Patents

Literature

31results about How to "Does not affect biocompatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

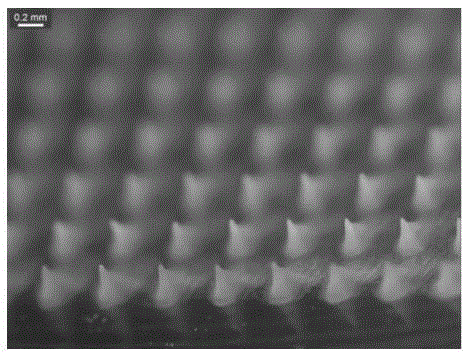

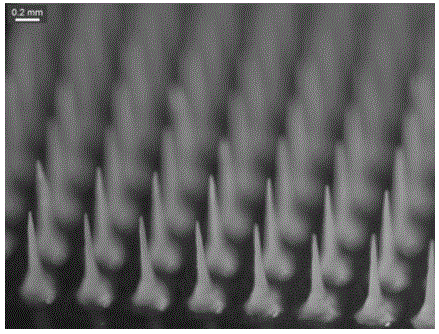

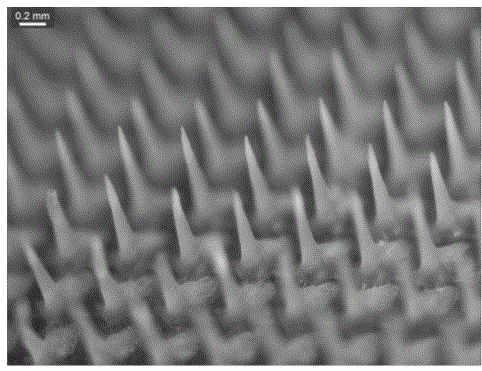

Silk fibroin gel microneedle system and manufacturing method thereof

ActiveCN103800998ASimple methodDoes not affect biocompatibilityMicroneedlesMedical devicesBrute forceBiocompatibility Testing

The invention discloses a silk fibroin gel microneedle system and a manufacturing method of the silk fibroin gel system microneedle system. Silk fibroin solution with the mass concentration between 3 percent to 15 percent is processed through ultrasonic oscillation and then is poured on a polydimethylsiloxane film needle hole die array obtained through laser boring, dies are placed in a vacuum drying box and vacuumized, the solution is made to enter holes, the vacuum degree is kept, the dies are dried to constant weight, and then the silk fibroin gel microneedle system is obtained. The microneedle system is an insoluble gel microneedle and has certain brute force to puncture into the skin, the microneedle system swells after making contact with body fluid in the skin, and medicine in the microneedle system is released. The gel microneedle system is good in biocompatibility, easy to prepare, moderate in condition and capable of biodegradation, and the system can be used in the aspects of cosmetology, transdermal drug absorption devices and the like.

Owner:PHARSUN MEDICAL BIOTECHNICS (SHANGHAI) CO LTD

Preparation method for paclitaxel coating on surface of drug balloon

InactiveCN104984412AImprove adhesionIncrease the amount of crystallizationSurgeryCoatingsMedicineCrystallization

The invention relates to a preparation method for paclitaxel coating on the surface of a drug balloon. The preparation method comprises the steps that a hydrophilic balloon surface is pretreated; the balloon surface is coated with a first organic solution to obtain a modified balloon, wherein the first organic solution contains both a hydrophilic group and a lipophilic group; and the modified balloon is immersed into a paclitaxel coating solution, placed into a low-temperature device to be frozen for a period of time and then is dried, and the crystallization process is repeatedly executed. The preparation method for the paclitaxel coating solution comprises the step of dissolving paclitaxel and a carrier into a second organic solution according to the certain mass percentage, wherein the carrier has the effect of increasing the paclitaxel dissolvability. The preparation technology is simple and reliable, and is low in cost. The preparation method allows precise control of the drug loading capacity of the paclitaxel coating on the surface of the drug balloon and is beneficial to mass production.

Owner:XIANGTAN UNIV

Hydroxyapatite/aluminum oxide composite bioceramic and preparation method thereof

InactiveCN104744025AImprove mechanical propertiesGood mechanical propertiesApatiteBiocompatibility Testing

The invention discloses a hydroxyapatite / aluminum oxide composite bioceramic and a preparation method thereof, relating to the field of biomaterials. The hydroxyapatite / aluminum oxide composite bioceramic is prepared from the following components in parts by mass: 40-60 parts of hydroxyapatite, 10-20 parts of shell powder, 15-25 parts of nano aluminum oxide, 5-12 parts of zirconium oxide, 3-8 parts of magnesium oxide, 5-10 parts of calcium hydrogen phosphate and 2-5 parts of nano zinc oxide. The preparation method comprises the following steps: (1) weighing; (2) ball milling; (3) cold-press molding; (4) high-temperature calcination; and (5) cooling. The hydroxyapatite / aluminum oxide composite bioceramic has higher biocompatibility, maintains the excellent actions of the hydroxyapatite, further enhances the mechanical properties of the bioceramic, and thus, is a very ideal skeleton substitute repair material.

