Patents

Literature

476results about "Electrode holder supporters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

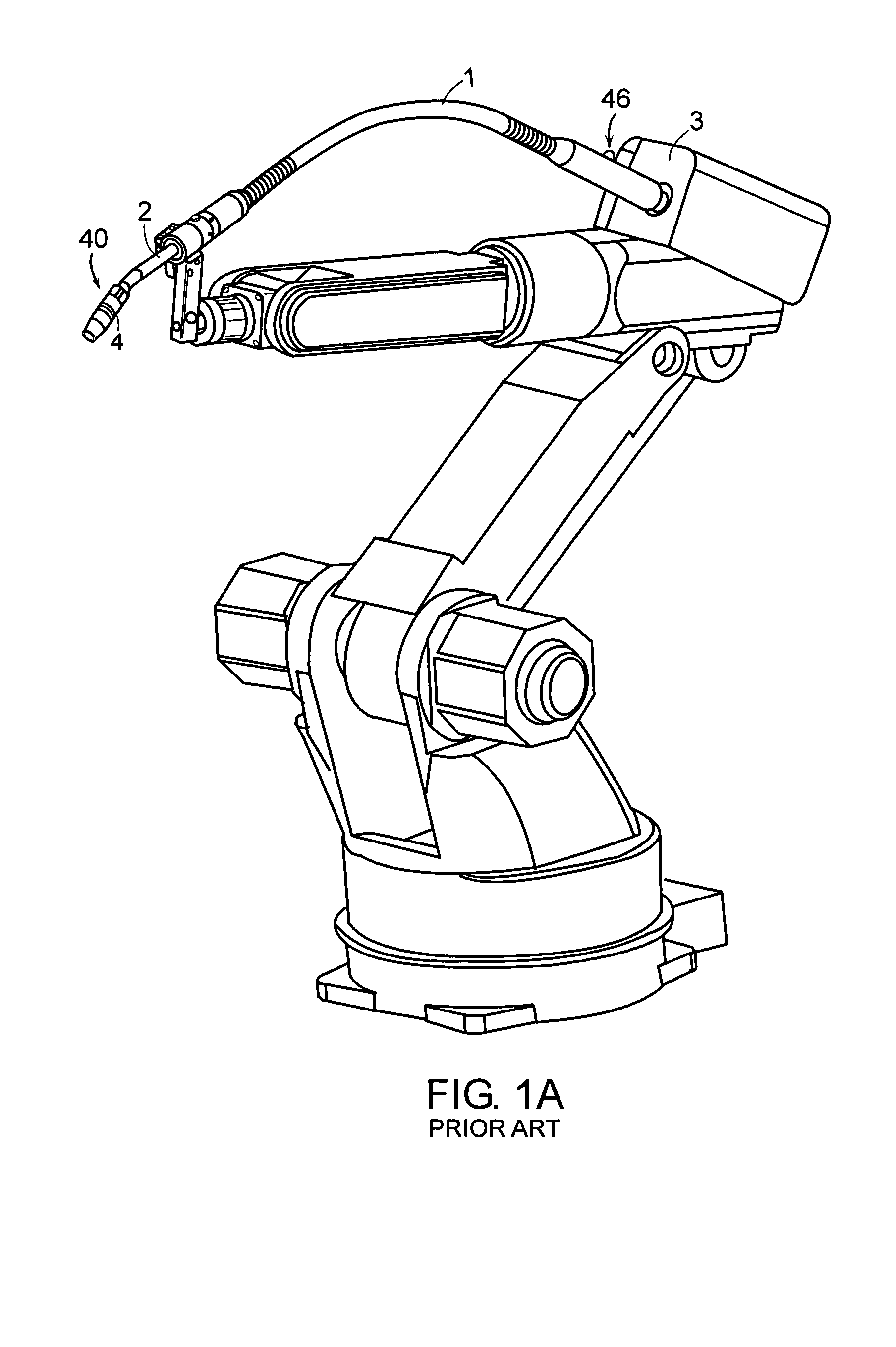

Industrial Robot

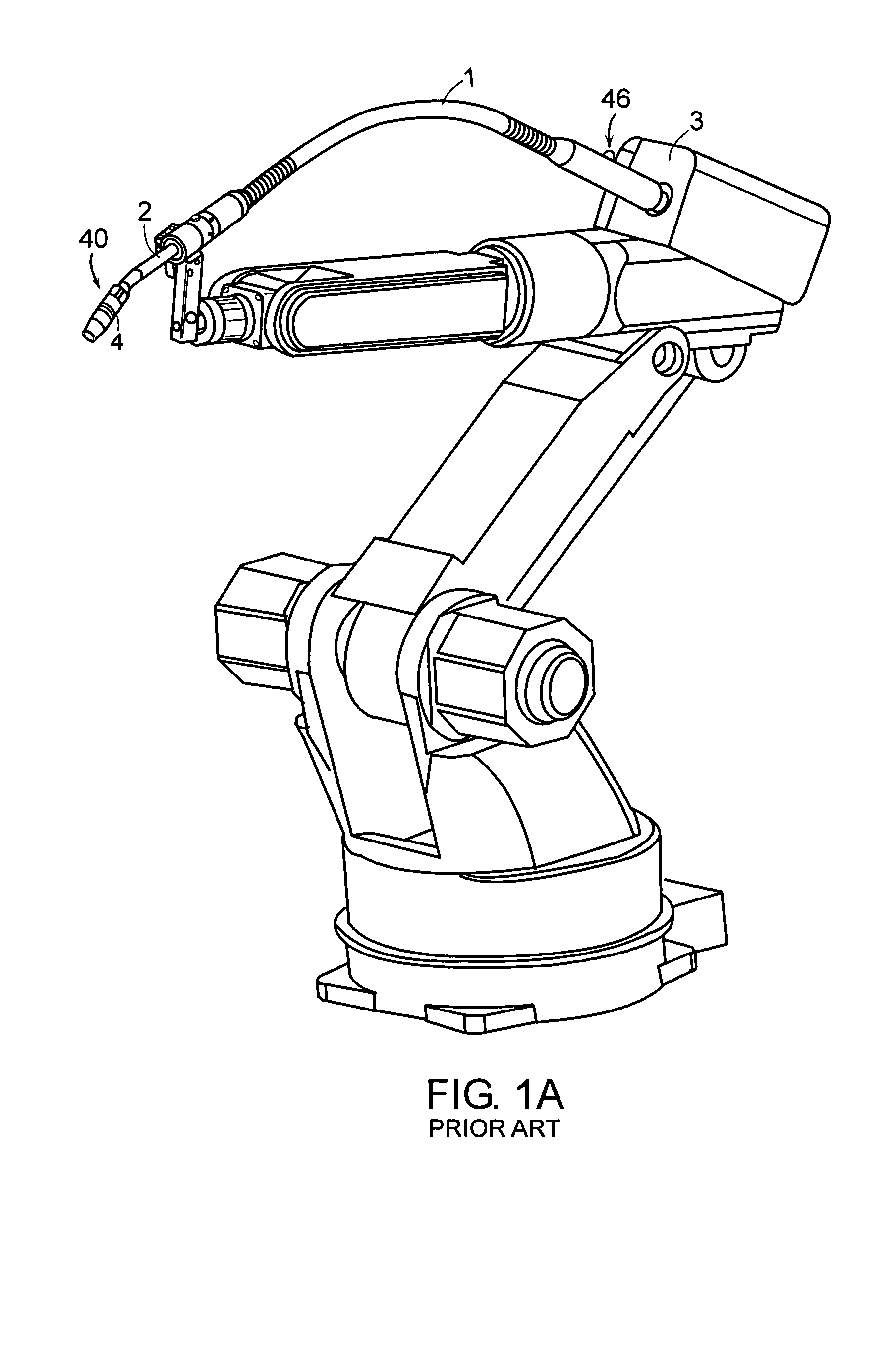

InactiveUS20080271561A1Possible to useControlling membersProgramme-controlled manipulatorIndustrial engineeringWelding torch

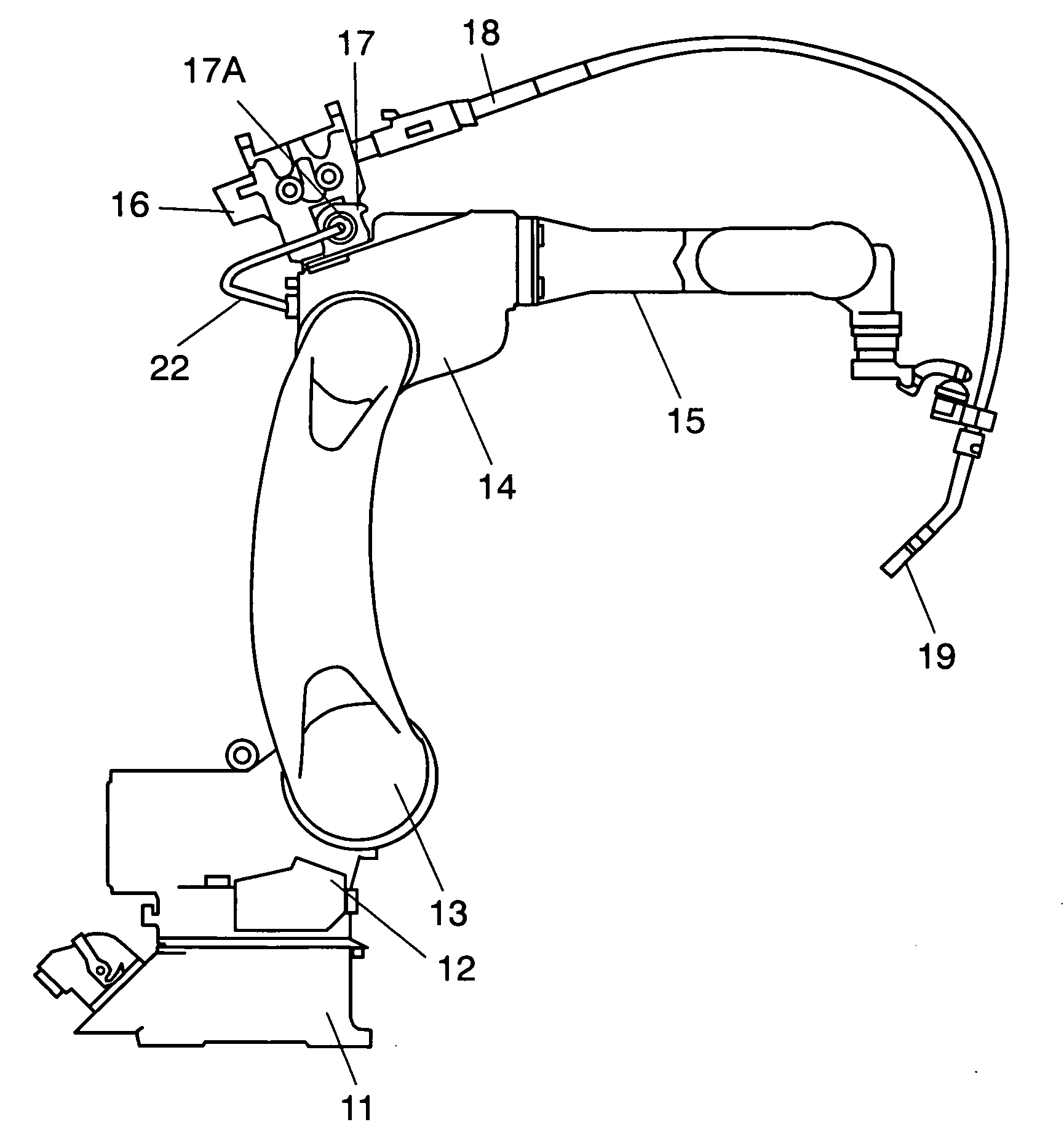

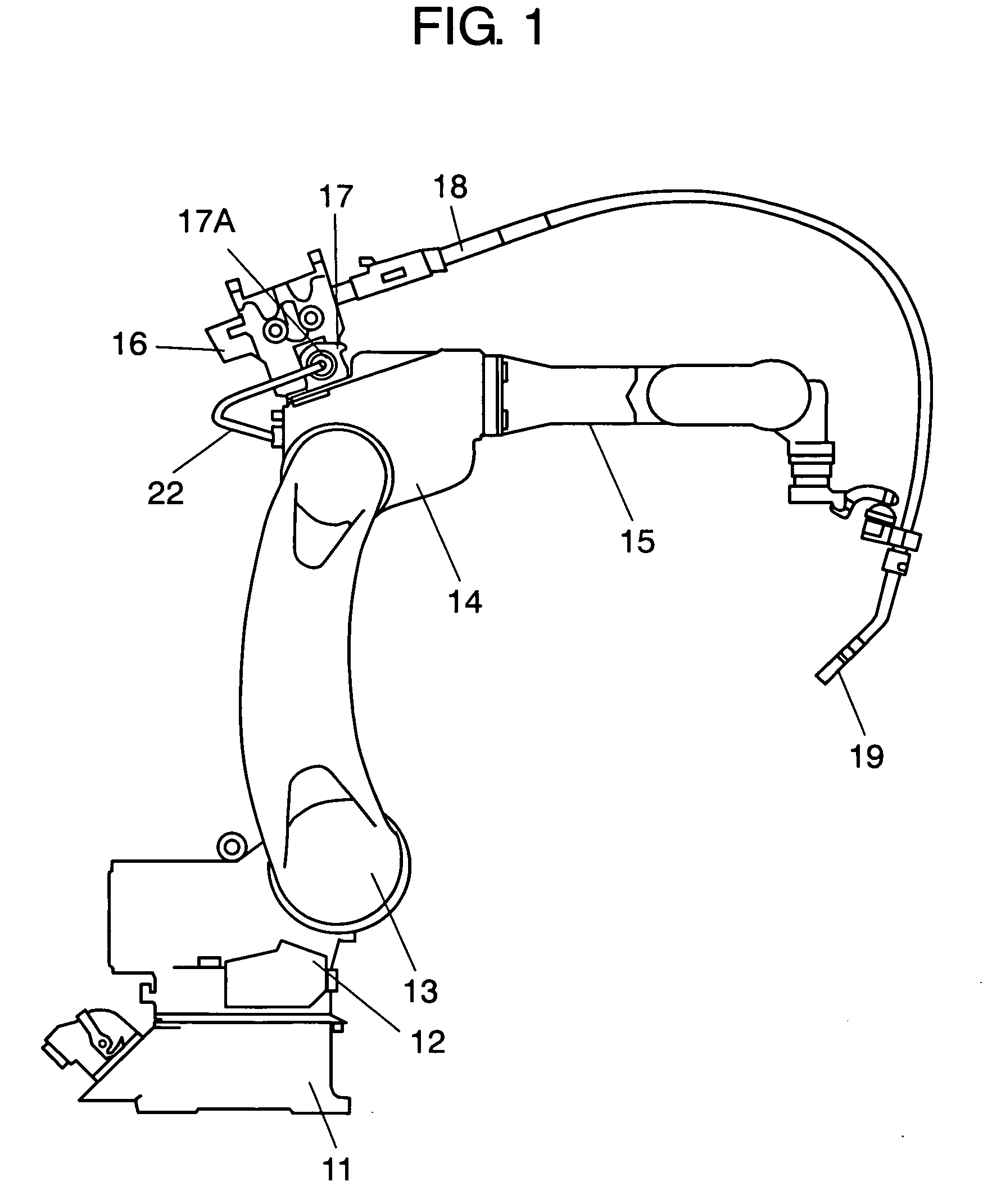

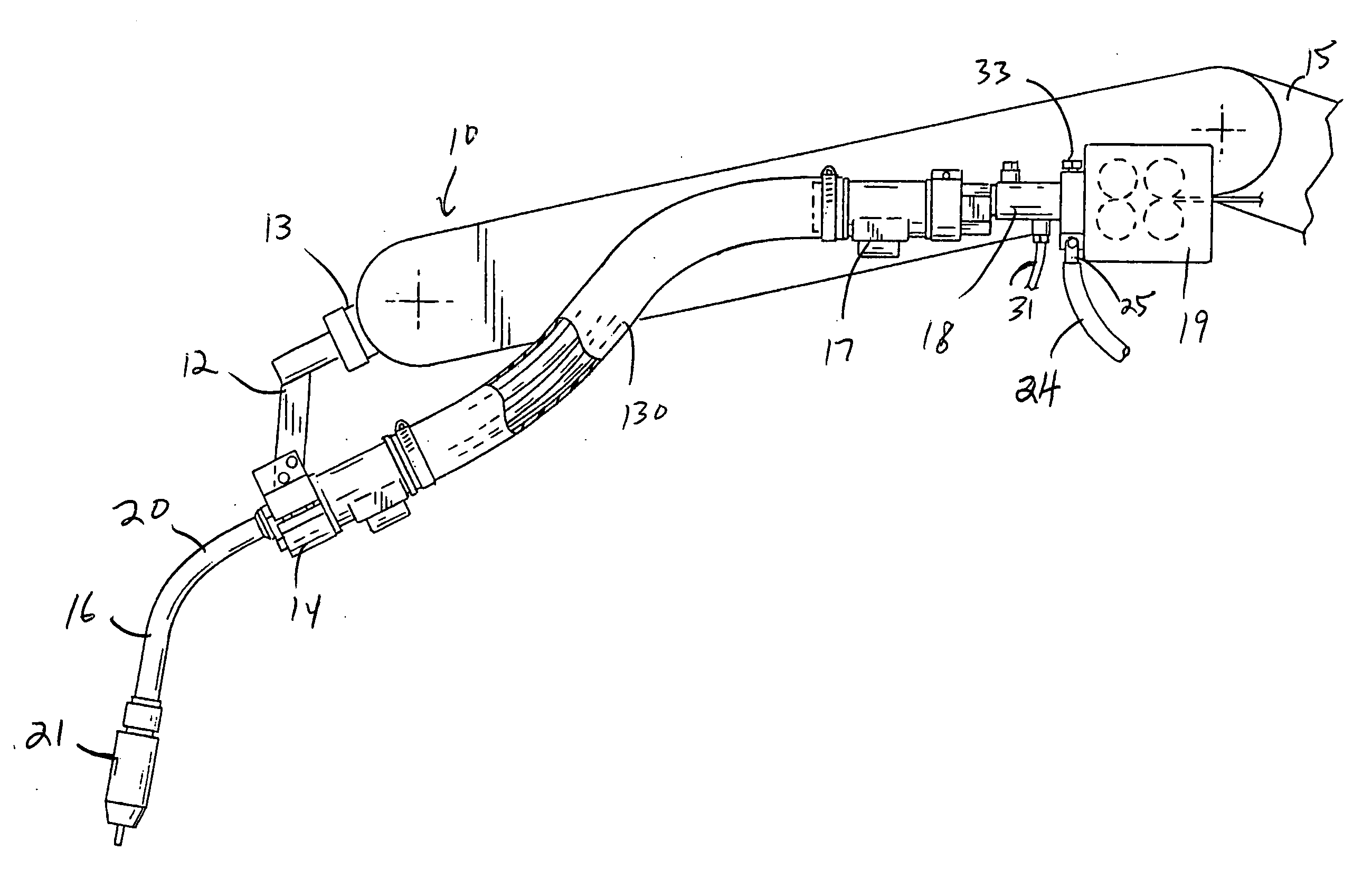

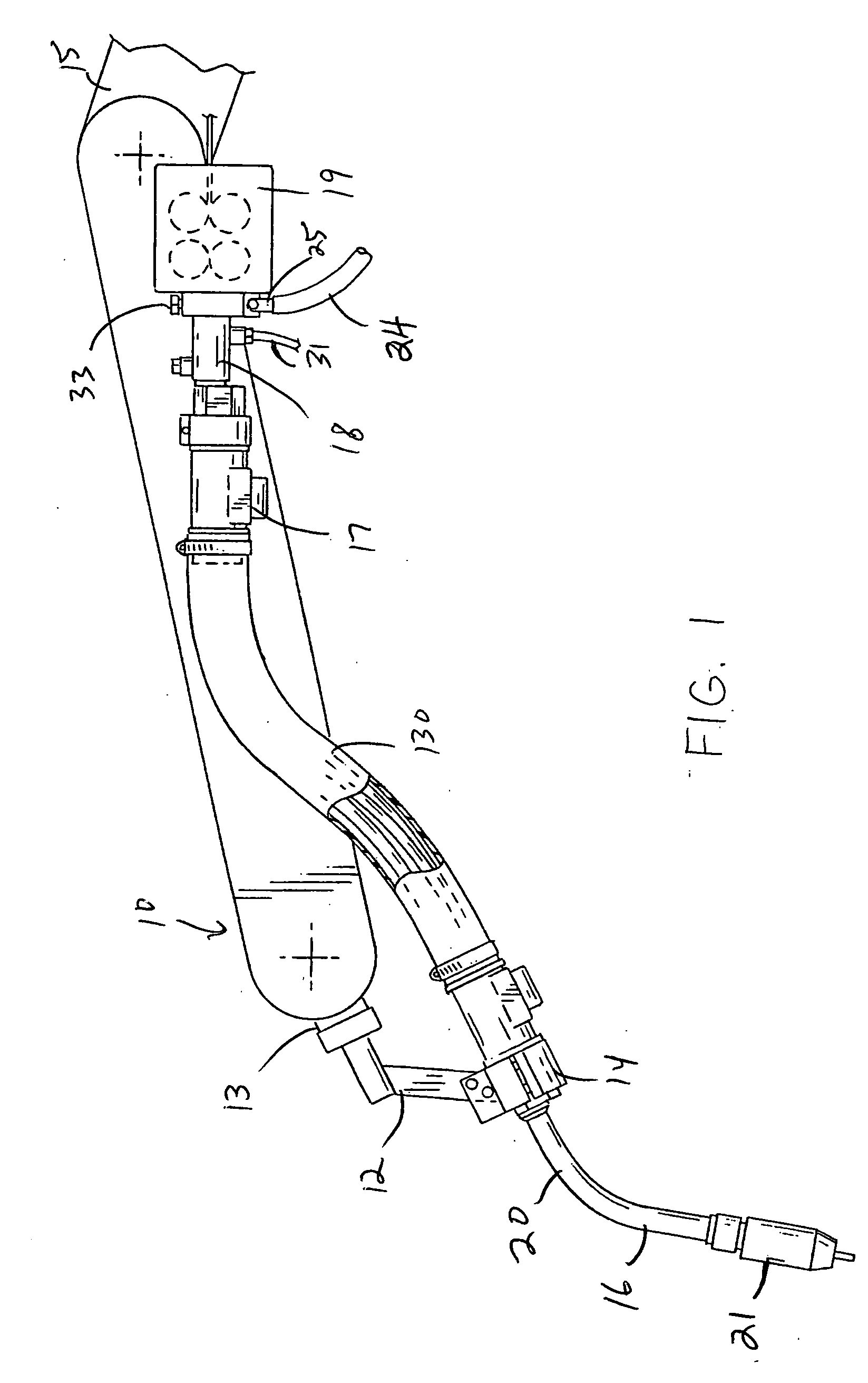

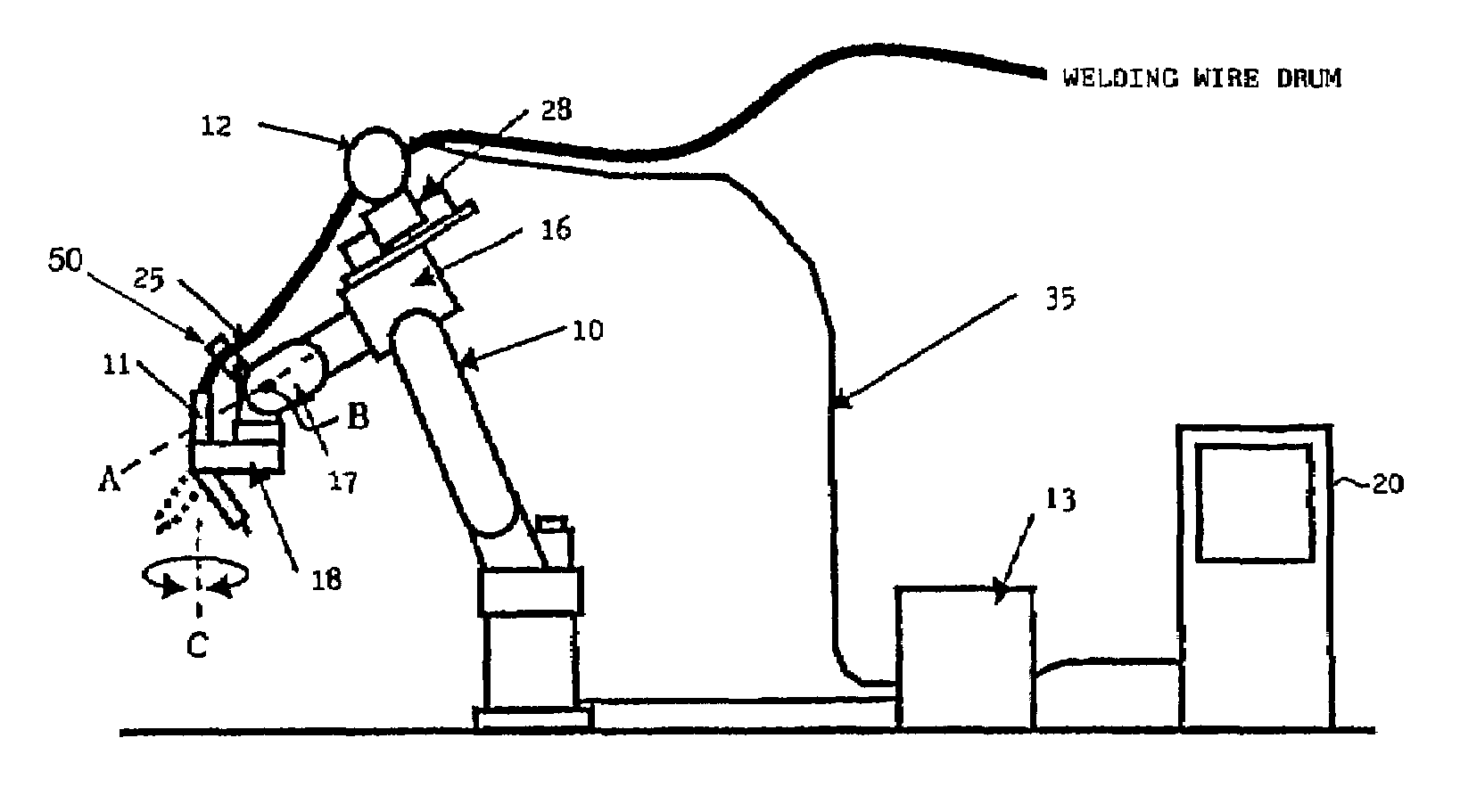

An industrial robot has a base for installation, a first arm, a second arm, a third arm, a wire feeder, a welding torch, and a torch cable. The first arm rotates with respect to the base. The second arm pivots with respect to the first arm. The third arm pivots with respect to the second arm. The torch cable is coupled to the wire feeder and feeds a welding wire to a welding torch. The wire feeder is provided to the second arm and is rotatable around a rotation axis.

Owner:KOWA CO LTD

Electric arc additive manufacturing method

InactiveCN108723549AReduce mistakesNo crackElectrode holder supportersWelding accessoriesLoop controlSource type

The invention discloses an electric arc additive manufacturing method which comprises the following steps of (1) selecting a corresponding heat source type, a forming wire material, and a material type of a base plate according to the material requirement of a forming target part; (2) building a computer-aided design (CAD) geometric model of the forming target part, extracting a standard templatelibrary (STL) model, slicing the STL model, generating a G code file required for printing, and transmitting the G code to a printer; (3) setting printing parameters, starting the printer, and printing metal thin layers according to a planned route layer by layer; and (4) after finishing printing all layer sheets through the printer, carrying out arc failure through a welding gun, and obtaining the forming target part. An additive piece printed through the method provided by the invention is less in error and flawless, has the advantage of good surface quality, and is stable in process, high in dimensional accuracy and surface quality, short in processing period, and low in cost at the same time; the printing process is in closed-loop control, so that the automation degree is high, and thelabor intensity of operating personnel can be reduced; and continuous manufacturing can be realized, and the manufacturing efficiency is high.

