Patents

Literature

341 results about "Source type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for profiling system events in a fine grain multi-threaded multi-core processor

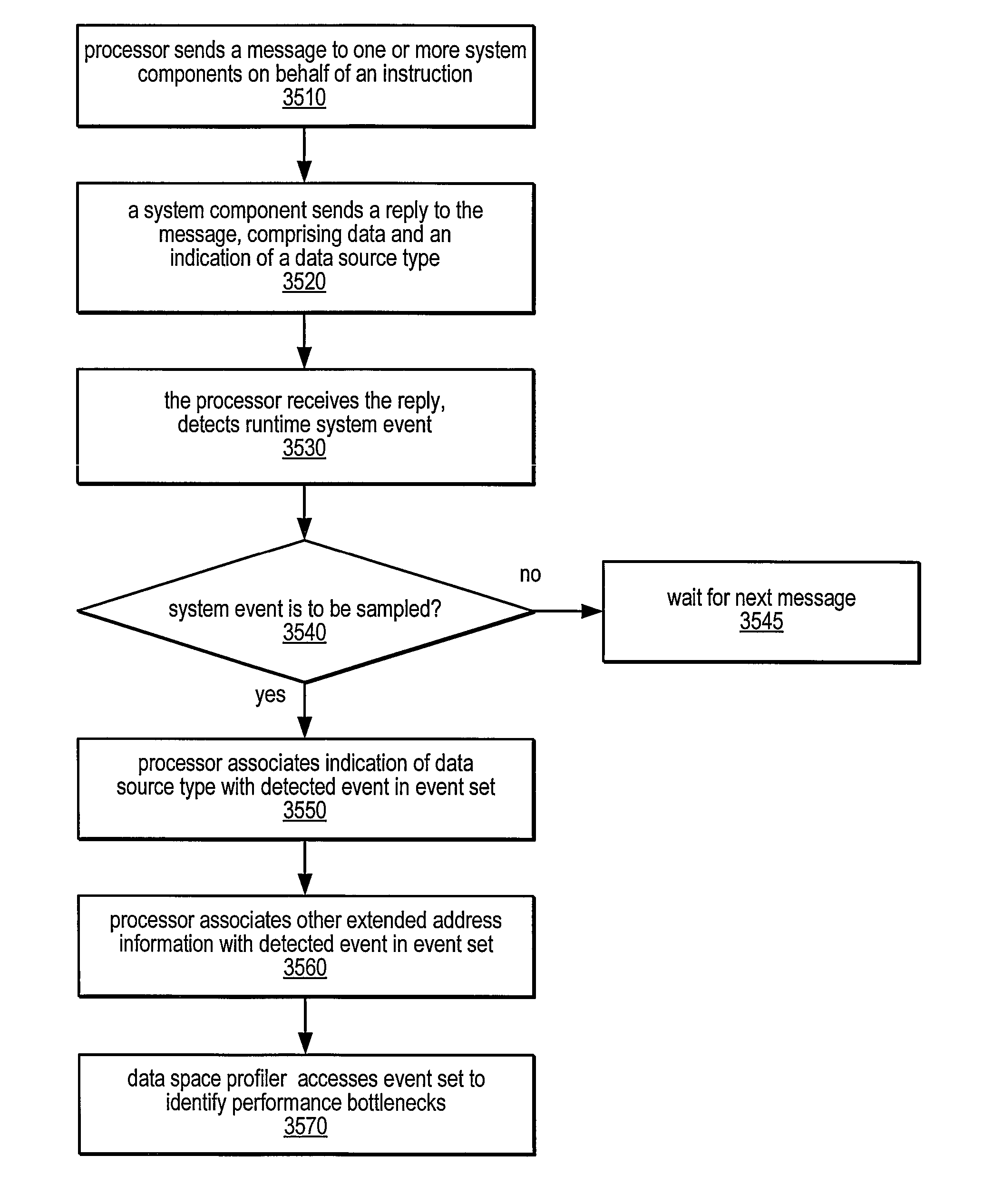

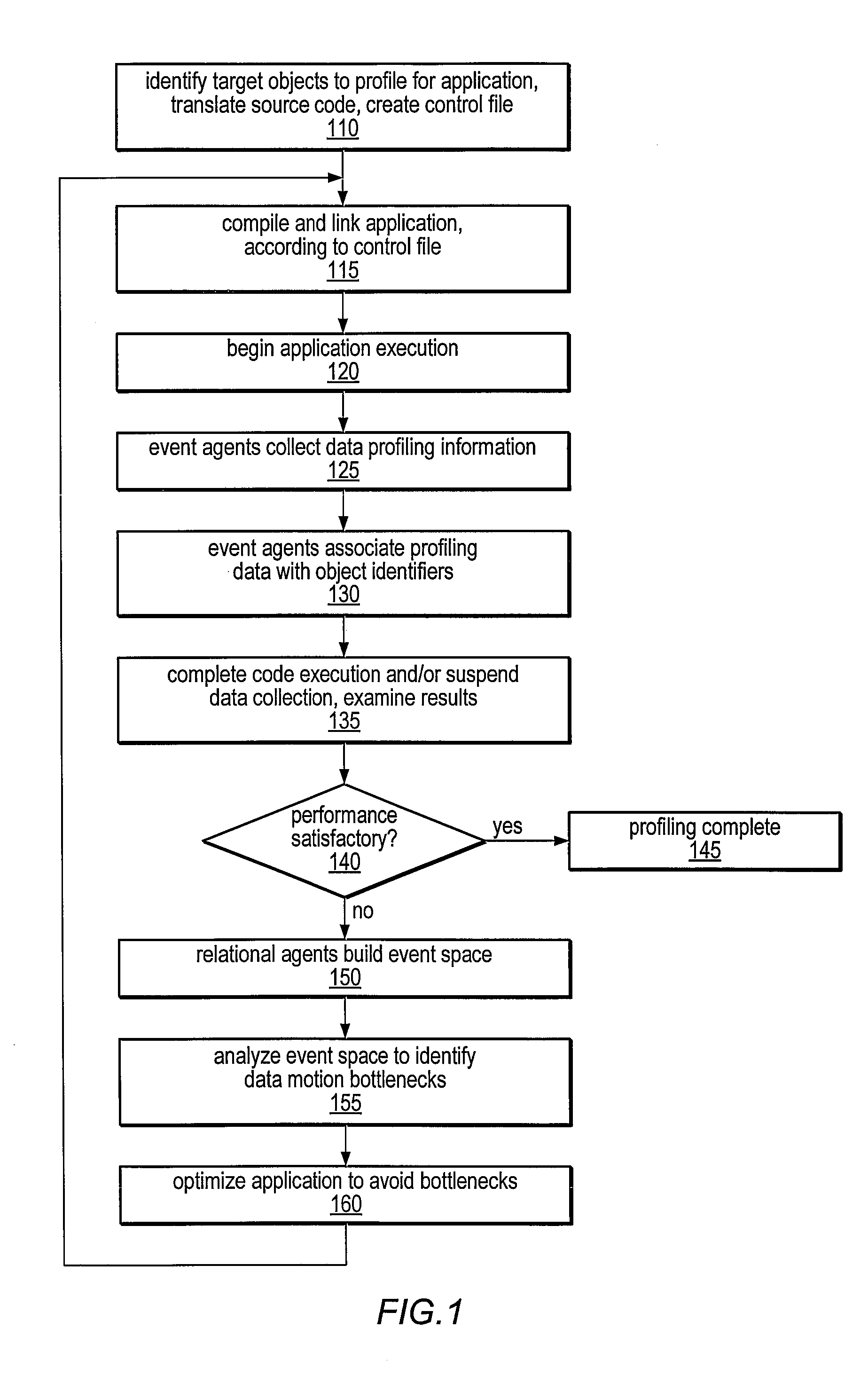

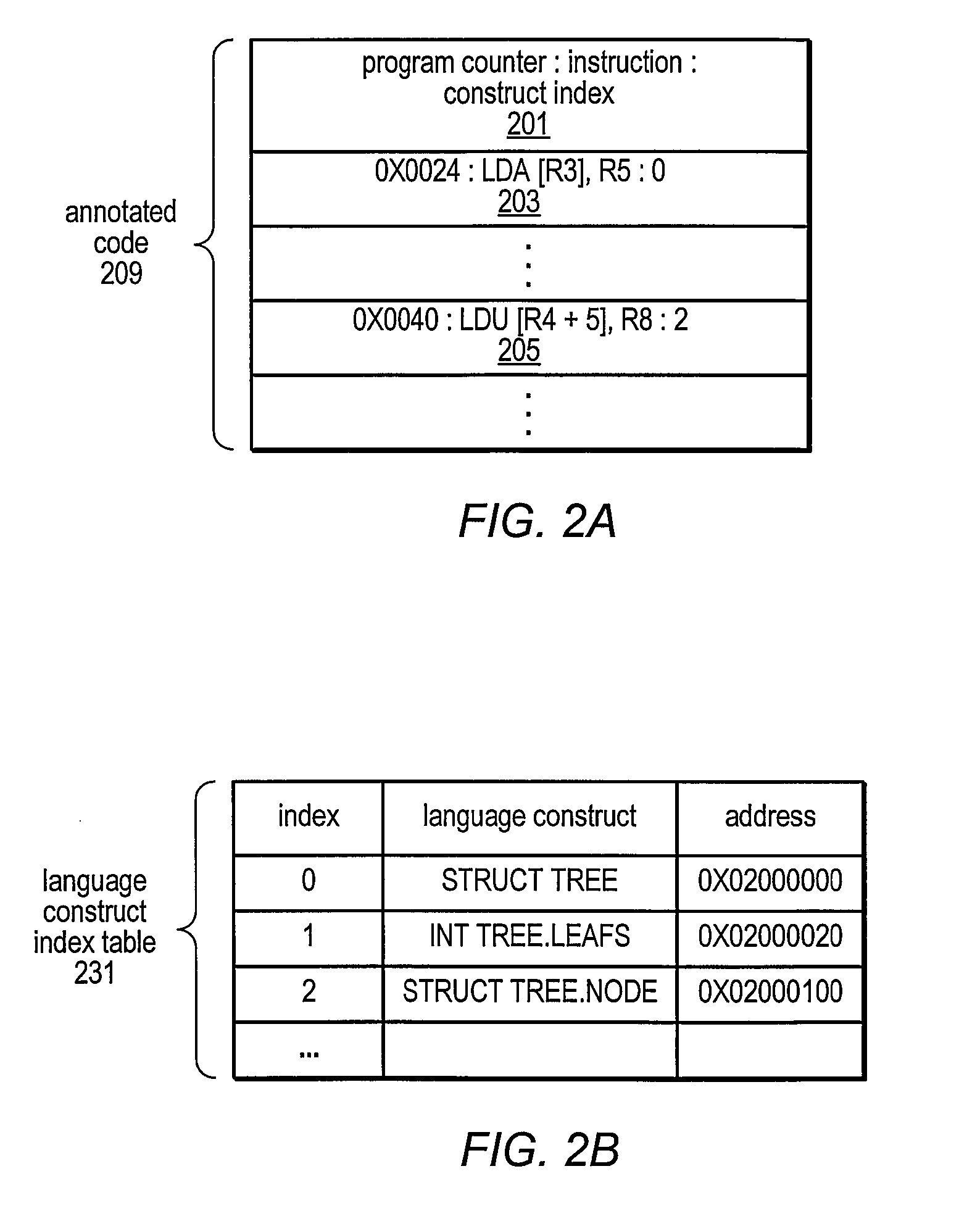

A system and method for profiling runtime system events of a computer system may include associating a data source type with detected system events. The system events may be detected dependent on information included in a reply message received by a processor in response to a data request or other transaction request message. The reply message may include information characterizing a source type of a source of data included in the reply message. The source type information may indicate that the source is remote or local; that it is a shared or a private storage location; that the data is supplied via a cache-to-cache transfer; or that the data is sourced from a coherency domain other than that of the requesting process. Instructions, events, messages, and replies may be sampled, and extended address information corresponding to the samples may be stored in an event set database for performance analysis.

Owner:SUN MICROSYSTEMS INC

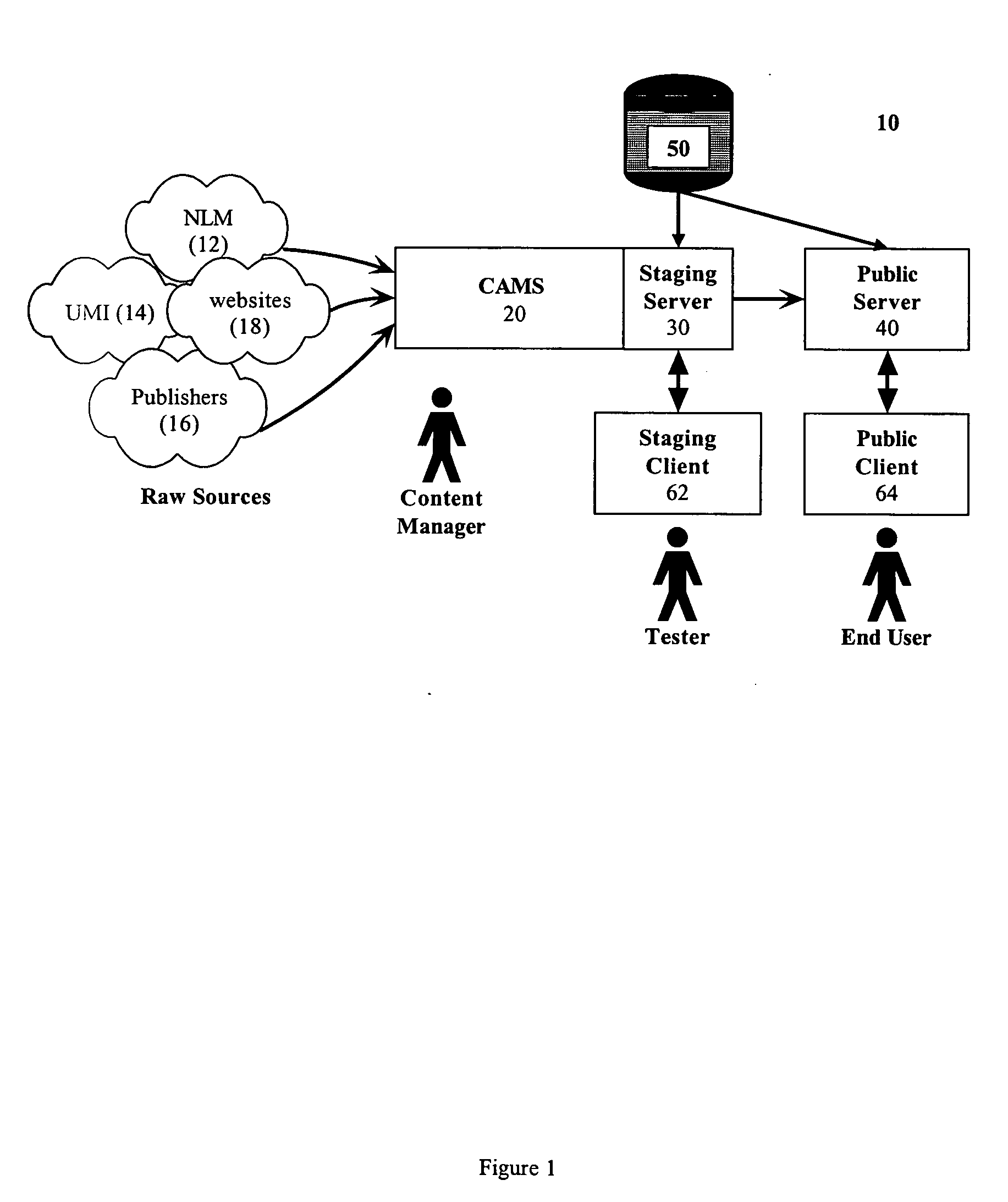

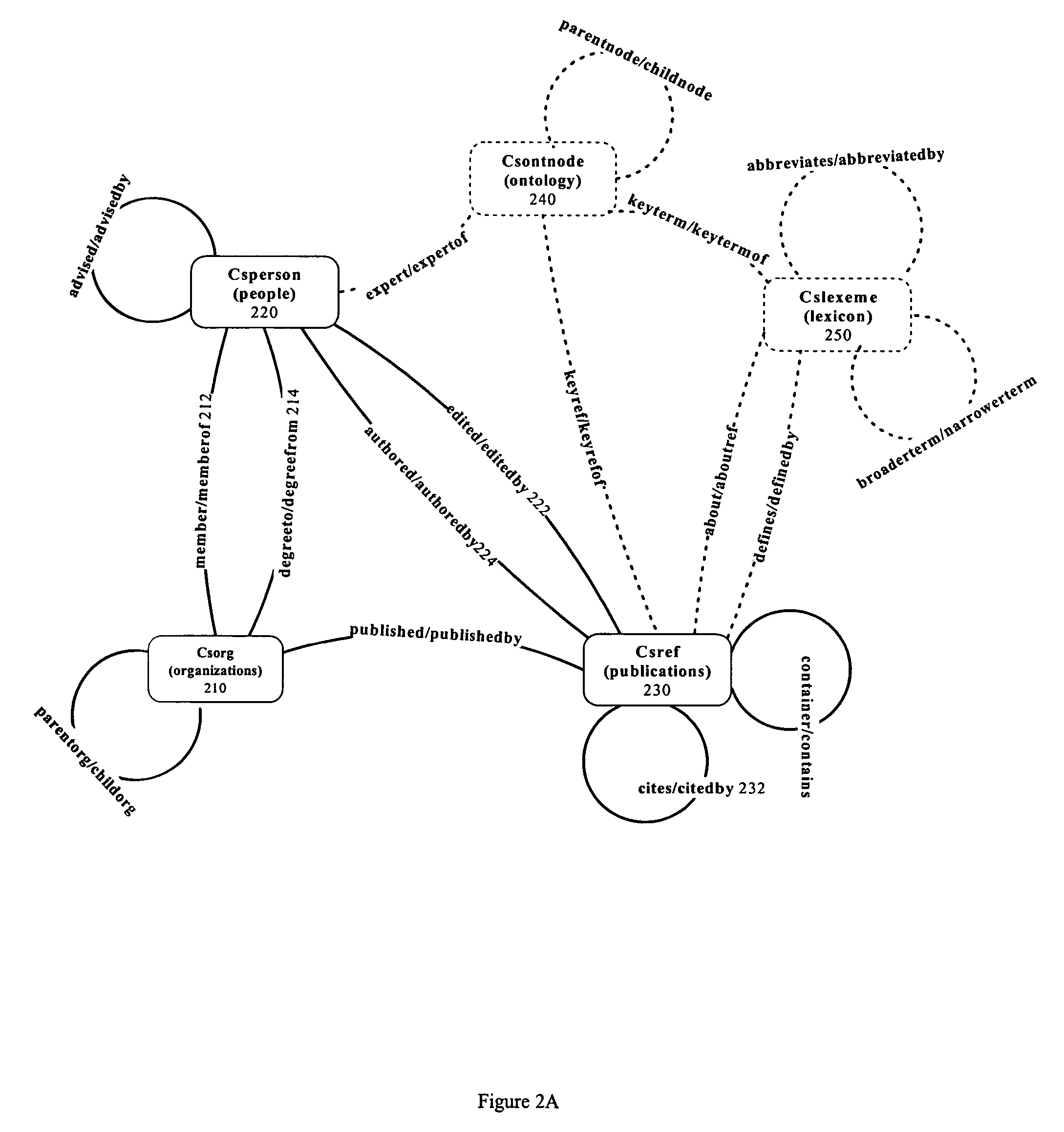

Systems and methods for creating and publishing relational data bases

InactiveUS20050149538A1Digital data processing detailsWebsite content managementEntity typeSource type

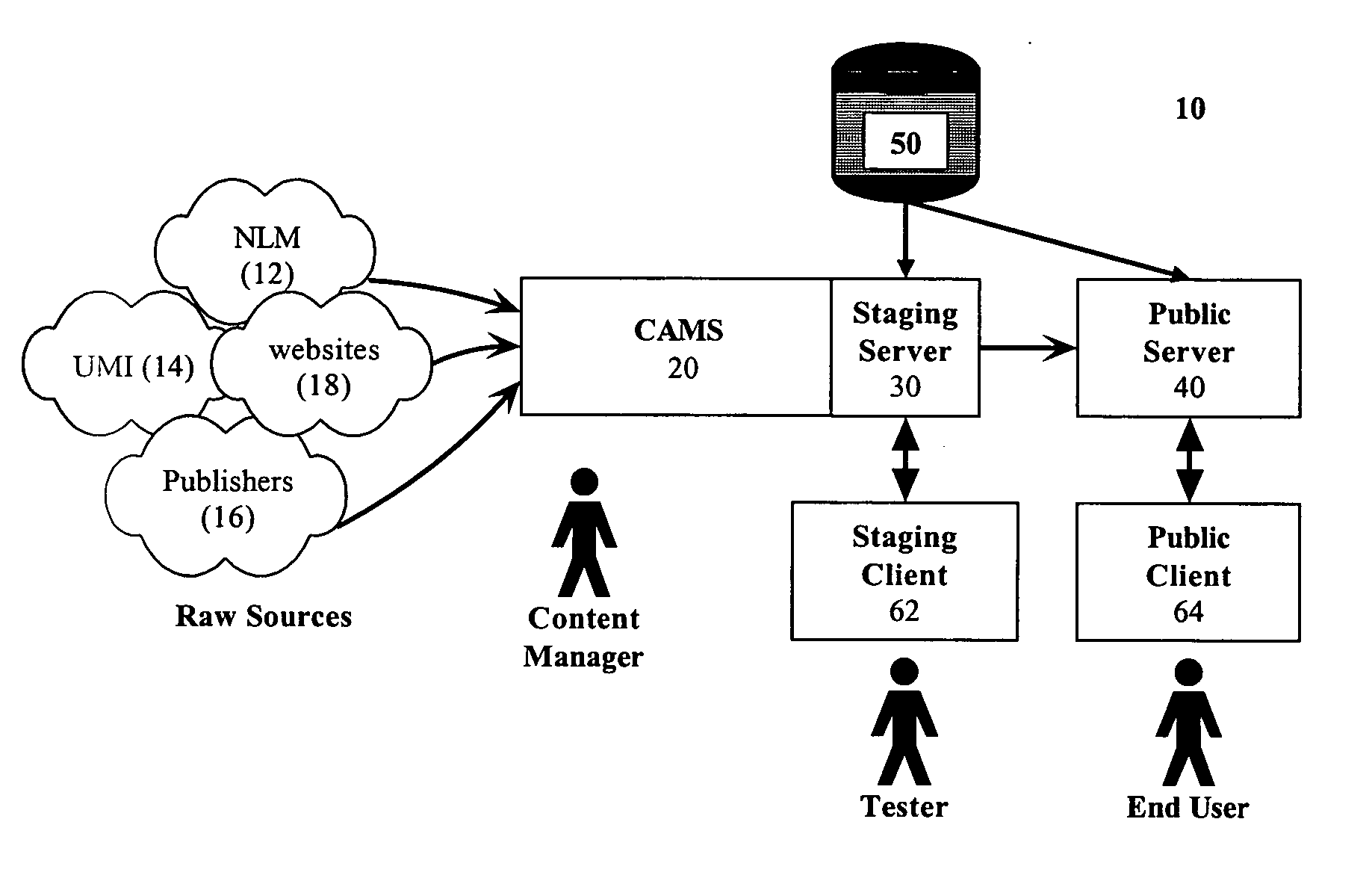

A searchable electronic database system that can return search results independent of reference source type. The electronic database system includes information that can be content or discipline specific. The database can be focused to allow research to be limited to the discipline specific universe of information. The database can include person, organization, publication, and other entity types. The publications can include journal articles, books, dissertations, grants, clinical trials, and web resources. The database can also include ontology and lexicon entities. The entities are interconnected through relationships. Searches performed on the database return results across all entity types. A single search can return results from each of the different publication types. Details of the results can be displayed. Dynamic links to one or more fields in a particular result detail can link to a result categorized according to the field.

