Patents

Literature

219results about How to "Improve combustion intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

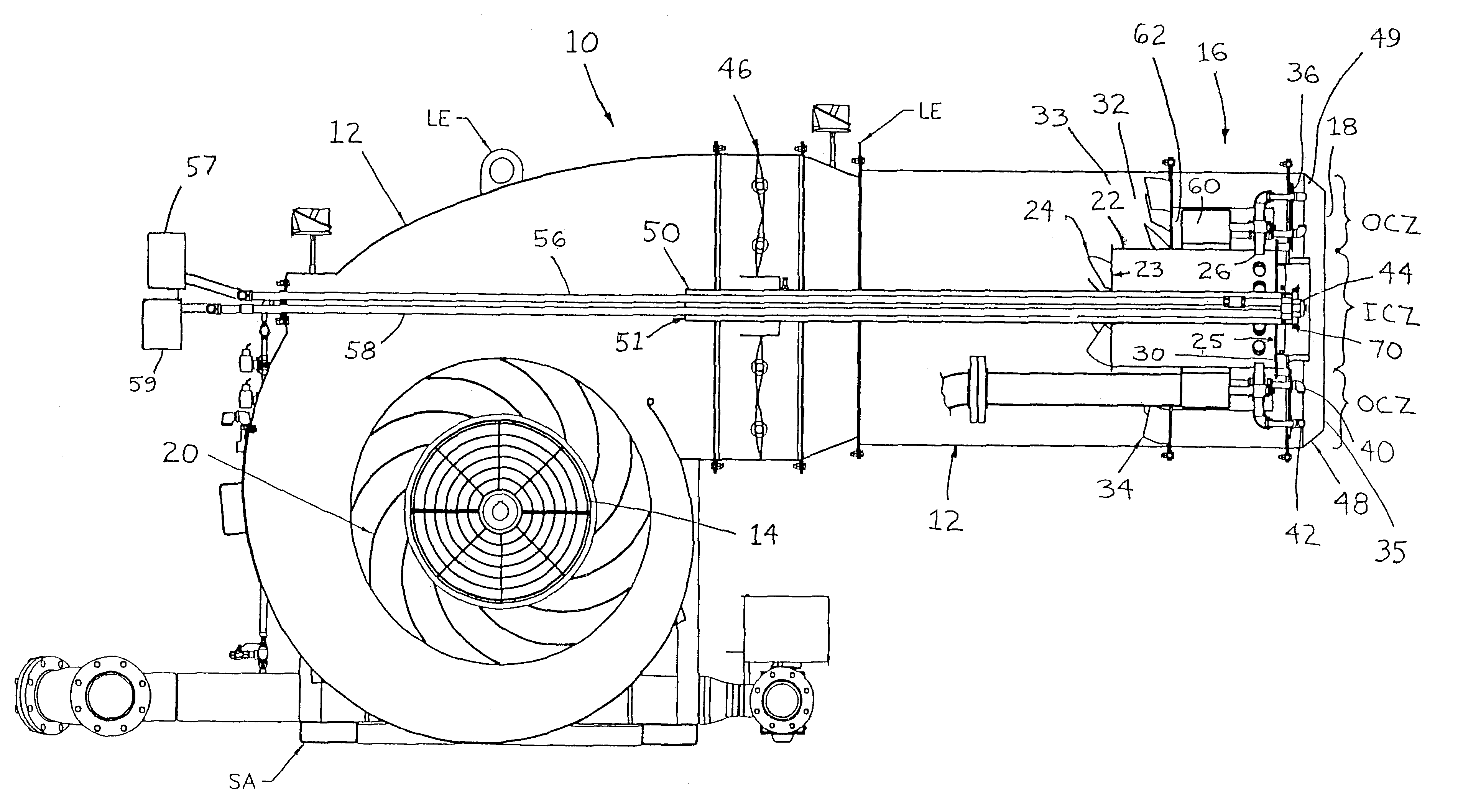

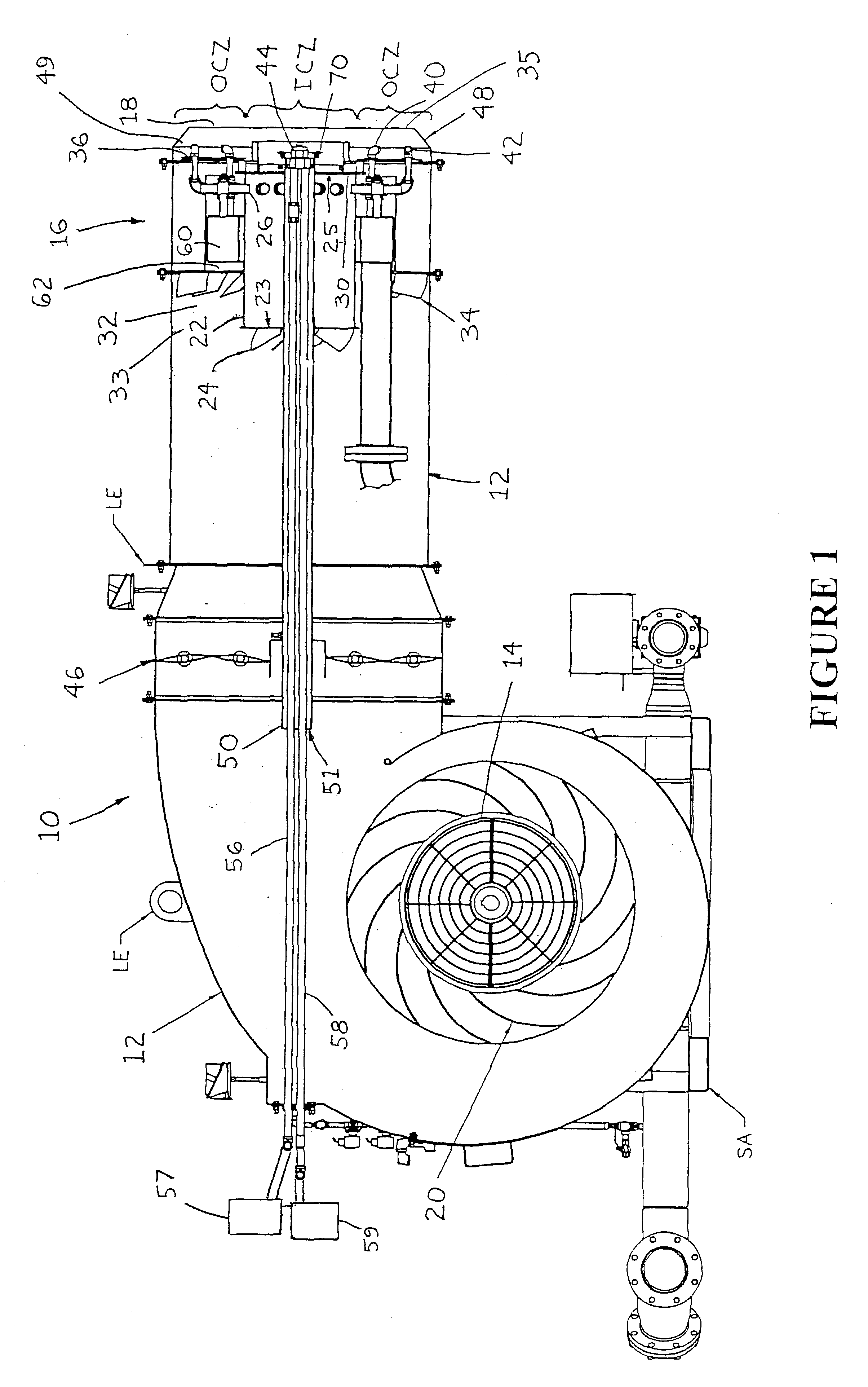

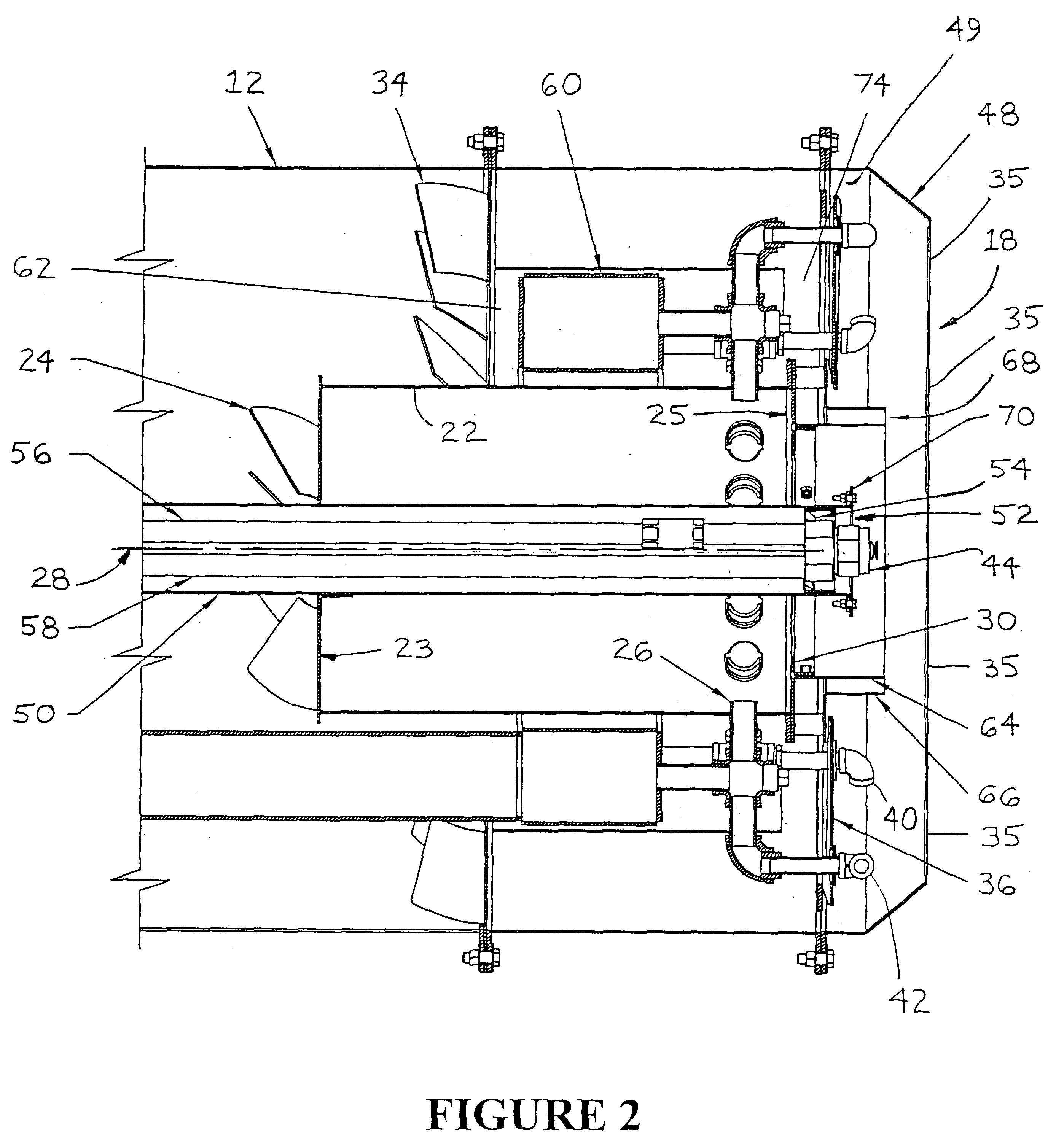

Burner assembly

InactiveUS6652268B1Improve combustion intensityReducing combustion space requiredPilot flame ignitersBafflesImpellerCombustor

A burner assembly including a housing having an air inlet and a burner end. An impeller that is mounted in the housing is in communication with the air inlet and adapted to direct air toward the burner end of the housing. The burner assembly also includes an inner air tube that is mounted in the burner end of the housing so as to define an inner combustion zone and an outer combustion zone. The assembly further includes a plurality of radiation plates that are mounted in the burner end of the housing adjacent to the outer combustion zone, an inner air spin vane that is mounted on the inner air tube so as to direct some of the air from the impeller into the inner combustion zone, an inner gas injection nozzle mounted on the inner air tube so as to direct gaseous fuel into the inner combustion zone, an outer air spin vane that is mounted in the burner end of the housing so as to direct some of the air from the impeller into the outer combustion zone, and a plurality of outer gas injection nozzles that are mounted in the burner end of the housing so as to direct gaseous fuel into the outer combustion zone. A first castellated ring is mounted around the periphery of the inner air tube, and a second castellated ring is mounted around the periphery of the burner end of the housing.