Owner:SUZHOU VIVOTIDE BIOTECH

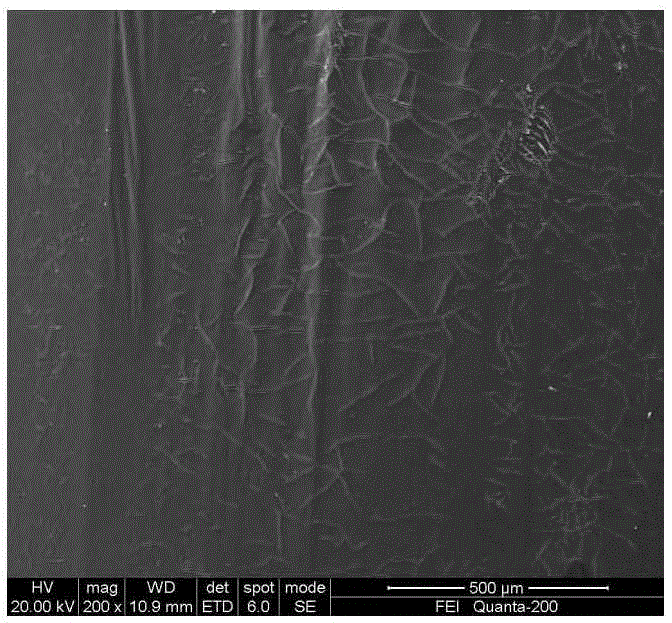

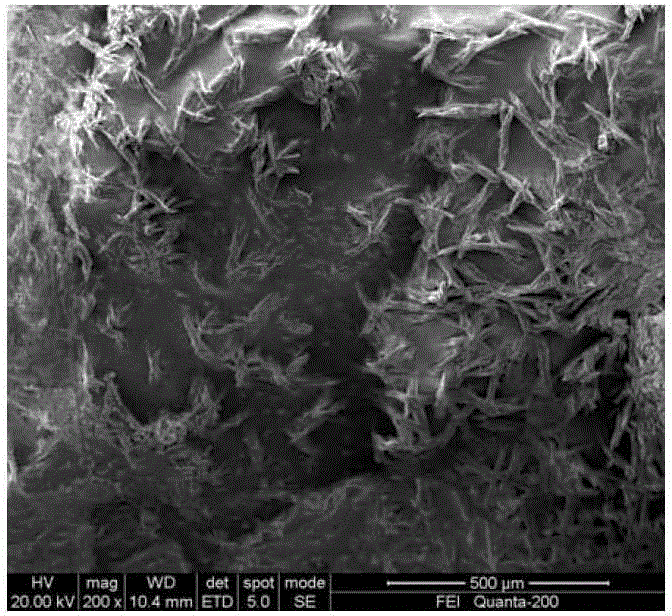

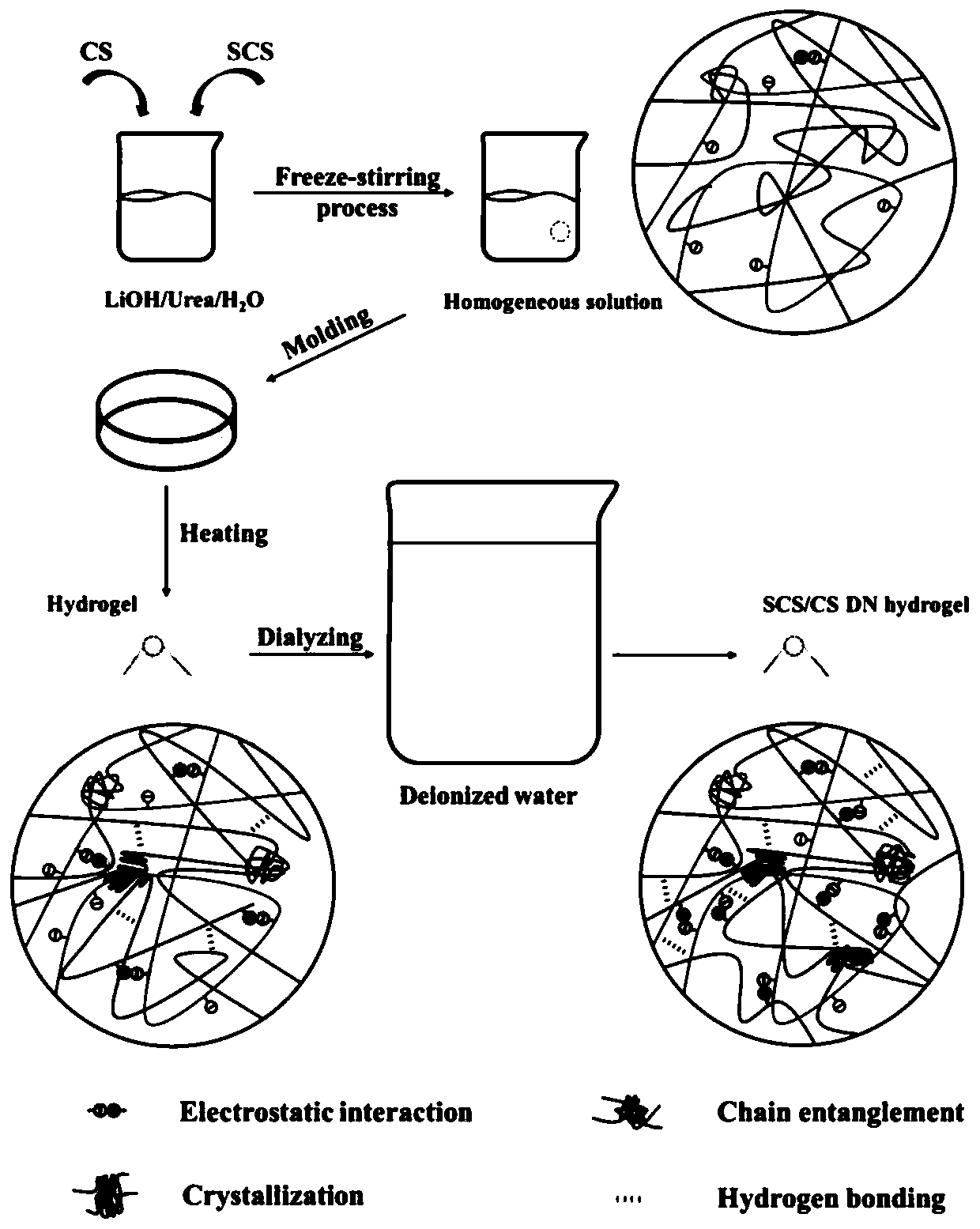

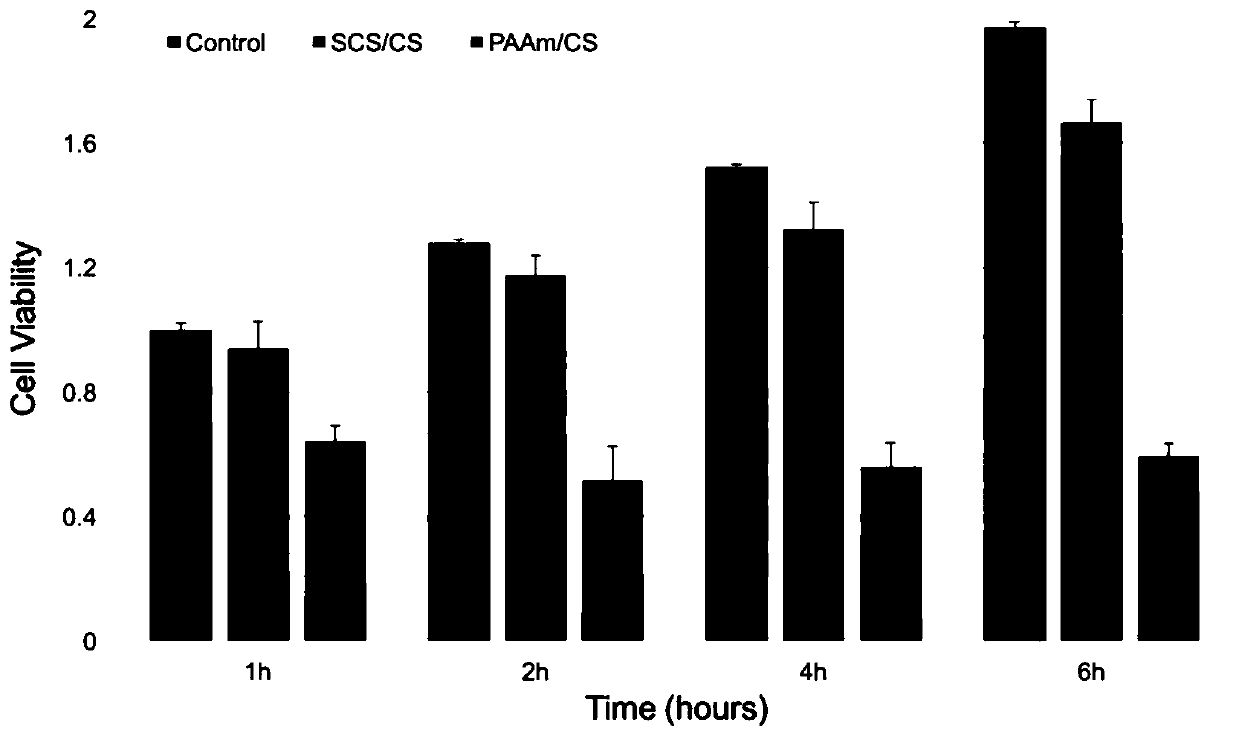

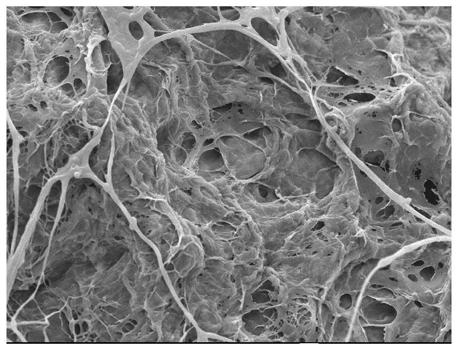

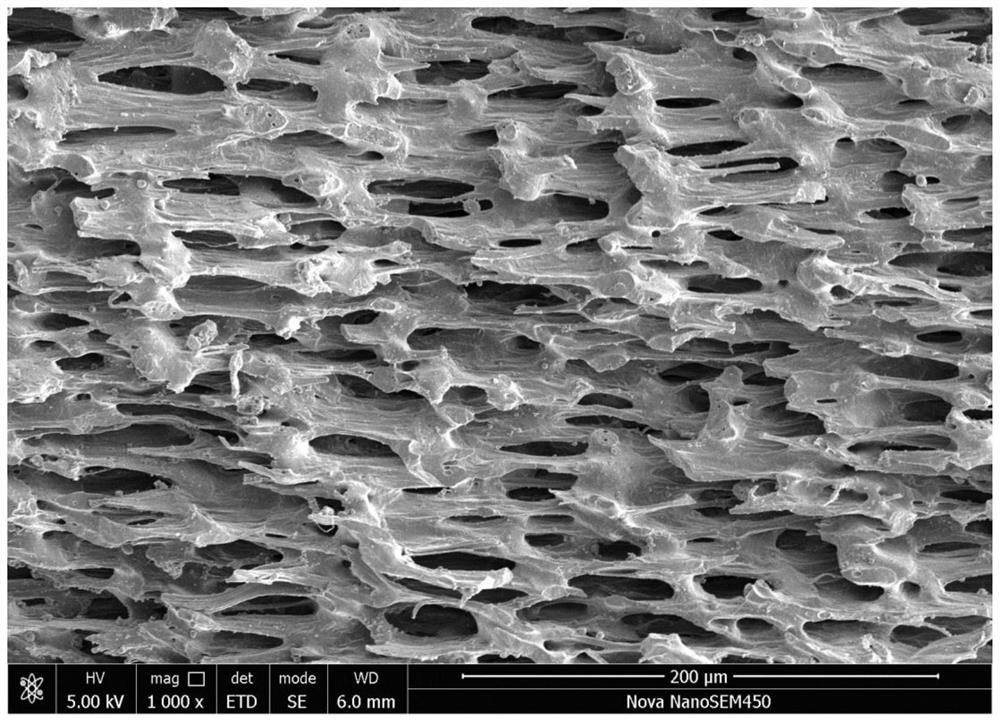

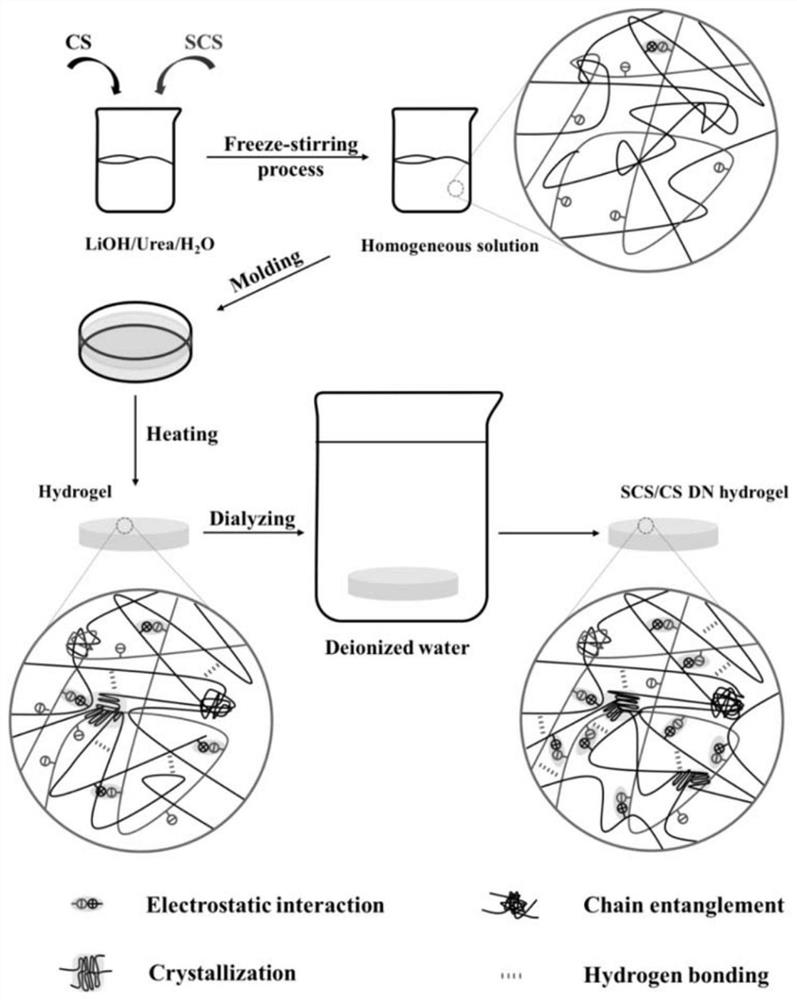

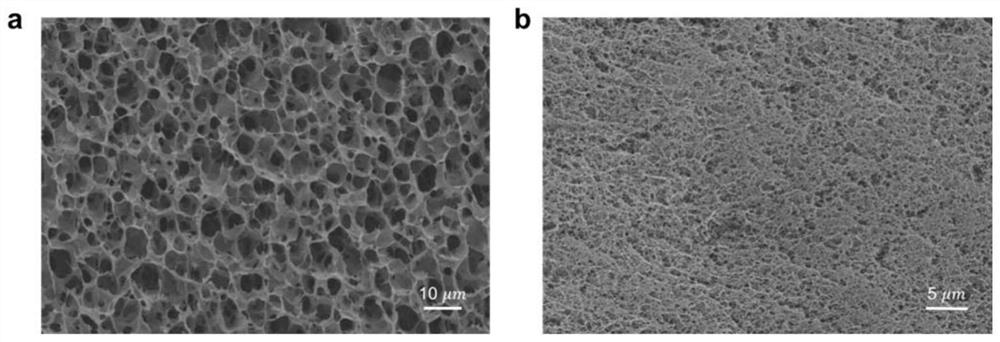

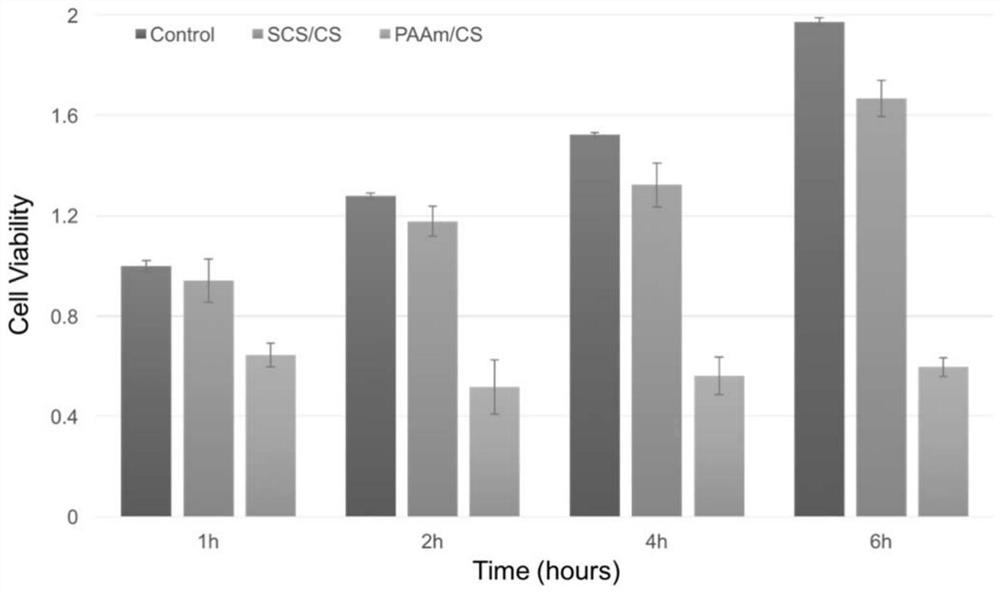

Chitosan-based pure physically-crosslinked double-network hydrogel and preparation method thereof

The invention discloses a chitosan-based pure physically-crosslinked dual-network hydrogel and a preparation method thereof. With the method provided by the invention, a double-network hydrogel crosslinked by pure physical action is constructed by using chitosan and succinylated chitosan as raw materials and an alkaline solvent system as a basis; and the obtained hydrogel is further subjected to biomimetic mineralization to improve mechanical properties. Compared with a pure chitosan hydrogel, the chitosan-based pure physically-crosslinked double-network hydrogel provided by the invention is regular and compact in structure, and is significantly improved in the mechanical properties. Meanwhile, compared with a traditional chemically-physically crosslinked chitosan-based double-network hydrogel, the chitosan-based pure physically-crosslinked dual-network hydrogel has obvious advantage in good biocompatibility. The pure physically-crosslinked double-network hydrogel prepared by using thepreparation method provided by the invention has good mechanical properties and good biocompatibility, and has good application prospect in the field of biomedicine application.

Owner:ZHEJIANG UNIV

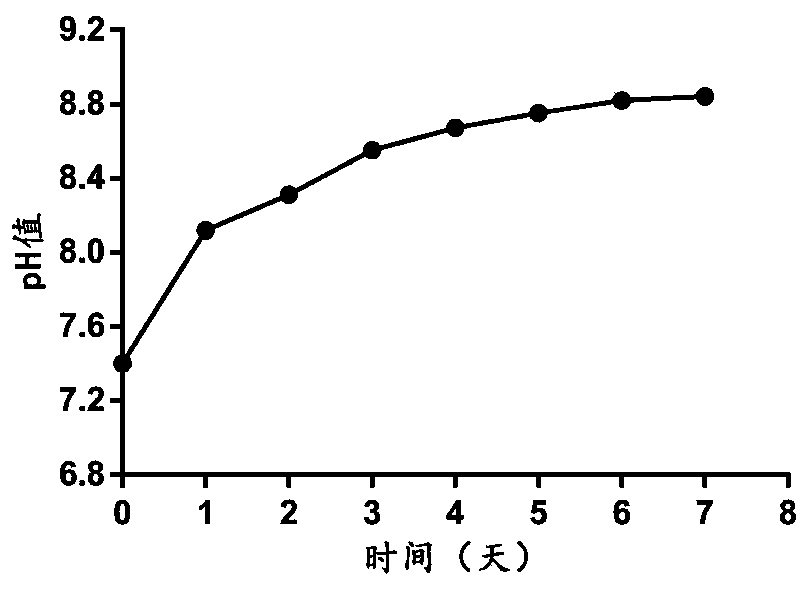

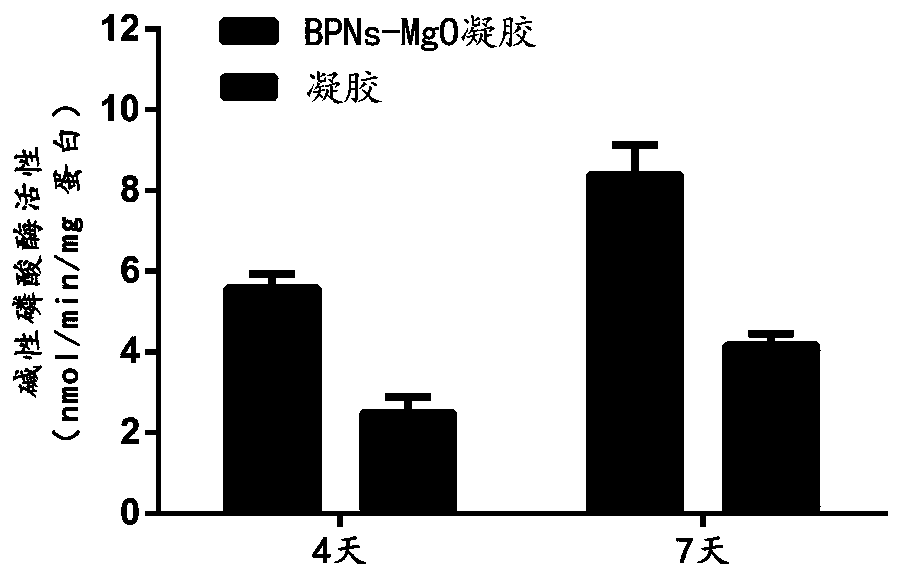

Multifunctional bone filling material containing black phosphorus nanosheets and preparation method thereof

InactiveCN111494721AFacilitate cross-linkingDoes not affect biocompatibilityPharmaceutical delivery mechanismTissue regenerationPolyvinyl alcoholBone defect

The invention discloses a multifunctional bone filling material containing black phosphorus nanosheets and a preparation method thereof. The multifunctional bone filling material is prepared from black phosphorus nanosheets, nano magnesium oxide, polyvinyl alcohol and chitosan. The specific preparation method comprises the following steps: preparing black phosphorus nanosheets; preparing a polyvinyl alcohol and chitosan hydrogel compound; loading the black phosphorus nanosheets and a nano magnesium oxide hydrogel compound, and the like. The multifunctional hydrogel bone filling stent disclosedby the invention overcomes the defects of poor complex disease resistance and poor osteogenesis induction of a stent system in the prior art, and the progress of bone defect repair under complex disease conditions is improved effectively.