Owner:HOHAI UNIV CHANGZHOU

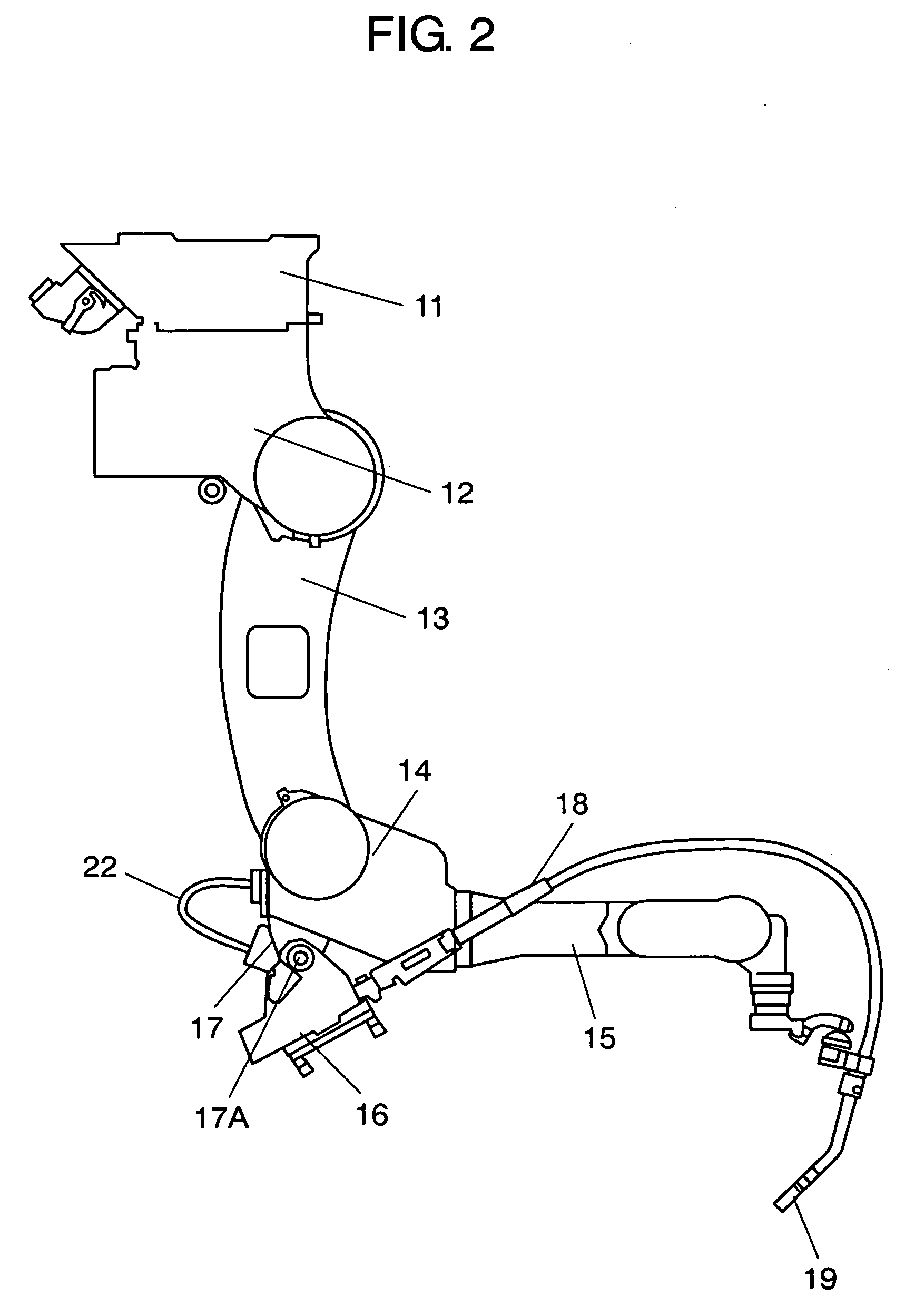

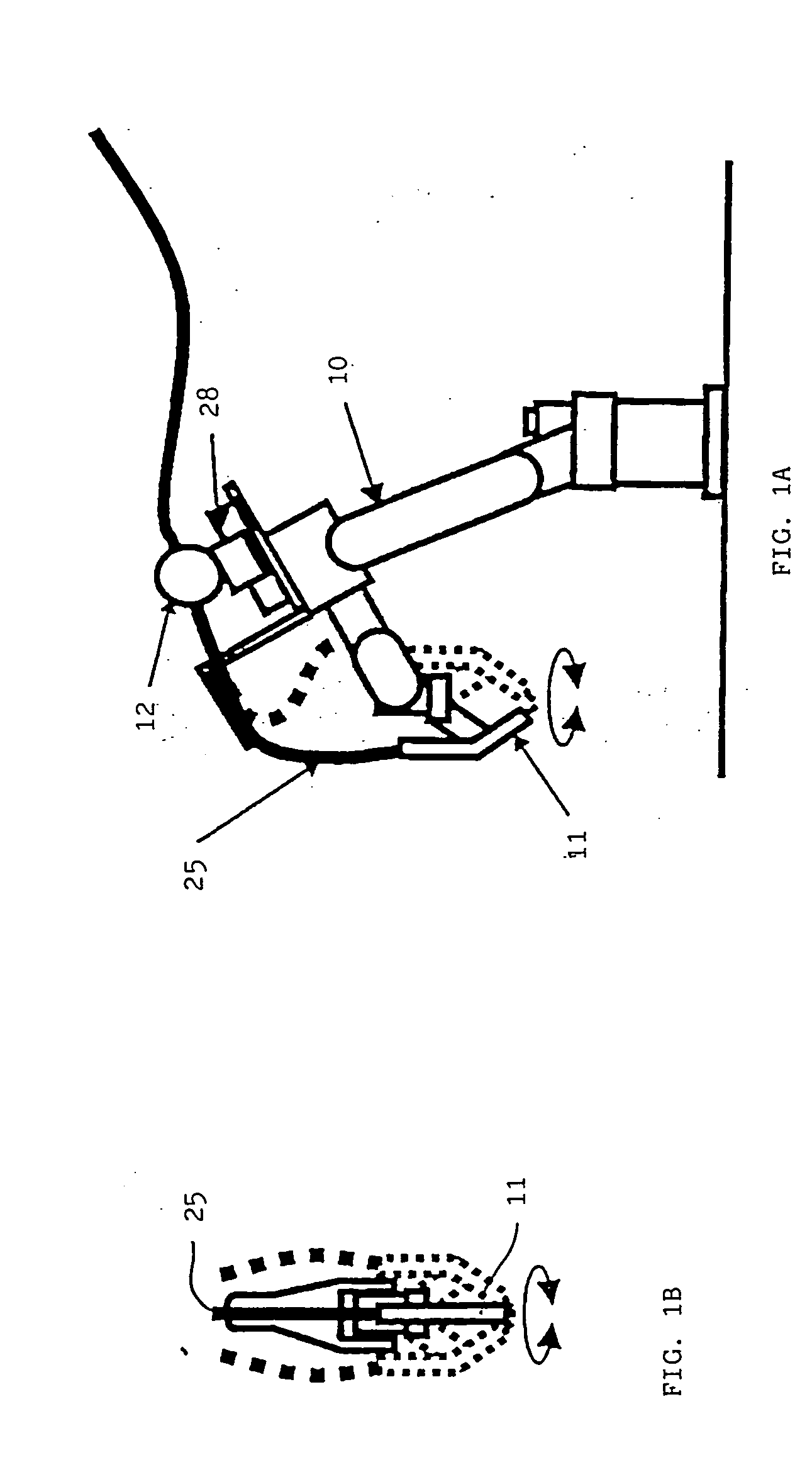

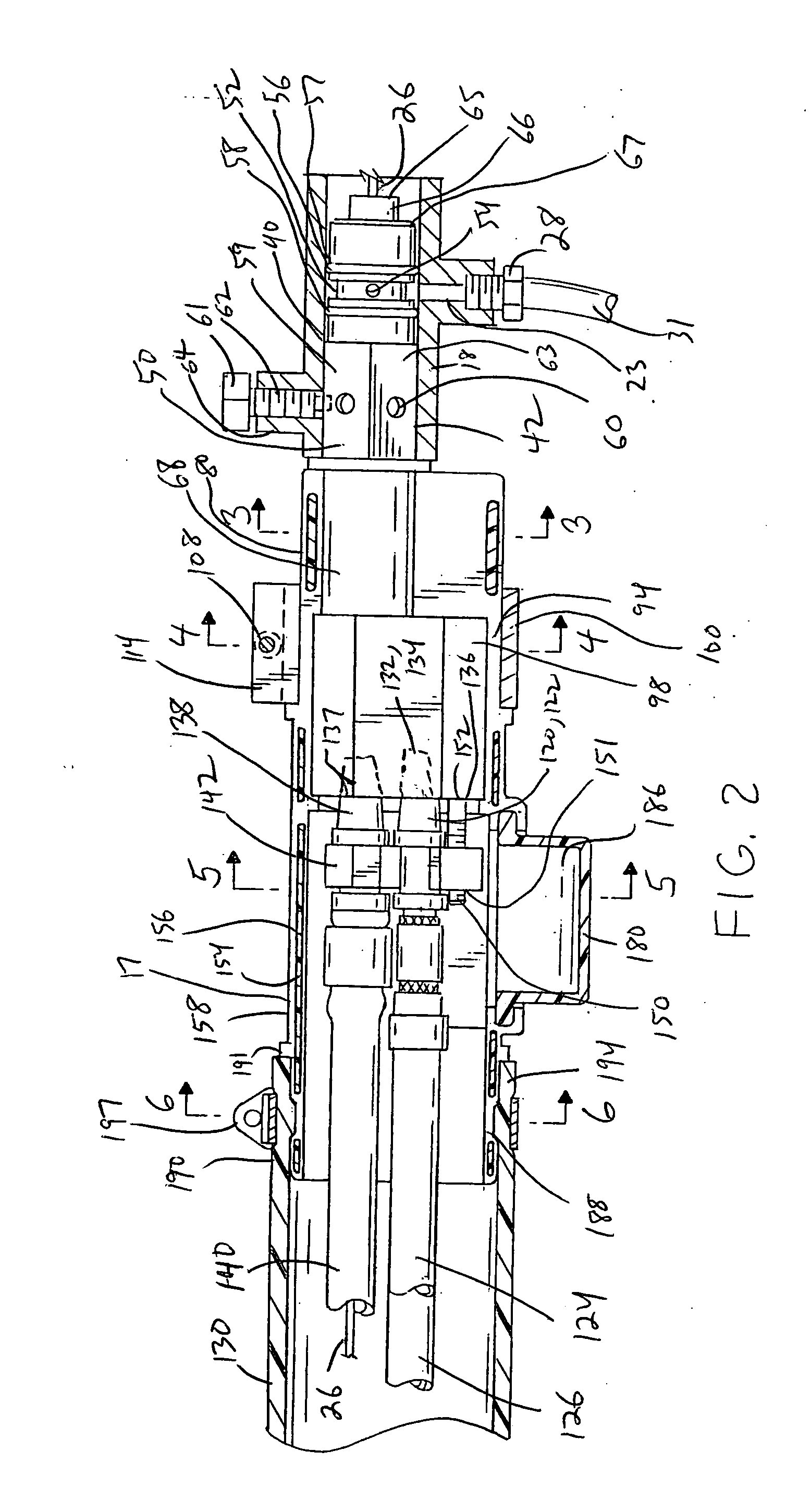

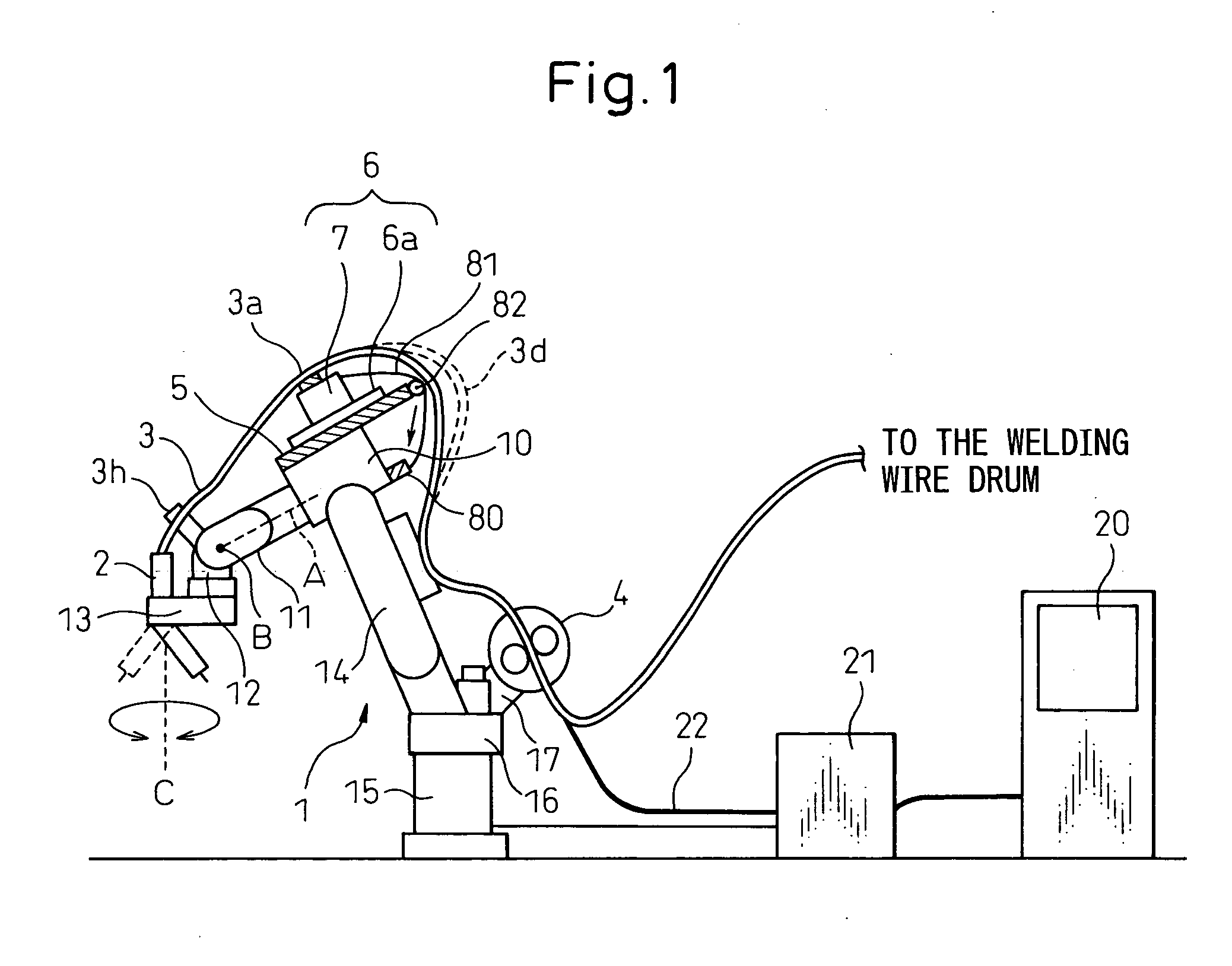

Torch cale accommodating structure of arc welding robot

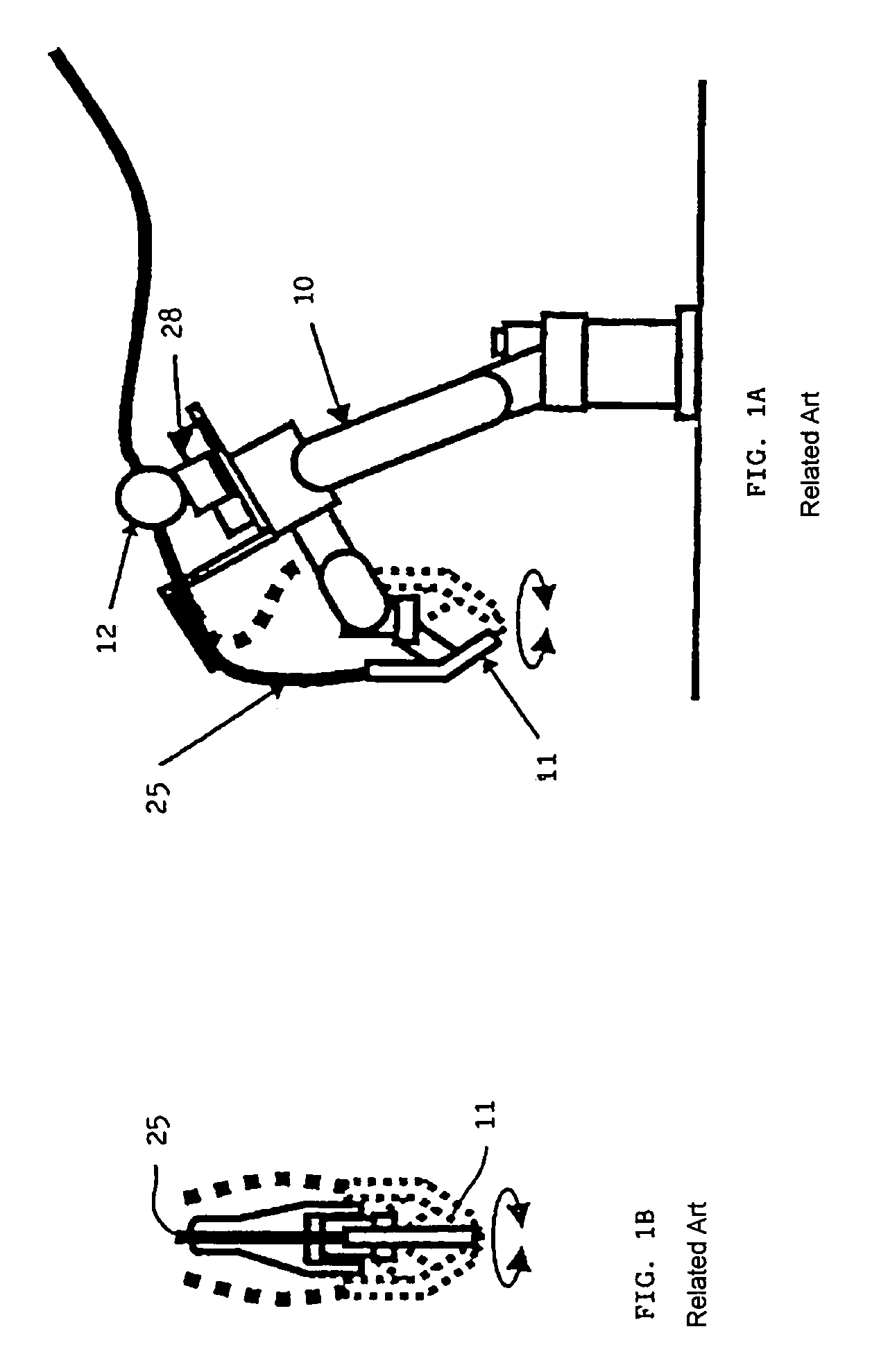

InactiveUS20040144764A1Welding/cutting auxillary devicesCable arrangements between relatively-moving partsReciprocating motionEngineering

A first wrist element is provided at a distal end of a front arm of an arc welding robot rotatably about a first axial line, a second wrist element is provided on the first wrist element rotatably about a second axial line, and a welding torch is supported on the second wrist element about a third axial line. A slide mechanism which can reciprocate in a direction approximately parallel to the first axial line is provided at a proper position from an upper portion of the front arm to an upper portion of the first wrist element and a wire feeding apparatus is mounted on the slide mechanism. By sliding the position of the wire feeding apparatus in response to the attitude of the welding torch, an extending state of the torch cable can be maintained properly.

Owner:FANUC LTD

Integral handle

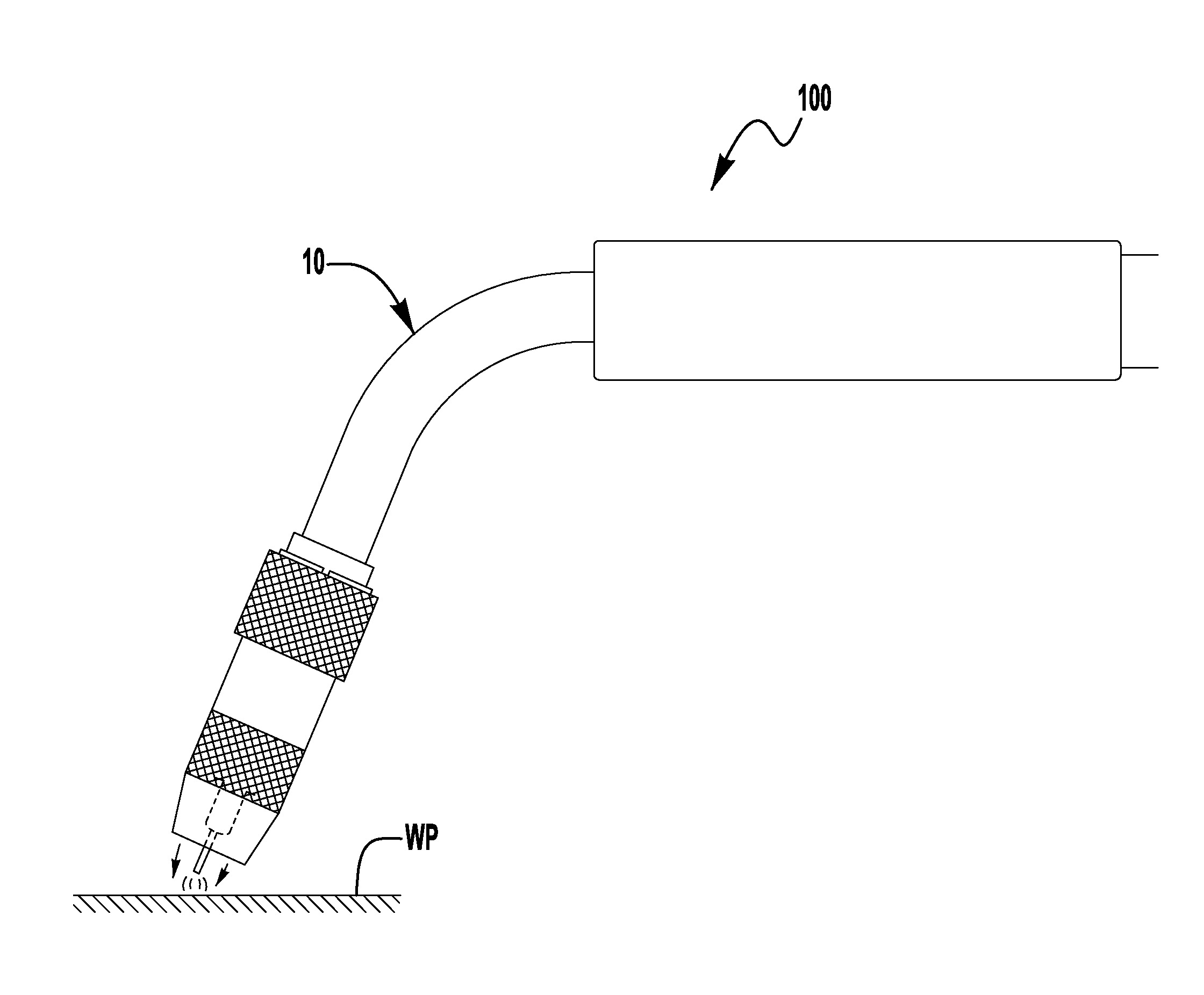

InactiveUS20070108173A1Easy to assemblePrevent kinkingElectrode holder supportersWelding accessoriesEngineeringTorch

A welding gun assembly for directing a welding wire toward a workpiece, having a torch at a forward portion of the gun; a welding wire feeder at a rearward portion of the gun; and handles positioned adjacent the torch and wire feeder. Each handle has a first, cylindrical portion and a second, hexagonally shaped portion adjacent the first, cylindrical portion. The hexagonal portion has a cylindrical opening and a hexagonal opening adjacent the cylindrical opening. The handle further has an extension member having an access opening therein. A conduit is connected to each handle.

Owner:LINCOLN GLOBAL INC

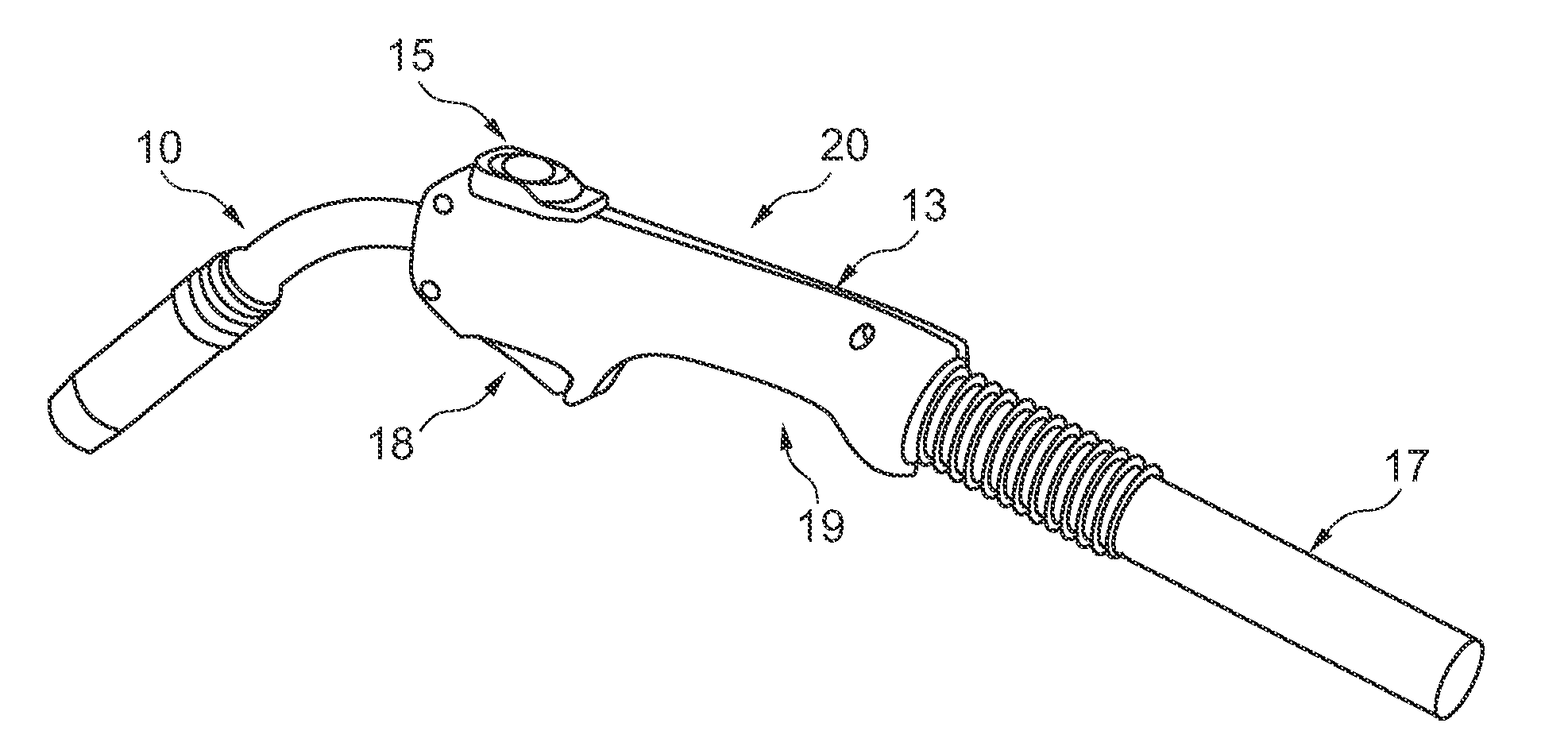

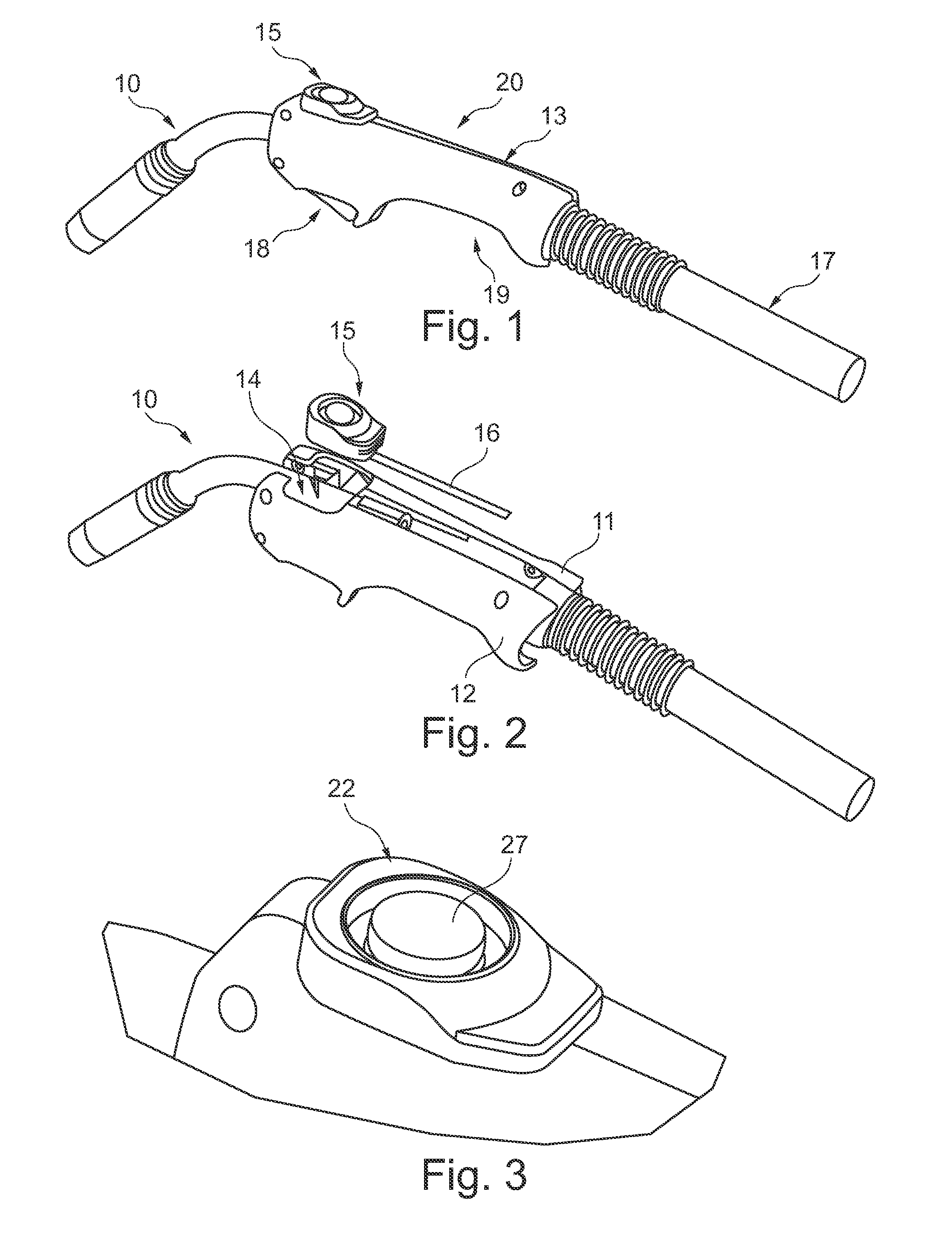

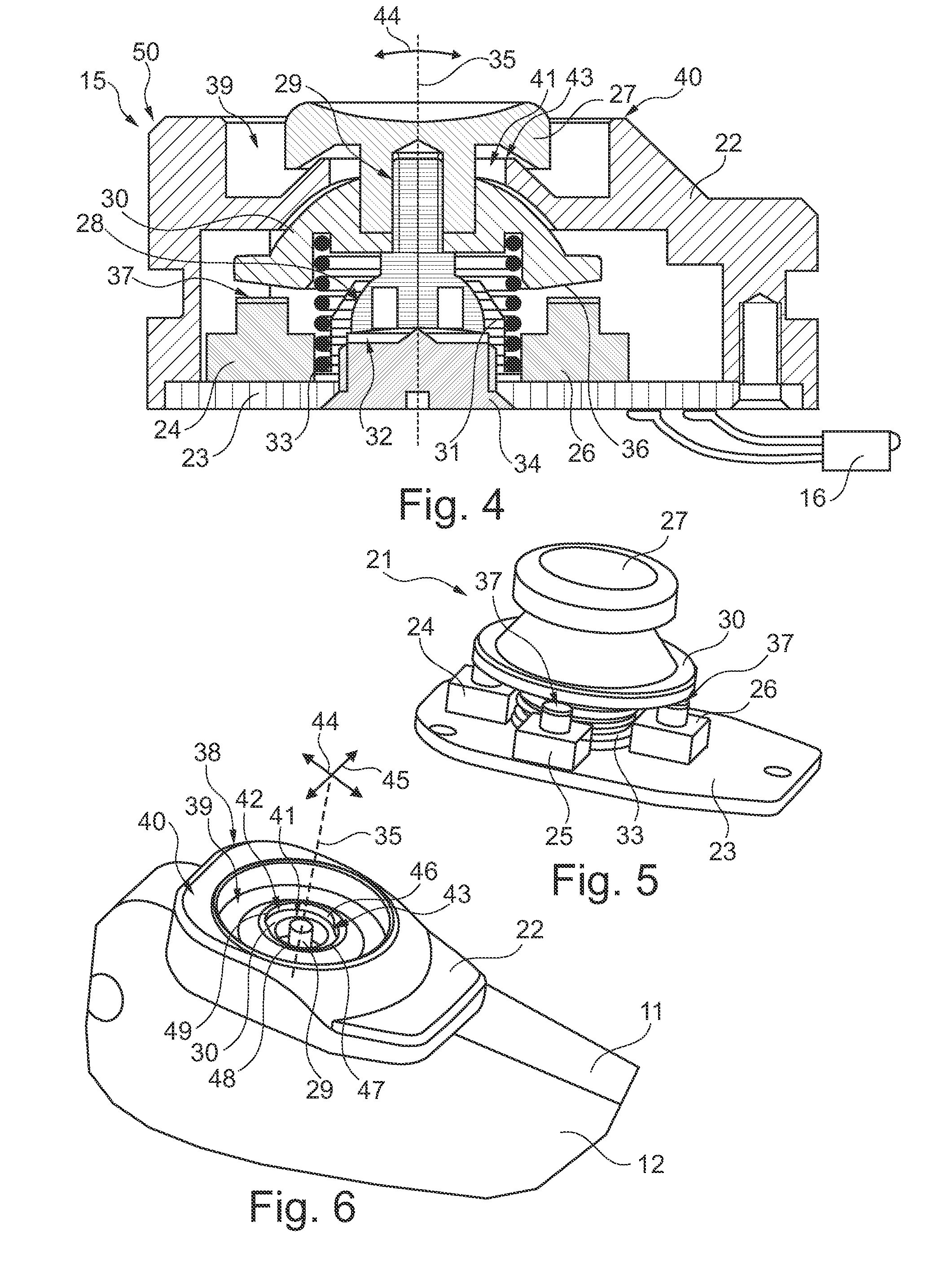

Hand welding torch

InactiveUS20110062131A1Easy to operateNot to damageElectrode holder supportersWelding accessoriesActuatorTwo degrees of freedom

The invention relates to a hand welding torch (10) provided with a switching device (15), wherein the switching device is formed from a switching element and actuators, wherein the switching element is mounted in such a manner that it can move relatively to the actuators, wherein the actuators can be actuated by means of the switching element, and wherein the switching element can be moved in at least two degrees of freedom.

Owner:TBI IND

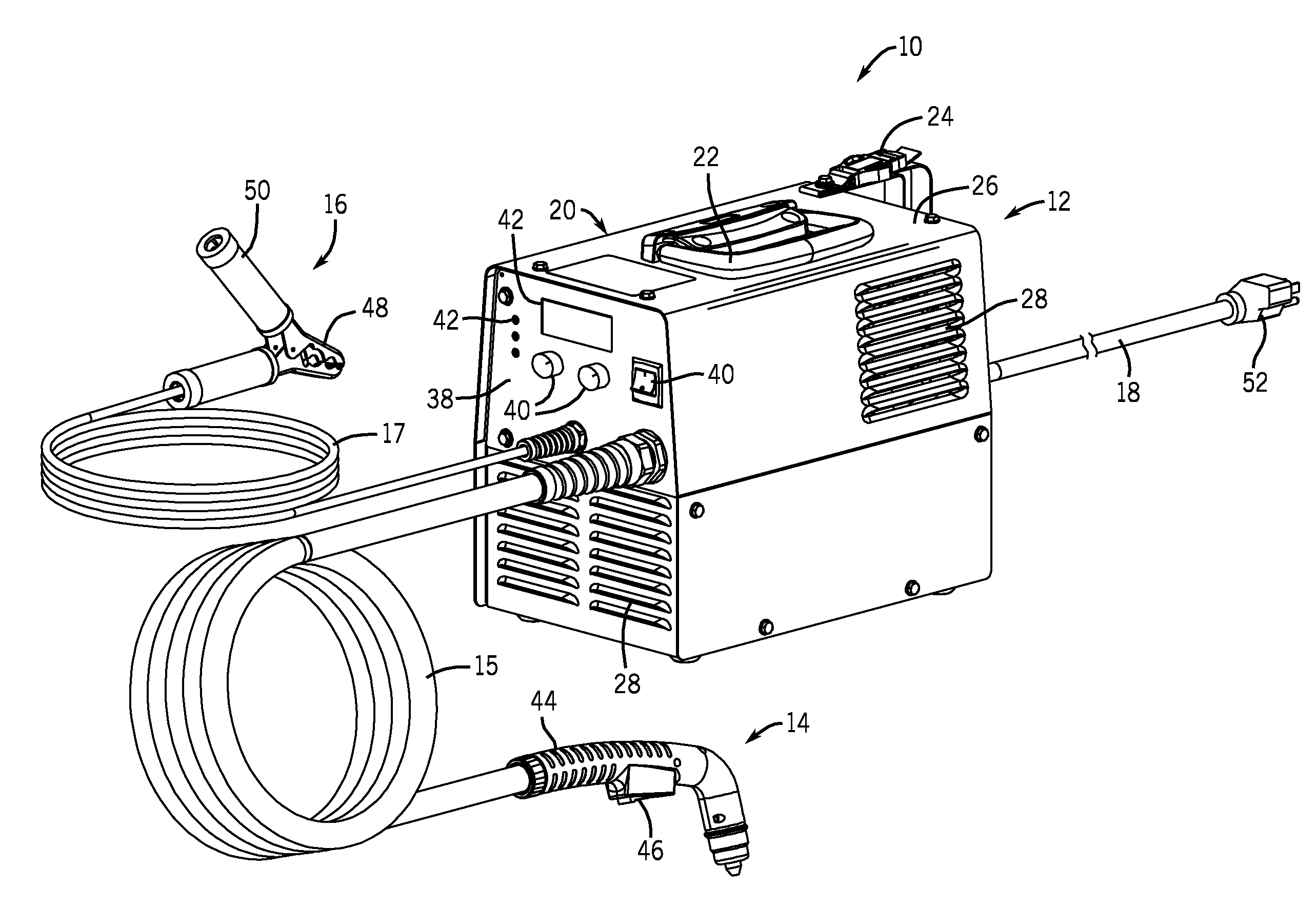

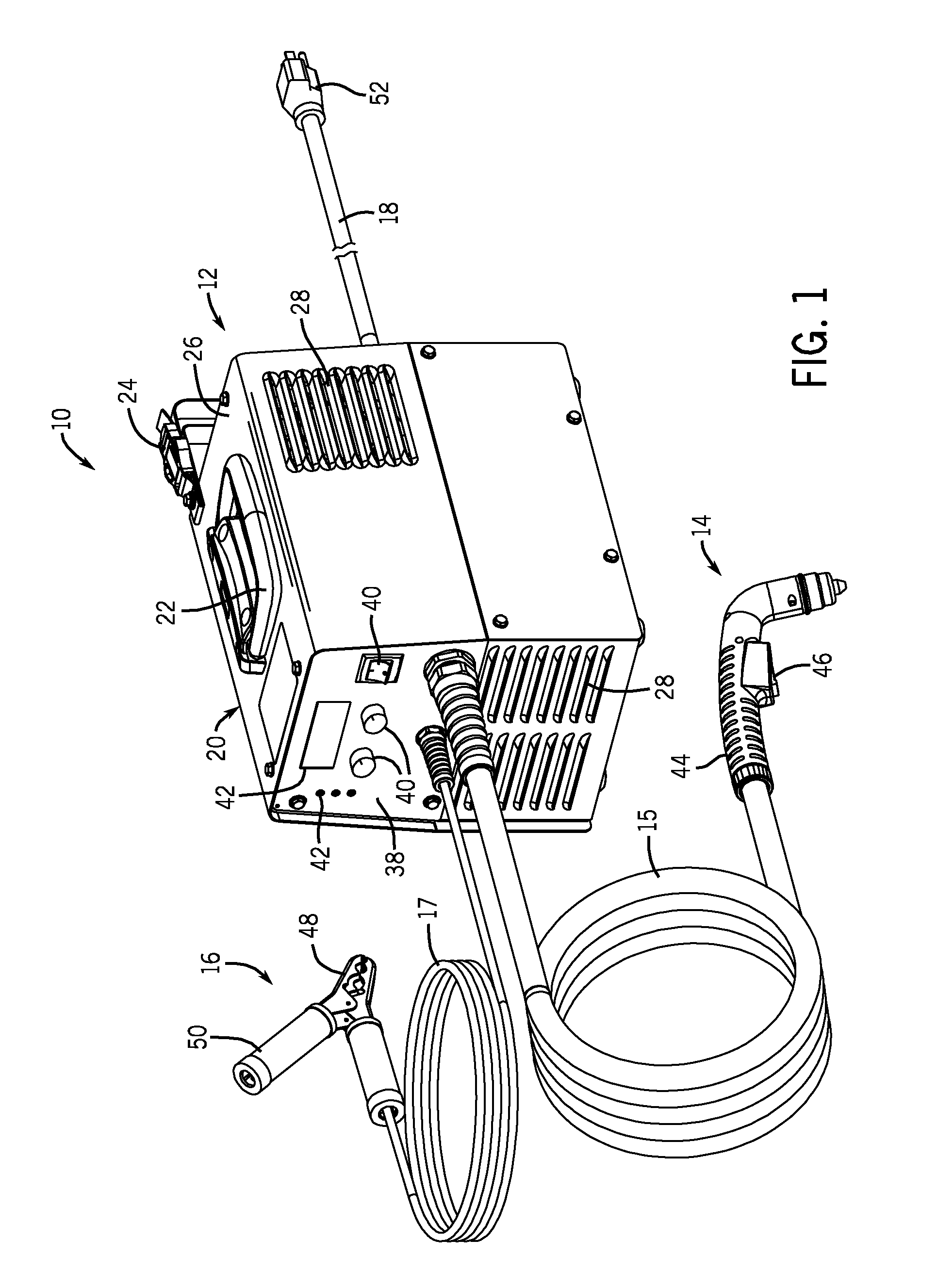

Plasma torch and retaining cap with fast securing threads

A retaining cap for a plasma torch is provided that includes fast securing threads. The retaining cap includes internal threads that couple to external threads of a torch body of the plasma torch. The internal and external threads may be multiple start threads having a thread angle greater than 60°. Plasma torches and plasma cutting systems are also provided.