Owner:ASTEC

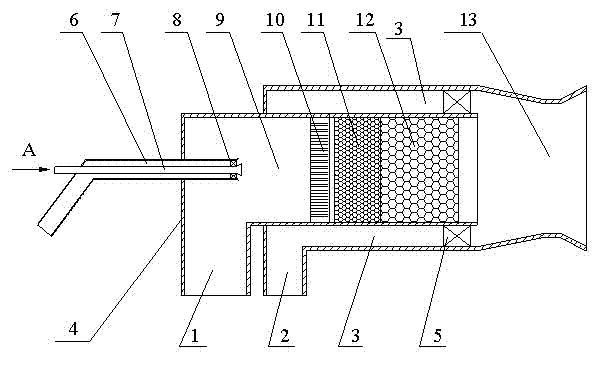

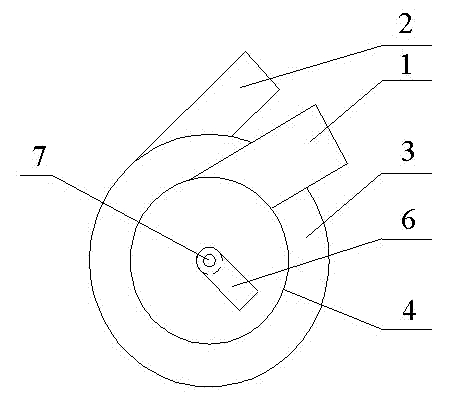

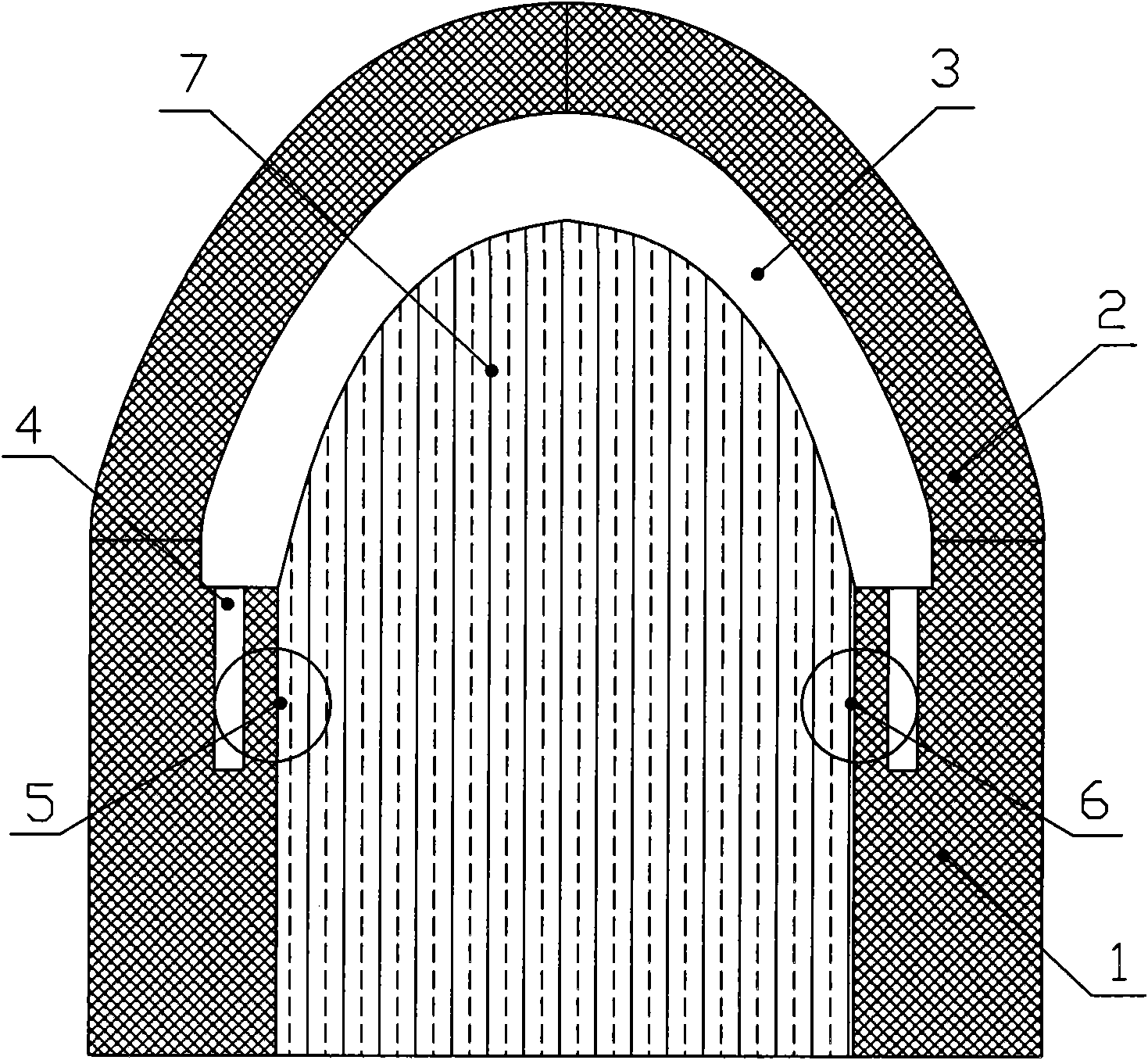

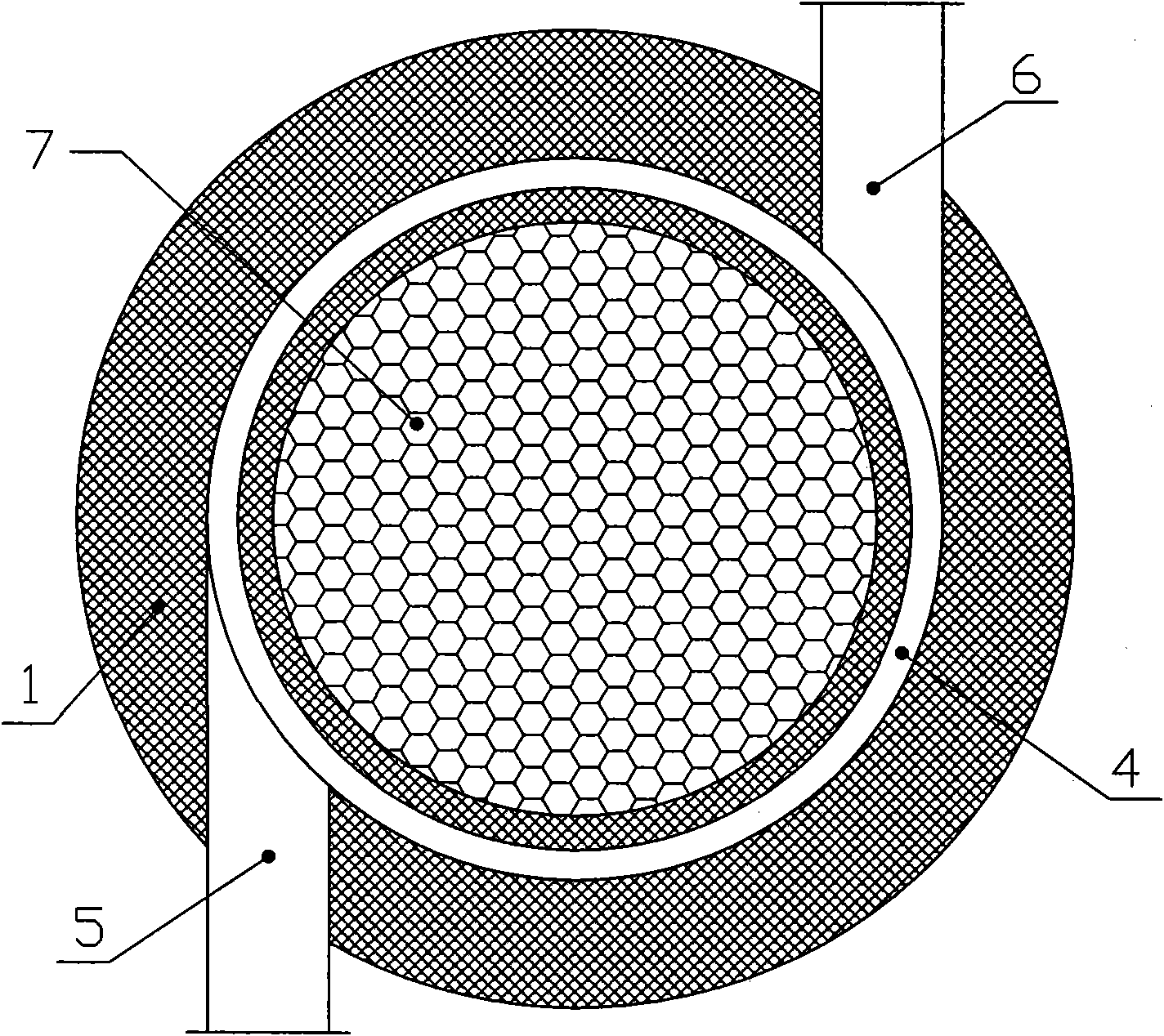

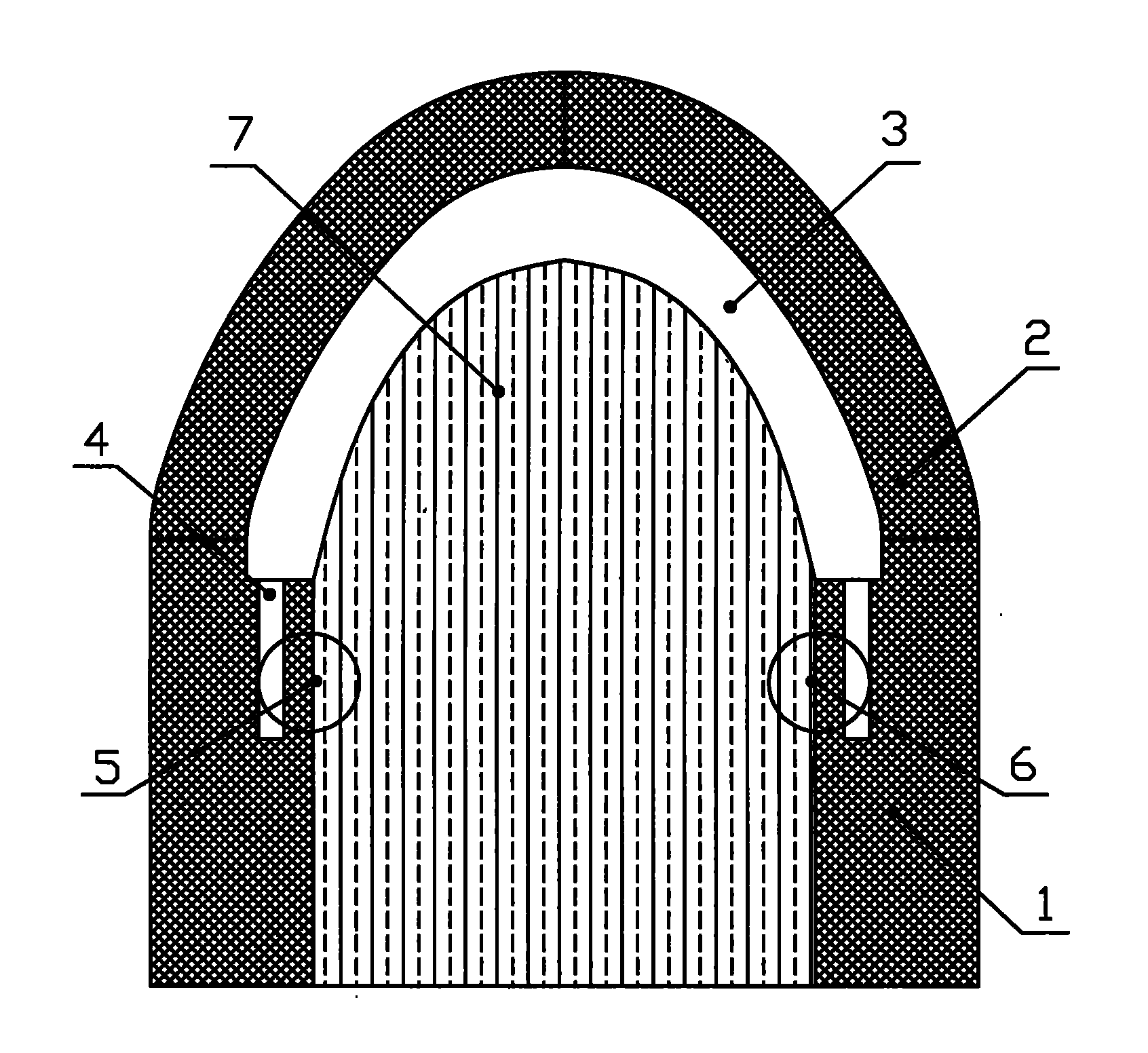

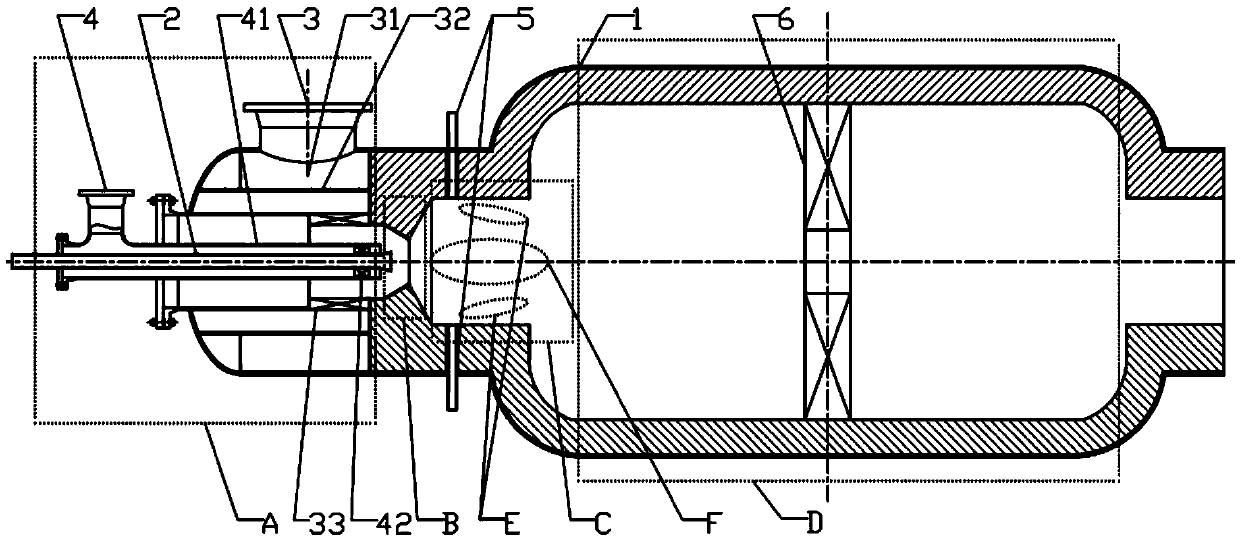

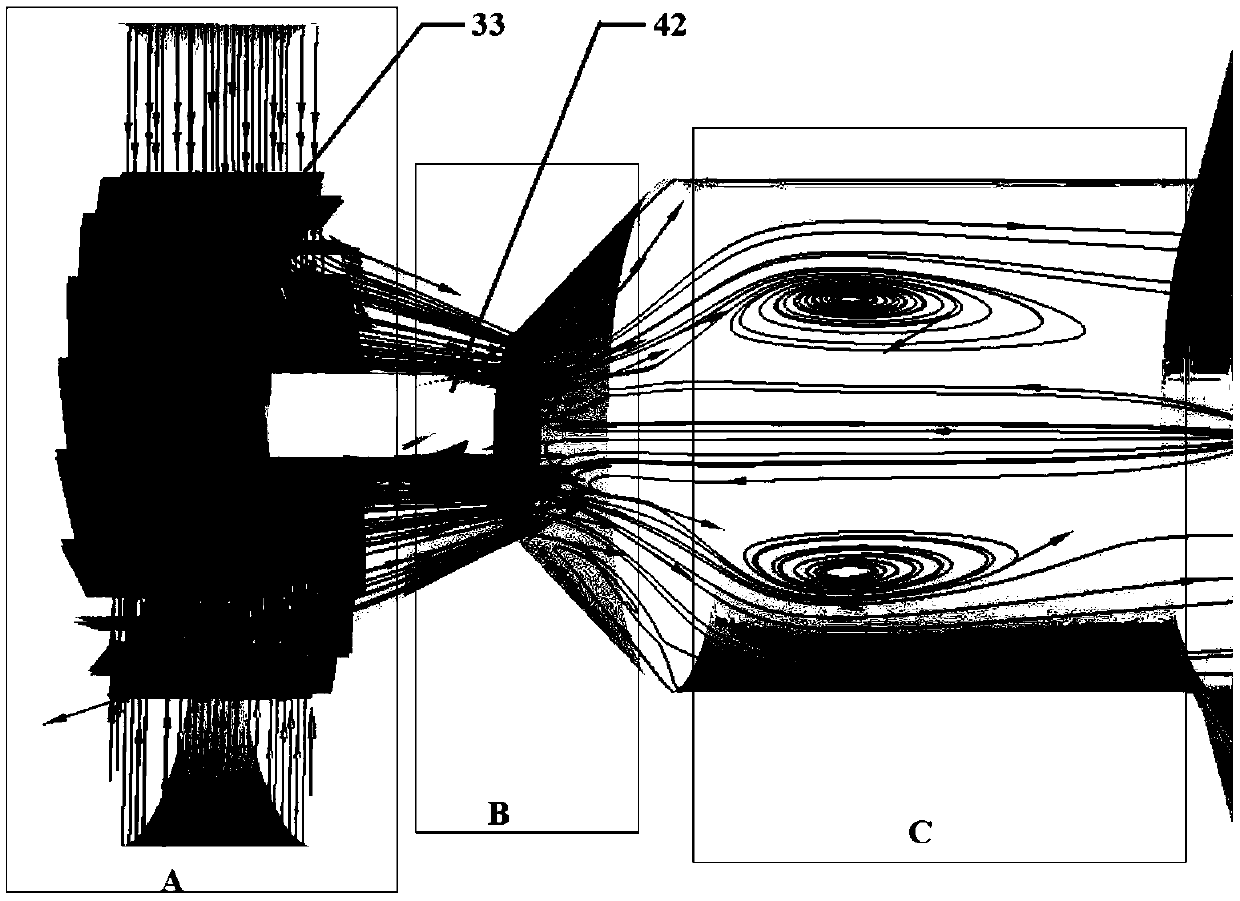

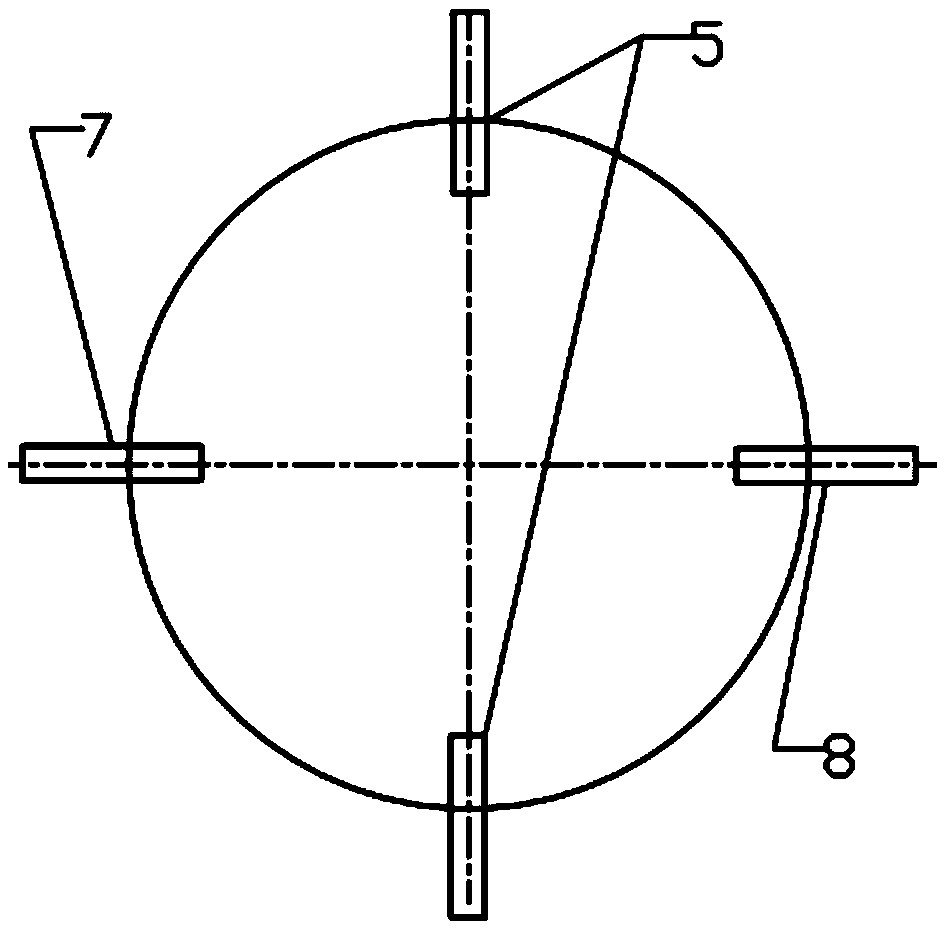

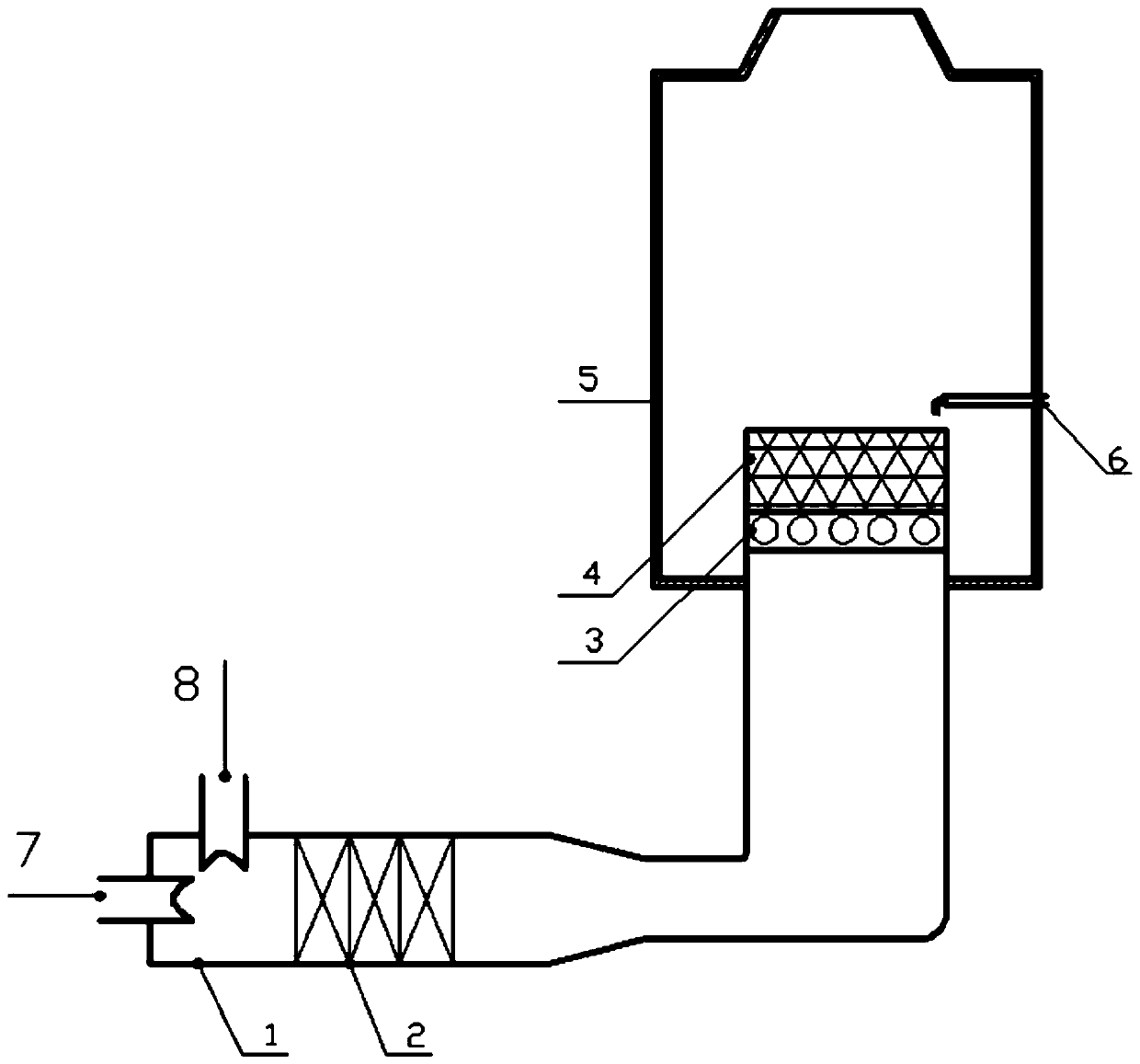

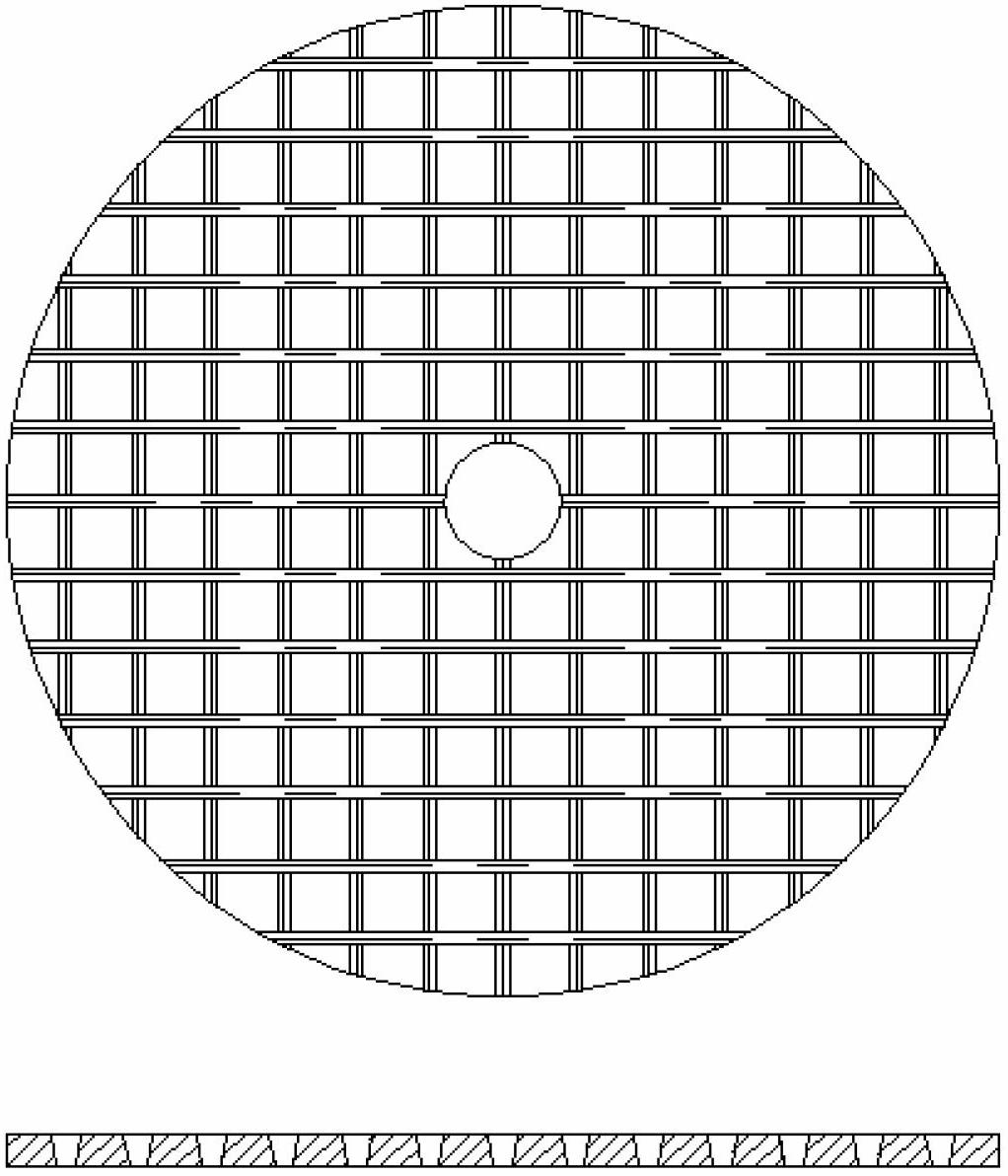

A Porous Media Burner Using Low Calorific Value Gas Fuel

InactiveCN102287819AImprove stabilityImprove combustion intensityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberPorous medium

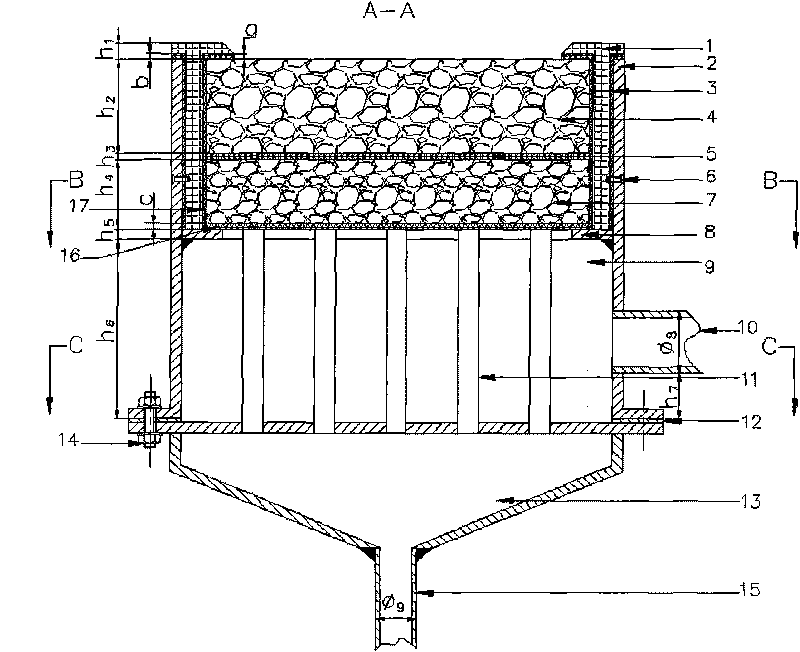

The invention discloses a porous medium combustor for a low-caloric-value gas fuel. The porous medium combustor comprises an oxygen-enriched conduit, an ignition air gun, a premixed combustion chamber, secondary air pipes and a combustor nozzle of which the central axes are coincident; the secondary air pipes are coaxially sleeved outside the premixed combustion chamber; air pipelines and fuel pipelines which circumferentially incline are correspondingly arranged on respective pipe walls of the secondary air pipes and the premixed combustion chamber; a mixing chamber, a mixed fuel gas uniformdistributor, a small porous medium and a large porous medium are sequentially arranged in the premixed combustion chamber along an airflow direction; air holes of the small porous medium and the large porous medium adopt a honeycomb arrangement structure; the oxygen-enriched conduit is coaxially sleeved outside the ignition air gun; and outlet ends of the oxygen-enriched conduit and the ignition air gun pass through a wall surface of the premixed combustion chamber and extend into the mixing chamber. By adopting the segmental type porous medium, the combustion stability of the low-caloric-value gas fuel can be obviously improved, the combustion intensity of the low-caloric-value gas fuel is enhanced, the combustion volume is reduced, the combustion efficiency is improved, and the discharge of pollutant can be effectively reduced.

Owner:CHINA JILIANG UNIV

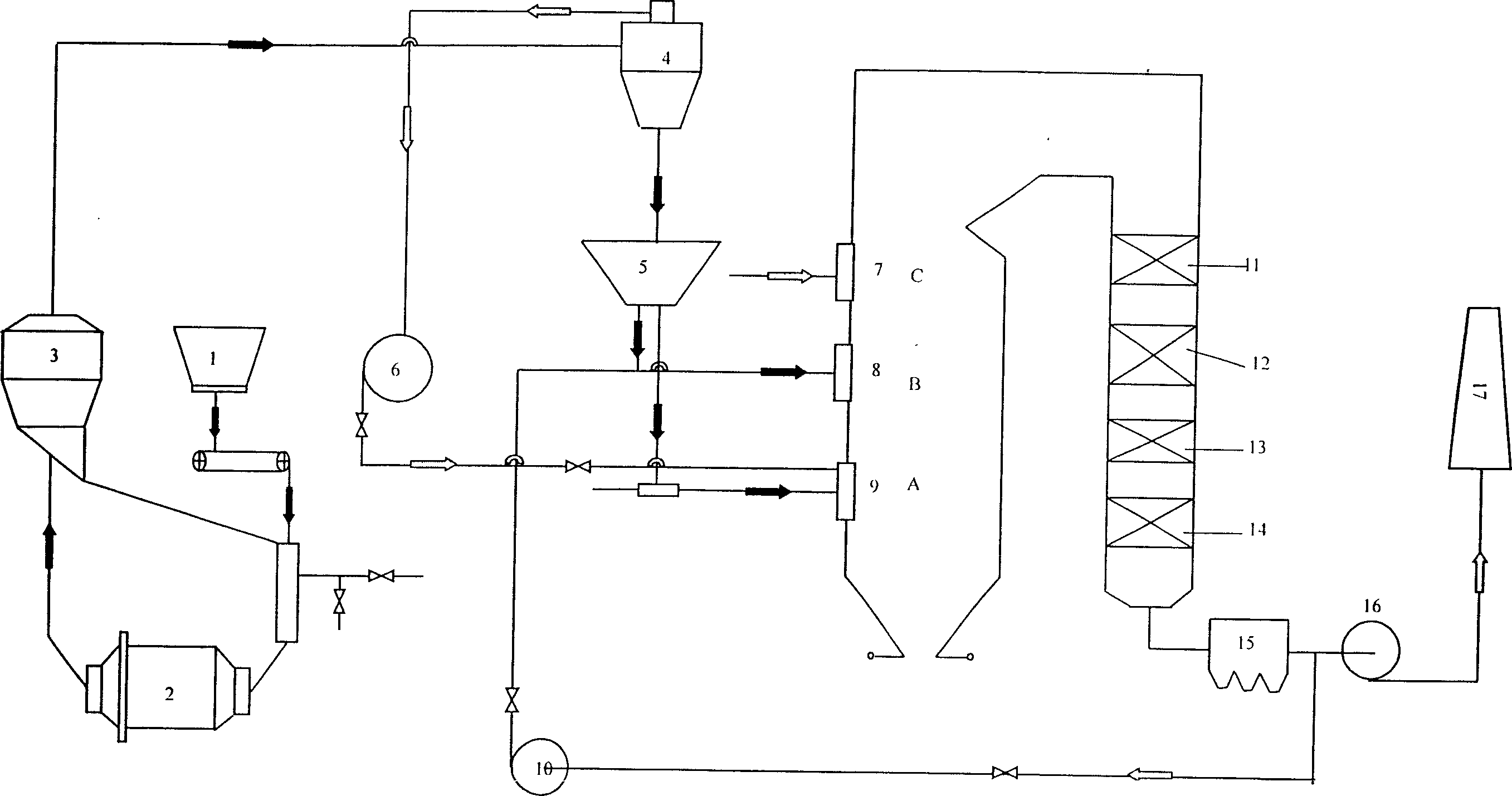

Fine coal powder recombustion denitrificating method

InactiveCN1587802AReduce initial investment costLow running costSolid fuel combustionCombustion apparatusCombustorNitrogen

The invention discloses a method and device for using tiny coal powder as reiguition fuel to reduce the NOX, which belongs to coal powder cleaning and combusting field. The method is: uses separator of raw and tiny coal powder to decrease the thin rate of all coal powder and improve the homogeneity, and uses part of tiny coal powder as reiguition fuel, extracts part of smoke form the tail smoke channel and then transmits the reiguition fuel into the reacting area, the NOX generated in the primary combustion area into N2; pours in part of combustion air from the top of the reacting area, ensures the coal powder combustion safety. The invention can decrease the discharge of nitrogen-oxygen material for 60% based on guaranteeing the boiler efficiency. In order to realize the technology, the primary combustor on the furnace is arranged with a reiguition fuel, burned wind aperture, and assembled with advanced raw powder separator and smoke extracting and transmitting system. The method in the invention has high denitration efficiency, it does not affect the combustion efficiency, the structure is reasonable, the investment is little, and the running cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

Decoupling combustion furnace and decoupling combustion method

ActiveCN101650025AIncrease combustion spaceImprove combustion intensityAir supply regulationCarburetting by solid carbonaceous material pyrolysisCombustionProcess engineering

The invention provides a decoupling combustion method, which comprises the following steps: a) firstly, performing pyrolysis and gasification of fuels to generate semicoke and gas; b) secondly, combusting part of gas and semicoke to perform oxidation reaction and reduction reaction to generate coke, and applying the generated heat to the pyrolysis and gasification in step a); c) thirdly, combusting the coke and the left gas generated in step a) under the condition that an excess air coefficient is less than 1, and simultaneously generating smoke in the combustion; and d) finally, performing full secondary combustion of the smoke and the remained gas after the steps. The decoupling combustion method can increase the decoupling combustion space and intensity with a smaller floor area; the increase of the gasification zone and the gasification intensity greatly improve the load increasing capability of a decoupling combustion furnace; and in addition, because the high-temperature smoke strongly heats the fuels in the upper part of a pyrolysis and gasification chamber and has higher pyrolysis and gasification intensity, the gas output is increased and the combustion amount of solid semicoke is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