Owner:SINGH SADANAND +5

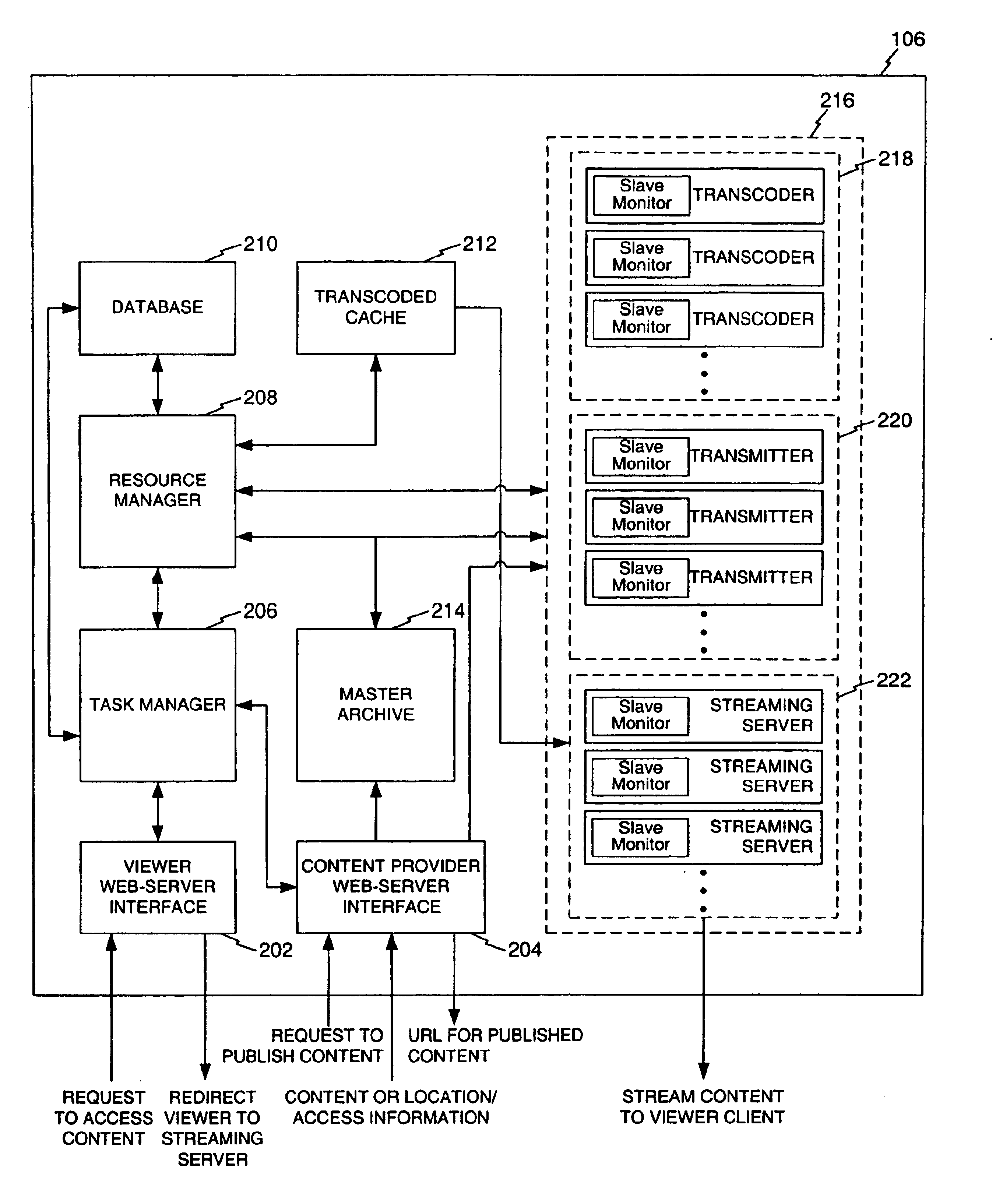

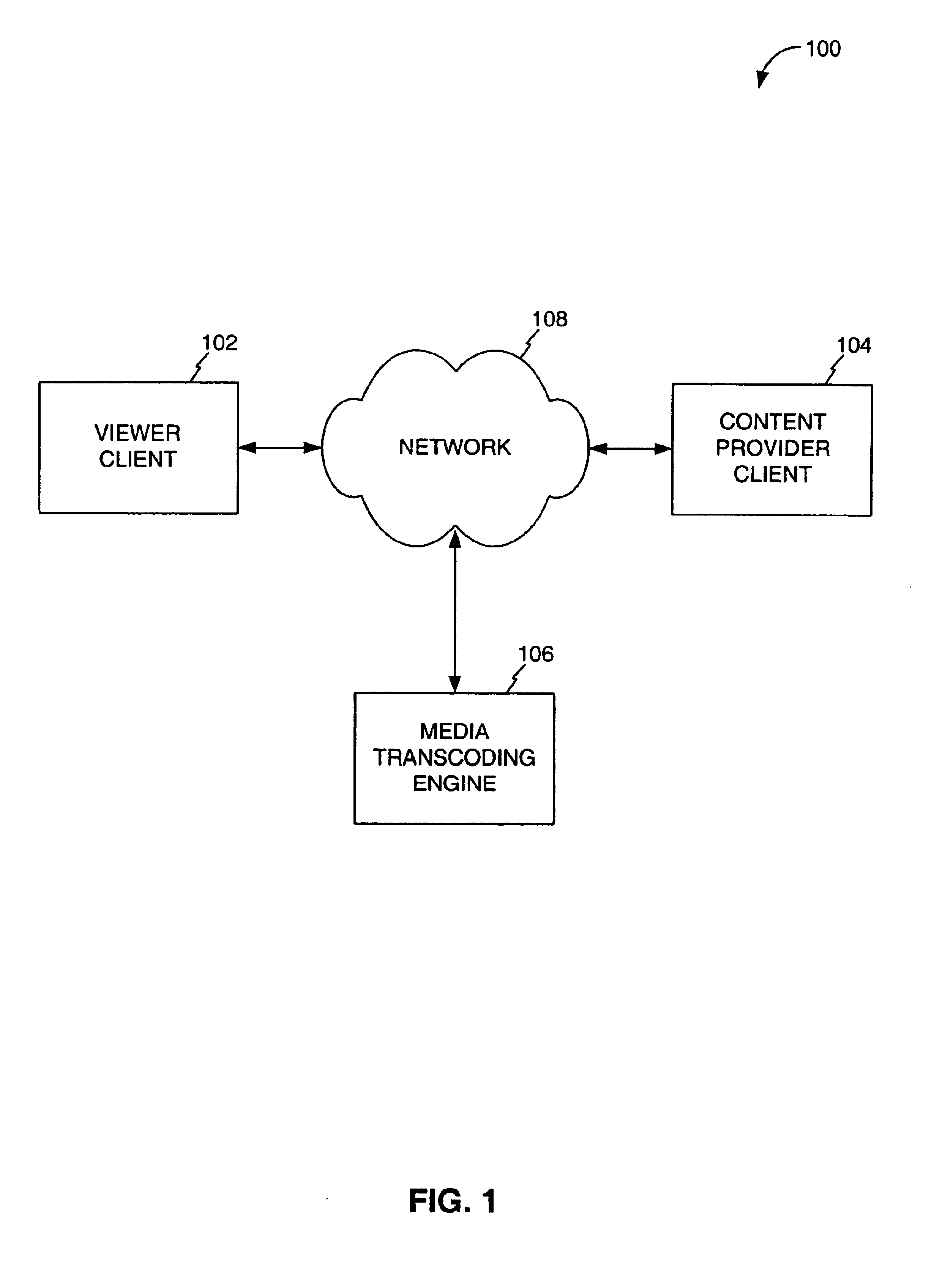

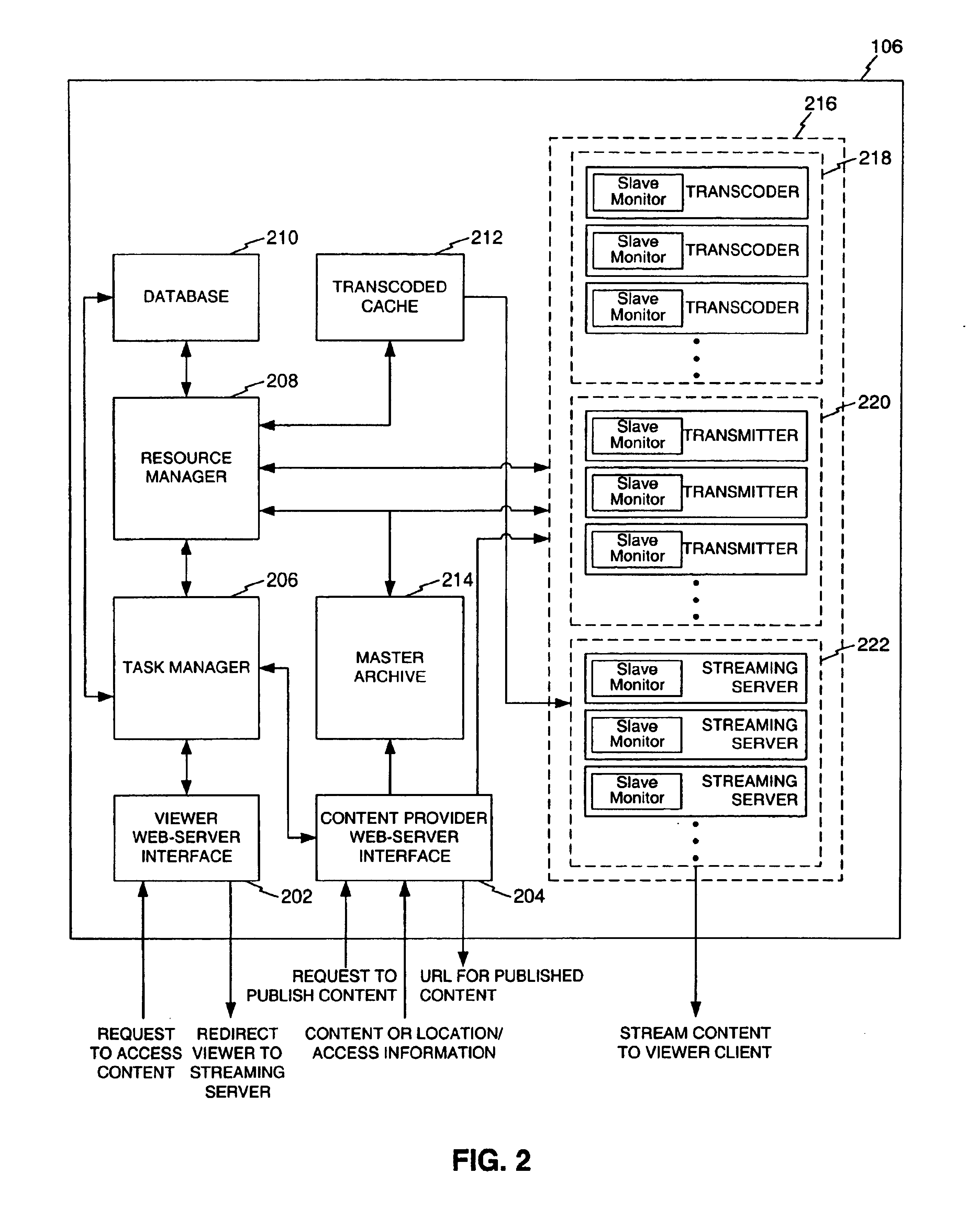

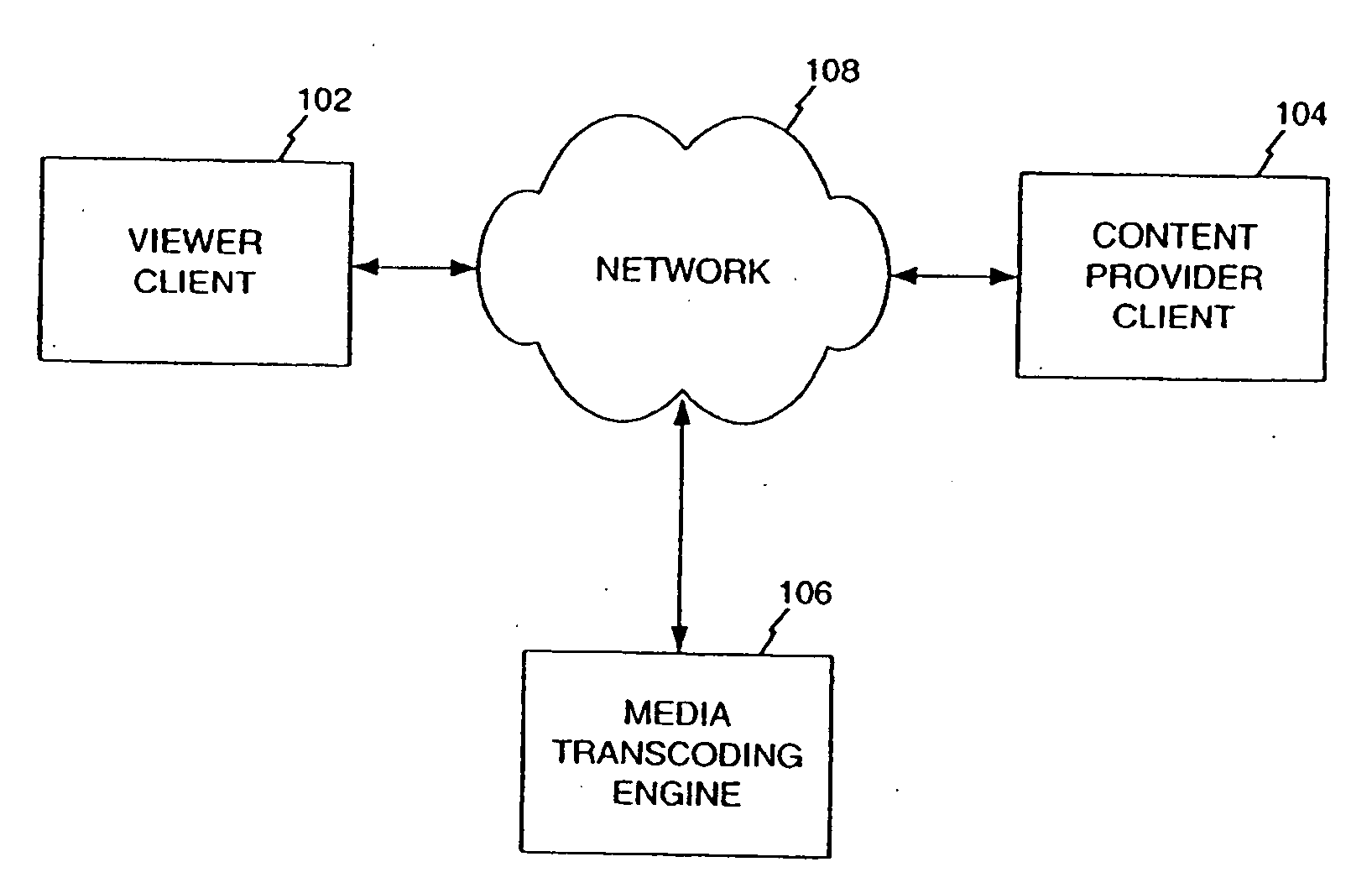

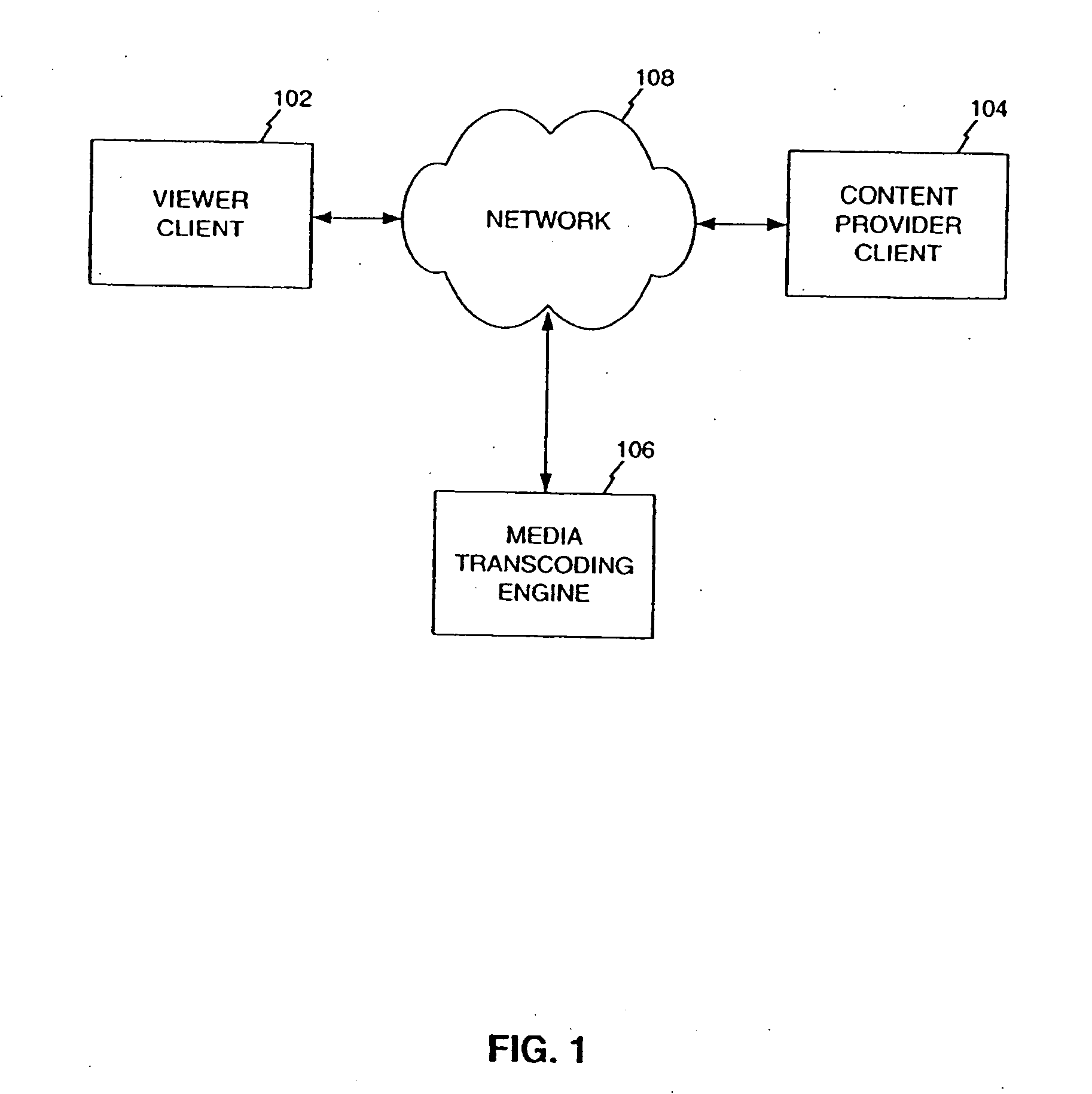

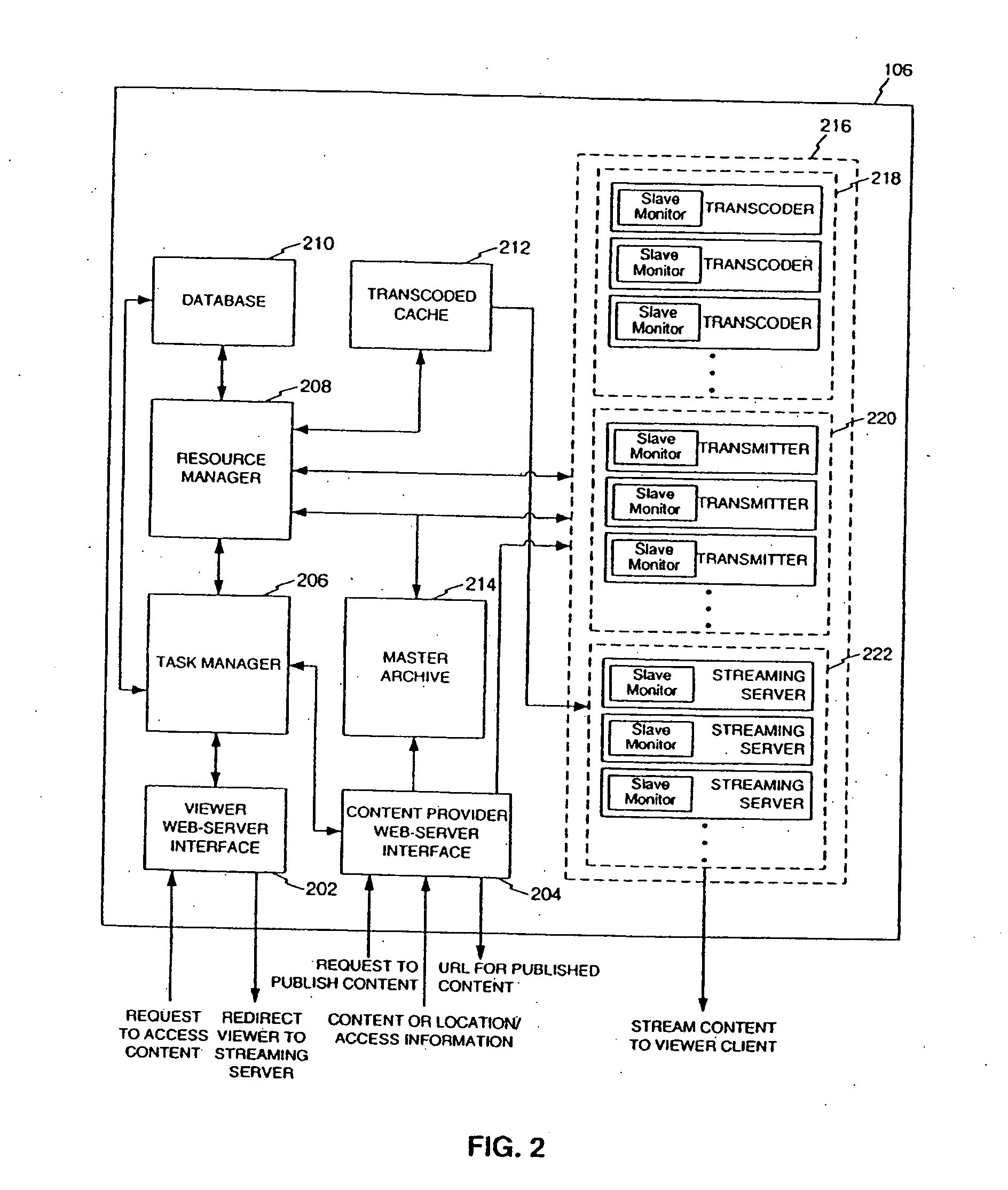

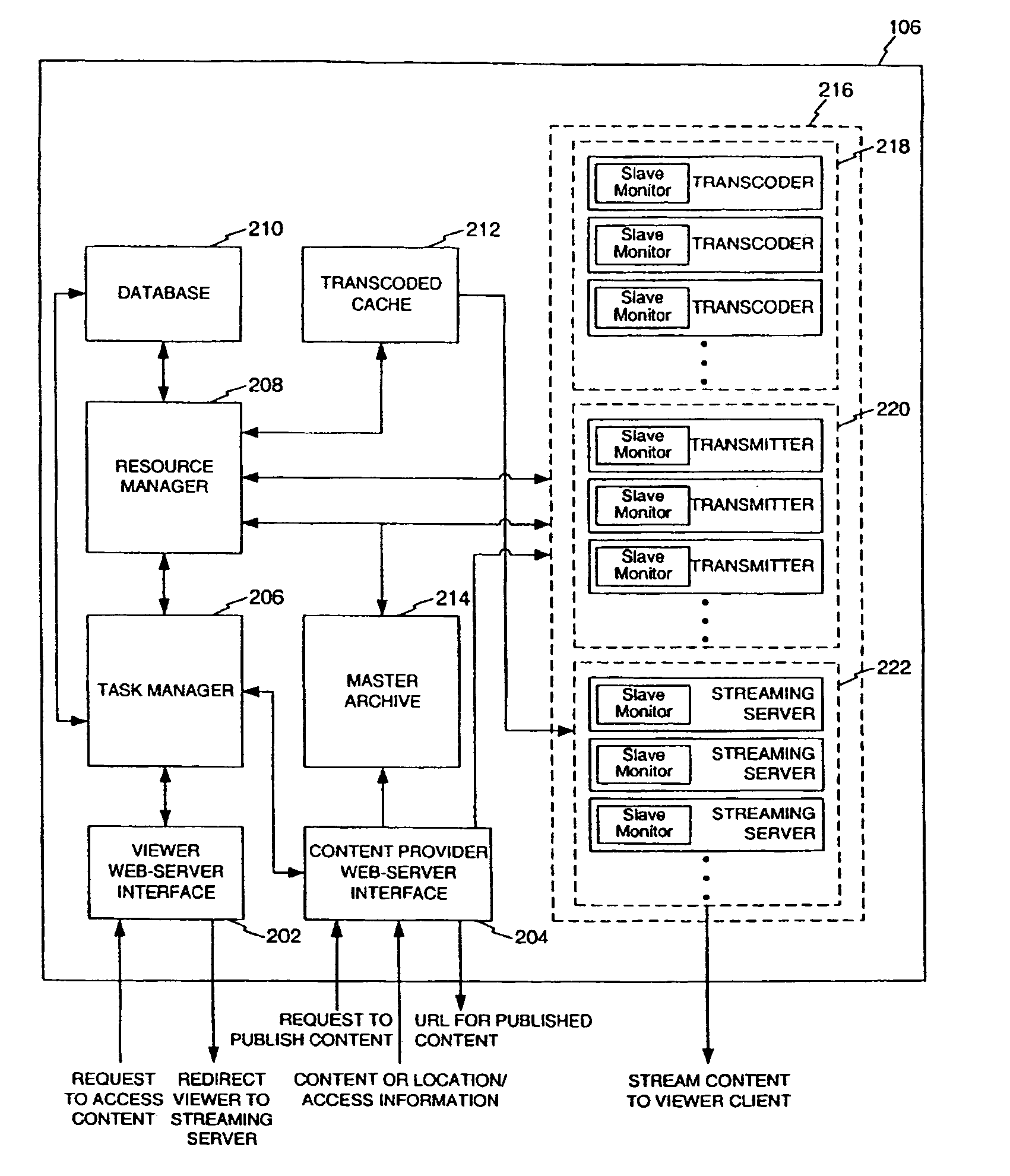

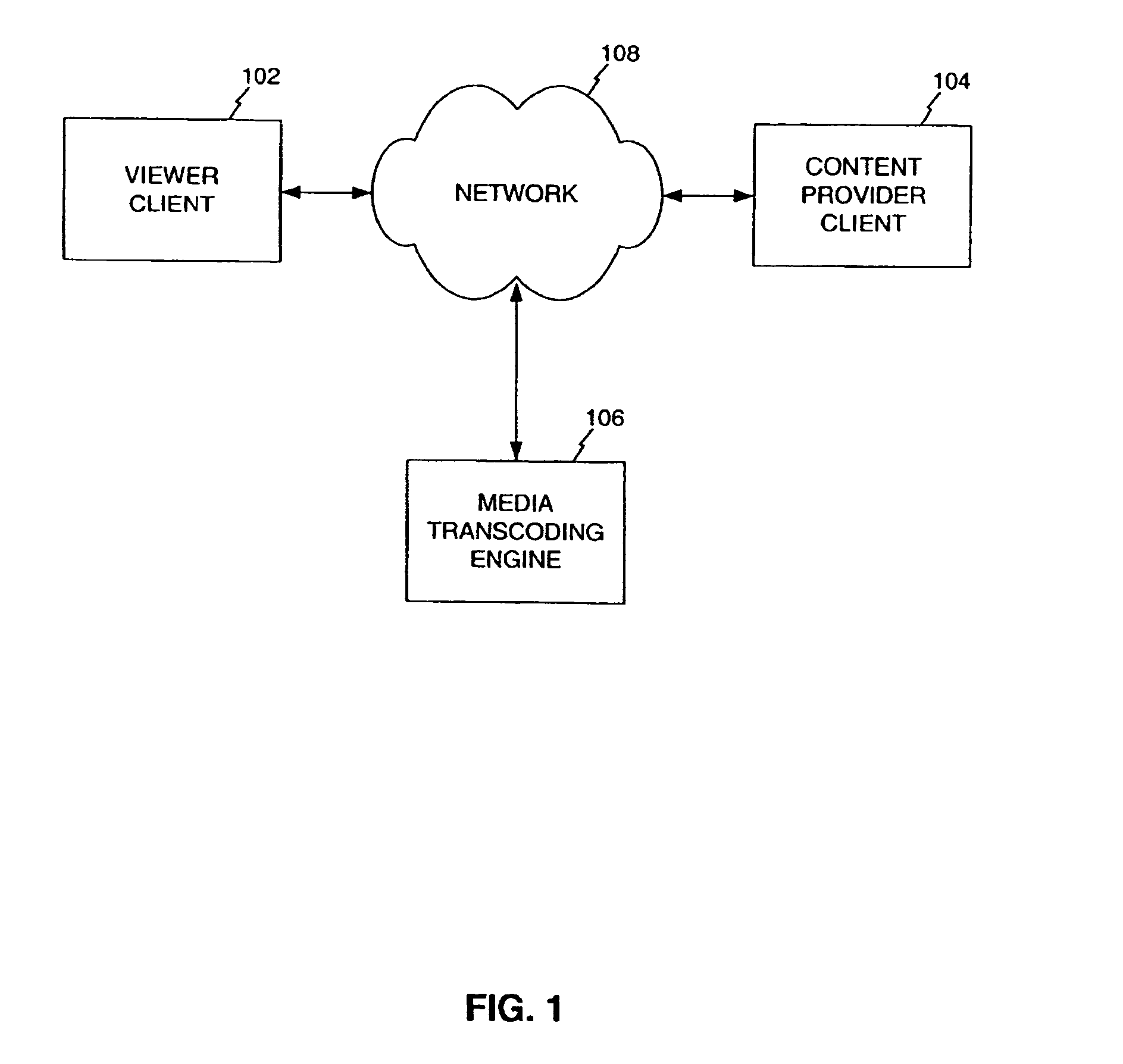

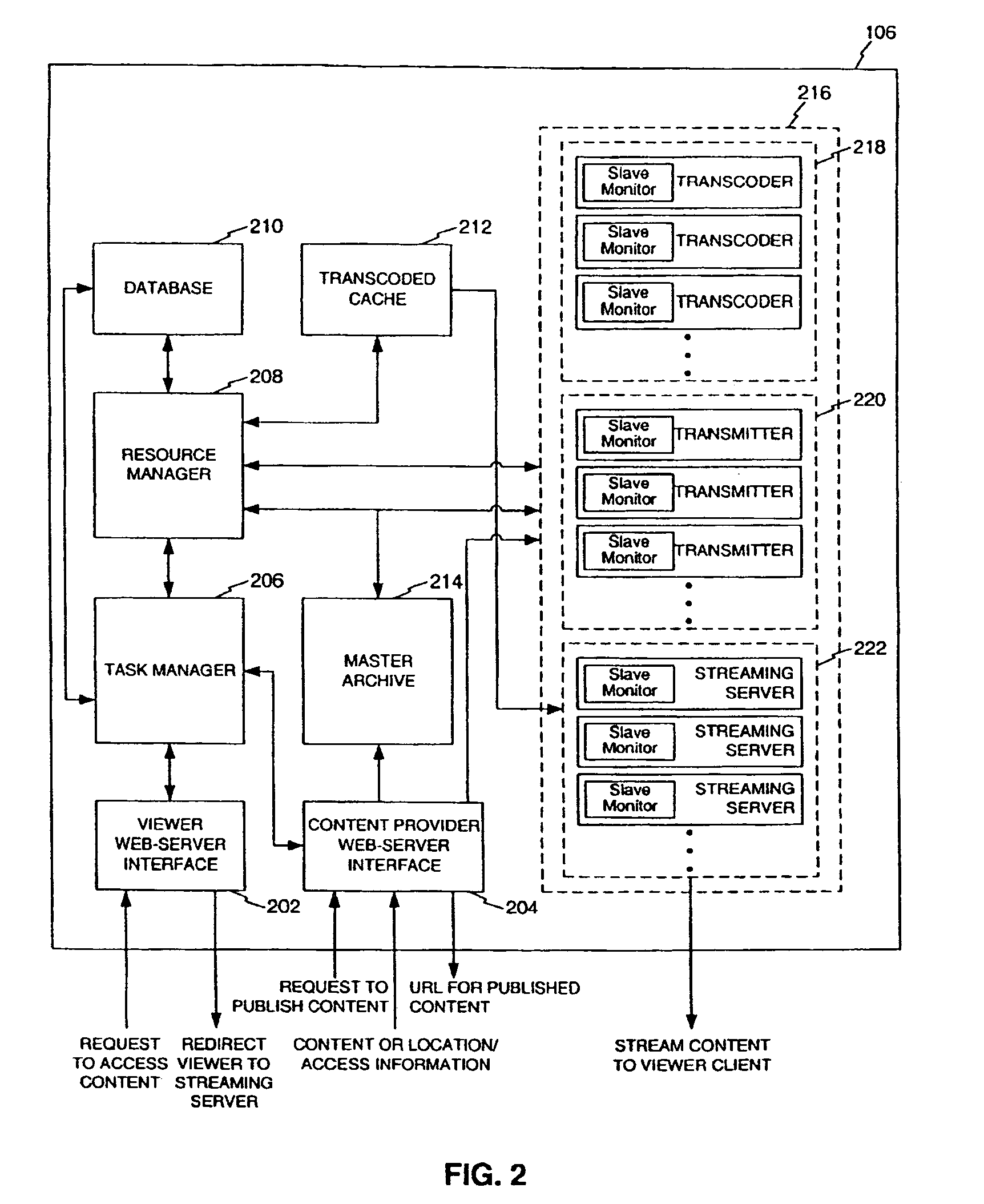

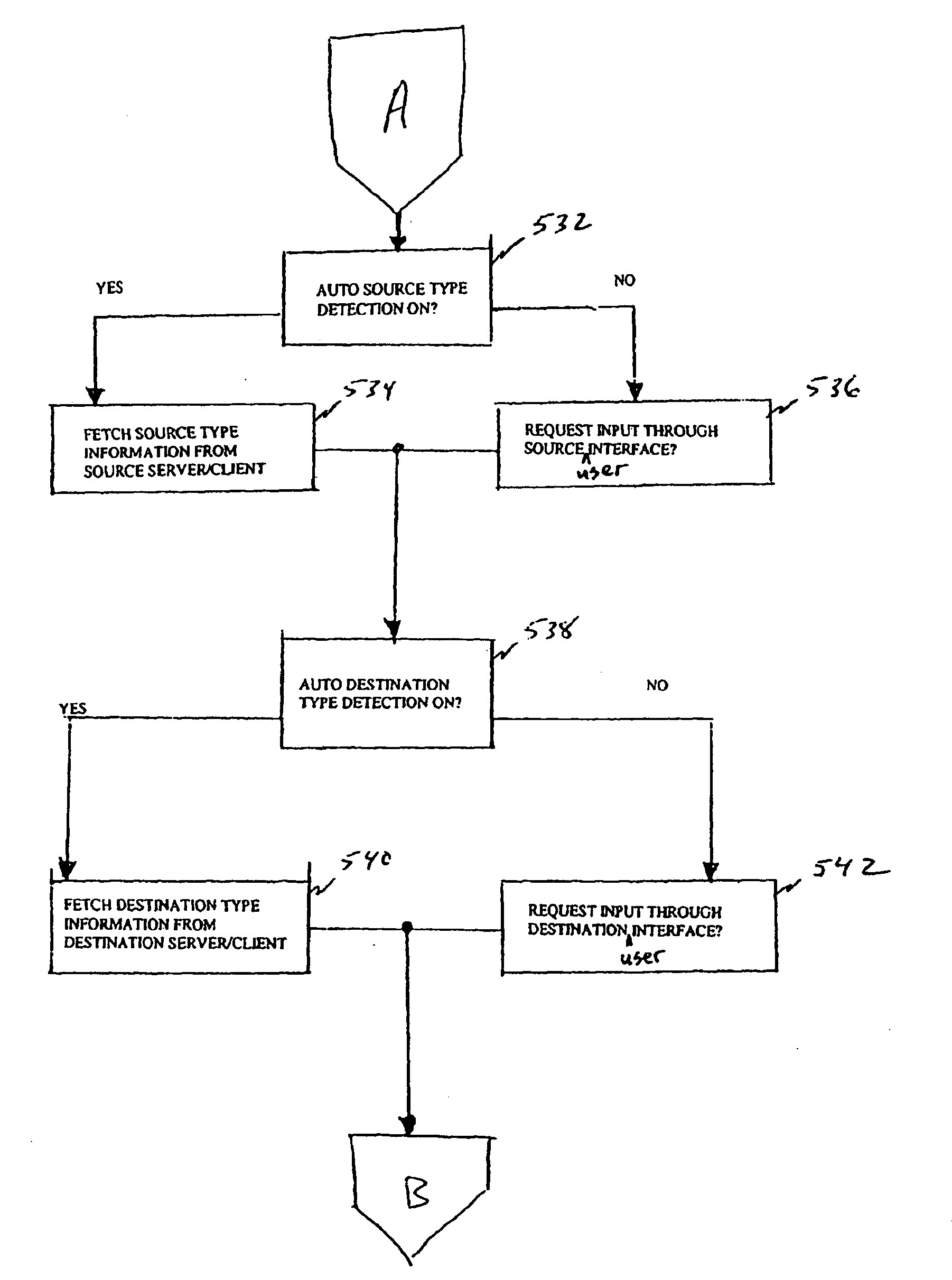

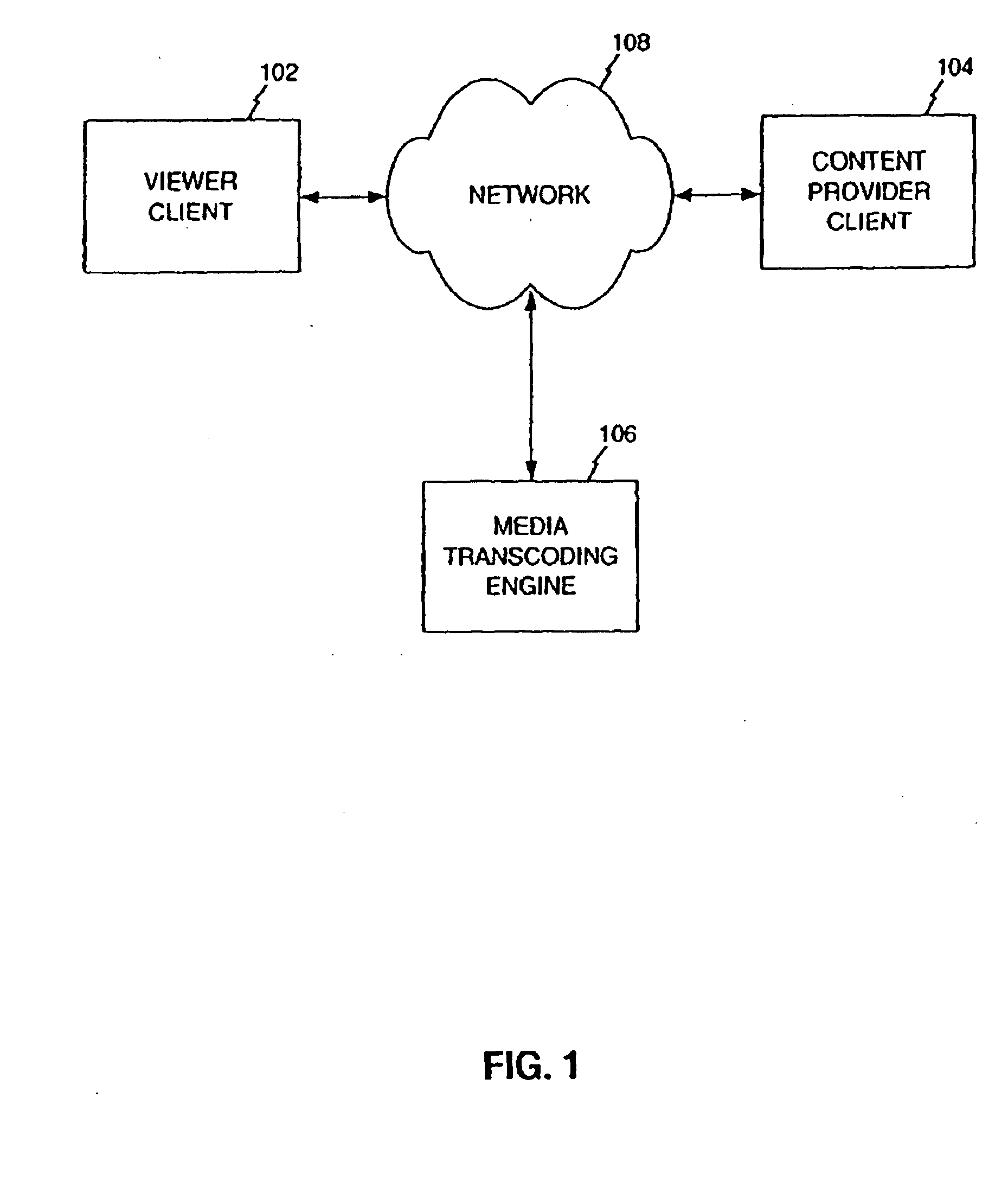

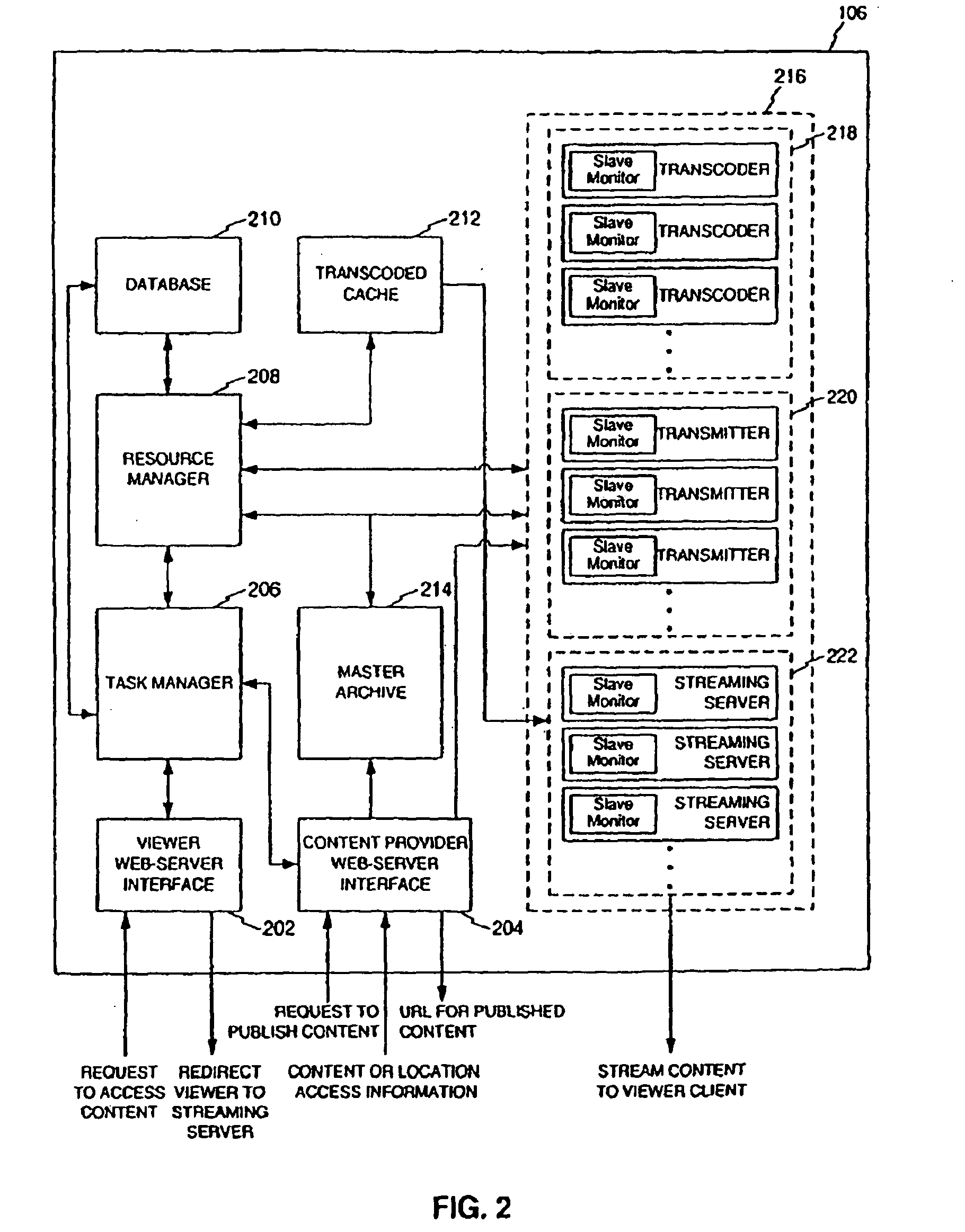

Distributed on-demand media transcoding system and method

InactiveUS6888477B2Eliminate needExpedites publishing processTransmission control/equalisingIndividual digits conversionDigital dataSource type

A system and method for the on-demand transcoding of media content from a source type to a destination type is provided, wherein the system includes a plurality of transcoders for transcoding from a plurality of source types to a plurality of destination types, and wherein the system receives a transcoding request for media content, fetches the media content in response to the transcoding request, sends the media content to one of the plurality of transcoders based on the source type and destination type, transcodes the media content from the source type to the destination type, thereby generating transcoded media content, and transmits the transcoded media content. The system fetches, sends, and transcodes the media content and transmits the transcoded media content in a pipelined fashion. The system also provides for the publication of media content as a file or stream of digital data, for the archiving of media content, and the caching of transcoded media content to improve system efficiency.