Owner:ILLINOIS TOOL WORKS INC

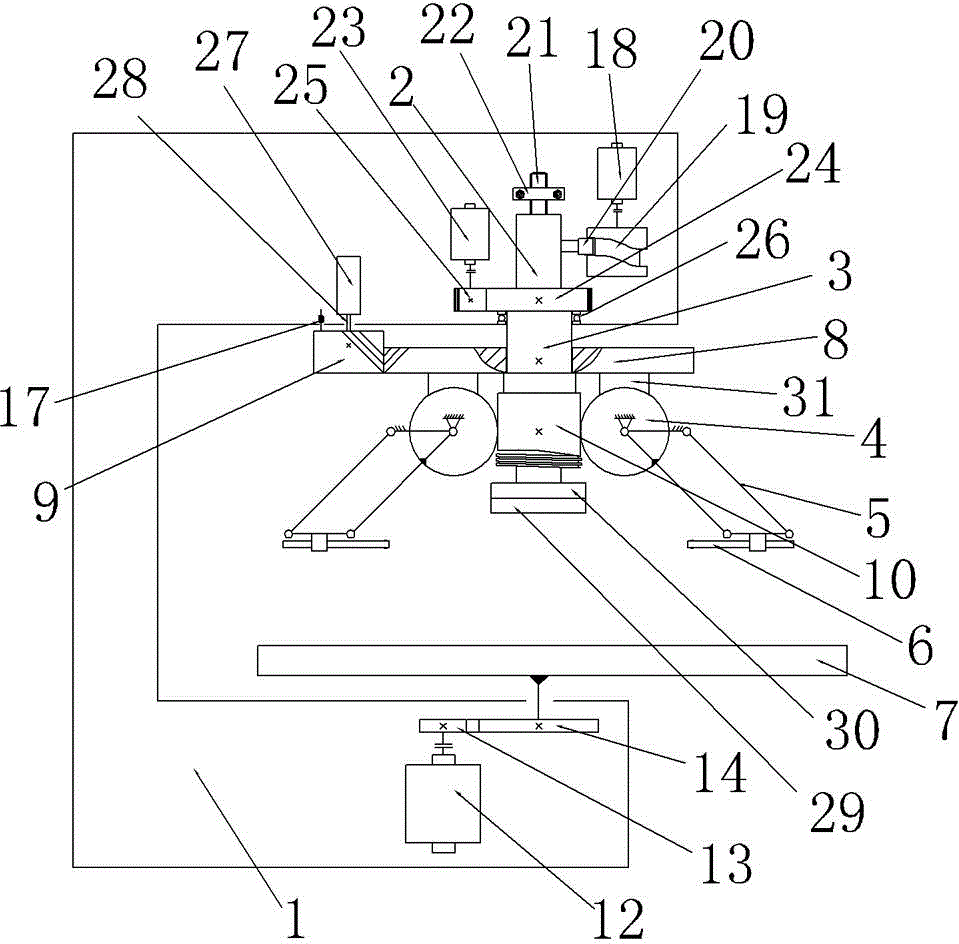

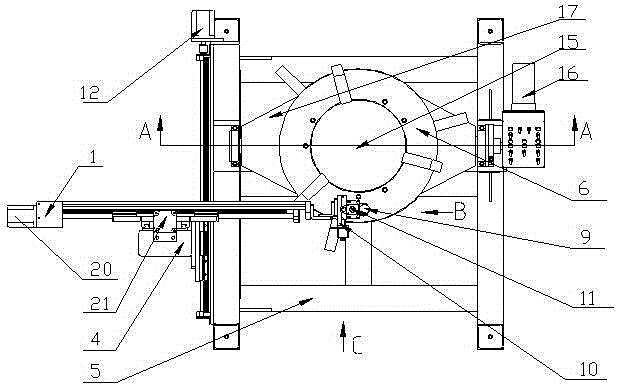

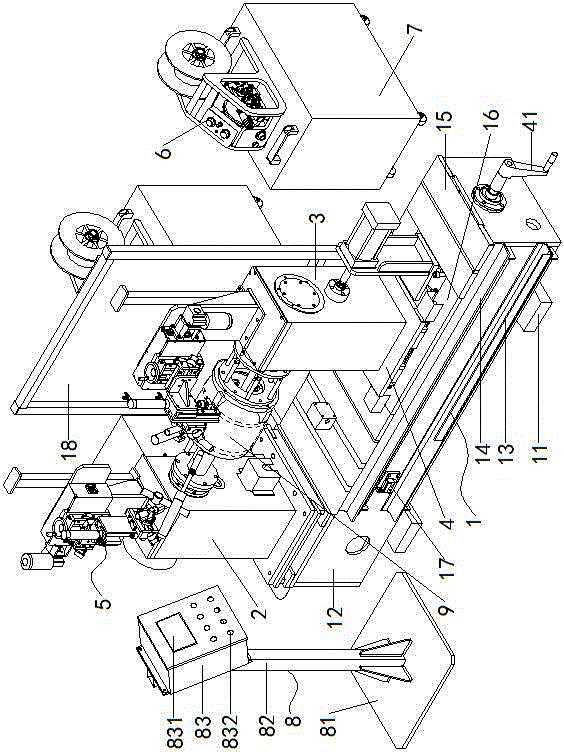

Vertical multi-claw welding machine

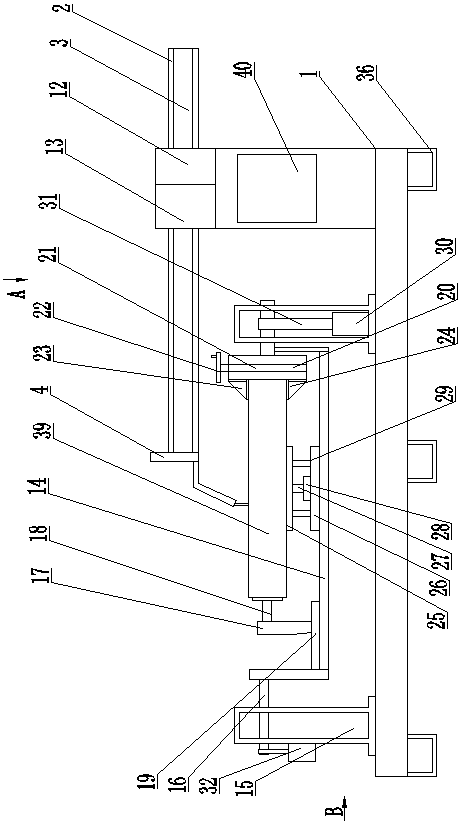

InactiveCN104816069ARealize automatic feedingImprove work efficiencyElectrode holder supportersDomestic vesselsGear wheelBevel gear

The invention relates to welding devices, in particular to a vertical multi-claw welding machine. The vertical multi-claw welding machine comprises a frame, a first power member, a second power member, a third power member, a spindle, a hollow shaft, a worm wheel, a parallelogram link mechanism, welding torches, a rotating plate and an intermittent feeding unit. The first power member drives the spindle to move downwards to firmly fix a workpiece by being matched with a fixing member and a clamping groove. The second power member transmits the workpiece to the hollow shaft, a worm and the worm wheel sequentially, so that the parallelogram link mechanism swings to adjust the distance between the welding torches and portions to be welded, of a steel cylinder. The third power member drives a second bevel gear to move downwards at the same time. A first bevel gear performs circumferential rotational displacement and then drives a plurality of welding torches to rotate circumferentially and move a certain distance, the welding of a section of the circumferential portion to be welded, of the steel cylinder is completed at one time, and the intermittent feeding unit drives the rotating plate to rotate intermittently to feed, so that automatic feeding and one-time welding are achieved actually. The vertical multi-claw welding machine is high in working efficiency, safe, reliable and easy to operate.

Owner:武铭旗

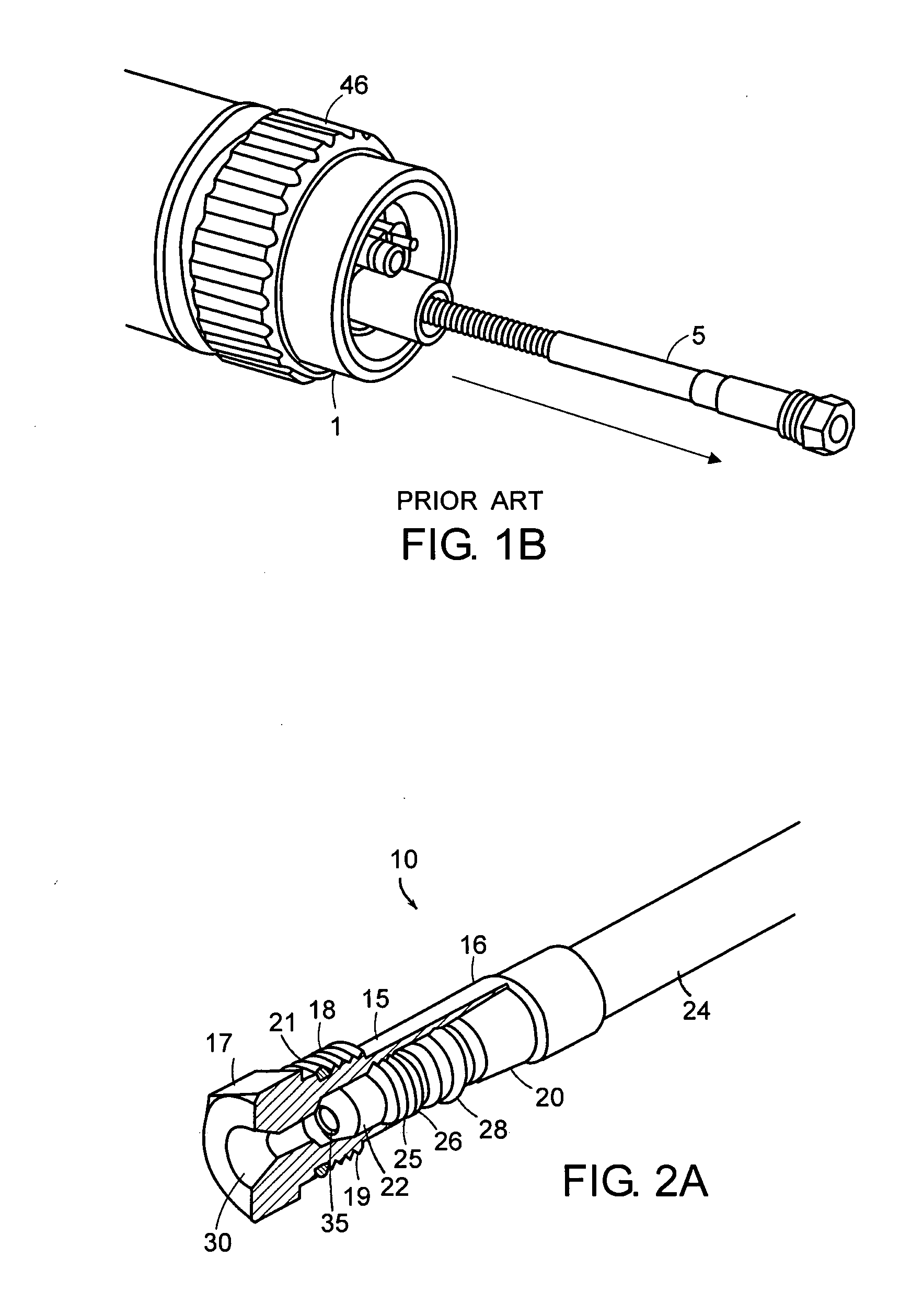

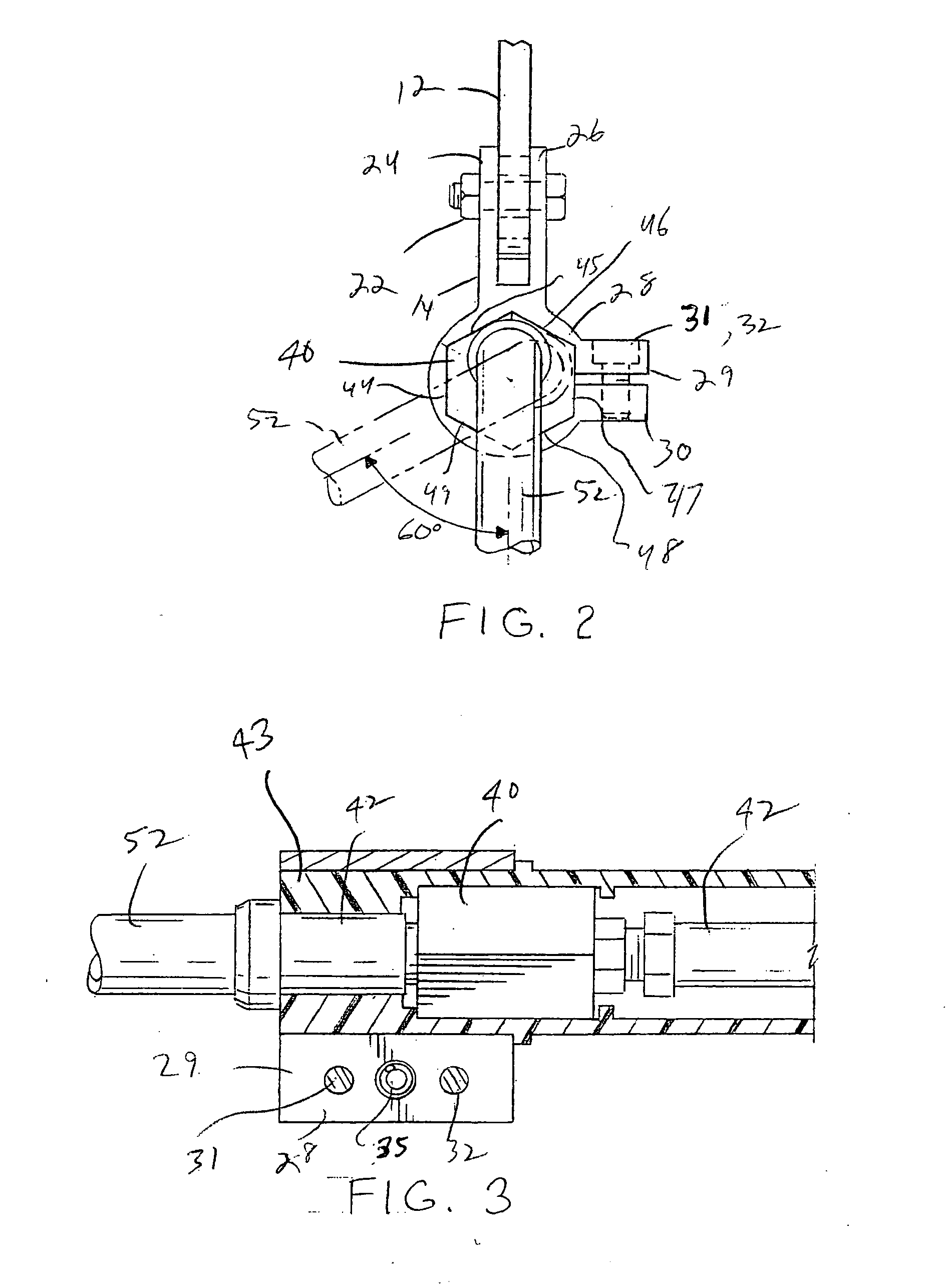

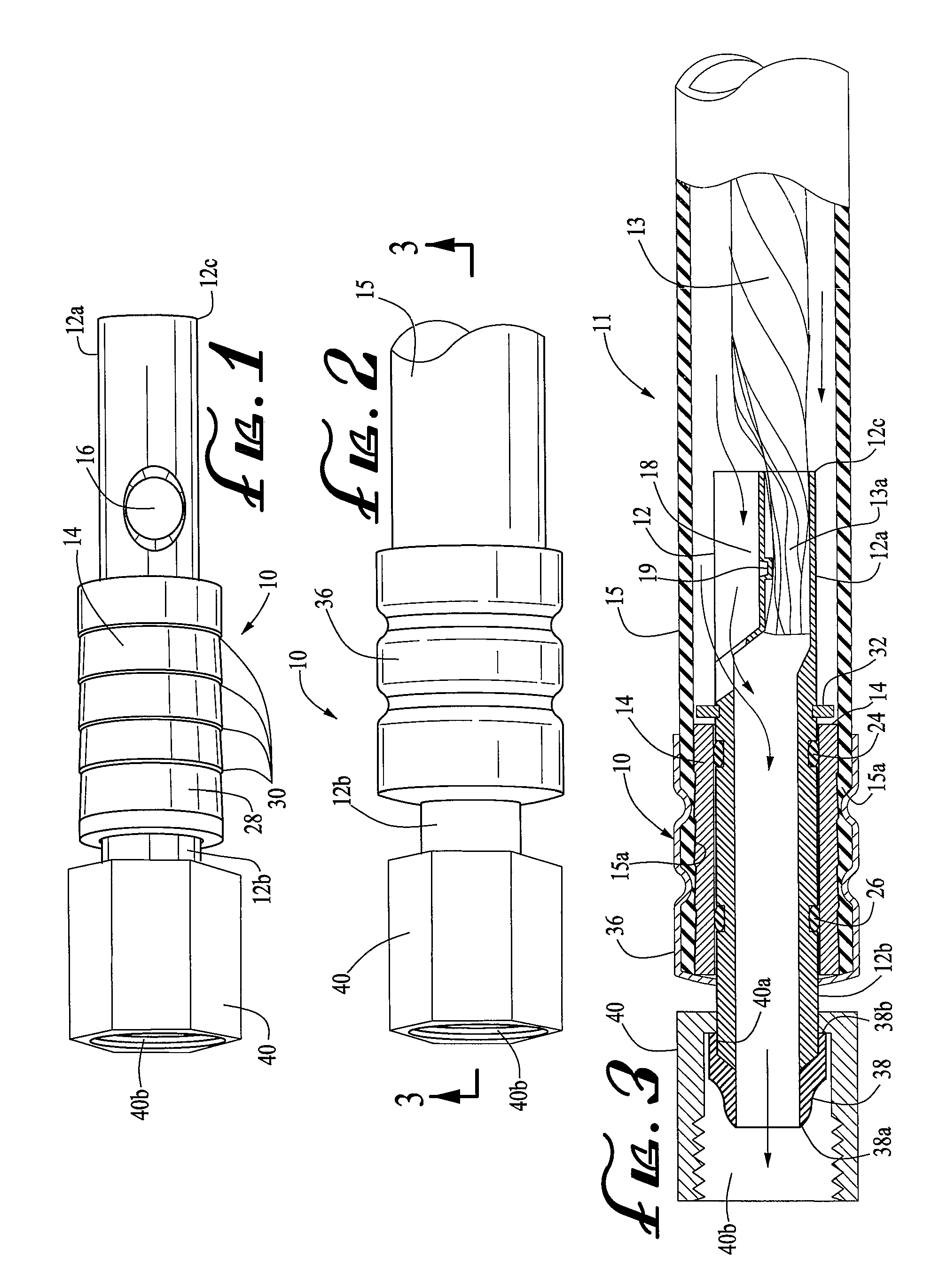

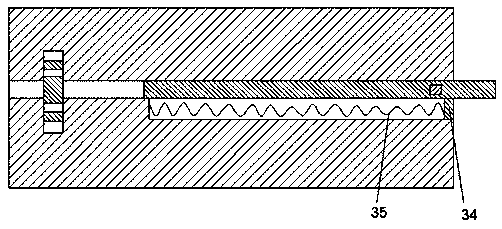

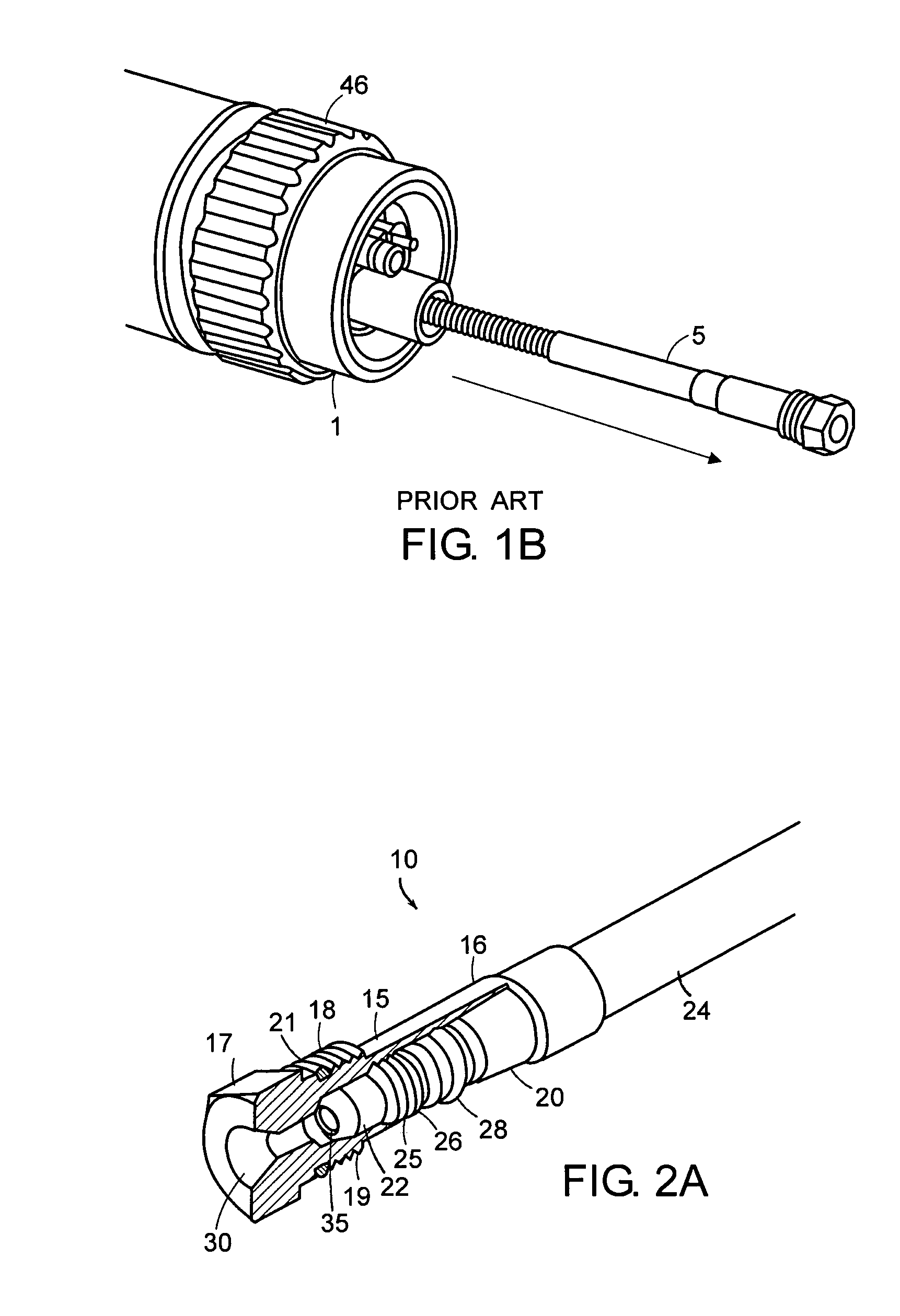

Multi-piece front loading liner

ActiveUS20050072764A1Prevent leakageReduce the possibilityWelding/cutting auxillary devicesElectrode holder supportersEngineeringFront loading

An improved liner for protecting an electrode wire within a body of a welding torch. The liner includes a liner retainer, which is removably coupled to a liner insert. The liner retainer is secured to a distal end of the welding torch and the liner insert is inserted and coupled to the liner retainer through a proximal end of the welding torch.

Owner:ILLINOIS TOOL WORKS INC

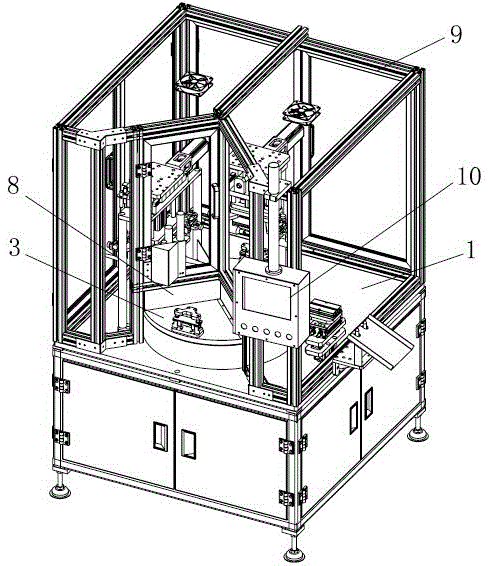

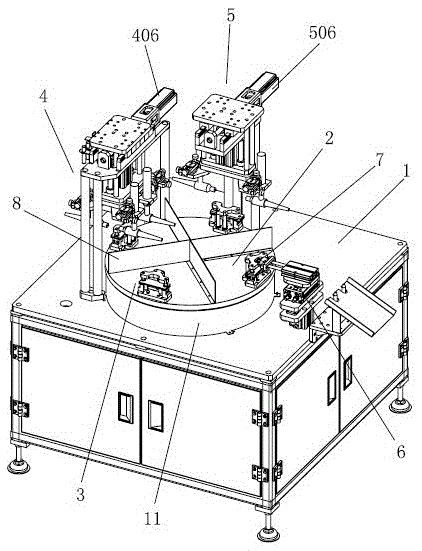

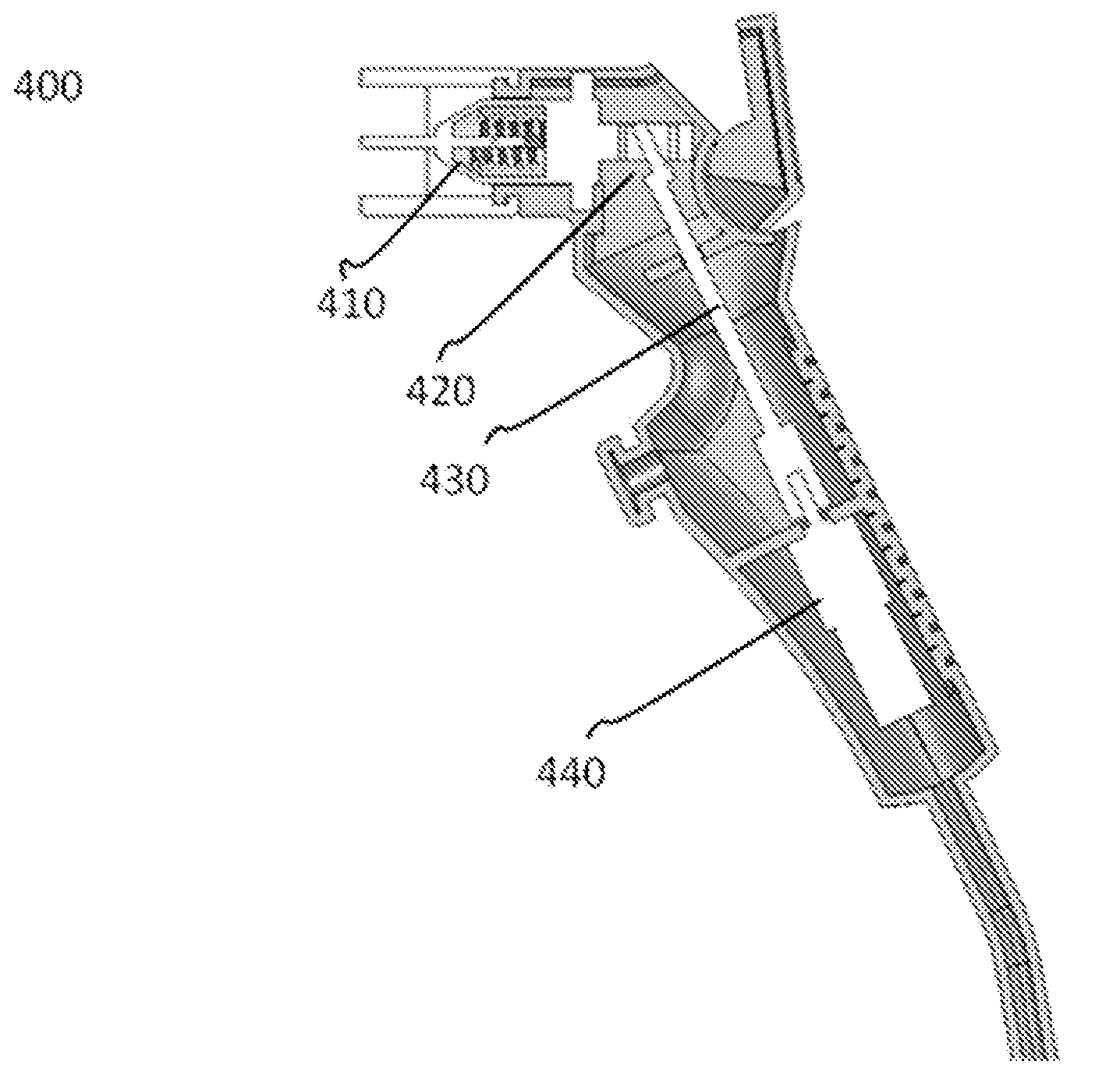

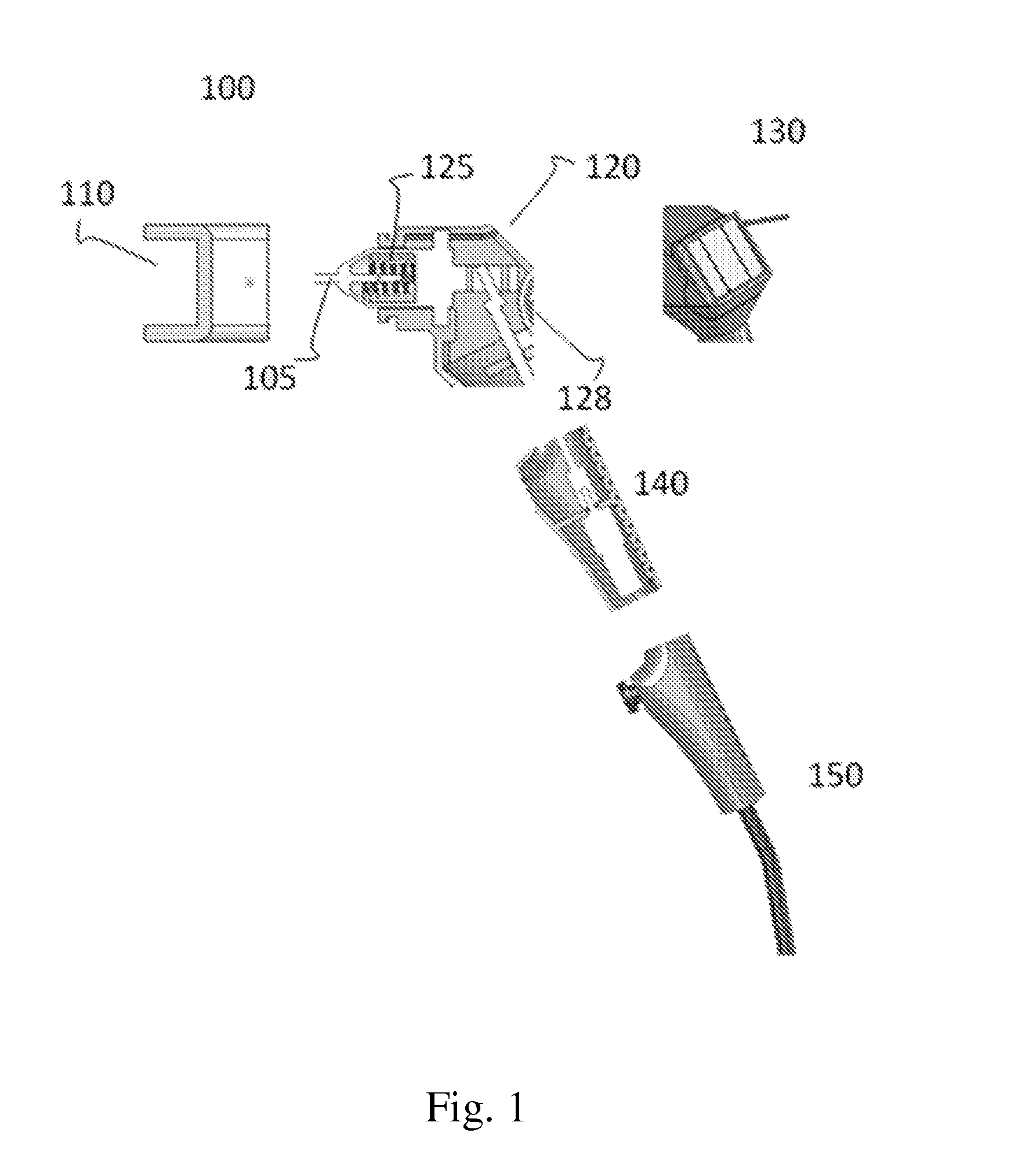

Four-station connecting plate welder

PendingCN105618894AReduce manufacturing costIncrease productivityWelding/cutting auxillary devicesElectrode holder supportersRotary stageCam

The technical scheme of the invention is to disclose a four-station connecting plate welder. The four-station connecting plate welder comprises a worktable; a rotary table is arranged on the upper surface of the worktable; a feeding part, a first welding part, a second welding part and a discharging part are arranged at uniform angle on the worktable at the outer side of the rotary table; the lower part of the center of the rotary table is connected with a cam indexer; the upper surface, close to the edge, of the rotary table is provided with a work piece clamping part; the work piece clamping part comprises a lower positioning part and an upper pressing part. The four-station connecting plate welder disclosed by the invention is low in manufacturing cost, high in production efficiency, good in equipment flexibility, capable of directly regulating the welding stroke and replacing a tool clamp on the equipment according to product requirements of different specifications and models so as to realize production, and suitable for large-scale production of different types of products.