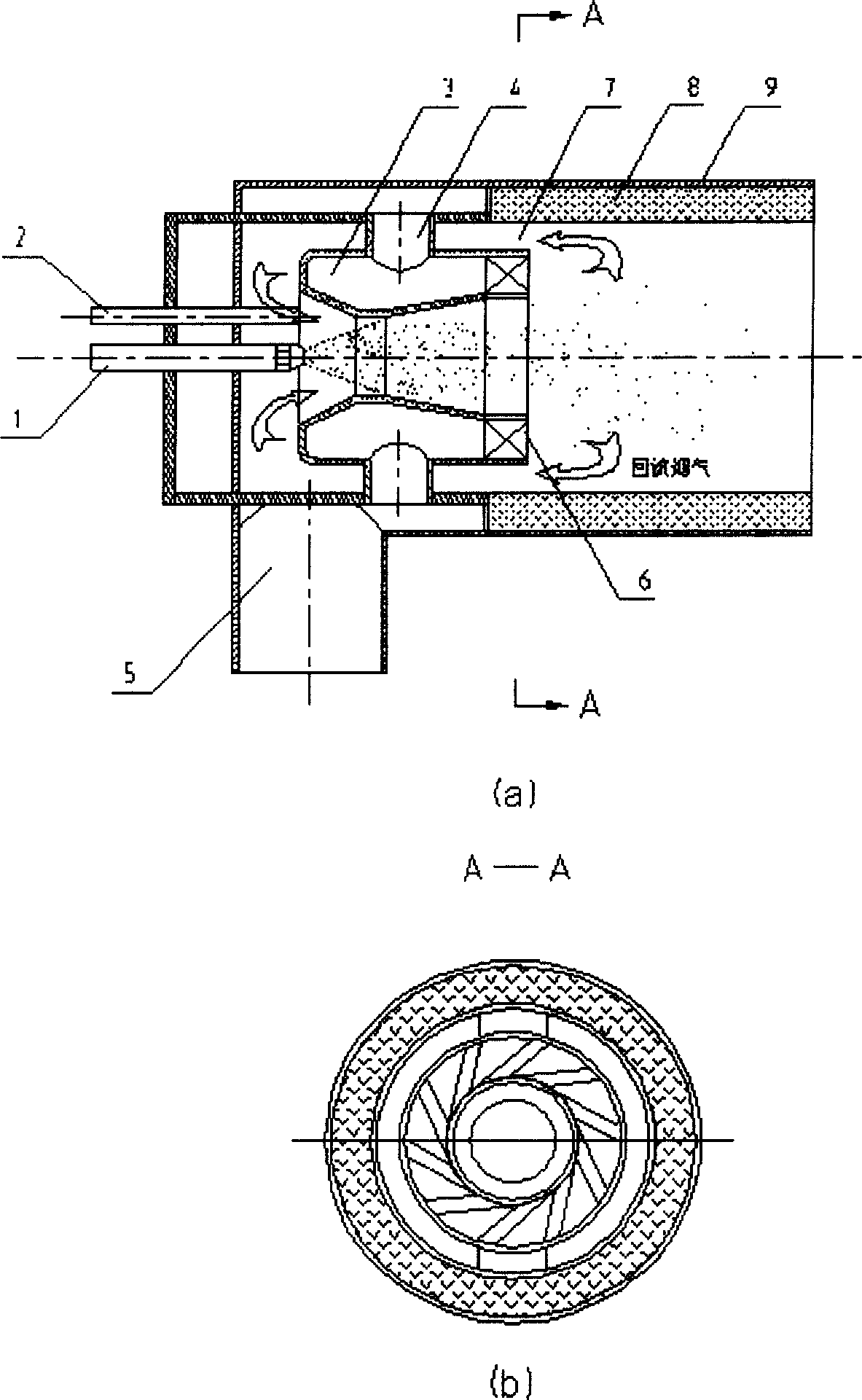

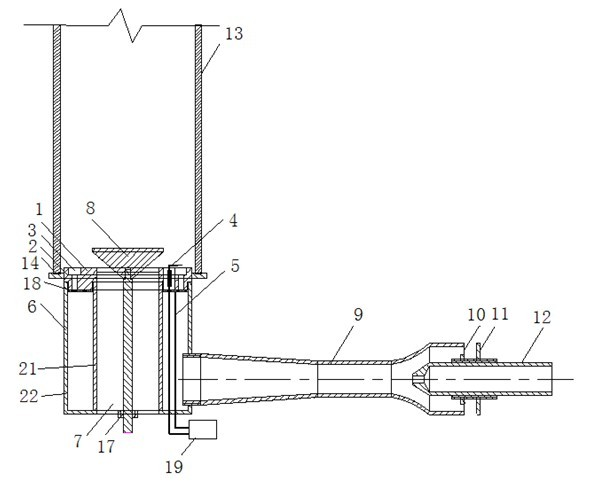

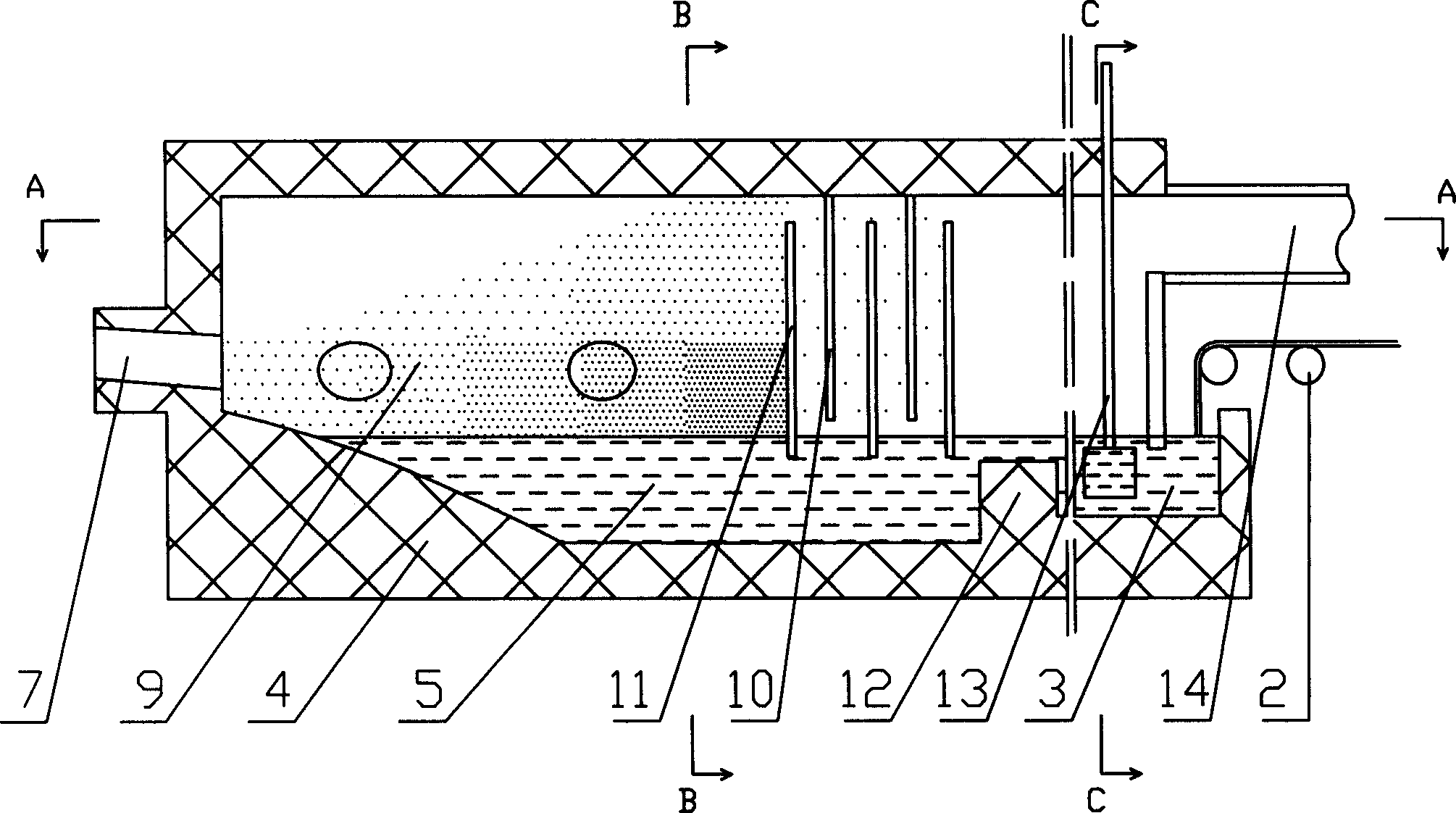

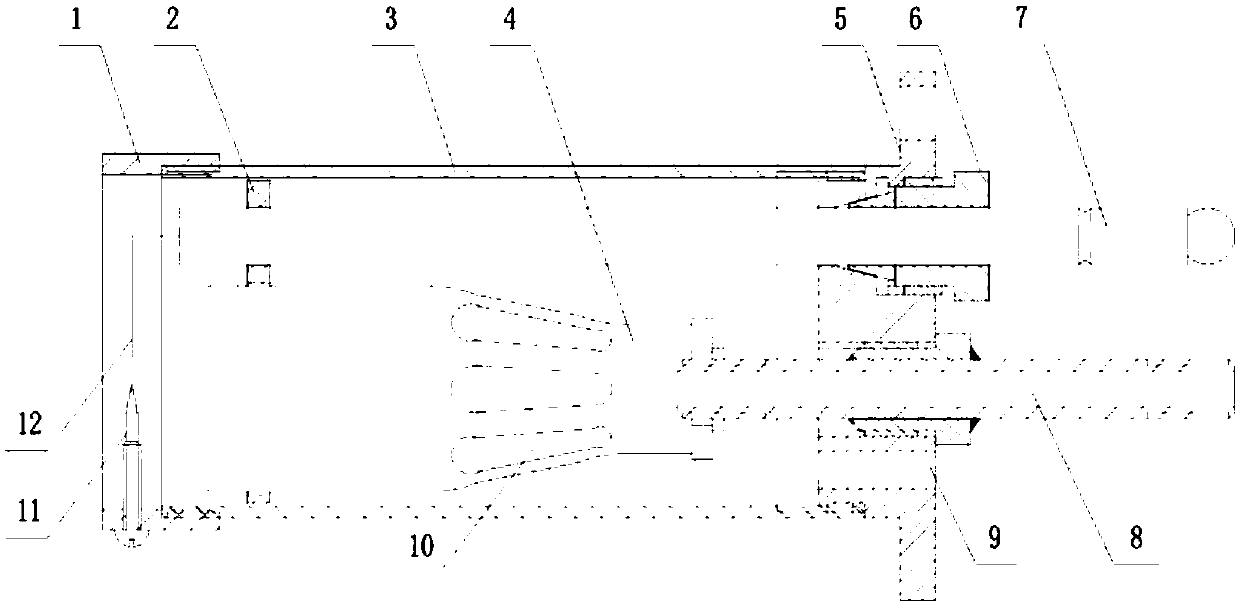

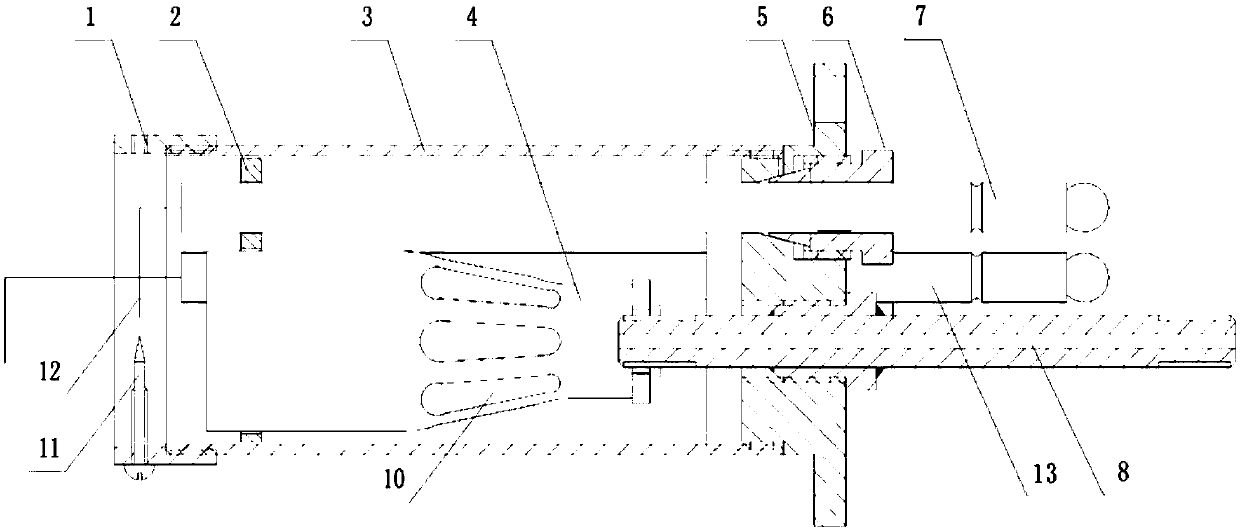

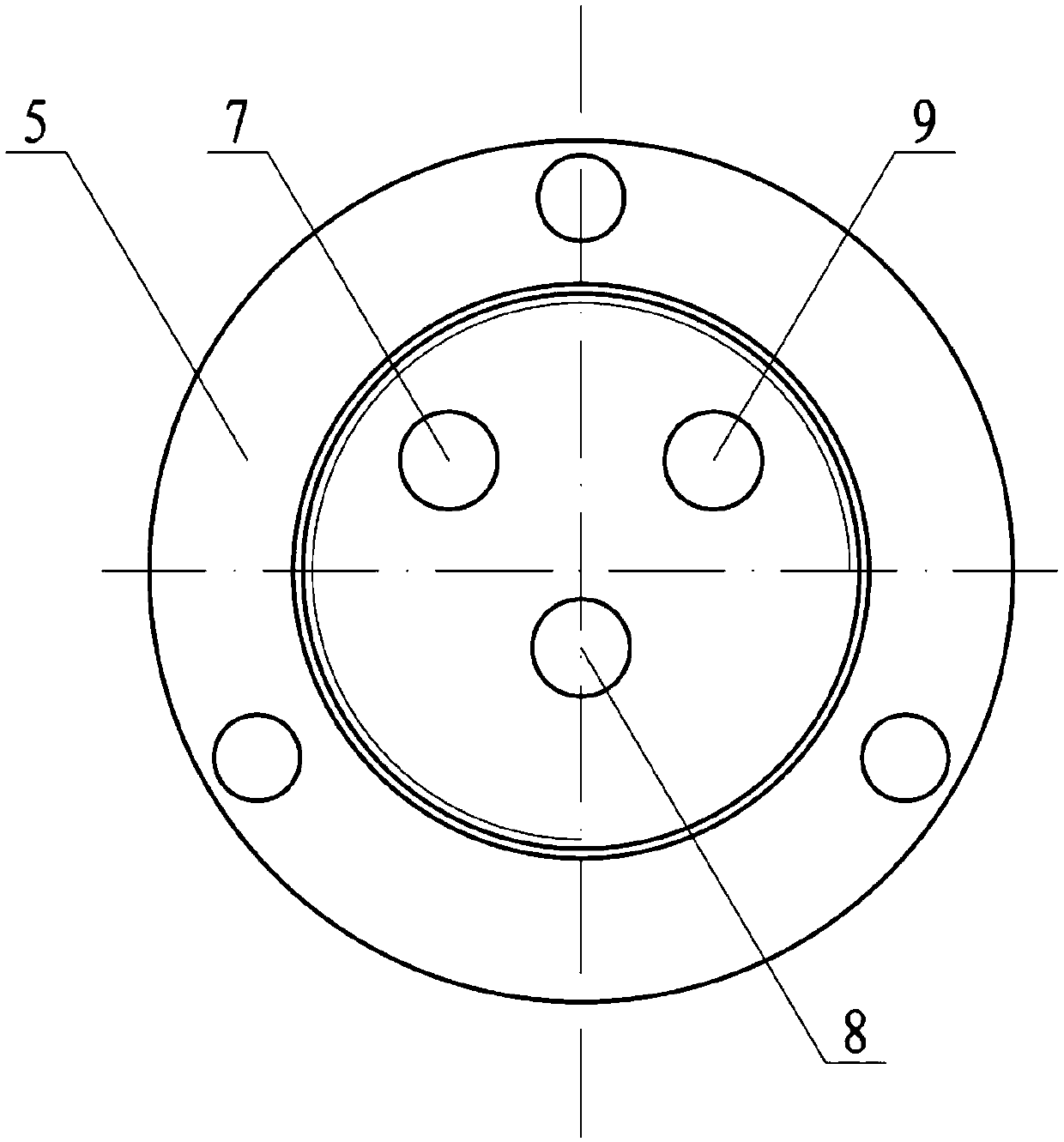

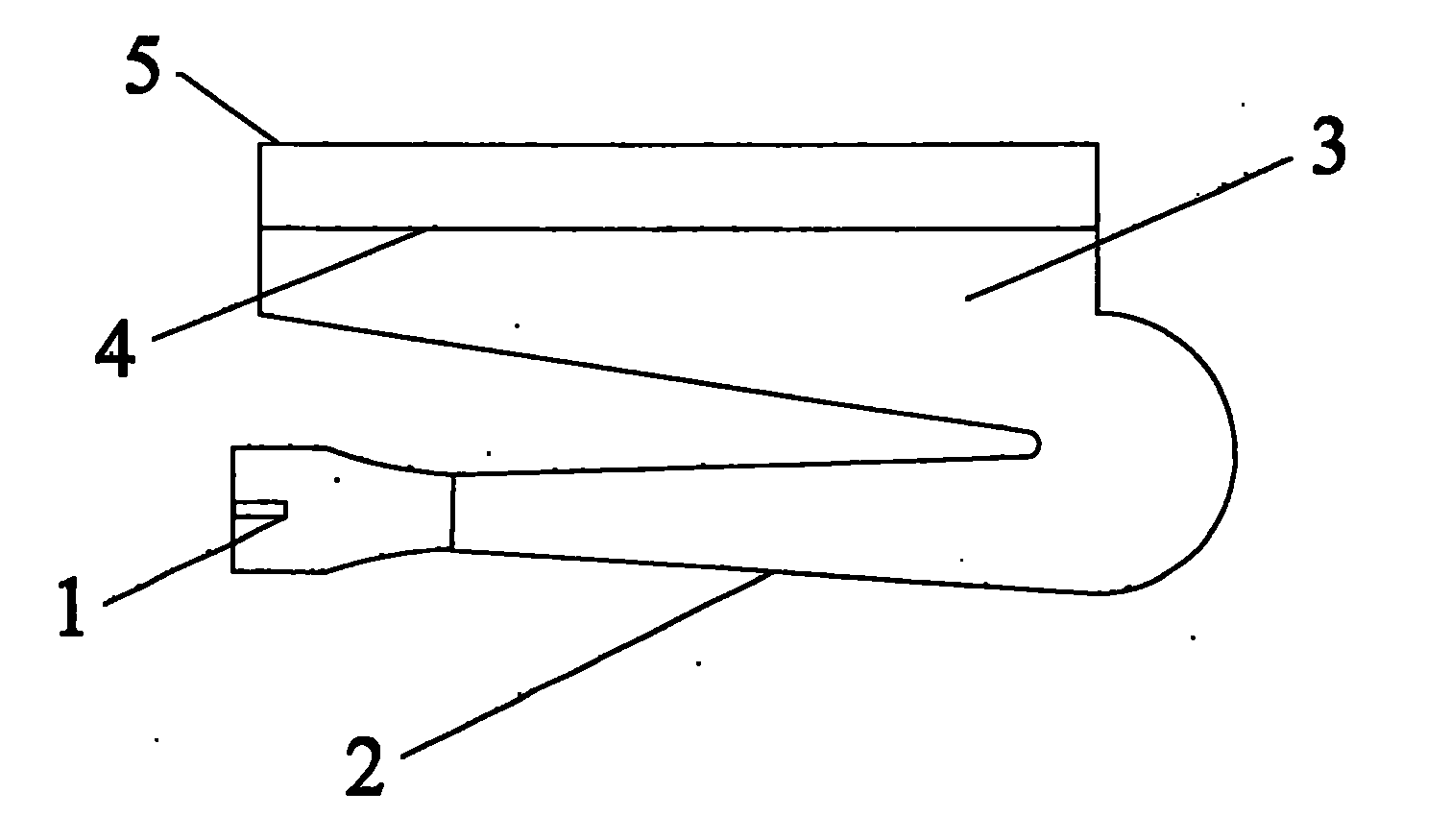

Concentrated phase high-temperature oxygen-enriched oilless ignition combustion apparatus

ActiveCN101424398ALow ignition energyLow ignition temperaturePilot flame ignitersPulverulent fuel combustion burnersOil freeOxygen delivery

The invention relates to a dense-phase high-temperature oxygen-enriched oil-free ignition combustion device, which solves the defects that the prior art is high in energy consumption, unstable in fire, low in combustion intensity, easily worn in equipment and narrow in the adaptation range to coal types. The device comprises an ignition pulverized-coal nozzle which is arranged in the center of a shell. An outer port of the ignition pulverized-coal nozzle and an ignition chamber are connected with a central shaft, and an inner port of the ignition pulverized-coal nozzle is communicated with an ejection opening of an ignition device, wherein the ignition device comprises a pulverized-coal conveying pipe the inside of which is provided with an oxygen conveying pipe; an outlet of the pulverized-coal conveying pipe and a gas outlet of the oxygen conveying pipe are communicated with the inner port of the ignition pulverized-coal nozzle respectively so as to form the ejection opening; and a heating system is arranged outside the pulverized-coal conveying pipe the inside of which is provided with the oxygen conveying pipe. The device has the advantages of low energy consumption, stable reliable fire, high combustion intensity, equipment not easy to wear and wide adaptation range to coal types.

Owner:郑平安

Low NOx oil gun device heated by backheating

InactiveCN1912460ABack smoothlyIngenious designSolid fuel combustionCombustion ignitionCombustion chamberHigh energy

A low NOx oil gun utilizing returned heat to heat is prepared as setting ceramic combustion chamber and swirler in shell, connecting swirler with Venturi wind channel being set with Venturi wind inlet, setting general wind inlet tube on shell and setting oil gun of micro oil and ignition gun of high energy on inlet end of Venturi wind channel.

Owner:傅宁娟

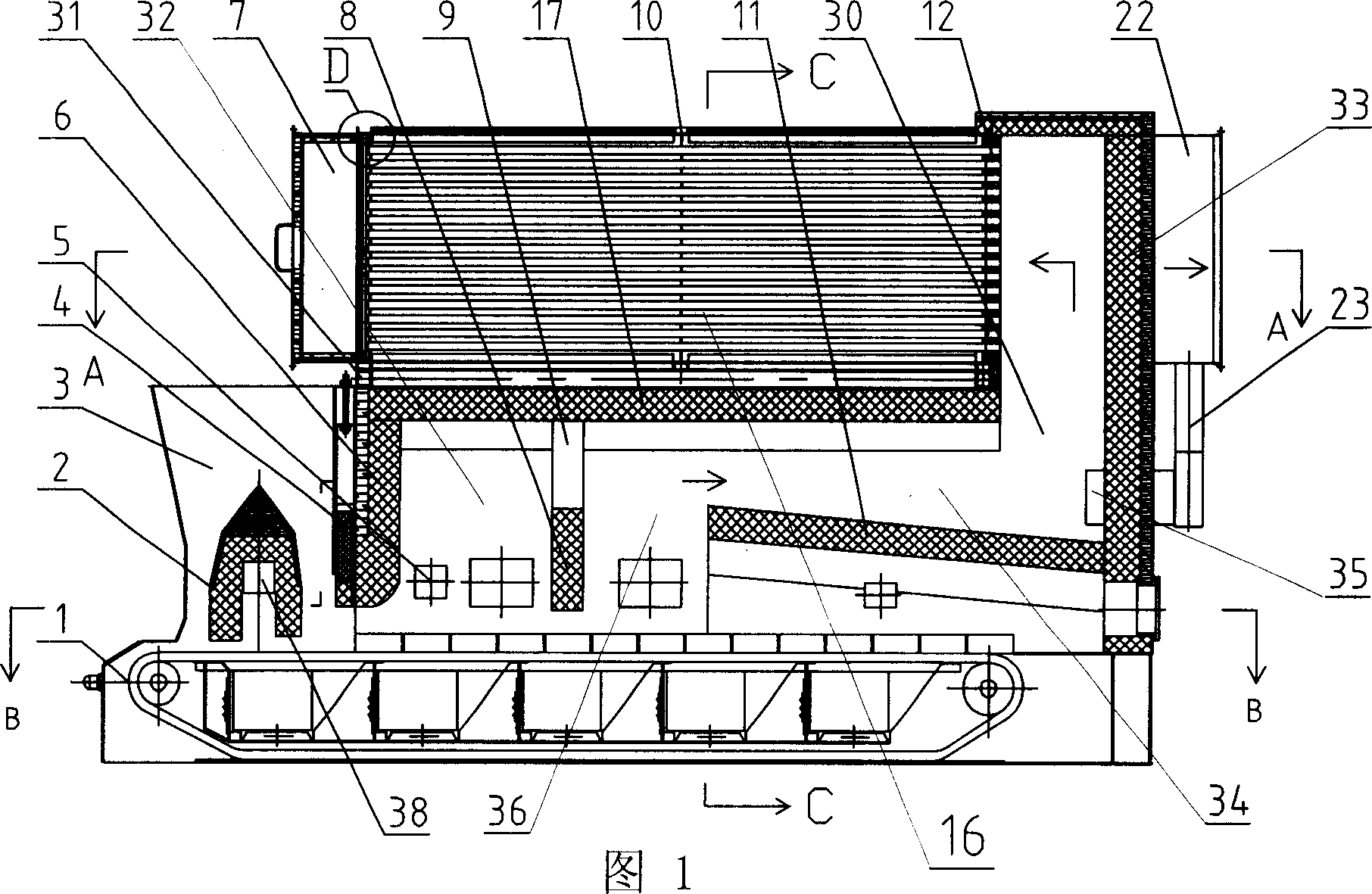

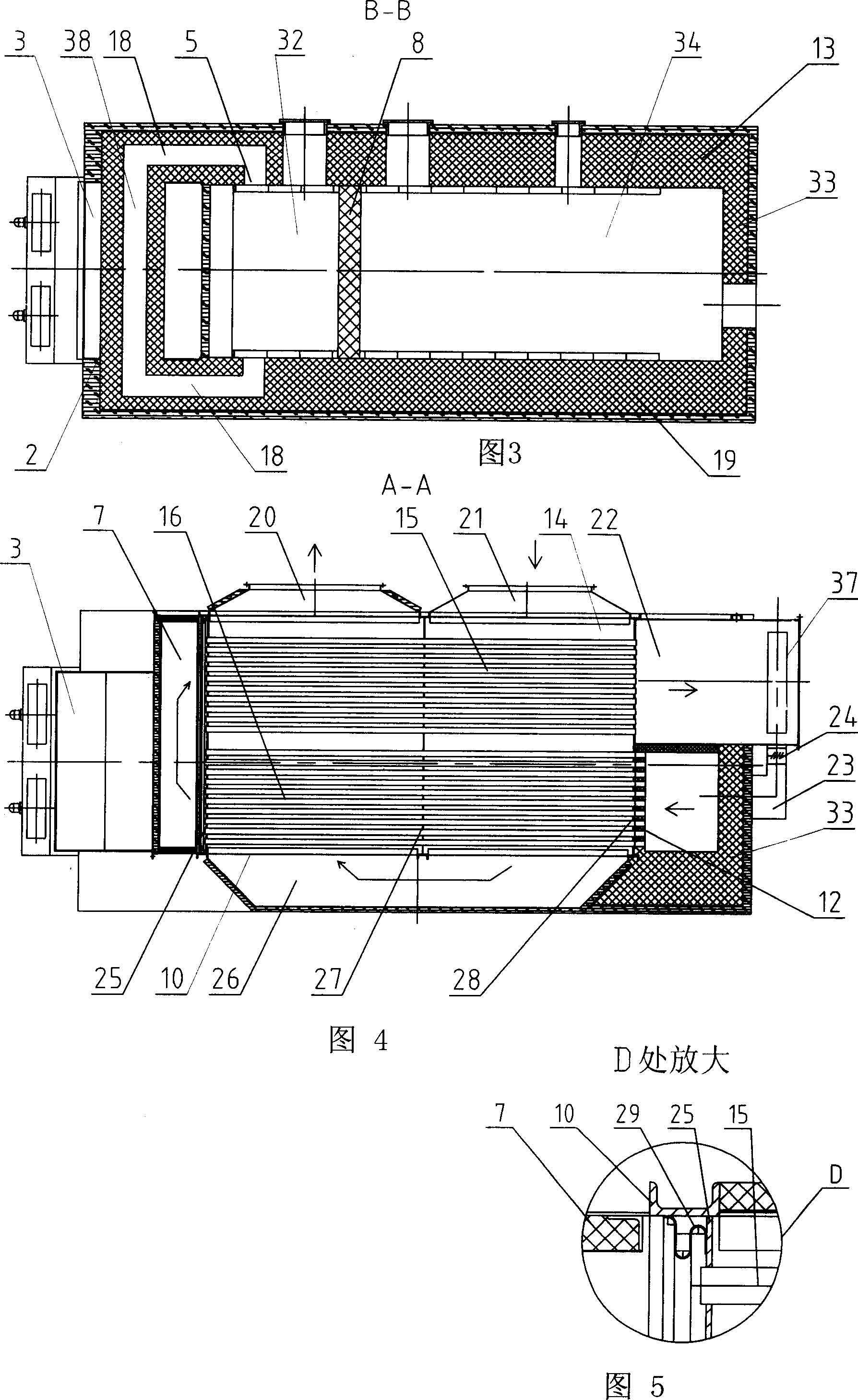

Coal-fired hot blast furnace with pre-combustion hearth and smoke circulating device

The invention discloses a coal air heater with a preignition hearth and a smoke recycler, which can solve the problems of present product with short service life, lower heating efficiency and worse environment pollution. Wherein, the wind inlet of cycle fan (24) via the cycle smoke channel (23) is through to the side opening (37) of smoke outlet channel (22)); the wind outlet of cycle fan (24) via the outlet (35) of cycle smoke channel (23) is through to the smoke channel (30); the preignition hearth (2) is fixed on the lower pat of coal hopper (3) between the left and right side walls (13). The inventive preignition hearth is thermal-insulated, with higher burning strength, and high application to variable coals. At the back of furnace row, the burnt coke can make the fire bed in open fire condition, to burn the gas fully; said air heater can avoid black smoke to reduce environment pollution; the cycle smoke channel can reduce the temperature of heat exchanger, to improve the service life and efficiency of air heater.

Owner:HARBIN INST OF TECH

Highly effective coal combustion improver and preparation thereof

The invention relates to the fuel additive technical field, in particular to fuel coal additives and a method for preparing the same. The invention discloses the high-efficiency fuel coal additives, which mainly comprises raising agent, combustion improver and sulfur retention smoke agent and also comprises nano silicon dioxide with a weight ratio between 0.5 and 10 percent. The high-efficiency fuel coal additives makes fuel coal in the high temperature state; the boiler steam rate is gradually increased; the furnace temperature is improved by 100 DEG; the boiler thermal efficiency is improved by over 15 percent; the coal-saving rate reaches 5 to 20 percent; the desulfurization is obvious and the desulfurization degree is as high as 40 to 70 percent; the decoking process is quick; the total discharge of clinker is reduced by about 26 percent, thereby the carbon content of furnace cinder is reduced; by addition of the fuel coal additives, metals on the boiler heating surface can not be eroded, thereby the function of protecting equipment is brought into play and the service life of the equipment is prolonged. Moreover, the high-efficiency fuel coal additives can greatly reduce the environmental pollution and the atmospheric greenhouse effect, and greatly reduce the energy consumption so as to obtain obvious economic benefit.