Owner:SONY CORP

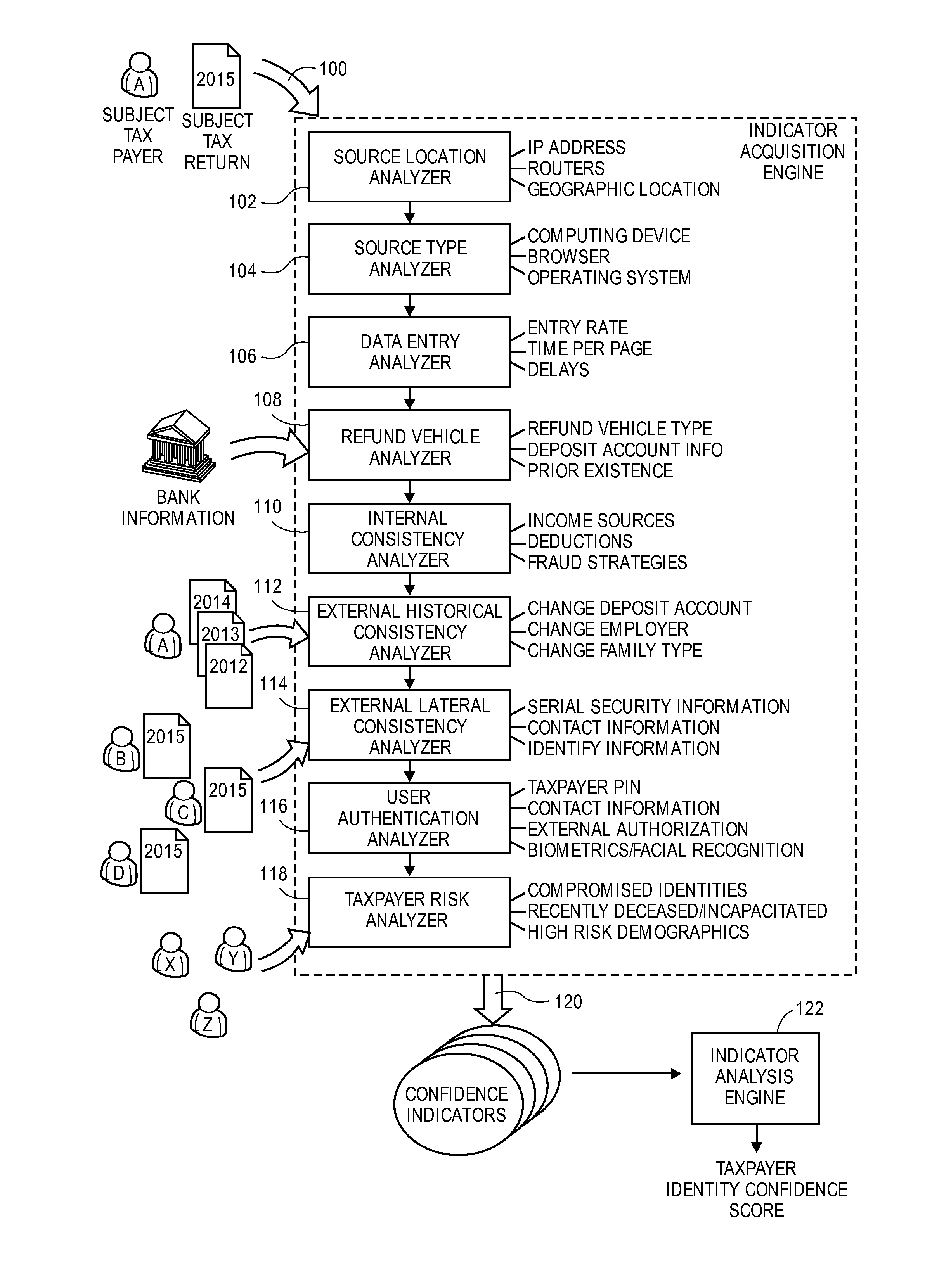

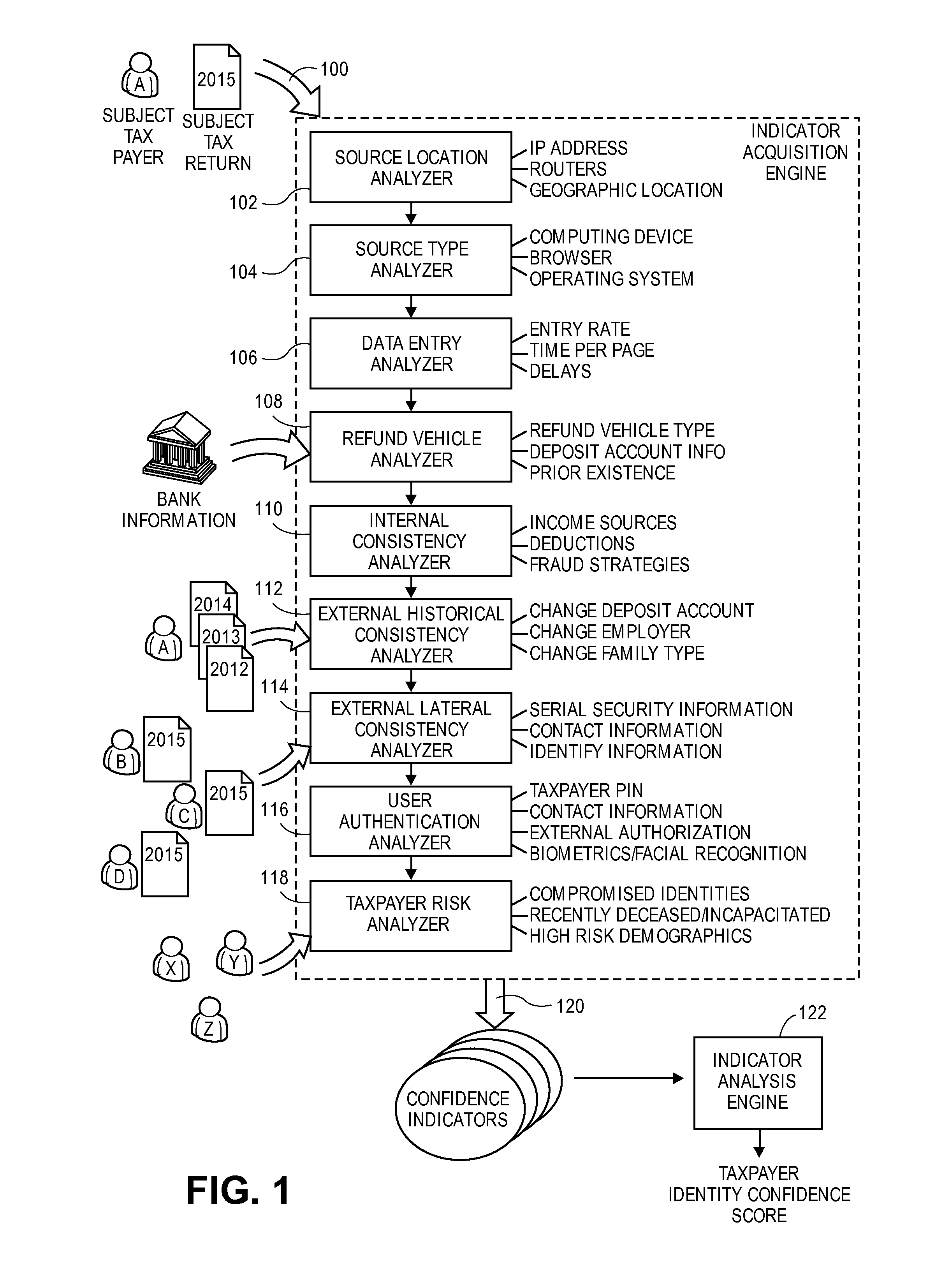

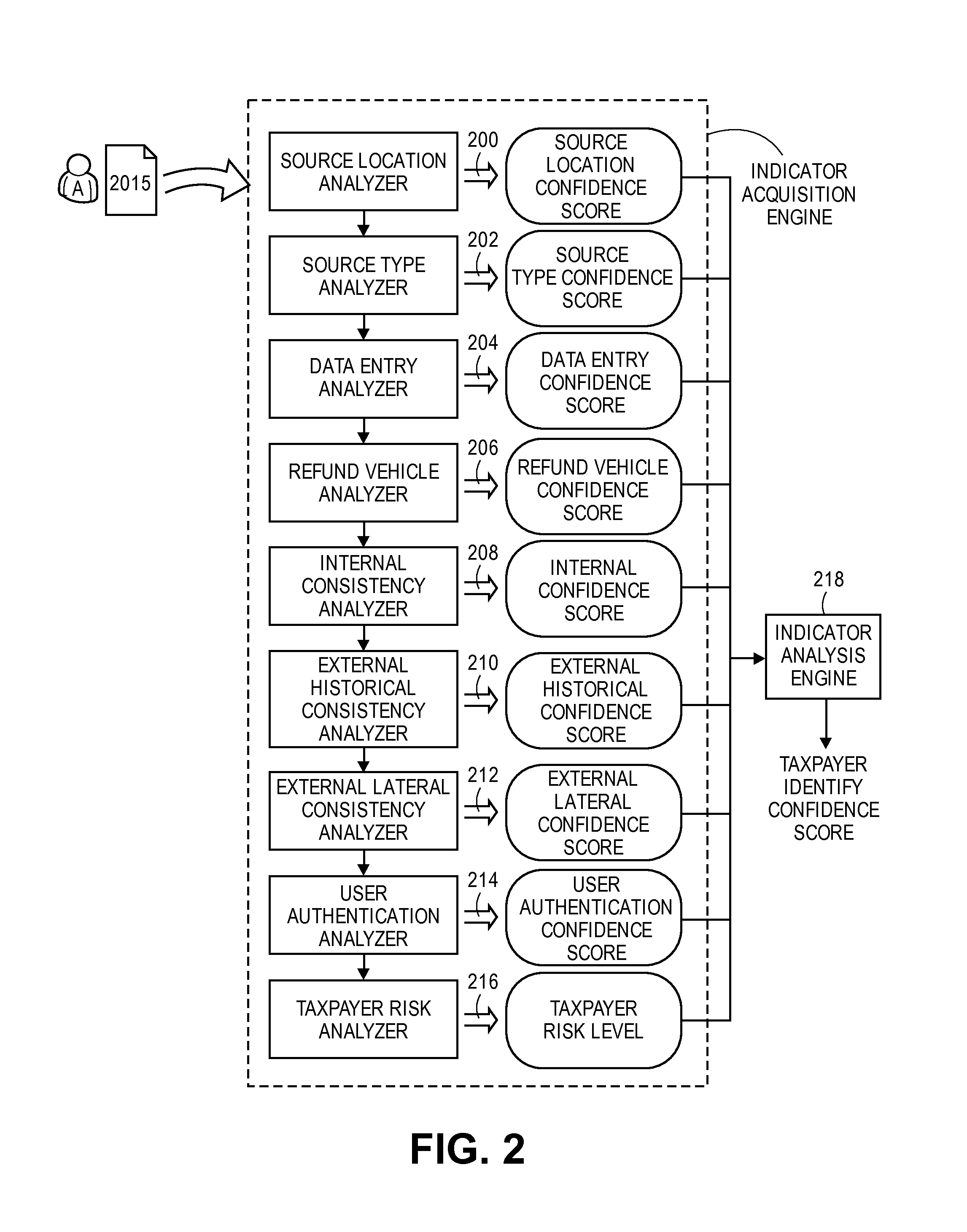

Computer program, method, and system for detecting fraudulently filed tax returns

Embodiments of the invention detect fraudulently filed tax returns when a user prepares or submits a subject tax return that relates to a subject taxpayer for filing with a government taxing authority. Embodiments analyze tax information of various sources to determine whether the subject tax return is genuine (i.e., not fraudulent). The invention determines confidence indicators based upon some or all of a source location, a source type, data entry characteristics, refund vehicle characteristics, internal consistencies, external historical consistencies, external lateral consistencies, user authentication methods, and a taxpayer risk level. Based upon these analyses the invention calculates a taxpayer identity confidence score, which may be utilized to allow or deny the filing of the subject tax return.

Owner:HRB INNOVATIONS

Distributed on-demand media transcoding system and method

Owner:SONY CORP

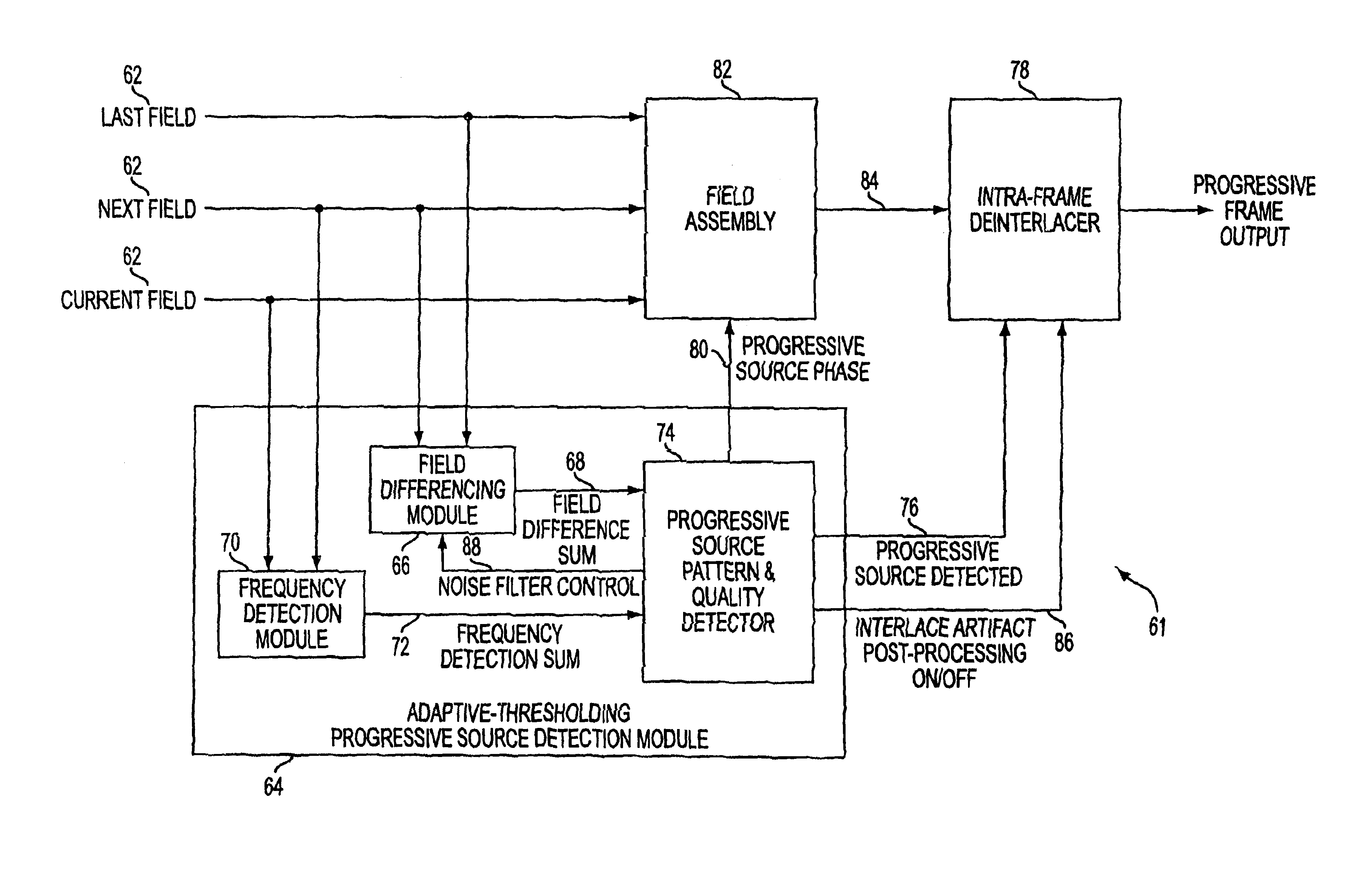

Method, system and article of manufacture for identifying the source type and quality level of a video sequence

InactiveUS6867814B2Reduce Motion ArtifactsAccurately determineTelevision system detailsColor signal processing circuitsQuality levelInterlaced video

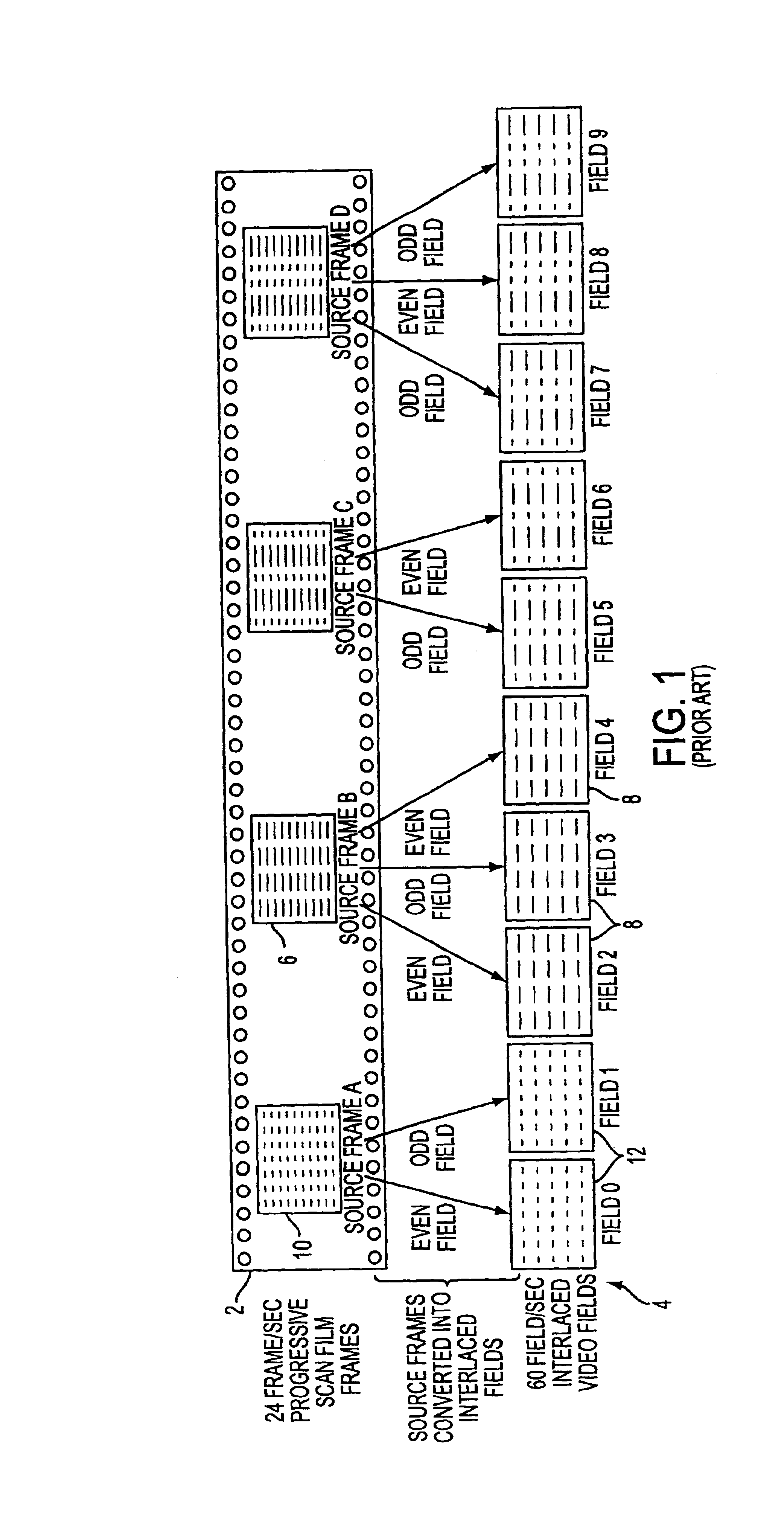

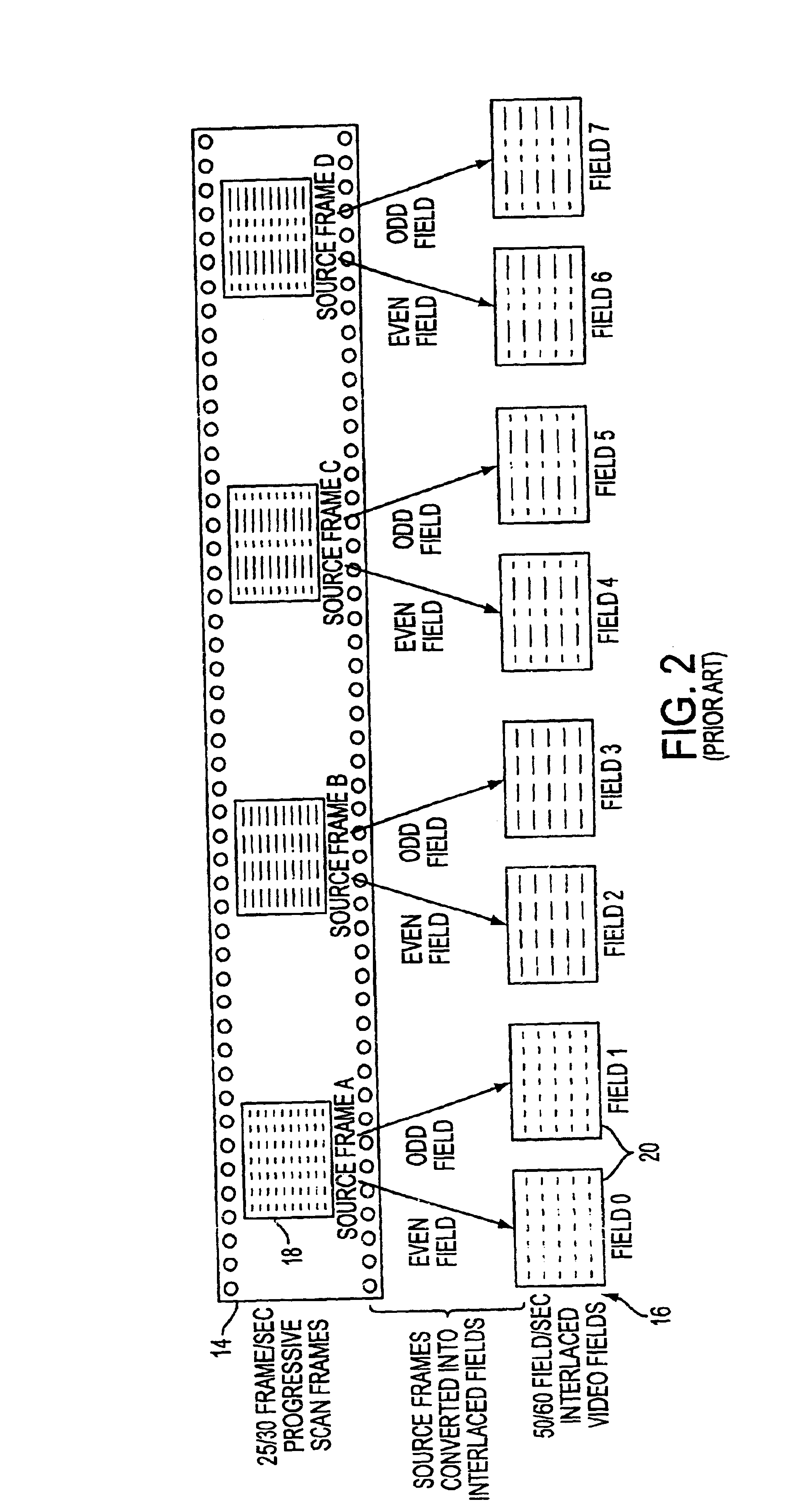

A deinterlacing system which converts an interlaced video stream into a progressive video stream is disclosed. The deinterlacing system includes a field assembly responsive to a last field, a next field, a current field and progressive source phase and operative to develop a progressive output frame, a source detection module responsive to last, next and current fields and operative to develop a progressive source phase and a progressive source detected and an intra-frame deinterlacer responsive to the progressive output frame and the progressive source detected and operative to develop a progressive frame output.

Owner:LATTICE SEMICON CORP

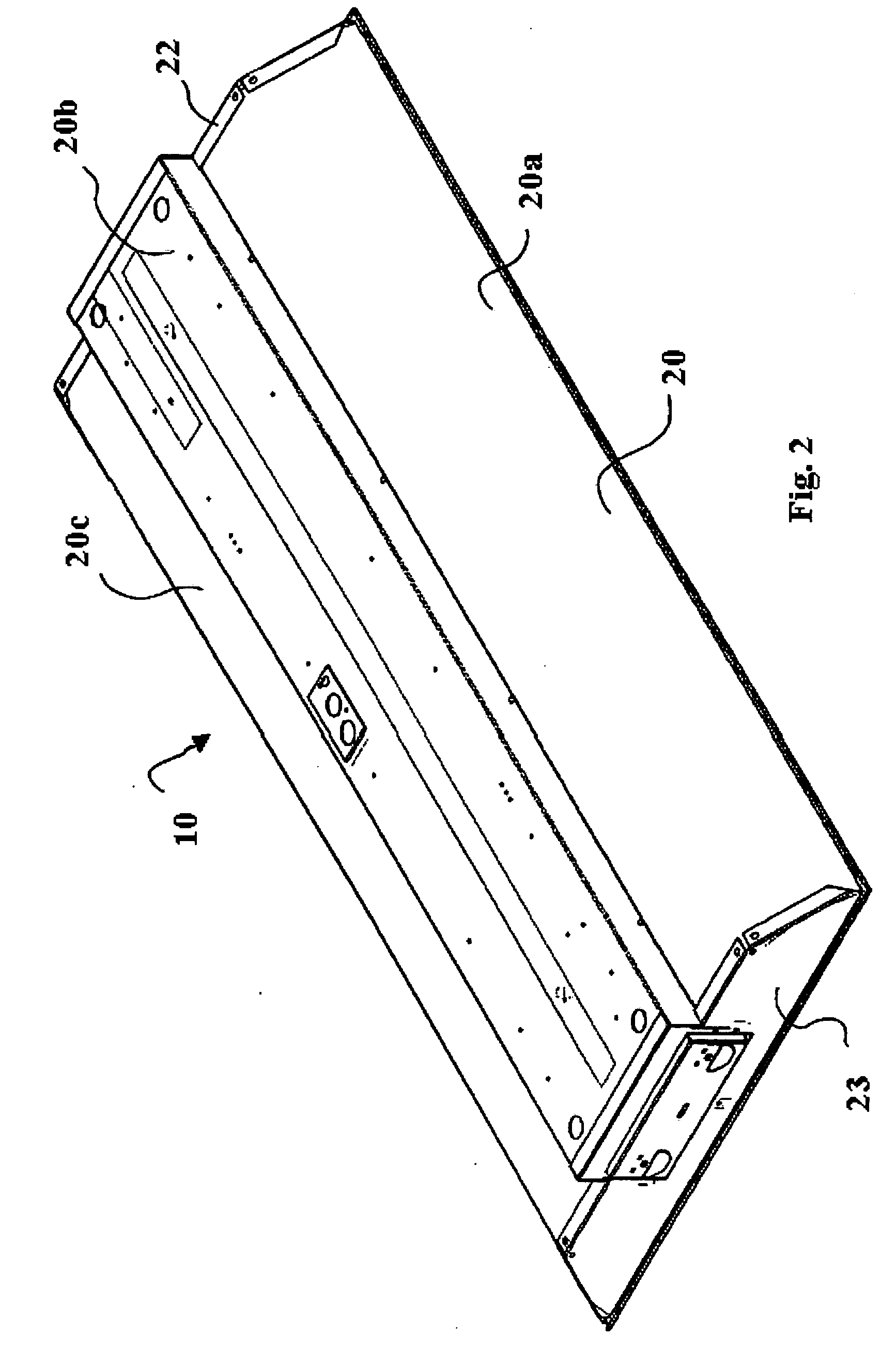

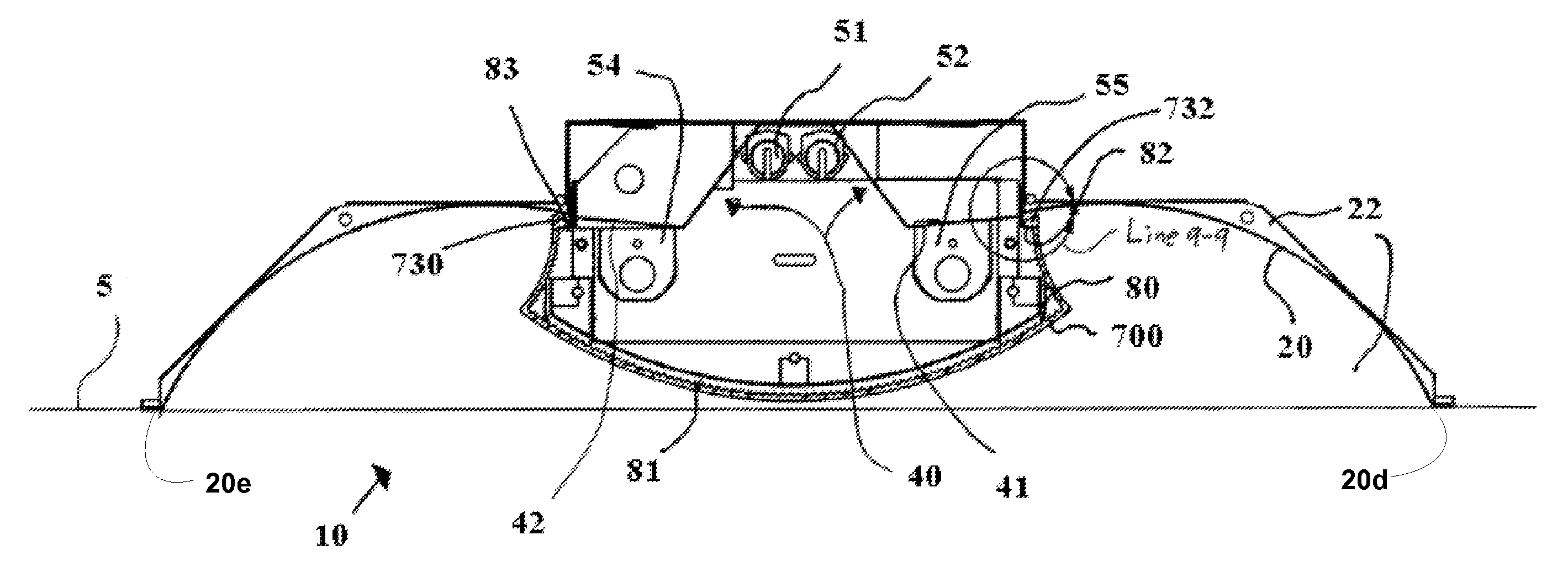

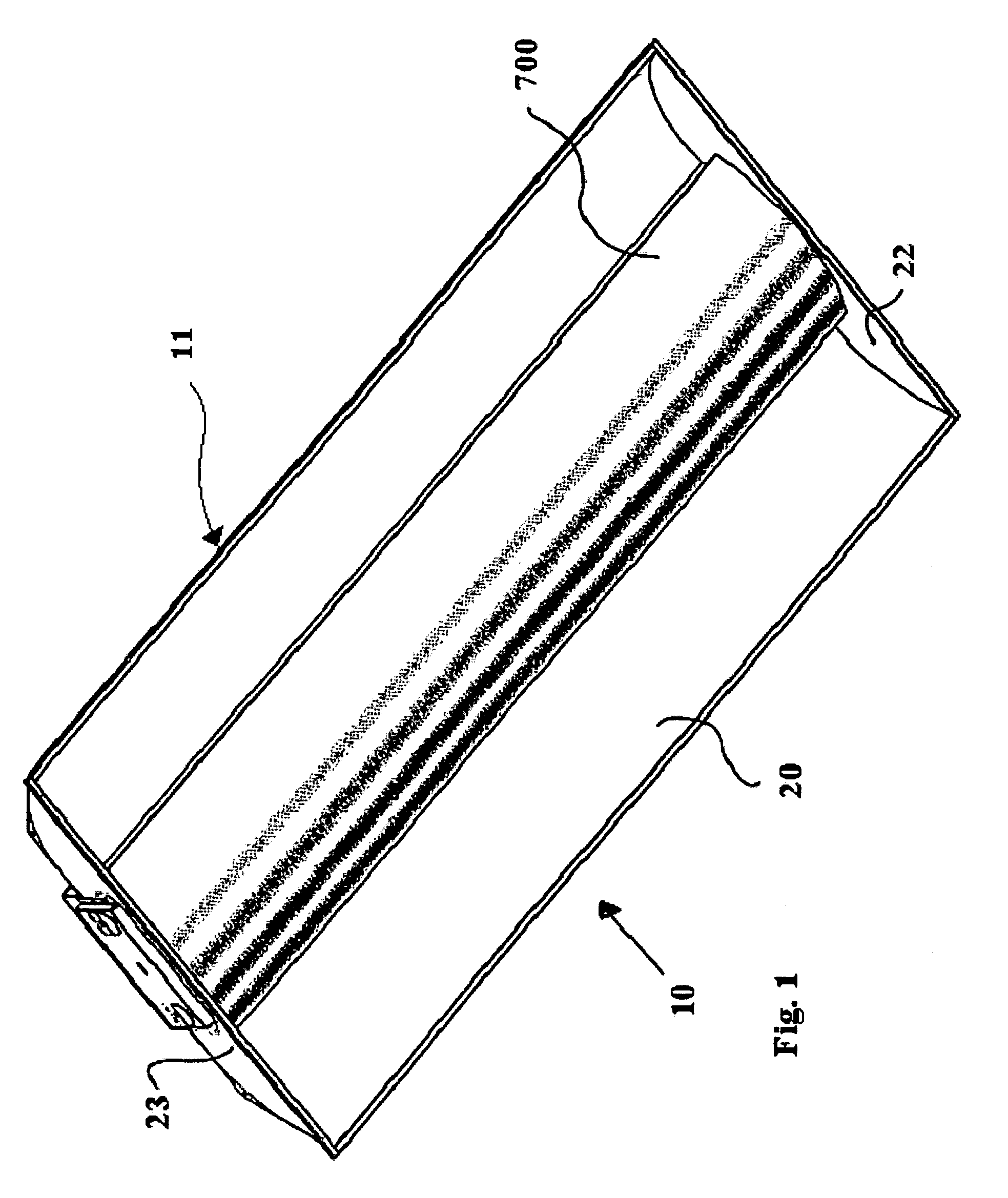

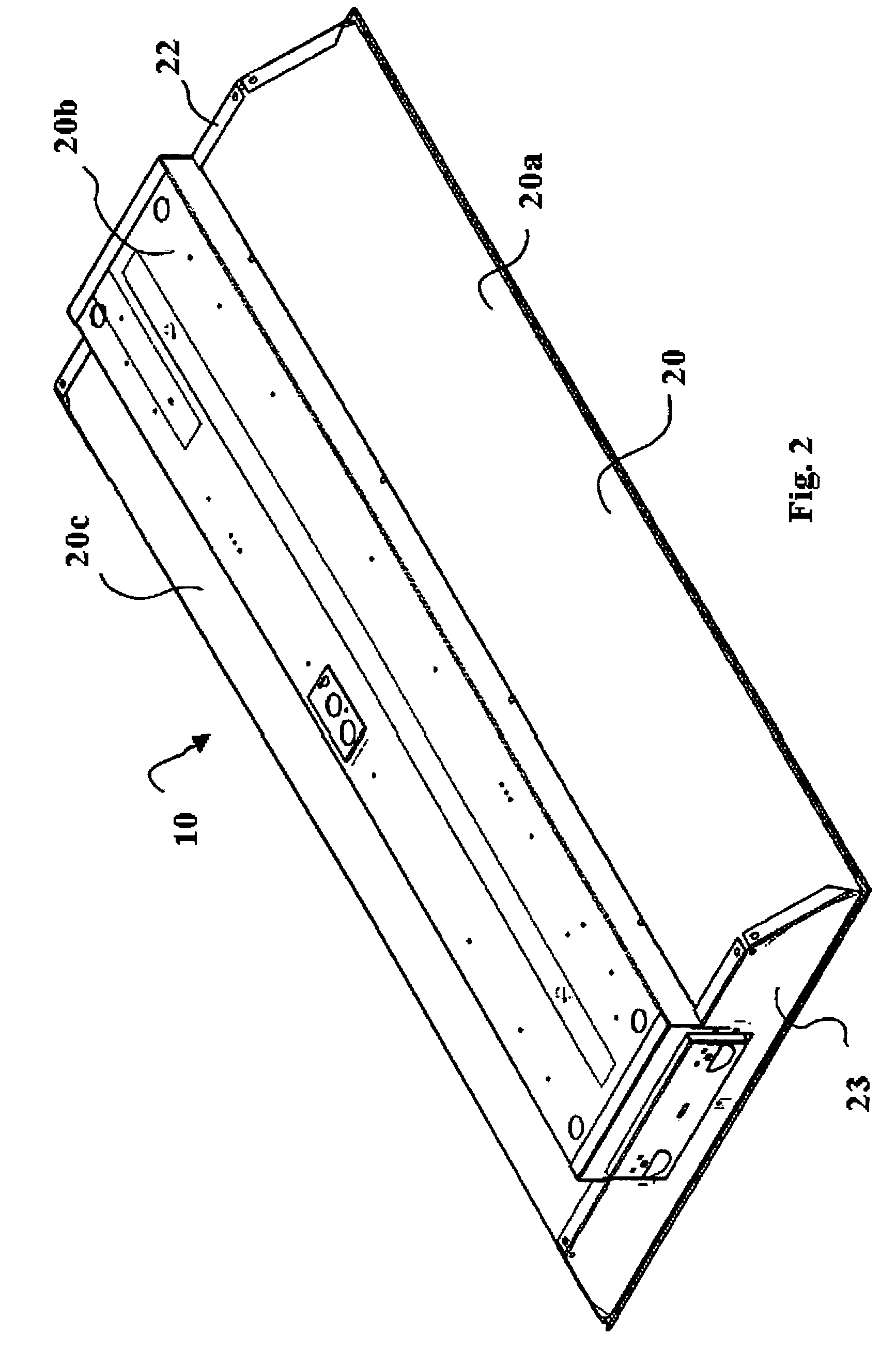

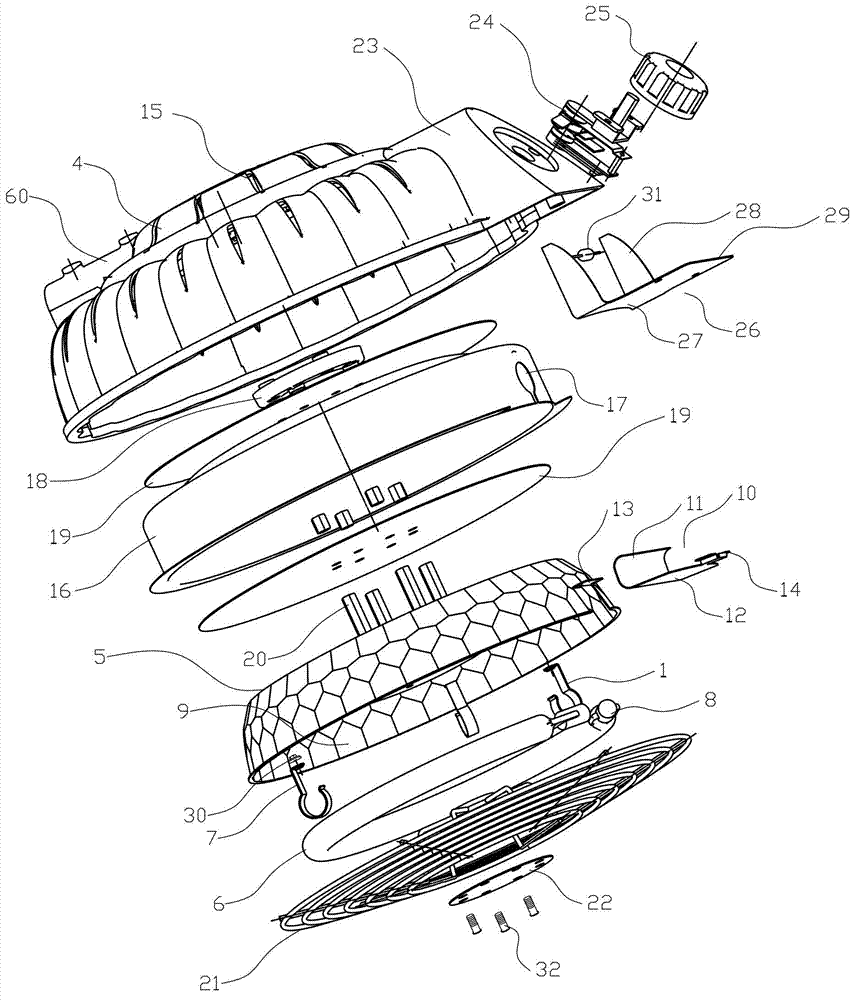

Recessed sealed lighting fixture

InactiveUS20060023450A1Minimize dustMinimize bacteria collectionMechanical apparatusLight source combinationsSource typeEffect light

