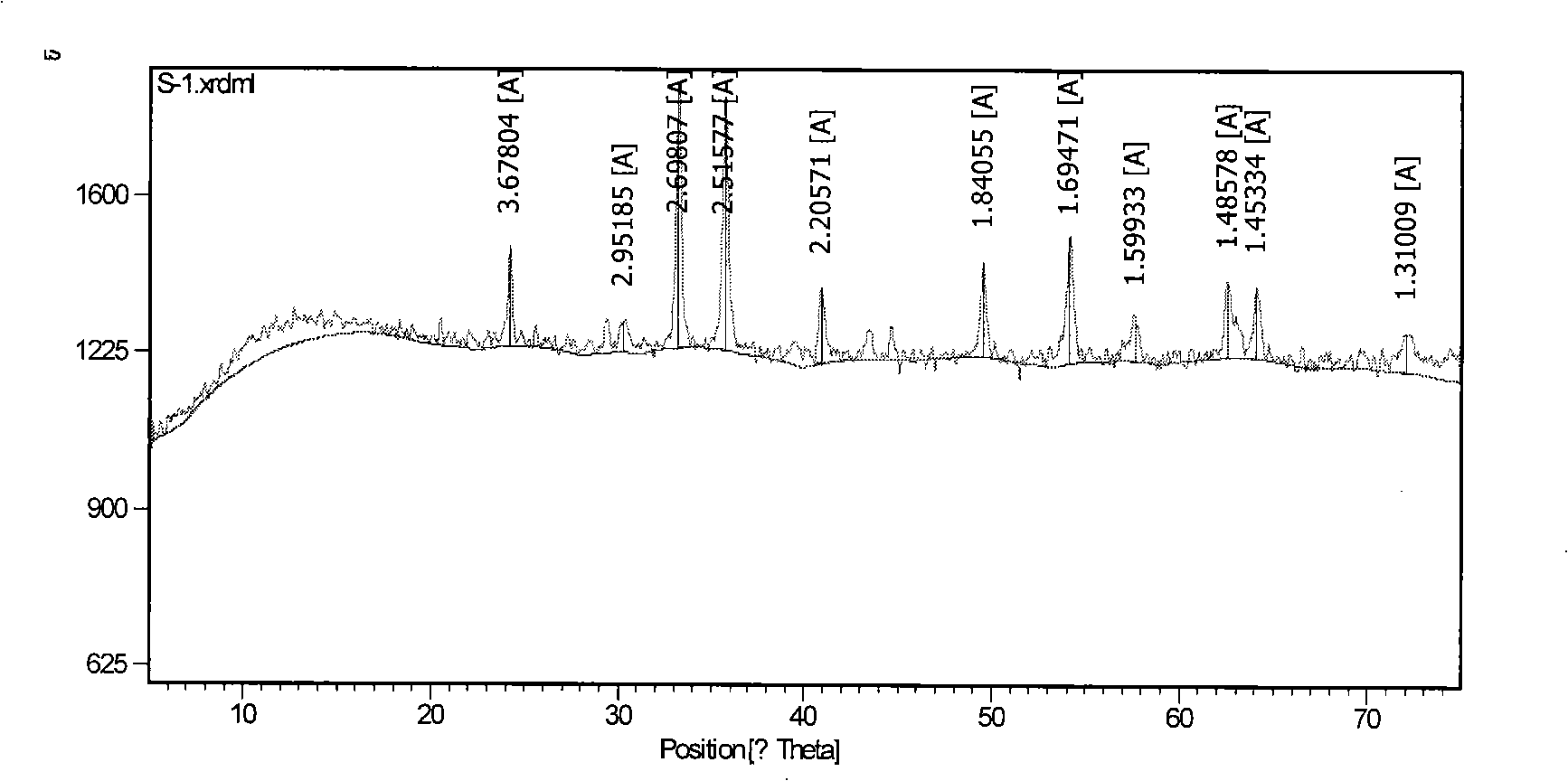

Reduction-oxidation graphene-Fe3O4 nano composite, preparation method thereof, and application of reduction-oxidation graphene-Fe3O4 nano composite in absorbing bisphenol A

InactiveCN103418340AImprove adsorption capacityEasy to separateOther chemical processesWater contaminantsBisphenol AGraphite oxide

The invention discloses a reduction-oxidation graphene-Fe3O4 nano composite, a preparation method thereof, and an application of the reduction-oxidation graphene-Fe3O4 nano composite in absorbing bisphenol A. The reduction-oxidation graphene-Fe3O4 nano composite comprises Fe3O4 nano particles and reduction-oxidation graphene. The reduction-oxidation graphene-Fe3O4 nano composite and a solution containing the bisphenol A are in full contact in an ambient temperature, the bisphenol A is absorbed and removed. Compared with the prior art, the advantages of small material dose, simplicity in operation, mild processing condition, fast processing speed, and no harm for the environment, and recycling nano-composite materials, and the like are achieved.

Owner:上海出入境检验检疫局工业品与原材料检测技术中心 +1

Silk fibroin gel microneedle system and manufacturing method thereof

ActiveCN103800998ASimple methodDoes not affect biocompatibilityMicroneedlesMedical devicesBrute forceBiocompatibility Testing

The invention discloses a silk fibroin gel microneedle system and a manufacturing method of the silk fibroin gel system microneedle system. Silk fibroin solution with the mass concentration between 3 percent to 15 percent is processed through ultrasonic oscillation and then is poured on a polydimethylsiloxane film needle hole die array obtained through laser boring, dies are placed in a vacuum drying box and vacuumized, the solution is made to enter holes, the vacuum degree is kept, the dies are dried to constant weight, and then the silk fibroin gel microneedle system is obtained. The microneedle system is an insoluble gel microneedle and has certain brute force to puncture into the skin, the microneedle system swells after making contact with body fluid in the skin, and medicine in the microneedle system is released. The gel microneedle system is good in biocompatibility, easy to prepare, moderate in condition and capable of biodegradation, and the system can be used in the aspects of cosmetology, transdermal drug absorption devices and the like.

Owner:PHARSUN MEDICAL BIOTECHNICS (SHANGHAI) CO LTD

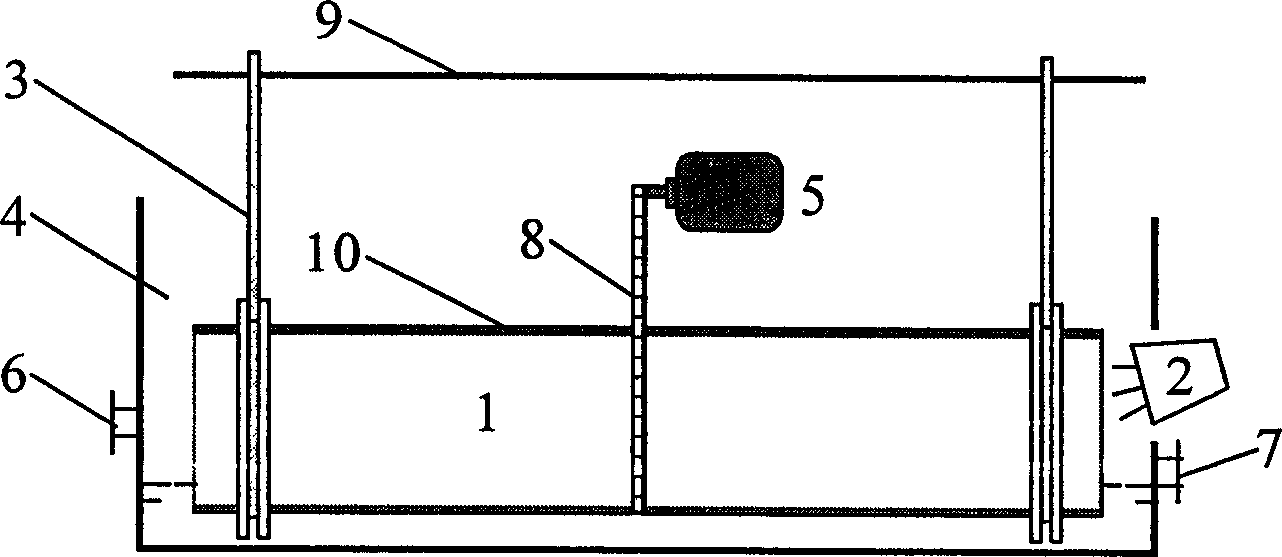

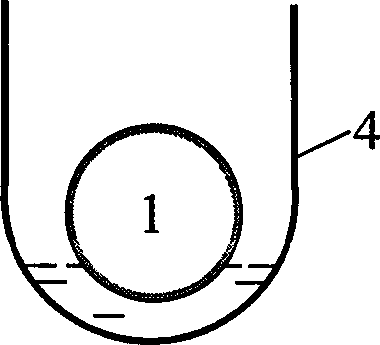

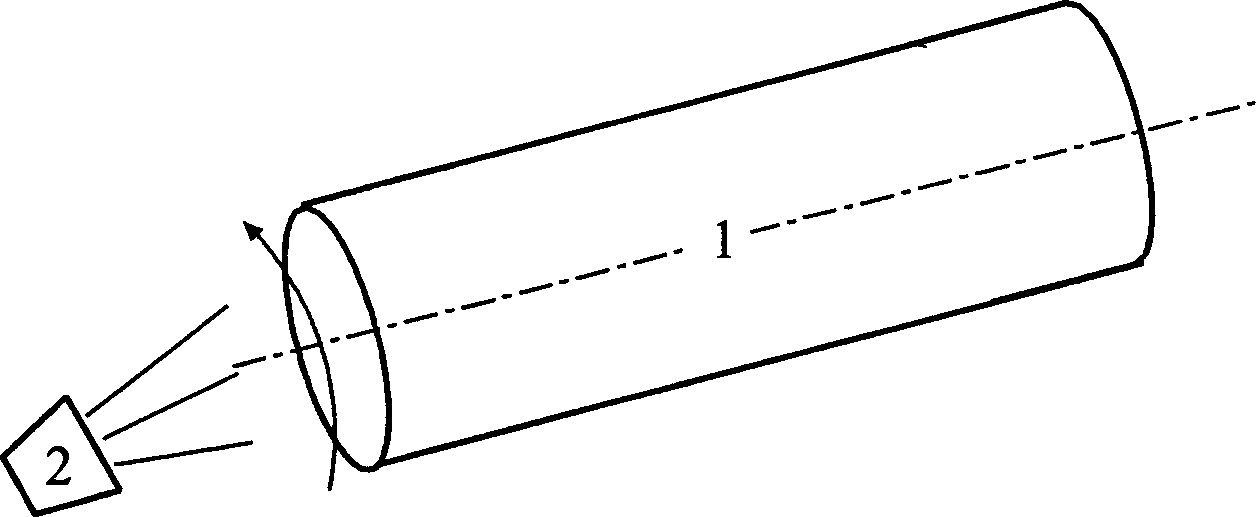

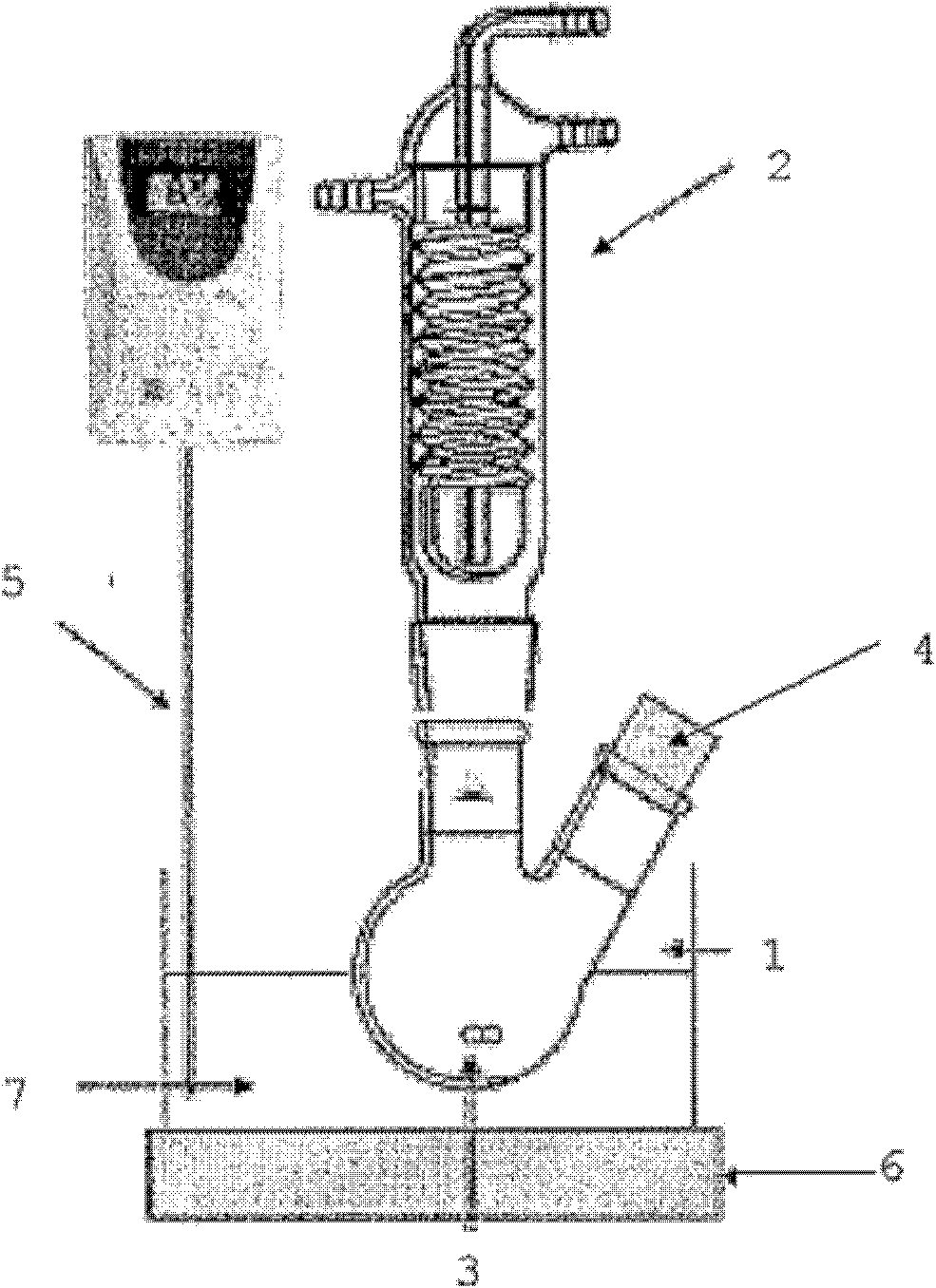

Rotary tubular photo-catalytic reactor and its water treating method

InactiveCN1587085AIncrease contact surfaceFast updateWater/sewage treatment by irradiationPhoto catalyticPhotocatalytic reaction

The rotary tubular photocatalytic reactor includes water trough with water inlet and water outlet, ultraviolet lamp set onto side of the water trough, rotary drum, which has bearing plates and supports in two ends and is set inside the water trough, speed regulating motor meshed to gear on the outer wall of the rotary drum for driving, and thin titania photocatalyst layer painted to the inner wall of the water trough. The present invention has rotary drum as the main body of the reactor and titania photocatalyst layer loaded onto the rotary drum, regulates the rotation speed of the rotary drum to alter the distribution of treated waste water and photocatalyst and to increase the contact area between the catalyst, reactant and light source, and has low power consumption, low treating cost, mild treating condition and other advantages.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