Owner:JILIN UNIV

Multi-purpose gelatin fiber preparing method based on closed type waterborne polyurethane in-situ cross linking

InactiveCN105821519AGood compatibilityImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsFiberCross-link

The invention relates to a multi-purpose gelatin fiber preparing method based on closed type waterborne polyurethane in-situ cross linking .The preparing method comprises the steps that firstly, a gelatin aqueous solution and closed type waterborne polyurethane emulsion are mixed evenly, and a spinning solution is obtained; secondly, the spinning solution is spun into gelatin / closed type waterborne polyurethane composite fibers with a dry or wet spinning technology; finally, in the subsequent drying process, closed type waterborne polyurethane is subjected to closed-form solution, isocyanate groups obtained through closed-form solution further react with active groups in gelatin, and thus the effects of in-situ cross linking and great improvement of the mechanical property of the composition fibers are achieved .Due to the fact that waterborne polyurethane and gelatin are in good compatibility, the adding quantity of the gelatin component in the composite fibers is large, and the excellent performance of gelatin is fully embodied; besides, waterborne polyurethane is nontoxic, and the biological compatibility of the composite fibers cannot be influenced after cross-linking modification is performed on gelatin; a covalence reaction exists between waterborne polyurethane and gelatin, the mechanical property of the composition fibers can be greatly improved in a lasting mode, and the composite fibers have application prospects in biomedical, tissue engineering and textile and garment fields and the like .

Owner:SICHUAN UNIV

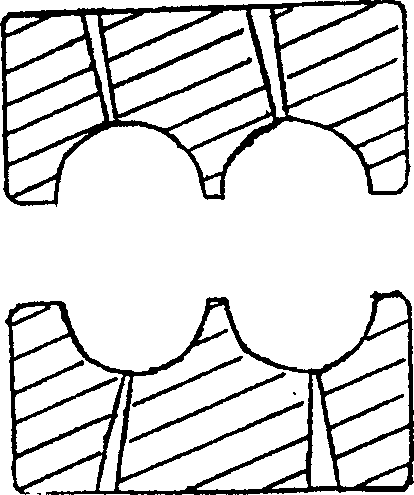

Preparation method of microsphere close-packed shape memory porous scaffold

InactiveCN104740688AGood biocompatibilityFacilitate adhesionProsthesisBiocompatibility TestingPorous scaffold

The invention discloses a preparation method of a microsphere close-packed shape memory porous scaffold. Medicine delivery and a porous structure are formed in a material with a shape memory function under the action of a pore-foaming agent and a medicine, so as to prepare the porous scaffold with the shape memory function and the medicine function. A porous scaffold material loaded with medicine factors is prepared by (1) preparation of drug-loaded calcium alginate hydrogel microspheres, and (2) preparation of the porous structure; the prepared porous scaffold has a good shape memory property, biocompatibility and biodegradability, also has a drug release effect, and has a great application prospect in the field of tissue engineering. An experiment proves that the preparation method has the advantages of controllable aperture, uniform dimension and the like, and does not need to sacrifice a pore-forming material; and the raw materials are cheap and easily available.

Owner:SOUTHWEST JIAOTONG UNIV

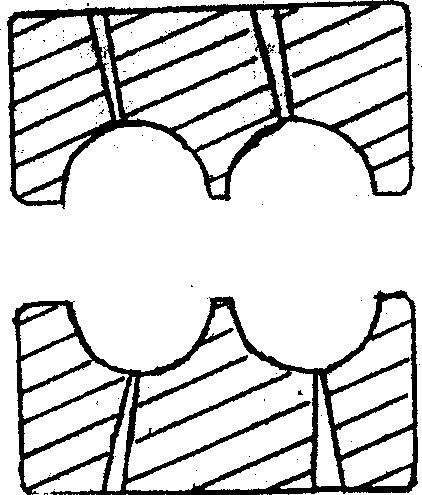

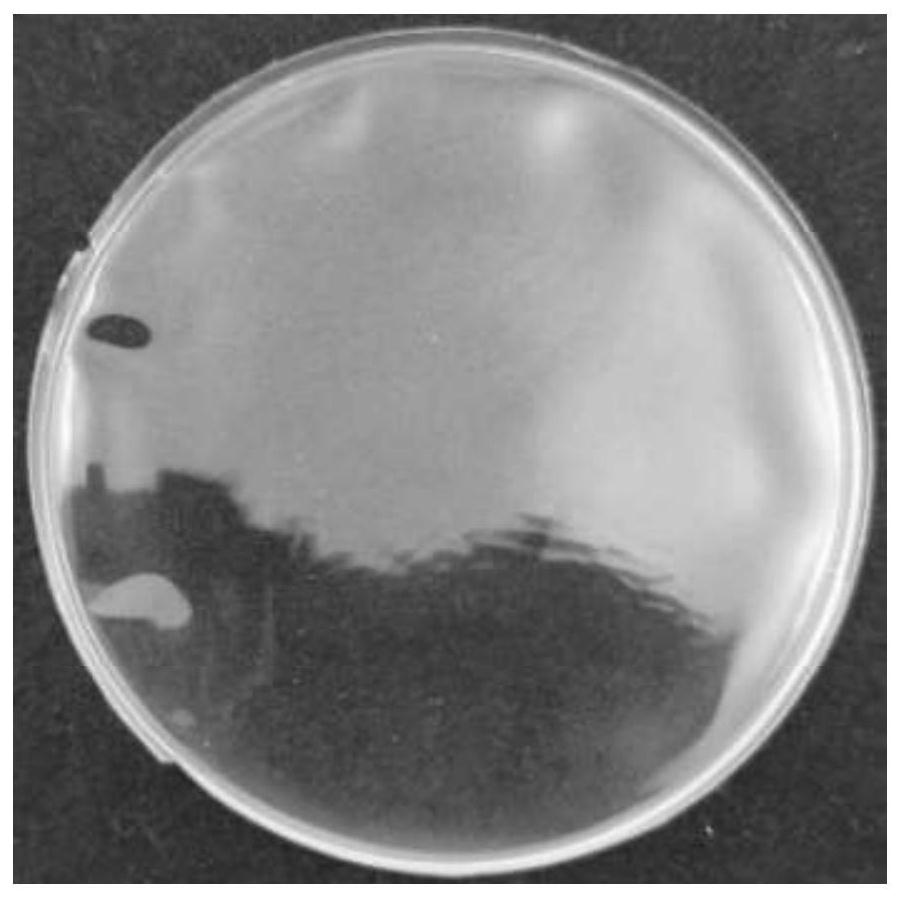

Swelled polymer particles filter process for preparing artificial eye holder

A process for preparing artificial eye ball includes such steps as dissolving the biocompatible polymer in solvent to obtain saturated solution, mixing it with sieved pore-forming agent (300-600 microns), die pressing to obtain circular ball, volatilizing solvent, immersing the ball in the swelling solution prepared from trigger, cross-linking agent and polymer monomer, introducing nitrogen gas, sealing, swelling for 3-100 hr, putting the ball in reactor, introducing nitrogen gas, sealing, polymerizing, and immersing the ball in deionized water for 72 hr. Its advantages are high precision of size, high porosity (more than 80%), and high performance.

Owner:TSINGHUA UNIV

Degradable super-tough silk protein-based material and preparation method and application thereof

ActiveCN113527895AWide variety of sourcesControllable outputMonocomponent fibroin artificial filamentArtifical filament manufacturePolymer scienceLithium chloride

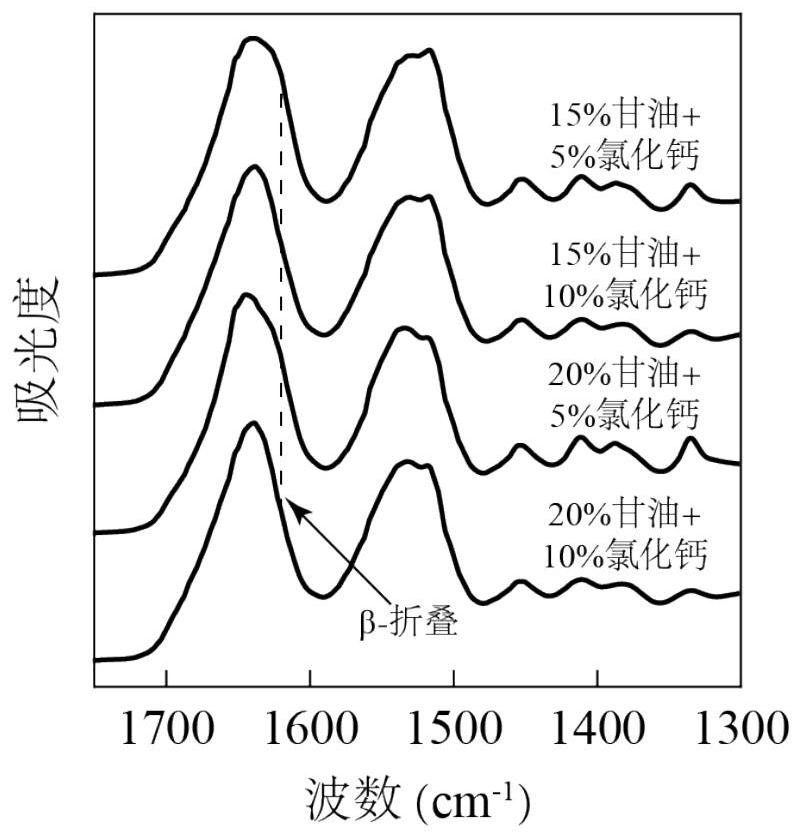

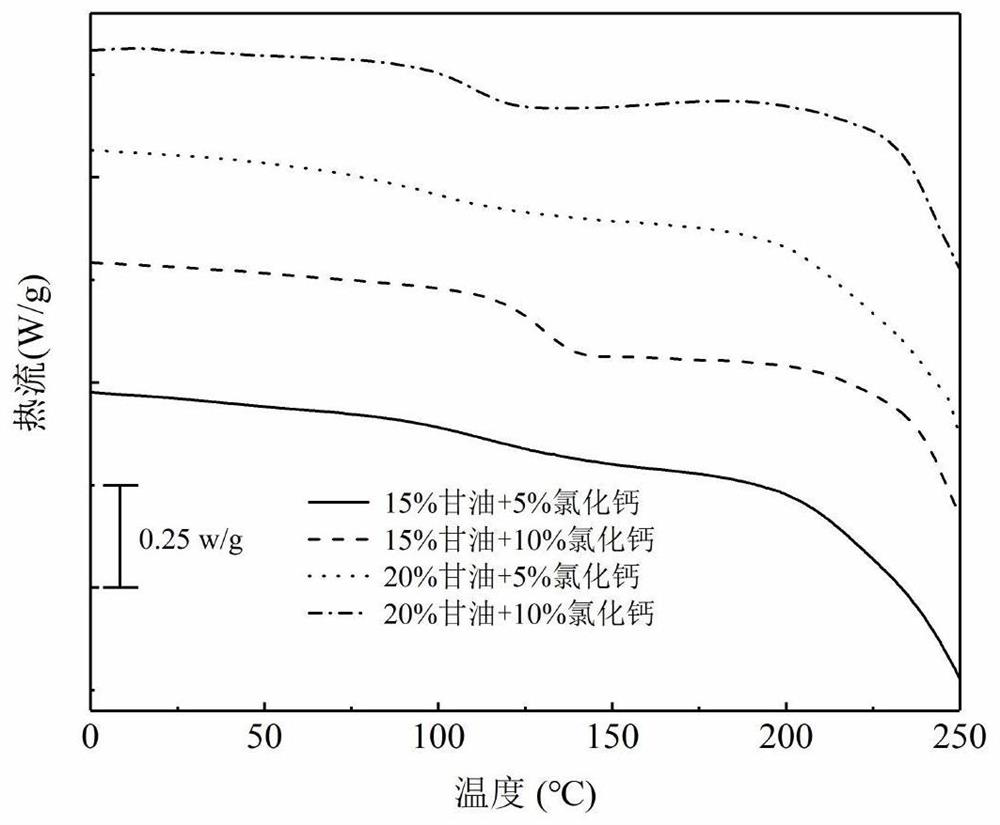

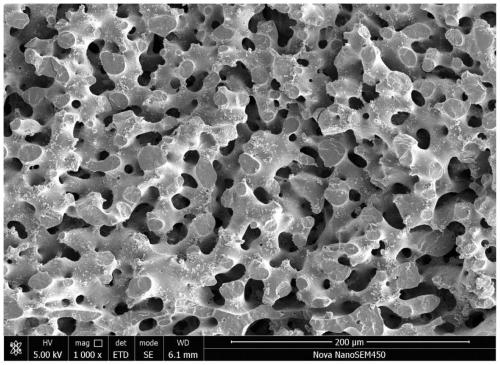

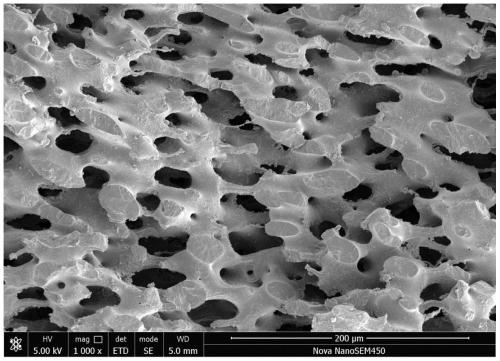

The invention relates to a degradable super-tough silk protein-based material and a preparation method and application thereof. The degradable super-tough silk protein-based material comprises a plasticizer, salt and silk protein, the plasticizer is selected from one or more of glycerin, sorbitol and polyethylene glycol, and the salt is selected from one or more of calcium chloride, lithium chloride and lithium bromide. By adjusting the ratio of the plasticizer to the salt in the super-tough silk protein-based material, the super-tough silk protein-based material has adjustable mechanical properties, degradation properties and water solubility, and can be developed into raw materials of various biological engineering materials depending on specific application.

