Casein calcium phosphorus microsphere collagen filling agent, preparation method of filling agent and preparation method of casein calcium phosphorus microspheres

A technology of calcium caseinate and collagen, which is applied in the field of medical materials, can solve the problems of ineffective stimulation of collagen repair and short maintenance time, and achieve the effect of improving effectiveness and maintenance time, improving effectiveness, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

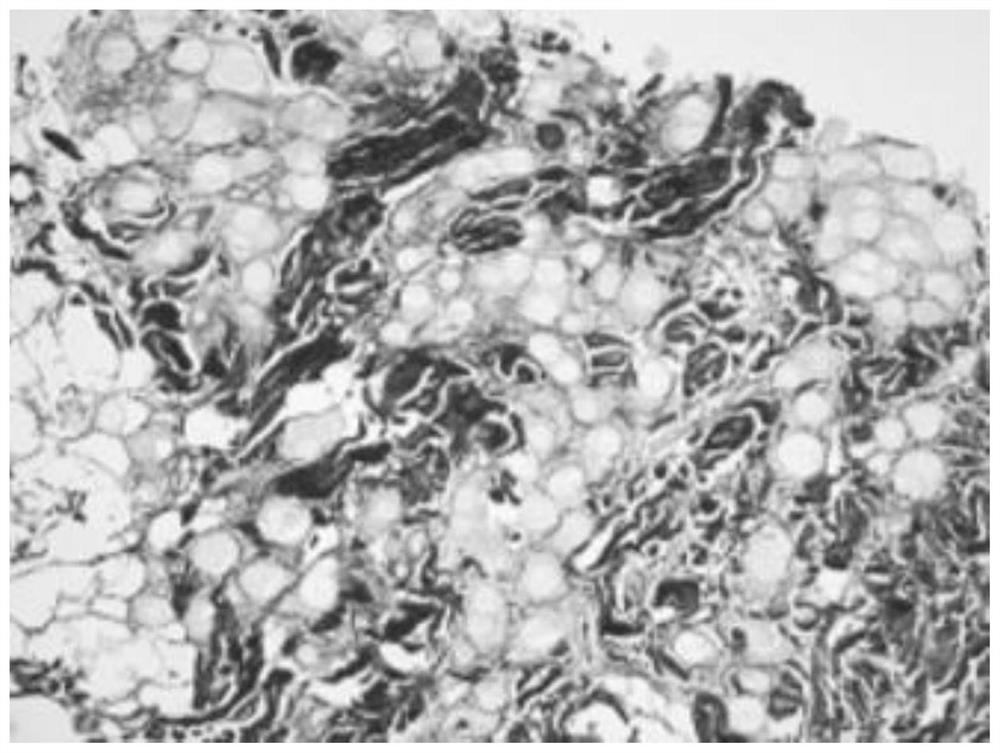

Image

Examples

preparation example Construction

[0040] The present invention also proposes a preparation method of casein calcium phosphorus microsphere collagen filler, comprising the following steps:

[0041] Step 1: Select collagen. As the collagen, select animal source type I collagen without atelopeptide and animal source type III collagen without atelopeptide, and proceed to step 2 and step 3;

[0042] When the collagen chooses atelopeptide animal source type I collagen, atelopeptide animal source type III collagen, genetically recombinant human type I collagen and genetically recombinant human type III collagen, skip step 2 and step 3, Go to step 4 directly.

[0043] Step 2: Rinse the collagen without atelopeptide with purified water, add 100ml of 0.1-1.0mol / L acetic acid solution for every 1-10g of collagen, and then add 1-10mL of specific pepsin for stirring and hydrolysis to remove the telogen Peptide; the stirring speed is 50-1000RPM, the temperature is 10-30℃, and the hydrolysis time is 2-36h.

[0044] Step 3:...

Embodiment 1

[0056] Embodiment 1: a kind of casein calcium phosphorus microsphere collagen filler, the specific preparation method is as follows:

[0057] 1) Prepare 2 L of 0.3 mol / L calcium nitrate solution, add 2 g of casein to dissolve and mix well, add ammonia water to adjust to pH = 8.0, and obtain the first solution;

[0058] 2) Prepare 2L of 0.252mol / L diammonium hydrogen phosphate solution, adjust to pH=8.0, add the first solution for mixing, stir, adjust pH=8.0, react at 10°C for 48h, use 0.1 The μm membrane is suction-filtered to extract the precipitate to obtain a filter cake to obtain the first precipitate, wherein the stirring speed is 50rpm;

[0059] 3) Wash the filter cake formed by the first precipitate with 4L of purified water, then wash with 2L of absolute ethanol, and centrifuge to obtain the second precipitate after washing;

[0060] 4) Prepare 1 L of casein aqueous solution with a concentration of 10 mg / mL as a buffer, and resuspend the second precipitate using the b...

Embodiment 2

[0069] Embodiment 2: a kind of casein calcium phosphorus microsphere collagen filler, the specific preparation method is as follows:

[0070] 1) Prepare 5L of 3moL / L calcium nitrate solution, add 100g of casein to dissolve and mix well, add ammonia water to adjust to pH=10.5, and obtain the first solution;

[0071] 2) Prepare 5L of 5.04moL / L ammonium dihydrogen phosphate solution, adjust to pH = 10.5, add the first solution for mixing, stir, adjust pH = 10.5, react at 90°C for 12 hours, use the dish after the reaction is completed A disc centrifuge extracts the precipitate to obtain the first precipitate, wherein the stirring speed is 800rpm, and the disc centrifuge rotates at 300rpm;

[0072] 3) Wash the filter cake formed by the first precipitate with 12L of purified water, then wash with 8L of absolute ethanol, and centrifuge to obtain the second precipitate after washing;

[0073] 4) Prepare 2.5 L of casein aqueous solution with a concentration of 200 mg / mL as a buffer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com