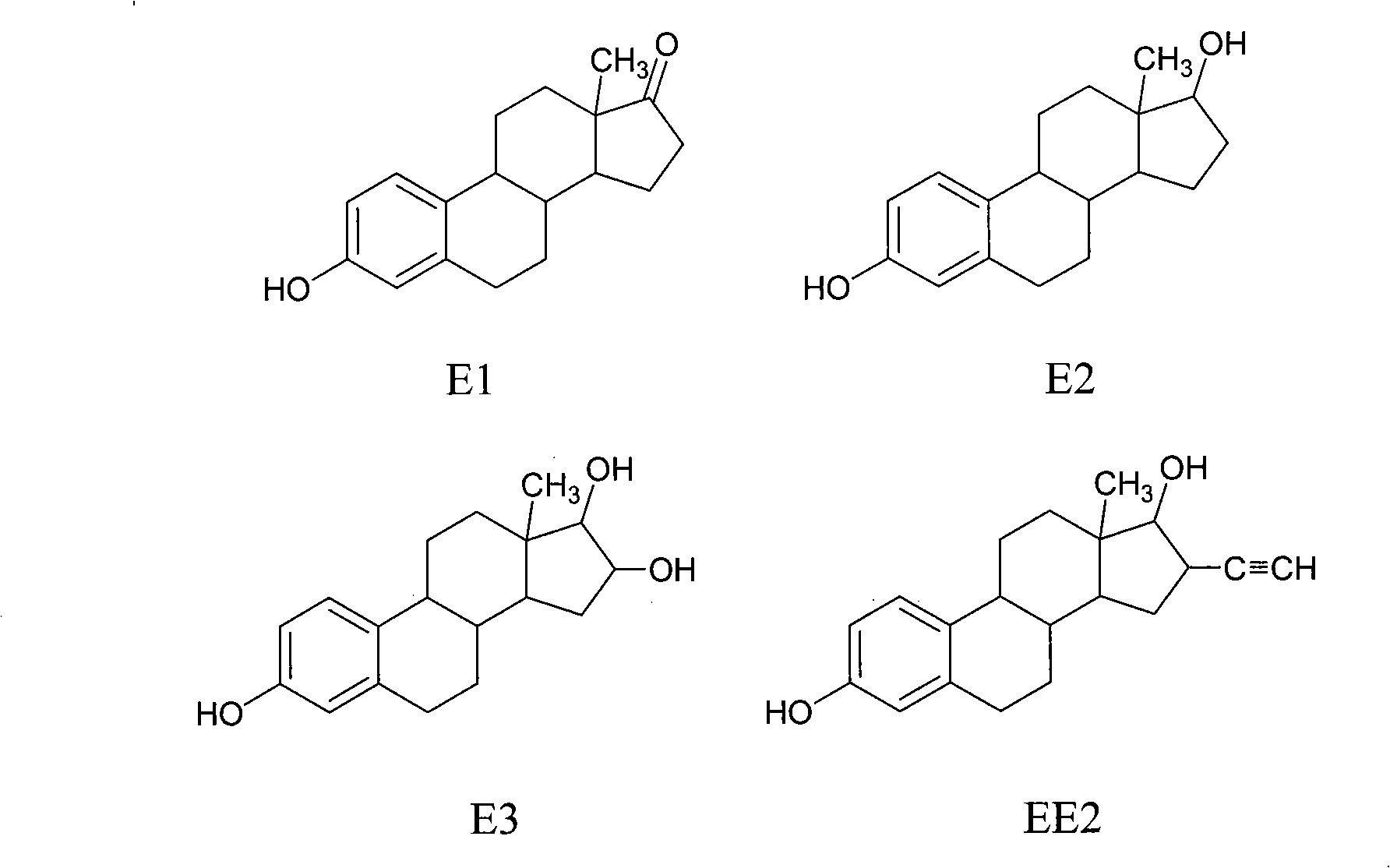

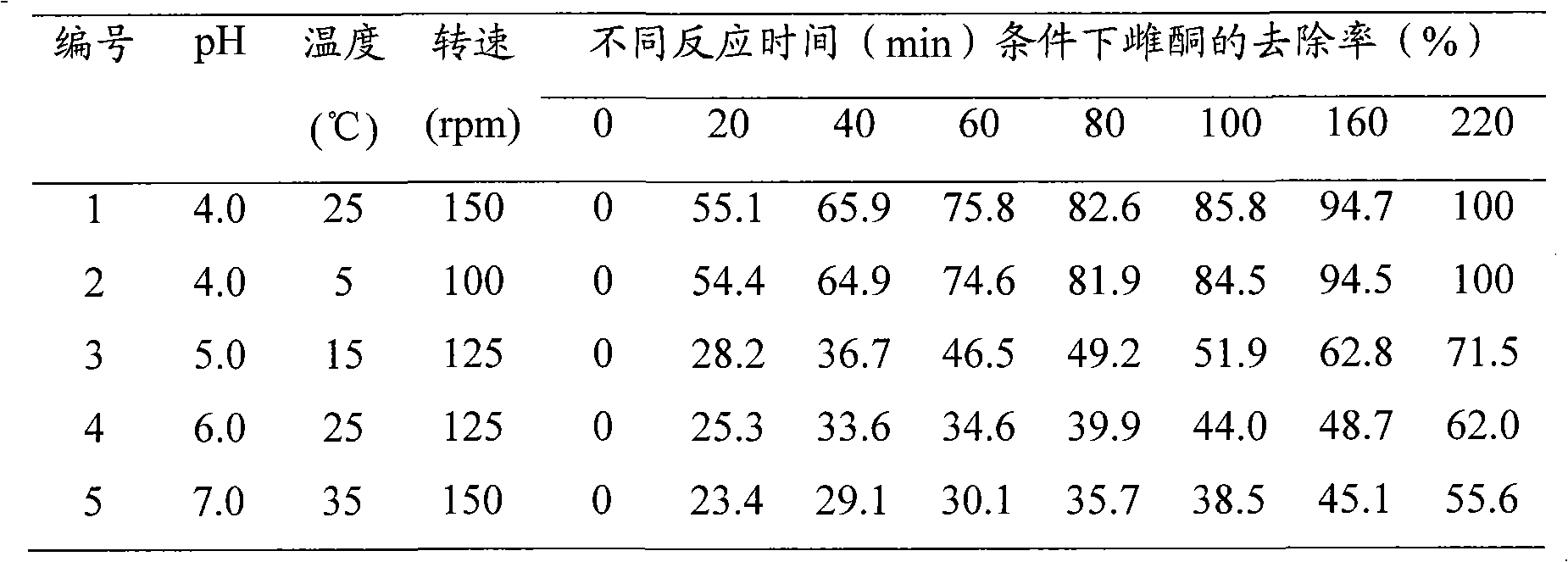

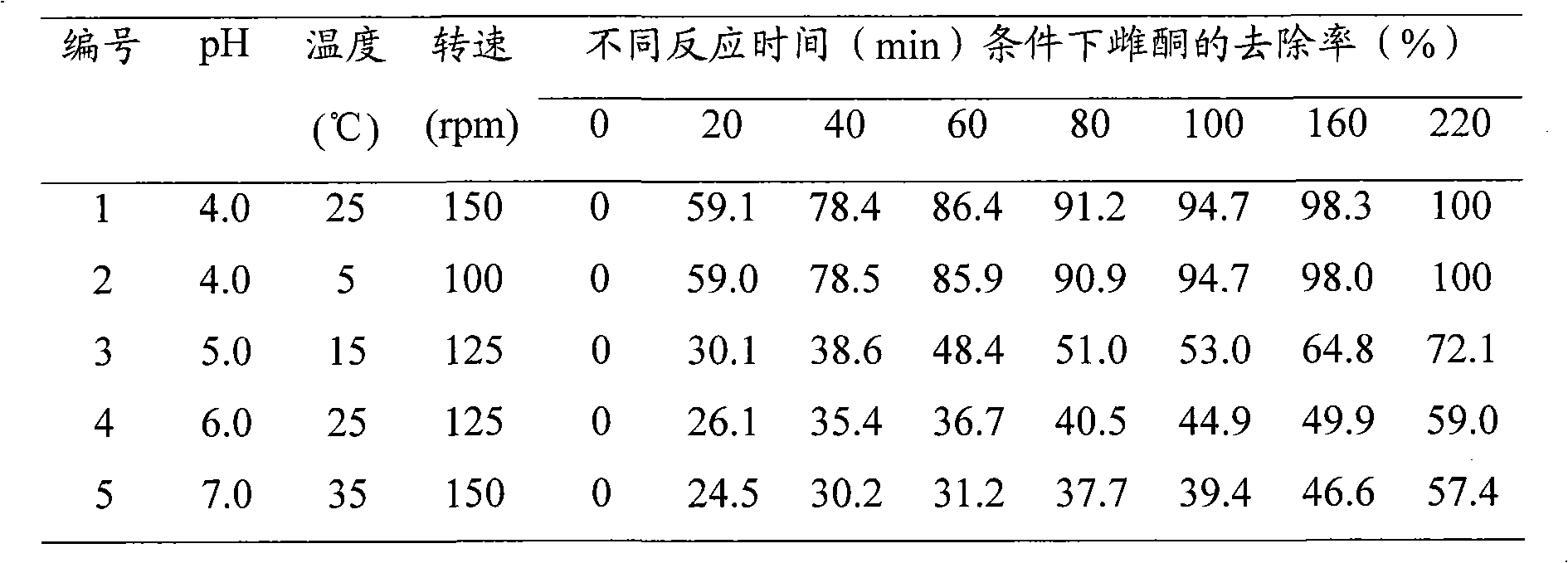

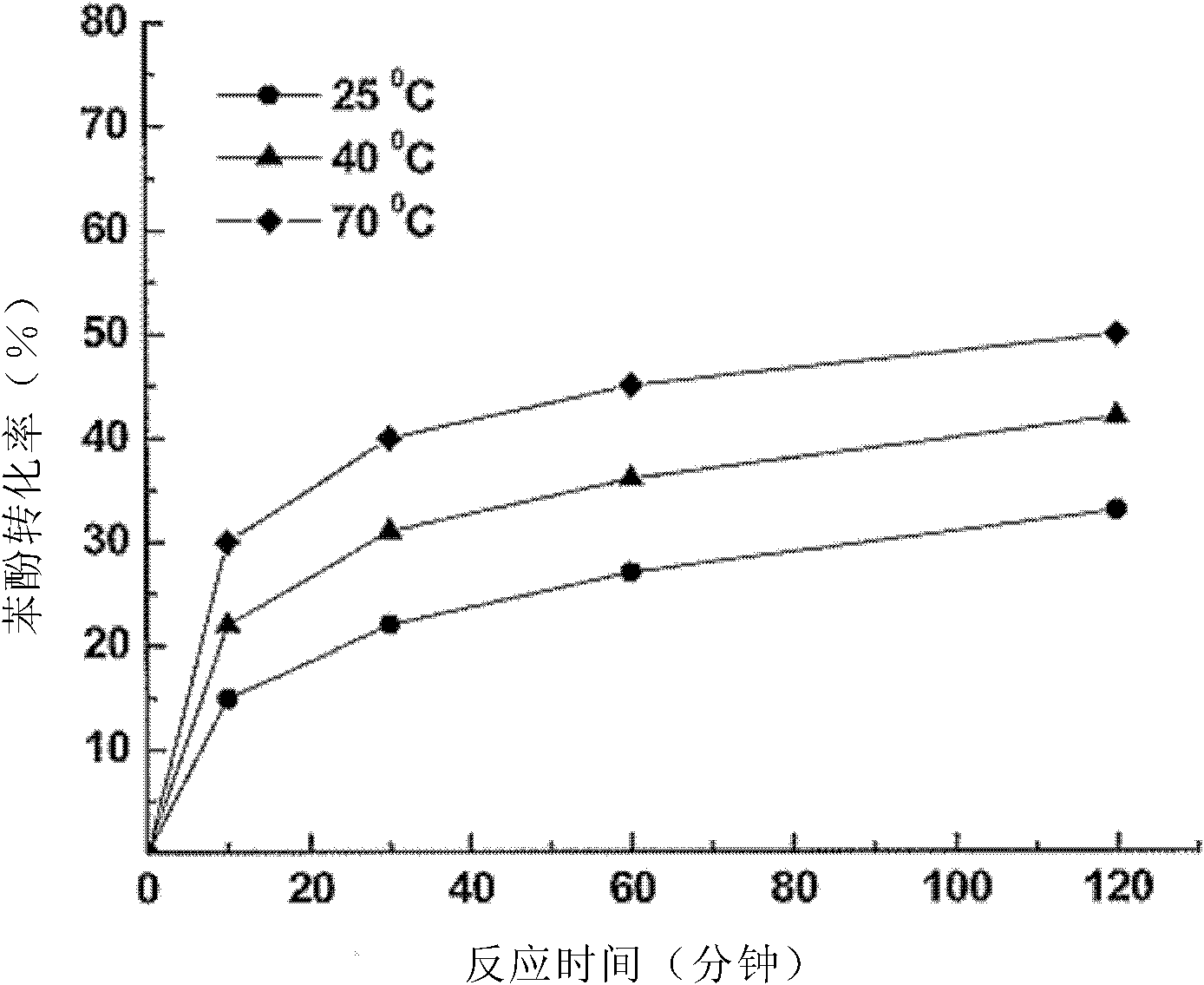

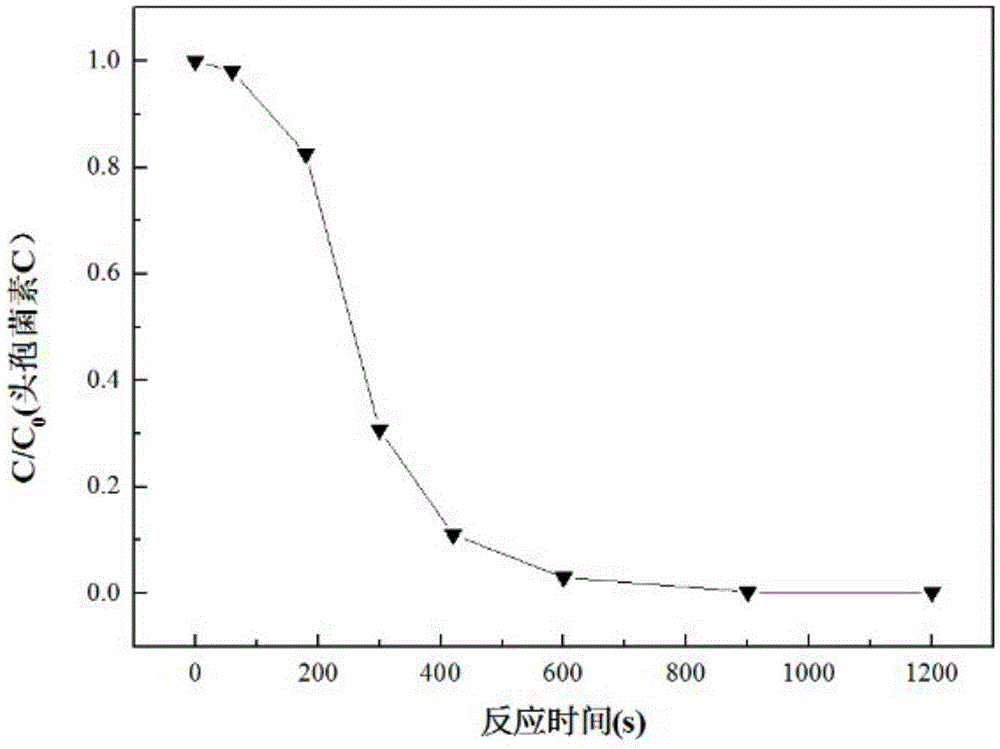

Degradation process for environment estrogenic pollutant in water body

InactiveCN101306864ANo interventionMild treatment conditionsWater/sewage treatment by oxidationField conditionsColloid

The invention provides a method for degrading environmental estrogen pollutants in a water body. The method comprises the steps of adding nascent state hydration manganese dioxide colloid into water containing estrogen pollutants with a concentration of between 0.1 and 10 mu mol / l, controlling a concentration of the manganese dioxide in the system of between 0.25 and 25 mu mol / l, a PH value of between 4.0 and 7.0 and a temperature of between 5 and 35 DEG C and stirring or oscillating the system solution with a rotating speed of between 100 and 150 rmp to degrade the environmental estrogen pollutants in the water body. The method is low in treatment cost, free of the restriction of field conditions, high in degradation efficiency, uneasy to generate secondary pollution, applicable to the degradation and removal of environmental estrogen pollutants in various natural water bodies and man-made water bodies, possessing a good industrialization promotion prospect.