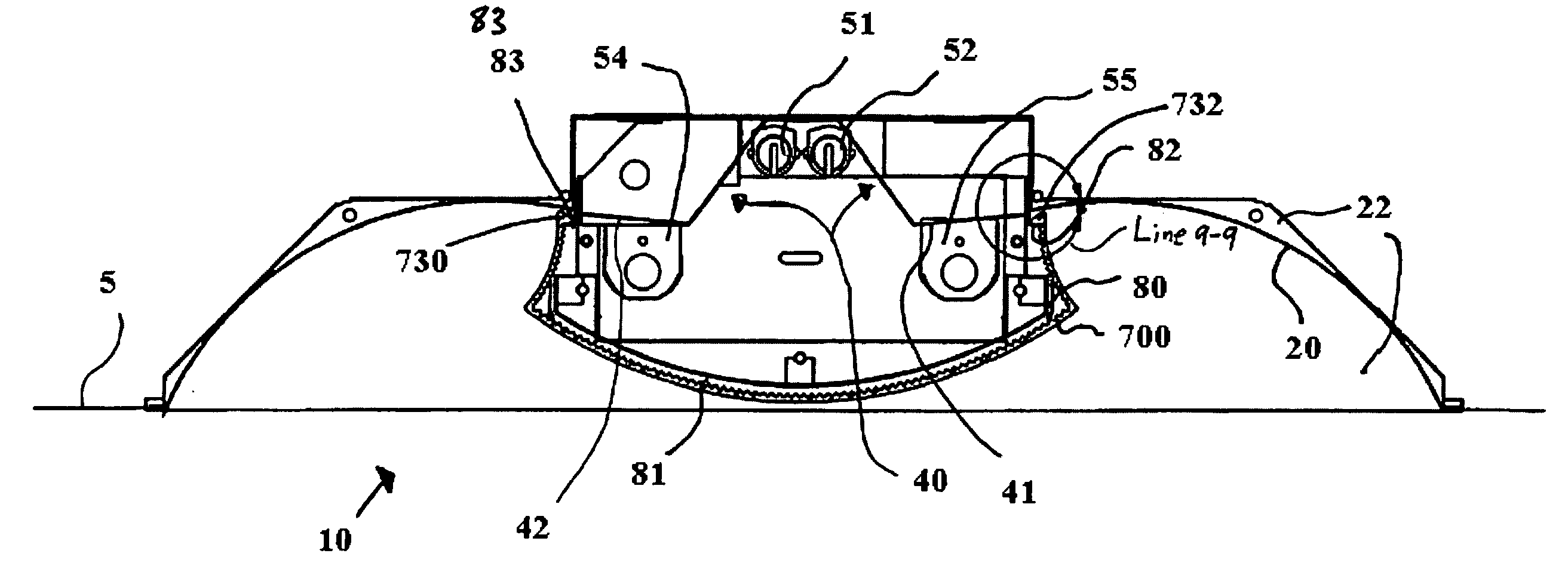

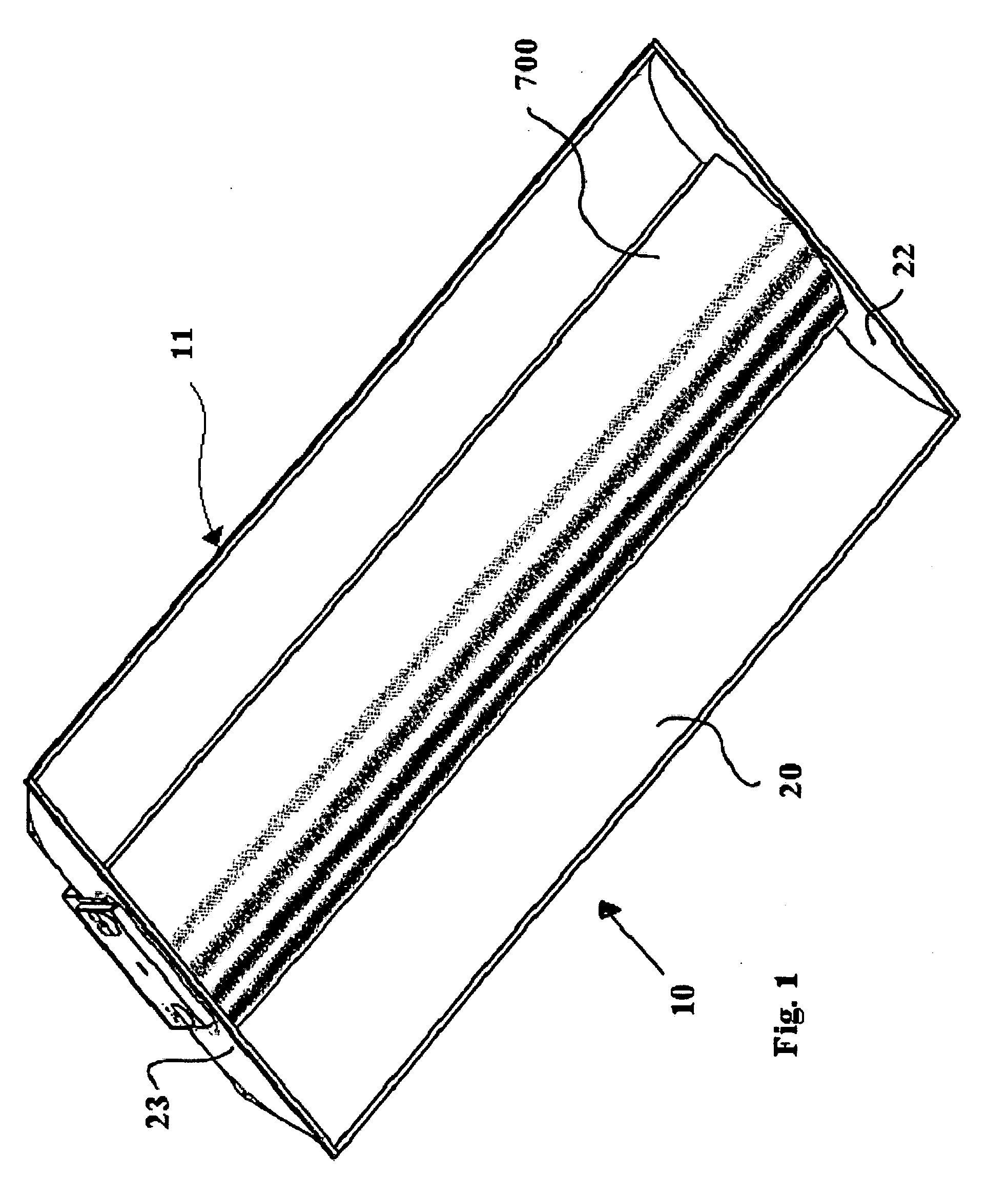

In an embodiment, a recessed light fixture includes a structural reflector and two end caps that form a light fixture housing. A first, second and third optics areas are provided. At least one first light source type is mounted near the first optics area. A second light source type is mounted near the second optics area and the second light source type is mounted near the third optics areas, the second light source type having a light output level substantially lower than the light output level of the first light source type. A diffuser is configured to sealably mount to the light fixture housing so as to substantially seal an interior portion of the light fixture. In operation, the light fixture can be switch between an ambient mode and an examination mode while providing a cost effective and attractive design.

Owner:FOCAL POINT

Recessed sealed lighting fixture

InactiveUS7674005B2Minimize dust and bacteria collectionEasy to cleanMechanical apparatusLight source combinationsSource typeEffect light

In an embodiment, a recessed light fixture includes a structural reflector and two end caps that form a light fixture housing. A first, second and third optics areas are provided. At least one first light source type is mounted near the first optics area. A second light source type is mounted near the second optics area and the second light source type is mounted near the third optics areas, the second light source type having a light output level substantially lower than the light output level of the first light source type. A diffuser is configured to sealably mount to the light fixture housing so as to substantially seal an interior portion of the light fixture. In operation, the light fixture can be switch between an ambient mode and an examination mode while providing a cost effective and attractive design.

Owner:FOCAL POINT

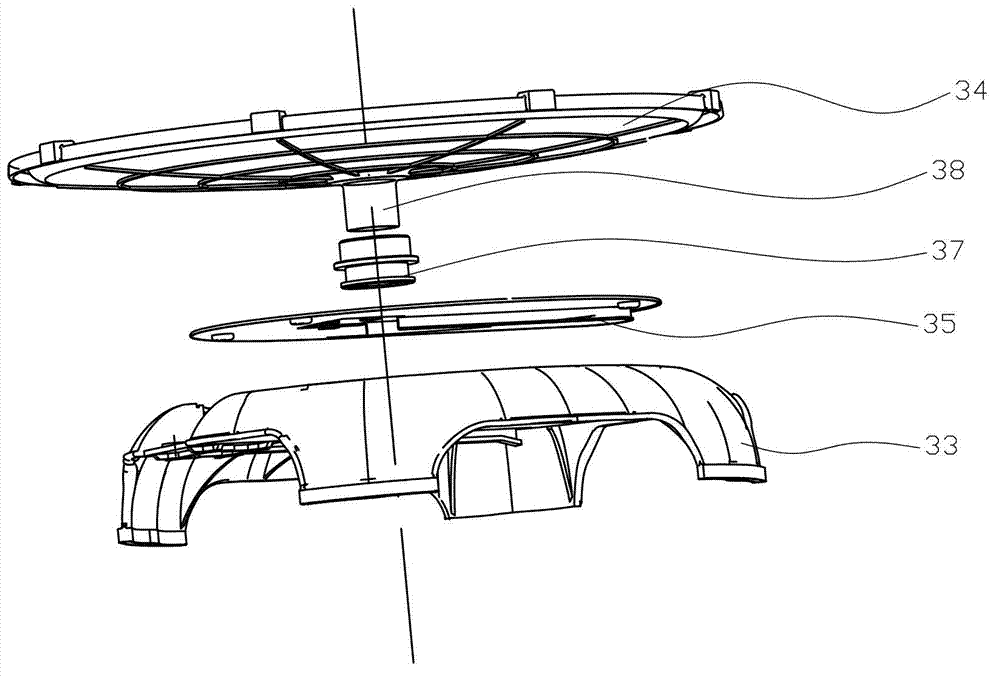

Upper heat source and movable adjusting type electric oven

InactiveCN102755120AAvoid safety hazardsExtend the lifespanCooking vesselsRoasters/grillsElectricityCurrent electric

The invention relates to the technical field of electric ovens, and in particular relates to an upper heat source and movable adjusting type electric oven. For solving the technical defects that the current electric oven adopts an underneath electric heater structure so that the barbecuing effects are poor due to the smoke caused by the dropped oil and the side arrangement of the electric heater, the invention provides the upper heat source and movable adjusting type electric oven. The upper heat source and movable adjusting type electric oven comprises an electric heater, and a baking platform having a barbecuing frame, and is characterized in that the electric heater is placed above the baking platform; and a biased supporting device is arranged on the baking platform and fixedly connected with the electric heater. According to the upper heat source and movable adjusting type electric oven, the electric heater is upwards arranged above the baking platform, thus the smoke caused by the dropped oil in barbecuing is reduced; the upper electric heater can provide thermal radiation area the same as that of the current lower heat source type electric oven, so that the barbecuing effects are ensured; the upper electric heater is used for downwards heating the surfaces of foods, and the baking face can be conveniently observed, and the foods can be conveniently overturned for being barbecued.

Owner:李琎熙

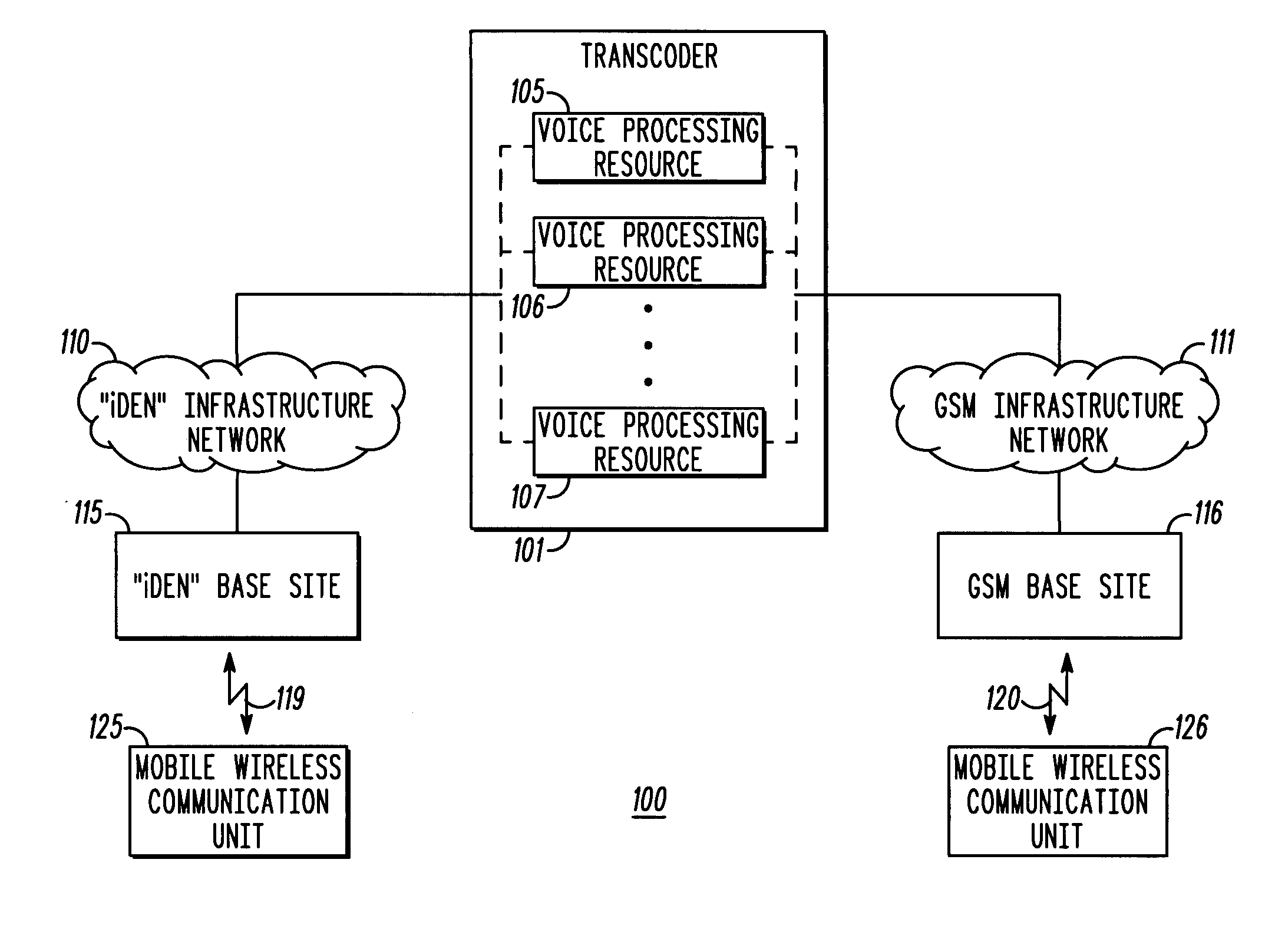

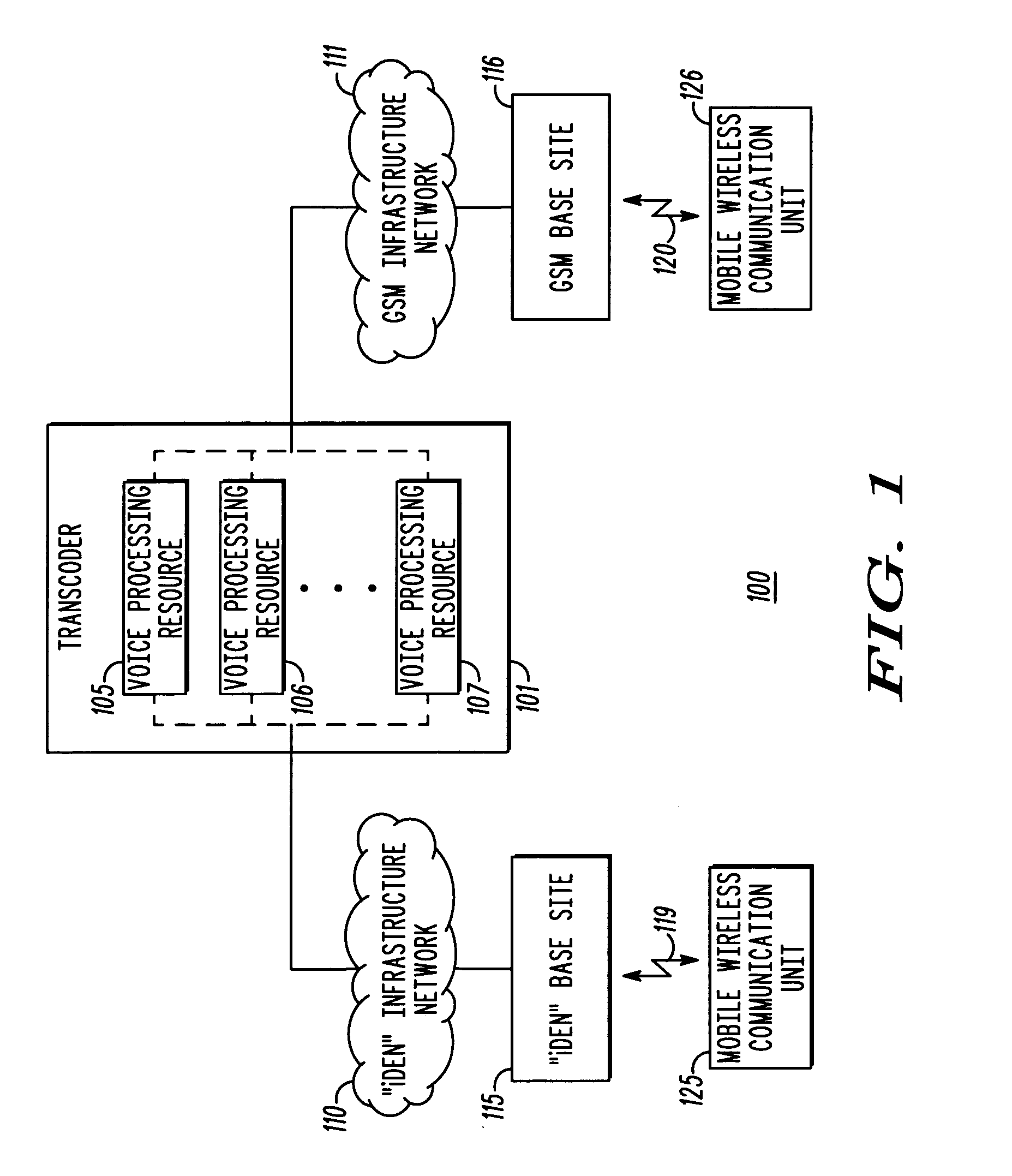

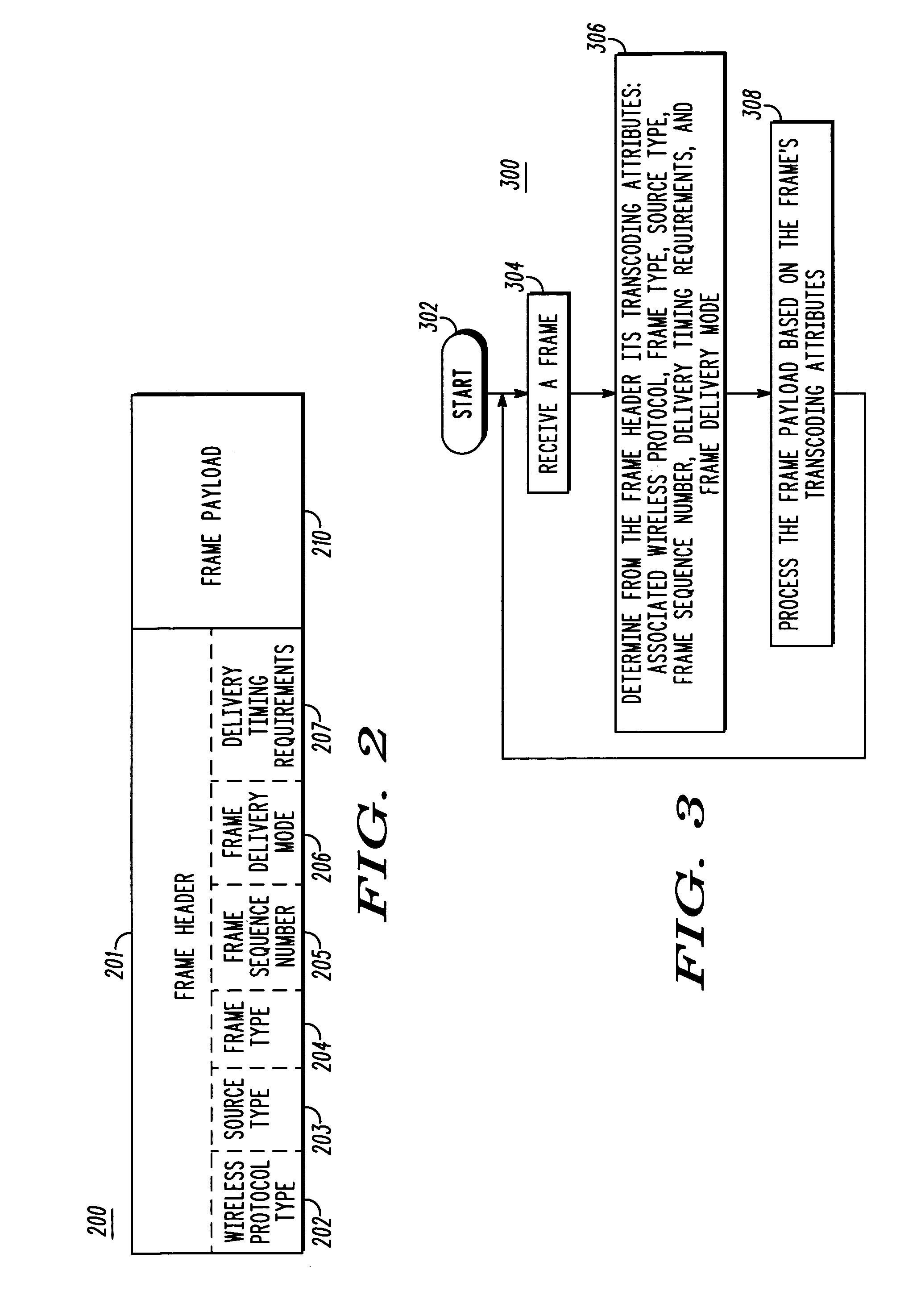

Communication equipment, transcoder device and method for processing frames associated with a plurality of wireless protocols

To address the need for an apparatus and method for transcoding among multiple wireless protocols, the present invention provides a framework for more generalized transcoding. A voice processing resource (e.g., 105) of a transcoder (101) receives the dynamic transcoding attributes (e.g., 201–207) for a frame and then transcodes that frame according to the requirements of the transcoding attributes. These dynamic attributes may contain information such as the wireless protocol involved, the frame type, the source type, the sequence number, the delivery timing requirements, and the delivery mode of subsequent frames.

Owner:GOOGLE TECH HLDG LLC

Distributed on-demand media transcoding system and method

A method for delivering media content over a network includes transcoding the media content to generate multiple copies of the media content, each of the multiple copies having a different destination type or a different source type or both, storing the multiple copies in a cache, receiving requests for the media content, and selecting and delivering a copy of one of the multiple copies in response to each of the requests. A further method for providing media content transcoding services includes fetching media content, selecting one of multiple transcoders for transcoding from multiple source types to multiple destination types, wherein the one transcoder is selected based at least on the destination type, sending the media content to the selected transcoder, transcoding the media content to the destination type, thereby generating transcoded media content, and transmitting the transcoded media content.

Owner:SONY CORP

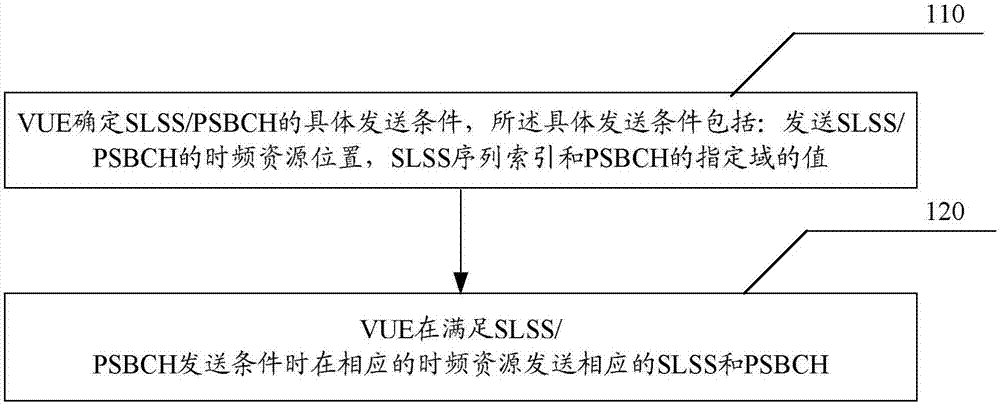

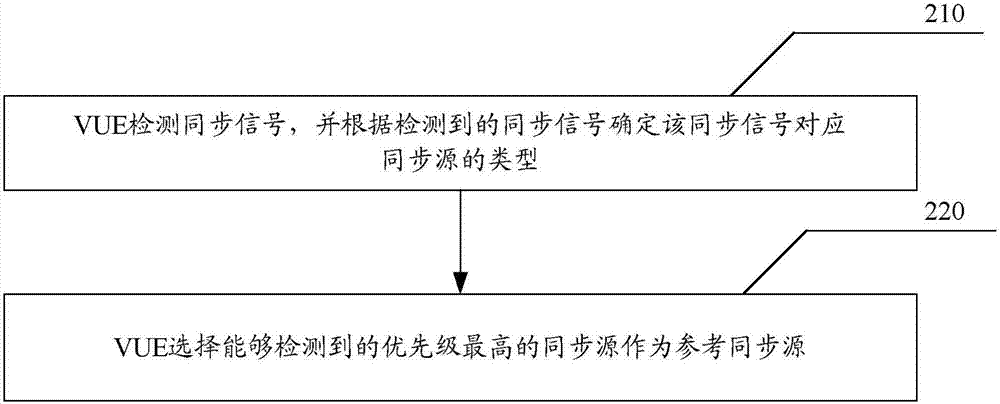

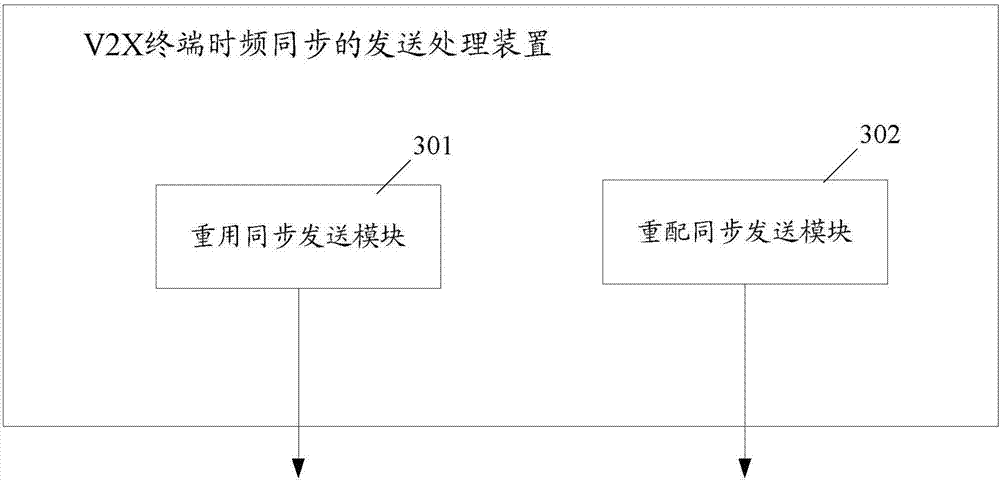

Sending and receiving processing method and device of V2X terminal time frequency synchronization

ActiveCN107046461ATime-Frequency Resource SupportSynchronisation arrangementAssess restrictionSource typeComputer science

The application provides a sending and receiving processing method and device of V2X terminal time frequency synchronization. The method comprises the following steps: when a to-be-sent synchronization signal is the same as a synchronization signal of the existing D2D terminal, sending the synchronization signal by reuse of the configured time frequency resource of the D2D terminal in a cell; when the sent synchronization signal is different from the synchronization signal of the existing D2D terminal, sending the synchronization signal by use of a reconfigured time frequency resource, wherein the corresponding synchronization source type is indicated by use of a SLLS sequence index and / or a value of a PSBCH specified domain in the synchronization signal sent by the V2X terminal. For the V2X terminal for receiving the synchronization signal, the synchronization source type is determined according to the received synchronization signal; furthermore, a reference synchronization source is selected on the basis of the fixed priority according to the detected synchronization source. According to the method provided by the application, the time frequency synchronization between the terminals in the V2X communication environment can be supported in small improvement cost aiming at the prior art.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