Owner:WESTLAKE UNIV

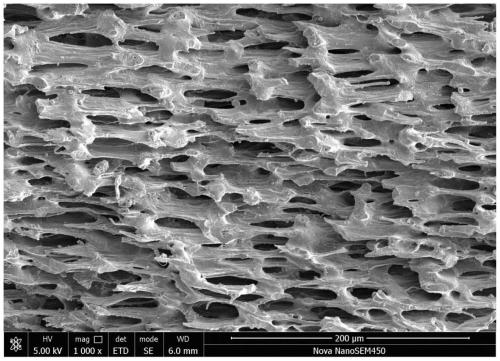

Preparation method of oriented communicated porous biomedical stent, as well as stent prepared by method and application of stent in preparation of medical products

The invention discloses a preparation method of a polycaprolactone oriented communicated porous biomedical stent. The method comprises the following steps of (1) melting and blending polycaprolactoneand polyethylene oxide to obtain a co-continuous blending material, and performing compression moulding on the co-continuous blending material to obtain a polycaprolactone / polyethylene oxide co-continuous substrate; (2) performing water extraction on the polycaprolactone / polyethylene oxide co-continuous substrate obtained in step (1) so as to remove a water-soluble polyethylene oxide phase to obtain a polycaprolactone porous stent; and (3) performing solid phase stretching on the polycaprolactone porous stent obtained in step (2) so as to enable the form of holes to generate orientation deformation in a stretching direction to obtain the polycaprolactone oriented communicated porous biomedical stent. The polycaprolactone oriented communicated porous biomedical stent prepared by the methodhas an obvious highly-communicated anisotropic porous structure. The invention further discloses the polycaprolactone oriented communicated porous biomedical stent and the application of the stent inthe preparation of medical products.

Owner:SICHUAN UNIV

A silk fibroin gel microneedle system and preparation method thereof

ActiveCN103800998BSimple methodDoes not affect biocompatibilityMicroneedlesMedical devicesBrute forceBiocompatibility Testing

The invention discloses a silk fibroin gel microneedle system and a manufacturing method of the silk fibroin gel system microneedle system. Silk fibroin solution with the mass concentration between 3 percent to 15 percent is processed through ultrasonic oscillation and then is poured on a polydimethylsiloxane film needle hole die array obtained through laser boring, dies are placed in a vacuum drying box and vacuumized, the solution is made to enter holes, the vacuum degree is kept, the dies are dried to constant weight, and then the silk fibroin gel microneedle system is obtained. The microneedle system is an insoluble gel microneedle and has certain brute force to puncture into the skin, the microneedle system swells after making contact with body fluid in the skin, and medicine in the microneedle system is released. The gel microneedle system is good in biocompatibility, easy to prepare, moderate in condition and capable of biodegradation, and the system can be used in the aspects of cosmetology, transdermal drug absorption devices and the like.

Owner:PHARSUN MEDICAL BIOTECHNICS (SHANGHAI) CO LTD

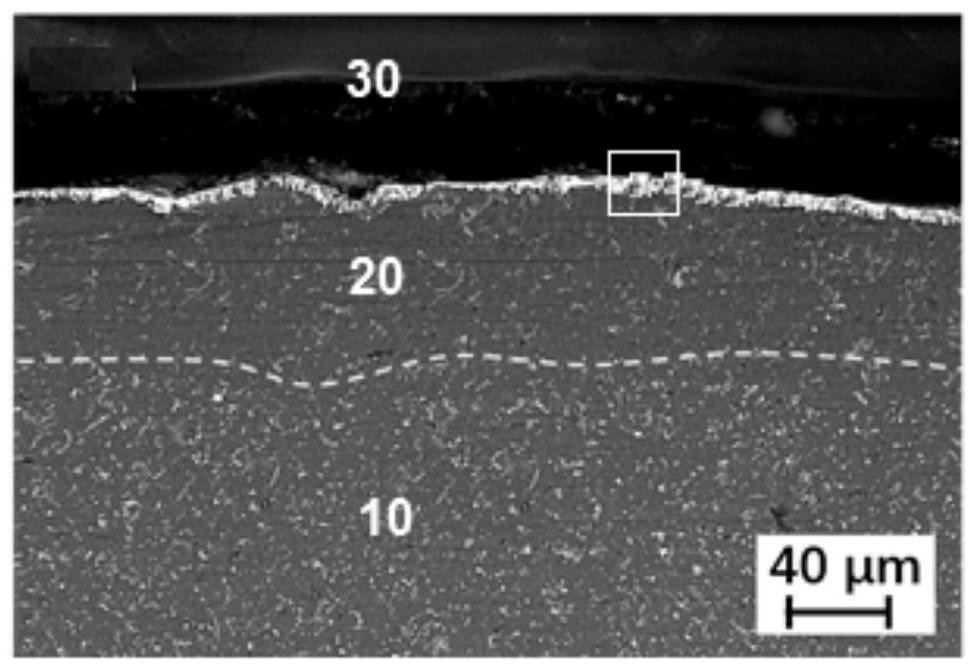

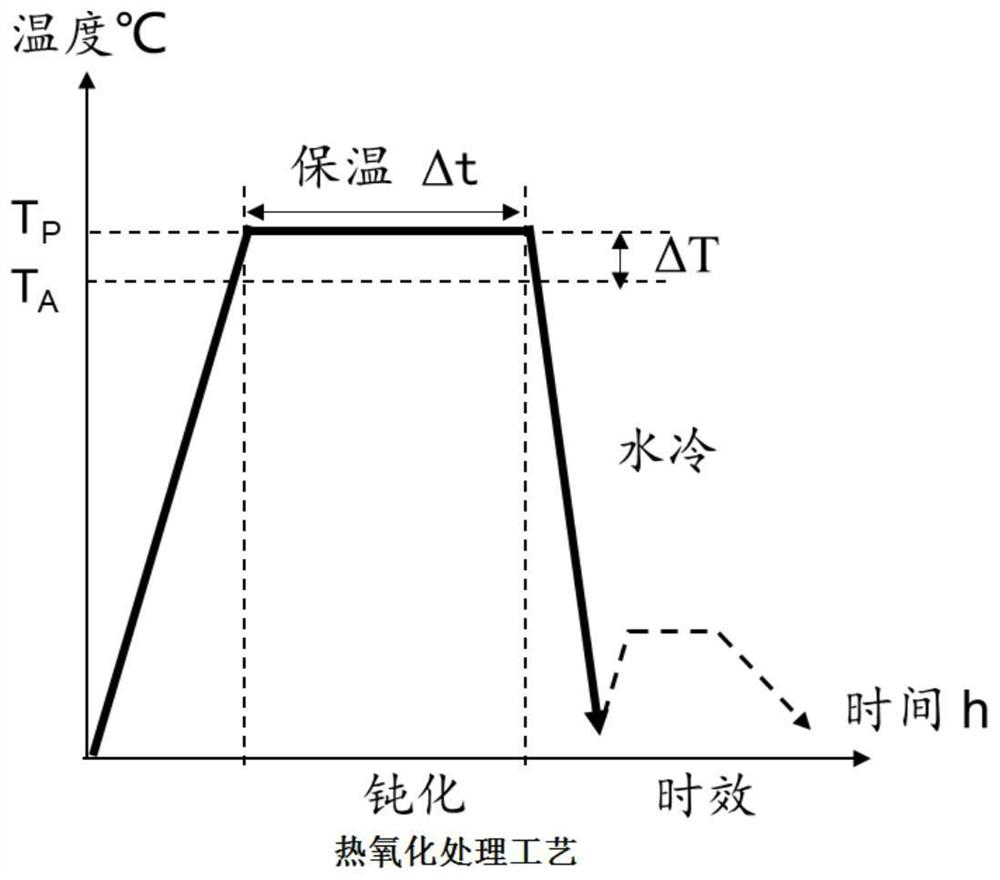

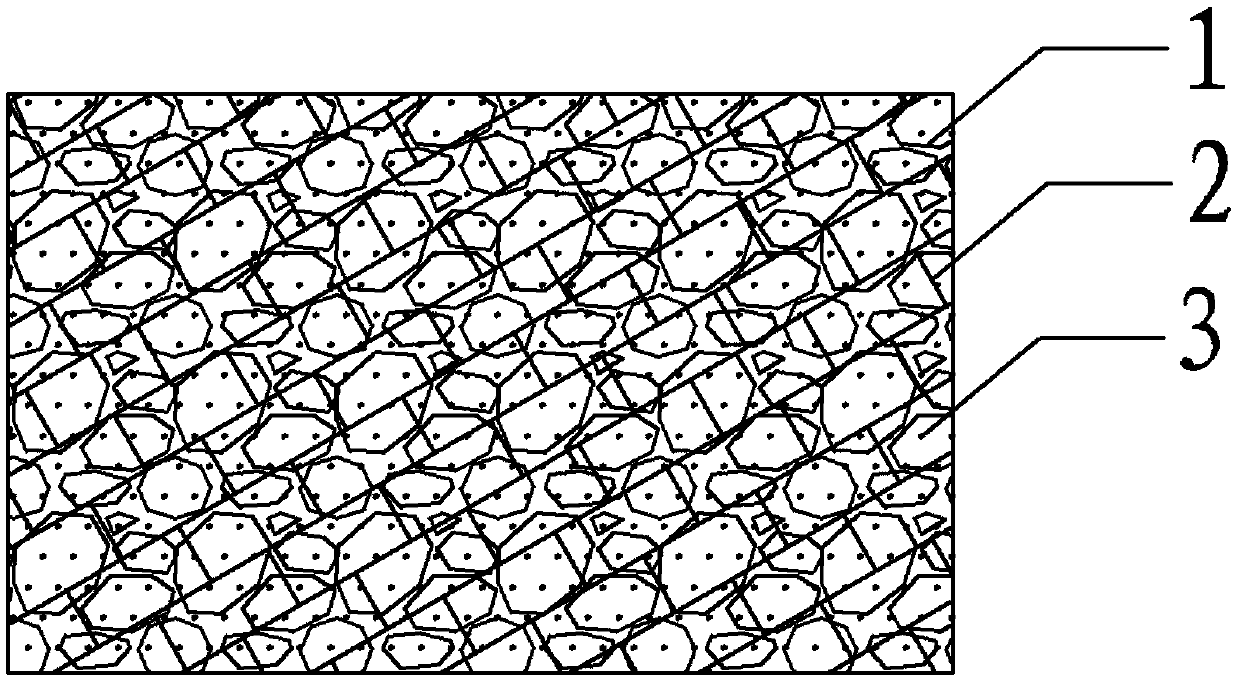

Magnesium alloy medical implant and preparation method thereof

PendingCN114288471AReduce the rate of degradationDoes not affect biocompatibilityAdditive manufacturing apparatusSuperimposed coating processMg alloysSkeletal tissue

The invention provides a magnesium alloy medical implant and a preparation method thereof, and the preparation method comprises the following steps: providing a magnesium alloy which comprises magnesium and at least one active element; the magnesium alloy is sequentially subjected to thermal oxidation treatment and post-treatment, the magnesium alloy medical implant is obtained, and the magnesium alloy medical implant comprises an oxide passivation layer, a middle layer and a magnesium alloy base body. The magnesium alloy medical implant has a customized appearance matched with bone defects and a composite structure comprising the oxide passivation layer on the surface, the middle layer and the magnesium alloy base body, the oxide passivation layer and the middle layer are degraded slowly in body fluid, the magnesium alloy base body is separated from the body fluid, the degradation rate of the magnesium alloy medical implant is decreased, and the service life of the magnesium alloy medical implant is prolonged. The degradation period is matched with bone tissue reconstruction and functional recovery, and the bone defect repair effect is improved. The preparation method is not influenced by geometric structures, no other materials are added, the degradation period is adjustable, the effect is stable, operability is high, and industrial production and clinical application are facilitated.

Owner:TSINGHUA UNIV +1

Zirconia biological ceramic used for making hip joint and its preparation method

InactiveCN104829228AImprove overall fracture toughness and fracture strengthGood chemical stabilityProsthesisNano zinc oxideCeramic

The invention discloses a zirconia biological ceramic used for making hip joint and a preparation method thereof, and relates to the field of biological materials, the zirconia biological ceramic used for making the hip joint comprises the following components by mass: 65-85 parts of zirconia, 3-7 parts of nano titanium oxide, 2-8parts of nano aluminum, 1-3 parts of nano zinc oxide, 2-5 parts of carbon fiber and 5-10 parts of calcium oxide. The preparation steps of the preparation method of the zirconia biological ceramic used for making the hip joint are as follows: (1) weighing; (2) ball milling; (3) cold pressing molding; (4) high temperature calcination, and (5) cooling. The zirconia biological ceramic used for making the hip joint has high wear-resisting property and toughness, and good biological compatibility, and has good application prospect as a material for making the hip joint.