Owner:ZHEJIANG UNIV OF TECH

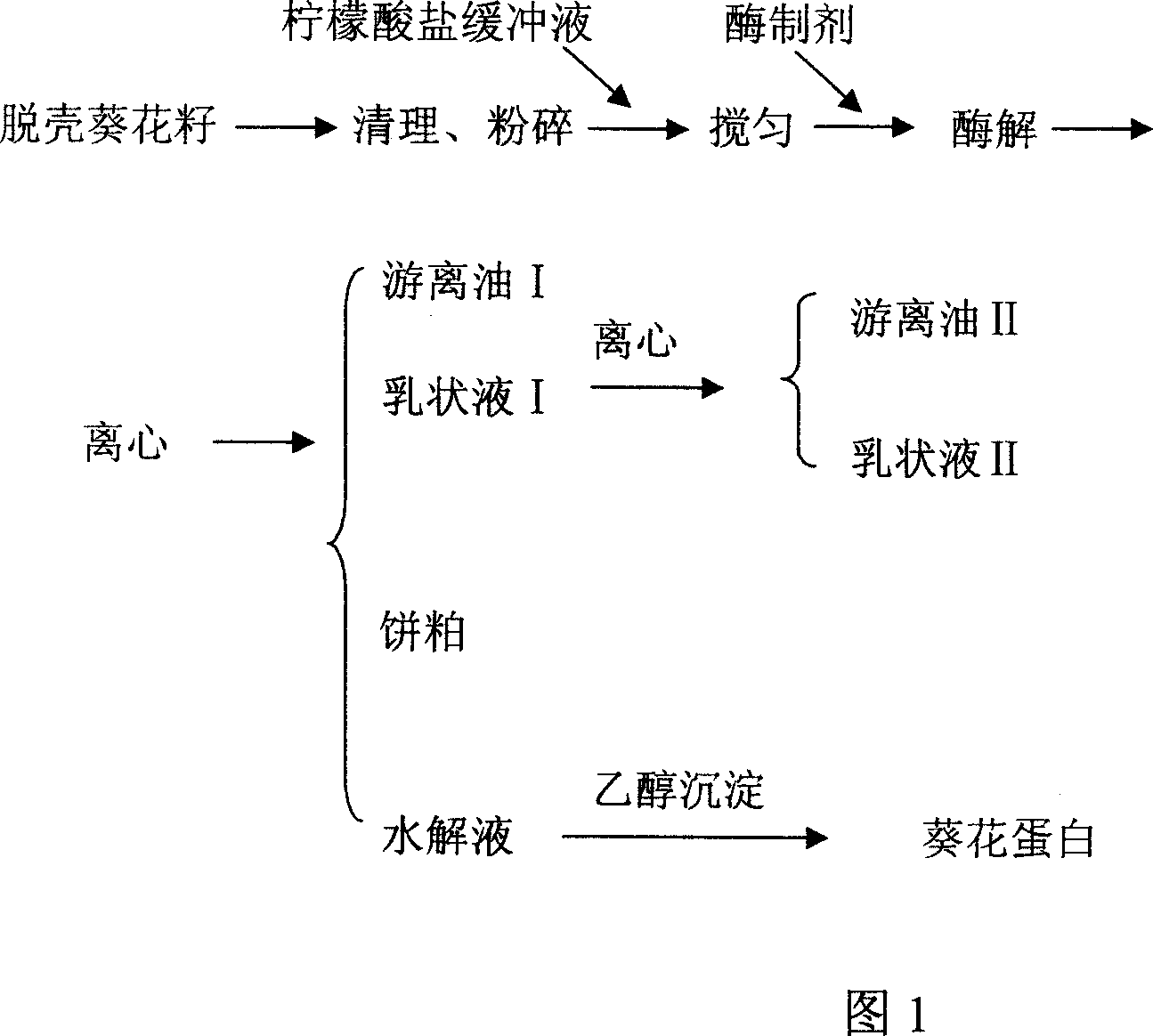

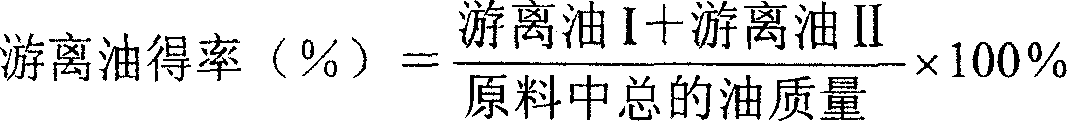

Process for extracting sunflower seed oil and recovering protein by aqueous enzymatic method

InactiveCN1952094AQuality improvementMild treatment conditionsEnzymesFatty-oils/fats productionCelluloseNutritive values

The method relates to the method to extract the sunflower oil and recover the protein by water-enzyme method. The producing procedure comprises the following steps: dry-pulverizing the uncoated sunflower seed, adding citrate buffer to the powder and decomposing the powder by compound cellulose; centrifugalizing to get free oil, emulsion, digest and tablet; high speed centrifugalizing to get some free oil; filtering, vacuum concentrating, alcohol precipitating, centrifugalizing and freeze-drying to recycle the protein. The special treatment in the invention has substantially increased the free oil yield and the quality of the free oil is better than the refined oil. The water-extracting and alcohol-precipitating method to get the protein is simple and efficient; besides, the method has maintained the sunflower protein's nutritive value and functional value very well. Compared with the traditional squeezing and water-extracting technologies, the invention has many advantages such as simple producing equipments, safe operation, less energy expenditure and less pollution.

Owner:JIANGNAN UNIV

Biophysical method for removing endopleura of walnut

InactiveCN102972850AEasy to operateMild treatment conditionsFood preservationHuskingPectinaseWalnut Nut

The invention provides a biophysical method for removing the endopleura of a walnut. The walnut with the shell is soaked by tap water for 12 to 24 hours, the shell is removed, the kernel is taken out, pectinase with the activity being 30000 IU is dissolved into disodium hydrogen phosphate-citric acid buffer liquid with the pH being 3.2 to 3.8, and 3 percent to 5 percent of pectic enzyme liquid is prepared and is heated to 50 DEG C. The soaked walnut kernel is soaked in the pectic enzyme liquid and is placed into an ultrasonic generator with the power being 250W and the work frequency being 40KHZ, the enzymolysis and the ultrasonic treatment are carried out for 2.5 to 5 hours at the constant temperature being 50 DEG C, the walnut kernel is fished out and is sprayed and flushed by flowing water with the pressure being 7 to 10 MPa until the endopleura is completely removed, the walnut kernel with the advantages that the color and the luster are opacified, the kernel fruit is complete, the texture is flexible, the mouth feeling and the flavor are pure and sweet as those of the fresh walnut kernel can be obtained, and when the walnut kernel is in vacuum package and freezing storage, a fresh walnut kernel storage method is obtained. The biophysical method adopts the advanced biological enzyme technology to be combined with the ultrasonic physical technology and has the obvious characteristics that the operation is simple, the processing condition is mild, no chemical pollution exists, the kernel and the nutrition are kept complete, and the sensory quality is good.

Owner:BEIJING UNION UNIVERSITY

Efficient biological desulfurization method for coal

InactiveCN103937576AEffectively retain active ingredientsEasy to operateSolid fuelsThiobacillus ferrooxidansThiobacillus

The invention discloses an efficient biological desulfurization method for coal, which is characterized in that coal is crushed through a crusher until the particle size is below 150 meshes; and three bacteria, namely Thiobacillus thioxidans, Thiobacillus caldus and Pseudomonas stutzeri, are adopted. The desulfurization process comprises the following sequential steps: removing organic sulfur in the coal through the Pseudomonas stutzeri; after the primary desulfurization is finished, preparing the Thiobacillus thioxidans and the Thiobacillus caldus into a desulfurization solution according to a certain total bacterial count ratio, and removing inorganic sulfur of the coal; and washing the desulfurized coal with water, filtering, and drying. The total sulfur removal ratio of the desulfurized coal is up to 57.8%; and the method is simple to operate, mild in treatment conditions and low in cost, and effectively retains effective components in the coal, thus being a desulfurization technology having very wide market prospects.

Owner:CENT SOUTH UNIV

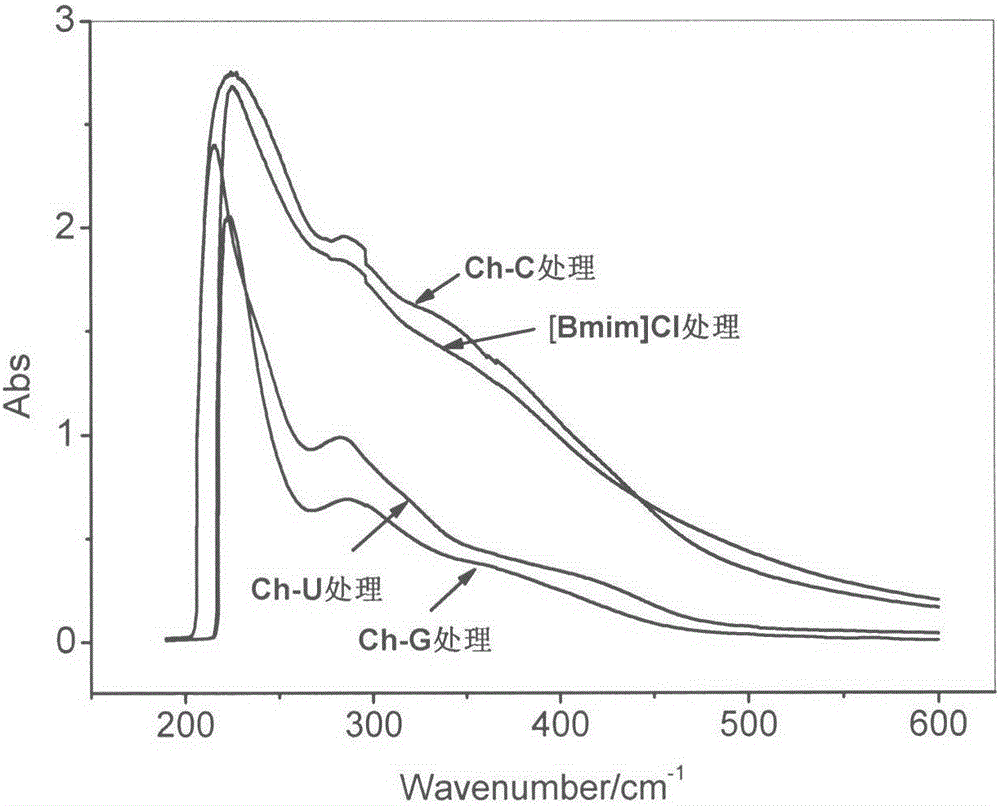

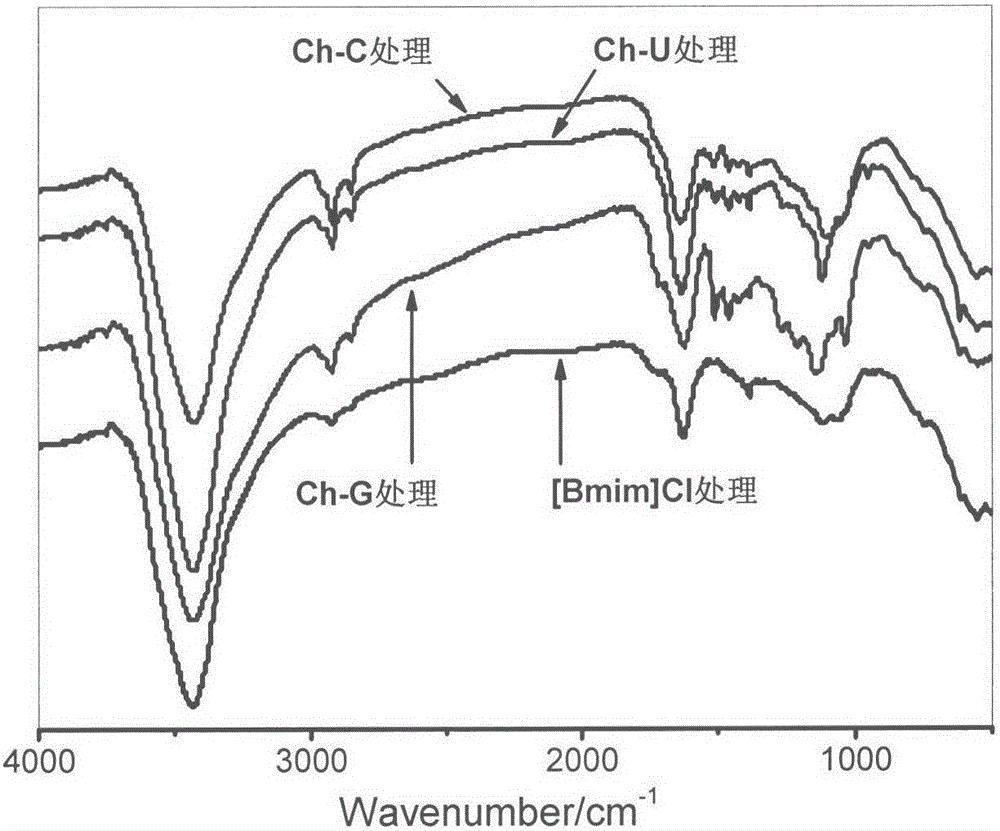

Method for separating and extracting straw lignin by using eutectic ionic liquid

The invention relates to a process method for separating and extracting straw lignin by using eutectic ionic liquid. The method comprises the following steps of: adding a straw powder raw material and eutectic ionic liquid into a normal pressure reactor according to a certain mass ratio, performing mixing and stirring for reaction at 110-160 DEG C for a certain period of time, then regulating the pH value of the mixture to about 11 by using an alkali, performing high-speed centrifugation, and keeping an upper layer solution; and then regulating the pH value of the solution to be less than 3 by using an acid, performing centrifugation again, then washing and centrifuging a deposit by using distilled water until the supernatant is neutral, and performing freeze drying on the final deposit to obtain lignin. The method has the characteristics that the eutectic ionic liquid is prepared under a very mild condition by using low-price and nontoxic choline chloride and an H-bond donor as raw materials, and is used for separating and extracting lignin from rice straws, the raw materials are easy to obtain, the price is low, the process is simple, the condition is mild, the reaction is easy to control, and the energy consumption can be effectively reduced.