Owner:CHANGYING XINZHI TECH CO LTD

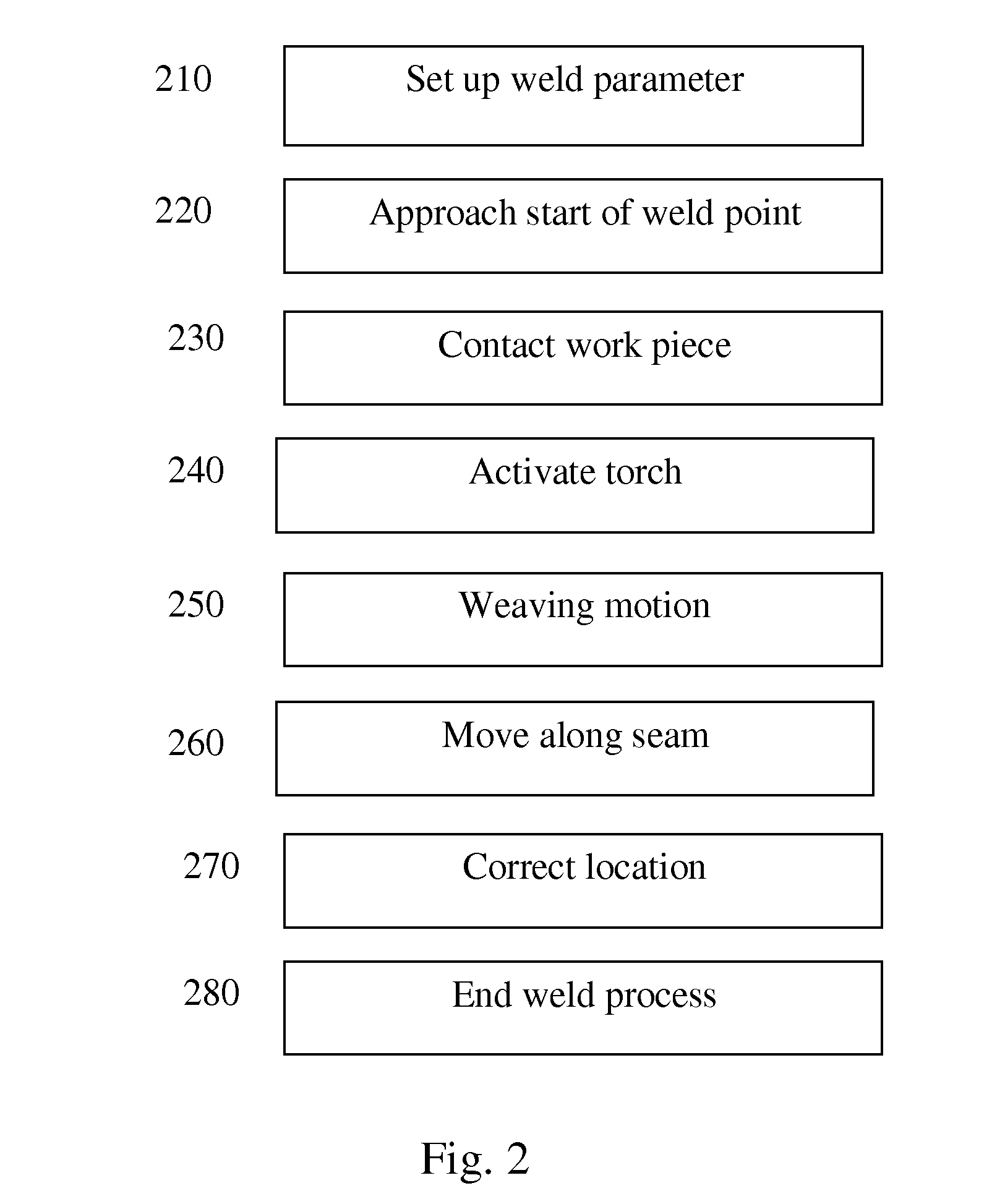

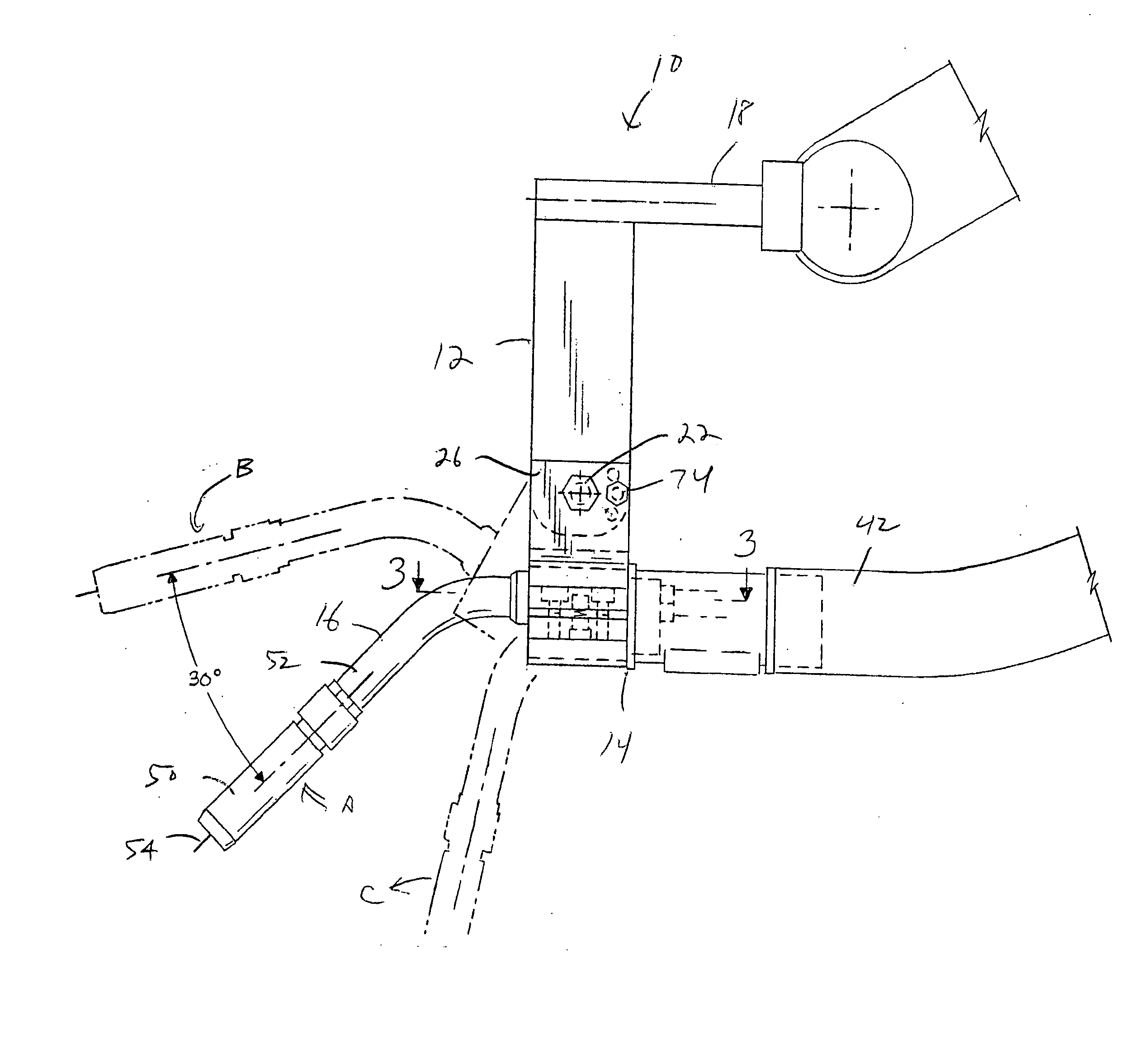

System and method for manual seam tracking during welding and welding assistance system

A system for improved manual welding is provided. The system includes a novel nozzle for maintaining fixed electrode-work piece distance, sensors such as optical, temperature, ultrasound and the like for providing feedback on weld quality, and indicators such as a video screen indicating actual vs. desired weld characteristics (such as speed, size, position, and the like). Furthermore actuators in the device allow for control over movement either perpendicular to the weld seam, parallel to it, or both. For example an eccentric axis allows for automation of the welding weave motion.

Owner:WELDOBOT

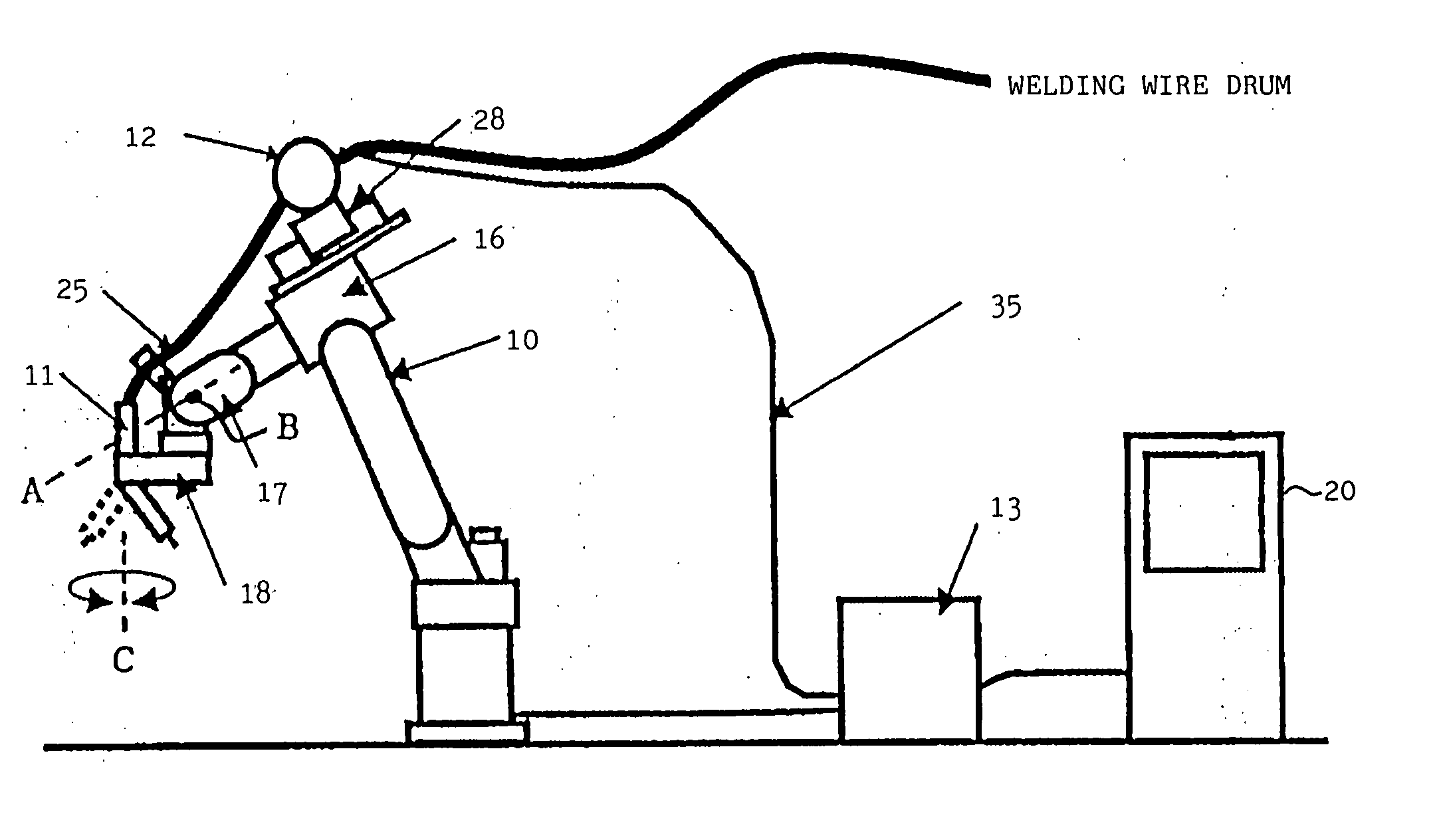

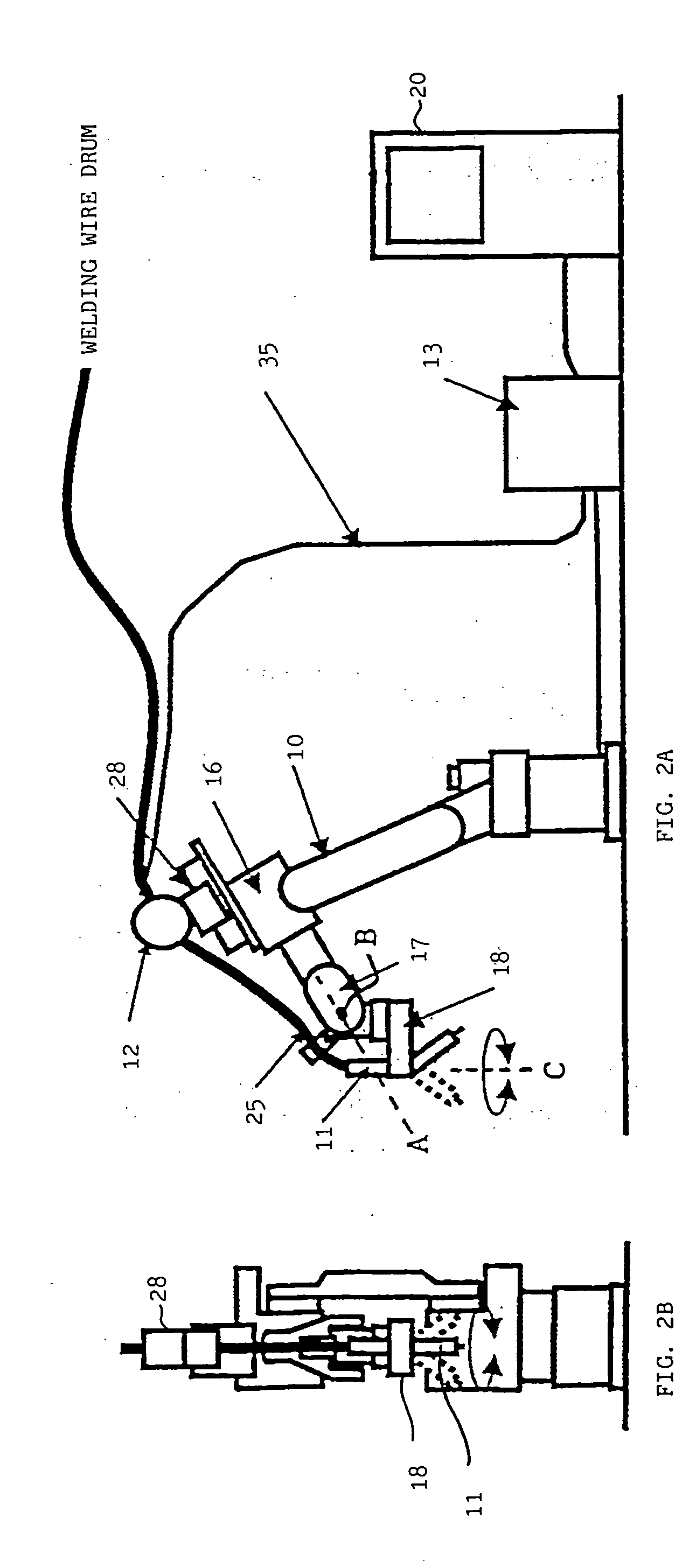

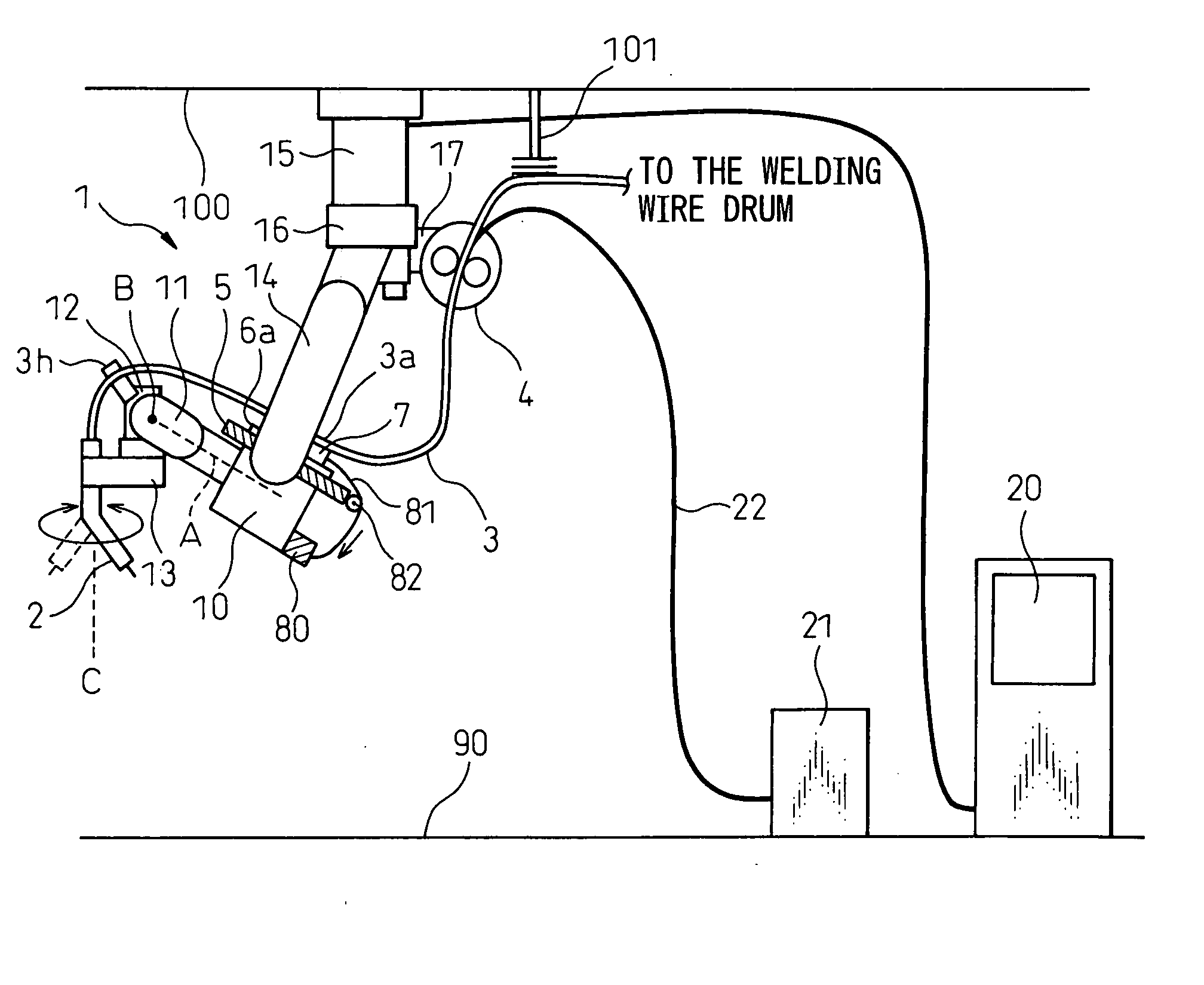

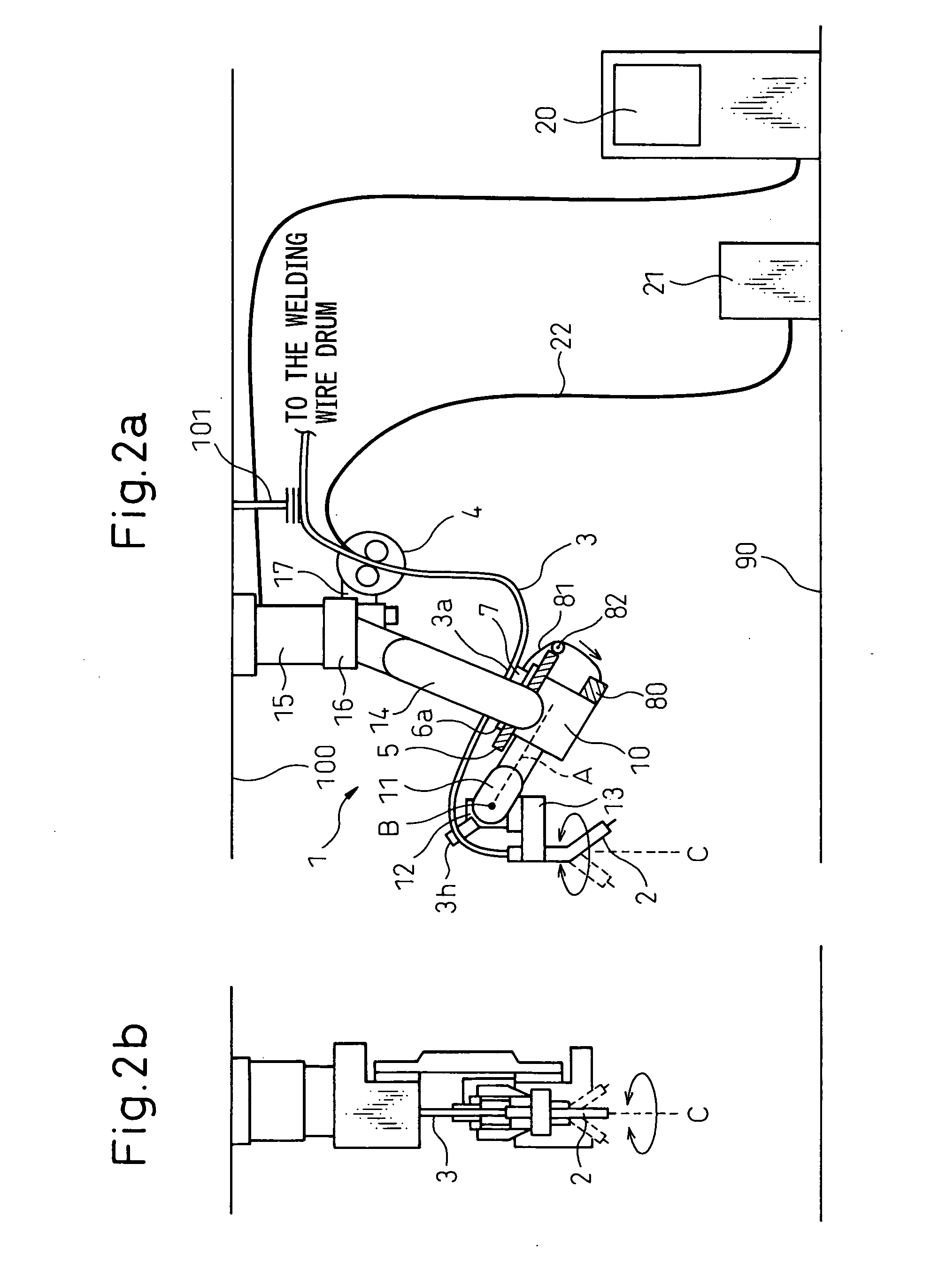

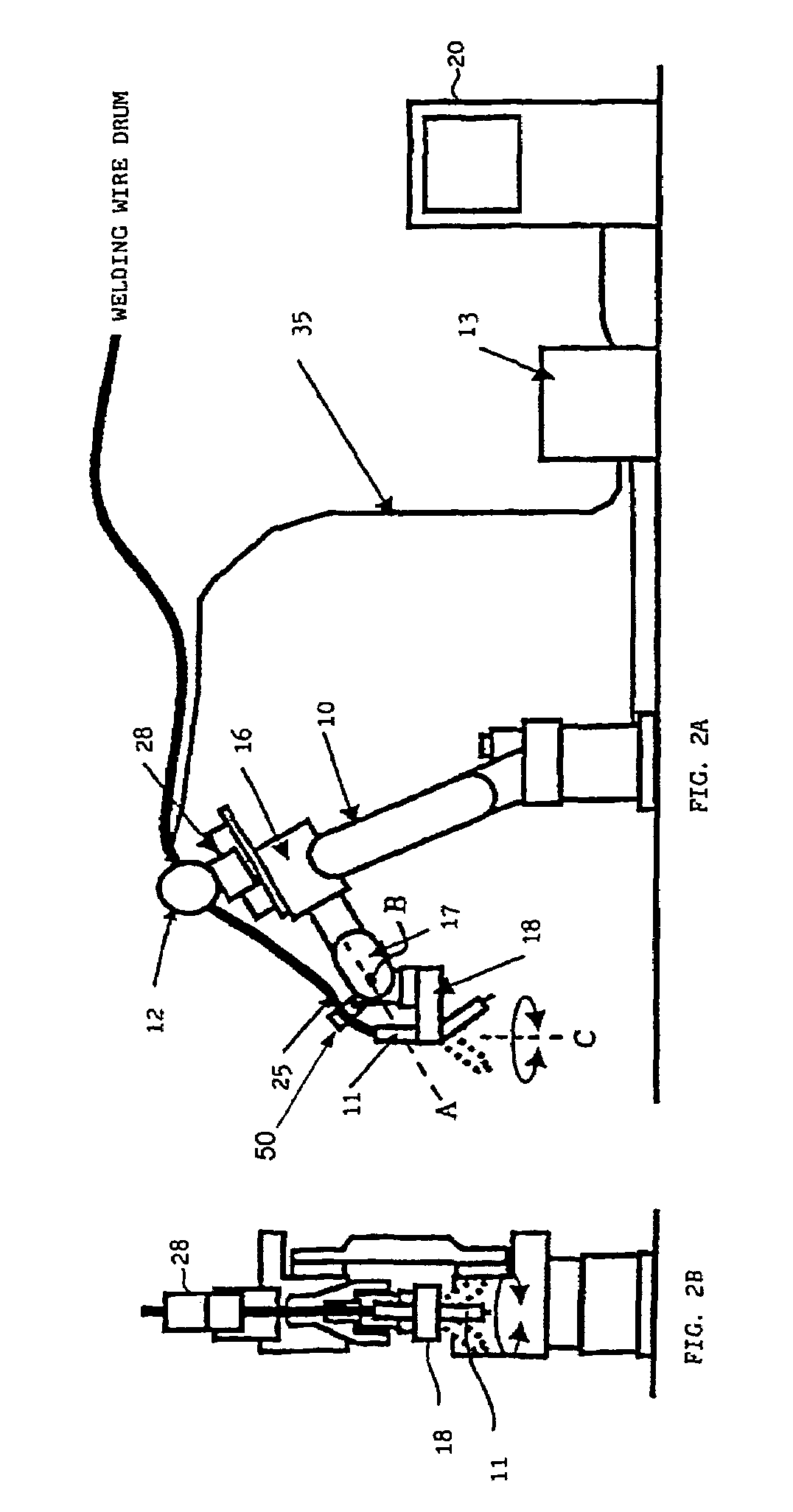

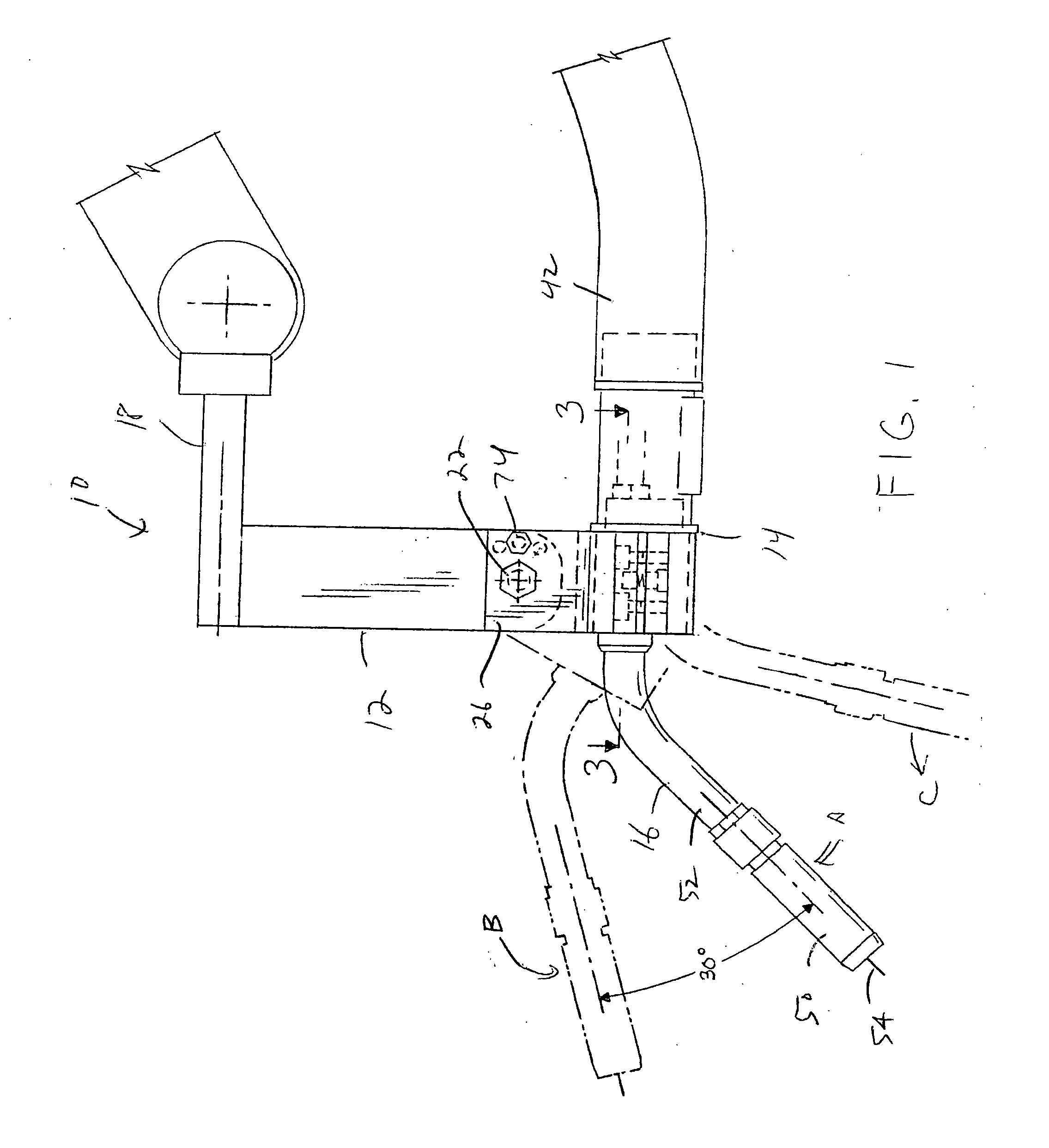

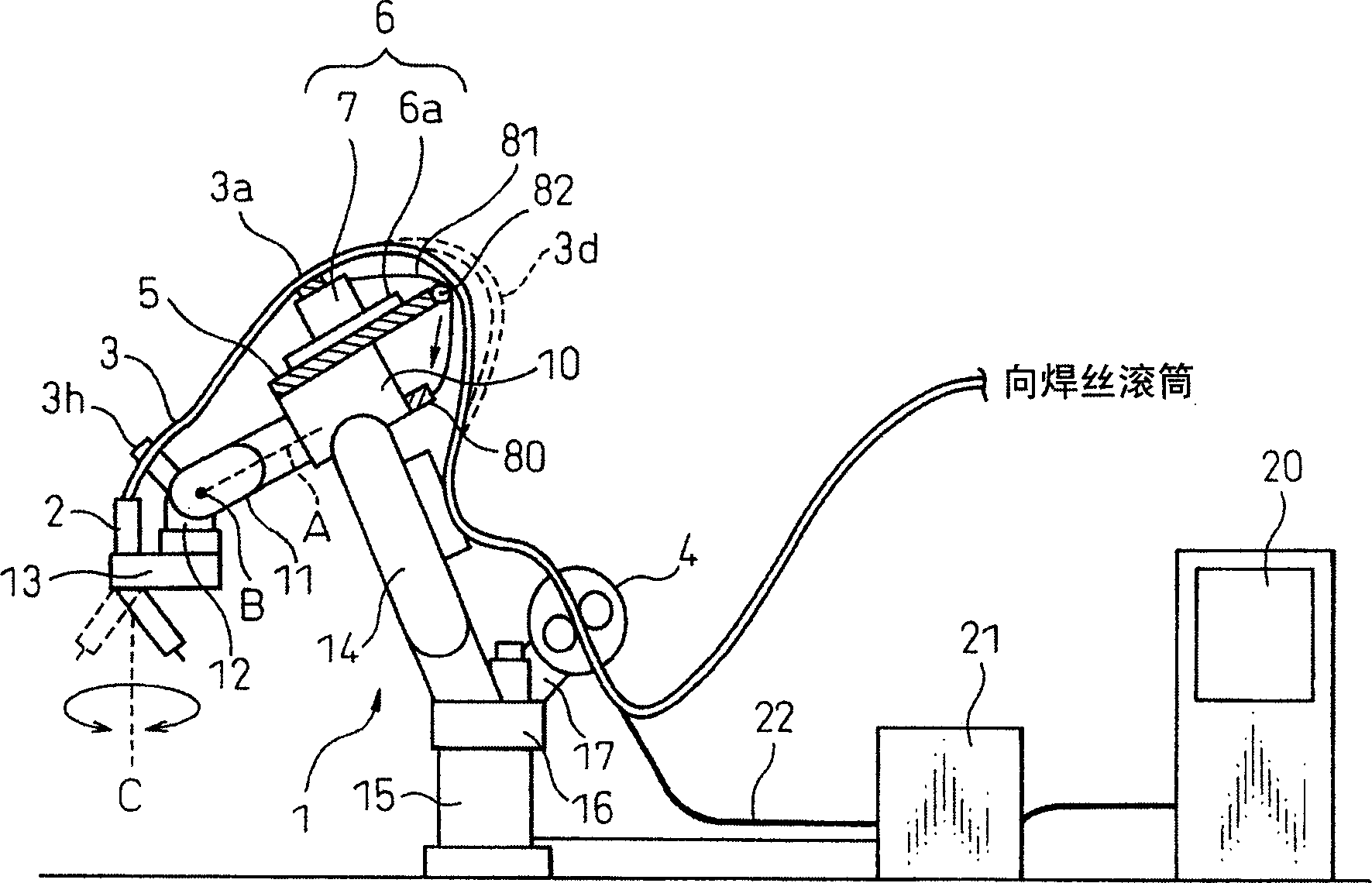

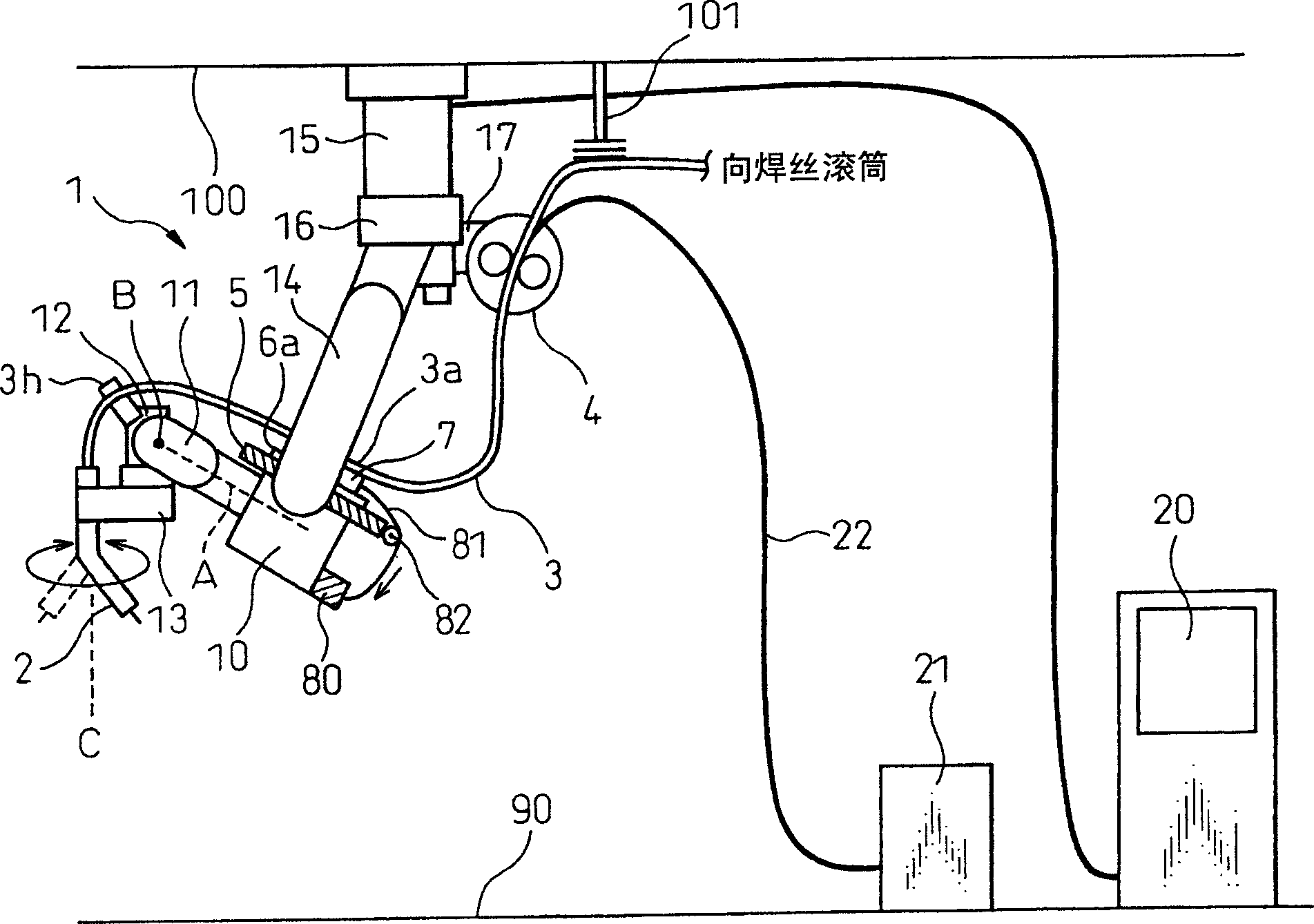

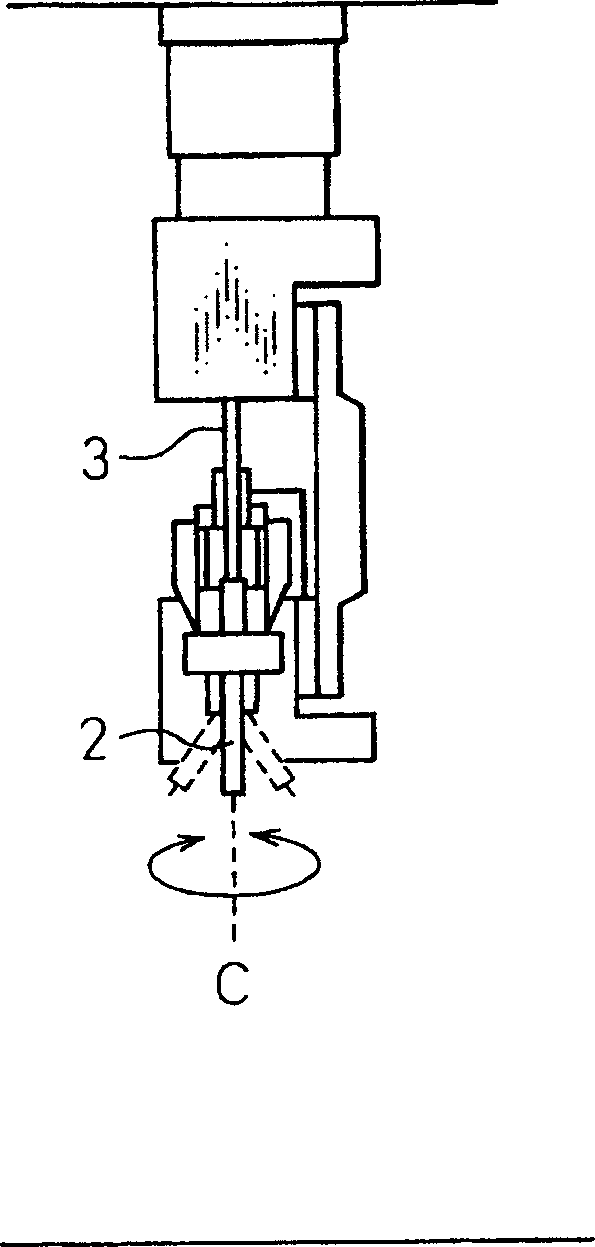

Structure for treating torch cable for arc welding robot

InactiveUS20060049159A1Stable deliveryEconomical to useProgramme-controlled manipulatorWelding/cutting auxillary devicesElectric cablesWelding torch

A robot base 15 is installed on a ceiling 100, and a first wrist element 11 is attached to a front arm base 10 to be rotatable about a first axis A. A second wrist element 12 is attached to the first wrist element 11 to be rotatable about a second axis B, and a welding torch 2 is supported via a transmission mechanism 13 to be rotatable about an offset axis C. The welding torch 2 is attached so that a tip end thereof is directed downward in the illustrated posture of the robot. A linear guide 6a and a slider 7 are provided via a support base 5, and an intermediate portion of a torch cable 3 (or a welding wire delivery device 4) is fixed thereto to draw a tensioning device 80. Such a structure is applicable to a wall-hanging type robot. Thereby, a structure for treating a torch cable is realized in an arc welding robot of a ceiling-suspension type / a wall-hanging type, capable of maintaining the behavior of the torch cable in a stable state as well as minimizing the interference of the torch cable with other objects.

