Prefabricated tube pile embankment structure and construction method thereof

A technology for prefabricated pipe piles and pavement structures, applied in infrastructure engineering, roads, roads, etc., can solve problems such as limiting the scope of application of the replacement method, uneven grouting pressure, and pavement waves. The effect of preventing post-construction settlement and reducing the upper load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

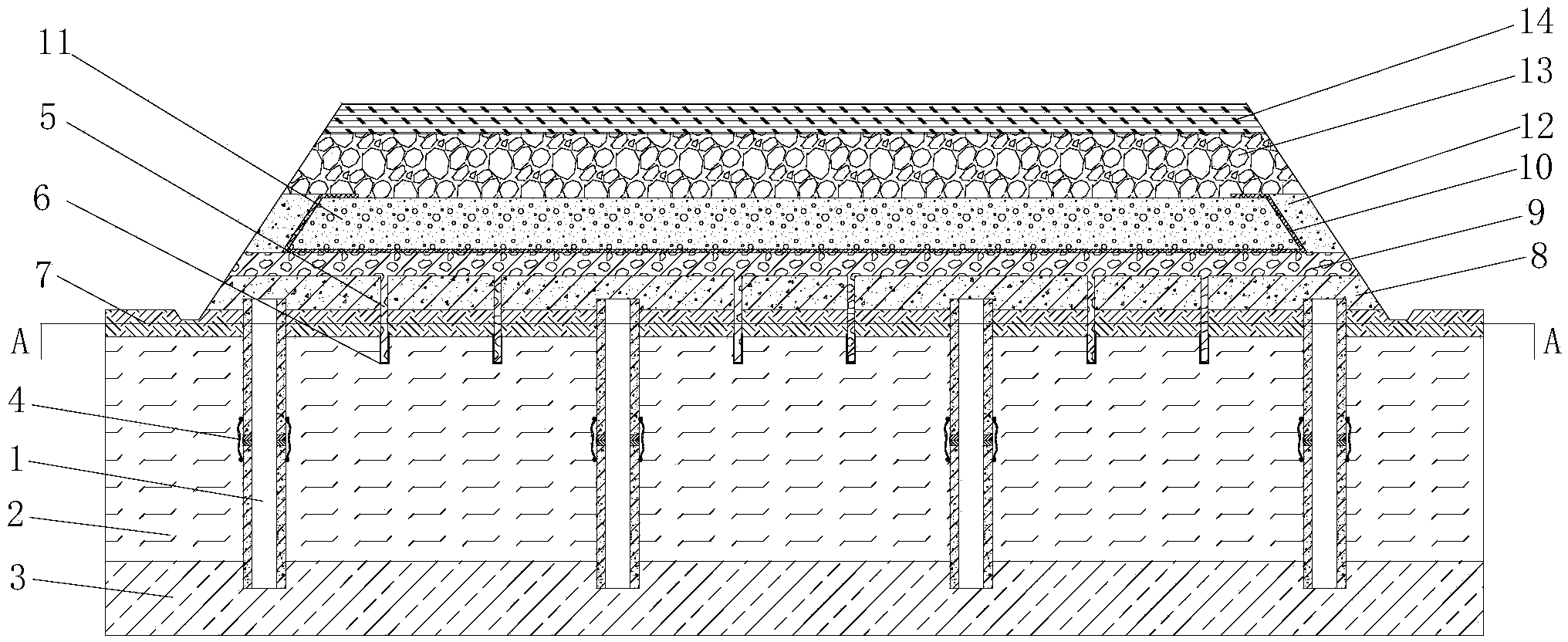

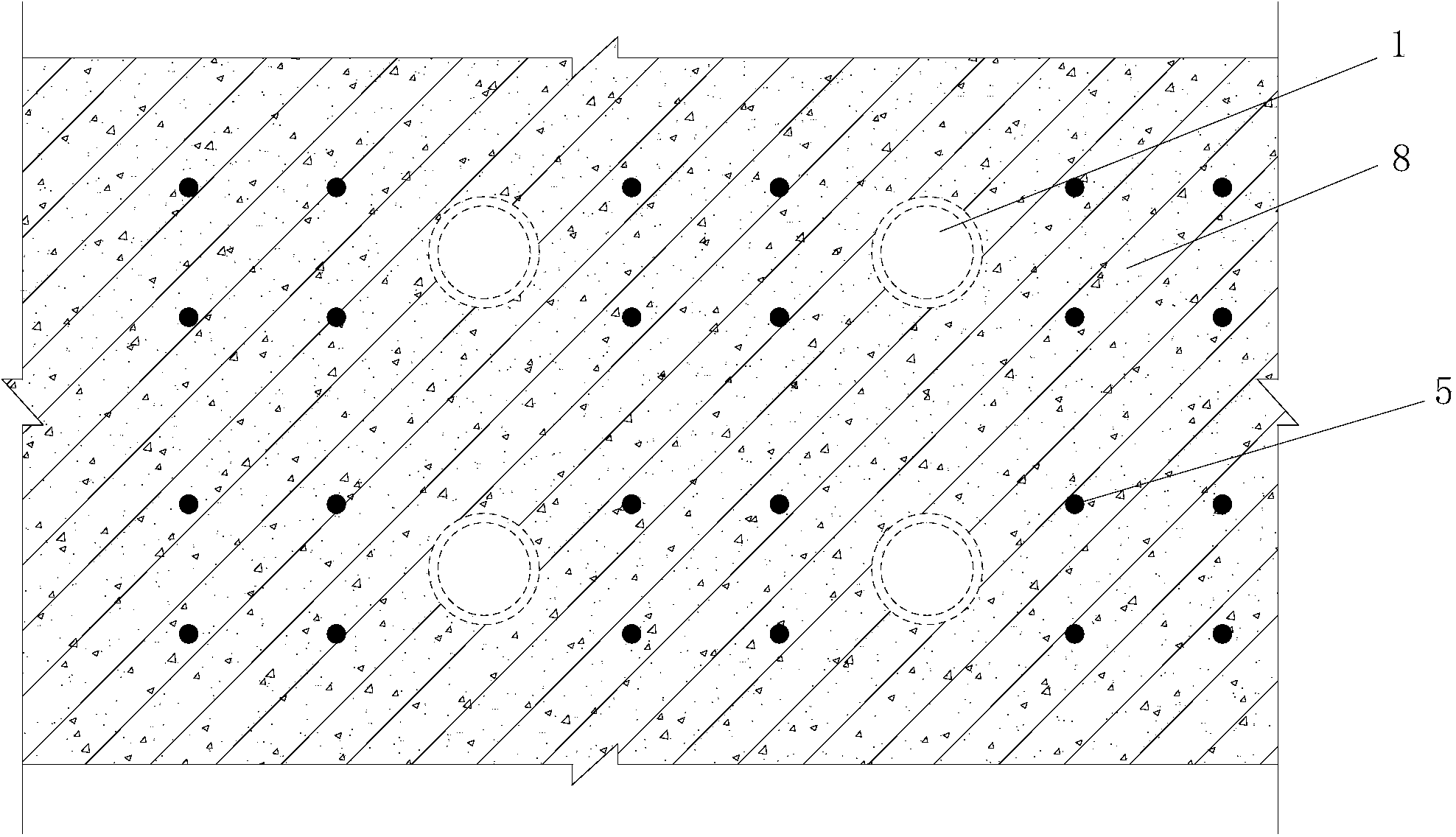

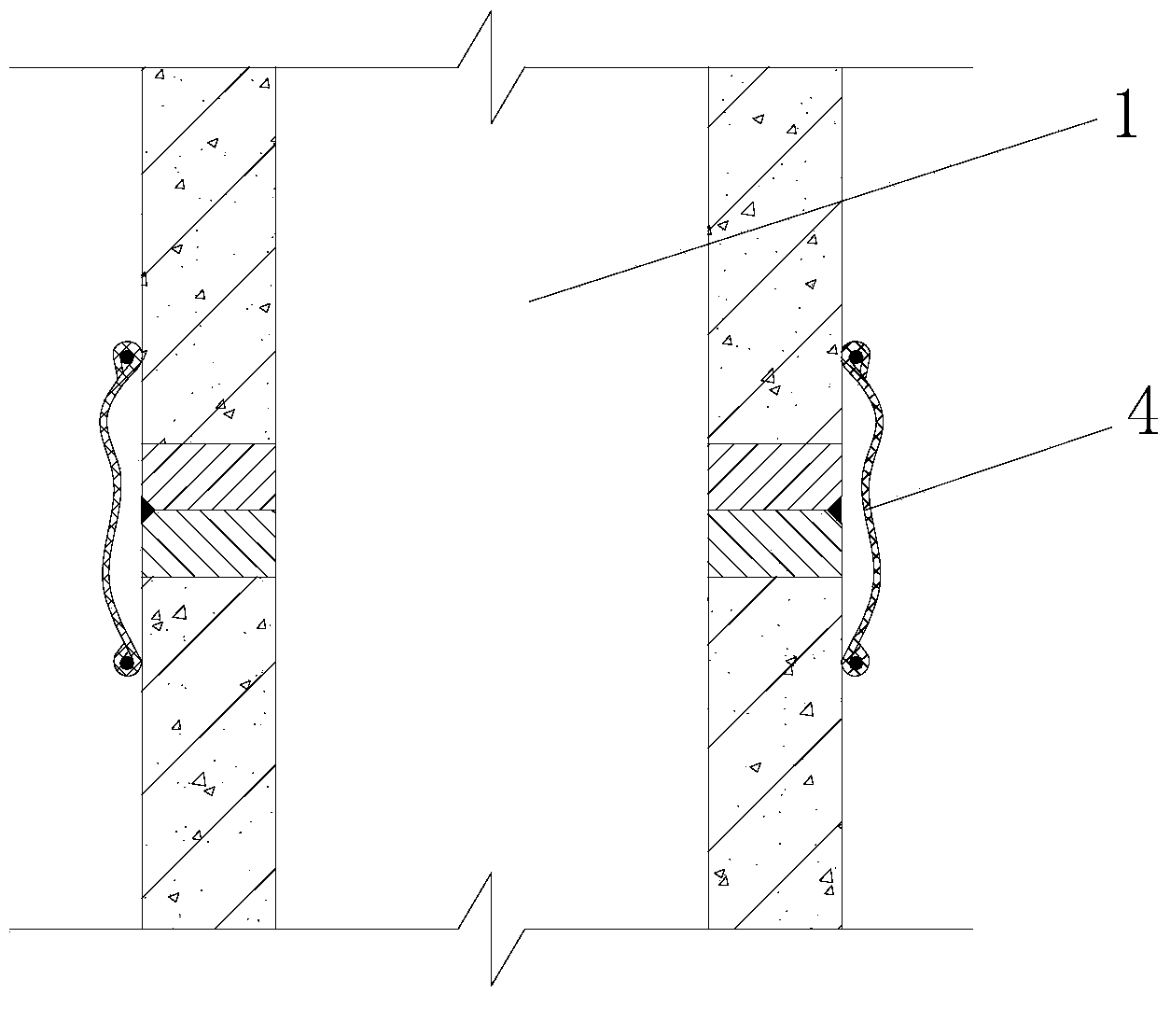

[0037] figure 1 It is the elevation view of the prefabricated tubular pile embankment structure of the present invention, figure 2 yes figure 1 Sectional view along line A-A. refer to Figure 1~2 As shown, the prefabricated pipe pile embankment structure is mainly composed of prefabricated pipe piles 1, vertical drainage pipes 5, shallow solidified slabs 7, thin reinforced concrete continuous slabs 8, crushed stone layers 9, filter geotextiles 10, air bubble concrete anti-rolling Layer 11, concrete protection layer 12, slag layer 13, pavement structure 14 and other parts.

[0038] Prefabricated pipe pile 1 adopts prefabricated pipe piles with a pile diameter of Φ400mm and a wall thickness of 90mm. The prefabricated pipe piles penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com