Bentonite mud water pressurization equilibration shield machine

A technology of bentonite mud and shield machine, which is applied in earth square drilling, mining equipment, tunnels, etc. It can solve the problems of threatening the health of operators, depletion of water wells, and pollution of groundwater, etc., and achieves wide application range of soil quality, small settlement, and small disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

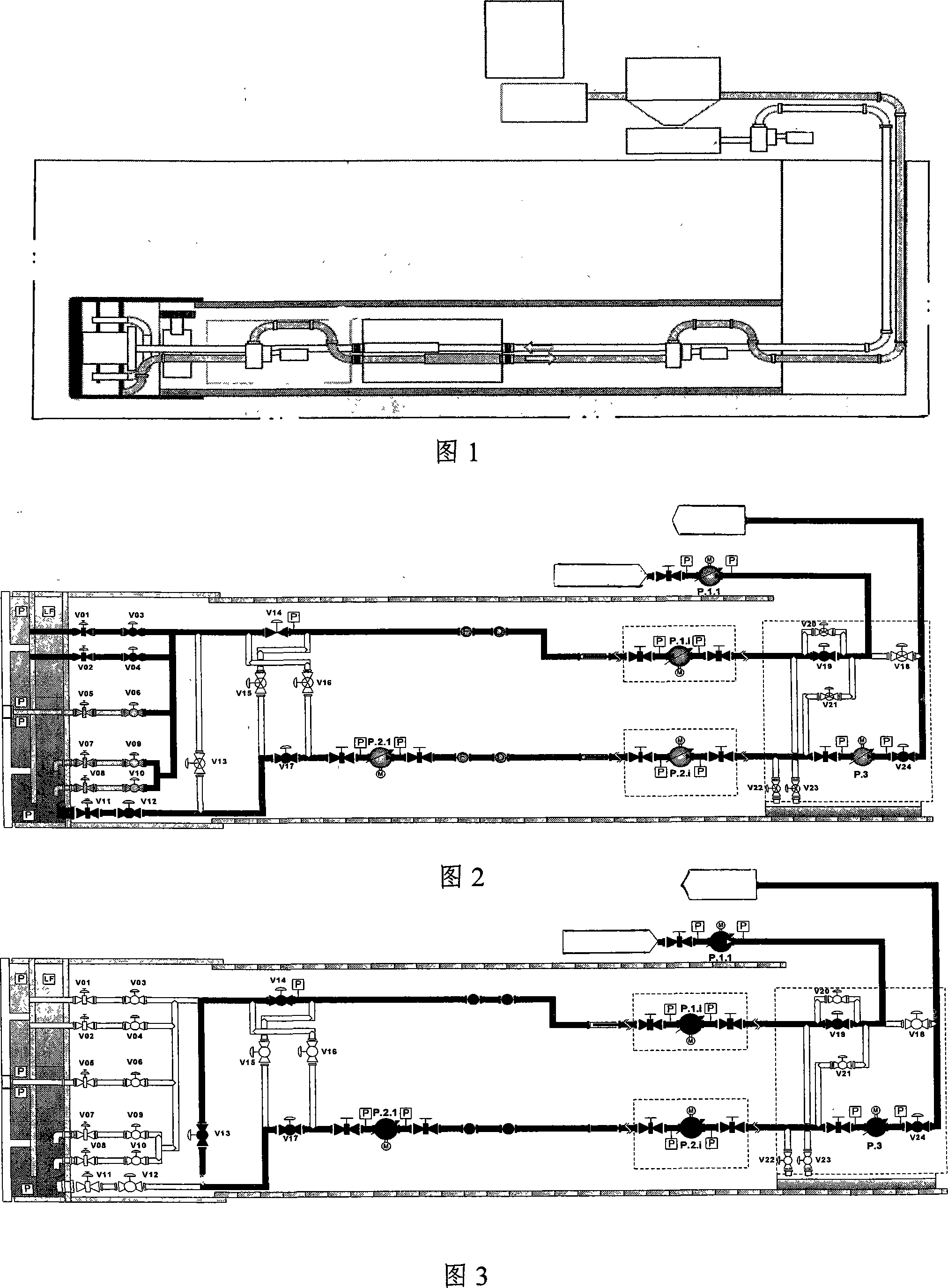

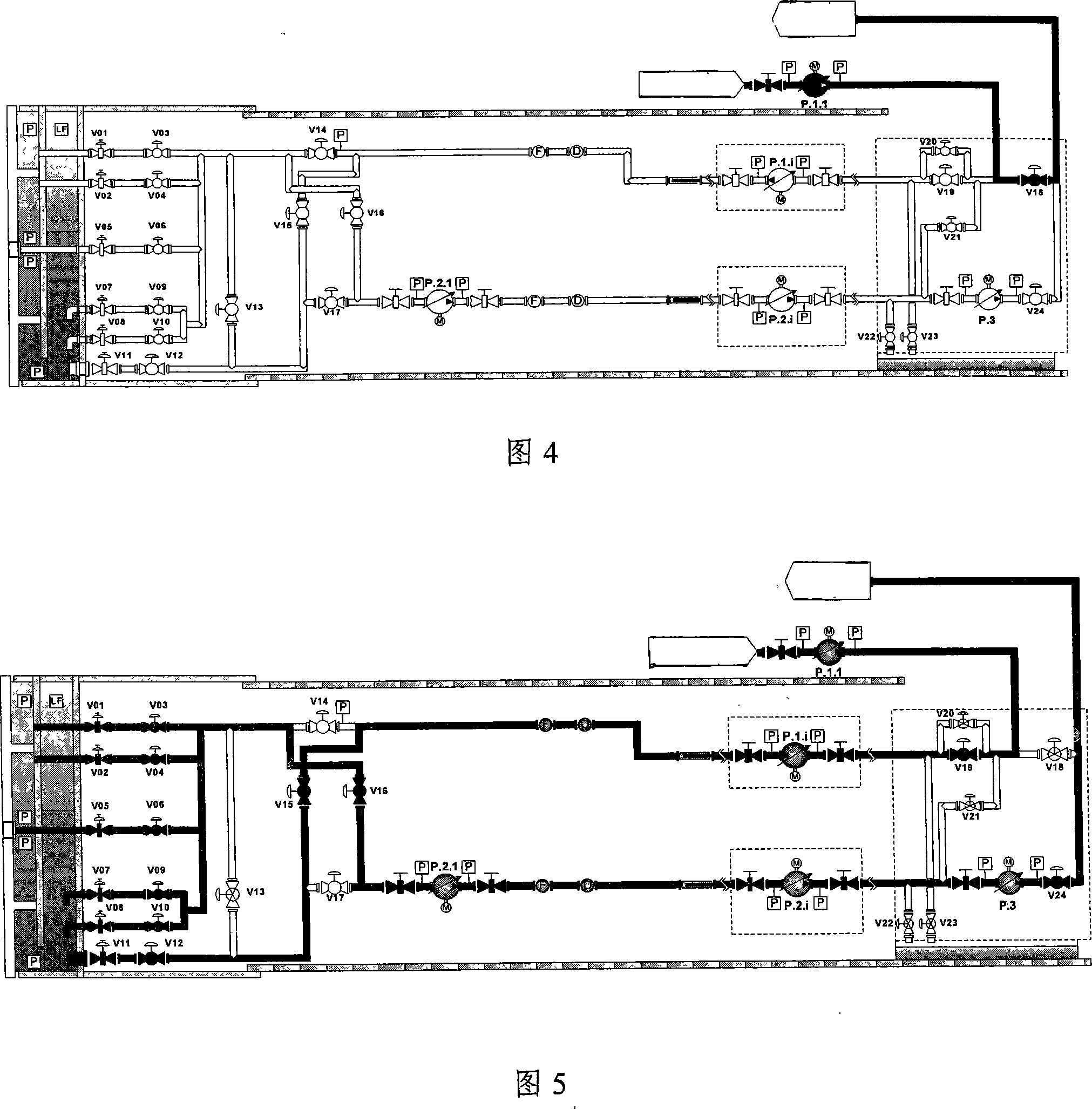

[0013] Referring to the accompanying drawings, the bentonite slurry pressurized balance shield machine has four operating modes: excavation mode, bypass mode, isolation mode, and reverse mode. Its working principle is that the bentonite slurry pressurized balance shield machine passes through the front shield The pressurized bentonite mud, that is, the prepared mixture of bentonite and water, is injected into the sealed compartment where the partition is installed to form a pressurized mud tank, and the stability of the excavation surface is sought through the pressurization and pressure maintenance system; the pressurized mud is injected The bentonite upper mud can penetrate several centimeters deep into the ground and embed into the gaps between soil particles to form a layer of "mud film"; this layer of "mud film" makes the soil layer more stable and impermeable, which can support and stabilize the front Soil: When the cutter head cuts the soil, the cut soil enters the mud t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com