Owner:陈睿红

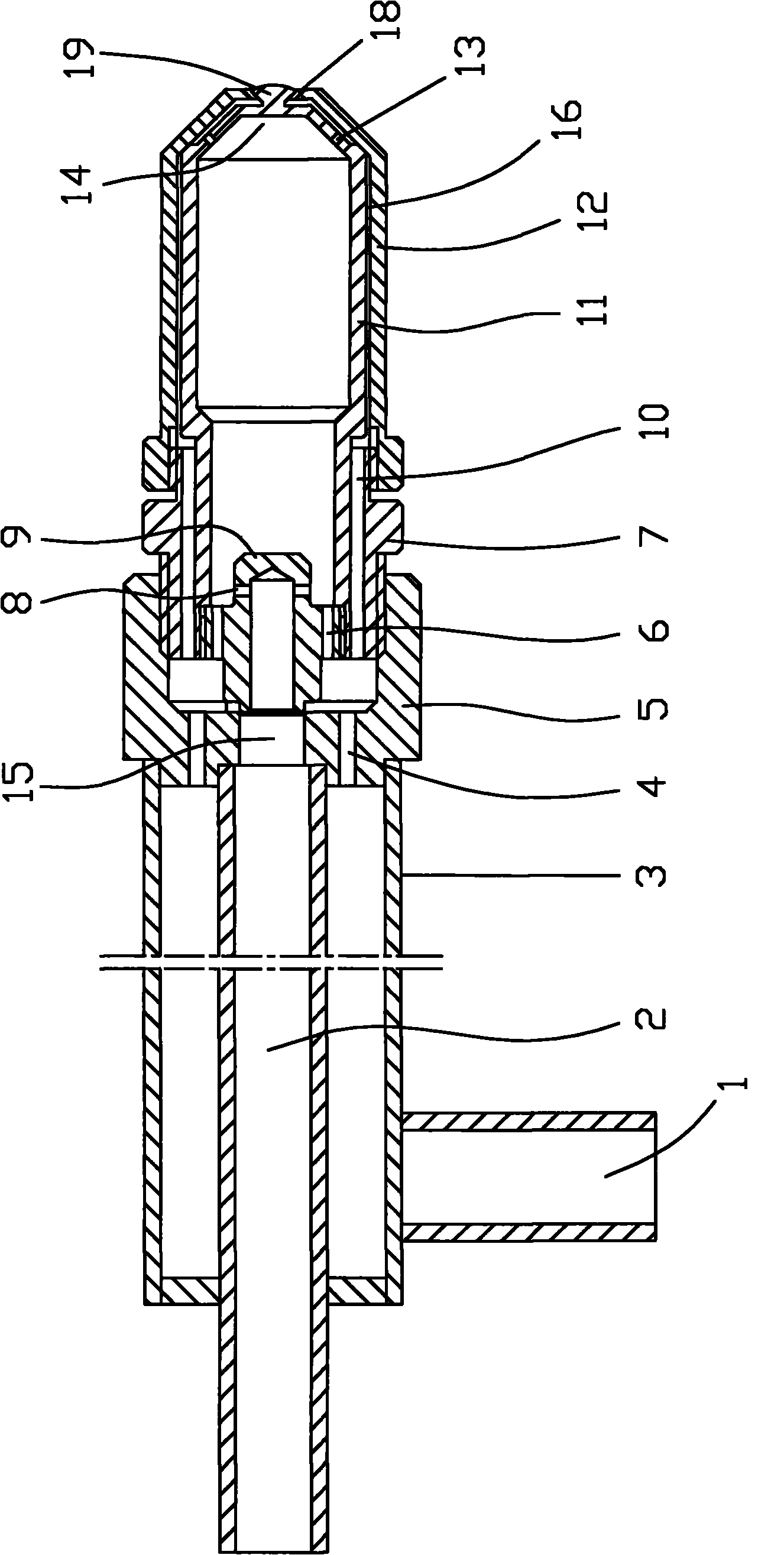

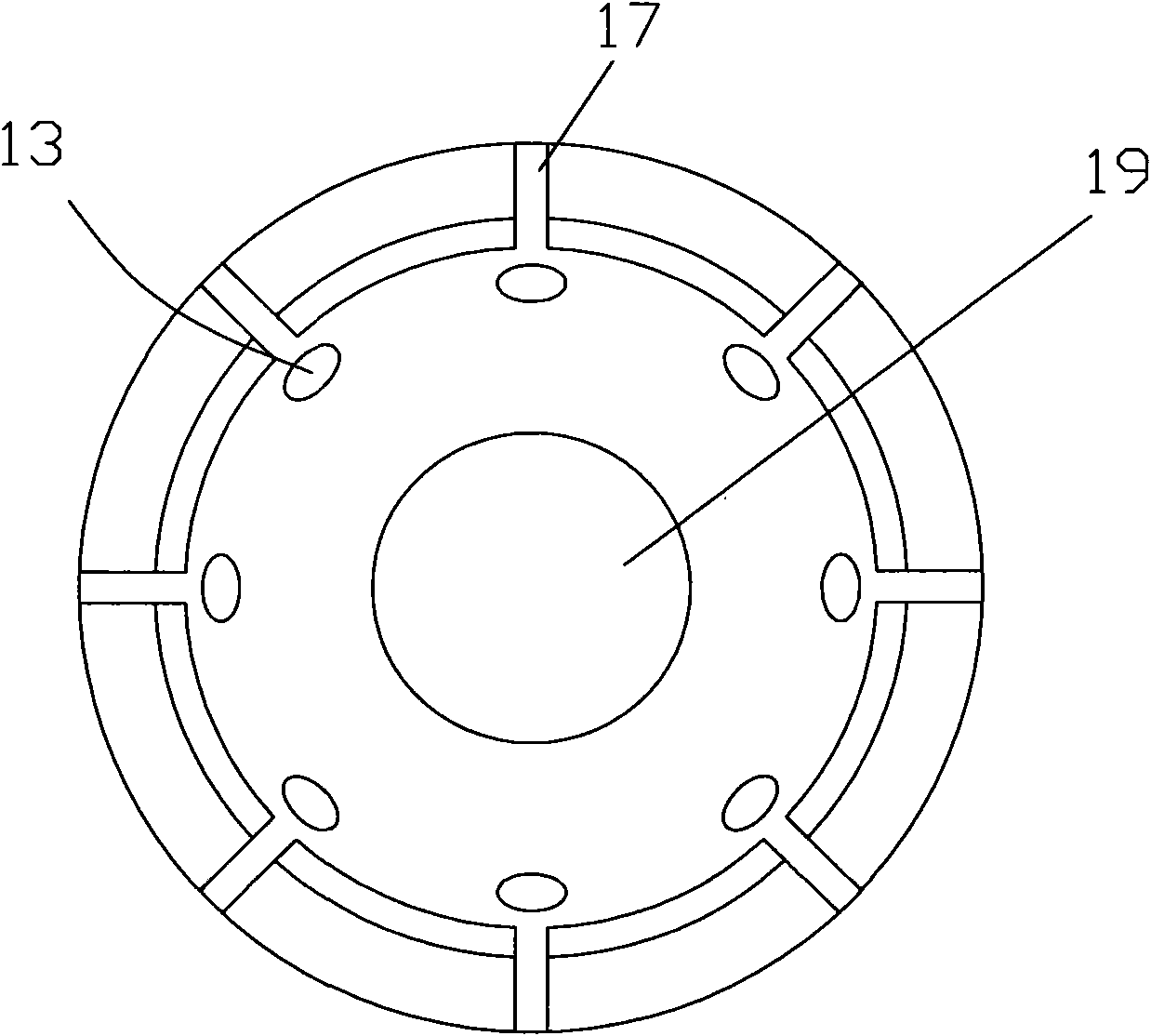

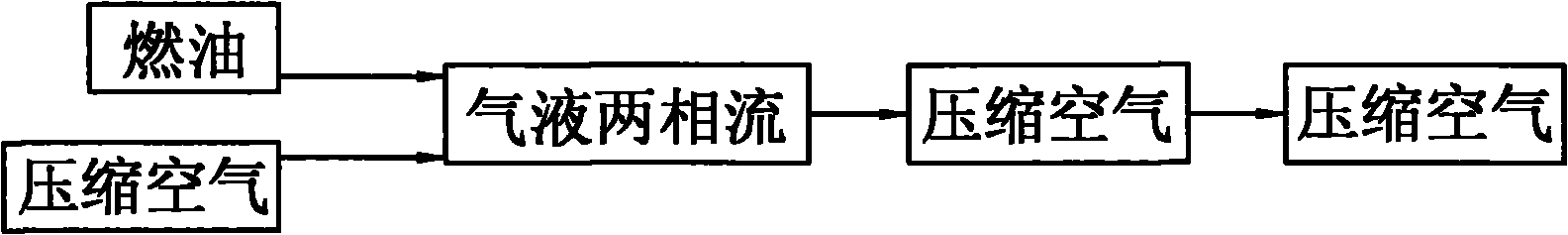

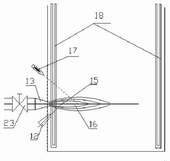

Low-pressure oil film breaking and atomizing technology and device thereof

The invention discloses low-pressure oil film breaking and atomizing technology and device thereof. The low-pressure oil film breaking and atomizing technology is characterized in that fuel oil and an auxiliary gas are formed into gas-liquid two-phase fluids, the gas-liquid two-phase fluids are jetted into a furnace cavity through an oil gun, and the jetted gas-phase fluids enable a formed oil film to be broken by overcoming the surface tension of the jetted gas-phase fluids so as to realize the superfine atomization of the fuel oil; the outlet of a circular jet hole is provided with a secondary transverse ultrasonic air flow, the jet direction of the secondary transverse ultrasonic air flow is perpendicular to that of the circular jet hole, and the secondary transverse ultrasonic air flow further impacts initially-atomized fuel oil jetted from the circular jet hole to carry out secondary breakage and atomization on the fuel oil. The invention has the advantages of smaller average diameter of an oil drop, high penetrating capability of oil mist, good adjustability of an atomized taper angle and very little change of the average dimension of the oil drop when the viscidity of the fuel oil is enhanced or the ejection force of the oil gun is smaller; and in addition, the invention only needs lower fuel oil pressure of 0.4-0.5 MPa, thereby lowering the pressure of a fuel oil system, reducing the electricity consumption of an oil pump and saving the plant electrical consumption.

Owner:艾佩克斯科技(北京)有限公司

Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

ActiveCN103267279AReduce generationReduce carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention relates to a low-nitric-oxide direct-current pulverized coal combustor adaptive to a meager coal boiler, which can achieve stable and economical combustion, and also reduces nitric oxide emission to the lowest level, so that the low-nitrogen combustion modifying technique of the meager coal boiler is improved. The low-nitric-oxide direct-current pulverized coal combustor adaptive to the meager coal boiler comprises main combustor groups which are arranged on four corners of a hearth of the meager coal boiler in a four-angle tangential circle combustion mode, are matched with a water-cooling wall high-temperature-prevention corrosion system of the hearth, and are identical in structure; each main combustor group comprises pulverized coal combustors arranged at intervals and secondary air spray ports; the upper parts of the main combustor groups are provided with corresponding separation burnout air groups; a layer of precombustion chamber back flow combustor is arranged in each n-layer of pulverized coal combustors; the jet flow rotation direction of the main combustor groups is the anticlockwise direction; the rotation direction of secondary air ports close to the upper parts of the precombustion chamber back flow combustors is the clockwise direction, and the imaginary tangential circle diameter is greater than the imaginary tangential circle diameter of the main combustors; separation burnout air groups include upper groups and lower groups; and the jet flow of the lower groups is in an imaginary tangential circle mode, and the jet flow of the upper groups is in an opposed combustion mode.

Owner:STATE GRID CORP OF CHINA +1

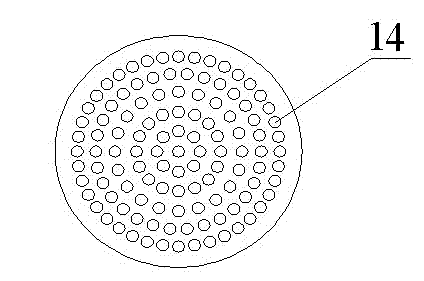

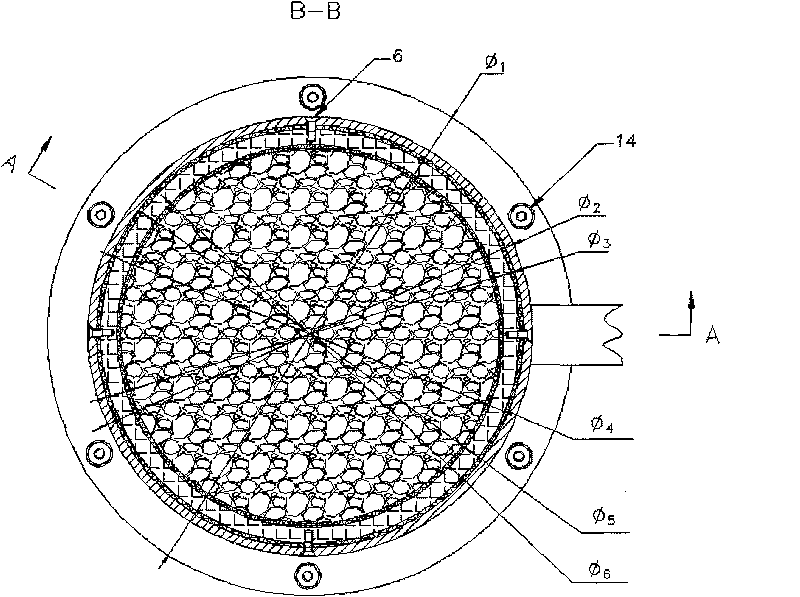

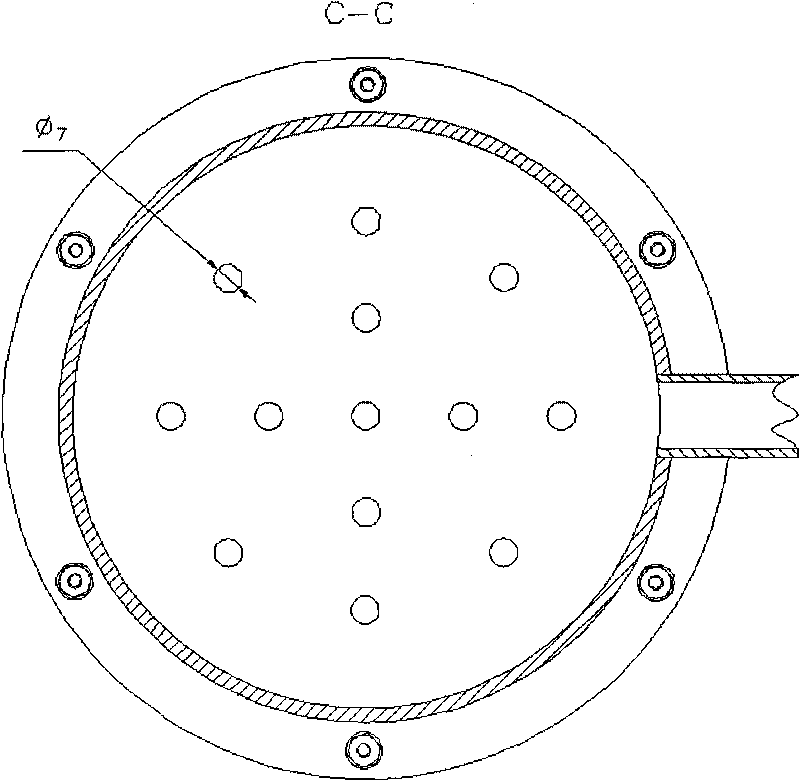

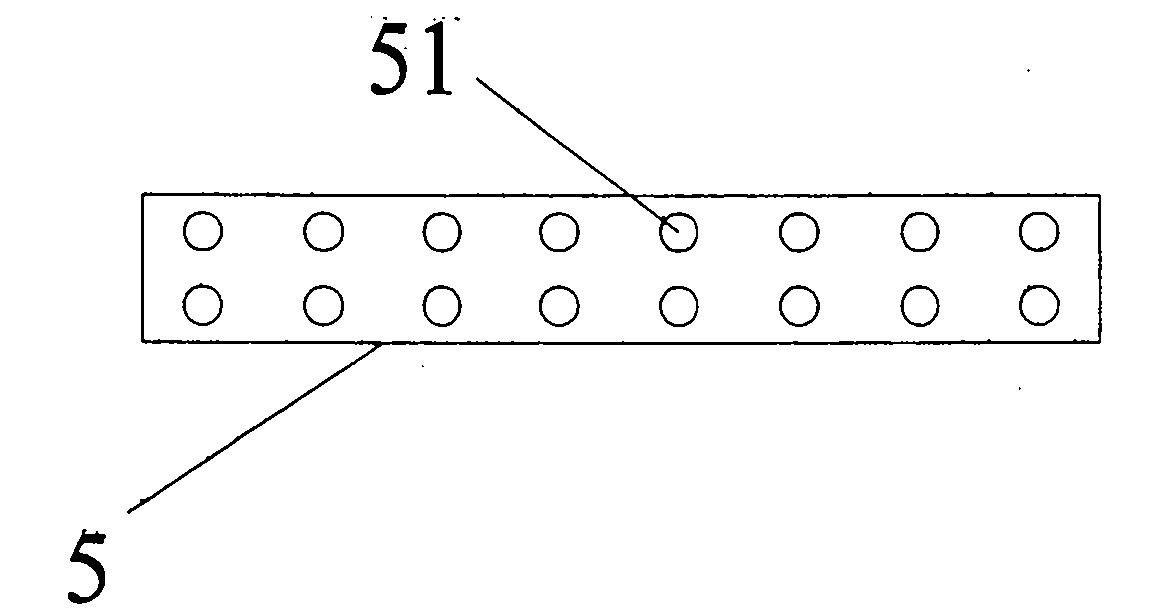

Diffusion type porous medium gas fuel combustor

InactiveCN101737778AUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV

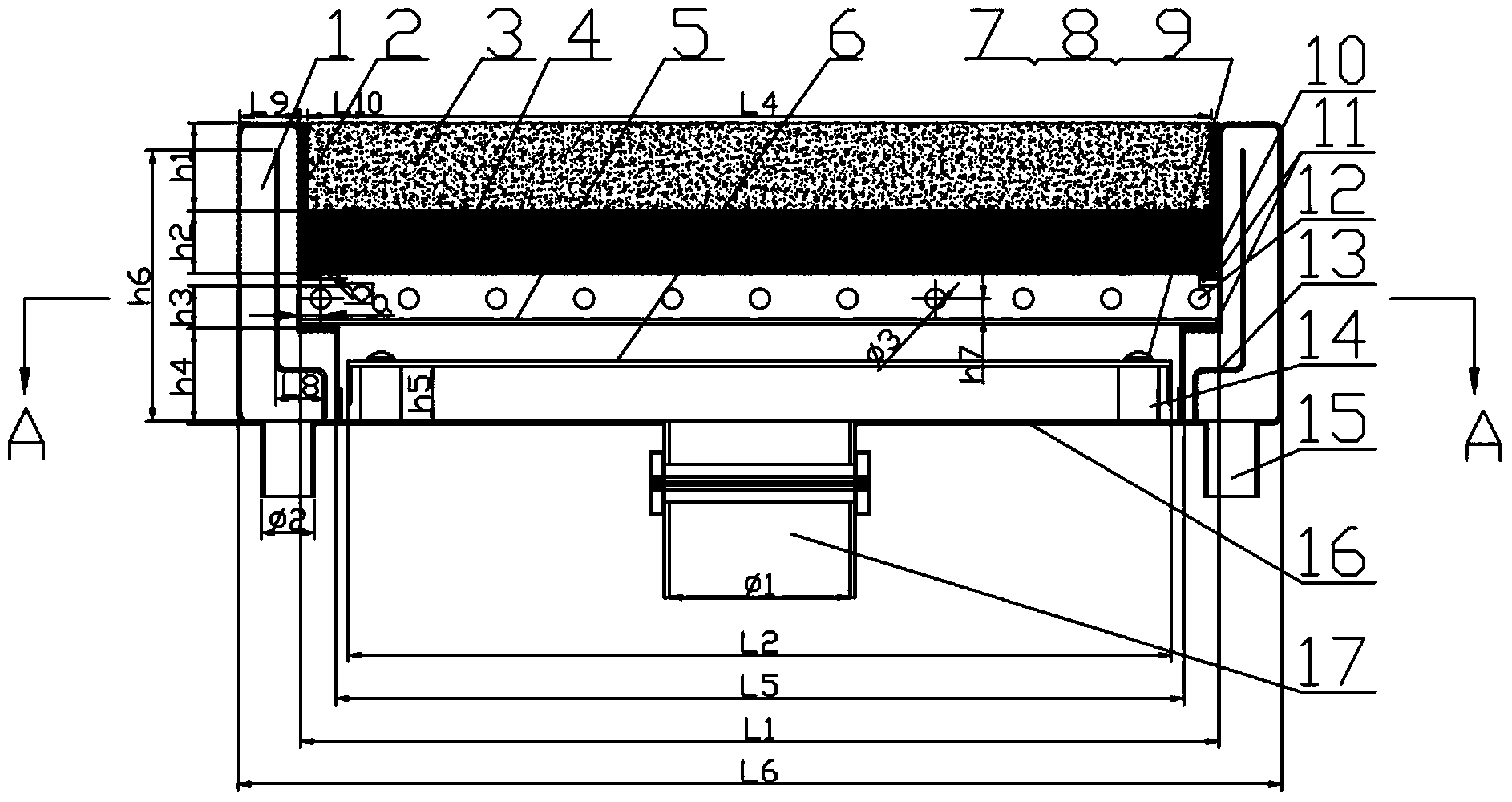

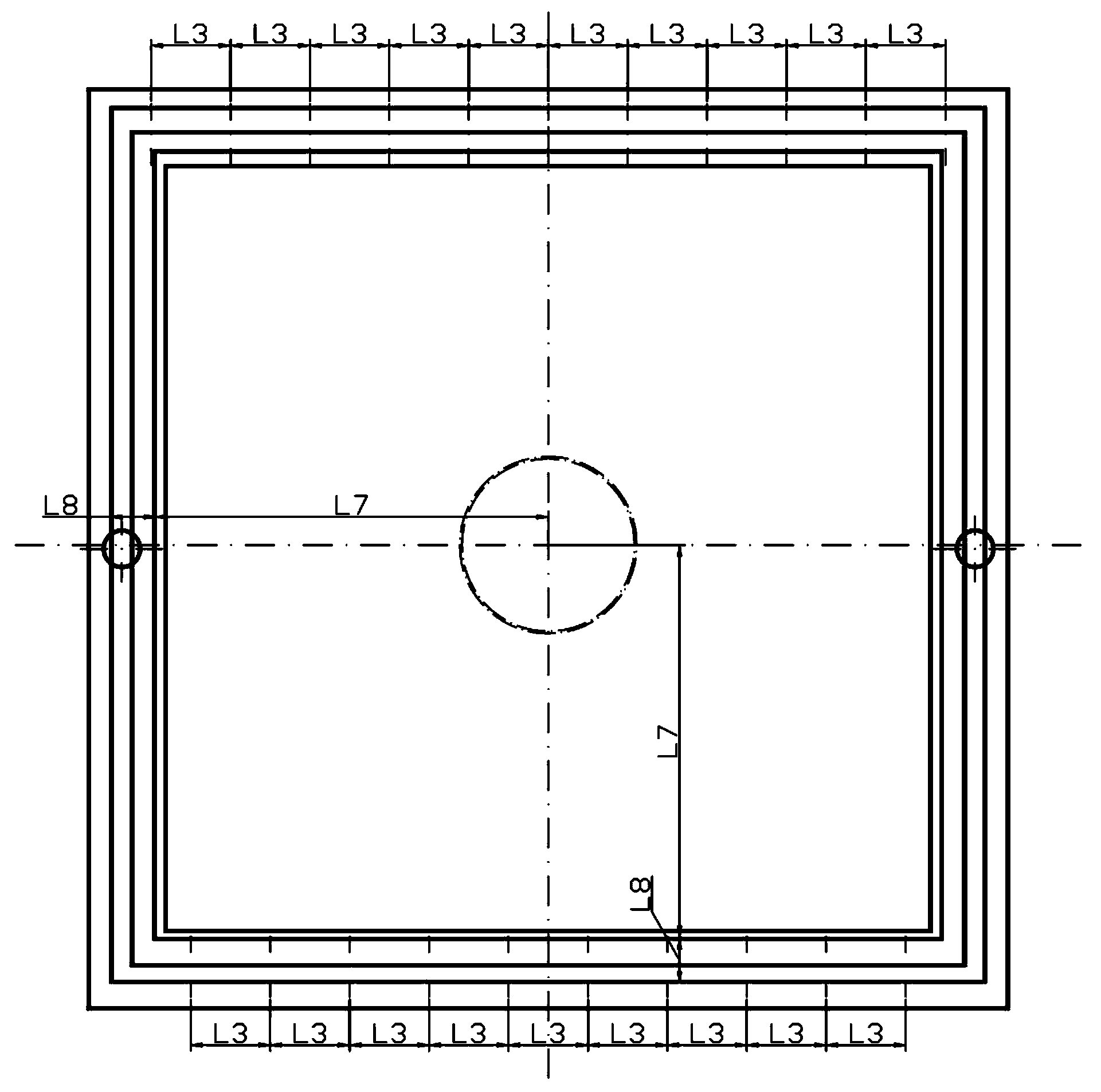

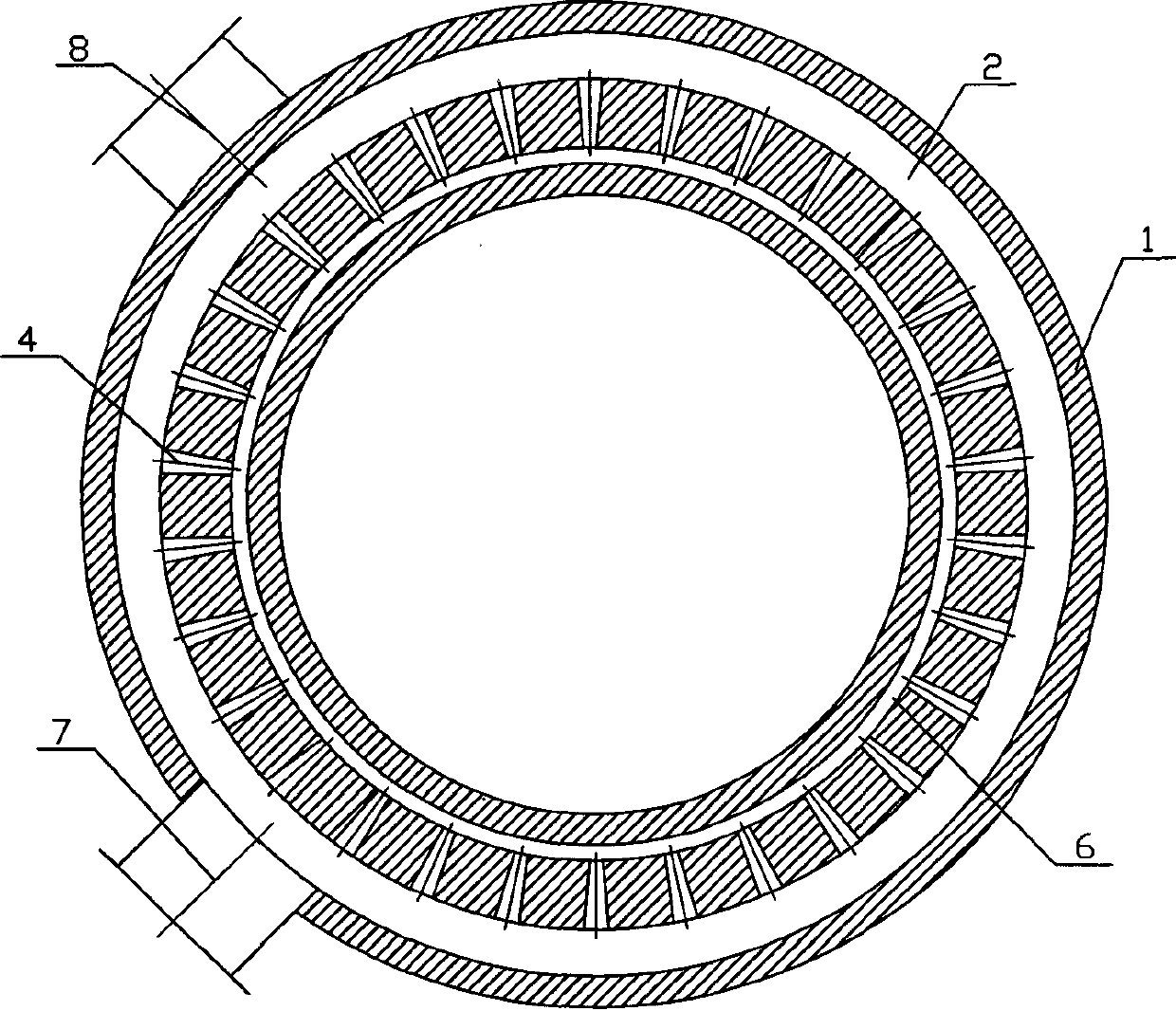

Partially premixed gas fuel burner of bi-layer porous foamed ceramic plate

The invention discloses a partially premixed gas fuel burner of a bi-layer porous foamed ceramic plate. The partially premixed gas fuel burner comprises a shell, a macroporous foamed ceramic plate, a microporous foamed ceramic plate, a top air distributor and a bottom air distributor, wherein the shell comprises a cooling cavity in an annular structure and a shell base-plate arranged on the cooling cavity, the cooling cavity is provided with a cooling cavity used for providing secondary air to pass through, and the bottom of the cooling cavity is provided with a secondary air inlet communicated with the cooling cavity; the inner side wall of the cooling cavity is provided with a secondary air outlet communicated with the cooling cavity, an annular frame formed by the cooling cavity is sequentially provided with the macroporous foamed ceramic plate, the microporous foamed ceramic plate and the top air distributor from top to bottom; the bottom air distributor and a shell base-plate, the secondary air outlet is located between the microporous foamed ceramic plate and the top air distributor, and the shell base-plate is provided with a mixed gas inlet for providing mixed gas of fuel and air to enter. According to the burner provided by the invention, the heating efficiency can be improved, and the heating uniformity can be improved.