Owner:NANJING FORESTRY UNIV

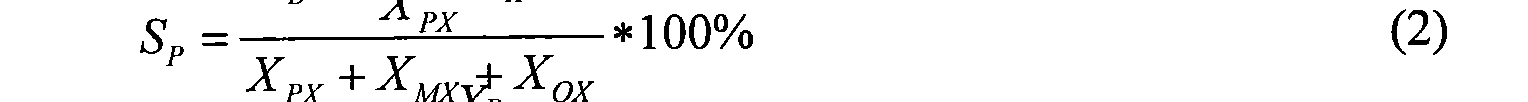

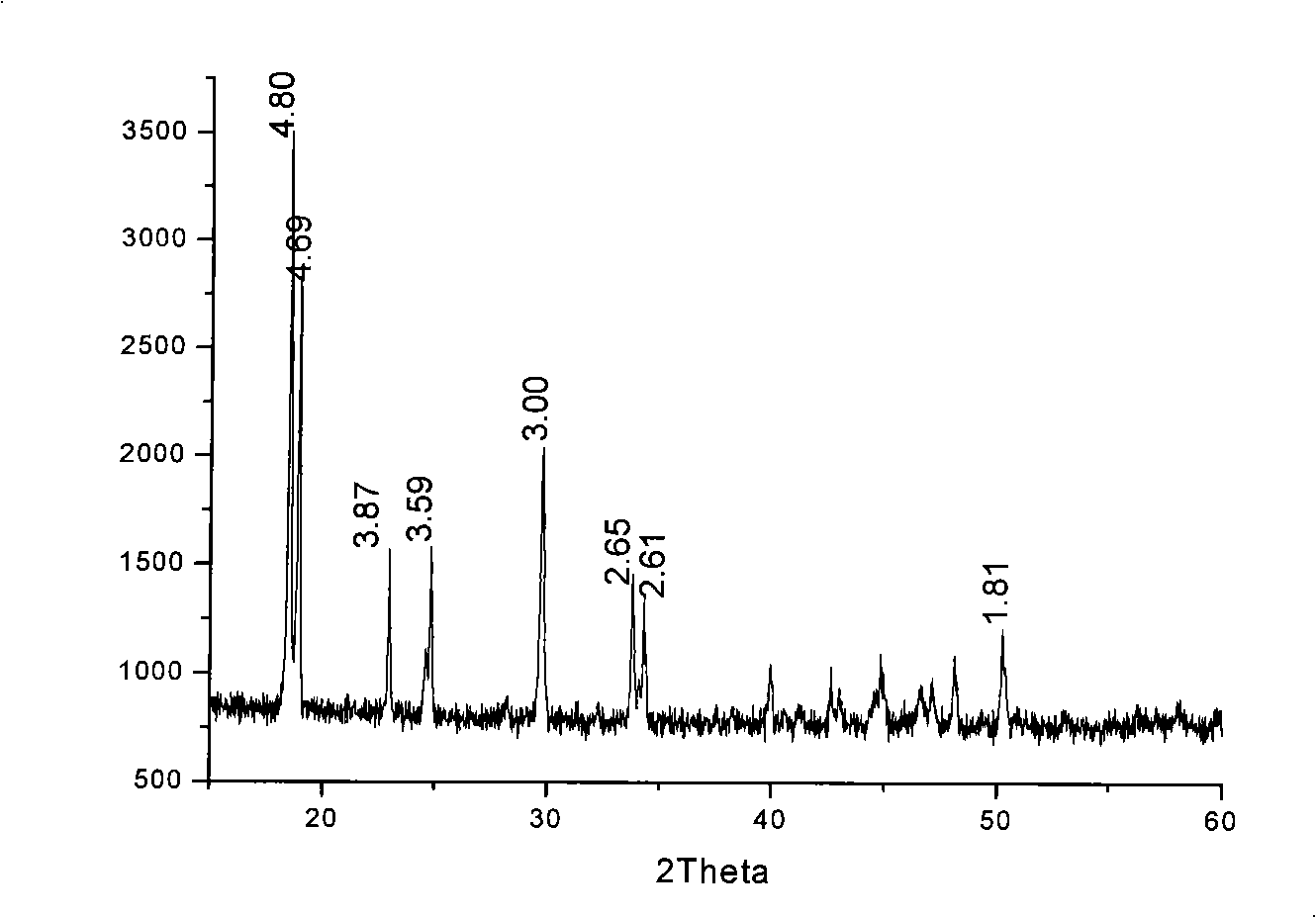

Preparation method of modified ZSM-5 zeolite toluene disproportionation catalyst by soda treatment

InactiveCN101380591AEasy accessHigh conversion rate of tolueneMolecular sieve catalystsHydrocarbonsBenzeneOrganic acid

The invention relates to a preparation method of a modified ZSM-5 zeolite toluene disproportionation catalyst which is treated by alkali. The zeolite powder which takes ZSM-5 as active components is added in a caking agent to be formed, and then the formed zeolite is treated by 0.01-0.4mol / L of alkali solution at the temperature of 25-75 DEG C and is exchanged into hydrogen type zeolite; after being washed by organic acid and dried by the catalyst, the hydrogen type zeolite is modified by chemical liquid deposition with cyclohexane solution of ethyl orthosilicate, dried and calcined to obtain the catalyst. The obtained catalyst is especially used for preparing benzene and paraxylene by shape selection and disproportionation of toluene, thus obviously improving the transformation ratio of the toluene, and after the catalyst is used in the toluene disproportionation, the transformation ratio of the toluene is increased by 6-10% and secondary reaction is reduced.

Owner:NANJING UNIV OF TECH

Method for extracting chitin from shrimp and crab shells by using eutectic ionic liquid

The invention relates to a method for extracting chitin from shrimp and crab shells by using eutectic ionic liquid. The method comprises the following steps: clearing the shrimp and crab shells, soaking in ethanol, cleaning, drying, crushing and the like to obtain shrimp and crab shell powder; mixing choline chloride and thiourea according to a certain proportion, adding into a reaction container, heating in a water bath, and stirring to obtain the eutectic ionic liquid; adding the shrimp and crab shell powder into the eutectic ionic liquid according to a certain mass ratio, heating, stirring and reacting for a certain period of time, taking water as a reverse-phase solvent, centrifugating, separating and drying to obtain the chitin. The method has the characteristics as follows: by virtue of a synergistic effect of the cheap, non-toxic and easily-prepared eutectic ionic liquid prepared from the choline chloride and the thiourea, the solvent and a catalyst, the chitin in the shrimp and crab shells is separated and extracted at an atmospheric pressure, so that the method has the characteristics of a mild treatment condition, a simple extraction process, and high easiness in controlling the reaction; meanwhile, the eutectic ionic liquid is recyclable, so that environment pollution and energy consumption are reduced.

Owner:NANJING FORESTRY UNIV

Extraction of hickory nut oil from water enzyme

The invention relates to the pecan oil which is a kind of natural health product, it is essentially an aqueous enzymatic extraction method of the pecan oil, the following is the process: (1) the peeled pecan kernel is milled according to the ratio of the weight of the material and the volume of the liquid is 1:3-5, the pecan kernel is milled approximately to 60-150 sieve number, and the juice is put out. (2) The pH of the juice will be adjusted: the pH of the juice from the milling process will be adjusted to 4.0-5.5 with chlorhydric acid and citric acid. (3) The process of thermolysis catalyzing: put the juice in the water bath, the temperature of which is 50-60DEG C,to thermolysis catalyze it for 1-5h,after the pH of it has been adjusted (4) Centrifuging to isolate it: the juice or above will be centrifuged at 4000-6000r / min for 15-3o minutes, the boiled oil which is at the super layer of the juice after the isolation will be exsucted out, and the boiled oil is just the the pecan oil that we need. The excellence of the method is: the oil yield and the oil quality are high, the technology is simple and secure, tand the cost is very lower.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

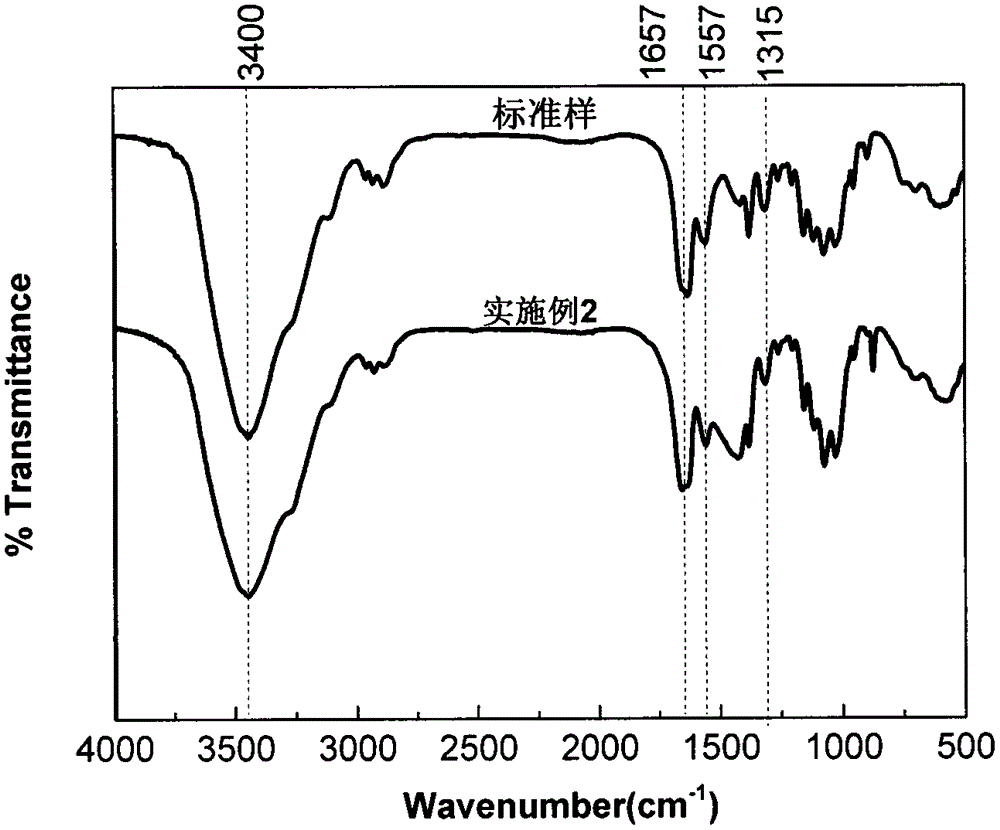

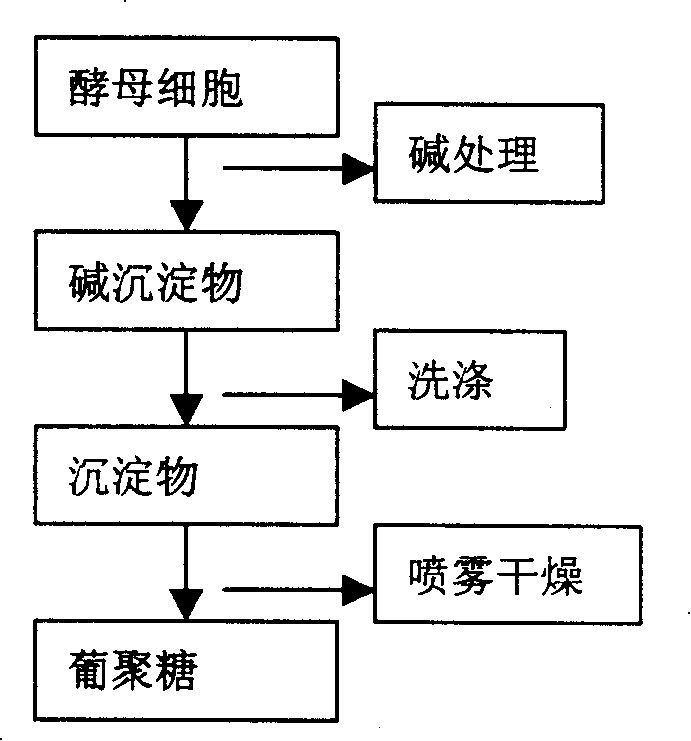

Method for preparing yeast cell wall beta-1,3-dextran

The invention relates to a preparation method for yeast cytoderm beta-1,3-glucans, comprising the following steps: firstly, impurity treatment, namely yeast dry powder is dispersed into water and impurities in the yeast dry powder are filtered; secondly, alkali treatment, namely alkalis are added into filtered yeast suspension and final concentration of alkalis in the suspension is still 0.5 to 7 percent; thirdly, cleaning, namely supernatants are absorbed by means of siphonage until that the supernatants are clear without impurities and PH value is 7 to 8; fourthly, sponging drying, and beta-1,3-glucan solid powder is obtained finally. The invention has the advantages that: firstly, commercial process cost is reduced; secondly, because operating procedures and devices used are simple, the method is easy to realize commercial process; thirdly, protein removal rate in raw materials is high, and yield and purity of the product beta-1,3-glucans are high.

Owner:天津市工业微生物研究所有限公司

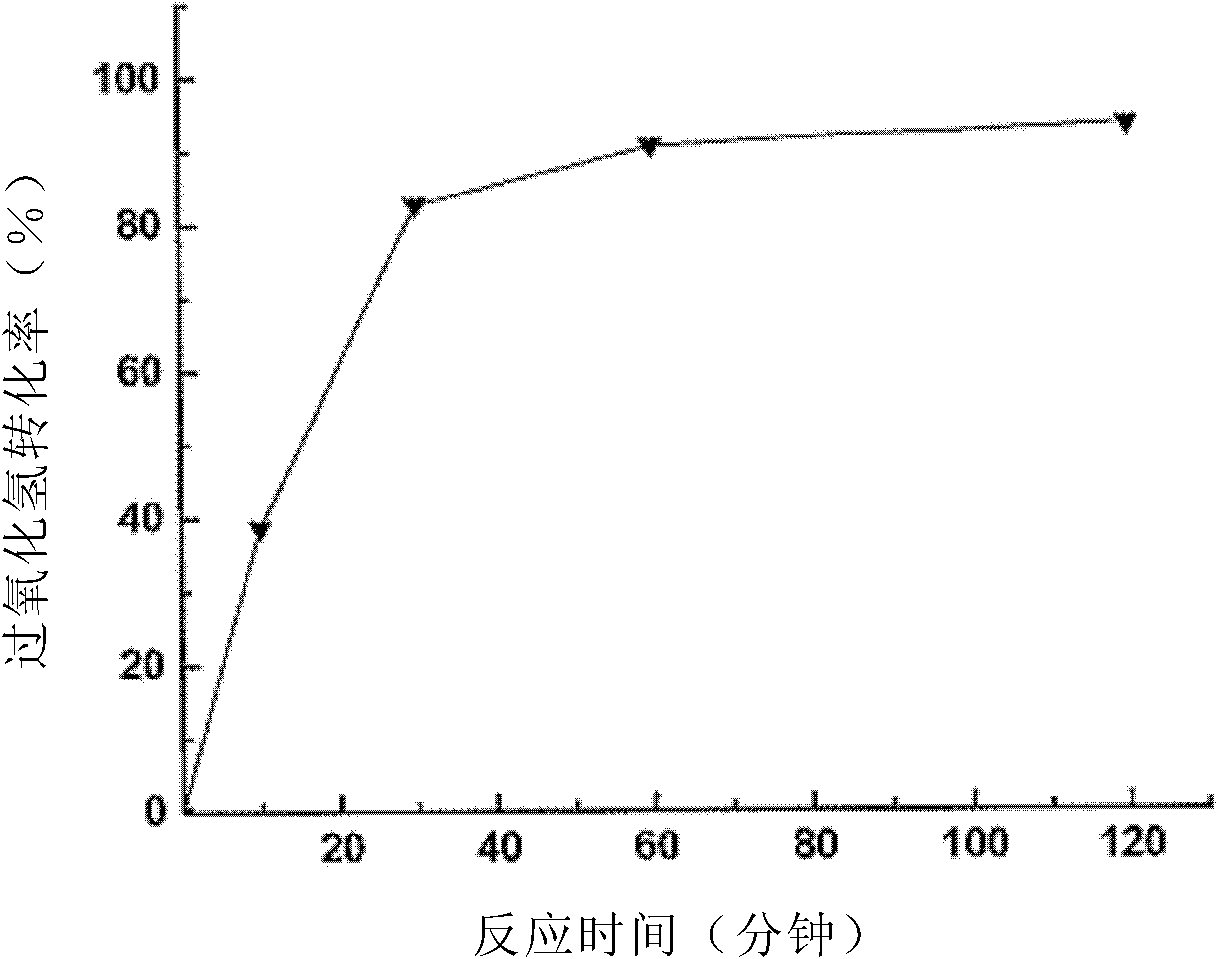

Load type solid catalyst for heterogeneous phase Fenton system and application thereof in water treatment

InactiveCN102059132AHigh activityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a load type solid catalyst for a heterogeneous phase Fenton system and an application thereof in water treatment. The load type solid catalyst for the heterogeneous phase Fenton system comprises an active ingredient aurum and a carrier, wherein the aurum is loaded on the carrier or in the carrier. The invention also provides a water treatment method.