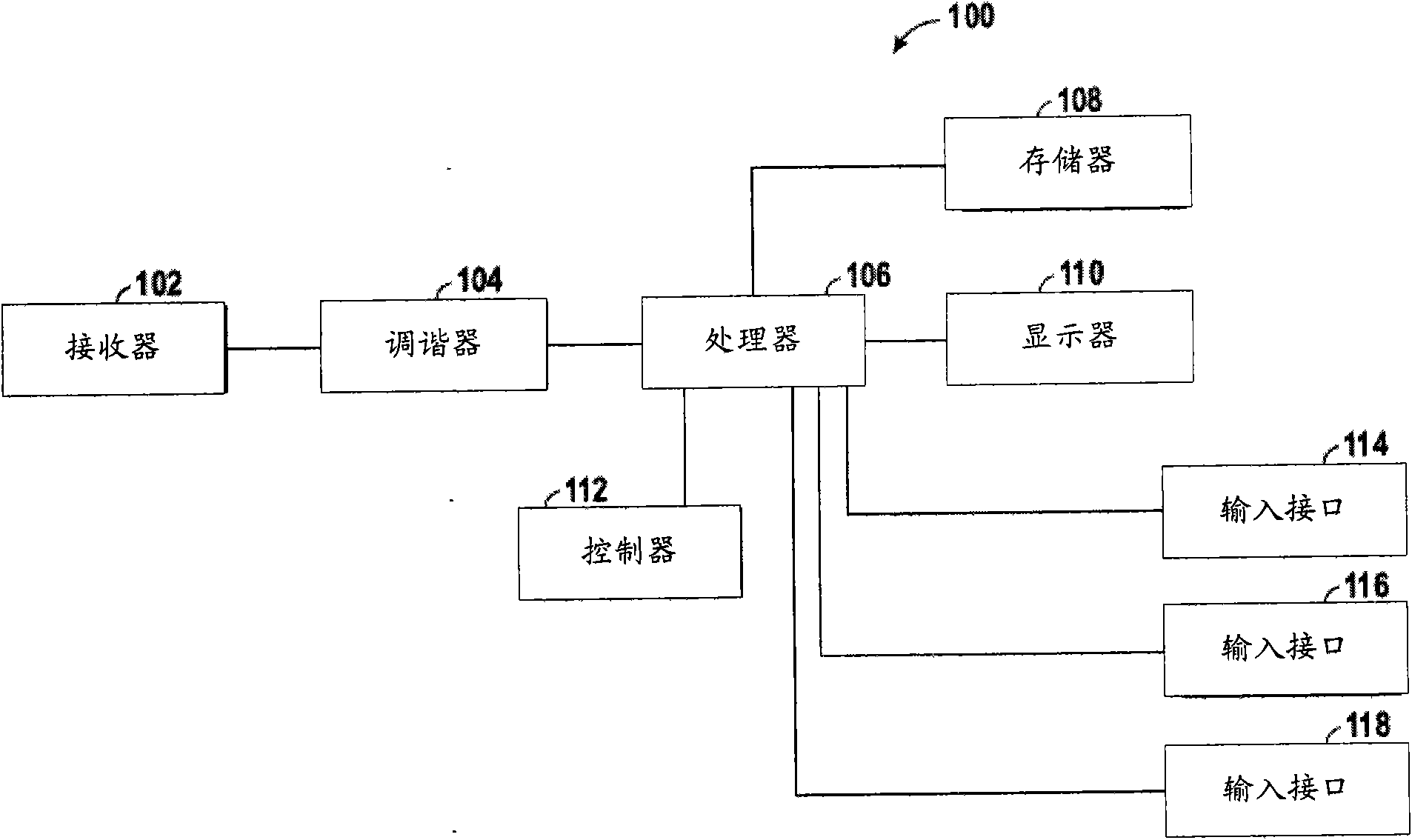

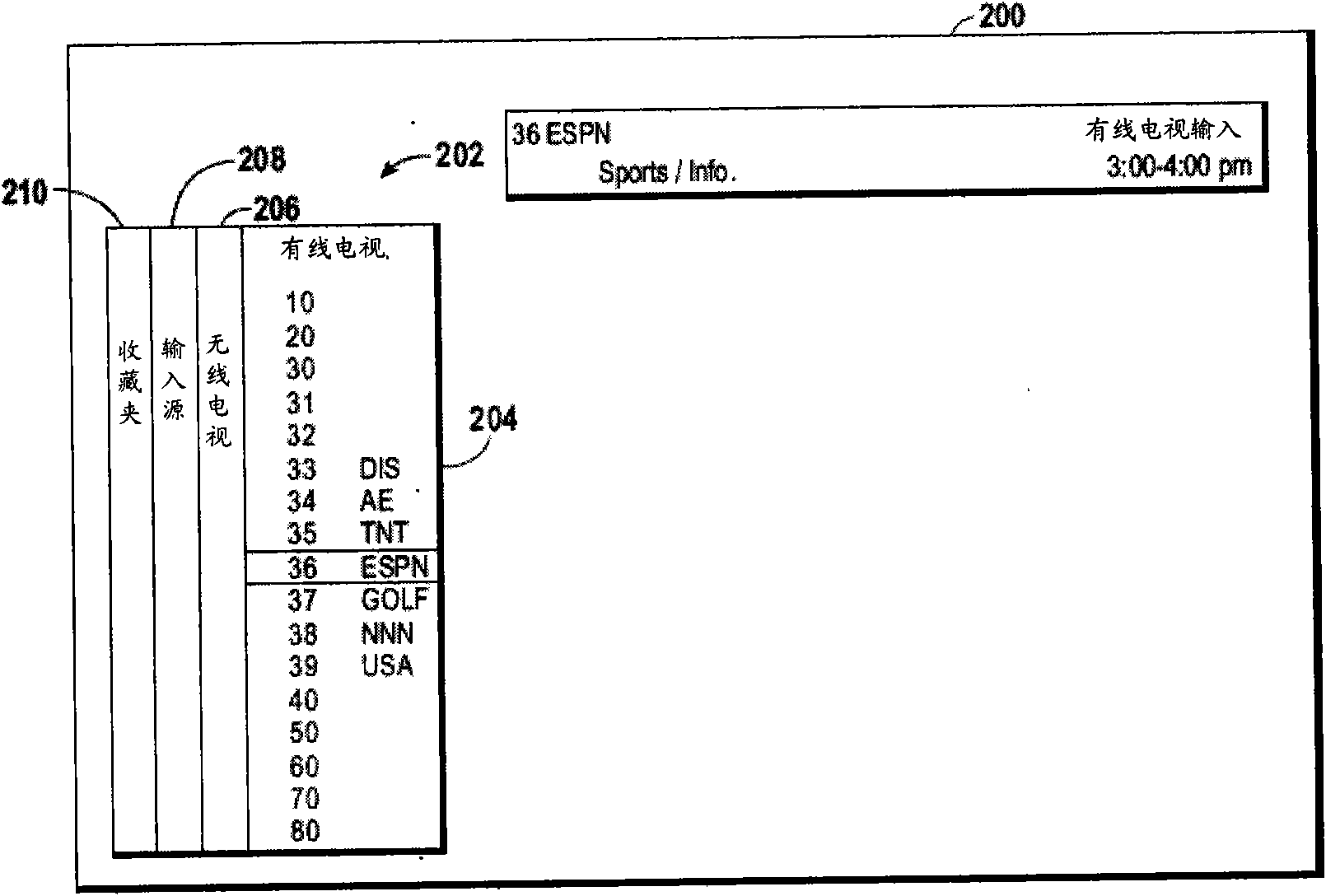

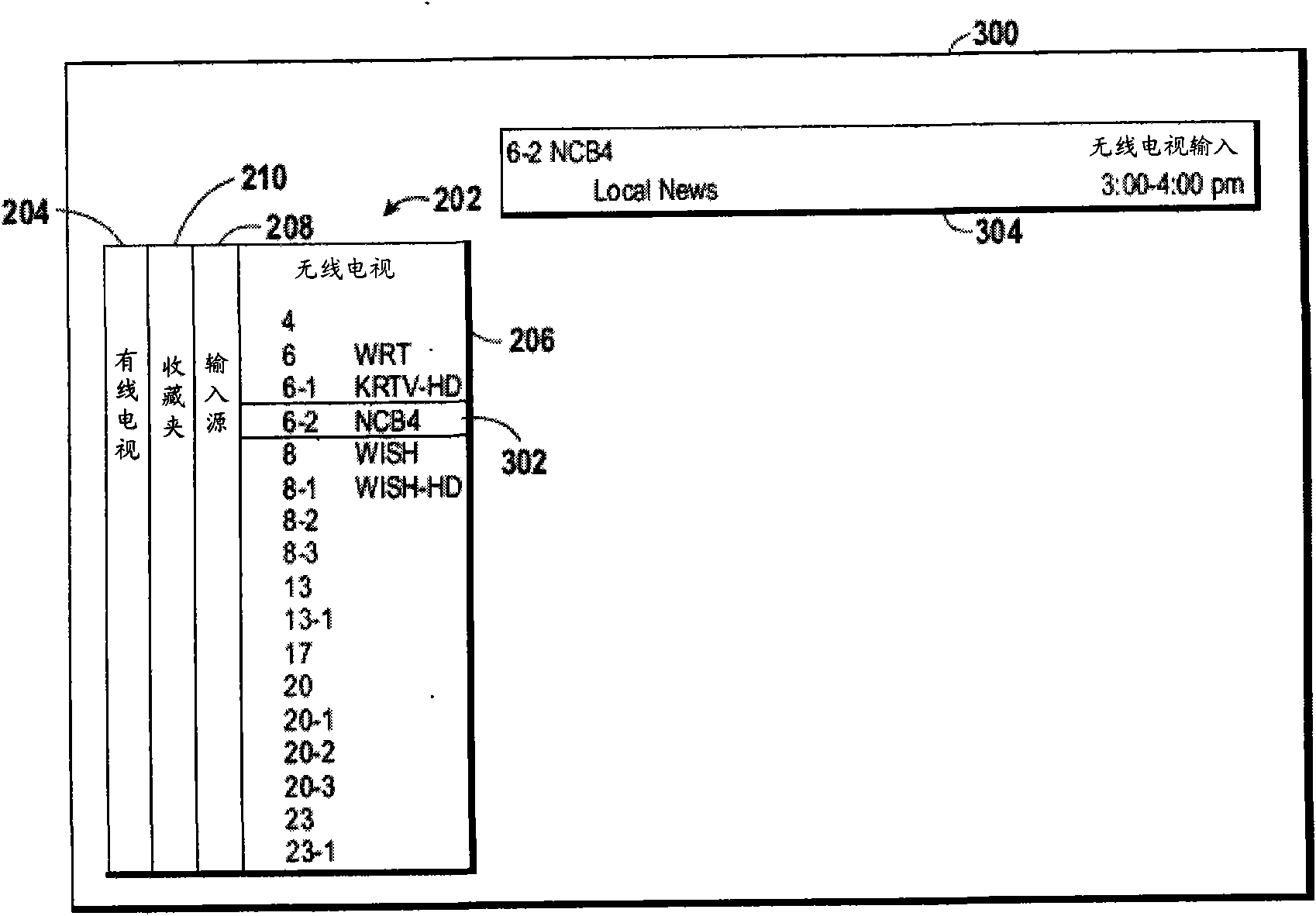

System and method for selecting television programs

InactiveCN101540850ASolve operational problemsEasy to useTelevision system detailsTelevision system scanning detailsGraphicsSource type

The invention discloses a system for selecting television programs, which comprises a processor and a display, wherein the processor can acquire video data from various sources and generate a selection interface of screen display content on the display, and the selection interface of the screen display content provided with a graphic label respectively corresponds to each source type of the video data. The technical proposal of the invention solves the operating problems for users caused by different forms of television interfaces, and is convenient for the users to use the system.

Owner:SHENZHEN TCL NEW-TECH CO LTD

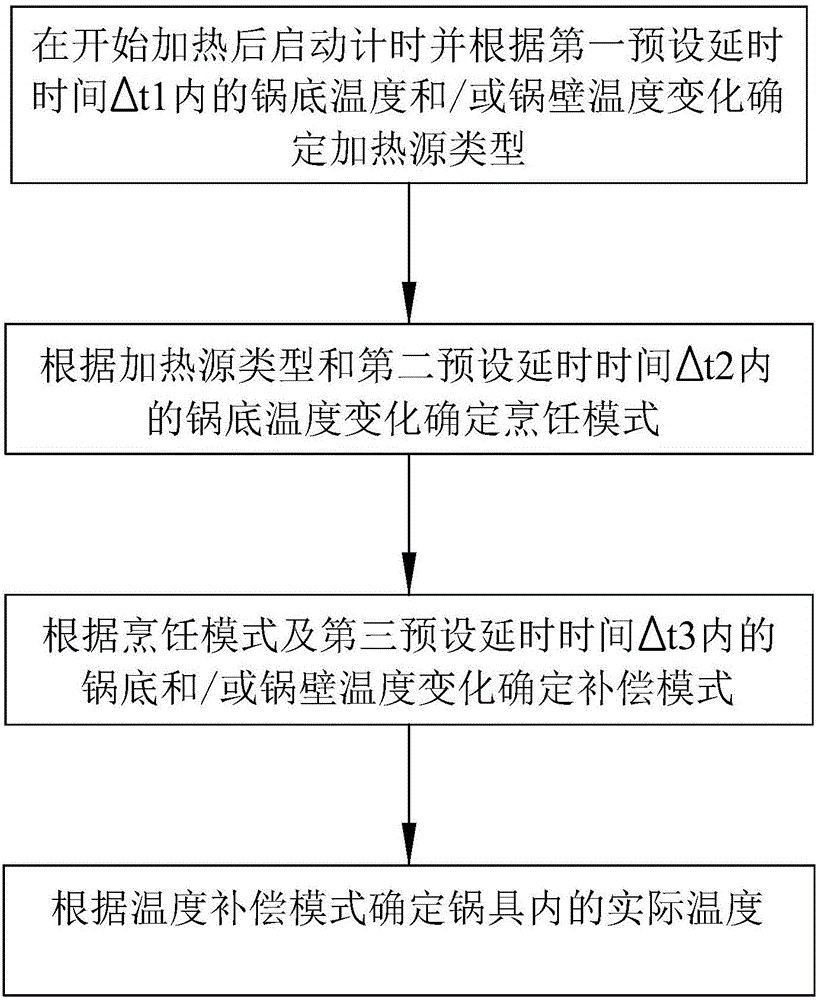

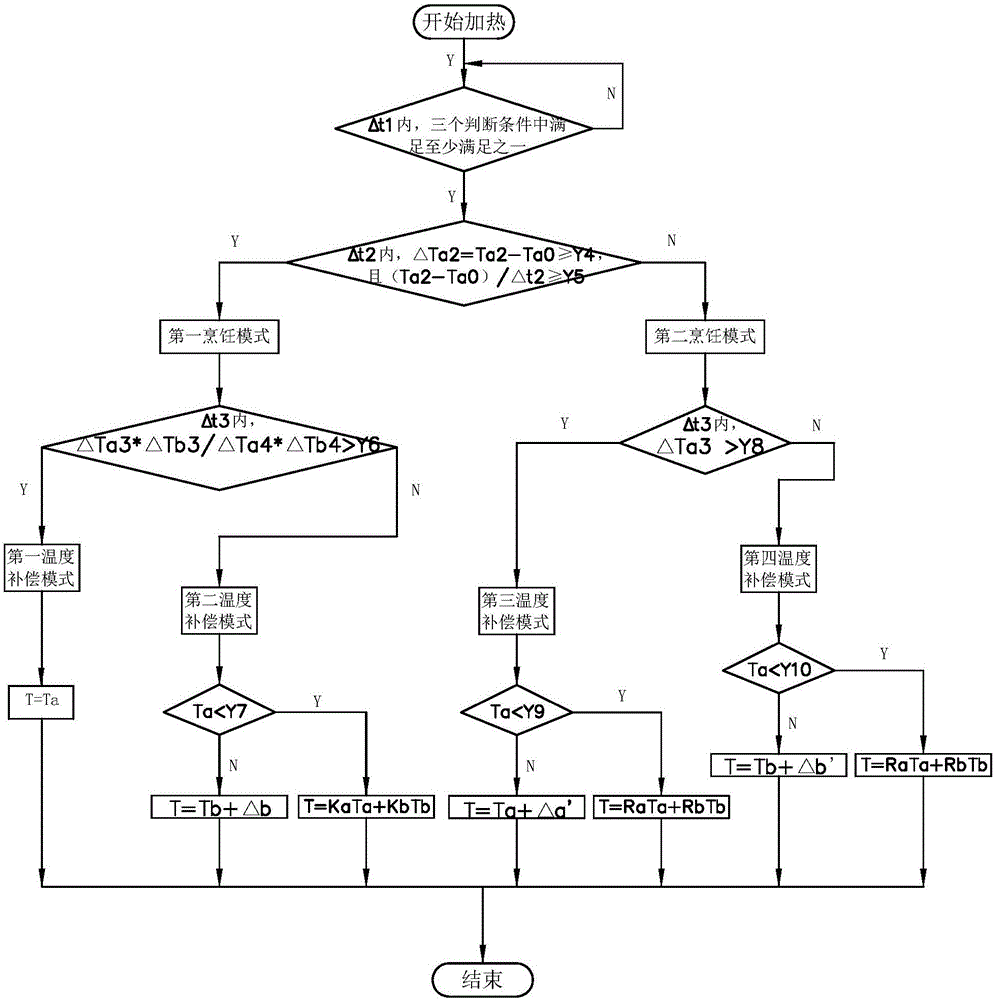

Temperature measurement method of cooking pot, cooking pot and cooking system

ActiveCN106647392AImprove qualityAccurate Temperature ReferenceCooking vesselsThermometer applicationsSource typeTime delays

The invention belongs to the household electrical appliance technical field and relates to a temperature measurement method of a cooking pot, a cooking pot and a cooking system. The temperature measurement method of the cooking pot includes the following steps that: after heating is started, timing is started, a heating source type is determined according to pot bottom temperature and / or pot wall temperature change within a first preset time delay delta t1; a cooking mode is determined according to the heating source type and pot bottom temperature change within a second preset time delay delta t2; a temperature compensation mode is determined according to the cooking mode as well as pot bottom and / or pot wall temperature change within a third preset time delay delta t3; and actual temperature in the pot is determined according to the temperature compensation mode. According to the temperature measurement method delta t1, delta t2 and delta t3 satisfy the relational expression that deltat1<=deltat2<=deltat3. With the temperature measurement method adopted, temperature compensation modes can be determined according to different heating source, different cooking modes and pot bottom temperature and / or cooker wall temperature change, and the actual temperature in the pot can be obtained through fitting, and therefore, temperature measured by the pot can provide more accurate temperature reference for a user, and thus, food cooked by the pot can taste better.

Owner:JOYOUNG CO LTD

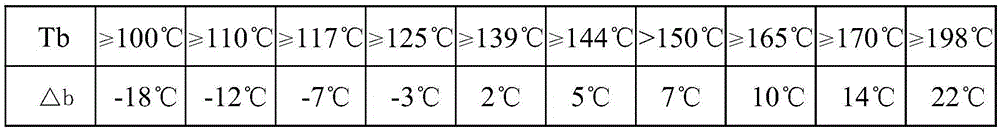

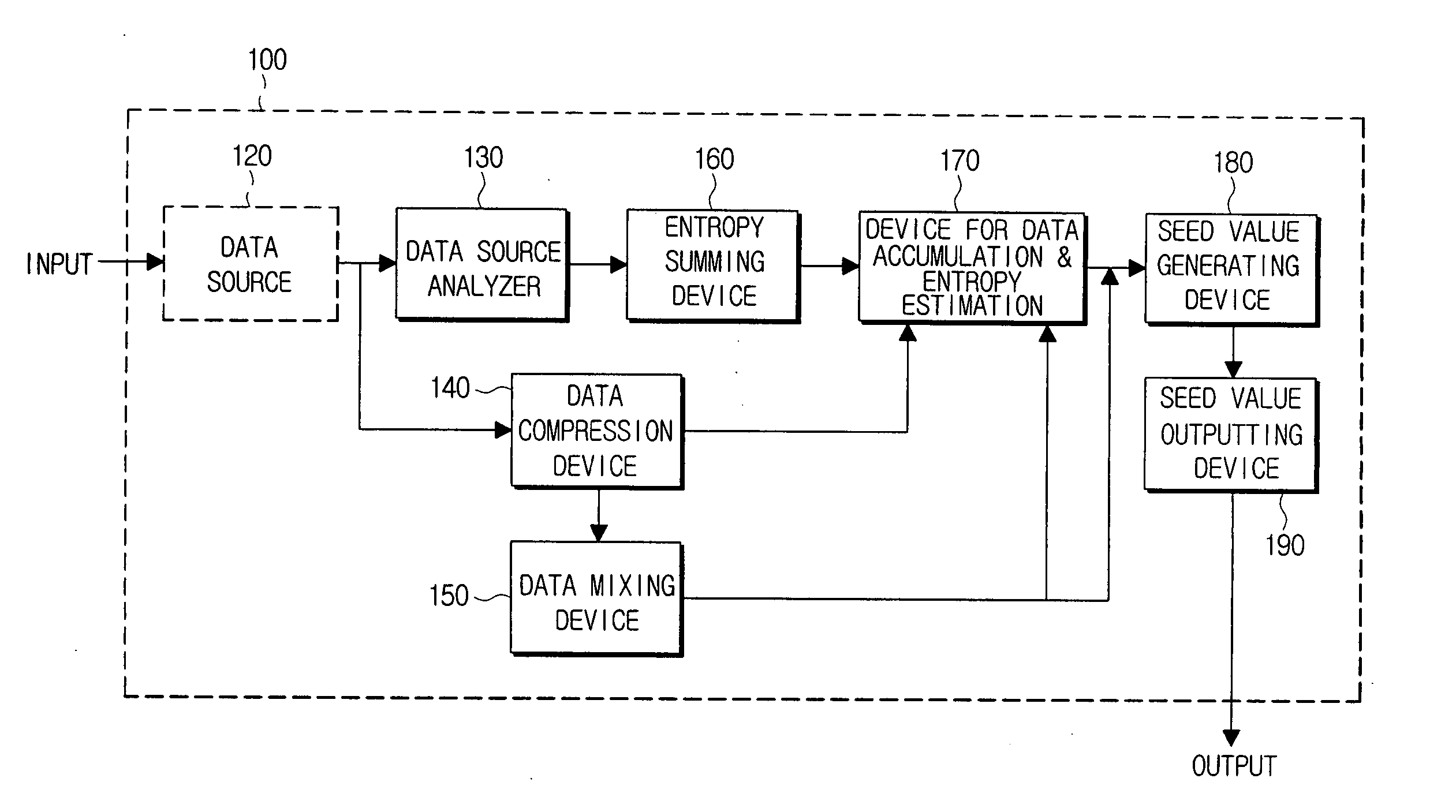

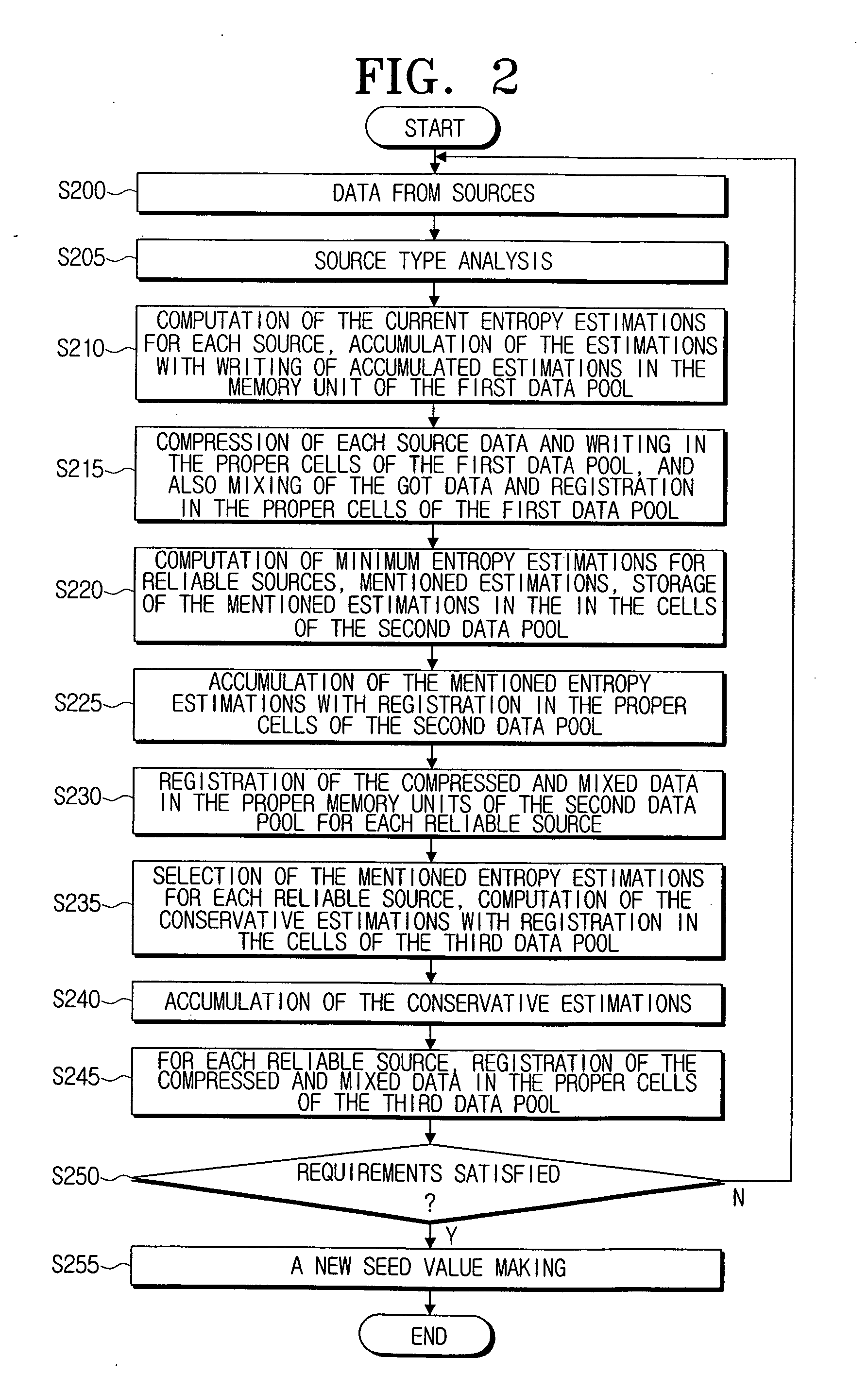

Method for making seed value used in pseudo random number generator and device thereof

InactiveUS20060067527A1Computation using non-contact making devicesSecuring communicationSource typeData profiling

A seed value making method and device for a PRNG (Pseudo Random Number Generator) are provided. The seed value making method includes the steps of: accumulating in memory units of a First Data Pool data from various external sources, analyzing the data to determine a source type, computing entropy estimations for each of the external sources basing on the source type as determined, and generating a seed value by using the entropy estimations and the data accumulated in the memory units of the First Data Pool. Accordingly, in generating a seed value, dynamic estimation of random sources rate, and classification of sources on slow and fast ones, and reliable and unreliable ones, can be provided, and also, seed values can be made with taking in account rate and reliability of the sources.

Owner:SAMSUNG ELECTRONICS CO LTD

Distributed on-demand media transcoding system and method

A method for delivering media content over a network includes transcoding the media content to generate multiple copies of the media content, each of the multiple copies having a different destination type or a different source type or both, storing the multiple copies in a cache, receiving requests for the media content, and selecting and delivering a copy of one of the multiple copies in response to each of the requests. A further method for providing media content transcoding services includes fetching media content, selecting one of multiple transcoders for transcoding from multiple source types to multiple destination types, wherein the one transcoder is selected based at least on the destination type, sending the media content to the selected transcoder, transcoding the media content to the destination type, thereby generating transcoded media content, and transmitting the transcoded media content.

Owner:SONY CORP

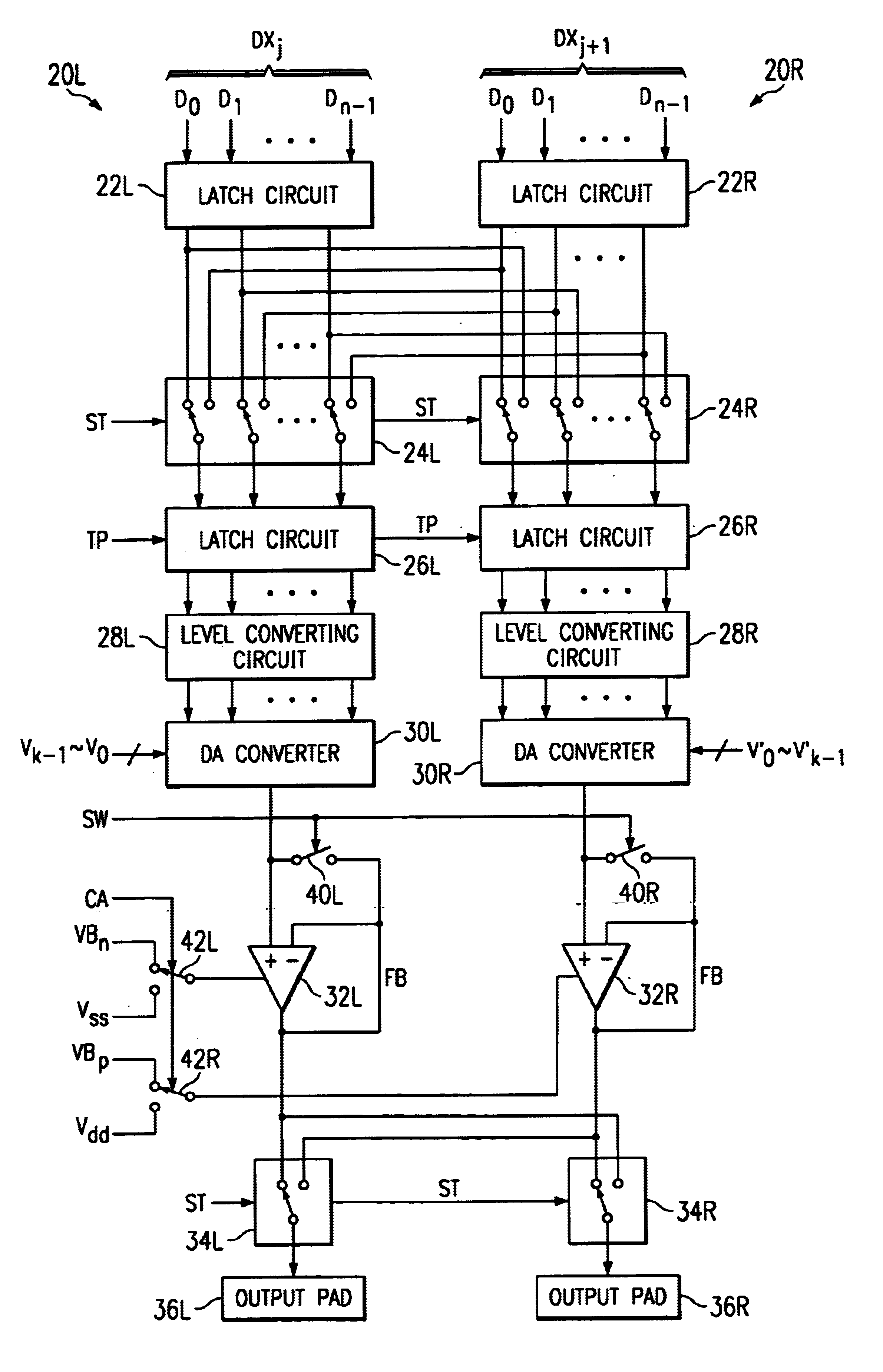

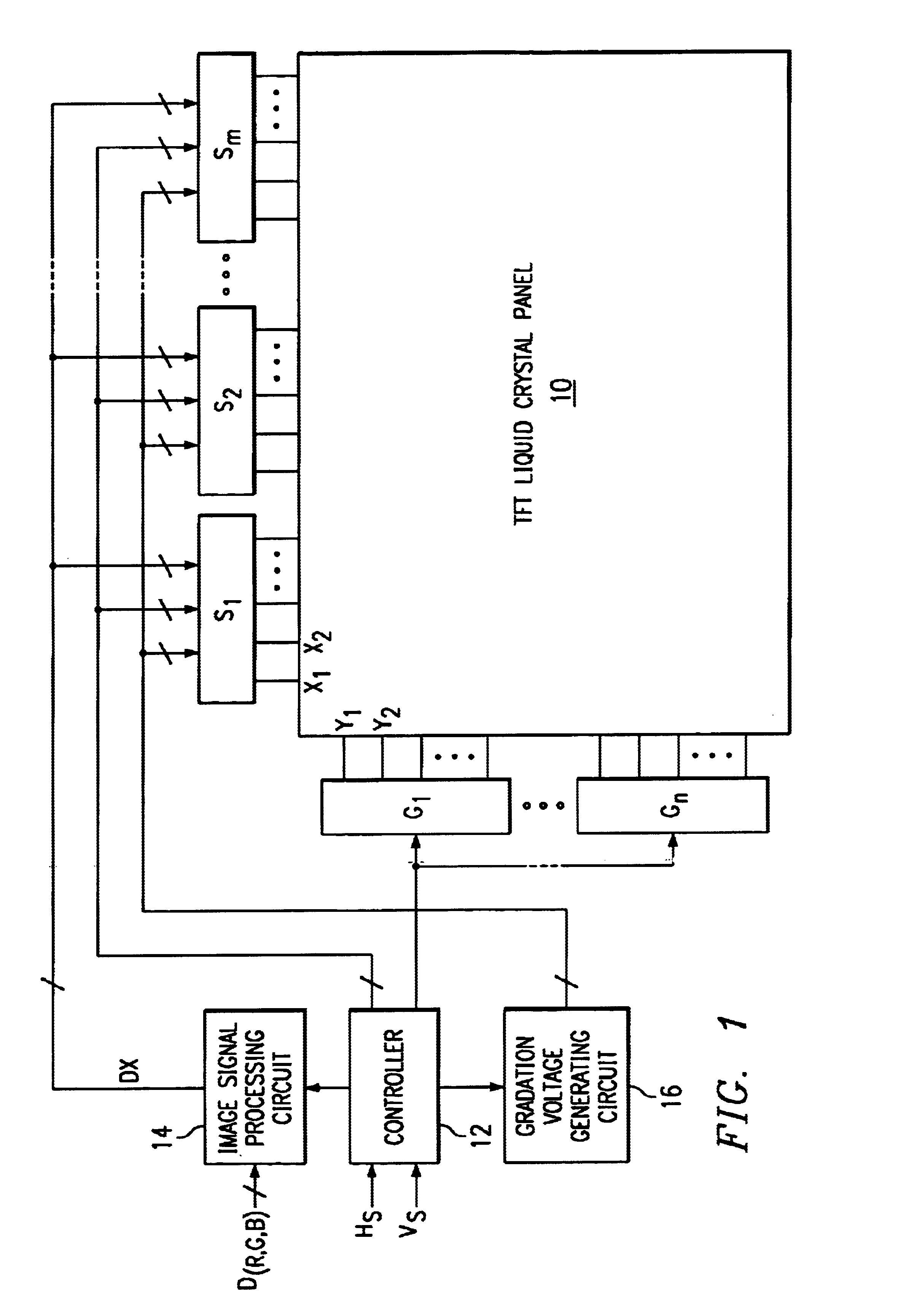

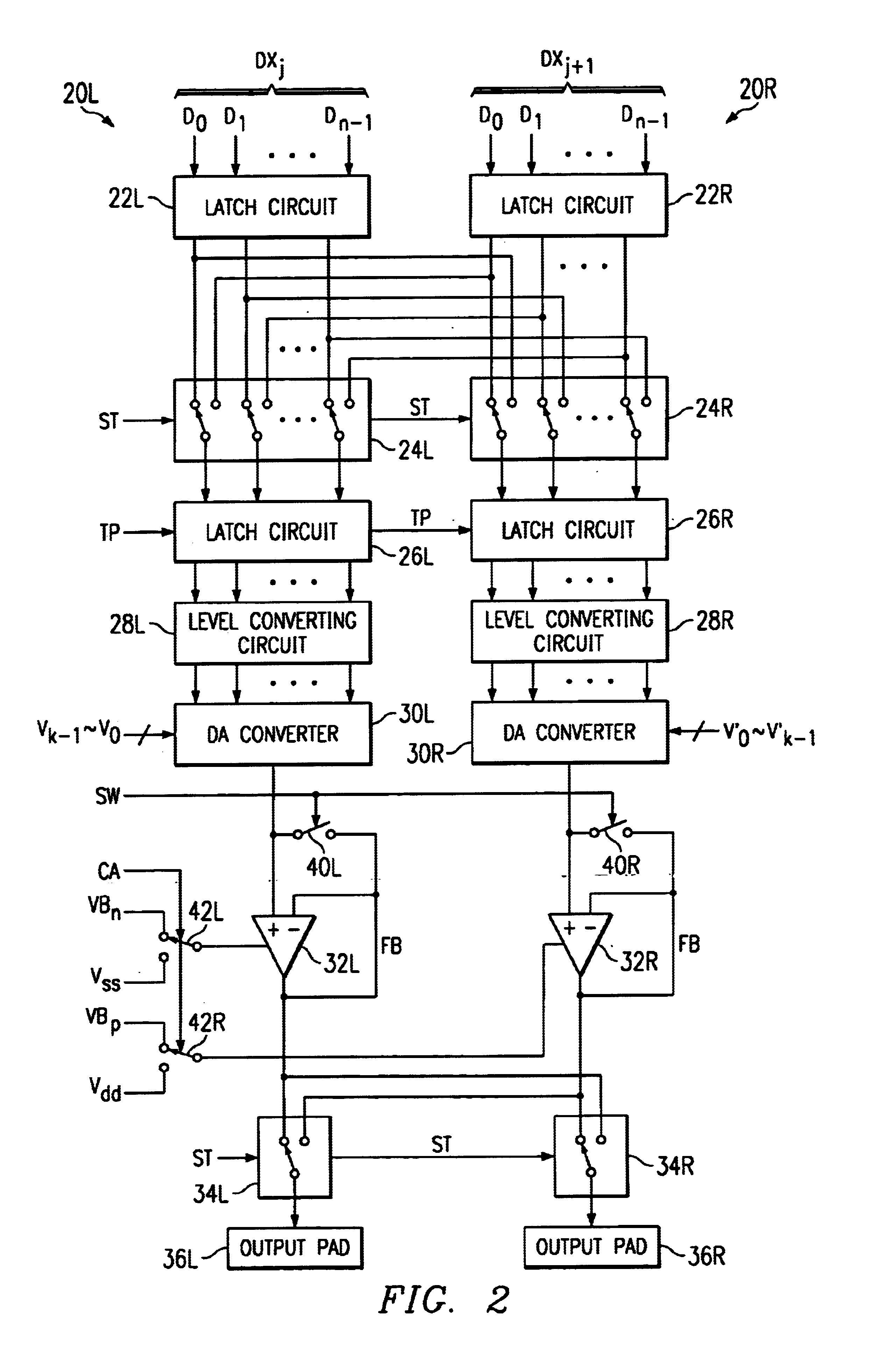

Driving circuit

InactiveUS6919870B2Reliability increasing modificationsGated amplifiersSource typeCurrent consumption

The objective of this invention is to compensate or avoid the influence of offset in an easy and efficient manner, to correctly match the voltage of the output signal with the voltage of the input signal, that is, the target value, and to significantly reduce the current consumption. When voltage follower 32L supplies bias voltage VBn to each of constant current source circuits 58L, 60L, it acts as a source-type voltage follower. However, when the bias voltage applied to each of constant current source circuits 58L, 60L is changed from VBn to Vss of the power supply voltage level, each of constant current source circuits 58L, 60L is turned off, and no current flows through them. When the constant current source circuit 58 is turned off in differential input part 44L, the potential at the output terminal (node) NL rises almost to the level of the power supply voltage Vdd. In this way, the driving transistor 62L is also turned off in output part 46L.