Owner:SUZHOU VIVOTIDE BIOTECH

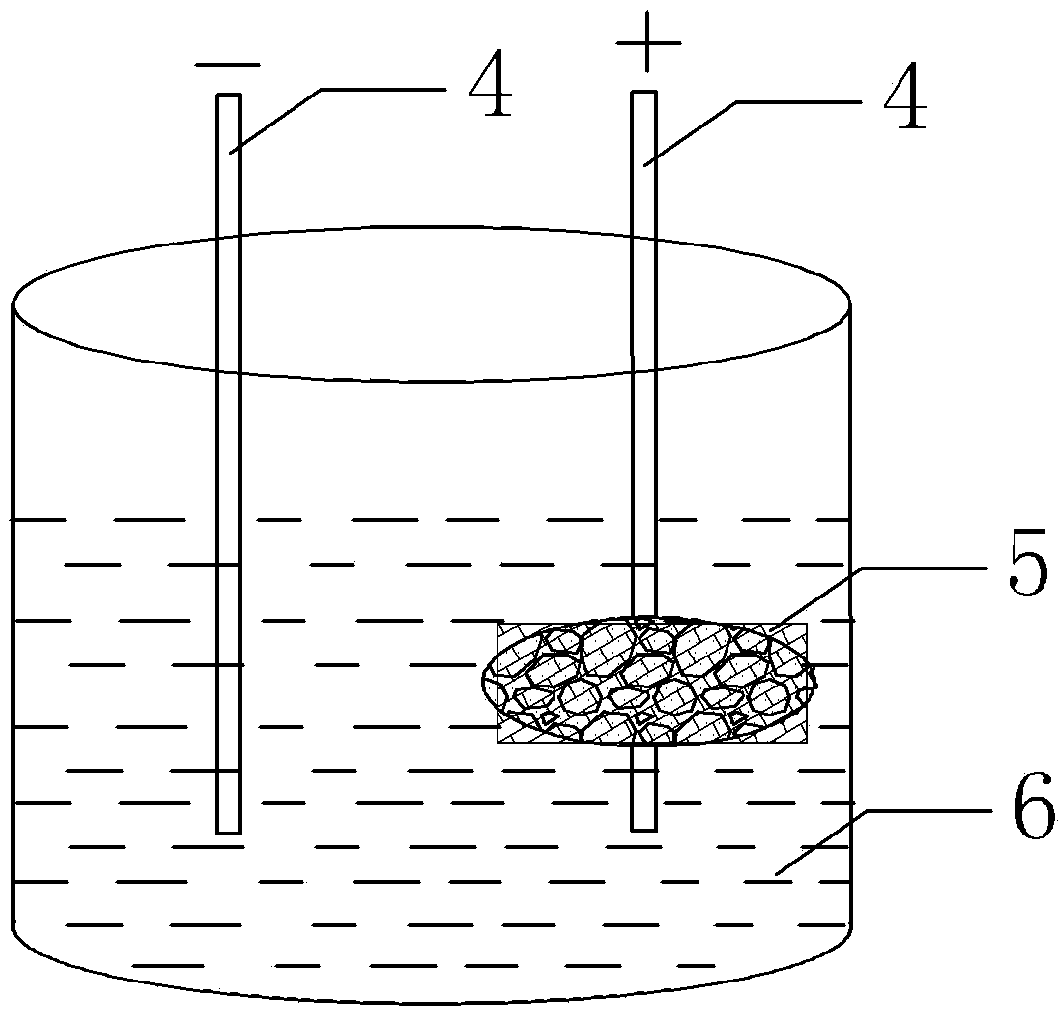

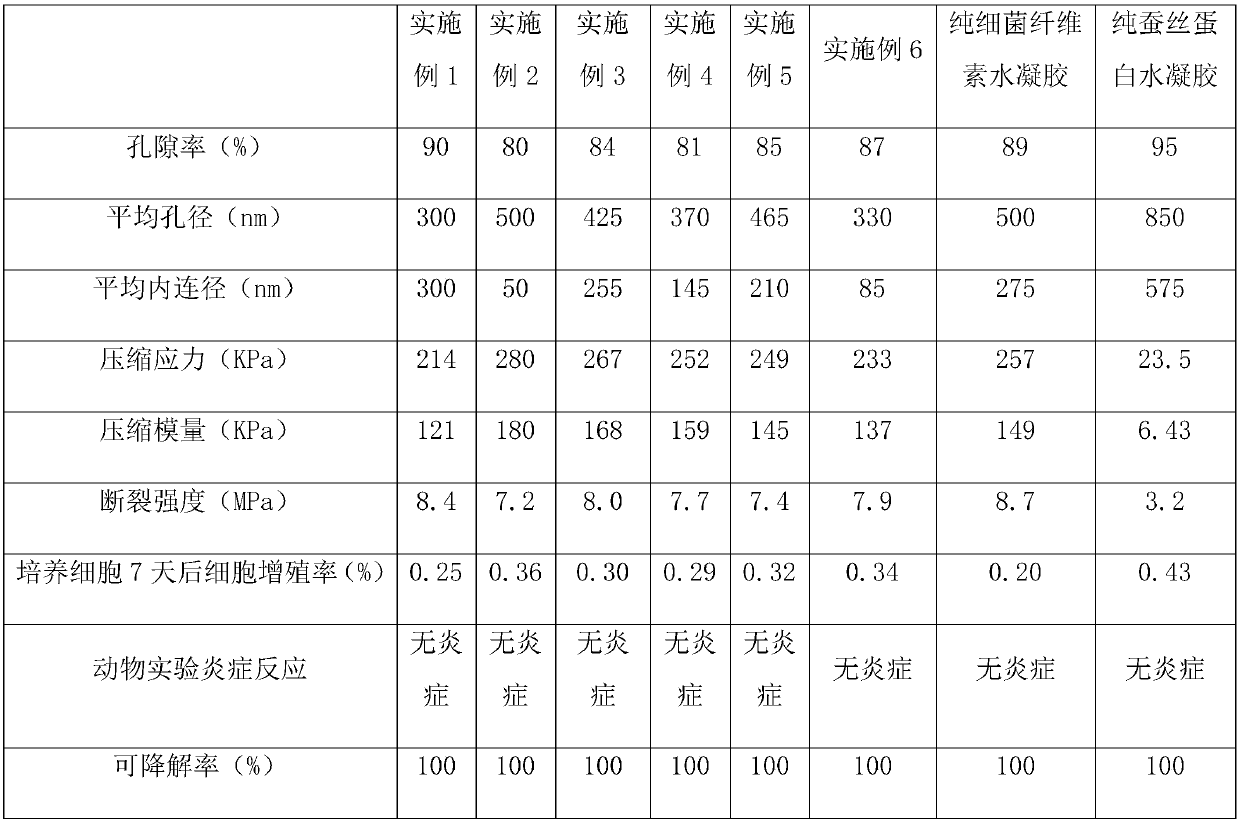

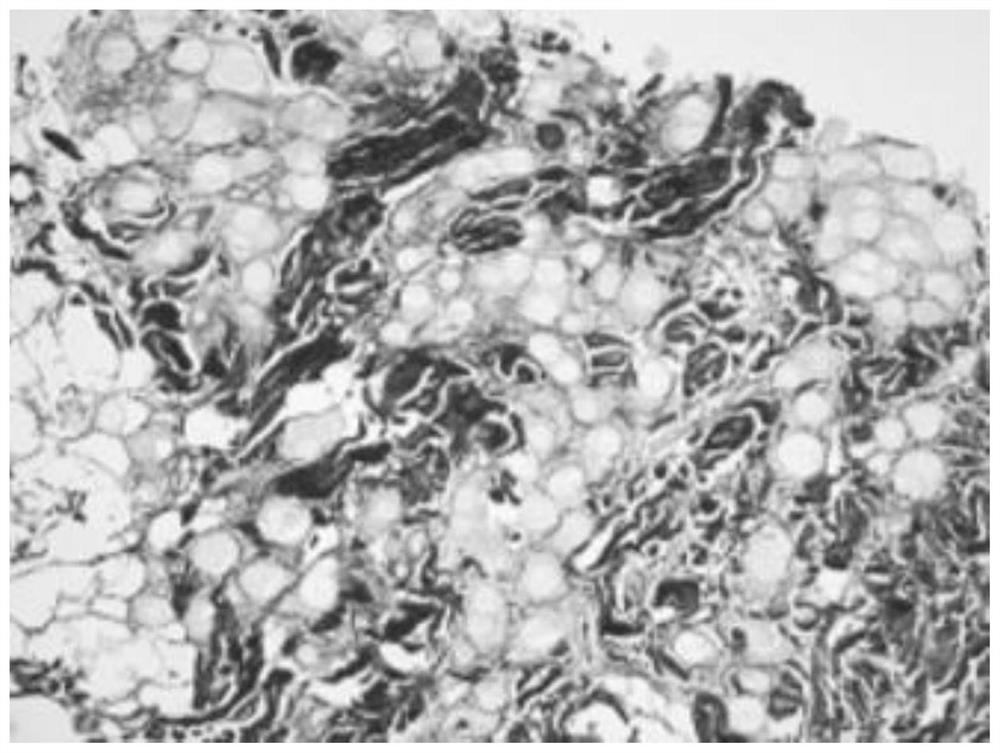

A kind of fibroin/bacterial cellulose composite hydrogel and its preparation method and application

ActiveCN106492286BPromote repairIncrease loadTissue regenerationProsthesisPorosityBiocompatibility Testing

The invention provides a fibroin / bacterial cellulose composite hydrogel, and a preparation method and application thereof. According to the invention, bacterial cellulose hydrogel surface-modified by glycidyl trimethyl ammonium chloride, bone morphogenetic protein-2 and fibroin are used as raw materials; electrical gel technology is employed for formation of a network pore structure by the fibroin on the surface and in the internal network pore structure of the surface-modified bacterial cellulose hydrogel so as to compose a dual-network pore structure; and the morphogenetic protein-2 is adhered into the dual-network pore structure so as to form the fibroin / bacterial cellulose composite hydrogel. The preparation method is simple, highly efficient, green and environment-friendly; and the prepared composite hydrogel has high mechanical strength, high porosity, good connectivity of the interiors of pores and good biocompatibility, and is applicable as a cartilage repairing scaffold to the field of cartilage-repairing tissue engineering.

Owner:江苏臻中滤料科技有限公司

Casein calcium phosphorus microsphere collagen filling agent, preparation method of filling agent and preparation method of casein calcium phosphorus microspheres

PendingCN112121233AImprove effectivenessExtended durationPharmaceutical delivery mechanismTissue regenerationBiotechnologyMicrosphere

The invention provides a casein calcium phosphorus microsphere collagen filling agent, a preparation method of the filling agent and a preparation method of casein calcium phosphorus microspheres. Thecasein calcium phosphorus microspheres as a novel material are adopted, so that the effectiveness and the maintaining time of a traditional collagen filling agent are improved and prolonged, the biological safety is high, and expression of collagen can be stimulated; and the casein calcium phosphorus microspheres have extremely high application prospect and value. Terminal peptide-free animal collagen or genetic recombinant human collagen is used, the material immunogenicity is low, and the material purchasing / preparing cost is low, so that the collagen is suitable for large-scale industrialproduction. Auxiliary components such as glycerin or small molecular hyaluronic acid are added into the filling agent, so that the rheological property of the filling agent can be improved, and the filling agent has stronger filling performance and is easier to inject. The process provided by the invention has the advantages of wide application prospect, low cost, no harmful wastes, industrial production, high practicability and the like.

Owner:SHANGHAI MOYANG BIOTECHNOLOGY CO LTD

A kind of composite ceramic material and its preparation method and application

ActiveCN106830899BImprove connectivityEasy to transportTissue regenerationCoatingsAluminium chloridePolyester

The invention belongs to the field of preparation of ceramic materials, and particularly relates to a composite ceramic material and a preparation method and application thereof. The preparation method comprises the following steps of using polyvinylpyrrolidone and three-block polyester P123 as template agents, mixing with a precursor of a skeleton formed by butyl zirconate and aluminum chloride, hydrolyzing the precursor under the acid condition, depositing around a template agent aggregate, forming an ordered mesostructure, and removing the template agent by calcining, so as to obtain a nanometer aluminum oxide-zirconium oxide composite material with a mesoporous structure; under the condition of pH (potential of hydrogen) value of 8 to 11, using calcium hydroxide and phosphoric acid as reaction matters to form a nanometer hydroxyapatite crystal nucleus at the surface of the nanometer aluminum oxide-zirconium oxide composite material, so as to obtain the nanometer aluminum oxide-zirconium oxide composite material of which the surface is coated with hydroxyapatite; further performing cold press molding on the composite material, and sintering, so as to obtain the composite ceramic material. The prepared composite ceramic material is an ideal bone replacing repair material.

Owner:哈工宁伯医疗科技泰州有限公司

Swelled polymer particles filter process for preparing artificial eye holder

InactiveCN1172723CHigh compressive strengthDoes not affect biocompatibilityEye implantsPorosityCross-link

A process for preparing artificial eye ball includes such steps as dissolving the biocompatible polymer in solvent to obtain saturated solution, mixing it with sieved pore-forming agent (300-600 microns), die pressing to obtain circular ball, volatilizing solvent, immersing the ball in the swelling solution prepared from trigger, cross-linking agent and polymer monomer, introducing nitrogen gas, sealing, swelling for 3-100 hr, putting the ball in reactor, introducing nitrogen gas, sealing, polymerizing, and immersing the ball in deionized water for 72 hr. Its advantages are high precision of size, high porosity (more than 80%), and high performance.