Owner:WISDRI WUHAN WIS IND FURNACE

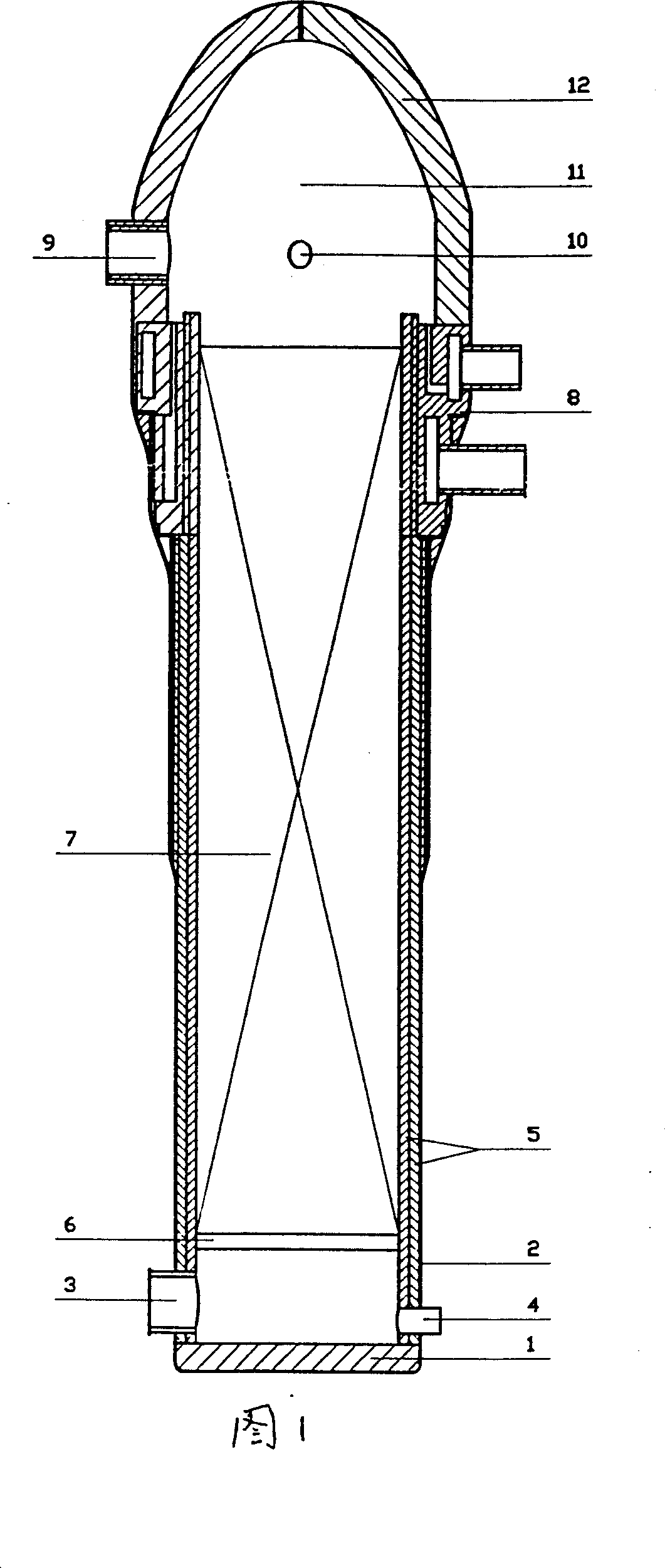

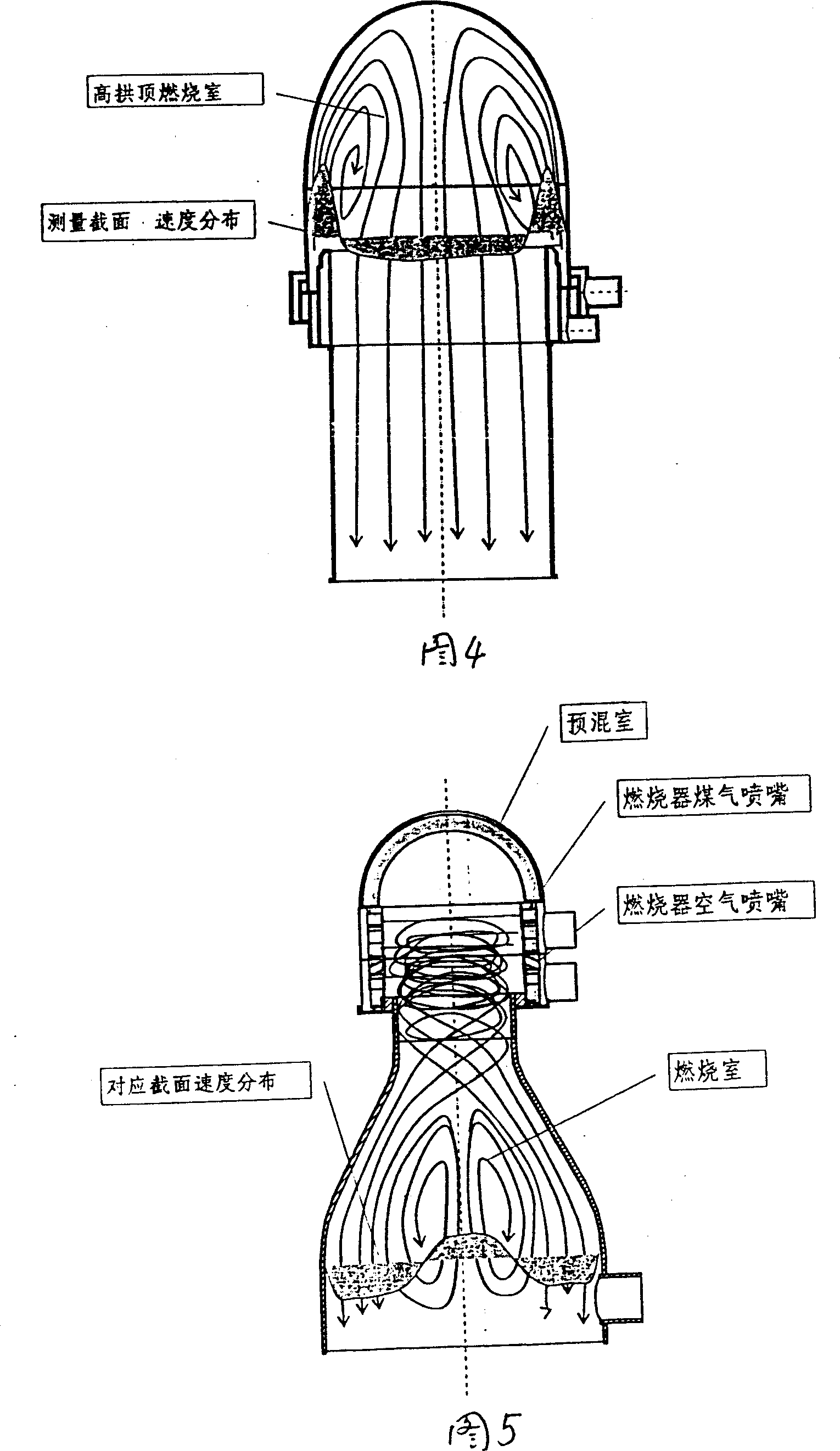

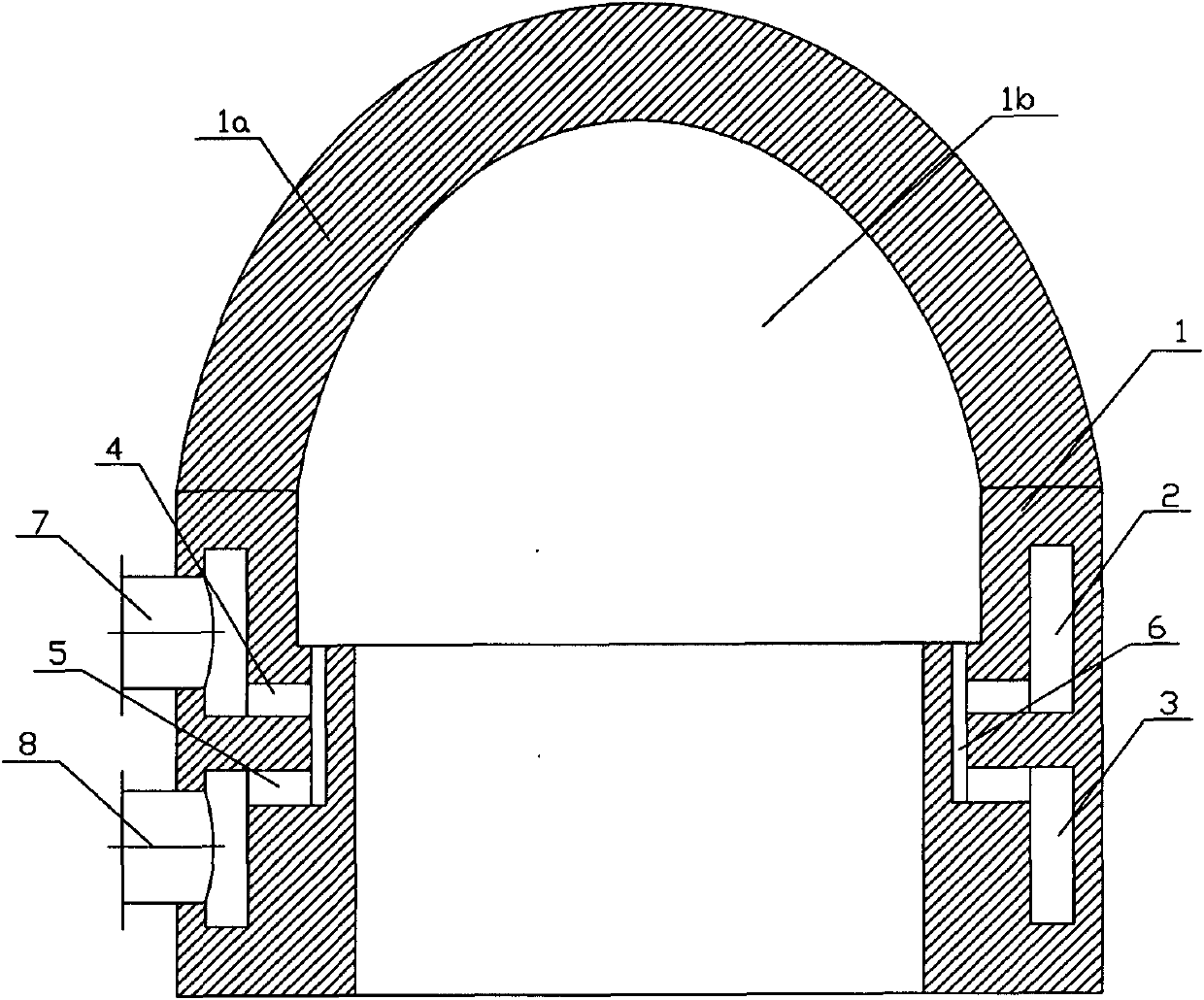

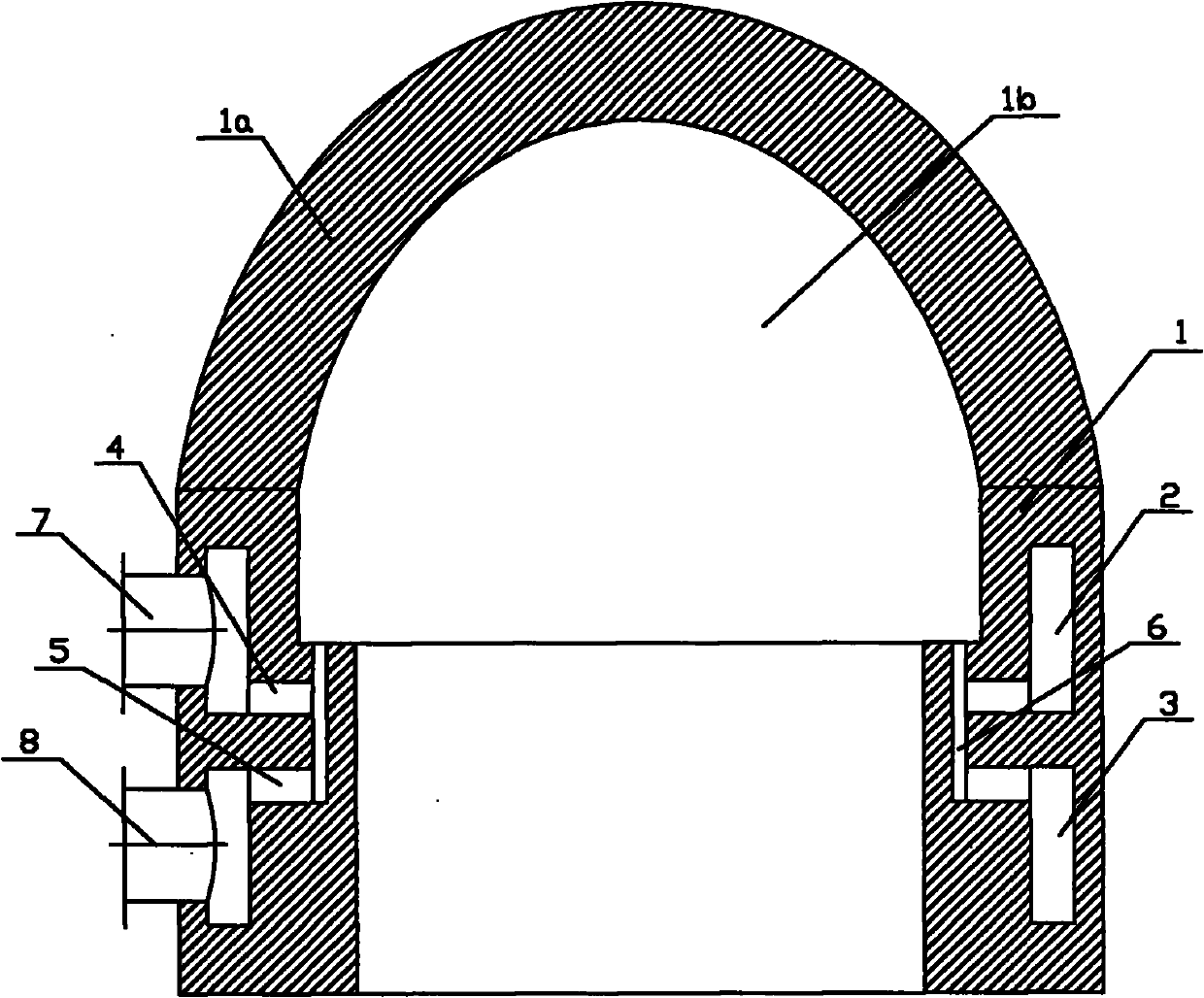

Spiral flow up jet premix and preheat burner with circuit and porous regenerator

InactiveCN101865467ASimple structureUnique structureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention relates to a spiral flow up jet premix and preheat burner with a circuit and a porous regenerator, which can effectively solve the problems of complex ceramic burner structure, uneven burning airflow distribution, poor controllability and stable high hot air temperature realization. The burner comprises a cylindrical wall, an arch roof of hemispheric or inverse catenary spinning structure and a burning chamber, wherein the cylindrical wall and the arch roof form a spherical head cylindrical lower opening; the airflow can spin and burn in the burning chamber structure; an airflow premixing circuit is annularly arranged on the inner wall of the cylindrical wall, is provided with an opening on the upper part and has rectangular section; a gas inlet tube and an air inlet tube which are symmetrically arranged are connected with the airflow premixing circuit through rotary cutting; and the porous regenerator is filled in the burning chamber structure. The burner is simple in structure, unique and good in using effect and can effectively reduce the excess air coefficient, improve the burning temperature and burning intensity and further greatly simplify the burner structure and lighten the burner weight by realizing rapid premixing, preheating and burning in limited space by utilizing the porous material characteristics.

Owner:河南省豫兴热风炉工程技术有限公司

Environment friendly energy-saving super strength combustion supporting efficient synthetic coal

The invention discloses environment-friendly energy-saving extra-strong combustion-supporting high-efficiency synthetic coal, which is characterized by comprising the following steps: adopting plant charcoal power and natural coal powder of powerful renewable resources to prepare into a main material through a scientific formula according to the variety and the quality of coal; adding a mixed material of coal gangue powder and fly ash powder of industrial waste to synthesize a filling auxiliary material, and reconstructing and changing structures, the performance and the characteristics of the coal to make the coal reach the highest efficiency; then adding a strong-oxygen combustion-supporting high-efficiency coal-saving synergistic fire-slowing agent which has quick firing, can prolong the combustion time of the coal, can make low-grade coal completely combusted, improve thermal efficiency, save the coal, has no pollution, and can achieve the aims of eliminating smoke, dedusting, supporting combustion and desulfurizing; and finally adding a certain amount of water , evenly stirring , and performing coal molding and manufacturing by special coal-making machinery . The coal is high-efficiency coal, has the use efficiency three to six times of that of the prior ordinary coal, is a novel energy-saving high-efficiency energy source, has the coal-saving rate reaching 80 percent or so, has extremely high coal-saving rate and convenient use, is safe, reliable and easy to store, and is called 'overground coal mine' and 'green coal'.

Owner:万金林

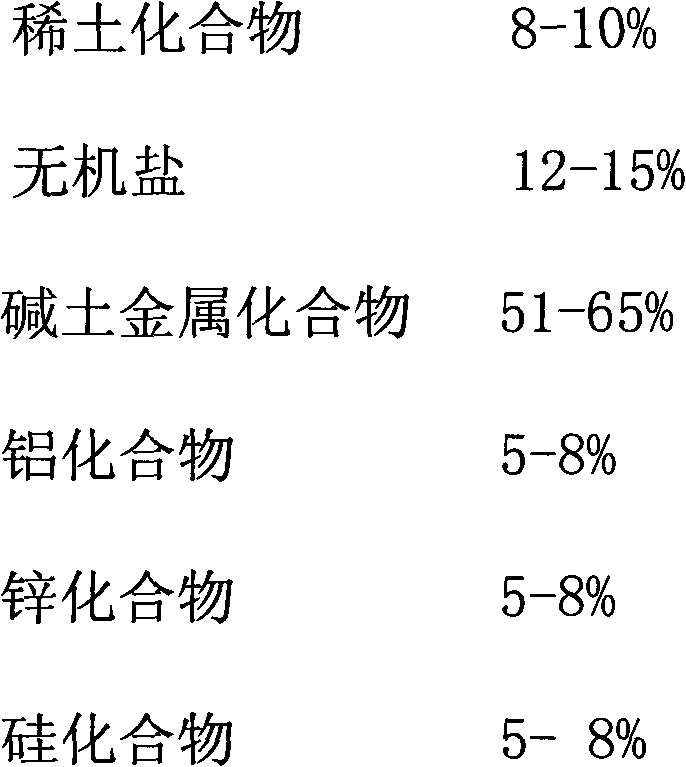

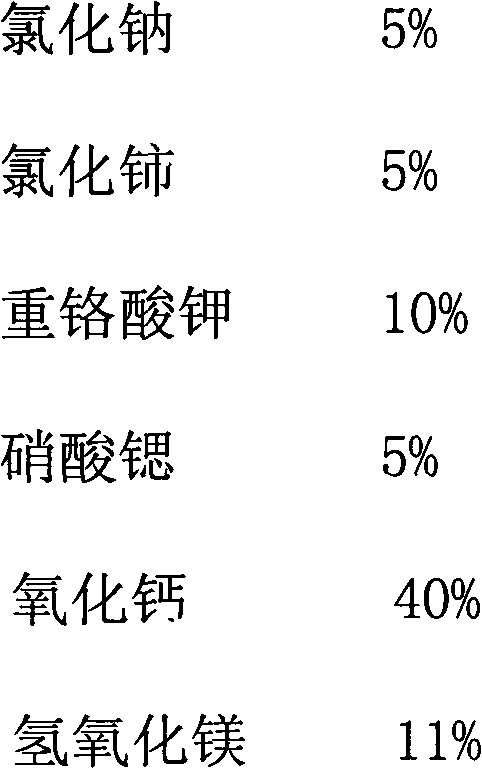

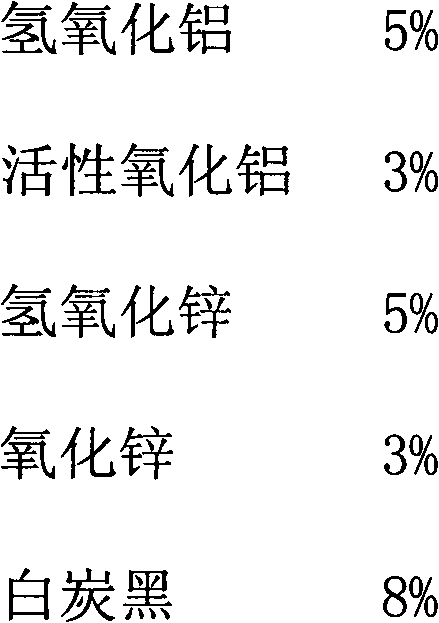

Multifunctional rare earth sulfur-fixing denitration energy-conservation additive

The invention discloses a multifunctional rare earth sulfur-fixing denitration energy-conservation additive, which solves the problems that the conventional sulfur-fixing agent has relatively low sulfur-fixing rate and does not have the function of reducing NOx emission. The additive is characterized by consisting of the following raw materials in percentage by mass: 8 to 10 percent of rare earth compound, 12 to 15 percent of inorganic salt, 51 to 65 percent of alkaline earth metal compound, 5 to 8 percent of aluminum compound, 5 to 8 percent of zinc compound and 5 to 8 percent of silicon compound. The additive is prepared by the following steps of: grinding the raw materials into fine particles with the particle size of 100 to 300 meshes; proportioning the particles according to the mass percentage at normal temperature; uniformly stirring and mixing; preparing powder from the mixture; and compounding. The additive has the advantages of capability of being popularized in a large area, high sulfur-fixing rate and denitration function and is suitable for coal-smoke type heavily-polluted production links.

Owner:阳泉鑫环高新技术有限责任公司

Atmospheric gas radiation heating device

ActiveCN101900324AHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringPetrochemical

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

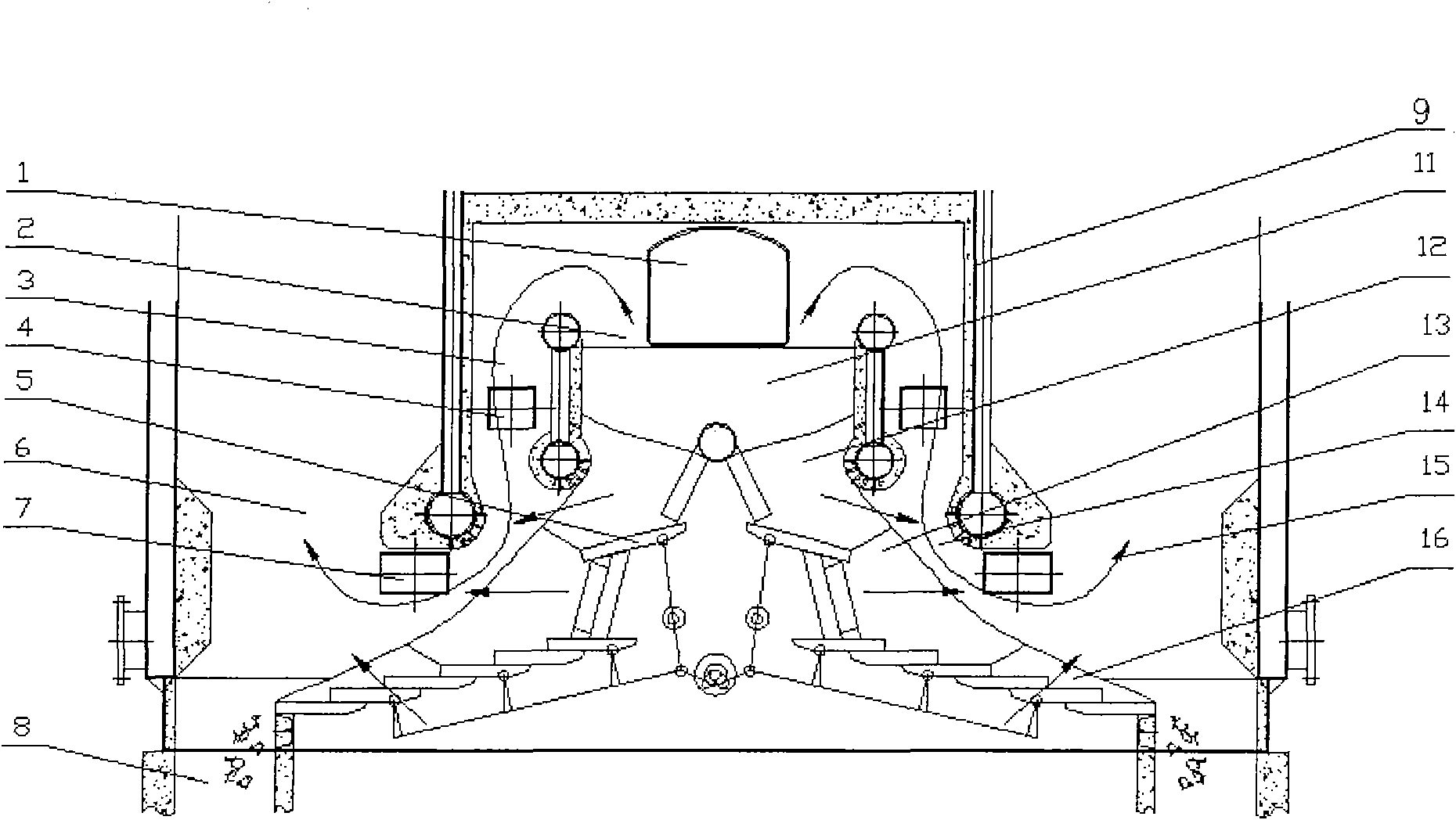

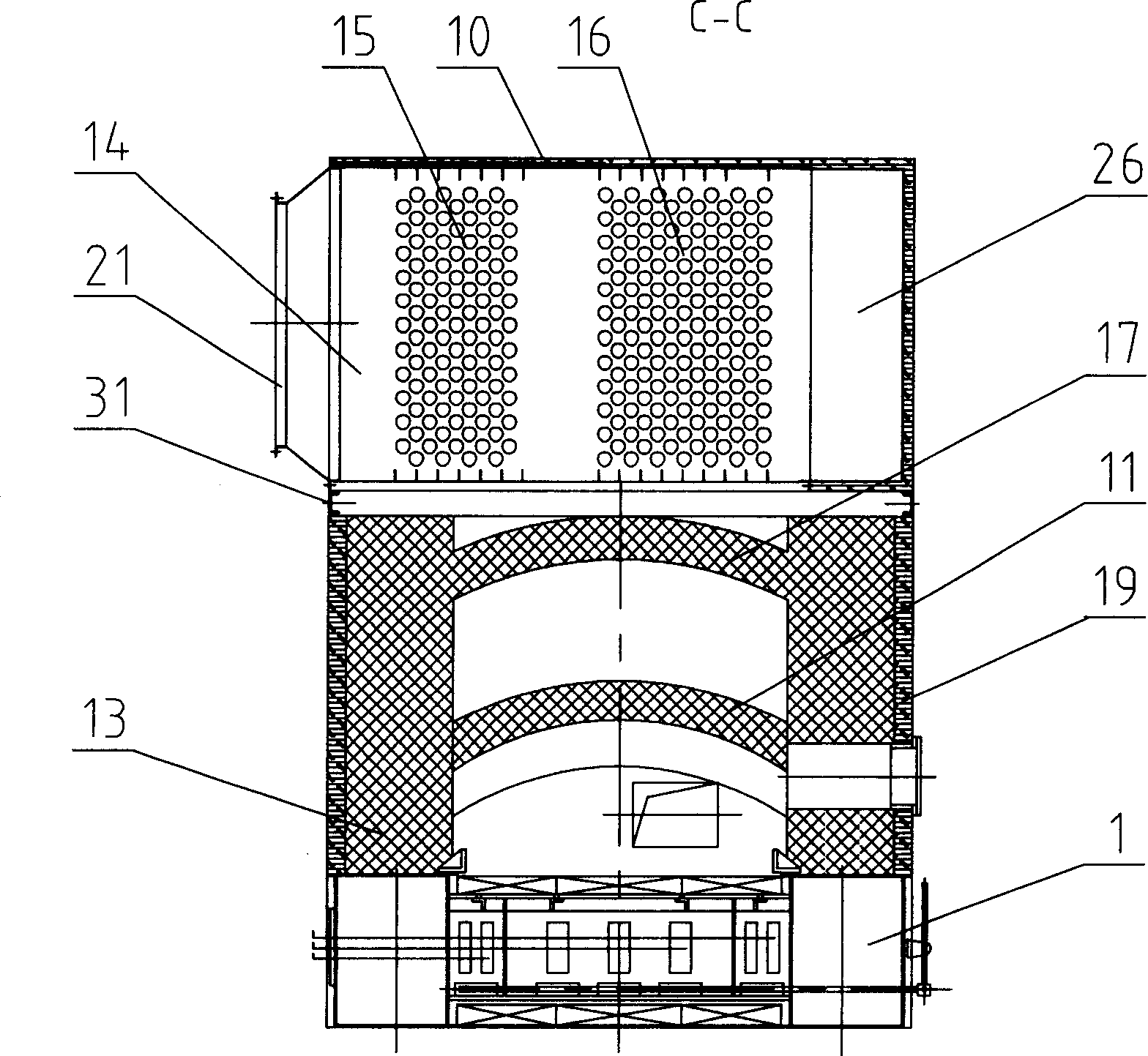

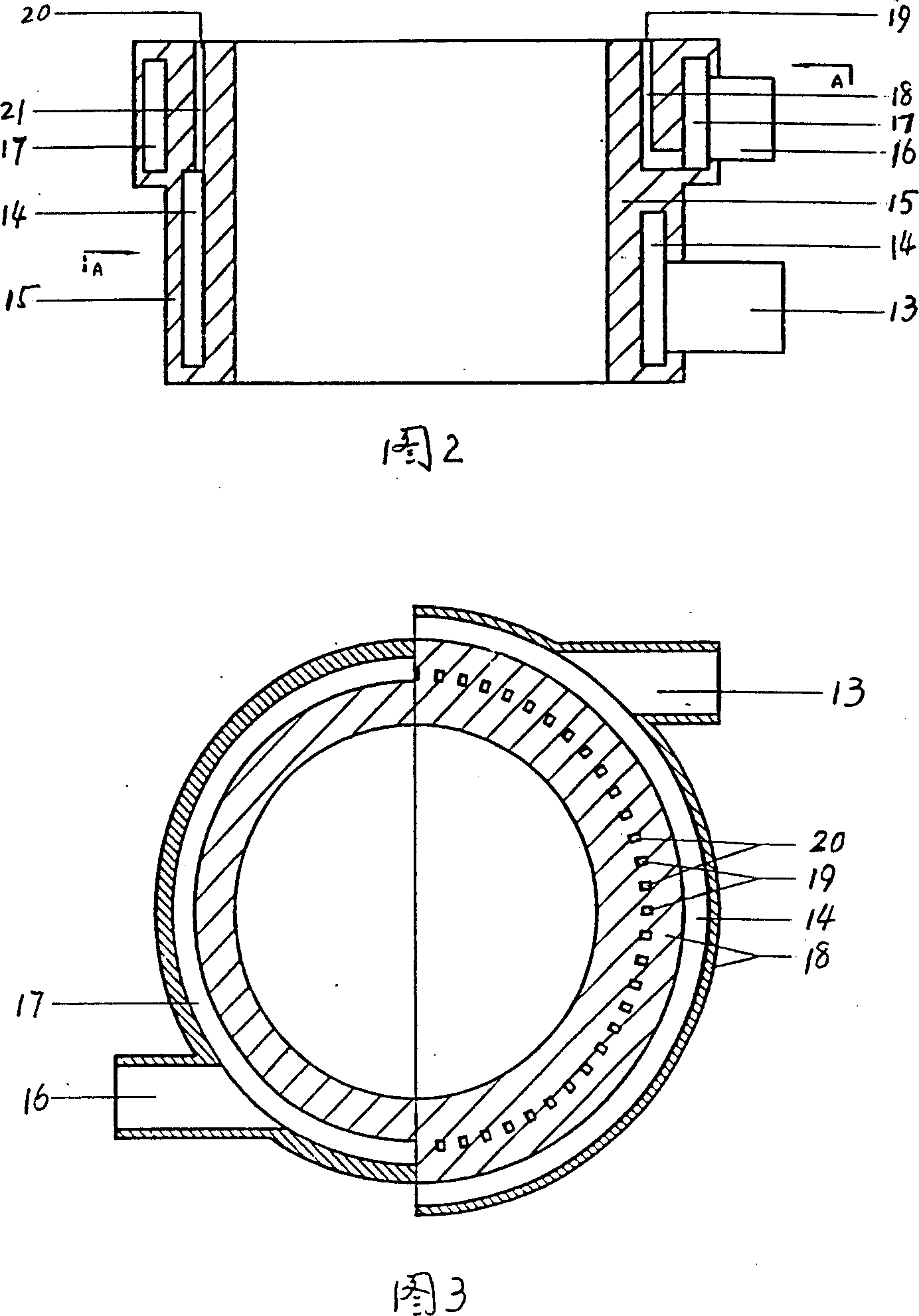

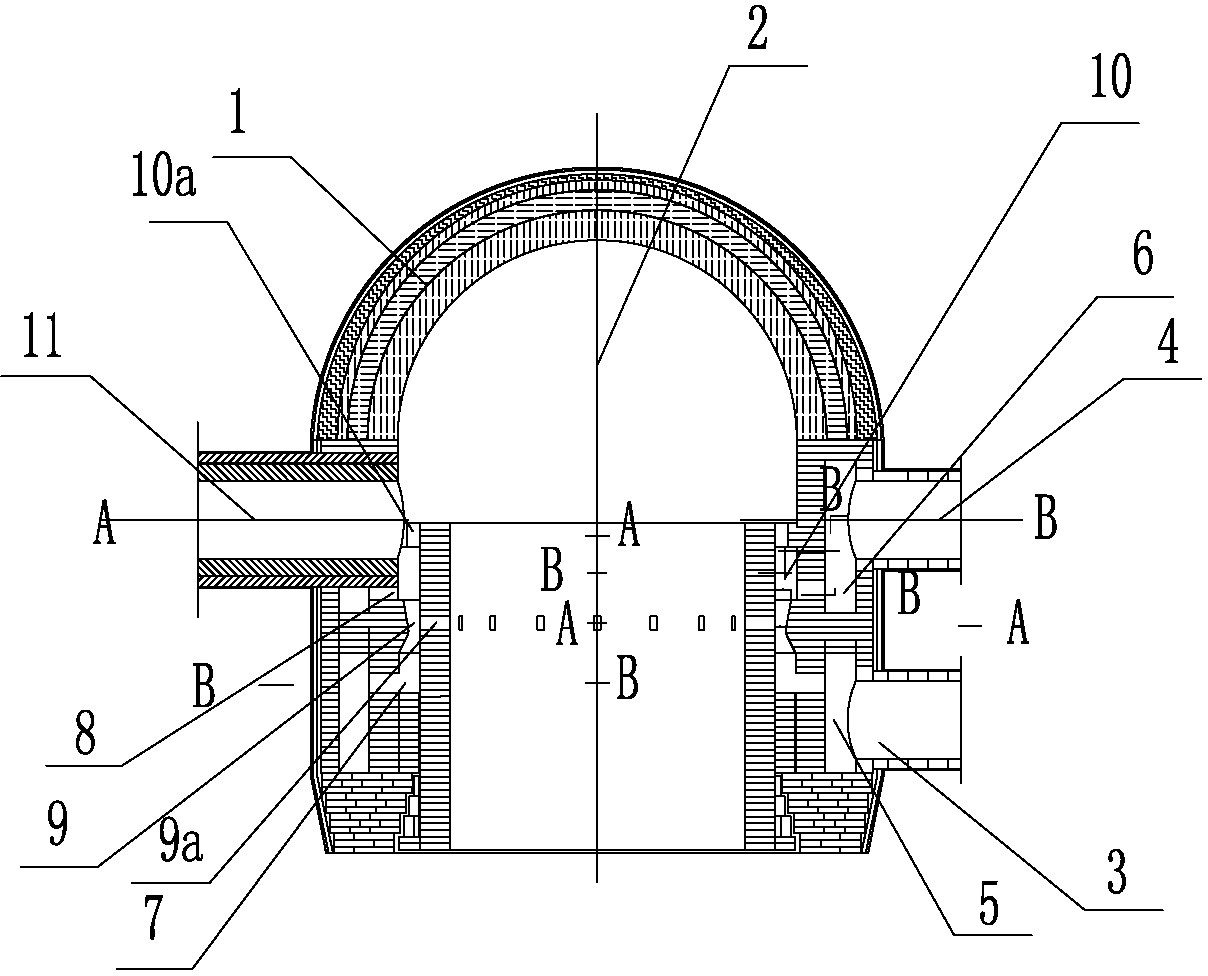

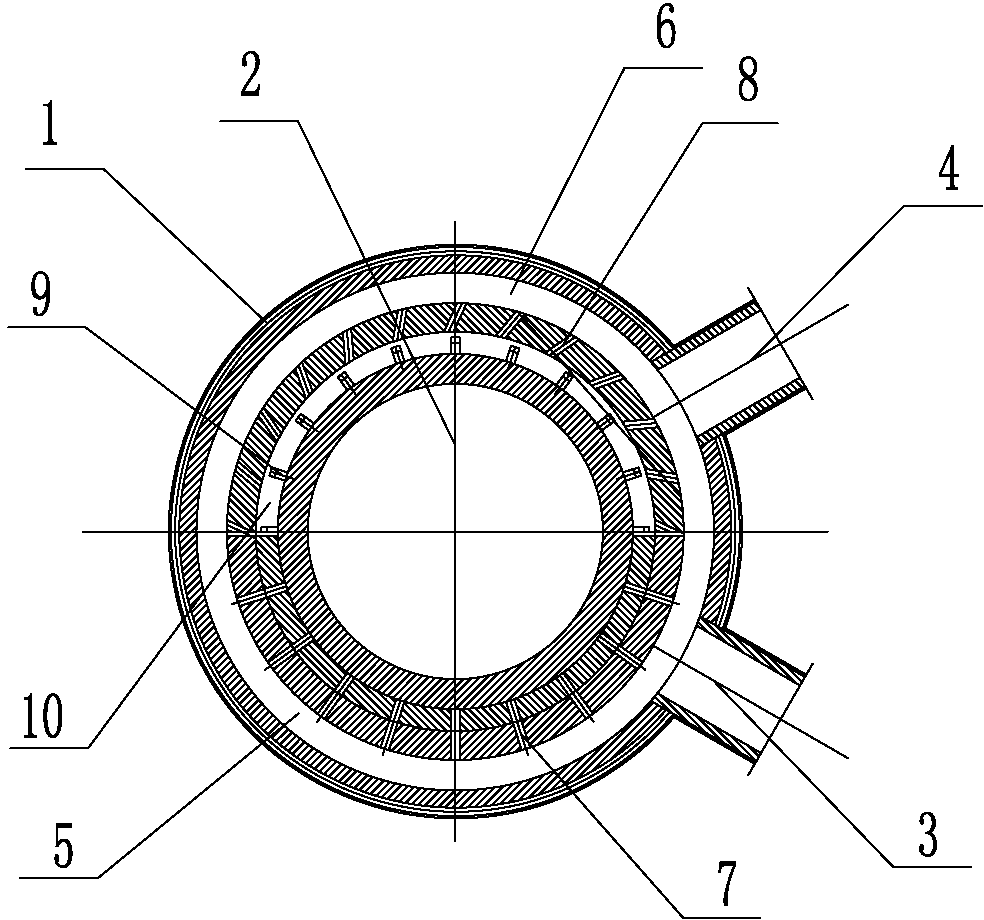

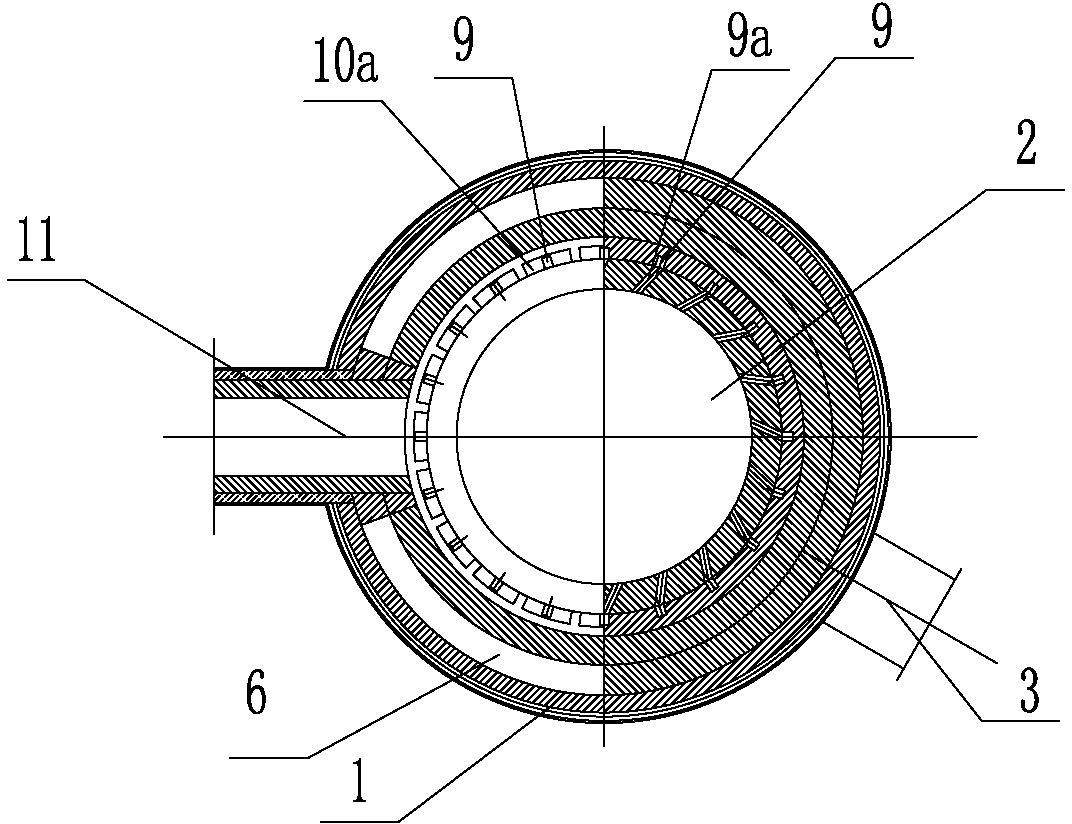

Ball-shape top-burning type hot-air furnace with annular-arranged vertical up-spray burner

InactiveCN101024859AExtended service lifeReduce the temperatureBlast furnace detailsIndirect carbon-dioxide mitigationCombustorEngineering

The invention relates to a spherical top combustion hot air furnace with annularly distributed and vertically upward-jetting burner, and its structure: the lower part of the furnace body is equipped with flue hole, furnace bottom and furnace grate, a heat storage room is in the furnace body, there is a burner between the upper part of the furnace body and the furnace top, the furnace top is made with hot air outlet, there is coal gas preheating loop in the wall body of the burner, there is combustion supporting air preheating loop in swelling body at the upper part of the coal gas preheating loop, there are coal gas outlet and top nozzle at the upper part of the coal gas preheating loop, the wall body of the burner is equipped with coal gas inlet connected with the coal gas preheating loop, the wall body of the burner at the upper part of the coal gas inlet is equipped with combustion supporting air preheating loop connected with combustion supporting air inlet and outlet, the upper part of the air outlet is equipped with air nozzle. And the invention has a special and novel structure, and skillfully solves the key problems in the gas-flow mixing, gas-flow distribution, fume preheating and other combustion courses and has huge economic and social benefits.

Owner:河南省豫兴热风炉工程技术有限公司

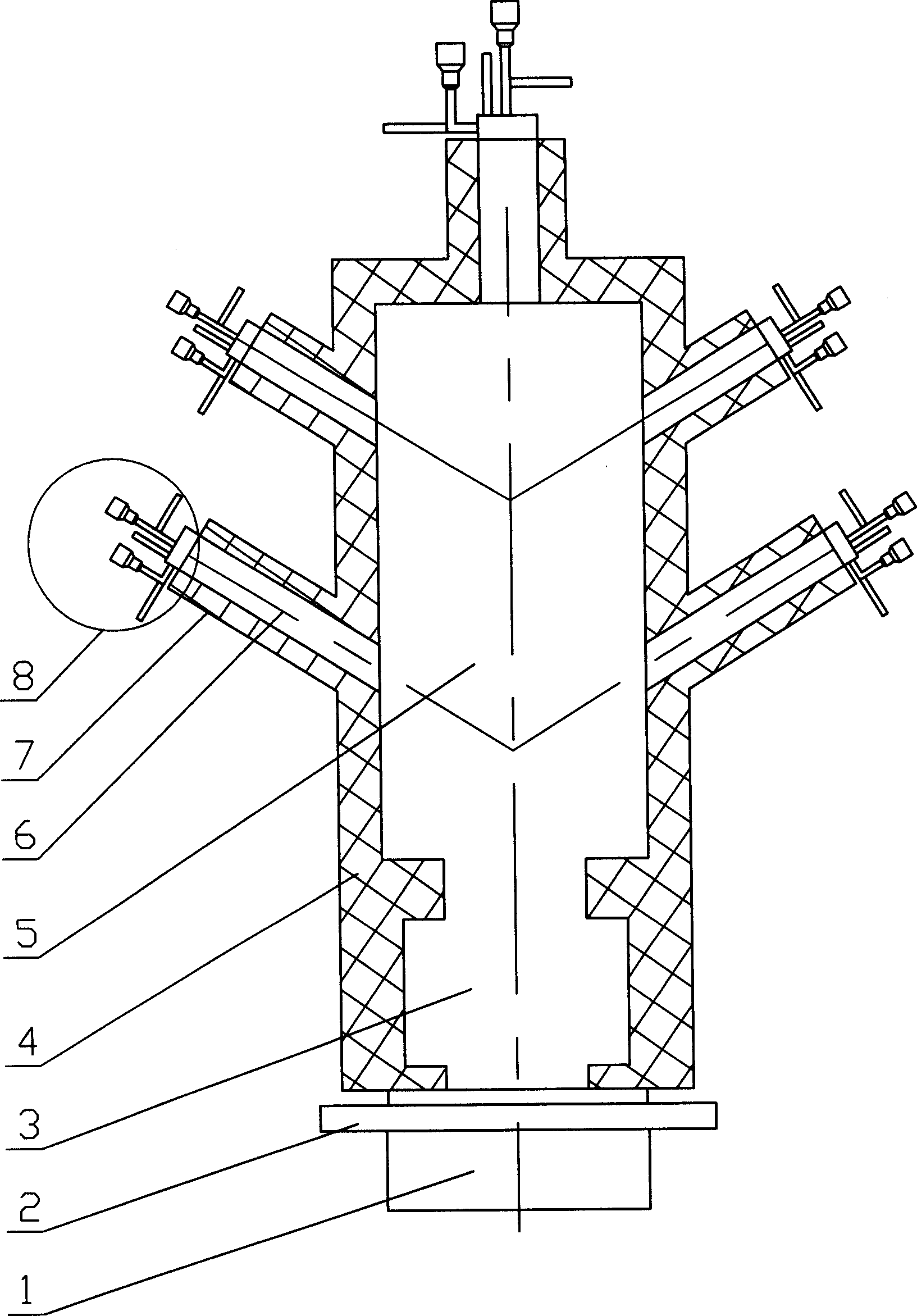

Full premixed combustion smelting method and smelting furnace for producing glass using the method

InactiveCN1594149AAvoid wastingSolve pollutionCharging furnaceGlass furnace apparatusCombustionHeat energy

The invention relates to a full premixed combustion smelting method and smelting furnace for producing glass using the method, wherein the method consists of disintegrating the raw materials, mixing and loading into flame for full contact with the flame, thus realizing completely premixed combustion and smelting, the droplets formed in smelting fall into the smelting pool through colliding each other and forming shaped liquid. The disclosed method can increase utilization factor of heat energy substantially.

Owner:谢西平

Industrial combustion furnace for treating exhaust gas and waste liquid and treatment method

ActiveCN105509071AReduce generationImprove combustion efficiencyIncinerator apparatusExhaust fumesProcess engineering

The invention discloses an industrial combustion furnace for treating exhaust gas and waste liquid and a treatment method. The combustion furnace comprises a furnace body, and the furnace body sequentially comprises a feeding area, a mixing area, a main combustion area and a rear combustion area; a center air gun, an air inlet pipeline and a waste pipeline are arranged in the feeding area; the air enters the mixing area from the center air gun and the air inlet pipeline and sequentially flows through an outer air cavity, an air deflector and a first swirling device; the exhaust gas and the waste liquid enter the mixing area from the waste pipeline and sequentially flow through a waste gun and a second swirling device; the waste gun is arranged on the outer side of the center air gun in a sleeving mode, and the waste gun and the center air gun are uniform in extension direction and are communicated with the mixing area. The method comprises the steps that a, the air enters the mixing area from the center air gun and the air inlet pipeline; b, fuel gas enters the main combustion area and is mixed with the air for combustion; c, the exhaust gas and the waste liquid enter the mixing area from the waste pipeline; d, the mixtures of the air, the exhaust gas and the waste liquid enter the main combustion area and are ignited; e, the exhaust gas and the waste liquid enter the rear combustion area after being ignited. According to the invention, the reaction area of the exhaust gas and the waste liquid and the reaction area of the oxygen are separated, the combustion time of the exhaust gas and the waste liquid and the combustion time of the oxygen are separated, the combustion efficiency is improved, and pollutant residues in tail gas are reduced.

Owner:KEYON PROCESS +1

Method for improving combustion temperature of combustion furnace by local oxygen-enriched oxygenation jet combustion-supporting technology and device thereof

InactiveCN101893253ALower fuel ignition pointImprove combustion intensityIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyThermal radiationJet flow

The invention provides a method for improving combustion temperature of a combustion furnace by a local oxygen-enriched oxygenation jet flow combustion-supporting technology, comprising the following steps: oxygen-enriched gas with higher linear velocity is delivered to some combustion flame position for combustion-supporting through an oxygen-enriched nozzle with a small spread angle; and after pressurization, the oxygen-enriched gas enters a fuel flow area for mixing and combusting at 12-45 degrees with the jet fuel and with linear velocity which is 1.5-5.0 times of the fuel flow velocity in a jet flow manner, wherein the position in which the oxygen-enriched gas enters is at the center of the combustion flame position and is slightly deviated from a fuel nozzle. The invention further provides a corresponding device. The invention has the advantage that by adopting the special oxygen-enriched jet nozzle with the small spread angle and a thermal radiation principle, under the conditions that fuel consumption is not increased, any structure of the original furnace is not changed and only an oxygen-enriched preheating system and the oxygen-enriched nozzle are contacted with a furnace body, the temperature of a combustion flame area is improved maximally.

Owner:魏伯卿

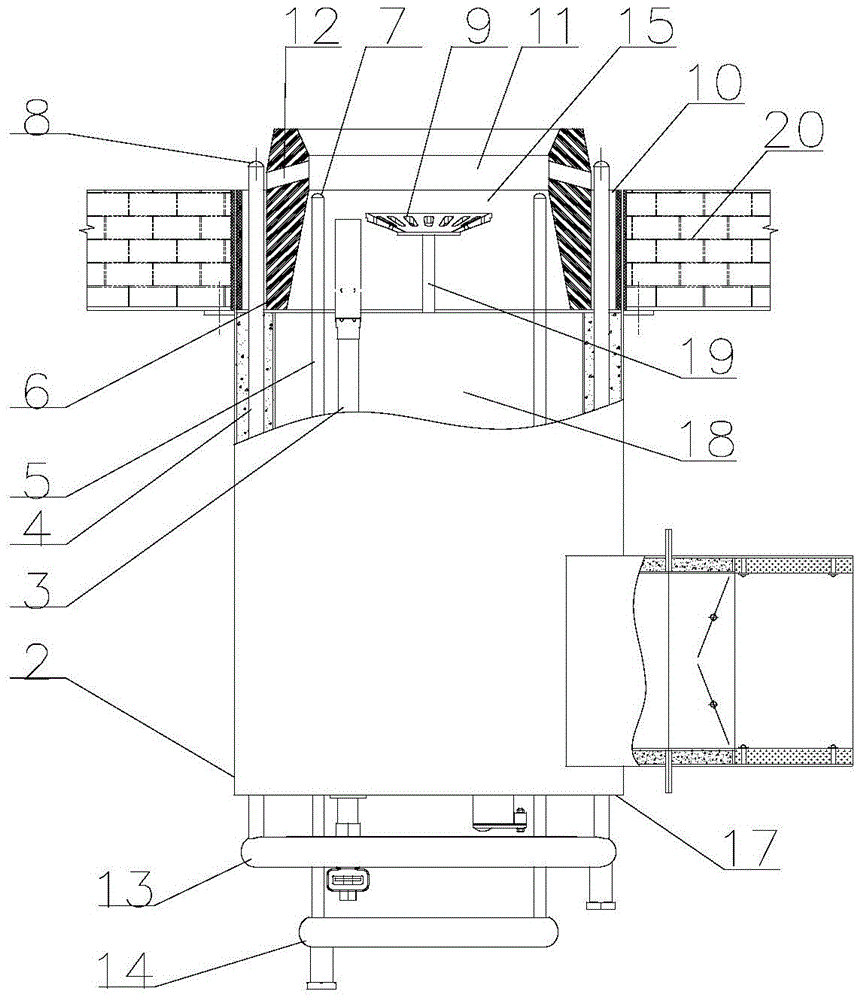

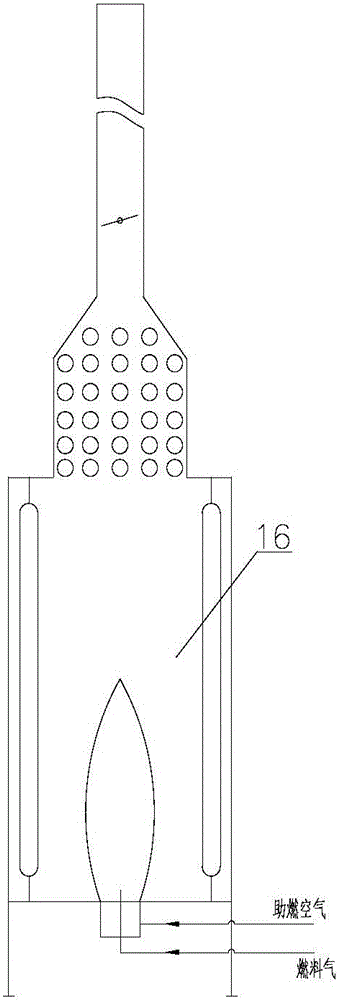

Double-preheating environmental protection combustor for tube heating furnace and applications thereof

InactiveCN104964282AIncrease temperatureReduce the temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFlue gas

The invention relates to a double-preheating environmental protection combustor for a tube heating furnace and applications thereof. The combustor is disposed in a hearth (16) of the tube heating furnace, and comprises a cylinder (2), a firebrick (6), outer spray guns (4), and inner spray guns (5). The firebrick (6) is arranged at the upper portion of the cylinder (2). A flue (15) concentric with the cylinder (2) is formed inside the firebrick (6). The height of an outer spray gun nozzle (8) of each outer spray gun (4) is larger than the height of an inner spray gun nozzle (7) of each inner spray gun (5), and the portions, between the outer spray gun nozzles (8) and the inner spray gun nozzles (7), of the firebrick (6) are provided with firebrick inclined holes (12), so that combustion gas passing through the outer spray guns (4) and the inner spray guns (5) can burn in stages. According to the invention, a problem that a conventional combustor cannot be used for dual-preheating gas is solved, and fuel staging and flue gas multistage circulation technologies are employed, so that flame combustion high-temperature regions can be reduced, and the combustion can be stabilized.

Owner:上海浩用工业炉有限公司 +1

Combustor for medium-high temperature solid fuel cell and application thereof

PendingCN110360555AUniform porosityUniformityBurner ignition devicsFuel cellsCombustion chamberEngineering

The invention belongs to the field of fuel cells, and particularly discloses a combustor for a medium-high temperature solid fuel cell and an application thereof. An air inlet and a fuel inlet are arranged at an inlet end of a static mixing cavity in the combustor and are used for mixing air and fuel to obtain mixed gas; a shunting orifice plate is connected with an outlet end of the static mixingcavity to provide a buffer area for the mixed gas and shunt the mixed gas; a metal mesh structure is connected with the shunting orifice plate, so that the phenomena of tempering and flamelifting areprevented; a combustion chamber is arranged on the outer side of the static mixing cavity and provides a space for mixed gas combustion; and a pulse igniter is arranged above the metal mesh structureand used for igniting the mixed gas. According to the combustor, the shunting orifice plate is utilized to provide the buffer area for the high-flow-rate mixed gas, meanwhile, flame generated by combustion is divided into a plurality of fine flame flows by utilizing the metal mesh structure, and stable gas flow and temperature gradient are formed, so that the phenomena of the tempering and flamelifting are prevented.