Owner:TEXAS INSTR INC

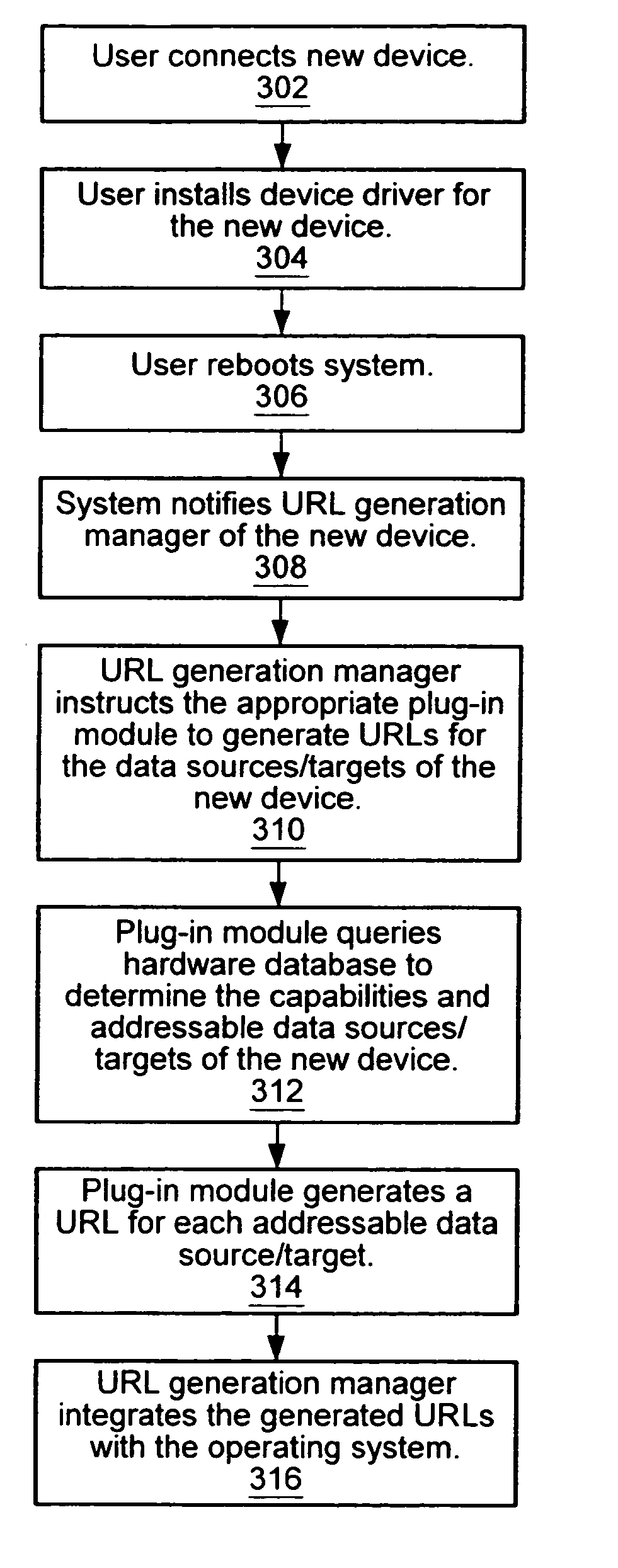

System and method for automatically creating URLs for accessing data sources and data targets

InactiveUS7152116B1Easy accessMultiple digital computer combinationsTransmissionSource typeData source

A system and method for automatically generating URLs which reference one or more data sources or data targets connected to a computer. The data sources / targets may be of any type including files, http servers, ftp servers, hardware devices, etc. The generated URLs may be used together with a system such as the Data Socket system to seamlessly read data from disparate data source types or write data to disparate data target types without having to manually perform configuration, connection operations, data format conversion, etc. The URLs are generated automatically and contain all the information necessary for accessing the data source / target. This greatly abstracts a user or application from the I / O process.

Owner:NATIONAL INSTRUMENTS

Electric arc additive manufacturing method

InactiveCN108723549AReduce mistakesNo crackElectrode holder supportersWelding accessoriesLoop controlSource type

The invention discloses an electric arc additive manufacturing method which comprises the following steps of (1) selecting a corresponding heat source type, a forming wire material, and a material type of a base plate according to the material requirement of a forming target part; (2) building a computer-aided design (CAD) geometric model of the forming target part, extracting a standard templatelibrary (STL) model, slicing the STL model, generating a G code file required for printing, and transmitting the G code to a printer; (3) setting printing parameters, starting the printer, and printing metal thin layers according to a planned route layer by layer; and (4) after finishing printing all layer sheets through the printer, carrying out arc failure through a welding gun, and obtaining the forming target part. An additive piece printed through the method provided by the invention is less in error and flawless, has the advantage of good surface quality, and is stable in process, high in dimensional accuracy and surface quality, short in processing period, and low in cost at the same time; the printing process is in closed-loop control, so that the automation degree is high, and thelabor intensity of operating personnel can be reduced; and continuous manufacturing can be realized, and the manufacturing efficiency is high.

Owner:HOHAI UNIV CHANGZHOU

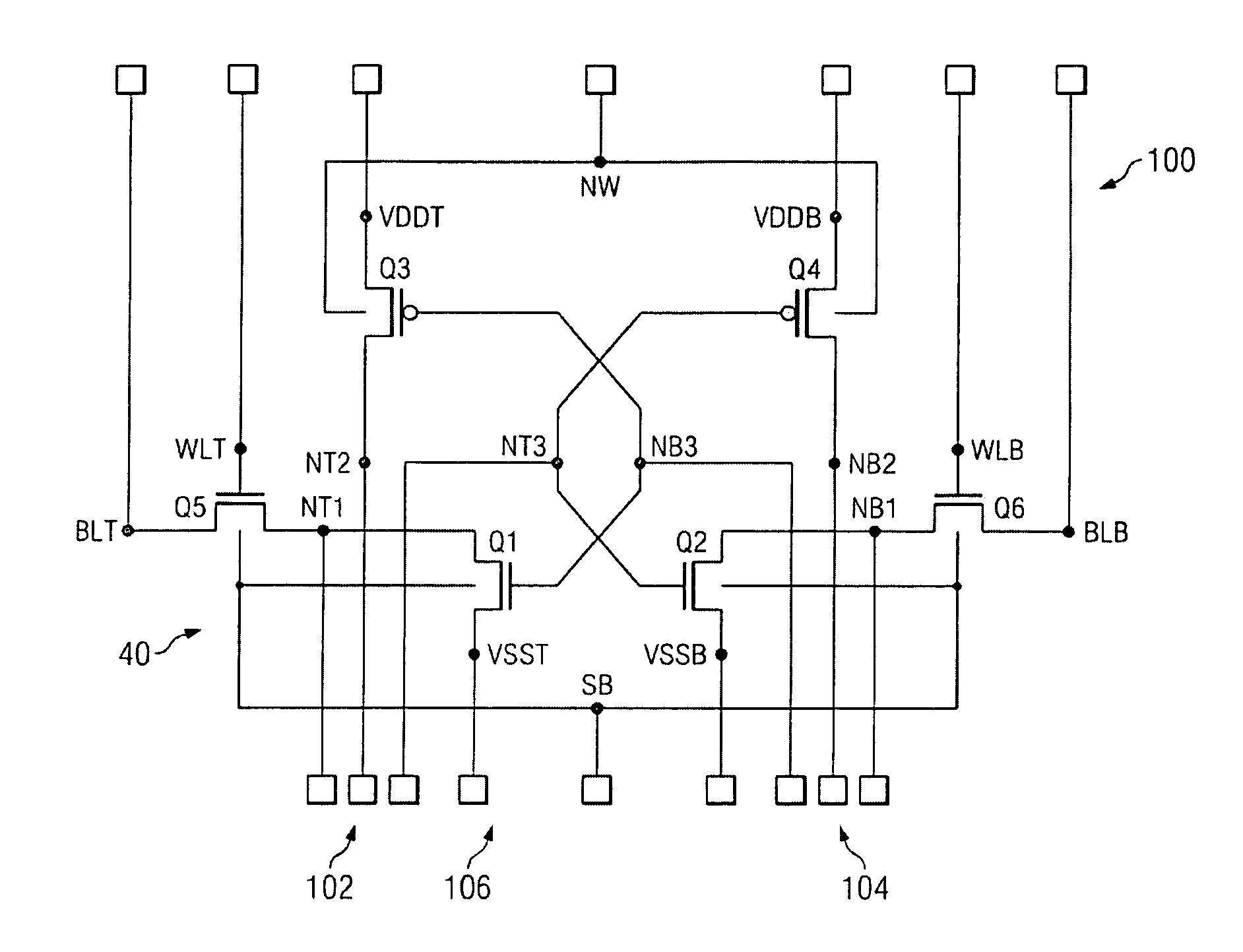

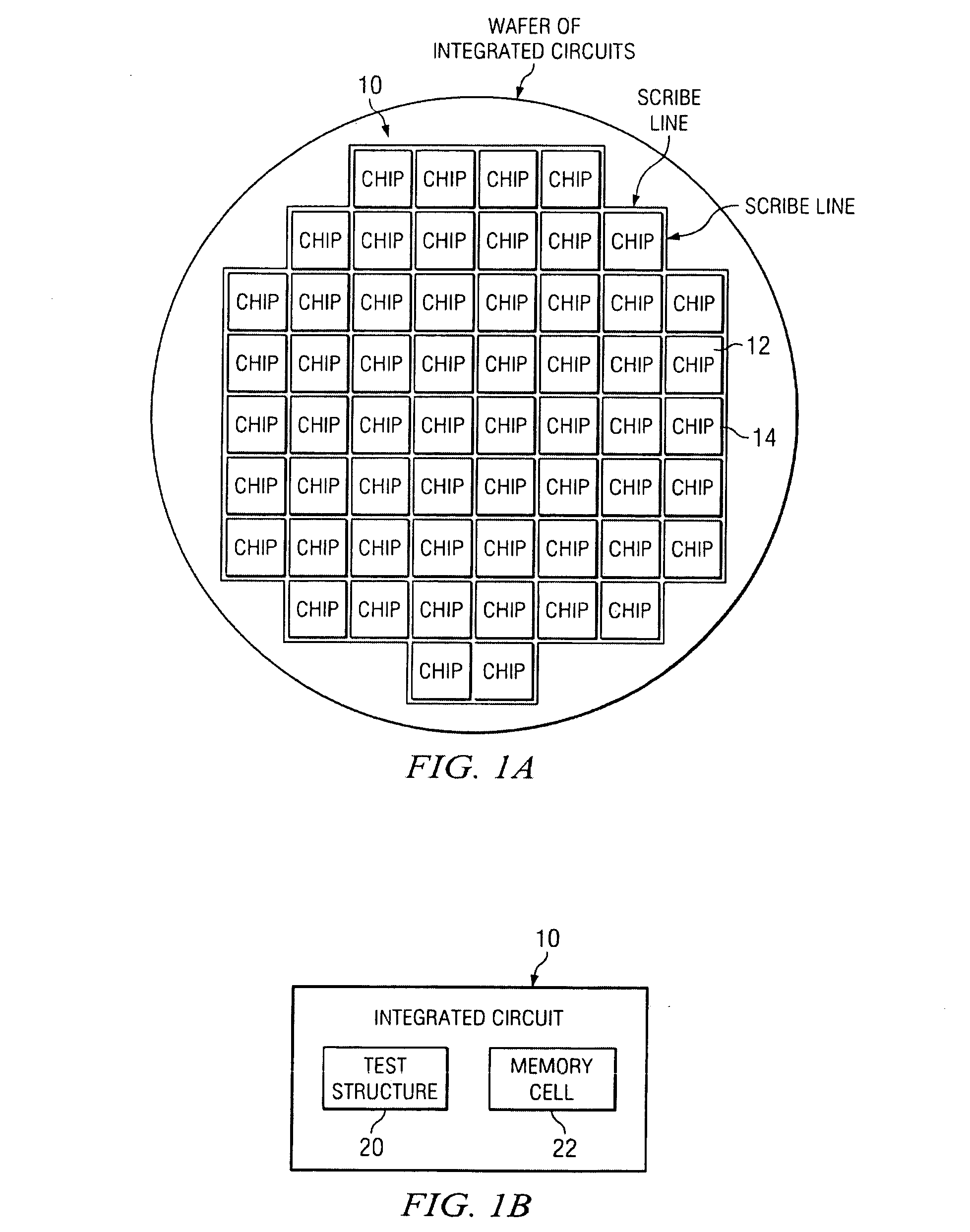

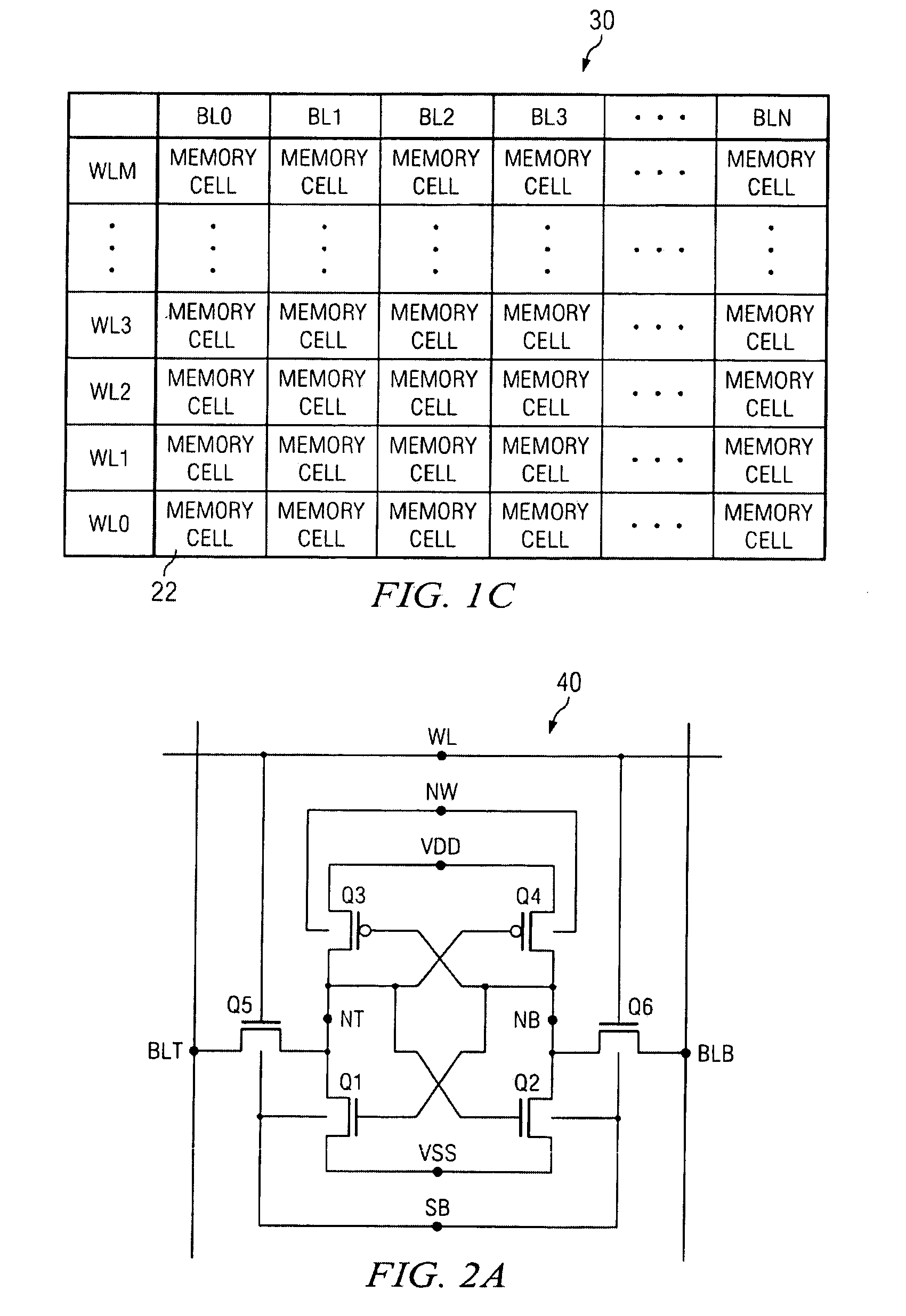

Universal structure for memory cell characterization

ActiveUS20080144421A1Accurate measurementComplete characterizationTransistorWave amplification devicesSource typeUniversal structure

An integrated circuit includes a structure, where the structure includes a memory base cell, a first port set, a second port set, and a set of other ports, where the memory base cell includes a first storage node set, a second storage node set, and a set of other nodes, where the set of other nodes includes a first data node for accessing the first storage node set, a first access control node for controlling the access of the first storage node set, a first supply node for supplying the first storage node set, and a second supply node for supplying the second storage node set, where the first and second supply nodes are of the same sinking or sourcing type and are not connected together, where each node in the first storage node set is connected to a port in the first port set, where each node in the second storage node set is connected to a port in the second port set, where each of the other nodes is connected to one of the other ports, and where each of the other ports is connected to one and only one of the other nodes.

Owner:TEXAS INSTR INC

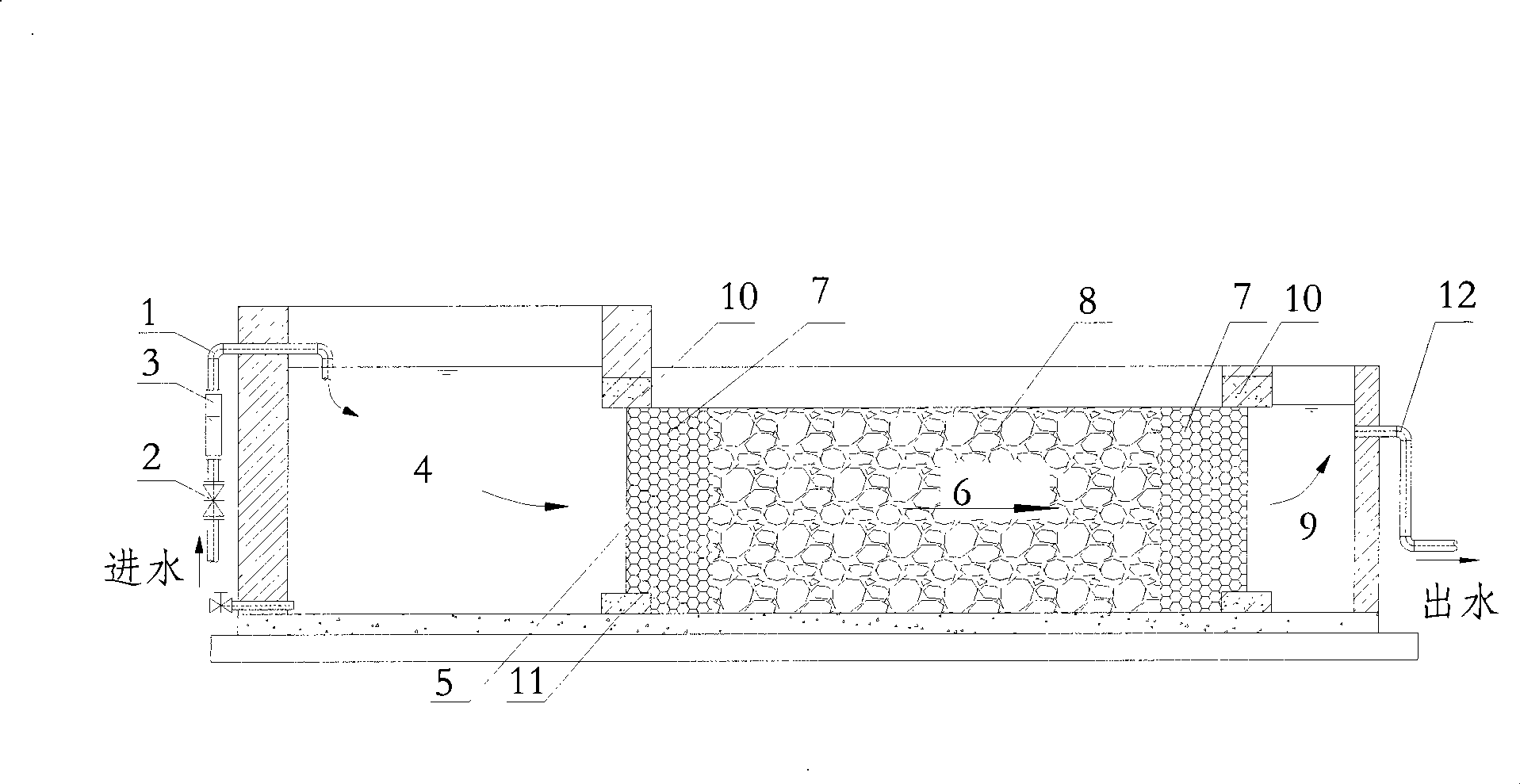

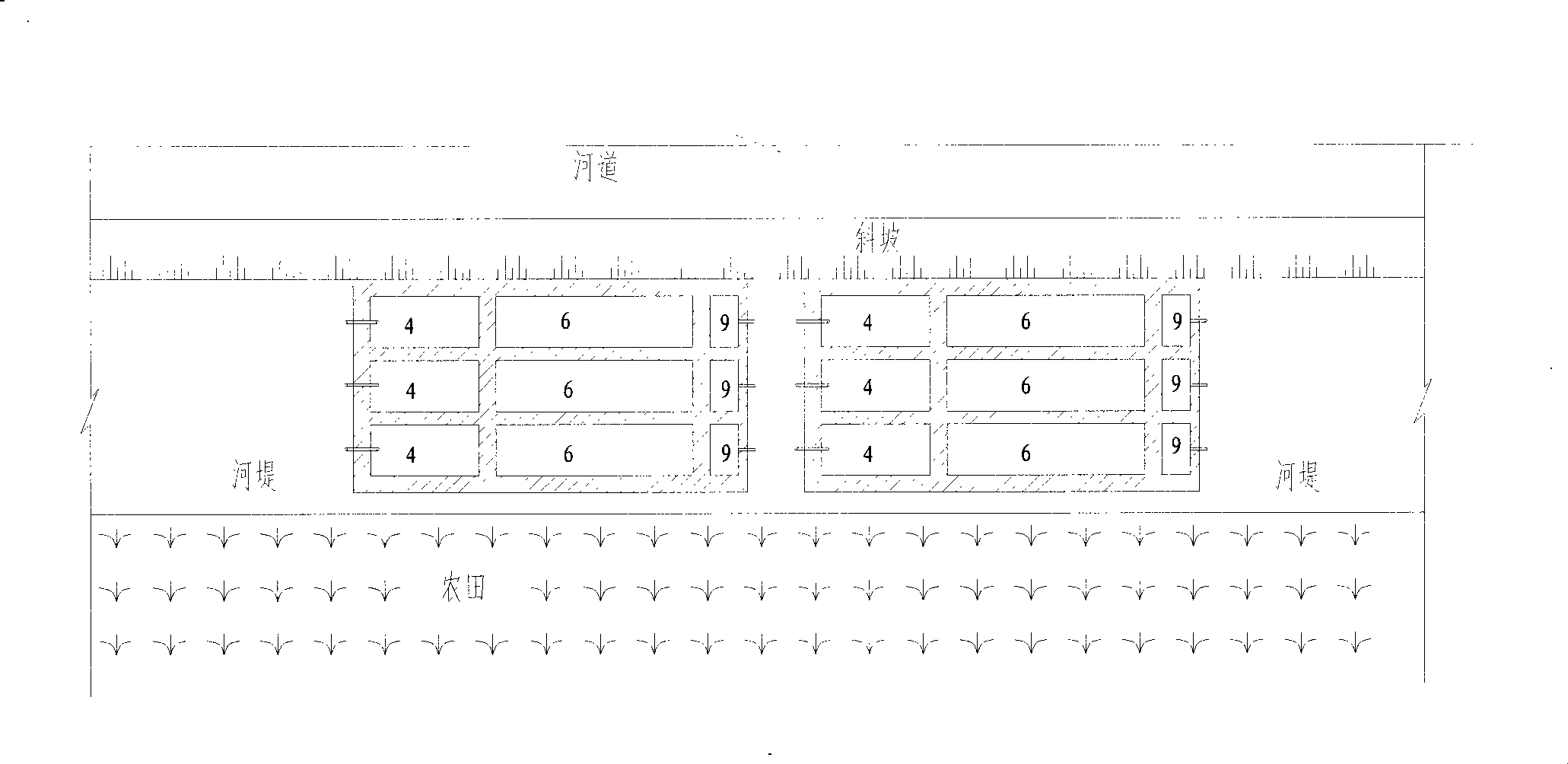

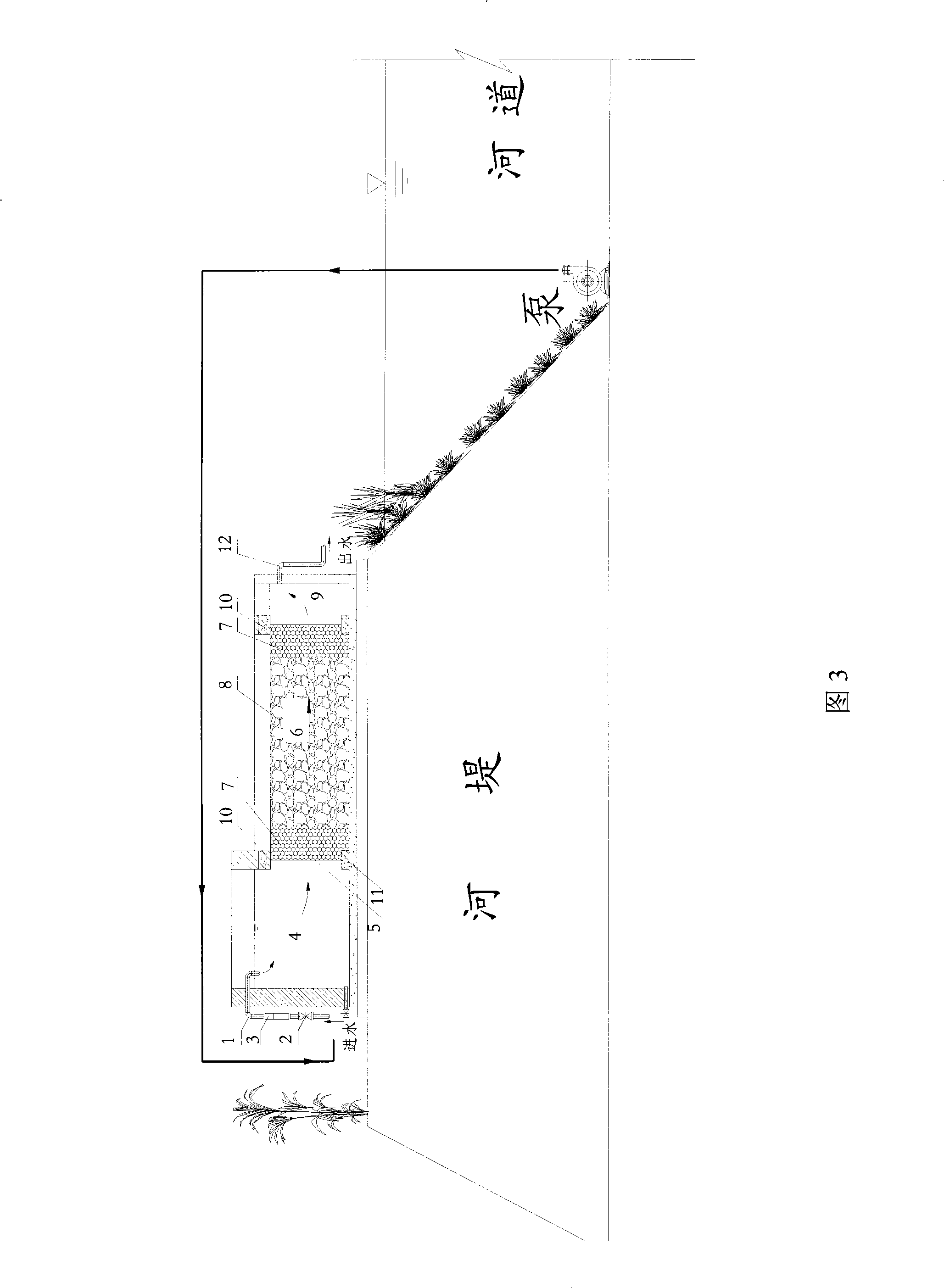

Riverway permeable reaction wall system and use thereof

ActiveCN101434420ALow running costReduce management costsWater/sewage treatmentBiological water/sewage treatmentGratingLand resources

The invention discloses a river channel permeable reaction wall system and the application thereof in water pollution treatment. In the system, one or a plurality of water treatment units are arranged on water banks in a ground mode, a half-buried mode or an all-buried mode; a water distribution system leads the river water to be continually treated by the water treatment units and then be returned to the river channel, or the water distribution system leads the surface-source type polluted water body near the river channel to be treated by the water treatment units and then be returned to the river channel; the water treatment unit comprises an water inlet groove, a permeable reaction wall and a water outlet groove, wherein, the water inlet groove is separated from the permeable reaction wall by a reticular grating. The system properly alters the water banks without occupying other land resources. Based on the original PRB technical principle, the system alters the water banks to cause the water to agree with river channel water quality purification and river-entering pollution control without affecting the function of the river channel. The system has remarkable effect to the water quality treatment of lake-entering rivers and urban pollutant holding rivers and the control of river surface source type pollution.

Owner:安徽环境科技集团股份有限公司

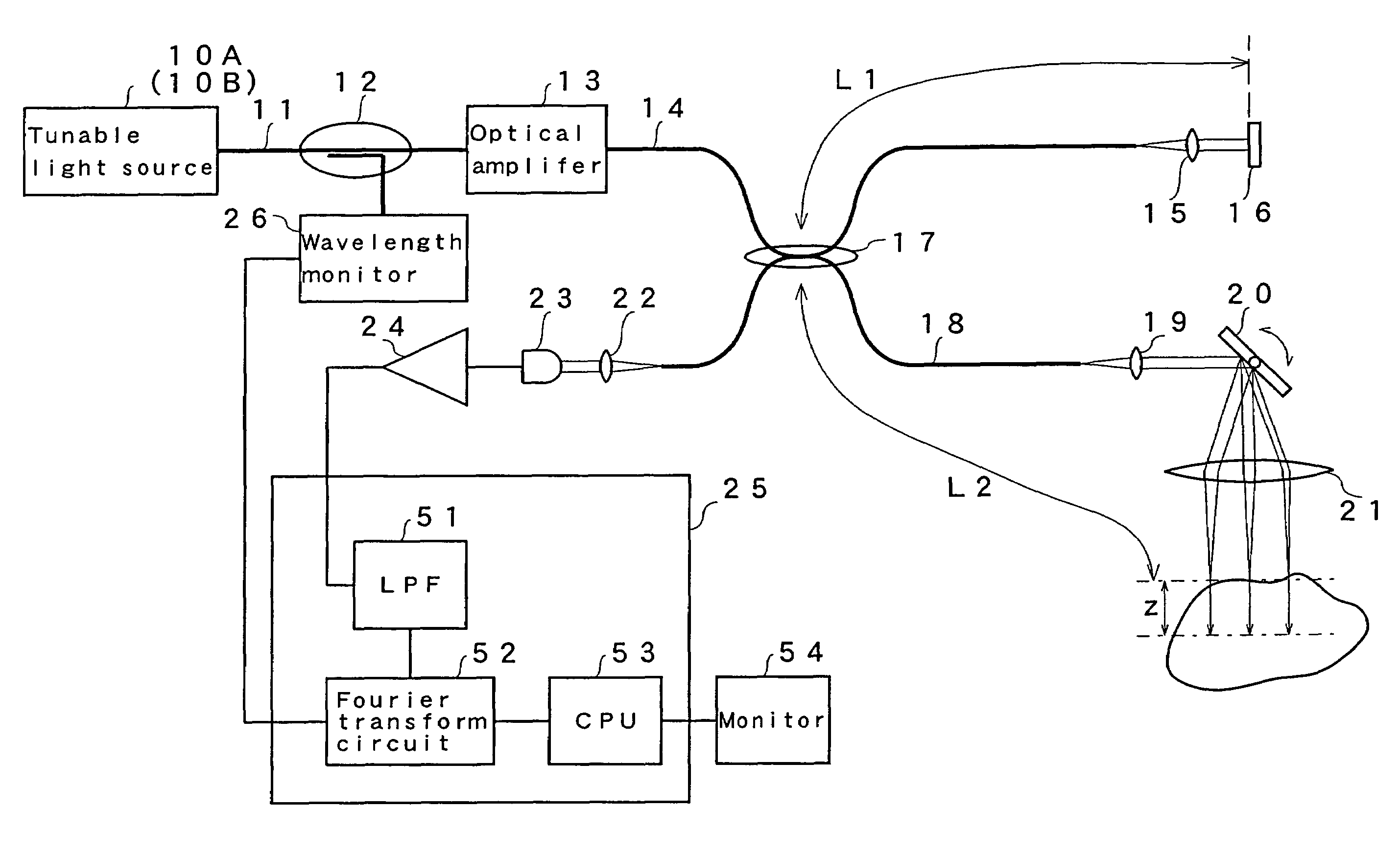

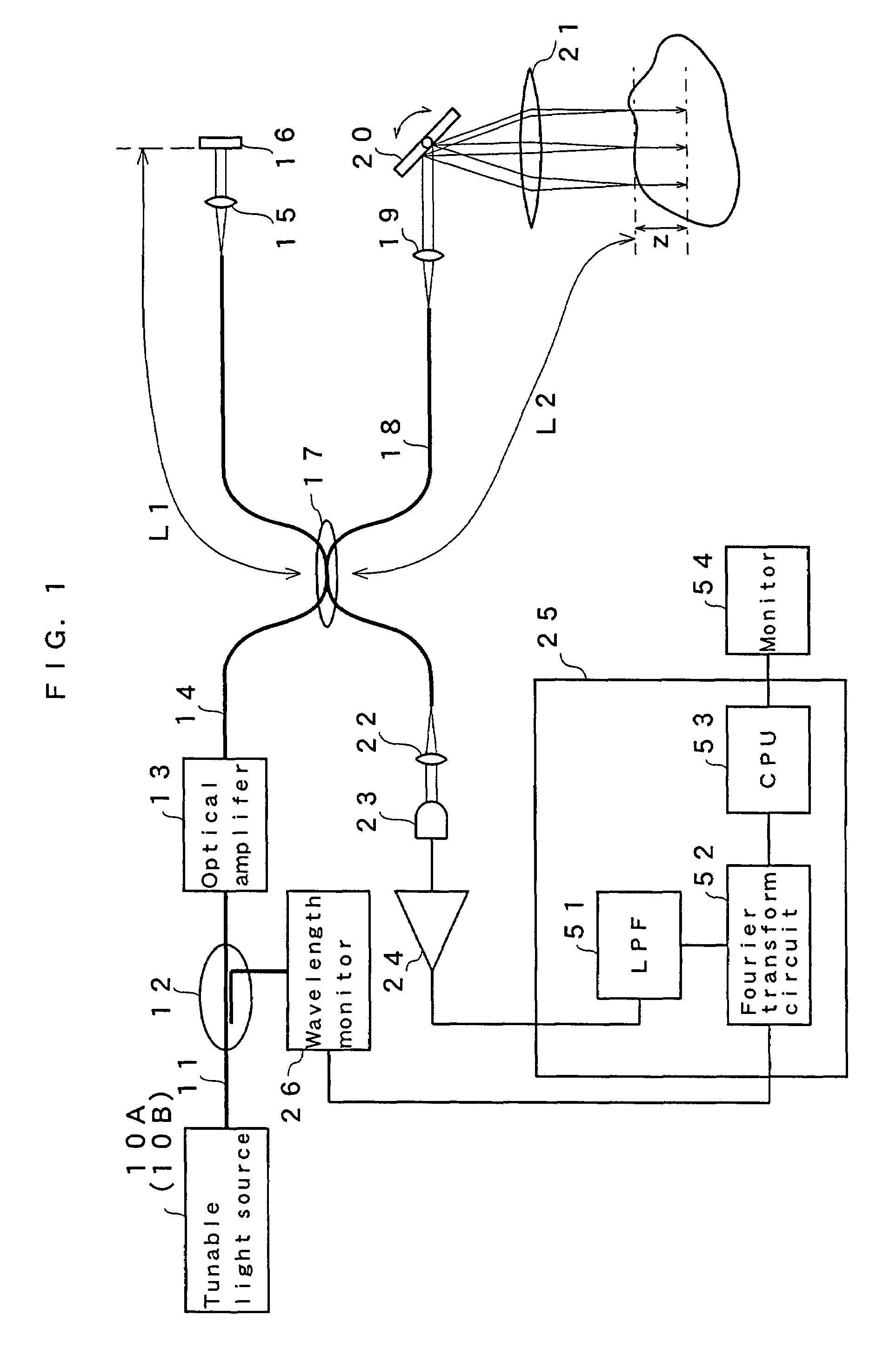

Swept source type optical coherent tomography system

ActiveUS7701588B2Large measuring depthLow priceMaterial analysis by optical meansDiagnostics using tomographyFast Fourier transformSource type

A surface emission laser light source is used as a tunable laser light source. Since the surface emission laser light source can realize a broad frequency scanning range at a high speed and in the single mode, a coherent length is longer than that of a multi mode light source. For this reason, when a tomography image is calculated by executing the Fourier transform for an output obtained from an interference optical device, measuring depth can be deepened.