Owner:EAST CHINA UNIV OF SCI & TECH

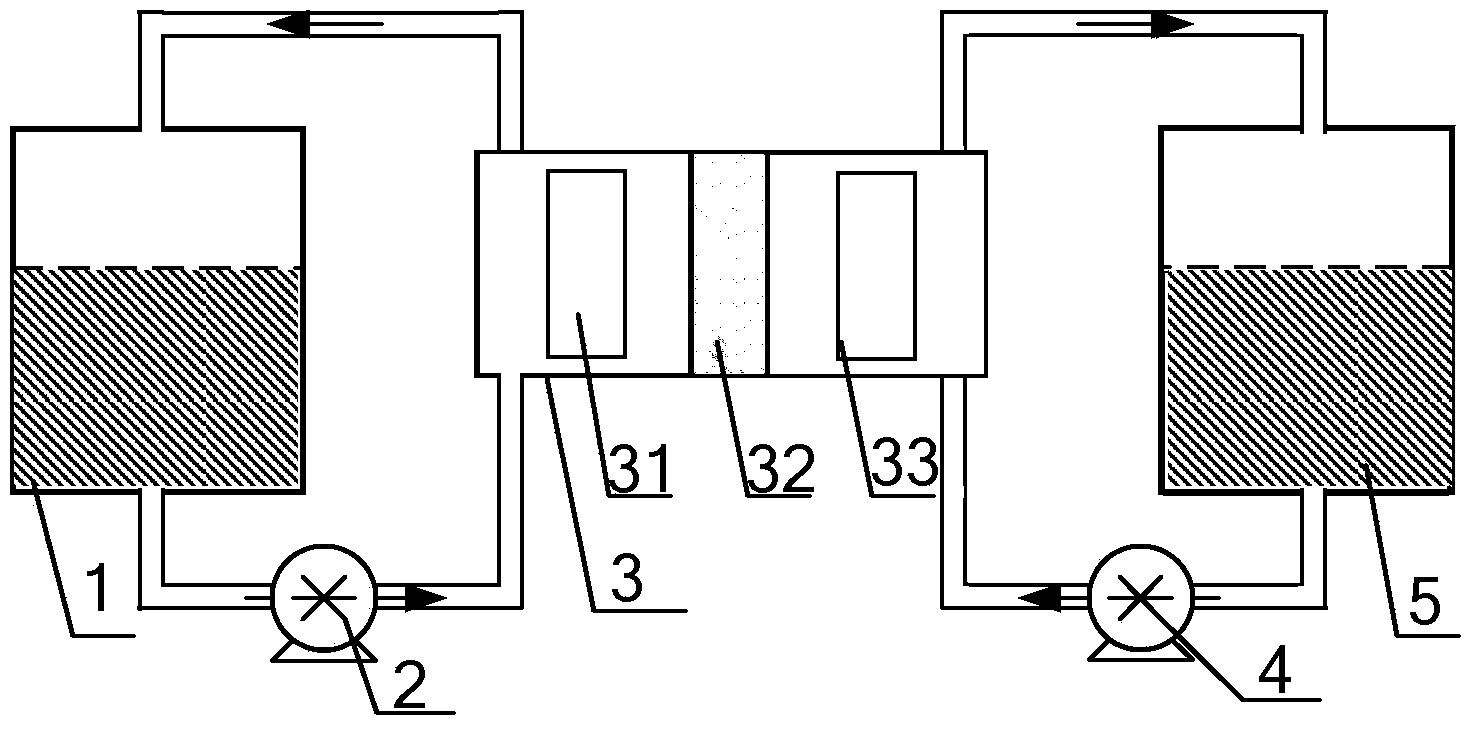

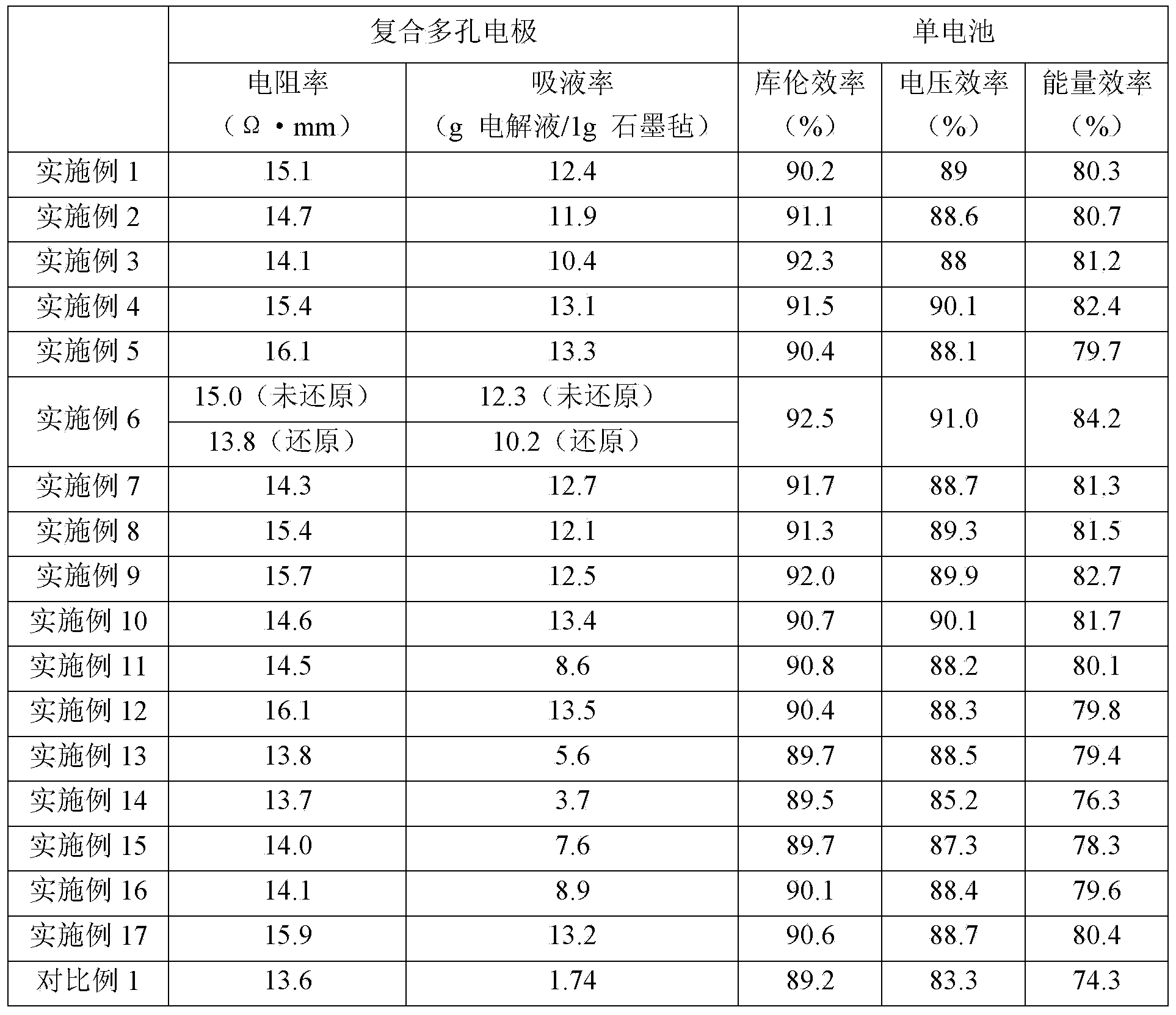

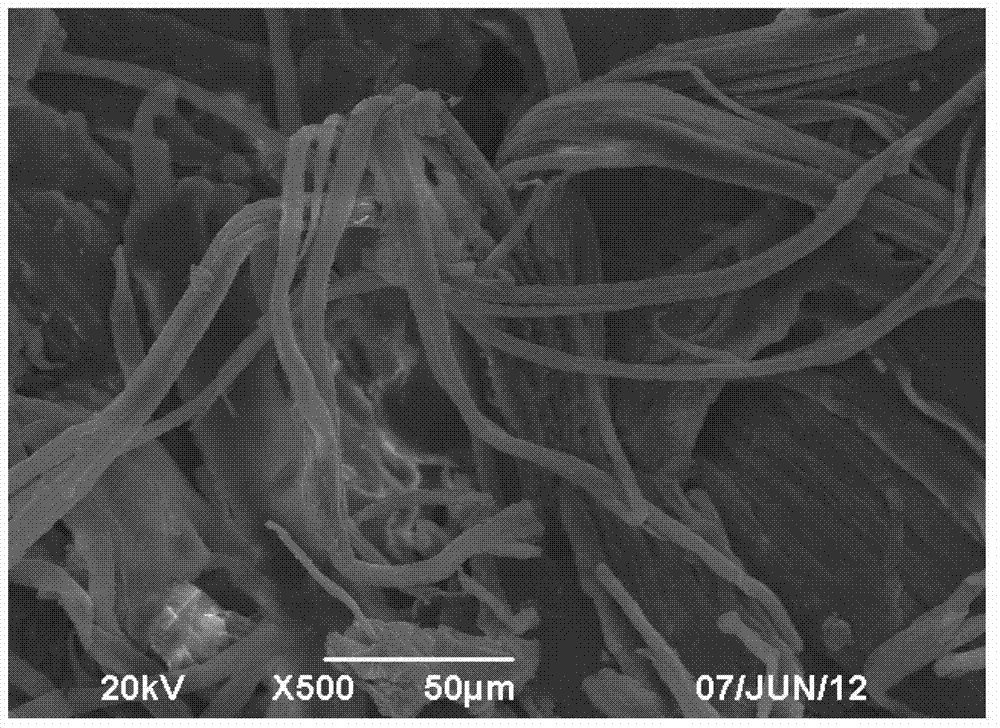

Compound porous electrode and preparation method thereof as well as flow battery comprising compound porous electrode

ActiveCN103413949AImprove conductivityImprove electrochemical activityCell electrodesIndirect fuel cellsElectrochemical responseOxygen

The invention provides a compound porous electrode and the preparation method thereof as well as a flow battery comprising the compound porous electrode. The preparation method of the compound porous electrode comprises the following steps of: step S1, dispersing the solution with a graphene oxygen-containing derivative to a porous electrode body, thus obtaining a prefabricated body of the compound porous electrode; step S2, removing the solvent of the solution in the prefabricated body of the compound porous electrode, thereby obtaining the compound porous electrode. According to the preparation method provided by the invention, oxygen-containing groups on the surface of the graphene oxygen-containing derivative of the acquired compound porous electrode can catalyze the electrochemical reactions between vanadium ion electrons, the conduction performance of electrons is optimized, the electrochemical activity of the electrode is improved, furthermore, during the compounding process of the graphene oxygen-containing derivative and the porous electrode body, the graphene oxygen-containing derivative cannot cause an overoxidation effect on the porous electrode body, and furthermore no negative effect is caused to the stability and service life of electrode materials; meanwhile, the preparation method is simple in technical process, mild in treatment conditions and suitable for industrial application.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

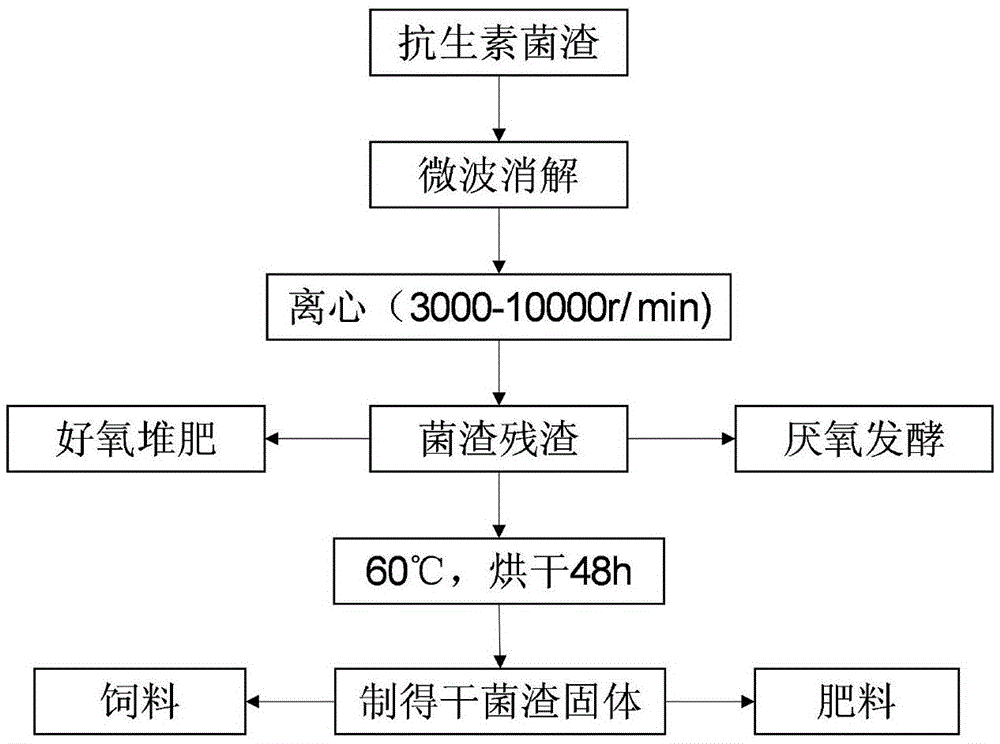

Treatment method and application of antibiotic bacterial residues

InactiveCN105537251ALow moisture content requirementRealize resourcesTransportation and packagingSolid waste disposalAfter treatmentAntibiotic Y

The invention relates to a treatment method and an application of antibiotic bacterial residues, and aims to solve problems that existing bacterial residue treatment methods are long in period, still have the environmental risk after treatment and the like. The method comprises steps as follows: 1) fresh bacterial residues are placed in a reaction tank, the moisture content is controlled between 85% and 95%, and the bacterial residues are evenly mixed; 2) the reaction tank containing the bacterial residues is placed in a microwave reactor, heated to 100 DEG C by a microwave generator with the microwave power of 100-900 W and kept for 10 min; 3) the antibiotic bacterial residues after the reaction are subjected to centrifugal separation, and obtained bacterial residues are precipitated and dried. With the adoption of the method, antibiotic residues in the bacterial residues can be removed quickly, and harmless treatment and recovery of the bacterial residues are realized.

Owner:HARBIN INST OF TECH

Method for separating high-purity lignin

The invention discloses a method for separating high-purity lignin by treating agricultural and forestry wastes with a green solvent. The method comprises the following steps that 1, a hydrogen bond acceptor and a hydrogen bond donor are heated and dissolved to obtain a low eutectic solvent system of a uniform transparent solution; 2, the agricultural and forestry wastes serve as raw materials, alow eutectic solvent serves as a reaction solvent, and the raw materials and the reaction solvent react in a reaction kettle; 3, after the reaction is completed, cooling is conducted, solid and liquidare centrifugally separated, and the separated liquid is precipitated through deionized water, centrifuged and freeze-dried to obtain the high-purity lignin; 4, rotary evaporation is carried out on the liquid obtained through centrifugation to recover the eutectic solvent. The reaction raw materials in the separation method are the agricultural and forestry wastes, low in cost and environmentallyfriendly, and the low eutectic solvent is easy to prepare, low in cost, free of toxins, recyclable and free of a complex preparation process. According to the method, the treatment conditions are mild, the extraction process is simple, the reaction is easy to control, and the energy consumption is effectively reduced. The obtained lignin is high in purity.