Owner:TSINGHUA UNIV

A kind of biological glass fiber-modified polyester composite dressing and preparation method thereof

ActiveCN107362388BIncrease flexibilityChange the ratio flexiblyGlass making apparatusBandagesGlass fiberPolymer science

The invention belongs to the technical field of biological materials and provides a biological glass fiber-modified polyester composite dressing and a preparation method thereof. The composite dressing obtained by the method at least comprises a modified polyester binder and borate bio-glass fibers. The modified polyester binder is a tetraethoxysilane-modified polyester binder. The composite dressing obtained by the preparation method has good biocompatibility, biological activity and biodegradability, reduces the patient pain caused by dressing exchange, stimulates the blood vessel regeneration around the wound, promotes the rapid healing of the wound and can also be used as a carrier for various types of functional ions and lipid-soluble drug carriers. The preparation method is simple and realizes a low cost.

Owner:TONGJI UNIV

Drug-loaded biopolymer composite nanofiber membrane and preparation method thereof

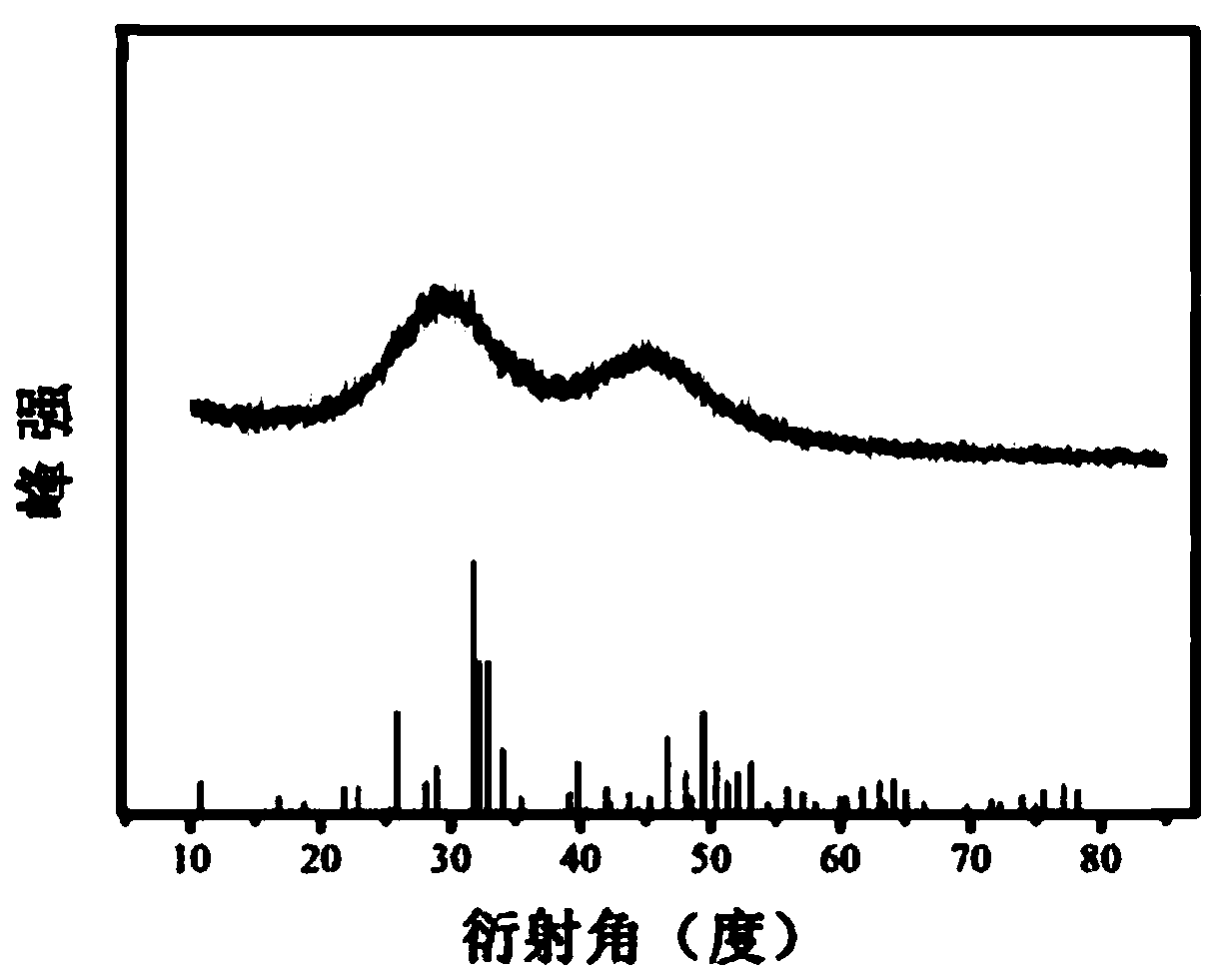

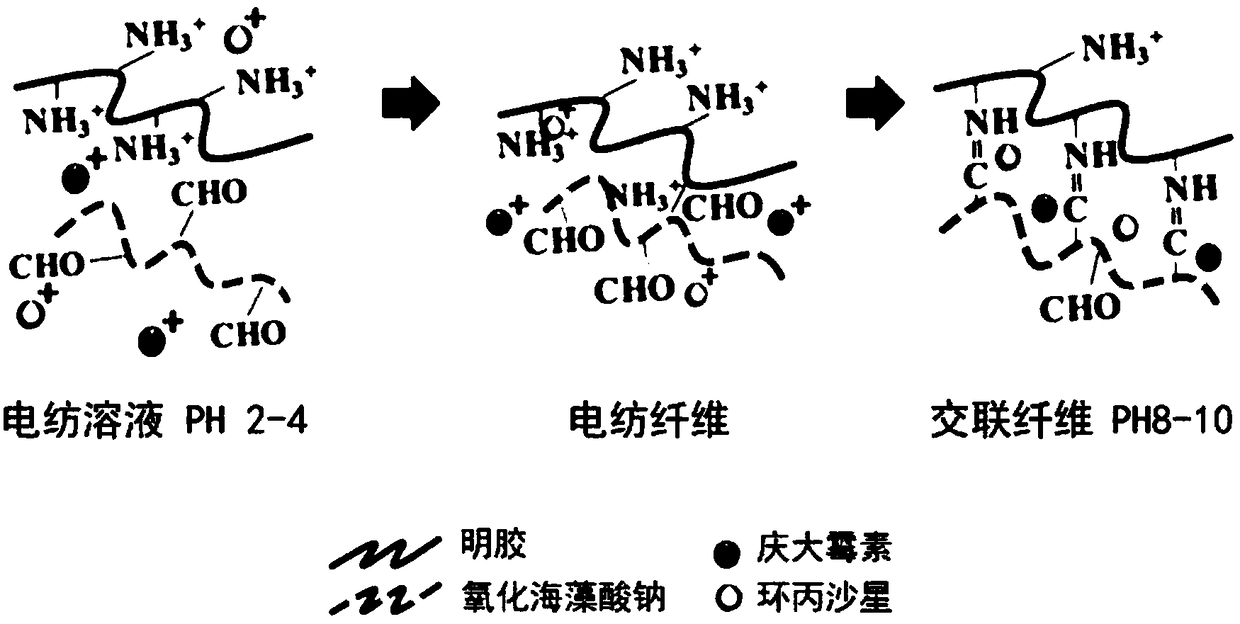

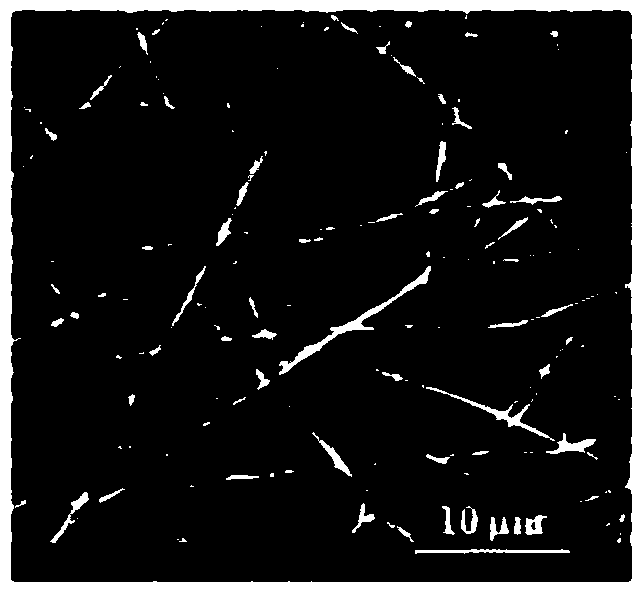

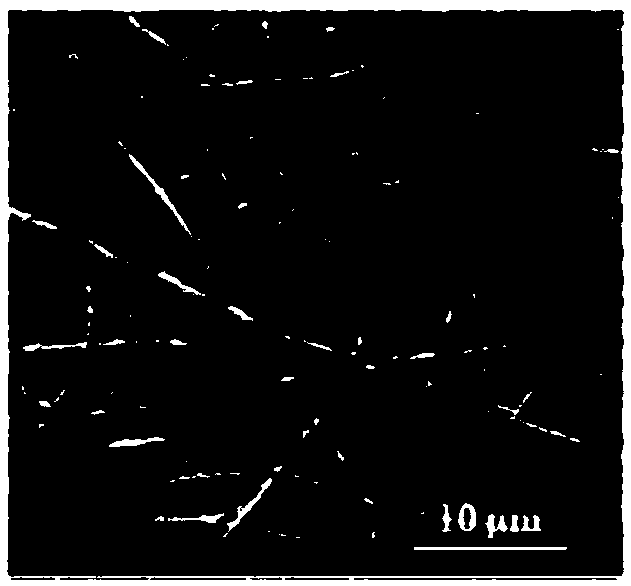

InactiveCN105727358BEfficient and biodegradableSafe biodegradableVegetal fibresBandagesCross-linkBiopolymer

The invention discloses a drug-loaded biopolymer compound nanofiber membrane and a preparation method thereof. The method includes the following steps that firstly, an acidic mixed solution where drug to be loaded and biopolymer are dissolved is prepared; secondly, the acidic mixed solution is contained in a feeding device of electrostatic spinning equipment for electrostatic spinning, and a compound polymer nanofiber membrane is prepared; thirdly, the compound polymer nanofiber membrane is sequentially placed into alkaline ethyl alcohol solutions with the volume fractions of ethyl alcohol gradually reduced to be soaked for at least two times of cross-linking; fourthly, the cross-linked compound polymer nano cellulose membrane is washed with a neutral ethyl alcohol solution with the volume fraction not higher than those of alkaline ethyl alcohol solutions used for cross-linking for many times, and the drug-loaded biopolymer compound nanofiber membrane is obtained after drying. The drug-loaded biopolymer compound nanofiber membrane can maintain a relatively stable fiber structure in the wound healing stage, the shape of a spinning membrane is kept, and drug loaded on the membrane can be continuously released.

Owner:GUANGXI YIDEJIA MEDICAL EQUIP CO LTD

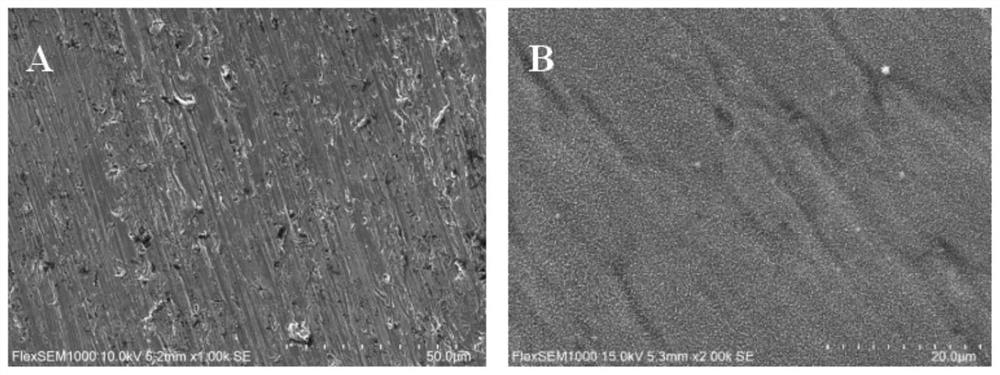

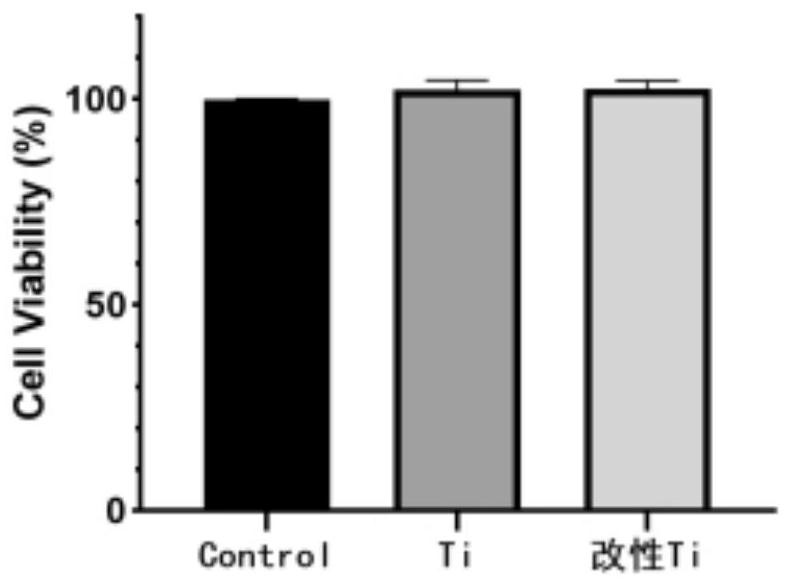

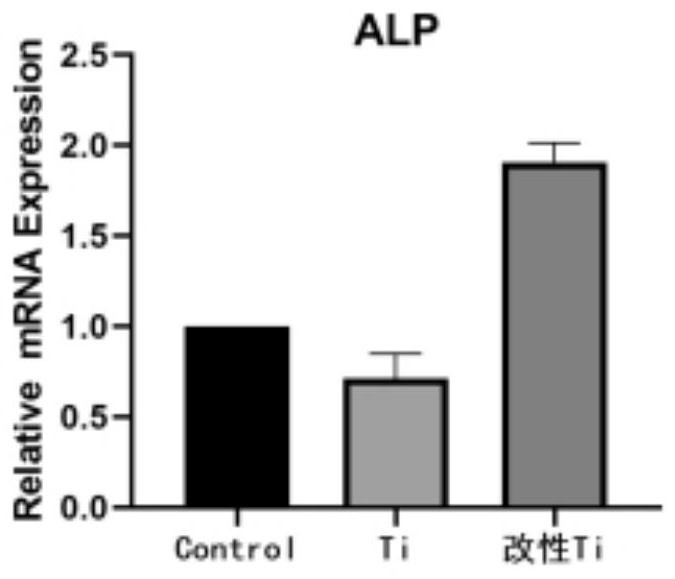

Paint for medical instrument, and preparation method and application thereof

PendingCN113797391ADoes not affect biocompatibilityUniform film formationPharmaceutical delivery mechanismTissue regenerationEngineeringBiocompatibility