Owner:SANTEC

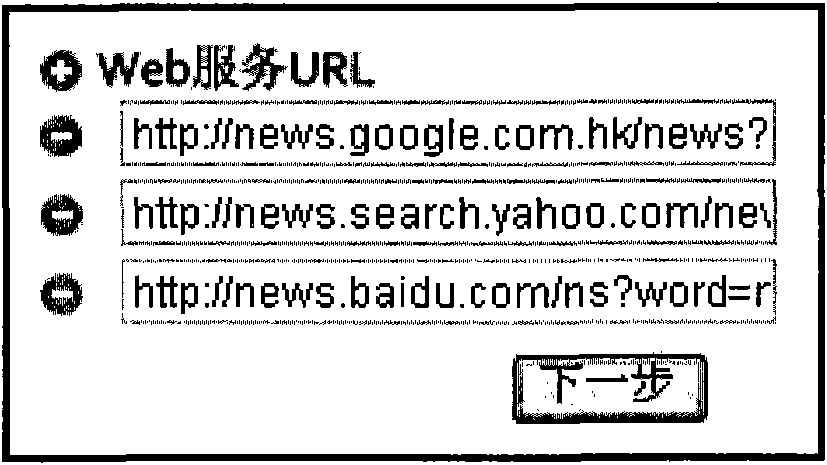

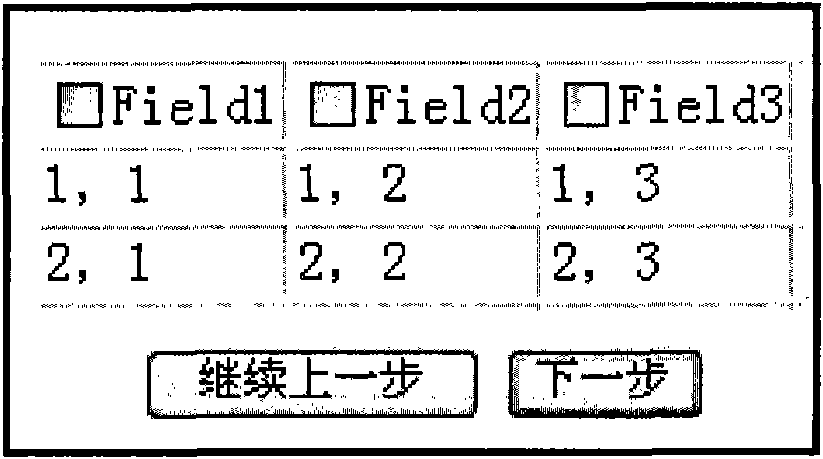

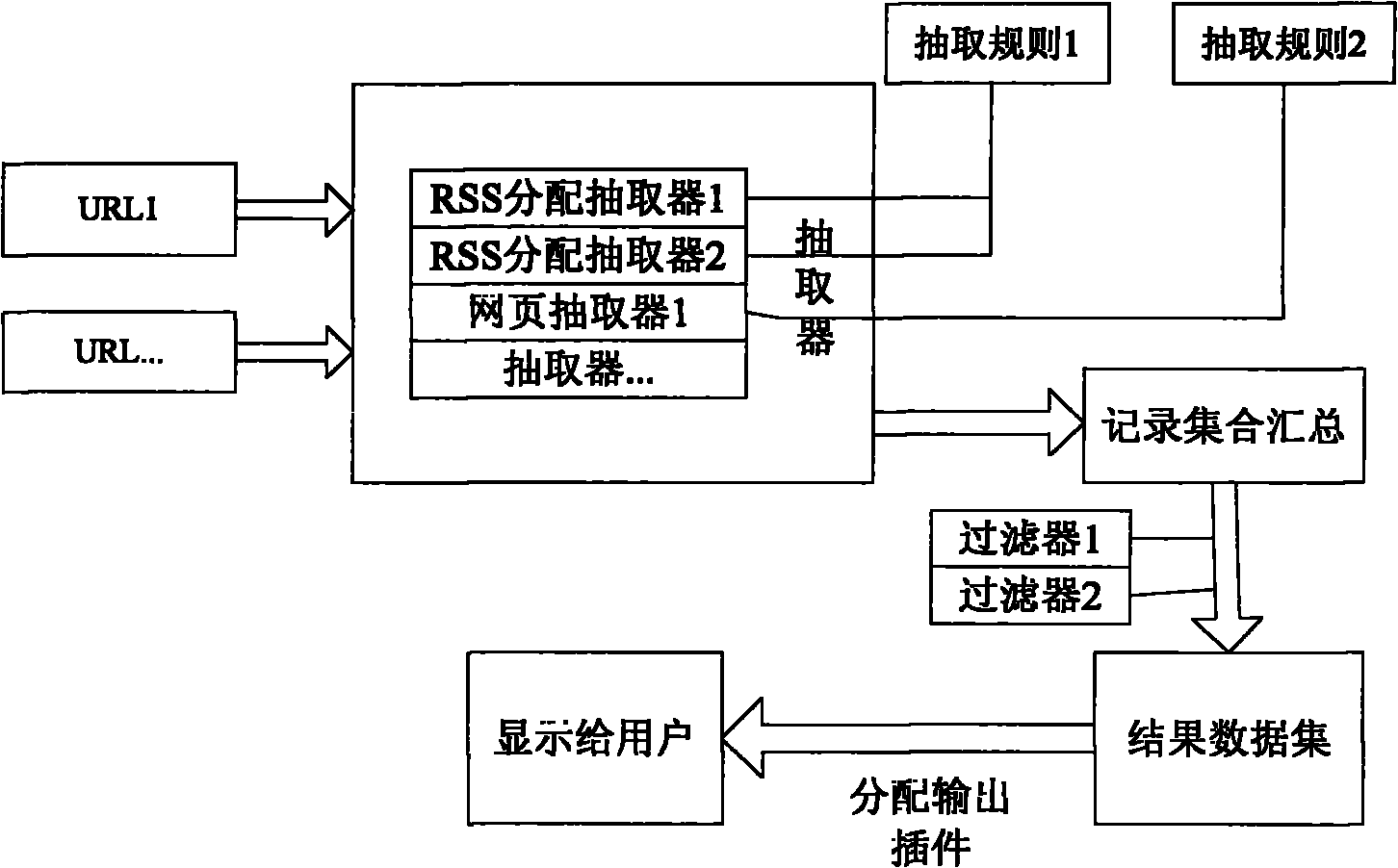

Customizable Web information integration method and system

ActiveCN102004777AEasy to set upImprove the display effectSpecial data processing applicationsData displayPersonalization

The invention discloses a customizable Web information integration method and a customizable Web information integration system. The method comprises the following steps of: 1) appointing uniform resource locator (URL) sets with different service data sources by a user; 2) acquiring record sets from the service data sources by using a data extraction server according to the difference of service data source types; and generating extraction rules corresponding to the data sources according to data fields appointed by the user; 3) acquiring data from different data sources according to the generated extraction rules and organizing the data to obtain a result record set; and 4) filtering the result record set by using a filter; and outputting and displaying integration data. The method and the system are suitable to be used for establishing Mashup of a structure with a large amount of data and complex data, and do not need a terminal user to participate and program in the secondary development in an establishment process; personalized extraction and aggregation can be provided on a data plane, so that the user can design a personalized display style and a personalized data display style conveniently; and the rapid establishment of logical Mashup can be ensured.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

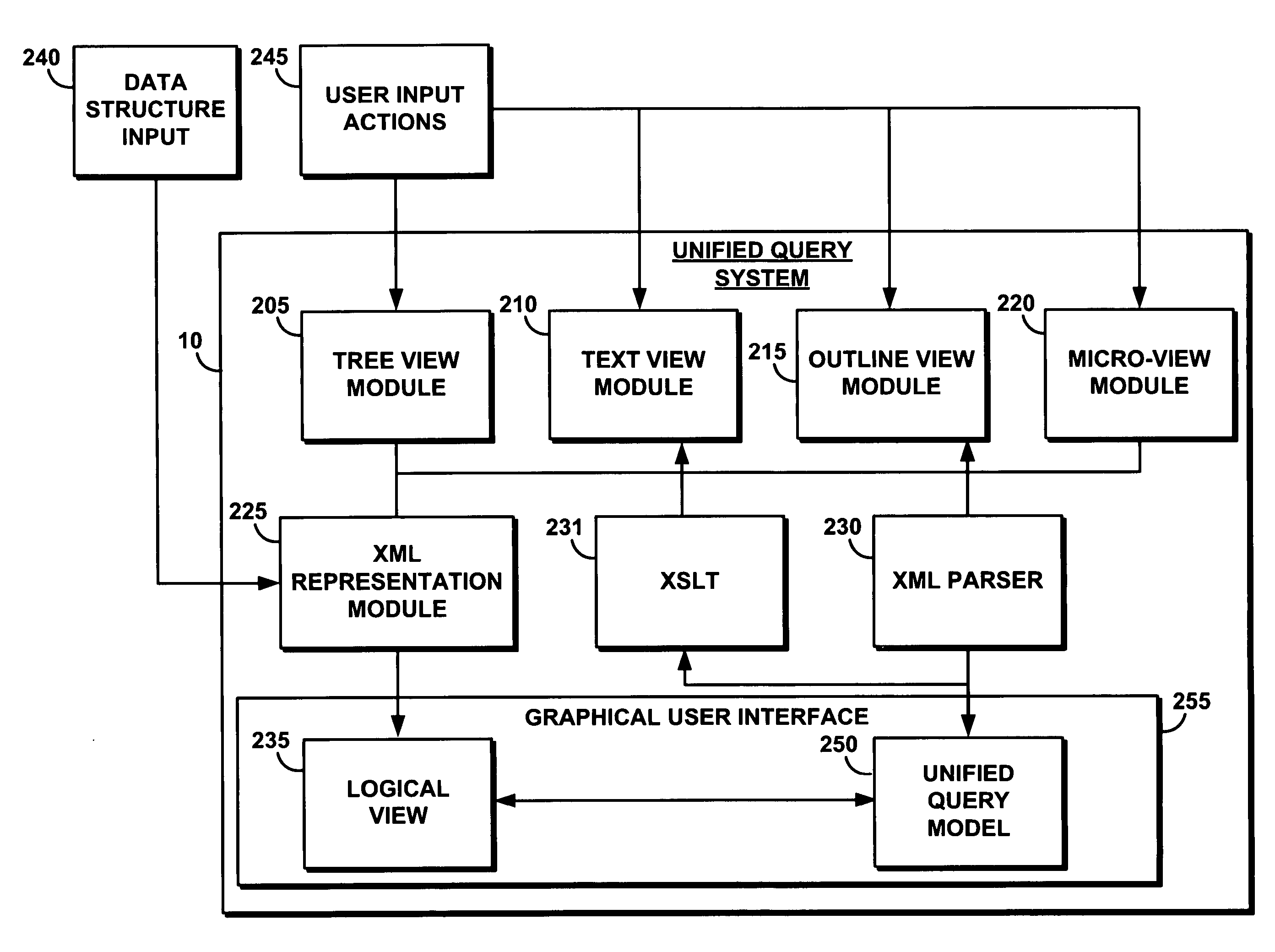

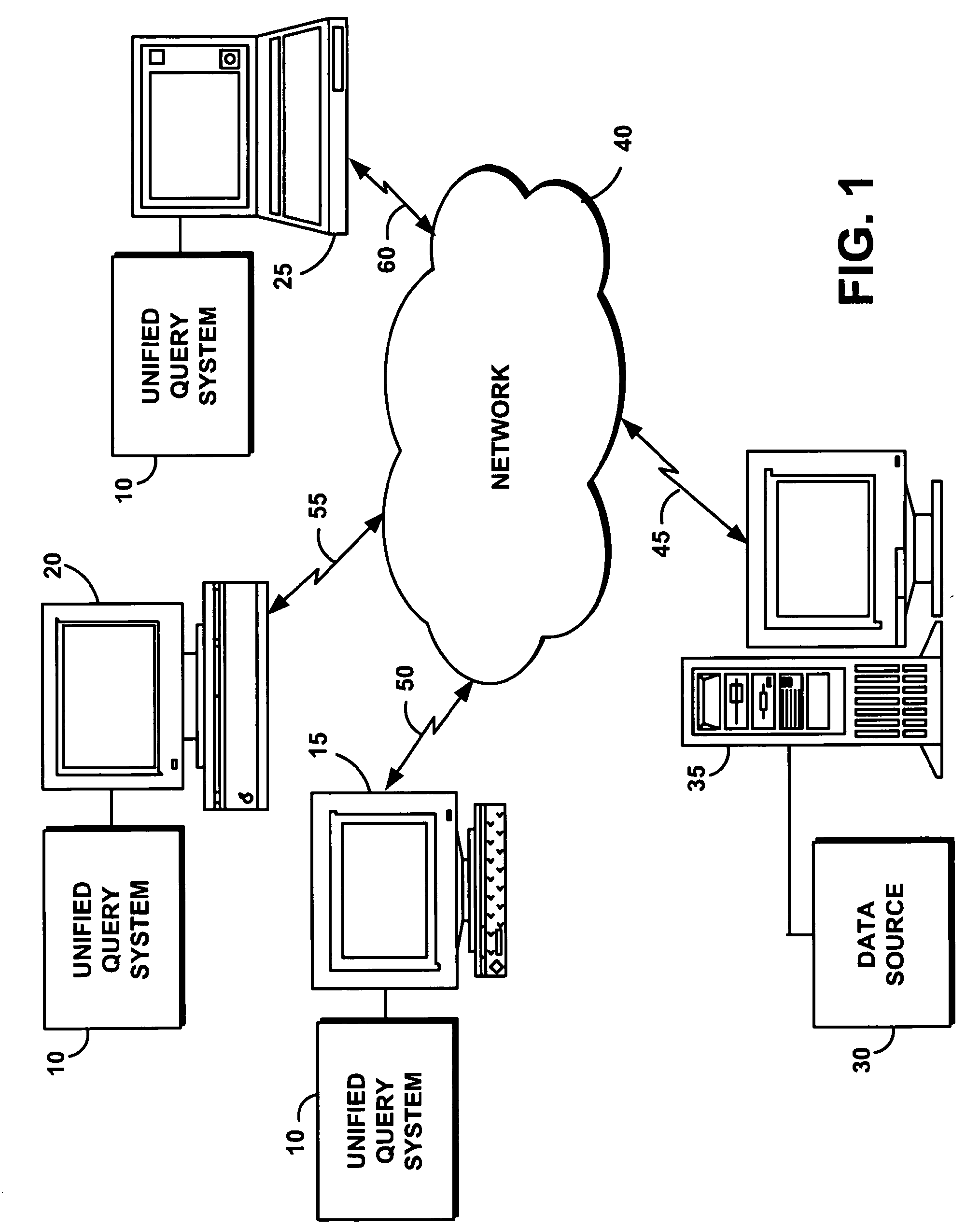

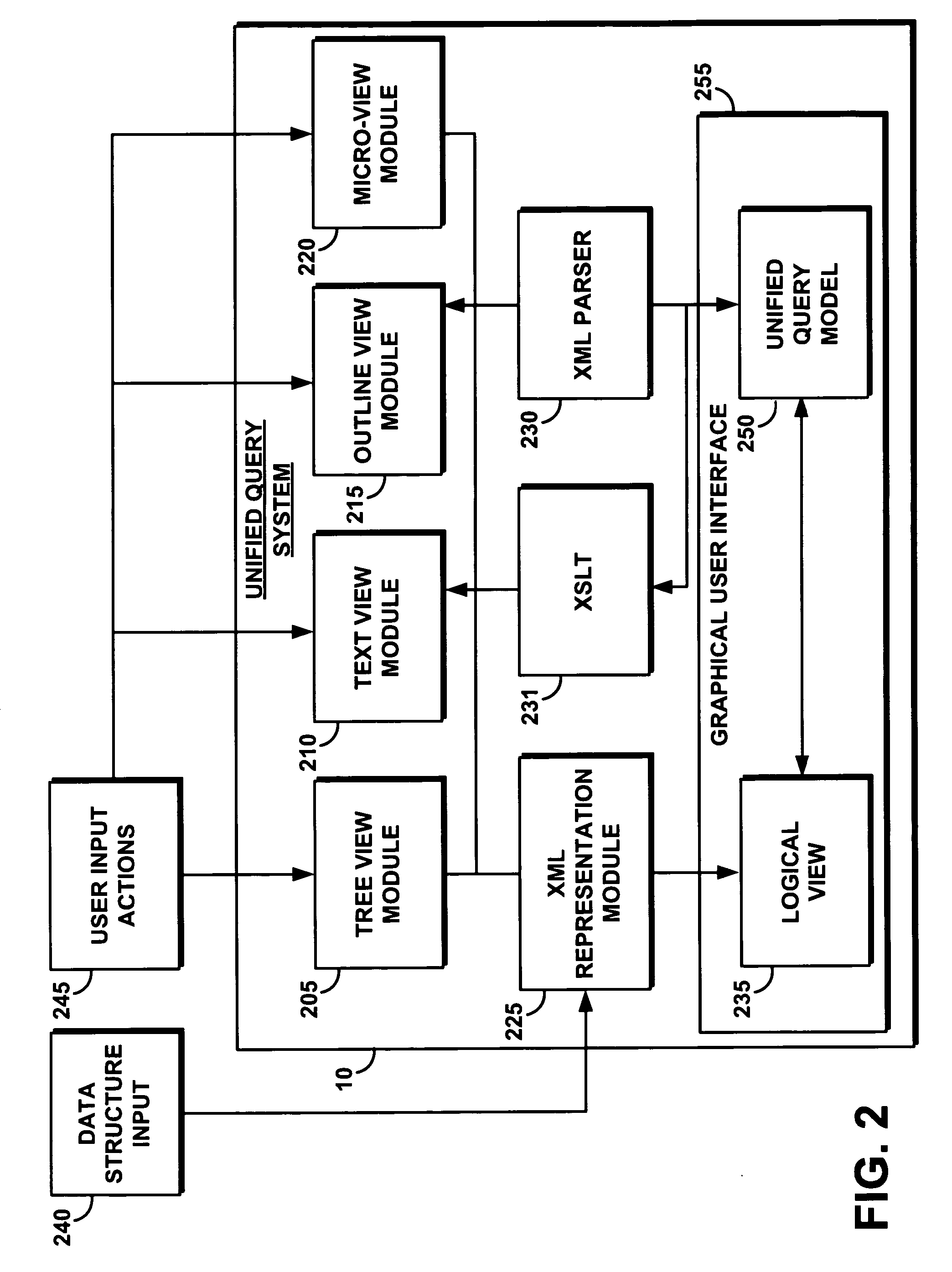

Building A Unified Query That Spans Heterogeneous Environments

InactiveUS20080281802A1Data processing applicationsSemi-structured data retrievalGraphicsGraphical user interface

A unified query building system generates a source structure comprising nodes from a data structure input of an identified data source, displays the generated source structure in a logical view, adds a selected node or element from the nodes to a design query canvas, generates a query object from the selected node based on a source type of the selected node, presents a logical view of a query function of a selected query object, and generates a unified query comprising the generated query objects. The logical view is displayed in a graphical user interface comprising a design query canvas comprising grids corresponding to functions in a query language such as SQL or XML. The generated unified query is displayed in an actual query view and is outlined in a query outline view.

Owner:INT BUSINESS MASCH CORP

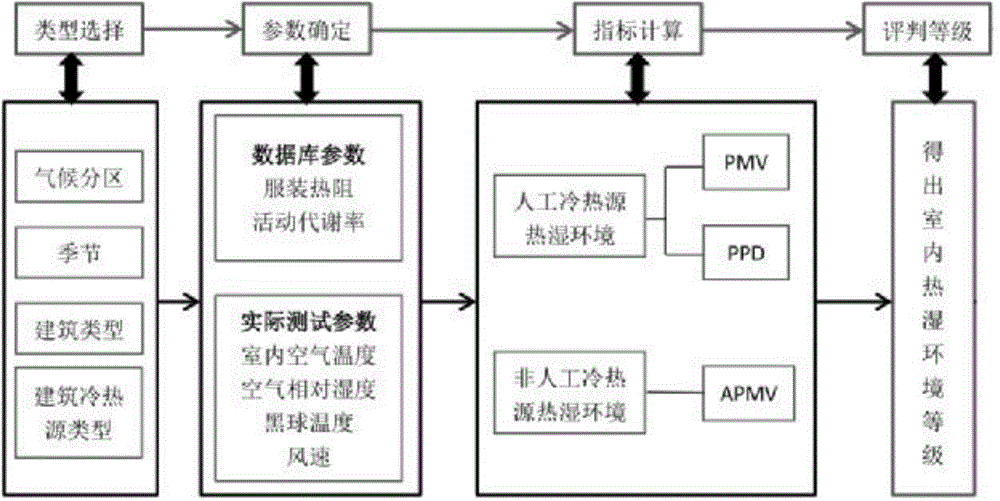

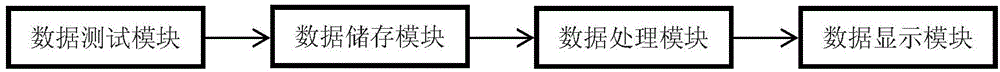

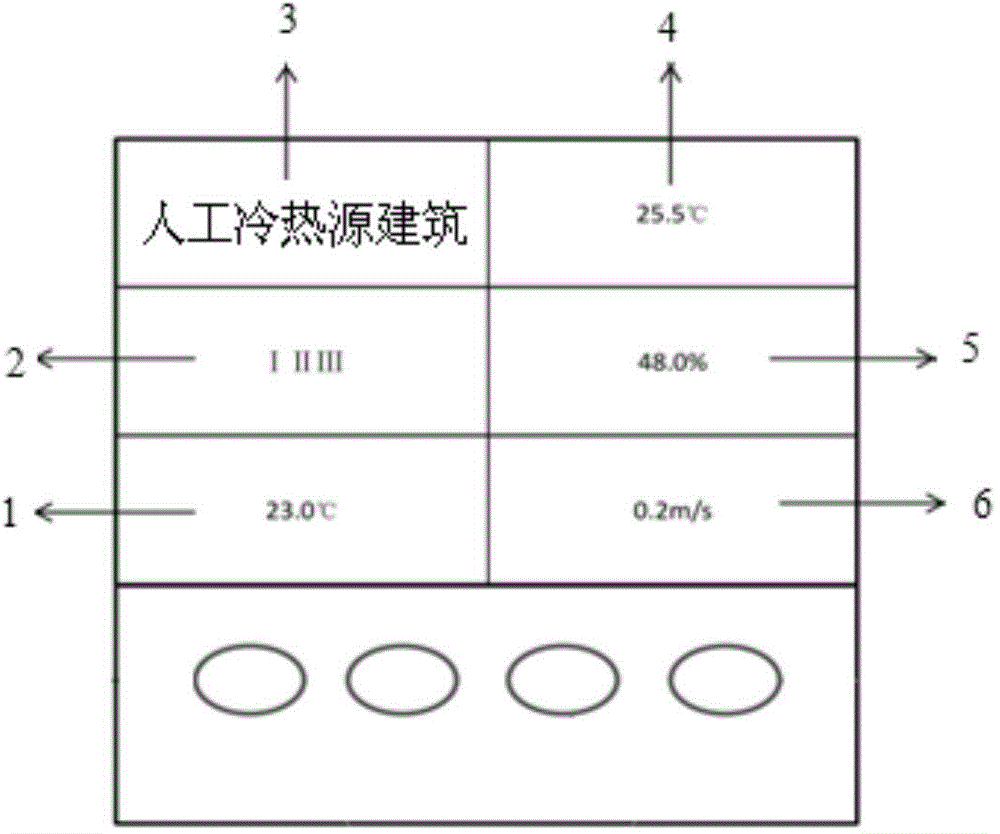

System and method for evaluating building hot and humid environment levels

ActiveCN104102789AImprove thermal comfortReduce building energy consumptionData processing applicationsSpecial data processing applicationsBuilding energySource type

The invention provides a system and a method for evaluating the building hot and humid environment levels. Different evaluating methods can be selected according to different building cold and heat source types; the system and the method are applicable to artificial cold and heat source buildings and non-artificial cold and heat source buildings; the building hot and humid environment levels and the building indoor comfortable temperature range can be objectively obtained; the indoor hot comfortable environment can be favorably and effectively improved; and the building energy consumption is reduced. The building hot and humid environment levels in different regions, different seasons, different buildings and different environments can be judged, and the evaluating method is more comprehensive.

Owner:CHONGQING UNIV

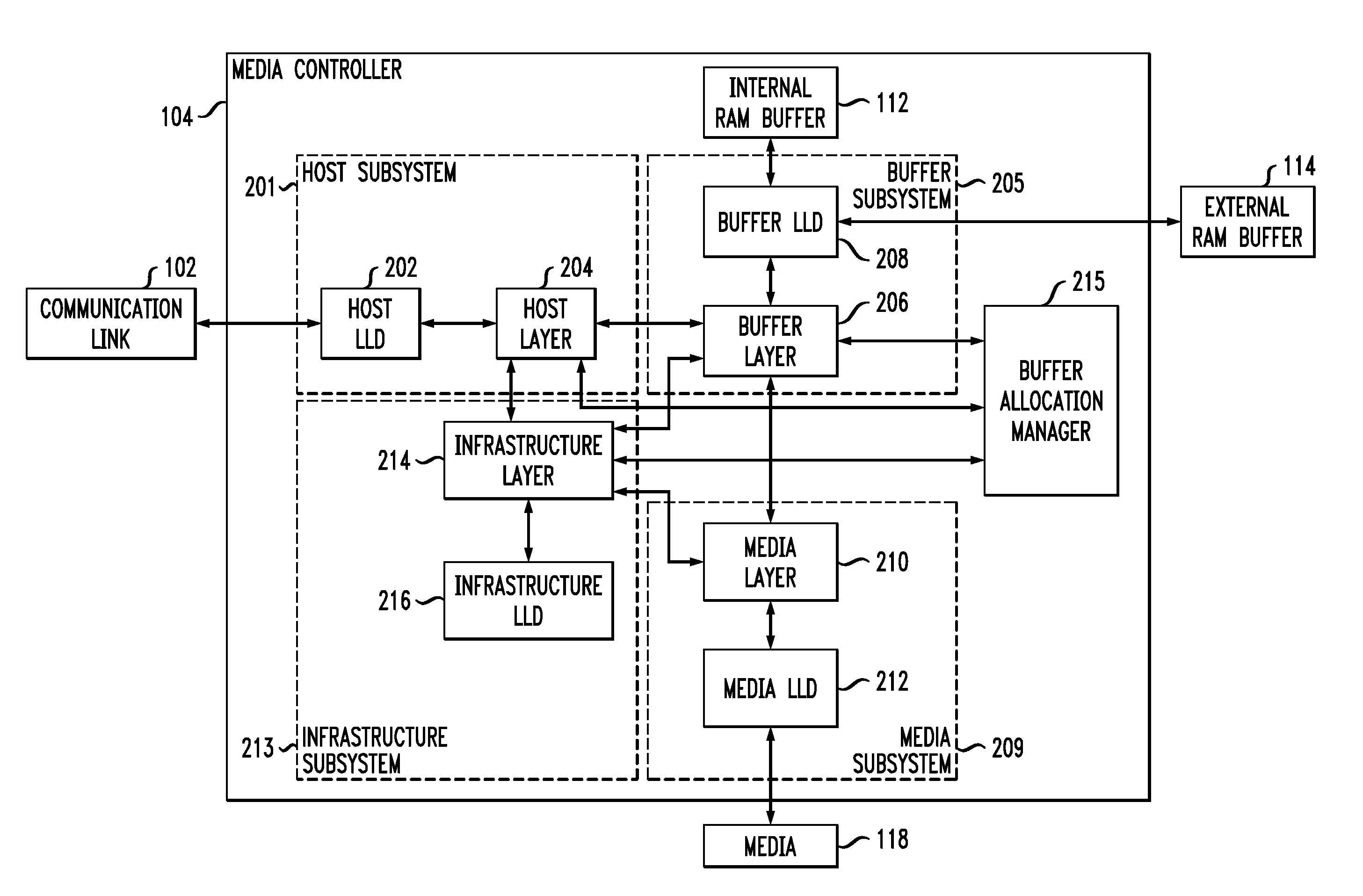

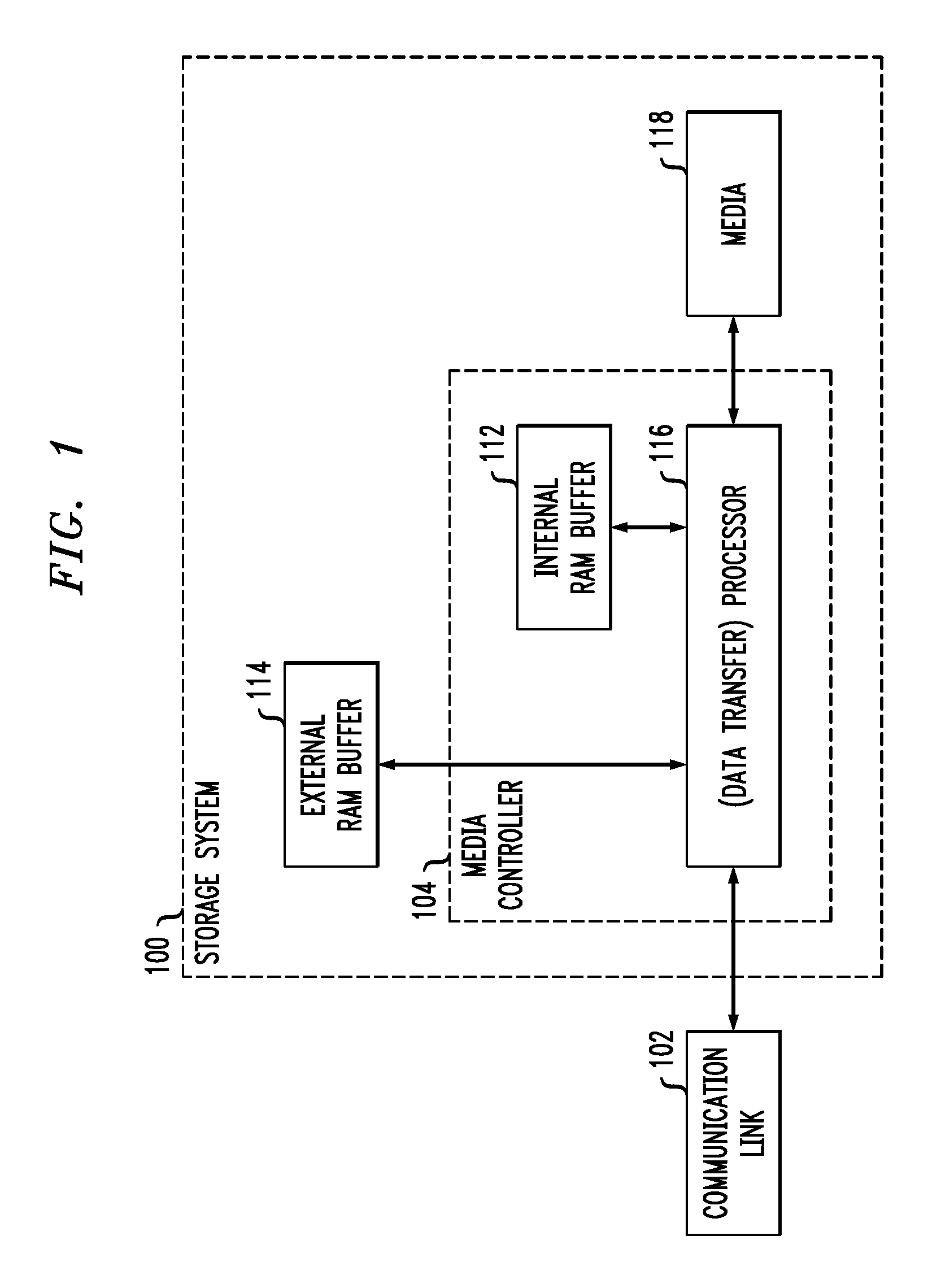

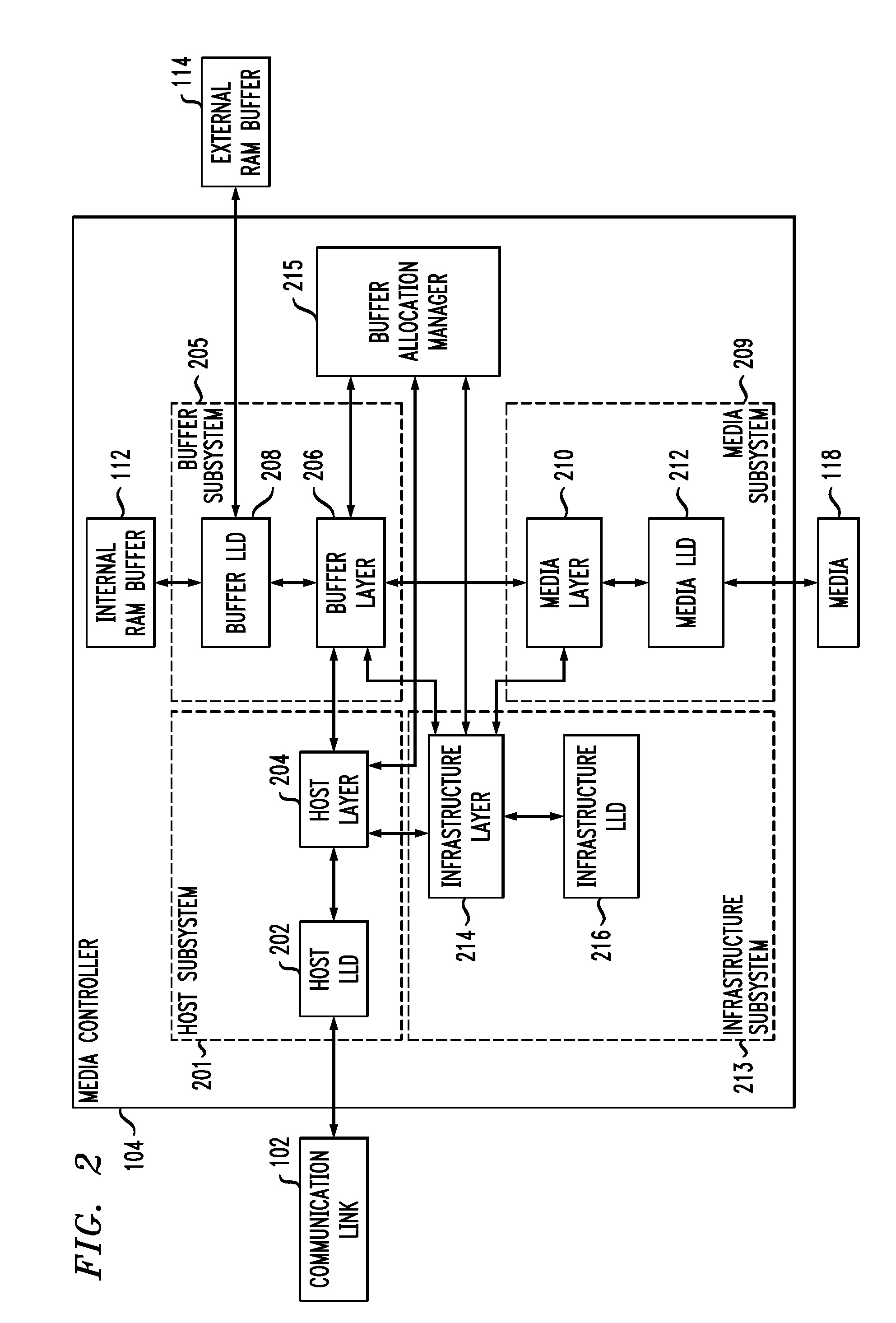

Processing Diagnostic Requests for Direct Block Access Storage Devices

ActiveUS20110072209A1Well formedMemory architecture accessing/allocationError detection/correctionSource typeComputer module

Described embodiments provide a media controller for processing a diagnostic request received from a diagnostic source. The received diagnostic request is parsed by a corresponding request handling module of the media controller, where each diagnostic source type has a corresponding request handling module. If the received diagnostic request requires allocation of buffer space, a common diagnostic handling module of the media controller allocates buffer space in a buffer for the received diagnostic request. The common diagnostic handling module is common for all diagnostic source types. The common diagnostic handling module provides the received diagnostic request to a corresponding one of a plurality of end diagnostic handling modules. The end diagnostic handling module performs the diagnostic tasks. If the received diagnostic request requires a transfer of data to the diagnostic source, the common diagnostic handling module performs the data transfer between the media controller and the diagnostic source.