Owner:FANUC LTD

Torch cable accommodating structure of arc welding robot

InactiveUS7105771B2Stable welding wire feedingSuppress interferenceWelding/cutting auxillary devicesCable arrangements between relatively-moving partsReciprocating motionWelding torch

A first wrist element is provided at a distal end of a front arm of an arc welding robot rotatably about a first axial line, a second wrist element is provided on the first wrist element rotatably about a second axial line, and a welding torch is supported on the second wrist element about a third axial line. A slide mechanism which can reciprocate in a direction approximately parallel to the first axial line is provided at a proper position from an upper portion of the front arm to an upper portion of the first wrist element and a wire feeding apparatus is mounted on the slide mechanism. By sliding the position of the wire feeding apparatus in response to the attitude of the welding torch, an extending state of the torch cable can be maintained properly.

Owner:FANUC LTD

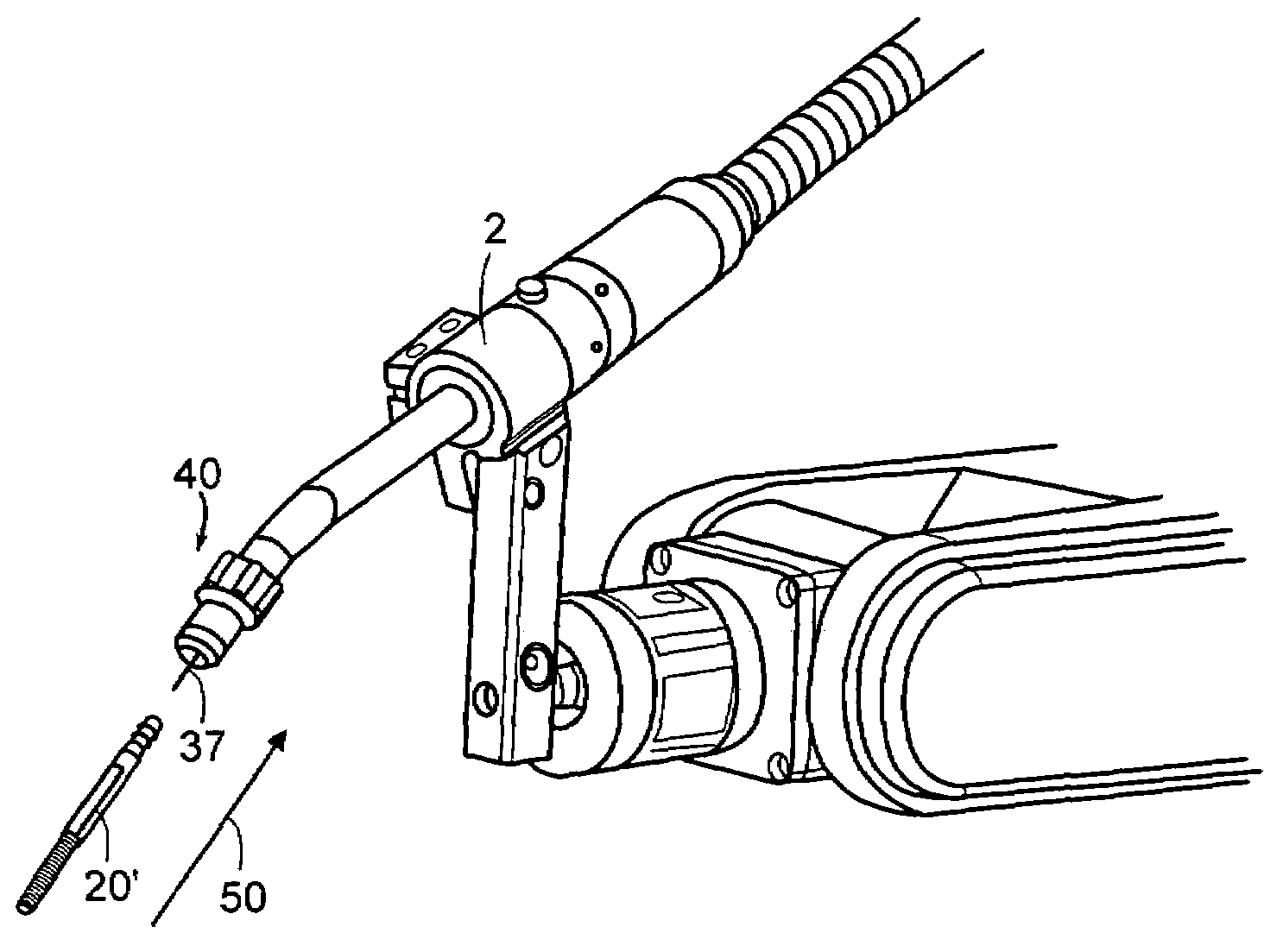

Hex mount for welding torch

InactiveUS20070007264A1Change positionDown timeElectrode holder supportersMechanical engineeringWelding torch

A mounting apparatus for a welding torch has a bracket having a body with an opening therein and first and second arms extending from the body. The opening of the body is hex-shaped and adapted to enable an associated welding torch to be mounted in various positions. A mounting arm has a first opening therethrough and is received between the first and second arms. Openings of the first and second arms align with one of a second, third or fourth opening of mounting arm and the bracket is secured into a raised, lowered or level position.

Owner:LINCOLN GLOBAL INC

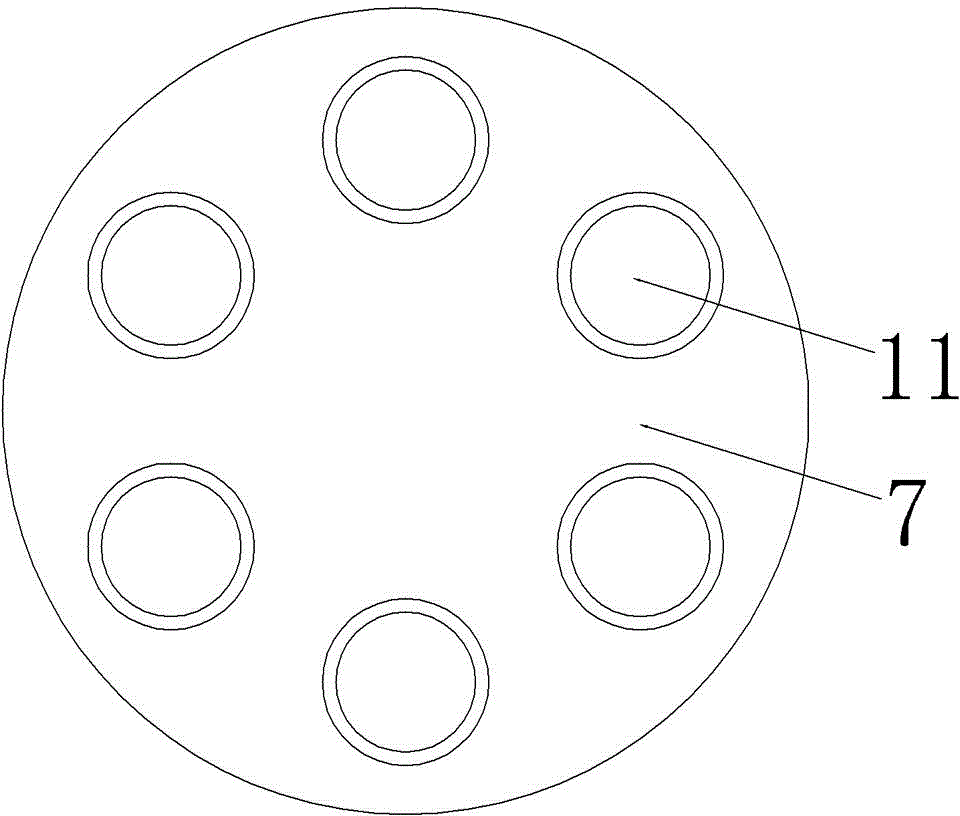

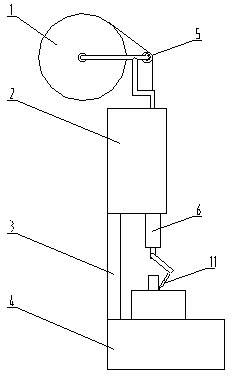

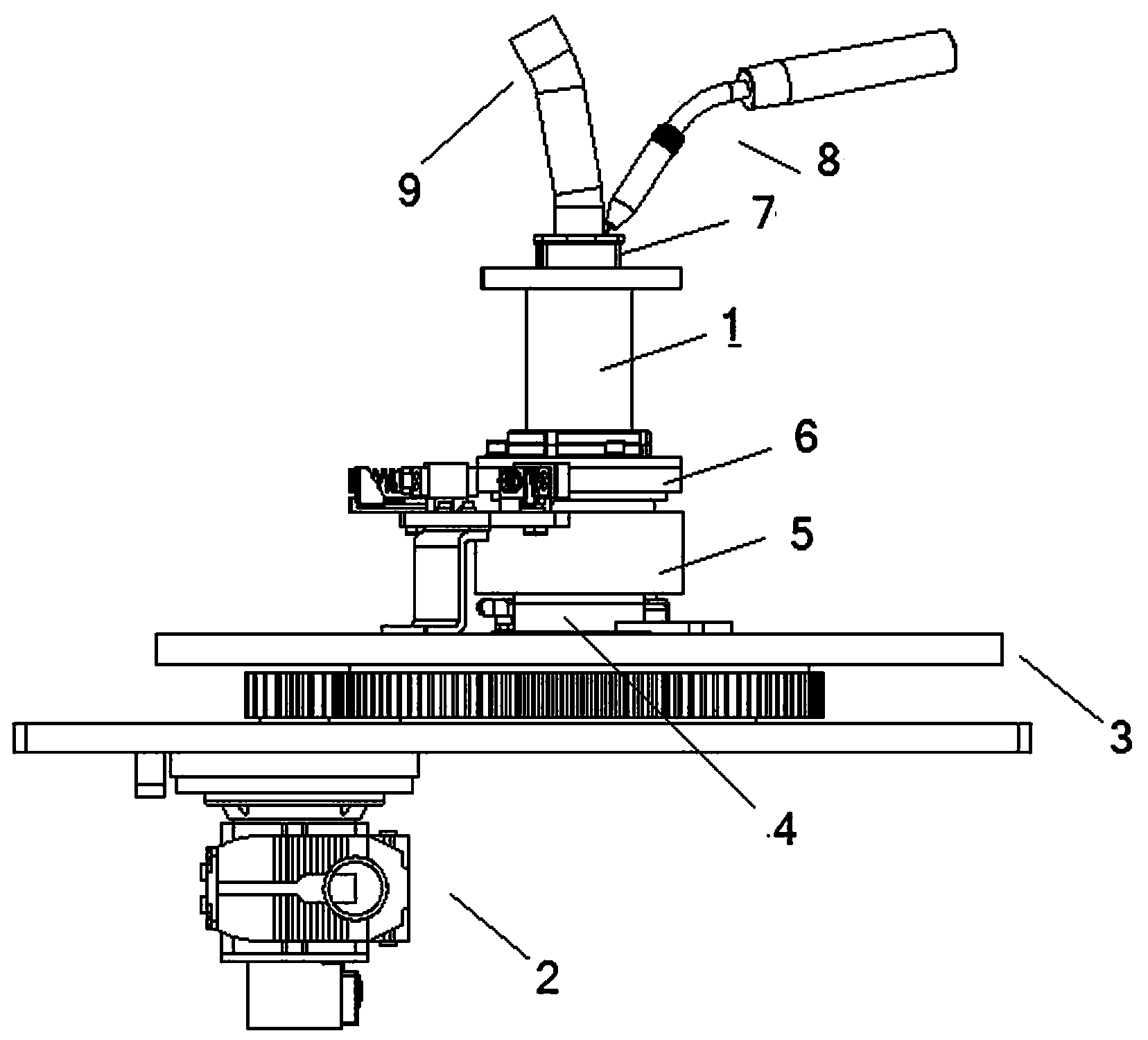

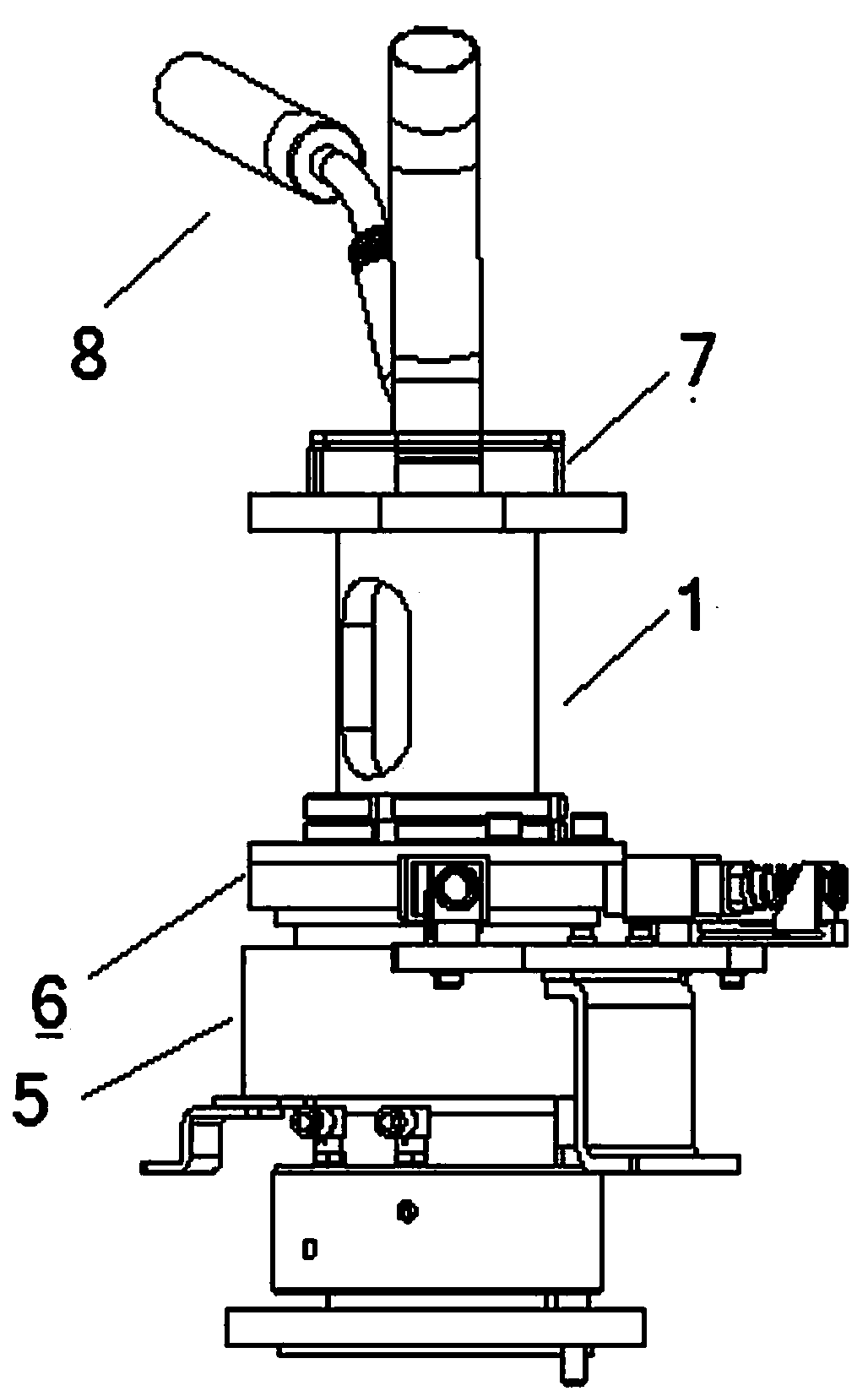

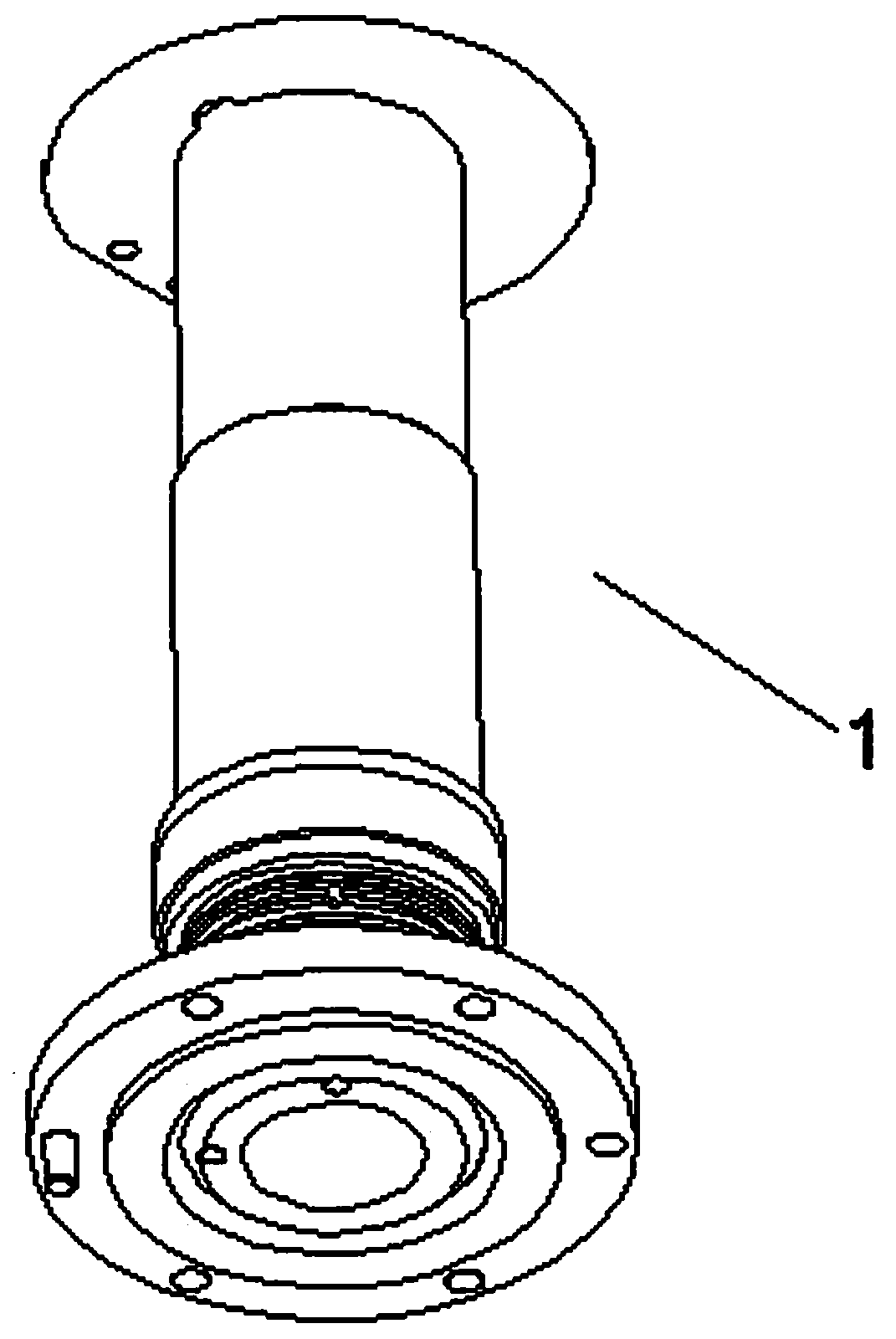

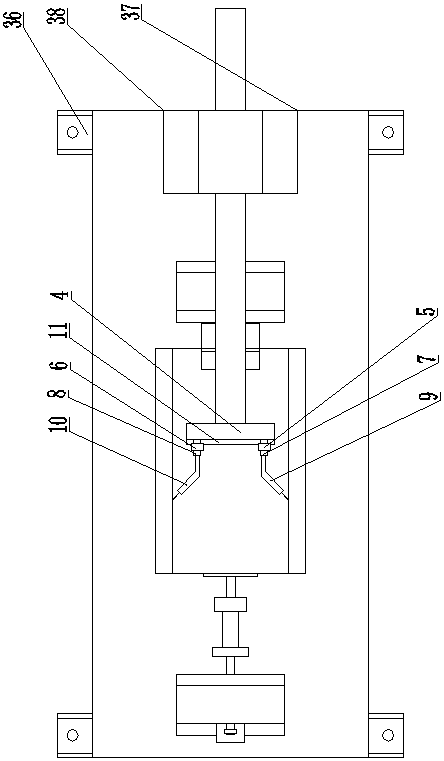

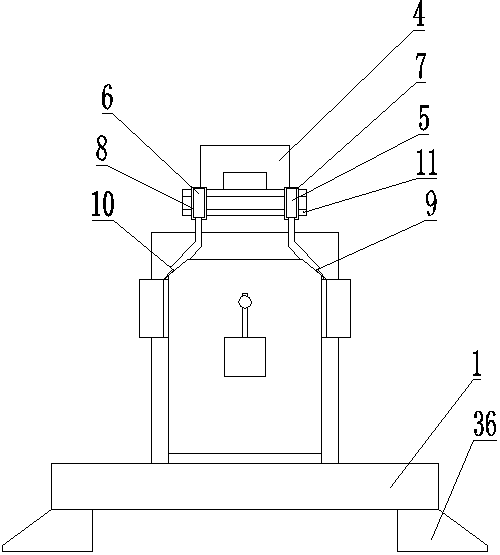

Equipment for continuously welding circular welds

InactiveCN104014908AMeet welding needsElectrode holder supportersHydraulic cylinderMechanical engineering

Equipment for continuously welding circular welds is composed of a welding wire winch (1), a hydraulic power control cabinet (2), a stand column (3), a workbench (4), a welding wire guide wheel (5), a welding torch main shaft (6), an electric slip ring (7), a hydraulic cylinder (8), a motor (9), a belt (10) and a welding torch head (11). The equipment for continuously welding circular welds is characterized in that the welding torch main shaft (6) is connected with a belt pulley, the motor (9) drives the welding torch main shaft (6) to rotate via the belt (10), the hydraulic cylinder (8) compresses a workpiece, a power source is switched on, the welding torch head (11) rotates according to a track circle set by a telescopic rod (12), and then circular welds of different diameters are welded. The equipment for continuously welding circular welds can meet the welding requirement of welds of different diameters, manual intervention is not required in the rotation welding process, and the equipment can continuously rotate by 360 degrees and is free of power interruption.

Owner:丹阳市长江汽车部件有限公司

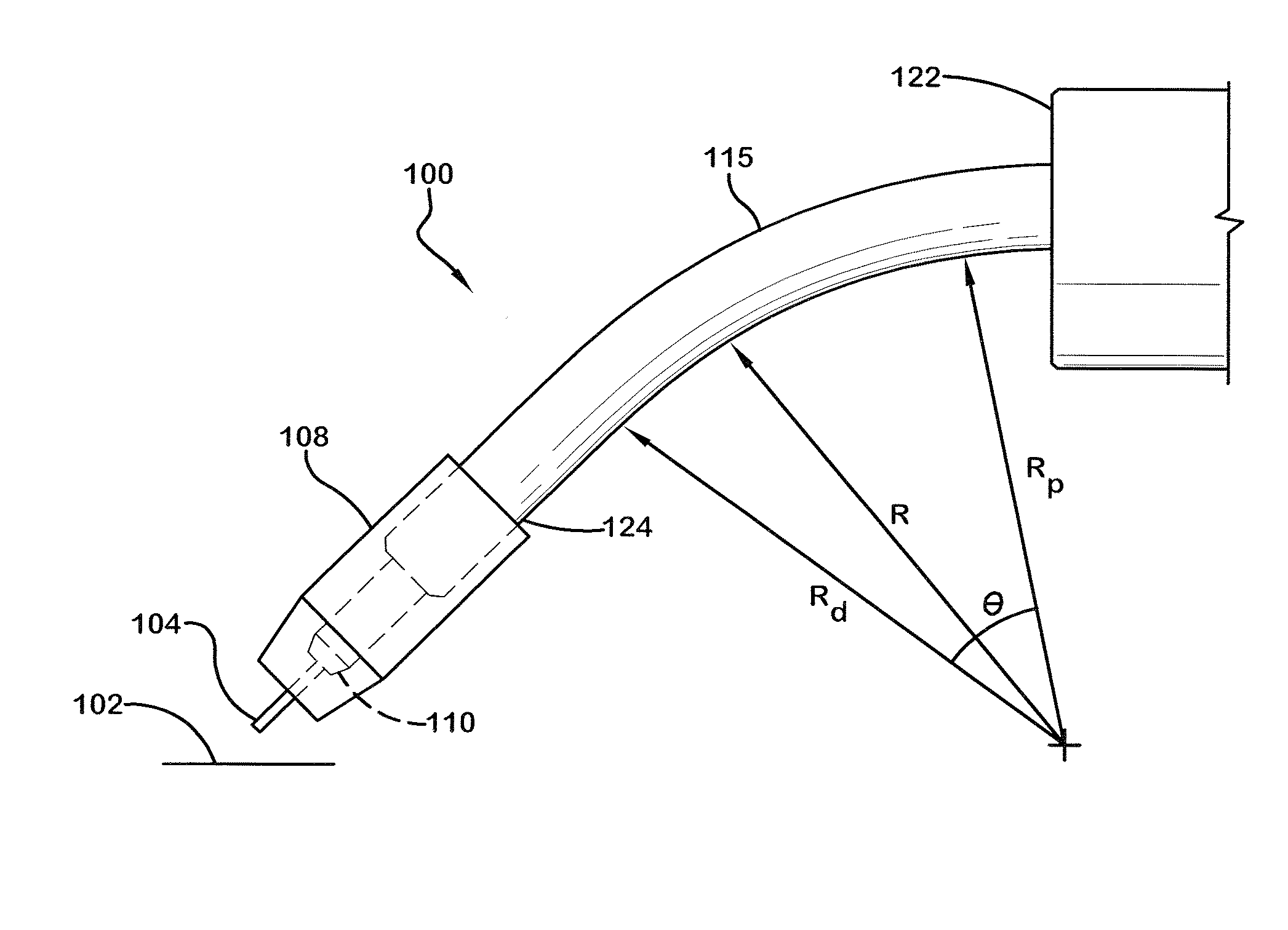

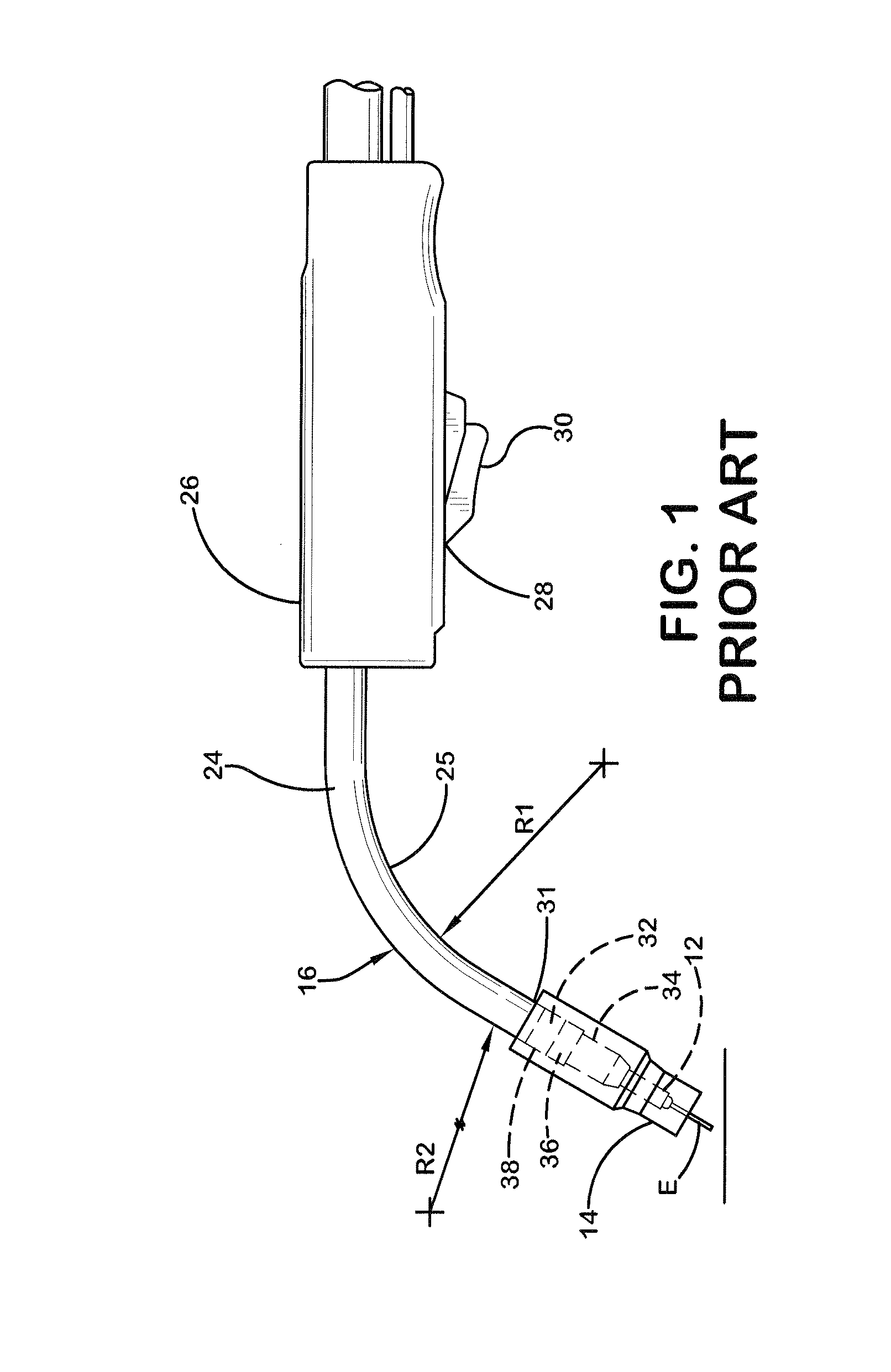

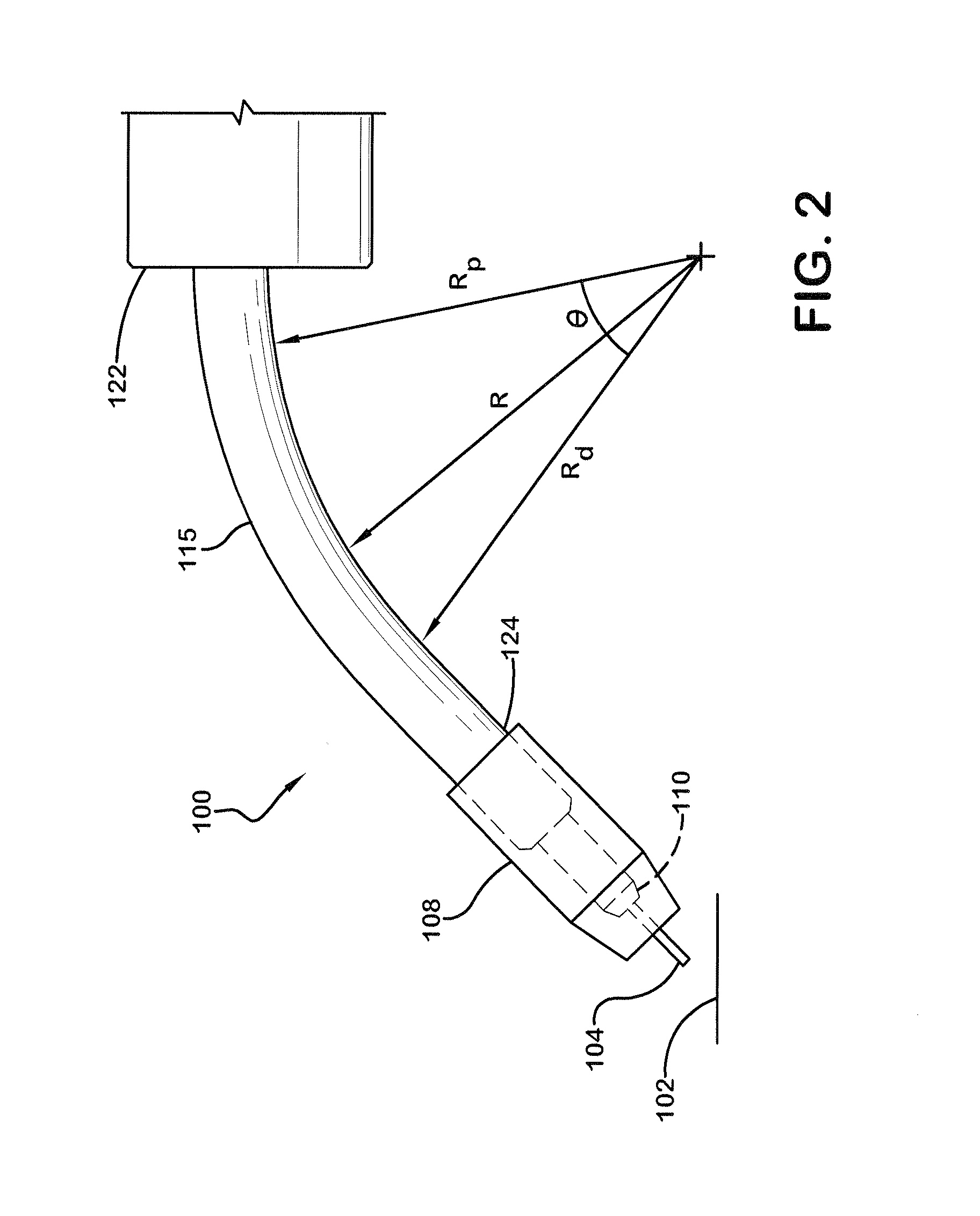

Welding gooseneck with variable radius

InactiveUS20140263254A1Support devices with shieldingElectrode holder supportersEngineeringMechanical engineering

Owner:LINCOLN GLOBAL INC

Structure for treating torch cable for arc welding robot

InactiveCN1745953AStable deliveryStable welding workProgramme-controlled manipulatorWelding/cutting auxillary devicesStable stateMechanical engineering

The invention relates to a welding torch treatment structure for a robot in the electric arc welding industry, wherein, a robot base is arranged on a ceiling part, and a first wrist unit which can rotate around a first shaft line is arranged on a front arm base; a second wrist unit which can rotate around a second shaft line is arranged on a first wrist unit; depending on the transmission mechanism, the welding torch which can rotate around an offset shaft is supported; the welding torch is arranged as the front end directing downward in the illustrated posture of the robot; the invention is provided with a linear guide and a slider via a support base, and a middle part of a torch cable or a welding wire delivery device is fixed and drawn by a tensioning device; the structure is also applicable to a wall-mounted type robot. Thereby, a welding torch cable structure is realized in an arc welding robot of a ceiling-suspension type or a wall-mounted type, capable of maintaining the behavior of the welding torch cable in a stable state as well as minimizing the interference of the welding torch cable with other objects.