The invention belongs to the technical field of biological materials, and particularly relates to a paint for a medical instrument, and a preparation method and application thereof. The paint comprises the following components: metal salt, polyphenol and an oxidizing agent, wherein the metal salt is selected from zinc salt and strontium salt. The medical instrument comprises a base material and a coating on the surface of the base material; and the coating is formed by the paint. The paint is applied to medical instruments through interaction of the zinc salt, the strontium salt, the polyphenol and the oxidizing agent, and has the advantages of uniform film formation, no influence on the biocompatibility of the base material, improvement of the antibacterial property and the osteogenesis promoting effect, wide application range, simple and convenient preparation process, good repeatability, strong controllability and the like.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

Titanium alloy packaging barrel manufacturing process

A titanium alloy packaging barrel manufacturing process is provided. The surface of the titanium barrel body of the present invention is polished sequentially by rough polishing with a nylon wheel, fine polishing with a wool wheel, and superfine polishing with a yellow cloth wheel, so that scratches, trachoma, and mottling do not exist on the surface , rough grain defects, achieve a complete mirror effect, improve the uniformity of polishing quality, simple process steps, convenient implementation, high polishing efficiency; for the surface treatment of the titanium barrel, firstly clean it with cleaning solution, rinse with ultra-pure water by RO penetration, After drying, the electrolytic polishing liquid is electrolyzed, and RO is infiltrated with ultra-pure water to rinse, so as to ensure that the impurities and oil stains on the inner surface of the titanium alloy barrel are completely removed, so that the surface can achieve the purpose of ultra-clean; A dense oxide layer improves the corrosion resistance of the titanium barrel and prolongs the service life of the titanium barrel.

Owner:陕西恒立科技有限公司

Titanium alloy packing barrel manufacturing technology

ActiveCN111250937AImprove uniformityImprove polishing efficiencyElectrolysisManufacturing technology

The invention provides a titanium alloy packing barrel manufacturing technology. The surface of a titanium barrel body is subjected to nylon wheel rough polishing, felt wheel finishing polishing and yellow cloth wheel super-finishing polishing in sequence, there are no defects, such as scratches, blisters, piebald and bastard cut, on the surface of the titanium barrel body, a full-mirror effect isachieved, the uniformity of the polishing quality is improved, the technical steps are simple, the technology is easy to implement, and the polishing efficiency is high. For the treatment of the internal surface of the titanium barrel body, the internal surface is subjected to cleaning by using a cleaning solution, washing with RO ultrapure water, drying, electrolysis by using an electrolytic polishing solution and washing with RO ultrapure water in sequence, it is ensured that the impurities and oil contaminations on the internal surface of the titanium alloy barrel body are removed thoroughly, and the aim that the surface is super clean is achieved; afterwards, through oxidation treatment, a dense oxidation layer is naturally formed on the internal surface of the titanium alloy barrel body, the corrosion resistance of the titanium barrel is improved, and the service life of the titanium barrel is prolonged.

Owner:陕西恒立科技有限公司

A kind of antibacterial and biocompatible bone implant material and its preparation method and application

The present invention disclosed a method and application method and application of antibacterial and biocompatible bone bone implantation materials.The invention provides a antibacterial and biocompatible bone implant material, including bone implant material and a composite antibacterial layer formed on the surface of the bone implant material;The surface layer of the body is injected into the bone implant material to get the transition layer, and then the nitrogen -containing plasma or phosphorus -containing plasma is injected into the transition layer;The body does not contain hydrogen and oxygen; the relative surface potential of antibacterial and biochemical bone implant materials is 0.01 ~ 0.5V.The present invention uses plasma injection technology to build a high potential surface, giving bone implantation materials on the surface of antibacterial and biological safety.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