Owner:AVAGO TECH INT SALES PTE LTD

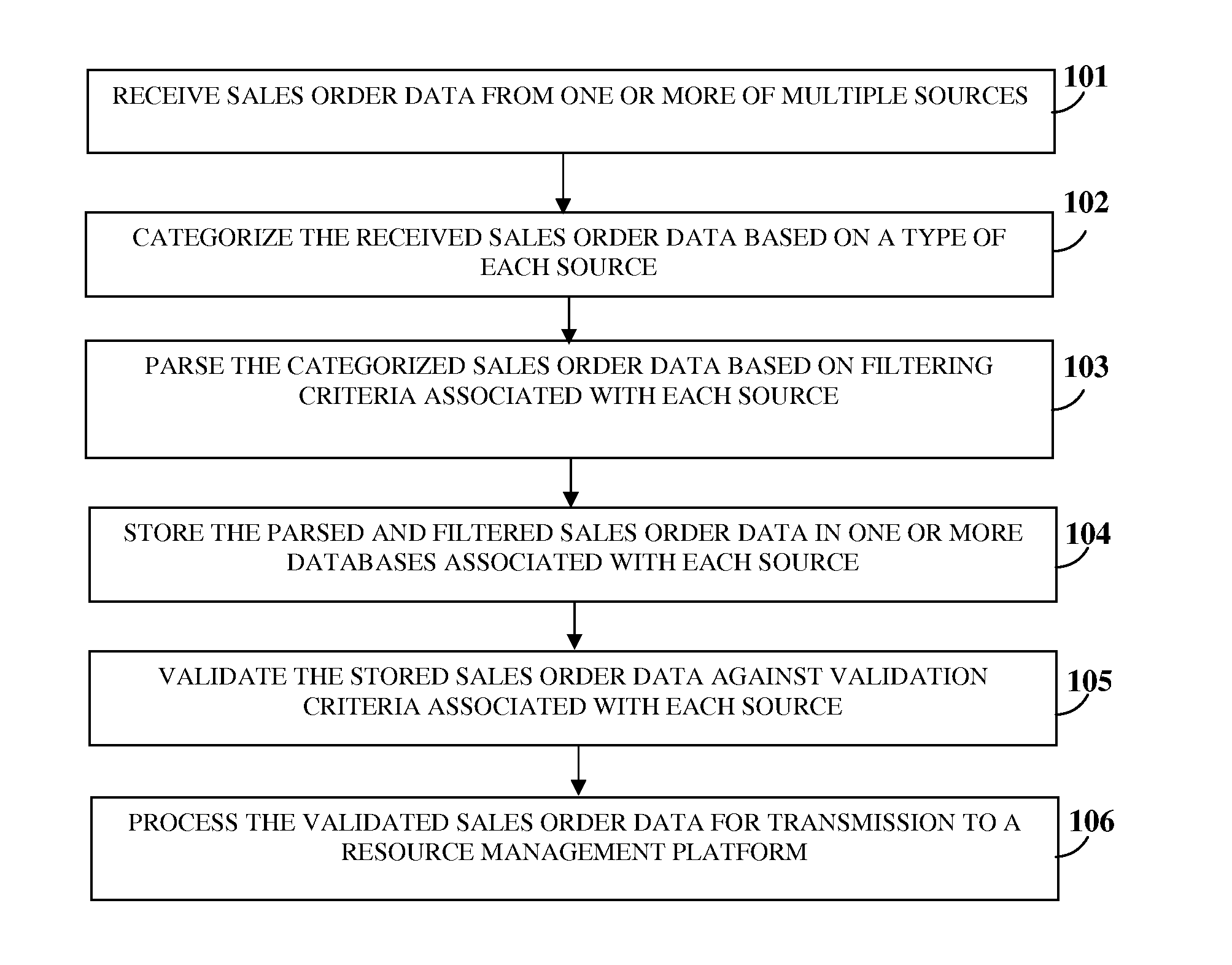

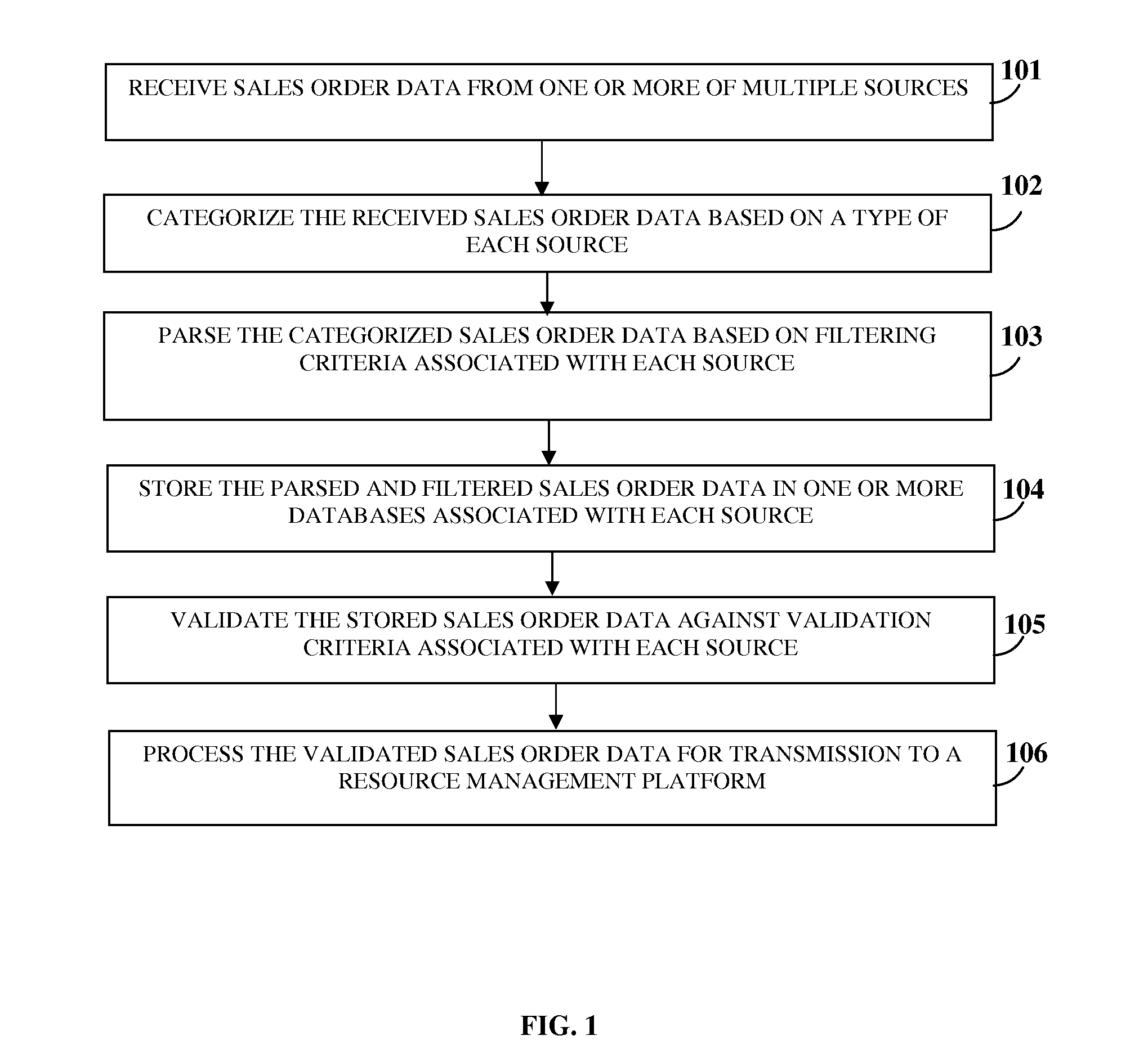

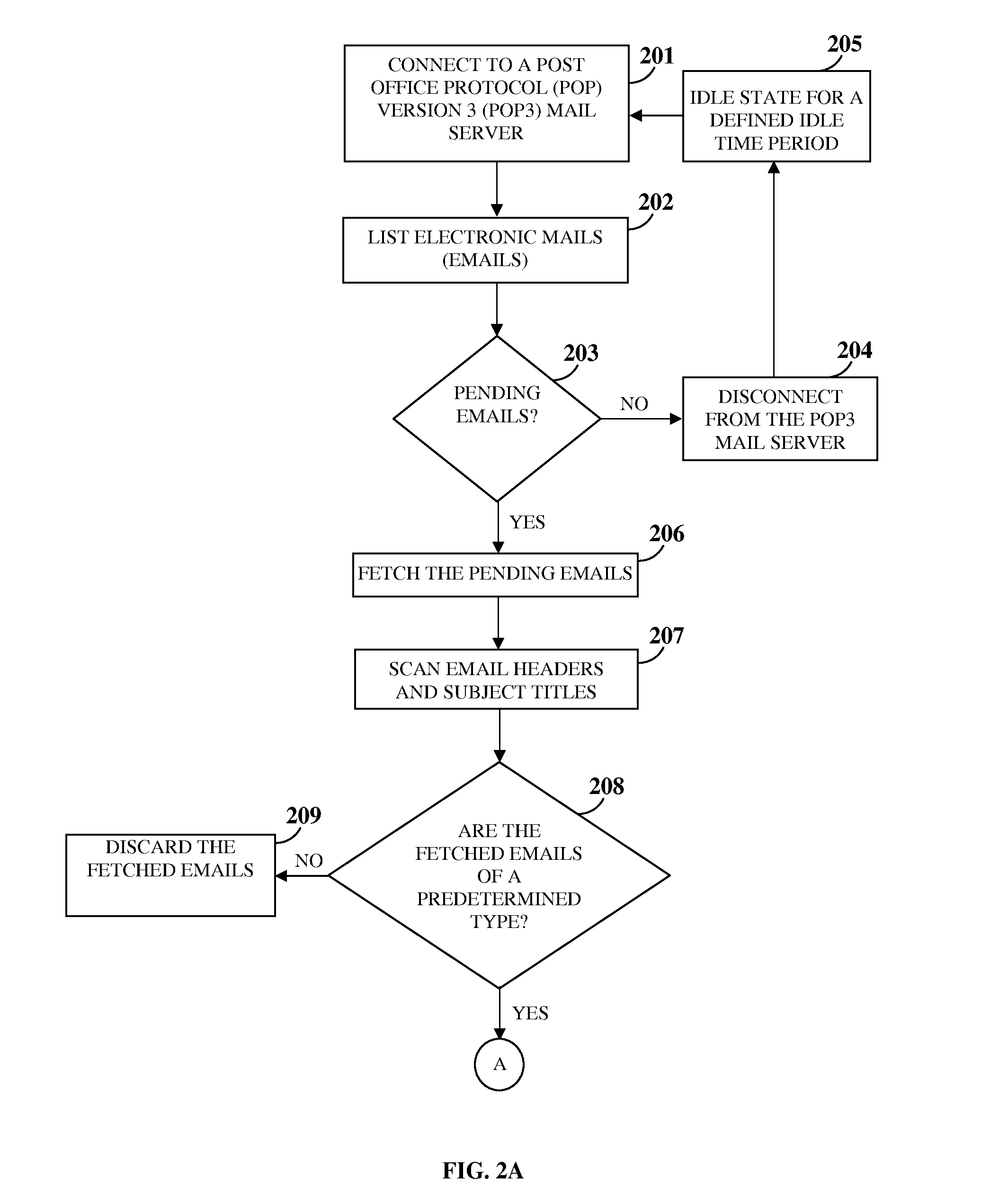

Sales Order Data Collection And Management System

ActiveUS20150081485A1Shorten the timeComplete banking machinesDatabase management systemsThird partySource type

A computer implemented method and a sales order data collection and management system (SODCMS) collect and manage sales order data including data from a web based sales order, a manual sales order, a sales order over a communication device, a third party consumer to consumer web based sales order, etc. The SODCMS receives sales order data from one or more sources and categorizes the sales order data based on a source type. The SODCMS parses the categorized sales order data based on filtering criteria, stores the parsed sales order data in one or more databases, and validates the stored sales order data against validation criteria. The SODCMS processes the validated sales order data and transmits the processed sales order data to a resource management platform. The SODCMS renders messages on modifications and discrepancies associated with the sales order data to consumers based on the validation of the sales order data.

Owner:MACE ENGINEERING GROUP PTY LTD

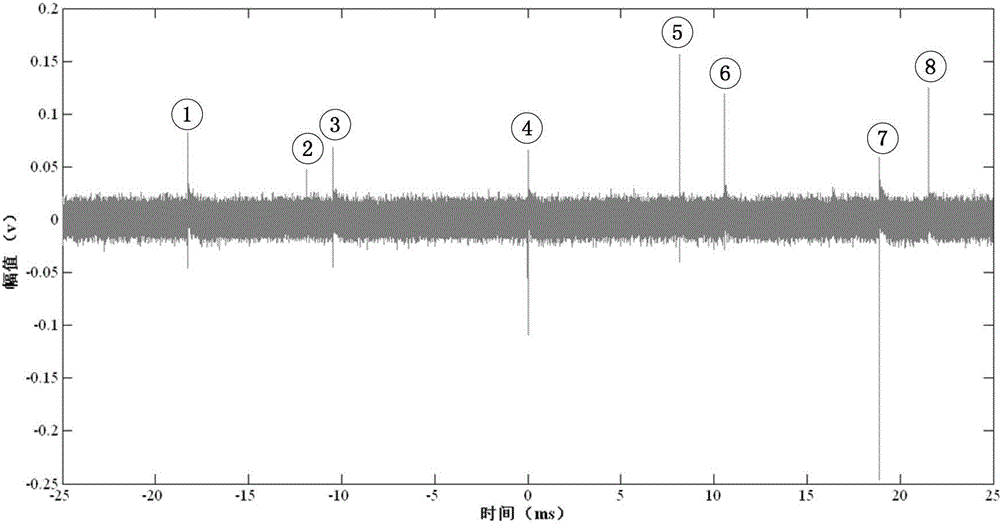

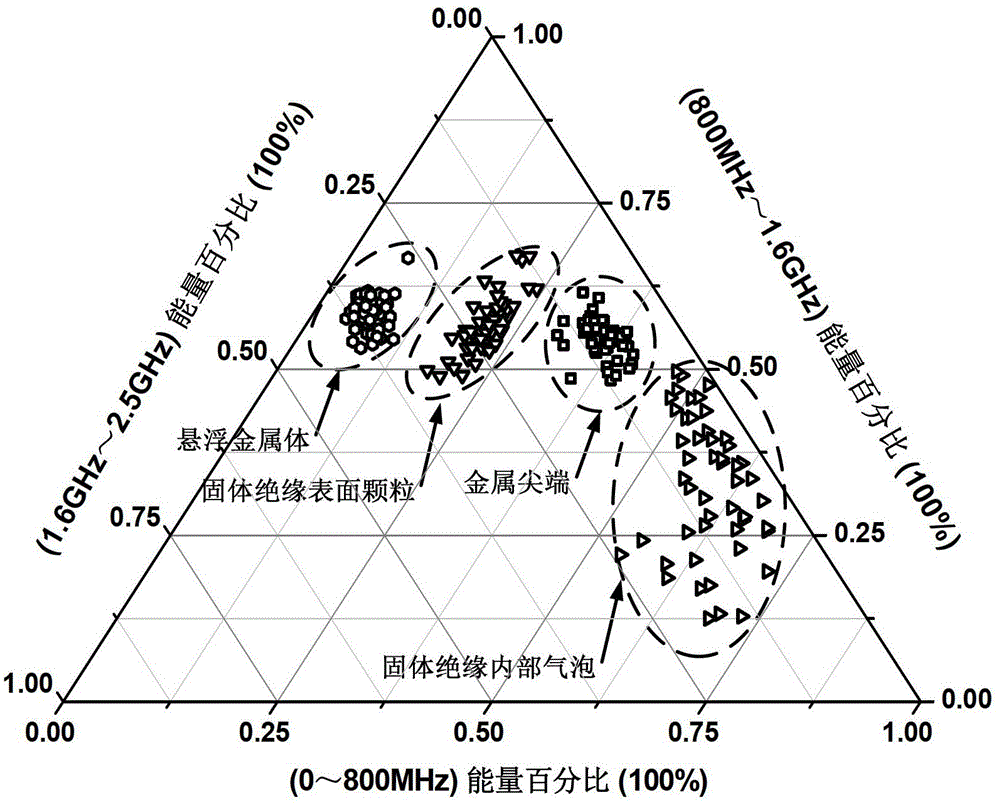

Identification method of various partial discharge source types in gas insulated substation (GIS)

ActiveCN103336226AAccurate extractionShorten the timeTesting dielectric strengthFrequency spectrumWavelet denoising

The invention relates to an identification method of various partial discharge source types in a gas insulated substation (GIS), and belongs to the electrical equipment technology field. In the method, a data acquisition card with a high sampling rate and a long record length is utilized to record long time partial discharge signals; a wavelet denoising method is used for a noise reduction treatment of the partial discharge signals, and then the discharge signals are extracted to obtain a frequency spectrum energy distribution of the discharge signals; and finally, a support vector machine is used to distinguish discharge types to realize the partial discharge source identification in the GIS. The method of the invention utilizes the acquisition card with the long record depth and the high sampling rate, so that the identification time for different discharge sources is reduced; according to an ultrahigh frequency signal energy ratio, a least square support vector machine is trained; according to an ultrahigh frequency signal in the long time record data, various discharge source types are identified; and the accuracy of the discharge source identification is improved.

Owner:TSINGHUA UNIV +1

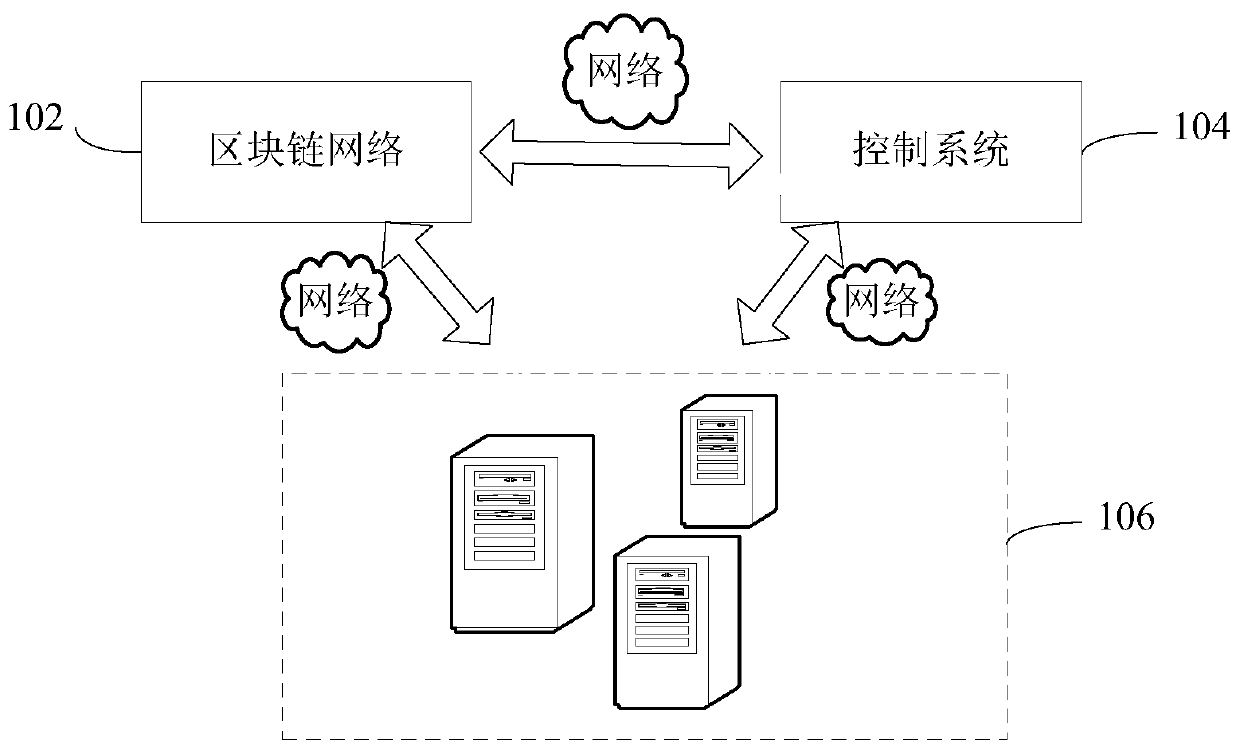

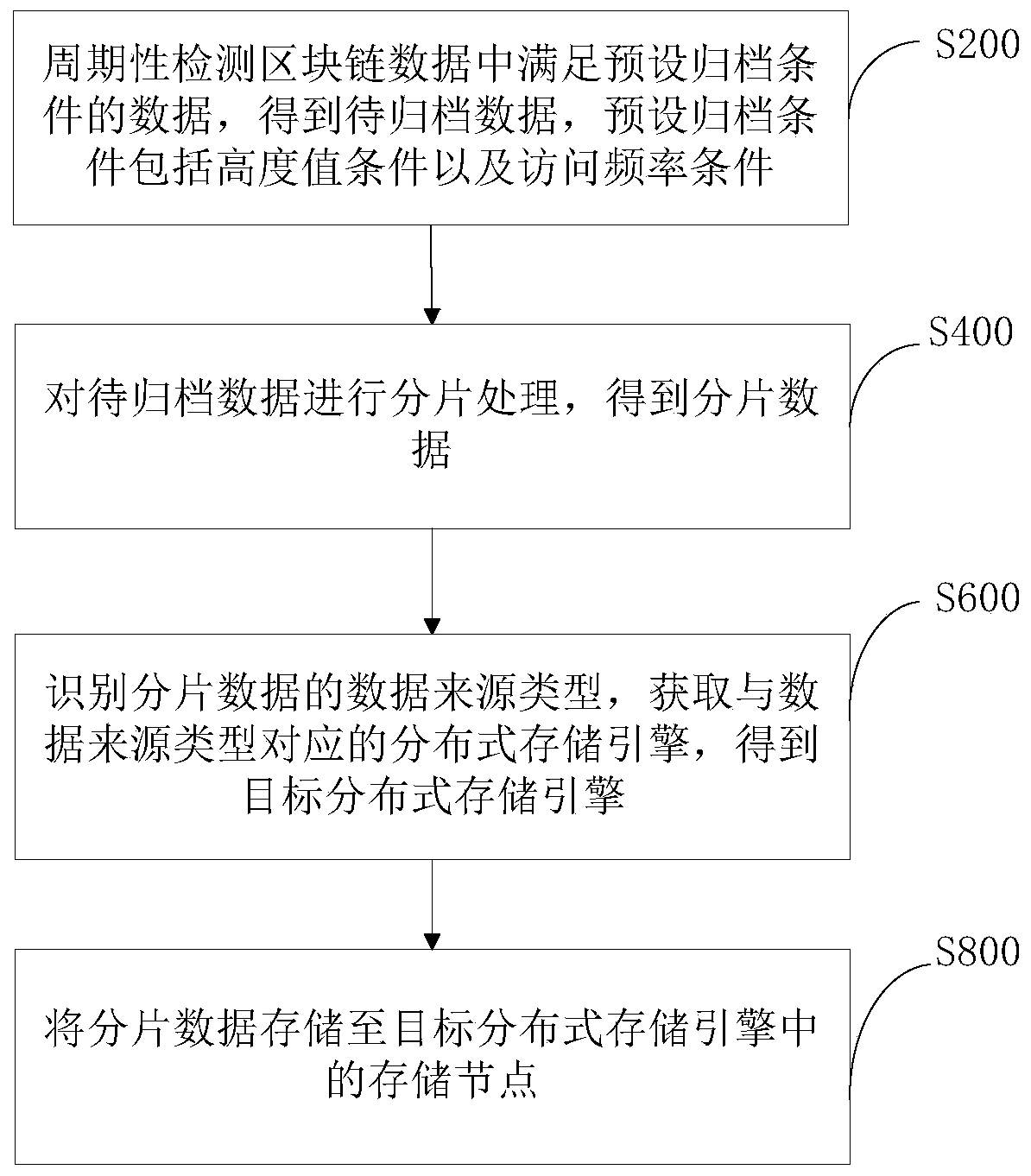

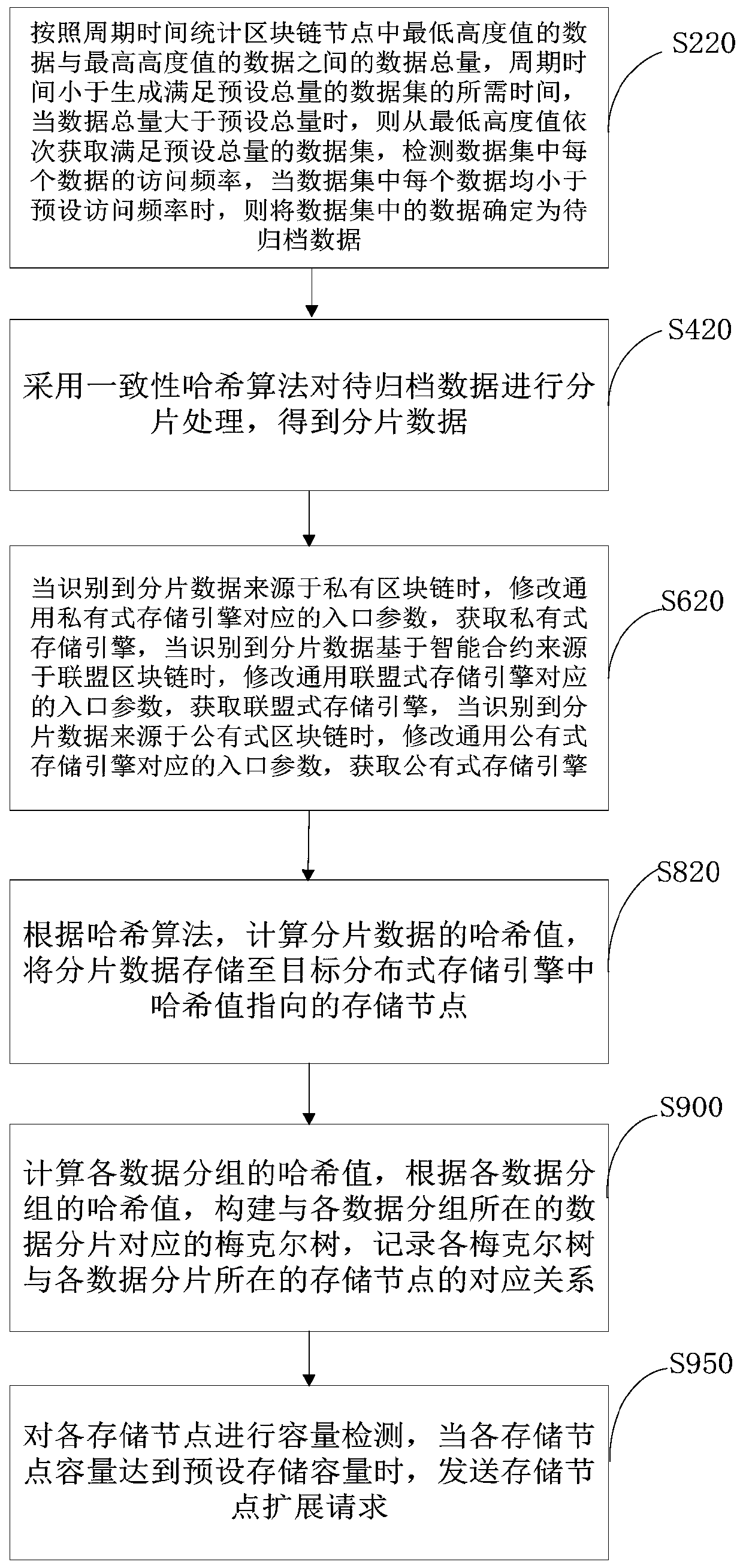

Block chain data archiving storage method and device, computer equipment and storage medium

PendingCN110442644AImprove processing efficiencyAchieve expansionDatabase distribution/replicationSpecial data processing applicationsLinear growthSource type

The invention relates to the field of block storage systems, and a blockchain data archiving storage method and device, computer equipment and a storage medium. The method comprises the following steps: periodically detecting to-be-archived data and fragmenting the to-be-archived data; and completing data archiving. Data redundancy is avoided, the storage mode can be flexibly selected according tothe fragmented data source type; the safety availability of the data is guaranteed, the fragmented data is distributed to the storage nodes in the corresponding distributed storage engines, the capacity expansion of the storage space of the block chain data is realized in a distributed storage mode, the requirement of the linear growth of the block chain data on the storage space is met, and thedata processing efficiency is improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

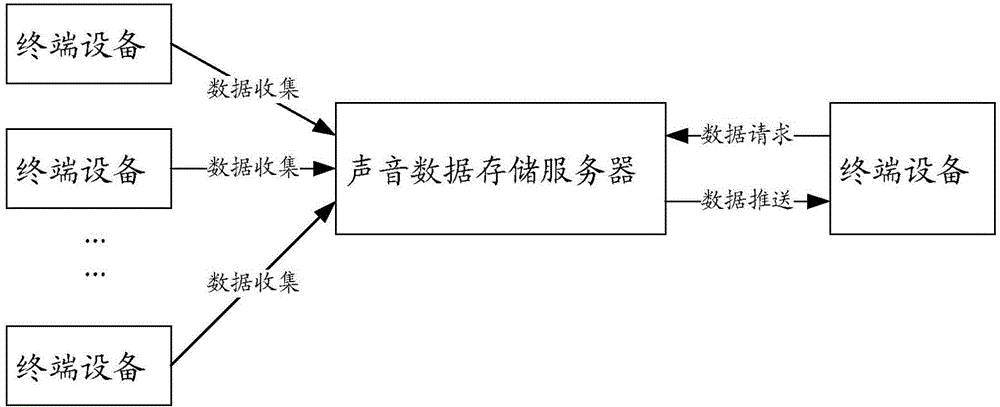

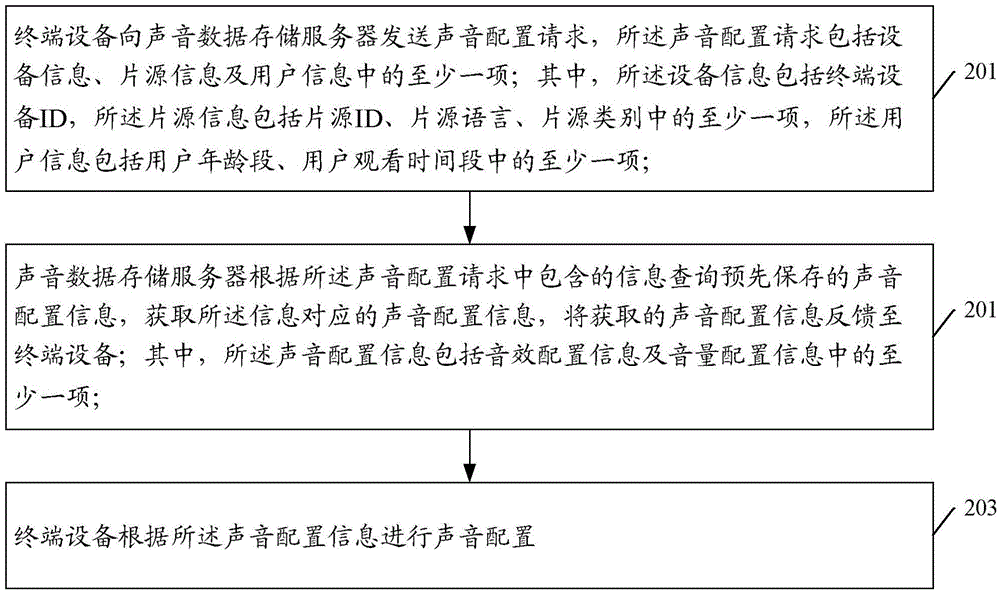

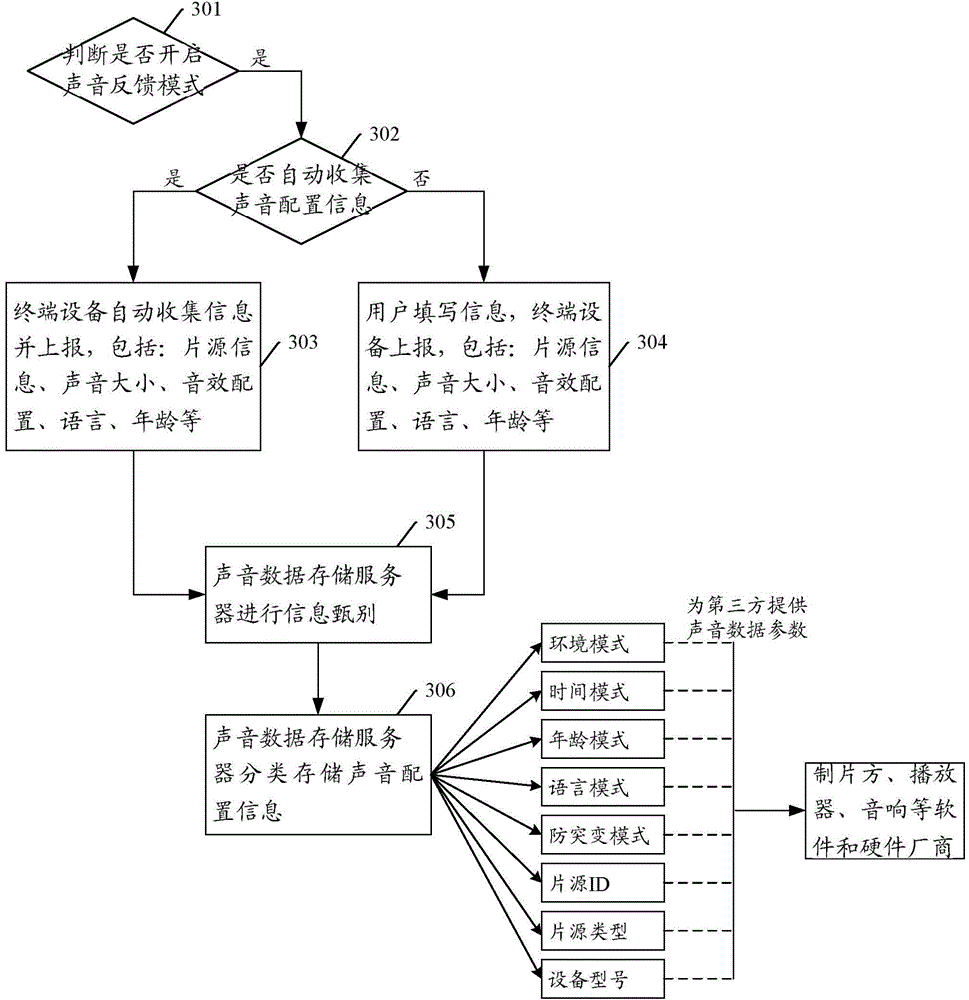

Automatic sound configuration method, system and device

ActiveCN104602045AImplement adaptive automatic sound configurationSelective content distributionSource typeTerminal equipment

The invention provides an automatic sound configuration method, system and device. The automatic sound configuration method includes that terminal equipment transmits sound configuration requests to a sound data storage server including at least one of equipment information, film source information and user information, the equipment information comprises terminal equipment ID, the film source information comprises at least one of film source ID, film source language and film source types, and the user information comprises at least one of user ages and user observation time spans. A sound data server inquires prestored sound configuration information according to information contained in the sound configuration requests, acquires sound configuration information corresponding to the information, and feeds the acquired sound configuration information back to the terminal equipment; the sound configuration information comprises at least one of sound effect configuration information and volume configuration information. The terminal equipment configures sound according to the sound configuration information. By the automatic sound configuration method, system and device, self-adaptive automatic sound configuration can be realized for various conditions.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com