Owner:FANUC LTD

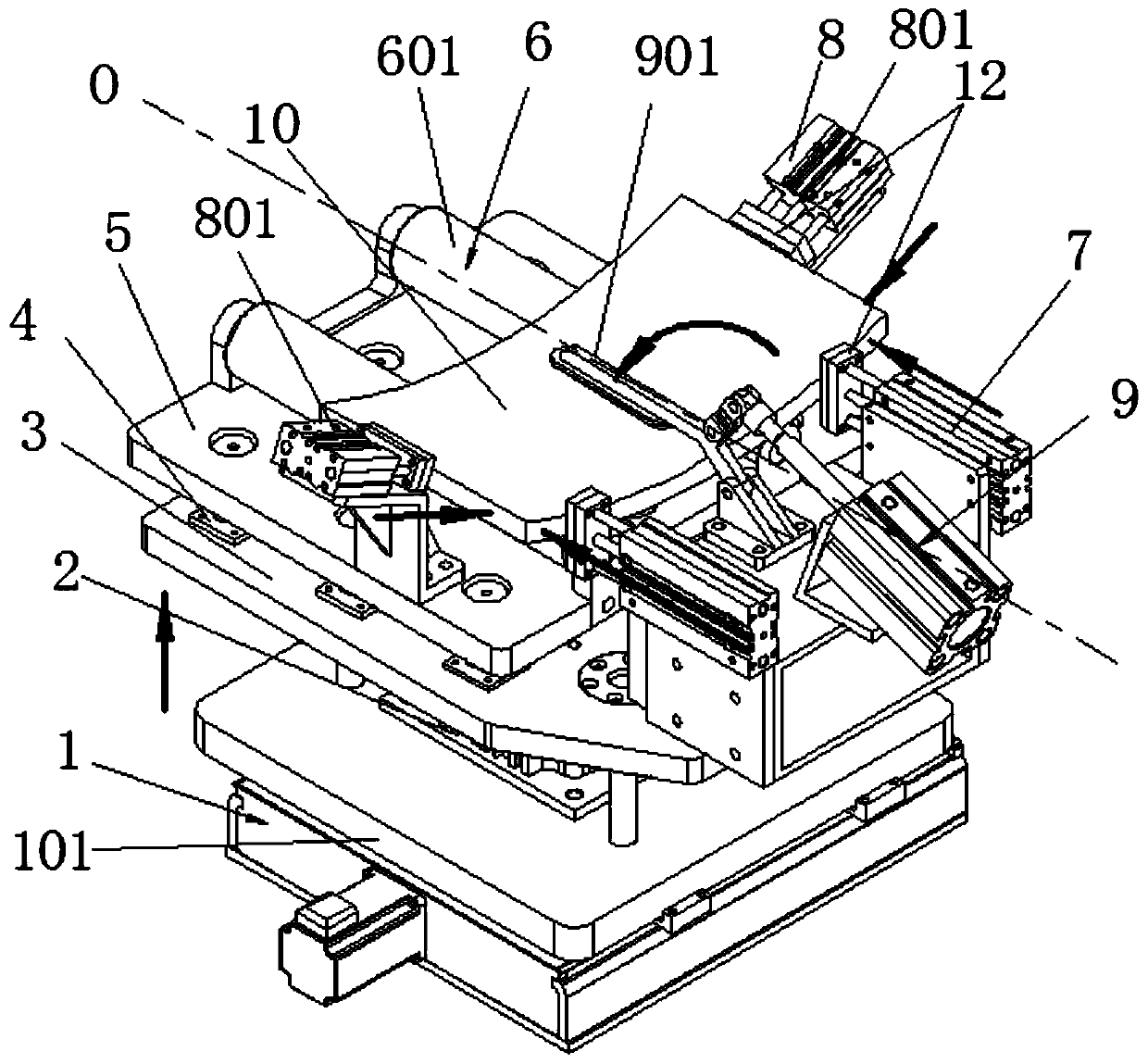

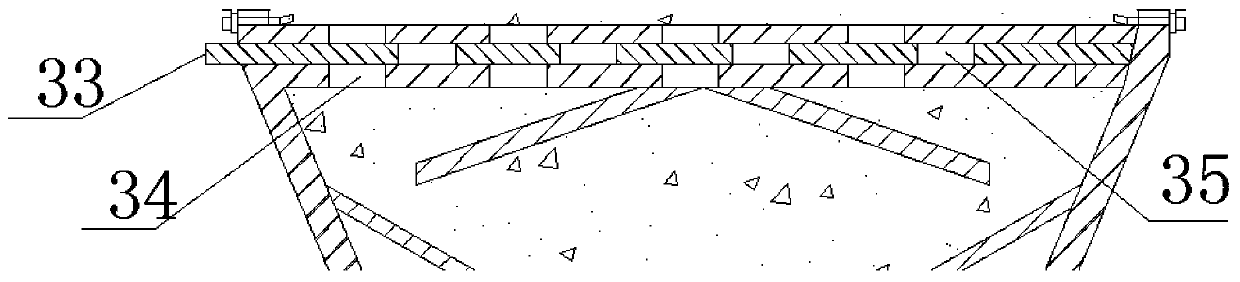

Butting positioning tool for arc striking and quenching plates and positioning butting method thereof

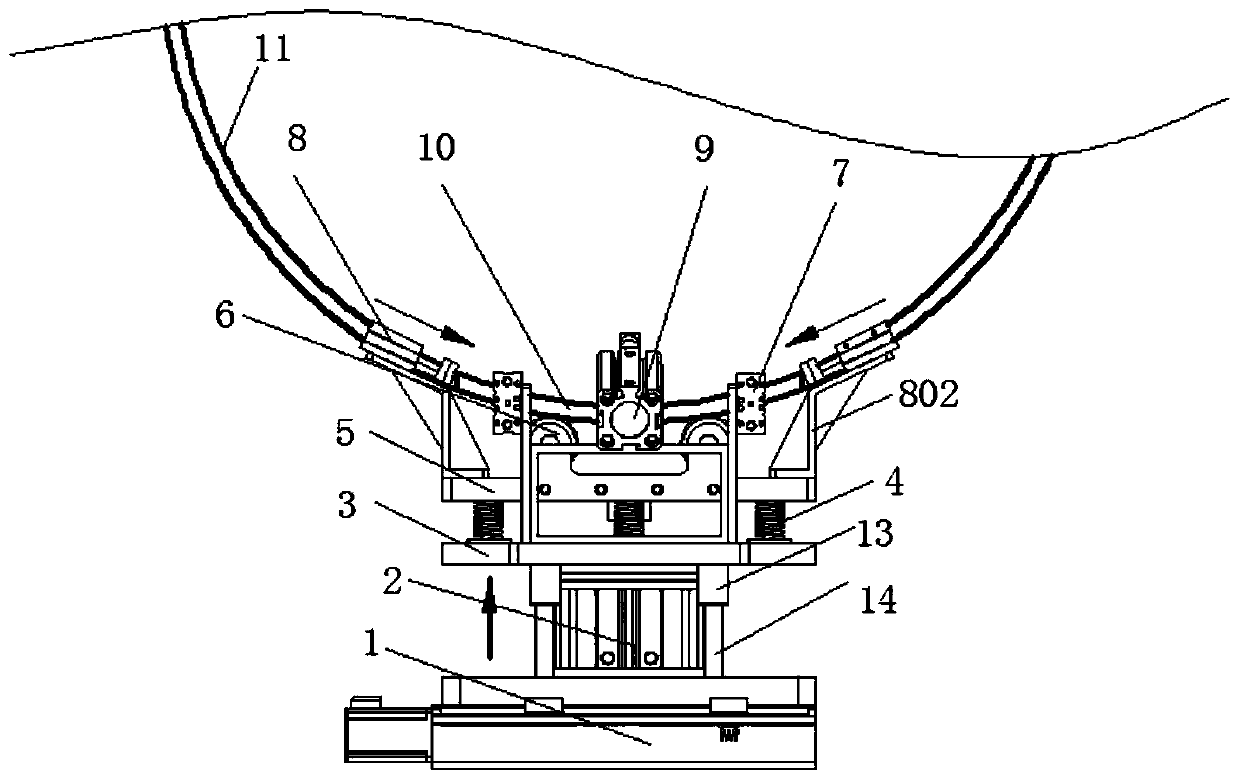

PendingCN111266699ARealize automatic liftingMeet the needs of unmanned productionElectrode holder supportersWelding/soldering/cutting articlesStructural engineeringMechanical engineering

The invention provides a butting positioning tool for arc striking and quenching plates and a positioning butting method thereof. The tool is provided with a translation sliding table for aligning thetool and a pipe end; the translation sliding table drives a lifting platform to lift through a vertical lifting cylinder, the lifting platform is provided with a loading platform in parallel throughflexible self-adaptive assemblies, the loading platform is provided with profiling roller assemblies for aligning the arc plates and the pipe end, the loading platform is provided with a pair of positioning and clamping mechanisms, and the lifting platform is provided with a pair of horizontal pushing mechanisms and a pressing mechanism; and automatic lifting, pushing, approaching, clamping, centering, fixing, abutting and downward pressing and aligning operations of the arc places with respect to the pipe end are realized through the mechanisms. The manpower is replaced, and the automatic plate aligning and positioning operation before welding of the arc striking and quenching plates is realized in a high efficiency, labor-saving and accurate mode.

Owner:陕西戴爱盟德电子科技有限公司

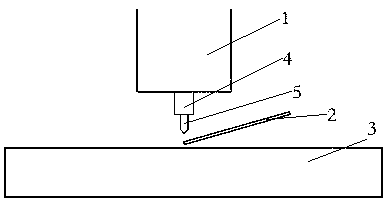

Welding method

ActiveCN103692070APrototype good performanceGood crystal formWelding/cutting auxillary devicesElectrode holder supportersMolten bathWeld strength

The invention provides a welding method. In the whole process that a workpiece is welded by a welding gun, an ultrasonic wave impact device aims at high-temperature weld metal which is solidified on the workpiece and does not recover strength to carry out ultrasonic wave impact; in such a way, the ultrasonic wave impact device and a welding gun body synchronously move in a companying way; during welding, the impact in ultrasonic frequency is applied to the high-temperature weld metal which is solidified on a certain position behind a molten bath and does not recover strength along the thickness direction of a workpiece to be welded; the metal in a condensation shrinkage state is impacted to produce ductile extension under the exciting force effect of ultrasonic wave; compressed plastic strain produced in the heating process is compensated, so as to reduce the welding deformation; the texture of the weld metal is refined, the directivity of crystalline grain crystallization is changed, and the texture tends to be more uniform. Compared with the prior art, the stress and deformation of the weld metal are effectively eliminated, the workpiece does not easily deform, the welding strength is high, the method is concise, clear and reliable, and the practicability is high.

Owner:HUAQIAO UNIVERSITY

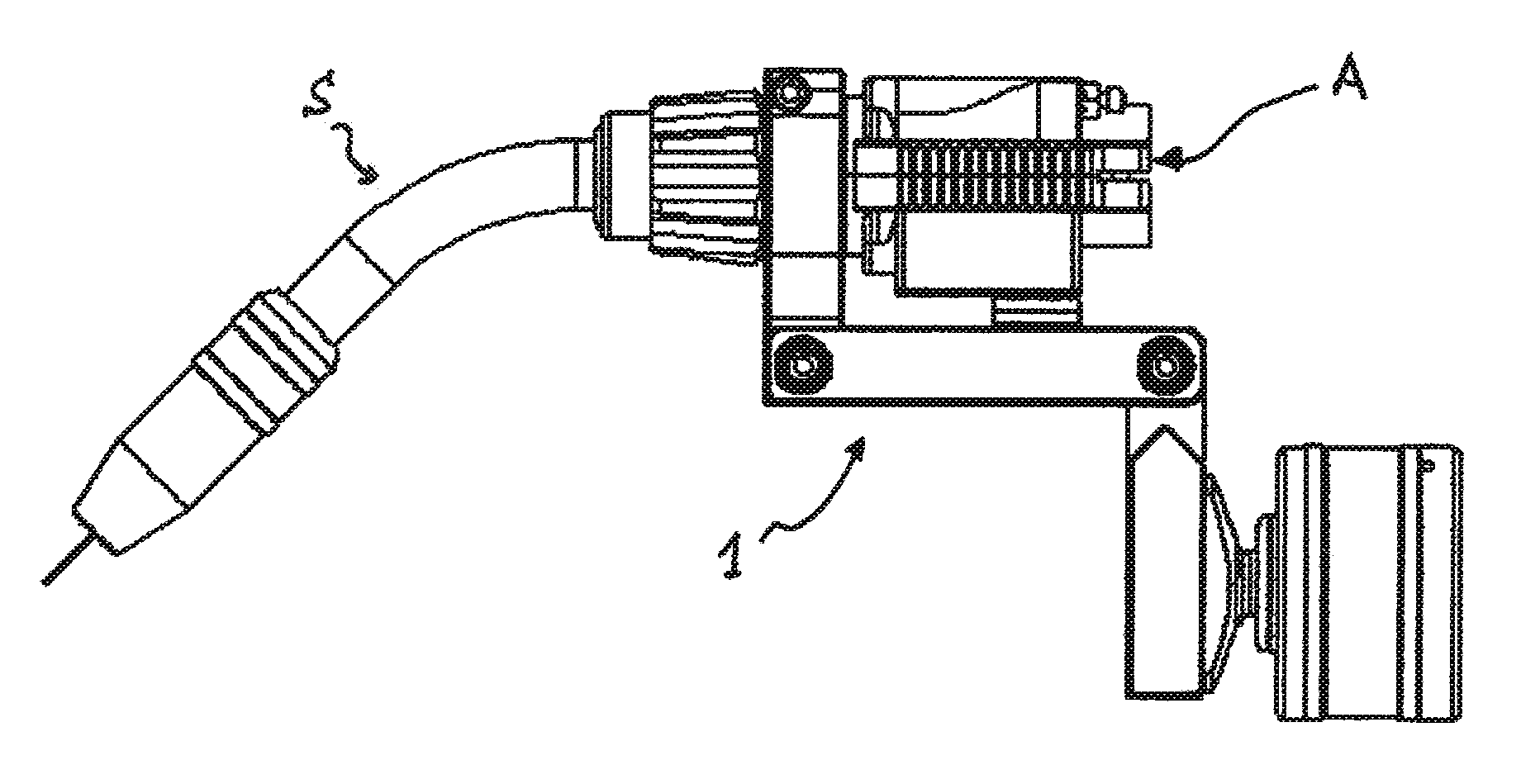

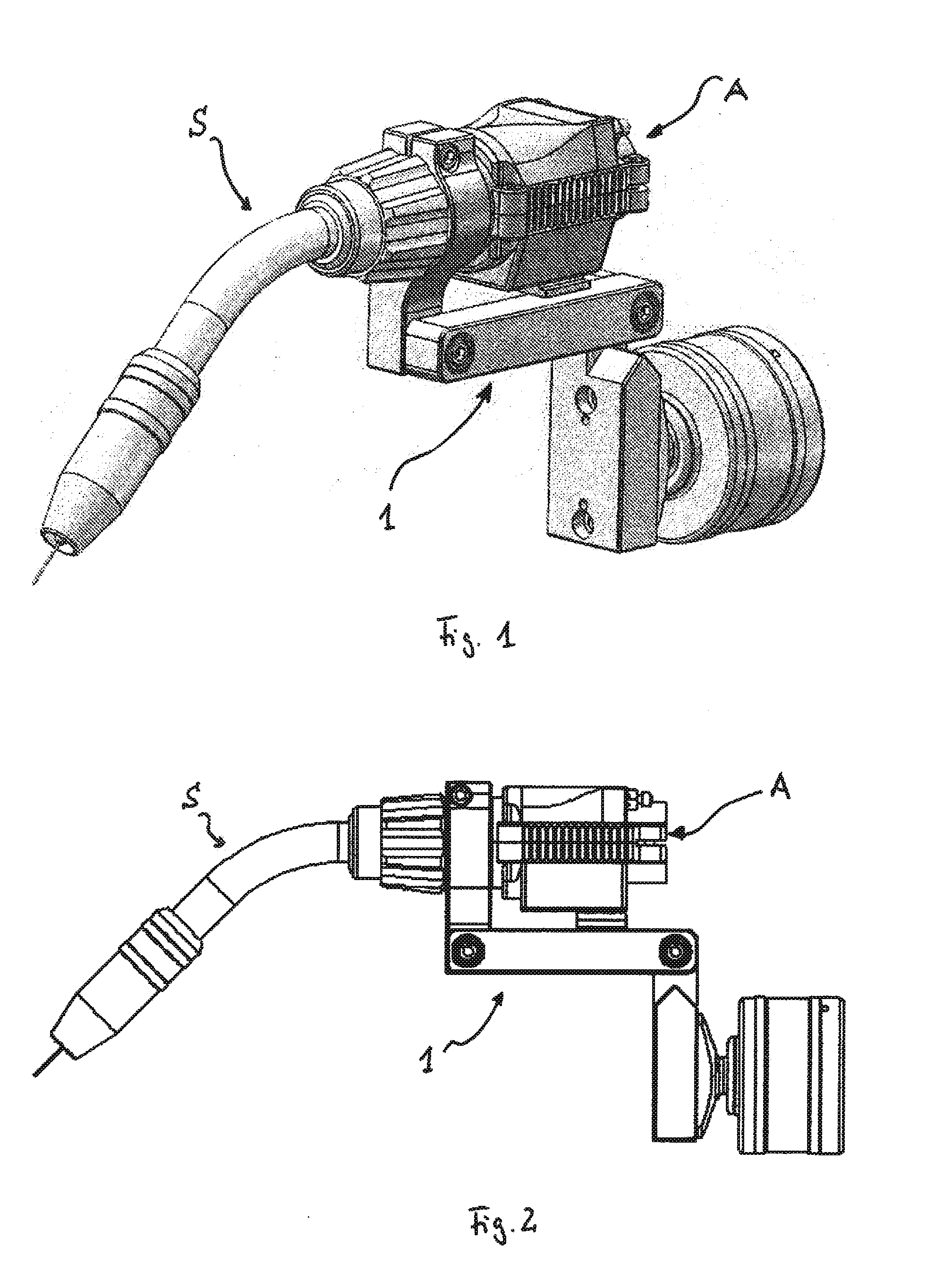

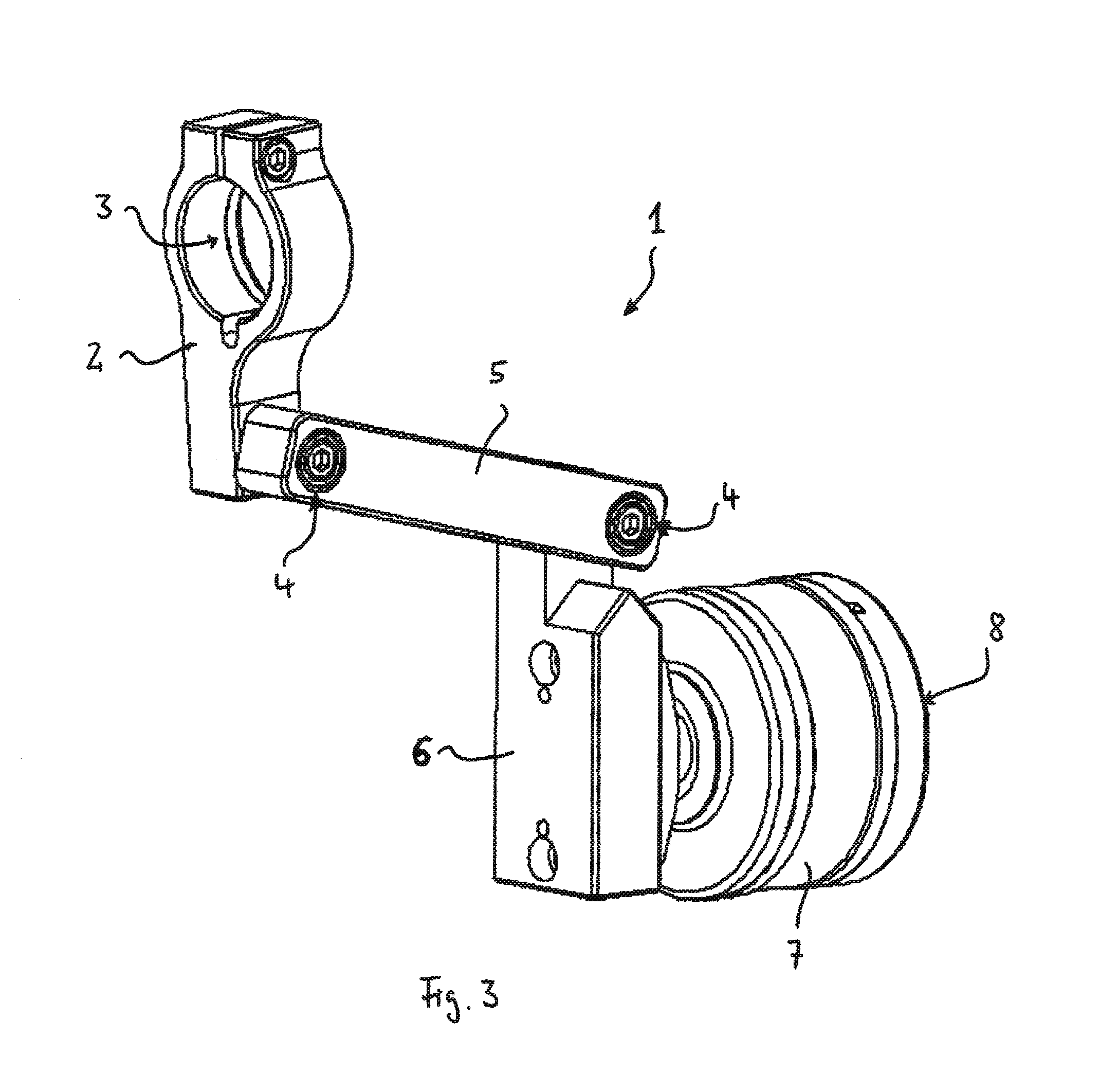

Mount for a welding gun for connecting said welding gun to an arm of a welding robot

InactiveUS20150069039A1Simple designSimple processWelding/cutting auxillary devicesElectrode holder supportersEngineeringScrew thread

A mount for connecting a welding gun to a welding robot's arm. An articulated joint is provided between two rigid elements of the mount. The joint includes a sleeve securable to a first element. A first bore is provided on the second element. The sleeve is inserted into the bore. The bore's inner diameter and the sleeve's outer diameter are such as to allow the second element to turn with the first bore relative to the sleeve. An expansion element provided in the interior of the sleeve is displaceable in the longitudinal direction of the sleeve. The expansion element has a central opening through which a tensioning bolt is passed. The bolt threadably engages a support element causing expansion of the sleeve, thereby causing the sleeve to seize around the circumference thereof in the bore. The expansion and seizing of the sleeve is neutralized by a release and stop.