Owner:BEIJING FORESTRY UNIVERSITY

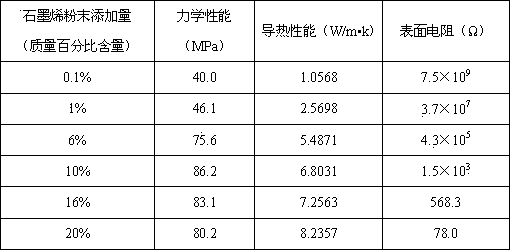

Preparation method of graphene

InactiveCN105366671AImprove conductivityImprove thermal conductivityBulk chemical productionHeat conductingTechnical grade

The invention discloses a preparation method of graphene. The method is simple in technology and easy to operate, and the obtained graphene is excellent in electric conduction, heat conduction and mechanical performances. With the method, the mechanical strength, heat-conducting property and anti-static function of polypropylene resin can be greatly improved, and the additional value of plastics is improved. The method belongs to physical exfoliation processes in which the treatment condition is mild and the quality of graphene cannot be damaged; and the exfoliation degree of the graphene is high through the two times of physical exfoliation processes. Therefore, the number of layers of graphene can be reduced; the yield of single-layer graphene is improved; and the high-quality graphene is finally obtained. Moreover, the influence of the preparation conditions of the method on the quality and yield of the graphene product is little; the product quality and yield are easy to control; and the method is suitable for large-scale production. Besides, the raw materials used in the method disclosed by the invention are all industrial products, and are easy to obtain and low in cost; and the production process is free of pollution.

Owner:JIANGSU JINJU ALLOY MATERIAL

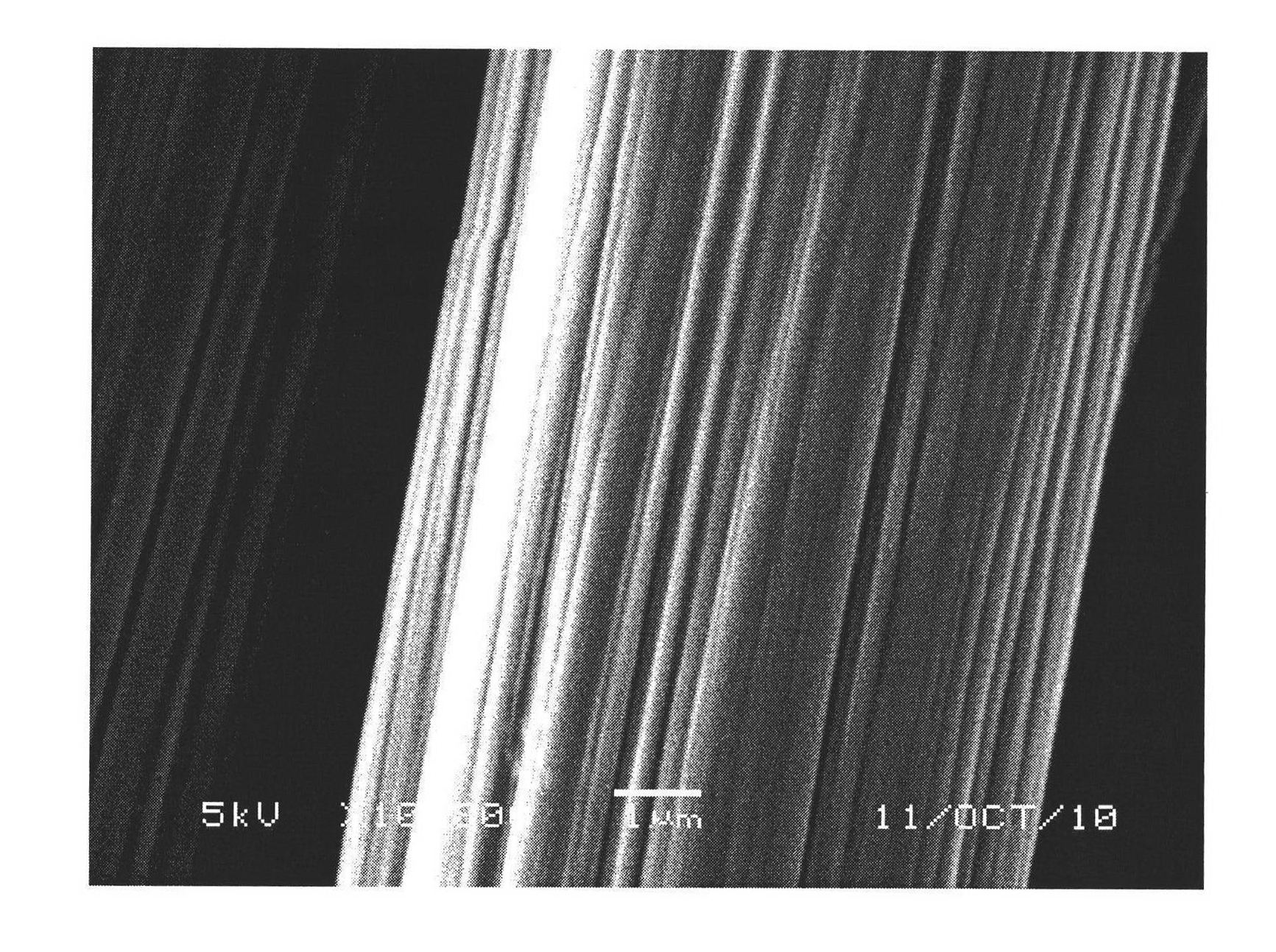

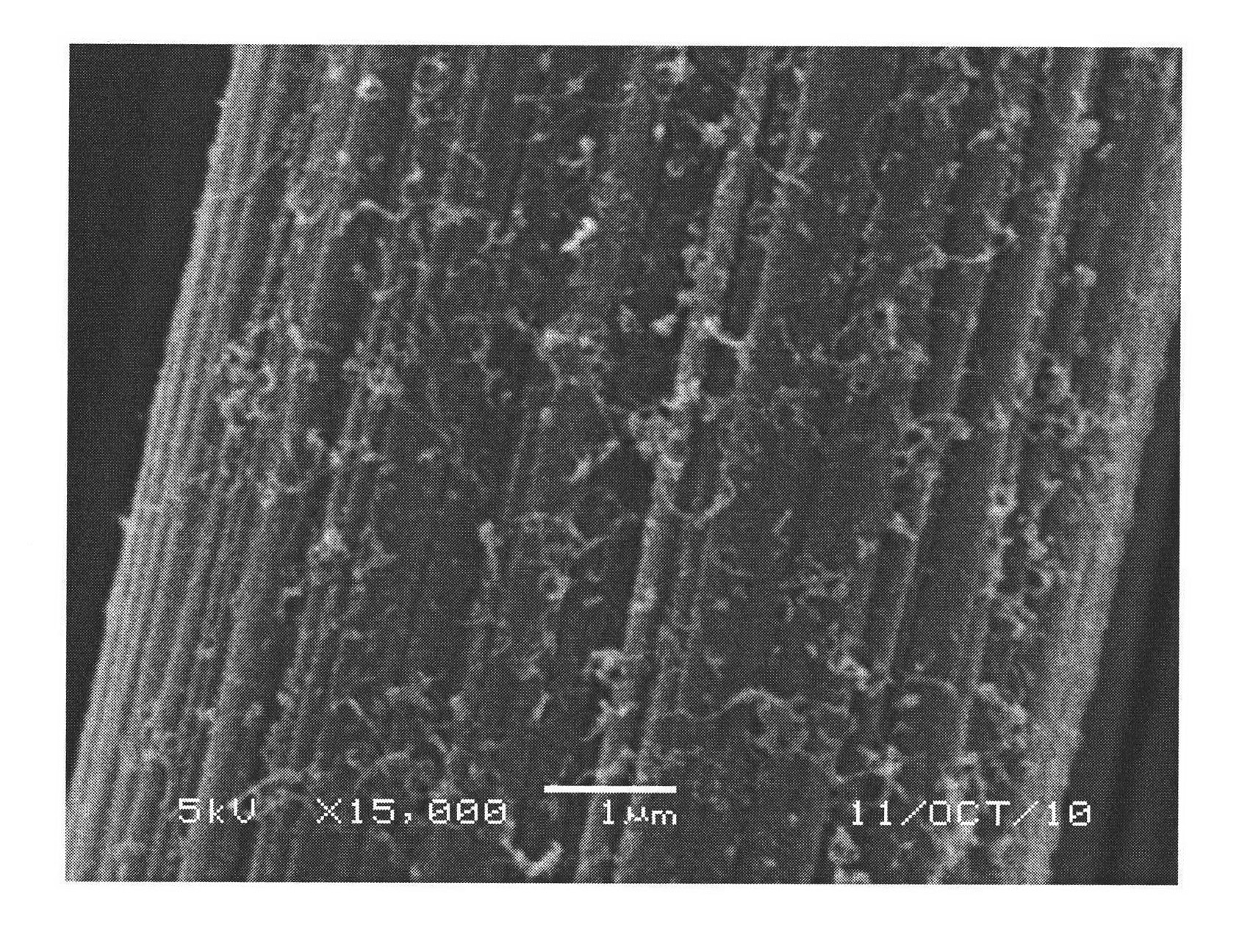

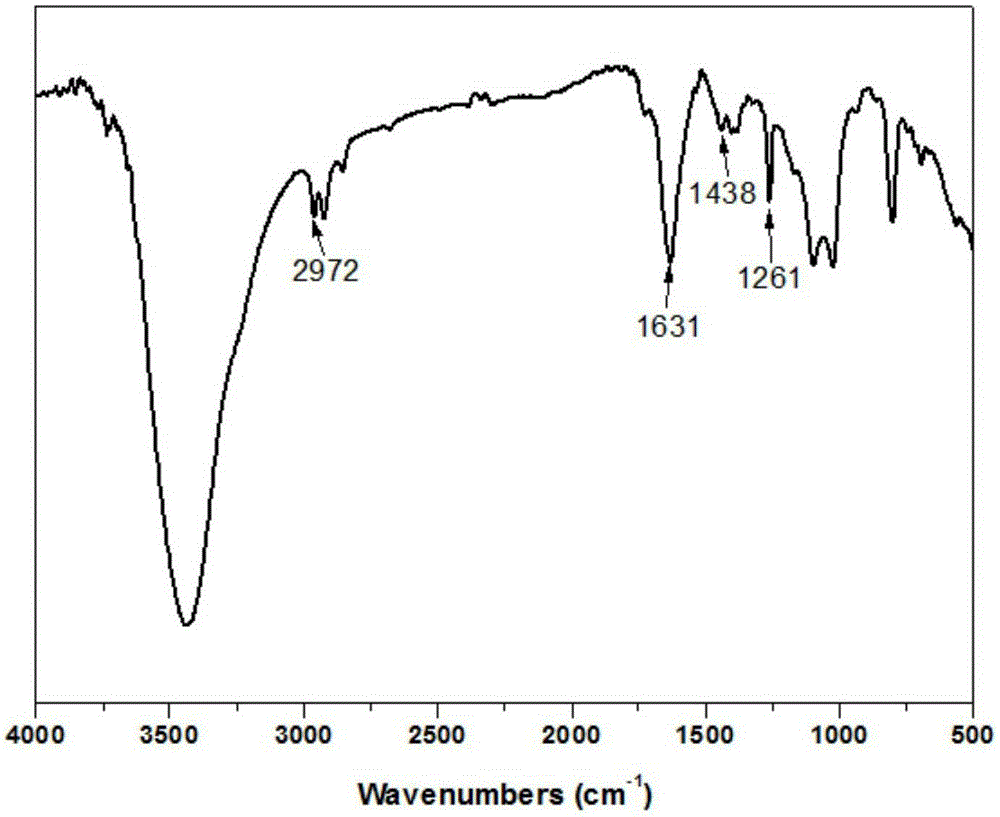

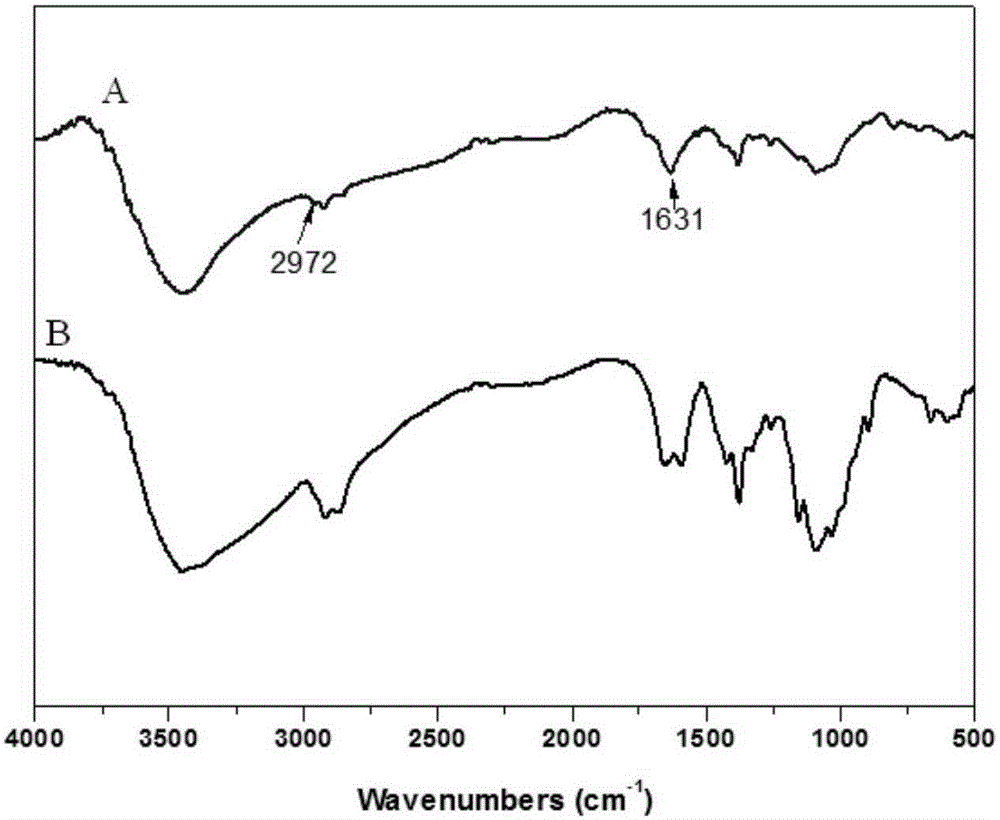

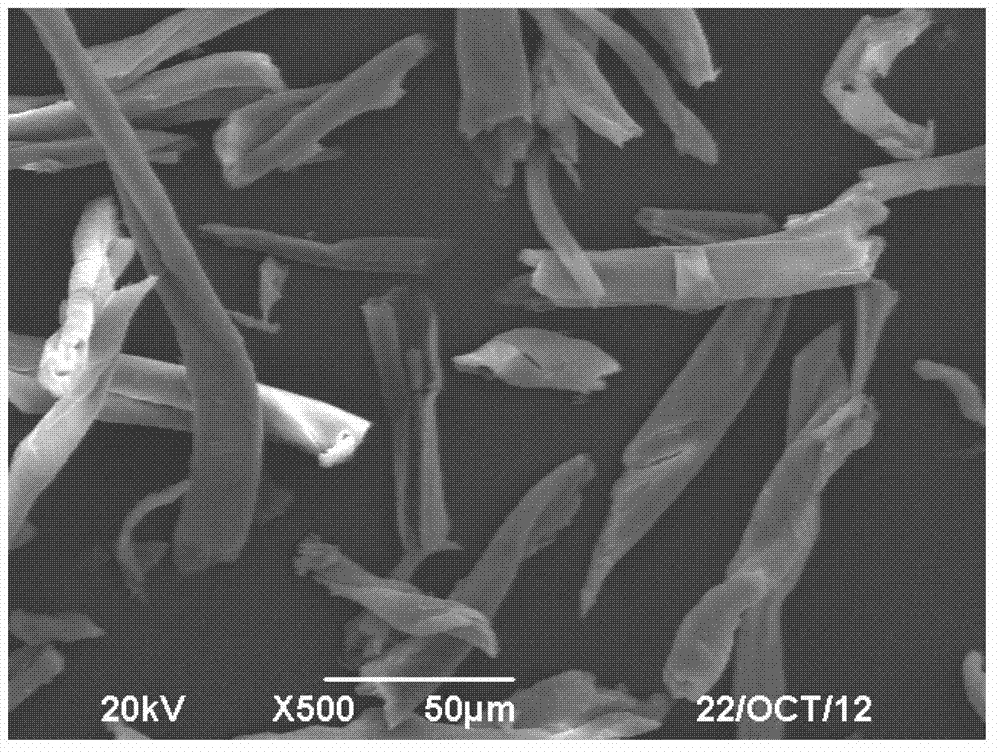

Electrochemical modification treatment method of carbon fiber surface

InactiveCN102505449AEasy to operateMild treatment conditionsAnodisationPhysical treatmentFiberCarbon fibers

