Double-seam automatic welder

An automatic seam and welding machine technology, applied in the characteristics of welding rods, welding equipment, welding equipment, etc., can solve the problems of not being able to apply welding of different workpieces at the same time, inconvenient adjustment of welding torches, etc., so as to improve the welding qualification rate, improve welding quality and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

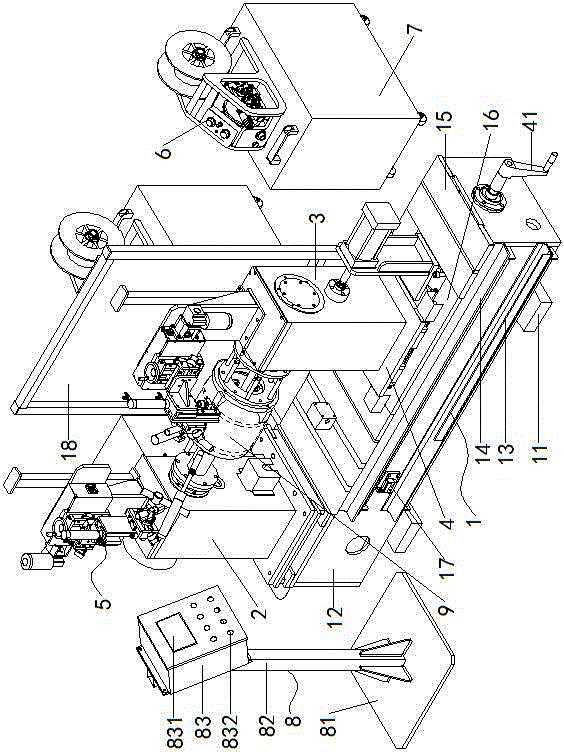

[0035] As shown in the figure, the double-seam automatic welding machine provided by the embodiment of the present invention includes a bed 1, a left clamp 2 fixedly installed at one end of the bed in the length direction, and a connecting seat 4 movably arranged at the other end of the bed in the length direction. The right clamp 3, the welding torch mechanism 5 installed on the left clamp and the right clamp, the power supply box 7 and the wire feeder 6 for feeding the welding wire during the welding process, and the control device 8 for controlling each component.

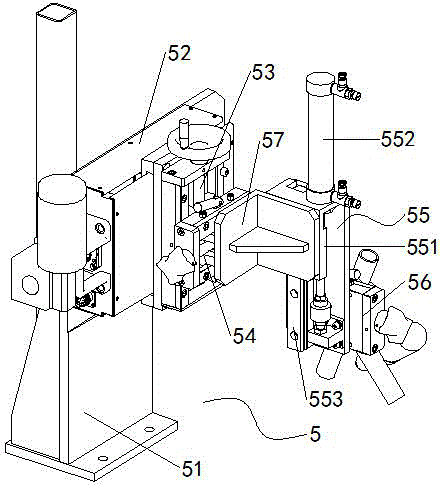

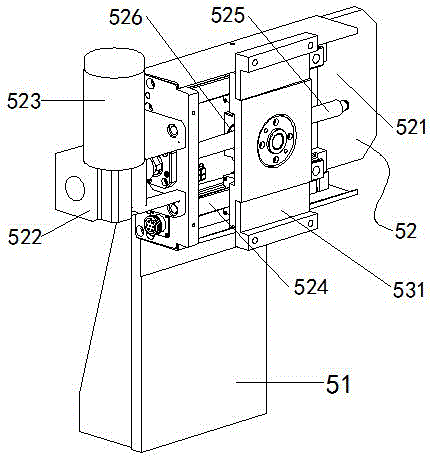

[0036] The welding torch mechanism 5 includes a support 2 51 for fixing the whole, a horizontal coarse adjustment device 52 fixed on the support 2, a vertical adjustment device 53 connected to the horizontal coarse adjustment device, and a horizontal fine adjustment device connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com