Owner:DINSE GMBH

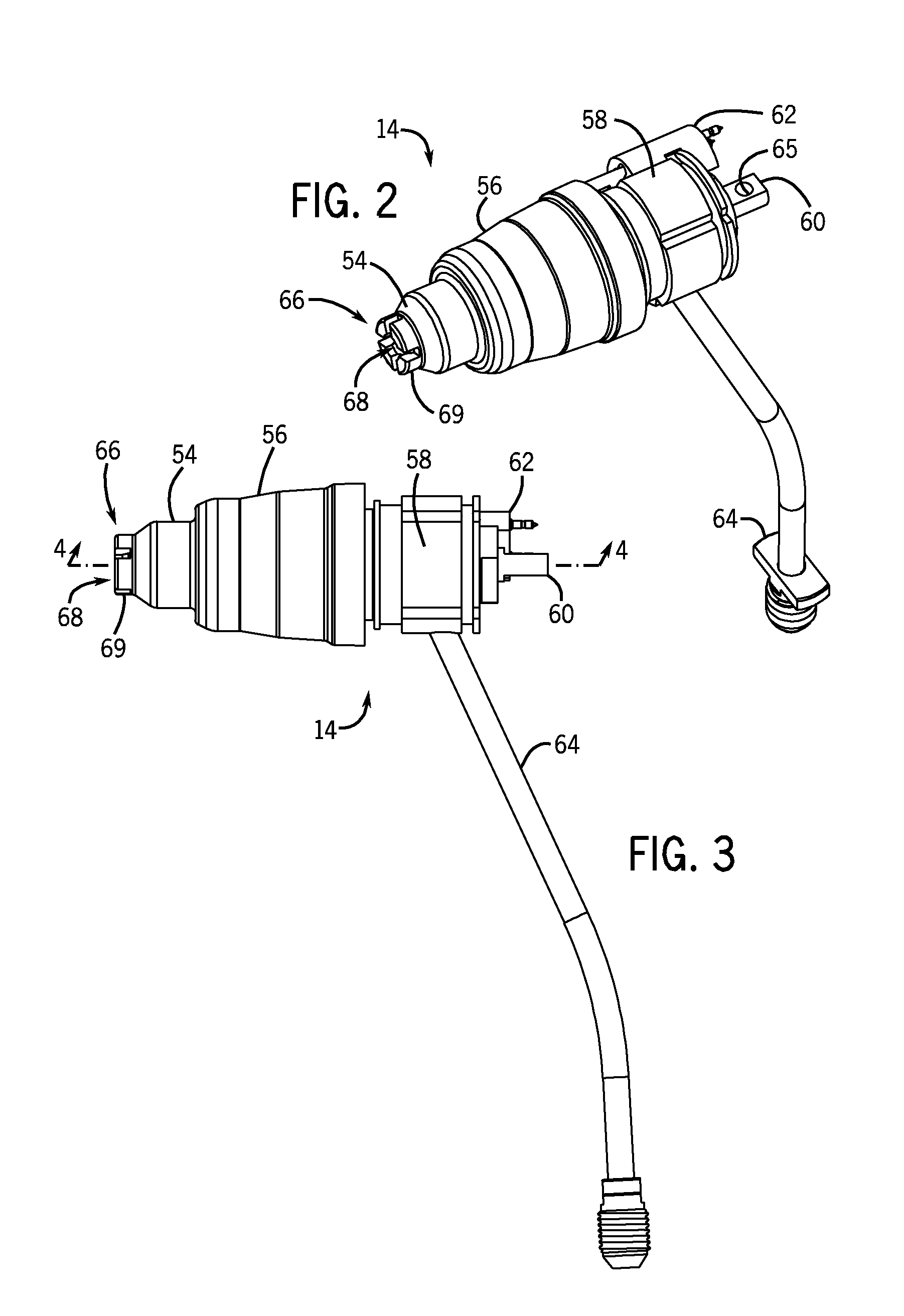

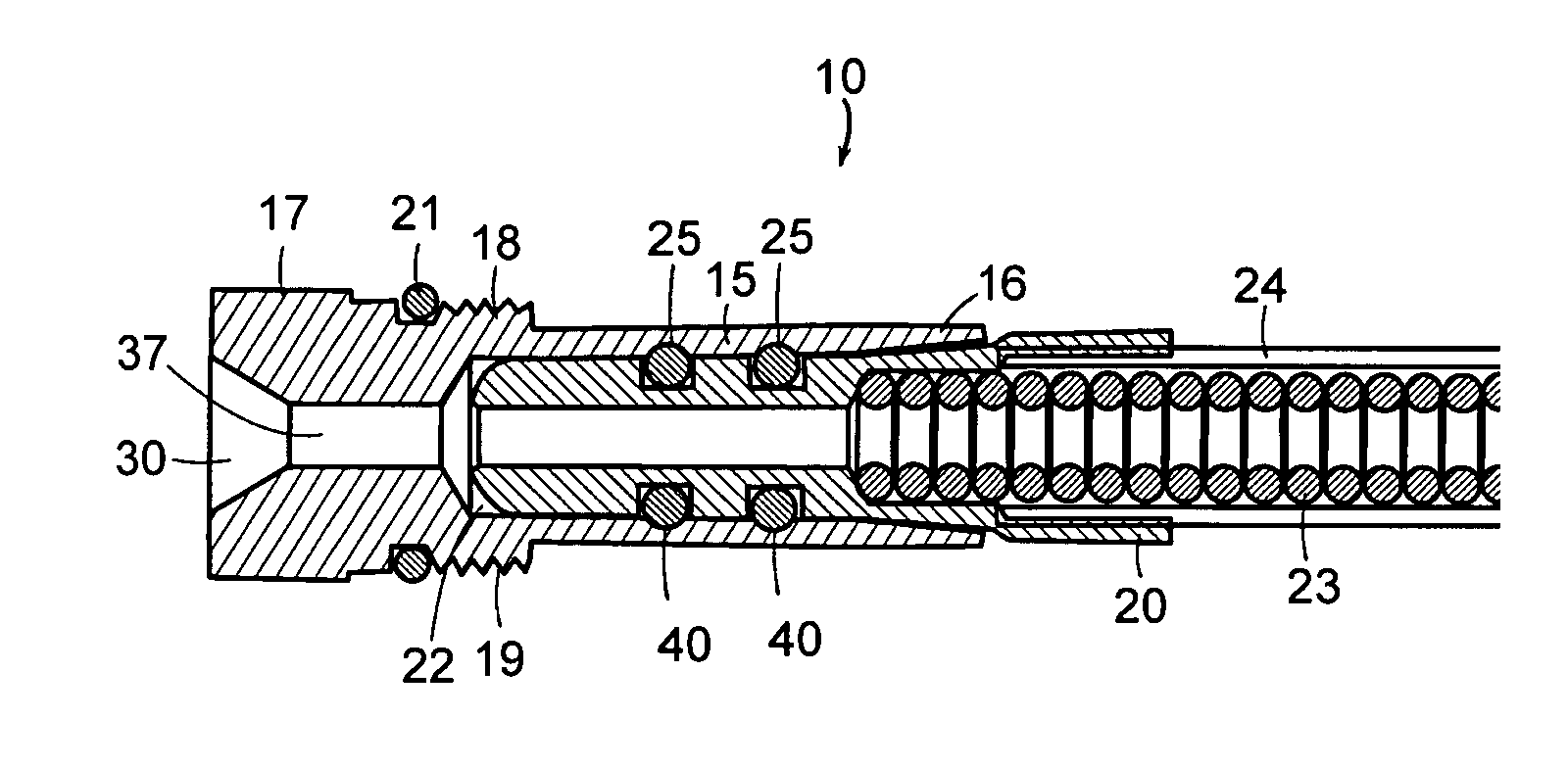

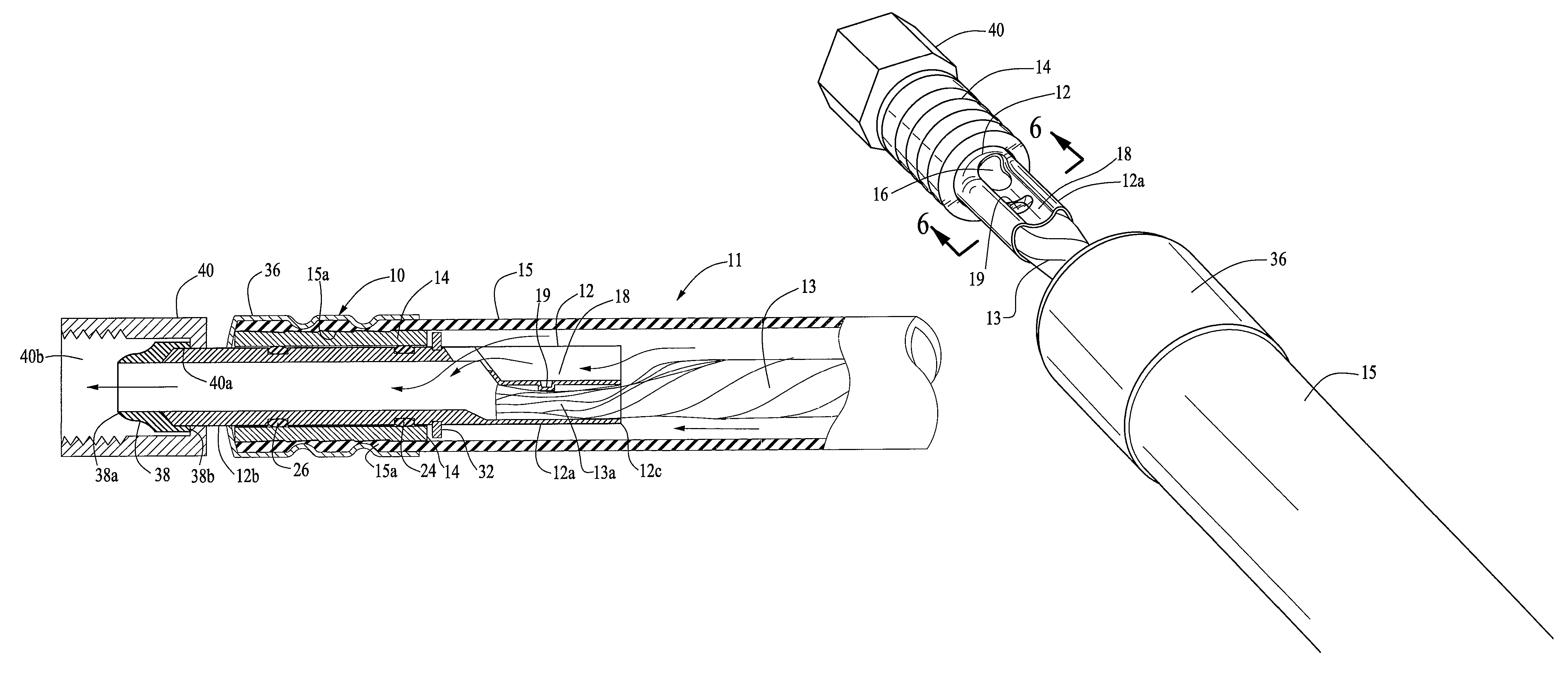

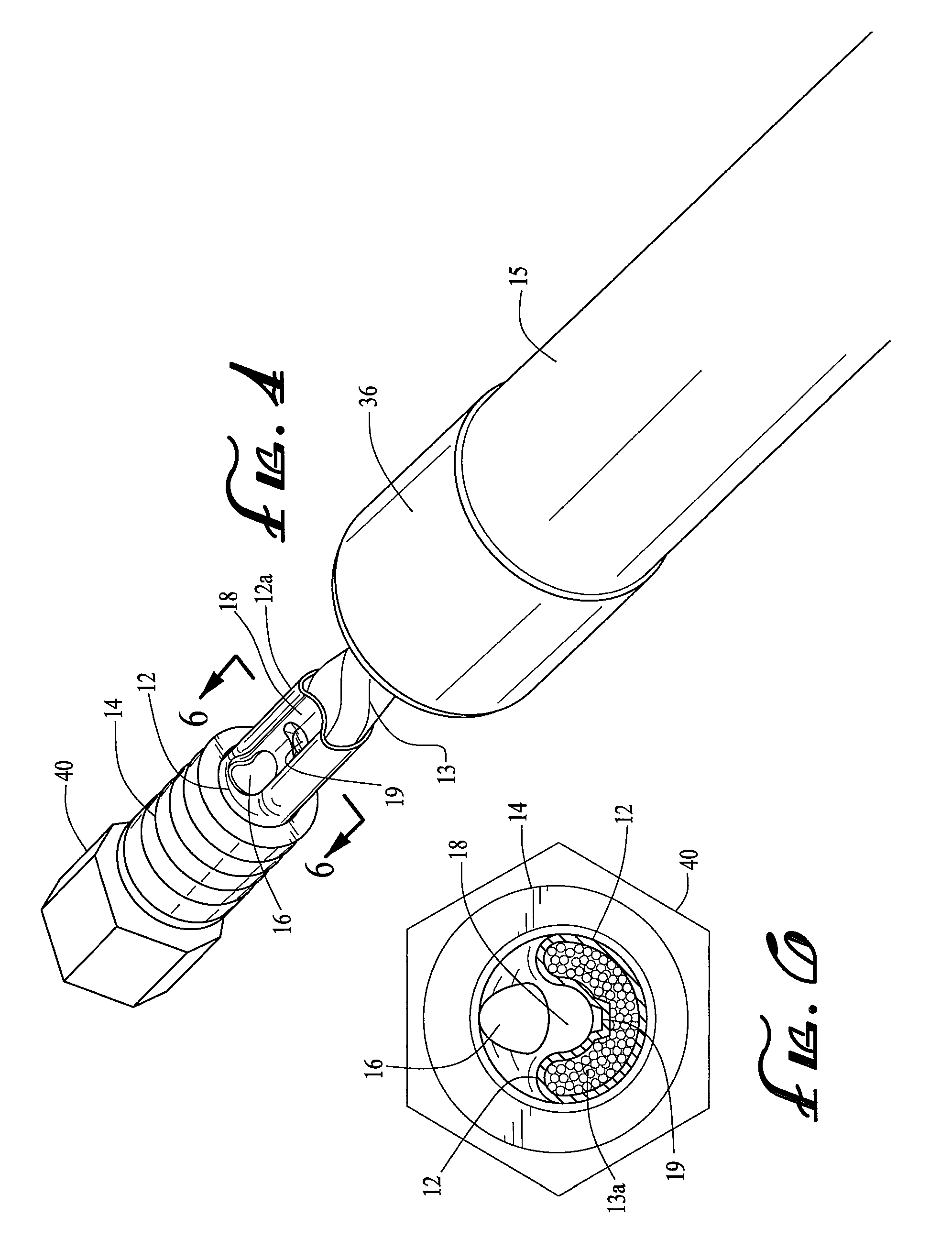

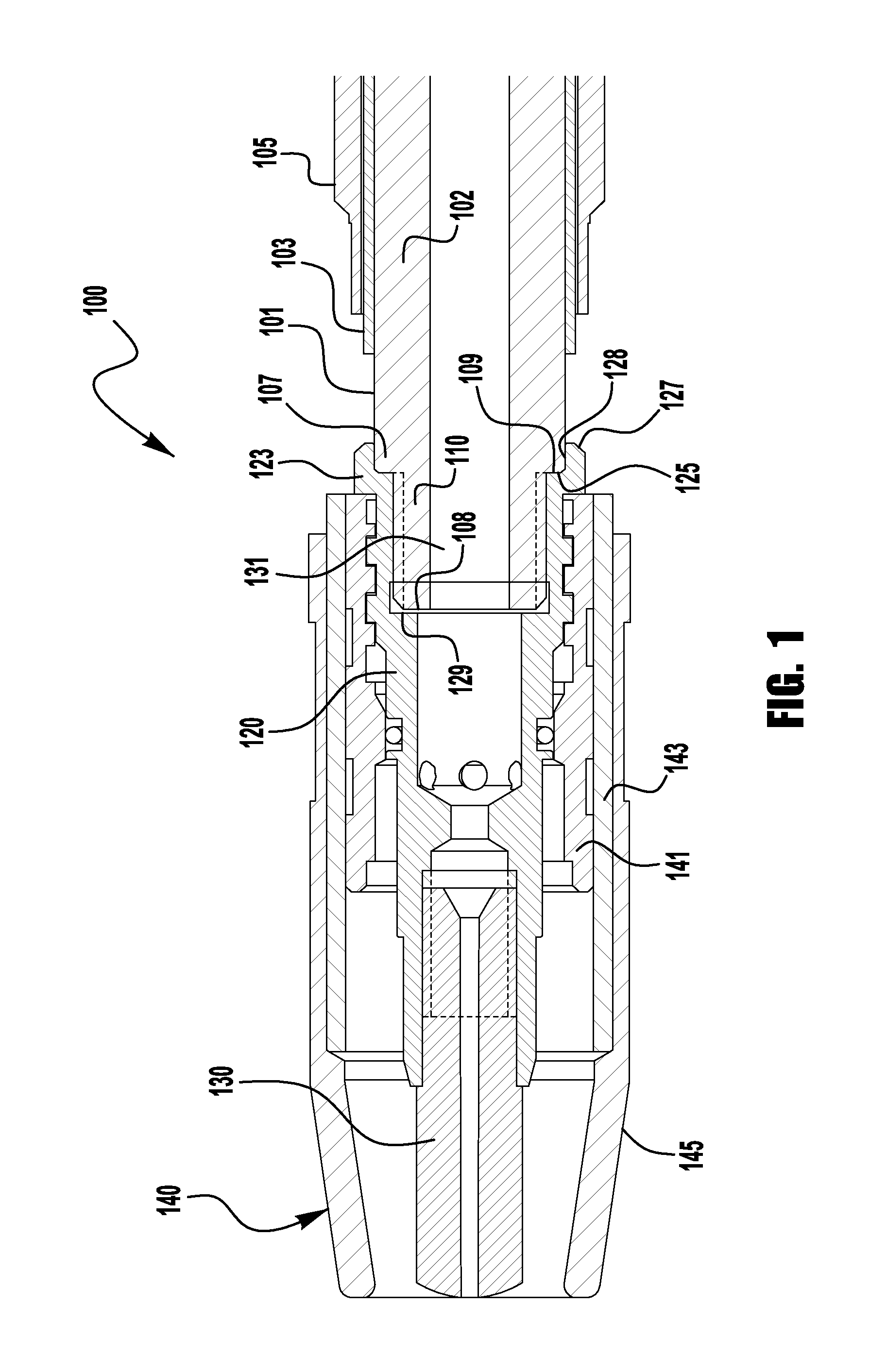

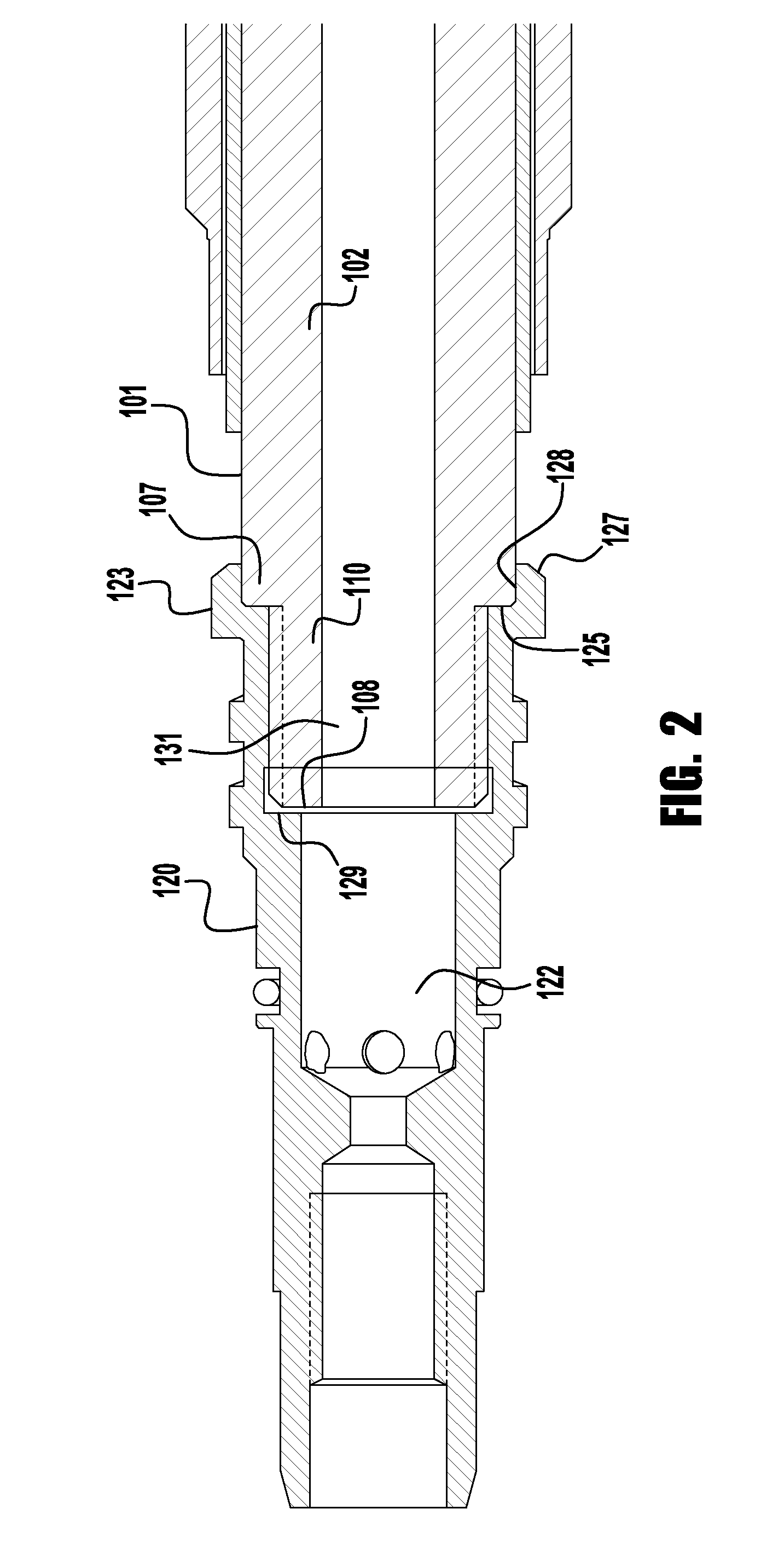

Power cable assembly connector

A connector assembly for releasably securing a welding torch to an extended end portion of a power cable assembly having an outer hose disposed about an electrically conductive cable for directing gas therethrough to the torch. An aperture is provided in the side wall of an electrically conductive tubular member between upstream and downstream portions thereof. An upstream portion of the tubular member is crimped about an end of the cable so as to define a generally U-shaped trough extending along the upstream portion of the tubular member, creating a gas flow path extending therealong to and through the aperture, into and through the downstream portion of the tubular member. A hose attachment sleeve is rotatably and sealably mounted on a pair of axially spaced sealing members on the downstream portion of the tubular member so that the torch can be rotated with respect to the hose during use, reducing strain on the welder.

Owner:REHRIG RICHARD B

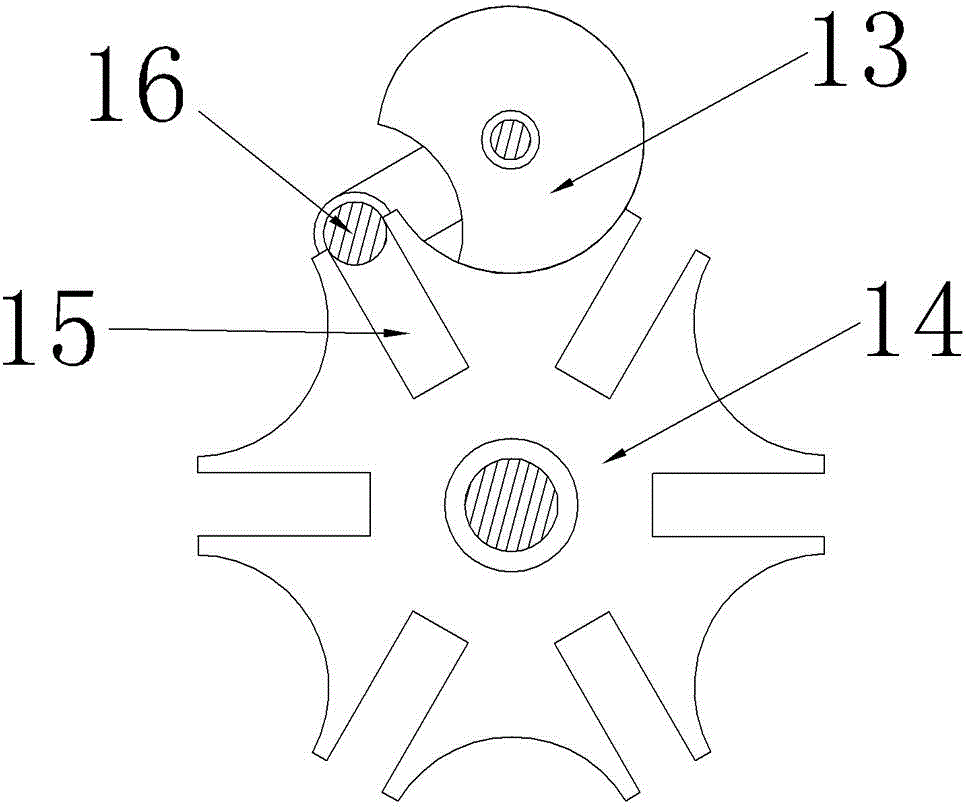

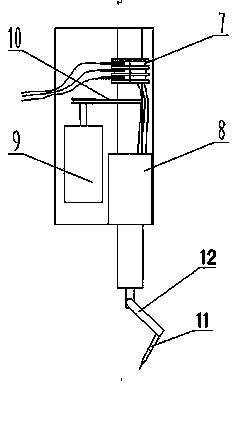

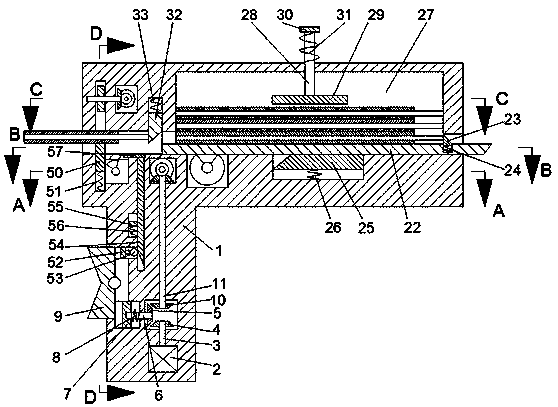

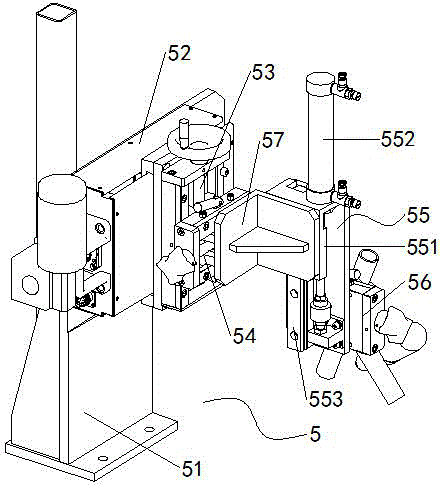

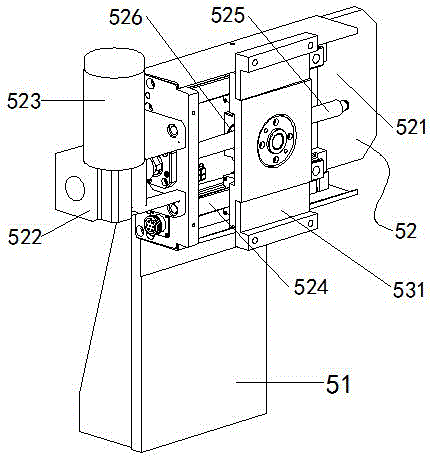

Electric welding gun capable of automatically replacing welding rods

InactiveCN111215734AEasy to operateImprove securityElectrode holder supportersElectric machineryStructural engineering

The invention discloses an electric welding gun capable of automatically replacing welding rods. The electric welding gun comprises a gun body, a clamping mechanism is arranged on the upper middle portion of the gun body, a pushing mechanism is arranged on the right portion of the gun body, an electrifying mechanism is arranged in the middle of the gun body, a power mechanism is arranged on the lower portion of the gun body, and the power mechanism comprises a motor which is arranged at the lower end of the gun body. According to the electric welding gun capable of automatically replacing thewelding rods, a used welding electrode on the electric welding gun can be removed under the condition that the welding electrode is not in contact, the standby welding electrode which is stored in theelectric welding gun is replaced and installed in a clamp, the operation is rapid and easy and convenient, and meanwhile, the welding electrode cannot be powered on in the welding electrode replacingprocess through the design of the electric welding gun, so that the use safety coefficient is improved.

Owner:温州新兰智能科技有限公司

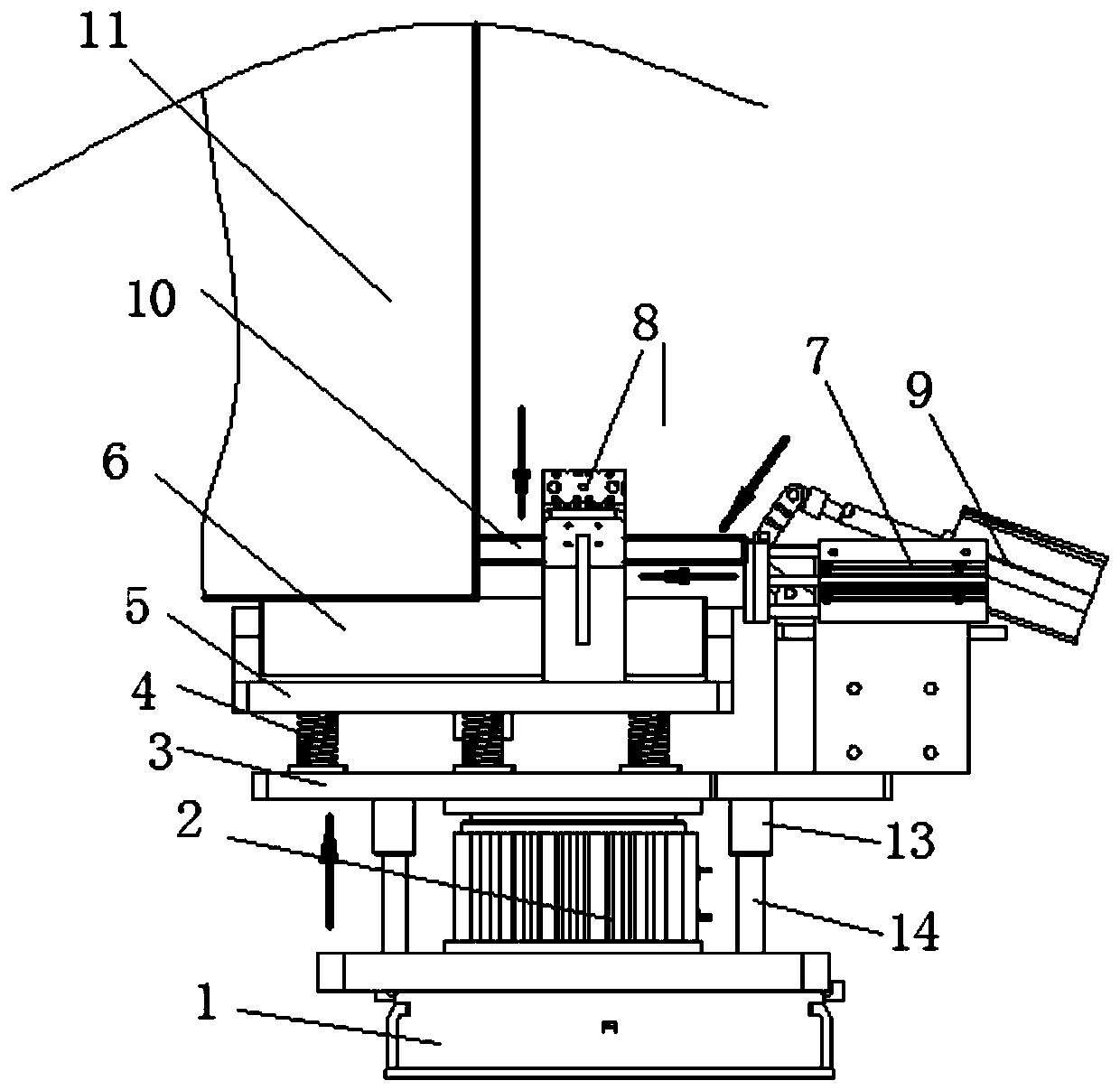

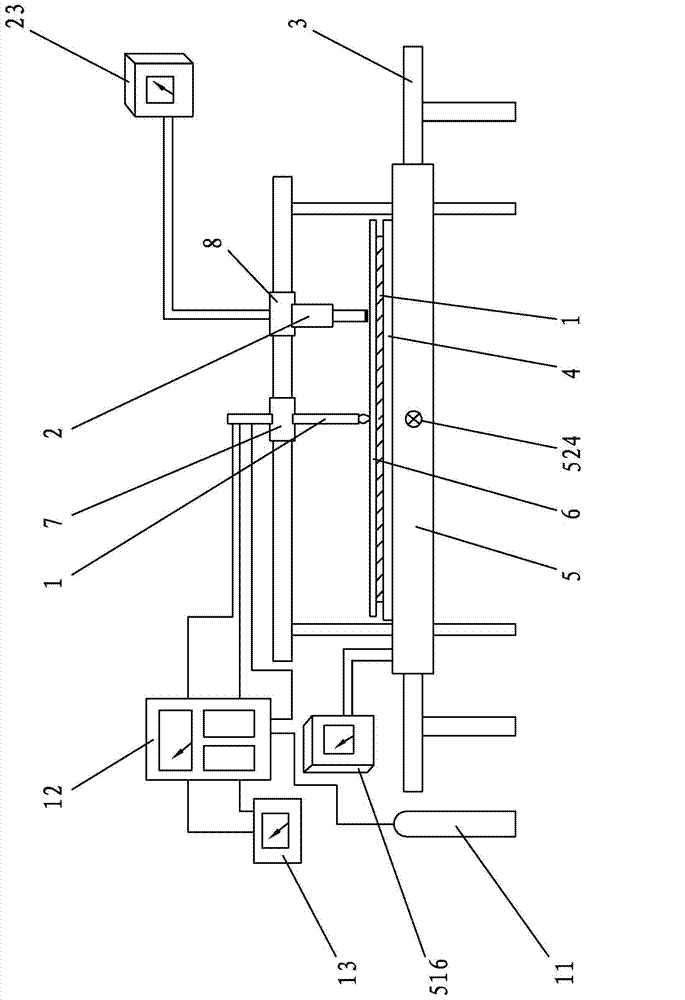

Vertical annular welding tool

ActiveCN104028884AImprove welding qualitySolve the entanglementWelding/cutting auxillary devicesElectrode holder supportersEngineeringStructural engineering

The invention discloses a vertical annular welding tool. The vertical annular welding tool comprises a rotatable platform and a hollow upright column, wherein the hollow upright column is perpendicular to the rotatable platform and sleeves the rotatable platform via a clearance; a gas guiding ring, a conductive ring and a ground wire grounding copper ring sleeve the upright column; a gas circuit, an electric control circuit and a welding ground wire are arranged in a hollow cavity of the upright column; a workpiece positioning mechanism is fixed on the upper portion of the upright column; and a wire feeding machine and a welding gun mechanism are fixed on the rotatable platform. Rotating power is provided by using a speed reducer; circuit transmission is carried out by using the conductive ring; and gas is turned on, turned off and changed over via the gas guiding ring, the welding gun can be adjusted multi-dimensionally in space, namely, the welding gun can be adjusted in the up-down direction and the left-right direction at an angle, annular welding between tubes, annular welding between a tube and a flange and annular welding between a tube and a plane can be performed, the product differentiation switching efficiency and the welding quality are improved, the welding angle and the welding speed can be freely adjusted, annular welding can be performed rotatably without limitation, workpieces do not need to rotate, and the time can be greatly saved. The vertical annular welding tool is suitable for annular welding between the tubes, annular welding between the tube and the flange and annular welding between the tube and the plane, or is suitable for welding an arc.

Owner:GREAT WALL MOTOR CO LTD

Multi-piece front loading liner

ActiveUS7309844B2Prevent leakageReduce the possibilityWelding/cutting auxillary devicesElectrode holder supportersEngineeringFront loading

An improved liner for protecting an electrode wire within a body of a welding torch. The liner includes a liner retainer, which is removably coupled to a liner insert. The liner retainer is secured to a distal end of the welding torch and the liner insert is inserted and coupled to the liner retainer through a proximal end of the welding torch.

Owner:ILLINOIS TOOL WORKS INC

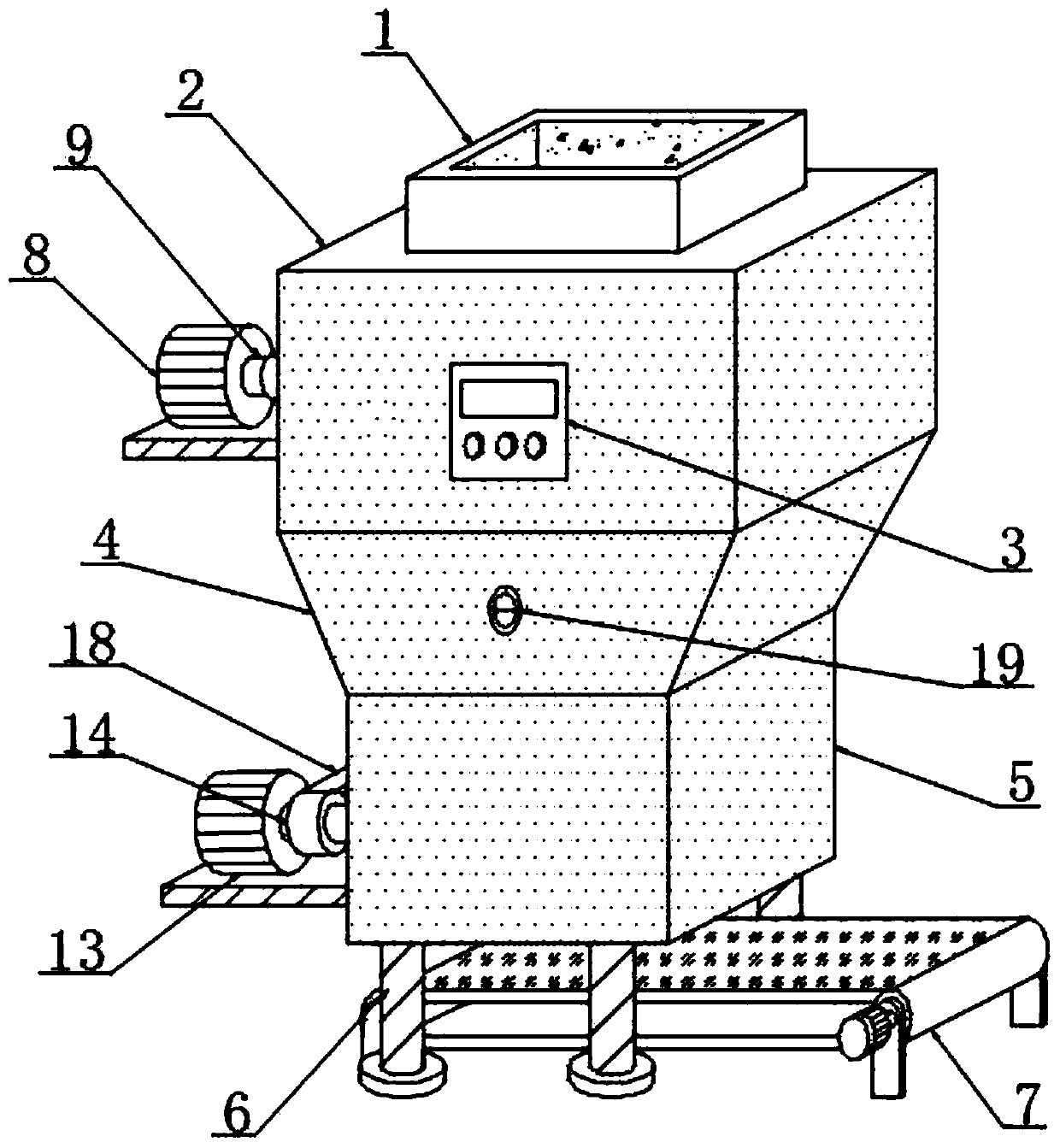

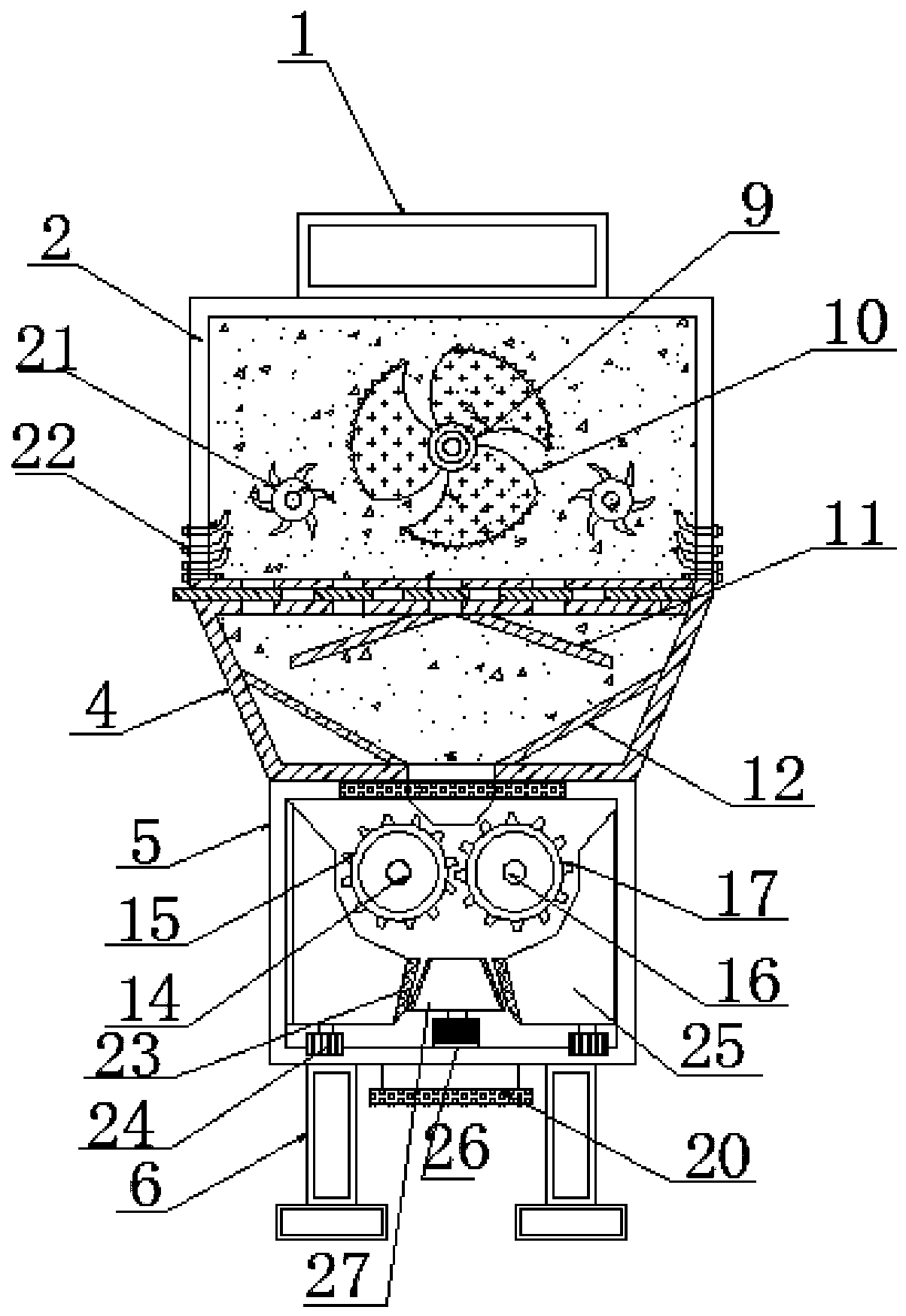

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

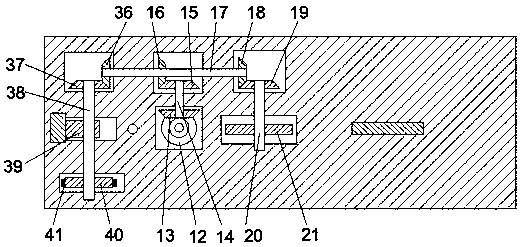

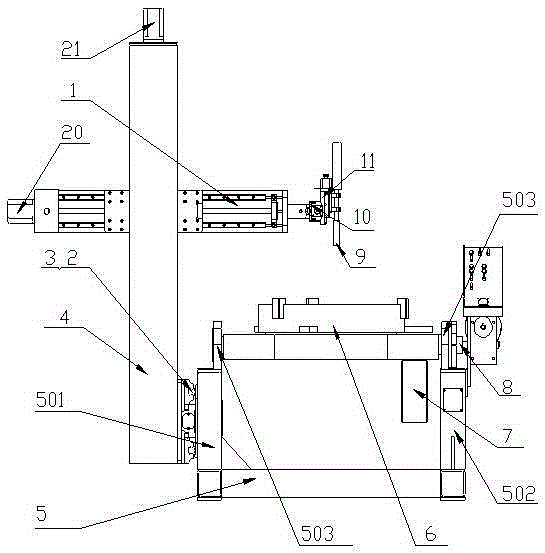

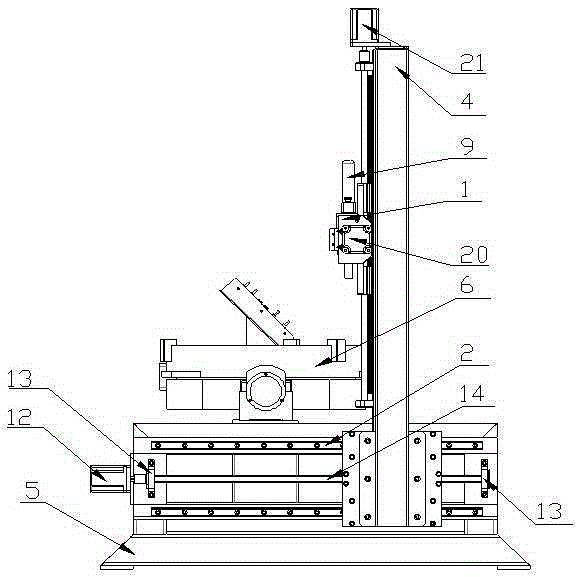

Automatic integrated flange welding equipment with center through hole

ActiveCN105269116AReduce labor intensityImprove welding efficiencyWelding/cutting auxillary devicesElectrode holder supportersWelding power supplyClosed loop

The invention discloses automatic integrated flange welding equipment with a center through hole. A welding cross-shaped arm of the equipment is connected with a base of a position changing machine in a slide mode and can move front and back relative to the base. A welding chuck is connected with a main motor through a rotary support fixed to an overturn frame. The overturn frame is provided with the center through hole. A workpiece can penetrate through the center through hole. Any parts of the workpiece can be clamped by the welding chuck so that position changing machine, a welding power source and a welding gun can be of an integrated type structure. Not only is the automatic integrated flange welding equipment adapted to welding of a long pipe, but also all weld joints in the workpiece can be welded without repeated changing of the relative positions of the welding cross-shaped arm and the position changing machine when the workpiece is provided with the multiple weld joints. The welding cross-shaped arm is provided with a welding oscillator and an arc-length adjuster. The welding gun is installed on the arc-length adjuster. Swinging and up-down adjustment can be achieved automatically, so that the automatic integrated flange welding equipment is adapted to welding of a workpiece with the requirement for a groove and a workpiece with obvious ovality, and no human adjustment or intervention are needed. Closed-loop control is achieved, and the welding quality is easy to ensure.