Owner:HUAZHONG UNIV OF SCI & TECH

Ignition device for fireman fire extinguishment training system

InactiveCN105509091AReasonable structureReduce volumeElectric spark ignitersIgnition coilEngineering

The invention belongs to the technical field of design of ignition equipment, and in particular, relates to an ignition device for a fireman fire extinguishment training system. The device comprises a shell, a base, an ignition rod, a gas-air mixer, an ignition rod fixed base, a gas pipe and an electric conducting needle; the ignition rod penetrates through the base to be fixed in the shell; the ignition rod and the base, and the ignition rod and the shell are in insulation contact; the gas-air mixer is arranged in the shell; one end of the gas-air mixer is a gas inlet hole, and is connected with the gas pipe penetrating through the base; the other end of the gas-air mixer is a gas-air mixed outlet; an electrode rod is arranged in the ignition rod; the shell is connected with the electric conducting needle; and the electrode rod and the electric conducting needle are arranged at intervals, and are fixed in front of the gas-air mixed outlet of the gas-air mixer. The ignition device can generate stable ignition flame with a certain length and rigidity under the condition of no special arrangement of air distribution facilities.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

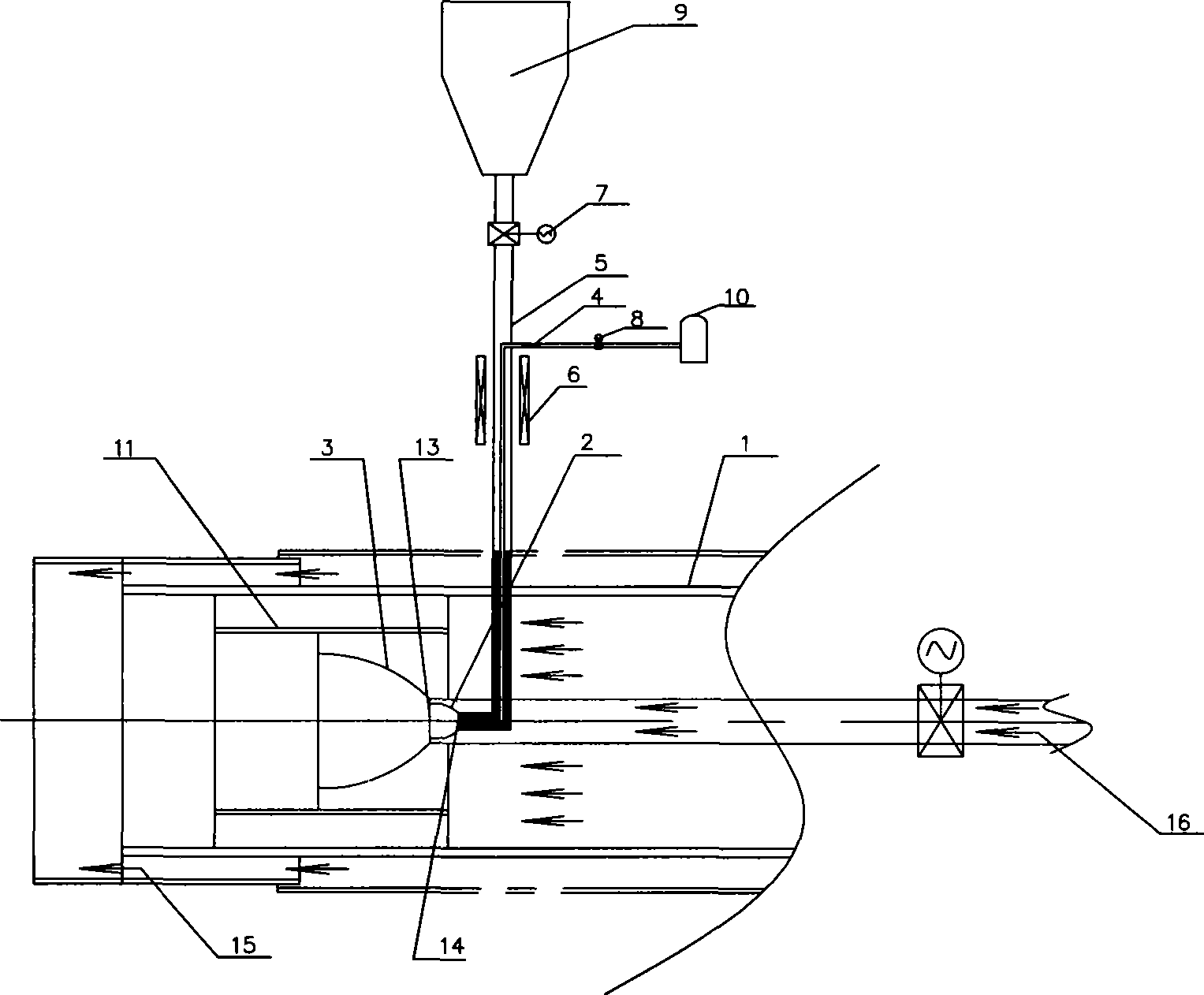

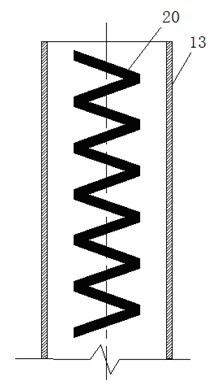

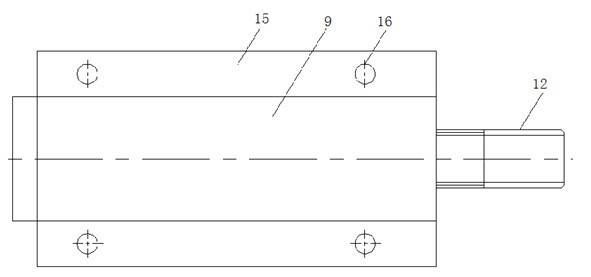

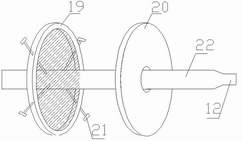

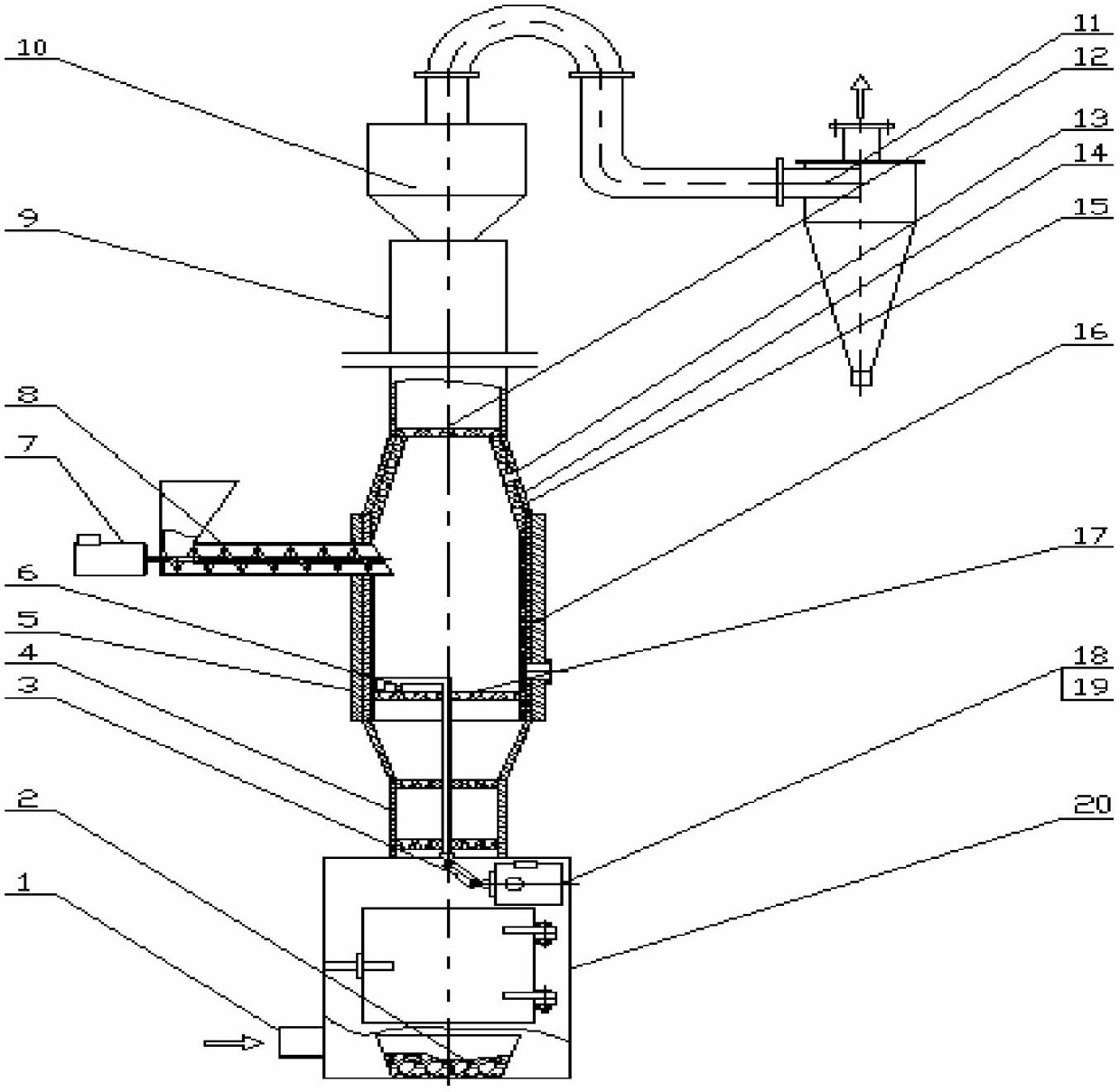

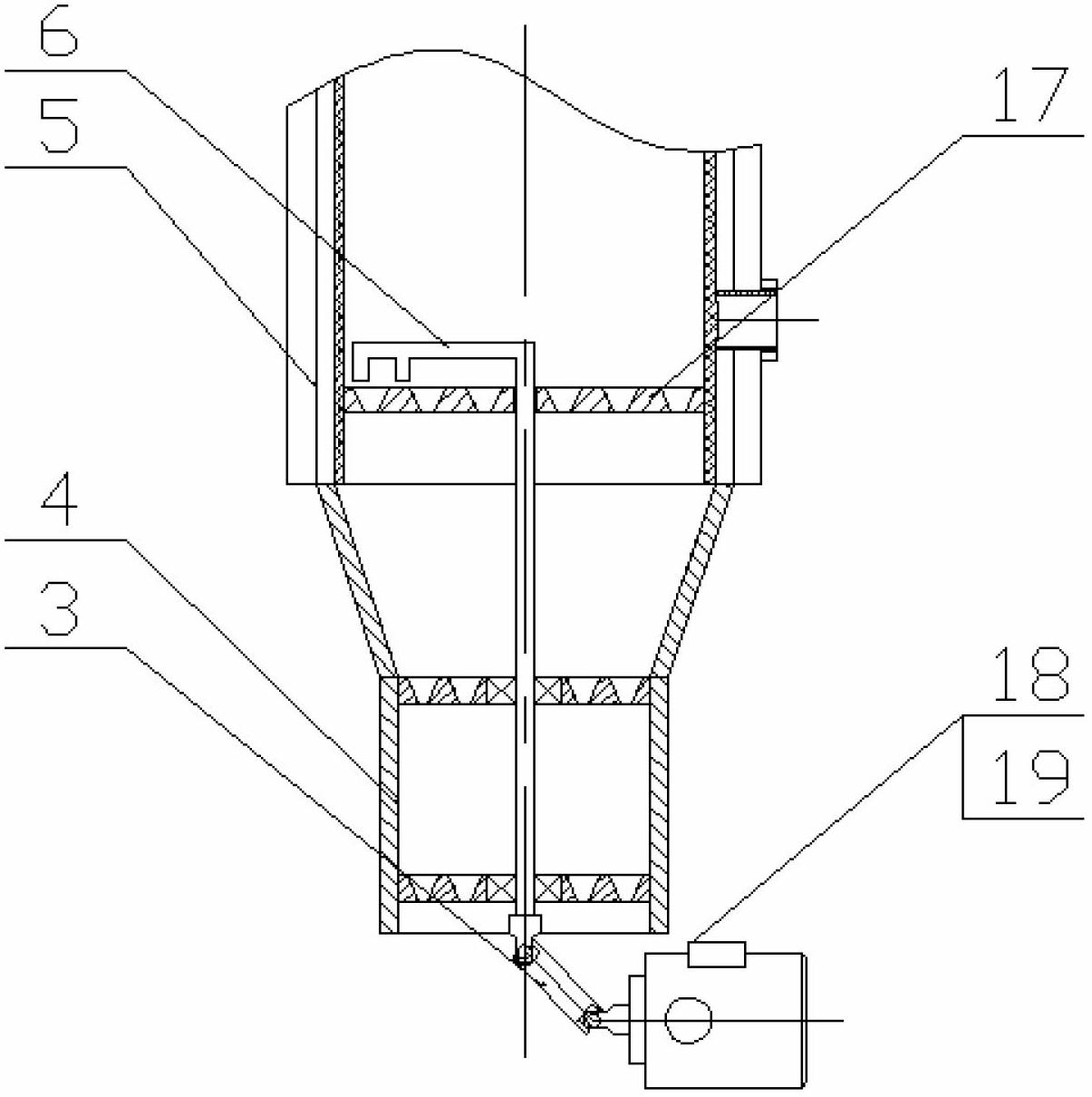

Biomass fuel pulse combustion hot blast device and use method thereof

The invention discloses a biomass fuel pulse combustion hot blast device and a use method thereof. The biomass fuel pulse combustion hot blast device adopts the technical scheme by including a base (20), wherein a Rijke pulse combustor main body is mounted on the base (20); the Rijke pulse combustor main body includes a furnace chamber barrel body (16), a lower air pipe (4) and an upper air outlet pipe (9) from bottom to top; a grate (17) is mounted at the L position x=(0.12 to 0.26) away from the lower end of the Rijke pulse combustor main body; a rotary distributing rod (6) is arranged on the grate (17); and a feeding device including a feeding and speed regulating motor (7) and a spiral feeder (8) is arranged on the side wall of the furnace chamber barrel body (16). When the biomass fuel pulse combustion hot blast device is in use, the temperature in the combustion chamber is kept between 800 to 950 degrees. The biomass fuel pulse combustion hot blast device and the use method thereof solve the problems of insufficient combustion, caking and slag bonding during the biomass fuel combusting process, and provide a heat source with simple structure, efficiency in combustion and low manufacturing and use costs for drying agricultural products and the like.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

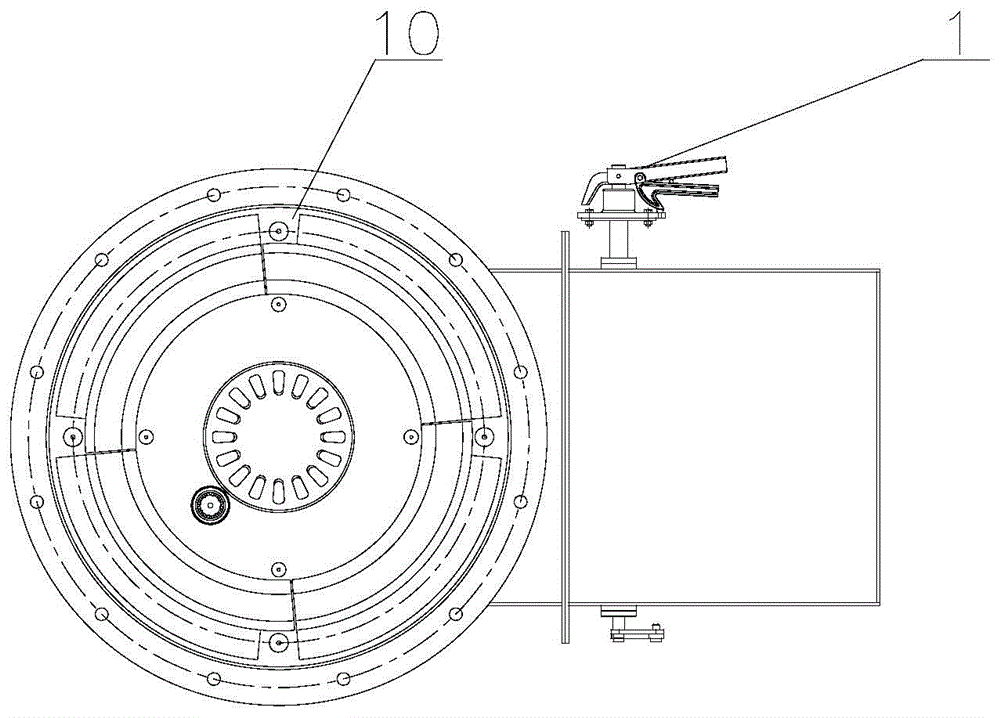

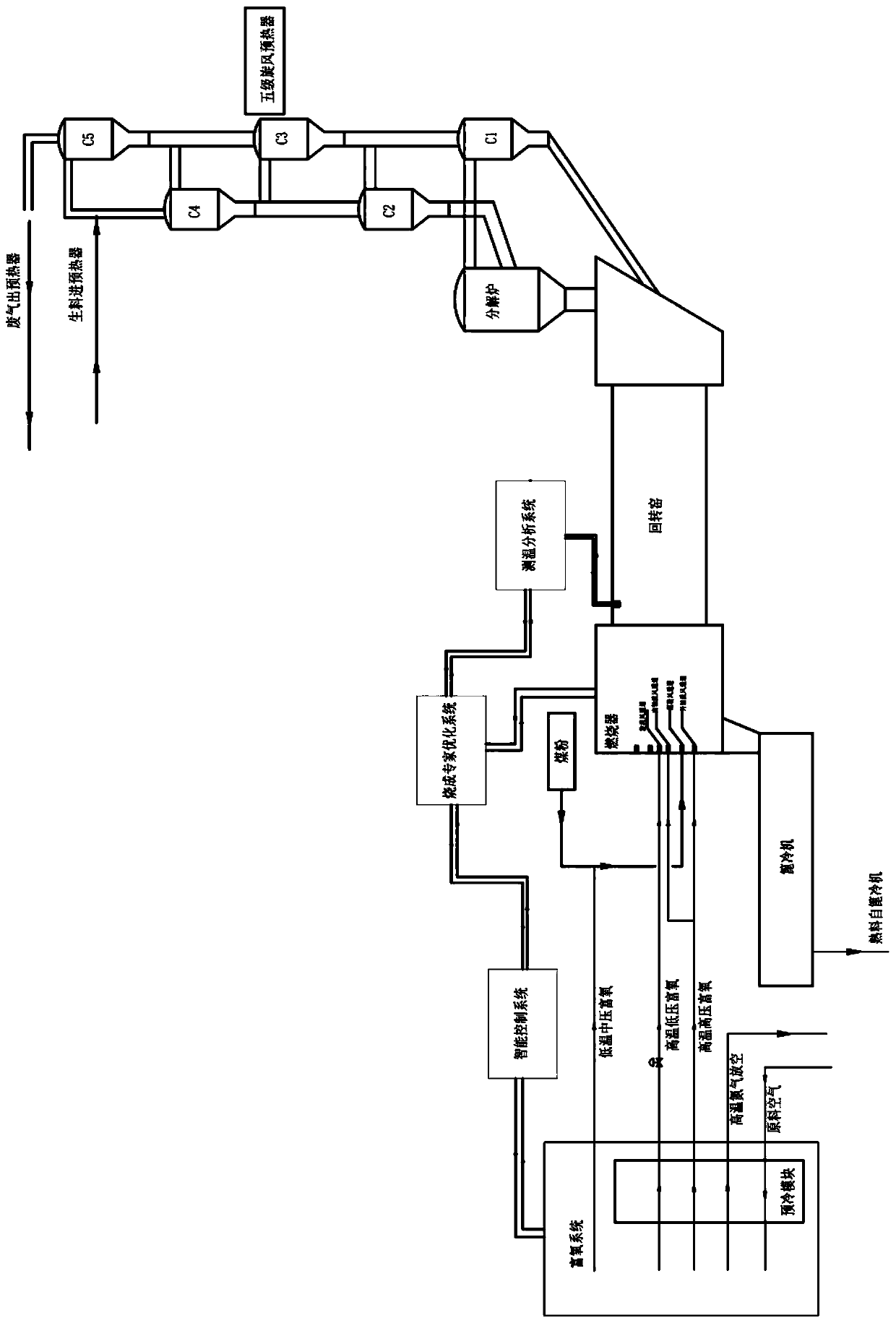

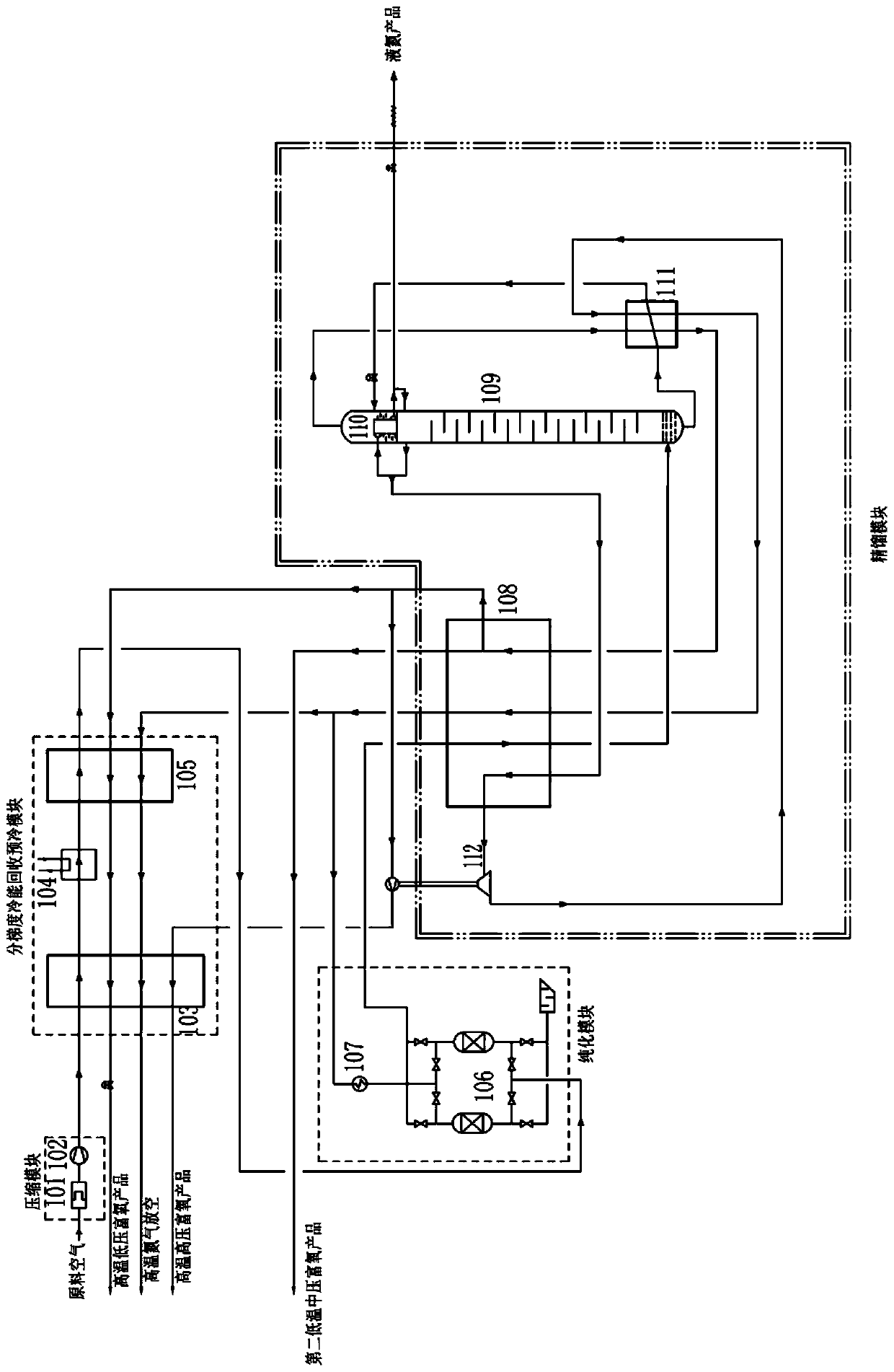

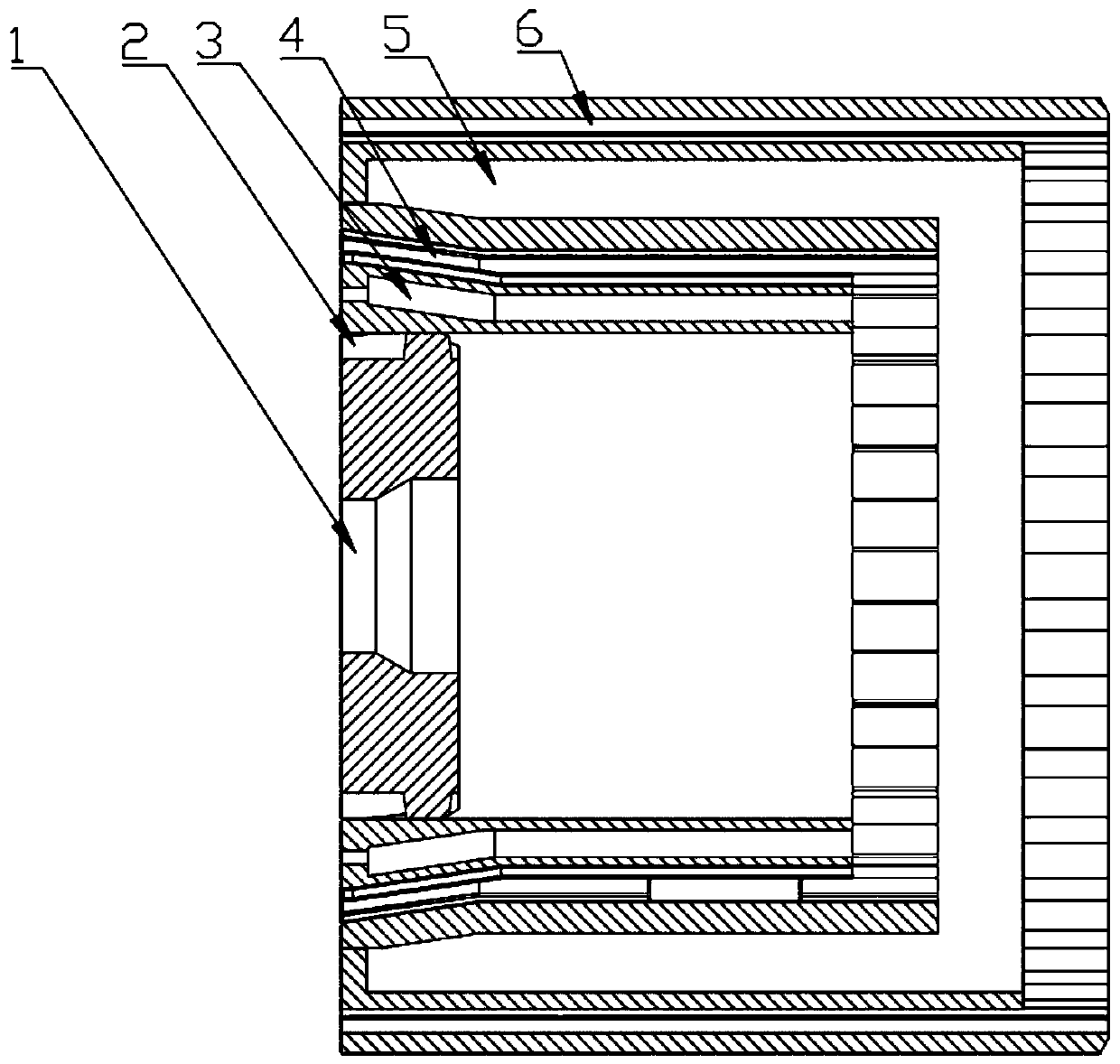

Intelligent control oxygen-enriched firing system and method for kiln

ActiveCN111521003ASmall fluctuationReduce dosageSolidificationLiquefactionThermodynamicsProcess engineering

The invention discloses an intelligent control oxygen-enriched firing system for a kiln. The intelligent control oxygen-enriched firing system for the kiln comprises an oxygen-enriched system, an oxygen-enriched burner, a temperature measurement and analysis system, a firing expert optimization system and an intelligent control system. According to the intelligent control oxygen-enriched firing system for the kiln, the oxygen enrichment is produced and provided by a special oxygen-enriched system; the novel oxygen-enriched burner is adopted; according to different coal powder types, coal powder amount and grinding granularity of a kiln system, the shapes and temperature distribution of flames are obtained by the accurate temperature measurement and analysis system, all on-site actual thermal parameters and on-site states of the kiln are combined, the system analysis and the prediction and judgment are carried out by the firing expert optimization system, and the intelligent regulationand dynamic matching of the special oxygen-enriched system are controlled by the intelligent control system, so that the optimal operation state of the firing system of the kiln is kept, the efficientand stable burning of coal powder in the oxygen-enriched burner is realized, the consumption of the coal powder is reduced, the quality of burned materials is improved, the generation and emission ofNOx are effectively reduced, meanwhile, the fluctuation of the kiln system caused by the debugging experience and level difference of operators is reduced, and the normal and stable operation of thekiln system is guaranteed.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

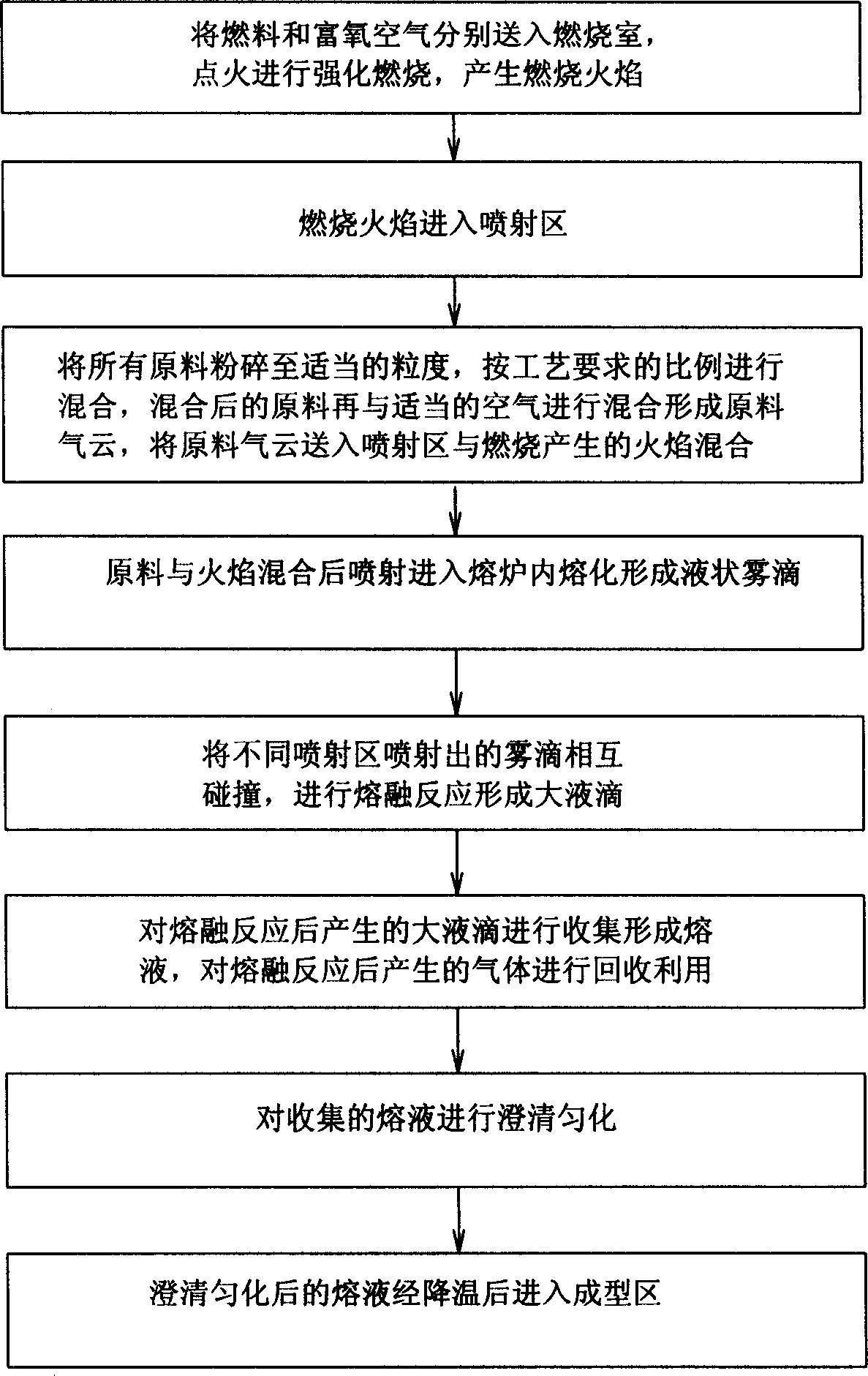

Combustion device for upper spraying, combustion, exhumation and outflow of premixed annular airflow