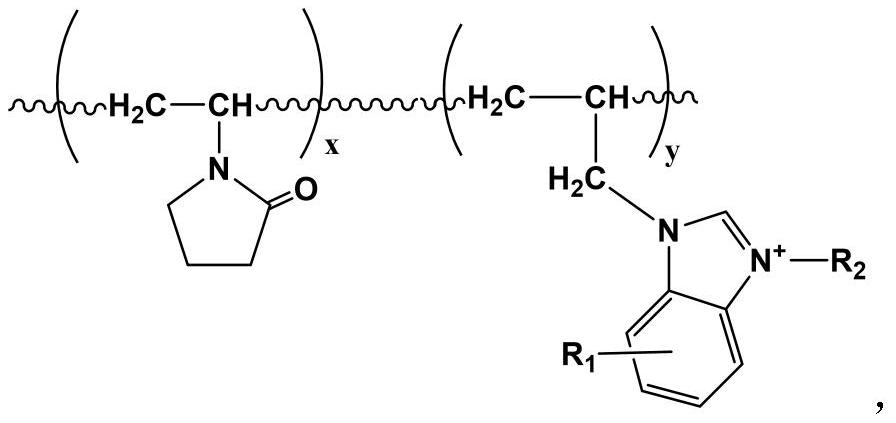

Super-lubricating anti-microorganism medical coating and use method thereof

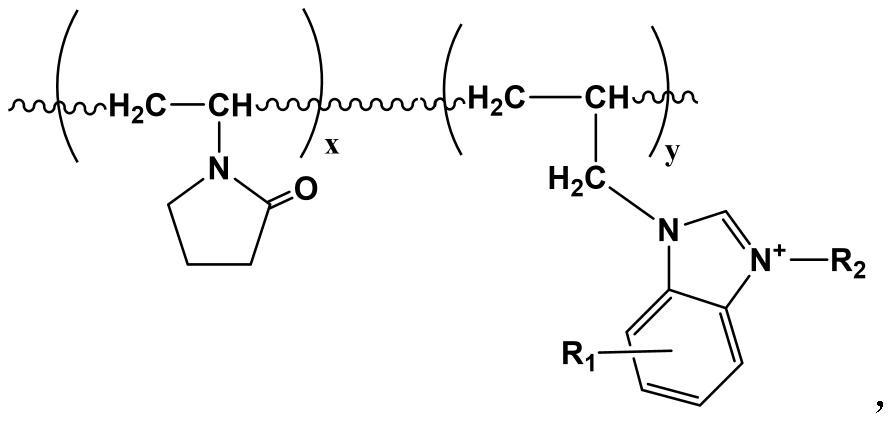

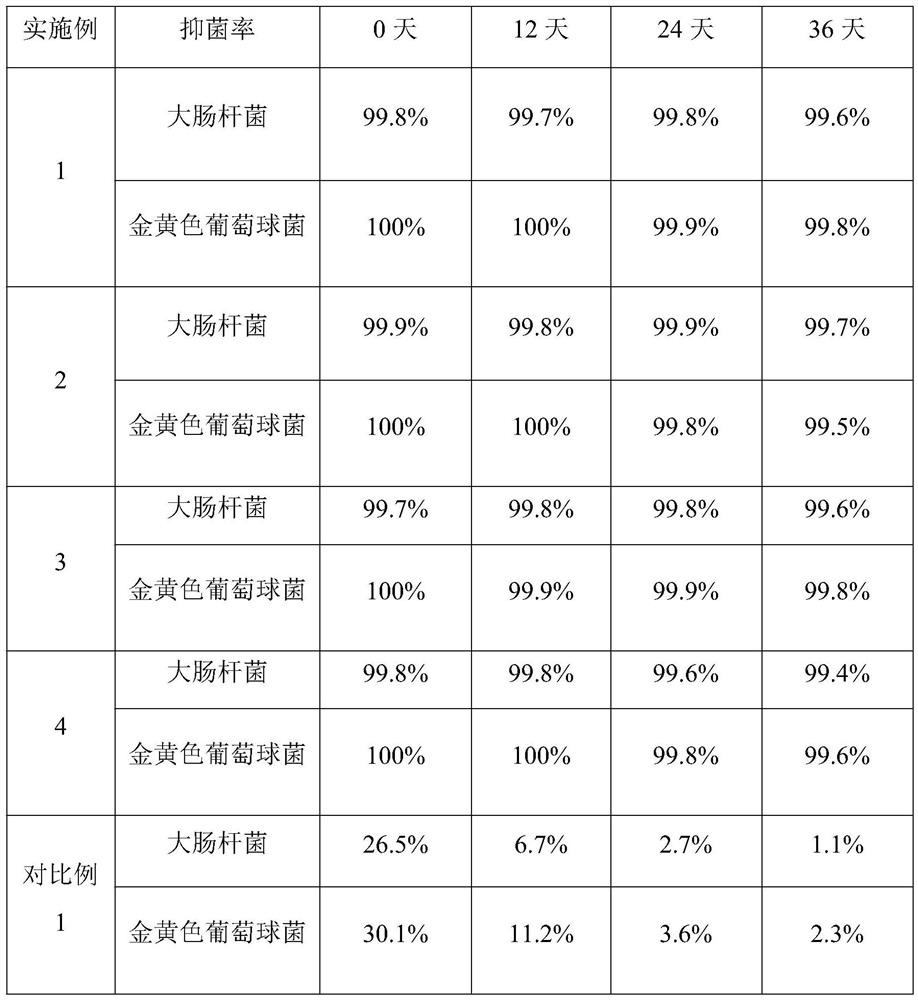

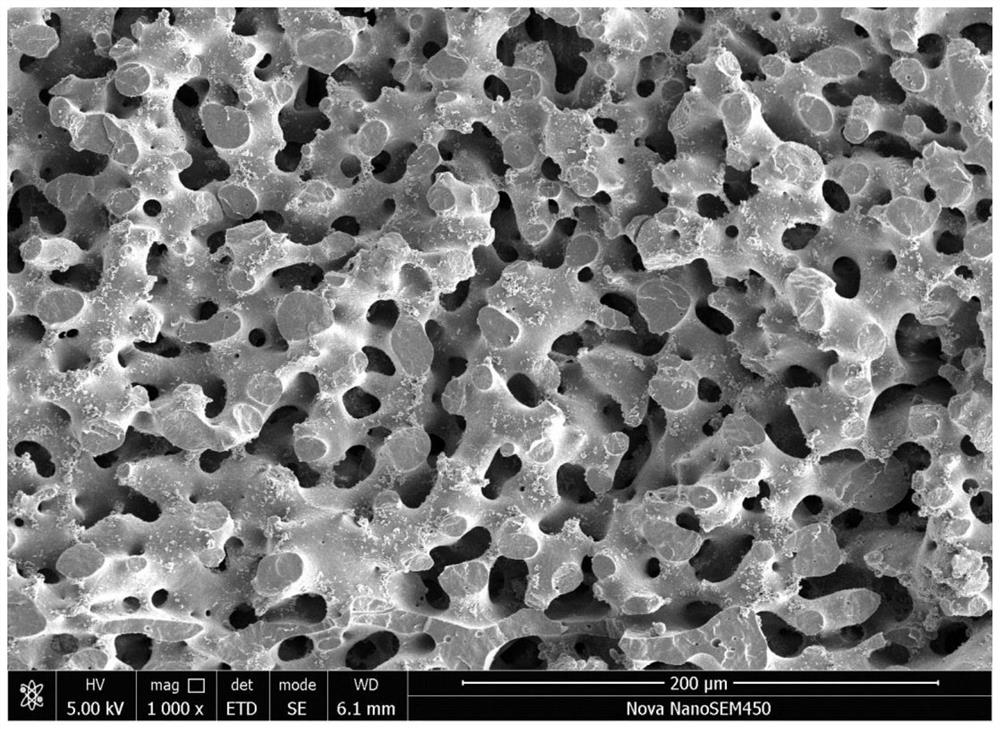

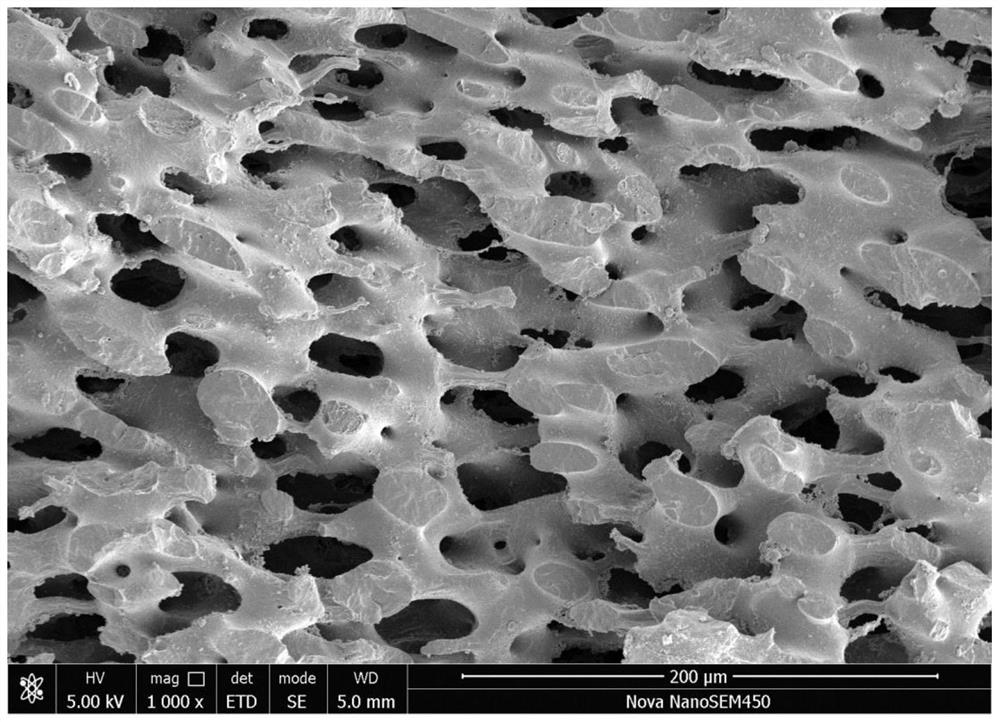

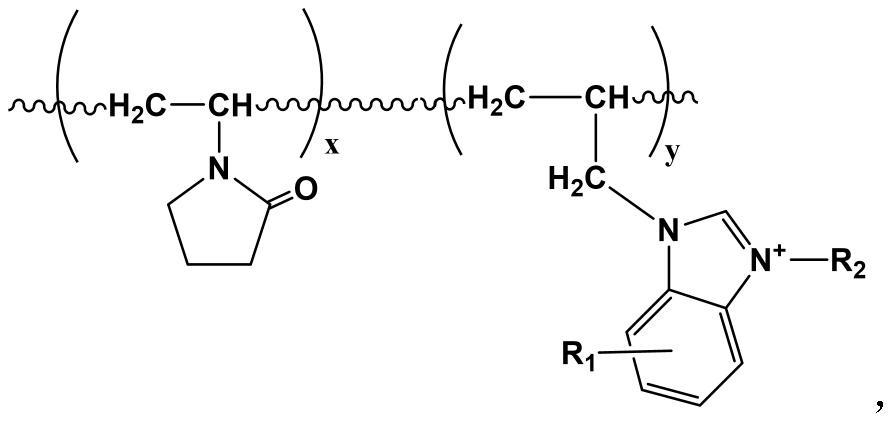

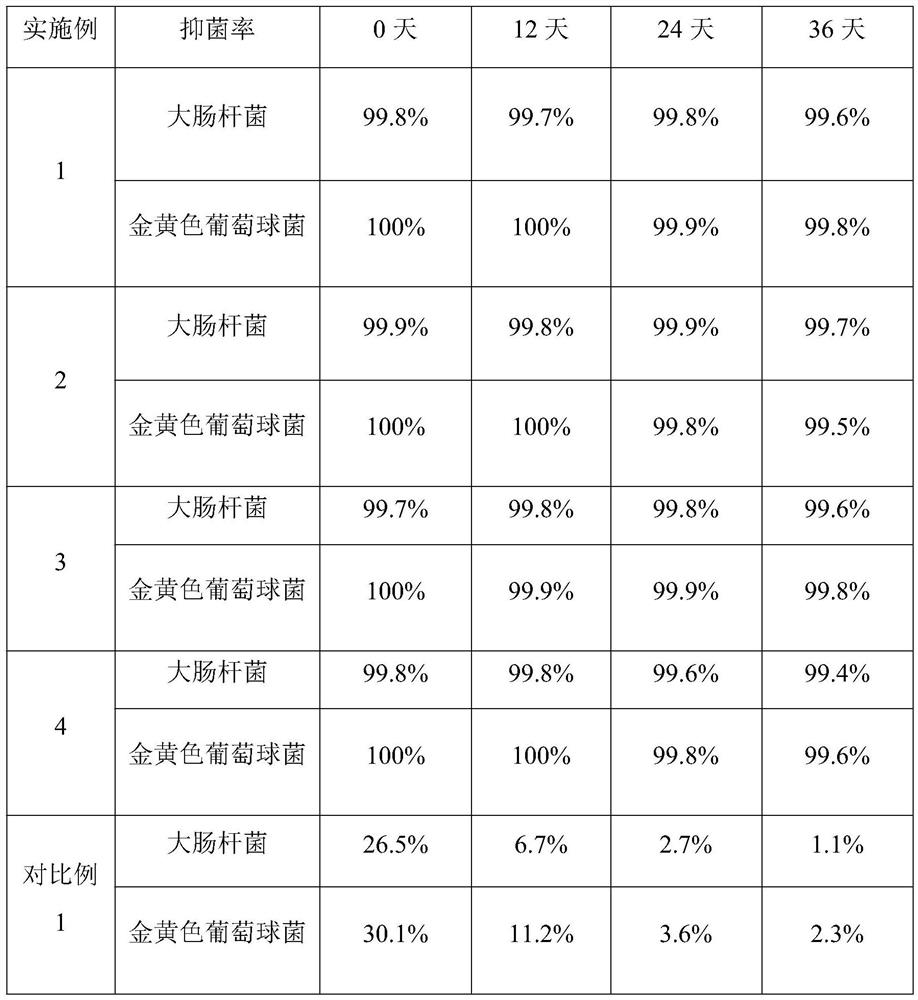

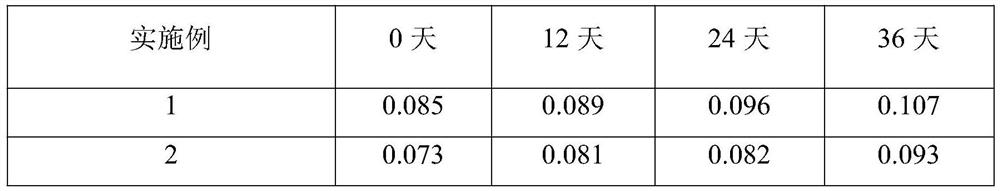

The invention discloses a super-lubricating anti-microorganism medical coating. The super-lubricating anti-microorganism medical coating is prepared by mixing the following raw materials in parts by mass: 0.5-10 parts of an N-allyl benzimidazole-modified vinyl pyrrolidone polymer, 0.1-5 parts of isocyanate, 0.1-5 parts of a cross-linking agent, 0.05-1 part of epoxy resin and 79-99.25 parts of a solvent. The super-lubricating anti-microorganism medical coating has an excellent anti-microorganism effect, good biocompatibility and low cytotoxicity. A polyurethane-epoxy resin elastic double-network structure formed after the coating is cured can achieve firm adhesion and attachment of the coating on a medical device. The super-lubricating anti-microorganism medical coating is suitable for being popularized and used on implantation / intervention medical devices.

Owner:成都德信安创新医疗技术有限公司

Method for preparing oriented interconnected porous biomedical scaffold, scaffold prepared therefrom, and use of the scaffold in the preparation of medical products

The invention discloses a method for preparing a polycaprolactone oriented interconnected porous biomedical stent, which comprises the following steps: (1) melting and blending polycaprolactone and polyethylene oxide to obtain a co-continuous blend, the blend Continuous blend compression molding obtains polycaprolactone / polyethylene oxide co-continuous substrate; (2) polycaprolactone / polyethylene oxide co-continuous substrate obtained in step (1) is extracted with water to Removing the water-soluble polyethylene oxide phase to obtain a polycaprolactone porous scaffold; (3) stretching the polycaprolactone porous scaffold obtained in step (2) in the solid phase, so that the pore morphology is oriented and deformed along the stretching direction , to obtain polycaprolactone aligned porous biomedical scaffold. The polycaprolactone oriented interconnected porous biomedical scaffold prepared by it presents an obvious highly interconnected and anisotropic porous structure. The invention also discloses the polycaprolactone orientation interconnected porous biomedical support and the use of the support in preparing medical products.

Owner:SICHUAN UNIV

A chitosan-based pure physical cross-linked double network hydrogel and preparation method thereof

The invention discloses a chitosan-based pure physically-crosslinked dual-network hydrogel and a preparation method thereof. With the method provided by the invention, a double-network hydrogel crosslinked by pure physical action is constructed by using chitosan and succinylated chitosan as raw materials and an alkaline solvent system as a basis; and the obtained hydrogel is further subjected to biomimetic mineralization to improve mechanical properties. Compared with a pure chitosan hydrogel, the chitosan-based pure physically-crosslinked double-network hydrogel provided by the invention is regular and compact in structure, and is significantly improved in the mechanical properties. Meanwhile, compared with a traditional chemically-physically crosslinked chitosan-based double-network hydrogel, the chitosan-based pure physically-crosslinked dual-network hydrogel has obvious advantage in good biocompatibility. The pure physically-crosslinked double-network hydrogel prepared by using thepreparation method provided by the invention has good mechanical properties and good biocompatibility, and has good application prospect in the field of biomedicine application.

Owner:ZHEJIANG UNIV

Antisticking particle and powder containing sodium hyaluronate and their preparation process

InactiveCN1116044CHigh molecular weightLong retention time in the bodyOrganic active ingredientsAerosol deliveryAdditive ingredientActive matter

The present invention relates to medicine. Of the antisticking particle and powder, the main component is sodium hyaluronate, which is also named as sodium hyaluronate and may be also compounded into compounded preparation with other separating agent and pharmacological active matters, such as anticoagulant, antiphlogistic, calcium passage retarder, cytostatic agent and proteolytic enzyme. The antisticking particle and powder of the present invention consists of sodium hyaluronate 1-100 wt%, separating agent 0-99 wt% and active component in the amound based on relevant pharmacopeia. The antisticking particle and powder of the present invention is used for antisticking after operation in abdominal cavity, gynaecological and obstetrical operation, orthopedical operation and thoracic operation and has excellent antisticking effect.

Owner:凌沛学

Preparation method of a microsphere stacked shape memory porous scaffold

InactiveCN104740688BDoes not affect biocompatibilityGood biocompatibilityProsthesisFoaming agentBiocompatibility Testing

The invention discloses a method for preparing a microsphere-stacked shape memory porous scaffold, in which a drug-carrying and porous structure is formed through the action of a porogen and a drug in a material with a shape memory function to prepare a shape memory function and a drug function The porous scaffold material loaded with drug factors is prepared through 1) preparation of drug-loaded calcium alginate hydrogel microspheres and 2) preparation of porous structure. The prepared porous scaffold has good shape memory, biocompatibility and biodegradability, and also has drug sustained release function, and will have great application prospects in tissue engineering. Tests have proved that the preparation method of the present invention has the advantages of controllable and uniform pore size, no need to sacrifice porogenous materials, and low-cost and easy-to-obtain raw materials.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of super lubricating antibacterial medical coating and application method thereof

The invention discloses an ultra-lubricating antibacterial medical coating, which is prepared by mixing the following raw materials in parts by mass: 0.5 to 10 parts of N-allylbenimidazole-modified vinylpyrrolidone polymer, 0.1 parts to 5 parts of isocyanate, 0.1 to 5 parts of crosslinking agent, 0.05 to 1 part of epoxy resin, and 79 to 99.25 parts of solvent. The invention has the following beneficial effects: the ultra-lubricating antibacterial medical coating of the present invention has excellent antibacterial effect, good biocompatibility, low cytotoxicity, and the polyurethane-epoxy resin elastic double network structure formed after the coating is cured It can realize the firm adhesion and adhesion of the coating on the medical device, and is suitable for popularization and use on the implantation / interventional medical device.

Owner:成都德信安创新医疗技术有限公司

A preparation method of multi-purpose gelatin fiber based on in-situ crosslinking of blocked waterborne polyurethane

InactiveCN105821519BGood compatibilityFully reflect the excellent performanceConjugated cellulose/protein artificial filamentsWet spinning methodsCross-linkFiber

The invention relates to a multi-purpose gelatin fiber preparing method based on closed type waterborne polyurethane in-situ cross linking .The preparing method comprises the steps that firstly, a gelatin aqueous solution and closed type waterborne polyurethane emulsion are mixed evenly, and a spinning solution is obtained; secondly, the spinning solution is spun into gelatin / closed type waterborne polyurethane composite fibers with a dry or wet spinning technology; finally, in the subsequent drying process, closed type waterborne polyurethane is subjected to closed-form solution, isocyanate groups obtained through closed-form solution further react with active groups in gelatin, and thus the effects of in-situ cross linking and great improvement of the mechanical property of the composition fibers are achieved .Due to the fact that waterborne polyurethane and gelatin are in good compatibility, the adding quantity of the gelatin component in the composite fibers is large, and the excellent performance of gelatin is fully embodied; besides, waterborne polyurethane is nontoxic, and the biological compatibility of the composite fibers cannot be influenced after cross-linking modification is performed on gelatin; a covalence reaction exists between waterborne polyurethane and gelatin, the mechanical property of the composition fibers can be greatly improved in a lasting mode, and the composite fibers have application prospects in biomedical, tissue engineering and textile and garment fields and the like .

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com