The invention relates to an electrochemical modification treatment method of carbon fiber surface. The electrochemical modification treatment method comprises the steps of: modifying carbon nanotubes by adopting a nitric acid and sulfuric acid chemical oxidization method or an electrochemical method; dissolving modified carbon nanotubes in ethanol, acetonitrile, dimethyl formamide, dimethyl sulfoxide, tetrahydrofuran, protoporphyrin disodium, carbon tetrachloride, petroleum ether, acetone, chloroform or water, and carrying out ultrasonic treatment or stirring to form uniformly dispersed emulsion or suspension so as to prepare an electrolyte solution containing 0.01-10 mg / mL of carbon nanotubes; and applying voltage or current on a carbon fiber electrode in the electrolyte solution containing the carbon nanotubes with carbon fiber as an anode electrode and a conductive metal or graphite material as a cathode electrode while controlling the temperature of the electrolyte solution at 20-80 DEG C, then cleaning and drying. The electrochemical modification treatment method provided by the invention has the advantages of being simple, practical and capable of being industrialized.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Lignin nanoparticles as well as preparation method and application thereof

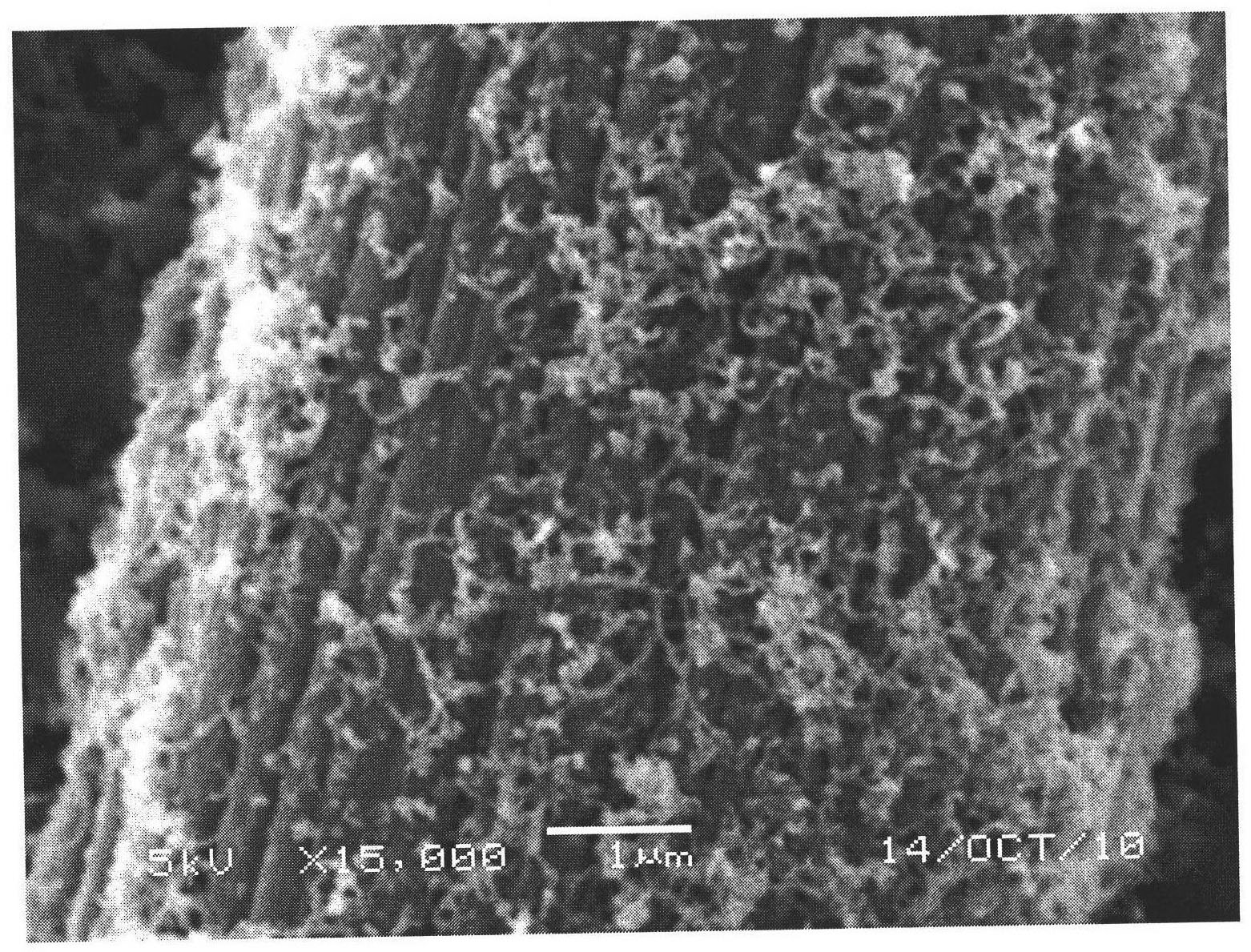

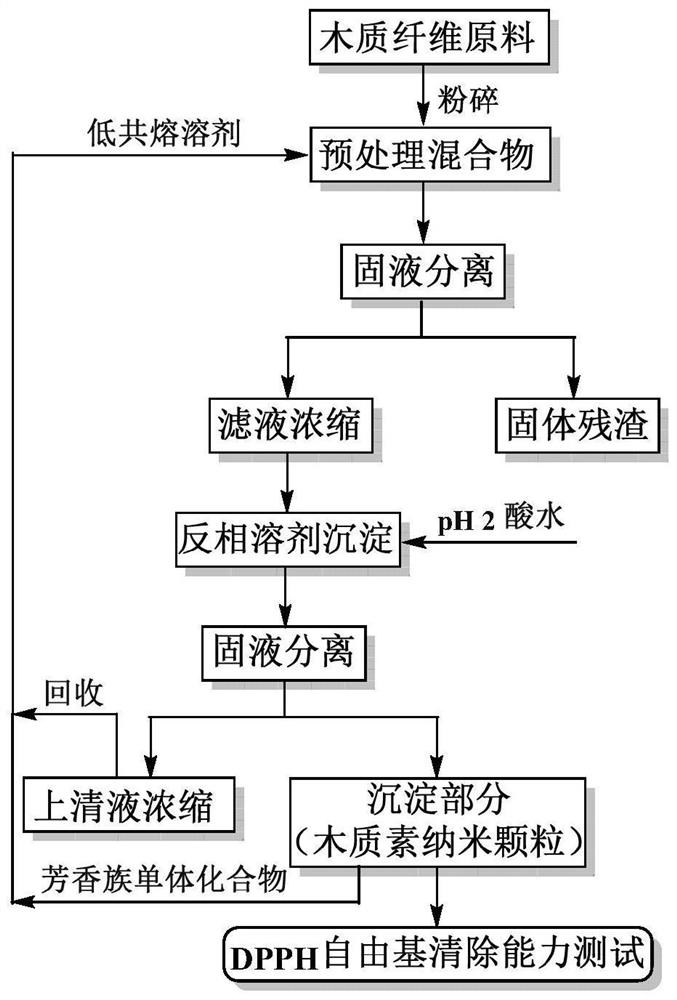

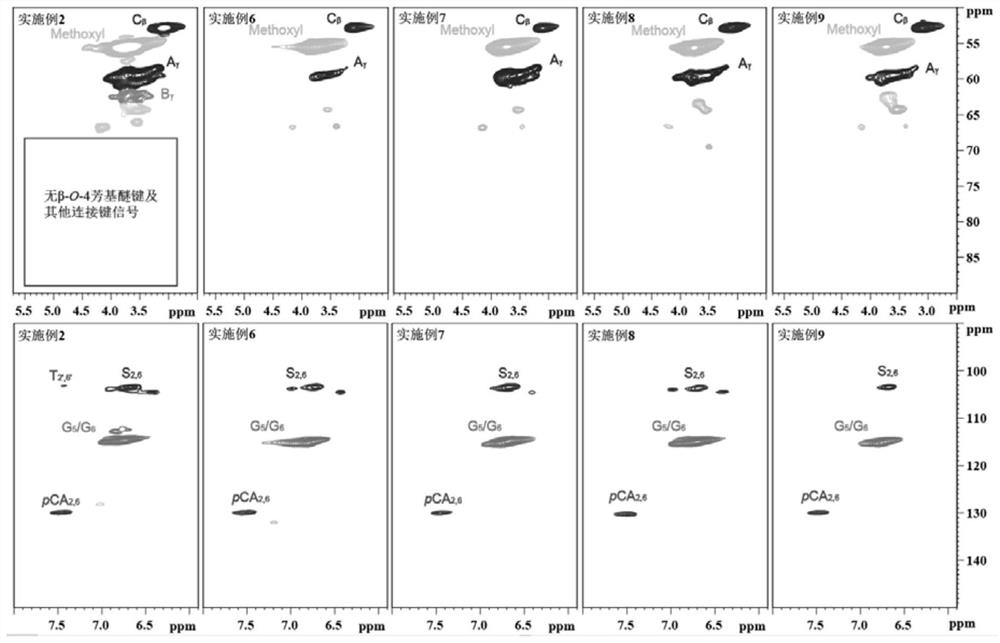

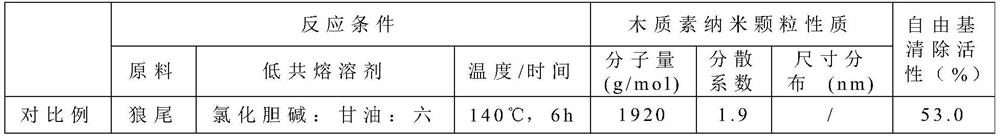

ActiveCN112851977AWide variety of sourcesLow costMaterial nanotechnologyCosmetic preparationsCelluloseFluid phase

The invention relates to lignin nanoparticles and a preparation method and an application thereof, the method comprises the following steps: mixing a hydrogen bond acceptor and a hydrogen bond donor, heating to obtain a homogeneous transparent eutectic solvent, and cooling to room temperature; uniformly mixing a lignocellulose raw material with a deep-eutectic solvent to form a solid-liquid mixture; carrying out heat treatment on the solid-liquid mixture to obtain a pretreated mixture; cooling and washing the pretreated mixture, then carrying out solid-liquid separation to obtain solid-phase pretreated cellulose residues and a liquid-phase component, drying the solid-phase pretreated cellulose residues, and collecting the dried solid-phase pretreated cellulose residues; evaporating and concentrating the liquid component, adding the liquid component into a reversed-phase solvent to precipitate lignin nanoparticles, centrifuging, drying and collecting; and step E, recovering the eutectic solvent in the centrifugate for recycling. The lignin nanoparticles have antioxidant activity comparable with that of a commercial antioxidant dibutylated hydroxytoluene, and have wide application prospects in the industries of food packaging materials, skin care medicine and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis

The invention provides a method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis, comprising the following steps of: grinding walnut raw materials into walnut powder, adding 100,000 to 1000,000 units of protease or composite protease to 1kg of walnut powder, adding water in the mass ratio of the walnut powder to the water is 1: (0.5-20), and then performing microwave processing for 1-10 minutes under the stirring condition of 60 to 300rpm when the microwave power is 10 to 1000 W / L and the temperature is 35 to 65 DEG C, and performing centrifugal separation of oil phase, aqueous phase and solid phase after the reaction ends, wherein the oil phase is walnut oil, the aqueous phase is walnut protein peptide, and the solid phase is residues. The method provided by the invention has mild extraction condition and excellent product performance, and can improve the efficiency of ingress of oil. Furthermore, the obtained walnut oil is higher in quality and is easy to refine; the processing time is greatly shortened by microwave-assisted extraction; the oil phase, the aqueous phase and the solid phase residues can be separated at the same time, therefore, the production efficiency is efficiently improved; and no waste water, waste air or waste residues exists in the producing process, therefore, the invention is environmentally-friendly.

Owner:KUNMING UNIV OF SCI & TECH

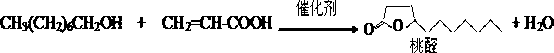

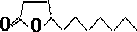

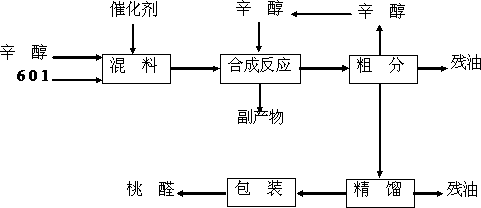

Extracting method of synthetic peach aldehyde

The invention provides an extracting method of synthetic peach aldehyde and relates to the industrial field. The extracting method comprises the following steps that 1, octanol, crylic acid and peroxides are placed in a container, and a stirrer is used for full stirring so that the octanol, the crylic acid and the peroxides are uniformly mixed; 2, octanol and cocatalysts are added into a reactor provided with a stirrer, a backflow condensing device and a dropping device; the stirrer is started, materials are heated to a preset temperature, and mixtures of the octanol, the crylic acid and the peroxides are dropped into the reactor within 4 to 10 hours; and under the stirring effect, the backflow reaction is carried out until no moistures or the like are distilled off from a by-product collector, the reaction is finished, and reaction mixtures containing the peach aldehyde are obtained; 3, the reaction mixtures are transferred into a vacuum distillation device, and unreacted octanol is recovered through distillation at 133.3 Pa; 4, the reaction mixtures after the octanol recovery are transferred into the vacuum distillation device, reaction products are extracted through fractionation, and peach aldehyde is obtained; and 5, the peach aldehyde is placed into a special fragrance processing device, and peach aldehyde finished products are obtained. The extracting method has the advantages that the process is simple, the equipment requirement is lower, the treatment condition is mild, the treatment cost is low, the energy consumption is low, in addition, no harmful emission is generated, and the extracting method is suitable for mass production; and the prepared peach aldehyde is colorless clear liquid, has intense peach and amygdaloid fragrance and has no miscellaneous odor.