InactiveCN101793396ASimple structureReduce productionFluid heatersGaseous fuel burnerCombustion chamberEngineering

The invention relates to a combustion device for upper spraying, combustion, exhumation and outflow of premixed annular airflow, which effectively solves the problems that gas and blasting air rapidly combust in the combustion chamber after flowing into the premixing loop and the gas flow in the flue flow field is uniform and stable. The combustion device is a combustion chamber which consists of a dome cylinder type lower opening, a cylinder type wall body and a semi-spherical dome and is used for flow and combustion of premixed gas flow, a gas loop and an air loop are separately arranged along the vertical direction in the inner wall of the cylinder type wall body, the periphery of the inner side of the gas loop is uniformly provided with gas nozzles with rectangular sections, and the periphery of the inner side of the air loop is uniformly provided with air nozzles with rectangular sections; the outer sides of the gas loop and the air loop are respectively connected with a gas inlet pipe and an air inlet pipe; the spouts of the gas nozzles and the air nozzles are vertically communicated with the outer side of a premixing loop; and the premixing loop is an annular loop with the upper opening on the rectangular section of the combustion chamber and is tightly and coaxially connected with the inner wall of the combustion chamber. The invention has the advantages of low manufacturing and installation difficulty and high stability, and can reduce the excess air coefficient, enhance the combustion intensity and increase the combustion temperature.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

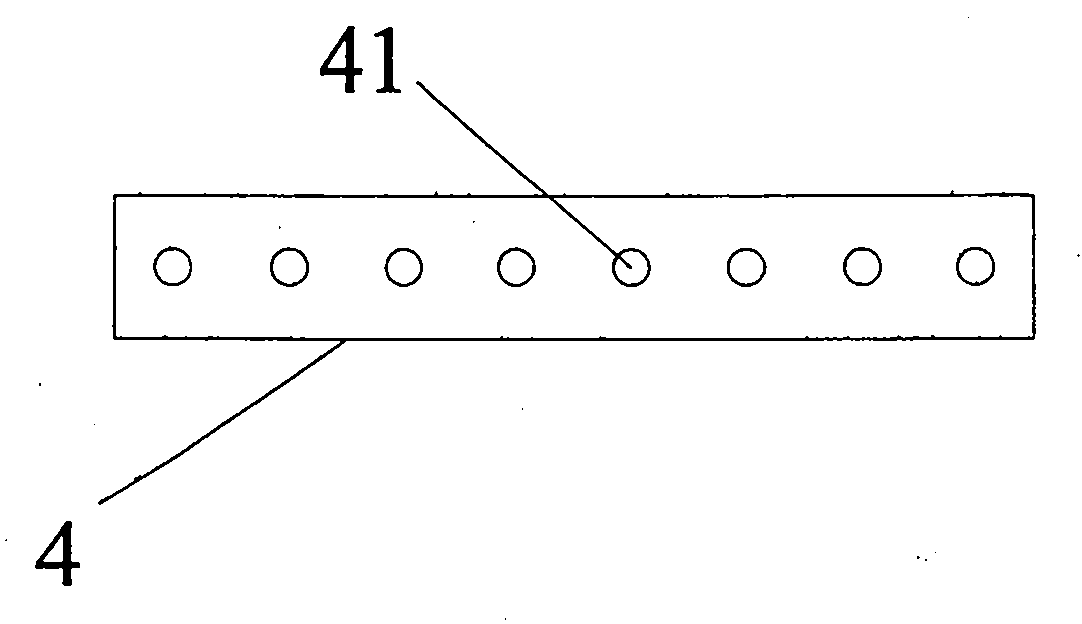

Completely-premixed gas burner

The invention relates to a completely-premixed gas burner, which comprises a nozzle, an ejector, a distribution chamber, a shunting plate and a burning fire-hole plate, wherein the nozzle is arranged on one end of the ejector, and the other end of the ejector is connected with the distribution chamber; the shunting plate is arranged on the distribution chamber; the burning fire-hole plate is arranged above the shunting plate; gas is injected into the ejector via the nozzle and is evenly mixed with air ejected and boosted by the ejector in the distribution chamber; and the mixture flows into the burning fire-hole plate after being shunted by the shunting plate. Compared with the prior art, the completely-premixed gas burner has the advantages of complete burning, low pollutant discharge amount in smoke and the like.

Owner:SHANGHAI HESEN ELECTRO MACHINERY

Turbulent combustor allowing premixed gas flow to force flue gas to flow back for preheating combustion

ActiveCN103900084AGuaranteed uptimeEmission reductionBlast furnace detailsIndirect carbon-dioxide mitigationCombustion chamberCombustor

The invention relates to a turbulent combustor allowing premixed gas flow to force flue gas to flow back for preheating combustion. The turbulent combustor effectively solves the problems that the mixing rate of coal gas and air is low, mixing of the coal gas and the air is not uniform, combustion intensity is low, temperature is low, mixing is incomplete, space is large, and the structure is unreasonable. A combustion chamber is formed in a combustion chamber wall. An air inlet pipe and a coal gas inlet pipe on the combustion chamber wall are connected with an air distribution channel and a coal gas distribution channel. The coal gas distribution channel is provided with a coal gas lead-out nozzle which is connected with a coal gas and air premixing channel. The air distribution channel is provided with an air lead-out pipe which is connected with an air ejecting nozzle. The air ejecting nozzle is connected with the coal gas and air premixing channel. The top of the coal gas and air premixing channel is provided with a vertically upward premixed gas nozzle. The combustion chamber wall is provided with a hot air outlet pipe. According to the turbulent combustor, it is guaranteed that a hot-blast stove efficiently operates in high heat intensity at high air supply temperature under the premise of being safe and stable, so that the good effects of saving fuel, reducing investments, lowering exhaust gas temperature and harmful gas emissions and reducing environmental pollution are achieved.

Owner:陈维汉

Alcohol-base fuel burner with radiant panel fuel nozzle

An alcohol-base fuel burner with radiant panel fuel nozzle comprises an air chamber, a mixed combustion chamber, an atomization injection pipe, wherein one end of the air chamber is opened, and the other end thereof is provided with an air inlet; the mixed combustion chamber is sleeved in the air chamber and is provided with air holes along the wall of the mixed combustion chamber; the center of the atomization injection pipe is a through hole, one end is provided with a radiant panel, the other end is installed on the soleplate of the mixed combustion chamber and is communicated with one end of a fuel supply pipe, and at least two fuel injection holes are uniformly distributed on the same cross section of the wall of the atomization injection pipe. The invention has high combustion efficiency, low energy consumption and less pollutant emission; compared with the existing technology, the discharge amount of CO and NOx is relatively reduced by 50% to 70%, and the heat efficiency reaches up to more than 40%. The burner is safe, environment-friendly, stable in combustion, high in combustion strength, easy and safe for combustion, good in fire adjustment, high-temperature and corrosion resistant, high impact resistant, mechanical impact resistant, low in thermal inertia and long in service life; and the burner is suitable for being applied to various special cookers in catering industry.

Owner:湖南中能力华新能源技术有限公司 +1

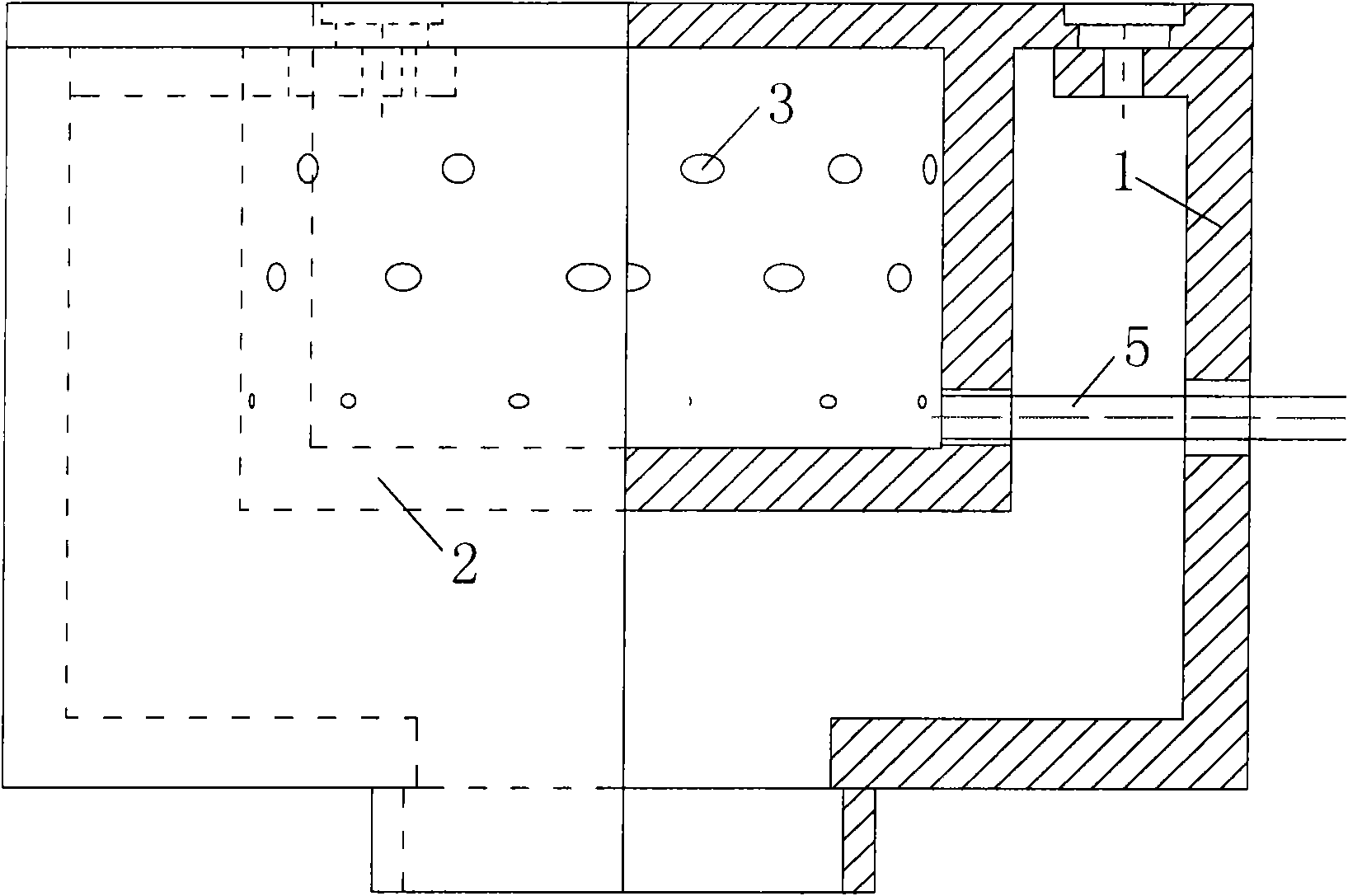

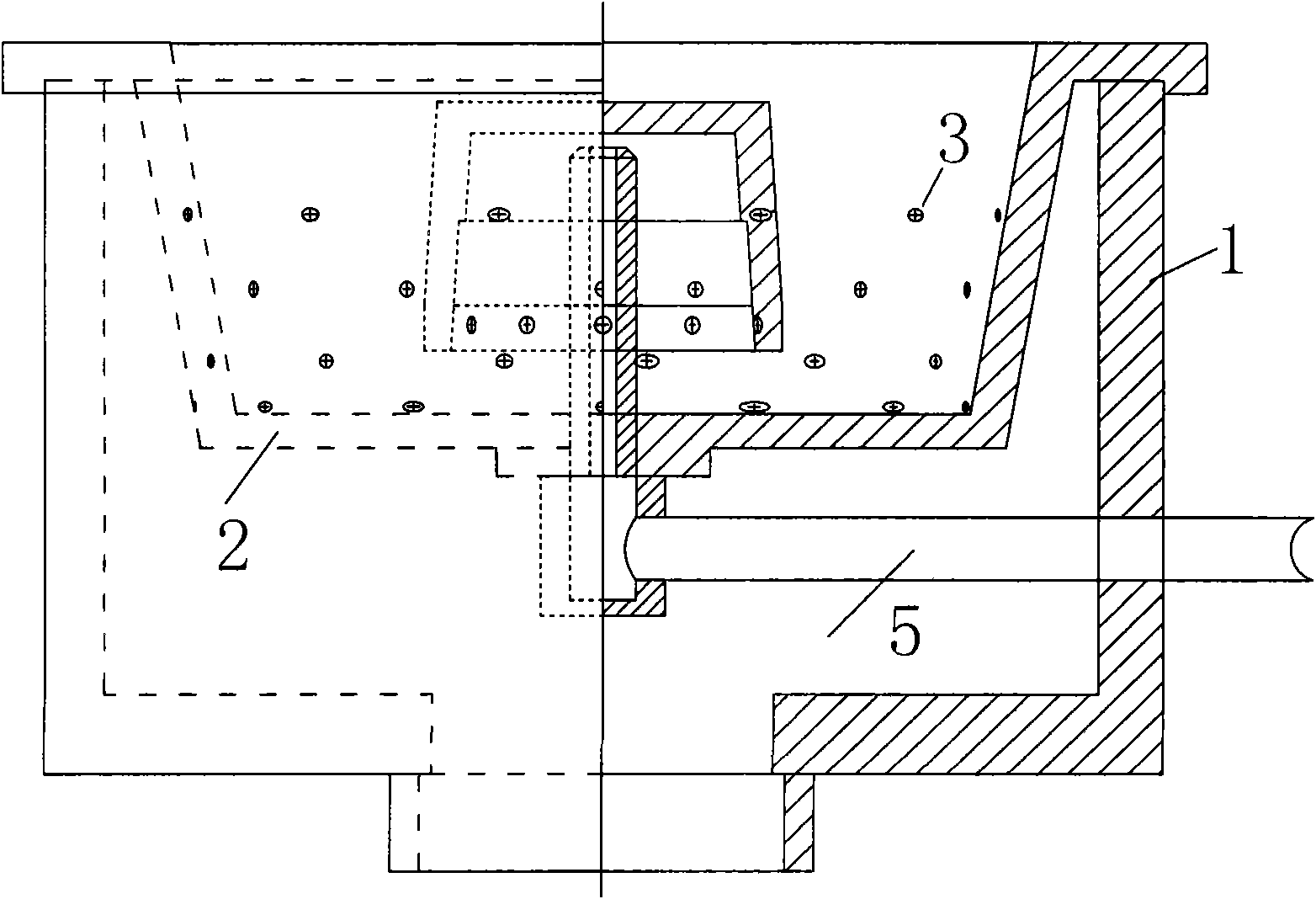

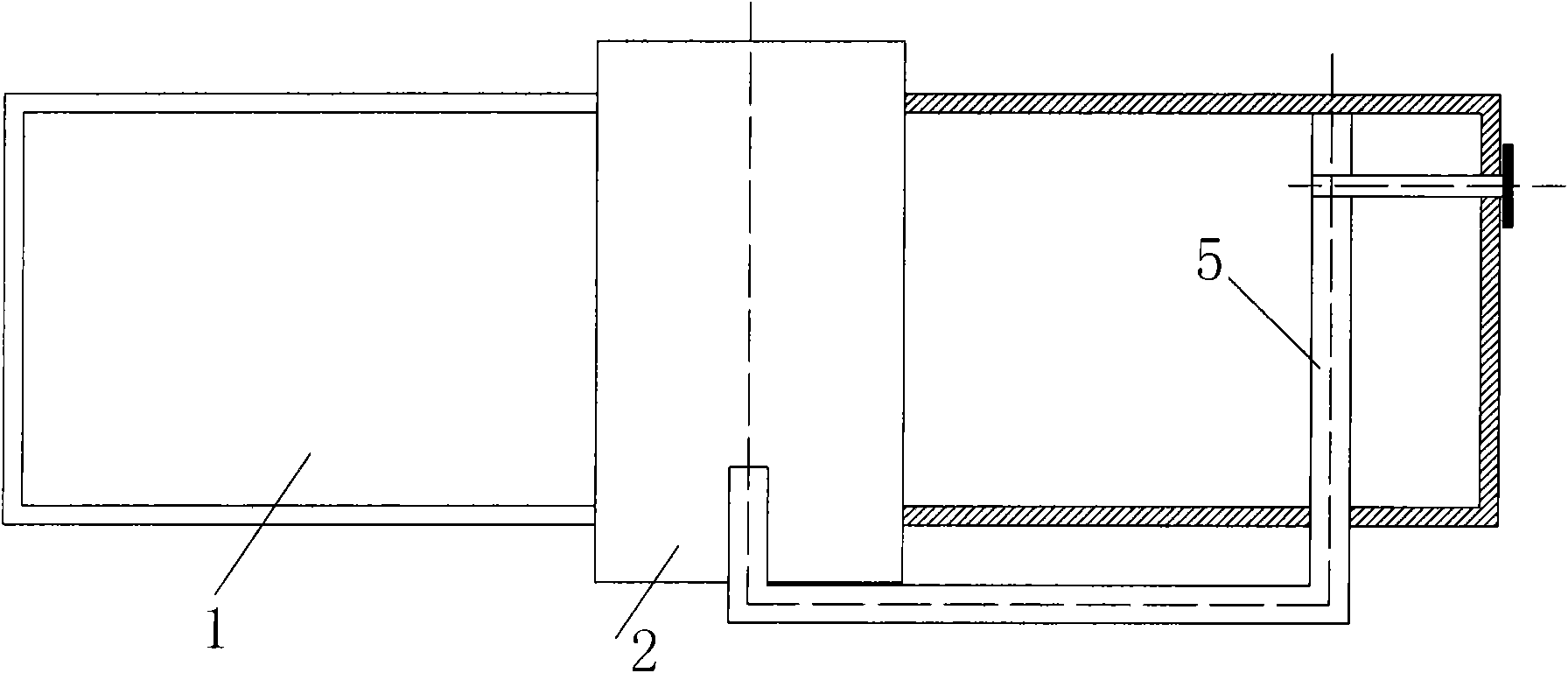

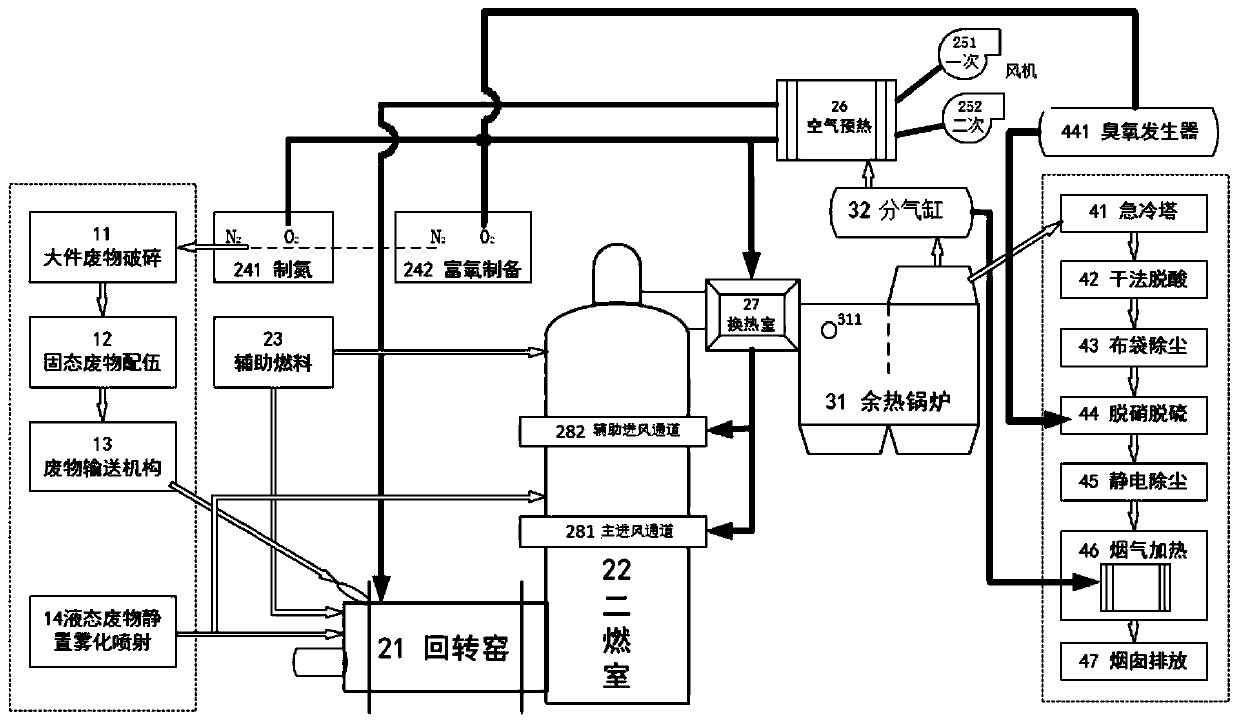

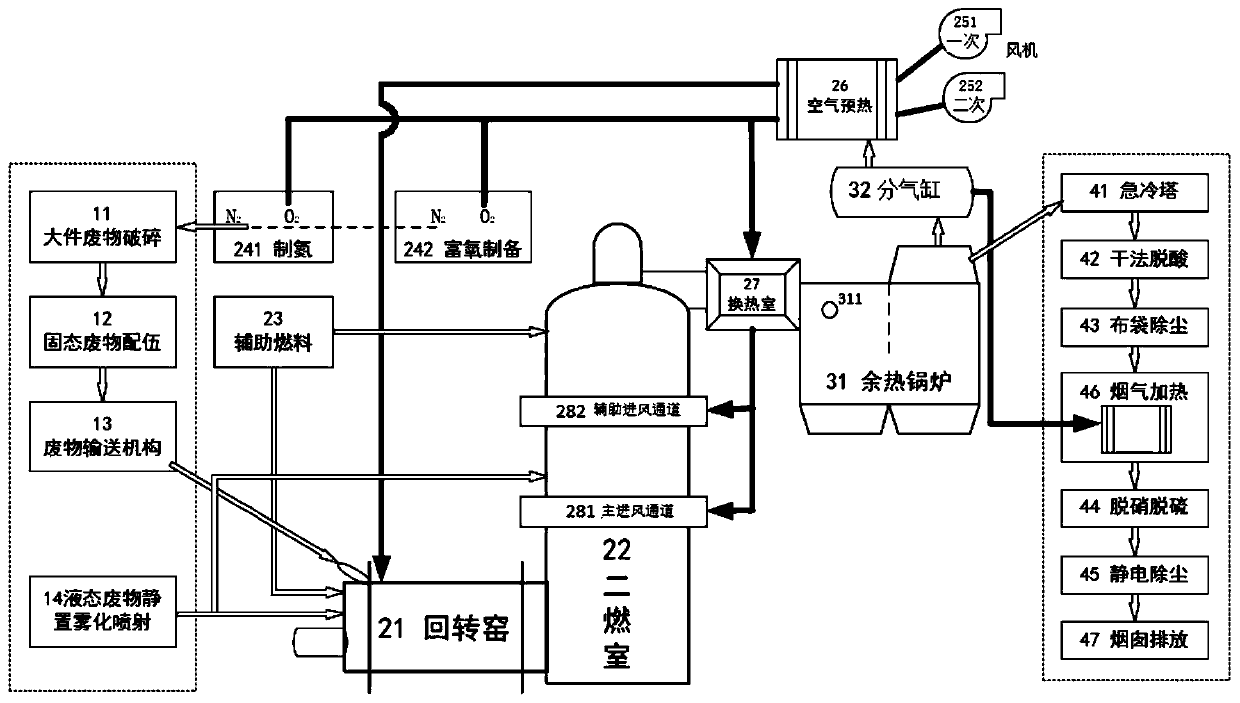

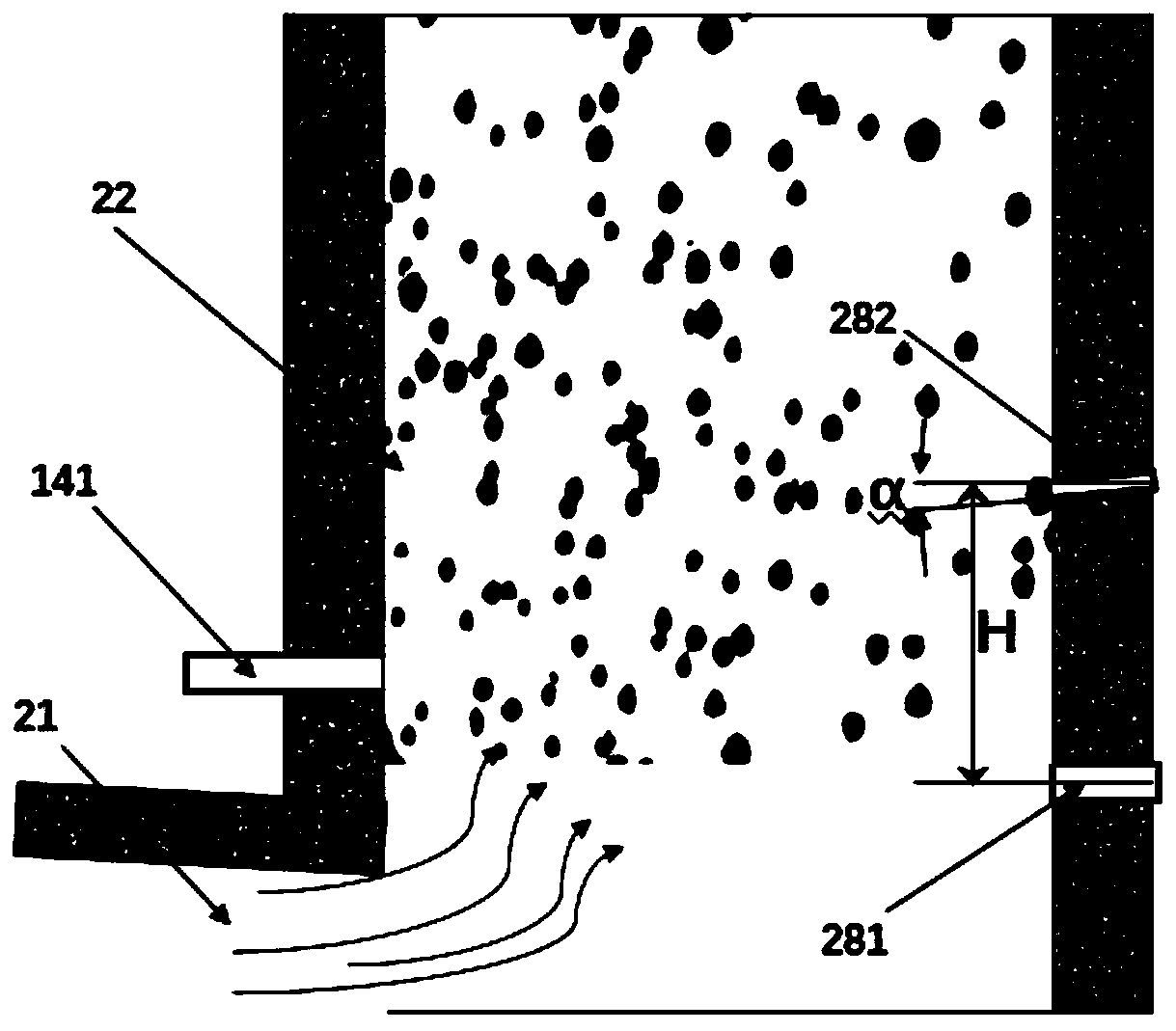

Green and efficient incineration method for hazardous waste in rotary kiln based on oxygen enriched air supply in secondary combustion chamber

PendingCN111306549ARaise the incineration temperatureInhibit synthesisEnergy inputIndirect carbon-dioxide mitigationLiquid wasteCombustion chamber

The invention discloses a green and efficient incineration method for hazardous waste in a rotary kiln based on oxygen enriched air supply in a secondary combustion chamber. The method comprises the steps of (1) adding solid waste, liquid waste and a first combustion-supporting gas to the rotary kiln for performing treatment; (2) feeding the waste and the liquid waste which are treated by means ofthe rotary kiln and a second combustion-supporting gas into a secondary combustion chamber for performing combusting treatment; and (3) exhausting the gas which is obtained after the combustion in the secondary combustion chamber, wherein the second combustion-supporting gas is formed by mixing air and an oxygen enriched gas; the incineration temperature in the secondary combustion chamber is risen to 1,100 to 1,200 DEG C; the oxygen concentration of the second combustion-supporting gas is 23 to 28 percent; the oxygen content of a combustion environment in the secondary combustion chamber isimproved, and a technical means of the preheating is effectively utilized, which are beneficial to removing nitrogen oxides from flue gas in a waste heat utilization system under the condition of ensuring complete decomposition of the harmful substances, such as dioxin; the production and emission of secondary environment pollution substances in an incineration processing process are avoided or remarkably reduced; and efficient and green treatment of maximum reduction of the hazardous waste is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com