Owner:JINAN JINLUDING WELDING TECH CO LTD

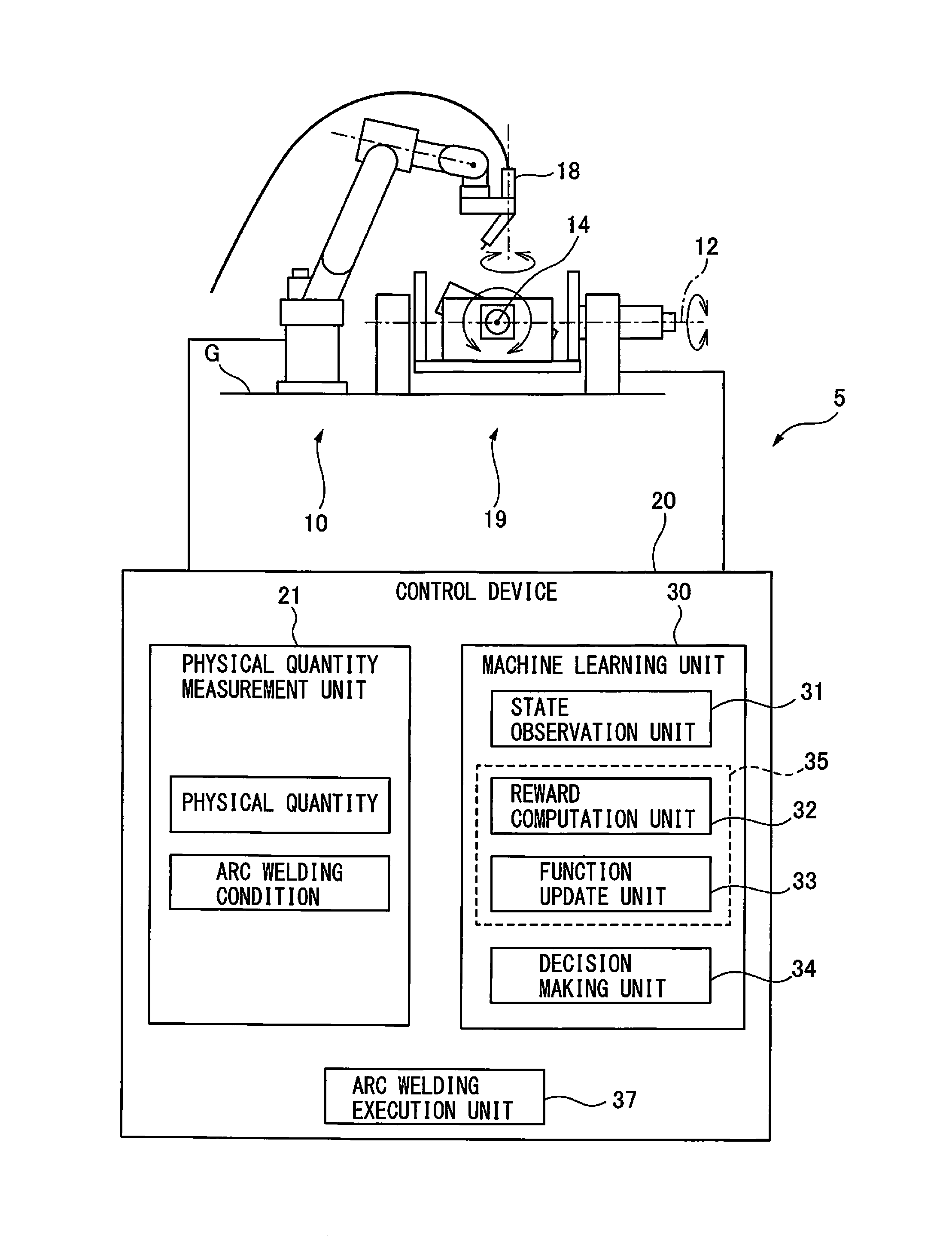

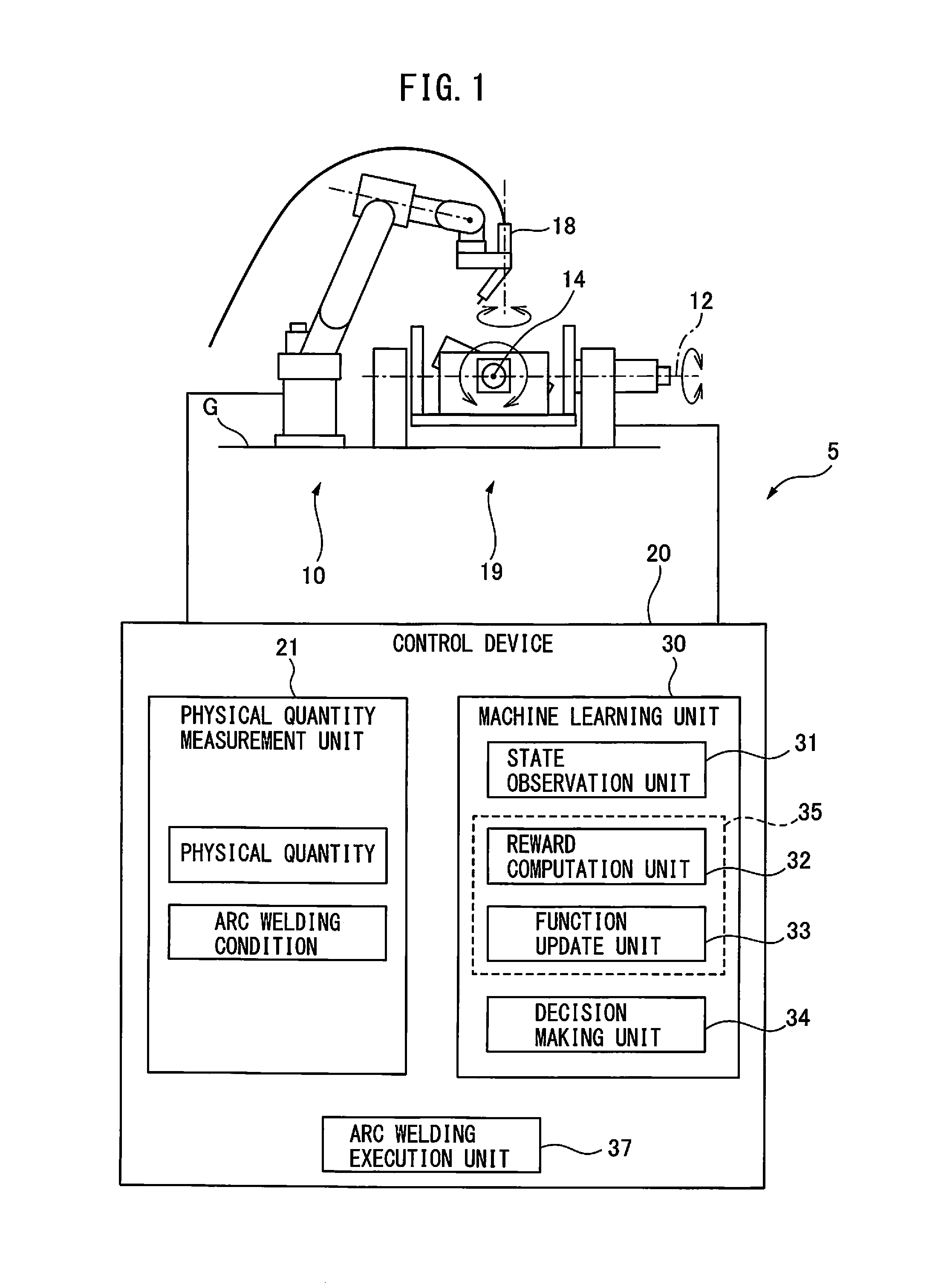

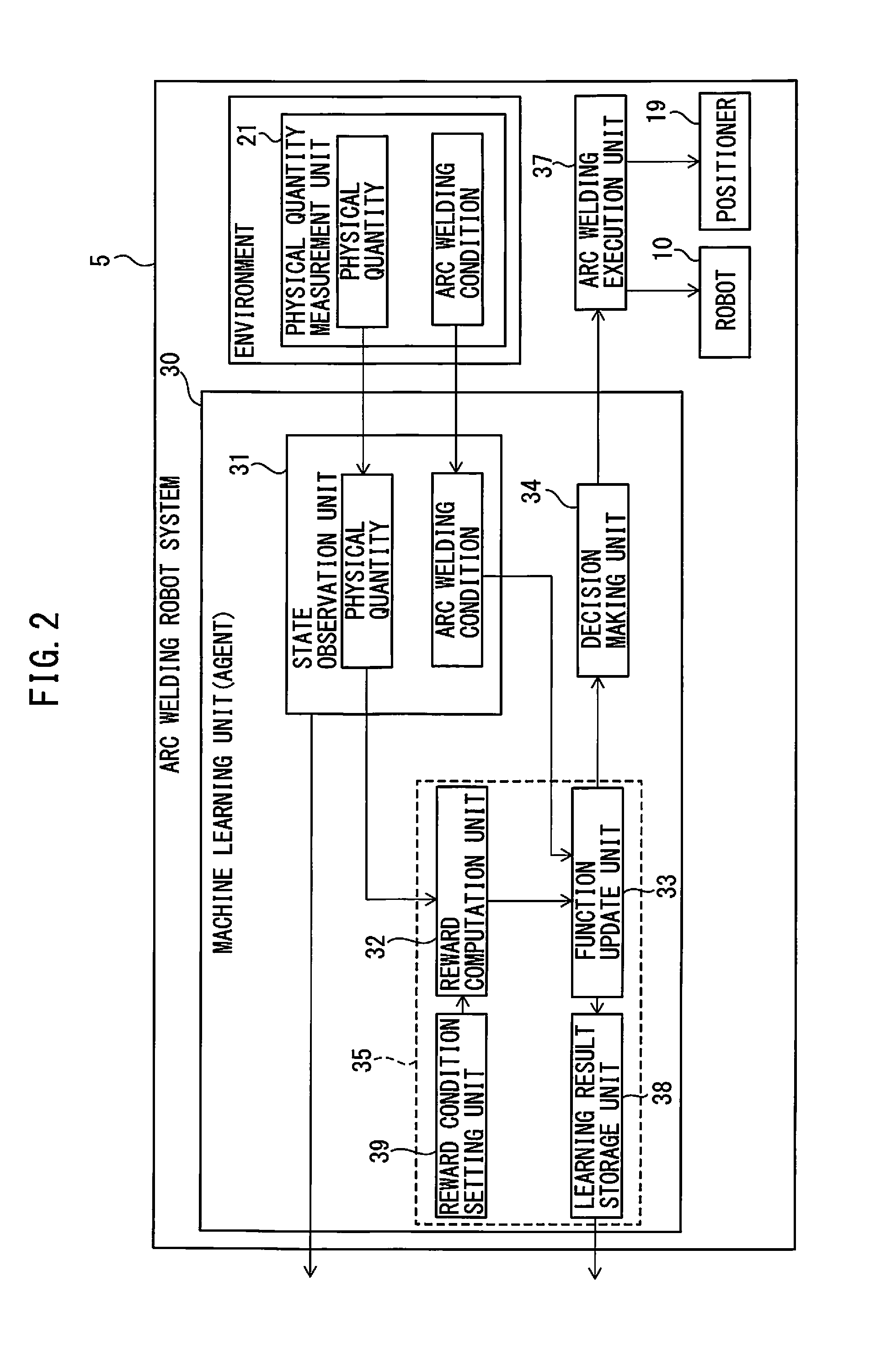

Machine learning device, arc welding control device, arc welding robot system, and welding system

ActiveUS20170028499A1Programme-controlled manipulatorElectrode holder supportersRobotic systemsLearning unit

A machine learning device which learns to determine at least one arc welding condition includes a state observation unit which observes a state variable consisting of at least one physical quantity regarding the arc welding and the at least one arc welding condition at least during or after the arc welding, and a learning unit which learns a change in the at least one physical quantity observed by the state observation unit and the at least one arc welding condition in association with each other.

Owner:FANUC LTD

Double-seam automatic welder

ActiveCN104625523AGuarantee welding qualityReasonable structural designWelding/cutting auxillary devicesElectrode holder supportersEngineeringWeld seam

The invention provides a double-seam automatic welder and relates to the technical field of welding devices. The double-seam automatic welder comprises a lathe bed, a left clamp, a right clamp and welding gun mechanisms, the left clamp and the right clamp are arranged on the lathe bed and used for clamping a workpiece, the welding gun mechanisms are arranged on the left clamp and the right clamp respectively, and each welding gun mechanism comprises a transverse rough adjustment device, a vertical adjustment device, a transverse fine adjustment device, a vertical linkage device and an angle adjustment device which are connected with one another in sequence. By means of the double-seam automatic welder, the whole structure design is reasonable, double-seam welding works can be synchronously finished, only one welding gun mechanism can be started according to work demands, positions of the right clamp and welding guns can be adjusted according to size of the workpiece, and welding requirements of various workpieces can be met. Besides, the welding gun mechanisms can accurately adjust positions of the welding guns according to workpiece size and welding seam positions so that the welding requirements can be met, and welding qualities can be guaranteed.

Owner:杭州焊林科技有限公司

Increased durability welding torch assembly and components

ActiveUS20150190879A1High strengthAvoid accidental damageElectrode holder supportersUltimate tensile strengthMechanical engineering

A welding gun assembly having a connection between a diffuser and the inner gun tube which provides increased strength between the diffuser and the gun tube to prevent inadvertent damage to the welding torch and upstream components. The diffuser comprises an engagement portion which engages with, and overlaps, at least a part of a sturdier portion of the inner gun tube. This engagement provides a stronger and more stable connection between the gun tube and the diffuser.

Owner:LINCOLN GLOBAL INC

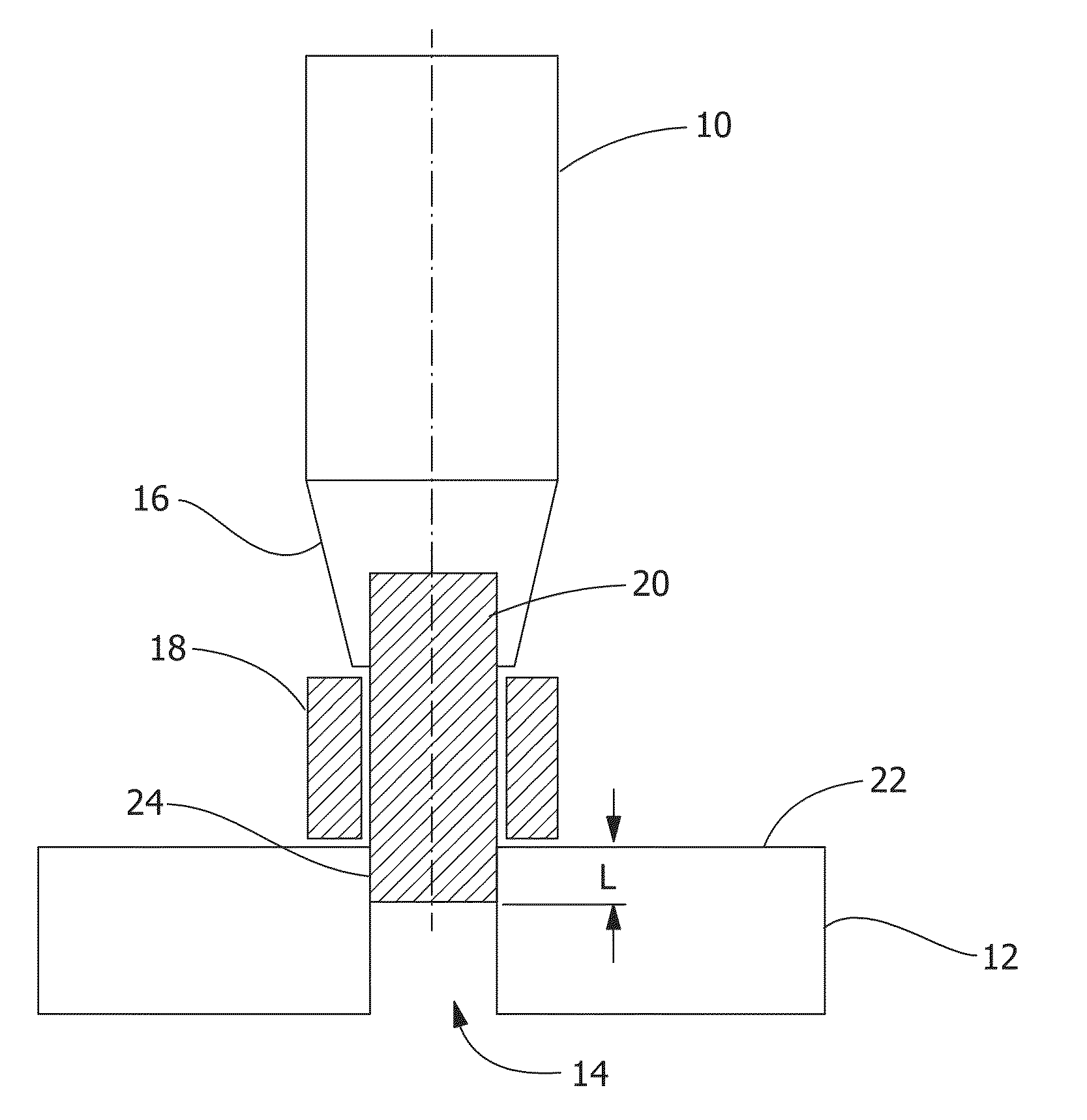

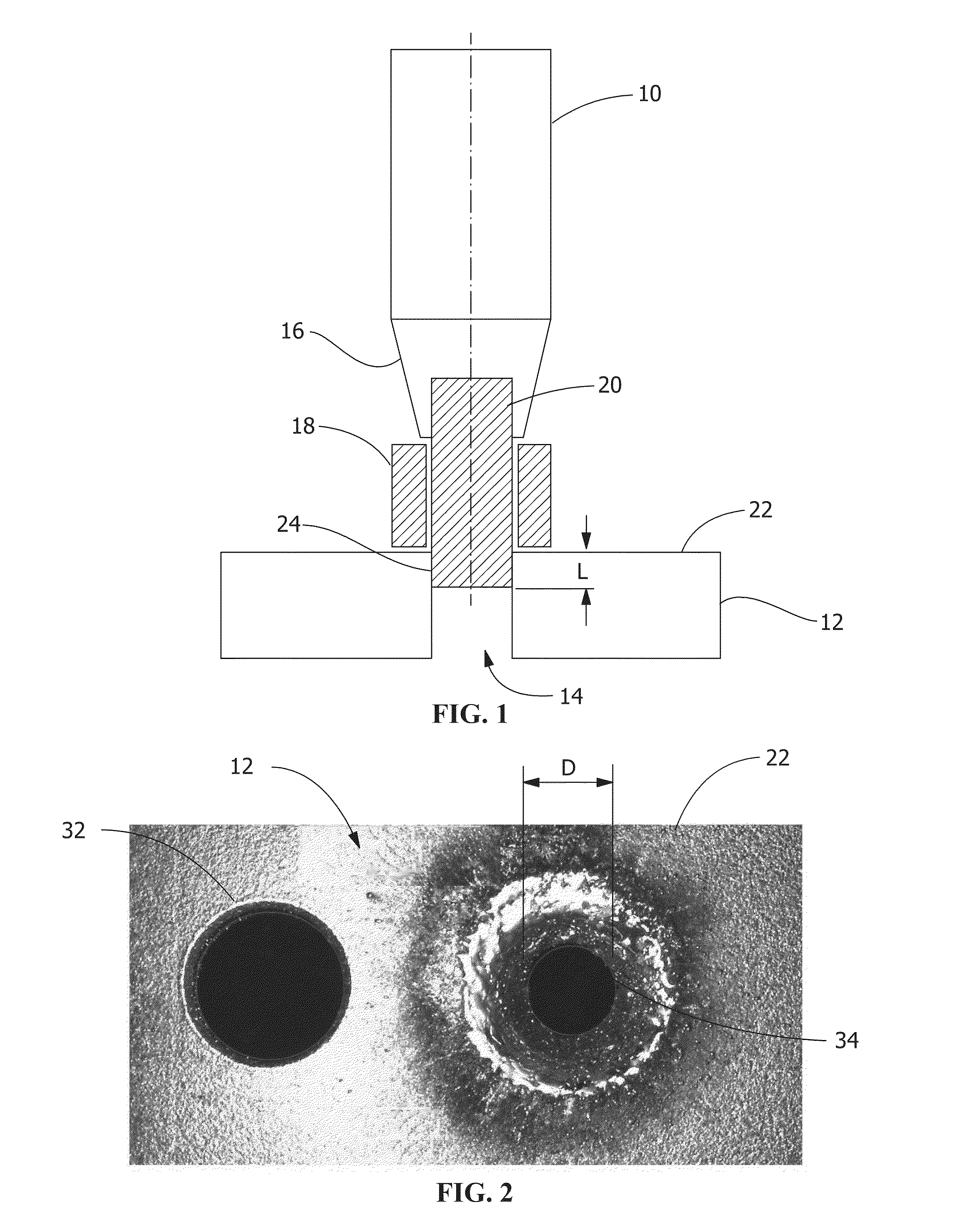

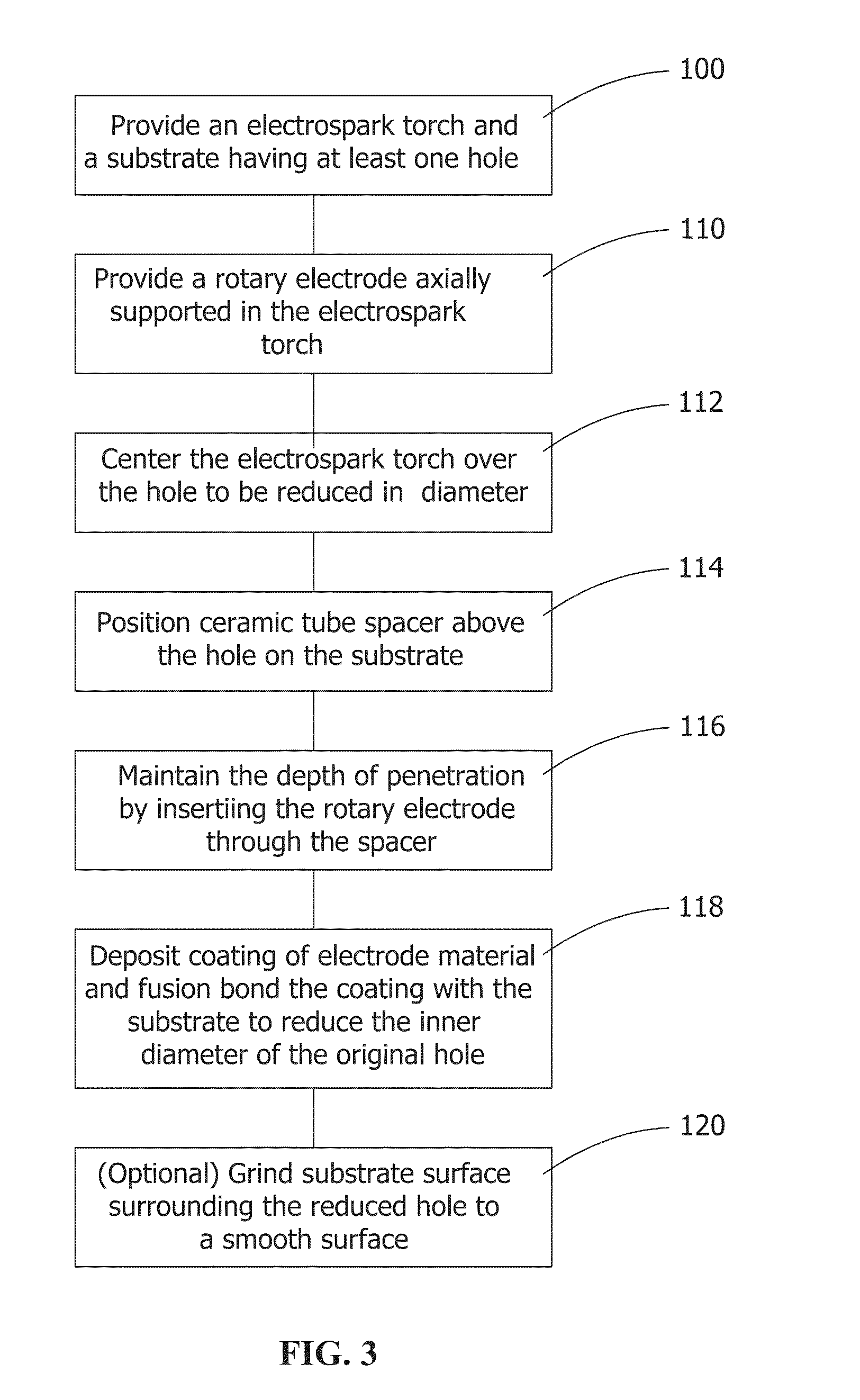

Method and system for reducing oversized holes on turbine components

A system is disclosed for reducing an internal diameter of a hole in a metal substrate. The system includes an electrospark device having an electrospark torch and an electrode holder rotatable about an axis. An electrode is removably supported in the electrode holder. The electrospark device configured to apply a coating of a material of which the electrode is formed, to the substrate on an inner wall of the hole when the electrode is rotated within the hole.

Owner:GENERAL ELECTRIC CO

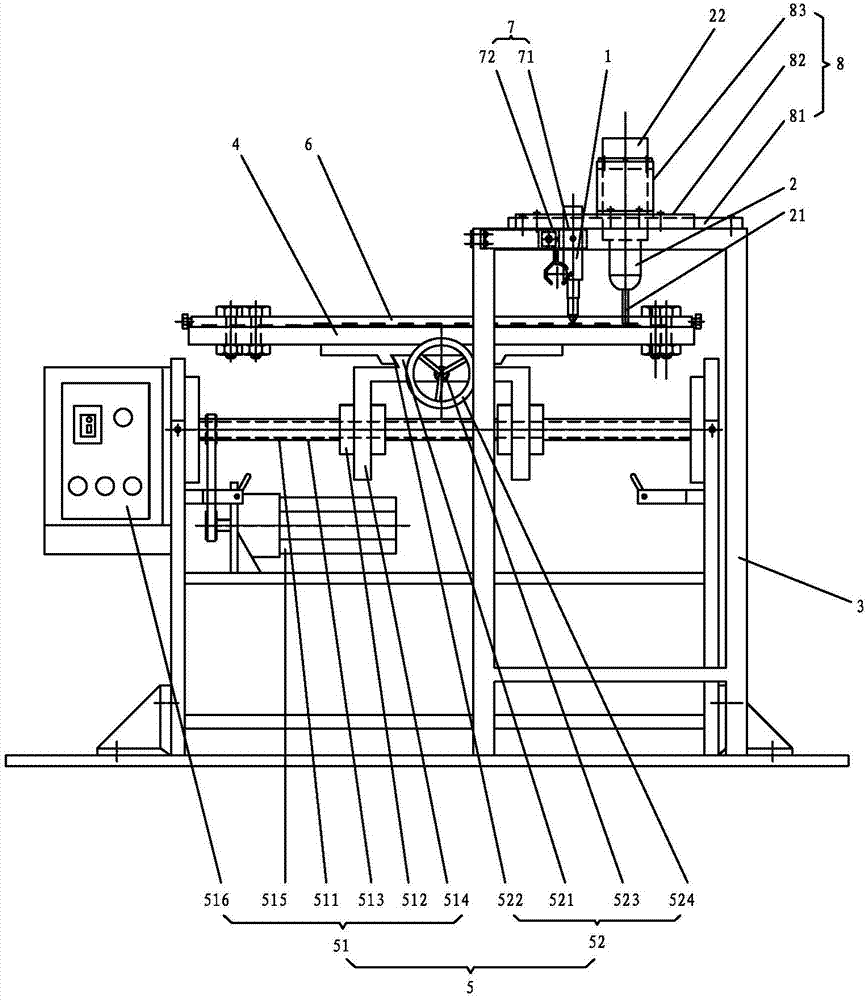

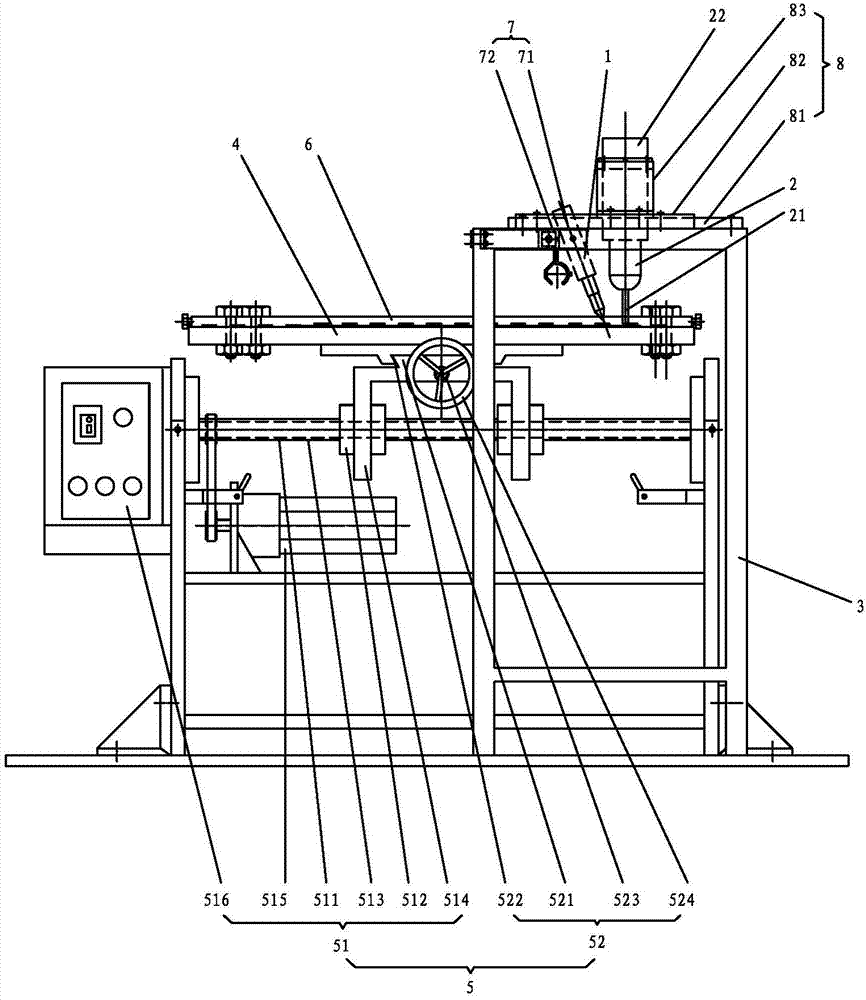

Automatic welding machine and automatic welding method for double straight seams of radiator

ActiveCN105945391AFlexible operationSimple and fast operationWelding/cutting auxillary devicesElectrode holder supportersEngineeringHeat spreader

The invention discloses an automatic welding machine and an automatic welding method for double straight seams of a radiator. The automatic welding machine and the automatic welding method for the double straight seams of the radiator belong to welding equipment for the radiator, and aims to solve the technical problem so as to realize the automatic welding of the radiator, improve the work efficiency, and reduce the manual labor intensity. The technical scheme is characterized in that the automatic welding machine for the double straight seams of the radiator structurally comprises a rack, two welding guns, a controller, a double-welding gun transverse walking device, a workpiece positioning device and turnover devices. The rack comprises bases and a cross beam on the top part; the controller is connected with and controls the welding gun, the double-welding gun transverse walking device, the workpiece positioning device and the turnover devices; the turnover devices are arranged above the bases; the workpiece positioning device is arranged on the turnover devices; the turnover devices can turn over the workpiece positioning device; the double-welding gun transverse walking device is arranged on the cross beam; the workpiece positioning device is located below the double-welding gun transverse walking device; and the turnover devices are located at two sides of the workpiece positioning device.

Owner:山东厚丰汽车散热器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com