Owner:南昌洋浦天然香料香精有限公司

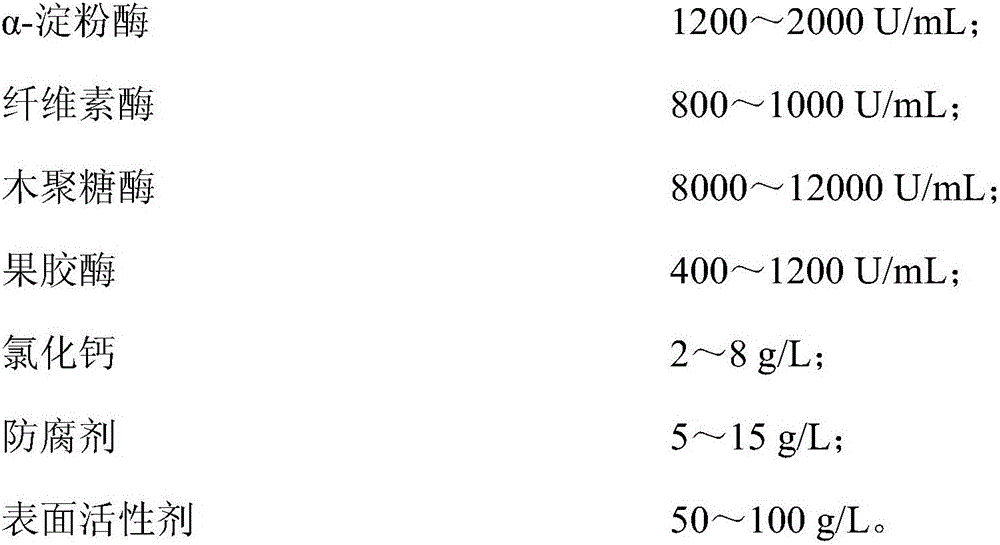

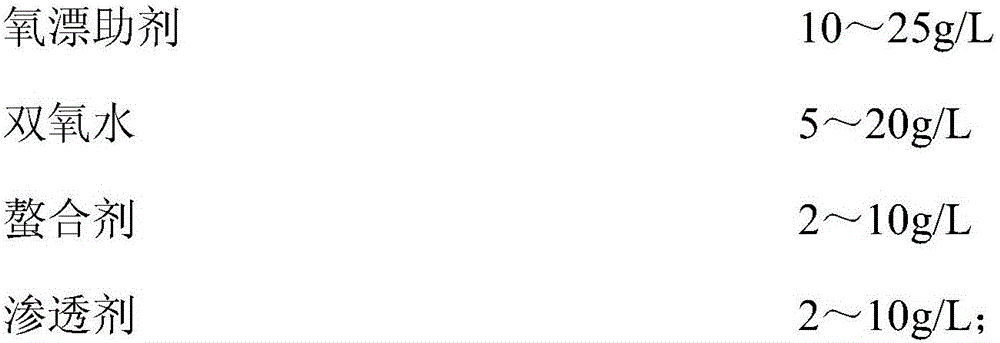

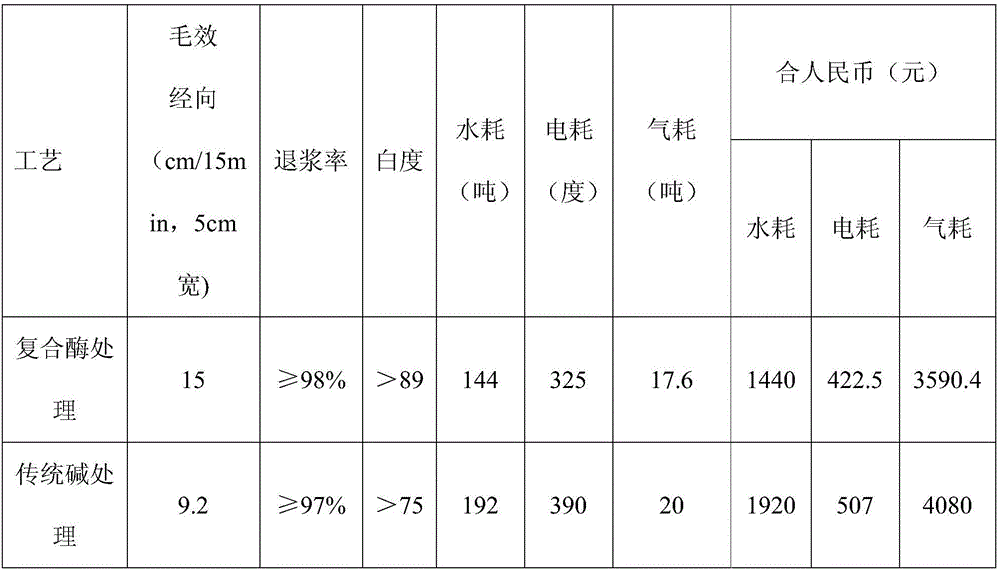

Biological enzyme pretreatment method for textiles

ActiveCN105970632AImprove qualityAvoid damageDry-cleaning apparatus for textilesBleaching apparatusPretreatment methodWastewater

The invention provides a biological enzyme pretreatment method for textiles. The biological enzyme pretreatment method comprises the following steps: padding a textile in a biological compound enzyme liquid at 20 to 70 DEG C till the liquid content is 80 to 100%; carrying out cold batching at 20 to 40 DEG C for 6 to 12 hours, or carrying out steaming with 50 to 70 DEG C saturated steam for 0.5 to 1 hour; washing with 70 to 80 DEG C hot water for 2 to 4 times; carrying out oxygen bleaching with an oxygen bleaching liquid till the liquid content is 80 to 100%; carrying out steaming with 100 DEG C saturated steam for 10 to 30 minutes; washing with 70 to 80 DEG C hot water for 2 to 4 times again; drying. The biological enzyme pretreatment method has the advantages that treatment before desizing and refining is realized with the biological compound enzyme in one step; a bleaching auxiliary agent replaces caustic soda in the oxygen bleaching step, so that the neutralizing step of the conventional alkali wastewater treatment process is eliminated, energy and water are saved, and pollution and cost are reduced; meanwhile, the quality of a textile treated according to the biological enzyme pretreatment method is higher than that of a textile treated according to the conventional process, the desizing rate of the textile subjected to enzymatic treatment is equal to or higher than 98%; the capillary effect is equal to or higher than 10cm / 15min (radial); the whiteness is equal to or higher than 89.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Supercritical carrot extractive juice, and its application in perfuming of cigarette

ActiveCN1860947AIncrease cigarette aromaMask cigarette fumesTobacco treatmentAlcoholSodium borohydride

A liquid extract of carrot used for flavouring the cigarettes is prepared from carrot through pulverizing, loading the powdered carrot into extractor, adding alcohol, supercritical CO2 extracting, adding alcohol to the liquid extract, dripping H2O2, refluxing to obtain the oxidized product, adding sodium bromohydride, refluxing, cooling and filtering.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

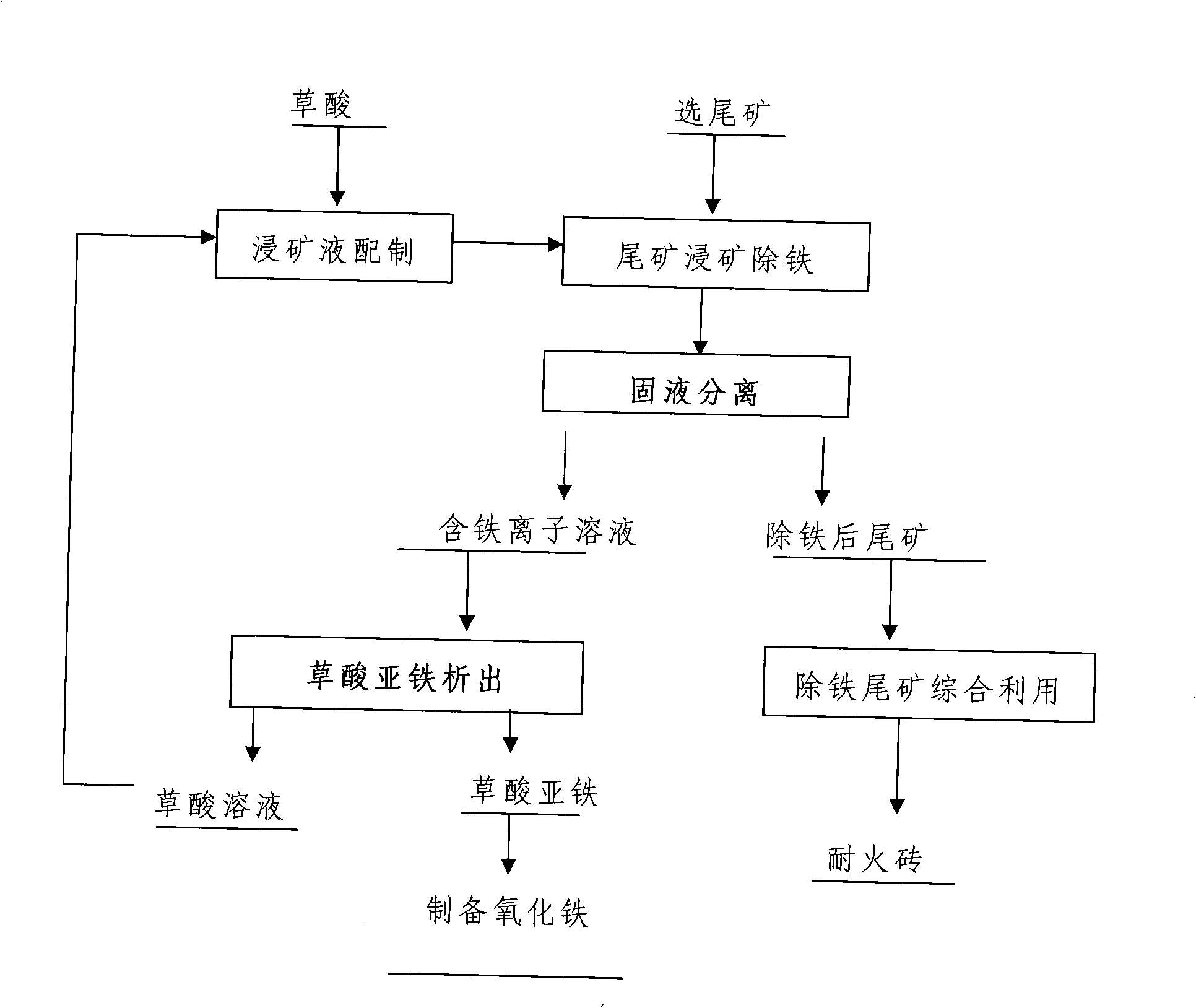

Process for preparing clay firebrick by flotation tailing of bauxite

InactiveCN101306953AReduce iron oxide contentDoes not destroy the crystal structureOxalateFire brick

A method for the treatment of bauxite flotation tailings relates to a method for making clay fire brick by means of bauxite flotation tailings and reclaiming the iron mineral in the tailings to make ferrous oxalate and ferric oxide. The method is characterized in that: firstly, the making process adopts oxalic acid leach bauxite cradling tailings iron mineral so as to remove iron; then, tailings is filtered and separated to make clay fire bricks. The method removes most impurity iron in the tailings at first so as to ensure that the content of ferric oxide in the tailings drops to less than 1.5 percent; meanwhile, only less than 1 percent of aluminum is leached out, and the crystal structure of the aluminum mineral in the tailings is not damaged basically; moreover, the flotation tailings with iron removed can be used to make qualified clay fire bricks.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

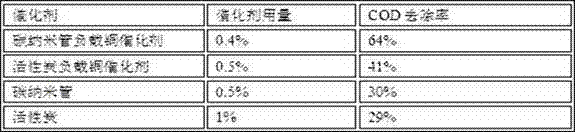

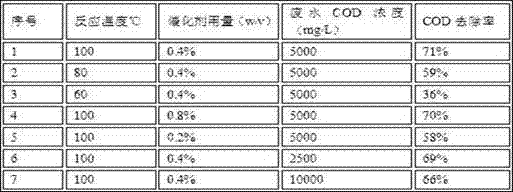

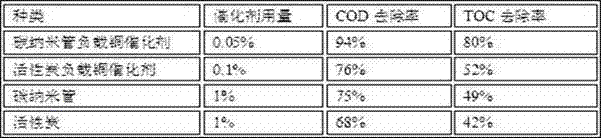

Microwave-induced catalytic oxidization method of high-concentration organic wastewater

PendingCN107986382AMild treatment conditionsImprove adsorption capacityWater/sewage treatment by irradiationWater contaminantsHigh concentrationFiber

The invention provides a microwave-induced catalytic oxidization method of high-concentration organic wastewater. The method comprises the following steps: A, preparing activated carbon, silicon carbide, activated carbon fibers and carbon nanotube loaded metal catalysts through a dipping-microwave, dipping-roasting or ethylene glycol liquid phase chemical reduction method; and B, adding the obtained catalysts into wastewater containing organic substances; and charging oxidant gas or liquid for oxidizing the organic substances in the wastewater into inorganic small molecular compounds through microwave, thus achieving the purpose of reducing pollutant mission. According to the method for treating the organic wastewater, the activated carbon, silicon carbide, the activated carbon fibers andthe carbon nanotubes are used as the catalyst carriers; the service life is long; the catalyzing activity is high; the wastewater treatment condition is mild; and other advantages are also realized.

Owner:北京科瑞博远科技有限公司

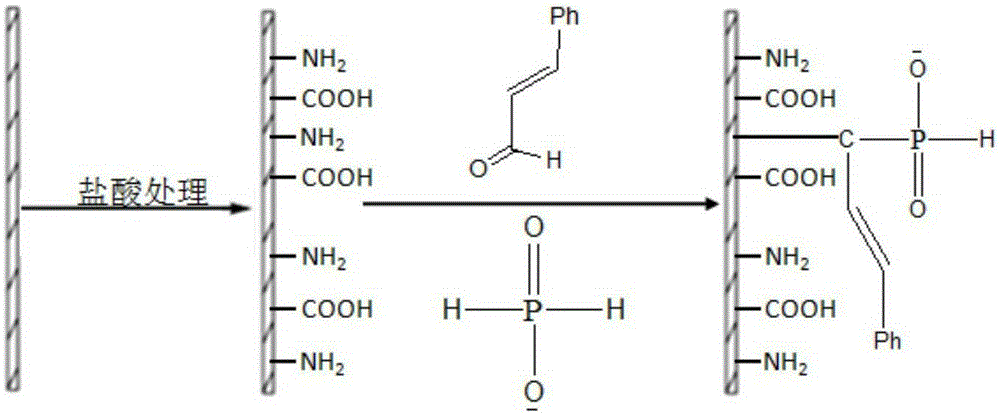

Anionic polyelectrolyte and nylon fabric after-finish flame retarding method

ActiveCN105175738ASmall mechanical propertiesImprove flame retardant performanceFibre treatmentNylon materialCationic polyelectrolytes

The invention provides an anionic polyelectrolyte and a nylon fabric after-finish flame retarding method. The after-finish flame retarding method comprises the following steps: carrying out surface modification on the nylon fabric; alternately immersing the surface-modified nylon fabric in an anionic polyelectrolyte solution and a cationic polyelectrolyte solution to form a flame-retardant coating, thereby obtaining a flame-retardant-coating-containing nylon fabric; and carrying out crosslinking treatment on the flame-retardant-coating-containing nylon fabric to form the flame-retardant coating. Compared with the prior art, layer-by-layer self-assembly is utilized to construct the flame-retardant coating under the acting force of static electricity; and the introduced polyelectrolyte structure contains phosphorus, nitrogen, sulfur and many other flame-retardant elements, thereby displaying the synergistic effects among the multiple flame-retardant elements and enhancing the flame retardancy of the nylon fabric. The crosslinking treatment is performed to enhance the durability of the flame-retardant coating of the nylon fabric. The method has the advantages of simple production technique, low requirements for technical equipment and mild treatment conditions, and satisfies the requirements for greenness and environment friendliness.

Owner:UNIV OF SCI & TECH OF CHINA

New process for preparing microcrystalline cellulose from lignocelluloses biomass

ActiveCN103397554ALoose physical structureReduce crystallinityPaper material treatmentProcess engineeringChemistry

The invention discloses a new method for preparing microcrystalline cellulose from lignocelluloses biomass and particularly relates to a new method for utilizing lignocelluloses biomass and preparing the microcrystalline cellulose, belonging to the field of biomass material process transfer and application. The prepared microcrystalline cellulose has the cellulose content being more than or equal to 97.3 percent, the crystallinity being more than or equal to 80 percent, the ignition residue being less than or equal to 0.2 percent and the pH being 5.0-7.5 and can be widely applied to the fields of medicines, foods, chemical engineering, daily chemicals and the like as a novel cellulose function material.

Owner:安徽安生生物化工科技有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com